Page 1

Installation - Parts

™

Xtreme Mix

Plural Component Mixer, OEM Unit

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 4 for model information, including maximum working pressure and approvals.

OEM

309521J

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2005, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Xtreme Mix OEM Models . . . . . . . . . . . . . . . . . . . . . 4

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 7

Assemble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pumps and Sensors . . . . . . . . . . . . . . . . . . . . . . 9

Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fluid Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Proper Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation and Repair . . . . . . . . . . . . . . . . . . . . . . 15

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . 16

Pneumatic Schematic . . . . . . . . . . . . . . . . . . . . . . 18

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Xtreme Mix Proportioner . . . . . . . . . . . . . . . . . . 20

Pneumatic Control 245803 . . . . . . . . . . . . . . . . 22

User Interface 245804 . . . . . . . . . . . . . . . . . . . . 24

Pump Air Manifold 245802 . . . . . . . . . . . . . . . . 25

Metering Valve Manifold 245824 . . . . . . . . . . . . 26

Sampling Valve 245143 . . . . . . . . . . . . . . . . . . . 26

Metering Valve 245846 . . . . . . . . . . . . . . . . . . . 27

Fluid Manifold 245833 . . . . . . . . . . . . . . . . . . . . 28

Sensor 245825 . . . . . . . . . . . . . . . . . . . . . . . . . 29

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 309521J

Page 3

Manual Conventions

Warning Caution

Manual Conventions

WARNING

A warning alerts you to possible serious injury or

death if you do not follow instructions.

Symbols, such as fire and explosion (shown), alert you

to a specific hazard and direct you to read the indicated hazard warnings (pages 5-6).

CAUTION

A caution alerts you to possible equipment damage or

destruction if you do not follow instructions.

Note

A note indicates additional helpful information.

Related Manuals

Refer to the following manuals for detailed component information.

Component Manuals This manual available in following languages:

Manual Description

309535 Xtreme Mix Operation

309518 Xtreme Mix Repair

311762 Xtreme Displacement Pump

309347 King Air Motor

or 309348 King Quiet Air Motor

312145 XTR Spray Gun

309524 VISCON HP Heater

309525 Heated Hose Kit

308981 Husky 716 Diaphragm Pump

309615 Heater Bracket Kit

309568 Remote Manifold Kit

Manual Language Manual Language

309521 English 309540 German

309538 French 309546 Swedish

309539 Spanish 309604 Japanese

309521J 3

Page 4

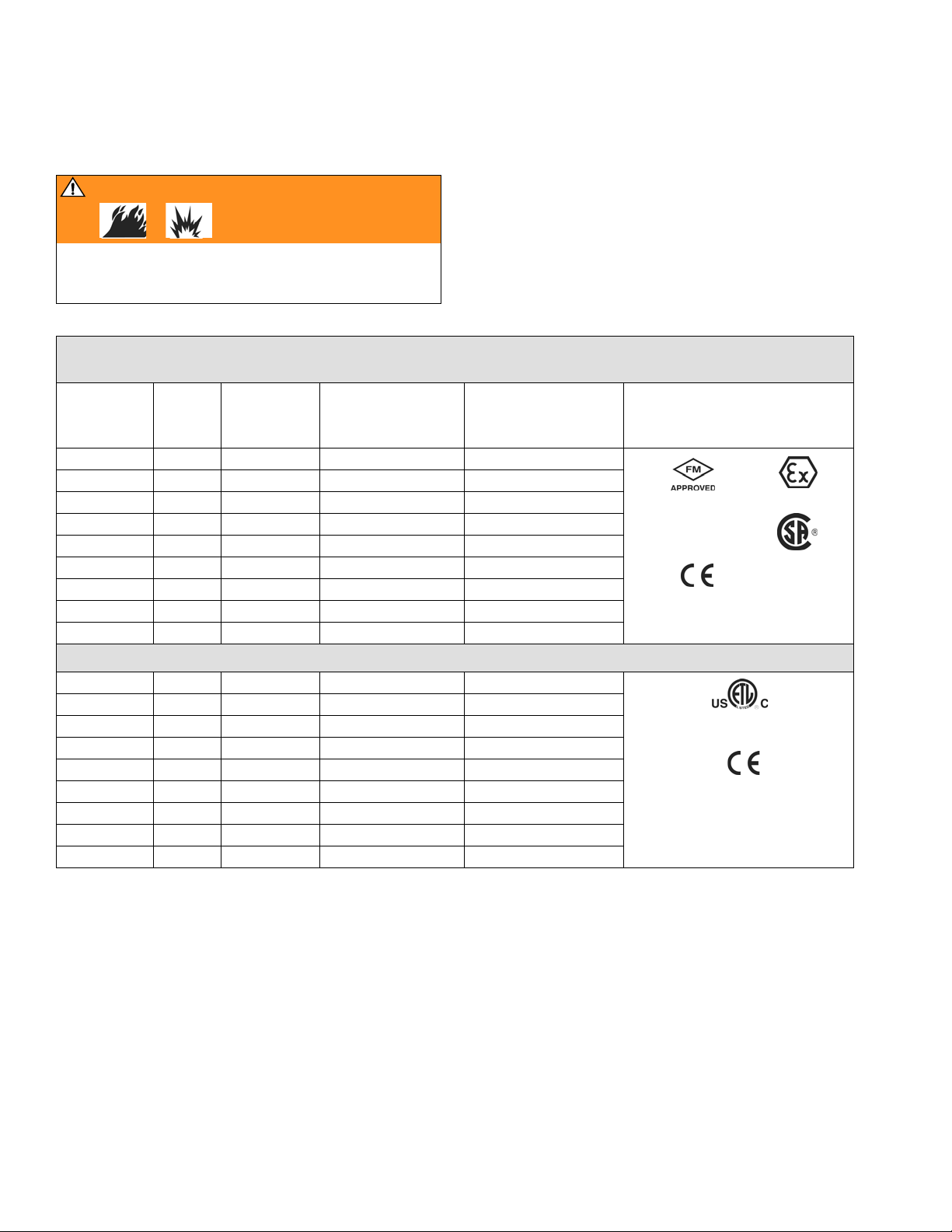

Xtreme Mix OEM Models

WARNING

Do not install equipment approved only for non-hazardous location in a hazardous area. Substitution of

components may impair intrinsic safety. See page 5.

Approved for Hazardous Location

Class I, Div 1, Group D

Xtreme Mix OEM Models

Xtreme

Mix

Part No. Series

Pump

Part No.

