Hitachi RAS-8FSNM, RAS-10FSNM, RAS-12FSNM, RAS-8FSNMQ, RAS-10FSNMQ Installation & Maintenance Manual

...

Installation

&

Maintenance

Manual

INVERTER-DRIVEN

SPLIT SYSTEM

HEAT PUMP

AIR CONDITIONERS

- DC INVERTER UTOPIA IVX -

Model:

Outdoor Unit;

RAS-8FSNM

RAS-10FSNM

RAS-12FSNM

IMPORTANT:

READ AND UNDERSTAND

THIS MANUAL BEFORE

USING THIS HEAT-PUMP

AIR CONDITIONERS.

KEEP THIS MANUAL FOR

FUTURE REFERENCE.

P00104Q

(Q)

(Q)

(Q)

i

IMPORTANT NOTICE

l HITACHI pursues a policy of continuing improvement in design and performance of products. The right is

therefore reserved to vary specifications without notice.

l HITACHI cannot anticipate every possible circumstance that might involve a potential hazard.

l This heat pump air conditioner is designed for standard air conditioning only. Do not use this heat pump

air conditioner for other purposes such as drying clothes, refrigerating foods or for any other cooling or

heating process.

l The installer and system specialist shall secure safety against leakage according to local regulations or

standards. The following standards may be applicable if local regulations are not available.

British Standard, BS4434 or Japan Standard, KHKS0010.

l No part of this manual may be reproduced without written permission.

l Signal words (DANGER, WARNING and CAUTION) are used to identify levels of hazard seriousness.

Definitions for identifying hazard levels are provided below with their respective signal words.

: Immediate hazards which WILL result in severe personal injury

or death.

: Hazards or unsafe practices which COULD result in severe personal

injury or death.

: Hazards or unsafe practices which COULD result in minor personal

injury or product or property damage.

: Useful information for operation and/or maintenance.

l It is assumed that this heat pump air conditioner will be operated and serviced by English speaking

people. If this is not the case, the customer should add safety, caution and operating signs in the native

language.

l If you have any questions, contact your distributor or dealer of HITACHI.

l This manual gives a common description and information for this heat pump air conditioner which you

operate as well as for other models.

l Perform installation work according to local codes and regulations.

l This heat pump air conditioner has been designed for the following temperatures. Operate the heat pump

air conditioner within this range.

NOTE

This manual should be considered as a permanent part of the air conditioning equipment and should

remain with the air conditioning equipment.

Temperature

(

o

C)

Maximum Minimum

Cooling Indoor 23 WB 15 WB

Operation Outdoor 43 DB -15 DB

Heating Indoor 30 DB 15 DB

Operation Outdoor 17 WB -20 WB

DB: Dry Bulb, WB: Wet Bulb

ii

SAFETY SUMMARY

l Use refrigerant R410A in the refrigerant cycle. Do not charge oxygen, acetylene

or other flammable and poisonous gases into the refrigerant cycle when performing a

leakage test or an air-tight test. These types of gases are extremely dangerous and

can cause an explosion. It is recommended that compressed air, nitrogen or

refrigerant be used for these types of tests.

l Do not pour water into the indoor or outdoor unit. These products are equipped with

electrical parts. If poured, it will cause a serious electrical shock.

l Do not touch or adjust safety devices inside the indoor or outdoor units. If these

devices are touched or readjusted, it may cause a serious accident.

l Do not open the service cover or access panel for the indoor or outdoor units without

turning OFF the main power supply.

l Refrigerant leakage can cause difficulty with breathing due to insufficient air. Turn OFF

the main switch, extinguish any naked flames and contact your service contractor, if

refrigerant leakage occurs.

l The installer and system specialist shall secure safety against refrigerant leakage

according to local regulations or standards.

l Use an ELB (Electric Leakage Breaker). In the event of a fault, there is danger of an

electric shock or a fire if it is not used.

l Do not install the outdoor unit where there is a high level of oil mist, flammable gases,

salty air or harmful gases such as sulphur.

l Do not use any sprays such as insecticide, lacquer, hair spray or other flammable

gases within approximately one (1) meter from the system.

l If circuit breaker or fuse is often activated, stop the system and contact your service

contractor.

