PRODUCT NAME

Hitachi 18 V Cordless Strip Nailer

Models NR 1890DC NR 1890DBCL

NR 1890DR NR 1890DBRL

TROUBLESHOOTING GUIDE --------------------------------------------------------------------------------------- 1

1. Troubleshooting and corrective action --------------------------------------------------------------- 1

2. Corrective action when the orange LED blinks ---------------------------------------------------- 6

3. Maintenance mode --------------------------------------------------------------------------------------- 7

4. Resetting error mode (when the orange LED is blinking) --------------------------------------- 7

REPAIR GUIDE ---------------------------------------------------------------------------------------------------------- 8

1. Precautions on disassembly and reassembly ------------------------------------------------------ 8

• Preparation before disassembly --------------------------------------------------------------------- 8

• Disassembly and reassembly of the magazine section ---------------------------------------- 9

• Disassembly and reassembly of the output section ------------------------------------------ 12

• Replacement of the piston ass'y -------------------------------------------------------------------- 23

• Replacement of sensor (B) --------------------------------------------------------------------------- 26

• Feeding compressed air ----------------------------------------------------------------------------- 27

• Checking after reassembly ------------------------------------------------------------------------- 29

• Tightening torque ------------------------------------------------------------------------------------- 30

• Connecting diagram ---------------------------------------------------------------------------------- 31

STANDARD REPAIR TIME (UNIT) SCHEDULES ------------------------------------------------------------- 32

CONTENTS

CONFIDENTIAL

NR 1890DC: K858

NR 1890DBCL:

NR 1890DR: K859

NR 1890DBRL:

Jul. 2017

NR 1890DR

NR 1890DC

N

Page

Overseas Sales Division

-1-

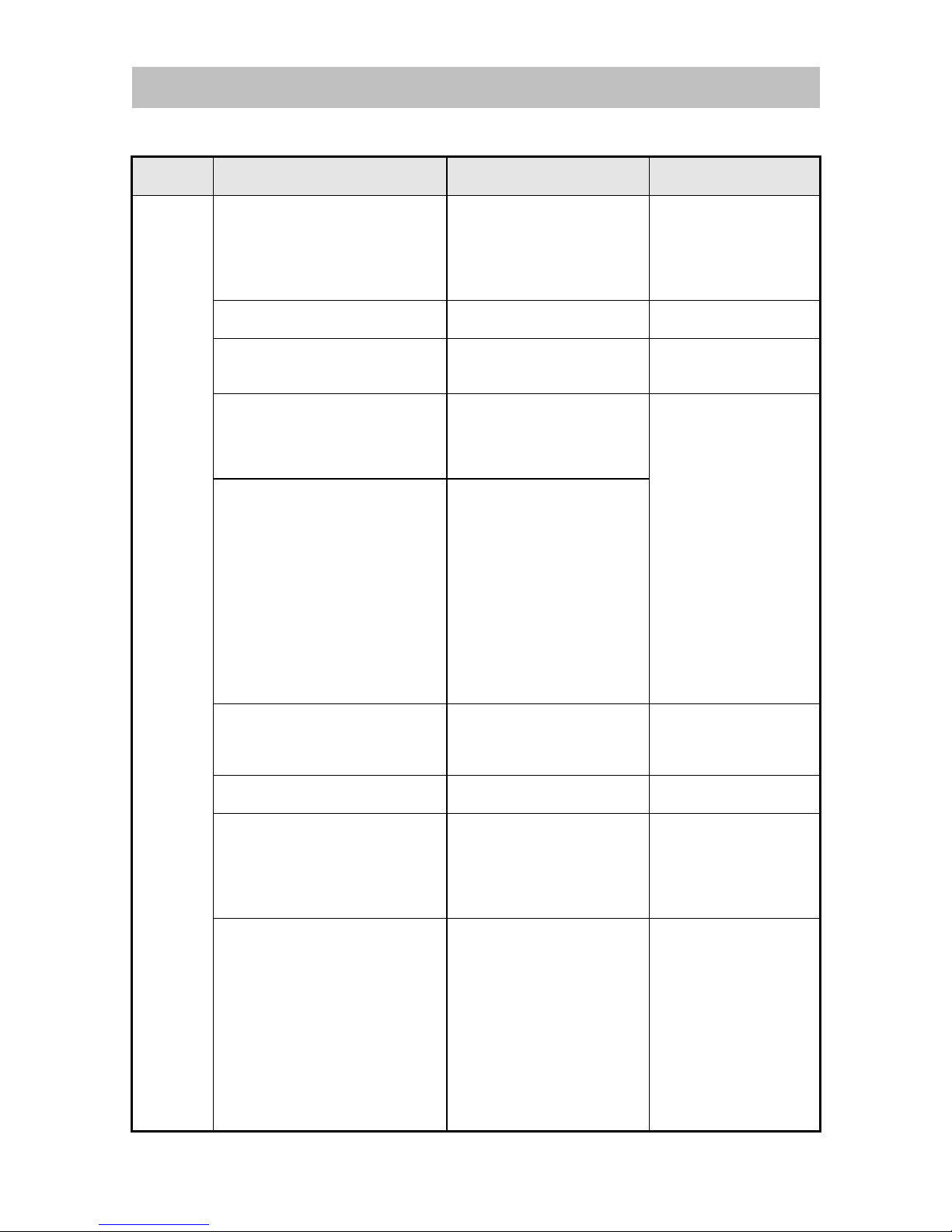

1. Troubleshooting and corrective action

Problem

Possible cause

(*: Most common cause)

Inspection method Corrective action

1.

Nails

cannot be

driven.

<Nails>

• Magazine is not loaded with

specified Hitachi genuine nails.

• Magazine is loaded with

abnormal nails (e.g., bent nails,

abnormal collation)

• Check whether the

magazine is correctly

loaded with specified nails.

• Use specified nails.

• Remove abnormal

nails and load the

nailer with proper

nails.

• Worn-out piston tip • Check whether the piston

tip is excessively worn.

• Replace defective

parts. See page 23.

• Piston trouble • Check the piston for any

trouble (e.g., deformation,

burring, break).

• Replace defective

parts. See page 23.

<Magazine section>

• Nail feeder trouble (deformation,

burring, break)

• Worn-out nail rail or magazine

plate

• Check the nail feed section

for any trouble (e.g.,

burring, deformation,

break, excessive wear).

• Remove burring.

• Correct the deformed

portion.

• Replace defective

parts.

• Nail guide groove of blade guide

(B) too narrow or wide

• Nail guide groove trouble

(protrusion or burring) of blade

guide (B)

• Step in the nail shank guide

groove between blade guide (B)

and magazine

• Nail guide groove of the

magazine too narrow or wide

• Nail guide groove trouble

(deformation or burring) of the

magazine

• Load nails in the nailer and

make sure the nailer works

normally.

* Unwanted objects (e.g., dust,

wood dust, adhesives) in the nail

guide groove of blade guide (B),

magazine and nail feeder

• Load nails in the nailer and

make sure the nailer works

normally.

• Remove unwanted

objects (e.g., dust,

wood dust,

adhesives).

• Loose bolts of the output section

and the magazine section

—

• Tighten the bolts at the

specified torque.

• Nail feeding trouble • Check the nail feeder slide

surface for dust.

• Check the nail feeder slide

surface for deformation.

• Check the ribbon spring for

damage.

• Replace defective

parts.

• No compressed air in the nailer

• Compressed air leak

• Fill up the nailer with

compressed air, leave the

nailer still for one day, and

then check the nailing

work.

• Check the sealing surfaces,

X-rings, and O-rings inside

the cylinder, piston,

chamber cover, and

chamber base for flaws,

unwanted objects, and

other failures.

• Supply compressed

air.

• Disassemble the nailer

and clean the

chamber, piston, and

their vicinity.

• Replace the sealing

parts.

TROUBLESHOOTING GUIDE

-2-

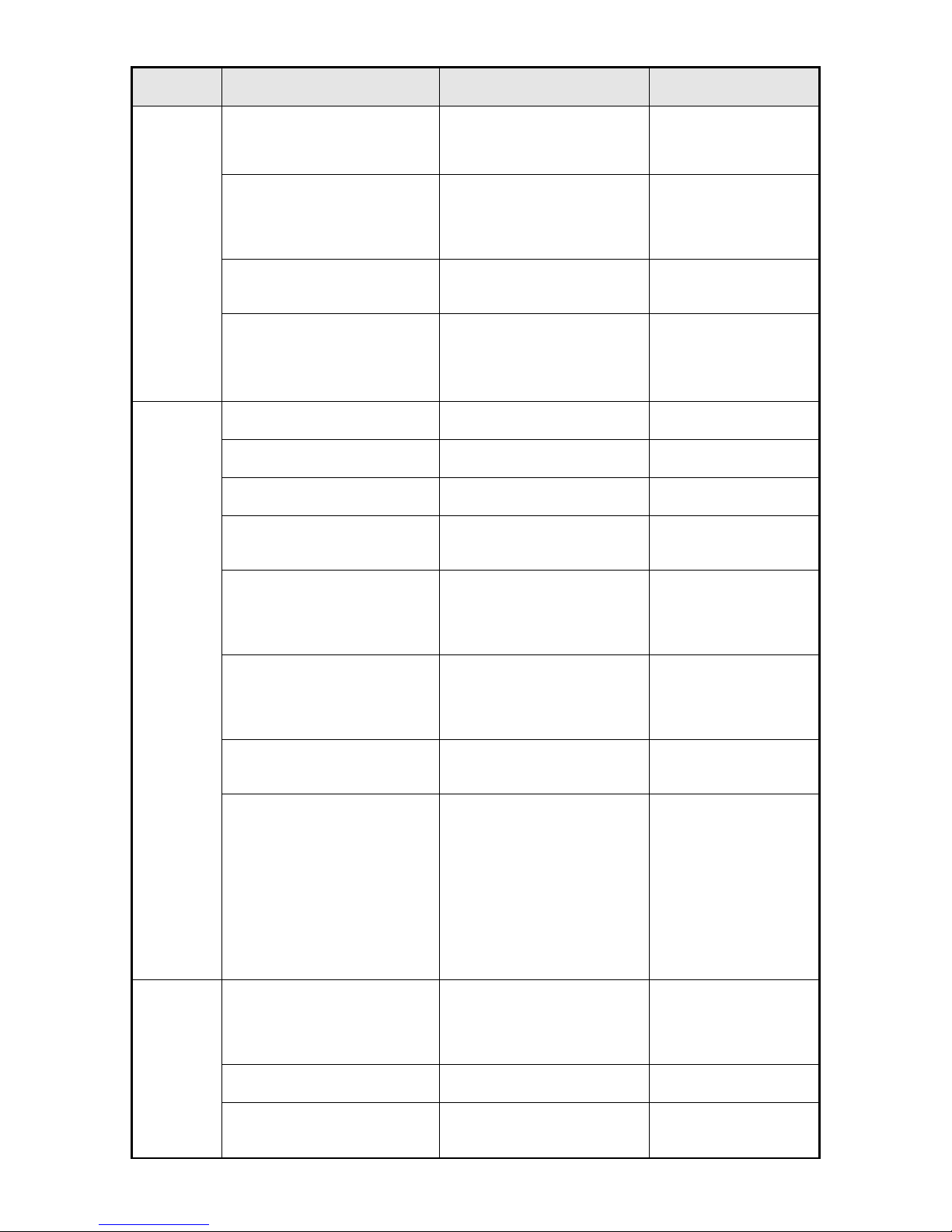

Problem

Possible cause

(*: Most common cause)

Inspection method Corrective action

2.

Nails are

driven but

bent.

*• Worn-out piston tip

*• Broken or worn-out blade

rack

• Check the piston tip for

excessive wear.

• Check the blade rack for

break or wear.

• Replace defective

parts. See page 23.

• Nails are not completely fed

into the injection port.

• Unspecified nails are used.

• Check whether the

magazine is correctly loaded

with specified nails.

• Use specified nails.

• Remove abnormal

nails and load the

nailer with proper

nails.

• Wood material too hard to be

nailed

• Drive nails into soft wood

and check whether the

driven nails are bent.

• This nailer is not for

hard wood.

• Deformed output section • Check the tips of the

pushing lever and blade

guide for warp, deformation

and excessive wear.

• Replace defective

parts.

3.

Nails

cannot be

driven into

the

workpiece

completely:

the heads

cannot be

made flush.

• Worn-out piston tip • Check the piston tip for

excessive wear.

• Replace defective

parts. See page 23.

*• Worn-out piston rack • Check the piston rack for

excessive wear.

• Replace defective

parts. See page 23.

• Inadequate adjuster control • Set the adjuster to nail

deeper and then nail again.

