Page 1

Instruction and safety manual

Mode d’emploi et consignes de sécurité

Manual de instrucciones y seguridad

Model

Modèle

Modelo

N2503AF

Flooring Stapler

Brocheuse à plancher

Grapadora para pisos

Improper use of this Stapler can result in death or serious injury!

This Manual contains important information about product safety.

Read and understand this Manual before operating the Stapler.

Never allow anyone (to handle this Stapler) who has not reviewed this manual.

L’utilisation inadéquate de cette brocheuse peut causer une blessure grave et même mortelle!

Ce manuel contient d’importantes consignes de sécurité.

Lire le manuel attentivement avant d’utiliser la brocheuse.

Ne jamais laisser une personne qui n’a pas lu le manuel utiliser la brocheuse.

¡El uso incorrecto de esta grapadora puede ocasionar lesiones graves o la muerte!

Este manual contiene información importante acerca de la seguridad del producto.

Lea y comprenda este manual antes de usar la grapadora.

No permita nunca el uso de esta grapadora por parte de alguien que no haya leído este manual.

DANGER

DANGER

PELIGRO

Page 2

English

Page Page

IMPORTANT SAFETY INFORMATION ……………………………………………. 3

DEFINITIONS OF SIGNAL WORDS ………………….……………………………… 3

SAFETY

IMPORTANT SAFETY INSTRUCTIONS FOR USING

N2503AF STAPLERS ……………………………..………………………………….. 4

EMPLOYER’S RESPONSIBILITIES …………………...……………………………… 7

OPERATION

NAME OF PARTS ……………………………………...………………………………….. 8

SPECIFICATIONS ……………………………………...…………………………………… 9

STAPLE SELECTION ………………………………….…………………………………… 9

APPLICATIONS ………………………………………..……………………………………. 9

ACCESSORIES ………………………………………...…………………………………….. 9

STANDARD ACCESSORIES …………….……...………………………………….. 9

Français

Page

SÉCURITÉ …………………………………………………………………………...………. 19

DÉFINITION DES TERMES DE SIGNALISATION ………….…………………… 19

SÉCURITÉ

IMPORTANTES CONSIGNES DE SÉCURITÉ POUR L’UTILISATION DE LA

BROCHEUSE N2503AF ……………………………..…………………………….. 20

RESPONSABILITÉS DE L’EMPLOYEUR …………………………………………… 23

FONCTIONNEMENT

NOM DES PIÈCES ……………………………………...……………………………….. 24

FICHE TECHNIQUE ……………………………………...……………………………… 25

SÉLECTION DES BROCHES …………………………………………………………… 25

UTILISATIONS .……………………………………..…………………………………….. 25

ACCESSORIES ………………………………………...…………………………………….. 25

ACCESSOIRES STANDARDS …………….……...……………………………….. 25

CONTENTS

BEFORE OPERATION …………………………………..……………………………….. 9

WORKING ENVIRONMENT ……………….……...……………………………… 9

AIR SUPPLY …………………………………….…..…………………………………… 10

LUBRICATION ………………………………….…..………………………………….. 10

COLD WEATHER CARE ……………………….….…………………………………. 10

TESTING THE STAPLER …………………….…...…………………………………. 11

ADJUSTING AIR PRESSURE ……………….…...………………………………… 11

LOADING STAPLES ………………………….…...………………………………….. 11

STAPLER OPERATION ………………………………..…………………………………. 12

METHODS OF OPERATION ................................……………………………. 12

DUAL TRIGGER OPERATION …………………………………………………….. 12

FASTENER POSITIONING ADJUSTMENT ……………………………………….. 13

ADJUSTING THE STAPLING DEPTH ....................……………………………. 13

MAINTENANCE

MAINTENANCE AND INSPECTION ......................…………………………… 14

SERVICE AND REPAIRS .....................................……………………………… 14

EXPLODED VIEW ………………………………………………………………………….. 17

PARTS LIST .....................................................……………………………….. 18

CONTENU

Page

AVANT DE COMMENCER ...………………………..……………………………….. 25

ENVIRONNEMENT DE TRAVAIL ……….……...……………………………… 25

ALIMENTATION EN AIR ………………….…..…………………………………… 26

LUBRIFICATION ……………………………….…..…………………………………..26

SOINS PAR TEMPS FROID ………………….….…………………………………. 26

ESSAI DE LA BROCHEUSE ……………….…...…………………………………. 27

RÉGLAGE DE LA PRESSION D’AIR …….…...………………………………… 27

CHARGEMENT DES BROCHES ……….…...………………………………….. 27

FONCTIONNEMENT DE LA BROCHEUSE …..…………………………………. 28

MODES D’UTILISATION ................................……………………………….. 28

FONCTIONNEMENT DE LA GÂCHETTE DOUBLE ……………………….. 28

RÉGLAGE DU DISPOSITIF DE POSITIONNEMENT DES ATTACHES ….. 28

RÉGLAGE DE LA PROFONDEUR DE BROCHAGE ……………………………. 28

ENTRETIEN

ENTRETIEN ET INSPECTION ......................……………………………………. 30

SERVICE ET RÉPARATION ...............................………………………………. 30

VUE ÉCLATÉE ……………………………………………………………………………….. 33

LISTE DES PIÈCES ...........................................……………………………….. 34

Español

INFORMACION IMPORTANTE PARA LA SEGURIDAD …………….………. 35

DEFINICIONES DE LAS PALABRAS DE AVISO …………….…………………… 35

SEGURIDAD

INSTRUCCIONES IMPORTANTES PARA LA SEGURIDAD EN EL USO DE LAS

GRAPADORAS N2503AF ……………………………..…………………………… 36

RESPONSABILIDADES DEL EMPLEADOR …………………...……………….… 39

FUNCIONAMIENTO

NOMBRES DE LAS PIEZAS ………..……………...………………………………….. 40

ESPECIFICACIONES ……………………………………...………………………..…… 41

SELECCION DE GRAPAS ………………………………….………………………….… 41

APLICACIONES ………………………………………..………………………...……….. 41

ACCESORIOS ………………………………………...…………………………….………. 41

ACCESORIOS ESTANDARES …………….……...……………………………….. 41

CONTENIDO

Página

ANTES DEL FUNCIONAMIENTO …………………..……………………………….. 41

AMBIENTE DE TRABAJO ……………….……...………………………………... 41

SUMINISTRO DE AIRE …………………….…..…………………………………… 42

LUBRICACION ..……………………………….…..………………………………….. 42

CUIDADO EN EL CLIMA FRIO …………….….…………………………………. 43

PRUEBA DE LA GRAPADORA .………….…...…………………………………. 43

AJUSTE DE LA PRESION DE AIRE ……….…...…………………………………43

COLOCACION DE GRAPAS .…………….…...………………………………….. 43

FUNCIONAMIENTO DE LA GRAPADORA …..……………………………….…. 44

METODOS DE FUNCIONAMIENTO ....................……………………………. 44

FUNCIONAMIENTO CON DOBLE GATILLO ...…………………………….. 44

AJUSTE DE LA POSICION DE LOS SUJETADORES …………………………... 45

AJUSTE DE LA PROFUNDIDAD DE LAS GRAPAS .……………………………. 45

MANTENIMIENTO

MANTENIMIENTO E INSPECCION ......................…………………………… 46

SERVICIO Y REPARACIONES .............................……………………………… 46

VISTA MAGNIFICADA …………………………………………………………………… 49

LISTA DE PIEZAS ............................................……………………………….. 50

2

Página

Page 3

IMPORTANT SAFETY INFORMATION

Read and understand tool labels and all of the operating instructions, safety precautions and warnings in

this manual before operating or maintaining this Stapler. Failure to follow warnings could result in DEATH

or SERIOUS INJURY.

Most accidents that result from the operation and maintenance of Staplers are caused by the failure to observe basic safety rules and

precautions. An accident can often be avoided by recognizing a potentially hazardous situation before it occurs, and by observing appropriate safety procedures.

Basic safety precautions are outlined in the "SAFETY" section of this Manual and in the sections which contain the

operation and maintenance instructions.

Hazards that must be avoided to prevent bodily injury or machine damage are identified by DANGERS and WARNINGS on the Stapler

and in this Manual.

Never use this Stapler for applications other than those specified in this Manual.

English

DEFINITIONS OF SIGNAL WORDS

DANGER indicates an imminently hazardous situation, which if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which if not avoided, may result in minor or moderate injury, or may cause machine

damage.

NOTE emphasizes essential information.

3

Page 4

SAFTEY

IMPORTANT SAFETY INSTRUCTIONS FOR USING STAPLERS

READ ALL INSTRUCTIONS

DANGER

1. OPERATORS AND OTHERS IN WORK AREA MUST WEAR SAFETY GLASSES WITH SIDE SHIELDS.

• When operating the Stapler, always wear eye safety glasses with side shields, and make sure others in the

work area wear safety glasses, too.

• Safety glasses must conform to the requirements of American National Standards Institute, ANSI Z87.1

and provide protection against flying particles both from the front and side.

• The employer must enforce the use of safety glasses by the Stapler operator and others in work area.

2. NEVER USE OXYGEN OR OTHER BOTTLED GASES. EXPLOSION MAY OCCUR.

• Never use oxygen, combustible gases or any other bottled gases as a power source for the Stapler.

• Use of the above gases is dangerous, as the Stapler will explode.

• Use only clean, dry, regulated compressed air.

English

WARNING

3. NEVER POINT TOOL AT YOURSELF OR OTHERS IN WORK AREA.

• Always assume the Stapler contains fasteners.

• Never point the Stapler at yourself, toward yourself or others whether it contains fasteners or not.

• If fasteners are mistakenly driven, it can lead to severe injuries.

• Never engage in horseplay with the Stapler.

• Respect the Stapler as a working implement.

4. KEEP FINGERS AWAY FROM TRIGGER WHEN NOT DRIVING STAPLES TO AVOID ACCIDENTAL FIRING.

• Never carry the Stapler with finger on trigger since you could drive a fastener unintentionally and injure yourself or someone else.

• Always carry the Stapler by the handle only.

5. CHOICE OF TRIGGERING METHOD IS IMPORTANT.

• Read and understand section titled “METHODS OF OPERATION.” (page 12)

6. DO NOT EXCEED 100 psi. (6.9 bar 7.0 kgf/cm2)

• Do not exceed maximum recommended air pressure 100 psi

(6.9 bar 7.0 kgf/cm2)

• Never connect the Stapler to pressure which potentially exceeds 200 psi

(13.7 bar 14 kgf/cm2) as the Stapler can burst.

7. ALWAYS WEAR EAR AND HEAD PROTECTION.

• Always wear ear protection to protect your ears from loud noise.

• Always wear head protection conforming to ANSI Z89.1-1986 protect your head from flying objects.

4

Page 5

English

SAFTEY — Continued

WARNING

8. STORE STAPLER PROPERLY.

When not in use, the Stapler should be stored in a dry place.

Keep out of reach of children. Lock the storage area.

9. KEEP WORK AREA CLEAN.

Cluttered areas invite injuries. Clear all work areas of unnecessary

Staplers, debris, furniture, etc.

10. NEVER USE IN PRESENCE OF FLAMMABLE

LIQUIDS OR GASES.

The Stapler produces sparks during operation. Never use the

Stapler in sites containing lacquer, paint, benzine, thinner,

gasoline, gases, adhesive agents, and other materials which are

combustible or explosive.

11. KEEP VISITORS AWAY.

Do not let visitors handle the Stapler. All visitors should be kept

away from work area.

12. DRESS PROPERLY.

Do not wear loose clothing or jewelry as they can be caught in

moving parts. Rubber gloves and nonskid footwear are

recommended when working indoors. Wear protective hair

covering to contain long hair.

13. NEVER USE NON RELIEVING COUPLER ON

STAPLER.

If a non relieving coupler is used on the Stapler, the Stapler can

remain charged with air after disconnecting and thus will be able

to drive a Staple even after disconnecting. The Stapler and air

hose must have a hose coupling such that all pressure is removed

from the Stapler when the coupling joint is disconnected.

