Models 27MM20BA and 27MMV30B are in the same Solid State Color Television family. The

difference between the 27MM20BA and the 27MMV30B is the DDC2B and instruction Book.

Please refer to Model 27MM20B and 27MM20BA schematics, assembly, wiring, test, and

troubleshooting information when servicing Model 27MMV30B. Refer to Service Manual PA No.

0092 issued in March 1998. Refer to Service Manual PA No. 0092 for the technical information

regarding the “Description of Circuit” and “IC’s and Transistors Functions” issued in March 1998.

REPLACEMENT PARTS LIST

This parts list only gives parts which are different from the Service Manual PA No. 0092.

PRODUCT SAFETY NOTE: Components marked with aA have special characteristics important

to safety. Before replacing any of these components, read carefully, the PRODUCT SAFETY

NOTICE of this Service Manual. Do not degrade the safety of the receiver through improper

servicing.

For 27MMV30B (Same as 27MM20BA except below parts)

SYMBOL

NO.

N201

B

Above parts list of 27MMV30B plus attached replacement parts

list are parts which are different from the Service Manual PA

No. 0092.

PART

NO.

QR26891

JK03655(H)

DESCRIPTION

Instruction Book English

PA2 DDC2B P.W.B.

SPECIFICATIONS AND PARTS ARE SUBJECTTO CHANGE FOR IMPROVEMENT

SOLID STATE COLOR TELEVISION

JULY 1998

HHEA-MANUFACTURING DIVISION

PA2

SAFETY PRECAUTIONS

NOTICE: Comply with all cautions and safety-related notes

located on or inside the cabinet and on the chassis or

picture tube.

WARNING: Since the chassis of this receiver is connected

to one side of the AC power supply during operation,

whenever the receiver is plugged in, service should not be

attempted by anyone unfamiliar with the precautions

necessary when working on this type of receiver.

The following precautions should be observed:

1. Do not install, remove, or handle the picture tube in any

manner unless shatterproof goggles are worn. People

not so equipped should be kept away from the picture

tube while handling.

2. When service is required, an isolation transformer

should be inserted between power line and the receiver

before any service is performed on a “HOT” chassis

receiver.

3. When replacing a chassis in the receiver, all the

protective devices must be put back in place, such as

barriers,

nonmetallic knobs, adjustment and

compartment cover-shields, isolation resistors,

capacitors, etc.

4. When service is required, observe the original lead

dress in the high voltage circuitry area.

