Page 1

+,7$&+,

CC

PA

No. 0138

27GX01B-501

SERVICE MANUAL

176&

1$&+$66,6

27GX01B-511

R/C:

CLU-351U

CAUTION: Before servicing this chassis, it is important that the service technician read the “Safety

Precaution” and “Product Safety Notices” in this Service Manual.

This television will display television Closed

Captioning ( or ) in accordance

with paragraph 15.119 of the FCC rules.

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRODUCT SAFETY NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SERVICE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CIRCUITS AND BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . 32

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

SOLID STATE COLOR TELEVISION

JUNE 2000 HHEA-MANUFACTURING DIVISION

Page 2

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety-related

notes located on or inside the cabinet and on the chasis or

picture tube.

WARNING: Since the chasis of this receiver is connected

to one side of the AC power supply during operation,

whenever the receiver is plugged in, service shoul d not be

attempted by anyone unfamiliar with the precautions

necessary when working on this type of receiver.

The following precautions should be observed:

1. Do not install, remove, or handle the picture tube in any

manner unless shatterproof goggles are worn. People

not so equipped should be kept away from the picture

tube while handling.

2. When service is required, an isolation transformer

should be inserted between power line and the receiver

before any service is performed on a “HOT” chassis

receiver.

3. When replacing a chassis in the receiver, all protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistors, capacitors, etc.

4. When service is required, observe the original lead

dress in the high voltage circuitry area.

Leakage Current Hot Check

Plug the AC cord directly into a 120V AC 60Hz outlet (do

not use an isolated transformer for this check). Turn the

AC power ON. Using a Leakage Current Tester

(Simpson’s Model 229 or equivalent), measure for current

from all exposed metal parts of the cabinet (antennas,

screwheads, overlays, control shafts, etc.). Any current

measured must not exceed 0.5 milliamps.

(READING

SHOULD NOT BE

ABOVE 0.5mA)

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

+-

EARTH

GROUND

5. Always use the manufacturer’s replacement

components. Critical components as indicated on the

circuit diagram should not be replaced by another

manufacturer’s. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

6. Before returning a serviced receiver to the customer, the

service technician must thoroughly test the unit to be

certain that it is completely safe to operate without

danger of electrical shock, and be sure that no

protective device built into the receiver has become

defective, or inadvertently defeated during servicing.

Therefore, the following checks should be performed for

the continued protection of the customer and service

technician.

Leakage Current Cold Check

With the AC plug removed from the 120V AC 60Hz source,

place a jumper across the two plug prongs. Turn the AC

power switch ON. Using an insulation tester (DC500V),

connect one lead to the jumpered AC plug and touch the

other lead to each exposed metal part (antennas,

screwheads, metal overlays, control shafts, etc.),

particularly any exposed metal part having a return path to

the chassis should have a minimum resistor reading of

0.24MΩ and a maximum resistor reading of 12MΩ. Any

resistance value below or above this range indicates an

abnormality which requires corrective action. An exposed

metal part not having a return path to the chassis will

indicate an open circuit.

AC LEAKAGE TEST

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A

POTENTIAL SHOCK HAZARD AND MUST BE

CORRECTED BEFORE RETURNING THE

RECEIVER TO THE CUSTOMER.

High voltage

This receiver is provided with a hol d down circuit for clearly

indicating that voltage has increased in excess of a

predetermined value. Comply with all notes described in

this service manual regarding this hold down circuit when

servicing, so that this hold down circuit is operated

correctly.

Serviceman Warning

With minimum BRIGHTNESS, CONTRAST,

SHARPNESS, and COLOR, the operating high voltage in

this receiver is lower than 28.30kV ±1.25kV. In case any

component having influence on the high voltage is

replaced, confirm that high voltage with minimum

BRIGHTNESS, CONTRAST, SHARPNESS, and COLOR

is lower than 28.30kV ±1.25kV. To measure high voltage

use a High Impedance High Voltage meter. Connect (-) to

chassis earth and (+) to the CRT ANODE button. (See the

connection diagram on page 4.)

Note: Turn power switch OFF without fail before the

connection to the Anode Button

- 2 -

Page 3

Important Safety Notice . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . 2

Product Safety Notice . . . . . . . . . . . . . . . . . . . . 4

Horizontal Oscillator Disable Circuit . . . . 5

Receiver Feature Table . . . . . . . . . . . . . . . . . . . 6

Location of Controls (Receiver)

Receiver Front Control Panel . . . . . . . . . 7

Location of Controls (Remote). . . . . . . . . . . . . 8

Disassembly for Service. . . . . . . . . . . . . . . . . 13

Disassembly for CRT Replacement . . . . . . . . 13

Chassis Service Adjustment Procedures . . . 14

131.0V B+ Voltage Confirmation . . . . . 14

Source Voltage Chart . . . . . . . . . . . . . . 14

B+ 5V Source Voltages. . . . . . . . . . . . . 14

MPU 5V . . . . . . . . . . . . . . . . . . . . . . . . 14

Stand-by 5V . . . . . . . . . . . . . . . . . . . . . 14

B+ 9V Source Voltage . . . . . . . . . . . . . 14

B+ 12V (Stand-by) . . . . . . . . . . . . . . . . 14

High Voltage Check . . . . . . . . . . . . . . . 14

Purity and Convergence Procedures . . . . . . 15

Service Adjustments

(Electronic Control). . . . . . . . . . . . . . . . . . 28

Sub-Brightness. . . . . . . . . . . . . . . . . . . 28

Sub-Contrast. . . . . . . . . . . . . . . . . . . . . 28

Tint/Color Adjustment . . . . . . . . . . . . . . 28

Color Temperature Adjustment. . . . . . . 29

Horizontal Centering. . . . . . . . . . . . . . . 30

MTS Circuit Adjustment . . . . . . . . . . . . 30

Clock Adjustment (S7) . . . . . . . . . . . . . 31

Vertical Size . . . . . . . . . . . . . . . . . . . . . 31

Service Adjustments

(Mechanical Controls). . . . . . . . . . . . . . . . 31

Focus (Part of T551). . . . . . . . . . . . . . . 31

Audio Signal Path Block Diagram . . . . . . . . . 32

Video-Chroma Signal Path

Block Diagrams. . . . . . . . . . . . . . . . . . . . . 33

IC101 VCJ IN/OUT Pins and Functions . . . . . 34

IC001 MPU IN/OUT Pins and Functions. . . . . 35

Components Identification . . . . . . . . . . . . . . . 36

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Serviceman Mode (Electronic Controls) . . . . 18

Entering Serviceman Mode . . . . . . . . . 18

Toggle between Modes. . . . . . . . . . . . . 18

Exiting the Serviceman Mode. . . . . . . . 18

Sub-Data Adjustment . . . . . . . . . . . . . . 19

Cut-Off Adjustment. . . . . . . . . . . . . . . . 19

Pin Cushion Adjustment . . . . . . . . . . . . 20

MTS Adjustment. . . . . . . . . . . . . . . . . . 20

PIP Adjustment. . . . . . . . . . . . . . . . . . . 21

Options Adjustment . . . . . . . . . . . . . . . 22

Comb Filter Adustment. . . . . . . . . . . . . 23

To Check Purity . . . . . . . . . . . . . . . . . . 24

Helpful Hints . . . . . . . . . . . . . . . . . . . . . 24

Instructional Flow Chart

for Serviceman Mode . . . . . . . . . . . . . . . . 25

- 3 -

Page 4

PRODUCT SAFETY NOTICE

HIGH

IMPEDANCE

H.V. METER

CRT ANODE

+-

CHASSIS

GROUND

CRT

Many electrical and mechanical parts in HITACHI

television receivers have special safety-related

characteristics. These are often not evident from visual

inspection nor can the protection afforded by them

necessarily be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts

which have these special safety characteristics are

identified in this Service manual.

Electrical components having such features are identified

with a mark in the schematics and parts list in this

!

Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

HITACHI recommended replacement component, shown

in the parts list in this Service Manual, may create shock,

fire, X-radiation, or other hazards.

Production safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current HITACHI Service

Manual. [A subscription to, or additional copies of

HITACHI Service Manuals may be obtained at a nominal

charge from HITACHI Sales Corporation.]

This Service Manual is intended for qualified service

technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment

and tools, and have been trained to properly and safely

repair complex products such as those covered by this

manual. Improperly performed repairs can adversely

affect the safety and reliability of the product and may void

warranty. Consumers should not risk trying to do the

necessary repairs and should refer to a qualified service

technician.

WARNING

Lead in solder used in this product is listed by the California

Health and Welfare agency as a known reproductive

toxicant which may cause birth defects or other

reproductive harm (California Health and Safety Code,

Section 25249.5).

When servicing or handling circuit boards and other

components which contain lead in solder, avoid

unprotected skin contact with solder. Al so, when soldering

do not inhale any smoke or fumes produced.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

X-Radiation

TUBE: The primary source of X-Radiation in this receiver

is the picture tube. The tube utilized in this chassis is

specially constructed to limit X-Radiation emissions. For

continued X-Radiation protection, the replacement tube

must be the same type as the original HITACHI-approved

type.

When troubleshooting and making test measurements in a

receiver with excessive high voltage problem, avoid being

unnecessarily close to the picture tube and high voltage

components.

Components having special safety characteristics

identified by on the parts list in this service manual and

!

its supplements and bulletins. Before servicing this

product, it is important that the service technician read and

follow the “Safety Precautions” and the “Product Safety

Notices” in this Service Manual.

For continued X-Radiation protection, replace picture tube

with original type or HITACHI equivalent type.

POWER SOURCE

This television receiver is designed to operate on 120Volt/

60Hz, AC house current. Insert the power cord into a

120Volts/60Hz outlet.

NEVER CONNECT THE TV TO OTHER THAN THE

SPECIFIED VOLTAGE OR TO DIRECT CURRENT.

Do not operate the chassis longer than is necessary to

locate the cause of excessive voltage.

- 4 -

Page 5

Service Notes

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires an d CRT DAG wire

are securely connected.

