Page 1

HITACHI

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

L100-M Series Inverter

Quick Reference Guide

• Single-phase Input 100V Class

Hitachi Industrial Equipment Systems Co., Ltd.

Manual No. NB5741XD • December 2003

Page 2

Caution: Be sure to read the L100 Inverter Manual and

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

follow its Cautions and Warnings for the initial product

installation. This Quick Reference Guide is intended for

reference use by experienced users in servicing existing

installations.

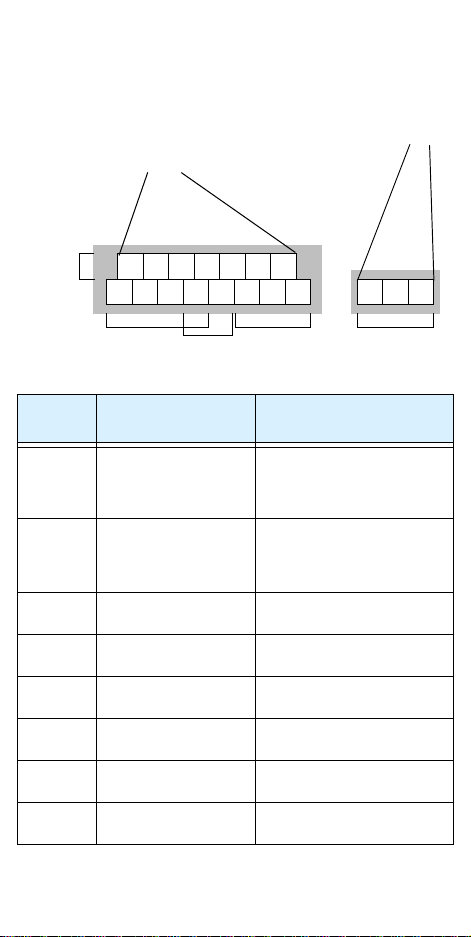

Power Circuit Terminals

–002NFE/NFU, –004NFE/NFU, –005NFE

Jumper

(/) +1 + –

L1 L2 N/L3 U/T1 V/T2 W/T3

Chassis

Ground

–007 to 022NFE/NFU, –037LFU, 004 to 040HFE/HFU

Jumper

(/) +1 + –

L1 L2 N/L3 U/T1 V/T2 W/T3

Chassis

Ground

–055LFU, –075LFU, 055HFE/HFU, 075HFE/HFU

Jumper

(/) +1 + –

L1 L2 N/L3 U/T1 V/T2 W/T3

Chassis

Ground

1

Page 3

Control Circuit Terminals

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Logic

inputs

Terminal

Name

L

5 4 3 2 1

H O OI

Analog

inputs

FM

L

Analog

outputs

Description Ratings and Notes

CM2

P24

12 11

Logic

outputs

AL0 AL1 AL2

Alarm

relay

P24 +24V for logic inputs 24VDC supply, 30 mA max.

(Notes: Do not use for

network power

Do not short to terminal L)

1, 2, 3, 4, 5Intelligent (program-

mable) discrete logic

inputs

11, 12 Discrete logic outputs 50 mA max. ON current,

L (top

row)

CM2 Common for logic

GND for logic inputs Sum of input 1 to 5 currents

outputs

FM PWM output 0 to 10VDC, 1 mA max.,

L (bottom

row)

Common for analog

inputs

OI Analog input, current 4 to 19.6 mA range, 20 mA

27VDC max. (use P24 or an

external supply referenced to

terminal L), 4.7kΩ input

impedance

27 VDC max. OFF voltage

(Note: Do not ground)

100 mA max for sum of

terminals 11 and 12 currents

50% duty cycle

Sum of OI, O, and H

currents (return)

nominal

2

Page 4

Terminal

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Name

Description Ratings and Notes

O Analog input, voltage 0 to 9.6 VDC range, 10VDC

nominal, 12VDC max., input

impedance 10 kΩ

H +10V analog reference 10VDC nominal, 10 mA

AL0 Relay common contact

AL1 Relay contact,

normally closed

during RUN

AL2 Relay contact,

normally open during

RUN

max.