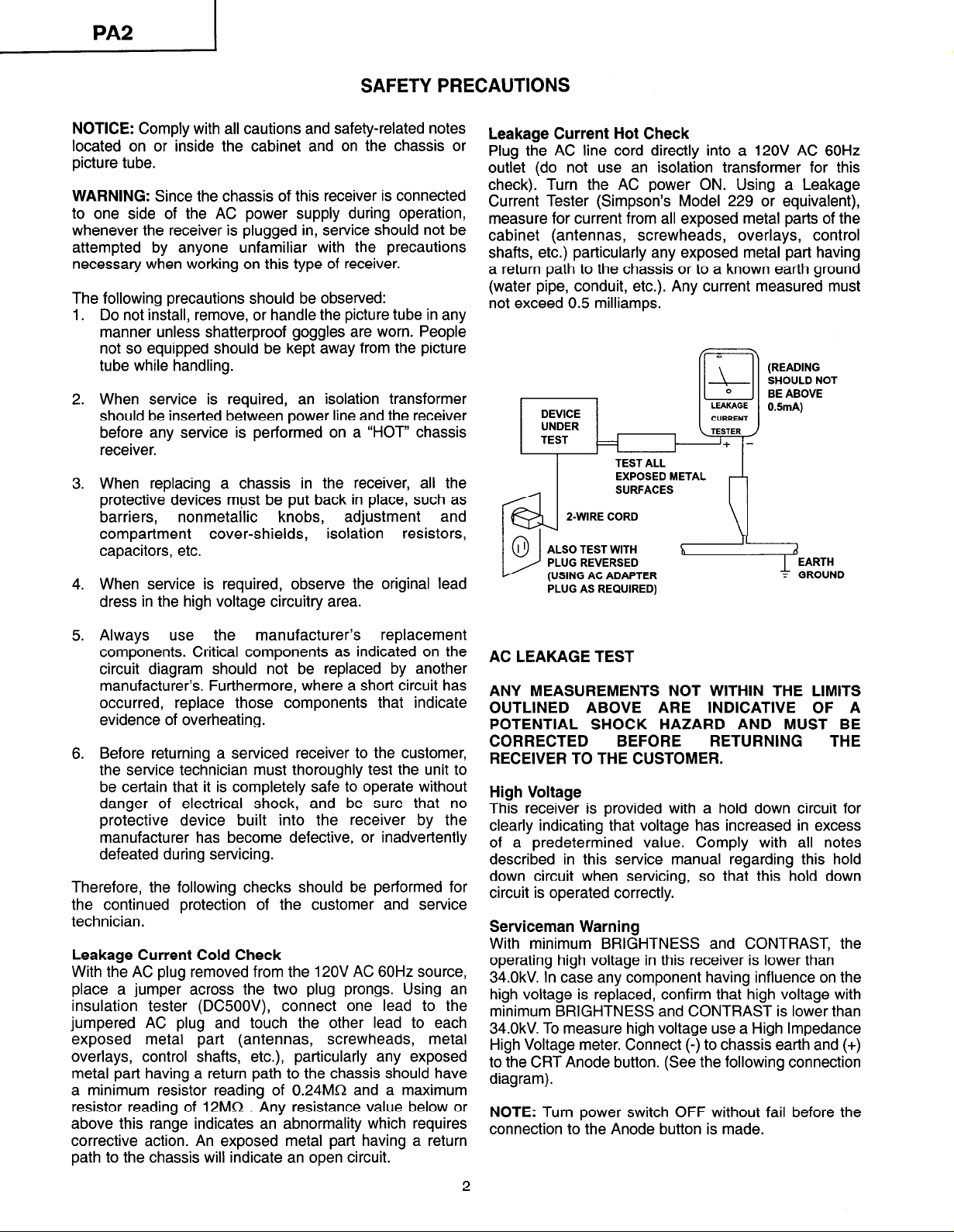

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC 60Hz

outlet (do not use an isolation transformer for this

check). Turn the AC power ON. Using a Leakage

Current Tester (Simpson’s Model 229 or equivalent),

measure for current from all exposed metal parts of the

cabinet (antennas, screwheads, overlays, control

shafts, etc.) particularly any exposed metal part having

a return path to the chassis or to a known earth ground

(water pipe, conduit, etc.). Any current measured must

not exceed 0.5 milliamps.

(READING

SHOULD NOT

BE ABOVE

0.5mA)

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

fUSlNG AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

<TESTER /

1

5. Always use

the manufacturer’s replacement

components. Critical components as indicated on the

circuit diagram should not be replaced by another

manufacturer’s Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

6. Before returning a serviced receiver to the customer,

the service technician must thoroughly test the unit to

be certain that it is completely safe to operate without

danger of electrical shock, and be sure that no

protective device built into the receiver by the

manufacturer has become defective, or inadvertently

defeated during servicing.

Therefore, the following checks should be performed for

the continued protection of the customer and service

technician.

Leakage Current Cold Check

With the AC plug removed from the 12OV AC 60Hz source,

place a jumper across the two plug prongs. Using an

insulation tester (DC500V), connect one lead to the

jumpered AC plug and touch the other lead to each

exposed metal part (antennas, screwheads, metal

overlays, control shafts, etc.), particularly any exposed

metal part having a return path to the chassis should have

a minimum resistor reading of 0.24MQ and a maximum

resistor reading of 12MR . Any resistance value below or

above this range indicates an abnormality which requires

corrective action. An exposed metal part having a return

path to the chassis will indicate an open circuit.

AC LEAKAGE TEST

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A

POTENTIAL SHOCK HAZARD AND MUST BE

CORRECTED BEFORE

RETURNING THE

RECEIVER TO THE CUSTOMER.

High Voltage

This receiver is provided with a hold down circuit for

clearly indicating that voltage has increased in excess

of a predetermined value. Comply with all notes

described in this service manual regarding this hold

down circuit when servicing, so that this hold down

circuit is operated correctly.

