Page 1

SM0174

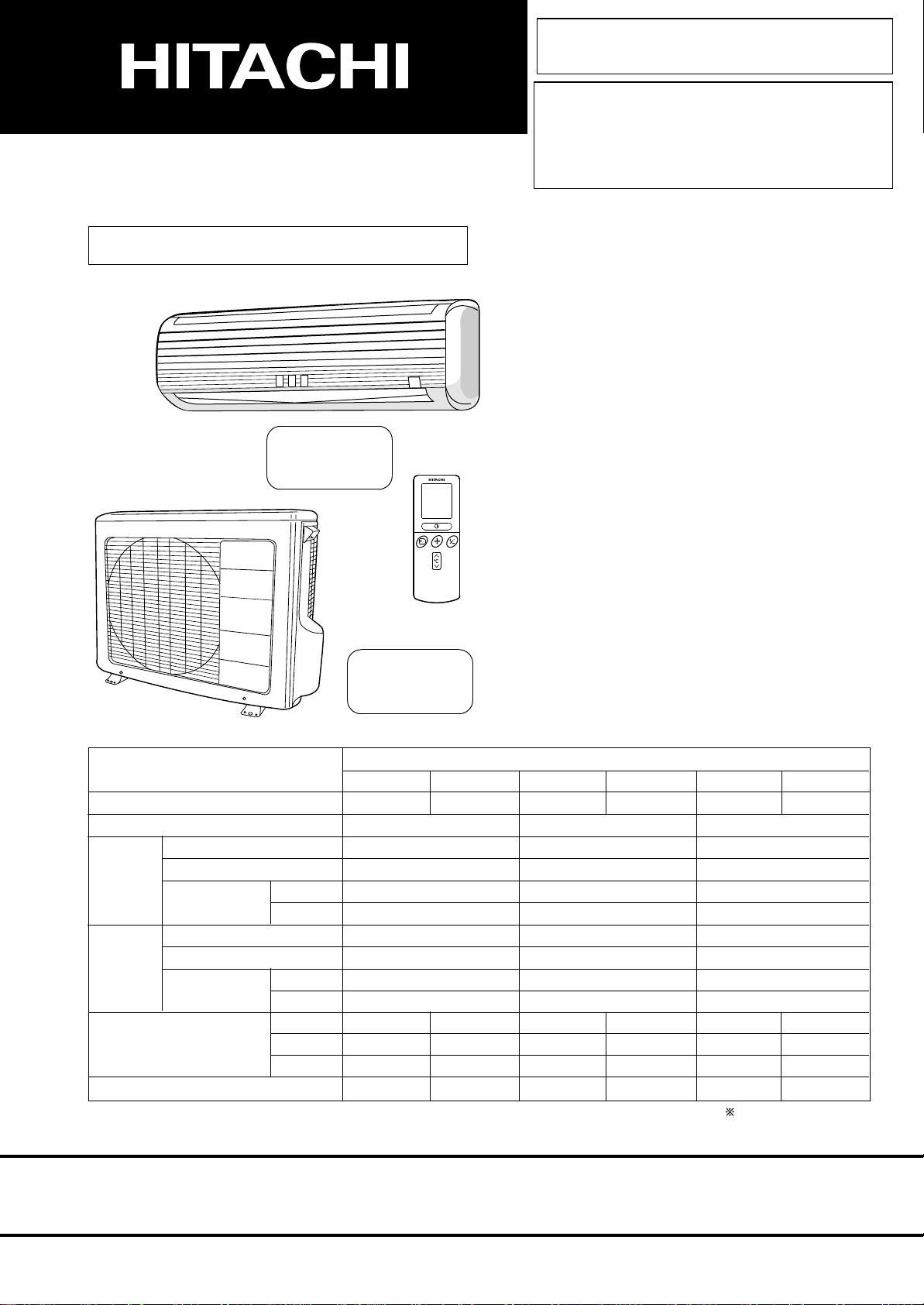

RAK25NH4 RAC25NH4

RAK35NH4 RAC35NH4

SERVICE MANUAL

TECHNICAL INFORMATION

FOR SERVICE PERSONNEL ONLY

RAK-25NH4

RAK-35NH4

RAK-50NH4

RAC-25NH4

RAC-35NH4

RAC-50NH4

RAK50NH4 RAC50NH4

REFER TO THE FOUNDATION MANUAL

CONTENTS

SPECIFICATIONS ------------------------------------------------------------------- 5

CONSTRUCTION AND DIMENSIONAL DIAGRAM --------------------- 6

MAIN PARTS COMPONENT --------------------------------------------------- 8

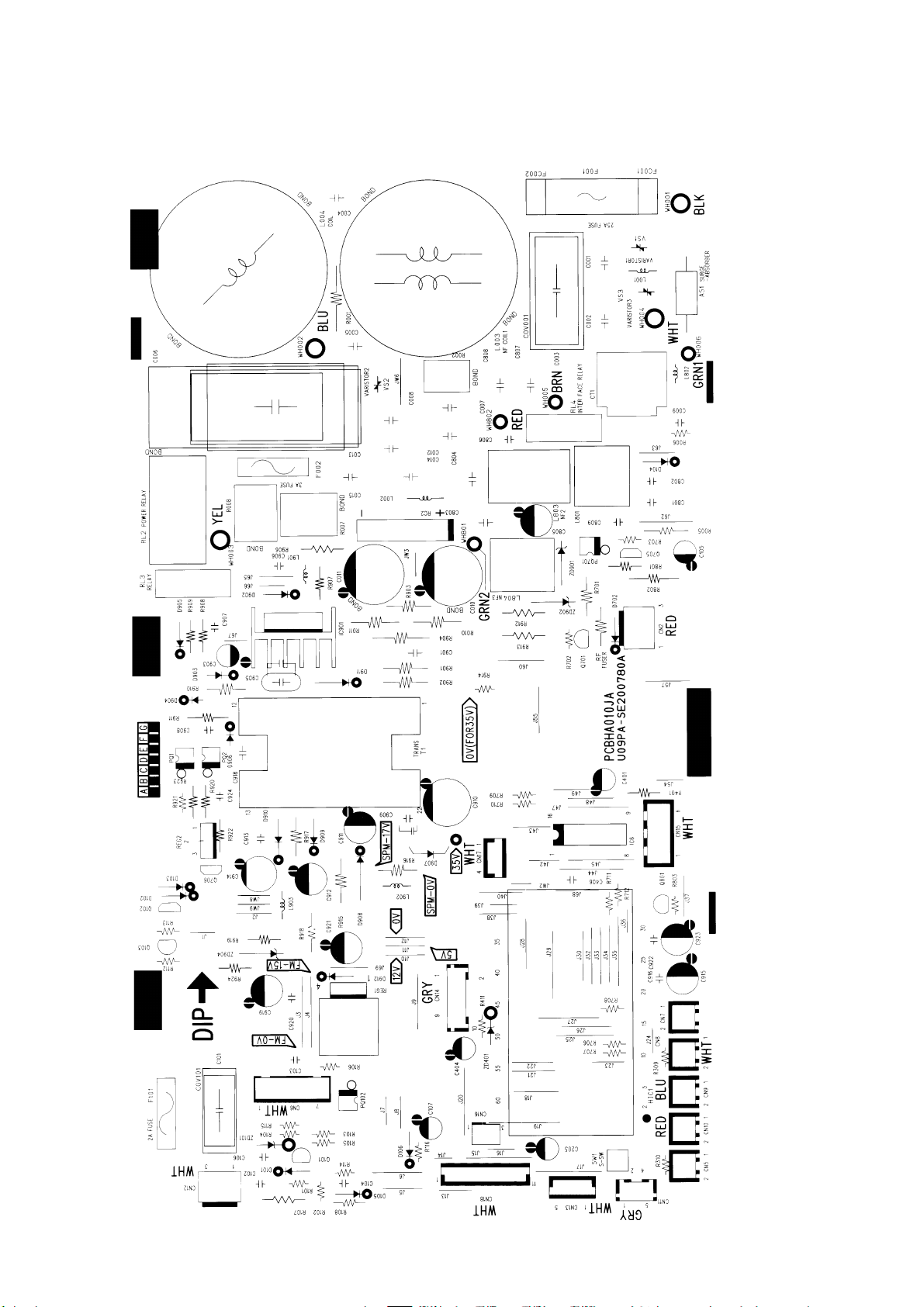

WIRING DIAGRAM ---------------------------------------------------------------- 10

CIRCUIT DIAGRAM --------------------------------------------------------------- 12

PRINTED WIRING BOARD LOCATION DIAGRAM ---------------------

BLOCK DIAGRAM ----------------------------------------------------------------- 20

BASIC MODE ----------------------------------------------------------------------- 22

REFRIGERATING CYCLE DIAGRAM --------------------------------------- 35

AUTO SWING FUNCTION ------------------------------------------------------ 37

DESCRIPTION OF MAIN CIRCUIT OPERATION ----------------------- 38

SERVICE CALL Q & A ---------------------------------------------------------- 69

TROUBLE SHOOTING ----------------------------------------------------------- 72

PARTS LIST AND DIAGRAM ------------------------------------------------- 92

18

SPECIFICATIONS

TYPE

MODEL

POWER SOURCE

TOTAL INPUT

COOLING

HEATING

DIMENSIONS

(mm)

NET WEIGHT

TOTAL AMPERES

CAPACITY

TOTAL INPUT

TOTAL AMPERES

CAPACITY

(W)

(A)

(kW)

(B.T.U./h)

(W)

(A)

(kW)

(B.T.U./h)

W

H

D

(kg)

INDOOR UNIT

RAK-25NH4 RAC-25NH4

1 PHASE, 50 Hz, 220-230V

695 (155~1,050)

2.50 (0.90 ~ 3.00)

900 (115 ~ 1,400)

3.50 (0.90 ~ 5.00)

860

285

183

9.0

OUTDOOR UNIT

3.20-3.05

8,540

4.15-4.00

11,950

750

570

280

38

DC INVERTER (WALL TYPE)

INDOOR UNIT

RAK-35NH4 RAC-35NH4

1 PHASE, 50 Hz, 220-230V

1,080 (155~1,280)

3.50 (0.90 ~ 4.00)

1,320 (115 ~ 1,920)

4.80 (0.90 ~ 6.60)

860

285

183

9.0

OUTDOOR UNIT

4.94-4.72

11,950

6.04-5.77

16,390

750

570

280

38

INDOOR UNIT

RAK-50NH4 RAC-50NH4

1 PHASE, 50 Hz, 220-230V

1,780 (155~2,200)

5.00 (0.90 ~ 5.20)

1,970 (115 ~ 2,100)

6.50 (0.90 ~ 8.10)

860

285

183

9.0

OUTDOOR UNIT

8.17-7.82

17,070

9.04-8.65

22,200

850

650

298

60

After installation

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

ROOM AIR CONDITIONER

MAY 2003

Refrigeration & Air-Conditioning Division

INDOOR UNIT + OUTDOOR UNIT

Page 2

FOR SERVICE PERSONNEL ONLY

●

Carefully read through the procedures of proper

installation before starting installation work.

●

The sales agent should inform customers regarding

the correct operation of installation.

SPLIT UNIT AIR CONDITIONER

INSTALLATION MANUAL

Outdoor Unit RAC-35NH4

HFC

R410A

SAFETY PRECAUTION

●

Read the safety precautions carefully before operating the unit.

●

The contents of this section are vital to ensure safety. Please pay special attention to the following sign.

WARNING ........ Incorrect methods of installation may cause death or serious injury.

!

!

CAUTION ......... Improper installation may result in serious consequence.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper way of operating

the unit as described in the user’s guide.

RAC-25NH4

RAC-50NH4

Tools Needed For Installation Work

●

+ – Screwdriver

●

Saw ● ø 65mm Power Drill ● Hexagonal Wrench

Key ( 4mm)

●

Gas Leakage Detector ● Pipe Cutter

●

Vinyl Tape ● Pliers ● Flare Tool

●

Measuring Tape

●

Wrench (14, 17, 22, 26, 27mm)

●

Knife

●

Putty

!

WARNING

●

Please request your sales agent or qualified technician to install your unit. Water leakage, short circuit or fire may occur if you

do the installation work yourself.

●

Please observe the instructions stated in the installation manual during the process of installation. Improper installation may

cause water leakage, electric shock and fire.

●

Make sure that the units are mounted at locations which are able to provide full support to the weight of the units. If not, the

units may collapse and impose danger.

●

Observe the rules and regulations of the electrical installation and the methods described in the installation manual when

dealing with the electrical work. Use power cables approved by the authorities of your country.

●

Be sure to use the specified wire for connecting the indoor and outdoor units. Please ensure that the connections are tight

after the conductors of the wire are inserted into the terminals. Improper insertion and loose contact may cause over-heating

and fire.

●

Please use the specified components for installation work. Otherwise, the units may collapse or water leakage, electric shock

and fire may occur.

●

Be sure to use the specified piping set for R-410A. Otherwise, this may result in broken copper pipes or faults.

●

When installing or removing an air conditioner, only specified refrigerant (R410A) shall be allowed, do not allow air or moisture

to remain in the refrigeration cycle. Otherwise, pressure in the refrigeration cycle may become abnormally high so that a rupture

may be caused.

●

Be sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact with fire, a poisonous

gas may occur.

