Page 1

APRIL 2001 HHEA-MANUFACTURING DIVISION

PA

No. 0145

60DX10B 50GX30B

50DX10B 43GX10B

R/C: CLU-4311UG

NNTTSSCC

HHPP1111 HHPP1122

CChhaassssiiss

SERVICE MANUAL

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TECHNICAL CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CIRCUIT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR . . . . . .12

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . .15

SERVICE ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

ADJUSTMENT LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

DC VOLTAGE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

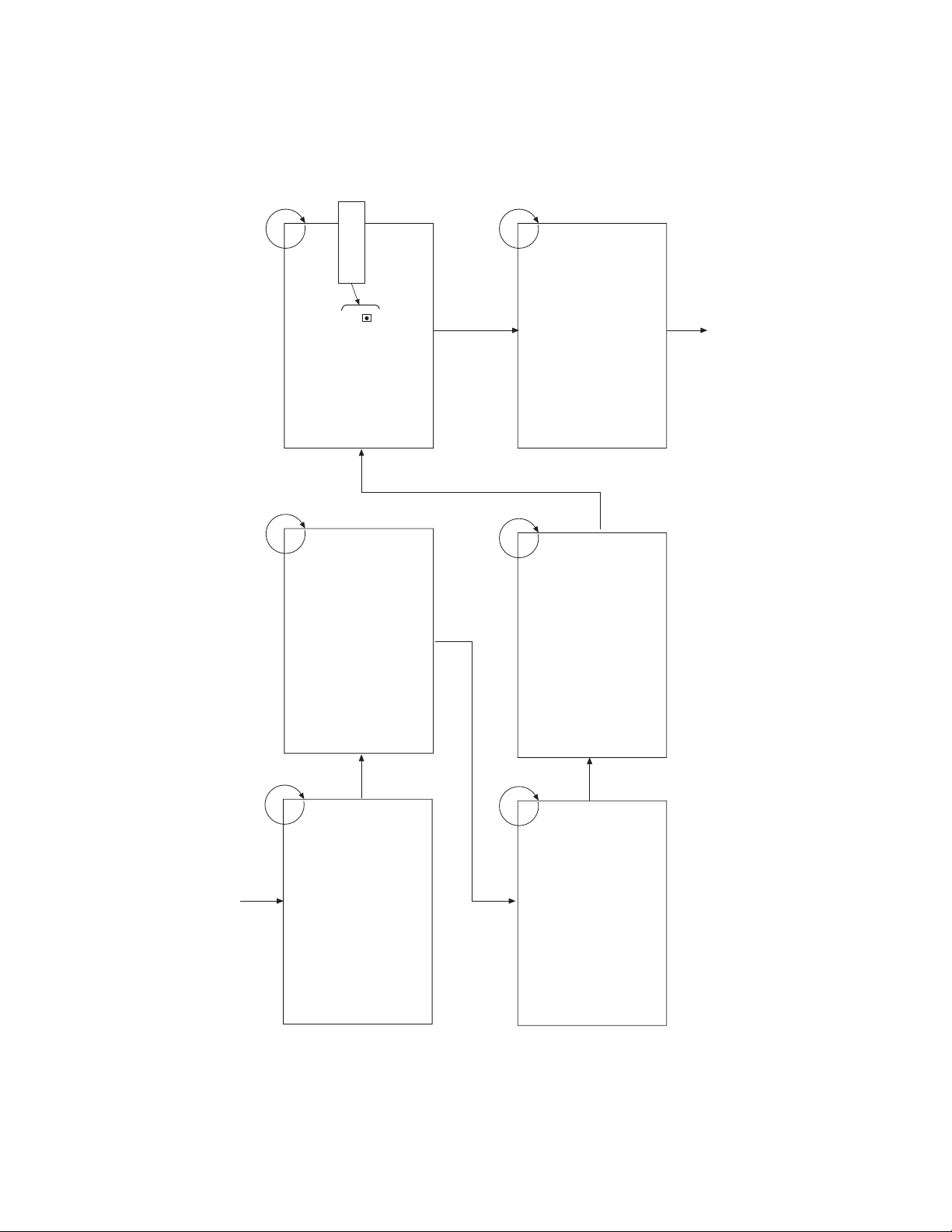

PROTECTION CIRCUIT BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

BASIC CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

CHASSIS WIRING DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

QUICK REFERENCE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so. Before servicing this chassis, it is important that the service

technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

read and follow the “Important Safety Instructions” in this Service Manual.

PROJECTION COLOR TELEVISION

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

!

Page 2

2

Components having special safety characteristics are identified by a on the schematics and on the parts list in this service

manual and its supplements and bulletins. Before servicing this chassis, it is important that the service technician read and

follow the “Important Safety Instructions” in this Service Manual.

For continued X-Radiation protection, replace picture tube with original type or Hitachi approved equivalent type.

This Service Manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified

technicians have the necessary test equipment and tools, and have been trained to properly and safely repair complex

products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void warranty. If you

are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so and refer the

repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact

with solder. Also, when soldering do not inhale any smoke or fumes produced.

This television receiver provides display of television closed captioning in accordance with section 15.119 of the FCC rules.

FEDERAL COMMUNICATIONS COMMISSION NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

¥ Reorient or relocate the receiving antenna.

¥ Increase the separation between the equipment and the receiver.

¥ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

¥ Consult the dealer or an experienced radio/television technician for help.

IMPORTANT SAFETY INSTRUCTIONS

USE ISOLATION TRANSFORMER WHEN SERVICING

!

Page 3

3

IMPORTANT SAFETY INSTRUCTION

1. Before returning an instrument to the customer, always

make a safety check of the entire instrument, including

but not limited to the following items.

a. Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly

in the cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpaper,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning. Servicers who defeat safety features

or fail to perform safety checks may be liable for

any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to (1) spacing

between the picture tube and cabinet mask, (2)

excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet

back cover.

c. Antenna Cold Check Ð With the instrument AC plug

removed from any AC source, connect an electrical

jumper across the two AC plug prongs. Place the

instrument AC switch in the on position. Connect one

lead of an ohmmeter to the AC plug prongs tied

together and touch the other ohmmeter lead in turn to

each tuner antenna input, exposed terminal screw

and, if applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohms or

greater than 5.2 megohms, an abnormality exists that

must be corrected before the instrument is returned to

the customer. Repeat this test with the instrument AC

switch in the off position.

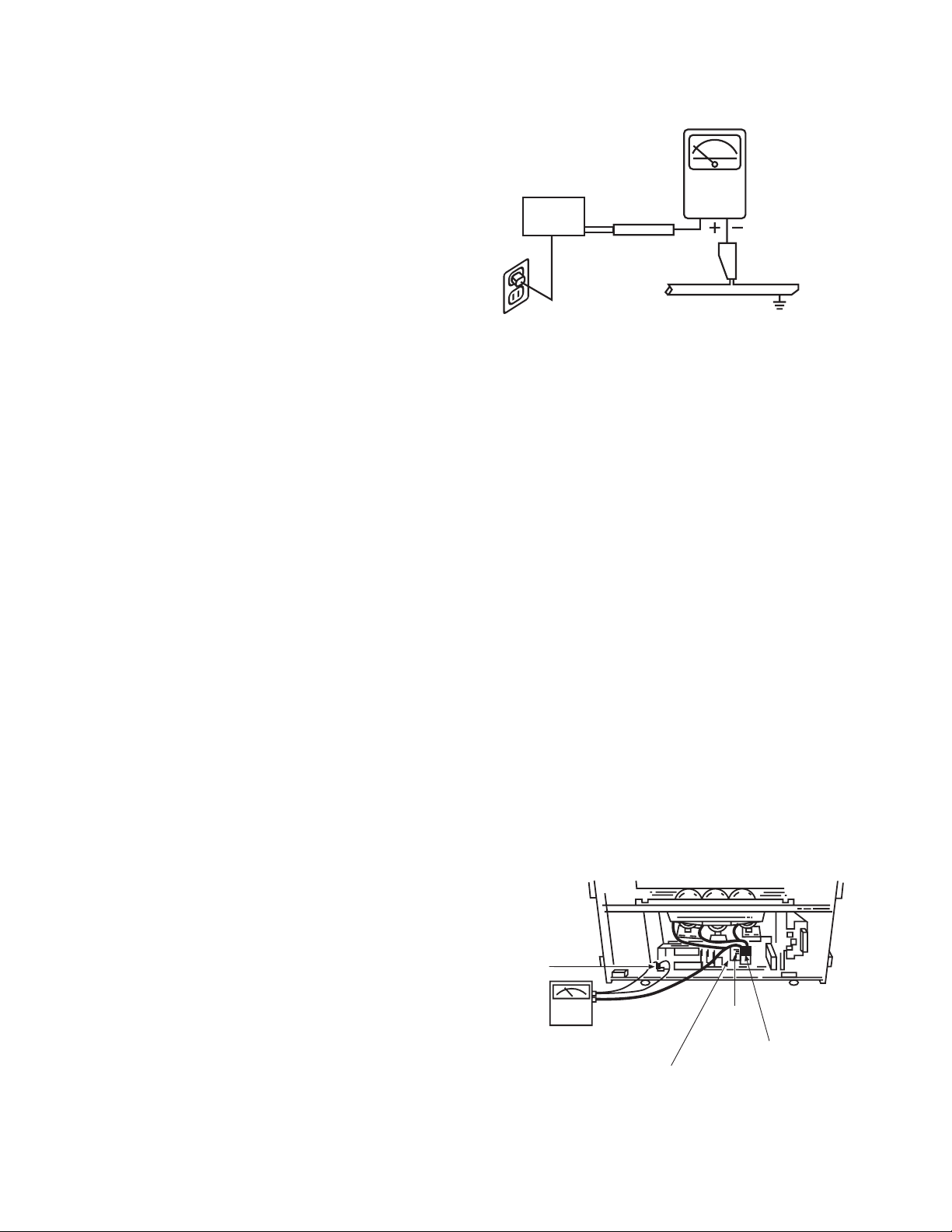

d. Leakage Current Hot Check Ð With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current

tester or a metering system that complies with

American National Standards Institute (ANSI) C101.0

Leakage Current for Appliances and Underwriters

Laboratories (UL) 1410, (50.7). With the instrument

AC switch first in the on position and then in the off

position, measure from a known earth ground (metal

waterpipe, conduit, etc.) to all exposed metal parts of

the instrument (antennas, handle bracket, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal parts that

offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamps.

Reverse the instrument power cord plug in the outlet

and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER OR BEFORE CONNECTING THE

ANTENNA OR ACCESSORIES.

e. High Voltage — This receiver is provided with a hold

down circuit for clearly indicating that voltage has

increased in excess of a predetermined value.

Comply will all notes described in this Service Manual

regarding this hold down circuit when servicing, so

that this hold down circuit may correctly be operated.

f. Service Warning — With maximum contrast, operating

high voltage in this receiver is lower than 31.5 kV. In

case any component having influence on high voltage

is replaced, confirm that the high voltage with

maximum contrast is lower than 31.5 kV.

To measure H.V. use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT anode

button. (See the following connection diagram.)

Note: Turn power switch off without fail before the

connection to the anode button is made.

LEAKAGE

CURRENT

TESTER

(READING

SHOULD NOT

BE ABOVE 0.5mA)

EARTH

GROUND

TEST ALL

EXPOSED

METAL SURFACES

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

AC Leakage Test

Chassis

ground

FBT

High Impedance

H.V. meter

Deflection P.W.B.

(TH01)

High voltage

connector

Page 4

4

g. X-radiation – TUBE: The primary source of X-

radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original, Hitachi

approved type.

When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, avoid being unnecessarily close to the picture tube and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