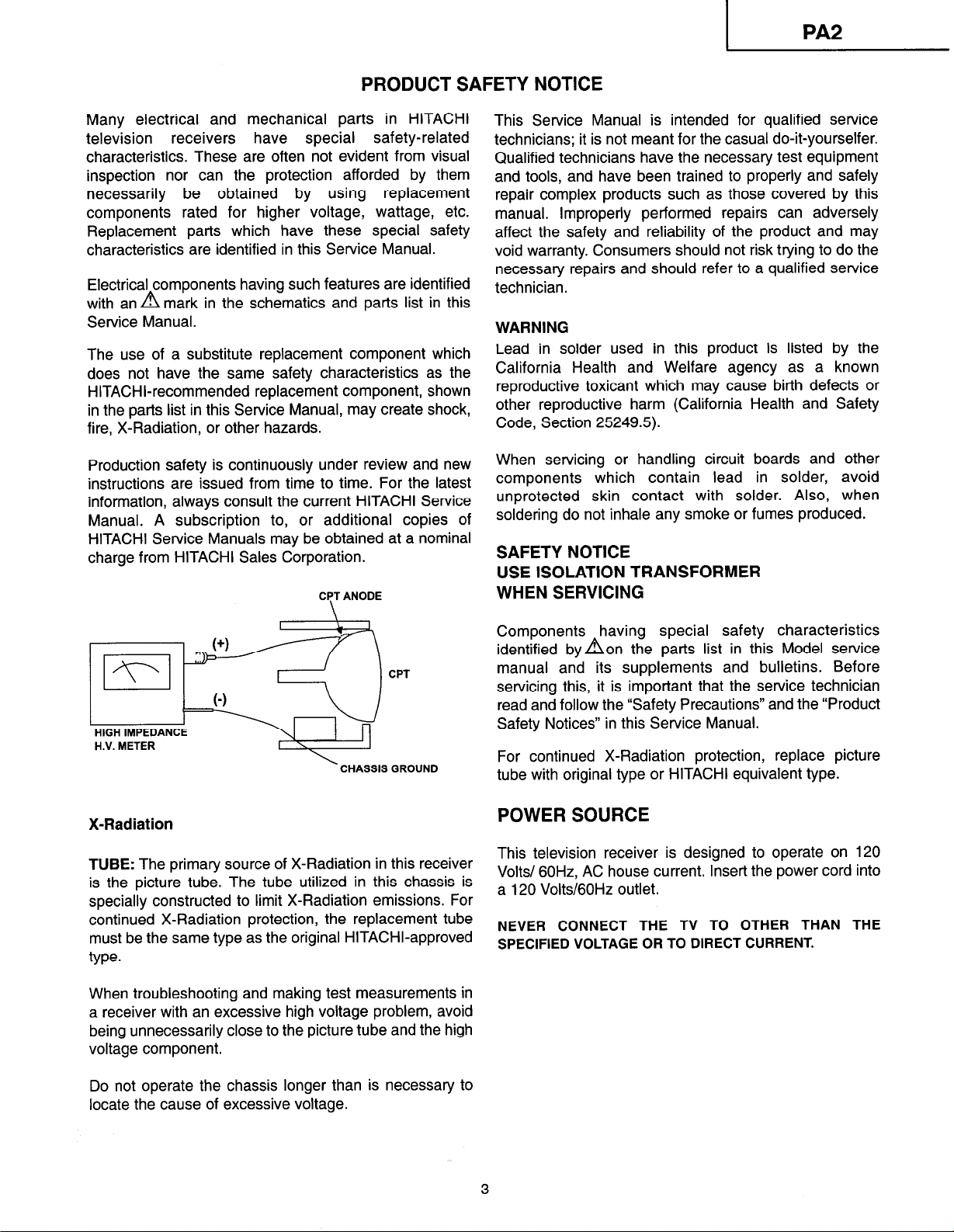

Serviceman Warning

With minimum BRIGHTNESS and CONTRAST, the

operating high voltage in this receiver is lower than

34.0kV. In case any component having influence on the

high voltage is replaced, confirm that high voltage with

minimum BRIGHTNESS and CONTRAST is lower than

34.0kV. To measure high voltage use a High Impedance

High Voltage meter. Connect (-) to chassis earth and (+)

to the CRT Anode button. (See the following connection

diagram).

NOTE: Turn power switch OFF without fail before the

connection to the Anode button is made.

2

I

PRODUCT SAFETY NOTICE

?A2

Many electrical and mechanical parts in HITACHI

television receivers have special safety-related

characteristics. These are often not evident from visual

inspection nor can the protection afforded by them

necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

with an a mark in the schematics and parts list in this

Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

HITACHI-recommended replacement component, shown

in the parts list in this Service Manual, may create shock,

fire, X-Radiation, or other hazards.

