Page 1

AUGUST 2002 HHEA-MANUFACTURING DIVISION

PA

No. 0163

51XWX20B DP26

57XWX20B DP26

65XWX20B DP26

R/C: CLU-5721TSI

CLU-120S

NN TT SS CC

DD TT VV

DDPP2266 CChhaassssiiss

SERVICE MANUAL

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TECHNICAL CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CIRCUIT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR . . . . . .12

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . .15

REAR PANEL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

DISPLAY PICTURE FORMATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

SERVICE ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

DC VOLTAGE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

PROTECTION CIRCUIT BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

DIGITAL MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

CIRCUIT SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .134

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

FINAL WIRING DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

QUICK REFERENCE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

DISASSEMBLY/ASSEMBLY INSTRUCTIONS FOR 65” SPLIT PTV . . . . . . . . . . . . . .193

CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

read and follow the “Important Safety Instructions” in this Service Manual.

PROJECTION COLOR TELEVISION

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

!

TO GO TO A CHAPTER, CLICK ON ITS HEADING BELOW

Page 2

2

DP26

Components having special safety characteristics are identified by a on the schematics and on the parts list in this service

manual and its supplements and bulletins. Before servicing this chassis, it is important that the service technician read and

follow the “Important Safety Instructions” in this Service Manual.

For continued X-Radiation protection, replace picture tube with original type or Hitachi approved equivalent type.

This Service Manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified

technicians have the necessary test equipment and tools, and have been trained to properly and safely repair complex

products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void warranty. If you

are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so and refer the

repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact

with solder. Also, when soldering do not inhale any smoke or fumes produced.

This television receiver provides display of television closed captioning in accordance with section 15.119 of the FCC rules.

FEDERAL COMMUNICATIONS COMMISSION NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/television technician for help.

IMPORTANT SAFETY INSTRUCTIONS

USE ISOLATION TRANSFORMER WHEN SERVICING

!

Page 3

3

DP26

IMPORTANT SAFETY INSTRUCTION

1. Before returning an instrument to the customer, always

make a safety check of the entire instrument, including

but not limited to the following items.

a. Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly

in the cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpaper,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning. Servicers who defeat safety features

or fail to perform safety checks may be liable for

any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to (1) spacing

between the picture tube and cabinet mask, (2)

excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet

back cover.

c. Antenna Cold Check – With the instrument AC plug

removed from any AC source, connect an electrical

jumper across the two AC plug prongs. Place the

instrument AC switch in the on position. Connect one

lead of an ohmmeter to the AC plug prongs tied

together and touch the other ohmmeter lead in turn to

each tuner antenna input, exposed terminal screw

and, if applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohms or

greater than 5.2 megohms, an abnormality exists that

must be corrected before the instrument is returned to

the customer. Repeat this test with the instrument AC

switch in the off position.

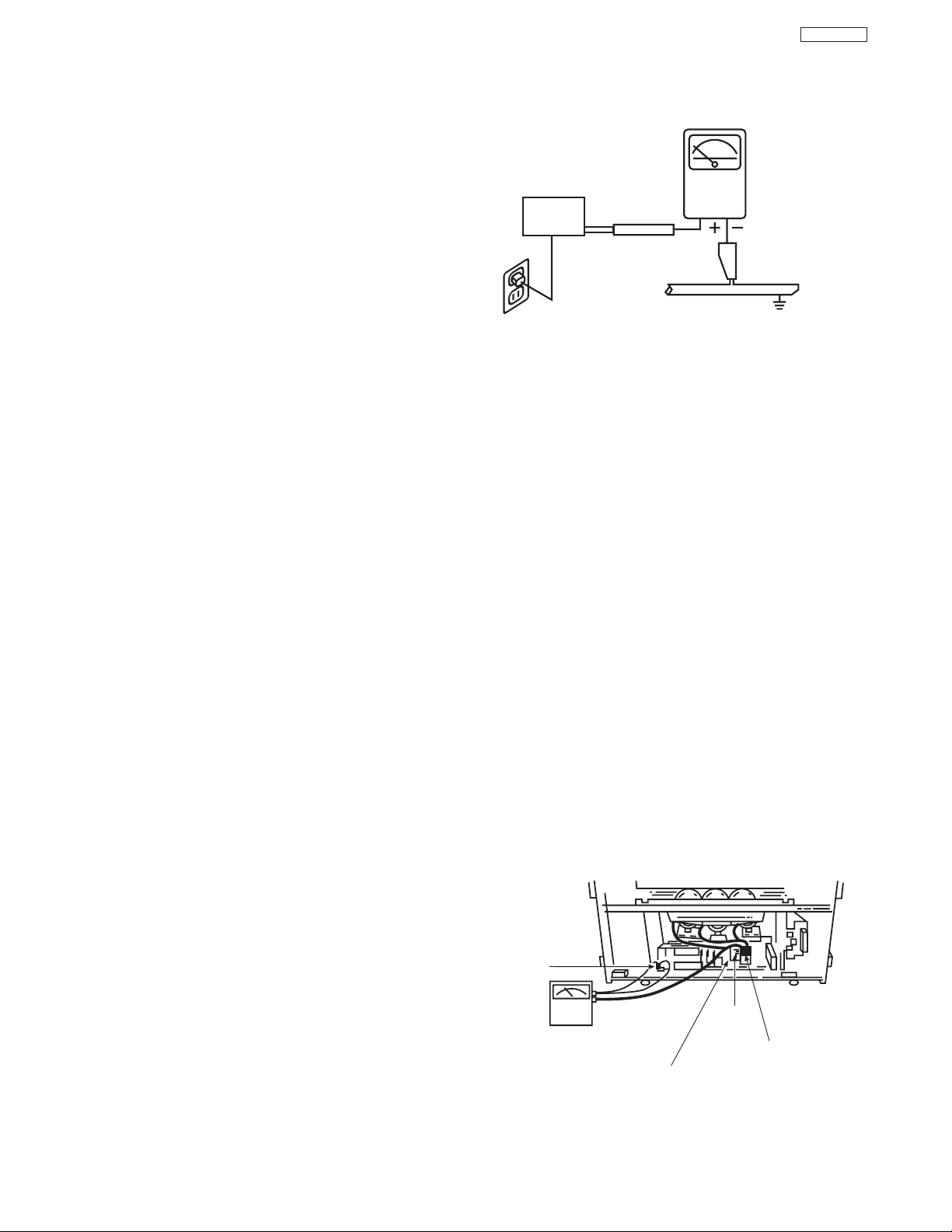

d. Leakage Current Hot Check – With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current

tester or a metering system that complies with

American National Standards Institute (ANSI) C101.0

Leakage Current for Appliances and Underwriters

Laboratories (UL) 1410, (50.7). With the instrument

AC switch first in the on position and then in the off

position, measure from a known earth ground (metal

waterpipe, conduit, etc.) to all exposed metal parts of

the instrument (antennas, handle bracket, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal parts that

offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamps.

Reverse the instrument power cord plug in the outlet

and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER OR BEFORE CONNECTING THE

ANTENNA OR ACCESSORIES.

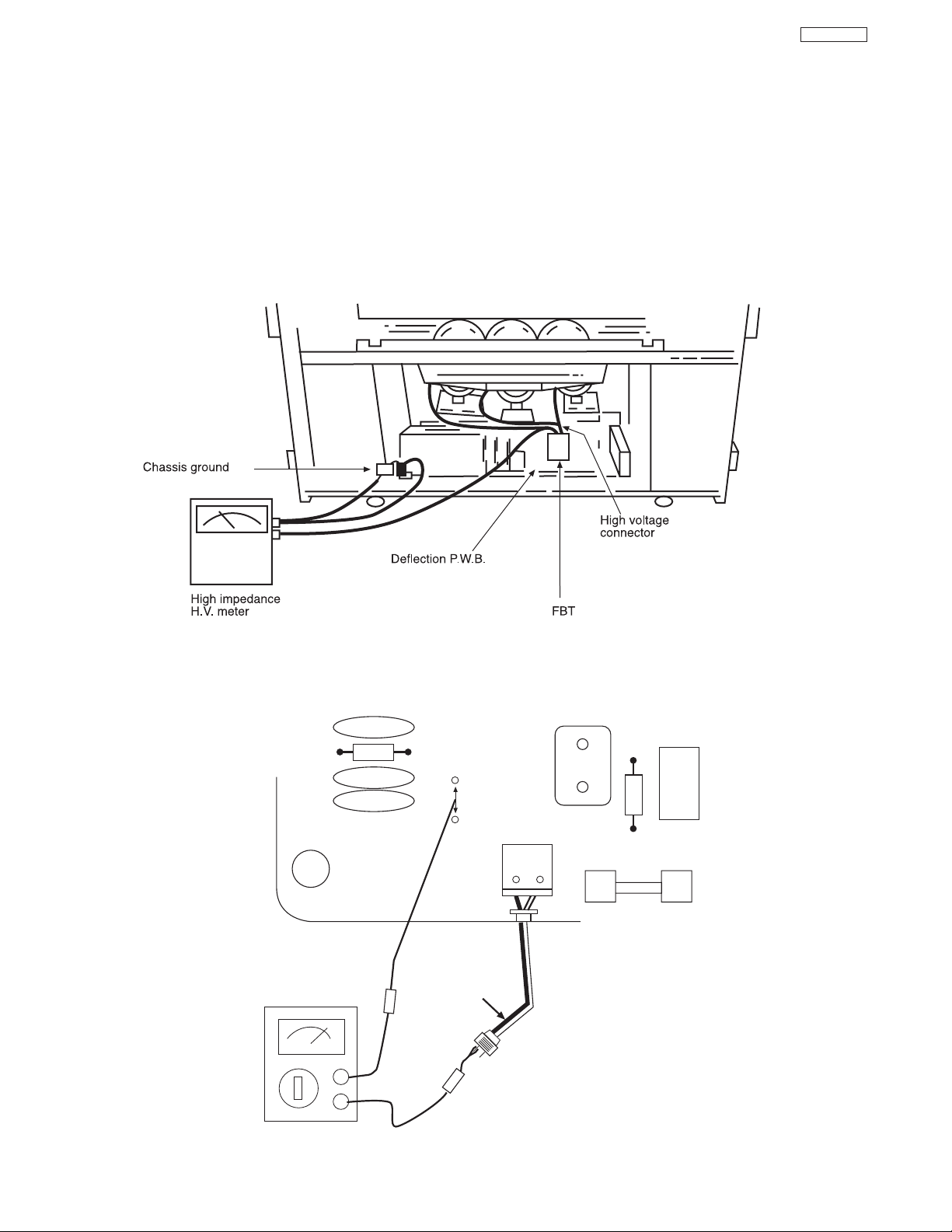

e. High Voltage – This receiver is provided with a hold

down circuit for clearly indicating that voltage has

increased in excess of a predetermined value.

Comply will all notes described in this Service Manual

regarding this hold down circuit when servicing, so

that this hold down circuit may correctly be operated.

f. Service Warning – With maximum contrast, operating

high voltage in this receiver is lower than 30.5 kV. In

case any component having influence on high voltage

is replaced, confirm that the high voltage with

maximum contrast is lower than 30.5 kV.

To measure H.V. use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT anode

button. (See the following connection diagram.)

Note: Tu rn power switch off without fail before the

connection to the anode button is made.

LEAKAGE

CURRENT

TESTER

(READING

SHOULD NOT

BE ABOVE 0.5mA)

EARTH

GROUND

TEST ALL

EXPOSED

METAL SURFACES

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

AC Leakage Test

Chassis

ground

FBT

High Impedance

H.V. meter

Deflection P.W.B.

(TH01)

High voltage

connector

Page 4

4

DP26

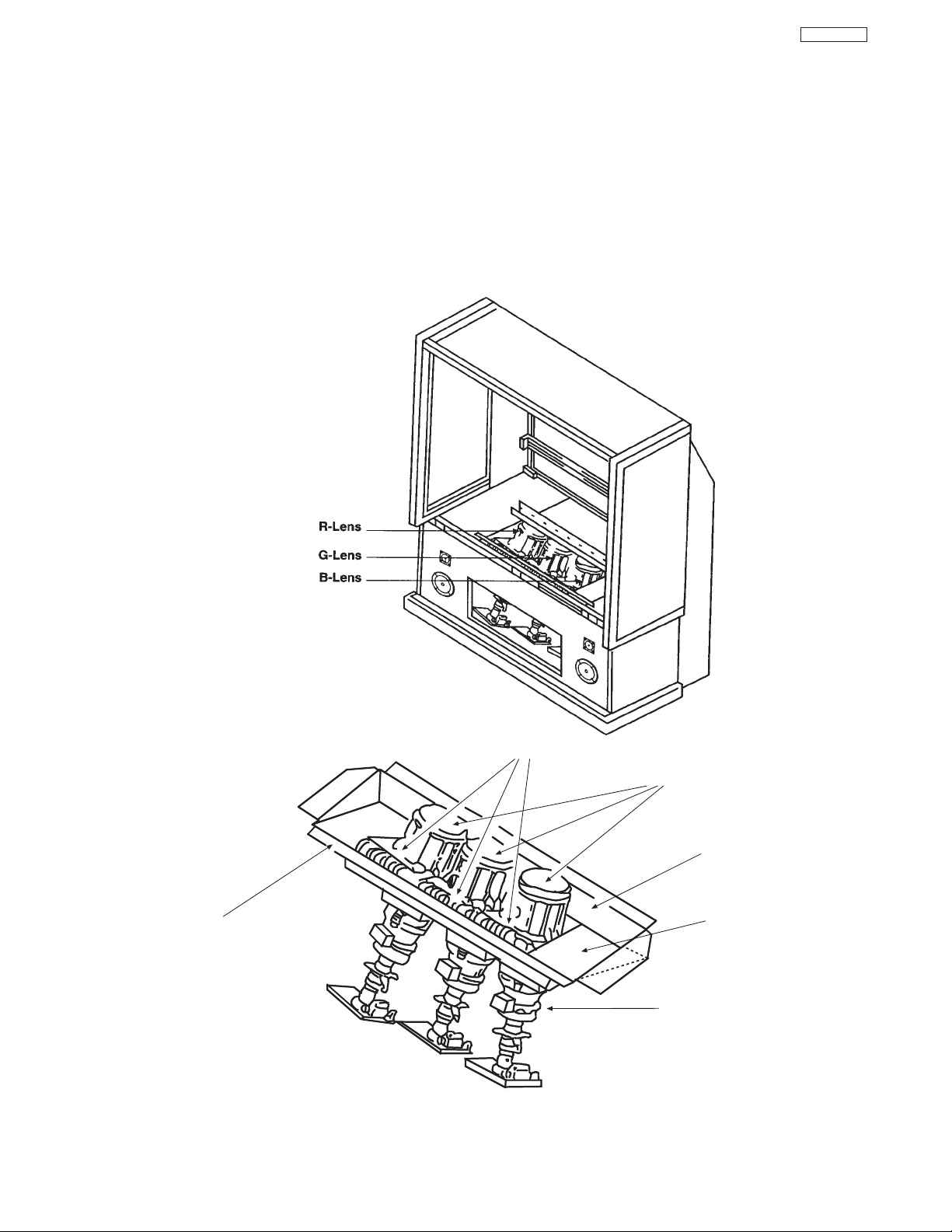

g. X-radiation – TUBE: The primary source of X-

radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original, Hitachi

approved type.