l Do not perform installation work, refrigerant piping work, drain piping and electrical

wiring connection without referring to our installation manual. If the instructions are

not followed, it may result in a water leakage, electric shock or a fire.

l Check that the ground wire is securely connected. If the unit is not correctly grounded,

it lead electric shock. Do not connect the ground wiring to gas piping, water piping,

lightning conductor or ground wiring for telephone.

l Connect a fuse of specified capacity.

l Do not put any foreign material on the unit or inside the unit.

l Make sure that the outdoor unit is not covered with snow or ice, before operation.

l Before performing any brazing work, check to ensure that there is no flammable

material around.

When using refrigerant be sure to wear leather gloves to prevent cold injuries.

l Protect the wires, electrical parts, etc. from rats or other small animals.

If not protected, rats may gnaw at unprotected parts and which may lead to a fire.

l Fix the cables securely. External forces on the terminals could lead to a fire.

iii

SAFETY SUMMARY

l Do not install the indoor unit, outdoor unit, remote control switch and cable within

approximately 3 meters from strong electromagnetic wave radiators such as medical

equipment.

l Supply electrical power to the system to energize the oil heater for 12 hours before

start-up after a long shutdown.

l Do not step or put any material on the product.

l Provide a strong and correct foundation so that;

a. The outdoor unit is not on an incline.

b. Abnormal sound does not occur.

c. The outdoor unit will not fall down due to a strong wind or earthquake.

NOTE:

l It is recommended that the room be ventilated every 3 to 4 hours.

l The heating capacity of the heat pump unit is decreased according to the outdoor air

temperature. Therefore, it is recommended that auxiliary heating equipment be used in

the field when the unit is installed in a low temperature region.

iv

CHECKING PRODUCT RECEIVED

l Upon receiving this product, inspect it for any shipping damage.

Claims for damage, either apparent or concealed, should be filed immediately with the shipping

company.

l Check the model number, electrical characteristics (power supply, voltage and frequency) and

accessories to determine if they are correct.

The standard utilization of the unit shall be explained in these instructions.

Therefore, the utilization of the unit other than those indicated in these instructions is not recommended.

Please contact your local agent, as the occasion arises.

Hitachi's liability shall not cover defects arising from the alteration performed by a customer without

Hitachi's consent in a written form.

This product shall not be mixed with general household waste at the end of its life and it

shall be retired according to the appropriated local or national regulations in an environmentally

correct way Due to refrigerant, oil and other components contained in the Air Conditioner,

its dismantling must be done by a professional installer accordingly to the applicable

regulations.

ATTENTION :

Contact the Hitachi Customer Care for more information.

!

v

TABLE OF CONTENTS

1. Safety Summary....................................................................................................................... 1

2. Structure................................................................................................................................... 1

2.1 Outdoor Unit & Refrigerant Cycle .................................................................................... 1

2.2 Necessary Tools and Instrument List for Installation ....................................................... 3

3. Transportation and Handling .................................................................................................... 4

3.1 Transportation ................................................................................................................. 4

3.2 Handling of Outdoor Unit ................................................................................................. 4

4. Outdoor Unit Installation........................................................................................................... 5

4.1 Factory-Supplied Accessories ......................................................................................... 5

4.2 Initial Check ..................................................................................................................... 5

4.3 Service Space ................................................................................................................. 6

4.4 Installation Work .............................................................................................................. 8

5. Refrigerant Piping Work ......................................................................................................... 10

5.1 Piping Materials ............................................................................................................. 10

5.2 Refrigerant Piping Work ................................................................................................ 11

5.3 Piping Connection ......................................................................................................... 13

5.4 Air Tight Test.................................................................................................................. 15

5.5 Vacuum Pumping .......................................................................................................... 16

5.6 Caution of the Pressure by Check Joint ........................................................................ 18

5.7 Collecting Refrigerant .................................................................................................... 19

6. Electrical Wiring ...................................................................................................................... 19

6.1 General Check .............................................................................................................. 19

6.2 Electrical Wiring Connection ......................................................................................... 20

7. Test Run ................................................................................................................................. 24

8. Safety and Control Device Setting.......................................................................................... 28

1

l Do not perform installation work, refrigerant

piping work, drain piping and electrical

wiring connection without referring to the

installation manual.

l Check that the ground wire is securely

connected.

l Connect a fuse of specified capacity.

