Page 1

INSTRUCTION MANUAL

FOR

MODEL L-2100 PUMP

Copyright

Hitachi High-Technologies Corporation 2002. All rights reserved. Printed in Japan. Part No. 890-9101

Page 2

PREFACE

Thank you very much for purchasing Hitachi Model L-2100/2130

pump, which has been specifically designed for automatic

analysis in a liquid chromatograph system.

The Model L-2100/2130 pump is intended for use by persons

having a basic knowledge of chemical analysis.

Remember that improper use of analytical instruments,

chemicals or samples would result not only in wrong analytical

data but also in consequences adverse to safety.

Carefully read this instruction manual before attempting

operation. For proper use of the pump, please acquaint yourself

with it.

ABOUT THIS MANUAL

The operating procedures and maintenance/checkup instructions

for the L-2100/2130 pump are described in this manual.

First of all, read "IMPORTANT" and "SAFETY SUMMARY" at the

beginning of this manual for ensuring safety in operation of the

pump.

If installation of the pump is not yet completed, refer to Section 2.

Before attempting operation, read through Sections 3 and 4 to

become acquainted with the structure of the instrument and its

basic operations.

- 1 -

Page 3

- 2 -

Page 4

IMPORTANT

Precautions on Electromagnetic Wave Interference

1. Possible Electromagnetic Wave Interference Caused by This Instrument

Where this instrument is used in a residential area or an

adjacent area thereto, it may cause interference to radio and

television reception.

To prevent this, use the specified system connection cables in

strict accordance with the instruction manual. The instrument is

designed to minimize possible electromagnetic wave

interference caused by it if the specified cables are connected

properly.

However, there is no guarantee that electromagnetic wave

interference will not be caused by the instrument.

If the instrument does cause interference to radio or television

reception, which can be determined by turning the instrument off

and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

Reorient the antenna of the radio/television receiver.

•

Increase separation between the instrument and the radio/TV

•

receiver.

Connect the instrument to an outlet on a circuit different from

•

that to which the radio/TV receiver is connected.

2. Possible Electromagnetic Wave Interference Affecting This Instrument

Where this instrument is used near an intense electromagnetic

source, interference noise may be given to the instrument to

incur an adverse effect on its performance or functionality.

To present this, use the specified system connection cables in

strict accordance with the instruction manual. The instrument is

designed to minimize possible electromagnetic wave

interference affecting it if the specified cables are connected

properly.

However, there is no guarantee that electromagnetic wave

interference will not occur in the instrument. If the instrument

does incur electromagnetic wave interference, which can be

determined by turning on and off possible sources of

electromagnetic interference nearby, the user is encouraged to

try to correct the interference by one or more of the following

measures:

- 3 -

Page 5

Warranty on Product

Reorient the instrument.

•

Increase separation between the instrument and possible

•

sources of electromagnetic interference.

Connect the instrument to an outlet on a circuit different from

•

that to which possible sources of electromagnetic interference

are connected.

Check that any other device connected with the instrument is

•

not affected by electromagnetic interference.

The Model L-2100 pump is warranted to be free from defects in

material or workmanship under normal use within the product

specifications indicated in this manual and under conditions

given below. This warranty is void if the instrument is not used

according to the instruction manual.

(1) Scope of Warranty

Any parts which prove to be defective in design or

workmanship during the warranty period will be repaired,

adjusted or replaced without charge. A substitute part may

be used for repair, or replacement with an equivalent

product may be made instead of repair. Such system

components as a personal computer and printer to be

updated frequently for improvement may not be available in

original versions at the time of replacement. Note that this

warranty does not apply to the instrument if modified by the

user or resold without permission from the manufacturer,

consumable parts, and any failure of lifetime-expired parts.

(2) Warranty Period

One year from the date of initial installation

(3) Availability of Technical Support Service

Technical support service for this instrument is available

within regular working hours on workdays specified by

Hitachi High-Technologies Corporation.

- 4 -

Page 6

(4) Limitations and Exclusions on Warranty

Note that the following cases are excluded from the scope

of this warranty.

(a) Failure due to operation at a place not meeting the

installation requirements specified by Hitachi HighTechnologies Corporation.

(b) Failure due to power supply voltage/frequency other

than specified by Hitachi High-Technologies

Corporation or due to abnormality in power supply.

(c) Corrosion or deterioration of the tubing due to

impurities contained in reagent, gas, air or cooling

water supplied by the user.

(d) Corrosion of the electric circuits or deterioration of the

optical elements due to highly corrosive atmospheric

gas.

(e) Failure due to use of hardware, software or spare parts

other than specified by Hitachi High-Technologies

Corporation.

(f) Failure due to improper handling or maintenance by

the user.

(g) Failure due to maintenance or repair by a service

agent not approved or authorized by Hitachi HighTechnologies Corporation.

(h) After disposal of this instrument, or after its resale

without Hitachi High-Technologies Corporation

approval.

(i) Failure due to relocation or transport after initial

installation.

(j) Failure due to disassembly, modification or relocation

not approved by Hitachi High-Technologies

Corporation.

(k) Consumables, and failure of parts that have reached

the end of specified useful life.

(l) Failure of parts excluded from the warranty in the

instruction manual or other documents.

(m) Failure due to acts of God, including fire, earthquake,

storm, flood, lightning, social disturbance, riot, crime,

insurrection, war (declared or undeclared), radioactive

pollution, contamination with harmful substance, etc.

(n) Failure of the hardware, or damage to the system

software, application software, data or hard disk due to

computer virus infection.

- 5 -

Page 7

(o) Failure of the personal computer connected with the

instrument, or damage to the system software,

application software, data or hard disk due to power

interruption or momentary power voltage drop caused

by lightning.

(p) Failure of the personal computer connected with the

instrument, or damage to the system software,

application software, data or hard disk due to

disconnection of main power to the personal computer

without taking the specified normal shutdown

procedure.

(5) Disclaimer of Warranty

THE MANUFACTURER MAKES NO WARRANTIES,

EITHER EXPRESS OR IMPLIED, EXCEPT AS PROVIDED

HEREIN, INCLUDING WITHOUT LIMITATION THEREOF,

WARRANTIES AS TO MARKETABILITY,

MERCHANTABILITY, FOR A PARTICULAR PURPOSE

OR USE, OR AGAINST INFRINGEMENT OF ANY

PATENT. IN NO EVENT SHALL THE MANUFACTURER

BE LIABLE FOR ANY DIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING FROM ANY

DEFECTIVE PRODUCT OR THE USE OF ANY PRODUCT.

NO ORAL OR WRITTEN INFORMATION OR ADVICE

GIVEN BY THE MANUFACTURER, ITS DEALERS,

DISTRIBUTORS, AGENTS OR EMPLOYEES SHALL

CREATE A WARRANTY OR IN ANY WAY INCREASE

THE SCOPE OF THIS WARRANTY.

(6) Warranty Card

The warranty card will not be reissued. Keep it in a safe

place.

Installation, Relocation and After-sale Technical Service

Installation of the instrument shall be carried out by or under

supervision of qualified service personnel of the manufacturer or

its authorized service agent.

Before installation of the instrument, the customer is requested

to prepare necessary utilities referring to this manual.

When relocation of the instrument becomes necessary after

initial installation (delivery), please notify your local Hitachi HighTechnologies sales representative or service office.

- 6 -

Page 8

Technical Seminars and Training for Customers

For the customers to acquire in-depth understanding of the

analytical instruments, technical seminars and customer training

courses are available at Hitachi High-Technologies Corporation

or your site. For further information, contact your local Hitachi

High-Technologies Corporation sales representative.

(The technical seminars and customer training courses are

available on a chargeable basis.)

Other Precautions

1. Handling of Chemicals and Samples

(1) The user is responsible for following relevant legal

standards and regulations in the handling, storage and

discarding of chemicals and samples used in analytical

operations of the instrument.

(2) Reagents, standard solutions and accuracy-control

samples shall be handled, stored and discarded as

instructed by the respective suppliers.

2. Notice on This Instruction Manual

(1) The information contained in this manual is subject to

change without notice for product improvement.

(2) This manual is copyrighted by Hitachi High-Technologies

Corporation with all rights reserved.

(3) No part of this manual may be reproduced or transmitted in

any form or by any means without the express written

permission of Hitachi High-Technologies Corporation.

- 7 -

Page 9

1

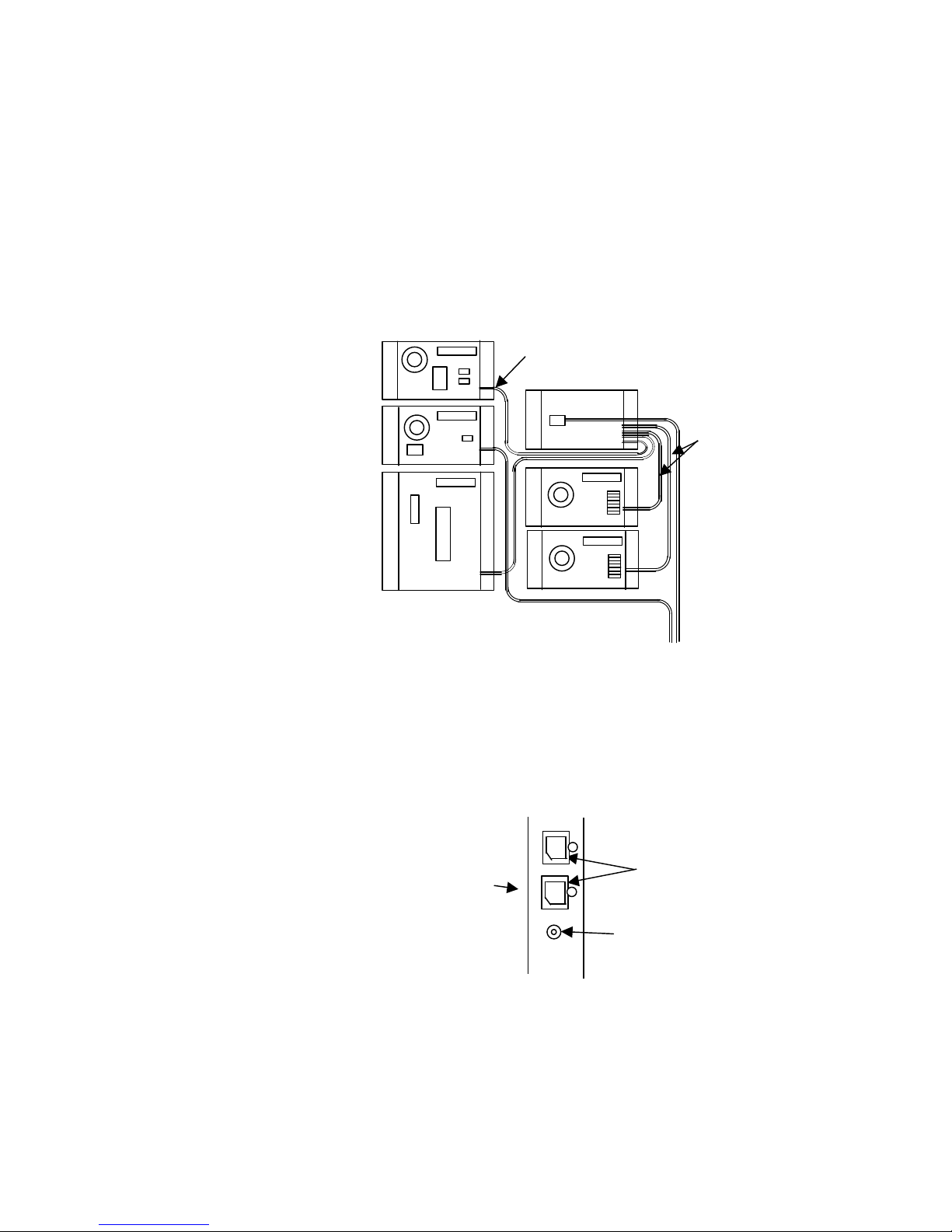

1.1 Isocratic System

1.1

1. OUTLINE

The liquid chromatograph system consists of a pump for feeding

an eluent, a sample introducing section (autosampler, manual

injector) for injecting a sample, a column for chromatographic

separation of the injected sample, a column oven for maintaining

the column at a constant temperature, and a detector section for

detecting a signal of a separated component of the sample.

In addition, a degasser for deaerating an eluent, a gradient

device for varying a mixing ratio of eluents with time, and other

optional devices are incorporated in the system.

The isocratic system has a simple configuration in which singlesolvent analysis is performed.

Washing solution

Degasser

Column

Eluent

System power supply unit

Model L-2400 UV detector

Model L-2300 column oven

Model L-2200 autosampler

Model L-2100/2130 pump

Drain

1 -

Page 10

2

1.1 Isocratic System

(1) An eluent is fed by the pump through the degasser.

(2) A sample is injected from the autosampler.

(3) The injected sample is separated through the column which

is maintained at a constant temperature by the column

oven.

(4) Each component separated from the sample is then

detected as a signal by the detector.

