Hitachi PJ656, CP-S245, ED-X8255, CP-X255 Service Manual

SM0560

CP-S245(CC9SMN)

SERVICE MANUAL

CP-X255(CC9XMN)

ED-X8255(CC9XMN)

PJ656(CC9XM)

Warning

The technical information and parts shown in this

manual are not to be used for: the development,

design, production, storage or use of nuclear, chemical,

biological or missile weapons or other weapons of

mass destruction; or military purposes; or purposes that

endanger global safety and peace. Moreover, do not

sell, give, or export these items, or grant permission for

use to parties with such objectives. Forward all inquiries

to Hitachi Ltd.

Caution

Be sure to read this manual before servicing. To assure safety from fi re, electric shock, injury, harmful

radiation and materials, various measures are provided in this Hitachi Multimedia LCD Projector. Be

sure to read cautionary items described in the manual to maintain safety before servicing.

Service Warning

1. When replace the lamp, to avoid burns to your fi ngers. The lamp becomes too hot.

2. Never touch the lamp bulb with a fi nger or anything else. Never drop it or give it a shock. They may

cause bursting of the bulb.

3. This projector is provided with a high voltage circuit for the lamp. Do not touch the electric parts of

power unit (circuit) and power unit (ballast), after turn on the projector.

4. Do not touch the exhaust fan, during operation.

5. The LCD module assembly is likely to be damaged. If replacing to the LCD LENS/PRISM assembly,

do not hold the FPC of the LCD module assembly.

6. Use the cables which are included with the projector or specifi ed.

Contents

1. Features -----------------------------------------------2

2. Specifi cations -----------------------------------------2

3. Names of each part ---------------------------------3

4. Adjustment -------------------------------------------- 6

5. Troubleshooting ------------------------------------ 12

6. Service points -------------------------------------- 18

7. Wiring diagram ------------------------------------- 33

8. Disassembly diagram ----------------------------- 41

9. Replacement parts list ---------------------------- 48

10.RS-232C commands ----------------------------- 50

11. Block diagram -------------------------------------- 59

12. Connector connection diagram ---------------- 60

13.Basic circuit diagram ------------------------------ 61

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.

Multimedia LCD Projector

November 2005 Digital Media Division

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)

1. Features

• High Brightness

• Low Noise

• Rich Connectivity

•Compact Body

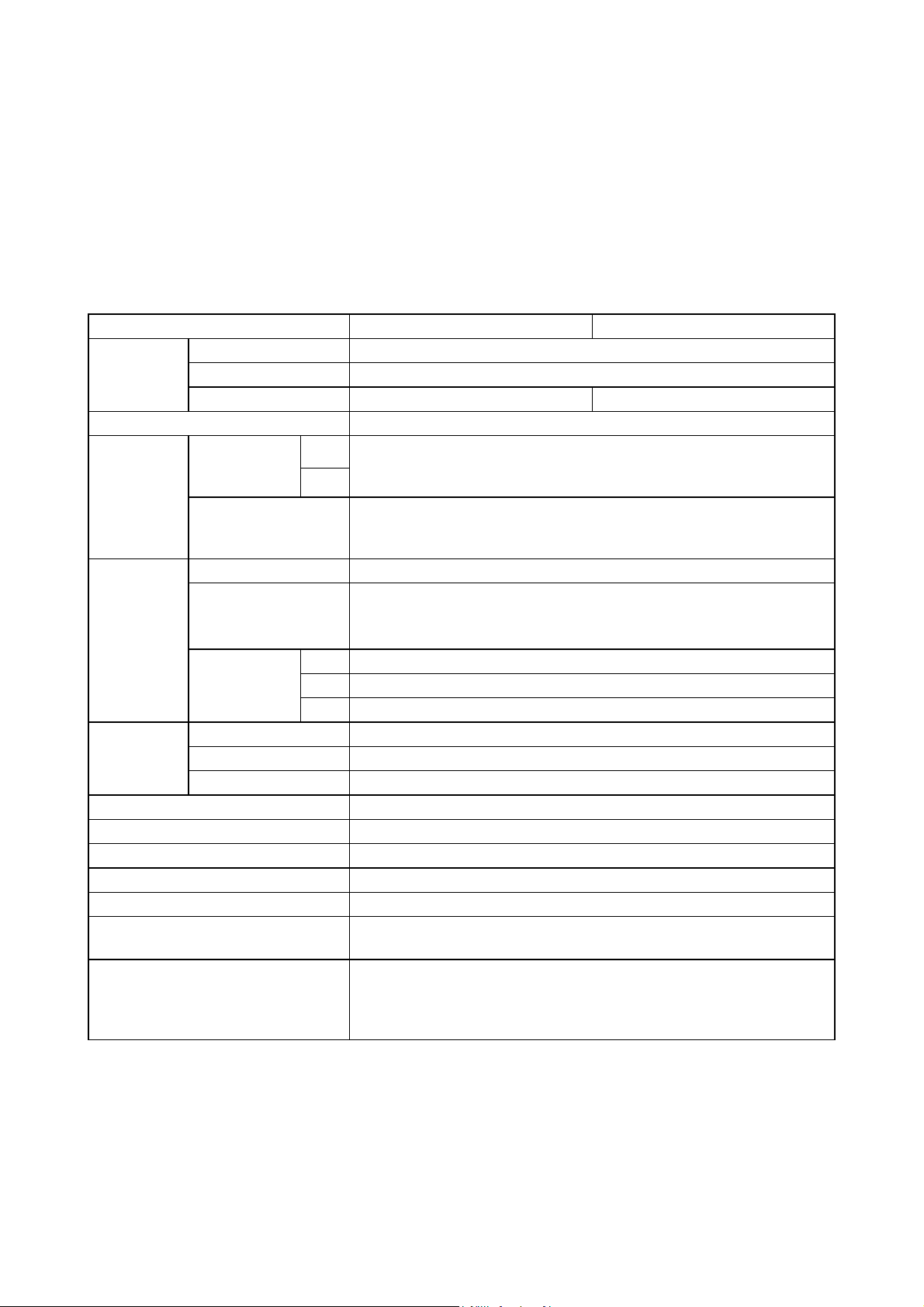

2. Specifications

CP-S245CP-X255 / ED-X8255

Liquid crystal

panel

Lamp 180W UHB

RGB

signal

VIDEO

signal

AUDIO

signal

Speaker output 1W x 1

Power supply AC100~120V/3.1A, AC220~240V/1.7A

Power consumption 290W

Dimensions 306 (W) x 86 (H) x 249 (D) mm (Not including protruding parts)

Weight 3.0kg

Temperature range

Accessories

*) This port is used as both RGB IN 2 and RGB OUT. Its function is selected with RGB IN/OUT switch.

Drive system TFT active matrix

Panel size 1.5cm(0.6 type)

Number of pixels 800 (H) x 600 (V) 1024 (H) x 768 (V)

Video : Analog 0.7Vp-p(75Ω termination)

RGB IN

RGB OUT*

VIDEO IN 1.0Vp-p (75Ω termination)

S-VIDEO IN

COMPONENT

VIDEO

AUDIO IN 1 200mVrms, 47kΩ or more (max. 3.0Vp-p)

AUDIO IN 2 L/R 200mVrms, 47kΩ or more (max. 3.0Vp-p)

AUDIO OUT 0~200mVrms, output impedance 1kΩ (max. 5.0Vp-p)

1

H/V. sync. : TTL level (positive/negative)

2*

Composite sync. : TTL level

Video:Analog 0.7Vp-p, 75Ω output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

Y signal: 1.0±0.1Vp-p, (75Ω termination)

C signal: 0.286±0.1Vp-p (NTSC burst signal, 75Ω termination)

0.3±0.1Vp-p (PAL/SECAM burst signal, 75Ω termination)

Y 1.0±0.1Vp-p, 75Ω termination (positive)

CB/PB0.7±0.1Vp-p, 75Ω termination (positive)

R/PR

C

0.7±0.1Vp-p, 75Ω termination (positive)

Operation : 5~35°C

Storage : -20~60°C

Remote control x1

RGB cable x 1

Audio/Video cable x 1

Power cords x 3

Batteries x 2

User’s manuals x 1

Soft case x 1 (not ED-X8255)

2

1. Features

• High Brightness

• Low Noise

• Rich Connectivity

•Compact Body

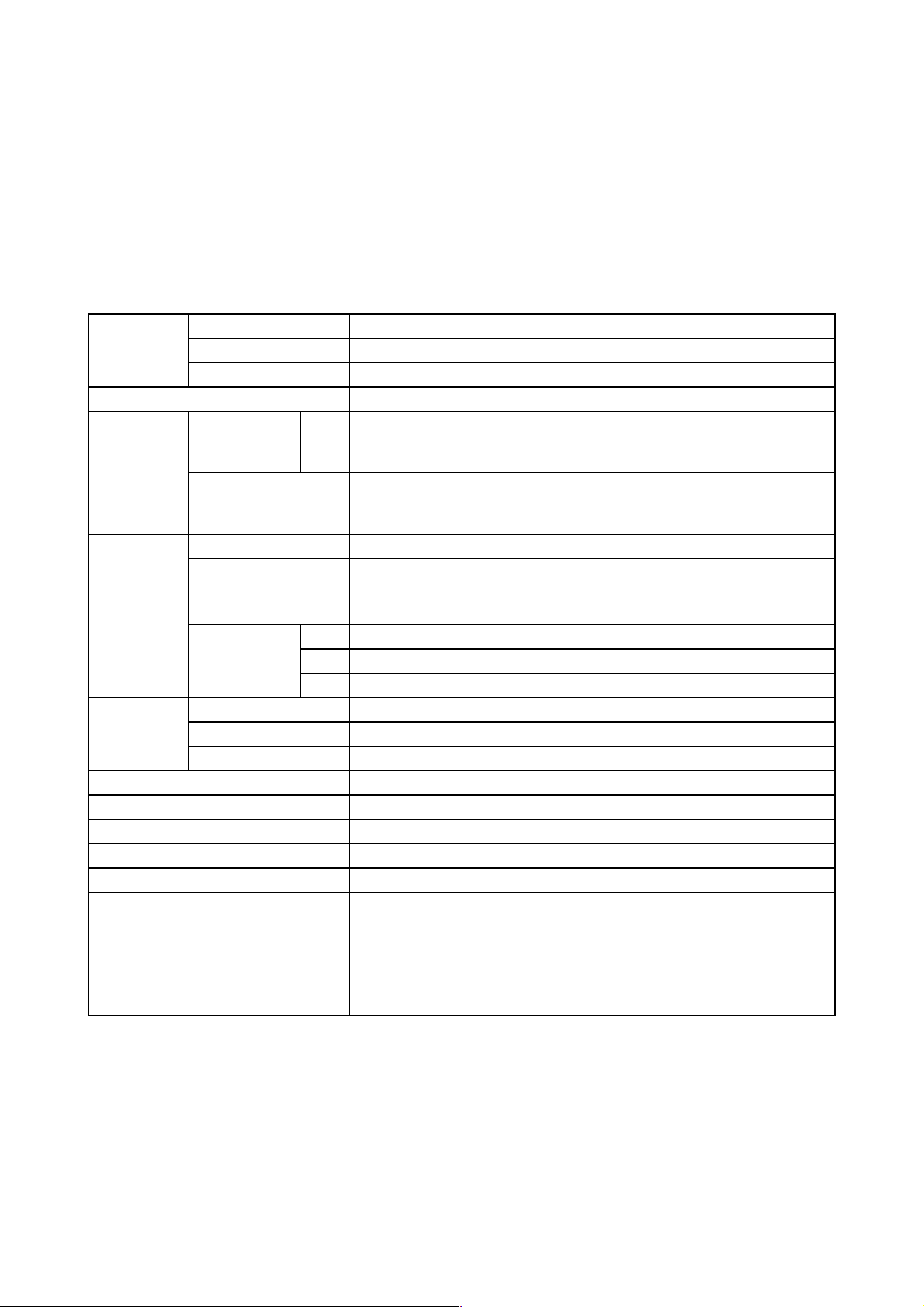

2. Specifications

PJ656(CC9XM)

Liquid crystal

panel

Lamp 180W UHB

RGB

signal

VIDEO

signal

AUDIO

signal

Speaker output 1W x 1

Power supply AC100~120V/3.1A, AC220~240V/1.7A

Power consumption 290W

Dimensions 306 (W) x 83 (H) x 249 (D) mm (Not including protruding parts)

Weight 2.8kg

Temperature range

Accessories

Drive system TFT active matrix

Panel size 1.5cm(0.6 type)

Number of pixels 1024 (H) x 768 (V)

Video : Analog 0.7Vp-p(75Ω termination)

RGB IN

RGB OUT*

VIDEO IN 1.0Vp-p (75Ω termination)

S-VIDEO IN

COMPONENT

VIDEO

AUDIO IN 1 200mVrms, 47kΩ or more (max. 3.0Vp-p)

AUDIO IN 2 L/R 200mVrms, 47kΩ or more (max. 3.0Vp-p)

AUDIO OUT 0~200mVrms, output impedance 1kΩ (max. 5.0Vp-p)

1

H/V. sync. : TTL level (positive/negative)

2*

Composite sync. : TTL level

Video:Analog 0.7Vp-p, 75Ω output impedance (positive)

H/V. sync.: TTL level (positive/negative)

Composite sync.: TTL level

Y signal: 1.0±0.1Vp-p, (75Ω termination)

C signal: 0.286±0.1Vp-p (NTSC burst signal, 75Ω termination)

0.3±0.1Vp-p (PAL/SECAM burst signal, 75Ω termination)

Y 1.0±0.1Vp-p, 75Ω termination (positive)

B/PB

C

CR/PR0.7±0.1Vp-p, 75Ω termination (positive)

0.7±0.1Vp-p, 75Ω termination (positive)

Operation : 5~35°C

Storage : -20~60°C

Remote control x1

RGB cable x 1

Audio/Video cable x 1

Power cords x 3

Batteries x 2

User’s manuals x 1

Soft case x 1

*) This port is used as both RGB IN 2 and RGB OUT. Its function is selected with RGB IN/OUT switch.

