Hitachi RAM-90QH5 Service Manual

NO. 0371E

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

ROOM AIR CONDITIONER

OUTDOOR UNIT

APRIL 2007

Refrigeration & Air-Conditioning Division

SERVICE MANUAL

PM

REFER TO THE FOUNDATION MANUAL

TECHNICAL INFORMATION

FOR SERVICE PERSONNEL ONLY

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 5

INSTALLATION --------------------------------------------------------------------- 16

CONSTRUCTION AND DIMENSIONAL DIAGRAM --------------------- 20

WIRING DIAGRAM ---------------------------------------------------------------- 21

MAIN PARTS COMPONENT --------------------------------------------------- 24

CIRCUIT DIAGRAM --------------------------------------------------------------- 25

BLOCK DIAGRAM ----------------------------------------------------------------- 29

BASIC MODE ----------------------------------------------------------------------- 31

REFRIGERATING CYCLE DIAGRAM --------------------------------------- 51

DESCRIPTION OF MAIN CIRCUIT OPERATION ----------------------- 52

TROUBLE SHOOTING ----------------------------------------------------------- 88

PARTS LIST AND DIAGRAM -------------------------------------------------- 94

After installation

(W)

(A)

COOLING CAPACITY

DC INVERTER FIVE SYSTEM MULTI

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

TOTAL AMPERES

SPECIFICATIONS

RAM-90QH5

HEATING CAPACITY

DIMENSIONS (mm)

NET WEIGHT

1ø, 220 - 240V, 50/60Hz

W

H

D

(kg)

(kW)

(B.T.U.)

REFER TO THE SPECIFICATIONS PAGE

OUTDOOR UNIT

RAM-90QH5

RAM-90QH5

950

800

370

71

NOTE:

This manual describes only points that differ from

PM No. 0322E, PM No. 0355E and PM No. 0366E

for items not described in this manual.

– 1 –

SAFETY DURING REPAIR WORK

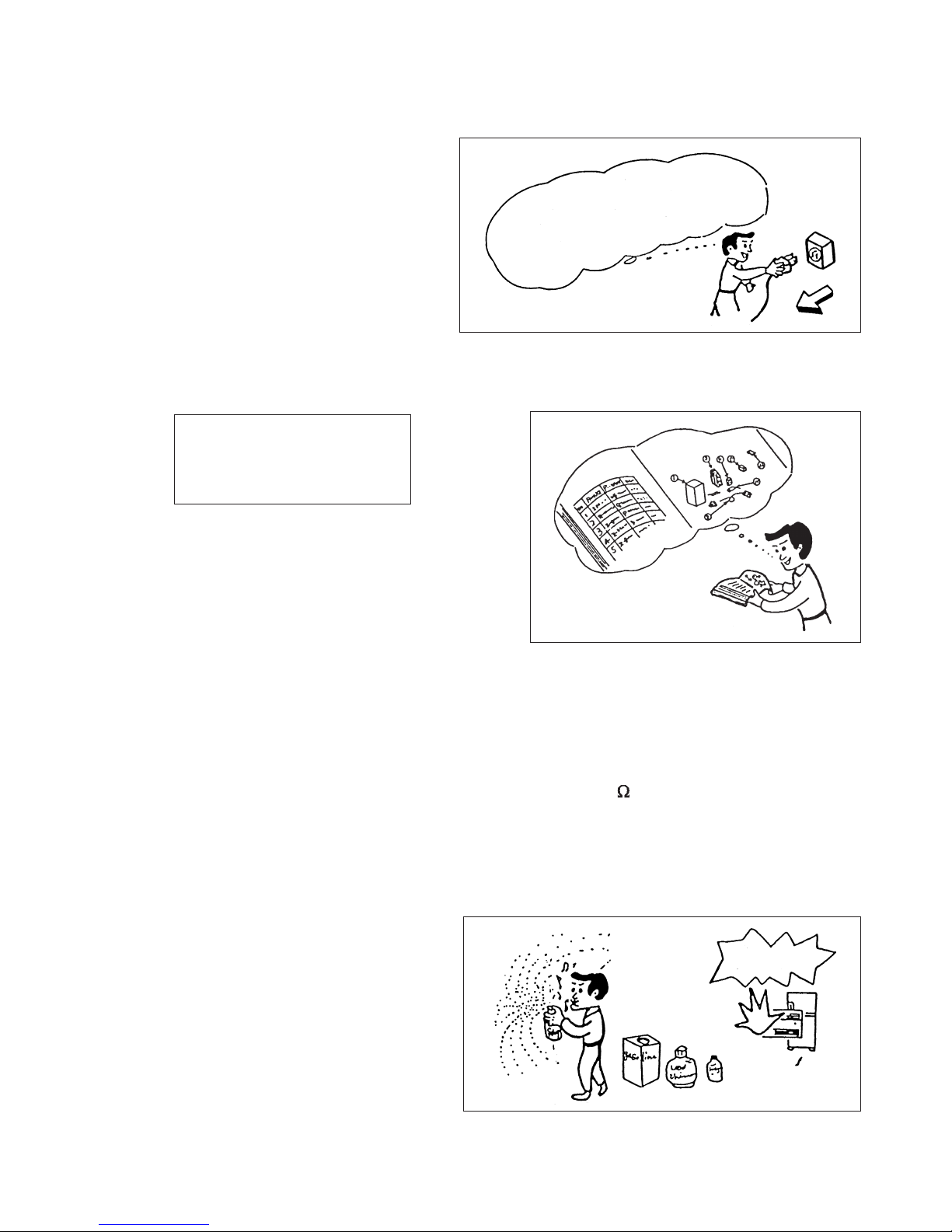

1. In order to disassemble and repair

the unit in question, be sure to

disconnect the power cord plug

from the power outlet before starting

the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and

the replacement must be effected in correct manner according to the instructions in the Service Manual of

the unit.

If the contacts of electrical parts

are defective, replace the

electrical parts without trying to

repair them.

3. After completion of repairs, the initial state

should be restored.

4. Lead wires should be connected and laid as

in the initial state.

5. Modification of the unit by user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7. In installing the unit having been repaired, be careful to prevent the occurence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit. The insulation resistance should be 1M or more as measured by a 500V

DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being and safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location reinforced or at a new

location.

10. Any inflammable thing should never

be placed about the location of

installation.

11. Check the grounding to see whether

it is proper or not, and if it is found

improper, connect the grounding

terminal to the earth.

DANGER

First, I must disconnect

the power cord plug

from the power outlet.

– 2 –

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in relative

manufacturers during maintenance and handling thereof. (They apply the same to handling of abnormal goods

such as rejected goods being returned).

2. Object parts

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) P.C. boards or the like on which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

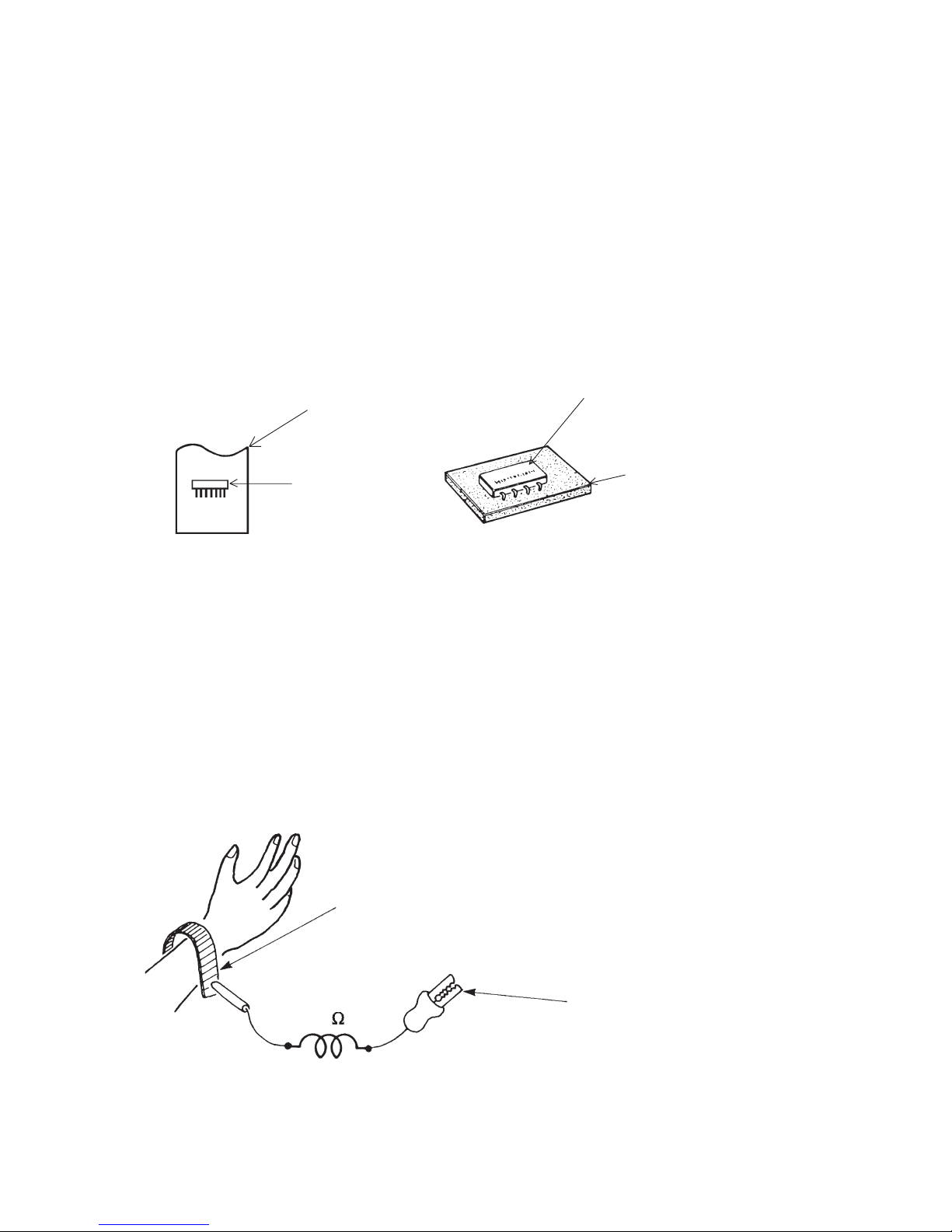

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way).

Fig. 1. Conductive Container

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must always

use himself as a body earth. (Make yourself a body earth by passing one M ohm earth resistance through

a ring or bracelet).

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is being

taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time, try

to repair the printed circuit board on a grounded metal plate.

1M

Fig. 2. Body Earth

Body earth

(Elimik conductive band)

Clip for connection with a

grounding wire

IC

A conductive polyvinyl bag

IC

Conductive sponge

– 3 –

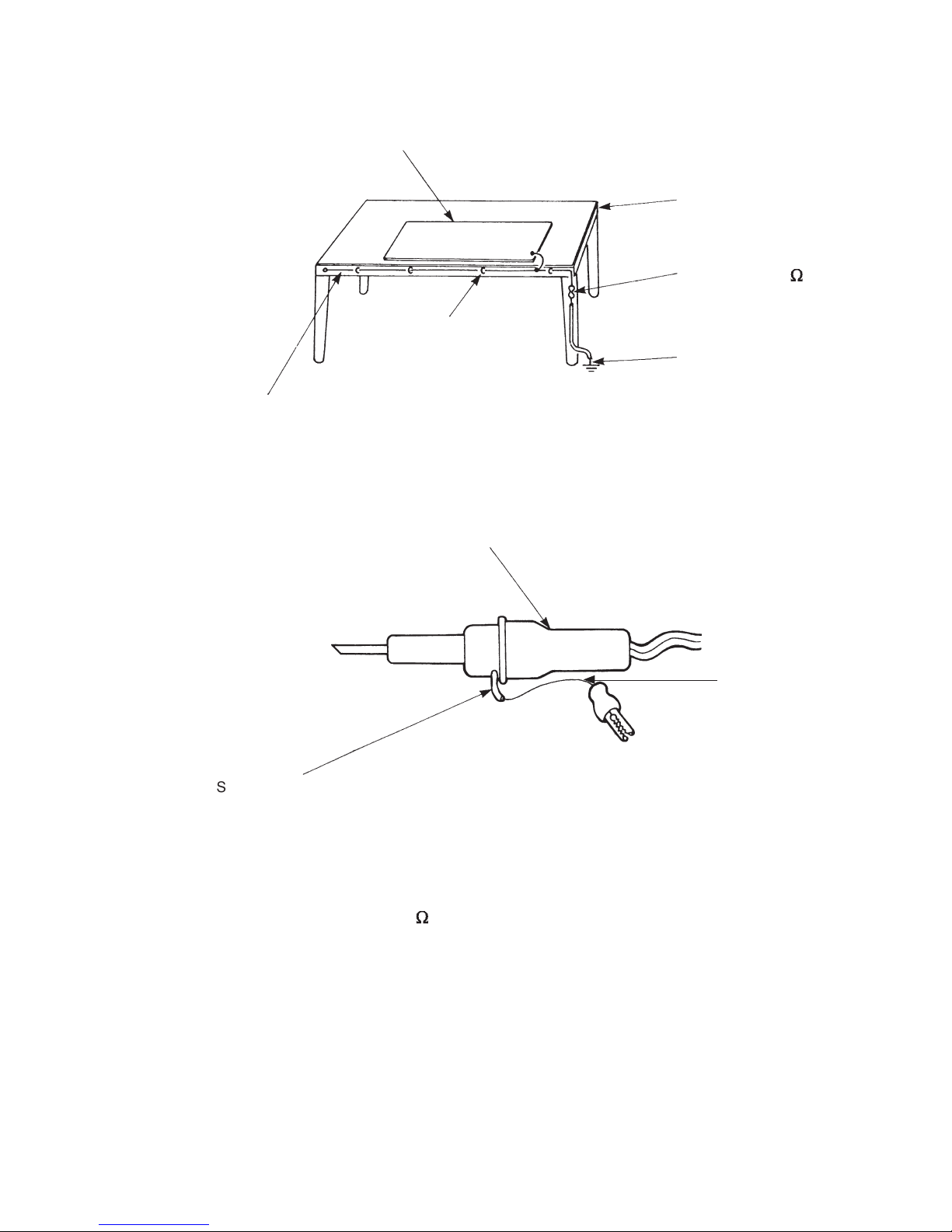

(6) Use a three wire type soldering iron including a grounding wire.

