MODEL NR 83A

1. PREAUTIONS IN DISASSEMBLY AND REASSEMBLY:

For general reference purposes, the Model NR83A can be said to consist of three major sections: the

Output Section, the Valve Section and the Magazine Section. The descriptions below explain important

points in the disassembly and reassembly of these sections. The circled numbers in the descriptions

correspond to the item numbers in the Parts List and exploded assembly diagram.

[CAUTION] Prior to disassembly/reassembly, ensure without fail that the air hose is disconnected from

the Nailer, compressed air is completely discharged, and all nails are removed.

1 -1. Disassembly and Reassembly of the Output Section:

(1) Piston Damper

31

, Packing (A) 32, and Related Parts:

Tools Required:

z#

8 mm, 6 mm and 5 mm Hexagon Bar Wrenches

z#

3 mm Roll Pin Remover

z#

5 mm Spanner

(a) Disassembly:

z#

Loosen the two M5 x 25 Hexagon Socket Hd. Bolts 72 and two M6 x 20 Hexagon Socket

Hd. Bolts

33

which fix the Magazine Base Ass’y 69, and remove the Magazine Base Ass’y

by withdrawing it from the Tail Cover

38

.

−#1#−

Body (B) Ass’y

26

Cylinder O-Ring

28

Cylinder Damper

29

31

Piston Damper

Damper Ring

30

32

Packing (A)

[CAUTION] Prior to loosening the t wo M6 x 20 Hexagon Socket Hd. Bolts 33, shift the

Nail Feeder

remove the front-side M6 x 20 Hexagon Socket Hd. Bolts

Extract the D3 x 30 Roll Pin 47, remove the four M8 x 25 Hexagon Socket Hd. Bolts

z#

which fix the Tail Cover 38, and remove the Tail Cover 38 and Push Lever Ass’y

64

to the Tail Cover 38 side without fail. Also, do not fully

33

.

50

from the Body (B) Ass’y 26.

On completion of the above disassembly procedures, Packing (A) 32, the Piston Damper

z#

31

, Damper Ring 30 and Cylinder Damper 29 can be taken out from the lower portion

of the Body (B) Ass’y

assembled as described in Pare. 1 -1 (2) below, the Cylinder O-Ring

from the Body (B) Ass’y

26

. Please note that if the Cylinder 19 has not been already dis-

28

cannot be removed

26

at this time.

47 D3 x 30 Roll Pin

58

Plunger (B)