1 -

Page 11

3

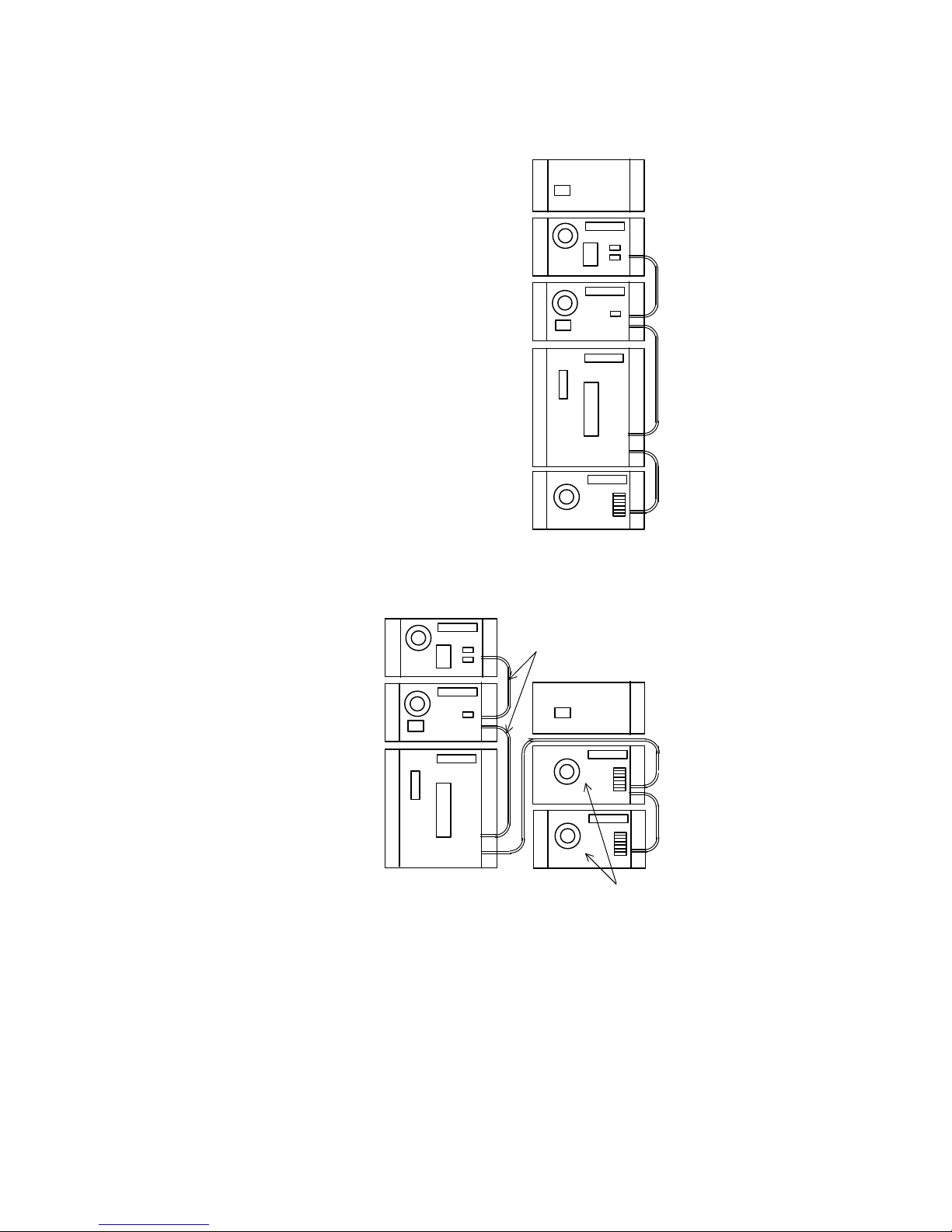

1.2 Low-Pressure Gradient System

pressure

In the low-pressure gradient system, two or more solvents are

mixed in its low-pressure section from which a liquid feed is

performed by a single pump. The composition of an eluent is

made to vary with time in chromatographic separation.

Washing solution

Mixer

Degasser

(1) Each of plural eluents is fed from the degasser to the low-

pressure unit.

(2) In the low-pressure unit, the eluents are mixed at a pre-

specified ratio.

(3) Through the mixer, the mixture eluent is delivered.

(4) A sample is injected by the autosampler.

(5) The injected sample is separated through the column which

is maintained at a constant temperature by the column

oven.

(6) Each component separated from the sample is detected as

a signal by the detector.

Column

1.2

Eluent

System power supply unit

Model L-2400 UV detector

Model L-2300 column oven

Model L-2200 autosampler

Lowgradient unit

Model L-2100/2130 pump

Drain

1 -

Page 12

4

1.3 High-Pressure Gradient System

2130 pump

1.3 High-Pressure Gradient System

In the high-pressure gradient system, two or more solvents are

fed by respective pumps and mixed in the high-pressure section

for liquid delivery.

System power

supply unit

Model L-2100/

2130 pump

Model L-2100/

Degasser

Washing

solution

Mixer

(1) From the degasser, each of plural eluents is applied to the

(2) The plural eluents are fed at a flow rate corresponding to a

(3) The plural eluents thus fed are mixed in the high-pressure

(4) A sample is injected by the autosampler.

(5) The injected sample is separated through the column which

(6) Each component separated from the sample is detected as

Eluent

pump.

pre-specified mixing ratio.

gradient section. Through the mixer, the mixture eluent is

delivered.

is maintained at a constant temperature by the column

oven.

a signal by the detector.

Column

Model L-2400

UV detector

Model L-2300

column oven

Model L-2200

autosampler

Drain

1 -

Page 13

1

2.1 Unpacking

2.1

2. INSTALLATION

CAUTION

Beware of heavy objects!

This instrument is as heavy as 15 kg.

When carrying this instrument, exercise care not to incur injury

by dropping it off accidentally. Be sure to hold the front and

rear parts of the instrument securely when moving it.

Carefully unpack the shipping case, take out module units and

standard accessories, and place them on a sturdy, level desk or

bench.

NOTICE:

Installation of this instrument shall be carried out by

or under supervision of qualified service personnel

of Hitachi High-Technologies Corporation or its

authorized service agent.

Before installation of this instrument, the customer

shall make preparations for satisfying the

installation requirements in accordance with this

manual.

When relocation of this instrument becomes

necessary after initial installation (delivery), please

notify your local Hitachi High-Technologies sales

representative or service office.

2 -

Page 14

2

2.2 Installation Place

2.2 Installation Place

When selecting an installation place for this instrument, be sure

to check the following conditions:

(1) Operating Ambient Temperature

4 to 35 °C

Temperature variations during measurement should be

minimized. Take sufficient care to prevent dew

condensation.

(2) Operating Ambient Humidity

45 to 85% RH

(3) Atmosphere

(a) Well ventilated.

(b) Free from acidic or alkaline gases that could corrode

metals significantly.

(c) Free from vapors of solvents (e.g., benzene, thinner)

that could affect the paint coating on the instrument.

(4) Other Requirements

(a) Not exposed to direct sunlight.

Exposure to direct sunlight could result in deteriorated

performance or discoloration of the instrument.

Avoid installing the instrument near a window of the

laboratory room.

(b) Not exposed to drafts directly.

(c) Free from intense vibrations and shocks.

(d) Apart from a heat source such as a gas burner,

electric heater, or oven.

(e) Apart from a strong magnetism source such as an

electronic welder, high-frequency electronic furnace, or

voltage transformer.

2 -

Page 15

3

(f) Free from an amount of dust and dirt.

Contamination with dust and dirt could deteriorate the

performance of the instrument.

(g) No abrupt fluctuations in power voltage.

Fluctuations in power voltage could cause noise in

analytical data.

(h) Do not connect the instrument to a power line used by

an electric device that is not equipped with a noise

suppressor circuit (e.g., stirrer, vibrator).

2.2

2 -

Page 16

4

2.3 Items to be Prepared by the User

2.3 Items to be Prepared by the User

2.3.1 Power Supply

(1) Power voltage : 100 to 240 V AC

(2) Frequency : 50 or 60 Hz

(3) Power

consumption : 500 VA or more in total system

(4) Grounding : Grounding connection of Electric

Fluctuation.......Within ±10% with respect

to rated voltage

Fluctuation.......Within ±0.5 Hz with respect

to rated frequency

Provide power supply sufficient for

combinational use with other devices.

Installation Technical Standard Class 3 or

higher should be provided.

WARNING

Ground Properly to Prevent Electric Shock Hazard!

Be sure to use the power cable supplied with the

•

instrument. Use of a different power cable could result in

an electric shock hazard.

This instrument is of a "plug-connected type" specified in

•

European Norm EN61010-1, so connect the power cable to

a grounded three-wire outlet.

If a grounded three-wire outlet is not available, the power

•

cable may be connected to a two-wire outlet through an

adapter plug. In this case, be sure to provide proper

grounding connection as required.

2 -

Page 17

5

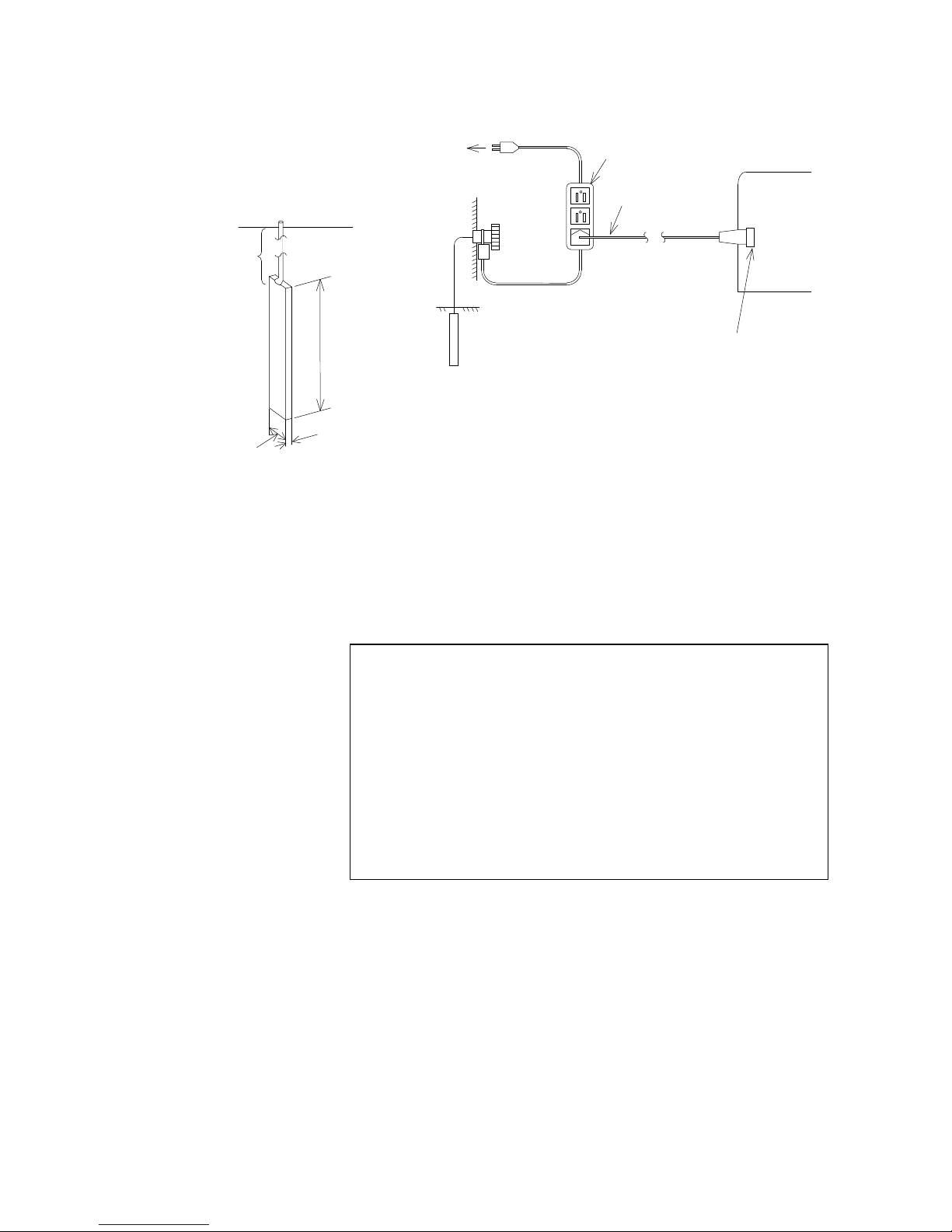

2.3.2

Ground resistance:

Less than 100 ohms

More than

750 mm

under ground

300 mm

Copper plate

2 mm

10 mm

2.3.2 Installation Space

Power outlet

Table tap with

ground cable

Ground

terminal

Power cord

L-2100/2130

Ground

Ground wire

(green)

Connector

For installation of this system, it is required to provide a space of

at least 640 mm (width) × 550 mm (depth). Prepare a sturdy,

level desk or bench capable of supporting a weight load of at

least 150 kg. On the rear of the main unit, allow at least

100 mm of clearance.

NOTICE

2.4 Checking the Contents

After unpacking, check the contents of each case against the

packing list attached to it.

: Installation of the instrument shall be carried out by

or under supervision of qualified service personnel

of the manufacturer or its authorized service agent.

Before installation of the instrument, the customer

is requested to prepare necessary utilities referring

to this manual.

When relocation of the instrument becomes

necessary after initial installation (delivery), please

notify your local Hitachi High-Technologies sales

representative or service office.

2 -

Page 18

6

2.5 Assembly

2.5 Assembling

2.5.1 Power Supply

Unit

The L-2000 Series system is provided with a system power

supply unit which is capable of connecting two pumps, one

autosampler, and one detector. The column oven has its own

power cord. In an instance where provision of a single system

power supply unit is insufficient for the use of two detectors, use

an AC adapter suitable for each instrument (50 W AC adapter

for the pump/autosampler, 100 W AC adapter for the detector).

The power cable from the system power supply unit and the AC

adapter power cable should be connected to the power

connector equipped on the left rear side of the instrument.