Contact rating

Max resistive load = 250VAC,

2.5A; 30VDC 3A;

Max inductive load = 250VAC,

0.2A; 30VDC 0.7A

Minimum load = 5VDC 100mA,

100VAC, 10mA

3

Page 5

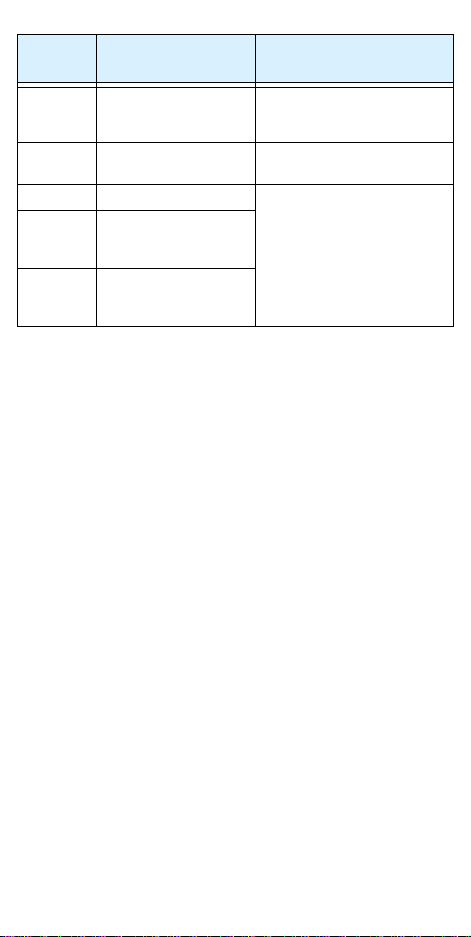

Basic Wiring Diagram

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

The following wiring diagram shows the power and motor connections for basic operation. The optional signal input wiring supports

external Fwd and Rev Run command, and a speed potentiometer.

L100

From 3-phase

power input

source (See

specifications

label on inverter

for details)

Inputs:

Forward

Reverse

Analog reference

External

speed

reference

pot.

Analog common

R

(L1)

S

(L2)

T

(N/L3)

P24

1

2

H

O

L

U

(T1)

V

(T2)

W

(T3)

AL1

Alarm contacts,

AL0

AL2

Open collector

outputs:

Run signal

12

arrival signal

11

CM2

Motor

1 Form C

Load

Load

Frequency

Logic output

common

4

Page 6

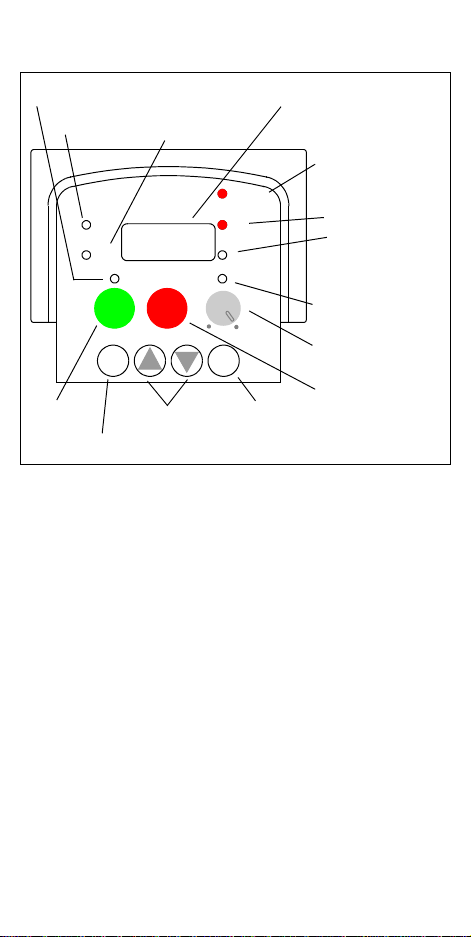

Inverter Keypad Operation

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Run Key Enable LED

Run/Stop LED

RUN

PRG

RUN

FUNC.

Run Key

Up/Down Keys

Function Key

Parameter Display

Program/Monitor LED

HIT ACHI

50.0

STOP

RESET

MIN

2

1

STR

POWER

Hz

A

MAX

Store Key

Power LED

Display Units LEDs

Hertz

Amperes

Potentiometer

Enable LED

Potentiometer

Stop/Reset Key

• Run/Stop LED – ON when the inverter output is ON and the

motor is developing torque, and OFF when the inverter output is

OFF (Stop Mode).

