Page 1

L100DN

™

DeviceNet

Series Inverters

Addendum to L100 Series

Inverter Instruction Manual

In This Addendum.... page

— Getting Started ................................................. 3

— Inverter Mounting and Installation .................... 9

— Configuring Drive Parameters........................ 26

— Operations and Monitoring............................. 31

— Network Control and Monitoring..................... 39

— Troubleshooting and Maintenance ................. 70

In the Appendices:

— DeviceNet Object Lists................................... 71

— Network Register Map.................................... 78

— Drive Parameter Settings Tables.................... 88

— Restoring Factory Default Settings ................ 94

READ THIS FIRST!

Addendum Number: NB642X

Addendum for Manual: NB576X

Page 2

2

Revisions

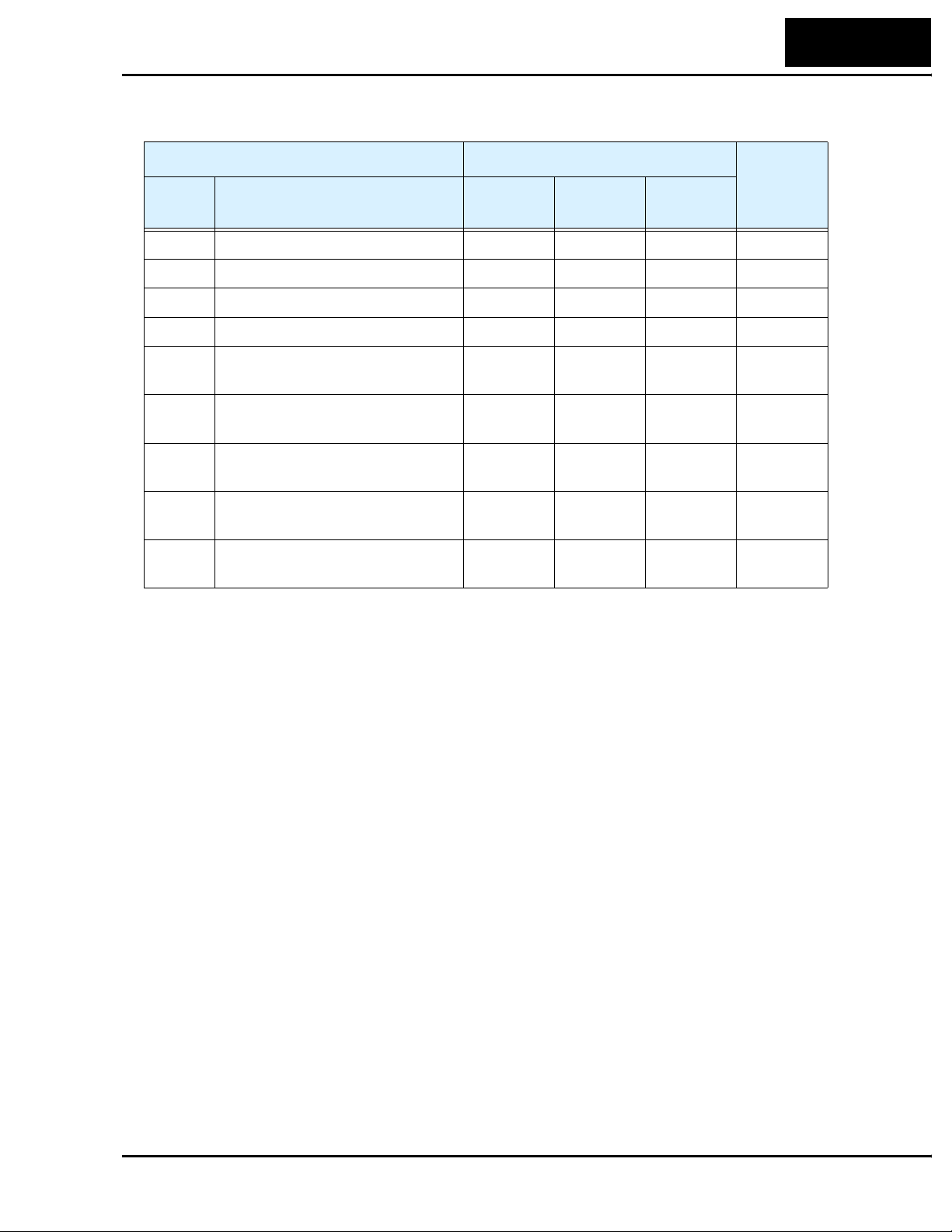

Revision History Table

No. Revision Comments Date of Issue

Initial Release of Addendum NB642X Jan. 2003 NB642X

Addendum

No.

DeviceNet™ is a trademark of Open DeviceNet Vendor Association, Inc.

Page 3

Getting Started

This section provides specification details for L100DN DeviceNet™ Series inverters

corresponding to Chapter 1, “Getting Started,” in the L100 Inverter Instruction Manual.

Main Features

Congratulations on your purchase of a Hitachi

L100DN DeviceNet Series inverter! Like the

standard L100 Series inverters, this inverter

drive features state-of-the-art circuitry and

components, exceptionally small footprint,

and high performance. The Hitachi L100DN

product line includes all the horsepower and

power input versions, but each inverter can

also connect to a DeviceNet network for

control and monitoring. The main features are:

• 200V and 400V Class inverters

• UL or CE version available

L100DN Inverter

3

• Convenient keypad for parameter settings

• Built-in DeviceNet network interface to

allow control and monitoring via a

DeviceNet network

• Sixteen programmable speed levels

• Three-wire control interface

• Up/Down electronic motorized speed pot function

• Two-step acceleration and deceleration curves

The design in Hitachi inverters overcomes many of the traditional trade-offs between

speed, torque and efficiency. The performance characteristics are:

• Output frequency range from 0.5 to 360 Hz

• Continuous operation at 100% torque within a 1:10 speed range (6/60 Hz / 5/50 Hz)

