Page 1

Impact Drill

日立牌手提震動電鑽

FDV 16VB2

Handling instructions

使用說明書

Read through carefully and understand these instructions before use.

使用前務請詳加閱讀。

Page 2

1

12

3

4

2

2

1

4

5

3

5

6

34

A

0

4

L

9

8

7

R

6

E

B

D

C

1

Page 3

1

Ring 套環

2

Sleeve 套管

3

Tighten 擰緊

4

Loosen 擰鬆

5

Side handle 邊柄

6

Chuck wrench 卡盤扳手

7

Push button 按鈕

8

9

0

A

B

C

D

E

mark

R

mark

L

Impact 衝擊

Rotation 旋鑽

Speed control dial 速度控制撥盤

High speed 高轉速

Low speed 低轉速

Stopper 擋塊

標記

R

標記

L

2

Page 4

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including

the following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children and infirm persons away. Do not

let visitors touch the tool or extension cord. All

visitors should be kept away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children and infirm persons.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree limbs

or logs.

8. Dress properly. Do not wear loose clothing or

jewelry, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades,

bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, free running

of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not

use the tool if the switch does not turn it on and

off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

3

Page 5

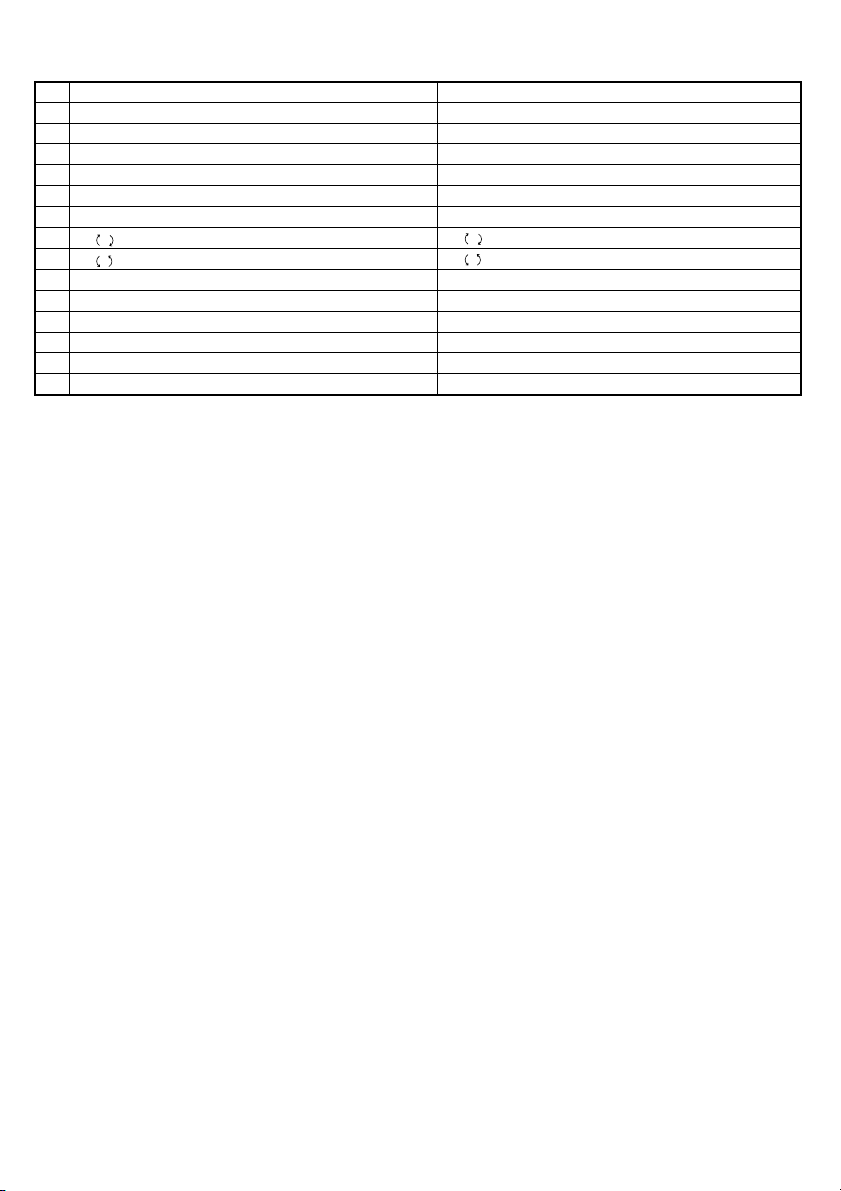

SPECIFICATIONS

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input 550W*

No load speed 0–2900/min

Steel 13 mm

Capacity Concrete 16 mm

Wood 25 mm

Weight (without cord) 1.6 kg

*Be sure to check the nameplate on product as it is subject to change by areas.

