Page 1

HITACHI PROGRAMMABLE CONTROLLER

APPLICATION MANUAL

NJI-350B (X)

Page 2

WARNING

To ensure that the equipment described by this manual. As well as all equipment connected to and used

with it, operate satisfactorily and safely, all applicable local and national codes that apply to installing and

operating the equipment must be followed. Since codes can vary geographically and can change with

time, it is the user’s responsibility to determine which standard and codes apply, and to comply with

them.

FAILURE TO COMPLY WITH APPLICABLE CODES AND STANDARDS CAN RESULT IN

DAMAGE TO EQUIPMENT AND / OR SERIOUS INJURY TO PERSONNEL.

INSTALL EMERGENCY POWER STOP SWITCH WHICH OPERATES INDEPENDENTLY OF

THE PROGRAMMABLE CONTROLLER TO PROTECT THE EQUIPMENT AND / OR

PERSONNEL IN CASE OF THE CONTROLLER MALFUNCTION.

Personnel who are to install and operate the equipment should carefully study this manual and any

others referred to by it prior to installation and / or operation of the equipment. Hitachi, Ltd. constantly

strives to improve its products, and the equipment and the manual(s) that describe it may be different

from those already in your possession.

If you have any questions regarding the installation and operation of the equipment, or if more

information is desired, contact your local Authorized Distributor or Hitachi, Ltd.

IMPORTANT

THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENERGY AND, IF

NOT INSTALLED AND USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE

INTERFERENCE TO RADIO COMMUNICATIONS. AS TEMPORARILY PERMITTED BY REGULATION,

IT HAS NOT BEEN TESTED FOR COMPLIANCE WITH THE LIMITS FOR CLASS A COMPUTING

DEVICES PURSUANT TO SUBPART J OF PART 15 OF FCC RULES, WHICH ARE DESIGNED TO

PROVIDE REASONABLE PROTECTION AGAINST SUCH INTERFERENCE.

OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE INTERFERENCE

IN WHICH CASE THE USER, AT HIS OWN EXPENSE, WILL BE REQUIRED TO TAKE WHATEVER

MEASURES MAY BE REQUIRED TO CORRECT THE INTERFERENCE.

Page 3

LIMITED WARRANTY AND IMITATION OF LIABILITY

Hitachi, Ltd. (Hitachi) warrants to the original purchaser that the programmable controller (PLC)

manufactured by Hitachi is free from defects in material and workmanship under normal use and

service. The obligation of Hitachi under this warranty shall be limited to the repair or exchange of any

part or parts which may prove defective under normal use and service within eighteen (18) months from

the date of manufacture or twelve (12) months from the date of installation by the original purchaser

which ever occurs first, such defect to be disclosed to the satisfaction of Hitachi after examination by

Hitachi of the allegedly defective part or parts. This warranty in expressly in lieu of all other warranties

expressed or implied including the warranties of merchantability and fitness for use and of all other

obligations or liabilities and Hitachi neither assumes, nor authorizes any other person to assume for

Hitachi, any other liability in connection with the sale of this PLC. This warranty shall not apply to this

PLC or any part hereof which has been subject to accident, negligence, alteration, abuse, or misuse.

Hitachi makes no warranty whatsoever in respect to accessories or parts not supplied by Hitachi. The

term "original purchaser", as used in this warranty, shall be deemed to mean that person for whom the

PLC in originally installed.

In no event, whether as a result of breach of contract, warranty, tort (including negligence) or otherwise,

shall Hitachi or its suppliers be liable for any special, consequential, incidental or penal damages

Including, but not limited to, loss of profit or revenues, loss of use of the products or any associated

equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities,

services or replacement power, down time costs, or claims of original purchaser’s customers for such

damages.

To obtain warranty service, return the product to your distributor, or send it with a description of the

problem, proof of purchase, post paid, insured, and in a suitable package to:

Quality Assurance Dep.

Hitachi Industrial Equipment Systems Co., Ltd.

46-1, Ooaza-Tomioka Nakajo-machi

Kitakanbara-gun, Niigata-ken

959-2608 JAPAN

Page 4

Copyright 2000 by Hitachi Industrial Equipment Systems Co., Ltd.

All Rights reserved - Printed in Japan

The information and/or drawings set forth in this document and all rights in and to inventions disclosed herein and

patents which might be granted thereon disclosing or employing and the materials, techniques or apparatus described

herein are the exclusive property of Hitachi, Ltd.

No copies of the information or drawings shall be made without the prior consent of Hitachi, Ltd.

Hitachi, Ltd. provides customer assistance in varied technical areas. Since Hitachi does not posses full access to data

concerning all of the uses and applications of customer‘s products, responsibility is assumed by Hitachi neither for

customer product design nor for any infringements of patents or rights of others which may result from Hitachi

assistance.

The specifications and descriptions contained in this manual were accurate at the time they were approved for printing.

Since Hitachi, Ltd. Incorporated constantly strives to improve all its products, we reserve the right to make changes to

equipment and/or manuals at any time without notice and without incurring any obligation other than as noted in this

manual.

Hitachi, Ltd. assumes no responsibility for errors that may appear in this manual.

As the product works with user program and Hitachi, Ltd. cannot test all combination of user program components, it is

assumed that a bug or bugs may happen unintentionally. If it is happened: please inform the fact to Hitachi, Ltd. or its

representative. Hitachi will try to find the reason as much as possible and inform the countermeasure when obtained.

Nevertheless Hitachi, Ltd. intends to make products with enough reliability, the product has possibility to be damaged at

any time. Therefore personnel who are to install and operate the equipment has to prepare with the counter-measure such

as power off switch can be operated independently of the controller. Otherwise, it can result in damage to equipment

and/or serious injury to personnel.

Page 5

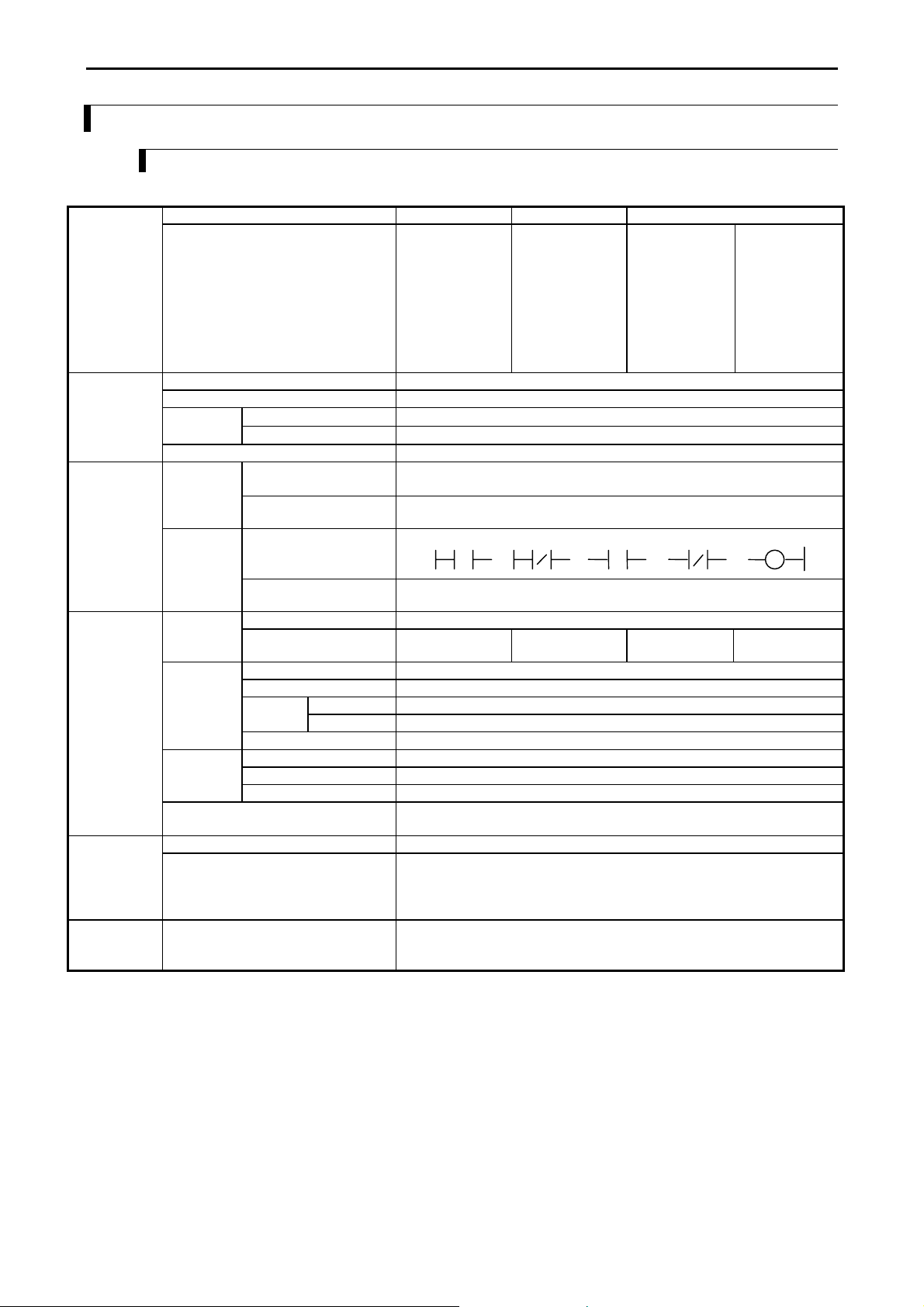

Safety Precautions

Read this manual and attached documents thoroughly before installing and operating this unit, and performing

maintenance or inspection of this unit in order to use the unit correctly. Be sure to use this unit after acquiring adequate

knowledge of the unit, all safety information, and all precautionary information. Also, be sure to deliver this manual to

the person in charge of maintenance.

Safety caution items are classified as “Danger” and “Caution” in this document.

DANGER

CAUTION

However, depending on the situation, items marked with may result in major accidents.

Both of these items contain important safety information, so be sure to follow them closely.

Icons for prohibited items and required items are shown below:

: Indicates a prohibited item (item that cannot be performed). For example, when open flames are prohibited,

is shown.

: Indicates a required item (item that must be performed). For example, when grounding must be performed,

is shown.

: Cases in which, if handled incorrectly, a dangerous situation may occur, resulting in

possible death or severe injury.

: Cases in which, if handled incorrectly, a dangerous situation may occur, resulting in

possible minor to medium injury to the body, or only mechanical failure.

CAUTION

1. Installation

CAUTION

• Use this product in an environment as described in the catalogue and this document.

If this product is used in an environment subject to high temperature, high humidity, excessive dust, corrosive

gases, vibration or shock, it may result in an electric shock, fire or malfunction.

• Installation this product according to the instructions in this manual.

If installation is not performed correctly, it may result in falling, malfunction, or an operational error of the unit.

• Never allow foreign objects such as wire chips to enter the unit.

They may cause a fire, malfunction, or failure.

Page 6

2. Wiring

REQUIRED

• Always perform grounding (FE terminal).

If grounding is not performed, there is a risk of an electric shock or malfunction.

CAUTION

• Connect a power supply that meets the rating.

If a power supply that does not meet the rating is connected, it may result in a fire.

• Any wiring operation should only be performed by a qualified technician.

If wiring is performed incorrectly, it may result in a fire, failure, or electric shock.

3. Precautions When Using the Unit

DANGER

• Never touch the terminals while the power is on.

There is a risk of an electric shock.

• Configure the emergency stop circuit, interlock circuit and other related circuits external to the programmable

controller (referred to as the PLC in this document).

Otherwise, a failure in the PLC may damage the equipment or result in a serious accident.

Never interlock the unit with the external load via the relay drive power supply of the relay output module.

CAUTION

• Before performing program change, forced output, run, stop and other operations while the unit is in operation, be

sure to check the validity of the applicable operation and safety.

An operation error may damage the equipment or result in a serious accident.

• Be sure to power on the unit according to the designated power-on sequence.

Otherwise, an erroneous operation may damage the equipment or result in a serious accident.

Page 7

4. Maintenance

DANGER

• Never connect the

short circuit the battery.

There is a risk of an explosion or fire.

and of the battery in reverse. Also, never charge, disassemble, heat, place in fire, or

PROHIBITED

• Never disassemble or modify the unit.

These actions may result in a fire, malfunction, or failure.

CAUTION

• Be sure to turn off the power supply before removing or attaching the module/unit.

Otherwise, it may result in an electric shock, malfunction, or failure.