• Set the adjuster

properly.

• Wood material too hard to be

nailed

• Drive nails into soft wood

and check whether the nail

heads are lifted.

• This nailer is not for

hard wood.

• Weak thrusting force against

wood to be nailed

• Firmly thrust the nailer

against wood to be nailed

and start nailing. Check

whether the nail heads are

still lifted.

• Follow the nailer

operation guide.

• Deformed output section • Check the nail guide groove

of the pushing lever and

blade guide for any trouble

(e.g., deformation,

excessive wear, burrs).

• Replace defective

parts.

• Insufficient grease on the

cylinder and piston section

• Check the greasing

condition of the cylinder and

piston section.

• Replenish grease.

• No compressed air in the

nailer

• Compressed air leak

• Fill up the nailer with

compressed air, leave the

nailer still for one day, and

then check the nailing work.

• Check the sealing surfaces,

X-rings, and O-rings inside

the cylinder, piston,

chamber cover, and

chamber base for flaws,

unwanted objects, and other

failures.

• Supply compressed

air.

• Disassemble the

nailer and clean the

chamber, piston, and

their vicinity.

• Replace the sealing

parts.

4.

Nails jam.

*• Abnormal nails are used

(e.g., bent nails, abnormal

collation)

• Nails are not completely fed

into the injection port.

• Check whether the

magazine is correctly loaded

with specified nails.

• Use specified nails.

• Remove abnormal

nails and load the

nailer with proper

nails.

• Worn-out piston tip • Check whether the piston tip

is excessively worn.

• Replace defective

parts. See page 23.

• Wood material too hard to be

nailed

• Drive nails into soft wood

and check whether nails

jam.

• This nailer is not for

hard wood.

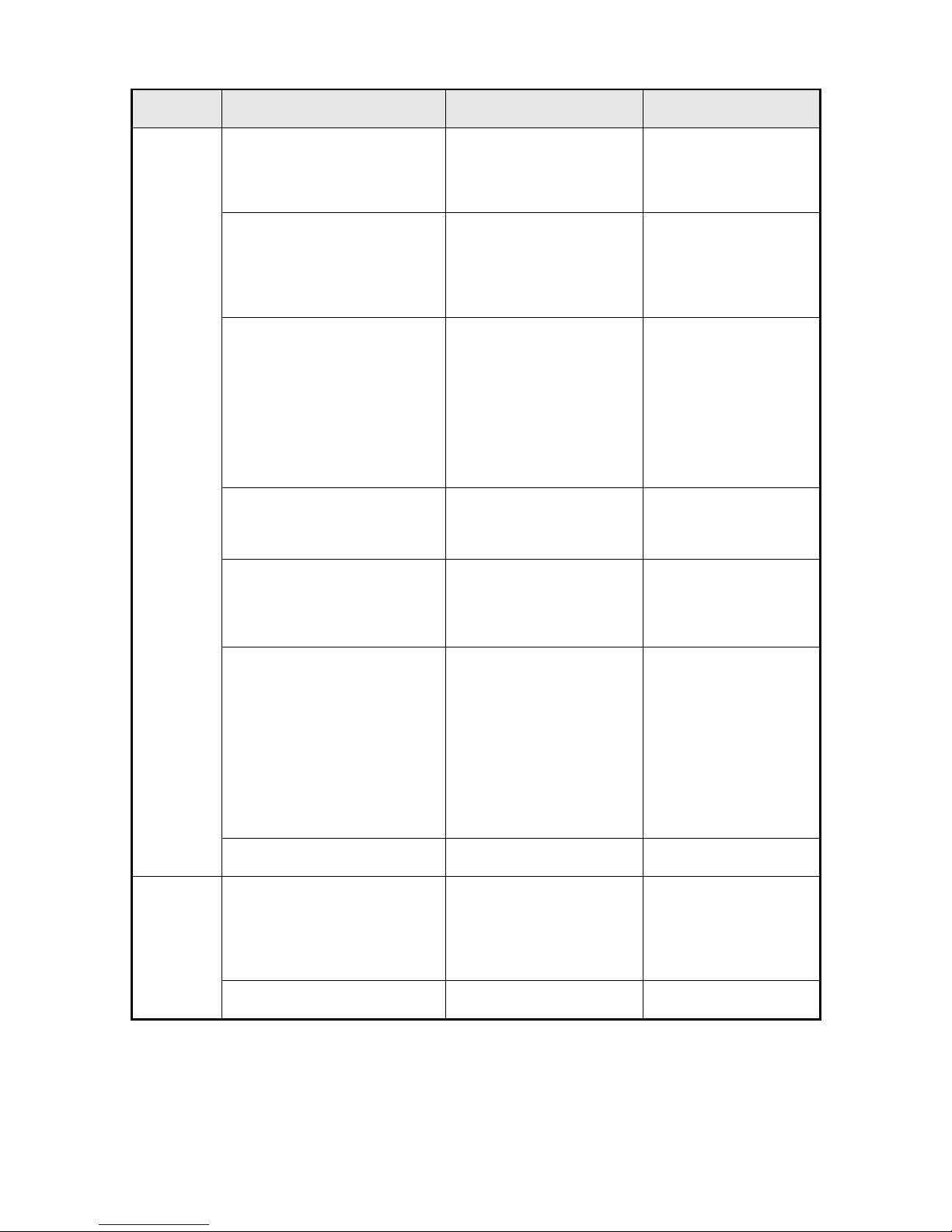

-3-

Problem

Possible cause

(*: Most common cause)

Inspection method Corrective action

4.

Nails jam.

• Piston slide surface trouble

(e.g., galling, break)

• Check the surfaces on

which the piston slides

(blade guides (A) and (B)

and pushing levers (A)

and (B)).

• Replace defective

parts.

<Magazine section>

• Nail feeder trouble (e.g.,

deformation, burring, break)

• Check the nail feed section

for any trouble (e.g.,

burring, deformation,

break, excessive wear).

• Remove burring.

• Correct the deformed

portion.

• Replace defective

parts.

• Nail guide groove of the blade

guide (B) too narrow or wide

• Nail guide groove trouble (e.g.,

protrusion, burrs, excessive

wear) of blade guide (B)

• Nail guide groove of the

magazine too narrow or wide

• Nail guide section trouble (e.g.,

deformation, burrs) of the

magazine

• Load nails in the nailer and

check that the nailer works

normally.

• Remove burring.

• Replace defective

parts.

• Unwanted objects (e.g., dust,

wood dust, adhesives) in the

nail guide groove of the

magazine and nail feeder

• Load nails in the nailer and

check that the nailer works

normally.

• Remove unwanted

objects (e.g., dust,

wood dust, adhesives).

• Deformed output section • Check pushing lever (A)

and blade guides (A) and

(B) for deformation,

excessive wear, and burrs.

• Replace defective

parts.

• Misaligned assembly of blade

guide (B) and magazine

• Set Hitachi genuine nails

in the nailer and lightly

push them against the

magazine. Make sure the

nail tips closely touch the

nail guide surface of blade

guide (B).

(See "Disassembly and

reassembly of the

magazine section.")

• Reassemble blade

guide (B). See page 11.

• Loose bolts of the output

section and magazine section

―

• Tighten the bolts at the

specified torque.

5.

Nailing

started by

single

triggering.

*• Malfunction caused by

unwanted objects (e.g.,

adhesive, dust) near pushing

lever (A), (B) or blade guide

(A) or by deformation of the

lever or blade guide

• Check that pushing lever

(A) moves smoothly (in a

body).

• Clean the pushing lever

and the blade guide.

Then apply oil to them.

• Replace defective

parts.

• Broken or worn-out pushing

lever spring (B)

• Check the spring for any

trouble.

• Replace defective

parts.

-4-

Problem

Possible cause

(*: Most common cause)

Inspection method Corrective action

6.

No nailing

operation

without

motor

rotation

sound.

• Dry-fire lockout mechanism

is activated.

• Count the number of

remaining nails. There

should be 9 or more

remaining nails.

• Load nails.

*• Wire-related trouble of

wiring, switch cable (A), and

sensor (B)

• Check whether the wires and

sensor (B) are firmly

soldered.

• Check whether the rotor

emits a parching smell.

• Check the conductivity of the

switch and microswitch by

using a multimeter.

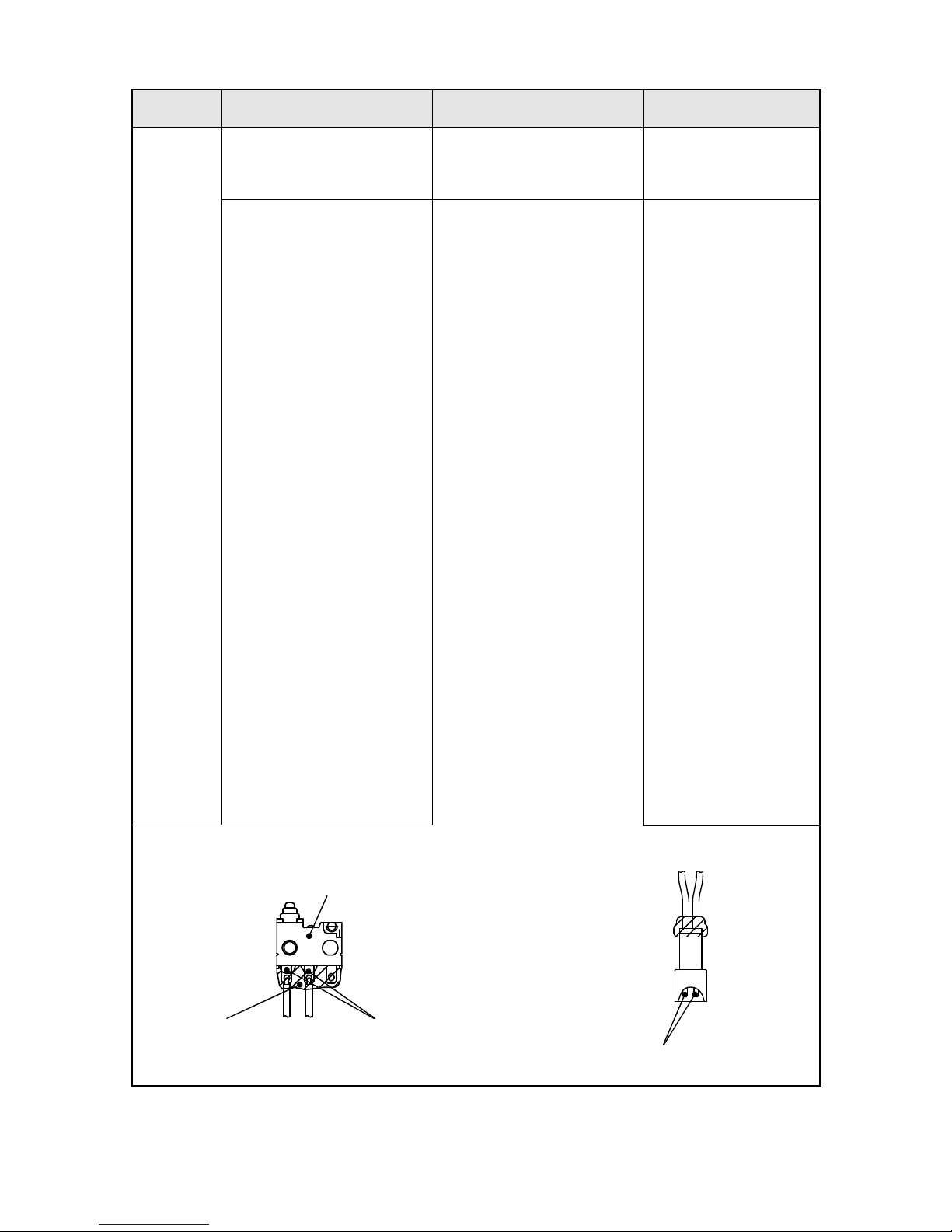

[Checking procedure]

(1) When switch cable (A) is

not defective:

• Set the switch to OFF and

apply tester probes to the

points shown in the figure

below. Make sure the

terminals are not electrically

connected.

• Set the switch to ON and

apply tester probes to the

points shown in the figure

below. Make sure the

terminals are electrically

connected.

(2) When the microswitch is

not defective:

• Set the switch to ON and

apply tester probes to the

points shown in the figure

below. Make sure the

contacts are electrically

connected.

• Set the switch to OFF and

apply tester probes to the

points shown in the figure

below. Make sure the

contacts are not electrically

connected.

• Firmly resolder the

disconnected wires.

• Replace defective

parts.

Microswitch

Silicone

Apply multimeter probes here.

NOTE: Remove the silicone a little and apply the

multimeter probes to the exposed terminal metal.

Apply multimeter probes here.

