Page 1

High pixel CMOS camera

KP-FM200WCL

KP-FMR200WCL

Operation Manual

Hitachi Kokusai Electric Inc.

The third edition in August, 2012.

RoHS Compliant

These products comply with the requirement of the RoHS (Restriction of the

use of Certain Hazardous Substances in Electrical and electronic Equipment)

Directive 2002/95/EC.

Thank you for purchase this fine Hitachi Kokusai Electric CMOS camera.

Before using the camera, please read this operation manual carefully.

Page 2

A

IMPORTANT SAFETY INSTRUCTIONS

1. Read Instructions

All the safety and operating instructions should be read before the product is operated.

2. Retain Instructions

The safety and operating instructions should be retained for future reference.

3. Heed Warnings

All warnings on the product and the operating instructions should be adhered to.

4. Follow Instructions

All operating and use instructions should be followed.

5. Cleaning

Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners. Use a damp cloth for cleaning.

6. Attachments

Do not use attachments not recommended by the product manufacturer as they may cause hazards.

7. Water and Moisture

Do not use this product near water - for example, near a bath tub, wash bowl, kitchen sink, or laundry tub; in a wet basement; or near a swimming pool; and

the like.

8. Accessories

Do not place this product on an unstable cart, stand, tripod, bracket, or table. The product may fall, causing serious injury to a child or adult, and serious

damage to the product. Use only with a cart, stand, tripod, bracket, or table recommended by the manufacturer, or sold with the product. Any mounting

of the product should follow the manufacturer's instructions, and should use a mounting accessory recommended by the manufacturer.

9. Moving

A product and cart combination should be moved with care.

Quick stops, excessive force, and uneven surfaces may cause the product and cart combination to overturn.

10. Ventilation

Slots and openings in the cabinet are provided for ventilation and to ensure reliable operation of the product and to protect it from overheating, and these

openings must not be blocked or covered.

The openings should never be blocked by placing the product on a bed, sofa, rug, or other similar surface. This product should not be placed in a built-in

installation such as a bookcase or rack unless proper ventilation is provided or the manufacturer's instructions have been adhered to.

11. Power Sources

This product should be operated only from the type of power source indicated on the marking label. If you are not sure of the type of power supply to your

home, consult your product dealer or local power company. For products intended to operate from battery power, or other sources, refer to the operating

instructions.

12. Grounding or Polarization

This product is equipped with a three-wire grounding-type plug a plug having a third (grounding) pin. This plug will only fit into a grounding-type power

outlet. This is a safety feature. If you are unable to insert the plug into the outlet, contact your electrician to replace your obsolete outlet. Do not defeat

the safety purpose of the grounding-type plug.

13. Power-Cord Protection

Power-supply cords should be routed to that they are not likely to be walked on or pinched by items placed upon or against them, paying particular attention

to cords at plug, convenience receptacles, and the point where they exit from the product.

14. Lightning

For added protection for this product during a lightning storm, or when it is left unattended and unused for long periods of time, unplug it from the wall outlet.

This will prevent damage to the product due to lightning and power-line surges.

15. Overloading

Do not overload wall outlets, extension cords or integral convenience receptacles as this can result in a risk of fire or electric shock.

16. Object and Liquid Entry

Never push objects of any kind into this product through openings as they may touch dangerous voltage points or short-out parts that could result in a fire or

electric shock. Never spill liquid of any kind on the product.

17. Inflammable and Explosive Substance

Avoid using this product where there are gases, and also where there are inflammable and explosive substances in the immediate vicinity.

18. Heavy Shock or Vibration

When carrying this product around, do not subject the product to heavy shock or vibration.

19. Servicing

Do not attempt to service this product yourself as opening or removing covers may expose you to dangerous voltage or other hazards. Refer all servicing to

qualified service personnel.

20. Damage Requiring Service

Unplug this product from the wall outlet and refer servicing to qualified service personnel under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally by following the operating instructions. Adjust only those controls that are covered by the operating instructions

as an improper adjustment of other controls may result in damage and will often require extensive work by a qualified technician to restore the product to

its normal operation.

e. If the product has been dropped or damaged in any way.

f. When the product exhibits a distinct change in performance-this indicates a need for service.

21. Replacement Parts

When replacement parts are required, be sure the service technician has used replacement parts specified by the manufacturer or have the same

characteristics as the original part.

Unauthorized substitutions may result in fire, electric shock, or other hazards.

22. Safety Check

Upon completion of any service or repairs to this product, ask the service technician to perform safety checks to determine that the product is in proper

operating condition.

23. Wall or Ceiling Mounting

The product should be mounted to a wall or ceiling only as recommended by the manufacturer.

24. Heat

The product should be situated away from heat sources such as radiators, heat registers, stoves, or other products (including amplifiers) that produce heat.

Page 3

B

1. Alle Anweisungen lesen

Vor Betrieb des Erzeugnisses sollten alle Sicherheits-und Bedienungsanleitungen gelesen werden.

2. Die Anweisungen aufbewahren

Die Sicherheits-und Bedienungsanleitungen sollten fünftigen Bezug aufbewahrt werden.

3. Warnungen beachten

Die Warnungen auf dem Erzeugnis und in den Bedienungsanleitungen solten beachtet werden.

4. Anweisungen befolgen

Alle Bedienungsanleitung-und Verwendungsanweisungen sollten befolgt werden.

5. Reinigung

Den Stecker des Geräts vor Reinigung aus der Steckdose ziehen. Keine flüssigen Reinigungsmittel oder Aerosolreiniger verwenden. Zum Reinigen einen

feuchten Lappen verwenden.

6. Zubehör

Nur vom-Hersteller des Erzeugnisses empfohlenes Zubehör verwenden, da es sonst zu Störungen kommen kann.

7. Wasser und Feuchtigkeit

Dieses Erzeugnis nicht in der Nähe von Wasser verwenden - z.B, in der Nähe einer Badewanne, eines Waschbeckens, einer Küchenspüle, eines

Waschzubers, in einem nassen Keller, in der Nähe eines Schwimmbeckens usw.

8. Aufstellung

Das Erzeugnis nicht auf einen unstabilen Wagen, Stand, Dreifuß, Träger oder Tisch stellen.Das Erzeugnis kann sonst herunterfallen und ein kind oder

einen Erwachsenen schwer verietzen.Außerdem kann das Gerät schwer beschädigt werden. Nur mit einem Wagen, Stand, Dreifuß, Träger oder Tisch

verwenden, der vom Hersteller empfohlen oder mit dem Erzeugnis verkauft worden ist. Für jegliche Anbringung sollten die Anweisungen des Herstellers

befolgt werden, und das vom Hersteller empfohlene Anbringungszubehör sollte verwendet werden.

9. Eine Kombination von Erzeugnis und Wagen sollte vorsichtig bewegt werden

Schneller Halt, übermäßige Krafteinwirkung und unebene Oberflächen können Umkippen der kombination von Erzeugnis und Wagen verursachen.

10. Ventilation

Schlitze und Öffnungen im Gehäuse dienen der Ventilation. Sie sind für zuverlässigen Betrieb des Gerätes und Schutz vor Überhitzung erforderlich und

dürfen nicht blockiert oder abgedeckt werden. Die Öffnungen sollten niemals dadurch blockiert werden, daß, das Gerät auf ein Bett, ein Sofa, einen Teppich oder

eine ähnliche Oberfläche gestellt wird.

Das Gerät sollte nur dann in Einbauinstallierung wie in einem Bücherschrank oder einem Gestell verwendet werden, wenn angemessene Ventilation

vorgesehen ist bzw. Die Anweisungen des Herstellers befolgt worden sind.

11. Stromversorgung

Dieses Erzeugnis sollte nur an der auf dem Typenschild angegebenen Stromversorgungsart betrieben werden. Wenn Sie nicht sicher sind, was für eine

Stromversorgung Sie haben, so wenden Sie sich bitte an Ihren Erzeugnishändler oder an das lokale Elektrizitätswerk. Beziehen Sie sich für Batteriebetrieb

oder andere Stromquellen vorgesehene Erzeugnisse bitte auf die Bedienungsanleitungen.

12. Erdung oder Polarisierung

Dieses Erzeugnis ist mit einem Schutzkontaktstecker mit drei Leitern ausgerüstet, mit einem Erdungskontakt. Dieser Stecker paßt nur in ein

schuko-Steckdose. Dies ist eine Sicherheitsmaßnahme. Wenn Sie den Stecker nicht in die Steckdose stecken können, so wenden Sie sich bitte an

ihren Elektriker, damit er die veraltete Schuts des Schutzkontaktsteckers unwirksam.

13. Netzkabelschutz

Netzkabel sollten so verlegt werden, deß möglichst nicht darauf getreten wird und daß sie nicht eingeklemmt werden, mit besonderer Beachtung der kabel

an Stackern, Verlängerungskabeln und dem Austritt des Kabels aus dem Erzeugnis.

14. Blitzschlag

Für zusätzlichen Schutz des Erzeugnisses während eines Gewitters oder bei Nichtverwendung für lange Zeit den Stecker aus der Steckdose ziehen. Dies

verhütet Beschädigung durch Blitzschlag und Netzspannungsstöße.

15. Überlastung

Wandsteckdosen, Verlängerungskabel und eingebaute Bequemlickkeitssteckdosen nicht überlasten, da dies Feuer oder elektrischen Schlag verursachen

kann.

16. Eindringen von Fremdkörpern und Flüssigkeit

Niemals Objekte irgendwelcher Art durch die Öffnungen in das Gerät schieben, da diese unter hoher Spannung stehende Teile berühren oder

kurzschließen können, wodurch es zu Feuer oder elektrischem Schlag kommen kann. Niemals Flüssigkeiten irgendwelcher Art auf das Erzeugnis

verschütten.

17. Entflammbare und explosive Substanzen

Vermeiden Sie Verwendung dieses Erzeugnisses an Orten mit Gasen bzw. entflammbaren oder explosiven Substanzen in der direkten Umgebung.

18. Starke stöße oder Vibrationen

Setzen Sie das Erzeugnis beim Transport nicht starken Stößen oder Vibrationen aus.

19. Wartung

Versuchen Sie nicht, dieses Erzeugnis Selbst zu warten, da Sie sich durch Öffnen bzw. Entfernen von Abdeckungen hohen Spannungen und sonstigen

Gefährdungen ausserzen können. Beziehen Sie sich für jegliche Wartung auf qualifiziertes Wartungspersonal.

20. Beschädigung, die Wartung erfordert

Ziehen Sie den Stecker dieses Erzeugnisses aus der Steckdose und wenden Sie sich an qualifiziertes Wartungspersonal, wenn eine der folgenden

Bedingungen vorliegt:

a. Wenn das Netzkabel oder der Stecker beschädigt ist.

b. Bei Eindringen von Flüssigkeit oder Fremdkörpern in das Gerät.

c. Wenn das Erzeugnis Regen oder Wasser ausgesetzt worden ist.

d. Wenn das Erzeugnis bei Befolgen der Bedienungsanleitungen nicht normal funktioniert.Nur die Regelelemente verstellen, die in den

Bedienungsanleitungen behandelt werden, da unangemessene Einstellung anderer Regelelemente Beschädigung verursachen kann und oft

beträchtliche Arbeit durch einen qualifizierten Techniker erfordert, um das Erzeugnis wieder, zu normalem Betrieb zurückzubringen.

e. Wenn das Erzeugnis fallen gelassen oder beschädigt worden ist.

f. Wenn das Erzeugnis eine klare Änderung in der Leistung zeigt-dies weist darauf hin, daß Wartung erforderlich ist.

