Page 1

SERVICE MANUAL

MANUEL D'ENTRETIEN

WARTUNGSHANDBUCH

CAUTION:

Before servicing this chassis, it is important that the service technician read the “Safety

Precautions” and “Product Safety Notices” in this service manual.

SM00026

CL43WP910TAN

CL55WP910AN

Data contained within this Service

manual is subject to alteration for

improvement.

ATTENTION:

Avant d’effectuer l’entretien du châassis, le technicien doit lire les «Précautions de sécurité»

et les «Notices de sécurité du produit» présentés dans le présent manuel.

VORSICHT:

Vor Öffnen des Gehäuses hat der Service-Ingenieur die „Sicherheitshinweise“ und „Hinweise

zur Produktsicherheit“ in diesem Wartungshandbuch zu lesen.

Les données fournies dans le présent

manuel d’entretien peuvent faire l’objet

de modifications en vue de perfectionner

le produit.

Die in diesem Wartungshandbuch

enthaltenen Spezifikationen können sich

zwecks Verbesserungen ändern.

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

COLOUR TELEVISION

DECEMBER 1999

Page 2

ENGLISH

SAFETY PRECAUTIONS

WARNING: The following precautions must be observed.

ALL PRODUCTS

Before any service is performed on the chassis an

isolation transformer should be inserted between the

power line and the product.

1. When replacing the chassis in the cabinet, ensure

all the protective devices are put back in place.

2. When service is required, observe the original

lead dressing. Extra precaution should be taken to

ensure correct lead dressing in any high voltage

circuitry area.

3. Many electrical and mechanical parts in

HITACHI products have special safety related

characteristics. These characteristics are often not

evident from visual inspection, nor can the

protection afforded by them necessarily be

obtained by using replacement components rated

for higher voltage, wattage, etc. Replacement

parts which have these special safety

characteristics are identified by marking with a

! on the schematics and the replacement parts

list.

The use of a substitute replacement component

that does not have the same safety characteristics

as the HITACHI recommended replacement one,

shown in the parts list, may create electrical

shock, fire, X-radiation, or other hazards.

4. Always replace original spacers and maintain lead

lengths. Furthermore, where a short circuit has

occurred, replace those components that indicate

evidence of overheating.

5. Insulation resistance should not be less than 2M

ohms at 500V DC between the main poles and

any accessible metal parts.

6. No flashover or breakdown should occur during

the dielectric strength test, applying 3kV AC or

4.25kV DC for two seconds between the main

poles and accessible metal parts.

7. Before returning a serviced product to the

customer, the service technician must thoroughly

test the unit to be certain that it is completely safe

to operate without danger of electrical shock. The

service technician must make sure that no

protective device built into the instrument by the

manufacturer has become defective, or

inadvertently damaged during servicing.

CE MARK

1. HITACHI products may contain the CE mark on

the rating plate indicating that the product

contains parts that have been specifically

approved to provide electromagnetic

compatibility to designated levels.

2. When replacing any part in this product, please

use only the correct part itemised in the parts list

to ensure this standard is maintained, and take

care to replace lead dressing to its original state,

as this can have a bearing on the electromagnetic

radiation/immunity.

PICTURE TUBE

1. The line output stage can develop voltages in

excess of 25kV; if the E.H.T. cap is required to be

removed, discharge the anode to chassis via a

high value resistor, prior to its removal from the

picture tube.

2. High voltage should always be kept at the rated

value of the chassis and no higher. Operating at

higher voltages may cause a failure of the picture

tube or high voltage supply, and also, under

certain circumstances could produce X-radiation

levels moderately in excess of design levels. The

high voltage must not, under any circumstances,

exceed 29kV on the chassis (except for projection

Televisions).

3. The primary source of X-radiation in the product

is the picture tube. The picture tube utilised for

the above mentioned function in this chassis is

specially constructed to limit X-radiation. For

continued X-radiation protection, replace tube

with the same type as the original HITACHI

approved type

4. Keep the picture tube away from the body while

handling. Do not install, remove, or handle the

picture tube in any manner unless shatterproof

goggles are worn. People not so equipped should

be kept away while picture tubes are handled

LASERS

If the product contains a laser avoid direct exposure to

the beam when the cover is open or when interlocks are

defeated or have failed.

2

Page 3

FRANÇAIS

CONSIGNES DE SECURITE

AVERTISSEMENT: vous devez respecter les précautions suivantes

POUR TOUS LES PRODUITS

Avant d’effectuer une intervention d’entretien sur le

châssis, vous devez insérer un transformateur d’isolement

entre la ligne d’alimentation électrique et le produit.

1. Lors de la remontage du châssis dans le coffret,

vérifiez que tous les dispositifs de protection sont

remis en place.

2. Lorsqu’une intervention d’entretien s’avère

nécessaire, respectez l’agencement d’origine des

conducteurs. Vous devez prendre des précautions

supplémentaires pour garantir un agencement correct

des conducteurs dans toutes les zones où des circuits

haute tension sont présents.

3. De nombreux composants électriques et mécaniques

des appareils HITACHI ont des caractéristiques

spéciales de sécurité. Bien souvent, ces

caractéristiques ne sont pas évidentes lors d’un

examen visuel et la protection qu’ils offrent n’est pas

forcément garantie si vous utilisez des composants de

rechange conçus, par exemple, pour une tension plus

élevée, une puissance plus forte. Les pièces de

rechange qui offrent des caractéristiques spéciales de

sécurité sont identifiées par un repérage comportant

le symbole ! sur les schémas et sur la

nomenclature des pièces de rechange.

L’emploi d’un composant de rechange qui ne

respecte pas les mêmes caractéristiques de sécurité

que la pièce de rechange que recommande HITACHI

et qui figure dans la nomenclature risque de

provoquer un choc électrique, un incendie, des rayons

X ou d’autres dangers.