without motor derating

Model L100DN–002NFU2

Page 4

4

Getting Started

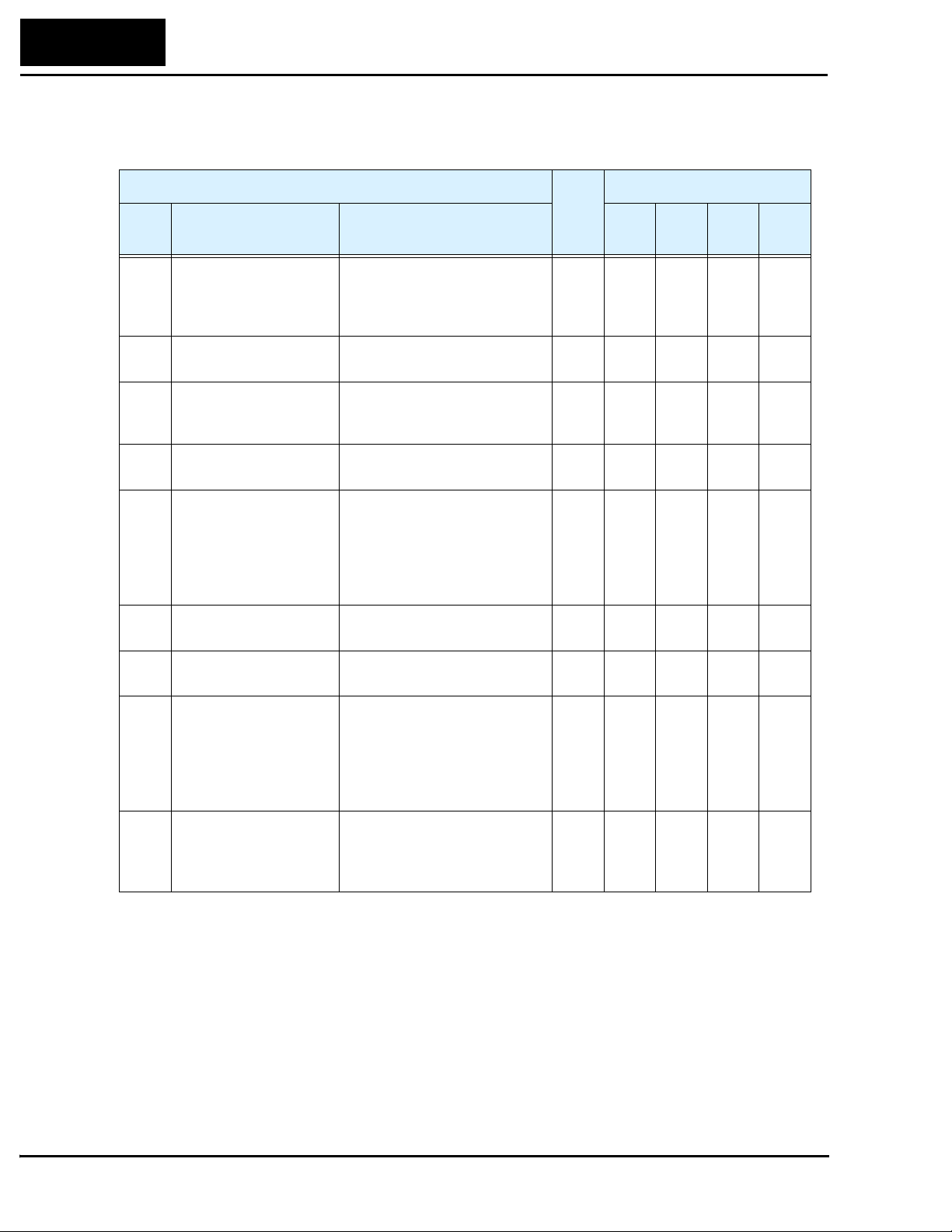

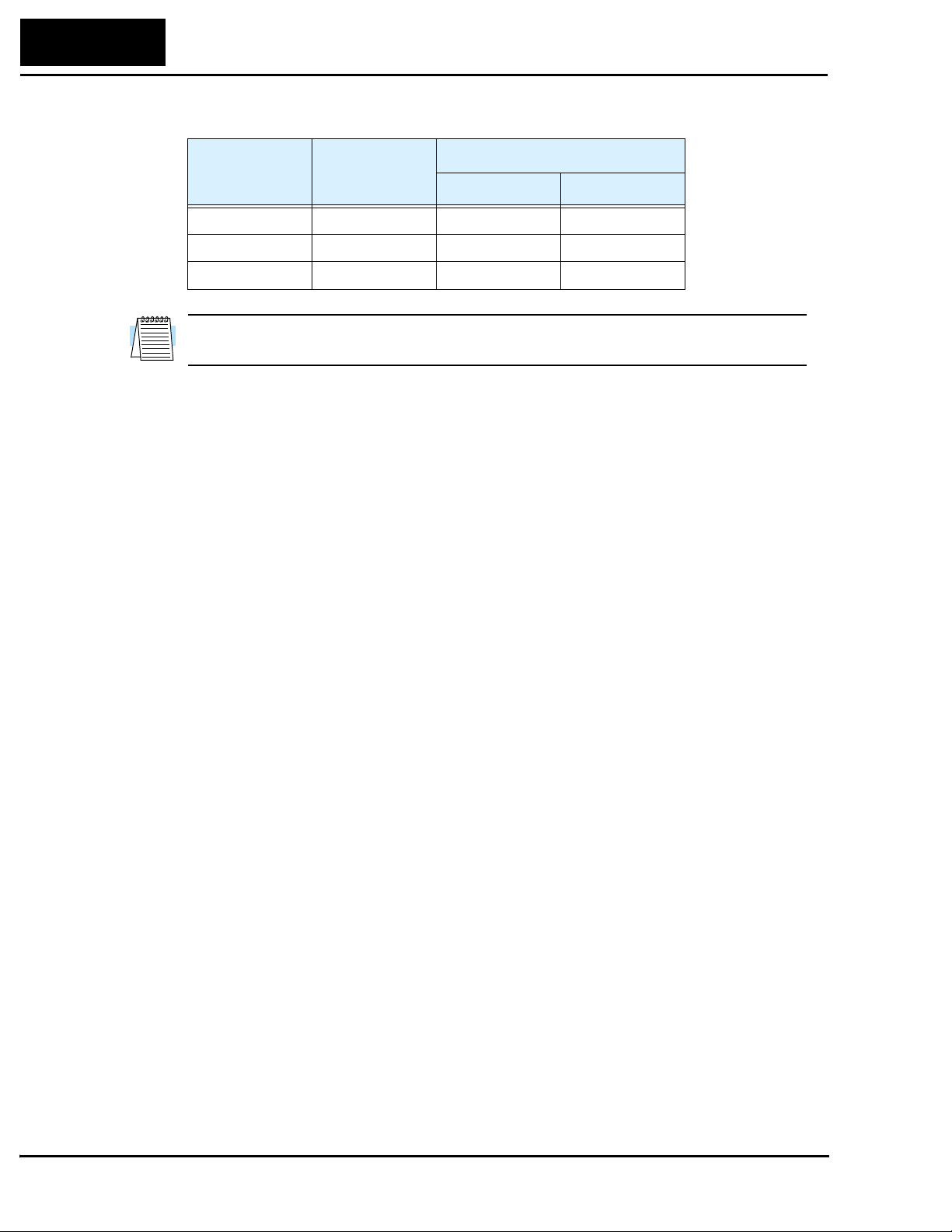

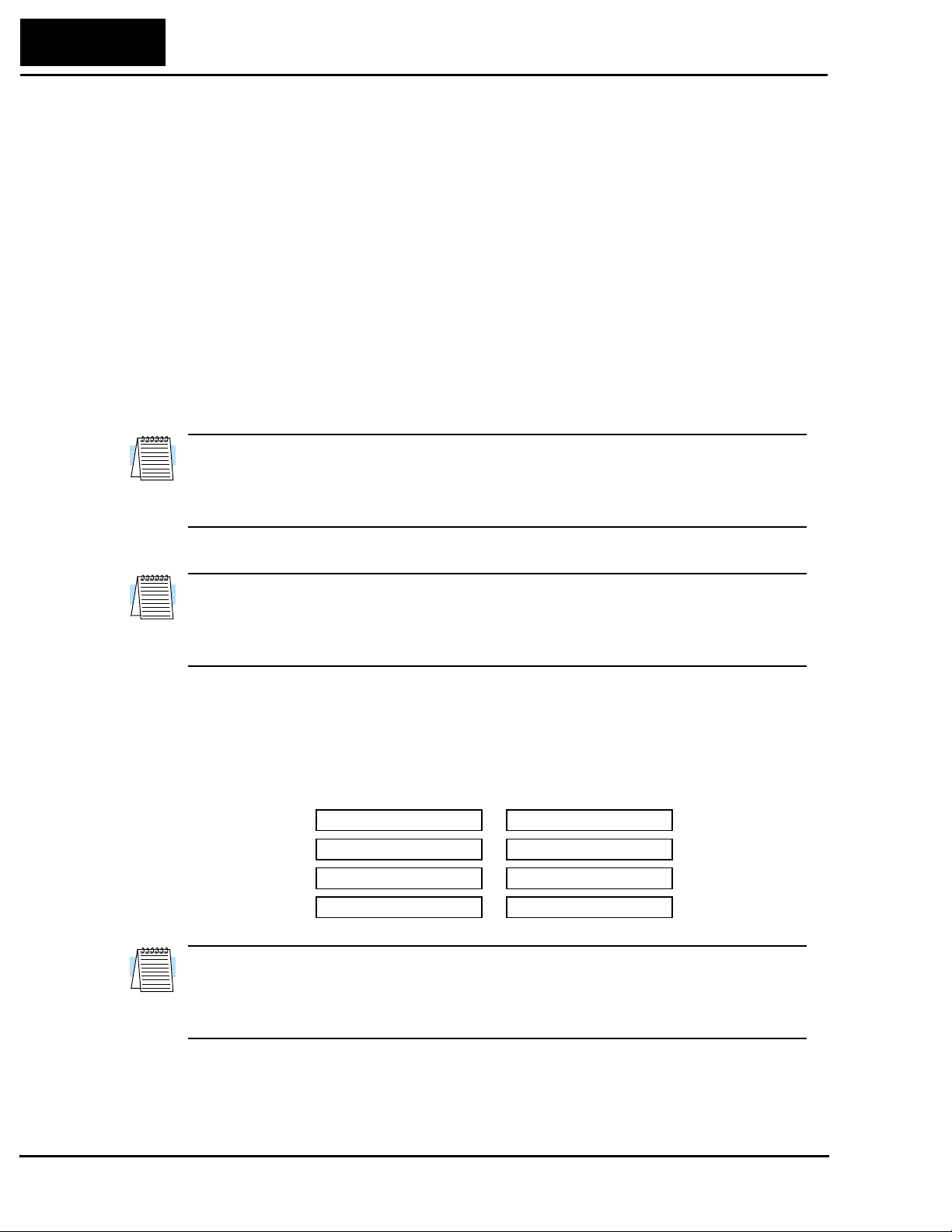

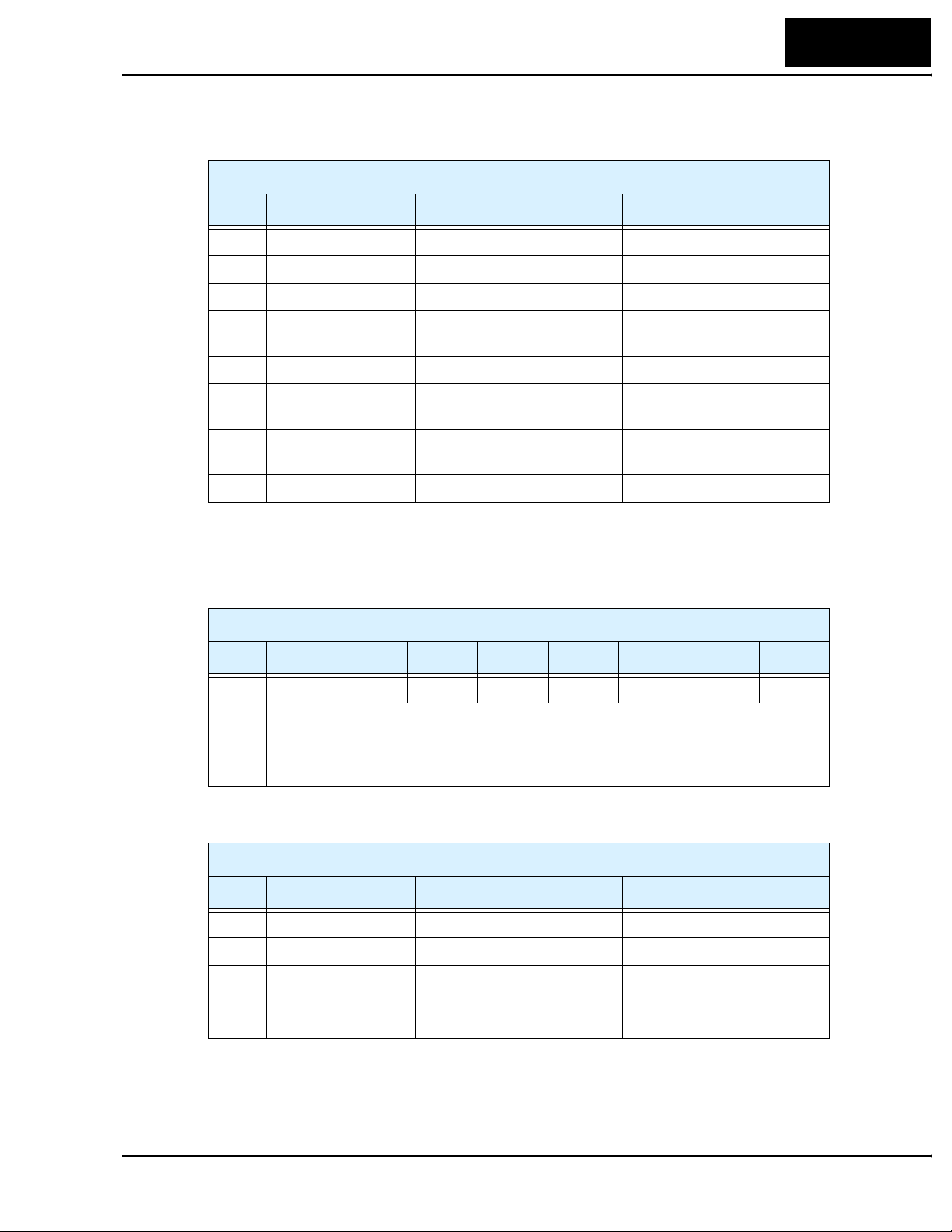

Comparison Summary, Standard vs. DeviceNet Series

The Hitachi L100DN DeviceNet Series inverters generally have the same motor control

capability as the standard L100 inverters. However, a few important differences do exist.

The addition of DeviceNet network connectivity to Hitachi inverters is accompanied by

some changes to the available parameters, functions, front panel keypad, and intelligent

terminals. Together, these changes provide a complete inverter solution with DeviceNet

network capability, while removing some features that are generally unused in

networked applications.

Feature L100 (standard) L100DN (DeviceNet)

Front panel speed control Potentiometer, output freq. —

Front panel LEDs for

networking

Front panel door Half door for programming keys

and control terminals

Analog input terminals [H], [O], [OI], [L] —

PWM output terminal [FM] —

Intelligent input terminals [1], [2], [3], [4], [5] [1], [2], [3] only

Intelligent input functions Includes [AT] Includes [STA], [STP], [F/R],

Intelligent output terminals [11], [12], [AL0] to [AL2] [11], [12] only

Intelligent output functions Includes [OD] —

Digital operator configuration B_89 —

Network connector on front

panel

Network connector for cable — DeviceNet on removable Phoenix

DeviceNet network settings — P_41to P_49

Frequency source selection A_01 (selects potentiometer,

RS422 or RJ11 modular DeviceNet on Phoenix

control terminal, or F_01)

— MS – Module Status LED,

NS – Network Status LED

—

[UP], [DWN], [DNT], [OPE]

5-terminal conn., male

5-terminal conn., female

A_01 does not exist, so freq.

source is always F_01 or the

DeviceNet network host

Analog input settings A_11 to A_16, B_81, C_81, C_82 —

Analog output settings C_23 —

PID control settings D_04, A_71 to A_76, C_44 —

Intelligent input terminal

settings for [4] to [6]

Intelligent output terminal

settings for [AL0] to [AL2]

C_04, C_05, C_06,

C_14, C_15, C_16

C_24, C_33 —

—

TIP: When using the standard L100 Series manual with your L100DN DeviceNet series

inverter, refer to this page for a summary of the exceptions to that manual. Also note that

your L100DN inverter comes with its own Quick Reference Guide (QRG).

Page 5

Inverter Specifications Label

The Hitachi L100DN Series inverters have product labels located on the right side of the

housing, as pictured below. Be sure to verify that the specifications on the labels match

your power source, motor, and application safety requirements.

Specifications label

Inverter model number

L100DN Inverter

5

Regulatory agency approvals

Motor capacity for this model

Power Input Rating:

frequency, voltage, phase, current

Output Rating:

Frequency, voltage, current

Manufacturing codes:

Lot number, date, etc.

Model Number Convention

The model number for a specific inverter contains useful information about its operating

characteristics. Refer to the model number legend below:

L100DN 002 H F U

Series name

2

Version number (_, 1, 2, ...)

Restricted distribution:

E=Europe, U=USA

Configuration type

F = with digital operator (keypad)

Input voltage:

N = single or three-phase 200V class

H = three-phase 400V class

L = three phase only, 200V class

Applicable motor capacity in kW

002 = 0.2 kW

004 = 0.4 kW

005 = 0.55 kW

007 = 0.75 kW

011 = 1.1 kW

015 = 1.5 kW

022 = 2.2 kW

030 = 3.0 kW

037 = 3.7 kW

040 = 4.0 kW

055 = 5.5 kW

075 = 7.5 kW

Page 6

6

Getting Started

DeviceNet Networking Overview

Hitachi L100DN DeviceNet Series inverters are optimized for use on a DeviceNet

network. The inverter can respond to commands such as Run/Stop from a network host

device, for example. L100DN inverters can also drive a motor in stand-alone mode,

without a network connection. In that case, you use the inverter’s keypad or input terminals for Run/Stop commands. However, this addendum will use stand-alone operation

only for initial powerup tests of your L100DN inverter during installation. After the

installation material, the addendum covers network operation in detail.

The diagram below shows L100DN inverters connected to a DeviceNet network. Each

connection is called a node, and the L100DN connects to the network via the 5-pin,

color-coded Phoenix connector on the front panel as shown.

Network host computer L100DN inverter L100DN inverter

DeviceNet network

A DeviceNet network supports up to 64 devices, each with their own node address. One

device will be the network master; all other device(s) will be network slaves. The

L100DN inverter will operate as a network slave, as the network master (also called host

computer) will send commands to the slaves.

A factory network such as DeviceNet allows you to integrate devices of many different

types, even from various manufacturers, all into an integrated control system. A common

application that uses DeviceNet is a conveyor line. Typical devices on the network

include a PLC (programmable logic controller) or host computer (such as a PC), inverter

drives to run motors, proximity sensors, limit switches, diverter actuators, barcode

scanners, label printers, and other packaging or shipping devices. Note that Hitachi also

provides the L100DN DeviceNet Series inverters, which can also reside on the

DeviceNet network.

For detailed DeviceNet network configuration instructions, see “Network Control and

Monitoring” on page 39.

Page 7

L100DN Inverter

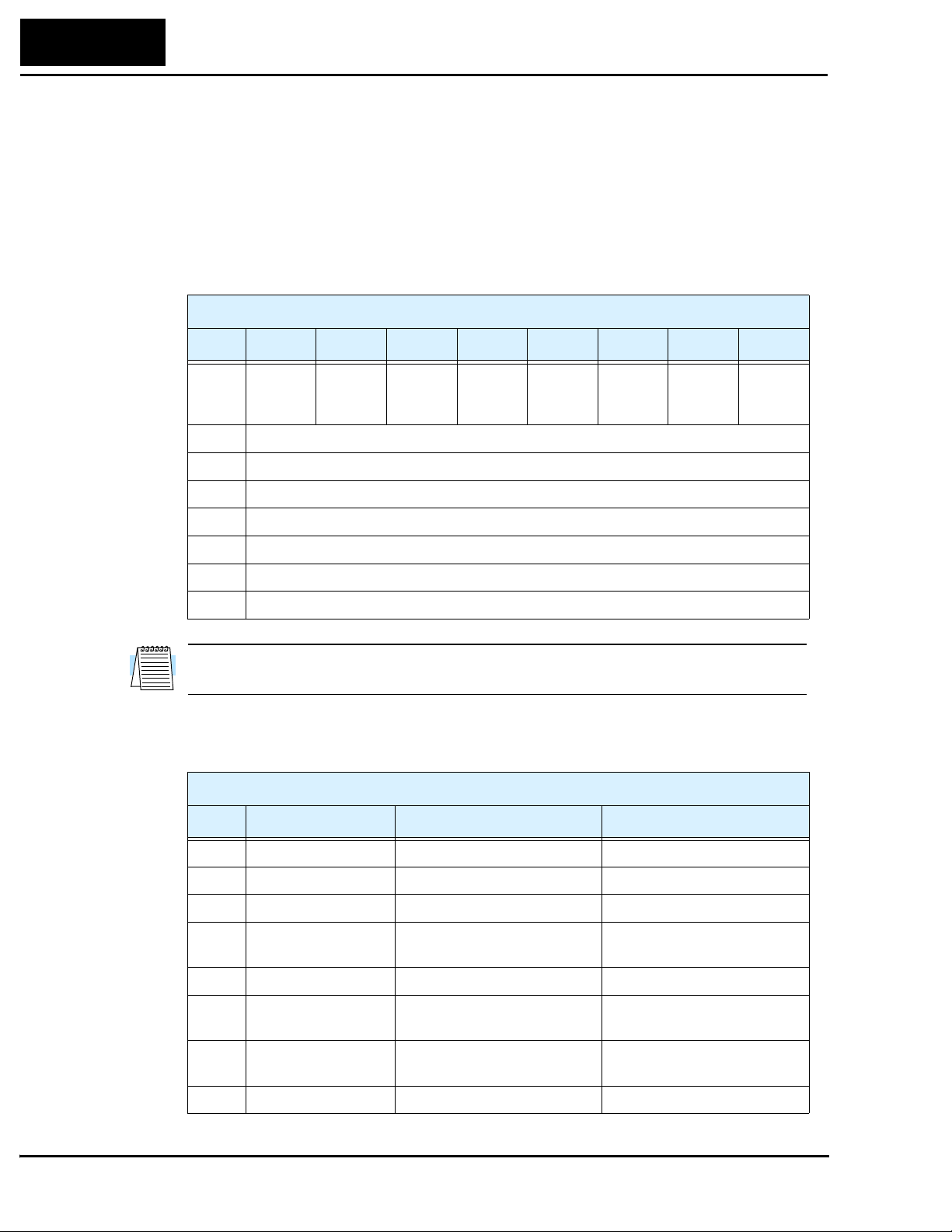

General Specifications

L100DN DeviceNet Series inverters have the same electrical characteristics for driving

the motor as the standard L100 inverters. So, refer to the L100 instruction manual for the

electrical specifications tables and derating curves. The general specifications in this

section will be similar to the those for the standard L100 inverters, but they reflect the

differences given in “Comparison Summary, Standard vs. DeviceNet Series” on page 4.

