Page 1

Disc Grinder

Model

G 18SE3 • G 18SG2 • G 23SF2

G 23U2 • G 23SE2 • G 23UB2

Handling instructions

G23SE2

NOTE:

Before using this Electric Power Tool, carefully read through these

HANDLING INSTRUCTIONS to ensure efficient, safe operation. It

is recommended that these INSTRUCTIONS be kept readily

available as an important reference when using this power tool.

Page 2

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including

the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in damp

or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children and infirm persons away. Do not let

visitors touch the tool or extension cord. All visitors

should be kept away from work area.

5. Store idle tools. When not in use, tools should be

stored in a dry, high or locked up place, out of reach

of children and infirm persons.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do

not use tools for purposes not intended; for example,

do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or jewelry,

they can be caught in moving parts. Rubber gloves

and non-skid footwear are recommended when

working outdoors. Wear protecting hair covering to

contain long hair.

9. Use eye protection. Also use face or dust mask if the

cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work. It

is safer than using your hand and it frees both hands

to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing accessories.

Inspect tool cords periodically and if damaged, have

it repaired by authorized service center. Inspect

extension cords periodically and replace, if damaged.

Keep handles dry, clean, and free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades, bits

and cutters.

16. Remove adjusting keys and wrenches. Form the habit

of checking to see that keys and adjusting wrenches

are removed from the tool before turning it on.

17. Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is

off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the tool,

a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check for

alignment of moving parts, free running of moving

parts, breakage of parts, mounting and any other

conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired

or replaced by an authorized service center unless

otherwise indicated in this handling instructions. Have

defective switches replaced by an authorized service

center. Do not use the tool if the switch does not turn

it on and off.

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions,

may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger to

the user.

PRECAUTIONS ON USING DISC GRINDER

1. Never operate these power tools without Wheel

Guards.

2. Check that speed marked on the wheel is equal to or

greater than the rated speed of the grinder.

Use only depressed center wheels rated at 80m/s or

more.

3. Ensure that the wheel dimensions are compatible

with the grinder and that the wheel fits the spindle.

4. Abrasive wheels shall be stored and handled with

care in accordance with manufacturer’s instructions.

5. Inspect the depressed center wheel before use, do

not use chipped, cracked or otherwise defective

products.

6. Always hold the body handle and side handle of the

power tool firmly. Otherwise the counterforce

produced may result in inaccurate and even

dangerous operation.

7. Do not use cutting-off wheels for side grinding.

8. Do not use of separate reducing bushings or adapters

to adapt large hole abrasive wheels.

9. The wheel continues to rotate after the tool is switched

off.