14. CHECK PUSH LEVER BEFORE USE.

Make sure the push lever operates properly. (The push lever may

be called "safety".) Never use the Stapler unless the push lever is

operating properly., otherwise the Stapler could drive a fastener

unexpectedly,. Do not tamper with or remove the push lever,

otherwise the push lever becomes inoperable.

15. KEEP ALL SCREWS AND COVERS TIGHTLY IN

PLACE.

Keep all screws and covers tightly mounted. Check their condition

periodically. Never use the Stapler if parts are missing or

damaged.

16. DO NOT LOAD FASTENERS WITH TRIGGER

PULLED OR PUSH LEVER DEPRESSED.

When loading fasteners into the Stapler or when connecting the

air hose,

1) do not pull the trigger;

2) do not depress the push lever; and

3) keep the Stapler pointed downward.

17.KEEP FACE, HANDS AND FEET AWAY FROM DISCHARGE AREA

DURING USE.

Never place your face, hands or feet closer than 8 inches

(200 mm) from discharge area. A serious injury can result if the

Staples are deflected by the work piece, or are driven away from

the point of entry.

18. PLACE STAPLER PROPERLY ON WORKPIECE.

Do not drive fasteners on top of other fasteners or with the

Stapler are too steep of an angle; the Staples can ricochet and

hurt someone.

19. BE CAREFUL OF DOUBLE FIRE DUE TO RECOIL.

If the push lever is unintentionally allowed to recontact the work

piece following recoil, an unwanted fastener will be driven.

In order to avoid this undesirable double fire,

1) Do not push the Stapler on the work piece with strong force;

2) Take the Stapler completely away from the work piece using

recoil, and keep the push lever away from the work piece until

the next desirable shot; and

3) Pull the trigger and release it QUICKLY when performing intermittent operation.

20. DO NOT DRIVE STAPLES INTO THIN BOARDS OR NEAR COR-

NERS AND EDGES OF WORK PIECE.

The Staples can be driven through or away from the work piece

and hit someone.

21. NEVER DRIVE STAPLES FROM BOTH SIDES OF A WALL AT THE

SAME TIME.

The Staples can be driven into and through the wall and hit a

person on the opposite side.

22. CHECK FOR LIVE WIRES.

Avoid the risk of severe electrical shock by checking for live

electrical wires that may be hidden by walls, floors or ceilings.

Turn off the breaker switch to ensure there are no live wires.

23. NEVER CARRY STAPLER BY HOSE.

5

Page 6

English

SAFTEY — Continued

WARNING

24. DO NOT OVERREACH.

Keep proper footing and balance at all times.

25. NEVER USE STAPLER WHICH IS DEFECTIVE OR OPERATING

ABNORMALLY.

If the Stapler appears to be operating unusually, making strange

noises, or otherwise appears defective, stop using it immediately

and arrange for repairs by a Hitachi authorized service center.

26. DO NOT DISCONNECT AIR HOSE FROM STAPLER WITH

FINGER ON TRIGGER.

The Stapler can operate when re-connected to an air supply.

27. DISCONNECT AIR HOSE FROM STAPLER WHEN:

1) Doing maintenance and inspection;

2) Loading fasteners;

3) Clearing a jam;

4) It is not in use;

5) Leaving work area;

6) Moving it to another location;

7) Handing it to another person; and

8) Adjusting the knobs.

Never attempt to clear a jam or repair the Stapler unless you

have disconnected air hose from the Stapler and removed all

remaining Staples from the Stapler. The Stapler should never be

left unattended since people who are not familiar with the

Stapler might handle it and injure themselves.

28. STAY ALERT.

Watch what you are doing. Use common sense. Do not operate

the Stapler when you are tired. The Stapler should never be used

by you if you are under the influence of alcohol, drugs or

medication that makes you drowsy.

29. HANDLE STAPLER CORRECTLY.

Operate the Stapler according to the Manual. Never allow the

Stapler to be operated by children, individuals unfamiliar with its

operation or unauthorized personnel.

30. NEVER USE STAPLER FOR APPLICATIONS OTHER THAN

THOSE SPECIFIED IN THIS MANUAL.

31. HANDLE STAPLER CAREFULLY.

Because of high air pressure in the Stapler, cracks in the surface

are dangerous. To avoid this, do not drop the Stapler or strike the

Stapler against hard surfaces; and do not scratch or engrave signs

on the Stapler. Handle the Stapler carefully.

32. MAINTAIN STAPLER WITH CARE.

Keep the Stapler clean and lubricated for better and safer

performance.

33. USE ONLY PARTS, ACCESSORIES OR STAPLES SUPPLIED OR

RECOMMENDED BY HITACHI.

Unauthorized parts, accessories, or Staples may void your

warranty and can lead to malfunction and resulting injuries. Only

service personnel trained by Hitachi, distributor or employer shall

repair the Stapler.

34. NEVER MODIFY OR ALTER A STAPLER.

Doing so may cause it to malfunction and personal injuries may

result.

6

Page 7

English

SAFTEY — Continued

WARNING

EMPLOYER’S RESPONSIBILITIES

1. Ensure that this MANUAL is available to operators and personnel performing maintenance.

2. Ensure that Staplers are used only when operators and others

in work area are wearing EYE PROTECTION.

3. Enforce the use of EYE PROTECTION by operators and others in

work area.

SAVE THIS MANUAL AND

KEEP IT AVAILABLE FOR OTHERS!

4. Keep Staplers in safe working order.

5. Maintain Staplers properly.

6. Ensure that Staplers which require repair are not further used

before repair.

7

Page 8

NOTE:

The information contained in this Manual is designed to assist you in the safe operation of the Stapler.

Some illustrations in this Manual may show details or attachments that differ from those on your own Stapler.

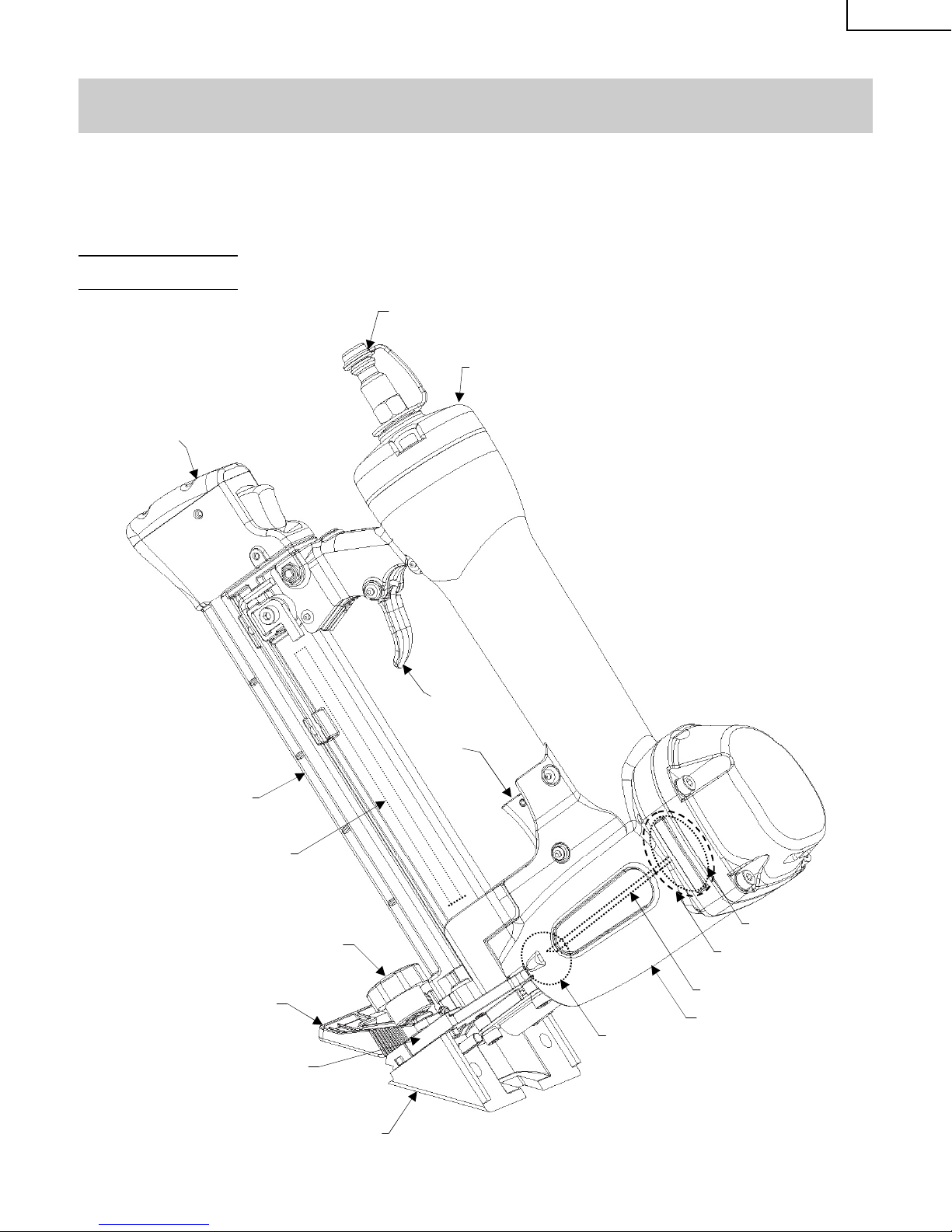

NAME OF PARTS

English

OPERATION

AIR PLUG

L

A

T

C

H

C

O

V

E

R

TRIGGER

MAGAZINE

HANDLE CAP

SECONDARY

TRIGGER

PUSHER

KNOBS

FRONT GUIDE

NOSE

PISTON

O-RING

DRIVER BLADE

BODY

BUMPER

FOOT

8

Page 9

SPECIFICATIONS

Operating Pressure 70-100 psi (4.8-6.9 bar 4.9-7.0 kgf/cm2)

Actuation Trigger operated - Sequential

English

Dimensions

Length x Height x Width

Weight 3.2 lbs (1.4 kg)

