HITACHI

Series Inverter

Instruction Manual

• Single-phase input 200V class

• Three-phase input 400V class

After reading this manual, keep

it handy for future reference

Manual Number: NUL100IPV6

MADE IN SLOVENIA

P

lease read this manual carefully before you install and operate an L100IP series inverter and observe all of

the instructions given in there. This manual may also serve as a reference guide und therefore should always

be kept at hand.

Symbols used

There are several safety instructions in this manual which are marked with a special hazard alert symbol

(flash or exclamation mark in the center of a triangle). Additionally, either the word CAUTION or

WARNING is added following the triangle with the exclamation mark.

This symbol means hazardous high voltage. It is used to call your attention to items or operations

that could be dangerous to your or other persons life. Please read the safety message carefully and

follow all the instructions given.

This symbol is used to call your attention to situations which are potentially dangerous to persons.

Please read the safety message carefully and follow all the instructions given.

The safety messages given following this symbol are further divided into two categories:

WARNING This message indicates a situation which may lead to serious injury or even

death if the instruction is not observed.

CAUTION This message indicates a situation which may lead to minor or moderate

injury, or damage of product.

HAZARDOUS HIGH VOLTAGE

Motor control equipment or electronic controllers are connected to hazardous line

voltages. When servicing drives and electronic controllers there migh exist exposed

components with cases or protrusions at or above line potential. Extreme care should

be taken to protect against shock.

For these reasons, the following safety guidelines should be observed:

Stand on an insulating pad and make it a habit to use only one hand when checking

components. Disconnect power before checking controllers or performing

maintenance. Be sure that equipment is grounded properly. Wear safety glasses

whenever working on an electronic controller or rotating electrical equipment.

WARNING This equipment should be installed, adjusted and serviced only by qualified electrical

maintenace personnel familiar with the construction and operation of the equipment

and the hazards involved. Failure to observe this precaution could result in bodily

injury.

WARNING The user is responsible that all driven machinery, drive train mechanism not supplied

by Hitachi, Ltd., and process line material are capable of safe operation at an applied

frequency of 150% of the maximum selected frequency range to the AC motor. Failure

to do so can result in destruction of equipment and injury to personnel should a single

point failure occur.

WARNING HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER

BEFORE WORKING ON THIS CONTROL.

WARNING SEPARATE MOTOR OVERLOAD AND OVERCURRENT PROTECTION

DEVICES ARE REQUIRED TO BE PROVIDED IN ACCORDANCE WITH THE

SAFETY CODES REQUIRED BY JURISDICTIONAL AUTHORITIES.

CAUTION These instructions should be read and clearly understood before working on L100IP

series equipment.

CAUTION Proper grounds, disconnecting devices (e.g. fuses) and other safety devices and their

location are the responsibility of the user and are not provided by Hitachi, Ltd.

CAUTION DANGEROUS VOLTAGE EXISTS UNTIL THE POWER LIGHT ON THE

DIGITAL OPERATOR IS OFF.

CAUTION Rotating shafts and electrical potentials above ground level can be hazardous.

Therefore it is strongly recommended that all electrical work conform to the national

electrical codes and local regulations. Installation, maintenance and alignment should

be performed by qualified personnell only.

Factory recommended test procedures included in this instruction manual should be

followed. Always disconnect electrical power before working on the unit.

WARNING a) Any motor used must be of suitable rating.

b) Motors may have hazardous moving parts so that suitable protection must be

provided in order to avoid injury.

CAUTION Alarm connections may have hazardous live voltages even when the inverter is

disconnected. In case of removing the front cover for maintenance or inspection,

confirm that incoming power for alarm connections is surely disconnected.

CAUTION Main terminals or other hazardous terminals for any interconnection (terminals for

connecting the motor, contact breaker, filter etc.) must be inaccessible in end

installation.

CAUTION If the unit is used in a manner not specified by the manufacturer the protection

provided by the unit may be impaired..

All of the above instructions, together with any other requirements, reccommendations,

and safety messages highlighted in this manual must be strictly complied with for continued LVD

compliance.

NOTES ON EMC (ELECTRO MAGNETICAL COMPATIBILITY)

WARNING This equipment should be installed, adjusted and serviced by qualified personnel

familiar with construction and operation of the equipment and the hazards

involved. Failure to observe this precaution could result in bodily injury.

When using L100IP series inverters in EU countries, the EMC directive 89/336/EEC must be observed. To

satisfy the EMC directive and to comply with the standard, the following provisions should be obeyed:

A) Environmental conditions for the inverter:

• Ambient temperature: -10°C to 40°C.

• Relative Humidity: 20% to 90% (no dew condensation)

• Vibrations: max. 5,9m/s

2

(0.6 g) at 10–55Hz.

• Location: 1000 meter or less altitude, indoors (no corrosive gas or dust).

B) The power supply to the L100IP inverter must conform to the conditions stated below. If one of the

conditions mentioned is not satisfied then an appropriate L100IP AC reactor will have to be installed.

• Voltage fluctuation +/-10% or less

• Voltage unbalance +/-3% or less

• Frequency variation +/-4% or less

C) Wiring

• Shielded wiring (screened cable) is required for motor wiring, and total length has to be kept to less

than 50m. When using motor cables longer than 50m L100IP motor filters should be installed.

Directions for installing filters can be found in the L100IP installation manual.

• The carrier frequency setting must be less than 5 kHz to satisfy EMC requirements.

• Separate the mains circuit wiring from the wiring used for signals or process circuit. Please refer to

the L100IP installation manual.

D) Installation

• For L100IP series inverters, the filters described hereafter have to be used and the installation notes

have to be observed.

If installed according to the following directions, the frequency inverters comply with the following standards:

Emmissions: EN 61800-3 (EN 55011 group 1, class B)

Immunity: EN 61800-3, industrial environments

For the best possible damping of interference, special line filters have been developed which guarantee

you easy assembly and installation along with the necessary electrical reliability. However, effective

EMC is only ensured if the suitable filter is selected for the particular drive and installed in accordance

with these EMC recommendations. Please order the appropriate filter when ordering L100IP inverter.

Note: All filters are designed for 50Hz/60Hz +/-5%.

The amount of line-conducted interference also increases as motor cable length increases. Adherence to the

interference limits for line-conducted interference is guaranteed on following way:

• If maximum motor cable length is 10 m at maximum elementary frequency:

Class „B“.

• If maximum motor cable length is 20 m at elementary frequency 5 kHz:

Class „B“.

• If maximum motor cable length is 50 m at maximum elementary frequency:

Class „A“.

Observe the following provisions for an electromagnetically compatible setup of your drive system:

1. As user you must ensure that the HF impedance between frequency inverter, filter and ground is as small

as possible.

• See to it that the connections are metallic and have the largest possible areas (zink-plated mounting

plates)

2. Conductor loops act like antennas, especially when they encompass large areas. Consequently:

• Avoid unnecessary conductor loops

• Avoid parallel arrangement of „clean“ and interference-prone conductors

3. Lay the motor cable and all analog and digital contol lines shielded.

• You should allow the effective shield area of these lines to remain as large as possible; i.e., do not

move the shield further away than absolutely necessary.

• With compact systems, if for example the frequency inverter is communicating with the steering unit,

in the same control cabinet connected at the same PE-potential, the screen of control lines should be

put on, on both sides with PE. With branch systems, if for example the communicating steering unit is

not in the same control cabinet and there is a distance between the systems, we recommend to put on

the screen of control lines only on the side of the frequency inverter. If it is possible, direct in the cable

entry section of the steering unit. The screen of motor cables always must be put on, on both sides with

PE.

• The large area contact between shield and PE-potential you can realise with a metal PG screw

connection or a metallic mounting clip.

• Use only copper mesh cable (CY) with 85% coverage

• The shielding should not be interrupted at any point in the cable. If the use of reactors, contactors,

terminals or safety switches in the motor output is necessary, the unshielded section should be kept as

small as possible.

• Some motors have a rubber gasket between terminal box and motor housing. Very often, the terminal

boxes, and particularly the threads for the metal PG screw connections, are painted. Make sure there is

always a good metallic connection between the shielding of the motor cable, the metal PG screw

connection, the terminal box and the motor housing, and carefully remove this paint if necessary.

4. Very frequently, interference is coupled in through installation cables. This influence you can minimize:

• Lay interfering cables separately, a minimum of 0.25 m from cables susceptible to interference.

• A particularly critical point is laying cables parallel over larger distances. If two cables intersect, the

interference is smallest if they intersect at an angle of 90°. Cables susceptible to interference should

therefore only intersect motor cables, intermediate circuit cables, or the wiring of a rheostat at right

angles and never be laid parallel to them over larger distances.

5. The distance between an interference source and an interference sink (interference-threatened device)

essentially determines the effects of the emitted interference on the interference sink.

• You should use only interference-free devices and maintain a minimum distance of 0.25 m from the

drive.

6. Safety measures

• Ensure that the protective conductor terminal (PE) of the filter is properly connected with the protective

conductor terminal of the frequency inverter. An HF ground connection via metal contact between the

housings of the filter and the frequency inverter, or solely via cable shield, is not permitted as

protective conductor connection. The filter must be solidly and permanently connected with the ground

potential so as to preclude the danger of electric shock upon touching the filter if a fault occurs. You

can achieve this by connecting it with a grounding conductor of at least 10 mm² or connecting a second

grounding conductor, connected with a separate grounding terminal, parallel to the protective

conductor (the cross section of each single protective conductor terminal must be designed for the

required nominal load).

Revision history table:

Revision contents Date of issue Manual no.

1

2

3

CONTENTS

CHAPTER 1 – SAFETY PRECAUTIONS

I

NSTALLATION ...................................................................................................................................1-1

WIRING..............................................................................................................................................1-1

C

ONTROL AND OPERATION ................................................................................................................1-2

M

AINTENANCE AND INSPECTION .......................................................................................................1-3

O

THERS .............................................................................................................................................1-3

CHAPTER 2 – INSPECTION UPON UNPACKING .....................................................................2-1

CHAPTER 3 – APPEARANCE AND NAMES OF PARTS...........................................................3-1

CHAPTER 4 – INSTALLATION .....................................................................................................4-1

CHAPTER 5 – WIRING

W

IRING THE POWER SUPPLY AND MOTOR..........................................................................................5-1

W

IRING THE CONTROL TERMINALS....................................................................................................5-2

G

ENERAL REMARKS...........................................................................................................................5-3

W

IRING EQUIPMENT AND OPTIONS ....................................................................................................5-5

TERMINALS........................................................................................................................................5-6

CHAPTER 6 – GENERAL OPERATION NOTES

B

EFORE STARTING OPERATION..........................................................................................................6-1

T

EST RUN...........................................................................................................................................6-1

CHAPTER 7 – CONTROL CIRCUIT TERMINAL FUNCTIONS

O

VERVIEW.........................................................................................................................................7-1

FM

TERMINAL ...................................................................................................................................7-3

T

ERMINALS 1 - 5 (PROGRAMMABLE DIGITAL INPUTS)

General notes ................................................................................................................................7-4

FW: Start/stop forward run...........................................................................................................7-5

RV: Start/stop reverse run.............................................................................................................7-5

CF1 – CF4: Multistage speed settings..........................................................................................7-6

AT: Analog set value using current 4-20mA .................................................................................7-7

2CH: Second stage acceleration/deceleration..............................................................................7-7

FRS: Free run stop........................................................................................................................7-8

EXT: External trip.........................................................................................................................7-8

USP: Prevention of restart upon power recovery.........................................................................7-9

RS: Reset .....................................................................................................................................7-10

JG: Jogging run ..........................................................................................................................7-11

PTC: Thermistor input ................................................................................................................7-12

SFT: Software lock......................................................................................................................7-12

T

ERMINALS 11, 12 (PROGRAMMABLE DIGITAL OUTPUTS)

General notes ..............................................................................................................................7-13

FA1, FA2: Frequency arrival signals .........................................................................................7-14

RUN: Motor running...................................................................................................................7-14

OL: Overload signal....................................................................................................................7-15

OD: PID deviation ......................................................................................................................7-15

AL: Alarm signal .........................................................................................................................7-16

T

ERMINALS AL0, AL1, AL2 (ALARM RELAY).................................................................................7-17

CHAPTER 8 – USING THE DIGITAL OPERATOR

THE DIGITAL OPERATOR CONTROL PANEL .........................................................................................8-1

O

PERATING PROCEDURE EXAMPLE....................................................................................................8-1

D

IGITAL OPERATOR KEYS..................................................................................................................8-2

OVERVIEW OF PARAMETER SETTINGS

Display functions...........................................................................................................................8-3

Basic functions ..............................................................................................................................8-4

Extended functions of group A ......................................................................................................8-4

Extended functions of group B ....................................................................................................8-10

Extended functions of group C ....................................................................................................8-13

CHAPTER 9 – MESSAGES

T

RIP MESSAGES .................................................................................................................................9-1

O

THER MESSAGES..............................................................................................................................9-2

CHAPTER 10 – TROUBLE SHOOTING...................................................................................... 10-1

CHAPTER 11 – TECHNICAL SPECIFICATIONS ..................................................................... 11-1

CHAPTER 12 – WIRING EXAMPLES

S

ET VALUE SUPPLIED BY EXTERNAL POTENTIOMETER ....................................................................12-1

I

NVERTER OPERATION USING ANALOG SET VALUE ..........................................................................12-2

I

NVERTER OPERATION USING FIXED SET VALUES ............................................................................ 12-3

CHAPTER 13 – THE OPTIONAL REMOTE OPERATORS

C

ONNECTION OF THE REMOTE OPERATOR .......................................................................................13-1

T

HE MONITOR MODE........................................................................................................................13-2

THE FUNCTION MODE ......................................................................................................................13-3

P

ROTECTIVE FUNCTIONS..................................................................................................................13-6

D

IMENSIONS OF ACCESSORIES.........................................................................................................13-7

U

SING THE COPY UNIT .....................................................................................................................13-8

CHAPTER 14 – SERVICE AND WARRANTY............................................................................ 14-1

APPENDIX A – PRINTED FORM FOR USER DEFINED PARAMETER SETTINGS ..........A-1

APPENDIX B – PRINTED FORM FOR USER DEFINED PARAMETER SETTINGS

(REMOTE OPERATOR) ................................................................................................................. B-1

APPENDIX C – INITIALIZING THE INVERTER ......................................................................C-1

APPENDIX D – PERIODICAL MAINTENANCE ........................................................................ D-1

Chapter 1 – Safety precautions

1-1

Chapter 1 – Safety precautions

Installation

The following safety precautions are to be observed when installing the frequency inverter:

CAUTION Be sure to install the inverter on flame resistant material such as metal. Otherwise,

there is a danger of fire.