2a

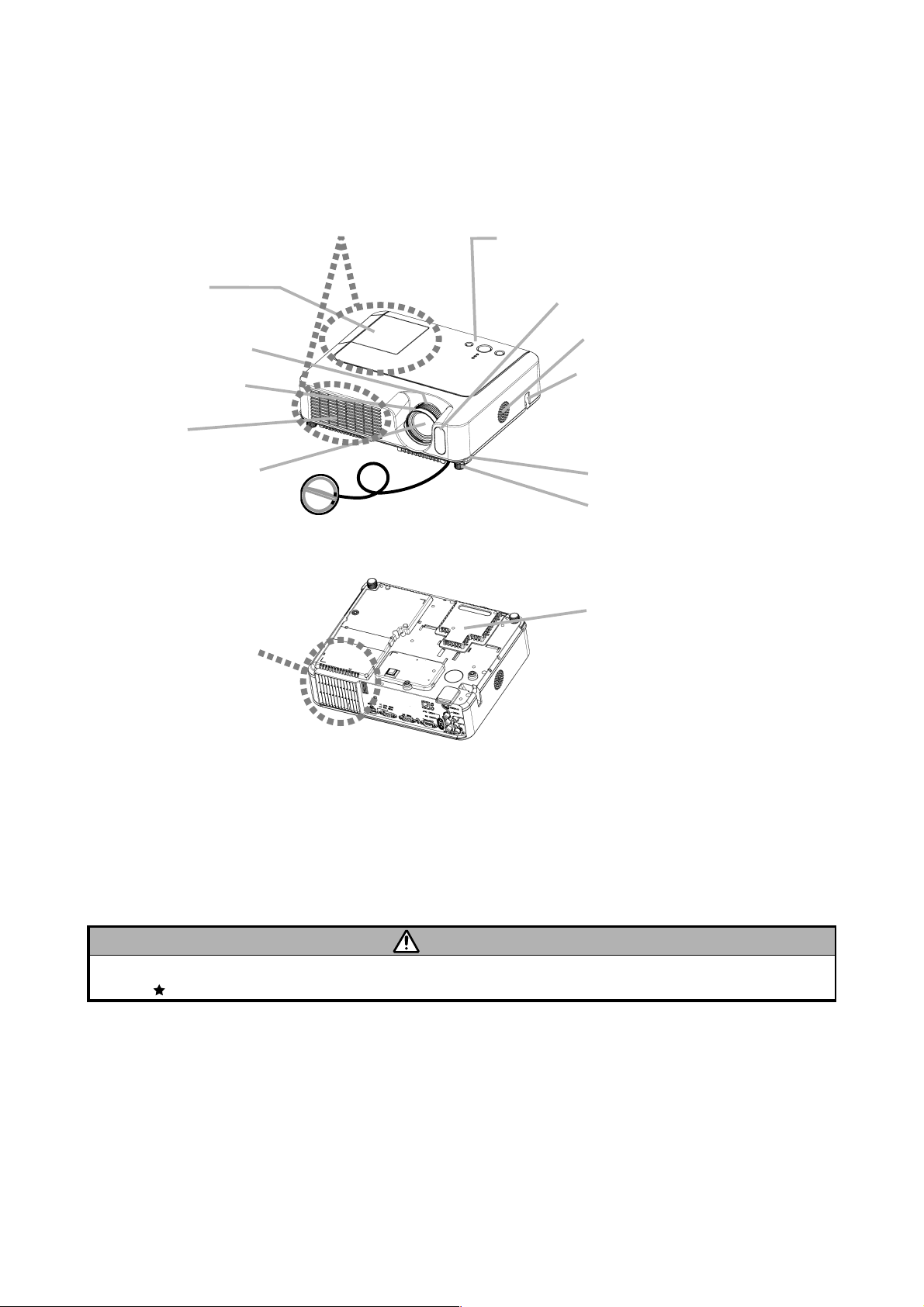

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

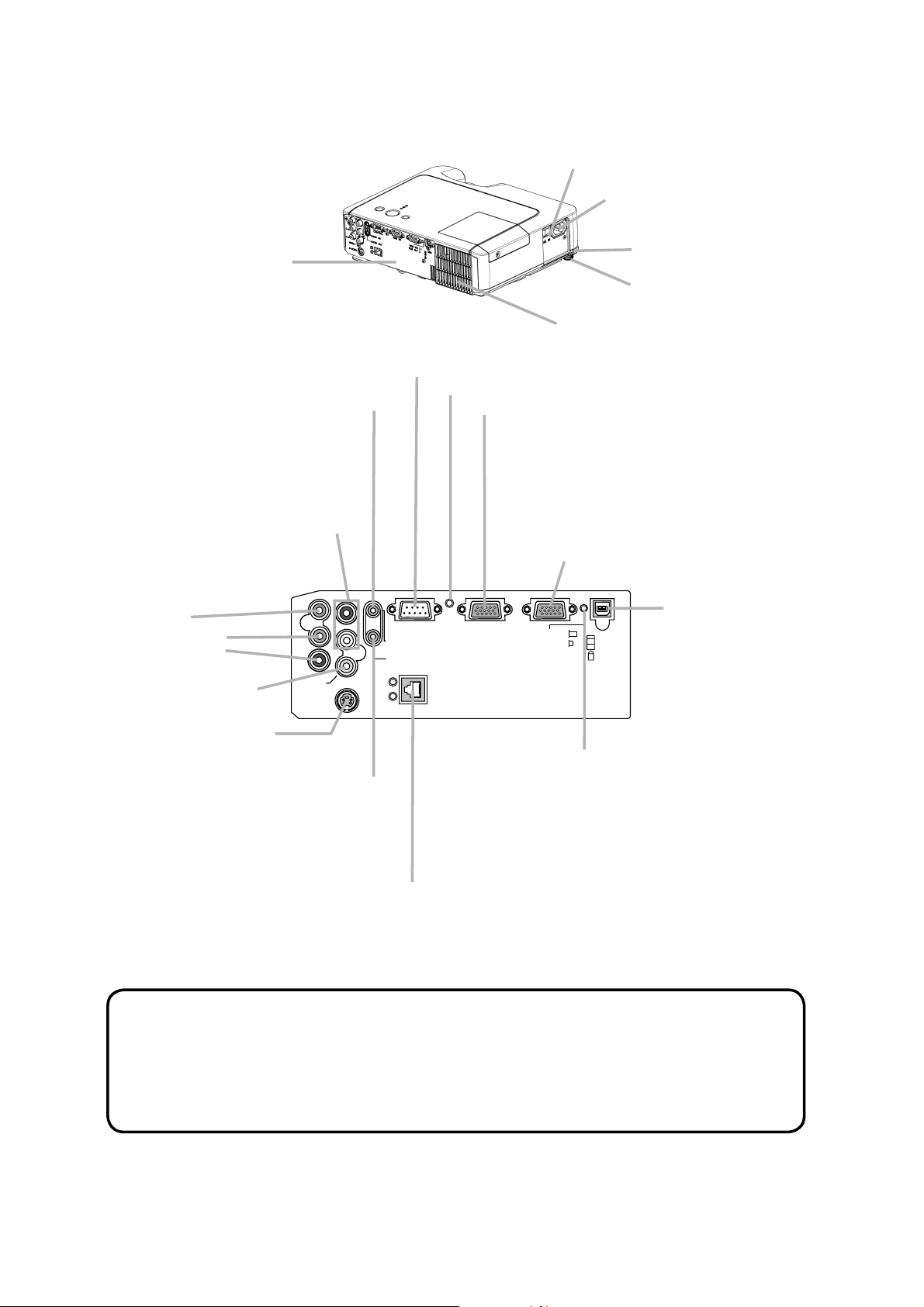

3. Names of each part

Projector

●

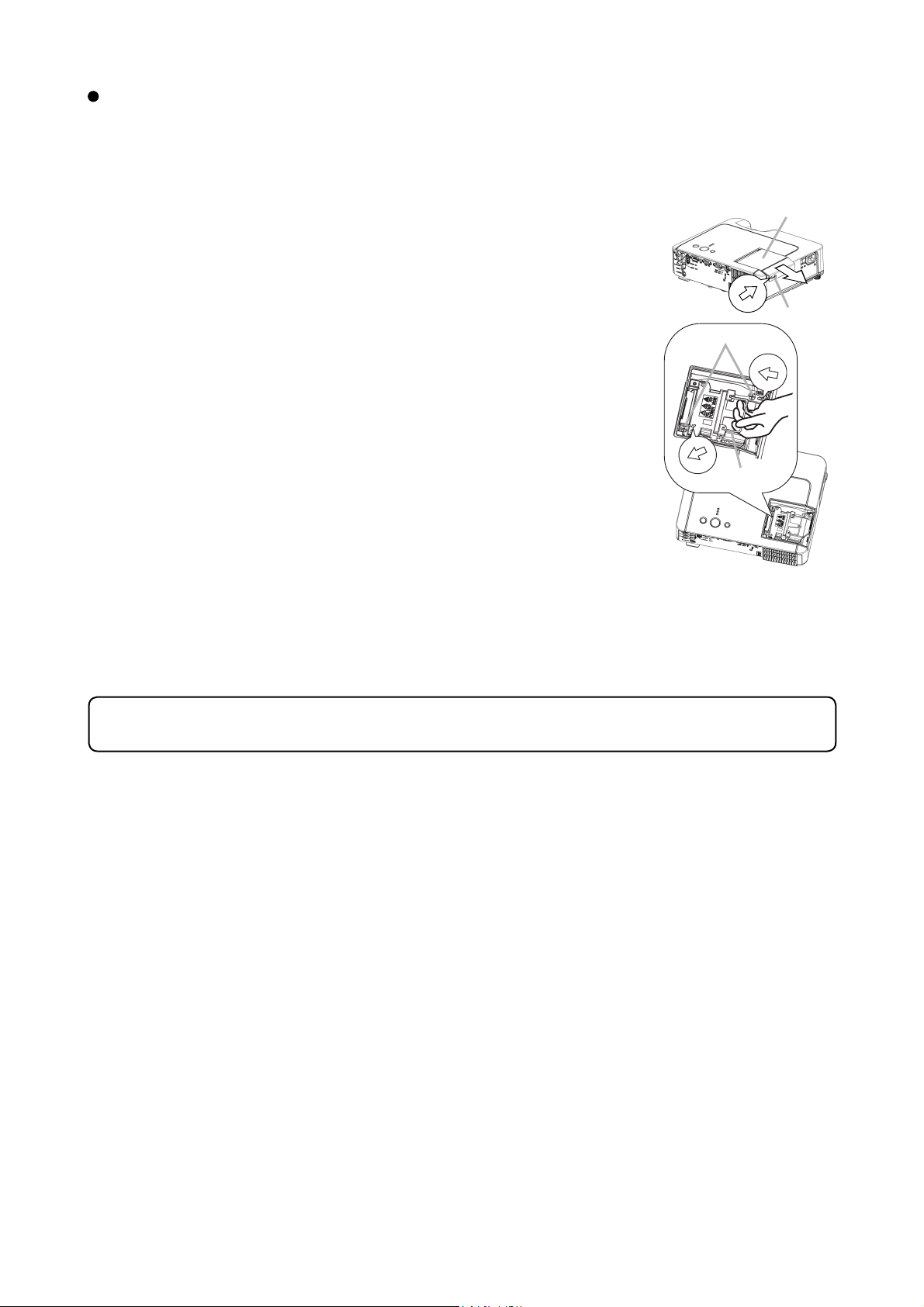

Lamp cover

(Lamp unit is inside.)

Zoom ring

Focus ring

Vent

Lens

Lens cover

Control buttons

Front-Right side

Remote sensor

Speaker

Security bar

(Use for attaching a

commercial anti-theft

chain or wire.)

Elevator button

Elevator foot

Filter cover

(Air filter and intake vent

are inside.)

Bottom side

WARNING

During use or immediately after use, do not touch around the lamp and vents of the projector. (

) It could cause a burn.

3

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)

Power switch

AC inlet

Ports (See below.)

CONTROL port

AUDIO-OUT port

AUDIO IN2 L/R port

(In the default setting, the

AUDIO IN2 L/R port is the audio

port for the VIDEO, S-VIDEO

and COMPONENT VIDEO

ports, however it is possible to

change the settings.)

COMPONENT

VIDEO ports

AUDIO IN2

YR

Y

B/PB

C

R

CR/P

VIDEO port

B

B

C

/

P

/

R

R

C

P

VIDEO

S-VIDEO

L

Rear-Left side

Restart switch (*)

CONTROL RGB IN1

AUDIO OUT

AUDIO IN1

LINK

ACT

LAN

Elevator button

Elevator foot

Vent

RGB IN1 port

RGB IN2 /RGB OUT port

(Use the RGB IN OUT switch to select

RGB IN2 or RGB OUT for this port.)

RGB IN2 port: Inputs the RGB signal from

a PC.

RGB OUT port: When connected to a

monitor, outputs the signal input via RGB

IN1.

USB port

RGB IN2

RGB OUT

USB

K

S-VIDEO port

AUDIO IN1 port

(In the default setting, the AUDIO

IN1 port is the audio port for the

RGB IN1 and RGB IN2 ports,

however, it is possible to change

the settings.)

Ports

RGB IN OUT switch

Use this button to select either RGB IN2

or RGB OUT for the corresponding port.

When this switch is not pushed in, RGB

IN2 is selected.

When this switch is pushed in, RGB OUT

is selected.

LAN Port

Used for Ethernet input/output.

This port is used when utilizing network functions.

NOTE (*) About Restart switch: This projector is controlled by an internal

microprocessor. Under certain exceptional circumstances, the projector may not

operate correctly and the microprocessor will need to be reset. In such a case,

please push the Restart switch by using a cocktail stick or similar, and before

turning on again, make the projector cool down at least 10 minutes without

operating. Only push the Restart switch in these exceptional instances.

4

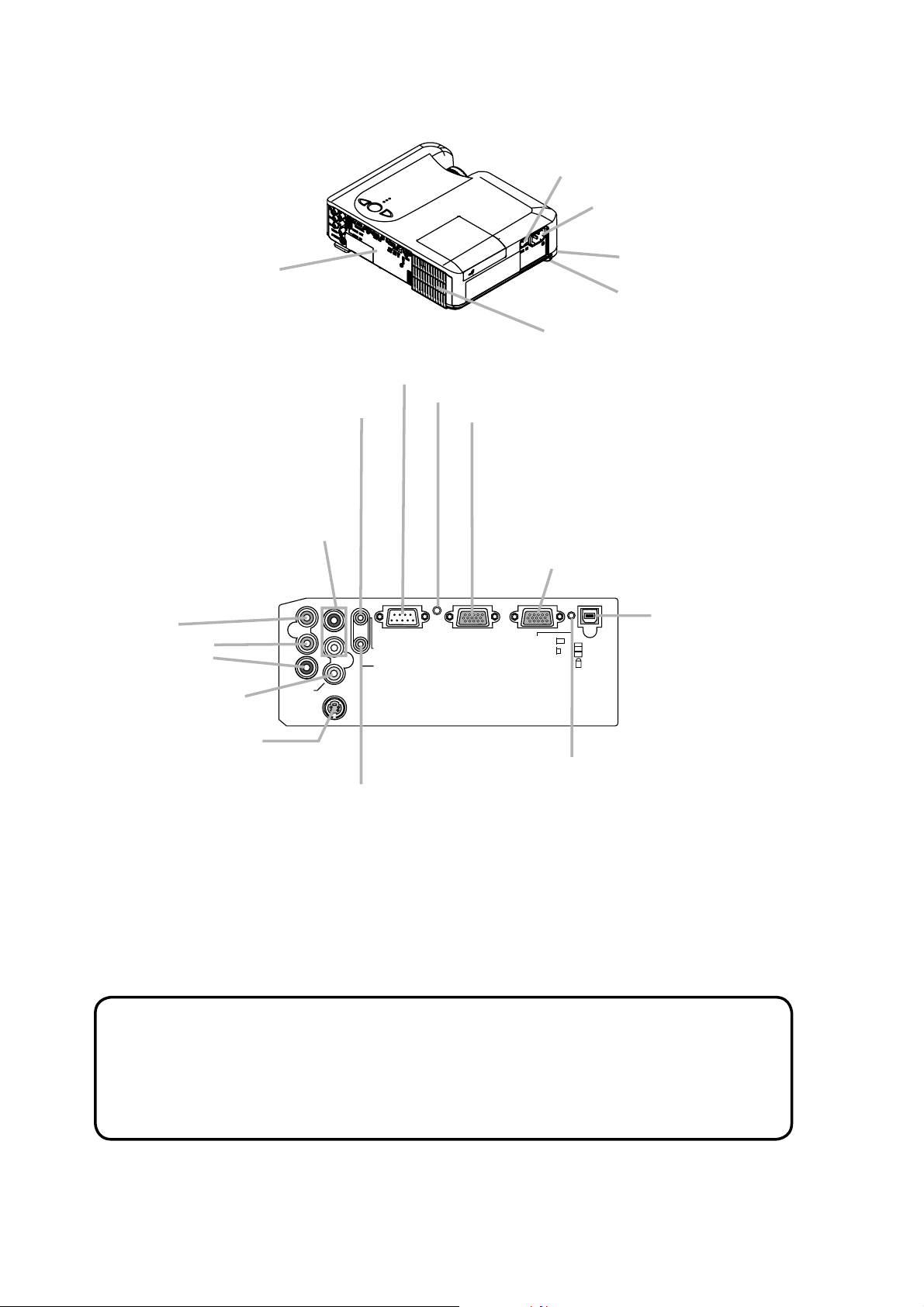

PJ656(CC9XM)

Power switch

AC inlet

Ports (See below.)

CONTROL port

AUDIO-OUT port

AUDIO IN2 L/R port

(In the default setting, the

AUDIO IN2 L/R port is the audio

port for the VIDEO, S-VIDEO

and COMPONENT VIDEO

ports, however it is possible to

change the settings.)

COMPONENT

VIDEO ports

AUDIO IN2

YR

Y

B/PB

C

R

CR/P

VIDEO port

B

B

C

/

P

/

C

R

P

R

VIDEO

S-VIDEO

L

Rear-Left side

Restart switch (*)

CONTROL RGB IN1

AUDIO OUT

AUDIO IN1

Elevator button

Elevator foot

Vent

RGB IN1 port

RGB IN2 /RGB OUT port

(Use the RGB IN OUT switch to select

RGB IN2 or RGB OUT for this port.)

RGB IN2 port: Inputs the RGB signal from

a PC.

RGB OUT port: When connected to a

monitor, outputs the signal input via RGB

IN1.

USB port

RGB IN2

RGB OUT

USB

K

S-VIDEO port

AUDIO IN1 port

(In the default setting, the AUDIO

IN1 port is the audio port for the

RGB IN1 and RGB IN2 ports,

however, it is possible to change

the settings.)

Ports

RGB IN OUT switch

Use this button to select either RGB IN2

or RGB OUT for the corresponding port.

When this switch is not pushed in, RGB

IN2 is selected.

When this switch is pushed in, RGB OUT

is selected.

NOTE (*) About Restart switch: This projector is controlled by an internal

microprocessor. Under certain exceptional circumstances, the projector may not

operate correctly and the microprocessor will need to be reset. In such a case,

please push the Restart switch by using a cocktail stick or similar, and before

turning on again, make the projector cool down at least 10 minutes without

operating. Only push the Restart switch in these exceptional instances.