Pump

Description

Maximum Working

Pressure

psi (MPa, bar) Approvals

233871 A 249274 45:1 King 4500 (31, 310)

233872 A 249275 56:1 King 5600 (38.6, 386)

233873 A 249276 68:1 King 6800 (46.9, 469)

233874 A 249277 80:1 King 7250 (50, 500)

233875 A 249278 45:1 Quiet King 4500 (31, 310)

233876 A 249279 56:1 Quiet King 5600 (38.6, 386)

233877 A 249280 68:1 Quiet King 6800 (46.9, 469)

233878 A 249281 80:1 Quiet King 7250 (50, 500)

234024 A none

Approved for Non-hazardous Location

233879 A 249274 45:1 King 4500 (31, 310)

233880 A 249275 56:1 King 5600 (38.6, 386)

233881 A 249276 68:1 King 6800 (46.9, 469)

233882 A 249277 80:1 King 7250 (50, 500)

233883 A 249278 45:1 Quiet King 4500 (31, 310)

233884 A 249279 56:1 Quiet King 5600 (38.6, 386)

233885 A 249280 68:1 Quiet King 6800 (46.9, 469)

233886 A 249281 80:1 Quiet King 7250 (50, 500)

234025 A none

Conforms to

FM std 3600 & 3610 for

use in Class I Div 1

Group D

T3 Hazardous locations

Conforms to UL std 61010A-1

CSA std C22.2 No 1010.1-92

CAN/CSA

22.2 No. 157-92

& No. 1010.1-92

ll 2 G

4 309521J

Page 5

Xtreme Mix OEM Models

Warning

Skin Injection Hazard

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point the gun at anyone or at any part of the body.

• Do not put your hand or fingers over the gun fluid nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not “blow back” fluid; this is not an air spray system.

• Follow Pressure Relief Procedure, page 7, when you stop spraying and before cleaning, checking,

or servicing equipment.

• Use lowest possible pressure when flushing, priming, or troubleshooting.

• Never spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. High pressure hose cannot be recoupled; replace the entire hose.

Fire and Explosion Hazard

Solvent and paint fumes in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as pilot lights, cigarettes and plastic drop cloths (potential static

arc).

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Keep the work area free of debris, including solvent, rags, and gasoline.

• Ground equipment and conductive objects. See Grounding, page 11.

• Hold gun firmly to side of grounded pail when triggering into pail.

• Use only grounded hoses.

• If there is static sparking or you feel an electric shock, stop operation immediately. Do not use

equipment until you identify and correct the problem.

• If connecting PC for data download, PC must be in non-hazardous location and a safety barrier must

be installed. See Xtreme Mix software documentation.

• Keep a fire extinguisher in the work area.

Electric Shock Hazard

Improper grounding, wiring, or usage of the system can cause electric shock.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

• Connect only to grounded power source.

• Turn off and disconnect power at the main switch before disconnecting any cables and before servicing equipment.

309521J 5

Page 6

Xtreme Mix OEM Models

Warning

Moving parts hazard

Moving parts can pinch or amputate fingers and other body parts. Pressurized equipment can start accidentally and cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Before checking or servicing equipment, follow Pressure Relief Procedure, page 7. Disconnect

power or air supply.

• Do not move or lift pressurized equipment.

Equipment Misuse Hazard

Misuse can cause serious injury or death.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Read manuals, warnings, tags, and labels before operating equipment. Follow instructions.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment. Use only Graco parts and accessories.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system com-

ponent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or overbend hoses or use hoses to pull equipment.

• To lift equipment, follow instruction, page 15.

• Comply with all applicable approval requirements and safety regulations.

Burn Hazard

This equipment is used with heated fluid, which can cause equipment surfaces to become very hot. To

avoid severe burns:

• Do not touch hot fluid or equipment.

• Allow equipment to cool completely before touching it.

• Wear gloves if fluid temperature exceeds 110° F (43° C).

Toxic Fluid or fumes Hazard

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read Material Safety Data Sheet (MSDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

Personal Protective Equipment

You must wear proper protective equipment when operating, servicing, or when in the operating area of

the equipment to help protect you from serious injury, including eye injury; inhalation of toxic fumes; and

hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Gloves, clothing, and respirator as recommended by the fluid and solvent manufacturer

• Hearing protection

Recoil Hazard

The gun can recoil when triggered at a very high pressure. If unprepared, this could force your hand back

or cause you to fall and injure yourself. Be sure you have firm footing and hold the gun securely.

6 309521J

Page 7

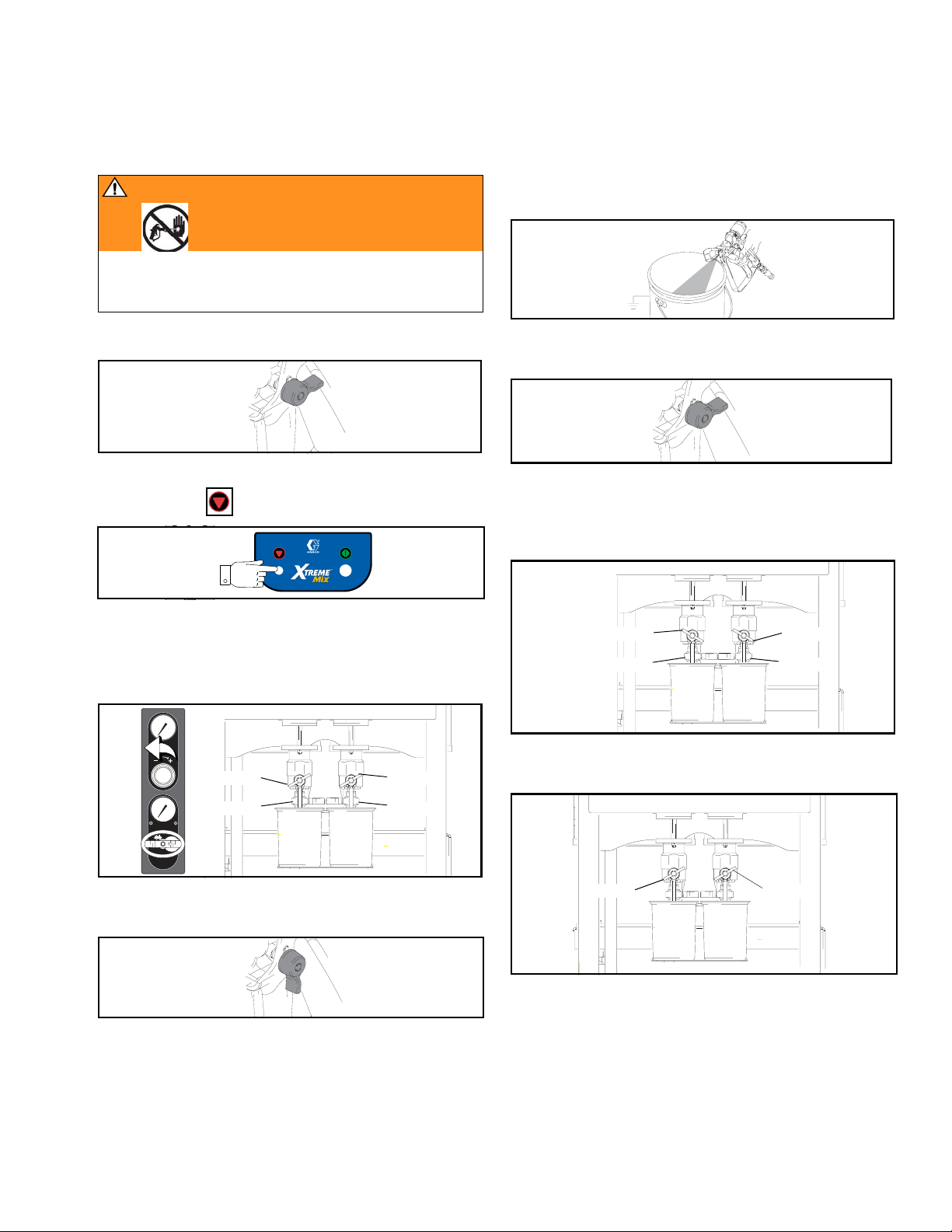

Pressure Relief Procedure

Pressure Relief Procedure

WARNING

Follow Pressure Relief Procedure when you stop

spraying and before cleaning, checking, servicing, or

transporting equipment. Read warnings, page 5.