Equipment needed to check the disabled circuit:

1. Voltmeter (0 - 200V scale)

2. High Voltage Meter (0 - 50kV)

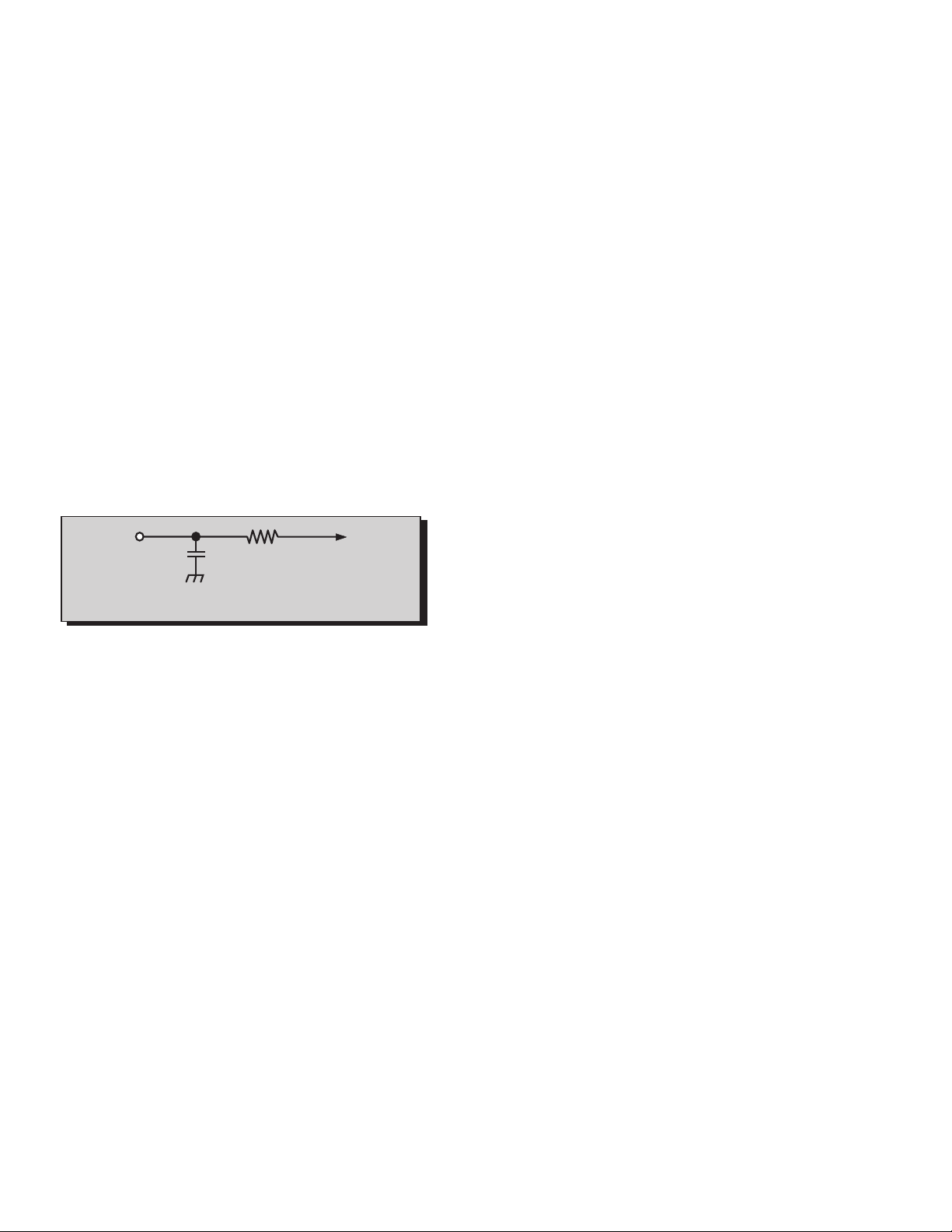

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when servicing the Receiver to

avoid damage to the test equipmen t or to the chassis.

Connect the test equipment to the proper ground ( ) or

( ) when servicing, or incorrect voltages will be

measured.

WARNING: This Receiver has been designed to mee t

or exceed applicable safety and X-ray radiation

protection as specified by government agencies and

independent testing laboratories.

To maintain original product safety design standards

relative to X-ray radiation and shock and fire hazard,

parts indicated with the s ymbol

must be replaced with identical parts. Order parts from

the manufacturer’s parts center using the parts

numbers shown in t his service manual, or provide the

chassis number and the part reference number.

For optimum performanc e and reli ability, all other parts

should be replaced with components of

identical specification.

on the schematic

!

Horizontal Oscillator Disable Circuit

3. Variac or Isolation Transformer

Procedure:

1. Tune in a station to verify that the horizontal is

in sync.

2. Obtain a Monoscope pattern or a signal generator

crosshatch pattern

3. Set Bright and Picture level to zero (0).

4. Turn the Receiver OFF. Connect a jumper across

IC803 pin 3 and pin 4. Apply +9V DC to cathode of

D001.

5. Reduce the AC supply voltage to approximately

45V. Connect the high voltage meter to the CRT

anode. (H.V. button).

Note: Use the Dag Ground (C10 on the CRT Board)

to connect the (-) lead of the meter.

6. Turn the Receiver ON. Slowly increase the AC

supply voltage and verify that the high voltages

does not exceed 37.1kV, when horizontal just

begins to pull ou t of sync . If the hig h voltage is not

within the specified limit, the cause must be

determined and corrected before the Receiver is

returned to the customer.

This chassis employs a special circuit to protect

against excessive high voltage and beam current. If, for

any reason, the high voltage and beam current e xc ee d

a predetermined level this protective circuit activates

and detunes the horizontal oscillator that limits the high

voltage. The over-voltage protection circuit is not

adjustable. However, if components indicated by the

symbol

sweep system or the over-voltage protection circuit

itself are changed, the operation of the circuit should be

checked using the following procedure:

on the schematic in either the horizontal

!

- 5 -

Page 6

Receiver Feature Table

FEATURE\MODEL

Chassis NA8

Tuning system 96K

# of channels 181

Menu language Eng/Span/Fr

Closed Caption X

V-Chip X

75 Ω input X

Remote Model # HL00761

Picture tube M68LGLO61X

V/A norm (X=both) X

MTS/SAP/DBX X

Volume Correction X

Built-in audio power 5Wx2 (10%)

# of speakers 2

A/V in (rear/front) 3(2/1)

Dimensions mm

(HxWxD) in

27GX01B-501

27GX01B-511

594.8x665.2x544.5

23.4x26.1x21.4

Weight (kg/lbs) 38/83.6

Power source (V/Hz) 120/60

Anode voltage

Video input jack

Audio input jack 500mV RMS 47kΩ

A-Board TNP2AH017 AD

C-Board TNP2AA047 AP

28.30kV ±1.25kV

75Ω, phon o jack

1V

p-p

Table 1. Receiver Features

Specifications are subject to change without notice or obligation.

Dimensions and weights are approximate.

- 6 -

Page 7

Location of Controls (Receiver)

1 2 3 4 5 6

Figure 1. Location of Controls Receiver

Quick Reference Control Operation

Quick Reference

Control Operation

1

Power Button - Press to turn ON or OFF.

Volume Buttons - Press to adjust Sound Level, or to adjust Audio Menus, Video

2

Menus, and select operating features when menus are displayed

Channel Buttons - Press to selec t programmed c hannels. Pres s to highlight de sired

3

features when menus are displayed.

Menu Button - Press to display Main Menu and access On Screen feature and

4

Adjustment Menus.

5

Input Button - Press to select TV or one of two Video Inputs.

6

Front A V In Jacks - Front audio, video and earphone jacks.

- 7 -

Page 8

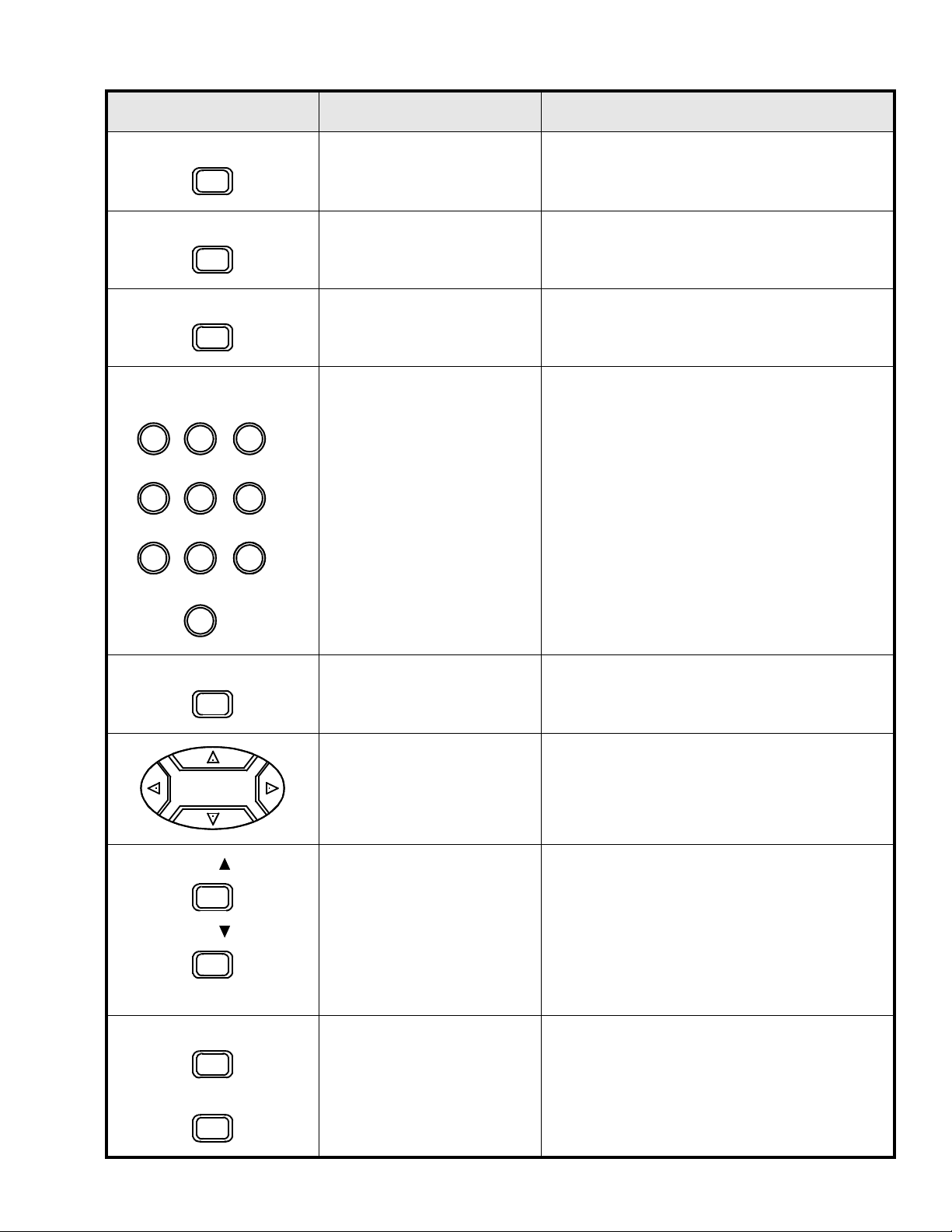

Location of Controls (Remote )

REMOTE CONTROL

Power Button

Press to turn On or Off.