Bare copper wire (for body earth)

Working

table

Resistor of 1 M (1/2W)

Earth wire

Fig. 3. Grounding of the working table

2

Screw stop at the screwed

part using a rag plate

Soldering iron

Grounding

wire

Fig. 4. Grounding a soldering iron

Use a high insulation mode (100V, 10M or higher) when ordinary iron is to be used.

(7) In checking circuits for maintenance, inspection or some others, be careful not to have the test probes of the

measuring instrument shortcircuit a load circuit or the like.

Metal plate (of aluminium, stainless steel, etc.)

Staple

– 4 –

1. In quiet operation or stopping the operation, slight flowing noise of refrigerant in the refrigerating cycle is

heard occasionally, but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and to disconnect the power cord plug

from the power outlet for safety.

3. The room air conditioner does not start automatically after recovery of the electric power failure for

preventing fuse blowing. Re-press START/STOP button after 3 minutes from when unit stopped.

4. If the room air conditioner is stopped by setting the temperature, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal

and this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no

danger of blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below –10°C (14°F).

6. This room air conditioner (the reverse cycle) should not be used when the outside temperature is below

–15°C (5°F).

If the reverse cycle is used under this condition, the outside heat exchanger will be frosted and its

efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

!

CAUTION

– 5 –

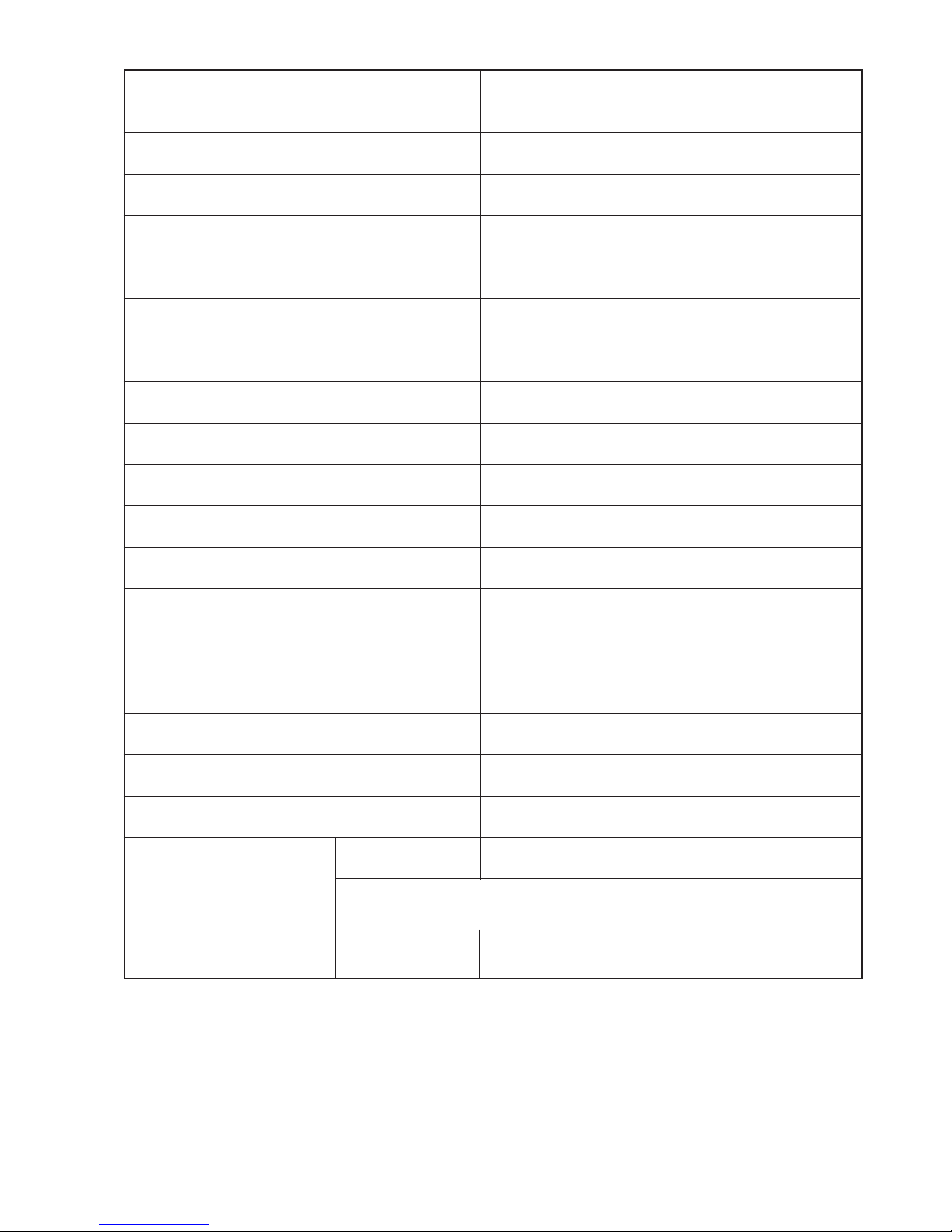

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

POWER SWITCH

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

138 W

NO

NO

NO

YES

YES

5.0A

G4A

NO

NO

YES

NO

450NR

YES

YES(IC)

NO

2700g

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

UNIT

PIPES

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

RAM-90QH5

JU1318D1

MAX. 75m

In case the pipe length is more than 30m, add refrigerant R410 at 15gram per every meter exceeds.

– 6 –

SPECIFICATIONS FOR INDOOR UNITS COMBINATION

OPERATION SCOPE

TYPE

DC INVERTER FIVE SYSTEM MULTI COOLING AND HEATING

MODEL OUTDOOR UNIT

PHESE/VOLTAGE/FREQUENCY

CIRCUIT AMPERES TO CONNECT (A)

COOLING

(FIVE UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

HEATING

(FIVE UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

MAXIMUM LENGTH OF PIPING

STANDARD

RAM-90QH5

1ø, 220 - 240V, 50/60Hz

30

9.00 (3.20 - 9.90)

30,720 (10,920 - 33,780)

2,360 (600 - 3,040)

13.02

10.8 - 9.9

99

11.00 (3.40 - 12.10)

37,540 (11,610 - 41,290)

2,460 (610 - 2,910)

15.26

11.3 - 10.4

99

MAX. 75m (FIVE UNIT TOTAL)

CE (EMC&LVD)

RAM-90QH5

MODEL

W

PACKING

(mm)

H

D

cu.ft.

1,073

867

510

16.61

78

GROSS WEIGHT (kg)

6.35DX5/9.52DX3/12.70X2

FLARENUTSIZE (SMALL/LARGE)

INDOOR SUCTION

TEMPERATURE (˚C)

COOLING OPERATION SCOPE

OUTDOOR SUCTION

TEMPERATURE (˚C)

INDOOR SUCTION

HUMIDITY (%)

DEHUMIDIFYING

OPERATION

HEATING OPERATION

SCOPE

16 - 32 –10 ~ 43 BELOW 80

16 - 32 –10 ~ 43 BELOW 80

BELOW 27 –15 ~ 23

—

– 7 –

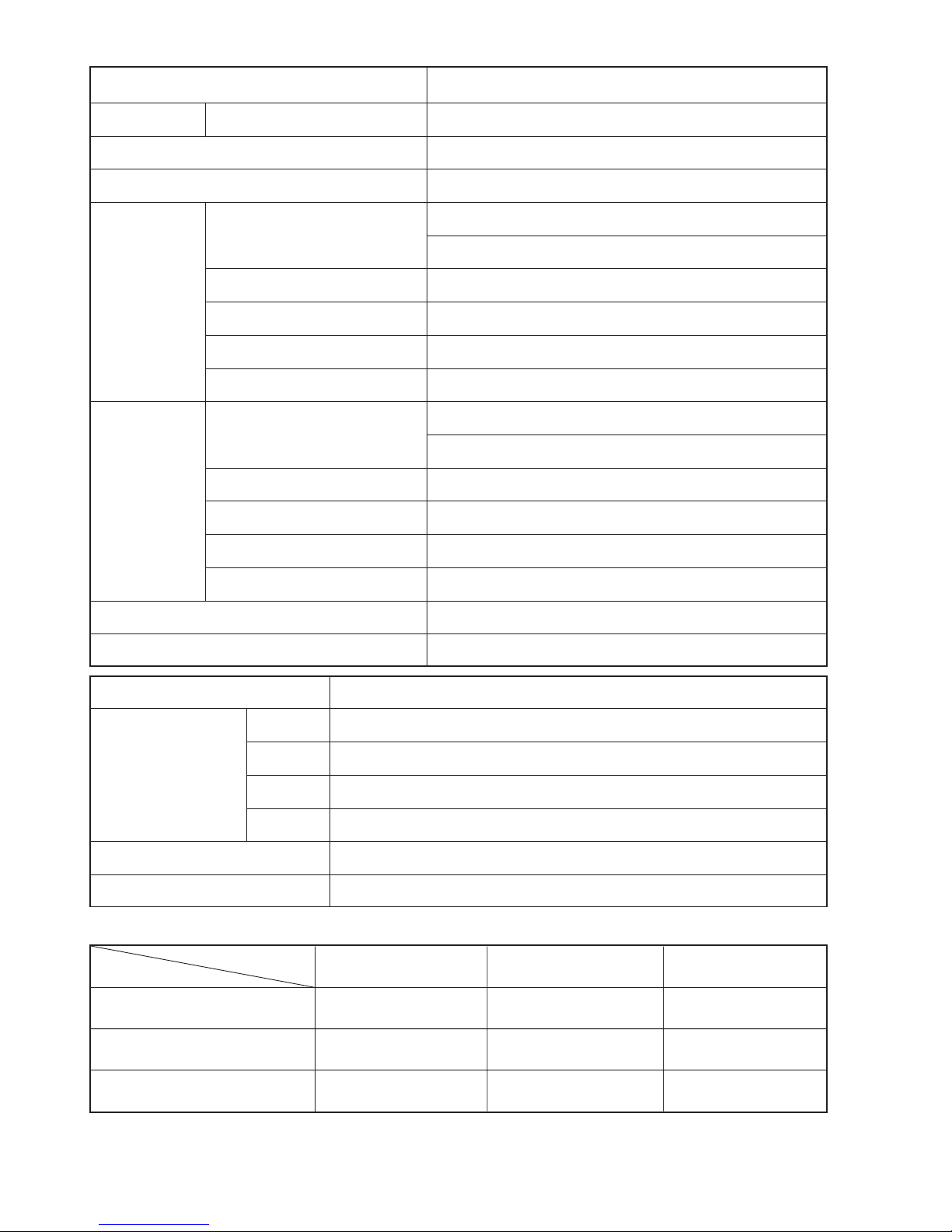

DC INVERTER SYSTEM MULTI R.A.C.

RAM-90QH5

COOL / HEAT CAPACITY SPEC. FOR INDOOR UNITS

COMBINATIONS TO BE ABLE TO OPERATE SIMULTANEOUSLY

Whichever indoor units are installed, cooling and heating capacity depends on how many and which indoor units

are operating at that time.

12.6

2740

3.28

3.32

3.28

3.54

3.32

3.24

3.24

3.27

3.25

2710

2740

2120

2560

2780

2780

2750

2770

11.5

12.4 11.4

12.6 11.5

9.7 8.9

11.8 10.8

12.8 11.7

12.8 11.7

12.6 11.6

12.7 11.7

(Reference value)

5 ROOM MULTI-SPLIT INVERTER TYPE ROOM AIR CONDITIONER

POSSIBLE COMBINATION TO OPERATE (SAME TIME OPERATION)

– 8 –

RATING CONDITON (DRY BLUB / WET BULB)

COOLING

HEATING

INDOOR OUTDOOR

27 / 19 ˚C

20 / –˚C

35 / 24˚C

7 / 6˚C

1.88

1.88 3.22 3.22

1.65 2.85 2.85 2.85

1.56 2.69 2.69 4.06

1.8+3.5+3.5+5.0

1.15+2.30+2.30+3.25

9.00 2530

2.18 2.74 2.74 2.74

<REMARKS>

* ONE UNIT INDICATED ARE ONLY FOR ONE UNIT OPERATION WHEN TWO OR MORE INDOOR UNITS ARE CONNECTED.

* TWO UNITS INDICATED ARE ONLY FOR TWO UNITS OPERATION WHEN TWO OR MORE INDOOR UNITS ARE CONNECTED.

* THREE UNITS INDICATED ARE ONLY FOR THREE UNITS OPERATION WHEN THREE OR MORE INDOOR UNITS ARE CONNECTED.

* FOUR UNITS INDICATED ARE ONLY FOR FOUR UNITS OPERATION WHEN FOUR OR FIVE INDOOR UNITS ARE CONNECTED.

– 9 –

FIVE INVERTER SYSTEM MULTI R.A.C.

RAM-90QH5

INDOOR UNITS COMBINATIONS TO BE ABLE TO INSTALL

Two, three, four or five indoor units can be installed with one outdoor unit.

And total nominal cooling capacity should not be more than 15.5kW

Be sure to connect two or more indoor units to this outdoor unit. If not, condensed water may drop, resulting in

trouble.