1. Engage trigger lock.

2. Press Stop .

SUPPLY AIR

PRESSURE

I

O

PLURAL COMPONENT PROPORTIONER

3. Close main air shutoff valve on air supply line and on

unit. Turn off air regulator.

4. Close fluid sampling and shutoff valves A and B.

6. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure.

7. Engage trigger lock.

8. Place waste container under sampling valves, then

open valves A and B slowly to relieve pressure

between pump and metering valves.

Open

Close

Open

Close

AB

PSI

Bar

MPa

Close

Close

PSI

Bar

MPa

I

O

AB

Close

Close

9. Close sampling valves A and B.

Close Close

5. Disengage trigger lock.

AB

309521J 7

Page 8

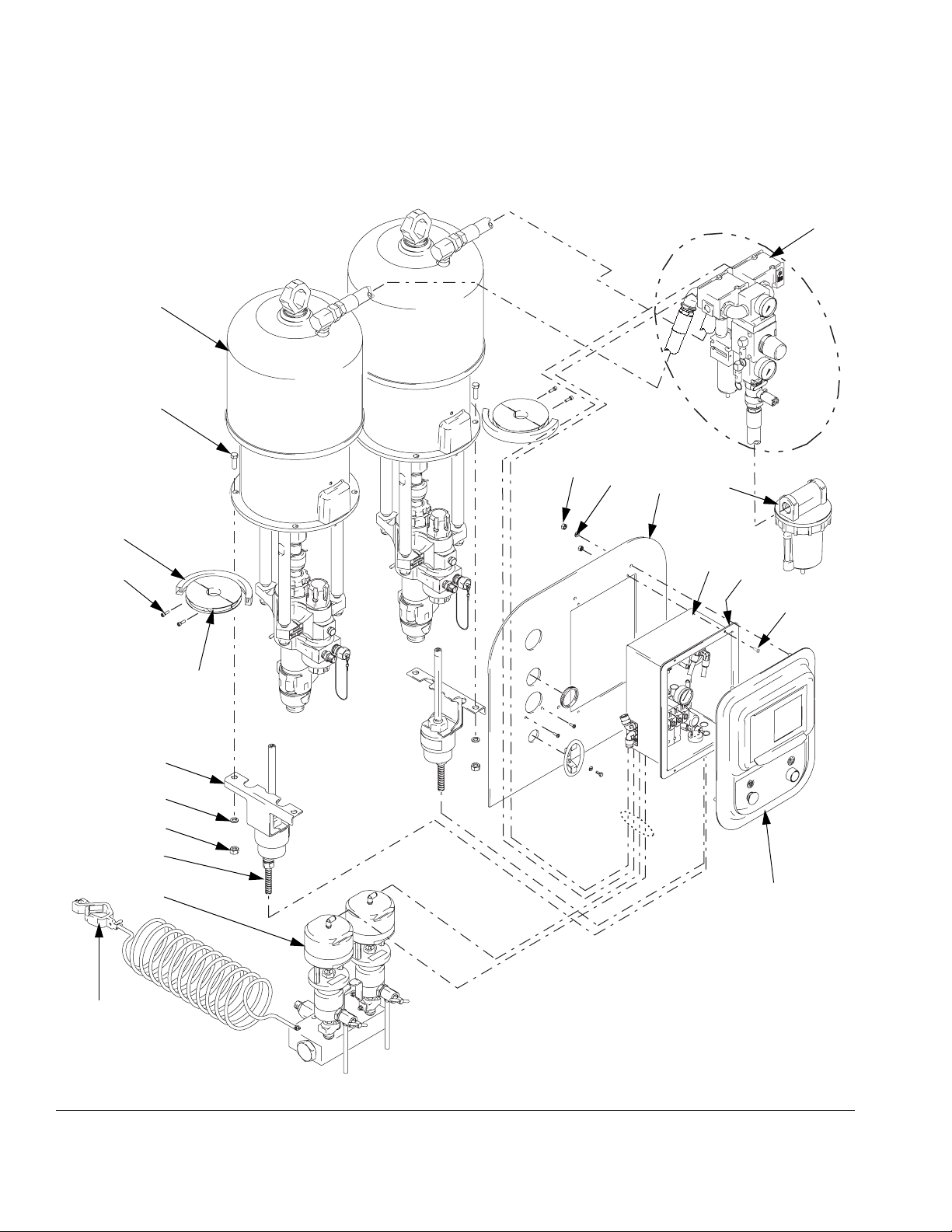

Assemble

2

913913

910

911

10

Assemble

5

901

904

905

914

915

721

3

307

912

903

7

6

4

902

FIG. 1

8 309521J

Page 9

Assemble

Pumps and Sensors

• If using feed pumps, do not allow feed pressure

to exceed 25% of spray pressure.

• For accurate ratios, pump lowers must be

same size.

• If installing 234024 or 234025, the pump size

has not been set in the software. To set pump

A and B size and A and B sensor calibration

factors, you need Xtreme Mix Data Download

software, part no. 246322 for proportioners

located in a non-hazardous area, or part no.

246397 for proportioners located in a hazardous area.

Calibration values are on pump A and B sensors.

Pump Size Values

Pump Size Value

(cc/cycle)

45:1 250

56:1 220

68:1 180

80:1 145

1. Secure magnet holders (903) to the pump (2) motor

displacement rods with screws (905). F

2. Install a short magnet strip then a long one (904) on

each magnet holder (903). Secure with tape supplied.

3. Secure pumps (2) on mounting brackets with two

3/8 x 1-1/4” screws (913), lockwashers (914), and

nuts (915).

4. Secure sensors (7) on pumps and pump mounting

brackets with two screws (913), lockwashers (914),

and nuts (915).

IG. 1.

Control Box

1. Mount control box (3) to mounting plate (10). FIG. 1.

a. Slide gasket (307) over back of pneumatic con-

trol box (3), against lip. Insert box through

mounting plate (10).

b. Secure box (3) to plate (10) with 8-32 UNC

screws (912).

Mount box (3) vertically for optimum alternator and

component life.

2. Secure mounting plate (10) to cart/stand. Install fasteners (provided by installer) through six 0.3” (7.62

mm) mounting plate holes.

3. Connect conduit (721) from two sensors (7) to pneumatic control box (3).

Conduit must be used. Approximately 62” (1575

mm) of cable and conduit provided; do not

lengthen.

4. Wire two sensors (7) to control box 18-pin connector. Connect sensor A, then sensor B wires in pairs

sequentially – black/green, black/red, black/white –

to pins 2-13. See Electrical Schematic, page 16.

