Instruction and safety manual

Manuel d’instructions et de sécurité

Instrucciones y manual de seguridad

Model

Modèle

NT 65MA4 (S)

Modelo

DANGER

Improper use of this Nailer can result in death or serious injury!

This Manual contains important information about product safety.

Read and understand this Manual before operating the Nailer.

Never allow anyone who has not reviewed this manual.

Finish Nailer

Cloueur de fi nition

Clavadora de acabado

DANGER

Une utilisation incorrecte et sans respecter la sécurité de ce cloueur risque d’entraîner la mort

ou des blessures graves !

Ce manuel renferme des instructions importantes sur la sécurité de l’outil.

Lire et bien assimiler ce manuel avant d’utiliser le cloueur.

Ne jamais laisser les personnes n’ayant pas étutdié le manuel utiliser l’outil.

PELIGRO

¡La utilización inadecuada e insegura de este clavador puede resultar en lesiones serias o

en la muerte!

Este manual contiene información importante sobre la seguridad del producto.

Lea y entienda este manual antes de utilizar el clavador.

No deje manejar esta herramienta a nadie que no haya leído este manual.

English

IMPORTANT INFORMATION ..................................3

DEFINITIONS OF SIGNAL WORDS ........................3

EXPLANATION OF THE NAILING ACTION OF

THE HITACHI NAILER .......................................... 3

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR

USING NAILERS ...................................................4

EMPLOYER’S RESPONSIBILITIES.........................6

OPERATION

NAME OF PARTS ....................................................7

SPECIFICATIONS ................................................... 8

NAIL SELECTION ....................................................8

ACCESSORIES ....................................................... 8

Standard accessories ..........................................8

Optional accessories ...........................................8

APPLICATIONS ....................................................... 8

CONTENTS

Page Page

BEFORE OPERATION ............................................8

Working environment ........................................... 9

Air supply ............................................................. 9

Lubrication ......................................................... 10

Cold weather care ..............................................10

Testing the nailer................................................10

Adjusting air pressure ........................................12

Loading nails ......................................................12

NAILER OPERATION ............................................13

Methods of operation .........................................13

Adjusting the nailing depth ................................. 15

Using the blow nozzle ........................................16

Changing the exhaust direction ..........................16

Using the nose cap ............................................16

MAINTENANCE

MAINTENANCE AND INSPECTION......................18

SERVICE AND REPAIRS ......................................20

Français

INFORMATION IMPORTANTE .............................22

DEFINITION DES MOTS DE SIGNALISATION .....22

EXPLICATION DE L’ACTION DE CLOUAGE

DU CLOUEUR HITACHI .....................................22

SECURITE

CONSIGNES DE SECURITE IMPORTANTES

POUR L’UTILISATION DU CLOUEUR ................23

RESPONSABILITES DE L’EMPLOYEUR .............. 26

UTILISATION

NOM DES PIECES ................................................27

SPECIFICATIONS ................................................. 28

SELECTION DES CLOUS .....................................28

ACCESSOIRES ..................................................... 28

Accessoires standard ........................................28

Accessoires en option .................................................28

APPLICATIONS ..................................................... 28

Español

INFORMACIÓN IMPORTANTE ............................. 43

DEFINICIÓN DE LAS PALABRAS CLAVE ............43

EXPLICACIÓN LA ACCIÓN DE CLAVADO

DEL CLAVADOR HITACHI .................................43

SEGURIDAD

INSTRUCCIONES IMPORTANTES DE

SEGURIDAD PARA LA UTILIZACIÓN

DEL CLAVADOR .............................................. 44

RESPONSABILIDADES DEL EMPRESARIO ........ 47

OPERACIÓN

NOMENCLATURA ................................................. 48

ESPECIFICACIONES ............................................ 49

SELECCIÓN DE CLAVOS ..................................... 49

ACCESORIOS ....................................................... 49

Accesorios estándar ..........................................49

Accesorios opcionales ....................................... 49

APLICACIONES ....................................................49

TABLE DES MATIÈRES

Page Page

Página Página

AVANT L’UTILISATION .........................................29

Environnement de travail ...................................29

Alimentation d’air ...............................................29

Graissage ..........................................................30

Entretien par temps froid ....................................30

Essai du cloueur ................................................30

Reglage de la pression d’air ...............................32

Chargement des clous ....................................... 32

UTILISATION DU CLOUEUR ................................33

Methodes d’utilisation ........................................34

Reglage de la profondeur de clouage ................36

Utilisation de la buse de projection d’air .............36

Changement du sens d’echappement ...............37

Utilisation du capuchon de bec ..........................37

ENTRETIEN

ENTRETIEN ET INSPECTION ...............................39

ENTRETIEN ET REPARATIONS ...........................41

ÍNDICE

ANTES DE LA OPERACIÓN..................................50

Entorno de trabajo .............................................50

Suministro de aire ..............................................50

Lubricación ........................................................51

Cuidados para climas fríos .................................51

Prueba del clavador ........................................... 51

Ajuste de la presión de aire ................................53

Carga de clavos ................................................. 53

OPERACIÓN DEL CLAVADOR ............................. 54

Métodos de operación .......................................55

Ajuste de la profundidad de clavado .................. 57

Empleo de la boquilla de soplo ..........................58

Cambio del sentido del aire de escape ..............58

Utilización de la tapa para el morro .................... 58

MANTENIMIENTO

MANTENIMIENTO E INSPECCIÓN ......................60

SERVICIO Y REPARACIONES..............................61

2

English

IMPORTANT INFORMATION

Read and understand tool labels and all of the operating instructions,

safety precautions and warnings in this manual before operating or

maintaining this nailer.

Failure to follow warnings could result in DEATH or SERIOUS INJURY.

Most accidents that result from the operation and maintenance of Nailers are caused by

the failure to observe basic safety rules or precautions. An accident can often be avoided

by recognizing a potentially hazardous situation before it occurs, and by observing

appropriate safety procedures.

Basic safety precautions are outlined in the “SAFETY” section of this Manual and in the

sections which contain the operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identifi ed

by DANGERS and WARNINGS on the Nailer and in this Manual.

Never use this Nailer for applications other than those specifi ed in this Manual.

DEFINITIONS OF SIGNAL WORDS

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor

NOTE emphasizes essential information.

EXPLANATION OF THE NAILING ACTION OF THE HITACHI NAILER

○ SINGLE SEQUENTIAL ACTUATION MECHANISM:

First, press the push lever against the wood; next, pull the trigger to drive the fastener.

After fastening once, fastening will not be possible again until the trigger is released and

pressed again.

○ CONTACT ACTUATION MECHANISM:

First, press the push lever against the wood; next, pull the trigger to drive the fastener.

First, pull the trigger; next, press the push lever against the wood to drive the fastener.

If the trigger is held back, a fastener will be driven each time the push lever is pressed against

the wood.

or serious injury.

or moderate injury, or may cause machine damage.

3

English

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USING NAILERS

READ ALL INSTRUCTIONS

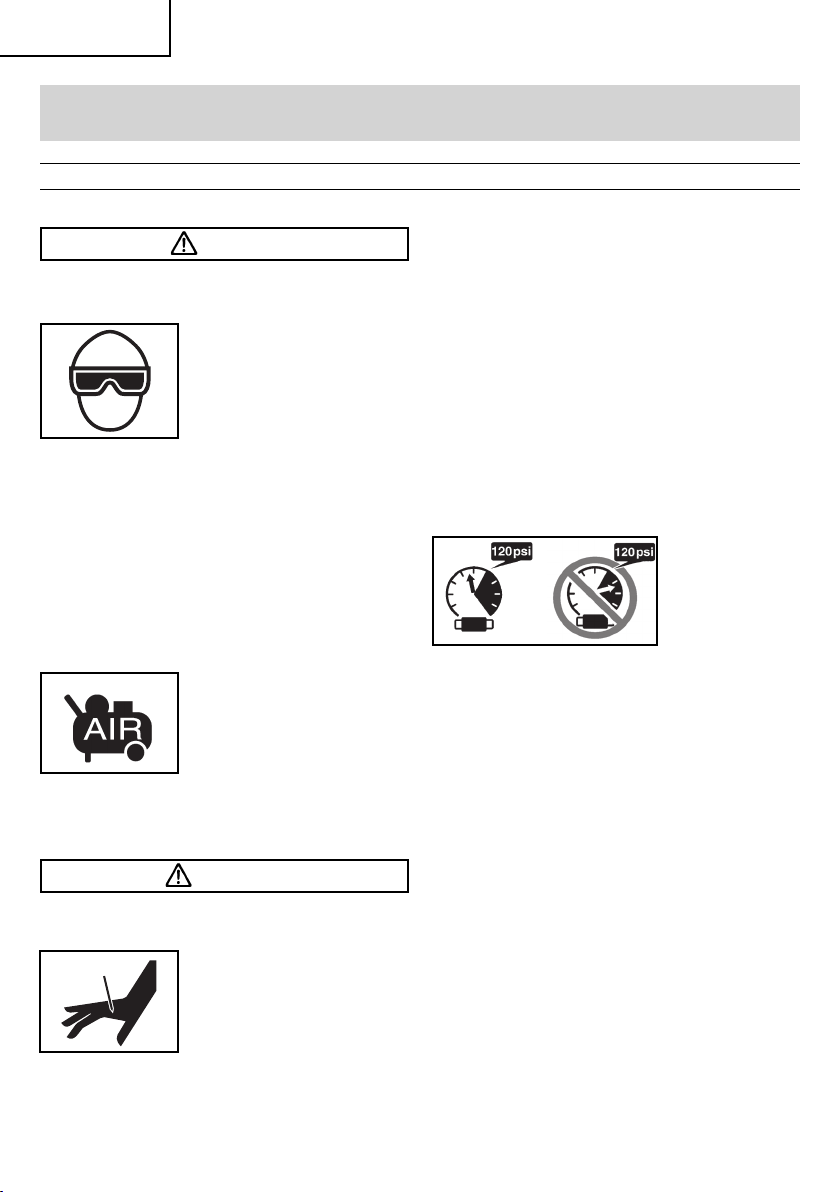

DANGER

1. Operators and others in work area must

wear safety glasses with side shields.

When operating the Nailer,

always wear safety glasses

with side shields, and

make sure others in work

area wear safety glasses,

too.

Safety glasses must conform to the

requirements of American National

Standards Institute, ANSI Z87.1 and

provide protection against fl ying particles

both from the front and side.

The employer must enforce the use of

safety glasses by the Nailer operator and

others in work area.

2. Never use oxygen or other bottled

gases. Explosion may occur.

Never use oxygen,

combustible gases or any

other bottled gases as

a power source for the

Nailer.

Use of the above gases is

dangerous, as the Nailer will explode.

Use only clean, dry, regulated compressed

air.

WARNING

3. Never point tool at yourself or others in

work area.

Always assume the Nailer

contains fasteners.

Never point the Nailer at

yourself toward yourself or

others, whether it contains

fasteners or not.

If fasteners are mistakenly driven, it can

lead to severe injuries.

Never engage in horseplay with the Nailer.

Respect the Nailer as a working

4

implement.

4. Keep fi ngers away from trigger when

not driving fasteners to avoid accidental

fi ring.

Never carry the Nailer with fi nger on

trigger since you could drive a fastener

unintentionally and injure yourself or

someone else.

Always carry the Nailer by the handle only.

5. Choice of triggering method is

important.

Read and understand section titled

“Methods of operation.” (pages 13 – 15)

6. Do not exceed 120 psi. (8.3 bar 8.5 kgf/

2

cm

)

Do not exceed

maximum

recommended

air pressure

120 psi (8.3 bar

8.5 kgf/cm

2

).

Never connect the Nailer to pressure which

potentially exceeds 200 psi (13.7 bar 14

2

kgf/cm

) as the Nailer can burst.

7. Be careful of the following when using

blow nozzle.

1) Do not touch the trigger.

2) Do not point the air outlet at a person.

3) Do not touch the push lever or set it to

pushed up status.

Flying nails can cause severe injury.

8. Always wear ear and head protection.

Always wear ear protection to protect your

ears from loud noise.

Always wear head protection to protect

your head from fl ying objects.

9. Store nailer properly.

When not in use, the Nailer should be

stored in a dry place. Keep out of reach of

children. Lock the storage area.

10. Keep work area clean.

Cluttered areas invite injuries. Clear all

work areas of unnecessary tools, debris,

furniture, etc.

SAFETY — Continued

English

11. Never use in presence of fl ammable

liquids or gases.

The Nailer produces sparks during

operation.

Never use the Nailer in sites containing

lacquer, paint, benzine, thinner, gasoline,

gases, adhesive agents, and other materials

which are combustible or explosive.

12. Keep visitors away.

Do not let visitors handle the Nailer.

All visitors should be kept safely away from

work area.

13. Dress properly.

Do not wear loose clothing or jewelry as

they can be caught in moving parts.

Rubber gloves and nonskid footwear are

recommended when working outdoors.

Wear protective hair covering to contain

long hair.

14. Never use non relieving coupler on

nailer.

If a non relieving coupler is used on the

Nailer, the Nailer can remain charged

with air after disconnecting and thus will

be able to drive a fastener even after

disconnecting.

The Nailer and air hose must have a hose

coupling such that all pressure is removed

from the Nailer when the coupling joint is

disconnected.

15. Check push lever before use.

Make sure the push lever operates properly.

(The push lever may be called “Safety”.)

Never use the Nailer unless the push

lever is operating properly, otherwise the

Nailer could drive a fastener unexpectedly.

Do not tamper with or remove the push

lever, otherwise the push lever becomes

inoperable.

