ANGLE DRILL

MODEL

D 10YB

POWER TOOLS

D

TECHNICAL DATA

AND

D 10YB

SERVICE MANUAL

LIST No. 0193 Jun. 2000

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

Notice for use

Specifications and parts are subject to change for improvement.

Refer to Hitachi Power Tool Technical News for further information.

CONTENTS

Page

1. PRODUCT NAME

2. MARKETING OBJECTIVE

3. APPLICATIONS

4. SELLING POINTS

4-1. Selling Point Descriptions

5. SPECIFICATIONS

6. COMPARISONS WITH SIMILAR PRODUCTS

6-1. Specification Comparisons

6-2. Drilling Speed Comparisons

7. PRECAUTIONS IN SALES PROMOTION

7-1. Handling Instructions

7-2. Caution on Name Plate

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• •

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

8-1. Disassembly

8-2. Reassembly

8-3. Wiring Diagram and Internal Wire Arrangement

8-4. Lubrication

8-5. Tightening Torque

8-6. Insulation Tests

8-7. No-load Current Value

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• •

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

1

1

1

1

2

3

4

4

5

6

6

6

7

7

10

12

15

15

15

15

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

Assembly Diagram for D 10YB

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

16

17

1. PRODUCT NAME

Hitachi Angle Drill, Model D 10YB

2. MARKETING OBJECTIVE

The Model D 10YB has been developed based on the current Model D 10YA (10 mm) to meet the market demand

for an angle drill with a forward/reverse changeover switch, a small-diameter housing, and a small head.

The key features of the Model D 10YB are as follows.

(1) Easy-to-grip small-diameter housing

(2) Forward/reverse changeover switch

(3) Small head

(4) Powerful 500 W motor

(5) Fast drilling speed

With the introduction of the Model D 10YB, we aim to make the angle drill series more competitive and to expand

the market share.

3. APPLICA TIONS

Drilling in metal, wood and plastics

4. SELLING POINTS

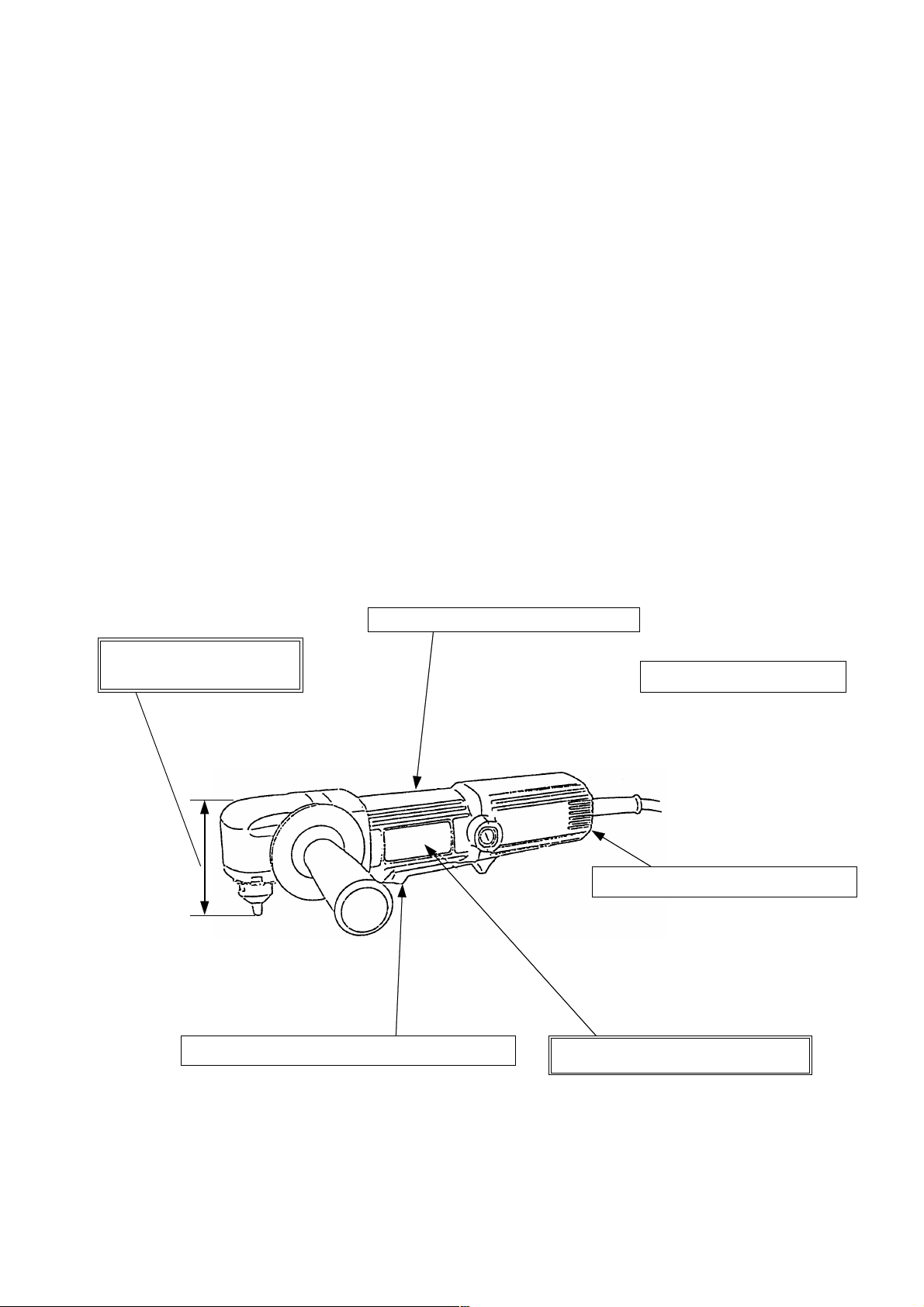

Smallest head in this class

(83 mm (3-1/4"))

Powerful 500 W motor* (class leader)

* Subject to change by area.

Lightweight 1.5 kg (3.3 lbs.)

Forward/reverse changeover switch

Slide switch located in a convenient position

--- 1 ---

Easy-to-grip small-diameter housing

4-1. Selling Point Descriptions

4-1-1. Easy-to-grip small-diameter housing

As in the case of disc grinders, a small-diameter housing makes it easy to grip and improves operability.