5. Connect 18-pin connector to main control board

connector (F). F

3

IG. 2.

10 9 8 7 6 5 4 3

J2

5

3

4

F

J1

6

10

9

7

8

-

+

F

IG. 2 Control Box

309521J 9

Page 10

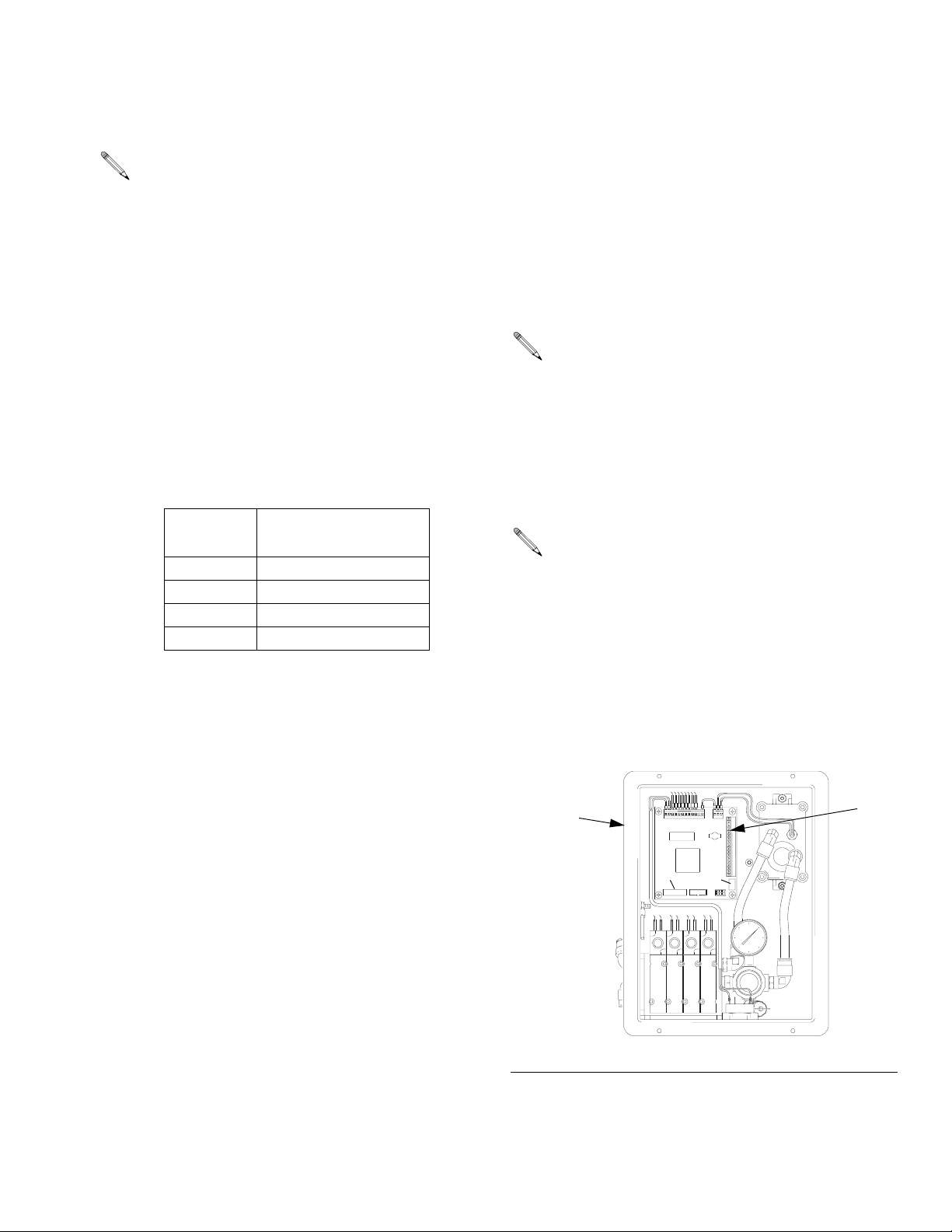

Assemble

A

33

B

2

3

2

501

C

F

G

1

H

J

D

E

5

K

Key:

A Pump A Air

B Pump B Air

C Pump A Pilot Air

D Pump B Pilot Air

E Air Supply

F Metering Valve A - CLOSE

G Metering Valve A - OPEN

H Metering Valve B- CLOSE

J Metering Valve B- OPEN

K Sensor A Cable

L Sensor B Cable

2Pump

FIG. 3

902

6

901

L

3 Pneumatic Control

6 Metering Valve Manifold

501 Pneumatic Valve

901 Air Filter

902 Ground Wire Assembly

1

Ground manifold to true earth ground.

2

Ground by connecting ground wire from control box (3) to

manifold (6).

3

Ground by connecting ground wire from pumps (2) to

manifold (6).

10 309521J

Page 11

Assemble

Grounding

WARNING

Read warnings, page 5, and follow instructions below.

1. Connect 12 gauge ground wire (provided by

installer) from pneumatic control box (3) ground

screw (312, page 22) to metering valve manifold (6).

Refer to F

2. Connect ground wire from each pump (2) to metering valve manifold (6).

3. Connect ground wire assembly (902) to fluid manifold (6). Connect clamp end to a true earth ground

before starting unit.

IG. 3.

Air Controls

Do not use air supply hose smaller than 3/4” (19

mm) ID. Smaller hose could restrict air flow and

cause alternator, solenoids, or Mac valves to malfunction. Check air supply gauge at pump

changeover; air pressure should not drop.

Standard Setup

FIG. 1 and FIG. 3

1. Mount pneumatic control assembly (3) to mounting

plate (10). F

2. Connect an air line (A and B) between each pneumatic valve (501) and pump air motor inlet. F

36” (914 mm) hoses provided. Installer may provide different lengths.

3. Connect air supply from air manifold’s 5 micron air

filter (518) to control box air inlet (not shown).

The alternator requires 12-15 scfm of air to function correctly.

• Do not use 3/8” (9.5 mm) ID air supply tubing

longer than 24” (610 mm) from air filter to

control box air inlet.

• Do not restrict control box exhaust air.

Increased back pressure can cause a drop in

alternator power output, resulting in delayed valve

action and processor shutdown and reboot.

IG. 1.

IG. 3.

4. Connect tubing (C and D) from solenoids to each

pneumatic valve (501).

