Hitachi NT 65M2, NT 65M2 S User Manual

11-(6)

Switching

Device

Downward position

11-(4)

Switching

Device

Pull Trigger

Upward position

11-(1)

Do not

connect

air hose

Trigger

Push

Lever

Exhaust Cover

Bolt

10

11-(2)(3)

Do not pull

Trigger

Depress

Push Lever

Switching

Device

Upward position

9

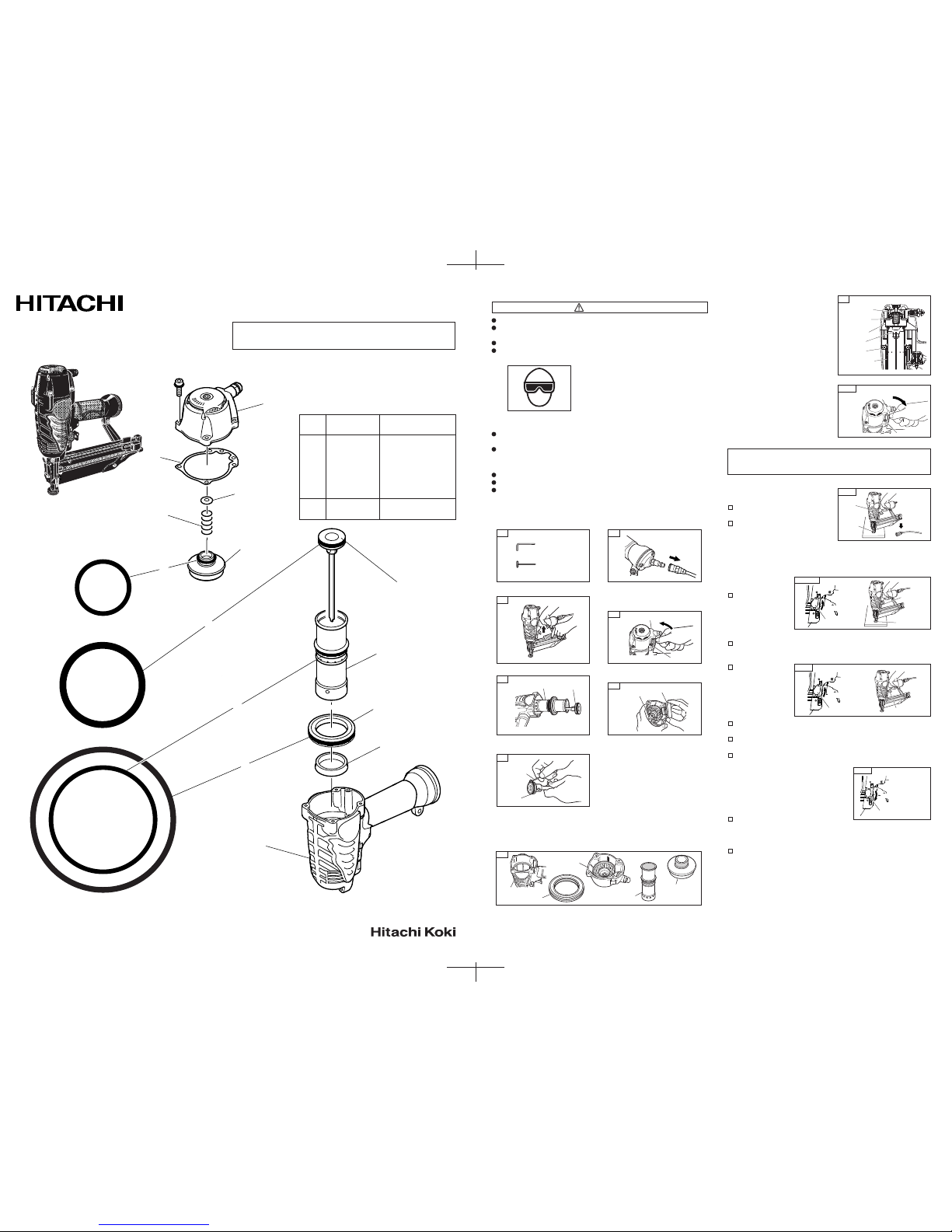

Head Valve

Spring

Head

Valve

Piston

Cylinder

Head

Bamper

Cylinder

Plate

2

1

Allen Wrench For

M5 Screw

O-Ring Pick

Bolt

Exhaust Cover

4

Cylinder

Piston

6

Head Valve

Exhaust

Cover

7

O-Ring Pick

Old O-Ring

8

Body

Cylinder Plate

Head

Valve

Exhaust

Cover

Cylinder

3

5

For air leakage or sluggish operation.

FOR USE BY ONLY SERVICE PERSONNEL TRAINED

BY HITACHI, DISTRIBUTOR OR EMPLOYER.

FINISH NAILER

MODEL NT 65M2 / NT 65M2 (S)

Item

No.

1 885-672 Gasket

2 883-992 O-Ring

3 885-668 O-Ring

4 880-362 O-Ring

5 885-665 O-Ring

6 885-666 Cylinder Ring

O-Ring Pick

Tube Grease

Code No. Part Name

O-Ring Shown Actual Size

GENUINE PARTS

Body

6

Cylinder Plate

Cylinder

Piston

Exhaust Cover

Head Valve Spring

Head Valve

1

Head Bumper

2

3

5

4

Kit-

READ AND UNDERSTAND THIS MANUAL BEFORE DOING REPAIRS.

Only service personnel trained by Hitachi, distributor or employer shall

