Page 1

L26-H03B

L26-H03W

L32-H03B

L32-H03W

LCD TV 2009-3

HITACHI

Caution: Be sure to read this manual before servicing. To ensure safety from fire, electric shock, injury, harmful

radiation and materials, various measures are provided in this LCD TV. Be sure to read cautionary items described

in the manual before servicing. These servicing instructions are for use by qualified service personnel only. To

reduce the risk of electric shock, do not perform any servicing other than that described in the operating instructions

unless you are qualified to do so.

L26-H03B/ L26-H03W L32-H03B/ L32-H03W

1. Summary

VHF1ch ~ 12ch, UHF13ch ~ 62ch, CATV (C13 ~ C63), Digital BS 110 degree CS digital and terrestrial digital (CATV

support pass-through, except for one-segment broadcasting)

Table of Contents

1. Summary………..........……..........................……….........1

2. Features…….………..........................................……......4

3. Dimensions……..……………………………………………5

4. General Specification................................…………........6

5. Service points…………….…………….……………..........7

6. Adjustment……………..………..…….………..….…….....8

7. Troubleshooting………...……………………….…….......17

9. Block Diagram.....……………..………….………......27

10. Connection Diagram……….………….……..……..28

11. Wiring Diagram.………..………………....…….......29

12. PCB Layout……………………………....……….....31

13. Exploded View…………………..……….................38

14. Service Parts List…...............................................40

15. Different Parts List.………………..……………......48

8. Self Diagnosis Function…..……………...……….....26

HITACHI

Page 2

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

Caution for Safety

Please read this page before repair the TV.

The following safety precautions are designed to help you stay safe and prevent accidents during the repair work.

2

Page 3

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

3

Page 4

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

2. Features

● Enhanced definition LCD display panel

L26-H03B/L26-H03W

This specification applies to the 26.0 inch Color TFT-LCD Module T260XW02 VQ. This LCD module has a TFT

active matrix type liquid crystal panel 1366x768 pixels, and diagonal size of 26.0 inch. This module supports

1366x768 XGA-WIDE mode (Non-interlace).

Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in vertical stripes. Gray scale

or the brightness of the sub-pixel color is determined with a 8-bit gray scale signal for each dot.

The T260XW02 VQ has been designed to apply the 8-bit 1 channel LVDS interface method. It is intended to support

displays where high brightness, wide viewing angle, high color saturation, and high color depth are very important.

The T260XW02 VQ model is RoHS verified which can be distinguished on panel label.

L32-H03B/L32-H03W

This specification applies to the 31.51 inch Color TFT-LCD Module T315XW02 VS. This LCD module has a TFT

active matrix type liquid crystal panel 1366x768 pixels, and diagonal size of 31.51 inch. This module supports

1366x768 XGA-WIDE mode (Non-interlace).

Each pixel is divided into Red, Green and Blue sub-pixels or dots which are arranged in vertical stripes. Gray scale

or the brightness of the sub-pixel color is determined with a 8-bit gray scale signal for each dot.

The T315XW02 VS has been designed to apply the 8-bit 1 channel LVDS interface method. It is intended to support

displays where high brightness, wide viewing angle, high color saturation, and high color depth are very important.

The T315XW02 VS model is RoHS verified which can be distinguished on panel label.

● Easy-to-use remote control and on-screen display system

The included remote control operates all TV functions. Furthermore, the on-screen display system shows the status

of the control settings in an easy-to-view fashion.

● Power saving system

When connected to a VESA DPMS-compliant PC, the TV cuts its power consumption while idle.