The following table applies to all L100DN DeviceNet Series inverters.

Item General Specifications

Protective housing *1 IP20

Control method Sine wave pulse-width modulation (PWM) control

Output frequency range *2 0.5 to 360 Hz

Frequency accuracy Digital command: 0.01% of the maximum frequency

Frequency setting resolution Digital: 0.1 Hz; DeviceNet: 0.01 Hz

Volt./Freq. characteristic V/f optionally variable, V/f control (constant torque, reduced torque)

Overload current rating 150%, 60 seconds

7

Acceleration/deceleration time 0.1 to 3000 sec., (linear accel/decel), second accel/decel setting

available

Input

signal

Output

signal

Other functions AVR function, curved accel/decel profile, upper and lower limiters,

Freq.

setting

FWD/

REV

Run

Intelligent input

terminal

Intelligent output

terminal

Operator panel Up and Down keys / Value settings

Network DeviceNet polled I/O – continuous update of output frequency

Operator panel Run/Stop (Forward/Reverse run change by command)

External signal Forward run/stop, Reverse run/stop (on intelligent terminals)

Network Forward run/stop, Reverse run/stop

FW (forward run command), RV (reverse run command), CF1~CF4

(multi-stage speed setting), JG (jog command), 2CH (2-stage accel./

decel. command), FRS (free run stop command), EXT (external

trip), USP (startup function), SFT (soft lock), RS (reset), PTC

(thermal protection), STA (start, 3-wire interface), STP (stop, 3-wire

interface), F/R (FW/RV, 3-wire interface), DNT (DeviceNet select),

UP (remote control accel.), DWN (remote control decel.), OPE

(Force Operation from Digital Operator)

RUN (run status signal), FA1,2 (frequency arrival signal), OL

(overload advance notice signal), AL (alarm signal)

16-stage speed profile, fine adjustment of start frequency, carrier

frequency change (0.5 to 16 kHz) frequency jump, gain and bias

setting, process jogging, electronic thermal level adjustment, retry

function, trip history monitor

Protective function Over-current, over-voltage, under-voltage, overload, extreme high/

low temperature, CPU error, memory error, ground fault detection at

startup, internal communication error, electronic thermal, DeviceNet

comm. error

Page 8

8

Getting Started

Item General Specifications

Operating

Environ

ment

Coating color Light purple, cooling fins in base color of aluminum

Options Braking unit, braking resistor, AC reactor, DC reactor, noise filter,

Temperature Operating (ambient): -10 to 50°C (*3) / Storage: -25 to 70°C (*4)

Humidity 20 to 90% humidity (non-condensing)

Vibration *5

Location Altitude 1,000 m or less, indoors (no corrosive gasses or dust)

5.9 m/s

DIN rail mounting

2

(0.6G), 10 to 55 Hz

Note 1: The protection method conforms to JEM 1030.

Note 2: To operate the motor beyond 50/60 Hz, consult the motor manufacturer for

the maximum allowable rotation speed.

Note 3: If operating the inverter in an ambient temperature of 40–50

° C, reduce the

carrier frequency to 2.1 kHz, derate the output current by 80%, and remove

the top housing cover. Note that removing the top cover will nullify the

NEMA rating for the inverter housing.

Note 4: The storage temperature refers to the short-term temperature during transport.

Note 5: Conforms to the test method specified in JIS C0911 (1984). For the model

types excluded in the standard specifications, contact your Hitachi sales representative.

Page 9

Inverter Mounting and Installation

This section describes the L100 Series installation corresponding to Chapter 2, “Inverter

Mounting and Installation,” in the L100 Inverter Instruction Manual.

Orientation to Inverter Features

Please take a few moments to unpack your new L100DN inverter and do these steps:

1. Look for any damage that may have occurred during shipping.

2. Verify the contents of the box include:

a. One L100DN inverter

b. One Addendum for L100DN inverter (read this addendum first!)

c. One L100 Instruction Manual

d. One L100DN Quick Reference Guide

e. One packet of desiccant—discard (not for human consumption)

3. Inspect the specifications label on the side of the inverter. Make sure it matches the

product part number you ordered.

L100DN Inverter

9

The L100DN DeviceNet Series inverters vary in size according to the current output

rating and motor size for each model number. All feature the same basic keypad and

connector interface for consistent ease of use. The inverter construction has a heat sink at

the back of the housing. The larger models include a fan(s) to enhance heat sink performance. The mounting holes are pre-drilled in the heat sink for your convenience. Never

touch the heat sink during or just after operation; it can be very hot.

The electronics housing and front panel are built onto the front of the heat sink. The front

panel has two levels of physical access designed for convenience and safety:

• First-level access – for basic use of inverter, editing parameters, and wiring control

signals or network connection (power ON)

• Second-level access – for wiring the inverter power supply or motor (power OFF)

1. First-level Access – View the unit just as it

came from the box as shown. The four-digit

display can show a variety of performance

parameters. LEDs indicate whether the

display units are Hertz or Amperes. Other

LEDs indicate AC Power (external), Run/

Stop Mode, Program/Monitor Mode,

Module Status, and Network status.

Membrane keys Run and Stop/Reset

control motor operation. And, you can

access the two chassis GND screws on the

metal tab at the bottom of the inverter.

Page 10

10

Inverter Mounting and Installation

The FUNC., , , and STR keys allow an operator to access and change the

2

1

inverter’s functions and parameter values. The top 8-position connector provides the

interface for logic-level control signals. The bottom 5-position connector is the

DeviceNet interface. It comes with a removable connector for connecting to a DeviceNet

cable. These signals are generally low-voltage in nature and are appropriate for firstlevel access.

Controls for mode

and parameter

changes

Control signal

connector

DeviceNet

connector

2. Second-level access – First, ensure no

power source of any kind is connected to

the inverter. If power has been connected,

wait five minutes after powerdown and

verify the Power LED is OFF to proceed.

Then locate the recessed retention screw

on the left side main front panel (it is

along the left hinge area on some models,

or behind the first access door on others).

Use a small screwdriver (Regular or

Phillips) to loosen the screw. Swing the

door around to the right to reveal the

internal components of the drive. The twolevel tiered 12-position terminal block

Auxiliary network power

connector

Retention screw

accepts wires for the power input and

wires to the motor.

NOTE: The 3-terminal connector located on the circuit board behind the hinged front

door can be used to connect DeviceNet network power. See “Step 2 – Connect Network

Devices” on page 43 for more information.

Page 11

Notice the housing partition that lifts out to

allow full access to the terminals for wiring

as shown. Never operate the inverter drive

with the partition removed or the full access

door opened.

Never directly touch any terminal or circuit

component. This protects you from touching

a n unexpected live circuit, and it protects the

inverter from electrostatic discharge (ESD).

The power and motor connector terminals are

accessible with the removal of the housing

partition. The input power and motor connections use the lower row of terminals. The

upper row is for connecting dynamic braking

components.

L100DN Inverter

11

Housing partition

Power and motor

connector terminals

Page 12

12

Inverter Mounting and Installation

System Description and Basic Installation

The Basic System Description and Step-by-Step Basic Installation sections in Chapter 2

of the standard L100 manual (included) will show you how to choose a mounting

location and wire the inverter’s power input and motor output terminals. Wire gauge,

terminal torque specifications, fuse or breaker size, and many important Warning and

Caution messages are included. So, all of the information you need to physically install

your L100DN DeviceNet inverter is in the standard manual—with the exception of the

dimension drawings, which follow below.

NOTE: After doing the basic installation (physical mounting and power wiring) per the

instructions in Chapter 2 of the L100 manual, be sure to return to this addendum for the

Powerup Test and Front Panel Keypad orientation.

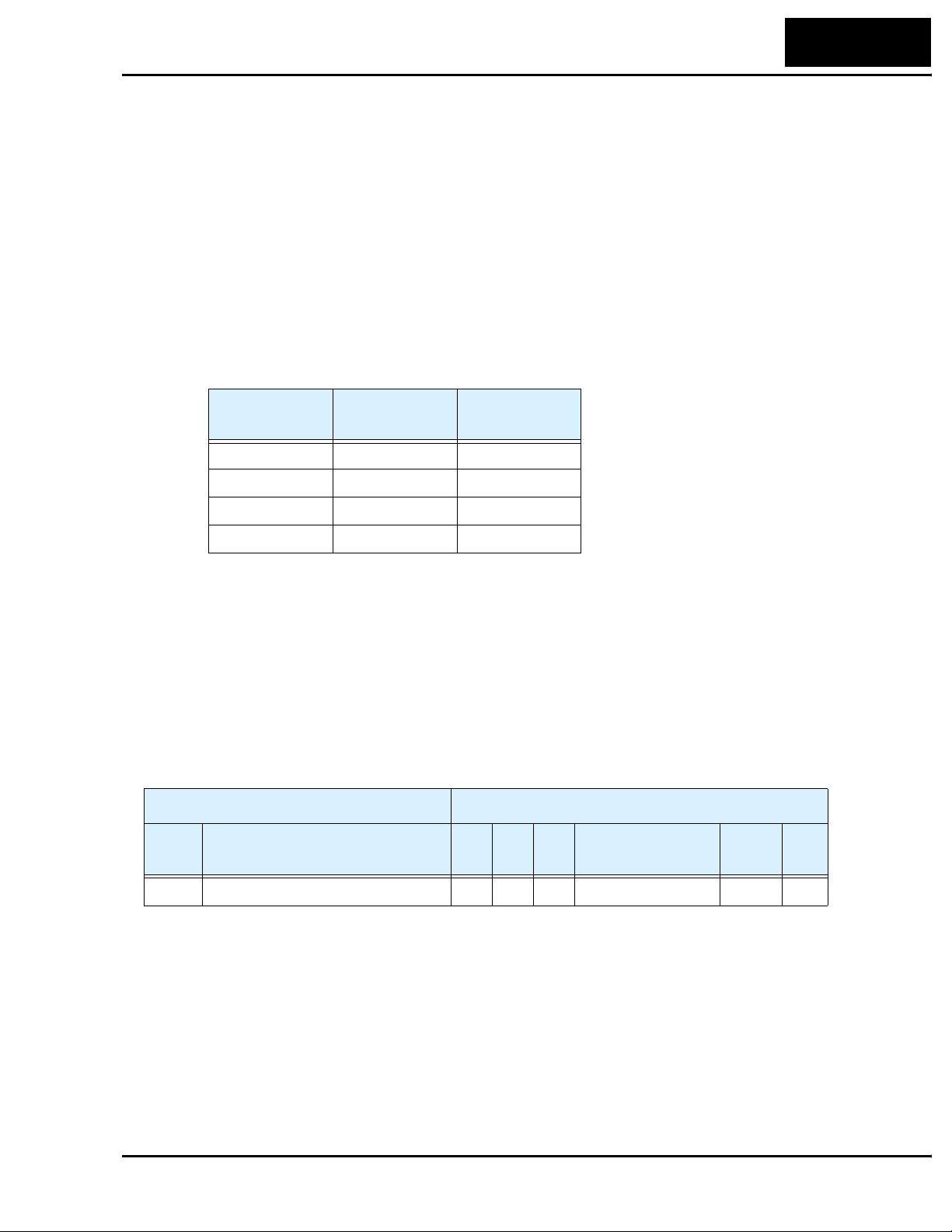

Check Inverter Dimensions – Locate the applicable drawing on the following pages for

your inverter.

Dimensions are given in millimeters (inches) format.

L100DN

MODEL H mm (in.)

-002NFE2

-002NFU2

-004NFE2

-004NFU2

-005NFE2

93 (3.66)

93 (3.66)

107 (4.21)

107 (4.21)

107 (4.21)

110(4.33)

67(2.64)

5(0.20)

80(3.15)

120(4.72)

Ground Terminal

10(0.39)

H=93(3.66)

H=107(4.21)

2.5(0.10)

Page 13

Dimensional drawings, continued...

MODEL

L100DN

-004HFE2

-004HFU2

-007NFE2

-007NFU2

-011NFE2

118(4.65)

5(0.20) 5(0.20)

10(0.39)

L100DN Inverter

13

98(3.86)

130(5.12)

Ground Terminal

110(4.33)

L100DN

-007HFE2 (no fan)

-007HFU2 (no fan)

-015HFE2

-015HFU2

-022HFE2

-022HFU2

118(4.65)

5(0.20) 5(0.20)

129(5.08)

2.5(0.10)

98(3.86)

130(5.12)

110(4.33)

Ground Terminal

156(6.14)

6(6.24)

Page 14

14

Inverter Mounting and Installation

Dimensional drawings, continued...

140(5.51)

128(5.04)

L100DN

-015NFE2

-015NFU2

168(6.61)

10(0.39)

180(7.09)

5(0.20)

Ground Terminal

153(6.02)

6(0.24)

140(5.51)

128(5.04)

L100DN

-022NFE2

-022NFU2

-037LFU2

-030HFE2

-040HFE2

-040HFU2

168(6.61)

180(7.09)164(6.46)

5(0.20)5(0.20)

6(0.24)

Page 15

Dimensional drawings, continued...

182(7.17)

160(6.30)

L100DN

1(0.04)

-055LFU2

-075LFU2

-055HFE2

-055HFU2

-075HFE2

-075HFU2

L100DN Inverter

15

236(9.29)

257(10.12)

7(0.28)7(0.28)

Ground Terminal

170(6.69)

6(0.24)

Page 16

16

Inverter Mounting and Installation

Powerup Test Overview

After wiring the inverter and motor, you’re ready to do a powerup test. The procedure

that follows is designed for the first-time use of the drive. Please verify the following

conditions before conducting the powerup test:

• You have followed all the steps in this chapter up to this step.

• The inverter is new, and is securely mounted to a non-flammable vertical surface

• The inverter is connected to a power source and motor.

• No additional wiring of inverter connectors or terminals has been done.

• The power supply is reliable, and the motor is a known working unit, and the motor

nameplate ratings match the inverter ratings.

• The motor is securely mounted, and is not connected to any load.

Goals for the Powerup test

If there are any exceptions to the above conditions at this step, please take a moment to

take any measures necessary to reach this basic starting point. The specific goals of this

powerup test are:

1. Verify that the wiring to the power supply and motor is correct.

2. Demonstrate that the inverter and motor are generally compatible.

3. Give a brief introduction to the use of the built-in operator keypad.

The powerup test gives you an important starting point to ensure a safe and successful

application of the Hitachi inverter. We highly recommend performing this test before

proceeding to the other chapters in this manual.

Pre-test and Operational Precautions

The following instructions apply to the powerup test, or to any time the inverter is

powered and operating. Please study the following instructions and messages before

proceeding with the powerup test.

1. The power supply must have fusing suitable for the load. Check the fuse size chart

presented in the inverter manual in Chapter 2, if necessary.