When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, avoid being unnecessarily close to the picture

tube and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

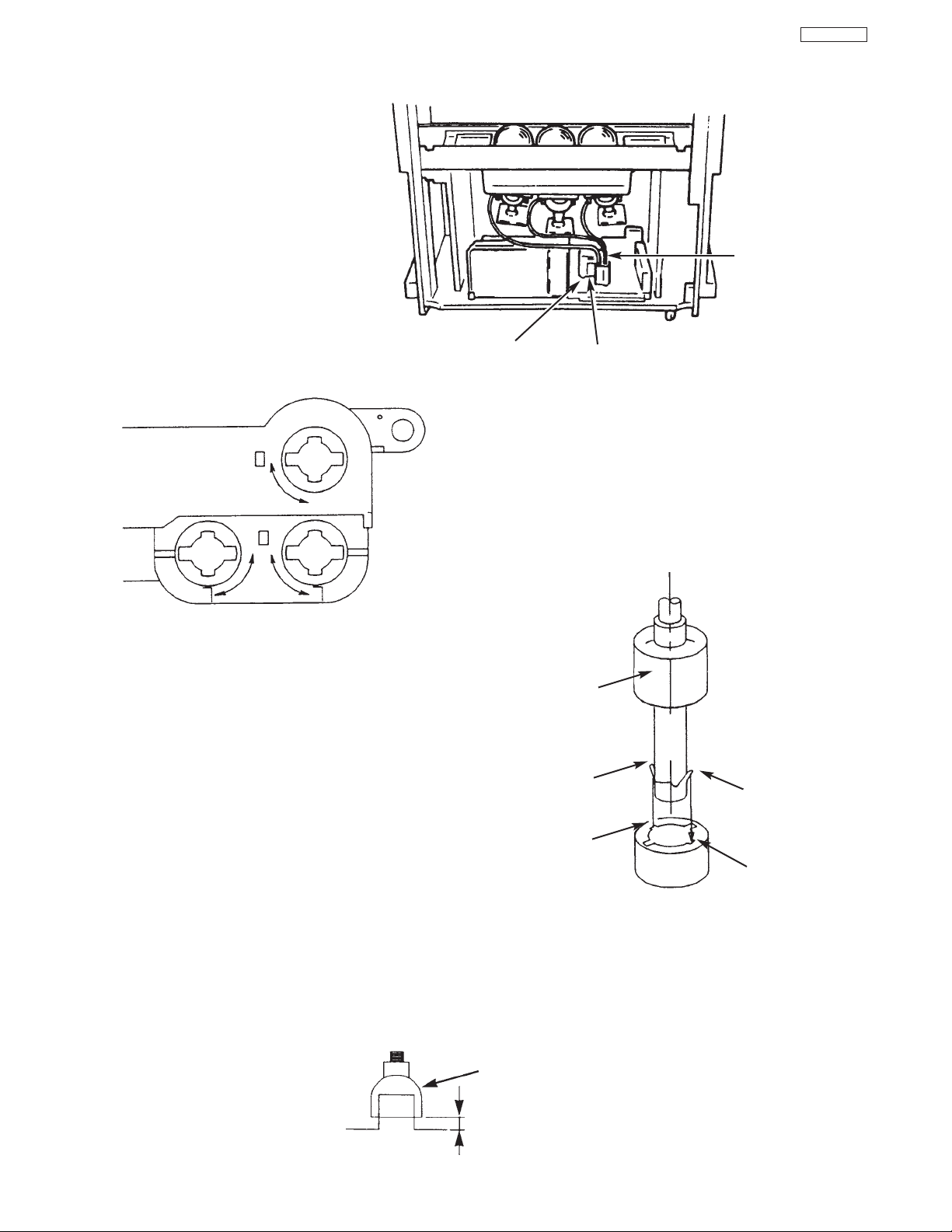

h. X-radiation Shield –

1. This receiver is provided with X-ray shield plates

for protection against X-radiation. Do not remove

X-ray shield plates A, B, or C shown in Fig. 1

unnecessarily, when troubleshooting and/or

making test measurements.

2. To prevent X-radiation, after replacement of

picture tube and lens, confirm these components

to be fixed correctly to bracket and cabinet, and

not to be taken off easily.

Shield Plate A

Glass Lens for Shielding

Shield Plate B

Shield Plate C

Shield Plate D

Detailing X-radiation shield

Shield Plate C

Fig. 1. Installation of shield lens, shield cover and shield plates (oblique view).

IMPORTANT SAFETY INSTRUCTIONS

Page 5

5

DP26

2. Read and comply with all caution and safety-related

notes on or inside the receiver cabinet, on the receiver

chassis, or on the picture tube.

3. Design Alteration Warning – Do not alter or add to

the mechanical or electrical design of this TV receiver.

Design alterations and additions including but not

limited to circuit modifications and the addition of

items such as auxiliary audio and/or video output

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alterations or additions may void the

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4. Picture Tube Implosion Protection Warning – The

picture tube in this receiver employs integral implosion

protection. For continued implosion protection,

replace the picture tube only with one of the same

type number. Do not remove, install, or otherwise

handle the picture tube in any manner without first

putting on shatterproof goggles equipped with side

shields. People not so equipped must be kept safely

away while picture tubes are handled. Keep the

picture tube away from your body. Do not handle the

picture tube by its neck.

5. Hot Chassis Warning – a. Some TV receiver chassis

are electrically connected directly to one conductor of

the AC power cord and may be safely serviced without

an isolation transformer only if the AC power plug is

inserted so that the chassis is connected to the

ground side of the AC power source. Confirm that the

AC power plug is inserted correctly with an AC

voltmeter by measuring between the chassis and a

known earth ground. If a voltage reading in excess of

1.0V is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure the

voltage potential between the chassis and a known

earth ground. b. Some TV receiver chassis normally

have 85V AC (RMS) between chassis and earth

ground regardless of the AC plug polarity. These

chassis can be safely serviced only with an isolation

transformer inserted in the power line between the

receiver and the AC power source, for both personnel

and test equipment protection. c. Some TV receiver

chassis have a secondary ground system in addition

to the main chassis ground. This secondary ground

system is not isolated from the AC power line.The two

ground systems are electrically separated by

insulating material that must not be defeated or

altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress in the following areas: a. near sharp

edges, b. near thermally hot parts – be sure that leads

and components do not touch thermally hot parts, c.

the AC supply, d. high voltage and e. antenna wiring.

Always inspect in all areas for pinched, out-of-plate, or

frayed wiring. Do not change spacing between

components and the printed circuit board. Check AC

power cord for damage.

7. Components, parts, and/or wiring that appear to have

overheated or are otherwise damaged should be

replaced with components, parts, or wiring that meet

original specifications. Additionally, determine the

cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

8. PRODUCT SAFETY NOTICE – Many TV electrical

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified in Hitachi service data by shading on

schematics and by a in the parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended replacement part in Hitachi service data parts list might

create shock, fire, and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate. For the

latest information, always consult the appropriate

current Hitachi service literature. A subscription to, or

additional copies of service literature may be obtained

at a nominal charge from Hitachi.

!

IMPORTANT SAFETY INSTRUCTIONS

Page 6

6

DP26

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

follow the “Important Safety Instructions” on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit

board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device

(DVM, FETVOM, etc.) equipped with a suitable high

voltage probe. Do not test high voltage by “drawing an

arc.” The H.V. Distribution Box has an internal 400MΩ

resistor (bleeder resistor) connected from the high

voltage to ground. After power is removed from the

instrument the high voltage will discharge through the

high voltage bleeder resistor. If the tubes have high

voltage after power is removed, then the bleeder resistor

is defective or the bleeder ground is disconnected.

3. Discharge the picture tubes anode at any of the R, G, or

B outputs on the H.V. Distribution Box only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield at

the point where the picture tube socket ground lead is

connected, and then (b) touch the other end of the

insulated clip lead to the picture tube high voltage

distribution box R, G, or B output, using an insulated

handle to avoid personal contact with high voltage.

4. Do not spray chemicals on or near this instrument or any

of its assemblies.

5. Unless specified otherwise in these service data, clean

electrical contracts by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%99% strength).

CAUTION: This is a flammable mixture. Unless

specified otherwise in these service data,

lubrication of contacts is not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service data might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

8. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

9. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only can anti-static type solder removal device.Some

solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ES

device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are ready

to install it. (Most replacement ES devices are packaged

with leads electrically shorted together by conductive

foam, aluminum foil or comparable conductive material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ES device.)

SERVICING PRECAUTIONS

Page 7

7

DP26

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate gauge of resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts. Quickly

draw away the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

d. Closely inspect the solder area and remove any excess

or splashed solder with a small wire-bristle brush.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect to replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

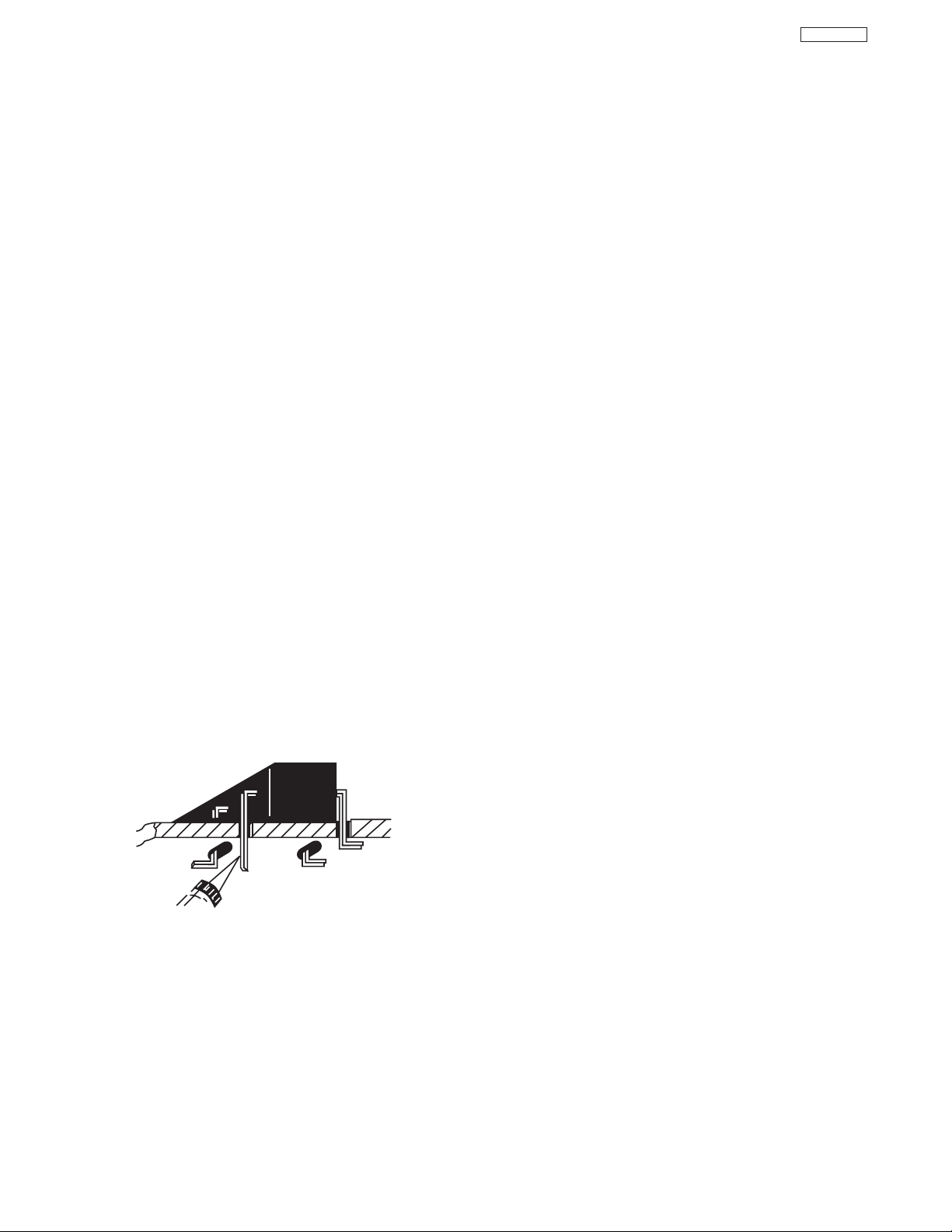

Use Solding Iron to Pry Leads

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are the

slotted type, the following technique should be used to

remove and replace the IC.When working with boards using

the familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

SERVICING PRECAUTIONS

Page 8

8

DP26

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent

components and the circuit board, to

prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “lift-off,”

the board. The following guidelines and procedures should

be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small “U” in one end of a small-gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of the

pattern break and locate the nearest component directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

Frequency Synthesis (FS) Tuning Systems

1. Always unplug the instrument AC power cord before

disconnecting or reconnecting FS tuning system cables

and before removing or inserting FS tuning system

modules.

2. The FS tuner must never be disconnected from the FS

tuning control module while power is applied to the

instrument.

3. When troubleshooting intermittent problems that might be

caused by defective cable connection(s) to the FS tuning

system, remove the instrument AC power as soon as the

defective connector is found and finish confirming the bad

connection with a continuity test. This procedure will

reduce the probability of electrical overstress of the FS

system semi-conductor components.

CRIMP AND

SOLDER

BARE JUMPER

WIRE

Install Jumper Wire and Solder

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

SERVICING PRECAUTIONS

Page 9

9

DP26

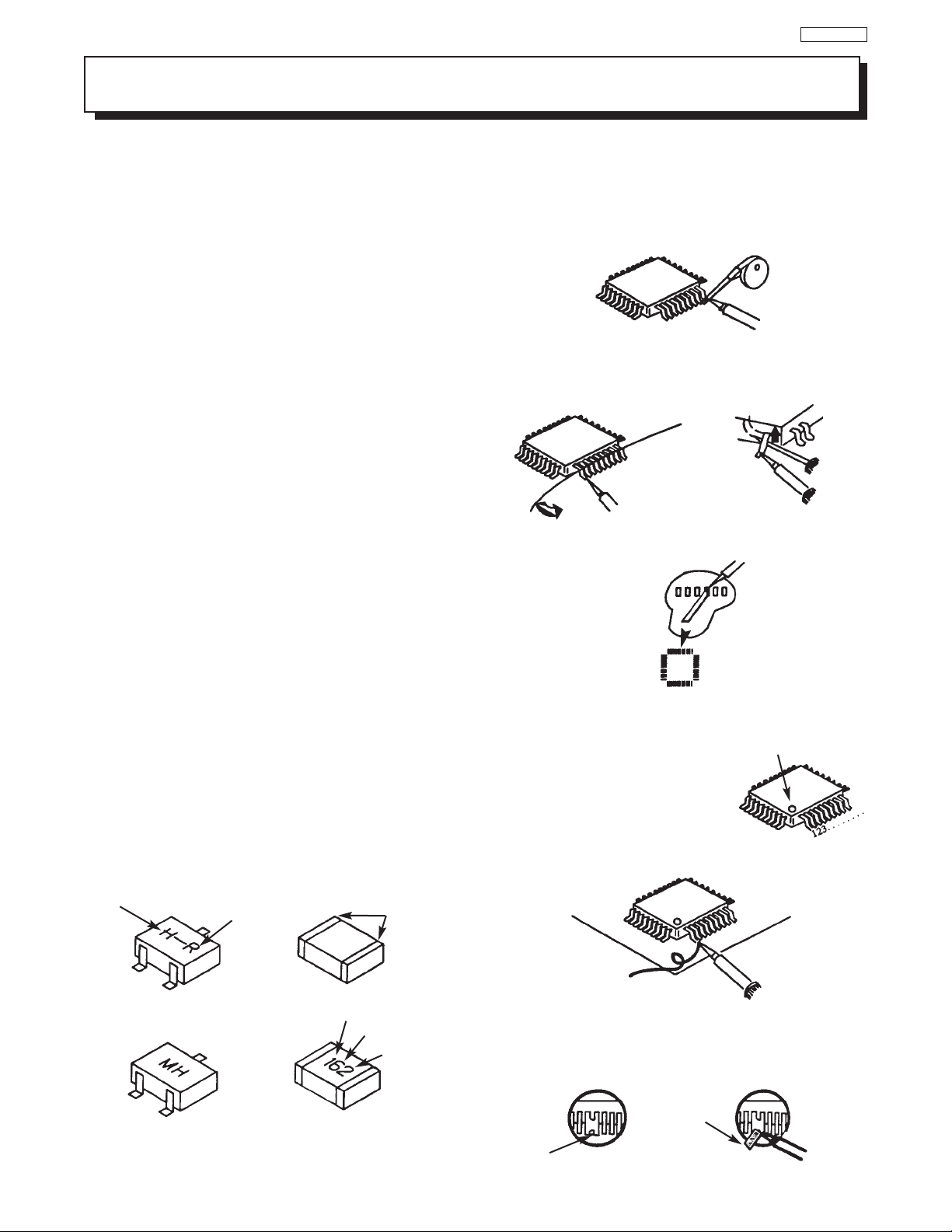

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor.The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code.The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as per

the code chart and are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

•De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

soldering pads and pins by

correctly aligning the polarity

symbol.

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder braid

as shown in the figure below.