STANDARD ACCESSORIES

For entire area

(1) Side handle ............................................................... 1

(2) Depth stopper ........................................................... 1

For partial areas

(1) Chuck wrench............................................................ 1

(For drill chuck with chuck wrench)

(2) Plastic case ................................................................ 1

Standard accessories are subject to change without

notice.

APPLICATIONS

䡬 By combined actions of ROTATION and IMPACT:

Boring holes in concrete, marble, granite, tile, and

similar materials.

䡬 By ROTATIONAL action:

Boring holes in metal, wood and plastic.

Tightening wood screws.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, inviting serious

accident.

3. Extension cord

When the work area is removed from the power

source. Use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Fixing the side handle

Attach the side handle to the mounting part.

Rotate the side handle grip in a clockwise direction

to secure it.

Set the side handle to a position that is suited to

the operation and then securely tighten the side

handle grip.

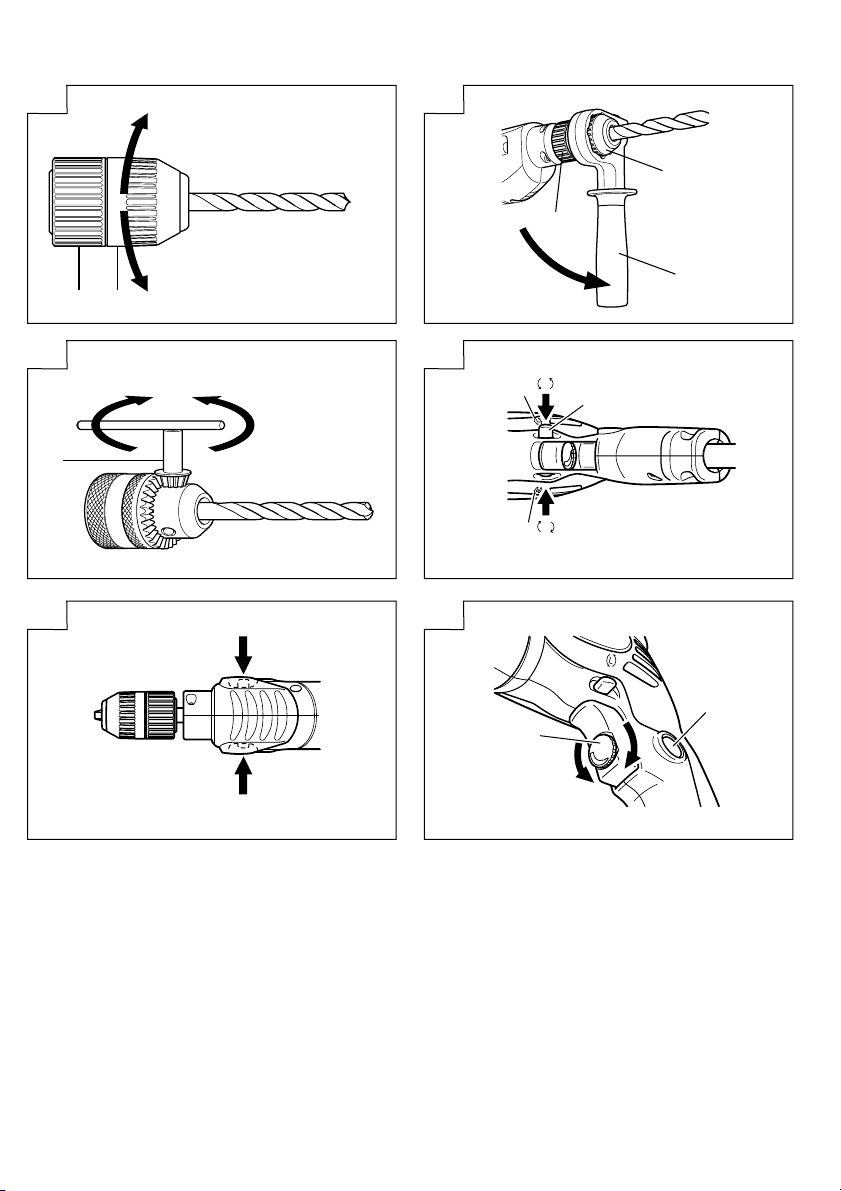

5. Mounting and dismounting of the bit.

For keyless chuck

(1) Mounting the bit

After inserting a driver bit, etc. into the keyless drill

4

chuck, firmly grasp the ring and tighten the sleeve

by turning it toward the right (in the clockwise

direction as viewed from the front). (See Fig. 1)

