Page 1

RAM-52QH5

RAM-53QH5

NO. 0428E

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

ROOM AIR CONDITIONER

OUTDOOR UNIT

AUGUST 2008

Refrigeration & Air-Conditioning Division

SERVICE MANUAL

PM

REFER TO THE FOUNDATION MANUAL

TECHNICAL INFORMATION

FOR SERVICE PERSONNEL ONLY

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 5

INSTALLATION --------------------------------------------------------------------- 14

CONSTRUCTION AND DIMENSIONAL DIAGRAM --------------------- 21

MAIN PARTS COMPONENT --------------------------------------------------- 23

CAPACITY DIAGRAM ------------------------------------------------------------ 25

WIRING DIAGRAM ---------------------------------------------------------------- 33

CIRCUIT DIAGRAM --------------------------------------------------------------- 37

BLOCK DIAGRAM ----------------------------------------------------------------- 43

BASIC MODE ----------------------------------------------------------------------- 45

REFRIGERATING CYCLE DIAGRAM --------------------------------------- 71

DESCRIPTION OF MAIN CIRCUIT OPERATION ----------------------- 75

TROUBLE SHOOTING ---------------------------------------------------------- 106

DISASSEMBLY AND REASSEMBLY --------------------------------------- 113

PARTS LIST AND DIAGRAM ------------------------------------------------- 116

RAM-52QH5

RAM-53QH5

After installation

NOTE:

This manual describes only points that differ from RAF-25, 35,

50NH5, RAD-25, 35NH5, RAD-25, 35NH5 and RAM-80QH5

(TC No. 0771EF), RAI-25, 35NH5 (PM No. 0271E), RAI-50NH5

and RAC-50NH5 (PM No. 0274E), RAK-18, 25, 35NH5 (PM

No. 0269E), RAK-50NH5 and RAC-50NH5 (PM No. 0302E)

for items not described in this manual.

850

650

298

50

(W)

(A)

COOLING CAPACITY

DC INVERTER DUAL AND TRIPLE SYSTEM MULTI

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

TOTAL AMPERES

SPECIFICATIONS

OUTDOOR UNIT

RAM-52QH5

HEATING CAPACITY

DIMENSIONS (mm)

NET WEIGHT

1ø, 220 - 240V, 50Hz

W

H

D

(kg)

(kW)

(B.T.U.)

REFER TO THE SPECIFICATIONS PAGE

RAM-53QH5

Page 2

– 1 –

SAFETY DURING REPAIR WORK

1. In order to disassemble and repair

the unit in question, be sure to

disconnect the power cord plug

from the power outlet before starting

the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and

the replacement must be effected in correct manner according to the instructions in the Service Manual of

the unit.

If the contacts of electrical parts

are defective, replace the

electrical parts without trying to

repair them.

3. After completion of repairs, the initial state

should be restored.

4. Lead wires should be connected and laid as

in the initial state.

5. Modification of the unit by user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7. In installing the unit having been repaired, be careful to prevent the occurence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit. The insulation resistance should be 1M or more as measured by a 500V

DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being and safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location reinforced or at a new

location.

10. Any inflammable thing should never

be placed about the location of

installation.

11. Check the grounding to see whether

it is proper or not, and if it is found

improper, connect the grounding

terminal to the earth.

DANGER

First, I must disconnect

the power cord plug

from the power outlet.

Page 3

– 2 –

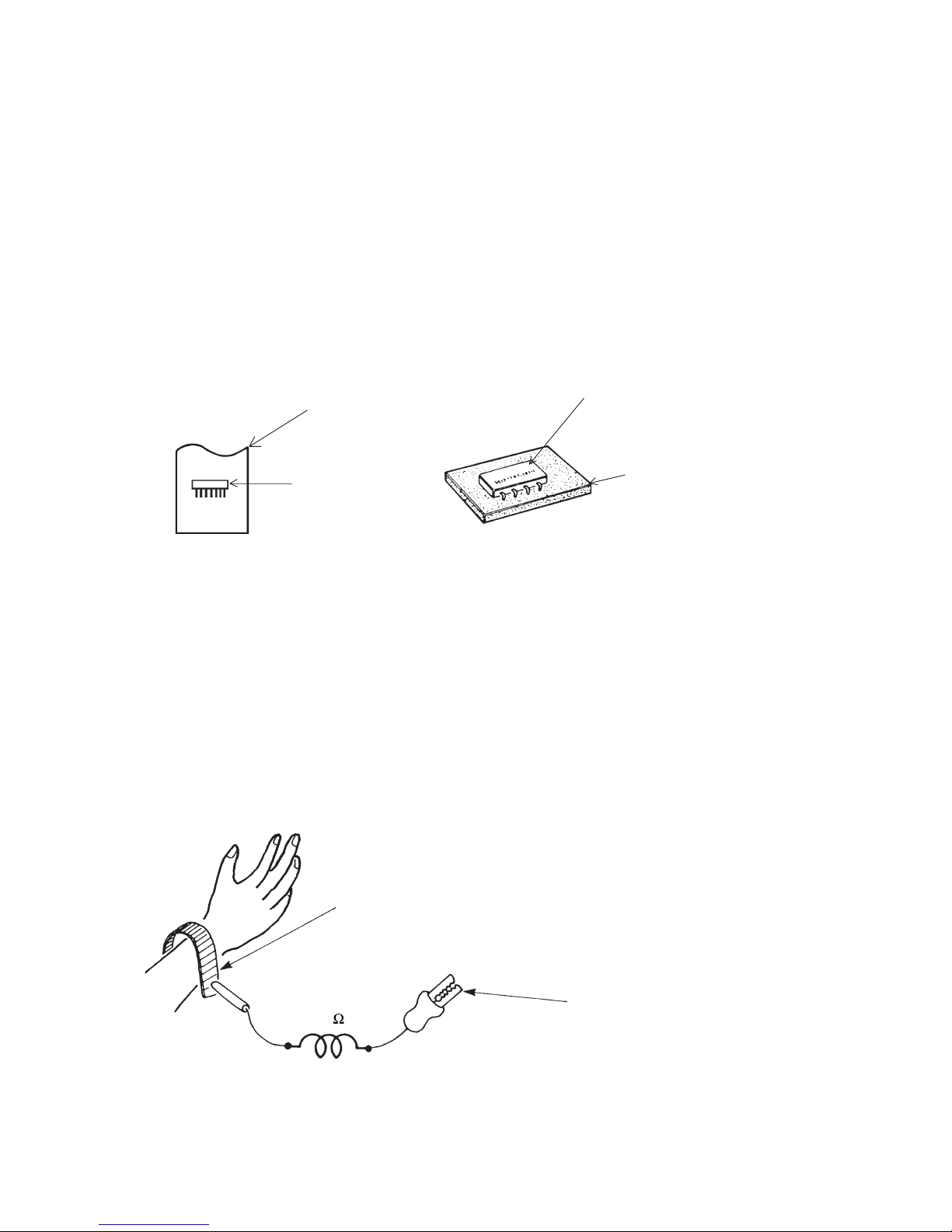

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in relative

manufacturers during maintenance and handling thereof. (They apply the same to handling of abnormal goods

such as rejected goods being returned).

2. Object parts

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) P.C. boards or the like on which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way).

Fig. 1. Conductive Container

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must always

use himself as a body earth. (Make yourself a body earth by passing one M ohm earth resistance through

a ring or bracelet).

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is being

taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time, try

to repair the printed circuit board on a grounded metal plate.

1M

Fig. 2. Body Earth

Body earth

(Elimik conductive band)

Clip for connection with a

grounding wire

IC

A conductive polyvinyl bag

IC

Conductive sponge

Page 4

– 3 –

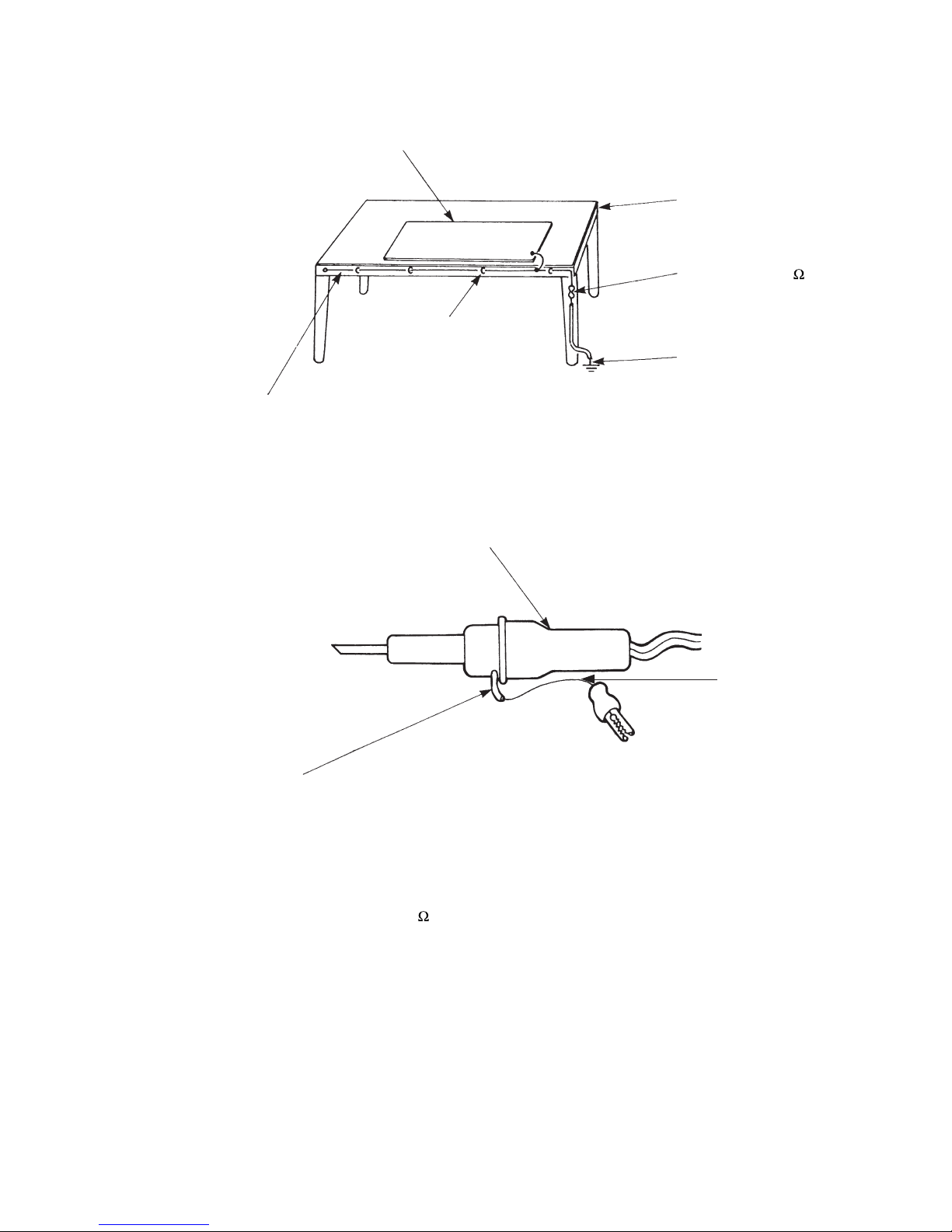

(6) Use a three wire type soldering iron including a grounding wire.

Bare copper wire (for body earth)

Working

table

Resistor of 1 M (1/2W)

Earth wire

Fig. 3. Grounding of the working table

Screw stop at the screwed

part using a rag plate

Soldering iron

Grounding

wire

Fig. 4. Grounding a soldering iron

Use a high insulation mode (100V, 10M or higher) when ordinary iron is to be used.

(7) In checking circuits for maintenance, inspection or some others, be careful not to have the test probes of the

measuring instrument shortcircuit a load circuit or the like.

Metal plate (of aluminium, stainless steel, etc.)

Staple

Page 5

– 4 –

1. In quiet operation or stopping the running, slight flowing noise of refrigerant in the refrigerating cycle is

heard occasionally, but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and to disconnect the power cord plug

from the power outlet for safety.

3. The room air conditioner does not start automatically after recovery of the electric power failure for

preventing fuse blowing. Re-press START/STOP button after 3 minutes from when unit stopped.

4. If the room air conditioner is stopped by adjusting thermostat, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal

and this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no

danger of blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below –10°C (14°F).

6. This room air conditioner (the reverse cycle) should not be used at heating operation when the outside

temperature is below –15°C (5°F). If the reverse cycle is used under this condition, the outside heat

exchanger is frosted and efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

!

CAUTION

Page 6

– 5 –

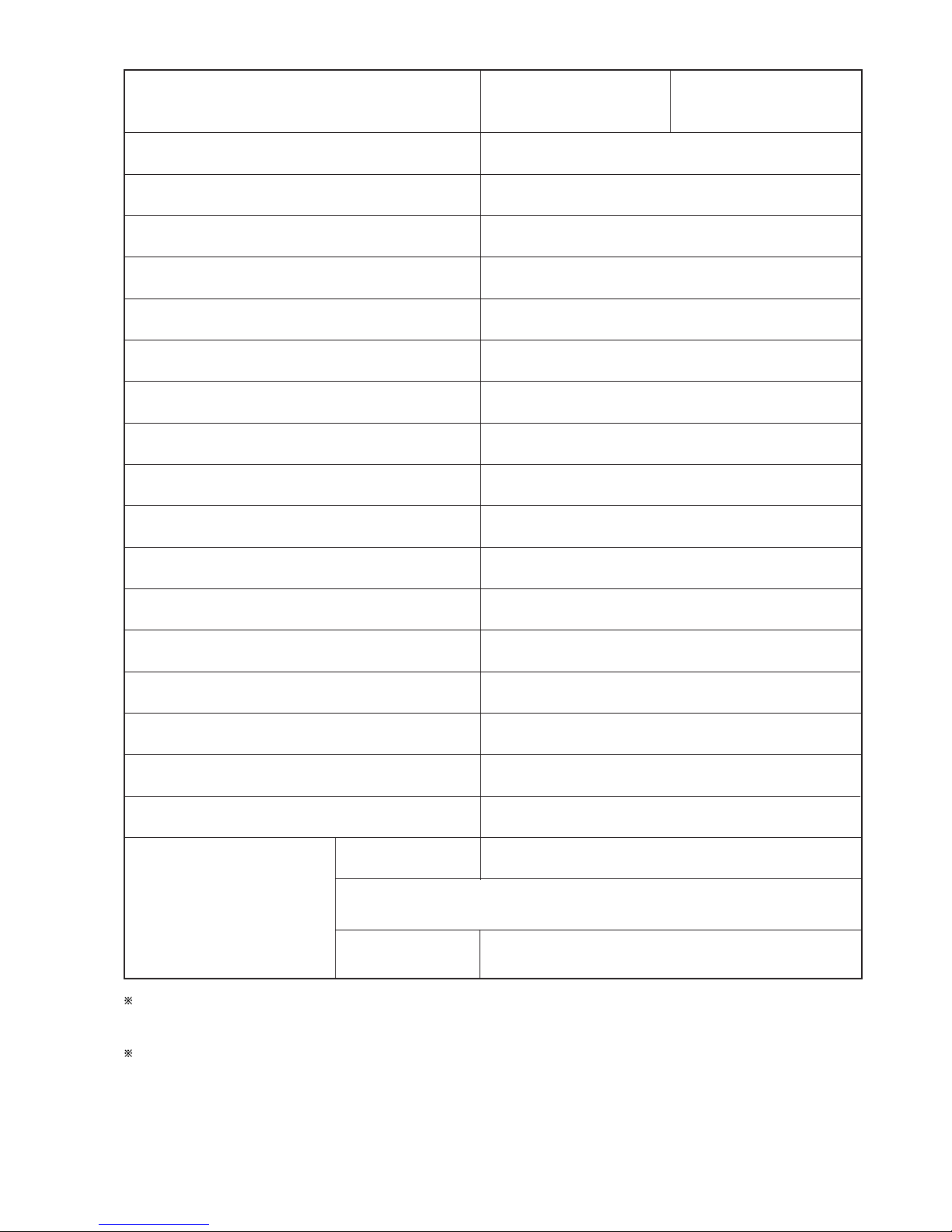

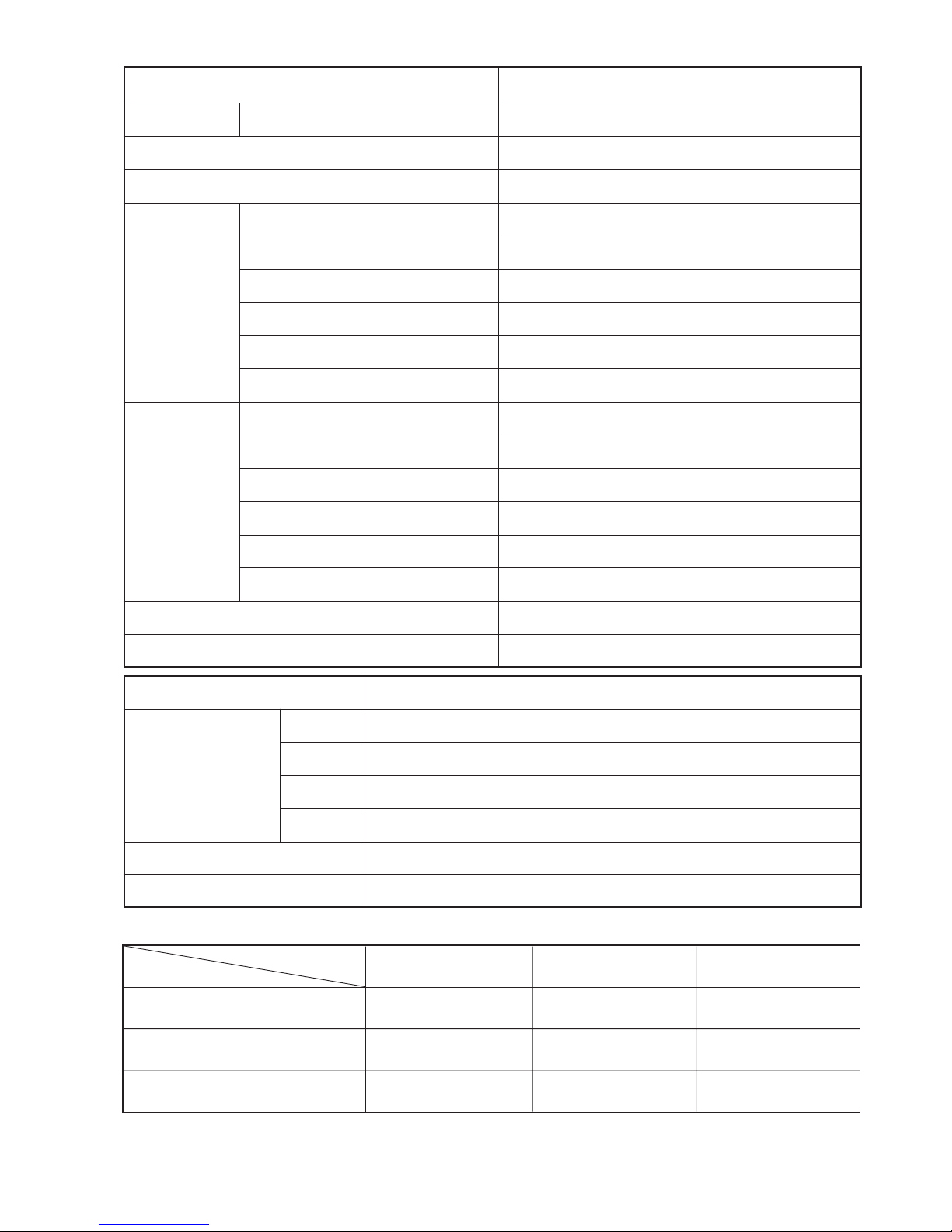

SPECIFICATIONS

MODEL

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

POWER SWITCH

TEMPORARY SWITCH

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

40 W

NO

NO

NO

YES

YES

5.0A

G4A

NO

NO

YES

NO

450NR

YES

YES(IC)

NO

1650g

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

UNIT

PIPES

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

RAM-52QH5

JU1013DA

MAX. 45m

RAM-53QH5

In case the pipe length is more than 35m, add refrigerant R410 at 20gram per every meter exceeds.

