Hitachi DVP-588-A Service manual

TK No. 9304E

DV-P588A(S)

SERVICE MANUAL

DV-P588A(ME)

DV-P588A(AU)

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

DVD PLAYER

2003 Digital Media Division, TokaiApril

CONTENTS

1 CAUTIONS FOR SAFETY IN PERFORMING

REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-1 LASER BEAM SAFETY PRECAUTIONS . . . . . . . . 1-1

1-2 IMPORTANT SAFETY PRECAUTIONS . . . . . . . . . 1-2

1-2-1 Product Safety Notice . . . . . . . . . . . . . . . . . . . . . 1-2

1-2-2 Precautions during Servicing. . . . . . . . . . . . . . . . 1-2

1-2-3 Safety Check after Servicing. . . . . . . . . . . . . . . . 1-3

1-3 STANDARD NOTES FOR SERVICING. . . . . . . . . . 1-4

1-3-1 Circuit Board Indications . . . . . . . . . . . . . . . . . . . 1-4

1-3-2 Instructions for Connectors . . . . . . . . . . . . . . . . . 1-4

1-3-3 How to Remove/Install Flat Pack-IC . . . . . . . . . . 1-4

1-3-4 Instructions for Handling Semi-conductors . . . . . 1-6

1-4 NOTES WHEN USING SERVICE MANUAL. . . . . . 1-7

2 GENERAL INFORMATION. . . . . . . . . . . . . . . . .2-1

2-1 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 COMPARISON OF MODELS . . . . . . . . . . . . . . . . . 2-2

2-3 OPERATING CONTROLS AND FUNCTIONS . . . . 2-4

3 MAINTENANCE AND INSPECTION. . . . . . . . . .3-1

3-1 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 FIRMWARE RENEWAL MODE. . . . . . . . . . . . . . . . 3-7

3-2-1 How to Update the Firmware Version . . . . . . . . . 3-7

3-2-2 How to Verify the Firmware Version . . . . . . . . . . 3-7

SCHEMATIC CIRCUIT BOARD AND BLOCK

DIAGRAMS

1 WIRING DIAGRAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 SCHEMATIC DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . 2

2-1 DVD Main 1/3 Schematic Diagram . . . . . . . . . . . . . . . 2

2-2 DVD Main 2/3 Schematic Diagram . . . . . . . . . . . . . . . 3

2-3 DVD Main 3/3 Schematic Diagram . . . . . . . . . . . . . . . 5

2-4 AV 1/3 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . 6

2-5 AV 2/3 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . 7

2-6 AV 3/3 & Function Schematic Diagram . . . . . . . . . . . . 8

3 WAVEFORMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 CIRCUIT BOARD DIAGRAMS . . . . . . . . . . . . . . . . . . . 10

4-1 AV CBA Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4-2 AV CBA Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . 11

4-3 Function CBA Top/Bottom View . . . . . . . . . . . . . . . . 12

5 BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5-1 System Control/Servo Block Diagram . . . . . . . . . . . . 13

5-2 Digital Signal Process Block Diagram . . . . . . . . . . . . 14

5-3 Video/Audio Block Diagram. . . . . . . . . . . . . . . . . . . . 15

5-4 Power Supply Block Diagram . . . . . . . . . . . . . . . . . . 16

6 SYSTEM CONTROL TIMING CHARTS . . . . . . . . . . . . 17

7 IC PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . 18

8 LEAD IDENTIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . 19

4 DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-1 CABINET DISASSEMBLY INSTRUCTIONS. . . . . . 4-1

4-1-1 Disassembly Flowchart . . . . . . . . . . . . . . . . . . . . 4-1

4-1-2 Disassembly Method. . . . . . . . . . . . . . . . . . . . . . 4-1

5 EXPLODED VIEW AND PARTS LIST . . . . . . . .5-1

5-1 EXPLODED VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 REPLACEMENT PARTS LIST. . . . . . . . . . . . . . . . . 5-2

5-2-1 Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . 5-2

5-2-2 Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . 5-3

D

R

1

CAUTION FOR SAFETY IN PERFORMING REPAI

1-1 LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against

your skin.