4

Page 5

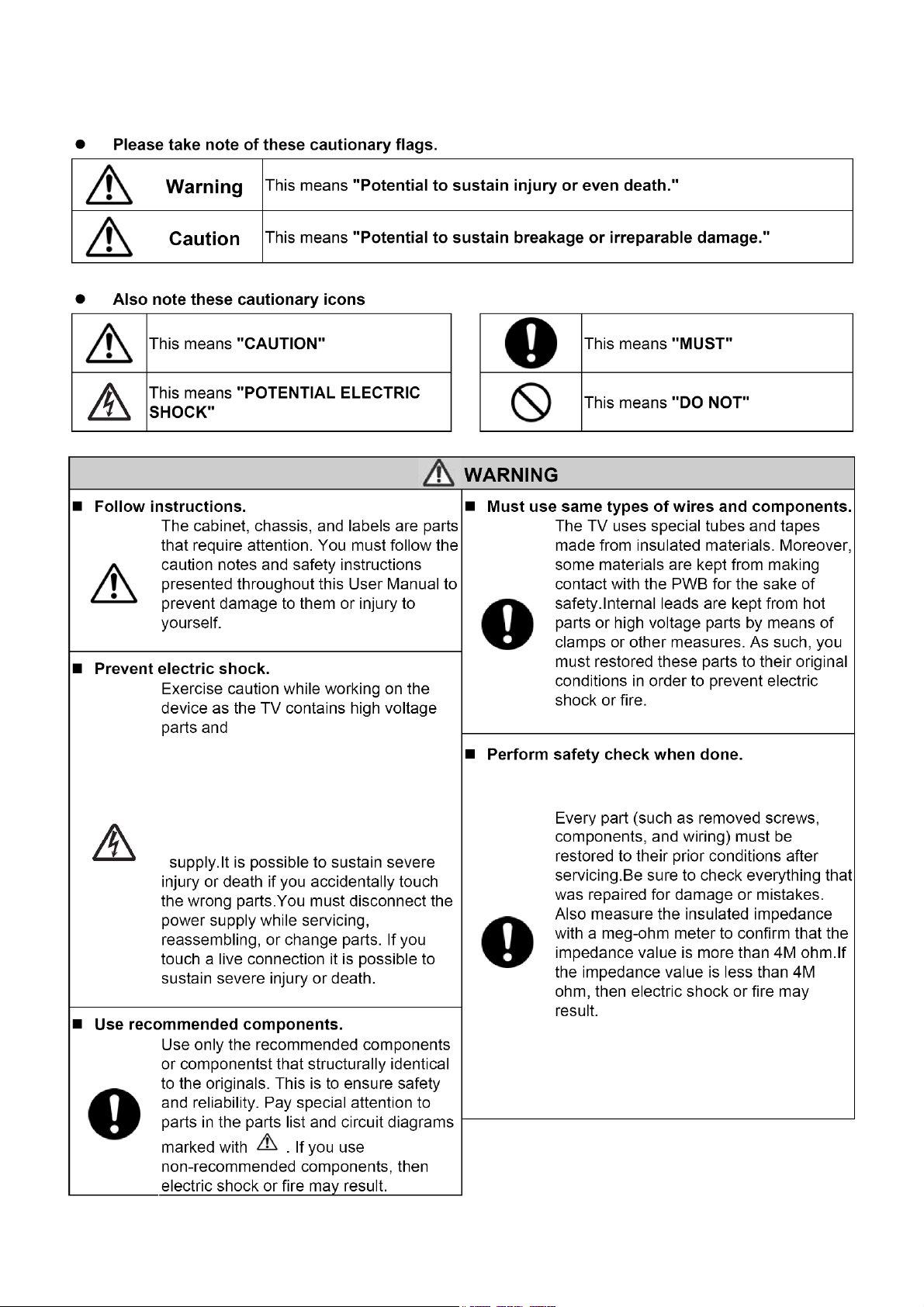

3. Dimensions

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

5

Page 6

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

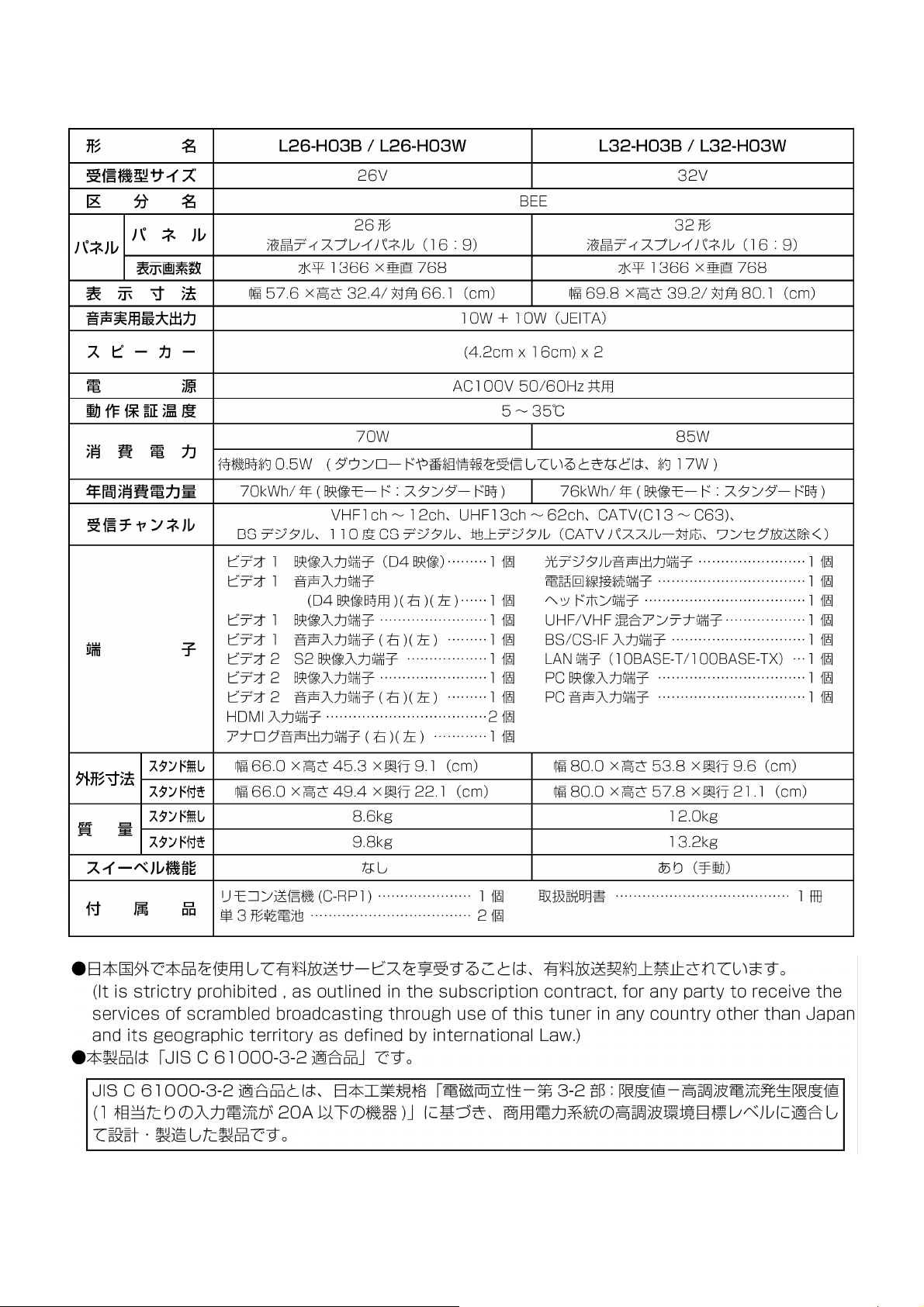

4. General Specification

6

Page 7

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

5. Service points

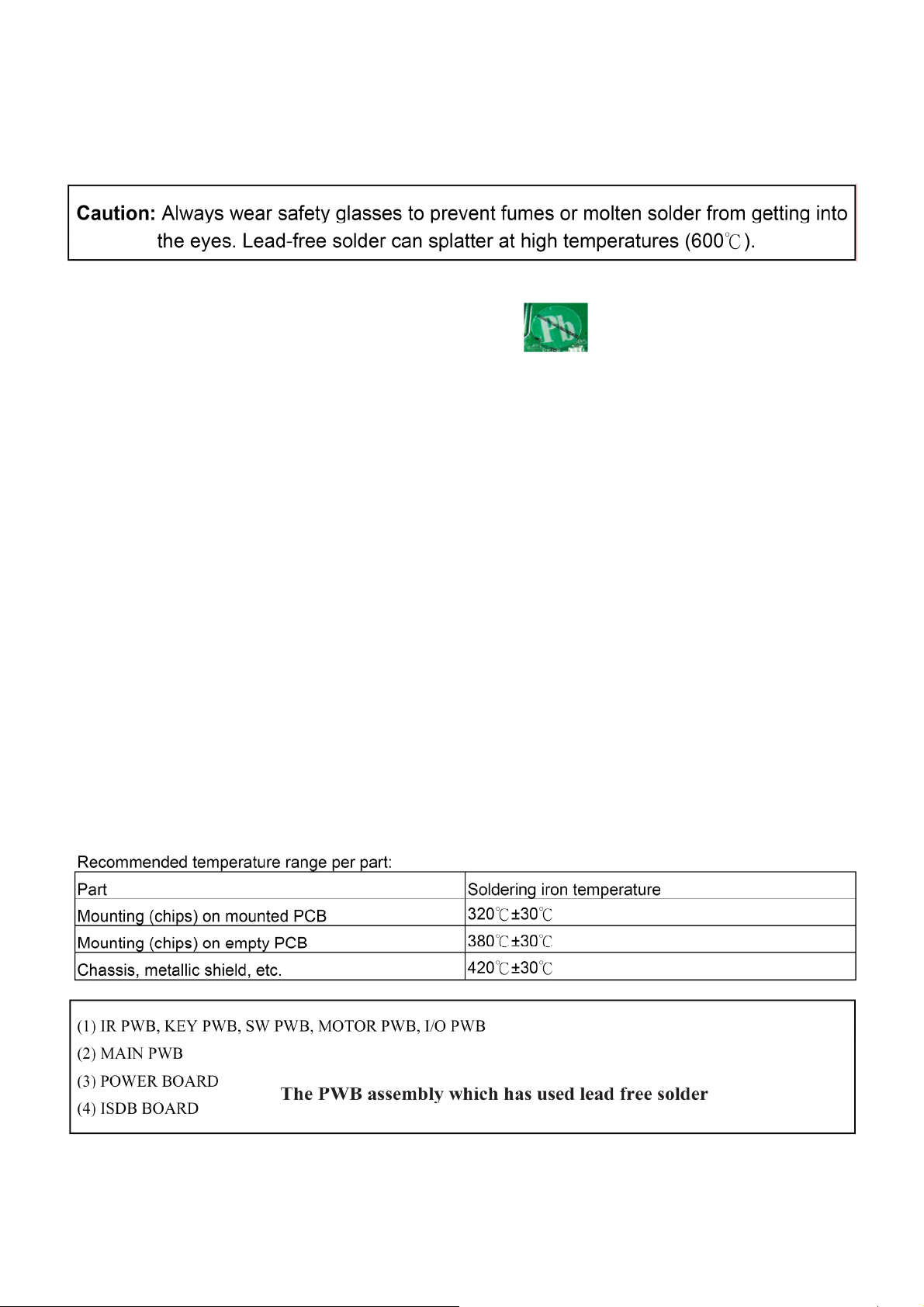

Lead-free solder

This product uses lead-free solder (unleaded) to help protect the environment. Please read these instructions

before attempting any soldering work.

1) Lead-free solder indicator

Printed circuit boards using lead-free solder are engraved with an

2) Properties of lead-free solder

The melting point of lead-free solder is 40-50 ℃ higher than leaded solder.

3) Servicing solder

Solder with an alloy composition of Sn-3.0Ag-0.5Cu or Sn-0.7Cu is recommended. Although servicing with

leaded solder is possible, there are a few precautions that have to be taken. (Not taking these precautions

may cause the solder to not harden properly, and lead to consequent malfunctions.)

label.

Precautions when using leaded solder

● Remove all lead-free solder from soldered joints when replacing components.

● If leaded solder should be added to existing lead free joints, mix in the leaded solder thoroughly after the

lead-free solder has been completely melted (do not apply the soldering iron without solder).

4) Servicing soldering iron

A soldering iron with a temperature setting capability (temperature control function) is recommended.

The melting point of lead-free solder is higher than leaded solder. Use a soldering iron that maintains a high

stable temperature (large heat capacity), and that allows temperature adjustment according to the part being

serviced, to avoid poor servicing performance.

Recommended soldering iron:

● Soldering iron with temperature control function (temperature range: 320-450℃)

7

Page 8

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

6. Adjustment

6.1 White Balance Adjustment

Approximately 2 hours should be allowed for warm up before proceeding white balance adjustment.

Before White balance adjustment, you must set the color analyzer CA210.

6.1.1 Calibration

1. Receive XGA 60Hz 100% white signal by PC input.

2. Select PC input by R/C Input Select button.

3. Enter FACTORY MODE by R/C [べんり][青][9][1][1][1] (as picture 1, picture 2)

Picture 1 Remote Controller Picture 2 FACTORY MODE Menu

4. Choose "OPTION" by R/C [上/下] button.

Then press R/C [決定] button. -> Enter to OPTION menu. (as picture 3)

Picture 3 OPTION Menu

5. Choose "PC CALIBRATE" by R/C [上/下] button.

Then press R/C [右] button. -> Value changes 0 to 1 (red letter).

Then press R/C [決定]. -> PC CALIBRATE executed, and value returns to 0.

6. Press R/C [もどる] -> Return to FACTORY MODE menu.

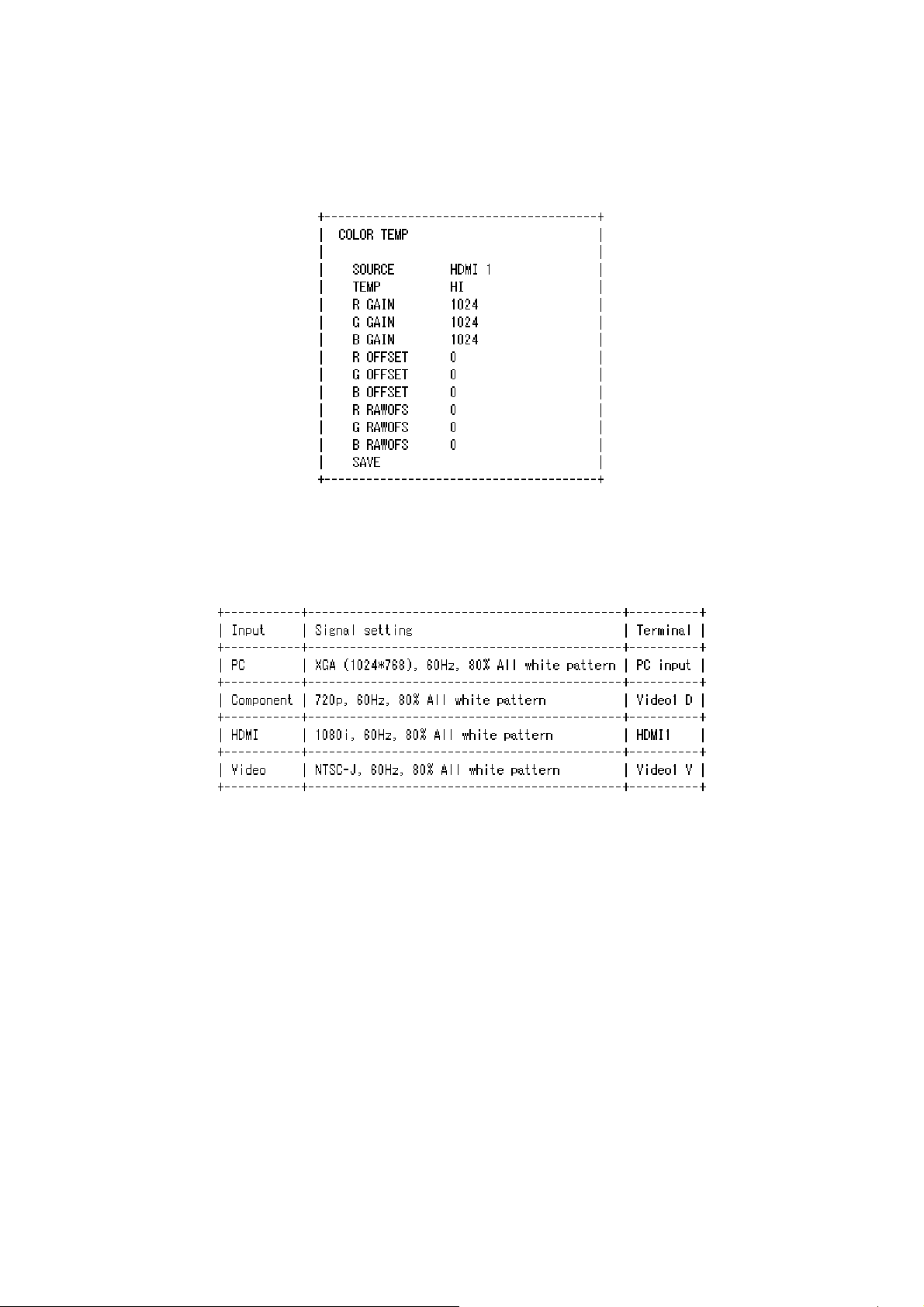

6.1.2 Color Temperature Adjustment

1. Set picture mode "スーパー" by Menu.

1.1 Exit FATORY MODE by [メニュー] button.

1.2 Enter the "トップメニュー" by R/C [メニュー] button. Then forward to "映像設定" - "画質設定". ("画質設定"

menu indicated.)