1

Page 3

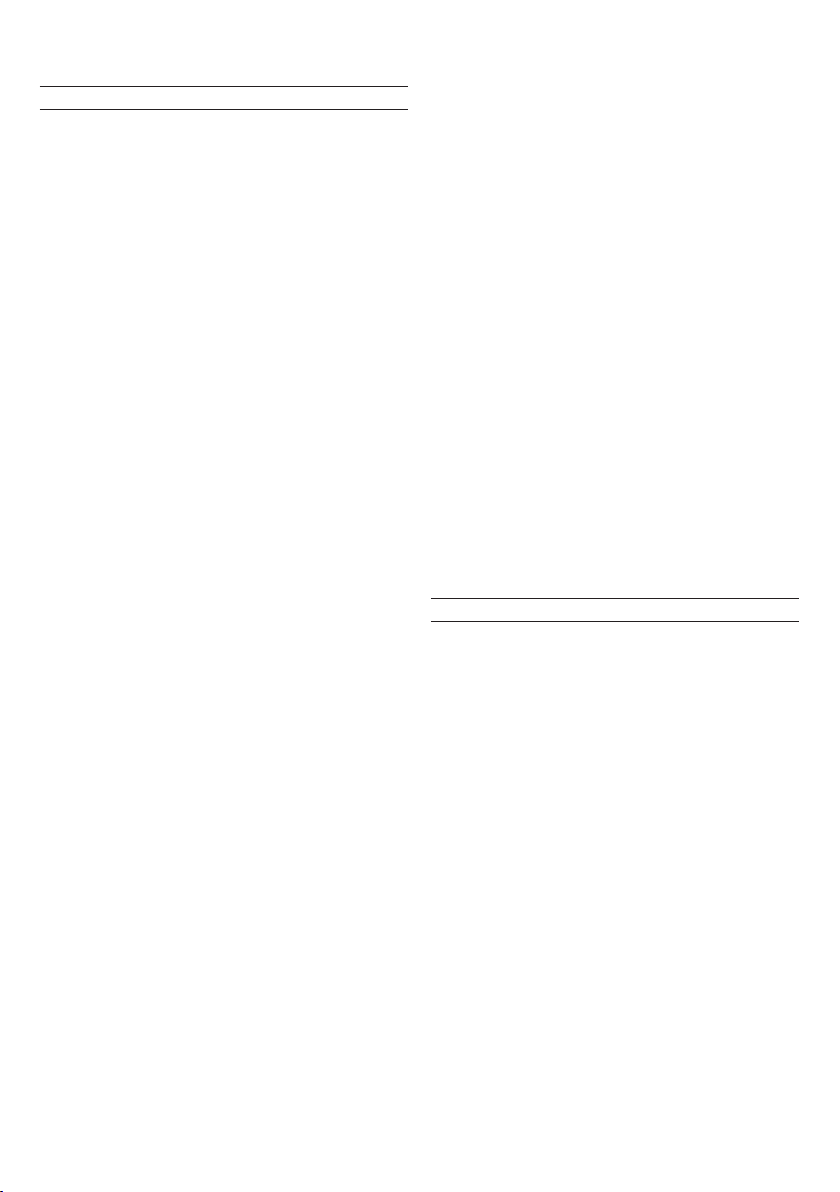

SPECIFICATIONS

Model G18SE3 G18SG2 G23SF2 G23U2 G23SE2 G23UB2

Voltage (by areas)*

1

Input*

No-load speed 8500 min

1

(110V, 220V, 230V, 240V)

2300 W 2500 W 2000 W 2400 W, 2500 W

-1

6600 min

-1

Outer dia. 180 mm 230 mm

Wheel Inner dia. 22 mm

Peripheral speed 80 m/s

2

Weight*

Starting current limiter*

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 Weight: Only main body

*3 The starting current limiter produces the starting current to such an extent that a fuse (16A, slow-blow) is not

tripped.

3

STANDARD ACCESSORIES

(1) Wrench ........................................................................ 1

(2) Side handle ................................................................ 1

Depressed center wheels are not provided as standard

accessories.

Standard accessories are subject to change without

notice.

APPLICATIONS

䡬 Removal of casting fin and finishing of various types

of steel, bronze and aluminum materials and castings.

䡬 Grinding of welded sections or sections cut by means

of a cutting torch.

䡬 Grinding of synthetic resins, slate, brick, marble, etc.

䡬 Cutting of synthetic concrete, stone, brick, marble

and similar materials.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, which could cause a serious

accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Fitting and adjusting the wheel guard

The wheel guard is a protective device to prevent

injury should the depressed center wheel shatter

during operation. Ensure that the guard is properly

fitted and fastened before commencing grinding

operation.

5.0 kg 4.3 kg 5.0 kg

No No Yes No Yes

[Adjusting the wheel guard, For G23SF2, G23U2 only]

䡬 By slightly loosening the setting screw, the wheel

guard can be turned and set at any desired angle for

maximum operational effectiveness.

䡬 Ensure that the setting screw is thoroughly tightened

after adjusting the wheel guard.

[Installing and adjusting the wheel guard, For G18SE3,

G18SG2, G23SE2, G23UB2 only]

䡬 Open the lever and insert the locating pin of wheel

guard, bringing it into line with the across flats of

packing ground.

䡬 Then, turn the wheel guard to a desired position (for

use).

䡬 Close the lever and fix it. If and when required, carry

out adjustments by tightening or loosening the screw.