4a

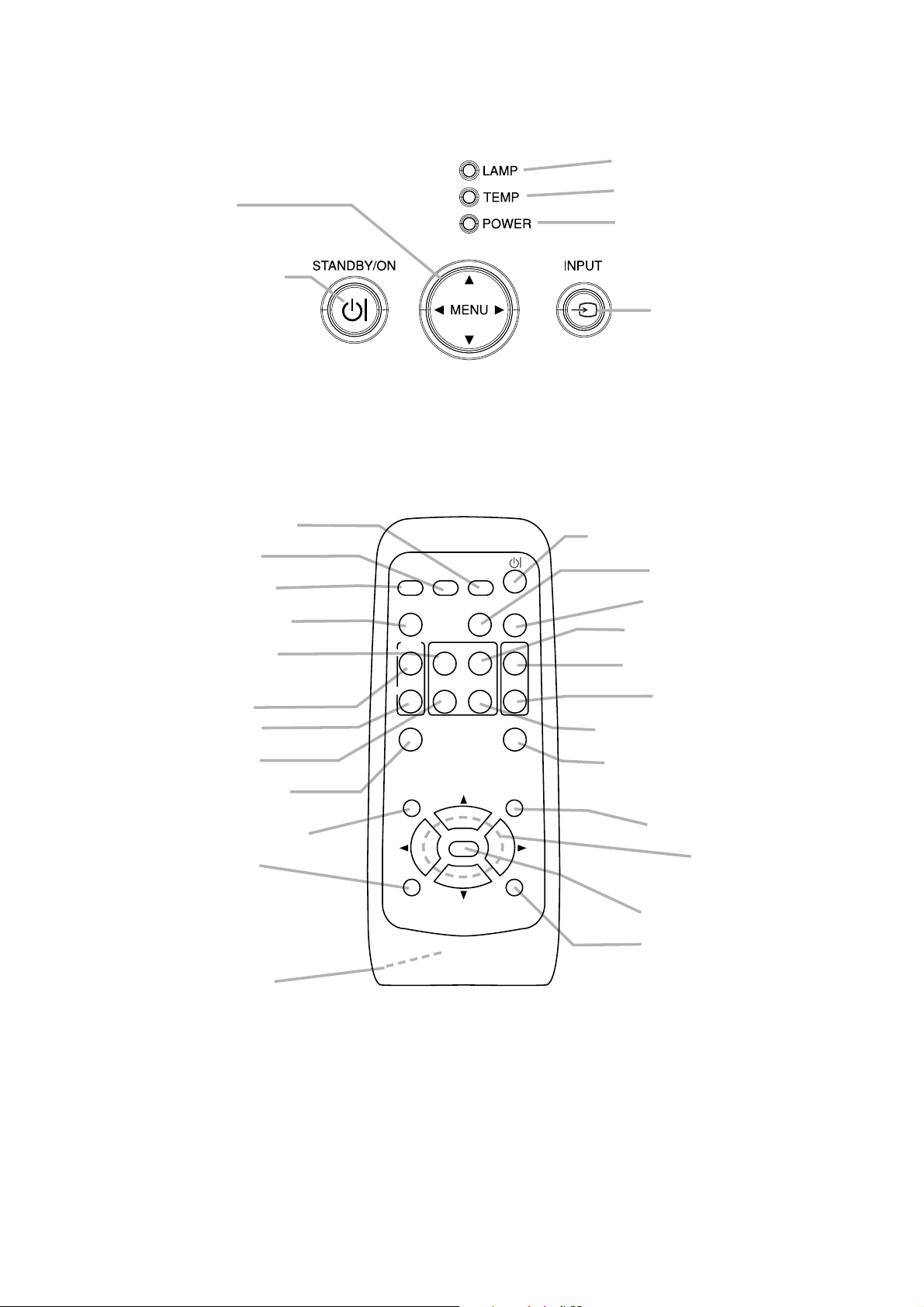

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

Control buttons

LAMP indicator

Cursor buttons

▲,▼,◄,►

STANDBY/ON button

Remote control

SEARCH button

RGB button

VIDEO button

ASPECT button

HOME button

MAGNIFY

ON button

OFF button

VIDEO

RGB

ASPECT AUTO

MAGNIFY

ON

OFF

HOME

END

FREEZE

SEARCH

PAGE UP

PAGE DOWN

KEYSTONE

BLANK

VOLUME

MUTE

TEMP indicator

POWER indicator

INPUT button

STANDBY/ON button

AUTO button

BLANK button

PAGE UP button

VOLUME button

MUTE button

PAGE DOWN button

END button

FREEZE button

POSITION button

ESC button

Battery cover

(on the back)

POSITION

ESC

ENTER

MENU

RESET

KEYSTONE button

MENU button

Cursor buttons

▲,▼,◄,►

ENTER button

RESET button

5

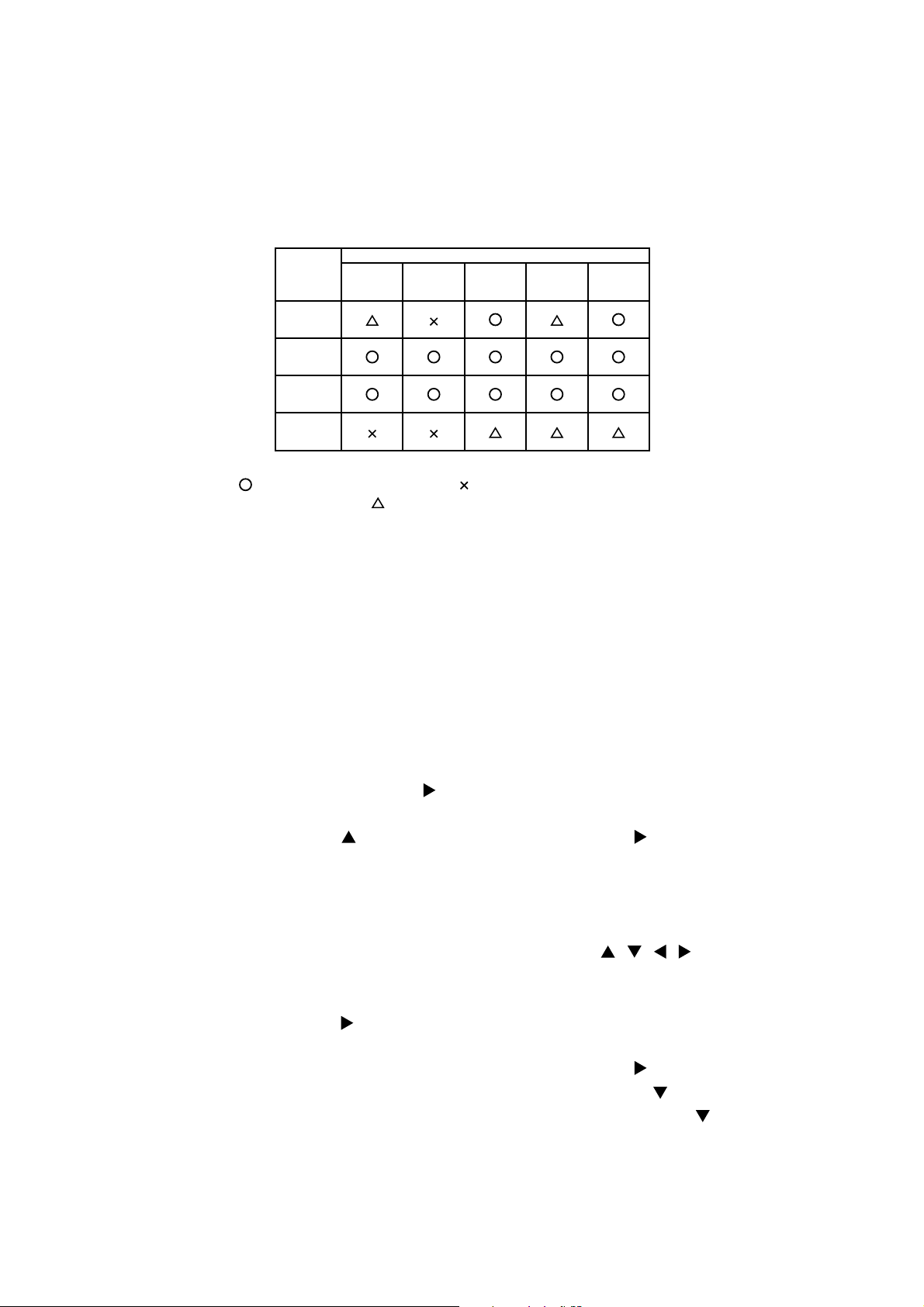

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

4. Adjustment

4-1 Before adjusting

4-1-1 Selection of adjustment

When any parts in the table 4-1 are changed, choose the proper adjusting items with the chart.

Table 4-1: Relation between the replaced part and adjustment

Replaced

Dichroic

optics unit

LCD/LENS

prism

assembly

PWB

assembly

Main

Lamp

assembly

part

unit

Convergence

(Chap.4-2)

(Chap.4-3)

: means need for adjustment. : means not need for djustment.

: means recommended.

Ghost

Adjustment

Flicker

(Chap.4-4)

White

balance

(Chap.4-5)

Color

uniformity

(Chap.4-6)

4-1-2 Setting of condition before adjustment

1. Before starting adjustment, warm up projector

for about 10 minutes.

2. Set Zoom Wide to Max. And project an image

with more than 1m (40 inches) in diagonal size.

3. Normalizing the video adjustment

Press the [MENU] button to display the Easy

menu. If Advance menu comes up, move to the

Easy menu.

Select RESET in the Easy menu and press [

or [ENTER] button to open the RESET menu

window. Choose EXECUTE with [ ] button.

Note that no signal input may not allow to reset

the adjustments.

4. Select PICTURE > GAMMA in the Advance

menu to set to DEFAULT1.

Note that PICTURE menu is not selectable with

no signal input displayed.

5. Select PICTURE > COLOR TEMP > CUSTOM

in the Advance menu, then press [

] or [ENTER]

button to display the equalizing window. Set all

the values of OFFSET and GAIN in the window

to zero.

Caution: Before this performance, make a note

of your customer’s adjustments, because the

data is overwritten.

6. Perform all adjustments from the FACTORY

MENU.

Perform the following operations to display the

FACTORY MENU.

< When you use the remote control… >

a. Press the [MENU] button of remote control to

display the Easy menu. (If the Advance menu

appears, move to the Easy menu from EASY

]

MENU.)

b. Select the [RESET] in the Easy menu, and

then press the [ ] or [ENTER] button.

c. Next, press the [RESET] button one time.

And hold the [RESET] button for 3 seconds

or more (the FACTORY MENU will appear).

< When you use the keypad… >

a. Press the [ ]/[ ]/[ ]/[ ] button of the projec-

tor to display the Easy menu. (If the Advance

menu appears, move to the Easy menu from

EASY MENU.)

b. Select the [

RESET

] in the Easy menu, and

then press the [ ] button.

c. Next, press the [

] button one time. And

repress and hold the [ ] button together

with the [INPUT] button for 3 seconds or

more (the FACTORY MENU will appear).

6

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

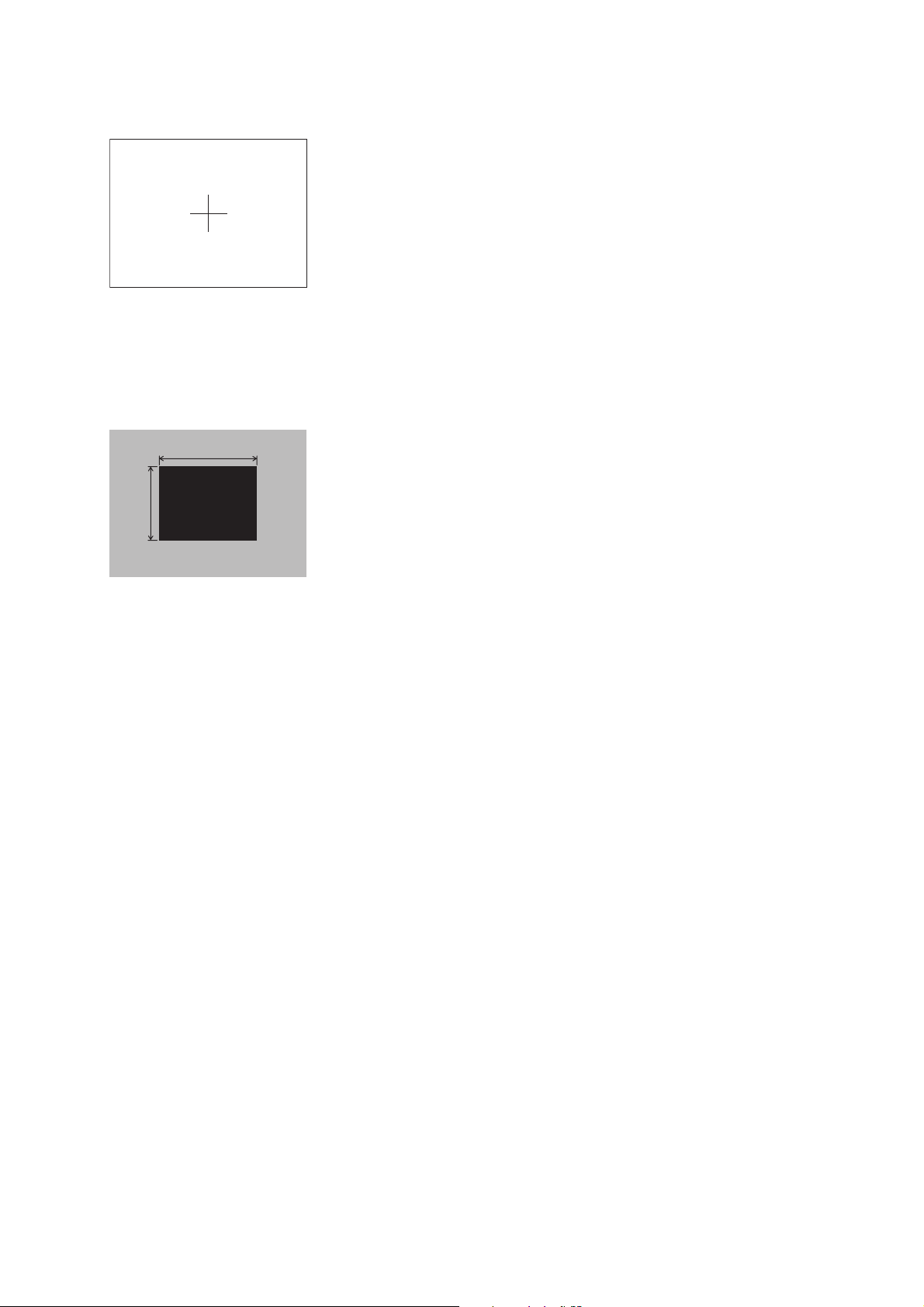

4-2 Convergence adjustment

Signal pattern for internal adjustment

Adjustment procedure

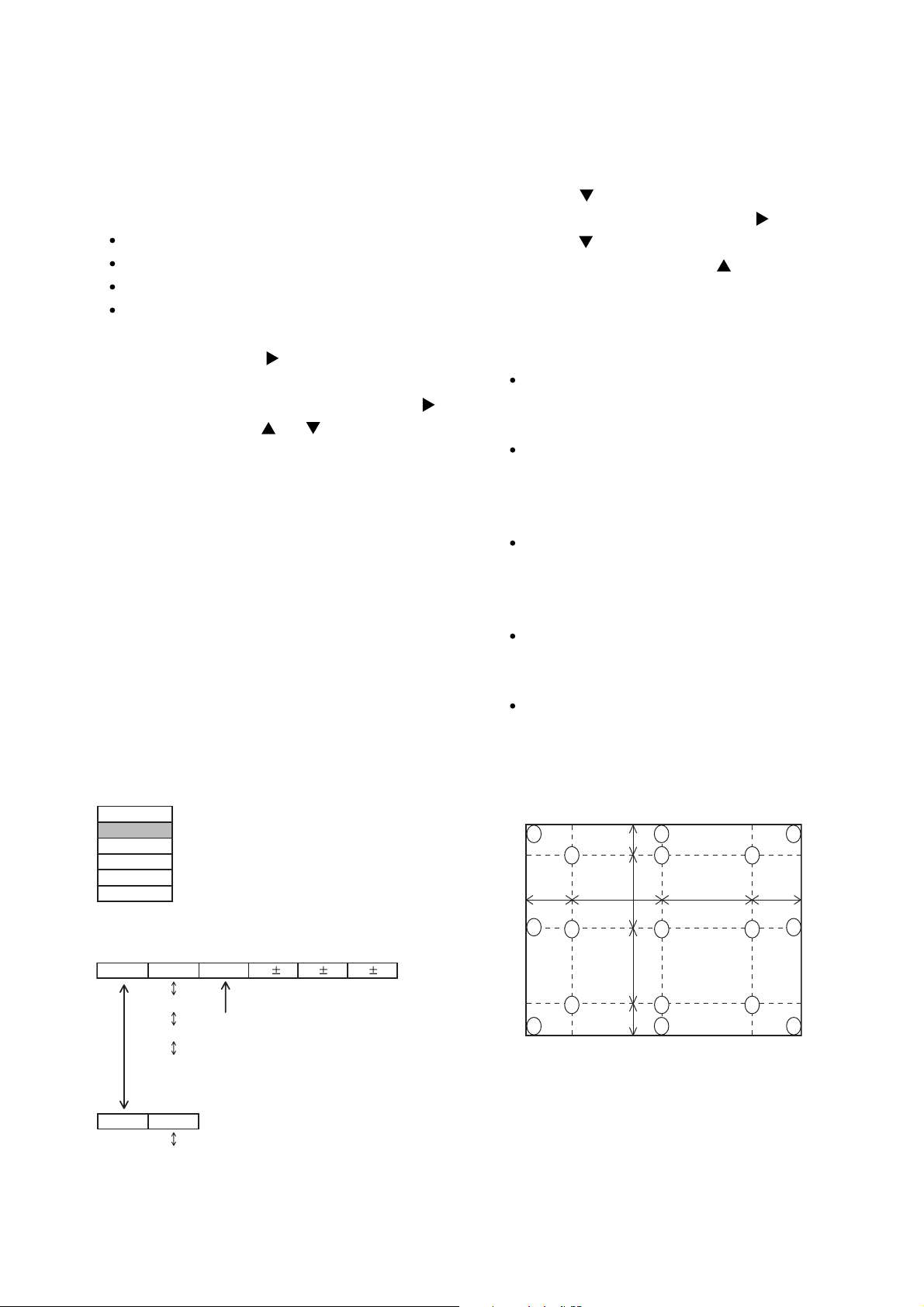

4-3 Ghost adjustment

Signals for internal adjustment

30%

30%

0/255

112/255

Perform this adjustments only when the conver-

gence is not good.