Staple Capacity 100 Staples

Air Consumption

Air Inlet 1/4" NPT Thread

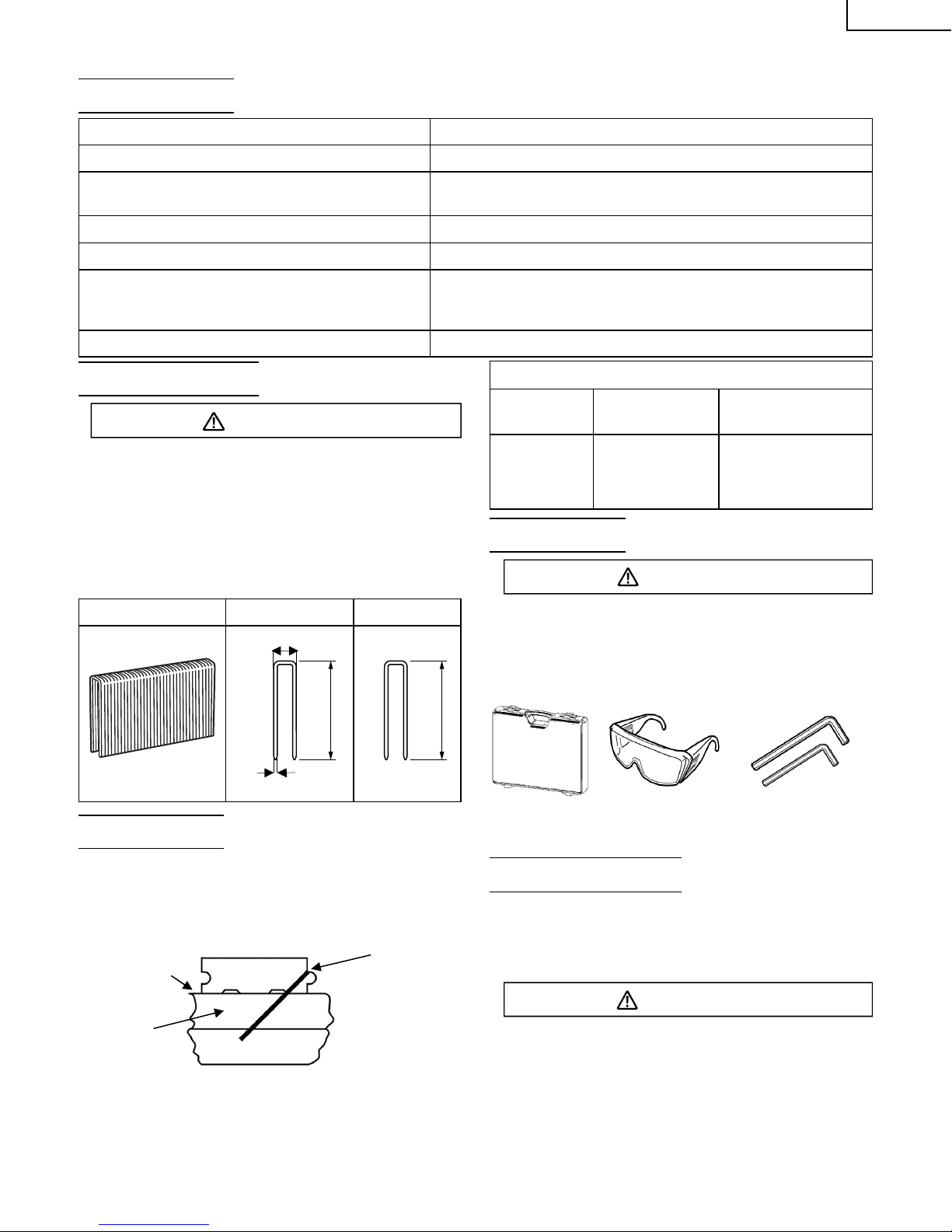

STAPLE SELECTION

STAPLE APPLICATION T&G FLOORING

10-1/8" x 9-5/8" x 2-5/16"

(257mm x 244mm x 59mm)

.026 ft3/cycle @ 80 psi

(.74 ltr/cycle @ 5.5 bar)

(.74 ltr/cycle @ 5.6 kgf/cm2)

STAPLE APPLICATION CHART

WARNING

• Be sure to use only the genuine HITACHI staples for the

N2503AF. The use of any other staples can result in tool

malfunction and/or staple breakdown, leading to serious

injuries.

Only Staples shown in the table below can be driven with this

Stapler.

1" STAPLE Angle fastener onto

5/8" - 3/4"

underlayment over

joist construction.

ACCESSORIES

WARNING

20 GAUGE STAPLE MIN. MAX

.188" (4.8mm)

• Accessories other than those shown below can lead to

malfunction and resulting injuries.

STANDARD ACCESSORIES

1. Carrying Case

2. Safety Glasses 3. Wrench Set

THICKNESS

1/4", 5/16", 3/8", 7/16"

1" (25mm)

.04" (.95mm)

APPLICATIONS

• TONGUE AND GROOVE FLOORING

• MOISTURE BARRIER

• SUBFLOOR

Tongue and Groove

Flooring

Moisture

Barrier

Subfloor

The N2503AF Pneumatic Flooring Stapler, with the standard

shoe, drives 1" Staples into the tongue and groove flooring at a

45 degree angle. The orientation of the Staple is as depicted

above.

1" Staple

1" (25mm)

1. Carry Case

NOTE: Accessories are subject to change without

any obligation on the part of HITACHI.

BEFORE OPERATION

Read over section titled "SAFETY" (pages 4 - 7)

Make sure of the following before operation.

WORKING ENVIRONMENT

WARNING

• No flammable gas, liquid or other flammable objects at

worksite.

• Clear the area of children or unauthorized

personnel.

9

Page 10

English

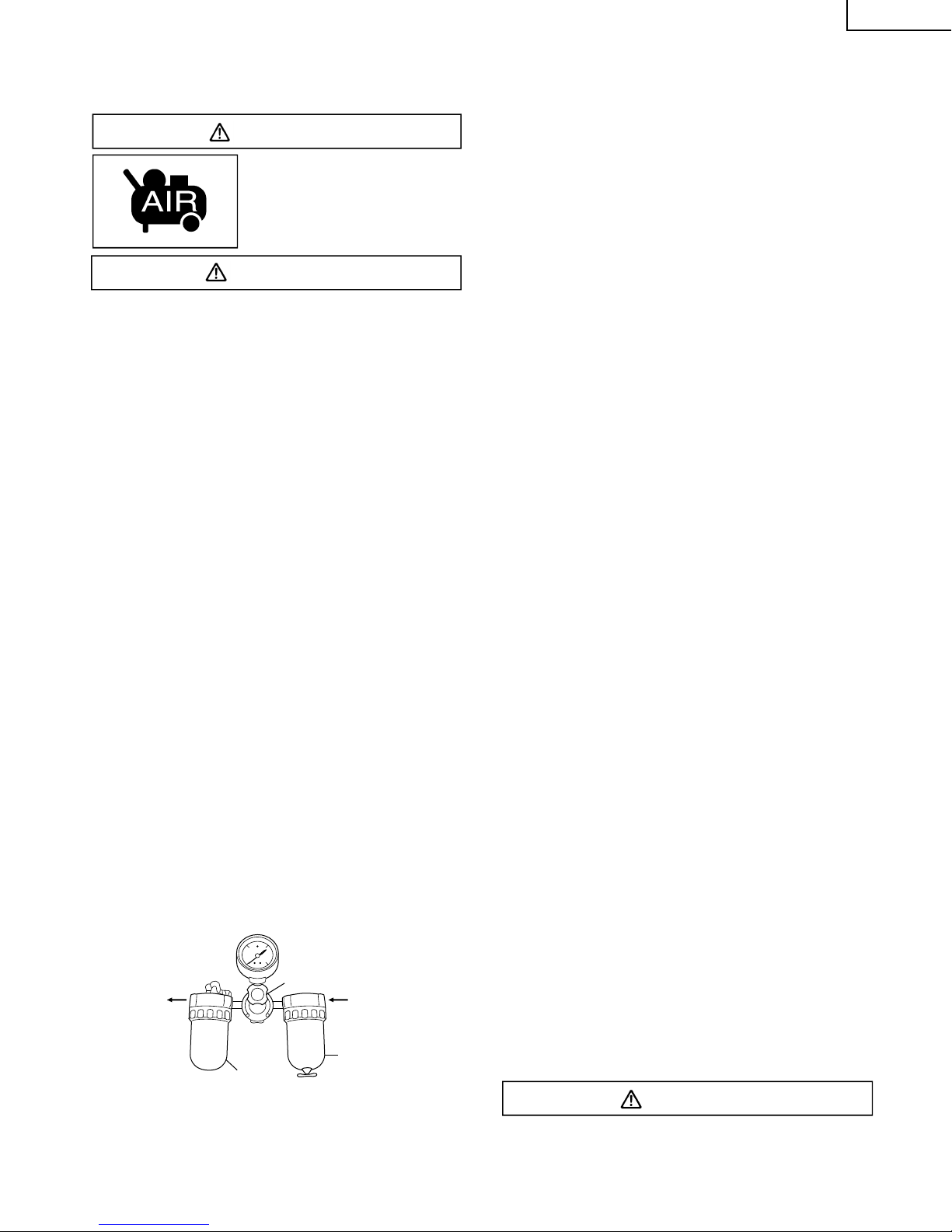

AIR SUPPLY

DANGER

• NEVER use oxygen or other

bottled gases. Explosion may

occur.

WARNING

• Never connect Stapler to pressure which

potentially exceeds 200 psi (13.7 bar 14 kgf/cm2).

• Never use non relieving coupler on Stapler.

1) Power Source

• Use only clean, dry, regulated compressed air as a power

source for this Stapler.

• Air compressors used to supply compressed air to this

Stapler must comply with the requirements of the latest

version of ANSI Standard B 19.3 "Safety Standard For

Compressors For Process Industries."

• Moisture or oil in the air compressor may accelerate wear

and corrosion in the Stapler.

• Drain daily.

3) Air hose

• Air hoses should have a minimum of 150 psi (10.4 bar 10.6

kgf/cm2) working pressure rating or 150 percent of the

maximum pressure that could be produced in the air system.

The supply hose should contain a fitting that will provide

"quick disconnecting" from the male plug on the Tool.

4) Hose Coupling

• This tool uses a free-flow connector plug, 1/4 NPT. The

inside diameter should be .200" (5mm) or larger. The fitting

must be capable of discharging tool air pressure when

disconnected from the air supply.

5) Air Consumption

• The model N2503AF requires 3.1 cfm of free air to operate

at the rate of 100 fasteners per minute, at 80 psi. Take the

actual rate at which the tool will be run to determine the

amount of air required. For instance, if your fastener usage

averages 50 fasteners per minute, you need 50% of the

tool’s cfm which is required to operate the tool at 100

fasteners per minute.

6) Operating Pressure

• 70 to 100 psi. Select the operating pressure within this

range for best Staple performance. DO NOT EXCEED THIS

RECOMMENDED OPERATING PRESSURE.

2) Filter-Regulator-Lubricator

• A pressure regulator with an operating pressure of

0-125 psi (0-8.6 bar 0-8.8 kgf/cm2) is required to control

the operating pressure for safe operation of this tool. Do not

connect this tool to air pressure which can potentially

exceed 200 psi as tool may fracture or burst, possibly

causing injury.

• Filter-Regulator-Lubricator units supply an optimum

condition for the Stapler and extend the Stapler life.

These units should always be used:

Filter—The filter removes moisture and dirt mixed in compressed

air. Drain daily unless fitted with an automatic drain. Keep the

filter clean by regular maintenance.

Regulator—The regulator controls the operating pressure for

safe operation of the Stapler. Inspect the regulator before

operation to be sure it operates properly.

Lubricator—The lubricator supplies an oil mist to the Stapler.

Inspect the lubricator before operation to be sure the supply of

lubricant is adequate. Use Hitachi pneumatic tool lubricant.

Regulator

Stapler side

Lubricator

Compressor side

Filter

LUBRICATION

Frequent, but not excessive, lubrication is required for best

performance. Oil added through the air line connection will

lubricate the internal parts. Use Air Tool Lubricant, Mobil Velocite

#10, or equivalent. Do not use detergent oil or additives as these

lubricants will cause accelerated wear to the seals and piston

cushion in the Tool, resulting in poor Tool performance and

frequent Tool maintenance.

If no airline lubricator is used, add oil during use into the air

fitting on the Tool once or twice a day. Only a few drops of oil at

a time are necessary. Too much oil will only collect inside the

Tool and will be noticeable in the exhaust cycle.

COLD WEATHER CARE

For cold weather operation, near and below freezing, the

moisture in the air line may freeze and prevent Tool operation.

We recommend the use of WINTER FORMULA Air Tool lubricant

(NEW-MATIC Winter Formula or equivalent) or permanent

anti-freeze (ethylene glycol) as a cold weather lubricant.

CAUTION: Do not store Staplers in a cold weather environment to

prevent frost or ice formation on the Staplers operating valves

and mechanisms that could cause Stapler failure.

NOTE: Some commercial air line drying liquids are harmful to

O-rings and seals – do not use these low temperature air dryers

without checking compatibility.

CAUTION

• Do not operate the Stapler at high pressure without

Staples

10

Page 11

English

TESTING THE STAPLER

DANGER

• Operators and others in work

area MUST wear safety glasses

with side shields which

conforms to ANSI Z87.1

specifications.

WARNING

• Never use Stapler unless push lever is working properly

Manufacturer recommends before each use, check all Screws and

Nuts to make sure they are tight and have not "jarred loose"

from vibration and use. (Shoe, Shoe Base and Pad, Magazine,

Magazine Retainer Bracket, Handle, etc.).

Manufacturer recommends before each use, check the Driver

Blade tip for deformation & breakage to prevent improper driving

of Staples and/or to prevent damage to the Stapler and Flooring.