INDOOR UNIT

MODEL

NOMINAL

COOLING

CAPACITY

(kW)

CAPACITY (kW)

at one unit operation

SUITABLE ROOM SIZE (m2)

at one unit operation

COOLING HEATING COOLING HEATING

RAK-18NH5

RAK-18NH6

1.8 1.00 - 2.50 1.10 - 3.20

8 - 12 9 - 11

RAK-25NH5

RAK-25NH6

2.5 1.00 - 2.80 1.10 - 4.70

11 - 17 14 - 18

RAF-25NH5

2.5 1.00 - 2.80 1.10 - 4.70

11 - 17 14 - 18

RAD-25NH5

RAD-25NH7

2.5 1.00 - 2.80 1.10 - 4.70

11 - 17 14 - 18

RAI-25NH5

2.5 1.00 - 2.80 1.10 - 4.70

11 - 17 14 - 18

RAK-35NH5

RAK-35NH6

3.5 1.00 - 3.90 1.10 - 5.80

16 - 24 17 - 22

RAF-35NH5 3.5 1.00 - 3.90 1.10 - 5.80

16 - 24 17 - 22

RAD-35NH5

RAD-35NH7

3.5 1.00 - 3.90 1.10 - 5.80

16 - 24 17 - 22

RAI-35NH5

3.5 1.00 - 3.90 1.10 - 5.80

16 - 24 17 - 22

RAK-50NH5

RAK-50NH6

5.0 1.00 - 5.60 1.10 - 7.20

23 - 34 23 - 29

RAF-50NH5

5.0 1.00 - 5.60 1.10 - 7.20

23 - 34 23 - 29

RAI-50NH5

5.0 1.00 - 5.60 1.10 - 7.20

23 - 34 23 - 29

RAD-50NH7

5.0 1.00 - 5.60 1.10 - 7.50

23 - 34 23 - 29

RAK-65NH5

6.0 1.00 - 6.50 1.10 - 9.00

27 - 41 25 - 32

– 10 –

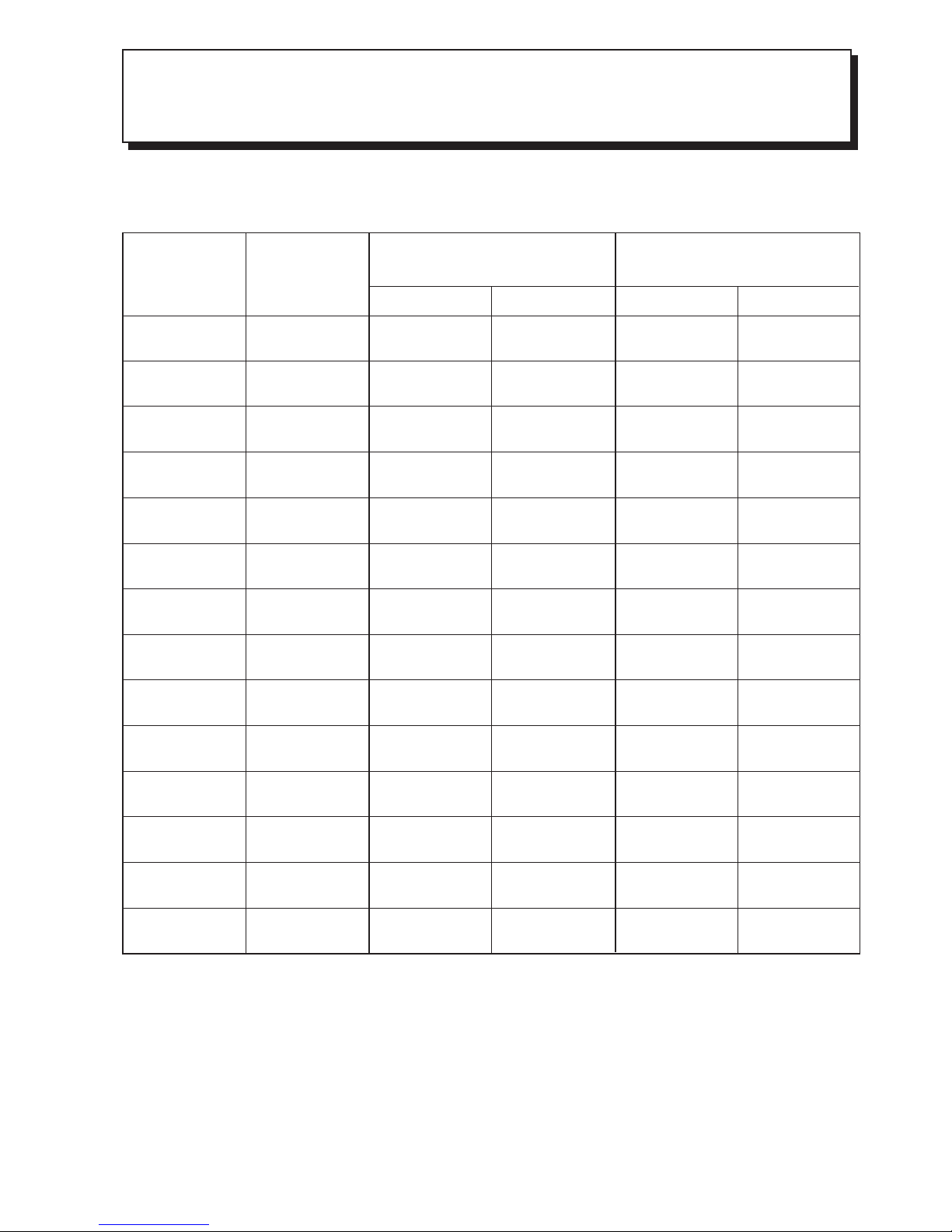

QUADRUPLE SYSTEM MULTI R.A.C.

RAM-90QH5

INDOOR UNITS COMBINATIONS TO BE ABLE TO INSTALL

No. 1 No. 2 No. 3 No. 4 No. 5

6.35/9.52D 6.35/9.52D 6.35/9.52D 6.35/12.7D 6.35/ 12.7D

1.8+1.8 ( 8 ~ 12 ) + ( 8 ~ 12 ) 1.8 1.8

1.8+2.5 ( 8 ~ 12 ) + ( 11 ~ 17 ) 1. 8 2.5

1.8+3.5 ( 8 ~ 12 ) + ( 16 ~ 24 ) 1.8 3.5

1.8+5.0 ( 8 ~ 12 ) + ( 23 ~ 34 ) 1.8 5.0

1.8+6.0 ( 8 ~ 12 ) + ( 27 ~ 41 ) 1.8 6.0

2.5+2.5 ( 11 ~ 17 ) + ( 11 ~ 17 ) 2.5 2.5

2.5+3.5 ( 11 ~ 17 ) + ( 16 ~ 24 ) 2.5 3.5

2.5+5.0 ( 11 ~ 17 ) + ( 23 ~ 34 ) 2.5 5.0

2.5+6.0 ( 11 ~ 17 ) + ( 25 ~ 39 ) 2.5 6.0

3.5+3.5 ( 16 ~ 24 ) + ( 16 ~ 24 ) 3.5 3.5

3.5+5.0 ( 15 ~ 23 ) + ( 21 ~ 32 ) 3.5 5.0

3.5+6.0 ( 14 ~ 21 ) + ( 24 ~ 36 ) 3.5 6.0

5.0+5.0 ( 19 ~ 29 ) + ( 19 ~ 29 ) 5.0 5.0

5.0+6.0 ( 18 ~ 28 ) + ( 21 ~ 32 ) 5.0 6.0

6.0+6.0 ( 20 ~ 31 ) + ( 20 ~ 31 ) 6.0 6.0

1.8+1.8+1. 8 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) 1.8 1.8 1.8

1.8+1.8+2. 5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) 1.8 1.8 2.5

1.8+1.8+3. 5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 16 ~ 24 ) 1.8 1.8 3.5

1.8+1.8+5. 0 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 23 ~ 34 ) 1.8 1.8 5.0

1.8+1.8+6. 0 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 26 ~ 39 ) 1.8 1.8 6.0

1.8+2.5+2. 5 ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 1.8 2.5 2.5

1.8+2.5+3. 5 ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 16 ~ 24 ) 1.8 2.5 3.5

1.8+2.5+5. 0 ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 22 ~ 33 ) 1.8 2.5 5.0

1.8+2.5+6. 0 ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 24 ~ 36 ) 1.8 2.5 6.0

1.8+3.5+3. 5 ( 8 ~ 12 ) + ( 16 ~ 24 ) + ( 16 ~ 24 ) 1.8 3.5 3.5

1.8+3.5+5. 0 ( 7 ~ 11 ) + ( 14 ~ 21 ) + ( 20 ~ 30 ) 1.8 3.5 5.0

1.8+3.5+6. 0 ( 7 ~ 10 ) + ( 13 ~ 19 ) + ( 22 ~ 33 ) 1.8 3.5 6.0

1.8+5.0+5. 0 ( 6 ~ 10 ) + ( 17 ~ 26 ) + ( 17 ~ 26 ) 1.8 5.0

1.8+5.0+6. 0 ( 6 ~ 9 ) + ( 16 ~ 24 ) + ( 19 ~ 29 ) 1.8 5.0

1.8+6.0+6. 0 ( 5 ~ 8 ) + ( 18 ~ 27 ) + ( 18 ~ 27 ) 1.8 6.0

2.5+2.5+2. 5 ( 11 ~ 17 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 2.5 2.5 2.5

2.5+2.5+3. 5 ( 11 ~ 17 ) + ( 11 ~ 17 ) + ( 16 ~ 24 ) 2.5 2.5 3.5

2.5+2.5+5. 0 ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 20 ~ 31 ) 2.5 2.5 5.0

2.5+2.5+6. 0 ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 22 ~ 34 ) 2.5 2.5 6.0

2.5+3.5+3. 5 ( 11 ~ 16 ) + ( 15 ~ 23 ) + ( 15 ~ 23 ) 2.5 3.5 3.5

2.5+3.5+5. 0 ( 9 ~ 14 ) + ( 13 ~ 20 ) + ( 19 ~ 28 ) 2.5 3.5 5.0

2.5+3.5+6. 0 ( 9 ~ 13 ) + ( 12 ~ 18 ) + ( 20 ~ 31 ) 2.5 3.5 6.0

2.5+5.0+5. 0 ( 8 ~ 12 ) + ( 16 ~ 25 ) + ( 16 ~ 25 ) 2.5 5.0 5.0

2.5+5.0+6. 0 ( 8 ~ 12 ) + ( 15 ~ 23 ) + ( 18 ~ 28 ) 2.5 5.0 6.0

2.5+6.0+6. 0 ( 7 ~ 11 ) + ( 17 ~ 26 ) + ( 17 ~ 26 ) 2.5 6.0 6.0

3.5+3.5+3. 5 ( 14 ~ 21 ) + ( 14 ~ 21 ) + ( 14 ~ 21 ) 3.5 3.5 3.5

3.5+3.5+5. 0 ( 12 ~ 18 ) + ( 12 ~ 18 ) + ( 17 ~ 26 ) 3.5 3.5 5.0

3.5+3.5+6. 0 ( 11 ~ 17 ) + ( 11 ~ 17 ) + ( 19 ~ 29 ) 3.5 3.5 6.0

3.5+5.0+5. 0 ( 10 ~ 16 ) + ( 15 ~ 23 ) + ( 15 ~ 23 ) 3.5 5.0 5.0

3.5+5.0+6. 0 ( 10 ~ 15 ) + ( 14 ~ 21 ) + ( 17 ~ 26 ) 3.5 5.0 6.0

3.5+6.0+6. 0 ( 9 ~ 14 ) + ( 16 ~ 24 ) + ( 16 ~ 24 ) 3.5 6.0 6.0

5.0+5.0+5. 0 ( 14 ~ 21 ) + ( 14 ~ 21 ) + ( 14 ~ 21 ) 5.0 5.0 5.0

1.8+1.8+1. 8+1.8 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) 1.8 1.8 1.8 1.8

1.8+1.8+1. 8+2.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) 1.8 1.8 1.8 2.5

1.8+1.8+1. 8+3.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 16 ~ 24 ) 1.8 1.8 1.8 3.5

1.8+1.8+1. 8+5.0 ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 20 ~ 30 ) 1.8 1.8 1.8 5.0

1.8+1.8+1. 8+6.0 ( 6 ~ 10 ) + ( 6 ~ 10 ) + ( 6 ~ 10 ) + ( 22 ~ 33 ) 1.8 1.8 1.8 6.0

1.8+1.8+2. 5+2.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 1.8 1.8 2.5 2.5

1.8+1.8+2. 5+3.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 16 ) + ( 15 ~ 23 ) 1.8 1.8 2.5 3.5

1.8+1.8+2. 5+5.0 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 9 ~ 14 ) + ( 19 ~ 28 ) 1.8 1.8 2.5 5.0

1.8+1.8+2. 5+6.0 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 8 ~ 13 ) + ( 20 ~ 31 ) 1.8 1.8 2.5 6.0

1.8+1.8+3. 5+3.5 ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 14 ~ 20 ) + ( 14 ~ 20 ) 1.8 1.8 3.5 3.5

1.8+1.8+3. 5+5.0 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 12 ~ 18 ) + ( 17 ~ 26 ) 1.8 1.8 3.5 5.0

1.8+1.8+3. 5+6.0 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 11 ~ 17 ) + ( 19 ~ 28 ) 1.8 1.8 3.5 6.0

1.8+1.8+5. 0+5.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 15 ~ 23 ) + ( 15 ~ 23 ) 1.8 1.8 5.0 5.0

1.8+1.8+5. 0+6.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 14 ~ 21 ) + ( 17 ~ 26 ) 1.8 1.8 5.0 6.0

1.8+2.5+2. 5+2.5 ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 1.8 2.5 2.5 2.5

1.8+2.5+2. 5+3.5 ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) + ( 14 ~ 21 ) 1.8 2.5 2.5 3.5