1. Open FACTORY MENU and then select

OPTION > CNV-V. Use R and/or B so that

three colors of images can be converged at

center, top and bottom of the screen.

2. In the same way, select OPTION > CNV-H and

use R and/or B so that three colors of images

can be converged at center, left and right of the

screen.

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-2.

2. Choose Advance menu > OPTION > SERVICE

> GHOST > R,G and B, and set them to zero.

3. Open the FACTORY MENU and choose DAC-P

> GHOST > R,G and B to display each color of

test patterns for adjustments.

Confirm if there is ghosting on the both sides of

black pattern. If visible, perform this adjustment

as following procedure.

4.

Use DAC-P - GHOST - R: in the FACTORY MENU

to adjust so that R color ghost is at a minimum.

(Set the adjustment value to default, and then

raise the value. When a ghost appears to the left

of a vertical line, reduce the value by 3 steps.

Then, if a ghost image is visible on the right of

an original image, raise the number by 1 step.)

5. In the same way, use DAC-P - GHOST-G: in

the FACTORY MENU to adjust so that G color

ghost is at a minimum.

6. In the same way, use DAC-P - GHOST-B: in

the FACTORY MENU to adjust so that B color

ghost is at a minimum.

7

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

4-4 Flicker adjustment

Signals for internal adjustment

4-5

White balance adjustment

Preparations

1. Perform these adjustments after the Flicker

adjustment described in Section 4-4.

Adjustment procedure

1. First, adjust the G color.

Select GAMMA, SUB-CNT, and G: in the FACTORY

2.

MENU. If the background is white solid, press the

[ENTER] key on the remote control to change to [G]

monochrome in the 33-tone grayscale.

3. Adjust GAMMA, SUB-CNT, and G: in the FACTORY MENU so that brightness of 33 steps is

best.

4. Don’t adjust GAMMA, SUB-BRT, and G: in the

FACTORY MENU because we want to keep the

best contrast ratio.

5. Then adjust colors R and B.

(V.COM adjustment)

(visual inspection)

Adjustment procedure

1. Make this adjustment after completing the

adjustment in 4-3 Ghost adjustment.

2.

Use DAC-P - V.COM - R: in the FACTORY

MENU to adjust so that the flicker at the center of

the screen is less than the flicker at the periphery.

(When the flicker is about the same across the

whole screen, adjust so that the flicker at the center

of the screen is somewhat less than elsewhere.)

3. In the same way, use DAC-P - V.COM-G: in the

FACTORY MENU to adjust the G color flicker.

4. In the same way, use DAC-P - V.COM-B: in the

FACTORY MENU to adjust the B color flicker.

2. Reset gamma correction before adjustment.

Place the cursor on [GAMMA] in the FACTORY

MENU, press the [RESET] key and select RESET.

6.

Select GAMMA, SUB-CNT, and G: in the FACTORY

MENU. If the background is white solid, press the

[ENTER] key on the remote control to change to [W]

monochrome in the 33-tone grayscale.

7. Adjust GAMMA, SUB-BRT, R: and B: in the

FACTORY MENU so that low-brightness white

balance is best.

8. Adjust GAMMA, SUB-CNT, R: and B: in the

FACTORY MENU so that middle-brightness

white balance is best.

9. Repeat steps 7 to 8 above, and adjust so that

brightness white balance of 33 steps is best.

8

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

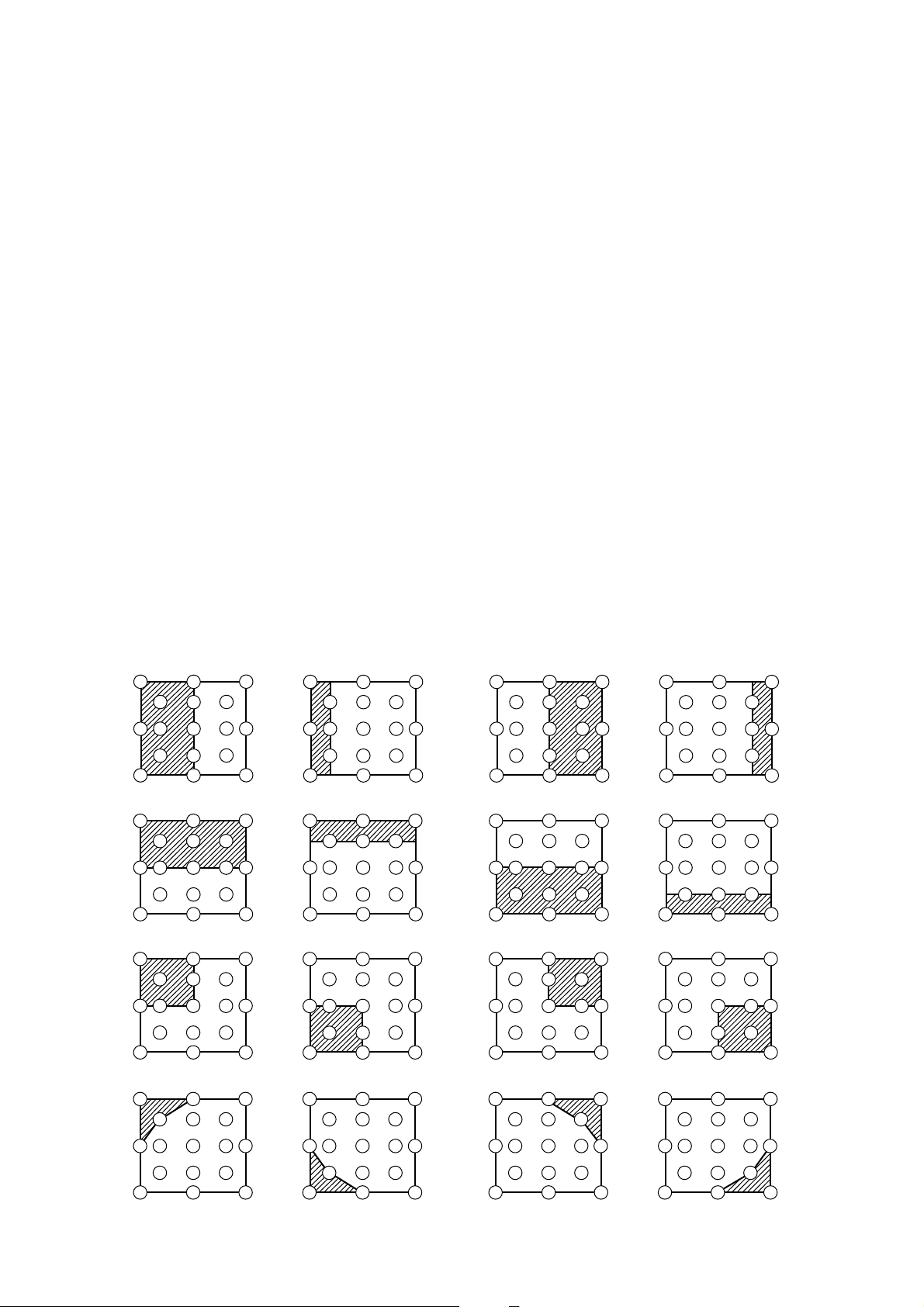

4-6 Color uniformity adjustment

Preparations

1.

Perform these adjustments after the white balance

adjustment described in Section 4-5.

2. Make a color uniformity adjustment for the follow-

ing four tones.

MIN tone (approx. 7% input signal)

MID-L tone (approx. 14% input signal)

MID-H tone (approx. 46% input signal)

MAX tone (approx. 70% input signal)

3. Place the cursor on [C.UNIF.] in the FACTORY

MENU and press the [ ] key. This displays the

Adjust Tone menu at the bottom of the screen.

To choose the tone to be adjusted, press the [ ]

key and then use the [ ] or [ ] key.

Select the major adjustment lattice point No.

and color, and then adjust them.

4. The major adjustment lattice point numbers (a

total of 17 points) corresponds to the major

adjustment lattice point positions in the diagram

on the right. The color uniformity of the entire

screen can be adjusted by adjusting the white

balance for each of the points starting in order

from the low numbers.

5. Adjustment point No.1 should not be adjusted,

because it controls the brightness of the entire

screen.

To temporarily turn correction off, place the

6.

cursor on [C.UNIF.] in the Adjust Tone menu and

press the [

] key. The ON/OFF menu appears.

Place the cursor on [ON] with the [ ] key and

press the [ ] key. To turn it on again, place the

cursor on [OFF] and press the [ ] key.

7. Although this adjustment can also be made

using internal signals, we will here use the

[ENTER] key on the remote control to select the

following two signals.

Solid monochrome adjustment color (use G

color adjustment when a color differential

meter is used).

Solid white (use for adjustment other than

above).

8. Reset color-shading correction before adjust-

ment.

When 4 tones and all colors are to be reset,

place the cursor on [C.UNIF.] in the FACTORY

MENU, press the [RESET] key and select

RESET.

When only 1 tone is to be reset, place the

cursor on the tone to be reset, press the

[RESET] key and select RESET.

Single tone and monochrome resets cannot

be performed.

FACTORY MENU

VID-AD

C. UNIF.

DAC-P

GAMMA

STRIPE

OPTION

Adjust tone menu

C.UNIF

ON/OFF ON

MIN

MID-L

MID-H

MAX

OFF

No. 1 R 0

Major adjustment lattice point No.

G 0 B 0

Major adjustment lattice point position

14 12

H/6 H/3 H/3 H/6

10 11

15 17

V/6

6 4 8

V/3

2 1 3

V/3

7 5 9

V/6

13

16

9

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

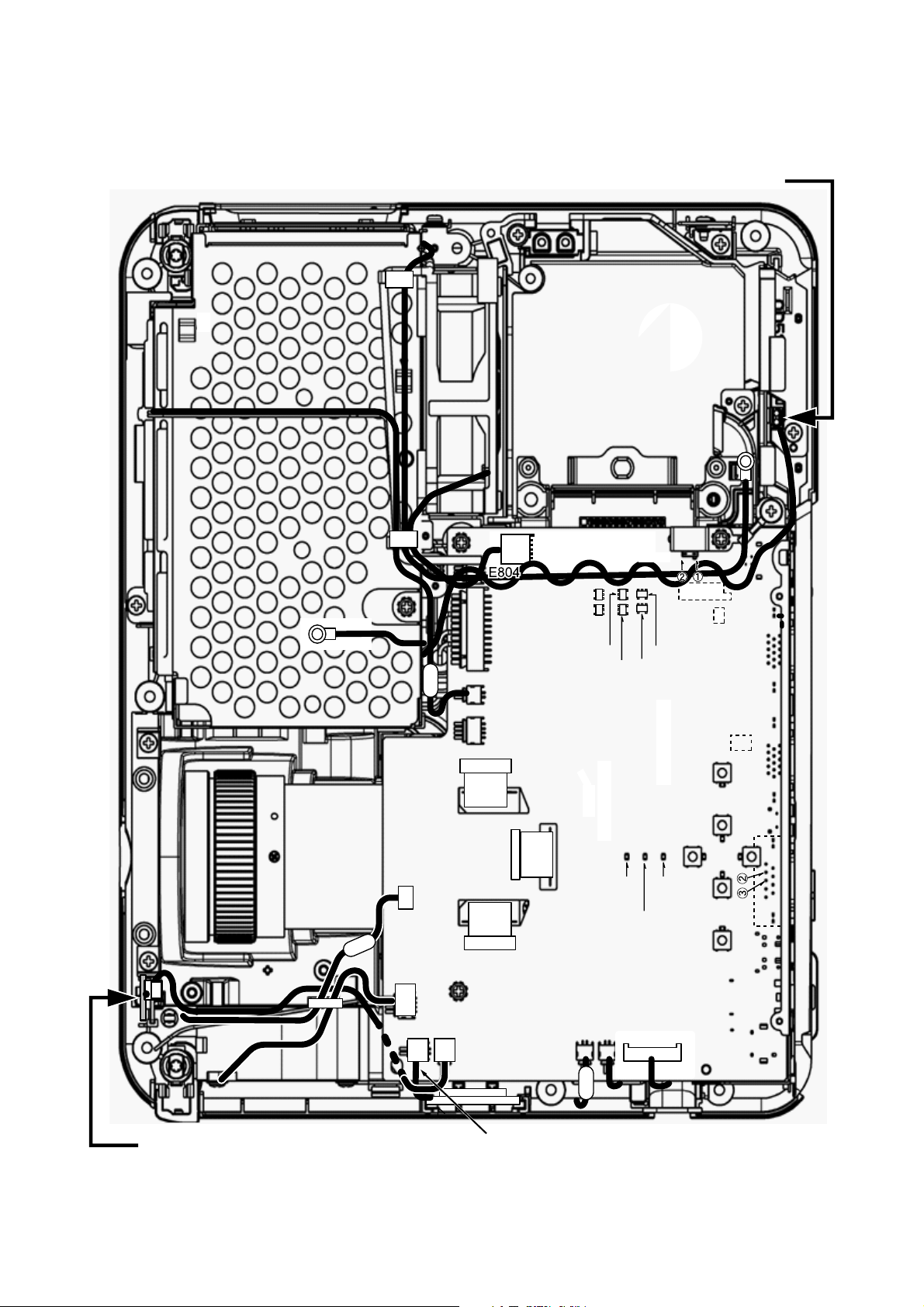

Adjustment procedure 1

(When a color differential meter is used)

1. First adjust [MID-L] tone [G:].

2. Select adjustment point [No.2][G:].

When the background is not [G] monochrome,

press the [ENTER] key on the remote control to

change to solid [G] monochrome.

3. Measure the illumination at adjustment points

No. 2, No.3, No.10 and No.11.

The values should be:

No.2 = Y2 [lx] No.10 = Y10 [lx]

No.3 = Y3 [lx] No.11 = Y11 [lx]

4. No.2 and No.3 adjustment point have the aver-

age of Y2 and Y3.

Y2 = ( Y2 + Y3 ) / 2 ± 2 [%]

Y3 = ( Y2 + Y3 ) / 2 ± 2 [%]

5. No.10 and No.11 adjustment point have the

average of Y10 and Y11.

Y10 = ( Y10 + Y11 ) / 2 ± 2 [%]

Y11 = ( Y10 + Y11 ) / 2 ± 2 [%]

6. Then adjust [MID-L] tone [R] and [B].

When the background is [G] monochrome,

press the [ENTER] key on the remote control to

change to solid white.

7. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

Note: When the CL-100 color and color differ-

ence meter is used, the [∆](delta) mode

is convenient. When adjustment point

[No.1] color coordinate has been

selected, set the slide switch on the side

to [∆](delta) while holding down the [F]

button on the front panel. The measure-

ment shown after this displays the devia-

tion from measurement point 1.

8. Measure the color coordinates of measurement

point [No.2] and adjust [No.2][R:] and [B:] so

that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010

9. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes adjustments required for [MIN].

Note: Since excessive correction may lead to a

correction data overview during internal

calculations, use the following values for

reference.

[No.2] to [No.5] ± 40 or less

[No.6] to [No.9] ± 50 or less

[No.10] to [No.13] ± 70 or less

[No.14] to [No.17] ± 120 or less

10. Then adjust [MIN] tone [G] so that the adjust-

ment data set two times as much as [MID-L]

tone [G].

This completes [G] color adjustments.

11. Then adjust [MIN] tone [R] and [B].

Select [No.2] [B:] and press the [ENTER] key

on the Remote control transmitter to change to

solid white.

12. Measure the color coordinates of adjustment

point [No.1] and make a note of them.

Assume that they are x = x1, y = y1.

13. Now measure the color coordinates of mea-

surement point [No.2] and adjust [No.2][R:] and

[B:] so that the coordinates are as follows.

x = x1 ± 0.005 , y = y1 ± 0.010 (Target)

x = x1 ± 0.020 , y = y1 ± 0.040

14. Similarly, measure adjustment points [No.3] to

[No.17] and adjust their color coordinates start-

ing in order from the small number points.

This completes [MIN] tone adjustments.

15. Now make similar adjustments for [MID-H] tone.

(Adjust [MID-H] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

16. Now make similar adjustments for [MAX] tone.

(Adjust [MAX] tone [G] so that the adjustment

data set half as many as [MID-L] tone [G].)

10

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

Adjustment procedure 2

(visual inspection)

1. First adjust [MIN] tone [G:].

2. Select [No.2] [G:].

If the background is [G] monochrome, press the

[ENTER] key on the remote control to change

to solid white.

3. View measurement point [No.2] and [No.3].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1].

4. View measurement point [No.10] and [No.11].

Lower the [G] color intensity only of the color

point whose [G] color is more intense than

measurement point [No.1], and raise the inten-

sity of the point whose color intensity is lower

than measurement point [No.1].