Mute Button

Press to mute sound. A second

press resumes sound. Pr ess also

to toggle Closed Captioning.

Input Button

Press to select TV or video input.

Menu Button

Press to display main menu and

access or exit onscreen features

or Adjustment menus.

Recall Button

Press to display Time status of

sleep timer, channel, video mode,

channel I.D. and audio mode.

Precoded VCR Buttons

These buttons transmit the

chosen precoded VCR codes.

POWER TV CABLE VCR

1

4

789

MUTE

MENU

RECALL

REC

TV/VCR

23

LST-CH

0

SLEEPINPUT

STOP

tt t uu

65

CURSOR

CONTROL

PAUSE

CH

CH

VOL

VOL

REMOTE CONTROL

Mode Buttons

These buttons allow the remote to

control your TV, VCR, or cable box

depending on which mod e button is

selected.

Channel Buttons

Press to select channels.

Keypad Buttons

Press desired channel number to

access channel .

Volume Buttons

Press to adjust TV sound level.

LST-CH (Last Channel) Button

Press to switch to the previously

tuned channel.

Sleep Button

Press to turn TV Off in 30, 60, or 90

minutes.

HITACHI

CLU-351U

Figure 2. Location of Controls (Remote)

Cursor Button

Press to adjust Aud io menus, Video

menus, and select operating

features when menus are displayed.

- 8 -

Page 9

Remote Control Quick Reference Functional Key Chart

0

98

6

321

45

7

Key Operates

POWER

INPUT

MENU

TV

CABLE

VCR

TV Selects the TV Input Mode

TV Activates and Exits TV Menus

TV

VCR

CABLE

Turns TV On and Off

Turns Cable Box On and Off

Turns VCR On and Off

Selects Channel

Selects code in Video Lock Menu

Selects Channel in Channel I.D. Menu

Selects Channel in Timer Menu

Selects Precoded VCR codes when programming

remote

Selects Precoded CABLE codes when programming

remote

RECALL

TV Display Channel, Time, Channel I.D. and Audio Mode

TV Menu Navigation

CH

CH

TV

CABLE

Channel Up/Down

Channel Up/Down

VOL p

VOL q

TV Volume Up/Down

- 9 -

Page 10

Key Operates

SLEEP

MUTE

LST-CH

Mode Selection Buttons

TV

CABLE

VCR

TV

TV

TV Select previously tuned channel

TV

CABLE

VCR

Selects 30, 60 or 90 minutes for Automatic Turn Off.

Also use to turn Sleep Timer off by selecting NO

Mutes TV Audio

Access and exit Closed Caption ing

Selects TV Mode for the remote control

Selects Cable Mode for the remote control

Selects VCR Mode for the remote control

Standard VCR Control Buttons

REC

STOP

PAUSE

TV/VCR

VCR

VCR

VCR

VCR

VCR

VCR

VCR

CABLE

Record

Rewind

Fast Forward

Play

Stop

Pause

Selects TV or VCR Mode

Selects A/B Mode

- 10 -

Page 11

Using the Remote to Control VCR and Cable box Funtions

Operating the Precoded

Function for Your VCR

This remote is designed to operate

different types of VCRs. You must first

program the remote to match the

remote system in your VCR. (Refer to

the VCR Code Index section.)

1. Turn on your VCR.

2. Aim the remote control at the front

of your VCR.

3. Press the VCR button to s witch to

VCR precoded mode.

4. While holding down the VCR

button, enter the 2-digit preset

code that matches your VCR*.

The remote will turn on your VCR

when the correct 2-digit preset

code is entered. When this occurs,

the remote contr ol is programme d

for your VCR. If your VCR does

not turn off after 5 s econds, try a

different 2-digit preset code.

5. The remote will now control your

VCR.

NOTES:

• If your VCR cannot be operated

after performing the above

procedures, this means that your

VCR codes have not been

precoded into the remote.

• In the unlikely event that your VCR

cannot be operated after

performing the above pro cedures,

consult your VCR operating guide.

• The remote control will remember

the codes you have programmed

in until the batteries ar e removed.

After replacing the batteries repeat

the entire programming proc edure

stated above.

• If your VCR does not have a

power function, the remote will

issue the CHANNEL UP function.

POWER TV CABLE VCR

1

4

789

MUTE

MENU

RECALL

REC

TV/VCR

23

LST-CH

0

SLEEPINPUT

STOP

tt t uu

65

CURSOR

CONTROL

PAUSE

CH

CH

VOL

VOL

HITACHI

CLU-351U

* (Codes are listed on page 12)

Operating the Precoded

Function for Your Cable Box

1. Turn on your cable box.

2. Aim the remote control at th e fron t

of your cable box.

3. Press the cable box button to

switch to cable box precoded

mode.

4. While holding down the CABLE

button, enter the 2-digit preset

code that matches your cable

box*. The remote will turn on your

cable box when the cor rect 2-digit

preset code is entered. When this

occurs, the remote control is

programmed for your cable box. If

your cable box does not turn off

after 5 seconds, try a different 2digit preset code.

5. The remote will now control your

cable box.

NOTES:

• If your cable box cannot be

operated after performing the

above procedures, this means that

your cable box codes have not

been precoded into the remote.

• In the unlikely event that your

cable box cannot be operated

after performing the above

procedures, consult your cable

box operating guide.

• The remote control will remember

the codes you have programmed

in until the batteries are removed.

After replacing the batteries repeat

the entire programm ing pr ocedure

stated above.

• If your cable box does not have a

power function, the remote will

issue the CHANNEL UP function.

• For some models, the remote

control’s channel and will

control the cable box channel. The

number buttons will control your

television channel although you

are in cable mode.

- 11 -

Page 12

VCR and Cable Box Codes Index

The remote is capable of operating many brands of V CRs and cable boxes. You must first program the remote

control to match the remote system in your VCR or cable box.

NOTE:

The remote control memory is limited. Some models of VCRs or cable bo xes may no t operate. The remote con trol is

not designed to control all features that are available in all models.

Code Index For VCRs

VCR Brand Code (s)

Emerson

Funai

GE

Hitachi

JVC

Magnavox

Mitsubishi

Panasonic

RCA

Sony

Toshiba

Zenith

00,01,10,16,23,33,

37,40, 43

00

09,22

00,14,15

14,26

09,12,28

16,23,26,45

09,35,46

15,22

06,07,08,09

16,17,42

07,08,12

Code Index for Cable Boxes

Cable Box

Brand

G.I.

Jerrold

Magnavox

Philips

Pioneer

Samsung

Scientific Atlantic

Zenith

Code(s)

09

03, 09, 10, 12, 13,

51

40

40

39

39

04, 06, 14, 52, 56

00

- 12 -

Page 13

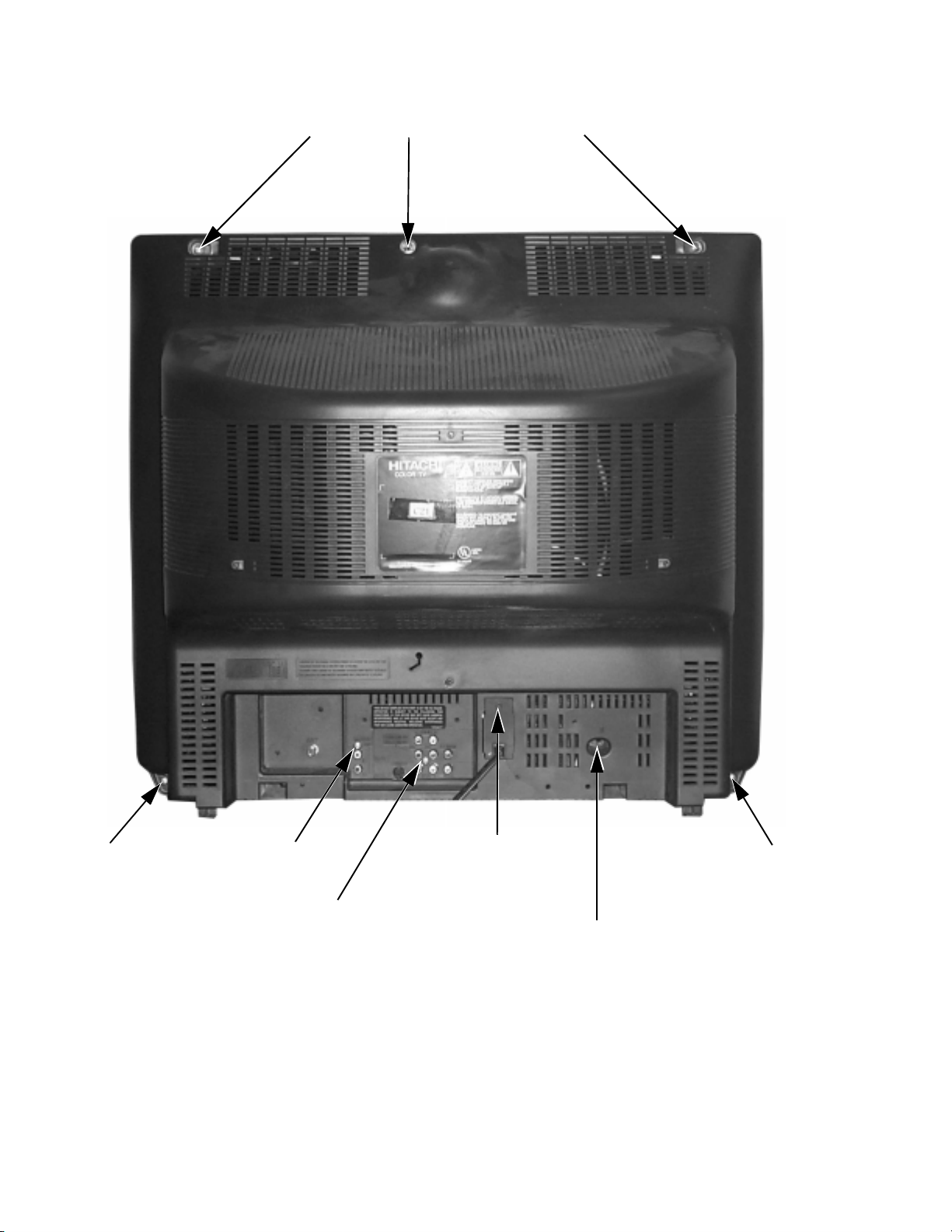

Disassembly for Service

Disassembly for CRT

Back Cover

Remove all the screws marked with an arrow( )

from the back of the Receiver.