4. Remettez toujours en place les entretoises d’origine

et respectez la longueur des conduites. En outre, à la

suite d’un court-circuit, remplacez les composants

présentant des signes de surchauffe.

5. La résistance d’isolement doit être supérieure ou

égale à 2 méga ohms à 500 V c.c. entre les pôles

principaux et des composants métalliques

accessibles, quels qu’ils soient.

6. Aucun claquage et aucune rupture ne doit se produire

pendant l’essai de résistance diélectrique à la suite de

l’application d’une tension de 3 kV c.a. ou de 4,35

kV c.c. pendant deux secondes entre les pôles

principaux et des composants métalliques

accessibles.

7. Avant de remettre au client un produit qui a fait

l’objet d’un entretien, le technicien qui s’est chargé

de cette intervention doit tester à fond cet ensemble

pour s’assurer qu’il ne présente aucun danger

opérationnel et aucun risque de choc électrique. Ce

technicien doit s’assurer qu’aucun des dispositifs de

protection intégrés à cet instrument par le fabricant

n’est défectueux ou n’a été endommagé de façon

accidentelle lors de l’entretien.

3

LABEL CE

1. Les produits HITACHI peuvent avoir reçu le label

CE qui figure sur la plaque signalétique pour indiquer

que cet ensemble contient des composants qui ont fait

l’objet d’une homologation spécifique de respect des

normes de compatibilité électromagnétique en

fonction de niveaux bien spécifiés.

2. Lors du remplacement d’un des composants de ce

produit, utilisez uniquement le composant correct

identifié dans la nomenclature afin de maintenir le

respect de cette norme ; en outre, vous devez

également ramener l’agencement des conducteurs à

son état d’origine car cela peut avoir une influence au

niveau des rayonnements électromagnétiques et sur la

protection contre ces rayons.

PICTURE TUBE

1. L’étage de sortie des lignes peut développer des

tensions de plus de 25 kV ; s’il faut retirer le chapeau

de protection contre les tensions extrêmement

élevées, il convient de décharger l’anode contre le

châssis par le biais d’une résistance de forte valeur

avant de déposer ce chapeau du tube image.

2. La haute tension doit toujours se maintenir à la valeur

nominale du châssis et ne pas dépasser cette dernière.

Un fonctionnement à des températures élevées peut

provoquer une défaillance du tube image ou l’entrée

d’une tension élevée. Dans certains cas, cela peut

même provoquer des rayons X d’un niveau

légèrement supérieur aux valeurs de calcul. Cette

haute tension ne doit en aucun cas dépasser 29 kV sur

le châssis (à l’exception des téléviseurs de

projection).

3. La principale source de rayons X de cet appareil est

le tube image. Le tube image employé pour assurer la

fonction susmentionnée dans ce châssis est

spécialement construit pour limiter des rayons X.

Pour maintenir cette protection contre les rayons X, il

faut remplacer le tube d’origine d’un type agréé par

HITACHI par un autre tube de même type.

4. Lors des manipulations, ne tenez jamais le tube

image contre le corps. Pendant toutes les opérations

d’installation, de dépose et de manipulation de ce

tube image, quelle que soit la méthode employée,

vous devez toujours porter des lunettes de sécurité

anti-éclatements. Les personnes qui ne portent pas ce

type de lunettes doivent se tenir à l’écart du tube

image lors de la manipulation de ce dernier.

RAYONS LASER

Si ce produit contient un rayon laser, évitez toute

exposition directe à ce faisceau lors de l’ouverture du

couvercle ou lors de l’élimination des verrouillages de

sécurité ou après défaillance de ces verrouillages.

Page 4

DEUTSCH

SICHERHEITSVORKEHRUNGEN

WARNUNG: Die folgenden Vorkehrungen müssen eingehalten werden.

ALLE PRODUKTE

Bevor die Grundplatte gewartet wird, sollte ein Trenntrafo

zwischen die Netzleitung und das Produkt eingebracht

werden.

1. Wenn die Grundplatte in das Gehäuse zurückgestellt

wird, stellen Sie sicher, dass alle

Schutzvorrichtungen wieder an ihrem Ort sind.

2. Wenn Wartung erforderlich ist, halten Sie die

originale Verdrahtungsart ein. Besondere Vorsicht ist

nötig, um die korrekte Verdrahtungsart in jedem

Hochspannungsstromkreis zu gewährleisten.

3. Viele elektrische und mechanische Teile von

HITACHI Produkten haben besondere

sicherheitsbezogene Eigenschaften. Diese

Eigenschaften fallen oft nicht ins Auge, aber der

durch sie gewährte Schutz kann nicht unbedingt

erreicht werden, wenn man Ersatzteile benutzt, die

für höhere Spannung, Leistung usw. ausgelegt sind.

Ersatzteile, die diese besonderen

Sicherheitsmerkmale haben, sind in den

Prinzipskizzen und Ersatzteillisten an einem ! zu

erkennen.

Der Gebrauch von Ersatzteilen, die nicht dieselben

Sicherheitsmerkmale haben wie die empfohlenen

HITACHI Ersatzteile, wie sie in der Ersatzteilliste

aufgeführt sind, kann zu elektrischem Schlag, Feuer,

Röntgenstrahlung und anderen Gefahren führen.

4. Immer die originalen Abstandsstücke ersetzen und

die Leitungslängen beibehalten. Wo ein Kurzschluss

passiert ist, die Teile ersetzen, bei denen Überhitzung

nachzuweisen ist.

5. Der Isolierwert sollte bei 500 V Gleichstrom

zwischen den Hauptpolen und allen zugänglichen

Metallteilen nicht unter 2M Ohm liegen.