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

Chip Components

TYPE

GRADE

C

B

E

SOLDER

CAPS

TRANSISTOR

CAPACITOR

1ST DIGIT

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

ANODES

MH DIODE

RESISTOR

SOLDER CAPS

COMMON CATHODE

Flat-IC

De-Solder

Braid

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

De-Solder

Braid

Flat-IC

Solder

Bridge

Solder

De-Solder

Braid

Iron

Wire

Pull

Awl

Polarity Symbol

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

SERVICING PRECAUTIONS

Page 10

10

DP26

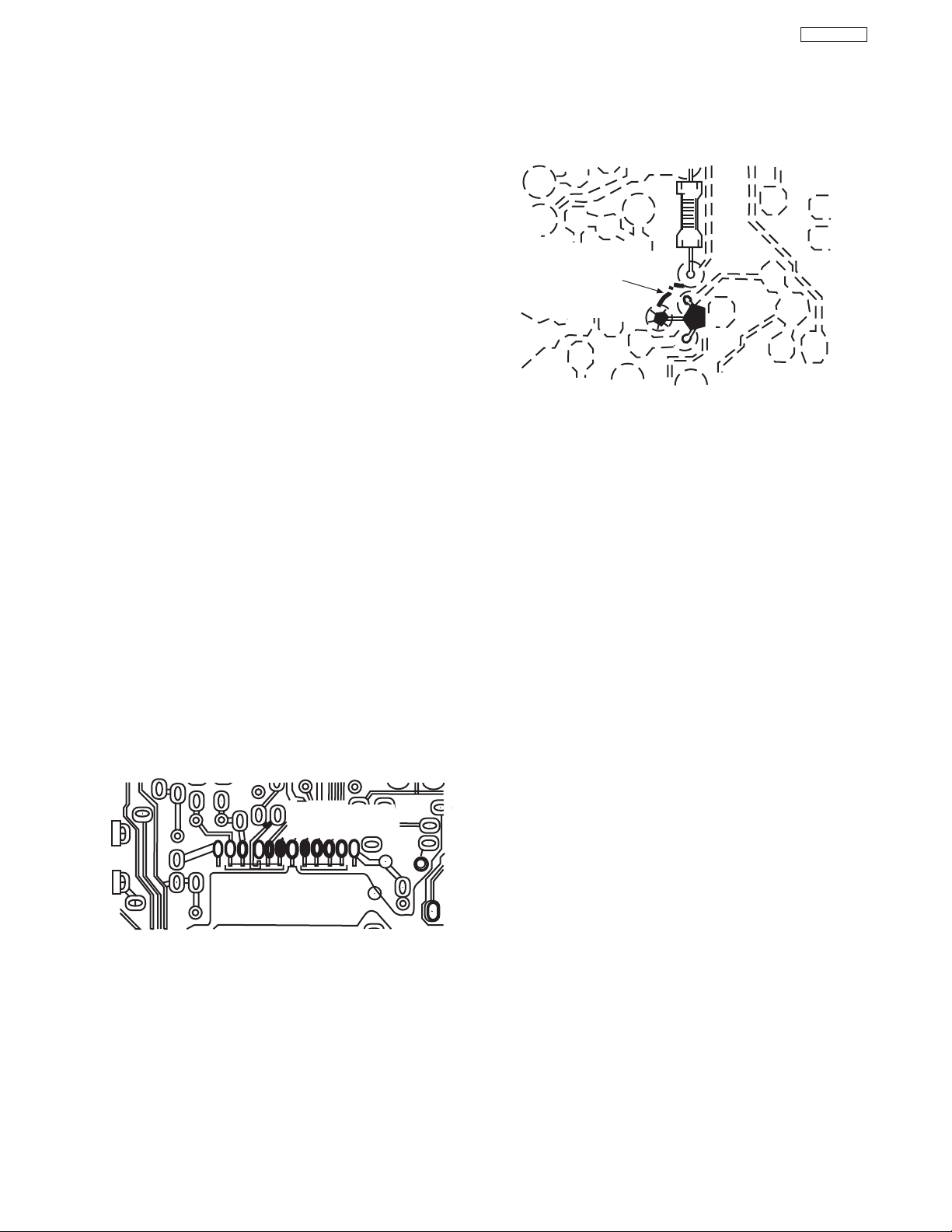

High Voltage limiter circuit operation check.

1. Turn off TV and connect jig as shown in Figure 2. Adjust

jig fully counter-clockwise for minimum resistance.

2. Set the AC input to 120V AC and turn on TV.

3. Confirm test pattern on CRT is a usable picture, then

slowly adjust jig until the picture disappears and TV shuts

down.

4. When the limiter circuit is operating properly, High

Voltage will be less than 30.5 kV at 1.4mA when TV shuts

down.

5. Turn off set immediately after checking circuit operation.

6. Unplug set for one minute to reset shutdown circuit.

Remove jig and voltmeter.

TECHNICAL CAUTIONS

(TH01)

WHITE side

GND side

TESTER

C901

R901

EF901

EF901

F901

KP01

PA

1

2

X901

R903

C981

R980

AC CORD POLARITY

This check is based on the UL standard. Use the jigs specified by the production technology section. The GND side (wider

blade) of the AC power cord should be connected to K9Y1

Page 11

11

DP26

Models: 65XWX20B

57XWX20B

51XWX20B

Cathode-Ray Tube:

51XWX20B R=P16LXT00RFA01(U)

57XWX20B G=P16LXT00HHA01(U)

65XWX20B B=P16LXT00BMB01(U)

Power Input: 120 volts AC, 60 Hz

Power Consumption:

• Stand-By Power

51/57/65XWX20B . . . . . . . . . . . . . . . .6.5W

•Power Consumption (operating)

51/57/65XWX20B . . . . . . . . . . . . . . . .226W

•Power Consumption (maximum)

51/57/65XWX20B . . . . . . . . . . . . . . . .279W

Antenna Impedance: 75 Ohm Unbalanced

VHF / UHF / CATV

Receiving Channel: BAND CH

VHF 2~13

UHF 14~69

EXT. Mid (A-5)~(A-1), 4+

CATV Mid. A~I

CATV Super J~W

CATV Hyper (W+1)~(W+28)

CATV Ultra (W+29)~(W+84)

Intermediate Frequency: Picture l-F Carrier 45.75 MHz

Sound l-F Carrier 41.25 MHz

Color Sub Carrier 42.17 MHz

Video Input: 1 Volt p-p, 75 Ohm

Video Output: 1 Volt p-p, 75 ohm

Audio Input: 470 mVrms, 47 k Ohm

Stereo Audio Output: 470 mVrms, 1 k Ohm

Audio Output Power:

Front: 20 watts per channel at 10% distortion,

6 ohm Impedance. Max output – 40 watts.

Anode Voltage:

DP26

30.2±0.3kv (1.20±0.2mA)

Brightness: 51” 57” 65”

(white screen) 220cd/m

2

180cd/m

2

140cd/m

2

Speakers: 2 Woofers - 5 inch (12 cm) round

2 Tweeters - 2 inch (5 cm) round

Dimension:

51” 57” 65”

Height (in.) 50 1/8 54 3/16 59 7/8

Width (in.) 44 1/2 54 1/64 61

Depth (in.) 25 1/32 25 1/32 28

Weight (Ibs.) 238 265 319

Circuit Board Assemblies:

C.P. T. (B) P.W.B. IR P.W.B.

C.P. T. (G) P.W.B. IR Sub P.W.B.

C.P. T. (R) P.W.B. Terminal P.W.B.

Power Supply P.W.B. Signal P.W.B.

Control P.W.B. Def/Convergence P.W.B.

Sensor Distribution P.W.B. DVI P.W.B

Digital Main P.W.B. Digital Sub P.W.B.

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details.The following symbol near the fuse

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

Example:

SPECIFICATIONS

“RISK OF FIRE - REPLACE FUSE AS MARKED”

The rating of fuse F901 is 6A - 125V.

Replace with the same type fuse for continued protection

against fire.

F

6 A 125V

125V

6A

Page 12

12

DP26

During Insertion

1. Please refer to direction for insertion as shown in Fig. B (L position). Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

CAUTIONS WHEN CONNECTING / DISCONNECTING THE HV CONNECTOR

Perform the following when the

HV connector (anode connector)

is removed or inserted for CPT

replacement, etc.

Deflection P.W.B.

Silicon cover

Wing

L Position

L Position

Wing

FBT

Anode

connector

3. Remove the connector slowly

by pulling it away from the

case.

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees

following the arrow (0 position), push the connector

slightly towards the case. (Fig. A)

Fig. A

Fig. B

Silicon Cover

less than 1mm

PUSH

PUSH

Page 13

13

DP26

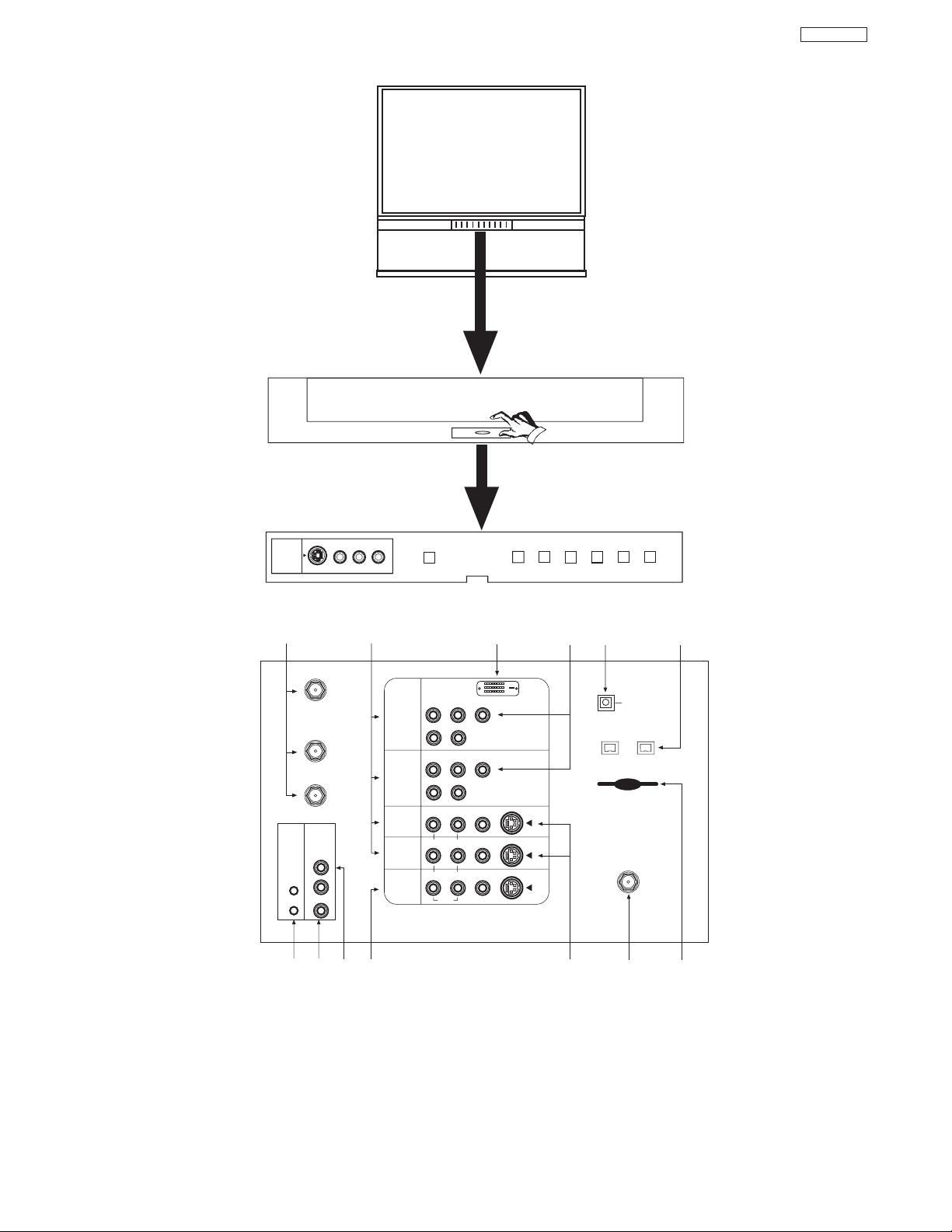

GENERAL INFORMATION

Antenna Input/Output Component Input Y-P

BPR

Audio/Video Inputs 1, 2, 3 and 4 IR BLASTER

MONITOR OUT DVI-HDTV Input (Input 1)

AUDIO TO HI-FI Output OPTICAL OUT (Digital Audio)

