Page 1

MODELS G 12SE/G 13SE

1. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

Describes procedures and precautions for disassembly and reassembly. The

the numbers in the G 13SE or G 12SE Parts List.

1-1. Disassembly of the Armature Ass’y

(1) Open the Lever

[37]

.

(2) Loosen the two D4 x 35L Tapping Screws

Tail Covers A and B

(3) Remove the two Carbon Brushes

(4) Remove the four D5 x 25 Tapping Screws

The Armature Ass’y

Packing Gland

(5) Remove the four M5 x 16L Seal Lock Screws

(6) After removing the three M4 x 10 Seal Lock Screws

with the Bearing Cover

(7) Carefully wrap the Armature Ass’y

clamp it securely in a vise. Then, remove the M7 Special Nut

[33]

, loosen the M5 x 25 Machine Screw

[50]

[58] [49]

[13]

[27]

, and related parts.

.

[54]

from the Brush Holders

[2]

.

can then be taken out simultaneously with the Gear Cover Ass’y

[12]

, and related parts.

[13]

with a soft, clean rag to protect it from being damaged, and

and the D4 x 20L Tapping Screw

[28]

.

[34]

, and remove the Wheel Guard Ass’y

[55]

[1]

, the Armature

[5]

.

, and extract the Pinion

bold

numerals in

[53]

[13]

can be extracted together

[ ]

, and remove

[4]

[6]

denote

.

.