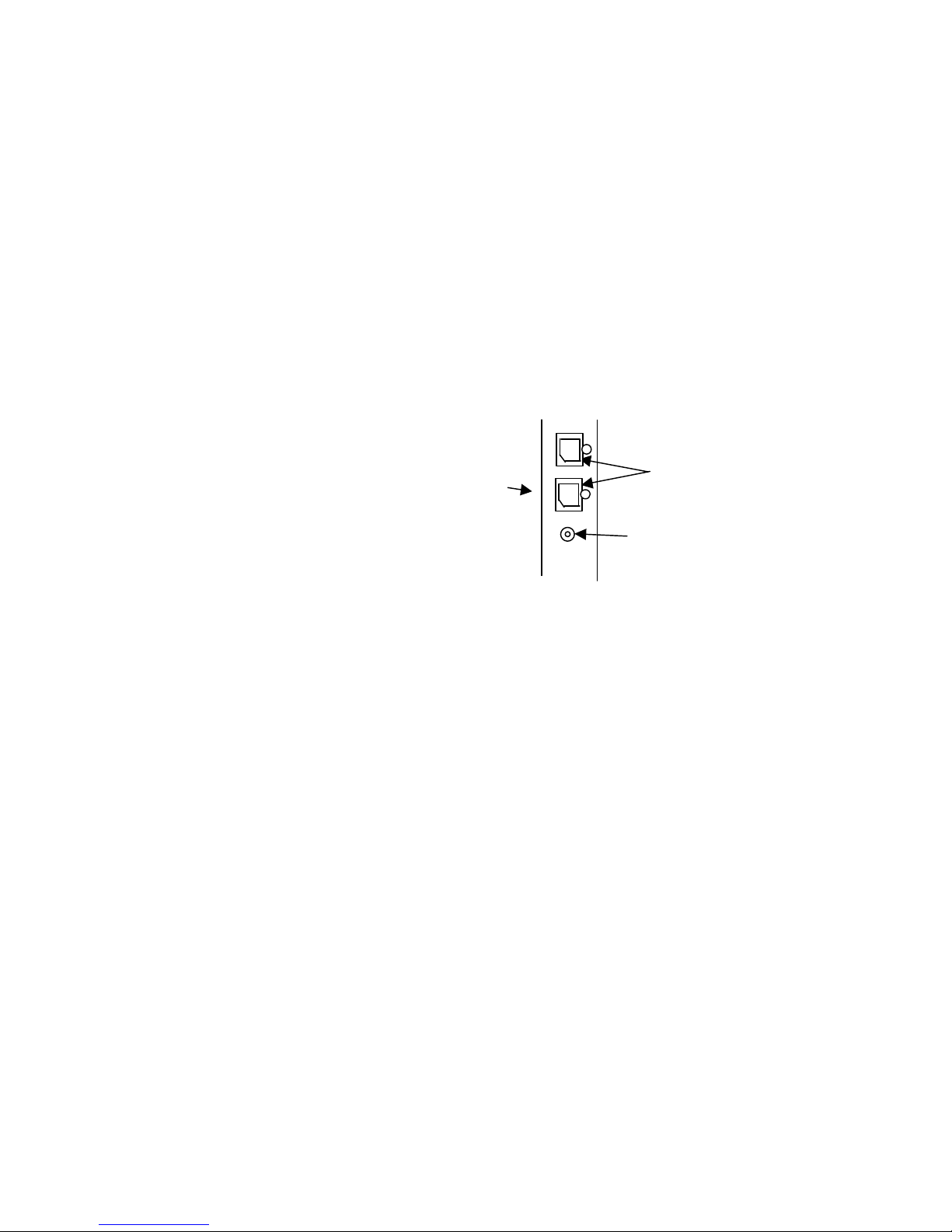

Rear of

instrument

e-Line connector

Power connector

2 -

Page 19

7

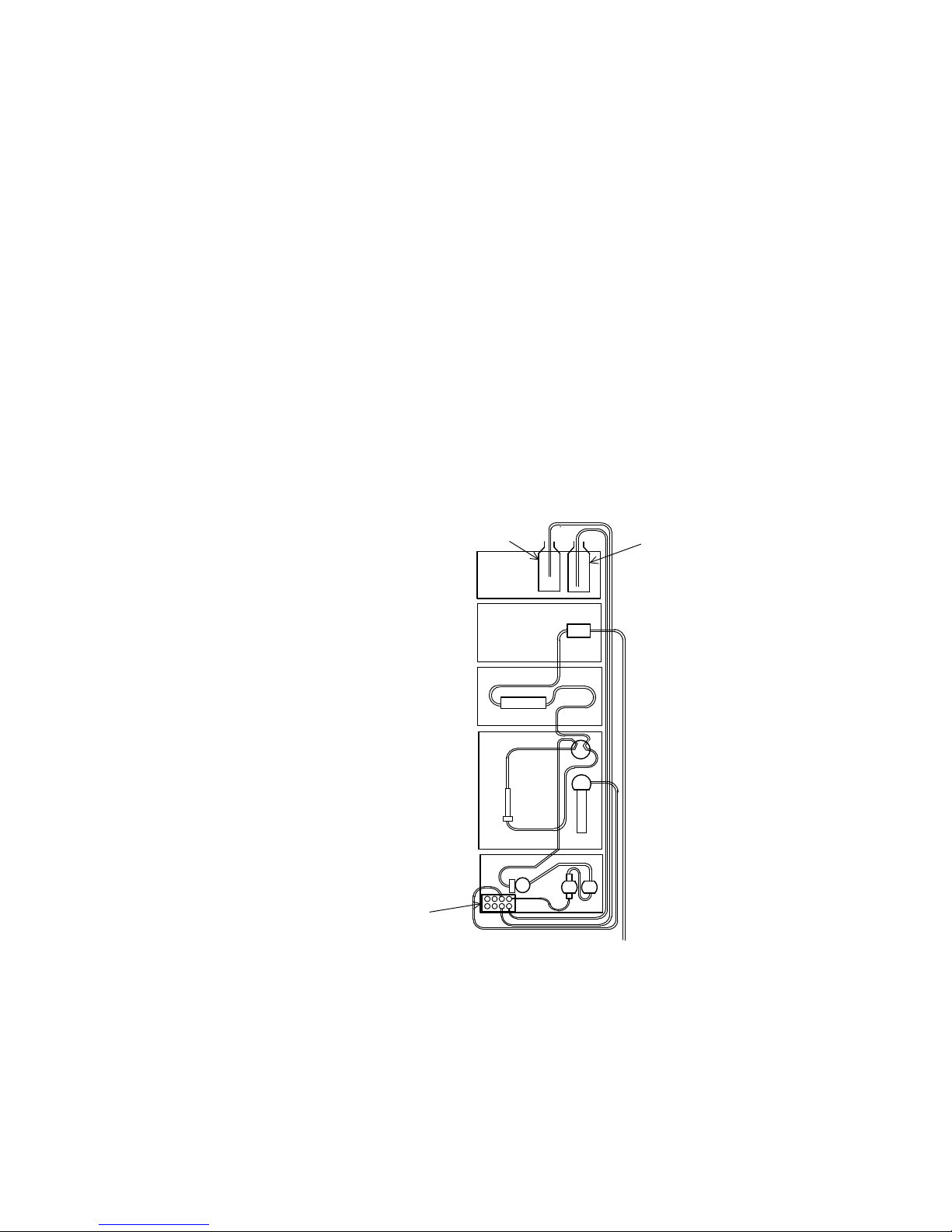

(1) Isocratic System/Low-Pressure Gradient System

pump

To AC power

source

Connect the power cables of the system power supply unit

and column oven to AC power source. For the L-2100/

2130 pump and L-2100 pump, connect the 50 W cable

from the system power supply unit to the instrument power

connector. For the L-2400 UV detector, connect the 100

W cable from the system power supply unit to the

instrument power connector.

System power

supply nit

Model L-2400 UV

detector

100 W cable

Model L-2300

column oven

Model L-2100

pump

50 W cable

Model L-2100/2130

2.5.2

2 -

Page 20

8

source

2.5 Assembly

Model L-2400

UV detector

L-2300 column oven

Model L-2100

pump

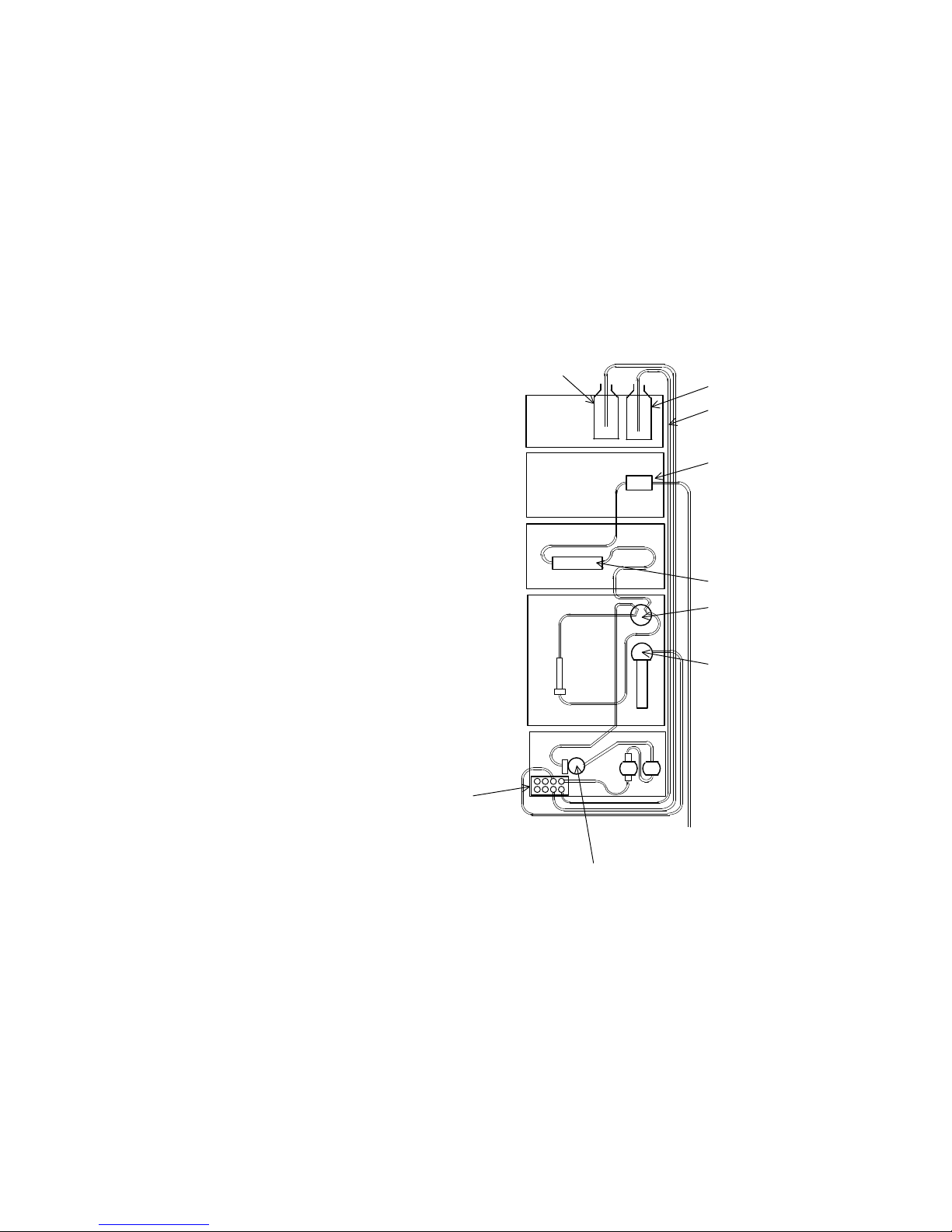

2.5.3 Wiring

Arrangement

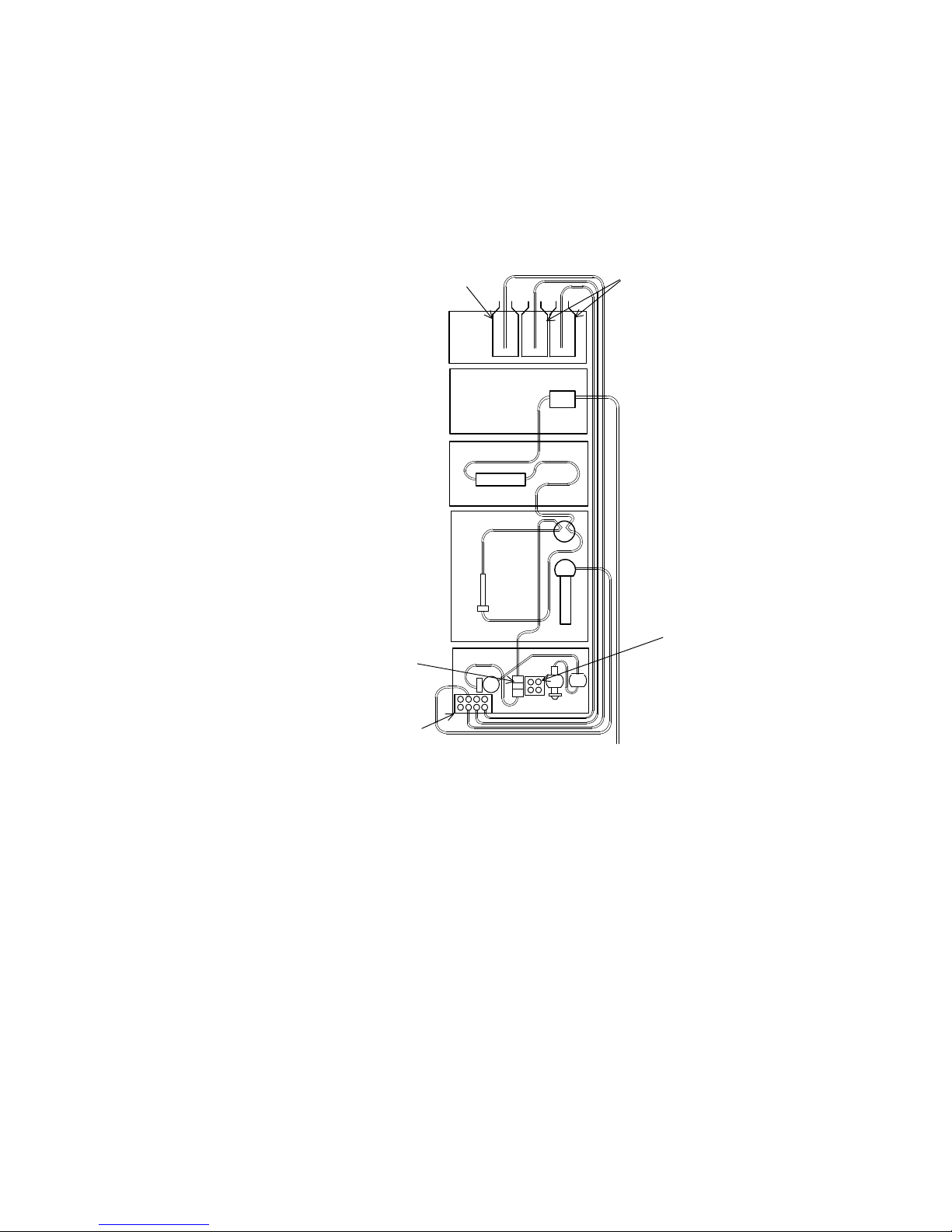

(2) High-Pressure Gradient System

Connect the power cables of the system power supply unit

and column oven to AC power source. For the L-2100/

2130 pump and L-2100 pump, connect the 50 W cable

from the system power supply unit to the instrument power

connector. For the L-2400 UV detector, connect the 100

W cable from the system power supply unit to the

instrument power connector.

100 W cable

System power supply unit

50 W cable

Model L-2100/

2130 pump

Model L-2100/

2130 pump

To AC power

In the L-2000 Series, connect the e-Line cable to the e-Line

connector equipped on the left rear of each instrument for

instrument-to-instrument wiring connection.