Before actually beginning the stapling work, test the Stapler by

using the check list below.

Conduct the tests in the following order.

If abnormal operation occurs, stop using the Stapler and contact

a Hitachi authorized service center immediately.

1) Adjust the air pressure to 70psi (4.8 bar, 4.9 kgf/cm2)

Connect the air hose.

Do not load any staples in the Stapler.

The Stapler must not leak air.

ADJUSTING AIR PRESSURE

WARNING

DO NOT EXCEED 100 psi. (6.9 bar 7.0 kgf/cm2)

Adjust the air pressure at recommended operating pressure

70 – 100 psi (4.9 – 6.9 bar 5 – 7.0 kgf/cm2) according to the

hardness of work piece.

The correct air pressure is the lowest pressure which will do the

job. Using the Stapler at a higher than required air pressure

unnecessarily over stresses the Stapler.

LOADING STAPLES

WARNING

When loading fasteners into the Tool,

1) Do not pull the trigger;

2) Do not depress push lever

1. DEPRESS MAGAZINE RELEASE BUTTON.

2. PULL BACK MAGAZINE.

3. OPEN MAGAZINE FULLY.

4. INSERT FASTENERS, POINTS MUST BE AGAINST BOTTOM

OF MAGAZINE.

5. PUSH MAGAZINE FORWARD. CONTINUE PUSHING UNTIL

LATCH IS ENGAGED.

2) Pull the safety trigger.

The Tool must not operate.

3) Remove the finger from the trigger and contact the push

lever.

The Tool must not operate.

4) First, pull the safety trigger. Next, contact the push lever.

The Stapler must not operate.

5) First, contact the push lever. Next, pull the trigger.

The Stapler must operate.

11

Page 12

English

STAPLER OPERATION

Read section titled "SAFETY" (pages 4-7)

DANGER

• Operators and others in work

area MUST wear safety glasses

with side shields which

conforms to ANSI Z87.1

specifications.

WARNING

• NEVER point Stapler at

yourself or others in work

area.

• Keep fingers AWAY from trigger when not driving Staples to avoid

accidental operation.

• Never place your face, hands or feet closer than 8 inches (200 mm)

from discharge area when using. The Stapler may bounce from the

recoil of driving a Staple and an unwanted second Staple may be

driven possibly causing injury.

• Check operation of the safety mechanism frequently. Do not use the

Stapler if the safety is not working correctly as accidental driving of

a Staple may result. Do not interfere with the proper operation of

the safety mechanism.

• Never clamp or tape the trigger or contact trip in an

actuated position.

• Do not drive Staples on top of other Staples or with Stapler at too

steep of an angle; Staples can ricochet and hurt someone.

• Do not drive Staples into thin boards or near corners and edges of

work piece. Staples can be driven through or away from work piece

and hit someone.

• Do not overdrive Staples. NOFMA states that one reason for split

tongues is overdriving.

• Never use Stapler which is defective or operating abnormally.

• Do not use Stapler as a hammer.

• Disconnect air hose from Stapler when:

1) It is not in use;

2) Leaving work area;

3) Moving it to another location; and

4) Handing it to another person.

• Wear safety glasses and safety shoes for protection against foreign

objects.

• Use only Staples from Hitachi.

• Air supply hoses should have a minimum working pressure rating of

150 psi or 150 percent of the maximum pressure produced in the

power source, whichever is higher.

• Check all hoses before connecting to ensure that they are free from

dirt, grit, or particles that could alter the

performance of the Stapler.

• An airline Filter and In-Line Air Regulator adjustable to 125 psi max

are required.

• NEVER use a defective Stapler. Replace worn or damaged parts

immediately. Be sure that the Safety Trigger and

operating mechanisms operate correctly and that all screws and

seals are securely tightened at all times.

METHODS OF OPERATION

The Stapler is equipped with the push lever and does not operate

unless the push lever is depressed (upward position).

SEQUENTIAL TRIP SAFETY OPERATION

The model N2503AF Flooring Stapler operates on a sequential

trip system. The sequential trip system requires the operator to

hold the Tool against the work before pulling the trigger. This

makes accurate fastener placement easier. The sequential trip

allows exact fastener location without the possibility of driving a

second fastener on recoil.

SEQUENTIAL TRIP OPERATION:

1) Press the contact trip against the work surface, without

touching the trigger.

THE TOOL MUST NOT CYCLE.

2) Hold the Tool off the work surface and pull the trigger.

THE TOOL MUST NOT CYCLE.

Release the trigger. The trigger must return to the trigger stop on

the frame

3) Pull the trigger and press the contact trip against the work

surface.

THE TOOL MUST NOT CYCLE.

4) With finger off the trigger, press the contact trip against the

work surface. Pull the trigger.

THE TOOL MUST CYCLE.

DUAL TRIGGER OPERATION (PATENT PENDING)

The dual trigger feature gives you multiple options for hand

orientation and trigger actuation to allow you to choose the

actuation method that works best for you for a given application.

The following illustrations are two examples.

WARNING

• Keep your finger off the trigger except during stapling

operation, because serious injury could result if the push

lever accidentally contacts you or others in the work area.

• Keep hands and body away from the discharge area. The

Stapler may bounce from recoil of driving a fastener and

unwanted subsequent fastener may be driven, possibly

causing injury.

• Some types of loaded Staples can spark out of the muzzle

during a driving operation.

• Exercise caution!

12

Page 13

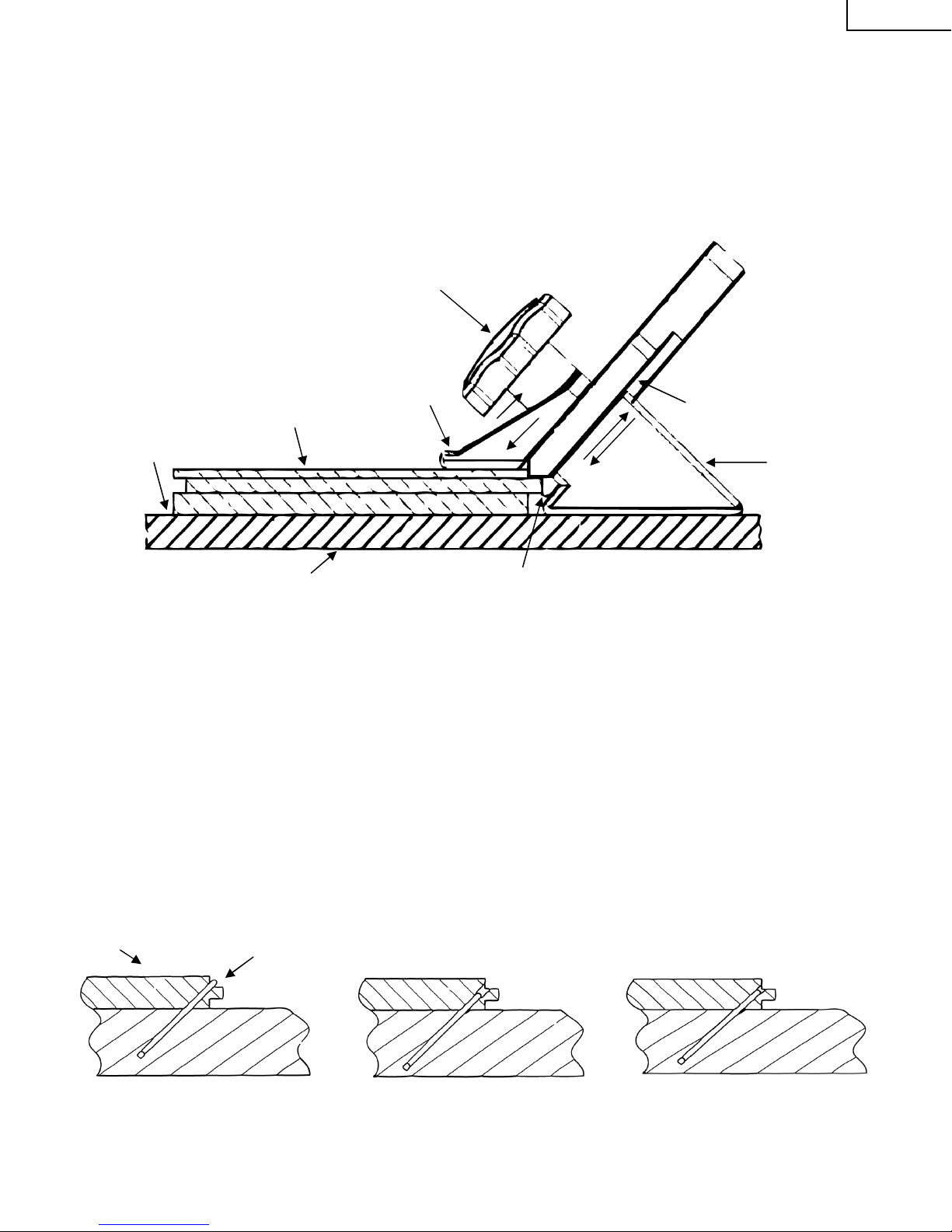

FASTENER POSITIONING ADJUSTMENT

The fastener position can be adjusted to accommodate 1/4" - 7/16" thicknesses of flooring by way of the adjustment knobs located on

the positioning shoe. The shoe adjustment feature provides close control of the fastener positioning to reduce occurrence of split tongues

or dimples in the flooring surface.

First set the air pressure for consistent drive in the specific work as described on page 11, then use the shoe adjustment knobs to set the

desired position of drive. The fastener should be positioned so that it enters the vertical face of the flooring at the point where the tongue

meets the vertical face.

KNOB

English

FOOT

FLOOR

NOSE

VAPOR

BARRIER

FRONT

GUIDE

SUBFLOOR

TO ADJUST THE TOOL TO THE FLOORING:

1. Loosen both Knobs until the Foot and Front Guide move freely.

2. Engage the Nose with the Tongue of Flooring.

3. Push the Front Guide to the subfloor and the Foot to the flooring.

4. Tighten both Knobs.

Note: periodically check the Knobs to ensure that they are tight during use.

**Important: Test the tool on a scrap piece of flooring to ensure proper staple placement and compatibility.

TONGUE OF

FLOORING

ADJUSTING THE STAPLING DEPTH

Air volume is as important as air pressure. The air volume supplied to the tool may be inadequate because of undersized fittings and

hoses or from the effects of dirt and water in the system. Restricted air flow will prevent the tool from receiving an adequate volume of

air, even though the pressure reading is high. The results will be slow operation, jamming, misfeeds or reduced driving power. Before

evaluating tool problems for these symptoms, trace the air supply from the tool to the supply source for restrictive connectors, swivel

fittings, low points containing water and anything else that would prevent full volume flow of air to the tool.

Floor

• Air pressure too low.

• Staple crown above tongue.

• Increase air pressure.

Staple

• Air pressure too high

• Staple crown below tongue.

• Lower air pressure.

13

• Correct air pressure

• Staple just below surface

Page 14

MAINTENANCE

NOTE:

The information contained in this Manual is designed to assist you in the safe maintenance of the Stapler.

Some illustrations in this Manual may show details or attachments that differ from those on your own Stapler.

MAINTENANCE AND INSPECTION

Read section titled "SAFETY" (page 4-7)

WARNING

• Disconnect air hose and remove all Staples from Stapler

when:

1) doing maintenance and inspection; and

2) clearing a jam.

English

6) Service Parts List

• A. Item No.

• B. Code No.

• C. Description

CAUTION

1) Inspecting the Magazine

• DISCONNECT THE AIR HOSE

• Clean the magazine. Remove dust or wooden tips which may

have accumulated in the magazine.

2) Storing

• When not in use for an extended period, apply a thin coat of

the lubricant to the steel parts to avoid rust.

• Do not store the Stapler in a cold weather environment.

When not in use, the Stapler should be stored in a warm and

dry place.

• Keep out of reach of children.

3) Warning Label

• Change the WARNING LABEL if missing or damaged. A new

WARNING LABEL is available from a Hitachi Authorized

Service Center.