6. Bei der Prüfung auf Durchschlagsfestigkeit sollte

kein Überschlag oder Durchschlag vorkommen,

wenn zwei Sekunden lang 3 kV Wechselstrom oder

4,25 kV Gleichstrom zwischen den Hauptpolen und

allen zugänglichen Metallteilen angelegt wird.

7. Bevor das gewartete Produkt dem Kunden

zurückgegeben wird, muss der Wartungstechniker

das Gerät gründlich prüfen, um sicherzustellen, dass

es betriebssicher ist ohne das Risiko eines

elektrischen Schlages. Der Wartungstechniker muss

sicherstellen, dass keine vom Hersteller im Gerät

eingebaute Schutzvorkehrung schadhaft geworden ist

oder bei der Wartung unabsichtlich beschädigt

wurde.

CE KENNZEICHEN

1. HITACHI Produkte enthalten eventuell das CE

Kennzeichen auf dem Leistungsschild, welches

angibt, dass das Produkt Teile enthält, die eigens

zugelassen sind, um bis zu einem spezifizierten

Niveau elektromagnetische Störfreiheit zu bewirken.

2. Wenn Sie irgendein Teil in diesem Produkt ersetzen,

benutzen Sie bitte nur das korrekte Teil, das in der

Ersatzteilliste aufgeführt ist, um sicherzustellen, dass

dieser Standard eingehalten wird, und geben Sie acht,

die Verdrahtungsart in ihren ursprünglichen Zustand

zurück zu versetzen, weil das einen Einfluss auf die

elektromagnetische Abstrahlung/Störsicherheit haben

kann.

BILDRÖHRE

1. Die Leitungsausgangsstufe kann Spannungen von

mehr als 25 kV entwickeln; wenn die

Höchstspannungskappe entfernt werden muss,

entladen Sie die Anode zum Gehäuse über einen

hochohmigen Widerstand, bevor Sie sie aus der

Bildröhre entfernen.

2. Hochspannung sollte immer auf den festgelegten

Wert des Gehäuses beschränkt bleiben und nicht

mehr. Betrieb bei höherer Spannung kann zum

Versagen der Bildröhre oder zu hoher

Spannungszufuhr führen und kann unter Umständen

auch Röntgenstrahlung hervorbringen, die leicht über

dem Konstruktionsniveau liegt. Die Hochspannung

darf auf keinen Fall 29 kV am Gehäuse überschreiten

(außer bei Projektionsfernsehern).

3. Die Hauptquelle der Röntgenstrahlung im Produkt ist

die Bildröhre. Die Bildröhre, die für die oben

erwähnte Funktion in diesem Gehäuse benutzt wird,

ist eine Spezialkonstruktion zur Begrenzung der

Röntgenstrahlung. Um den Schutz vor der

Röntgenstrahlung zu behalten, ersetzen Sie bitte die

Röhre durch denselben Typ wie den ursprünglichen

von HITACHI zugelassenen.

8. Halten Sie die Bildröhre bei der Handhabung vom

Körper weg. Sie dürfen die Bildröhre nur dann

installieren, entfernen oder handhaben, wenn Sie eine

nicht splitternde Schutzbrille tragen. Personen ohne

derartigen Schutz sollten ferngehalten werden,

solange Bildröhren gehandhabt werden.

LASER

Wenn das Produkt einen Laser enthält, setzen Sie sich

keinesfalls direkt dem Strahl aus, wenn die Abdeckung

geöffnet ist oder wenn die Verriegelung versagt.