The laser beam is emitted from the location shown in the figure. W hen checki ng the laser diode , be sure to keep

your eyes at leas t 30cm away f rom the pi ckup lens wh en the diod e is turned on. Do not l ook directl y at the las er

beam.

Caution: Use of controls and a djustments, or doing proce dures other than those s pecified herein, may r esult in

hazardous radiation exposure.

rive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

CAUTION - VISIBLE LASER

RADIATION WHEN OPEN AND

INTERLOCK DEFEATED.

AVOID EXPOSURE TO BEAM.

Location: Inside Top of DVD mechanism.

1-1

1-2 IMPORTANT SAFETY PRECAUTIONS

1-2-1 Product Safety Notice

Some electrical and mechanical parts have special

safety-related charac teristics which are often not evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have spe cial safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Pro duct’s Safety is und er review con tinuously and new instructions are issued whenever

appropriate. Prior to shipment from the factory, our

products are carefully inspected to confirm with the

recognized product s afety and electrical codes of the

countries in which they are to be sold. However, in

order to maintain such comp lianc e, it is equ ally impor tant to implement the following precautions when a set

is being serviced.

1-2-2 Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spur ious rad iation. T hese m ust also be

replaced only with specified re pla ce men ts.

Examples: RF converters, RF c ables, noise blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1)Wires covered with PVC tubing

2)Double insulated wires

3)High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1)Insulation tape

2)PVC tubing

3)Spacers

4)Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before soldering.

F. O bs erv e t hat the wi r es do n ot co ntact h eat pr od uc -

ing parts (heatsinks, oxide metal fil m re sisto rs, fus ible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been r eplaced, ch eck that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power tr ansformer uses crimp type connectors

which connect the power cord and the primary side

of the transformer. When replacing the transformer,

follow these steps carefully and precisely to prevent shock hazards.

Replacement procedure

1)Remove the old connector by cutting the wires at a

point close to the connector.

Important: Do not re-use a connector. (Discard it.)

2)Strip about 15 mm of the insulation from the ends

of the wires. If the wires are stranded, twist the

strands to avoid frayed conductors.

3)Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4)Use a crimping tool to crimp the metal sleeve at its

center. Be sure to crimp fully to th e complete closure of the tool.

L. When connecting or disconnecting the internal con-

nectors, first, disco nnect the AC plug from th e AC

outlet.

1-2

1-2-3 Safety Check after Ser vicing

r

e)

Examine the area surrounding the repaired location for

damage or deterio ration. Observe that screws , parts,

and wires have been returned to their original positions. Afterwards, do the following tests and confirm

the specified values to verify compliance with safety

standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified cleara nce distanc e (d) and (d’) between sol dered terminals, and between terminals and surrounding metallic parts. (See Fig. 1-2-1)

T able 1-2-1: Ratings for selected area

Clearance

AC Line Voltage

110 to 240 V (Auto)

[ DV-P588A(S)/P588A(ME) ],

240 V [ DV-P588A(AU) ]

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

Distance

(d) (d’)

≥ 3mm(d)

≥ 6mm(d’)

Chassis or Secondary Conducto

Primary Circuit Terminals

dd'

Fig. 1-2-1

Exposed Accessible Part

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs)

and externally exposed accessible parts (RF terminals, antenna terminals, video and audio input and

output terminals, microphone jacks, earphone jacks,

etc.) is lower than or equal to the specified value in the

table below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure acr oss the ter minals of l oad

Z. See Fig. 1-2-2 and the following table.

Table 1-2-2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

110 to 240 V (Auto)

[ DV-P588A(S)/P588A(ME) ],

240 V

[ DV-P588A(AU) ]

2kΩ RES.

Connected in

parallel

50kΩ RES.