Do not install the indoor unit, outdoor unit,

remote control switch and cable within

approximately 3 meters from strong

electromagnetic wave radiators such as

medical equipment.

1. Safety Summary

2. Structure

2.1 Outdoor Unit & Refrigerant Cycle

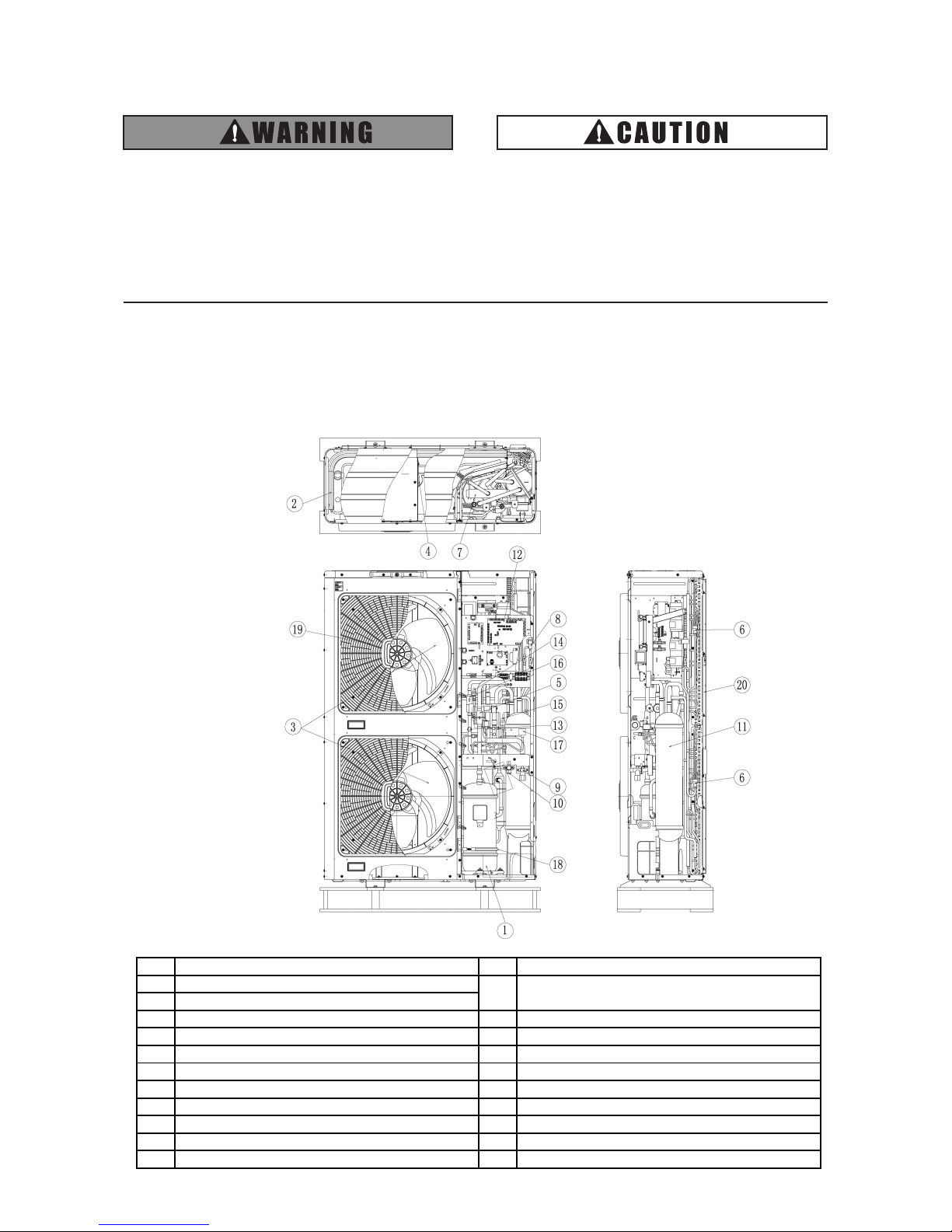

<Outdoor Unit>

No. Part Name No. Part Name

1 Compressor

2 Heat Exchanger

3 Propeller Fan 13

4 Fan Motor 14

High Pressure Switch for Protection

5 Strainer 15 High Pressure Sensor

6 Distributor 16 Check Valve