2. Be sure you have access to a disconnect switch for the drive input power if necessary.

However, do not turn OFF power during inverter operation unless it is an emergency.

CAUTION: The heat sink fins will have a high temperature. Be careful not to touch

them. Otherwise, there is the danger of getting burned.

CAUTION: The operation of the inverter can be easily changed from low speed to high

speed. Be sure to check the capability and limitations of the motor and machine before

operating the inverter. Otherwise, there is the danger of injury.

Page 17

CAUTION: If you operate a motor at a frequency higher than the inverter standard

default setting (50Hz/60Hz), be sure to check the motor and machine specifications with

the respective manufacturer. Only operate the motor at elevated frequencies after getting

their approval. Otherwise, there is the danger of equipment damage and/or injury.

CAUTION: Check the following before and during the powerup test. Otherwise, there is

the danger of equipment damage.

• Is the shorting bar between the [+1] and [+] terminals installed? DO NOT power or

operate the inverter if the jumper is removed.

• Is the direction of the motor rotation correct?

• Did the inverter trip during acceleration or deceleration?

• Were the RPM and frequency meter readings as expected?

• Were there any abnormal motor vibrations or noise?

Powering the Inverter

If you have followed all the steps, cautions and warnings up to this point, you’re ready to

apply power. After doing so, the following events should occur:

L100DN Inverter

17

• The POWER LED will illuminate.

• The numeric (7-segment) LEDs will display a test pattern, then stop at 0.0.

• The Hz LED will be ON. (This assumes the inverter is in Monitor Mode and is

displaying D_01, the output frequency.)

• The MS (Module Status) and NS (Network Status) LEDs will exhibit a test pattern;

each LED will briefly show green, then red. The ending state of powerup pattern is:

MS = Green; NS = OFF.

If the motor starts running unexpectedly or any other problem occurs, press the STOP

key. Only if necessary should you remove power to the inverter as a remedy.

NOTE: If the inverter has been previously powered and programmed, the LEDs (other

than the POWER LED) may illuminate differently than as indicated above. If necessary,

you can initialize all parameters to the factory default settings. See “Restoring Factory

Default Settings” on page 94 or refer to the L100DN Quick Reference Guide.

Page 18

18

Inverter Mounting and Installation

Using the Front Panel Keypad

Please take a moment to familiarize yourself with the keypad layout shown in the figure

below. These are the visible controls and indicators when the front panel door is closed.

The display is used in programming the inverter’s parameters, as well as monitoring

specific parameter values during operation. Many functions are applicable only during

the initial installation, while others are more useful for maintenance or monitoring.

Parameter Display

Run/Stop LED

Program/Monitor LED

Run Key Enable LED

Run Key

RUN

PRG

RUN

FUNC.

HITACHI

50.0

STOP

RESET

2

1

STR

POWER

Hz

A

MS

NS

Power LED

Display Units

Hertz / Amperes LEDs

Module Status LED

Network Status LED

Stop/Reset Key

Function

Key

Up/Down

Keys

Store

Key

• Run/Stop LED - ON when the inverter output is ON and the motor is developing

torque (Run Mode), and OFF when the inverter output is OFF (Stop Mode).

• Program/Monitor LED - This LED is ON when the inverter is ready for parameter

editing (Program Mode). It is OFF when the parameter display is monitoring data

(Monitor Mode).

• Run Key Enable LED - is ON when the inverter is ready to respond to the Run key,

OFF when the Run key is disabled.

• Run Key - Press this key to run the motor (the Run Enable LED must be ON first).

Parameter F_04, Keypad Run Key Routing, determines whether the Run key generates

a Run FWD or Run REV command.

• Stop/Reset Key - Press this key to stop the motor when it is running (uses the

programmed deceleration rate). This key will also reset an alarm that has tripped.

• Module Status LED - ON (green) when the inverter has power. The Module Status

LED may also be flashing and/or red in color. For a description of all LED states and

their meanings, see the table in “Step 6 – Monitor Test – Verify Network Host Can

Monitor Inverter” on page 51.

• Network Status LED - ON (green) when the inverter is connected to the network.

The Network Status LED may also be flashing and/or red in color. For a description of

all LED states and their meanings, see the table in “Step 6 – Monitor Test – Verify

Network Host Can Monitor Inverter” on page 51.

• Parameter Display - A 4-digit, 7-segment display for parameters and function codes.

• Display Units, Hertz/Amperes - One of these LEDs will be ON to indicate the units

associated with the parameter display.

• Power LED - This LED is ON when the power input to the inverter is ON.

Page 19

L100DN Inverter

• Function Key - This key is used to navigate through the lists of parameters and

functions for setting and monitoring parameter values.

19

• Up/Down ( , ) Keys - Use these keys alternately to move up or down the lists of

2

1

parameter and functions shown in the display, and increment/decrement values.

• Store ( ) Key - When the unit is in Program Mode and you have edited a parameter

STR

value, press the Store key to write the new value to the EEPROM.

Keys, Modes, and Parameters

Purpose of the keypad is to provide a way to change modes and parameters. The term

function applies to both monitoring modes and parameters. These are all accessible

through function codes that are primarily 3-character codes. The various functions are

separated into related groups identifiable by the left-most character, as the table shows.

Function

Group

“D” Monitoring functions Monitor

“F” Main profile parameters Program

“A” Standard functions Program

“B” Fine tuning functions Program

“C” Intelligent terminal functions Program

Type (Category) of Function Mode to Access

PGM LED

Indicator

“P” DeviceNet network settings Program

“E” Error codes — —

For example, function “A_04” is the base frequency setting for the motor, typically

50 Hz or 60 Hz. To edit the parameter, the inverter must be in Program Mode (PGM

LED will be ON). You use the front panel keys to first select the function code “A_04.”

After displaying the value for “A_04,” use the Up/Down ( or ) keys to edit it.

1

2

NOTE: The inverter 7-segment display shows lower case “b” and “d,” meaning the same

as the upper case letters “B” and “D” used in this manual (for uniformity “A to F”).

The inverter automatically switches into Monitor

Mode when you access “D” Group functions. It

switches into Program Mode when you access any

other group, because they all have editable parameters. Error codes use the “E” Group, and appear

automatically when a fault event occurs. Refer to

MONITOR PROGRAM

“A” Group

“B” Group

“D” Group

“C” Group

“P” Group

“F” Group

Chapter 6 in the L100 inverter instruction manual

for error code details.

Page 20

20

Inverter Mounting and Installation

Keypad Navigational Map

The L100DN Series inverter drives have many programmable functions and parameters.

Chapter 3 in the manual will cover these in detail, but you need to access just a few items

to perform the powerup test. The menu structure makes use of function codes and

parameter codes to allow programming and monitoring with only a 4-digit display and a

few keys and LEDs. So, it is important to become familiar with the basic navigational

map of parameters and functions in the diagram below.

Program ModeMonitor Mode

PRG LED=ONPRG LED=OFF

Display Data

000.0

1

FUNC.

d 16

1

2

d 01

1

2

P - -

1

2

C - -

1

b --

1

2

2

A - -

1

2

powerdown

Select

Function

or Group

FUNC.

Select Parameter

1

P 4 9

1

2

P 4 1

1

2

C 4 3

1

2

C 0 1

1

b 88

1

b 01

1

2

2

2

A 9 8

1

2

Edit Parameter

Store as

powerup

Increment/

decrement

FUNC.

FUNC.

123.4

EEPROM

default

value

2

1

Edit

STR

Write

data to

FUNC.

F 0 4

1

F 0 1

2

FUNC.

2

A 0 1

2

Return to

parameter

list

Page 21

Selecting Functions and Editing Parameters

In order to run the motor for the powerup test, this section will show how to:

• select the inverter’s maximum output frequency to the motor

• set the value of parameter F_01 to the output frequency for the powerup test

• select the keypad as the source of the RUN command

The following series of programming tables are designed for successive use. Each table

uses the previous table’s final state as the starting point. Therefore, start with the first and

continue programming until the last one. If you get lost or concerned that some of the

other parameters settings may be incorrect, refer to “Restoring Factory Default Settings”

on page 94.

CAUTION: If you operate a motor at a frequency higher than the inverter standard

default setting (50Hz/60Hz), be sure to check the motor and machine specifications with

the respective manufacturer. Only operate the motor at elevated frequencies after getting

their approval. Otherwise, there is the danger of equipment damage.

Setting the Motor Base Frequency – The motor is designed to operate at a specific AC

frequency. Most commercial motors are designed for 50/60 Hz operation. First, check

the motor specifications. Then follow the steps in the table below to verify the setting or

correct for your motor. DO NOT set it for greater than 50/60 Hz unless the motor

manufacturer specifically approves operation at the higher frequency.

L100DN Inverter

21

Action Display Func./Parameter

Press the

Press the

Press the

Press the

Press the key.

FUNC.

key.

1

or keys until ->

FUNC.

key.

1

key twice.

FUNC.

d 01

2

A--

A02

A03

60

or

Monitor functions

“A” Group selected

First “A” parameter

Base frequency setting

Default value for base frequency.

US = 60 Hz, Europe = 50 Hz.

50

Press the

Press the

1

STR

2

or key as needed.

key.

60

A03

TIP: If you need to scroll through a function or parameter list, press and hold the or

2

key to auto-increment through the list.

Set to your motor specs (your

display may be different)

Stores parameter, returns to “A”

Group list

1

Page 22

22

Inverter Mounting and Installation

Select the Keypad for the RUN Command – The RUN command causes the inverter to

accelerate the motor to the selected speed. For local (non-network) inverter control, you

can program the inverter to respond to either the control terminal signal (default) or the

keypad RUN key. Follow the steps in the table below to select the front panel RUN key

as the source for the RUN Command (the table resumes action from the end of the

previous table).

Action Display Func./Parameter

Press the

Press the

Press the

Press the

NOTE: When you press the STR key in the last step above (and the display = 02), the

Run Key Enable LED above the RUN key on the keypad will turn ON. This is normal,

and does not mean the motor is trying to run. It means that the RUN key is now enabled.

DO NOT press the RUN key at this time—finish out the programming exercise first.

2

FUNC.

1

STR

key.

key.

key.

key.

A02

01

02

A02

Run command source

1 = control terminals (default)

2 = keypad

2 = keypad (selected)

Stores parameter, returns to “A”

Group list

Page 23

L100DN Inverter

Set the Output Frequency – Note that the standard L100 Series inverter uses parameter

A_01 Frequency Source Setting to select from sources that include a front panel potentiometer and input terminals. In contrast, the L100DN DeviceNet inverter is optimized for

network control and does not have these two alternate frequency sources. Therefore, the

L100DN does not need (or have) parameter A_01. The default frequency source for the

L100DN is setting F_01 Output Frequency Setting. The frequency setting works in the

following way:

• Operator (local) Control – When using the inverter’s front panel Run and Stop keys to

control the motor, the inverter uses parameter F_01 Output Frequency Setting.

• Network Control – When the inverter is under network control, Run and Stop

commands typically arrive via the network. In this case, you have the additional

option of using the inverter’s parameters (includes F_01 Output Frequency Setting), or

the network host device can send the output frequency setting via the network upon

each network scan. More details are in “Network Control and Monitoring” on

page 39.

This step in the powerup test will set F_01 Output Frequency Setting to 15Hz.

CAUTION: Be sure to set F_01 Output Frequency Setting to a safe value for your motor

and application. The step below only uses 15Hz as an example.

23

Action Display Func./Parameter

Press the

Press the

Press the

Press and hold the

Use the key also as necessary.

Press the

This step concludes the parameter setups for the inverter. You are almost ready to run the

motor for the first time!

TIP: If you became lost during any of these steps, first observe the state of the PRG

LED. Then study the “Keypad Navigational Map” on page 20 to determine the current

state of the keypad controls and display. As long as you do not press the STR key, no

parameters will be changed by keypad entry errors. Note that power cycling the inverter

will not cause it to reset to a particular programming state.

FUNC.

key.

2

key six times until ->

FUNC.

key.

1

key until ->.

2

FUNC.

key.

A--

F01

0.0

15.0

F01

“A” Group List

Output frequency setting

Default output frequency

Set to 15.0 Hz, or a safe level

(motor speed) for your application.

Stores parameter, returns to “F”

Group list

The next section will show you how to monitor a particular parameter from the display.

Then you will be ready to run the motor.

Page 24

24

Inverter Mounting and Installation

Monitoring Parameters with the Display

After using the keypad for parameter editing, it’s a good

idea to switch the inverter from Program Mode to

Monitor Mode and close the panel door (puts the keys

for parameter editing out of sight). This will also turn

out the PRG LED, and the Hertz or Ampere LED

indicates the display units.

For the powerup test, monitor the motor speed indirectly

by viewing the inverter’s output frequency. The output

frequency must not be confused with base frequency

(50/60 Hz) of the motor, or the carrier frequency (switching frequency of the inverter, in

the kHz range). The monitoring functions are in the “D” list, located near the top left of

the “Keypad Navigational Map” on page 20.

Output frequency (speed) monitor - Resuming the keypad programming from the

previous table, follow the steps in the table below.

Action Display Func./Parameter

RUN

PRG

FUNC.

RUN

HITACHI

50.0

STOP

RESET

2

1

STR

POWER

Hz

A

MS

NS

Press the

Press the

When the

1

key 9 times until ->.

FUNC.

key.

d 01 function code appeared, the PRG LED went OFF. This confirms the

inverter is no longer in programming mode, even while you are selecting the particular

monitoring parameter. After pressing the Function key, the display shows the current

speed (is zero at this point).

Running the Motor

If you have programmed all the parameters up to this point, you’re ready to run the

motor! First, review this checklist:

1. DO NOT connect the inverter to the DeviceNet network or supply +24V network

power yet.

2. Verify the Power LED and Module Status (MS) LEDs are ON (green, not flashing). If

not, check the power connections.

3. Verify the Run Key Enable LED is ON. If not, review the programming steps to find

the problem.

4. Verify the PRG LED is OFF. If it is ON, review the instructions above.

d 01

Output frequency selected

Output frequency displayed

0.0

5. Make sure the motor is disconnected from any mechanical load.

6. Now, press the RUN key on the keypad. The RUN LED will turn ON.

7. The motor should accelerate to 15.0 Hz, and the display will indicate “15.0.”

8. Press the STOP key to stop the motor rotation.

Page 25

Powerup Test Observations and Summary

Reading this section will help you make some useful observations when first running the

motor.

Error Codes – If the inverter displays an error code (format is “E x x”), see Chapter 6 in

the L100 instruction manual for instructions on how to interpret and clear the error.

Acceleration and Deceleration - The L100DN inverter has programmable acceleration

and deceleration values. The test procedure left these at the default value, 10 seconds.

