Page 1

Page 2

Page 3

Page 4

3

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in damp

or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should be

stored in a dry, high or locked up place, out of reach

of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool. Do

not use tools for purposes not intended; for example,

do not use circular saw to cut tree limbs or logs.

8. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are

recommended when working outdoors. Wear

protecting hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask if

the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle.

Keep the cord away from heat, oil and sharp edges.

12. Secure work. Use clamps or a vise to hold the work.

It is safer than using your hand and it frees both

hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing

accessories. Inspect tool cords periodically and if

damaged, have it repaired by authorized service

center. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean, and

free from oil and grease.

15. Disconnect tools. When not in use, before servicing,

and when changing accessories such as blades, bits

and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a pluggedin tool with a finger on the switch. Ensure switch is

off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

20. Check damaged parts. Before further use of the tool,

a guard or other part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment of moving parts, free running of

moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A

guard or other part that is damaged should be

properly repaired or replaced by an authorized

service center unless otherwise indicated in this

handling instructions. Have defective switches

replaced by an authorized service center. Do not use

the tool if the switch does not turn it on and off.

21. Warning

The use of any accessory or attachment, other than

those recommended in this handling instructions,

may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

PRECAUTIONS ON USING DRILL

1. Hold the drill and side handle securely with both hands

when using.

2. Do not wear gloves made of stuff liable to roll up such

as cotton, wool, cloth or string, etc.

3. Prior to drilling into walls, ceilings or floors, ensure

there are no electric cables or conduits inside.

Page 5

4

STANDARD ACCESSORIES

(1) Side handle ................................................................. 1

(2) Stopper ........................................................................ 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

(1) Hook

(2) Plastic case

Optional accessories are subject to change without notice.

APPLICATIONS

䡬 Boring holes in metal, wood and plastic.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, inviting serious accident.

3. Extension cord

When the work area is removed from the power

source. Use an extension cord of sufficient thickness

and rated capacity. The extension cord should be kept

as short as practicable.

4. Selecting the appropriate drill bit:

䡬 When boring metal or plastic

Use ordinary metalworking drill bits.

䡬 When boring wood

Use ordinary woodworking drill bits.

However, when drilling 6.5 mm or smaller holes, use

a metalworking drill bit.

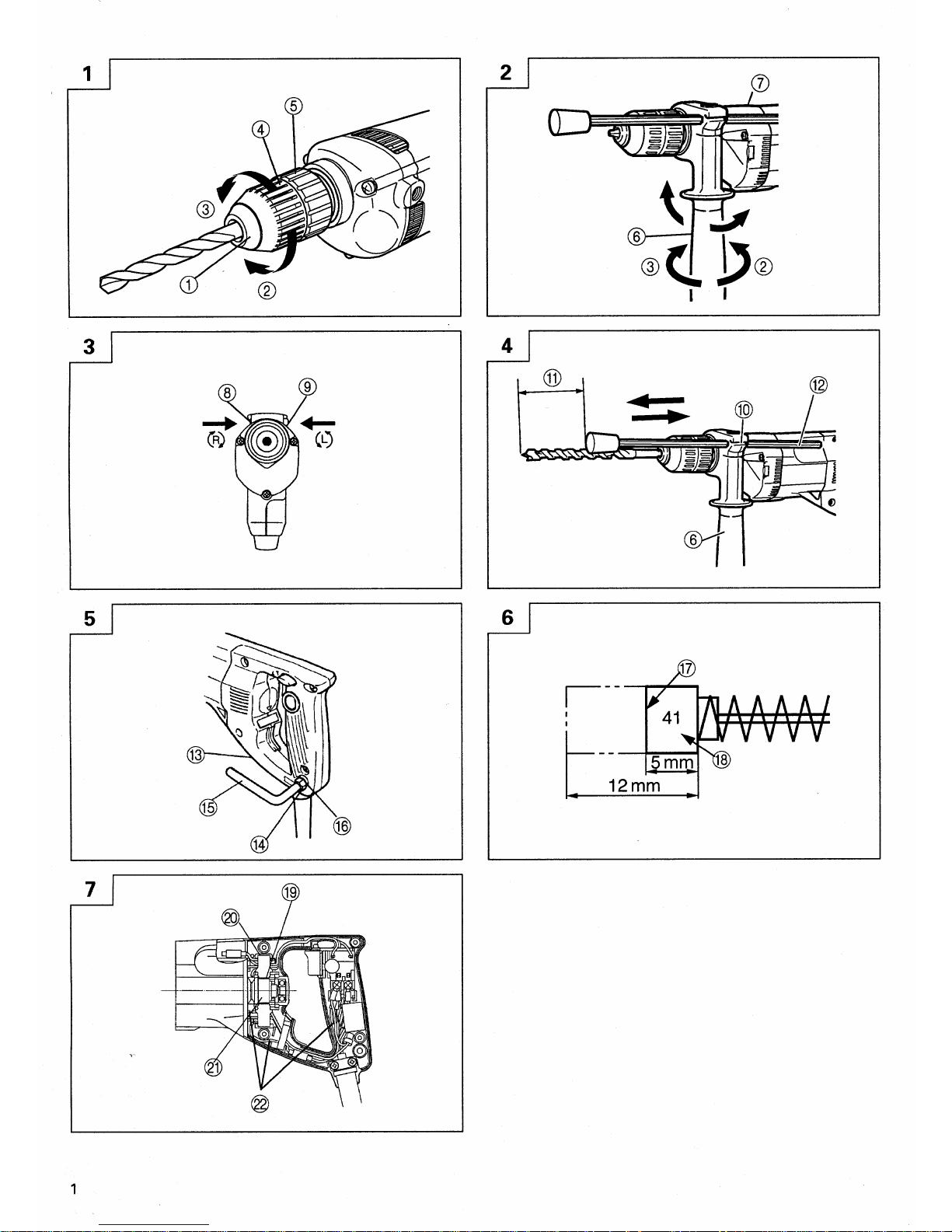

5. Mounting and dismounting of the bit (Fig. 1)

(1) Open the chuck jaws, and insert the bit into the chuck.