1.8+2.5+2. 5+5.0 ( 6 ~ 10 ) + ( 9 ~ 13 ) + ( 9 ~ 13 ) + ( 17 ~ 26 ) 1.8 2.5 2.5 5.0

1.8+2.5+2. 5+6.0 ( 6 ~ 9 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 19 ~ 29 ) 1.8 2.5 2.5 6.0

1.8+2.5+3. 5+3.5 ( 6 ~ 10 ) + ( 9 ~ 14 ) + ( 13 ~ 19 ) + ( 13 ~ 19 ) 1.8 2.5 3.5 3.5

1.8+2.5+3. 5+5.0 ( 6 ~ 9 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 16 ~ 24 ) 1.8 2.5 3.5 5.0

1.8+2.5+3. 5+6.0 ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 10 ~ 16 ) + ( 18 ~ 27 ) 1.8 2.5 3.5 6.0

1.8+2.5+5. 0+5.0 ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 14 ~ 22 ) + ( 14 ~ 22 ) 1.8 2.5 5.0 5.0

1.8+2.5+5. 0+6.0 ( 5 ~ 8 ) + ( 7 ~ 10 ) + ( 13 ~ 20 ) + ( 16 ~ 24 ) 1.8 2.5 5.0 6.0

1.8+3.5+3. 5+3.5 ( 6 ~ 9 ) + ( 12 ~ 18 ) + ( 12 ~ 18 ) + ( 12 ~ 18 ) 1.8 3.5 3.5 3.5

1.8+3.5+3. 5+5.0 ( 5 ~ 8 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 15 ~ 22 ) 1.8 3.5 3.5 5.0

1.8+3.5+3. 5+6.0 ( 5 ~ 8 ) + ( 10 ~ 14 ) + ( 10 ~ 14 ) + ( 17 ~ 26 ) 1.8 3.5 3.5 6.0

1.8+3.5+5. 0+5.0 ( 5 ~ 7 ) + ( 9 ~ 14 ) + ( 13 ~ 20 ) + ( 13 ~ 20 ) 1.8 3.5 5.0 5.0

2.5+2.5+2. 5+2.5 ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) 2.5 2.5 2.5 2.5

2.5+2.5+2. 5+3.5 ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 13 ~ 20 ) 2.5 2.5 2.5 3.5

2.5+2.5+2. 5+5.0 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 16 ~ 25 ) 2.5 2.5 2.5 5.0

2.5+2.5+2. 5+6.0 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 18 ~ 28 ) 2.5 2.5 2.5 6.0

2.5+2.5+3. 5+3.5 ( 9 ~ 13 ) + ( 9 ~ 13 ) + ( 12 ~ 18 ) + ( 12 ~ 18 ) 2.5 2.5 3.5 3.5

2.5+2.5+3. 5+5.0 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 16 ) + ( 15 ~ 23 ) 2.5 2.5 3.5 5.0

2.5+2.5+3. 5+6.0 ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 17 ~ 26 ) 2.5 2.5 3.5 6.0

2.5+2.5+5. 0+5.0 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 14 ~ 21 ) + ( 14 ~ 21 ) 2.5 2.5 5.0 5.0

2.5+3.5+3. 5+3.5 ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 2.5 3.5 3.5 3.5

2.5+3.5+3. 5+5.0 ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) + ( 14 ~ 21 ) 2.5 3.5 3.5 5.0

2.5+3.5+3. 5+6.0 ( 7 ~ 10 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 16 ~ 24 ) 2.5 3.5 3.5 6.0

3.5+3.5+3. 5+3.5 ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) 3.5 3.5 3.5 3.5

3.5+3.5+3. 5+5.0 ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 13 ~ 20 ) 3.5 3.5 3.5 5.0

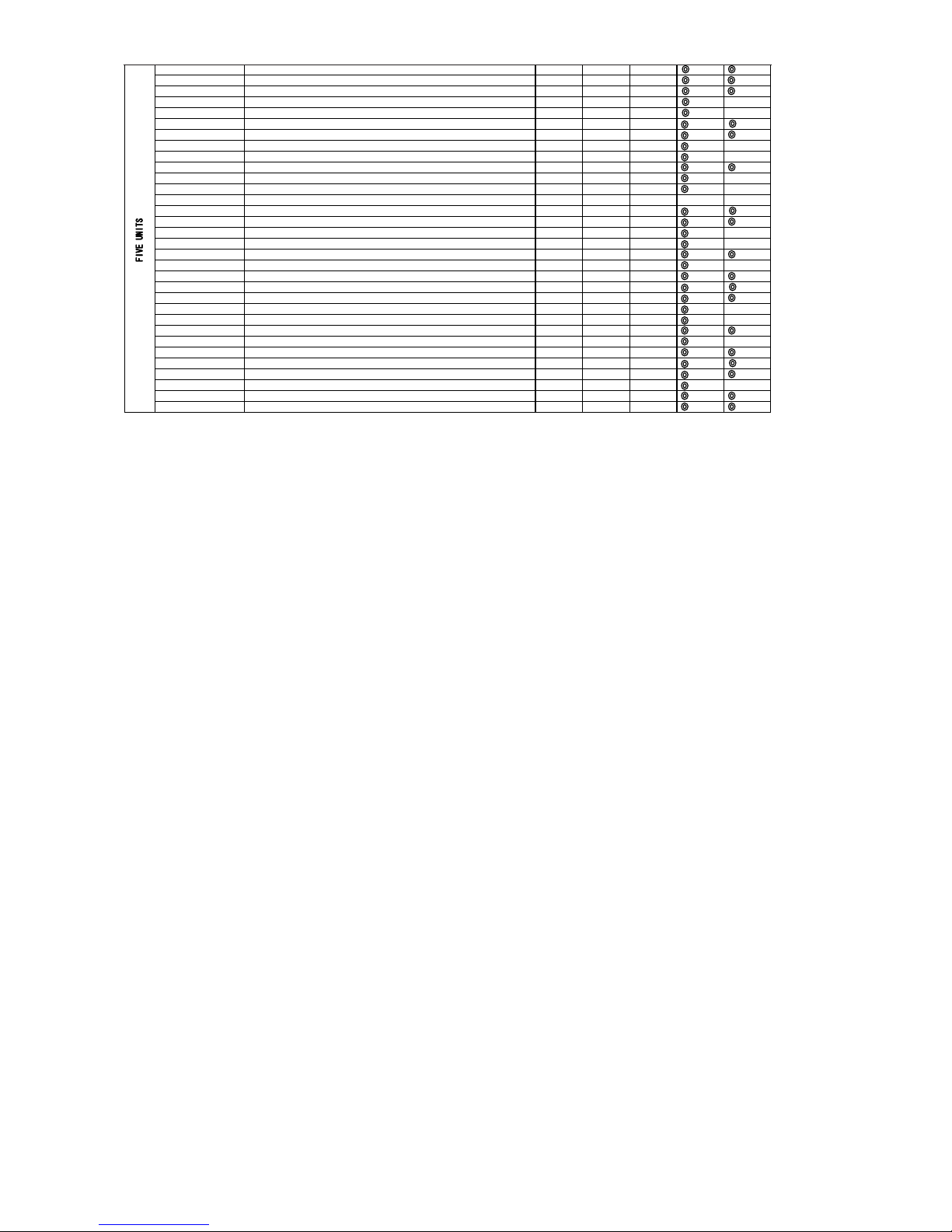

POSSIBLE CO MBINATIONS

TO INSTALL (kW)

TW

OUN

I

TS

(

VALVE DIAMETER

)

(mm)

SUITABLE ROO M SIZE

TO INSTALL

(

m

2

)

CONNECTING POSIT ION ON

OUTDOOR UNIT

– 11 –

2.5, 3.5, 4.0, 5.0 & 6.0 means indoor units cooling capacity class.

(1) Marking

: needs flare adapter (9.52 ➝ 12.7D): Part No. TA261D-4 001

: needs flare adapter (12.7 ➝ 9.52D): Part No. TA261D-6 002

(2) Suitable room size is determined based on the conditions below:

• Climate is in the temperate zone like Tokyo, Japan.

• For usual residential use.

• Smaller figure is for light construction which means light thermally sealed.

• Larger figure is for heavy constructions, which means well thermally sealed.

1.8+1.8+1. 8+1.8+1.8 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) 1.8 1.8 1.8 1.8 1.8

1.8+1.8+1. 8+1.8+2.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 16 ) 1.8 1.8 1.8 1.8 2.5

1.8+1.8+1. 8+1.8+3.5 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 13 ~ 20 ) 1.8 1.8 1.8 1.8 3.5

1.8+1.8+1. 8+1.8+5.0 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 17 ~ 25 ) 1.8 1.8 1.8 1.8 5.0

1.8+1.8+1. 8+1.8+6.0 ( 6 ~ 8 ) + ( 6 ~ 8 ) + ( 6 ~ 8 ) + ( 6 ~ 8 ) + ( 19 ~ 28 ) 1.8 1.8 1.8 1.8 6.0

1.8+1.8+1. 8+2.5+2.5 ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) 1.8 1.8 1.8 2.5 2.5

1.8+1.8+1. 8+2.5+3.5 ( 6 ~ 10 ) + ( 6 ~ 10 ) + ( 6 ~ 10 ) + ( 9 ~ 14 ) + ( 13 ~ 19 ) 1.8 1.8 1.8 2.5 3.5

1.8+1.8+1. 8+2.5+5.0 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 8 ~ 12 ) + ( 16 ~ 24 ) 1.8 1.8 1.8 2.5 5.0

1.8+1.8+1. 8+2.5+6.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 18 ~ 27 ) 1.8 1.8 1.8 2.5 6.0

1.8+1.8+1. 8+3.5+3.5 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 12 ~ 18 ) + ( 12 ~ 18 ) 1.8 1.8 1.8 3.5 3.5

1.8+1.8+1. 8+3.5+5.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 10 ~ 16 ) + ( 15 ~ 22 ) 1.8 1.8 1.8 3.5 5.0

1.8+1.8+1. 8+3.5+6.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 10 ~ 15 ) + ( 16 ~ 25 ) 1.8 1.8 1.8 3.5 6.0

1.8+1.8+1. 8+5.0+5.0 ( 5 ~ 7 ) + ( 5 ~ 7 ) + ( 5 ~ 7 ) + ( 13 ~ 20 ) + ( 13 ~ 20 ) 1.8 1.8 1.8 5.0 5.0

1.8+1.8+2. 5+2.5+2.5 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) 1.8 1.8 2.5 2.5 2.5

1.8+1.8+2. 5+2.5+3.5 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 8 ~ 13 ) + ( 8 ~ 13 ) + ( 12 ~ 18 ) 1.8 1.8 2.5 2.5 3.5

1.8+1.8+2. 5+2.5+5.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 8 ~ 11 ) + ( 8 ~ 11 ) + ( 15 ~ 23 ) 1.8 1.8 2.5 2.5 5.0

1.8+1.8+2. 5+2.5+6.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 17 ~ 26 ) 1.8 1.8 2.5 2.5 6.0

1.8+1.8+2. 5+3.5+3.5 ( 6 ~ 9 ) + ( 6 ~ 9 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) + ( 11 ~ 17 ) 1.8 1.8 2.5 3.5 3.5

1.8+1.8+2. 5+3.5+5.0 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 14 ~ 21 ) 1.8 1.8 2.5 3.5 5.0

1.8+1.8+3. 5+3.5+3.5 ( 5 ~ 8 ) + ( 5 ~ 8 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) 1.8 1.8 3.5 3.5 3.5

1.8+2.5+2. 5+2.5+2.5 ( 6 ~ 9 ) + ( 9 ~ 13 ) + ( 9 ~ 13 ) + ( 9 ~ 13 ) + ( 9 ~ 13 ) 1.8 2.5 2.5 2.5 2.5

1.8+2.5+2. 5+2.5+3.5 ( 6 ~ 9 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 17 ) 1.8 2.5 2.5 2.5 3.5

1.8+2.5+2. 5+2.5+5.0 ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 14 ~ 22 ) 1.8 2.5 2.5 2.5 5.0

1.8+2.5+2. 5+2.5+6.0 ( 5 ~ 7 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 16 ~ 24 ) 1.8 2.5 2.5 2.5 6.0

1.8+2.5+2. 5+3.5+3.5 ( 5 ~ 8 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 10 ~ 16 ) + ( 10 ~ 16 ) 1.8 2.5 2.5 3.5 3.5

1.8+2.5+2. 5+3.5+5.0 ( 5 ~ 7 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 9 ~ 14 ) + ( 13 ~ 20 ) 1.8 2.5 2.5 3.5 5.0

1.8+2.5+3. 5+3.5+3.5 ( 5 ~ 8 ) + ( 7 ~ 10 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) 1.8 2.5 3.5 3.5 3.5

2.5+2.5+2. 5+2.5+2.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) 2.5 2.5 2.5 2.5 2.5

2.5+2.5+2. 5+2.5+3.5 ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 8 ~ 12 ) + ( 11 ~ 16 ) 2.5 2.5 2.5 2.5 3.5

2.5+2.5+2. 5+2.5+5.0 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 14 ~ 21 ) 2.5 2.5 2.5 2.5 5.0

2.5+2.5+2. 5+3.5+3.5 ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 7 ~ 11 ) + ( 10 ~ 15 ) + ( 10 ~ 15 ) 2.5 2.5 2.5 3.5 3.5

2.5+2.5+3. 5+3.5+3.5 ( 7 ~ 10 ) + ( 7 ~ 10 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) + ( 9 ~ 14 ) 2.5 2.5 3.5 3.5 3.5