Page 8

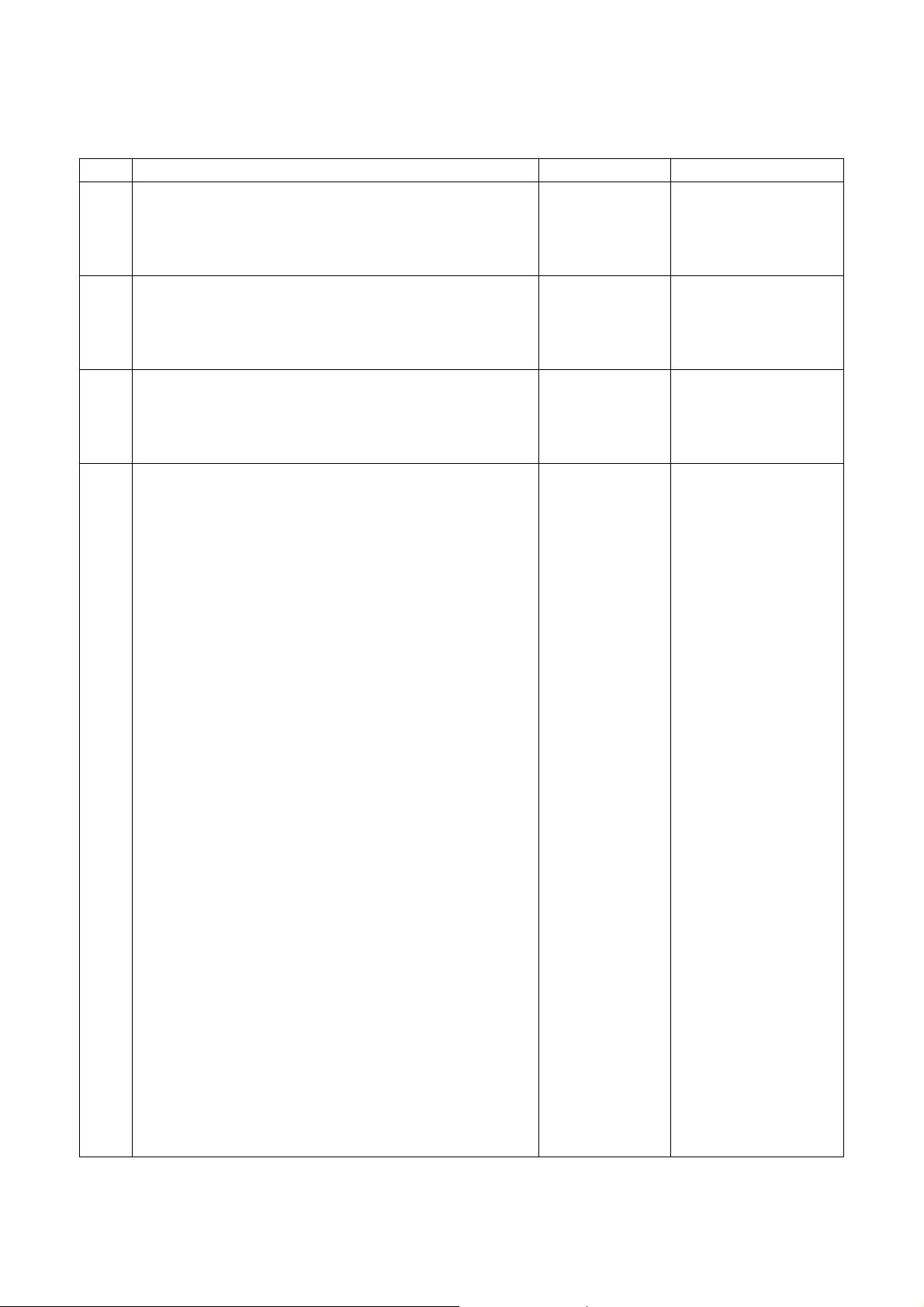

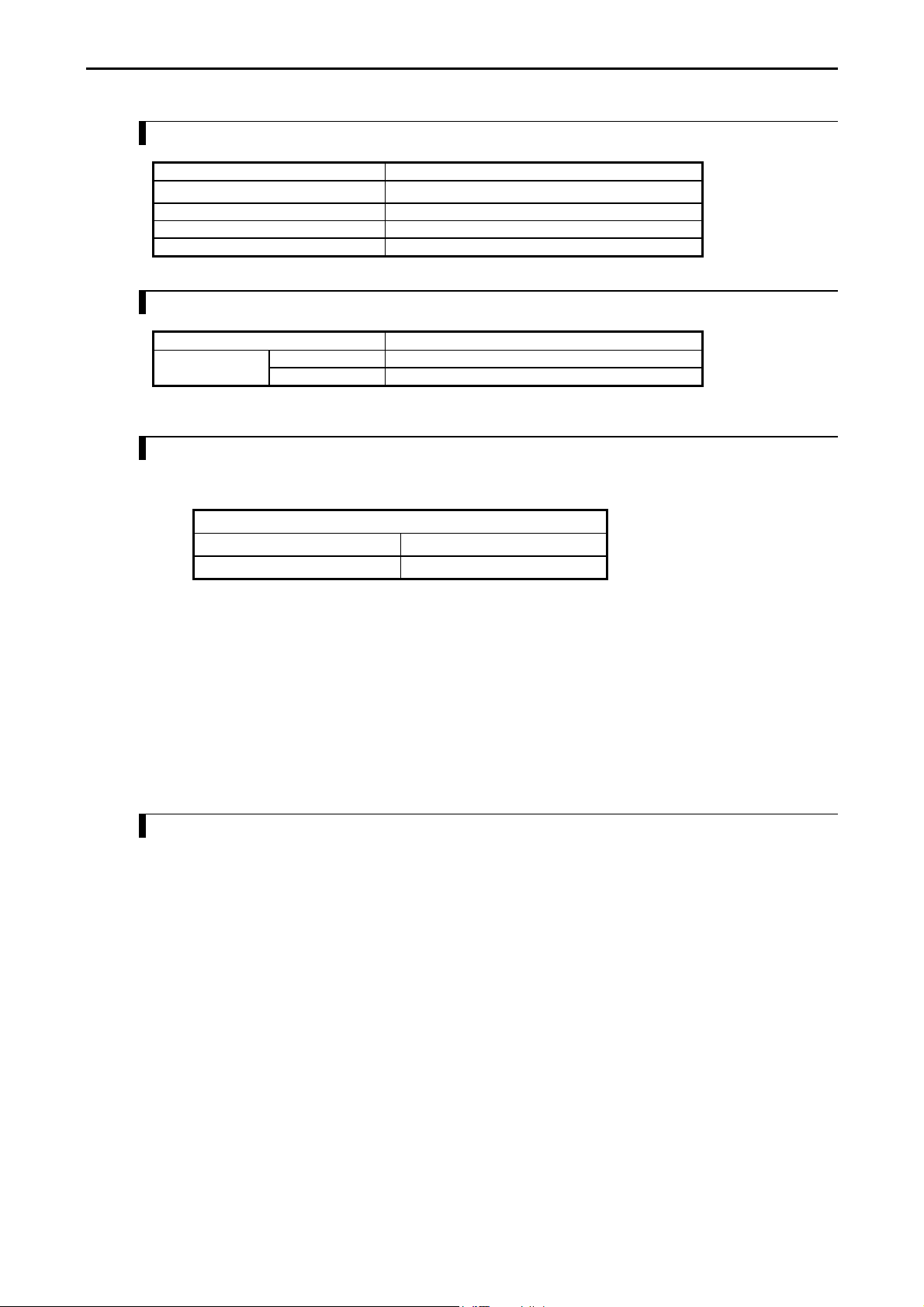

Revision History

No. Description of Revision Date of Revision Manual Number

1 Appendix-1 Instruction Support

FUN92 to 96 of H-4010

{ -> ×.

2000/11 NJI-350 (X)

Appendix-2 Task code H28

Corrected explanation of Timer counter number.

2 Postscript of battery error detection. (3.2 chapters item

2000/12 NJI-350A (X)

number 26, 15 chapters (4) )

Correct a description of digital filter . (8.7 chapters)

Addition of appendix 3.

3 28 points expansion units added.

2003/10 NJI-350B (X)

Analog expansion module added.

Circuit diagram added in chapter 3

FUN 5, TRNS/RECV command added in chapter 5.

Page 9

Table of Contents

Chapter 1 Features ..................................................................................................................................... 1-1 to 1-2

Chapter 2 System Overview....................................................................................................................... 2-1 to 2-2

Chapter 3 Function and Performance Specifications ...............................................................................3-1 to 3-14

3.1 General Specifications ............................................................................................................. 3-1

3.2 Function Specifications............................................................................................................ 3-2

3.3 Performance Specifications...................................................................................................... 3-6

3.3.1 Calculation Specifications ............................................................................................ 3-6

3.3.2 Input Specifications ...................................................................................................... 3-7

3.3.3 Output Specifications.................................................................................................... 3-8

3.3.4 High-Speed Counter Specifications............................................................................ 3-12

3.3.5 PWM Output/Pulse Train Output Specifications........................................................ 3-12

3.3.6 Analogue Input Specifications.................................................................................... 3-12

3.3.7 Analogue Output Specifications ................................................................................. 3-13

3.3.8 Potentiometer Analogue Input Specifications............................................................. 3-14

3.3.9 Interrupt Input Specifications ..................................................................................... 3-14

3.3.10 Backup ........................................................................................................................ 3-14

3.3.11 Expansion ................................................................................................................... 3-14

3.3.12 Clock Function............................................................................................................3-15

3.3.13 Power Supply for Sensor ............................................................................................ 3-16

Chapter 4 Product lineup and wiring .......................................................................................................4-1 to 4-18

4.1 Product lineup.......................................................................................................................... 4-1

4.2 10-Point Basic Unit.................................................................................................................. 4-3

4.3 14-Point Basic Unit.................................................................................................................. 4-4

4.4 23-Point and 28-Point Basic Unit ............................................................................................ 4-5

4.5 Expansion Unit......................................................................................................................... 4-6

4.6 Terminal Layout and Wiring.................................................................................................... 4-7

4.7 Weights and Power Consumption .......................................................................................... 4-16

4.8 Exterior Dimensions .............................................................................................................. 4-17

Chapter 5 Instruction Specifications...................................................................................................... 5-1 to 5-146

5.1 Instruction Classifications ........................................................................................................ 5-1

5.2 List of Instructions................................................................................................................... 5-2

5.3 Instruction Specification Details............................................................................................5-13

Chapter 6 I/O Specifications...................................................................................................................... 6-1 to 6-6

6.1 I/O Assignment ........................................................................................................................ 6-2

6.2 External I/O Numbers.............................................................................................................. 6-3

6.3 Internal Output Numbers.......................................................................................................... 6-6

Page 10

Chapter 7 Programming............................................................................................................................. 7-1 to 7-8

7.1 Memory Size and Memory Assignment ................................................................................... 7-1

7.2 Programming Devices .............................................................................................................. 7-2

7.3 Programming Methods............................................................................................................. 7-3

7.4 Program Transfer ..................................................................................................................... 7-7

Chapter 8 High speed counter, PWM/Pulse train output and Analogue I/O............................................ 8-1 to 8-22

8.1 Input/Output Function.............................................................................................................. 8-1

8.1.1 Initial Setting for Input/Output Function ...................................................................... 8-1

8.1.2 Operation Mode............................................................................................................ 8-2

8.1.3 Input/Output Setting .................................................................................................... 8-3

8.1.4 Input/Output Setting (Mode 10) ................................................................................... 8-4

8.1.5 Special Output Operation in CPU STOP Status ........................................................... 8-5

8.1.6 Pulse / PWM Output adjustment................................................................................... 8-5

8.2 High-Speed Counter (Single-Phase) ........................................................................................ 8-6

8.2.1 Operation of Single-Phase Counter............................................................................... 8-6

8.2.2 Setting of Single-Phase Counter ................................................................................... 8-8

8.3 High-Speed Counter (Two-Phase Counter)............................................................................ 8-10

8.3.1 Operation of the Two-Phase Counters........................................................................ 8-10

8.3.2 Setting of Two-Phase Counter.................................................................................... 8-13

8.4 PWM Output.......................................................................................................................... 8-15

8.4.1 Operation of PWM Output ......................................................................................... 8-15

8.4.2 Setting of PWM Output .............................................................................................. 8-16

8.5 Pulse Train Output ................................................................................................................. 8-18

8.5.1 Operation of Pulse Output .......................................................................................... 8-18

8.5.2 Setting of Pulse Output ............................................................................................... 8-19

8.6 Interrupt Input........................................................................................................................ 8-21

8.7 Digital Filter........................................................................................................................... 8-21

8.8 Potentiometers........................................................................................................................ 8-22

8.9 Analogue Input....................................................................................................................... 8-23

8.10 Analogue Output.................................................................................................................... 8-23

8.11 Analogue Expansion unit ....................................................................................................... 8-24

Chapter 9 PLC Operation ........................................................................................................................9-1 to 9-12

9.1 RUN Start ................................................................................................................................ 9-2

9.1.1 Normal Scan ................................................................................................................. 9-3

9.1.2 Periodical Scan ............................................................................................................. 9-5

9.1.3 Interrupt scan ................................................................................................................ 9-6

9.1.4 Relationship of Each Scan Type ................................................................................... 9-8

9.2 Online Change in RUN ............................................................................................................ 9-9

9.3 Instantaneous Power Failure ..................................................................................................9-10

9.4 Operation Parameter .............................................................................................................. 9-11

9.5 Test Operation........................................................................................................................ 9-12

9.6 Forced Set/Reset .................................................................................................................... 9-12

9.7 Forced Output ........................................................................................................................ 9-12

Page 11

Chapter 10 PLC Installation, Mounting, Wiring......................................................................................10-1 to 10-8

10.1 Installation ............................................................................................................................. 10-1

10.2 Wiring .................................................................................................................................... 10-3

Chapter 11 Communication Specifications............................................................................................11-1 to 11-10

11.1 Port function .......................................................................................................................... 11-1

11.2 Port 1...................................................................................................................................... 11-1

11.3 Port 2...................................................................................................................................... 11-3

11.4 General purpose port (Port 1,2) ............................................................................................. 11-4

11.5 Modem Control Function....................................................................................................... 11-5

11.5.1 Configuration.............................................................................................................. 11-5

11.5.2 AT Commands............................................................................................................ 11-5

11.6 Connecting to the Ports .......................................................................................................... 11-8

11.6.1 Port 1 .......................................................................................................................... 11-8

11.6.2 Port 2 .......................................................................................................................... 11-9

Chapter 12 Error Code List and Special Internal Outputs .....................................................................12-1 to 12-14

12.1 Error Codes ............................................................................................................................ 12-1

12.2 Syntax and Assembler Error Codes........................................................................................ 12-3

12.3 Operation Error Codes ........................................................................................................... 12-4

12.4 Bit Special Internal Output Area............................................................................................ 12-5

12.5 Word Special Internal Output Area........................................................................................ 12-9

Chapter 13 Troubleshooting ..................................................................................................................13-1 to 13-16

13.1 Error Display and Actions...................................................................................................... 13-1

13.2 Checklist when Abnormality Occurred .................................................................................. 13-5

13.3 Procedures to Solve Abnormality .......................................................................................... 13-6

Chapter 14 Operation Examples............................................................................................................ 14-1 to 14-16

Chapter 15 Daily and Periodic Inspections.............................................................................................. 15-1 to 15-2

Appendix 1 H-Series Instruction Support Comparison Chart.................................................................................A-1

Appendix 2 Standards...........................................................................................................................................A-11

Page 12

MEMO

Page 13

Chapter 1 Features

1. Multifunctional all-in-one type PLC

The MICRO-EH is a multifunctional all-in-one type PLC that contains all necessary parts—a power supply and

CPU parts as well as I/O units--within one unit.

Three sizes of PLCs are available: 10, 14, and 28 points. A type with 23 points plus three points of analog I/O

having the same size as the 28-point PLC is also available. Moreover, for PLCs with more than 14 points, it is

possible to install additional 14 or 28 point expansion units up to four units. Thus, the MICRO-EH can control a

wide range of systems from small to medium size.

2. Simplified positioning by counter inputs and pulse train outputs

The function of inputs/outputs can be selected from four modes. By selecting a mode, inputs/outputs that are used as

normal inputs/outputs can be set as counter inputs and pulse train outputs. Through a combination of these special

inputs/outputs, it is possible to control positioning without using special modules.

3. Simplified instrument system by analog integration

For the 23-point PLC, there are two points of analog input and one point of analog output for which both current

and voltage can be selected. High performance analog channels, with a resolution of 12 bits and an overall accuracy

of ±1 % or less, can be used without requiring special settings of the channels; thus, a simplified instrument system

can easily be implemented.

4. Superior upward compatibility

The MICRO-EH has been developed as a part of the EH/H series family.

Debugging and programming can be performed using the same concept as for the EH/H series.

In addition, the MICRO-EH software property can effectively be applied to the EH/H series for future system

expansion.

Chapter 1 Features

5. Easy maintenance through removable terminal blocks and installation on a DIN rail

All models of the MICRO-EH series support the DIN rail so that the PLC can easily be mounted and dismounted. In

addition, the I/O section of the 14-point PLC or more utilizes a removable terminal block. Thus, erroneous and

faulty wiring that may occur when connecting to external devices can be reduced.

6. Remote maintenance through modem connection

Communication with remote sites can be performed via dial-up line by connecting a modem to port 1 on the 14point PLC or more of the MICRO-EH series. It is possible to monitor and manage remote systems from an office or

monitor room.

7. Easily adjustable potentiometer

The 14-point PLC or more of the MICRO-EH series supports two potentiometers.

By using these potentiometers, it is possible to rewrite internal output values in real-time by one driver without using

peripheral devices. Since the resolution of the potentiometer is 10 bits, it is possible to set any value from 0 to 3FFH.

To obtain stable analog values of the potentiometers, it is possible to sample 1 to 40 analog values of the

potentiometers and average them.

8. Maintaining programs without a battery

It is possible to retain user programs in case of out-of battery or no battery, since FLASH memory is used as the

backup memory for the user programs. However, a battery is necessary for data memory backup. (See the Notes in

Chapter 7.1 for a list of precautionary details.)

9. Support for various programming languages

The MICRO-EH supports “Pro-H,” the programming software that allows creating programs in five programming

languages regulated in IEC1131-3. This means that customers who have learned languages other than Ladder can

easily create programs with this programming software.

10. Compliant with overseas specifications as standard

All types of MICRO-EH PLCs have obtained the CE mark, C-TICK and UL. Therefore, systems in which these

PLCs are installed can be exported without requiring any modification.

1-1

Page 14

MEMO

Chapter 1 Features

1-2

Page 15

Chapter 2 System Overview

This chapter describes the system configuration of the MICRO-EH.

The MICRO-EH is an all-in-one type programmable controller, and has the following system configuration.