1.3 Confirm that "対象コンテンツ" is set to "共通".

1.4 Set "映像モード" to "スーパー". Then exit "トップメニュー" by [メニュー] button.

1.5 Re-enter FACTORY MODE. (see 6.1.1 item 3.)

8

Page 9

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

2. Choose "PQCOFF" by R/C [上/下] button. Then choose value "1" by R/C [左/右] button, then press [決定].

3. Choose "SAVE" by R/C [上/下] button. Then choose value "1" by R/C [左/右] button, then press [決定]. (After

this, value returns to "0" automatically.)

4. Return to "FACTORY MODE" by R/C [もどる] button. Then choose "COLOR TEMP" by R/C [上/下] button.

(Enter COLOR TEMP menu.)

Picture 4 COLOR TEMP Menu

5. Color Temp. adjustment (HI)

5.1 Choose "TEMP" by R/C [上/下] button. Then choose value "HI" by R/C [左/右] button, then press [決定].

5.2 Input signal from specified terminal as shown below.

Table 1 Signal setting for adjustment of Color temperature

5.3 Choose "SOURCE" by R/C [上/下] button. Then choose the input from

the Input names (see below) in "SOURCE" by R/C [左/右] button.

Input names: PC (to adjust PC input)

D (to adjust Component input)

HDMI1 (to adjust HDMI input)

CVBS1 (to adjust Video input)

Input names indicated by red letters.

Then press R/C [決定] button. -> Change to selected input.

5.4 Adjust Color temperature of HI.

Do not change B GAIN (keep the value 1024), change R GAIN and G GAIN, to meet the specified x and y value:

x = 0.266 +/-0.005, y = 0.270 +/-0.005.

5.5 After adjusting, write down the R GAIN, G GAIN, B GAIN value to paper as memo. Then calculate Gb and Bb as

shown below

Rb = [R GAIN] / [R/GAIN] * 1024 = 1024 (Always)

Gb = [G GAIN] / [R/GAIN] * 1024 = ____ (Calculated)

9

Page 10

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

Bb = [B GAIN] / [R/GAIN] * 1024 = ____ (Calculated)

5.6 Change R GAIN value to Rb, G GAIN value to Gb, B GAIN value to Bb.

5.7 To adjust color temp of another input, change input name and input signal, then repeat 5.1 to 5.6.

6. Set picture mode "スタンダード" by Menu.

6.1 Exit FATORY MODE by [メニュー] button.

6.2 Enter the "トップメニュー" by R/C [メニュー] button. Then forward to "映像設定" - "画質設定". ("画質設定"

menu indicated.)

6.3 Confirm that "対象コンテンツ" is set to "共通".

6.4 Set "映像モード" to "スタンダード". Then exit "トップメニュー" by [メニュー] button.

6.5 Re-enter FACTORY MODE. (see 6.1.1 item 3.)

7. Color Temp. adjustment (MID)

7.1 Choose "TEMP" by R/C [上/下] button. Then choose value "MID" by R/C [左/右] button, then press [決定].

7.2 Input signal from specified terminal as shown in 5.2.

7.3 Choose "SOURCE" by R/C [上/下] button. Then choose the input from the input names in "SOURCE" by R/C

[左/右] button. Then press R/C [決定] button. -> Change to selected input.

7.4 Adjust Color temperature of MID.

Do not change R GAIN (keep the value 1024), change G GAIN and B GAIN, to meet the specified x and y value:

x = 0.285 +/-0.005, y = 0.293 +/-0.005.

7.5 To adjust color temp of another input, change input name and input signal, then repeat 7.1 to 7.4.

8. Color Temp. adjustment (LOW)

8.1 Choose "TEMP" by R/C [上/下] button. Then choose value "LOW" by R/C [左/右] button, then press [決定].

8.2 Input signal from specified terminal as shown in 5.2.

8.3 Choose "SOURCE" by R/C [上/下] button. Then choose the input from the input names in "SOURCE" by R/C

[左/右] button. Then press R/C [決定] button. -> Change to selected input.

8.4 Adjust Color temperature of LOW.

Do not change R GAIN (keep the value 1024), change G GAIN and B GAIN, to meet the specified x and y value:

x = 0.314 +/-0.005, y = 0.316 +/-0.005.

8.5 To adjust color temp of another input, change input name and input signal, then repeat 8.1 to 8.3.

9. Choose "SAVE" by R/C [上/下] button. Then choose value "1" by R/C [左/右] button, then press [決定].

(After this, value returns to "0" automatically.)

10. Choose "PQCOFF" by R/C [上/下] button. Then choose value "0" by R/C [左/右] button, then press [決定].

10

Page 11

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

6.2 Firmware update

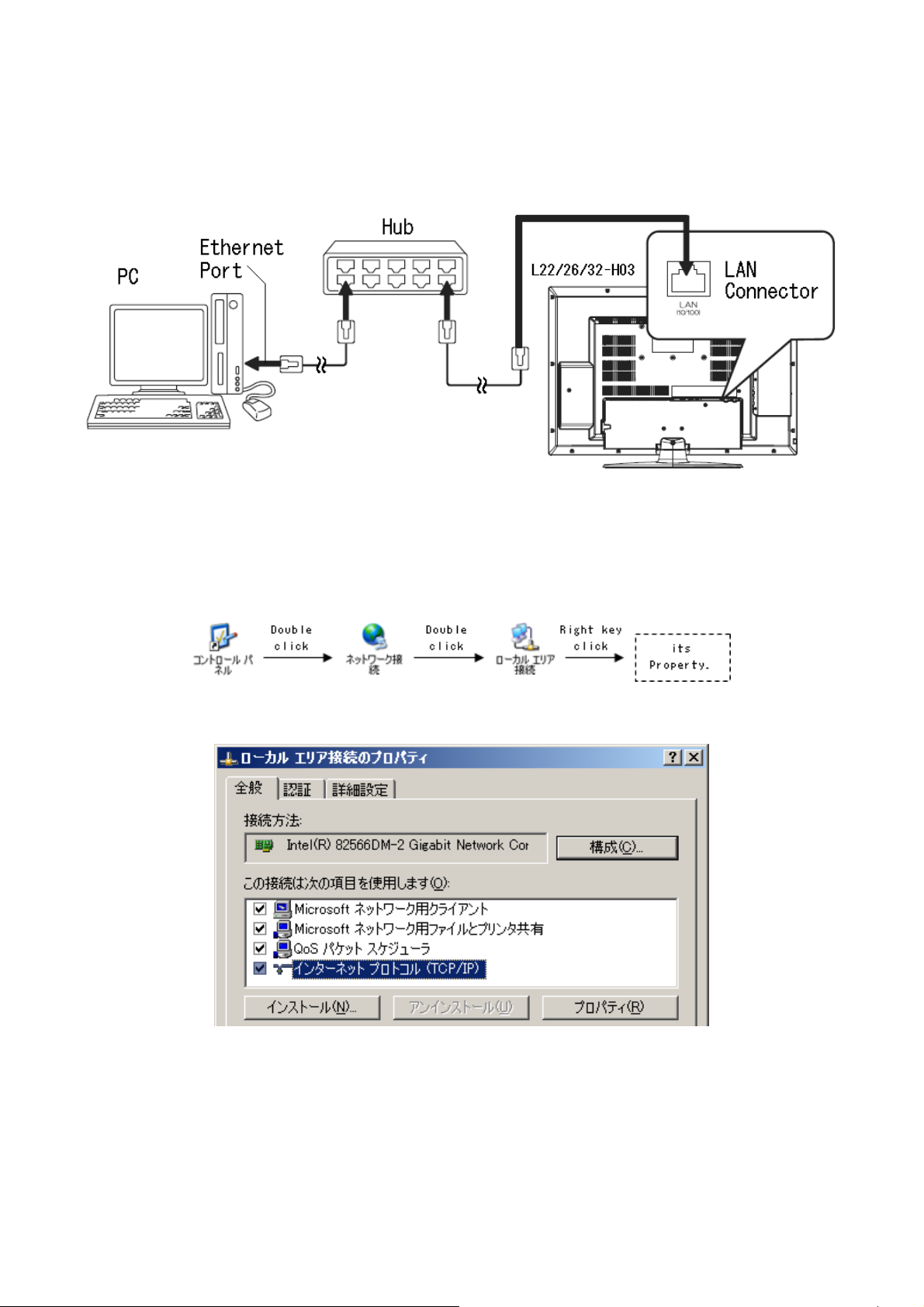

1. Preparation (as picture 5)

1) Connect to 1 port of Hub from Ethernet port of PC with Ethernet cable(straight type).

2) Connect to another port of Hub from LAN connector of L22/26/32-H03 with Ethernet cable (straight type).

Caution: Do not connect other PC.