CAUTION Be shure not to place anything inflammable in the vicinity. Otherwise, there is a

danger of fire.

CAUTION Be sure not to let foreign matter (such as cut wire refuse, spatter from welding, iron

refuse, wires, dust etc.) enter the inverter. Otherwise, there is a danger of fire.

CAUTION Install the inverter in a room which is not exposed to direct sunlight and is well

ventilated. Avoid environments which tend to be high in temperature, high in

humidity or which have dew condensation, as well as places with dust, corrosive

gas, explosive or inflammable gas, grinding-fluid mist, salt damage etc. Otherwise,

there is a danger of fire.

CAUTION The wall surface on which the inverter is mounted must be of a nonflammable

material, such as a steel plate.

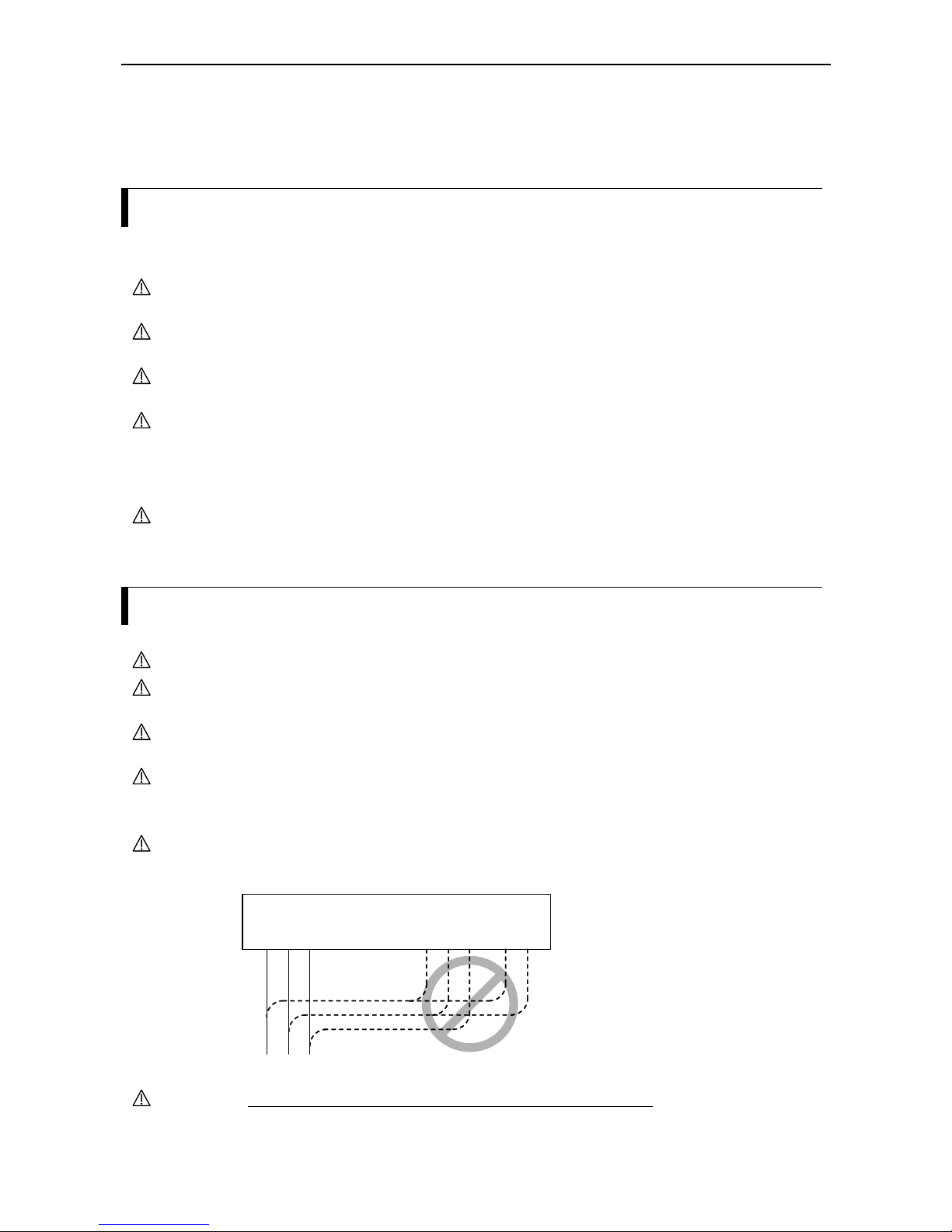

Wiring

WARNING The inverter has to be grounded properly. Otherwise, there is a danger of fire.

WARNING Wiring work must only be carried out when the power supply is off. Otherwise,

there is a danger of electric shock and/or fire.

WARNING Before carrying out the wiring work, the inverter has to be mounted properly.

Otherwise, there is a danger of electric shock or injury.

CAUTION Make shure that the input voltage is as follows (please also refer to chapter 11):

Single/three phase: 200~240V, 50/60Hz (models up to 2,2kW)

Three phase: 380~460V, 50/60Hz

CAUTION Don´t connect AC power supply to the inverter output terminals U, V, and W or fan

supply terminals F, F. Otherwise, there is a danger of injury and/or fire.

INPUTS

(L1) (N)

L1 L2 L3

OUTPUTS

U V W

Note)

Power

su

pply

Note) Terminals L1, N: single phase power supply

Terminals L1, L2, L3: three phase power supply

Not allowed

F F

CAUTION Remarks for using earth leakage circuit breakers in the mains supply:

Frequency inverters with CE-filters (RFI-filter) and screened motor cables have a

higher leakage current against earth. Especially in the moment of switching this can

cause unintentional triggering of earth leakage circuit breakers. Because of the rectifier

Chapter 1 – Safety precautions

1-2

on the input side of the inverter there is the possibility to stall the switch-off function

through amounts of DC current. For these reasons, the following items should be

observed:

Only pulse current sensitive earth leakage circuit breakers which have a short term

delay and a higher trigger current (500mA) should be used. Other components should

be secured with separate earth leakage circuit breakers. Earth leakage circuit breakers

in front of an inverter´s rectifier are not an absolute protection against direct touching.

CAUTION Each phase of the power supply has to be provided with a fuse. Otherwise, there is a

danger of fire.

Control and operation

WARNING Be sure to turn on the input power supply only after closing the front case. While

being energized, don´t open the front case. Otherwise, there is a danger of electric

shock.

WARNING Never operate the switches with wet hands. Otherwise, there is a danger of electric

shock.

WARNING If the retry mode is selected, the inverter may suddenly restart during a stop which

was caused by a trip. In such a case, be sure not to approach the machine. Provisions

have to be taken that the driven motor or machine does not endanger personnell even

in the case of a sudden restart. Otherwise, there is a danger of injury.

WARNING Even if the power supply is cut off for a short period of time, the inverter may restart

operation after the power supply has recovered if the operation command is given. If

this may incur danger to personnell, provisions have to be made in order to prevent a

restart after power recovery. Otherwise, there is a danger of injury.

WARNING The STOP key is effective only if the corresponding parameters have been set.

Otherwise, there is a danger of injury.

WARNING If a reset is carried out following a trip condition the motor will restart if the

operation command has been given. Be sure to acknowledge this trip condition with

a reset only after confirming that no operation command is active. Otherwise, there

is a danger of injury.

WARNING When the power to the inverter is turned on while the operation command is active

the motor starts immediately. So before turning power supply on be sure to confirm

that no operation command is active.

WARNING If the inverter has been configured for the stop command not to be given using the

STOP key, pressing the STOP key does not stop the motor. In this case a separate

emergency stop switch is necessary.

CAUTION Operate the motor and machine connected to the inverter only within the

manufacturer´s speed specifications. Otherwise, there is a danger of injury.

CAUTION If a motor is to be operated at a frequency higher than the standard setting value of

50 or 60Hz, be sure to check the allowable speed of the motor and the machine

with each manufacturer, and operate them only after getting their consent.

CAUTION Check the following during and after the test run. Otherwise, there is a danger of

machine breakage:

Was the short cut bar between terminals +1 and + removed by mistake?

Was the running direction of the motor correct?

Was the inverter tripped during acceleration or deceleration?

Were the indications of the rpm and the frequency meter correct?

Were there any abnormal motor vibrations or noise?

Chapter 1 – Safety precautions

1-3

Maintenance and inspection

WARNING Before carrying out maintenance and inspection wait for at least five minutes after

having turned off the input power supply. Otherwise, there is a danger of electric

shock.

WARNING When removing connectors (e.g. from fans and printed circuit boards) never pull the

attached wires. Otherwise, there is a danger of fire due to wire breakage and/or

injury.

Others

CAUTION Withstand voltage tests and insulation resistance tests (megger tests) are executed

before the units are shipped, so that there is no need to conduct these tests before

operation.

CAUTION Do not attach or remove wiring or connectors when power is applied. Also, do not

check signals (e.g. using a multimeter) during operation.

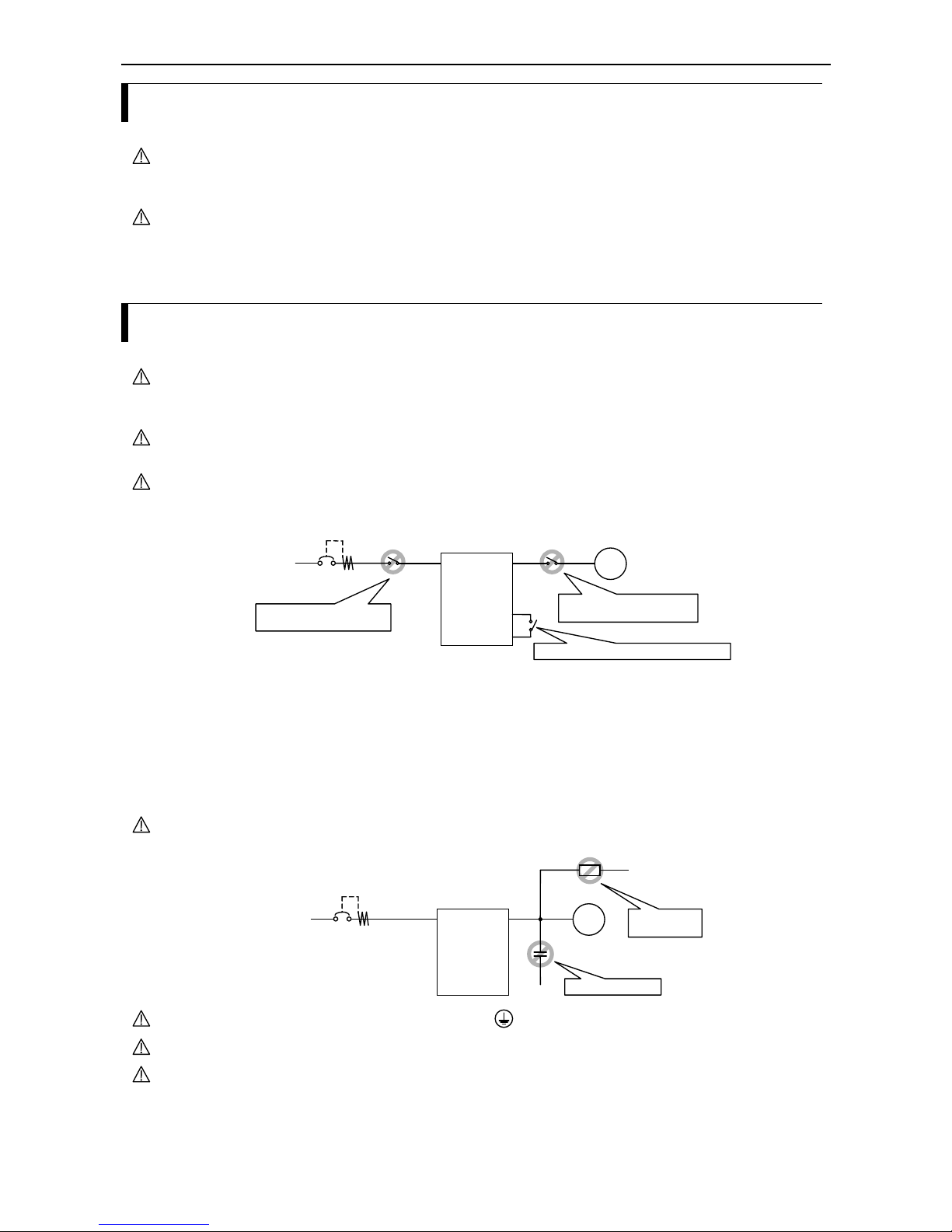

CAUTION Never stop motor operation by switching off the electromagnetic contactors on the

primary or secondary side of the inverter.

Motor

Inverte

r

Earth leakage

circuit breaker

L1(L1)

L2

L3(N)

T1(U)

T2(V)

T3(W)

Powe

r

supply

S2

FW

P24

CORRECT: Start and stop using FW terminal

S1

WRONG: Start and stop using

secondary side contactor

WRONG: Start and stop using

primary side contactor

When there has been an instantaneous power failure, and if an operation instruction

has been given, then the inverter may restart operation after the power failure has

ended. If there is a possibibility that such an occurrence may harm humans, then install

an electromagnetic contactor on the primary (power supply) side of the inverter, so

that the circuit does not allow automatic restarting after the power supply has

recoverd. If the optional remote operator is used and the retry function has been

selected, this will also cause automatic restarting when an operation instruction has

been input, so please be careful.

CAUTION Do not insert leading power factor capacitors or surge absorbers between the output

terminals of the inverter and the motor.

Motor

Inverte

r

Earth leakage

circuit breaker

L1(L1)

L2

L3(N)

T1(U)

T2(V)

T3(W)

Powe

r

supply

WRONG: Capacitor

WRONG:

Surge absorber

CAUTION Be sure to ground the grounding terminal properly.

CAUTION Before inspecting the unit wait at least five minutes before opening the inverter .