1] Basic unit

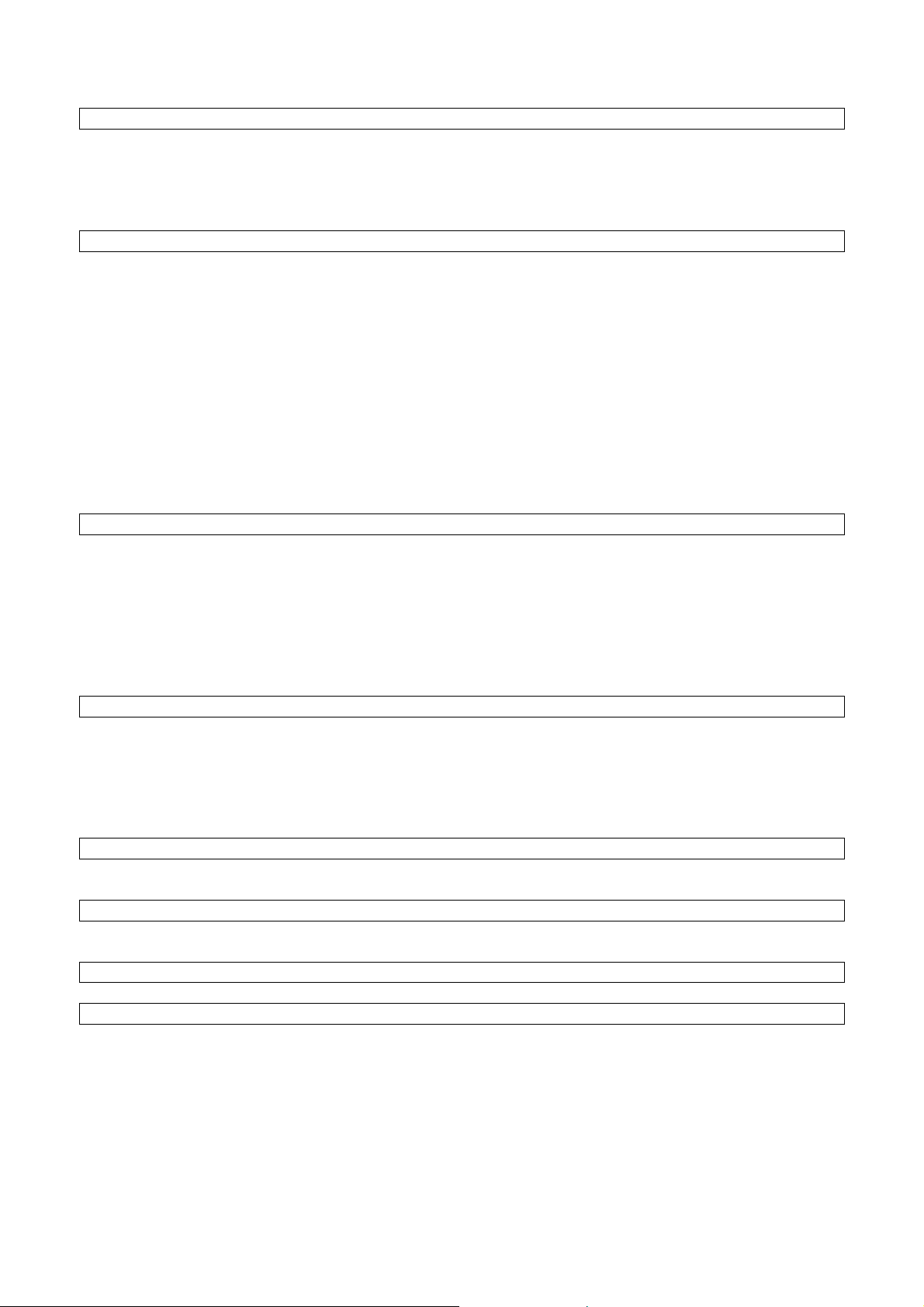

Figure 2.1 10-point type system configuration diagram

Chapter 2 System Overview

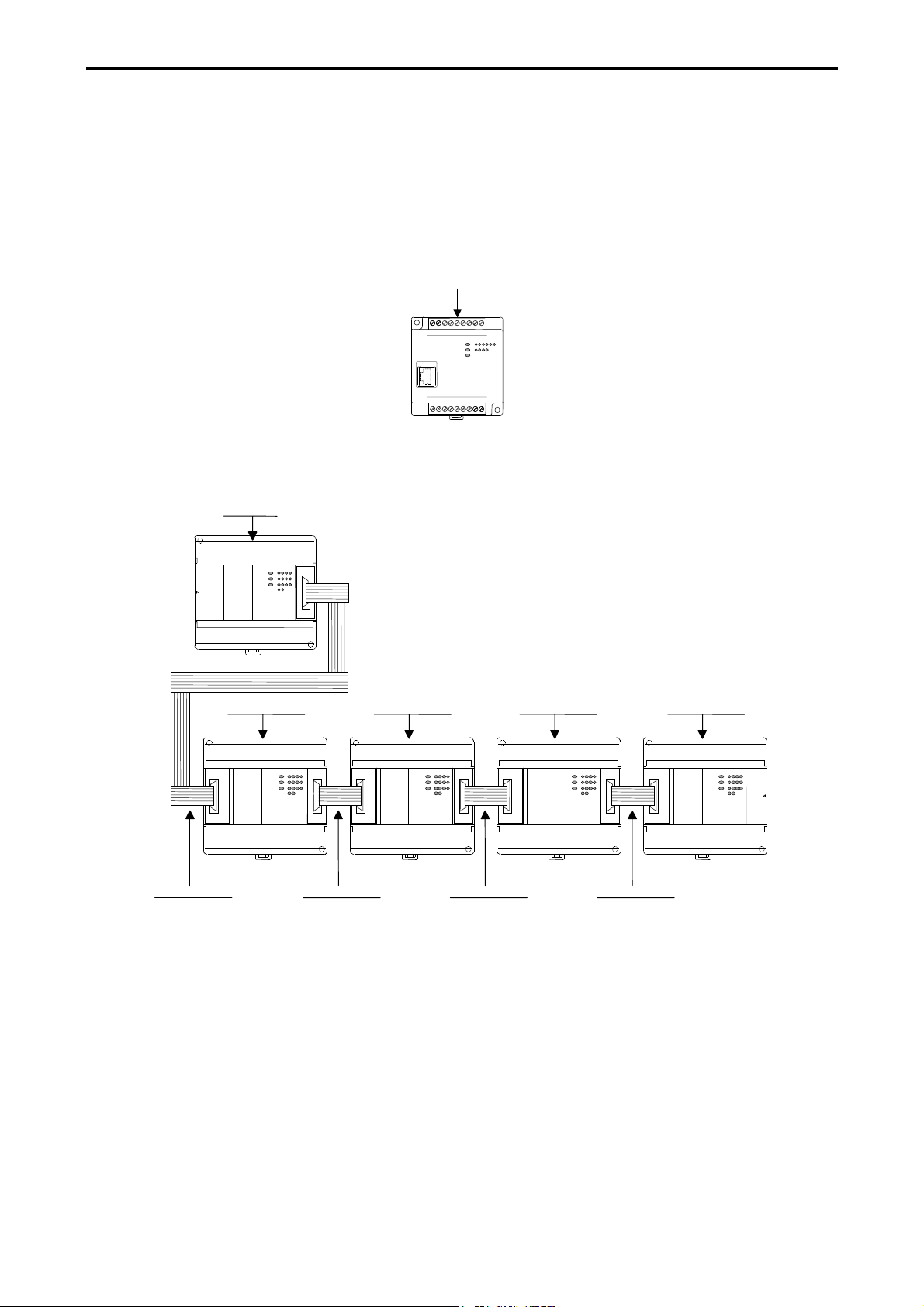

1] Basic unit

2] Expansion unit2] Expansion unit2] Expansion unit2] Expansion unit

3] Expansion cable3] Expansion cable3] Expansion cable3] Expansion cable

Figure 2.2 14-point type system configuration diagram

2-1

Page 16

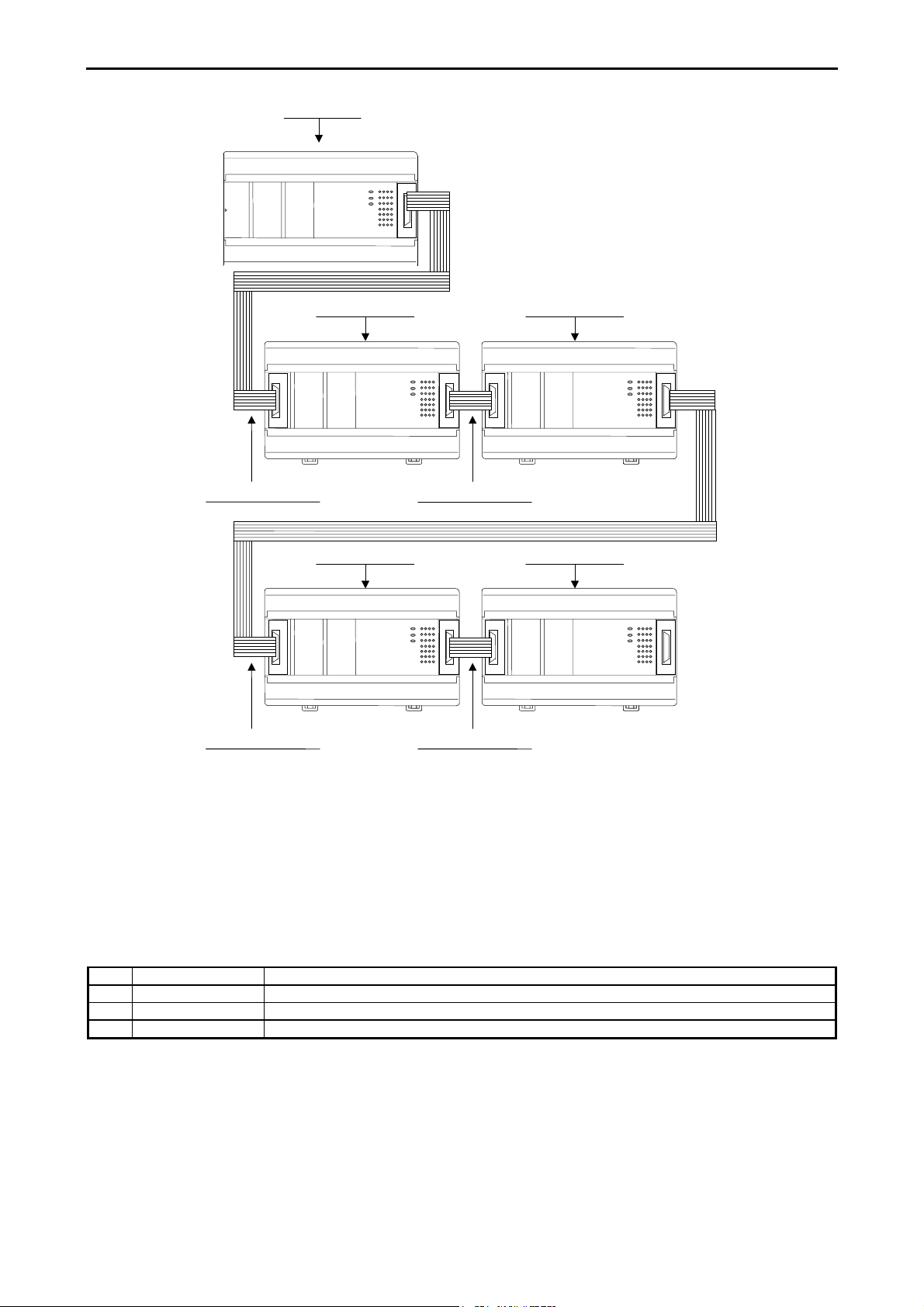

[1] Basic unit

Chapter 2 System Overview

[2] Expansion unit

[3] Expansion cable

[2] Expansion unit [2] Expansion unit

[3] Expansion cable [3] Expansion cable

[3] Expansion cable

[2] Expansion unit

Figure 2.3 23,28-point type system configuration diagram

No restriction for combination of 14,23,28 points, and basic/expansion unit.

14 points basic unit can handle any type of expansion units, and 23/28 points basic unit as well.

No. Device name Description

1] Basic unit Calculates, imports inputs, and controls outputs according to the contents of user programs.

2] Expansion unit 14 points digital unit, 4 in/2 out analog unit

3] Expansion cable Cable for connecting the basic unit and expansion unit, or between expansion units.

2-2

Page 17

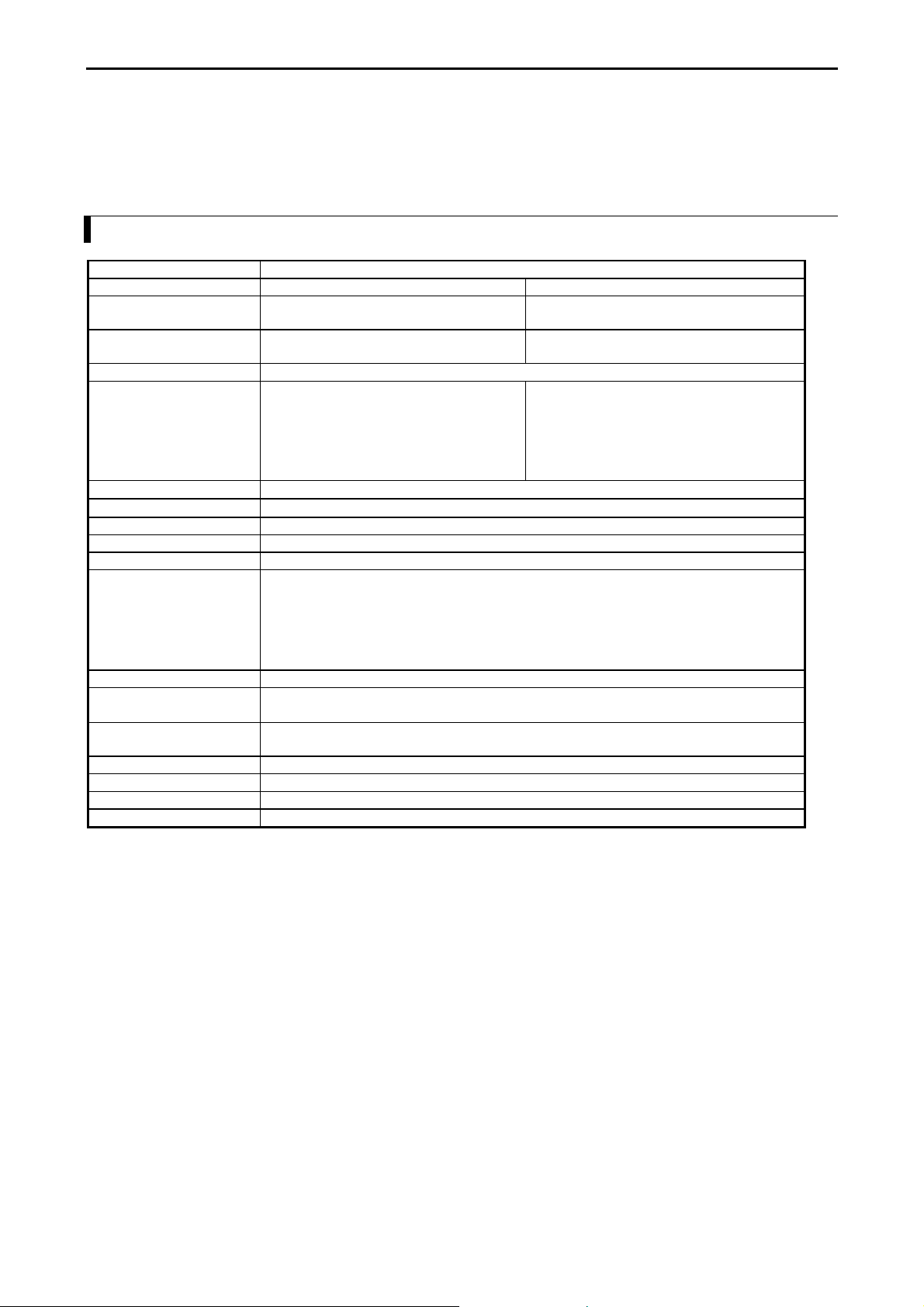

Chapter 3 Function and Performance Specifications

Chapter 3 Function and Performance

Specifications

3.1 General Specifications

Item Specification

Power supply type AC DC

Power voltage 100/110/120 V AC (50/60 Hz),

200/220/240 V AC (50/60 Hz)

Power voltage fluctuation

range

Current consumption Please refer to 4.7, “Weights and Power Consumption.”

Allowable momentary power

failure

Operating ambient temp.

Storage ambient temp.

Operating ambient humidity 5 to 95 % RH (no condensation)

Storage ambient humidity 5 to 95 % RH (no condensation)

Vibration proof Conforms to JIS C 0911

Noise resistance

Supported standards Conforms with UL, CE markings and C-TICK

Insulation resistance

Dielectric withstand voltage 1,500 V AC for one minute between the AC external terminal and the protection earth (PE)

Grounding Class D dedicated grounding (grounded by a power supply module)

Environment used No corrosive gases and no excessive dirt

Structure Attached on an open wall

Cooling Natural air cooling

85 to 100 V AC: For a momentary power

100 to 264 V AC: For a momentary power

{ Noise voltage 1,500 Vpp Noise pulse width 100 ns, 1 µs

{ Based on NEMA ICS 3-304

{ Static noise: 3,000 V at metal exposed area

{ Conforms with EN50081-2 and EN50082-2

20 MΩ or more between the AC external terminal and the protection earth (PE) terminal (based

85 to 264 V AC wide range 19.2 to 30 V DC

19.2 to 30 V DC: For a momentary power

failure of less than 10 ms,

operation continues

failure of less than 20 ms,

operation continues

0 to 55 °C

-10 to 75 °C

(Noise created by the noise simulator is applied across the power supply module's input

terminals. This is determined by our measuring method.)

on 500 V DC mega)

terminal

24 V DC

failure of less than 10 ms,

operation continues

3-1

Page 18

Chapter 3 Function and Performance Specifications

3.2 Function Specifications

The functions available in the MICRO-EH are described in the table below.