14

Piston Ass’y

72 M5 x 25 Hexagon

Socket Bolt

40

Tail Cover

38

40

M7 x 25 Hexason

Socket Hd. Bolts

50

Push Lever Ass’y

66 Ribbon Spring Ass’y

64

Nail Feeder

65

Spring Shaft

37

Washer

33

M6 x 20 Hexagon

Socket Bolts with

Bonding Agent

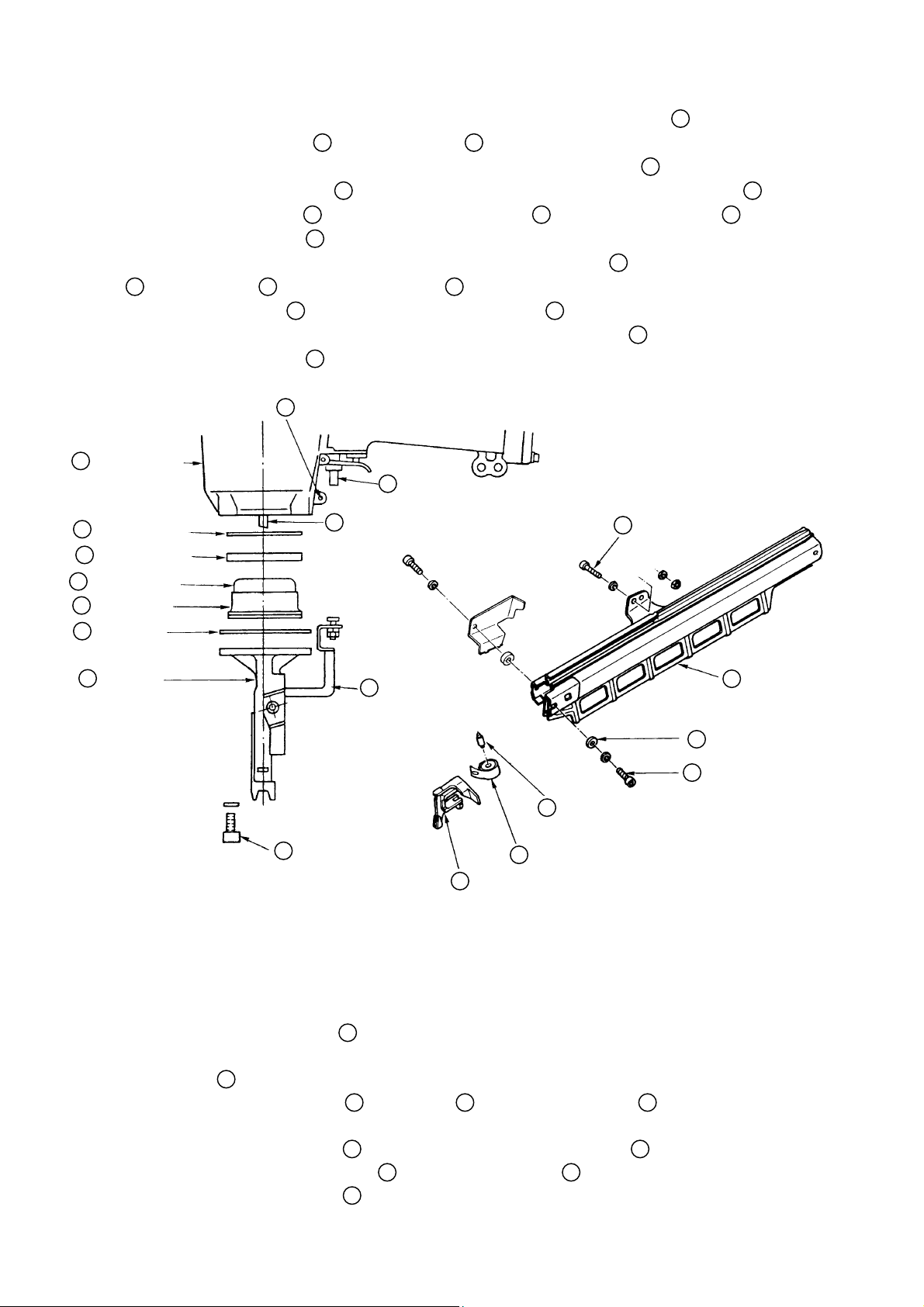

Fig. 7 Disassembly and Reassembly of the Piston Damper, Packing (A), etc.

(b) Reassembly:

Reassembly can be accomplished by following the disassembly procedures in reverse. However,

special attention should be given to the following items:

Ensure that the Piston Ass’y 14 is positioned so its semicircular groove faces toward the

z#

Magazine side (see Fig. 8 below).

Plunger (B) 58 may drop out during disassembly. Ensure it is properly assembled.

z#

Assemble the Body (B) Ass’y 26, Tail Cover 38, and Magazine Ass’y 81 in the following

z#

manner:

50

I) With the Push Lever Ass’y

Fig. 7, assemble the Tail Cover

Hexagon Socket Hd. Bolts

properly mounted on the Tail Cover 38 as illustrated in

38

to the Body (B) Ass’y 26 with the four M8 x 25

40

, and tighten them to rated torque (see para. 1-4).

69

Magazine Base Ass’y

−#2#−

[CAUTION] Please note that the Push Lever Ass’y 50 cannot be assembled after the

Tail Cover

II) Connect the Push Lever Ass’y

47

.

III) Temporarily attach the Ribbon Spring Ass’y

38

with the M6 x 20 Hexagon Socket Hd. Bolts 33 (please note that this step is not

necessary if the front-side M6 x 20 Hexagon Socket Hd. Bolt

38

has been assembled to Body (B) Ass’y 26.

50

to the Body (B) Ass’y 26 with the D3 x 30 Roll Pin

66

and Nail Feeder 64 to the Tail Cover

33

was only loosened and

not fully removed during reassembly [refer to Fig. 16] ), and assemble the Magazine Base

Ass’y

69

(refer to Para. 1-3- (1)).

[NOTE] Please refer to Para. 1-4 below for appropriate tightening torques for nuts

and bolts.