Connected in

parallel

Z

1.5k

Earth Ground

B

Power Cord Plug Prongs

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

AC Voltmeter

0.15 F

One side of power cord plug

(High Impedanc

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 1-2-2

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

1-3

1-3 STANDARD NOTES FOR SERVICING

O

P

P

1-3-1 Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is indicated as shown.

Top View

Input

ut

2. For other ICs, pin 1 and every fifth pin are indicated

as shown.

In

in 1

3. The 1st pin of every male connector is indicated as

shown.

in 1

Bottom View

5

10

1-3-3 How to Remove / Install Flat

Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:.

(1) Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. 1-3-1)

Fig. 1-3-1

(2) Remove the flat pack-IC with tweezers while apply-

ing the hot air.

(3) Bottom of the flat pack-IC is fixe d with glue to the

CBA; when removing entire fl at pack-IC, fir st apply

soldering iron to center of the fla t pack-IC and hea t

up. Then remove (glue will be melted). (Fig. 1-3-6)

(4) Release the flat pack-IC from the CBA using twee-

zers. (Fig. 1-3-6)

1-3-2 Instructions for Connectors

1. When you connec t o r dis con nect the F FC (Flex ib le

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Caution:

1. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage to

the chip parts may occur. Put maskin g tape a r ound

the flat pack-IC to protect other parts from damage.

(Fig. 1-3-2)

2. The flat pack-IC on th e CB A i s affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when removing

it.

Hot-air

Flat Pack-IC

Desoldering

CBA

Masking

Tape

Tweezers

Machine

Flat Pack-IC

Fig. 1-3-2

1-4

With Soldering Iron:

F

F

S

rp

or

n

(1)Using desoldering braid, remove the solder from all

pins of the flat pack-IC. Wh en you use solder flux

which is applied to all pins of the f lat pack-IC, you

can remove it easily. (Fig. 1-3-3)

lat Pack-IC

Desoldering Braid

(4) Bottom of the flat pack-IC is fixe d with glue to the

CBA; when removing entire fl at pack-IC, fir st apply

soldering iron to center of the fla t pack-IC and hea t

up. Then remove (glue will be melted). (Fig. 1-3-6)

(5) Release the flat pack-IC from the CBA using twee-

zers. (Fig. 1-3-6)

Note:

When using a sold ering iron, care must be taken

to ensure that the flat pack-IC is not being hel d by

glue. When the flat pack-IC is removed from the

CBA, handle it ge ntl y bec au se it may be damaged

if force is applied.

Soldering Iron

Hot Air Blower

Fig. 1-3-3

(2) Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which sold er will

not adhere (iron wir e). When heati ng the pins, us e

a fine tip soldering iron or a hot air desoldering

machine. (Fig. 1-3-4)

Iron Wire

Soldering Iron

To Solid

Mounting Point

Sha

Fig. 1-3-5

Pin

ine Tip

oldering Iron

CBA

Fine Tip

Soldering Iro

Fig. 1-3-4

(3)B ottom of the flat pack-IC is fixed with glue to the

CBA; when removing enti re flat pack-IC, fi rst apply

soldering iron to c en ter o f th e f lat pack-I C an d h eat

up. Then remove (glue will be melted). (Fig. 1-3-6)

(4)Re lease the fla t pack-IC from the CBA us ing twee-

zers. (Fig. 1-3-6)

Tweezers

Flat Pack-IC

With Iron Wire:

(1)Using desoldering braid, remove the solder from all

Fig. 1-3-6

pins of the flat pack-IC. Wh en you use solder flux

which is applied to all pins of the f lat pack-IC, you

can remove it easily. (Fig. 1-3-3)

(2) Affix the wire to a workbench or solid mounting

point, as shown in Fig. 1-3-5.

(3) While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solde r

melts so as to lift the IC leads from the CBA contact

pads as shown in Fig. 1-3-5.

1-5

2. Installation

P

i

d

(1) Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replac ement flat pack-IC more

easily.

(2) The “I” mark on the flat pack-IC indicates pin 1.

(See Fig. 1-3-7.) Be sure this m ark matches the 1

on the PCB when position ing for installation. Then

presolder the four corners of the flat pack-IC. (S ee

Fig. 1-3-8.)