Rear of

instrument

e-Line connector

Power connector

2 -

Page 21

9

2100 pump

Model L-2300 column oven

2100 pump

ctor

Model L-2400 UV dete

Model L-2300 column oven

Model L-

(1) Isocratic System/Low-Pressure Gradient System

System power supply unit

Model L-2400 UV detector

e-Line cable

Model L-

e-Line cable

Model L-2100/2130 pump

e-Line cable

(2) High-Pressure Gradient System

e-Line cable

System power

supply unit

e-Line cable

e-Line cable

Model L-2100/

2130 pump

2.5.3

2 -

Page 22

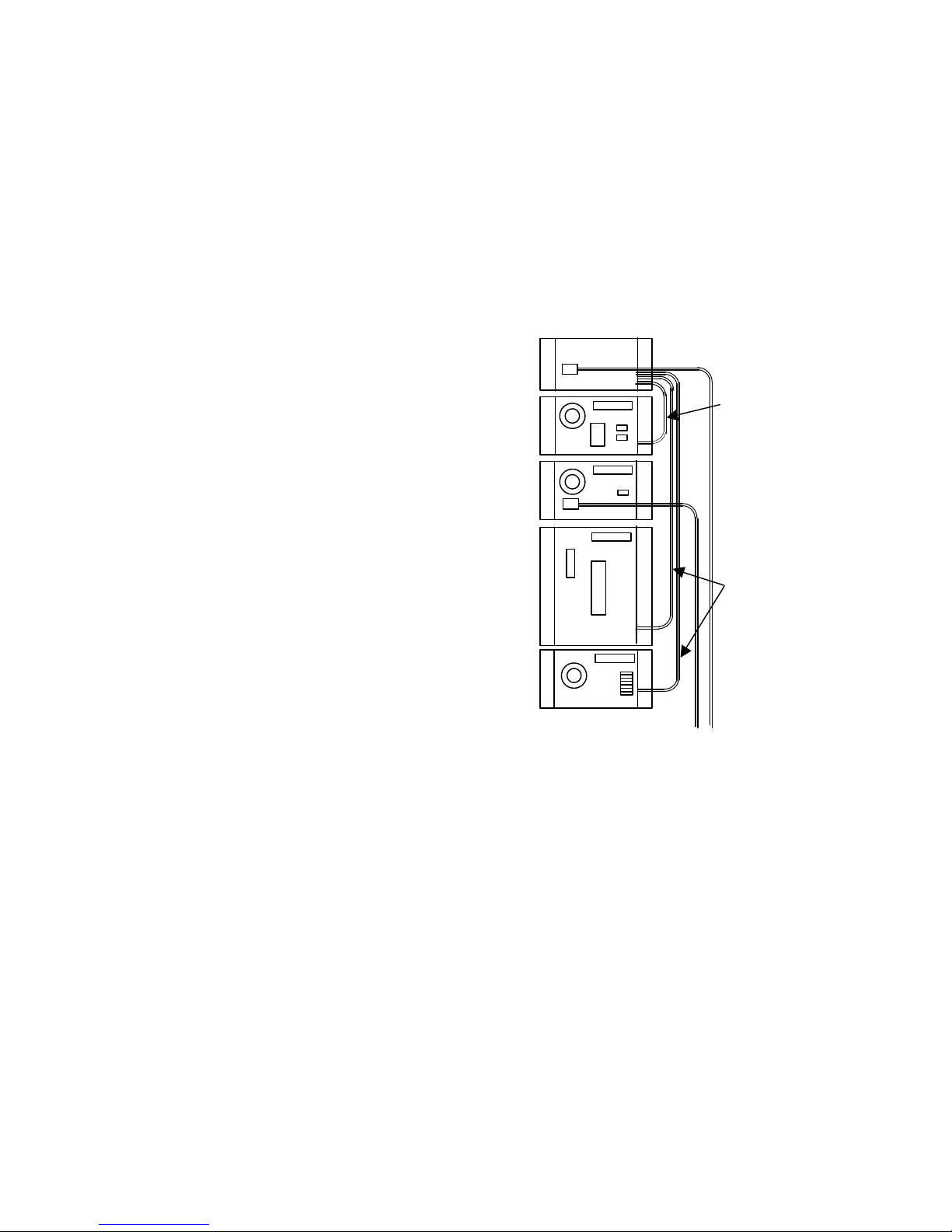

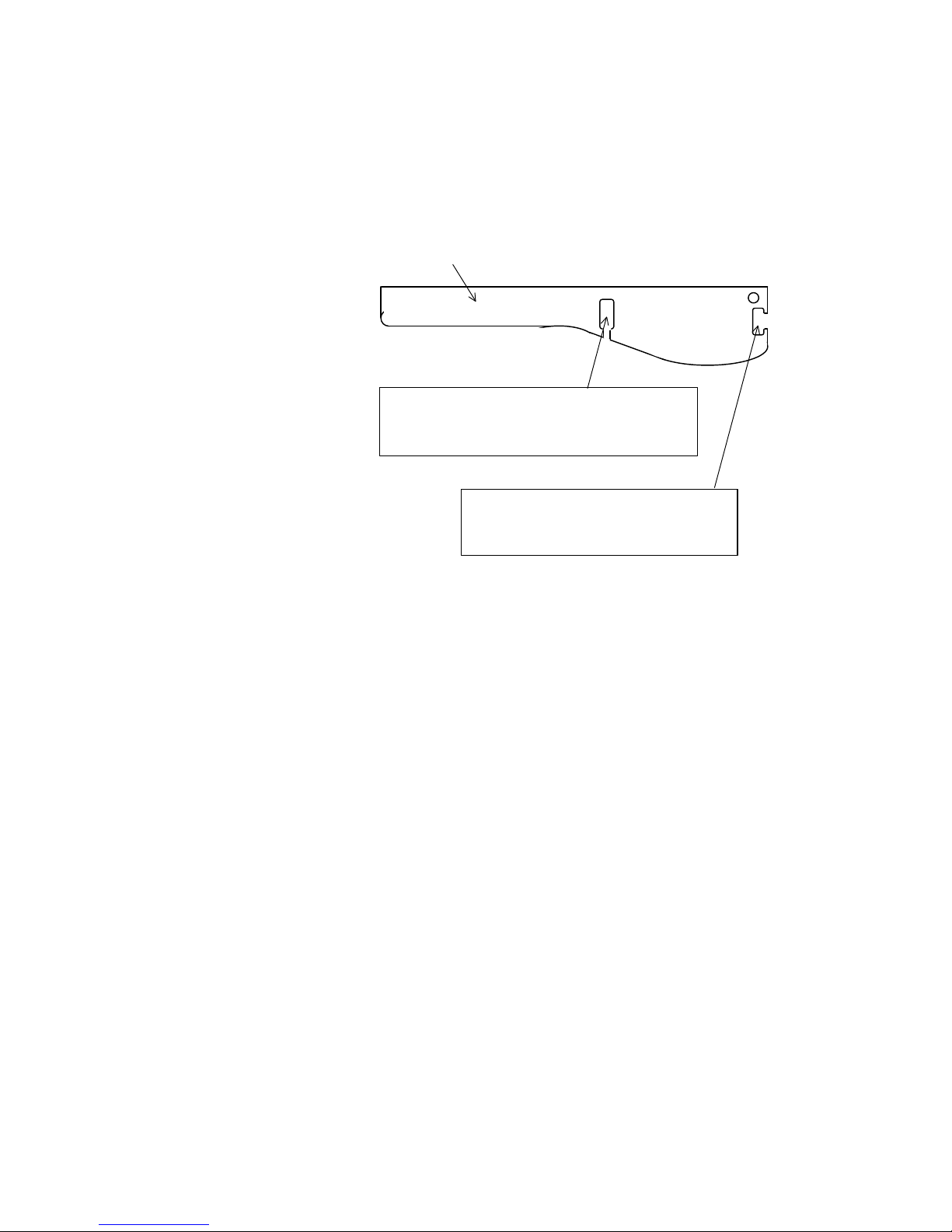

Run tubes from the pump to the autosampler,

Run inlet tubing to the pump and waste

2.5 Assembly

2.5.4 Piping

Arrangement

In the L-2000 Series, provide inlet tubing to the pump and waste

solution tubing through the right piping section of the drain

reservoir. Provide tubing from the pump to the autosampler,

column and detector through the center piping section of the

drain reservoir.

Drain reservoir

Center Piping Section

column and detector.

Right Piping Section

solution tubing.

2 - 10

Page 23

(1) Isocratic System

2100 pump

2100/2130 pump

Connect the inlet tube of eluent to the IN port of the

degasser. Connect the OUT port of the degasser to the

inlet of the pump. Connect the drain valve of the pump to

port 1 of the injection valve of the autosampler.

Connect port 2 of the injection valve to the column inlet.

Connect the column outlet to the inlet tube of the detector

cell. For washing solution, provide connection to port 1 of

the syringe valve of the autosampler through the degasser.

Washing solution

Model L-2400 UV detector

Model L-2300 column oven

Model L-

Model L-

Degasser

Drain valve

Eluent

Inlet tube

Detector cell

Column

Injection valve

Syringe valve

Drain

2.5.4

2 - 11

Page 24

2100 pump

2.5 Assembly

(2) Low-Pressure Gradient System

Connect the inlet tube of eluent to the IN port of the

degasser. Connect the OUT port of the degasser to the IN

port of the proportioning valve. Connect the OUT port of

the proportioning valve to the four-way joint.

Connect the mixer of the pump to port 1 of the injection

valve of the autosampler. Connect port 2 of the injection

valve to the column inlet. Connect the column outlet to the

inlet tube of the detector cell. For washing solution,

provide connection to port 1 of the syringe valve of the

autosampler through the degasser.

Washing solution

system power supply unit

Model L-2400 UV detector

Model L-2300 column oven

Model L-

Drain valve

L-2100/2130 pump

Degasser

Mixer

Proportioning valve

Eluent

Inlet tube

Detector cell

Column

Injection valve

Syringe valve

Drain

Four-way joint

2 - 12

Page 25

System power supply

Washing solution

unit

Model L-2100/

2130 pump

2.5.5 Module Unit

Operating

Procedure

2.5.5

(3) High-Pressure Gradient System

Connect the inlet tube of eluent to the IN port of the

degasser. Connect the OUT port of the degasser to the IN

port of the pump. Connect the drain valve of the pump to

the mixer. Connect the mixer of the pump to port 1 of the

injection valve of the autosampler. Connect port 2 of the

injection valve to the column inlet. Connect the column

outlet to the inlet tube of the detector cell.

For washing solution, provide connection to port 1 of the

syringe valve of the autosampler through the degasser.

Inlet tube

Eluent

Column

Detector cell

Model L-2400 UV detector

Model L-2300 column oven

Injection valve

Syringe valve

Model L-2100 pump

Drain valve

Drain

Where the chromato data station is not used for controlling

operations, each module can be operated using the optional UI

pad.

This section describes how to use the UI pad for operations.

The UI pad is provided with common control keys available for

different modules and unique control keys for particular modules.

The functions of the common control keys are mentioned below.

2 - 13

Page 26

SET UP

2.5 Assembly

(1) Using the UI Pad

(a) Functions of common control keys

INSERT

PROG GLP UTLTY

7 8 9 0

4 5 6

1 2 3

LOCK OFF

ESC

DEL

CL ENT

Key Designation

UTLTY Starts instrument parameter setting.

GLP Starts GLP function setting. Available for displaying a logbook of component

parts of each module, triggering a reset, and locking the UI pad keys.

PROG Starts program editing.

ESC Returns control to the monitor window.

DEL Deletes a cursor-pointed step.

This key is effective only in program editing.

When the cursor is positioned on the TIME input part, pressing the DEL key

removes a step pointed by the cursor. When the cursor is positioned on

another input part, pressing the DEL key removes an item pointed by the cursor.

Pressing the ESC key on a window where "-" is indicated returns control to the

monitor window, causing cancellation of a DEL key action.

• Pump/detector time program

When the DEL key is pressed, "-" is indicated. This deletion can then be

defined by pressing the ENT key.

• Autosampler sequential program

When the DEL key is pressed, the relevant step number is deleted and "-" is

indicated. This deletion can then be defined by pressing the ENT key.

CL Clears an input numeric value during input (after a numeric value or the decimal

point is entered; before the

ENT

The cursor is indicated at the top of the input part. The previous input value is

presented as a preset value.

ENT Defines the current entry of a parameter.

INSERT Use this key in program editing.

• Pump/detector

A new line is presented following the last line of the current program.

• Autosampler

A new step is inserted.

,

(Arrows)

(1) Monitor window

key : Goes to the next window.

•

key : Goes back to the previous window.

•

(2) Program editing

key : The next line is presented. Pressing this key at the last line

•

causes the first line to appear in a circular fashion.

key : The previous line is presented. Pressing this key at the first

•

line causes the last line to appear in a circular fashion.

Function

key is pressed).

2 - 14

Page 27

(b) Contents on screen

The parameter input window and the program setup

window are described below.

1) Input of a single numeric value:

Parameter name Input range

PROGRAM No. (1 - 9)

1

Input part

2) Input of plural numeric values

Parameter name

Input item

LAMP CHANGE (MM, DD, YYYY)

<1 - 12>

Input range Input part

3) Selection of a numeric value:

Parameter name

Selectable items

TIME CONSTANT (0.1s = 1, 0.5s = 2, 2.0s = 3,

3 4.0s = 4, 8.0s = 5)

Input part

4) Program setup window:

Input item

NO. R.NO VIALS INJ.VOL INJ/VIAL S.TIME

1 1 80 50 1 10.0

Input part

2.5.5

2 - 15

Page 28

2.5 Assembly

(c) Numeric Value Input Procedure

1) The cursor is indicated at the top of the input part.

The previous numeric value is presented in the

input part.

2) Numeric and decimal point key inputs are

accepted in each allowable range.

3) To define an input numeric value, press the ENT

key. The cursor will then move to the next item.

If an erroneous numeric value is input, the cursor

is brought back to the top of the input part with

the input numeric value displayed. In this state,

you are prompted to enter a correct numeric value.

Pressing the ESC key brings you back to the

initial window (monitor window).

If the ESC key is pressed during numeric key

input, the parameter being entered is discarded

(the previous numeric value is set).

NOTICE:

At power-on, a default number is indicated in each

item selection part.

Pressing the CL key in the input part clears its contents.

The cursor is then brought back to the top of the input part.

In program editing, pressing the DEL key in the input part

removes an item pointed by the cursor.

If the ESC key is pressed in the course of setting plural

parameters, the items preceding the press of the ESC key

remain intact.

2 - 16

Page 29

(2) Mounting the UI Pad

(a) Remove the front panel from the instrument.

Front panel

(b) Remove the metal lid from the instrument.