16. Keep all screws and covers tightly in

place.

Keep all screws and covers tightly mounted.

Check their condition periodically.

Never use the Nailer if parts are missing or

damaged.

17. Do not load fasteners with trigger pulled

or push lever depressed.

When loading fasteners into the Nailer or

when connecting the air hose,

1) do not pull the trigger;

2) do not depress the push lever; and

3) keep the Nailer pointed downward.

18. Keep face, hands and feet away from

fi ring head at all times.

Never place your face, hands or feet near

the fi ring head.

19. Place nailer properly on workpiece.

Do not drive fasteners on top of other

fasteners or with the Nailer at too steep of

an angle; the fasteners can ricochet and

hurt someone.

20. Before starting work, check the

fastening operation switching device.

This Hitachi nailer includes a fastening

operation switching device.

Before starting work, check the setting of

the operation switching device.

If the switching device is not set properly,

the nailer will not operate correctly.

21. Be careful of double fi re due to recoil.

If the push lever is unintentionally allowed

to re-contact the workpiece following recoil,

an unwanted fastener will be driven.

In order to avoid this undesirable double

fi re,

○ Intermittent operation (Trigger fi ring)

1) Set the switching device to SINGLE

SEQUENTIAL ACTUATION

MECHANISM.

2) Pull the trigger rapidly and fi rmly.

○ Continuous operation (Push lever fi ring)

1) Do not press the nailer against the wood

with excessive force.

2) Separate the nailer from the wood as it

recoils after fastening.

22. Do not drive fasteners into thin boards

or near corners and edges of workpiece.

The fasteners can be driven through or

away from the workpiece and hit someone.

23. Never drive fasteners from both sides

of a wall at the same time.

The fasteners can be driven into and

through the wall and hit a person on the

opposite side.

24. Check for live wires.

Avoid the risk of severe electrical shock by

checking for live electrical wires that may

be hidden by walls, fl oors or ceilings. Turn

off the breaker switch to ensure there are

no live wires.

5

English

SAFETY — Continued

25. Never carry nailer by hose.

26. Do not overreach.

Keep proper footing and balance at all

times.

27. Never use nailer which is defective or

operating abnormally.

If the Nailer appears to be operating

unusually, making strange noises, or

otherwise appears defective, stop using it

immediately and arrange for repairs by a

Hitachi authorized service center.

28. Do not disconnect air hose from nailer

with fi nger on trigger.

The Nailer can fi re when re-connected to

an air supply.

29. Disconnect air hose from nailer when:

1) doing maintenance and inspection;

2) loading fasteners;

3) turning the adjuster and top cover;

4) attaching or removing the nose cap;

5) clearing a jam;

6) it is not in use;

7) leaving work area;

8) moving it to another location; and

9) handing it to another person.

Never attempt to clear a jam or repair the

Nailer unless you have disconnected air

hose from the Nailer and removed all

remaining fasteners from the Nailer.

The Nailer should never be left unattended

since people who are not familiar with

the Nailer might handle it and injure the

themselves.

30. Stay alert.

Watch what you are doing. Use common

sense.

Do not operate the Nailer when you are

tired.

The Nailer should never be used by you if

you are under the infl uence of alcohol, drugs

or medication that makes you drowsy.

31. Handle nailer correctly.

Operate the Nailer according to this

Manual.

Never allow the Nailer to be operated by

children, individuals who have not reviewed

this manual.

32.

Never use nailer for applications other

than those specifi ed in this manual.

33. Handle nailer carefully.

Because of high air pressure in the Nailer,

cracks in the surface are dangerous.

To avoid this, do not drop the Nailer or

strike the Nailer against hard surfaces;

and do not scratch or engrave signs on the

Nailer. Handle the Nailer carefully.

34. Maintain nailer with care.

Keep the Nailer clean and lubricated for

better and safer performance.

35. Use only parts, accessories or fasteners

supplied or recommended by Hitachi.

Unauthorized parts, accessories, or

fasteners may void your warranty and can

lead to malfunction and resulting injuries.

Only service personnel trained by Hitachi,

distributor or employer shall repair the

Nailer.

36. Never modify or alter a nailer.

Doing so may cause it to malfunction and

personal injuries may result.

EMPLOYER’S RESPONSIBILITIES

1. Ensure that this MANUAL is available

to operators and personnel performing

maintenance.

2. Ensure that Nailers are used only when

operators and others in work area are

wearing EYE PROTECTOR.

3. Enforce the use of EYE PROTECTOR by

operators and others in work area.

4. Keep Nailers in safe working order.

5. Maintain Nailers properly.

6. Ensure that Nailers which require repair are

not further used before repair.

SAVE THIS MANUAL AND

KEEP IT AVAILABLE FOR OTHERS!

6

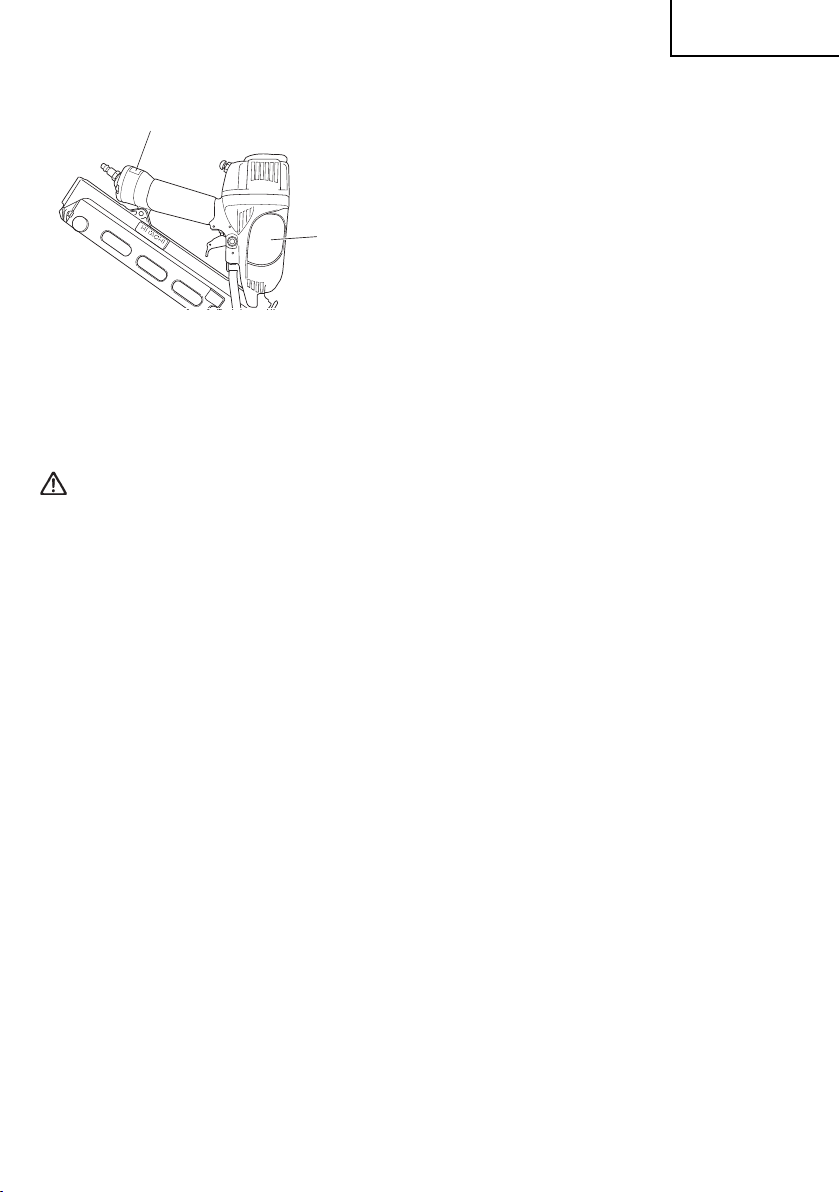

OPERATION

NOTE

The information contained in this Manual is designed to assist you in the safe operation of

the Nailer.

Some illustrations in this Manual may show details or attachments that diff er from those

on your own Nailer.

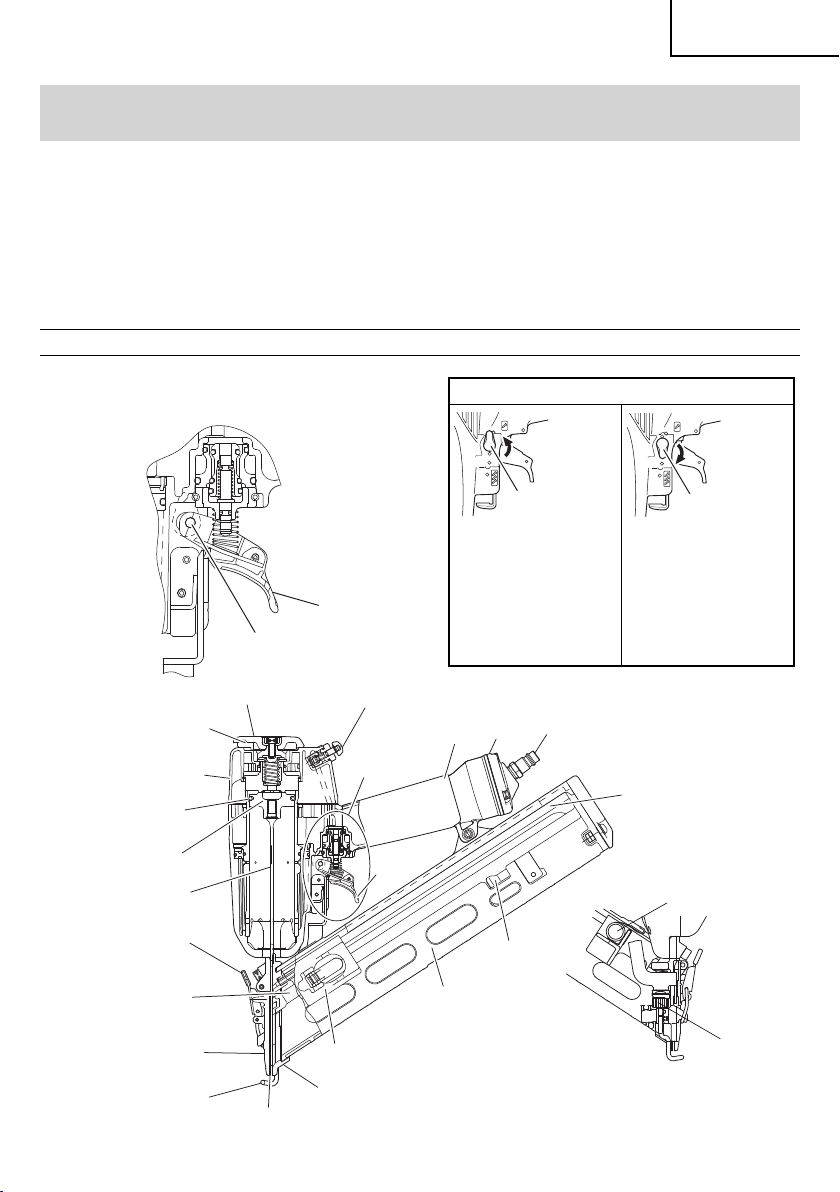

NAME OF PARTS

English

Enlarged view

of the valve part

Air Outlet

Exhaut Cover

Piston O-ring

Piston

Driver Blade

Lock Lever

Switching Device

Top Cover

Trigger

Blow Nozzle Knob

Valve part

Trigger

Nailing operation Switching device

Switching

Device

SINGLE

SEQUENTIAL

ACTUATION

MECHANISM

(Switching device:

upward position)

Air Plug

Cap

Body

Nail Stopper

CONTACT

ACTUTION

MECHANISM

(Switching device:

downward position)

Nail Rail

Switching

Device

Ribbon Spring

Nail Feeder (A)

Guide Plate (A)

Push Lever

Nail Feeder (B)

Blade Guide

Outlet (Firing Head)

Magazine

Adjuster

7

English

SPECIFICATIONS

Operating pressure 70 – 120 psi (4.9 – 8.3 bar 5 – 8.5 kgf/cm2)

Dimensions

Length × Height × Width

Weight 4.2 lbs. (1.9 kg)

Nail capacity 100 Nails

Air consumption

13-1/2” × 12” × 3-1/4”

(344 mm × 304 mm × 82 mm)

3

/cycle at 100 psi

.045 ft

(1.29 ltr/cycle at 6.9 bar)

(1.29 ltr/cycle at 7 kgf/cm

2

)