CENTER IN (Input) IEEE1394

S-VIDEO Inputs 3 and 4 Multi Media Card Slot

P

B

P

R

CENTER

IN

P

B

P

R

DVI-HDTV

ANT A

TO

CONVERTER

ANT B

L

Y

R

(MONO)/L

IR

BLASTER

AUDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

INPUT 5

S-VIDEO

VIDEO

-AUDIO-

L/MONO

R

EXIT

INPUT

SELECT

MENU

MAGIC FOCUS

VOL- VOL+ CH- CH+

POWER

PULL

FRONT CONTROL PANEL

REAR PANEL JACKS

Page 14

14

DP26

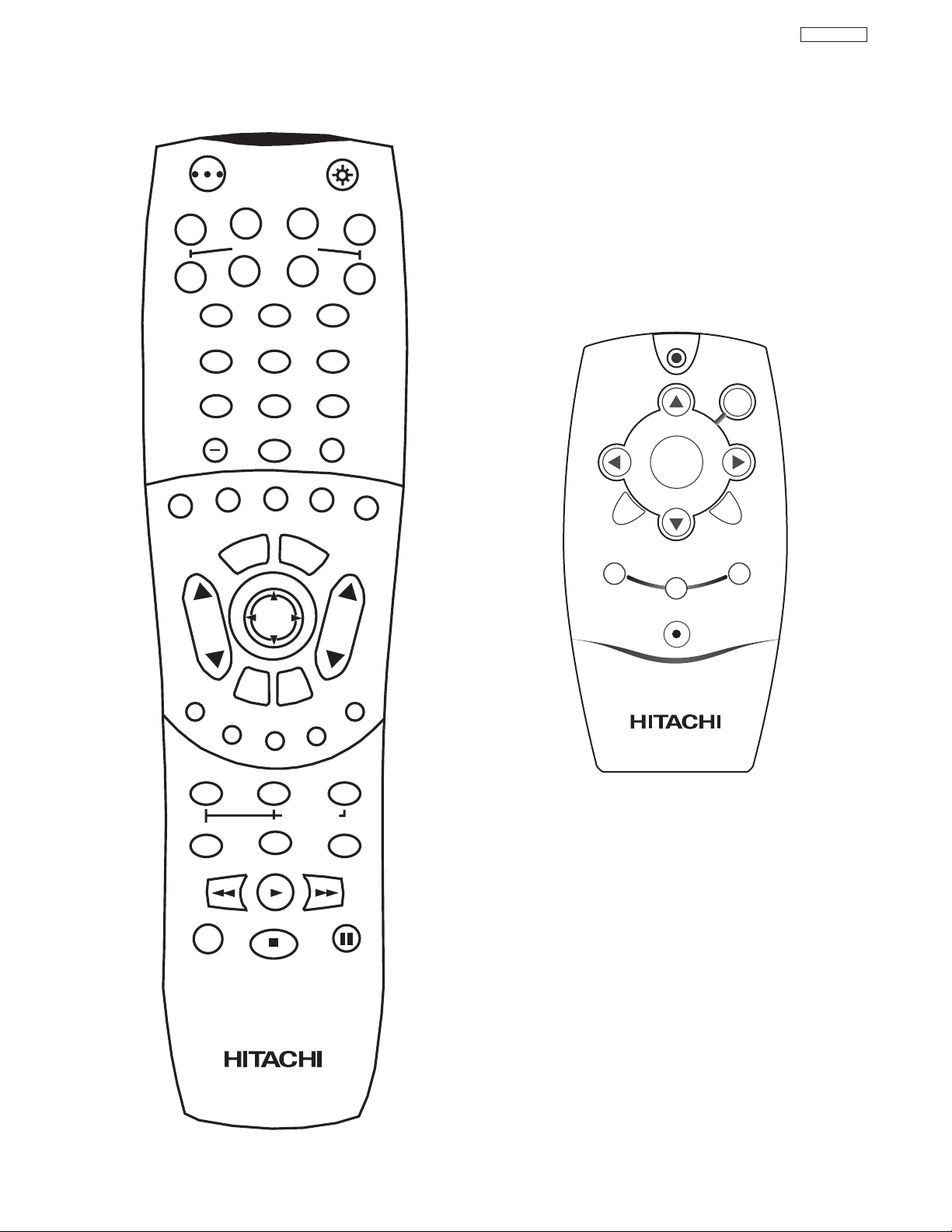

REMOTE CONTROL

POWER

TV

VCR

CBL

DVD

1

2

4

56

3

7

89

0

INFOSLEEP

GUIDE

EXIT

MENU

CHVOL

MUTE

PIP PIP CH

SWAP

FREEZE

PIP MODE

PIP ACCESS

VIDEO

SOURCE WIZARD

REC

SELECT

A/V NET

ASPECT

STB

ANT

LAST CH

SVCS

SCHD

VID 1

VID 2

VID 3

VID 4

VID 5

TAPE

CD

AMP

VIRTUAL HD

CLU-5721TSI

CLU-5721TSI

CLU-120S

MUTE

VOL -

MENU

A/V NET

CH +

VOL +

SELECT

FAV CH

CH -

ANT

EXIT

POWER

Page 15

15

DP26

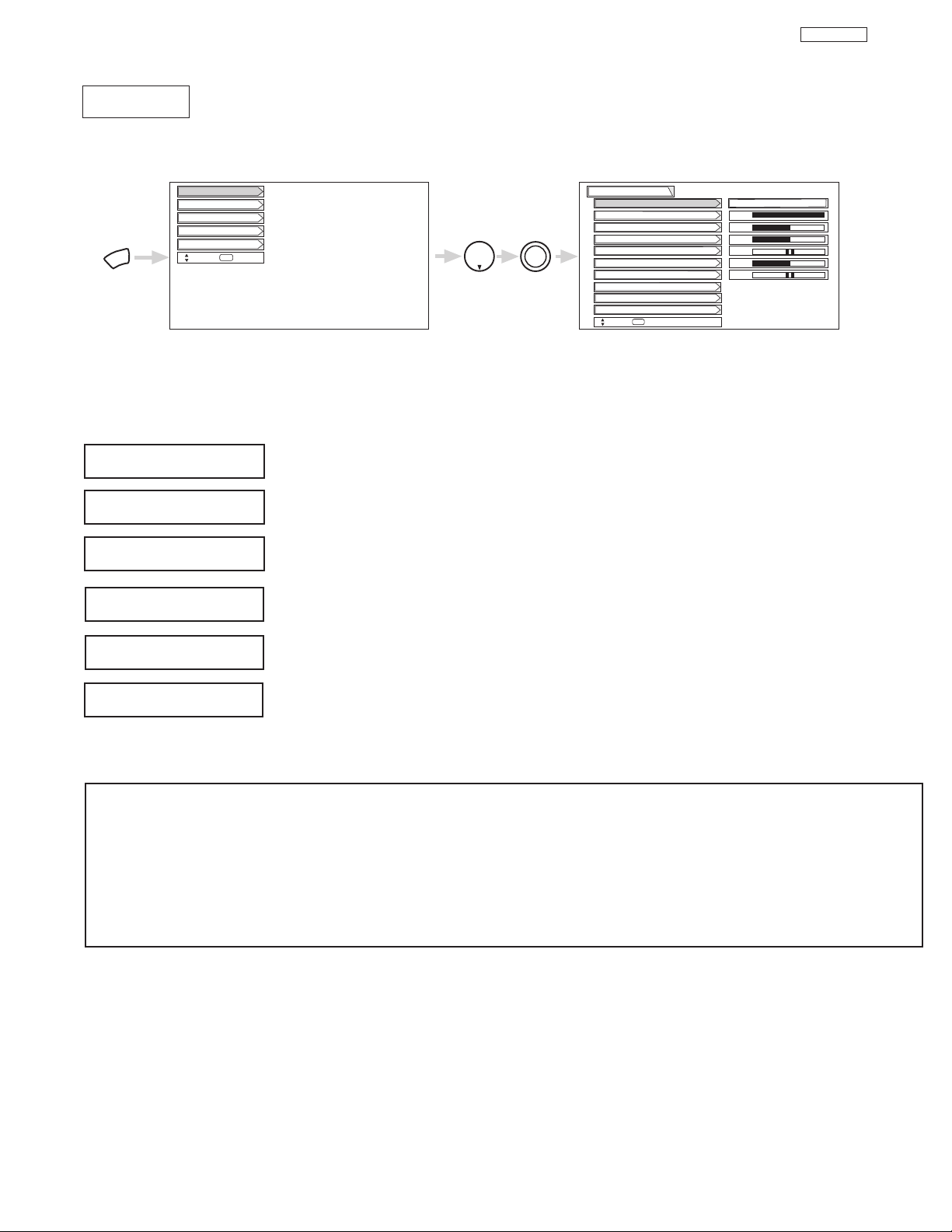

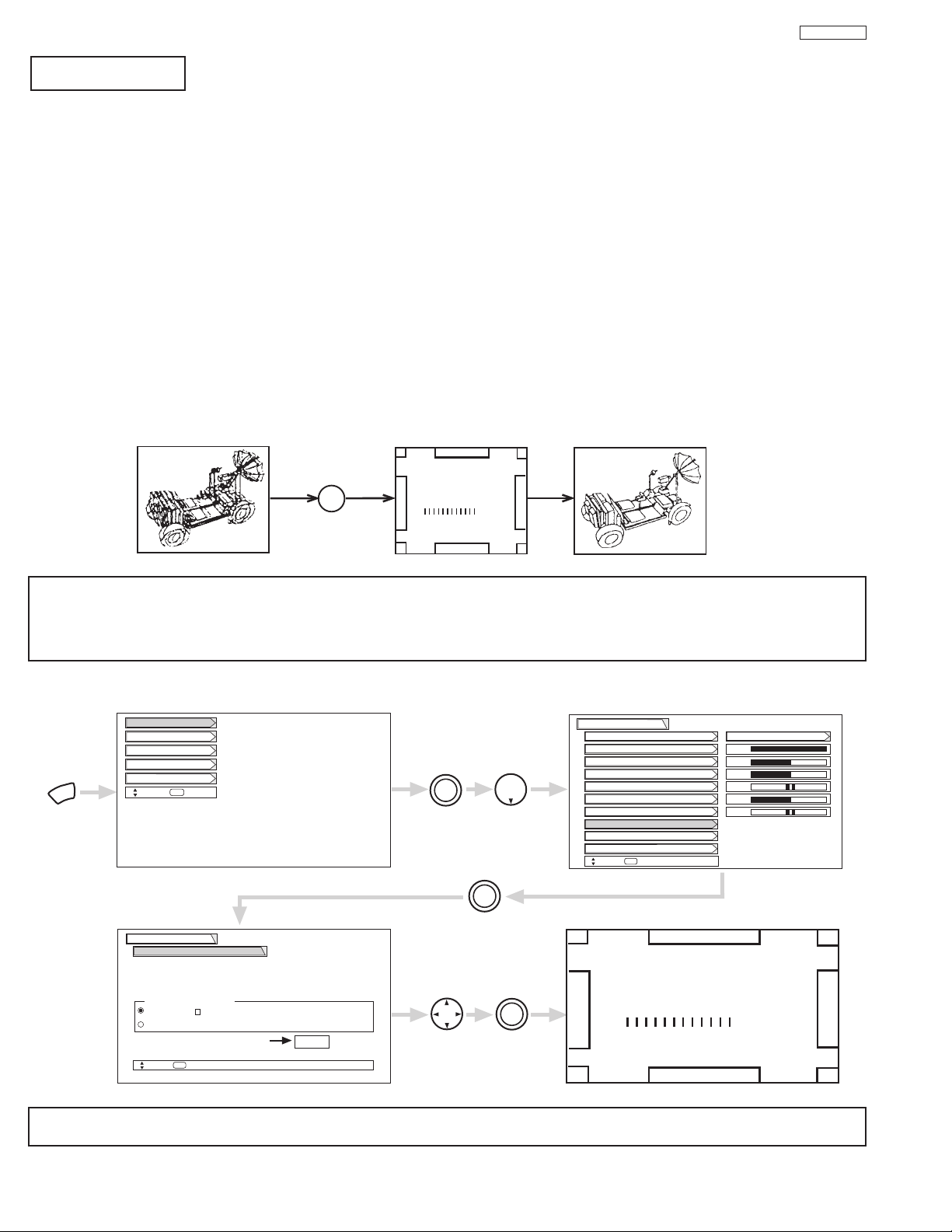

Select VIDEO to adjust picture settings and improve picture quality.

M

E

N

U

THUMB

STICK

THUMB

STICK

SELECT

Setup

Locks

Ch. Manager

Audio

Video

Move

SEL

Sel

Color

Brightness

Contrast

Picture Mode

Video

Move

SEL

Select

Vertical Position

Sharpness

Tint

Advanced Settings

Color System

100%

50%

50%

50%

0

Magic Focus

Sports

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Use this function to change the contrast between black and white levels in the picture. This adjustment

will only affect the picture when ADVANCED SETTINGS DIMMER is OFF.

Use the THUMB STICK or to highlight the function to be adjusted.

Press the THUMB STICK or to adjust the function. Press down on THUMB STICK to select the function settings.

Press MENU to return to main menu or select PICTURE MODE to return to previous menu.

Press EXIT to quit menu.

Use this function to adjust the level of color in the picture.

Use this function to adjust overall picture brightness.

This function allows you to select when aspect style is either 4:3 EXPANDED/ZOOM1/ZOOM2. Vertical

position can be changed with this mode. Adjustable range is -10 (video center is toward bottom of

screen) to +10 (video center is toward top of screen).

Contrast

Color

Brightness

Vertical Position

NOTES: 1. If CONTRAST is selected, you are adjusting CONTRAST. The additional menu items BRIGHTNESS, COLOR, TINT,

and SHARPNESS can be selected and adjusted in the same manner.

2. It may be necessary to adjust TINT to obtain optimum picture quality when using the COMPONENT VIDEO Y-PBP

R

input jacks.

3. If you are using the COMPONENT VIDEO input jacks (Y-PBPR) and notice that the TINT and COLOR are abnormal,

check to make sure that VIDEO- Color System is set properly.

4. ANT A/ANT B and ANT C have different Video settings. Also, each of the video inputs have their own settings.

5. If COLOR is set to minimum level, the On-Screen Display (OSD) will be difficult to see.

Use this function to adjust flesh tones so they appear natural.

Tint

Use this function to adjust the amount of fine detail in the picture.

Sharpness

Video

Page 16

16

DP26

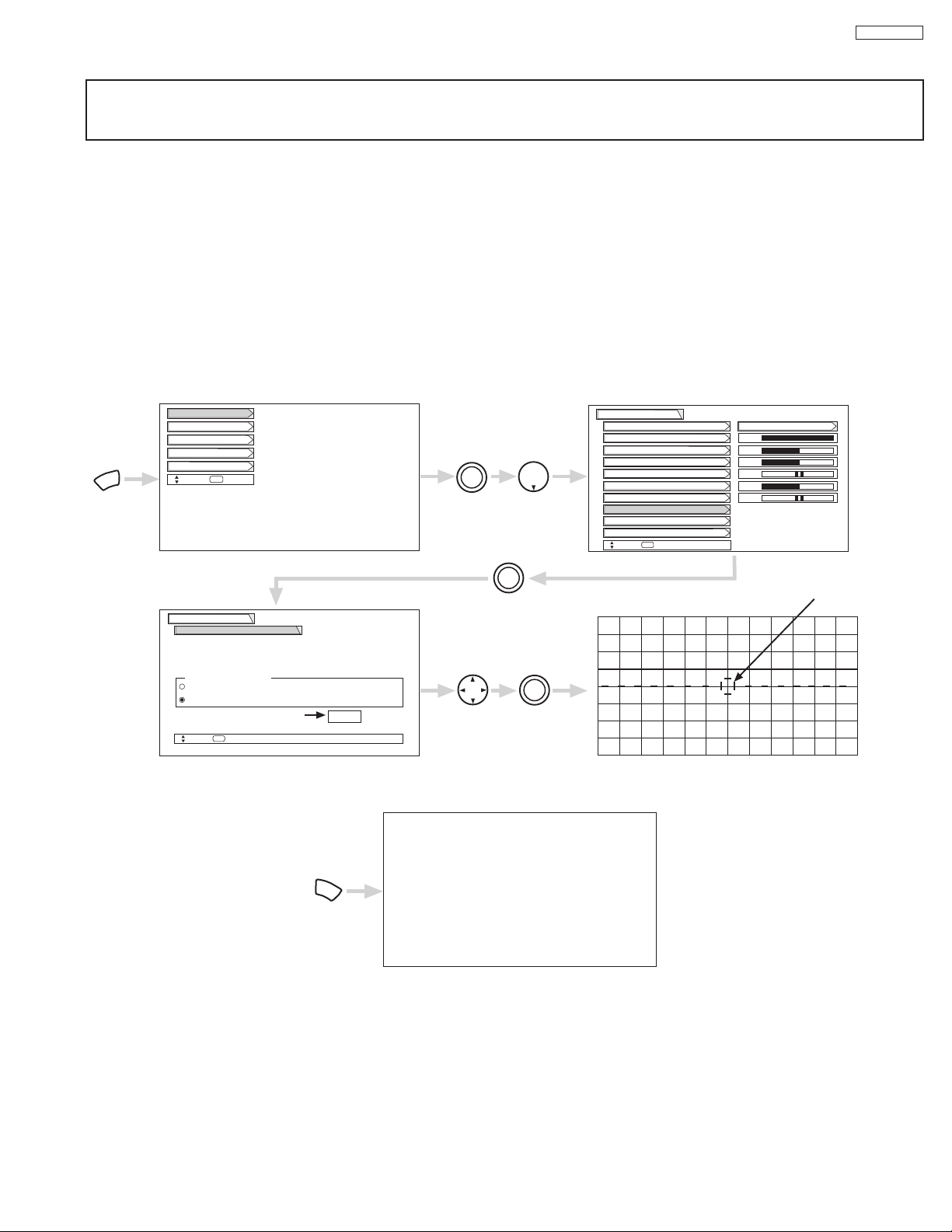

MAGIC

FOCUS

MAGIC FOCUS

Auto Digital Convergence Adjustment

Please turn ON your television for at least 20 minutes before using this feature.

The Magic Focus button on the control panel will not work when Adjustment Mode is set to Manual (see page 17).

Your HITACHI Projection TV has three color projection tubes: one for red, one for green, one for blue. When mixed together in the proper

proportion, the output of these three color tubes can produce any color. To produce these colors, however, the beams must be precisely

aligned over each other so that the colors can be mixed. The process of aligning these picture beams is called “convergence”.

Over a period of time, the picture tubes can drift out of alignment due to normal bumps and vibrations or moving the TV. If you move

your TV, or if, after a time, you notice color rings or halos around objects in the picture, you may want to converge (align) the colors.

Properly converged, the lines appear white, which is actually a combination of the outputs of the three color tubes. The output of the

green tube is stationary. The outputs of the red and blue tubes can be adjusted. When properly aligned, the outputs of all three tubes

should be directly over each other to produce the white lines.

To simplify convergence, HITACHI incorporates a function called MAGIC FOCUS located on the front control panel, which allows the TV

to self-adjust. Press this MAGIC FOCUS button and the convergence self adjustment will start and this process will take approximately

20 seconds. If this button is pressed during this process, no change in picture quality will occur. After this 20 second self-adjust period,

picture quality will be optimum. (Do not move the TV during self-adjust.)

You may also select Magic Focus from the VIDEO menu.

Magic Focus

NOTE: Only a momentary press of the MAGIC FOCUS button is necessary to start AUTO DIGITAL CONVERGENCE. At any

time during this convergence correction process, you may press the MAGIC FOCUS button to exit the MAGIC FOCUS

mode. However, the convergence correction process needs to be completed to SAVE the new corrected convergence

data.

Magic Focus

Video

Move

SEL

Return

Aligns the Red, Green, and Blue

colors to correct for Magnetic

Influences.