7 Reversing Valve 17 Solenoid Valve

8 Micro-Computer Control Expansion Valve 18 Crankcase Heater

9 Stop Valve for Gas Line 19

Air Outlet

10 Stop Valve for Liquid Line 20 Air Inlet

11 Accumulator 21

12

Electrical Box

Low Pressure Sensor

2

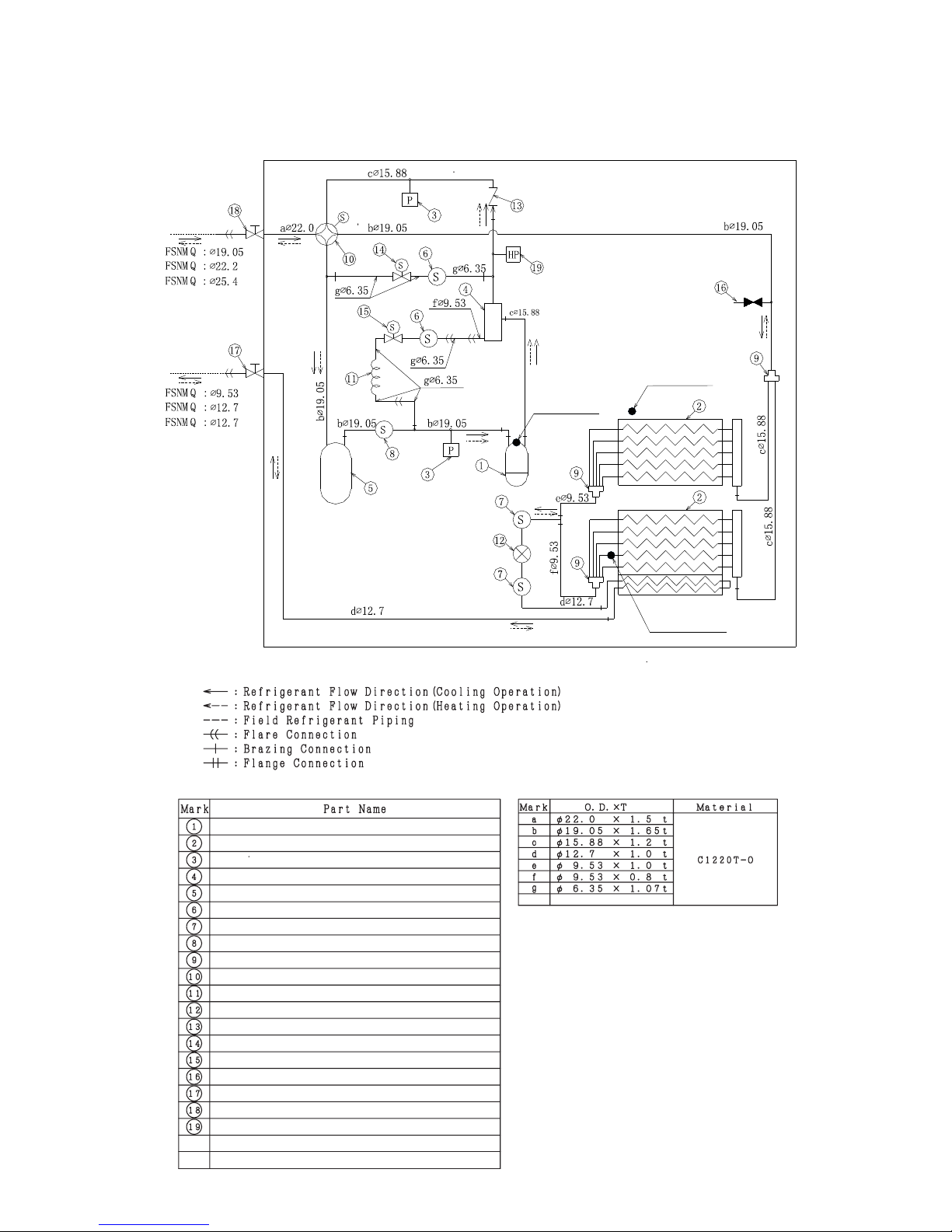

<Refrigerant Cycle>

Discharge Gas

Thermistor

Thermistor

Ambient

Thermistor

Discharge Gas Thermistor

Compressor

Heat Exchanger

Sensor for Regrigerant Pressure

Oil Separator

Accumulator

8

10

12

8

10

12

Strainer(3/8)