Picture 5 How to Setup (example)

2. Settings

1) If the update tool "Boisclair updater window" is not installed, install it. ( Please see Page17)

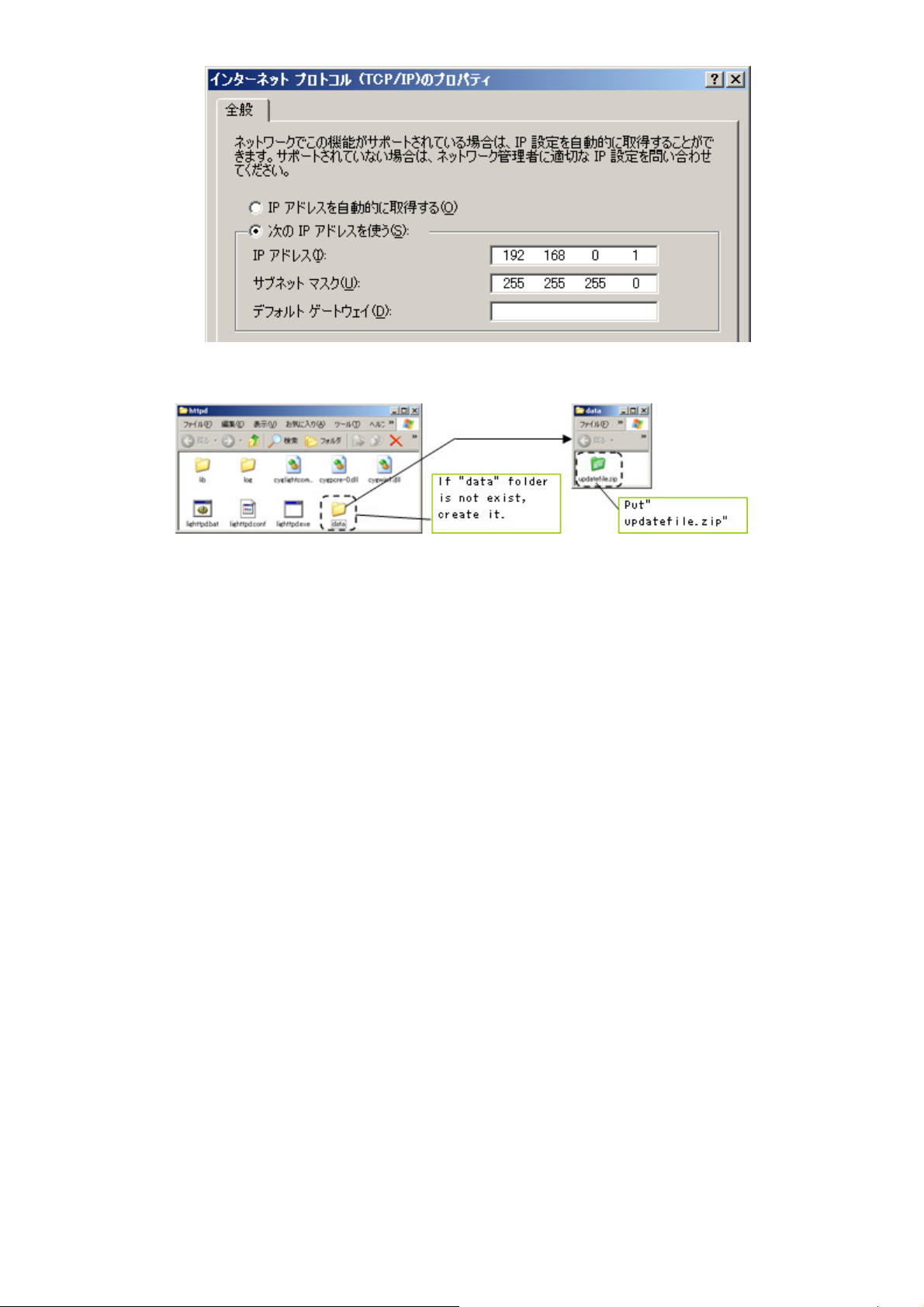

2) Open the "Control Panel" - "Network" - "Local Area Network", and open its Property. (as picture 6)

Picture 6 Open Property

3) Choose "Internet Protocol" and open its Property as shown below.

4) Set IP address and Subnet mask as below;

IP address: 192.168.0.1

Subnet mask: 255.255.255.0

Picture 7 Property

11

Page 12

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

Picture 8 Internet protocol (TCP/IP) setting

5) Put "updatefile.zip"(datas for FW update) into "FirmUpdateTool_XXX\httpd\data". (as picture 9)

Picture 9

Note: To avoid the data damage of "updatefile.zip" file, it is recommended that once delete the previous

"updatefile.zip" file, then put new "updatefile.zip" file.

6) Other PC setting

① Disable "system standby" and "HardDisk power off".

② Disable "screen saver".

12

Page 13

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

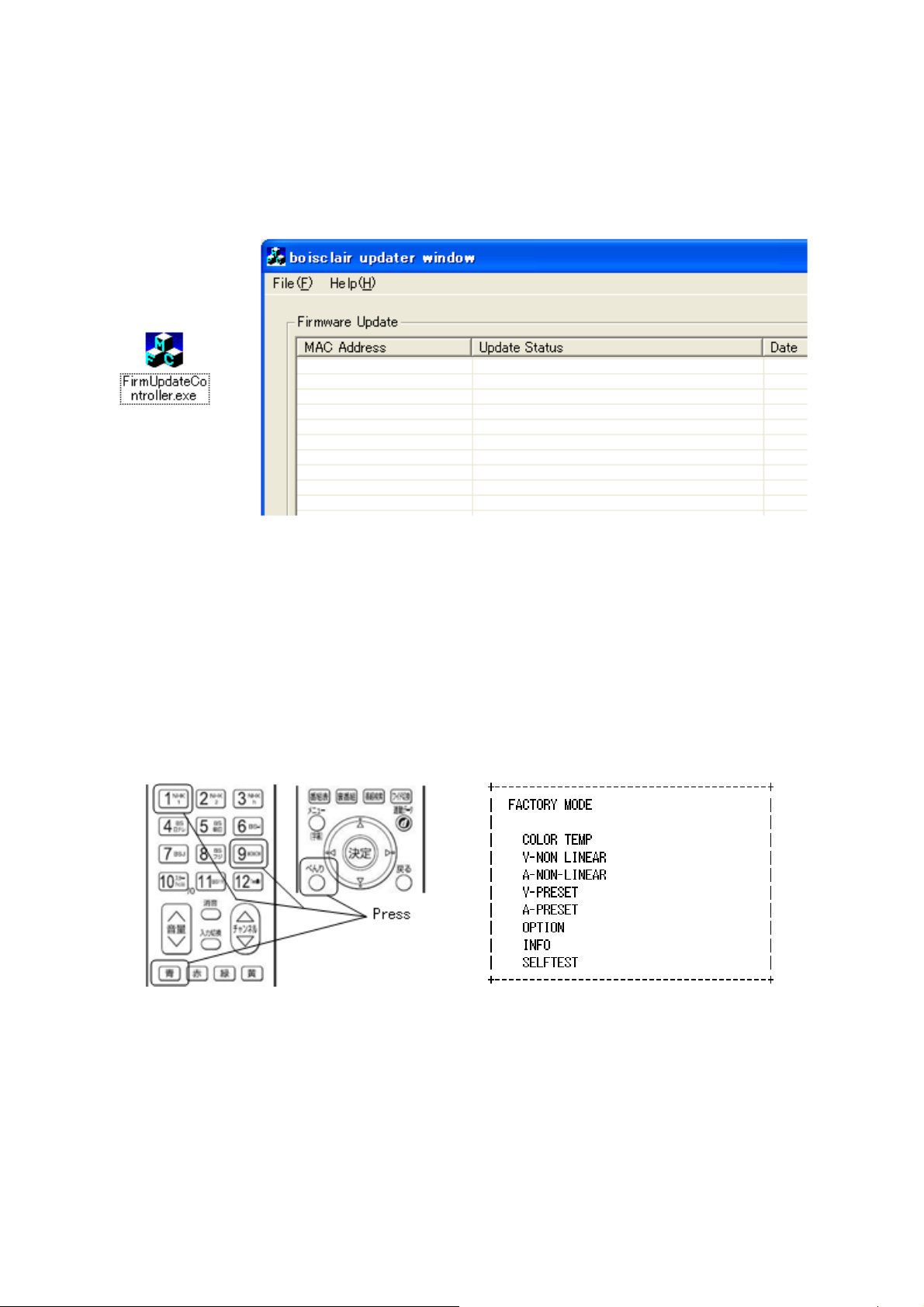

3. Execute FW Update

1) Start PC.

2) Turn on TV

3) Execute FirmUpdateTool.exe

When Windows firewall is valid, the dialog is displayer at the first start, click in "Unblock", then "boisclair updater

window" is displayed.

Picture 10 FirmUpdateTool.exe Icon and Update Tool Image

In case that "boisclair updater window isn't displayed, Please confirm as shown below.

- Please confirm that Hub is turned on, and Link indicator of Hub blinks.

- Please confirm that PC network setting is correct.

- Please confirm that the Hub is connected to PC and TV correctly and firmly.

- Please confirm that "updatefile.zip" exists in the folder "FirmUpdateTool_XXX\httpd\data".

- Please confirm that other network applications (ex. Skype, MSN, etc) aren't working.

- If not improved, please use other PCs and try again.

4) Enter FACTORY MODE by R/C [べんり][青][1][1][1][9]

Picture 11 Remote Controller Picture 12 FACTORY MODE Menu

5) Choose "OPTION" by R/C [上/下] button.

Then press R/C [決定] button. -> Enter to OPTION menu.