(1) (2)

-5-

Problem

Possible cause

(*: Most common cause)

Inspection method Corrective action

7.

No nailing

operation

with the

orange LED

blinking.

*See page 6.

*• Broken movable part that

disabled nailing work.

• Check the movable part for

any trouble (e.g., deformation,

break, excessive wear).

• Replace defective

parts.

• Disconnected wiring and

stator

• Check the wires and sensor

assemblies for breaks or

disconnection.

• Check the conductivity of the

stator.

• Replace defective

parts.

*• Power transmission

failure due to broken

gears

• Check that the gear turns

smoothly. See page 18.

• Check the gear box ass'y for

breaks.

• Replace defective

parts.

• Sensor (C) trouble • Visually check the sensor

wires for breaks.

• Replace defective

parts.

• Excessively charged

compressed air

• Check the LED lighting

pattern.

• Move the piston down

to the bottom dead

point. Discharge the

compressed air. Use

the reduction valve

set to feed

compressed air

again. See pages 27

to 28.

8.

No nailing

operation

with the red 2

LEDs blinking

*• Overheat protector is

activated.

• Cool the nailer body and

check the nailing work.

―

*• Overcool protector is

activated

• Warm the nailer body and

check the nailing work.

―

9.

No nailing

operation

with the red

LED blinking

*• Low battery voltage • Use a fully charged battery

and check the nailing work

again.

• Charge or replace the

battery.

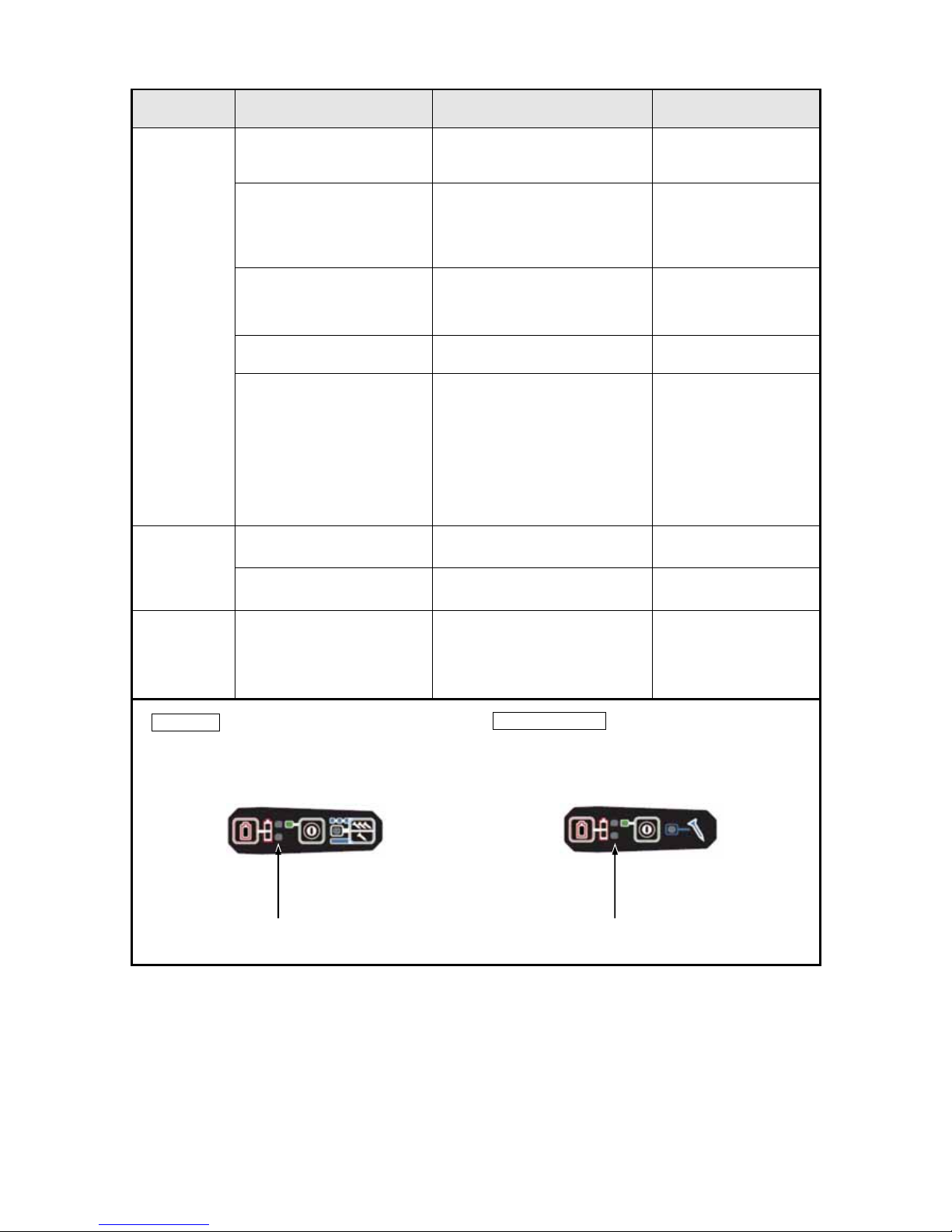

Red LED Red LED

For others

Select the nailing operation mode.

(Full sequential actuation/Contact actuation)

For New Zealand

Select the nailing operation mode.

(Contact actuation only)

-6-

Power ON*1

Reset the error.

(See page 7.)

Pull the trigger.*3

See No. 4 in the table.

See No. 3 and 6 in the table.

See No. 1, 2, and 5 in the table.

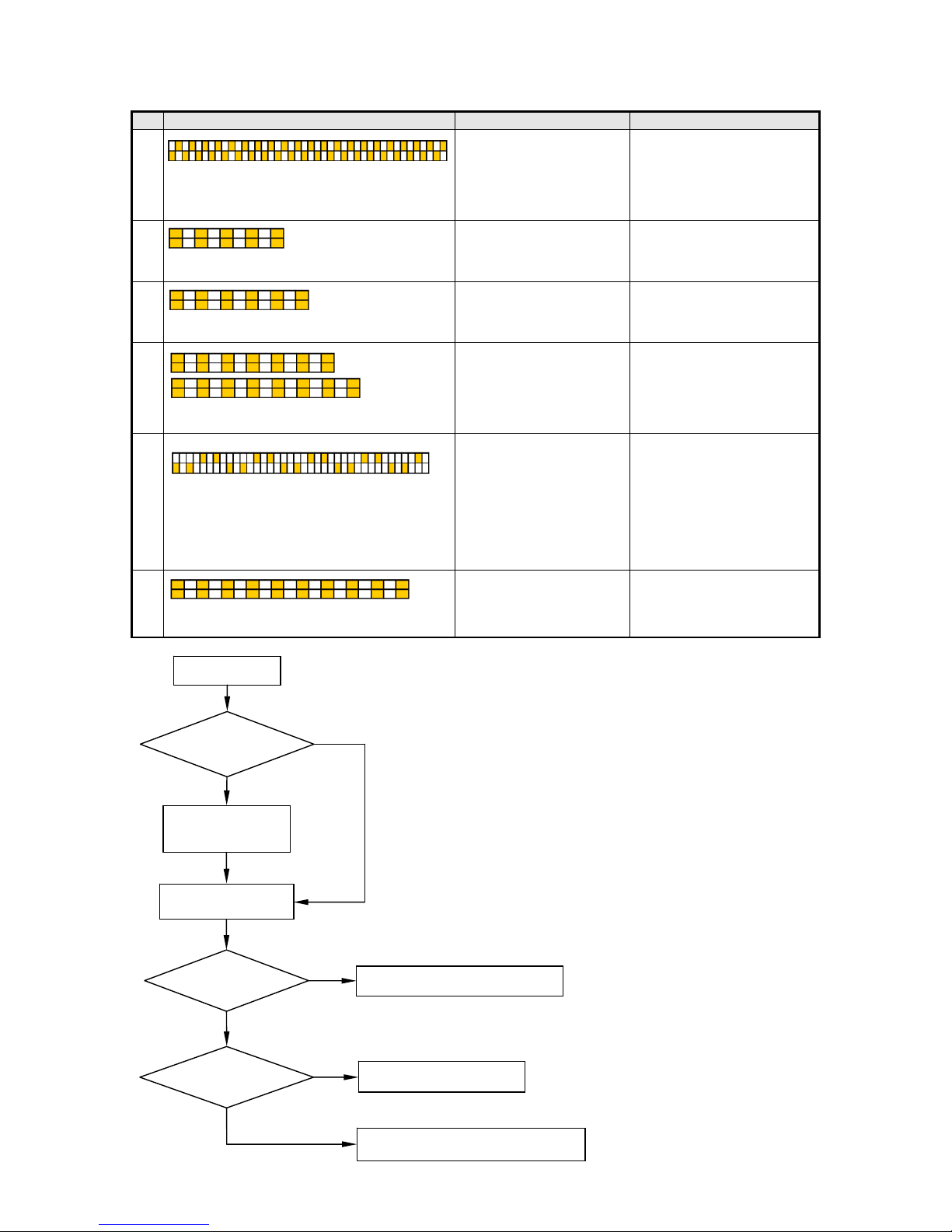

2. Corrective action when the orange LED blinks

No. Orange LED lighting pattern Possible cause Corrective action

1 Power switch is automatically turned off after

about 10 seconds.

• Reversed magnet polarity

of position detector

• Sensor (C) failure or

disconnection

• Failure of one-way clutch

in gear box

• Replace defective parts.

2

Power switch is automatically turned off after

blinking 5 times (about 5 seconds).

• Idle by broken gear • Replace defective parts.

3

Power switch is automatically turned off after

blinking 6 times (about 6 seconds).

• Broken wiring • Replace defective parts.

4

Power switch is automatically turned off after

blinking 7 to 8 times (about 7 to 8 seconds).

• Lock by broken gear

• Lock by worn-out piston

rack

• Lock by broken piston

bumper

• Broken wiring

• Replace defective parts.

5

Power switch is automatically turned off after

about 9 seconds.

• Excessively charged

compressed air

• Deformed or broken

moving parts

• Moving parts are out of

grease.

• Replace defective parts.

• Move the piston down to the

bottom dead point. Discharge

the compressed air. Use the

reduction valve set to feed

compressed air again.

• Replace moving parts.

• Lubricate the moving parts

with grease.

6

Power switch is automatically turned off after

blinking 10 times (about 10 seconds).

• Broken wiring • Replace defective parts.

*1: Do not press the pushing lever and/or

pull the trigger during the process of

turning the power switch ON. Doing so

will prevent the power switch from

turning ON.

*2: LED of battery indicator

*3: Press the pushing lever against the

wood before pulling the trigger.

Does the

motor run?

No

Does the orange

LED*

2

blink?

Yes

Does the

piston move?

