Page 1

1

EN

FOR

SERVICE

PERSONNEL ONLY

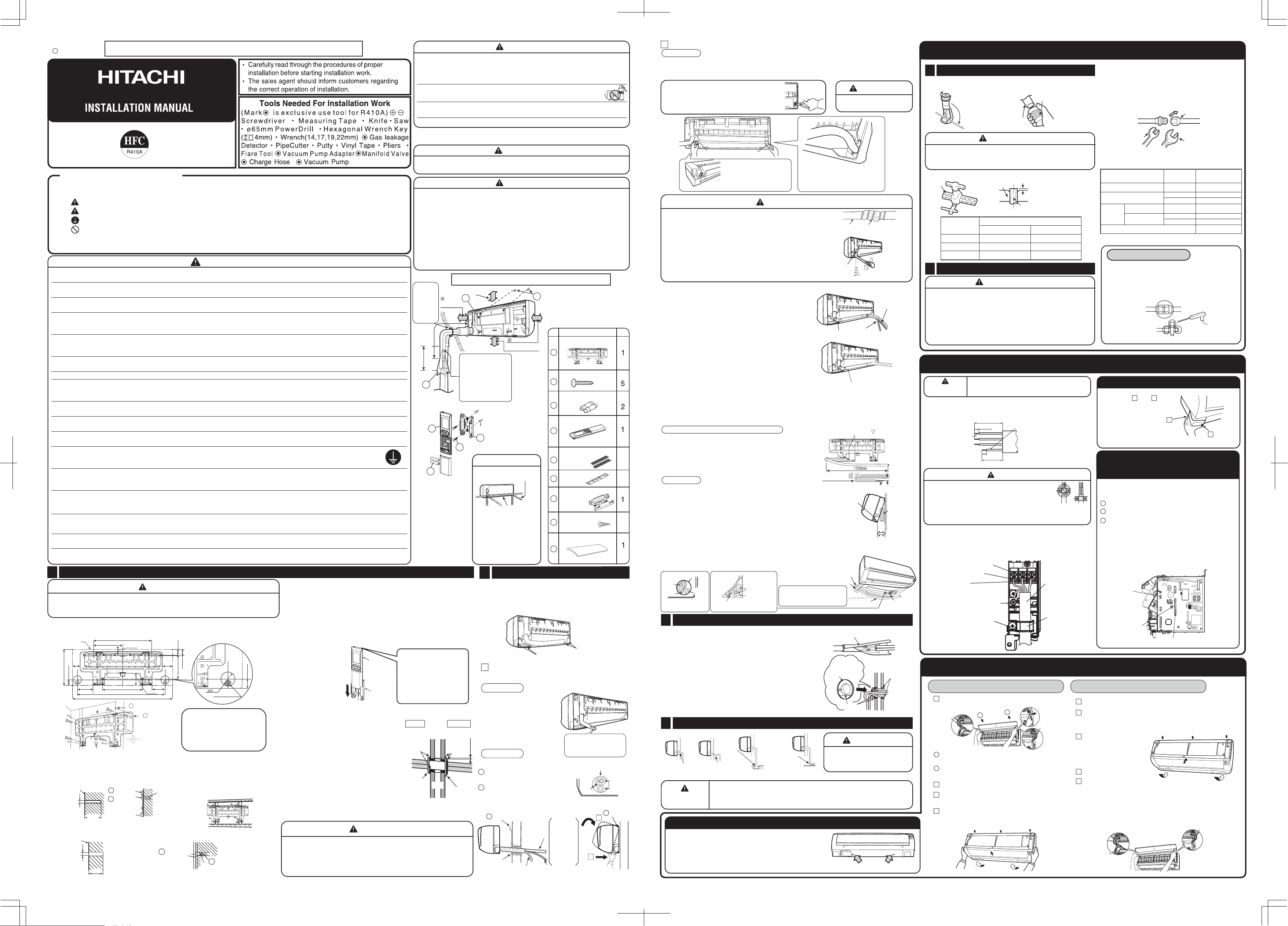

INDOOR UNIT

RAK-35RPC

MODEL

RAK-50RPC

SAFETY PRECAUTION

s Read the safety precautions carefully before operating the unit.

s The contents of this section are vital to ensure safety. Please pay special attention to the following sign.

WARNING .......... Incorrect methods of installation may cause death or serious injury.

CAUTION .......... Improper installation may result in serious consequence.

Make sure to connect earth line.

This sign in the figures indicates prohibition.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper operation and maintenance of

the unit as described in the user' s guide. Ask a customer to keep this installation manual together with the instruction manual.