●

After completion of installation work, check to make sure that there is no refrigeration gas leakage. If the refrigerant gas leaks

into the room, coming into contact with fire in the fan-driven heater, space heater, etc., a poisonous gas may occur.

●

Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call a qualified air conditioner

technician or electrician. Improper repairs may result in water leakage, electric shock and fire, etc.

!

CAUTION

●

A circuit breaker or fuse (16A time delay) must be installed. Without a circuit breaker or fuse the danger of electric shock exists.

A main switch with a contact gap of more than 3mm has to be installed in the power supply line to the outdoor unit.

●

Do not install the unit near a location where there is flammable gas. The outdoor unit may

catch fire if flammable gas leaks around it.

●

Please ensure smooth flow of water when installing the drain hose.

●

Piping shall be suitable supported with a maximum spacing of 1m between the supports.

<

I477: A

>

Page 3

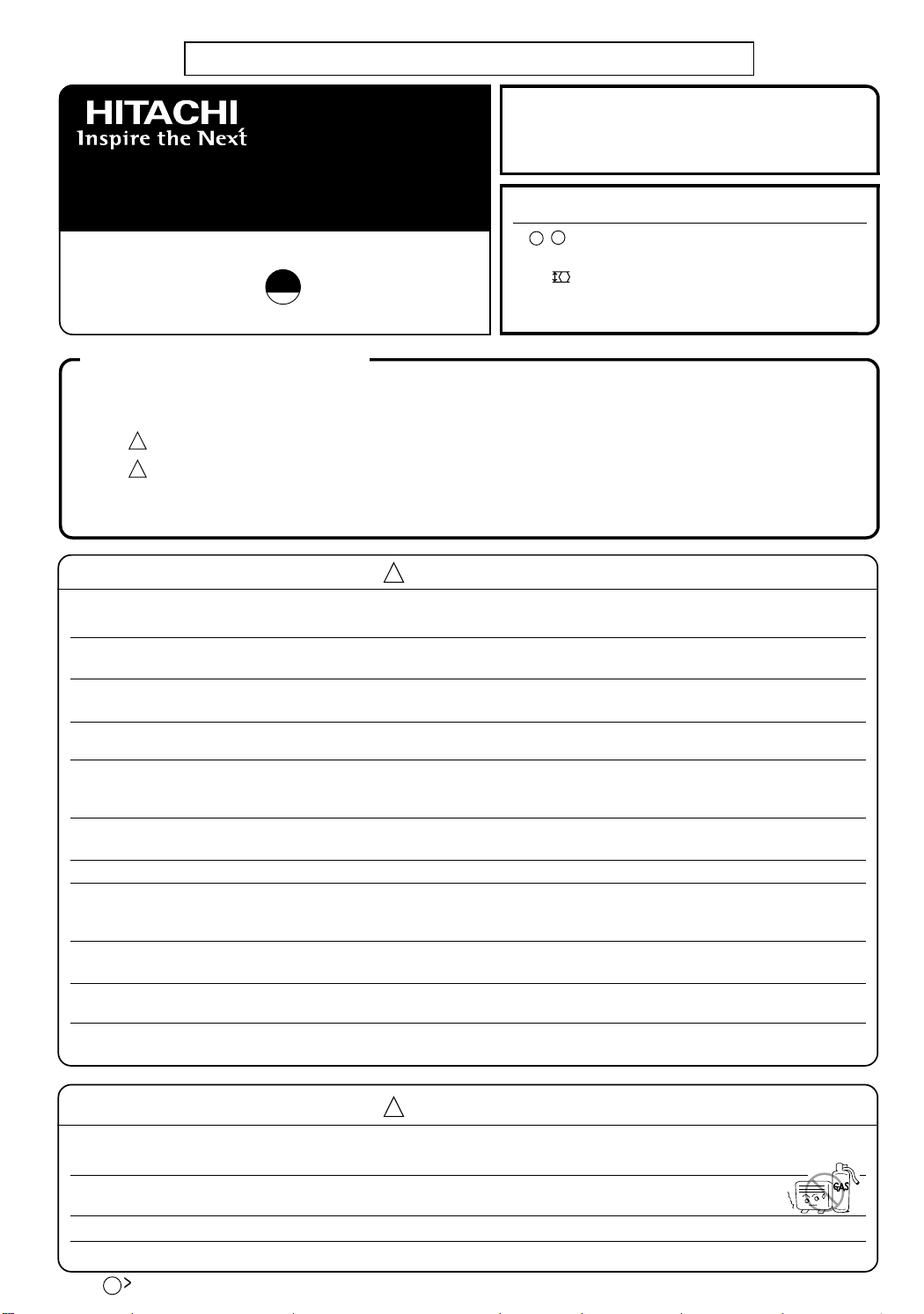

THE CHOICE OF MOUNTING SITE (Please note the following matters and obtain permission from customer before installation).

!

WARNING

●

The Outdoor unit must be mounted at a location which can support heavy weight. Otherwise, noise and vibration will increase.

!

CAUTION

●

Do not expose the unit under direct sunshine or rain. Besides, ventilation must be good and clear of obstruction.

●

The air blown out of the unit should not point directly to animals or plants.

●

The clearances of the unit from top, left, right and front are specified in figure below. At least 3 of the above sides must be open air.

●

Be sure that the hot air blown out of the unit and noise do not disturb the neighbourhood.

●

Do not install at a location where there is flammable gas, steam, oil and smoke.

●

The location must be convenient for water drainage.

OUTDOOR UNIT

●

Place the Outdoor unit and its connecting cord at least 1m away from the antenna or signal line of television, radio or telephone. This is to

avoid noise interference.

Names of Outdoor Components

QtyNo. Item

Bush

0

(RAC-25NH4,

RAC-35NH4)

(RAC-50NH4)

2

3

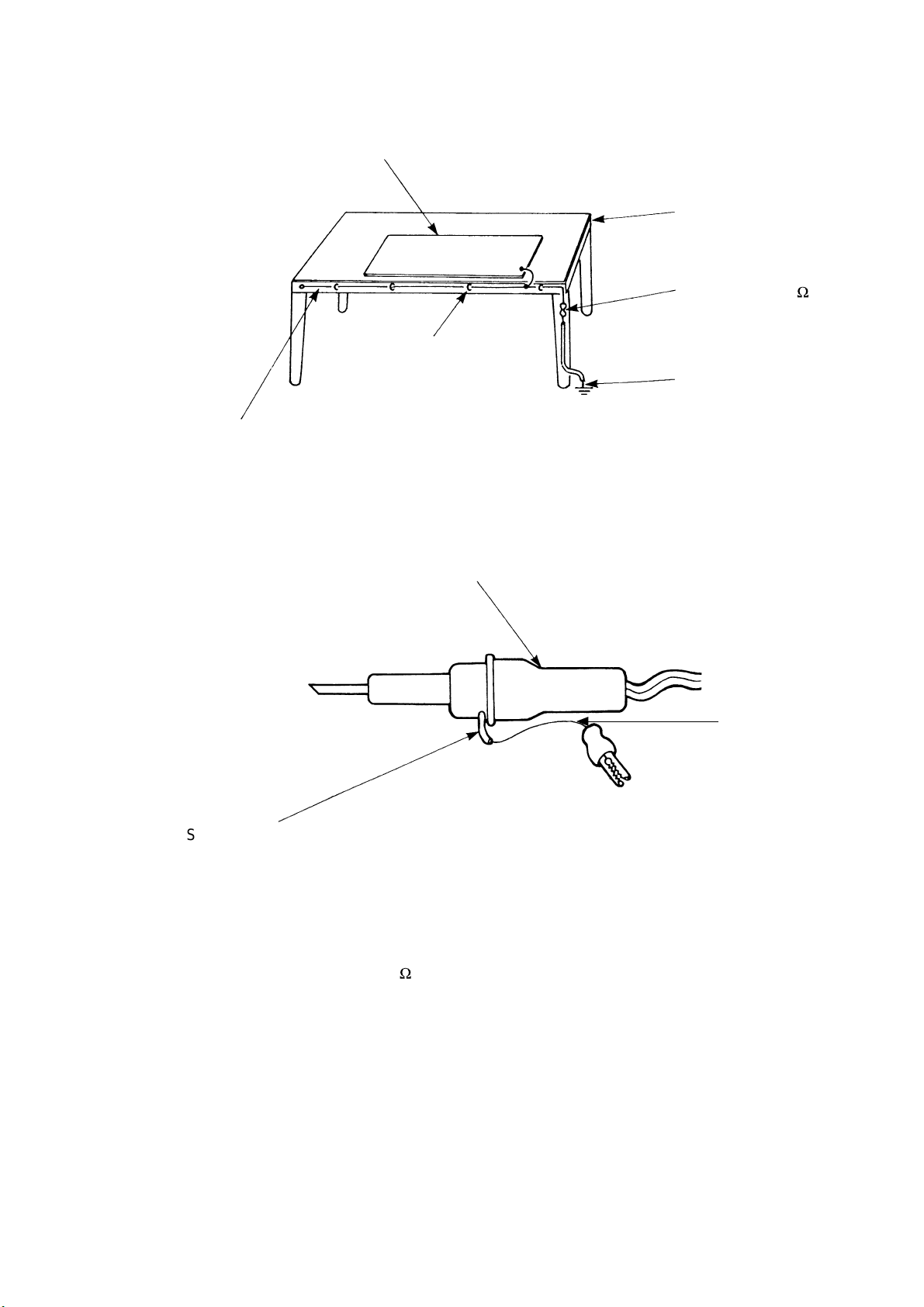

Figure showing the Installation of Outdoor Unit.

Drain Pipe

!

1

Bush

#

1

Dimension of Mounting Stand

of the Outdoor unit

(unit: mm)

mounting stand

Dimension of Mounting Stand

of the Outdoor unit

(unit: mm)

mounting stand

●

Please mount the Outdoor unit on stable ground to prevent

12

35

500

12

35

508

(RAC-25NH4,

RAC-35NH4)

57

10

320

340

20

(10)

124

(RAC-50NH4)

57

10

320

340

35

(10)

198

above 100mm

above 700mm

vibration and increase of noise level.

●

Decide the location for piping after sorting out the different types

of pipe available.

●

When removing side cover, please pull the handle after undoing

the hook by pulling it downward.

Please face this side (suction

side) of the unit to the wall.

Please remove side cover

when connecting the piping

and connecting cord.

Pull downward

above 200mm

above 50mm when

installed on the

(

ceiling of balcony

CONDENSED WATER DISPOSAL OF OUTDOOR UNIT

There are holes on the base of Outdoor unit for condensed

In order to flow condensed water to the drain, the unit is installed on

At first insert one portion of the hook to the base (Portion A), then

When Using and Installing In Cold Areas

When the air conditioner is used in low temperature and in snowy

conditions, water from the heat exchanger may freeze on the base

surface to cause poor drainage. When using the air conditioner in such

areas, do not install the bushings. Keep a minimum of 250mm between

the drain hole and the ground. When using the drain pipe, consult your

sales agent.

For more details, refer to the installation Manual for Cold Areas.

● The difference in height

between the indoor and

outdoor unit should be

kept max 5m.

● The connecting pipe, no

matter big or small,

should all be insulated

with insulation pipe and

then wrapped with vinyl

tape. (The insulator will

deteriorate if it is not

wrapped with tape).

The connection of insulated

drain hose.

inner diameter ø 16mm

Maximum pipe length 20m

)

above 100mm

Please use insulated drain

hose for the indoor piping

(commercial product).

give clearance as

wide as possible

above 200mm

water to exhaust.

a stand or a block so that the unit is 100mm above the ground as

shown figure. Join the drain pipe to one hole.

pull the drain pipe in the direction shown by the arrow while inserting

the hook into the base. After installation, check whether the drain

pipe cling to the base firmly.