Strainer(1/2)

Strainer(3/4)

Distributor

Reversing Valve

Capillary Tube

Electronic Expansion Valve

Check Valve

Solenoid Valve

Solenoid Valve

Check Joint

Stop Valve for Liquid Line

Stop Valve for Gas Line

High Pressure Switch for Protection

<Outdoor Unit>

3

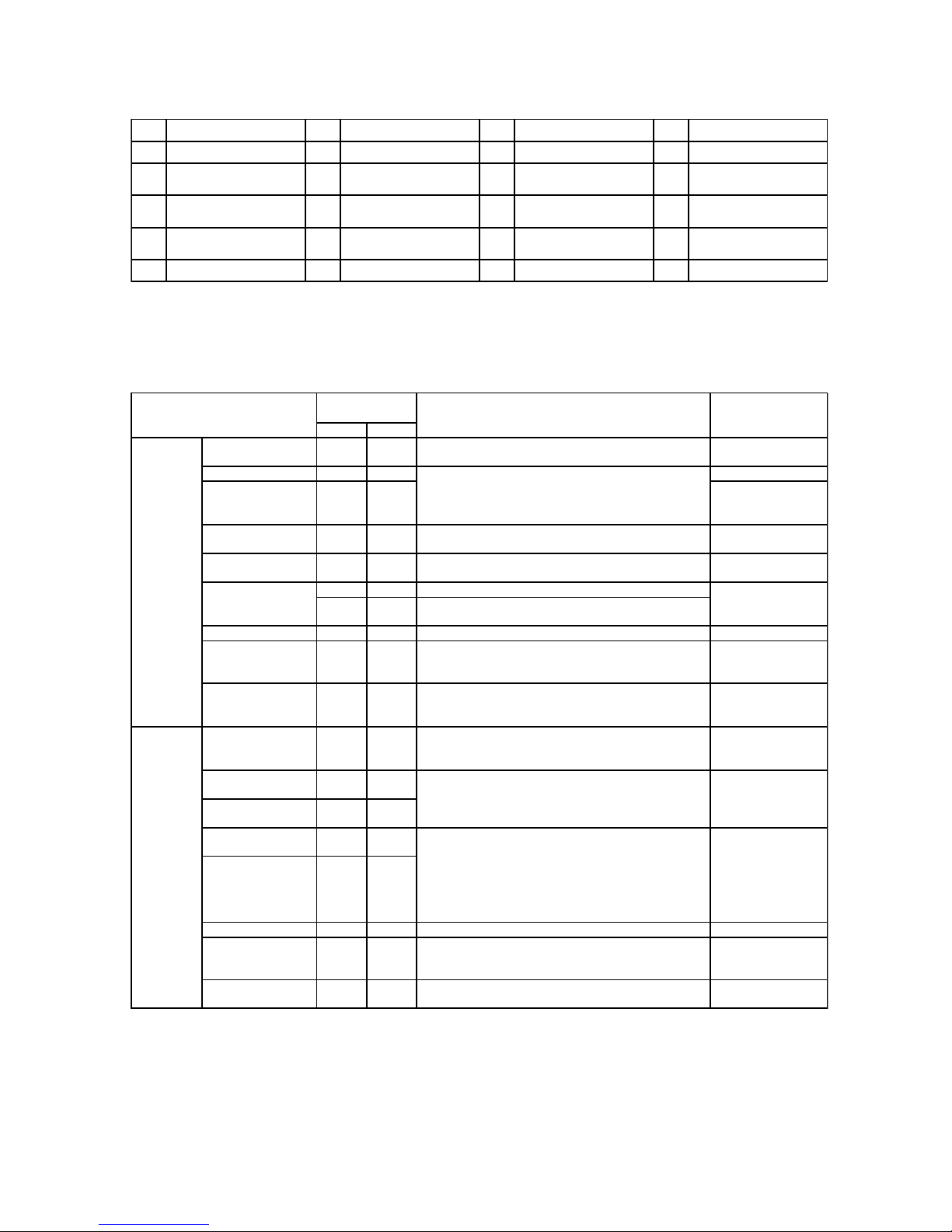

2.2 Necessary Tools and Instrument List for Installation

Use tools and measuring instruments only for the new refrigerant which is directly touch to refrigerant.

No. Tool No. Tool No. Tool No. Tool

1 Handsaw 6 Copper Pipe Bender 11 Spanner 16 Leveller

2

Phillips

Screwdriver

7

Manual Water Pump

12

Charging Cylinder

17

Clamper for Solder less Terminals

3 Vacuum Pump 8 Pipe Cutter 13 Gauge Manifold 18

Hoist

(for Indoor Unit)

4

Refrigerant Gas

Hose

9 Brazing Kit 14 Cutter for Wires 19 Ammeter

5 Megohmmeter 10 Hexagon Wrench 15 Gas Leak Detector 20 Voltage Meter

G: Interchangeability is available with current R22 l: only for Refrigerant R410A (No Interchangeability with R22)

5: Prohibited F: only for Refrigerant R407C (No Interchangeability with R22)

R410A R407C

Pipe Cutter

Chamfering Reamer

G G

-

Cutting Pipe

Removing Burrs

Flaring Tool G l G * The flaring tools for R407C are applicable to R22. Flaring for Tubes

* If using flaring tube, make dimension of tube

larger for R410A.

* In case of material 1/2H, flaring is not available.

Pipe Bender

G G

* In case of material 1/2H, bending is not available.

Use elbow for bend and braze.

Bending

Expanding Tool

G G

* In case of material 1/2H, expanding of tube is not

available. Use socket for connecting tube.

Expanding Tubes

l G *

For

12.7, 15.88, spanner size is up 2mm.

G G

*

For

6.35, 9.53, 19.05, spanner size is

the same.