Meal cover

2.5.5

2 - 17

Page 30

2.5 Assembly

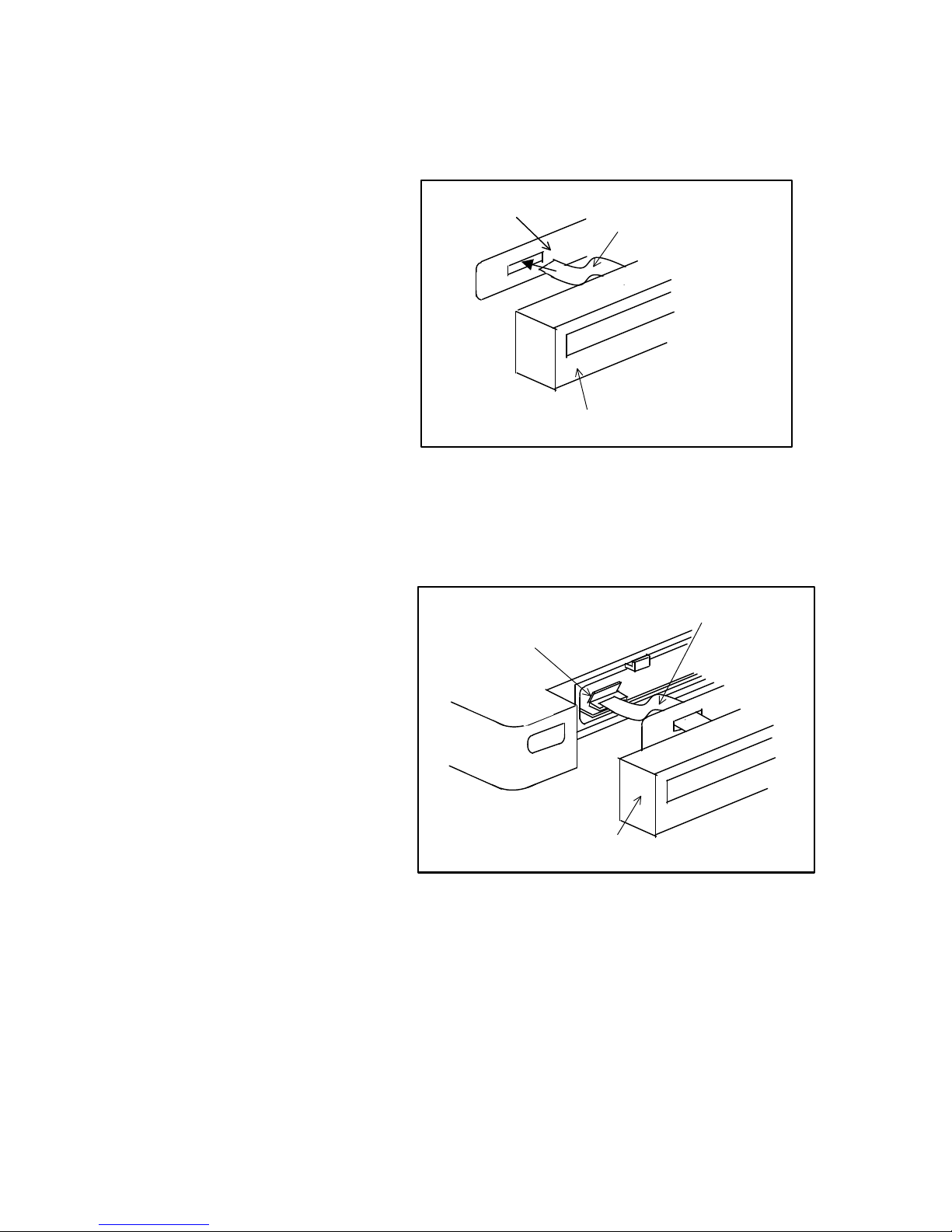

(c) Run the flexible tube of the UI pad through the metal

lid.

Metal cover

Flexible tube

UI pad

(d) Turn up the lid of the connector, and insert the flexible

tube of the UI pad as far as it will go.

Connector

Flexible tube

UI pad

2 - 18

Page 31

2.5.5

(e) Turn down the connector lid, and mount the UI pad.

Connector

Flexible tube

UI pad

(f) Attach the metal lid dedicated for the UI pad.

Flexible tube

Metal cover

UI pad

2 - 19

Page 32

2.5 Assembly

(g) Set the of the UI pad to the of the instrument.

Tab

UI pad

(h) Mount the front panel dedicated for the UI pad on the

instrument.

Front panel

2 - 20

Page 33

2.5.6

2.5.6 Instrument-toInstrument

Fastening

The wiring cover is provided on the rear of each instrument.

Instrument-to-instrument fastening can be made by shifting each

wiring cover as shown below.

(1) Remove the retaining screws, and detach the wiring cover.

Wiring cover

Retaining

screw

(2) Shift the mounting position of each wiring cover.

Wiring cover

Retaining

screw

2 - 21

Page 34

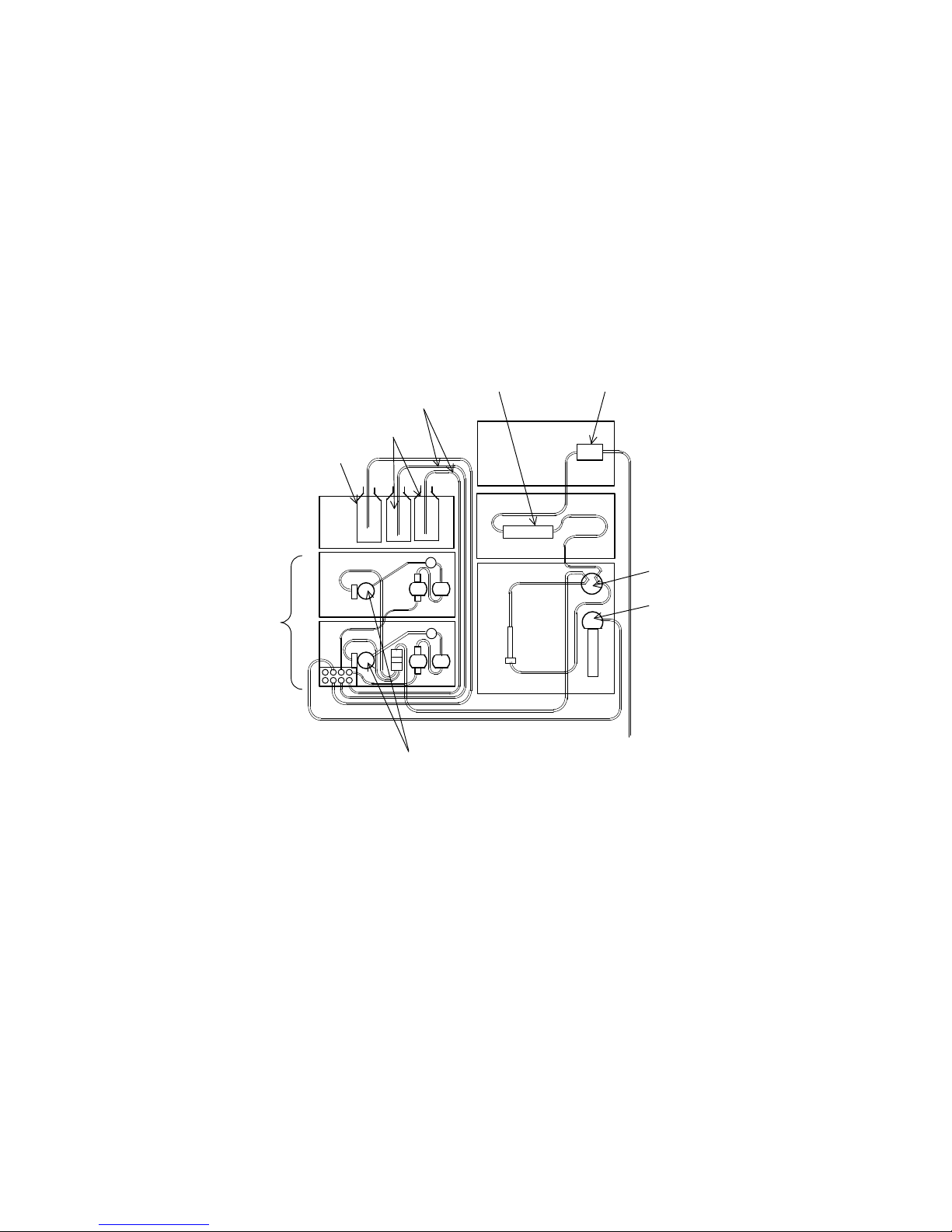

1

3.1 The Instrument Keypad

3.1.1 Name and

Function of Each

Part

LED

Main switch

3. FUNCTION

Right door

Drain Valve

Main switch : Turns on/off power supply.

•

Doors : Two doors are provided.

•

Drain Valve : This valve is opened for purging the system.

•

Leak sensor : Detects fluid leakage.

•

UI-PAD : A keypad required for operating the pump

•

LED : There are 4 LEDs, and each LED lights in a

•

A (green, orange) Green : POWER ON as the pump A

B (green, orange) Green : POWER ON as the pump B

PURGE (green) Green : Under purge

PROG. RUN (green) Green : Under the time program

Left door

Drain

Leak sensor

Fig. 3-1 Front View

independently (available at option).

specific color for the determined indication.

Name (color) LED Status

Orange : Pump A error

Orange : Pump B error

running

3 -

Page 35

2

3.1.1

Wiring covers

Ground terminals

Pump can start by an

external signal.

I/F board mounting

space

Pump can stop by an

external signal.

Pressure value is output

to the exterior (Approx.

49 MPa)/1 V.

Wiring covers

Fig. 3-2 Rear View

Wiring covers : Upon detaching the left-side cover (as

viewed from the front), the e-Line

connector used for connection between

L-2000 series units appears.

These wiring covers are also usable as

retaining plates for other units of the

L-2000 series.

Ground terminals : Three terminals for grounding the

instrument. I/F board mounting

IF board space : Space for mounting the I/F board required

for connecting the PC (data station) and

HPLC system.

3 -

Page 36

3

Contents of

CLOSE

1 s CLOSE

OPEN

Classification

Output

Input

Table 3-1 Name and Function of Each Terminal at Rear Panel

Name Function

TIMER

(1 to 4)

PRESS

OUT

PUMP

ON IN

PUMP

OFF IN

Contact

turns

on/off

according

to coded

setting in

EVENT of

the

program.

Pressure

value is

output to

the

exterior.

Pump ON

from

external

system.

Pump OFF

from

external

system.

Signal

• Timer

ON: CLOSE

OFF: OPEN

• Pulse

OPEN

0 to 1 V DC

OPEN ∗

50 ms

or longer

Contents of

Processing

The ON/OFF

signal can

output to

each TIMER by

specifying an

ON/OFF EVENT

code at a

desired time

of a time

program.

1-second

CLOSE signal

can output at

each TIMER by

specifying

pulse EVENT

code at a

desired time

of a time

program.

Maximum current connectable: 10 mA

• TIMER No. and Event code

TIMER

No.

•

Pump can be stopped by specifying

00 for EVENT, and buzzer can be

rung by specifying 92.

1) Becomes OFF when the pulse is

output in the ON status.

2) OFF has priority over ON.

3) Contact output specification of

each terminal

Voltage ... 30 V DC max.

Current ... 100 mA max.

• 1 V = Approx. 49 MPa

∗ Edge jugement

OFF ON

1 10 11 12

2 20 21 22

3 30 31 32

4 40 41 42

(Approx. 7106 psi)

Remarks

Signal

3.10

Pulse

3 -

Page 37

4

SET UP

PUMP

A B

C D

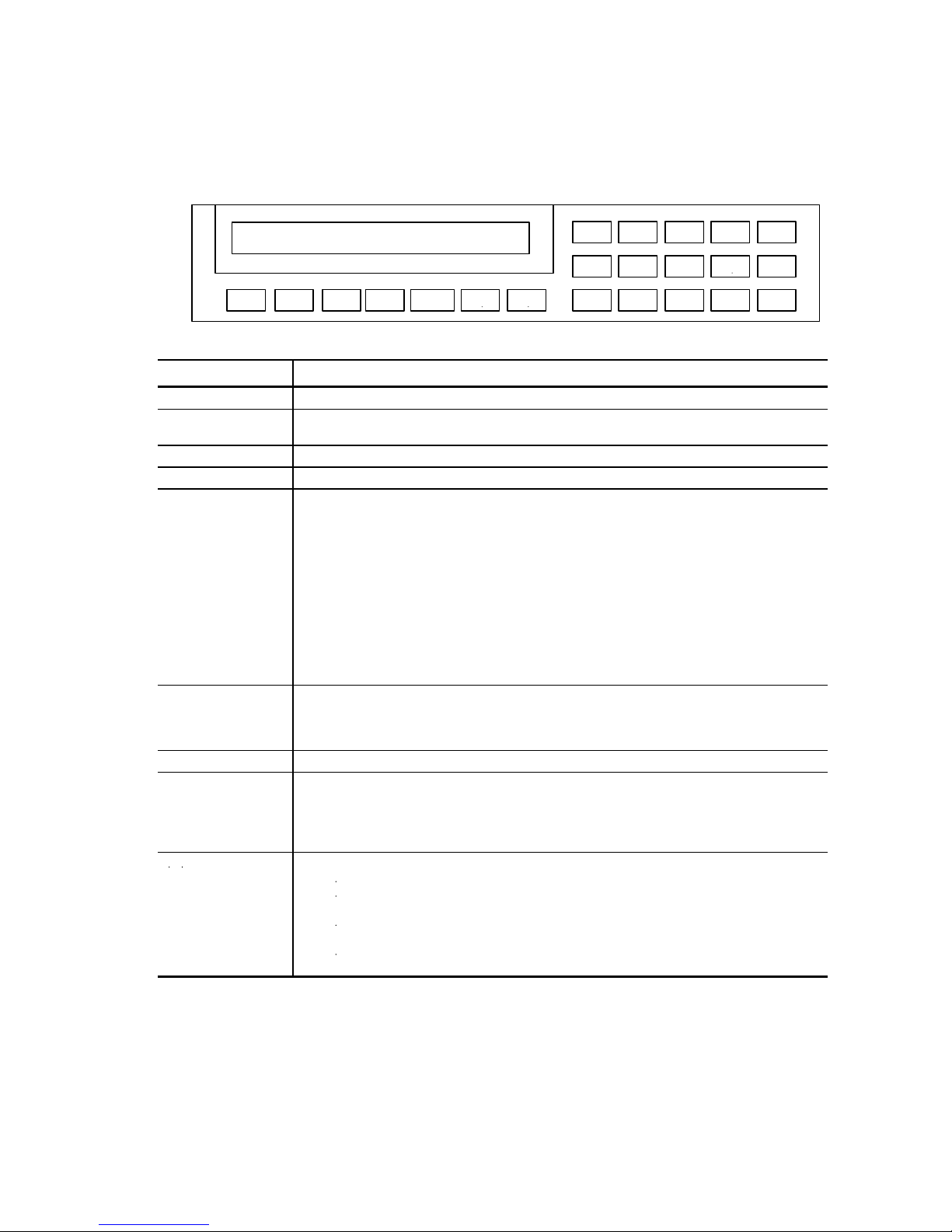

3.1.2 Part Name and

Function of UI

Pad (option)

PURGE

(1) Operation Keys

Each key on the UI pad (option) type operation panel is

explained here.

INSERT INITIAL

PROG GLP UTLTY

START

STOP

7 8 9 0 ESC

4 5 6

1 2 3

MANUAL

CL ENT

LOCK OFF

DEL

PUMP

ON/OFF

PURGE Starts/stops purging the flow path.

UTLTY

/

SET UP

GLP Used for confidence-level reporting.

PROG Selects, generates, edits, or deletes a pump program.

, Scroll up and down display.

START Starts the time program. You can activate the start key

STOP Stops the time program.