RAM-53QH5

RAM-52QH5

Additional charge of refrigerant is not required.

Page 7

– 6 –

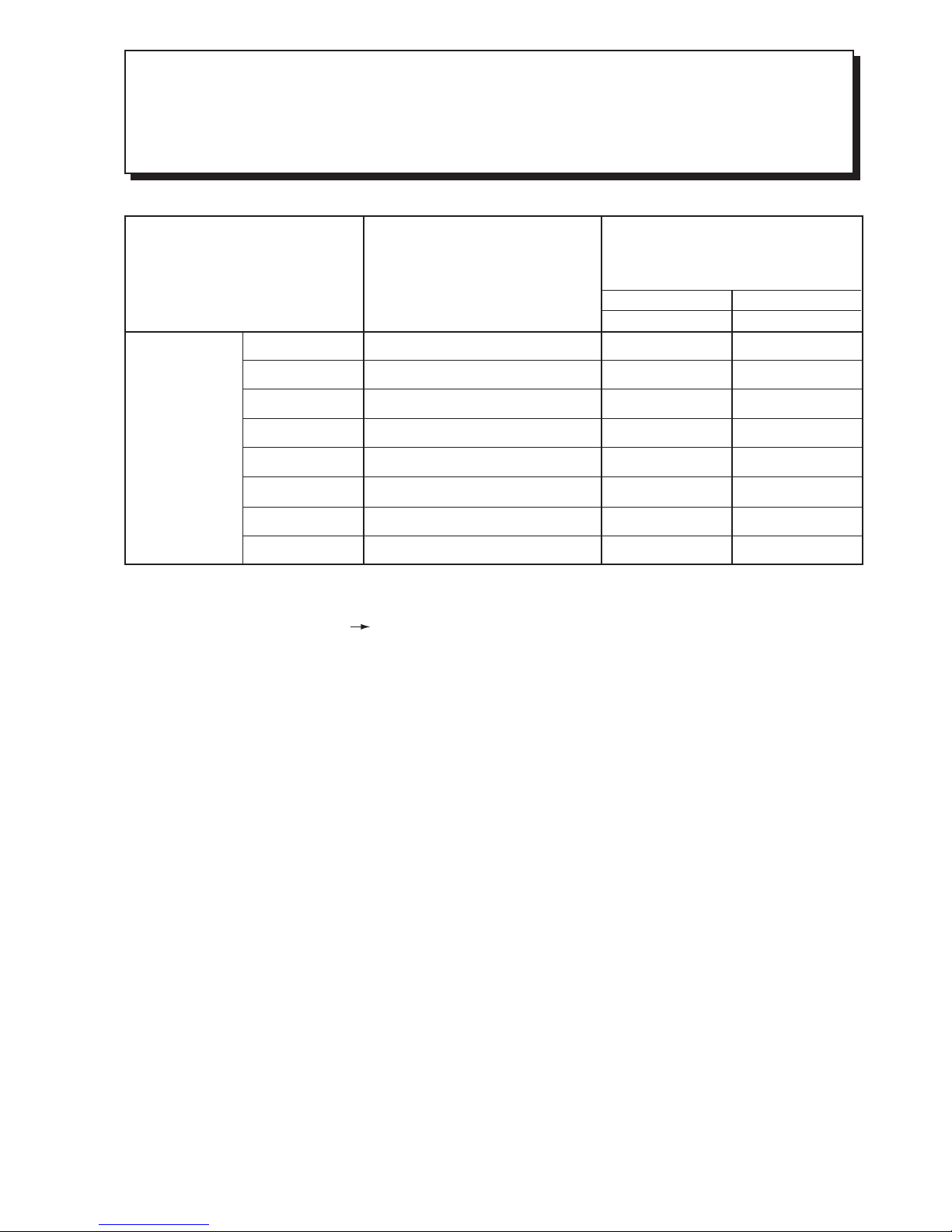

SPECIFICATIONS FOR INDOOR UNITS COMBINATION

OPERATION SCOPE

TYPE

DC INVERTER DUAL SYSTEM MULTI COOLING AND HEATING

MODEL OUTDOOR UNIT

PHESE/VOLTAGE/FREQUENCY

CIRCUIT AMPERES TO CONNECT (A)

COOLING

(TWO UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

HEATING

(TWO UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

MAXIMUM LENGTH OF PIPING

STANDARD

RAM-52QH5

1ø, 220 - 240V, 50Hz

16

5.20

17,740

1,500

11.79

6.9 - 6.3

99

6.80

23,200

1,790

12.68

8.2 - 7.5

99

MAX. 35m (TWO UNIT TOTAL)

CE (EMC&LVD)

RAM-52QH5

MODEL

W

PACKING

(mm)

H

D

cu.ft.

1,008

698

394

9.79

55

GROSS WEIGHT (kg)

6.35D/9.52DX2

FLARENUTSIZE (SMALL/LARGE)

INDOOR SUCTION

TEMPERATURE (˚C)

COOLING OPERATION SCOPE

OUTDOOR SUCTION

TEMPERATURE (˚C)

INDOOR SUCTION

HUMIDITY (%)

DEHUMIDIFYING OPERATION

HEATING OPERATION SCOPE

16 - 32 22 - 41 BELOW 80

16 - 32 22 - 42 BELOW 80

BELOW 27 –15 - 23

—

Page 8

– 7 –

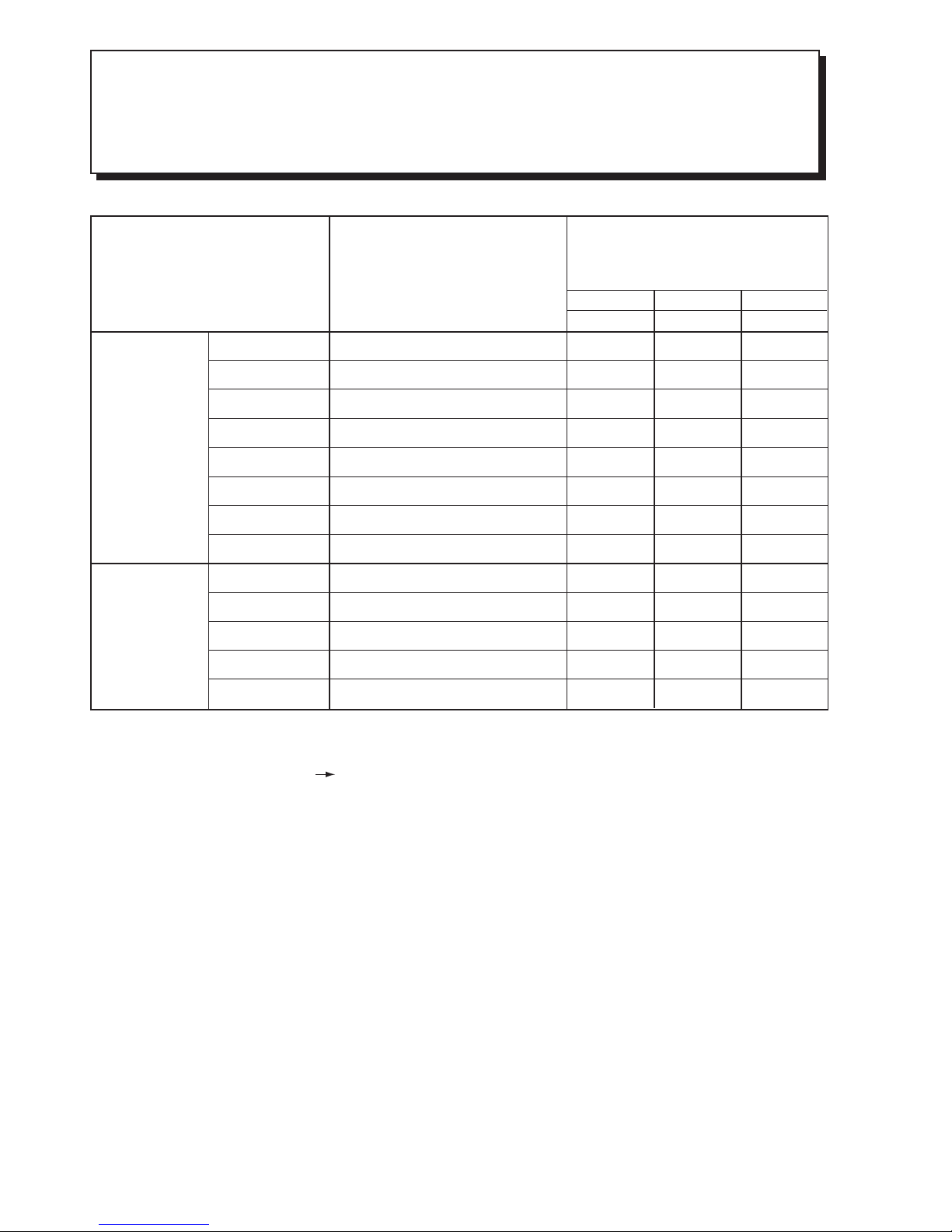

SPECIFICATIONS FOR INDOOR UNITS COMBINATION

TYPE

DC INVERTER TRIPLE SYSTEM MULTI COOLING AND HEATING

MODEL OUTDOOR UNIT

PHESE/VOLTAGE/FREQUENCY

CIRCUIT AMPERES TO CONNECT (A)

COOLING

(THREE UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

HEATING

(THREE UNITS)

CAPACITY (kW)

(B.T.U./h)

TOTAL INPUT (W)

EER (B.T.U./hW)

TOTAL AMPERES (A)

POWER FACTOR (%)

MAXIMUM LENGTH OF PIPING

STANDARD

RAM-53QH5

1ø, 220 - 240V, 50Hz

16

5.20

17,740

1,525

11.63

7.0 - 6.4

99

6.80

23,200

1,687

13.75

7.7 - 7.1

99

MAX. 45m (THREE UNIT TOTAL)

CE (EMC&LVD)

RAM-53QH5

MODEL

W

PACKING

(mm)

H

D

cu.ft.

1,008

698

394

9.79

55

GROSS WEIGHT (kg)

6.35D/9.52DX3

FLARENUTSIZE (SMALL/LARGE)

OPERATION SCOPE

INDOOR SUCTION

TEMPERATURE (˚C)

COOLING OPERATION SCOPE

OUTDOOR SUCTION

TEMPERATURE (˚C)

INDOOR SUCTION

HUMIDITY (%)

DEHUMIDIFYING OPERATION

HEATING OPERATION SCOPE

16 - 32 22 - 41 BELOW 80

16 - 32 22 - 42 BELOW 80

BELOW 27 –15 - 23

—

Page 9

– 8 –

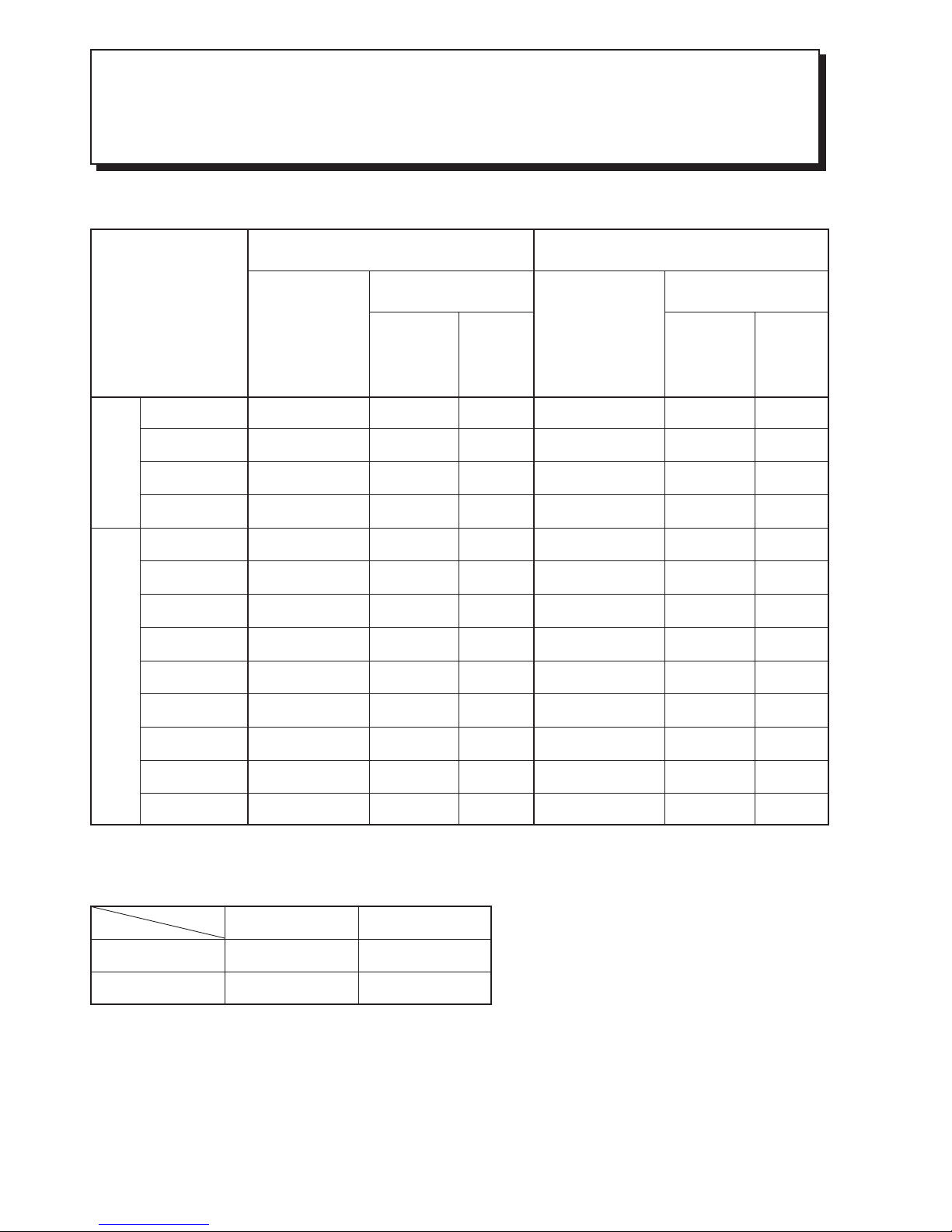

DUAL SYSTEM MULTI R.A.C.

RAM-52QH5

COOL / HEAT CAPACITY SPEC. FOR INDOOR UNITS

COMBINATIONS TO BE ABLE TO OPERATE SIMULTANEOUSLY

Whichever indoor units are installed, cooling and heating capacity depends on how many and which indoor units

are operating at that time.

RATING CONDITON (DRY BLUB / WET BULB)

COOLING

HEATING

INDOOR OUTDOOR

27 / 19 ˚C

20 / –˚C

35 / 24˚C

7 / 6˚C

ONE UNIT

TWO UNITS

POSSIBLE

COMBINATIONS

TO OPERATE

AMPERE

(A)

220-240V

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

ONE UNIT : The values indicated are only for one unit operation when two indoor units are connected.

OUTDOOR UNIT

COOLING

AMPERE

(A)

220-240V

CAPACITY RATING

(kW) (RANGE)

POWER

CONSUMPTION

(W)

OUTDOOR UNIT

HEATING

(Reference value)

1.8

2.5

3.5

5.0

1.8 + 1.8

1.8 + 2.5

1.8 + 3.5

1.8 + 5.0

2.5 + 2.5

2.5 + 3.5

3.5 + 3.5

2.5 + 5.0

3.5 + 5.0

1.80

2.50

3.50

5.00

1.80 + 1.80

1.76 + 2.44

1.70 + 3.30

1.38 + 3.82

2.50 + 2.50

2.17 + 3.03

2.60 + 2.60

1.73 + 3.47

2.14 + 3.06

495

700

1030

1510

1015

1167

1472

1540

1472

1525

1500

1500

1500

2.3 - 2.1

3.2 - 2.9

4.7 - 4.3

6.9 - 6.4

4.7 - 4.3

5.4 - 4.9

6.8 - 6.2

7.1 - 6.5

6.8 - 6.2

7.0 - 6.4

6.9 - 6.3

6.9 - 6.3

6.9 - 6.3

2.50

3.90

4.80

6.50

2.50 + 2.50

2.60 + 3.60

2.31 + 4.49

1.80 + 5.00

3.40 + 3.40

2.83 + 3.97

3.40 + 3.40

2.27 + 4.53

2.8 + 4.00

690

1060

1320

1800

1290

1650

1790

1790

1885

1790

1790

1790

1790

3.2 - 2.9

4.9 - 4.5

6.1 - 5.6

8.3 - 7.6

5.9 - 5.4

7.6 - 6.9

8.2 - 7.5

8.2 - 7.5

8.7 - 7.9

8.2 - 7.5

8.2 - 7.5

8.2 - 7.5

8.2 - 7.5

Page 10

– 9 –

TRIPLE SYSTEM MULTI R.A.C.

RAM-53QH5

COOL / HEAT CAPACITY SPEC. FOR INDOOR UNITS

COMBINATIONS TO BE ABLE TO OPERATE SIMULTANEOUSLY

Whichever indoor units are installed, cooling and heating capacity depends on how many and which indoor units

are operating at that time.

RATING CONDITON (DRY BLUB / WET BULB)

COOLING

HEATING

INDOOR OUTDOOR

27 / 19 ˚C

20 / –˚C

35 / 24˚C

7 / 6˚C

(Reference value)

* ONE UNIT INDICATED ARE ONLY FOR ONE UNIT OPERATION WHEN TWO INDOOR UNITS ARE CONNECTED.