䡬 If the lever does not move smoothly, apply some

lubricating oil to the sliding section between the set

piece and the lever.

䡬 Fasten the wheel guard at the position where the

across flats of the wheel guard positioning pin and

packing ground are aligned (the position where the

wheel guard is inserted), but do not use it.

Lever

Set piece

Screw

Locating pin

Fig. 1

2

Page 4

5. Ensure that the depressed center wheel to be utilized

is the correct type and free of cracks or surface defects.

Also ensure that the depressed center wheel is

properly mounted and the wheel nut is securely

tightened, refer to the section on “Depressed Center

Wheel Assembly”.

6. Conducting a trial run

Ensure that the abrasive products is correctly mounted

and tightened before use and run the tool at no-load

for 30 seconds in a safe position, stop immediately if

there is considerable vibration or if other defects are

detected.

If this condition occurs, check the machine to

determine the cause.

7. Confirm the spindle lock mechanism

Confirm that the spindle lock is disengaged by pushing

push button two or three times before switching the

power tool on (See Fig. 3).

8. Fixing the side handle

Screw the side handle into the gear cover.

PRACTICAL GRINDER APPLICATION

1. Pressure

To prolong the life of the machine and ensure a first

class finish, it is important that the machine should

not be overloaded by applying too much pressure. In

most applications, the weight of the machine alone is

sufficient for effective grinding. Too much pressure

will result in reduced rotational speed, inferior surface

finish, and overloading which could reduce the life of

the machine.