MANUAL Used for manual operation selection display and

ESC

/

LOCK

OFF

A,B,C,D If you are in manual status and you press the [A]

INITIAL Puts the systems to the initial setting of program

Starts/stops operation of the pump. Pressing this key

starts the pump.

Then, pressing it again stops the pump.

For specifying a purging flow rate, use the UTILITY

function.

The upper pressure limit (PRESS MAX) is set at 2.9

MPa (30 kgf/cm2), and the lower pressure limit

(PRESS MIN) is set at 0 MPa (0 kgf/cm2).

Pressing this key again stops the purging operation.

1.Used to display/set up auxiliary function conditions

(UTILITY).

• Pressure zero-point correction

• Purge flow rate setting

• Pressure unit assignment

2.For pump mode selection.

The low-pressure gradient mode, high-pressure

gradient mode, and single-liquid feed mode are

available (SET UP).

only when the pump is at the initial mode.

setting (mobile phase mixing ratio, FLOW, P-MAX, PMIN, %B, %C, %D).

1. Pressing this key brings you from the numeric value

input state (input state in each mode) back to the

MONITOR screen.

2. For key unlocking.

key %A is set immediately to 100. [B], [C], and [D]

keys provide the same function.

whose no. is selected by [PROG] key (time program: 0

minutes)

3 -

Page 38

5

CL Used for erasure of data under input. Also usable for

DEL Used for deleting a step in a sequential program.

ENT Inputs a numeral.

erasure of an error message at occurrence of an error.

NOTE: If a mistake is made during operation, press the

ESC key. In almost all cases, the initial status

returns when pressing this key.

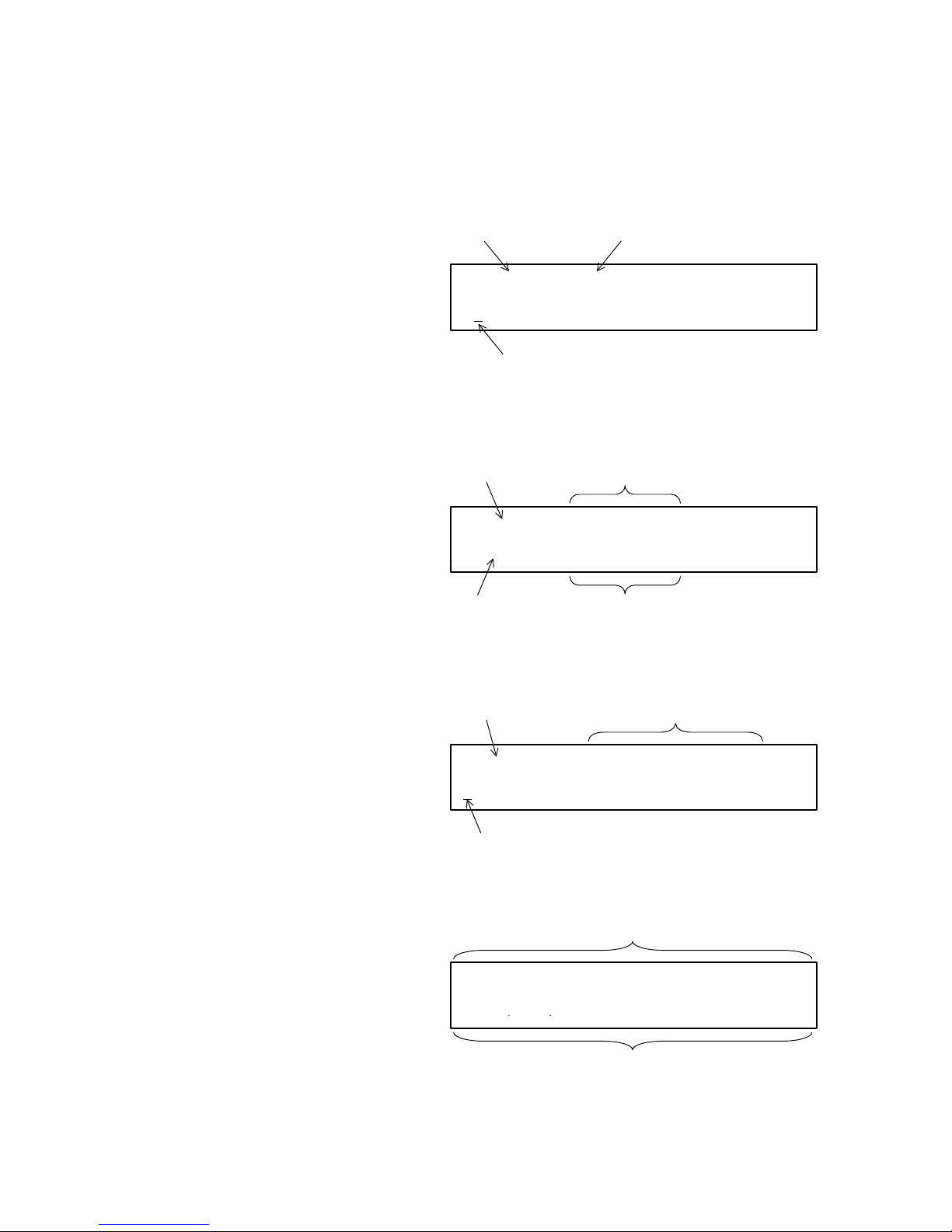

(2) Monitor Screen

The UI pad is provided with an LCD monitor on which

instrument status can be indicated. The screen which

indicates instrument status is called a monitor screen.

Operation method of the monitor screen and example

indications on it are shown below.

(a) 1st monitor screen

This screen mainly indicates information about the

pump main frame.

TIME %A %B %C %D FLOW P RESS [ --]

0.0 100 0 0 0 0.000 0.0 1

Indication Description

TIME

%A

%B

%C

%D

FLOW

PRESS

[--]

Elapsed time of analytical program execution

Mixing ratio of liquid A

Mixing ratio of liquid B

Mixing ratio of liquid C

Mixing ratio of liquid D

Pump flow rate

Pump pressure

Pump status indication

Since two-liquid low-pressure gradient operation is performed in

this system, %C and %D are always zero.

The status indications at the upper right of the

MONITOR screen are as follows:

[GR] The gradient program is in execution.

3 -

Page 39

6

[IN] Waiting for execution of analysis. A liquid is being fed.

[--] Waiting for execution of analysis. The pump is being

stopped.

[MN] The MANUAL mode is selected.

[PG] The purging operation is under execution.

[LK] The keyboard of the operation panel is locked.

(b) 2nd monitor screen

P-UNIT P.MAX P.MIN [--]

MPa 20.0 0.0 1

Indication Description

P-UNIT Indicates a unit of pressure. In this system, MPa is

P. MAX Indicates a specified upper limit of pressure. If

P. MIN Indicates a specified lower limit of pressure. If

indicated.

pressure exceeds the specified upper limit, the pump

is forced to stop.

pressure decreases below the specified lower limit,

the pump is forced to stop.

(c) 3rd monitor screen

EVENT 1 2 3 4 PUMP FLUSH [--]

OFF OFF OFF OFF A(Micro) OFF 1

Indication Description

EVENT Indicates a state of the EVENT terminals 1 to 4. ‘ON’

PUMP Indicates a pump station number. In pump station

FLUSH Always indicated as ‘OFF’ in this system.

represents that the contact is closed, and ‘OFF’

represents that the contact is open.

number assignment, PUMP A, PUMP B or PUMP C

can be specified.

3 -

Page 40

7

(c) Changeover of monitor screen

The monitor screen transition is as follows. If the link program

function is OFF, the 4th monitor screen will not appear.

1) 1st MONITOR screen

TIME %A %B %C %D FLOW PRESS [--]

0.0 100 0 0 0 0.000 0.0 1

2) 2nd MONITOR screen

P-UNIT P.MAX P.MIN [ --]

MPa 20.0 0.0 1

3) 3rd MONITOR screen

EVENT 1 2 3 4 PUMP FLUSH [--]

OFF OFF OFF OFF A (Micro) OFF 1

4) 4th MONITOR screen

LINK PROG STEP CYCLE [ --]

O N 1 1/99 1

or

ESCAPE

3 -

Page 41

8

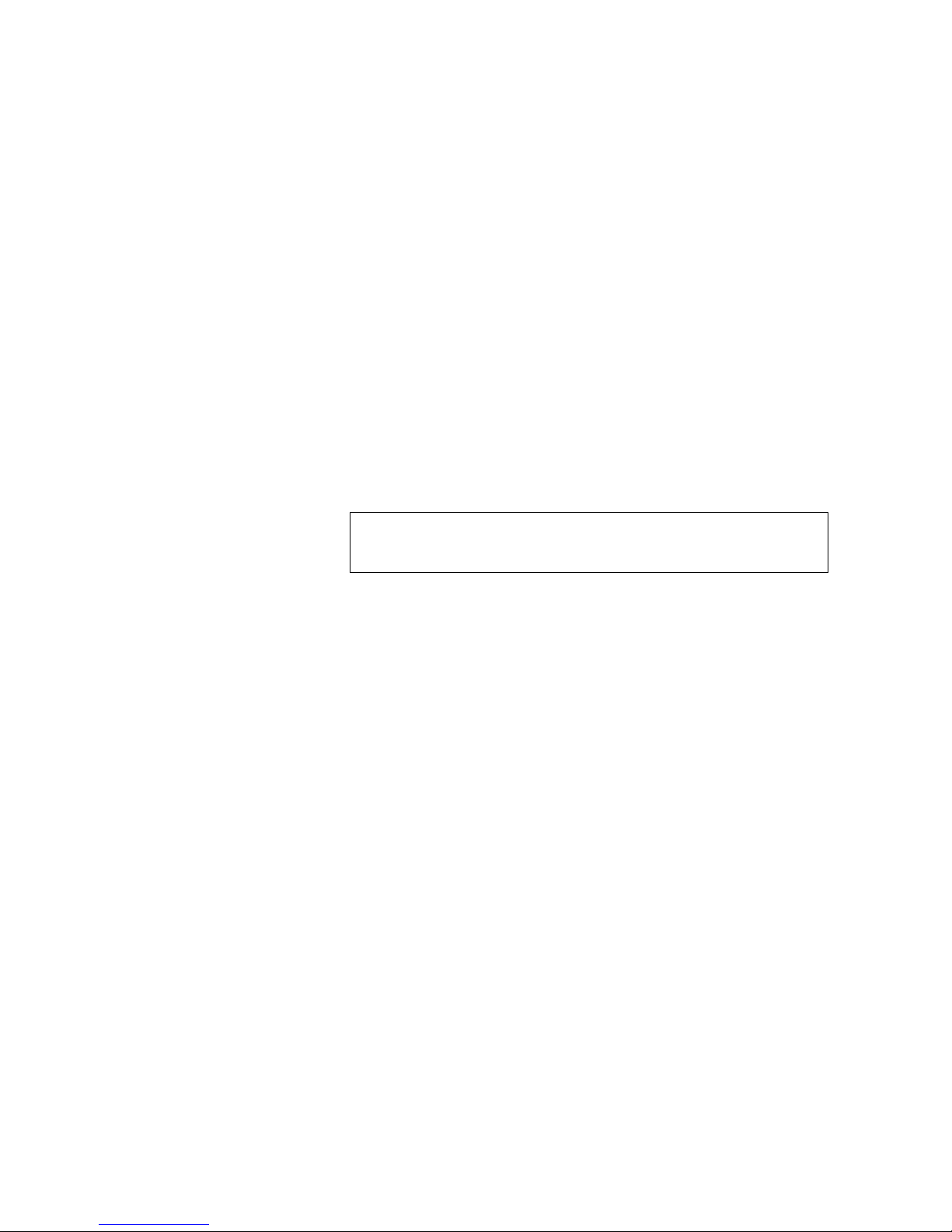

3.2 Operation Status

Fig. 3-3 is a flow chart that shows the transition of operational

status. ( indicates depression of a key.)

<Turning on power>

(does not function unless the pump is on)

START/STOP

INITIAL

INIT

START/STOP

MANUAL

SET

MANUAL

RUN

MANUAL

SET

INITIAL : Programming mode status in which

system waits for start.

MANUAL : Operation is made under constant

conditions without using program.

RUN : Gradient mode is executed.

Fig. 3-3 Operational Status Transition

3 -

Page 42

9

3.3 Specifications

(1) L-2100

(a) Liquid feed system:

Dual plunger type reciprocating pump( Tandem Type)

(b) Maximum operating pressure:

39.2 MPa

(c) Flow rate range

0.001 to 2.499 mL/min

(d) Pressure limit range

0 - 39.2 MPa

(e) Delivery volume of No.1 plunger stroke

25 uL/stroke

(f) Flow accuracy (at constant room temperature of

20 for water)

+/- 2 uL/min (0.005 - 0.050 mL/min, 1.0 - 39.2 MPa)

+/- 2 % (0.051 – 2.000 mL/min, 1.0 - 39.2 MPa)

+/- 4 % (2.000 - 2.499 mL/min, 1.0 - 39.2 MPa)

(g) Flow precision

0.075% RSD or 0.02min SD, whichever is greater,

based on retention time using L-2200 autosampler

(Flow 0.2 mL/min at constant room temperature of

20 for water )

(h) Pressure display accuracy

+/- 5%

(i) Constant pressure liquid feed

2.0 to 39.2 MPa (Flow range 0 to 1.25 mL/min)

(j) Material of wetted parts

SUS 316, ruby, sapphire, ceramic, PTFE,

carbon-impregnated PTFE

(k) Display data using UI-Pad (Option):

Parameters

Gradient monitor Elapsed time, mixing ratio, flow rate,

pressure, timer value, etc.

(l) Pump control mode:

Single-Liquid delivery mode

Low pressure gradient mode

High pressure gradient mode

(m) Contact input/output terminals:

Event timer; 4 channels

(n) Communication:

e-Line

OUTPUT: BUSY

INPUT: 1) GRADIENT START IN

2) ERROR IN

(o)Pressure zero adjustment:

3 -

Page 43

Possible

(p) Ambient temperature :

4 to 35°C (condensation unallowable)

(q) Humidity:

45 to 85% RH

(r) Power supply:

24V DC, 21.A

(s) Dimensions:

260(W) × 500(D) × 235(H) mm

(t) Weight:

About 15 kg

(2) L-2130

(a) Liquid feed system:

Dual plunger type reciprocating pump( Tandem Type)

(b) Maximum operating pressure:

39.2 MPa

(c) Flow rate range

0.001 to 9.999 mL/min

(d) Pressure limit range

0 - 39.2 MPa

(e) Delivery volume of No.1 plunger stroke

25 uL/stroke

(f) Flow accuracy (at constant room temperature of

20 for water)

+/- 2 uL/min (0.01 - 0.10 mL/min, 1.0 - 39.2 MPa)

+/- 2 % (0.101 – 5.000 mL/min, 1.0 - 39.2 MPa)

+/- 2 % (5.001 – 8.000 mL/min, 1.0 – 19.6 MPa)

+/- 4 % (8.001 - 9.999 mL/min, 2.0 – 19.6 MPa)

(g) Flow precision

0.075% RSD or 0.02min SD, whichever is greater,

based on retention time using L-2200 autosampler

(Flow 1.0mL/min at constant room temperature of

20 for water )

(h) Pressure display accuracy

+/- 5%

(i) Constant pressure liquid feed

2.0 to 39.2 MPa (Flow range 0 to 5.0 mL/min)

(j) Material of wetted parts

SUS 316, ruby, sapphire, ceramic, PTFE,

carbon-impregnated PTFE

(k) Display data using UI-Pad (Option):

Parameters

Gradient monitor Elapsed time, mixing ratio, flow rate,

pressure, timer value, etc.