The slide switch located on the lower portion of the housing can be operated while gripping the tool.

4-1-2. Forward/reverse changeover switch

The Model D 10YB is equipped with a forward/reverse changeover switch. This switch expands the application

range to such tasks as loosening screws and locked drill bits.

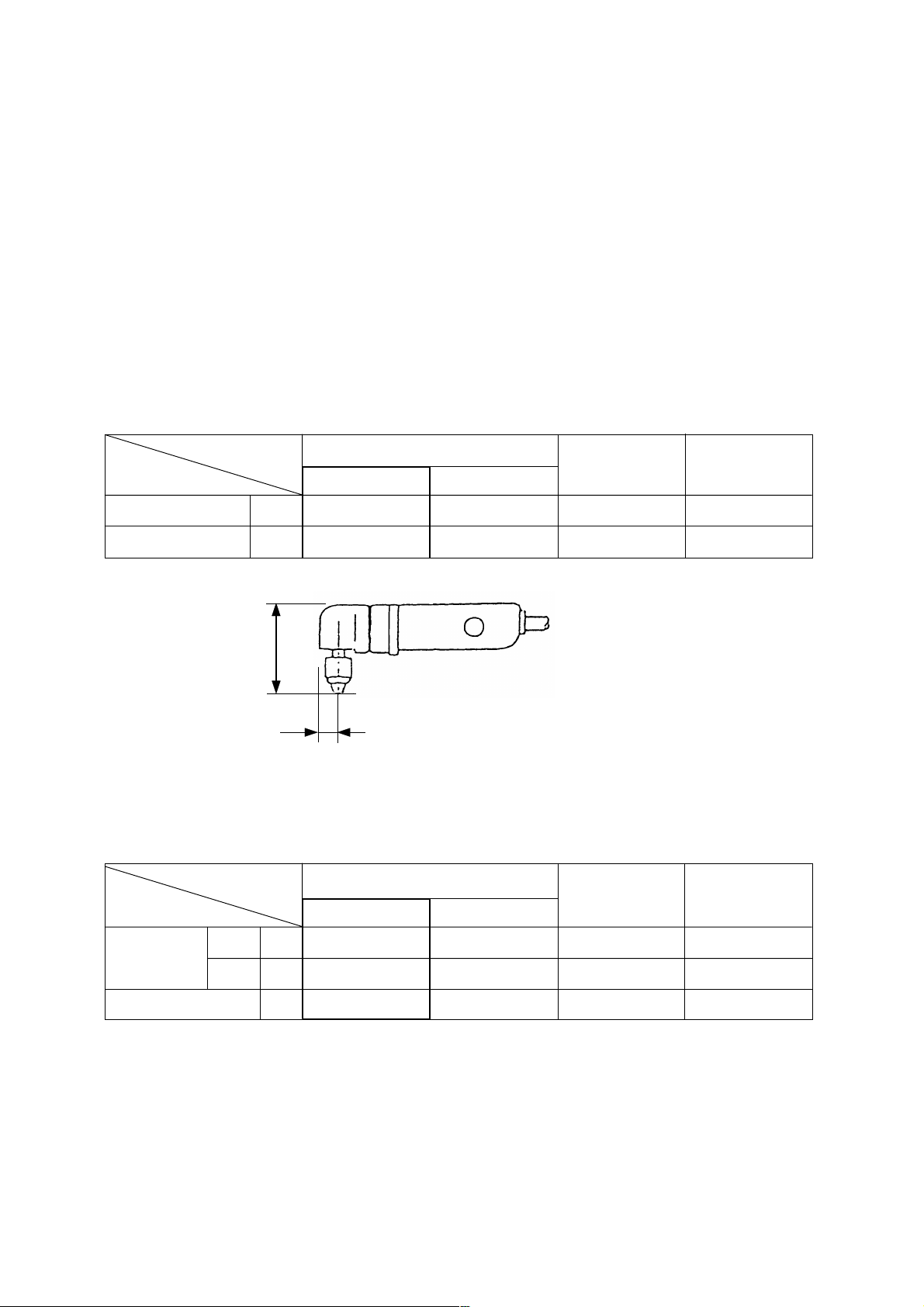

4-1-3. Smallest head in this class

The Model D 10YB has the smallest head (head height (h) 83 mm, center height (L) 22.5 mm) in this class for

efficient drilling in confined spaces.

Maker • Model

Item

h (Head height) mm

L (Center height) mm

D 10YB D 10YA

83 (3-1/4")

22.5 (7/8")

Hitachi

96 (3-3/4")

23 (15/16")

B

C

88 (3-1/2") 87 (3-3/8")

23 (15/16") 25 (1")

h

L

4-1-4. Powerful 500 W motor

Thanks to the powerful 500 W motor, the maximum drilling capacity in wood is increased to 22 mm dia.

The Model D 10YB can be used for a wider range of drilling work.

Maker • Model

Item

D 10YB D 10YA

Hitachi

B

C

Drilling

capacity

Steel mm

Wood mm

Power consumption W

10 (3/8")

22 (7/8")

10 (3/8")

15 (5/8")

500 (0.67 HP) 400 (0.54 HP)

--- 2 ---

10 (3/8") 10 (3/8")

22 (7/8") 15 (5/8")

400 (0.54 HP)

300 (0.40 HP)