(3)Solder all pins of the flat pack-IC. Be sure that none

of the pins have solder bridges.

Example :

in 1 of the Flat Pack-IC

s indicated by a " " mark.

Fig. 1-3-7

1-3-4 Instructions for Handling

Semi-conductors

Electrostatic breakdown of the semi-conductors may

occur due to a po tential difference ca used by electr ostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a gr oundin g band (1MΩ) that is properly grounded to re move any static electricity th at m ay

be charged on the body.

2. Ground for Workbench

(1) Be sure to place a conductive sheet or copper plate

with proper groundin g (1MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will no t escape through the body grounding band, be careful to avoid contacting semi-conductors with your clothing.

< Incorrect >

CBA

Presolder

Flat Pack-IC

Fig. 1-3-8

CBA

< Correct >

Grounding Ban

1MΩ

CBA

1MΩ

Conductive Sheet or

Copper Plate

1-6

(

l

[

[

[

1-4 NOTES WHEN USING SERVICE MANUAL

The following shows the contents to be noted when using service manual:

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot nece ssar ily b e ob tai ned by us ing repl ac ement components rated for higher voltage, wattage,

etc. Replacement parts that have th ese spe cial safety

characteristics are identified in this manual and its

supplements; electrical comp onents having such features are identified by the mark " ! " in the schematic

diagram and the parts list. Before replacing any of

these components, read the parts list in this manual

carefully. The use of substitute replacement parts that

do not have the same s afety character istics as specified in the parts list may create shock, fire, or other

hazards.

Capacitor Temperature Markings

Mark

(B)

Capacity

change rate

±10%

(F) +30 - 80% 20°C -25~+85°C

(SR)

±15%

(Z) +30 - 80% 20°C -10~+70°C

Standard

Temperature

temperature

20°C -25~+85°C

20°C -25~+85°C

range

Notes:

1. Do not use th e part numb er shown o n these drawings for ordering. The correct part number is shown

in the parts list, and may be slightly different or

amended since these drawings were prepared.

2. All voltages are DC voltages unless otherwise

speci-fied.

Values in schematic diagrams

The values, dielec tric strength ( power capacitance )

and tolerances of the resistors ( excluding variable

resistors ) and capacitors are indicated in the schematic diagrams using abbreviations.

Resistors ]

Item Indication

No indication...........................

Value

Power

capacitance

K............................................k

M..........................................M

No indication............1/4W,1/6W

All capacitances other than the

above are indicated in schematic

diagrams.

Capacitors and transistor s are represented by the following symbols.

CBA Symbols

(Top View) (Bottom View)

Bottom View)

E C B

(Top View)

E C B

(Top View)

E C B

Schematic Diagram Symbols

+

Transistor or Digital Transistor

NPN

Transistor

NPN Digital

Transistor

Digital Transistor

Electrolytic Capacitor

(Top View)

PNP

E C B

(Top View)

E C B

Transistor

PNP Digita

Transistor

Capacitors ]

Item Indication

Value

No indication...........................

P..............................................pF

No indication...........................50V

Dielectric

strength

All dielectric strengths other than

50V are indicated in schematic

diagrams.

Coils ]

Item Indication

Value

...............................................

m.............................................mH

F

H

1-7

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON THE FOLLOWING

T

b

e

e

1

".

".

3

2

1

PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE FUSE.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, fi rst check to s ee that all compon ents in the power su pply circuit are no t defective before you conn ect the AC plug to the AC po wer su ppl y. Otherwise it may ca us e some components in the

power supply circuit to fail.

3. Note:

(1) Do not use the part number shown on the drawings for ordering. The correct part number is shown in the parts

list, and may be slightly different or amended since the drawings were prepared.

(2) T o maintain original function and reliability of repaired units, use only original replacement parts which are listed

with their part numbers in the parts list section of the service manual.

4. Wire Connectors

(1) Prefix symbol "CN" means "connector" (can disconnect and reconnect).

