1

IMPORTANT:

READ AND UNDERSTAND THIS MANUAL BEFORE USING THIS WIRED REMOTE CONTROL SWITCH.

KEEP THIS MANUAL FOR FUTURE REFERENCE.

IMPORTANT NOTICE:

No part of this manual may be reproduced without written permission.

Signal words (DANGER, WARNING and CAUTION) are used to identify levels of hazard seriousness. Denitions of

identifying hazard levels are provided below with their respective signal words.

1. SAFETY SUMMARY

DANGER

DO NOT pour water into the remote control switch (hereafter called “controller”). This product is equipped

with electrical parts. If poured, it will cause a serious electrical shock.

: Immediate hazards which WILL result in severe personal injury or death.

: Hazards or unsafe practices which COULD result in severe personal injury or death.

: Hazards or unsafe practices which COULD result in minor personal injury or product or property

damage.

DANGER

WARNING

CAUTION

NOTE: Useful information for operation and/or maintenance.

WARNING

DO NOT perform installation work and electrical wiring connection by yourself. Contact your distributor or

dealer of HITACHI and ask them for installation work and electrical wiring by service person.

CAUTION

DO NOT install the indoor unit, outdoor unit, controller and cable at such places as;

1. Where there is oil vapor and the oil is dispersed

2. Where the hot springs are near (in a sulfuric environment)

3. Wheregeneration,owing,stayingorleakingofammablegasisdetected

4. Where the sea is near (in the salty environment)

5. An acid or alkaline environment

DO NOT install the indoor unit, outdoor unit, controller and cable within approximately 3 meters from strong

electromagnetic wave radiators such as medical equipment. In case that the controller is installed in a place

where there is electromagnetic wave direct-radiation, shield the controller and cables by covering with the

steel box and running the cable through the metal conduit tube.

Incasethatthereiselectricnoiseatthepowersourcefortheindoorunit,provideanoiselter.

2. Installation Work

[2.1 Selection of Installation Place]

1) Select a suitable place for handling and determine the installation place of the controller with the customer’s

acceptance. Do not install the controller at such places as;

where children can touch

where the air from the air conditioner is directly discharged

[2.2 Before Installation]

This packing contains the following parts.

[A] Remote Control Switch (Q’ty: 1, For Operation Control)

[B] Screw <M4x16L> (Q’ty: 2, For Fixing the Holding Bracket onto the Wall)

[C] Ring Core (Q’ty: 1)

[D] Band (Q’ty: 1, For Fixing Cable to Ring Core)

[E] Operation Manual (Q’ty: 1)

The box

is for checking work. Check the box after checking.

Installation & Maintenance Manual

Wired Remote Control Switch (Model: PC-AR)