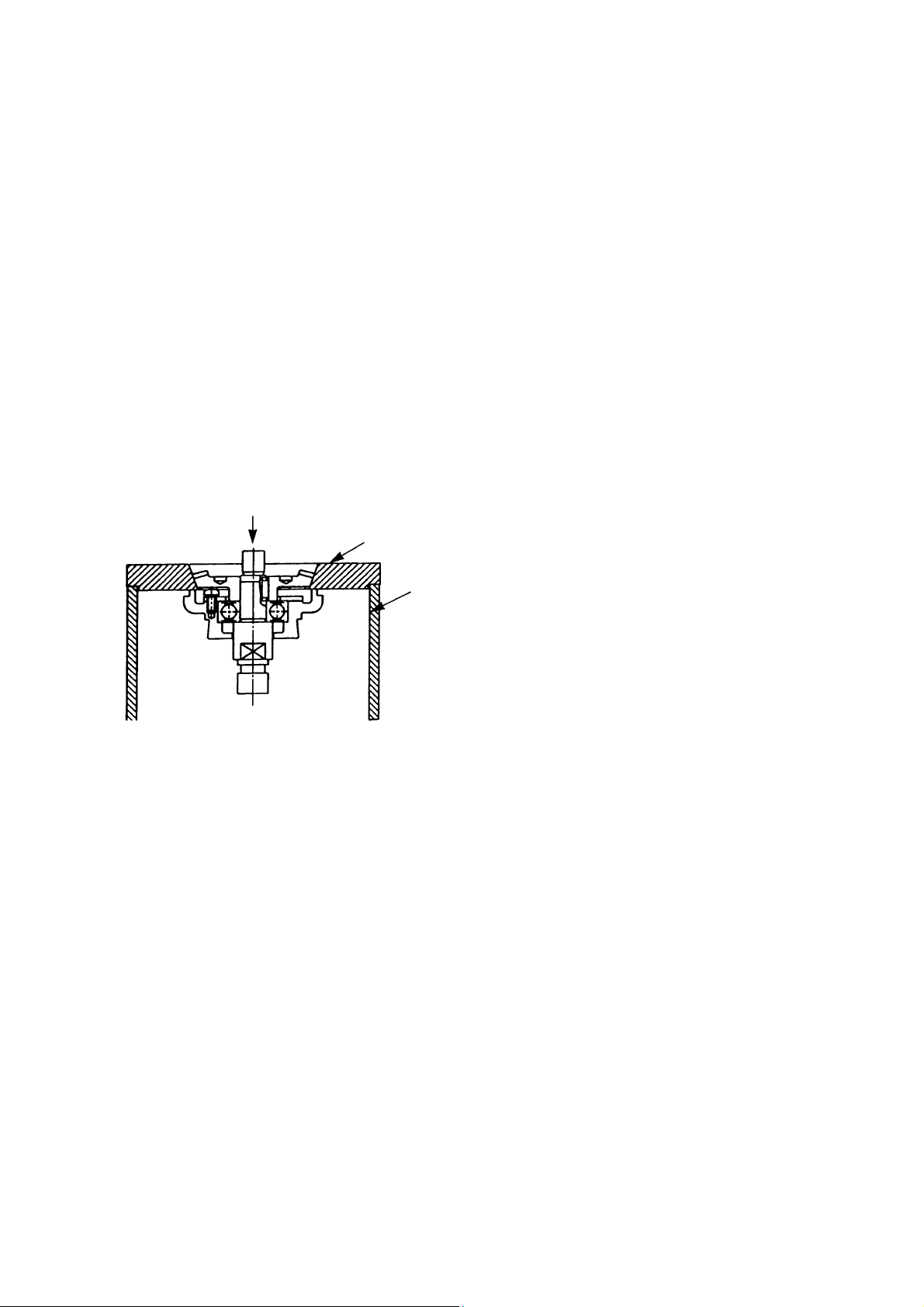

(8) For the models indicated under Fig. 4, the Ball Bearing

by utilizing a J-204 Bearing Puller (special repair t ool, Code No. 970982) as illustrated. After the Ball

Bearing has been removed, the Bearing Cover

[12]

[9]

can be removed from the Armature

can be easily taken off.

Bearing Puller (Code No. 970982)

[13]

Fig. 4

−

−#

1

Page 2

1-2. Disassembly of the Stator Ass’y:

(1) After removing the Armature Ass’y

the Brush Holders

[55]

.

and Switch Box

[13]

(2) Loosen the two D4 x 70L Hex. Hd. Tapping Screws

Housing

can be facilitated by heating the Housing

. If the Stator Ass’y

[43]

cannot be easily removed from the Housing

[16]

[43]

an appropriate heating device.

1-3. Disassembly of the Gear:

(1) Loosen the four M5 x 16L Seal Lock Screws

the Spindle

(2) When it is necessary to remove the Gear

, and Gear

[30]

from the Gear Cover Ass’y

[21]

[21]

the special repair tools described below be utilized.

Push

J-129-2

Gear Puller

J-130

Sleeve

, disconnect the lead wires connected to

[46]

and remove the Stator Ass’y

[15]

[43]

from the

[16]

, disassembly

to a temperature of approximately 60°C (140°F) with

, and remove the Packing Gland

[28]

in a single body.

[4]

from the Spindle

, it is highly recommended that

[30]

together with

[27]

As illustrated in Fig. 5, support the angled surface

of the Gear

with a J-129-2 Gear Puller

[21]

(special repair tool, Code No. 970906), rest the

J-129-2 Gear Puller on a J-130 Sleeve (special

repair tool, Code No. 970907), and push down on

the tip of the Spindle

remove the Gear

[21]

with a hand press to

[30]

.

Fig. 5

1-4. Reassembly:

Reassembly can be accomplished by following the disassembly procedures in reverse. However,

special attention should be given to the following items.

(1) After disassembly, thoroughly remove old grease from the inside of the Gear Cover Ass’y

[4]

insert 18 g of new grease (Nippeco JF-375, Code No. 930036, is recommended) prior to

reassembly. When inserting grease, apply it to the Pinion Gear tooth surfaces, and to the Needle

Bearing inside the Gear Cover.

(2) When replacing the Ball Bearing on the commutator side of the Armature, be very careful to ensure

that the Dust Seal (A)

is assembled in the proper direction. The Dust Seal (A)

[18]

[18]

plays an

important role in dustproofing of the Ball Bearing, and must be replaced with a new one if

disassembled. Do not forget to insert the Thrust Washer

(A)

[18]

.

on the Armature side of the Dust Seal

[17]

(3) Apply Three Bond TB 1406 Screw Locking Agent to the following screws.

, and

Three M4 x 10 Seal Lock Screws

Three M4 x 8 Seal Lock Screws

Four M5 x 16 Seal Lock Screws

which fix Bearing Cover

[1]

which fix Bearing Cover (B)

[22]

which fix Packing Gland

[28]

−#2 −

[12]

[27]

in place.

in place.

[23]

in place.