To open the chuck jaws, hold the ring while turning

the sleeve in the counterclockwise direction (viewed

from the front side).

(2) Firmly grasp the ring and turn the sleeve in the

clockwise direction. Tighten securely.

(3) To remove the bit, firmly grasp the ring and turn the

sleeve in the counterclockwise direction.

6. Side handle attachment (Fig. 2)

Attach the side handle to the mounting part.

Rotate the side handle grip in a clockwise direction to

secure it.

Set the side handle to a position that is suited to the

operation and then securely tighten the side handle

grip.

7. Check the rotational direction (Fig. 3)

The bit rotates clockwise (viewed from the rear side)

by pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise.

(The

and marks are provided on the body.)

8. Install the stopper (Fig. 4)

(1) Loosen the side handle and insert the straight portion

of the stopper into the handle bolt hole.

(2) Move the stopper to the specified position and rotate

the grip of the side handle clockwise to fix the stopper.

9. Installing the hook (optional accessory) (Fig. 5)

(1) Insert the hook into the hole of Section A on the main

body and turn it clockwise.

When the nut reaches the washer surface of the handle

cover, tighten it with a wrench.

(2) It is also possible to install the hook on the opposite

side. To do so, follow the same procedures mentioned

above.

(3) It is possible to hang the hook on a waist belt or a

pipe up to maximum 28 mm in diameter, and so on.

CAUTION:

When the power tool is used with a hook fixed to it, pay

attention to the following points:

䡬 Before hanging the main unit from the waist belt,

make sure that the drill has come to a complete stop.

While it is suspended from the waist belt, the power

plug must be disconnected from the power source.

䡬 Do not walk about with the power tool hanging from

the waist belt.

䡬 In the case of operation in a high place, it is

dangerous to drop the tool accidentally. If the hook

is deformed or hung from the wrong position, there

is danger that the hook will slip off and the tool will

fall.

Be careful to avoid danger.

䡬 In making a through hole, the power tool sometimes

shakes violently when the workpiece is pierced, from

example. Be careful you are not hurt by the hook

even if such situation happens.

SPECIFICATIONS

Voltage 110V 50/60 Hz

Power input 500 W

No-load speed 1700/min

Drill chuck capacity 10 mm

Capacity

Steel 10 mm

Wood 25 mm

Weight (without cord) 1.6 kg

Page 6

5

HOW TO USE

1. Switch operation

䡬 When the trigger is depressed, the tool rotates.

When the trigger is released, the tool stops.

䡬 Pulling the trigger and pushing the stopper, it keeps

the switched-on condition which is convenient for

continuous running. When switching off, the stopper

can be disconnected by pulling the trigger again.

2. Drilling

䡬 Always apply pressure in a straight line with the bit.

Use enough pressure to keep drilling, but do not push

hard enough to stall the motor or deflect the bit.

䡬 To minimize stalling or breaking through the material,

reduce pressure on drill and ease the bit through the

last part of the hole.

䡬 If the drill stalls, release the trigger immediately,

remove the bit from the work and start again. Do not

click the trigger on and off in an attempt to start a

stalled drill. This can damage the drill.

䡬 The larger the drill bit diameter, the larger the reactive

force on your arm.

Be careful not to lose control of the drill because of

this reactive force.

To maintain firm control, establish a good foothold,

use side handle, hold the drill tightly with both hands,

and ensure that the drill is vertical to the material being

drilled.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of an abraded drill bits will cause motor

malfunctioning and degraded efficiency, replace the

drill bits with a new one or resharpening without delay

when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do

so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes (Fig.6)

The motor employs carbon brushes which are

consumable parts. Since an excessively worn carbon

brush could result in motor trouble, replace a carbon

brush with a new one which has the same brush No.

shown in the figure when it becomes worn to or near

the ‘wear limit’. In addition, always keep carbon

brushes clean and ensure that they slide freely within

the brush holders.

5. Replacing a carbon brush (Fig.7)

<Disassembly>

(1) Loosen four machine screws and remove the handle

cover.

(2) Pull out the brush holder together with the carbon

brushes. Exercise adequate care not to excessively

strain the lead wire or damage it.

(3) Remove the carbon brushes from the brush holder.

<Assembly>

(1) Insert new carbon brushes in the brush holder .

(2) Insert the brush holder together with carbon brushes

into the brush holder chamber in the housing.

(3) Carefully ascertain that the internal wiring and so on

are located at their regular positions, and that there

is no possibility of the rotray part (armature) being

contacted by the internal wiring or other items.

(4) Reinstall the handle cover while exercising adequate

care not to allow the internal wiring and so on to

become caught in the housing, then tighten the handle

cover with four machine screws.

CAUTIONS

䡬 When reassembling after replacing the carbon

brushes, be sure to follow this assembling procedure.

䡬 When replacing the carbon brushes, do not tamper

with parts other than those necessary for replacing.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

Page 7

Page 8

Page 9

Page 10

9

Page 11

10

Page 12

Page 13

Loading...

Loading...