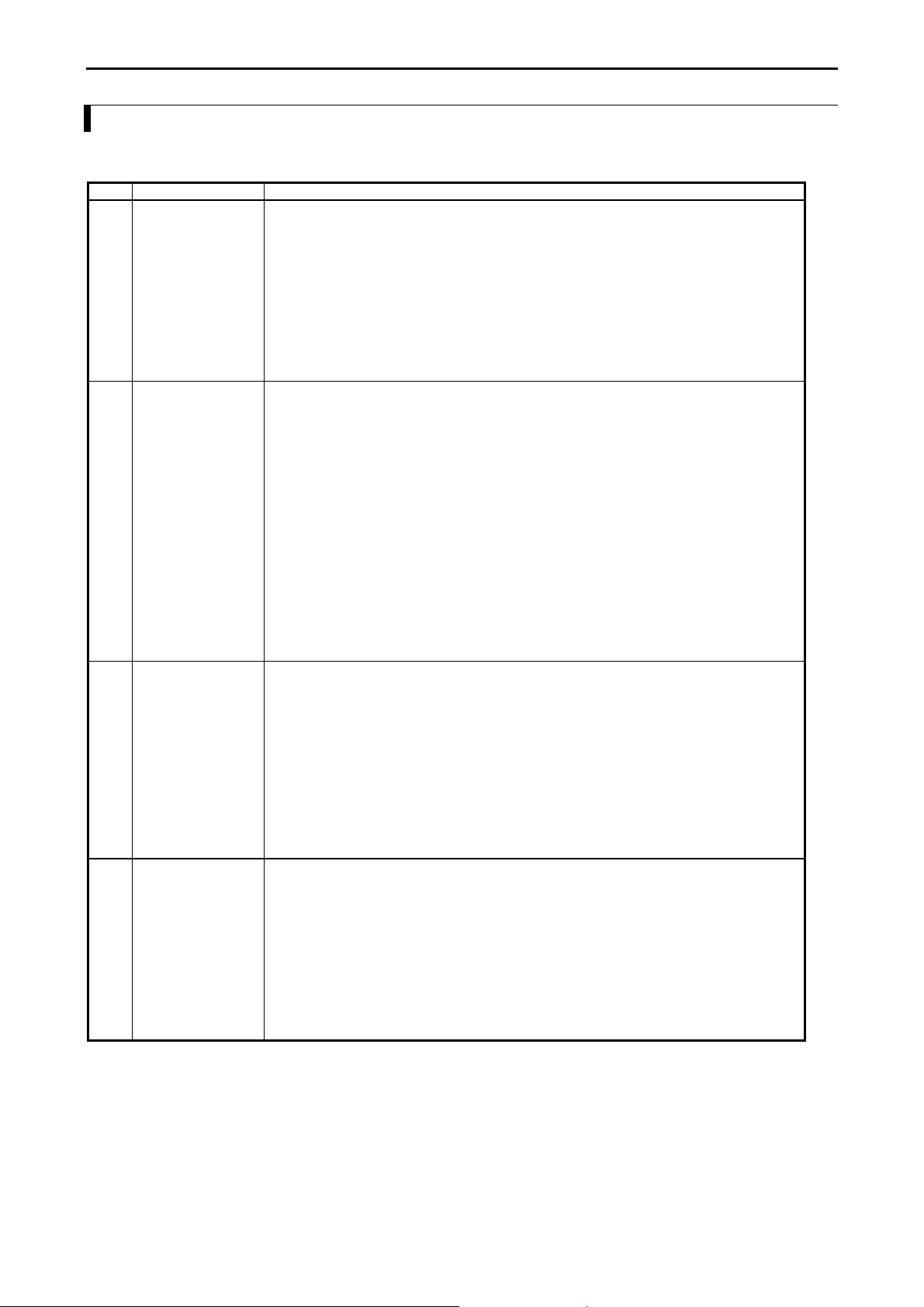

No. Item Description

1 Basic functions The following functions can be executed when constructing a system using the PLC.

1] An input signal is received from the control object, operations are performed according to

the contents of the program created by the user and the results are output as an output signal.

Also, operation results and progress information can be retained in the internal output area.

2] Power is supplied to the main module, system starts to run, and the operation described

above is performed continuously until the power is shut down or the system stops running.

3] The information retained internally can be extracted by a device connected externally or can

be set in other information. Also, this information is initialized at the time the system starts

running, but it can also be retained depending on the user settings.

4] Operating status can be confirmed with the LED display of each unit or with an external

device that has been connected.

2 Setting and display The following have been provided for the user to set or confirm various types of operation

status:

1] DIP switch (basic unit)

This specifies the CPU communication function setting and operation mode, etc. (except for

10-point type)

2] RUN switch (basic unit)

It can instruct to run and stop. (external input for 10-point type)

3] LED display (basic unit and expansion unit)

Indicates the power system status, operating status and I/O operation status.

4] Communication connector (basic unit)

This can connect external devices using RS-232C, RS-485, RS-422. (only the 23-point and

28-point types with RS-485, RS-422)

5] Expansion connector (basic unit and expansion unit)

This allows installation of additional input/output. (except for 10-point type)

6] Terminal block (basic unit and expansion unit)

This performs the connections for supplying power, and for handling signals with the

control object.

3 Number of I/O points The number of points that can be controlled with respect to the control object is as follows:

1] External inputs/outputs

The number of points that can be use for external inputs/outputs differs depending on the

basic unit. The 10-point type cannot expand the inputs/outputs. For the 14-point, 23-point

and 28-point types, a maximum of 4 expansion units can be connected. The I/O numbers for

inputs are indicated by X, WX, DX and outputs are indicated by Y, WY, DY.

2] Internal outputs

These are areas for temporarily storing information. The I/O numbers include M, WM, DM,

R, WR, DR.

3] A timer counter is provided internally.

4] Array (corresponding to a substitution statement only)

An array of I/O numbers can be expressed by enclosing by parentheses.

4 User program

memory

The program in which the control contents have been described can be stored. This FLASH

memory resides in the basic unit.

1] The contents of this memory will be maintained even if the power is shut off. Because of

this, it is necessary to initialize the memory since it may have undefined after the unit is

purchased.

2] Programming is done using peripheral units such as programming software (LADDER

EDITOR) for the H-series programmable controllers.

3] The instructions that can be used are those designated by the H-series ladder. See the list of

instructions for details.

4] A battery is not required to retain the contents of the user program. Always save the created

programs to a floppy disk just in case an unexpected problem occurs.

3-2

Page 19

Chapter 3 Function and Performance Specifications

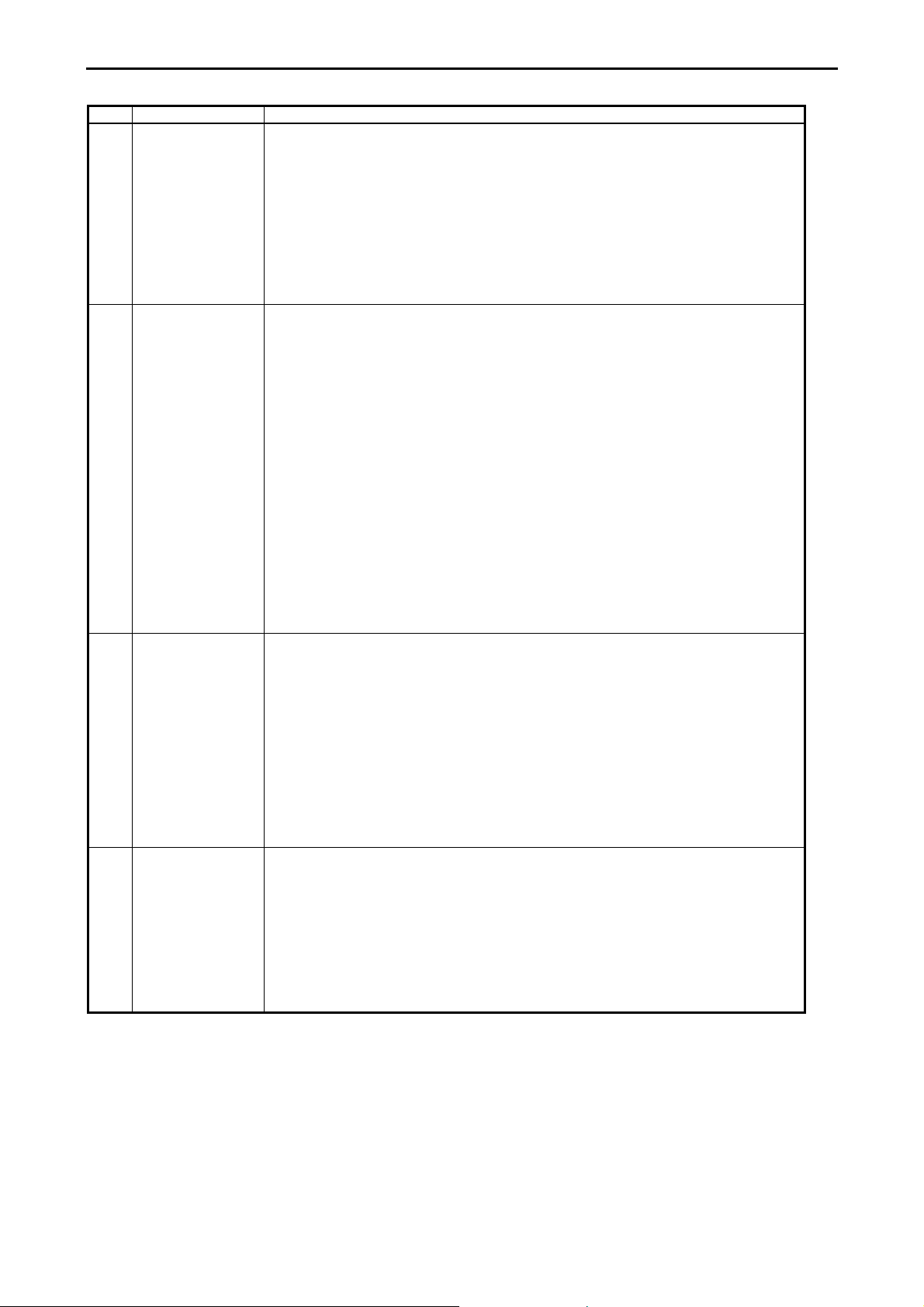

No. Item Description

5 Control method With the PLC, the user programs are converted in batch at operation startup, and the programs

after conversion will be executed in order as they are read one by one.

1] The method used for data I/O is that after the I/O data (information) is scanned (execution

from the head of the program to the end), it is updated in group. If refresh of external I/O is

required during scanning (refresh method), use the refresh instruction.

2] Apart from the program that will be normally executed, a periodic scan program which

interrupts the normal program at a fixed time intervals and is executed, can be created. The

time intervals are 10 ms, 20 ms and 40 ms.

3] The user programs are executed from the head of the program to the end, and are once again

repeated after performing the system processing that updates the lapsed timer value,

refreshes I/O, and performs communication with peripheral units.

6 Run/stop control Running and stopping the PLC is normally performed by the user.

1] Turn on the RUN switch to start operation for the 14-point type or higher. Turn this switch

off to stop operation.

For the 10-point type, turn on the RUN input terminal to start operation. Turn it off to stop

operation.

2] The start and stop operations can be performed with designated external inputs or internal

outputs by designating the operation control inputs with a programming unit.

3] Apart from the operation described above, if a malfunction is detected in the system while it

is running, operation stops and the outputs are aborted (OFF).

4] If the power is shut off and then turned back on while the system is running, operation starts.

When the power shuts off, turn off the power to the PLC, then shut off the external input

power. When turning the power back on, turn on the external input power before turning on

the power to the PLC.

5] When starting operation, do so after clearing internal information which is not designated

for storage during power failure. When stopping operation, leave the internal information as

is, turn off the outputs and then stop the operation.

6] When the power has been cut off for longer than the time allowed for the momentary power

failure, then depending on the system load status, either operation continues or the system

perceives that a power shut off has occurred and restarts operation. To resume operation

securely, have the power remain off for 1 minute or longer.

7 Operation parameters Each type of condition for operating the PLC can be set. The possible settings for operation

when an error occurs are provided below.

1] Operation may be continued when I/O information does not match.

2] Overload check time can be set. The initial value is 100 ms and the module stops when the

time for one scan takes longer than the set overload check time. (overload error)

3] Operation may be continued when an overload error occurs.

4] When a power failure (power shutoff) occurs, the internal output area for retaining

information and the timer counter range can be designated.

And, the setting below is possible.

1] The name of the user program can be registered.

2] A password can be set up so that the third party cannot reference the program.

3] It is necessary to register the type of I/O module used as an I/O assignment table. In order to

create this I/O assignment table, the types of I/O modules that are connected can be read.

8 Change while in

operation

A part of a program can be modified during operation.

1] If a modification is made with a programming unit and a change is performed while in

operation, the user program in the CPU is changed and the altered program is switched

internally at the end of scanning, and operation continues with the new program.

2] When a control instruction is included in the modification to the program, make the changes

after first performing the control instruction change procedure in the programming unit to

check for safety.

3] Until operation starts to continue with the new program, a pause [halt period] occurs when

the module does not run. External input information is not being received during this time,

so leave a sufficient time for executing a change while in operation.

3-3

Page 20

Chapter 3 Function and Performance Specifications

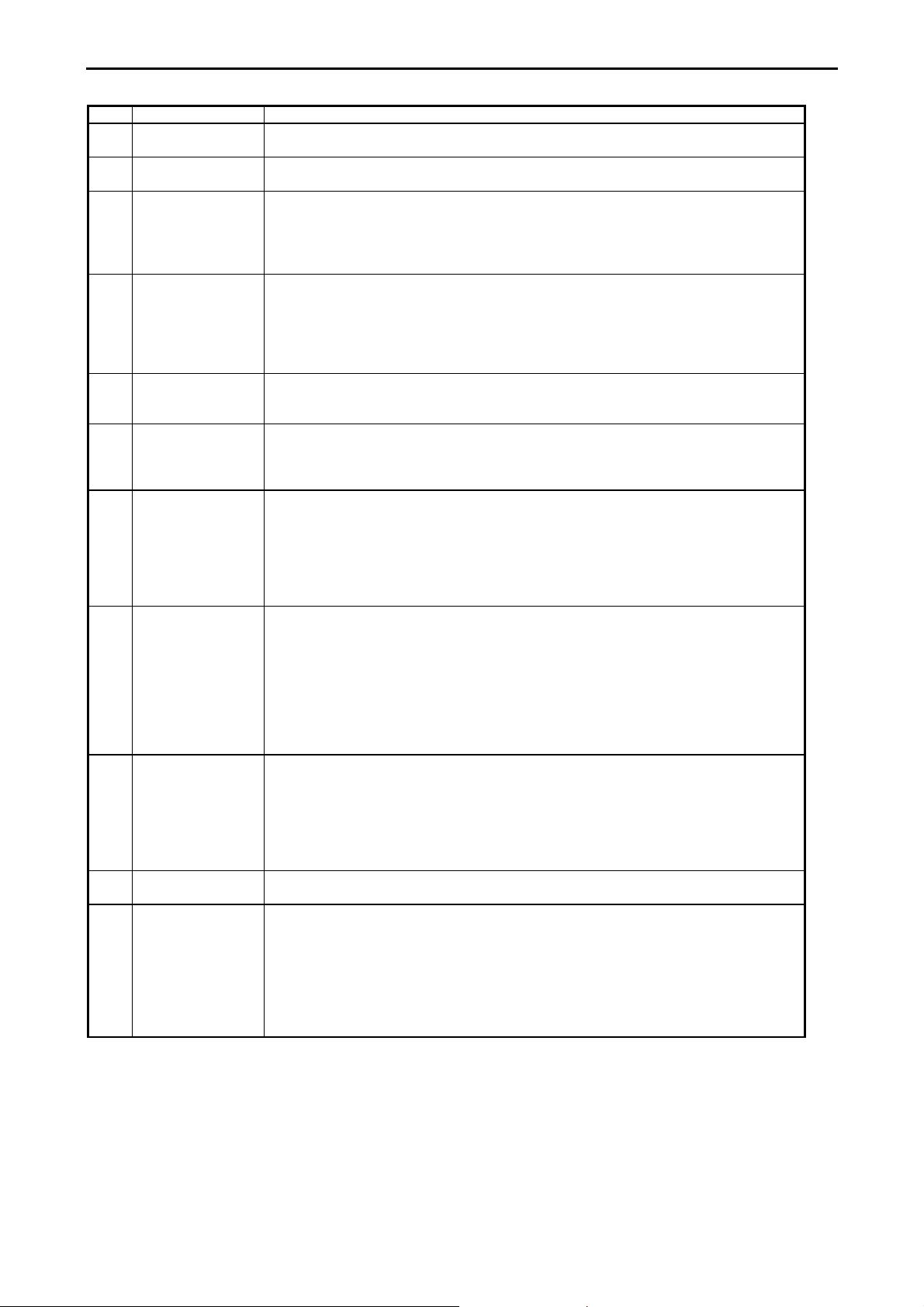

No. Item Description

9 Forced set/reset Forced set and forced reset of the designated I/O can be performed from the programming unit

connected to the CPU module.