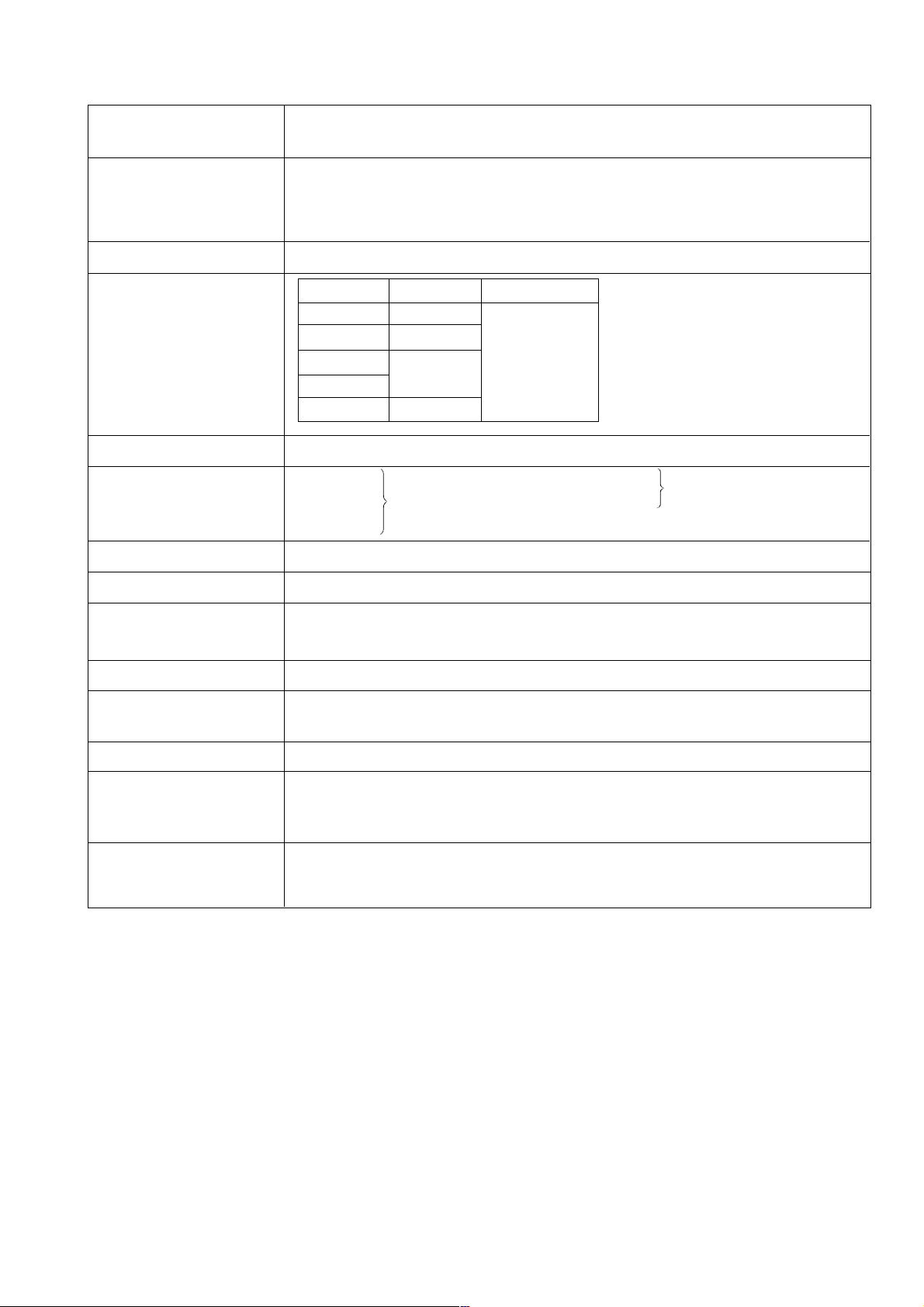

5. SPECIFICATIONS

Capacity

Drill chuck

Power source

Voltage, current and

power input

Type of motor

Enclosure

Insulation structure

Steel: 10 mm (3/8")

Wood: 22 mm (7/8")

Mount type: 3/8"-24UNF

Chuck: 10 TLRD

Capacity: 1.5 to 10 mm (1/16" to 3/8")

AC single phase 50/60 Hz

Voltage (V) Current (A) Power input (W)

110 4.8

115 4.6

220

2.3

500

(0.67 HP)

230

240

2.2

Single-phase series commutator motor

Housing

Tail cover

Polyamide resin

Inner cover

Double insulation

Gear cover

Chuck cover

Aluminum alloy die casting

Type of switch

Speed

Full-load output

Weight

Packaging

Cord

Standard accessories

* Net weight excludes cord.

Slide switch

No-load speed: 2,300/min.

Full-load speed: 1,820/min.

250 W (0.34 HP)

Net: 1.5 kg (3.3 lbs.)*

Packaged: 2.0 kg (4.4 lbs.)

Corrugated cardboard box

Type: 2-core cabtire cord

Nominal sectional area: 0.75 mm

Length: 2.5 m (8.2 ft.)