– 12 –

– 13 –

– 14 –

– 15 –

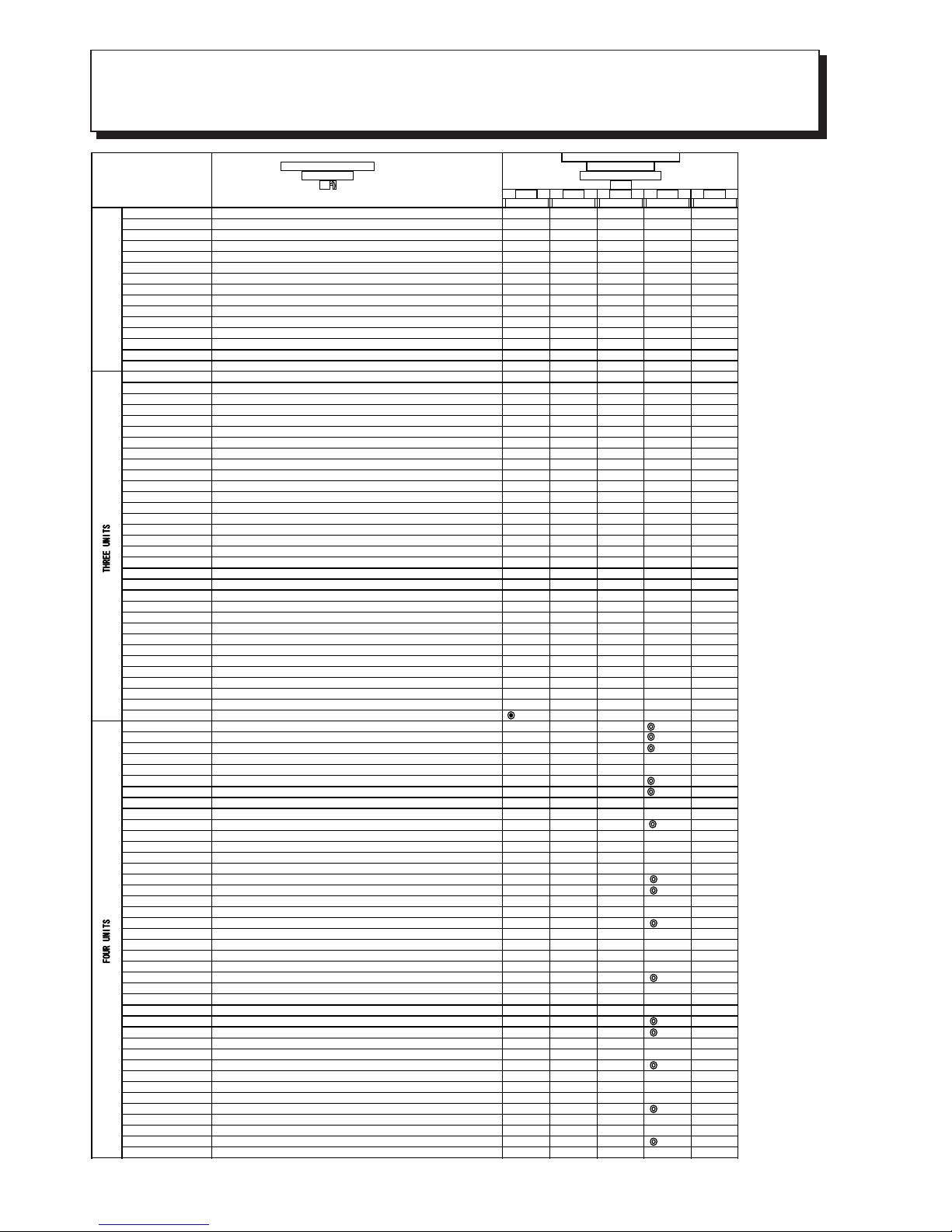

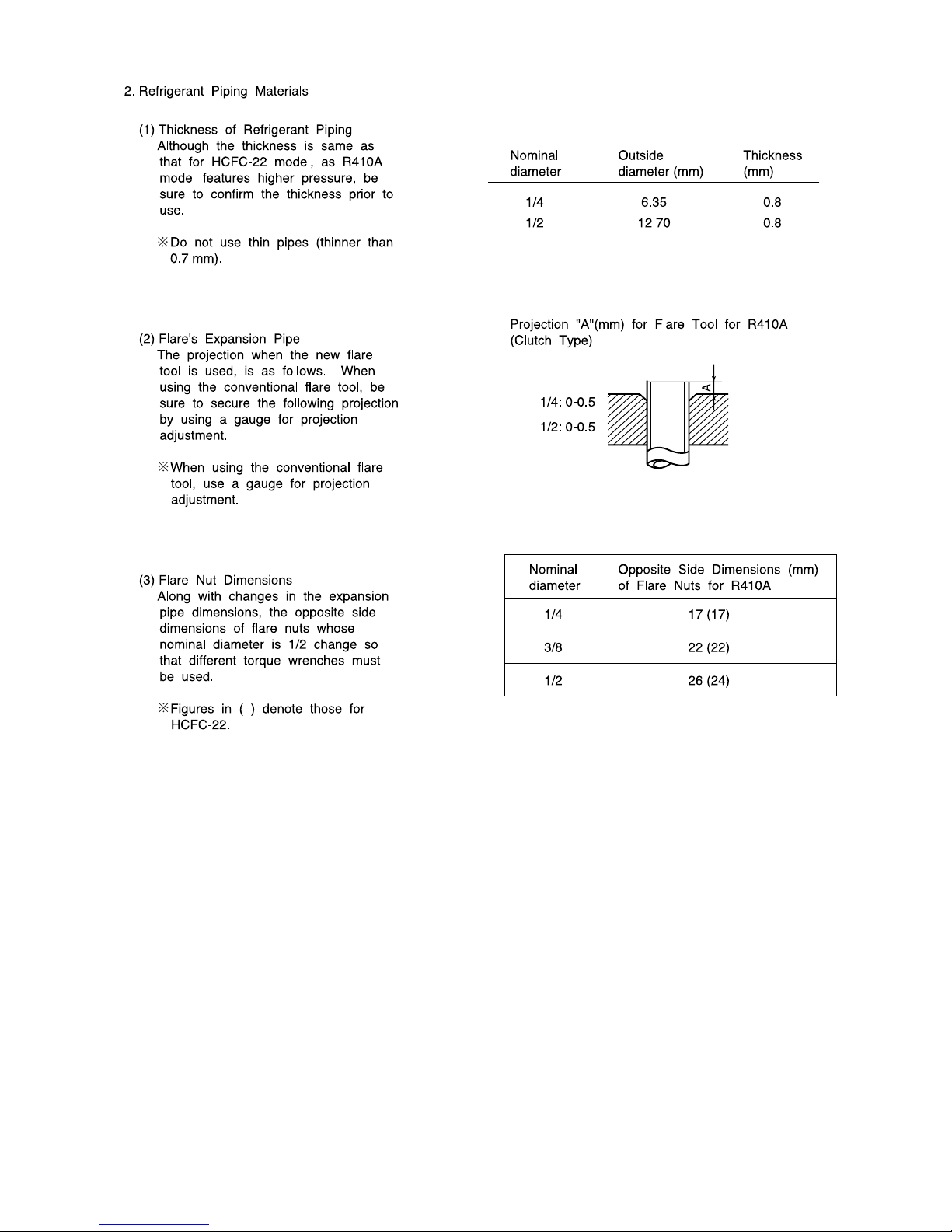

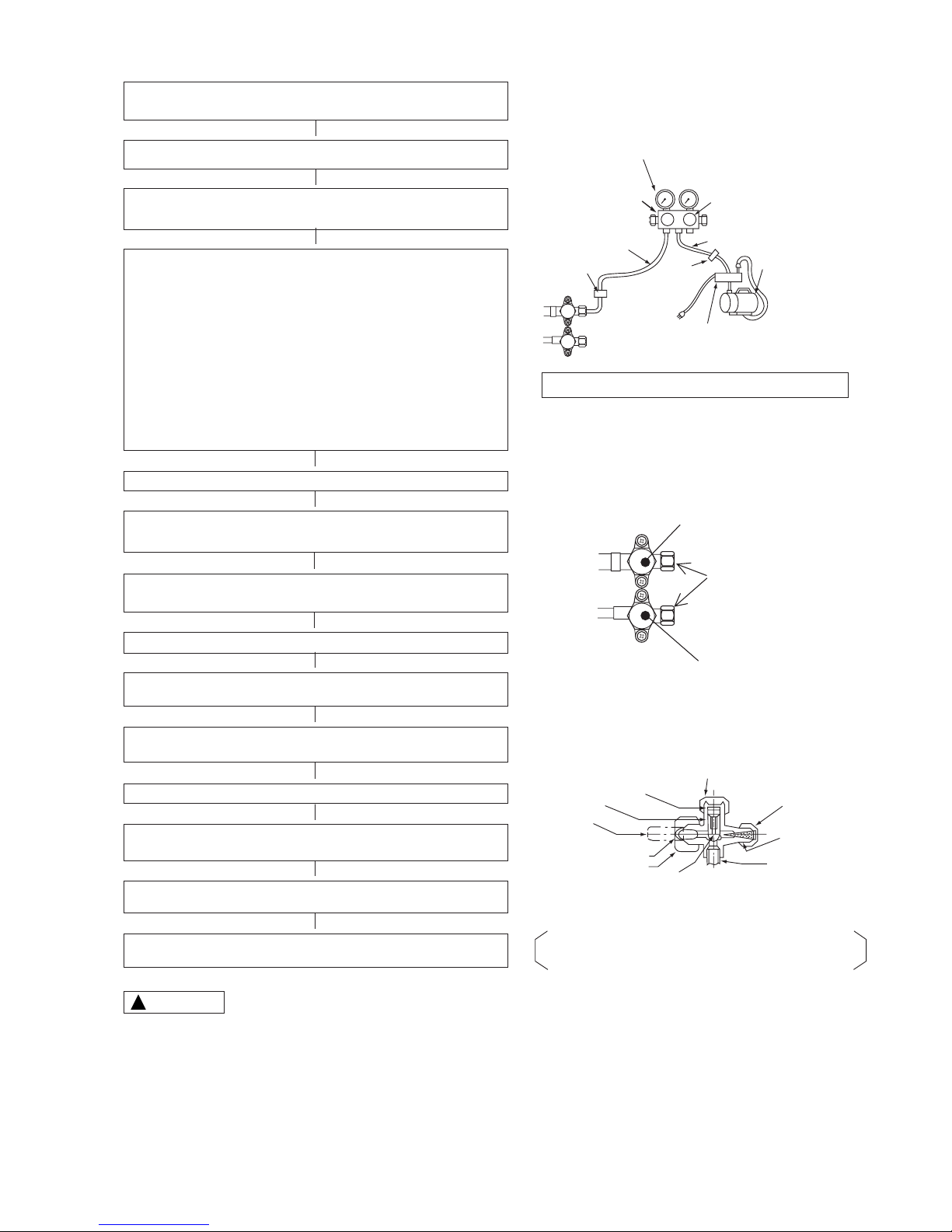

Fig. 6-1

Fig. 6-2

Fig. 6-3

Lo Hi

Stop valve

Charge hose A

Charge hose B

Stop

valve

Vacuum pump adapter

Valve cap

Valve cap

Valve cap of valve core

Valve cap

Valve core

Valve cap of

valve core

Stopper

O-Ring

Pipe

Pipe

Seal cap

Flare nut

Spindle

When the meter reaches -101KPa (-76cmHg) during

pumping, fully tighten the shuttle.

Air purging by vacuum pump

Closed

Vacuum pump

R410A

Manifold valve

Be sure the stop valve is always fully opened.

The refrigerant channel is opened so that the refrigerant

will flow from the outdoor unit into the indoor unit.

Meter showing pressure

Remove the valve cap from the service valves located at both the

large and small pipe rims

➤

Connect the charging hose A to the large service valve.

After connecting the vacuum suction pump adaptor, connect the

charging hose B to the adaptor.

During relocation or re-installed, there is a possibility of electric-powered

valve to be closed. Should the electric-powered valve be closed, even

with air purging being conducted, certain amount of air is still trapped

within that area, hence, there is a need to open up the electric-powered

valve to do an air purging. Under such circumstances, before using

the vacuum-suction pump, the main power supply (LN terminal) should

be connected to enable a complete opening up of the valve. After

connecting the power supply for approximately 90 seconds, the valve

will be fully opened, after which disconnect the power supply and start

using the vacuum suction pump.

(Refer to “Power Supply Terminal Connections” in regards to the LN

terminal)

CAUTION: Ingress of air during the operating cycle may cause increase

in pressure and other breakdowns.

Switch off the outdoor unit’s power supply

Shut the manifold valve handle Hi, handle Lo need to be open and

operate the vacuum pump for approximately 60 minutes.

Upon a full shut of manifold valve handle Lo, the vacuum pump can

be stopped.

Check to ensure that there is no gas leakage.

After removing the charging hose A, rotate the service valve spindles

in an anti-clockwise direction to fully open for both valves.

Reinstall the cap nuts to their original positions and tighten them to

their specified torque.

Disconnect the charge hose from the service valve.

Tighten the valve cap of valve core.

[Torque 12.3 - 15.7 N·m (125 - 160 kgf·cm)]

Fix the valve cap to the spindles of each large and small dia. pipe

side service valves.

Tighten the valve cap of the spindle.

[Torque 19.6 - 24.5 N·m (200 - 250 kgf·cm)]

4. Air purging by using vacuum pump

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

➤

!

CAUTION

1. Be sure to use the vacuum pump, vacuum pump adapter and manifold gauge and refer to their instruction manuals beforehand.

2. Ascertain that the vacuum pump is filled with oil to the level designated on the oil gauge.

3. After closed the ball valve of charge hose, it should be disconnected at service port side and refrigerant cylinder side at first.

Next, after discharging the remained gas in the charge hose by opening the ball valve a little, disconnect it at manifold gauge side. You

can prevent sudden release of refrigerant by connecting the ball valve to service port. And you can work more safety.