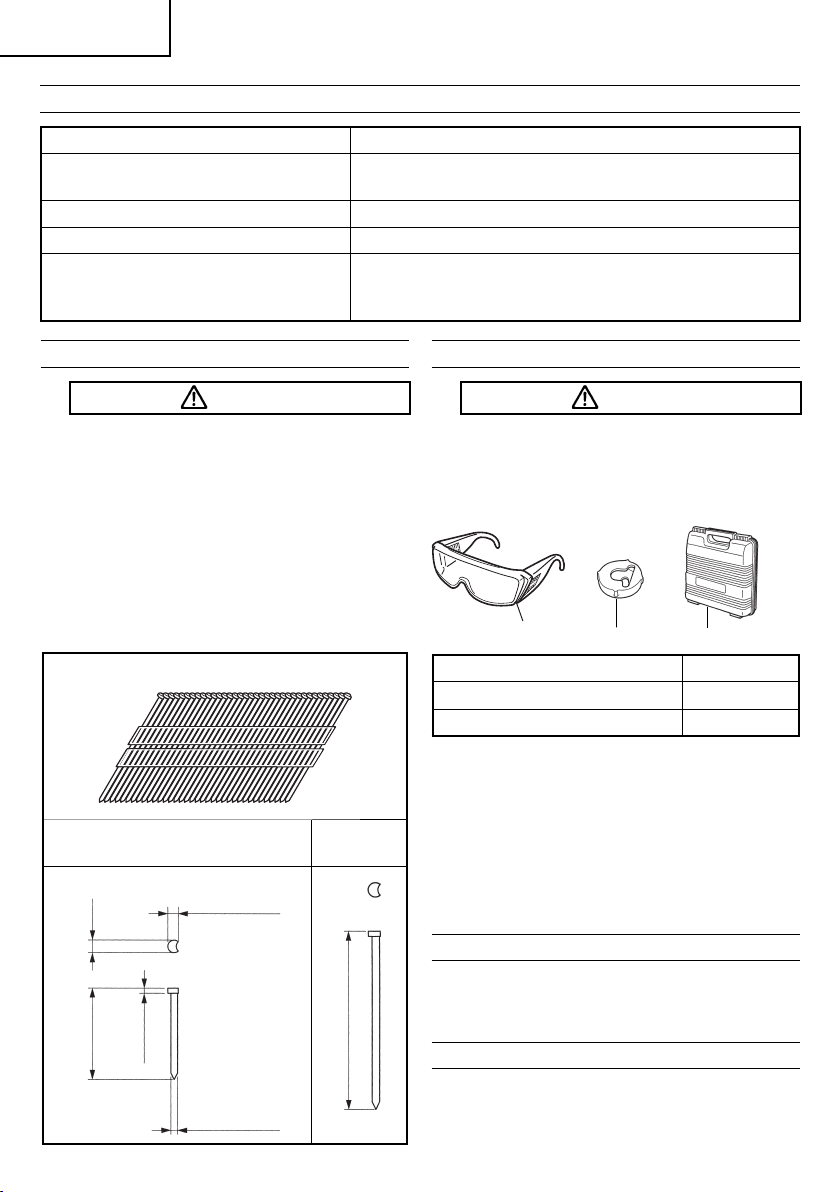

NAIL SELECTION

WARNING

● Be sure to use only the genuine

HITACHI nails for the NT65MA4 (S).

The use of any other nails can

result in tool malfunction and/or

nail breakdown, leading to serious

injuries.

Only nails shown in the Table below can be

driven with this Nailer.

Dimensions of nails

15 Gauge fi nish nails

Min. Max.

.095” (2.4mm)

.12”

(3.0mm)

.045”

(1.1mm)

1-1/4” (32mm)

2-1/2” (65mm)

.072” (1.8mm)

8

ACCESSORIES

WARNING

● Accessories other than those shown

below can lead to malfunction and

resulting injuries.

Standard accessories

1

Safety glasses 1

1

Nose cap 1

2

Case 1

3

2

3

Optional accessories ... sold separately

○ Pneumatic Tool Lubricant

1 oz. (30 cc) oil feeder (Code No.877153)

4 oz. (120 cc) oil feeder (Code No.874042)

1 quart (1 ltr) can (Code No.876212)

NOTE

Accessories are subject to change without

any obligation on the part of HITACHI.

APPLICATIONS

○ Manufactured Housing, On-site and Mobile

Home Construction.

○ Cabinets, Furniture, and Woodworking.

BEFORE OPERATION

Read section titled “SAFETY” (pages 4 –

6).

Make sure of the followings before operation.

English

Working environment

WARNING

● No fl ammable gas, liquid or other

fl ammable objects at worksite.

● Clear the area of children or

unauthorized personnel.

Air supply

DANGER

● NEVER use

oxygen or other

bottled gases.

Explosion may

occur.

WARNING

● Never connect Nailer to pressure

which potentially exceeds 200 psi

(13.7 bar 14 kgf/cm

2

).

● Never use non relieving coupler on

Nailer.

1. Power source

○ Use only clean, dry, regulated compressed

air as a power source for this Nailer.

○ Air compressors used to supply compressed

air to this Nailer must comply with the

requirements of the latest version of ANSI

Standard B 19.3 “Safety Standard For

Compressors For Process Industries.”

○ Moisture or oil in the air compressor may

accelerate wear and corrosion in the

Nailer.

Drain daily.

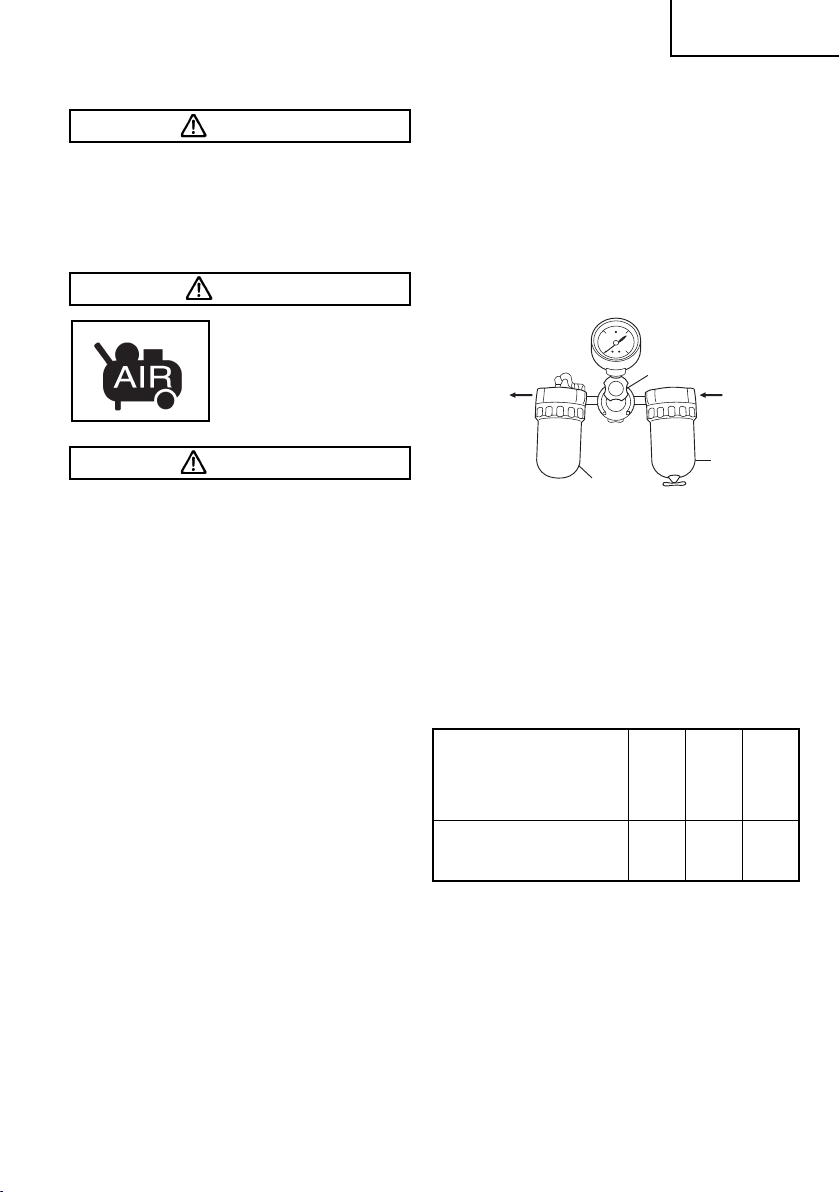

2. Filter-Regulator-Lubricator

○ Use a regulator with a pressure range of 0 –

120 psi (0 – 8.3 bar 0 – 8.5 kgf/cm

2

).

○ Filter-regulator-lubricator units supply an

optimum condition for the Nailer and extend

the Nailer life. These units should always be

used.

Filter

The fi lter removes moisture and

dirt mixed in compressed air.

Drain daily unless fi tted with an automatic

drain.

Keep the fi lter clean by regular

maintenance.

Regulator

The regulator controls the operating

pressure for safe operation of the Nailer.

Inspect the regulator before operation to be

sure it operates properly.

Lubricator

The lubricator supplies an oil mist to the

Nailer.

Inspect the lubricator before operation to

be sure the supply of lubricant is adequate.

Use Hitachi pneumatic tool lubricant.

Regulator

Nailer Side

Compressor

Side

Filter

3. Air hose

Lubricator

Air hose must have a minimum working

pressure rating of 150 psi (10.4 bar 10.6

2

kgf/cm

) or 150% of the maximum pressure

produced in the system, whichever is

higher.

4. Air consumption

Using the Air consumption table and the

Air compressor size formula, fi nd a correct

compressor size.

Air consumption table

psi 80 90 100

Operating

pressure

Air

consumption

(bar) (5.5) (6.2) (6.9)

2

(kgf/cm

ft

) (5.6) (6.3) (7)

3

/cycle .038 .042 .045

(ltr/cycle) (1.07) (1.18) (1.29)

Air compressor size formula

Amount of air required

= number of Nailers

× average nails driven each minute

per Nailer

× air consumption at given air pressure

× safety factor (always 1.2)

Example: 3 Nailers operating at 100 psi

driving 30 nails per minute

Amount of air required

= 3 × 30 × .045 (1.29) × 1.2

= 4.9 CFM (ft

3

/min) (139 ltr/min)

9

English

After making the calculations as shown

above, you should fi nd a compressor

providing 4.9 CFM of air that is required.

Lubrication

It is important that the Nailer be properly

lubricated.

Without proper lubrication, the Nailer will not

work properly and parts will wear prematurely.

○ Use Hitachi pneumatic tool lubricant.

Do not use detergent oil or additives. These

lubricants will harm the O-rings and other

rubber parts. This will cause the Nailer to

malfunction.

○ Filter-regulator-lubricator units should

always be used.

Keep the lubricator fi lled with Hitachi

pneumatic tool lubricant.

○ If a lubricator is not available, supply 5 – 10

drops of Hitachi pneumatic tool lubricant

into the air plug on the Nailer twice a day.

Cold weather care

○ Do not store the Nailer in a cold weather

environment. Keep the Nailer in a warm

area until beginning the work.

○ If the Nailer is already cold, bring it in a

warm area and allow the Nailer to warm up

before use.

1 Reduce the air pressure to 64 psi (4.4

bar 4.5 kgf/cm

2

).

2 Remove all nails from the Nailer.

3 Connect the air hose and free-fi re

(blank-fi re) the Nailer.

The lowered air pressure will be enough

to free-fi re the Nailer.

Slow speed operation tends to warm up

the moving part.

CAUTION

● Do not free-fi re the Nailer at high

pressure.

Testing the nailer

DANGER

● Operators and

others in work

area MUST wear

safety glasses

with side shields

which conforms

to ANSI Z87.1

specifi cations.

WARNING

● Never use Nailer unless push lever

is operating properly.

Before actually beginning the nailing work,

test the Nailer by using the check list below.

Conduct the tests in the following order.

If abnormal operation occurs, stop using the

Nailer and contact a Hitachi authorized service

center immediately.

(1) Disconnect air hose from nailer.

Remove all nails from nailer.

□ All crews must be tightened.

If any screws are loose, tighten them.

□ The push lever and trigger must move

smoothly.

Trigger

10

Do not connect

air hose

Push

Lever

English

(2) Adjust the air pressure to 70 psi (4.9 bar 5

kgf/cm

2

).

Connect the air hose.

Do not load any nails in the Nailer.

Set the switching device to the upward

position (SINGLE SEQUENTIAL

ACTUATION MECHANISM).

(Set the switching device to the upward

position completely as shown in the

diagram. Otherwise, it will not operate

properly.)

Upward position

Switching Device

□ The nailer must not leak air.

(3) Remove the fi nger from the trigger and

press the push lever against the wood.

□ The nailer must not operate.

Pull Trigger

(5) 1 Without touching the trigger, depress

the push lever against the workpiece.

Pull the trigger.

□ The nailer must operate.

2 Remove the fi nger from the trigger.

□ Nailer operation will end (the driver

blade will return to the top).

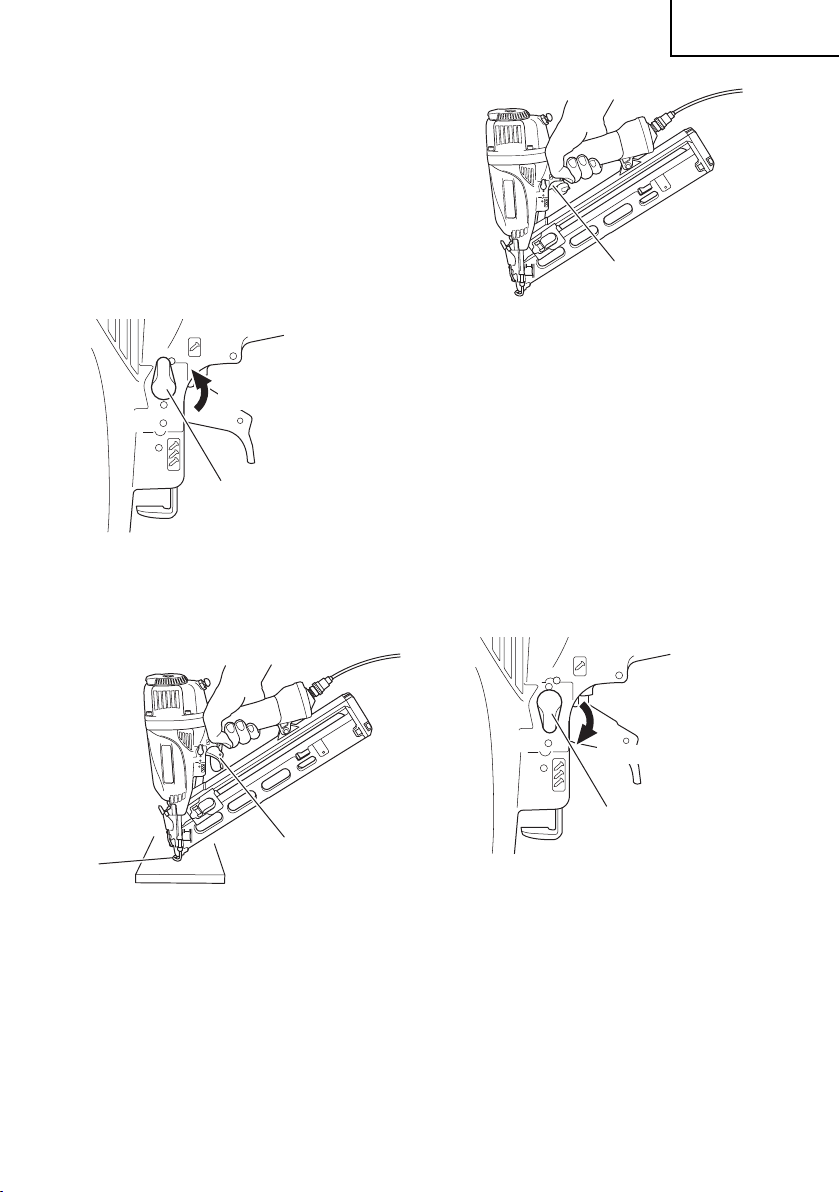

(6) Set the switching device to the downward

position (CONTACT ACTUATION

MECHANISM).