3 - 10

Page 44

(l) Pump control mode:

Single-Liquid delivery mode

Low pressure gradient mode

High pressure gradient mode

(m) Contact input/output terminals:

Event timer; 4 channels

(n) Communication:

e-Line

OUTPUT: BUSY

INPUT: 1) GRADIENT START IN

2) ERROR IN

(o)Pressure zero adjustment:

Possible

(p) Ambient temperature :

4 to 35°C (condensation unallowable)

(q) Humidity:

45 to 85% RH

(r) Power supply:

24V DC, 21.A

(s) Dimensions:

260(W) × 500(D) × 235(H) mm

(t) Weight:

About 15 kg

3 - 11

Page 45

1

4. OPERATION

The method of pump operation using the optional UI pad is

described here.

4.1 Preparatory Operations

Explained here is the operating method for using the L-2130

pump.

4.1.1 Setting of Pump Mode

This section shows how to set the pump in the single-liquid

delivery mode (FLOW mode).

NOTICE: Once this setting is made, it is memorized and need not

be made each time.

<POWER ON> + [(SETUP) UTILITY]

When pressing the [POWER] and [(SETUP) UTILITY]

keys simultaneously, the pump mode setting screen

appears. It may be necessary to continue pressing

[(SETUP) UTILITY] until the setting screen appears.

SETUP PUMP MODE CONTRAST S.NO.

A LOW 4 02AB-111

[ENTER]

SETUP ITEMS PUMP=1 CONTRAST =2

[1][ENTER]

PUMP A=1 B=2

[1][ENTER]

4 -

Page 46

2

GR MODE LOW HIGH V. HIGH

4 FLOW 4

[4][ENTER] LOW: Low pressure gradient mode

HIGH: High pressure gradient mode

V.HIGH: High pressure gradient with

solenoid valves mode

SETUP PUMP MODE CONTRAST S.NO.

A FLOW 4 02AB-111

FLOW: Isocratic mode

<POWER OFF>

Turn the power off once.

<POWER ON>

Turn the power on again.

TIME FLOW PRESS [ ]

0.0 1.000 0.0 1

4 -

Page 47

3

4.1.2 Programming Operation

This section discusses the programming of the FLOW mode.

An example is given where upper pressure limit is 20.0 MPa,

lower pressure limit is 0 MPa, analysis time is 0 min, flow rate is

1.0 mL/ min.

PROGRAM No. = 1

PRESSURE VALUE : MAX MIN MPa

TIME FLOW EVENT

(min) (ml/min) 1 2 3 4

0.0 1.000 12 22 32 42

Monitor screen

If manual setting screen is displayed, press INITIAL to

obtain the programming mode.

PROG

Program generation is started.

SET PROGRAM: No. [--]

<1-9> 1

Input program No. Valid program numbers are from 1 to

9.

MODIFY=0, NEW=1 [--]

0

Generates a new program or modifies an existing

program.

20.0 0.0

4 -

Page 48

4

PRESSURE: MAX MIN [--]

20.0 0.0 1

Input the upper and lower limit pressure values.

TIME FLOW EVENT [--]

0.0 1.000 1

Input time, flow rate and event. Up to 4 entries can be

made per step for event. Input an event to be

executed within the entered time.

TIME FLOW EVENT [--]

1

A new input screen will appear, so enter time, flow

rate and event.

[ ESCAPE ]

Monitor screen

NOTICE: A maximum of 99 steps can be entered for program

Nos. 1 to 9.

NOTICE: The entered program is saved. When power is turned on

next time, the initial screen (TIME=0) of the program used just before

power was turned off will appear.

4 -

Page 49

5

when power is turned off. Conditions must be set each time power

4.1.3 Manual Operation

This is used for supplying liquid under constant conditions

without using a program.

(1)Constant Flow Rate Mode

This section explains the setting of liquid delivery system at

constant flow rate. An example is given where flow rate at 1.0

mL/min, upper pressure limit at 15.0 MPa and lower pressure

limit at 0 MPa.

Monitor screen

MANUAL

MANUAL: FLOW=1, PRESS=2 [MN]

CONSTANT FLOW: FLOW MAX MIN [MN]

CONSTANT FLOW: FLOW PRESS [MN]

Monitor screen

NOTICE: The set conditions for manual operation will be erased

1

Select the constant flow rate mode.

1.000 15.0 0.0

Input the flow rate, and the upper and lower limit pressure

values.

0.000 0.0

The monitor screen will apper.

is turned on.

4 -

Page 50

6

power is turned off. Conditions must be set each time power is turned

(2)Constant Pressure Mode

This section explains the setting of liquid delivery system at

constant pressure. An example is given where initial flow rate is

1.0 mL/min, at a pressure of 15.0 MPa.

Monitor screen

MANUAL

MANUAL: FLOW=1, PRESS=2 [MN]

2

Select the constant pressure mode.

CONSTANT PRESS: INITIAL FLOW PRESS [MN]

1.000 15.0

Input the flow rate, and the pressure values.

CONSTANT FLOW: FLOW PRESS [MN]

0.000 0.0

The monitor screen will apper.

Monitor screen

Before stating the pump, check that the pressure level is 0 Mpa.

NOTICE: The liquid delivery will not start unless the starting pressure

is 0 MPa

NOTICE:

The set conditions for manual operation will be erased when

on.

4 -

Page 51

7

4.2 Measuring Operation

Ignition of Flammable Chemicals!

Beware of ignition hazard when using flammable chemicals such

•

as organic solvents.

Always check the following conditions. If an abnormality is

•

found, stop operation immediately.

Leakage of solvent or waste solution

•

Leakage of solvent inside the instrument

•

Inadequate ventilation of the laboratory room

•

This instrument is not explosion-proof. Although aqueous

•

solvents or organic solvents having an ignition point of 70°C or

higher are usable, do not use organic solvents having an ignition

point below 70°C.

When using flammable chemicals, be careful about possible

•

ignition due to static electricity. Particularly when using nonconductive chemicals, employ a conductive vessel made of metal

or the like and provide grounding connection correctly.

WARNING

WARNING

Explosion of Vapor from Flammable Chemicals!

If a flammable chemical such as organic solvent leaks from the

•

flow path of the instrument and its vapor concentration exceeds

the explosion limit, it may cause spontaneous combustion with

dangerously explosive results.

When using a flammable and readily volatile chemical, be sure to

•

check for leakage from the instrument flow path and ventilate the

laboratory room adequately.

4 -

Page 52

8

4.2.1 Basics of Operation

When the settings are all finished, carry out operation in the

following procedure.

(1) Make sure the pump, column, detector and data

processor are properly connected.

(2) Set the mobile phase and waste solution bottle in place.

(3) Start the pump and wait until the flow path is filled with

the mobile phase.

(4) Warm up the pump, column and detector and wait until

the baseline stabilizes.

(5) Inject a sample.

(6) When analysis is finished, turn the power off and dispose

of the waste solution.

NOTICE: Before connecting a new column, make sure the flow

path is filled with mobile phase so that air won’t enter the

column.

NOTICE: The whirring sound of the pump during operation

varies depending on such operating conditions as flow rate and

pressure. Although the whirring sound may become larger

anywhere in the high-pressure range, it is not a symptom of

abnormality.

4 -

Page 53

9

4.2.2 Analyzing Operation

(1) SET PROGRAM allows the generation of a maximum of 9 programs.

You can execute any of the programs selected or generated via the SET PROGRAM.

For a gradient analysis, implement the following procedure.

(a) Select [INITIAL] , and select or generate a program for eluent.

(b) Turn on each pump.

(c) Start the program.

(2) Contents of SET PROGRAM

For the SET PROGRAM, enter the upper limit pressure level, lower limit pressure

level, mixing ratio, flow rate, and event.

PROG No.=1

PRESSURE MAIN MAX MIN (MPa)

20.0 0

(a)

TIME FLOW EVENT

0.0 1.000

10.0 1.000 11 21 31 41

10.1 1.000

20.0 1.000

(b) 25.0 10 20 30 40

30.0 2.000

30.1 1.000

40.0 1.000 00 92

Fig. 3-4 Example of Program

(a) For EVENT, up to 4 event codes are settable at each time point. It is

possible to generate contact outputs at each EVENT terminal at the same

time. You can also obtain an internal action, such as a pump stop and the

ringing of a buzzer.

Example) EVENT= 1 - 1 - ENTER - 2 - 1 - ENTER

4 -

Page 54

3.9

(b) In case that an event setting is desired independent of FLOW , only the event

code showed be entered. Press ENTER to skip all the entries you do not

want until you reach event column.

In the SET PROGRAM mode, the interpolation of mixing ratio, flow rate, etc. that

occurs in a time program is as follows.

Parameter Flow Rate

Interpolation Linear

TN T

N+1

TN, T

: Preset time

N+1

NOTICE: For generating a stepwise gradient program, utilize T

- TN = 0.1.

N+1

4 - 10

Page 55

(1) New Generation of a Program

This section shows the generation of a new program.

SET PROG (SET PROG No.) ENTER

(MODIFY=0, NEW=1) 1 ENTER

(MAX) ENTER (MIN) ENTER

(TIME) Set time (Ti) ENTER

(FLOW) Set flow rate (Fi) ENTER

(EVENT) Event code (E1i) ENTER

Event code (E2i) ENTER

Event code (E3i) ENTER

Event code (E4i) ENTER

3 4

Upper limit pressure

level

5

6

7

7

7

7

8 Repeat steps 5 to 7 until you define all programs lines.

9 To terminate the program generation press [ESC]

2

1

No. of program to be

generated (m)

Lower limit pressure

level

4 - 11

Page 56

1 Program number can be from 1 to 9.

2 When you want to define a new program, enter 1.

As a result, you will delete the previous program.

For modifying the contents of program, enter 0.

3 If pump pressure rises beyond the level set here, the pump automatically stops.

4 If pump pressure falls below the level set here, the pump automatically stops.

5 The set time can be from 0.0 to 600.0.

6 Flow rate valid entries are from 0.00 to 2.499 (L-2100). Flow rate valid entries are

from 0.00 to 9.999 (L-2130).

7 Input the event code. At the set time point, you can stop the pump, generate an

audible signal, markers, timers, etc. When properly interfaced, these signals can

be output to an external system. No display will show on the screen unless an

event is set.

8 Repeat steps 5 to 7 until you complete the program and then press [ESC] .

9 Program generation will be terminated and the monitor screen will reappear.

For confirming the input conditions, check the parameters at each time point by using

keys.

4 - 12

Page 57

2) Deletion of Program

(

How to delete a program is shown next.

SET PROG (SET PROG No.)

ENTER (MODIFY=0, NEW=1) 1 ENTER ESCAPE

1

No. of program to be

deleted (m)

2 3

(3) Deletion of Step

How to delete one step in a program is shown next.

SET PROG (SET PROG No.)

1

ENTER (MODIFY=0, NEW=1) No. of program containing step to be

deleted (m)

2 3

0 ENTER (MAX) ENTER (MIN)

4 5 6 7

Lower limit pressure

level

ENTER DELETE ENTER ESCAPE

Upper limit pressure

level

4 - 13

Page 58

1 Program number can be from 1 to 9.

2 The contents of the existing program will be deleted.

3 The monitor screen reappears.

1 Program number can be from 1 to 9.

2 For editing, input 0. For generating a new program, input 1.

3 If pump pressure rises beyond the level set here, the pump automatically stops.

4 If pump pressure falls below the level set here, the pump automatically stops.

.

5 Press the key until the step you want to delete appears on the screen. If display

advances beyond that step, press the

key.

6 Press the [DEL] key when the cursor is on the TIME line want to delete.

7 To finish editing, press the [ESC] key. The display should then return to the

monitor screen.

4 - 14

Page 59

(4) Addition of Step

SET PROG (SET PROG No.) ENTER

(MODIFY=0, NEW=1) 0 ENTER

(MAX) ENTER (MIN) ENTER

(TIME) Time point of step added (Ti) ENTER

(FLOW) Set flow rate (Fi) ENTER

(EVENT) Event code (E1i) ENTER

Event code (E2i) ENTER

Event code (E3i) ENTER

Event code (E4i) ENTER

3 4

Upper limit pressure

level

5

6

7

7

7

7

2

1

No. of program for adding

a step (m)

Lower limit pressure

level

4 - 15

Page 60

1 Program number can be from 1 to 9.

2 For editing, input 0. For generating a new program, input 1.

3 If pump pressure rises beyond the level set here, the pump automatically stops.

.

4 If pump pressure falls below the level set here, the pump automatically stops. The

.

5 Input the time point of the step you want to add.

6 Flow rate valid entries are from 0.00 to 2.499 (L-2100). Flow rate valid entries are

from 0.00 to 9.999 (L-2130).

7 Input the event code. At the set time point, you can stop the pump, generate an

audible signal, markers, times, etc. When properly interfaced, these signals can be

output to an external system. No display will show on the screen unless an event is

set.

4 - 16

Page 61

(5) Correction of Step

Step correction method is explained here.

SET PROG (SET PROG No.)

1

ENTER No. of program containing step to be

deleted (m)

(MODIFY=0, NEW=1) 0 ENTER

(MAX) ENTER (MIN) ENTER

5

(TIME) Time point of step added (Ti) ENTER

(FLOW) Set flow rate (Fi) ENTER

(EVENT) Event code (E1i) ENTER

Event code (E2i) ENTER

Event code (E3i) ENTER

Event code (E4i) ENTER

3 4

Upper limit pressure

level

6

7

8

8

8

8

2

Lower limit pressure

level

4 - 17

Page 62

1 Program number can be from 1 to 9.

2 For correction, input 0. For generating a new program, input 1.

3 If pump pressure rises beyond the level set here, the pump automatically stops. ]

4 . If pump pressure falls below the level set here, the pump automatically stops.

5 Press the key until the step to be corrected appears on the screen. If the display

advances beyond that step, press the key.

6 When a correction is unnecessary, press the ENTER key only. The allowable

input range is 0.00 to 2.499.