A

BASE

DRAIN PIPE

100 mm ABOVE

10

BUSH

12

11

DRAIN PIPE

BUSH

Page 4

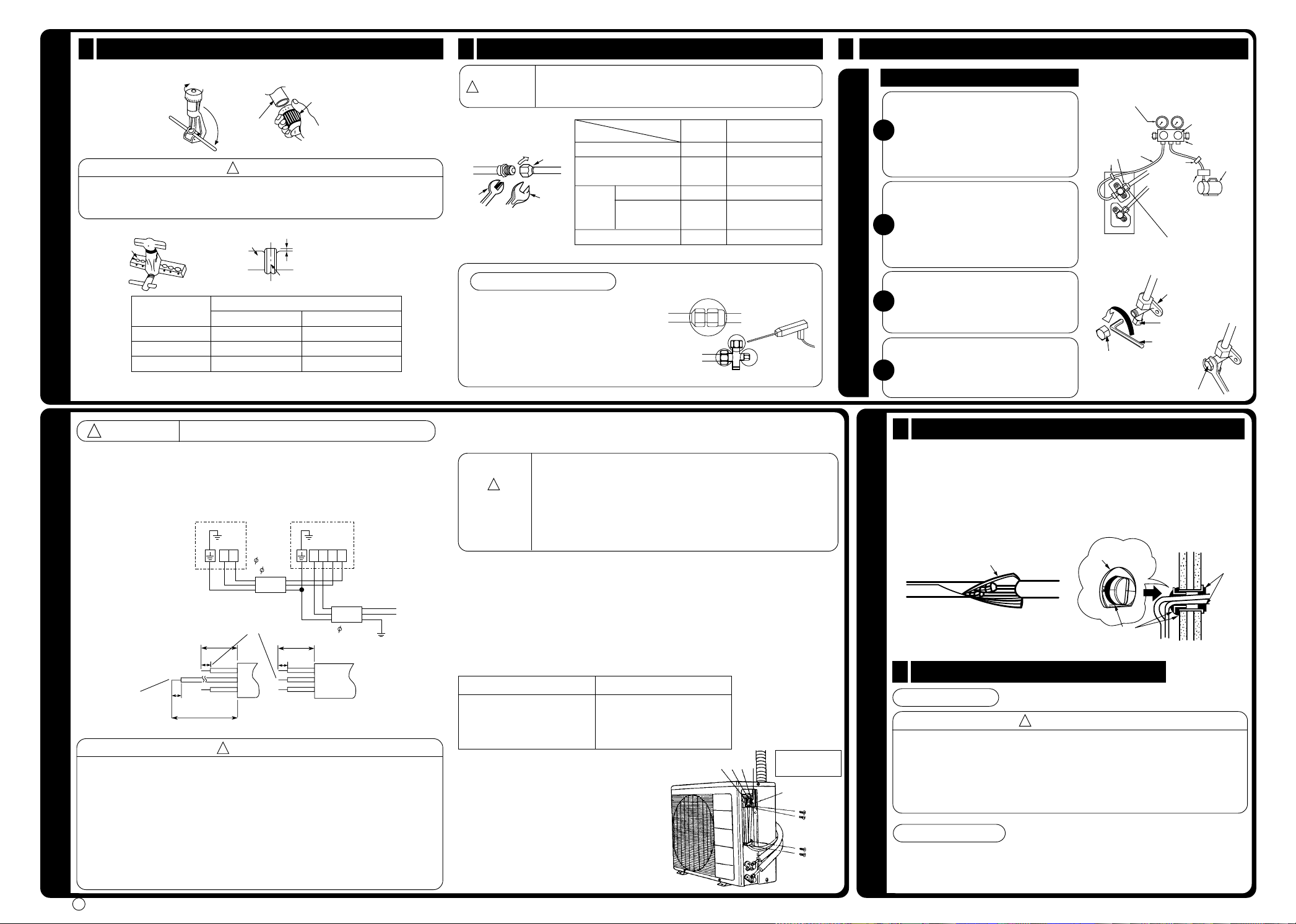

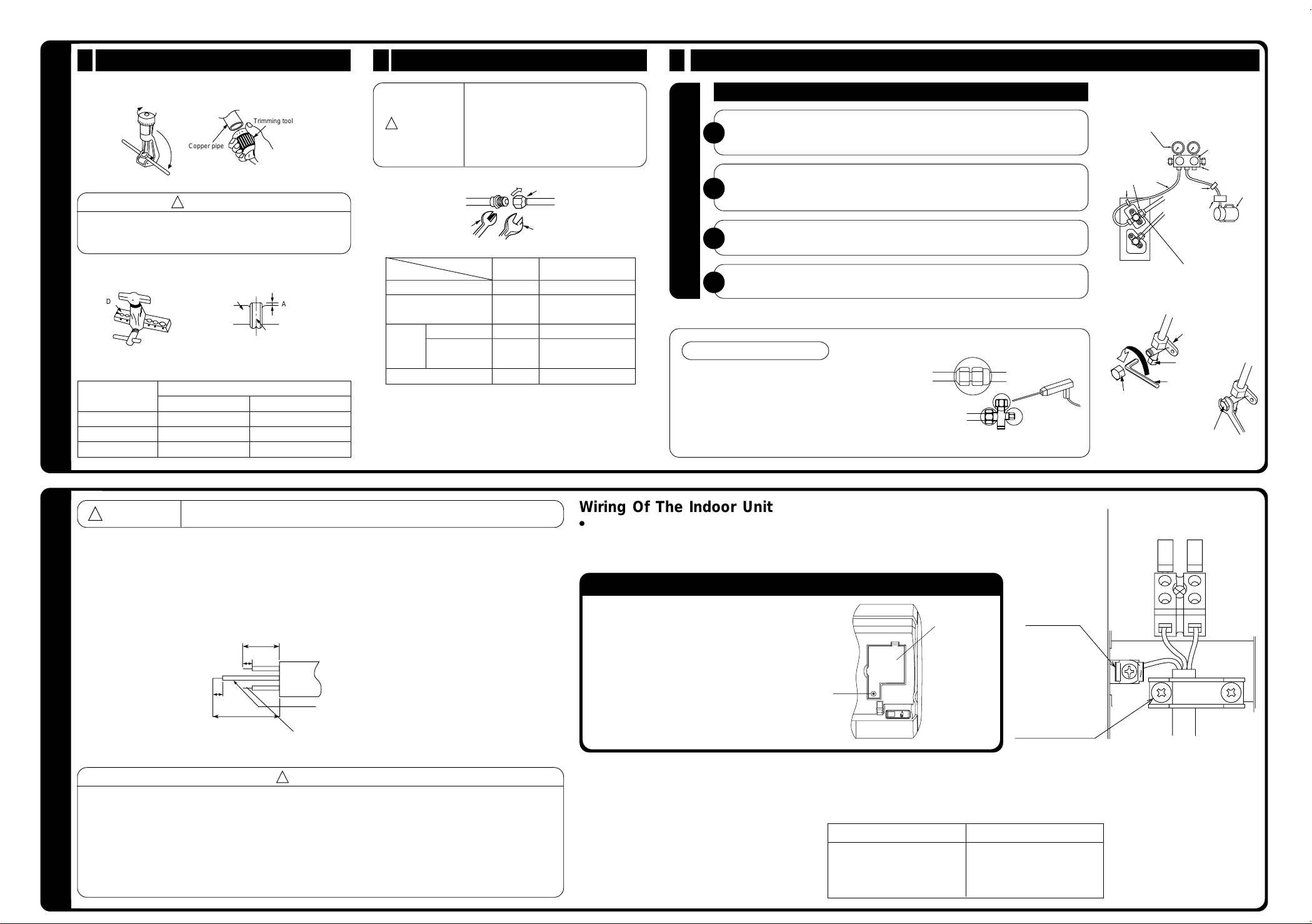

Preparation of Pipe1

●

Use a pipe cutter to cut the copper pipe.

Trimming tool

Copper pipe

!

CAUTION

●

Jagged edge will cause leakage.

●

Point the side to be trimmed downwards during trimming to prevent copper

chips from entering the pipe.

●

Before flaring, please put on the flare nut.

Die

Outer

Diameter (mm)

6.35

9.52

12.7

Die

Copper pipe

For R410A tool

0.0

0.5mm

~

0.0

0.5mm

~

0.5mm

0.0

~

A

A (mm)

●

Recommend to use

R410A flaring tool.

For R22 tool

1.0mm

1.0mm

1.0mm

INSTALLATION OF REFRIGERATING PIPES AND AIR REMOVAL

Pipe Connection2

In case of removing flare nut of an Indoor unit, first remove a nut

!

CAUTION

Wrench

Gas Leakage Inspection

Please use gas leakage detector to check if

leakage occurs at the connection of Flare

nut as shown on the right.

If gas leakage occurs, further tighten the

connection to stop leakage. (Use the detector

provided for R410A)

of small diameter side, or a seal cap of big diameter side will fly

out. Prevent water from entering into the piping when working.

Torque

wrench

Small dia. side

Large dia. side

Small dia. side

Valve

head cap

Valve core cap

Large dia. side

Flare nut

Outer

dia.of pipe

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

Torque N·m

(kgf · cm)

13.7 – 18.6 (140 – 190)

34.3 – 44.1 (350 – 450)

44.1 – 53.9 (450 – 550)

19.6 – 24.5 (200 ~ 250)

19.6 – 24.5 (200 ~ 250)

29.4 – 34.3 (300 – 350)

12.3 – 15.7 (125 ~ 160)

Removal Of Air From The Pipe And Gas Leakage Inspection

3

Procedures of using Vacuum Pump for Air Removal

As shown in right figure, remove the cap

of valve core. Then, connect the charge

hose. Remove the cap of valve head.

1

Connect the vacuum pump adapter to

the vacuum pump and connect the

charge hose to the adapter.

Fully tighten the “Hi” shuttle of the

When the meter reaches - 101KPa

(-76cmHg) during pumping, fully

tighten the shuttle.

Valve

Meter showing pressure

Charge hose

Lo Hi

Valve

Vacuum pump

adapter

manifold valve and completely unscrew

the “Lo” shuttle. Run the vacuum pump

2

for about 10–15 minutes, then completely

AIR REMOVAL

tighten the “Lo” shuttle and switch off

the vacuum pump.

Completely unscrew the spindle of the

service valve (at 2 places) in anti-

3

clockwise direction to allow the flow of

coolant (using Hexagonal Wrench key).

Remove the charge hose and tighten the

cap of valve head. Check the cap’s

4

periphery if there is any gas leakage.

The task is then completed.

When pumping starts, slightly loosen the

flare nut to check of air sucked in. Then

tighten the flare nut.

The body of

service valve

Cap of

valve core

Hexagonal

Cap of valve head

Wrench Key

Cap of valve head

Closed

R410A

Manifold valve

Vacuum

pump

●

WARNING

!

THIS APPLIANCE MUST BE EARTHED.

Power supply shall be connected at the rated voltage, otherwise the unit will be

broken or could not reach the specified capacity.

Procedures of Wiring

In case that power is supplied from Outdoor Unit

Indoor Unit Outdoor Unit

1.6 or

2.0

Connecting Cord

Strip wires

Outdoor

Unit

GRN + YEL

25mm

10mm

10mm

25mm

10mm

35mm

Power line Control line

!

WARNING

●

The naked part of the wire core should be 10 mm and fix it to the terminal

tightly. Then try to pull the individual wire to check if the contact is tight. Improper

CONNECTION OF POWER CORD

insertion may burn the terminal.

●

Be sure to use only power cables approved from the authorities in your country.

For example in Germany: Cable type: NYM 3x1.5mm

●

Please refer to the installation manual for wire connection to the terminals of the

units. The cabling must meet the standards of electrical installation.

●

There is a AC voltage of 230V between the L and N terminals. Therefore,

before servicing, be sure to remove the plug from the AC outlet or switch off

the main switch.

<

I477: A

>

DCNLDC

Connecting Cord

2.0

AC 220 - 230V

2

.

Wiring of The Outdoor Unit

●

Please remove the side cover for wire connection.

●

If you cannot attach the side cover due to the connecting cord,

!

WARNING

press the connecting cord in direction to the front panel to fix it.

●

Be sure that the hooks of the side cover is fixed in certainly.

Otherwise water leakage may occur and this causes short circuit

or faults.

●

The connecting cord should not touch to service valve and pipes.

(It becomes high temperature in heating operation.)

Checking for the electric source and the

voltage range

●

Before installation, the power source must be checked and necessary wiring work

must be completed. To make the wiring capacity proper, use the wire gauges list

below for the lead-in from a pole transformer and for the wiring from a switch board

of fuse box to the main switch and outdoor unit in consideration of the locked rotor

current.

IMPORTANT

Cable length

up to 16m

up to 15m

up to 25m

●

Investigate the power supply capacity and

other electrical conditions at the installation

location.

Depending on the model of room air

conditioner to be installed, request the

customer to make arrangements for the

necessary electrical work etc.

The electrical work includes the wiring work

up the outdoor. In localities where electrical

conditions are poor, use of a voltage

regulation is recommended.

Wire cross-section

2

1.5mm

2

2.5mm

2

4.0mm

CD

N

L

Use 16A Time

Delay Fuse

Earth terminal

1

Insulation And Maintenance Of Pipe Connection

●

The connected terminals should be completely sealed with heat insulator and

then tied up with rubber strap.

●

Please tie the pipe and power line together with vinyl tape as shown in the figure

showing the installation of Indoor and Outdoor units. Then fix their position with

holders.

●

To enchance the heat insulation and to prevent water condensation, please

cover the outdoor part of the drain hose and pipe with insulation pipe.

●

Completely seal any gap with putty.

Sleeve of

Insulation material for pipe connection

2

Power Source And Operation Test

protection pipe

Putty

Power Source

!

CAUTION

●

Please use a new socket. Accident may occur due to the use of old socket

because of poor contact.

●

Please plug in and then remove the plug for 2 – 3 times. This is to ensure that

the plug is completely plugged into the socket.

●

Keep additional length for the power cord and do not render the plug under

FINAL STAGE OF INSTALLATION

external force as this may cause poor contact.

●

Do not fix the power cord with U-shape nail.

Operation Test

●

Please ensure that the air conditioner is in normal operating condition during

the operation test.

●

Explain to your customer the proper operation procedures as described in the

user’s manual.

Putty

Page 5

above 50mm

above 100mm

above

0.45m

above 300mm

must not bend

above 100mm

2

7

4

5

3

9

Maximum pipe length 20m

Plug

2,300mm or more

1

!

!

!

!

FOR SERVICE PERSONNEL ONLY

!

!

0.9m

1.6m

!

Connection

Horizontally

perpendicular

to the unit

inner diameter ø 16mm

HFC

R410A

●

Carefully read through the procedures of proper

installation before starting installation work.