No

Yes

Yes

No

-7-

Fig. 2

Fig. 1

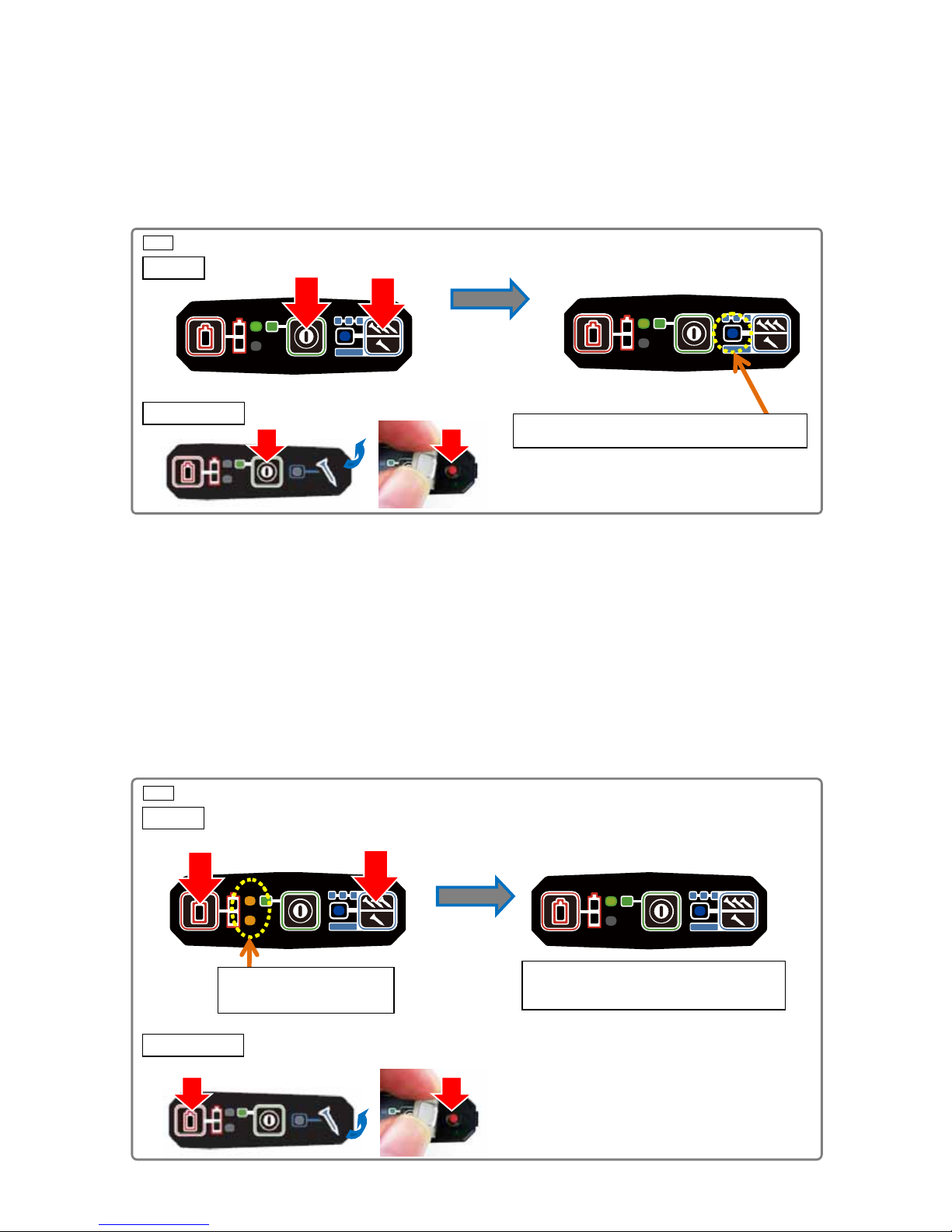

3. Maintenance mode

Maintenance mode is used to move the piston down to the bottom dead point in preparation for feeding

compressed air or overhauling the nailer. To set MAINTENANCE mode, hold down both the nailing

operation switch* and the power switch on the operation panel for at least five seconds.

*: The nailing operation switch is not provided for the products intended for New Zealand. Peel back the

operation panel and press the inside button (red).

Indication: Indicated by the blue LED on the operation panel blinking (at intervals of 0.5 second).

Be careful not to mistake the blinking for contact actuation mode (at intervals of 1.0 second).

Function: Starts the motor when the pushing lever is pressed against wood and the trigger is pulled.

Stops the motor when detecting two motor rotations.

4. Resetting error mode (when the orange LED is blinking)

Error indication: Indicated by the orange battery level indicators blinking (at intervals of 0.5 second).

The power indicator turns off automatically 10 seconds later.

To reset the mode: Hold down both the battery indicator switch and the nailing operation switch for at least

five seconds.

5 seconds later

Full sequential actuation mode is set.

(The blue LED goes on.)

Push

Push

5 seconds later

Push

Push

Orange LED blinking

(

at intervals of 0.5 sec.)

Blue LED blinking (at intervals of 0.5 sec.)

Push Push

Push Push

For others

For New Zealand

For others

For New Zealand

-8-

Fig. 3

The following describes the most essential precautions on disassembly and reassembly of the nailers.

The cordless strip nailer Models NR 1890DC, NR 1890DBCL, NR 1890DR, and NR 1890DBRL mainly

consist of two sections: the output section and the magazine section.

1. Precautions on disassembly and reassembly

[Bold] numbers in the description below correspond to the item numbers in the parts list and exploded

assembly diagram for the Models NR 1890DC and NR 1890DBCL, and (Bold) numbers to those for the

Models NR 1890DR and NR 1890DBRL.

WARNING: Always remove the battery from the main body before starting repair or maintenance

work. Because the tool is cordless, inadvertently activating the switch with the battery

left in the main body will start the motor rotating unexpectedly, and could cause serious

injury.

1. Removal of the hook

Remove the Hook [57](57) by removing the Low Head Hex. Socket Bolts M4 x 8 [58](58) for easy

disassembly work, although disassembly can be done without removing the Hook [57](57).

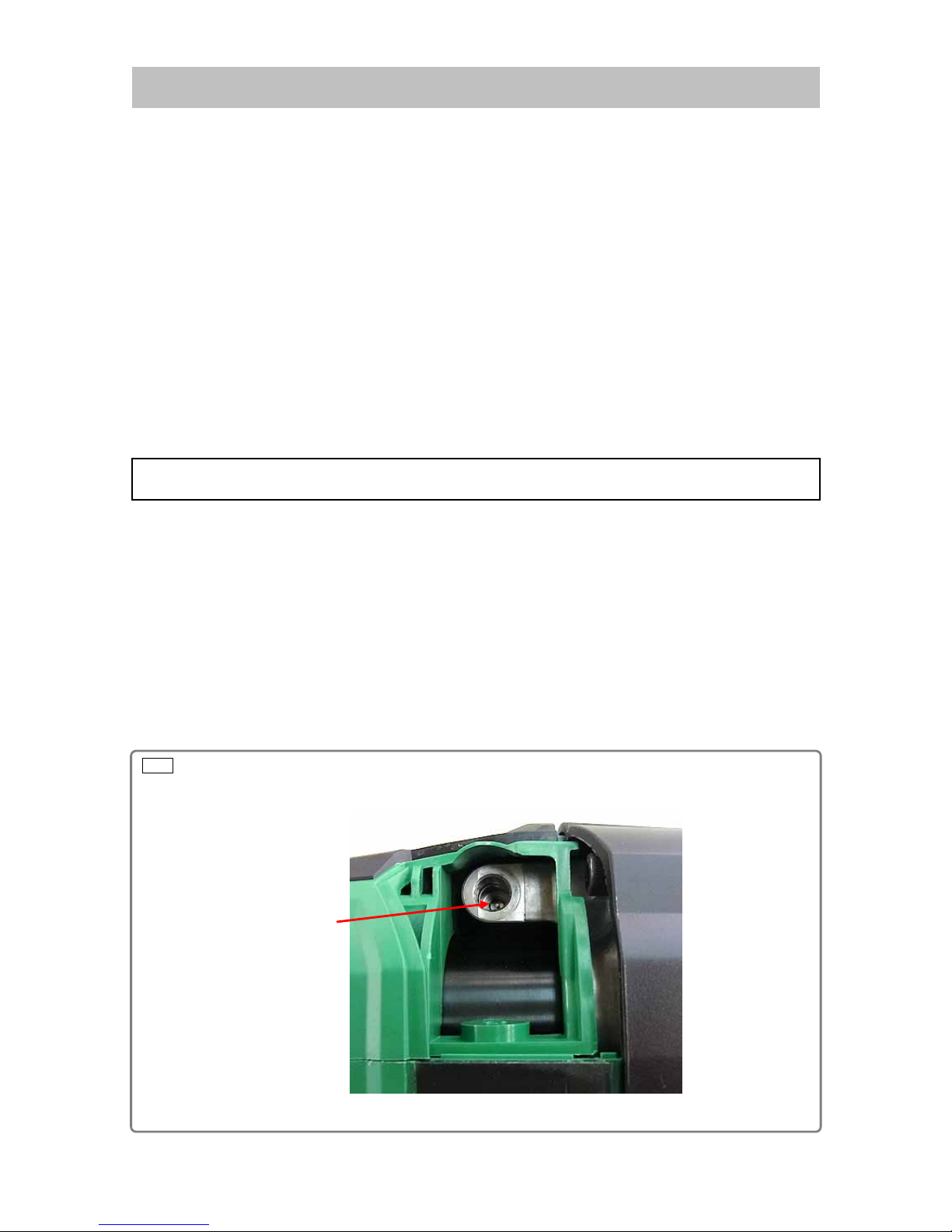

2. Removal of housing (C)

• When the nailer is enabled to nail, set MAINTENANCE mode and move the Piston Ass'y [15](15) down to

the bottom dead point referring to "Feeding compressed air" on page 27.

• Remove the Tapping Screw D4 x 20 [44](44) and remove Housing (C) [45](45).

• Remove the Charge Cap [8](8) by using a hexagonal socket wrench.

• Push the valve core to release compressed air as shown below.

REPAIR GUIDE

Preparation before disassembly

Val v e cor e

-9-

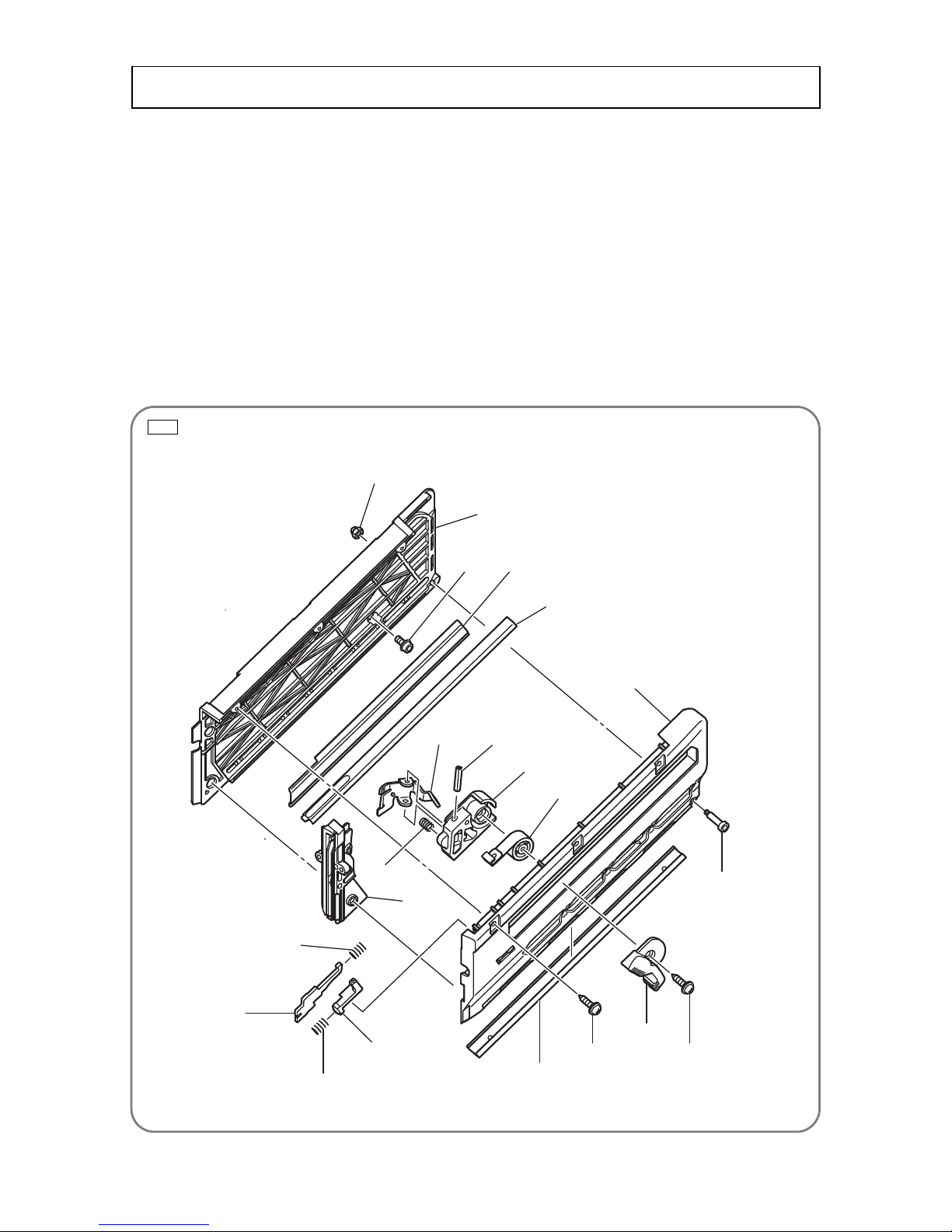

Fig. 4 • Models NR 1890DC and NR 1890DBCL

1. Disassembly

(1) Models NR 1890DC and NR 1890DBCL

• Remove the Nylock Bolt M5 [85] that fastens the magazine ass'y to the Housing Set [46] and two Nylock

Bolts M5 x 22 [34] that fasten the magazine ass'y to the Nose [17].

• Remove the three Tapping Screws D4 x 16 [91], Cap Nut M3 [81], and Step Bolt M3 [89].

• Remove the Magazine Guard [90] from the magazine ass'y and remove Magazine Cover (B) [84] from

Magazine Cover (A) [88]. Then remove Blade Guide (B) [76].

• Remove the Tapping Screw D5 x 20 [93] that fastens Magazine Cover (A) [88] to Nail Feeder (B) [79].