Brazing Tool G G * Perform correct brazing work. Brazing for Tubes

Nitrogen Gas

G G

* Strict Control against Contamin

(Blow nitrogen during brazing.)

Prevention from

Oxidation during

Brazing

Lubrication Oil

(for Flare Surface)

* Use a synthetic oil which is equivalent to the oil

used in the refrigeration cycle.

Applying Oil to the

Flared Surface

* Synthetic oil absorbs moisture quickly.

* Check refrigerant cylinder color. Refrigerant Charging

H

Liquid refrigerant charging is required regarding

zeotoropic refrigerant.

Vacuum Pump

G G

H

Vacuum Pumping

Adapter for

Vacuum Pump

l F

Manifold Valve

l F

* No interchangeability is available due to higher

pressures when compared with R22.

Charging Hose

l F

H

Do not use current ones to the different refrigerant.

If used, mineral oil will flow into the cycle and cause

sludges, resulting in clogging or compressor failure.

Connection diameter is different; R410A: UNF1/2,

R407C: UNF7/16.

Charging Cylinder 5 5 * Use the weight scale. Weight Scale

G G -

Measuring

Instrument for

Refrigerant Charging

Refrigerant Gas

Leakage Detector

l F

* The current gas leakage detector (R22) is not

applicable due to different detecting method.

Gas Leakage Check

T: Interchangeability with R407C.

Vacuum Pumping,

Vacuum Holding,

Refrigerant Charging

and Check of

Pressures

l F

l F

Measuring Instrument and Tool

Interchangeability

with R22

Reason of Non-Interchangeability and Attention

(H: Strictly Required)

Torque Wrench

Vacuum

Drying

.

Refrigerant

Charge

Refrigerant

Cylinder

The current ones are applicable. However, it is

required to mount a vacuum pump adapter which

can prevent from reverse flow when a vacuum

pump stops, resulting in no reverse oil flow.