(2) Prefix symbol "CL" means "wire-solder holes of the PCB" (wire is soldered directly).

5. Voltage indications for PLAY mode on the schematics are as shown below:

6. How to read converged lines

-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to area "D3

2. "1-B1" means that line number "1" goes to area "B1

7. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

1

(Unit: Volt)

he same voltage for

oth PLAY & STOP modes

5.0

2

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mod

STOP mod

AREA D3

1-B1

AREA B1

1-D3

ABCD

: Used to indicate a test point with a test pin.

1-8

GENERAL INFORMATION2

2-1 SPECIFICATIONS

[ DV-P588A(S)/(ME) ]

[ DV-P588A(AU) ]

2-1

2-2 COMPARISON OF MODELS

A

E

G

L

V

O

A

O

T

Y

: The halftone parts are the differences from the previous model.

ITEM

Dimensional 435(W) x 55(H) x 211(D) mm 435(W) x 75(H) x 216(D) mm

Weight 1.8 kg 2.1 kg

Tray Panel Clear Silver

Color Front / Button Silver/Silver Black/Silver

Hot Stamp --- ---

PPEARANC

Ultra Vision Badge --- --Drive Speed 1x 1x

Laser 2 2

DVD/VCD/SVCD/CD-DA O / O / --- / O O / O / --- / O

CD-R/CD-RW/DVD-R (Video Format) O / O / O O / O / O

DVD-RAM (VR Format) --- --MP3 O O

ENERA

OSD languages

Jog Shuttle on Front --- Only switch shuttle

Headphone Jack / Volume --- / --- --- / --PAL Disc NTSC Out O --Video Out Mode NTSC/PAL/PAL60 O / O / O --- / O / O

S-Video / Component / Composite O / O / O O / O / O

Video D/A Converter 10bit 10bit

IDE

Black Level Select --- O

Picture Control --- --Progressive Out --- --Audio D/A Converter 192kHz / 24bit 192kHz / 24bit

Digital Audio Out Optical / Coaxial O / O O / O

Dolby Digital 5.1 ch Decode --- --DTS Digital Out O O

Virtual Surround O O

UDI

Dynamic Range Compression (Dolby

Digital)

DVD Audio --- --Power on sound --- ---

Search Speed

Slow Speed 1/16, 1/8, 1/2 (FORWARD/REWIND) 1/16, 1/8, 1/2 (FORWARD only)

IP Search (Smooth 2x Play) O O

2x Play with Audio --- ---

RICK PLA

Step Forward / Reverse O / --- O / --Still Picture Select (Frame/Field) Auto Only Auto Only

DV-P588A(S)/P588A(ME)/P588A(AU) DV-P388A(S)/P388A(ME)/P388A(AU)

2 (English, Chinese) [(ME)/(AU)]

2 (English, Russian) [(S)]

OO

2 to 100 (FORWARD/REWIND)

(DVD: 2, 8, 50, 100/CD: 16)

2 (English, Chinese)

2 to 60 (FORWARD/REWIND)

(DVD: 2, 8, 30, 60/CD: 16)

2-2

ITEM

F

S

C

R

Disc Navigation O --DVD Zoom x2 / x4 / x16 O / O / --- O / O / --Program and Random Play of DVD /

VCD

A-B Repeat O O

Repeat O O

Resume Play

EATURE

Front Panel Display Dimmer O O

Screen Saver O O

Auto Power Off O O

Jog Shuttle on Remote --- ---

REMOTE

TV Control --- ---

ONTROLLE

DV-P588A(S)/P588A(ME)/P588A(AU) DV-P388A(S)/P388A(ME)/P388A(AU)

--- ---

O (Resume is not effected

affer power off)

O

2-3

ANALOG

AUDIO OUT

DIGTAL

AUDIO OUT

VIDEO

OUT

COAXIALOPTICAL

S-VIDEO OUT

COMPONENT

VIDEO OUT

LYC

R

C

B

R

1

2345

h

B

g

C

A

2-3 OPERATING CONTROLS AND FUNCTIONS

FRONT PANEL

7

y/I

H/ED/GABC

1 6

1. y/I (POWER/STANDBY)

to switch the player to ON or OFF

(As to the indication of the Operate switch, “I” indicates

ON and “y” indicates electrical power STANDBY)

2. H /

h

(SKIP/FR)

goes to previous chapter or track during playback;

press and hold for 1.5 seconds for a reverse search

B

3.