Then remove the Feeder Knob [92] and Ribbon Spring [80].

• Remove Pushing Lever Stopper (A) [72], Pushing Lever Stopper (B) [74], and two Springs [73] from

Magazine Cover (A) [88].

• Remove the Nail Rail [87] from Magazine Cover (B) [84] and remove the Magazine Plate [87].

[81]

[84]

[85]

[86]

[87]

[88]

[89]

[93]

[91]

[90]

[74]

[72]

[73]

[76]

[80]

[79]

[78]

[77]

[75]

[93]

Disassembly and reassembly of the magazine section

[73]

-10-

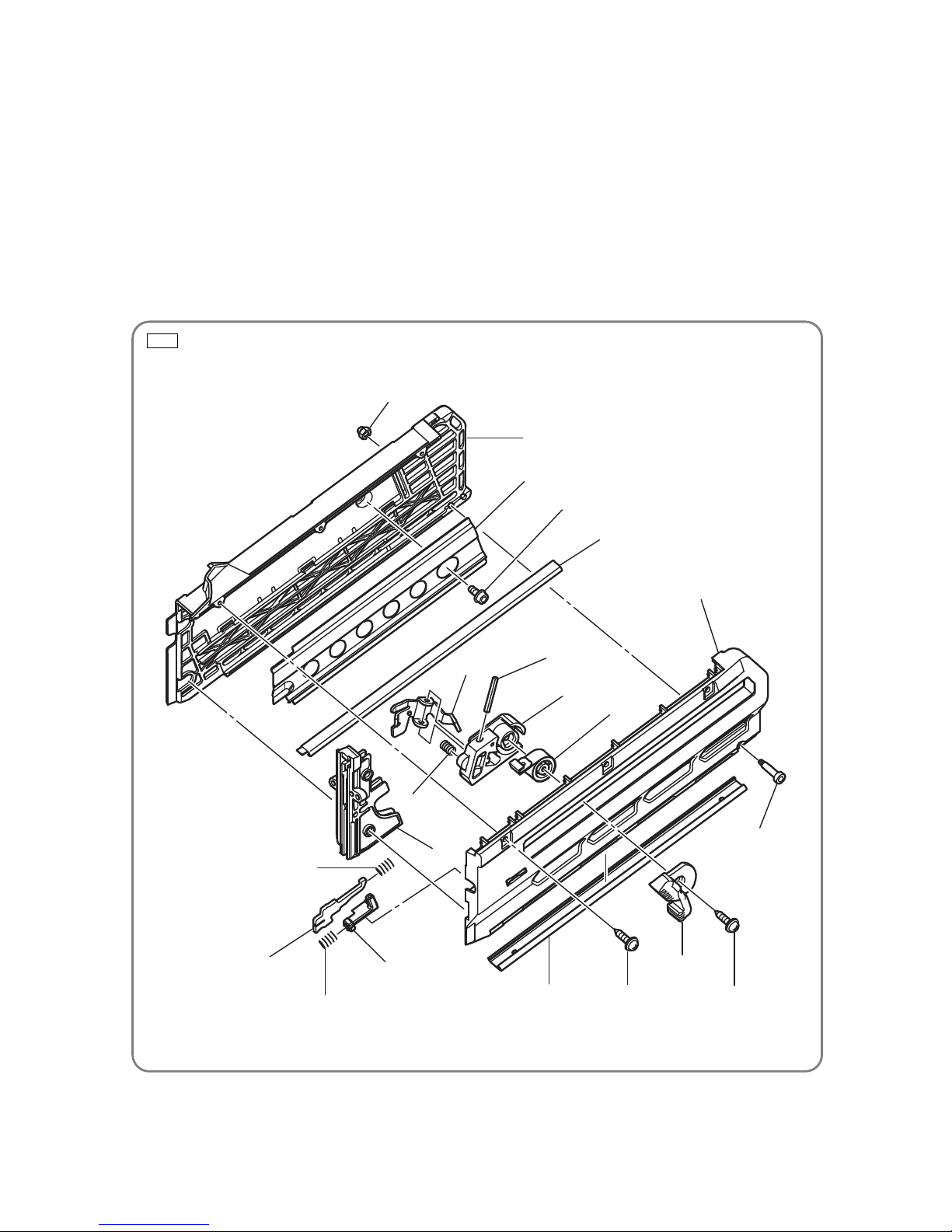

Fig. 5 • Models NR 1890DC and NR 1890DBRL

(2) Models NR 1890DR and NR 1890DBRL

• Remove the Nylock Bolt M5 x 18 (86) that fastens the magazine ass'y to the Housing Set (46) and two

Nylock Bolts M5 x 22 (34) that fastens the magazine ass'y to the Nose (17).

• Remove the three Tapping Screws D4 x 16 (91), Cap Nut M3 (81), and Step Bolt M3 (89).

• Remove the Magazine Guard (90) from the magazine ass'y and remove Magazine Cover (B) (84) from

Magazine Cover (A) (88). Then remove Blade Guide (B) (76).

• Remove the Tapping Screw D5 x 20 (93) that fastens Magazine Cover (A) (88) to Nail Feeder (B) (79).

Then remove the Feeder Knob (92) and Ribbon Spring (80).

• Remove Pushing Lever Stopper (A) (72), Pushing Lever Stopper (B) (74), and two Springs (73) from

Magazine Cover (A) (88).

• Remove Nail Rail (C) (87) from Magazine Cover (B) (84) and remove the Magazine Plate (85).

(81)

(84)

(85)

(86)

(87)

(88)

(78)

(79)

(80)

(77)

(89)

(93)

(92)

(91) (90)

(73)

(72)

(73)

(74)

(75)

(76)

-11-

Fig. 7

2. Reassembly

(1) Models NR 1890DC and NR 1890DBCL

Reverse the disassembly procedure to reassemble. Note the following points:

• Insert the protrusion of the Nail Rail [87] into the nail head inlet of Blade Guide (B) [76].

(2) Models NR 1890DR and NR 1890DBRL

Reverse the disassembly procedure to reassemble. Note the following points:

• Position the concave portion of Blade Guide (B) (76) on Magazine Cover (B) (84) side between the

Magazine Plate (85) and Magazine Cover (B) (84) as shown below.

• Insert the protrusion of Nail Rail (C) (87) into the nail head inlet of Blade Guide (B) (76).

Nail head inlet of blade guide (B)

Protrusion of the nail rail

Fig. 6

Fig. 8

Concave portion of blade guide (B)

Nail head inlet of blade guide (B)

Protrusion of nail rail (C)

(76)

-12-

1. Removal of the power assembly and wiring

• The nailer has two Housing Set [46](46) halves: housing (A) with a HITACHI logo mark on one side and

housing (B) on the other side.

• For safety, push the valve core once more and check that compressed air is completely released.

• Remove the Hex. Socket Bolt M6 [1](1) and detach the Top Cover [2](2).

• Remove the fourteen Tapping Screws D4 x 20 [44](44) that fasten housing (A) and housing (B).

• Holding the battery portion of housing (B), gently open and remove the Housing Set [46](46).

• Remove the Trigger [54](54) and Spring (T) [53](53) from housing (A).

• Remove Rubber Cushion (A) [18](18) from housing (A).

• Disconnect the connectors of Sensor (B) [63](63), Sensor (C) [60](60), Switch Cable (A) [52](52), and

Wiring [51](51).

• Remove the two O-rings (I.D 2.5) [50](50) from Switch Cable (A) [52](52). Be careful not to lose the

O-rings.

• Carefully lift the Chamber Base [10](10) and Nose [17](17) to remove the power assembly from housing

(A) and Rotor [83](83).

• Remove the Gear Box [82](82) and Bumper (B) [59](59) from the power assembly.

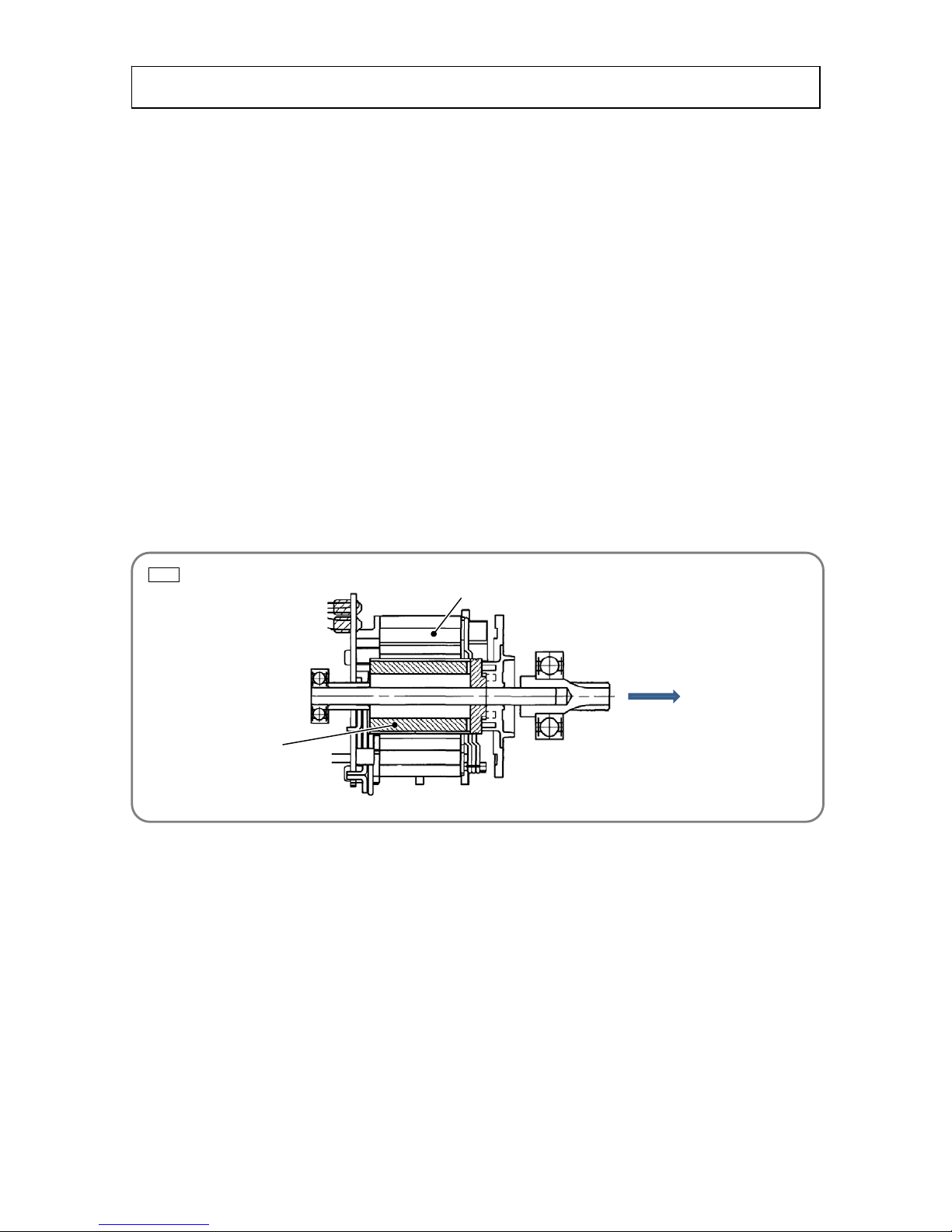

• Firmly hold the stator of the Wiring [51](51) (as the Rotor [83](83) has strong magnetic force), slowly push

the ball bearing (opposite to the pinion) of the Rotor [83](83) in direction "A" to separate the Wiring

[51](51) from the Rotor [83](83) as shown in the figure below.

• Remove the Wiring [51](51) from housing (A).

• Remove Lever (C) [55](55) from Lever (A) [56](56).

• Remove Lever (A) [56](56) from housing (A).

Disassembly and reassembly of the output section

Fig. 9

A

Rotor

Stator

-13-

2. Disassembly of the power assembly

NOTE: • See pages 23 to 25 for replacement of only the Piston Ass'y [15](15).

• Make alignment marks on the Chamber Base [10](10) and Cylinder [5](5) as shown in the

figure below so as to indicate the coupling positions before disassembling the power

assembly.

Fig. 10

[1](1)

[2](2)

[3](3)

[4](4)

[5](5)

[6](6)

[7](7)

[9](9)

[11](11)

[12](12)

[13](13)

[8](8)

[14](14)

[13](13)

[16](16)

[17](17)

[18](18)

[19](19)

[29](29)

[28](28)

[27](27)

[20](20)

[26](26)

[10](10)

[34](34)

[35](35)

[33](33)

[36](36)

[32](32)

[31](31)

[30](30)

[37](37)

[15](15)

[21](21)

[22](22)

[23](23)

[24](24)

[25](25)

[38](38)

[39](39)

[40](40)

[41](41)

[42](42)

[68](68)

[69](69)

[18](18)

[67](67)

[66](66)

[63](63)

[64](81)

[65](82)

[61](61)

[60](60)

Alignment marks

-14-

Fig. 11

• Remove the valve core from the Chamber Base [10](10) by using a commercial valve core tool. (See Fig.