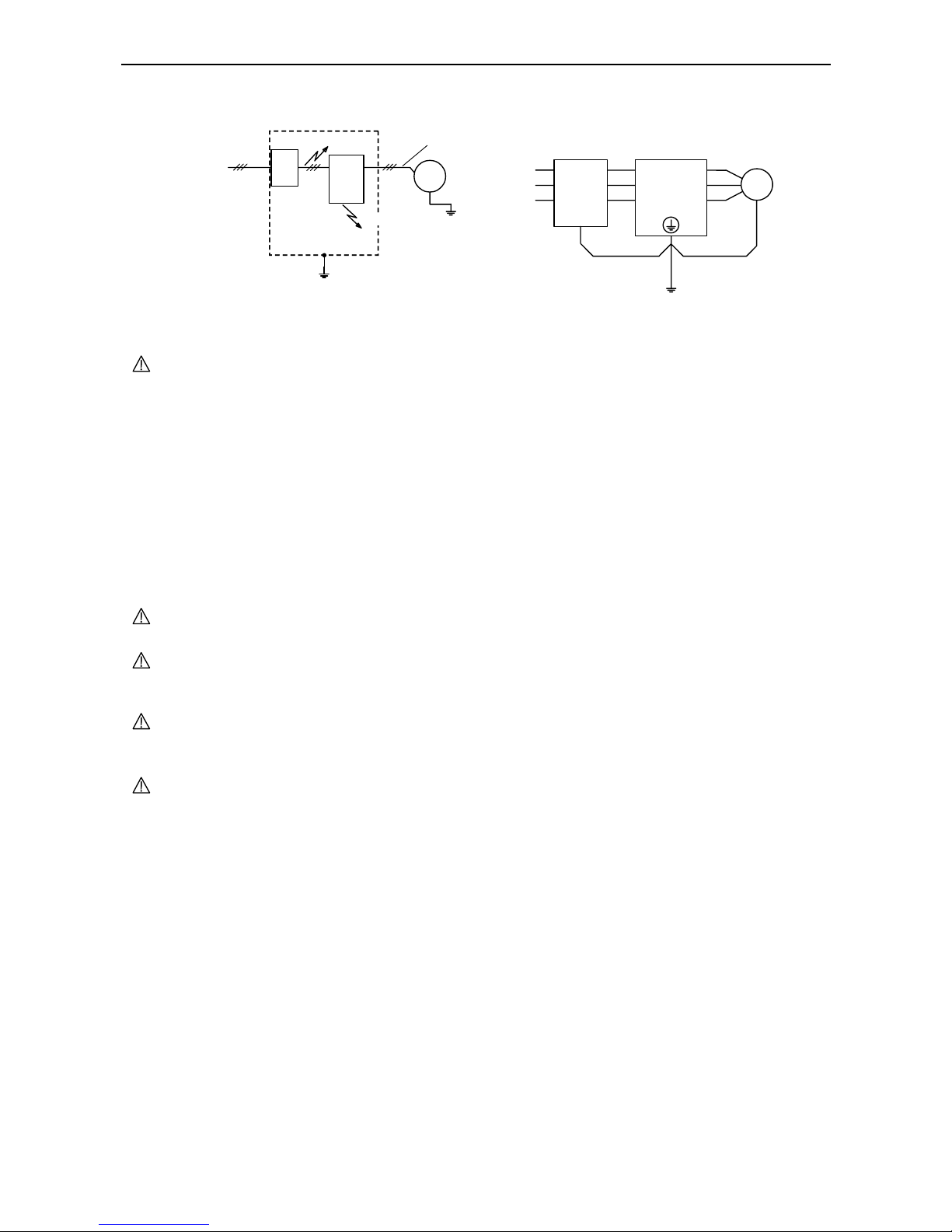

CAUTION PROTECTION AGAINST NOISE INTERFERENCE FROM THE INVERTER

L100IP series inverters use many semiconductor switching elements such as

transistors and IGBTs. For this reason, a radio set or measuring instrument located

near the inverter is susceptible to noise interference. To protect the instruments from

erreneous operation due to noise interference produced by the inverter, they should be

Chapter 1 – Safety precautions

1-4

installed well apart from the inverter. It is also effective to shield the whole inverter

structure (refer to figure below, left part).

Motor

Inverte

r

L1(L1)

L2

L3(N)

T1(U)

T2(V)

T3(W)

R2

S2

T2

Power

supply

R1

S1

T1

EMI filter +

Grounding

Inverter

EMI

filter

Motor

Power

supply

Noise

Noise

Grounded

frame

Completely ground the frame

with as short a wire as possible.

Grounded piping

or shielded wire

Added EMI filter on the input side of the inverter also reduces the effect of noise from

commercial power lines on external devices (refer to figure above).

CAUTION EFFECTS OF DISTRIBUTER LINES ON INVERTERS

In the cases mentioned below involving a general purpose inverter, a large peak

current flows on the power supply side, sometimes destroying the converter module:

A) The unbalance factor of the power supply is 3% or higher.

B) The power supply capacity is set at least ten times greater than the inverter

capacity (i.e. 500kVA or more)

C) When abrupt power supply changes are to be expected. Some examples:

1) Several inverters are interconnected using a short bus to the same power

supply.

2) A thyristor converter and an inverter are interconnected using a short bus.

3) An installed power factor compensating device is connected or disconnected.

In the cases mentioned above we recommend installing an AC reactor of 3% voltage

drop at rated current with respect to the supply voltage on the power supply side.

CAUTION When an EEPROM error occurs (trip E 08) all parameter values have to be checked

for correctness (especially the RS input).

CAUTION When the intelligent digital inputs FW or RV are configured as normally closed

contact (standard setting is normally open), then the inverter starts automatically. Do

not configure these inputs as normally closed inputs unless absolutely necessary.

CAUTION Factory setting of the carrier frequency is different for diferent types of the inverter.

This setting is at the same time also highest allowable carrier frequency without

derating output power. See bottom of the terminal cover for reference.

GENERAL NOTICE

In all the illustrations and figures in this manual, covers and safety devices are

occasionally omitted in order to better describe the details. When the inverter is

operated make shure that all the covers and safety devices are placed in their correct

positions.

Chapter 2 – Inspection upon unpacking

2-1

Chapter 2 – Inspection upon unpacking

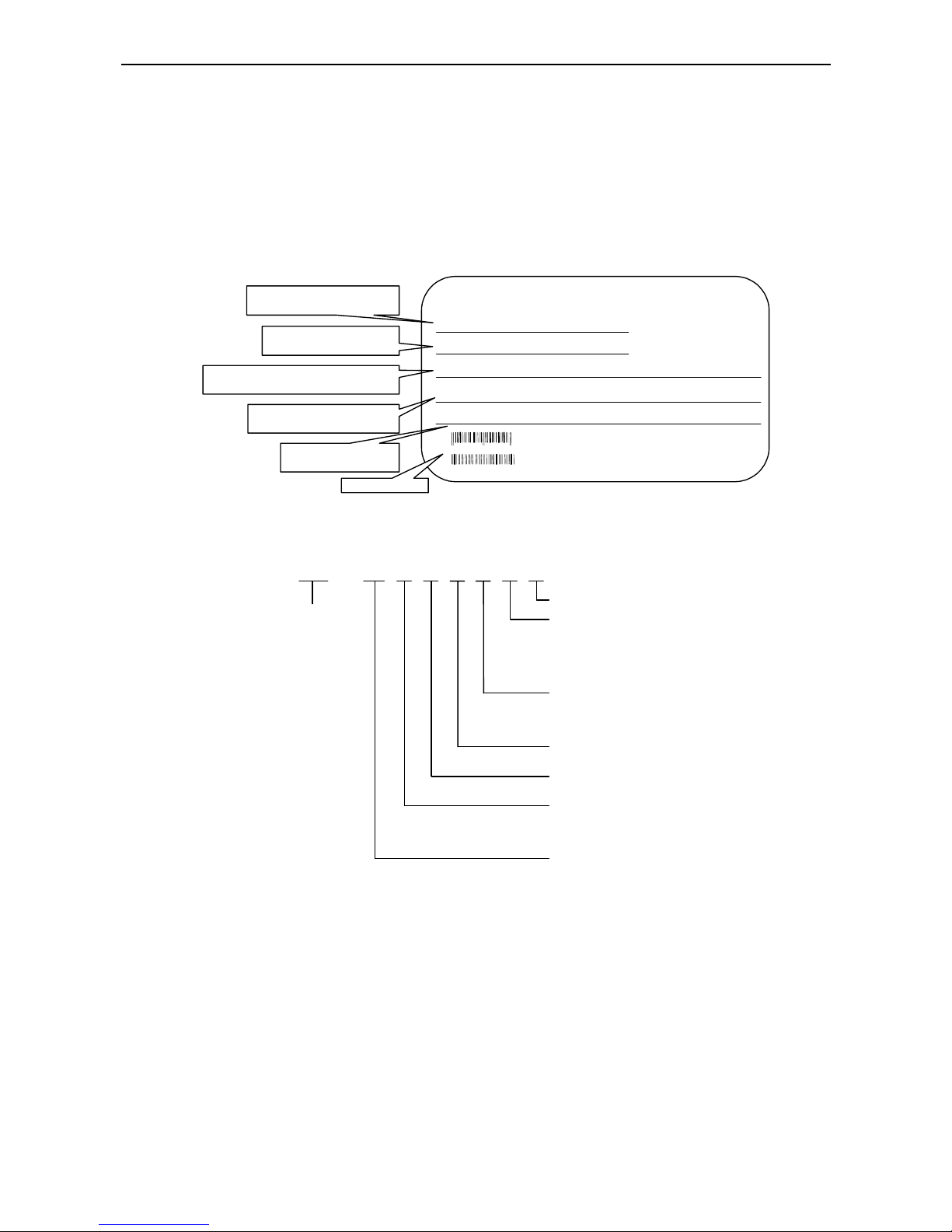

Please check the shipment by the time of delivery for damages and completeness. Check that the inverter and

the accompanying instruction manual has been provided. Using the specification label attached to the side of

inverter make sure that the inverter model delivered is the one you ordered.

The specifications included on the specification label are described below:

Model : L100IP – 007NFE 510

kW/HP: 0.75 / 1

Input : 50,60Hz 200-240V 1 Ph 9.0A

Hitachi Industrial Equipemnt Systems Co,. Ltd.

MADE IN SLOVENIA

Output : 1-360Hz 200-240V 3 Ph 4.0A

Serial No. : 030300067 Date: 0403

HITACHI

Model designation:

(example for L100IP-007NFE 510)

Applicable motor capacity

(example: 0.75kW/1HP)

Inverter input specifications:

Frequency, voltage, numbe r of phases, current

Inverte r outp ut specifications :

Frequency, voltage, rated current

Manufac turing number,

date (example: April 2003)

8310793 298046

030300067

EAN code

www.hitachi-ds.com (Hitachi Europe GmbH)

In the illustration below, the contents of the model designation used for L100 series inverters is explained:

L100IP - 007 H F E 5

Inverter series

Distribution for

(E: Europa U: USA)

Type of inverter

(F: with digital operator)

Input voltage

(N: 200V single phase)

(H: 400V three phase)

Motor capacit

y

004: 0.40kW 040: 4.00kW

007: 0.75kW 055: 5.50kW

015: 1.50kW 075: 7.50kW

022: 2.20kW

1

0

Option

Input side

1: EMI filter

2: AC reactor

3: EMI filter & AC reactor

Protection class

0: IP00 5: IP54

2: IP20 6: IP65

Chapter 2 – Inspection upon unpacking

2-2

Chapter 3 – Appearance and names of parts

3-1

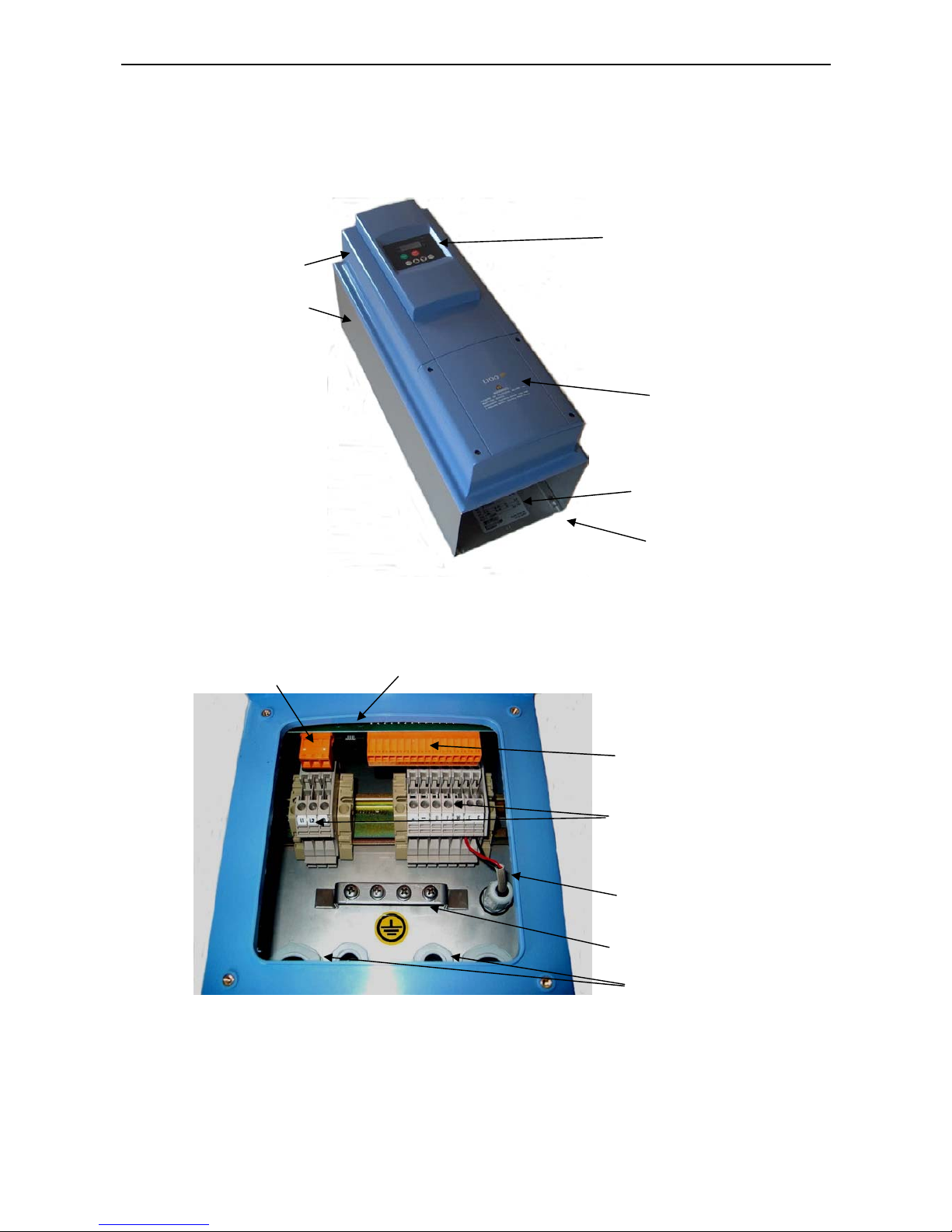

Chapter 3 – Appearance and names of parts

Terminal cover revealed:

Specification label

Terminal cover

Digital operator

Casing – plastic part

Casing – metal part

Fan inside

(air inlet)

Cable glands

Grounding terminal (PE)

Mains circuit terminals

Fan cable

Control terminals

Serial interface

Alarm terminals

Chapter 3 – Appearance and names of parts

3-2

Chapter 4 – Installation

4-1

Chapter 4 – Installation

Explanation of IP54 protection provided by enclosure

Generally, the enclosure must provide sufficient protection for persons who use them and for equipment itself.