Side handle

Chuck handle

••••••••••••••••••••••••••••• 1

•••••••••••••••••••••••••••• 1

2

--- 3 ---

6. COMPARISONS WITH SIMILAR PRODUCTS

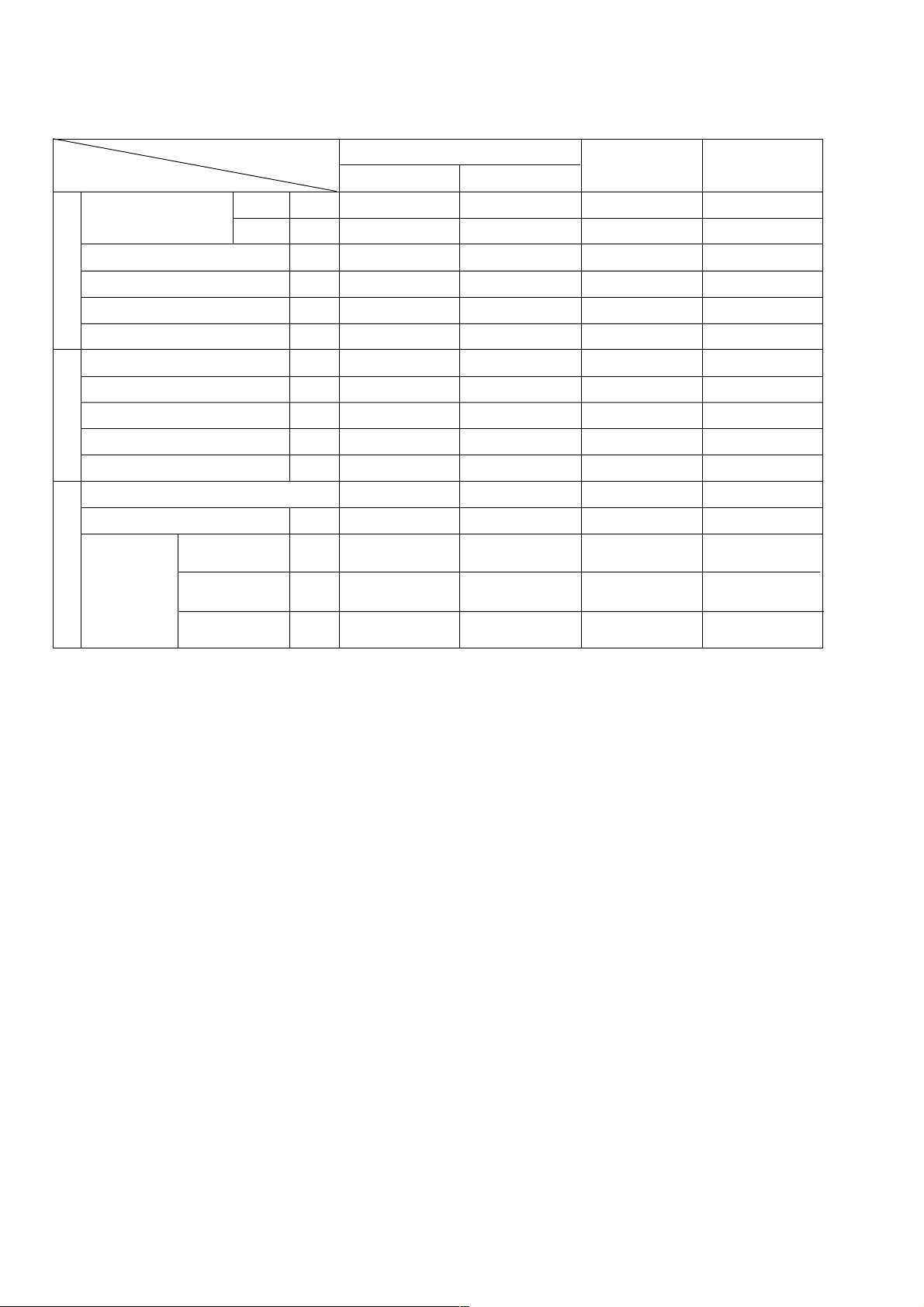

6-1. Specification Comparisons

Model

Item

Capacity

Drill chuck capacity

Input

No-load rotation speed

Weight**

Catalog specifications

Full-load rotation speed

Full-load output

Max. output

Max. torque

Characteristics

No-load sound pressure level

Side handle

Cord

Length x Width

Steel

Wood

mm

mm

mm

W

/min.

kg

/min.

W

W

N•m

dB(A)

m

mm

D 10YB

10 (3/8")

22 (7/8")

10 (3/8")

500* (0.67HP)

500 to 2,300

1.5 (3.3 lbs.)

1,650

250 (0.34 HP)

490 (0.66 HP)

12

78

Equipped

2.5 (8.2 ft.)

290 x 74

(11-7/16" x 2-29/32")

Hitachi

D 10YA

10 (3/8")

15 (5/8")

10 (3/8")

400 (0.54HP)

300 to 2,300

1.7 (3.8 lbs.)

230 (0.31 HP)

460 (0.62 HP)

Equipped

2.5 (8.2 ft.)

268 x 78

(10-9/16" x 3-1/16")

1,700

11

78

B

10 (3/8")

22 (7/8")

10 (3/8")

400 (0.54HP)

0 to 1,100

1.6 (3.5 lbs.)

950

120 (0.16 HP)

260 (0.35 HP)

10

81

None

2.5 (8.2 ft.)

290 x 59

(11-7/16" x 2-5/16")

C

10 (3/8")

15 (5/8")

10 (3/8")

300 (0.40HP)

0 to 1,400

1.6 (3.5 lbs.)

1,130

120 (0.16 HP)

250 (0.34 HP)

10

83

None

2.0 (6.6 ft.)

270 x 76

(10-5/8" x 3")

Dimensions Head height

Structural features

Center height

mm

mm

83 (3-1/4")

22.5 (7/8")

* Power input is subject to change by areas.

** Weight excludes cord.

96 (3-3/4")

23 (15/16")

88 (3-1/2")

23 (15/16")

87 (3-3/8")

25 (1")