13

Page 14

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

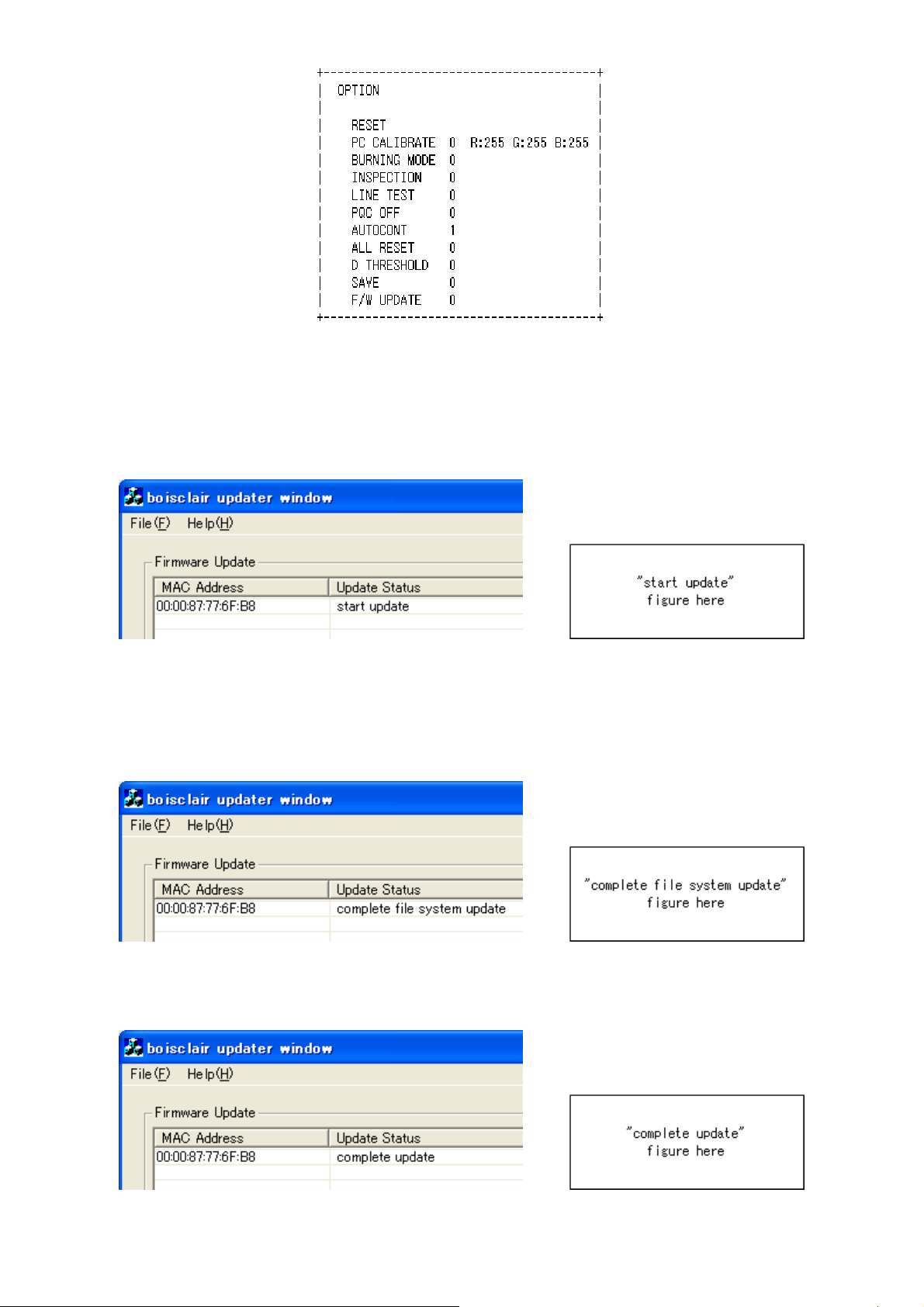

Picture 13 OPTION Menu

6) Choose "F/W UPDATE" by R/C [上/下] button.

Then press R/C [右] button. -> Value changes 0 to 1 (red letter).

Then press R/C [決定]. -> F/W UPDATE started.

7) "Start update" message displayed on boisclair updater window.

Picture 14 "start update"

In case that "start update" comment not displayed.

- Please confirm that the Hub controller is connected to Main Board with Ethernet cable correctly and firmly.

- Please confirm that PC network setting is correct.

8) After a few minutes, "complete file system update" message displayed.

Picture 15 "complete file system update"

9) After "complete update" message displayed, please turn main power switch off TV, and close "boisclair updater

window". -> FW update has finished.

Picture 16 "complete update"

14

Page 15

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

In case that after 10 minutes "complete file system update" or "complete update" message not displayed.

- Please confirm that Hub is turned on, and Link indicator of Hub blinks. If not, please close "boisclair updater

window" and repeat from Item 3.

10) Disconnect the Ethernet cable from TV, then turn Main power switch off.

In case that "failed file system update" message displayed.

- There is some possibility that updatefile.zip is broken. Close "boisclair updater window", and repeat from Item 5.

4. Confirm F/W Version

1) Just after F/W updated, after turn Main power switch on, "はじめて設定" is displayed. Follow the steps to exit "は

じめて設定" as shown below.

(1) "STEP 1 はじめて設定を行います" is indicated. Confirm "次へ" is high light, then press [決定] button.

(2) "STEP 2 お住まいの地方/都道府県域の選択" is indicated. Press R/C [右] button, confirm [次へ] is high light,

then press [決定] button.

(3) "STEP 3 チャンネル設定方法の選択(地上アナログ放送)" is indicated. Press R/C [上/下] button, confirm "自

動設定" is high light, then press R/C [決定] button.

(4) "STEP 5 リモコンボタン割り当て(地上アナログ放送)" is indicated. Press R/C [右] Confirm "次へ" is high light,

then press R/C [決定] button.

(5) "STEP 6 地上デジタル放送の設定" is indicated. Press R/C [上/下] button, confirm "いいえ" is high light, then

press R/C [決定] button.

(6) "地上デジタル放送を視聴する場合は、各種設定から地上デジタル 放送の設定を行ってください" is indicated.

Confirm "次へ" is high light, then press R/C [決定] button.

(7) "STEP 10 BS/CSデジタル放送のコンバーター電源を設定します" is indicated. Press R/C [右] Confirm "次へ"

is high light, then press R/C [決定] button.

(8) "STEP 11 郵便番号の設定" is indicated. Press R/C [下] Confirm"次へ" is high light, then press R/C [決定] button.

(9) "STEP 12 電話回線テスト" is indicated. Press R/C [上/下] button, confirm "いいえ" is high light, then press R/C

[決定] button.

(10) "STEP 13 はじめて設定完了" is indicated. Confirm "設定完了" is high light, then press R/C [決定] button.

(11) TV starts in Terrestrial Analog TV mode.

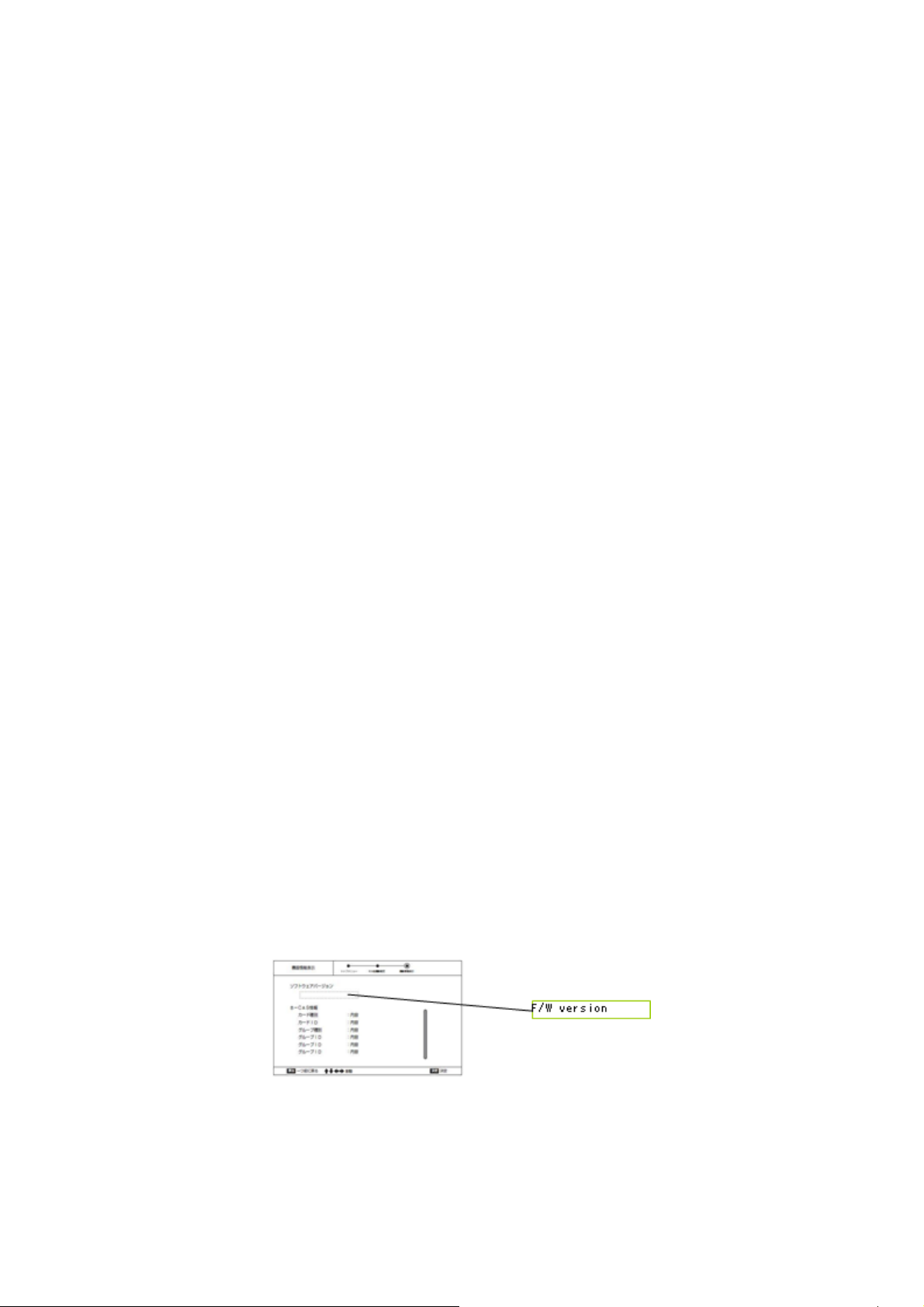

2) Confirm F/W version by following as shown below.

(1) Press R/C "メニュー" button, then "トップメニュー" is displayed. Forward [その他機器設定] - [機器情報表示].

Then confirm the F/W version indicated near [ソフトウェアバージョン] indication.

(2) Press R/C "メニューボタン", then exit F/W version confirmation.