• Program/Monitor LED – ON when the inverter is ready for

parameter editing (Program Mode). It is OFF when the parameter

display is monitoring data (Monitor Mode).

• Run Key Enable LED – ON when the inverter is ready to

respond to the Run key, OFF when the Run key is disabled.

• Run Key – Press this key to run the motor (the Run Enable LED

must be ON first). Parameter F_04, Keypad Run Key Routing,

determines whether the Run key generates a Run FWD or Run

REV command.

• Stop/Reset Key – Press this key to stop the motor when it is

running (uses the programmed deceleration rate). This key will

also reset an alarm which has tripped.

(continued, next page...)

5

Page 7

• Potentiometer – Allows an operator to directly set the motor

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

speed when the potentiometer is enabled for output frequency

control.

• Potentiometer Enable LED – ON when the potentiometer is

enabled for value entry.

• Parameter Display – A 4-digit, 7-segment display for parame-

ters and function codes.

• Display Units: Hertz/Amperes – One of these LEDs will be ON

to indicate the units associated with the parameter display.

• Power LED – ON when the power input to the inverter is ON.

• Function Key – This key is used to navigate through the lists of

parameters and functions for setting and monitoring parameter

values.

• Up/Down Keys – Use these keys alternately to move up or down

the lists of parameter and functions shown in the display, and to

increment/decrement values.

• Store Key – When the unit is in Program Mode and the operator

has edited a parameter value, press the Store key to write the new

value to the EEPROM.

6

Page 8

Keypad Navigation Map

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Monitor Mode Program Mode

Display data

o.0

FUNC.

d

09

1

2

d

01

1

2

C––

1

2

b

––

1

2

A––

1

2

F04

1

2

Select Parameter Edit Parameter

powerdown

c91

1

2

c01

1

2

b

89

01

FUNC.

2

FUNC.

2

FUNC.

1

b

1

A98

1

2

A01

FUNC.

Store as

powerup

default

Increment/

decrement

value

1

2

Edit

123.4

STR

Write data

to

EEPROM

F01

Return to

parameter list

7

Page 9

Powerup Test

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

The Powerup Test procedure uses minimal parameter settings to run

the motor. The procedure describes two alternative methods for

commanding the inverter: via the inverter keypad, or via the logic

terminals.

• Check power input and motor output wiring (see page 4 diagram).

• If using logic terminals for testing, verify correct wiring on [P24],

[FW], [H], [O], and [L] (bottom row) per the diagram on page 4.

• Reverse [RV] input wiring (defaults to terminal [2]) is optional.

Step Description Via Keypad

1 Set speed command

source setting

2 Set Run FW command

source

3 Set Run REV command

source

4 Set motor base freq. A_03 = 60

5 Set keypad display to

monitor freq.

Perform safety check Disconnect load from motor

6 Turn keypad pot.

7 Run Forward command Press Run key Turn ON the

8 Increase speed Rotate keypad

9 Decrease speed Rotate keypad

10 Stop motor Press Stop key Turn OFF the

11 Run Reverse command

(optional)

12 Stop motor — Turn OFF the

A_01 = 00

(keypad pot.)

A_02 = 02

(Run key)

— C_02 = 01,

Access D_01, press Func key, display

will show

0.0

to MIN position

pot. CW dir.

pot. CCW dir.

— Turn ON the [RV]

Via Logic

Terminals

A_01 = 01,

[H–O–L] input

A_02 = 01,

[FW] input

[RV] input

Ensure voltage on

[O]—[L] terminals= 0V

[FW] terminal

Increase voltage

at [O]

Decrease voltage

at [O]

[FW] terminal

terminal

[RV] terminal

8

Page 10

Error Codes

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

The L100 series inverters will trip on over-current, over -voltage, and

under-voltage to protect the inverter. The motor output turns OFF,

allowing the motor to free-run to a stop. Press the Stop/Reset key to

reset the inverter and clear the error.