5. Now adjust the [MIN] tone for colors [R] and [B].

6. View measurement points [No.2], [No.3],

[No.10] and [No.11]. Adjust the [R] and [B] of

each measurement point so that they have the

same color as measurement point [No.1].

Adjustment technique:

First, adjust [B:] of the point whose color is to

be adjusted so that it approximates that of

[No.1]. If [R:] is low at this time, the image will

have cyan cast, in which case [R:] is increased.

On the other hand, if [R:] is excessive, the

image will have a magenta cast, in which case

[R:] is decreased.

Overall, a cyan cast makes it easy to see color

shading.

7. Next, view measurement points [No.4], [No.5],

[No.12], [No.13] and make similar adjustments.

8.

Then adjust measurement points [No.6], [No.7],

[No.8], [No.9], [No.14], [No.15], [No.16] and [No.17].

This completes the [MIN] tone adjustments.

9. Make similar another three tones as described

in steps 1 to 8 above.

No. 2 deviation range No. 10 deviation range No. 3 deviation range No. 11 deviation range

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

11

3

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

11

3

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

No. 4 deviation range No. 12 deviation range No. 5 deviation range No. 13 deviation range

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14

10

15

12

4

6

1

2

5

7

13

16

8

3

11

9

17

14

10

15

12

4

6

1

2

5

7

13

16

8

3

11

9

17

No. 6 deviation range No. 7 deviation range No. 8 deviation range No. 9 deviation range

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

11

3

9

17

14

10

15

12

6

4

2

1

5

7

13

16

8

3

11

9

17

14

10

15

12

4

6

2

1

5

5

7

13

16

8

3

11

9

17

No. 14 deviation range No. 15 deviation range No. 16 deviation range No. 17 deviation range

14

12

4

6

16

8

14

12

4

6

16

8

14

12

6

4

16

8

14

12

6

4

16

8

10

15

1

3

2

5

7

13

11

9

17

10

15

2

7

13

3

1

5

11

9

17

10

15

13

3

1

5

11

9

17

2

7

10

15

2

1

3

11

5

5

13

9

17

7

11

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

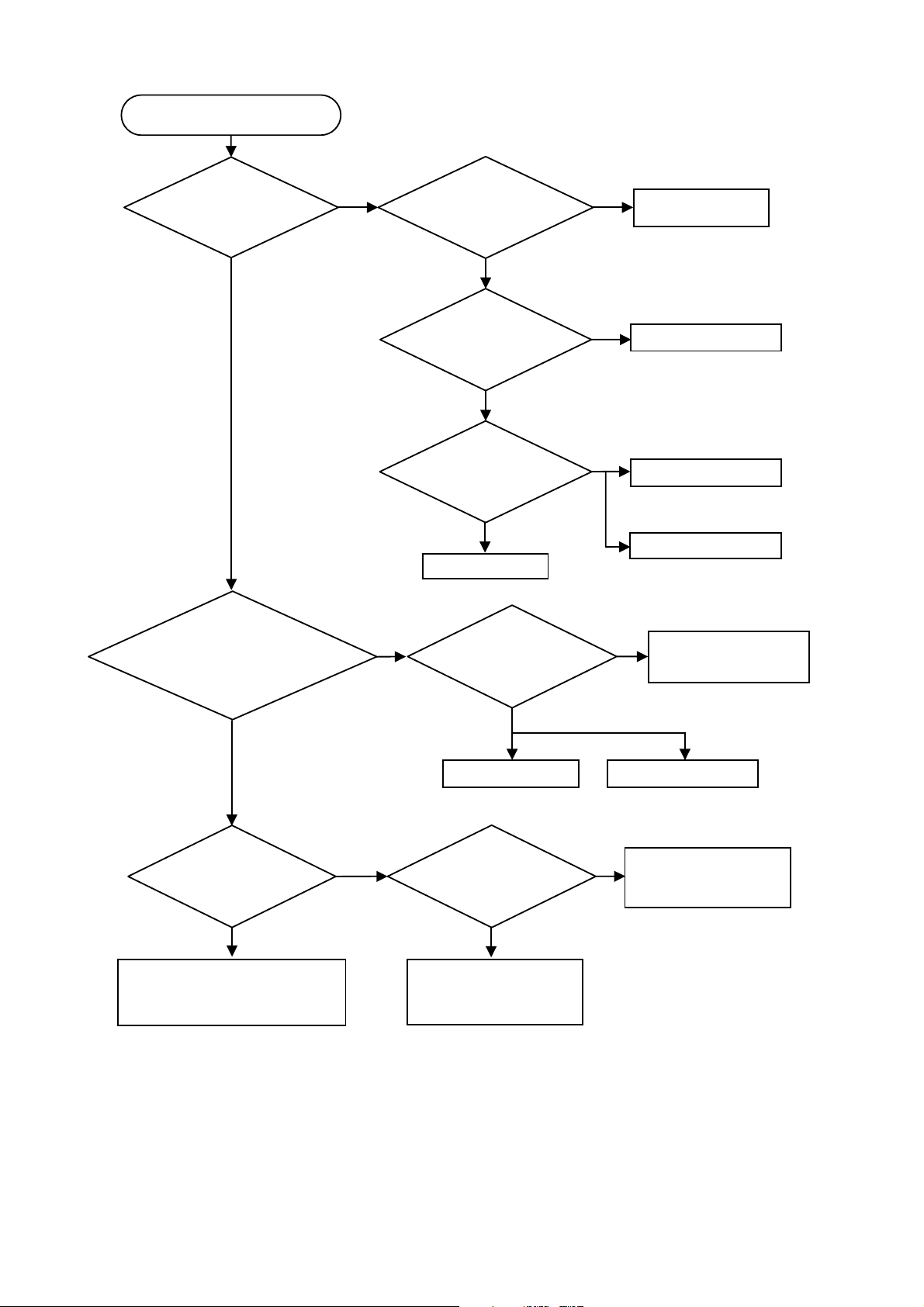

5. Troubleshooting

Check points

THERMAL SWITCH (TSW)

E1

E304

E807

E2

E301

E802

P601

P701

E801

IS14

IS13

E800

IS12

IS11

P501

(LAMP)

PWB assembly MAIN

D303

S801

IS42

IS41

D301

(POWER)

D302

(TEMP)

IS01

IS40

IS10

EK01

EASP

E805

E302 E806 EE01

PWB assembly REMOTE Speaker cable

12

E3

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

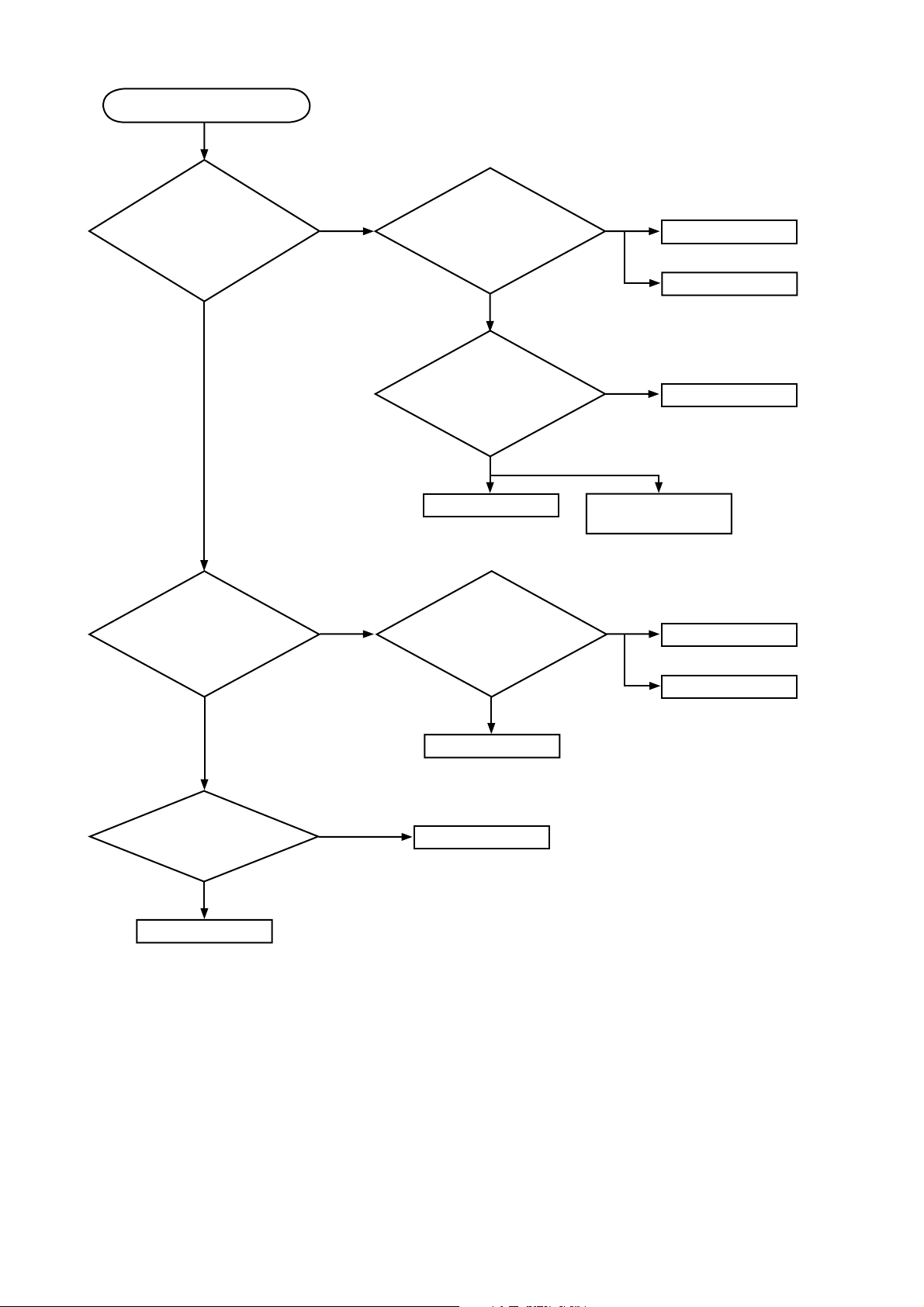

Power can not be turned on

Are

voltage

supplied at pins (6)

and (8) of E800 on the PWB

assembly MAIN in

standby mode?

(6): +6.6V

(8): +4.1V

YES

(10): GND

*: Be sure to unplug the power cord before measuring resistance.

Measure

NO

resistance* between pins

(6) and (10), and between

pins (8) and (10) of

E800.

Open

Are all

of the pictures

from video, s-video and

component video ports dis-

played correctly?

Short

Power unit (circuit)

0Ω

Open

Fuse on the power unit

(circuit)

PWB assembly MAIN

Power unit (circuit)

Termal switch (TSW)

Are

voltage supplied

at pins (1) and (3) of E800

on the PWB assembly MAIN

in standby mode?

(1): +14V

(2): GND(for +14V)

YES

(3): +16V

(4): GND(for +16V)

Does LAMP

(D303) or TEMP (D302)

indicator light or

blink?

NO

PWB assembly MAIN

NO

YES

Mea-

sure resistance*

between pins (1) and (2),

and between pins (3) and (4)

of E800.

Open

Power unit (circuit)

Go to the next page

0Ω

PWB assembly MAIN

Power unit (circuit)

13

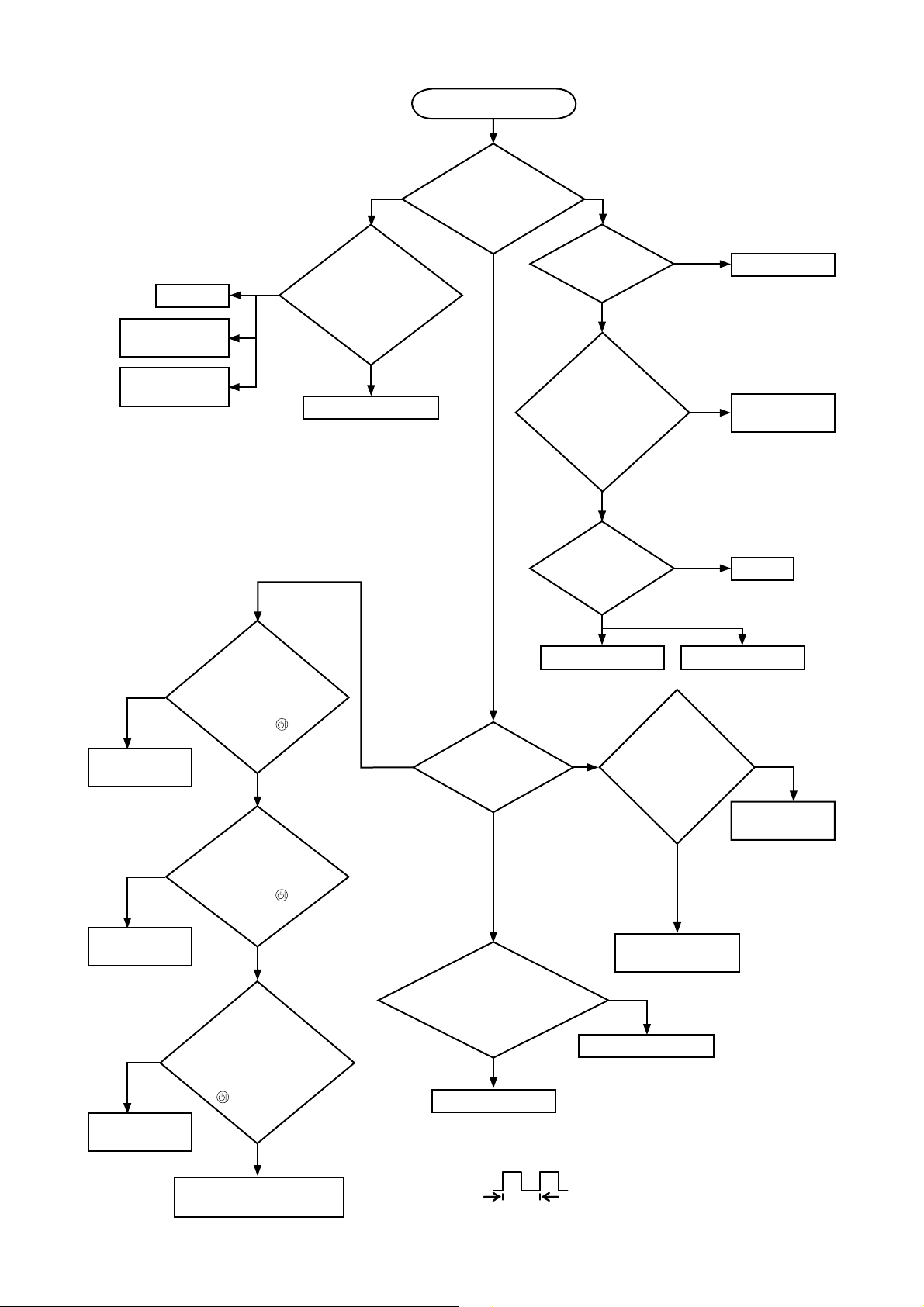

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

Open

Lamp door

Re-attach lamp

door

Re-attach PWB

assembly MAIN

**: DC fan connectors are E801,

E802, E806, and E807.

Blinks

Measure

resistance* between

pins (1) and (2) of S801

when the lamp door

is secure.

0Ω

PWB assembly MAIN

LAMP indicator D303

Lamp does not light

What

is the state of

during operation?

Not light

and blink

*: Be sure to unplug the power cord

before measuring resistance.

Light

Is the

LAMP installation

correct?

YES

Is

the voltage

at the (1) of

E804 on the PWB

assembly MAIN fixed

to "L" during

warming-

up?

Not light

Change the

lamp. Does lamp

light?

NG

install the Lamp

YES

“L” = 0V

PWB assembly

MAIN

Light

Lamp

NO (0V)

PWB assembly

MAIN

NO (0V)

PWB assembly

MAIN

Correct

PWB assembly

MAIN

Are

the voltage

supplied to the pin

(2) of connectors** for

DC fans soon after

the button is

pressed?

YES

(5V or higher)

Is

the voltage

supplied to the pin

(4) of E801 soon after

the button is

pressed?

YES

(1V or higher)

Observe

the voltage

waveforms at pin (1) of

connectors for DC fans**

soon after the button

is pressed.

incorrect

Power unit (ballast) Power unit (circuit)

Blinks

E804 on the PWB assembly

MAIN set to "L" during

Correct waveform is drawn below.

What

is the state of

TEMP indicator

D302?

Not light

and blink

Is the

voltage at the (3) of

warming-up?

No

Power unit (ballast)

No

Measure

Lights

PWB assembly MAIN

resistance of

E1, E2 and E3 after

disconnecting them

from MAIN

board.