Page 11

– 10 –

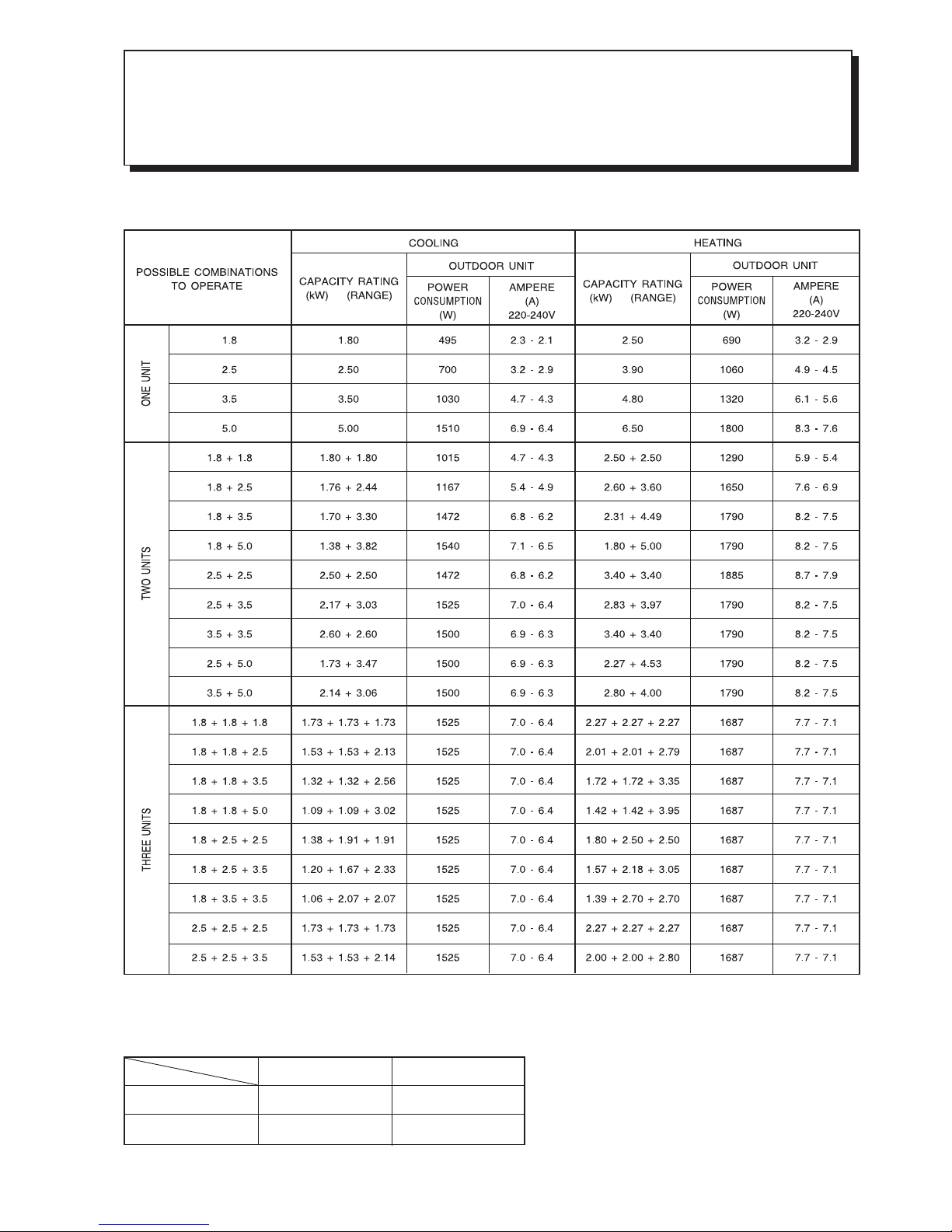

DUAL AND TRIPLE SYSTEM MULTI R.A.C.

RAM-52QH5 & RAM-53QH5

INDOOR UNITS COMBINATIONS TO BE ABLE TO INSTALL

Two or three indoor units can be installed with one outdoor unit.

And total nominal cooling capacity should not be more than 9.0kW

Be sure to connect two or three indoor units to this outdoor unit. If not, condensed water may drop, resulting in

trouble.

INDOOR UNIT

MODEL

NOMINAL

COOLING

CAPACITY

(kW)

CAPACITY (kW)

at one unit operation

SUITABLE ROOM SIZE (m2)

at one unit operation

COOLING HEATING COOLING HEATING

RAK-18NH5

RAK-18NH6

RAK-18NH6A

RAK-18QH8

RAK-25NH5

RAK-25NH6

RAK-25NH6A

RAK-25QH8

RAI-25NH5

RAI-25NH5A

RAF-25NH5

RAF-25QH8

RAD-25NH5

RAD-25NH7

RAD-25NH7A

RAK-35NH5

RAK-35NH6

RAK-35NH6A

RAK-35QH8

RAI-35NH5

RAI-35NH5A

RAF-35NH5

RAF-35QH8

RAD-35NH5

RAD-35NH7

RAD-35NH7A

RAK-50NH5

RAK-50NH6

RAK-50NH6A

RAK-50QH8

RAI-50NH5

RAI-50NH5A

RAF-50NH5

RAF-50QH8

RAD-50NH7

RAD-50NH7A

1.8kW

1.00 – 1.80

1.00 – 1.80

1.00 – 1.80

1.00 – 1.80

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 1.80

1.00 – 1.80

1.00 – 1.80

1.00 – 1.80

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 2.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 3.50

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

1.00 – 5.00

8 – 12

8 – 12

8 – 12

8 – 12

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

11 – 17

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

16 – 24

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

23 – 34

9 – 11

9 – 11

9 – 11

9 – 11

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

14 – 18

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

17 – 22

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

23 – 29

2.5kW

3.5kW

5.0kW

Page 12

– 11 –

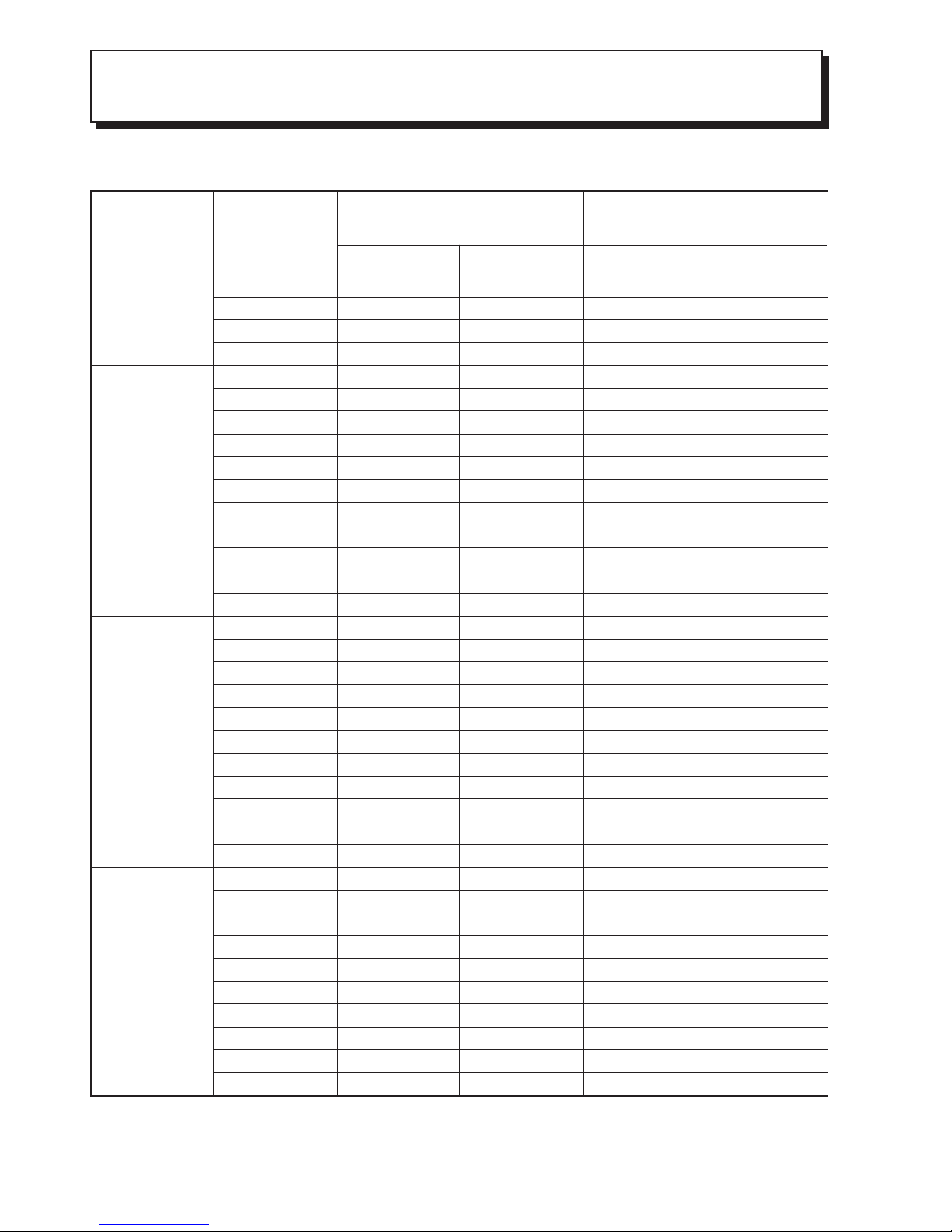

DUAL SYSTEM MULTI R.A.C.

RAM-52QH5

CONNECTING POSISION TO BE ABLE TO INSTALL

POSSIBLE COMBINATIONS

TO INSTALL

(kW)

CONNECTING POSITION ON

OUTDOOR UNIT

(VALVE DIAMETER)

(mm)

No.1 No.2

SUITABLE ROOM SIZE

TO INSTALL

(m2)

6.35/9.52D 6.35/9.52D

TWO UNITS

1.8+1.8

1.8+2.5

1.8+3.5

1.8+5.0

2.5+2.5

2.5+3.5

(8-12) + (8-12)

(8-12) + (10-16)

(7-9) + (15-22)

(6-9) + (18-27)

(12-15) + (12-15)

(11-14) + (14-18)

1.8

1.8

1.8

1.8

2.5

2.5

1.8

2.5

3.5

5.0

2.5

3.5

2.5, 3.5, 4.0, 5.0 means indoor units cooling capacity class.

(1) Marking

: needs flare adapter (9.52 12.7D): Part No. TA261D-4 001

(2) Suitable room size is determined based on the conditions below:

• Climate is in the temperate zone like Tokyo, Japan.

• For usual residential use.

• Smaller figure is for light construction which means light thermally sealed.

• Larger figure is for heavy constructions, which means well thermally sealed.

3.5+3.5 (13-16) + (13-16) 3.5 3.5

2.5+5.0 (10-12) + (18-20) 2.5 5.0

Page 13

– 12 –

TRIPLE SYSTEM MULTI R.A.C.

RAM-53QH5

CONNECTING POSISION TO BE ABLE TO INSTALL

POSSIBLE COMBINATIONS

TO INSTALL

(kW)

CONNECTING POSITION ON

OUTDOOR UNIT

(VALVE DIAMETER)

(mm)

No.1 No.2

SUITABLE ROOM SIZE

TO INSTALL

(m2)

No.3

6.35/9.52D 6.35/9.52D 6.35/9.52D

TWO UNITS

THREE UNITS

1.8+1.8+1.8

1.8+1.8+2.5

(8-12) + (8-12) + (8-12)

(8-12) + (8-12) + (11-17)

1.8

1.8

1.8

1.8

1.8

2.5

1.8+1.8

1.8+2.5

1.8+3.5

1.8+5.0

2.5+2.5

2.5+3.5

(8-12) + (8-12)

(8-12) + (10-16)

(7-9) + (15-22)

(6-9) + (18-27)

(12-15) + (12-15)

(11-14) + (14-18)

1.8

1.8

1.8

1.8

2.5

2.5

1.8

2.5

3.5

5.0

2.5

3.5

3.5+3.5 (13-16) + (13-16) 3.5 3.5

2.5+5.0 (10-12) + (18-20) 2.5 5.0

2.5, 3.5, 4.0, 5.0 means indoor units cooling capacity class.

(1) Marking

: needs flare adapter (9.52 12.7D): Part No. TA261D-4 001

(2) Suitable room size is determined based on the conditions below:

• Climate is in the temperate zone like Tokyo, Japan.

• For usual residential use.

• Smaller figure is for light construction which means light thermally sealed.

• Larger figure is for heavy constructions, which means well thermally sealed.

1.8+1.8+3.5 (7-11) + (7-11) + (14-21) 1.8 1.8 3.5

1.8+2.5+2.5 (7-11) + (10-15) + (10-15) 1.8 2.5 2.5

2.5+2.5+2.5 (10-11) + (10-11) + (10-11) 2.5 2.5 2.5

Page 14

– 13 –

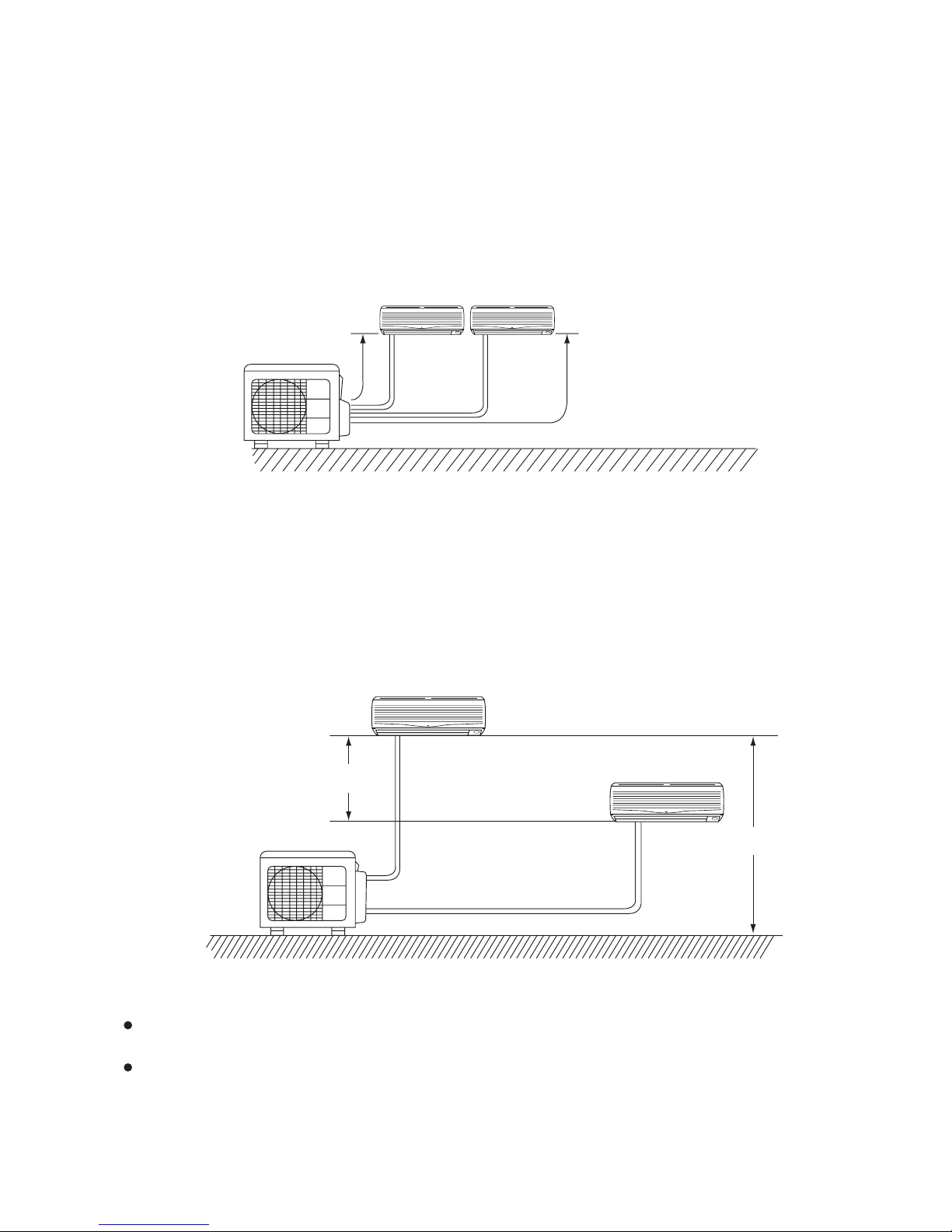

Indoor unit 1

Outdoor unit

Outdoor unit

Maximum 5m

Maximum –10m

Indoor unit

Indoor unit

Indoor unit 2

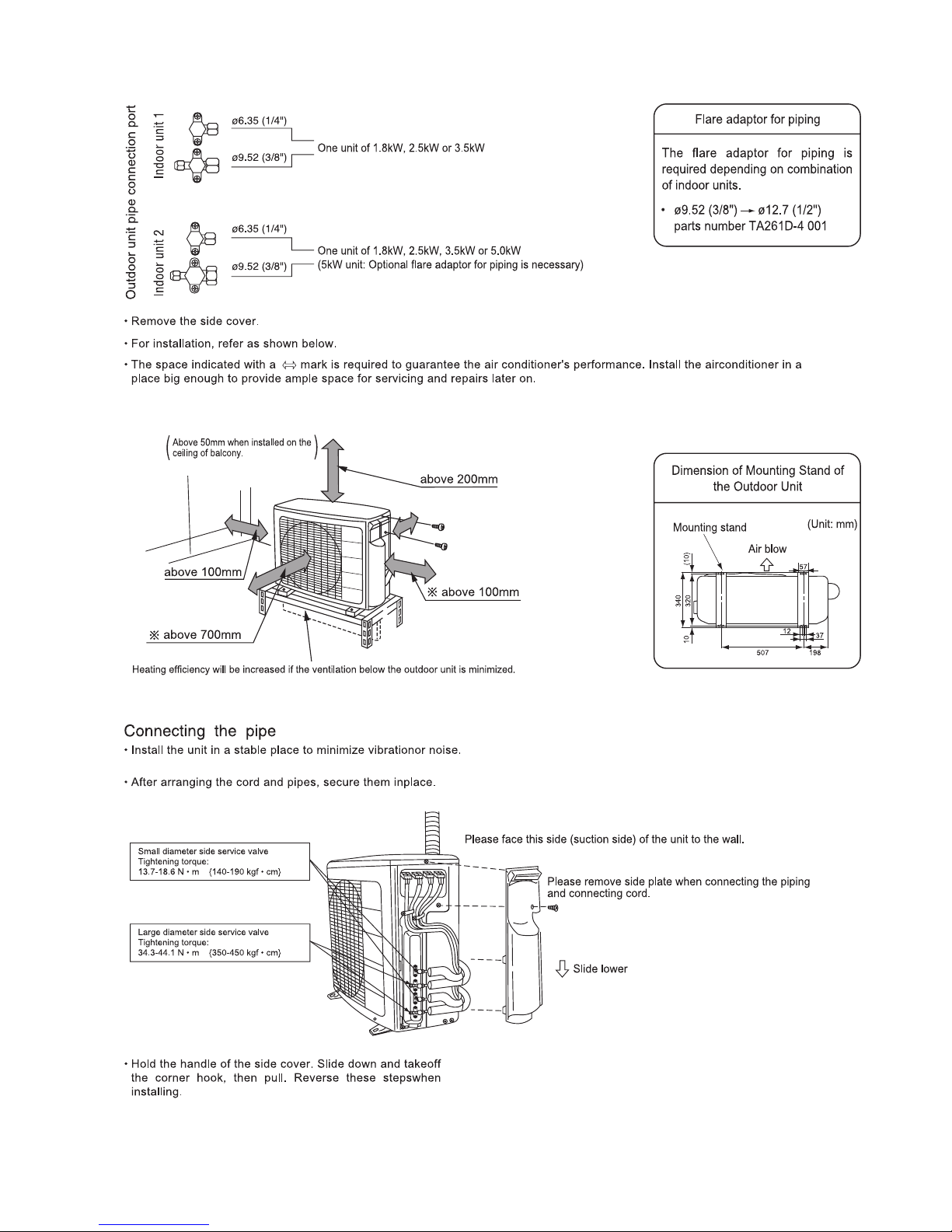

INSTALLATION

PIPE LENGTH

(1) Total 35m maximum pipe length.