WARNING

s Please request your sales agent or qualified technician to install your unit. Water leakage, short circuit or fire may occur if you do the

installation work yourself.

s Please observe the installation stated in the installation manual during the process of installation. Improper installation may cause

water leakage, electric shock and fire.

s Make sure that the units are mounted at locations which are able to provide full support to the weight of the units. If not, the units may

collapse and impose danger.

s Observe the rules and regulations of the electrical installation and the methods described in the installation manual when dealing

with the electrical work. Use cables which are approved official in your country. Be sure to use the specified circuit. A short circuit and

fire may occur due to the use of low quality wire or improper work.

s Be sure to use the specified cables for connecting the indoor and outdoor units. Please ensure that the connections are tight after the

conductors of the wire are inserted into the terminals to prevent the external force is being applied to the connection section of the

terminal base. Improper insertion and loose contact may cause over-heating and fire.

s Please use the specified components for installation work. Otherwise, the unit may collapse or water leakage, electric shock, fire or

stronger vibration may occur.

Be sure to use the specified piping set for R410A. Otherwise, this may result in broken copper pipes or faults.

s

When installing or transferring an air conditioner to another location, make sure that air other than the specified refrigerant (R410A)

s

does not enter the refrigeration cycle. If other air should enter, the pressure level of the refrigeration cycle may increase abnormally

which could result in a rupture and injury.

s Be sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact with fire, a poisonous gas may

occur.

s After completion of installation work, check to make sure that there is no refrigeration gas leakage. If the refrigerant gas leaks into the

room, coming into contact with fire in the fan-driven heater, space heater, etc., a poisonous gas may occur.

s Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call a qualified air conditioner

technician or electrician. Improper repairs may result in water leakage, electric shock and fire, etc.

s Be sure to connect the earth line from the power supply wire to the outdoor unit and between

the outdoor and indoor unit. Do not connect the earth line to the gas tube, water pipe, lighting rod or the earth line of the

telephone unit. Improper earthing may cause electric shocks.

s When finishing the refrigerant collection (pumping down), stop the compressor and then remove the coolant pipe.

If you remove the refrigerant pipe while the compressor is operating and the service valve is released, air is sucked and a

pressure in the freezing cycle system will build up steeply, causing an explosion or injury.

s When installing the unit, be sure to install the refrigerant pipe before starting the compressor.

If the refrigerant pipe is not installed and the compressor is operated with the service valve released, air is sucked and the

pressure level of the refrigeration cycle may increase abnormally which could result in a rupture and injury.

s

The electric cables should neither be reworked nor added.

Make sure to use an exclusive circuit breaker.

Otherwise fire or electric shock might occur by connection failure, isolation failure or over current.

Make sure to connect cables to terminal properly and terminal cover should close firmly.

s

Otherwise, over heating at terminal contact, fire or electric shock might occur.

Make sure that there is no dust on any connected points of electric cables and fix firmly.

s

Otherwise, fire or electric shock might occur.

1 Installation of Hanger , Wall Penetration and Installation of Protection Pipe

CAUTION

s The draining of the water container inside the Indoor unit can be done from the left.

Therefore the hanger must be fixed horizontally or slightly tilted towards the side of

drain hose. Otherwise, condensed water may overflow the water container.

Direct Mounting On The Wall

s Please use hidden beams in the wall to hold the hanger.

Visible outline of the

Indoor Unit

100

mm

295 mm

42.5 mm

180 mm

Line

Level

Weight

275 mm

668 mm

550 mm

284 mm

772 mm

900 mm

23 mm

160 mm

115 mm

Screw for Hanger

Hanger

Wall hole

100

mm

37 mm

39 mm

193 mm

Drain Hose

Screw the hanger at the

positions possibly near the

upper and lower hooks where

the indoor unit is hung. Use 4 or

more screws to fix the hanger.

42.5 mm

Procedures of Installation and Precautions

s Procedures to fix the hanger.

1.Drill holes on wall.

(As shown below)

Wall

.4

32mm

ømm8

s Procedures to fix the holder of remote control.

1.Drill holes on wall.

Wall

.4

ømm4

2.Push plug into the holes.

(As shown below)

Hanger

1

Screw

2

Wall

(As shown below)

20mm

3.Fix the hanger on wall

with 4.1 x 32 screw.

Plug

(Procure

locally)

(As shown in figure below)

Ceiling

2.Push plug into the holes.

Remote

7

Control

Holder

Screw

8

Plug (Procure locally)

(As shown below)

Installation Of Remote Controller

s

The remote controller can be placed in its holder which is fixed on

wall or beam.