Page 3

1-5. Tightening Torque of Each Screw:

D3 Tapping Screw

D4 Tapping Screw (W/Flange)

...........................................0.74 ± 0.15 N

[56]

[50] [53] [60]

and D4 Hex. Hd. Tapping Screw

.................................................................................1.96 ± 0.49 N

D5 Tapping Screw

M4 Seal Lock Screw (W/Sp. Washer)

M5 Seal Lock Screw (W/Sp. Washer)

M7 Special Nut

.............................................2.94 ± 0.49 N

[2]

[1] [22]

[28]

..................................................5.88 ± 0.98 N

[5]

.......1.76 ± 0.39 N

.............3.43 ± 0.96 N

⋅⋅⋅⋅

m (7.5 ± 1.5kgf-cm,0.5 ± 0.4 ft-lb)

[15]

⋅⋅⋅⋅

m (20 ± 5kgf-cm, 1.4 ± 0.4 ft-lb)

⋅⋅⋅⋅

m (30 ± 5kgf-cm, 2.2 ± 0.4 ft-lb)

⋅⋅⋅⋅

m (18 ± 4kgf-cm, 1.3 ± 0.3 ft-lb)

⋅⋅⋅⋅

m (35 ± 7kgf-cm, 2.5 ± 0.5 ft-lb)

⋅⋅⋅⋅

m (60 ± 10kgf-cm, 3.6 ± 0.7 ft-lb)

−#3 −

Page 4

1-6. Wiring Diagrams

For European countries

Stator

[16]

Noise

Suppressor

For Asian countries (except Singapore)

Stator

[16]

Pillar Terminal

[52]

BlueBlue

[47]

Black Brown

Pillar Terminal

1 2

Switch

[59]

[52]

BlueBlue

Cord

Cord

[64]

[64]

Black Brown

For New Zealand

Stator

[16]

Noise

Suppressor

[47]

Black Brown

For U.S.A., Canada, Australia and Si ngapor e

Stator

[16]

White or Brown

1 2

Switch

Connector

1 2

Switch

Connector

White or

Blue

[59]

[51]

BlueBlue

[59]

[51]

Cord

[64]

Yellow or

Black

−#4 −

1 2

Switch

Black or

Brown

[59]

Cord

[64]

Page 5

1-7. Insulation Tests:

On completion of disassembly and repair, measure the insulation resistance and dielectric strength.

Insulation Resistance: 7 MΩ or more with DC 500 V Megohm Tester.

Dielectric Strength: AC 4000 V for 1 minute, with no abnormalities........220 V - 240 V

(and 110 V for U. K. products)

AC 2500 V for 1 minute, with no abnormalities........110 V -127 V

(except U. K. products)

1-8. Gear Backlash Value:

Gear backlash should be maintained at a value of 2 mm or less measured at the outer edge of a fresh

Depressed-Center Wheel.

1-9. No-Load Current Value:

After no-load operation for 30 minutes, the no-load current value should be as follows:

Voltage

Current (A) Max.

110 V 115 V 220 V 230 V 240 V

3 A 2.5 A 1.5 A 1.5 A 1.5 A

−#5 −

Page 6

2. STANDARD REPAIR TIME (UNIT) SCHEDULES

Model 10 20 30 40 50 60

G 12SE

G 13SE

Variable

Fixed

General

Assembly

Fixed Costs

Switch

Wheel

Guard

Tail

Cover (A)

Tail

Cover (B)

Cord

10 min.

Other

20 min.

Work Flow

0

min.

Wheel Guard

Ass’y

Tail Cover (A)

Tail Cover (B)

Carbon Brush

x 2 pcs.

Spring x 2 pcs.

Switch

Cord

Cord Armor

Paddle Lever

Lock Lever

Spring

Spring (F)

Pinion

Armature Ass’y

Gear Cover

Seal Ring (A)

Washer (C)

Ball Bearing

(629T12)

Rubber Ring

Felt

Bearing Cover

Dust Seal (A)

Ball Bearing

(608VVMC2)

Pushing Button

Lock Pin

Gear

Seal Packing

Switch Box

Rubber Ring

Brush Holder

x 2 pcs.

Housing

Stator

Bearing

Cover (B)

Ball Bearing

(6201DD)

Felt Packing

Packing Gland

Spindle

Key (3 x 3 x 8)

−#6 −

Loading...

Loading...