21. Ersatzteile

Wenn Ersatzteile erforderlich sind, darauf achten, daß der Wartungstechniker nur die vom Hersteller festgelegten Ersatzteile oder Teile mit den gleichen

Charakteristiken wie die ursprünglichen Teile verwendet. Unautorisierte Ersatzteile können Feuer, elektrischen Schlag oder sonstige Gefährdungen

verursachen.

22. Sicherheitsprüfung

Bitten Sie den Wartungstechniker nach der Vollendung von Wartung oder Reparaturarbeiten an diesem Erzeugnis um die Durchführung von

Sicherheitsprüfungen, um zu bestimmen, daß das Erzeugnis im angemissenen Betriebszustand ist.

23. Anbringung an der Wand oder an der Decke

Das Erzeugnis sollte nur entsprechend den Empfehlungen des Herstellers an einer Wand oder an der Decke angebracht werden.

24. Wärme

Das Erzeugnis sollte fern von Wärmequellen wie Radiatoren, Heizwiderständen, Öfen und anderen Wärme erzeugenden Erzeugnissen (einschließlich

Verstärkern) aufgestellt werden.

WICHTIGE SICHERHEITSANWEISUNGEN

Page 4

C

MISES EN GARDE IMPORTANTES

1. Lire les instructions

Lire toutes les instructions de sécurité et de fonctionnement avant de faire fonctionner l’appareil.

2. Conserver ces instructions

Conserver les instructions de sécurité et de fonctionnement á des fins de référence ultérieure.

3. Tenir compte des avertissements

Tous les avertissements qui figurent sur l’appareil et dans le mode d’emploi devront être respectés.

4. Observer les instructions

Observer toutes les instructions de fonctionnement et d’utilisation.

5. Nettoyage

Avant de procéder au nettoyage, débrancher l’appareil de la prise secteur. Ne pas utiliser de produits de nettoyage liquides ou en aérosol.

Nettoyer l’appareil avec un chiffon humide.

6. Fixations

Ne pas utiliser de fixations non recommandées par le fabricant de l’appareil car elles pourraient être source de danger.

7. Eau et humidité

Ne pas utiliser l’appareil á proximité d’eau-ar exemple prés d’une baignoire, d’un lavabo, d’un évier ou d’un bac á lessive, dans un sous-sol humide, ou prés d’une

piscine, etc.

8. Accessoires

Ne pas placer l’appareil sur un chariot, un socle, un pied, un support ou one table instables L’appareil pourrait tomber, blessant griévement des enfants ou

des adultes, et étant sérieusement endommagé.

Utiliser exclusivement le chariot, le socle, le pied, le support ou la table recommandés par le fabricant, ou vendus avec l’appareil. Pour tout montage de

l’appareil, respecter les instructions du fabricant, et utiliser á cette fin l’accessoire de montage recommandé par le fabricant.

9. L’appareil monté sur son chariot devra être déplacé avec précaution

Des arrêts brusques, une force excessive et des surfaces irréguliéres pourraient provoquer le renversement de l’ensemble appareil-chariot.

10. Ventilation

Les fentes et les ouvertures du coffret sont prévues pour la ventilation ainsi que pour garantir un fonctionnement en toute sécurité de l’appareil et le

protéger de toute surchauffe, et ces ouvertures ne devront donc être ni obstruées ni recouvertes. Ne jamais obstruer les ouvertures en placant l’apparei

sur un lit, un sofa, un tapis ou toute surface similaire. Ne jamais placer l’appareil dans un support confiné, par exemple une bibliothéque ou une é tagé re,

sans ventilation suffisante ou sans repecter les instructions du fabricant.

11. Sources d’allmentation

L’appareil devra être alimenté exclusivement sur le type d’alimentation indiqué sur l’étiquette signalétique. Sil’on n’est pas sûr du type d’alimentatio du local,

consulter le revendeur de l’appareil ou la compagnie d’électricité locale. Pour les appareils qui fonctionnent sur batterie ou sur d’autres sources, voir le

mode d’emploi.

12. Mise á la terre ou polarisation

L’appareil est doté d’une fiche trifilaire avec mise á la terre, dont la troisiéme broche assure la mise á la terre. Cette fiche ne rentrera que dans les prises

trifilaires de mise á la terre. Ceci est une mesure de sécurité. Si la fiche ne rentre pas dans la prise, faire remplacer la prise désuéte par un électricien.

Ne pas rendre vaine la measure de sécurité assurée par cette prise avec mise á la terre.

13. Protection du cordon d’alimentation

Acheminer les cordons d’alimentation de facon qu’on ne risque pas de marcher dessus ou de les coincer sous un objet placé dessus ou contre eux.

Faire particuliérement attention aux fiches des cordons, á la proximité des prises, et á l’endroit oú ils ressortent de l’appareil.

14. Foudre

Pour renforcer la protection de l’appareil pendant un orage, ou si l’on s’en éloigne ou qu’on reste longtemps sans l’utiliser, le débrancher de la source

d’alimentation. Ceci permettra d’éviter tout dommage de l’appareil dú á la foudre et aux surtensions de ligne.

15. Surcharge

Ne pas surcharger les prises, rallonges et prises multiples car cela pourrait entraîner un risque de feu ou de choc électrique.

16. Pénétration d’objets et de liquides

Ne jamais enfoncer d’objets d’aucune sorte dans les ouvertures de l’appareil car ils pourraient toucher des points de tension dangereuse ou court-circuiter

des piéces, ce qui pourrait provoquer un feu ou un choc électrique. Ne jamais renverser de liquide d’aucune sorte sur l’appareil.

17. Substances inflammabes et explosives

Eviter d’utiliser l’appareil en présence de gaz, ainsi qu’á proximité immédiate de substances inflammables et explosives.

18. Chocs ou vibrations violents

Lorsqu’on transporte l’appareil, ne pas le soumettre á des chocs ou des vibrations violents.

19. Réparations

Ne pas tenter de réparer l’aapareil soi-même car le fait d’ouvrir ou de retirer les caches risque d’exposer l’utilisateur á des tensions dangereuses

notamment. Confier toute réparation á un personnel qualifié.

20. Dommages nécessitant réparations

Débrancher l’appareil de la source d’alimentation et confier les réparations á un personnel qualifié dans les cas suivants:

a. Lorsque le cordon d’alimentation ou sa fiche sont endommagés

b. Si du liquide s’est renversé sur l’appareil ou que des objets sont tombés dedans

c. Si l’appareil a été exposé á la pluie ou á l’eau.

d. Si l’appareil ne fonctionne pas normalement lorsqu’on observe les instructions d’utilisation.

Ne régler que les commandes couvertes par le mode d’emploi ; en effet, un réglage incorrect des autres commandes pourrait entrainer des dommages et

nécessiteront souvent des travaux de réparation coûteux par un technicien qualifié pour remettre l’appareil en état de marche.

e. Si l’appareil est tombé ou qu’il a été endommagé.

f. Si l’appareil affiche une nette modification de ses performances, cela signifie qu’il a besoin d’être réparé.

21. Piéces de rechange

Si l’on a besoin de piéces de rechange, veiller á ce que le technicien de réparation utilise exclusivement les piéces de rechange spécifiées par le fabricant

ou des piéces ayant les mêmes caractéristiques que les piéces d’origine. Les piéces de rechange non autorisées risquent de provoquer un feu, un choc

électrique et autres dangers.

22. Vérificaton de sécurité

Aprés tout travail d’entretien ou de réparation de l’appareil, demander au technicien de réparation d’effectuer les vérifications de sécurité pour s’assurer que

l’appareil est en bon état de marche.

23.Montage au mur ou au plafond

L’appareil ne pourra être monté au mur ou au plafond que de la maniére recommandée par le fabricant.

24. Chaleur

Eloigner l’appareil des sources de chaleur, telles que radiateurs, appareils de chauffage, cuisiniéres, et de tour produit engendrant de la chaleur (y compris

les amplificateurs).

Page 5

D

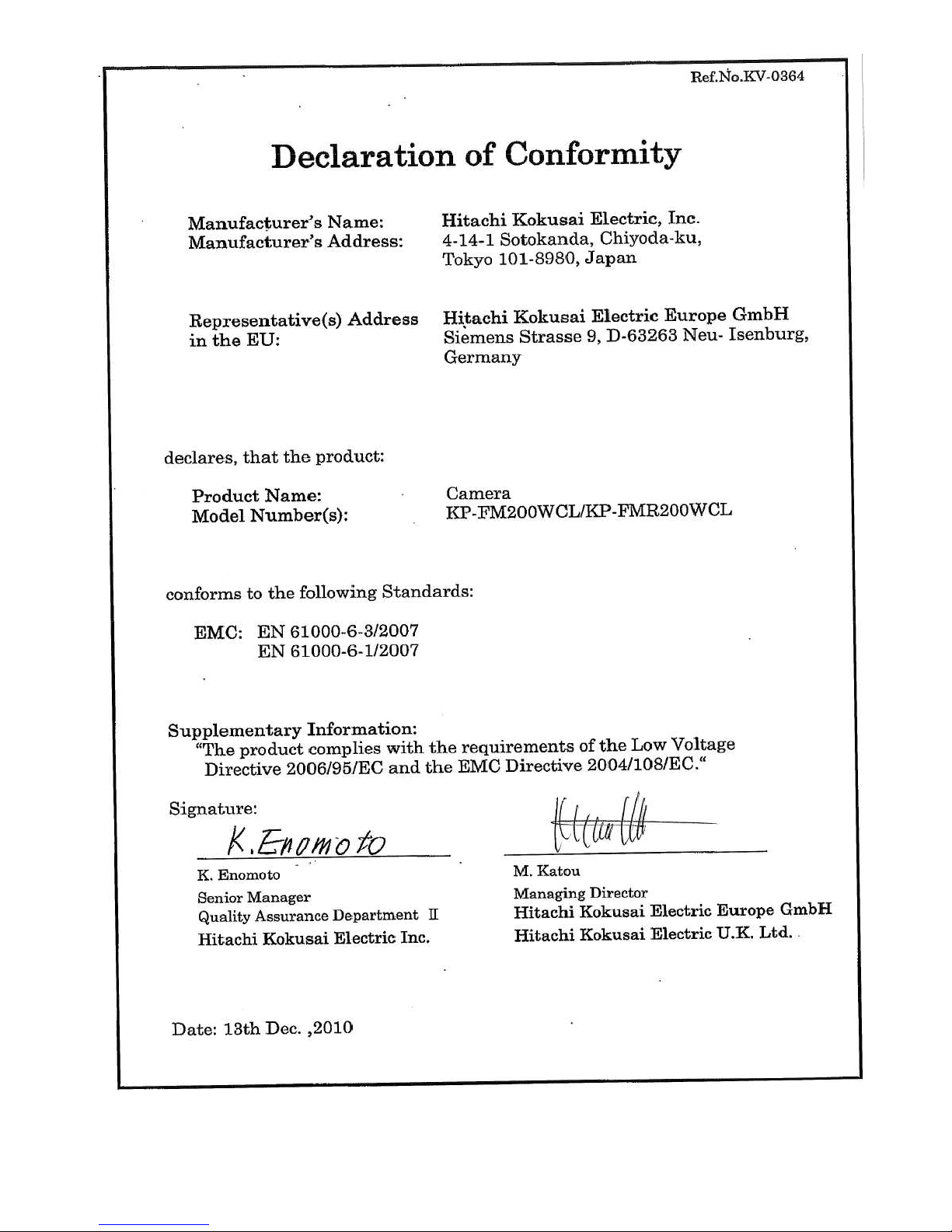

The following statement is related to the regulation on “ Measures for the Administration of the control of Pollution by Electronic

Information Products “ , known as “ China RoHS “.