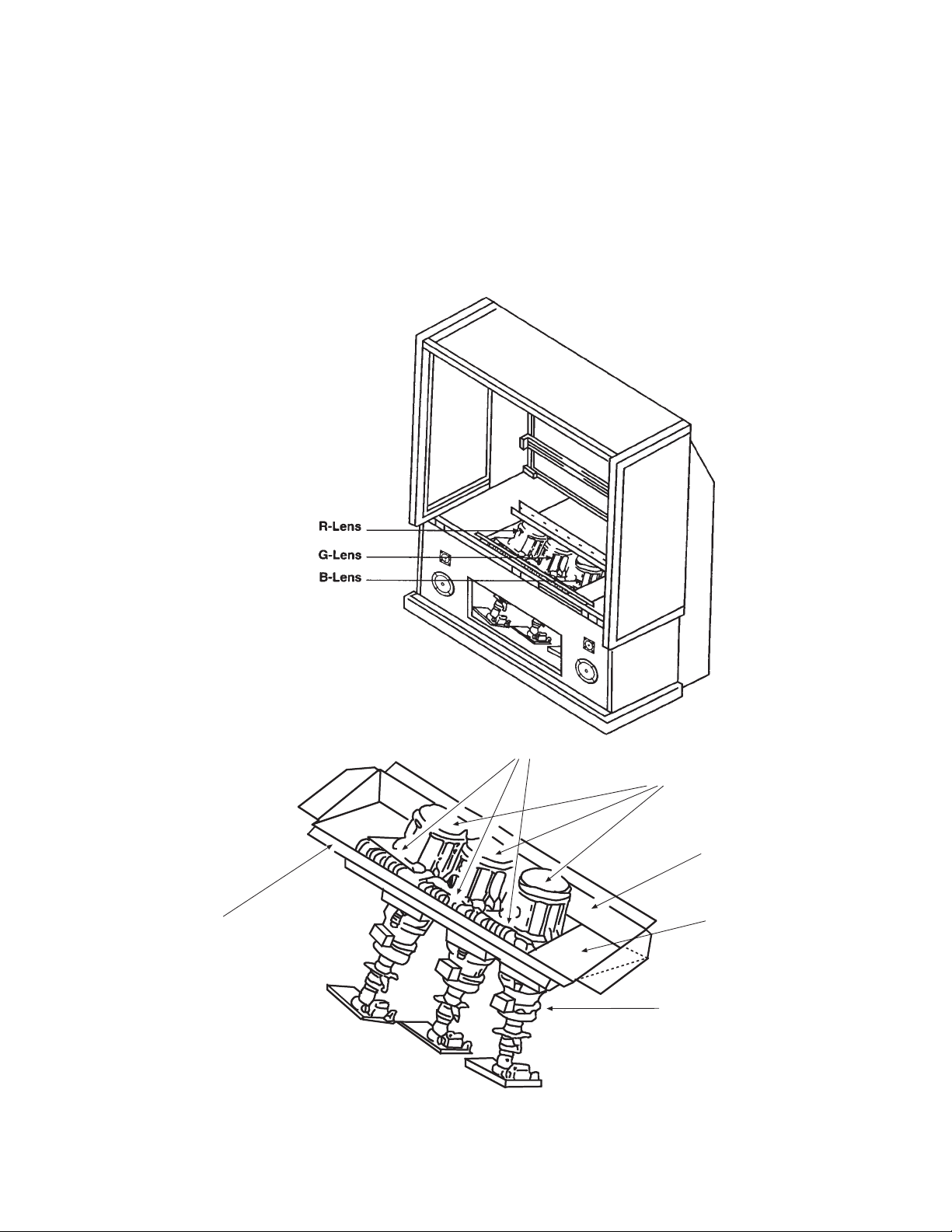

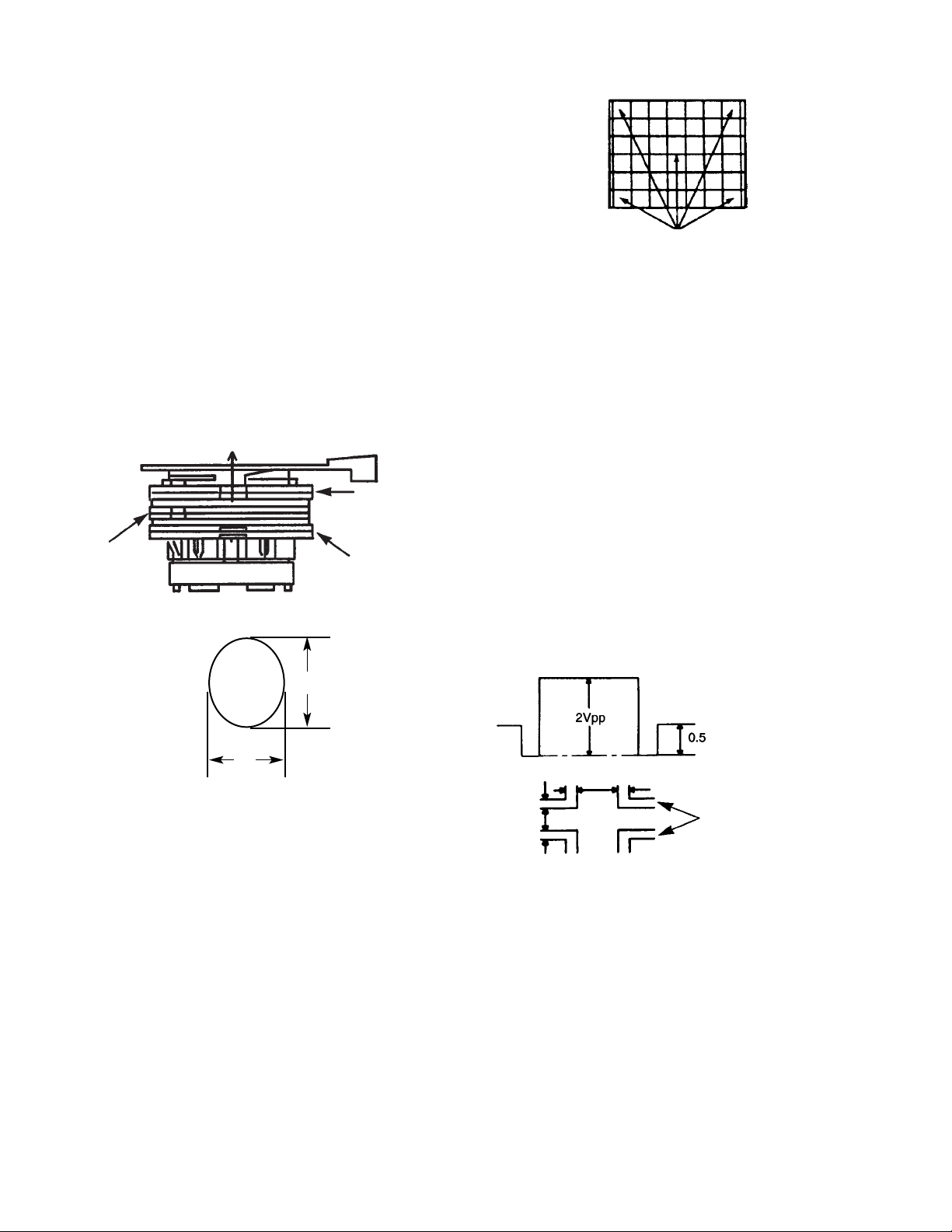

h. X-radiation Shield –

1. This receiver is provided with X-ray shield plates

for protection against X-radiation. Do not remove

X-ray shield plates A, B, or C shown in Fig. 1

unnecessarily, when troubleshooting and/or

making test measurements.

2. To prevent X-radiation, after replacement of

picture tube and lens, confirm these components

to be fixed correctly to bracket and cabinet, and

not to be taken off easily.

Shield Plate A

Glass Lens for Shielding

Shield Plate B

Shield Plate C

Shield Plate D

Detailing X-radiation shield

Shield Plate C

Fig. 1. Installation of shield lens, shield cover and shield plates (oblique view).

IMPORTANT SAFETY INSTRUCTIONS

Page 5

5

2. Read and comply with all caution and safety-related

notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning – Do not alter or add to

the mechanical or electrical design of this TV receiver.

Design alterations and additions including but not

limited to circuit modifications and the addition of

items such as auxiliary audio and/or video output

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alterations or additions may void the

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4. Picture Tube Implosion Protection Warning – The

picture tube in this receiver employs integral

implosion protection. For continued implosion

protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles equipped

with side shields. People not so equipped must be

kept safely away while picture tubes are handled.

Keep the picture tube away from your body. Do not

handle the picture tube by its neck.

5. Hot Chassis Warning – a. Some TV receiver chassis

are electrically connected directly to one conductor of

the AC power cord and may be safely serviced

without an isolation transformer only if the AC power

plug is inserted so that the chassis is connected to the

ground side of the AC power source. Confirm that the

AC power plug is inserted correctly with an AC

voltmeter by measuring between the chassis and a

known earth ground. If a voltage reading in excess of

1.0V is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure the

voltage potential between the chassis and a known

earth ground. b. Some TV receiver chassis normally

have 85V AC (RMS) between chassis and earth

ground regardless of the AC plug polarity. These

chassis can be safely serviced only with an isolation

transformer inserted in the power line between the

receiver and the AC power source, for both personnel

and test equipment protection. c. Some TV receiver

chassis have a secondary ground system in addition

to the main chassis ground. This secondary ground

system is not isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated or

altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress in the following areas: a. near

sharp edges, b. near thermally hot parts – be sure

that leads and components do not touch thermally hot

parts, c. the AC supply, d. high voltage and e. antenna

wiring. Always inspect in all areas for pinched, out-ofplate, or frayed wiring. Do not change spacing

between components and the printed circuit board.

Check AC power cord for damage.

7. Components, parts, and/or wiring that appear to have

overheated or are otherwise damaged should be

replaced with components, parts, or wiring that meet

original specifications. Additionally, determine the

cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

8. PRODUCT SAFETY NOTICE – Many TV electrical

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified in Hitachi service data by shading on

schematics and by a in the parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended replacement part in Hitachi service data parts list might

create shock, fire, and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate. For the

latest information, always consult the appropriate

current Hitachi service literature. A subscription to, or

additional copies of service literature may be obtained

at a nominal charge from Hitachi.

!

IMPORTANT SAFETY INSTRUCTIONS

Page 6

6

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

follow the “Important Safety Instructions” on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit

board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

d. Discharging the picture tube anode.

2. T est high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device

(DVM, FETVOM, etc.) equipped with a suitable high

voltage probe. Do not test high voltage by “drawing an

arc.” The H.V. Distribution Box has an internal 400MW

resistor (bleeder resistor) connected from the high

voltage to ground. After power is removed from the

instrument the high voltage will discharge through the

high voltage bleeder resistor. If the tubes have high

voltage after power is removed, then the bleeder resistor

is defective or the bleeder ground is disconnected.

3. Discharge the picture tube’s anode at any of the R, G, or

B outputs on the H.V. Distribution Box only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield at

the point where the picture tube socket ground lead is

connected, and then (b) touch the other end of the

insulated clip lead to the picture tube high voltage

distribution box R, G, or B output, using an insulated

handle to avoid personal contact with high voltage.

4. Do not spray chemicals on or near this instrument or any

of its assemblies.

5. Unless specified otherwise in these service data, clean

electrical contracts by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%99% strength).

CAUTION: This is a flammable mixture. Unless

specified otherwise in these service data,

lubrication of contacts is not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service data might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

8. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

9. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only can anti-static type solder removal device.

Some solder removal devices not classified as “antistatic” can generate electrical charges sufficient to

damage ES device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive

material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

SERVICING PRECAUTIONS

Page 7

7

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate gauge of resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts.

Quickly draw away the melted solder with an antistatic, suction-type solder removal device or with

solder braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect to replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

Use Solding Iron to Pry Leads

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are the

slotted type, the following technique should be used to

remove and replace the IC. When working with boards using

the familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Page 8

8

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent

components and the circuit board, to

prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “liftoff,” the board. The following guidelines and procedures

should be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small “U” in one end of a small-gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of

the pattern break and locate the nearest component

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

Frequency Synthesis (FS) Tuning Systems

1. Always unplug the instrument AC power cord before

disconnecting or reconnecting FS tuning system cables

and before removing or inserting FS tuning system

modules.

2. The FS tuner must never be disconnected from the FS

tuning control module while power is applied to the

instrument.

3. When troubleshooting intermittent problems that might be

caused by defective cable connection(s) to the FS tuning

system, remove the instrument AC power as soon as the

defective connector is found and finish confirming the

bad connection with a continuity test. This procedure will

reduce the probability of electrical overstress of the FS

system semi-conductor components.

CRIMP AND

SOLDER

BARE JUMPER

WIRE

Install Jumper Wire and Solder

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

Page 9

9

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as

per the code chart and are a dual diode pack with

either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

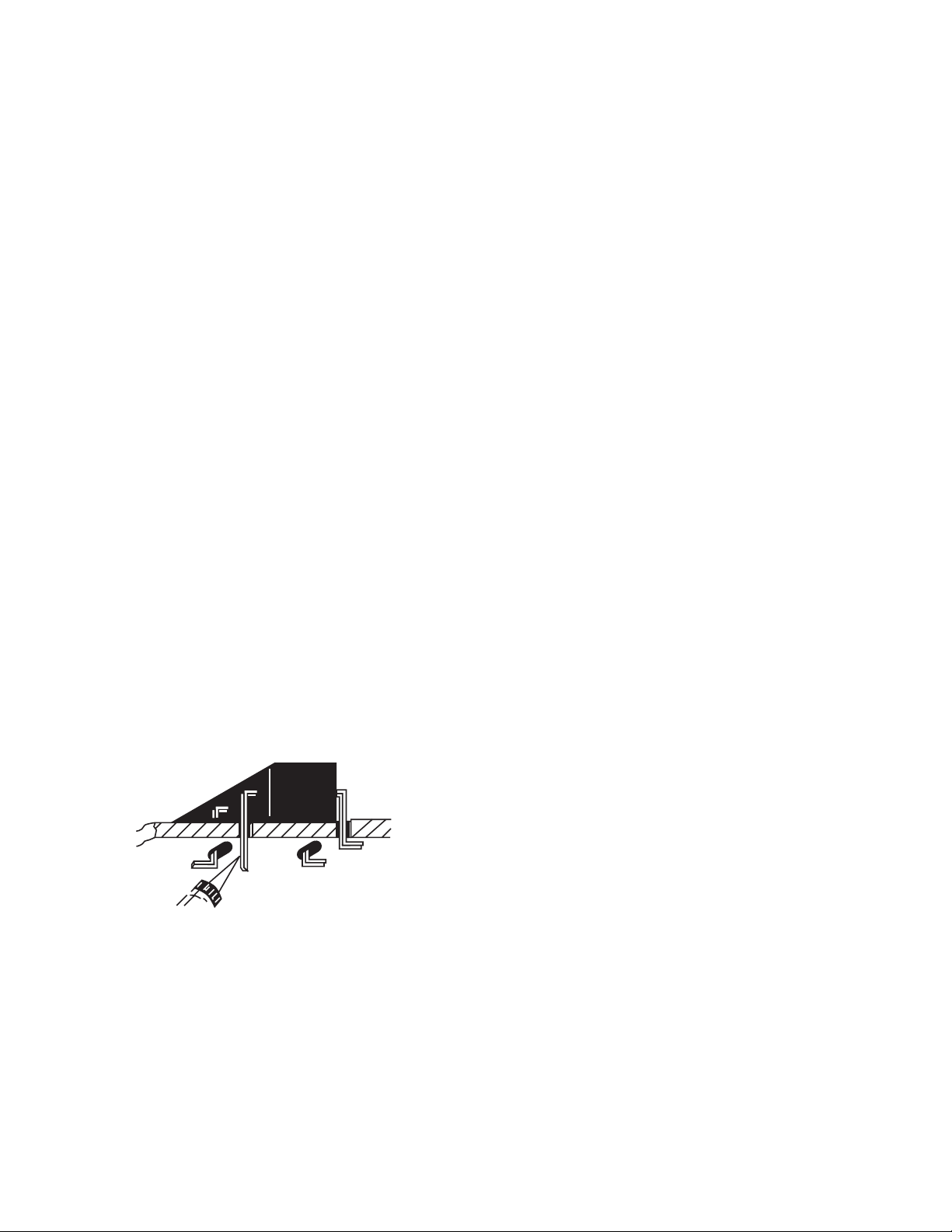

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

soldering pads and pins by

correctly aligning the polarity

symbol.