– 16 –

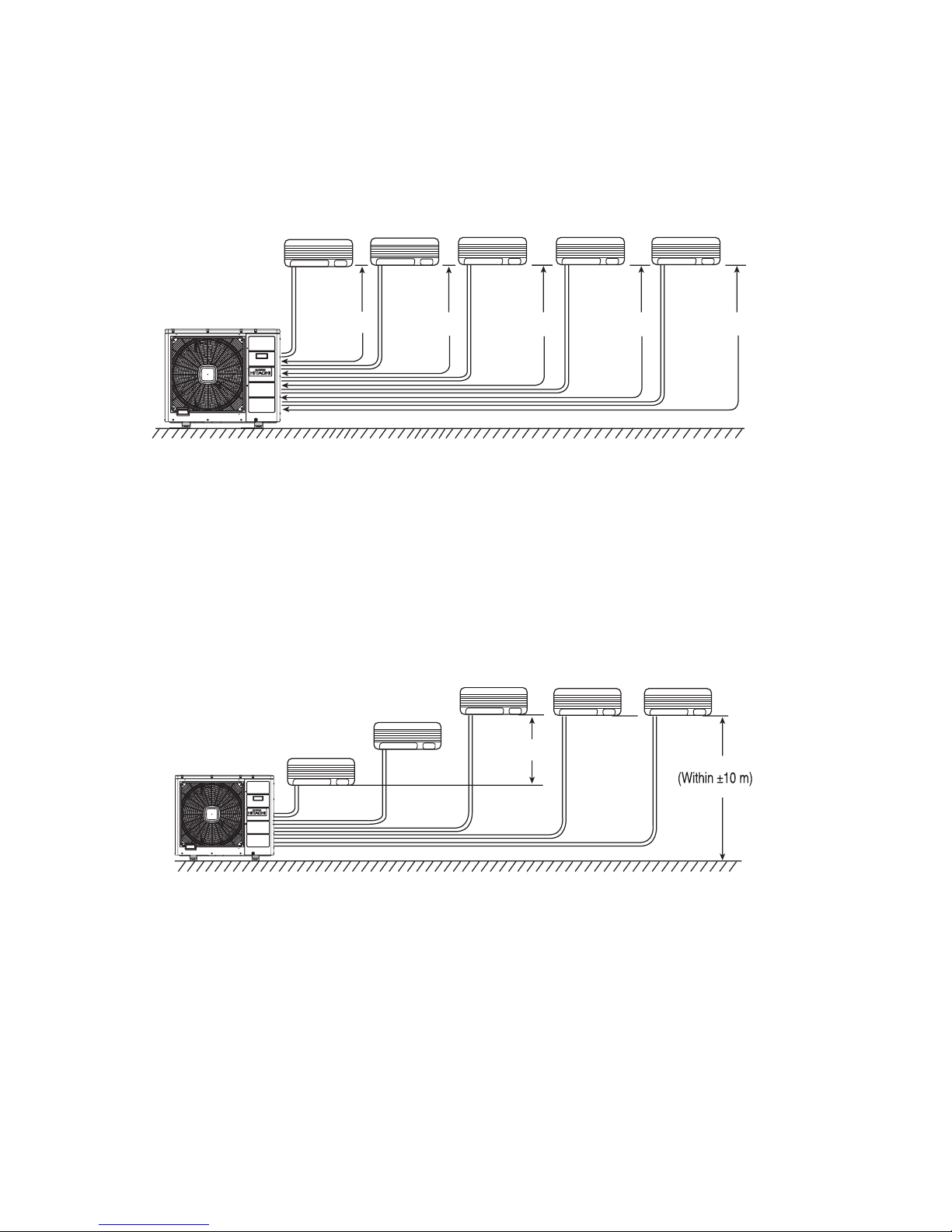

INSTALLATION

PIPE LENGTH

(1) Total 75m maximum pipe length.

(2) Pipe length for one indoor unit : maximum 25m.

: minimum 5m.

HIGHT DIFFERENCE

(1) Height : maximum ± 10m

(2) Height difference between each indoor unit ≤ 5m.

To the outdoor unit, up to five indoor units can be connected until the total value of capacity to 15.5kW.

Make sure to connect two or more indoor units.

L2

L1

L3

Indoor unit 3L4Indoor unit 4L5Indoor unit 5Indoor unit 2

Indoor unit 1

Outdoor unit

Indoor unit 2

Indoor unit 3

Indoor unit 4

Indoor unit 5

Indoor unit 1

5m

– 17 –

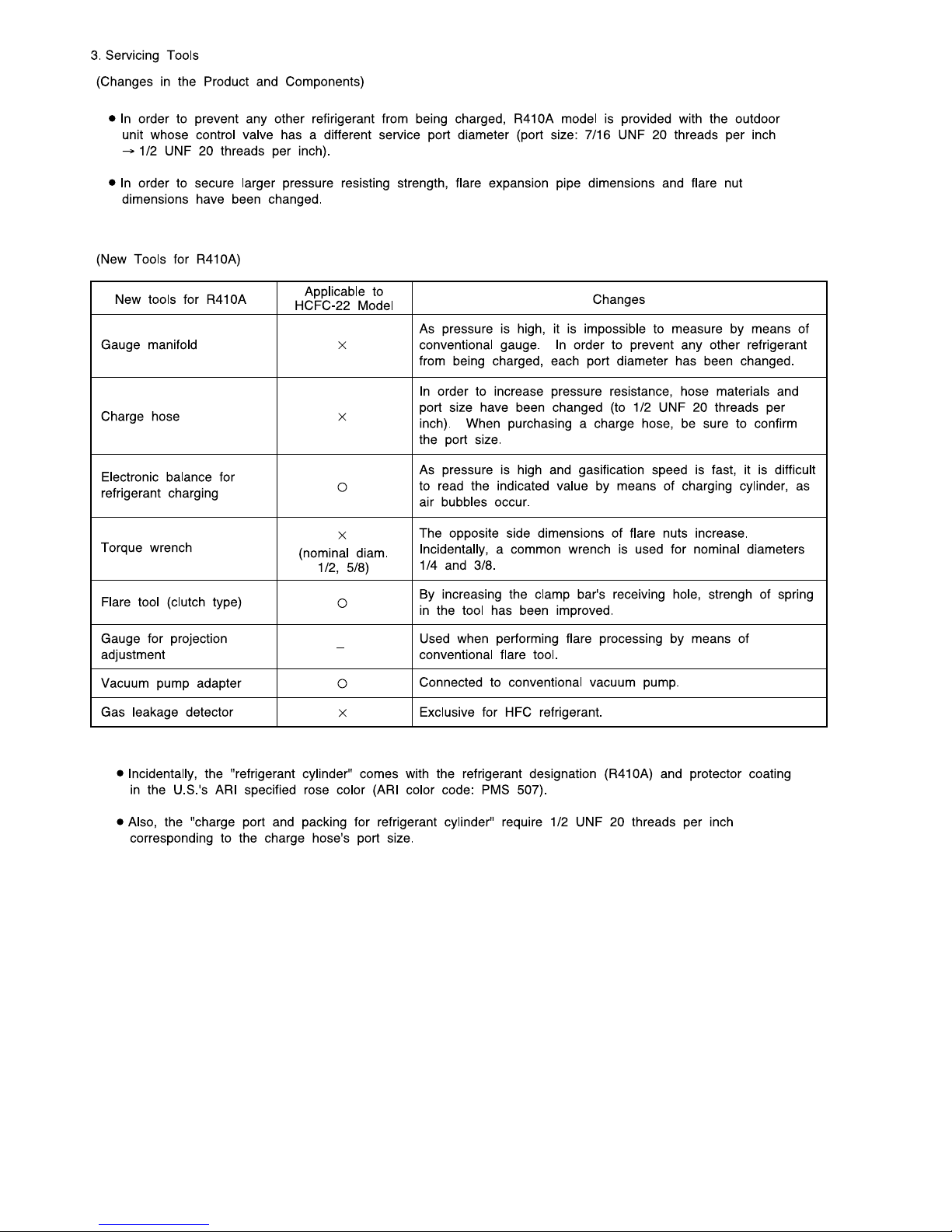

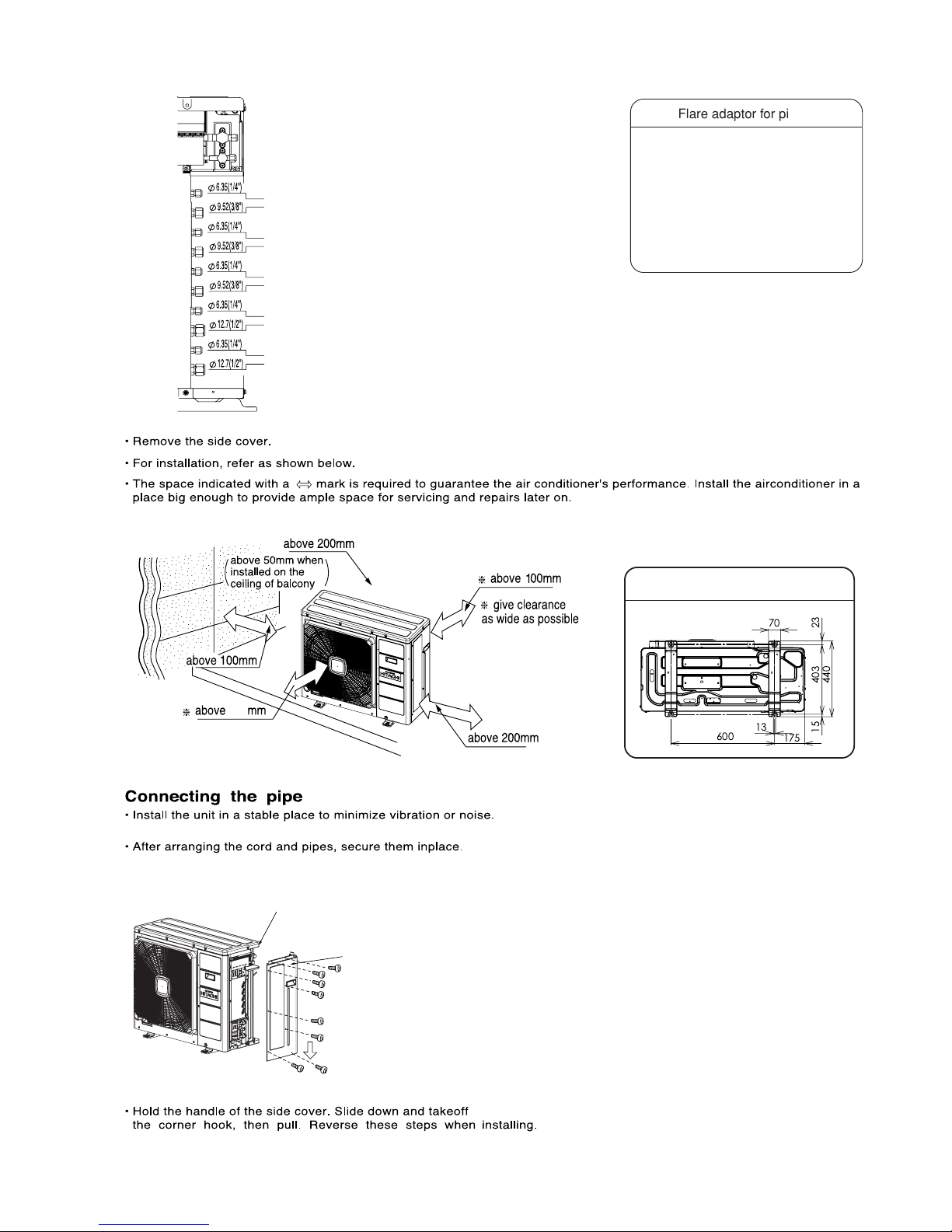

MODEL: RAM-90QH5

Indoor unit 5 Indoor unit 4

Indoor unit 3

Indoor unit 2

Indoor unit 1

Outdoor unit pipe connection port

Dimension of Mounting Stand

of the Outdoor unit

(unit: mm)

700

One unit of 1.8kW, 2.5kW, 3.5kW, 5.0kW or 6.0kW

(5.0kW, 6.0kW unit: Optional flare adaptor for piping is necessary.)

One unit of 1.8kW, 2.5kW, 3.5kW, 5.0kW or 6.0kW

(5.0kW, 6.0kW unit: Optional flare adaptor for piping is necessary.)

One unit of 1.8kW, 2.5kW, 3.5kW, 5.0kW or 6.0kW

(5.0kW, 6.0kW unit: Optional flare adaptor for piping is necessary.)

One unit of 1.8kW, 2.5kW, 3.5kW, 5.0kW, 6.0kW or 7.1kW

(1.8-3.5kW unit: Optional flare adaptor for piping is necessary.)

One unit of 1.8kW, 2.5kW, 3.5kW, 5.0kW, 6.0kW or 7.1kW

(1.8-3.5kW unit: Optional flare adaptor for piping is necessary.)

Face this side (suction

side) of the unit to the wall.

Remove side cover when

connecting the piping and

connecting cord.

Pull downward

13

70

23

44015403

600

175

Flare adaptor for piping

The flare adaptor for piping is

required depending on combination

of indoor units.