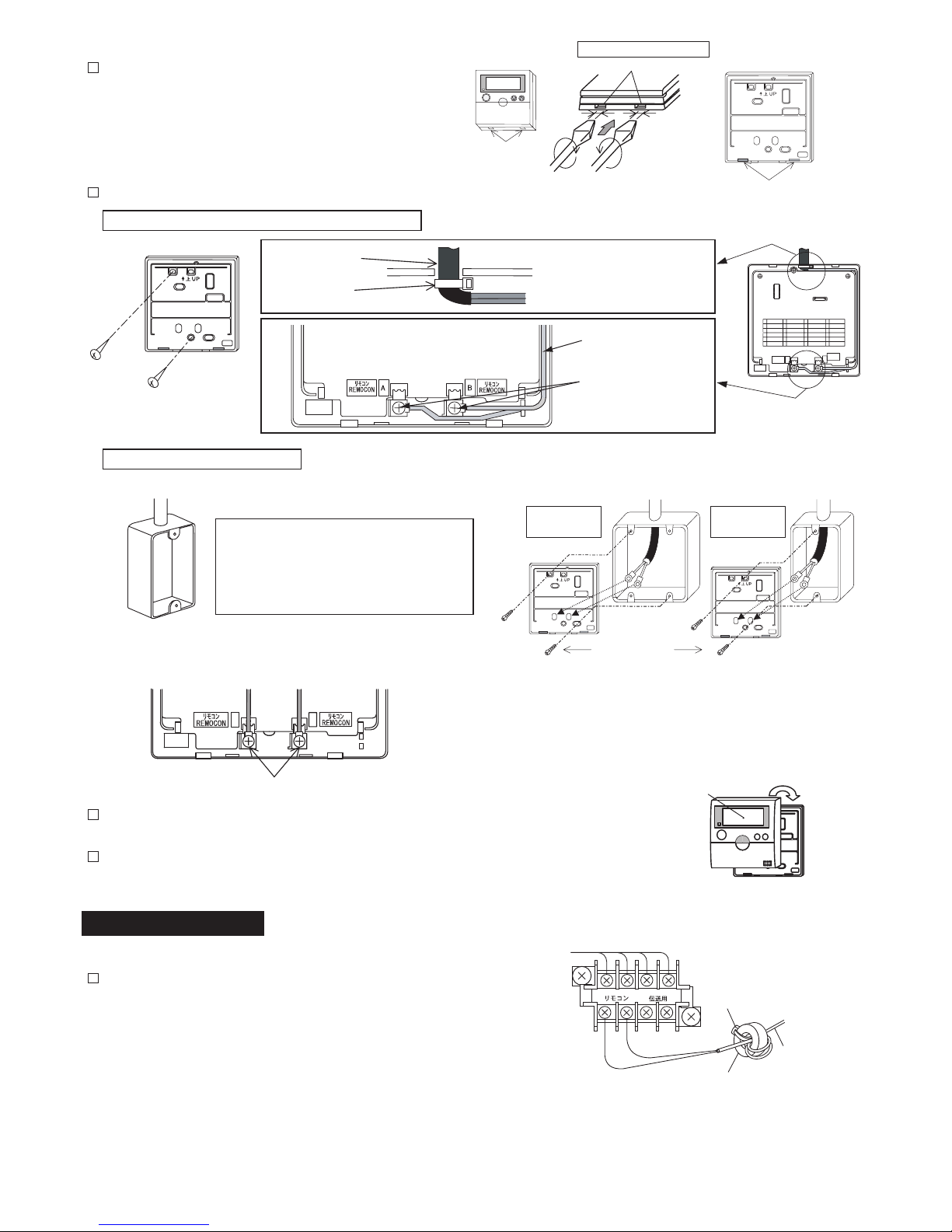

[2.3 Installation Space]

1) In case of installing the controllers in vertical line, keep a distance more than 50mm

between the controllers vertically. If the distance is insufcient, the front cover of

the controller can not be opened wide enough.

More than 50m

m

317B39060

2

A. In Case of Exposing Remote Control Cable

2) Attach the controller to the holding bracket and connect the cable as follows.

3. Peel the insulation at the end of the cable and

clamp the M3 solderless terminals (eld-supplied).

3) Attach the controller to the holding bracket. Be careful not to pinch the cable

when attaching it.

4) Remove the protection lm from the liquid crystal display.

1. Prepare eld-supplied JIS Box (JIS C 8340)

Band Stopper

(Field-Supplied)

Cable

Attach the stopper to the

cable at the inside of the

draw-out hole.

Fix the holding bracke

t

onto the wall with

screws (accessory).

B. When Using Switch Box

The following 5 types are available.

1. Switch Box for 1 controller (Without Cover)

2. Switch Box for 2 controllers (Without Cover)

3. Switch Box for 1 controller (With Cover)

4. Switch Box for 2 controllers (With Cover)

5. Outlet Box (With Cover)

2. Lead the cable through the conduit tube in the wall.

3. Electrical Wiring

JIS Box for

2 Controllers

JIS Box for

1 Controller

M4 Screws

(Field-Supplied)

Remove

the protection film.

A

B

Connect the terminals.

[2.4 Installation Procedures]

1) Insert the edge of the slotted screwdriver into the

groove at the bottom of the holding bracket, push

and turn the slotted screwdriver and then remove

the controller from the holding bracket.

Groove Part

Groove for Attaching Controller

Approx. 6mm.

Slotted Screwdriver

Figure Seen from Bottom Side

Groove Part for Removing Controller

[3.1 Standard Wiring]

1) Attach the ring core (color: black, accessory) when installing the

indoor unit as follows.

[Procedures]

Insert the control cable into the hole of ring core and wind it at

two turns as shown in the right gure before connecting it to the

terminal block. Fix the control cable with the band (accessory).

TB2

Ring Core

Band

Control Cab

le

12A B

Lead the cable with its

sheath peeled through

the groove.

Peel the insulation at

the end of the cable and

clamp the M3 solderless

terminals (field-supplied)

.

3

ATTENTION: Always make sure to turn off the power of the indoor unit when performing electrical wiring work. Performing

electrical wiring work with the power on can damage the circuit boards of the indoor unit and the controller.

Twist Pair Cable (1P-0.75mm2)

Diameter: φ7

Color: Ivory

50mm

100mm

Solderless Terminal

(X Type)

1.25-3X

● Remote Control Cable <Option>

Model: PRC-

K

The number of indicates the length (m) of the cable

(

= 5,10,15).

*for Australia

Connect the both ends of shield net of the shield tube to the

earth as shown right gure.

REMOCONAREMOCON

B

REMOCONAREMOCON

B

AA

B

B

Max. 16 Indoor Units

Controller

Controller

(Subsidiary)

Electrical Box

of Indoor Unit

Electrical Box

of Indoor Unit

M3

Screws

Terminal BoardTerminal Board

M3.5

Screws

M3.5

Screws

Twist Pair Cable with Shield Tube: 1P- 0.75mm2 or more

Remote

Control

Cable

Earth Screw

TB2

TB1

Power Source Cable

Controller

Electrical Box

Indoor Unit

[3.2 Electrical Wiring for Multiple Units]

CAUTION

A. Use a 0.3 to 0.75mm2 cable for connecting. The maximum total cable length is up 30m. If the total cable length

exceeds 30m, use a twist pair cable with shield tube(1P - 0.75mm2 or more). In that case, the maximum total cable

length is up to 500m. If using in combination with the control timer, the allowable total cable length is up to 100m.

The use of a cable other than that specied above can cause of malfunction due to the effects of noise.

B. Keep a distance more than 30cm between the transmission line (remote control cable and transmission wires) and

power source of the indoor units.

If not, the air-conditioner may not operate properly or malfunction may occur due to effect of power source noise.

C. In case of simultaneously controlling multiple indoor units, set the refrigerant cycle numbers and addresses of the

indoor units without overlapping.

D. Refer to the Technical Catalog provided with each indoor unit when performing electrical wiring work between the

controller and indoor units for setting the refrigerant cycle number and the indoor unit address.