15

Page 16

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

5. Execute All Reset.

1) Enter FACTORY MODE by R/C [べんり][青][1][1][1][9]

2) Choose "OPTION" by R/C [上/下] button. Then press R/C [決定] button. -> Enter to OPTION menu.

3) Choose "ALL RESET" by R/C [上/下] button. Then press R/C [右] button. -> Value changes 0 to 1 (red letter).

Then press R/C [決定]. -> ALL RESET executed, then TV re-starts and "はじめて設定" is displayed.

4) Turn R/C power off, then turn Main power switch off.

* How to install firmware update tool.

1. Put the "FirmUpdateTool_xxx.zip" into the optional folder. (The name and root pass of this folder don't include

Chinese characters or Japanese characters, named with only alphabet.)

2. Decompress "FirmUpdateTool_xxx.zip" into the optional folder. "FirmUpdateTool_xxx" folder is created.

3. Confirm the folders and file are exist in the "FirmUpdateTool_xxx" folder

Folders: dhcpd, httpd, log

File: FirmUpdateController.exe

16

Page 17

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

7. Troubleshooting

1). No Picture, No Sound

First, confirm the status of Stand-by / On lamp (LED), then survey by following the flowchart as shown below.

17

Page 18

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

18

Page 19

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

2). No Picture, Picture failed (Color failed, Dark picture, Beat noise, etc.)

First, confirm the connection of all connectors between PCB's, then survey by following the flowchart as shown

below.

19

Page 20

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

3). No Sound, Sound failed (Loading interrupt, Noise, etc.)

First, confirm the connection of all connectors between PCB's and speakers, then survey by following the flowchart

as shown below.

20

Page 21

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

21

Page 22

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

4). Network terminal (LAN) communication failure

22

Page 23

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

23

Page 24

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

5). Telephone line, when Execution the "Simplified connection test", "Cannot

connect" is indicated.