IP54 enclosure provides protection to some extent and it is not foreseen for very severe environmental

conditions. Here is the explanation of the two digits:

Protection of persons against access to hazardous parts inside the enclosure indicated by the first

characteristic numeral 5:

Protected against access to hazardous parts with wire.

Protection of the equipment inside the enclosure against ingress of solid foreign objects indicated by the

first characteristic numeral 5:

Dust-protected: Ingress of dust is not totally prevented, but dust shall not penetrate in a quantity to interfere with

satisfactory operation of the apparatus or to impair safety.

The inverter shall not be exposed to severe environmental conditions for more than 8 h (test condition).

Protection of the equipment inside the enclosure against harmful effects due to the ingress of water

indicated by the second characteristic numeral 4:

Protected against splashing water: Water splashed against the enclosure from any direction shall have no harmful

effects.

The inverter shall not be exposed to splashing water for more than 10 minutes (test condition).

The unit is not intended for outdoor usage.

Other than in the time specified above, inverter must be operated in the condition of 90% humidity or less.

WARNING the above explanation is intended as an indication. Refer always to the a.m.

standard in the case of any doubt.

Chapter 4 – Installation

4-2

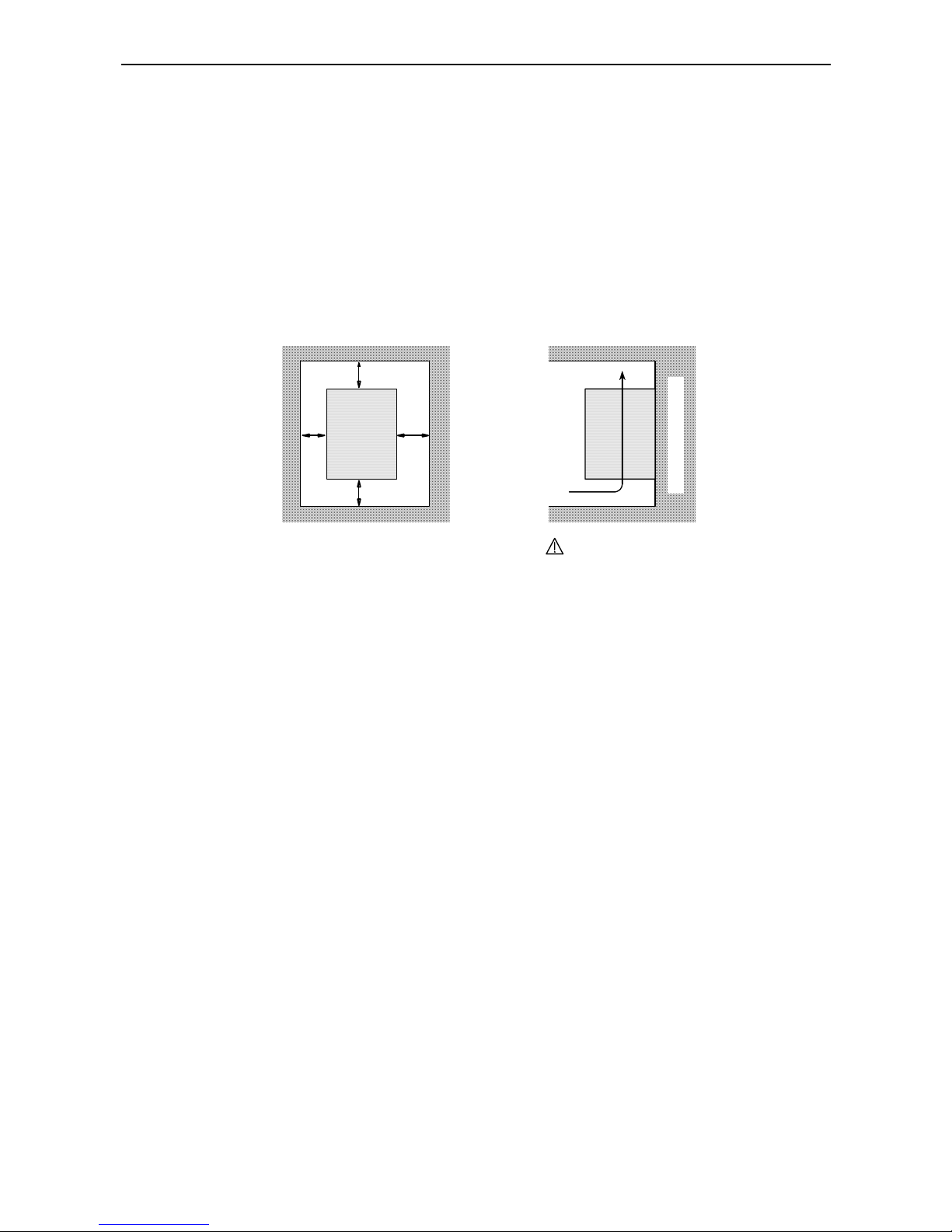

The inverter must be mounted vertically on a non-flammable wall in order to prevent from overheating and

fire. The minimum clearances to the surrounding walls shown in the figure below must be complied with to

ensure a good ventilation. Foreign matter (especially conductive objects) must nut be dropped into the

inverter since they not only cause malfunction and damage but may also lead to electrical and fire hazards.

Cover all ventilation holes on the inverter during installation so that no foreign objects can enter the inverter.

Be sure to remove those covers from the inverter before you put the inverter to work.

approx. 10cm

approx. 1c

m

approx.

1cm

Inverter

Air flow

The inverter must be installed vertically

(do not install it on the floor or horizontally)

Wall or mounting surface

The mounting base must be a non-

flammable material (e.g. metal)

approx. 10cm

The minimum clearances to the surrounding walls shown in the figure are only meant for reference. A more

compact installation (back to back or side by side) may well be possible and should be discussed with

Hitachi. Please always leave enough room for the teminal cover to be opened without problems in order to

connect wires to the control terminals.

The ambient temperature should be in the range of -10°C to 40°C. Higher ambient temperature causes shorter

inverter life. So if there is hot equipment in the vicinity of the inverter, keep it away from the inverter as far

as possible.

The end application must be in accordance with the BS EN 60204-1 standard.

Chapter 5 – Wiring

5-1

Chapter 5 – Wiring

CAUTION Fasten the screws with the specified fastening torque so that they will not loosen

unintentionally. Check all terminals for loose screws. Otherwise there is a danger of

fire.

CAUTION Remarks for using earth leakage circuit breakers in the mains supply

Frequency inverters with CE-filters (RFI-filter) and screened motor cables have a

higher leakage current against earth. Especially in the moment of switching this can

cause unintentional triggering of earth leakage circuit breakers. Because of the rectifier

on the input side of the inverter there is the possibility to stall the switch-off function

through amounts of DC current. For these reasons, the following items should be

observed:

Only pulse current sensitive earth leakage circuit breakers which have a short term

delay and a higher trigger current (500mA) should be used. Other components should

be secured with separate earth leakage circuit breakers. Earth leakage circuit breakers

in front of an inverter´s rectifier are not an absolute protection against direct touching.

CAUTION Each phase of the power supply has to be provided with a fuse. Otherwise, there is a

danger of fire.

CAUTION As for motor leads, earth leakage breakers, and electromagnetic contactors, be sure to

use the ones that have the correct rating. Otherwise, there is a danger of fire.

CAUTION Make sure that the mains supply leads are reliably fixed.

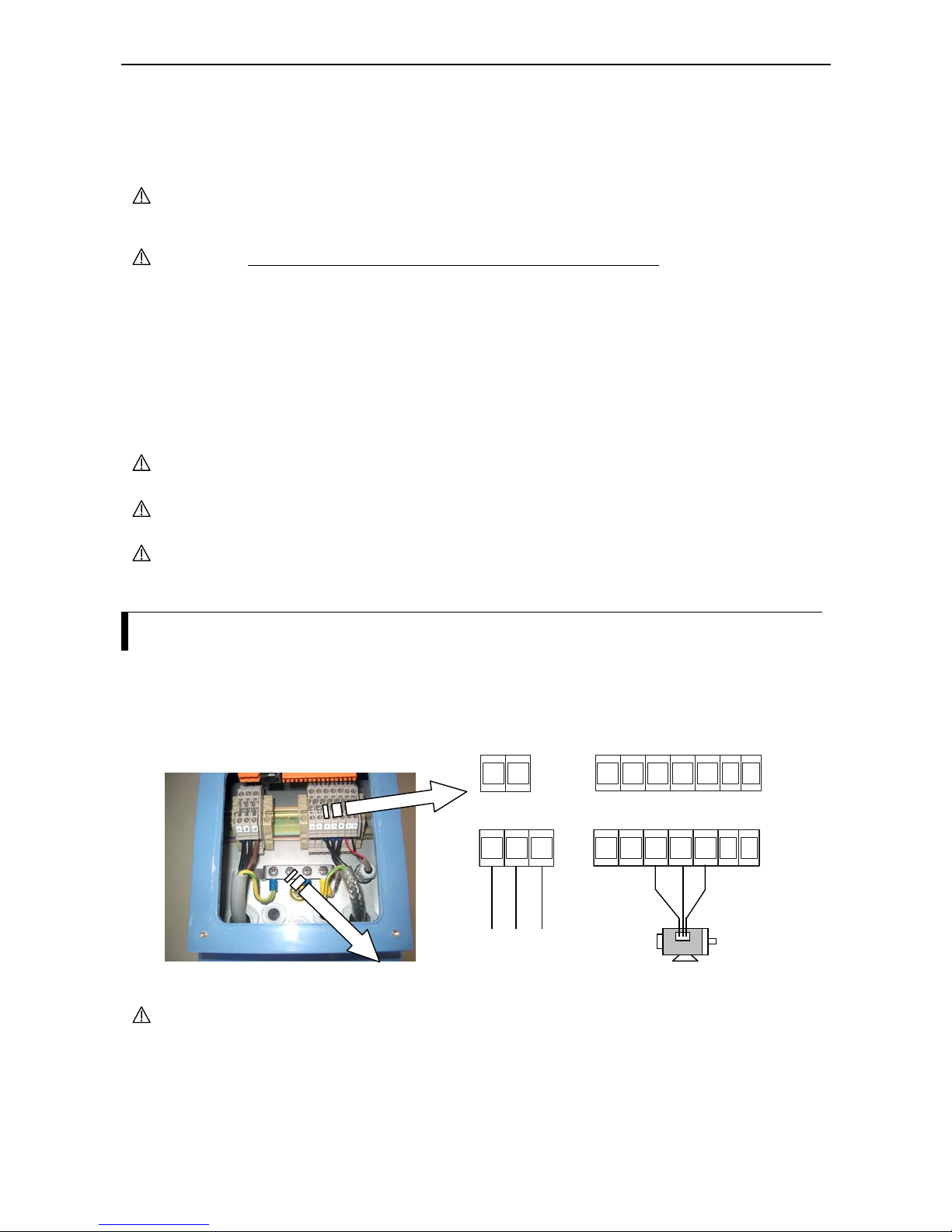

Wiring the power supply and motor

In order to connect cables to the power supply and other terminals the terminal cover has to be opened. For

this, first of all the four corresponding screw has to be loosened. The location of the terminals is depicted in

the figure below:

CAUTION Don’t disconnect wires attached to F terminals (fan power supply), otherwise

inverter may overheat. In case the wires are exchanged, the fan doesn’t work. This

terminals cannot be used for the power supply for external device.

When connecting cables, the following details have to be considered:

1) Power supply cables must only be connected to the terminals L1, L2, L3 or L, N.

2) Refer the page 5-5 for wiring equipment and options.

L1 L3L2 +VUFF-W

Motor

To the power supply

Mains circuit terminals

LN +VUFF-W

NFE:

HFE:

Grounding terminal (PE)

Chapter 5 – Wiring

5-2

3) If more than one motor is to be driven by a single inverter, thermal relays have to be provided for each

motor.

Therma l relay

L100IP

4) The leads from the power supply must be connected to the mains circuit terminals as follows:

Connect single phase power supply (50/60Hz) to terminals L1, N.

Connect three phase power supply (50/60Hz) to terminals L1, L2, L3.

Wiring the control terminals

The following figure shows the location of the control terminals. The exact use of each of the control

terminals is described later in this chapter.

The figure below contains an example for control terminal wiring:

Reset (RS)

FA1

Prevention of

restart (USP)

Jogging run (JG)

Reverse run (RV)

Forward run (FW)

24VDC

(Common fo

r

inputs)

RUN

Potentiometer

(1k-2kOhm)

for frequency

set value

Frequenc

y

meter

24V DC,

max. 50 mA

L 3 4 5 2 1 H O OI FML 12 11

NOTE: Function of digital inputs and outputs can be changed

Control terminals

Alarm circuit

terminal

REMOVABLE

CONNECTOR

Control circuit terminal

REMOVABLE CONNECTOR

L

3

4

5

2 1 H

O OI

FM L 12 11

Chapter 5 – Wiring

5-3

General remarks

When connecting cables, the following items must be observed:

- When changing the power supply of the motor between the inverter and commercial power line, be sure

to install mechanically interlocked switches (S1 and S2) as shown in the figure below:

Motor

Inverter

Earth leakage

circuit breakers

L1 (L)

L2

L3 (N)

U

V

W

Power

supply

S1

S2

- Install an earth leakage breaker at the input of the inverter. Select an earth leakage breaker which has a

short term delay and a higher trigger current.