E. No gap shall exist between the remote control cable and hole of the controller case. If there is a gap, cover the gap

with vinyl tape.

If not, malfunction may occur due to entrance of water droplets or insects.

F. In case of operating with two controllers (Main and Sub), set the main and sub controllers by selecting the appropriate

function with the controllers according to the section 5. After setting it, turn off the power supply of all the indoor unit

connected to the controllers.

4. Checking Procedures

1) Turn ON the power supply for all the indoor units.

NOTE:

Although a portion of the LCD (liquid crystal display) of the controller may light immediately after the power is turned on,

this is not a malfunction.

2) For the models with the auto-address function, wait for 3 minutes approximately. The addressing is automatically

performed. (There is a case that 5 minutes is required according to the setting condition.)

3) Set the “TEST RUN” mode by pressing the “MODE” and “CHECK” switch simultaneously for more than 3 seconds.

NOTES:

A. “TEST RUN” is displayed on the LCD.

B. The total number of the indoor units connected

is indicated on the LCD.

C. In case that the indicated number is not correct, the auto-address function is not performed correctly due to incorrect

wiring, the electric noise or etc. Turn OFF the power supply and correct the wiring after checking the following

points;

(Do not repeat turning ON and OFF within 10 seconds.)

1. Power Supply for Indoor Unit is Not Turned ON or Incorrect Wiring.

2. Incorrect Connection of Connecting Cable between Indoor Units or Incorrect Connection of Remote Control Cable

3. Incorrect Setting of Rotary Switch and Dip Switch (The setting is overlapped.) on the Indoor Units PCB

D. Check to ensure that the “TEST RUN” mode is not set.

unit

Example when 5 indoor units are connected.

4

4) Canceling “TEST RUN” Mode

1. When the unit is not operating, press the RESET switch.

2. When the unit is operating, press the RUN/STOP switch.

ATTENTION:

When “00” is indicated, the auto-address function may be performing.

Cancel the “TEST RUN” mode and set it again.

5. Optional Setting and Input / Output Setting of Indoor Unit

SERVICE

AC/

HIGH

COLO

SET TEMP.

COLO

HIGH

ADDS

RN

SERVICE

AC/

COLO

HIGH

AC/

SERVICE

ADDS RN

COLO

HIGH

AC/

SERVICE

COLO

HIGH

AC/

SERVICE

COLO

HIGH

AC/

SERVICE

COLO

HIGH

AC/

SERVICE

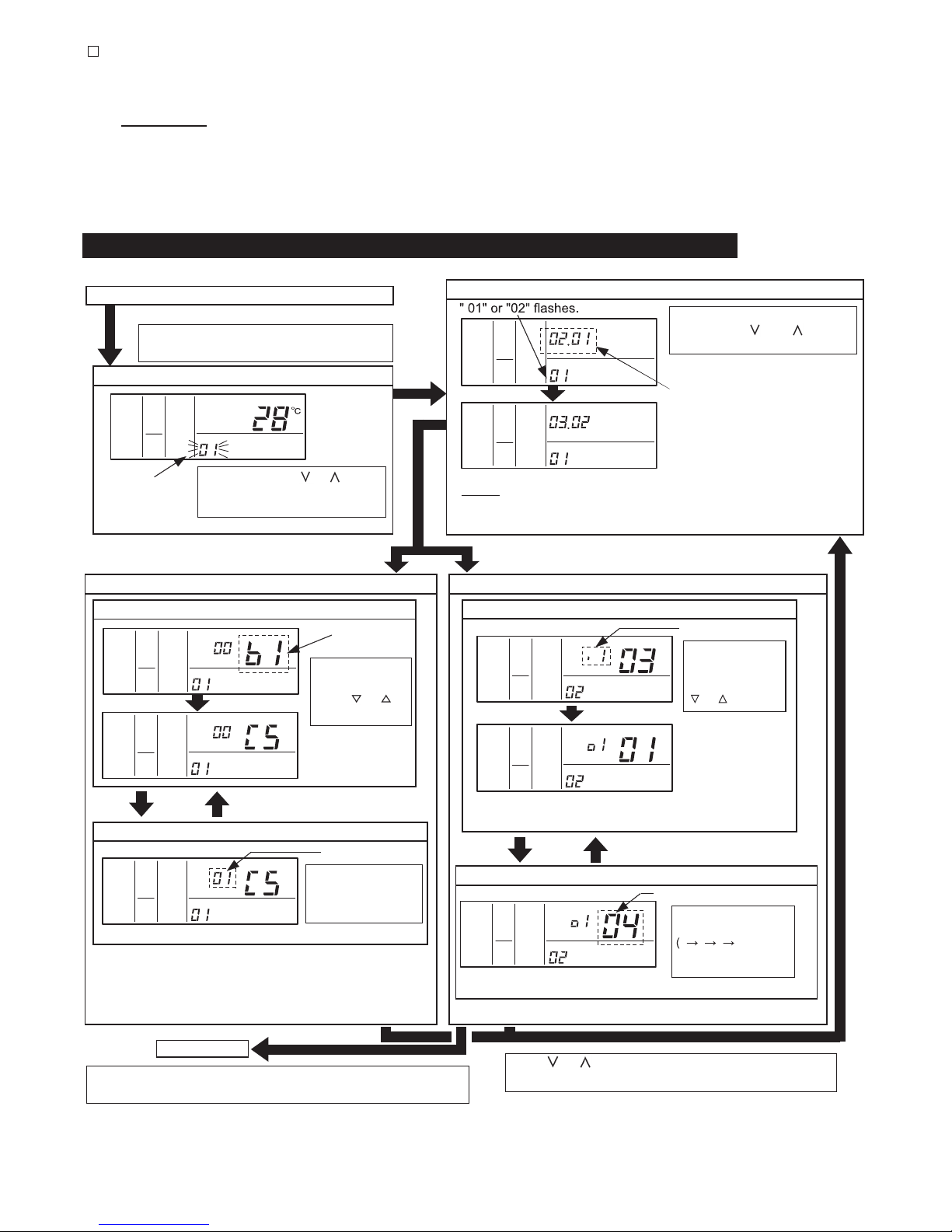

Normal Mode (When unit is not operating)