Thermistor

(E1/E2/E3)

YES

“L” = 0V

OK

PWB assembly

MAIN

E1/E2: 5 to 20kΩ

E3: 0.5 to 2kΩ

NG(open/short)

DC fan

(failed in above check)

f ≥ 40Hz

14

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

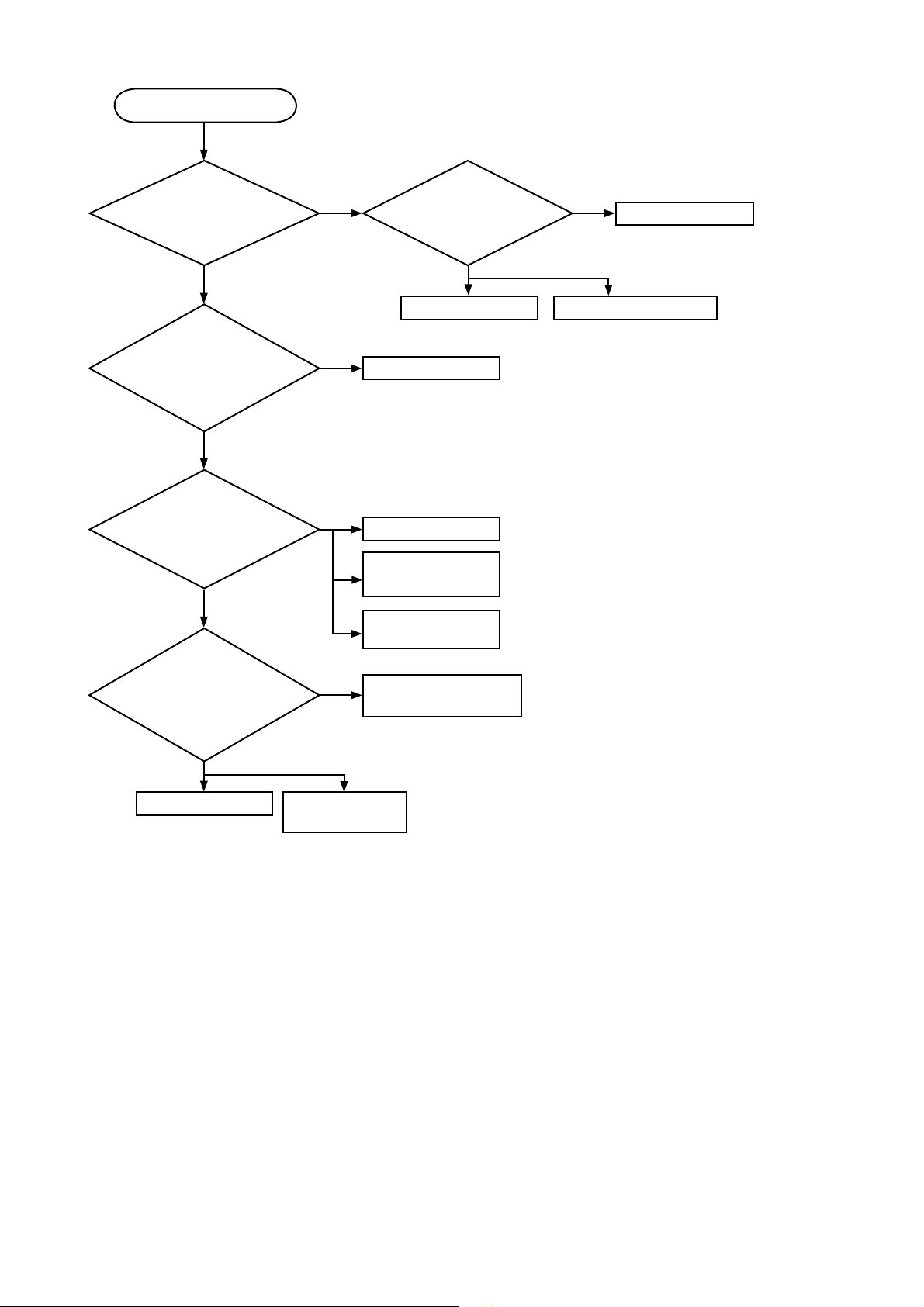

Picture is not displayed.

Are

the splash screen

and the user menu displayed

correctly?

YES

Are all

of the pictures

from video, s-video and

component video ports

displayed correctly?

YES

Is the

picture from RGB

out port displayed correctly

on another monitor

display?

YES

Is the

message of ”

No input is detected on

**” or “Sync is out of range on

**” displayed on the

screen?

No

No

No

YES

Confirm

the LCD Panels

connection to the MAIN

board.

OK

PWB assembly MAIN LCD/Lens prism assembly

PWB assembly MAIN

PWB assembly MAIN

SN74LVC1G126

(IS13/IS14)

EL83021U

(IS10/IS40)

SN74LVC1G126

(IS11/IS12/IS41/IS42)

NG

CPC30 connector A/B

No

PWB assembly MAIN EL83021U

(IS10/IS40)

15

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

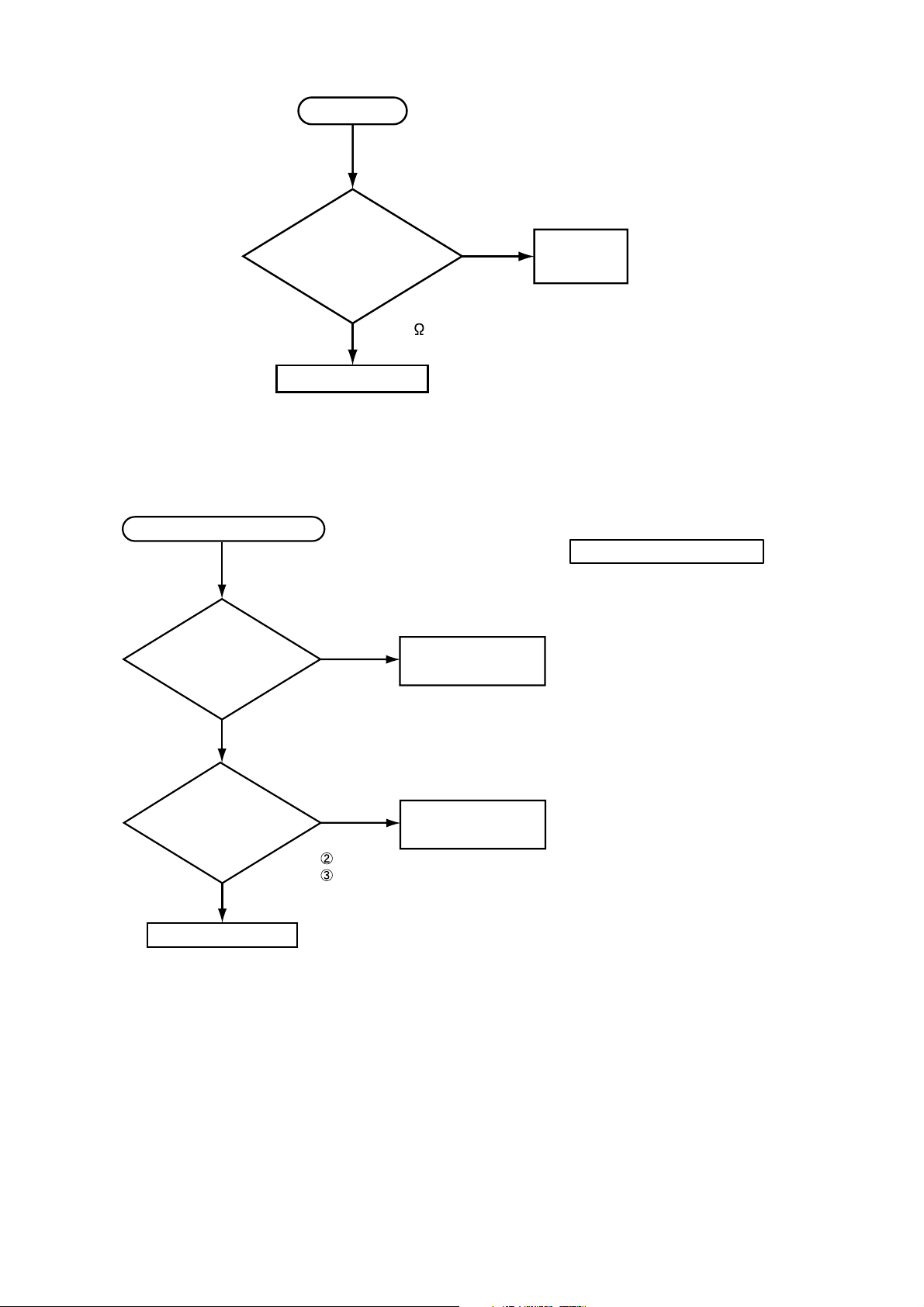

No sound

Check at operating mode

(Make sure the state of MUTE and Volume)

Disconnect

the speaker from the

PWB assembly Main, and

measure its

resistance.

about 8

PWB assembly Main

infinity

Speaker

Can not control to RS-232C

Check the

RS-232C cable.

Are pin No. 2 and 3

crossed?

YES

Are the

signals input at each

pins on the PWB assembly

Main?

EK01

YES

Make sure PC setup

EK01

NO

NO

: RX

: TX

Use cross cable

PWB assembly MAIN

The check after parts change

1. PC power supply OFF

2. Connection of cable

3. Projector starting

4. PC starting

*When not operating :

PC set up change of cable.

16

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)

Can’t communicate with computer

via NETWORK terminal.

Check at operating mode

Does the Lamp

on upper left of the

Network connector light

in green?

YES

Are

both IP Address

and Subnetmask in the Setting >

Network > Network Info menu set to

"0.0.0.0" after waiting more than

1 minute?

YES

NO

Is the computer

connected with the

projector directly?

YES

Is IP Address in

the Network > Information menu

set to “0.0.0.0” after waiting

more than 1 minute?

YES

Are there

any damage to the cable

between computer and

projector?

YES

Use new LAN cable

NO

"xxx.yyy.zzz" portion of IP address

Subnet Mask is

"255.255.255.0", are

setting of computer and

projector

same?

If

YES

NO

Make sure Network

hardware

NO

PWB assembly Network

NO

PWB assembly Network

PWB assembly Main

Use the same IP address

NO

setting except for "N" on

computer and projector.

IP address: xxx.yyy.zzz.N

Is

the DHCP in the

Advanced Menu > Network

> DHCP is on?

NO

Set IP address and Subnet Mask

in the Advanced Menu > Network

> IP ADORESS and > SUBNETMASK

menu with manual operation.

YES

PWB assembly Main

Is there

DHCP server on

the network which the

projector is connected

to?

NO

Set IP address and Subnet

Mask in the Settings >

Network menu with manual

operation.

PWB assembly Network

Make sure those settings

YES

of the projector and

computer are correct.

17

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6. Service points

6-1 Lead free solder [CAUTION]

This product uses lead free solder (unleaded) to help preserve the environment. Please read these

instructions before attempting any soldering work.

CAUTION

Always wear safety glasses to prevent fumes or molten solder from getting into the eyes. Lead free solder

can splatter at high temperatures (600˚C).

Lead free solder indicator

Printed circuit boards using lead free solder are engraved with an "F" or "LF".

Properties of lead free solder

The melting point of lead free solder is 40-50˚C higher than leaded solder.

Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended.

Although servicing with leaded solder is possible, there are a few precautions that have to be taken. (Not

taking these precautions may cause the solder to not harden properly, and lead to consequent malfunctions.)

Precautions when using leaded solder

Remove all lead free solder from soldered joints when replacing components.

If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead free solder has been completely melted (do not apply the soldering iron without solder).

Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

Soldering iron with temperature control function (temperature range: 320-450˚C)

Recommended temperature range per part:

Part Soldering iron temperature

Mounting (chips) on mounted PCB 320˚C±30˚C

Mounting (chips) on empty PCB 380˚C±30˚C

Chassis, metallic shield, etc. 420˚C±30˚C

The PWB assembly which has used lead free solder

(1) PWB assembly MAIN

(2) PWB assembly REMOTE

(3) PWB assembly NETWORK (not PJ656)

(4) PWB assembly BATTERY (not PJ656)

(5) POWER UNIT (BALLAST)

(6) POWER UNIT (CIRCUIT)

18

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

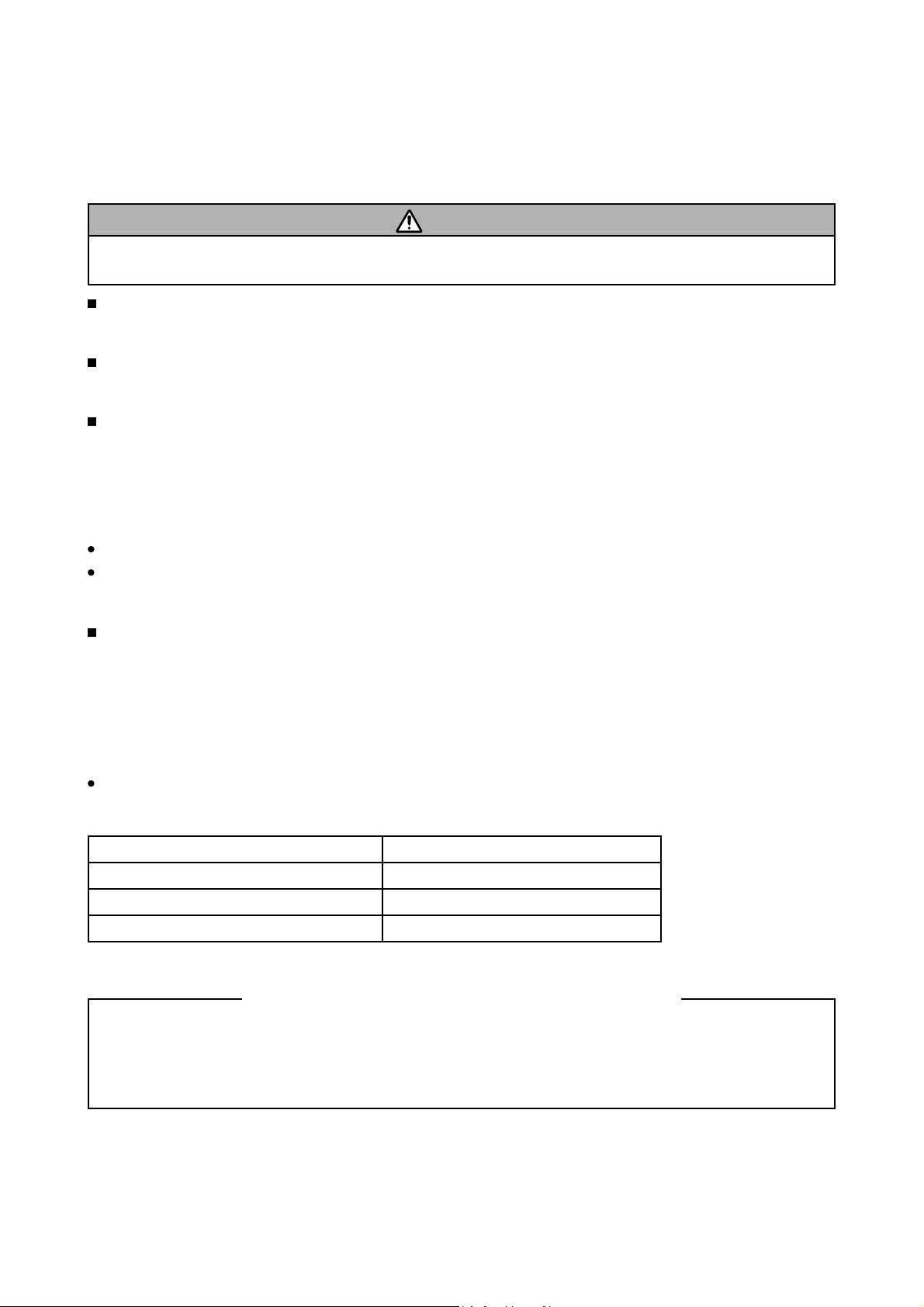

6-2 Before Replacing The LCD/Lens Prism

You should not replace separately the parts of the liquid crystal LCD/Lens prism because it works properly

only when used together. Therefore, regarding these parts, you can either replace part, LCD/Lens prism

assembly, or send the whole unit LCD/Lens prism assembly back to HITACHI, where we will replace the

malfunctioning part, recondition the device and send it back to you.

G Panel

HITACHI

DISTRIBUTOR

Do not disassemble the unit

because replacement of separate

parts is not possible.