The table shows contained Hazardous Substances in this camera.

说明书(环境方面:补充资料)

对象产品:CMOS 摄像机

1.电子产品污染控制标志

此标志是根据 2006年 2月 28 日公布的《电子信息产品污染控制管理办法》以及SJ/T11364-2006

《电子信息产品污染控制标识要求》而制定的,是用来表示适用于在中华人民共和国流通的电子

信息产品的环保使用期限。

只要遵守此类产品的安全事项以及使用上应注意的问题,从制造日起到此年限内,不会发生产

品中的有害物质外泄、突变等,不会对环境、人体以及财产产生严重影响。同时,此年限是除去

必须定期交换的保守部品的,是其他产品的环保使用期限。

产品在正常情况下使用完毕要废弃时,请遵守各地区对电子信息产品的回收・再利用的相关各项法律、法规。

另外,从第三者处转买的情况下即使在本期限内也视为失去效力。

2.产品中有毒有害物质或元素的名称及含量

有毒有害物质或元素

部件名称

铅

(Pb)

水银

(Hg)

镉

(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

1 主机 × ○ ○ ○ ○ ○

○:表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下。

×:表示该有毒有害物质至少在该部件的某一均材料中的含量超出 SJ/T11363-2006 标准规定的限量要求。

IMPORTANT NOTICE

China RoHS

These products have been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this product in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

WARNING

Changes or modifications not expressly approved by Hitachi Denshi responsible for compliance could void the user’s

authority to operate the equipment.

This product does not exceed the class A/class B limits for radio noise emissions from digital apparatus as set out in the

radio interference regulations.

Le présent appareil n’émet pas de bruits radioélectriques dépassant les limités applicable aux appareils numériques de

classe A prescrites dans le rVglement sur le brouillage radioélectrique édicter par le ministére des communications du

canada.

For U.S.A.

For Canada

Page 6

E

Page 7

F

Operating considerations Notes to users

1. Important safety notes

・ Use this camera with a 12VDC power supply. Time will be needed for about four seconds by the time the camera works

normally after turning on the power supply.

・ Observe that flammable objects, water or metal do not enter the camera interior. These may lead to failure or accident.

・ Do not modify the camera or use the camera with external covers removed. These may cause failure, void any warranties and

pose a safety hazard.

・ Stop using the camera at the approach of electrical storm (thunder audible). Protect the camera from rain if using it outdoors.

・ In event the camera shows any abnormality, switch off the camera and disconnect the power cord. Contract a Hitachi Denshi

service representative.

2. Handling

・ Do not attempt to remove cover.

・ When installing or removing a lens, be sure to use care that water or dust dose not enter the inside of the camera.

3. Installing and storage

Avoid installing or storing the camera in the following environments.

・ Environments exposed to direct sunlight, rain or snow.

・ Environments where combustible or corrosive gas exists.

・ Excessively warm or cold environment (Operating ambient temperature: -10 to 50℃).

・ Humid or dusty environment.

・ Place subjected to excessive vibration or shock.

・ Environment exposed to strong electric or magnetic field.

・ Do not aim the camera lens at the sun.

・ Do not shoot strong light.

When such a scene is shot, vertical trailing will appear. However, this is not due to failure. In case strong light enters camera

through the lens, partial deterioration in picture quality will result.

4. To obtain stable performance for long time

When the camera is used continuously for long time under high ambient temperature, the inside electrical parts become

deteriorated, resulting in shortening its life. To use the camera continuously for long time, the highest temperature must be below

40℃.

5. Connectors

Confirm the power is off before connecting or disconnecting a signal cable. Grasp connectors by the body, not the attached wires.

6. Cleaning

・ Use a blower or a lens brush to remove dusts on the lens or the optical filter.

・ Wipe dirts on the case off with dry soft cloth. If dirts are hardened, wipe them off with cloth moistened with neutral detergent

liquid; wipe the cover with dry cloth.

・ Do not use benzene, thinner, alcohol, liquid cleaner or spray-type cleaner.

・ In event dust or other debris is lodged between the CMOS and optical filter, consult dealer for cleaning by an optical technician.

7. Phenomena inherent to CMOS imaging device

The following phenomena are inherent to a charge coupled device imaging element and do not indicate malfunction.

1) Fixed pattern noise

High ambient temperature can cause fixed pattern noise to appear throughout the scene.

2) Moire

Interaction between patterns can produce an additional "phantom" pattern to appear. The CMOS picture elements (pixels) are

arranged in a pattern, which can interact with a pattern in the scene (e.g., a performer wearing a finely striped necktie) to result

in a Moire pattern. The effect should be considered when selecting costumes, props and other scene elements.

3) Ghosting

Strong direct or reflected light near an object of interest can cause ghosting of the object to appear in the picture. The effect is

more obtrusive with certain iris settings and lens types. Select the scene layout and camera pointing direction carefully in

order to avoid this effect.

4)Defective pixels

Imperceptible white spots may rarely come up on the screen due to cosmic rays and so on. It becomes easy to appear when

the sensitivity of the camera is raised in the operation at the high temperature.

5)Monochrome reversing

When taking picture of personally strong light, the part where white is saturated might become CMOS element with a black

image. Please adjust quantities of light at such time.

6)Horizontal pull phenomenon of image

Subject might became bright when there is strong light (strong reflection of the light, the fluorescent lamp, and sunlight etc.)

next to subject. It becomes easy to see by raising the camera sensitivity. It appears only when using it by the Full configuration.

7)Horizontal line noise when electronic shutter is used

The horizontal line noise might appear by setting the exposure time when using it in a normal mode. It becomes easy to see by

raising the camera sensitivity.

8. Attention about laser light

Laser light may do damage to CMOS image sensor. When you use laser light, be careful not to irradiate it on the CMOS image

sensor surface. The CMOS image sensor breakage by laser light irradiation is out of warranty. (The repair is not free of charge.)

Page 8

G

Table of Contents

1. Overview ··········································································································································· 1

2. Standard Composition ······················································································································· 1

3. Features ············································································································································ 1

4. System example ································································································································ 2

5. Section name and functions ·············································································································· 2

6. Camera mounting ······························································································································ 3

7. Lens ·················································································································································· 3

8. Optical filter ······································································································································· 3

9. Connector ········································································································································· 4

10. Functions and operations ·················································································································· 5

11. Remote control ·································································································································· 7

12. Command list ·································································································································· 14

13. Camera Link output timing chart ····································································································· 17

14. Trigger operation and timing chart ·································································································· 26

15. Input / Output signal ························································································································ 31

16. Spectral response ··························································································································· 32

17. Specifications ·································································································································· 33

18. Dimensions ····································································································································· 34

Page 9

1

Overview

KP-FM200WCL are Camera Link output type black and white camera which utilized the 2/3 –inch progressive scan

CMOS image sensor with square pixel. KP-FMR200WCL are RAW data output type.

The high resolution image of two million pixels is output in no interlace by 280 frames per second.

Because square pixel CMOS is adopted, the image that is appropriate for the picture processing is obtained.

Standard composition

Check when unpacking

Camera ········································································ 1

Composition table ························································· 1

Features

High resolution

The 2/3-inch 2,000,000 pixels square lattices CMOS achieve a high resolution.

Global shutter

The clear image is obtained even by subject with a fast movement by CMOS sensor adoption of the global shutter

type.

Frame on demand

It is possible to import images according to arbitrary timing by the input of the trigger signal.

Change of frame rate

The frame rate can be changed by setting the camera link configuration and the camera link clock frequency. A further

frame rate can improve if partial scan and vertical sub sampling function is used.

Small and lightweight

The small SDR connector for digital output allows the camera size and mass to be drastically reduced to

44(W) x 44(H) x 41(D) mm / approx. 130g.

Automatic power supply change

The power supply through the Camera Link cable is possible from the PoCL frame grabber board. Because the power

supply from the DCIN/SYNC connector is also possible, it is possible to make the camera work by using usual frame

grabber board.

The power supply from the DCIN/SYNC connector is given to priority when the power supply is supplied from both.

Optional accessories

(1) 12 pin plug HR10A-10P-12S(01)

(2) Junction box JU-F30/JC-100

(3) Dummy glass (AR coated) ARC1616

(4) IR cut filter IRC1616

(5) Tripod adaptor TA-FM200

(6) Mini-Camera Link cable

(7) Camera cable

Molded type

Shield type

2m C-201KSM

C-

201KSS

5m C-501KSM

C-

501KSS

10m C-102KSM

C-

102KSS

In the CE Marking region, use the shied type and install

clamp filter (ZCAT 2035-0930A: TDK) at both ends (camera

and video processor ends).