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

NOTE:

These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

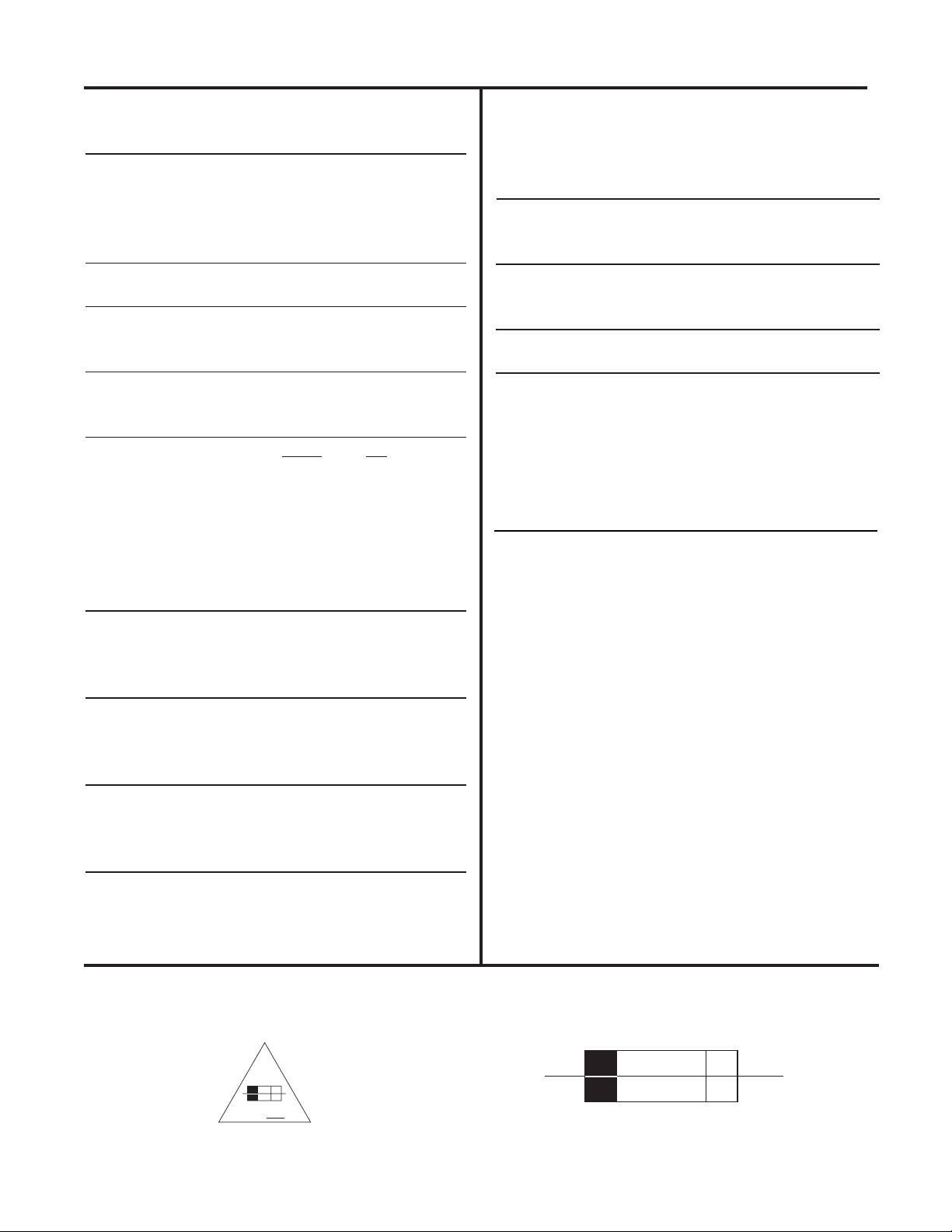

Chip Components

TYPE

GRADE

C

B

E

SOLDER

CAPS

TRANSISTOR

CAPACITOR

1ST DIGIT

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

ANODES

MH DIODE

RESISTOR

SOLDER CAPS

COMMON CATHODE

De-Solder

Braid

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

De-Solder

Braid

Flat-IC

Bridge

Solder

De-Solder

Braid

Iron

Wire

Pull

Awl

Polarity Symbol

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Page 10

10

High Voltage limiter circuit operation check.

1. Turn off TV and connect jig as shown in Figure 2.

2. Set the AC input to 120V AC and turn on TV.

3. Confirm test pattern on CRT is a usable picture, then

slowly adjust jig until the picture disappears and TV shuts

down.

4. When the limiter circuit is operating properly, High

Voltage will be less than 31.5 kV at 1.7mAwhen TV shuts

down.

5. Turn off set immediately after checking circuit operation.

6. Unplug set for one minute to reset shutdown circuit.

Remove jig and voltmeter.

TECHNICAL CAUTIONS

(TH01)

Figure 2

Page 11

11

Model: 60DX10B 43GX10B

50DX10B 43GX10B

Cathode-Ray Tube:

50GX30B/43GX10B R=P16LM00EURFA

60DX10B/50DX10B G=P16LFM00EUHHA

B=P16LFM00EUBMB

Power Input: 120 volts AC, 60 Hz

Power Consumption: 189 Watts - Maximum

149 Watts - Operating

1.7 Watts - Stand-by

Antenna Impedance: 75 Ohm Unbalanced

VHF / UHF / CATV

Receiving Channel: BAND CH

VHF 2~13

UHF 14~69

EXT. Mid (A-5)~(A-1), 4+

CATV Mid. A~I

CATV Super J~W

CATV Hyper (W+1)~(W+28)

Intermediate Frequency: Picture l-F Carrier 45.75 MHz

Sound l-F Carrier 41.25 MHz

Color Sub Carrier 42.17 MHz

Video Input: 1 Volt p-p, 75 Ohm

1 Volt p-p, 75 Ohm (Y)

0.7 Volt p-p, 75 Ohm, (P

B

, PR)

Video Output: 1 Volt p-p, 75 ohm

Audio Input: 470 mVrms, 47 k Ohm

Stereo Audio Output: 470 mVrms, 1 k Ohm

Audio Output Power:

Front: 12 watts per channel at 10% distortion,

8 ohm Impedance. Max output Ð 15 watts.

Anode Voltage:

29.5±1.5kv (1.35±0.2mA)

Brightness: 43GX10B 50DX10B 60DX10B

(white screen) 250cd/m

2

205cd/m

2

140cd/m

2

Speakers: 2 Front Speakers

Dimension:

43GX10B 50DX10B/ 60DX10B

50GX30B

Height (in.) 43

3

/

4

52 60

1

/

2

Width (in.) 39 43

1

/

4

61

1

/

2

Depth (in.) 20 23

1

/

2

26

3

/

4

Weight (Ibs.) 143 183 233

Circuit Board Assemblies:

C.P.T. (B) P.W.B. Terminal P.W.B.

C.P.T. (G) P.W.B. VM P.W.B.

C.P.T. (R) P.W.B. Power/Deflection P.W.B.

Control P.W.B. Control Sub P.W.B.

Signal P.W.B. Sensor Distribution P.W.B.

Covergence P.W.B. Trusur/SRS/BBE P.W.B.

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details. The following symbol near the fuse

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

Example:

SPECIFICATIONS

RISK OF FIRE - REPLACE FUSE AS MARKED

The rating of fuse F901 is 5A - 125V.

Replace with the same type fuse for continued protection

against fire.

F

5 A 125V

125V

5A

Page 12

12

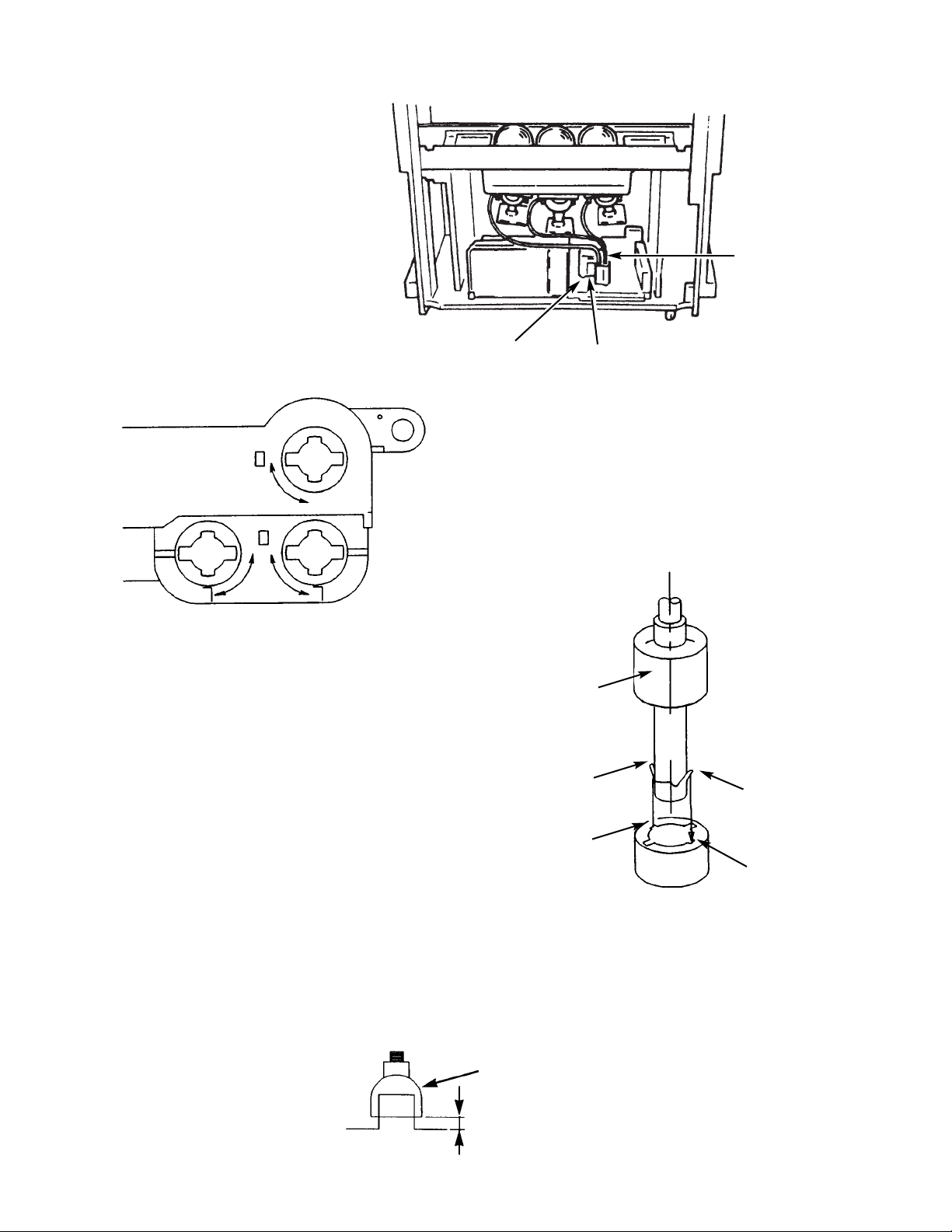

During Insertion

1. Please refer to direction for insertion as shown in Fig. B (L position). Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

CAUTIONS WHEN CONNECTING / DISCONNECTING THE HV CONNECTOR

Perform the following when the

HV connector (anode connector)

is removed or inserted for CPT

replacement, etc.

Deflection P.W.B.

Silicon cover

Wing

L Position

L Position

Wing

FBT

Anode

connector

3. Remove the connector slowly

by pulling it away from the

case.

During Removal

1. Roll out silicon cover from FBT’s contact area slowly .

2. While turning the connector about 90 degrees

following the arrow (0 position), push the connector

slightly towards the case. (Fig. A)

Fig. A

Fig. B

Silicon Cover

less than 1mm

PUSH

PUSH

Page 13

13

DIGITAL

ARRAY

POWER

INPUT

EXIT

SELECT

f e b a c

d i j

Push open door and

pull forward and down

PUSH

POWER

INPUT

h

g

EXIT

VOL+VOL-

CH-

CH+

VOL+VOL-

CH-

CH+

MENU

SELECT

MENU

DIGITAL

ARRAY

POWER

EXIT

SELECT

i j

Push open door and

pull forward and down

PUSH

MENU

ab d c

INPUT VOL- VOL+ CH- CH+

FEHG

fgh

POWER

EXIT

SELECT

MENU

INPUT VOL- VOL+ CH- CH+

FEHG

43GX10B/50GX30B

50DX10B/60DX10B

2

3

4

5

1

f

8

7

STOP

CONNECT ONLY 8 OHM SPEAKERS

DO NOT SHORT CIRCUIT

THESE TERMINALS.

(Such damage is NOT COVERED

by your television warranty)

SP. MATRIX

SURROUND

EXT.