(2) Pipe length for one indoor unit : maximum 25m.

HIGHT DIFFERENCE

(1) Hight : maximum ± 10m

(2) Hight difference between each indoor unit ≤ 5m.

L

1

L

2

To the outdoor unit, up to two indoor units can be connected until the total value of

capacity from 7.5kW.

Make sure to connect to two indoor units.

Page 15

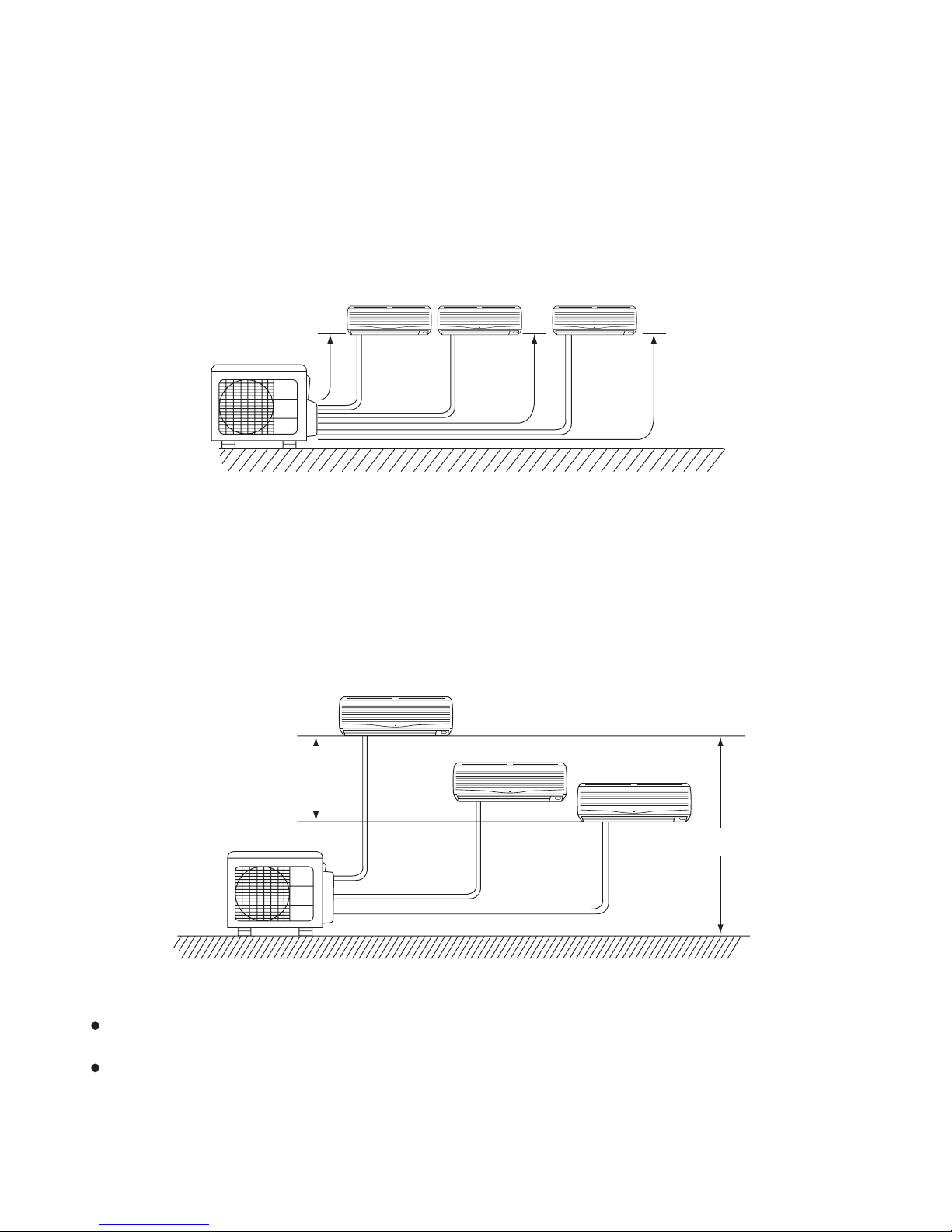

– 14 –

Indoor unit 1

Outdoor unit

Outdoor unit

Maximum 5m

Maximum –10m

Indoor unit

Indoor unit

Indoor unit

Indoor unit 2 Indoor unit 3

INSTALLATION

PIPE LENGTH

(1) Total 45m maximum pipe length.

(2) Pipe length for one indoor unit : maximum 25m.

HIGHT DIFFERENCE

(1) Hight : maximum ± 10m

(2) Hight difference between each indoor unit ≤ 5m.

L

1 L

2

L

3

To the outdoor unit, up to three indoor units can be connected until the total value of

capacity from 7.5kW.

Make sure to connect to two or three indoor units.

Page 16

– 15 –

MODEL: RAM-52QH5

Page 17

– 16 –

MODEL: RAM-53QH5

Page 18

– 17 –

Above 100mm

Drain hole

Bushing

Outer diameter above 16mm

b

•

•

•

•

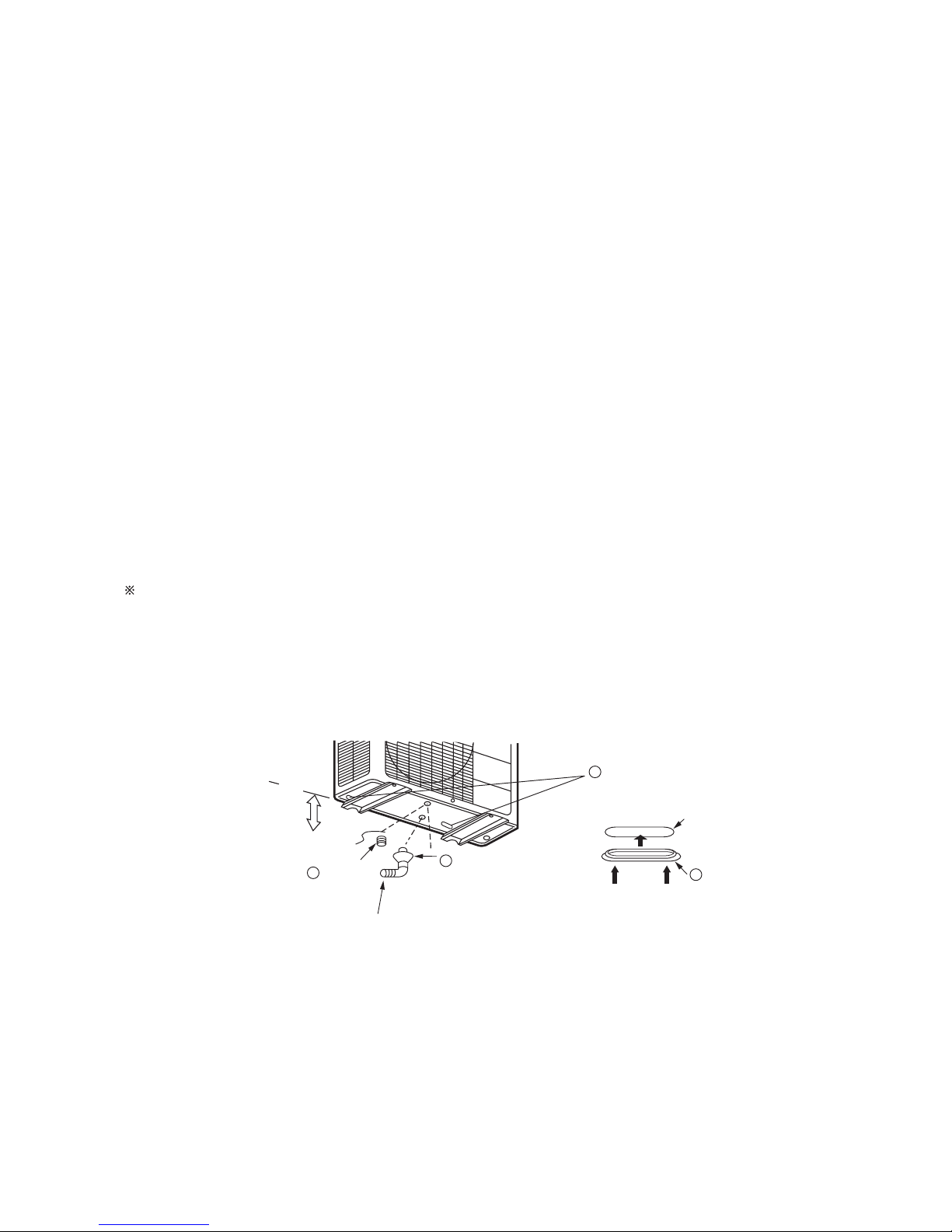

Condensed water disposal of outdoor unit

When Using and Installing in Cold Areas

There is holes on the base of outdoor unit for condensed water to exhaust.

To lead condensed water to the drain hole, place the outdoor unit on the mounting stand (optional) or on blocks to raise its

level more than 100mm from the ground surface. Connect the drain pipe as shown in the figure. Cover two other water

drain holes with the bushings included. (To insall a bushing, push in both ends of the bushing so that it aligns with the drain

hole.)

When connecting the drain pipe, make sure that the bushing does not lift off or deviate from the base.

1.

Remove flare nut from service valve.

4.

Perform air purge and gas leak inspection.

2.

Apply refrigerant oil to flare nut sections of servicevalve and pipings.

5.

Wrap the provided insulating material around sidepiping using vinyl tape.

3.

Match center of piping to large diameter side service valve and tank assembly, and tighten flarenut first by hand,

then securely tighten using torque wrench.

Install the outdoor unit on a stable, flat surface and check to see that the condensed water drains.

For more details, refer to the Installation Manual for Cold Areas.

When the air conditioner is used in low temperature and in snowy conditions, water from the heat exchanger may freeze

on the base surface to cause poor drainage. When using the air conditioner in such areas, do not install the bushings. Keep a

minimum of 250mm between the drain hole and the ground. When using the drain pipe, consult your sales agent.

Bushingb

Bushingb

Drain pipe

Drain hole

Push Push

a

Page 19

– 18 –

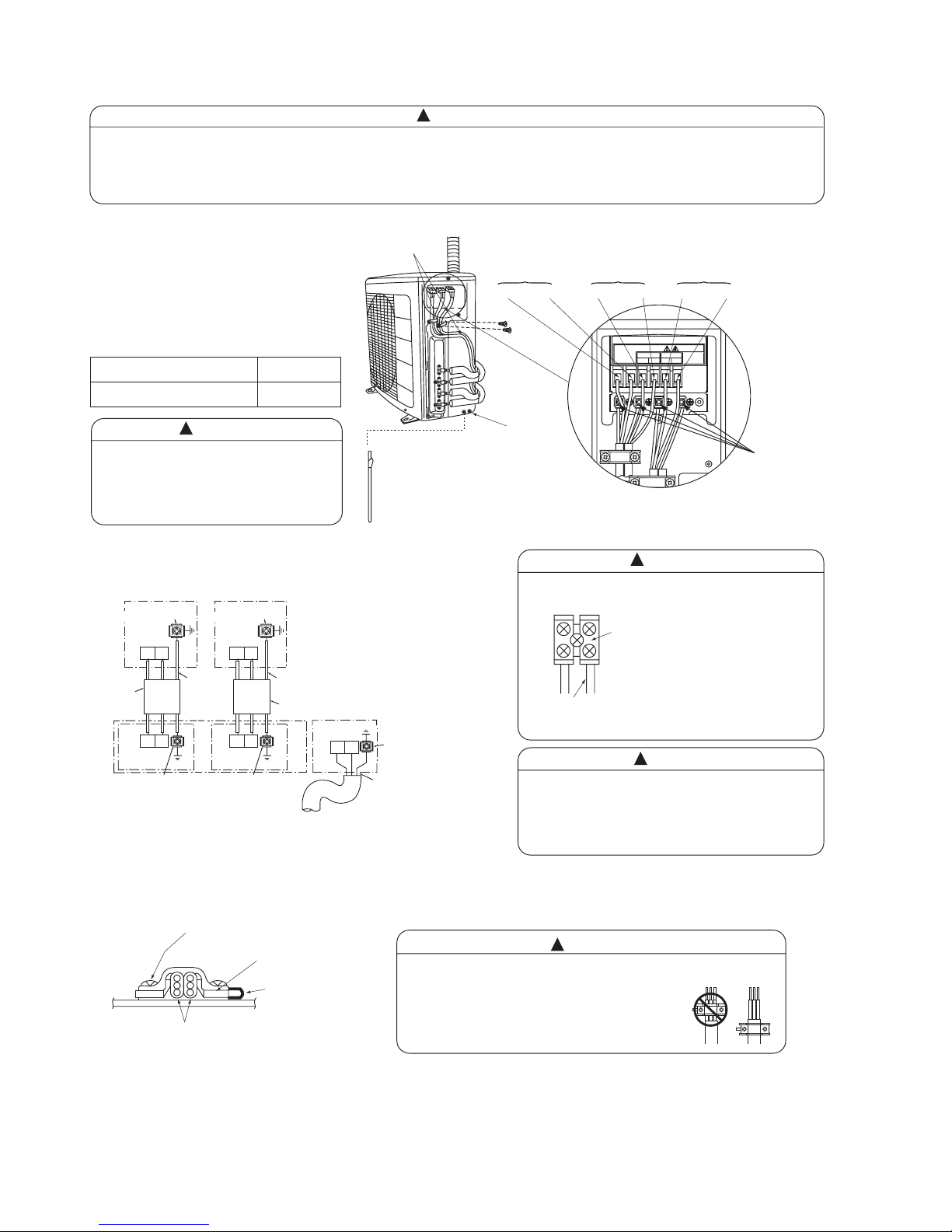

Outdoor Unit

Wiring pattern

Indoor Unit

Fig. 1

Power cord

Screw

Insulating plate

Cord band

Connecting cord

CD

C1 D1

Indoor unit No. 1

Screw for ground, earth screw

Screw for ground, earth screw

For Indoor unit No. 1

Terminal board

Terminal board

Connecting cord

Ø1.6 or 2.0

Connecting cord

Ø1.6 or 2.0

Green-andYellow

CD

C2 D2

Indoor unit No. 2

Screw for ground, earth screw

Screw for ground, earth screw

For Indoor unit No. 2

Terminal board

Terminal board

Green-andYellow

LN

Screw for ground,

earth screw

Terminal board

Green-and-Yellow

AC 220V~240V ONLY

LN

INDOOR 1

C1D1C2 D2

INDOOR 2

Connection of the connecting cords and power cord. (Outdoor unit)

RAM-52QH5

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

Connecting cord should be connected according to Fig.1, that the Indoor unit No. shall match with terminal board No.

of Outdoor unit.

Be sure to fix the connecting cord with the band as shown below. Otherwise water leakage causes short circuit or faults.

Bind connecting cords to

make them fit between the

convex sections.

Earth wire

Earth

Circuit breaker

LN C1D

1

C

2

D

2

Indoor unit 1 Indoor unit 2

Terminal indications

Grounding rod (optional)

Earth line and grounding rod are not supplied.

Please use optional items below.

•

•

•

•

•

•

•

( )

If earth line cannot be taken from

the power supply connection, use

the optional grounding rod to do

earthing.

Type of grounding rod

SP-EB-2

Length

900mm

Connection of the power cord and connecting

cord

Securely screw in the power cord

and connecting cord so that it will not

get loose or disconnect.

Tightening torque reference value:

1.2 to 1.6 N•m (12 to 16 kgf•cm)

Excessive tightening may damage

the interior of the cord requiring

replacement.

Power cord and

Connecting cord

To prevent a connection error, connecting cords

should be bundled and taped to each respective

pipe. If connecting cords are mixed with other indoor

units, a refrigeration cycle abnormality may occur,

causing dripping.

Leave some space in the connecting cord for maintenance purpose

and be sure to secure it with the cord band.

Secure the connecting cord along the coated part

of the wire using the cord band. Do not exert

pressure on the wire as this may cause

overheating or fire.

When putting two connecting cords through the band.

•

Hold the handle of the side cover, slide down and take off the corner hook, then pull. Reverse these steps when installing.

Page 20

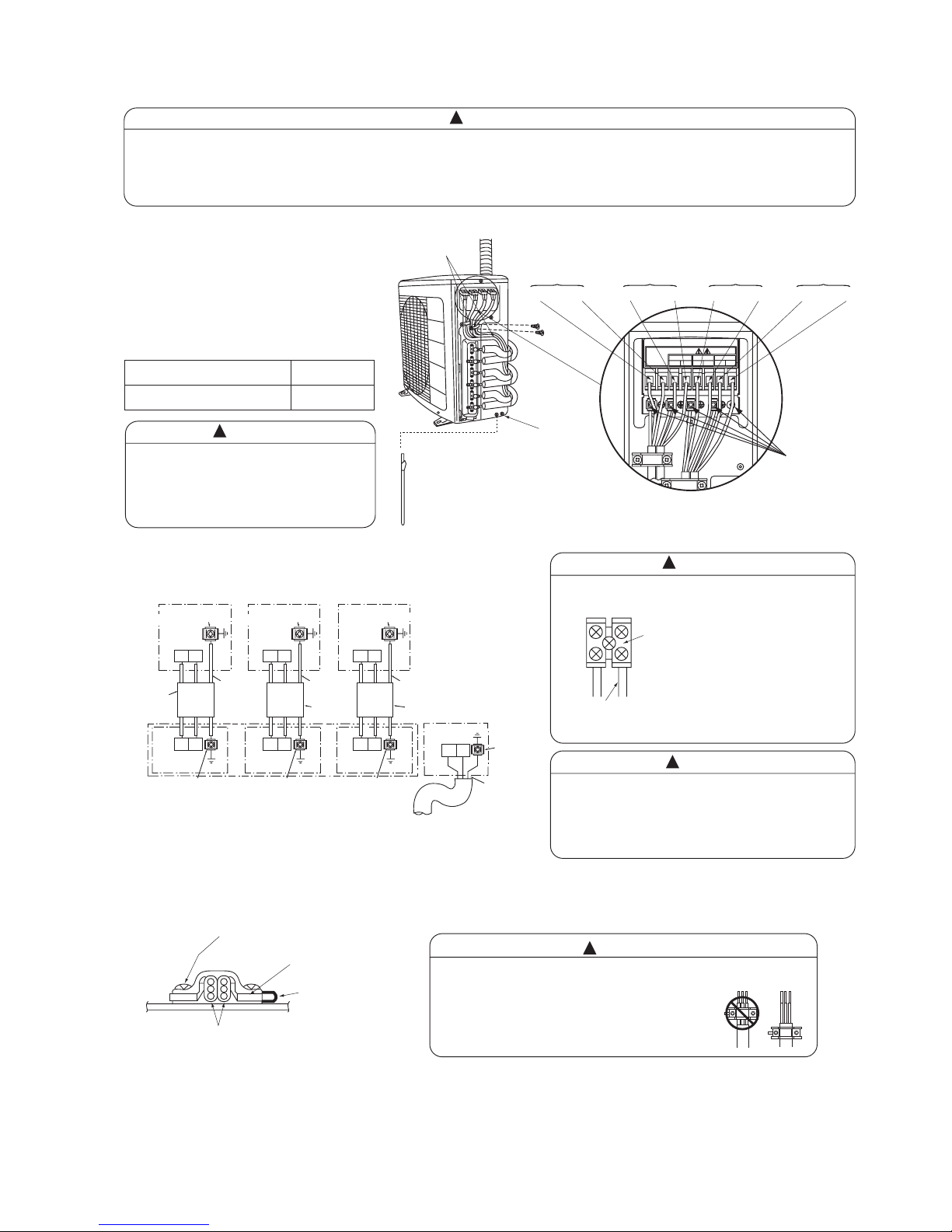

– 19 –

Screw for ground, earth screw

Outdoor Unit

Wiring pattern

Indoor Unit

Fig. 1

Power cord

Screw

Insulating plate

Cord band

Connecting cord

CD

C1 D1

Indoor unit No. 1

Screw for ground, earth screw

Screw for ground, earth screw

For Indoor unit No. 1

Terminal board

Terminal board

Connecting cord

Ø1.6 or 2.0

Green-andYellow

CD

C2 D2

Indoor unit No. 2

Screw for ground, earth screw

Screw for ground, earth screw

For Indoor unit No. 2

Terminal board

Terminal board

Green-andYellow

CD

C3 D3

LN

Indoor unit No. 3

Screw for ground, earth screw

Screw for ground,

earth screw

For Indoor unit No. 3

Terminal board

Terminal board

Terminal board

Connecting cord

Ø1.6 or 2.0

Connecting cord

Ø1.6 or 2.0

Green-and-Yellow

Green-and-Yellow

AC 220V~240V ONLY

LN

INDOOR 1

C1D1C2 D2

INDOOR 2

C3 D3

INDOOR 3

Connection of the connecting cords and power cord. (Outdoor unit)

RAM-53QH5

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

Connecting cord should be connected according to Fig.1, that the Indoor unit No. shall match with terminal board No.

of Outdoor unit.