Page 10

2

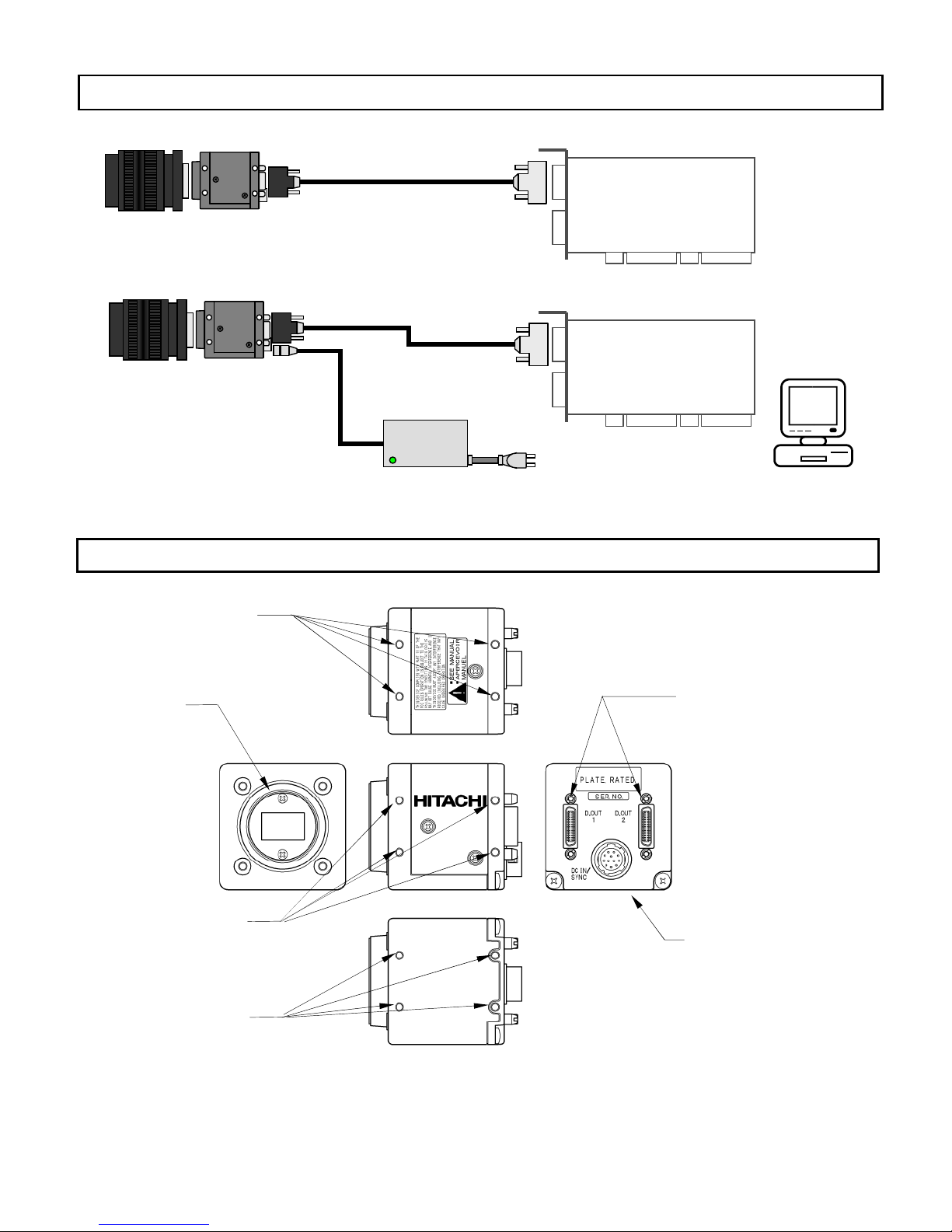

System example

KP-FM200WCL and KP-FMR200WCL connect to frame grabber board using Camera Link cable.

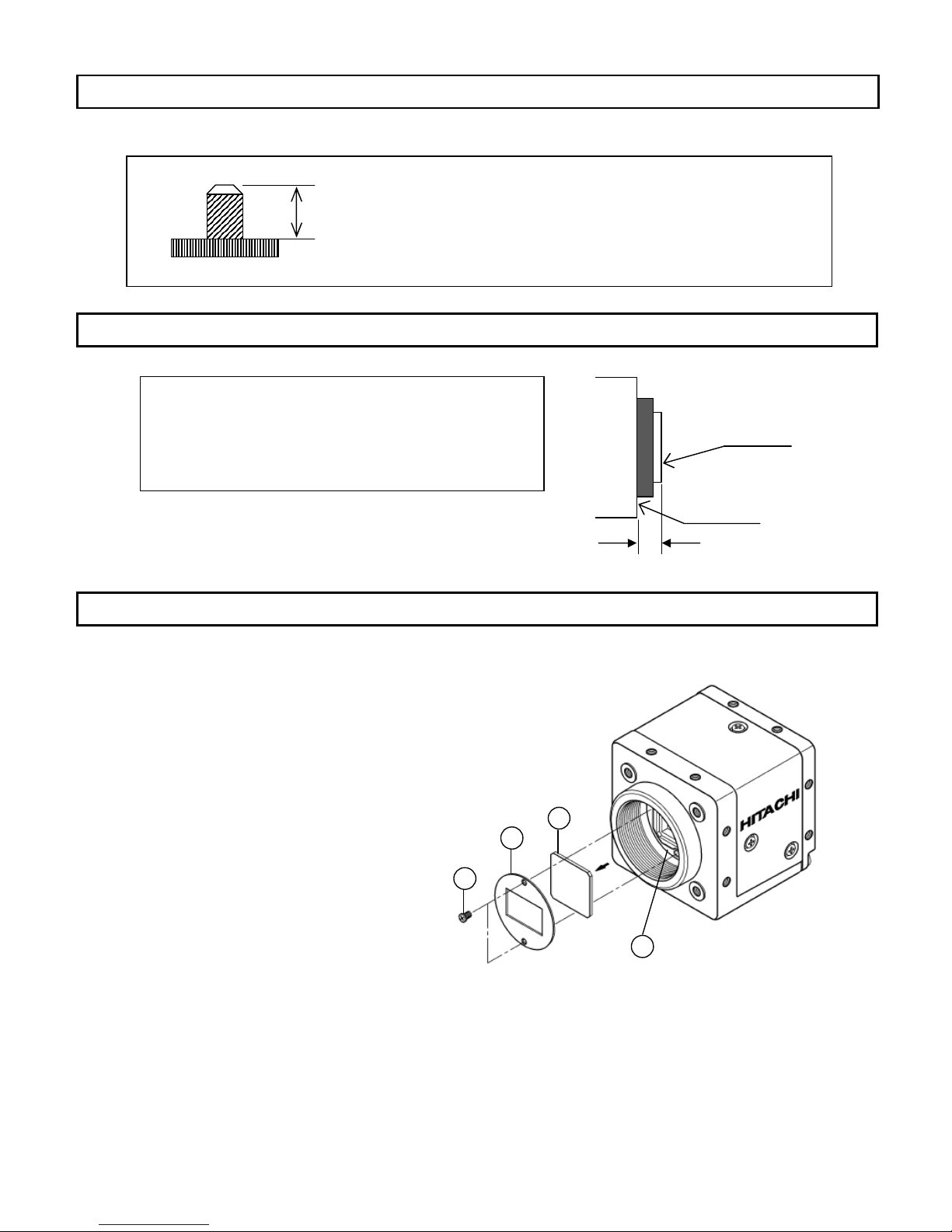

Section name and functions

Camera

Link connectors

Use for digital video output

and camera control signal

input/output signal.

The power supply from the

board is also possible.

Camera / Tripod adaptor

mounting screw holes

Lens mo

unt

(

C mount

)

AC adaptor

Power over type Camera Link

frame grabber board

Camera Link

frame grabber board

Power over type

Mini-Camera Link cable

(x2 when Medium/Full configuration)

Mini-Camera Link cable

(x 2 when Medium/Full configuration)

HIT ACH I

HIT ACH I

DC IN/SYNC 12pin connector

Use for DC+12V power

and external trigger input.

When the board supplies the

power supply by way of the

Camera Link connector, the

connection is unnecessary.

Camera / Tripod adaptor

mounting screw holes

Camera / Trip

od adaptor

mounting screw holes

Page 11

3

1

2

4

3

Camera mounting

Attached optional accessory the tripod adaptor "TA-FM200", mount the camera to a tripod or mounting bracket.

Lens

Optical filter

How to remove the optical filter.

(1) Remove two screws ① and filter holder ② will come off.

(2) Remove the optical filter ③ from filter frame ④.

(3) Then, reinstall and secure filter holder ② with two screws ①.

Note: Prior to removing the optical filter, be sure to turn off the power.

Since garbage etc. invades into image reception surface camera,

please work under the clean air, such as a CLEAN ROOM.

CAUTION

Observe the dimensions of the lens mounting selection as

illustrated at the right.

If the dimensions are not observed, do not use such a lens,

because the lens and the camera will be damaged.

Lens flange

Lens optics

Max

Screw type: U1/4-20

Length L = 4 to 5.5mm

Screws longer than 5.5 mm can cause internal damage, while less

than 4 mm prevents secure fastening and risks dropping to cause

damage and injury.

L

Page 12

4

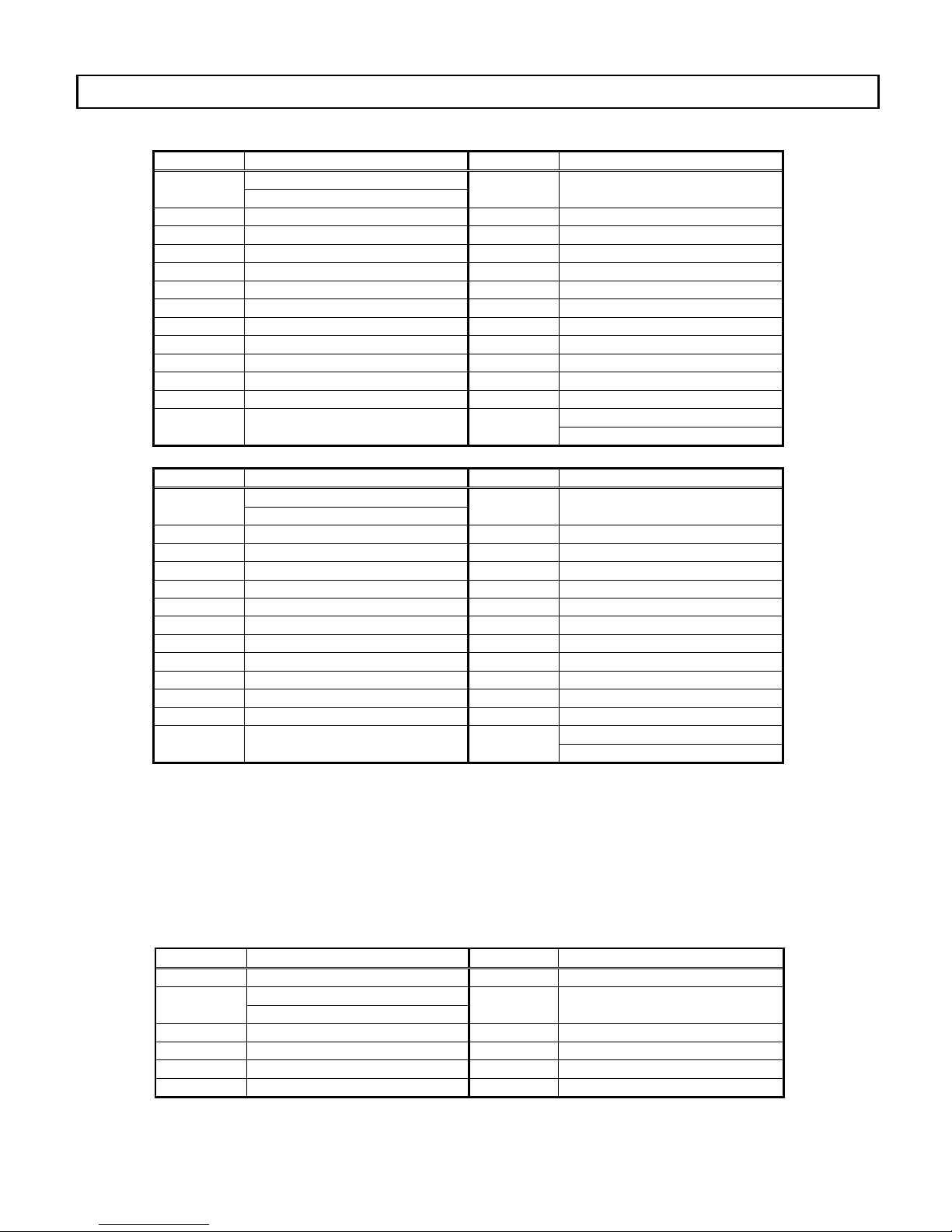

Connector

1. Camera Link connector

D.OUT1 (Connector 1)

Pin No. Signal Pin No. Signal

+12V (PoCL)

1

GND (non-PoCL)