10 Forced output Output can be forced with respect to the designated I/O number from the programming unit

connected to the CPU module. For I/O that is not designated, outputs are shut off.

11 Calendar clock

function

(only for 23- and 28point types)

12 Dedicated port This is a communication port with dedicated protocol for the H-series. The communication

13 General purpose port General purpose port function is supported from software version H0130 (WRF051=H0130) or

14 Modem control A modem can be used to connect externally. It becomes operable when data receives from the

15 Self-diagnosis Self-diagnostic tests for the following items are performed:

16 Abnormal handling When a problem occurs, the error code that indicates the error description is output to special

17 Task code By combining individual task codes, the following functions can be achieved by the programs in

18 Instruction Programming can be performed for various purposes and usage by combining Ladder and the

19 High-speed counter The external input of the basic unit can be used as a high-speed counter by specifying it as a

23-point and 28-point types have the calendar clock function.

1] The year, month, date, day of the week, hour, minute and second can be set.

2] There is a function for making adjustments in 30-second units.

3] When a battery is not installed, the calendar clock information is not retained when power

goes off. The calendar clock must be reset. (The battery is an optional. Purchase separately.)

command called the task code is defined in the port.

1] A programming unit can be connected. (However, the command language programmer

PGM-CHH and the portable graph programmer PGM-GPH cannot be used.)

2] Port 1 and port 2 can be used as dedicated ports. Transmission speed, etc. can be switched

using the DIP switch. (Port 2 is supported only by the 23-point and 28-point type models.)

newer. This function enables serial communication to any standard devices like bar code reader

by using TRNS/RECV command in user program.

external media, and task code communication can afterward be performed.

Port 1 can be assigned for this function by switching the DIP switch. (The 10-point type is not

supported.)

1] Microcomputer check

2] System program area check

3] Memory check

4] User program check

5] Internal output area check

6] Mounted I/O check

internal output WRF000 as a hexadecimal value. Also, errors are notified to the external devices

through the OK LED. If the error level is high, the CPU stops operation, but depending on the

error, the operation may be continued using the user settings.

If multiple errors occur, the error code with higher error severity is set. The detailed information

is also set to the special internal output. Also, this information is always recorded in the power

failure memory, so the information can be referenced even after the power is cut off. (However,

a battery is required.) The clearing of the error information can be conducted by turning on

R7EC.

the host computer:

1] CPU control (RUN/STOP control of CPU, occupy/release, CPU status read, etc.)

2] I/O control (various types of monitoring)

3] Memory write (all clear, batch transfer, etc.)

4] Memory read (reading of programs, etc.)

5] Response (various responses from CPU)

instruction language.

counter input. The following can be set.

1] Single-phase counter, 2 channels

2] Single-phase counter, 4 channels (For the 10-point type, it is single-phase, 3 channels.)

3] Two-phase counter 1 channel, single-phase counter 1 channel (For the 10-point type, it is

two-phase, 1 channel.)

The functions include a count operation (up/down, leading/trailing), coincidence output control,

preset by preloaded input, and count value reading by strobe input.

3-4

Page 21

Chapter 3 Function and Performance Specifications

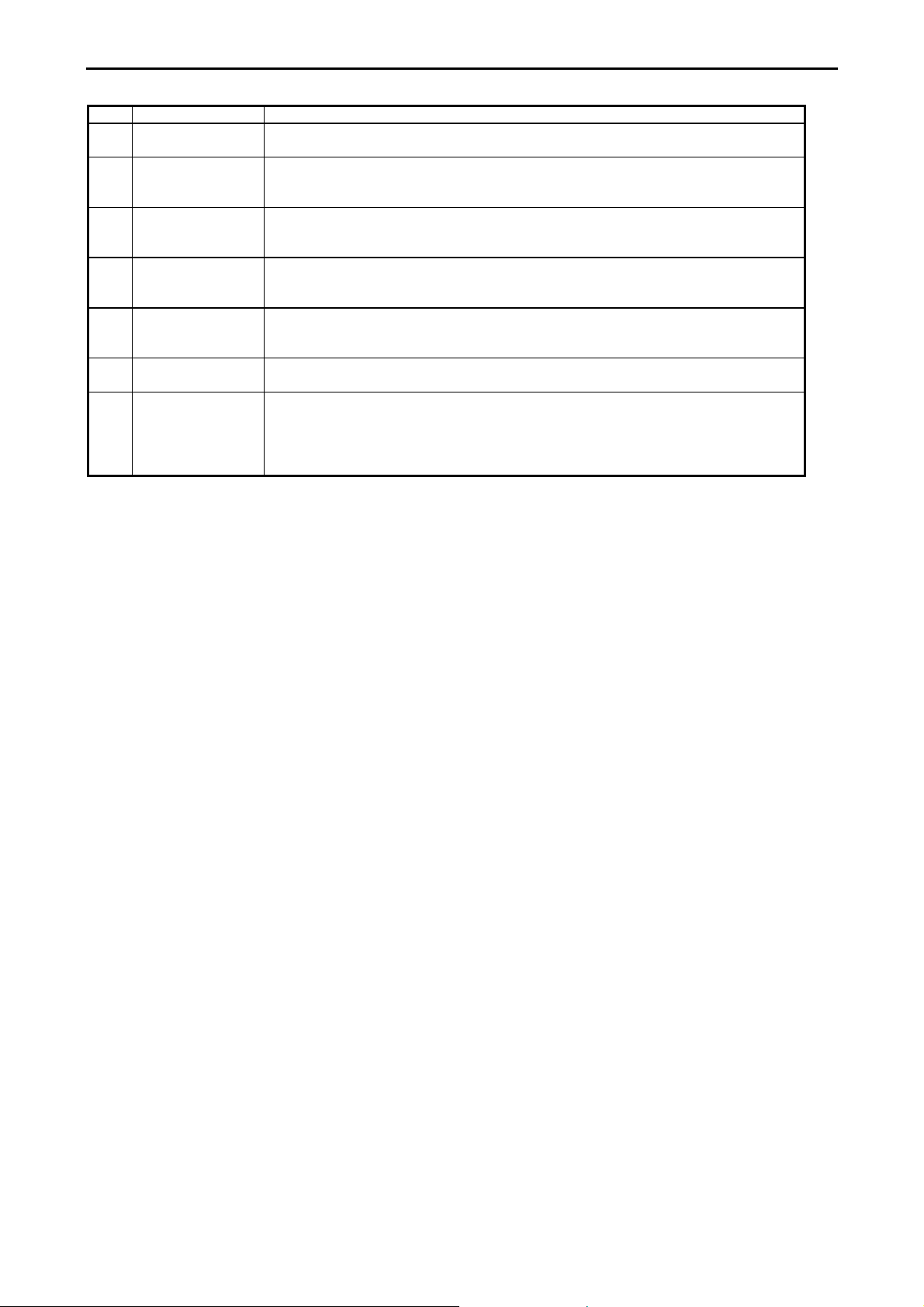

No. Item Description

20 Interrupt input The external input of the basic unit can be specified for interrupt input. With the interrupt input,

the corresponding interrupt program can be executed.

21 PWM output The external output of the basic unit can be specified for pulse width modulated output. In this

case, pulses are output at the specified frequency with a duty between 0 and 100 %. A maximum

of 4 points, including the pulse array output, can be set.

22 Pulse train output The external output of the basic unit can be specified for pulse output. In this case, pulses are

output at the specified frequency with a duty between 30 and 70 %. A maximum of four points,

including the pulse output, can be set.

23 Analogue input The analogue input function is available in the 23-point type and analog exp. unit. The

resolution is 12 bits and it can be used by either selecting a current input between 0 and 20 mA

or a voltage input between 0 and 10 V.

24 Analogue output The analogue output function is available in the 23-point type and analog exp. unit. The

resolution is 12 bits and it can be used by either selecting a current output between 0 and 20 mA

or a voltage output between 0 and 10 V.

25 Potentiometer 14-point, 23-point, and 28-point types have two potentiometers, with which setting values etc.

can be changed without using the programming units.

26 Battery A dedicated battery can be installed in the 23-point and 28-point types so that data in the data

memory can be maintained even when the power supply to the main unit is shut off. In addition,

the data of the calendar clock in the 23-point and 28-poins types can be maintained. The battery

is an optional (model EH-MBAT).

Please refer to Chapter 15 (4) Life of the battery.

Note: There are functions supported by H series that are not supported by this PLC (debug, trace, force, and simulation functions).

3-5

Page 22

Chapter 3 Function and Performance Specifications

3.3 Performance Specifications

3.3.1 Calculation Specifications

The calculation specifications of the PLC are described below.

Model Name 10-point type 14-point type 23/28-point type

Control

specifications

Operation

processing

specifications

Type

CPU

Processing system

Processing

speed

User program memory

Instruction

language

Ladder Basic instructions

Basic instructions

Application instructions

Basic instructions

Arithmetic instructions

Application instructions

EH-D10DT

EH-D10DTP

EH-D10DR

39 types such as LD, LDI, AND, ANI, OR, ORI, ANB, ORB, OUT, MPS,

62 types (arithmetic, application, control, FUN command etc.)

EH-D14DT

EH-D14DTP

EH-A14DR

EH-D14DR

EH-A14AS

32-bit RISC processor

Stored program cyclic system

0.9 µs / instruction

Several 10 µs / instruction

3 k steps max. (FLASH memory)

MRD, MPP, etc.

39 types, such as

EH-A23DRP

EH-A23DRT

EH-D23DRP

EH-D28DT

EH-D28DTP

EH-A28DRP

EH-A28DRT

EH-A28DR

EH-D28DRP

EH-D28DRT

EH-D28DR

EH-A28AS

Arithmetic instructions

Application instructions

I/O

processing

specifications

Peripheral

equipment

Maintenance

functions

*1: The same numbers cannot be used with the timer counter.

*2: Only timers numbered 0 to 63 can use 0.01 s for their timer base.

External

I/O

Internal

output

Timer

counter

Edge detection

Program system

Peripheral unit

Self-diagnosis

I/O processing system

Maximum number of

points

Bit

Word

Special

Bit/word shared

Number of points

Timer set value

Counter set value

Bit

Word

10 points 126 points 135 points 140 points

0 to 65,535, timer base 0.01 s, 0.1 s, 1 s (0.01s has maximum 64 points *2)

Instruction language programmer and form graphic display programmer cannot

PLC error (LED display): Microcomputer error, watchdog timer error, memory

error, program error, system ROM/RAM error, scan time monitoring, battery

voltage low detection, etc.

62 types (arithmetic, application, control, FUN command etc.)

Refresh processing

1,984 points (R0 to R7BF)

4,096 words (WR0 to WRFFF)

64 points (R7C0 to R7FF)

512 words (WRF000 to WRF1FF)

16,384 points, 1,024 words (M0 to M3FFF, WM0 to WM3FF)

256 points (TD + CU) *1

1 to 65,535 times

512 points (DIF0 to DIF511: Decimal)

+ 512 points (DFN0 to DFN511: Decimal)

Instruction language, ladder diagram

Programming software

(LADDER EDITOR DOS version/Windows® version, Pro-H)

be used.

3-6

Page 23

Chapter 3 Function and Performance Specifications

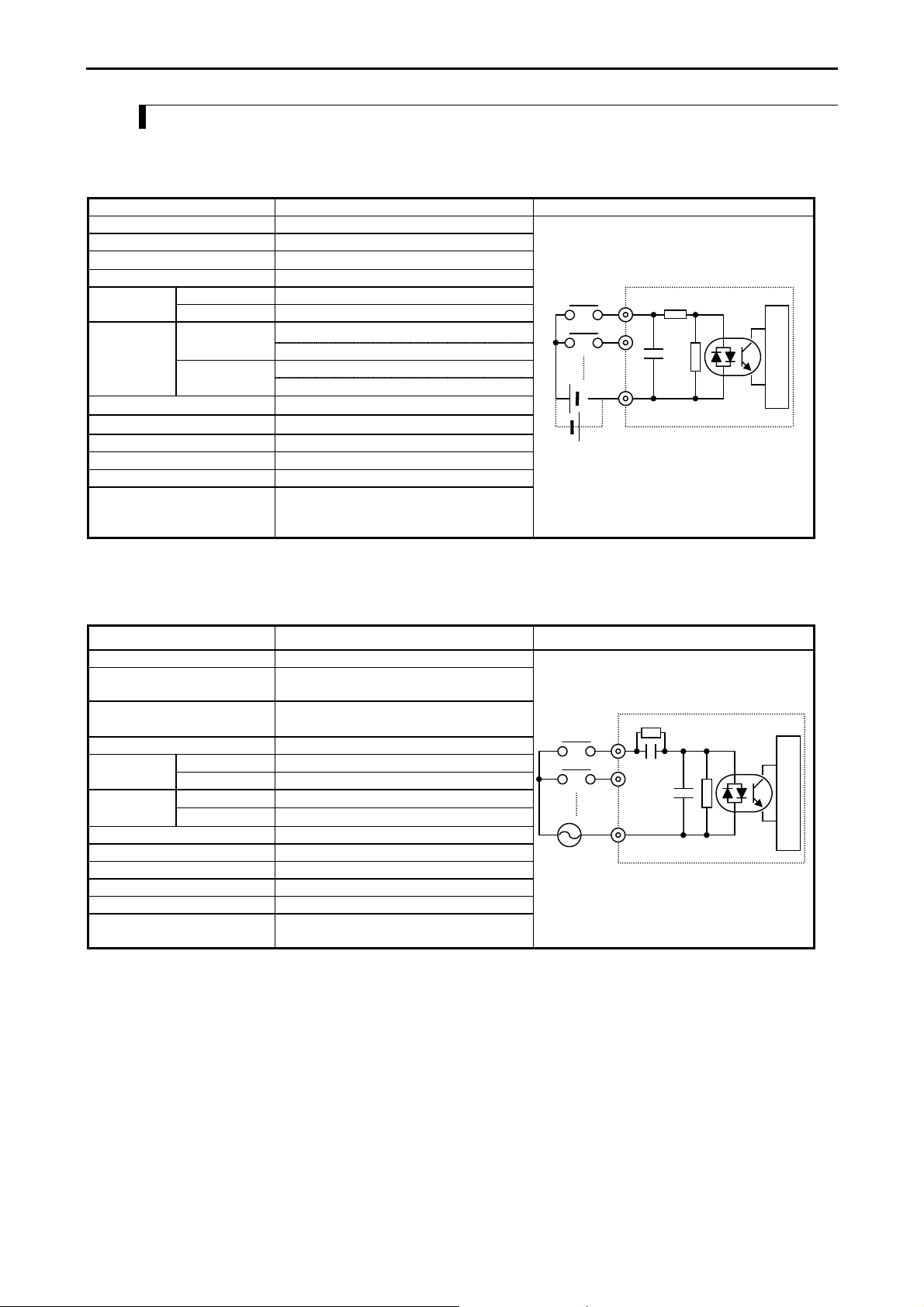

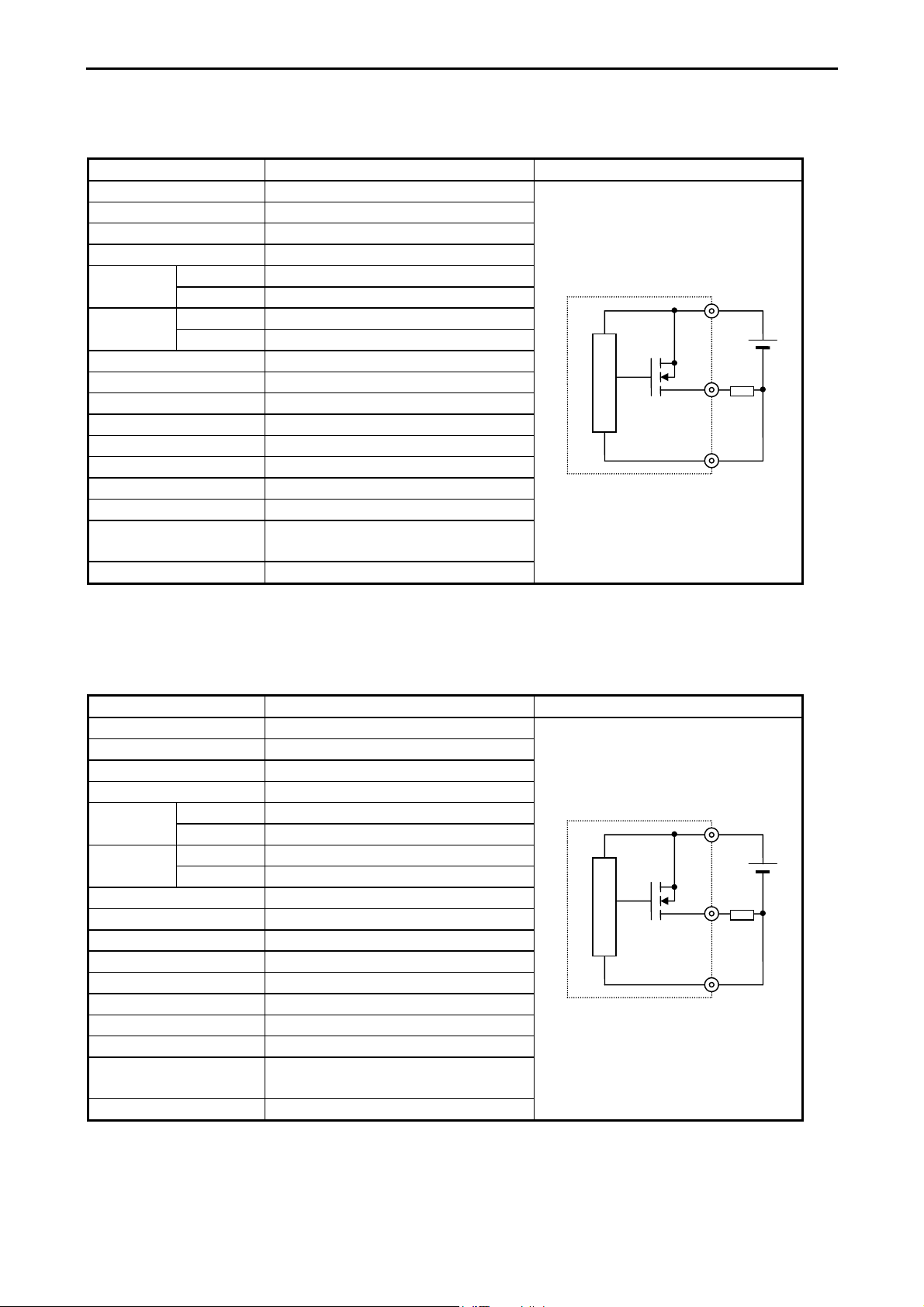

3.3.2 Input Specifications

The input circuit consists of DC input and AC input, with the following specifications.