repair the Nailer.

Use only parts supplied or recommended by Hitachi for repair.

Before doing repairs,

1)WEAR SAFETY GLASSES;

2)DISCONNECT AIR HOSE FROM NAILER; and

3)REMOVE ALL NAILS FROM NAILER.

After doing repairs,

TEST NAILER PER ITEM No. 11 OF THIS MANUAL BEFORE USE.

If you have any questions regarding repair, use or safety warnings, call a

Hitachi authorized service center.

CAUTION ON REPAIR

Oily or greasy hands can slip easily.

Do not allow dust or foreign matter to enter Nailer.

Do not scratch the O-rings or O-ring contacting surface of any parts.

This will cause air leakage from Nailer.

DANGER

Pay attention not to scratch exhaust

cover and body when remove old

gasket.

Install new o-rings and cylinder ring as

shown right.

Install cylinder and piston into body.

Make sure that head bumper, head

valve spring and o-ring are properly

placed in head valve.

Install head valve into exhaust cover.

9.

8.

Wipe body, exhaust cover, head valve, cylinder plate and cylinder with

clean cloth.

Put an adequate amount of grease on shaded area of body, exhaust cover,

head valve, cylinder plate and cylinder. Put an adequate amount of grease on

new o-rings and cylinder ring.

[MODEL NT65M2]