•ø9.52 (3/8”) ➝ ø 12.7 (1/2”)

Parts number TA261D-4 001

•ø12.7(1/2”) ➝ ø 9.52 (3/8”)

Parts number TA261D-6 002

•ø12.7(1/2”) ➝ ø 15.88(5/8”)

Parts number TA261D-6 003

– 18 –

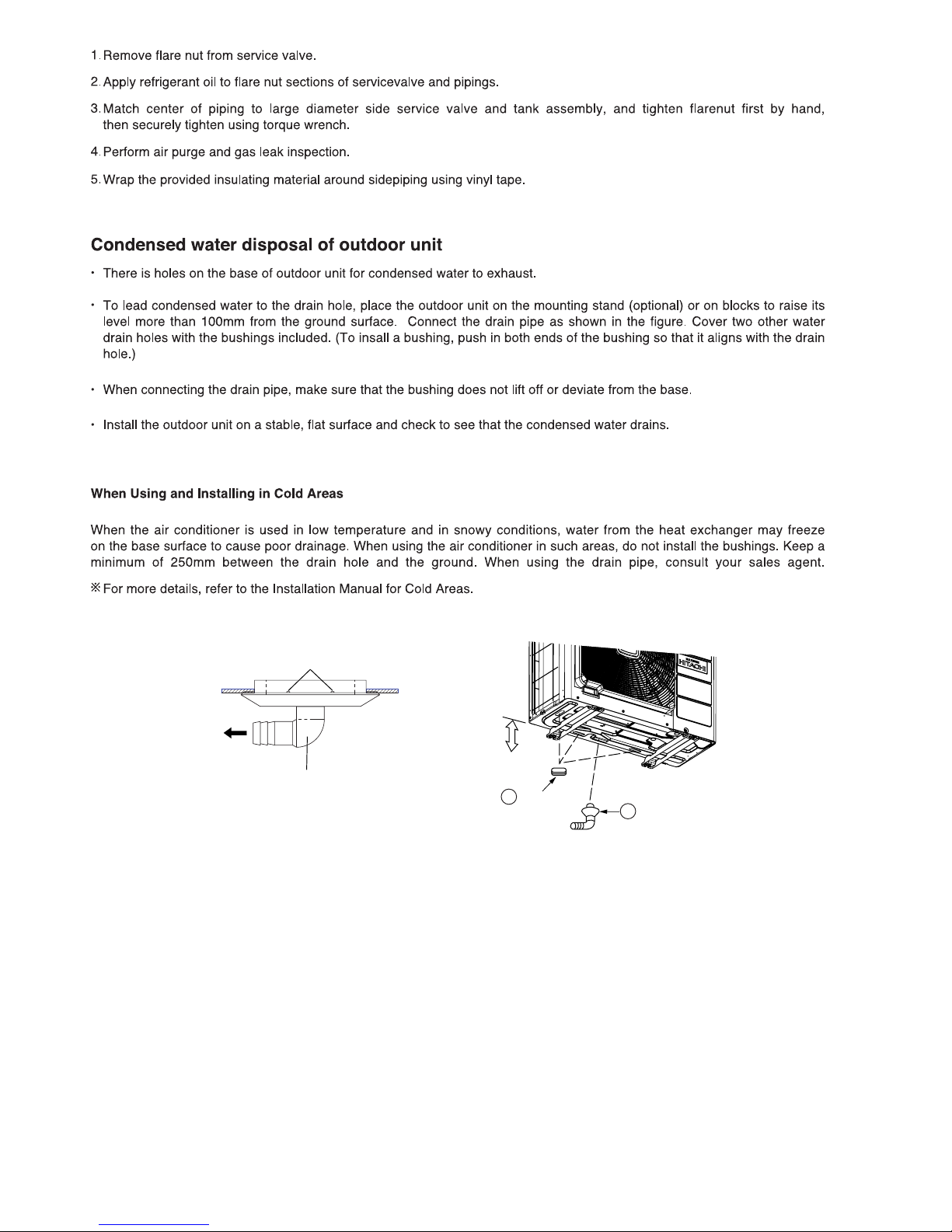

BASE

DRAIN PIPE

A

DRAIN PIPE

BUSH

100 mm ABOVE

10

11

– 19 –

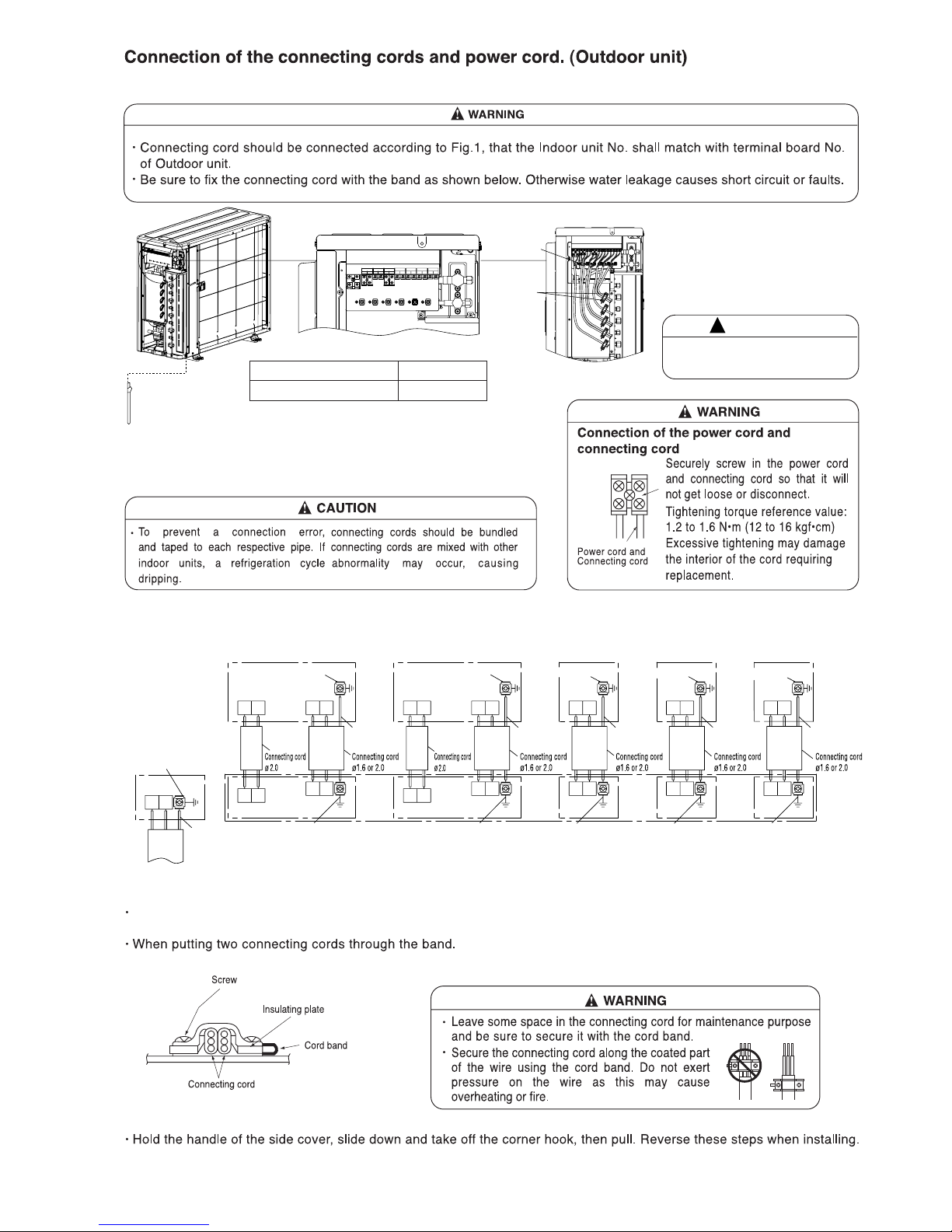

Terminal A and B at Indoor unit 4 and 5 is for 7 kw and 8 kw indoor which using high voltage motor.

Arrange power cord so they do

not touch service valve.

CAUTION

!

Grounding rod (optional)

(Earth wire and grounding rod are not supplied. Please use optional items

below.)

Type of grounding rod

SP-EB-2

Length

900mm

C1 D1C2 D2C3 D3C4 D4A4 B4C5 D5A5 B5

L N

AC200-240V

INDOOR 1INDOOR 2INDOOR 3INDOOR 4INDOOR 4INDOOR 5INDOOR 5

Connect the

earth cord

After remove

the screw

and cover, put

the connecting

cords and fix

the cover with

screw

Wiring Pattern

Indoor Unit

Indoor unit No. 5 Indoor unit No. 4 Indoor unit No. 3 Indoor unit No. 2 Indoor unit No. 1

Screw for ground, earth screw

Screw for ground, earth screw

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Terminal

board

Power cord

CD

D1C1

CD

D2C2

CD

C3

D3

CD

C4

D4

AB

B4A4

CD

C5 D5

AB

A5 B5

LN

Screw for ground, earth screw

Screw for ground, earth screw

Screw for ground, earth screw

Screw for ground, earth screw

Green-andYellow

Green-andYellow

Green-andYellow

Green-andYellow

Green-andYellow

Green-andYellow

Screw for ground, earth screw

For Indoor unit No. 1

Screw for ground, earth screw

For Indoor unit No. 2

Screw for ground, earth screw

For Indoor unit No. 3

Screw for ground, earth screw

For Indoor unit No. 4

Screw for ground, earth screw

For Indoor unit No. 5

Fig. 1

Outdoor Unit

RAM-90QH5

– 20 –

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAM-90QH5

Service space

MODEL RAM-90QH5

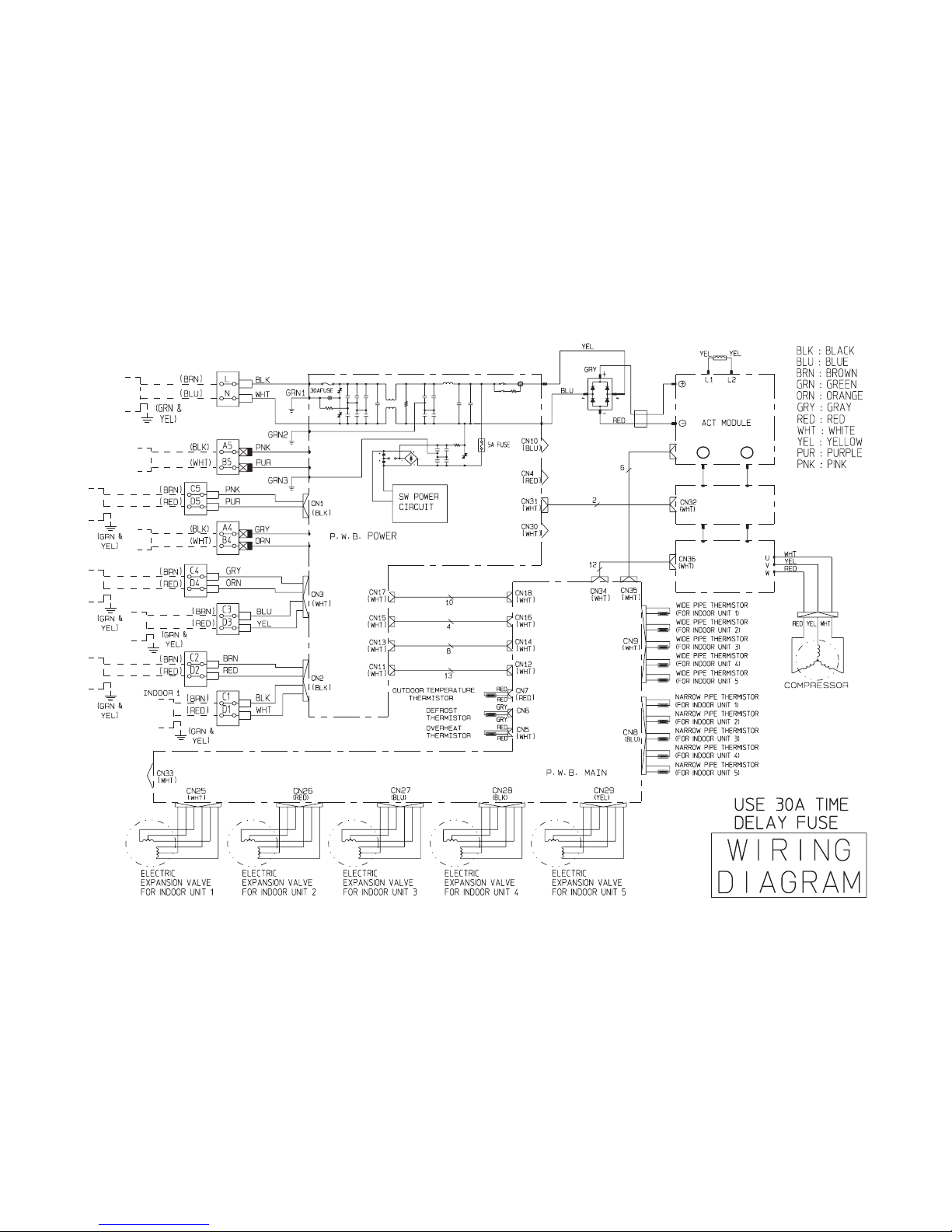

WIRING DIAGRAM

– 21 –

POWER SOURCE

AC220 - 240V

50/60Hz

TERMINAL

BOARD

INDOOR 5

INDOOR 5

INDOOR 4

INDOOR 2

(BLU)