Return

Replacement of G Panel & Reconditioning

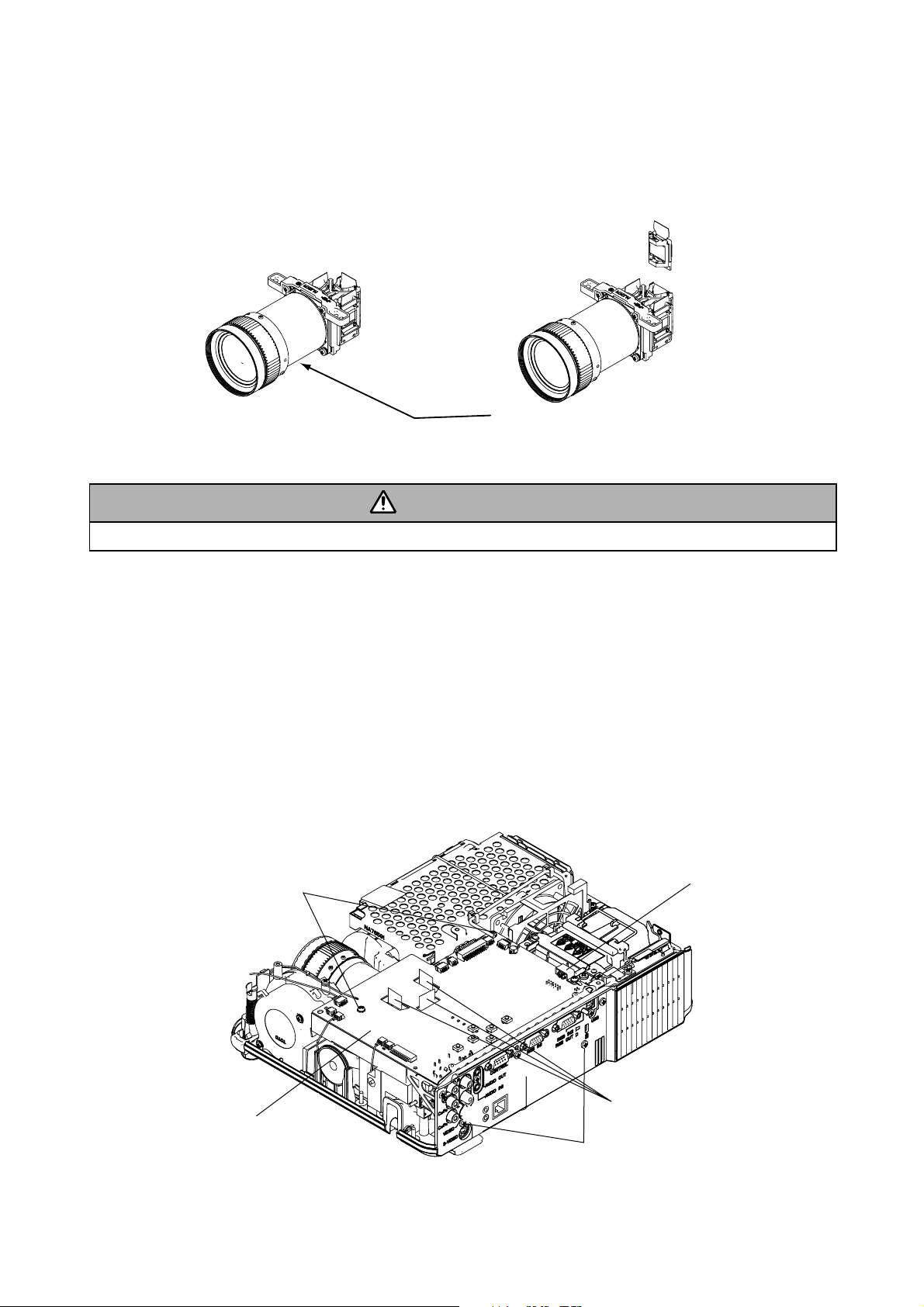

6-3 Cleaning up dust from panels and optical filters

WARNING

Wear sunglasses to protect your eyes when you maintain the projector with its lamp on.

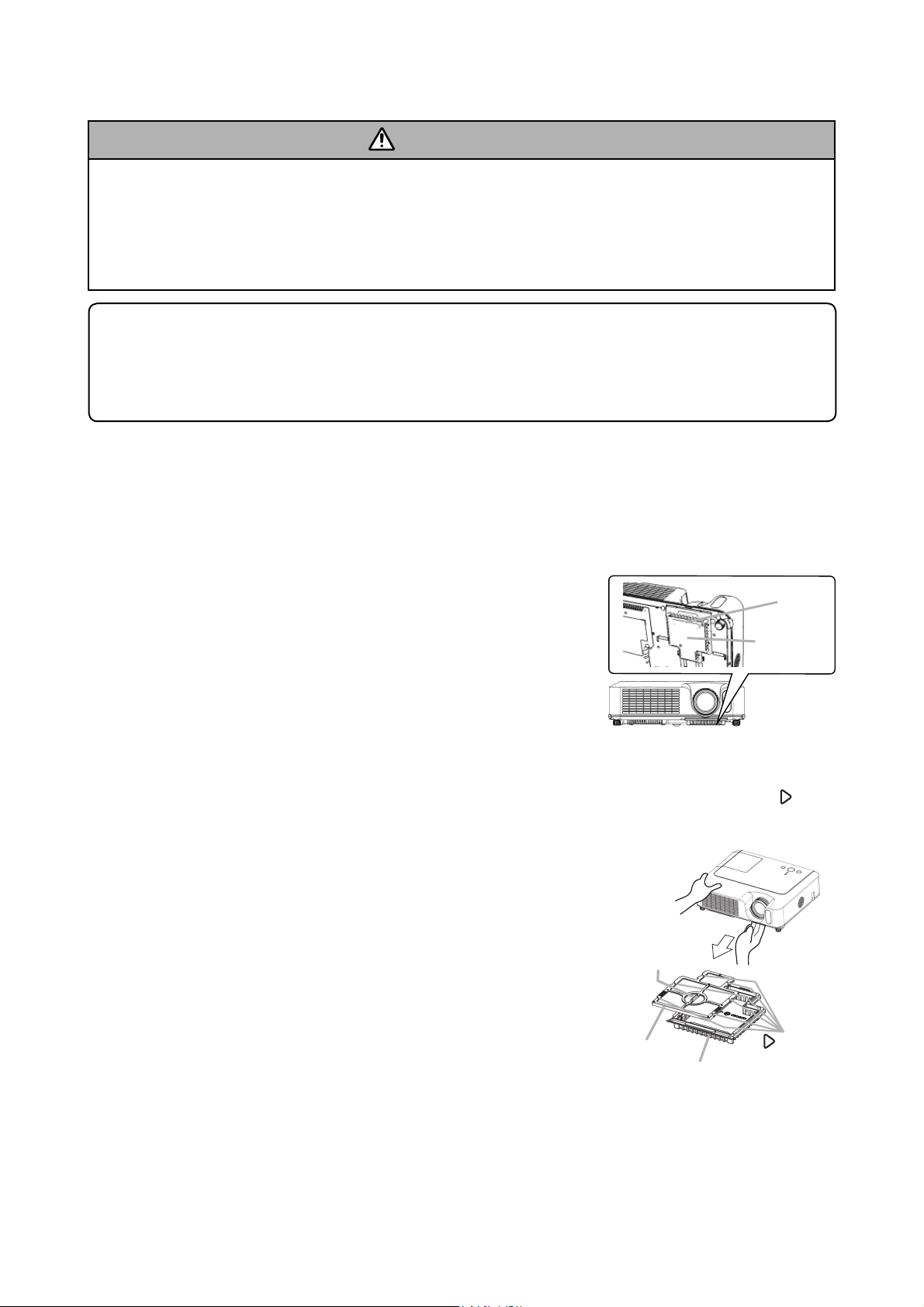

1. Preparation

Please prepare cleaning tools and materials as follows. And prepare relatively clean room not to work in

additional dust, while removing operation.

(1) Swab for cleaning : P#: NX08061, "Cotton stick L147"

(2) Air duster (Dust blower, spray can)

(3) Vacuum cleaner

2. Disassemble and setting up.

(1) Turn off the projector, and unplug the power cord.

(2) Remove the lamp cover and upper case, according to the disassembling diagram of chapter 8.

(3) Unscrew the shild sheet and disconnect the LCD panel flexible cables.

(4) Unscrew PWB assembly MAIN to make it free.

Remove these screw

PWB assembly MAIN

Remove these screws

(5) Press and hold the switch S801 using an insulator during maintenance.

(6) Keep the unscrewed wires away from all of electric parts.

19

S801

Frexible cables of LCD panel

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

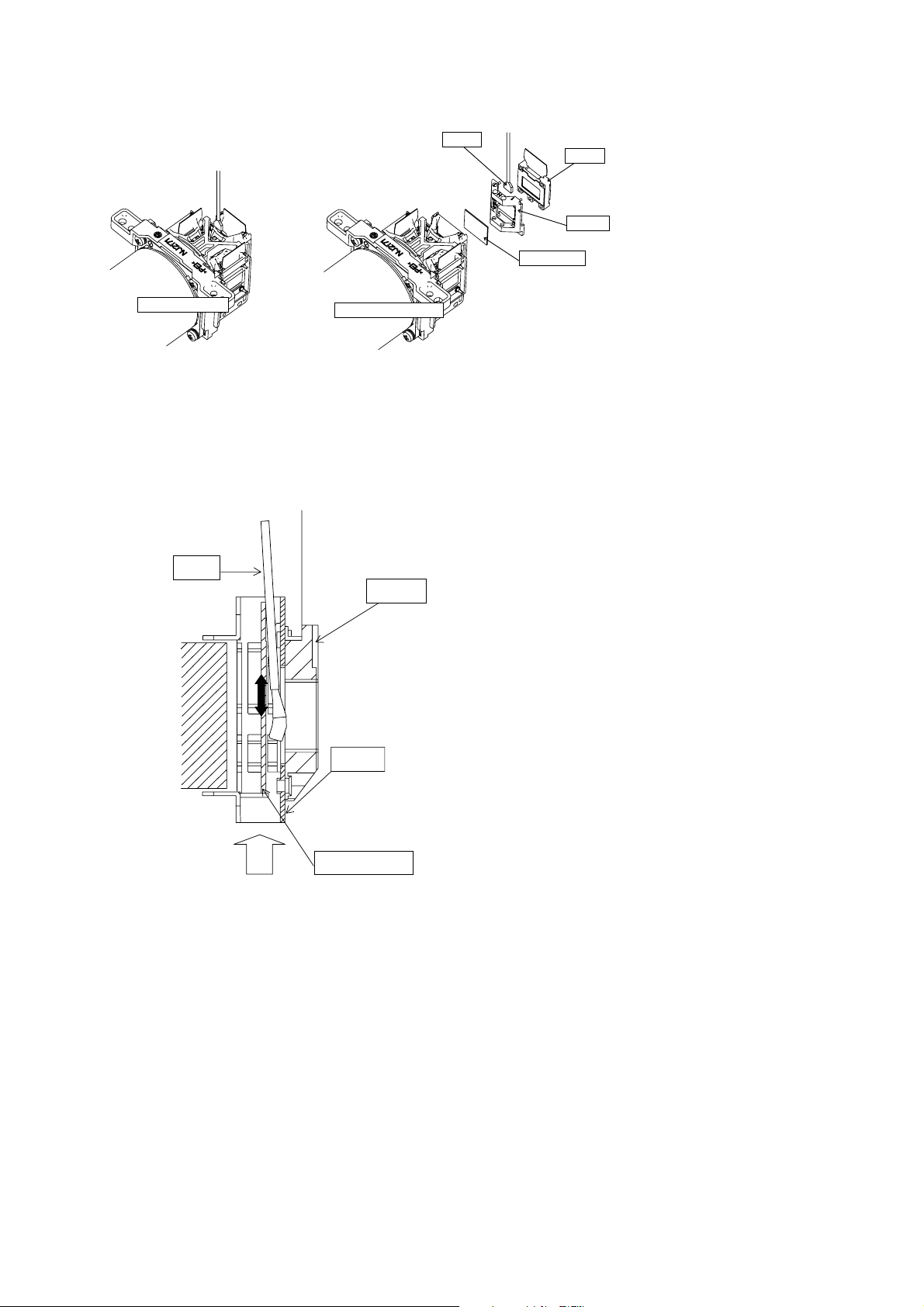

3. Maintenance point

Swab

Optical filter

Panel

Holder

Each color part has same

construction.

By using swab and air duster,

you can easily remove dust

from panel and optical filter.

Actual formation

Separatied formation

4. Cleaning the panels and optical filters

(1) Turn on the set and lit on the lamp.

(2) By using swab and air duster, remove the dust. Focusing dust makes you check the dust on screen.

Swab

Panel

• While removing the dust, separated dust will

be blown off by air cooling system.

• Please pay attention not to damage panels

and optical filters.

Holder

Air

Optical filter

5. Re-assembly

(1) Turn off the set and unplug the power cord.

(2) Remove an insulator from S801.

Screw down the PWB assembly MAIN and connect the LCD panel flexible cables to the PWB assembly MAIN.

(3)

(4) Re-assemble the set.

(5)

While re-assembling, please clean the air filter and the filter cover by using a vacuum cleaner.

20

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6-4 Battery

6-4-1 Replacing Internal Clock Battery

Consumption of the battery makes the clock not to work correctly. When the clock is wrong or it has stopped,

please replace the battery according to the following procedures.

WARNING

Always handle the batteries with care and use them only as directed. Battery may explode if mistreated.

Do not recharge, disassemble or dispose of in fire.

And also improper use may result in cracking or leakage, which could result in fire, injury and/or pollution

of the surrounding environment.

• Be sure to use only the batteries specified. Do not use batteries of different types at the same time. Do

not mix a new battery with used one.

• Make sure the plus and minus terminals are correctly aligned when loading a battery.

If the battery is placed in the battery holder upside-down, it may be hard to remove.

• Keep a battery away from children and pets. If swallowed consult a physician immediately for emergency

treatment.

• Do not short circuit or solder a battery.

• Do not allow a battery in a fire or water. Keep batteries in a dark, cool and dry place.

• If you observe a leakage of a battery, wipe out the flower and then replace a battery. If the liquid adheres

to your body or clothes, rinse well with water immediately.

• Obey the local laws on disposing the battery.

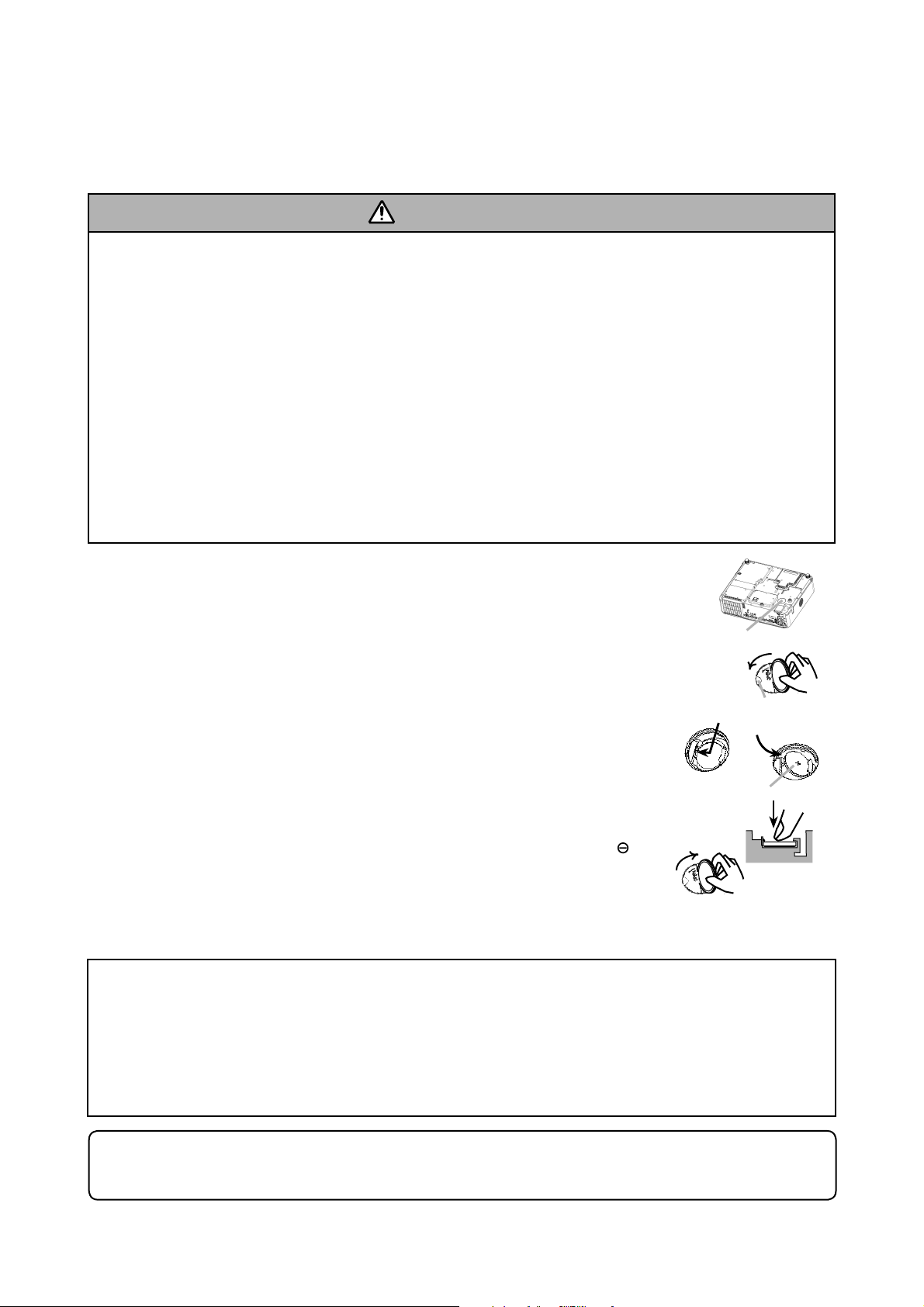

1. Turn the projector off, and unplug the power cord. Allow the projector to cool

sufficiently.

2. After making sure that the projector has cooled adequately, slowly turn over the

projector, so that the bottom is facing.

3. Remove the battery cover.

Turn the battery cover in the direction indicated “OPEN” using such as coins.

Then the battery cover will come up. While removing the battery cover, pick its

knob.