You can observe this by setting the potentiometer at about half speed before running the

motor. Then press RUN, and the motor will take 5 seconds to reach a steady speed. Press

the STOP key to see a 5 second deceleration to a stop.

State of Inverter at Stop – If you adjust the motor’s speed to zero, the motor will slow

to a near stop, and the inverter turns the outputs OFF. The high-performance L100DN

can rotate at a very slow speed with high torque output, but not zero (must use servo

systems with position feedback for that feature). This characteristic means you must use

a mechanical brake for some applications.

Interpreting the Display - First, refer to the output frequency display readout. The

maximum frequency setting (parameter A_04) defaults to 50 Hz or 60 Hz (Europe and

United States, respectively) for your application.

L100DN Inverter

25

Example: Suppose a 4-pole motor is rated for 60 Hz operation, so the inverter is configured to output 60 Hz at full scale. Use the following formula to calculate the RPM.

Speed in RPM

Frequency 60×

----------------------------------------

Pairs of poles

Frequency 120×

---------------------------------------- ---

# of poles

60 120×

--------------------- 1800RPM== ==

4

The theoretical speed for the motor is 1800 RPM (speed of torque vector rotation).

However, the motor cannot generate torque unless its shaft turns at a slightly different

speed. This difference is called slip. So it’s common to see a rated speed of approximately 1750 RPM on a 60 Hz, 4-pole motor. Using a tachometer to measure shaft speed,

you can see the difference between the inverter output frequency and the actual motor

speed. The slip increases slightly as the motor’s load increases. This is why the inverter

output value is called “frequency,” since it is not exactly equal to motor speed. You can

program the inverter to display output frequency in units more directly related to the load

speed by entering a constant (discussed in Chapter 3 in the L100 instruction manual).

Run/Stop Versus Monitor/Program Modes –

The Run LED on the inverter is ON in Run Mode,

and OFF in Stop Mode. The Program LED is ON

Run Stop

STOP

RESET

RUN

when the inverter is in Program Mode, and OFF for

Monitor Mode. All four mode combinations are

possible. The diagram to the right depicts the

modes and the mode transitions via keypad.

Monitor Program

FUNC.

NOTE: Some factory automation devices such as PLCs have alternate Run/Program

modes; the device is in either one mode or the other. In the Hitachi inverter, however,

Run Mode alternates with Stop Mode, and Program Mode alternates with Monitor

Mode. This arrangement lets you program some values while the inverter is operating—

providing flexibility for maintenance personnel.

Page 26

26

Configuring Drive Parameters

Configuring Drive Parameters

This section provides details for L100DN DeviceNet Series configuration corresponding

to Chapter 3, “Configuring Drive Parameters,” in the L100 Inverter Instruction Manual.

Hitachi L100DN DeviceNet Series inverters have additional parameters and functions

beyond the L100 standard set. Also, several parameters that are not needed for a

network-controlled inverter have been removed.

New parameters for L100DN DeviceNet Series

• P_41 to P_49 – DeviceNet network settings

Removed parameters (present only in standard L100)

• D_04 – Process variable (PV) monitor for PID control

• A_01 – Frequency source selection

• A_11 to A_16, B_81, C_81, C_82 – Analog input settings

• B_89 – Data select for digital operator OPE-J

• A_71 to A_76, C_44 – PID control settings

• C_04, C_05, C_06, C_14, C_15, C_16 – Intelligent output terminal settings for

[4] to [6]

• C_23 – FM signal selection

• C_33 – Intelligent output terminal settings for [AL0] to [AL2]

New intelligent input terminal functions (not present in standard L100)

• [STA] – Start Motor (option code 20)

• [STP] – Stop Motor (option code 21)

• [F/R] – Forward/Reverse (option code 22)

• [DNT] – Select DeviceNet (option code 25)

• [UP] – Remote control Up function (option code 27)

• [DWN] – Remote control Down function (option code 28)

• [OPE] – Force Operation from Digital Operator (option code 31)

Removed intelligent input terminal functions (present in standard L100)

• [AT] – Analog Input Voltage/current Select (option code 16)

Removed intelligent output terminal functions (present in standard L100)

• [OD] – Output Deviation for PID Control

The tables in this section list only the new parameters and intelligent inputs for the

L100DN DeviceNet Series inverters. Refer to Chapter 3 in your L100 instruction manual

for the main set of inverter parameters and intelligent terminal functions.

Page 27

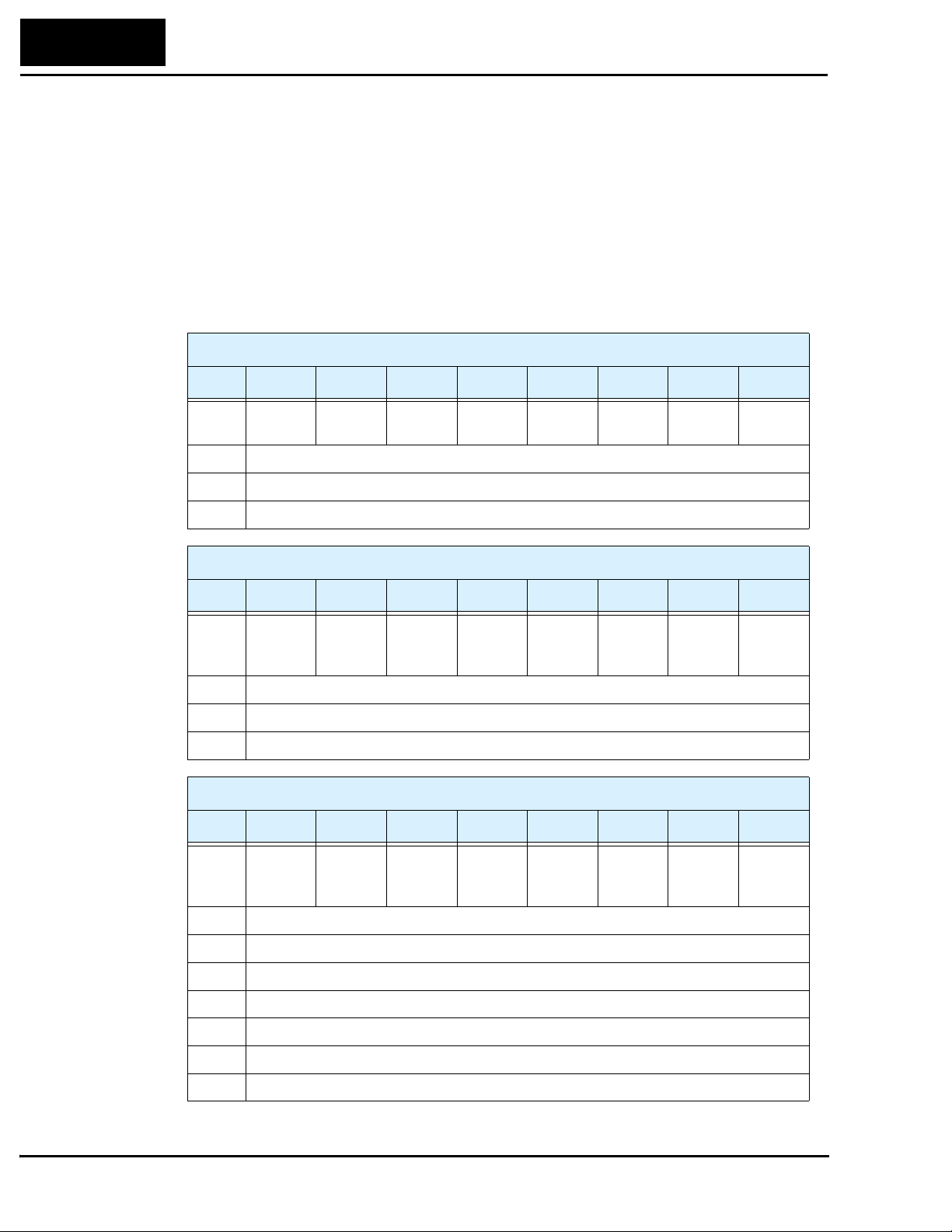

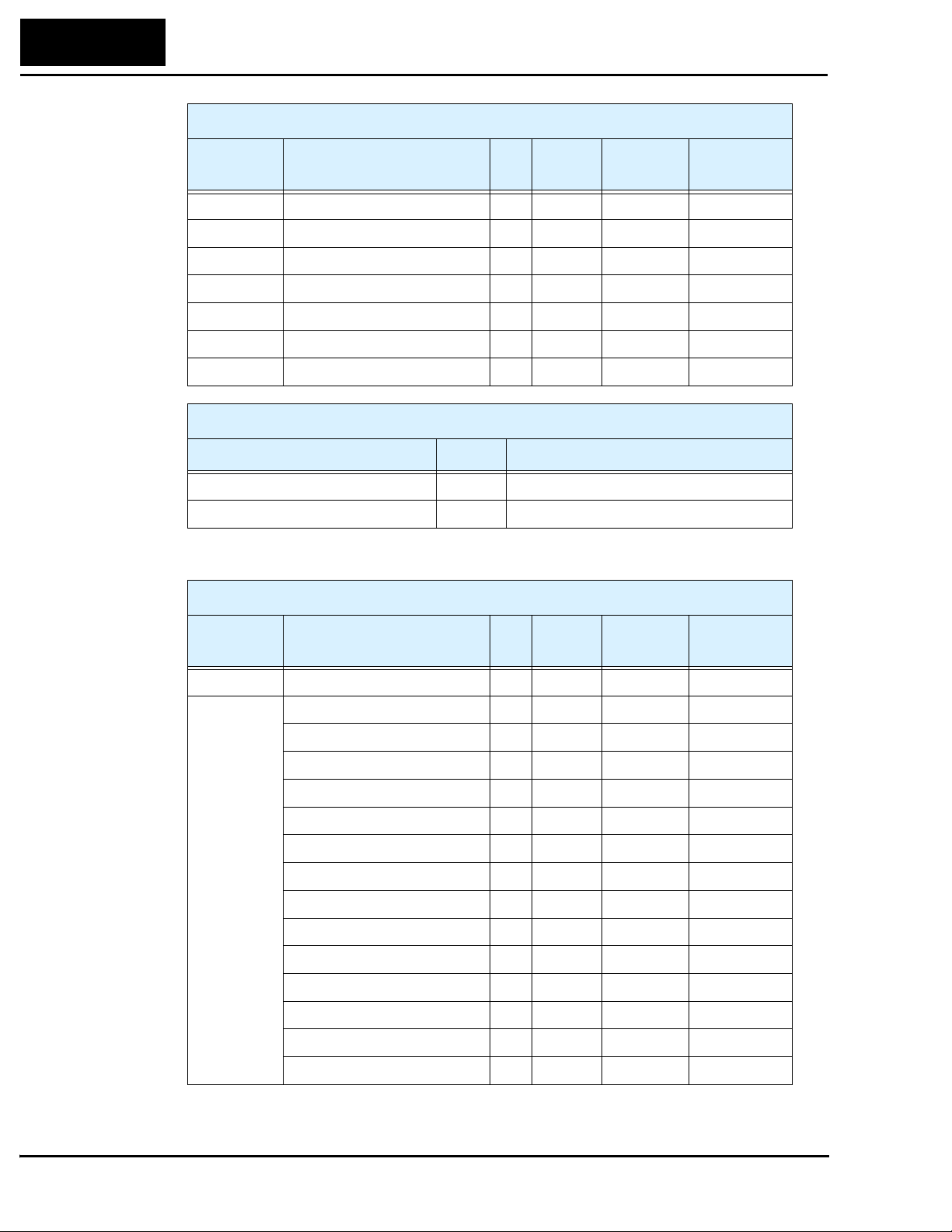

“C” Group: Intelligent Terminal Functions

Intelligent Input Terminals – The three intelligent input terminals for L100DN

DeviceNet Series inverters have 20 possible option assignments.

L100DN Inverter

27

“C” Function

Func.

Code

C_01 Terminal [1] function Select function for terminal [1]

C_02 Terminal [2] function Select function for terminal [2]

C_03 Terminal [3] function Select function for terminal [3]

Name Description

20 options (see inverter

manual)

20 options (see inverter

manual)

21 options (see inverter manual

and Note below)

NOTE: Terminal [3] can operate as the PTC (thermistor thermal protection) input. Thus,

it has the additional [PTC] terminal input (option code 19) that may be assigned.

The input logic convention is programmable for each of the three inputs. The inputs

default to normally open (active high), but you can select normally closed (active low) in

order to invert the sense of the logic.

Run

Mode

Edit

✘

✘

✘

Defaults

–FE

(CE)

[FW]00[FW]00[FW]

[STP]21[STP]21[STP]

[EXT]12[EXT]12[EXT]

00

21

12

–FU

(UL)

–F

(Jpn)

Units

—

—

—

“C” Function

Func.

Code

C_11 Terminal [1] active state Select logic convention, two

C_12 Terminal [2] active state Select logic convention, two

C_13 Terminal [3] active state Select logic convention, two

Name Description

option codes:

00... normally open [NO]

01... normally closed [NC]

option codes:

00... normally open [NO]

01... normally closed [NC]

option codes:

00... normally open [NO]

01... normally closed [NC]

Run

Mode

Edit

–FE

(CE)

✘ 00 00 00 —

✘ 00 00 00 —

✘ 00 00 00 —

Defaults

–FU

(UL)

–F

(Jpn)

Units

Page 28

28

Configuring Drive Parameters

To the 15 option codes for standard L100 inverters, L100DN Series inverters remove the

code for the [AT] input, and add the following 7 options:

Input Function Summary Table

Option

Code

20 STA Start Motor ON Start motor rotation on momentary contact (uses

21 STP Stop Motor ON Stop motor rotation on momentary contact (uses

22 F/R FWD/REV ON Select reverse direction of rotation

25 DNT DeviceNet Select ON Inverter operates under DeviceNet network

27 UP Remote Control

28 DWN Remote Control

Terminal

Symbol

Function Name Description

acceleration profile)

OFF No change to motor operation

deceleration profile)

OFF No change to motor operation

OFF Select forward direction of rotation

control

OFF Inverter operates under local control (keypad and

input terminals)

ON Accelerates (increases output frequency) motor

UP Function (motorized speed pot.)

DOWN Function

(motorized speed

pot.)

OFF No change to output frequency

ON Decelerates (decreases output frequency) motor

OFF No change to output frequency

from current frequency

from current frequency

31 OPE Force Operation

from Digital

Operator

ON Forces the operator interface Run command to

over-ride commands from input terminals (such

as [FW], [RV])

OFF Run command operates normally, as configured

by A_02

NOTE: The assignment of [DNT] to an input terminal is optional. It is useful if you

need to switch between DeviceNet network control and local control during running.

Alternatively, you can use parameter P_43 DeviceNet Control Enable, which works

similarly but does not require an input terminal. If assigned, the [DNT] setting has precedence over the P_43 setting. More information is in “Step 7 – Control Test – Verify

Network Host Can Control Inverter” on page 54.