R

L

REAR SPEAKER

AUDIO TO HI-FI

VHF/UHF

AUDIO

(MONO)/L

R

AUDIO

(MONO)/L

R

AUDIO

(MONO)/L

R

MONITOR

OUT

INPUT 2

INPUT 1

S-VIDEO

VIDEO

S-VIDEO

VIDEO

VIDEO

AUDIO

R

L

INPUT 4

Y/VIDEO

PB

PR

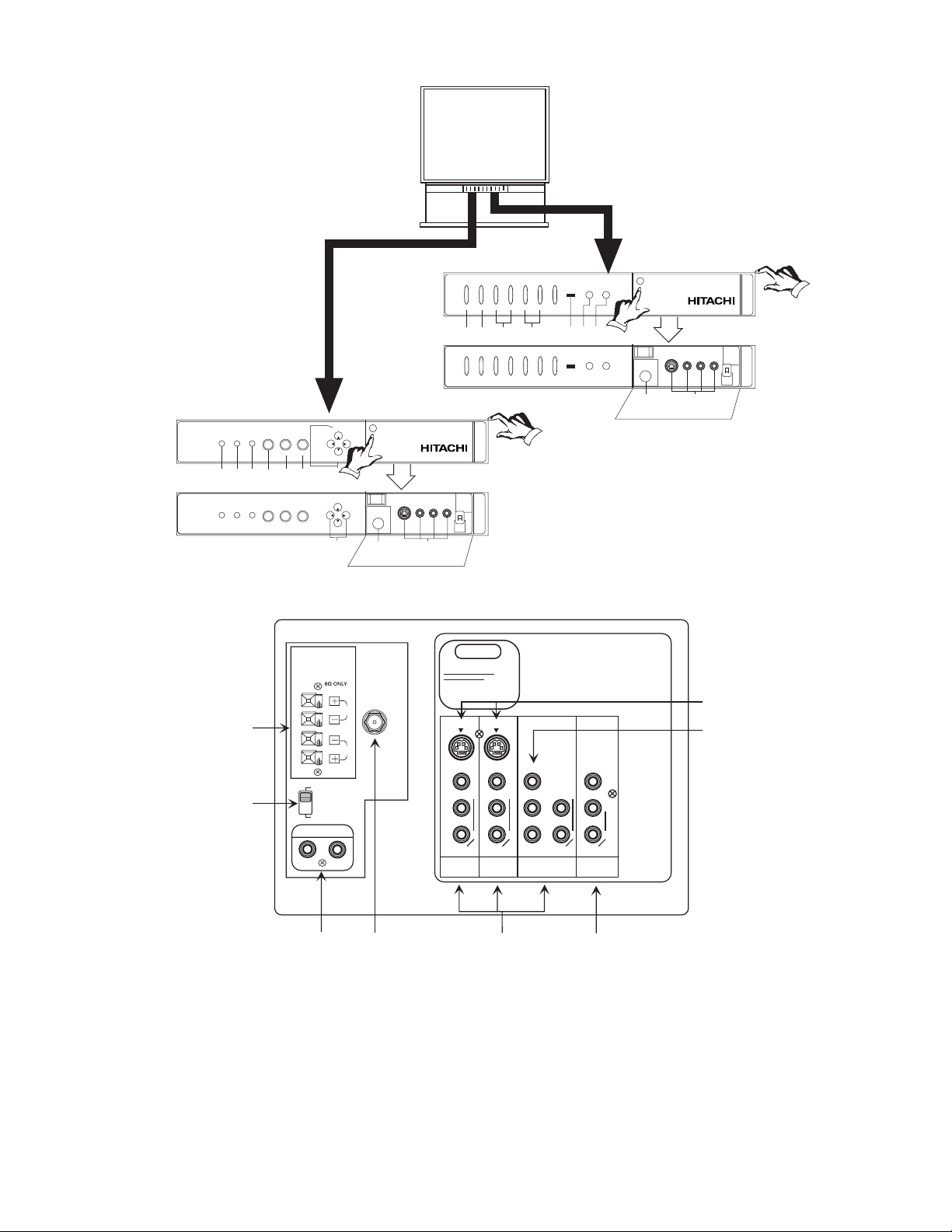

GENERAL INFORMATION

Fig. 3. Front Control Panel

Fig. 4. Rear Panel Jacks

a Antenna Input/Output g Speaker Matrix Surround Switch

b Audio/Video Inputs 1, 2 h Rear Speaker Terminals

c Monitor Out

d Audio to Hi-Fi

e S-Video Inputs 1 and 2

f Component Input Y-PBP

R

Page 14

14

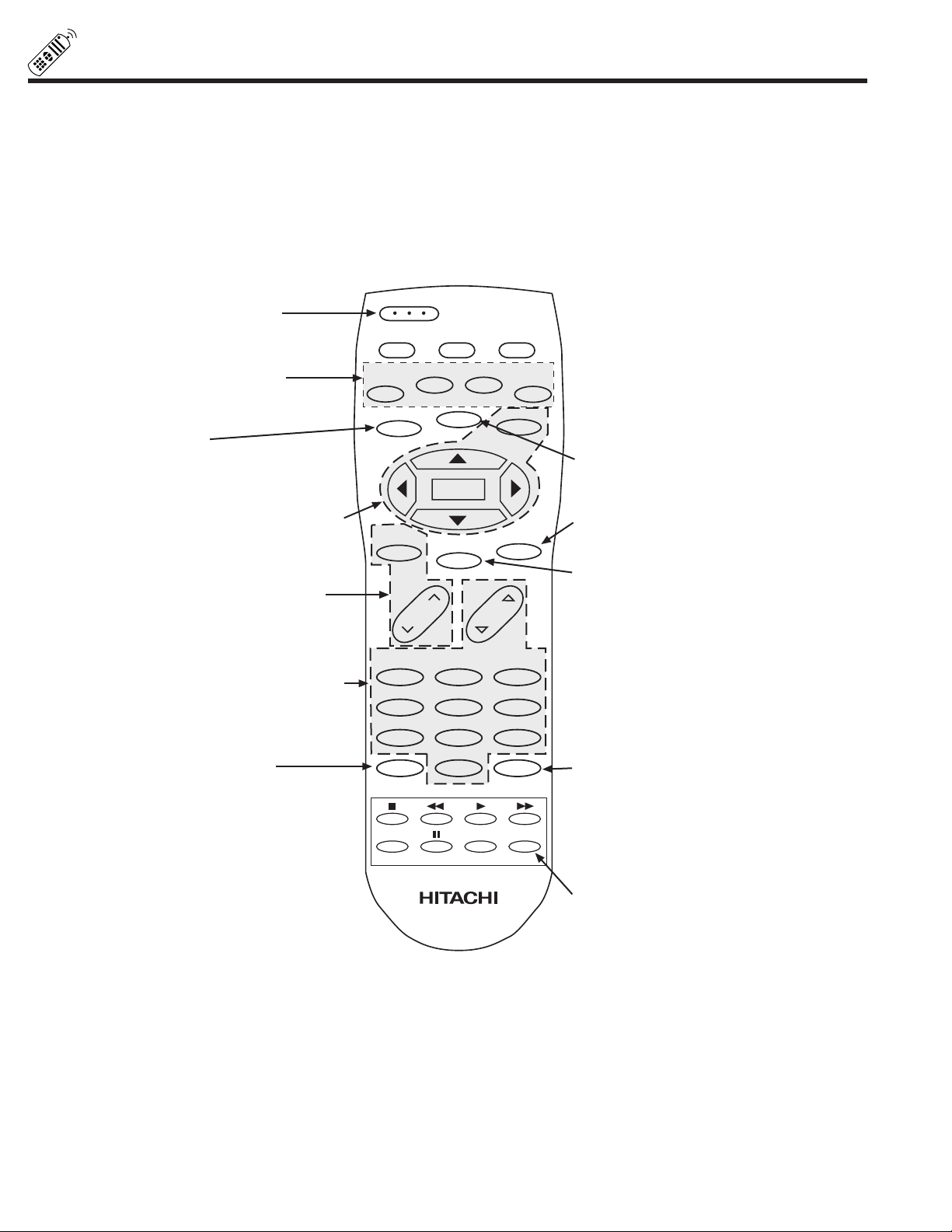

USE THE REMOTE TO CONTROL YOUR TV

VOLUME, MUTE buttons

Use these buttons to obtain the

desired sound level.

123

456

789

0

INPUT

STATUS

VOL CH

POWER

TV CBL/SAT DVD/VCR

PIP

SWAP MOVE

FREEZE

HELP

MENU

MUTE

EXIT

LAST CH

REC

TV/VCR

PIX

SELECT

PIP CH

SELECT, MENU, CURSOR buttons

Use these buttons to set or adjust all

of the On-Screen Display features.

PICTURE-IN-PICTURE

See separate section on pages

23-25 for a detailed description.

HELP button

Press this button to display or cancel

the help messages of the On-Screen

Display.

CHANNEL SELECTOR buttons

Use these buttons to select the

CHANNEL you wish to watch.

INPUT button

Use this button to select the

main or sub-picture video

source from the antenna or

video inputs.

PIP CH button

Use this button to select between

main picture and sub-picture tuning.

a TV POWER button

Press this button to turn

the TV set On or Off

h

k

c

g

d

f

i

EXIT button

Use this button to exit all On-Screen

Display menus.

j

LAST CHANNEL (LAST CH) button

Use this button to select between the last

two channels viewed.

e

STATUS button

Press this button to check the

channel being received, or if it

has Stereo (ST), Second Audio

(SAP), and Channel and Video I.D.

b

PIX button

Press this button repeatedly to

directly access THEATER mode

between Sport, TV, Movies and Music.

l

Page 15

15

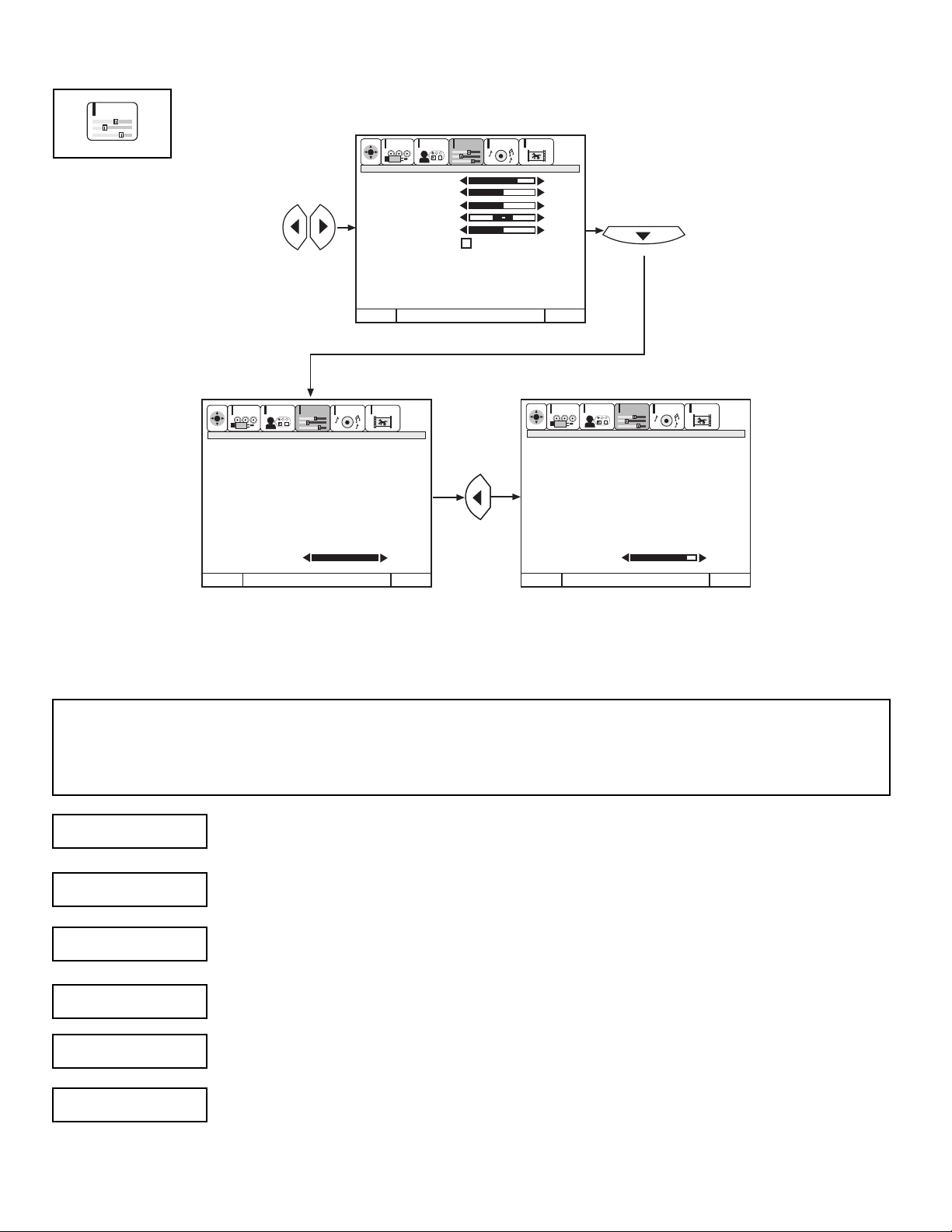

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

VIDEO

Select VIDEO to adjust picture settings and improve picture quality.

Use this function to change the contrast between black and white levels in the picture. This adjustment will

only affect the picture when ADVANCED SETTINGS PERFECT PICTURE is OFF. (see page 48)

Use the CURSOR G or H buttons to highlight the function to be adjusted.

Press the CURSOR F or E buttons to adjust the function.

Press EXIT to quit menu.

NOTE: ¥ If CONTRAST is selected, you are adjusting CONTRAST. The additional menu items BRIGHTNESS, COLOR, TINT,

and SHARPNESS can be selected and adjusted in the same manner.

¥ Contrast and Brightness adjustments will affect only the main picture. These adjustments will not affect the sub-picture.

Use this function to adjust the level of color in the picture.

Use this function to adjust flesh tones so they appear natural. (It may be necessary to adjust TINT to obtain

optimum picture quality when using the COMPONENT VIDEO: Y-PBPRINPUT 4 jacks).

Use this function to adjust overall picture brightness.

Use this function to adjust the amount of fine detail in the picture.

When RESET is selected, press SELECT button to return video adjustments to factory preset conditions.

CONTRAST

COLOR

TINT

BRIGHTNESS

SHARPNESS

RESET

Exit

75%

50%

50%

50%

Exit

Contrast

100%

Exit

Contrast

85%

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

Cursor

Menu To Menu Bar To Quit

Contrast

Brightness

Color

Tint

Sharpness

Reset

Advanced

Settings

Menu To Menu Bar To Quit Menu To Menu Bar To Quit

Cursor

Page 16

16

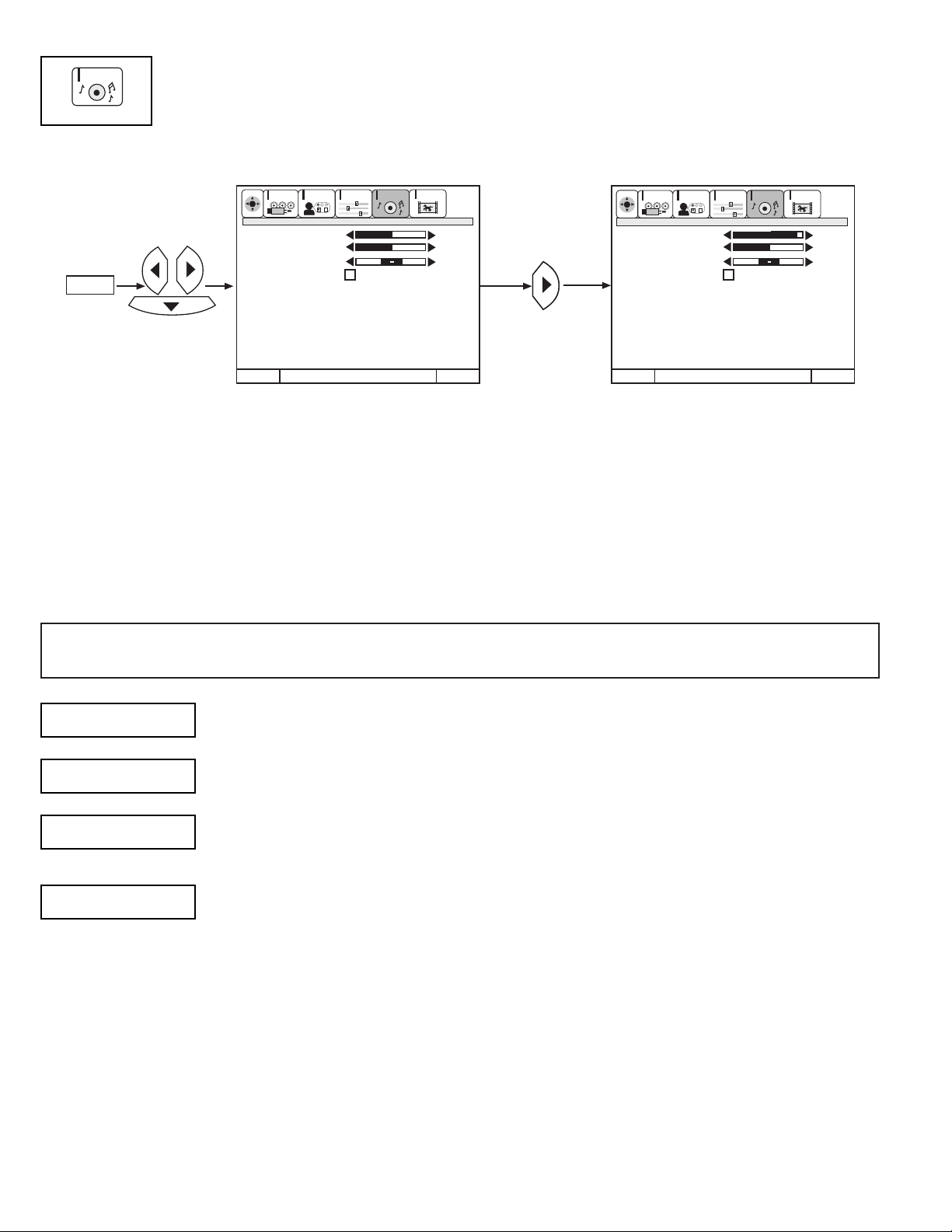

Select AUDIO SETTINGS to adjust the TV to your preference and to improve the sound quality.