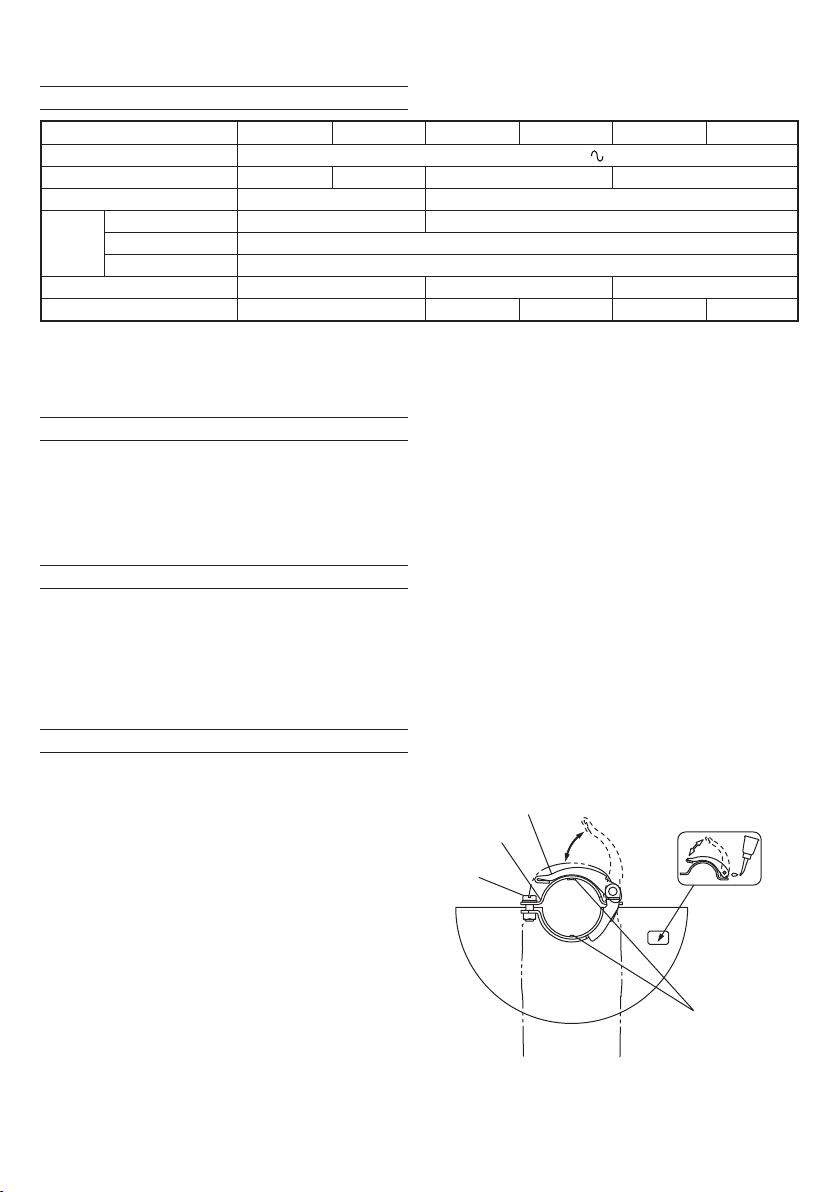

2. Grinding angle

Do not apply the entire surface of the depressed

center wheel to the material to be ground. As shown

in Fig. 2, the machine should be held at an angle of

15° – 30° so that the external edge of the depressed

center wheel contacts the material at an optimum

angle.

15 – 30°

AB

Fig. 2

3. To prevent a new depressed center wheel from

digging into the workpiece, initial grinding should be

performed by drawing the grinder across the

workpiece toward the operator (Fig. 2 direction B).

Once the leading edge of the depressed center wheel

is properly abraded, grinding may be conducted in

either direction.

4. Switch operation

Switch ON: Push the locking button forward and

then press the switch lever.

* For continuous use, press the switch

lever. The switch lever is locked by

pushing the locking button forward

once again.

(*Subject to change depending on

Switch OFF: Press and release the switch lever.

5. Precautions immediately after finishing operation

After switching off the machine, do not put it down

until the depressed center wheel has come to a

complete stop. Apart from avoiding serious accidents,

this precaution will reduce the amount of dust and

swarf sucked into the machine.

CAUTION:

䡬 Check that the work piece is properly supported.

䡬 Ensure that ventilation openings are kept clear when

working in dusty conditions.

If it should become necessary to clear dust, first

disconnect the tool from the mains supply (use nonmetallic objects) and avoid damaging internal parts.

䡬 Ensure that sparks resulting from use do not create a

hazard e.g. do not hit persons, or ignite flammable

substances.

䡬 Always use protective safety glasses and hearing

protectors, use other personal protective equipment

such as gloves, apron and helmet when necessary.

䡬 Always use eye and ear protection.

Other personal protective equipment such as dust

mask, gloves, helmet and apron should be worn

when necessary.

If in doubt, wear the protective equipment.

䡬 When the machine is not use, the power source

should be disconnected.

area.)

ASSEMBLING AND DISASSEMBLING THE

DEPRESSED CENTER WHEEL AND OTHER

TOOLS

CAUTION:

Be sure to switch OFF and disconnect the attachment

plug from the receptacle to avoid a serious accident.