14 GND

2 TXOUT 0 (-) 15 TXOUT 0 (+)

3 TXOUT 1 (-) 16 TXOUT 1 (+)

4 TXOUT 2 (-) 17 TXOUT 2 (+)

5 TXCLKOUT (-) 18 TXCLKOUT (+)

6 TXOUT 3 (-) 19 TXOUT 3 (+)

7 RX (+) [ SERTC (+) ] 20 RX (-) [ SERTC (-) ]

8 TX (-) [ SERTFG (-) ] 21 TX (+) [ SERTFG (+) ]

9 TRIG(-) [ CC1 (-) ] 22 TRIG (+) [ CC1 (+) ]

10 N.U. [ CC2 (+) ] 23 N.U. [ CC2 (-) ]

11 N.U. [ CC3 (-) ] 24 N.U. [ CC3 (+) ]

12 N.U. [ CC4 (+) ] 25 N.U. [ CC4 (-) ]

+12V (PoCL)

13 GND 26

GND (non-PoCL)

D.OUT2 (Connector 2: used for Medium/Full configuration)

Pin No. Signal Pin No. Signal

+12V (PoCL)

1

GND (non-PoCL)

14 GND

2 TYOUT 0 (-) 15 TYOUT 0 (+)

3 TYOUT 1 (-) 16 TYOUT 1 (+)

4 TYOUT 2 (-) 17 TYOUT 2 (+)

5 TYCLKOUT (-) 18 TYCLKOUT (+)

6 TYOUT 3 (-) 19 TYOUT 3 (+)

7 100Ω(+) 20 100Ω(-)

8 TZOUT 0 (-) 21 TZOUT 0 (+)

9 TZOUT 1 (-) 22 TZOUT 1 (+)

10 TZOUT 2 (-) 23 TZOUT 2 (+)

11 TZCLKOUT (-) 24 TZCLKOUT (+)

12 TZOUT 3 (-) 25 TZOUT 3 (+)

+12V (PoCL)

13 GND 26

GND (non-PoCL)

SDR connector (3M) or equivalent N.U.: Not used

- The digital out cable should be comprised of a twisted pair of wires having 100Ω characteristic impedance and an

outer heath shield type conductor.

- Connect the shield (ground) of the digital out cable to the ground terminal of the video equipment, frame grabber, etc.

- TX: Transmit data from camera to machine

- RX: Transmit data from machine to camera

(Note) Please do not unplug and insert cable (digital out cable) with a power supplied to a camera.

2. DCIN/SYNC connector

PIN NO. Signal PIN NO. Signal

1 GND 7 Trigger IN

---- (PoCL)

2

+12V (non-PoCL)

8 GND

3 GND 9 ---4 ---- 10 FLASH OUT / VD OUT

5 GND 11 ---6 ---- 12 GND

Connector (camera side) : SNH-10-12(RPCB) SAMWOO or equivalent

Plug (matching cable plug) : HR10A-10P-12S(01) HIROSE or equivalent

Page 13

5

Functions and operations

Various mode setup and adjustment of KP-FM200WCL and KP-FMR200WCL are performed by the remote control via

Camera Link. Operation and adjustment way of function utilized are described below.

See "Remote control" and "Command list" (page 7 to 16) about communication method of each command.

1. Main functions

(1) TRIGGER : Setting about external trigger

MODE : Select of mode

OFF (Factory setting) : Trigger mode set to OFF (normal mode).

FIXED SHUTTER : Trigger mode set to Fixed shutter.

ONE TRIGGER : Trigger mode set to ONE trigger.

BURST TRIGGER : Trigger mode set to Burst trigger.

POLARITY : Select of trigger polarity

POSITIVE (Factory setting) : Input polarity HIGH is made into trigger signal.

NEGATIVE : Input polarity LOW is made into trigger signal.

SOURCE : Select of trigger source

CL-CC1 (Factory setting) : Input trigger signal from Camera Link signal CC1 (see page 4 "Connector").

12pin : Input trigger signal from 7 pin of 12 pin DCIN/SYNC connector.

BURST NUM : Setting of number of output frames at Burst trigger mode

1 to 65535 frames : The number of continuous output frames at the burst-trigger mode is set.

(Factory setting : 1 frame).

*Please refer to "Trigger operation and timing chart" from 26 page to 30 page for details concerning

an external trigger mode.

(2) SHUTTER : Setting of electronic shutter

OFF (Factory setting) : Shutter operation set to OFF (NORMAL shutter).

1/71, 1/100, 1/250, 1/500,

1/1000, 1/2000,

1/10000, 1/50000 second : Electronic shutter set to preset shutter speed (PRESET shutter).

VARIABLE : Electronic shutter set to variable shutter speed (VARIABLE shutter).

VARIABLE VALUE- : Setting speed of VARIABLE shutter.

16.125μs to 211367μs : Electronic shutter can be set in the range of 16.125μs to 211367μs

in 65535 steps.(Factory setting: 14070.7μs)

Shutter speed setting value and exposure time can be derived as follows.

Exposure time (μs)=16.125(μs) + Shutter speed setting value X 3.225 (μs)

MULTI SHUT NUM- : Setting of number of frames of multi shutter speed

1 to 255 frames : The number of frames of one cycle of multi shutter speeds is set.

(Factory setting : 1 frame)

INC EXP STEP- : The increase amount setting of exposure time of multi shutter speed

0 to 211350μs : The exposure time of every one frame amount of an increase is set.

(Factory setting : 0μs)

(3) ACCEL : Setting of off between vertical lines

x1(OFF) to x10 : The magnification of the off reading between vertical lines is set.

(Factory setting : OFF)

Page 14

6

(4) DATA BIT : Setting of output bit depth

8bit (Factory setting) : Image is outputted by 8 bit.

10bit : Image is outputted by 10 bit.

(5) CONFIG : Setting of Camera Link configuration

BASE(Factory setting) : Camera Link configuration is set to Base configuration.

MEDIUM : Camera Link configuration is set to Medium configuration.

FULL : Camera Link configuration is set to Full configuration.

(6) CLK : Setting of Camera Link clock frequency

80MHz(Factory setting) : Camera Link clock frequency set to 80MHz.

40MHz : Camera Link clock frequency set to 40MHz.

(7) FLIP : Setting of upper and lower, right and left reversing output

OFF(Factory setting) : Image is usually output.

H : Image is reversed right and left.

V : Image is reversed up and down.

HV : Image is reversed right and left, up and down.

(8) TEST PATTERN : Setting of test pattern output

OFF(Factory setting) : Image is usually output.

H : The horizontal lamp image is output.

V : The vertical lamp image is output.

HV : The horizontal and vertical lamp image is output.

(9) OUTPUT SIGNAL : Setting of the tenth pin of DCIN/SYNC connector

OFF(Factory setting) : No output(LOW

)

FLASH : The flash pulse (strobe) is output.

VD : The VD pulse of the camera is output.

(10) GAIN : Adjustment of digital gain

x1~x4 : x1 to x4 are set by 769 steps(0 to 768). (Factory setting : x1)

GAIN = 1 + Setting value×0.00390625

(11) BLACK LEVEL : Adjustment of offset level

0/255~127/255 : Offset level is set by 128 steps.(Factory setting : 0/255)

(12) PARTIAL SCAN : Setting of partial scanning

OFF(Factory setting),

1AREA to 8AREA : The number of areas of partial scan is set.

AREA START(1th to 8th) : Setting of starting position in scan area(1th to 8th).

1 to 1088 : Scan is started from the line set up in 1 to 1088.

AREA WIDTH(1th to 8th) :Setting of width of scan area(1th to 8th).

1 to 1088 : Scan is performed number of line set up in 1 to 1088.

(13) FACTORY SETTING

SET : Return to the factory settings.

Page 15

7

Remote control

1. Comms* specifications

・Control system : Start-stop synchronization system

・Transmission rate : 9600 bps

・Data length : 8 bit

・Star bit : 1 bit

・Stop bit : 1 bit

・Parity : None

・Bit transfer : LSB first

*Comms: Communications

2. Comms control

The remote control software controls all communications. Data send/receive (BSC handshake) is by transferring

TEXT data to the camera controller chip.

3. Comms procedure

The following pages indicate the camera controller chip and remote control software data protocol. In the description,

the camera is designated as slave and the software as master.

・Receive protect timer (time out error)

The receive protect timer for master and slave processes is 1 second. For example, if 1 block of TEXT data is being

received, if the data interval exceeds 1 second, error is produced and the data are lost. An acknowledgment of data

receipt is not produced.

Page 16

8

(1) Transmission from master (normal process)

① Session starts when ENQ is sent from master to slave.

② Slave acknowledges by returning ACK to master.

③ Master sends data to slave.

④ Slave acknowledges receipt of data by again returning ACK to master and end the handshake.

(2) Master reads data (normal process)

① Session starts when ENQ is sent from master to slave.

② Slave acknowledges by returning ACK to master.

③ Master sends read command to slave.

④ Slave receives read command, then acknowledges by returning ACK code to master.

⑤ Slave sends read data to master.

⑥ Master receives read data, then acknowledges by returning ACK code to slave.

Master (Machine)

1

2

3

4

ENQ code (05H)

ACK code (06H)

Re

ad command (ASCII code)

ACK code (06H)

6 5

Read data (ASCII code)

ACK code (06H)

Slave

(KP-FM200WCL

KP-FMR200WCL)

HIT ACH I

Slave

(KP-FM200WCL

KP-FMR200WCL)

Master (Machine)

1

3

4

ENQ code (05H)

ACK code (06H)

ACK code (06H)

Transmit data (ASCII code)

HIT ACH I

Page 17

9

(3) Data transmitted by master (control abort process)

① Master sends ENQ code to slave.

② Since ACK code cannot be sent, slave sent NACK code to master.

③ Sequence is repeated 3 times in attempts to retransmit.

After receiving the 3rd successive NACK code, communications control is aborted

(4) Data transmitted by master (data error process)

① Session starts when ENQ is sent from master to slave.

② Slave acknowledges by returning ACK to master.

③ Master sends data, but slave detect error (framing, over-run error).

④ Slave detects error and does not accept data.

⑤ Sequence 3 and 4 repeats, then master transfers normal data.

⑥ Slave detects normal data and returns ACK code to master to end the session.

Master (Machine)

1 23

ENQ code (05H)

NACK code (15H)

ENQ code (05H)

NACK code (15H)

ENQ code (05H)

NACK code (15H)

ENQ code (05H)

NACK code (15H)

Slave

(KP-FM200WCL

KP-FMR200WCL)

HIT ACH I

Master (Machine)

1 2

3

ENQ code (05H)

ACK code (06H)

Send data (error occurs)

Send data (error occurs)

Send data (data normal)

ACK code (06H)

4 5 6

3 second

elapse

3 second

elapse

Slave

(KP-FM200WCL

KP-FMR200WCL)

HIT ACH I

Page 18

10

(5) Data frame error (Master transmission)

① Session starts when ENQ is sent from master to slave.

② Slave acknowledges by returning ACK to master.

③ Master sends data.

④ For some reason, slave does not receive data.

⑤ Master does not receive acknowledgment to the send code and repeats the sequence every 3

seconds for 3 times.

⑥ If unsuccessful after 3 attempts, master aborts the sequence and ends communication.