--- 4 ---

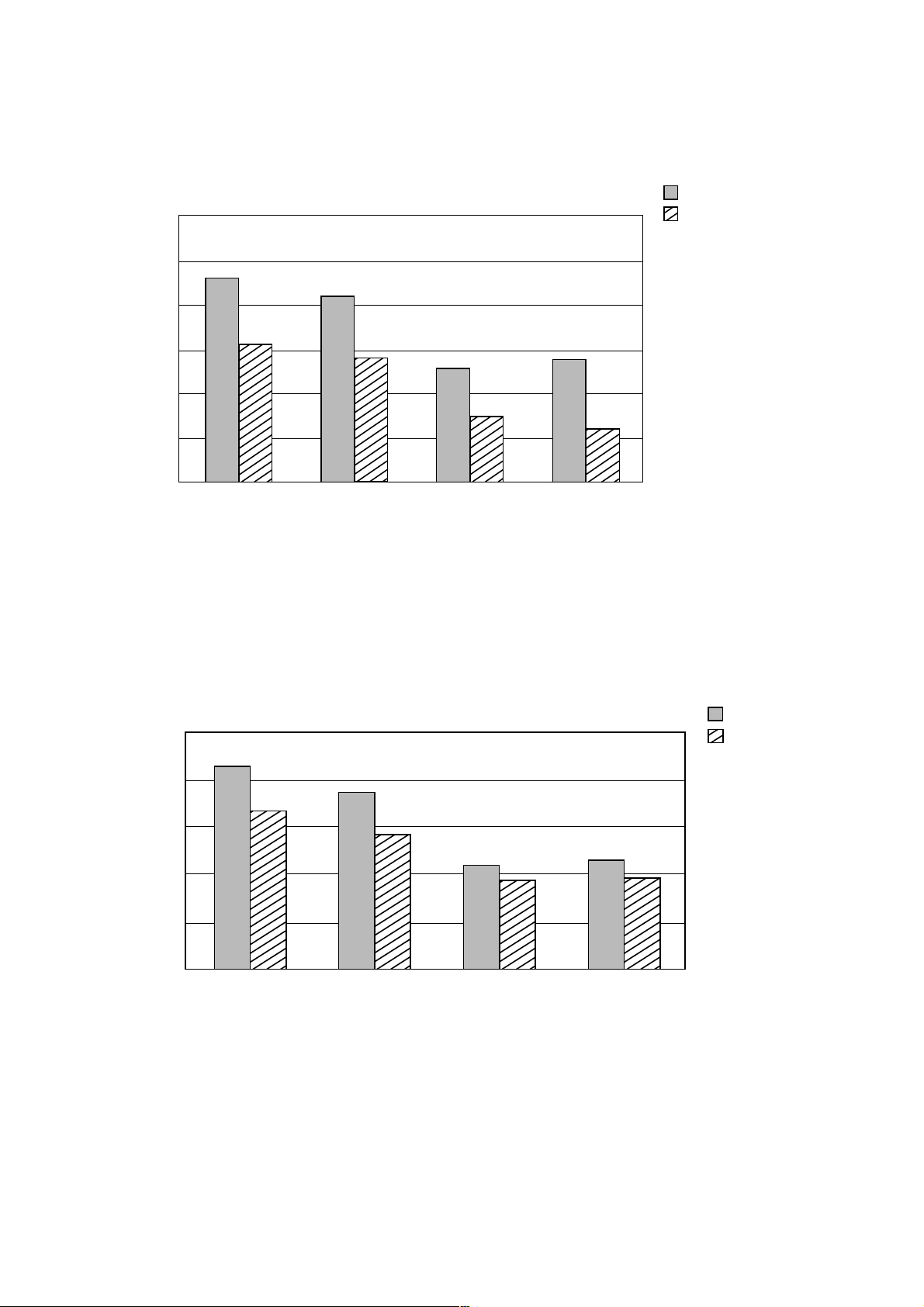

6-2. Drilling Speed Comparisons

The figures below show the drilling speed of the Model D 10YB compared with the competitors' existing models.

(1) Drilling in steel

6.5 mm dia.

30

25

20

15

10

5

10 mm dia.

Drilling speed (mm/min.)

0

D 10YB

Hitachi

D 10YA

Hitachi

B

C

(2) Drilling in wood

2,500

2,000

1,500

1,000

500

Drilling speed (mm/min.)

0

D 10YB

Hitachi

Model name

D 10YA

Hitachi

15 mm dia.

22 mm dia. *

* Note that 22 mm dia.

drilling is more than the

maximum capacity of

the Model D 10YA and

C.

B

C

Model name

--- 5 ---

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Model D 10YB Angle Drill by all of our

customers, it is very important that at the time of sale the salesperson carefully ensures that the buyer seriously

recognizes the importance of the contents of the Handling Instructions, and fully understands the meaning of the

precautions listed on the Name Plate attached to each tool.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric power tool cannot be completely eliminated.

Accordingly, general precautions and suggestions for the use of electric power tools, and specific precautions

and suggestions for the use of the Angle Drills are listed in the Handling Instructions to enhance the safe, efficient

use of the tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling

Instructions to be able to offer appropriate guidance to the customer during sales promotion.

7-2. Caution on Name Plate

Each Model D 10YB unit is provided with a Caution Plate (illustrated below) which lists basic safety precautions

for its use. Carefully ensure that the customer fully understands and follows these precautions before using the

tool.

(1) For Australia, New Zealand and China

(2) For the U.S.A. and Canada

--- 6 ---

8. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY

The [Bold] numbers in the descriptions below correspond to the item numbers in the parts list and exploded

assembly diagram.

8.1 Disassembly

(1) Replacement of the drill chuck

(a) Insert the Chuck Handle 10TLRD [26] into the Drill Chuck 10TLRD [25] until the Drill Chuck 10TLRD [25] is

secured to the Chuck Cover [21] (See Fig. 1). To avoid damage to the Chuck Cover [21], put a cloth between

the Chuck Cover [21] and the Chuck Handle 10TLRD [26].

(b) Insert a flat-blade screwdriver into the Drill Chuck 10TLRD [25] and remove the Flat Hd. Screw (Left Hand)

M5 x 15 [27].

(c) The Drill Chuck 10TLRD [25] is secured to the Spindle [19] with screws. Insert the Chuck Handle 10TLRD

[26] into the Drill Chuck 10TLRD [25] and strongly tap it with a wooden hammer counterclockwise viewing

from the Drill Chuck 10TLRD [25] side. Then the Drill Chuck 10TLRD [25] can be removed.

Put a cloth to avoid damage to the chuck cover.

Chuck Handle 10TLRD [26]

Flat Hd. Screw (Left Hand) M5 x 15 [27]

Fig. 1

(Note) When the drill chuck cannot be removed by tapping:

Remove the four Tapping Screws D5 x 40 [1] and the pinion ass'y (assembly of the First Gear [5], Ball Bearing

[3] and the Second Pinion [4]).

Remove the four Seal Lock Hex. Socket Hd. Bolts M3 x 12 [22] and tap the Gear Cover [2] strongly with a

wooden hammer to remove the Chuck Cover [21], Spindle [19] and others together (See Fig. 2). At this time,

be sure to tap on the two screw holes, not the center of the Gear Cover [2]. Otherwise, the Gear Cover [2] may

be deformed.

Secure the J-309 tool in a vise. Insert the pin of the J-309 tool into the hole at the rear of the Gear [20] and

Drill Chuck 10TLRD [25]

loosen the Drill Chuck 10TLRD [25]. When it is difficult to loosen the Drill Chuck 10TLRD [25] with a hex. bar

wrench, use another tool such as a pipe to lengthen the handle and increase leverage (See Fig. 3).

--- 7 ---

Gear Cover [2]

Tap on these two holes

from the bottom.

J-309 tool

Fig. 2

(2) Disassembly of the spindle section

(a) Remove the four Seal Lock Hex. Socket Hd. Botls M3 x 12 [22] and remove the Chuck Cover [21].