(1) DC input

Item Specification Circuit diagram

Input voltage 24 V DC

Allowable input voltage range 0 to 30 V DC

Input impedance

Input current 7.5 mA typical

ON voltage 15 V DC (min) / 4.5 mA (max)Operating

voltage

Input lag

OFF voltage 5 V DC (max) / 1.5 mA (max)

OFF → ON

ON → OFF

Basic unit : 0.5 to 20 ms (configurable)

Exp. unit : 0.5 ms or less

Basic unit : 0.5 to 20 ms (configurable)

Exp. unit : 0.5 ms or less

Number of input points

Number of common

Polarity None

Insulation system Photocoupler insulation

Input display LED (green)

External connection 10-point type: fixed type terminal block

14-, 23-, 28-point types: Removable type

*1: Common terminals are separated each other.

Approx. 2.8 kΩ

See Chapter 4

See Chapter 4

screw terminal block (M3)

0

Internal circuit

1

C

(2) AC input

Item Specification Circuit diagram

Input voltage 100 to 120 V AC

Allowable input voltage range 85 to 132 V AC

50 -5 % to 60 +5 % Hz

Input impedance

Input current Approx. 7 mA RMS (100 V AC/60 Hz)

ON voltage 80 V AC (min.) 4.5 mAOperating

voltage

Input lag

Number of input points See Chapter 4.

Number of common See Chapter 4.

Polarity None

Insulation system Photocoupler insulation

Input display LED (green)

External connection 14-, 28-point types: Removable type screw

*1: Delay by hardware only. Delay by digital filter (software filter) 0.5 to 20 ms is not included.

*2: Common terminals are separated each other.

OFF voltage 30 V AC (max.) 2 mA

OFF → ON

ON → OFF

Approx. 14.6 kΩ (60 Hz)

Approx. 17.6 kΩ (50 Hz)

25 ms (max.) *1

30 ms (max.) *1

terminal block (M3)

0

1

C

Internal circuit

3-7

Page 24

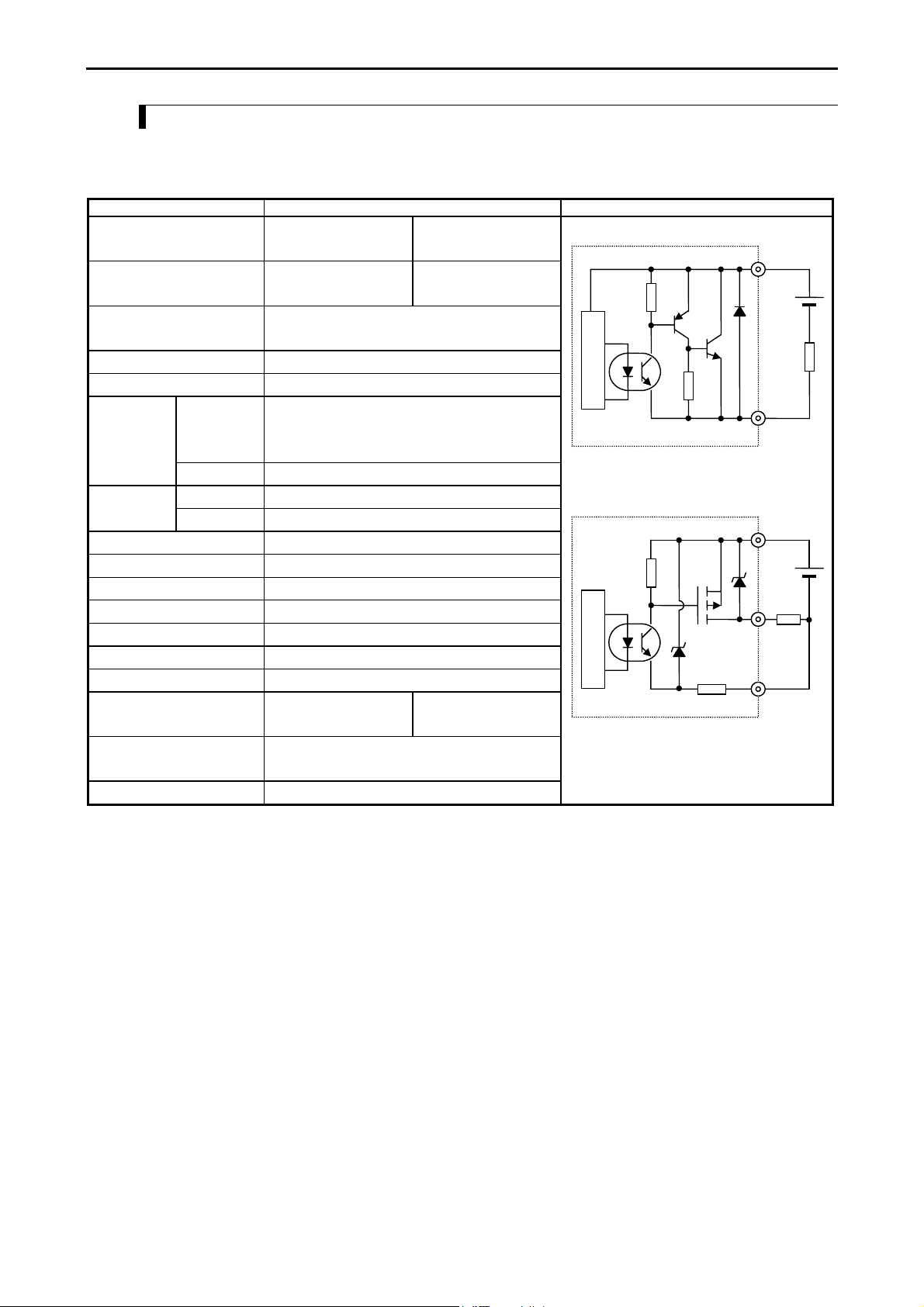

Chapter 3 Function and Performance Specifications

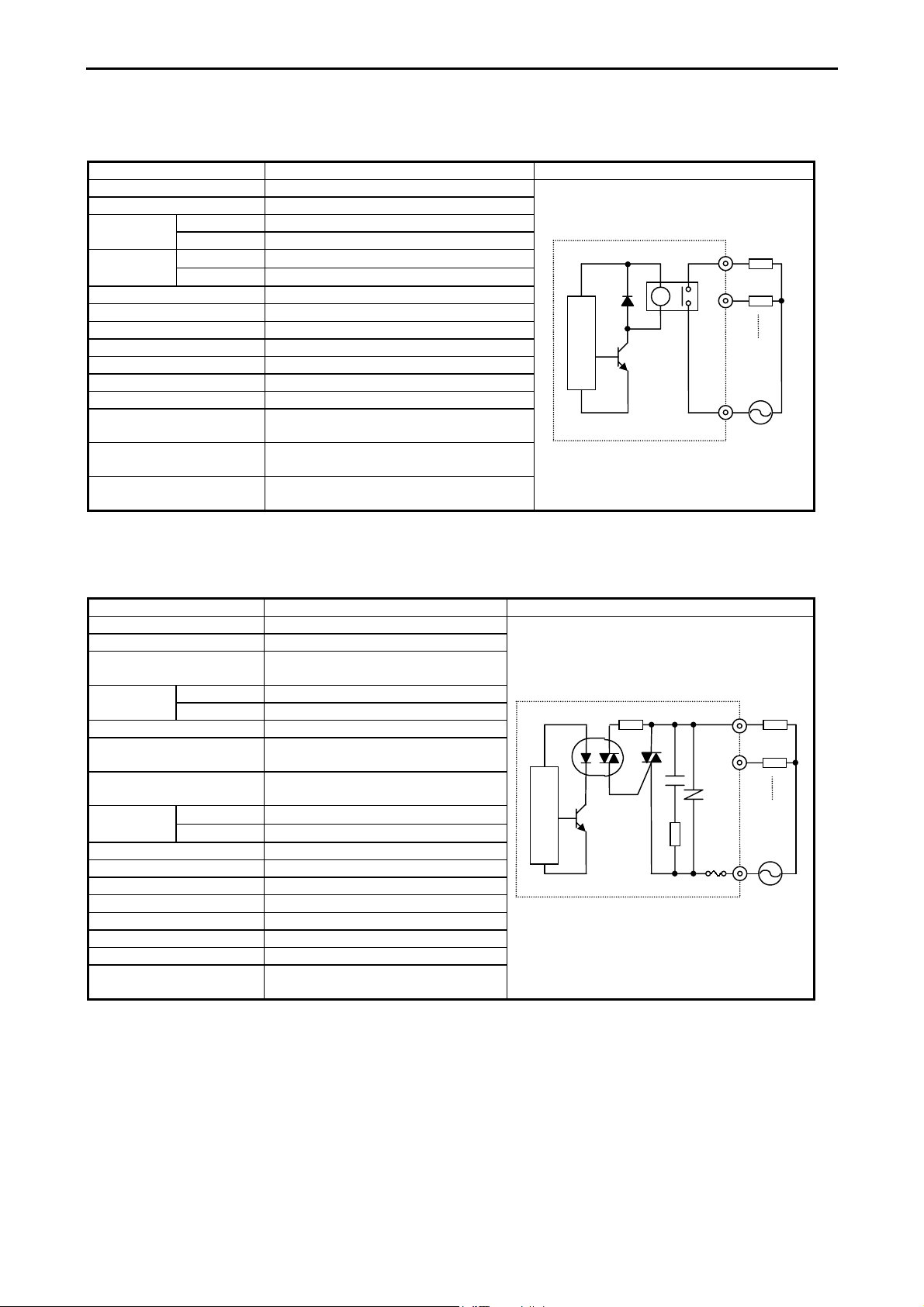

3.3.3 Output Specifications

(1) DC output

(Y100 of EH-*23DRP/A23DRT/*28DRP/*28DRT)

Item Specification Circuit diagram

Type EH-A23DRT

EH-*28DRT

Y100 output specifications Transistor output

(sink type)

EH-*23DRP

EH-*28DRP

Transistor output

(source type)

Rated load voltage 24 / 12 / 5 V DC

24 V DC +20 %, -80 %

Minimum switching current 1 mA

Leak current 0.1 mA (max)

Maximum

load current

1 circuit 0.75 A 24 V DC

0.5 A 12 V DC

0.25 A 5 V DC

1 common 0.75 A

OFF → ON 0.1 ms (max) 24 V DC 0.2 AOutput

response time

ON → OFF 0.1 ms (max) 24 V DC 0.2 A

Number of output points 1

Number of common 1

Surge removing circuit None

Fuse None

Insulation system Photocoupler insulation

Output display LED (green)

External connection Removable type screw terminal block (M3)

External power supply *1

Not necessary 30 to 16 V DC

to V terminal

Insulation 1500 V or more (external-internal)

500 V or more (external-external)

Output voltage drop 0.3 V DC (max)

*1: It is necessary to supply 16 to 30 V DC between the V and C terminals externally for the source type.

The sink type operates by load power supply only. See “4.6 Terminal Layout and Wiring” for the details.

Sink type (23/28DRT)

Internal circuit

Source type (23/28DRP)

Internal circuit

0

C0

V0

0

C0

3-8

Page 25

Chapter 3 Function and Performance Specifications

(2) DC output: LCDC-Low Current

(All points of EH-D10DT/DTP, Y102-Y105 of EH-D14DT/DTP, Y102-Y109 of EH-D28DT/DTP,

Y*018-Y*021 of EH-D14EDT/D14EDTP)

Item Specification

Output specification Transistor output

Sink type (EH-D**DT)

Rated load voltage 24/12 V DC (+10 %, -15 %)

Minimum switching current 1 mA

Leak current 0.1 mA (max)

Maximum

load current

1 circuit 0.75 A 24 V DC

0.5 A 12 V DC

Internal circuit Internal circuit

1 common 3 A

OFF → ON 0.1 ms (max) 24 V DC 0.2AOutput

response time

ON → OFF 0.1 ms (max) 24 V DC 0.2A

Number of output points See Chapter 4.

Number of common See Chapter 4.

Source type (EH-D**DTP)

Surge removing circuit None

Fuse None

Insulation system Photocoupler insulation

Output display LED (green)

Internal circuit

External connection Removable type screw terminal block (M3)

Externally supplied power *1 30 to 12 V DC

Insulation 1500 V or more (external-internal)

500 V or more (external-external)

Output voltage drop 0.3 V DC (max)

*1: It is necessary to supply 12 to 30 V DC between the V and C terminals externally. See “4.6 Terminal Layout and Wiring.”

Circuit diagram

V0

0

C0

V0

0

C0

(3) DC output: HCDC-High Current

Y100,Y101

(

Y*016, Y*017

of EH-D14DT/DTP,

of EH-D14EDT/D14EDTP)

Item Specification

Output specification Transistor output

Rated load voltage 24/12 V DC (+10 %, -15 %)

Minimum switching current 1 mA

Leak current 0.1 mA (max)

1 circuit 1A 24 V DCMaximum

load current

1 common 3 A

OFF → ON 0.1 ms (max) 24 V DC 0.2AOutput

response time

ON → OFF 0.1 ms (max) 24 V DC 0.2A

Number of output points See Chapter 4.

Number of common See Chapter 4.

Surge removing circuit None

Fuse None

Insulation system Photocoupler insulation

Output display LED (green)

External connection Removable type screw terminal block (M3)

Externally supplied power *1 30 to 12 V DC

Insulation 1500 V or more (external-internal)

Output voltage drop 0.3 V DC (max)

*1: It is necessary to supply 12 to 30 V DC between the V and C terminals externally. See “4.6 Terminal Layout and Wiring.”