11.)

• Remove the four Nylock Bolts M6 [11](11) that fasten the Chamber Base [10](10) and Chamber Cover

[4](4), and remove the Chamber Base [10](10).

NOTE: If it is difficult to remove the Chamber Base [10](10), temporarily tighten at least two Nylock

Bolts M6 [11](11) so that the threaded portion is shown 3.5 mm to 6.5 mm as shown in Fig.

12. Mount the reduction valve set and feed compressed air to remove the Chamber Base

[10](10).

• Remove the O-ring (I.D 94.5) [7](7) from the Chamber Base [10](10).

• Push in the Piston Ass'y [15](15) from Blade Guide (A) [70](70) side to the Cylinder [5](5) side to remove

it.

• Remove the Hex. Socket Hd. Bolt M5 [64](64) from the Nose [17](17).

• Move the Chamber Base [10](10) from the Cylinder [5](5) contact surface to the Nose [17](17) side and

secure the Cylinder [5](5) and Chamber Base [10](10) with tape as shown below.

Bit type Tip shape

Fig. 13

[64](64)

Fig. 14

[10](10)

Tape

[17](17)

Fig. 12

Reduction valve set

Temporarily tighten the Nylock Bolts

M6 [11](11) so that the threaded

portion is shown 3.5 to 6.5 mm.

[10](10)

-15-

Fig. 15

• Fix the hexagonal portion of the J-400 special socket. Fit the claws of the J-400 special socket in the

notches on the end surface of the Cylinder [5](5). Loosen the Special Nut M58 [12](12) and turn the Nose

[17](17) to remove it from the Cylinder [5](5).

• Turn the Special Nut M58 [12](12) and remove it from the Cylinder [5](5).

• Remove the Chamber Base [10](10) from the Cylinder [5](5) being careful not to damage the sealing

surfaces.

• Remove the two O-rings (I.D 55.5) [6](6) from the Cylinder [5](5).

• Remove the Slide Ring [13](13) and X-ring [14](14) from the Piston Ass'y [15](15).

• Remove the Piston Bumper [16](16) from the Nose [17](17).

• Remove the Retaining Ring D52 [21](21) from the Nose [17](17) and pull out the Bearing Holder [22](22)

and Pin Wheel [27](27).

NOTE: The Pin Wheel [27](27) can be removed only after removing the Piston Ass'y [15](15).

• Remove the Ball Bearing 6000VV [23](23) and Ball Bearing 6902VV [29](29) from the Pin Wheel

[27](27).

• Remove the Needle Roller D3 [30](30) from the Pin Wheel [27](27) and then remove the Position

Detector [25](25).

• Remove the eight Needle Rollers D4 [32](32) and one Needle Roller D4.5 [26](26) from the Pin Wheel

[27](27). Remove Wheel Spring (A) [31](31), Wheel Spring (B) [28](28), and Pin (A) [33](33).

• Remove Felt (P) [20](20) from the Pin Wheel [27](27).

• Remove the Roll Pin D3 x 20 [71](71) from Blade Guide (A) [70](70)

. Turn the Adjuster [41](41) and

remove Pushing Lever (A) [42](42), Pushing Lever (B) [38](38), and Pushing Lever Spring (B) [36](36).

Fit the claws of the J-400 special socket in the

notches on the Cylinder [5](5) (4 places).

J-400

Repair tool number "J-400"

-16-

Fig. 16

• Remove the Special Bolt M6 [37](37), Adjuster [41](41), Adjuster Spring [40](40), and Steel Ball D3.175

[39](39) from Pushing Lever (B) [38](38).

• Remove the two Nylock Bolts M4 x 14 [35](35) and one Nylock Bolt M4 x 25 [19](19) from the Nose

[17](17), then remove Blade Guide (A) [71](71).

• Remove the Nylock Hex. Socket Hd. Bolt M3 [69](69) and Guide Plate Holder [65](65) from the Nose

[17](17), then remove Guide Plate (P) [68](68).

• Cut the two Wire Bands [61](61) that fixes Sensor (B) [63](63) and Sensor (C) [60](60), then remove

Sensor (C) [60](60).

• Remove the Roll Pin D2.5 [66](66) and Roll Pin D2.5 x 16 [67](67) that fix Sensor (B) [63](63) referring to

page 26.

NOTE: Sensor (C) [60](60) can be removed only after removing Blade Guide (A) [71](71).

3. Reassembly of the power assembly

Reverse the disassembly procedure to reassemble. Note the following points:

• Use the specified tightening torques. (See page 30.)

• Protect the sealing parts (e.g., O-rings, X-rings, valve core, etc.) against contaminants and scratches

during reassembly.

• Always use brand-new seal lock bolts. Never reuse the old bolts.

• Use the alignment marks (made before disassembly) for precise positioning when mounting the Chamber

Base [10](10) on the Cylinder [5](5).

• Slowly tighten the four Nylock Bolts M6 [11](11) to fasten the Chamber Base [10](10) and Chamber Cover

[4](4). Be careful not to pinch and damage the O-ring (I.D 94.5) [7](7).

• Impregnate Felt (P) [20](20) with about 1 g of Molub-Alloy 777-1 grease by hand before reassembly.

• Mount the Pin Wheel [27](27) to the Position Detector [25](25) so that the end surface side of Pin (A)

[33](33) is aligned with the notch of the Position Detector [25](25) as shown in Fig. 16.

NOTE: If the Position Detector [25](25) is not precisely located, an error (causing the orange LED

of the battery indicator to blink) may occur.

• Remove dust from between the Pin Wheel [27](27) and Needle Roller D3 [30](30) and apply about 1.5 g

of Molub-Alloy 777-1 grease to the Needle Roller D3 [30](30), eight Needle Rollers D4 [32](32), and

Needle Roller D4.5 [26](26) evenly.

• Apply about 1.0 g of Isoflex Topas NB52 grease to the X-ring [14](14) and Slide Ring [13](13) of the

Piston Ass'y [15](15) evenly.

Pay special attention to the position of

the Position Detector [25](25).

If the Position Detector [25](25) is

misaligned, the standby position of the

piston is also misaligned. (See page 29.)

[27](27)

[25](25)

Notch

Notch

-17-

Fig. 17

Fig. 18

Fig. 19

• Put the Pin Wheel [27](27) in the Nose [17](17). Facing the notch of the Pin Wheel [27](27) to Blade

Guide (A) [70](70), push the Piston Ass'y [15](15) down to the bottom dead point without meshing with

the eight Needle Rollers D4 [32](32) and Needle Roller D4.5 [26](26) as shown in Fig. 17.

• Mount the Chamber Base [10](10), Special Nut M58 [12](12), and Nose [17](17) to the Cylinder [5](5) in

this order. Apply Three-Bond TB1342H adhesive in the form of a line circling around the cylinder two

times as shown in Fig. 18. Then mount the Special Nut M58 [12](12).

• Mount Sensor (B) [63](63) using a round bar of 2 to 2.5 mm in diameter as shown in Fig. 19 to protect the

root of the wire from being applied force. After mounting Sensor (B) [63](63), remove the round bar.

Round bar

(Remove it after mounting Sensor (B) [63](63).)

Apply TB1342H adhesive here (2 places).

[12](12)

[17](17)

Notch of the Pin Wheel [27](27)

[15](15)

[17](17)

[70](70)

M58 threaded portion

-18-

Fig. 20

Fig. 21

Fig. 21

• Apply Molub-Alloy 777-1 grease to the following area on the Nose [17](17) and then mount Pushing Lever

(B) [38](38).

• Be sure to check Sensor (B) [63](63) according to pages 21 to 22 after reassembling the power assembly.

• Be sure to mount the Hex. Socket Hd. Bolt M5 [64](64) to the Nose [17](17).

• Insert the Rotor [83](83) into the Gear Box [82](82) and check that the Rotor [83](83) turns smoothly by

hand as shown in Fig. 21.

NOTE: If the Rotor [83](83) cannot turn smoothly, the gear may be deformed or damaged. Replace

the Gear Box [82](82) with new one.

• Be sure to mount Bumper (B) [59](59) to the Nose [17](17) as shown in Fig. 22 and then mount the Gear

Box [82](82).

Apply grease here.

[83](83)

[82](82)

[59](59)

-19-

Fig. 22

• If it is difficult to mount the Gear Box [82](82) due to improperly meshed gears, turn the Rotor [83](83) by

hand so that the gears are properly meshed.

• Push the wires in housing (A) of Housing Set [46](46) with a flat-blade screwdriver being careful not to

damage the coating as shown in Fig. 22.

Do not protrude

the wires.

Do not pinch

the wires.

Do not protrude

the wires.

Sensor (C)

Black, blue, red

Sensor (B)

Black, white, red

Black, blue, red

Black, white, red

Ferrite core

Models NR 1890DBCL

and NR 1890DBRL only

Ferrite core

Models NR 1890DBCL

and NR 1890DBRL only

-20-

Fig. 23

Fig. 24

• Check that the wires are not caught and there is no clearance between housings (A) and (B) when putting

housing (A) and housing (B) together.

• After reassembly, check that the terminal of the Wiring [51](51) is properly mounted without mismatch and

it is slightly movable as shown in Fig. 24.

[51](51)

-21-

Fig. 25

4. Checking after reassembly of the power assembly

• Check that Pushing Lever (A) [42](42) moves smoothly without any catch.

• Check that the Adjuster [41](41) rotates smoothly.

• Connect Sensor (B) [63](63) and Sensor (C) [60](60) to the Wiring [51](51) and then connect the terminal

to the battery as shown in Fig. 25 in order to check Sensor (B) [63](63) for normal response.

Operation panel

Power switch

Battery

[51](51)

Operation panel

-22-

Fig. 26

• Insert a pin punch of 5±0.1 mm in diameter between Pushing Lever (B) [38](38) and the wall of the Nose

[17](17) where Sensor (B) [63](63) is inserted. Then push in Pushing Lever (A) [42](42) and keep

pressing the power switch on the operation panel for at least 2 seconds. Check that the LED light on the

operation panel turns on. Next, insert a pin punch of 2.4±0.1 mm in diameter and push in Pushing Lever

(A) [42](42). Keep pressing the power switch on the operation panel for at least 2 seconds. Check that the

LED light on the operation panel remains turned off. (See Fig. 26.)

NOTE: If a pin punch of 5±0.1 mm (0.2±0.0039") in diameter and a pin punch of 2.4±0.1 mm

(0.095±0.0039") in diameter are not available, use the shank of a drill of 5 mm in diameter

and a drill of 2.4 mm in diameter.

• If the LED light remains turned off when inserting a pin punch of 5 mm in diameter during the operation

check of Sensor (B) [63](63) or if the LED light turns on when inserting a pin punch of 2.4 mm in diameter,

Pushing Lever (B) [38](38), Blade Plate (P) [68](38) or Sensor (B) [63](63) may be damaged or deformed.

Check and replace the damaged or deformed part and then perform the operation check of Sensor (B)

[63](63) again.

Pin punch

(5 mm/2.4 mm in diameter)

Push in.

-23-

Fig. 27

NOTE: When replacing only the Piston Ass'y [15](15) with new one, also replace the Needle Roller

D4.5 [26](26) mounted in the Pin Wheel [27](27) with new one included in the brand-new

Piston Ass'y [15](15).

1. Disassembly

• Remove Housing (C) [45](45), magazine ass'y, and Top Cover [2](2) to take out the power assembly and

Wiring [51](51) referring to pages 8 to 12.

Replacement of the piston ass'y

[1](1)

[2](2)

[3](3)

[4](4)

[5](5)

[6](6)

[7](7)

[9](9)

[11](11)

[12](12)

[13](13)

[8](8)

[14](14)

[13](13)

[16](16)

[17](17)

[18](18)

[19](19)

[29](29)

[27](27)

[20](20)

[26](26)

[10](10

)

[34](34)

[35](35)

[33](33)

[36](36)

[32](32)

[31](31)

[30](30)

[37](37)

[21](21)

[23](23)

[24](24)

[25](25)

[38](38)

[39](39)

[40](40)

[41](41)

[42](42)

[68](68)

[69](69)

[18](18)

[66](66)

[64](81)

[65](82)

[60](60)

[61](61)

[63](63)

[22](22)

[28](28)

[15](15)

[67](67)

-24-

Fig. 28

Fig. 29

• Check that compressed air is completely released. Then remove the four Nylock Bolts M6 [11](11) from

the Chamber Base [10](10) and Chamber Cover [4](4) to remove the Chamber Cover [4](4).