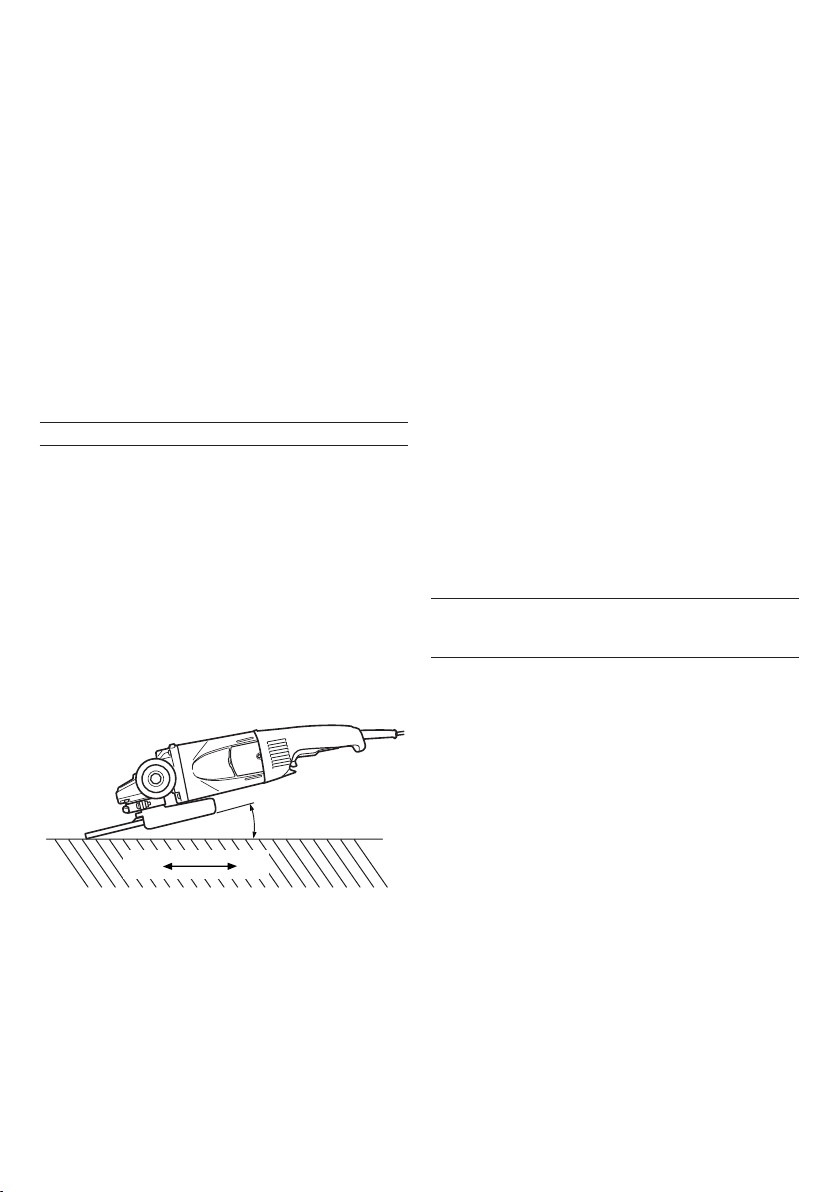

1. Assembling (Fig. 3)

(1) Turn the machine upside down so that the spindle is

facing upward.

(2) Mount the wheel washer onto the spindle.

(3) Fit the protruding part of the depressed center wheel

or cutting wheel or diamond wheel onto the wheel

washer.

(4) Screw the wheel nut onto the spindle.

(For diamond wheel assembling, use the wheel nut

with the convex side against the diamond wheel.)

(5) Insert the push button to prevent rotation of the

spindle, and tighten the wheel nut with the accessory

wrench, as shown in Fig. 3.

2. Disassembling

Follow the above procedures in reverse.

CAUTION:

䡬 Comfirm that the depressed center wheel is mounted

firmly.

䡬 Confirm that the push button is disengaged by

pushing push button two or three times before

switching the power tool on.

3

Page 5

Push button

(Spindle lock)

Spindle

Wheel

guard

Wheel

washer

Depressed

center

wheel

Socket for

side

handle

Brush cover

Side handle

Across flats

Switch

Lock button

Wheel

washer

Cutting

wheel

Wheel

washer

Diamond

wheel

Wheel

nut

Wrench

MAINTENANCE AND INSPECTION

1. Inspecting the depressed center wheel

Ensure that the depressed center wheel is free of

cracks and surface defects.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by a Hitachi

Authorized Service Center.

4. Replacing supply cord

If the supply cord of Tool is damaged, the Tool must

be returned to Hitachi Authorized Service Center for

the cord to be replaced.

5. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

6. Service parts list

A: Item No.

B: Code No.

C: No. Used

D: Remarks

Wheel

nut

Fig. 3

CAUTION:

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS:

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts (i.e. code numbers and/or

design) may be changed without prior notice.