This function controls the low frequency audio to all speakers.

Use CURSOR G or H to highlight the function to be adjusted.

Press CURSOR F or E to adjust the function.

Press EXIT to quit MENU.

NOTE: If BASS is selected you are adjusting BASS. The additional menu items TREBLE and BALANCE can be selected and

adjusted in the same manner.

This function controls the high frequency audio to all speakers.

This function will control the left to right balance of the TV internal speakers and the AUDIO TO HI FI output.

When RESET is selected, press SELECT to return audio adjustments to factory preset conditions.

AUDIO

BASS

BALANCE

RESET

TREBLE

ExitExit

90%

50%

BASS

TREBLE

BALANCE

RESET

ADVANCED

SETTINGS

50%

50%

SELECT

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

Cursor

Menu To Menu Bar To QuitMenu To Menu Bar To Quit

BASS

TREBLE

BALANCE

RESET

ADVANCED

SETTINGS

Page 17

17

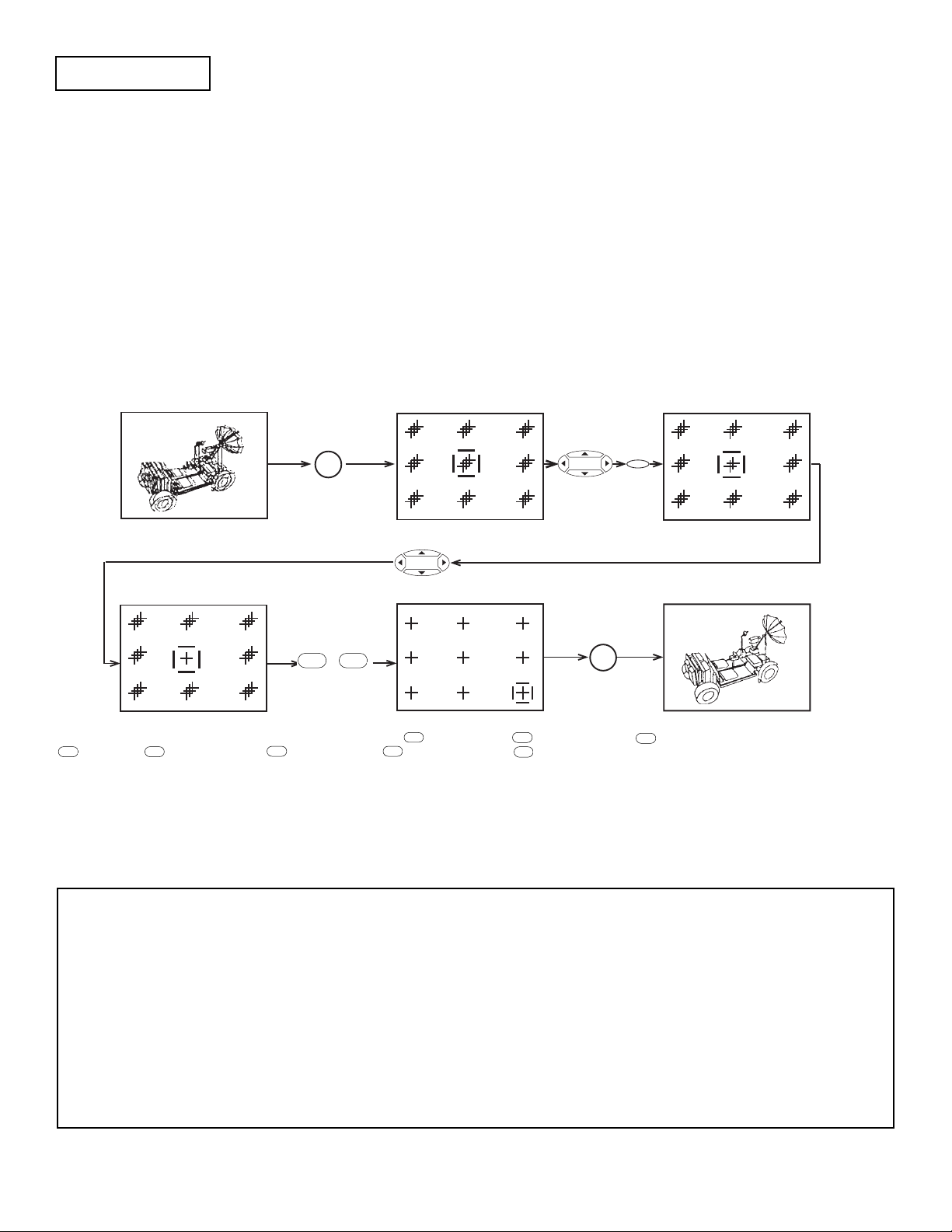

Use the number buttons to select which point to adjust: - Upper Left, - Upper Middle, - Upper Right, - Center Left,

- Center, - Center Right, - Bottom Left, - Bottom Middle, - Bottom Right.

Press the CURSOR buttons to move the displayed color up, down, left, or right.

Press MENU to change the color you want to adjust.

Press the front panel DIGITALARRAY button or the remote control MOVE button when adjustment is done. This will save your

adjustment into memory.

CURSOR

CURSOR

MENU

Your HITACHI Projection TV has three color projection tubes: one for red, one for green, one for blue. When mixed together in the

proper proportion, the output of these three color tubes can produce any color. To produce these colors, however, the beams must be

precisely aligned over each other so that the colors can be mixed. The process of aligning these picture beams is called ÒconvergenceÓ.

Over a period of time, the picture tubes can drift out of alignment due to normal bumps and vibrations or moving the TV. If you move

your TV, or if, after a time, you notice color rings or halos around objects in the picture, you may want to converge (align) the colors.

Properly converged, the lines appear white, which is actually a combination of the outputs of the three color tubes. The output of the

green tube is stationary. The outputs of the red and blue tubes can be adjusted. When properly aligned, the outputs of all three tubes

should be directly over each other to produce the white lines.

To simplify convergence, HITACHI incorporates a feature to allow you to display a test pattern of horizontal and vertical lines at 9

different locations on the screen. Simply use the remote control to adjust the red and blue colors to match the green. When properly

aligned, the outputs of all three tubes should be directly over each other to produce the white lines.

To enter this adjustment mode, you may also select DIGITAL ARRAY from the Set Up menu. However, this will display a message

prompting you to press the front panel DIGITAL ARRAY button.

NOTE: Only a momentary press of the DIGITAL ARRAY button is necessary to enter DIGITAL ARRAY convergence adjustment

mode.

Do not press the DIGITALARRAY button for more than three seconds. This is only for extreme cases of misconvergence

and requires assistance from service.

Four lines surrounding a crosshatch indicate the point being adjusted. The color of these surrounding lines indicates the

color being adjusted.

To save your adjustment data into memory, press the front panel DIGITAL ARRAY button or the remote control MOVE

Button. If you do NOT wish to save your adjustment data into memory, turn the TV OFF or press the remote control PIP

button. When the TV is turned ON again, your old convergence data will be restored.

When adjusting convergence, always start at the center of the screen.

DIGITAL ARRAY

1

2

3

4

5 6

7 8

9

1 ~ 9

DIGITAL

ARRAY

Red

Blue

DIGITAL

Blue

1

9

~

Blue

ARRAY

Page 18

18

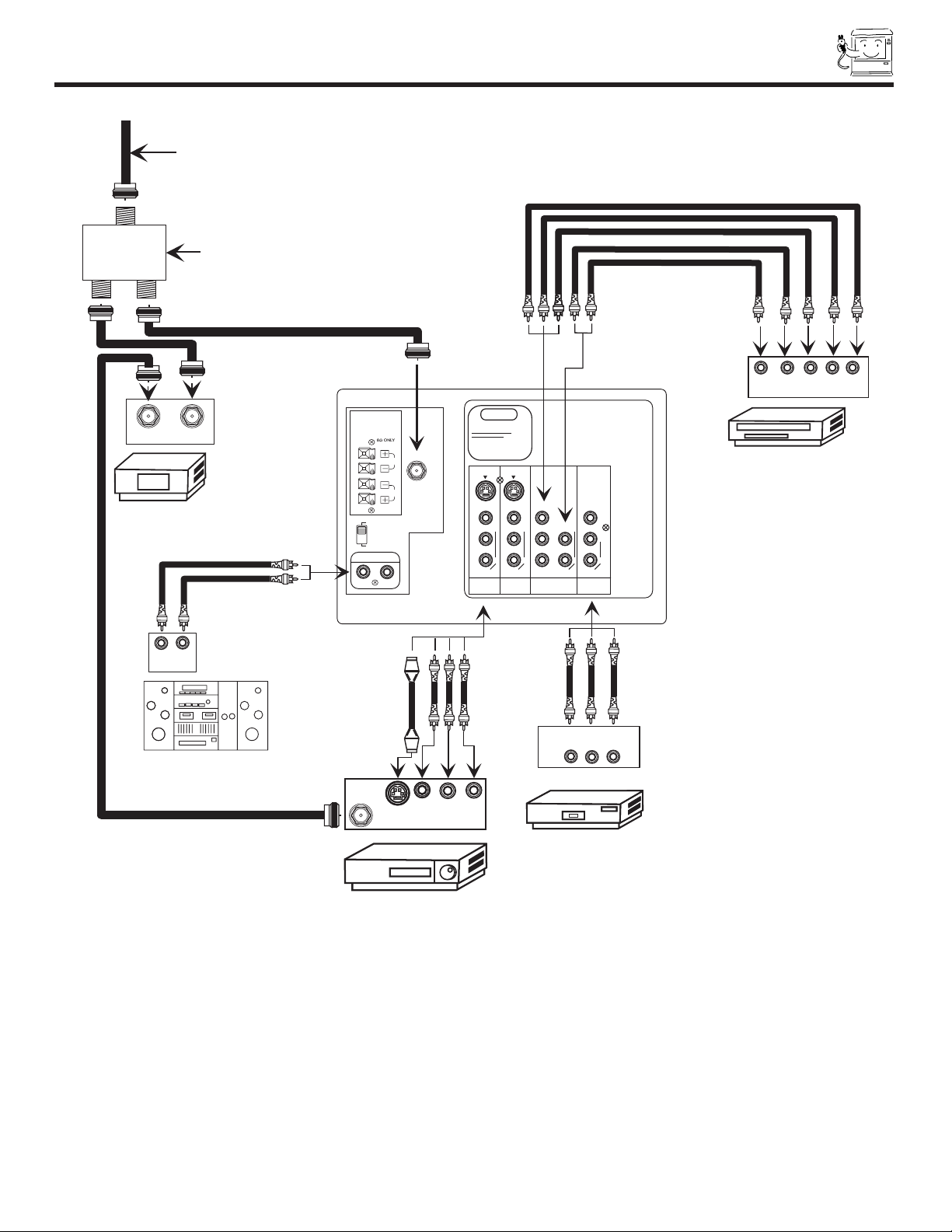

REAR PANEL CONNECTIONS

Typical full feature setup. Follow connections that pertain to your personal entertainment system.

STOP

CONNECT ONLY 8 OHM SPEAKERS

DO NOT SHORT CIRCUIT

THESE TERMINALS.

(Such damage is NOT COVERED

by your television warranty)

SP. MATRIX

SURROUND

EXT.

R

L

REAR SPEAKER

AUDIO TO HI-FI

AUDIO

(MONO)/L

R

AUDIO

(MONO)/L

R

AUDIO

(MONO)/L

R

RL

OUTPUT

Y P P

L R

DVD Player,

Laserdisc player, etc.