When the cable between the inverter and the motor is more than 10 meters long, the thermal relay may

malfunction due to high-frequency waves. To prevent this, install an AC reactor on the output side of the

inverter or use a current sensor rather than a thermal relay.

- In case a relay is connected to the digital output terminals 11 or 12 be sure to install a surge absorbing

diode in parallel to the relay. Otherwise the surge voltage created when the relay goes on or off may

damage the output circuit.

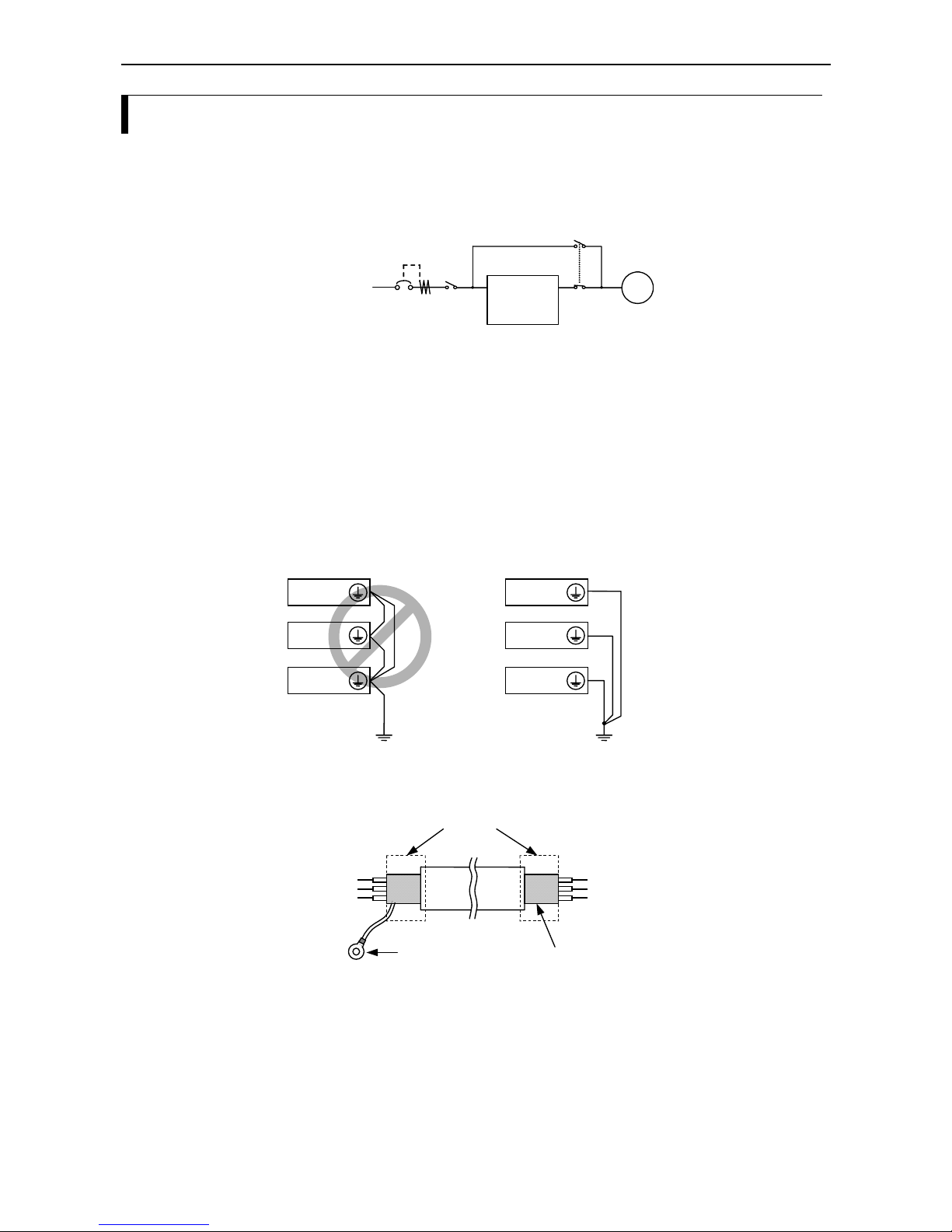

- Be sure that the specified grounding is carried out. Separate the inverter´s grounding pole from those of

other heavy electric machinery and avoid using common grounding poles when multiple inverters are

employed.

Inverter 1

Inverter 2

Inverter 3

Ground ing poi nt Ground ing poi nt

WRONG CORRECT

Inverter 1

Inverter 2

Inverter 3

- Use a twisted and shielded wire when connecting signal lines to the control terminals and cut the

shielded covering as shown in the figure below. Make sure that the length of the signal line is 20 m or

less. If the line must be longer than 20 m then an appropriate signal amplifier should be used.

Frame ground

Isolate here

No grou nding

necessary here

- Use relays which are capable of reliably switching at a voltage of 24VDC and a current of 3mA.

- Install the mains circuit cables at a safe distance from the control circuit cables. If the mains circuit

cables and the control circuit cables have to cross each other, this should be done at an angle of 90

degrees because interference can be minimized in this case.

Chapter 5 – Wiring

5-4

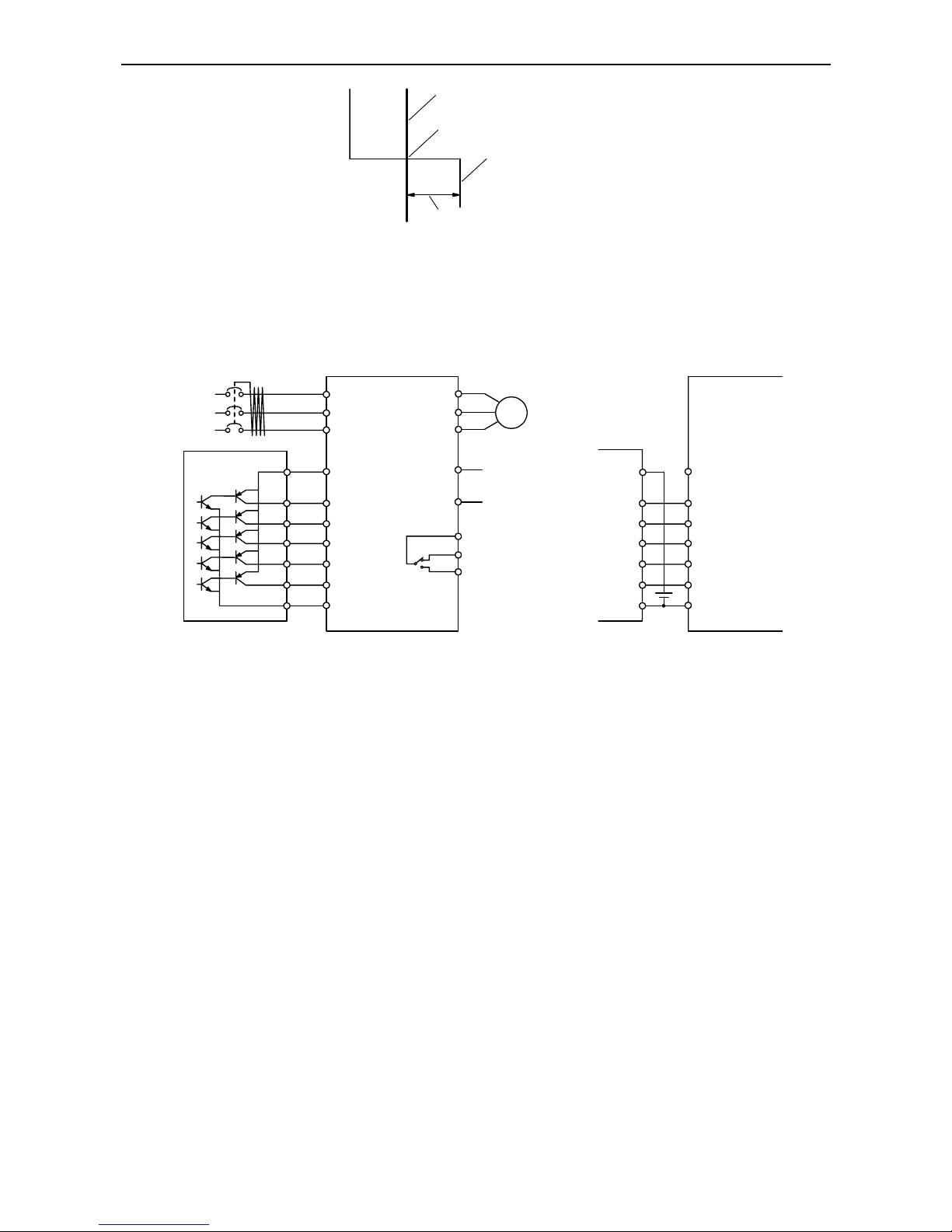

90°-angle

Mains circuit power cable

(L1, L2, L3 (L, N), U, V, W, +1, +, - )

Signal line (H, O, OI, L, FM, 1,

2, 3, 4, 5, 11, 12, CM2, P24)

Separate by 10cm or more

- Do not short circuit the terminals P24 and L, H, OI, or FM by mistake, because this may cause a

malfunction.

- Do not short circuit the terminals H and L because this may cause a malfunction.

The following figure shows an example for connecting a driver-IC to the digital inputs when using the

inverter´s internal 24VDC power supply terminal (left half of figure below) and when using a separate

external 24VDC power supply (right half of figure below).

L100IP series

frequency inverter

L1 (L)

L2

L3 (N)

U

V

W

1

2

3

4

5

L

P24

AL0

AL1

AL2

Motor

+

Alarm

terminals

1

2

3

4

5

S

COM

Transistor output driver

YTS48 or similar

24VDC

(

Note)

Note: Do not short circuit the terminals P24 and L by mistake because this may lead to a malfunction.

-

Terminals for

braking unit

1

2

3

4

5

L

P24

1

2

3

4

5

S

COM

24VDC

(

Note)

24V

b

attery

L100IP series

frequency inverter

(terminals not shown here

are exactly like those of

the inverter shown in the

left part of this figure).

Transistor output driver

YTS48 or similar

Chapter 5 – Wiring

5-5

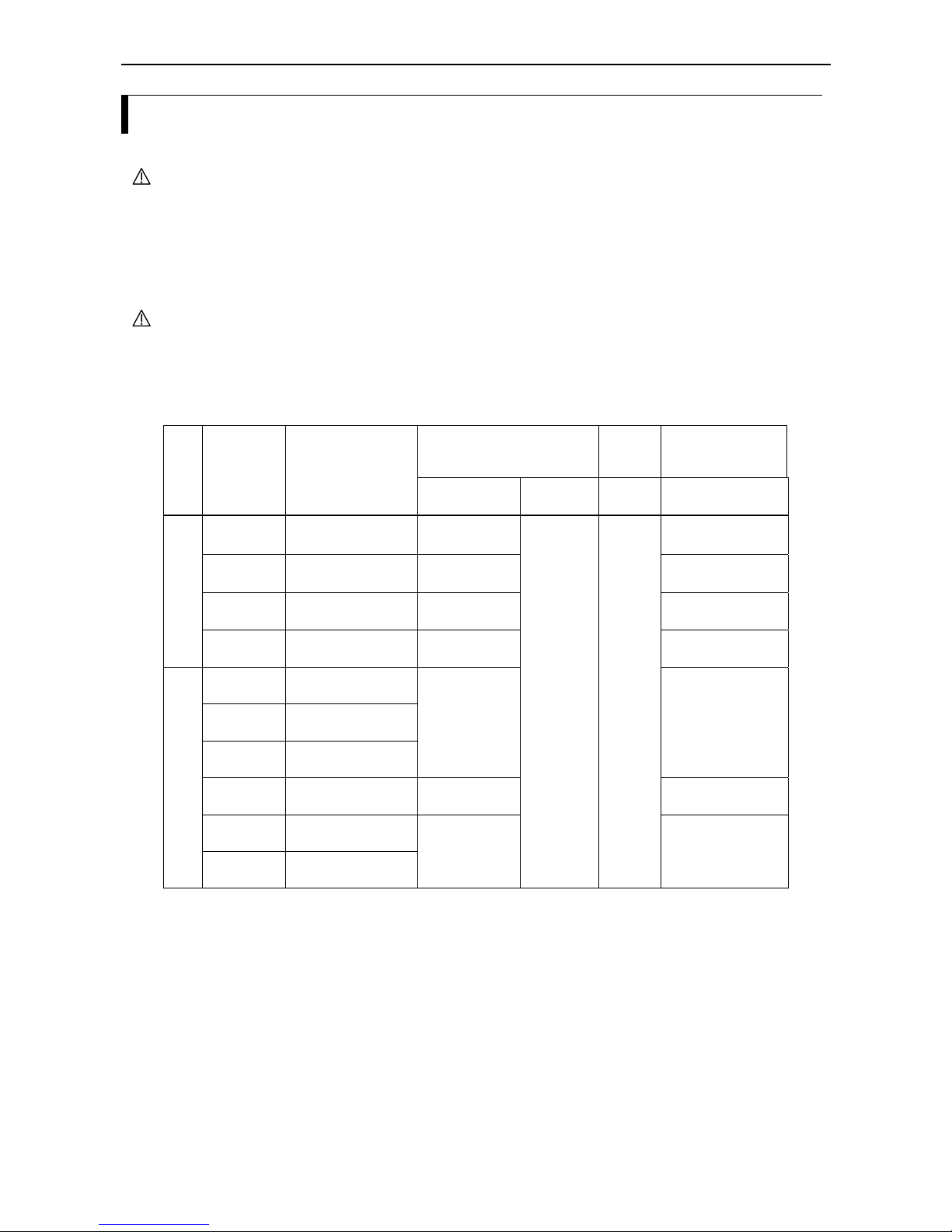

Wiring equipment and options

CAUTION A switch or circuit breaker shall be included in the building installation. It shall be

marked as the disconnecting device for the equipment and should meet the

requirements of the IEC947-1 and IEC947-3 standard. Ratings should be in

accordance with table below. For single phase there should be a double pole and for

three phase there should be a three pole disconnecting device. The switch or circuit

breaker should be near the equipment (close proximitly to the equipment and in easy

reach to the operator).