Auto

Manual

MENU

THUMB

STICK

THUMB

STICK

SELECT

Setup

Locks

Ch. Manager

Audio

Video

Move

SEL

Sel

Color

Brightness

Contrast

Picture Mode

Video

Move

SEL

Select

Vertical Position

Sharpness

Tint

Advanced Settings

Color System

100%

50%

50%

50%

Magic Focus

Sports

THUMB

STICK

SELECT

Adjustment Mode

If you want to adjust now

THUMB

STICK

THUMB

STICK

SELECT

Start

MAGIC FOCUS

At Turn Off

(After 90 days)

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

NOTE: When Auto Start at Turn Off is selected, the TV will adjust itself after 90 days.

Page 17

17

DP26

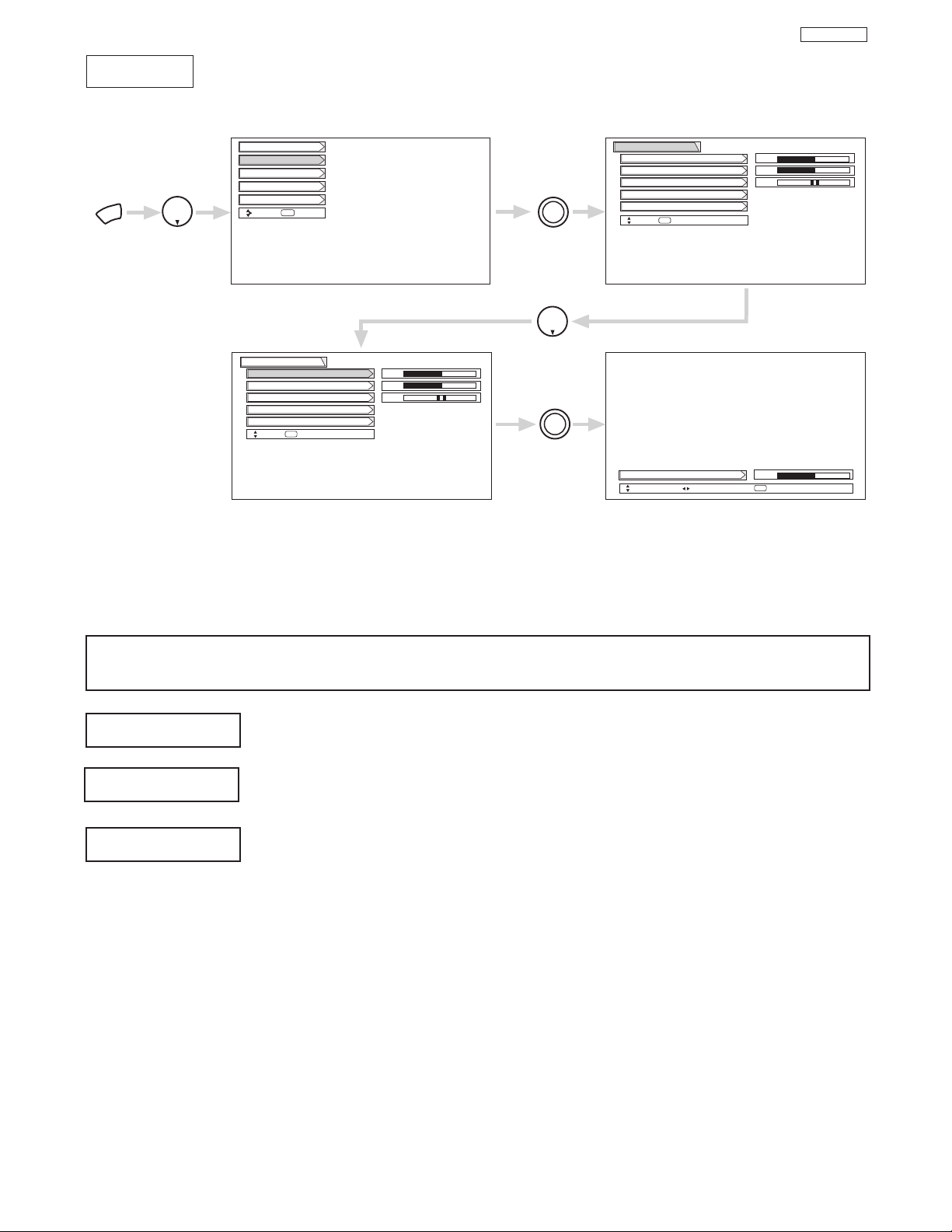

NOTES: 1. Please turn ON your television for at least 20 minutes before using this feature.

2. Auto Adjustment Mode is recommended. If convergence is still not acceptable, use the Manual Adjustment Mode.

DO NOT press MAGIC FOCUS or use Auto Adjustment Mode after using Manual Adjustment Mode.

Manual Convergence Adjustment Mode

Using the Remote Control, select VIDEO-MAGIC FOCUS-MANUAL ADJUSTMENT MODE-START to access convergence crosshatch

pattern. The adjustment point is indicated by the Adjustment Point Cursor.

To Move Adjustment Point

To move the adjustment point cursor using the THUMBSTICK, the Adjustment Cursor must be WHITE. Another way to move the

Adjustment Point Cursor is to press the following buttons: [2] up, [4] left, [5] down, [6] right. If you use the number buttons while the

adjustment point is WHITE, it will change to RED.

To Change the Color of Adjustment Point

Press the SELECT button repeatedly (WHITE-RED-BLUE-WHITE...). Green color is fixed and cannot be adjusted.

To Adjust the Convergence

Move the Adjustment Cursor to the point to be adjusted. Use the THUMB STICK to match the RED and BLUE colors to GREEN

(reference color). Properly aligned, all three colors should appear white.

If convergence is acceptable after Manual Convergence adjustment, press EXIT button to access menu mode.

Press the [1] button on the remote control to SAVE adjusted data and return to main picture.

Press the [2] button on the remote control to CANCEL adjusted data and return to main picture.

Press the [3] button on the remote control to recall the factory pre-set convergence data.

Press the [4] button on the remote control to return to the manual convergence adjustment mode (crosshatch pattern).

Press the [9] button on the remote control to read the SAVED adjusted data. If there is no Saved data, pressing the [9] button will recall

the factory pre-set data.

Magic Focus

Video

Move

SEL

Return

Aligns the Red, Green, and Blue

colors to correct for Magnetic

Influences.

Auto

Manual

M

E

N

U

THUMB

STICK

THUMB

STICK

SELECT

Setup

Locks

Ch. Manager

Audio

Video

Move

SEL

Sel

Color

Brightness

Contrast

Picture Mode

Video

Move

SEL

Select

Vertical Position

Sharpness

Tint

Advanced Settings

Color System

100%

50%

50%

50%

Magic Focus

Sports

THUMB

STICK

SELECT

Adjustment Mode

If you want to adjust now

THUMB

STICK

THUMB

STICK

SELECT

Start

Adjustment Point

Cursor

E

X

IT

DONE : [1]

CANCEL : [2]

INI. RESET : [3]

BACK : [4]

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Page 18

18

DP26

Select AUDIO to adjust the TV to your preference and to improve the sound quality.

Audio

M

E

N

U

THUMB

STICK

THUMB

STICK

SELECT

THUMB

STICK

SELECT

Setup

Locks

Ch. Manager

Audio

Video

Move

SEL

Sel

Next/Prev Change Value Return

SEL

Sound Enhancement

Balance

Bass

Treble

Audio

Move

SEL

Return

50%

50%

Sound Enhancement

Balance

Bass

Treble

Audio

Move

SEL

Select

50%

50%

Treble

50%

THUMB

STICK

Advanced Settings

Advanced Settings

LR

LR

This function controls the low frequency audio to all speakers.

Use THUMB STICK to highlight functions.

Press down on THUMB STICK to select the function setting.

Press THUMB STICK or to adjust the function.

Press EXIT to quit MENU, or select Audio to return to the main menu.

NOTE: If TREBLE is selected you are adjusting treble. The additional menu items Bass and Balance can be selected

and adjusted in the same manner.

This function controls the high frequency audio to all speakers.

This function will control the left to right balance of the TV internal speakers and the AUDIO TO HIFI output.

Bass

Balance

Treble

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

Page 19

19

DP26

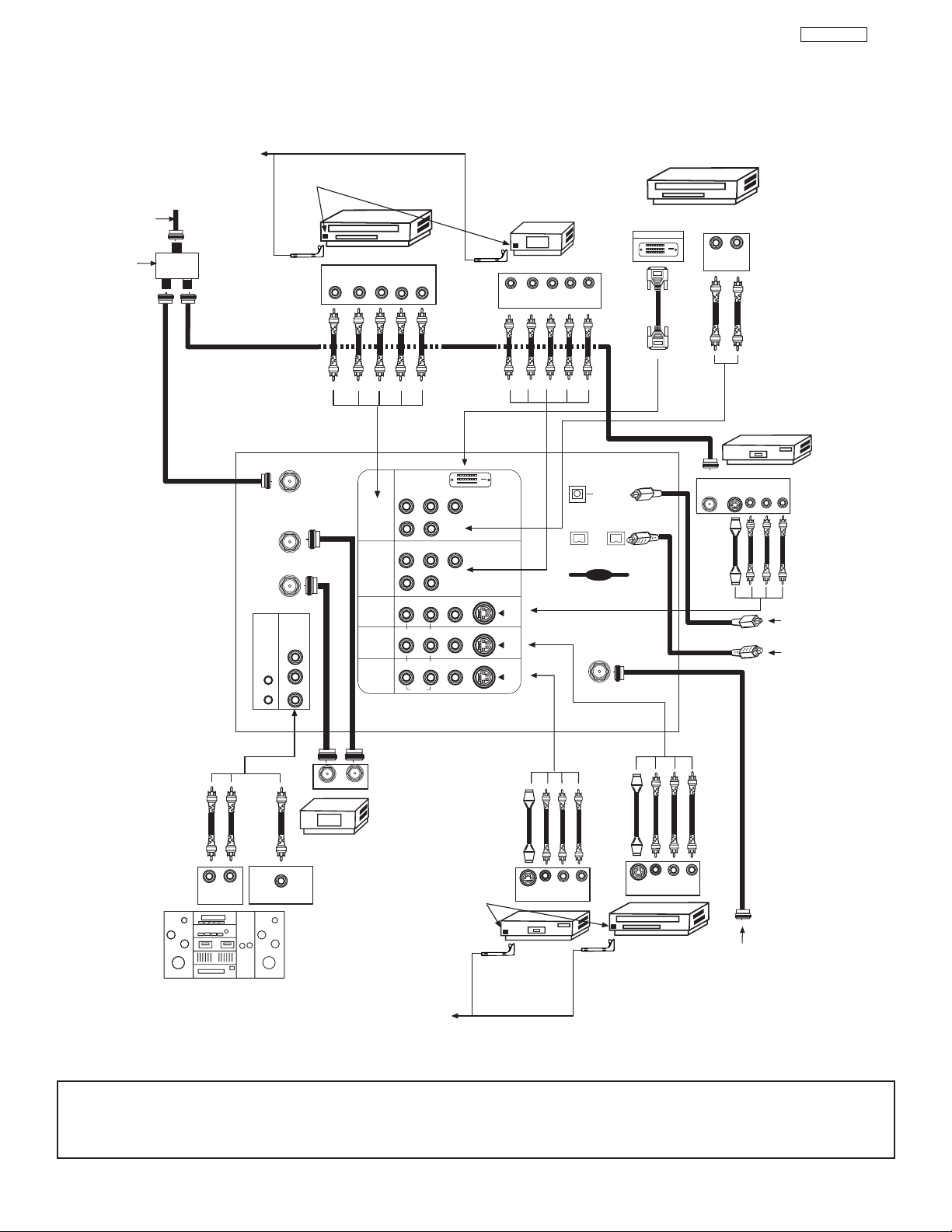

REAR PANEL CONNECTIONS

NOTES: 1.

Connect only 1 component to each input jack.

2. Follow connections that pertain to your personal entertainment system.

3. Composite video signal can be input to Input2~Input5.

4. Cables are not included with the purchase of this TV, except when noted as “provided”.

TYPICAL FULL-FEATURE SETUP

Outside antenna or

cable TV coaxial cable

2-Way signal splitter

CONNECT TO

IR BLASTER

IR

BLASTER

IR

Sensor

ANT A

TO

CONVERTER

ANT B

AUDIO

TO HI-FI

CENTER

IN

L

R

(Provided)

DVD Player

YP

B/CBPR/CR

OUTPUT

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

L R

P

R

R

P

R

R

R

R

R

AUDIO

DVI-HDTV

P

B

(MONO)/L

AUDIO

P

B

(MONO)/L

AUDIO

(MONO)/L VIDEO

(MONO)/L VIDEO

LVIDEO

Y

Y/VIDEO

HDTV Set-Top Box

Y P

S-VIDEO

S-VIDEO

S-VIDEO

P

B

OUTPUT

L R

R

OPTICAL OUT

Digital Audio

IEEE1394

Multi Media Card

ANT C

(DTV)

DIGITAL OUTPUT

D-VHS

LR

OUTPUT

ANT

IN

S-VIDEO

VCR #1

OUTPUT

VLR

To an amplifier/receiver

with optical input capability.

To a digital IEEE1394 capable

device, such as a Digital VCR

or Set-Top-Box.

INPUT

OUTPUT

Cable TV Box

LR

INPUT

CENTER OUTPUT

IR

Sensor

S-VIDEO

VCR #2

V L R

INPUT

S-VIDEO

Laserdisc player, VCR,

camcorder, etc.

Stereo System Amplifier

CONNECT TO

IR BLASTER

(Provided)

V L R

OUTPUT

Outside antenna or

cable TV coaxial cable

Page 20

20

DP26

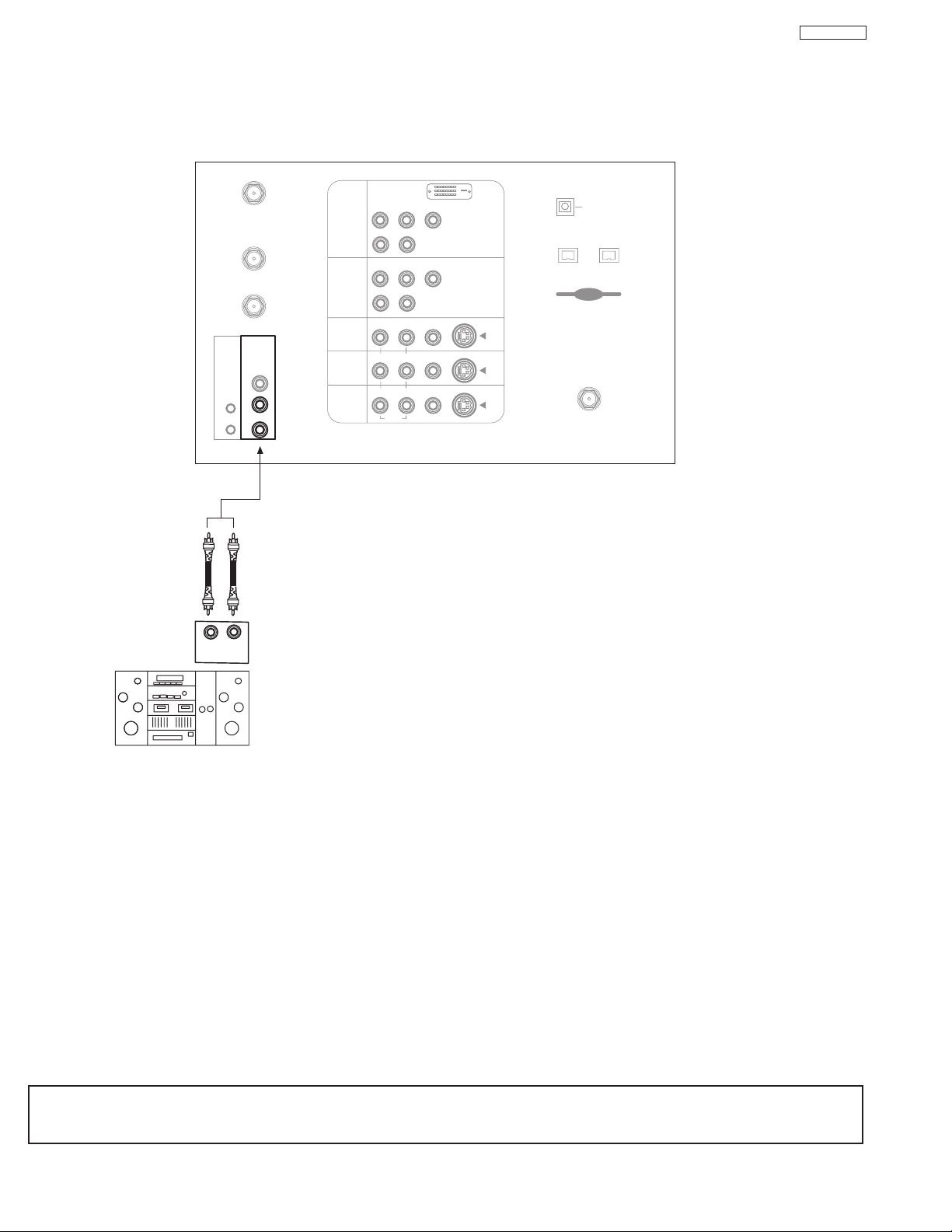

CONNECTING EXTERNAL AUDIO SOURCES

To control the audio level of an external audio amplifier with the TV remote control, connect the system as shown below.