RB

LR

INPUT

Stereo System Amplifier

2-Way signal splitter

INPUT

V L R

VCR #2VCR #2

Outside antenna or

cable TV coaxial cable

Cable TV Box

OUTPUT

INPUT

VCR #1

OUTPUT

V L R

S-VHS

ANT

IN

MONITOR

OUT

INPUT 2

INPUT 1

S-VIDEO

VIDEO

S-VIDEO

VIDEO

VIDEO

AUDIO

R

L

INPUT 4

Y/VIDEO

P

B

P

R

VHF/UHF

Page 19

19

SERVICE ADJUSTMENTS

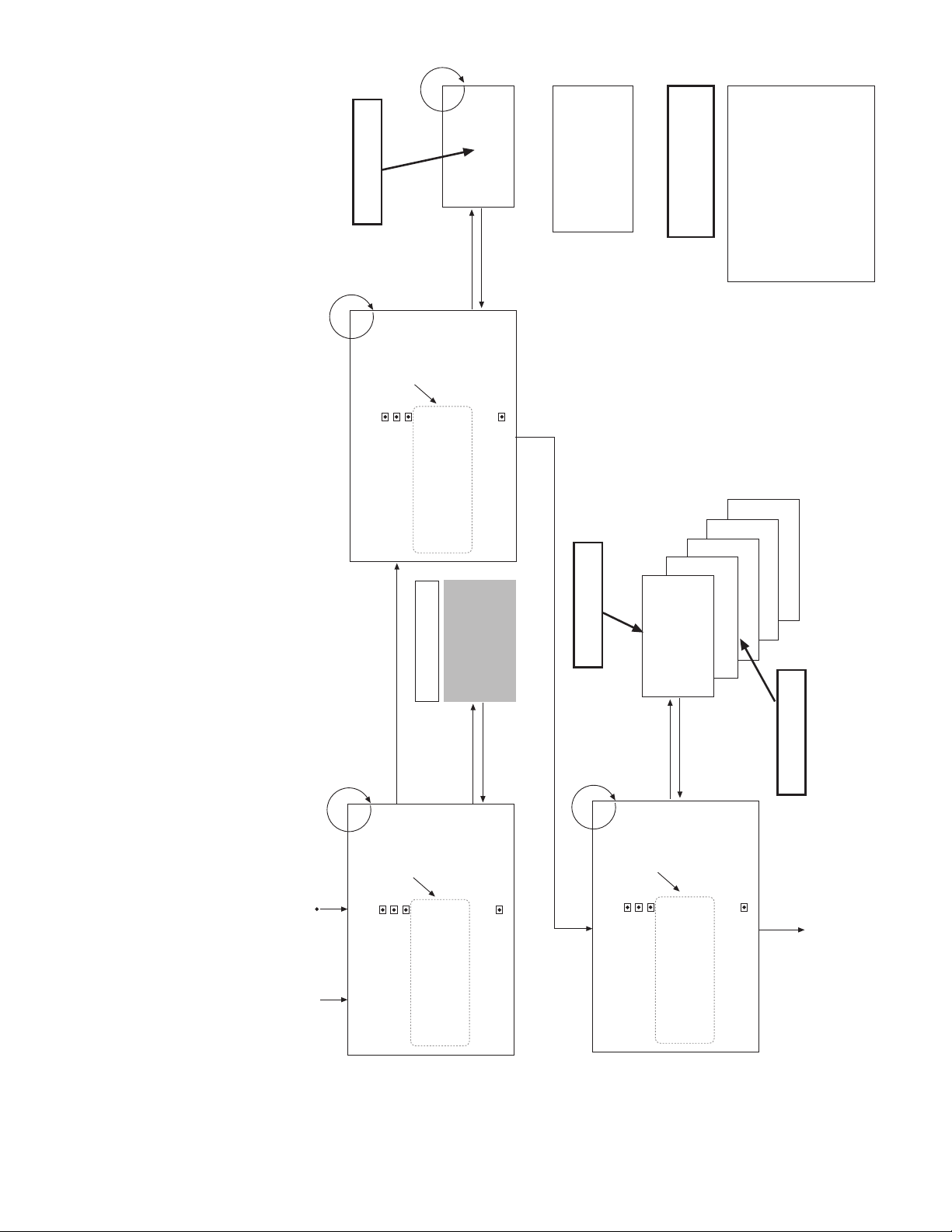

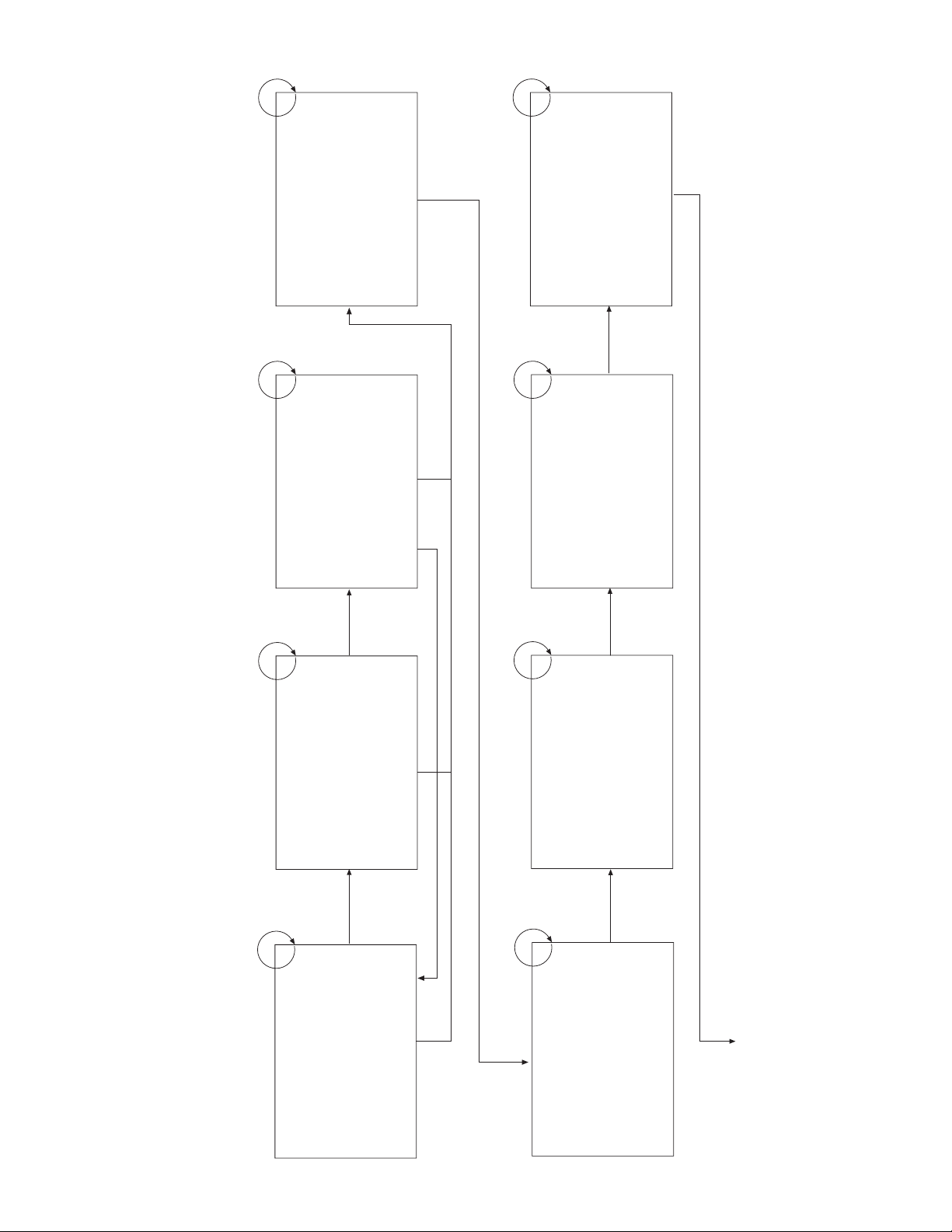

1. ASSEMBLED P.W.B ADJUSTMENT..................................................................................................................20

1-1. Memory Initialization (NTSC, SDTV and HDTV) ....................................................................................20

1-2. Comb Filter Operation Check ................................................................................................................25

1-3. Scanning Area Check ............................................................................................................................25

2-0. Final Assembly Adjustment ....................................................................................................................26

2-1. Graphic Equalizer Operation Check ................................................................................................34

2-2. Perfect Volume Operation Check ....................................................................................................34

2-3. Dynamic Bass Operation Check......................................................................................................34

2-4. Input Source Operation Check ........................................................................................................35

2-5. Surround Mode Operation Check....................................................................................................35

2-6. Speaker Setup Operation Check ....................................................................................................37

1-4. High Voltage Adjustment ........................................................................................................................39

2. FINAL ASSEMBLY ADJUSTMENT (Adjustment should be according to below order) ..............................26

2-1. Cut Off ....................................................................................................................................................26

2-2. Raster Inclination Adjustment (Deflection Yoke) ....................................................................................26

2-3. Horizontal AFC Adjustment ....................................................................................................................26

2-4. Lens Focus Adjustment ..........................................................................................................................27

2-5. Static Focus Adjustment ........................................................................................................................28

2-6. Raster Position........................................................................................................................................29

2-7. Vertical Size ..........................................................................................................................................29

2-8. Horizontal Size ......................................................................................................................................29

2-9. Beam Shape ..........................................................................................................................................30

2-10. Static Focus ............................................................................................................................................30

2-11. Blue Focus ..............................................................................................................................................30

2-12. Digital Convergence................................................................................................................................30

2-12-1. Phase Adjustment ......................................................................................................................31

2-12-2. Raster Position ..........................................................................................................................32

2-12-3. Convergence Point ....................................................................................................................32

2-12-4. Digital Convergence Remote Control ........................................................................................32

2-13. Sub-Brightness........................................................................................................................................33

2-14. White Balance ........................................................................................................................................33

2-15. Sub-Picture Adjustment ..........................................................................................................................33

2-16. Sub-Picture Black Level Check ..............................................................................................................33

2-17. Sub-Picture White Balance ....................................................................................................................33

2-18. Sub-Picture Position................................................................................................................................34

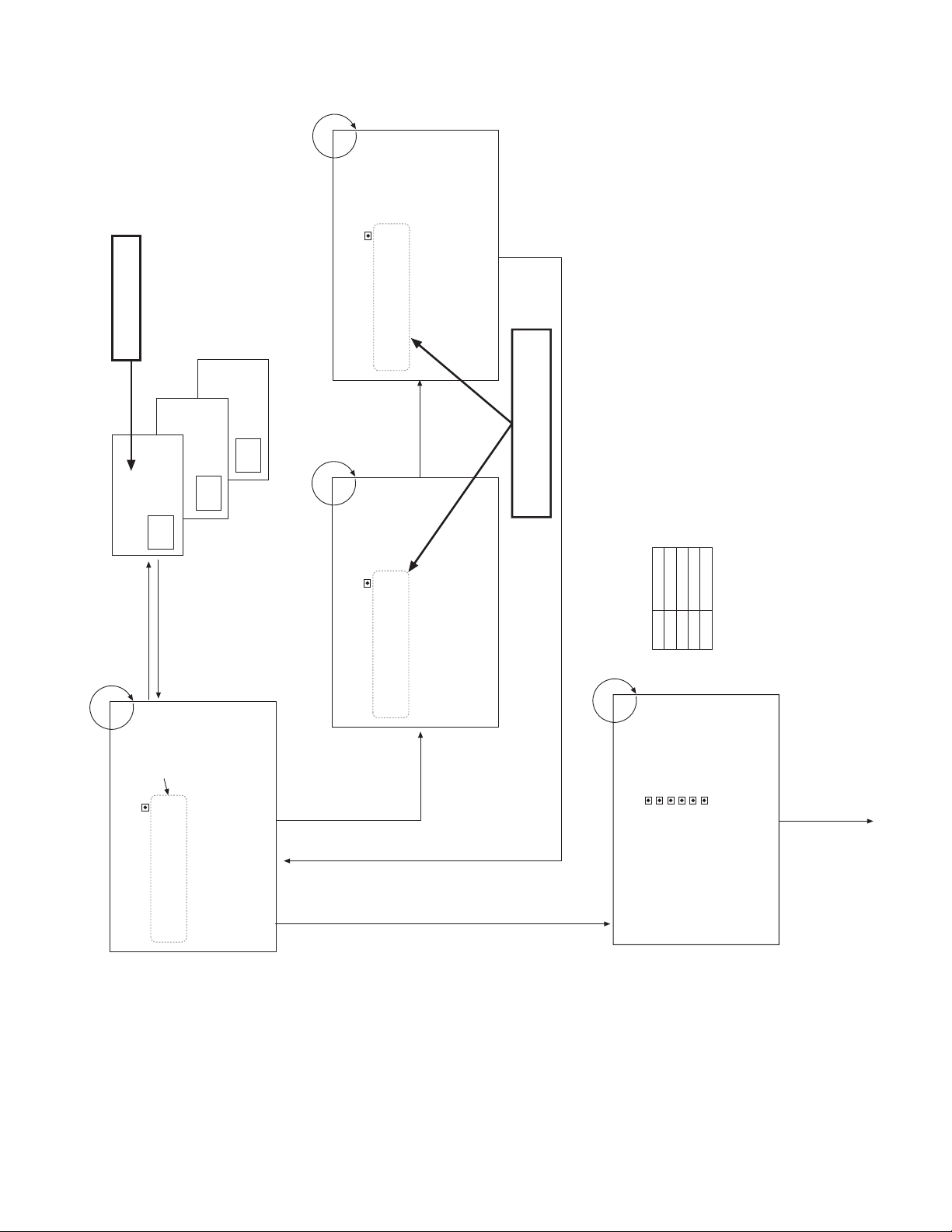

3.0 ADJUSTMENT LOCATIONS............................................................................................................................35

3-1. CRT (R)(G)(B), Cabinet Locations..........................................................................................................35

3-2. Main Chassis (Signal P.W.B.) ................................................................................................................36

3-3. Main Chassis (Power/Deflection P.W.B.) ................................................................................................37

3-4. Convergence P.W.B. ..............................................................................................................................38

Page 20

20

1. ASSEMBLED P.W.B. ADJUSTMENT

1.1 Memory Initialization

Adjustment Procedure

(1) Press INPUT key on

Control Panel and then

Power On to access adjustment

mode.

(2) Receive signal on main picture.

(3) Check the OSD according to

table below, using G,H buttons

on Remote Control.

(4) Press EXIT key to exit I

2

C

ADJUST mode.

NOTE: 1. If there is a

different value

than shown in

the table above,

for fixed data,

adjust it using

F E buttons

(only in this case).

2. When exchanging

microprocessor and

TV is turned on for

first time. It requires

initialization of

MEMORY INITIALIZE.

1.3 Sub-Picture (PIP) position adjustment

Adjustment Preparation

(1) Select signal on main picture.

(2) Video settings have to be

at normal condition.

Adjustment Procedure

(1) Press the INPUT and

POWER button on Control

Panel at same time to acces

VIDEO CHROMA ADJUST

mode.

(2) Select HP POSI (Single) and

VP POSI (Single) using H G

buttons.

(3) Adjust the HP POSI (Single)

(HORIZONTAL) and VP POSI

(Single) (VERTICAL) position

using F E buttons.

(4) Press EXIT button to exit I

2

C

ADJUST mode.

(5) Select single PINP mode and

move the sub picture, using the

MOVE button. Distance between

PINP and edge of screen should

be equal when moved. If it is not,

repeat (1)~(5).