5. Mount air supply filter (901) to cart/stand and connect air supply (E) to air manifold (5) air inlet.

309521J 11

Page 12

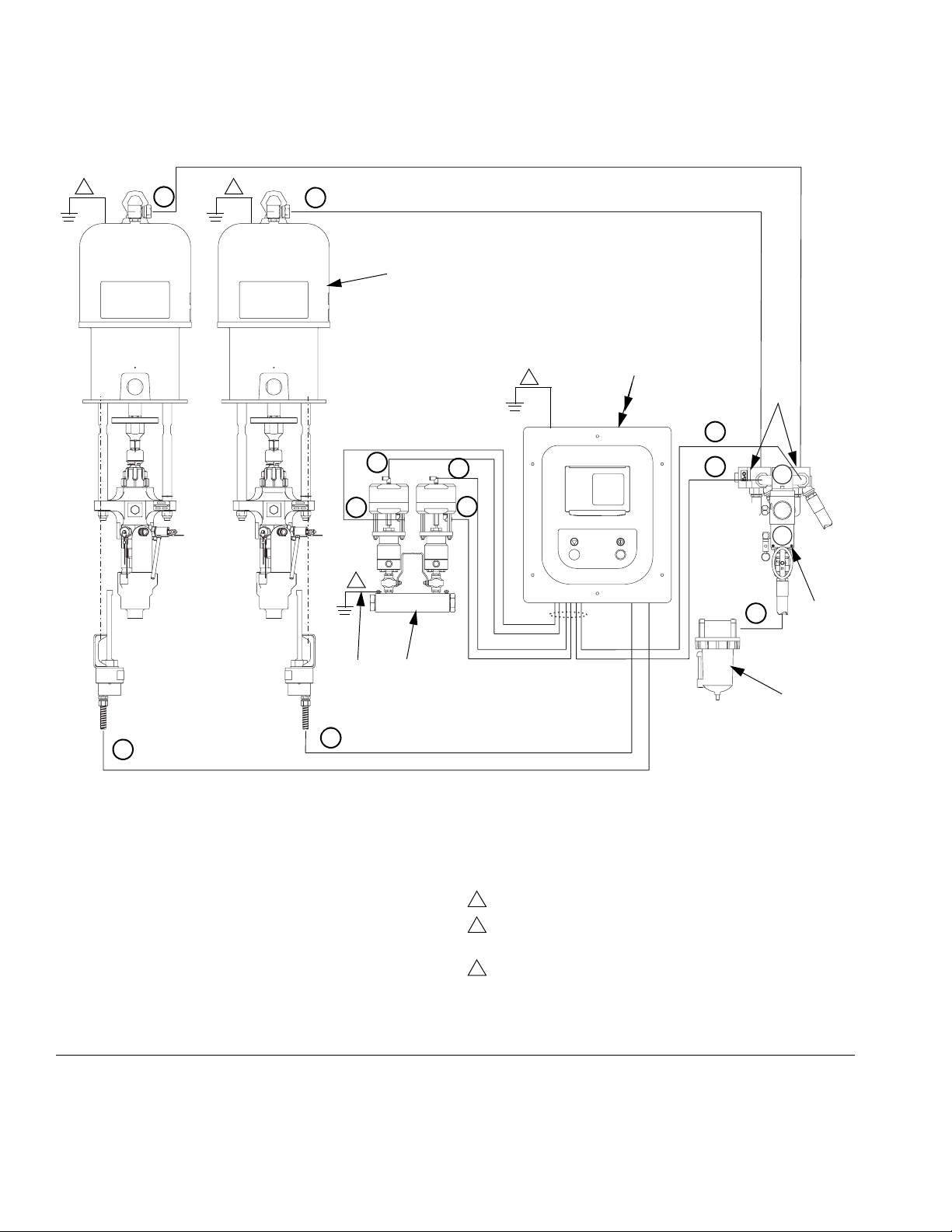

User Interface

FIG. 4 and FIG. 5

1. Connect display board (410) communication cable

(416) to J1 on main circuit board (301).

2. Connect data cable (406 - 7-pin connector) to J2.

WARNING

The user interface must be grounded. Read warnings,

page 5.

3. Connect ground wire (315) to ground stud on back

of cover with nut (311).

4. Secure cover (4) to mounting plate (10) with lockwashers (911) and nuts (910). F

IG. 1.

301

3

315

IG. 5 Control Box

F

3

Fluid Manifold

J2

4

10 9 8 7 6 5 4 3

6

5

Assemble

J1

10

9

7

8

-

+

410

416

IG. 4: Cover - back view

F

406

4

311

CAUTION

Do not assemble static mixer directly to fluid manifold.

Install static mixer after first 50 ft. (15 m) of hose to

ensure material is completely mixed. Spraying

unmixed material could necessitate rework of part

sprayed. See Setup in Xtreme Mix Operation manual.

Install Sampling Valves 244683

Install sampling valves (918) into the metering valves

(601). Install barb fitting (919) and tubing (920) into each

sampling valve. F

IG. 7.

12 309521J

Page 13

Cart-mounted

1. Secure metering valve assembly (6) to cart/stand

with screws (913), washer (914), and nuts (915).

F

IG. 1, page 8.

2. Connect fluid lines (provided by installer) between

pumps and metering valves.

3. Cut air line tubing (included) to length needed to

connect between metering valves (601) and solenoid outlets. F

IG. 3, page 10, and FIG. 6.

Assemble

601

918

607

919, 920

Bottom of Valve A

Bottom of Valve B

DOSING VALVES AIR MOTOR

OPEN

CLOSE

F

IG. 6: Control Box - bottom

PILOT VALVES

Pilot Valve A side

Pilot Valve B side

Top of Valve B

Top of Valve A

Remote Fluid Manifold

To install remote fluid manifold, order part no.

15A898. All other parts referred to in the following

procedure are parts you remove from the standard manifold and reuse or parts the installer

must supply.

FIG. 7

914

915

A side 606

B side 611

913

606

15A898

607

611

E

1. Remove metering valves (601) and shutoff valves

(606, 611) from fluid manifold (607). F

IG. 7.

F

IG. 8

2. Install metering valves (601) and shutoff valves

(606, 611) onto fluid metering manifold 15A898. F

8.

IG.

CAUTION

Do not assemble static mixer directly to fluid manifold.

Install static mixer after first 50 ft. (15 m) of hose to

• Maximum length of tubing is 36” (914 mm).

Locate fluid manifold as close as possible.

ensure material is completely mixed. Spraying

unmixed material could necessitate rework of part

sprayed. See Setup in Xtreme Mix Operation manual.

3. Secure fluid metering manifold 15A898 on the

cart/stand with 2 screws (913), washers (914) and

nuts (915).

309521J 13

Page 14

Assemble

4. Screw ball valves (606, 611 - purchased separately)

into fluid mix manifold (607).

5. Select appropriate fittings and fluid hose sizes and

lengths to connect between fluid metering manifold

15A898 and mix manifold (607).

Balance pressure drops in the 2 lines as

instructed below to assure an accurate mix ratio.

6. Connect fluid lines (provided by installer) between

pumps and metering valves (601).

7. Connect mixed material hose to fluid mix manifold

(607) outlet (E).

8. Cut air line tubing (included) to length needed to

connect between metering valves (601) and solenoid outlets. F

9. Cut air line tubing, included, (F, G, H, J - F

IG. 3, page 10, and FIG. 6, page 13.

IG. 3,

page 10) to length needed to connect between

metering valves (601) and solenoid outlets.

10. Connect ground wires.

To calculate pressure loss:

Pressure Loss = 0.000273 x Q x V L

4

D

Q= Flow (GPM)

V = Viscosity in centipoise

L = Length of pipe in feet

4

D

= Pipe diameter to the 4th power

Example: If you need to pump 1 gpm of high solids paint

(40 seconds in a Zahn #2 cup = 100 cp) 100 ft. in a system using 1/4” pipe:

Pressure Loss = 0.000273 x 1 gpm x 100 cp x 100 ft.