4

Page 5

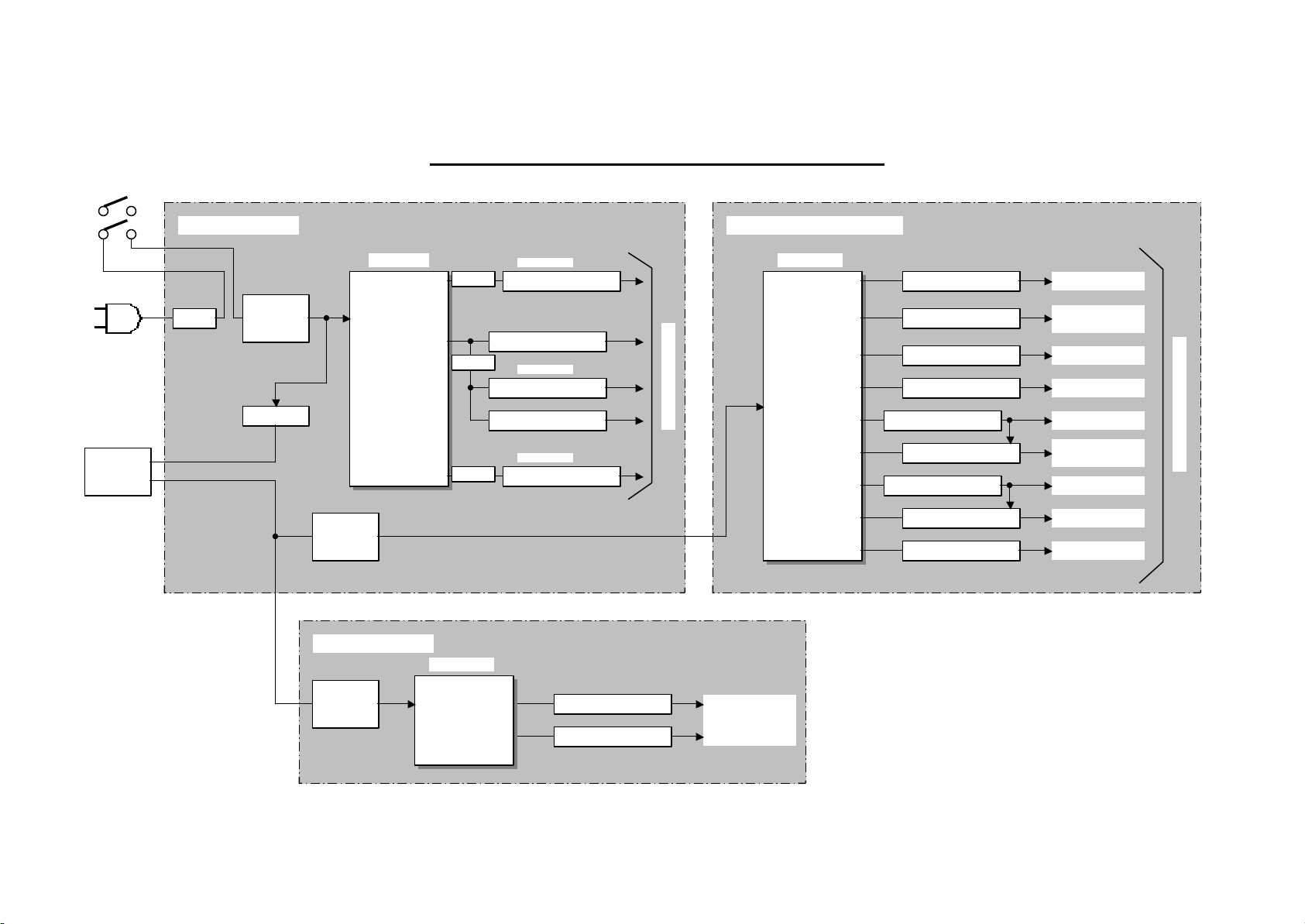

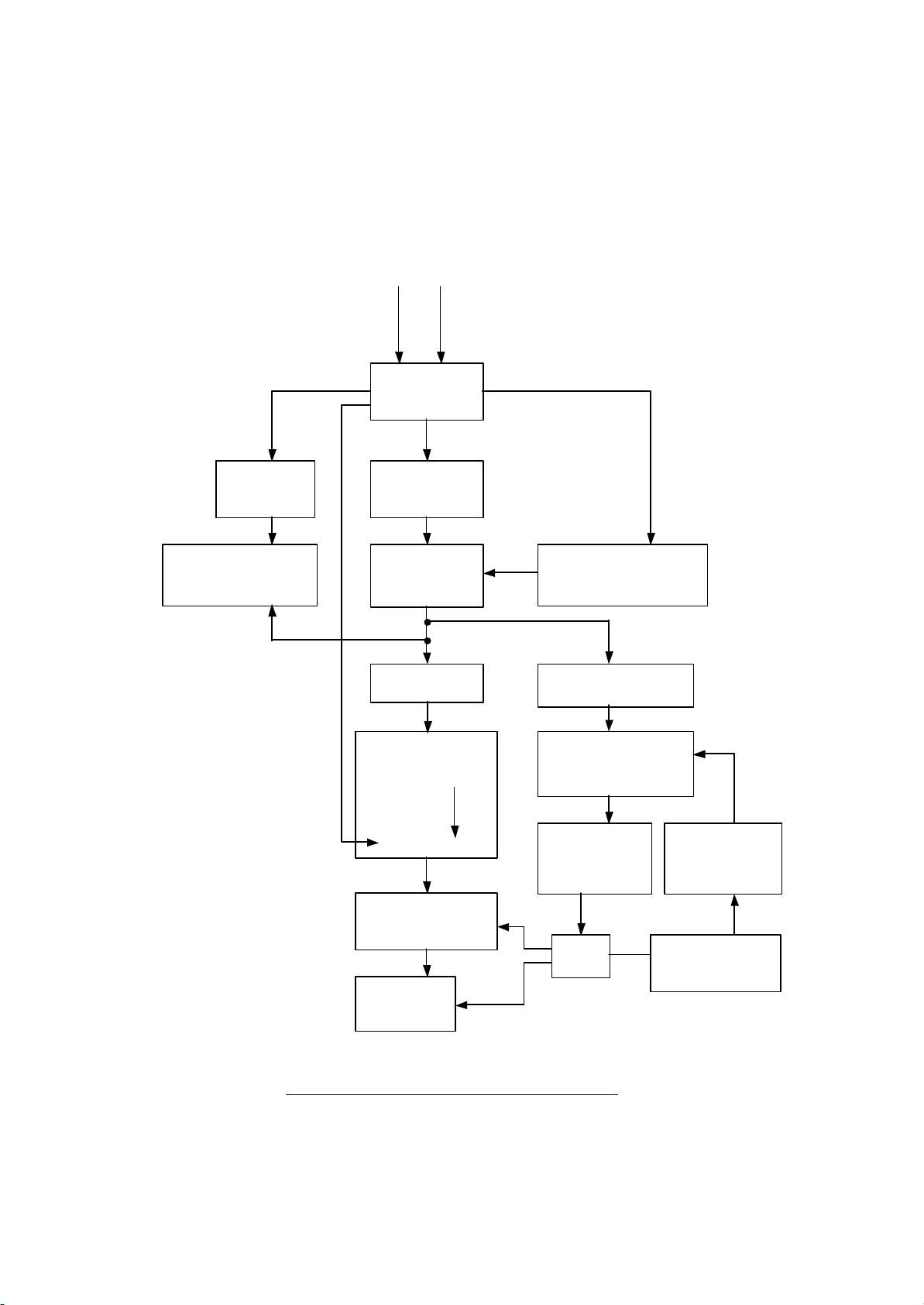

BLOCK DIAGRAM EXPLANATION POWER SUPPLY BLOCK

Normally Power Supply switching is operated as following.