Be sure to fix the connecting cord with the band as shown below. Otherwise water leakage causes short circuit or faults.

Bind connecting cords to

make them fit between the

convex sections.

Earth wire

Earth

Circuit breaker

LN C1D

1

C

2

D

2

C

3

D

3

Indoor unit 1 Indoor unit 2 Indoor unit 3

Terminal indications

Grounding rod (optional)

Earth line and grounding rod are not supplied.

Please use optional items below.

•

•

•

•

•

•

•

( )

If earth line cannot be taken from

the power supply connection, use

the optional grounding rod to do

earthing.

Type of grounding rod

SP-EB-2

Length

900mm

Connection of the power cord and connecting

cord

Securely screw in the power cord

and connecting cord so that it will not

get loose or disconnect.

Tightening torque reference value:

1.2 to 1.6 N•m (12 to 16 kgf•cm)

Excessive tightening may damage

the interior of the cord requiring

replacement.

Power cord and

Connecting cord

To prevent a connection error, connecting cords

should be bundled and taped to each respective

pipe. If connecting cords are mixed with other indoor

units, a refrigeration cycle abnormality may occur,

causing dripping.

Leave some space in the connecting cord for maintenance purpose

and be sure to secure it with the cord band.

Secure the connecting cord along the coated part

of the wire using the cord band. Do not exert

pressure on the wire as this may cause

overheating or fire.

When putting two connecting cords through the band.

•

Hold the handle of the side cover, slide down and take off the corner hook, then pull. Reverse these steps when installing.

Page 21

– 20 –

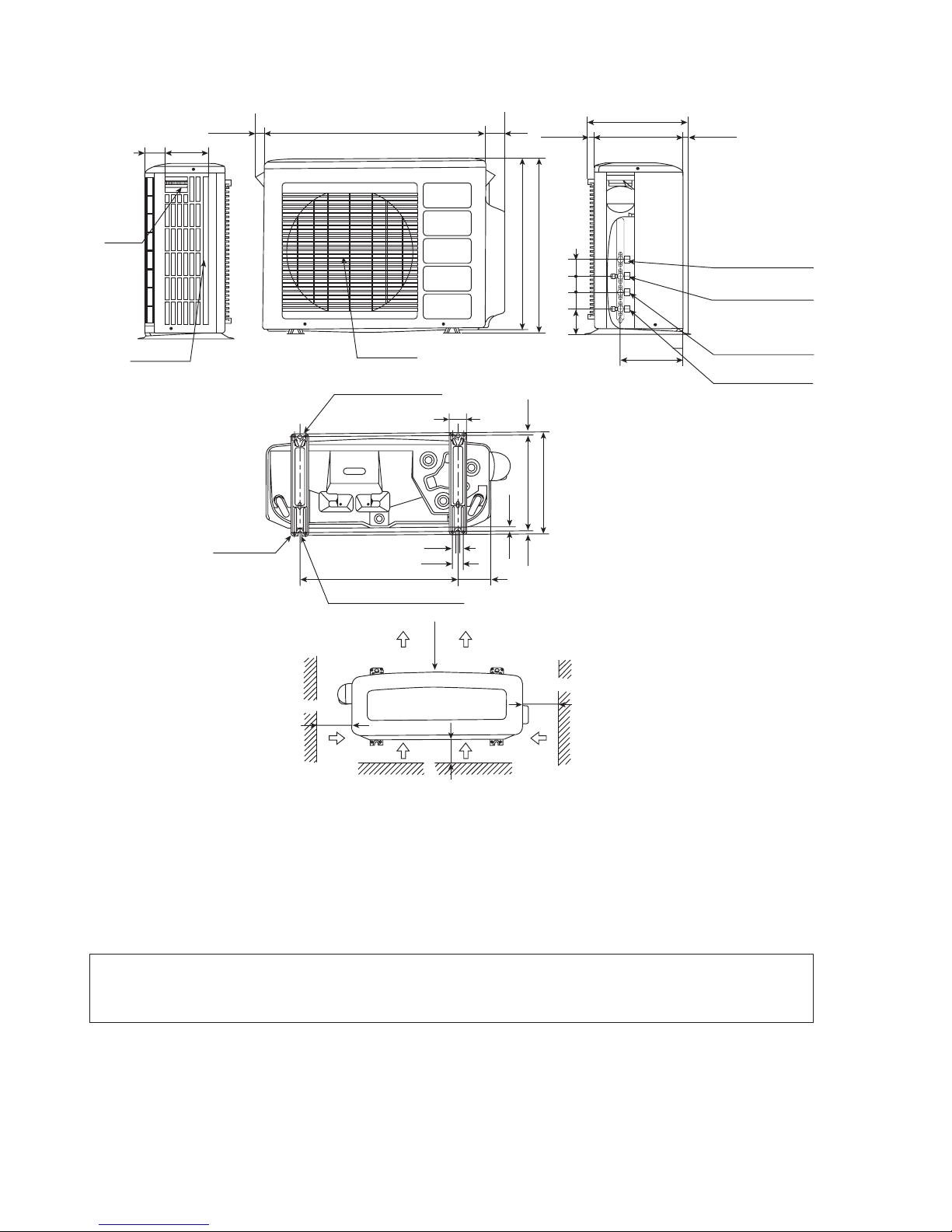

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAM-52QH5

Handle

Air suction

grille

10464

26 850 79

22 20

Indoor unit 1

Service valve (ø6.35)

Indoor unit 2

Service valve (ø6.35)

Indoor unit 1

Service valve (ø9.52)

Indoor unit 2

Service valve (ø9.52)

298

340

Unit: mm

201

107.5 52 52 52

650

638

Air outlet

1010

10

320

340

Holes for anchor bolt

(2-ø12)

Fixing hole

507 198

57

12

37

Notch for anchor bolt

(2-ø12 Notchs)

More than

More than

More than

100

More than

700

100

100

Service space

ATTENTION

During service, before opening the side cover, please switch off power supply.

Note:

1. Insulated pipes should be used for both small and large diameter pipes.

2. Piping length should be within 25m for one room and within 35m in total.

3. Height difference of piping between indoor unit and outdoor unit should be within 10m.

4. Overhead clearance of outdoor unit should be 200mm to allow servicing.

5. For electrical connection, please refer to the installation manual.

Page 22

– 21 –

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAM-53QH5

Handle

Air suction

grille

10464

26 850 79

22 20

Indoor unit 1

Service valve (ø6.35)

Indoor unit 2

Service valve (ø6.35)

Indoor unit 3

Service valve (ø6.35)

Indoor unit 1

Service valve (ø9.52)

Indoor unit 2

Service valve (ø9.52)

Indoor unit 3

Service valve (ø9.52)

298

340

Unit: mm

201

107.5 52 52 52 52 52

650

638

Air outlet

1010

10

320

340

Holes for anchor bolt

(2-ø12)

Fixing hole

507 198

57

12

37

Notch for anchor bolt

(2-ø12 Notchs)

More than

More than

More than

100

More than

700

100

100

Service space

ATTENTION

During service, before opening the side cover, please switch off power supply.

Note:

1. Insulated pipes should be used for both small and large diameter pipes.

2. Piping length should be within 25m for one room and within 45m in total.

3. Height difference of piping between indoor unit and outdoor unit should be within 10m.

4. Overhead clearance of outdoor unit should be 200mm to allow servicing.

5. For electrical connection, please refer to the installation manual.

Page 23

– 22 –

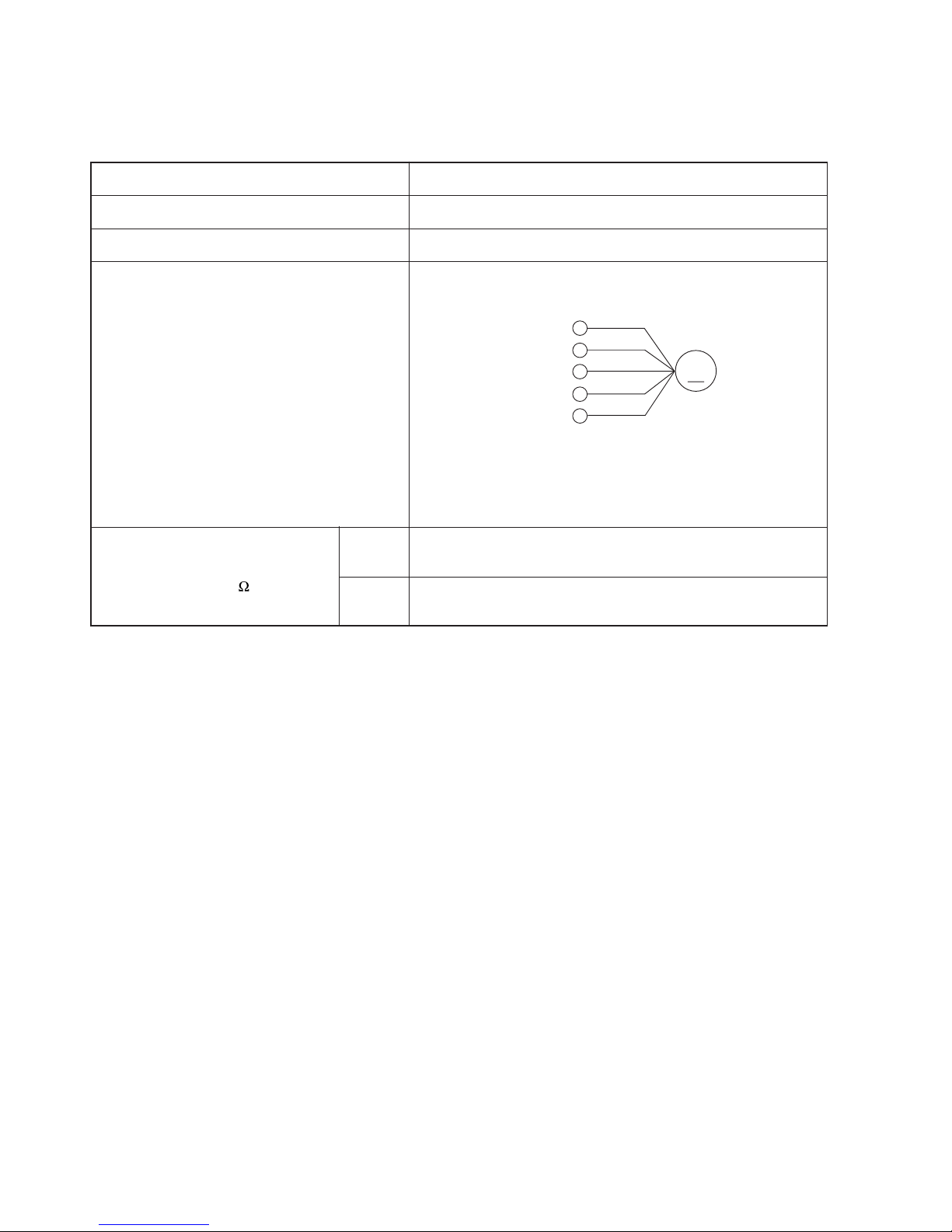

MAIN PARTS COMPONENT

FAN MOTOR

Fan Motor Specifications

CONNECTION

MODEL

POWER SOURCE

OUTPUT

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

RAM-52QH5 / RAM-53QH5

DC : 140-330V

40W

RESISTANCE VALUE

( )

20˚C

(68˚F)

75˚C

(167˚F)

—

—

M

RED

BLK

WHT

YEL

BLU

(Control circuit built in)

140-330V

15V

0V

0-6V

0-15V

Page 24

– 23 –

MODEL

COMPRESSOR MODEL

PHASE

RATED VOLTAGE

RATED FREQUENCY

POLE NUMBER

COMPRESSOR

Compressor Motor Specifications

CONNECTION

25°C

(68°F)

75°C

(167°F)

( )

RESISTANCE VALUE

2M = 1.063

2M = 1.268

RAM-52QH5 / RAM-53QH5

JU1013DA

SINGLE

DC: 280-330V

50Hz

4

(U)

(V)

(W)

M

M

M

WHITE

YELLOW

RED

WHITE

RED

YELLOW

Page 25

– 24 –

7

6

RATING

CAPACITY

WHEN

TWO

COOLING CAPACITY ( ROOM TEMPERATURE 27˚C )

INDOOR

UNITS

OPERATE

5

5. 10

1060

1520

1740

1795

1920

5. 42

5. 55

5. 40

5. 00

4

3

2

1

0

3000

2000

1000

INPUT (W)

AMBIENT TEMP (˚C)

COOLING CAPACITY (kW)

0

20 25 30 35 40

45

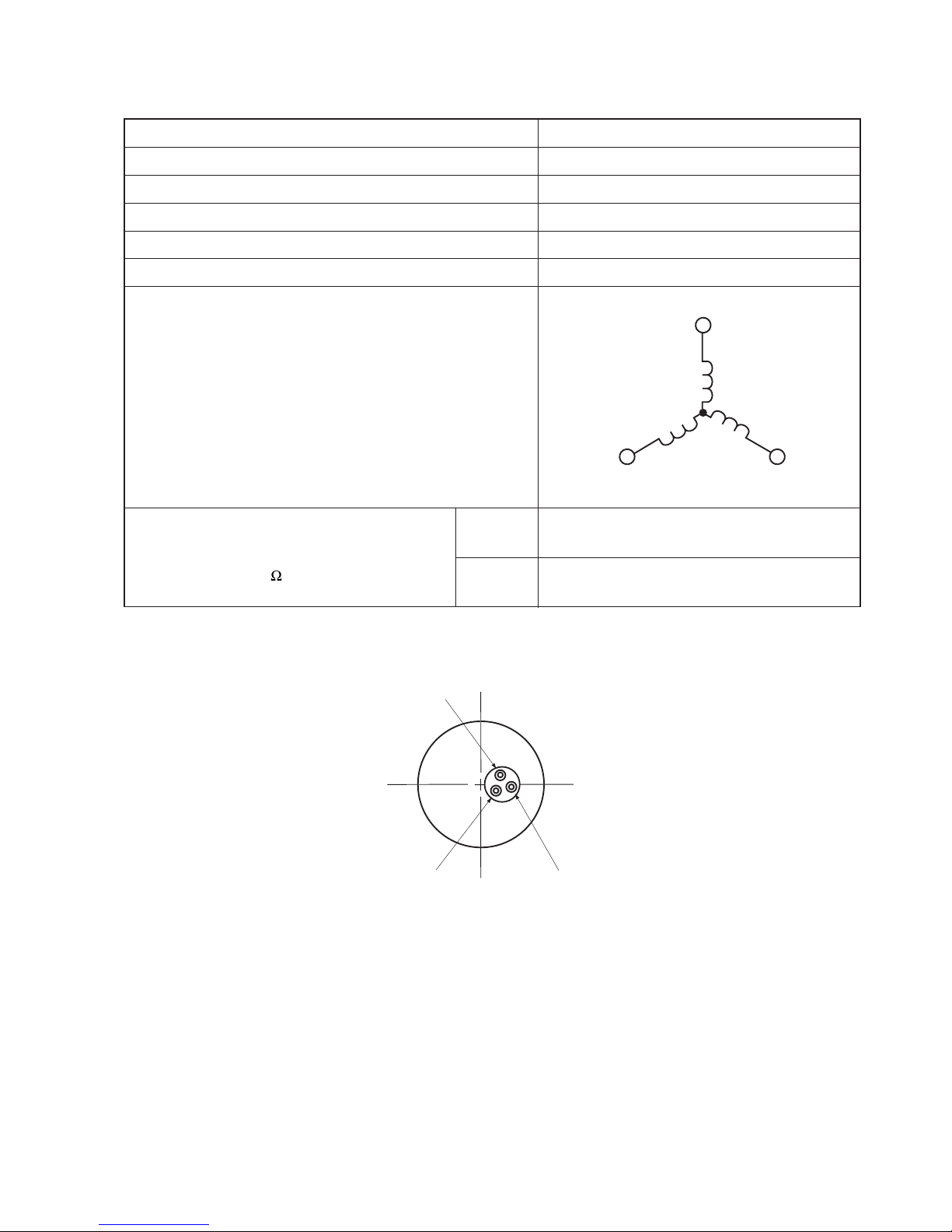

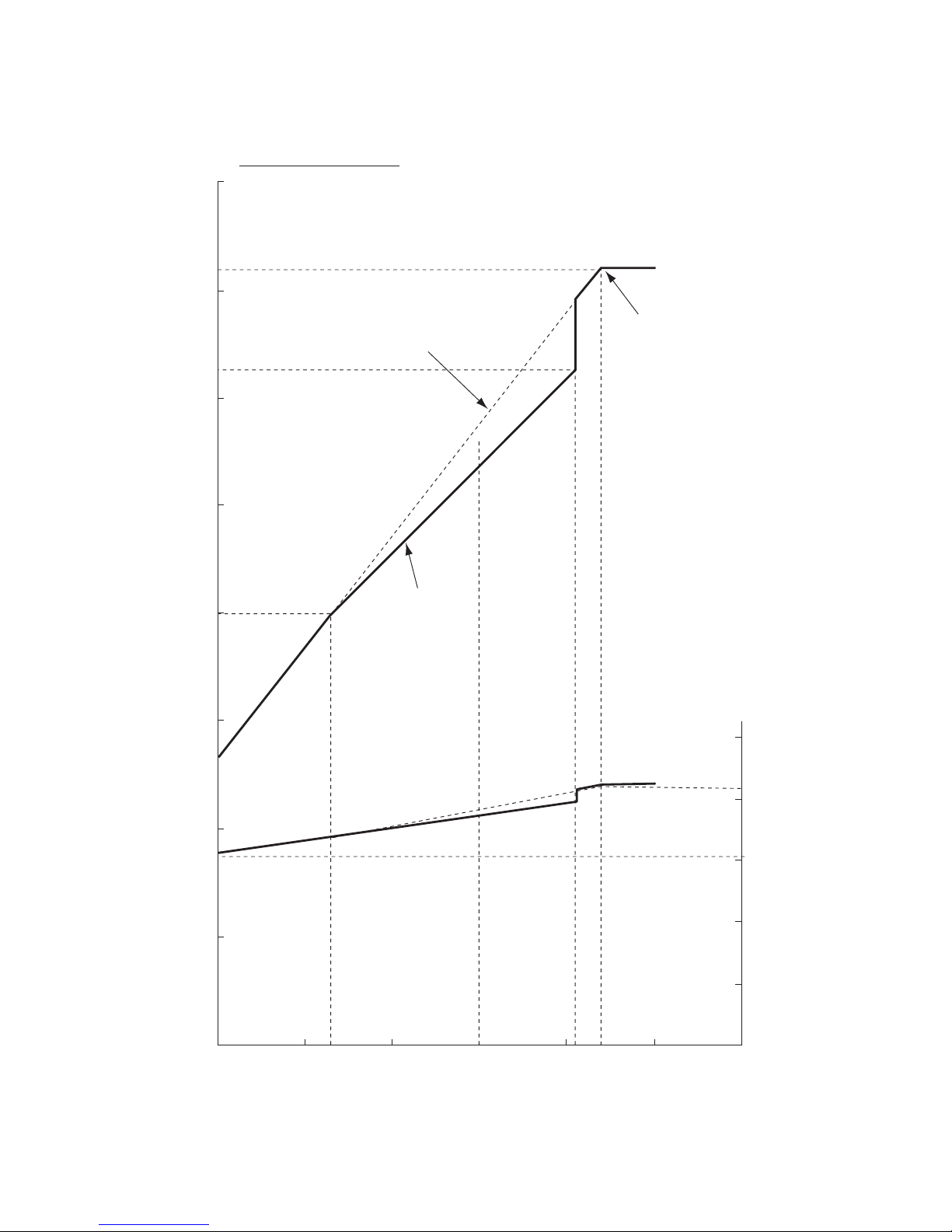

CAPACITY DIAGRAM (RELATED TO THE AMBIENT TEMPERATURE)