䡬 If the sleeve becomes loose during operation, tighten

it further. The tightening force becomes stronger

when the sleeve is tightened.

(2) Dismounting the bit

Firmly grasp the ring and loosen the sleeve by

turning it toward the left (in the counterclockwise

direction as viewed from the front). (See Fig. 1)

NOTE

When the sleeve does not become loose any further,

fix the side handle to the sleeve. Then, strike the

grip of the side handle to the left in order to loosen

the sleeve,while holding the ring by hand. (Fig. 2)

CAUTION

Do not fix the side handle to the ring of the keyless

chuck because of a risk that doing so may damage

the ring.

For Drill chuck with chuck wrench

Fit the drill bit into the chuck and use the chuck

wrench to secure it, tightening the chuck by each

of the three holes in turn. (Fig. 3)

6. Selecting the appropriate drill bit

䡬 When boring concrete or stone

Use the drill bits for concrete.

䡬 When boring metal or plastic

Use an ordinary metalworking drill bit.

䡬 When boring wood

Use an ordinary woodworking drill bit.

However, when drilling 6.5 mm or smaller holes,

use a metalworking drill bit.

7. Selecting the driver bit

Screw heads or bits will be damaged unless a bit

appropriate for the screw diameter is employed to

drive in the screws.

8. Check the rotational direction (Fig. 4)

The bit rotates clockwise (viewed from the rear

side) by pushing the R-side of the push button.

The L-side of the push button is pushed to turn

the bit counterclockwise.

and R marks are provided on the body.)

(The

L

CAUTION

䡬 Never change the direction of bit rotation during

operation.

Turn the power switch OFF before changing the

direction of bit rotation; otherwise, the motor

will burn.

䡬 Always use with clockwise rotation, when using

it as an impact drill.

Page 6

9. IMPACT to ROTATION changeover (Fig. 5)

The impact drill can be switched from IMPACT

(impact plus rotation) to ROTATION (rotation only)

by simply sliding the change lever. When boring

concrete, stone, tile or similar board materials, slide

the change lever right. The drill head impacts against

the material while continuing to rotate.

When boring metal, wood or plastic, slide the change

lever fully to the left. The drill simply rotates as

an ordinary electric drill.

CAUTION

Do not use the impact drill in the IMPACT mode

if the material can be bored by rotation only. Such

action will not only reduce drill efficiency, but may

also damage the drill tip.

When changing over, ensure the change lever is

slid as far as it will go.

HOW TO USE

1. Pressure

Drilling will NOT be accelerated by placing heavy

pressure on the drill. Such action will only result

in a damaged drill bit, decreased drilling efficiency

and/or shortened service life of the drill.

2. Using a large diameter drill bit

The larger the drill bit diameter, the larger the

reactive force on your arm. Be careful not to lose

control of the drill because of this reactive force.

To maintain firm control, establish a good foothold,

hold the drill tightly with both hands, and ensure

that the drill is vertical to the material being drilled.

3. When drilling completely through the material

When the drill bit bores completely through the

material, careless handling often results in a broken,

drill bit or damage to the drill body itself due to

the sudden movement of the drill. Always be alert

and ready to release pushing force when drilling

through the material.

4. Switch operation

䡬 When the trigger is depressed, the tool rotates.

When the trigger is released, the tool stops.

䡬 The rotational speed of the drill can be controlled

by varying the amount that the trigger switch is

pulled. Speed is low when the trigger switch is

pulled slightly and increases as the trigger switch

is pulled more.

䡬 The desired rotation speed can be pre-selected with

the speed control dial.

Turn the speed control dial clockwise for higher speed

and counterclockwise for lower speed. (Fig. 6)

䡬 Pulling the trigger and pushing the stopper, it keeps

the switched-on condition which is convenient for

continuous running. When switching off, the stopper

can be disconnected by pulling the trigger again.