(Set the switching device to the downward

position completely as shown in the

diagram. Otherwise, it will not operate

properly.)

Depress

Push

Do not pull Trigger

Lever

(4) Separate the push lever from the wood.

Next, point the nailer downward, pull the

trigger and then wait in that position for 5

seconds or longer.

□ The nailer must not operate.

Downward position

Switching Device

With the Nailer off the workpiece, pull the

trigger.

Depress the push lever against the

workpiece.

□ The nailer must operate.

11

English

(7) If no abnormal operation is observed, you

may load nails in the Nailer.

Drive nails into the workpiece that is

the same type to be used in the actual

application.

□ The nailer must operate properly.

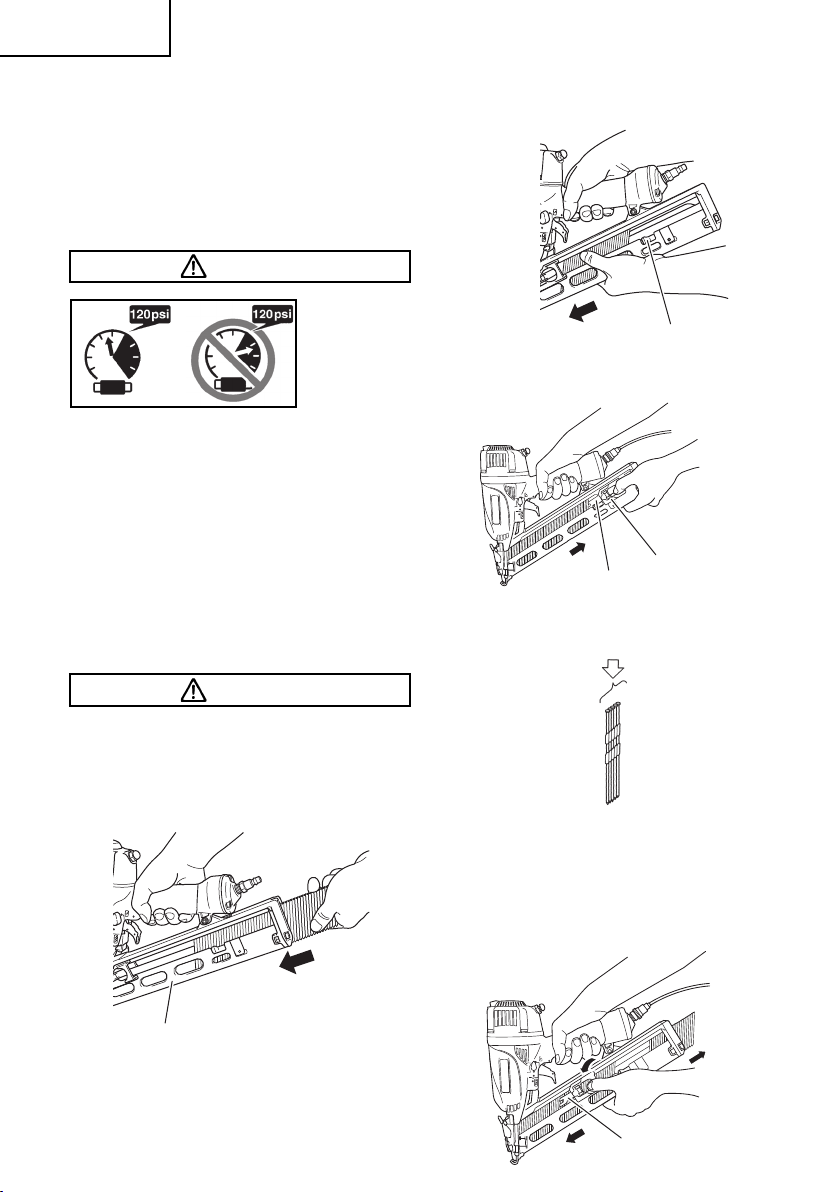

Adjusting air pressure

WARNING

● Do not exceed 120 psi (8.3 bar 8.5

kgf/cm

2

).

Adjust the air pressure at recommended

operating pressure 70 – 120 psi (4.9 – 8.3

bar 5 – 8.5 kgf/cm

2

) according to the length

of nails and the hardness of workpiece.

The correct air pressure is the lowest

pressure which will do the job. Using the

Nailer at a higher than required air pressure

unnecessarily over stresses the Nailer.

Loading nails

(2) Slide the nail strip forward in the magazine.

The nail strip should pass the nail stopper.

Nail Stopper

(3) Pull the nail feeder (B) back to engage the

nail feeder (A) to the nail strip.

Nail Feeder (B)

Nail Feeder (A)

NOTE

○ Use nail strip at least 5 nails remaining.

WARNING

● When loading nails into the nailer,

be sure to remove your fi nger from

the trigger and disconnect the air

hose from the nailer.

(1) Insert nail strip into rear of magazine.

Magazine

12

The Nailer is now ready to operate.

Removing the nails:

1 Depress the nail feeder (A) slightly and

slowly slide the nail feeder (B) forward.

2 Remove the nails from the Nailer.

2

Nail Feeder (A)

1

English

NAILER OPERATION

Read section titled “SAFETY”(pages 4 – 6).

DANGER

WARNING

● Choice of triggering method is

important.

Please read and understand

“METHODS OF OPERATION” found

below.

● Before starting work, check the

nailing operation switching device.

This Hitachi nailer includes a nailing

operation switching device.

Before starting work, make sure that

the switching device is properly set.

If the switching device is not set

properly, the nailer will not operate

correctly.

● Never place your face, hands or feet

near fi ring head when using.

● Do not drive nails on top of other

nails or with Nailer at too steep of

an angle; nails can ricochet and hurt

someone.

● Do not drive nails into thin boards

or near corners and edges of

workpiece. Nails can be driven

through or away from workpiece

and hit someone.

● Operators and

others in work

area MUST wear

safety glasses

with side shields

which conforms

to ANSI Z87.1

specifi cations.

● NEVER point tool

at yourself or

others in work

area.

● Keep fi ngers

AWAY from

trigger when not

driving nails to

avoid accidental

fi ring.

● Never drive nails from both sides of

a wall at the same time. Nails can be

driven into and through the wall and

hit a person on the opposite side.

● Never use Nailer which is defective

or operating abnormally.

● Do not use Nailer as hammer.

● Disconnect air hose from Nailer

when:

1) turning the adjuster and top

cover;

2) attaching or removing the nose

cap;

3) it is not in use;

4) leaving work area;

5) moving it to another location;

and

6) handing it to another person.

This Hitachi nailer is equipped with a nailer

operation switching device.

Use SINGLE SEQUENTIAL ACTUATION

MECHANISM or CONTACT ACTUATION

MECHANISM in accordance with the work to

be performed.

Explanation of the various nailing operations

○ SINGLE SEQUENTIAL ACTUATION

MECHANISM: First, press the push lever

against the wood; next, pull the trigger to

drive the nail.

After nailing once, nailing will not be

possible again until the trigger is released

and pressed again.

○ CONTACT ACTUATION MECHANISM:

First, press the push lever against the wood;

next, pull the trigger to drive the nail.

First, pull the trigger; next, press the push

lever against the wood to drive the nail.

If the trigger is held back, a nail will be

driven each time the push lever is pressed

against the wood.

Methods of operation

This Nailer is equipped with the push lever

and does not operate unless the push lever is

depressed (upward position).

There are two methods of operation to drive

nails with this Nailer.

They are:

13

English

1. Intermittent operation (Trigger fi re):

2. Continuous operation (Push lever fi re):

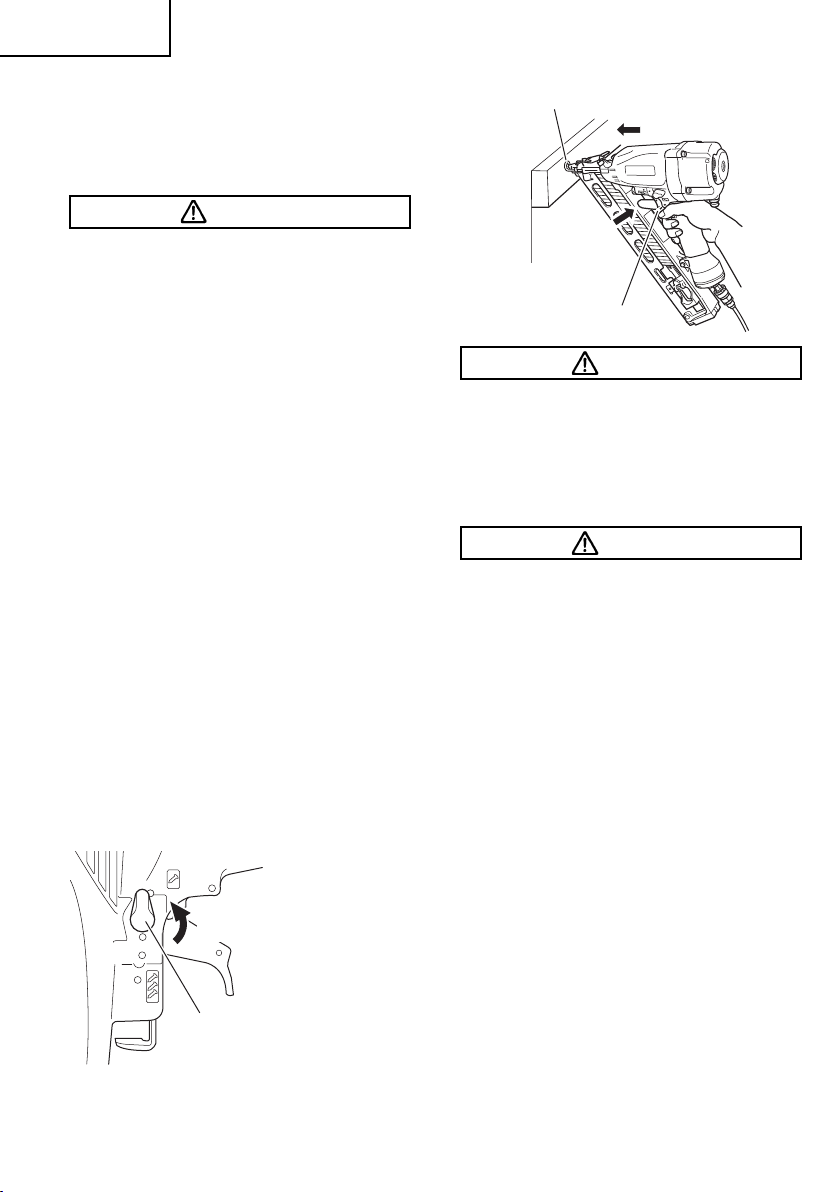

(1) Intermittent operation (Trigger fi re)

Use the SINGLE SEQUENTIAL

ACTUATION MECHANISM setting.

WARNING

● For intermittent operation, set the

switching device to the upward

position completely. (i.e. Set to

SINGLE SEQUENTIAL ACTUATION

MECHANISM.)

● To avoid double fi ring or accidental

fi ring due to recoil.

1) Set the switching device

to SINGLE SEQUENTIAL

ACTUATION MECHANISM.

2) Pull the trigger rapidly and fi rmly.

1 Set the switching device to the

upward position (to set to SINGLE

SEQUENTIAL ACTUATION

MECHANISM).

(Set the switching device to the

upward position completely as shown

in the diagram. Otherwise, it will

be set to CONTACT ACTUATION

MECHANISM.)

2 Position the nail outlet on the workpiece

with fi nger off the trigger.

3 Depress the push lever fi rmly until it is

completely depressed.

4 Pull the trigger to drive a nail.

5 Remove fi nger from the trigger.

To continue nailing in a separate location,

move the nailer along the wood, repeating

steps 2 - 5 as required.

1 Upward position

Switching Device

Push Lever

● A nail will fi re each time the trigger

is depressed as long as the push

lever remains depressed.