●

The sales agent should inform customers regarding

the correct operation of installation.

SPLIT UNIT AIR CONDITIONER

INSTALLATION MANUAL

RAK-25NH4

Indoor Unit

SAFETY PRECAUTION

●

Read the safety precautions carefully before operating the unit.

●

The contents of this section are vital to ensure safety. Please pay special attention to the following sign.

WARNING ........ Incorrect methods of installation may cause death or serious injury.

CAUTION ......... Improper installation may result in serious consequence.

Be sure that the unit operates in proper condition after installation. Explain to customer the proper way of operating

the unit as described in the user’s guide.

RAK-35NH4

RAK-50NH4

Tools Needed For Installation Work

●

+ – Screwdriver

●

Saw ● ø 65mm Power Drill ● Hexagonal Wrench

Key ( 4mm)

●

Gas Leakage Detector ● Pipe Cutter

●

Vinyl Tape ● Pliers ● Flare Tool

●

Measuring Tape

●

Wrench (14, 17, 22, 26, 27mm)

●

Knife

●

Putty

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

WARNING

Please request your sales agent or qualified technician to install your unit. Water leakage, short circuit or fire may occur if you

do the installation work yourself.

Please observe the instructions stated in the installation manual during the process of installation. Improper installation may

cause water leakage, electric shock and fire.

Make sure that the units are mounted at locations which are able to provide full support to the weight of the units. If not, the

units may collapse and impose danger.

Observe the rules and regulations of the electrical installation and the methods described in the installation manual when

dealing with the electrical work. Use power cables approved by the authorities of your country.

Be sure to use the specified wire for connecting the indoor and outdoor units. Please ensure that the connections are tight

after the conductors of the wire are inserted into the terminals. Improper insertion and loose contact may cause over-heating

and fire.

Please use the specified components for installation work. Otherwise, the units may collapse or water leakage, electric shock

and fire may occur.

Be sure to use the specified piping set for R-410A. Otherwise, this may result in broken copper pipes or faults.

When installing or removing an air conditioner, only specified refrigerant (R410A) shall be allowed, do not allow air or moisture

to remain in the refrigeration cycle. Otherwise, pressure in the refrigeration cycle may become abnormally high so that a rupture

may be caused.

Be sure to ventilate fully if a refrigerant gas leak while at work. If the refrigerant gas comes into contact with fire, a poisonous

gas may occur.

After completion of installation work, check to make sure that there is no refrigeration gas leakage. If the refrigerant gas leaks

into the room, coming into contact with fire in the fan-driven heater, space heater, etc., a poisonous gas may occur.

Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call a qualified air conditioner

technician or electrician. Improper repairs may result in water leakage, electric shock and fire, etc.

A circuit breaker or fuse (16A time delay) must be installed. Without a circuit breaker or fuse the danger of electric shock exists.

A main switch with a contact gap of more than 3mm has to be installed in the power supply line to the outdoor unit.

Do not install the unit near a location where there is flammable gas. The outdoor unit may

catch fire if flammable gas leaks around it.

Please ensure smooth flow of water when installing the drain hose.

Piping shall be suitable supported with a maximum spacing of 1m between the supports.

CAUTION

Page 6

above 50mm

above 100mm

above

0.45m

above 300mm

must not bend

above 100mm

2

7

4

5

3

9

Maximum pipe length 20m

Plug

2,300mm or more

1

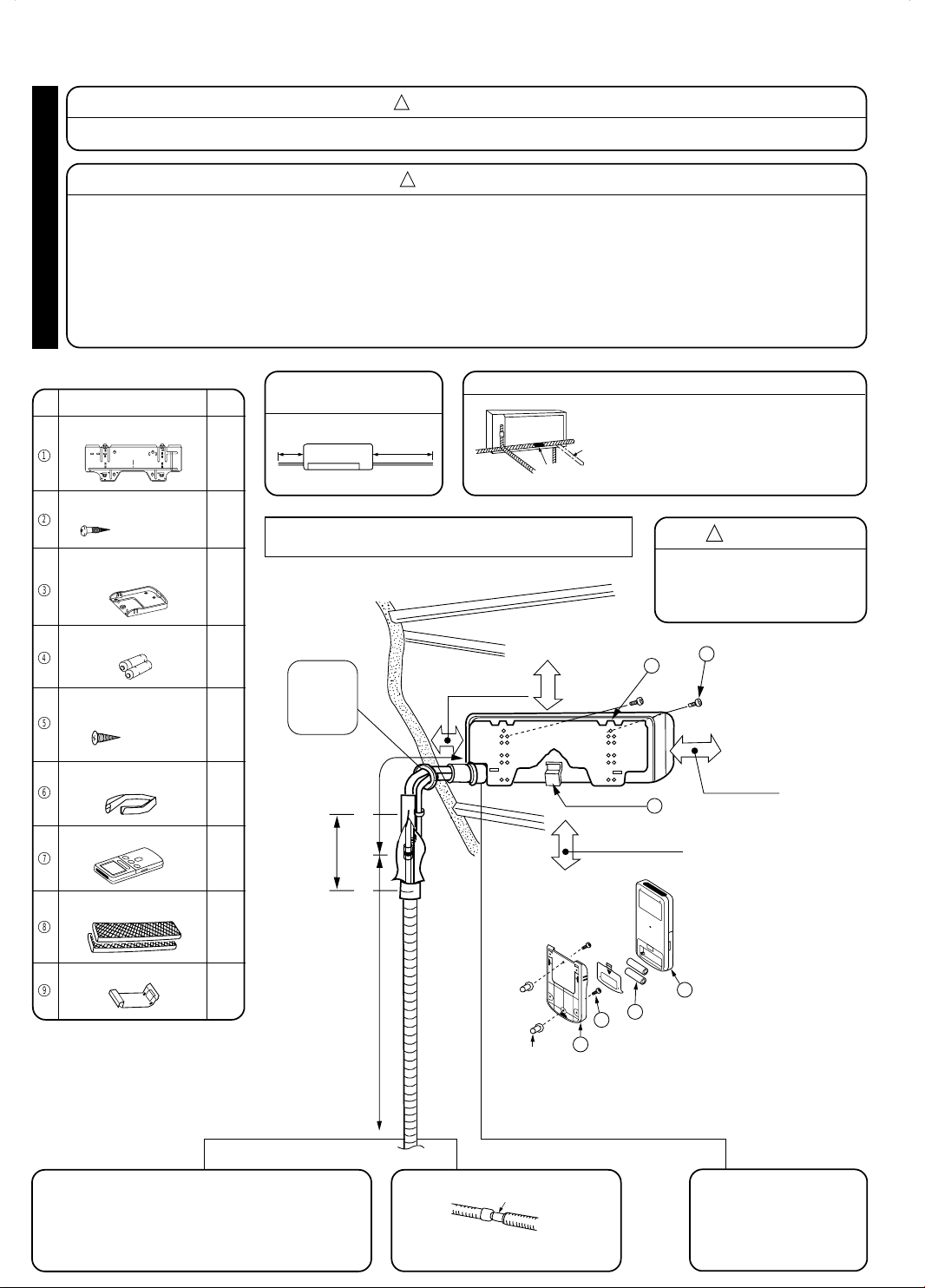

THE CHOICE OF MOUNTING SITE (Please note the following matters and obtain permission from customer before installation).

!

!

0.9m

1.6m

!

Connection

Horizontally

perpendicular

to the unit

inner diameter ø 16mm

WARNING

●

The unit should be mounted at stable, non-vibratory location which can provide full support to the unit.

CAUTION

●

No nearby heat source and no obstruction near the air outlet is allowed.

●

The clearance distances from top, right and left are specified in figure below.

●

The location must be convenient for water drainage and pipe connection with the Outdoor unit.

●

To avoid interference from noise please place the unit and its remote controller at least 1m from the radio, television and inverter

INDOOR UNIT

type fluorescent lamp.

●

To avoid any error in signal transmission from the remote controller, please put the controller far away from high-frequency

machines and high-power wireless systems.

●

The installation height of indoor unit must be 2.3m or more in a non public area.

Names of Indoor Components

QtyNo. Item

Hanger

1

Screw for Hanger

2

Holder for Remote

Controller

3

AAA Size Battery

4

Screw for holder of

Remote Controller

5

Insulation pipe

6

Remote Controller

7

Purifying Filter

8

(4.1x32)

(3.1x16)

1

6

1

2

2

1

1

1

The Length of Indoor Unit

Connecting Cord

Figure showing the Installation of Indoor Unit.

Be sure to

completely

seal any

gap with

putty.

Direction of Piping

There are 4 directions allowed, namely,

horizontally perpendicular to the unit,

vertically down from right, horizontally out

from right and horizontally out to left.

Don’t form the piping downward at the

left of the unit.

CAUTION

The installation height of indoor

•

unit must be 2.3m or more in

a non public area.

Holder

9

● The difference in height between the indoor and outdoor

unit should be kept max 5m.

● The connecting pipe, no matter big or small, should all

be insulated with insulation pipe and then wrapped with

vinyl tape. (The insulator will deteriorate if it is not wrapped

with tape).

1

The connection of insulated drain hose.

Please use insulated drain hose for the

indoor piping (commercial product).

The indoor piping should be

insulated with the enclosed

insulation pipe. (If the

insulator is insufficient,

please use commercial

products).

Page 7

above 50mm

above 100mm

above

0.45m

above 300mm

must not bend

above 100mm

2

7

4

5

3

9

Maximum pipe length 20m

Plug

2,300mm or more

1

!

!

!

!

!

!

0.9m

1.6m

1

!

!

!

!

!

!

!

External dimension of

indoor unit

160mm

160mm

80mm

860mm

40mm

45mm

30mm

Drain Hose

45mm

298mm

Level

Line

Hole for

pipe

Mark

Weight

Screw for Hanger

Please use more

than 4 screws.

Hanger

32mm

20mm

ø4.8mm

ø4.4mm

Wall

1 Hanger

2 Screw

Plug

Wall

above 50mm

Ceiling

4.1 x 32 Screw

Wall

Remote

Control

Holder

5 Screw

Plug

3

Sleeve of

protection

pipe

WALL

Protection

pipe

Seal with

putty

Seal with

putty

2 ~ 5mm

OutdoorIndoor

Connecting cords,

pipe and drain hose

must be tied together

with Vinyl tape.

Hanger

Hook

Refrigerating

Pipe

Connecting

Cord

Drain Hose

Protection

Pipe

Lift the body

of the unit

upwards and

then force

it downwards.

Hanger

Projection

Screw driver

Claw of indoor unit

Circle hole

2

1

!

Drain hoseDrain cap

Drain cap

Please insert

until here

Drain hose

Please insert

until here

Pipe

support

Pull up the pipe after

bending downward

Openings

Pipe

Connecting cord

Drain hose

Insulation pipe (must be wrapped with

vinyl tape at every 120mm).

Holder

9

Insulation pipe

6

Pipe

Rubber strap tied with great force

below

5mm

Please bend at a small

radius to form an arc

about 15cm

Projection

Temporary stand

Connected

section

Holder

Connecting cord

Drain hose

Protection

pipe

Bending

upwards

Condensed

water pond

Ditch

Condensed

water pond

!

Connection

Horizontally

perpendicular

to the unit

inner diameter ø 16mm

HFC

R410A

Installation of Hanger, Wall Penetration and Installation of Protection Pipe

CAUTION

●

The draining of the water container inside the indoor unit can be done from the left.

Therefore the hanger must be fixed horizontally or slightly tilted towards the side of

drain hose. Otherwise, condensed water may overflow the water container.

Direct Mounting On The Wall

●

Please use hidden beams in the wall to hold the hanger.

Procedures of Installation and Precautions

●

Procedures to fix the hanger.

1. Drill holes on wall. 2. Push plug into the holes. 3. Fix the hanger on wall

(As shown below) (As shown below) with 4.1 x 32 screw

(As shown in figure below)

INDOOR UNIT

●

Procedures to fix the holder of remote control.

1. Drill holes on wall. 2. Push plug into the holes.

(As shown below) (As shown below)

2

Installation of the Indoor Unit

VERTICALLY DOWNWARD PIPING

Preparation

●

Connect connecting cord.

●

Pull out the pipe, connecting cord and drain hose.

Installation

●

The upper part of the Indoor unit is hanged on the hanger.

●

The projection at the lower part of the Indoor unit is hooked onto the hanger.

CAUTION

Please pull the lower part of

the Indoor unit outwards to

check if the unit is hooked

onto the hanger. Improper

installation may cause

vibration and noise.

HOW TO REMOVE INDOOR UNIT FROM HANGER

●

Pull down PULL section on the bottom of indoor

unit and pull it towards you, then claws are

released from hanger. (Indicated by 2 arrows in

the drawing on the right.)

●

When bottom face of indoor unit cannot be

pulled due to obstacles, etc. Remove front cover,

insert screw driver into circle hole, pull claws

down and pull indoor unit towards you.

●

Please check how to remove and attach front

cover in this instruction manual.

HORIZONTAL PIPING

Preparation

Change of Drain Hose and Installation Procedures.

●

Exchange the location of drain hose and drain cap during horizontal piping as shown in

figure below. Be sure to plug in the drain hose until the insulating material folds upon itself.

●

Please use pliers to pull out the drain cap.

(This is an easier way to remove the drain cap).