Basic Error Codes

Error

Code

E01

E02

E03

E04

E05

E07

E08

E09

E11

Name Probable Cause(s)

Over current event while

at constant speed

Over current event during

deceleration

Over current event during

acceleration

Over current event for

other conditions

Overload protection • Motor overload is detected by the

Over voltage protection • DC bus voltage exceeds a threshold,

EEPROM error • Built-in EEPROM memory experi-

Under-voltage error • DC bus voltage decreased enough to

CPU error • Built-in CPU had internal error

• Inverter output was short-circuited

• Motor shaft is locked

• Load is too heavy

• A dual-voltage motor is wired

incorrectly

Note: The L100 will over current trip

at nominally 200% of rated current

• DC braking power(A_54) set too

high

• Current transformer / noise error

electronic thermal function

due to regenerativ e en ergy from motor

enced noise, high temperature, etc.

cause a control circuit fault

E22

External trip • [EXT] input signal detected

E12

USP (Unattended Start

E13

Protection)

Ground fault • A ground fault was detected

E14

Input over-voltage • Input voltage was higher than the

E15

Inverter thermal trip • Inverter internal temperature is

E21

• When (USP) was enabled, an error

occurred when power was applied

while a Run signal was present

between the inverter output and the

motor. This feature protects the

inverter, and does not protect humans.

specified value, 60 sec. after powerup

above the threshold

9

Page 11

Error

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

E35

---

Name Probable Cause(s)

Thermistor • Thermistor input, [THM] and [L], is

Under-voltage (brown-

out) with output shutoff

over the temp. threshold

• Low input voltage caused the

inverter to turn OFF the motor output

and try to restart. If unsuccessful, a

trip occurs.

Error Trip Conditions

Use function code D_08 to access the error trip conditions for the

current error as shown in the table below. Use the Up and Down

arrow keys to scroll through the trip condition parameters.

Step Display

1. Access D_08

2. Press Function Key If no error:

d 08

_ _ _

If error exists:

Exx

(error code)

3. Press Up/Dn key (if

error exists)

Output frequency at

trip point:

10.0

Motor current at trip

1

point:

0.025

2

DC bus voltage at trip

point:

189.8

10

Page 12

Restoring Factory Default Settings

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Action Display Function/Parameter

1

FUNC.

Press , or as

needed.

FUNC.

Press .

Press/hold until...

Press . If setting is

correct, then skip next step.

1

FUNC.

b --

2

b 01

b 85

02

“B” Group selected

First “B” Group parameter

Country code for

initialization selected

00 = Japan

01 = Europe

02 = United States

To change country code, press

FUNC.

Press .

2

Press .

FUNC.

Press .

1

Press .

STR

Press .

1

Press/hold , , and

2

Press/hold (STOP) for

3 seconds, then release.

Now release the all keys

together, only after “D_00”

display begins blinking.

FUNC.

. Do not release yet.

STOP

RESET

b 85

b 84

00

01

b 84

b 84

d 00

EU

USA

1

2

or to set; to store.

Country code for

initialization selected

Initialization function

selected

0 = disable initialization,

clear trip history only

1 = enable initialization

Initialization now

enabled to restore all

defaults

First part of key sequence

Final part of special

sequence, “D_00” is

flashing

Default parameter

country code shown

during initialization

STR

JP

Initialization is complete.

d 01

Function code for output

frequency monitor shown

11

Page 13

Note: After initializing the inverter, use the Powerup Test

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

on page 8 to get the motor running again.

Parameter Tables

“D” Group: Monitoring Functions

Func.

Code

D_01 Output frequency monitor Hz

D_02 Output current monitor A

D_03 Rotation direction monitor —

D_04 Process variable (PV), PID feedback monitor %

D_05 Intelligent input terminal status —

D_06 Intelligent output terminal status —

D_07 Scaled output frequency monitor

(output frequency x B_86 scale factor)