T901:43k–91kHz(Normal),100-125kHz(Stand by)

TP91:31k-59kHz(Normal)

POWER SUPPLY UTILIZED FOR THE SIGNAL AND AUDIO CIRCUITS:

(POWER SUPPLY P.W.B.)

The voltages produced are;

+33V

Stand By +12V also called A12V

TV +8.3V

TV +5V

+36V for Audio Out circuit.

The A12V supply runs anytime the set is plugged into an AC outlet and Main Power SW is turned ON.

Other voltages supplies only operates when the set is turned ON.

POWER SUPPLY UTILIZED FOR THE DEFLECTION AND DIGITAL CONVERGENCE CIRCUITS:

(DEFLECTION SUPPLY P.W.B.)

This supply only operates when the set is turned ON.When the ON command is received relay S901 energizes

and delivers AC to the main bridge rectifier D903 located on the Power Supply P.W.B.

This supplies power primarily to the Deflection circuit for the collector of the High Voltage generation circuit and

the collector of the Deflection Output transistor.

Also,the Convergence output amps derive their voltages from here as well.

The voltages produced are;

+130V used for Deflection and High Voltage circuits.

+220V used for the collectors of the R,G,B drivers on the CRT P.W.B. and the Velocity Modulation circuits.

+28V for the Convergence circuit.

-28V for the Convergence circuit.

+13V for Vertical and also converted down to the 5V for Deflection and Digital Convergence Unit.

-13V for Vertical and also converted down to the –5V for the Digital Convergence Unit.

+6.3V to drive the CRT Heaters.

The A12V from the Power Supply P.W.B. is used as a switched ON/OFF for the Deflection Vcc by the

Rainforest IC.

POWER SUPPLY UTILIZED FOR THE AUDIO CIRCUIT:

(SUB POWER SUPPLY P.W.B.)

This supply only operates when the set is turned ON.

The voltages produced are;

+13V for Audio Out Circuit.

-13V for Audio Out Circuit.

Page 6

+130 REG.

UP91 POWER SUPPLY BLOCK DIAGRAM

VIDEO

VM OUT

CONVERGENC

VERTICAL

+220V

+28V

-28V

+13V REG.

+5V REG.

-13 SW.REG.

VT(+33V)

STBY 12V SW.REG.

+8.3V SW.REG.

+5V SW.REG.

+36V(AUDIO FRONT)

TO SIGNAL BLOCK

TO DEFLECTION

BLOCK

(POWER / DEFLECTION P.W.B.)

(POWER SUB P.W.B.)

AUDIO REAR

+13V

-13V

(SUB POWER P.W.B.)

HEATER

-5V REG.

+6.3V

DEF

DCU

SUB POWER

RELAY

FUSE

LINE

LINE

LINE

CHOKE

POWER SW

SWITCHED

24.5V

35V

SWITCHED

SWITCHED

SWITCHED

SWITCHED

STAND BY

RELAY

RELAY

RELAY

FILTER

COIL

FILTER

FILTER

SUB

SWITCHING

REGULATOR

I901

T901

SUPPLY

I9000

T9000

CENTER

WOOFER

MAIN

SWITCHING

REGULATOR

IP01

TP91

+B

CONVERGENC

VERTICAL

DCU

Page 7

Audio Circuit

The output from the Tuner U101 is fed via a gain and buffer stage formed by Q209 and

Q210 to the SAW Filter X208. The saw filter has two separate characteristics depending on

which of the two inputs (on pin 1 and 2 of the SAW Filter) the signal is applied to. Selection

is achieved by the combination of Q211 and Q212. For most standards, pin 1 is selected.

However, when an L’ Signal has been selected, the micro (I001) instructs I201 via an I2C

command to take pin 19 high. When this happens Q211 conducts taking pin 1 low and

switching Q212 and D202 off. This means that the collector of Q212 goes high allowing

D201 to conduct and hence the signal to be applied to pin 2. To return to other broadcast

standards, pin 19 of I201 is obviously returned to the low condition.

The output of the SAW is applied to pins 63 and 64 of I201. Here the Signal is transformed

from the 1st IF (33.4 – 40.4 MHz depending on transmission standard) to the sound IF (5.5

to 6.5 MHz depending on the transmission standard).

I201 also provides AM demodulation for the L’ and L standards. The demodulated signal

appears superimposed on the Sound IF on pin 5 of I201.

This signal then takes two paths. The first takes it through a Low pass filter formed by R410

and C412 and coupling capacitor C411. This is then applied to pin 55 of I401 and forms the

AM sound Input. The second path takes the signal through a amplifier and buffer stage

formed by Q402 and Q401.

After these stages some high pass filtering is applied by C406 and R409 before the sound IF

is applied to pin 60 of I401.

I401 is The MSP3410D. This IC provides NICAM, FM Mono and FM Stereo demodulation

as well as matrixing of the SCART inputs.

The AV1 input is applied on pins 52 and 53, the AV2 input on pins 49 and 50, the AV3

input on pins 43 and 44, AV4 input on pins 46 and 47. In Each case a 100R resistor and 330n

capacitor is used.

The MSP3410D also has an analogue to digital conversion function. Selected analogue

signal is transferred to I2S digital signal and is sent to digital dolby decode section.

Page 8

The SCART outputs on I401 use the following protocol.

SCART output Output signal

AV1 TV audio

AV2 Monitor

AV3 Monitor

The device is I2C Controlled via pins 9 and 10 and receives a reset from the micro at power

up on pin 24. The clock is provided by X401 on pins 62 and 63. The device has three supply

rails, 5V Digital (Pin 18), 5v Analogue (Pin 57), and 8v Analogue (Pin 39).