(b) Remove the four Tapping Screws D5 x 40 [1] from the Gear Cover [2] and remove the Gear Cover [2] from the

Inner Cover [8]. At this time, the pinion ass'y (assembly of the Ball Bearing [3], Second Pinion [4] and First

Gear [5]) can be removed. If the pinion ass'y remains in the Inner Cover [8], tap the end surface of the Inner

Fig. 3

Secured to the vise.

Hex. bar wrench

Drill Chuck 10TLRD [25]

Gear [20]

Secure two pins of the

J-309 tool into the holes

at the rear of the gear.

Pin (J-309)

Cover [8], and the pinion ass'y can be removed.

(c) Tap the flush surfaces of the Gear Cover [2] and the Inner Cover [8] with a wooden hammer. Then the pinion

ass'y (assembly of the Ball Bearing [3], Second Pinion [4] and First Gear [5]) can be removed from the Gear

Cover [2] with the First Gear [5] and the Ball Bearing [3] press-fitted.

(d) Use the J-310 tool for disassembly of the Spindle [19] because the Spindle [19] is press-fitted to the Ball

Bearing [18] which is secured to the Gear Cover [2] with the two Flat Fillister Hd. Screws M4 x 10 [17].

Set up the J-310 tool as shown in Fig. 4 and then pull out the Spindle [19] by turning the sleeve clockwise with

a wrench.

(e) Place the Gear [20] on a cylindrical jig and press down on the Spindle [19] to remove the Gear [20] from the

Spindle [19] (See Fig. 5).

(f) Remove the Flat Fillister Hd. Screw M4 x 10 [17] from the Ball Bearing [18] and tap the Gear Cover [2] with a

wooden hammer. Then, the Ball Bearing [18] can be removed.

Sleeve (J-136)

Holder plate (J-310)

Sleeve nut (J-310)

22 mm wrench

Left-hand screw

Spindle [19]

Flat Fillister Hd. Screw M4 x 10 [17]

Gear Cover [2]

--- 8 ---

Gear [20]

Ball Bearing [18]

Fig. 4

(3) Disassembly of the second pinion

(a) Place the end surface of the First Gear [5] on a cylindrical jig and press down on the Second Pinion [4] with a

hand press. Then the Second Pinion [4] can be removed (See Fig. 6).

Press down

Press down

Second Pinion [4]

Spindle [19]

Gear [20]

First Gear [5]

Cylindrical jig

Cylindrical jig

18 mm dia.

15 mm dia.

Fig. 5

Fig. 6

(4) Disassembly of the power source section

(a) Loosen the two Tapping Screws (W/Flange) D4 x 16 [41], remove the Tail Cover [40] from the Housing Ass'y

[32] and then remove the Spring [47].

(b) Disconnect the terminal of the neutral conductor internal wire (transparent) for the noise suppressor coming

from the Controller Circuit Holder [34] from the Housing Ass'y [32] (only the products with noise suppressor).

(c) The Connector 50091 [49] which clamps the internal wire (black) coming from the Controller Circuit Holder

[34] and the internal wire coming from the Stator Ass'y [13] is secured at the protrusion of the Controller

Circuit Holder [34]. Remove the Connector 50091 [49] by lifting the tip portion with a small screwdriver

(See Fig. 7).

Connector 50091 [49]

(connecting the stator ass'y and the controller circuit holder)

Protrusion of the controller circuit holder

Fig. 7

Remove the connector by lifting the tip portion

with a small screwdriver.

(d) Remove the Brush Holder [28] from the Housing Ass'y [32]. Pull out the terminals of the internal wires (blue

and brown) from the Reversing Switch [48] from the Brush Holder [28].

(e) Remove the Reversing Switch [48] by slightly pushing the protrusion of the Controller Circuit Holder [34] which

holds the Reversing Switch [48]. Be careful not to apply excessive force to the protrusion to prevent damages

to the protrusion.

(f) Disconnect the two internal wires of the Stator Ass'y [13] from the Reversing Switch [48] terminals.

(g) Loosen the two Tapping Screws (W/Flange) D4 x 16 [36] on the Cord Clip [35] and the machine screw M3.5

on the Switch [46]. Remove the Cord [42] from the Controller Circuit Holder [34].

--- 9 ---

(h) Remove the Switch [46] by slightly pushing the two protrusions of the Controller Circuit Holder [34].

Be careful not to apply excessive force to the protrusions to prevent damages to the protrusions.

(i) Loosen the two Tapping Screws (W/Flange) D4 x 20 [37] and remove the Controller Circuit Holder [34] from

the Housing Ass'y [32].

(5) Disassembly of the armature and the stator

(a) Remove the four Tapping Screws D5 x 40 [1] from the Gear Cover [2] and insert a screwdriver between the

Inner Cover [8] and the Housing Ass'y [32]. Pry the assembly of the Gear Cover [2], Inner Cover [8] and

Armature [10] off with the screwdriver. At this time, be sure to remove the Carbon Brushes [29].

(b) Remove the Fan Guide [11]. Remove the two Hex. Hd. Tapping Screws D4 x 70 [12] from the Stator Ass'y

[13] and tap the end surface of the Housing Ass'y [32] slightly with a wooden hammer. Then, the Stator Ass'y

[13] can be removed. Before removing the Stator Ass'y [13], disconnect the internal wires and remove the

Brush Holders [28] from the Housing Ass'y [32].

8.2 Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to the following items.

8.2.1 Reassembly of the spindle section

(1) First, mount the Chuck Cover [21], Felt Packing (A) [23], Felt Packing [24] and the Drill Chuck 10TLRD [25]

and then tighten the Spindle [19] and the Drill Chuck 10TLRD [25] at the proper tightening torque using the

J-309 tool. Next, tighten the Flat Hd. Screw (Left Hand) M5 x 15 [27] (See Fig. 8).

(2) Secure the Ball Bearing [18] to the Gear Cover [2] with the Flat Fillister Hd. Screw M4 x 10 [17]. Hold the

head of the Gear Cover [2] and press down on the end surface of the Drill Chuck 10TLRD [25] with a hand

press to press-fit the spindle section into the above assembly.

End surface of drill chuck

Flat. Hd. Screw (Left Hand) M5 x 15 [27]

Drill Chuck 10TLRD [25]

Chuck Cover [21]

Felt Packing [24]

Felt Packing (A) [23]

Gear [20]

Spindle [19]

J-309

Secure with a vise.