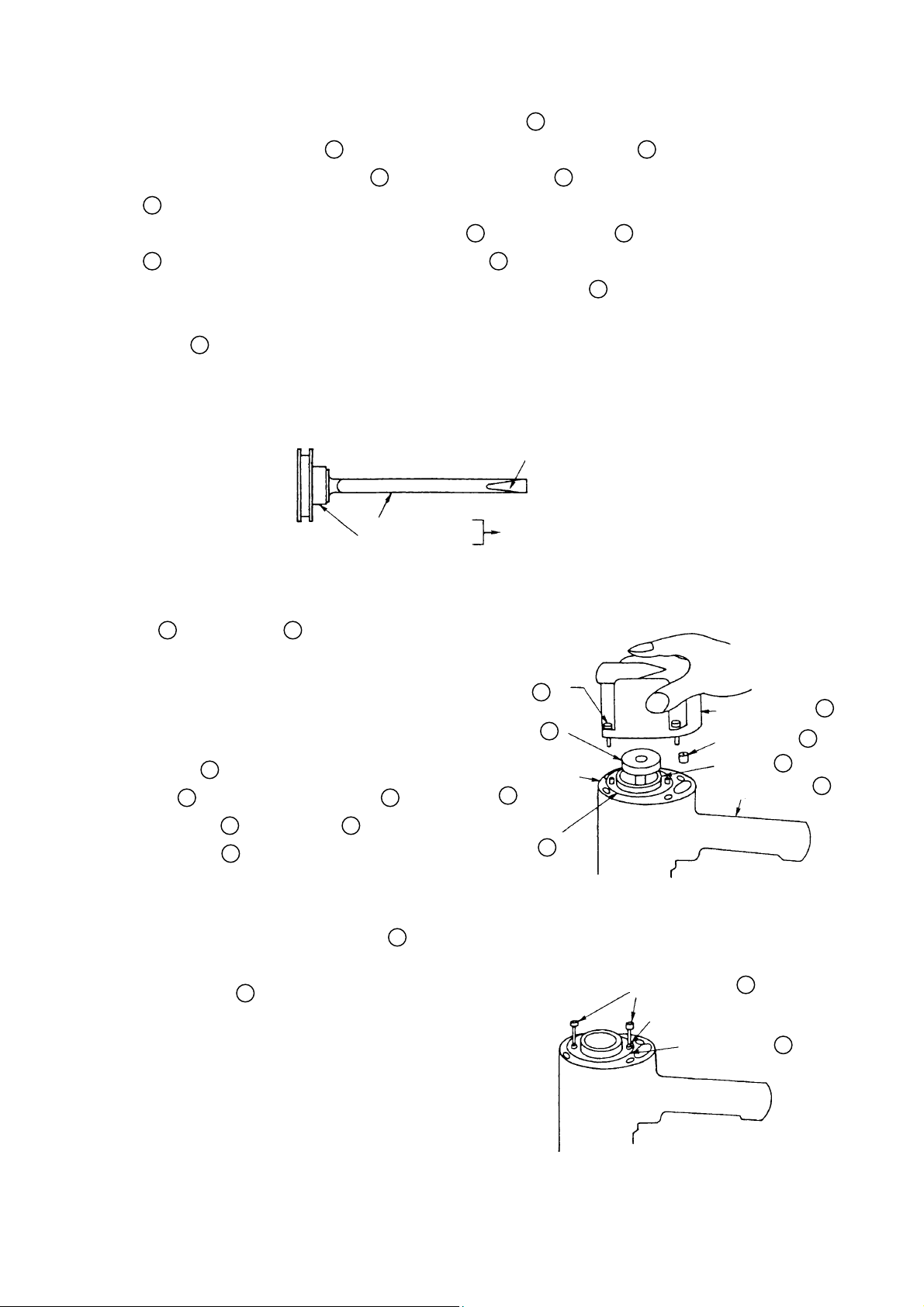

Semi-circle Groove

Drive bit

Piston

Piston Ass’y

Fig. 8 Semi-circle groove of piston ass’y

19

(2) Cylinder

, Piston Ass’y 14 and Related Parts:

Tool Required:

6 mm Hexagonal Bar Wrench

z#

(a) Disassembly:

Loosen the four M6 x 25 Hexagon Socket

z#

Hd. Bolts

Cover

Packing (G)

piston Ass’y

4

, and remove the Exhaust

5

from the Body (B) Ass’y 26.