7 When a correction is unnecessary, press the ENTER key. Valid flow is from 0.00

to 2.499(L-2100). Valid flow is from 0.00 to 9.999(L-2130).

8 Enter the event code. When a correction is unnecessary, press the ENTER key.

4 - 18

Page 63

(6) Deletion of Parameter

The parameter deletion method is shown next.

SET PROG (SET PROG No.)

ENTER No. of program containing parameter to

be deleted (m)

(MODIFY=0, NEW=1) 0 ENTER

(MAX) ENTER (MIN) ENTER

5 1 6 7

ENTER DELETE ENTER

3 4

Upper limit pressure

level

2

Lower limit pressure

level

4 - 19

Page 64

1 Program number can be from 1 to 9.

2 For correction, input 0. For generating program, input 1.

3 If pump pressure rises beyond the level set here, the pump automatically stops.

4 If pump pressure falls below the level set here, the pump automatically stops.

5 Press the key until the step to be corrected appears on the screen. If display

advances beyond that step, press the

key.

6 Move the cursor to the parameter to be deleted.

7 To delete the parameter, press the DELETE key and then press ENTER key.

4 - 20

Page 65

4.3 Setting of Utility Functions

Utility functions such as zero adjustment of pump pressure, selection of pump pressure unit

and column flushing are settable as follows.

4.3.1 Pressure Zero Adjustment

You do not need to perform a pressure zero adjustment every day. The zero point may

change due to a secular change of the pressure sensor, etc. Check the pressure zero point

once a month. If it has drifted, then stop the pump, open the drain valve and carry out the

following operation.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

1 EVENT 4 LINK= OTHERS=6

Select CONDITION .

CONDITION SET Z-ADJ=1 MOTOR-CTRL=2

1 PURGE=3, CALIBRATION=4

Select Z-ADJ (PRESS ZERO ADJUST).

PRESS ZERO ADJUST: YES=1, NO=0 [--]

(OPEN DRAIN VALVE) 0

Open the drain valve, and then enter 1.

Monitor screen

PRESS indication becomes “0” and the pressure zero adjustment is finished.

4 - 21

Page 66

Pump Motor Control Method

4.3.2

Automatic flow rate control method (STANDARD) and constant flow rate control method

(FIX) are available as pump motor control methods.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

EVENT 4 LINK= OTHERS=6

Select CONDITION .

CONDITION SET Z-ADJ=1 MOTOR-CTRL=2

2 PURGE=3, CALIBRATION=4

Select MOTOR-CTRL (MOTOR CONTROL).

MOTOR CONTROL: STANDARD=1, FIX=2 [--]

1

STANDARD

Monitor screen

MOTOR CONTROL is set to STANDARD.

FIX

FIX STEP AREA

<0, 30-300> 100

Enter a FIX STEP AREA.

Input range is 0, and from 30 to 300.

Monitor screen

NOTICE: Select “STANDARD” for Model L-2100/2130 pump.

4 - 22

Page 67

4.3.3 Purge Flow Rate

Set a flow rate when executing purge.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

1 EVENT 4 LINK= OTHERS=6

Select CONDITION.

CONDITION SET Z-ADJ=1 MOTOR-CTRL=2

2 PURGE=3, CALIBRATION=4

Select PURGE.

PURGE FLOW: FLOW [--]

<0.001-2.499> 2.499

Enter a purge flow rate.

Monitor screen

Pressing the Purge key in PUMP ON status activates purging at the set flow rate. Pressing

the Purge key again during purge will reset the purge function. During purge, the upper

pressure limit is set at 2.9 MPa (30 kgf/cm2) and the lower pressure limit at

0 MPa (0 kgf/cm2).

4 - 23

Page 68

4.3.4 Flow Calibration

Set a parameter of flow rate calibration.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

1 EVENT 4 LINK= OTHERS=6

Select CONDITION.

CONDITION SET Z-ADJ=1 MOTOR-CTRL=2

4 PURGE=3, CALIBRATION=4

Select CALIBRATION.

CALIBRATION FLOW=1PRESS=2

Select FLOW.

FLOW CALIB. 0.97 – 1.03

1.000

Enter a parameter o flow rate calibration

Monitor screen

.

4 - 24

Page 69

4.3.5 Pressure Calibration

Set a parameter of pressure calibration.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

EVENT 4 LINK=5 OTHERS=6

Select CONDITION.

CONDITION SET Z-ADJ=1 MOTOR-CTRL=2

4 PURGE=3, CALIBRATION=4

Select CALIBRATION.

CALIBRATION FLOW=1PRESS=2

2

Select PRESS.

FLOW CALIB. 0.900 – 1.100

1.000

Enter a parameter of pressure calibration

Monitor screen

.

4 - 25

Page 70

4.3.6 Pressure Unit

Pump pressure unit is selectable from bar, psi, kgf/cm2 and MPa.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

2 EVENT 4 LINK= OTHERS=6

Select UNIT.

PRESS UNIT: <bar=1, psi=2, kgf/cm2=3, [--]

<1-4> 1 MPa=4>

Select pressure unit.

Monitor screen

Pressure indication unit is set to selected one.

The set pressure unit is retained in memory even after turning off power supply. The

relationship among selectable pressure units is listed below.

bar psi kgf/cm

2

MPa

10.0 145 10.2 1.00

4 - 26

Page 71

4.3.7 Column Flushing

Automatic pump stop and/or column flushing after completion of analysis is settable.

By setting for column flushing, the flushing will be done automatically after the end of

analysis. When a salt solution has been used for analysis, for example, elution of the salt

component can be prevented by flushing the column with water.

An example is given where the column is flushed for 30 minutes with 100% liquid C 15

minutes after the end of analysis.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

4 EVENT 4 LINK= OTHERS=6

Select FLUSH.

PUMP AUTO STOP: YES=1, NO=0 [--]

1

Select YES (PUMP AUTO STOP).

COLUMN FLUSH: YES=1, NO=0 [--]

0

[YES]

SET DELAY TIME: TIME (min) [--]

<1.0-600.0> 600.0

Input the time point of pump stop after completion of

analysis.

Monitor screen

4 - 27

Page 72

FLUSH MODE: PARAM.=1, PROG.(NO.9)=2 [--]

1

Enter “1” for column flushing under constant conditions, or “2” for column flushing

using a gradient.

[PARAM]

SET DELAY TIME: TIME (min) [--]

<1.0-600.0> 600.0

Input the time period from the end of analysis to the

start of column flushing.

COLUMN FLUSH: FLOW [--]

1.000

Input column flushing conditions (flow rate).

FLUSHING TIME: TIME (min) [--]

<1.0-600.0> 30.0

Column flushing time can be input within 1.0 to 600.0

min.

Monitor screen

[NO]

Monitor screen

When the time for column flushing arrives, the flushing is

executed according to No.9 program.

NOTICE: The program for column flushing is fixed at No. 9.

Upon selecting column flushing, program No. 9 is

automatically set for flushing.

When column flushing is set, program No. 9 is not

usable as a gradient program. But program No. 9 is

usable with a link program.

The pump is stopped automatically when program

No. 9 ends.

4 - 28

Page 73

Following is the relation between delay time and column flush.

Analysis 1

Analysis 2

Analysis 3

Analysis n

∗

Analysis 1

Analysis 2

Analysis 3

Analysis n

∗

Analysis 1

Analysis 2

Analysis 3

Analysis n

∗

Delay time Column flush

Gradient end

(1) With AUTO STOP at YES

(a) When YES is selected for COLUMN FLUSH

Stabilizing time

“n” indicates number of analyses specified with autosampler, etc.

∗

Stabilizing time is the time from the end of one analysis until the start of the

next analysis.

Column flushing starts when delay time has ended.

(b) When NO is selected for COLUMN FLUSH

Stabilizing time

“n” indicates number of analyses specified with autosampler, etc.

∗

Stabilizing time is the time from the end of one analysis until the start of the

next analysis. The pump stops when delay time has ended.

(2) With AUTO STOP at NO

“n” indicates number of analyses specified with autosampler, etc.

∗

Stabilizing time

The pump remains in liquid delivery status.

Delay time COLUMN FLUSH

Pump stop

Pump stop

Delay time

Pump remains in

liquid delivery status.

4 - 29

Page 74

4.3.8 Event Signal Code

The event should be executed manually. The event function works upon input of an event

code. It is used for starting an external device, for stopping the pump, for sounding the

buzzer, etc.

Also, if a pressure limiter error occurs, a signal can be output at event code No. 4.

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

4 EVENT 4 LINK= OTHERS=6

Select EVENT.

EVENT SET: PRESS LIMIT=1, EVENT CODE=2, [--]

1

[PRESS LIMIT]

PRESS LIMIT: NONE=0, PULSE=1, LEVEL=2 [--]

<0-2> 1 (EVENT NO. 4)

Enter the desired code. If a pressure limit error is

detected, an event signal is output at EVENT No. 4.

Monitor screen

SET EVENT CODE: [--]

<0-92>

Input event code.

Monitor screen

4 - 30

Page 75

Event codes and related operations are explained below.

Contact

Contact

Signal

marker

Control Item Event Code Remarks

Timer

1

2

3

4

Action

10

20

30

40

opens.

Start

point

turns

off.

11

21

31

41

Start

point

closes.

Signal

turns on.

Open

12

22

32

42

1 s

Close

1st digit:

Timer no.

2nd digit:

Action pattern

Contact closes for 1 sec.

∗

∗

Pump 00 Pump stops

Buzzer 92 Buzzer sounds for 5 sec

4 - 31

Page 76

4.3.9 Error In Signal

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

6 EVENT 4 LINK= OTHERS=6

Select OTHERS.

OTHERS ERROR IN=1LEAK SENSOR =2

1

Select ERROR IN.

ERROR IN SIGNAL DISABLE=0PUMP OFF=1

1

DISABLE: The pump is not used ERROR signal to stop the unit in e-Line

PUMP OFF: The pump stops the flow when it received the ERROR signal

Monitor screen

in e-Line

4 - 32

Page 77

4.3.10 Leak Sensor

Monitor screen

UTLTY

UTILITY CONDITION=1 UNIT=2 FLUSH=

6 EVENT 4 LINK= OTHERS=6

Select OTHERS.

OTHERS ERROR IN=1LEAK SENSOR =2

2

Select LEAK SENSOR.

LEAK SENSOR OFF=0 ON=1

0

Select “ON” for using the leak sensor or “OFF” for avoiding its

use

Monitor screen

4 - 33

Page 78

4.4 Setting of GLP Functions

Explained here are the confidence functions such as logbook display and resetteng.

4.4.1 Logbook

Logbook can be displayed or reset.

(1) Logbook Display

Logbook can be displayed in the following procedure.

Monitor screen

GLP

GLP: LOGBOOK=1, PRESS M.=2, [--]

1 KEY LOCK=3

Select LOGBOOK

LOG BOOK: REPORT=1, RESET=2, [--]

1

Select REPORT for displaying logbook or RESET for resetting the logbook.

REOPORT

LOGBOOK/REPORT [--]

SOLVENT=99999 1 (2 25 2002)

Total flow after replacement of the pump seal will be

displayed. Pump seal replacement date (month, day,

year) is indicated in parentheses.

ESC

Monitor screen

4 - 34

Page 79

RESET

LOGBOOK/RESET: [--]

(MM, DD, YYYY) 2 25 2002

Logbook is reset.

NOTICE: Input the date of pump seal replacement.

Input is allowed in the order of month (M),

day (D) and year (Y).

Upon resetting, total flow value is reduced to

0 and the integration of flow starts. Unless

the ENTER key is pressed after entry of

all date values, resetting does not become

effective.

Even when the year is the same as the

displayed one, you should enter all values

and then press the ENTER key.

Monitor screen

4 - 35

Page 80

4.4.2 Pressure Monitor

The number of double-speed section errors in each measurement can be indicated.

A double-speed section error indicates that the pressure did not return to the reference level

(previous pressure) even after double-speed control (an increase of pump motor speed) was

effected to compensate for a pressure drop. This may be caused by formation of air

bubbles in the flow path.

Monitor screen

GLP`

GLP: LOGBOOK=1, PRESSURE M.=2, [--]

2 KEY LOCK=

Select PRESSURE M.

PRESSURE MONITOR [--]

9999 TIMES

Display the number of double-speed section errors.

ESC

Monitor screen

Resetting occurs on the following occasions.

On input of [PUMP ON] or [PUMP OFF]

•

On activation of contact

•

On start of gradient elution

•

On reception of start signal from integrator in D-line configuration

•

On external start of pump

•

On input of [PURGE ON] or [PURGE OFF]

•

4 - 36

Page 81

4.4.3 Key Lock

Keyboard keys can be locked.

Monitor screen

GLP

GLP: LOGBOOK=1, PRESSURE M.=2, [--]

3 KEY LOCK=3

Select KEY LOCK.

KEY LOCK: YES=1, NO=0

1

Locks the keys on the operation panel in order to prevent undesired key entries.

Monitor screen

(LOCK OFF)

ESC

Key lock can be released by the [ ESCAPE (LOCK OFF) ] key.

Monitor screen

3.8.3

4 - 37

Page 82

1

5. MAINTENANCE

5.1 Checking the Performance and Specifications

Performance checking method is explained here.

5.1.1 Items to be

Prepared for

Performance

Check

The following items are required for performance check.

(1) Component Units of Liquid Chromatography System

Pump (Hitachi L-2100/2130 or equivalent)

•

Detector (Hitachi L-2400 or equivalent)

•

Data processing unit

•

Waste liquid bottle

•

: If deaeration of detergent is inadequate, full

NOTE

performance may not be provided. In this

case, deaerate the detergent sufficiently of

connect it through a degasser.

(2) Items for Performance Check

Prepare the following items for performance check.

Load resistance coil

•

A coiled stainless tube with an inner diameter of

0.25 mm and a length of 10 m

60% methanol in about 1000 mL

•

A mixture of methanol 60% and distilled water 40% in

volume. This should be prepared separately.

Distilled water in about 500 mL

•

(3) Performance Check Parts Attached to Model L-2200

Autosampler

Standard sample

•

60% methanol solution of methylparaben

(Methylparaben 6 mg in methanol 60 mL + distilled

water 40 mL)

Sample vial, cap, septum

•

Standard rack

•

5 -

Page 83

2

(Injection valve)

Waste liquid

5.1 Checking the Performance and Specifications

5.1.2 Preparing the

System for

Operation

(1) Figure 5-1 shows how to connect the units for performance

check. According to this figure, carry out tubing.

Before energizing the system, ensure that the tubing

between the autosampler and pump/detector is properly

connected.

Detector (wavelength 250 nm, time constant 0.1 s)

Load resistance coil

stainless pipe 0.1 mm i.d. × 10 m long(L-2100)

stainless pipe 0.25 mm i.d. × 10 m long(L-2130)

Autosampler

bottle