B CUT 3F

G CUT 3F

R CUT 3F

G DRV 3F

ADJUST MODE

SERVICE

SUB BRT*

WHITE BAL

R DRV (COOL)* 48

B DRV (COOL)* 37

R CUTOFF (COOL)* 80

G CUTOFF (COOL)* 80

B CUTOFF (COOL)* 80

H POSITION* 12

V POSITION* 00

FACT RESET

CH U/D, INPUT

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (COOL) 48

B DRV (COOL) 37

R CUTOFF (COOL) 80

G CUTOFF (COOL) 80

B CUTOFF (COOL) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

Select SERVICE

and press E key

Press EXIT key

(OSD OFF)

CUT OFF ADJUST MODE

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (COOL) 48

B DRV (COOL) 37

R CUTOFF (COOL) 80

G CUTOFF (COOL) 80

B CUTOFF (COOL) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

MENU

Select SERVICE

and press E key

Press EXIT key

R DRV 3F

MENU

MENU

MACRO

MACRO

Select SERVICE

and press E key

Press EXIT key

SUB BRT 80

Press Adjust

MACRO

VIDEO SETTINGS

(1) CONTRAST : MIN

(2) COLOR : MIN

VIDEO SETTINGS

(1) CONTRAST : MAX

(2 ) COLOR,TINT,SHARP,BRIGHT:CENER

(3) COLOR TEMP : COOL

ADJUST

(1) Press E to select the R DRV.,

G DRV., R CUT, G CUT, B CUT.

(2) Press E to adjust.

WHITE BALANCE

ADJ. MODE

POWER + INPUT

Adjust in cool

mode only.

Adjust in cool

mode only.

Adjust in cool

mode only.

*: Adjustable data

others: Fixed data (be careful not to change)

Page 21

21

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (COOL) 48

B DRV (COOL) 37

R CUTOFF (COOL) 80

G CUTOFF (COOL) 80

B CUTOFF (COOL) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (COOL) 48

B DRV (COOL) 37

R CUTOFF (COOL) 80

G CUTOFF (COOL) 80

B CUTOFF (COOL) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

SELECT

Adjust in cool

mode only.

Cursor E to

adjust.

Press EXIT to

exit white

balance mode.

Adjust in cool

mode only.

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (WARM) 48

B DRV (WARM) 37

R CUTOFF (WARM) 80

G CUTOFF (WARM) 80

B CUTOFF (WARM) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

Do not adjust WHITE BALANCE in

WARM or NTSC mode. Adjust in

COOL mode only.

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (NTSC) 48

B DRV (NTSC) 37

R CUTOFF (NTSC) 80

G CUTOFF (NTSC) 80

B CUTOFF (NTSC) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

Adjust in cool

mode only.

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (WARM) 48

B DRV (WARM) 37

R CUTOFF (WARM) 80

G CUTOFF (WARM) 80

B CUTOFF (WARM) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

Adjust in cool

mode only.

SELECT

SELECT

SELECT

E

ADJUST MODE

SERVICE

SUB BRT

WHITE BAL

R DRV (NTSC) 48

B DRV (NTSC) 37

R CUTOFF (NTSC) 80

G CUTOFF (NTSC) 80

B CUTOFF (NTSC) 80

H POSITION 12

V POSITION 00

FACT RESET

CH U/D, INPUT

Adjust in cool

mode only.

SELECT

H POSITION ADJ. MODE

Press FE to adjust

V POSITION ADJ. MODE

Press FE to adjust

Press E to set to

Factory settings

MENU

Page 22

22

ADJUST MODE

PIP WHITE BAL

PIP R (COOL)* 2C

PIP G (COOL)* 2C

PIP B (COOL)* 2C

CH U/D, INPUT

Select PIP WHITE BAL.

and press E key

Press EXIT key

SELECT

MACRO

Adjust in cool

mode only.

PIP B 3F

PIP G 3F

PIP R 3F

ADJUST MODE

PIP WHITE BAL

PIP R (WARM) 2C

PIP G (WARM) 2C

PIP B (WARM) 2C

CH U/D, INPUT

Do not adjust PIP WHITE BALANCE

in WARM or NTSC mode. Adjust in

COOL mode only.

ADJUST MODE

PIP WHITE BAL

PIP R (NTSC) 2C

PIP G (NTSC) 2C

PIP B (NTSC) 2C

CH U/D, INPUT

SELECT

MENU

SELECT

ADJUST MODE

VCJ RESET

3DYC RESET

PIP RESET

BBE RESET

MEMORY INIT

I2COPEN

CH U/D, INPUT

MENU

Item Device

VCJ TA1222BN

3DYC uPD64082

PIP SDA9589

BBE NJW1132

Page 23

23

ADJUST MODE

TA1222 (RF)

SUB CONT 1F

SUB COLOR 40

SUB TINT 40

SUB SHARP 38

TOP FO 00

TOF Q 00

COLOR SYS 00

R-Y PHASE 03

R/B LEVEL 00

G/B LEVEL 00

CH U/D, INPUT

ADJUST MODE

TA1222 (RF)

RGB BRIGHT 40

RGB CONT 60

H BLK PHAS 00

V BLK PHAS 00

GPPHS 01

CH U/D, INPUT

ADJUST MODE

TA1222 (VIDEO)

SUB CONT 1F

SUB COLOR 1A

SUB TINT 40

SUB SHARP 38

TOP FO 00

TOF Q 00

COLOR SYS 00

R-Y PHASE 03

R/B LEVEL 00

G/B LEVEL 00

CH U/D, INPUT

ADJUST MODE

TA1222 (480I)

SUB CONT 1F

SUB COLOR 1A

SUB TINT 40

SUB SHARP 38

TOP FO 00

TOF Q 00

COLOR SYS 00

R-Y PHASE 03

R/B LEVEL 00

G/B LEVEL 00

CH U/D, INPUT

ADJUST MODE

TA1222

YG 00

Y DL 00

TXACL 01

COLOR G 00

CLT 00

CDE 01

C TRAP 00

DC POINT 00

DCRATIO 00

CH U/D, INPUT

SELECT

SELECT

MENU

ADJUST MODE

TA1222

DC LIMIT 00

BEP LIMIT 00

BEP POINT1 05

BEP POINT2 00

B.L.S. 00

B.L.C. 01

B.S.G. 00

B.D.L. 00

BSARE 00

WPDL 01

CH U/D, INPUT

MENU

MENU

ADJUST MODE

TA1222 (480I)

S-TRCK 01

AP PEAK F0 00

STR-MD 00

CH U/D, INPUT

ADJUST MODE

TA1222

HI BRT 01

OS ACL 00

OSD-SL 01

WHITE PEAK 00

DABL POINT 00

D ABLE GAIN 07

ABL POINT 05

ABL GAIN 07

COLOR GAIN 15

CH U/D, INPUT

MENU

MENU

MENU

MENU

SELECT

MENU

Page 24

24

ADJUST MODE

uPD64082

DY GAIN 09

DC GAIN 06

YC VAPINV 0B

YC VAPGAIN 05

YHCOR 00

CH U/D, INPUT

MENU

MENU

ADJUST MODE

SDA9589-2

CONTRAST 0F

BRIGHT 00

LM OFFSET 00

YPEAK 03

YCDEL 00

SELDEL 0F

COLOR SUB 10

V OFSET 00

H OFSET 00

CH U/D, INPUT

MENU

ADJUST MODE

SDA9589-2

COLOR SAT (NTSC) 08

HUE (NTSC) 20

ITCPLL (RF) 02

NRIPLL (RF) 02

HFPOSI (SINGLE) 00

VFPOSI (SINGLE) 0F

H P POSI (SINGLE) 37

V P POSI (SINGLE) 18

CH U/D, INPUT

SELECT

ADJUST MODE

SDA9589-2

COLOR SAT (480I) 08

HUE (480I) 20

ITCPLL (VIDEO) 02

NRIPLL (VIDEO) 00

HFPOSI (MV4) 00

VFPOSI (MV4) 0A

H P POSI (MV4) 27

V P POSI (MV4) 0C

CH U/D, INPUT

NJW1132

BBE HIGH 07

BBE LOW 07

V CHIP RATING

POLLING 0F

TIMEOUT 05

STATUS 02

AFC/CLOCK TEST

OSD H POSI **

OSD V POSI **

CH U/D, INPUT

32ms*POLLING DATA

FROM RATING OFF

DETECTIVE COUNT

MENU

MENU

SELF-DIAGNOSIS

RESET START 00

REMOTE POWER 00

MATRIX POWER 00

REMOTE MEM INIT 00

MATRIX MEM INIT 00

ADJUST MEM INIT 00

ADJUST FAC RESET 00

EEP READ ERROR 00

EEP WRITE ERROR 00

LAST EVENT 0000

CH U/D, INPUT

MENU

Page 25

25

1.2 Comb filter operation check

Adjustment preparation

(1) Receive the color bar signal at the regular tuning

point.

(2) Set the CONTRAST control to MAX and the

other controls to center.

(3) Set the PERFECT PICTURE to OFF.

Adjustment procedure

(1) Check that between the color bars there are line

dots every second color bar as shown in the

drawing.

A

A A

B

LINE DOT

AX

BX

Check and line dots.

B

A

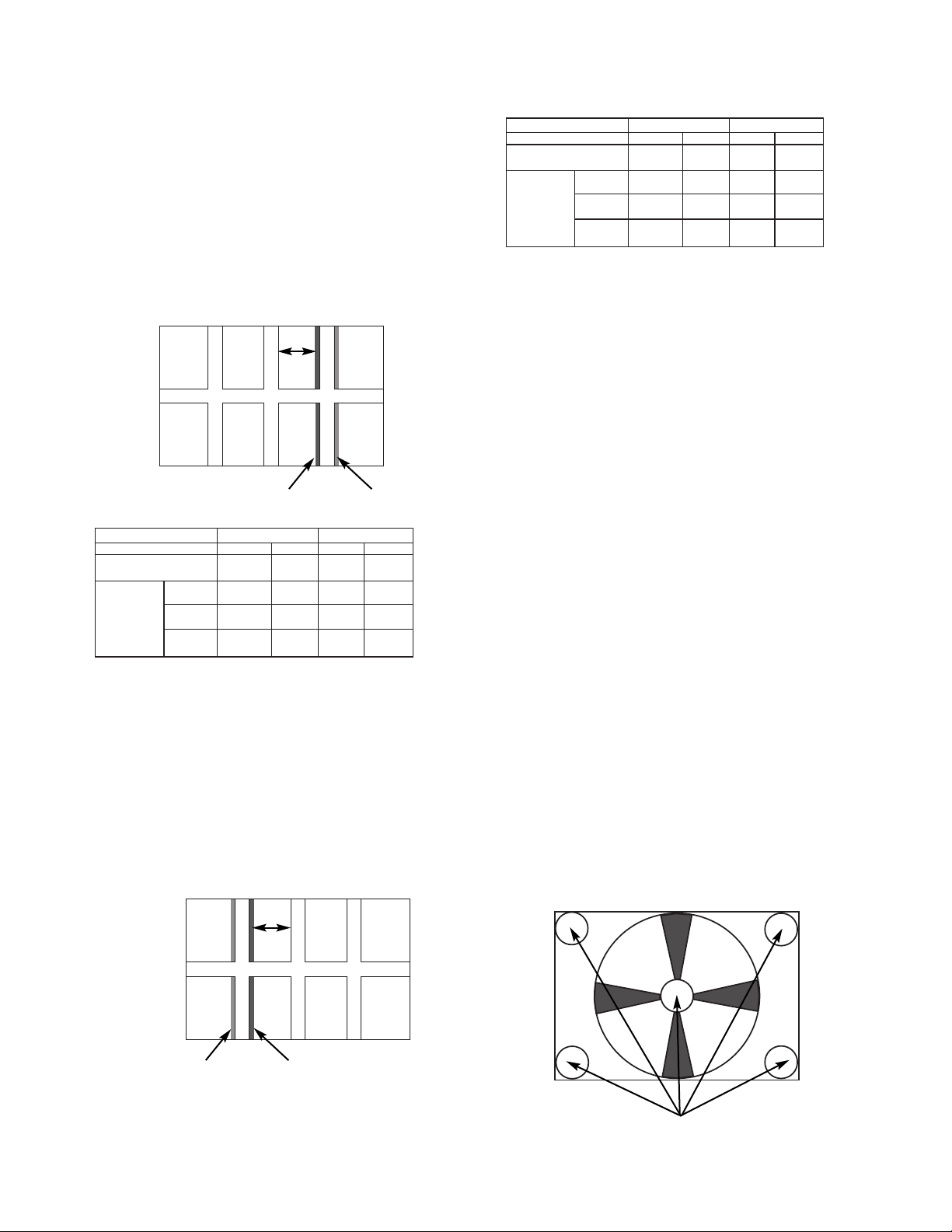

Item Symbol 43Ó 50Ó 60Ó

Top/Bottom pincushion distortion A,B ±5 ±6 ±6

Right/Left pincushion distortion C,D ±4 ±4 ±5

Center line Vertical line E 5 6 6

tilt Horizontal line F 5 6 6

Center line Vertical line G ±3 ±3 ±4

winding Horizontal line H ±3 ±3 ±4

Trapezoidal distortion Vertical line I,J 4 5 5

Skew distortion Horizontal line K,L 5 6 6

(unit: mm)

G

I

J

D

C

A

B

F

E

K

H

L

1.3 Scanning Area Check

Checking Condition

(1) Digital convergence adjustment should have been

completed.

(2) Receive the circle pattern signal.

(3) Brightness/Contrast - Standard condition

Contrast: Max

Other Controls: Center position

(4) Check that the scanning area matches with the next

drawing.

1.3 Raster Distortion Check

Checking Condition

(1) Digital convergence adjustment should have been

completed.

(2) Receive the cross-hatch signal.

(3) Brightness/Contrast - Standard condition

Contrast: Max

Other Controls: Center position

(4) Check the raster distortion.

Specification: Value shown in the table below or

less.

A~D

I~L

- Measure the winding of the outside line.

Page 26

26

2. FINAL ASSEMBLY ADJUSTMENT

2.1 Cut Off Adjustment

Adjustment preparation

(1) Set R and G drive VRÕs on CPT P.W.B. to center.

(2) Adjust screen VRÕs on Focus Pack fully

counterclockwise.

(3) Adjust Focus VRÕs on Focus Pack fully

clockwise.

(4) Set video conditions to factory preset.

(5) The vertical incident illumination on the screen

should be 20 lux or less (room should be dark).

Adjustment procedure

(1) Press and hold INPUT key on control panel and

then POWER ON to access I

2

C adjustment

mode.

(2) Choose “SERVICE” item from I

2

C adjustment

menu by pressing CURSOR E.

(3) Screen VR should be turned clockwise gradually

and set so that retrace line begins to appear.