Note: Screw configuration, type, and number of

screws vary depending on the model of the

Receiver serviced a nd the appli cation; v arious

models are covered in this Manual. Use same

hardware when reassembling the receiver.

• 3 screws at the top edge of the Receiver.

• 1 screw at each lower corner of the Receiver.

• 1 screw by the retainer plate of the AC power cord.

• 1 screw by the Flyback assembly.

• 1 screw by the A/V jacks.

A-Board - Main Chassis

1. Slide the chassis completely out of the guide rails.

2. Stand the Receiver on its edge. The underside of

the board is completely acc essible for component

replacement.

Note: Some tie- wraps th at s ec ure t he wi r e dres s ing s

may need to be unfastened for chassis

removal.

C-Board - CRT Output

Plugs into the socket on the CRT neck.

Speakers

Each speaker is sec ured to the cabinet’s front with

4 screws.

Keyboard Push Button Assembly

Fastened to the inside of the cabinet front wit h up

to 3 screws.

Replacement

1. Discharge the CRT as instructed in the Safety

Precautions (see page 2).

2. Disconnect the yoke (DY) plug, degaussing coil

(DEG) plug and th e CRT 2nd anod e button from

the main board.

3. Remove the C-Board from the CRT base and

unplug the black wire (CRT dag ground) C10.

4. Disconnect the A11, A12, and Speakers plugs

from the A-Board.

5. Lift the Main Chassis (A-Board) and all mounted

boards completely out with the CRT Board

attached.

CRT Replacement

1. Perform Disassembly for CRT Replacement

procedure.

2. Insure that the CRT H.V. Anode button is

discharged before handling the CRT. Read the

Safety Precautions (see page 2) on handling the

picture tube.

3. Remove the compon ents from the CRT neck and

place the cabinet face down on a soft pad.

4. Note the original order for the CRT mounting

hardware as they are removed from the CRT

mounting brackets at each corner of the CRT.

5. Remove the CRT with the degaussi ng coil and the

dag ground braid attached.

6. Note the original locations and mounting of the

degaussing coil a nd the dag ground assembly to

insure proper reinstallation on the replacement

CRT.

To remove and re-mount the degaussing coil:

The degaussing coil is hel d in place by clampers

fastened to the CRT corner ea rs. These clampers

must be installed on to the replacement CRT prior

to mounting the degaussing coil.

To remove and re-mount the dag ground braid:

a.Unhook the coil spri ng from the bottom corne rs

of the CRT ears.

b.Release the braid loop from the upper corners of

the CRT ears.

7. Mount the dag ground braid on the replacement

CRT. Position the degaussing coil with new ties.

Dress coil as was on the original CRT.

8. Replace the components on CRT neck and

re-install into cabinet. Verify that all ground wires

and circuit board plugs get connected.

- 13 -

Page 14

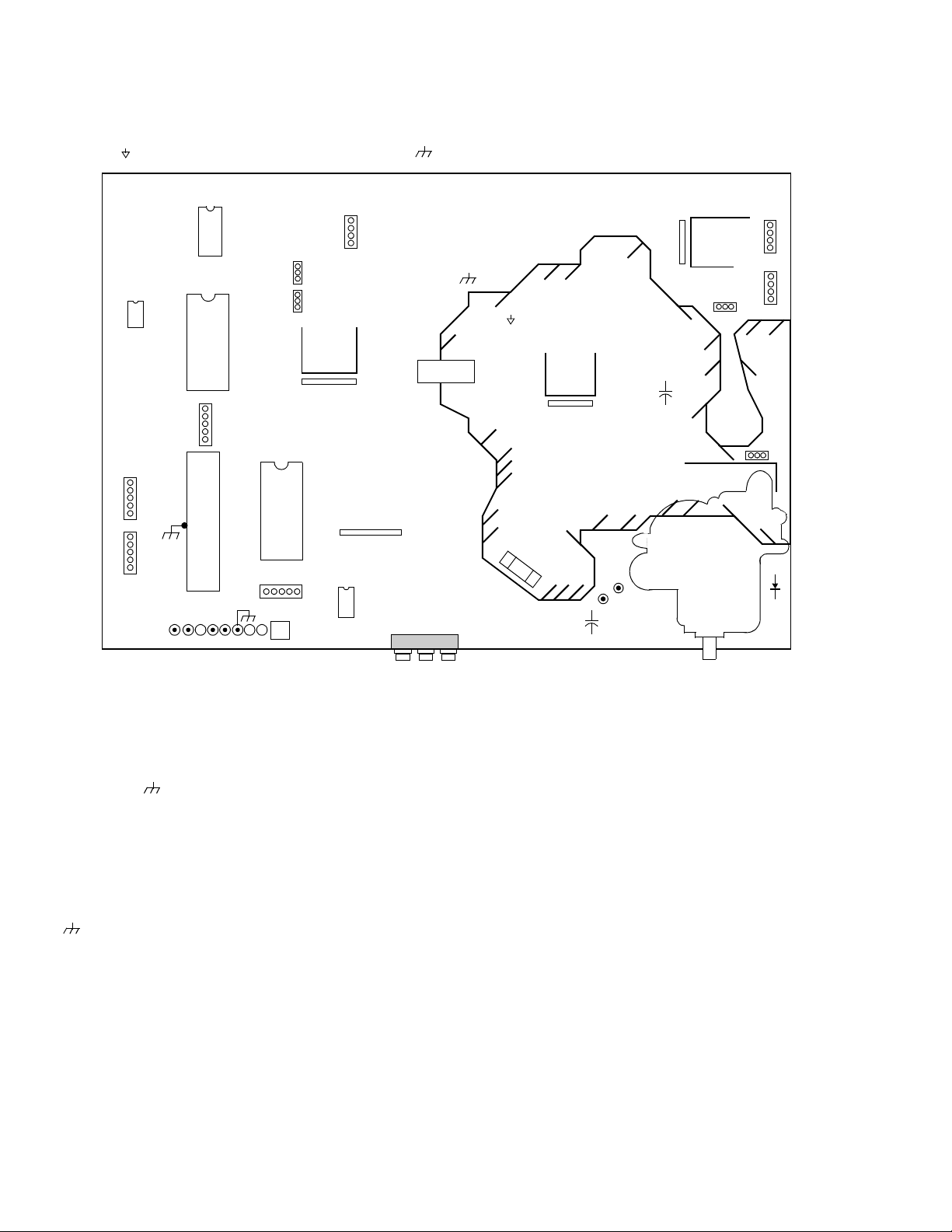

Chassis Service Adjustment Procedures

All service adjustments are factory preset and should not require adjustment unless controls and/or

associated components are replaced.

Note: Connect the (-) lead of the voltmeter to the appropriate ground. Use IC803’ s heat sink when the HOT ground

symbol ( ) is used. Otherwise, use COLD ground ( ) — Tuner shield, IC451’s heat sink or FA2.

A-BOARD

COLD ( )

HOT ( )

RL801

F801

IC 803

C552

C809

TPD9

TPD8

IC 002

A32

IC 6501

IC 001

164

32 33

A31

T

U

N

E

R

FA1

DAT A

TP15

A11

IC 101

152

26 27

CLK

FA2

TP

SP

IC 551

IC 552

IC 2302

Figure 3. A-Board

Main Components

and Test Points

IC 4402

A61

IC 2321

MOMENTARILY CONNECT A JUMPER FOR ENTERING SERVICE MODE (FA1 to FA2 )

IC 451

A7

A8

Q501

FOCUS SCREEN

Q551

D554

131.0V B+ Voltage Confirma tion

1. Set the Bright and the Picture to Minimum by

using the Picture Menu.

2. Connect the DVM between C809(+ sid e) and cold

ground ( ).

3. Confirm that B+ voltage is 131.0V ± 2.5V. This

voltage supplies B+ to the Horizontal Output &

Flyback circuits.

Source Voltage Chart

120V AC line input. Se t the Bright and the Picture to

Minimum by using th e Picture Menu. Use cold ground

(

) for the (-) lead of the DVM.

C572 (+) +5.0V ± 0.25V

TPD9 +13.0V ± 2V

C552(+) +8.0V ± 1V

TPD8 +27.4V ± 2V

IC551 pin3 +9.0V ± 0.5V

CATHODE OF D554 +220.0V ± 15V

Adjust Picture Menu for normalized video adjustments.

B+ 5V Source Voltages

Volatile 5V:

C572, + side = IC552 pin 3, Tuner BP, IC101 (IF 5V).

MPU 5V:

Emitter Q002 = IC001 (VDD, AVDD).

Stand-by 5V:

IC001 (key in 1), I2C EEPROM (IC002), Remote

Receiver.

B+ 9V Source Voltage

IC551 pin 3 = IC101 (IF 9V), Tuner (BM).

B+ 12V (Stand- by)

Note: +16V when power is on

Cathode D001 = RL801 (on-off relay), Q002 (+5V

Reg).

High Voltage Check

1. Select an active TV channel and confirm that

horizontal is in sync.

2. Adjust Brightness and Picture using Picture Icon

menu so video just disappears.

3. Confirm B+ 131V is within limit.

4. Using a high voltage meter confirm that the High

Voltage is

28.30kV ±1.25kV.

- 14 -

Page 15

Purity and Convergence Procedure

Adjustment is necessary only if the CRT or the

deflection yoke is replaced or if the setting was

disturbed. The complete procedure consists of:

1. Vertical Raster Shift Adjustment. (Only for Models

with Purity/Convergence Assembly with 4 Pairs

of Rings).