CAUTION Provide the wiring equipment in accordance with the safety codes required by

jurisdictional authorities (IEC example: supply wires should meet the requirements

of the IEC 60227 or IEC 60245... They should be made of suitable heat-resistant

material). If specified in standards or laws and regulations, follow their istructions.

In the following table some guidelines for choosing an appropriate wire gauge are

presented:

Cable specifications

600V fuse to be

used

(rated current / A)

Input

voltage

Motor

output

(kW)

Inverter

model

Power lines

Cable

diameter

Signal

lines

0.4

L100IP-004NFE

L100IP-004NFU

1.5 mm

2

(AWG 15)

10 A

0.75

L100IP-007NFE

L100IP-007NFU

2.5 mm

2

(AWG 13)

16A

1.5

L100IP-015NFE

L100IP-015NFU

4.0 mm

2

(AWG 11)

25 A

200V single phase

2.2

L100IP-022NFE

L100IP-022NFU

4.0 mm

2

(AWG 11)

40 A

0.75

L100IP-007HFE

L100IP-007HFU

1.5

L100IP-015HFE

L100IP-015HFU

2.2

L100IP-022HFE

L100IP-022HFU

1.5 mm

2

(AWG 15)

10A

4.0

L100IP-040HFE

L100IP-040HFU

2.5 mm

2

(AWG 13)

16A

5.5

L100IP-055HFE

L100IP-055HFU

400V three phase

7.5

L100IP-075HFE

L100IP-075HFU

4.0 mm

2

(AWG 11)

10-17mm

Shielded wire (max. 1.5mm

2

)

*)

cable diameter 5-10 mm.

25A

Notes:

- Field wiring connections for PE wire must be made by a certified closed-loop terminal connector sized

for the wire gauge involved. The connector must be fixed using the crimp tool specified by the connector

manufacturer.

- Only use a fuse that has the appropriate rated current.

- Be sure to use bigger wires for mains circuit cables and motor cables if the distance exceeds 20m.

- Tighten firmly the cable gland nuts after pulling through the cable. The round rubber protection is to be

removed before wiring. Leave rubber protectection in unused glads in order to keep IP54 protection.

*)

Use max. 1,5mm2 for the alarm signal wire. The wire stripping length should be approximately 6–7 mm.

Chapter 5 – Wiring

5-6

Part description Function

AC reactor

This part is used when the unbalance ratio is 3% or

more and the power supply is 500kVA or more, and

there are rapid changes in the power supply. This part

also improves the power factor.

EMI filter

(Note)

This part is used to conform with the applicable

EMC standards.

Radio noise filter

This part reduces noise generated at the output of the

inverter (this type of filter supplies an almost perfect

sine shaped output voltage between phase-phase and

phase-PE).

Motor filter

Motors that are driven by an inverter are to a larger

extent subject to voltage fluctuations than motors directly

driven (without inverter) by power lines. An AC reactor

installed between inverter output and motor smoothens

motor run and so reduces torque ripple. When the cable

between the inverter and the motor is too long, this part

also forces the voltage dv/dt to be limited and so protects

the isolation of the motor.

Note: Usage of an EMI filter is necessary for the European EMC

directive, for the Australian C-TICK and others. In comparison, the other

parts mentioned in the table above are not intended for this special use.

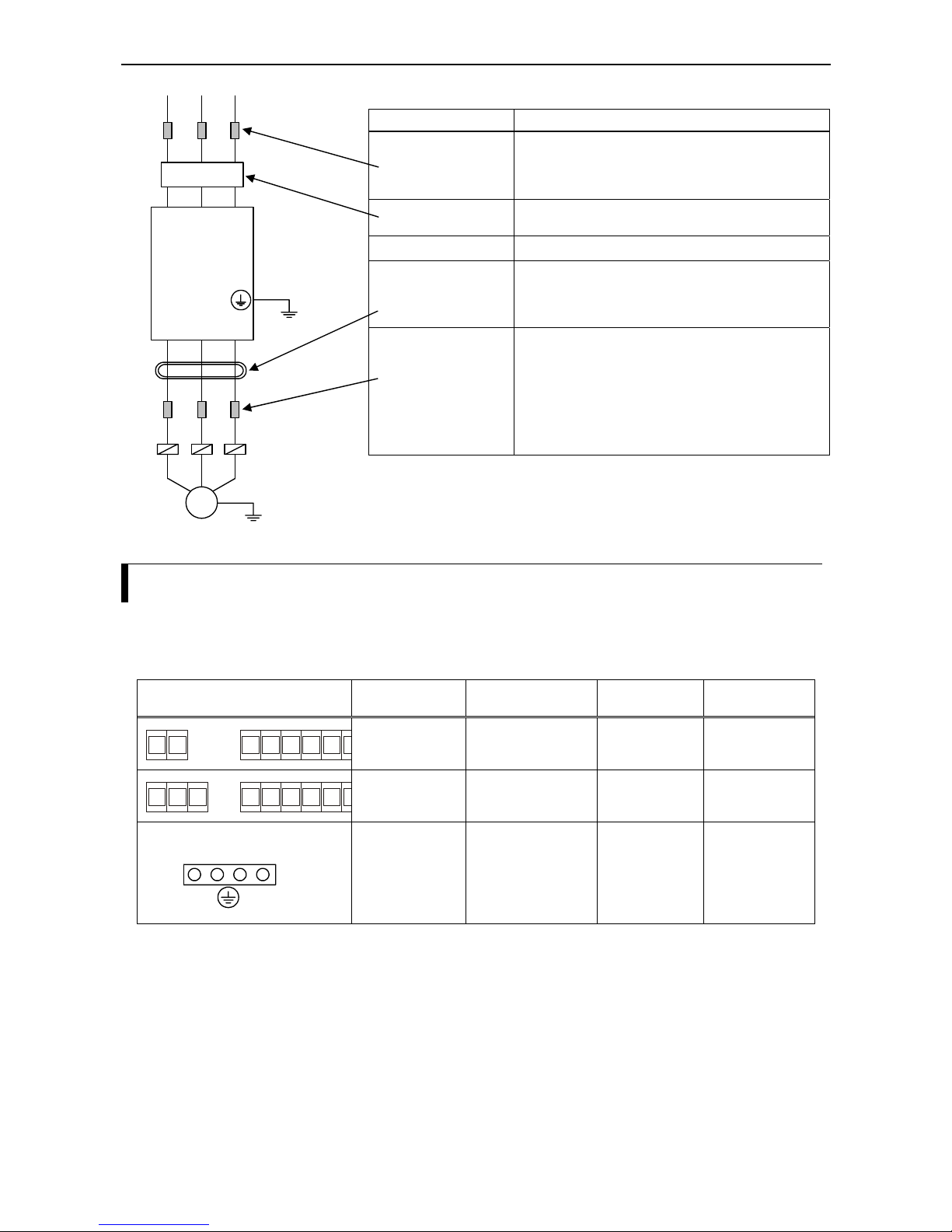

Terminals

In the table below the location and dimensions of the power terminals (terminals for power supply and

motor) are listed:

Location of power terminals Inverter model

Screw size

(Screwdriver type)

Cross section

of cable

Tightening

torque range

LN +VUF-W

All NF models

M3

(0.6x3.5mm)

0.5…6mm

2

(AWG 22...10)

0.5…1.0 Nm

L1 L3L2 +VUF-W

All HF models

M3

(0.6x3.5mm)

0.5…6mm

2

(AWG 22..10)

0.5…1.0 Nm

View of grounding terminal

All

M4

(PH2)

Ring or fork type

cable terminal

diameter: 4mm

1.2…1.3 Nm

L1

(L1)

L2

L3

(N)

(T1) U (T2) V (T3)

W

Motor

Thermal

relays

Chapter 5 – Wiring

5-7

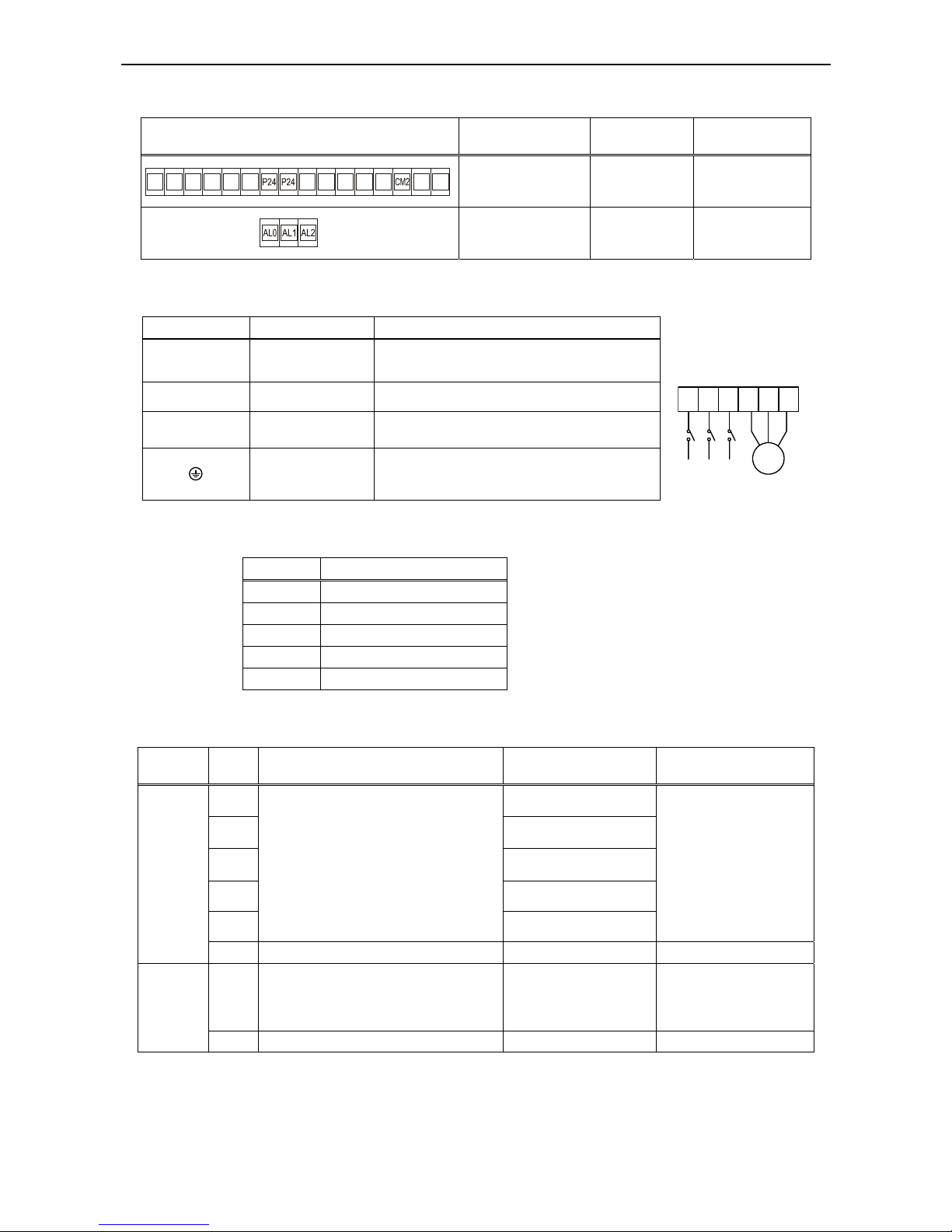

The following table shows the location and dimensions of control and alarm terminals:

Location of terminals

(REMOVABLE CONNECTOR)

Screw size

(Screwdriver type)

Cross section

of cable

Tightening

torque range

M2

(0.4x2.5mm)

0.5…1.5mm

2

(AWG 22...14)

0.2...0.25 Nm

M2.5

(0,6x3,5mm)

0,5-2.5mm

2

(AWG 22..12)

0.4…0.5 Nm

In the following table the purpose of the power terminals is shown:

Terminal symbol Purpose Description

L1, L2, L3

(L, N)

Mains supply

Single phase supply: connect to L, N

Three phase supply: connect to: L1, L2, L3

U, V, W

Inverter output Connect a three phase motor

+, - Braking unit

Connect the optional braking unit (when high

braking torque is required).

Grounding

Ground must be connected to prevent electric shock

should the inverter case carry dangerous voltages

due to a malfunction. Also to connect cable shield.

L1

(L)

L

2

L3

(N)

U

V W

Motor

The following table lists the tightening torque values for tightening the screws:

Screw Torque in Nm

M2 Typ. 0.20 Max. 0.25

M3 Typ. 0.50 Max. 0.60

M3.5 Typ. 0.80 Max. 0.90

M4 Typ. 1.20 Max. 1.30

M5 Typ. 2.00 Max. 2.20

The next table describes the purpose of each control terminal: (To be continued on next page)

Terminal

category

Sym

bol

Purpose Initial setting Remarks

5 Reset input

4

Multistage frequency

input / USP function

3

Multistage frequency

input / use 4-20mA input

2 Reverse run

1

These inputs have different purposes

depending on the user programmed

configuration:

Forward and reverse running command,

up to 4 multistage speed settings,

jogging run, 2nd stage acceleration/decel.,

free run stop, external trip, USP function,

terminal software lock, reset, PTC, input

for choosing current as analogue set value

Forward run

Input closed (ON):

Function active

Input opened (OFF):

Function not active

Input must be ON for a

minimum of 12ms

Digital

Inputs

P24 Common for input signals 24V DC; max. 30mA

FM

Connection of an analogue or digital meter

for measuring frequency;

connection of an analogue meter for

current measurement

Frequency monitor

(analogue)

Monitor

signal

L Common for monitor signal

L 3 4 5 2 1 H

O OI

FM L 12 11

Chapter 5 – Wiring

5-8

Terminal

category

Sym

bol

Purpose Initial setting Remarks

H Reference for frequency command input 10V DC; max. 10mA

O Voltage frequency command

Set value 0-10V;

Input impedance 10k

Ohm

OI Current frequency command

Set value 4-20mA;

Input impedance 250

Ohm

Frequency

command

input

L Common for frequency command input

11

Frequency arrival signal

(signal when reaching

set value)

12

The digital outputs can be user

programmed to provide different signals

for the following situations:

Signal when reaching set value or

passing a configurable frequency;

signal during motor run;

overload signal;

PID deviation signal; alarm signal

Signal during

motor run

Outputs of

open collector type for

connection to a relay

(max. 27V DC and

max. 50mA)

Digital

output

CM2 Common for digital outputs

AL0

AL1

Fault

alarm

output

AL2

AL0 AL1 AL2

Initial setting: During normal operation AL0-AL1 is closed; during a trip condition

or cut off power supply AL0-AL1 is opened (i.e. AL0-AL2 is closed).