25

14

(see Fig. 9)

As illustrated in Fig. 10, screw two of the

z#

M6 x 25 Hexagon Socket Hd. Bolts

partially into their matching holes on the

Cylinder Plate

the Cylinder Plate upward while turning

it to remove it from the Body.

, Packing (B) 6, and the

can then be removed.

4

17

. Using the bolts, pull

M6 x 25

Hexagon

Socket Hd.

4

#

Bolt

Piston

14

Ass’y

Packing (B)

6

Cylinder

17

Plate

Fig. 9 Disassembly of Upper

Exhaust Cover

Packing (G)

Cylinder

Body (B) Ass’y

Part of Main Body

M6 x 25 Hexagon

Socket Hd. Bolt

M6 Threaded Hole

Cylinder Plate

#

5

25

19

26

4

17

−#3#−

Fig. 10 Removal of cy linder plate

The Cylinder 19, Cylinder Spring 22, and

other components which constitute the Output

System (see Fig. 11) can then be removed.

As it should be difficult to remove the Cylinder

z#

19

, first remove the Tail Cover 38 as described

in section 1-1-(1), and push the Cylinder upwards and out from below.

(b) Assembly:

Assembly can be accomplished by following the

disassembly procedures in reverse. However, special

attention should be given to the following items:

Ensure that the Piston Ass’y 14 is positioned

z#

so its semicircular groove faces toward the

Magazine (see Fig. 8 above).

Ensure that Packing (G) 25 is properly fitted

z#

to the shape of its matching hole in the Body

(B) Ass’y

26

, properly aligned with the

assembly as shown in Fig. 11, and properly contacts

the base of the Exhaust Piece Ass’y

8

(see

Cylinder Plate

Cylinder

Cylinder Spring

Cylinder Guide

Packing (G)

25

19

22

24

17

Packing (G) Hole (B)

Body (B) Ass’y

26

Fig. 12).

(3) Head Cap Ass’y

12

Related Parts:

Tool Required:

6 mm Hexagonal Bar Wrench

z#

(a) Disassembly;

Remove the Exhaust Cover 5 as described in

z#

section 1-1-(2).

Loosen the three M6 x 45 Hexagon Socket Hd.

z#

Bolts

1

and, as illustrated in Fig. 12, remove

the Head Cap Ass’y

11

, Exhaust Piece Ass’y 8, Packing (C) 9,

and Packing (F)

(b) Reassembly:

Reassembly can be accomplished by following the

disassembly procedures in reverse. However,

special attention should be given to the following

items.

Packing (C) 9 and Packing (F) 7 should be

z#

replaced with new genuine Hitachi parts.

Tighten the M6 x 45 Hexagon Socket Hd. Bolts

z#

1

to rated torque (see Para. 1-4.).

Exhaust Piece Ass’y 8, and

12

Valve Rubber Ass’y

7

.

Fig. 11 Main body output disassembly

M6 x 45 Hexaton

Socket Bolt

Top Cover

Exhaust Cover

Packing (F)

Exhaust

Piece Ass’y

Packing (C)

Valve Rubber

11

Ass’y

1

3

5

7

8

9

Head Cap Ass’y

12

Fig. 12 Disassembly of main body ,

upper part

:

−#4#−

1-2. Dsassembly and Reassembly of the Val ve Section:

Tools Required:

3 mm Roll Pin Remover

z#

Minus-Hd. Screwdriver

z#

(a) Disassembly:

(please refer to Fig. 13)

Remove the Magazine Ass’y 81 as described in

z#

section 1-1- (1).

Remove the Push Lever Ass’y 50 as described in

z#

section 1-1- (1).

With the 3 mm Roll Pin Remover, take out the D3 x 30

z#

Roll Pin

Plunger

Insert the minus-Hd. screwdriver into the groove of

z#

the Trigger Valve Bushing

47

, and remove the Trigger 57, Trigger

63

, and Plunger (B) 58.

62

, and loosen it by

turning it to the left, being careful not to damage the

groove.