2. Initial static convergence.

3. Setting the purity.

4. Final static convergence.

When the CRT or the Yoke is Replaced

Place the yoke on the CRT neck (do not tighten

the clamp).

For a 2-piece assembly (see Fig. 4):

Position purity/convergence assembly as shown and

tighten clamp snugly. Remove the hot-melt glue seal

on assembly and position like tabs of purity device

together at 12 o’clock to reduce its magnetic field

effect.

R&B Convergence Rings

R&B&G Convergence Rings

G3 G4

Purity Rings Centered

Over G3/G4 Gap

For a 1-piece assembly (see Fig. 7):

Position like tabs of purity devices together at 12

o’clock to reduce an y magnetic field effect. (For better

results, note part numb er and look fo r specif ications at

Service Center)

Figure 7. Positioning of Purity/Convergence

Assembly (1-piece assembly)

For either assemblies:

Turn the Receiver ON. Operate the Receiver for 60

minutes using the first Purity Check field (white screen)

to stabilize the CRT.

Fully degauss the Receiver by using an external

degaussing coil.

Slide the defle ction yoke back and forth on t he ne ck o f

the CRT until it produces a near white, uniform raster.

Figure 4. Positioning of Purity/Convergence Assembly

(2-piece assembly)

For models using 4 pairs of rings, place the vertical

raster shift tabs at 3 o’clock (90

o

from the purity and

convergence tabs, see Fig. 5 and Fig. 6)

R&B Convergence Rings

R&B&G Convergence Rings

Vertical Raster Shift Ring

G3 G4

Purity Rings Centered

Over G3/G4 Gap

Figure 5. Positioning of Purity/Convergence Assembly

(4 Pairs of Rings)

R&B&G Convergence Rings

R&B Convergence Rings

Vertical Raster

Shift Rings

Purity Rings

90

o

Figure 6. Positioning of Purity/Convergence Assembly

(4 Pairs of Rings)

Vertical Raster Shift Adjustment (Only for

Models with Purity/Convergence Assembly with 4

Pairs of Rings).

Apply a green pattern with a horizontal line, adjust the

Deflection Yoke so that has no tilt, then secure it.

Adjust center line of the pattern with the mechanical

center of the CRT, this center is determined by two

marks at the side edges of the screen. To adjust the

line, once the vertical raster shift tabs are place at 3

o’clock to reduce its magnetic field effect (see Fig. 5

and Fig. 6) open the tabs the same angle from the

center, until the center line of the pattern becomes a

straight line, center ed with the marks of the CRT. (see

Fig. 8)

Center line

from pattern

Mechanical

Center Marks

Vertical Raster Shift tabs

Figure 8. Vertical Raster Shift Adjustment

(4 pairs of rings assembly)

Open the

same angle

from center

- 15 -

Page 16

Initial Center Static Convergence

NOTES:

1. CRT warm up with white screen

(three guns activated) is needed

to stabilize the shadow mask

expansion.

2. Initial center static convergence

(roughly centers three gun

beams) is required in order to

perform purity adjustment.

Figure 9. Green Raster Adjustment

Green Raster

Connect a dot/cross hatch generator to the Receiver

and tune in a signal. Observe misconvergence at

center of the screen only.

Adjust the R&B pole magne ts; by separating tabs and

rotating to converge blue with red.

Adjust the R&B and R&B&G pole magnets: by

separating tabs and rotating to converge blue an d red

(magenta) with green.

Note: Precise convergence at this point is

not important.

Purity Adjustment

When the Receiver is in the Serviceman Mode for

making electronic adjustments, press the Recall button

on the Remote Control to ente r Purity Check. (Se e the

Service Adjustments Electronic Controls

procedure).

Operate the Receiver for 60 minutes using the first

Purity Check field (white screen) to stabilize the CRT.

Fully degauss the Receiver by using an external

degaussing coil.

Press the Recall button on the Remote Control again

until the Purity Check (green screen) appears.

For a 2-piece assembly (see Fig. 4):

Loosen the deflection yok e clamp screw an d move the

deflection yoke back as close to the purity magnet

as possible.

Adjust the Purit y rings to set the vertical green raster

precisely at the center of the screen (see Fig. 9).

Final Convergence Procedure (see Fig. 10

through Fig. 12):

Note: Vertical size and focus adjustments must be

completed prior to performing the convergence

adjustment. Connect a dot pattern generator to the

Receiver. The Brightness level should not be higher

than necessary to obtain a clear pattern.

Converge the red and the blue dots at the center of the

screen by rotating the R&B pole Static Convergence

Magnets.

Align The converged red/blue dots with the green dots

at the center of the screen by rotating the R&B&G pol e

Static Convergence Magnets. Melt wax with soldering

iron to reseal the magnets.

Slightly tilt vertica lly and ho rizontally (do not ro tate) the

deflection yoke to obtain a good overall convergence.

If convergence is not reached at the edges, insert

permalloy (see fo llowing section) from the DY corners

to achieve proper convergence. Recheck for purity and

readjust if necessary.

After vertical adjustment of the yoke, insert wedge at 11

o’clock position, then make the horizontal

tilt adjustment.

Secure the deflection yoke by inserting two side

wedges at 3 and 7 o’clock positions.

Apply adhesive between tab (thin portion) of wedge

and CRT and place tape over the tab to secure to

the CRT.

Permalloy Convergence Corrector Strip

(Part No. 0FMK014ZZ)

Slowly move the deflecti on yoke forward until the best

overall green screen is displayed.

For a 1-piece assembly (see Fig. 7):

Slowly move the deflection yoke and purity rings

assembly toward the CRT board and adju st the purity

magnet rings to set vertical green raster at center of

screen (see Fig. 9).

Gradually move the deflection yoke & purity rings

forward and adjust for best overall green screen.

Continue from here for either assemblies:

Tighten the deflection yoke clamp screw.

Press the Recall button on the Remote Control again

until the purity check (blue screen) and (red screen)

appear and observe that good purity is obtained on

each respective field.

Press the Recall button on the Remote Control again

until Purity check (white screen) app ears. Obse rve the

screen for uniform white. If purity has not been

achieved, repeat the above procedure.

This strip is used in some sets to match the yoke and

CRT for optimum convergence. If the y oke or CRT is

replaced, the strip may not be required.

First converge the set without the strip and observe

the corners.

If correction is needed:

1. Place strip between CRT and yoke, in quadrant

needing correction. Slowly move it around for

desired results.

2. Press adhesive tightly to the CRT and secure

with tape.

- 16 -

Page 17

As the yoke is tilted

RGB

Figure 10. Vertical Yoke Movement

vertically, the rasters

produced by the

outside guns rotate in

opposite directions.

RGB

As the yoke is tilted horizontally, one

raster gets larger while the other gets

smaller

Figure 11. Horizontal Yoke Movement

Raster produced from one of the

outside electron beams

Raster from the other side electron

beam

Static convergence magnets are set for

center convergence

Static Convergence Magnets

Converges

R/B with G

Purity/Convergence

Assembly Clamp

Purity Rings Adj. on

Green Raster

11 o’clock Position

Converges

R with B

Double sided adhesive tape

3 o’clock Position

Y oke Positioning Wedges

for Dynamic Convergence

7 o’clock Position

Figure 12. Convergence Magnets and Wedges Location

Note: For models using 4 pairs of rings

assemblies see Fig. 5 for details

- 17 -

Page 18

Serviceman Mode (Electronic Controls)

This Receiver has electronic technology using the I²C Bus Concept. It performs as a control function and it

replaces many mechanical controls. Instead of adjusting mechanical controls individually, many of the control

functions are now performed by using “On Screen Display Menu”. (The Serviceman Adjustment Mode.)

Note: It is suggested that the techni cian reads all the way through and understand the following procedure for

Entering/Exiting the Serviceman Adjustment Mode; then proceed with the in structions workin g with the

Receiver. When becoming fa mi li ar w ith th e pr oc edu re, the Flow Chart for S ervi ceman Mode may be u sed

as a quick guide.

Quick Entry t o Servicema n Mode:

At times when minor adjustments need to be done to the electronic controls, the method of Entering the

serviceman Mode without removal of the cabinet back is as follows using the Remote Control:

1. Select SET-UP icon and select CABLE mode.

2. Select CLOCK icon and set SLEEP time for 30 Min.

3. Press MENU button twice to exit menus.

4. Tune to the Channel 124.

5. Adjust VOLUME to minimum (0).

6. Press the VOL button (decrease) on Receiver. Red “CHK” appears in upper corner.

To toggle between Aging and Serviceman modes:

While the “CHK” is displayed on the left top corner of the CRT, pressing the Ac tion and the Volume Up buttons

on the Receiver simultaneously will toggle between the modes. Red “CHK” for Serviceman and yellow “CHK” for

Aging.

7. Press the Power Button on the Remote Control to select one of seven Serviceman Adjustment Modes.

1) B= Serviceman VCJ SUB-DATA ADJUSTEMENT.

2) C= Serviceman VCJ CUT-OFF ADJUSTMENT.

3) D= Serviceman PIN CUSHION ADJUSTMENT.

4) M= Serviceman MTS ADJUSTMENTS.

5) P= Serviceman PIP ADJUSTMENT.

6) S= Serviceman OPTIONS ADJUSTMENTS.

7) X = Serviceman COMB FILTER ADJUSTMENT.

8) “CHK” = Normal operation of CHANNEL and VOLUME .

(Models with PIP only)

Note: Only the applicable settings for

b

32 B 0 2 215 C 0

a

b

a

the Receiver serviced will be

available (See

a

in Fig. 13).

An address Menu appears in the right

hand corner of the screen

Figure 13. Serviceman Mode Menu Adjustments.

Exiting the Serviceman Mode:

Press the Menu and the Power buttons on the Receiver simultaneously for at least 2 seconds.

THE RECEIVER EXITS SERVICEMAN MODE.

The Receiver momentarily shuts off; then comes back on tuned to channel 3 with a preset level of sound.

Any programmed channels, channels caption data and some others user defined settings will be erased.

IMPORTANT NOTE:

Always Exit the Serviceman Mode

Following Adjustments.

- 18 -

Page 19

Press the Power Button on the Remote Control to select the Serviceman Adjustment .