1. Change to the optional setting mode.

Press the "CHECK" switch and the "RESET"

switch simultaneously for more than 3 seconds.

Optional Setting Mode (Mode Number "01")

4. Selection of Optional Setting Items

Item Code of

Optional Setting

Select the item code

by pressing the

"TIME"

or

switch.

<Example>

When selecting C5

(Increasing Fan

Speed)

3. Selection of Indoor Unit for Optional Setting

Select the indoor unit to set by

pressing the " " or " " switch

and press the "CHECK" switch.

The address of the indoor unit (ADDS)

to set and the refrigerant cycle number

(RN) are indicated by 0 to 15. (The left

figure shows the No.1 cycle and No.2

indoor unit.)

<Example>

When selecting No.2 cycle and No.3 indoor

unit (The address is indicated by 0 to 15.)

NOTES: (1) In case that the both indications of the "ADDS." and "RN" show "AA",

the same setting is performed to all the indoor units.

(2) The address of indoor unit not connected is not indicated.

"SERVICE" is

indicated and the

mode number is

flashed.

Press the "TEMP." or switch

and set "01" or "02". Then press

the "CHECK" switch.

2. Selection of Optional Setting Mode

Input / Output Setting Mode (Mode Number "02")

4. Selection of Input / Output Number

Input / Output Number

Select the input /

output number by

pressing the "TIME"

or switch.

<Example>

When selecting o1

(Output 1)

In Case of Setting Other Items

In Case of Setting Other Items

COLO

HIGH

AC/

SERVICE

COLO

HIGH

AC/

SERVICE

5. Change of Setting Conditions

Setting Condition

The optional setting

condition is changed

by pressing

the "CHECK" switch.

<Example> When setting 01(Increasing Fan Speed 1)

5. Change of Setting Conditions

Contents of Input / Output Setting

<Example> When setting 04 (Output: Thermo-ON for Cooling)

The optional setting

condition is changed

...

) by

pressing the "CHECK"

switch.

Normal Mode

Press the "RESET" switch in the condition of 4 or 5 to cancel the

optional setting mode.

Press or switch in step 4 or 5 when selecting

settings for another unit.

* Refer to the contents of the setting codes for the Table A of

“Optional Setting Items”.

120

* Refer to Table B (Page 8) for contents of the input / output setting.

* Refer to the Table C for the contents of the input / output setting.

5

● Table A Optional Setting Items

6. Initialization of Optional Setting and Input / Output Setting

Normal mode (when unit is not operating)

COLO

HIGH

AC/

SERVICE

SET TEMP.

COLO

HIGH

AC/

SERVICE

ADDS RN

COLO

HIGH

AC/

SERVICE

ADDS RN

COLO

HIGH

AC/

SERVICE

ADDS RN

Press the "CHECK" switch and the "RESET"

switch simultaneously for more than 3 seconds.

1. Change to the optional setting mode.

2. Selection of Optional Setting Mode

Press the "TEMP."

"V" or "" switch,

select "07" for

the optional input

/ output setting

cancel mode, and

then press the

"CHECK" switch.

3. Selection of Indoor Unit

Select the address of the indoor unit

to be returned to the optional setting-

"07" flashes.

input/output factory settings.

Press the "TEMP." control or

switch and select the address of the

indoor unit.

NOTES:

* In case of control by using two controllers (Main and Sub),

settings shall be operated by the main controller.

* In case of selecting the address of the indoor unit not to initialize the

optional and input / output setting, "NO FUNCTION" is displayed.

* If selecting the indoor unit address "AA", the indoor units that do not

have these initialization function cannot be restore to the factory setting.

4. Optional Setting and Input/Output Setting Initialization

Press "CHECK" switch and the

initialization is performed.

It takes approximately 15 to 30

seconds.

When displayed "CL",

the optional and input

/ output settings are

initialized. (restore to

factory settings.)

In case of performing to initialize the other indoor units, repeat

the procedure from step 3.

In this case, the indoor unit address is completed to initialize,

the indication "CL" is displayed.

Normal Mode

V

V

V

"SERVICE" is indicated and the mode

number is flashed.

In case that initialization is not required, press the “RESET” switch in step 4.

Check to ensure that there are no problems

to restore the factory settings, and perform

to initialize.

Optional Setting Items

No. Items Optional Function

Individual

Setting

Setting

Condition

Contents

1b1

Removal of Heating

Temperature Compensation

due to Uneven Heat Load

00

01

02

Standard (Set Temp. +4

o

C)

Removal (Set Temp.)