INSTALLATION OF REFRIGERATING PIPES AFTER CONNECTION

●

The refrigerating pipes should be adjusted to fit into

the hole on the wall and then ready for further

connection.

●

The terminals of 2 connected pipes must be covered

with insulator used for terminal connection. Then the

pipes are wrapped with insulation pipe.

●

Connect the connecting cord after removing electrical

cover. (Refer to “CONNECTION OF POWER CORD”)

●

After adjustment, fit the connecting cord and pipes

into the space available under the indoor unit. Use

holder to hold them tight.

CAUTION

●

The rubber strap used for

fixing the insulator should

not be tied with great force.

Otherwise, this will damage

heat insulation and causes

water condensation.

●

Holder can be attached at the either of 2 places.

Please select the easier position.

THE CONNECTION OF REFRIGERATING PIPE DURING THE

INSTALLATION OF INDOOR UNIT

Preparation To Install Refrigerating Pipes

●

The refrigerating pipes and connecting cord

transform and are attached.

●

The end of the refrigerating pipes are at locations

marked with “

” symbol.

Installation

Hang the Indoor unit onto the hanger. Use the temporary stand

at the back of the Indoor unit to push its lower part 15cm

forwards.

●

Place the drain hose through the hole on the wall.

●

Wrap the refrigerating pipes with insulation pipe after

connecting refrigerating pipe.

●

Connect the connecting cord after removing electrical cover.

(Refer to “Connection of Power Cord”)

●

After adjustment, the connecting cord and refrigerating pipes

are placed into the space available under the Indoor unit.

●

The projection of Indoor unit must hook to the hanger.

CAUTION

●

Please fix in the plastic core

after flaring to avoid plastic

chips entering the pipes.

Wall Penetration and Installation of Protection Pipe

●

Drill a ø 65mm hole on

wall which is slightly tilted

towards the outdoor side.

Drill the wall at a small

angle.

●

Cut the protection pipe

according to the wall

thickness.

●

Empty gap in the sleeve

of protection pipe should

be completely sealed

with putty to avoid

dripping of rain water into

the room.

<

I477: A

>

WARNING

Be sure that the wire is not

in contact with any metal

in the wall. Please use the

protection pipe as wire

passing through the hollow

part of the wall so as to

prevent the possibility of

damaged by mouse.

Unless it seals completely,

any air with high humidity

flows from outdoor and

any dew may drop.

CAUTION

Condensed water may leak out if not inserted properly.

HORIZONTAL & DOWNWARD PIPING – MAKING OPENINGS

●

During horizontal or downward piping, use a knife to cut

openings as shown in figure. Then smoothen the edges of

openings with a file.

●

Turn the piping while holding down the lower

portion of pipe-support by hand.

Heat insulation pipe

Connecting

cord

Refrigerating pipe

3

Installation of Drain Hose

Pull this to the front

during the connection

of refrigerating pipes

to ease task.

You are free to choose the side (left or right) for the installation of drain

CAUTION

hose. Please ensure the smooth flow of condensed water of the Indoor

unit during installation. (Carelessness may result in water leakage.)

CAUTION

Be sure that the

drain hose is not

loosely connected

or bend.

Page 8

1

!

!

Copper pipe

Trimming tool

A

Die

Die

Copper pipe

Wrench

Torque

wrench

Flare nut

!

Lo Hi

The body of

service valve

Cap of

valve core

Hexagonal

Wrench Key

Cap of valve head

Cap of valve head

30mm

10mm

10mm

70mm

!

CD

AUTO

RESTART

SWITCH

Preparation of Pipe

●

Use a pipe cutter to cut the copper pipe.

CAUTION

●

Jagged edge will cause leakage.

●

Point the side to be trimmed downwards during trimming to

prevent copper chips from entering the pipe.

●

Before flaring, please put on the flare nut.

●

Recommend to use

R410A flaring tool.

Outer

Diameter (mm)

INSTALLATION OF REFRIGERATING PIPES AND AIR REMOVAL

6.35

9.52

12.7

For R410A tool

0.0

0.5mm

~

0.0

0.5mm

~

0.0

0.5mm

~

A (mm)

For R22 tool

1.0mm

1.0mm

1.0mm

2

Pipe Connection

CAUTION

Small dia. side

Large dia. side

Small dia. side

Valve

head cap

Valve core cap

Large dia. side

In case of removing flare nut of an

Indoor unit, first remove a nut of small

diameter side, or a seal cap of big

diameter side will fly out. Prevent

water from entering into the piping

when working.

Outer

dia.of pipe

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

Torque N·m

(kgf · cm)

13.7 – 18.6 (140 – 190)

34.3 – 44.1 (350 – 450)

44.1 – 53.9 (450 – 550)

19.6 – 24.5 (200 ~ 250)

19.6 – 24.5 (200 ~ 250)

29.4 – 34.3 (300 – 350)

12.3 – 15.7 (125 ~ 160)

3

Removal Of Air From The Pipe And Gas Leakage Inspection

Procedures of using Vacuum Pump for Air Removal

As shown in right figure, remove the cap of valve core. Then, connect the charge

hose. Remove the cap of valve head. Connect the vacuum pump adapter to the

1

vacuum pump and connect the charge hose to the adapter.

Fully tighten the “Hi” shuttle of the manifold valve and completely unscrew the

“Lo” shuttle. Run the vacuum pump for about 10–15 minutes, then completely

2

tighten the “Lo” shuttle and switch off the vacuum pump.

Completely unscrew the spindle of the service valve (at 2 places) in anti-clockwise

3

AIR REMOVAL

direction to allow the flow of coolant (using Hexagonal Wrench key).

Remove the charge hose and tighten the cap of valve head. Check the cap’s

4

periphery if there is any gas leakage. The task is then completed.

Gas Leakage Inspection

Please use gas leakage detector to check if leakage

occurs at the connection of Flare nut as shown on

the right.

If gas leakage occurs, further tighten the connection

to stop leakage. (Use the detector provided for

R410A).

When the meter reaches - 101KPa

(-76cmHg) during pumping, fully

tighten the shuttle.

Valve

When pumping starts, slightly loosen the

flare nut to check of air sucked in. Then

tighten the flare nut.

Meter showing pressure

Charge hose

Vacuum pump

adapter

Valve

Closed

R410A

Manifold valve

Vacuum

pump

●

WARNING

THIS APPLIANCE MUST BE EARTHED.

Power supply shall be connected at the rated voltage, otherwise the unit will be broken or could not reach the

specified capacity.

Procedures of Wiring

In case that power is supplied from Indoor Unit

Indoor Unit

GRN + YEL

Strip wires

WARNING

●

The naked part of the wire core should be 10 mm and fix it to the terminal tightly. Then try to pull the

individual wire to check if the contact is tight. Improper insertion may burn the terminal.

●

Be sure to use only power cables approved from the authorities in your country. For example in Germany:

Cable type: NYM 3x1.5mm

CONNECTION OF POWER CORD

●

Please refer to the installation manual for wire connection to the terminals of the units. The cabling must

meet the standards of electrical installation.

●

There is a AC voltage of 230V between the L and N terminals. Therefore, before servicing, be sure to

remove the plug from the AC outlet or switch off the main switch.

2

.

Wiring Of The Indoor Unit

●

For wire connection of the Indoor unit, you need to remove front panel and electrical cover.

Method to remove front panel

●

Refer to “FINAL STAGE OF INSTALLATION – How to Remove The Front Cover”.

Method to remove electrical cover

●

Remove the screw and electrical cover.

●

Insert the connecting cord (C, D) from the bottom of

unit.

●

Fixed the wire to terminal wires firmly as shown in

figure at right side.

Electrical cover

Screw

Connect the

earth cord

After remove the screw

and band, put the

connecting cords and fix

the band with screw.

Checking for the electric source and the voltage range

●

Before installation, the power source must be checked and necessary wiring work must be completed. To make the wiring capacity proper, use the wire

gauges list below for the lead-in from a pole transformer and for the wiring from a switch board of fuse box to the main switch and outdoor unit in

consideration of the locked rotor current.

IMPORTANT

Cable length

up to 16m

up to 15m

up to 25m

Wire cross-section

2

1.5mm

2

2.5mm

2

4.0mm

Page 9

1

!

!

!

Copper pipe

Trimming tool

A

Die

Die

Copper pipe

Wrench

Torque

wrench

Flare nut

Sleeve of

protection pipe

Putty

Putty

Insulation material for pipe connection

Remote

Controller

Holder for

Remote Controller

Screw (2 pieces)

1

2

!

Lo Hi

The body of

service valve

Cap of

valve core

Hexagonal

Wrench Key

Cap of valve head

Cap of valve head

30mm

10mm

10mm

70mm

!

CD

AUTO

RESTART

SWITCH

Insulation And Maintenance Of Pipe Connection

●

The connected terminals should be completely sealed with

heat insulator and then tied up with rubber strap.

●

Please tie the pipe and power line together with vinyl tape as

shown in the figure showing the installation of Indoor and

Outdoor units. Then fix their position with holders.

●

To enchance the heat insulation and to prevent water

condensation, please cover the outdoor part of the drain hose

and pipe with insulation pipe.

●

Completely seal any gap with putty.

3

Power Source And Operation Test

Power Source

FINAL STAGE OF INSTALLATION

●

Please use a new socket. Accident may occur due to the use of old

socket because of poor contact.

●

Please plug in and then remove the plug for 2 – 3 times. This is to

ensure that the plug is completely plugged into the socket.

●

Keep additional length for the power cord and do not render the

plug under external force as this may cause poor contact.

●

Do not fix the power cord with U-shape nail.

CAUTION

2

Installation Of Remote Controller

●

The remote controller can be placed in its holder which is

fixed on wall or beam.

●

To operate the remote controller at its holder, please ensure

that the unit can receive signal transmitted from the controller

at the place where the holder is to be fixed. The unit will beep

when signal is received from the remote controller. The signal

transmission is weaken by the fluorescent light. Therefore,

during the installation of the remote control holder, please

switch on the light, even during day time, to determine the

mounting location of the holder.

The controller must

be hooked onto the

hook at the lower

part of the holder.

Push in the remote

controller in the

direction as shown

in figure below.

Operation Test

●

Please ensure that the air conditioner is in normal

operating condition during the operation test.

●

Explain to your customer the proper operation

procedures as described in the user’s manual.

How to Remove The Front Cover

1 Remove the front panel.

●

Please remove and attach the front panel by both hands.

●

After opening the front panel by both hands.

11

Undo the right arm while pushing it inside.

1

11

22

2

Slide the front panel to right as shown in figure. Then

22

remove while pulling it to front.

2 Remove the filters.

3 Remove the caps and screws at the lower portion of the

front cover.

Cap

Screw

4 Pull the front cover upward as far as the location where

the lower portion of the front cover is on the deflector.

Lower portion of front cover

5 Remove while pulling the front cover in direction to arrow

as shown in figure to hold the both sides of front cover.

Deflector

How to Attach the Front Cover

11

1

After covering the front cover to the unit, certainly hook at

11

the upper portion (three places). Then, check that the drain

pan is certainly attached. Push the center of front cover in

the direction of arrow.

22

2

Fix the front cover at lower portion by screws and attach

22

the caps.

33

3

Attach the front panel.

33

●

Certainly insert the left shaft of the front panel to the hole

of the front cover. Next insert the right shaft as same as

the left.

44

4

Attach the filters which are placed the surface written

44

“FRONT” up.

●

After attaching the filters, push the front panel at three

arrow portion as shown in figure and close it.

Hole

Shaft

Guide

<

I477: A

>

Page 10

SAFETY DURING REPAIR WORK

1. In order to disassemble and repair

the unit in question, be sure to

disconnect the power cord plug

from the power outlet before starting

the work.

2. If it is necessary to replace any parts, they should be replaced with respective genuine parts for the unit, and

the replacement must be effected in correct manner according to the instructions in the Service Manual of

the unit.

If the contacts of electrical parts

are defective, replace the

electrical parts without trying to

repair them.

First, I must disconnect

the power cord plug

from the power outlet.

3. After completion of repairs, the initial state

should be restored.

4. Lead wires should be connected and laid as

in the initial state.

5. Modification of the unit by user himself should

absolutely be prohibited.

6. Tools and measuring instruments for use in repairs or inspection should be accurately calibrated in advance.

7. In installing the unit having been repaired, be careful to prevent the occurence of any accident such as

electrical shock, leak of current, or bodily injury due to the drop of any part.

8. To check the insulation of the unit, measure the insulation resistance between the power cord plug and

grounding terminal of the unit. The insulation resistance should be 1M or more as measured by a 500V

DC megger.

9. The initial location of installation such as window, floor or the other should be checked for being and safe

enough to support the repaired unit again.

If it is found not so strong and safe, the unit should be installed at the initial location reinforced or at a new

location.

10. Any inflammable thing should never

be placed about the location of

installation.

DANGER

11. Check the grounding to see whether

it is proper or not, and if it is found

improper, connect the grounding

terminal to the earth.

– 1 –

Page 11

WORKING STANDARDS FOR PREVENTING BREAKAGE OF SEMICONDUCTORS

1. Scope

The standards provide for items to be generally observed in carrying and handling semiconductors in relative

manufacturers during maintenance and handling thereof. (They apply the same to handling of abnormal goods

such as rejected goods being returned).