NOTE:

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Wheel

nut

4

Page 6

ABC D

37 937-908Z 1

38 316-824 1 180MM A24R

39 937-909Z 1

40 320-218 1

41 306-890 1

42 320-241 1 “7, 20”

43 320-216 1

47 ———— 1

48 320-232 2

44 600-0VV 1 6000VVCMPS2L

45 321-536 1

49 305-812 8 D4×16

46 321-535 1 “45”

50 999-061 2

51 320-231 1

52 ———— 1

53 320-233 2

54 320-245 2

55 320-238 1

56 960-266 1

57 984-750 2 D4×16

58 320-230 1

59 981-373 2

60 958-049 1 D8.2

61 500-408Z 1

501 937-913Z 1

502 937-917Z 1

ABC D

G18SE3

41”

1 315-636 2 M5×14

2 301-654 4 D5×35

3 306-888 1

4 320-219 1

5 320-217 1 “3, 4, 17, 40,

6 320-226 1 M10

7 320-243 1

8 320-221 1

9 320-222 1

10 630-1DD 1 6301DDCMPS2L

501 502

13

12

11

10

9

8

7

6

5

4

3

2

1

42

41

40

“9, 10, 43, 44”

11 994-208 1

12 320-220 1

13 1 360-594U 1 “ 110V-120V”

15

14

13 2 360-594E 1 220V-230V

16

44

43

14 320-215 1

13 3 360-594F 1 240V

46

45

15 984-271 2 D5×75

16 1 340-546C 1 110V-120V

48

47

17 937-033 1

18 321-542 1

16 2 340-546E 1 220V-230V

16 3 340-546F 1 240V

49

51

50

49

52

48

49

19 939-542 1

20 320-242 1

21 949-236 2 M5×10

22 320-229 1

23 630-2DD 1 6302DDCMPS2L

24 990-852 1

25 320-234 1

26 320-228 1

27 320-227 1

28 994-192 4 M5×16

29 311-492 1

30 321-546 1

31 321-545 1

32 306-887 1 M8×22

33 949-457 1 M8

34 321-544 1

35 673-489 1

36 321-543 1 “29-35”

57

55

54

53

54

53

49

56

58

50

61

60

59

29

17

18

19

202122

25

23

24

27

28

26

323334

30

31

37

35

36

39

38

5

Page 7

G18SG2

“NZL”

ABC D

38 316-824 1 180MM A24R

1 315-636 2 M5×14

2 301-654 4 D5×35

ABC D

39 937-909Z 1

40 320-218 1

41 306-890 1

”

3 306-888 1

4 320-219 1

5 320-217 1 “3, 4, 17, 40, 41

42 320-241 1 “7, 20”

43 320-216 1

44 600-0VV 1 6000VVCMPS2L

6 320-226 1 M10

7 320-243 1

8 320-221 1

9 320-222 1

45 321-536 1

46 321-535 1 “45”

47 ———— 1

48 320-232 2

49 305-812 8 D4×16

10 630-1DD 1 6301DDCMPS2L

11 994-208 1

12 320-220 1

13 360-594E 1 220V-230V

14 320-215 1

15 984-271 2 D5× 75

51 320-231 1

50 1 999-061 1

50 2 999-089 1

16 340-546E 1 220V-230V

17 937-033 1

18 321-542 1

19 939-542 1

52 ———— 1

53 320-233 2

54 320-245 2

20 320-242 1

21 949-236 2 M5×10

22 320-229 1

56 960-266 1

57 984-750 2 D4×16

58 320-230 1

55 1 320-238 1

55 2 320-239 1 “ESP, AUT”

23 630-2DD 1 6302DDCMPS2L

24 990-852 1

59 981-373 2

25 320-234 1

26 320-228 1

27 320-227 1

28 994-192 4 M5×16

60 1 940-778 1 D10.7

29 311-492 1

30 321-546 1

60 2 958-049 1 D8.2

31 321-545 1

61 ———— 1

501 937-913Z 1

502 937-917Z 1 “NZL”

32 306-887 1 M8×22

33 949-457 1 M8

34 321-544 1

35 673-489 1

36 321-543 1 “29-35”

37 1 937-907Z 1

37 2 937-908Z 1 “NZL”

6

Page 8

ABC D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

41

46

42

47

48

48

49

51

54

55

501

502

53

52

50

43

49

56

39 320-214 1 ”38"