4. Take the old battery out.

Battery Cover

12'0

Metal claw

Knob

Press the metal claw of the battery holder. Then the battery will come up.

Remove the battery.

5. Put a new battery in.

“+” marking

Replace battery with HITACHI MAXELL, Part No.CR2032 only. Use of another

battery may present a risk of fire or explosion.

Insert a new battery in the battery holder according to its minus terminal

as

%.15'

indicated in the battery holder, so that the side marked by + is facing. And push

the battery into the battery holder fully to fix.

6. Close the battery cover. Replace the battery cover in place, then turn it in the

direction indicated “CLOSE” using such as coins, to fix.

If the battery is placed in the battery holder upside-down, follow the procedure below to remove and reload

it properly.

1. Remove the battery cover as described in steps 1 through 3 above.

2. Turn the projector over again, so that the top of the projector is facing up.

3. While lifting the side of the projector closest to the lens, press the metal claw of the battery holder. The

battery will fall out of the holder, so be careful not to lose it.

4. Turn the projector over once more, so that the bottom faces up, and reload the battery correctly.

NOTE

• The internal clock’s time will be reset when the battery is removed. Please reconfigure the time via the

menu or a web browser after replacing the battery.

21

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6-4-2 Putting batteries into the remote control

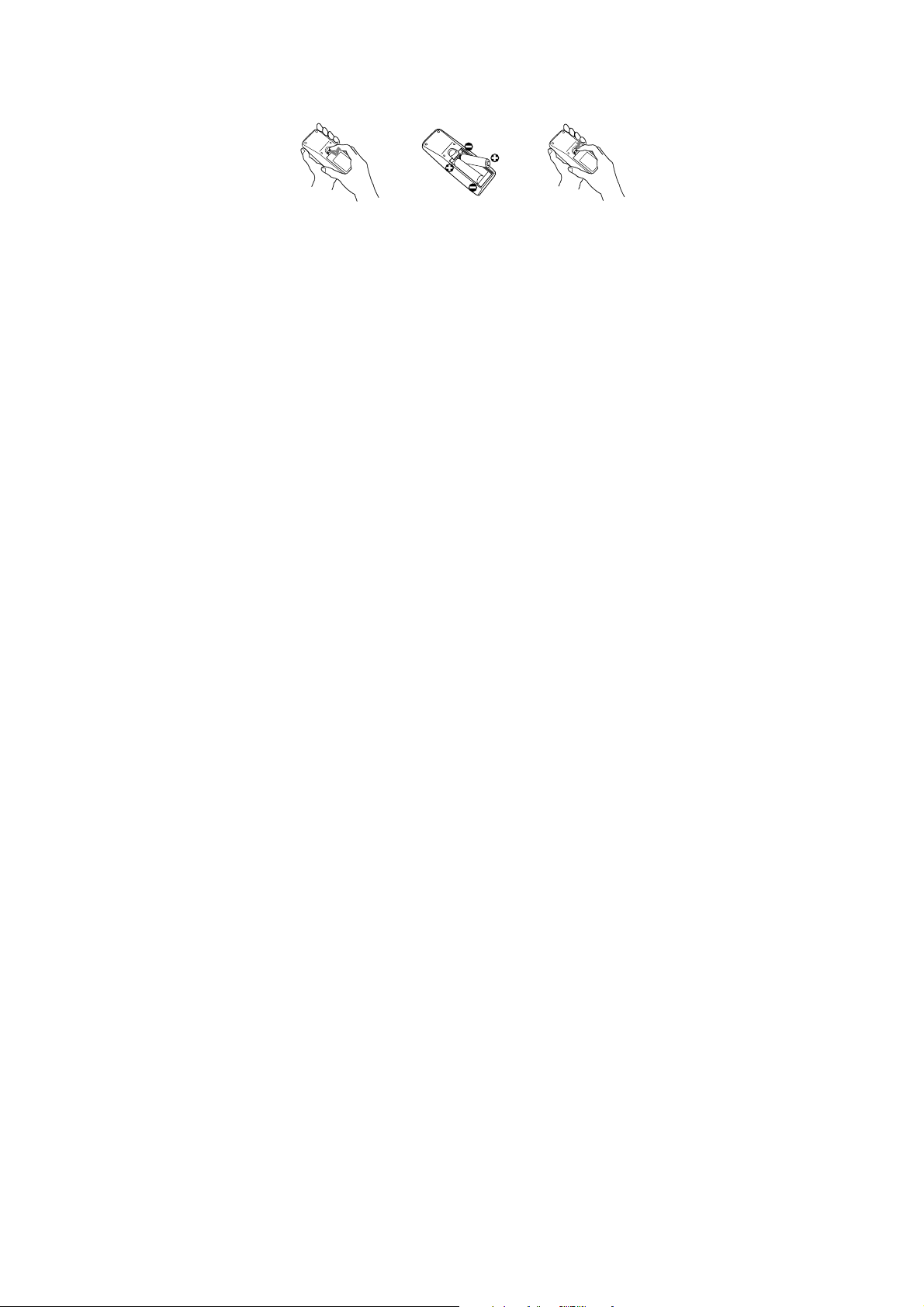

1. Remove the battery cover.

Slide back and remove the battery cover in the direction of the arrow.

2. Insert the batteries.

Align and insert the two AA batteries according to their plus and minus terminals as indicated in the

remote control.

3. Close the battery cover.

Replace the battery cover in the direction of the arrow and snap it back into place.

22

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6-5 Air filter

WARNING

• Before caring, make sure the power switch is off and the power cable is not plugged in, then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause an electric

shock, a burn and/or malfunction to the projector.

• Use only the air fi lter of the specifi ed type. Do not use the projector with the air fi lter and the fi lter cover

removed. It could result in a fi re and/or malfunction to the projector.

• The air fi lter should be cleaned periodically. If the air fi lter becomes clogged by dust or the like, internal

temperatures rise and could cause a fi re, a burn and/or malfunction to the projector.

NOTE

• Please replace the air fi lter when it is damaged or too soiled, and also when you replace the lamp.

• Please reset the fi lter time only when you have cleaned or replaced the air fi lter, for a suitable indication

about the air fi lter.

• The projector may display the message such as “CHECK THE AIR FLOW” or turn itself off, to prevent the

internal heat level rising.

If the air fi lter becomes clogged by dust or the like, internal temperatures rise and could cause a fi re, a burn

and/or malfunction to the projector. When the indicators or a message prompts to clean the air fi lter, clean

the air fi lter as soon as possible.

Please check and clean the air fi lter periodically, even if there is no message.Please replace the air fi lter

when it is damaged or too soiled.

And also when you replace the lamp, please replace the air filter. An air filter of specified type will come

together with a replacement lamp for this projector.

1. Turn the projector off, and unplug the power cord. Allow the lamp to

cool for at least 45 minutes.

2. When the projector is suspended from the ceiling, apply the vacuum

cleaner to and around the fi lter cover fi rst, to prevent penetration of

dust or the like.

3. While supporting the projector with one hand, use your other hand to

pull the fi lter cover forward in the direction of the arrow. Remove the

air fi lter.

4. Apply a vacuum cleaner to the air fi lter and the fi lter cover. Please replace the air fi lter when it is damaged

or too soiled.

5. Replace the air fi lter in its original position. Secure the air fi lter in place by pressing each of the six

locations.

Make sure there is no dust or dirt remaining after the cover is in place.

If any dust or dirt remains, use a vacuum cleaner to remove it as when

placing the fi lter cover on the air fi lter.

Reattach the fi lter cover to the projector by aligning the fi lter cover with

the grooves on the projector. While holding the handle, push down on

the fi lter cover until it locks fi rmly in place.

6. Turn the projector on and reset the fi lter time using the FILTER TIME

function.

(1) Press the MENU button to display a menu. When the EASY MENU has

appeared, please skip the next step (2).

(2) Point at the “OPTION” in the left column of the menu using ▼/▲

button, then press the ► button.

(3) Point at the “FILTER TIME” using ▼/▲ button, then press the ► button. A dialog will appear.

(4) Press the ▲ button to select “RESET” on the dialog. It performs resetting the fi lter time.

Air fi lter’s

knob

Air fi lter

Filter cover

Handle

Filter cover

mark

23

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6-6 Lamp

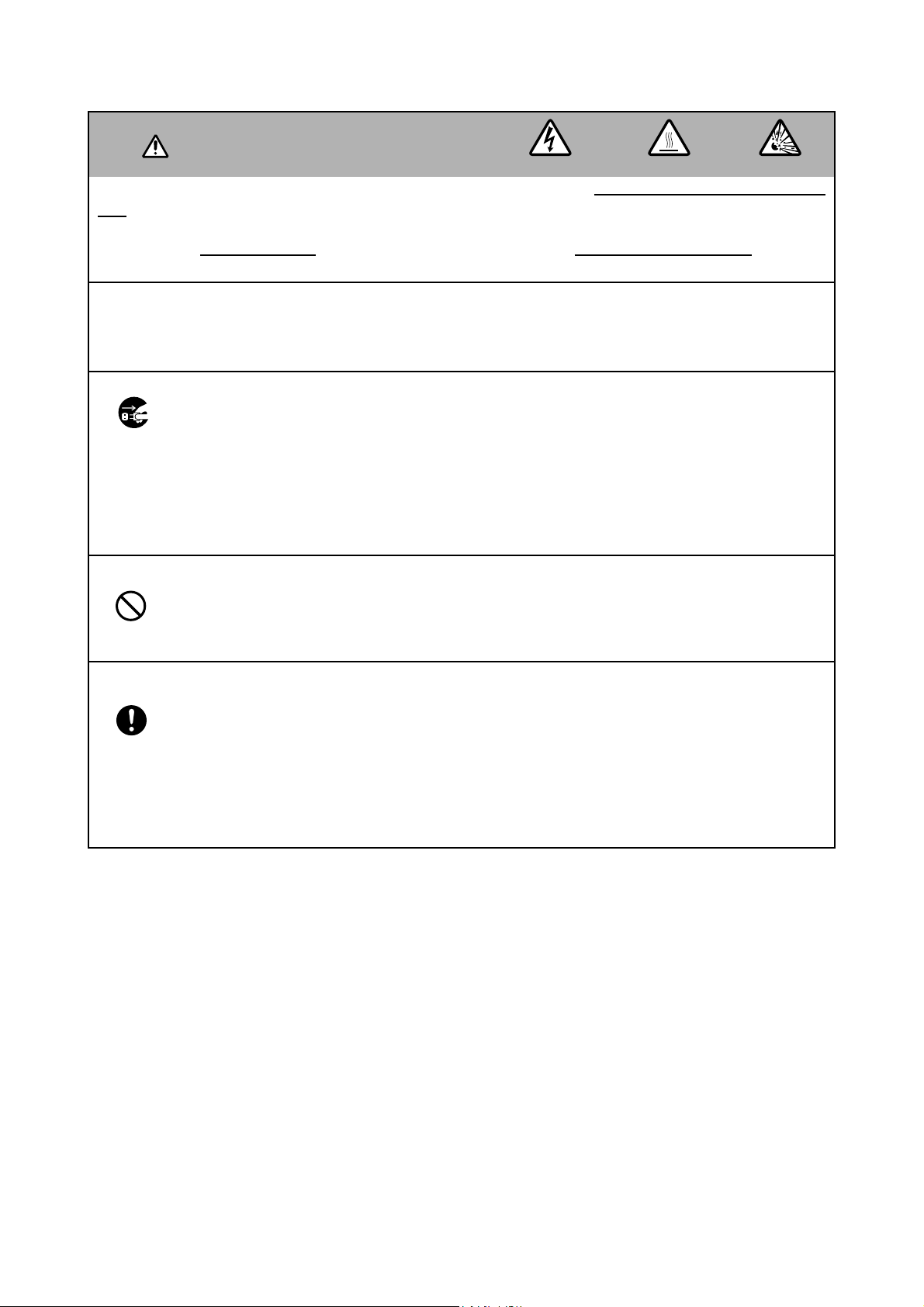

WARNING

●

The projector uses a high-pressure mercury glass lamp. The lamp can break with a loud bang, or burn

out, if jolted or scratched, handled while hot, or worn over time. Note that each lamp has a different lifetime, and some may burst or burn out soon after you start using them. In addition, when the bulb bursts, it

is possible for shards of glass to fly into the lamp housing, and for gas containing mercury to escape

from the projector’s vent holes.

●

About disposal of a lamp • This product contains a mercury lamp; do not put it in the trash. Dispose of

in accord with environmental laws.

For lamp recycling, go to www.lamprecycle.org. (in the US) For product disposal, contact your local government agency or www.eiae.org (in the US) or www.epsc.ca (in Canada).

• If the lamp should break (it will make a loud bang when it does), unplug the power cord from

the outlet. Note that shards of glass could damage the projector’s internals, or cause injury

during handling.

Disconnect

the plug

from the

power

outlet

• If the lamp should break (it will make a loud bang when it does), ventilate the room well, and

make sure not to breathe the gas that comes out of the projector vents, or get it in your eyes

or mouth.

• Before replacing the lamp, turn the projector off and unplug the power cord, then wait at least

45 minutes for the lamp to cool suffi ciently. Handling the lamp while hot can cause burns, as

well as damaging the lamp.

HIGH VOLTAGE HIGH TEMPERATURE HIGH PRESSURE

• Never unscrew except the appointed (marked by an arrow) screws.

• Do not open the lamp cover while the projector is suspended from above. This is dangerous,

since if the lamp’s bulb has broken, the shards will fall out when the cover is opened.

• Do not use the projector with the lamp cover removed. At the lamp replacing, make sure that

the screws are screwed in fi rmly. Loose screws could result in damage or injury.

• Use only the lamp of the specifi ed type.

• If the lamp breaks soon after the fi rst time it is used, it is possible that there are electrical

problems elsewhere besides the lamp. If this happens, contact your local dealer or a service

representative.

• Handle with care: jolting or scratching could cause the lamp bulb to burst during use.

• Using the lamp for long periods of time could cause it dark, not to light up or to burst. When

the pictures appear dark, or when the color tone is poor, please replace the lamp as soon as

possible. Do not use old (used) lamps; this is a cause of breakage.

24

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

Replacing the Lamp

A lamp has a fi nite product life. Using the lamp for long periods of time could cause the pictures darker or

the color tone poor. Note that each lamp has a different lifetime, and some may burst or burn out soon after

being started using.

1. Turn the projector off, and unplug the power cord. Allow the lamp to cool for

at least 45 minutes.

2. Prepare a new lamp.

3. Loosen the lamp cover screw (marked by arrow) and then slide the lamp

cover to the side to remove it.

4. Loosen the 2 screws (marked by arrow) of the lamp, and slowly pick up the

lamp by the handles.

5. Insert the new lamp, and retighten fi rmly the two screws that are loosened

in the previous process to lock it in place.

6. Slide the lamp cover back in place and fi rmly fasten the lamp cover screw.

7. Turn the projector on and reset the lamp time using the LAMP TIME

function in the OPTION menu.

(1) Press the MENU button to display a menu. Only when the EASY MENU

has appeared, please perform the next step (2).

(2) Point at the “Go To Advance Menu …” in the menu using ▼/▲ button, then

press the ► button.

(3) Point at the “OPTION” in the left column of the menu using ▼/▲ button,

then press the ► button.

(4) Point at the ”LAMP TIME” using ▼/▲ button, then press the ► button. A

dialog will appear.

(5) Press the ▲ button to select “RESET” on the dialog. It performs resetting the lamp time.

Lamp cover

Screw

Screws

Handle

NOTE

• Please reset the lamp time only when you have replaced the lamp, for a suitable indication about the lamp.

25

CP-S245(CC9SMN)/CP-X255/ED-X8255(CC9XMN)/PJ656(CC9XM)

6-7 Other care

WARNING

Before caring, make sure the power switch is off and the power cable is not plugged in, and then allow the

projector to cool suffi ciently. The care in a high temperature state of the projector could cause a burn and/

or malfunction to the projector.

Avoid wetting the projector or inserting liquids in the projector. It could result in a fi re, an electric shock, and

and/or malfunction to the projector.

• Don’t put a container containing water , cleaner or chemicals near the projector.

• Don’t use aerosols or sprays.

CAUTION

Please take right care of the projector according to the following. Incorrect care could cause not only an

injury but adverse influence such as discoloration, peeling paint, etc.

• Do not use cleaner or chemicals other than those listed below.

• Do not polish or wipe with hard objects.

Inside of the projector

In order to ensure the safe use of the projector, it needs to clean and inspect the projector about once a year.

Caring for the lens

If the lens is flawed, soiled or fogged, it could cause deterioration of display quality. Please take care of the

lens, being cautions of the handling.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe the lens with a commercially available

lens-cleaning wipe. Do not touch the lens directly with your hand.

Caring for the cabinet and remote control

Incorrect care could have adverse influence such as discoloration, peeling paint, etc.

1. Turn the projector off, and unplug the power cord. Allow the projector to cool sufficiently.

2. After making sure that the projector is cool adequately, lightly wipe with gauze or a soft cloth.

If soiling is severe, dip soft cloth in water or a nautral cleaner dilute in water, and wipe lightly after wringing

well. Then, wipe lightly with a soft, dry cloth.

26

Loading...

Loading...