CAUTION

Drill at a maximum rotation speed when drilling

wooden materials.

5. When driving wood screws

(1) Selecting a suitable driver bit

Employ plus-head screws, if possible, since the

driver bit easily slips off the heads of minus-head

screws.

(2) Driving in wood screws

䡬 Prior to driving in wood screws, make holes suitable

for them on the wooden board. Apply the bit to

the screw head grooves and gently drive the screws

into the holes.

䡬 After rotating the screwdriver at low speed for a

while until a wood screw is partly driven into the

wood, squeeze the trigger more strongly to obtain

optimum driving force.

CAUTION

䡬 Exercise care in preparing a hole suitable for the

wood screws taking the hardness of the wood into

consideration.

Should the hole be excessively small or shallow,

requiring much power to drive the screw into it,

the thread of the wood screw may sometimes be

damaged.

䡬 Do not drive machine screws.

MAINTENANCE AND INSPECTION

1. Inspection the drill bit

Continued use of a worn and/or damaged drill bit

will result in reduced drilling efficiency and may

seriously overload the drill motor. Inspect the drill

bit often and replace it with a new bit as necessary.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Servicing

Consult an authorized Service Center in the event

of power tool failure.

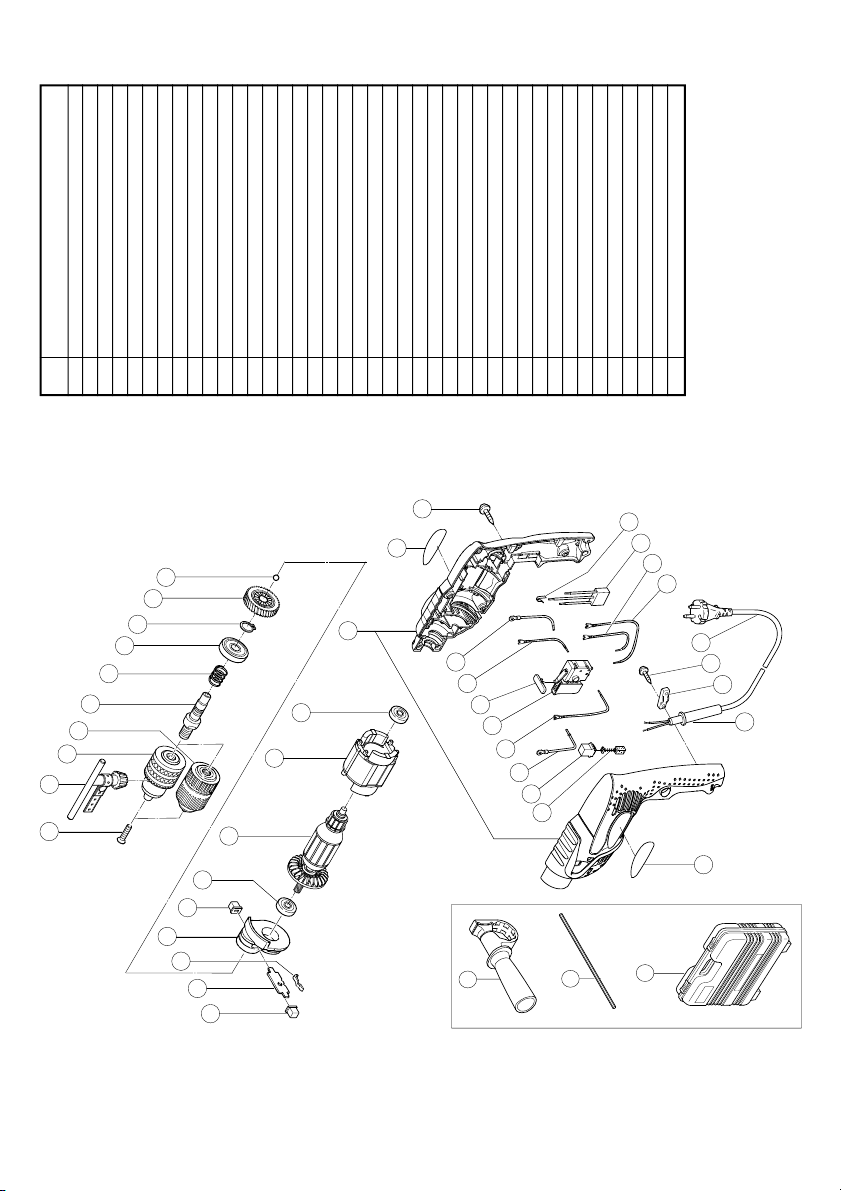

5. Service parts list

CAUTION:

Repair, modification and inspection of Hitachi Power

Tools must be carried out by an Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools,

the safety regulations and standards prescribed in

each country must be observed.