Y100, Y101, Y110, and Y111

500 V or more (external-external)

of EH-D28DT/DTP,

Circuit diagram

Sink type (EH-D**DT)

V0

Internal circuit

0

C0

Source type (EH-D**DTP)

V0

0

C0

3-9

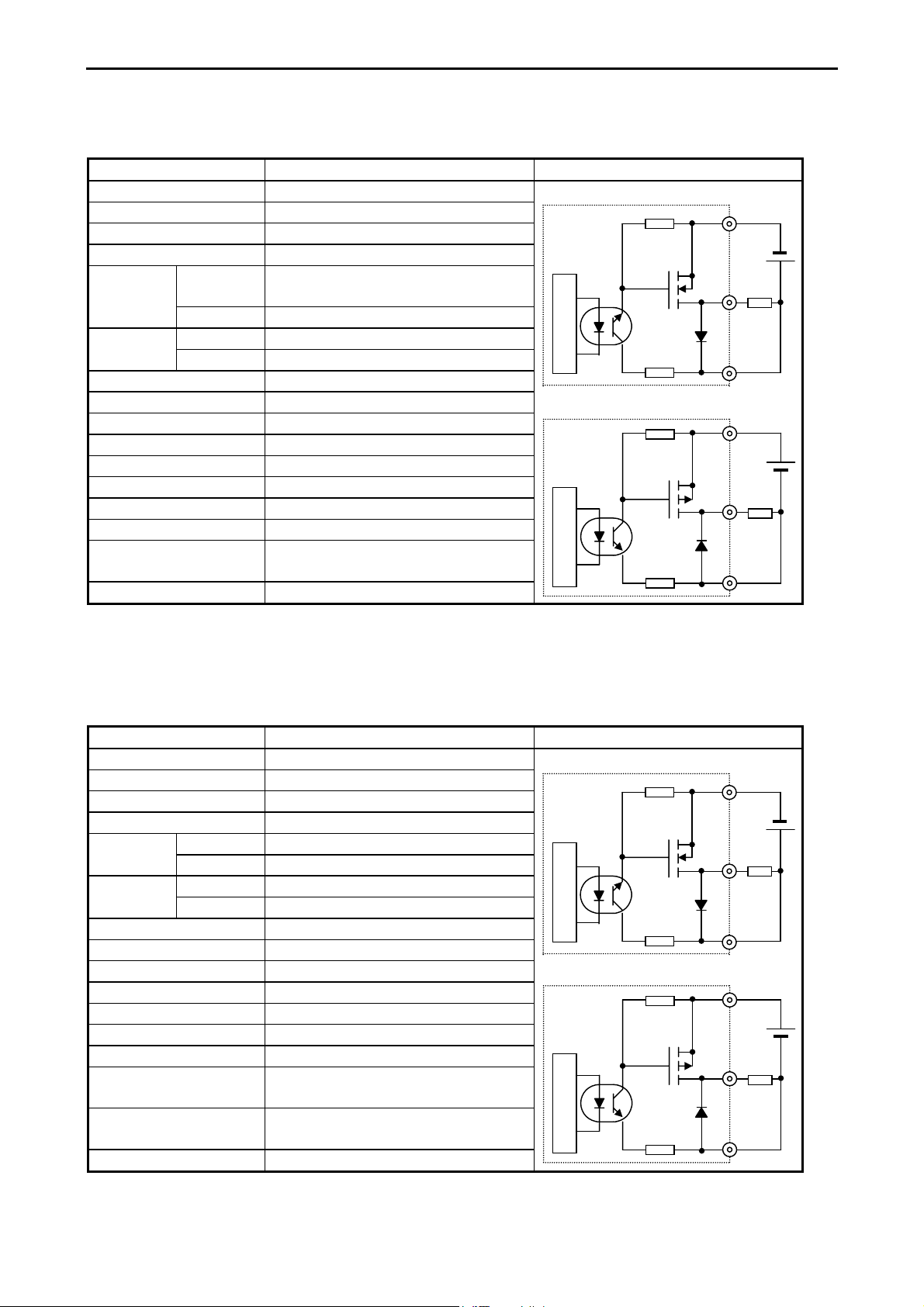

Page 26

Chapter 3 Function and Performance Specifications

(4) DC output (ESCP type): HCDC-High Current

(Y100,Y101 of EH-D14DTPS, Y100-Y103 of D28DTPS)

Y*016,Y*017 of EH-EDTPS, Y*016-Y*019 of EH-D28EDTPS)

Item Specification

Output specification Transistor output

Rated load voltage 24/12 V DC (+10 %, -15 %)

Minimum switching current 10 mA

Leak current 0.1 mA (max)

load current

1 circuit 1 AMaximum

1 common 3 A

Source type (EH-D**DTPS)

OFF → ON 0.05 ms (max) 24 V DC 0.2AOutput

response time

ON → OFF 0.05 ms (max) 24 V DC 0.2A

Number of output points See Chapter 4.

Number of common See Chapter 4.

Surge removing circuit None

Fuse None

Insulation system Photocoupler insulation

Output display LED (green)

External connection Removable type screw terminal block (M3)

Externally supplied power *1 30 to 12 V DC

Insulation 1500 V or more (external-internal)

500 V or more (external-external)

Output voltage drop 0.3 V DC (max)

*1: It is necessary to supply 12 to 30 V DC between the V and C terminals externally. See “4.6 Terminal Layout and Wiring.”

Circuit diagram

V0

Internal circuit

0

C0

(5) DC output (ESCP type): LCDC-Low Current

(Y102-Y105 of EH-D14DTPS, Y104-Y111 of EH-D28DTPS

Y*018-Y*021

of EH-D14EDTPS,

Item Specification

Output specification Transistor output

Rated load voltage 24/12 V DC (+10 %, -15 %)

Minimum switching current 10 mA

Leak current 0.1 mA (max)

1 circuit 0.7 AMaximum

load current

1 common 3 A

OFF → ON 0.5 ms (max) 24 V DC 0.2AOutput

response time

ON → OFF 0.5 ms (max) 24 V DC 0.2A

Number of output points See Chapter 4.

Number of common See Chapter 4.

Surge removing circuit None

Fuse None

Insulation system Photocoupler insulation

Output display LED (green)

External connection Removable type screw terminal block (M3)

Externally supplied power *1 30 to 12 V DC

Insulation 1500 V or more (external-internal)

Output voltage drop 0.3 V DC (max)

*1: It is necessary to supply 12 to 30 V DC between the V and C terminals externally. See “4.6 Terminal Layout and Wiring.”

Y*020-Y*027

of EH-D28EDTPS)

500 V or more (external-external)

Circuit diagram

Source type (EH-D**DTPS)

V0

Internal circuit

0

C0

3-10

Page 27

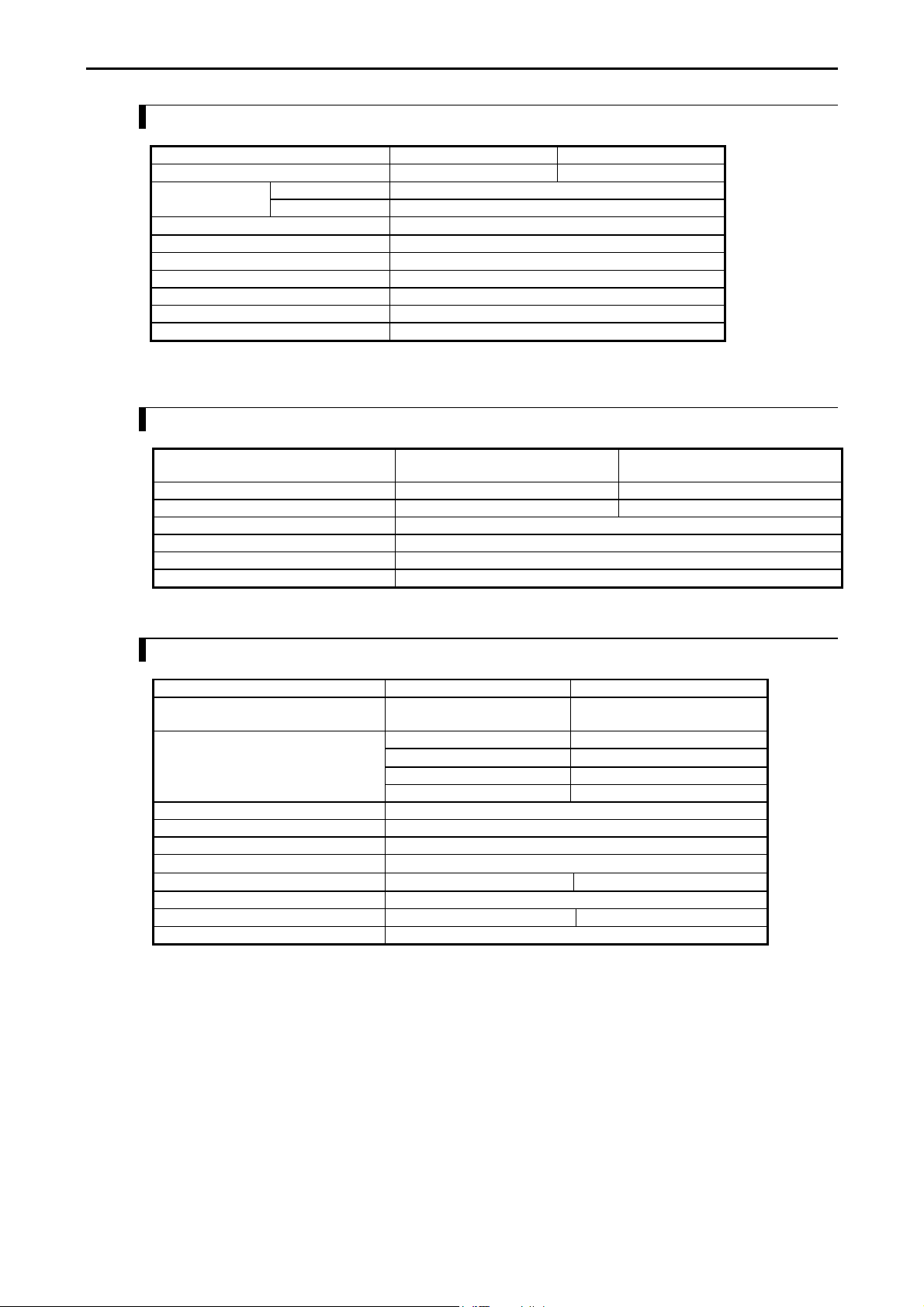

Chapter 3 Function and Performance Specifications

(6) Relay output

Item Specification Circuit diagram

Rated load voltage 5 to 250 V AC, 5 to 30 V DC

Minimum switching current 1 mA

1 circuit 2 A (24 V DC, 240 V AC)Maximum

load current

Output

response time

Number of output points See Chapter 4.

Number of common See Chapter 4.

Surge removing circuit None

Fuse None

Insulation system Relay insulation

Output display LED (green)

External connection Removable type screw terminal block (M3)

Externally supplied power

(for driving the relays)

Contact life *1 20,000,000 times (mechanical)

Insulation 1500 V or more (external-internal)

*1: Refer to the Life curve of relay contacts in Chapter 10 for the details.

1 common 5 A

OFF → ON

ON → OFF

15 ms (max)

15 ms (max)

Not necessary

200,000 times (electrical: 2 A)

500 V or more (external-external)

0

Internal circuit

1

C

(7) AC output (SSR)

Item Specification Circuit diagram

Output specification Triac output

Rated voltage 100/240 V AC

Output voltage 100 –15 % to 240 +10 % V AC

50 –5 % to 60 +5 % Hz

1 circuit 0.5 A 240 V ACMaximum

load current

Minimum load current 100 mA

Maximum leakage current 1.8 mA 115 V AC(max)

Maximum inrush current 5 A (at 1 cycle or less)/point

Maximum

delay time

Output common See Chapter 4.

Polarity See Chapter 4.

Insulation system Phototriac insulation

Fuse *2 Used

Surge removing circuit Sunabar circuit + varistor

External connection Removable terminal block

Voltage drop 1.5 V RMS (max)

Insulation 1500 V or more (external-internal)

*2: It is necessary to repair the module if the load short-circuits and causes the fuse to melt.

Note that the fuse cannot be replaced by users.

1 common 2 A

3.5 mA 230 V AC(max)

10 A (at 1 cycle or less)/common

Off → On

On → Off

1 ms or less

1 ms + 1/2 cycle or less

500 V or more (external-external)

Internal circuit

0

1

C

3-11

Page 28

Chapter 3 Function and Performance Specifications

3.3.4 High-Speed Counter Specifications

Single phase Two phase

Available input X0, X2, X4, X6 X0 and X2 in pair

Input voltage ON 15 V

OFF 5 V

Count pulse width

Maximum count frequency 10 kHz each channel

Count register 16 bits

Coincidence output Allowed

On/Off-preset Allowed

Upper/lower limit setting Not allowed

Preload/strobe Allowed

Since 10 points type does not have input X6, counter channel is up to 3 ch.

100 µs

3.3.5 PWM Output/Pulse Train Output Specifications

23-point and 28-point type

Relay Output

Available outputs Y100 (optional) Y100-Y103 (optional)

Load voltage 5/12/24 V 12/24 V

Minimum load current 1 mA

PWM max. output frequency *1 2 kHz total channels

Pulse train max. output frequency *1 5 kHz total channels

Pulse acceleration/deceleration By FUN 151.

*1: Relay outputs cannot keep up with high frequencies; these outputs should be used at the operating frequency upon confirmation.

10/14/28-point

Transistor Output

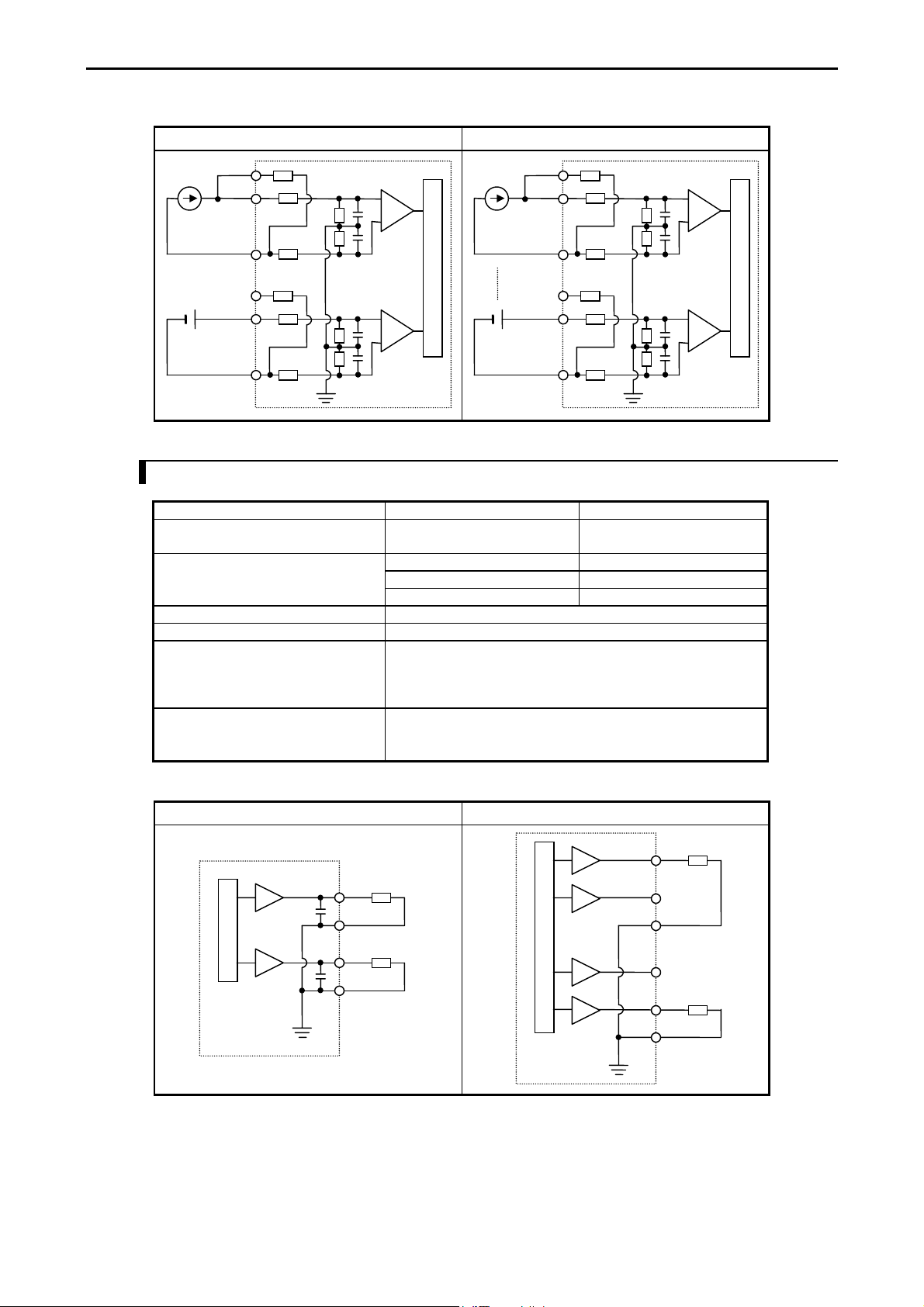

3.3.6 Analogue Input Specifications

Module type 23 points module Analog exp. unit

Input channel WX30, WX31 WX u01 - WX u04

(u : unit number)

Input range

Resolution 12 bits

Accuracy ±1 % of full scale

Linearity Max. +/-3 units

Current input impedance

Voltage input impedance

Input delay time 20 ms

Channel to internal circuit insulation Not insulated Insulated

Channel-to-channel insulation Not insulated

0-10 V (10.24V max.) 0-10V (10.24V max.)