Set Temp. +2

o

C (*1)

2b2

Circulator Function at

Heating Thermo-OFF

00

01

Not Available

Available

3b3

Enforced 3 Minutes

Minimum Operation Time of

Compressor

00

01

Not Available

Available

4b4 Change of Filter Cleaning Time

00

01

02

03

04

Standard

100 hours

1,200 hours

2,500 hours

No Indication

5b5 Fixing of Operation Mode

00

01

Not Available

Available

6b6 Fixing of Setting Temperature

00

01

Not Available

Available

7b7

Fixing of Operation as

Exclusive Cooling Unit

00

01

Not Available

Available

8b8 Automatic COOL/HEAT Operation

00

01

Not Available

Available

9b9 Fixing of Fan Speed

00

01

Not Available

Available

10 bA Not Prepared "- -" Fixed Not Used

11 bb

Cooling Temperature Compensation

due to Uneven Heat Load

00

01

02

Standard (No Compensation)

Set Temp. -1

o

C

Set Temp. -2

o

C

12 bC Not Prepared-

00

01

Not Used

(Use as 00 conditions)

13 bd Not Prepared-

00

01

Not Used

(Use as 00 conditions)

14 bE Not Prepared-

00

01

Not Used

(Use as 00 conditions)

X

X

X

X

X

X

The procedure for initialization of optional settings and input / output settings are as follows.

6

No. Items Optional Function

Individual

Setting

Setting

Condition

Contents

15 C1 Not Prepared-

00

01

Not Used

(Use as 00 conditions)

16 C2 Not Prepared-"- -" Fixed Not Used

17 C3 Not Prepared

00

01

Not Used

(Use as 00 conditions)

18 C4 Not Prepared

00

01

Not Used

(Use as 00 conditions)

19 C5 Hi Speed

00

01

02

Not Available

Hi Speed 1 (*2)

Hi Speed 2 (*2)

20 C6 Hi Speed at Heating Thermo-OFF

00

01

Not Available

Available

21 C7

Canceling of Enforced 3 Minutes

Minimum Operation Time of

Compressor

00

01

Available

Not Available

22 C8 Thermistor of Remote Control Switch

00

01

02

Control by Indoor Suction Thermistor

Control by Thermistor of

Remote Control Switch

Control by Average Value of

Indoor Suction Thermistor and

Thermistor of Remote Control Switch

23 C9 Not Prepared-"- -" Fixed Not Used

24 CA Not Prepared-"- -" Fixed Not Used

25 Cb Selection of Forced Stoppage Logic

00

01

Forced Stoppage Input: A Contact

Forced Stoppage Input: B Contact

26 CC Not Prepared

00

01

Not Used

(Use as 00 conditions)

27 Cd Not Prepared

00

01

Not Used

(Use as 00 conditions)

28 CE Not Prepared-

00

01

Not Used

(Use as 00 conditions)

29 CF Change of Louver Swing Angle

00

01

02

Standard (7 Steps)

Draft Prevention (5 Steps)

High Ceiling (5 Steps) (*3)

30 d1 Not Prepared

00

01

Not Used

(Use as 00 conditions)

31 d2 Not Prepared-"- -" Fixed Not Used

32 d3 Power Supply ON/OFF 2

00

01

Not Available

Available

33 d4

Prevention for Cooling Discharge Air

Temp. Decrease

00

01

Not Available

Available

34 d5

Prevention for Heating Discharge Air

Temp. Decrease

00

01

Not Available

Available

35 d6

Room Temp. Control for Energy

Saving

00

01

Not Available

Available

36 d7 Not Prepared

00

01

02

03

04

05

06

07

Not Used(Use as 00 conditions)

37 E1 Ventilation Mode

00

01

02

Automatic Ventilation

Ventilation by Total Heat Exchanger

Bypass Ventilation

(No Total Heat Exchanging)

38 E2 Increasing Supply Air Volume

00

01

Not Available

Available

39 E3 Not Prepared

00

01

Not Used

(Use as 00 conditions)

40 E4 Precooling / Preheating Period

00

01

02

Standard

30 min.

60 min.

41 E5 Not Prepared

00

01

Not Used

(Use as 00 conditions)

42 E6

Indoor Fan Operation Time After

Cooling Operation Stoppage

00

01

02

Not Available

60 min.

120 min.

X

X

7

No. Items Optional Function

Individual

Setting

Setting

Condition

Contents

43 E7 Not Prepared-

00

01

Not Used

(Use as 00 conditions)

44 E8

Fan Operation Control at Heating

Thermo-OFF

00

01

Not Available

Available

45 E9 Not Prepared-

00

01

Not Used

(Use as 00 conditions)

46 EA Not Prepared

00

01

02

Not Used

(Use as 00 conditions)

47 Eb

Fan Operation Control at Cooling

Thermo-OFF

00

01

02

Not Available

LOW

SLOW

48 EC

Forced Thermo-ON Stoppage at

Cooling

00

01

Not Available

Available

49 Ed Not Prepared

00

01

Not Used

(Use as 00 conditions)

50 EE Automatic Fan Speed Control

00

01

Not Available

Available

51 F1 Automatic OFF Timer Setting

00

01

02

23

24

0A

0B

No Function

OFF Timer by 1 hour

OFF Timer by 2 hours

OFF Timer by 23 hours

OFF Timer by 24 hours

OFF Timer by 0.5 hour

OFF Timer by 1.5 hours

52 F2 Remote Control Main-Sub Setting

00

01

Main

Sub

53 F3

Automatic Reset of Setting

Temperature (*4)

00

01

Not Available

Available

54 F4 Automatic Reset Time

00

01

02

03

30 min. (Factory-Setting)

15 min.