To operate the remote controller at its holder, please ensure that the

s

unit can receive signal transmitted from the controller at the place where

the holder is to be fixed.The unit will beep when signal is received from

the remote controller . The signal transmission is weaken by the fluorescent

light. Therefore, during the installation of the remote control holder, please

switch on the light, even during day time, to determine the mounting

of

the holder

.

Remote

Controller

The remote controller

must be slide in

the remote controller

holder, in the direction

as shown in the figure,

Remote

Controller

Holder

Screw (2 pieces)

until it hooks at the

lower end of the remote

controller holder.

Wall Penetration and Installation of Protection Pipe

s Drill a ø65mm hole on wall which is

slightly tilted towards the outdoor side.

Drill the wall at a small angle.

s

Cut the protection pipe according to the

wall thickness.

Empty gap in the sleeve of protection

s

pipe should be completely sealed with

putty to avoid dripping of rain water into

the room.

Please ensure smooth flow of water

s

when installing the drain hose. Improper

installing may wet your funiture.

s

An IEC approved power cord should be

used. Power cord type: NYM.

Indoor

Seal with

putty

Protection

pipe

WARNING

Be sure that the wire is not in contact with any metal in the wall.

Please use the protection pipe as wire passing through the

hollow part of the wall so as to prevent the possibility of

damaged by mouse. Unless it seals completely,any air with high

humidity flows from outdoor and any dew may drop.

CAUTION

s

A circuit breaker must be installed in the house distribution box for the direct

connected power supply cables to the outdoor unit. In case of other

installations

a main switch with a contact gap or more than 3mm has to be installed.

Without a circuit breaker, the danger of electric shock exists.

Do not install the unit near a location where there is flammable gas.

s

The outdoor unit may catch fire if flammable gas leaks around it.

s

Please ensure smooth flow of water when installing the drain hose. Improper

installing may wet your fu niture.

An IEC approved power cord should be used. Power cord type:

s

r

NYM.

THE CHOICE OF MOUNTING SITE

(Please note the following matters and obtain permission from customer before installation.)

WARNING

The unit should be mounted at stable, non-vibratory location which can provide

s

full support to the unit.

CAUTION

s No nearby heat source and no obstruction near the air outlet is allowed.

s

The clearance distances from top, right and left are specified in figure

below.

The location must be convenient for water drainage and pipe connection

s

with the Outdoor unit.

s To avoid interference from noise, please place the unit and its remote

controller at least 1m from the radio and television.

To avoid any error in signal transmission from the remote controller, please

s

put the controller far away from high-frequency machines and high-power

wireless systems.

The installation height should be at least 2300 mm or more

s

Figure showing the Installation

Be sure to

completely

seal any

gap with

above

above

50mm

1

50mm

2

from the floor.

of Indoor Unit.

putty.

Names of Indoor Components

No. Item Qty

above

mm003 tuoba

dneb

ton tsu

m

9

4

3

about 450mm

The indoor piping

should be insulated

with the enclosed

insulation pipe. (If the

please use commercial

products.)

8

50mm

2300 mm or more

insulator is insufficient,

Plug

7

Direction of Piping

Backward piping

from left

Connection

There are 6 directions

allowed,namely,backward

piping, backward piping

from left,horizontally piping

from right,horizontally piping

from left,vertically down from

right,vertically down from left.

Hanger

1

Screw for Hanger

2

AAA size Battery

3

Remote Controller

4

Wasabi-Nano Titanium

Air Cleaning Mesh

5

C-case

6

Remote Controller Holder

7

Screw for Remote

Controller Holder

8

Insulation sheet

9

2

2

2

2

2 Installation Of The Indoor Unit

Cutting Low Cover bush

s

While installing the pipe from the right, left or bottom

side, use a knife to cut openings as shown in figure.

Then smoothen the edges of openings with a file.

WALL

location

Outdoor

2-5mm

Seal with

putty

Sleeve of

protection

pipe

Openings

1

PIPING FROM THE RIGHT SIDE

(BACKWARD, DOWNWARD, HORIZONTAL)

Preparation

Connect connecting cord.

s

s

Pull out the pipe, connecting

cord and drain hose.

Installation

Insert the pipe through the wall hole.

s

1 The

upper part of the Indoor unit

is hanged on the hanger.

2

The projection at the lower part

of the Indoor unit is hooked onto

the hanger.

Hanger

1

Lift the body

of the unit

upwards and

then force it

downwards.

Connecting Cord

Protection

Pipe

Refrigerating

Pipe

Drain Hose

Openings

Connecting cords, pipe and

drain hose must be laid

together with Vinyl tape.