-10 to +10V (±10.24V max.)

0-20 mA (20.48 mA max.) 0-20 mA (20.48 mA max.)

- 4-20 mA (20.38 mA max.)

Approx. 249 Ω

Approx. 100 kΩ Approx. 200 kΩ

3-12

Page 29

Chapter 3 Function and Performance Specifications

Circuit diagram (23 points type) Circuit diagram (Analog expansion unit)

Current

Voltage

IN2JP

IN2+

Internal circuit

IN2-

IN1JP

IN1+

IN1-

IN4JP

IN4+

Current

IN4-

IN1JP

IN1+

Voltage

IN1-

3.3.7 Analogue Output Specifications

Module type 23 points type module Analog exp. unit

Output channel WY40 WY u06, WY u07

(u : unit number)

Output range

Resolution 12 bits

Accuracy ±1 % of full scale

Current output

Allowable load

Output allowable capacity

Output allowable inductance

Voltage output

Allowable load

Output allowable impedance

0-10V (10.24V max.) 0-10V (10.24V max.)

0-20mA (20.48mA max.) 0-20mA (20.48mA max.)

4-20mA (20.38mA max.)

10 to 500 Ω

Maximum 2000 pF

Maximum 1 H

Maximum 10 kΩ

Maximum 1 µF

Internal circuit

Circuit diagram (23 points type) Circuit diagram (Analog expansion unit)

Voltage

Internal circuit

Voltage

Current

Internal circuit

IO7

IO6

Current

3-13

Page 30

Chapter 3 Function and Performance Specifications

3.3.8 Potentiometer Analogue Input Specifications

Number of potentiometer inputs 2

Stored in

Input range 0-1023 (H0-H3FF)

Resolution 10 bits

Input filter By user settings

Ch.1 : WRF03E, Ch.2 WRF03F

3.3.9 Interrupt Input Specifications

Input that can be used X1, X3, X5, X7 (by user settings)

ON 15 VInput voltage

OFF 5 V

3.3.10 Backup

(1) Battery

Data memory (retentive area) can be kept by EH-MBAT battery as below.

Battery life time (total power off time) [Hr] *

Guaranteed value (Min.) @55°C Actual value (Max.) @25°C

9,000 18,000

* Battery life time has been changed since Oct. 2002 production (MFG NO.02Jxx) due to hardware modification.

Battery can be mounted inside of front cover.

Battery is available only for 23-point and 28-point types.

If the calendar clock function is used with the 23-point or 28-point type, be sure to use the battery.

(2) Capacitor

14-point type: Data can be kept for 72 hours (at 25 °C) by the capacitor.

23 and 28-point types: Data can be kept for 24 hours (at 25 °C) by the capacitor.

Please note that data memory of 10 point type cannot be retained.

3.3.11 Expansion

• Up to 4 times of expansion units can be installed.

• 14 points and 28 points digital units, and 4ch. input / 2 ch. output analog expansion units available.

• A cable with a length of up to 1 m can be used to connect between units.

• The total extension cable length can be up to 2 m (from the basic unit to the expansion unit at the end).

• The 10-point type unit cannot be expanded.

3-14

Page 31

Chapter 3 Function and Performance Specifications

3.3.12 Clock Function

23-point and 28-point types have calendar function. This can be operated either by internal output area or task code.

* 10-point and 14-point types do not have this function.

(1) Reading the clock data

By turning on the read request (R7F8), the clock data is read out in the reading value area (WRF01B to WRF01F).

(2) Writing the clock data

By turning on the write request (R7F9), the clock data stored in writing value area (WRF01B to WRF01F) is written

to the current data area (WRF00B to WRF00F). If the data is wrong, error flag (R7BF) will turn on. If data is right,

clock data will be written and writing flag R7FB will turn off.

(3) Adjusting the clock data ± 30 seconds

By turning on the ± 30 seconds adjustment request (R7FA), one of the following operations is performed depending

on the second value:

• If the second digits are 00 to 29, the second digits are set to 00.

• If the second digits are 30 to 59, the minute is incremented by 1 and the second digits are set to 00.

(4) Special internal output definitions

• Operation bits

I/O number Name Description

R7F8 Request to read calendar and

clock data

R7F9 Request to write calendar and

clock data

R7FA

R7FB Calendar and clock setting data

Clock ± 30 seconds adjustment

request

error

Calendar and clock data is read out to

WRF01B-F01F.

Calendar and clock data in WRF01B-F01F is

written to the current data in WRF00B-F00F.

Sets the second digits of the RTC to 00.

Turns on when the setting data is abnormal.

• Current data monitor area : Current data of the clock given always (all BCD data).

I/O number Name Description

WRF00B Year 4-digit year [yyyy]

WRF00C Month and date [mmdd]

WRF00D Day of the week 0 to 6 : Sunday to Saturday

WRF00E Hour and minute [hhmm] (24-hour system).

WRF00F Second [00ss]

• Reading/writing area : Clock data to be read or written.

(All BCD data)

I/O number Name Description

WRF01B Year 4-digit year [yyyy]

WRF01C Month and date [mmdd]

WRF01D Day of the week 0 to 6 : Sunday to Saturday

WRF01E Hour and minute [hhmm] (24-hour system).

WRF01F Second [00ss]

Note 1: The day of the week data is expressed as follows.

0: Sunday, 1: Monday, 2: Tuesday, 3: Wednesday, 4: Thursday, 5: Friday, 6: Saturday

3-15

Page 32

Chapter 3 Function and Performance Specifications

3.3.13 Power Supply for Sensor

The 24 V terminal at the input terminal part can supply current to external equipment (not for all units).

If this terminal is used as the power supply for the input part of this unit, the remaining can be used as power supply for the

sensors.

The following current (I) can be supplied as power supply for the sensors.

(1) EH-*14*** (14-point type basic unit)

EH-*14E*** (14-point type extension unit)

I = 350 mA – (7.5 mA x number of input points that are turned on at the same time)

(2) EH-A28DR* (28-point type basic unit)

EH-A23DR*** (23-point type basic unit)

I = 280 mA – (7.5 mA x number of input points that are turned on at the same time)

3-16

Page 33

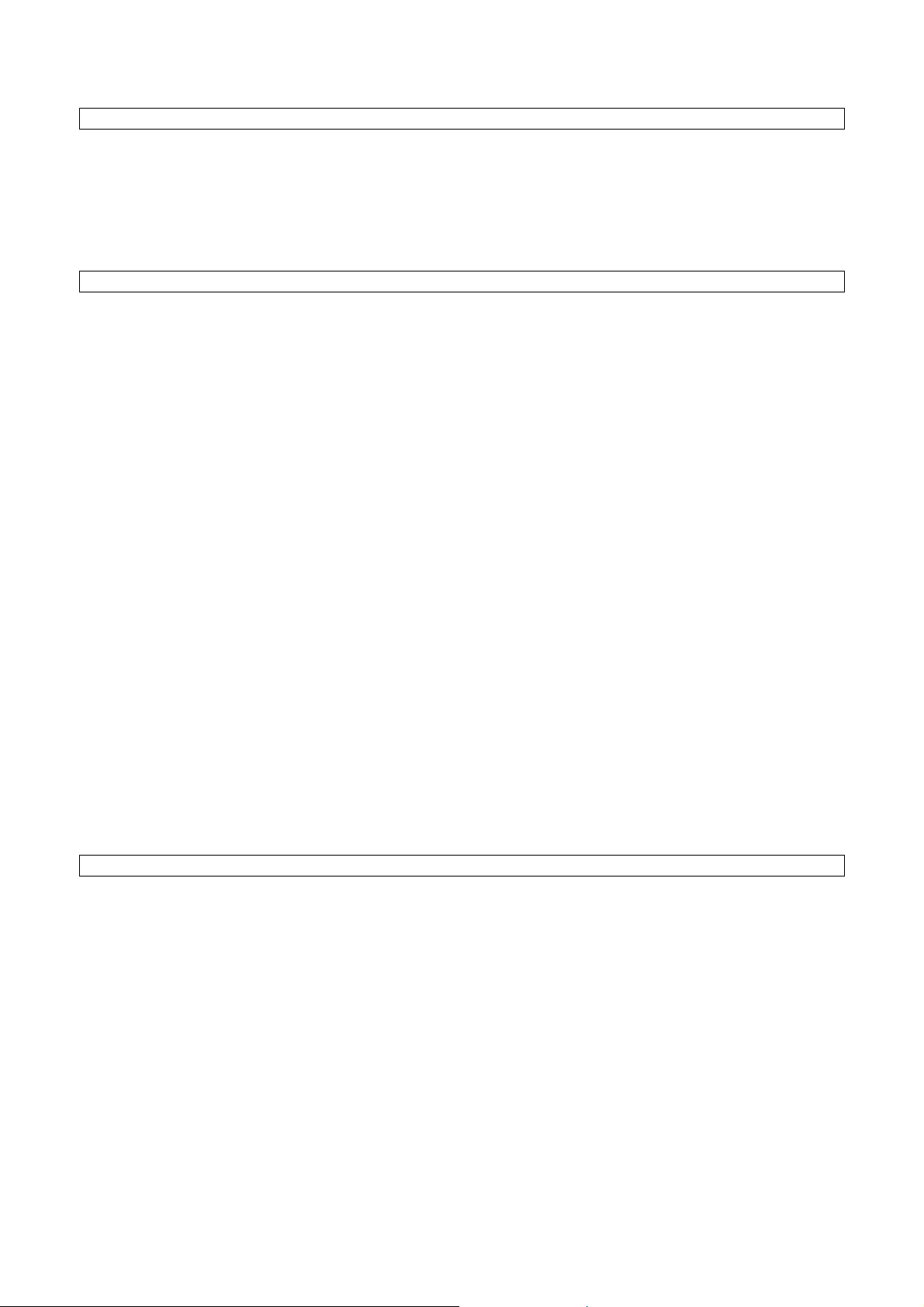

Chapter 4 Product lineup and wiring

Chapter 4 Product lineup and wiring

4.1 Product lineup

(1) Basic units

Table 4.1 Product lineup list

Type Specifications

EH-D10DT

EH-D10DTP

EH-D10DR

EH-D14DT

EH-D14DTP

EH-A14DR

EH-D14DR

EH-A14AS

EH-D23DRP

EH-A23DRT

EH-A23DRP

EH-D28DT

EH-D28DTP

EH-D28DTPS

EH-D28DRT

EH-D28DRP

EH-A28DRT

EH-A28DRP

EH-A28DR

EH-A28AS

EH-D14EDT

EH-D14EDTP

EH-D14EDTPS

EH-D14EDR

EH-A14EDR

EH-D28EDT

EH-D28EDTPS

EH-D28EDR

EH-A28EDR

EH-D6EAN Expansion unit, DC power, Analog input × 4, Analog output × 2

EH-A6EAN Expansion unit, AC power, Analog input × 4, Analog output × 2

DC power, DC input × 6, Transistor (sink) output × 4

DC power, DC input × 6, Transistor (source) output × 4

DC power, DC input × 6, Relay output × 4

DC power, DC input × 8, Transistor (sink) output × 6

DC power, DC input × 8, Transistor (source) output × 6

AC power, DC input × 8, Relay output × 6

DC power, DC input × 8, Relay output × 6

AC power, AC input × 8, SSR output × 6

DC power, DC input × 13, Relay output × 9, Transistor output (source) × 1,

Analog input × 2, Analog output × 1

AC power, DC input × 13, Relay output × 9, Transistor output (sink) × 1,

Analog input × 2, Analog output × 1

AC power, DC input × 13, Relay output × 9, Transistor output (source) × 1,

Analog input × 2, Analog output × 1

DC power, DC input × 16, Transistor (sink) output × 12

DC power, DC input × 16, Transistor (source) output × 12

DC power, DC input × 16, Transistor (source) output (ESCP) × 12

DC power, DC input × 16, Relay output × 11, Transistor output (sink) × 1

DC power, DC input × 16, Relay output × 11, Transistor output (source) × 1

AC power, DC input × 16, Relay output × 11, Transistor output (sink) × 1

AC power, DC input × 16, Relay output × 11, Transistor output (source) × 1

AC power, DC input × 16, Relay output × 12

AC power, AC input × 16, SSR output × 12

Expansion unit, DC power, DC input × 8, Transistor (sink) output × 6

Expansion unit, DC power, DC input × 8, Transistor (source) output × 6

Expansion unit, DC power, DC input × 8, Transistor (source) output (ESCP) × 6

Expansion unit, DC power, DC input × 8, Relay output × 6

Expansion unit, AC power, DC input × 8, Relay output × 6

Expansion unit, DC power, DC input × 16, Transistor (sink) output × 12

Expansion unit, DC power, DC input × 16, Transistor (source) output (ESCP) × 12

Expansion unit, DC power, DC input × 16, Relay output × 12

Expansion unit, AC power, DC input × 16, Relay output × 12

I/O assignment

symbol

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/

empty16/WX4/WY4

X48/Y32/

empty16/WX4/WY4

X48/Y32/

empty16/WX4/WY4

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

X48/Y32/empty16

B1/1

B1/1

B1/1

B1/1

B1/1

B1/1

B1/1

B1/1

B1/1

FUN 0

FUN 0

Each digit in the type name has the following meaning:

EH - D

28

D T P

[None]: Sink, T: Sink, P: Source (except in the cases of relay output and SSR output)

R: Relay output, T: Transistor (DC) output, S: SSR (AC) output

D: DC input, A: AC input

[None]: Basic unit, E: Expansion unit

10: 10-point type, 14: 14-point type, 23: 23-point type, 28: 28-point type

A: AC power supply type, D: DC power supply type

4-1

Page 34

Chapter 4 Product lineup and wiring

(2) Peripheral Units

Table 4.2 List of peripheral units

Product Form Specification Remarks

Graphic input

device support

software

Note: HI-LADDER (attached to the GPCL01H) may also be used.

However, HL-GPCL and HI-LADDER cannot be used for the 10-point type.

and expansion unit

Conversion cable for

connecting peripheral units

Peripheral equipment GPCB02H Length: 2 m, between CPU and graphic input unit

*: Required when connecting the MICRO-EH with PC98, IBM PC/AT compatible PC or other system using one of the cables

marked with **.

HL-GPCL Ladder diagram/Instruction language editor LADDER EDITOR (for GPCL)

HL-PC3 Ladder diagram/Instruction language editor LADDER EDITOR (for PC98

series) with CPU connection cable

HL-AT3E Ladder diagram/Instruction language editor LADDER EDITOR (for PC/AT

compatible personal computer)

HLW-PC3 Ladder diagram/Instruction language editor LADDER EDITOR (for Windows®

95/NT 4.0)

HLW-PC3E Ladder diagram/Instruction language editor LADDER EDITOR (for Windows®

95/98/NT 4.0)

Pro-H HITACHI H-series PLC Programming Software According to IEC 61131-3 (for

Windows® 95/98/NT 4.0)

(3) Connection Cables

Table 4.3 List of connection cables

Product Form Specification Remarks

EH-MCB10 Length: 1 m (basic unit–exp. unit, exp. unit - exp. unit) Total 2 mCable for connecting basic unit

EH-MCB05 Length: 0.5 m (basic unit–exp. unit, exp. unit - exp. unit) Total 2 m

EH-MCB01 Length: 0.1 m (basic unit–exp. unit, exp. unit - exp. unit) Total 2 m

EH-RS05 Length: 0.5 m *

GPCB05H Length: 5 m, between CPU and graphic input unit

GPCB15H Length: 15 m, between CPU and graphic input unit

CBPGB Length: 2 m, between graphic input unit and printer

LP100 Length: 2 m, between graphic input unit and kanji printer

KBADPTH Length: 15 m, between graphic input unit and JIS keyboard

PCCB02H Length: 2 m, between CPU and PC98 series **

WPCB02H Length: 2 m, between CPU and PC98 series (25-pin) **

WVCB02H Length: 2 m, between CPU and DOS/V (9-pin) **

EH-VCB02 Length: 2 m, between CPU (8P modular terminal) and DOS/V

(9-pin)

(4) Others

Model Usage Remarks

EH-MBAT Lithium battery

4-2

Page 35

4.2 10-Point Basic Unit

Chapter 4 Product lineup and wiring

Name and function of each part

9] Mounting hole

4] Serial port

8] Power terminal

5] RUN input

Type EH-D10DT, EH-D10DTP, EH-

D10DR

6] Input terminals

1] POW LED

2] OK LED

3] RUN LED

7] Output terminals

10] DIN rail installation clip

No. Item Detailed explanation Remarks

Explanation of operation Operations are performed according to the contents of the program created

by the user.

The programming unit connected to the CPU module communication port

writes and reads the user programs.