Master (Machine)

1 23

ENQ code (05H)

ACK code (06H)

Send data (ASCII code)

Send data (ASCII code)

Send

data (ASCII code)

4

5

Send data (ASCII code)

6

3 second

elapse

3 second

elapse

3 second

elapse

Slave

(KP-FM200WCL

KP-FMR200WCL)

HIT ACH I

Page 19

11

(6) Transmission frame error (Master receive)

① Session starts when ENQ is sent from master to slave.

② Slave acknowledges by returning ACK to master.

③ Master sends read command.

④ Slave returns ACK code to acknowledge read command.

⑤ Slave sends read data to master.

⑥ For some reason, master fails to receive read data.

⑦ Slave fails to receive acknowledgment of read data and attempts to resend every 3 seconds for 3

times.

⑧ After the third failure, slave aborts the sequence and ends communication.

Master (Machine)

1

26

ENQ code (05H)

ACK code (06H)

Read data (ASCII code)

Read data (ASCII code)

Read data (ASCII code)

7

Read data (ASCII code)

8

3

4

Read command (ASCII code)

ACK code (06H)

5

3 second

elapse

3 second

elapse

3 second

elapse

Slave

(KP-FM200WCL

KP-FMR200WCL)

HIT ACH I

Page 20

12

4. Comms command data format

(1) Send data and read command (master to slave)

(a) Command data are converted into ASCII code and transmitted.

(b) Comms byte quantity is 18.

(c) Comms data format (transmission sequence).

・STX (start code) : Code indicating start of text.

1 byte (02H)

・Text data : Transmit / receive data.

14 byte (ASCII code)

・ETX (end code) : Code indicating end of text.

1 byte (03H)

・SUM : XOR result (FFH), of adding STX, Text data, and ETX.

2 byte (ASCII code)

(d) Text data format details (transmission sequence).

・Status : Transmission data status.

2 byte (ASCII code)

Used for EEPROM write (0: write absent, 1: write present).

・ID No. : Camera peculiar ID.

KP-FM200WCL and KP-FMR200WCL have (FFH).

2 byte (ASCII code)

・Area address : Classification of Send data (01H) and Read command (81H).

2 byte (ASCII code)

・Relative No. : Sets number (0 to 255) for each adjustment item.

2 byte (ASCII code)

・Data (note) : Sets data to be transmitted.

2 byte x 3 (ASCII code)

S T X

1 byte

Text data

14 byte

E T X

1 byte

S U M

2 byte

18 byte

Status

2 byte

ID No.

2 byte

Area address

2 byte

Relative No.

2 byte

Data

2 byte x 3

14 byte

Page 21

13

(2) Read (receive) data (slave to master)

(a) Command data are converted into ASCII code and transmitted.

(b) Comms byte quantity is 10.

(c) Comms data format (transmission sequence)

・STX (start code) : Code indicating start of text.

1 byte (02H)

・Text data : Transmit / receive data.

6 byte (ASCII code)

・ETX (end code) : Code indicating end of text.

1 byte (03H)

・SUM : XOR result (FFH), of adding STX, Text data, and ETX.

2 byte (ASCII code)

(d) Text data details (transmission sequence)

・Data (note) : Sets Read data to be transmitted.

2 byte x 3 (ASCII code)

Note: Data transfer sequence

Data bytes 1st byte 2nd byte 3rd byte

1 Data 0x00 0x00

2 Upper Lower 0x00

3 Upper Mid Lower

5. Calculation method of checksum

Example

1 2 3 4 5 6 7

STX

STATUS ID NO

AREA

ADDRESS

RELATIVE NO

DATA

ETX SUM

02 01 FF 01 04 00 00 00 03 28

1. STAUTUS to DATA are transformed into hexadecimal number on the basis of the ASCII code.

'0'→(30)

16

'1'→(31)16 '4'→(34)16 'F'→(46)16 STX: (02)16 ETX: (03)16

2. STX to ETX are added all.

(02)16+(30)16+(31)16+(46)16+(46)16+(30)16+(31)16+(30)16+(34)16+(30)16+(30)16+(30)16+(30)16+(30)16+(30)16+(03)

16

=(2D7)16

STX STATUS ID AREA RELATIVE DATA ETX

3. The XOR (Exclusive OR) between the value obtained in 2 clause and (FF)16 are taken, then two column

under the answer become SUM

(2D7)16 XOR (FF)16 = (228)16

S T X

1 byte

Text data

6 byte

E T X

1 byte

S U M

2 byte

10 byte

Data

2 byte x 3

6 byte

Page 22

14

1. Send data (Setting command. Note: 1 to 7 and SUM need to be transformed into ASCII code)

1 2 3 4 5 6 7

Item STX

STATUS ID NO.

AREA

ADDRESS

RELATIVE

NO.

DATA

ETX SUM

OFF 02 01 FF 01 04 00 00 00 03 28 FIXED

02 01 FF 01 04 01 00 00 03 27

1TRIG

02 01 FF 01 04 02 00 00 03 26

MODE

BURST

02 01 FF 01 04 03 00 00 03 25

POSITIVE

02 01 FF 01 0F 00 00 00 03 16

POLARITY

NEGATIVE 02 01 FF

01 0F 01 00 00 03 15

CL-CC1 02

01 FF

01 05 00 00 00 03 27

SOURCE

12pin 02

01 FF

01 05 01 00 00 03 26

1 Frame 02

01 FF

01 07 00 01 00 03 24

TRIGGER

BURST NUM

(2Byte) (*1)

65535 Frame 02

01 FF

01 07 FF FF 00 03 CD

OFF 02 01 FF

01 06 00 00 00 03 26

FLASH OUT 02 01 FF

01 06 01 00 00 03 25

OUTPUT SIGNAL

VD OUT 02 01 FF

01 06 02 00 00 03 24

OFF 02 01 FF 01 08 00 00 00 03 24 1/71 02 01 FF 01 08 01 00 00 03 23

1/100

02 01 FF 01 08 02 00 00 03 22

1/250

02 01 FF 01 08 03 00 00 03 21

1/500

02 01 FF 01 08 04 00 00 03 20

1/1000

02 01 FF 01 08 05 00 00 03 1F

1/2000

02 01 FF 01 08 06 00 00 03 1E

1/10000

02 01 FF 01 08 07 00 00 03 1D

1/50000

02 01 FF 01 08 08 00 00 03 1C

PRESET

VARIABLE

02 01 FF 01 08 FF 00 00 03 F8

MIN(16.125us)

02 01 FF 01 11 00 00 00 03 2A

14070.7us 02 01 FF 01 11 11 06 00 03 22

VARIABLE(*3)

VALUE (2Byte)

MAX (211367us)

02 01 FF 01 11 FF FF 00 03 D2

1 Frame

02 01 FF 01 09 01 00 00 03 22

MULTI SHUT

NUM(*4)

255 Frame

02 01 FF 01 09 FF 00 00 03 F7

0us 02 01 FF 01 0A 00 00 00 03 1B

SHUTTER

SPEED

(*2)

INC EXP STEP

(2Byte) (*5)

211350us

02 01 FF 01 0A FF FF 00 03 C3

BASE

02 01 FF 01 12 00 00 00 03 29

MEDIUM

02 01 FF 01 12 01 00 00 03 28

CONFIG

FULL

02 01 FF 01 12 02 00 00 03 27

80MHz

02 01 FF 01 19 00 00 00 03 22

CLK

40MHz

02 01 FF 01 19 01 00 00 03 21

OFF(x1)

02 01 FF 01 13 00 00 00 03 28

ACCEL

x10 02 01 FF 01 13 09 00 00 03 1F 8bit 02 01 FF 01 14 00 00 00 03 27

DATA BIT

10bit 02 01 FF 01 14 01 00 00 03 26 x1 (0)

02 01 FF 01 0C 00 00 00 03 19

GAIN (2Byte) (*6)

x4 (768)

02 01 FF 01 0C 03 00 00 03 16

MIN (0/255)

02 01 FF 01 17 00 00 00 03 24

BLACK LEVEL(*7)

MAX (127/255)

02 01 FF 01 17 7F 00 00 03 07

OFF 02 01 FF 01 50 00 00 00 03 27

H 02 01 FF 01 50 01 00 00 03 26 V 02 01 FF 01 50 02 00 00 03 25

TEST PATTERN

HV 02 01 FF 01 50 03 00 00 03 24 OFF 02 01 FF 01 51 00 00 00 03 26 H 02 01 FF 01 51 01 00 00 03 25 V 02 01 FF 01 51 02 00 00 03 24

FLIP

HV 02 01 FF 01 51 03 00 00 03 23

(*1) BURST NUM becomes effective at the BURST trigger mode. It is selectable in the range from 000116 to FFFF

16.

(*2) The setting of SHUTTER SPEED becomes invalid at the ONE trigger mode.

(*3) VARIABLE VALUE becomes effective only when VRIABLE is selected. It is selectable in the range from 000016 to FFFF

16.

(*4) MULTI SHUT NUM is selectable in the range from 00

16

to FF

16.

(*5) INC EXP STEP is selectable in the range from 0000

16

to FFFF

16.

(*6) GAIN is selectable in the range from 0000

16

to 0300

16.

(*7) BLACK LEVEL is selectable in the range from 0016 to 7F

16.

Command list

Page 23

15

1 2 3 4 5 6 7

Item STX

STATUS ID NO.

AREA

ADDRESS

RELATIVE

NO.

DATA

ETX SUM

OFF 02 01 FF 01 1E 00 00 00 03 16 1AREA

02 01 FF 01 1E 01 00 00 03 15

AREA

8AREA

02 01 FF 01 1E 08 00 00 03 0E 1 02 01 FF 01 1F 00 01 00 03 14

AREA1 START

(2Byte)

1088 02 01 FF 01 1F 04 40 00 03 0D

1 02 01 FF 01 20 00 01 00 03 29

AREA1 WIDTH

(2Byte)

1088 02 01 FF 01 20 04 40 00 03 22

1 02 01 FF 01 21 00 01 00 03 28

AREA2 START

(2Byte)

1088 02 01 FF 01 21 04 40 00 03 21 1 02 01 FF 01 22 00 01 00 03 27

AREA2 WIDTH

(2Byte)

1088 02 01 FF 01 22 04 40 00 03 20 1 02 01 FF 01 23 00 01 00 03 26

AREA3 START

(2Byte)

1088 02 01 FF 01 23 04 40 00 03 1F

1 02 01 FF 01 24 00 01 00 03 25

AREA3 WIDTH

(2Byte)

1088 02 01 FF 01 24 04 40 00 03 1E

1 02 01 FF 01 25 00 01 00 03 24

AREA4 START

(2Byte)

1088 02 01 FF 01 25 04 40 00 03 1D

1 02 01 FF 01 26 00 01 00 03 23

AREA4 WIDTH

(2Byte)

1088 02 01 FF 01 26 04 40 00 03 1C

1 02 01 FF 01 27 00 01 00 03 22

AREA5 START

(2Byte)

1088 02 01 FF 01 27 04 40 00 03 1B

1 02 01 FF 01 28 00 01 00 03 21

AREA5 WIDTH

(2Byte)

1088 02 01 FF 01 28 04 40 00 03 1A 1 02 01 FF 01 29 00 01 00 03 20

AREA6 START

(2Byte)

1088 02 01 FF 01 29 04 40 00 03 19 1 02 01 FF 01 2A 00 01 00 03 18

AREA6 WIDTH

(2Byte)

1088 02 01 FF 01 2A 04 40 00 03 11 1 02 01 FF 01 2B 00 01 00 03 17

AREA7 START

(2Byte)

1088 02 01 FF 01 2B 04 40 00 03 10 1 02 01 FF 01 2C 00 01 00 03 16

AREA7 WIDTH

(2Byte)

1088 02 01 FF 01 2C 04 40 00 03 0F 1 02 01 FF 01 2D 00 01 00 03 15

AREA8 START

(2Byte)

1088 02 01 FF 01 2D 04 40 00 03 0E 1 02 01 FF 01 2E 00 01 00 03 14

PARTIAL

SCAN

(*8)

AREA8 WIDTH

(2Byte)

1088 02 01 FF 01 2E 04 40 00 03 0D F

ACTORY SETTING

SET 02 01 FF 01 45 01 00 00 03 22

(*8) PARTIAL SCAN START/WIDTH are selectable in the range from 000116 to 044016 and the sum total of START and WIDTH

is 1089 or less.