2. Object parts

(1) Micro computer

(2) Integrated circuits (IC)

(3) Field-effect transistors (FET)

(4) P.C. boards or the like on which the parts mentioned in (1) and (2) of this paragraph are equipped.

3. Items to be observed in handling

(1) Use a conductive container for carrying and storing of parts. (Even rejected goods should be handled in

the same way).

A conductive polyvinyl bag

IC

Fig. 1. Conductive Container

(2) When any part is handled uncovered (in counting, packing and the like), the handling person must always

use himself as a body earth. (Make yourself a body earth by passing one M ohm earth resistance through

a ring or bracelet).

(3) Be careful not to touch the parts with your clothing when you hold a part even if a body earth is being

taken.

(4) Be sure to place a part on a metal plate with grounding.

(5) Be careful not to fail to turn off power when you repair the printed circuit board. At the same time, try

to repair the printed circuit board on a grounded metal plate.

IC

Conductive sponge

Body earth

(Elimik conductive band)

1M

Fig. 2. Body Earth

Clip for connection with a

grounding wire

– 2 –

Page 12

(6) Use a three wire type soldering iron including a grounding wire.

Metal plate (of aluminium, stainless steel, etc.)

Staple

Bare copper wire (for body earth)

Fig. 3. Grounding of the working table

Working

table

Resistor of 1 M (1/2W)

Earth wire

Soldering iron

2

Screw stop at the screwed

part using a rag plate

Fig. 4. Grounding a soldering iron

Use a high insulation mode (100V, 10M or higher) when ordinary iron is to be used.

(7) In checking circuits for maintenance, inspection or some others, be careful not to have the test probes of the

measuring instrument shortcircuit a load circuit or the like.

Grounding

wire

– 3 –

Page 13

CAUTION

!

1. In quiet operation or stopping the running, slight flowing noise of refrigerant in the refrigerating cycle is

heard occasionally, but this noise is not abnormal for the operation.

2. When it thunders near by, it is recommend to stop the operation and to disconnect the power cord plug

from the power outlet for safety.

3. The room air conditioner does not start automatically after recovery of the electric power failure for

preventing fuse blowing. Re-press START/STOP button after 3 minutes from when unit stopped.

4. If the room air conditioner is stopped by adjusting thermostat, or missoperation, and re-start in a moment,

there is occasion that the cooling and heating operation does not start for 3 minutes, it is not abnormal

and this is the result of the operation of IC delay circuit. This IC delay circuit ensures that there is no

danger of blowing fuse or damaging parts even if operation is restarted accidentally.

5. This room air conditioner should not be used at the cooling operation when the outside temperature is

below 10°C (50°F).

6. This room air conditioner (the reverse cycle) should not be used when the outside temperature is below

–10°C (14°F).

If the reverse cycle is used under this condition, the outside heat exchanger is frosted and efficiency falls.

7. When the outside heat exchanger is frosted, the frost is melted by operating the hot gas system, it is not

trouble that at this time fan stops and the vapour may rise from the outside heat exchanger.

– 4 –

Page 14

SPECIFICATIONS

MODEL

RAK-25NH4

RAK-35NH4

RAK-50NH4

RAC-25NH4 RAC-50NH4RAC-35NH4

FAN MOTOR

FAN MOTOR CAPACITOR

FAN MOTOR PROTECTOR

COMPRESSOR

COMPRESSOR MOTOR CAPACITOR

OVERLOAD PROTECTOR

OVERHEAT PROTECTOR

FUSE (for MICROPROCESSOR)

POWER RELAY

POWER SWITCH

TEMPORARY SWITCH

PWM DC35V

NO

NO

–

NO

NO

NO

NO

NO

NO

YES

40 W

NO

NO

JU1012D JU1013D

NO

YES

YES

3.0A

G4A

NO

NO

SERVICE SWITCH

TRANSFORMER

VARISTOR

NOISE SUPPRESSOR

THERMOSTAT

REMOTE CONTROL SWITCH (LIQUID CRYSTAL)

REFRIGERANT CHARGING

VOLUME

(Refrigerant 410A)

UNIT

PIPES (MAX. 20m)

NO

NO

NO

NO

YES(IC)

YES

----------

WITHOUT REFRIGERANT BECAUSE

COUPLING IS FLARE TYPE.

450NR

YES(IC)

1150g1150g

YES

NO

YES

NO

1400g

– 5 –

Page 15

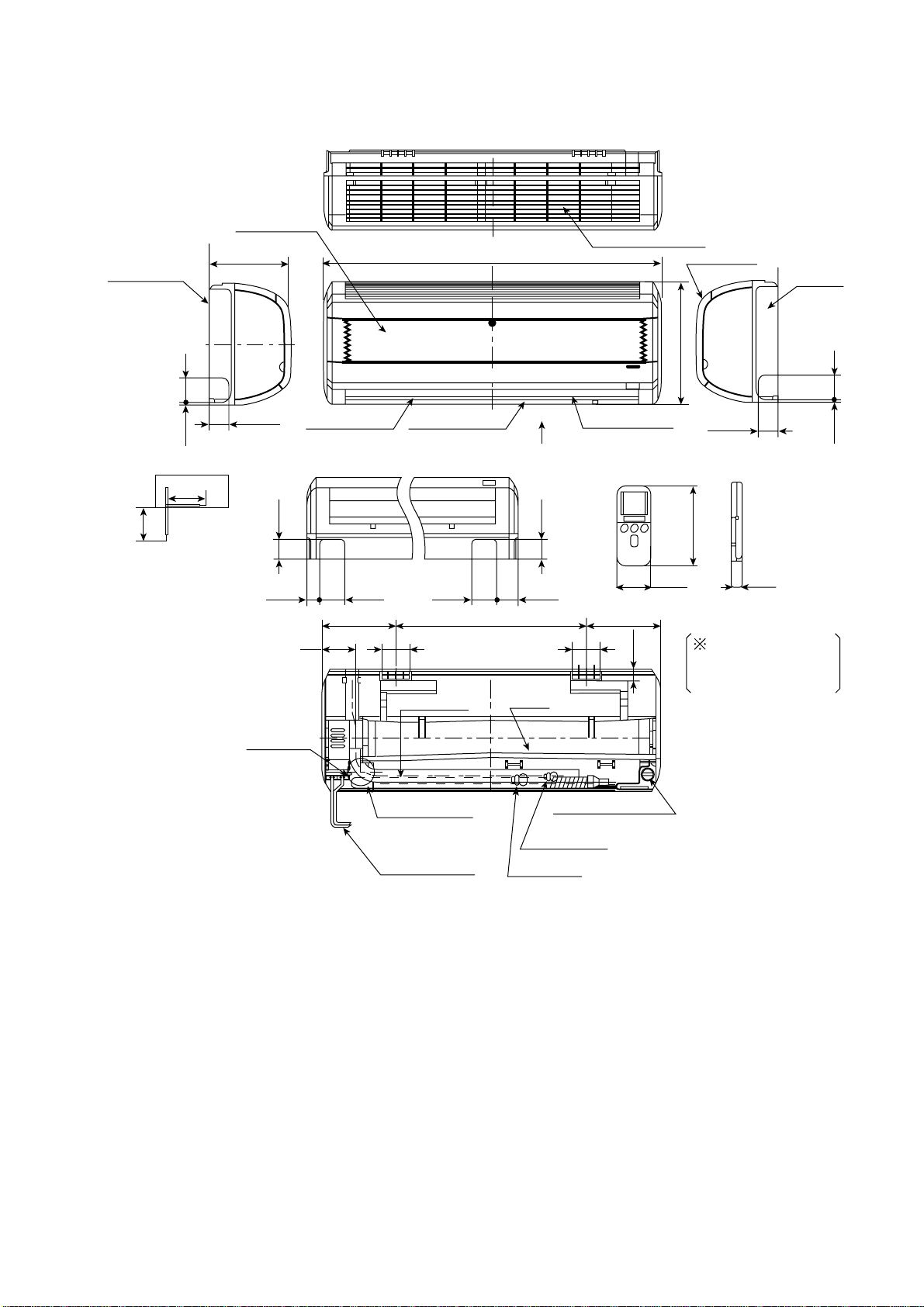

CONSTRUCTION AND DIMENSIONAL DIAGRAM

MODEL RAK-25NH4, RAK-35NH4, RAK-50NH4

Air suction grill

Mounting plate

183

860

Top air suction grill

Front panel

Cabinet

285

About

380

350

About

View from back

(Pipe lead-out)

6.5 60

47

47

31 120.5

Drain outlet

60 60

240 170450

Horizontal deflectorDischarge grill

Drain hose

Hole on the wall

for ø 65mm pipe

P

47

Drain

Narrow pipe

Vertical deflector

7070140

Drain cap

connection port

147

56 17.5

28

47

When piping is

drawn horizontally,

exchange the drain

hose for the drain cap

6.5 60

Connecting cable

– 6 –

Wide pipe

Page 16

CONSTRUCTION AND DIMENSIONAL DIAGRAM FOR OUTDOOR

MODEL RAC-25NH4, RAC-35NH4

852

28 750

16556

76

559

570

195

95

2616 280

166

MODEL RAC-50NH4

10464

Handle

Air suction

grille

955

26 850

Air outlet

79

638

650

340

201

280

2022 298

Handle

96

340

169.5

Fixing hole

Holes for anchor bolt

(2-ø12)

507 198

Notch for anchor bolt

(2-ø12 Notchs)

12

37

57

10

1010

320

340

– 7 –

More than

100

700

More than

100

More than

Service space

More than

100

Page 17

MAIN PARTS COMPONENT

RED

360V

BLK

0V

WHT

15V

M

YEL

0~6V

BLU

0~15V

THERMOSTAT

Thermostat Specifications

MODEL RAK-25NH4, RAK-35NH4, RAK-50NH4

THERMOSTAT MODEL IC

OPERATION MODE COOL HEAT

ON 15.6 (60.1) 20.0 (68.0)

OFF 15.3 (59.5) 20.7 (69.3)

ON 23.6 (74.5) 28.0 (82.4)

OFF 23.3 (73.9) 28.7 83.7)

ON 31.6 (88.9) 36.0 (96.8)

OFF 31.3 (88.3) 36.7 (98.1)

TEMPERATURE

°C (°F)

INDICATION

16

INDICATION

24

INDICATION

32

FAN MOTOR

Fan Motor Specifications

MODEL

RAK-25NH4, RAK-35NH4,

RAK-50NH4

POWER SOURCE DC: 0 ~ 35V

OUTPUT 23W

RED

BLK

WHT

YEL

BLU

CONNECTION

35V

0V

5V

0 ~ 5V

FG

RAC-25NH4, RAC-35NH4,

RAK-50NH4

DC360V

40W

M

(Control circuit built in)

BLU : BLUE YEL : YELLOW BRN : BROWN WHT : WHITE

GRY : GRAY ORN : ORANGE GRN : GREEN RED : RED

BLK : BLACK PNK : PINK VIO : VIOLET

– 8 –

Page 18

COMPRESSOR MOTOR

Compressor Motor Specifications

MODEL

COMPRESSOR MODEL

RAC-25NH4 RAC-50NH4RAC-35NH4

JU1012D JU1013D

PHASE SINGLE

RATED VOLTAGE AC 220 ~ 230 V

RATED FREQUENCY 50 Hz

POLE NUMBER 4

(U)

WHITE

CONNECTION

M

M

M

(W)

(V)

YELLOW

RESISTANCE VALUE

20°C

(68°F)

2M = 1.05

RED

75°C

(167°F)

YELLOW

2M = 1.28

WHITE

RED

!

CAUTION

( )

When the refrigerating cycle has been operated for a long time with the capillary tubes clogged or crushed

or with too little refrigerant, check the color of the refrigerating machine oil inside the compressor. If the

color has been changed conspicuously, replace the compressor.

– 9 –

Page 19

WIRING DIAGRAM

BLU

POWER

RELAY

COIL

NF

COIL 1

C003

C001

C002

VARISTOR1

L001

CT1

VARISTOR3

SURGE

ABSORBER

DIODE

STACK

R010

L002

R011

C011

C010

FAN

MOTOR

VARISTOR2

CN6

WHT

C008

C013

C015

M

WHT YEL

RED

WHT YEL

YEL

YEL

YEL

DIODE

STACK

RED

UVW

REACTOR

SYSTEM POWER

MODULE 2

L2

L1

CN14

CN13

CN11

C503

C502C501

10

CN14

CN10

RED

CN9

BLU

CN8

WHT

CN15

WHT

CN13

CN11

5

5

CN12

CN12

RED

GRY

2A FUSE

ICP RELAY

R008R007

3A FUSE

25A

FUSE

C006

R001

BLK GRN WHT

(WHT) (BRN) (RED)(BLK)

CONNECTING

CORD

BRN RED

BLK

BLK

GRN

RED

BLK

WHT

YEL

BLU

POWER

CIRCUIT

TERMINAL

BOARD

(GRN+YEL)

LNCD

SINGLE PHASE

AC220~230V

50Hz

(GRN+YEL)

THERE ARE SOME LEAD WIRES

WHICH HAVE SPIRAL STRIPES

WITH WHITE IN ADDITION TO

THE ORIGINAL COLOR

CN2

RED

MAIN P.W.B.