(.364 ID) .018 D4 factor

Pressure Loss = 152 psi

Reduce pressure loss by using:

• Large diameter pipe or tubing

• Constant tubing or pipe size

• Long runs without bends

• Long radius elbows

Balancing Back Pressure

This procedure is for the remote fluid manifold

only.

Flow rates and/or viscosity differences between component materials can create different pressure drops from

the proportioner to the manifold, causing unequal back

pressure. This will effect mix ratio accuracy.

You can balance differences in component back pressure by adjusting hose diameter and length.

4

D

= .018 for 1/4” pipe

.06 for 3/8” pipe

.15 for 1/2” pipe

Using the previous example (.000273 x 1 x 100 x 100 =

2.73):

Pressure drop: 1/4” pipe = 152 psi

3/8” pipe = 46 psi

1/2” pipe = 18 psi

14 309521J

Page 15

Proper Lifting

WARNING

Follow instructions below to avoid dropping or swinging unit or being struck by the cart handle, which can

cause serious injury or damage to equipment.

Either remove the cart handle or secure it to the cart

before lifting the unit. Connect a bridle swing, hooking

an end to each of the Xtreme Mix air motor rings. Hook

the center ring on a hoist. See F

Xtreme Mix unit; make sure it balances evenly.

IG. 9. Carefully lift the

Proper Lifting

Operation and Repair

For operating instructions, including data collection, see

Xtreme Mix Operation manual.

FIG. 9

For troubleshooting, alarm information, and repair

instructions, see Xtreme Mix Repair manual.

309521J 15

Page 16

Electrical Schematic

1

J6

1

2

3

Main Circuit

Board

245705

Jumper (15V)

1

J5

1

2

3

4

5

6

7

8

9

10

11

12

J4

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

1

J2

1

2

3

4

5

6

7

1

J1

2

3

4

5

6

Electrical Schematic

1

15VDC

COM

R

BL

Solenoids

S

W

BL-W

R

BL-R

G

BL-G

W

BL-W

R

BL-R

G

BL-G

W

BL

+

-

+

+

-

+

-

S

R

Metering Valve A

Metering Valve B

Pump A

Pump B

Metering

Valve s

Air Motors

3

6

1

4

2

5

3

6

1

4

2

5

Sensor

243678

Sensor

243678

Case Gnd Clip

11

2

3

4

5

6

J1

1

2

3

4

5

6

R

BL

R

BL

R

BL

R

BL

R

BL

2

3

1

2

3

4

5

6

7

8

9

10

11

12

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

1

2

3

4

5

6

Key:

BL Black

BR Brown

BL-GBlack with green

BL-RBlack with red

16 309521J

BL-WBlack with white

G Green

GNDGround

R Red

S Shield

W White

Page 17

Electrical Schematic

301

304

Air Input

Power

Supply

Power

Supply

Barrier

Board

Front Panel

Comport Pin

Front View

1

32

Alarm 15A849

Alarm +

Alarm COM

R

W

BL

COM Port

RS232

Connector

1

2

3

TX

RX

GND

Start

4

3

A

B

GND

Light

Display Board

245706

1

2

3

4

5

6

J2

1

2

3

4

5

J3

1

2

3

1

R

2

W

3

BR

4

G

5

BL

1

BL

2

R

3

G

1

2

2

7

+-

1

8

Key Switch

momentary

1

2

Start/Stop

Switch

15A851

Stop

1

2

GND

Key Switch

15A852

309521J 17

Page 18

Pneumatic Schematic

Pneumatic Schematic

Manifold

1/2” x 24” long

Air

Exhaust

Air Supply

e

os

12 VDC

Solenoid

A Metering

”

2

3

Cl

A

Position 1

Val ve

n

e

p

O

/

5

A

12 VDC

e

s

Solenoid

Val ve

B Metering

n

”

e

2

p

3

/

O

5

C

B

Position 2

B

12 VDC

o

l

Solenoid

A Pilot

To Pum p

Position 3

3-way valve

12 VDC

Solenoid

B Pilot

To Pum p

3-way valve

Position 4

304

306t

Turbine / Power Supply

26 psi (79 kPa, 1.8 bar)

Relief Valve

To Manifold

524

3/8” tube

306e

B Pilot

Alternator Air

Regulator

bleed type

501

Pump

90/110 psi 0.6/0.8

79

MPa, 6.2/8 bar)

Relief Valve

110 psi

(0.8 MPa,

8 bar) Relief

Val ve

518

3/8” Air Reg.

Auto Drain

5 micron

100 psi (0.7

Gauge

3/4” Ball Valve

MPa, 7 bar)

Pump A Pilot

King Motor B

507

King Motor A

Gauge

Air Regulator

3/4” Air Filter

Auto Drain

20 micron

FIG. 10

18 309521J

Page 19

Pneumatic Schematic

309521J 19

Page 20

Parts

Xtreme Mix Proportioner

2

Parts

5

904

905

913913

914

915

908/909

908

910

911

903

7

10

901

3

307

912

721

6

902

20 309521J

918, 919, 920

4

Page 21

Xtreme Mix Proportioner

Part Numbers

Parts

Approved for Hazardous Location

(Class 1, Div 1, Group D)

Xtreme Mix Pump (2) Plate (10)

233871 249274 (45:1) 246332

233872 249275 (56:1) 246334

233873 249276 (68:1) 246336

233874 249277 (80:1) 246338

233875 249278 (45:1) 246332

233876 249279 (56:1) 246334

233877 249280 (68:1) 246336

233878 249281 (80:1) 246338

234024 none 246338

Includes:

Ref.

No. Part No. Description Qty.

2 PUMP; see table above; see pump

manual for parts

3 245803 PNEUMATIC CONTROL; page 22 1

4 245804 USER INTERFACE; page 24 1

5 245802 PUMP AIR MANIFOLD 1

6 245824 METERING VALVE MANIFOLD;

page 26

7 245825 SENSOR; page 29 2

9 246149 KIT; includes 901-917 1

10 PLATE; see table above 1

918 245143 SAMPLING VALVE; parts page 26 2

919 116746 FITTING; 1/8 npt x 1/4” (6.4 mm)

tube; see page 26

920 116750 TUBE, nylon; 5 in. (12.7 cm); see

page 26

Approved for Non-hazardous Location

Xtreme Mix Pump (2) Plate (10)

233879 249274 (45:1) 246333

233880 249275 (56:1) 246335

233881 249276 (68:1) 246337

233882 249277 (80:1) 246339

233883 249278 (45:1) 246333

233884 249279 (56:1) 246335

233885 249280 (68:1) 246337

233886 249281 (80:1) 246339

234025 none 246339

Refer to page 4 for additional model information.

Kit 246149, Item 9

Ref.

No. Part No. Description Qty.