60 min.

90 min.

55 F5

Automatic Reset Temperature

for Cooling (*5)

19

20

25

29

30

19

o

C

20

o

C

25

o

C (Factory-Setting)

29

o

C

30

o

C

56 F6

Automatic Reset Temperature

for Heating (*6)

17

18

21

29

30

17

o

C

18

o

C

21

o

C (Factory-Setting)

29

o

C

30

o

C

57 F7

Operation Stoppage Prevention by

Remote Control Switch Operational

Error (*7)

00

01

Not Available

Available

58 F8

Lock Function for Operation Mode

Selection

00

01

Not Available

Available (Factory-Setting)

59 F9

Lock Function for Temperature

Setting

00

01

Not Available

Available (Factory-Setting)

60 FA

Lock Function for Fan Speed

Selection

00

01

Not Available

Available (Factory-Setting)

61 Fb

Lock Function for Swing Louver

Operation

00

01

Not Available

Available (Factory-Setting)

X

X

X

X

X

X

X

X

X

X

X

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

8

● Table B Input and Output Number Display and Connectors ● Table C Input and Output Settings and Display Codes

No. Items Optional Function

Individual

Setting

Setting

Condition

Contents

62 FC

Cooling Lower Limit for Setting

Temperature (*5)

00

01

02

09

10

Standard

Lower Limit +1

o

C

Lower Limit +2

o

C

Lower Limit +9

o

C

Lower Limit +10

o

C

63 Fd

Heating Upper Limit for Setting

Temperature (*6)

00

01

02

09

10

Standard

Upper Limit -1

o

C

Upper Limit -2

o

C

Upper Limit -9

o

C

Upper Limit -10

o

C

64

FE

Not Prepared

-

00

01

02

Not Used (Use as 00 condition)

65

FF

Lock Function for ON / OFF Timer

00

01

Not Available

Available (Factory-setting)

NOTES:

* After at least 3 minutes from the power ON, change the optional setting.

* When changing "CF" setting (change of louver swing range), restore the power supply or allow the louver to make one complete

swing fully in the auto swing mode to apply the optional setting.

* The optoinal settings are different according to the indoor and outdoor unit models. Check to ensure that the unit has the optional

setting or not.

* Record the setting conditions for each optional setting in the "Setting" column of the table.

(*1)

: The "02" setting may not be available according to the type of indoor unit.

(*2): In case of RPI models, 00: Increasing fan speed 1 (standard), 01: Increasing fan speed 2 (high static pressure)

,

02: Standard (low static pressure)

(*3): 00: Standard (7-step operation), 01: Draft Prevention (lower 2 steps cut of

f), 02: High ceiling (upper 2 steps cut off)

(*4): In case that the set temperature is changed and kept within the set time at "F4", the temperature is automatically change

d to "F5"

and "F6". (In case that the set temperature is out of range at "F5" and "F6", it is applied within upper and lower limit for the set

temperature.)

(*5)

: Applicable to fan, cooling and dry operation modes.

(*6)

: Applicable to heating operation mode.

(*7): Operation is stopped by pressing the "RUN/ST

OP" switch for 3 seconds.

X

X

X

..

..

..

..

Input and Output Number Display and Connectors

Input and Output Settings and Display Codes

Input Number Display

Port

Factory Setting

Setting

Input / Output Indication Setting Item Indication

Input1 CN3 1-2 Remote ON/OFF 1 (level)03

Input2 CN3 2-306

Output1 CN7 1-2 Operation01

Output2 CN7 1-3 Alarm02

Output3 CN8 1-2 Thermo-ON for Heating

Forbidding Remote Control

after Manual Stoppage

06

Indication Input Output

00 Not set Not set

01 Room Thermostat (for Cooling) Operation

02 Room Thermostat (for Heating) Alarm

03 Remote ON/OFF 1 (level) Cooling

04 Remote ON/OFF 2 (Operation)

Thermo-ON for

Cooling

05 Remote ON/OFF 2 (Stoppage) Heating

06

Forbidding Remote Control

after Manual Stoppage

Thermo-ON for

Heating

07

Remote Cooling / Heating

Change

Total Heat Exchanger

08 Elevating Grille Input

NOTES:

* After at least 3 minutes from the power ON, change the optional setting.

* The elevating grille input can be set to Input 2 only " " .

The elevating grille cannot be set to Input 1.

* The elevating grille output can be set to Output 1 or Output 2 only " " or " " .

The elevating grille output cannot be set to Output 3.

* Do not set the elevating grille for the total heat exchanger.

* Record the setting conditions for each input and output in the "Setting" column of the table.

Elevating Grille Output

9

7. Changing Indoor Unit Address from Controller

Normal Mode (when unit is not operating)

COLO

HIGH

AC/

SERVICE

SET TEMP.

"05" Indicates.

Press the "TEMP."

or

switch and select the address of

the indoor unit.

Select the address of the indoor

unit to be operated.

COLO

HIGH

AC/

SERVICE

ADDS RN

The address and refrigerant cycle

number of the indoor unit to be set are

displayed (the diagram at left shows the

No. 2 cycle and the No. 3 indoor unit).

Press the "TEMP" or switch,

select "05" for the address check

mode, and then press the "CHECK"

switch.

1. Change to the optional setting mode.

Press the "CHECK" switch and the "RESET"

switch simultaneously for more than 3 seconds.