NOTES: 1. To prevent damage to the speaker and distorted sound, set the volume control of the audio amplifier lower and adjust

the sound using the remote control of the TV set.

2. Follow connections that pertain to your personal entertainment system.

REAR PANEL OF TELEVISION

P

B

P

R

P

B

P

R

DVI-HDTV

CENTER

IN

ANT A

TO

CONVERTER

ANT B

Y

R

(MONO)/L

IR

BLASTER

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

L

AUDIO

TO HI-FI

R

LR

INPUT

Stereo System Amplifier

Page 21

21

DP26

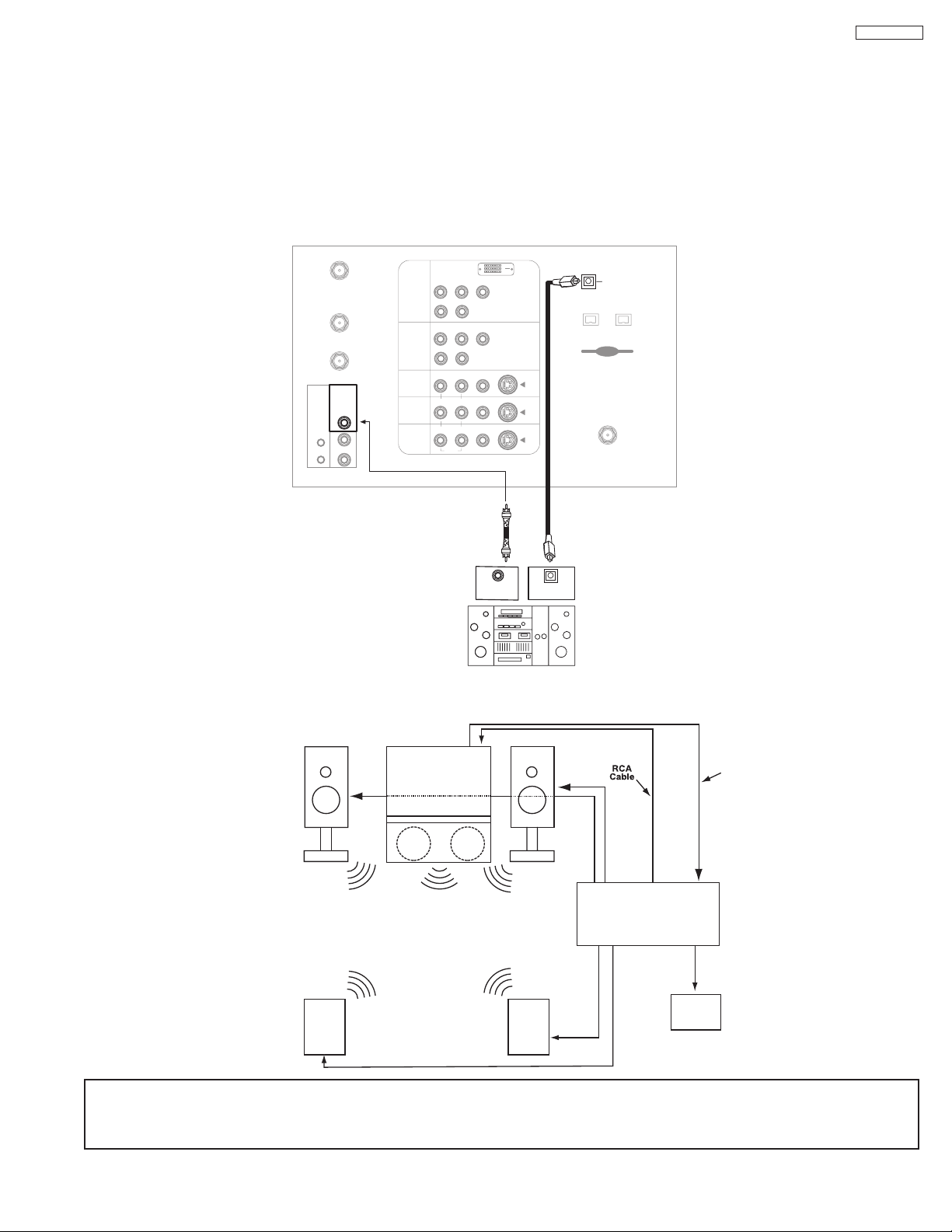

CONNECTING EXTERNAL AUDIO SOURCES

REAR PANEL OF TELEVISION

NOTES: 1. Only ANT C has optical audio output capability.

2. The Optical Out (Digital Audio) provides a fixed digital audio output to your external component such as an A/V

receiver with optical input capability. The audio level can only be controlled through the volume control of the

external audio amplifier. The Optical Out will always output ANT C audio.

Match the numbers below to the diagram for speaker placement.

The television’s internal speakers will act as center speaker (select Audio-Advanced Settings-TV as Center).

These FRONT left and right speakers are connected to the FRONT output of a separate audio amplifier.

These REAR left and right speakers are connected to the REAR output of a separate audio amplifier.

This subwoofer is connected to the LFE/Sub Out output of a separate audio amplifier.

L

R

S

S

REAR OUT

R L

L R

FRONT

OUT

CENTER

OUT

OPTICAL

IN

LFE/SUB

OUT

SUB

WOOFER

Stereo System Amplifier

Optical Cable

TYPICAL STEREO SYSTEM SETUP

IR

BLASTER

ANT A

TO

CONVERTER

ANT B

AUDIO

TO HI-FI

CENTER

L

R

INPUT 1

INPUT 2

INPUT 3

IN

INPUT 4

MONITOR

DVI-HDTV

P

Y

P

B

R

(MONO)/L

R

AUDIO

P

P

Y/VIDEO

B

R

(MONO)/L

R

AUDIO

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

R

OUT

AUDIO

S-VIDEO

S-VIDEO

S-VIDEO

OPTICAL OUT

Digital Audio

IEEE1394

Multi Media Card

ANT C

(DTV)

Stereo System Amplifier

CENTER

OUT

OPTICAL

INPUT

or DVD Player

Page 22

22

DP26

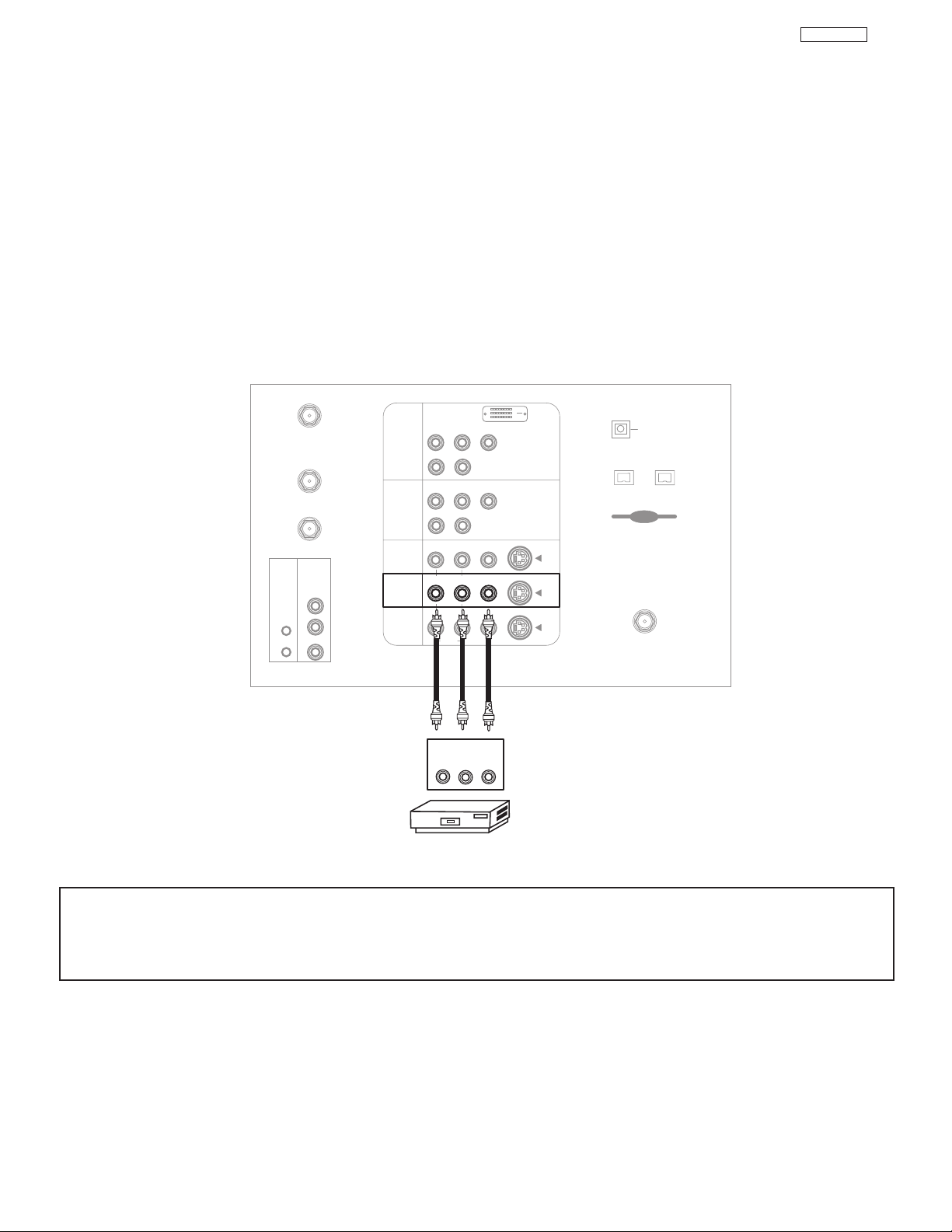

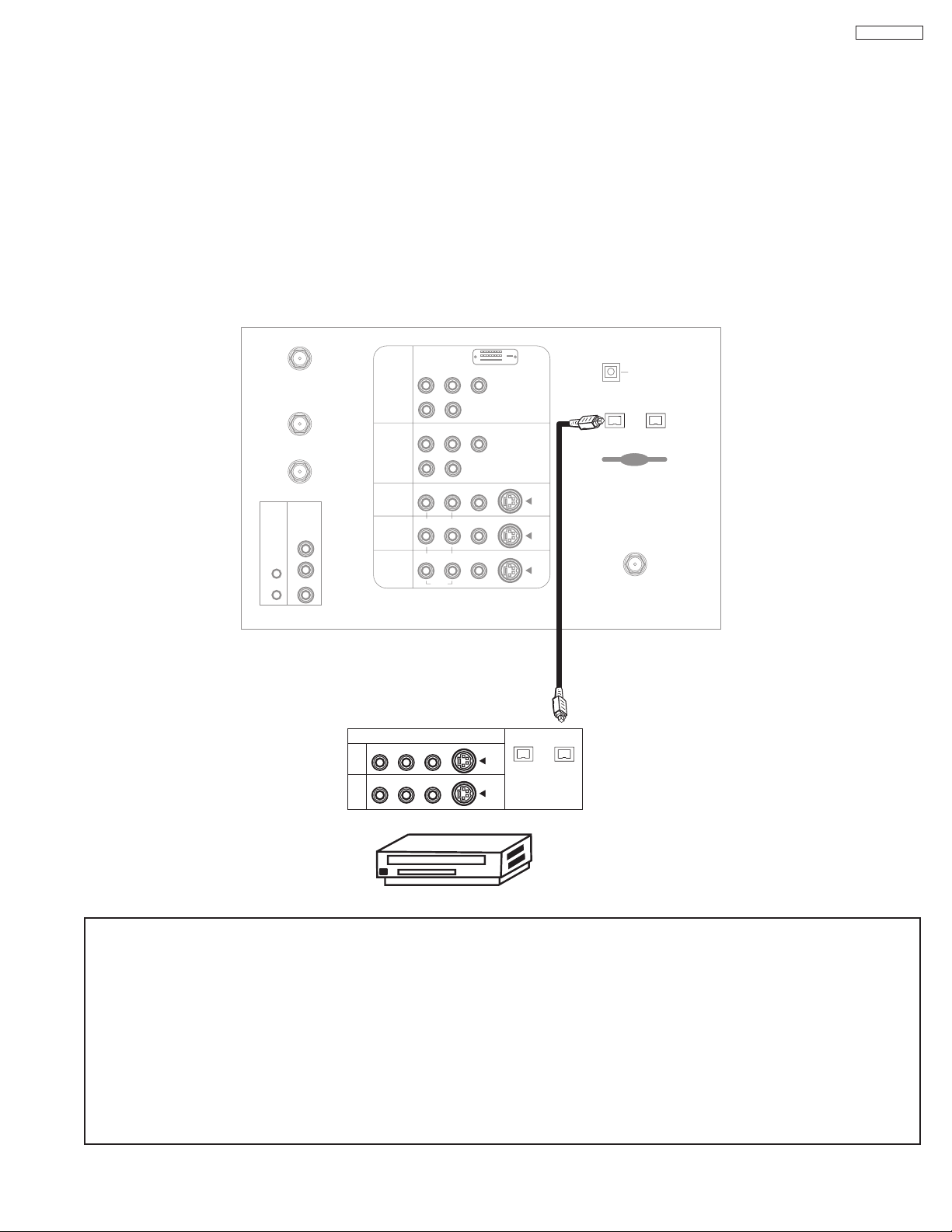

REAR PANEL CONNECTIONS

CONNECTING A STEREO SOURCE TO INPUT2~INPUT5

1. Connect the cable from the VIDEO OUT of the VCR or the laserdisc player to the INPUT (VIDEO) jack, as shown on the TV set

below.

2. Connect the cable from the AUDIO OUT R of the VCR or the laserdisc player to the INPUT (AUDIO/R) jack.

3. Connect the cable from the AUDIO OUT L of the VCR or the laserdisc player to the INPUT (AUDIO/L) jack.

4. Press the VID2~VID5 button to view the program from the VCR or laserdisc player. The VIDEO label disappears automatically

after approximately four seconds.

5. Press the ANT button to return to the previous channel.

NOTES: 1. Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

2. A single VCR can be used for VCR #1 and VCR #2 (see page 19), but note that a VCR cannot record its own video

or line output. Refer to your VCR operating guide for more information on line input-output connections.