WARNING

LABEL

4) Maintenance Chart (see page 15)

Repair, modification and inspection of Hitachi Power Staplers

must be carried out by an Hitachi Authorized Service Center.

This Parts List will be helpful if presented with the Stapler to

the Hitachi Authorized Service Center when requesting repair

or other maintenance. In the operation and maintenance of

power Staplers, the safety regulations and standards

prescribed in each country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved and modified

to incorporate the latest technological advancements.

Accordingly, some parts (i.e.: code numbers and/or design) may

be changed without prior notice.

SERVICE AND REPAIRS

WARNING

• Only service personnel trained by Hitachi, distributor or

employer shall repair the Stapler.

• Use only Hitachi parts supplied or recommended by

Hitachi for repair.

All quality Staplers will eventually require servicing or

replacement of parts because of wear from normal use.

In order to achieve the optimal performance of the N2503AF

Pneumatic Flooring Stapler preventative maintenance is

recommended.

NOTE:

Specifications are subject to change without any obligation on

the part of HITACHI.

5) Operator Troubleshooting (see page 16)

14

Page 15

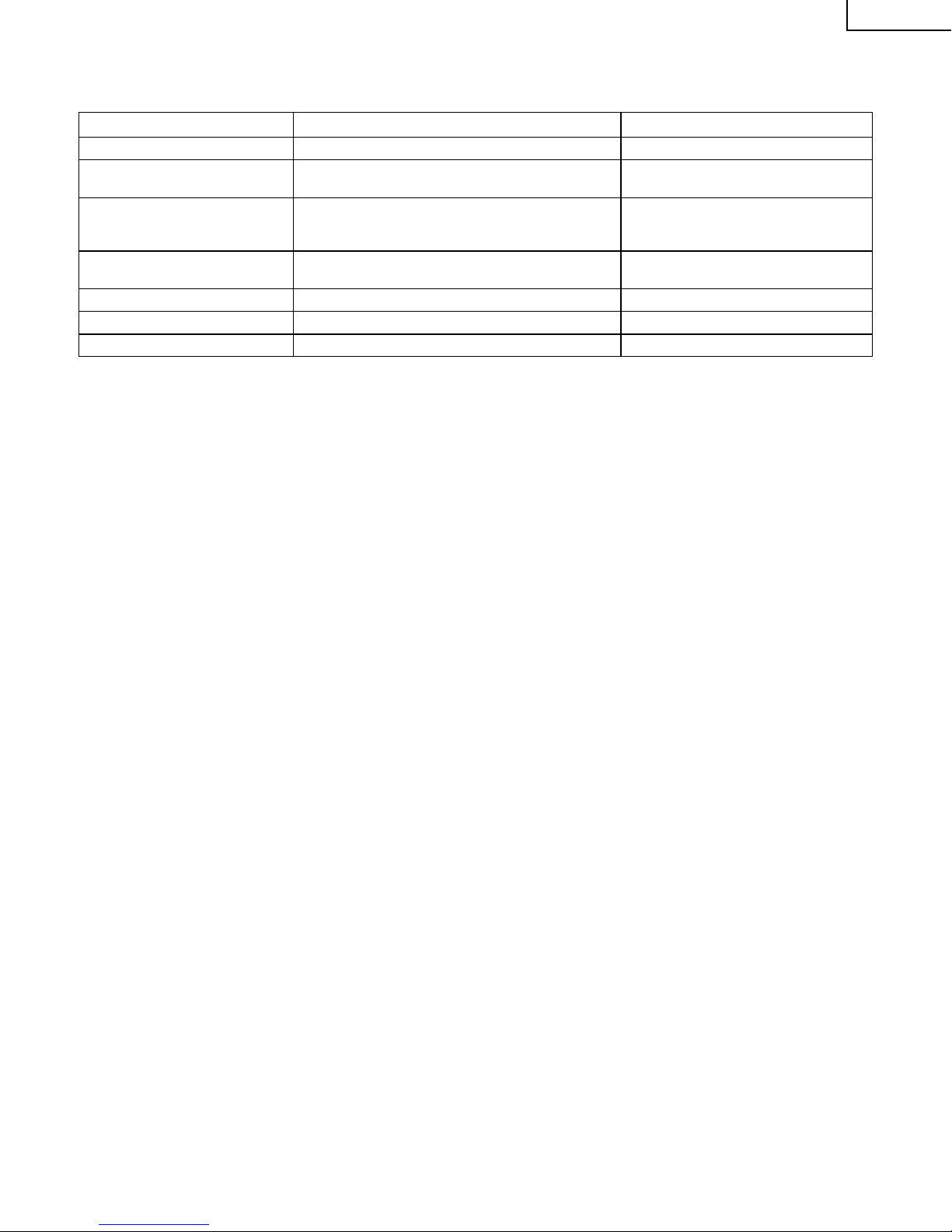

MAINTENANCE CHART

ACTION WHY HOW

Drain air line filter daily Prevent accumulation of moisture and dirt. Open manual petcock.

Keep lubricator filled. Keep the Tool lubricated.

Clean filter element - then blow air

through filter in direction opposite to

normal flow.

Clean magazine and feeder

mechanism.

Keep safety trigger working properly. Promote operator safety and efficient Tool operation. Blow clean daily.

Lubricate the Tool after use. Extend the life of the Tool. Supply 5-10 drops of lubricant into the Tool.

Drain air compressor. Keep the Tool operating properly. Open petcock on air compressor tank.

Prevent clogging of filter with dirt. Follow manufacturer's instructions.

Prevent a jam. Blow clean daily.

Fill with Hitachi pneumatic tool

lubricant.

English

15

Page 16

OPERATOR TROUBLESHOOTING

Most minor problems can be resolved quickly and easily using the table below.

If problems persist, contact a Hitachi authorized service center for assistance.

PROBLEM OR QUESTION CAUSE CORRECTIVE ACTION

Trigger valve housing leaks air O-ring cut or cracked Contact Hitachi for replacement.

Trigger valve stem leaks air O-ring/seals cut or cracked Contact Hitachi for replacement.

Frame/nose leaks air

Frame/cap leaks air

Failure to cycle

Lack of power; slow to cycle

Skipping Staples;

intermittent feed

Staples jam in Stapler

O-ring or gasket is cut or cracked Contact Hitachi for replacement.

Bumper is cracked / worn Contact Hitachi for replacement.

Damaged gasket or seal Contact Hitachi for replacement.

Cracked / worn head valve Contact Hitachi for replacement.

Loose cap screws Tighten and recheck.

Air supply restriction Check air supply equipment

Worn head valve Contact Hitachi for replacement.

Broken cylinder cap spring Contact Hitachi for replacement.

Head valve stuck in cap Contact Hitachi for replacement.

Broken cylinder cap spring Contact Hitachi for replacement.

Rings / seals cut or cracked Contact Hitachi for replacement.

Exhaust blocked Contact Hitachi for replacement.

Trigger assembly worn / leaks Contact Hitachi for replacement.

Dirt/tar build up on driver Contact Hitachi for replacement.

Cylinder sleeve not seated correctly on bottom bumper Contact Hitachi for replacement.

Air pressure too low Check air supply equipment

Worn bumper Contact Hitachi for replacement.

Tar/dirt in driver channel Contact Hitachi for replacement.

Air restriction/inadequate air flow through quick disconnect socket and plug Replace quick disconnect fittings

Worn piston ring Contact Hitachi for replacement.

Damaged pusher spring Contact Hitachi for replacement.

Low air pressure Check air supply equipment

Loose magazine nose screws Tighten all screws

Staples too short for Stapler Use only recommended Staples

Bent Staples Discontinue use of these Staples

Wrong size Staples Use only recommended Staples

Leaking head cap gasket Contact Hitachi for replacement.

Trigger valve O-ring cut / worn Contact Hitachi for replacement.

Broken/chipped driver Contact Hitachi for replacement.

Dry/dirty magazine

Worn magazine Contact Hitachi for replacement.

Driver channel worn Contact Hitachi for replacement.

Wrong size Staples Use only recommended Staples

Bent Staples Discontinue use of these Staples

Loose magazine nose screws Tighten all screws

Broken/chipped driver Contact Hitachi for replacement.

Clean / lubricate; Use Air Tool

Lubricant

English

16

Page 17

EXPLODED VIEW

English

87 85

86

17

Page 18

MODEL N2503AF - PARTS LISTING

ITEM NO. PART NO. DESCRIPTION

1, 1A 330469 Screw, SHCS (x6)

2 330470 Cap - Handle

3 330471 Gasket, Cap

4 330472 Top Seal

5 330473 Poppet

6 330474 O-Ring Head Valve

7 330475 O-Ring Head Valve

8 330476 Spring, Head Valve

9 330477 Head Valve

10 330478 Cylinder Top Seal

11 330479 Cylinder

12 330480 O-Ring

13 330481 Cylinder Ring

14 330482 O-Ring

15 330483 O-Ring

16 330484 Piston

17 330485 Pin

18 330486 Driver Blade

18U 330487 Piston/Driver Blade Ass'y

19 330488 Bumper

20 330489 Guide Driver

21 330490 Pin Retainer (x5)

22 330491 Body

23 330492 Nut

24 330493 Grip, Rubber

25 330494 Gasket, Handle

26 330495 Handle Cap

27 330496 Screw, SHCS (x3)

28 190001 Air Plug

29 330498 Plug Cap

30 330499 Trigger

31 330500 Spring Pin

32 330501 Trigger Plate

33 330502 Pin, Trigger

34 330503 Pin

35 330504 Roller

36 330505 Pin

37 330506 Screw, SHCS (x3)

38 330507 Pin

39 330508 Roller (x2)

40 330509 Pin

41 330510 O-Ring

42 330511 Trigger Valve Plunger

43 330512 Spring, Trigger Valve

44 330513 Trigger Valve Stem

45 330514 O-Ring (x2)

46 330515 O-Ring

ITEM NO. PART NO. DESCRIPTION

47 330516 Trigger Valve Housing

47U 330517 Trigger Valve Unit

48 330518 Hold Plate

49 330519 Screw

50 330520 Spring

51 330521 Arm Guide

52 330522 Spring

53 330523 Safety Arm B

54 330524 Screw, HHCS (x2)

55 330525 Front Guide

56 330526 Arm Cover

57 330527 Safety Arm A

58 330528 Insert, Nose (x2)

59 330529 Nose

60 330530 Plate, Driver

61 330531 Foot

62 330532 Knob (x2)

63 330533 Magazine, Fixed

64 330534 Stop Plate

65 330535 Screw, SHCS

66 330536 Plate

67 330537 Secondary Trigger

68 330538 Cap, Trigger Cable

69 330539 Trigger Cable

70 330540 Magazine Core

71 330541 Pusher

72 330542 Magazine, Slide

73 330543 Spring Pin

74 330544 Spring Pin

75 330545 Spring

76 330546 Latch

77 330547 Latch Cover

78 330548 Latch Stop

79 330549 Tip, Core

80 330550 Spring

81 330551 Shuttle, Pusher

82 330552 Pusher Spring

83 330553 Magazine Bumper

84 330554 Washer - 10001A

85 330555 Carrying Case

86 875769 Safety Glasses

87 330556 Wrench Set

88

89

Staples - 20ga - 1" x 3/16" - 10

x 5M

Staples - 20ga - 1" x 3/16" 5M pack

English

18

Page 19

SÉCURITÉ

Lire attentivement les étiquettes sur les outils et toutes les directives d’utilisation, consignes de sécurité et

avertissements qui figurent dans ce manuel avant d’utiliser ou d’entretenir cette brocheuse. Le

non-respect des avertissements peut causer une BLESSURE GRAVE OU MÊME MORTELLE.

La plupart des accidents qui surviennent pendant l’utilisation ou l’entretien d’une brocheuse sont causés par la non-observation des

règles de sécurité de base. Il est souvent possible d’éviter les accidents en repérant les dangers avant qu’ils se produisent et en

observant les consignes de sécurité qui s’appliquent.