REVERSING

VALVE

R002

C007

C012

C014

ELECTRIC EXPANSION

VALVE

OH

THERMISTOR

DEFROST

THERMISTOR

OUTDOOR

TEMPERATURE

THERMISTOR

GRY

GRY

GRY

GRY

RED

RED

COMPRESSOR

MODEL RAK-25NH4 / RAC-25NH4

RAK-35NH4 / RAC-35NH4

RAK-50NH4 / RAC-50NH4

INDOOR UNIT

CONNECTING CORD

FROM OUTDOOR UNIT

(BROWN)

(RED)

GREEN &

YELLOW

INDOOR ROOM

TEMPERATURE

THERMISTOR

HEAT

EXCHANGER

THERMISTOR

TERMINAL

BOARD

C

D

BLACK

BLACK

GRAY

GRAY

BROWN

RED

CN1

CN5 CN9

EEPROM / TEST HA

1234 1 2 3 4

5678

CN12

MAIN P. W. B.

C1 C2 M1 M2

CN4 CN11

4 LINES 5 LINES

CN8

CN10

9 LINES

STEPPING

MOTOR

M

M

INDOOR

FAN MOTOR

WIRELESS

REMOTE CONTROLLER

RECEIVER

P. C. B.

CN3A

CN2A

OUTDOOR UNIT

CN2

LED

P. C. B.

– 10 –

Page 20

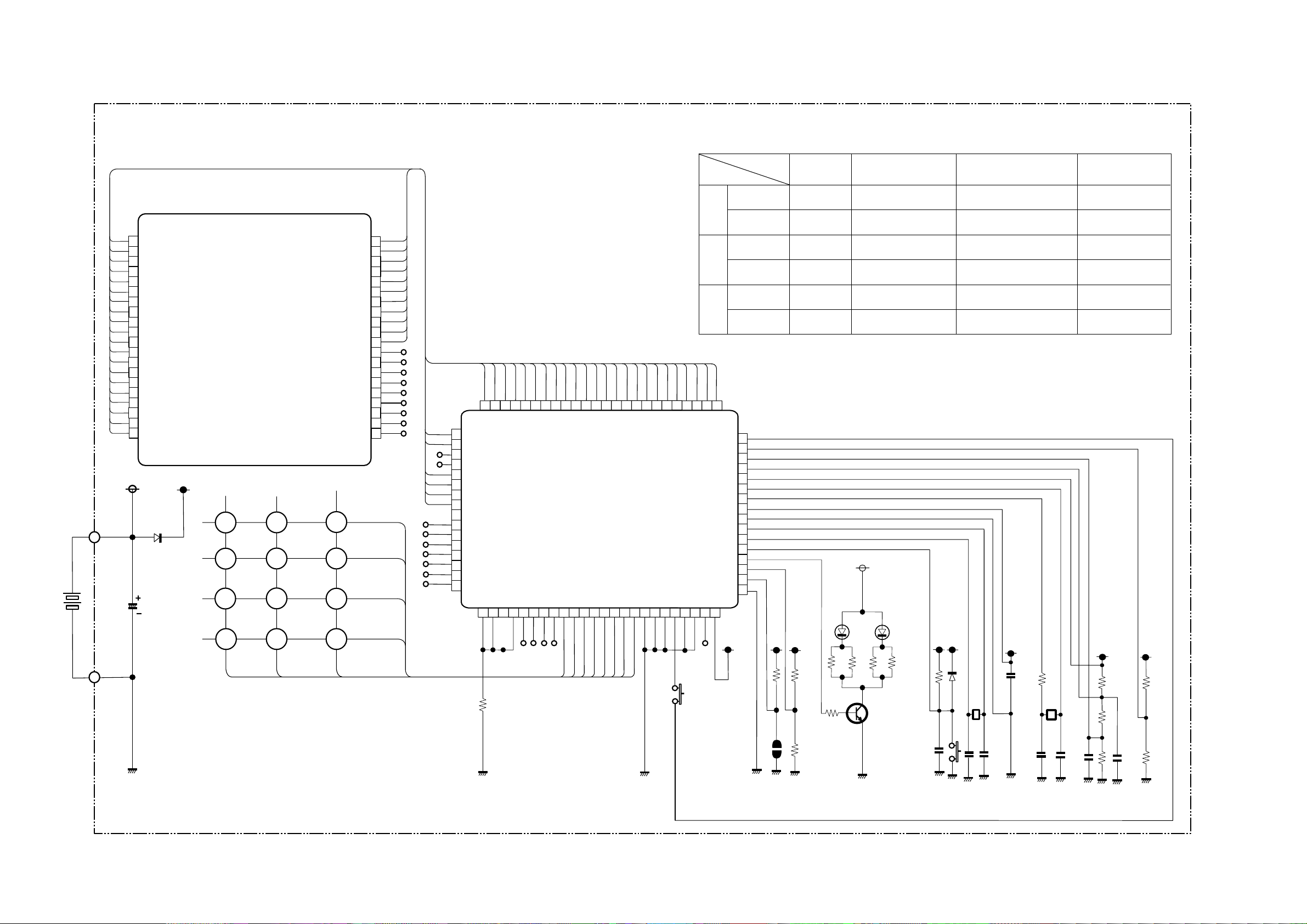

CIRCUIT DIAGRAM

Remote Control

Key matrix table

1

SEG5

2

SEG0

3

SEG1

4

SEG2

5

SEG3

SEG4

6

7

SEG5

8

SEG6

9

SEG7

10

COM3

11

COM2

12

COM1

13

COM0

14

SEG14

15

SEG13

16

SEG12

17

SEG11

18

SEG13

19

SEG9

20

SEG8

D3

RB425D(1/2)

C8

50v/1u

LCD 1

K 1

K2K3

K4

K5

P10

P11

K6

K7 K8

K9 K10

K11K12

SEG20

SEG19

SEG18

SEG17

SEG16

SEG21

SEG27

SEG28

P12

SEG24

SEG25

SEG26

NC

NC

NC

NC

NC

NC

NC

NC

NC

K13 K14

K15 K16

K17

K18

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

D0

D1

D2

D3

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

64

SEG20

SEG21

SEG22

SEG23

SEG24

SEG25

SEG26

SEG27

SEG28

SEG29

SEG30

SEG31

SEG32

SEG33

SEG34

SEG35

1

62

63

SEG19

SEG18

P41

P40

3

2

R1

100k

60

61

SEG17

SEG16

P42

P43

5

4

59

58

57

54

SEG14

SEG15

IC 1

56

SEG13

SEG12

55

SEG11

SEG10

SEG9

53

52

51

SEG8

SEG7

50

49

SEG5

SEG6

M3455OM6A-504FP

D2

P00

6

P01

7

P02

8

P03

9

P10

10

P11

11

P12

12

P13

13

D0

14

D1

15

16

48 47

SEG4

D3

17 18

SEG3

D5

D4

45

46

SEG1

SEG2

D6

20

19

Input

P10

P11

P12

43

44

42

SEG0

SEG42

SEG43

NCVL C1

XC OUT

D7

D9

D8

BEEP

22

21

23

SW1

SW-187-2P

Output

D0

Door open Automatic swingFan speed selectionOperation selectionStart/Stop

Door shut ––Automatic swingStart/Stop

Door open Day

Door shut Fan speedRoom temperature downRoom temperature up–

Door open CancelReservation–Off timer

Door shut –––Sleep

41

SEG41

SEG40

40

P30

P31

39

38

37

VL C2

VL C3

36

35

XC IN

34

33

VDD

32

VSS

X OUT

31

X IN

30

29

RESET

28

CARR

27

P23

26

P22

25

24

P21

P20

R2

100k

R3

100k

R5

330

P

R4

100k

R6

D1 D2

EL-1L7

D2D1

R8

R7

R6 R9

24(1/8W)

Q1

2SC3443

or 2SC2982

R9

R10

12M

D3

RB425D

(1/2)

K19

X1

910kHz

C9

105

R11

150k

X2

32.768

kHz

C6

104

• present timeHour downHour upOn timer

D3D2D1

R14

220k

220K

R13

C7

104

R15

100k

R16

100k

C1

334

C2

220p

C3

220p

C4

18p

C5

22p

R12

220k

– 11 –

Page 21

CIRCUIT DIAGRAM

MODEL RAK-25NH4, RAK-35NH4, RAK-50NH4

– 12 –

Page 22

CIRCUIT DIAGRAM

MODEL RAC-25NH4/RAC-35NH4/RAC-50NH4

– 13 –

Page 23

PRINTED WIRING BOARD LOCATION DIAGRAM

MODEL RAK-25NH4, RAK-35NH4, RAK-50NH4

MAIN P.W.B.

Marking on P.W.B.

COMPONENT SIDE

SOLDERING SIDE

1

IVORY

CN5

8

4

1

CN1

WHT

C621

C751

C132

C131 R111

ICP2

1

1

IC402

J29

J30

J17

R631

L751

R751

R114

Q113

R121

ICP1

WHT

CN4

CN8

WHT

J31

J18

J19

J10

5

IVORY

ZD131

Q111

R122

IC111

R112 C112

C111

ZD111

R125

R126

J20

CN6

4

5

BZ

J39

RES1

J33

J32

J34

J11

J12

1

1

HB-098-101A

Q131

C133

R132

Q112

D111

R115

Q115

C103

D821

C823

R825

R823

C822

IVORY

1

CN14

1

J52

J46

J44

J51

J50

J45

J42

J43

J49

J48

J40

J41

J21

J22

J14

J13

J15

CN9

4

BLK

ZD211

R201

R131

ZD121

C123

Q114

C113 R117

R828

R829

R826

R824

R822

1

IC801

4

Q801

R812

J72

Q821

C763

R612

R764

R609

R830

C115

J78

C651

C825

R118

R651

Q803

R119

R761

R120

R658

ID

8

C801

R804

C121

C116

R116

R124

Q116

R123

J79

R827

R821

C803

C804

J801

L801

R806

R805

R803

J16

J23

R811

4

J35

J24

R701

REG2

J37

J36

R606

32

33

R657

R610

C507

R807

R810

C631

R656

R503

J76

R403

J47

R605

R404

Q802

J53

J38

IC501

R500

R654

5

R763

R504

R813

J54

J25

C821

ICP3C762

R219

R653

WHT

CN11

J55

R743

R604

R603

17

C601

R505

1

C114

C122

J26

J27

C802

J83

Q722

R745

R742

R744R741

R611

C506

16

R501

R602

C824

R641

R601

J75

R652

J71

AUTO RESTART

CANCEL

L111

R506

R508

L501

R502

C501

C611

R514

R507

R655

IC711

C524

R746

C521

R509

J82

1

R515

R510

HB–098–101A

J56

L101

C101

D101

13

L743 L742 L741

16

J81

1

C522

IC521

R521

R522

C505

C304

R307

C302

R511

R512

R513

J74

R308

C104

R127

C502

Q521

D402

R650

C102

CN12

WHT

C711

R305

C523

C401

R128

F

No.

Lot

J28

J80

R301

1

CN10

IVORY

6

9

R749

8

R748

R747

IC401

R401

R402

J77

D403

D401

R306

C303

R303

J73

R302

J70

RECEIVING P.W.B.

Marking on P.W.B.

Lot No.

IR1

1 14

J57

C1

IVORY

CN2A

IVORY

CN3A

COMPONENT SIDE

F

SW1

9

HB-098-102A

– 14 –

R1

R2

SOLDERING SIDE

Page 24

MODEL RAC-25NH4, RAC-35NH4, RAC-50NH4

MAIN P.W.B. Marking on P.W.B

COMPONENT SIDE

– 15 –

Page 25

RAK-25NH4 / RAC-25NH4

RAK-35NH4 / RAC-35NH4

RAK-50NH4 / RAC-50NH4

LCD wireless

Room temperature

thermistor

Wireless receive

circuit

Filter.

Operation.

Timer.