Ratings of relay contacts:

Max. 250VAC / 2.5A (resistive) or 0.2A (cos phi = 0.4);

Min. 100VAC / 10mA

Max. 30VDC / 3.0A (resistive) or 0.7A (cos phi = 0.4); Min. 5VDC / 100mA

Chapter 6 – General operation notes

6-1

Chapter 6 – General operation notes

Before starting operation

Prior to the test run, the following items should be checked:

1) Make sure that the power lines (input power supply terminals L1, L2, L3 or L, N) and output terminals

(U, V and W) are connected correctly.

2) Make sure that there are no mistakes in the signal line connections.

3) The grounding terminal must be grounded.

4) Terminals other than those marked as grounding terminals must not be grounded.

5) The inverter must be installed vertically on a non-flammable mounting surface (e.g. steel).

6) Remove any residue from wiring work like stray pieces of wire and others. Also, make sure that no tolls

are left behind.

7) Make shure that the wires connected to the output terminals are not short-circuited or grounded.

8) All the terminal screws must be sufficiently tightened.

9) The configurable maximum output frequency parameter must be chosen in accordance with the

maximum frequency of the connected motor and machine.

Do not carry out any withstand voltage tests because the inverter has a surge absorber between the mains

circuit terminals and the ground.

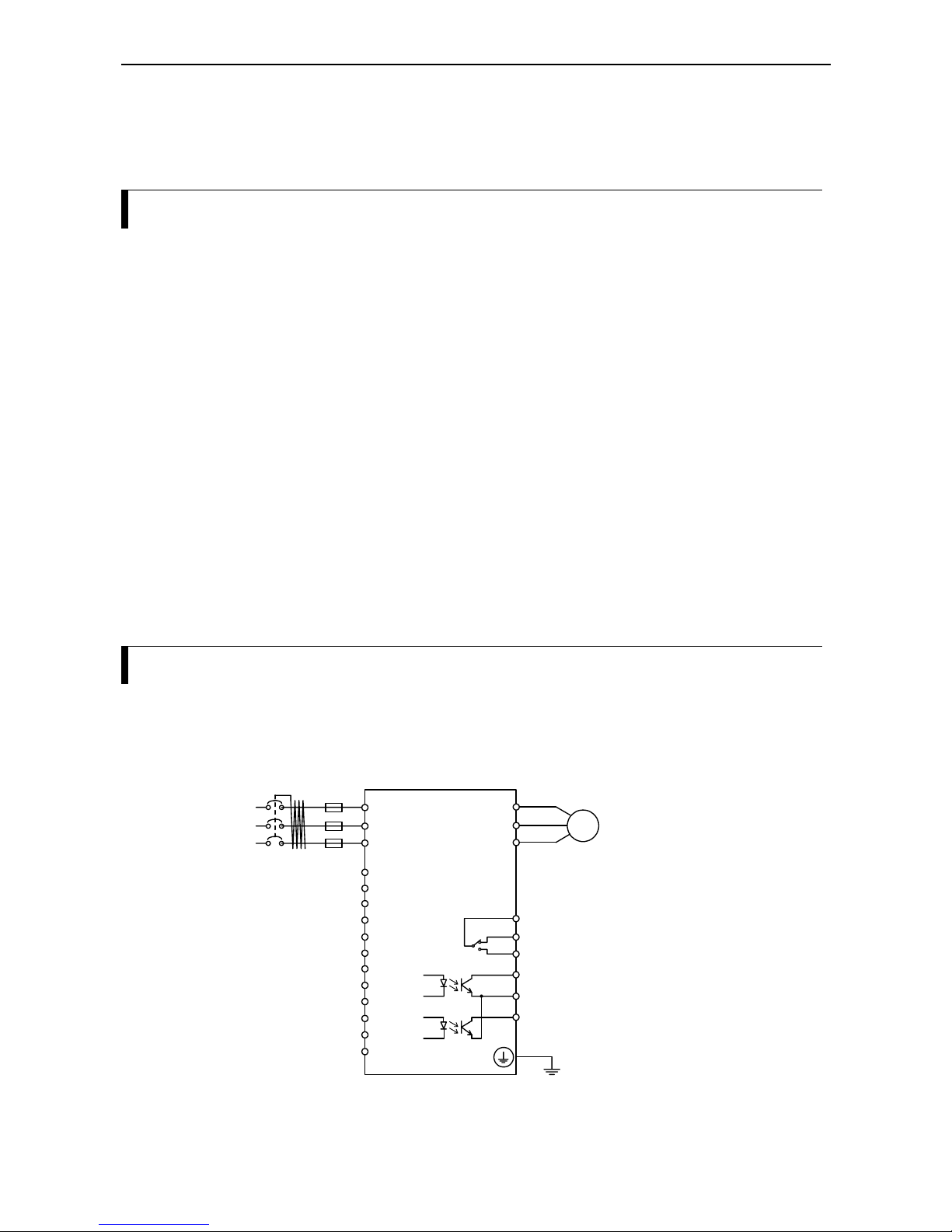

Test run

Below an example for an inverter connection is shown. For the initial tests, frequency adjustment and

forward and reverse running commands should be carried out via the digital operator in order to check the

inverter’s correct functioning.

Power supply

(three phase)

50/60 Hz

Fuses

Earth leakage

circuit breaker

Inverter

L100IP series

L1 (L)

L2

L3 (N)

U

V

W

1

2

3

4

5

L

P24

H

O

OI

L

FM

AL0

AL1

AL2

11

CM2

12

Motor

Ground

400V class:

Three phase 380~460V

200V class:

Single phase 200~240V

Fault alarm signal

Normal state: AL0-AL1

Trip and pow er off: AL0-A L2

Initial setting for maximum

frequency (-FE and -FU series)

is 50 or 60Hz and initial setting

for direction of rotation is

“forward run“.

Chapter 6 – General operation notes

6-2

In order to test the inverter, follow the procedure described below:

1) Turn on power supply to the inverter. The power LED on the digital operator will light up.

2) Set function A 02 to 02.

3) Set function A 01 to 02. Set the corresponding frequency using function F 01.

4) After pressing the RUN key the motor starts to run and the the RUN lamp lights up.

5) The actual frequency can be monitored using function d 01.

6) You can stop the test run by pressing the STOP key.

CAUTION After the test run has been completed, check the following items to ensure that the

motor will not be damaged:

Was the direction of the motor run correct? Was there any trip condition during

acceleration or deceleration? Were there any unusual motor sounds or vibrations?

When a trip occured during the test run due to overcurrent or overvoltage, increase

acceleration or deceleration time.

Chapter 7 – Control circuit terminal functions

7-1

Chapter 7 – Control circuit terminal functions

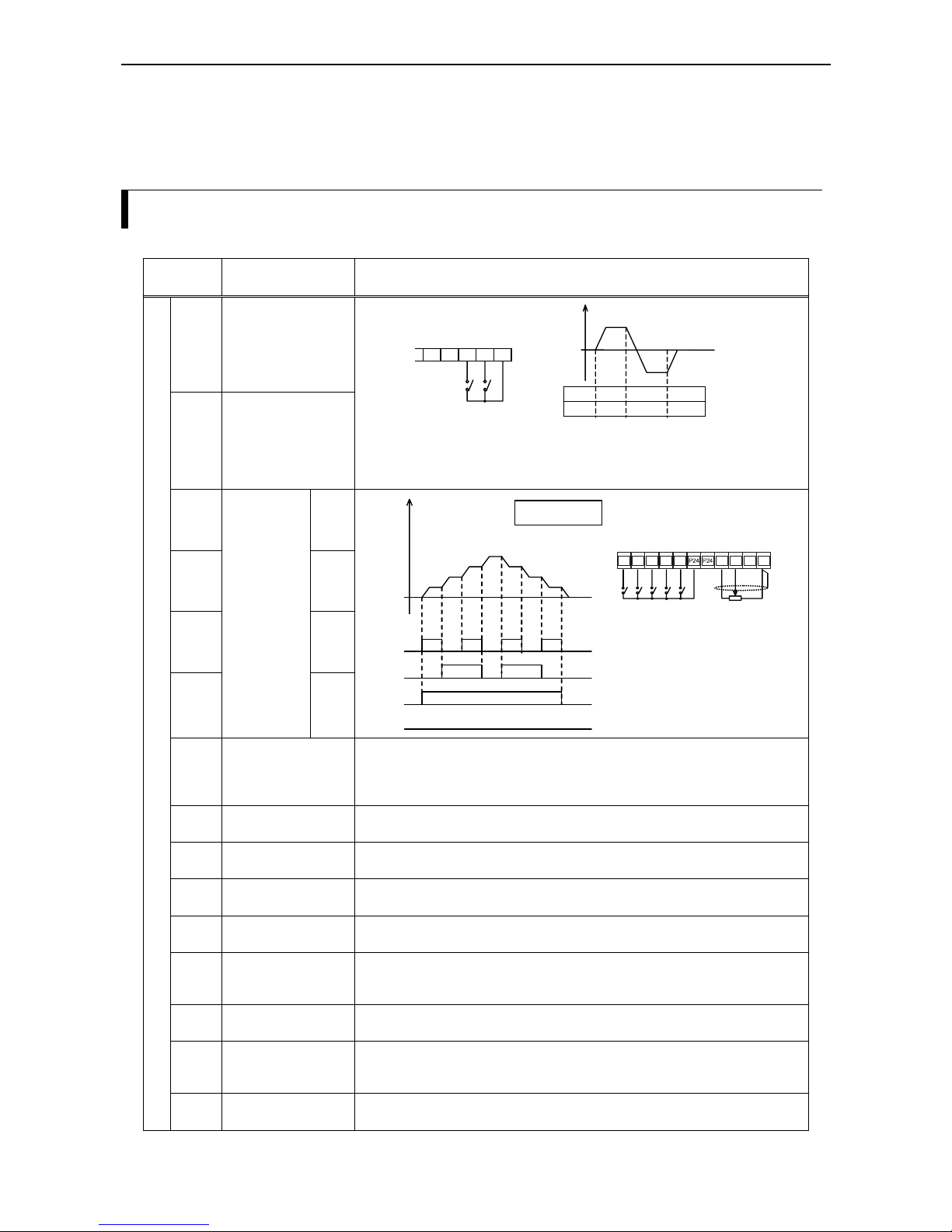

Overview

Terminal

symbol

Terminal function Description

FW

(00)

Forward run

(Start/Stop)

RV

(01)

Reverse run

(Start/Stop)

Freque nc

y

FW ON OFF OFF

RV OFF ON OFF

Forward run

Reverse run

4321P24

RV

FW

Input FW closed: Motor starts with forward running direction.

Input FW open: Motor decelerates from forward running.

(same for reverse run using input RV)

Inputs FW and RV both closed: motor decelerates.

CF1

(02)

1

CF2

(03)

2

CF3

(04)

3

CF4

(05)

4

Frequenc

y

CF1

Frequ. 1

Frequ. 2

Frequ. 3

Set value

ON ON ON ON

ON ON

ON

CF2

FW

RV

Example:

4 multistage speeds

Analog set value

2 multistage inputs (CF1 and

CF2) are necessary for 4

different multistage speeds

(3 programmable multistage

speeds plus 1 set value).

FR

S

CF2

CF1

RV

FW

345 2 1 H O OI L

JG

(06)

Jogging run

The jogging run activated using the terminal JG may serve for setting up a machine

in manual operation mode. When a forward or reverse run command is given, the

frequency configured using A 38 is then sent to the motor. For motor stop, one of

three operating modes can be chosen by configuring A 39.

PTC

(19)

Connection of exter-

nal PTC thermistor

Only digital input 5 can be programmed as a PTC thermistor input (using C 05).

The terminal L serves as common for the thermistor input.

AT

(16)

Activate input OI (current set value 4-20mA)

When the AT input is activated, then the set value will be a 4-20mA current

that has to be supplied at the terminals OI and L.

2CH

(09)

2. stage acceleration /

deceleration

Using this input the second stage acceleration and deceleration time

configured using A 92 and A 93 is activated.

FRS

(11)

Free run stop

function

When the terminal FRS is turned on, frequency to the motor is

switched off and the motor runs free.

EXT

(12)

External trip

When the terminal EXT is turned on, the inverter enters the trip state, stops output

to the motor, and displays E 12. The trip condition can be acknowledged, among

others, using the RS input.

USP

(13)

Prevention of restart

When the USP input is on, the motor does not restart when power supply recovers

following a power supply failure and a running command is active at the same time.

RS

(18)

Reset

A trip can be acknowledged by activating the RS input. If a reset is given during

normal inverter operation, the motor runs free. The RS input is always a normally

open contact and cannot be configured as normally closed input.

Programmable digital inputs 1 through 5

SFT

(15)

Software lock

When the SFT input is turned on, the configured parameters are protected

from being overwritten.

Pro

g

rammable multista

g

e s

p

eeds

Chapter 7 – Control circuit terminal functions

7-2

Terminal

symbol

Terminal function Description

P24

24V DC common for

digital inputs

Common terminal for the intelligent digital inputs

H

10V reference voltage

for analog set value

(using potentiometer)

O

Frequency set value

analog input (0-10V)

OI

Frequency set value

analog input (4-20mA)

Frequency command

L

Common terminal

for analog set value

inputs

HOOIL

Pot (1k – 2K)

HOOIL

0 - 9,6V DC (rated value 10V)

Input impedance 10k Ohms

HOOIL

4 - 19,6mA DC (rated value 20mA)

Input impedance 250 Ohms

Set value configured

usin

g p

otentiometer:

Set value configured

using voltage input:

Set value configured

using current input:

The OI input (set value using analog current 4..20mA) will only be used if

the input configured as AT has been closed before. If no digital input has

been configured as an AT input then the set values that are present at terminals O and OI will be added.