P

B

P

R

CENTER

IN

P

B

P

R

DVI-HDTV

ANT A

TO

CONVERTER

ANT B

L

Y

R

(MONO)/L

IR

BLASTER

AUDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

MONITOR

OUT

AUDIO

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

VCR

OUTPUT

RL V

S-VIDEO

R

(MONO)/L VIDEO

INPUT 4

Page 23

23

DP26

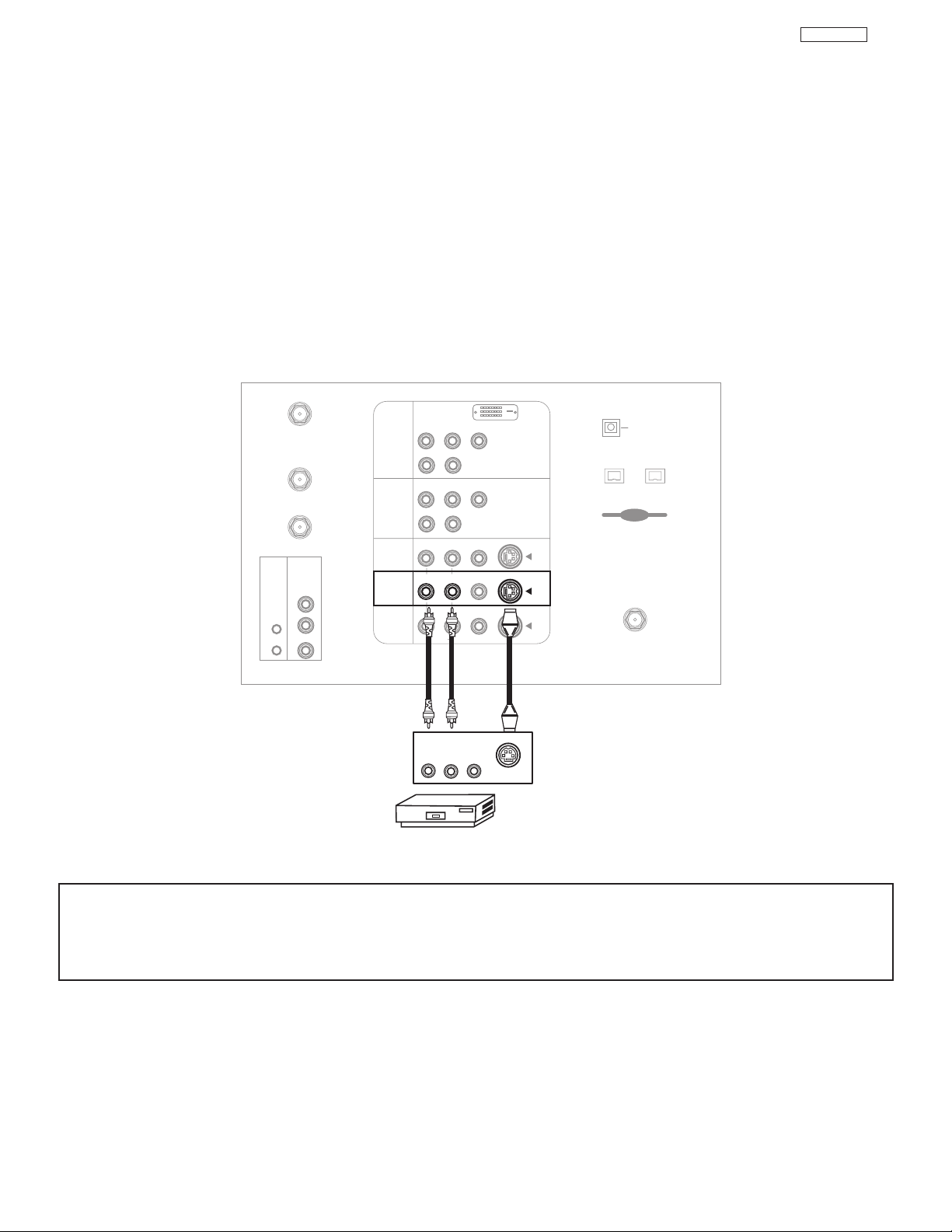

REAR PANEL CONNECTIONS

CONNECTING AN S-VIDEO SOURCE TO INPUT 3, 4 AND 5

1. Connect the cable from the S-VIDEO OUT of the VCR or the laserdisc player to the INPUT (S-VIDEO) jack, as shown on the TV

set below.

2. Connect the cable from the AUDIO OUT R of the VCR or the laserdisc player to the INPUT (AUDIO/R) jack.

3. Connect the cable from the AUDIO OUT L of the VCR or the laserdisc player to the INPUT (AUDIO/L) jack.

4. Press the VID3~VID5 button to view the program from the VCR or laserdisc player. The VIDEO label disappears automatically

after approximately four seconds.

5. Press the ANT button to return to the previous channel.

NOTES: 1. Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

2. A single VCR can be used for VCR #1 and VCR #2 (see page 19), but note that a VCR cannot record its own video

or line output. Refer to your VCR operating guide for more information on line input-output connections.

ANT A

DVI-HDTV

P

B

(MONO)/L

P

B

(MONO)/L

(MONO)/L VIDEO

(MONO)/L VIDEO

L VIDEO

AUDIO

AUDIO

AUDIO

Y

Y/VIDEO

S-VIDEO

S-VIDEO

S-VIDEO

OPTICAL OUT

Digital Audio

IEEE1394

Multi Media Card

ANT C

(DTV)

IR

BLASTER

TO

CONVERTER

ANT B

AUDIO

TO HI-FI

CENTER

IN

L

R

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

P

R

R

P

R

R

R

R

R

OUTPUT

RL V

S-VIDEO

VCR

Page 24

24

DP26

REAR PANEL CONNECTIONS

CONNECTING A COMPONENT SOURCE TO INPUT 1 OR 2: Y-PBPR.

1. Connect the cable from the Y OUT of the Laserdisc/DVD player or HDTV set top box

to the INPUT (Y) jack, as shown on the TV set at right.

2. Connect the cable from the CB/PBOUT or B-Y OUT of the Laserdisc/DVD player or

HDTV set top box to the INPUT (PB)jack.

3. Connect the cable from the CR/PROUT or R-Y OUT of the Laserdisc/DVD player or

HDTV set top box to the INPUT (PR) jack.

4. Connect the cable from the AUDIO OUT R of the Laserdisc/DVD player or HDTV set

top box to the INPUT (AUDIO/R) jack.

5. Connect the cable from the AUDIO OUT L of the Laserdisc/DVD player or HDTV set

top box to the INPUT (AUDIO/L) jack.

6. Press the VID1~VID2 button, to view the program from the Laserdisc/DVD player or

HDTV set top box. The VIDEO label disappears automatically after approximately

four seconds.

7. Press the ANT button to return to the previous channel.

CENTER

IN

P

B

P

R

P

B

P

R

DVI-HDTV

ANT A

TO

CONVERTER

ANT B

L

IR

BLASTER

AUDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

Y

R

(MONO)/L

INPUT 1

DVD Player

OUTPUT

P

RPB

Y

L R

CONNECTING A COMPONENT SOURCE WITH DVI-HDTV CAPABILITY TO INPUT 1

1. Connect the DVI connection cable from the output of the VCR or laserdisc player to the

DVI-HDTV input as shown on the TV set at right.

2. Connect the cable from the AUDIO OUT R of the VCR or the laserdisc player to the

INPUT (AUDIO/R) jack.

3. Connect the cable from the AUDIO OUT L of the VCR or the laserdisc player to the

INPUT (AUDIO/L) jack.

4. Press the VID1 button to view the program from the VCR or laserdisc player. The

VIDEO label disappears automatically after approximately four seconds.

5. Press the ANT button to return to the previous channel.

CENTER

IN

P

B

P

R

P

B

P

R

DVI-HDTV

ANT A

TO

CONVERTER

ANT B

L

IR

BLASTER

AUDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

LVIDEO

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

LR

OUTPUT

Y

R

(MONO)/L

INPUT 1

AUDIO

DIGITAL OUTPUT

D-VHS

NOTE: Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

Page 25

25

DP26

CONNECTING EXTERNAL VIDEO SOURCES

CONNECTING A COMPONENT SOURCE WITH DIGITAL INTERFACE CAPABILITY TO IEEE1394 TERMINALS

1. Connect the IEEE1394 cable from the output of the component with IEEE1394 capability, such as a Set-Top-Box or Digital VCR,

to the IEEE1394 input terminals shown on the TV set below. IEEE 1394 allows the television and the external device to

communicate with one another. When using IEEE1394 connections, you enable video and audio digital data exchange between

a compatible device. This connection also enables you to control basic equipment functions (such as VCR play, rewind, fast for

ward, stop, etc.) from your TV On-Screen Display. You must be tuned to ANT C to use this function.

2. Press the MENU button on the Remote Control and select SETUP.

3. Select Set-up - Set The Inputs - IEEE1394 (or press the A/V Net button twice (2x) when in ANT C mode.

4. Select IEEE1394 to verify that the component is properly connected.

P

B

P

R

CENTER

IN

P

B

P

R

DVI-HDTV

S-VIDEO

R

(MONO)/L VIDEO

1

DIGITAL INTERFACE

S-VIDEO

R

(MONO)/L VIDEO

2

LINE OUT

IEEE1394 Cable

IEEE1394

ANT A

TO

CONVERTER

ANT B

L

Y

R

(MONO)/L

IR

BLASTER

AUDIO

TO HI-FI

R

S-VIDEO

S-VIDEO

S-VIDEO

Y/VIDEO

R

(MONO)/L

R

(MONO)/L VIDEO

R

(MONO)/L VIDEO

R

L VIDEO

INPUT 1

INPUT 2

INPUT 3

INPUT 4

MONITOR

OUT

AUDIO

AUDIO

AUDIO

ANT C

(DTV)

Multi Media Card

IEEE1394

OPTICAL OUT

Digital Audio

Digital VCR (D-VHS)

NOTES: 1. To quickly enter IEEE1394 menu, press the A/V NET button on the remote control twice when in ANT C mode.

2. The external device that is connected to the IEEE 1394 terminals will not need the A/V Network feature.

3. This TV’s IEEE1394 connection is not compatible with a DV camcorder (Digital Video camcorder) and a PC.

4. With IEEE1394 connection, video and audio will be received by the TV. It will enable you to control the D-VHS from

the TV IEEE1394 menu.

5. The IEEE1394 interface contains the copy protection standard called 5C or Digital Transmission Content Protection

(DTCP).

6. This TV does not support full network control of several IEEE1394 devices simultaneously (the IEEE1394 will

disconnect from 1st device when making connection to 2nd device).

Page 26

26

DP26

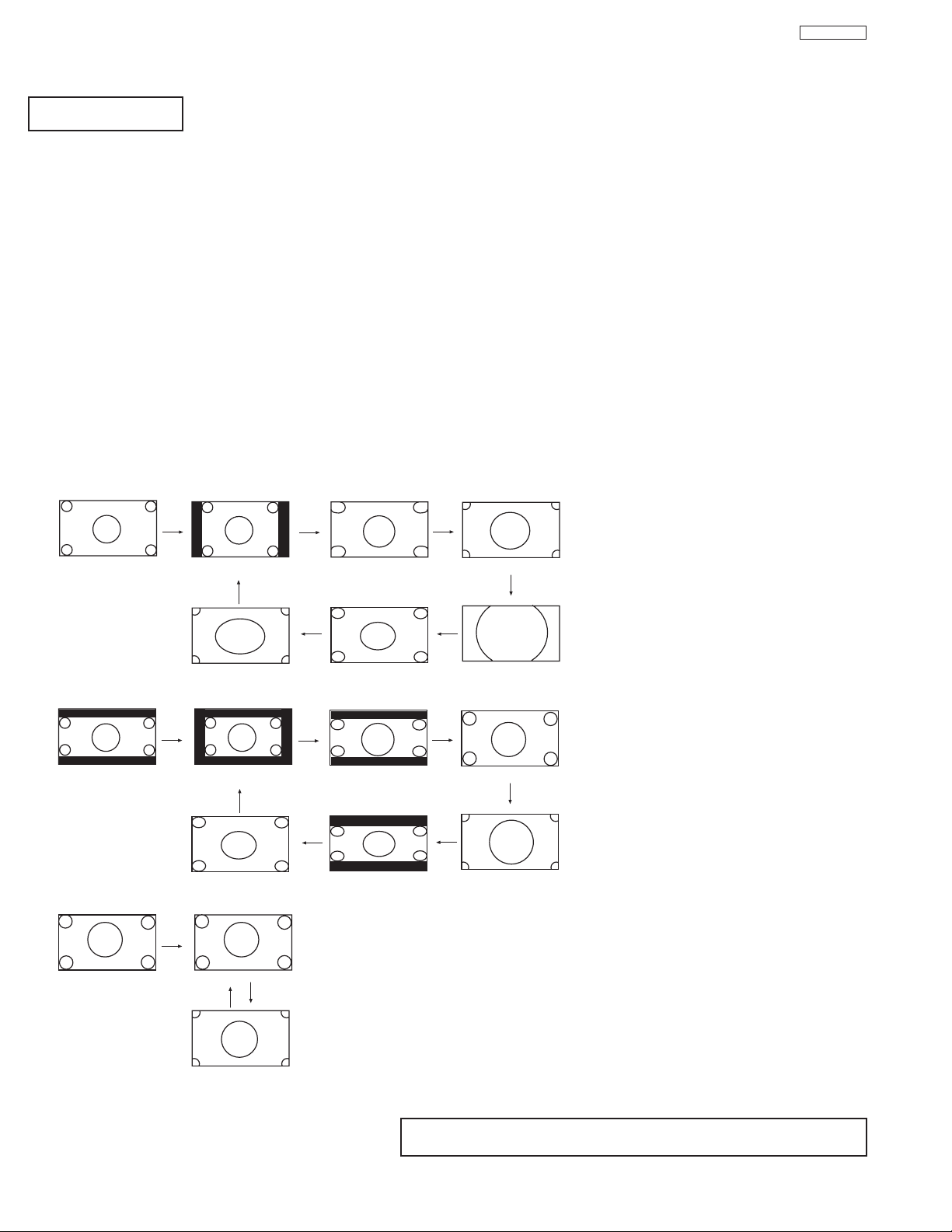

ASPECT STYLE

ASPECT STYLE

Press the ASPECT button on the Remote Control to quickly change the ASPECT ratio.

Depending on the input signal, the picture format ratio allows you to adjust the images through the following options.

4:3 STANDARD Use this aspect mode to display conventional (4:3) images. Side panels (gray areas) are placed to the

left and right of the image to preserve the original aspect ratio of the source. Note: Use this mode for

only 15% of your total viewing time to prevent uneven aging of the phosphors. Phosphors in the lighted

area of the picture will age more rapidly than the gray areas.

4:3 EXPANDED Use this aspect mode to display conventional (4:3) sources by expanding the outer edges of the image

to fill the 16:9 screen. The center of the image remains unaltered.

4:3 Zoom1/Zoom2 Use these aspect modes to zoom in on conventional (4:3) sources.

16:9 STANDARD Use this aspect mode to display 16:9 sources like HDTV and DVD’s preserving the original 16:9 aspect

ratio.

16:9 Zoom Use this aspect to Zoom-in once while in 16:9 aspect.