MODEL : RAM-52QH5

Page 26

– 25 –

RATING

CAPACITY

MAX CAPACITY

OUTDOOR UNIT

WITHOUT FROST

OUTDOOR UNIT

WITH FROST

WHEN

TWO

HEATING CAPACITY ( ROOM TEMPERATURE 20˚C )

INDOOR

UNITS

OPERATE

0. 0 0

7. 0˚C5. 5˚C–8. 5˚C

500

1000

2000

1500

2500

1. 0

2. 0

3. 0

4. 0

5. 0

6. 0

7. 0

8. 0

INPUT (W)

AMBIENT TEMP. (˚C)

HEATING CAPACITY (kW)

–15 –10 –50 51015

CAPACITY DIAGRAM (RELATED TO THE AMBIENT TEMPERATURE)

MODEL : RAM-52QH5

Page 27

– 26 –

7

6

RATING

CAPACITY

WHEN

THREE

COOLING CAPACITY ( ROOM TEMPERATURE 27˚C )

INDOOR

UNITS

OPERATE

5

4

3

2

1

0

3000

2000

1000

INPUT (W)

AMBIENT TEMP (˚C)

COOLING CAPACITY (kW)

0

20 25 30 35 40

45

5. 95

1240

1765

2030

2095

2240

6. 32

6. 50

6. 30

5. 85

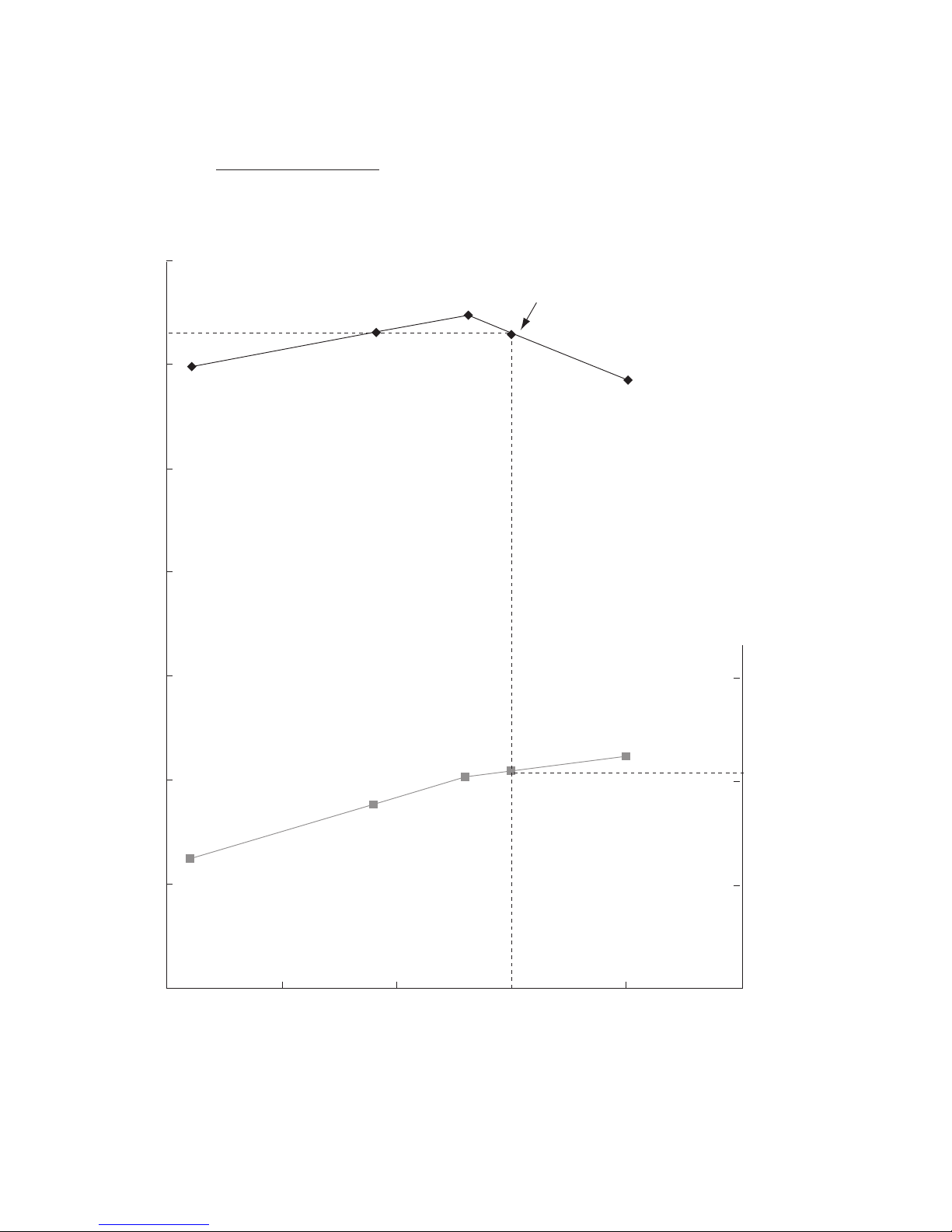

CAPACITY DIAGRAM (RELATED TO THE AMBIENT TEMPERATURE)

MODEL : RAM-53QH5

Page 28

– 27 –

RATING

CAPACITY

MAX CAPACITY

OUTDOOR UNIT

WITHOUT FROST

OUTDOOR UNIT

WITH FROST

WHEN

THREE

HEATING CAPACITY ( ROOM TEMPERATURE 20˚C )

INDOOR

UNITS

OPERATE

0. 0

0

7. 0˚C5. 5˚C

–8. 5˚C

500

1000

2000

1500

2500

1. 0

2. 0

3. 0

4. 0

5. 0

6. 0

7. 0

8. 0

INPUT (W)

AMBIENT TEMP. (˚C)

HEATING CAPACITY (kW)

–15 –10 –50 51015

CAPACITY DIAGRAM (RELATED TO THE AMBIENT TEMPERATURE)

MODEL : RAM-53QH5

Page 29

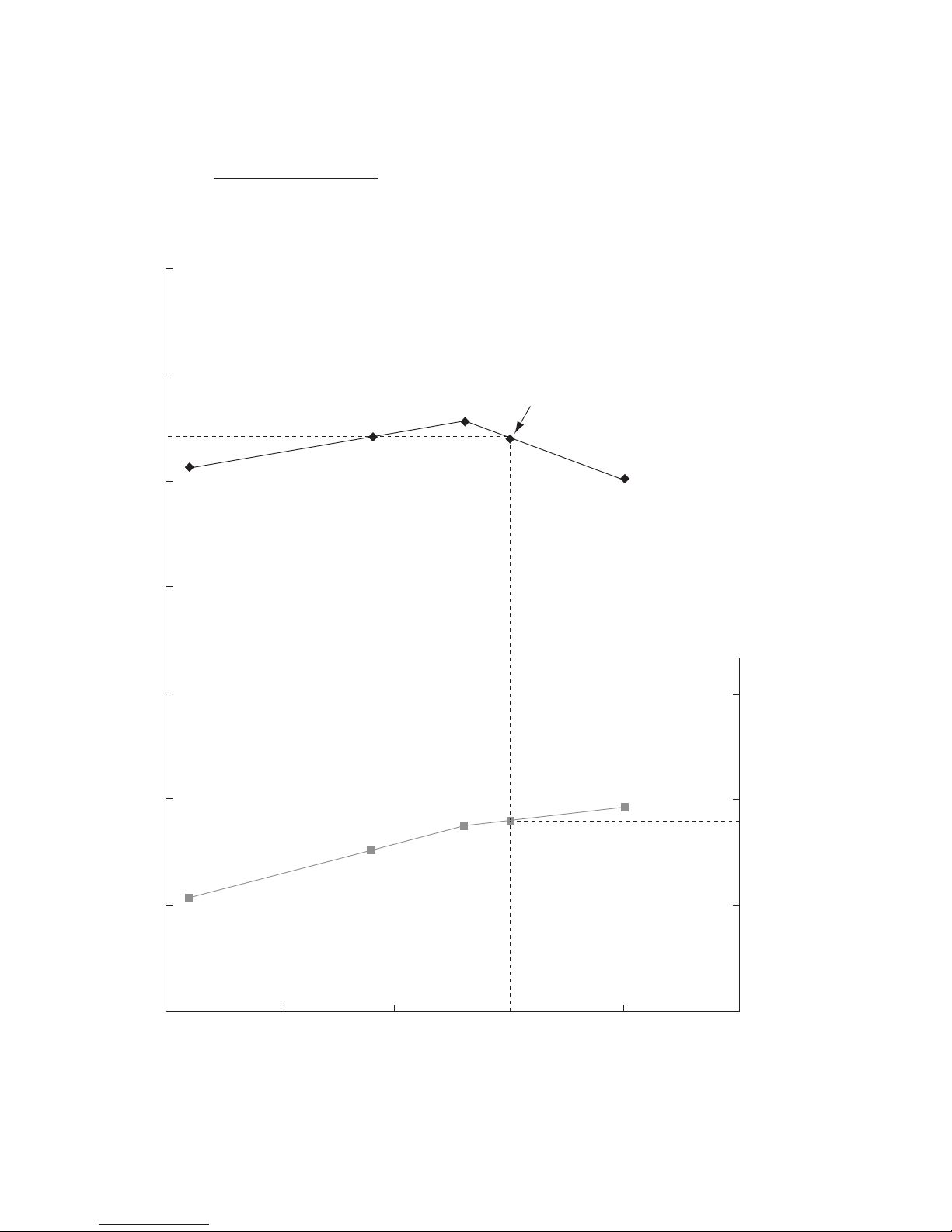

– 28 –

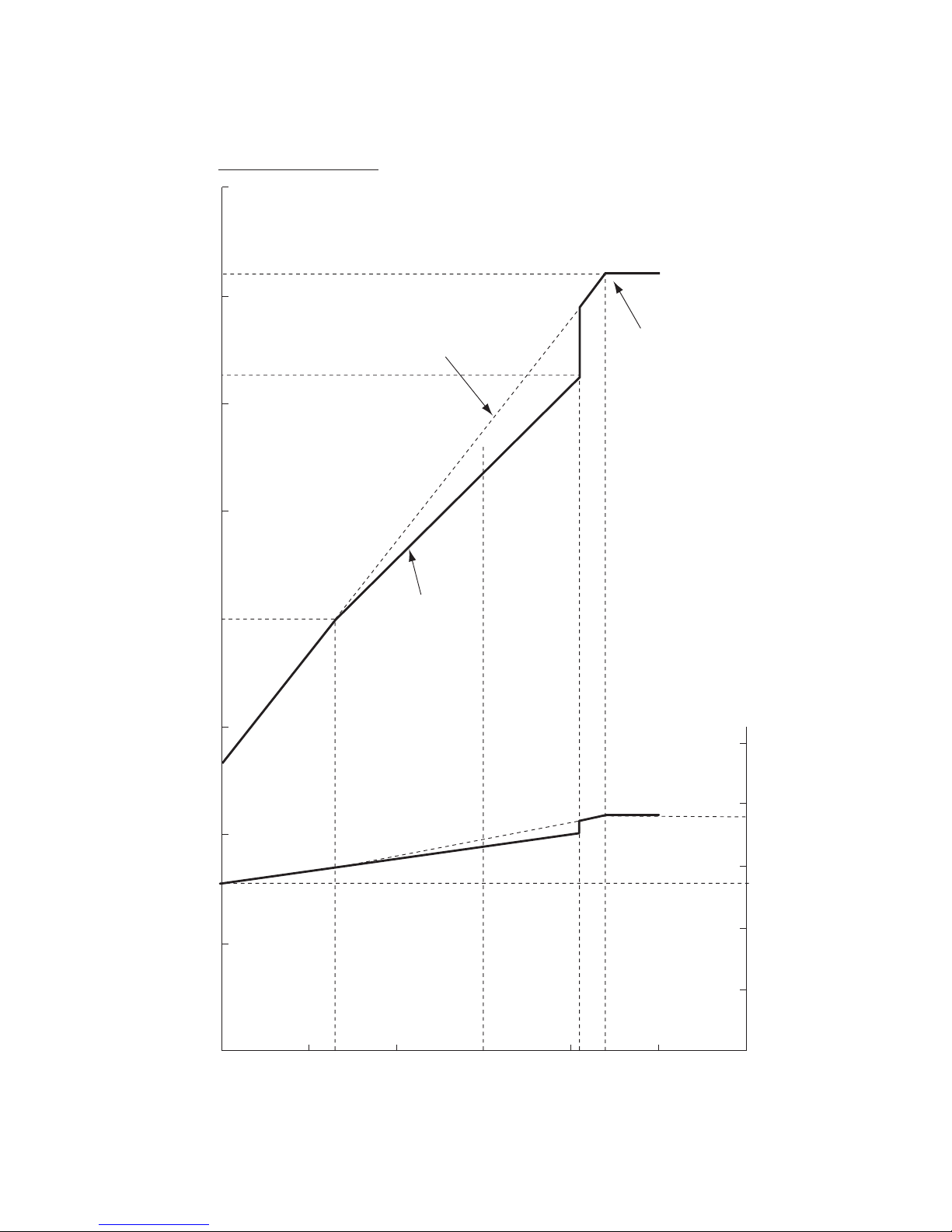

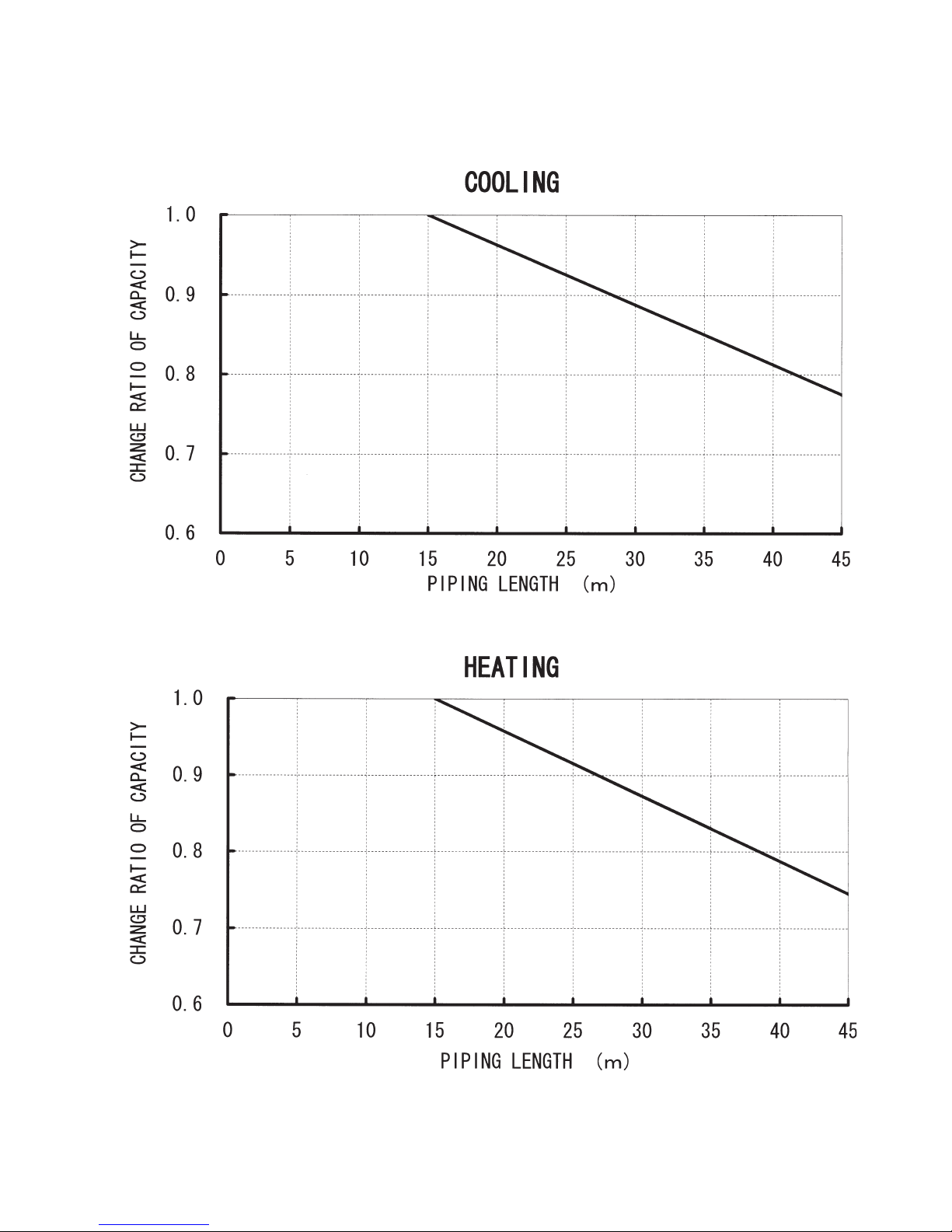

CAPACITY DIAGRAM (RELATED TO THE PIPING LENGTH)

MODEL : RAM-52QH5

1. 0

0. 9

0. 8

0. 7

0. 6

0 5 10 20 3025 3515

PIPING LENGTH (m)

CHANGE RATIO OF

CAPACITY

HEATING

1. 0

0. 9

0. 8

0. 7

0. 6

0 5 10 20 3025 3515

PIPING LENGTH (m)

CHANGE RATIO OF

CAPACITY

COOLING

Page 30

– 29 –

CAPACITY DIAGRAM (RELATED TO THE PIPING LENGTH)

MODEL : RAM-53QH5

Page 31

– 30 –

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

Sound Level

[

dB

]

wavelengthMainbandOctave

[

Hz

]

pressure

APPROXIMATE

THRESHOLD

FOR

NOISE

CONTINUROUS

HEARING

NC-40

NC-20

NC-30

NC-50

NC-60

NC-70

SOUND PRESSURE LEVEL

MODEL : RAM-52QH5 / RAM-53QH5 (Heating)

Page 32

– 31 –

90

80

70

60

50

40

30

20

10

63 125 250 500 1000 2000 4000 8000

Sound Level

[

dB

]

wavelengthMainbandOctave

[

Hz

]

pressure

APPROXIMATE

THRESHOLD

FOR

NOISE

CONTINUROUS

HEARING

NC-40

NC-20

NC-30

NC-50

NC-60

NC-70

SOUND PRESSURE LEVEL

MODEL : RAM-52QH5 / RAM-53QH5 (Cooling)

Page 33

GRY

5

WHT

10

RED

~

+

~

-

1111

CN6 (BLU)

(GRY)

CN3

(BLU)

CN4

CN2

(BLK)

CN1

(WHT)

(WHT)

CN40

CN7

(RED)

(WHT)

CN30

5

CN3A

(WHT)

CN11

(WHT)

CN41

(WHT)

CN14

(WHT)

CN15

(WHT)

ORN

GRY

CN5 (WHT)

(RED)

CN10

CN16

(RED)

CN13

(WHT)

CN8

(RED)

CN9

(WHT)

CN12

(WHT)

BRN

RED

GRN1

CN31

(WHT)

(WHT)

CN14

(WHT)

CN11

(WHT)

CN13

GRN3

5

U

V

YEL

RED

W

L2

YEL

+

L1

–

2

+

-

+

25A FUSE

5A FUSE

BLK

WHT

BLU

~

~

YEL

YEL

+

L

N

D1

C1

C2

D2

(BRN)

(BLU)

(GRN + YEL)

TERMINAL

BOARD

SW POWER

CIRCUIT

(RED)

(GRN + YEL)

(BRN)

POWER SOURCE

AC220-240V

50Hz

INDOOR UNIT 1

(GRN + YEL)

(RED)

INDOOR UNIT 2

(BRN)

U

V

W

WHT

YEL

RED

COMPRESSOR

!