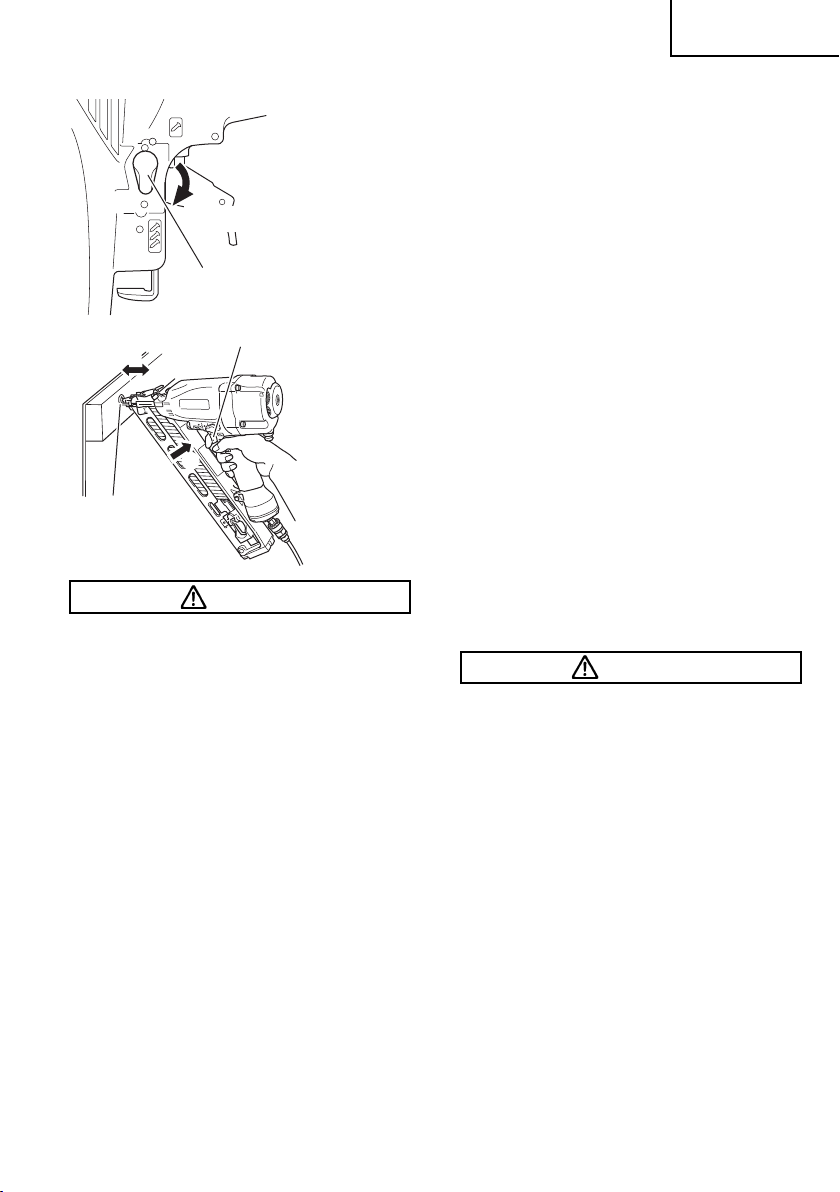

(2) Continuous operation (Push lever fi re)

Using CONTACT ACTUATION

MECHANISM

● To avoid double fi ring or accidental

fi ring due to recoil.

1) Do not press the nailer against the

wood with excessive force.

2) Separate the nailer from the wood

as it recoils after nailing.

1 Set the switching device to the

downward position (to set to CONTACT

ACTUATION MECHANISM).

(Set the switching device to the

downward position completely as

shown in the diagram. Otherwise, it will

not operate properly.)

2 Pull the trigger with the Nailer off the

workpiece.

3 Depress the push lever against the

workpiece to drive a nail.

4 Move the Nailer along the workpiece

with a bouncing motion.

Each depression of the push lever will

drive a nail.

As soon as the desired number of nails

have been driven, remove fi nger from the

trigger.

3

4

Trigger

WARNING

WARNING

14

Downward position

1

Switching Device

Previously pull the trigger

4

2

Push Lever

WARNING

● Keep your fi nger off the trigger

except during nailing operation,

because serious injury could result if

the push lever accidentally contacts

you or others in work area.

● Keep hands and body away from

the discharge area. This Hitachi

nailer may bounce from the recoil

of driving a nail and unwanted

subsequent nail may be driven,

possibly causing injury.

The SINGLE SEQUENTIAL ACTUATION

MECHANISM is for use where precision

fastener placement is desired.

The SINGLE SEQUENTIAL ACTUATION

MECHANISM may reduce the possibility of

bodily injury to you or others in the work area

compared to the CONTACT ACTUATION

MECHANISM. This is because it is less

likely to drive an unwanted nail if you keep

the trigger pulled and accidentally bump

the push lever against yourself or others.

English

The SINGLE SEQUENTIAL ACTUATION

MECHANISM may also reduce the speed

of operation compared to the CONTACT

ACTUATION MECHANISM. The SINGLE

SEQUENTIAL ACTUATION MECHANISM is

recommended to inexperienced users.

NOTE

● If all warnings and instructions are

followed, safe operation is possible with

all two systems: SINGLE SEQUENTIAL

ACTUATION MECHANISM and CONTACT

ACTUATION MECHANISM.

● Always handle nails and package carefully.

If nails are dropped, collating bond may be

broken, which will cause mis-feeding and

jamming.

● After nailing:

1) disconnect air hose from the Nailer;

2) remove all nails from the Nailer;

3) supply 5 – 10 drops of Hitachi pneumatic

tool lubricant into the air plug on the

Nailer; and

4) open the petcock on the air compressor

tank to drain any moisture.

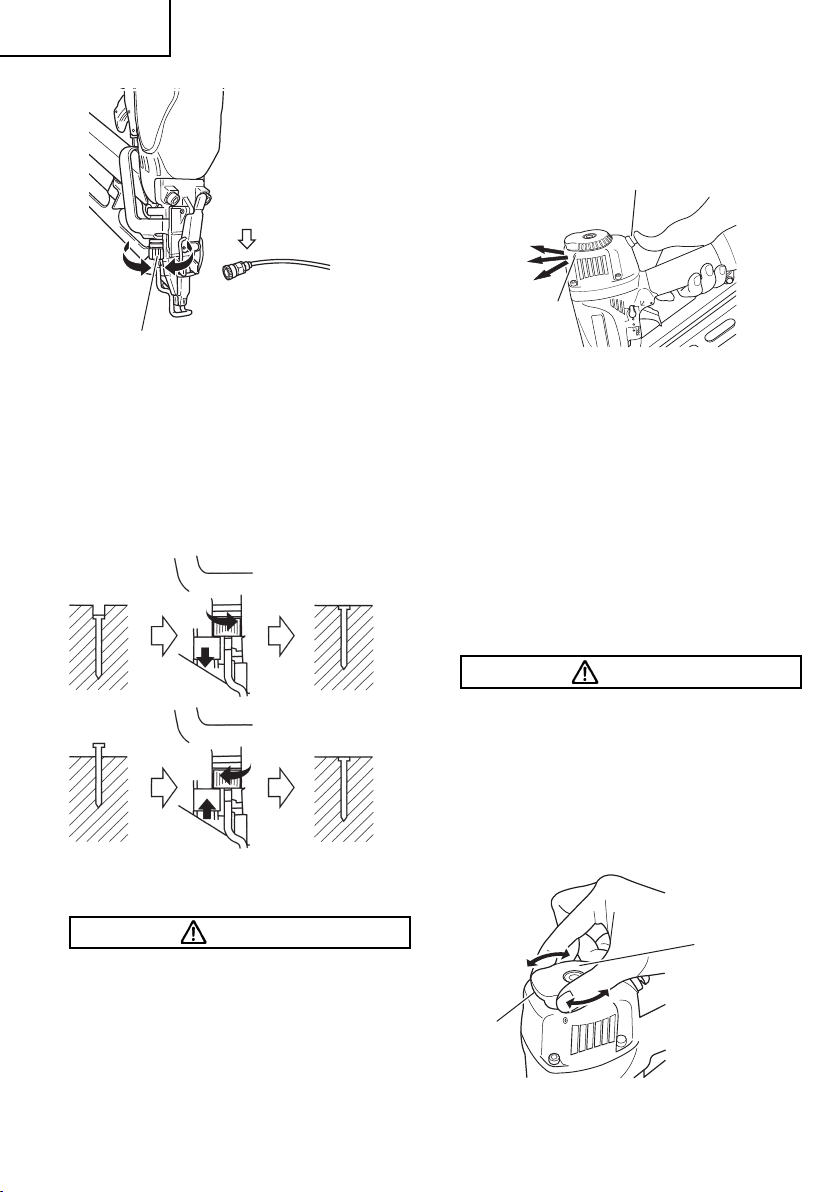

Adjusting the nailing depth

WARNING

● When adjusting the Adjuster, be

sure to remove your fi nger from the

trigger and disconnect the air hose

from the nailer.

To assure that each nail penetrates to the same

depth, be sure that:

1) the air pressure to the Nailer remains

constant (requlator is installed and working

properly), and

2) the Nailer is always held fi rmly against the

workpiece.

If nails are driven too deep or shallow into the

workpiece, adjust the nailing in the following

order.

1 DISCONNECT AIR HOSE FROM NAILER.

2 If nails are driven too deep, turn the adjuster

to the shallow side.

Adjustments are in half-turn increments.

15

English

15 Disconnect air

hose

Adjuster

If nails are driven too shallow, turn the adjuster

to the deep side.

3 Stop turning the adjuster when a suitable

position is reached for a nailing test.

4 Connect the air hose.

ALWAYS WEAR SAFETY GLASSES.

Perform a nailing test.

5 DISCONNECT AIR HOSE FROM NAILER.

6 Choose a suitable position for the adjuster.

2

Too Deep

Turn Adjuster

Flush

This Nailer has a blow nozzle that blows out

wood shavings which occur during work.

Press the knob with your thumb to use the blow

nozzle, as shown in the fi gure.

Knob

Air outlet

NOTE

● When the blow nozzle is used for a long time,

the nailing force may degrade temporarily.

In this case, allows the air supply pressure

to stabilize before starting work.

● Oil in the body or drained water from the

compressor can sometimes spout out

of the air outlet. It is recommended that

you once conduct a test before use and

see if such phenomenon happens at an

environment where spouted oil will cause

any inconvenience.

2

Too Shallow

Using the blow nozzle

● Be sure to release your fi nger from

the trigger before using the blow

nozzle.

● Do not point the air outlet at a

person.

● Do not use the blow nozzle with the

push lever left fi t.

16

Turn Adjuster

WARNING

Flush

Changing the exhaust direction

WARNING

● When changing the exhaust

direction, be sure to remove

your fi nger from the trigger and

disconnect the air hose from the

nailer.

The direction of the exhaust vent can be

changed by turning the top cover.

Top Cover

Exhaust

Vent

Using the nose cap

WARNING

● When attaching or detaching

the nose cap, be sure to remove

your fi nger from the trigger and

disconnect the air hose from the

nailer.

If you like to protect the surface of workpiece

against scratches or markings made by the

push lever, attach the accessory nose cap to

the push lever.

1 DISCONNECT AIR HOSE FROM NAILER.

2 Put the nose cap to the toe of the push

lever.

3 The nose cap is marked to indicate the exit

point of the nail, making alignment easier.

4 When not using the nose cap, secure in

the storage compartment located on the

reverse side of the magazine.

1

Nose Cap

Disconnect

air hose

English

2

Magazine

NOTE

● The nose cap may reduce nailing depth

due to its thickness. Re-adjustment of

nailing depth is required.

Push Lever

Nose Cap

17

English

MAINTENANCE

NOTE

The information contained in this Manual is designed to assist you in the safe maintenance

of the Nailer.

Some illustrations in this Manual may show details or attachments that diff er from those

on your own Nailer.

MAINTENANCE AND INSPECTION

Read section titled “SAFETY” (pages 4 –

6).

WARNING

● Disconnect air hose and remove all

nails from Nailer when:

1) doing maintenance and

inspection; and

2) clearing a jam.