Les mesures de sécurité de base sont décrites dans la section « SÉCURITÉ » de ce manuel et dans les sections qui contiennent les

directives d’utilisation et d’entretien.

Les situations à éviter pour prévenir les blessures et les bris d’équipement portent la mention DANGER ou AVERTISSEMENT sur la

brocheuse et dans le présent manuel.

Ne jamais utiliser la brocheuse à des fins autres que celles indiquées dans ce manuel.

Français

DÉFINITION DES TERMES DE SIGNALISATION

DANGER attire l’attention sur une situation éminemment dangereuse qui, si elle n’est pas évitée, causera une blessure grave ou mortelle.

AVERTISSEMENT attire l’attention sur une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer une blessure

grave ou mortelle.

ATTENTION attire l’attention sur une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait causer une blessure ou

endommager l’équipement.

REMARQUE attire l’attention sur un renseignement de nature essentielle.

19

Page 20

SÉCURITÉ

IMPORTANTES CONSIGNES DE SÉCURITÉ POUR L'UTILISATION DE LA BROCHEUSE N2503AF

LIRE TOUTES LES INSTRUCTIONS

DANGER

1. LES UTILISATEURS ET LES AUTRES PERSONNES PRÉSENTES DANS L’AIRE DE TRAVAIL DOIVENT PORTER DES LUNETTES DE SÉCURITÉ À

ÉCRANS LATÉRAUX.

• Pendant l’utilisation de la brocheuse, toujours porter des lunettes de sécurité à écrans latéraux et

s’assurer que les autres personnes présentes dans l’aire de travail en portent aussi.

• Les lunettes de sécurité doivent être conformes à la norme ANSI Z87.1 de l’American National Standards

Institute et fournir une protection avant et latérale contre les particules projetées.

• L’employeur doit veiller à ce que l’utilisateur de la brocheuse et les autres personnes présentes dans l’aire

de travail portent des lunettes de sécurité.

2. NE JAMAIS UTILISER DES BOUTEILLES D'OXYGÈNE OU D’AUTRES GAZ COMPRIMÉS. UNE EXPLOSION POURRAIT SE PRODUIRE.

Français

• Ne jamais brancher le circuit d’alimentation de la brocheuse à une bouteille d’oxygène, de gaz

combustible ou de tout autre gaz sous pression.

• L’utilisation de ces gaz est dangereuse et fera éclater la brocheuse.

• Utiliser uniquement de l'air comprimé propre, sec et régularisé.

AVERTISSEMENT

3. NE JAMAIS POINTER UNE BROCHEUSE VERS VOUS-MÊME OU VERS UNE AUTRE PERSONNE.

• Toujours présumer que la brocheuse contient des broches.

• Ne jamais pointer la brocheuse vers vous-même ou vers une autre personne, qu’elle contienne ou non

des broches.

• L’actionnement accidentel de l’outil peut causer des blessures graves.

• Ne jamais jouer avec la brocheuse.

• Manipuler la brocheuse uniquement en tant qu’outil de travail.

4. QUAND AUCUNE BROCHE NE DOIT ÊTRE POSÉE, GARDER LES DOIGTS LOIN DE LA GÂCHETTE AFIN DE NE PAS ACTIONNER

ACCIDENTELLEMENT LA BROCHEUSE.

• Ne jamais transporter la brocheuse en tenant le doigt sur la gâchette de sécurité car une broche pourrait être éjectée par

accident et causer des blessures.

• Toujours tenir la brocheuse par la poignée pendant son transport.

5. LE CHOIX DU MODE DE DÉCLENCHEMENT EST IMPORTANT.

• Lire attentivement la page 27 sur les « MODES D’UTILISATION ».

6. NE PAS DÉPASSER 100 lb/po² (6,9 bars | 7,0 kgf/cm²).

100 lb/po² 100 lb/po²

7. TOUJOURS PORTER DES PROTECTEURS D’OREILLES ET UN CASQUE DE SÉCURITÉ.

• Toujours porter des protecteurs d’oreilles afin de se protéger des sons puissants.

• Toujours porter un casque de protection afin de se protéger des objets projetés.

• Ne pas dépasser la pression d’air maximale recommandée : 100 lb/po² (6,9 bars

| 7,0 kgf/cm²).

• Ne jamais brancher la brocheuse à une source de pression qui pourrait être

supérieure à 200 lb/po² (13,7 bars | 14 kgf/cm²). Celle-ci pourrait éclater.

20

Page 21

Français

SÉCURITÉ — suite

AVERTISSEMENT

8. RANGER LA BROCHEUSE DE FAÇON APPROPRIÉE.

Quand elle n’est pas utilisée, la brocheuse doit être rangée dans

un endroit sec. Garder hors de la portée des enfants. Verrouiller

la salle d’entreposage.

9. GARDER L’AIRE DE TRAVAIL PROPRE.

Les aires de travail encombrées favorisent les blessures. Enlever

les outils inutiles, les déchets, les pièces d’ameublement, etc.,

présents dans l’aire de travail.

10. NE JAMAIS UTILISER L’OUTIL EN PRÉSENCE DE LIQUIDES OU

DE GAZ INFLAMMABLES.

La brocheuse produit des étincelles pendant son fonctionnement.

Ne jamais utiliser la brocheuse dans un endroit qui contient des

laques, des peintures, du benzène, des solvants, de l’essence, des

gaz, des colles ou d’autres substances combustibles ou

explosives.

11. GARDER LES VISITEURS À DISTANCE.

Ne pas laisser les visiteurs manipuler la brocheuse. L’accès à l’aire

de travail devrait leur être interdit.

12. SE VÊTIR DE FAÇON APPROPRIÉE.

Ne pas porter des vêtements amples ou des bijoux car ils

pourraient être happés par les pièces mobiles. Le port de gants

de caoutchouc et de chaussures antidérapantes est recommandé

pour le travail à l’intérieur. Recouvrir les cheveux longs.

13. NE JAMAIS UTILISER SUR LA BROCHEUSE UN RACCORD NON

MUNI D’UN DISPOSITIF DE DÉCOMPRESSION.

Si un raccord sans dispositif de décompression est utilisé, la

brocheuse pourrait rester sous pression et projeter une broche

après son débranchement de la source d’air. Le raccord qui relie

la brocheuse à la conduite d’air doit permettre la décompression

totale de la brocheuse quand la connexion est défaite.

14. VÉRIFIER LE LEVIER DE SÉCURITÉ AVANT DE COMMENCER.

S’assurer que le levier de sécurité fonctionne correctement. Ne

jamais utiliser la brocheuse si le levier de sécurité ne fonctionne

pas correctement. Sinon, la brocheuse pourrait éjecter une

broche de façon inopinée. Ne pas tenter de manipuler ou

d’enlever le levier de sécurité, sinon il deviendra inopérant.

15. GARDER LES COUVERCLES ET LES VIS BIEN SERRÉS.

Garder les vis et couvercles bien serrés. Vérifier leur état

régulièrement. Ne jamais utiliser la brocheuse si des pièces sont

manquantes ou endommagées.

16. NE PAS CHARGER DES BROCHES SI LA GÂCHETTE EST ENFONCÉE OU SI LE LEVIER DE SÉCURITÉ EST ACTIONNÉ.

Pendant le chargement des broches dans la brocheuse et le

branchement de la conduite d’air, prendre les mesures de

sécurité suivantes :

1) ne pas appuyer sur la gâchette;

2) ne pas actionner le levier de sécurité;

3) pointer la brocheuse vers le bas.

17. PENDANT L’UTILISATION DE L’OUTIL, GARDER LE VISAGE,

LES MAINS ET LES PIEDS LOIN DE L’ORIFICE DE SORTIE.

Ne jamais mettre le visage, les mains ni les pieds à moins de

200 mm de l’orifice de sortie. Si une broche est déviée ou qu’elle

bute contre le point d’entrée, une blessure grave pourrait

survenir.

18. POSITIONNER LA BROCHEUSE CORRECTEMENT SUR LA PIÈCE

À FIXER.

Ne pas enfoncer une broche par-dessus une autre ou alors que la

brocheuse est en position penchée; la broche pourrait ricocher et

causer une blessure.

19. PRENDRE GARDE AUX DÉCLENCHEMENTS DOUBLES DUS AU

RECUL DE L’OUTIL.

Si, par mégarde, le levier de sécurité entre de nouveau en contact

avec la pièce après son réenclenchement, une broche sera

éjectée. Pour éviter une double éjection, procéder comme suit :

1) Ne pas appuyer fortement la brocheuse contre la pièce à

brocher.

2) Éloigner complètement la brocheuse de la pièce au

réenclenchement et garder le levier de sécurité éloigné de la

pièce jusqu’au moment d’enfoncer une autre broche.

3) Pousser la gâchette et la relâcher RAPIDEMENT pendant les

utilisations intermittentes.

20. NE PAS ENFONCER DES BROCHES DANS UN PANNEAU

MINCE OU PRÈS D’UN COIN OU D’UN BORD DE LA PIÈCE.

Les broches pourraient passer au travers du panneau ou dévier et

causer une blessure.

21. NE JAMAIS POSER DES BROCHES DES DEUX CÔTÉS D’UN

MUR EN MÊME TEMPS.

Les broches pourraient traverser le mur et atteindre la personne

de l’autre côté.

22. VÉRIFIER S’IL Y A DES FILS ÉLECTRIQUES.

Vérifier si des fils électriques courent dans les murs, les plafonds

ou les planchers afin d’éviter les électrocutions. Couper le

courant au panneau pour s’assurer que les fils éventuels ne sont

pas sous tension.

23. NE JAMAIS TENIR LA BROCHEUSE PAR LA CONDUITE D’AIR

POUR LA TRANSPORTER.

21

Page 22

Français

SÉCURITÉ — suite

AVERTISSEMENT

24. NE PAS TRAVAILLER AU BOUT DES BRAS.

Toujours garder son équilibre et avoir les pieds bien plantés.

25. NE JAMAIS UTILISER UNE BROCHEUSE DÉFECTUEUSE OU

DONT LE FONCTIONNEMENT EST ANORMAL.

Si la brocheuse semble fonctionner anormalement, si elle fait des

bruits inhabituels ou si elle semble défectueuse d’une façon ou

d’une autre, cesser immédiatement de l’utiliser et la faire réparer

dans un centre de service agréé par Hitachi.

26. NE PAS DÉBRANCHER LA CONDUITE D’AIR EN MAINTENANT

LE DOIGT SUR LA GÂCHETTE.

La brocheuse pourrait être actionnée quand elle sera rebranchée

à une source d’alimentation en air.

27. DÉBRANCHER LA CONDUITE D’AIR DANS LES SITUATIONS

SUIVANTES :

1) avant l’entretien et l’inspection;

2) avant de charger des attaches;

3) pour débloquer l’outil s’il s’est enrayé;

4) quand l’outil n’est pas utilisé;

5) quand l’utilisateur quitte l’aire de travail;

6) pour transporter l’outil;

7) pour remettre l’outil à une autre personne;

8) pour régler les boutons.

Ne jamais tenter de débloquer ou de réparer la brocheuse sans

avoir préalablement débranché la conduite d’air et enlevé toutes

les broches encore dans l’outil. Ne jamais laisser la brocheuse

sans surveillance. Des personnes qui ne connaissent pas l’outil

pourraient le manipuler et se blesser.

28. RESTER SUR SES GARDES.

Toujours rester concentré sur ce que l’on fait. Faire preuve de

bon sens. Ne pas utiliser la brocheuse si l’on se sent fatigué. Ne

jamais utiliser la brocheuse sous l’influence de l’alcool, de la

drogue ou d’un médicament qui provoque la somnolence.

29. MANIPULER LA BROCHEUSE DE LA FAÇON APPROPRIÉE.

Procéder de la façon indiquée dans le manuel. Ne jamais laisser

un enfant ou une personne non autorisée ou qui n’en connaît pas

le fonctionnement utiliser la brocheuse.