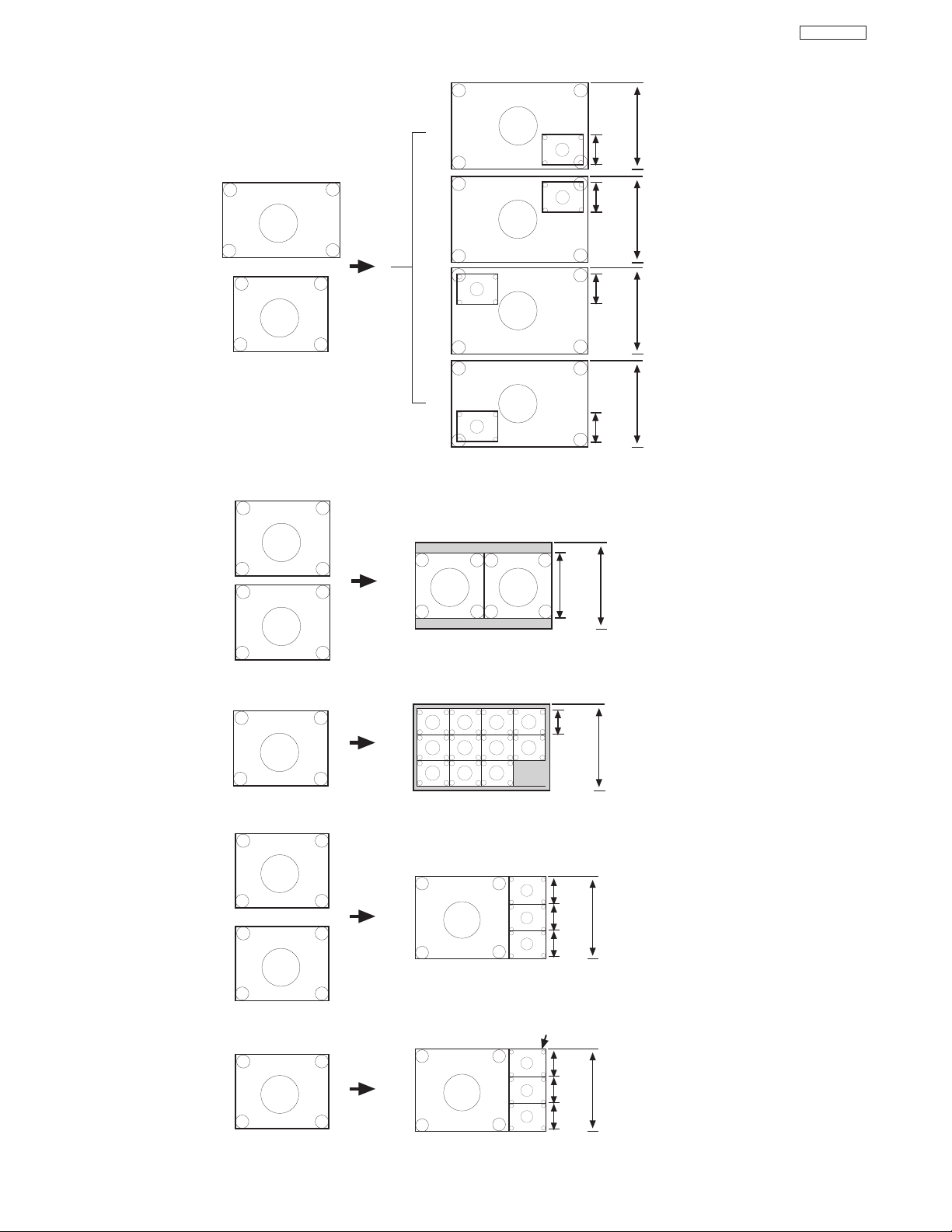

4:3

INPUT

4:3 EXPANDED

4:3 ZOOM1

4:3 ZOOM2

16:9 STANDARD

4:3 STANDARD

16:9

INPUT

4:3 EXPANDED

4:3 ZOOM1

4:3 ZOOM2

16:9 STANDARD

4:3 STANDARD

INPUT

16:9

16:9 STANDARD

16:9 ZOOM

16:9 ZOOM

16:9 ZOOM

(1) NTSC Signal Format received

(2) 480i/480P Signal Format received

(3) 720P/1080i Signal Format received

NOTE: When in ANT C, signal format is dependent on broadcaster.

Page 27

27

DP26

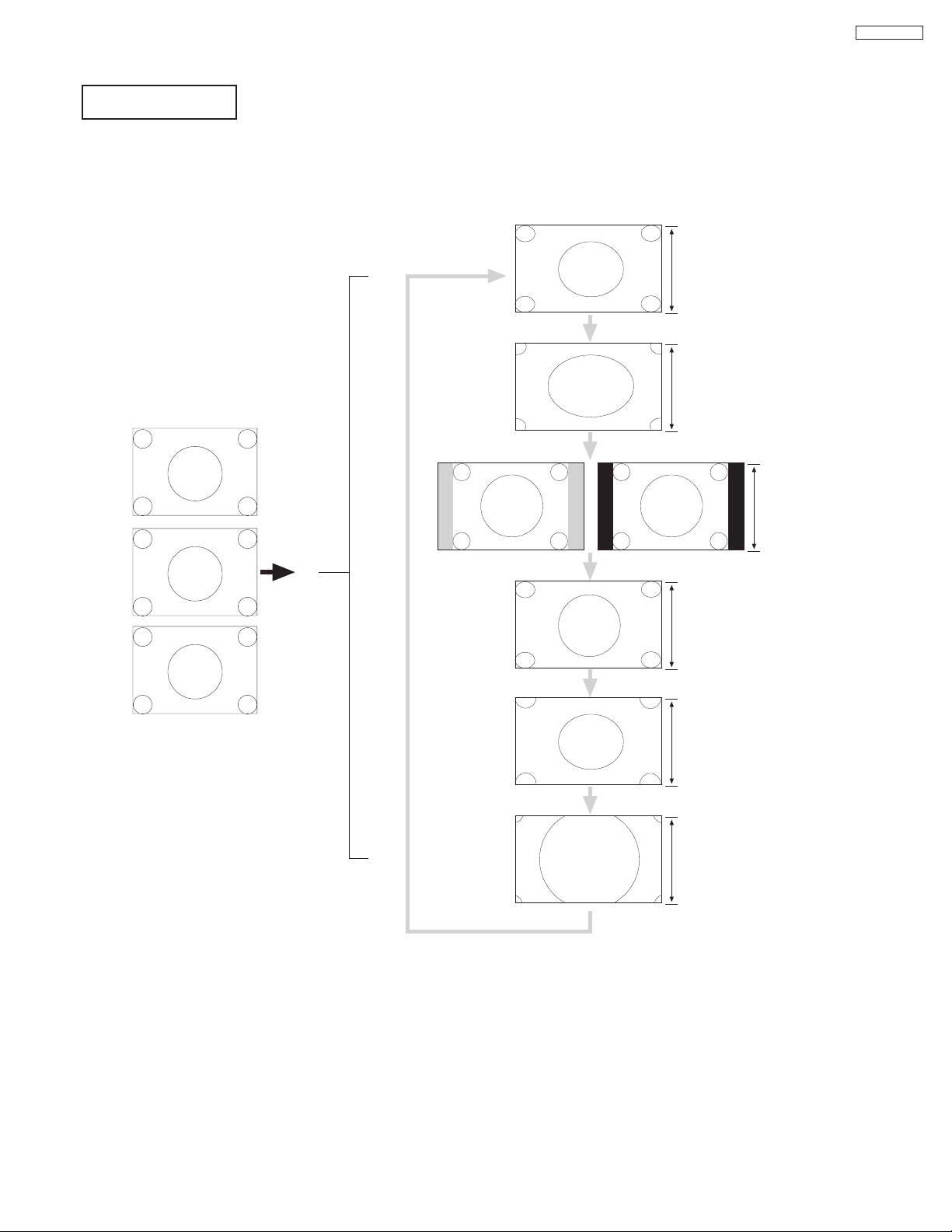

Depending on the input signal, the picture format aspect ration allows you to adjust the image through the

following options.

PICTURE FORMATS

(1) NTSC: 4x3 (15.734KHz) ➔ 1080i/540p (33.716KHz)

SDTV: 480i 4x3 (15.734KHz/15.75KHz) ➔ 1080i/540p (33.716KHz/33.75KHz)

SDTV: 480p 4x3 (31.468KHz/31.5KHz) ➔ 1080i/540p (33.716KHz/33.75KHz)

Picture Format: 16:9 Standard, 16:9 Zoom, 4:3 Standard, 4:3 Exploded, 4:3 Zoom1, 4:3 Zoom2.

1080 Lines (Interlace)

540 Lines (Progressive)

4x3

NTSC

fH:15.75kHz

4x3

480i

fH:15.75kHz

16:9 Standard

1080i

540p

4x3

480p

fH:15.75kHz

1080 Lines (Interlace)

540 Lines (Progressive)

16:9 Zoom

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Expanded

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Zoom1

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Zoom2

1080i

540p

Black Side Panel: OFF

Black Side Panel: ON

4:3 Standard

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Standard

1080i

540p

Aspect Key

Aspect Key

Aspect Key

Aspect Key

Aspect Key

Aspect Key

ASPECT STYLE

Page 28

28

DP26

1080 Lines (Interlace)

540 Lines (Progressive)

NTSC

Squeeze

16:9 Standard

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

16:9 Zoom

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Expanded

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Zoom1

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

4:3 Zoom2

1080i

540p

Black Side Panel: OFF

Black Side Panel: ON

4:3 Standard

1080i

540p

1080 Lines (Interlace)

540 Lines (Progressive)

Aspect Key

Aspect Key

Aspect Key

Aspect Key

Aspect Key

Aspect Key

4:3 Standard

1080i

540p

480i

16x9

540 (Progressive)

1080 (Interlaced)

16:9 Standard

1080i

540p

720p

16x9

540 (Progressive)

1080 (Interlaced)

16:9 Zoom

1080i

540p

Aspect Key

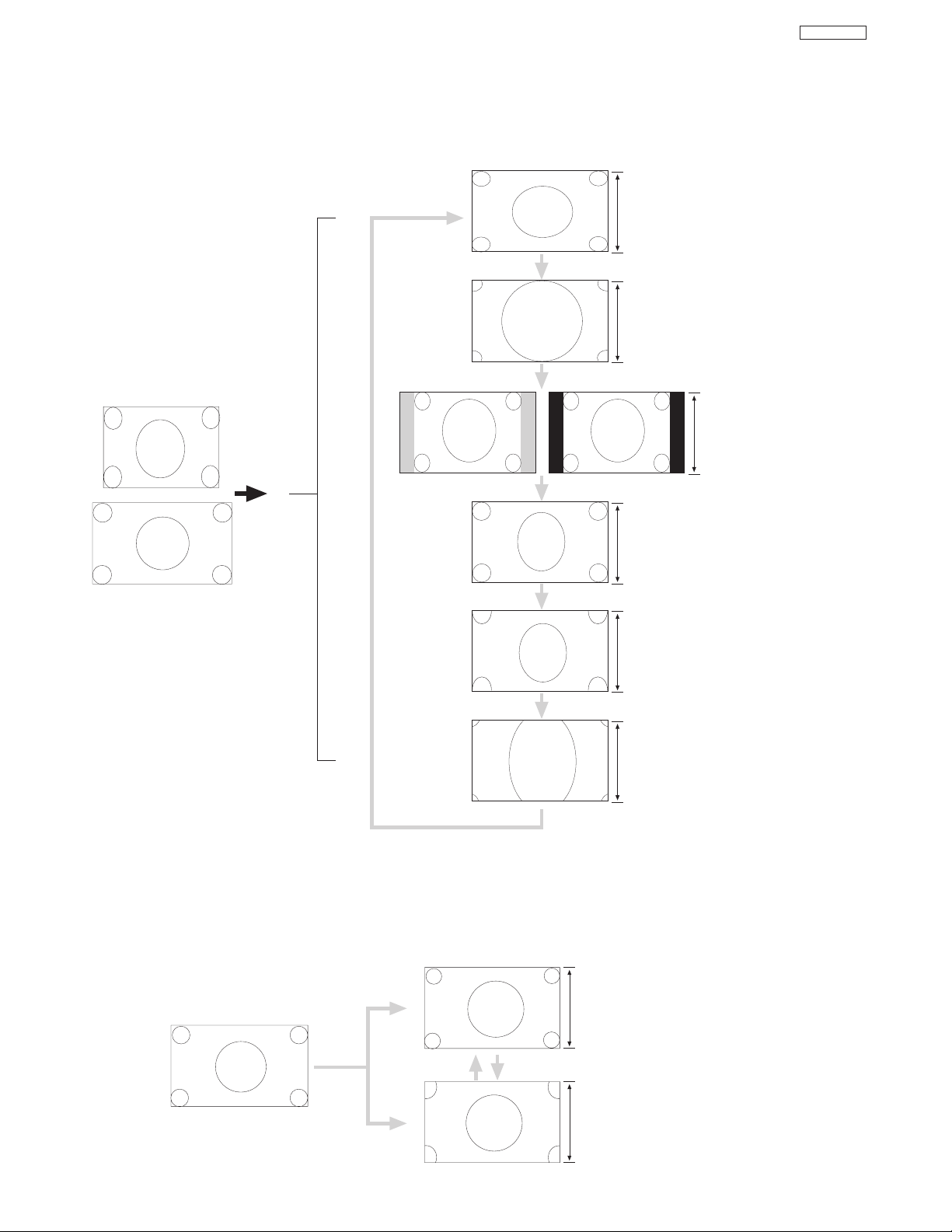

(2) NTSC: Squeeze (15.734KHz) ➔ 1080i/540p (33.716KHz)

SDTV: 480i 16x9 (15.734KHz/15.75KHz) ➔ 1080i/540p (33.716KHz/33.75KHz)

SDTV: 480p 16x9 (31.468KHz/31.5KHz) ➔ 1080i/540p (33.716KHz/33.75KHz)

Picture Format: 16:9 Standard, 16:9 Zoom, 4:3 Standard, 4:3 Exploded, 4:3 Zoom1, 4:3 Zoom2.

(3) HDTV: 720p 16x9 (44.995KHz/45KHz) ➔ 1080i/540p (33.716KHz/33.75KHz)

Picture Format: 16:9 Standard, 16:9 Zoom

ASPECT STYLE

Page 29

29

DP26

1080 (Interlaced)

16:9 Standard

1080i

1080i

16x9

1080 (Interlaced)

16:9 Zoom

1080i

Aspect Key

1080i

540p

Virtual HD

1080i

Virtual HD

Menu Black Side Panel: OFF

Menu Black Side Panel: ON

Gray Side Panel

Black Side Panel

1080i Real Mode

(4) HDTV: 1080i 16x9 (33.716KHz/33.75KHz) ➔ 1080i (33.716KHz/33.75KHz)

Picture Format: 16:9 Standard, 16:9 Zoom

(5) Virtual HD Operation (Scanning Format)

a. NTSC, SDTV: 480i/480p, HDTV: 720p

b. HDTV: 1080i

(6) Black Side Panel Operation

a. NTSC, SDTV: 480i/480p, HDTV: 720p

(7) Picture-in-Picture POP Mode

Main

Picture

180

Lines

SUB

Main

NTSC

480i

Sub

NTSC

480i

540

Lines

(Progressive)

Main

Picture

SUB

540

Lines

(Progressive)

180

Lines

Main

Picture

180

Lines

SUB

540

Lines

(Progressive)

ASPECT STYLE

Page 30

30

DP26

(8) Picture-In-Picture PIP Mode

(9) Picture-In-Picture SPLIT Mode

(10) Picture-in-Picture SURF 11 Mode

(11) Picture-in-Picture SURF 3 Mode

(12) Picture-in-Picture STROBE Mode

Main

Picture

360

Lines

Main

1080i

Sub

NTSC

480i

1080

Lines

(Interlaced)

SUB

Main

Picture

360

Lines

1080

Lines

(Interlaced)

SUB

Main

Picture

360

Lines

1080

Lines

(Interlaced)

SUB

Main

Picture

360

Lines

1080

Lines

(Interlaced)

SUB

Sub

ALL

Main

334

Lines

540

Lines

(Progressive)

Main

ALL

Sub

SPLIT

167

Lines

540

Lines

(Progressive)

ANT A/B

NTSC

Main

ANT A

Sub

ANT A

Main

Picture

180

Lines

540

Lines

(Progressive)

SUB

SUB

SUB

180

Lines

180

Lines

NTSC

480i

Main

Picture

180

Lines

540

Lines

(Progressive)

SUB

SUB

SUB

180

Lines

180

Lines

STROBE

ASPECT STYLE

Page 31

31

DP26

PIP Key Operation

Main

NTSC/480i

ANT C

Main

Main

1080i

ANT C

Main

1080i

ANT C

Main

ANT A/B/C

Main

All

Sub

All

SPLIT

NTSC

480i

ANT C

PIP

Key

PIP

Key

FREEZE Key Operation

Main

MOVING

Main

Main

ANT C

FROZEN

Main

ANT C

MOVING

Main

Main

Moving

SPLIT

Sub

Moving

Sub

Frozen

Freeze

Key

Freeze

Key

Main

FROZEN

Sub

Frozen

Sub

Moving

Sub

Strobe

Main

MOVING

Sub

Frozen

Page 32

32

DP26

PIP Mode Key Operation

Main

All

Sub

All

Main

NTSC

480i

NTSC/480i

ANT C

Main

Moving

SUB

SUB

SUB

Main

1080i

PIP Mode

key

Rating On

PIP Mode

key

PIP Mode

key

Main

Moving

Sub

Frozen

PIP Mode

key

PIP Mode

key

PIP Mode

key

Sub

Strobe

Sub

Moving

Main

1080i

ANT C

ANT A/B/C

Main

NTSC

480i

Main

1080i

Main

NTSC

480i

Main

1080i

Sub

Frozen

PIP Mode

key

FREEZE Mode Operation

Page 33

33

DP26

SERVICE ADJUSTMENTS

1. ASSEMBLED P.W.B ADJUSTMENT..................................................................................................................34

1-1. Service Menu Access (NTSC, SDTV and HDTV) ..................................................................................34

1-2. Comb Filter Operation Check ................................................................................................................39