(PLAY)

to start or resume disc playback

REAR PANEL

82 3 4 5

g

/ G (FF/SKIP)

4.

goes to next chapter or track during playback; press

and hold for 1.5 seconds for a forward search

C

5.

(STOP)

to stop playback

A

6.

(OPEN/CLOSE)

to open/close the disc tray

7. Disc tray

8. Display

1. ANALOG AUDIO OUT JACKS

Connect to the Audio input jacks of A/V-compatible TV

or wide screen TV, Stereo system.

2. DIGITAL AUDIO OUT JACKS:

Use either an optical or coaxial digital cable to connect

to a compatible Dolby Digital receiver. Use to connect to

a Dolby Digital decoder, DTS decoder or MPEG

decoder.

3. VIDEO OUT JACK

Use a video cable to connect one of the jack to Video

input on your A/V-compatible TV or wide screen TV,

4. COMPONENT VIDEO OUT

Connect to a TV with Component video in jacks.

5. S-VIDEO OUT JACK

Use the S-Video cable to connect this jack to the SVideo jack on your A/V-compatible TV or wide screen

TV for a higher quality picture.

Stereo system.

2-4

s

)

B

o

H

C

h

F

t

g

B

G

A

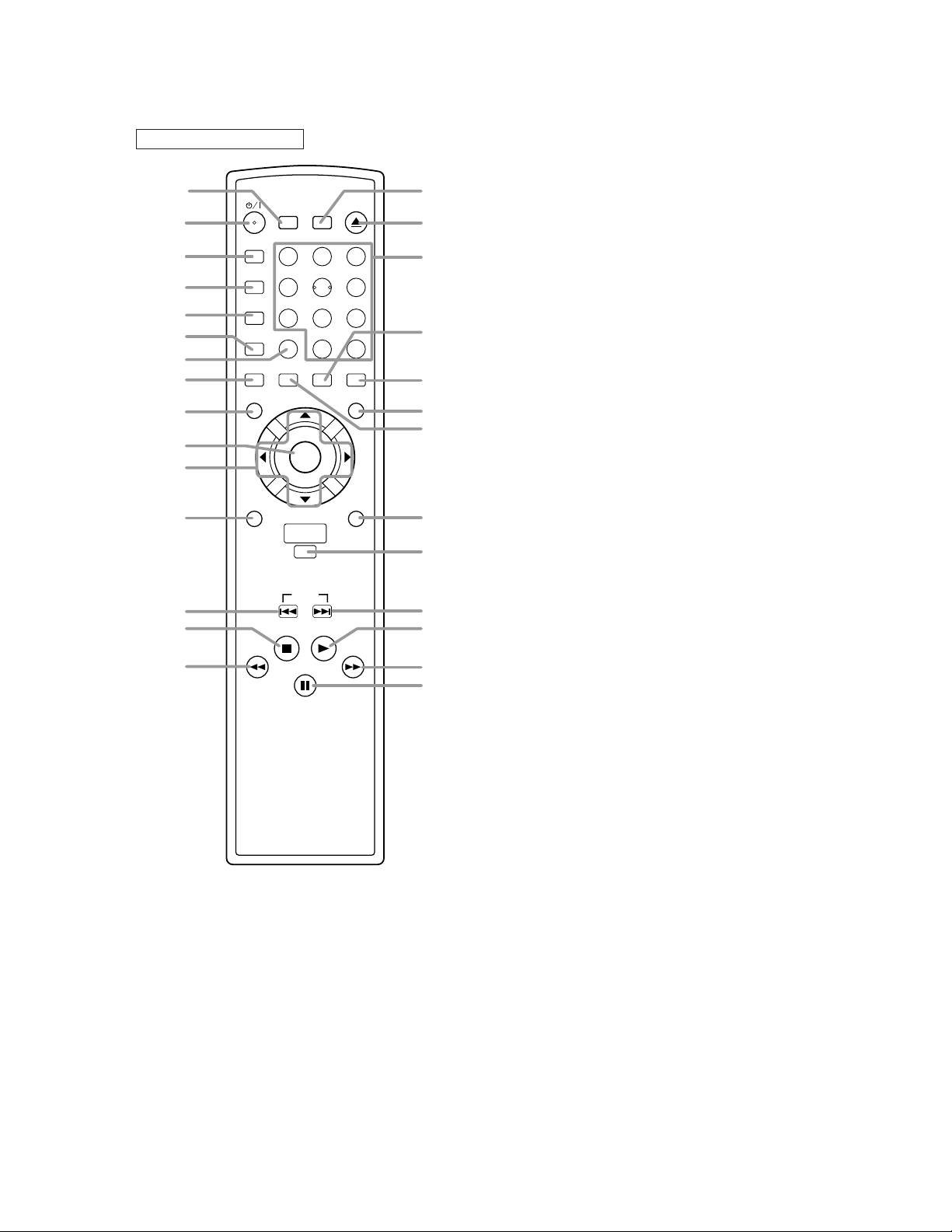

REMOTE CONTROL

1

SURROUND

2

A-B REPEAT

3

REPEAT

4

5

6

7

MODE

ZOOM

ANGLE

1

4

7

CLEAR

SUBTITLE

8

MENU

9

10

ENTER

11

12

RETURN

NAVIGATION

13

14

15

SEARCH OPEN/

MODE

2

56

8

0

AUDIO

DISC

SKIP

CLOSE

3

9

+10

DISPLAY

TOP MENU

SETUP

28

27

26

25

24

23

22

21

20

19

18

17

16

1. SURROUND

Press to activate the virtual sound.

2. y/I (POWER/STANDBY)

to switch the player to ON or OFF

(As to the indication of the Operate switch, “I” indicate

ON and “y” indicates electrical power STANDBY)

3. A-B REPEAT

Repeats playback of a selected section.

4. REPEAT