24

Page 25

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

25

Page 26

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

8. Self Diagnosis Function

26

Page 27

9. Block Diagram

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

27

Page 28

10. Connection Diagram

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

28

Page 29

11. Wiring Diagram

L26-H03B/L26-H03W

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

29

Page 30

L32-H03B/L32-H03W

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

30

Page 31

12. PCB Layout

IO Board

715G3356 I Top

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

BD201 C3

C201 C3

C202 B2

C203 A3

C204 C5

C205 C5

C206 B2

C207 A2

C208 A2

C209 A1

C210 B2

C211 C2

C212 C2

C213 C2

C214 C2

C215 C2

C216 B3

C217 C3

C218 B3

C219 C2

C220 B3

C221 B3

C222 C3

C223 C2

C224 C3

C225 C3

C226 C3

C227 C3

C228 C3

C229 C2

CN201 D2

CN202 A3

CN203 D5

CN204 D5

CN205 A2

CN206 D3

CN207 B1

CN208 A4

CN209 D4

CN210 D3

CN211 A3

D201 D5

D202 D5

D203 C4

D204 C4

D205 C4

D206 C4

FB201 C5

L201 C4

L202 D5

L203 D3

L204 D5

L205 C3

L206 C4

L207 C4

L208 C4

L209 C4

L210 C4

Q201 B3

Q202 B3

Q203 B3

Q204 B4

Q205 C3

R201 B3

R202 B2

R203 C4

R204 C2

R205 C4

R206 A2

R207 A2

R208 A2

R209 A2

R210 A2

R211 C4

R212 C4

R213 A2

R214 A2

R215 A2

R216 B2

R217 A2

R218 A2

R219 C4

R220 C4

R221 C4

R222 C4

R223 B3

R224 B3

R225 B3

R226 B3

R227 B3

R228 B3

R229 B3

R230 B3

R231 C3

R232 C3

R233 B3

R234 B3

R235 B2

R236 B3

R237 C3

R238 C3

R239 C3

R240 C3

R241 B3

R242 C3

R243 B3

R246 A2

U201 C2

U202 B2

U203 B3

U204 C3

X201 C2

ZD201 B3

ZD202 D4

ZD203 C3

ZD204 C4

ZD205 C4

31

Page 32

715G3356 I Bottom

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

32

Page 33

IR Board

715G3357 1 Top

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

CN001 A2

CN002 A1

GND1 A2

LED001 B2

U002 B2

715G3357 1 Bottom

C001 A2

C002 A2

C003 B1

D001 A1

FB001 B1

R001 B2

R002 B2

R003 A2

R005 A1

R006 B1

R007 A2

R008 B2

R009 A1

R011 A2

R012 B2

R013 B2

U001 A1

33

Page 34

Adapter Board

715G3031 1 3 Top

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

BD901 C1

C901 E1

C902 E1

C903 D1

C904 D1

C905 C1

C906 A1

C907 D2

C909 B1

C916 E2

C917 F2

C921 F2

C923 D2

C926 E3

C928 E4

C9308 A3

C9309 A4

C939 A1

C9401 C3

C9409 D4

C941 C2

C9412 D3

C943 C4

C944 B4

C946 C3

C947 C4

C950 C3

C951 B2

C952 D3

C953 D2

C963 A4

C9901 F1

C9902 E1

C9903 F3

CN901 F1

CN921 B4

CN923 C4

CN924 E4

D902 C2

D903 C2

D908 C2

D914 A3

D918 A4

D920 A3

D931 E2

D932 F2

D933 F2

D934 F2

D935 E3

D937 D3

D938 D4

D939 D4

D9400 D4

D951 B2

D952 A2

D9522 B1

D955 B3

D956 B3

D957 C3

D960 E3

D961 D4

D962 D4

F902 F1

F913 C4

F914 C4

FB901 E2

G901 F1

G902 A1

IC911 A3

IC932 E3

IC933 F4

IC934 F3

IC952 A3

IC953 A3

J901 D1

J902 D2

J903 E2

J904 B1

J905 B1

J906 A1

J907 A1

J908 A1

J909 F2

J910 E2

J911 E2

J912 F3

J913 A3

J914 C3

J915 F3

J916 F3

J917 F3

J918 E4

J919 E4

J920 D4

J921 D4

J922 C4

J923 B4

J924 A4

J925 A4

J926 A4

J927 A4

J928 A4

J929 E4

J930 E2

J931 B2

J932 B2

J933 C4

J934 B4

J935 C4

J937 D3

J938 B4

L901 E1

L902 D1

L903 C1

L906 C2

L931 C4

L932 E4

L9400 D4

L971 C4

NR901 E1

NR902 F2

Q901 C2

Q931 E2

Q932 F3

Q951 B2

Q952 A2

Q981 F4

R915 C2

R9241 B4

R926 E2

R937 D3

R9382 A4

R9407 D3

R965 A2

R983 B4

R9922 D2

R9924 C2

RV902 F1

T931 E3

T951 B3

ZD904 A3

ZD910 B1

ZD9111 F2

ZD931 C4

ZD932 C4

ZD933 F3

ZD934 F4

ZD9344 D4

ZD9345 D4

ZD9402 D3

ZD950 A1

34

Page 35

715G3031 1 3 Bottom

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

C910 B1

C911 B1

C9111 E2

C912 B1

C913 B2

C914 B2

C915 F2

C918 E2

C919 E2

C920 F2

C922 F2

C924 E4

C925 E4

C929 E4

C930 F4

C931 F3

C932 A1

C933 A1

C934 A2

C935 A1

C936 A2

C937 A2

C940 A1

C9400 D3

C9402 D3

C9403 D3

C9404 D3

C9405 D3

C9406 D4

C9407 D3

C9408 C4

C9410 D3

C9411 D3

C9413 D4

C942 A1

C945 B4

C948 A3

C949 A3

C960 A4

C976 C4

C979 F2

C980 F4

C981 F4

C982 E4

C9905 B1

C998 A3

D9401 D4

IC901 B1

IC910 A4

IC931 E2

IC9400 D3

IC951 A2

JP901 A3

JP902 F2

JP903 A1

JP904 A2

Q908 A3

Q9111 E2

Q933 E3

Q934 F3

Q9400 D3

Q980 E4

R901 D1

R902 D1

R903 D1

R905 B2

R906 B2

R907 B2

R908 B2

R909 B1

R910 B2

R911 B2

R9111 E2

R9112 E2

R9113 E2

R9114 E2

R9115 E2

R9116 E2

R9117 E2

R9118 E2

R9119 F2

R912 B2

R913 B2

R916 C2

R917 C2

R918 C2

R919 C2

R920 E2

R921 E2

R922 F2

R923 E2

R924 F2

R925 E3

R927 E2

R928 E2

R929 E2

R931 F3

R932 E2

R933 E2

R934 F2

R935 F2

R936 F2

R9363 A3

R9366 A3

R9377 A3

R938 E3

R9380 A4

R9381 A4

R939 E3

R940 E3

R9400 C4

R9401 D3

R9402 D3

R9403 D4

R9404 D3

R9405 C3

R9406 D3

R9408 D4

R9409 D4

R941 E3

R9410 C3

R9411 C4

R942 F3

R943 E3

R944 F4

R945 E4

R946 F4

R947 D4

R948 F4

R949 F3

R950 F4

R953 B2

R954 B2

R955 B2

R956 B2

R957 A2

R958 A1

R959 A1

R960 B2

R961 A2

R962 A2

R963 A2

R964 A2

R966 A1

R967 A1

R968 E4

R970 A3

R971 A3

R972 A3

R973 A3

R974 B4

R975 B4

R976 C4

R977 F3

R978 A4

R979 A4

R980 F4

R981 F4

R982 F4

R984 A4

R985 B4

R986 B4

R987 B4

R9901 E3

R991 A2

R992 A2

R993 E2

R994 A3

R995 A3

R996 A3

R997 A3

R998 A3

35

Page 36

Power Switch Board

715G3354 1 Top

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

715G3354 1 Bottom

36

Page 37

Key Board

715G3363 1 Top

715G3363 1 Bottom

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

CN100 A2

CN101 A1

GND1 A1

SW100 A3

SW101 A4

SW102 A4

SW103 A4

SW104 A3

SW105 A3

SW106 A2

C100 A2

D100 A2

D101 A2

D102 A2

D103 A2

R100 A2

R101 A2

R102 A2

R103 A4

R104 A4

R105 A4

R106 A3

R107 A3

R108 A3

R109 A2

37

Page 38

13. Exploded View

L26-H03B/ L26-H03W

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

38

Page 39

L32-H03B/ L32-H03W

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

39

Page 40

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

14. Service Parts List

L26-H03B E26RA4NJ2WHTN

Location Part No. Description Quantity Remark

017G MB512HIT MAIN BOARD FOR HITACHI E26R 1.000

049G 51 1A ERADICATOR 2.200

050G 500 1 CABLE TIE 3.000

052G 1150 C INSULATING TAPE 35.000

052G 1186 SMALL TAPE 10.000

052G 2191 A PAPER TAPE 12.000

089G401A18NHTA POWER CORD 1890MM 1.000

095G8014 6D 62 HARNESS 6P-6P 500MM 1.000

095G801830X182 LVDS CABLE 30P-30P 260MM 1.000

095G8021 4D 5 HARNESS 3P-4P 120MM 1.000

095T8013 4D 58 HARNESS 4P 450MM 1.000

095T801316D 2 HARNESS 16P-12P+8P 260MM 1.000

095T8014 8D 80 HARNESS 8P-5P+3P 500MM 1.000

095T801412D 88 HARNESS 12P-8P+4P 150MM 1.000

095T801414D133 HARNESS 14P-14P 300MM 1.000

095T801414D136 HARNESS 14P-14P 320MM 1.000

095T801416D 83 HARNESS 16P-16P 300MM 1.000

095T8022 8D 1 HARNESS 8P-8P 150MM 1.000

098TRACG4NJHTK HITACHI-ASSIGNED REMOTE CONTROL 1.000

0D1G 930 4120 SCREW 1.000

0D1G 930 4120 SCREW 2.000

0D1G 930 4120 SCREW 2.000

0D1G 930 4120 SCREW 2.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 4.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0M1G 130 6120 SCREW M3X6 3.000

0M1G 940 6120 SCREW (M4X6) 1.000

0M1G 940 6120 SCREW (M4X6) 1.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

40

Page 41

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 10120 SCREW 1.000

0M1G1140 6120 SCREW 1.000

0M1G1140 6120 SCREW 1.000

0Q1G 930 8120 SCREW 1.000

0Q1G 940 12120 SCREW 2.000

0Q1G 940 12120 SCREW 2.000

0Q1G 940 12120 SCREW 12.000

705TQ933E01 PLASTIC ASS`Y 1.000

0Q1G 930 8120 SCREW 2.000

A33T0567 VT 1A0100 BUTTON FUNCTION 1.000

A33T0568 VTA1A0118 COVER_FUNC 1.000

KEPF9QA1 KEY BOARD 1.000

GND1 095G 900631 WIRE HARNESS 1.000

715G3363 1 KEY BOARD PCB 1.000

Q52G6025 15255 INSULATING SHEET 1.000

705TQ934E02 REAR COVER ASS'Y 1.000

A34T1112 VT 1A0130 REAR COVER TV26W-9HITA 1.000

Q12G7039 1 VESA RUBBER 1.000

Q15T0257101 BKT-VESA-BTM 3.000

705TQ934E04 BEZEL 09 HITACHI ASS'Y 1.000

A34T1111ADTA1L0130 BEZEL TV26W-9HITA-1 1.000

Q36G 812 1 SPEAKER MESH 1.000

Q36T 600 18134 NONWOVEN FABRIC 1.000

Q36T 600 31 2 NONWOVEN FABRIC 1.000

Q36T 600 31 3 NONWOVEN FABRIC 2.000

Q36T 600 37 28 GP NONWOVEN FABRIC 2.000

705TQ934E05 STAND ASS'Y 1.000

0Q1G 130 6120 SCREW (T3X6) 6.000

A34T0560ADT 1L0100 STAND TV26W-9HITA 1.000

A34T0561ADT 1L0100 BASE TV26W-9HITA 1.000

AM1G1740 10125 SCREW 3.000

Q12G6300 25 1 RUBBER FOOT 6.000 2nd source

Q12T6083 1 RUBBER FOOT 2.000 2nd source

Q15T0306201 09 26"HITACHI TV 1.000

Q37T0132011 HINGE 1.000

750TVU260W2Q12N000 PANEL T260XW02 VQ00 SZ AUO 1.000

A15T0568101 BKT-HOLD_TOP 1.000

A15T0569101 BKT-HOLD_BOTTOM 1.000

A15T0570201 BKT_IO 1.000

A15T0571101 BKT-HOLDER_RIGHT 1.000

A15T0572101 BKT-SUPPORT-LEFT 1.000

A15T0573101 BKT-SUPPORT-RIGHT 1.000

A15T0574101 BKT-WALL-MOUNTING 1.000

A15T0575101 BKT-AC-INLET 1.000

A15T0641101 BKT-HOLD_LEFT 1.000

A15T0642101 BKT_STAND_SUPPORT 1.000

A33T0565 1 1C0100 LENS_FUNC 1.000

A33T0569 VT 1A0200 BUTTOM_POWER 1.000

A33T0590 ED 1C0130 LENS_IR 1.000

A85T0142101 SHIELD_COVER 1.000

41

Page 42

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

ADTV82412AAD ADAPTER BOARD 1.000

040G 45762412B CBPC LABEL 1.000

705TQ857019 Q951/Q952 ASS'Y 1.000

0M1G1730 8120 SCREW 2.000

705TQ857020 Q931 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ861008 NR901 ASS'Y 1.000

Q09T 203 8 PIN FOR NR901 2.000

705TQ884008 F902 ASS'Y 1.000

705TQ893030 BD901 ASS'Y 1.000

0M1G1730 10120 SCREW 42A9930016 1.000

705TQ893031 Q901/D902 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

0M1G1730 10120 SCREW 42A9930016 1.000

Q12G 372 8 SILICON 1.000

705TQ893032 D935 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ893033 D957 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ893034 D955/D956 ASS'Y 1.000

0M1G1730 8120 SCREW 2.000

Q90G0002 1 HEAT SINK 1.000

715G3031 1 3 ADAPTER BOARD PCB 1.000

Q51G 6 4509 GLUE_RTV 2.000

071FPC28201 14 MAGNETIC CORE DMR40 EC29G A634 1.000

071FPC35201 01 MAGNETIC CORE JR2KBF1 EC35 A556 1.000

IOPF8QA1 IOPF BOARD 1.000

040G 45762412B CBPC LABEL 1.000

CN201 088G 353 9FXSH D-SUB CONN 9PIN F 1.000

715G3356 I IOPF BOARD PCB 1.000

IRPF9QA1 IR BOARD 1.000

GND1 095G 900631 WIRE HARNESS 1.000

096G 29 6 GP SHRINK TUBE UL/CSA FOR LED001 8.000

Q11G5053 1 STRING FOR LED001 1.000

715G3357 1 IR BOARD PCB 1.000

PTPF8AA6 POWER SWITCH BOARD 1.000

715G3354 1 POWER SWITCH BOARD PCB 1.000

Q02T7020 1 STEEL_BOSS 2.000

Q11G5054 1 CABLE CLAMP 1.000

Q11G5054 1 CABLE CLAMP 1.000

Q11G6039 2 WIRE HOLDER 1.000

Q11T6039 2 WIRE HOLDER 1.000

Q36T 600 37 2 GP HEMIRON 2.000

Q36T 600 37 28 GP NONWOVEN FABRIC 5.000

Q44GE031101 EPS CUSHION 1.000

Q44GE031201 EPS CUSHION 1.000

Q44GE031301 EPS CUSHION 1.000

Q44GE031401 EPS 1.000

Q44GE031624 1A CARTON 1.000

Q45G 77 5 PE PACKING 500.000

Q45G 99626 37 PE BAG 1.000

42

Page 43

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

Q45T 99609 76 MH EPE COVER FOR MONITOR 1.000

Q45T 99609 88 MH EPE COVER FOR BASE 1.000

Q52G 1211825 AL TAPE 1.000

Q52T6025 15208 GP INSULATING SHEET 1.000

017G DW 24HIT HITACHI-CONSIGN B-CAS 1.000

092GB1TX1A23GA HITACHI-ASSIGNED BATTERY 1.5V R6P 2.000

0Q1T 940 30 47 CR3 SCREW 3.000

Q41G7830779 5A 1ST STEP GUIDE 1.000

0Q1G 930 8120 SCREW 3.000

Q34T0583 VT 1A0100 COVER_BCAS 1.000

Q36T 600 37 26 GP NONWOVEN FABRIC 1.000

Q40G0002779 6B SIDE LABEL 1.000

Q52G 1211823 AL TAPE 1.000

078T 522 1 Y SPEAKER 6 OHM 12W 160X40MM 2.000

0Q1G 940 10120 SCREW 1.000

Q11GP001 1 CABLE CLAMP 1.000

Q12G7040 2 HITACHI RUBBER FOR 26" 4.000

Q45G 76 28NV2 R PE BAG FOR CLAMP 1.000

Q45T 88525T24 PE BAG 1.000

43

Page 44

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

L32-H03B E32RA4NJ2WHTN

Location Part No. Description Quantity Remark

001T6021 1 SCREW 4.000

017G DW 24HIT HITACHI-CONSIGN B-CAS 1.000

017G MB513HIT MAIN BOARD FOR HITACHI E32R 1.000

049G 51 1A ERADICATOR 2.220

050G 500 1 CABLE TIE 1.000

052G 1186 SMALL TAPE 10.000

052G 2191 A PAPER TAPE 12.000

078T 522 1 Y SPEAKER 6 OHM 12W 160X40MM 2.000

089G401A18N HT POWER CORD 1870MM 1.000

092GB1TX1A23GA HITACHI-ASSIGNED BATTERY 1.5V R6P 2.000

095G801830X182 LVDS CABLE 30P-30P 260MM 1.000

095G8021 4D 7 HARNESS 3P-4P 180MM 1.000

095T8013 4D 59 HARNESS 4P 950MM 1.000

095T801316D 2 HARNESS 16P-12P+8P 260MM 1.000

095T8014 6D 61 HARNESS 6P-6P 900MM 1.000

095T8014 8D 81 HARNESS 8P-5P+3P 900MM 1.000

095T801412D 88 HARNESS 12P-8P+4P 150MM 1.000

095T801414D133 HARNESS 14P-14P 300MM 1.000

095T801414D137 HARNESS 14P-14P 450MM 1.000

095T801416D 83 HARNESS 16P-16P 300MM 1.000

095T8022 8D 1 HARNESS 8P-8P 150MM 1.000

098TRACG4NJHTK HITACHI-ASSIGNED REMOTE CONTROL 1.000

0D1G 930 4120 SCREW 2.000

0D1G 930 4120 SCREW 2.000

0D1G 930 4120 SCREW 4.000

0D1G1730 8120 SCREW 7.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 1.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 2.000