2

901 117628 AIR FILTER; 3/4 npt 1

902 244524 GROUND WIRE, with clamp 1

903 15A847 MAGNET HOLDER 2

904 15A814 MAGNET STRIP 2

905 104092 SCREW; 10-24 UNC 4

1

906 511352 STATIC MIXER, not shown 1

907 054753 TUBING, nylon, black; 0.156”

(4 mm), 10 ft. (3 m), not shown

908 113498 SAFETY RELIEF VALVE; 110 psi

(0.8 MPa, 8 bar)

909 116643 SAFETY RELIEF VALVE; 90 psi

(621 kPa, 6.2 bar)

910 100015 NUT; 1/4-20 UNC 4

2

911 100016 LOCKWASHER 4

912 103196 SCREW; 8/32 UNC 6

2

913 100004 SCREW; 3/8 UNC 8

914 100133 LOCKWASHER 8

915 100131 NUT; 3/8-16 UNC 8

916 054139 TUBING, nylon; 0.5” (13 mm); 3 ft.

917 C12508 TUBING, nylon; 0.375” (9.5 mm); 3

Order length needed from distributor.

★

(0.9 m), not shown

ft. (0.9 m), not shown

1

1

★

★

309521J 21

Page 22

Pneumatic Control 245803

Item 3, page 21

b

p

a

k

n

Parts

a

d

f

h

g

f

302

301

313

TO SOLENOIDS

306r

FROM TURBINE

POWER

TO PUMP POSITON

SENSOR

Ref. 304

314

MOTOR A

e

303

m

j

c

306

s

t

f

320

321

311

315

c

b

304

305

e

304

312

317

307

310

MOTOR B

306

22 309521J

B PUMP

A PUMP

REF

310

316

309

313

Page 23

Pneumatic Control 245803

Parts

Ref.

No. Part No. Description Qty.

301 245705 CIRCUIT BOARD 1

301a 15C318 FUSE, circuit board 1

302‡ SCREW; 8-32 UNC 4

303‡ COVER 1

304** 245854 ALTERNATOR MODULE; includes

items 304a-304e

304a 193154 • GASKET 1

304b 15A853 • WIRE HARNESS 1

304c 111225 • TUBE FITTING; 90° 2

304d 114380 • SCREW; M5 x 25 4

304e 249254 • TURBINE ALTERNATOR 1

305‡ LOCKNUT; 8-32 UNC 2

306‡ SOLENOID MODULE, IS; includes

items 306a-306t

306a 15A822 • MANIFOLD 1

306b 117356 • VALVE, 12 VDC, IS 4

306c 114263 • FITTING; 1/8 npt x 5/32” (4 mm)

tube

306d‡ • NIPPLE; 1/4 npt 1

306e 115243 • AIR REGULATOR; 1/4 npt 1

306f 115841 • ELBOW, swivel; 1/4 npt x 3/8”

(9.5 mm) tube

306g 160701 • ELBOW, street; 1/8 npt(m x f) 1

306h 108190 • GAUGE, 1

306j‡ • GASKET, neoprene 1

306k‡ • GASKET, neoprene 1

Ref.

No. Part No. Description Qty.

306n‡ • PLUG, pipe; 1/8-27 ptf 5

306p 114128 • ELBOW; 1/4 npt x 1/2” (13 mm)

tube

306q

† 112512 • WIRE FERRULE, orange, not

shown

306r 117369 • CONNECTOR, 12 position 1

1

306s 150278 • ADAPTER, 1/4 x 1/8 npt 1

306t 117480 • SAFETY RELIEF VALVE, 26 psi

(179 kPa, 1.8 bar)

307 15A800 GASKET, neoprene 1

309‡ SCREW; M5 x 10 2

310 590385 TUBE, poly-flo; 3/8” OD; 1 ft. (3 m) ★

311‡ NUT, KEPS; #10-24 1

312 104029 GROUNDING STUD 1

1

313 15A849 WIRE HARNESS, alarm 1

314 117442 CONNECTOR, 18 position 1

315 15B090 GROUNDING WIRE, door 1

6

316 15B056 LABEL, air connections 1

317 111307 LOCKWASHER 1

320 118132 LOCKWASHER, terminal 1

321 118129 SPACER, 8-32 UNC x 5” (127 mm) 1

3

IS = intrinsically safe

** Alternator bearing repair kit 223688 available.

‡ Not available for order from Graco.

★ Order length needed from distributor.

1

8

1

309521J 23

Page 24

User Interface 245804

Item 4, page 21

Parts

Ref.

407

Ref.

403

Ref.

416

416

Back View

412

418

414,

415

Ref.

406

413

406

407

405,419

15A804

401

404

Ref. 407

410

Ref. 405

411

409

403

Ref.

No. Part No. Description Qty.

401‡ COVER 1

403 15A851 WIRE HARNESS, start/stop 1

404 15A801 GASKET 1

405 15C335 KNOB 1

406 15A850 WIRE HARNESS, data port 1

407 15A852 WIRE HARNESS, key switch 1

409* LABEL, alarm code 1

410 245706 CIRCUIT BOARD 1

411‡ SCREW; 4-40 2

412 15A856 DISPLAY PANEL 1

413‡ NUT; 4-40 4

15A806

Ref. 403

Ref.

No. Part No. Description Qty.

414‡ MOUNT 3

415‡ STRAP 3

416 15A854 WIRE HARNESS, display 1

418‡ WASHER 4

419 107232 SET SCREW 1

Not available for order from Graco.

‡

* Alarm Code Labels

Item 409, English provided. To order other languages:

Part No. Languages

15B843 Chinese, Finnish, Portuguese, Greek, Swedish, Italian

15B844 English, Spanish, French, German, Korean, Japanese

24 309521J

Page 25

Pump Air Manifold 245802

Item 5, page 21

Parts

502

504

505

503

508

521

503

525

513

501

523

522

513

504

506

507

524

527

510

511

514

512

526

517

518

528

519

520

516

515

1

TI2295B

Ref.

No. Part No. Description Qty.

501 C59752 VALVE, 3-way 2

502 108307 ELBOW; 3/4 npt 2

503 101689 PRESSURE GAUGE 2

504 112166 SCREW; 1/4-20 UNC 4

505 15A820 MANIFOLD 1

506 15A821 PLATE, direction 1

507 117332 REGULATOR 1

508 100840 ELBOW; 1/4 npt 1

510 15A819 MANIFOLD BLOCK 1

511 160032 NIPPLE; 3/4 npt 1

512 117346 SHUTOFF VALVE, vented 1

513 117364 O-RING, nitrile 3

514 108849 SCREW; 1/4-20 UNC 2

515 15B554 HOSE; 3/4 npt; 4 ft. (1.2 m) 2

516 100549 ELBOW, 90°; 3/4 npt 2

517 165198 NIPPLE; 1/4 x 3/8 npt 1

518 119644 FILTER; 3/8 npt; 5 micron 1

519 114316 ELBOW, swivel; 3/8 npt 1

520 114151 ELBOW, swivel; 1/8 npt x 5/32” (4

mm) tube

521 100721 PLUG; 1/4-18 nptf 3

522 512912 MUFFLER; 1/2 npt 2

523 100896 BUSHING; 3/4 x 1/2 npt 2

524 113498 SAFETY RELIEF VALVE; 110 psi

(0.8 MPa, 8 bar)

525 117443 STANDOFF, aluminum, 8-32 UNC 2

526 240900 HOSE; 3/4 npt; 2.5 ft. (0.76 m) 1

527 158962 ELBOW, 1/8 (m) x 1/4 (f) 1

528 113911 GUAGE, 1/8, air 1

2

1

1

100 psi (0.7 MPa, 7 bar) setting.