FM Frequency monitor

Using the FM output the output frequency can be monitored and displayed using

an external analog or digital meter. If needed, the motor current can be displayed

instead of the frequency.

Monitor

L 0V Common terminal for the FM output

FA1

(01)

FA2

(02)

Frequency arrival

signals

Frequenc

y

FA1 active

Frequenc

y

FA2 active

f

2

f

1

f

soll

When a digital output is configured as FA1 then a signal

is output as long as the output frequency is held constant

at set value. With a digital output being configured as

FA2, a signal will be output as long as the actual output

frequency is above the values set under C 42 and C 43.

RUN

(00)

RUN signal

The RUN signal is active as long

as the motor is running.

OL

(03)

Overload signal

The OL signal will be output when the actual motor current

is above the threshold set under C 41.

OD

(04)

PID deviation signal

The OD signal will be output when the threshold set under

C 44 (level of PID deviation) is being passed.

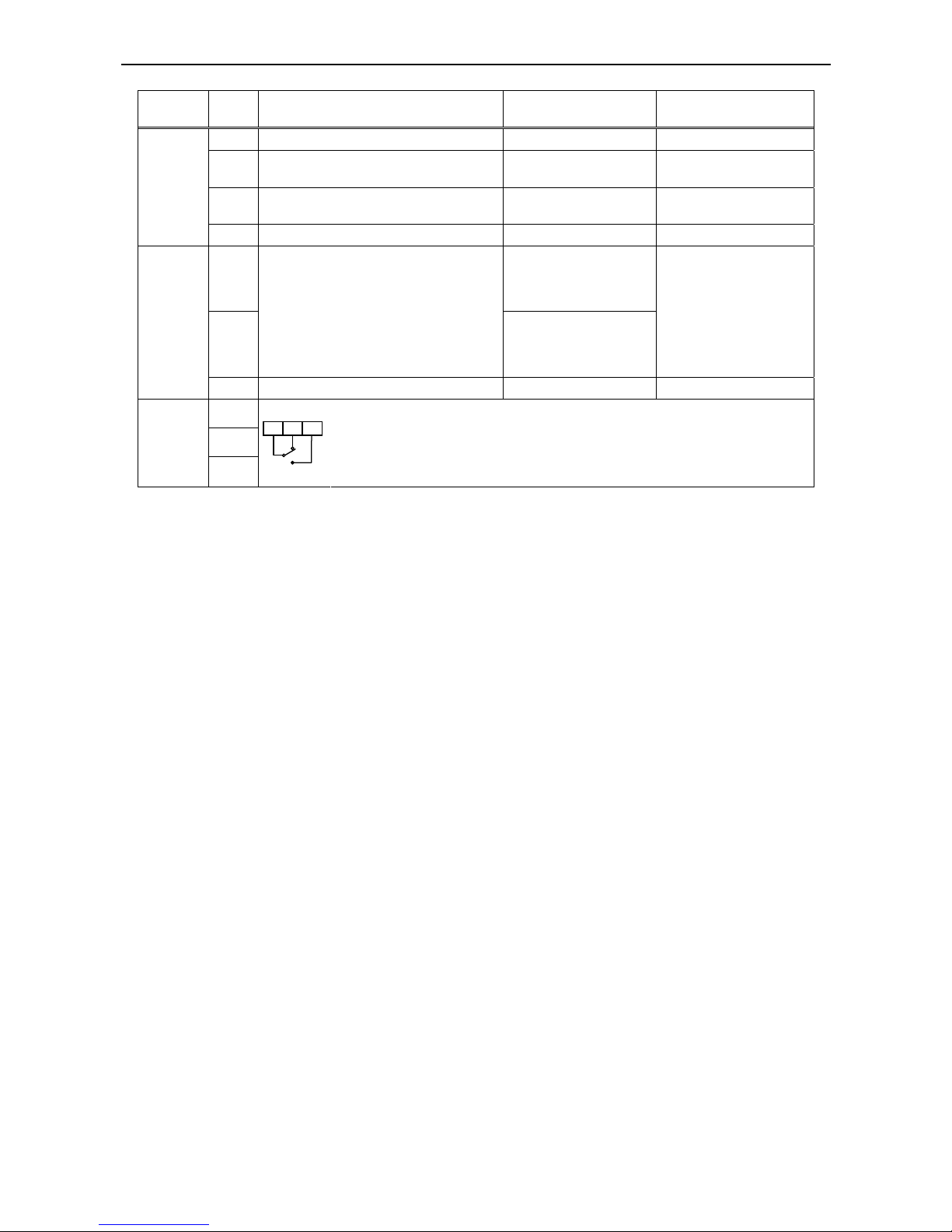

Programmable digital outputs 11 and 12

AL

(05)

Alarm signal The alarm signal is output in case a trip condition occurs.

Connection of a

signal relay to digital

output 11 or 12:

CM2

12 11

Open collector

type output

(max. 27VDC, 50mA)

CM2 0V

This is the 0V common for the programmable digital outputs 11 and 12. These

open collector type outputs are isolated using photocouplers and are separated

from L common.

AL0

AL1

AL2

Alarm terminals

During normal trouble-free operation the terminals AL0 and AL1 are shorted.

During a trip condition or while power to the inverter is off the terminals AL0 and

AL2 are shorted instead.

Absolute maximum relay contact ratings:

250VAC; max. load of 2.5A (purely resistive) or 0.2A (at an cos phi of 0.4)

30VDC; max. load of 3.0A (purely resistive) or 0.7A (at an cos phi of 0.4)

Minimum relay contact ratings:

100VAC at a load of 10mA or 5VDC at a load of 100mA

Chapter 7 – Control circuit terminal functions

7-3

FM terminal

Terminal function

This terminal is used for connecting an analog voltmeter or a digital frequency meter and thus to monitor and

display output frequency. Alternatively, motor current can be monitored instead (when output current is

selected the FM terminal can only supply an analog signal).

1) Frequency display using analog output signal

The analog output signal is a pulse train whose period remains constant. The width of the pulses ist

proportional to the actual output frequency (0 to 10V represent 0Hz to maximum frequency):

0 to 10V

1mA

t

T

10V

T

t

=variable

T=4ms

(

consta nt

)

Adjustment of this signal is done using function b 81. The signal accuracy following adjustment is

+/-5%

2) Frequency display using digital output signal

The frequency of this signal is proportional to the output frequency. The duty cycle is approximately

50%:

Digital fre-

quency meter

10V

f

T = 1/(outpu

t

fre

q

uency*factor

)

T

The signal frequency equals the actual output frequency multiplied by the factor configured under b 86.

3) Motor current display using analog output signal

This signal is identical to the one described under 1). The width of the pulses is proportional to the actual

motor current. The maximum voltage of 10V is reached when the motor current is two times the inverter

rated current. The signal accuracy is +/-20%. The connection to a meter is described under 1). A moving

iron type amperemeter should be used.

Configuration

C 23 b 81 b 86

1) In order to select analog frequency, digital frequency, or analog motor current, use function C 23.

2) When an analog output signal is used (frequency or current), the signal can be adjusted to the special

meter used by specifying a factor under b 81.

3) When the digital output signal (frequency only) is selected, the output signal can be adjusted to the

special meter used by specifying a factor under b 86.

U

82

k33k1µ

F

Example of a terminal

connection using

a low pass filter:

Chapter 7 – Control circuit terminal functions

7-4

Terminals 1 - 5 (programmable digital inputs)

General notes

Several functions can be assigned to the terminals 1 through 5. Depending on the application these terminals

can be configured to be forward (FW) or reverse run (RV) inputs, multistage speed setting inputs (CF1-CF4),

reset input (RS), and so on. The terminal function configuration of inputs 1 - 5 is done using C 01 – C 05,

i.e. C 01 is used to set the function of digital input 1, C 02 is used to set the function of digital input 2, etc.

However, two inputs can not be assigned to an identical function at the same time.

The programmable digital inputs 1 - 5 are factory set as normally open contacts. So when a terminal’s

function is to be activated, the digital input configured for this function has to be closed (i.e. the input

terminal must be connected to terminal P24). Likewise, deactivating of an input means opening this input.

Alternatively, the digital inputs can also be configured as normally closed contacts. To do this, the parameter

01 must be configured under functions C 11 – C 15 (corresponding to digital input 1 - 5). But there is an

exception for inputs configured as reset input (RS) or thermistor input (PTC). Those inputs can only be

configured as normally open contacts.

Chapter 7 – Control circuit terminal functions

7-5

FW: Start/stop forward run

Terminal function

When a digital input configured as FW is activated the motor starts running in the forward direction. When it

is deactivated the motor stops.

54321P24

FW

The motor stops if both the FW and the RV inputs are activated.

Configuration

A 02 C 01 – C 05

1) The initial factory setting determines that the running command is given using digital inputs configured

as FW or RV. If the running command is currently given using the RUN key on the digital operator, you

have to first set the parameter 01 under function A 02 (run command source is FW/RV terminal).

2) Configure one of the digital inputs 1 – 5 as FW input by entering the parameter 00 under C 01 – C 05.

WARNING If the power supply to the inverter is switched on and a running command is active

at the same time, the motor starts immediately. So take care that the run command is

not active prior to switching the power supply on.

WARNING If the FW input is opened (inactive state if FW is configured as normally open

contact) and is subsequently configured as a normally closed contact, the motor

starts as soon as the reconfiguration is complete.

RV: Start/stop reverse run

Terminal function

When a digital input configured as RV is activated the motor starts running in the reverse direction. When it

is deactivated the motor stops.

54321P24

RV

The motor stops if both the FW and the RV inputs are activated.

Configuration

A 02 C 01 – C 05

1) The initial factory setting determines that the running command is given using digital inputs configured

as FW or RV. If the running command is currently given using the RUN key on the digital operator, you

have to first set the parameter 01 under function A 02 (run command source is FW/RV terminal).

2) Configure one of the digital inputs 1 – 5 as RV input by entering the parameter 01 under C 01 – C 05.

WARNING If the power supply to the inverter is switched on and a running command is active

at the same time, the motor starts immediately. So take care that the run command is

not active prior to switching the power supply on.

WARNING If the RV input is opened (inactive state if RV is configured as normally open

contact) and is subsequently configured as a normally closed contact, the motor

starts as soon as the reconfiguration is complete.

Chapter 7 – Control circuit terminal functions

7-6

CF1 – CF4: Multistage speed settings

Terminal function

Using the digital inputs configured as CF1 – CF4 one of up to 16 freely selectable frequencies (including the

set value) can be sent to the motor depending on which terminals are activated or deactivated (refer to table

below). It is not necessary to use all four multistage speed setting terminals at the same time. If you need for

example only up to eight different frequencies it is sufficient to configure only CF1 – CF3; if only up to four

different frequencies are needed only 2 multistage speed setting terminals have to be configured.

The multistage speed settings have a higher priority than most of the other means of providing the set value.

Only when the jogging run is activated the jogging frequency priority is even higher than the priority of the

multistage speed settings. The multistage frequencies can be activated using the inputs CF1 – CF4 at any

time and need not be enabled in any way.

54321P24

CF4

CF3

CF2

CF1

Input configured as

Multi-

stage

speed #

CF4 CF3 CF2 CF1

0 0000

1 0001

2 0010

3 0011

4 0100

5 0101

6 0110

7 0111

8 1000

9 1001

10 1010

11 1011

12 1100

13 1101

14 1110

15 1111

Note

: 0 = Input deactivated

1 = Input activated

CF2

CF3

FW

RV

CF1

Frequ. 1

Frequ. 2

Frequ. 3

Fre

q

u. 5

Frequ. 6

Frequ. 7

Fre

q

u. 4

Fre

q

u. 0

Configuration

A 21 – A 35 C 01 – C 05 F 01

Configure one or more of the digital inputs 1 – 5 as CF1 – CF4 input by entering one or more parameters

under C 01 – C 05 (parameter setting range is 02 – 05).

Following this, the multistage frequencies can be programmed by one of two ways:

A) Enter the multistage frequencies under A 21 – A 35.

B) Activate those multistage speed inputs that are necessary for the desired frequency to be configured

(refer to table above) and enter the desired frequency under F 01 (note that the motor must be stopped

first e.g. using the STOP key or deactivating the FW input). The entered frequency value must be stored

using the STR key.

Remarks

• If you want one ore more of the multistage frequencies to be greater than 50Hz the maximum frequency

has to be raised first using A 04.

• A multistage speed setting of 0 (inputs CF1 – CF4 are all deactivated) corresponds to the frequency set

value. This set value can be configured either using the terminals O respectively OI, or by configuring

F 01 and A 20.

Chapter 7 – Control circuit terminal functions

7-7

AT: Analog set value using current 4-20mA

Terminal function

When a digital input configured as AT is activated then the frequency set value will be represented by the

current (4-20mA) fed into the OI terminal. When the AT input is not active then the frequency set value will

be represented by the voltage (0-10V) present at the O terminal.

54321P24

AT

Configuration

A 01 C 01 – C 05

1) First the frequency source setting must be configured under function A 01. The factory setting of 01

means that the voltage at the O terminal or the current into the OI terminal are used for setting the

frequency (depending on whether the AT input is activated or not). Set the parameter to 01 if it has not

already been set to this value.

2) Configure one of the digital inputs 1 – 5 as AT input by entering the parameter 16 under C 01 – C 05.

Remarks

• If none of the programmable digital inputs has been programmed as AT input then the voltage resp.

current set values present on terminal O resp. OI are added.

2CH: Second stage acceleration/deceleration

Terminal function

When a digital input configured as 2CH is activated then the motor is accelerated or decelerated using the 2.

stage acceleration or deceleration time. When the 2CH input is deactivated again the inverter is switched

back to acceleration respectively deceleration time 1.

54321P24

2CH

FW

Terminal 2CH

Output freque nc

y

Run command via

FW or RV

1. acceleration

2. acceleration

Configuration

A 92 – A 94 C 01 – C 05

1) Configure the desired value for 2. acceleration or deceleration time under functions A 92 and A 93.

Then enter the parameter 00 under A 94 so that the switchover to the 2. stage acceleration/deceleration

can be activated using the 2CH terminal (this is the factory setting).

2) Configure one of the digital inputs 1 – 5 as 2CH input by entering the parameter 09 under C 01 – C 05.

Remarks

• When a parameter of 01 is entered under A 94 then an automatic switchover to the 2. stage accelera-