D_08 Trip event monitor —

D_09 Trip history monitor —

Name / Description Units

Forward

Stop Reverse

Direction

ON

OFF

2 1435

Terminal Numbers

ON

OFF

12 11AL

Terminal Numbers

User-

defined

12

Page 14

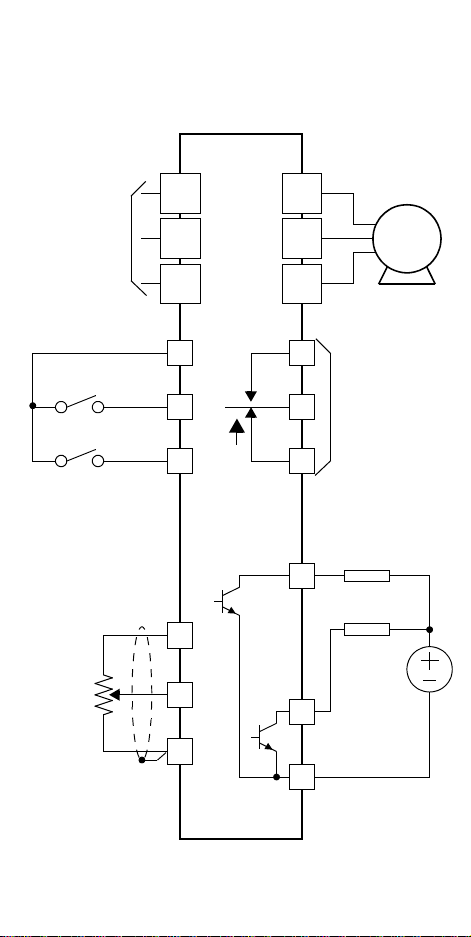

T r ip History Navigation Map

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Monitor Mode

Display data

o.0 0

FUNC.

1

2

d

08

1

2

d

09

1

2

FUNC.

FUNC.

FUNC.

Error

exists?

Yes

E07

1

60.0

1

4.0 0

1

270.0

(n-1)

Error

exists?

Yes

E03

FUNC.

No

Error code

2

Output frequency

at trip point

2

Motor current

at trip point

2

DC bus voltage

at trip point

No

No error

____

No

history

____

FUNC.

(n-2)

Yes

FUNC.

No

No

history

____

FUNC.

Error

exists?

E05

13

Page 15

Parameter tables for user-settable functions follow these conven-

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

tions:

• Some parameters specify an option code. Where applicable, the

options codes will be in a bulleted list in the Name/Description

column.

• The default values apply to all models unless otherwise noted for

each parameter... –FE (Europe) / – FU (U.S.) / –FR (Japan).

• Some parameters cannot be edited during Run Mode, and certain

Software Lock settings (B_31) can prohibit all edits. If in doubt,

place the inverter in Stop Mode or consult the inverter manual for

details.

“F” Group: Main Profile Parameters

Func.

Code

F_01 Output frequency setting 0.0

F_02 Acceleration (1) time setting 10.0

F_03 Deceleration (1) time setting 10.0

F_04 Keypad Run key routing

Name / Description

•00Forward •01Reverse

Default

Value

00

Set

Value

14

Page 16

“A” Group: Standard Functions

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Func.

Code

A_01 Frequency source setting

A_02 Run command source setting

A_03 Base frequency setting 50.0 / 60.0 /

A_04 Maximum frequency setting 50.0 / 60.0 /

A_11 O/OI–L input active range start

A_12 O/OI–L input active range end frequency 0.0

A_13 O/OI–L input active range start voltage 0

A_14 O/OI–L input active range end voltage 100

A_15 O/OI–L input start frequency enable

A_16 External frequency filter time constant 8

A_20 Multi-speed frequency setting 0

A_21

A_22

A_23

A_24

A_25

A_26

A_27

A_28

A_29..

..A_35

A_38 Jog frequency setting 1.0

A_39 Jog stop mode

Name / Description

• 00 Keypad potentiometer

• 01 Control terminal

• 02 Function F_01 setting

• 01 Input terminal FW or RV (assignable)

• 02 Run key on keypad, or digital

operator

frequency

• 00 Use A_11 starting value)