40 ———— 1

41 320-232 2

42 305-812 2 D4× 16

44 320-231 1

45 305-812 4 D4× 16

46 305-812 2 D4× 16

47 ———— 1

48 320-233 2

49 320-245 2

50 320-238 1

51 960-266 1

52 984-750 2 D4× 16

53 320-230 1

54 981-373 2

55 958-049 1 D8.2

56 500-439Z 1

501 937-913Z 1

43 1 999-061 1

43 2 999-089 1

502 937-917Z 1

7

ABC D

G23SF2

6301DDUCMPS2S

1 315-636 2 M5×14

2 301-654 4 D5×35

3 306-888 1

4 320-219 1

5 320-217 1 ”3, 4, 33, 34"

6 320-226 1 M10

7 320-225 1

8 320-221 1

9 320-222 1

10 630-1DD 1

11 994-208 1

12 320-220 1

13 360-558E 1 220V-240V

14 320-215 1

15 961-501 2 D5× 60

17 937-981 1

18 939-542 1

16 1 340-501E 1 220V-230V

16 2 340-501F 1 240V

19 320-224 1

20 949-236 2 M5×10

21 320-229 1

6302DDUCMPS2S

23 990-852 1

24 320-234 1

25 320-228 1

26 320-227 1

22 630-2DD 1

27 994-192 4 M5×16

28 306-887 1 M8×22

29 306-120 1 ”28"

30 937-908Z 1

31 316-825 1 230MM A24R

32 937-909Z 1 M14×2

33 320-218 1

34 306-890 1

35 320-223 1 ”7, 19"

36 320-216 1

37 600-0VV 1 6000VVCMPS2L

38 320-244 1

Page 9

ABC D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

41

46

42

47

48

49

51

54

55

501

502

53

52

50

43

56

48

49

57

41 320-232 2

42 305-812 2 D4× 16

44 320-231 1

45 305-812 4 D4× 16

46 305-812 2 D4× 16

47 ———— 1

48 320-233 2

49 320-245 2

50 320-236 1

51 320-371 1

52 960-266 1

53 984-750 2 D4× 16

54 320-230 1

55 981-373 2

56 958-049 1 D8.2

57 500-439Z 1

501 937-913Z 1

43 1 999-061 1

43 2 999-089 1

502 937-917Z 1

G23U2

ABC D

6301DDUCMPS2S

1 315-636 2 M5×14

2 301-654 4 D5×35

3 306-888 1

4 320-219 1

5 320-217 1 ”3, 4, 33, 34"

6 320-226 1 M10

7 320-225 1

8 320-221 1

9 320-222 1

10 630-1DD 1

11 994-208 1

12 320-220 1

13 360-558E 1 220V-240V

14 320-215 1

15 961-501 2 D5× 60

17 937-981 1

18 939-542 1

16 1 340-501E 1 220V-230V

16 2 340-501F 1 240V

6302DDUCMPS2S

19 320-224 1

20 949-236 2 M5×10

21 320-229 1

22 630-2DD 1

23 990-852 1

24 320-234 1

25 320-228 1

26 320-227 1

27 994-192 4 M5×16

28 306-887 1 M8×22

29 306-120 1 ”28"

30 937-908Z 1

31 316-825 1 230MM A24R

32 937-909Z 1 M14×2

33 320-218 1

34 306-890 1

35 320-223 1 ”7, 19"

36 320-216 1

37 600-0VV 1 6000VVCMPS2L

38 320-244 1

39 320-214 1 ”38"

40 ———— 1

8

Page 10

ABC D

39 937-909Z 1

40 320-218 1

1 315-636 2 M5×14

2 301-654 4 D5×35

ABC D

41 306-890 1

42 320-223 1 “7, 20“

43 320-216 1

3 306-888 1

4 320-219 1

5 320-217 1 “3, 4, 17, 40,

44 600-0VV 1 6000VVCMPS2L

45 321-536 1

46 321-535 1 “45”

47 ———— 1

48 320-232 2

49 305-812 8 D4× 16

41”