RED GRY

WHT BLK

INDOOR 4

INDOOR 3

Io P

P.W.B. CAPA

P.W.B. IPM

BOARD

TAB 01 TAB 02

– 23 –

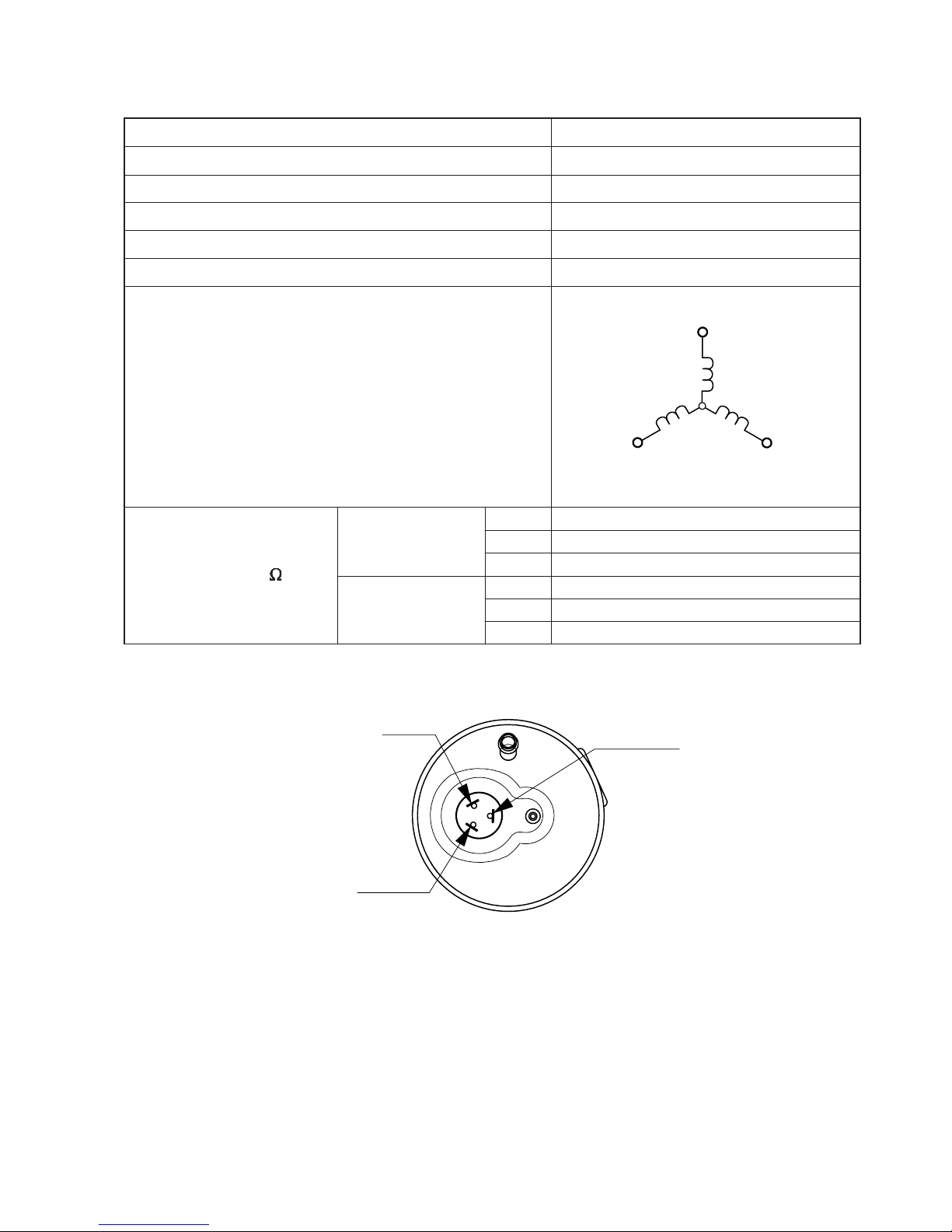

COMPRESSOR MOTOR

Compressor Motor Specifications

MODEL

COMPRESSOR MODEL

PHASE SINGLE

RATED VOLTAGE AC 220 ~ 240 V

RATED FREQUENCY 50/60 Hz

POLE NUMBER 4

CONNECTION

20°C

(68°F)

75°C

(167°F)

( )

RESISTANCE VALUE

0.410

0.397

0.390

RAM-90QH5

JU1318D1

WHITE(U)

(W)

(V)

RED

YELLOW

0.499

0.483

0.474

RED (S)

YELLOW (R)

WHITE (C)

U-V

V-W

W-U

U-V

V-W

W-U

– 24 –

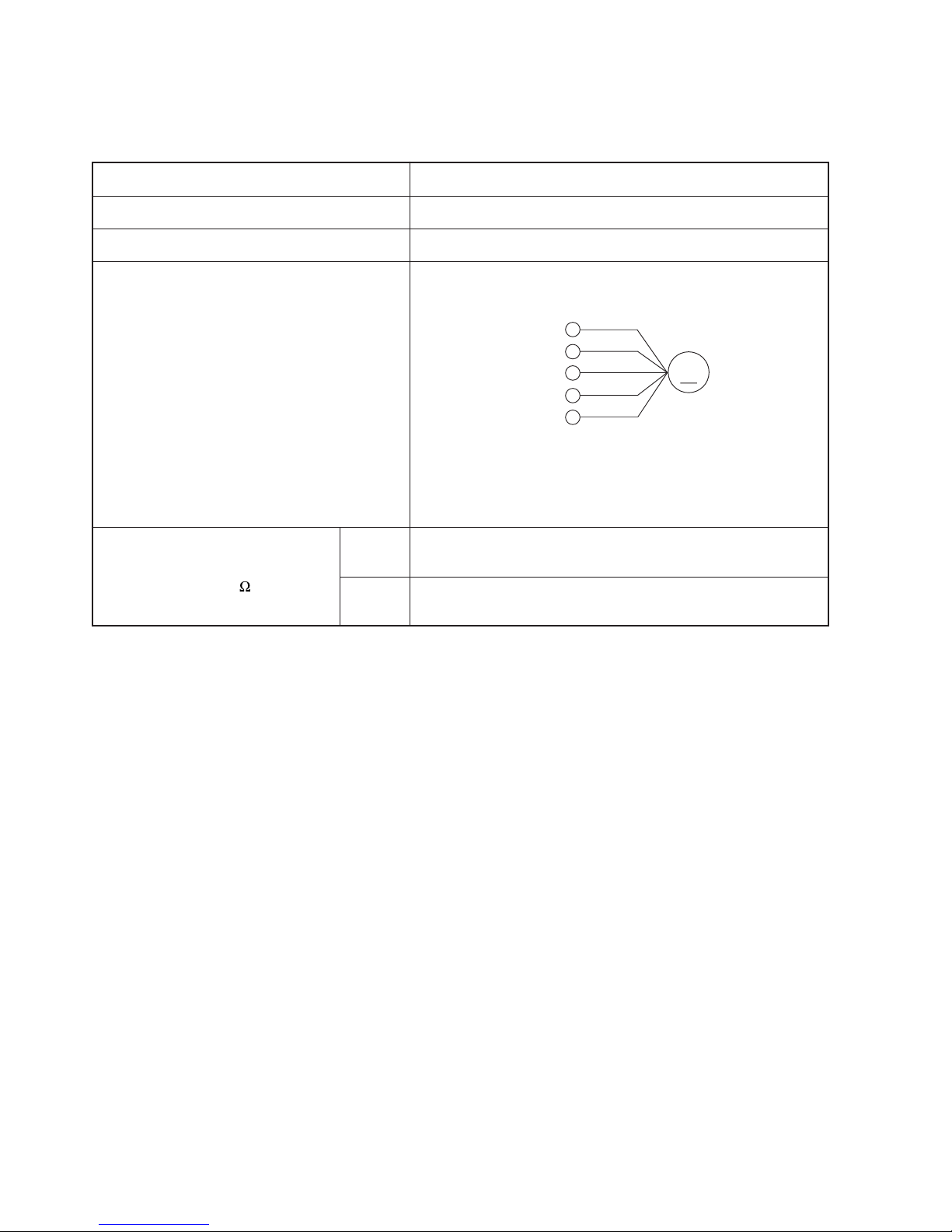

MAIN PARTS COMPONENT

FAN MOTOR

Fan Motor Specifications

CONNECTION

MODEL

POWER SOURCE

OUTPUT

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

RAM-90QH5

DC : 280V

138W

RESISTANCE VALUE

( )

20˚C

(68˚F)

75˚C

(167˚F)

—

—

M

RED

BLK

WHT

YEL

BLU

(Control circuit built in)

280V

15V

0V

0-6V

0-15V

Remote Control

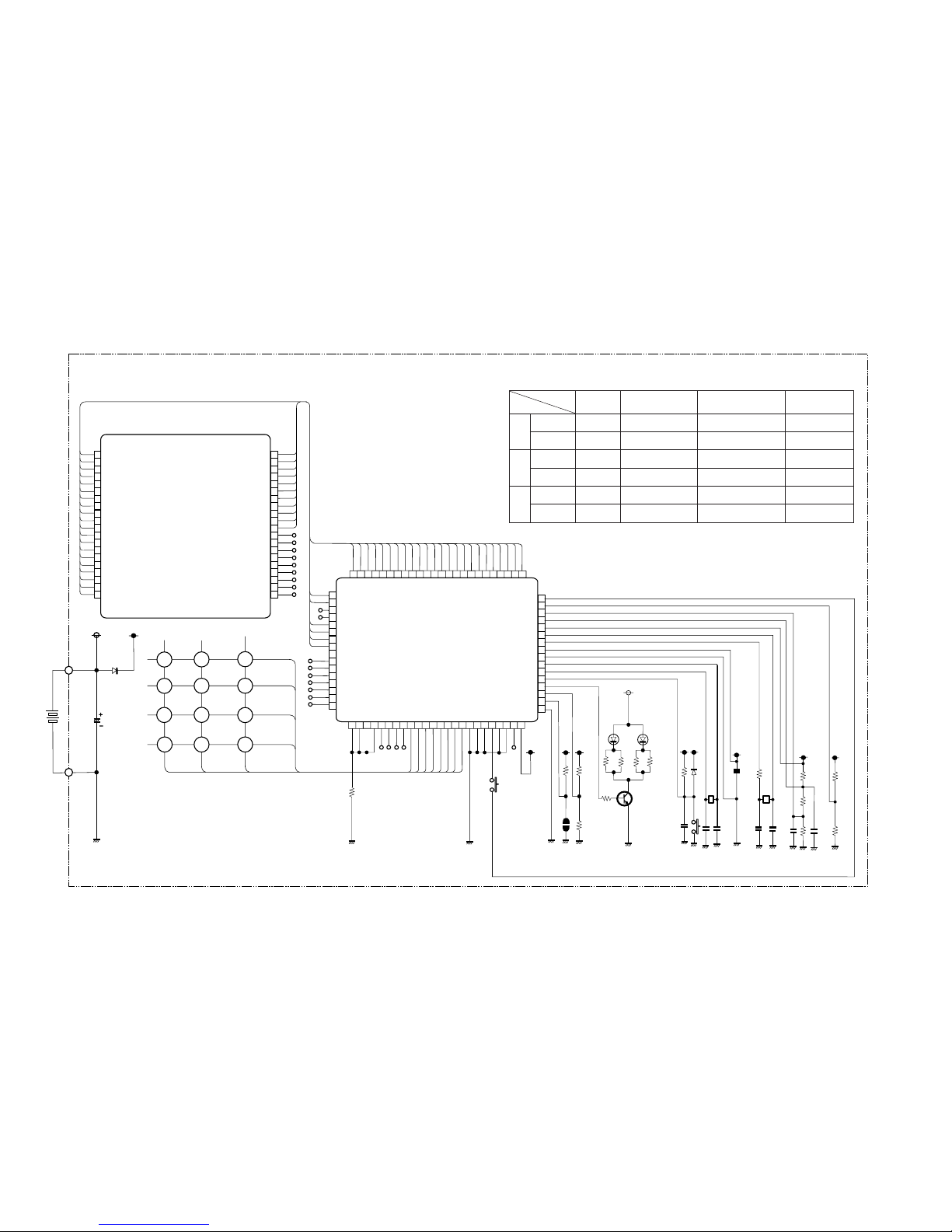

CIRCUIT DIAGRAM

– 25 –

1

2

3

4

5

6

7

8

10

11

13

14

15

16

17

19

20

9

12

18

SEG19

SEG18

SEG17

SEG16

SEG21

SEG24

SEG25

SEG26

SEG27

SEG28

NC

NC

NC

NC

NC

NC

NC

NC

NC

SEG20

SEG5

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

COM3

COM2

COM1

COM0

SEG14

SEG13

SEG12

SEG11

SEG13

SEG9

SEG8

40

39

38

37

36

35

34

33

31

30

28

27

26

25

24

22

21

32

29

23

40

39

38

37

36

35

34

33

31

30

28

27

26

25

32

29

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48 47

46

45

44

43

41

42

65

66

67

68

69

70

71

72

74

75

77

78

79

80

73

76

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18

19

20

21

22

24

23

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

SEG43

SEG42

SEG41

SEG40

P40

P41

P42

P43

P00

P01

P02

P03

P10

P11

P12

P13

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

BEEP

P20

P30

P31

NCVL C1

VL C2

VL C3

XC IN

XC OUT

VDD

X OUT

X IN

RESET

CARR

P23

P22

P21

VSS

IC 1

M3455OM6A-504FP

LCD 1

C8

50v/1u

K 1

D3

RB425D(1/2)

K2K3

K4

K5

P10

P11

P12

K6

K7 K8

K9 K10

K11K12

K18

K17

K15 K16

K13 K14

D0

D1

D2

D3

R1

100k

SW1

R2

P

100k

R3

100k

R4

100k

R5

Q1

2SC3443

or 2SC2982

R6

R7

R9

D2D1

D1 D2

EL-1L7

D3

(1/2)

RB425D

R10

12M

K19

X1

C9

R11

R15

R16

R13

R14

910kHz

105

104

104

150k

X2

kHz

C4

C5

C6

C7

18p

22p

R12

220k

220K

220k

100k

100k

32.768

C1

C2

C3

220p

220p

334

R6 R9

24(1/8W)

R8

330

SW-187-2P

Key matrix table

Input

D3D2D1

D0

Output

Door open Automatic swingFan speed selectionOperation selectionStart/Stop

Door shut ––Automatic swingStart/Stop

Door open Day

• present timeHour downHour upOn timer

Door shut Fan speedRoom temperature downRoom temperature up–

Door open CancelReservation–Off timer

Door shut –––Sleep

P10

P11

P12

Loading...

Loading...