NOTE: If it is difficult to remove the Chamber Base [10](10), temporarily tighten at least two Nylock

Bolts M6 [11](11) so that the threaded portion is shown 3.5 mm to 6.5 mm as shown in Fig.

28. Mount the reduction valve set and feed compressed air to remove the Chamber Base

[10](10).

• Push the Piston Ass'y [15](15) from Blade Guide (A) [70](70) side toward the Cylinder [5](5) side to

remove it from the Cylinder [5](5).

• Remove the Retaining Ring D52 [21](21) from the Nose [17](17) and pull out the Bearing Holder [22](22)

and Pin Wheel [27](27).

• Remove the Ball Bearing 6000VV [23](23) from the Pin Wheel [27](27).

• Remove the Needle Roller D3 [30](30) from the Pin Wheel [27](27). Then remove the Position Detector

[25](25).

• Remove the Needle Roller D4.5 [26](26) from the Pin Wheel [27](27). (See Fig. 29.)

2. Reassembly

Reverse the disassembly procedure to reassemble. Note the following points:

• Use the specified tightening torques.

• Insert the Needle Roller D4.5 [26](26) included in the brand-new Piston Ass'y [15](15) into the Pin Wheel

[27](27).

• Mount the Pin Wheel [27](27) to the Position Detector [25](25) so that the end surface side of Pin (A)

[33](33) is aligned with the notch of the Position Detector [25](25) as shown in Fig. 30.

[26](26)

[27](27)

Reduction valve set

Temporarily tighten the Nylock Bolts

M6 [11](11) so that the threaded

portion is shown 3.5 to 6.5 mm.

-25-

Fig. 30

Fig. 31

• Remove dust from between the Pin Wheel [27](27) and Needle Roller D3 [30](30) and apply about 1.5 g

of Molub-Alloy 777-1 grease to the Needle Roller D3 [30](30), eight Needle Rollers D4 [32](32), and

Needle Roller D4.5 [26](26) evenly.

• Apply about 0.2 g of Isoflex Topas NB52 grease to the two Slide Rings [13](13) included in the brand-new

Piston Ass'y [15](15) evenly. Then mount the two Slide Rings [13](13) to the Piston Ass'y [15](15).

• Apply about 1.0 g of Isoflex Topas NB52 grease to the X-ring [14](14) included in the brand-new Piston

Ass'y [15](15) evenly. Then mount the X-ring [14](14) to the Piston Ass'y [15](15).

• Put the Pin Wheel [27](27) in the Nose [17](17). Facing the notch of the Pin Wheel [27](27) to Blade

Guide (A) [70](70), push the Piston Ass'y [15](15) down to the bottom dead point without meshing with

the eight Needle Rollers D4 [32](32) and Needle Roller D4.5 [26](26) as shown in Fig. 31. Apply about

1.5 g of Isoflex Topas NB52 grease to the inside of the Cylinder [5](5) evenly.

NOTE: If the Position Detector [25](25) is not precisely located, an error (causing the orange LED

of the battery indicator to blink) may occur.

• Slowly tighten the four Nylock Bolts M6 [11](11) to fasten the Chamber Base [10](10) and Chamber Cover

[4](4). Be careful not to pinch and damage the O-ring (I.D 94.5) [7](7).

• Perform reassembly of the power assembly according to pages 16 to 20.

Pay special attention to the position of

the Position Detector [25](25).

If the Position Detector [25](25) is

misaligned, the standby position of the

piston is also misaligned. (See page 29.)

[27](27)

[25](25)

Notch

Notch

Notch of the Pin Wheel [27](27)

[15](15)

[17](17)

[70](70)

-26-

Fig. 32

Fig. 33

• Remove Housing (C) [45](45), magazine ass'y, and Top Cover [2](2) to take out the power assembly

referring to pages 8 to 12.

• Remove the Nylock Hex. Socket Hd. Bolt M3 [69](69) and Guide Plate Holder [65](65) from the Nose

[17](17), then remove Guide Plate (P) [68](68).

• Pull out the Roll Pin D2.5 [66](66) and Roll Pin D2.5 x 16 [67](67) protruding from the Nose [17](17) with

nippers as shown in Fig. 32.

• Remove Sensor (B) [63](63) from the Nose [17](17).

• Mount new Sensor (B) [63](63) to the Nose [17](17) and then mount the Roll Pin D2.5 [66](66) as shown

in Fig. 33.

A

Hold the roll pin with the blade edges of nippers.

Pressing against the end surface of the nose, move

the nippers in "A" direction to pull out the roll pin.

Use nippers having no

dent at the blade edges.

Replacement of sensor (B)

-27-

Model name and repair tool

number are indicated on the label.

Fig. 34

Fig. 35

CAUTION: • Be sure to set MAINTENANCE mode (see page 7) and move the Piston Ass'y [15](15)

down to the bottom dead point before feeding or discharging compressed air.

• Be sure to use the specified reduction valve set when feeding compressed air.

• An oil-free compressor should be used to feed compressed air to the nailer.

1. Moving the piston down to the bottom dead point

• Turn on the nailer and switch to MAINTENANCE mode. (See page 7.)

• Repeat the steps below three or four times until the Piston Ass'y [15](15) reaches the bottom dead point.

(1) Move the Feeder Knob [92](92) down to reset the dry-fire lockout mechanism.

(2) Press Pushing Lever (A) [42](42) against a piece of wood.

(3) Pull the Trigger [54](54).

• Check that the driver blade of the Piston Ass'y [15](15) protrudes from the blade guide.

2. Feeding compressed air

• Check that the battery is not mounted in the nailer body.

• Prepare the J-394 reduction valve set (16 GA) specified below.

Model

Model name

indicated on label

Repair tool number Preset feeding pressure

NR1890DC/DBCL

NR1890DR/DBRL

NT 1865DM J-394 (Code No. 371208) 0.5±0.03 MPa (5.1±0.3 kgf/cm

2

)

Blade guide

Pressure regulator

Charge screw

Repair tool number

and feeding pressure

Air plug*

*: Replace the air plug according to your air compressor.

(Air plug: 1/4" NPT pipe thread taper)

O-rings

[54[(54)

[92](92)

Driver blade

Feeding compressed air

[42[(42)

1

2

3

-28-

Fig. 36

Fig. 37

Fig. 38

• Push the valve core and check that no compressed air is left.

• Apply lubricant to the O-ring (S-5) (Code No. 872822) of the charge screw. Always replace a defective

O-ring with a new one.

• Screw in the charge screw into the pressure feeding port of the Chamber Base [10](10).

• Prepare an air compressor (0.7 MPa or higher) and set a delivery pressure of 0.7 to 1.2 MPa.

(See Fig. 37.)

• Connect the reduction valve set to the air compressor for at least 10 seconds to feed compressed air.

(See Fig. 38.)

• Reverse the procedure above for disconnection.

• Quickly mount the Charge Cap [8](8) on the feeding port within 30 seconds after feeding compressed air

to prevent air leaks from the valve section.

Before connecting the reduction valve set

After connecting the reduction valve set

Feeding port

-29-

• Check that no nail is loaded in the magazine.

• Check that Pushing Lever (A) [42](42) moves smoothly without any catch.

• Check that the Adjuster [41](41) rotates smoothly.

• Check that the Trigger [54](54) moves smoothly.

• Check that the Feeder Knob [92](92) slides smoothly.

• Push Pushing Lever (A) [42](42) of the empty nailer (without nails) against a wood material and make

sure the dry-fire lockout mechanism works normally.

• Move Lever (A) [56](56) to the LOCK position and make sure the Trigger [54](54) is completely locked

and cannot be pulled back.

• Turn on the nailer and make sure no LED is blinking to indicate an error state.

• Turn on the nailer and make sure the LEDs on the operation panel light.

• Load the longest nails in the nailer and start nailing. Check that no trouble (e.g., abnormal nailing, unusual

sound, nail head lift) occurs. Press Pushing Lever (A) [42](42) without pulling the Trigger [54](54) in the

contact actuation mode and make sure the nailer does not work.

• After checking the actual nailing, check the position-in-readiness according to the following procedure:

Measure the distance between the tip of Blade Guide (A) [70](70) and the tip of the Piston Ass'y [15](15)

with a caliper and make sure that the distance is 90.2 mm or shorter. If the distance is longer than 90.2

mm, the position detector may be incorrectly mounted. Check whether the position detector is correctly

mounted or not. (See page 16.)

• Do not use the nailer for one day after checking the actual nailing, and then check that the nailer works

normally without any nail heads lifted on the next day by loading the longest nails in the nailer (air leak

check).

Checking after reassembly

-30-

Item No.

Part name

Tightening torque

NR 1890DC

NR 1890DBCL

NR 1890DR

NR 1890DBRL

N•m lbf-ft

[1] (1)

Hex. Socket Bolt M6 9.8 ± 0.8 7.2 ± 0.6

[5] (5)

Cylinder 82 ± 3 60.5± 0.2

[8] (8)

Charge Cap 4.5 ± 0.5 3.3 ± 0.4

[11] (11)

Nylock Bolt M6 12.8 ± 0.8 9.4 ± 0.6

[12] (12)

Special Nut M58 50 ± 1 36.9 ± 0.7

[19][35] (19)(35)

Nylock Bolt (W/Flange) M4 3.4 ± 0.7 2.5 ± 0.5

[34][85] (34)(86)

Nylock Bolt (W/Flange) M5 6.9 ± 0.5 5.1 ± 0.5

[37] (37)

Special Bolt M6 12.7 ± 0.8 9.4 ± 0.6

[44] (44)

Tapping Screw (W/Flange) D4 x 20 (Black) 2.0 ± 0.5 1.5 ± 0.2

[58] (58)

Low Head Hex. Socket Bolt M4 x 8 3.4 ± 0.7 2.5 ± 0.5

[64] (64)

Hex. Socket Hd. Bolt M5 3.0 ± 0.3 2.2 ± 0.2

[69] (69)

Nylock Hex. Socket Hd. Bolt M3 2.45 ± 0.5 1.8 ± 0.4

[89] (89)

Step Bolt M3 1.7 ± 0.17 1.2 ± 0.1

[91] (91)

Tapping Screw (W/Flange) D4 x 16 (Black) 2.8 ± 0.5 2.0 ± 0.4

[93] (93)

Tapping Screw (W/Flange) D5 x 20 (Black) 2.9 ± 0.5 2.2 ± 0.4

Tightening torque

-31-

Fig. 39

Connecting diagram

1. Black

2. Yellow

Trigger switch

Push switch

Pin wheel

switch

Sensor ass'y (B) Sensor ass'y (C)

Battery terminal

Main PCB ass'y

Tact switch PCB ass'y

Sensor PCB

ass'y

M

LD

Black

White

Red

1. Red

2. Blue

3. Black

1. Red

2. White

3. Black

Red

Black

White

*: Alternative part

Ferrite core*

Ferrite core*

(Models NR 1890DBCL and

NR 1890DBRL only)

(Models NR 1890DBCL and

NR 1890DBRL only)

-32-

MODEL

Variable

10 20 30 40 50 60 min.