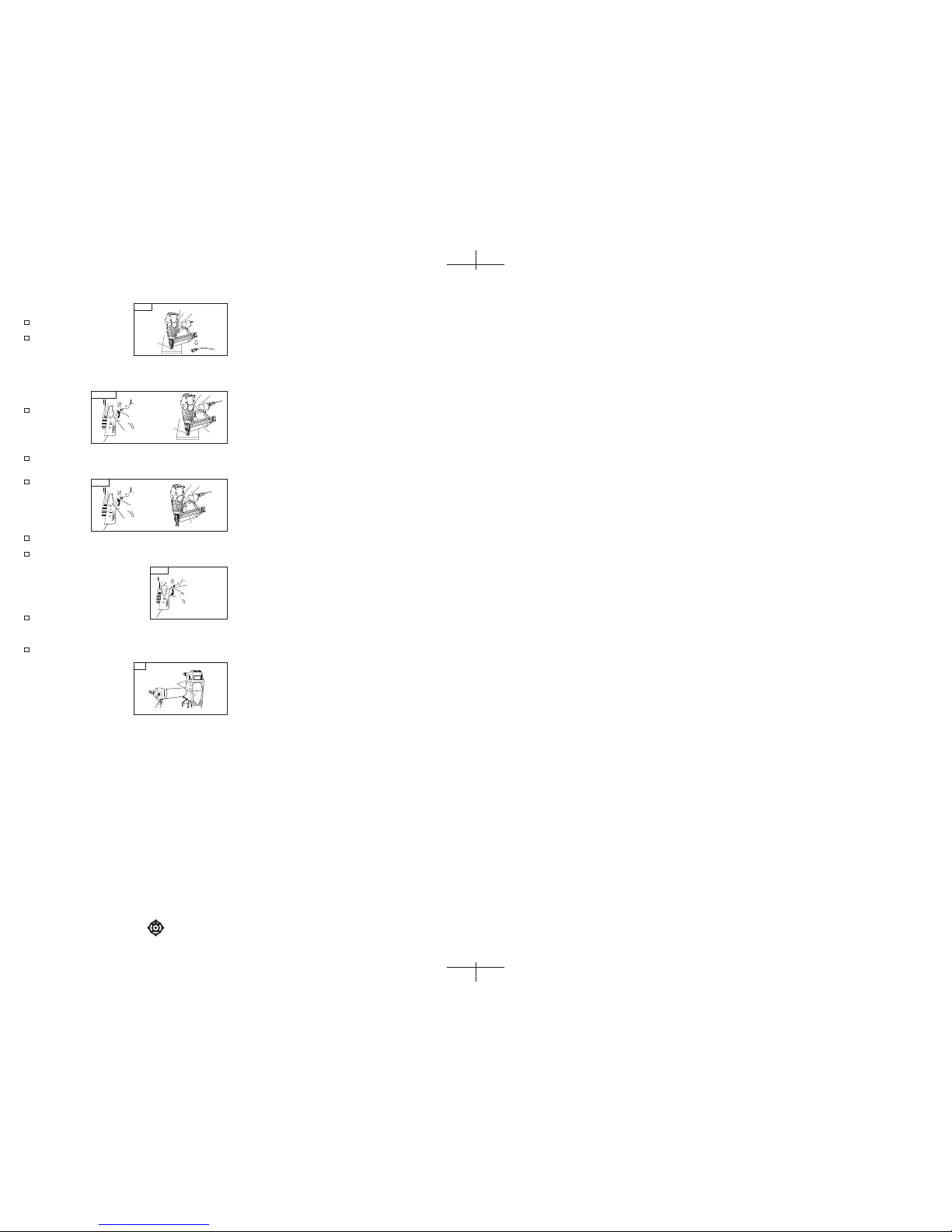

(1) DISCONNECT AIR HOSE FROM NAILER.

REMOVE ALL NAILS FROM NAILER.

ALL SCREWS MUST BE TIGHTENED.

If any screws are loose, tighten them.

THE PUSH LEVER AND TRIGGER

MUST MOVE SMOOTHLY.

(2) Adjust the air pressure to 70 psi. (4.9 bar 5 kgf/cm2). Connect the air hose.

Do not load any nails in the Nailer. Set the switching device to the upward

position (SINGLE SEQUENTIAL ACTUATION MECHANISM). (Set the

switching device to the upward position completely as shown in the diagram.

Otherwise, it will not

operate properly.)

THE NAILER MUST

NOT LEAK AIR.

(3) Remove the finger from

the trigger and press

the push lever against

the wood.

THE NAILER MUST NOT OPERATE.

(4) Separate the push lever from the wood. Next, point the nailer downward, pull

the trigger and then wait in that position for 5 seconds or longer.

THE NAILER MUST

NOT OPERATE.

(5) 1Without touching the

trigger, depress the

push lever against the

workpiece.

Pull the trigger.

THE NAILER MUST OPERATE.

2Hold the trigger back while separating the push lever from the wood.