Page 29

L100DN Inverter

Intelligent Output Terminals – The L100DN DeviceNet Series inverters have 5 of the

6 possible output option assignments for standard L100 inverters ([OD] is removed).

However, note that the alarm relay contact terminals [AL0], [AL1], and [AL2] are not

present on the L100DN DeviceNet Series inverters (so C_24 and C_33 are not present

on L100DN).

29

“C” Function

Func.

Code

C_21 Terminal [11] function Select function for terminal

C_22 Terminal [12] function Select function for terminal

Name Description

[11],

5 options (see inverter manual

[12],

5 options (see inverter manual)

The output logic convention is programmable for terminals [11] and [12]. The opencollector output terminals [11] and [12] default to normally open (active low), but you

can select normally closed (active high) for these terminals in order to invert the sense of

the logic.

“C” Function

Func.

Code

C_31 Terminal [11] active

state

Name Description

Select logic convention, two

option codes:

00... normally open [NO]

01... normally closed [NC]

Run

Mode

Edit

Run

Mode

Edit

–FE

(CE)

✘

✘

✘ 00 00 00 —

00

[RUN]00[RUN]00[RUN]

05

[AL]05[AL]05[AL]

–FE

(CE)

Defaults

–FU

(UL)

Defaults

–FU

(UL)

–F

(Jpn)

–F

(Jpn)

Units

—

—

Units

C_32 Terminal [12] active

state

Select logic convention, two

option codes:

00... normally open [NO]

01... normally closed [NC]

✘ 00 00 00 —

Page 30

30

Configuring Drive Parameters

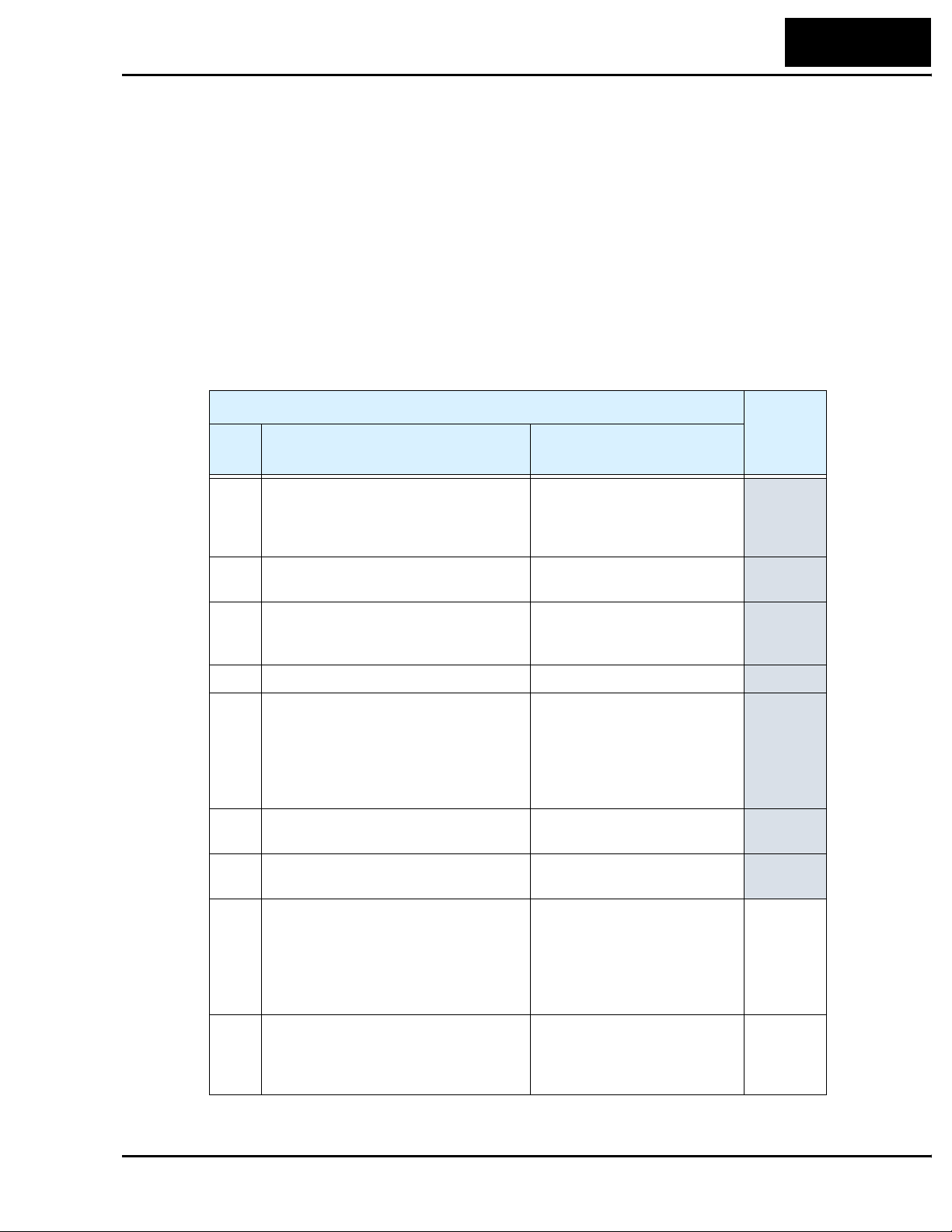

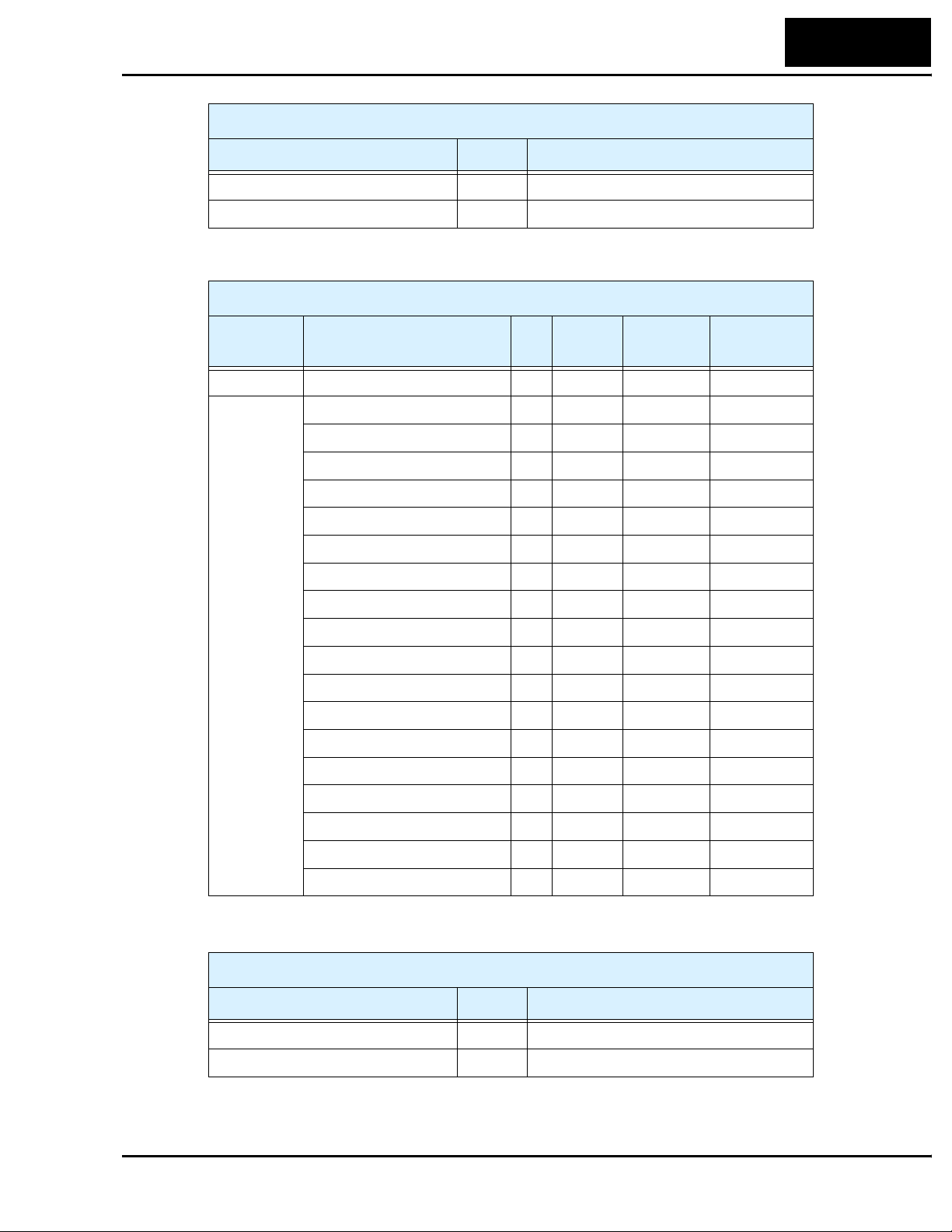

“P” Group: DeviceNet Network Settings

The following table describes the DeviceNet network settings for L100DN inverters.

“P” Function

Func.

Code

P_41 DeviceNet baud rate Three options; select codes:

P_42 DeviceNet MAC ID Selects the DeviceNet node

P_43 DeviceNet control

enable

P_44 DeviceNet comm

watchdog timer

P_45 Inverter action on

DeviceNet comm error

P_46 DeviceNet polled I/O:

Output instance number

Name Description

00... 125 kbps

01... 250 kbps

02... 500 kbps

address, range is 0 to 63

Two options; select codes:

00... Disable

01... Enable

Range is 0.00 to 99.99 seconds ✘ 1.00 1.00 1.00 —

Five options:

00... Trip

01... Decelerate and trip

02... Hold last speed

03... Free-run stop

04... Decelerate and stop

Three settings:

20, 21, 100 *1

Run

Mode

Edit

–FE

(CE)

✘ 00 00 00 —

✘ 63 63 63 —

✘ 01 01 01 —

✘ 01 01 01 —

✘ 100 100 100 —

Defaults

–FU

(UL)

–F

(Jpn)

Units

P_47 DeviceNet polled I/O:

Input instance number

P_48 Inverter action on

DeviceNet idle mode

P_49 DeviceNet motor poles

setting for RPM

Note 1: Functions P_46 and P_47 must be set as a corresponding pair. Valid settings

for P_46 / P_47 are 20 / 70, 21 / 71, or 100 / 101 (default). Other setting

combinations can cause a DeviceNet network error.

Three settings:

70, 71, 101 *1

Five options:

00... Trip

01... Decelerate and trip

02... Hold last speed

03... Free-run stop

04... Decelerate and stop

Range is 00 to 38 (even

numbers only), two types:

00... For freq. setting (Hz)

02 to 38... For speed (RPM)

✘ 101 101 101 —

✘ 01 01 01 —

✘ 00 00 00 —

Page 31

Operations and Monitoring

This section covers new or modified intelligent terminal functions for L100DN

DeviceNet Series inverters, corresponding to Chapter 4, “Operations and Monitoring,” in

the L100 Inverter Instruction Manual.

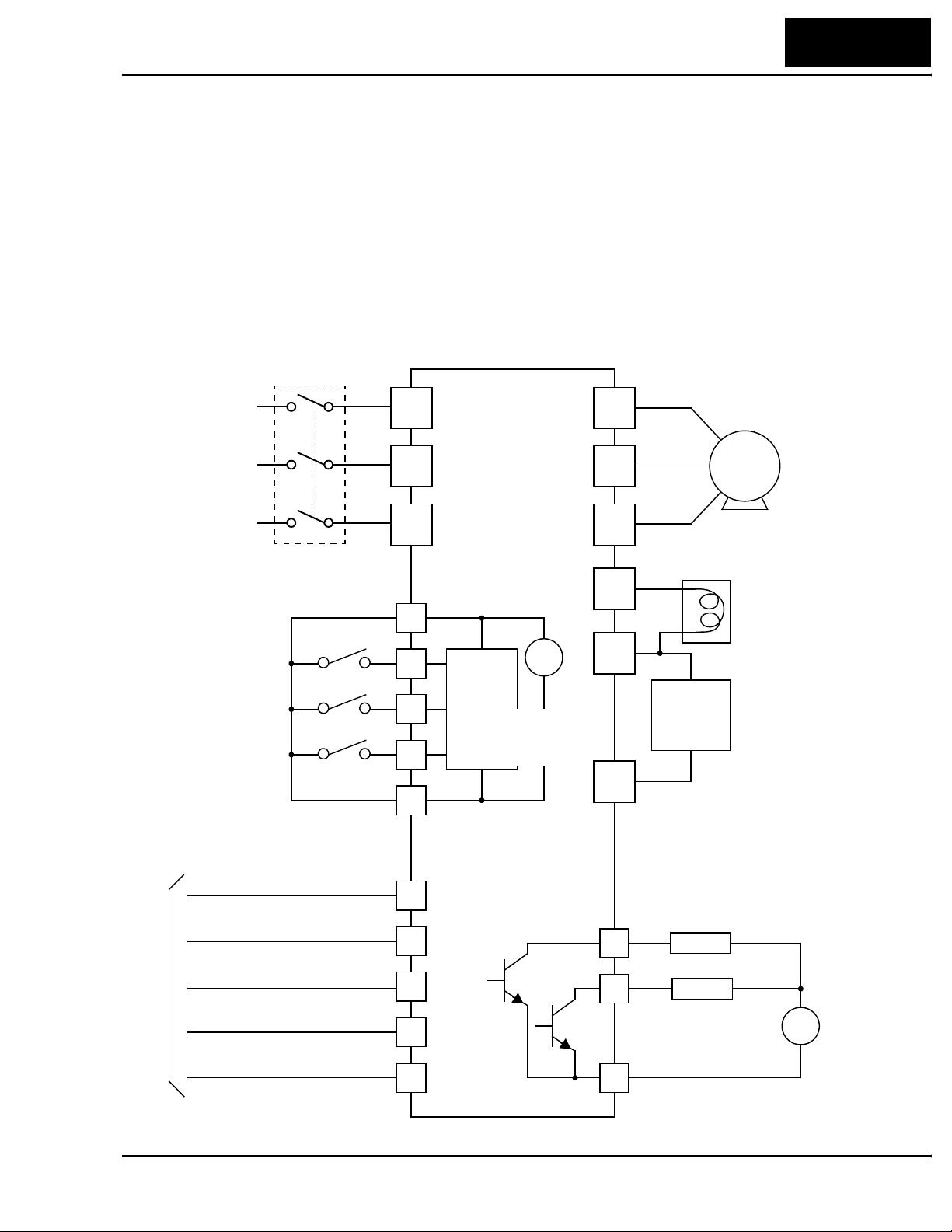

Example Wiring Diagram

The L100DN DeviceNet Series inverters have fewer intelligent I/O terminals and are

without analog I/O and relay outputs, in comparison to the standard L100 inverters. An

example wiring diagram for L100DN is shown below. The DeviceNet interface wiring is

discussed in detail in “Step 2 – Connect Network Devices” on page 43.