Fig. 8

--- 10 ---

8.2.2 Reassembly of the power source section

(1) Before inserting the Stator Ass'y [13] into the Housing Ass'y [32], be sure to mount the Slide Bar [45].

(2) Insert the Stator Ass'y [13] into the Housing Ass'y [32] in the direction shown in Fig. 9, paying attention to the

direction of the internal wires of the Stator Ass'y [13]. Connect the four internal wires of the Stator Ass'y [13]

to the parts specified in Fig. 9.

Connect to the terminal No. 3

of the reversing switch.

Connect to the terminal No. 3 of the switch

and secure with the machine screw M3.5.

Clamp with the internal wire (black)

of the controller circuit holder.

Connect to the terminal No. 1

of the reversing switch.

Fig. 9

(3) Secure the Connector 50091[49] that clamps the internal wires (black) of the Stator Ass'y [13] and the

Controller Circuit Holder [34] under the protrusion of the Controller Circuit Holder [34] by pushing it in as

shown in Fig. 10.

(4) Be sure to push the internal wire (brown) coming from the Reversing Switch [48] in the gap shown in Fig. 10.

Otherwise, the internal wire may be caught by the Spring [47] and the switch may be out of work.

Connector [49]

(connecting the stator ass'y and the controller circuit holder)

Push the internal wire in this gap.

Push in the connector under the protrusion.

Protrusion of the controller circuit holder

Fig. 10

--- 11 ---

8-3. Wiring Diagram and Internal Wire Arrangement

(1) For models with noise suppressor and choke coils

Blue

Choke coil

Armature

Choke coil

Brown

Red: from the control circuit

Control circuit

Reversing

switch

5

2

Black or blue

or white

CR unit *

Black Black

1

Control circuit

Stator

3

coil

Connector

Black

Wiring diagram

Black or blue or white:

from the control circuit

Black

Black or

blue or

white

Red

ON-OFF switch

3

Noise suppressor

Pillar terminal

* Only 230 V product for Europe

Black or blue or white:

from the stator

1

Cord

Cord

Brown: from the reversing switch

Black: from the

Black: from the stator

control circuit

Black: from the statorNoise suppressor

Black or blue or white:

from the stator

Choke coil

Blue: from the

reversing switch

Lead wire arrangement

Black:

from the stator

--- 12 ---

Reversing

switch

(2) For models without noise suppressor and choke coils (except for U.S.A. and Canada)

Brown

Control circuit

Cord

Blue

Reversing

switch

5

2

Red: from the

control circuit

Black

1

3

Black

or blue

Black

Stator

coil

Control circuitArmature

Stator

coil

Connector

Black

Wiring diagram

Black or blue:

from the control circuit

Black

ON-OFF switch

3

Black

or blue

Connector

Red

Black or blue:

from the stator

1

Cord

Brown:

from the reversing switch

Black:

from the stator

Blue:

from the reversing switch

Black:

from the control circuit

Black:

from the stator

Black:

from the stator

Black or blue:

from the stator

Reversing switch

Internal wire arrangement

--- 13 ---

(3) For U.S.A. and Canada

Blue

Armature

Brown

Control circuit

Cord

Reversing

switch

5

2

Red: from the

control circuit

Black

1

3

White

Black

Stator

coil

Control circuit

Stator

coil

Connector

BlackBlack

Wiring diagram

White :

from the control circuit

ON-OFF switch

3

White

Red

Pillar terminal

White: from the stator

1

Cord

Black:

from the stator

Blue: from the

reversing switch

Brown:

from the reversing switch

Black:

from the control circuit

Black:

from the stator

Internal wire arrangement

Black:

from the stator

White: from the stator

Reversing

switch

--- 14 ---

8-4. Lubrication

(1) Grease to be used: Motor Grease No. 29

(Code No. 930035)

(Code No. 930038)

•••

100 g tube

•••

2.5 kg can

(2) Apply Motor Grease No. 29 to the following portions.

Inside of the Gear Cover [2] (Apply 5 g of this grease to a new gear cover.)

Needle bearing in the Chuck Cover [21]

Tooth portion of the Gear [20]

Pinion portion of the Second Pinion [4]

Tooth portion of the First Gear [5]

Pinion portion of the Armature [10]

8-5. Tightening Torque

(1) Hex. Hd. Tapping Screw D4 x 70 [12]

(2) Tapping Screw (W/Flange) D4 x 16 [36]

(3) Tapping Screw (W/Flange) D4 x 20 [37]

(4) Tapping Screw (W/Flange) D4 x 16 (Black) [41]

(5) Tapping Screw D5 x 40 (Black) [1]

(6) Flat Fillister Hd. Screw M4 x 10 [17]

(7) Machine Screw M3.5 (for securing the Switch [46])

(8) Seal Lock Hex. Socket Hd. Bolt M3 x 12 [22]

(9) Flat Hd. Screw (Left Hand) M5 x 15 [27]

(10) Drill Chuck 10TLRD [25]

••••••••••••••••••••••••••••••••••••••••••••

••••••••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••••••••••••••

••••••••••••

••••••••••••••••••••••••••••••

•••••••••••••••••••••••••••••

•••••••

••••••••••••••••

•••••••••••••••••••••••

2.0 0.5 N•m (20 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

2.0 0.5 N•m (20 5 kgf•cm)

2.9 0.5 N•m (30 5 kgf•cm)

1.5 0.3 N•m (15 3 kgf•cm)

0.59 0.15 N•m (6 1.5 kgf•cm)

2.45 0.49 N•m (25 5 kgf•cm)

3.4 0.7 N•m (35 7 kgf•cm)

24.5 to 29.4 N•m (250 to 300 kgf•cm)

8-6. Insulation Tests

On completion of disassembly after repair, measure the insulation resistance and conduct a dielectric

strength test.

Insulation resistance: 7 MΩ or more with DC 500 V Megohm Tester

Dielectric strength: AC 4,000 V/1 minute, with no abnormalities

•••

220 V --- 240 V

(and 110 V for U.K. products)

AC 2,500 V/1 minute, with no abnormalities

•••

110 V --- 115 V

(except U.K. products)

8-7. No-load Current Value

After no-load operation for 30 minutes, the no-load current values should be as follows (dial setting "5"):

Voltage (V)

Current (A) max.