Production safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current HITACHI Service

Manual. A subscription to, or additional copies of

HITACHI Service Manuals may be obtained at a nominal

charge from HITACHI Sales Corporation.

CPT ANODE

\

CPT

This Service Manual is intended for qualified service

technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment

and tools, and have been trained to properly and safely

repair complex products such as those covered by this

manual. Improperly performed repairs can adversely

affect the safety and reliability of the product and may

void warranty. Consumers should not risk trying to do the

necessary repairs and should refer to a qualified service

technician.

WARNING

Lead in solder used in this product is listed by the

California Health and Welfare agency as a known

reproductive toxicant which may cause birth defects or

other reproductive harm (California Health and Safety

Code, Section 25249.5).

When servicing or handling circuit boards and other

components which contain lead in solder, avoid

unprotected skin contact with solder. Also, when

soldering do not inhale any smoke or fumes produced.

SAFETY NOTICE

USE ISOLATION TRANSFORMER

WHEN SERVICING

Components having special safety characteristics

identified by aon the parts list in this Model service

manual and its supplements and bulletins. Before

servicing this, it is important that the service technician

read and follow the “Safety Precautions” and the “Product

Safety Notices” in this Service Manual.

\

CHASSIS GROUND

X-Radiation

TUBE: The primary source of X-Radiation in this receiver

is the picture tube. The tube utilized in this chassis is

specially constructed to limit X-Radiation emissions. For

continued X-Radiation protection, the replacement tube

must be the same type as the original HITACHI-approved

type.

When troubleshooting and making test measurements in

a receiver with an excessive high voltage problem, avoid

being unnecessarily close to the picture tube and the high

voltage component.

Do not operate the chassis longer than is necessary to

locate the cause of excessive voltage.

For continued X-Radiation protection, replace picture

tube with original type or HITACHI equivalent type.

POWER SOURCE

This television receiver is designed to operate on 120

Volts/ 60H2, AC house current. Insert the power cord into

a 120 Volts/GOHz outlet.

NEVER CONNECT THE TV TO OTHER THAN THE

SPECIFIED VOLTAGE OR TO DIRECT CURRENT.