SYSTEM

POWER MODULE

REACTOR

DIODE STACK

(D15VBA60)

POWER RELAY

ICP RELAY

NF COIL 1 COILVARISTOR 1

VARISTOR 3

POWER P.W.B.

MAIN P.W.B.

C002 C001

C025 C024

C023 C022

L007

C003

R004

C006

R002

VARISTOR 2

R005

DIODE STACK

C021

C020

REVERSING

VALVE

FAN MOTOR

BLU : BLUE

GRY : GRAY

BLK : BLACK

YEL : YELLOW

ORN : ORANGE

PNK : PINK

BRN : BROWN

GRN : GREEN

VIO : VIOLET

WHT : WHITE

RED : RED

LEGEND

!

!

! !

!

!

!

!

!

!

!

!

!

!

!

CAUTION

The marked parts are very important ones for safety.

FM

OUTDOOR THERMISTOR

DEF THERMISTOR

OH THERMISTOR

NARROW PIPE THERMISTOR 1

NARROW PIPE THERMISTOR 2

WIDE PIPE THERMISTOR 1

WIDE PIPE THERMISTOR 2

M M

ELECTRIC EXPANSION

VALVE (FOR INDOOR 1)

ELECTRIC EXPANSION

VALVE (FOR INDOOR 2)

MODEL RAM-52QH5

WIRING DIAGRAM

– 33 –

OUTDOOR UNIT

Page 34

GRY

5

WHT

10

RED

~

+

~

-

1111

CN6 (BLU)

(GRY)

CN3

(BLU)

CN4

CN2

(BLK)

CN1

(WHT)

(WHT)

CN40

CN7

(RED)

(WHT)

CN30

5

CN3A

(WHT)

CN11

(WHT)

CN41

(WHT)

CN14

(WHT)

CN15

(WHT)

ORN

GRY

CN5 (WHT)

(RED)

CN10

CN16

(RED)

CN13

(WHT)

CN8

(RED)

CN17

(BLU)

CN9

(WHT)

CN12

(WHT)

BRN

RED

GRN1

CN31

(WHT)

(WHT)

CN14

(WHT)

CN11

(WHT)

CN13

YEL

GRN3

5

BLU

U

V

YEL

RED

W

L2

YEL

+

L1

–

2

+

-

+

25A FUSE

5A FUSE

BLK

WHT

BLU

~

~

YEL

YEL

+

L

N

D1

C1

D3

C3

C2

D2

(BRN)

(BLU)

(GRN + YEL)

TERMINAL

BOARD

SW POWER

CIRCUIT

(RED)

(GRN + YEL)

(BRN)

POWER SOURCE

AC220-240V

50Hz

INDOOR UNIT 1

(GRN + YEL)

(RED)

INDOOR UNIT 2

(BRN)

(GRN + YEL)

(RED)

INDOOR UNIT 3

(BRN)

U

V

W

WHT

YEL

RED

COMPRESSOR

!

SYSTEM

POWER MODULE

REACTOR

DIODE STACK

(D15VBA60)

POWER RELAY

ICP RELAY

NF COIL 1 COILVARISTOR 1

VARISTOR 3

POWER P.W.B.

MAIN P.W.B.

C002 C001

C025 C024

C023 C022

L007

C003

R004

C006

R002

VARISTOR 2

R005

DIODE STACK

C021

C020

REVERSING

VALVE

FAN MOTOR

BLU : BLUE

GRY : GRAY

BLK : BLACK

YEL : YELLOW

ORN : ORANGE

PNK : PINK

BRN : BROWN

GRN : GREEN

VIO : VIOLET

WHT : WHITE

RED : RED

LEGEND

!

!

! !

!

!

!

!

!

!

!

!

!

!

!

CAUTION

The marked parts are very important ones for safety.

FM

OUTDOOR THERMISTOR

DEF THERMISTOR

OH THERMISTOR

NARROW PIPE THERMISTOR 1

NARROW PIPE THERMISTOR 2

NARROW PIPE THERMISTOR 3

WIDE PIPE THERMISTOR 1

WIDE PIPE THERMISTOR 2

WIDE PIPE THERMISTOR 3

M M M

ELECTRIC EXPANSION

VALVE (FOR INDOOR 1)

ELECTRIC EXPANSION

VALVE (FOR INDOOR 2)

ELECTRIC EXPANSION

VALVE (FOR INDOOR 3)

MODEL RAM-53QH5

WIRING DIAGRAM

– 35 –

OUTDOOR UNIT

Page 35

Remote Control

CIRCUIT DIAGRAM

– 37 –

1

2

3

4

5

6

7

8

10

11

13

14

15

16

17

19

20

9

12

18

SEG19

SEG18

SEG17

SEG16

SEG21

SEG24

SEG25

SEG26

SEG27

SEG28

NC

NC

NC

NC

NC

NC

NC

NC

NC

SEG20

SEG5

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

COM3

COM2

COM1

COM0

SEG14

SEG13

SEG12

SEG11

SEG13

SEG9

SEG8

40

39

38

37

36

35

34

33

31

30

28

27

26

25

24

22

21

32

29

23

40

39

38

37

36

35

34

33

31

30

28

27

26

25

32

29

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48 47

46

45

44

43

41

42

65

66

67

68

69

70

71

72

74

75

77

78

79

80

73

76

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 18

19

20

21

22

24

23

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

SEG43

SEG42

SEG41

SEG40

P40

P41

P42

P43

P00

P01

P02

P03

P10

P11

P12

P13

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

BEEP

P20

P30

P31

NCVL C1

VL C2

VL C3

XC IN

XC OUT

VDD

X OUT

X IN

RESET

CARR

P23

P22

P21

VSS

IC 1

M3455OM6A-504FP

LCD 1

C8

50v/1u

K 1

D3

RB425D(1/2)

K2K3

K4

K5

P10

P11

P12

K6

K7 K8

K8 K10

K11K12

K18

K17

K15 K16

K13 K14

D0

D1

D2

D3

R1

100k

SW1

R2

P

100k

R3

100k

R4

100k

R5

Q1

2SC3443

or 2SC2982

R6

R7

R9

D2D1

D1 D2

EL-1L7

D3

(1/2)

RB425D

R10

12M

K19

X1

C9

R11

R15

R16

R13

R14

910kHz

105

104

104

150k

X2

kHz

C4

C5

C6

C7

18p

22p

R12

220k

220K

220k

100k

100k

32.768

C1

C2

C3

220p

220p

334

R6 R9

24(1/8W)

R8

330

SW-187-2P

Key matrix table

Input

D3D2D1

D0

Output

Door open Automatic swingFan speed selectionOperation selectionStart/Stop

Door shut ––Super silent coolingStart/Stop

Door open Day

• present timeHour downHour upOn timer

Door shut Super coolingRoom temperature downRoom temperature up–

Door open CancelReservation–Off timer

Door shut –––Sleep

P10

P11

P12

Page 36

CIRCUIT DIAGRAM

MODEL RAM-52QH5

– 39 –

L

C023

C022

C002

C001

C025

C024

N

Page 37

CIRCUIT DIAGRAM

MODEL RAM-53QH5

– 41 –

L

C023

C022

C002

C001

C025

C024

N

Page 38

– 43 –

BLOCK DIAGRAM

MODEL RAM-52QH5

Outdoor micro computer (6V01)

Magnetic relay

Inrush current

protection relay

M

L

N

Rotor position

detector

Overload current

detector

SPM driver

Overheat

thermistor

Defrost

thermistor

Outdoor temp

thermistor

Indoor/Outdoor

Interface 1

Indoor/Outdoor

Interface 2

Switching power supply 2

Switching power supply 1

Reset circuit

Clock circuit

Multiplexer

Expansion valve

thermistor 1

Expansion valve

thermistor 2

Expansion valve 1

Expansion valve 2

Expansion valve

drive circuit

Reversing valve

drive circuit

Reversing valve

EEPROM

Fan motor

drive circuit

M

compressor

fan motor

Indoor unit 1

Indoor unit 2

C1/D1

C2/D2

Power source

single phase 50Hz, 220-240V

Outdoor Unit

System

Power

Module

Page 39

– 44 –

BLOCK DIAGRAM

MODEL RAM-53QH5

Outdoor micro computer (6V01)

Magnetic relay

Inrush current

protection relay

M

L

N

Rotor position

detector

Overload current

detector

SPM driver

Overheat

thermistor

Defrost

thermistor

Outdoor temp

thermistor

Indoor/Outdoor

Interface 1

Indoor/Outdoor

Interface 2

Indoor/Outdoor

Interface 3

Switching power supply 2

Switching power supply 1

Reset circuit

Clock circuit

Multiplexer

Expansion valve

thermistor 3

Expansion valve

thermistor 1

Expansion valve

thermistor 2

Expansion valve 1

Expansion valve 2

Expansion valve 3

Expansion valve

drive circuit

Reversing valve

drive circuit

Reversing valve

EEPROM

Fan motor

drive circuit

M

compressor

fan motor

Indoor unit 1

Indoor unit 2

Indoor unit 3

C1/D1

C2/D2

C3/D3

Power source

single phase 50Hz, 220-240V

Outdoor Unit

System

Power

Module

Page 40

– 45 –

Page 41

– 47 –

LABEL NAMEPROM NO.

040 PSTARTH1$ 200

041 PSTARTH1S$ 250

042 PSTARTH2$ 100

043 PSTARTH2S$ 150

044 PSTARTH3$ 250

045 PSTARTH3S$ 250

046 PMIN$ 30

047 DFCTPS$ 100

048 DFCTPN$ 240

049 DFSPPS$ 44

04A DFPSMX$ 480

04B PCLOSH$ 60

0FD CMAX1 5400 min

-1

0FE CMAX2 6100 min

-1

101 CMAX3 6200 min

-1

104 CMAX4 6300 min

-1

108 WMAX1 6000 min

-1

109 WMAX2 6000 min

-1

10C WMAX3 6000 min

-1

10F WMAX4 6300 min

-1

11E STAROTP_C 25.0 ˚C

11F SDRCT1_C1 2000 min

-1

121 SDRCT1_C2 3000 min

-1

122 TSKTM_C2 60 sec

123 STAROTP_W 4.8 ˚C

124 SDRCT1_W1 2000 min

-1

125 TSKTM1_W1 60 sec

126 SDRCT1_W2 3000 min

-1

127 TSKTM1_W2 60 sec

128 SDSTEP 1000 min

-1

129 TSKSPT 8 sec

12A KYO_RPM 3000 min

-1

198 TDF414 90 sec

199 DFMXTM 12 min

-1

19A SDRCT2 2000 min

-1

19B TSKTM2 60 sec

19C DFSTEP 600 min

-1

19D TDFSPT 60 sec

19E DEFMAX 6000 min

-1

19F TDF415 120 sec

1A0 DFSTMB 55 min.

1A1 DFSTMB2 60 min.

1A2 DEFONH –1.9 ˚C

1A3 DEFON –5.1 ˚C

1A4 DEFONL –23.9 ˚C

1A5 DEF_a1 112/128

1A6 DEF_a2 138/128

1A7 DEFOFF 15.0 ˚C

120 TSKTM1_C1 40 sec

pulse

pulse

pulse

pulse

pulse

pulse

03A PSTARTC1$ 250

03B PSTARTC1K$ 300

03C PSTARTC2$ 150

03D PSTARTC2K$ 300

03E PSTARTC3$ 150

03F PSTARTC3K$ 300

pulse

pulse

pulse

pulse

pulse

pulse

pulse

pulse

pulse

pulse

pulse

pulse

MODEL RAM-52QH5 / RAM-53QH5

REQUIRED VALUE OF UNIT SIDE

Page 42

– 49 –

[Outdoor temperature >STAROTP_C] TSKTM1_C1

[Outdoor temperature ≤STAROTP_C] TSKTM1_C2

Page 43

– 51 –

Page 44

– 53 –

Page 45

– 55 –

Page 46

– 57 –

Page 47

– 58 –

Powe r

Heating output

Cooling output

Compressor

rotation speed

Unit 1

Unit 2

Hold

Hold

Hold 500ms

Hold 500ms

Hold

Hold

PSTARTC2$

PSTARTC2$

Initialization finished

< TD control + N correction + distribution control >

31.25pps

Start enabled

approx. 100ms

Start sequence

SDSTEP min

-1

/TSKSPT

sec.

CMAX2

Cooling

Cooling

100ms

1s

1s

1s

520

480

0

520

480

0

Outdoor fan

Turns on

for cooling

Turns on

for heating

Operation

Powe r

Rush-in

prevention

Compressor

Power relayExpansion valve

Reversing

valve

Unit 1

Unit 2

PSTARTC2K$

Outdoor temperature ≥ 40˚C

TSKTMI_C1

Outdoor temperature ≥ STARCTP_C

TSKTMI_C2

Outdoor temperature ≤ STARCTP_C

SDRCTI_C1

Outdoor temperature ≥ STARCTP_C

SDRCTI_C2

Outdoor temperature ≤ STARCTP_C

PSTARTC2K$

Outdoor temperature ≥ 40˚C

< TD control + N correction + distribution control >

MODEL RAM-52QH5

Expansion valves

The expansion valves are initialized when power is supplied. The valve for unit 1 is fully closed (–520

pulses), and then that for unit 2 is fully opened (480 pulses). The valve for unit 2 is fully closed (–520

pulses). When the valve for unit 1, 2 is fully closed (0 pulse), start-up is possible.

The start openings are held during the steady speed period when the compressor is started. After the

steady speed period is finished, the TD control is entered. The start openings are set to PSTARTH when

the outdoor temperature at start 40˚C or more, and to PSTART when it is less than 40˚C.

Compressor rotation speed

When the compressor is started, the SDRCT1 speed / TSTKTM1 second is held.

After the steady speed period is finished, the speed increases at the rate of SDSTEP speed / TSKSPT

second until the target speed is resched.

TSKTM1, SDRCT1, SDSTEP, TSKSPT, CMAX2, PSTART and PSTARTH are EEPROM data.

Page 48

– 59 –

Powe r

Heating output

Cooling output

Compressor

rotation speed

Unit 1

Unit 2

Hold

Hold

Hold 500ms

Hold 500ms

Hold 500ms

Hold

Hold

Hold

Hold

PSTARTC2$

PSTARTC2$

Initialization finished

PSTARTC2$

PSTARTC2K$

< TD control + N correction + distribution control >

31.25pps

Start enabled

approx. 100ms

Start sequence

SDSTEP min

-1

/TSKSPT

sec.

CMAX2

Cooling

Cooling

Cooling

100ms

1s

1s

1s

Unit 3

520

480

0

520

480

0

520

480

0

Outdoor fan

Turns on

for cooling

Turns on

for heating

Operation

Powe r

Rush-in

prevention

Compressor

Power relayExpansion valve

Reversing

valve

Unit 1

Unit 2

Unit 3

Outdoor temperature ≥ 40˚C

PSTARTC2K$

Outdoor temperature ≥ 40˚C

TSKTMI_C1

Outdoor temperature ≥ STARCTP_C

TSKTMI_C2

Outdoor temperature ≤ STARCTP_C

SDRCTI_C1

Outdoor temperature ≥ STARCTP_C

SDRCTI_C2

Outdoor temperature ≤ STARCTP_C

PSTARTC2K$

Outdoor temperature ≥ 40˚C

< TD control + N correction + distribution control >

< TD control + N correction + distribution control >

MODEL RAM-53QH5

Expansion valves

The expansion valves are initialized when power is supplied. The valve for unit 1 is fully closed (–520

pulses), and then that for unit 2 is fully opened (480 pulses). The valve for unit 2 is fully closed (–520

pulses), and then that for unit 3 is fully opened (480 pulses). When the valve for unit 1, 2, 3 is fully

closed (0 pulse), start-up is possible.

The start openings are held during the steady speed period when the compressor is started. After the

steady speed period is finished, the TD control is entered. The start openings are set to PSTARTH when

the outdoor temperature at start 40˚C or more, and to PSTART when it is less than 40˚C.

Compressor rotation speed

When the compressor is started, the SDRCT1 speed / TSTKTM1 second is held.

After the steady speed period is finished, the speed increases at the rate of SDSTEP speed / TSKSPT

second until the target speed is resched.

TSKTM1, SDRCT1, SDSTEP, TSKSPT, CMAX2, PSTART and PSTARTH are EEPROM data.