Breaker,

MCCB or GFI

L100DN

Power source,

3-phase or

1-phase, per

inverter model

R

(L1)

S

(L2)

U

(T1)

V

(T2)

L100DN Inverter

31

Motor

Intelligent inputs,

NOTE: For the wiring of intelligent I/O,

be sure to use

twisted pair /

shielded cable.

Attach the shield wire

for each signal to its

respective common

terminal at the

inverter end only.

Logic input common

DeviceNet interface

Bus supply +

CANbus High

Drain

CANbus Low

3 terminals

[FW]

[STP]

[EXT]

(Red)

(White)

(Bare)

(Blue)

T

N(L3)

P24

1

2

3

L

V+

CH

D

CL

24V

+

Input

circuits

[3] configurable

discrete inputs

–

Output

circuits

W

(T3)

+1

+

Braking

unit

(optional)

–

Open collector outputs

Run signal

12

11

Load

Alarm signal

Load

DC reactor

(optional)

+

–

Bus supply –

(Black)

V–

Logic output common

CM2

Page 32

32

Operations and Monitoring

Specifications of Control and Logic Connections

The control logic connector is located on the front panel, just below the keypad. The

color-coded DeviceNet connector is located directly below the logic connector. Connector labeling is shown below.

Logic inputs Logic outputs

L 3 12

Specifications for the logic connection terminals are in the following table:

Terminal Name Description Ratings

[P24] +24VDC for logic inputs 24VDC, 30 mA max

[1], [2], [3] Discrete logic inputs 27VDC max. (use P24 or an external supply refer-

[L] GND for logic inputs Sum of input 1, 2, and 3 currents (return)

[11], [12] Discrete logic outputs 50mA maximum ON state current,

[CM2] GND for logic outputs 100 mA: sum of 11 and 12 currents (return)

NOTE: The DeviceNet network must supply +24V to the inverter via the [V+] (Red)

and [V–] (Black) terminals on the DeviceNet connector. DO NOT attempt to use the

inverter’s internal 24VDC supply (on [P24] and [L]) for DeviceNet network power.

P24 CM2

12 11

DeviceNet network

connector

(Notes: Do not use for network power

Do not short to terminal L)

enced to terminal L)

(Note: Do not ground)

27 VDC maximum OFF state voltage

Auxiliary network

power connector

The DeviceNet connector signals must meet the electrical requirements given by the

DeviceNet industry standards. For more information, visit the Open DeviceNet Vendor

Association website at http://www.odva.org.

Page 33

Intelligent Input Summary

Intelligent input terminals for L100DN inverters include the standard L100 input terminals (see Chapter 3 in L100 Inverter Manual), with the following changes:

• Add [STA], [STP], and [F/R] terminals (three-wire interface inputs)

• Add [UP] and [DWN] remote control input terminals

• Add [DNT] terminal (DeviceNet Select)

• Add [OPE] Force Operation from Digital Operator input terminal

• Remove [AT] intelligent input terminals

The added terminals are described in the sections that follow.

Three-wire Interface Operation

The 3-wire interface is an industry standard motor control interface. This function uses

two inputs for momentary contact start/stop control, and a third for selecting forward or

reverse direction. To implement the 3-wire interface, assign 20 [STA] (Start), 21 [STP]

(Stop), and 22 [F/R] (Forward/Reverse) to the three intelligent input terminals. Use

momentary contact for Start and Stop. Use a selector switch such as SPST for the

Forward/Reverse input. Be sure to set the operation command selection A_02=01 for

input terminal control of motor. If you have a motor control interface that needs logiclevel control (rather than momentary pulse control), use the [FW] and [RV] inputs

instead.

L100DN Inverter

33

Option

Code

20 STA Start Motor ON Start motor rotation on momentary contact (uses

21 STP Stop Motor ON Stop motor rotation on momentary contact (uses

22 F/R FWD/REV ON Select reverse direction of rotation

Valid for inputs:

Required settings: A_02=01

Notes:

The [STP] input stops the motor, whether it is under

•

keypad control or under network control.

Terminal

Symbol

Function Name

C_01, C_02, C_03

Input

State

acceleration profile)

OFF No change to motor operation

deceleration profile)

OFF No change to motor operation

OFF Select forward direction of rotation

Example (requires input configuration—

see Chapter 3 in L100 Instruction Manual):

Description

STP

F/R STA

123L

P24

• [STP] is assigned to terminal [2} as a factory

default setting. This feature is especially important

for network-controlled applications.

• If you do not assign the [F/R] intelligent input

terminal, the three-wire operation will be limited to

the forward direction only.

See I/O specs in the L100 Instruction Manual

Page 34

34

Operations and Monitoring

Standard 3-wire control – By default, the

L100DN inverter comes with [STP] (Stop

Motor) assigned to terminal [2]. The Stop

command causes the motor to decelerate to

a stop when the inverter is in Run Mode.

Example (default input configuration shown—

see Chapter 3 in L100 Instruction Manual):

STP

123L

P24

When the inverter is controlled via keypad,

an operator will normally use the Stop/

Reset key on the front panel.

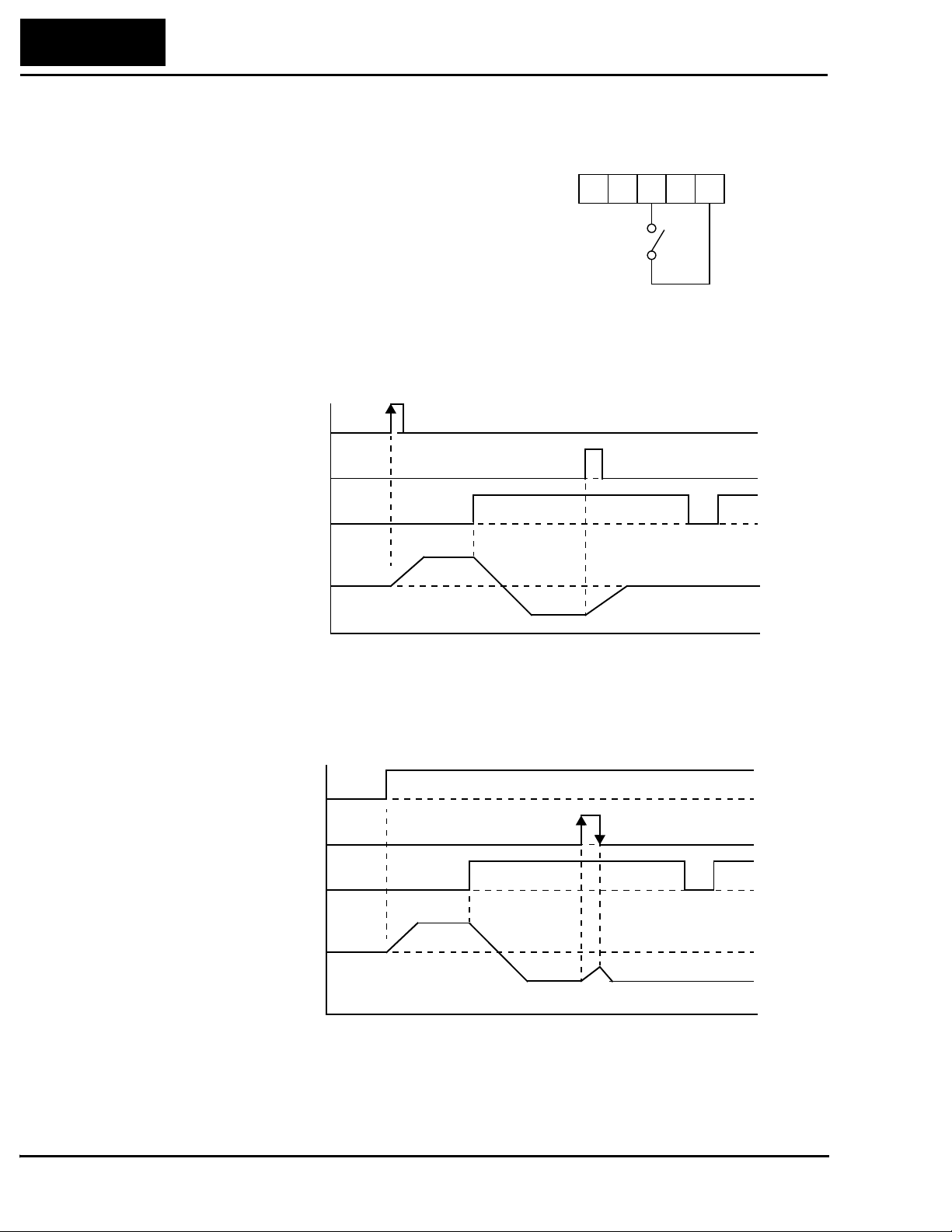

The diagram below shows the use of 3-wire control. STA (Start Motor) is an edge-sensitive input; an OFF-to-ON transition gives the Start command. The control of direction is

level-sensitive, and the direction may be changed at any time. STP (Stop Motor) is also a

level-sensitive input, and the Stop signal has priority over the Start signal.

STA

STP

F/R

Output

Frequency

t

When both STA and STP signals are ON, the STP signal has priority (motor output will

be OFF). However, the motor output resumes after STP signal is no longer active if the

STA input is still ON.

STA

STP

F/R

Output

Frequency

t

Page 35

L100DN Inverter

Use with DeviceNet operation – When the L100DN inverter is under network control,

Run and Stop commands will typically arrive via the DeviceNet network. However, a

network communications interruption is possible at any time. So for safety reasons, it is

important to provide a dedicated Stop signal input as shown below.

InverterNetwork host

[STP]

Run/Stop commands

DeviceNet network

In the graph below, the network FWD command places the inverter in Run mode. While

the motor is running, the local [STP] input terminal activates, causing the inverter to

decelerate the motor to a stop. It remains stopped even though the FW command is still

active. The FW command must turn OFF and ON again to resume motor operation.

35

Output

Frequency

Network FW command

[STP]

t

Page 36

36

Operations and Monitoring

DeviceNet Select

You can configure an intelligent input as [DNT] DeviceNet Select. It is not necessary to

assign an input terminal as [DNT] in order to control or monitor the inverter via the

DeviceNet network. Rather, the [DNT] input provides a way for an external control

system to selectively force the inverter to ignore DeviceNet commands and use only its

internal parameters and intelligent inputs for operation.

DeviceNet Control parameter P_43, DeviceNet Enable, serves a similar function—but it

is typically updated via the DeviceNet network. These two methods control essentially

the same thing, so it not meaningful to use both P_43 DeviceNet Enable and a [DNT]

input at the same time. If [DNT] is assigned to an input terminal, parameter P_43 is

ignored.

Option

Code

25 DNT DeviceNet Select ON The inverter operates per commands and param-

Valid for inputs:

Required settings:

Notes:

•

When any input terminal is assigned as [DNT],

parameter P_43 setting is ignored.

Terminal

Symbol

Function Name State Description

eters (output freq., accel, decel) from DeviceNet

OFF The inverter operates per local commands

(keypad or terminal Run/Stop) and its internal

parameters (speed, accel, decel).

C_01, C_02, C_03

Example (requires input configuration—

see Chapter 3 in L100 Instruction Manual):

DNT

123L

P24

• When [DNT] is OFF, the inverter is not under

control from DeviceNet commands. However, the

DeviceNet host computer can still monitor inverter

data via polled I/O, and it can still use Explicit

Messaging to individually change inverter parameters.

See I/O specs in the L100 Instruction Manual

• If you do not assign an input terminal as [DNT],

then parameter P_43 DeviceNet Enable is the sole

method of enabling/disabling control via the

DeviceNet network.

For more information on DeviceNet network configuration, see “Step 2 – Connect

Network Devices” on page 43.

Page 37

Remote Control Up and Down Functions

The [UP] [DWN] terminal functions can adjust the output frequency for remote control

while the motor is running. The acceleration time and deceleration time used with this

function is the same as for normal operation ACC1 and DEC1. The input terminals

operate as follows:

• Acceleration - When the [UP] contact is turned ON, the output frequency accelerates

from the current value. When it is turned OFF, the output frequency maintains its

current value.

• Deceleration - When the [DWN] contact is turned ON, the output frequency decelerates from the current value. When it is turned OFF, the output frequency maintains its

current value.

In the graph below, the [UP] and [DWN] terminals activate while the Run command

remains ON. The output frequency responds to the [UP] and [DWN] commands.

Output

Frequency

[UP]

L100DN Inverter

37

[DWN]

[FW] or [RV]

Option

Code

27 UP Remote Control

28 DWN Remote Control

Valid for inputs:

Required settings:

Terminal

Symbol

Function Name

UP Function

DOWN Function

C_01, C_02, C_03

Input

State

ON Accelerates (increases output frequency) motor

OFF Output to motor operates normally

ON Decelerates (decreases output frequency) motor

OFF Output to motor operates normally

Notes:

The availability of this feature does not depend on

•

A_01 (does not exist for DN Series models).

• This function is not available when [JG] is in use.

• The range of output frequency is 0 Hz to the value

in A_04 (maximum frequency setting).

• The Remote Control Up/Down function varies the

inverter speed by directly writing to the F_01

output frequency setting.

t

Description

from current frequency

from current frequency

Example (requires input configuration—

see Chapter 3 in L100 Instruction Manual):

UPDWN

123L

P24

See I/O specs in the L100 Instruction Manual

Page 38

38

Operations and Monitoring

Force Operation from Digital Operator

This function permits a digital operator interface to override the Run command source

setting (A_02) when it is configured for a source other than the operator interface. When

the [OPE] terminal is ON and the operator interface gives a Run command, the inverter

uses the standard output frequency settings to operate the motor.

Option

Code

31 OPE Force Operation

Valid for inputs:

Required settings:

Terminal

Symbol

Function Name State Description

ON Forces the operator interface Run command to

from Digital

Operator

OFF Run command operates normally, as configured

C_01, C_02, C_03

A_02=01

Notes:

When the [OPE] signal is ON, the keypad Run and

•

Stop keys are active, and [FW] or [RV] signal is

ignored. However, [OPE] cannot cause the keypad

to over-ride the DeviceNet host commands. To

enable/disable DeviceNet control via an input

terminal, use [DNT] (DeviceNet select).

• When changing the [OPE] state during Run Mode

(inverter is driving the motor), the inverter will stop

the motor before the new [OPE] state takes effect.