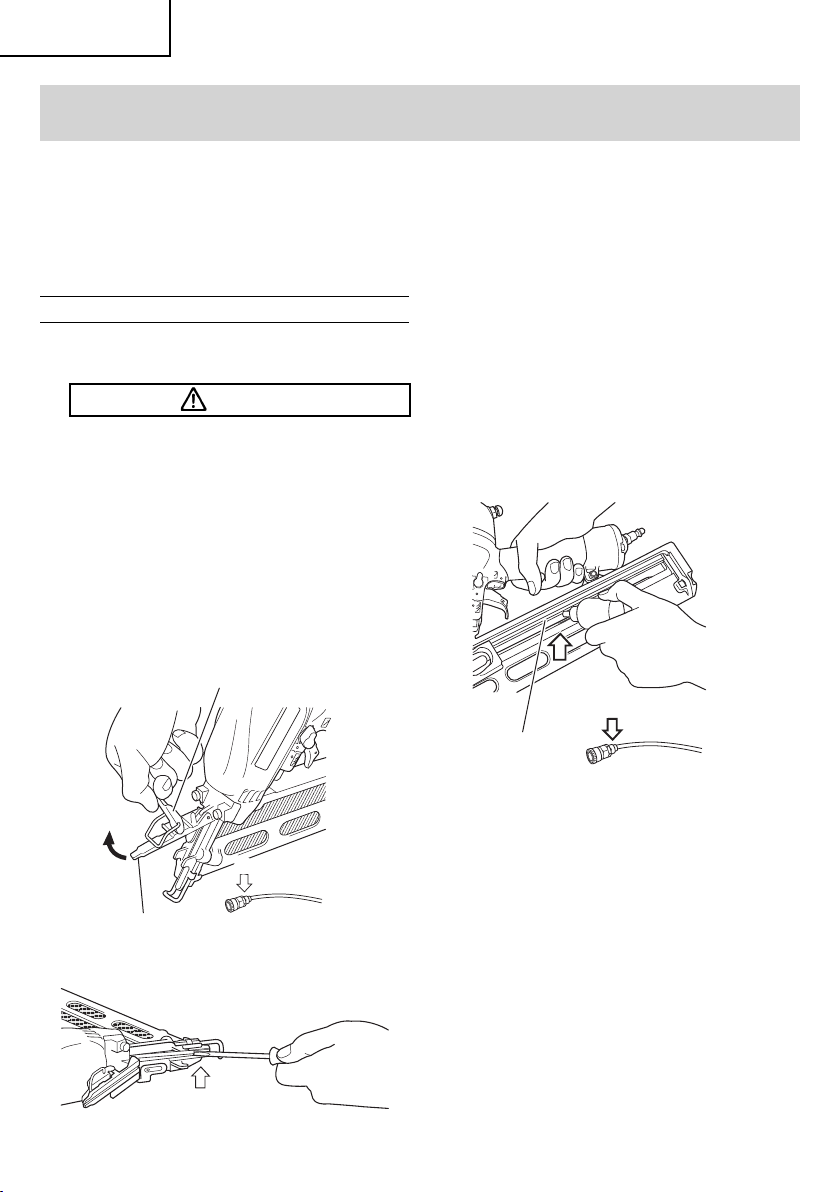

1. Clearing a jam

Remove a jammed nail in the following

order:

1 DISCONNECT AIR HOSE.

2 Remove all nails.

3 Release the lock lever and open guide

plate (A).

Lock lever

3

Guide Plate (A)

4 Remove the jammed nail with a slotted-

head screwdriver.

4

Disconnect

1

air hose

5 Close guide plate (A) and latch.

6 In case of frequent jam, contact a

Hitachi authorized service center.

2. Inspecting the magazine.

1 DISCONNECT AIR HOSE.

2 Clean the magazine. Remove dust

which may have accumulated in the

magazine.

3 Lubricate the nail rail with Hitachi

pneumatic tool lubricant.

3

1

Disconnect air

Nail Rail

3. Storing

○ When not in use for an extended period,

apply a thin coat of the lubricant to the steel

parts to avoid rust.

○ Do not store the Nailer in a cold weather

environment. Keep the Nailer in a warm

area.

○ When not in use, the Nailer should be stored

in a warm and dry place.

Keep out of reach children.

4. WARNING LABEL

Change the WARNING LABEL if missing or

damaged.

A new WARNING LABEL is available from

a Hitachi authorized service center.

hose

18

Warning

Label

Warning

Label

5. Maintenance chart (See page 20)

6. Operator troubleshooting (See page 21)

7. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

CAUTION

Repair, modifi cation and inspection of

Hitachi Power Tools must be carried out by

a Hitachi Authorized Service Center.

This Parts List will be helpful if presented

with the tool to the Hitachi Authorized

Service Center when requesting repair or

other maintenance.

In the operation and maintenance of power

tools, the safety regulations and standards

prescribed in each country must be

observed.

English

MODIFICATIONS

Hitachi Power Tools are constantly being

improved and modifi ed to incorporate the

latest technological advancements.

Accordingly, some parts (i.e. code numbers

and/or design) may be changed without

prior notice.

19

English

SERVICE AND REPAIRS

WARNING

● Only service personnel trained by

Hitachi, distributor or employer shall

repair the Nailer.

● Use only parts supplied or

recommended by Hitachi for repair.

All quality Nailers will eventually require

servicing or replacement of parts because of

wear from normal use.

NOTE

Specifi cations are subject to change without

any obligation on the part of HITACHI.

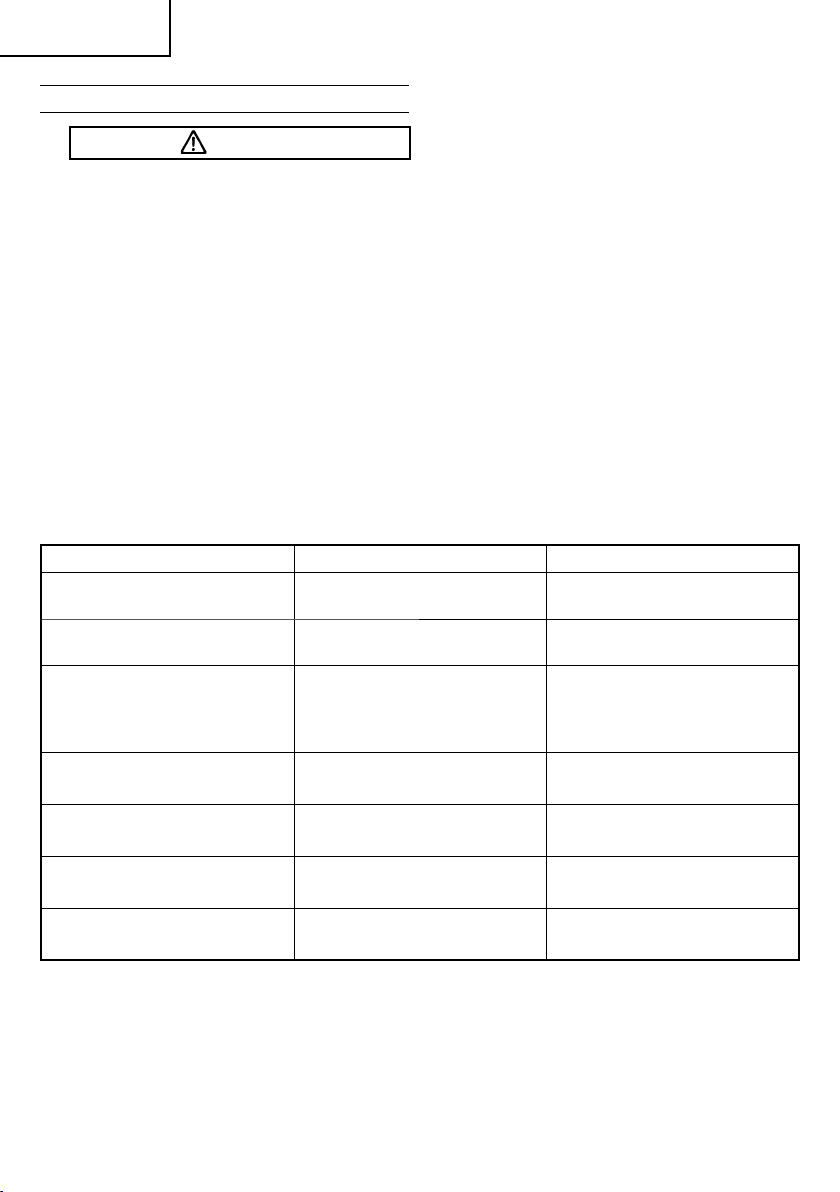

Maintenance chart

ACTION WHY HOW

Drain air line fi lter daily.

Keep lubricator fi lled. Keep the Nailer lubricated.

Clean fi lter element — then

blow air through fi lter in

direction opposite to

normal fl ow.

Clean magazine and feeder

mechanism.

Keep push lever working

properly.

Lubricate the Nailer after

nailing.

Drain air compressor.

Prevent accumulation of

moisture and dirt.

Prevent clogging of fi lter with

dirt.

Prevent a jam. Blow clean daily.

Promote operator safety and

effi cient Nailer operation.

Extend the Nailer life.

Keep the Nailer operated

properly.

Open manual petcock.

Fill with Hitachi pneumatic tool

lubricant.

Follow manufacturer’s

instructions.

Blow clean daily.

Supply 5 – 10 drops of

lubricant into the Nailer.

Open petcock on air

compressor tank.

20

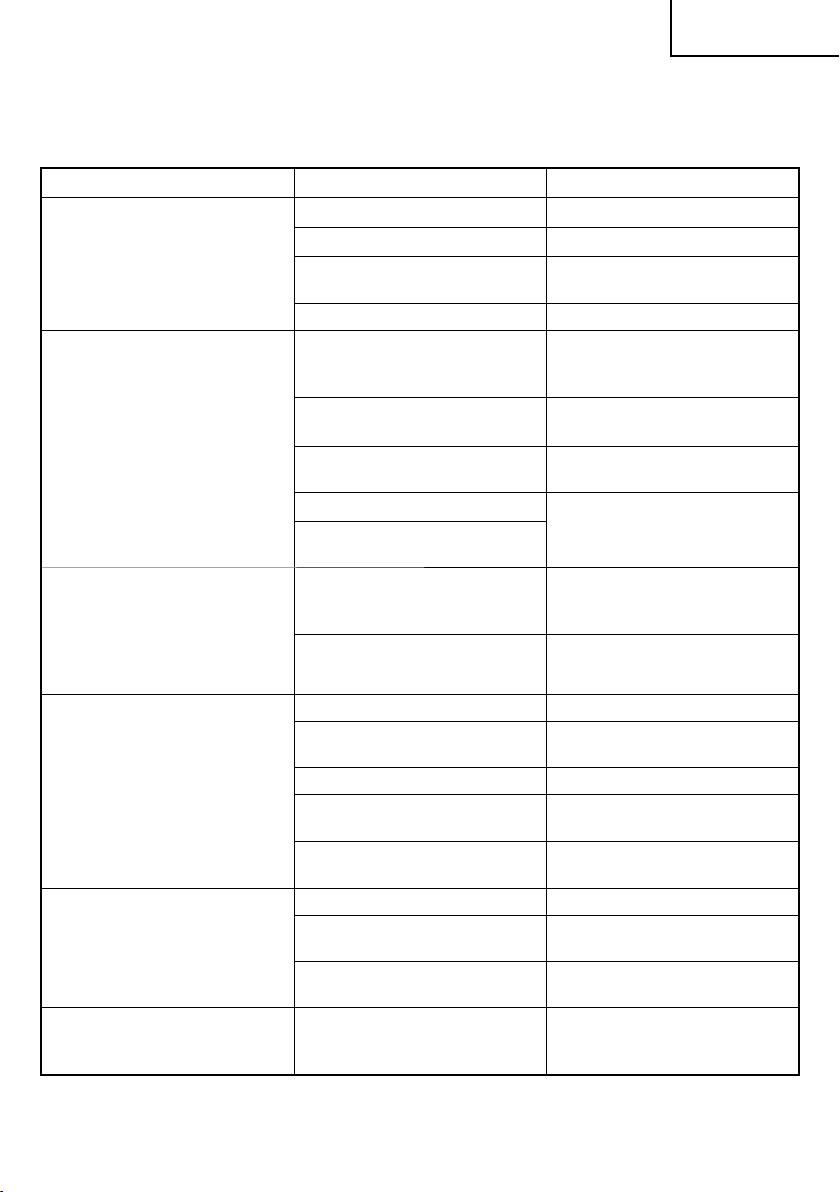

Operator troubleshooting

Most minor problems can be resolved quickly and easily using the table below.

If problems persist, contact a Hitachi authorized service center for assistance.

PROBLEM CHECK METHOD CORRECTION

Nailer operates, but no nail is

driven.

Check for a jam. Clear a jam page 18.

Nail feeder damaged? Replace nail feeder.

Ribbon spring weakend or

damaged?

Replace ribbon spring.

Check for proper nails. Use only recommended nails.

Weak drive.

Slow to cycle. Check air pressure.

Increase air pressure.

(Do not exceed 120 psi (8.3

bar 8.5 kgf/cm

Check position of nailing

depth adjustment adjuster.

———

Driver blade worn?

Piston O-ring worm or

damaged?

Drives too deep.

Check air pressure.

Readjust per page 15.

Use Hitachi pneumatic tool

lubricant.

Contact Hitachi for

replacement.

Reduce air pressure.

(Adjust 70 – 120 psi

(4.9 – 8.3 bar 5 – 8.5 kgf/cm

Check position of nailing

depth adjustment guide plate

Readjust per page 15.

(A).

Skipping nails.

Intermittent feed.

Check for proper nails. Use only recommended nails.

———

Lubricate the nail rail per page

18.

Nail feeder damaged? Replace nail feeder.

Nails jam.

Driven nail is bent.

Drives properly during normal

operation, but does not drive

fully at faster nailing speeds.

Ribbon spring weakend or

damaged?

Piston O-ring worn or

damaged?

Check for proper nails. Use only recommended nails.

———

Driver blade worn?

Check inside diameter of air

hose.

Replace ribbon spring.

Contact Hitachi for

replacement.

Lubricate the nail rail per page

18.

Contact Hitachi for

replacement.

Use larger air hose.

2

))

English

2

))

21

Français

INFORMATION IMPORTANTE

Lire et bien assimiler toutes les étiquettes de l’outil ainsi que toutes

les instructions de fonctionnement, les consignes de sécurité et les

avertissements de ce mode d’emploi avant d’utiliser ou d’entretenir ce

cloueur.

Le non respect des avertissements pourrait entraîner la MORT ou des

BLESSURES GRAVES.

La plupart des accidents résultant de l’utilisation ou de l’entretien des cloueurs sont

dus au non respect de certaines consignes et précautions de sécurité élémentaires.

Un accident peut souvent être évité en reconnaissant une situation potentiellement

dangereuse avant qu’elle ne se produise, et en respectant les procédures de sécurité

applicables.