MODIFICATION:

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without

prior notice.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

5

Page 7

作業上的一般注意事項

警告﹗當使用電動工具時,為了減少造成火災、電擊

和人身傷害,必須時刻遵守基本注意事項,以及下述

操作注意事項。

在操作本機之前,請通讀本說明書,並予以妥善保

管。

安全操作注意事項︰

1. 工作場所應打掃乾淨,清理妥當,雜亂無章將導

致事故。

2. 確保妥適的作業環境。電動工具不可任其風吹雨

打。不得在潮濕的地方作業。工作場所需保持充

分的亮度。請勿在有可能造成火災或爆炸的地方

使用電動工具。

3. 謹防觸電事故。應避免身體同大地或接地表面接

觸(例如︰管道、散熱器、爐灶、冰箱等)。

4. 不可讓孩童和体弱人士靠近工作場所。請勿讓訪

客觸摸電動工具或延伸線纜。所有訪客必須與工

作區保持安全距離。

5. 妥善存放不使用的工具。應將不使用的電動工具

存放到乾燥及孩童和体弱人士伸手不及的高處,

並加鎖保管。

6. 不得使勁用力推壓。電動工具需按設計條件才能

有效而安全地工作,絕不可勉強。

7. 妥選使用工具。不可用小型工具或附件去幹重

活。不可用於規定外的作業。舉例說,用圓鋸進

行伐木打枝或原木鋸切作業。

8. 工作時衣服穿戴要合適。不要讓鬆散的衣角和寶

石類捲入轉動部份。屋外作業時,最好手戴橡膠

手套,腳穿防滑膠鞋。同時要戴上能夠罩籠長髮

的工作帽。

9. 絕大多數的電動工具作業時,均需戴安全眼鏡。

進行粉塵飛揚的切削作業時,需戴防塵面罩。

10. 連接除塵設備。

如果提供連接除塵和集塵的設備,請確認是否已

經連接好並且使用正常。

11. 不要拿電線提起電動工具,也不得拉扯電線從電

源插座拆除插頭。電線需從熱源和油液隔開,並

避免與銳利的邊緣接觸。

12. 作業以安全第一為原則。工件要用夾具或台鉗卡

緊。這樣做,比用手按壓更為可靠,也能夠讓雙

手專心操作。

13. 作業時腳步要站穩,身體姿勢要保持平衡。

14. 工具應維護妥善,經常保持鋒利、清潔才能充分

發揮性能,落實作業安全的要求。應按規定加注

潤滑脂、更換附件。線纜應定期檢查,如發現損

傷應即委託專業性的服務單位加以修復。延伸電

纜如有損傷應予更換。手柄要保持乾燥,並防止

沾附油脂類。

15. 不使用時,維修前以及更換附件(如:刀具、鑽

頭、鋸具等)之前,都必須拆卸電源插頭才行。

16. 開動前務必把調整用鍵和扳手類拆除下來。這一

點與安全有關。應養成習慣,嚴格遵守。

17. 謹防誤開動。插頭一插上電源插座,指頭就不可

隨便接觸電源開關。插接電源之前,應先確認開

關是否切斷。

18. 屋外延伸線纜的使用。屋外作業時,必須使用專

用的延伸線纜。

19. 保持高度警覺,充分掌握情況,以正常的判斷力

從事作業。疲憊時切不可開動電動工具。

20. 檢查損壞部件。在繼續使用電動工具之前,應詳

細檢查各部零件以及防護裝置有無損壞,以便決

定能否正常工作,能否發揮正常效能。檢查轉動

部份的對準、空轉、各零件有無異常,安裝是否

妥善以及其它足以給工作帶來不良影響的情況。

如防護以及其它零件損傷了。除非本說明書中已

有記載否則應即委託服務中心進行修理或更換。

開關一發現缺陷,應即委託服務中心加以更換。

如開關不能正常地接通或切斷,絕不可使用該電

動工具。

21. 警告

為了防止人身傷害,不得使用電動工具去進行規

定外的作業。並祇能使用本說明書目錄中所指定

的附件。

22. 本工具必須委託有資格的維修人員進行維修。

本電動工具滿足相關的安全要求。維修必須由專

業人員使用純正配件來進行。否則有可能會給用

戶造成人身損害。

6

Page 8

規格

電壓(按地區)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

輸入功率 550W*(台灣 500W)