For Adjustments:

1.Press Channel Up/Down on the

Remote Control to select one of

the available Ser vice Adjustments

(a in Fig. 13).

Note: Write Down the original

value set (b in

Fig. 13

) for

each address before

modifying anything. It is

easy to erroneously adjust

the wrong item.

2.Press Volume Up/Down on the

Remote Control to adjust the

level of the selected Service

Adjustment (b in Fig. 13).

CH

Sub-Data Adjustment

B0 SUB-COLOR 31

B1 SUB-TINT 31

B2 SUB-BRIGHTNESS 31

B3 SUB-CONTRAST 16

B4 SUB-TINT VIDEO 16

B5 SUB-COLOR VIDEO 16

B6 SUB-TINT COMP 63

B7 SUB-COLOR COMP 31

B8 SUB SHARP TV/VIDEO 10

B9 SUB SHARP S-VHS/COMP 31

BA SUB-CONTRAST FIXED 15

Cut-Off Adjustment

Default

Level

Default

Level

CH

CH

PW

CH

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

C0 CUT-OFF R 128

C1 CUT-OFF G 128

C2 CUT-OFF B 128

C3 USER BRIGHTNESS 31

C4 G DRIVE 64

C5 B DRIVE 64

C6 DRIVE C TEMP 8

C7 CONTRAST C TEMP 5

PW

To D Items.

Note: Some adjustment s mode s ma y not be

available in some models depending

on available options.

- 19 -

Page 20

Press the Power Button on the Remote Control to select the Serviceman Adjustment

For Adjustments:

1.Press Channel Up/Down on the

Remote Control to select one of

the available Ser vice Adjustments

(a in Fig. 13).

Note: Write Down the original

value set (b in

Fig. 13

) for

each address before

modifying anything. It is

easy to erroneously adjust

the wrong item.

2.Press Volume Up/Down on the

Remote Control to adjust the

level of the selected Service

Adjustment (b in Fig. 13).

CH

Pin Cushion Adjustment

D0 H POSITION 16

D1 V SIZE 31

D2 V S CORRECTION 4

D3 V LIN CORRECTION 14

D4 E/W TRAPEZIUM 8

D5 V AGC 1

D6 V POSITION 1

D7 V CENTERING 63

D8 V CENTERING DAC SW 0

D9 V-BLK START PHASE 12

DA V-BLK STOP PHASE 14

MTS Adjustment

Default

Level

Default

Level

CH

CH

PW

M0 INPUT LEVEL 33

CH

Note: Some a dju stments modes m ay no t be

available in some models depending

on available options.

M1 LOW-LEVEL SEPARATION 6

M2 HIGH-LEVEL SEPARATION 25

Always Exit the Serviceman

Mode Following Adjustments.

PW

To P Items.

IMPORTANT NOTE:

- 20 -

Page 21

Press the Power Button on the Remote Control to select the Serviceman Adjustment

e

e

e

For Adjustments:

1.Press Channel Up/Down on the

Remote Control to select one of

the available Ser vice Adjustments

(a in Fig. 13).

CH

Note: Write Down the original

value set (b in

Fig. 13

) for

each address before

modifying anything. It is

easy to erroneously adjust

the wrong item.

PIP Adjustment

P0 PIP COLOR 92

P1 PIP TINT 54

P2 PIP BRIGHTNESS 22

P3 PIP CONTRAST 80

P4 UP 1/9 26

P5 DOWN 1/9 143

P6 LEFT 1/9 10

P7 RIGHT 1/9 101

P8 UP 1/16 26

Default

Level

2.Press Volume Up/Down on th

Remote Control to adjust th

level of the selected Servic

Adjustment (b in Fig. 13).

CH

CH

P9 DOWN 1/16 160

PA LEFT 1/16 10

PB RIGHT 1/16 116

PC PIP FREERUN N/A

PD PIP YDL 4

To S Items.

Note: Some adjustments modes may not be

available in some models depending

on available options.

PW

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

- 21 -

Page 22

Press the Power Button on the Remote Control to select the Serviceman Adjustment

e

e

e

For

Adjustments:

1.Press Channel Up/Down on the

Remote Control to select one of

the available Ser vice Adjustments

(a in Fig. 13).

Note: Write Down the original

value set (b in

Fig. 13

) for

each address before

modifying anything. It is

easy to erroneously adjust

the wrong item.

2.Press Volume Up/Down on th

Remote Control to adjust th

level of the selected Servic

Adjustment (b in Fig. 13).

CH

OPTIONS Adjustment

S0 ABL GAIN 3

S1 ABL POINT 3

S2 RGB BRIGHTNESS 8

S3 RGB GAMMA 1

S4 COLOR GAMMA 1

S5 VSM-G 0

S6 BS POINT 7

S7 CLOCK ADJUST 128

S8 LOUD COMP 31

S9 CAPTION DIG FILTER SW 0

SA CAPTION SCROLL 1

SB RGB MATRIX 6

SC RGB MATRIX COMP 5

Default

Level

CH

CH

PW

To X Items.

Note: Some a dju stm e n t s m odes may not be

available in some models depending

on available options.

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

- 22 -

Page 23

Press the Power Button on the Remote Control to select the Serviceman Adjustment

For Adjustments:

1.Press Channel Up/Down on the

Remote Control to select one of

the available Ser vice Adjustments

(a in Fig. 13).

Note: Write Down the original

value set (b in

Fig. 13

) for

each address before

modifying anything. It is

easy to erroneously adjust

the wrong item.

2.Press Volume Up/Down on the

Remote Control to adjust the

level of the selected Service

Adjustment (b in Fig. 13).

CH

Comb Filter Adjustment

X0 CLIP LEVEL 152

X1 CSOK 12

X2 COMB LIMIT 24

X3 COMB CORE 41

X4 COMB RF DELAY 20

X5 COMB VIDEO DELAY 18

X6 COMB VMLM 90

X7 COMB VMCO 24

X8 COMB SHARP 123

X9 COMB VM LEVEL 255

XA COMB VMPKF 1

XB H LOCK MODE 1

XC H LOCK 70

XD H SEP 1 313

Default

Level

CH

CH

XE H SEP 2 266

XF SUB H LOCK MODE 0

X10 SUB H LOCK 70

X11 SUB H SEP1 313

X12 SUB H SEP2 266

Note: Some adjustment s mode s may no t be

available in some models depending

on available options.

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

PW

To B Items.

- 23 -

Page 24

To Check Purity:

Press the Recall Button on the Remote Control whe n in Serv iceman Mod e (red “CHK” is display ed) to en ter the

Purity Field Check Mode.

NORMAL

SCREEN

Press Recall again to select desired field.

BLUE

SCREEN

GRN.

SCREEN

RED

SCREEN

WHITE

SCREEN

Figure 14. Purity Check Field Mode.

Helpful Hints

Entering Serviceman Mode (Back-Open Method)

1. While the Receiv er is ON and operatin g in Normal Mode, mome ntarily

short test point FA1 (TP8) to Cold Ground ( ) FA2 (TP3) A-Board.

The Receiver enters the Aging Mode

Yellow letters “CHK” appear in the upper left corner of the CRT.

(The Volume Up/Down will adjust rapidly).

2. Simultaneously press the Menu and the Volume Up buttons on the

Receiver Control Panel .

The Receiver enters the Serviceman Mode.

The letter in “CHK” turn red.

(The Volume Up/Down will adjust normally).

(All customer controls are set to nominal level).

.

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

- 24 -

Page 25

WHITE

SCREEN

Instructional Flow Chart for Serviceman Mode

NORMAL MODE

Momentarily short FA1 to FA2 ( ).

AGING MODE

• Yellow “CHK” appears in upper left corner of screen.

• Volume Up/Down operate rapidly.

• Custumer Controls are set to nominal level.

GRN.

SCREEN

RED

SCREEN

RECALL

(ON REMOTE)

BLUE

SCREEN

WHITE

SCREEN

QUICK ENTRY TO SERVICEMAN MODE

• Select CABLE Mode.

•Set SLEEP time for 30 Min.

• Tune to Channel 124.

• Adjust Volume to minimum.

• Press VOL DOWN. On Receiver.

EXIT

N

Adj.

needed?

Y

Press Menu + Volume Up Simultaneously (ON Receiver)

SERVICEMAN MODE

• “CHK” turns red.

• Volume Up/Down operate normally.

• Costumer Controls are set to nominal level.

RECALL

(ON REMOTE)

Adj.

needed?

Y

POWER

(ON REMOTE)

N

EXIT

Press Menu and Power on the Receiver

simultaneously for at least 2 seconds.

C

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

Note: Some adjustment s modes may not be

available in some models depending

on available options.

Figure 15. Flow Chart for Serviceman Mode.

SUB-DATA ADJUSTMENTS.

B ITEMS.

POWER

(ON REMOTE)

A

- 25 -

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

Page 26

Instructional Flow Chart for Serviceman Mode - Continued

A

CUT-OFF ADJUSTMENTS.

C ITEMS.

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

PINCUSHION ADJUSTMENTS.

Y

Adj.

needed?

POWER

(ON REMOTE)

D ITEMS.

Y

Adj.

needed?

N

N

IMPORTANT NOTE:

Always Exit the Serviceman

Mode Following Adjustments.

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

Note: Some adjustments m odes ma y no t be

available in some models depending

on available options.

Figure 16. Flow Chart for Serviceman Mode (cont).

POWER

(ON REMOTE)

MTS ADJUSTMENTS.

M ITEMS.

Adj.

Y

needed?

N

POWER

(ON REMOTE)

B

- 26 -

Page 27

Instructional Flow Chart for Serviceman Mode - Continued

B

PIP ADJUSTMENTS.

P ITEMS.

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

OPTIONS ADJUSTMENTS.

Adj.

Y

needed?

N

POWER

(ON REMOTE)

S ITEMS.

Adj.

Y

needed?

N

ON REMOTE CONTROL TO

CH

SELECT ADJUSTMENT

ON REMOTE TO ADJUST

VOL

VOL

THE LEVEL

Figure 17. Flow Chart for Serviceman Mode (cont).

Note: Some adjustments mo des may not be

available in some models depending

on available options.

POWER

(ON REMOTE)

COMB-FILTER ADJUSTMENTS.

X ITEMS.

Adj.

Y

N

needed?

N

EXIT

Press Menu and Power on the Receiver

simultaneously for at least 2 seconds.