Wall hole

Pipe

2

1

1

Projection

Drain hose

Hanger

Cable

Drain layout of

backward piping

2

PIPING FROM THE LEFT SIDE (BACKWARD, DOWNWARD, HORIZONTAL)

Preparation

INSTALLATION OF REFRIGERATING PIPES AND AIR REMOVAL

Changed of Drain Hose and Installation Procedures.

Exchange the location of drain hose and drain cap while installing the pipe from the left side as

s

shown in below. Be sure to plug in the drain hose until the insulating material folds upon itself.

s Please use pliers to pull out the drain cap .

(This is an easier way to remove the drain

cap).

Drain cap

Drain cap

Drain Hose

Remove low cover

s

s

Insert drain cap up to the

location securely till the

cap stops.

s

Push the pipe deeply until the insulating

section of the drain hose end gets over the

rib at the indoor unit side.

CAUTION

Insufficient insert may

result in water leakage.

1 Preparation of Pipe

s Use a pipe cutter to cut the copper pipe and remove burr.

s Remove burr and jagged edge will cause leakage.

s Point the side to be trimmed downwards during

trimming to prevent copper chips from entering the pipe.

s Before flaring, please put on the flare nut.

Die

CAUTION

s

The rubber strap used for fixing the insulator should not

be tied with great force. Otherwise,this will damage heat

insulation and causes water condensation.

Pipe

Rubber strap tied

with great force

s Please pull the lower part of the Indoor unit outwards to

check if the unit is hooked onto the hanger. Improper

installation may cause vibration and noise.

s Transform the piping while holding down the

lower portion

of pipe-support by hand.

INSTALLATION AFTER CONNECTION OF REFRIGERATING PIPES

s The refrigerating pipe should be adjusted to fit into

the hole on the wall and then ready for further

connection.

s The terminals of 2 connected pipes must be covered

with insulator used for terminal connection. Then the

pipes are wrapped with insulation pipe.

s Connect the connecting cord after removing low

Pipe

support

Pipe

Transform after

bending downward.

Drain hose

Connecting

cord

2 Pipe Connection

s In case of removing flare nut of a indoor unit, first remove

a nut of small diameter side, or a seal cap of big diameter

side will fly out. Free from water into the piping when

working.

s Be sure to tighten the flare nut to the specified torque with

a torque wrench.

If the flare nut is overtightened, the nut may be split after a

long period has passed, and may cause a refrigerant leak.

cover.

(Refer to "CONNECTION OF POWER CORD")

s After adjustment, fit the connecting cord and pipes

into the space available under the unit. Use holder to

hold them tight.

s Holder can be attached at the either of 2 places.

Please select the easier position.

THE CONNECTION OF REFRIGERATING PIPE DURING

THE INSTALLATION OF INDOOR UNIT

Preparation To Install Refrigerating Pipes

Insulation pipe (must be wrapped with

vinyl tape at every 120 mm)

Detail of Cutting the Connecting Cord

The end of the refrigerating pipes are at

locations marked with “

” symbol.

WARNING

s The refrigerating pipes and connecting cord

transform and are attached.

Installation

Please bend at a small

radius to form an arc

Hang the indoor unit onto the hanger. Use the temporary stan

at the back of the Indoor unit to push its lower part 15cm

forwards.

s Place the drain hose through the hole on the wall.

s Wrap the refrigerating pipes with insulation pipe afte

connecting refrigerating pipe.

s Connect the connecting cord after removing low cover.

(Refer to "Connection of Power Cord")

s After adjustment, the connecting cord and refrigerating pipes

are placed into the space available under the Indoor unit.

d

Projection

r

about 15cm

below

5mm

Hook

s

Leave some space in the connecting cord for

maintenance purpose and be sure to secure

it with the cord band.

Secure the connecting cord along the coated part of the wire using

s

the cord band. Do not exert pressure on the wire as this may cause

overheating or fire.

Wiring of The Indoor Unit

s

For wire connection of the Indoor unit, you need to remove the front

cover, the

s

Remove the cover from the terminal base and screw the cable.

s The projection of Indoor unit must hook to the hanger.

Wall hole

Pipe

Cable

Drain layout of

backward piping

from left

Drain

hose

Connecting

cord

Refrigerating

pipe

Heat

insulation pipe

Pull this to the front during the

connection of refrigerating

pipe to ease task.

Protection

pipe

Drain hose

Connecting cord

Connected

section

3 Heat Insulation and Finish of the Piping

s The connected terminals should be completed sealed

with heat insulator and then tied up with rubber strap.

s Do not tie the terminals with the tape too tight.