Page 9

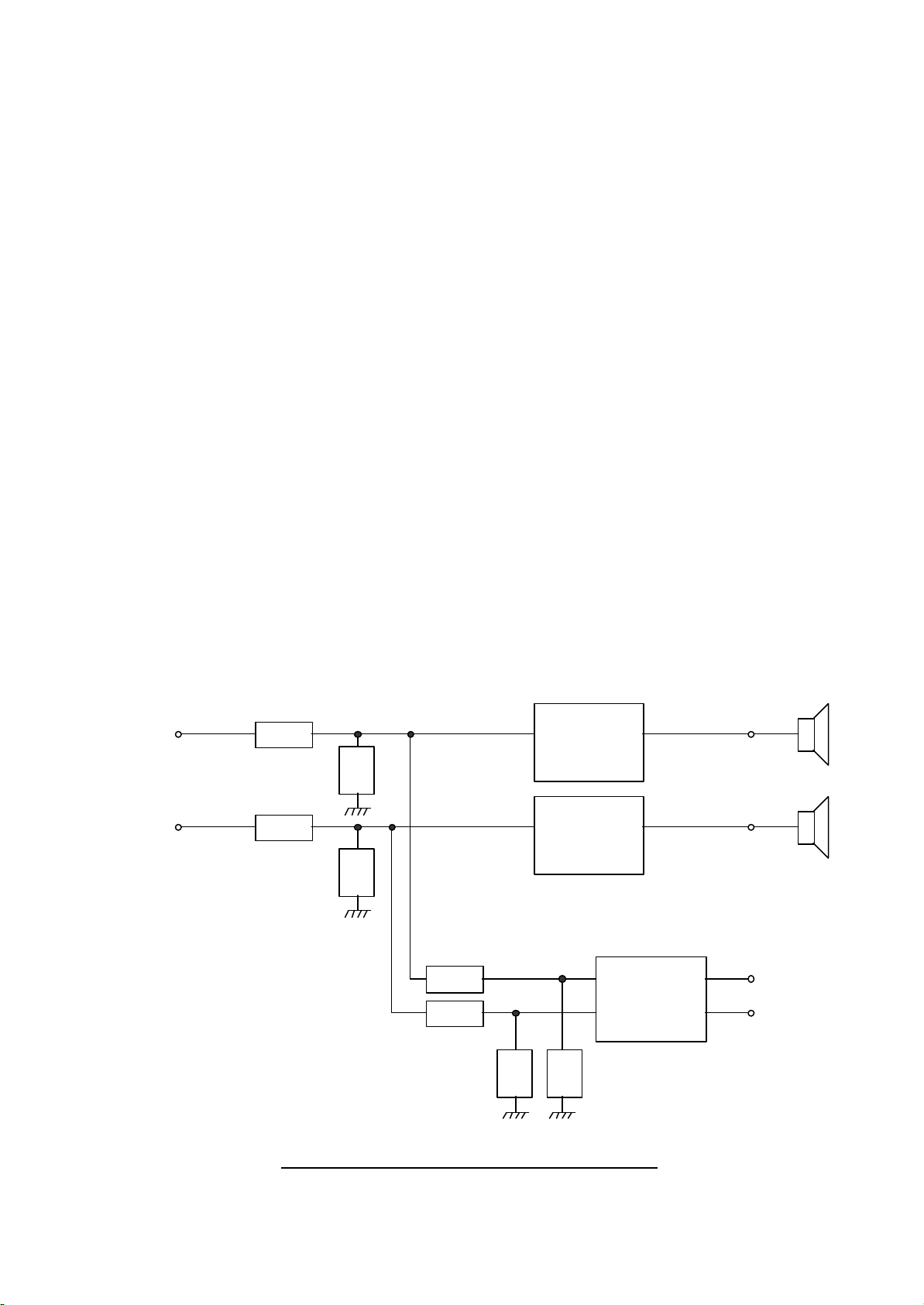

AUDIO OUTPUT

Class-D

R466

R473

R479

Class-D

Front L

R459

R468

R461

Front L

Front R

R480

R474

Head Phone

To Head

Front R

(PSA1 pin2)