110 115

2.1 2.2

220 230 240

1.0 1.1 1.1

--- 15 ---

9. STANDARD REPAIR TIME (UNIT) SCHEDULES

MODEL 10 20 30 40

Fixed

Variable

Work Flow

D 10YB

Housing Ass'y

Stator Ass'y

General Assembly

First Gear

Ball Bearing

(606ZZ)

Second Pinion

Ball Bearing

(6001VV)

Tail Cover

Cord

Controller

Circuit Holder

Switch

Reversing

Inner Cover

Ball Bearing

(608DD)

Ball Bearing

(626VV)

Armature

Gear Cover

Ball Bearing

(607VV)

Spindle

Gear

Chuck Cover

Switch

50

60 min.

--- 16 ---

Assembly Diagram for D 10YB

--- 17 ---

PARTS

ITEM

* 10 360-528U ARMATURE ASS'Y 110V-115V 1 INCLUD.9,15,16

* 10 360-528E ARMATURE 220V-230V 1

* 10 360-528F ARMATURE 240V 1

* 13 340-469C STATOR ASS'Y 110V-115V 1 INCLUD.14

* 13 340-469G STATOR ASS'Y 220V-230V 1 INCLUD.14

* 13 340-469E STATOR ASS'Y 220V-230V 1 INCLUD.14 FOR NZL,AUS,GBR(230V),ITA,

* 13 340-469F STATOR ASS'Y 240V 1 INCLUD.14

* 34 319-059 CONTROLLER CIRCUIT HOLDER 1

* 34 319-060 CONTROLLER CIRCUIT HOLDER 1 FOR UAE,AUS

* 34 319-058 CONTROLLER CIRCUIT HOLDER 1 FOR GBR (110V),USA

* 38 980-063 TERMINAL 1 FOR CORD

* 42 500-409Z CORD 1 (CORD ARMOR D8.8)

* 42 500-468Z CORD 1 (CORD ARMOR D8.8) FOR THA,CHN

CODE NO. DESCRIPTION

NO.

1 316-458 TAPPING SCREW D5X40 (BLACK) 4

2 318-828 GEAR COVER 1

3 600-1VV BALL BEARING 6001VVCMPS2L 1

4 318-833 SECOND PINION 1

5 318-834 FIRST GEAR 1

6 606-ZZM BALL BEARING 606ZZC2PS2L 1

7 931-701 BEARING LOCK 1

8 318-827 INNER COVER 1

9 608-DDM BALL BEARING 608DDC2PS2L 1

11 306-840 FAN GUIDE 1

12 982-021 HEX. HD. TAPPING SCREW D4X70 2

14 980-063 TERMINAL 1

15 313-775 DUST SEAL 1

16 626-VVM BALL BEARING 626VVC2PS2L 1

17 985-414 FLAT FILLISTER HD. SCREW M4X10 2

18 607-VVC BALL BEARING 607VVC2PS2L 1

19 318-830 SPINDLE 1

20 318-829 GEAR 1

21 318-831 CHUCK COVER 1

22 318-832 SEAL LOCK HEX. SOCKET HD. BOLT M3X12 4

23 936-973 FELT PACKING (A) 1

24 943-153 FELT PACKING 1

25 318-835 DRILL CHUCK 10TLRD 1 INCLUD.26

26 319-070 CHUCK HANDLE 10TLRD 1

27 317-995 FLAT HD. SCREW (LEFT HAND) M5X15 1

28 313-777 BRUSH HOLDER 2

29 999-021 CARBON BRUSH (1 PAIR) 2

30 936-551 BRUSH CAP 2

31 309-929 RUBBER BUSHING 1

32 318-839 HOUSING ASS'Y 1 INCLUD.31

33 NAME PLATE 1

35 937-631 CORD CLIP 1

36 984-750 TAPPING SCREW (W/FLANGE) D4X16 2

37 305-095 TAPPING SCREW (W/FLANGE) D4X20 2

39 953-327 CORD ARMOR D8.8 1

40 318-836 TAIL COVER 1

41 307-811

TAPPING SCREW (W/FLANGE) D4X16 (BLACK)

: ALTERNATIVE PARTS

*

--- 18 ---

NO.

USED

FRG,FRA,HOL,FIN,AUT,NOR,ESP,SUI,CHN

2

REMARKS

D 10YB

---

4

00

PARTS

ITEM

* 42 500-423Z CORD 1 (CORD ARMOR D8.8) FOR SIN,UAE

* 42 500-436Z CORD 1 (CORD ARMOR D8.8) FOR HKG,GBR (230V)

* 42 500-439Z CORD 1 (CORD ARMOR D8.8) FOR NZL,AUS

* 42 500-237Z CORD 1 (CORD ARMOR D8.8) FOR GBR (110V)

* 42 500-447Z CORD 1 (CORD ARMOR D8.8) FOR SUI

* 42 500-240Z CORD 1 (CORD ARMOR D8.8) FOR USA

* 46 314-603 SWITCH (1P SOLDER TYPE) 1

* 46 955-509 SWITCH (1P SCREW TYPE) 1 FOR THA,INA,SIN,HKG,UAE

* 48 319-061 REVERSING SWITCH 1

* 48 318-838 REVERSING SWITCH 1 FOR THA,INA,SIN,HKG,UAE,USA

* 50 938-307 PILLAR TERMINAL 1 EXCEPT FOR THA,INA,SUN,HKG,UAE

CODE NO. DESCRIPTION

NO.

43 HITACHI LABEL 1

44 318-825 SLIDE KNOB 1

45 318-826 SLIDE BAR 1

47 314-429 SPRING 1

49 959-140 CONNECTOR 50091 (10 PCS.) 2

NO.

USED

REMARKS

D 10YB

---

4

00

: ALTERNATIVE PARTS

*

--- 19 ---

STANDARD ACCESSORIES

ITEM

CODE NO. DESCRIPTION

NO.

501 956-633 SIDE HANDLE 1

NO.

USED

D 10YB

REMARKS

: ALTERNATIVE PARTS

*

--- 20 ---

Printed in Japan

(000425 N)

---

4

00

Loading...

Loading...