• 01 Use 0 Hz

Multi-speed frequency settings 0 / 0 / 5

• 00 Free-run stop, jogging disabled

during motor run

• 01 Controlled deceleration, jogging

disabled during motor run

• 02 DC braking to stop, jogging

disabled during motor run

Default

Value

–FE / –FU /

–FR

01 / 01 / 00

01 / 01 / 02

60.0

60.0

0.0

01

0 / 0 / 10

0 / 0 / 15

0 / 0 / 20

0 / 0 / 30

0 / 0 / 40

0 / 0 / 50

0 / 0 / 60

0 / 0 / 0

00

Set

Value

15

Page 17

Func.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

Name / Description

A_41 Torque boost method selection

• 00 Manual torque boost

• 01 Automatic torque boost

Default

Value

–FE / –FU /

–FR

00

A_42 Manual torque boost value 11

A_43 Manual torque boost frequency adjust-

ment

A_44 V/f characteristic curve selection

• 00 V/f constant torque

• 01 V/f variable torque

10.0

00

A_45 V/f gain setting 100

A_51 DC braking enable

• 00 Disable • 01Enable

00

A_52 DC braking frequency setting 0.5

A_53 DC braking wait time 0.0

A_54 DC braking force during deceleration 0

A_55 DC braking time for deceleration 0.0

A_61 Frequency upper limit setting 0.0

A_62 Frequency lower limit setting 0.0

A_63

Jump (center) frequency setting 0.0

A_65

A_67

A_64

Jump (hysteresis) frequency width

A_66

setting

A_68

A_71 PID Enable

• 00 PID operation OFF

• 01 PID operation ON

0.5

00

A_72 PID proportional gain 1.0

A_73 PID integral time constant 1.0

A_74 PID derivative time constant 0.0

A_75 PV scale conversion 1.00

A_76 PV source setting

• 00 [OI] terminal (current input)

• 01 [O] terminal (voltage input)

A_81 AVR function select

• 00 AVR enabled • 01 AVR disabled

• 02 AVR enabled except during decel

00

02 / 00 / 02

Set

Value

16

Page 18

Func.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

A_82 AVR voltage select 230/230/200

A_92 Acceleration (2) time setting 15.0

A_93 Deceleration (2) time setting 15.0

A_94 Select method to switch to Acc2/Dec2

A_95 Acc1 to Acc2 frequency transition point 0.0

A_96 Dec1 to Dec2 frequency transition point 0.0

A_97 Acceleration curve selection

A_98 Deceleration curve selection

Name / Description

profile

• 00 2CH input from terminal

• 01 transition frequency

• 00 Linear • 01 S-curve

• 00 Linear • 01 S-curve

Default

Value

–FE / –FU /

–FR

400/460/400

00

00

00

“B” Group: Fine-tuning Functions

Set

Value

Func.

Code

B_01 Selection of automatic restart mode

B_02 Allowable under-voltage power failure

B_03 Retry wait time before motor restart 1.0

Name / Description

• 00 Alarm output after trip, automatic

restart disabled

• 01 Restart at 0Hz

• 02 Resume operation after frequency

matching

• 03 Resume previous freq. after freq.

matching, then decelerate to stop and

display trip info

time

Default

Value

–FE / –FU /

–FR

00

1.0

Set

Value

17

Page 19

Func.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

Name / Description

B_12 Level of electronic thermal setting Rated

B_13 Electronic thermal characteristic

• 00 Reduced torqu e • 01 Const. torque

B_21 Overload restriction operation mode

• 00 Disabled

• 01 Enabled for accel and constant

speed

• 02 Enabled for constant speed only

B_22 Overload restriction setting Rated

Default

Value

–FE / –FU /

–FR

current of

each inverter

01 / 01 / 00

01

current

x 1.25

B_23 Deceleration rate at overload restriction 1.0

B_31 Software lock mode selection

• 00 Low-level access, [SFT] blocks

edits

• 01 Low-level access, [SFT] blocks

edits (except F_01 and Multi-speed

parameters)

• 02 No access to edits

• 03 No access to edits except F_01 and

Multi-speed parameters

B_32 Reactive current setting

Note: For Japanese (–FR) versions, only

–055LFR, –055HFR, –075LFR, and

–075HFR models support this function.