6 320-226 1 M10

7 320-225 1

8 320-221 1

9 320-222 1

10 630-1DD 1 6301DDCMPS2L

50 999-061 2

51 320-231 1

11 994-208 1

12 320-220 1

52 ———— 1

53 320-233 2

54 320-245 2

55 320-238 1

14 320-215 1

15 984-271 2 D5× 75

13 1 360-594E 1 220V-230V

13 2 360-594F 1 240V

56 960-266 1

57 984-750 2 D4× 16

58 320-230 1

59 981-373 2

17 937-033 1

18 321-542 1

16 1 340-546E 1 220V-230V

16 2 340-546F 1 240V

60 958-049 1 D8.2

19 939-542 1

61 500-408Z 1

501 937-913Z 1

502 937-917Z 1

20 320-224 1

21 949-236 2 M5×10

22 320-229 1

23 630-2DD 1 6302DDCMPS2L

24 990-852 1

25 320-234 1

26 320-228 1

27 320-227 1

28 994-192 4 M5×16

29 311-492 1

30 321-546 1

31 321-545 1

32 306-887 1 M8×22

33 949-457 1 M8

34 321-544 1

35 673-489 1

36 321-547 1 “29-35”

37 937-908Z 1

38 316-825 1 230MM A24R

G23SE2

9

502

501

13

12

11

10

9

8

7

6

5

4

3

2

1

17

41

40

18

16

15

14

48

47

46

45

44

43

42

21

20

222324

19

25

49

51

50

49

52

48

49

26

27

55

54

53

54

53

31

29

30

28

49

50

323334

57

56

58

35

36

61

60

59

37

39

38

Page 11

ABC D

36 321-547 1 “29-35”

37 937-908Z 1

38 316-825 1 “230MM A24R”

39 937-909Z 1

40 320-218 1

41 306-890 1

42 320-223 1 “7, 20“

43 320-216 1

46 ———— 1

48 320-232 2

44 600-0VV 1 6000VVCMPS2L

45 321-536 1

49 305-812 8 D4× 16

46 321-535 1 “45”

50 999-061 2

51 320-231 1

52 ———— 1

53 320-233 2

54 320-245 2

55 320-236 1

56 320-371 1

57 960-266 1

58 984-750 2 D4× 16

59 320-230 1

60 981-373 2

61 958-049 1 D8.2

62 500-408Z 1

501 937-913Z 1

502 937-917Z 1

G23UB2

1 315-636 2 M5×14

2 301-654 4 D5×35

ABC D

3

2

1

3 306-888 1

502

501

6

5

4

41”

4 320-219 1

5 320-217 1 “3, 4, 17, 40,

6 320-226 1 M10

10

9

8

7

7 320-225 1

8 320-221 1

12

11

40

9 320-222 1

10 630-1DD 1 6301DDCMPS2L

11 994-208 1

12 320-220 1

13 1 360-594U 1 “110V-120V”

16

15

14

13

42

41

“9, 10, 43, 44”

13 2 360-594E 1 220V-230V

13 3 360-594F 1 240V

45

44

43

14 320-215 1

47

46

15 984-271 2 D5× 75

16 1 340-546C 1 110V-120V

16 2 340-546E 1 220V-230V

49

48

16 3 340-546F 1 240V

50

52

48

17 937-033 1

18 321-542 1

19 939-542 1

20 320-224 1

21 949-236 2 M5×10

22 320-229 1

23 630-2DD 1 6302DDCMPS2L

24 990-852 1

25 320-234 1

26 320-228 1

27 320-227 1

28 994-192 4 M5×16

29 311-492 1

30 321-546 1

31 321-545 1

32 306-887 1 M8×22

33 949-457 1 M8

34 321-544 1

35 673-489 1

49

51

58

56

54

53

55

54

53

49

49

57

59

50

62

61

60

31

29

21

20

18

17

19

222324

26

25

27

30

28

37

36

39

38

35

323334

10

Page 12

Hitachi Koki Co., Ltd.

403

Code No. C99122514

Printed in Malaysia

Loading...

Loading...