2. Selection of Optional Setting Mode

"SERVICE" is

indicated and the

mode number is

flashed.

"CHECK"

Switch

3. Selection of Indoor Unit

NOTES:

* Unconnected indoor unit address is not displayed.

* In case of control by using two controllers (Main and Sub),

the indoor unit addresses cannot be checked.

4. Run and Stop Indoor Unit.

COLO

HIGH

AC/

SERVICE

ADDS RN

5. Ending Address Checking

COLO

HIGH

AC/

SET TEMP.

"RUN/STOP" switch "RESET" switch

After selecting the indoor unit, press the "RUN/

STOP" switch to operate the indoor unit of the

displayed address.

Pressing the "RUN/STOP" switch during the

indoor unit operation, returns to the indoor unit

selection procedure of step (3).

Repeat steps (3) and (4) until the address number of the indoor unit for which the address

is to be changed is able to be checked. When selecting another indoor unit, first stop the

operation of the indoor unit currently being checked.

NOTES:

* All operations other than operation of the "RUN/STOP" switch are not available during

the address checking.

* Do not operate from the central station during the address checking.

Press the "RESET" switch during the indoor

unit operation OFF to return to the normal

mode.

Once the address of the indoor unit to be

changed has been checked, change the

address of the indoor unit by proceeding to

step (3) Address Change Mode.

The address (unit number) of the indoor unit can be changed by using the controller (PC-AR).

(1) Check the Indoor Unit for which the address to be changed.

Address of Indoor Unit to be Changed is not known (check) . . . Proceed to (2) Address Check Mode.

Address of Indoor Unit to be Changed is known . . . Proceed to (3) Address Change Mode.

Initialize address set with the automatic address function or initialize address that has been changed with the

address change mode. . . Proceed to (4) Address Initialization Mode.

(2) Address Check Mode

This function is for two or more the indoor units are connected to the controller.

The indoor unit address can be checked by the indoor unit individual operation with selecting the indoor address.

NOTES:

* In case of operating with two controllers (Main and Sub), the address of the indoor units cannot be changed or

checked.

* The address may not be able to be changed depending on the type of indoor unit.

* Do not operate the central controller when in the address check mode or address change mode.

10

COLO

HIGH

AC/

SERVICE

SET TEMP.

"04" indicated.

Select the address of the indoor

unit to be changed.

COLO

HIGH

AC/

SERVICE

ADDS RN

COLO

HIGH

AC/

SERVICE

ADDS RN

The address and refrigerant cycle

number of the indoor unit to be set

change from flashing to remaining lit.

COLO

HIGH

AC/

ADDS RN

SERVICE

Press the "TEMP." or

switch to select the address of

the indoor unit and then press the

"CHECK" switch.

Press the temperature control or

switch, select "04" for the address

change mode, and then press the

"CHECK" switch.

Normal Mode (when unit is not operating)

1. Change to the optional setting mode.

Press the "CHECK" switch and the "RESET"

switch simultaneously for more than 3 seconds.

"CHECK"

switch

3. Selection of Indoor Unit

2. Selection of Optional Setting Mode

"SERVICE" is

indicated and the

mode number is

flashed.

NOTE:

* In case of selecting the address not to change, "NO FUNCTION" is

displayed.

"CHECK" switch

Select the new address to be used after

changing the address.

The refrigerant cycle number display can be

changed from 00 to 63 by pressing the "TIME"

or switch, and the unit number display can be

changed from 00 to 63 by pressing the "TEMP."

control or switch.

remaining lit when the "CHECK" switch is pressed

The address display changes from flashing to

after selecting an address.

NOTE:

A refrigerant cycle number of "99" is used in case

of temporarily avoiding setting an address when

all indoor unit refrigerant cycle numbers or unit

numbers are in use. If an address has been set

to "99", make sure to subsequently change the

address to an address within the normal address

range.

The result of changing the address is displayed several seconds after the "CHECK" switch has been pressed. "AH" is temporarily

displayed if address change processing has been completely succeeded, while "EE" is temporarily displayed if the address was unable

to be changed. If this happens, repeat the procedure for changing the address.

4. Change the address of the indoor unit.

5. Changing the address of another indoor unit.

Select the address of the indoor unit to be changed.

COLO

HIGH

AC/

SERVICE

ADDS RN

Pressing the "TEMP

." control

or switch after the result of an address change is displayed in step 4 for

changing the address of an indoor unit, returns to the selection of an indoor unit of step 3.

Repeat steps 3 and 4 until all indoor unit address changes have been completed.

6. Ending Address Change.

"AC" flashes while connections are

being checked.

Press the "RESET" switch

during selection of an indoor

unit of step 3, return to the

normal mode.

COLO

HIGH

AC/

SERVICE

ADDS RN

7. Turning ON Power of Indoor Unit.

Once turn OFF the power of the indoor unit 3 to 5 minutes after

completing step 6. After the display on the controller is no

longer displayed, turn ON the power of the indoor unit.

unit has been successfully

changed, processing for

checking connections begins.

Once the address of the indoor

NOTE:

After ending address change in step 6, make sure to turn off the

power of the indoor unit. If this procedure is not performed, the

automatic address function may not be performed properly.

NOTE:

In the case of having changed the address of the indoor unit with

the controller, make sure to record the new refrigerant cycle

number and unit number of the indoor unit that has been

changed in the entry column on the printed board.