The nailer will remain in operated status (the driver blade will remain at

the bottom). 3Remove the finger from the trigger.

Nailer operation will end (the driver blade will return to the top).

(6) Set the switching device to the downward position (CONTACT ACTUATION

MECHANISM). (Set the switching device to

the downward position completely as shown

in the diagram. Otherwise, it will not operate

properly.)

With the Nailer off the workpiece, pull the trigger.

Depress the push lever against the workpiece.

THE NAILER MUST OPERATE.

(7) If no abnormal operation is observed, you may load nails in the Nailer.

Drive nails into the workpiece that is the same type to be used in the actual

application.

THE NAILER MUST OPERATE

PROPERLY.

IMPORTANT SAFETY INSTRUCTIONS

HOW TO REPAIR

Install new gasket, exhaust cover and

four bolts. Using Allen wrench for M5

screw, tighten four bolts in a staggered

sequence.

10.

7.

Using o-ring pick, remove old o-rings.

Discard old o-rings.

6.

Remove head valve from exhaust

cover .

5.

Remove piston and cylinder.

3.

Remove all nails from the Nailer.

1.

The tools needed for repair are shown

below.

2.

Disconnect the air hose from the

Nailer.

4.

Using Allen wrench for M5 screw,

remove four bolts from exhaust cover.

Remove exhaust cover.

11. When reassembled, always conduct following tests in the following order.

If abnormal operation occurs, stop using the Nailer and contact a Hitachi

authorized service center immediately.

11-(6)

Switching

Device

11-(4)

11-(1)

Do not

connect

air hose

Trigger

Push

Lever

11-(2)(3)

Do not pull

Trigger

Depress

Push

Lever

Switching

Device

Upward position

Switching

Device

Upward position

Pull Trigger

Downward position

Warning

Label

12

Printed in Taiwan

Code No. C99520212

206

Hitachi Koki Co., Ltd.

Printed in Taiwan

Code No. C99520212

206

Hitachi Koki Co., Ltd.

[MODEL NT65M2 (S)]

(1) DISCONNECT AIR HOSE FROM NAILER.

REMOVE ALL NAILS FROM NAILER.

ALL SCREWS MUST BE TIGHTENED.

If any screws are loose, tighten them.

THE PUSH LEVER AND TRIGGER

MUST MOVE SMOOTHLY.

(2) Adjust the air pressure to 70 psi. (4.9 bar 5 kgf/cm2). Connect the air hose.

Do not load any nails in the Nailer. Set the switching device to the upward

position (SINGLE SEQUENTIAL ACTUATION MECHANISM). (Set the

switching device to the upward position completely as shown in the diagram.

Otherwise, it will not

operate properly.)

THE NAILER MUST

NOT LEAK AIR.

(3) Remove the finger from

the trigger and press

the push lever against

the wood.

THE NAILER MUST NOT OPERATE.

(4) Separate the push lever from the wood. Next, point the nailer downward, pull

the trigger and then wait in that position for 5 seconds or longer.

THE NAILER MUST

NOT OPERATE.

(5) 1Without touching the

trigger, depress the

push lever against the

workpiece.

Pull the trigger.

THE NAILER MUST OPERATE.

2Removethe finger from the trigger.

Nailer operation will end (the driver blade will return to the top).

(6) Set the switching device to the downward position (CONTACT ACTUATION

MECHANISM). (Set the switching device to

the downward position completely as shown

in the diagram. Otherwise, it will not operate

properly.)

With the Nailer off the workpiece, pull the trigger.

Depress the push lever against the workpiece.

THE NAILER MUST OPERATE.

(7) If no abnormal operation is observed, you may load nails in the Nailer.

Drive nails into the workpiece that is the same type to be used in the actual

application.

THE NAILER MUST OPERATE

PROPERLY.

12.Change the WARNING LABEL if missing

or damaged.

A new WARNING LABEL is available from

a Hitachi authorized service center.

Loading...

Loading...