01

58% rated

current

B_81 [FM] terminal analog meter adjustment 80

B_82 Start frequency adjustment 0.5

B_83 Carrier frequency setting 5.0 / 5.0 /

B_84 Initialization mode (parameters or trip

history)

• 00 Trip history clear

• 01Parameter initialization

B_85 Country code for initialization

• 00 Japan version • 01 Europe

version

•02US version

12.0

00

01 / 02 / 00

B_86 Frequency scaling conversion factor 1.0

B_87 STOP key enable

• 00 Enable • 01 Disable

00

Set

Value

18

Page 20

Func.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

B_88 Restart mode after FRS

B_89 Data select for digital operator OPE-J

Name / Description

• 00 Restart from 0Hz

• 01 Restart from frequency detected

from actual speed of motor

• 01 Output frequency (D_01)

• 02 Output current (D_02)

• 03 Motor direction (D_03)

• 04 PID PV feedback (D_04)

• 05 Input states for input terminals

(D_05)

• 06 Output states for output terminals

(D_06)

• 07 Scaled output frequency (D_07)

Default

Value

–FE / –FU /

–FR

00

01

“C” Group: Intelligent Terminal Functions

Set

Value

Func.

Code

C_01 Terminal [1] function Fifteen option

C_02 Terminal [2] function 01

C_03 Terminal [3] function 02 / 16 / 02

C_04 Terminal [4] function 03 / 13 / 03

C_05 Terminal [5] function 18

C_11 Terminal [1] active

C_12 Terminal [2] active

C_13 Terminal [3] active

C_14 Terminal [4] active

C_15 Terminal [5] active

state

state

state

state

state

Name / Description

codes available

(see page 21)

• 00 Normally

open [NO]

• 01 Normally

closed [NC]

Default

Value

–FE / –FU /

–FR

00

00

00

00

00 / 01 / 00

00

Set

Value

19

Page 21

Func.

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Code

C_21 Terminal [11] function Six option

C_22 Terminal [12] function 00

C_23 [FM] signal selection Three option

C_31 Terminal [11] active

C_32 Terminal [12] active

C_33 Alarm relay terminal

Name / Description

codes available

(see page 22)

codes available

(see page 22)

state (–FU)

Reserved (–FE / –FR) 00 / — / 00

• 00 Normally

open (NO)

• 01 Normally

closed (NC)

state (–FU)

Terminal [11] active

state (–FE / –FR)

active state

C_41 Overload level setting Rated

Default

Value

–FE / –FU /

–FR

01

00

— / 00 / —

— / 00 / —

00 / — / 00

01

current of

each inverter

C_42 Frequency arrival setting for accel 0.0

C_43 Arrival frequency setting for decel 0.0

C_44 PID deviation level setting 3.0

C_91 Debug mode enable

• 00 Display • 01No display

00

Set

Value

20

Page 22

Intelligent Input Terminal Listing

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Symbol Code Input Terminal Name

FWD 00 Forward Run/Stop

RV 01 Reverse Run/Stop

CF1 02 Multi-speed select, Bit 0 (LSB)

CF2 03 Multi-speed select, Bit 1

CF3 04 Multi-speed select, Bit 2

CF4 05 Multi-speed select, Bit 3 (LSB)

JG 06 Jogging

2CH 09 2-stage accel and decel

FRS 11 Free-run stop

EXT 12 External trip

USP 13 Unattended start protection

SFT 15 Software lock

AT 16 Analog input voltage/current sel.

RS 18 Reset inverter

PTC 19 PTC thermistor thermal protection

21

Page 23

Intelligent Output Terminal Listing

Clearwater Tech - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.clrwtr.com - Email: info@clrwtr.com

Symbol Code Input Terminal Name

RUN 00 Run signal

FA1 01 Freq. arrival type 1 – constant speed

FA2 02 Freq. arrival type 2 – over-frequency

OL 03 Overload advance notice signal

OD 04 Output deviation for PID control

AL 05 Alarm signal

Analog Input Configuration

The following tables show the parameter settings required for various analog input signal types.

[AT] External Frequency Command Input

OFF [O] — [L]

ON [OI] — [L]

(not assigned to any input

terminal)

Summation of [O] — [L] and [OI] — [L]

Analog Output Function Listing

The following table shows all three functions available for assignment to the analog output terminal:

• Terminal [FM], option set by C_23

Option

Code

Function

Name

00 Output

frequency

01 Output

current

02 Digital output

frequency

Description

Actual motor speed,

represented by PWM

signal

Motor current (% of

maximum rated output

current), represented by

PWM signal

Output frequency 0 to max. freq. in Hz

Corresponding

Signal Range

0 to max. freq. in Hz

0 to 200%

22

Loading...

Loading...