IMPORTANT NOTE:

Always Exit the Serviceman Mode

Following Adjustments.

POWER

(ON REMOTE)

C

- 27 -

Page 28

Service Adjustments (Electronic Controls)

Figure 18. TP47G waveform

White

Yellow

Cyan

Green

Magenta

Red

Blue

Black

SYNC

TIP

1.5V - 1.9V

p-p

2.0V

p-p

±0.1V

Sub-Brightness

Serviceman DAC Adjustment (B2)

Adjustment of this control is important for setting proper

operation of customer brightness and contrast controls.

This adjustment must be made after Sub-Contrast or

Color Temperature adjustments are made. Do not

adjust SCREEN after the Sub-Brightness is set.

Preparation:

Apply a color bar signal with 100 IRE white and 7.5

IRE black. (Switch Color to “OFF” on the signal

generator.) Operate the Receiver fo r a mini mum of

10 minutes prior to performing this adjustment.

Procedure:

In the Serviceman Mode for making electronic

adjustments, select the D AC adjustment (B2) and

adjust until the black starts to look gray. Then

decrease the level to the point where gray turns

to black.

Note: You may set the accurate value following the

Preparation steps and the Pro cedure step No.

2 of the Sub-Contrast adjustment described

below.

Sub-Contrast

Serviceman DAC Adjustment (B3)

This adjustment is factory set. Do not adjust unless

repairs are made to a ssociated circ uit, the CRT Board

or when the CRT is replaced.

Preparation:

1. Apply a color bar signal pattern with 87.5%

modulation, 70% saturated color bar with a 100

IRE white and 7.5 black.

Note:

2. Preset the following controls:

3. Connect the oscillos cope to TP47R. Se t the scope

4. Connect a jumper from TPD2 to ground ( ).

.

The pattern used in this procedure is an EIA color

bar pattern with 87.5% modulation with 100 IRE

white and 7.5 black. Correlate the information in this

procedure to the pattern used if another signal

is used.

• Brightness . . . . . . . .Center.

• Color . . . . . . . . . . . .Min.

• Contrast. . . . . . . . . .Max.

• Sharpness . . . . . . . .Center.

time base to 20µs (horiz onta l).

Procedure:

1. In the Serviceman Mode, select DAC SubBrightness Adjustment (B2) and adjust for 1.5-

1.9Vp-p between blan king and 7.5 IRE leve l. (See

video waveforms detail, Fig. 18)

2. In the Serviceman Mode for electronic

adjustments, select DAC Sub-Contrast Adjustment

(B3) and adjust for 2.0Vp-p ±0.1V white level to

black level on video waveform (see video

waveforms det ail, Fig. 18).

3. Remove the jumper (Preparation step 4).

Tint/Color Adjustment

Serviceman DAC Adjustment (B1) (B0)

Preparation:

1. Apply a rainbow color bar signal.

2. Preset the following controls:

• Brightness . . . . . . . .Min.

• Color . . . . . . . . . . . .Center.

• Tint. . . . . . . . . . . . . .Center.

• Contrast. . . . . . . . . .Max.

• Sharpness . . . . . . . .Min.

3. Connect the oscilloscope to TP47B (A-Board).

4. Connect a jumper from TPD2 to GND ( ).

5. Connect a jumper from IC101 pin 28 to GND ( ).

Procedure:

1. In the Serviceman Mode for making electronic

adjustments, select DAC Sub-Tint Adjustment

(B1). Adjust until the waveform measu red is as the

one shown in Fig. 19.

TP47B (A-Board)

A to B = 1 unit

B to C = 2 units

A

C

1 2 3 10

4 5 6 7 8 9

Figure 19. TP47B waveform

2. Connect the oscilloscope to TP47G (A-Board).

3. Select DAC Sub-Colo r Adjustme nt (B0) an d adjust

for peak to peak am plitude to be 0.65Vp-p ±0.05V

for 27” models as shown in Fig. 20.

TP47G (A-Board)

1 2 3 4 5 6

7 8 9 10

B

0.65Vp-p±0.05V

Figure 20. TP47G waveform

4. Remove the jumpers (Preparation steps 4 & 5).

- 28 -

Page 29

Color Temperature Adjustment

(B/W Tracking)

Serviceman DAC Adjust. (C0) (C1) (C2) (C4) (C5)

Minor Touch-Up Method

OBSERVE low and high brightness areas of a B/W

picture for proper t racking. Adjust only as requ ired for

“good gray scale and warm highlights”.

1. LOW LIGHT areas – In Serviceman Mode for

making electronic adjustments, select Cutoff (C0)

RED, (C1) GRN, (C2) BLU and adjust th e picture

for gray.

2. HIGH LIGHT areas – In Serviceman Mode for

making electronic adjustments, select Drive (C4)

GRN, (C5) BLU and adjust the picture for warm

whites.

8. View scope trace at Horizontal r ate and adjust the

Serviceman Mode DAC (C0) level until a scannin g

period of 195V above DC gro und is measured, as

indicated in Fig. 22.

9. Connect the scope to the GRN Cathode (KG).

10. In Serviceman Mode for making electronic

adjustments, select the GRN CUTOFF DAC (C1).

11. Press the LST-CH key on the Remote

195V DC

0V DC

Figure 22. Cathode Waveform, Adjustment

Waveform Detail

(Ground)

Complete Adjustment

Preparation:

1. Turn the Receiver “ON” and allow 10 minutes

warm up at h igh brightness.

2. Apply a color bar signal with color “OFF”.

3. Turn the SCREEN control (part of FBT T551) fully

counterclockwis e.

Procedure:

Preset the following Serviceman DACs for best results:

• C0 . . . . . . . . . . . . . . 128

• C1 . . . . . . . . . . . . . 128

• C2 . . . . . . . . . . . . . . 128

• C4 . . . . . . . . . . . . . . 64

• C5 . . . . . . . . . . . . . . 64

1. Connect the oscilloscope to C1-2 (CRT-Board).

2. In Serviceman Mode for making electronic

adjustment, select the Sub-Bright DAC (B2).

3. Press the LST-CH key on the remote.

4. Observe the oscilloscope waveform at Horizontal

rate and adjust the Serviceman Mode Sub-Bright

DAC (B2) level until a scanning period of 2.5V

above DC ground is measured, as indicated in

Fig. 21.

2.5V DC

0V DC

Figure 21. TP35 Waveform

12. View the scope trace and adjust the Serviceman

Mode DAC (C1) for the scanning period to be 195V

above DC ground. (See Fig. 22)

13. Connect the scope to the BLU Cathode (KB).

14. In Serviceman Mode for making electronic

adjustments, select the BLU CUTOFF (C2).

15. Press the LST-CH key on the Remote.

16. View the scope trace and adjust the Serviceman

Mode DAC (C2) for the scanning period to be 195V

above DC ground. (See Fig. 22)

17. Turn the Screen Control (part of FBT) slowly

clockwise until a color horizontal line appears.

18. Wi th the other two colors Ser viceman Mode DAC

CUTOFF adjustments (C0) RED, (C2) BLU;

increase the colors to create a white horizontal line.

19. Confirm that a good gray scale is established by

viewing B/W color bar pattern.

20. In the Serviceman Mode for making electronic

adjustments select the DAC DRIVE adjustments

(C4) GRN, (C5) BLUE and adjust for warm white in

a white color bar pattern.

21. EXIT the Serviceman Mode.

22. Adjust the Picture Menu Video Adjustments

Brightness and Contrast from low scale to high

scale and check Black and White tracking.

23. If correction is needed: Re-Enter the Serviceman

Mode and perform the Minor Touch – Up Method.

24. Perform Sub-Brightness Adjustment procedure if

needed.

5. Connect the scope to RED Cathode (KR) on the

CRT-Board.

6. In the Serviceman Mode for making electronic

adjustments, select the RED CUTOFF DAC (C0).

7. Press the LST-CH key on the remote.

- 29 -

Page 30

Service Adjustments (Electronic Controls, cont.)

10k

4700p

TPE11

RMS

METER

Figure 23. Filter Jig

Horizontal Centering

Serviceman DAC Adjustment (D0)

Preparation:

Connect a crosshatch generator.

Procedure:

1. In the Serviceman Mode for making electronic

adjustments. Select the Horizontal Centering

Adjustment DAC (D 0) and adjust until the cen ter of

the crosshatch pattern is centered on CRT.

2. EXIT the Serviceman Adjustment Mode.

MTS Circuit Adjustments

The MTS Circuit Adjustments require two steps:

1. Input Level Adjustment.

2. Stereo Separation Adjustment.

Input Level Adjustment (M0)

Preparation:

1. Connect an RMS meter with fil ter jig as shown in

Fig. 23.

Stereo Separation Adjustment (M1 & M2)

Preparation:

1. Connect an RF s ignal ge ner ato r to the RF antenna

input.

2. Connect a scope to TPE10.

Procedure:

1. Select Stereo Mode in Audio menu

2. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 100% modulation, stereo (le ft only)

(70 ±5dB, 75Ω OPEN, P/S 10dB).

3. Adjust the MTS L ow-Level Separation Adjus tment

(M1) until the amplitude displayed on the scope

is minimum.

4. Apply the following signal from the RF

signal generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 3KHz, 100% modulation, stereo (left only)

(70 ±5dB, 75Ω OPEN, P/S 10dB).

5. Adjust the MTS High-Level Separat ion Adjustment

(M2) until the amplit ude displayed on the s cope is

minimum.

6. Repeat above steps 2 through 5 until the amplitude

is at minimum for both signals.

2. Connect an RF signal generator to the RF

antenna input.

Procedure:

1. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 100% modulation, monaural

(70 ±5dB, 75Ω OPEN, P/S 10dB).

2. Adjust the MTS Input Level Adjustment (M0) until

the voltage measured is 106 ± 6.0mV rms.

- 30 -

Page 31

Service Adjustments (Electronic Controls, cont.)

Clock Adjustment (S7)

Preparation:

Connect the frequency counter from TPS1 (IC001

Pin 13) to cold ground ( ).

Note: Frequency Counter prob e capacitance should

be 8pF or less.

Procedure:

1. Turn the Receiver “OFF” with the AC

power applied.

2. Measure TPS1 (IC001 pin 13) for the frequency of

the waveform and record the reading.

Note: Pin 13 measurement must have at least four

digits of resolution followin g the decimal point.