NR 1890DC

NR 1890DBCL

NR 1890DR

NR 1890DBRL

General Assembly

Blade

Guide (B)

Magazine

Cover (A)

Magazine

Cover (B)

Nail Rail

Magazine

Guard

Magazine

Plate

Pushing

Stopper (A)

Pushing

Stopper (B)

Pushing

Stopper

Spri ng

Feeder

Knob

Nail Feeder

(B)

Ribbon

Spri ng

Nail Feeder

Pin Wheel

Position

Detector

Chamber

Cover

Chamber

Base

Special Nut

M58

O-ring x 2

Cylinder

Piston Blade

Slide Ring

X-Ring

Piston

Bumper

Housing

Trig ger

Rotor

Wiring

Sensor (C)

Gear Box

Adjuster

Pushing

Lever (A)

Pushing

Lever (B)

Magnet

Blade

Guide (A)

Sensor (B)

Nose

Work Flow

Top Cover

Housing (C)

Hook

Pushing

Lever

Spri ng

STANDARD REPAIR TIME (UNIT) SCHEDULES

PNEUMATIC TOOL PARTS LIST

Model NR 1890DC

CORDLESS STRIP NAILER

LIST NO. K858

(E1)

2017 · 7· 12

A

A

1

2

3

4

5

6

12

20

7

8

9

11

10

14

13

15

16

19

17

25

26

27

28

29

504

21

22

23

24

30

32

31

33

34

35

36

37

38

39

40

41

42

67

44

45

43

44

46

53

54

50

52

50

48

47

51

55

56

57

58

83

63

18

84

85

86

87

77

78

79

80

88

70

71

76

75

73

73

72

74

89

90

91 92 93

501

501

61

66

505

502

503

506

64

18

13

60

65

68

69

81

62

59

82

49

PARTS NR 1890DC

DESCRIPTION REMARKS

1 372298 HEX. SOCKET BOLT M6 4

2 372296 TOP COVER 1

3 371012 RUBBER CUSHION (C) 1

4 372337 CHAMBER COVER 1

5 372335 CYLINDER 1

6 372336 O-RING (I.D 55.5) 2

7 372334 O-RING (I.D 94.5) 1

8 371039 CHARGE CAP 1

9 872822 O-RING (S-5) 1

10 372388 CHAMBER BASE 1

11 372338 NYLOCK BOLT M6 4

12 372339 SPECIAL NUT M58 1

13 372320 SLIDE RING 2

14 372319 X-RING 1

15 372318 PISTON ASS'Y 1 INCLUD.13,14,26

16 372317 PISTON BUMPER 1

17 372387 NOSE 1

18 372343 RUBBER CUSHION (A) 2

19 372310 NYLOCK BOLT (W/FLANGE) M4 X 25 1

20 372330 FELT (P) 1

21 372332 RETAINING RING D52 1

22 372331 BEARING HOLDER 1

23 6000VV BALL BEARING 6000VVCMPS2L 1

24 372329 O-RING (I.D 20.22) 1

25 372327 POSITION DETECTOR 1

26 372326 NEEDLE ROLLER D4.5 1

27 372321 PIN WHEEL 1

28 372323 WHEEL SPRING (B) 1

29 6902VV BALL BEARING 6902VV 1

30 372328 NEEDLE ROLLER D3 1

31 372322 WHEEL SPRING (A) 1

32 372325 NEEDLE ROLLER D4 8

33 372324 PIN (A) 1

34 372355 NYLOCK BOLT (W/FLANGE) M5 X 22 2

35 372311 NYLOCK BOLT (W/FLANGE) M4 X 14 2

36 372307 PUSHING LEVER SPRING (B) 1

37 372316 SPECIAL BOLT M6 1

38 372305 PUSHING LEVER (B) 1

39 959148 STEEL BALL D3.175 (10 PCS.) 2

40 372315 ADJUSTER SPRING 2

41 372314 ADJUSTER 1

42 372308 PUSHING LEVER (A) 1

43 NAME PLATE 1

44 301653

TAPPING SCREW (W/FLANGE) D4 X 20 (BLACK) 14

45 372297 HOUSING (C) 1

46 372295 HOUSING SET 1 INCLUD.45

* 47 338890 BATTERY BSL 1860 (USA,CAN) 1 INCLUD.505

* 47 339782 BATTERY BSL 1830C (USA,CAN) 1 INCLUD.505

48 332668 RUBBER CUSHION 1

49 372803 PLATE (A) 1

- 2 - 7 - 17

*ALTERNATIVE PARTS

ITEM

NO.

NO.

USED

CODE NO. CODE NO.

PARTS NR 1890DC

DESCRIPTION REMARKS

50 371020 O-RING (I.D 2.5) 2

51 372291 WIRING 1

52 371019 SWITCH CABLE (A) 1

53 332000 SPRING (T) 1

54 371021 TRIGGER 1

55 331790 LEVER (C) 1

56 326276 LEVER (A) 1

57 372356 HOOK 1

58 331109 LOW HEAD HEX. SOCKET BOLT M4 X 8 3

59 372342 BUMPER (B) 2

60 372302 SENSOR (C) 1

61 6696839 WIRE BAND 2

62 371107 CAUTION LABEL 1

63 372301 SENSOR (B) 1 INCLUD.38

64 372340 HEX. SOCKET HD. BOLT M5 1

65 372313 GUIDE PLATE HOLDER 1

66 372304 ROLL PIN D2.5 1

67 878965 ROLL PIN D2.5 X 16 1

68 372312 BLADE PLATE (P) 1

69 331184 NYLOCK HEX. SOCKET HD. BOLT M3 1

70 372309 BLADE GUIDE (A) 1

71 949685 ROLL PIN D3 X 20 (10 PCS.) 1

72 372349 PUSHING LEVER STOPPER (A) 1

73 372350 SPRING 2

74 372351 PUSHING LEVER STOPPER (B) 1

75 883687 SPRING 1

76 372346 BLADE GUIDE (B) 1

77 885323 NAIL FEEDER (A) 1

78 949506 ROLL PIN D4 X 28 (10 PCS.) 1

79 885324 NAIL FEEDER (B) 1

80 885325 RIBBON SPRING 1

81 372353 CAP NUT M3 1

82 372341 GEAR BOX 1

83 361071 ROTOR 1

84 372345 MAGAZINE COVER (B) 1

85 372354 NYLOCK BOLT (W/FLANGE) M5 1

86 372347 MAGAZINE PLATE 1

87 885341 NAIL RAIL 1

88 372344 MAGAZINE COVER (A) 1

89 372352 STEP BOLT M3 1

90 372348 MAGAZINE GUARD 1

91 307811

TAPPING SCREW (W/FLANGE) D4 X 16 (BLACK) 3

92 886246 FEEDER KNOB 1

93 302089

TAPPING SCREW (W/FLANGE) D5 X 20 (BLACK) 1

7 - 17 - 3 -

*ALTERNATIVE PARTS

NO.

USED

CODE NO.

ITEM

NO.

NR 1890DC

DESCRIPTION REMARKS

* 501 CHARGER (MODEL UC 18YSL3) 1

* 501 CHARGER (MODEL UC 18YFSL) 1

502 943277 HEX. BAR WRENCH 3MM 1

503 944458 HEX. BAR WRENCH 4MM 1

504 875769 PROTECTIVE GLASSES 1

505 329897 BATTERY COVER 1

506 372294 TOOL BAG 1

- 4 - Printed in Japan 7 - 17

(170712N)

*ALTERNATIVE PARTS

STANDARD ACCESSORIES

NO.

USED

CODE NO.

ITEM

NO.

PNEUMATIC TOOL PARTS LIST

Model NR 1890DR

CORDLESS STRIP NAILER

LIST NO. K859

(E1)

2017 · 7· 12

13

69

67

66

64

81

62

48

94

A

1

2

3

4

5

6

12

7

8

9

11

10

14

13

15

16

19

17

25

26

27

28

29

21

22

23

24

30

31

32

33

34

35

36

37

38

39

40

41

42

44

45

43

44

46

53

54

50

52

50

49

47

51

55

56

57

58

83

63

18

84

85

87

77

78

79

80

88

70

71

76

75

73

73

72

74

89

90

91

92

93

A

86

20

18

65

60

61

59

68

504

501

501

505

502

503

506

82

PARTS NR 1890DR

DESCRIPTION REMARKS

1 372298 HEX. SOCKET BOLT M6 4

2 372296 TOP COVER 1

3 371012 RUBBER CUSHION (C) 1

4 372337 CHAMBER COVER 1

5 372335 CYLINDER 1

6 372336 O-RING (I.D 55.5) 2

7 372334 O-RING (I.D 94.5) 1

8 371039 CHARGE CAP 1

9 872822 O-RING (S-5) 1

10 372388 CHAMBER BASE 1

11 372338 NYLOCK BOLT M6 4

12 372339 SPECIAL NUT M58 1

13 372320 SLIDE RING 2

14 372319 X-RING 1

15 371810 PISTON ASS'Y 1 INCLUD.13,14,26

16 372317 PISTON BUMPER 1

17 372387 NOSE 1

18 372343 RUBBER CUSHION (A) 2

19 372310 NYLOCK BOLT (W/FLANGE) M4 X 25 1

20 372330 FELT (P) 1

21 372332 RETAINING RING D52 1

22 372331 BEARING HOLDER 1

23 6000VV BALL BEARING 6000VVCMPS2L 1

24 372329 O-RING (I.D 20.22) 1

25 372327 POSITION DETECTOR 1

26 372326 NEEDLE ROLLER D4.5 1

27 372321 PIN WHEEL 1

28 372323 WHEEL SPRING (B) 1

29 6902VV BALL BEARING 6902VV 1

30 372328 NEEDLE ROLLER D3 1

31 372322 WHEEL SPRING (A) 1

32 372325 NEEDLE ROLLER D4 8

33 372324 PIN (A) 1

34 372355 NYLOCK BOLT (W/FLANGE) M5 X 22 2

35 372311 NYLOCK BOLT (W/FLANGE) M4 X 14 2

36 372307 PUSHING LEVER SPRING (B) 1

37 372316 SPECIAL BOLT M6 1

38 372305 PUSHING LEVER (B) 1

39 959148 STEEL BALL D3.175 (10 PCS.) 2

40 372315 ADJUSTER SPRING 2

41 372314 ADJUSTER 1

42 372308 PUSHING LEVER (A) 1

43 NAME PLATE 1

44 301653

TAPPING SCREW (W/FLANGE) D4 X 20 (BLACK) 14

45 372297 HOUSING (C) 1

46 372295 HOUSING SET 1 INCLUD.45

* 47 338890 BATTERY BSL 1860 (USA,CAN) 1 INCLUD.505

* 47 339782 BATTERY BSL 1830C (USA,CAN) 1 INCLUD.505

48 332668 RUBBER CUSHION 1

49 372803 PLATE (A) 1

- 2 - 7 - 17

*ALTERNATIVE PARTS

ITEM

NO.

NO.

USED

CODE NO. CODE NO.

PARTS NR 1890DR

DESCRIPTION REMARKS

50 371020 O-RING (I.D 2.5) 2

51 372291 WIRING 1

52 371019 SWITCH CABLE (A) 1

53 332000 SPRING (T) 1

54 371021 TRIGGER 1

55 331790 LEVER (C) 1

56 326276 LEVER (A) 1

57 372356 HOOK 1

58 331109 LOW HEAD HEX. SOCKET BOLT M4 X 8 3

59 372342 BUMPER (B) 2

60 372302 SENSOR (C) 1

61 6696839 WIRE BAND 2

62 371107 CAUTION LABEL 1

63 372301 SENSOR (B) 1 INLCUD.38

64 372340 HEX. SOCKET HD. BOLT M5 1

65 372313 GUIDE PLATE HOLDER 1

66 372304 ROLL PIN D2.5 1

67 878965 ROLL PIN D2.5 X 16 1

68 372312 BLADE PLATE (P) 1

69 331184 NYLOCK HEX. SOCKET HD. BOLT M3 1

70 371804 BLADE GUIDE (A) 1

71 949685 ROLL PIN D3 X 20 (10 PCS.) 1

72 371809 PUSHING LEVER STOPPER (A) 1

73 372350 SPRING 2

74 372351 PUSHING LEVER STOPPER (B) 1

75 883687 SPRING 1

76 371805 BLADE GUIDE (B) 1

77 885621 NAIL FEEDER 1

78 949506 ROLL PIN D4 X 28 (10 PCS.) 1

79 885324 NAIL FEEDER (B) 1

80 885325 RIBBON SPRING 1

81 372353 CAP NUT M3 1

82 372341 GEAR BOX 1

83 361071 ROTOR 1

84 371807 MAGAZINE COVER (B) 1

85 371808 MAGAZINE PLATE 1

86 372809 NYLOCK BOLT (W/FLANGE) M5 X 18 1

87 372811 NAIL RAIL (C) 1

88 371806 MAGAZINE COVER (A) 1

89 372352 STEP BOLT M3 1

90 372348 MAGAZINE GUARD 1

91 307811

TAPPING SCREW (W/FLANGE) D4 X 16 (BLACK) 3

92 886246 FEEDER KNOB 1

93 302089

TAPPING SCREW (W/FLANGE) D5 X 20 (BLACK) 1

94 372810 WASHER D14.5 1

7 - 17 - 3 -

*ALTERNATIVE PARTS

NO.

USED

CODE NO.

ITEM

NO.

NR 1890DR

DESCRIPTION REMARKS

* 501 CHARGER (MODEL UC 18YSL3) 1

* 501 CHARGER (MODEL UC 18YFSL) 1

502 943277 HEX. BAR WRENCH 3MM 1

503 944458 HEX. BAR WRENCH 4MM 1

504 875769 PROTECTIVE GLASSES 1

505 329897 BATTERY COVER 1

506 372294 TOOL BAG 1

- 4 - Printed in Japan 7 - 17

(170712N)

*ALTERNATIVE PARTS

STANDARD ACCESSORIES

NO.

USED

CODE NO.

ITEM

NO.

Loading...

Loading...