3

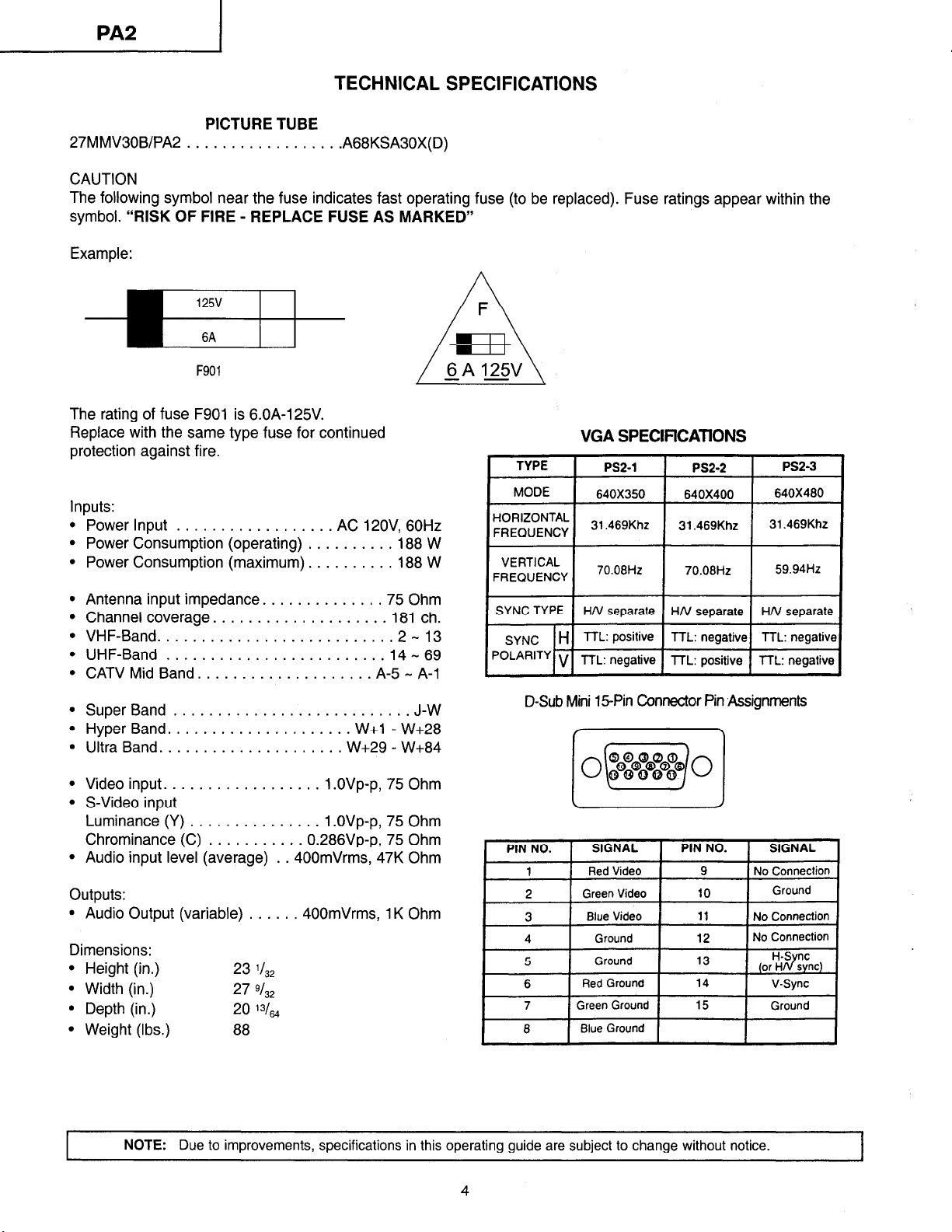

TECHNICAL SPECIFICATIONS

PICTURE TUBE

27MMV30B/PA2 . . . . . . . . . . . . . . . . .A68KSA30X(D)

CAUTION

The following symbol near the fuse indicates fast operating fuse (to be replaced). Fuse ratings appear within the

symbol. “RISK OF FIRE - REPLACE FUSE AS MARKED”

Example:

F901

The rating of fuse F901 is 6.OA-125V.

Replace with the same type fuse for continued

protection against fire.

Inputs:

l

Power Input .................. AC 12OV, 60Hz

l

Power Consumption (operating) .......... 188 W

l

Power Consumption (maximum). ......... 188 W

. Antenna input impedance. ............ .75 Ohm

l

Channel coverage. ................... 181 ch.

l

VHF-Band .......................... .2- 13

l

UHF-Band ......................... 14 - 69

l

CATV Mid Band. ................... A-5 - A-l

l

Super Band ........................... J-W

l

Hyper Band. .................... W+l - W+28

l

Ultra Band. .................... W+29 - W+84

. Video input. ................. 1 .OVp-p, 75 Ohm

l

S-Video input

Luminance (Y) ............... 1 .OVp-p, 75 Ohm

Chrominance (C) ........... 0.286Vp-p, 75 Ohm

l

Audio input level (average) . .400mVrms, 47K Ohm

outputs:

l

Audio Output (variable) ...... 400mVrms, 1K Ohm

Dimensions:

l

Height (in.)

l

Width (in.)

l

Depth (in.)

l

Weight (Ibs.)

23 ‘l32

27 9/32

20

‘3/64

88

--

VGA SPECIFICATONS

1 TYPE 1

MODE

HORIZONTAL

FREQUENCY

1 F;E;;&y 1 70.06Hz 1 70.06Hz 1 59.94Hz 1

SYNC TYPE

SYNC H TTL: positive TTL: negative TTL: negative

PoLAR’TY V TTL: negative TTL: positive TTL: negative

I

D-Sub Mini 15Pin Connector Pin ,Assignments

PIN NO. SIGNAL PIN NO. SIGNAL

1 Red Video 9 No Connection

2 Green Video

3 Blue Video 11 No Connection

4 Ground 12 No Connection

5

6

7

8

PS2-1 1 Ps2-2 1 PS2-3 i

640X350 640X400

31.469Khz

31.469Khz

HN separate HN separate HN separate

10

Ground 13

Red Ground 14 V-Sync

Green Ground 15

Blue Ground

640X480

31.469Khz

Ground

H-S nc

(or Hd sync)

Ground

NOTE:

Due to improvements, specifications in this operating guide are subject to change without notice.

4

I

TECHNICAL CAUTIONS

HV Protection circuit operation checking.

Hiah voltaae limiter circuit operation check and over voltaae protection circuit operation check.