Les consignes de sécurité élémentaires sont données dans la section “SECURITE” du

manuel et dans les sections relatives aux instructions d’utilisation et d’entretien.

Les dangers à éviter pour empêcher tout risque de blessures ou de dommage de l’outil

sont identifi és par les mots DANGER et AVERTISSEMENT, sur le cloueur et dans ce

manuel.

Ne jamais utiliser ce cloueur pour des applications autres que celles qui sont spécifi ées

dans ce manuel.

DEFINITION DES MOTS DE SIGNALISATION

DANGER indique une situation imminente dangereuse qui, si elle n’est pas évitée, entraînera la

AVERTISSEMENT indique une situation potentiellement dangereuse qui, si elle n’est pas

ATTENTION indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

REMARQUE met en relief les informations essentielles.

mort ou des blessures graves.

évitée, risque d’entraîner la mort ou des blessures graves.

risque d’entraîner des blessures légères ou modérées, ou d’endommager l’outil.

EXPLICATION DE L’ACTION DE CLOUAGE DU CLOUEUR HITACHI

○ MÉCANISME DE DÉCLENCHEMENT SÉQUENTIEL UNIQUE:

Appuyer tout d’abord le levier-poussoir contre le bois, puis tirer sur la gâchette pour enfoncer

le clou.

Quand un clou est enfoncé, il n’est plus possible d’enfoncer un autre clou tant que l’on n’a pas

relâché la gâchette et appuyé à nouveau.

○ MÉCANISME DE DÉCLENCHEMENT PAR CONTACT:

Appuyer tout d’abord le levier-poussoir contre le bois, puis tirer sur la gâchette pour enfoncer

le clou.

Tirer tout d’abord sur la gâchette, puis appuyer le levier-poussoir contre le bois pour enfoncer

le clou.

Si la gâchette est maintenue tirée, un clou s’enfonce chaque fois que l’on appuie le levier-

poussoir contre le bois.

22

SECURITE

CONSIGNES DE SECURITE IMPORTANTES POUR L’UTILISATION DU CLOUEUR

LIRE TOUTES CES INSTRUCTIONS

DANGER

1. Les opérateurs et les autres personnes

dans l’aire de travail doivent porter des

lunettes de protection avec visières

latérales.

Quand on utilise le cloueur,

toujours porter des lunettes

de protection avec visières

latérales, et veiller à ce

que les autres personnes

dans la zone de travail en

portent également.

Les lunettes de protection devront respecter

les exigences de l’ANSI (American National

Standards Institute) Z87.1 et assurer

la protection contre les projections de

particules arrivant par l’avant et par le côté.

L’employeur doit veiller à ce que la

personne qui utilise le cloueur et les autres

personnes dans l’aire de travail portent des

lunettes de protection.

2. Ne jamais utiliser d’oxygène ni aucun

autre gaz en bouteille. Il pourrait se

produire une explosion.

Ne jamais utiliser

d’oxygène, de gaz

combustibles ni aucun

autre gaz en bouteille

comme source

d’alimentation du cloueur.

L’utilisation de ces gaz serait dangereuse,

car le cloueur exploserait.

Utiliser exclusivement de l’air comprimé

propre, sec et régulé.

AVERTISSEMENT

3. Ne jamais diriger l’outil vers soi ni vers

quelqu’un d’autre dans l’aire de travail.

Toujours supposer que

le cloueur renferme des

clous.

Ne jamais diriger le cloueur vers soi ni vers

quelqu’un d’autre, qu’il renferme des clous

ou non.

Si l’on enfonce des clous par erreur, cela

risque de provoquer des blessures graves.

Ne jamais s’amuser avec le cloueur.

Le cloueur est un instrument de travail. Le

respecter.

4. Toujours éloigner le doigt de la gâchette

quand on n’eff ectue pas de clouage afi n

d’éviter tout risque de déclenchement

accidentel.

Ne jamais transporter l’outil avec le doigt

sur la gâchette, car on risquerait d’enfoncer

accidentellement un clou et de se blesser

ou de blesser quelqu’un d’autre.

Toujours transporter le cloueur

exclusivement par sa poignée.

5. Le choix de la méthode d’utilisation de

la gâchette est important.

Lire et bien assimiler la section intitulée

“Methodes d’utilisation”. (pages

34 - 36).

6. Ne pas depasser 120 psi. (8.3 bars 8.5

2

kgf/cm

)

bars 8.5 kgf/cm

2

).

Ne jamais raccorder le cloueur à une

pression susceptible de dépasser 200

psi (13.7 bars, 14 kgf/cm

2

pourrait exploser.

7. Prendre les précautions suivantes

lorsque la buse de projection d’air est

utilisée.

1) Ne pas toucher à la gâchette.

2) Ne jamais diriger la sortie de refoulement

d’air vers des personnes.

3) Ne pas toucher au levier poussorir ni

le placer en position repoussée vers

le haut. Les clous projetés peuvent

sérieusement blesser quelq’un.

Français

Ne pas

dépasser la

pression d’air

maximale

recommandée

de 120 psi (8.3

) car le cloueur

23

Français

SECURITE — suite

8. Toujours porter des protections antibruit et un casque.

Toujours porter des protections anti-bruit

pour ne pas s’endommager l’ouïe.

Toujours porter un casque pour se protéger

la tête contre les projectiles.

9. Ranger le cloueur correctement.

Quand on ne s’en sert pas, ranger le

cloueur dans un endroit sec. Le ranger hors

de portée des enfants. Verrouiller la zone

de rangement.

10. Maintenir l’aire de travail propre.

Une aire encombrée invite les blessures.

Enlever tous les outils inutiles, débris,

meubles, etc. de l’aire de travail.

11. Ne jamais utiliser en presence de

liquides ou de gaz infl ammables.

Le cloueur provoque des étincelles quand il

fonctionne.

Ne jamais utiliser le cloueur dans un endroit

renfermant de la laque, de la peinture, de

la benzine, du diluant, de l’essence, des

gaz, des agents adhésifs ni aucune autre

matière combustible ou explosive.

12. Eloigner les visiteurs.

Ne pas laisser les visiteurs manipuler le

cloueur.

Tous les visiteurs devront rester en dehors

de l’aire de travail.

13. Porter un habillement approprie.

Ne porter ni vêtements lâches ni bijoux qui

pourraient se prendre dans les pièces en

mouvement.

Porter des gants de caoutchouc et des

chaussures solides si l’on travaille dehors.

Si l’on a les cheveux longs, les maintenir

serrés dans un couvre-chef.

14. Ne jamais utiliser de coupleur non

degageant sur le cloueur.

Si l’on utilise un coupleur non dégageant

sur le cloueur, le cloueur risque de rester

chargé d’air après le débranchement, et

donc d’enfoncer un clou même après qu’il

est débranché.

Le cloueur et le tuyau d’air doivent avoir

un coupleur de tuyau tel que toute la

pression soit évacuée du cloueur quand on

débranche le joint de couplage.

15. Verifi er le levier-poussoir avant

l’utilisation.

S’assurer que le levier-poussoir fonctionne

correctement. (Le levier-poussoir est

parfois appelé “sécurité”.) Ne jamais

utiliser le cloueur si le levier-poussoir ne

fonctionne pas correctement. Un clou

pourrait s’enfoncer accidentellement. Ne

pas toucher au levier-poussoir ni le retirer,

car il pourrait ne plus fonctionner.

16. Veiller a ce que toutes les vis et les

couvercles soient en place et bien

serres.

Veiller à ce que les vis et les couvercles

soient solidement fi xés. Les vérifi er

périodiquement.

Ne jamais utiliser le cloueur si des pièces

manquent ou sont endommagées.

17. Ne pas charger de clous si la gachette

ou le levier-poussoir sont enfonces.

Quand on charge des clous dans le cloueur

ou qu’on raccorde le tuyau d’air,

1) ne pas tirer sur la gâchette;

2) ne pas actionner le levier-poussoir; et

3) diriger le cloueur vers le bas.

18. Tenir toujours eloigner, la tete, les mains

et les pieds de la tete de clouage.

Ne jamais approcher la tête, les mains ni

les pieds de la tête de clouage.

19. Placer le cloueur correctement sur la

piece.

Ne pas enfoncer de clous sur d’autres clous

ni avec le cloueur à un angle trop aigu;

les clous pourraient ricocher et blesser

quelqu’un.

20. Avant de commencer le travail, vérifi er

le dispositif de commutation de

l’opération de clouage.

Ce cloueur Hitachi comprend un dispositif

de commutation de l’opération de clouage.

Avant de commencer le travail, vérifi er le

réglage du dispositif de commutation de

l’opération de clouage.

Si le dispositif de commutation de l’opération

de clouage n’est pas réglé correctement, le

cloueur ne fonctionnera pas correctement.

24

SECURITE — suite

Français

21. Faire attention aux doubles activations

dues au rappel.

Si on laisse le levier-poussoir entrer

accidentellement en contact avec la pièce

après le rappel, un clou risque d’être

enfoncé.

Pour éviter ce risque,

○ Fonctionnement intermittent

(déclenchement par gâchette)

1) Régler le dispositif de commutation

sur la position MÉCANISME DE

DÉCLENCHEMENT SÉQUENTIEL

UNIQUE.

2) Tirer sur la gâchette rapidement et

fermement.

○ Fonctionnement continu (déclenchement

par levier-poussoir)

1) Ne pas appuyer trop fort le cloueur

contre le bois.

2) Eloigner le cloueur du bois car il eff ectue

un rappel après le clouage.

22. Ne pas enfoncer de clous dans des

planches minces ni pres des coins et

des bords de la piece.

Les clous pourraient traverser la pièce ou

s’enfoncer ailleurs que dans la pièce et

blesser quelqu’un.

23. Ne jamais enfoncer de clous des deux

cotes d’un mur en meme temps.

Les clous pourraient traverser le mur et

blesser quelqu’un de l’autre côté.

24. Verifi er s’il y a des fi ls sous tension.

Pour éviter tout risque d’électrocution

grave, vérifi er s’il y a des fi ls sous tension

dissimulés dans le mur, le plancher ou

le plafond. Couper le disjoncteur pour

s’assurer qu’il n’y a pas de fi ls sous

tension.

25. Ne pas transporter le cloueur par le

tuyau.

26. Ne pas trop se pencher.

Conserver une bonne assise et un bon

équilibre à tout moment.

27. Ne jamais utiliser un cloueur defectueux

ou qui ne fonctionne pas normalement.

Si le cloueur semble ne pas fonctionner

comme d’habitude, qu’il fait des bruits

bizarres ou qu’il semble défectueux, cesser

immédiatement de l’utiliser et le faire

réparer par un service après-vente Hitachi

agréé.

28. Ne pas debrancher le tuyau d’air du

cloueur avec le doigt sur la gachette.

Le cloueur pourrait se déclencher lorsque

l’air sera à nouveau alimenté.

29. Debrancher le tuyau d’air du cloueur

quand:

1) on entretient ou inspecte le cloueur;

2) on charge les clous;

3) on tourne l’ajusteur et le couvercle

4) fi xation et retrait du capuchon avant;

5) on retire des clous coincés;

6) on ne s’en sert pas;

7) on quitte l’aire de travail;

8) on le transporte dans un autre endroit;

9) on le passe à quelqu’un d’autre.

Ne jamais retirer des clous coincés ni

réparer le cloueur si le tuyau d’air n’est

pas débranché du cloueur et que les

clous restants ne sont pas tous retirés du

cloueur.

Ne jamais s’éloigner du cloueur car des

personnes non familiarisées avec son

fonctionnement pourraient le manipuler et

se blesser.

30. Rester sur ses gardes.

Regarder ce que l’on fait. Faire preuve de

bon sens.

Ne pas utiliser le cloueur lorsqu’on est

fatigué.

Ne jamais utiliser le cloueur si l’on est sous

l’infl uence de médicaments, d’alcool ou de

toute autre substance soporifi que.

31. Manipuler le cloueur correctement.

Utiliser le cloueur en suivant les instructions

du manuel.

Ne jamais permettre que le cloueur soit

utilisé par des enfants ou des personnes

qui n’ont pas étudié ce manuel.

32.

Ne jamais utiliser le cloueur pour des

applications autres que celles qui sont

specifi ees dans ce manuel.

33. Manipuler le cloueur avec precaution.

A cause de la pression d’air élevée à

l’intérieur du cloueur, les fi ssures en

surface sont dangereuses.

supérieur;

et

25

Français

SECURITE — suite

Pour éviter tout risque, ne pas faire tomber

le cloueur ni le heurter contre des surfaces

dures ; et ne pas le rayer ni graver des

inscriptions dessus. Manipuler le cloueur

avec précaution.

34. Entretenir soigneusement le cloueur.

Veiller à ce que le cloueur soit toujours propre

et graissé pour obtenir un fonctionnement

optimal et en toute sécurité.

35. Utiliser exclusivement des pieces,

accessoires ou clous fournis ou

recommandes par Hitachi.

Des pièces, accessoires ou clous non

autorisés pourraient annuler la garantie,

entraîner un mauvais fonctionnement et

provoquer des blessures.

Les réparations du cloueur seront confi ées

exclusivement au personnel d’entretien

formé par Hitachi, au distributeur ou à

l’employeur.

36. Ne jamais modifi er ni altérer un

cloueur.

Cela pourrait provoquer un mauvais

fonctionnement et entraîner des blessures

physiques.

RESPONSABILITES DE L’EMPLOYEUR

1. Veiller à ce que ce MANUEL reste à la

disposition des personnes qui doivent

utiliser ou entretenir le cloueur.