0D1G1730 8120 SCREW 3.000

0D1G1730 8120 SCREW 6.000

0M1G 130 6120 SCREW M3X6 3.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 1.000

0M1G 940 6120 SCREW (M4X6) 1.000

0M1G 940 6120 SCREW (M4X6) 1.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 2.000

0M1G 940 6120 SCREW (M4X6) 4.000

0M1G 940 6120 SCREW (M4X6) 5.000

0M1G 940 6120 SCREW (M4X6) 8.000

0M1G 940 10120 SCREW 1.000

0M1G1140 6120 SCREW 1.000

44

Page 45

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

0Q1G 930 8120 SCREW 3.000

0Q1G 930 8120 SCREW 1.000

0Q1G 930 8120 SCREW 1.000

0Q1G 930 8120 SCREW 1.000

0Q1G 940 12120 SCREW 2.000

0Q1G 940 12120 SCREW 2.000

0Q1G 940 12120 SCREW 2.000

0Q1G 940 12120 SCREW 13.000

0Q1G 940 14 47 CR3 SCREW 4.000

705TQ933J04 PLASTIC ASS'Y 32 1.000

0Q1G 930 8120 SCREW 2.000

A33T0567 VT 1A0100 BUTTON FUNCTION 1.000

A33T0568 VTA1A0118 COVER_FUNC 1.000

Q52G6025 15255 INSULATING SHEET 1.000

705TQ934J13 BEZEL ASS'Y 32 1.000

A34T1113ADTA1L0130 BEZEL TV32W-9HITA-1 1.000

Q35T0056BBV 1L0100 DECO 1.000

Q36G 813 1 SPEAKER MESH 1.000

Q36T 600 36 9 GP NONWOVEN FABRIC 1.000

Q36T 600 37 23 GP NONWOVEN FABRIC 9.000

Q36T 600 37 32 GP NONWOVEN FABRIC 1.000

705TQ934J14 REAR COVER ASSY 32 1.000

A34T1114 VT 1A0130 REAR COVER 1.000

Q12G7039 1 VESA RUBBER 1.000

Q15T0257101 BKT-VESA-BTM 3.000

Q36T 600 31 5 NONWOVEN FABRIC 1.000

Q36T 600 37 28 GP NONWOVEN FABRIC 1.000

705TQ934J15 STAND ASS'Y 32 1.000

0Q1G 130 6120 SCREW (T3X6) 4.000

A15T0384301 BKT-BASE-PLATE-A1-BIG 1.000

A34T0521ADT 1L0130 BASE 1.000

Q12G6300 25 RUBBER FOOT 6.000 2nd source

Q12G6300 25 1 RUBBER FOOT 2.000 2nd source

Q37T0131011 HINGE 1.000

750TVU315W2S12N000 PANEL T315XW02 VS00 SZ AUO 1.000

A15T0570101 BKT_IO 1.000

A15T0576102 MAINFRAME 1.000

A15T0577101 BRACKET_STAND 1.000

A15T0578101 BRACKET_STAND_SUPPORT 1.000

A15T0579101 BRACKET_PLATE 2.000

A15T0581101 BRACKET_WALL_MOUNTING 1.000

A15T0582101 BRACKET_SUPPORT_LEFT 1.000

A15T0583101 BRACKET_SUPPORT_RIGHT 1.000

A15T0692101 BKT_HOLD_LEFT 1.000

A15T0693101 BKT_HOLD_RIGHT 1.000

A33T0565 1 1C0100 LENS_FUNC 1.000

A33T0569 VT 1A0200 BUTTOM_POWER 1.000

A33T0573 VT 1A0100 COVER_STAND_TOP 1.000

A33T0590 ED 1C0130 LENS_IR 1.000

A85T0142201 SHIELD_COVER 1.000

ADTV82412AAD ADAPTER BOARD 1.000

45

Page 46

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

040G 45762412B CBPC LABEL 1.000

705TQ857019 Q951/Q952 ASS'Y 1.000

0M1G1730 8120 SCREW 2.000

705TQ857020 Q931 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ861008 NR901 ASS'Y 1.000

Q09T 203 8 PIN FOR NR901 2.000

705TQ884008 F902 ASS'Y 1.000

705TQ893030 BD901 ASS'Y 1.000

0M1G1730 10120 SCREW 42A9930016 1.000

705TQ893031 Q901/D902 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

0M1G1730 10120 SCREW 42A9930016 1.000

Q12G 372 8 SILICON 1.000

705TQ893032 D935 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ893033 D957 ASS'Y 1.000

0M1G1730 8120 SCREW 1.000

705TQ893034 D955/D956 ASS'Y 1.000

0M1G1730 8120 SCREW 2.000

Q90G0002 1 HEAT SINK 1.000

715G3031 1 3 ADAPTER BOARD PCB 1.000

Q51G 6 4509 GLUE_RTV 2.000

071FPC28201 14 MAGNETIC CORE DMR40 EC29G A634 1.000

071FPC35201 01 MAGNETIC CORE JR2KBF1 EC35 A556 1.000

AM1G1740 10125 SCREW 3.000

IOPF8QA1 IOPF BOARD 1.000

040G 45762412B CBPC LABEL 1.000

CN201 088G 353 9FXSH D-SUB CONN 9PIN F 1.000

715G3356 I IOPF BOARD PCB 1.000

IRPF9QB1 IR BOARD 1.000

096G 29 6 GP SHRINK TUBE UL/CSA FOR LED001 8.000

Q11G5053 1 STRING FOR LED001 1.000

715G3357 1 IR BOARD PCB 1.000

KEPF9QB1 KEY BOARD 1.000

GND1 095G 900576 WIRE HARNESS 1.000

715G3363 1 KEY BOARD PCB 1.000

PTPF8AA6 POWER SWITCH BOARD 1.000

715G3354 1 POWER SWITCH BOARD PCB 1.000

Q01G6070 1 SCREW 4.000

Q02T7020 1 STEEL_BOSS 2.000

Q11G5054 1 CABLE CLAMP 1.000

Q11G6039 2 WIRE HOLDER 1.000

Q11GP001 1 CABLE CLAMP 1.000

Q34T0583 VT 1A0100 COVER_BCAS 1.000

Q36T 600 18113 CLOTH_GRIDDING 1.000

Q36T 600 31 5 NONWOVEN FABRIC 2.000

Q36T 600 37 13 GP NONWOVEN FABRIC 2.000

Q36T 600 37 23 GP NONWOVEN FABRIC 2.000

Q36T 600 37 26 GP NONWOVEN FABRIC 1.000

Q36T 600 37 28 GP NONWOVEN FABRIC 2.000

46

Page 47

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

Q40G0002779 6B SIDE LABEL 1.000

Q44GJ036101 EPS CUSHION 1.000

Q44GJ036201 EPS CUSHION 1.000

Q44GJ036301 EPS CUSHION 1.000

Q44GJ036401 EPS CUSHION 1.000

Q44GJ036624 1A 32" TV CARTON 1.000

Q44T3231 21 35 EVA WASHER 1.000

Q45G 77 5 PE PACKING 550.000

Q45G 99626 37 PE BAG 1.000

Q45T 99609 87 MH EPE COVER FOR MONITOR 1.000

Q45T 99609 88 MH EPE COVER FOR BASE 1.000

Q52G 1211823 AL TAPE 1.000

Q52G 1211825 AL TAPE 1.000

Q52G6025 15256 INSULATING SHEET 1.000

Q52T 1150522 TAPE_INSULATING 35.000

Q41G7830779 5A 1ST STEP GUIDE 1.000

Q45G 76 28NV2 R PE BAG FOR CLAMP 1.000

Q12G7040 3 HITACHI RUBBER FOR 26" 2.000

Q12G7040 4 HITACHI RUBBER FOR 26" 2.000

Q44T3121510559 GP EVA WASHER 1.000

Q36T 600 31 5 NONWOVEN FABRIC 4.000

Q36T 600 37 19 GP NONWOVEN FABRIC 1.000

0Q1G 930 8120 SCREW 1.000

Q45T 88525T24 PE BAG 1.000

0M1G1140 6120 SCREW 1.000

0Q1G 940 10120 SCREW 1.000

Q36T 600 31 7 NONWOVEN FABRIC 1.000

47

Page 48

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

15. Different Parts List

Diversity of L26-H03W compared with L26-H03B

Diversity of E26RA4NJ2WHCN compared with E26RA4NJ2WHTN

Location Part No. Description quantity

705TQ934E01 BEZEL 09 HITACHI ASS'Y 1.000

A34T1111AFDA1L0130 BEZEL TV26W-HITACHI 1.000

Q36T 600 31 1 NONWOVEN FABRIC 1.000

705TQ934E03 STAND ASS`Y HITACHI 1.000

A34T0560AFD 1L0100 STAND 1.000

A34T0561AFD 1L0100 BASE 1.000

AM1T1740 10120 SCREW 3.000

Diversity of L32-H03W compared with L32-H03B

Diversity of E32RA4NJ2WHCN compared with E32RA4NJ2WHTN

Location Part No. Description quantity

705TQ933J01 PLASTIC ASS'Y 32 1.000

705TQ934J07 BEZEL ASS'Y 32 1.000

A34T1113AFDA1L0130 BEZEL TV32W-9HITA-1 1.000

705TQ934J08 REAR COVER ASSY 32 1.000

705TQ934J09 STAND ASS'Y 32 1.000

A34T0521AFD 1L0130 BASE 1.000

Q37T0131012 HINGE 1.000

48

Page 49

Accessories

L26-H03B/ L26-H03W/ L32-H03B/ L32-H03W

49

Loading...

Loading...