Example: 000.0000

3. Turn the Receiver back “ON”.

4. Place the Receiver into Serviceman Mode for

making electronic adjustment, select the Clock

Adjustment DAC (S7).

Service Adjustments (Mechanical Controls)

5. Calculate and set S7 based on the

followingformula:

–

pin

{}

244.1406

S7 128 0.9016×10

Note: Pin 13 measurement will not change

regardless of the value stored in S7.

----------------------------------------------------------------- -+=

244.1406

13 Hz[]

Vertical Size (D1)

1. Adjust the VERTICAL SIZE DAC control, D1, until

the top and the bottom edges of the raster are

visible.

2. Adjust the VERTICAL SIZE control, D1, until the

top and the bottom of the raster touch the bezel

edge. Then advance SIZE control to obtain an

approximately 10 % oversc an. Linear ity adjus tment

is done automatically when the size is being

adjusted. (Best results can de obtained with a

round test patter.)

Focus (part of T551)

Preparation:

Connect a Signal generator and select a dot pattern.

Procedure:

Adjust the FOCUS control to obtain the sharpest and

clearest dot pattern.

a. Adjust for best center.

b. Adjust for best area between the center and top

right corner.

- 31 -

Page 32

A

Tuner

IC2201

MTS

AN5849S-E1V

MPX In

14

L OUT

Audio Signal Path Block Diagram

JK3002

13

15

3

5

8

10

RAV3

L-AV1

R-AV1

L-AV2

R-AV2

IC3001

A/V SW

M52790SP

LAV3

LRF1

RRF1

L1 Out L In

R1 Out

35

33

30 22

28

Front

Figure 24. Audio Signal Path Block Diagram.

A/V

Input

A/V

- 32 -

Input 1

A/V

Input 2

Variable

Audio

Out

V

L

R

JK3001

L

R

V2

L2

R2

JK3004

L

R

L Out R Out

21 22

IC2351

Bass/Tre/Bal

Surround

CXA2021S

R In

1

L Out

R Out

14

R OUT

IC2302

Audio Out

AN5272

JK3002

L Out

R Out

7

12

IC001

L In

5

9

R In

2

VAO L VAO R

4 1

7

6

2

3

4

5

1

Headphone

Jack

MPU

Q2409

D2343

MN101C46FTA

S-Defeat

17

Q2410

Page 33

Video-Chroma Signal Path Block Diagram

CRT

C

Q351

Q352

Q353

A11-1 C1-1

A11-2 C1-2

A11-3 C1-3

13

14

15

IC6501

MN82840

Y In

Comb Filter

18

Y Out

22

C Out

24

Chroma

In

45

5V

R Out

+

C641

–

G Out

Sync In

38

B Out

YM/YS In

6

R In

3

G In

4

VCJ

IC101

B In

5

R-Y In

TA1310BN

B-Y In

52

53

C225 C226

A

Tuner

Q6504

Luma In Filter

36

JK3001

PBPRV2

Y/V1

Q6509

Q6516

C6529

RF1

Luma Out Filter

–

+

C3019

31

V1 Out

Video1

2

Q6510

–

+

32

Y In

Y-YUV

6

Q6502

Q6506

Chroma Out Filter

Video212Video3

7

JK3002

Q6501

V

Q6514

Q6519

Q6505

34

C In

IC3001

A/V SW

Q603

5V

5V

29

C1 Out

M52790SP

Y-AV 2

JK3003

11

Y

D014

D015

33

29

YS

25

YM

CVBS0

CVBS1

Q201

5V

Q303

–

C315

+

32

R

IC001

MPU

31

30

B

G

MN101C46FTA

24

C314

+

–

27

5V

Y1 Out

V2 Out

C-AV2

9

26

C

Q302

Video

Video

Input 1

Input 2

Front

Video

Input 3

S-Video

Figure 25. Video-Chroma Signal Path Block Diagram.

- 33 -

Page 34

IC101 IN/OUT Pins and Functions (VCJ)

IC101

TA1310BN

Velocity Scanning

Modulation

Green Input

Blue Input

RGB/Half Tone In

Hold Down

V Reg

1

VSM Out

2Ground

GND

3Red Input

R In

4

G In

5

B In

6

YS / YM In

Hold Down Reference

7HD Reference

8

Hold Down

9

V Reg

10Ground

RGB Mute

11Brightness Control

ABL In

12NC

VK Out

13Red Output

R Out

14Green Output

G Out

DC RC

BP DET

Y In

B-Y In

R-Y In

VCJ

CW Out

X-tal

R-Y Out

B-Y Out

APC

Chroma In

GND

DL Out

56

55 Black Peak Detection

54

53 R-Y Input

52 B-Y Input

51 VCC 5V

50 3.58MHz Clock Output

49 3.58MHz X-tal

48 NC

47

46

45

44

43

DC Restoration Correction

Luminance Signal Input

NC

APC Filter

Chroma Input

Ground

Delayed Y Signal

Green Cutoff

Blue Cutoff

15Blue Output

B Out

16VCC 9V

V

CC

17Red Cutoff

R Filter

18

G Filter

19

B Filter

20Noise filter

Noise Filter

21NC

V Centering

22NC

EW FB

23NC

EW Out

24Vertical Output

V Out

25Vertical Feedback

V NFB

26Automatic Gain

V AGC

27Vertical Ramp

V Ramp

28Vertical EHT Input

EHT V

9V

Bend Correction

32 fh VCO

AFC1

V Sep

Y/Sync In

DEF V

CC

Sync Out

H Out

FBP In

VD Out

HD Out

GND

SDA

SCL

42 Horizontal Correction

41 Horizontal Oscillation

40 AFC1 detection

39 Vertical Separation

38 Video Sync

37 9V

36 NC

35

34 Flyback Pulse

33

32 NC

31 Ground

30

29 I2C SCL Input

Horizontal Output

Vertical Drive Pulse

I2C SDA I/0

Figure 26. VCJ IN/OUT Pins and Functions.

- 34 -

Page 35

IC001 IN/OUT Pins and Functions (MPU)

IC001

MN101C46FTB

Remote signal in

SDA1

SCL1

AFC1

AFC2

Key Scan 1

Action

S-VHS

Version

FA1

YUV SW

10

11

1

2

3

4

5

6

7

8

9

RMIN

P01

P02

ADIN0

ADIN1

ADIN2

ADIN3

P07

ADIN5

ADIN6

P12

VSS

OSC1

OSC2

VDD (VPP)

P42

P41

P40

VSYNC

NRST

YM

ROUT

42

41

40

39

38

37

36

35

34

33

32

GND

14.32MHz X-tal

14.32MHz X-tal

+3.3V

SCL0

SDA0

Not used/open

V-Sync

NRST

YM

R Out

+3.3V

System Clock Out

Volume

RFAGC

TV / Video

Sound Defeat

Power

Speaker On / Off

+3.3V

Closed Caption

12

13

14

15

16

17

18

19

20

21

MMOD

SYSCLK

PWM0

PWM1

P16

P17

P20

PWM5

VDD

CLL

GOUT

BOUT

YS

FLASH

HSYNC

VREFH0

CVBS0

CVBS1

VREF1

CLH

31

30

29

28

27

26

25

24

23

22

G Out

B Out

YS

GND

H-Sync

Closed Caption 0

Closed Caption 0

Closed Caption 1

Closed Caption 1

Closed Caption

Figure 27. MPU IN/OUT Pins and Functions.

- 35 -

Page 36

Component Identification

3 screws at the top edge of the receiver

1 screw at the lower

edge of the receiver

1 screw by

audio out jacks

1 screw by the

A/V jacks

1 screw on the retainer

plate for the AC power cord

1 screw by the flyback

assembly

Figure 28. Back Cover Removal

- 36 -

1 screw at the lower edge

of the receiver

Page 37

Component Identification

CRT (secured to cabinet by

4 screws on corners of CRT)

Yoke

DAG

ground

Anode (high voltage)

Degaussing coil

C board

Speaker (4 screws)

Tuner

VAO Out

Flyback (T551)

A/V jacks

Note:

remember to dress the cables, as shown.

After servicing the receiver,

Figure 29. Rear View

- 37 -

Speaker (4 screws)

Page 38

Component Identification

4

1

2

7

3

8

9

13

14

17

12

6

5

11

10

16

MTS processor IC2201

is located on the other

side of the board.

NO. LOCATION OF COMPONENTS

INTEGRATED CIRCUITS CONNECTORS TRANSISTORS VARIOUS

1 IC 001 MPU 8 FRONT AV IN 13 Q501 H. DRIVE 15 T551 (FLYBACK)

2 IC 002 EEPROM 9 FRONT KEYPAD 14 Q551 H. OUT 16 FUSE

3 IC 101 VCJ 10 REAR AV IN 17 TUNER

4 IC 2302 AUDIO 11 S-VIDEO IN

5 IC 2351 BASS/TRE/BAL 12 VAO OUT

6 IC 3001 A/V SWITCH

7 IC 6501 COMB FILTER

Figure 30. View of Main Board Assemblies

15

- 38 -

Page 39

REPLACEMENT PARTS LIST

Models: 27GX01B-501 & 2 7GX 01B - 51 1

Important Safety Notice: Components printed in BOLD TYPE have special charact eristics important

for safety. When replacing any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

CAPRISTORS

CRA801 TP00842-51 TAPING GAP TERMINAL

CRA802 TP00842-51 TAP ING GAP TERMINAL

CAPACITORS

C001 ECA1CM470 CAP,E 47UF/16V

C002 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C003 ECA1HM4R7 CAP,E 4.7UF/50V

C005 ECA1CM470 CAP,E 47UF/16V

C006 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C008 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C010 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C013 ECA0JM101 CAP, E 100UF/6.3V

C016 ECJ2VC1H101J CAP,C 100PF-J-50V

C017 ECJ2VC1H270J CAP,C 27PF-J-50V

C018 ECJ2VC1H270J CAP,C 27PF-J-50V

C020 ECA0JM331 CAP, E 330UF/6.3V

C021 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C022 ECA1EM471 CAP,E 470UF/25V

C024 ECA1HM4R7 CAP,E 4.7UF/50V

C025 ECA1HM010 CAP,E 1.0UF/50V

C026 ECA1HM010 CAP,E 1.0UF/50V

C032 ECA1CM331 CAP,E 330UF/16V

C033 ECJ2VC1H680J CAP,C 68PF-J-50V