Adjustment Preparation

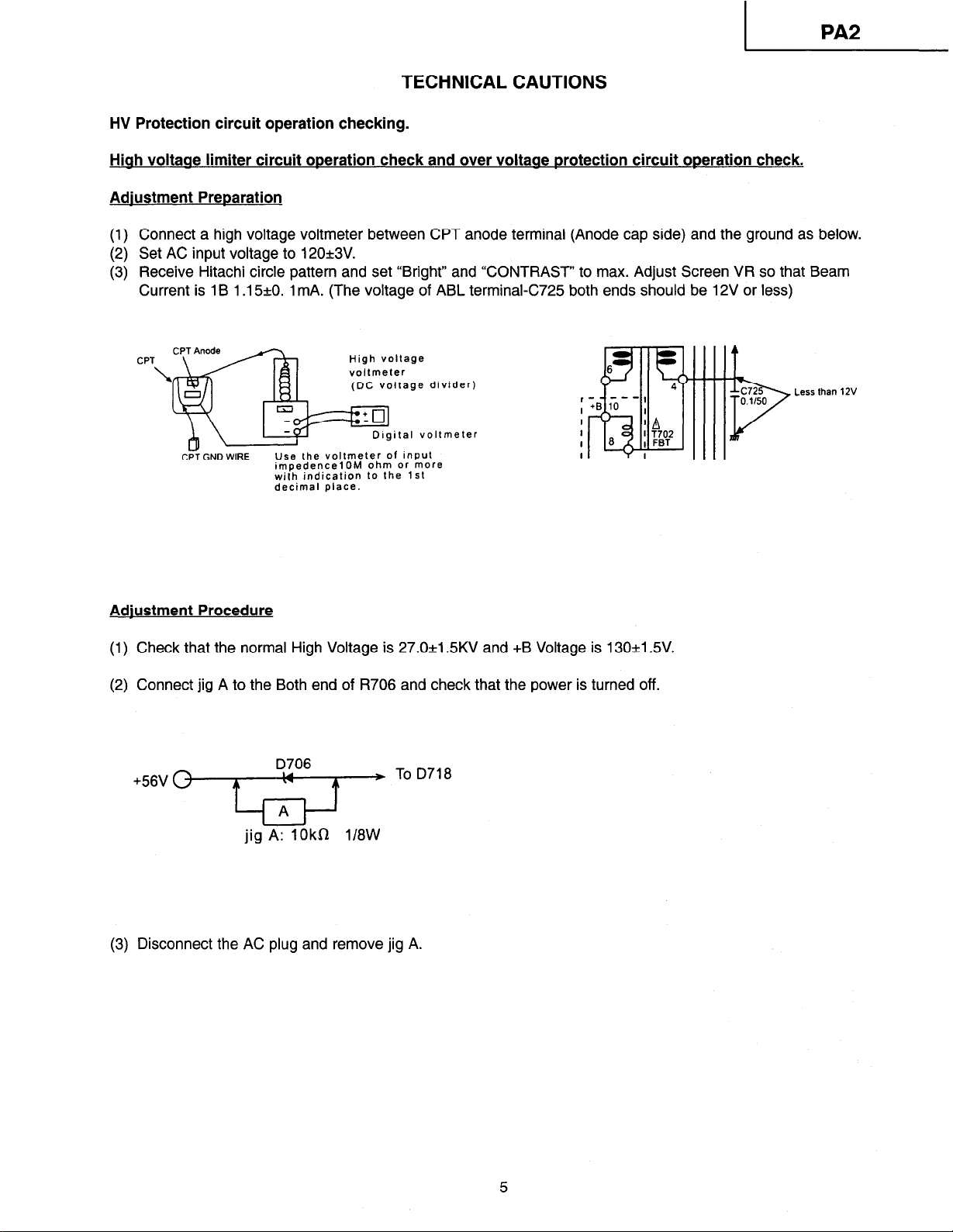

(1) Connect a high voltage voltmeter between CPT anode terminal (Anode cap side) and the ground as below.

(2) Set AC input voltage to 120&3V.

(3) Receive Hitachi circle pattern and set “Bright” and “CONTRAST” to max. Adjust Screen VR so that Beam

Current is 1 B 1 .15&O. 1 mA. (The voltage of ABL terminal-C725 both ends should be 12V or less)

CPT

\

GND WIRE

Adiustment Procedure

(1) Check that the normal High Voltage is 27.0+1.5KV and +B Voltage is 130+1.5V.

(2) Connect jig A to the Both end of R706 and check that the power is turned off.