Repeats playback of the current disc, title, chapter or

track.

5. MODE

to set up programmed or random playback (Audio CD

to set virtual surround during playback

6. ZOOM

enlarge DVD and Video CD image

7. CLEAR

8. ANGLE

select DVD camera angle

9. MENU

to display the menu of the DVD disc

10. ENTER

acknowledge menu selection

11. Arrow Buttons (

Move the cursor and determines its position.

12. RETURN

to return previous or remove setup menu

13. SKIP

14.

15.

16.

17.

18.

19. SKIP

20. DISC NAVIGATION

21. SETUP

22. SUBTITLE

23. TOP MENU

24. DISPLAY

25. AUDIO

26. Numerical Buttons

27.

28. SEARCH MODE

H

goes to previous chapter or track during playback

C

(STOP)

to stop playback

h

to view DVD picture in fast reverse motion

F

(PAUSE/STEP)

Press to pause Disc playback. Press repeatedly to

advance the DVD picture step by step (or one frame a

a time).

g

to view DVD picture in fast forward motion

B

(PLAY)

to start or resume disc playback

G

goes to next chapter or track during playback

Press to display the first scenes of each chapter of the

title being played.

Press to enter the setup mode.

Press to select the desired subtitle language.

Press to call up the title menu.

Press to access or remove the display screen during

DVD, Audio CD or Video CD playback.

Press to select a desired audio language or sound

mode.

Press to directly select a Title/Chapter(DVD)/Track

(Audio CD/Video CD) for playback.

A

(OPEN/CLOSE)

to open/close the disc tray

Press to access or remove the Search display, which

allows you to go directly to a specific

Title/Chapter/Track/Time/Marker.

ss B

ppo

)

2-5

Loading...

Loading...