Use

Refrigerant

Pipe

Extrusion

Adjustment Gauge

l

-

Connection of

Flare Nut

Dimensional Control

for Extruded Portion

of Tube after Flaring

TT

T

4

3. Transportation and Handling

3.1 Transportation

Transport the product as close to the installation

location as practical before unpacking.

Do not put any material on the product.

Apply two lifting wires onto the outdoor unit,

when lifting it by crane.

3.2 Handling of Outdoor Unit

Do not put any foreign material into the

outdoor unit and check to ensure that none

exists in the outdoor unit before the

installation and test run. Otherwise, a fire or

failure, etc. may occur.

Fig. 3.1 Hanging Work for Transportation

Over 60

o

Wire Rope

0.7 to 1.0m

Do not remove the plastic

band or the corrugated

paper frame.

Pass the wire ropes

through each lifting

hole in the wooden

base as shown.

l Hanging Method

When hanging the unit, ensure a balance of

the unit, check safety and lift up smoothly.

(1) Do not remove any packing materials.

(2) Hang the unit under packing condition with

two (2) ropes, as shown in Fig. 3.1.

l Lift the outdoor unit in its factory packaging

with 2 wire ropes.

l For safety reasons ensure that the outdoor

unit is lifted smoothly and does not lean.

l Do not attach lifting equipment to the plastic

band or the corrugated paper frame.

l Ensure the exterior of the unit is adequately

protected with cloth or paper.

l When Using Handles

When manually lifting the unit using the

handles, pay attention to the following points.

(1) Do not remove the wooden base from

outdoor unit.

(2) To prevent the unit from overturning, pay

attention to the center of gravity as shown

in the below figure.

(3) Two or more personnel should be used to

move the unit.

Fig. 3.2 Handling of Outdoor Unit

Approx. 20

o

410

620

Wooden

Base

Handle

Center of Gravity

Fall Angle of

This Product

(kg)

Model Unit Gross Weight

RAS-8FSNM(Q)

RAS-10FSNM(Q)

179

RAS-12FSNM(Q) 182

5

4. Outdoor Unit Installation

4.1 Factory-Supplied Accessories

Check to ensure that the following accessories

are packed with the outdoor unit.

If any of these accessories are not packed with

the unit, please contact your contractor.

Table 4.1 Factory-Supplied Accessories

4.2 Initial Check

• Install the outdoor unit where good ventilation is

available, and where it is dry.

• Install the outdoor unit where the sound or the

discharge air from the outdoor unit does not

affect neighbors or surrounding vegetation.

The operating sound at the rear or right/left

sides is higher than the value in the catalog at

the front side.

• Check to ensure that the foundation is flat, level

and sufficiently strong.

• Do not install the outdoor unit where there is a

high level of oil mist, salty air or harmful gases

such as sulphur.

• Do not install the outdoor unit where the

electromagnetic wave is directly radiated to the

electrical box.

• Install the outdoor unit as far as practical, being

at least 3 meters from the electromagnetic

wave radiator.

• When installing the outdoor unit in snowcovered areas, mount the field-supplied hoods

at the discharge side of the outdoor unit and

the inlet side of the heat exchanger.

• Install the outdoor unit where it is in the shade

or it will not be exposed to direct sunshine or

direct radiation from high temperature heat

source.

• Do not install the outdoor unit where dust or

other contamination could block the outdoor

heat exchanger.

• Install the outdoor unit in a space with limited

access to general public.

Aluminum fins have very sharp edges. Pay

attention to the fins to avoid any injury.