30. NE JAMAIS UTILISER LA BROCHEUSE À DES FINS AUTRES QUE

CELLES INDIQUÉES DANS CE MANUEL.

31. MANIPULER LA BROCHEUSE AVEC SOIN.

La brocheuse étant un outil sous pression, toute fissure

superficielle représente un danger. Éviter de la laisser tomber, de

la frapper contre un objet dur, de l’érafler ou de l’engraver.

Manipuler la brocheuse avec soin.

32. ENTRETENIR LA BROCHEUSE RÉGULIÈREMENT.

Garder la brocheuse propre et lubrifiée pour préserver son bon

fonctionnement et éviter les problèmes.

33. UTILISER EXCLUSIVEMENT DES PIÈCES, DES ACCESSOIRES ET

DES BROCHES FOURNIS OU RECOMMANDÉS PAR HITACHI.

Les pièces, accessoires et broches non autorisés peuvent annuler

la garantie, entraîner le mauvais fonctionnement de l’outil et

causer des blessures. Toute réparation doit être confiée à des

techniciens d’entretien formés par Hitachi, le distributeur ou

l’employeur.

34. NE JAMAIS MODIFIER LA BROCHEUSE.

Cela pourrait causer un mauvais fonctionnement et des blessures.

22

Page 23

Français

SÉCURITÉ — suite

AVERTISSEMENT

RESPONSABILITÉS DE L’EMPLOYEUR

1. Veiller à ce que ce MANUEL soit tenu à la disposition des

utilisateurs et du personnel d’entretien.

2. Veiller à ce que les utilisateurs et les autres personnes

présentes dans l’aire de travail portent toujours des LUNETTES DE

SÉCURITÉ quand des brocheuses sont utilisées.

4. Garder les brocheuses en bon état de fonctionnement.

5. Entretenir les brocheuses de façon appropriée.

6. Veiller à ce que les brocheuses à réparer ne soient plus

utilisées jusqu’à ce qu’elles aient été réparées.

3. Faire appliquer le port obligatoire de LUNETTES DE SÉCURITÉ

CONSERVER CE MANUEL ET LE GARDER À LA

DISPOSITION DES TRAVAILLEURS!

23

Page 24

Remarque :

L’information contenue dans ce manuel vise à permettre l’utilisation sécuritaire de la brocheuse.

Certaines illustrations de ce manuel peuvent contenir des détails ou des pièces qui diffèrent de ceux qui apparaissent

sur votre brocheuse.

NOM DES PIÈCES

C

o

u

v

e

r

c

l

e

d

e

v

e

r

r

o

u

i

l

l

a

g

e

Français

FONCTIONNEMENT

Obturateur

Coiffe de poignée

Chargeur

Guide avant

Poussoir

Boutons

Nez

Gâchette

secondaire

Gâchette

PISTON

Joint torique

Lame d’entraînement

Corps

Butoir

Pied

24

Page 25

FICHE TECHNIQUE

Pression de fonctionnement 70 - 100 lb/po2 (4,8 - 6,9 bars | 4,9 – 7,0 kgf/cm²)

Actionnement Par gâchette - séquentiel

Français

Dimensions

longueur x hauteur x largeur

Poids 1,4 kg

Contenance 100 broches

Consommation d’air

Prise d’air Filetage NPT 1/4 po

SÉLECTION DES BROCHES

BROCHE UTILISATION PAISSEUR DU BOIS

257 mm x 244 mm x 59 mm

0,026 pi³/cycle à 80 lb/po²

(0,74 L/cycle à 5,5 bars)

(0,74 L/cycle à 5,6 kgf/cm²)

Tableau De Sélection Des Broches

AVERTISSEMENT

• Utiliser exclusivement des broches HITACHI véritables

avec la N2503AF. L’emploi de toute autre broche peut

entraîner le mauvais fonctionnement de la brocheuse ou

la rupture de la broche, ce qui pourrait causer des

blessures graves.

Broche de 1 po Clou d’angle la sous de

5/8 po - 3/4 po recouvrant les solives.

ACCESSOIRES

Seules les broches indiquées dans le tableau ci-dessous peuvent

être utilisées avec cette brocheuse.

BROCHES DE CALIBER 20 MIN. MAX

4,8 mm

• L’emploi d'accessoires différents de ceux illustrés

ci-dessous peut causer un mauvais fonctionnement et des

blessures.

AVERTISSEMENT

EMBOUVETÉ

1/4 po, 5/16 po, 3/8 po,

7/16 po

25 mm

0,95

25 mm

UTILISATIONS

• BOIS EMBOUVETÉ

• COUPE-VAPEUR

• SOUS-PLANCHER

Bios Embouveté

Coupe-Vapeur

Sous-

Plancher

La brocheuse pneumatique à plancher N2503AF avec sabot

standard insère les broches de 1 po dans le bois embouveté à un

angle de 45 degrés. L’orientation de la broche est telle

qu’illustrée ci-dessus.

Broche De 1 PO

ACCESSOIRES STANDARDS

1. Étui de transport

REMARQUE : Les accessoires peuvent être changés sans

obligation pour HITACHI.

2. Lunettes de sécurité 3. Jeu de clés

AVANT DE COMMENCER

Lire la section intitulée « SÉCURITÉ » (pages 19 - 22).

Faire les vérifications suivantes avant de commencer.

ENVIRONNEMENT DE TRAVAIL

AVERTISSEMENT

• Aucun gaz, liquide ou autre objet inflammable dans l’aire

de travail.

• Interdire l’aire de travail aux enfants et aux personnes

non autorisées.

25

Page 26

Français

ALIMENTATION EN AIR

DANGER

• NE JAMAIS utiliser des bouteilles

d'oxygène ou d’autres gaz

comprimés. Une explosion

pourrait se produire.

AVERTISSEMENT

• Ne jamais brancher la brocheuse sur une source de

pression qui pourrait dépasser

200 lb/po² (13,7 bars | 14 kgf/cm²).

• Ne jamais installer sur la brocheuse un raccord non muni

d’un dispositif de décompression

1) Source d’alimentation

• Alimenter la brocheuse avec de l'air comprimé propre, sec et

régularisé.

• Le compresseur utilisé pour alimenter cette brocheuse doit

être conforme à la dernière version de la norme de sécurité

des compresseurs ANSI B 19.3 intitulée « Safety Standard

For Compressors For Process Industries ».

• La présence d’eau ou d’huile dans le compresseur peut

accélérer l’usure et la corrosion de la brocheuse.

• Purger l’outil à chaque jour.

2) Filtre-régulateur-lubrificateur

• La source d’alimentation doit comporter un régulateur de

pression à plage de fonctionnement de 0 à 125 lb/po²

(0 - 8,6 bars | 0 - 8,8 kgf/cm²) afin de régulariser la pression

d’alimentation de la brocheuse et assurer un

fonctionnement sécuritaire. Ne pas brancher cette brocheuse à une source d’alimentation dont la pression d’air

peut dépasser 200 lb/po². La brocheuse pourrait se fissurer

ou éclater et causer des blessures

• Les unités de filtration, régulation et lubrification

permettent d’obtenir les conditions optimales de

fonctionnement et prolongent la durée utile de la

brocheuse.

Il est recommandé de toujours utiliser ces unités.

Filtre—Le filtre capte l’eau et les saletés présentes dans l’air

comprimé. Purger le filtre à chaque jour, sauf s’il est pourvu d’un

dispositif de purge automatique. Procéder régulièrement à

l’entretien du filtre afin de le garder propre et fonctionnel.

Régulateur—Le régulateur régularise la pression de f

onctionnement de la brocheuse. Inspecter le régulateur avant

l’utilisation de l’outil afin de s'assurer qu'il fonctionne

correctement.

Lubrificateur—Le lubrificateur injecte un brouillard d’huile dans

la brocheuse. Inspecter le lubrificateur avant l'utilisation de l’outil

afin de s’assurer que celui-ci reçoit une quantité d'huile

adéquate. Utiliser le lubrifiant Hitachi pour outils pneumatiques.

Régulateur

Coté brocheuse

Lubrificateur

Côté compresseur

Filtre

3) Conduite d’air

• La pression de fonctionnement nominale de la conduite doit

être d’au moins 150 lb/po² (10,4 bars | 10,6 kgf/cm²) ou

150 pour cent de la pression maximale produite par la

source d’alimentation. Le raccord de la conduite

d’alimentation doit permettre le débranchement rapide du

raccord mâle de l’outil.

4) Raccord de conduite

• Cet outil utilise un raccord à circulation libre NPT de 1/4 po.

Il doit avoir un diamètre intérieur de 0,200 po (5 mm) ou

plus Le raccord doit évacuer la pression présente dans l’outil

à son débranchement de la source d’alimentation.

5) Consommation d’air

• Le modèle N2503AF nécessite 0,09 m³/min (3,1 pi³/min)

d’air libre pour fonctionner au rythme de 100 attaches par

minute à 80 lb/po². Pour établir la quantité d’air requise,

déterminer le rythme auquel l’outil sera utilisé. Par exemple,

si 50 attaches sont enfoncées à la minute en moyenne, il

faut alors prévoir 50 % du cubage d’air libre nécessaire pour

enfoncer 100 attaches à la minute.

6) Pression de fonctionnement

• 70 à 100 lb/po². Sélectionner la pression de

fonctionnement à l’intérieur de cette plage qui offre le

meilleur rendement. NE PAS DÉPASSER LA PRESSION DE

FONCTIONNEMENT RECOMMANDÉE.

LUBRIFICATION

Une lubrification fréquente mais non excessive est nécessaire

pour obtenir un rendement optimal. L’ajout d’huile dans la conduite d’alimentation permet de lubrifier les pièces internes. Employer le lubrifiant pour outils pneumatiques Mobil Velocite #10

ou un produit équivalent. Ne pas utiliser de l’huile détergente ou

des additifs car ces lubrifiants causeront l’usure accélérée des

joints et du coussin de piston de l’outil, diminueront l’efficacité

générale de l’outil et nécessiteront des entretiens fréquents.

En l’absence d’un lubrificateur en ligne, quand l’outil est utilisé

ajouter de l’huile dans son raccord d’alimentation une ou deux

fois par jour. Quelques gouttes suffisent. Une quantité excessive

d’huile produira une accumulation dans l’outil, qui sera visible

dans le cycle de sortie.

SOINS PAR TEMPS FROID

Pendant l’utilisation près du point de congélation ou sous le point

de congélation, l’eau présente dans la conduite d’alimentation

peut geler et couper l’arrivée d’air. Nous recommandons

l’utilisation du lubrifiant pour outils pneumatique par temps

froids NEW-MATIC Winter Formula (ou un produit équivalent) ou

d’un antigel permanent (ethylèneglycol).

ATTENTION : Ne pas entreposer les brocheuses au froid afin de

prévenir la formation de givre ou de glace dans les soupapes et

mécanismes de l'outil, ce qui pourrait provoquer sa défaillance.

REMARQUE : Certains liquides d’assèchement des conduites

pneumatiques à basse température s’attaquent aux joints – ne

pas utiliser ces liquides sans en vérifier d’abord la compatibilité.

26

Page 27

Français

ATTENTION

• Ne pas faire fonctionner la brocheuse à pression élevée

sans broches.

ESSAI DE LA BROCHEUSE

DANGER

• Les utilisateurs et les autres

personnes présentes dans l’aire

de travail DOIVENT porter des

lunettes de sécurité à écrans

latéraux conformes à la norme

ANSI Z87.1.

AVERTISSEMENT

• Ne jamais utiliser la brocheuse si le levier de sécurité ne

fonctionne pas correctement.

Le fabricant recommande de vérifier avant chaque utilisation

toutes les vis et tous les écrous pour s’assurer qu’ils sont bien

serrés (sabot, base de sabot et patin, chargeur, ferrure de

retenue du chargeur, poignée, etc.).

Le fabricant recommande de vérifier avant chaque utilisation que

l’extrémité de la lame d’entraînement n’est pas déformée ou

brisée afin que les broches soient correctement entraînées et

pour ne pas endommager la brocheuse ni le plancher.