After removing the Trigger Valve Bushing 62, pull

z#

down strongly on the Valve Bushing

the Valve Bushing

Plunger Spring

55

, Plunger (A) 54, and the

52

.

55

to remove

Plunger Spring

Plunger (A)

Valve

Bushing

Trigger

Plunger (B)

Plunger (A)

Plunger (B)

52

54

55

57

Valve Plate

Trigger Valve

Bushing

Trigger

Plunger

D3 x 30

Roll Pin

58

Fig. 13 Disassembly of v al ve

54

58

61

62

63

47

(b) Reassembly:

Reassembly can be accomplished by following the

disassembly procedures in revese. However, special

attention should be given to the following items:

Be very careful in handling the Plunger Spring 52,

z#

as it can become twisted very easily.

To prevent the two O-Rings on the outside of t he

z#

Valve Bushing

55

from being damaged when inserted into the Body, carefully apply grease t o t he

Body hole and the outer circumference of the O-Rings

prior to assembly.

(c) Adjustment of the Push Lever Ass’y

The Push Lever Ass’y 50 can be adjusted by loosening

z#

the M5 Nut

Perform adjustment to a point where the resistance of

z#

Plunger (B)

51

and turning the Safety Bolt 48.

58

pushing up Plunger (A) 54 is felt

50

(see Fig. 14):

when the Push Lever Ass’y is raised. At this point, t he

lower end of the Tail Cover

38

should be separated

Safety Bolt

51

50

Tail Cover

38

3.5 ± 0.5 mm

(.138 ± .020 )

M5 Nut

Push Lever

Ass’y

Fig. 14 Push lever assembly adj ustment

48

from the lower end of the Push Lever Ass’y by 3.5 mm

± 0.5 mm (.138"± . 020").

−#5#−

1-3. Disassembly and Reassembly of the Magazine Section:

69

(1) Magazine Base Ass’y

, Nail Feeder 64, Ribbon Spring Ass’y 66, and Related Parts:

Tools Required:

6 mm and 5 mm Hexagon Bar Wrenches

z#

5 mm Spanner

z#

(a) Disassembly:

Shift the Nail Feeder 64 to the Tail Cover 38 side in a state where it is held by the Ribbon

z#

Spring Ass’y

Remove the two M5 x 25 Hexagon Socket Hd. Bolts 72 and the M6 x 20 Hexagon Socket

z#

Hd. Bolt

Loosen the front-side M6 x 20 Hexagon Socket Hd. Bolt 33 (opposite from the Guard

z#

36B

side), and withdraw the Magazine Base Ass’y 69 from the Tail Cover 38. The

Magazine Ass’y

66

.

33

on the Guard

81

, Ribbon Spring Ass’y 66 and related parts can then be disassembled

36B

side.

(see Fig. 15).

Please note that if the front-side M6 x 20 Hexagon Socket Hd. Bolt

and not fully removed, the Nail Feeder

mounted on the Tail Cover

the Magagine Base Ass’y

Spring Shaft

65

38

. This facilitates disassembly and reassembly when only

69

need to be removed.

64

and Ribbon Spring Ass’y 66 can be kept

33 M6 x 20 Hexagon Socket Bolt

36

Guard

33

is only loosened

72

M5 x 25 Hexagon Socket Hd. Bolt

Ribbon Spring Ass’y

Nail Feeder

64

66

69

Magazine Base Ass’y

37 Washer

33 M6 x 20 Hexagon Socket Hd. Bolt

(with Bonding Agent)

Fig. 15 Disassembly / Reassembly of the Magazine Section

−#6#−

(b) Reassembly:

Reassembly can be accomplished by

following the disassembly procedures in

reverse. However, special attention

should be given to the following items.

As illustrated in Fig. 16, temporarily

z#

fix the Ribbon Spring Ass’y 66,

Spring Shaft 65 and Nail Feeder

64

onto the Tail Cover 38 with the

front-side M6 x 20 Hexagon Socket

Hd. Bolt 33, and slide the Magazine

Base Ass’y 69 onto the Tail Cover

38

. Then, secure the assembly by

tightening the M6 x 20 Hexagon

Socket Hd. Bolt 33 on the Guard

36B

side and the two M5 x 25

Hexagon Socket Hd. Bolts 72 to

rated torque (see Para. 1-4).