Page 24

16

2. Read command (Note: 1 to 7 and SUM need to be transformed into ASCII code)

1 2 3 4 5 6 7

Item STX

STATUS ID NO.

AREA

ADDRESS

RELATIVE

NO.

DATA

ETX SUM

MODE

02 00 FF 81 04 00 00 00 03 21

POLARITY

02 00 FF 81 0F 00 00 00 03 10

SOURCE

02 00 FF 81 05 00 00 00 03 20

TRIGGER

BURST NUM

02 00 FF 81 07 00 00 00 03 1E

PRESET

02 00 FF 81 08 00 00 00 03 1D

VARIABLE VALUE

02 00 FF 81 11 00 00 00 03 23

MULTI SHUT NUM

02 00 FF 81 09 00 00 00 03 1C

SHUTTER

SPEED

INC EXP STEP

02 00 FF 81 0A 00 00 00 03 14

OUTPUT SIGNAL 02 00 FF 81 06 00 00 00 03 1F

CONFIG

02 00 FF 81 12 00 00 00 03 22

CLK 02 00 FF 81 19 00 00 00 03 1B

ACCEL

02 00 FF 81 13 00 00 00 03 21

DATA BIT

02 00 FF 81 14 00 00 00 03 20

GAIN

02 00 FF 81 0C 00 00 00 03 12

BLACK LEVEL

02 00 FF 81 17 00 00 00 03 1D

TEST PATTERN

02 00 FF 81 50 00 00 00 03 20

FLIP 02 00 FF 81 51 00 00 00 03 1F

AREA

02 00 FF 81 1E 00 00 00 03 0F

AREA1 START

02 00 FF 81 1F 00 00 00 03 0E

AREA1 WIDTH

02 00 FF 81 20 00 00 00 03 23

AREA2 START

02 00 FF 81 21 00 00 00 03 22

AREA2 WIDTH

02 00 FF 81 22 00 00 00 03 21

AREA3 START

02 00 FF 81 23 00 00 00 03 20

AREA3 WIDTH

02 00 FF 81 24 00 00 00 03 1F

AREA4 START

02 00 FF 81 25 00 00 00 03 1E

AREA4 WIDTH

02 00 FF 81 26 00 00 00 03 1D

AREA5 START

02 00 FF 81 27 00 00 00 03 1C

AREA5 WIDTH

02 00 FF 81 28 00 00 00 03 1B

AREA6 START

02 00 FF 81 29 00 00 00 03 1A

AREA6 WIDTH

02 00 FF 81 2A 00 00 00 03 12

AREA7 START

02 00 FF 81 2B 00 00 00 03 11

AREA7 WIDTH

02 00 FF 81 2C 00 00 00 03 10

AREA8 START

02 00 FF 81 2D 00 00 00 03 0F

PARTIAL

SCAN

AREA8 WIDTH

02 00 FF 81 2E 00 00 00 03 0E

The reading data from the Slave is based on "4. Comms command data format(2)" of "Remote control" (page 13).

Page 25

17

1. Horizontal timing

(1) 80MHz Base configuration (1 clk = 12.5 ns)

(2) 40MHz Base configuration (1 clk = 25 ns)

(3) 80MHz Medium configuration (1 clk = 12.5 ns)

(4) 40MHz Medium configuration (1 clk = 25 ns)

Camera Link output timing chart

VIDEO

Active Picture

LVAL

1024 clk

8 clk

1025

・・・・

・・・・

・・・・

1

1026

2

1027

3

1028

4

2045

1021

2046

1022

2047

1023

2048

1024

1029

5

DA

DB

1024 clk

8 clk

VIDEO

Active Picture

LVAL

1025

・・・・

・・・・

・・・・

1

1026

2

1027

3

1028

4

2045

1021

2046

1022

2047

1023

2048

1024

1029

5

DA

DB

VIDEO

Active Picture

LVAL

512 clk

4 clk

1537

・・・・

・・・・

・・・・

1025

1538

1026

1539

1027

1540

1028

2045

1533

2046

1534

2047

1535

2048

1536

1541

1029

DC

DD

・・・・

1021

509

1022

510

1023

511

1024

512

513

・・・・

・・・・

1

514

2

515

3

516

4

517

5

DA

DB

VIDEO

Active Picture

LVAL

512 clk

4 clk

1537

・・・・

・・・・

・・・・

1025

1538

1026

1539

1027

1540

1028

2045

1533

2046

1534

2047

1535

2048

1536

1541

1029

DC

DD

・・・・

1021

509

1022

510

1023

511

1024

512

513

・・・・

・・・・

1

514

2

515

3

516

4

517

5

DA

DB

Page 26

18

(5) 80MHz Full configuration (1 clk = 12.5 ns)

(6) 40MHz Full configuration (1 clk = 25 ns)

VIDEO

Active Picture

LVAL

256 clk

2 clk

1793

・・・・

・・・・

・・・・

1537

1794

1538

1795

1539

1796

1540

2045

1789

2046

1790

2047

1791

2048

1792

1797

1541

DG

DH

・・・・

1533

1277

1534

1278

1535

1279

1536

1280

1281

・・・・

・・・・

1025

1282

1026

1283

1027

1284

1028

1285

1029

DE

DF

769

513

770

514

771

515

772

516

773

517

DC

DD

257

1

258

2

259

3

260

4

261

5

DA

DB

・・・・

・・・・

・・・・

・・・・

・・・・

1021

765

1022

766

1023

767

1024

768

・・・・

509

253

510

254

511

255

512

256

VIDEO

Active Picture

LVAL

256 clk

2 clk

1793

・・・・

・・・・

・・・・

1537

1794

1538

1795

1539

1796

1540

2045

1789

2046

1790

2047

1791

2048

1792

1797

1541

DG

DH

・・・・

1533

1277

1534

1278

1535

1279

1536

1280

1281

・・・・

・・・・

1025

1282

1026

1283

1027

1284

1028

1285

1029

DE

DF

769

513

770

514

771

515

772

516

773

517

DC

DD

257

1

258

2

259

3

260

4

261

5

DA

DB

・・・・

・・・・

・・・・

・・・・

・・・・

1021

765

1022

766

1023

767

1024

768

・・・・

509

253

510

254

511

255

512

256

Page 27

19

2. Vertical timing

One horizontal period and branking period (*1) are different because of the setting of the configuration and the clock

frequency.

Cameralink output setting One horizontal period Branking period (*1)

Base configuration 40MHz 1H = 25.800μs 3.25H

Base configuration 80MHz 1H = 12.900μs 4.5H

Medium configuration 40MHz 1H = 12.900μs 4.5H

Medium configuration 80MHz 1H = 6.450μs 7H

Full configuration 40MHz 1H = 6.450μs 7H

Full configuration 80MHz 1H = 3.225μs 12H

Active Picture

VIDEO

FVAL

1088 H (Set value of width at partial scanning ON.)

*1

Page 28

20

3. Transmitter LVDS output pulse position measurement

(1)Base configuration

(a)8bit

D.OUT1

N.U.: Not used

(b)10bit

D.OUT1

N.U.: Not used

* When using Base configuration, please be sure to connect to CameraLink cable to D.OUT1.

If the cable is connected to D.OUT2, the machine may break down.

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DA7-1 DA6-1 N.U. N.U. N.U. DB7 DB6 DA7 DA6 N.U. N.U. N.U. FVAL

LVAL

N.U. N.U. N.U. N.U. DB2-1 DB1-1 N.U. N.U. DB5 DB4 DB3 DB2 DB1 DA1-1 DA0-1 DB0 DA5 DA4 DA3 DA2 DA1 DA0

TXOUT 0

TXCLKOUT

Next Cycle

TXOUT 1

TXOUT 2

TXOUT 3

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DA7-1 DA6-1 N.U. DB7

DB6 N.U. N.U. DA7 DA6 DB3-1 DB2-1 N.U. FVAL

LVAL

DB5 DB4 DB3 DB2

N.U. DA9-1 DB1 DB0 DB9 DB8 N.U. N.U. DA9 DA1-1 DA0-1 DA8 DA5 DA4 DA3 DA2 DA1 DA0

Next Cycle

TXOUT 0

TXCLKOUT

TXOUT 1

TXOUT 2

TXOUT 3

Page 29

21

(2)Medium configuration

(a)8bit

D.OUT1

N.U.: Not used

D.OUT2

N.U.: Not used

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DA7-1 DA6-1 N.U. DC7 DC6 DB7 DB6 DA7 DA6 DC3-1 DC2-1 N.U. FVAL

LVAL

DC5 DC4 DC3 DC2 DB2-1 DB1-1 DC1 DC0 DB5 DB4 DB3 DB2 DB1 DA1-1 DA0-1 DB0 DA5 DA4 DA3 DA2 DA1 DA0

Next Cycle

TXOUT 0

TXCLKOUT

TXOUT 1

TXOUT 2

TXOUT 3

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DD7-1 DD6-1 N.U. N.U. N.U. N.U. N.U. DD7 DD6 N.U. N.U. N.U. FVAL

LVAL

N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. N.U. DD1-1 DD0-1 N.U. DD5 DD4 DD3 DD2 DD1 DD0

Next Cycle

TYOUT 0

TYCLKOUT

TYOUT 1

TYOUT 2

TYOUT 3

Page 30

22

(b)10bit

D.OUT1

N.U.: Not used

D.OUT2

N.U.: Not used

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DA7-1 DA6-1 N.U. DB7 DB6 N.U. N.U. DA7 DA6 DB3-1 DB2-1 N.U. FVAL

LVAL

DB5 DB4 DB3 DB2 N.U

DA9-1 DB1 DB0 DB9 DB8 N.U. N.U. DA9 DA1-1 DA0-1 DA8 DA5 DA4 DA3 DA2 DA1 DA0

Next Cycle

TXOUT 0

TXCLKOUT

TXOUT 1

TXOUT 2

TXOUT 3

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DD7-1 DD6-1 N.U. N.U. N.U. DC7 DC6 DD7 DD6 N.U. N.U. N.U. FVAL

LVAL

DD9 DD8 N.U. N.U. DC2-1 DC1-1 DC9 DC8 DC5 DC4 DC3 DC2 DC1 DD1-1 DD0-1 DC0 DD5 DD4 DD3 DD2 DD1 DD0

Next Cycle

TYOUT 0

TYCLKOUT

TYOUT 1

TYOUT 2

TYOUT 3

Page 31

23

(3)Full configuration

(a)8bit

D.OUT1

N.U.: Not used

D.OUT2

N.U.: Not used

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DA7-1 DA6-1 N.U. DC7 DC6 DB7 DB6 DA7 DA6 DC3-1 DC2-1 N.U. FVAL