Power source

1ø, 50Hz, 220~230V

L

N

Outdoor

unit

Terminal

board

SPM2

Trip signal

synthesis circuit

Heat exchanger

thermistor

Temporary switch

Initial setting circuit

Reset circuit

Auto sweep motor for

Air deflector

Indoor microcomputer (AX-7R11)

Outdoor microcomputer / HIC (AX-8N00)

Electric Expansion valve

drive circuit

Electric

Expansion

valve

– 16 –

Page 26

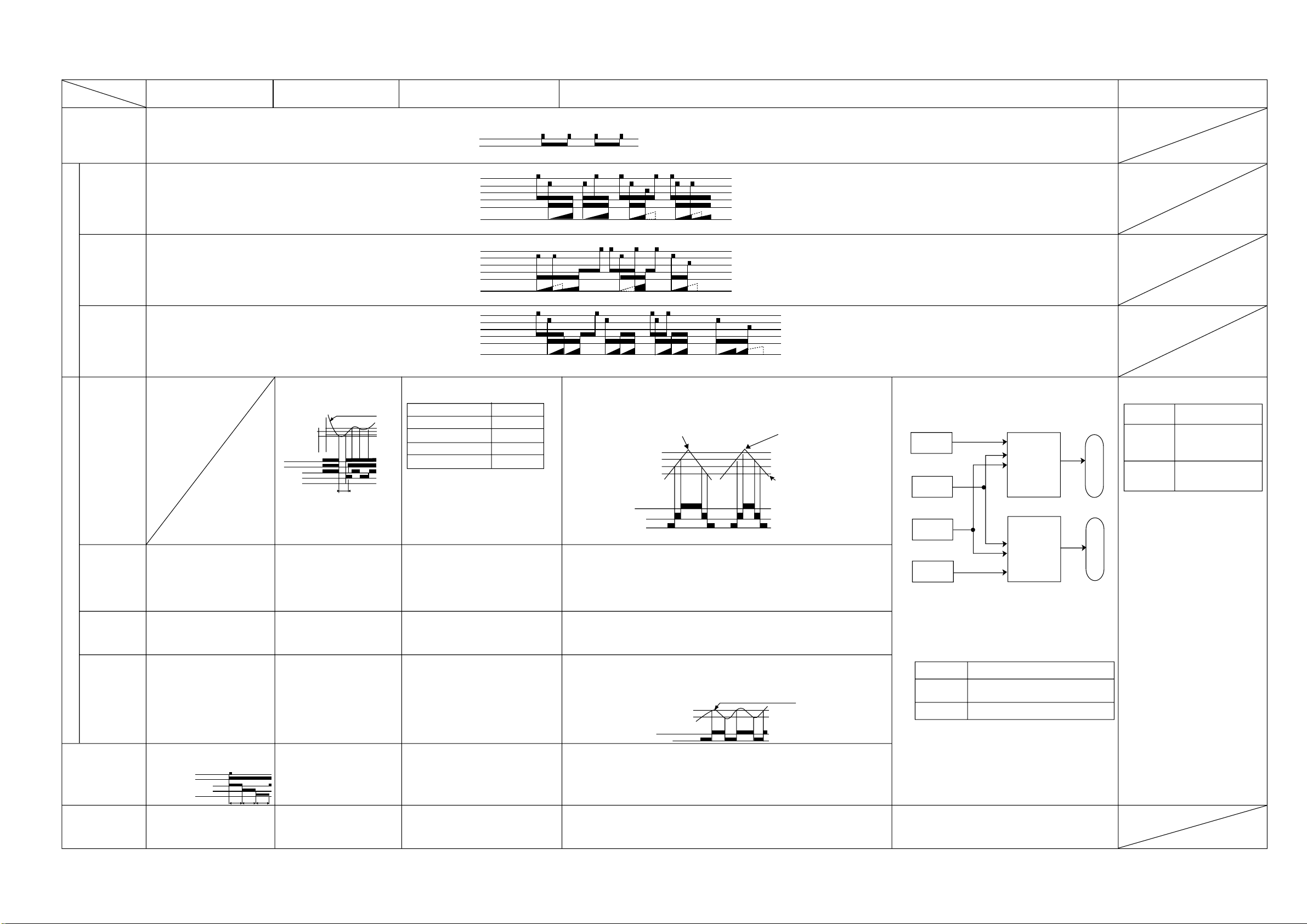

BASIC MODE

MODEL RAK-25NH4, RAK-35NH4, RAK-50NH4

Operation mode

Basic operation of

start/stop switch

Off-timer

On-timer

Timer functions

Off -> On

On -> Off timer

Auto

Hi

Med

Fan speed mode (indoor fan)

Lo

Basic operation of

temperature controller

Sleep operation

(with sleep button ON)

Operates at “Hi” regardless of the

room temperature.

Operates at “Med” regardless of

the room temperature.

Operates at “Lo” regardless of the

room temperature.

Performs only fan operation at the

set speed regardless of the room

temperature.

• Enters sleep operation after set

as on the left.

• Action during sleep operation

Lo (sleep) operation

Fan

Start/stop switch

Operation lamp

Hi

Med

Fan

Speed

Lo

Hi Med Lo

Changes from “Hi” to “Med” or

“Lo” depending on room

temperature.

Temperature set

for cooling

Thermo iudgment

Compressor

Hi

Med

Lo

1. Runs at “Hi” until first thermo

off after operation is started.

2. Runs at “Lo” when thermo is

off.

Set to “ultra-Hi” when the

compressor runs at maximum

speed, and to “Hi” in other modes.

Same as at left.

Same as at left.

See page 49.

• Same as at left

• See page 51.

(Compressor stopped

forcibly for 3 minutes)

Dehumidifying

(dehumidifying operation by the

function select button only, not including

that engaged by the dehumidify button)

Start/stop switch

Operation tamp

Start/stop switch

Operation tamp

Cancel switch

Operation temp

Timer tamp

Timer memory

Srart/stop switch

Reserve switch

Cancel switch

Operation temp

Timer tamp

Timer memory

Start/stop switch

Reserve switch

Cancel switch

Operation lamp

Timer lamp

Timer memory

Start

(Change in reserved time)

Changes between “Lo” and “Med”

depending on the room temperature.

Fan speedTemperature division

Division 1

Division 2

Division 3

Division 4

Lo

Lo

Med

Med

1. The indoor fan also stops when the

compressor is in stop status.

Set to “Hi” in modes other than when the

compressor stops.

Set to “Med” in modes other than when the

compressor stops.

Set to “Lo” in modes other than when the

compressor stops.

See page 53.

• Same as at left

• See page 53.

Stop

Start Stop

(Off-timer during stop)

(On-timer during operation)

ON ONONOFF OFF OFF ONOFF

(Off->On timer) (On->Off timer) (On->Off timer)

(Change in reserved time)

during operation)

(Off->On timer)

during stop)

Set to “ultra-Lo”, “Lo”, “Med”, “Hi”, “ultra-Hi” or “stop” depending on the room temperature,

time and heat exchange temperature. Set to “stop” if the room temperature is 18˚C in the

“ultra-Lo” mode other than during preheating (cooling is recovered at 18.33˚C).

When the compressor is running at maximum speed

during hot dash or when recovered from defrosting.

˚C

42. 66

37. 66

32. 66

29. 66

Hi or ultra-HI

(fan speed set

to “auto”)

Med

Lo

In modes other than

left

Heat exchanger

temperature

Set to “ultra-Lo”, “Lo”, “Med”, “Hi”, “ultra-Hi” or “stop” depending on the room temperature, and

time. Set to “stop” if the room temperature is 18˚C in the “ultra-Lo” mode other than during

preheating (cooling is recovered at 18.33˚C).

Set to “ultra-Hi” when the compressor is running at maximum speed during hot dash or when

recovered from defrosting.

Set to “ultra-Lo”, “Lo”, “Med” or “stop” depending on the room temperature and time. Set to

“stop” if the room temperature is 18˚C in the “ultra-Lo” mode other than during preseating

(cooling is recovered at 18.33˚C).

Set to “ultra-Lo”, “Lo”, or “stop” depending on the room temperature and time. Set to “stop” if

the room temperature is 18˚C in the “ultra-Lo” mode other than during preseating (cooling is

recovered at 18.33˚C). The fan speed is controlled by the heat exchanger temperature; the

overload control is executed as in the following diagram:

KAFON

KAFOF

“Med” with overload

“Lo”

Heat exchanger temperature

See page 55.

• Same as at left

• See page 57.

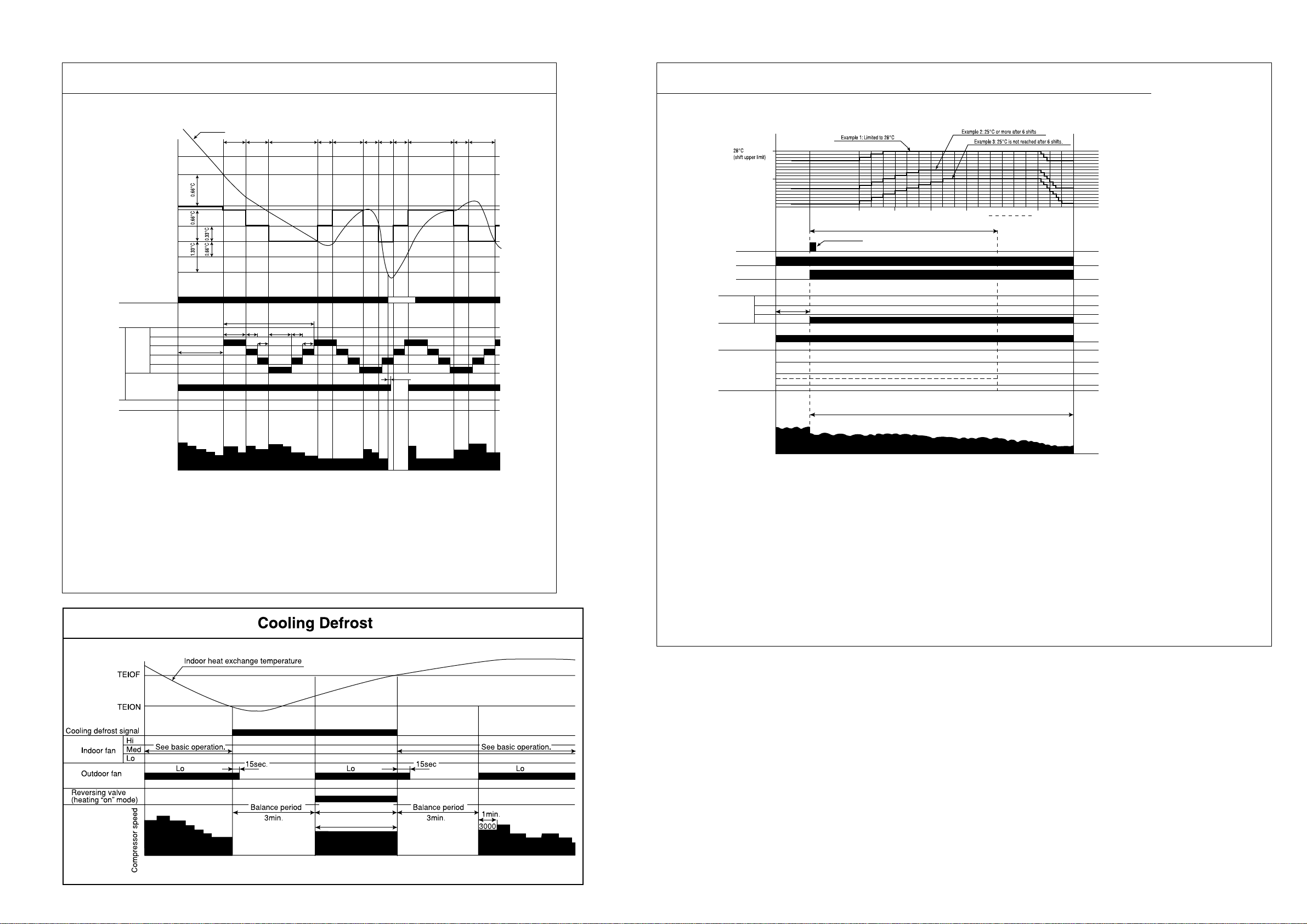

N&F autoHeatingCooling

The neuro & fuzzy control allows device to determine optimum

operation mode and set temperature. However, during auto

cooling, the new cool rhythm starts when the room temperature

is less than the set temperature plus 0.66˚C, after dash is

finished.

Room

temperature

Outdoor

temperature

Calendar

Humidity

Neuro

pattern

recognition

Fuzzy

control

Operation mode

Set temperature

Notes:

(1) The set temperature can be varied ±3˚C using the

temperature setting buttons and .

v

v

(2) If operation is started by tele-control or by temporary switch

in status where remote control has not been used after

power was supplied, the operation mode will be as follows

(since there is no stored calendar data):

Room temparature at

operation start (˚C)

Cooling

Dehumidifying

Heating

Set temperature: 28˚C

Fan mode: Auto

Set temperature: Room temperature at operation

Fan mode: Auto

Set temperature: 22˚C

Fan mode: Auto

start

• Same as at left.

• Performs the sleep operation of each operation mode.

Special auto (not normally used)

The special auto mode is based on N&F

auto, but the following is different:

Operation mode

N&F auto

Special auto

Mode change during

operation

Does not change as long as

outdoor temperature or

calendar data does not

change greatly.

The operation mode will be

judged the same as at

operation start every hour.

The special auto operation mode is

entered when operation is started in the

following status:

<Start condition>

Power is supplied white the tele-control

signal is being input. (Operation starts

automatically.)

<End condition>

The remote control restores the normal

operation mode.

Note

(1) Since there is no stored calendar

data, N&F control is not determined.

See Note (2) of N&F auto.

– 17 –

Page 27

Table 1 Mode data file

RAK-25NH4 RAK-35NH4 RAK-50NH4

LABEL NAME VALUE

WMAX 4500 min

WMAX2 4600 min

WSTD 3250 min

WBEMAX 2600 min

CMAX 2900 min

CMAX2 3000 min

CSTD 2500 min

CKYMAX 2200 min

CJKMAX 2000 min

CBEMAX 1800 min

WMIN 1200 min

CMIN 1500 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

5500 min

5600 min

4350 min

2800 min

3700 min

3800 min

3550 min

2800 min

2500 min

2200 min

1200 min

1500 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

6200 min

6250 min

5200 min

2600 min

5700 min

5800 min

5200 min

3550 min

2700 min

2000 min

1200 min

1500 min

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

–1

STARTMC 60 Seconds 60 Seconds 60 Seconds

DWNRATEW 80% 80% 80%

DWNRATEC 80% 80% 80%

SHIFTW 3.33°C 3.33°C 3.33°C

SHIFTC 1.00°C 1.00°C 0.33°C

CLMXTP 30.00°C 30.00°C 30.00°C