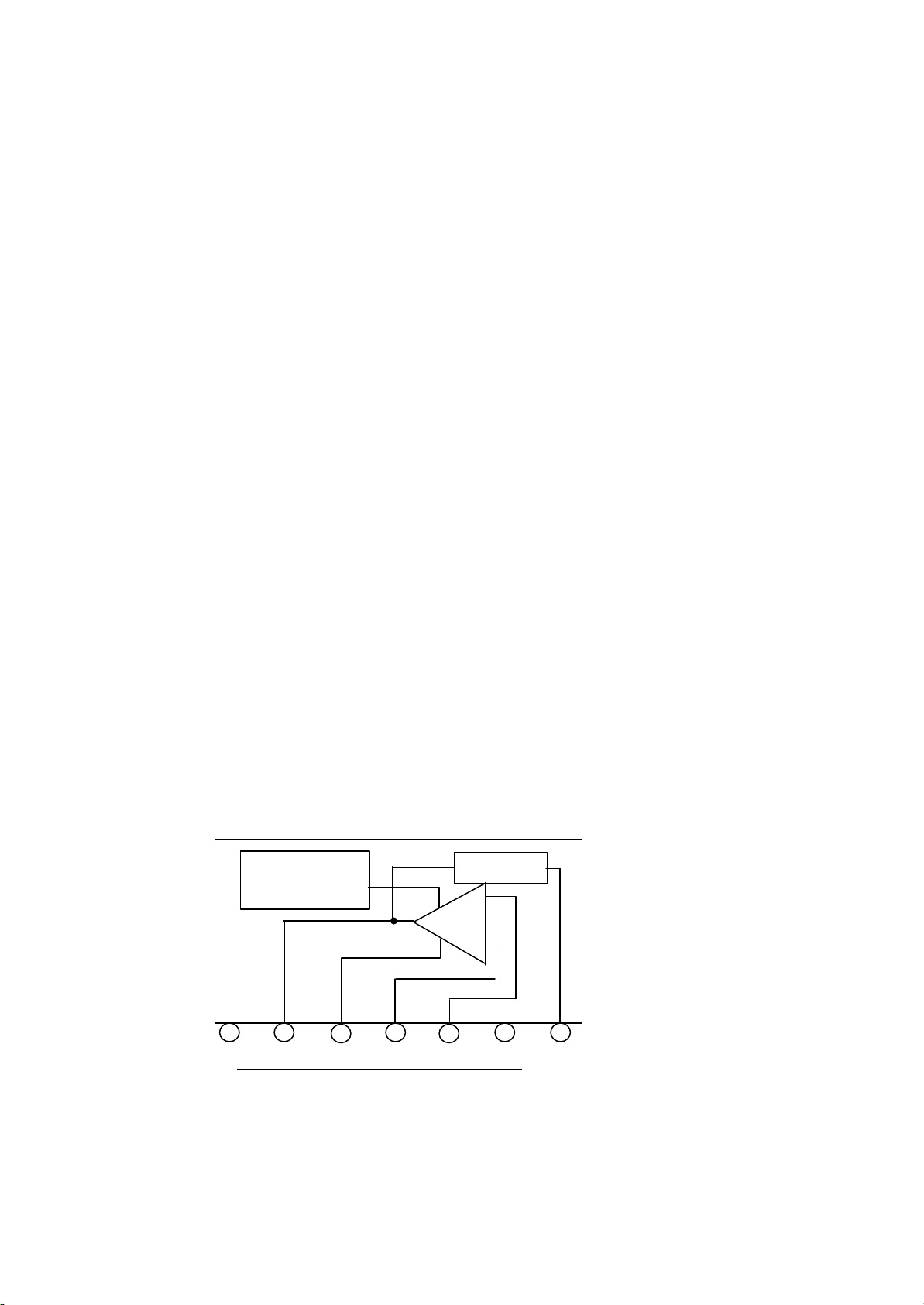

The left and right signals are output from pins 1 and 2 of the PSA1 connector and are then

applied to audio amplifier I402(TDA7482) and I403(TDA7482) via the attenuation networks

R459 / R461 & R466 / R468.

The left and right output stage consists of two TDA7482 which are Class-D amplifier which

in this case is driven to give 15W per channel @ 10% thd. The power output is limited by

the Vcc supply to pin 13.

The TDA7482 has mute control line on pin 10. This control input is high when the outputs

are active and low when muted.

Headphone

The left and right signals are output from pins 1 and 2 of the PSA1 connector and are then applied

to Headphone amplifier I404(TDA2822N) via the attenuation networks R473 /R474 & R479 / R480

The TDA2822N has dual low-voltage power amplifier.

(PSA1 pin1 )

I402

Amp.

TDA7482

Amp.