2. Veiller à ce que les cloueurs soient utilisés

exclusivement lorsque les opérateurs

et les autres personnes présentes dans

l’aire de travail portent des LUNETTES DE

PROTECTION.

3. Obliger les opérateurs et les autres

personnes présentes dans l’aire de travail à

porter des LUNETTES DE PROTECTION.

4. Maintenir les cloueurs en bon ordre de

marche.

5. Entretenir les cloueurs correctement.

6. Veiller à ce que les cloueurs qui ont besoin

d’être réparés ne soient plus utilisés avant

d’être réparés.

26

CONSERVER CE MANUEL ET LE

METTRE A LA DISPOSITION DES

UTILISATEURS !

UTILISATION

REMARQUE

Les informations contenues dans ce manuel ont pour but d’aider l’opérateur à utiliser le

cloueur en toute sécurité.

Certaines des illustrations du manuel peuvent montrer des détails ou des accessoires qui

diff èrent de ceux de votre cloueur.

NOM DES PIECES

Français

Vue agrandie de la

section de la valve

Prise de

refoulement d’air

Couvercle

d’échappement

Joint torique de

piston

Piston

Lame

d’entrainement

Dispositit de

commutation

Couvercle

supérieur

Dispositif de commutation

d’opération de clouage

Dispositif

de

commutation

MÉCANISME DE

Gâchette

Bouton de buse de projection d’airprojection d’air

Section de

la valve

DÉCLENCHEMENT

SÉQUENTIEL

UNIQUE (Dispositif de

commutation: position

relevée)

Capuchon

Corps

Gâchette

Bouchon d’air

Dispositif

commutation

MÉCANISME DE

DECLENCHEMENT

PARCONTACT

(Dispositif de

commutation: position

abaissée)

Rail à clous

Ressort à boudin

de

Levier de

verrouillage

Alimenteur de

clous (A)

Plaque de

guidage (A)

Levier-poussior

Alimenteur de clous (B)

Guide de lame

Tâte de clouge (sortie)

Butée de clou

Magasin

Ajusteur

27

Français

SPECIFICATIONS

Pression d’utilisation 70 – 120 psi (4.9 – 8.3 bars 5 – 8.5 kgf/cm2)

Dimensions

Longueur × Hauteur × Largeur

Poids 4.2 lbs. (1.9 kg)

Contenance de clous 100 clous

Consommation d’air

13-1/2” × 12” × 3-1/4”

(344 mm × 304 mm × 82 mm)

3

/cycle à 100 psi

.045 ft

(1.29 l/cycle à 6.9 bars)

(1.29 l/cycle à 7 kgf/cm

2

)

SELECTION DES CLOUS

AVERTISSEMENT

● Bien utiliser exclusivement les

clous HITACHI d’origine avec le

NT65MA4 (S). L’utilisation d’autres

clous risque de provoquer un

mauvais fonctionnement de l’outil

et/ou une rupture des clous, et

d’entraîner des blessures.

Seuls les clous indiqués dans le tableau cidessous pourront être utilisés avec ce cloueur.

Dimensions des clous

Clous de fi nition de calibre 15

Min. Max.

.095” (2.4mm)

.12”

(3.0mm)

ACCESSOIRES

AVERTISSEMENT

● Les accessoires autres que ceux

indiqués ci-dessous risquent de

mal fonctionner et de provoquer des

blessures.

Accessoires standard

1

Lunettes de protection 1

1

Capuchon de bec 1

2

Boîtier 1

3

2

3

Accessoires en option ... vendus séparément

○ Huile de machine pneumatique

Alimenteur d’huile 1 oz (30 cc)

(Code No. 877153)

Alimenteur d’huile 4 oz (120 cc)

(Code No. 874042)

Alimenteur d’huile 1 quart (1 l)

(Code No. 876212)

REMARQUE

Les accessoires sont sujets à modifi cation

sans préavis et sans aucune obligation de

la part de HITACHI.

1-1/4” (32mm)

28

.045”

(1.1mm)

.072” (1.8mm)

2-1/2” (65mm)

APPLICATIONS

○ Maison préfabriquée, construction de

maison sur site et mobile.

○ Armoires, meubles, menuiserie.

Français

AVANT L’UTILISATION

Lire la section intitulée “SECURITE” (pages

23 – 26).

Bien vérifi er les points suivants avant de

travailler.

Environnement de travail

AVERTISSEMENT

● Pas de gaz ou liquides infl ammables,

ni aucun autre objet infl ammable sur

le chantier.

● Evacuer les enfants et les personnes

non autorisées de l’aire de travail.

Alimentation d’air

DANGER

● NE JAMAIS

utiliser d’oxygène

ni aucun autre

gaz en bouteille.

Il pourrait se

produire une

explosion.

AVERTISSEMENT

● Ne jamais raccorder le cloueur à une

pression qui risque de dépasser 200

psi (13.7 bars 14 kgf/cm2).

● Ne jamais utiliser de coupleur non

dégageant sur le cloueur.

1. Alimentation

○ Utiliser exclusivement de l’air comprimé

propre, sec et régulé avec ce cloueur.

○ Les compresseurs d’air utilisés pour

alimenter l’air comprimé au cloueur devront

respecter les exigences ANSI B19.3

“Normes de sécurité pour les compresseurs

des industries de transformation”.

○ L’humidité ou l’huile dans le compresseur

d’air peuvent accélérer l’usure et la corrosion

du cloueur. Purger tous les jours.

2. Filtre-régulateur-lubrifi cateur

○ Utiliser un régulateur d’une pression

comprise entre 0 – 120 psi (0 – 8.3 bars,

0 – 8.5 kgf/cm

2

).

○ Les unités fi ltre-régulateur-lubrifi cateur

procureront les conditions optimales du

cloueur et accroîtront sa durée de service.

Toujours les utiliser.

Filtre

Le fi ltre enlève l’humidité et la

saleté mélangées à l’air comprimé.

Purger tous les jours, sauf si l’outil possède

une purge automatique.

Nettoyer régulièrement le fi ltre.

Régulateur

Le régulateur contrôle la pression de

fonctionnement afi n d’assurer la sécurité

du cloueur.

Inspecter le régulateur avant le travail pour

s’assurer qu’il fonctionne correctement.

Lubrifi cateur

Le lubrifi cateur alimente de

l’huile vaporisée au cloueur.

Inspecter le lubrifi cateur avant le travail

pour s’assurer que l’alimentation d’huile est

adéquate.

Utiliser une huile de machine pneumatique

Hitachi.

Régulateur

Côté cloueur

Côté

compresseur

Filtre

Lubrifi cateur

3. Tuyau d’air

Le tuyau d’air doit avoir une pression de

travail minimum de 150 psi (10.4 bars, 10.6

2

kgf/cm

) ou 150% de la pression maximum

produite par le système, à savoir la plus

élevée.

4. Consommation d’air

Sélectionner la taille du compresseur en se

reportant au tableau de consommation d’air

et aux formules de taille du compresseur.

Tableau de consommation d’air

psi 80 90 100

Pression de

fonctionnement

Consommation

d’air

(bars) (5.5) (6.2) (6.9)

2

(kgf/cm

ft3/cycle .038 .042 .045

) (5.6) (6.3) (7)

(l/cycle) (1.07) (1.18) (1.29)

Formules de taille du compresseur d’air

Quantité d’air requise

= nombre de clous

29

Français

× clous moyens enfoncés par minute

par le cloueur

× consommation d’air à une pression

donnée

× facteur de sécurité (toujours 1.2)

Exemple: 3 cloueurs fonctionnant à 100

psi et enfonçant 30 clous par minute

Quantité d’air requise

= 3 × 30 × .045 (1.29) × 1.2

= 4.9 CFM (ft

3

/min) (139 l/min)

Eff ectuer le calcul ci-dessus pour

obtenir un compresseur fournissant les

4.9 CFM d’air nécessaires.

Graissage

Il est essentiel que le cloueur soit graissé

correctement. Si le cloueur est mal graissé, il

ne fonctionnera pas correctement et les pièces

s’useront prématurément.

○ Utiliser une huile de machine Hitachi.

Ne pas utiliser d’huile détergente ni

d’additifs. Ces lubrifi ants endommageraient

les joints toriques et les autres pièces en

caoutchouc. Cela provoquerait un mauvais

fonctionnement du cloueur.

○ Toujours utiliser des unités fi ltre-régulateur-

lubrifi cateur.

Veiller à ce que le régulateur soit toujours

plein d’huile de machine pneumatique

Hitachi.

○ Si l’on ne possède pas de lubrifi cateur,

mettre 5 à 10 gouttes d’huile de machine

pneumatique Hitachi dans le bouchon d’air

du cloueur deux fois par jour.

Entretien par temps froid

○ Ne pas ranger le cloueur dans un

environnement froid. Le laisser dans un

endroit chaud jusqu’à ce que l’on soit prêt

à travailler.

○ Si le cloueur est déjà froid, l’amener dans

un endroit chaud et le laisser réchauff er

avant de l’utiliser.

1 Réduire la pression d’air à 64 psi (4.4

bars 4.5 kgf/cm

2

).

2 Sortir tous les clous du cloueur.

3 Raccorder le tuyau d’air et faire un

essai de clouage (clouage à blanc).

La pression d’air inférieure sera

suffi sante pour le clouage à blanc.

Les opérations à vitesse lente ont

tendance à chauff er les pièces

mobiles.

ATTENTION

● Ne pas faire un essai de clouage à blanc

à haute pression.

Essai du cloueur

DANGER

● Les opérateurs

et les autres

personnes dans

l’aire de travail

DOIVENT porter

des lunettes

de protection

avec visières

latérales respectant les exigences ANSI

Z87.1.

AVERTISSEMENT

● Ne jamais utiliser le cloueur si le

levier-poussoir ne fonctionne pas

correctement.

Avant de commencer le travail de clouage

proprement dit, faire un essai de clouage à

l’aide de la liste de vérifi cation ci-dessous.

Eff ectuer les essais dans l’ordre indiqué.

S’il se produit un fonctionnement anormal,

cesser immédiatement d’utiliser le cloueur

et contacter un service après-vente agréé

Hitachi.

(1) Debrancher le tuyau d’air du cloueur.

Sortir tous les clous du cloueur.

□ Toutes les vis doivent etre serrees a

fond.

Si certaines vis sont relâchées, les

revisser.

30

□ Le levier-poussoir et la gachette doivent

fonctionner avec souplese.

Gâchette

Ne pas

raccorder le

tuyau d’sair

Levierpoussoir

(2) Régler la pression d’air sur 70 psi (4.9 bars

5 kgf/cm

2

).

Raccorder le tuyau d’air.

Ne pas mettre de clous dans le cloueur.

Mettre le dispositif de commutation

en position relevée (MÉCANISME DE

DÉCLENCHEMENT SÉQUENTIEL

UNIQUE).

(Régler le dispositif de commutation

sur la position complètement relevée,

comme indiqué sur le schéma. Sinon, il ne

fonctionnera pas correctement.)

Français

Actionner

le levierpoussoir

(4) Eloigner le levier-poussoir du bois.

Ensuite, diriger le cloueur en position

abaissée, tirer sur la gâchette et attendre

pendant au moins 5 secondes dans cette

position.

□ Le cloueur ne doit pas fonctionner.

Tirer sur la gâchette

Ne pas tirer

sur la gâchette

Position relevée

Dispositif de commutation

□ Le cloueur ne doit pas avoir de fuite

d’air.

(3) Retirer le doigt de la gâchette et appuyer le

levier-poussoir contre le bois.

□ Le cloueur ne doit pas fonctionner.

(5) 1 Sans toucher la gâchette, actionner le

levier-poussoir contre la pièce.

Tirer sur la gâchette.

□ Le cloueur doit fonctionner.

2 Retirer le doigt de la gâchette.

□ Le fonctionnement du cloueur s’arrête

(la lame du tournevis revient en haut).

(6) Régler le dispositif de commutation sur

la position abaissée (MÉCANISME DE

DÉCLENCHEMENT PAR CONTACT).

(Régler le dispositif de commutation

sur la position complètement abaissée,

comme indiqué sur le schéma. Sinon, il ne

fonctionnera pas correctement.)

31

Français

Position abaissée

Dispositif de

commutation

Le cloueur ne touchant plus la pièce, tirer

sur la gâchette.

Actionner le levier-poussoir contre la pièce.

□ Le cloueur doit fonctionner.

(7) Si l’on ne remarque aucun fonctionnement

anormal, on pourra mettre des clous dans

le cloueur.

Enfoncer les clous dans un matériau du

même type que celui du travail proprement

dit.

□ Le cloueur doit fonctionner correctement.

Reglage de la pression d’air

le tuyau d’air du cloueur.

(1) Introduire la bande de clous par l’arrière du

magasin à clous.

Magasin

(2) Faire coulisser la bande de clous vers

l’avant dans le magasin.

La bande de clous doit passer par la butée

à clous.

AVERTISSEMENT

● Ne pas dépasser 120 psi (8.3

bars 8.5 kgf/cm

2

).

Régler la pression d’air à la pression de travail

recommandée de 70 – 120 psi (4.9 – 8.3 bars

5 – 8.5 kgf/cm2) en fonction de la longueur des

clous et de la dureté du matériau.

La pression d’air correcte est la pression la plus

basse capable d’eff ectuer le travail. L’utilisation

d’une pression d’air supérieure à la pression

nécessaire fatiguera inutilement le cloueur.

Chargement des clous

AVERTISSEMENT

● Lors du chargement des clous dans

le cloueur, s’assurer de retirer son

doigt de la gâchette et de débrancher

32

Butée de clou

(3) Tirer le dispositif d’alimentation de clous