(4) Return to “NORMAL” mode by pressing the

EXIT button.

(5) The blue line should be lighter thatn red and/or

green.

(6) Adjust Focus VR’s so that focus is even all

around screen.

FOCUS PACK

2.2 Raster Inclination adjustment (Deflection

Yoke)

Adjustment preparation

(1) The set can face east or west.

(2) Input the single cross test signal.

(3) Set video conditions to factory reset.

(4) The lens focus adjustment should have been

completed.

(5) The electric focus should have been coarse

adjusted.

(6) The digital convergence RAM should be cleared

(uncorrected state). With the TV set off, press

and hold the service switch located on the

Power/Deflection PWB and then press the

power button.

(7) Start adjustment 20 minutes or more after TV is

turned on

Adjustment procedure

(1) Apply covers to the R and B lenses and project

only green light.

(2) Turn the G deflection yoke and adjust the vertical

raster inclination.

(3) Then, remove the cover of R or B lens and project

red or blue light and green light together on the

screen.

(4) Turn the deflection yoke of R or B and set so that

the inclination of R or B with respect to the green

light is as shown below on the top and bottom

sides.

(5) After raster inclination adjustment, fixing screw

of DY should be screwed with 12±2kg-cm

torque.

2.3 Horizontal AFC Adjustment

Adjustment preparation

(1) Face the set East or West.

(2) Display the circle pattern signal.

(3) Contrast: Max, Brightness: Center.

(4) The electrical focus should have been coarse-

adjusted.

(5) The convergence should be in un-corrected

state.

Method of no correction state:

Turn power off and press POWER button and

DIGITAL CONV. SERVICE ONLY button at the

same time.

Then convergence is in correction.

NOTE:

DIGITAL CONV. SERVICE ONLY button:

on the CONVER/FOCUS P.W.B.

Adjustment procedure

(1) Project only G on the screen using any one of

the following procedures.

(a) Apply covers to the R and B lenses, or

(b) Short-circuit 2P sub mini connectors of the

R and B CPT P.W.B.

(2) Set the VR of horizontal adjustment R603

counter clockwise, and set the H size minimum.

(3) Check as shown below.

The “0” marker of circle pattern is visible.

NOTE: In the case of inability to see “0” marker, turn

the horizontal size adjustment VR at clockwise

until the marker is visible.

Static Focus VR

R

GB

R

GB

Screen VR

Focus VR

Screen VR

1

, 2 £ ± 2mm

1

1

£ ±2 m m

Notes: (1) If internal cross-hatch does not appear after

clearing RAM data, press service switch

again, on POWER/DEFLECTION PWB.

(2) To restore old RAM data, turn TV off and on.

CROSSHATCH (GREEN)

2

Page 27

27

2.4 LENS FOCUS ADJUSTMENT

Adjustment preparation

(1) The orientation of PTV set is arbitrary, west,

east, north and south.

(2) Centering DY inclination should have been

adjusted.

(3) FOCUS VR location adjustment should have

been completed. (Red : 12 OÕclock, Green : 1~2

OÕclock).

(4) Receive the cross-hatch pattern signal.

(5) Refer to setup below.

CONTRAST : HALF of full scale.

BRIGHTNESS : minimum

Adjustment procedure

(1) Loosen the fixing screw or wing nut on the lens

cylinder so that the lens cylinder can be turned.

(Be careful not to loosen too much). After

completing steps (4), (5), (6) below, tighten the

fixing screws or wing nuts for each lens with a

torque of 1.18N.m (12Kgf cm) ~ 1.67N.m (17Kgf

cm).

(Be careful the lens cylinder does not turn after

having tightened the screw or wing nuts. If it is

tightened too much, lens may tilt or screw may

break.)

(2) Apply covers to each color of R, G and B lenses.

And project a single color on the screen and

adjust in sequence. (The adjustment order of R,

G and B is only an example.)

(3) If the lens adjustment knob is turned clockwise

viewed from the front, the color Aberration

change as follows.

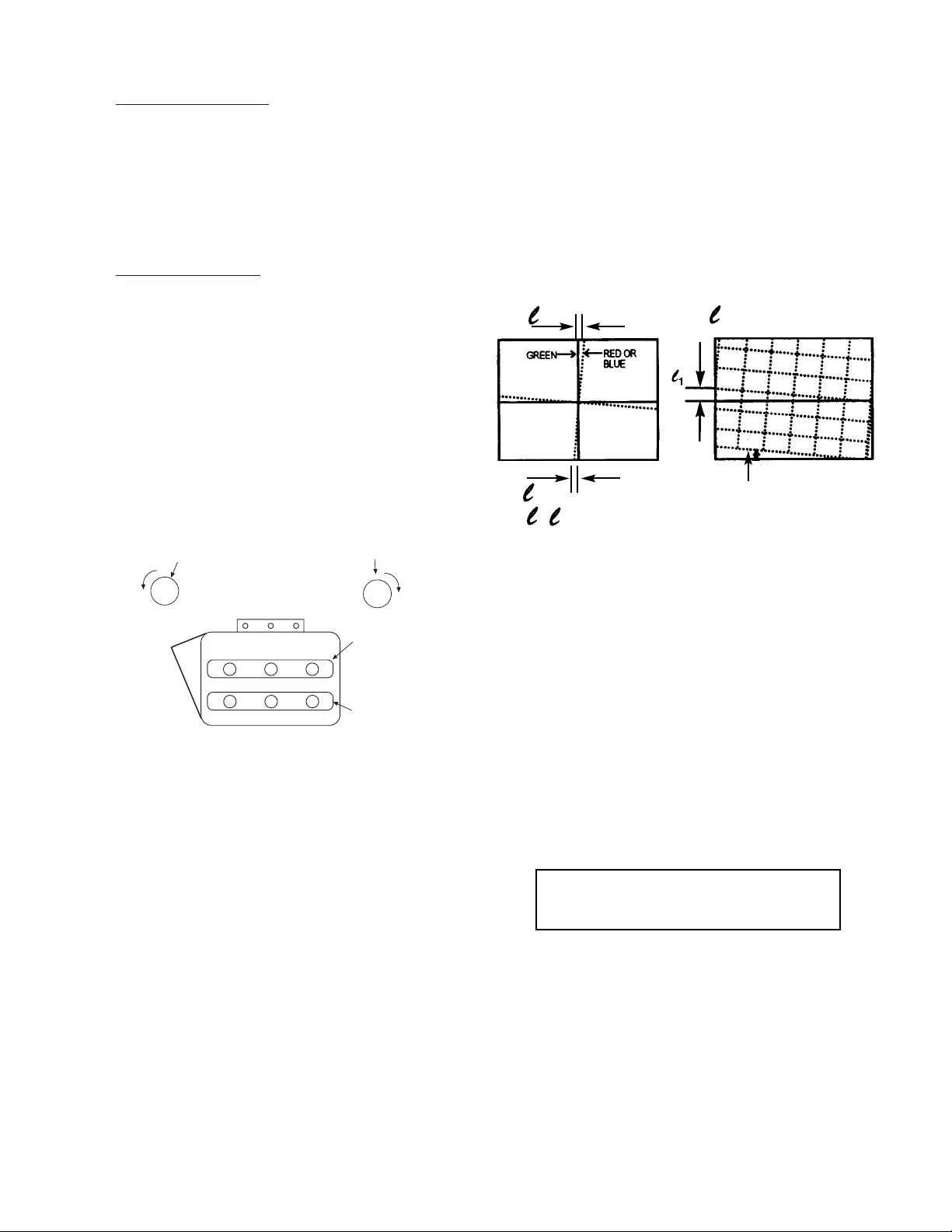

123

0

123

0

*2

*1

(NOTE 1)

Fixing Screw

(NOTE 2)

Fixing Wing Nut

TYPE 1 TYPE 2

Lens Assy

Lens Assy

(4) In case of G lens. Set to the point where the

chromatic aberration switches from blue to red.

If the chromatic aberration appearing all over

the screen is not the same, observe the vertical

bright line and adjust lens focus as specified in

table below. When the red chromatic aberration

appearing at both sides of the bright line is not

equal, observe the side with larger chromatic

aberration when adjusting.

Color

Aberration

Cross-Hatch

Change of Color Aberration

Short focus Long focus

RED LENS Orange Scarlet

GREEN LENS Blue Red

BLUE LENS Purple Green

O

I

L1

L2

Change the signal to the circle pattern and fine

adjust. Observe the corner part of the screen,

especially observe number in the small circle

when adjusting. If the focus performance at the

screen center exceeds the lower limit, it is

acceptable.

Small circle of circle pattern

CHASSIS 43GX10B/50GX10B 50DX10B/60DX10B

SCREEN SIZE 43Ó 50Ó 60Ó 50Ó

L1 and L2

(PITCHES from CENTER) 3.0 3.0 3.0 3.0

L1&L2 * * * *

COLOR * * * *

ABERRATION I 2mm MAX 3mm MAX 3mm MAX 3mm MAX

*******

O 2mm MAX 3mm MAX 3mm MAX 3mm MAX

(NOTE) * Slightly reddish or no color

** Slightly reddish or no color

OPTICAL FOCUSING ADJUSTMENT GREEN

There is no picture fold.

Page 28

28

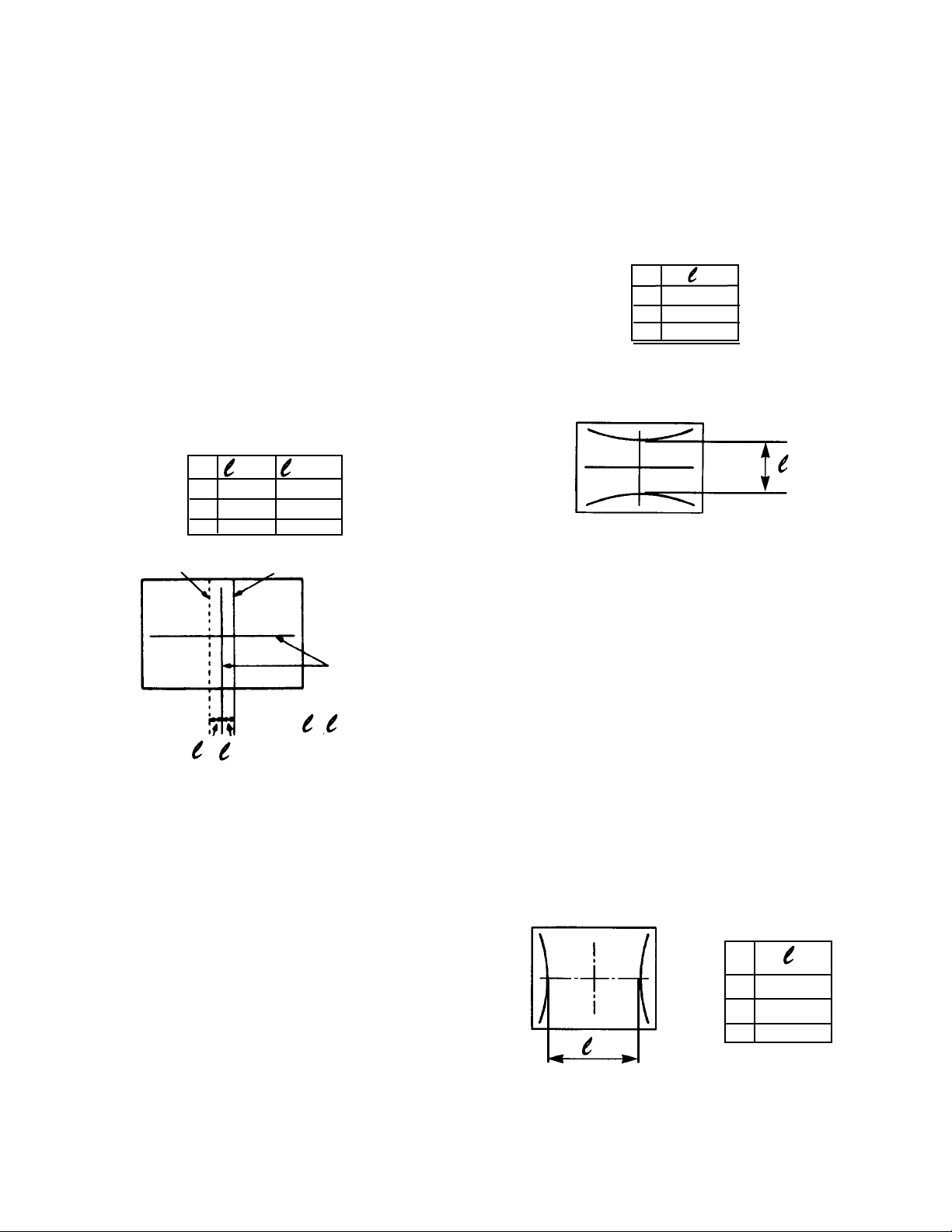

(5) In case of R lens. Set the position where the

chromatic aberration changes from red to

crimson. As shown below, observe the vertical

bright line and adjust lens focus where the

crimson or red chromatic aberration slightly

appears inside and crimson or red outside

(reference value : 1~3mm) at the point specified

in table below. Change the signal and fine-

adjust in the same way as the G lens.

O

I

L

NOTE: Setting the center between Red and crimson

is optimum.

(6) In case of B lens. Set the position where the

chromatic aberration changes from purple to

green. As shown below, observe the vertical

bright line and adjust lens focus where the

purple or green chromatic aberration slightly

appears inside and purple or green outside

(reference value : 1~3mm) at the point specified

in table below. Change the signal and fine-

adjust in the same way as the G lens.

O

I

L

NOTE: Setting to the center between purple and

crimson is optimum.

Adjustment Procedure

(7) After all colors have been adjusted, display all

colors with the cross-hatch pattern signal and

compare the focus (optical focus) performance

with the limit sample set.

(8) Then, select the circle pattern signal and

compare the focus (optical focus) performance

of each color and all colors together with the

limit sample set.

(9) If the focus performance is worse than the limit

sample set, re-adjust step (1) to (6).

CHASSIS 43GX10B/50GX10B 50DX10B/60DX10B

SCREEN SIZE 43Ó 50Ó 60Ó 50Ó

L1 and L2

(PITCHES from CENTER) 3.0 3.0 3.0 3.0

L1&L2 * * ** **

COLOR * * ** **

ABERRATION I 2mm MAX 3mm MAX 3mm MAX 3mm MAX

** ** * *

O 2mm MAX 3mm MAX 3mm MAX 3mm MAX

(NOTE) * Slightly reddish or no color