LVAL

DC5 DC4 DC3 DC2 DB2-1 DB1-1 DC1 DC0 DB5 DB4 DB3 DB2 DB1 DA1-1 DA0-1 DB0 DA5 DA4 DA3 DA2 DA1 DA0

Next Cycle

TXOUT 0

TXCLKOUT

TXOUT 1

TXOUT 2

TXOUT 3

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DD7-1 DD6-1 N.U. DF7 DF6 DE7 DE6 DD7 DD6 N.U. N.U. N.U. FVAL

LVAL

DF5 DF4 DF3 DF2 N.U. N.U. DF1 DF0 DE5 DE4 DE3 DE2 DE1 DD1-1 DD0-1 DE0 DD5 DD4 DD3 DD2 DD1 DD0

Next Cycle

TYOUT 0

TYCLKOUT

TYOUT 1

TYOUT 2

TYOUT 3

Previous Cycle

T

CLK

12.5ns (80MHz) or 25ns (40MHz)

DD7-1 DD6-1 N.U. N.U. N.U. DH7 DH6 DG7 DG6 N.U. N.U. N.U. FVAL

LVAL

N.U. N.U. N.U. N.U. N.U. N.U. N.U. N

.U. DH5 DH4 DH3 DH2 DH1

DD1-1 DD0-1 DH0 DG5 DG4 DG3 DG2 DG1 DG0

Next Cycle

TZOUT 0

TZCLKOUT

TZOUT 1

TZOUT 2

TZOUT 3

Page 32

24

4. Output sequence

DA, DB, DC, DD, DE, DF, DG and DH show output TAP of the cameralink.

Refer to “Transmitter LVDS output pulse position measurement“ for details.

(1) Base configuration

(2) Medium configuration

DA

1024 pixels

2048 pixels

1088

lines

DB DA

512 pixels

2048 pixels

1088

lines

DB DC DD

Page 33

25

(3) Full configuration

5. Color Output sequence(KP-FMR200WCL)

DA DB DC DD DE DF DG DH

256 pixels

2048 pixels

1088

lines

1088

lines

G B

R G

・・・・・・・・・・・・・・

・

・

・

・

・

2048 pixels

G B

R G G B R G G B R G G B R G

G B

R G

・・・・・・・・・・・・・・

G B

R G G B R G G B R G G B R G

Page 34

26

1. Normal mode

The exposure and the image output are repeated at the set shutter speed.

When the multi shutter speed is set, exposure time (Shutter time) increases every one frame,

and one cycle's worth of an image is output repeatedly.

One horizontal period and branking period (*1) are different because of the setting of the configuration and the clock

frequency.

Cameralink output setting One horizontal period Branking period (*1)

Base configuration 40MHz 1H = 25.800μs 3.25H

Base configuration 80MHz 1H = 12.900μs 4.5H

Medium configuration 40MHz 1H = 12.900μs 4.5H

Medium configuration 80MHz 1H = 6.450μs 7H

Full configuration 40MHz 1H = 6.450μs 7H

Full configuration 80MHz 1H = 3.225μs 12H

(*2) is 1088H at partial scan OFF, and set value of width at partial scan ON.

Trigger operation and timing chart

Shutter time

Shutter time

(Camera setting value)

Data output

FVAL

(*2)

(*1)

FLASH OUT

Page 35

27

Frame rate can be calculated from following equations using width of picture grabbing.

Cameralink output setting Total lines Frame rate(fps)

Base configuration 40MHz (Width+3.25)H 40000000/(Width+3.25)/1032

Base configuration 80MHz (Width+4.5)H 40000000/(Width+4.5)/516

Medium configuration 40MHz (Width+4.5)H 40000000/(Width+4.5)/516

Medium configuration 80MHz (Width+7)H 40000000/(Width+7)/258

Full configuration 40MHz (Width+7)H 40000000/(Width+7)/258

Full configuration 80MHz (Width+12)H 40000000/(Width+12)/129

Graph following shows frame rate in each of picture grabbing in the partial scan mode.

PartialScan Frame rate

10

100

1000

10000

100000

1 10 100 1000 10000

Width of picture grabbing[H]

Frame rate[fps]

Base 40MHz

Base 80MHz

Med 40MHz

Med 80MHz

Full 40MHz

Full 80MHz

Page 36

28

2. Fixed shutter mode

When trigger polarity setting is POSITIVE, after the trigger signal rise, exposure is start. The exposure time is set by

the camera electronic shutter speed. The video output is obtained immediately after the end of fixed exposure.

One horizontal period and Period from exposure end to the following trigger input (*1) are different because of the

setting of the configuration and the clock frequency.

Cameralink output setting One horizontal period (*1)

Base configuration 40MHz 1H = 25.800μs More than (*2) + 3.25H

Base configuration 80MHz 1H = 12.900μs More than (*2) + 4.5H

Medium configuration 40MHz 1H = 12.900μs More than (*2) + 4.5H

Medium configuration 80MHz 1H = 6.450μs More than (*2) + 7H

Full configuration 40MHz 1H = 6.450μs More than (*2) + 7H

Full configuration 80MHz 1H = 3.225μs More than (*2) + 12H

(*2) is 1088H at partial scan OFF, and set value of width at partial scan ON.

Trigger input

(POS)

High

Low

Shutter time

Shutter time

(Camera setting value)

Data output

More than 10μs

(*1)

FLASH OUT

FVAL

(*2)

Page 37

29

3. ONE trigger mode

When trigger polarity setting is POSITIVE, after the trigger signal rise, exposure is start. At the trigger signal falling

edge, the internal VD signal is reset and the video data are transmitted. The trigger signal width equals the exposure

time.

One horizontal period and Period from exposure end to the following trigger input (*1) are different because of the

setting of the configuration and the clock frequency.

Cameralink output setting One horizontal period (*1)

Base configuration 40MHz 1H = 25.800μs More than (*2) + 3.25H

Base configuration 80MHz 1H = 12.900μs More than (*2) + 4.5H

Medium configuration 40MHz 1H = 12.900μs More than (*2) + 4.5H

Medium configuration 80MHz 1H = 6.450μs More than (*2) + 7H

Full configuration 40MHz 1H = 6.450μs More than (*2) + 7H

Full configuration 80MHz 1H = 3.225μs More than (*2) + 12H

(*2) is 1088H at partial scan OFF, and set value of width at partial scan ON.

Trigger input

(POS)

High

Low

Shutter time

Shutter time

(Integration time)

Data output

More than 10μs

(*1)

FLASH OUT

FVAL

(*2)

Page 38

30

4. Burst trigger mode

When trigger polarity setting is POSITIVE, after the trigger signal rise, exposure is start. The exposure time is set by

the camera electronic shutter speed. The video output is obtained immediately after the end of fixed exposure.

Thereafter, images of the set number of burst-frame are continuously output. When the multi shutter speed is set,

exposure time (Shutter time) increases every one frame, and one cycle's worth of an image is output repeatedly.

(*1) is 1088H at partial scan OFF, and set value of width at partial scan ON.

Trigger input

(POS)

High

Low

Shutter time

Shutter time

(Camera setting value)

Data

More than 10μs

FLASH OUT

FVAL

(*1) (*1) (*1)

Shutter time

(Camera setting value)

Shutter time

(Camera setting value)

Page 39

31

1. Input signal

The level of the trigger signal input to KP-FM200WCL and KP-FMR200WCL is as follows.

(1) Input from CameraLink cable

LVDS level.

(2) Input from DCIN/SYNC connector

High level : +2.5 to +5.0 V

Low level : 0 to +0.3 V

2. Output signal

The level of the VD and FLASH output from KP-FM200WCL and KP-FMR200WCL is as follows.

High level : +5.0V

Low level : 0V

Input / Output signal

Page 40

32

Spectral response of KP-FM200WCL and KP-FMR200WCL are showing.

1. KP-FM200WCL

2. KP-FMR200WCL

Spectral response

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

300 400 500 600 700 800 900 1000 1100

Wave length(nm)

Relative Response

B G R

IR cut filter

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

300 400 500 600 700 800 900 1000 1100

Wave length(nm)

Relative Responce

Page 41

33

Specifications of KP-FM200WCL and KP-FMR200WCL are showing.

KP-FM200WCL KP-FMR200WCL

1) Imaging device 2/3-inch global shutter method CMOS

Effective pixels 2048 (H) x 1088 (V)

Pixel size 5.5μm (H) x 5.5μm (V)

Color filter None RGB primary color mosaic filter

2) Image area 11.264mm (H) x 5.984mm (V)

3) Scanning system Progressive scan

4) Frame rate MAX280 frame per second (full pixel readout)

5) Pixel frequency 40.000MHz

6)

Horizo

ntal

Full configuration(80MHz) : 310.078kHz

scanning frequency Full configuration(40MHz) : 155.039kHz

Medium configuration(80MHz) : 155.039kHz

Medium configuration(40MHz) : 77.519kHz

Base configuration(80MHz) : 77.519kHz

Base configuration(40MHz) : 38.759kHz

8)

Vertical scanning

Full configuration(80MHz) : 281.889Hz

(full pixel readout) Full configuration(40MHz) : 141.588Hz

Medium configuration(80MHz) : 141.588Hz

Medium configuration(40MHz) : 70.956Hz

Base configuration(80MHz) : 70.956Hz

Base configuration(40MHz) : 35.519Hz

9) Synchronization Internal

10) Lens mount C mount

11) Frange back 17.526mm (no adjustment)

12

)

Optical filter Dummy glass (AR coated) IR cut filter

13) Video output Digital output (CameraLink)

Base configuration 2TAP (80Hz or 40MHz)

Medium configuration 4TAP (80Hz or 40MHz)

Full configuration 8TAP (80Hz or 40MHz)

Output image size 2048 (H) x 1088 (V) (full pixel readout)

15) Resolution Horizontal / Vertical:1000TV lines Horizontal / Vertical:700TV lines

16) Sensitivity 400 lx、F5.6、3200K 2000 lx、F11、3200K

18) S/N 48dB

19) Electronic shutter

Preset OFF,1/71,1/100,1/250,1/500,1/1000,1/2000,1/10000,1/50000 second

Variable 16.125μs ~ 211367μs

20) Gamma γ=1

21) Frame on demand

Mode OFF (Normal mode), Fixed shutter mode, ONE trigger, Burst trigger

Trigger input From CameraLink (CC1) or DCIN/SYNC connector

22) Partial scan Selectable start position and width of picture grabbing in 1H step (max 8 areas)

25) Remote control

Control system Start-stop synchronization system

Control items

TRIGGER

、

SHUTTER

、

ACCEL

、

DATA BIT

、

CONFIG

、

CLK、FLIP

、

TEST

12pinOUT、GAIN、BLACK LEVEL、PARTIAL SCAN、FACTORY SETTING

26) Power supply DC12V±1V

27) Power consumption Approx. 230mA (Approx. 2.76W)

28) Ambient temperature

Performance 0℃ to +40℃ (+32 to +104F) / less than RH 90%