Finally, loosen the front-side M6 x 20

z#

Hexagon Socket Hd. Bolt 33, shift

the Nail Feeder 64 fully back into

the magazine, ensure the Magazine

Base Ass’y 69 is properly aligned,

and tighten the front-side M6 x 20

Hexagon Socket Hd. Bolt 33 to rated

torque (see Para. 1-4)

(2) Stop Lever 74, Stopper Spring 76, and

Related Parts:

Tools Required:

5 mm and 4 mm Hexagon Bar Wrenches

z#

5 mm and 4 mm Spanners

z#

(a) Disassembly: (see Fig. 17)

After removing the M5 x 45 Hexagon

z#

Socket Hd. Bolt 71 and M4 x 15

Hexagon Socket Hd. Bolt 77, the

parts illustrated in Fig. 17 can be

taken out.

(b) Reassembly: (see Fig. 18)

Reassembly can be accomplished by

following the disassembly procedures in

reverse. However, special attention

should be given to the following items.

As illustrated in Fig. 18, insert the

z#

Collar 75 into the Stop Lever 74,

and mount the Stopper Spring

76

with the M4 x 15 Hexagon Socket Hd.

Bolt 77 (see Para. 1-4 for tightening

torque). At this time, the Stopper

Washer

M6 x 20 Hexagon

Socket Hd. Bolt

Tail Cover

37

33

38

Fig. 16 Mounting of the Nail Feeder

74 Stop Lever

Fig. 17

71 M5 x 45 Hexagon

Socket Hd. Bolt

Fig. 18 Reassembly of the Stop Lever,

Stopper Spring, etc.

70 Sleeve

75

Collar

70 Sleeve

74 Stop Lever

75

76

Stopper Spring

64

Nail Feeder

65 Spring Shaft

66 Ribbon Spring Ass’y

71

M5 x 45 Hexagon

Socket Hd. Bolt

77

M4 x 12 Hexagon

Socket Hd. Bolt

76 Stopper Spring

77

M4 x 12 Hexagon

Socket Hd. Bolt

Collar

−#7#−

Spring 76 must be assembled so that one of its hooked portions is inserted into the Stop

Lever

Magazine Base Ass’y

Fix the Sleeve 70 in position with the M5 x 45 Hexagon Socket Hd. Bolt 71 (see Para.

z#

74

, and the other hooked portion is inserted into the small hole provided on the

69

.

1-4 for tightening torque).

1-4. General Precautions on Reassembly:

Apply grease (Hitachi Motor Grease No. 29, Code No. 930035, is recommended) to the O- Rings and t he

z#

O-Ring sliding portions. When reassembling the O-Rings, be particularly careful not to damage them,

or permit dust or other foreign matter to enter the mechanism.

If the Packings are damaged, replace them without fail and ensure that there is no air leakage after

z#

repair.

Be particularly careful not to permit dust or other foreign matter to enter the Valv e Section.

z#

Coat a small amount of grease (or sliding oil) on the sliding portions of the Nail Feeding Section.

z#

Rated tightening torques for fastening bolts, nuts, screws and t he Pist on Ass’y are as follows:

z#

Bolt / Nut type Rated Tightening Torque

Hexagon Socket Hd. Bolt M8 ................

40

260 ± 20 kg-cm (18.8 ± 1.4 ft-lb)

Hexagon Socket Hd. Bolt M6 ................1, 4,

Hexagon Socket Hd. Bolt M5 ................45, 71,

Hexagon Socket Hd. Bolt M4 ................

Nut M5....................................................

77

51

33

72

100 ± 8 kg-cm (7.2 ± 0.6 ft-lb)

65 ± 5 kg-cm (4.7 ± 0.4 ft-lb)

45 ± 3 kg-cm (3.2 ± 0.2 ft-lb)

35 ± 3 kg-cm (2.5 ± 0.2 ft-lb)

1-5. Inspection and confirmation After Reassembl y or Repair:

Confirm that the Nail Feeder 64 and Stop Lever 74 move smoothly.

z#

Operate the Nailer with an air pressure of 4 kg/cm2 (60 psi), and confirm that there is no abnormal

z#

driving or bending of nails.

With appropriate torque wrenches and / or torque drivers, confirm the correct tightening torque of all

z#

nut, screws and bolts.

−#8#−

Loading...

Loading...