If any clearance or over-tightening may cause

condensation.

s Please tie the pipe and power line together with vinyl

tape as shown in the figure showing the installation of

Indoor and Outdoor units.

s To enhance the heat insulation and to prevent water

condensation, please cover the outdoor part of the

drain hose and pipe with insulation pipe.

s Completely seal any gap with putty.

Insulation material for pipe

connection

Sleeve of

protection pipe

Putty

Putty

How to remove the front cover

1

4 Installation of Drain Hose

CAUTION

Bending upwards

CAUTION

Ditch

Condensed water

pond

Condensed water

pond

You are free to choose the side (left or right) for the installation of drain

hose. Please ensure the smooth flow of condensed water of the Indoor

unit during installation. (Careless may result in water leakage.)

Be sure that the drain hose is

not loosely connected bend or

proper condition like left figure.

1

2

2

3

4

HOW TO REMOVE INDOOR UNIT

s

Push up the [PUSH] sections at the bottom of the indoor unit

and pull the bottom plate towards you. Then the claws are

released from the stationary plate.

(The [PUSH] sections are indicated by 2 arrows in the right

figure)

[PUSH] mark positions

Trimming tool

Copper pipe

CAUTION

Die

Copper pipe

Outer A (mm) Rigid Flaring Tool

Diameter (Ø) For R410A tool For R22 tool

6.35 (1/4") 0 - 0.5 1.0

9.52 (3/8") 0 - 0.5 1.0

0 - 0.5 1.012.7 (1/2")

A

s Please use

exclusive tool for

refrigerant R410A.

CAUTION

s THIS APPLIANCE MUST BE EARTHED.

Indoor Unit

Strip

wires

10mm

70mm

10mm

45mm

1

2

3

Green + Yellow

(ground)

Connecting cord

WARNING

low cover under the body of the unit and terminal cover.

3

2

1

Earth

After remove the screw

and terminal cover, and

put the connecting cords

and fix the terminal cover

with screw.

Connecting

cord

Cord band

FINAL STAGE OF INSTALLATION

Remove the front panel

Arm

Push the end of the right-side arm outward to

release the tab.

Move the left-side arm outward to release the

left tab, and then pull the panel towards you.

Remove the filters.

After removing three screws, pull the center of

the front cover towards you and release the claws.

Pull the side faces (lower sections) of the front

cover towards you as shown in the figure and

remove the cover.

2

1

Push

Arm

s Please be careful when bending the copper pipe.

s Screw in manually while adjusting the center.

After that, use a torque wrench to tighten the

connection.

Flare nut

Wrench

Small diameter side

Large diameter side

Valve head

cap

Small diameter side

Large diameter side

Valve core cap

Torque

wrench

Outer diameter

of pipe (ø)

6.35 (1/4”) 13.7 – 18.6 (140 – 190)

2/1( 7.21

Torque N·m

(kgf·cm)

)”2/1( 7.21

44.1 – 53.9 (450 – 550)

12.3 – 15.7 (125 – 160)

Gas leakage inspection

Please use gas leakage detector to check if

leakage

occurs at

as shown

further tighten the connection

OP FO NOITCENNOC

Method to remove the low cover

s

Pull at the 1 and

the directions as shown

by arrows to remove the

cover.

connection of Flare nut

in below.

If gas leakage occurs,

DROC REW

2

in

2

to stop leakage.

1

How to connect the optional parts

(H-LINK RAC Adapter, Dry contact, Wired Remote

Controller)

s For cable connection to control P.W.B., you need to

remove front cover and electrical box cover.

Each connecting location is as below.

1

Dry contact: CN6

2

H-LINK RAC Adapter:CN7

3

Wired Remote Control : CN20

s Please check and confirm manuals attached to each

optional parts for more connection details.

s You can refer to this installation manual how to remove

and re-attach the front cover.

s Please be careful not to damage lead wires by edge of

plate when connecting the optional parts.

CN20

CN7

ler

CN21

CN7

CN6

CN6

How to Attach the Front Cover

1

Check that the drain pan is securely attached.

After installing the front cover onto the unit, hook three claws

2

at upper side of the cover securely. Then, push the center of

the front cover to lock the claws.

Tighten the three screws.

3

Install the filter.

4

5

Attaching the Front Panel

Insert the shaft of the left arm along the step on the unit into

s

the hole.

Securely insert the shaft of the right arm along the step on

s

the unit into the hole.

s

Make sure that the front panel is securely attached, and then

close the front panel.

Arm

Step

Arm

Step

)054 – 053( 1.44 – 3.43 )”8/3( 25.9

)052 – 002( 5.42 – 6.91 )”4/1( 53.6

)052 – 002( 5.42 – 6.91 )”8/3( 25.9

)053 – 003( 3.43 – 4.92 )”

Loading...

Loading...