309521J 25

Page 26

Metering Valve Manifold 245824

Parts

Item 6, page 21

Ref.

No. Part No. Description Qty.

601 245846 METERING VALVE; page 27 2

606 245861 SHUTOFF VALVE; see manual

306861

607 245833 FLUID MANIFOLD; page 28 1

611 245860 SHUTOFF VALVE; see manual

306861

Sampling Valve 245143

Item 918

Ref.

No. Part No. Description Qty.

918a 245110 KNOB 1

918b 197681 HOUSING 1

918c 197332 SEAT 1

918d 107536 BALL, carbide 1

918e 110082 RETAINING RING 1

918f 111457 O-RING, PTFE 2

918h 187060 GASKET 1

918

918d

1

1

918a

* See page 21 for part no. and description.

918f

918b

918e

*919

*920

918c

918h

918g

601

606 (A side)

611 (B side)

607

26 309521J

Page 27

Metering Valve 245846

†

†

621

622

*† 637

Parts

627

639*†

*

† 634

† 632

*

631

623

*† 633

† 635

624

*† 643

625

621

*† 638

▲ 629

626

628

636

630†

645*

644

645*

646

647

†

Ref.

No. Part No. Description Qty.

621 598140 ELBOW, 1/8 npt(m) x 5/32” (4 mm)

tube

622‡ VALVE CAP 1

623‡ PISTON 1

624‡ CYLINDER 1

625 15B545 PISTON ROD 1

626 15A834 TIE ROD 2

627 15A835 PACKING NUT 1

628 15A833 INLET HOUSING 1

629

▲ 180233 WARNING LABEL 1

630

† 245850 FLUID NEEDLE 1

631 111040 LOCKNUT, nylon; 5/16 UNC-3B 1

632*

† O-RING, nitrile 1

633*

† O-RING, nitrile 1

634*

† O-RING, nitrile 1

309521J 27

Ref.

No. Part No. Description Qty.

† 109141 SPRING 1

635

2

636 102040 LOCKNUT; 1/4 UNC 2

637*

† V-PACKING, UHMWPE 6

638*

† 189901 GLAND, male 1

639*

† V-PACKING, leather 5

643*

† O-RING, buna-n 1

644

† 15A830 SEAT 1

645*

† 107079 O-RING, PTFE 2

646 15A832 SEAT HOUSING 1

647 102637 SCREW; 3/8 UNC-2A 4

* Parts included in kit 234098.

† Parts included in kit 234131.

‡ Not available for order from Graco.

▲ Replacement Warning labels available at no cost.

Page 28

Fluid Manifold 245833

Item 607, page 26

661

*662

*663

*665

*664

*665

*666

*667

674

675

668

Parts

676

669

665

670

671

Ref.

No. Part No. Description Qty.

661 15A823 PLUG 2

662* 107098 O-RING, PTFE 2

663* 107313 O-RING, PTFE 2

664* SEAT 2

665* 103341 O-RING, PTFE 5

666* BALL, metallic 2

667* 117333 SPRING 2

668 PLUG; 3/8 npt 4

Ref.

No. Part No. Description Qty.

669 15A825 PIPE, outlet 1

670 192977 PIPE, center 1

671‡ HOUSING 1

674 111307 LOCKWASHER 2

675 116343 GROUND SCREW,; M5 x 0.8 2

676 159239 NIPPLE; 3/8 x 1/2 npt 1

* Parts included in kit 234100.

‡ Not available for order from Graco.

28 309521J

Page 29

Sensor 245825

Item 7, page 21

715

†714

Parts

716†

712†

704†

703†

720†

710*

†701

1

†707

†706

†708

Ref.

No. Part No. Description Qty.

701† 196280 CAP 1

702* 15A818 COVER 1

703† 243500 BOARD 1

704† 115925 SPACER 2

705* 117331 CABLE 1

706† 115917 SENSOR 1

707† 110004 O-RING, PTFE 1

708† 196289 CAP 1

709* 116024 TAB TERMINAL 1

710* 101855 SCREW; 4-24 UNC 1

711* 112546 SCREW; 4-40 taptite 2

709*

702*

705*

719*

713*

721*

711*

Ref.

No. Part No. Description Qty.

712† 15A817 NUT; 1/8 npt 1

713* 117569 FITTING; 3/8 npt x 5/16” conduit 2

714† 154741 O-RING, buna-n 1

715 245831 BRACKET 1

716† 104765 PLUG; 18-27 ptf 1

719* 117586 LOCKNUT; 3/8-18 npt 2

720† C20272 O-RING; fluoroelastomer 1

721* 117582 CONDUIT, 5 ft. (1.5 m) ★

* Parts included in kit 246345.

† Parts included in kit 246344.

★ Order length needed from distributor.

Calibration label.

1

309521J 29

Page 30

Technical Data

Technical Data

Mix ratio range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.0:1-10:1 (in 0.1 increments)

Ratio tolerance range . . . . . . . . . . . . . . . . . . . . . . . . . . . . +/- 5%

Flow rates

Minimum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 qt./min. (0.95 liter/min.)*

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 gal./min. (11.4 liter/min.)

Fluid viscosity range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200-20,000 cps (heavier viscosities can be mixed with use

of optional heaters, heated hoses, and hardware)

Fluid filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 mesh, (238 micron) standard

Maximum fluid working pressure

45:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4500 psi (31 MPa, 310 bar)

56:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5600 psi (38.6 MPa, 386 bar)

68:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6800 psi (46.9 MPa, 469 bar)

80:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7250 psi (50 MPa, 500 bar)

Air supply pressure range. . . . . . . . . . . . . . . . . . . . . . . . . 50-110 psi (345-800 kPa, 3.5-8 bar)

Maximum air consumption at 100 psi (0.7 MPa, 7 bar) in cfm (m

45:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 (3.1)

56:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 (3.5)

68:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155 (4.4)

80:1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 (5.1)

Ambient temperature range

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-130° F (0-54° C)

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-160° F (–1-71° C)

Environmental Conditions Rating . . . . . . . . . . . . . . . . . . . Indoor/outdoor use

Sound pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 dBA at 100 psi (0.7 MPa, 7 bar)

Wetted parts

Suction tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . aluminum

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . carbon steel, alloy steel, 303, 440 & 17-4ph grades stain-

Metering Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . carbon steel, zinc plating, carbide, polyethylene, leather

Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . carbon steel, zinc plating, carbide, 302 stainless steel

Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . stainless steel

Spray gun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See gun manual

PC Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . RS-232

3

/min.)

Altitude up to 4000 meters

Maximum relative humidity to 99% up to 54° C

Pollution degree (11)

Installation category (2)

less steel, zinc and nickel plating, ductile iron, tungsten

carbide, PTFE, leather

* Minimum flow rate is dependent on the material being sprayed and mixing capability. Test your material for spe-

cific flow rate.

30 309521J

Page 31

Technical Data

309521J 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance

of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309521

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

309521J

1/2008

Loading...

Loading...