+56V 0-w To D718

Use the voltmeter Of input

impedencelOM ohm or more

with indication to the 1st

decimal place.

D706

High voltage

voltmeter

(DC voltage divider)

ital voltmeter

c725

0.1150

Less than 12V

3

w

4-s-J

jig=kR 1/8W

(3) Disconnect the AC plug and remove jig A.

1 /XN&S;‘ELATORY 1

Federal Communications Commission Notice

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

l

Reorient or relocate the receiving antenna.

l

Increase the separation between the equipment and the receiver.

l

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

l

Consult the dealer or an experienced radio or television technician for help.

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that are not

expressly approved by Hitachi Home Electronics (America), Inc. may void the user’s authority to operate the

equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods to maintain

compliance with FCC Rules and Regulations.

Any cables that are supplied with the system must be replaced with identical cables in order to assure compliance

with FCC rules. Order Hitachi spares as replacement cables.

Declaration of Conformity

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Any cables that are supplied with the system must be replaced with identical cables in order to assure

compliance with FCC rules. Order Hitachi spares as replacement cables.

For questions regarding this declaration, contact:

Hitachi Home Electronics (America), Inc.

1855 Dornoch Court

San Diego, CA 92173

l-800-448-2244 (l -800-HITACHI)

Attn: Customer Relations

REPLACEMENT PARTS LIST

PRODUCT SAFETY NOTE: Components marked with aAhave special characters important to safety.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE of this service manual.

Don’t degrade the safety of the receiver through improper servicing.

ABBREVIATIONS

Capacitors:

CD: Ceramic Disc

PF: Polyester Film

EL: Electrolytic

PP: Polypropylene

PR: Paper

TA: Tantalum

TM: Trimmer

MC

Mvkr

SYMBOL

NO.

LJT0660

CYOI

CYO2

DYOl

DY02

DY03

IYOl

KY51

KY52

LYOI

PYOl

PYO2

RYOl

RY02

RY03

RY04

RY05

Resistor:

Carbon Film

CF:

Carbon Composition

cc:

MF: Metal Oxide Film

VR: Variable Resistor

WW: Wire Wound

FR: Fuse Resistor

MG: Metal Glaze

0880009R

0800039R CAP.-ELECTRO. 47UF-M 1OV

2339856M ZENER HZS7B3 TA

2339856M ZENER HZS7B3 TA

2339856M

CPOlO42U DIGITAL MONOLITHIC IC (24LC21AJP)

2974432M

2974432M

BH00697R COIL 1OOUH

2959051

0100041 M

0100041 M

0100041 M

0700063M

0700063M

Semiconductors:

TR: Transistor

DI: Diode

ZD: Zener Diode

VA: Varistor

TH: Thermistor

IC: Integrated Circuit

PART

DESCRIPTION

DDCPB P.W.B.

CAP.-POLYESTER 0.01 UF-K 50V

ZENER HZS783 TA

JUMPER WIRE (0.5 L=52MM)

JUMPER WIRE (0.5 L=52MM)

5P POST PIN 4P TYPE PH

PIN POST (PH 2P)

RES.-CARBON FLM 1/8W 1 00-JB

RES.-CARBON FLM 1/8W 1 00-JB

RES.-CARBON FLM 1/8W 1 00-JB

RES.-CARBON FLM 1/16W 47K-JB

RES.-CARBON FLM 1/16W 47K-JB

7

lpyoll

GND

Data

CLK

X-Sync

BASIC CIRCUIT DIAGRAM

DDC2B Circuit Schematic

lpvoll

+5v

+5v

I

a’ -

2

HZS7B3

-lhl

DYOI DY02

HZS7B3 HZS783 HZS7B3

nil nh

LYOI

100

DY03

-vv--

-..__ .__ ~o,,BJ

“103 I”“,

PA2 CHASSIS BLOCK DIAGRAM

I

RYOS

47K

I

II

PRODUCT SAFETY NOTE: Components marked with a A and shaded have special characteristics important to

safety. Before replacing any of these components, read carrefully the PRODUCT SAFETY NOTICE of this Service

Manual. Don’t degrade the safety of the receiver through improper servicing.

l

All DC voltage to be measured with a tester (100kWV). Voltage taken on a complex color bar signal including

a standard color bar signal.

l

Since this is a basic circuit diagram, the value of the parts is subject to be altered for improvement.

8

NOTES:

HITACHI

Loading...

Loading...