額定輸出功率 270W

無負荷速度 0∼2900 轉分

金屬 13 mm

能力 混凝土 16 mm

木材 25 mm

重量(不含線纜) 1.6 kg

* 當須改變地區時應檢查產品上的銘牌。

標 準 附 件

用於全地區

(1) 側柄 ................................... 1

(2) 停止器 ................................. 1

用於部分地區

(1) 夾持器扳手 ............................. 1

(用於帶夾持器扳手的鑽頭夾持器)

(2) 塑料套 ................................. 1

標準附件可能不預先通告而更改。

用 途

䡬 旋鑽加衝擊:混凝土、大理石、花崗岩、瓷鑽以

及其它類似材料的鑽孔。

䡬 專用旋轉方法的用途:

金屬、木材和塑料的鑽孔。

木螺絲的擰緊。

4. 側柄的安裝

把側柄安裝到底座部。

將側柄夾順時針方向固定起來。同時配合工作時

的位置、把它裝好之後,充分地把側柄夾擰緊。

5. 安裝和拆卸鑽頭

無鍵夾持器

(1) 安裝鑽頭

將螺絲刀頭等插入無鍵鑽頭夾持器後,抓緊環並

將其向右側(從前面看是朝順時針方向)旋轉以

擰緊套管。(圖 1)

䡬 如套管在作業中鬆弛,請將其進一步擰緊。套筒

被擰緊時,其擰緊力變得更強。

(2) 拆卸鑽頭

抓緊環並將其向左側(從前面看是朝逆時針方

向)旋轉以擰鬆套管。(圖 1)

註

當無法擰鬆套管時,請將側柄裝在套筒上,然

後用手抓住環,將側柄的把手撞擊至左側以便

擰鬆套筒。(圖 2)

作 業 之 前

1. 電源

確認所使用的電源與工具銘牌上標示的規格是否

相符。

2. 電源開關

確認電源開關是否切斷。若電源開關接通,則插

頭插入電源插座時電動工具將出其不意地立刻轉

動,從而招致嚴重事故。

3. 延伸線纜

若作業場所移到離開電源的地點,應使用容量足

夠、鎧裝合適的延伸線纜,並且要盡可能地短

些。

注意

請勿將側柄裝在無鍵夾持器的環上,因為這樣

可能會損傷環。

帶夾持器扳手的鑽頭夾持器

將鑽頭套入夾持器,用夾持器扳手加以固定。具

體上可將夾持器扳手插入夾持器上三個孔口,逐

一緊固。(圖 3)

6. 選擇合適的鑽頭

䡬 混凝土或石材:使用混凝土用鑽頭。

䡬 金屬或塑料:使用通常的金屬用鑽頭。

7

Page 9

䡬 木材的鑽孔:使用通常的木工用鑽頭。

但鑽開 6.5mm 或更小的孔口時,宜使用金屬用鑽

頭。

7. 螺絲刀頭的選擇

除非使用適合於螺絲直徑的鑽頭來旋入螺絲,否

則會損壞螺絲刀頭或鑽頭。

8. 確認鑽頭旋轉方向(圖 4)

按下按鍵的 R(右)側可使鑽頭沿順時針方向(前

視)旋轉。按下按鍵的 L(左)側可使鑽頭沿逆時

針方向旋轉。

(機身上有 L 和 R 標記。)

注意

䡬 操作中請勿改變鑽頭旋轉方向。

改變鑽頭旋轉方向之前,應先關掉開關,

否則馬達會燒壞。

䡬 作為震動電鑽使用時,一定要使用順時針

方向。

9. 衝擊與旋轉的切換(圖 5)