Entry column

V

V

(3) Address Change Mode

Change the address (unit number) of the indoor unit.

11

(4) Address Initialization

This is used to initialize an address that has been changed in the address change mode or to initialize an indoor

unit address that has been set with the automatic address function. When set this function, the address of the

indoor unit is returned to the dip switch setting. (Repeat automatic address setting if the dip switch setting is to the

automatic address setting.)

Normal Mode (when unit is not operating)

SETTEMP.

SERVICE

HIGH

AC/

COLO

3. Select an indoor unit.

COLO

HIGH

AC/

SERVICE

ADDS RN

4. Address Initialization

COLO

HIGH

AC/

SERVIC

ADDS RN

The displayed address is initialized. Check that there is no problem with initializing the address.

Automatic address initialization starts when the "CHECK" switch is pressed.

Once the address has been successfully initialized, processing for checking connections starts.

If the address has already been initialized or the indoor unit does not have an address initialization

function, the address and refrigerant cycle number to be set change from flashing to remaining lit.

Repeat the setting procedure from step 3 when initializing the addresses of other indoor units.

Press the "RESET" switch to end address initialization.

Press the "TEMP." or switch

and select the address of the indoor

unit.

Press the "TEMP."

or

switch, select either "06" for the

address initialization mode, and

then press the "CHECK" switch.

1. Change to the optional setting mode.

Press the "CHECK" switch and the "RESET"

switch simultaneously for more than 3 seconds.

2. Selection of Optional Setting Mode

"SERVICE" is

indicated and the

mode number is

flashed.

"CHECK"

switch

"06" Indicates.

Select the address of the indoor unit for

which the address is to be initialized.

NOTES:

* In case of control by two controllers (Main and Sub), settings shall be

operated by the main controller.

* In case of selecting the address not to change "NO FUNCTION" is

displayed.

* When selecting indoor address "AA", the indoor unit address that does

not have an address initialization cannot be cleared.

The address and refrigerant cycle

number of the indoor unit to be set

flash temporarily.

12

8. Elevating Grille Group Setting and Cancellation

Group setting of the elevating grille refers to a function that allows all settings for the elevating grille (setting of elevating

functions for input 2 and outputs 1 and 2) to be made all at once for all indoor units connected to the controller. Settings

are made by following the procedure as follows.

NOTES:

* In case of using by two controllers (Main and Sub), the settings shall be operated by the main controller.

* Group settings are made to all indoor units connected to the controller regardless of whether or not these are actually provided with

the elevating grille. The indoor unit to be set cannot be selected. (In this case, refer to section 5, “Optional Setting and Input/Output

Setting from Controller”.)

* Please note that when functions other than the elevating grille have been set for input 2 and output 1 and 2, those settings are

cleared (namely, there are overwritten by the elevating grille function).

1. Switch to the elevating grille group setting mode.

2. Elevating grille Group Setting Procedure

"GRL" is

displayed.

Press the "RUN/STOP" switch when making group

settings. (Press the "RESET" switch to return to the

normal mode without making group settings.)

"RESET"

Switch

"RUN/STOP"

Switch

3. Display Following Elevating Grille Group Setting Procedure

"SET" flashes

for 3 seconds.

The elevating grille settings are made for all indoor units

connected to the controller. "SET" flashes for 3 seconds after

settings have been made, and then automatically returns to the

normal mode.

OLOC

HIGH

/CA

OLOC

HIGH

/CA

SET

Normal mode (when unit is not operating)

Press the “CHECK” switch and the ”RESET”

switch simultaneously for more than 3 seconds.

2. Select the input/output setting mode.

"02" Indicates.

3. Select the unit to be set.

The address and refrigerant cycle

number of the indoor unit to be

set are displayed (the diagram at

left shows the No. 1 cycle and the

No. 2 indoor unit). All units are

displayed at once when "AA" is

set for both the refrigerant cycle

number and address.

Example: Display in case of

group cancellation of all units.

4. Group cancellation procedure

Press the " "

switch.

The elevating grille settings for the selected

units are canceled all at once and input

1 and output 1 and 2 are returned to the

factory settings. "NO FUNCTION" flashes

for 2 seconds following this procedure.

"NO FUNCTION" flashes for 2

seconds

Press the "RESET" switch to cancel the

cancellation procedure.

Normal mode

OLOC

HIGH

/CA

SERVICE

SET TEMP.

OLOC

HIGH

/CA

SERVICE

ADDS RN

OLOC

HIGH

/CA

SERVICE

ADDS RN

OLOC

HIGH

/CA

SERVICE

ADDS RN

NO FUNCTION

Press the "TEMP." or switch,

select the address of the indoor

unit to be set and then press the

"CHECK" switch.

Press the "TEMP." or switch,

select "02" for the input/output

setting mode, and then press the

"CHECK" switch.

When canceling elevating grille settings for

other units, repeat selection of the indoor units

by pressing the "TEMP." or switch.

Normal mode (when unit is not operating)

1. Change to the optional setting mode.

Press the “CHECK” switch and the “RESET”

switch simultaneously for more than 3 seconds.

“SERVICE” is

indicated and the

mode number is

flashed.

317B39060(Q), 2016

© 2016 Johnson Controls-Hitachi Air Conditioning Technology (Hong Kong) Ltd.

Elevating grille settings can be cancelled all at once by following the procedures as follows.

● Elevating Grille Group Cancellation Procedure

● Elevating Grille Group Setting Procedure

Loading...

Loading...