NOTE

NOTE

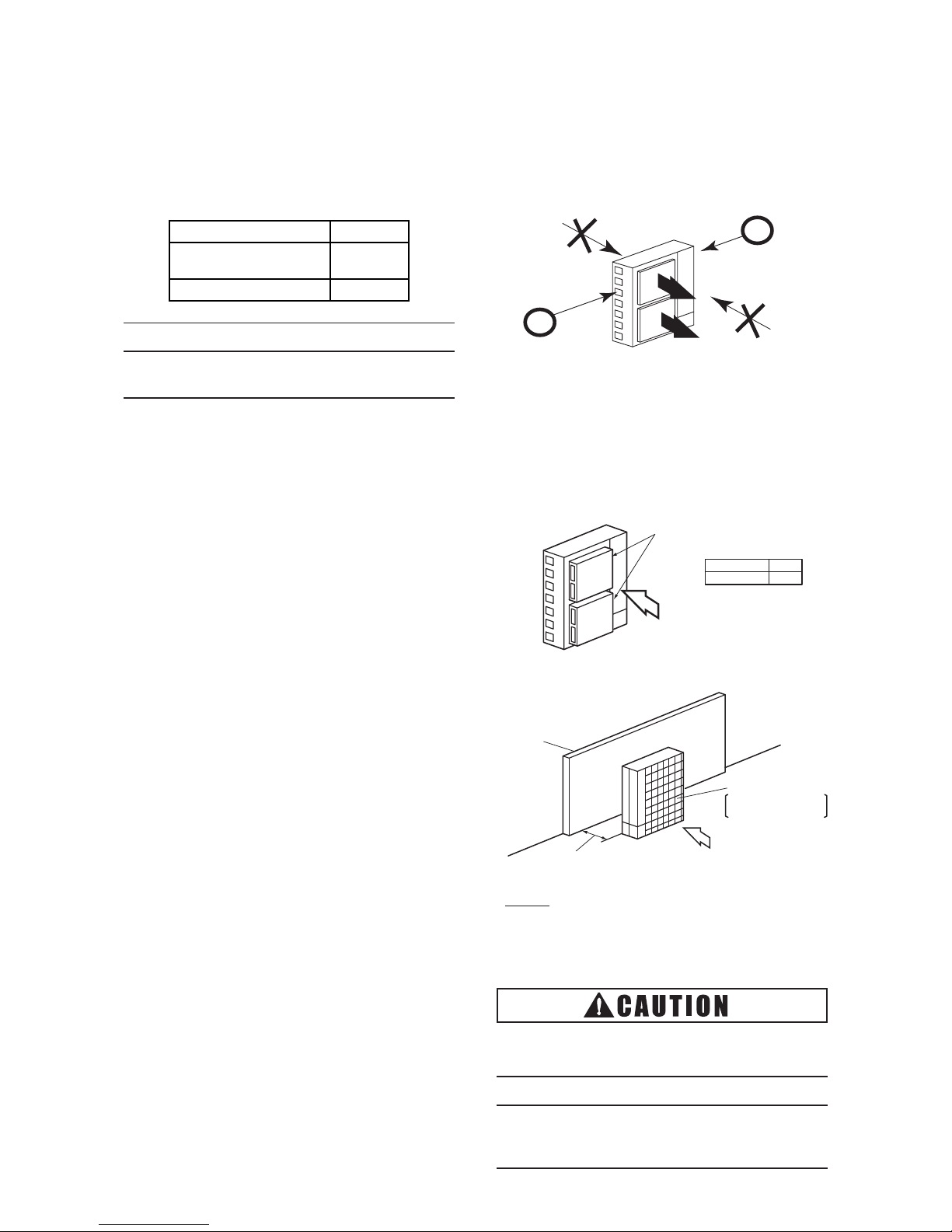

Direction of Strong Wind

Direction of Air Discharge

• Do not install the outdoor unit in a space where

a seasonal wind directly blows to the outdoor

heat exchanger or a wind from a building space

directly blows to the outdoor fan.

• In case of installation in the open spaces

unavoidably where there is no buildings or

surrounding structures, adopt the wind guard

set or install near the wall to avoid facing the

wind directly. Ensure that the service space

should be secured.

(1) Using Wind Guard

(2) A Wall to Guard Against Wind

NOTE:

If the extreme strong wind blows directly against

the air discharge portion, the fan may rotate

reversely and be damaged.

Install the outdoor unit on a roof or in an area

where people except service engineers can not

touch the outdoor unit.

Wing Guard Set

(Optional)

Strong Wind

Model

WSP-335A

Q'ty

2

Secure the adequate

service space.

Direction of Strong Wind

Air Intake Side

Face the air discharge

side to the wall.

Wall

Accessory Q'ty

Pipe with Flange

of Refrigerant Piping

1

Compressed Sheet 1

Loading...

Loading...