Page 49

– 60 –

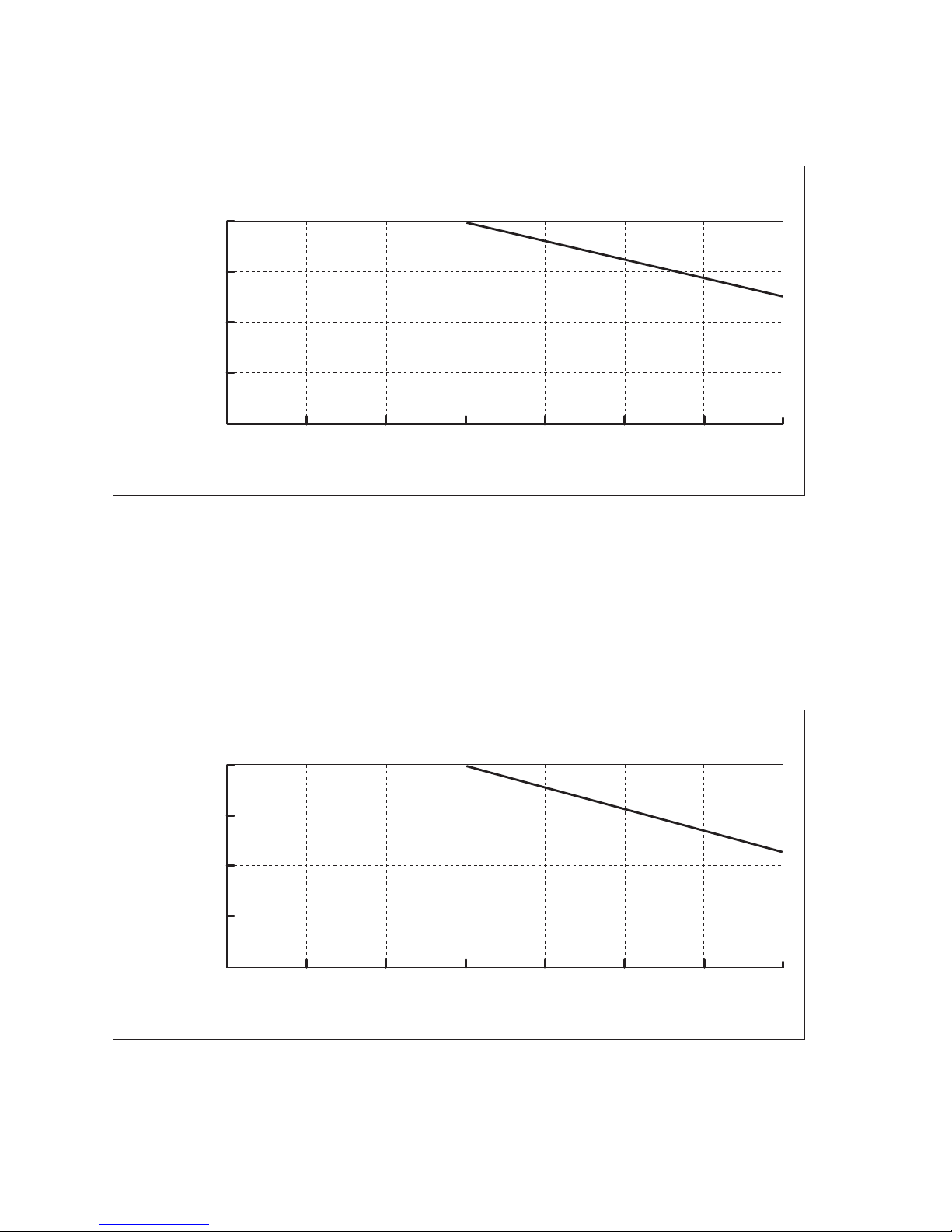

DEFROST

Reversing valve defrost system is employed: it consists of balancing period reversing cycle period balancing period.

When all the following conditions are established defrost is executed:

Normal operation

Defrost start condition(1)

Defrost inhibit period linked to outdoor temperature has passed.

Heat exchange temperature is within defrost range specified by outdoor temperature and heat exchange temperature.

1

3

2

If any one of the following conditions is established, defrost is released:

Defrost release condition(2)

Outputs during defrost(3)

Indoor defrost request: Transmitted to all units being operated in heating mode.

Electric expansion valve

Unit being stopped : [FULL CLOSE] 30 seconds after balancing period has passed [FULL CLOSE] during

reversing cycle period [PCLOSH$] 15 seconds before balancing period is finished

Unit being operated : [DFCTPS] 30 seconds before balancing period is finished Synchronized with step-up

of rotation speed of compressor, opened by [DFSPPS] pulses and reaches MAX opening

degree [DEFSMX] when rotation speed of compressor reaches [DEFMAX].

Compressor : Balancing period for [TDF414] seconds Starting of reversing cycle period by [SDRCT2] min-1 for

Released by condition 1 or 2 during reversing cycle period: [TDF415] Shifted to balancing period.

[TSKTM2] seconds Accelerating by [DFSTEP]min

-1

/[TDFSPT] seconds in remaining reversing cycle

period until defrost MAX speed [DEFMAX] is reached Balancing period for [TDF415] seconds

Released by condition 1 during balancing period: When remaining balancing period has elapsed, returned to initial

condition (ASTUS=0).

above graph is showing the ideal value by micon program.

Heat exchange temperature returns (heat exchange temperarure ≥ DEFOFF).

Defrost max time of 12 minutes has elapsed.

1

2

RAM- , RAM- DEFROST TEMPERATURE

OUTDOOR (˚C)

-20

-10

10

20

0

0-10 10-20 20

HEAT EXCHANGER (˚C)

DEFROST

START

TEMPERATURE

DEFROST END

TEMPERATURE

Page 50

– 61 –

Time chart when executing defrost ( unit 1 and unit 2 operated)

Time chart when executing defrost ( Only unit 1 operated, unit 2 stopped)

Unit 1

Unit 1

Unit 2

Unit 1

Unit 2

Unit 1

Unit 2

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

Operation

Compressor

Turns on for

cooling

Unit 2

Electric expansion valve

480

0

Hold

Hold 500ms

DFCTPS$

DFPSMX$

Balancing period [TDF415] sec.

Outdoor temperature ≥ STAROTP_W SDRCTI_W1

Outdoor temperature ≤ STAROTP_W

SDRCTI_W2

Balancing period [TDF414] sec.Defrosting inhibit period

Start sequence

T_DFCTPS

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

30sec.

15sec.

Defrosting sequence

DFSTEPmin

-1

/

TDFSPT sec.

Defrosting request

Defrosting request

T_4BEN_DEF

DFPSMX$

DFCTPS$

DFSPPS$ Pulse

DFCTPS$

DFCTPS$

PSTARTH$

PSTARTH$

DFSPPS$ Pulse

Hold 500ms

Hold

480

0

Outdoor temperature ≥ STAROTP_W TSKTMI_W1

Outdoor temperature ≤ STAROTP_W TSKTMI_W2

Unit 1

Unit 1

Unit 2

Unit 1

Unit 2

Unit 1

Unit 2

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

Operation

Compressor

Turns on for

cooling

Unit 2

Electric expansion valve

480

0

Hold

Hold 500ms

DFCTPS$

DFPSMX$

Balancing period [TDF415] sec.

TSKTM1-W1

SDRCT1-W1

Balancing period [TDF414] sec.Defrosting inhibit period

Start sequence

T_DFCTPS

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

30sec.

15sec.

Defrosting sequence

DFSTEPmin-1/

TDFSPT sec.

Defrosting request

T_4BEN_DEF

DFSPPS$ Pulse

DFCTPS$

PCLOSH$

PSTARTH$

480

0

30sec.

MODEL RAM-52QH5

Page 51

– 62 –

Time chart when executing defrost ( unit 1, unit 2 and unit 3 operated)

Time chart when executing defrost ( Only unit 1 operated, unit 2 and unit 3 stopped)

Unit 1

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

OperationCompressor

Turns on for

cooling

Unit 2

Unit 3

Electric expansion valve

480

0

Hold

Hold 500ms

DFCTPS$

DFPSMX$

Balancing period [TDF415] sec.

Outdoor temperature ≥ STAROTP_W SDRCTI_W1

Outdoor temperature ≤ STAROTP_W

SDRCTI_W2

Balancing period [TDF414] sec.Defrosting inhibit period

Start sequence

T_DFCTPS

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

30sec.

15sec.

Defrosting sequence

DFSTEPmin

-1

/

TDFSPT sec.

Defrosting request

Defrosting request

Defrosting request

T_4BEN_DEF

DFPSMX$

DFPSMX$

DFCTPS$

DFCTPS$

DFSPPS$ Pulse

DFCTPS$

DFCTPS$

DFCTPS$

PSTARTH$

PSTARTH$

PSTARTH$

DFSPPS$ Pulse

DFSPPS$ Pulse

Hold 500ms

Hold 500ms

Hold

Hold

480

0

480

0

Outdoor temperature ≥ STAROTP_W TSKTMI_W1

Outdoor temperature ≤ STAROTP_W TSKTMI_W2

Unit 1

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

OperationCompressor

Turns on for

cooling

Unit 2

Unit 3

Electric expansion valve

480

0

Hold

Hold 500ms

DFCTPS$

DFPSMX$

Balancing period [TDF415] sec.

TSKTM1-W1

SDRCT1-W1

Balancing period [TDF414] sec.Defrosting inhibit period

Start sequence

T_DFCTPS

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

30sec.

15sec.

Defrosting sequence

DFSTEPmin-1/

TDFSPT sec.

Defrosting request

T_4BEN_DEF

DFSPPS$ Pulse

DFCTPS$

PCLOSH$

PCLOSH$

PSTARTH$

480

0

480

0

30sec.

MODEL RAM-53QH5

Page 52

– 63 –

AUTO-FRESH DEFROST

During heating operation is stopped, and when auto-fresh condition is established, defrost operation will be performed while

operation is stopped.

Auto-fresh consists of balancing period at start of defrost for [TDF414] seconds Reverse cycle period for MAX 12

minutes.

When all the following conditions are established, auto-fresh is executed:

Defrost request signal is present.

Start conditions for auto-fresh(1)

15 minutes of auto-fresh inhibit period has elapsed.

All indoor units are stopped.

1

3

2

Compressor delay command is sent from indoor unit when operation is stopped.

Compressor is ON when operation is stopped.

5

4

If any one of following conditions is established, auto-fresh is released:

Unit auto-fresh not applied: FULL CLOSE when balancing for 30 seconds has elapsed at start of defrost.

Unit auto-fresh applied : Synchronized with step-up of rotation speed of compressor, opened by [DFSPPS] pulses and

reaches MAX opening degree [DEFSMX] when rotation speed of compressor reaches [DEFMAX].

Heat exchange temperature returns (heat exchange temperature ≥ DEFOFF)

Release condition of auto-fresh(2)

Outputs during auto-fresh

[Indoor unit defrost request]: Transmitted only to unit to which auto-fresh is applied (indoor unit stopped last).

[Compressor]: Accelerated by DFSTEP min

-1

/TDFSPT seconds and reaches defrost MAX speed [DEFMAX].

[Electric expansion valve]:

(3)

Failure occurred.

12 minutes of defrost MAX time has elapsed.

1

3

2

Shifted to auto-fresh in defrost mode when operation is stopped.

Note(4)

All indoor units must be stopped to fulfill condition for auto-fresh.

If signal is delayed, auto-fresh condition will not be established.

Either unit 1 or unit 2 or unit 3 started operation.

Released during start of balancing period : Stopped or started after remaining balancing period has elapsed.

Released during reverse cycle period : Stopped or started after balancing for 3 minutes.

4

Unit 1

Unit 2

Unit 1

Unit 2

Unit 1

Unit 2

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

Operation

Compressor

Turns on for

cooling

Balancing period 3min.

Balancing period [TDF414] sec.

Auto-fresh inhibit period 15min.

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

WMAX1

WMAX2

WMAX3

30sec.

30sec.

80sec.

Hold

Hold

DFCTPS$

DFPSMX$

DFSPPS$ Pulse

30sec.

15sec.

Defrosting sequence

DFSTEP min-1/

TDFSPT sec.

Defrosting request Balancing request

Balancing request

Unit 1

Unit 2

Electric expansion valve

480

0

480

0

520

520

MODEL RAM-52QH5

Page 53

– 64 –

AUTO-FRESH DEFROST

During heating operation is stopped, and when auto-fresh condition is established, defrost operation will be performed while

operation is stopped.

Auto-fresh consists of balancing period at start of defrost for [TDF414] seconds Reverse cycle period for MAX 12

minutes.

When all the following conditions are established, auto-fresh is executed:

Defrost request signal is present.

Start conditions for auto-fresh(1)

15 minutes of auto-fresh inhibit period has elapsed.

All indoor units are stopped.

1

3

2

Compressor delay command is sent from indoor unit when operation is stopped.

Compressor is ON when operation is stopped.

5

4

If any one of following conditions is established, auto-fresh is released:

Unit auto-fresh not applied: FULL CLOSE when balancing for 30 seconds has elapsed at start of defrost.

Unit auto-fresh applied : Synchronized with step-up of rotation speed of compressor, opened by [DFSPPS] pulses and

reaches MAX opening degree [DEFSMX] when rotation speed of compressor reaches [DEFMAX].

Heat exchange temperature returns (heat exchange temperature ≥ DEFOFF)

Release condition of auto-fresh(2)

Outputs during auto-fresh

[Indoor unit defrost request]: Transmitted only to unit to which auto-fresh is applied (indoor unit stopped last).

[Compressor]: Accelerated by DFSTEP min

-1

/TDFSPT seconds and reaches defrost MAX speed [DEFMAX].

[Electric expansion valve]:

(3)

Failure occurred.

12 minutes of defrost MAX time has elapsed.

1

3

2

Shifted to auto-fresh in defrost mode when operation is stopped.

Note(4)

All indoor units must be stopped to fulfill condition for auto-fresh.

If signal is delayed, auto-fresh condition will not be established.

Either unit 1 or unit 2 or unit 3 started operation.

Released during start of balancing period : Stopped or started after remaining balancing period has elapsed.

Released during reverse cycle period : Stopped or started after balancing for 3 minutes.

4

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Compressor

rotation speed

Outdoor fan

Heating output

Cooling output

Defrosting signal

Request

Reversing

valve

OperationCompressor

Turns on for

cooling

Balancing period 3min.

Balancing period [TDF414] sec.

Auto-fresh inhibit period 15min.

DEFMAX

Reverse cycle period (max. 12 minutes)

TSKTM2

SDRCT2

WMAX1

WMAX2

WMAX3

30sec.

30sec.

80sec.

Hold

Hold

DFCTPS$

DFPSMX$

DFSPPS$ Pulse

30sec.

15sec.

Defrosting sequence

DFSTEP min-1/

TDFSPT sec.

Defrosting request Balancing request

Balancing request

Balancing request

Unit 1

Unit 2

Unit 3

Electric expansion valve

480

0

480

0

480

520

520

520

0

MODEL RAM-53QH5

Page 54

– 65 –

FORCED COOLING

[Execution condition]

In order to accumulate refrigerant, units operate in cooling cycle.

Execution condition and operation status are shown below.

With neither indoor unit 1 and 2 not operated, when forced cooling switch is turned ON, forced cooling will be performed.

[Operation status]

Outdoor unit fan: Fixed in LO.

[Note]

During forced cooling, if failure occurs in outdoor unit, thermostat is turned off. However, it is not counted.

The following shows the operation state of forced cooling.

Since rotation speed of compressor is fixed in 3000min-1 during forced cooling, compressor fixed speed control at start is

not performed.

Expansion valve/reversing valve : Set in normal conditions.

Compressor rotation speed: Fixed in 3000min-1.

Always operation status of indoor units are monitored and forced cooling is inhibited when operation of any unit is detected.

Powe r

Heating output

Service switch

Cooling output

Outdoor fan

Turns on

for Cooling

Operation

Powe r

Compressor

rotation speed

In-rush Prevention

Compressor

Power relay

Electric expansion valve

Main microcomputer

Reversing

valve

Unit 1

Unit 2

Unit 1

Unit 2

Hold

Hold

Approx.100ms

100ms

1sec.

1sec.

1sec.

520

480

0

520

480

0

TSKTM1_C and PSTARTC2$ are EEPROM data.

Hold 500ms

Hold 500ms

31.25PPS

PSTARTC2$

PSTARTC2$

[Outdoor temperature < 40˚C]

[Outdoor temperature < 40˚C]

Initialization

finished

< TD control + N compensation + Diving control >

< TD control + N compensation + Diving control >

TSKTMI_C1

Outdoor temperature ≥ STARCTP_C

TSKTMI_C2

Outdoor temperature ≤ STARCTP_C

Forced cooling request

Forced cooling request

Balancing request

Balancing request

Balancing period 3min.

Lo

3000min

-1

15sec. +sub

30sec.

80sec.

MODEL RAM-52QH5

Page 55

– 66 –

FORCED COOLING

[Execution condition]

In order to accumulate refrigerant, units operate in cooling cycle.

Execution condition and operation status are shown below.

With neither indoor unit 1, 2 and 3 not operated, when forced cooling switch is turned ON, forced cooling will be performed.

[Operation status]

Outdoor unit fan: Fixed in LO.

[Note]

During forced cooling, if failure occurs in outdoor unit, thermostat is turned off. However, it is not counted.

The following shows the operation state of forced cooling.

Since rotation speed of compressor is fixed in 3000min-1 during forced cooling, compressor fixed speed control at start is

not performed.

Expansion valve/reversing valve : Set in normal conditions.

Compressor rotation speed: Fixed in 3000min-1.

Always operation status of indoor units are monitored and forced cooling is inhibited when operation of any unit is detected.

Powe r

Heating output

Service switch

Cooling output

Outdoor fan

Turns on

for Cooling

Operation

Powe r

Compressor

rotation speed

In-rush Prevention

Compressor

Power relay

Electric expansion valve

Main microcomputer

Reversing

valve

Unit 1

Unit 2

Unit 3

Unit 1

Unit 2

Unit 3

Hold

Hold

Hold

Approx.100ms

100ms

1sec.

1sec.

1sec.

520

480

0

520

480

0

520

480

0

TSKTM1_C and PSTARTC2$ are EEPROM data.

Hold 500ms

Hold 500ms

Hold 500ms

31.25PPS

PSTARTC2$

PSTARTC2$

PSTARTC2$

Initialization

finished

[Outdoor temperature < 40˚C]

[Outdoor temperature < 40˚C]

[Outdoor temperature < 40˚C]

Initialization

finished

< TD control + N compensation + Diving control >

< TD control + N compensation + Diving control >

< TD control + N compensation + Diving control >

TSKTMI_C1

Outdoor temperature ≥ STARCTP_C

TSKTMI_C2

Outdoor temperature ≤ STARCTP_C

Forced cooling request

Forced cooling request

Forced cooling request

Balancing request

Balancing request

Balancing request

Balancing period 3min.

Lo

3000min

-1

15sec. +sub

30sec.

80sec.

MODEL RAM-53QH5

Page 56

– 67 –

PROCESSING AT OVERHEAT THERMISTOR (OH) HIGH TEMPERATURE

Restriction Start Conditions

If any expansion valve is operated at 480 pulses and the OH temperature > [NDOWN_ON], the compressor speed will be

reduced at a rate of 100 min

-1

/30 seconds.

The restriction will be released when OH temperature < [NDOWN_OFF], and the compressor speed will be increased at a

rate of 50 min

-1

/30 seconds to restore the target speed.

This reduced rotation speed is based on the speed when the reduction started, and will be maintained until the reduction is

finished. However, the reference speed will be exchanged only if the target speed is lower than the speed when the

reduction started.

If [NDOWN_OFF] ≤ OH temperature ≤ [NDOWN_ON] and the OH temperature does not rise from that 20 seconds

before, the reduction of compressor speed will not occur.

Restriction Release Condition (in common for all)