只要滑動切換手柄,震動電鑽即可從衝擊(衝擊

加上旋轉)切換到旋轉(只旋轉)。對混凝土、

石頭、瓷磚或類似板材進行鑽孔時,請將切換手

柄往右推動。在繼續旋轉時,鑽頭會給材料以衝

擊。

對金屬、木材或塑膠進行鑽孔時,將切換手柄往

左推到盡頭。震動電鑽就像普通電鑽一樣只旋轉

而無衝擊力。

注意

如果材料只能用旋轉方法鑽孔時,請勿在衝擊

模態下使用震動電鑽。這種動作不僅會降低鑽

孔效率,而且也會損壞鑽尖。

切換時,一定要把切換手柄移到底。

使 用 方 法

3. 進行穿孔作業時

穿孔作業時,常因操作不慎,使電鑽突然移動而

損壞鑽頭或電鑽主體。因此,必需提高警覺,準

備隨時放鬆推力。

4. 開關操作

䡬 按下起動器時,電鑽旋轉;鬆開起動器時,電鑽

停止。

䡬 改變拉起動器開關的程度可以控制電鑽的轉速。

輕拉起動器開關轉速較慢,進一步拉起動器開關

則轉速變快。

䡬 可以用速度控制撥盤預選所需的旋轉速度。

順時針轉動速度控制撥盤提高速度,逆時針轉動

降低速度。(圖 6)

䡬 拉起動器並推制動器,保持開關合上狀態,便於

連續運轉。當開關斷開時,再次拉起動器便可釋

放制動器。

注意

在木材上開孔時,請用全速度開孔。

5. 旋入木螺絲時

(1) 選擇適當的螺絲刀頭

如果可能的話,要使用十字槽頭螺絲,因為螺絲

刀頭容易從一字槽頭螺絲滑脫。

(2) 旋入木螺絲

䡬 旋入木螺絲之前,先在木板上打出適合的孔,把

鑽頭放在螺絲頭槽裡,將螺絲輕輕旋入孔內。

䡬 使螺絲刀以低速旋轉一會兒,直到木螺絲有一部

份旋入木材裡,然後再多用點力扳緊扳機,以達

到最佳的驅動力。

注意

䡬 考慮到木材的硬度,小心備製適合於木螺絲的

孔。如果備製的孔太小或太淺,要多用點力把

螺絲旋入,但要注意,木螺絲的螺紋有時會損

壞。

䡬 請勿用於旋入機器螺絲。

1. 壓力

鑽孔作業時,絕不可使勁推壓鑽頭,以加快作業

速度。這樣做,只會使鑽頭受損,降低效率,從

而縮短鑽頭的使用壽命。

2. 使用大口徑鑽頭

鑽頭的口徑越大,手上受到的反力也越大,因而

必須注意會因反力過大而失去對鑽頭的控制。為

了得到良好的控制,腳步要站穩,並用雙手牢靠

地握住電鑽。同時,鑽頭與鑽面要保持垂直。

8

維 護 和 檢 查

1. 檢查鑽頭

繼續使用磨損或受傷的鑽頭,不僅使工作效率大

為降低,同時還會導致電動機過載。因此,鑽頭

必需時常檢查,並根據情況需要加以更換。

Page 10

2. 檢查安裝螺釘

要經常檢查安裝螺釘是否緊固妥善。若發現螺釘鬆

了,應立即重新扭緊,否則會導致嚴重的事故。

3. 電動機的維護

電動機繞線是電動工具的心臟部。應仔細檢查有

無損傷,是否被油液或水沾濕。

4. 維修

電動工具起故障時,請洽經授權的維修代理店。

5. 維修部件目錄

注意:

日立電動工具的修理、維護和檢查必須由日立所

認可的維修中心進行。

當尋求修理或其他維護時,將本部件目錄與工具

一起提交給日立所認可的維修中心會對您有所幫

助。

在操作和維護電動工具中,必須遵守各國的安全

規則和標准規定。

改進:

日立電動工具隨時都在進行改進以適應最新的技

術進步。

因此,有些部件可能未預先通知而進行改進。

註:

為求改進,本手冊所載規格可能不預先通告而徑予

更改。

9

Page 11

503

502

501

1

2

3

3

4

5

6

7

8

9

11

10

10

12

13

14

15

16

17

18

21

22

23

24

25

27

26

28

19

20

37

36

35

34

31

30

32

33

29

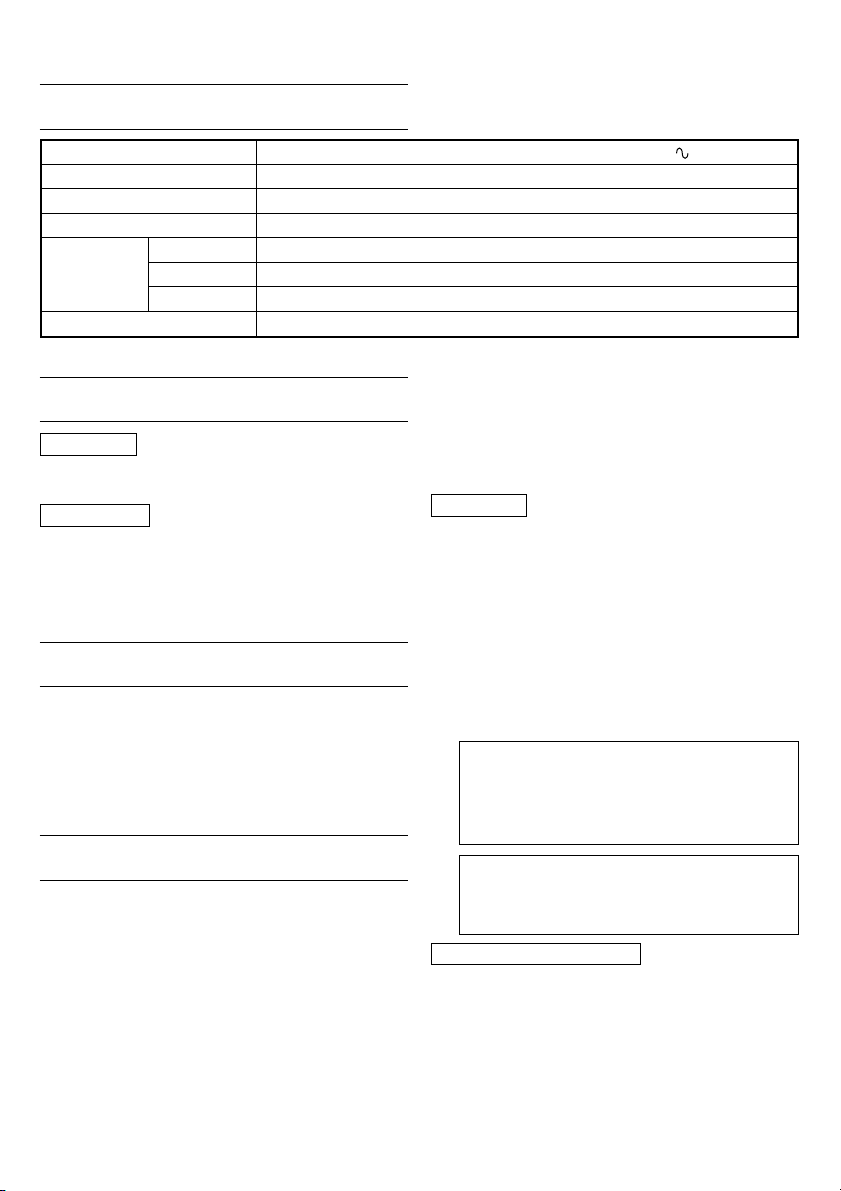

Part Name

1 Flat Hd. Screw (A) (Left Hand) M6 × 25

2 Chuck Wrench For 13VLB-D, 13VLR-D

3 Drill Chuck 13VLRB-D

3Drill Chuck 13VLRC-N (W/O Chuck Wrench)

4Spindle

5 Spring

6 Ball Bearing (6201VVCMPS2S)

7 Retaining Ring For D12 Shaft

Item

No.

8 Gear

9 Steel Ball D4.76

10 Change Knob

11 Change Plate

12 Spring (A)

13 Holder

14 Ball Bearing (608VVMC2EPS2L)

15 Armature

16 Stator

17 Ball Bearing (326VVMC2ERPS2S)

18 Housing (A), (B) Set

19 Nameplate

20 Tapping Screw (W/Flange) D4 × 20

21 Carbon Brush

22 Brush Holder

23 Choke Coil

24 Internal Wire (D)

25 Switch

26 Push Button

27 Internal Wire (C)

28 Choke Coil

29 HITACHI Label

30 Cord Armor

31 Cord Clip

32 Tapping Screw (W/Flange) D4 × 16

33 Cord

34 Internal Wire (B)

35 Internal Wire (A)

36 Noise Suppressor

37 Earth Terminal

501 Side Handle

502 Depth Gauge

503 Case

10

Page 12

11

Page 13

Hitachi Koki Co., Ltd.

408

Code No. C99126432

Printed in China

Loading...

Loading...