Avant de commencer à insérer des broches, vérifier la brocheuse

à l’aide de la liste de contrôle ci-dessous.

Effectuer la vérification dans l’ordre suivant.

En cas de fonctionnement anormal, cesser d’utiliser la brocheuse

1) Régler la pression d’air à 70 lb/po² (4,8 bars | 4,9 kgf/cm²).

RÉGLAGE DE LA PRESSION D’AIR

AVERTISSEMENT

Ne pas dépasser 100 lb/po² (6,9 bars | 7,0 kgf/cm²).

100 lb/po² 100 lb/po²

Régler la pression d’air à la pression de fonctionnement

recommandée : entre 70 et 100 lb/po² (4,9 - 6,9 bars | 5 - 7,0 kgf/

cm²), selon la densité de la pièce à fixer.

La pression souhaitable est la pression la plus basse qui fait le

travail. L’utilisation de la brocheuse à une pression plus élevée

que nécessaire use inutilement celle-ci.

CHARGEMENT DES BROCHES

AVERTISSEMENT

Voici quelques précautions à prendre lors du chargement de

l’outil :

1) ne pas appuyer sur la gâchette;

2) ne pas actionner le levier de sécurité.

1. APPUYER SUR LE BOUTON DE DÉGAGEMENT DU

CHARGEUR.

2. TIRER LE CHARGEUR VERS L’ARRIÈRE.

3. OUVRIR COMPLÈTEMENT LE CHARGEUR.

4. INSÉRER DES ATTACHES, LES POINTES DIRIGÉES VERS LE

BAS DU CHARGEUR.

5. POUSSER LE CHARGEUR VERS L’AVANT JUSQU’À CE QUE

LE LOQUET S'ENGAGE.

Brancher la conduite d’air.

Ne pas charger les broches dans la brocheuse.

La brocheuse ne doit pas laisser échapper d'air.

2) Appuyer sur la gâchette de sécurité.

L’outil ne doit pas fonctionner.

3) Retirer le doigt de la gâchette, puis contacter le levier

de sécurité.

L’outil ne doit pas fonctionner.

4) Appuyer premièrement sur la gâchette de sécurité. Ensuite,

contacter le levier de sécurité.

La brocheuse ne doit pas fonctionner.

5) Premièrement, contacter le levier de sécurité. Ensuite,

appuyez sur la gâchette.

La brocheuse doit fonctionner.

27

Page 28

Français

FONCTIONNEMENT DE LA BROCHEUSE

Lire la section intitulée « SÉCURITÉ » (pages 19 - 22).

DANGER

• Les utilisateurs et les autres

personnes présentes dans l’aire

de travail DOIVENT porter des

lunettes de sécurité à écrans

latéraux conformes à la norme

ANSI Z87.1.

AVERTISSEMENT

• NE JAMAIS pointer la brocheuse

vers vous-même ou vers une

autre personne.

• Quand aucune broche ne doit être posée, garder les doigts loin de la

gâchette afin de ne pas actionner accidentellement la brocheuse.

• Ne jamais mettre le visage, les mains ni les pieds à moins de

200 mm de l’orifice de sortie pendant l’utilisation de la brocheuse.

Celle-ci peut rebondir à cause du recul causé par l’éjection de la

broche et déclencher une seconde éjection non voulue qui pourrait

causer une blessure.

• Vérifier fréquemment le bon fonctionnement du mécanisme de

sécurité. Ne pas utiliser la brocheuse si le mécanisme ne fonctionne

pas correctement, car une broche pourrait être éjectée

accidentellement. Ne pas tenter de manipuler le mécanisme de

sécurité.

• Ne jamais attacher ni enrubanner la gâchette en position activée.

• Ne pas enfoncer une broche par-dessus d’autres broches ou alors

que la brocheuse est en position penchée; la broche pourrait

ricocher et causer une blessure.

• Ne pas enfoncer des broches dans un panneau mince ou près des

coins ou du bord de la pièce. Les broches pourraient passer au

travers du panneau ou dévier et causer une blessure.

• Ne pas enfoncer les broches trop profondément. La NOFMA déclare

que l’une des causes les plus fréquentes de la fissuration des

languettes est l’enfoncement excessif des attaches.

• Ne jamais utiliser une brocheuse défectueuse ou dont le

fonctionnement est anormal.

• Ne pas utiliser la brocheuse comme un marteau.

• Débrancher la conduite d’air dans les situations suivantes :

1) quand l’outil n’est pas utilisé;

2) quand l’utilisateur quitte l’aire de travail;

3) pour transporter l’outil;

4) pour remettre l’outil à une autre personne.

• Porter des lunettes de sécurité et des chaussures de sécurité afin de

se protéger contre les objets étrangers.

• Utiliser uniquement les broches fournies par Hitachi.

• La pression de fonctionnement nominale de la conduite doit être

d’au moins 150 lb/po2 (10,4 bars | 10,6 kgf/cm2) ou 150 pour cent

de la pression maximale produite par la source d’alimentation, selon

la valeur la plus élevée.

• Vérifier chaque conduite avant de la brancher afin de s’assurer

qu’elle est exempte de saletés ou de particules qui pourraient

modifier le rendement de la brocheuse.

• Un filtre d’air et un régulateur en ligne réglable à 125 lb/po2 max.

sont requis.

• Ne JAMAIS employer une brocheuse défectueuse. Remplacer

immédiatement les pièces usées ou endommagées. S’assurer que la

gâchette de sécurité et les mécanismes de l’outil fonctionnent

correctement et que toutes les vis et tous les joints sont bien serrés

en tout temps.

MODES D’UTILISATION

La brocheuse est équipée d’un levier de sécurité. Elle ne fonctionne pas à moins que ce levier soit actionné (en position haute).

FONCTIONNEMENT DU DISPOSITIF DE SÉCURITÉ À

DÉCLENCHEMENT SÉQUENTIEL

La brocheuse pour plancher N2503AF est dotée d’un système de

déclenchement séquentiel Ce système requiert que l’utilisateur

tienne l’outil contre la pièce avant d’appuyer sur la gâchette.

Cette méthode facilite le positionnement des attaches. Le

déclenchement séquentiel permet de positionner précisément

l’attache sans risquer d'éjecter une seconde attache au

réenclenchement.

FONCTIONNEMENT DU DÉCLENCHEMENT SÉQUENTIEL

1) Appuyer le déclencheur de contact contre la pièce sans

toucher à la gâchette.

L'OUTIL NE DOIT PAS FONCTIONNER.

2) Éloigner l’outil de la pièce et appuyer sur la gâchette.

L'OUTIL NE DOIT PAS FONCTIONNER.

Relâcher la gâchette. La gâchette doit appuyer contre sa butée

sur le châssis.

3) Appuyer sur la gâchette et appuyer le déclencheur de contact

contre la pièce.

L'OUTIL NE DOIT PAS FONCTIONNER.

4) Éloigner le doigt de la gâchette et appuyer le déclencheur de

contact contre la pièce. Appuyer sur la gâchette.

L’OUTIL FONCTIONNER.

FONCTIONNEMENT DE LA GÂCHETTE DOUBLE (BREVET EN

INSTANCE)

La gâchette double donne plusieurs options pour l’orientation de

la main et l’actionnement de la gâchette, ce qui permet de choisir

la position qui convient le mieux selon la tâche à effectuer. Les

illustrations qui suivent en donnent deux exemples.

AVERTISSEMENT

• Garder le doigt loin de la gâchette sauf pendant

l’opération de brochage, car des blessures graves peuvent

se produire si le levier de sécurité est heurté

accidentellement.

• Garder les mains et le corps à distance de l’orifice de

sortie de la brocheuse. Celle-ci peut rebondir à cause du

recul causé par l’éjection de l’attache et déclencher une

seconde éjection non voulue qui pourrait causer une

blessure.

• Certaines broches peuvent produire des étincelles à leur

sortie de l’outil. Faire attention! Exercise caution!

• Faire attention!

28

Page 29

RÉGLAGE DU DISPOSITIF DE POSITIONNEMENT DES ATTACHES

La position de l’attache peut être réglée pour les planchers de 1/4 po à 7/16 po d’épaisseur au moyen de boutons situés sur le sabot de

positionnement. Cette fonction permet de régler précisément le positionnement de l’attache afin de réduire l’occurrence des languettes

fissurées et l’apparition de fossettes sur la surface du plancher.

Régler premièrement la pression d’air de façon à obtenir un poussée constante, selon le type de revêtement installé (voir à la page 26),

puis utiliser les boutons de réglage du sabot pour obtenir la position d’insertion souhaitée. L'attache doit être positionnée de façon à

pénétrer la face verticale du revêtement de plancher au point de jonction de la languette et de la face verticale.

BOUTONS

Français

PIED

PLANCHER

NEZ

COUPE-VAPEUR

GUIDE

AVANT

SOUS-PLANCHER

POUR RÉGLER L’OUTIL EN FONCTION DU REVÊTEMENT DE PLANCHER :

1. Desserrer les deux boutons jusqu’à ce que le pied et le guide avant bougent librement.

2. Engager le nez à la languette du revêtement.

3. Appuyer le guide avant sur le sous-plancher et le pied sur le plancher.

4. Serrer les deux boutons.

Remarque : vérifier régulièrement les boutons pour s’assurer qu'ils sont bien serrés.

**Important : Essayer l’outil sur une pièce de bois inutilisée pour vérifier la compatibilité et le bon emplacement de la broche.

BOIS EMBOUVETÉ

RÉGLAGE DE LA PROFONDEUR DE BROCHAGE

Le volume d’air est un facteur aussi important que la pression d’air. Le volume d’air fourni pourrait être insuffisant si les raccords et

conduites sont de dimensions inadéquates ou si des saletés ou de l’eau sont présentes dans le système. Un débit limité empêchera l’outil

de recevoir un volume d’air suffisant, même si la pression est élevée. Cela peut causer un fonctionnement moins puissant, plus lent ou

erratique, ou encore enrayer l’outil. En présence de l’un de ces problèmes, avant de diagnostiquer l’outil passer en revue le circuit

d'alimentation en air, en partant de l'outil jusqu’à la source d’alimentation, à la recherche d’obstructions dans les raccords, d’eau dans les

points bas et de toute autre chose qui pourrait limiter le débit d’air fourni à l’outil.

Plancher de bois

• La pression d’air est trop basse.

• La couronne de la broche est plus

haute que la languette.

• Augmenter la pression d’air.

Broche

• La pression d’air est trop élevée.

• La couronne de la broche est plus

basse que la languette.

• Réduire la pression d’air.

29

• Corriger la pression d’air.

• La broche est juste sous la surface.

Page 30

ENTRETIEN

Remarque :

L’information contenue dans ce manuel vise à permettre l’entretien sécuritaire de la brocheuse.

Certaines illustrations de ce manuel peuvent contenir des détails ou des pièces qui diffèrent de ceux qui apparaissent

sur votre brocheuse.

ENTRETIEN ET INSPECTION

Lire la section intitulée « SÉCURITÉ » (page 19-22).

AVERTISSEMENT

Débrancher la conduite d’air et retirer toutes les broches dans

les situations suivantes :

1) avant l’entretien et l’inspection;

2) pour débloquer l’outil.

1) Inspection du chargeur

• DÉBRANCHER LA CONDUITE D’AIR

• Nettoyer le chargeur. Enlever les poussières et les éclats de

bois accumulés dans le chargeur.

2) Entreposage

• Quand l’outil n’est pas utilisé, appliquer une mince couche

de lubrifiant sur les pièces en acier afin de les protéger de la

rouille.

• Ne pas entreposer la brocheuse dans un endroit froid.

Quand elle n’est pas utilisée, la brocheuse doit être rangée

dans un endroit chaud et sec.

• Garder hors de la portée des enfants.

3) Étiquette d’avertissement

Français

6) Liste des pièces de rechange

• A. No d’article

• B. No de code

• C. Description

ATTENTION