• If the [OPE] input turns ON and the digital operator

gives a Run command while the inverter is already

running, the inverter stops the motor. Then the

digital operator can control the motor.

over-ride commands from input terminals (such

as [FW], [RV])

by A_02

Example (requires input configuration—

see Chapter 3 in L100 Instruction Manual):

OPE

123L

P24

See I/O specs in the L100 Instruction Manual

Intelligent Output Summary

Intelligent output terminals for L100DN inverters include the standard L100 output

terminals (see Chapter 3 in L100 Inverter Manual), with the following changes:

• Remove [OD] (Output deviation for PID control) intelligent output terminal

Page 39

Network Control and Monitoring

DeviceNet Overview

DeviceNet is a communications network typically used in factory automation applications. It is a specific implementation of a Controller Area Network (CAN), first developed for the automotive market. IC manufacturers produce CAN ICs by the millions, so

they are low-cost and reliable. DeviceNet adapts this technology for industrial control. It

allows a programmable logic controller (PLC) or other host computer to control up to 63

field devices such as relays, solenoids, and motor drives such as Hitachi’s DN Series

inverters. DeviceNet has several advantages which have helped make it a popular choice

for various applications. The advantages include:

• Physical layout – main trunk line with individual drop lines

• Reduced wiring costs – uses a 5-wire cable; communications and device power are in

the same cable (power devices such as motor drives still require a main power source)

• Devices may be connected or disconnected without powering down the network (if

daisy-chained)

• Flexible device definitions – the device protocol provides for many types of input and

output structures

L100DN Inverter

39

• Open standard – allows multiple vendors to produce many types of products that can

coexist on a network

Slave Slave SlaveMaster

(PLC or host

computer)

DeviceNet is an open network standard, meaning that it has a non-proprietary protocol

and no licensing requirements. Hundreds of vendors are members of the Open

DeviceNet Vendor Association (ODVA), who ensures the integrity of the technical

standards and oversees device conformance testing. Hitachi DN Series inverters are

listed with the ODVA. This ensure compatibility with a wide range of devices from

vendors making thousands of DeviceNet compatible industrial products. This also helps

to connect those same devices over long distances in the factory.

Slave (up to 63

Slaves)

Page 40

40

Network Control and Monitoring

Inverter Networking Overview

The L100DN DeviceNet Series inverters can operate under local control (via operator

input via the keypad or via input terminal signals). This control method was covered in

the previous section, “Operations and Monitoring,” and also in the L100 inverter

manual’s Chapter 4, also named “Operations and Monitoring.”

The “Network Control and Monitoring” section will first show you how to connect the

inverter to a DeviceNet network. Next, you will learn how to monitor and control the

inverter from the network master (host computer). These instructions are presented in a

series of steps, with each one preparing your application for the next one. Therefore, be

sure not to skip any steps in this section.

NOTE: Be sure to install the inverter and perform the powerup test described in the

“Inverter Mounting and Installation” on page 9 before attempting network operation.

The step to DeviceNet network control and monitoring are:

1. Design your network layout

2. Connect network devices

a. Add network termination

b. Add network power

3. Prepare network host computer

4. Prepare inverter for network

5. Understand the inverter’s I/O structure

a. Polled I/O

b. Explicit messaging

6. Monitor test – verify network host can monitor inverter

7. Control test – verify network host can control inverter

8. Use DeviceNet Explicit Messaging

9. Create a host computer control program

Note that the test to monitor the inverter from the network occurs before the test to

control the inverter via the network. The setup for monitoring is more simple, and helps

prepare the devices for the control step.

Page 41

Step 1 – Design Your DeviceNet Network Layout

Your DeviceNet network layout will be determined by several factors, including the

physical machine or plant layout. The network must have one network master, or host

computer such as a PLC or control PC. The L100DN Series inverter is a DeviceNet

slave. The network can have up to 63 slaves which can include inverter(s), sensors,

actuators, or other intelligent devices.

Master

Slave Slave

(network host)

Slave

L100DN Inverter

41

(up to 63

Slaves)

Addr=12Addr=04Addr=29 Addr=44

Addr=63

(default)

The network diagram above shows a network master (host computer), and four slave

devices. Each device constitutes a “node,” and each node must have a unique address.

The address is also called the MAC ID (Media Access Control Identification). As shown

in the diagram, the node addresses do not have to occur in a particular sequence in the

physical layout.

Showing node connections now in greater detail, the connection to each device in the

middle of the network may be a daisy-chain connection or a drop connection. The differ-

ence is that a daisy-chain connection enters and exits right at the connector, while a drop

connection inserts an extra segment just for the device. The device at each end of the

physical network must include a termination resistor. The host computer and the inverter

may be in the middle or at the ends of the network.

Drop

line

Daisy-

chain

Trunkline

Daisy-

chain

TerminationTermination Ta p

Page 42

42

Network Control and Monitoring

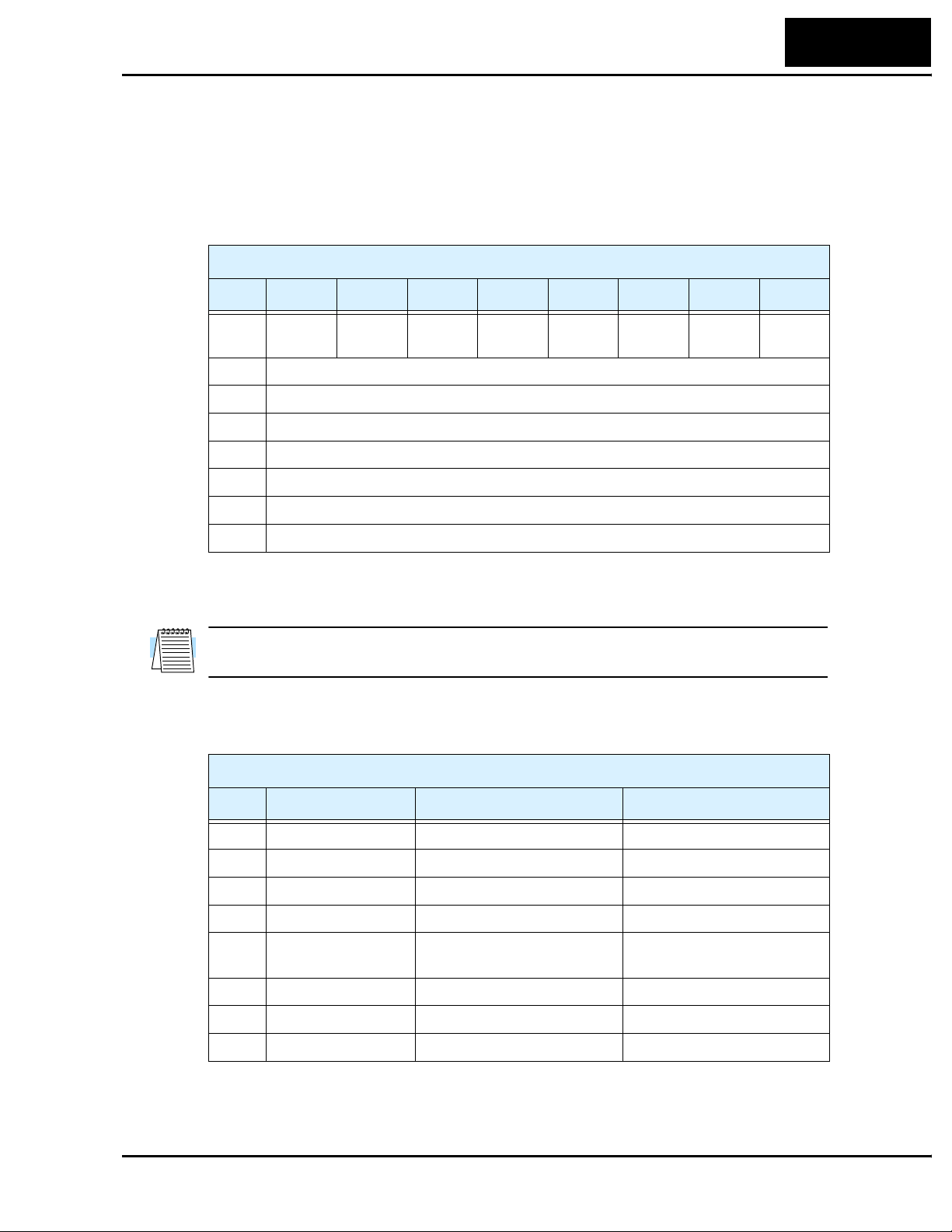

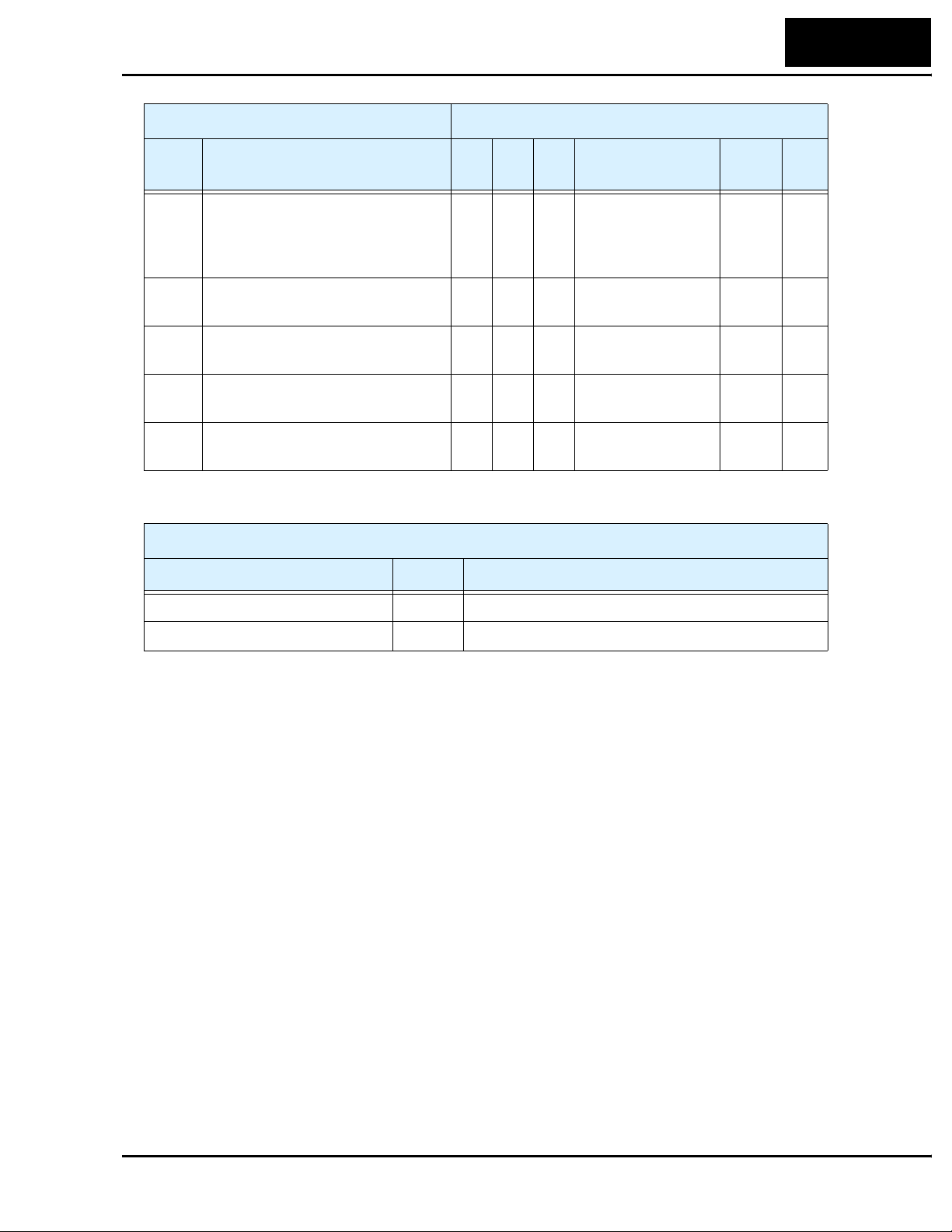

DeviceNet networks support three baud rates, listed in the following table.

Baud Rate

125 kbps 500m (1640 ft.) 6m (20 ft.) 156m (512 ft.)

250 kbps 250m (820 ft.) 6m (20 ft.) 78m (256 ft.)

500 kbps 100m (328 ft.) 6m (20 ft.) 39m (128 ft.)

NOTE: If thin cable is used for the trunk line, the maximum distance is 100m (for all

baud rates).

Trunk length

(thick cable)

Maximum Cumulative

Drop Length

Page 43

Step 2 – Connect Network Devices

A DeviceNet node connects to the network with five electrical connections. The diagram

below shows the inverter connection as an example. The cable uses two twisted pairs

with a shield. One twisted pair is for data, and the other is for +24V power. The color

code shown is standard for DeviceNet.

DeviceNet Connection

DeviceNet interface

L 3 12

L100DN Inverter

P24 CM2

12 11

43

Bus supply +

CANbus High

Drain

CANbus Low

Bus supply –

The diagram below shows L100DN inverters connected to a DeviceNet network. Each

connection is called a node, and the L100DN connects to the network via the 5-pin,

color-coded Phoenix connector on the front panel as shown.

Add network termination – A termination resistor (121Ω nominal) is required at each

physical end of a DeviceNet network (segment) as shown in the diagram below. Each

device does not typically have an internal termination resistor, as several such devices

together would overload a network. The terminations provides signal integrity and noise

immunity. Therefore, add two resistors as close to the endpoint connectors as possible.

DeviceNet Terminations

Device at end of network

(Red)

(White)

(Bare)

(Blue)

(Black)

L 3 12

P24 CM2

12 11

Bus supply +

CANbus High

Drain

CANbus Low

Bus supply –

TIP: To simplify configuration and startup, we recommend starting with just the

network host (PLC or computer) and the inverter. It is easier to resolve addressing or

other conflicts with fewer devices. With network wiring for just two devices, you will

need a termination resistor at both devices. After establishing network communications

with the inverter, you can add other devices individually with a minimum of problems.

Remember to maintain network termination at the endpoints at all times.

121Ω121Ω

Page 44

44

Network Control and Monitoring

Add network power – Many devices such as sensors and relays can be powered directly

from the network. However, inverters generally use much more power and a higher input

voltage than a network could provide. As demonstrated by the installation powerup test,

L100DN Series inverters need only the AC input power for stand-alone operation. For

network monitoring or control, you must also supply external +24V network power to

the DeviceNet connector. The inverter has internal optical isolation from the network,

and draws negligible network power as a result. DeviceNet specifications support up to

8A per network segment.

NOTE: Class II NEC Code limits the current for any network segment to 4A. DeviceNet

thick type cable is limited to 8A; thin type cable is limited to 3A.

Add a +24VDC supply to the network as shown below. It is not necessary to power it for