TDA7482

I403

I404

Amp

TDA2822N

Speaker

Speaker

Phone

Fig.3 Sound output circuit Diagram

Page 10

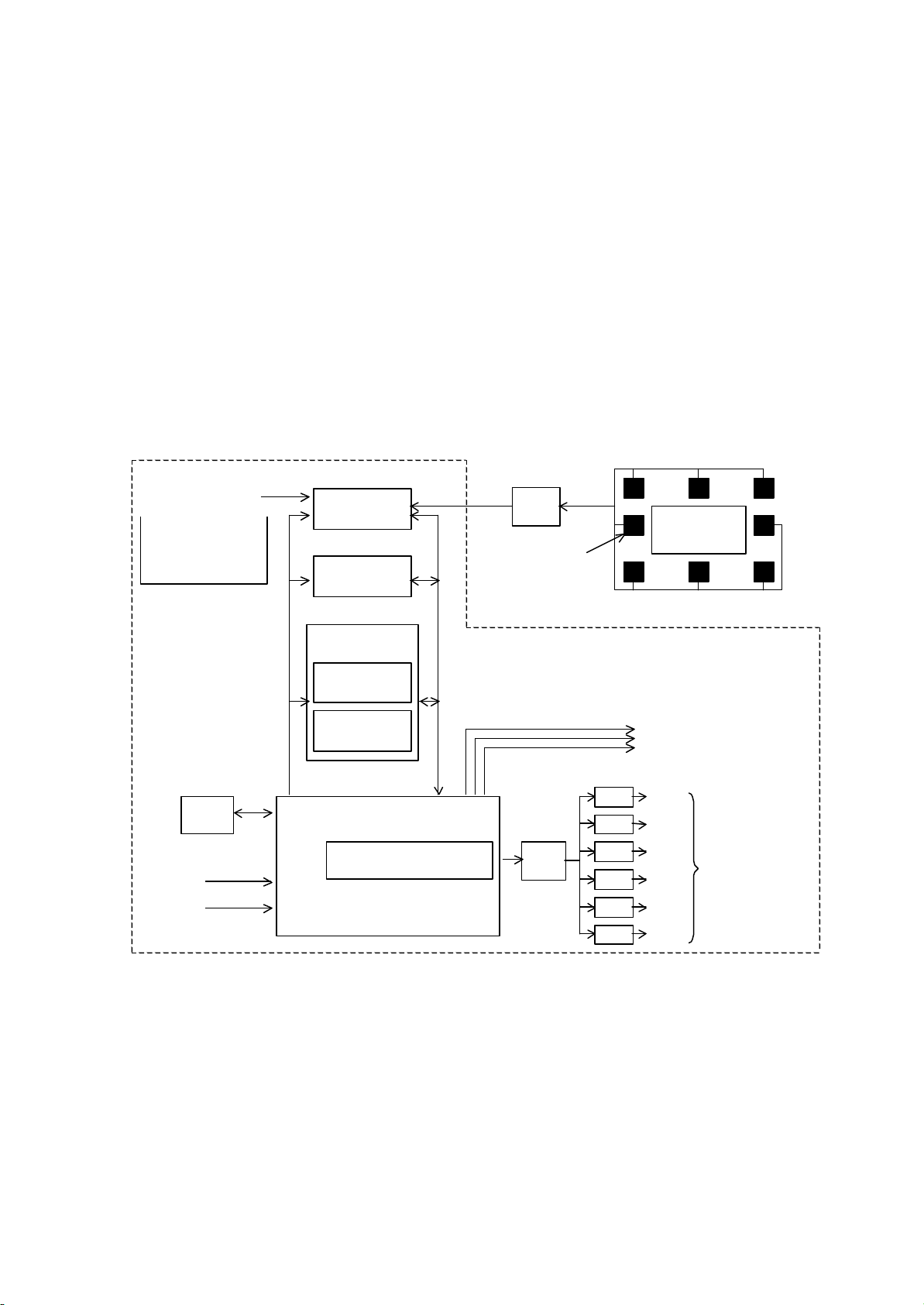

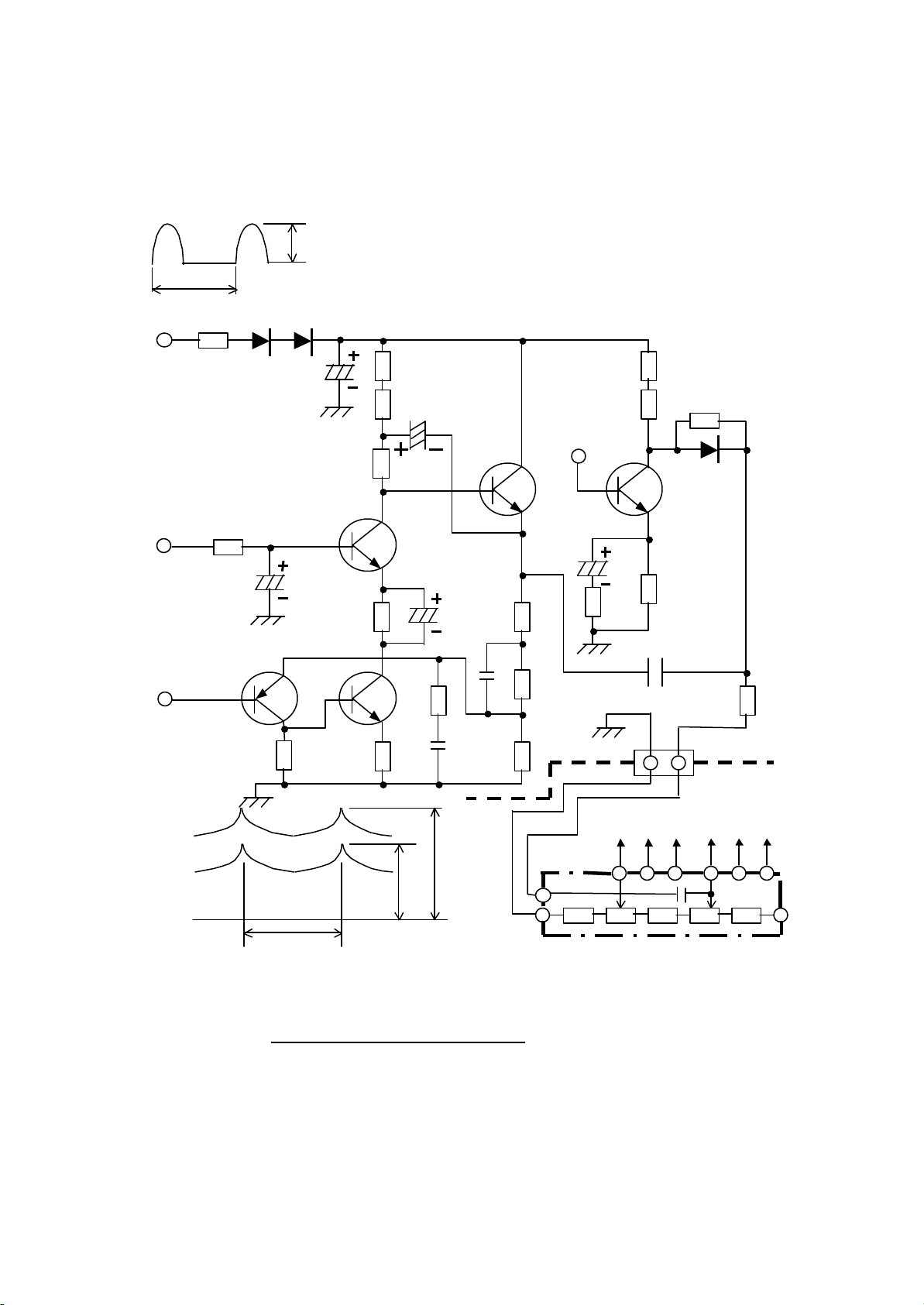

Auto Digital Convergence (MAGIC FOCUS) System

1M BITS

64K BITS

8 BIT BUS

10 BIT DATA

8000 GATES

ARRAY

The auto digital convergence system can readjust convergence with one touch operation.

The system is composed of 8 photo detectors, an A/D converter, and an optical pattern

generator internal GATE ARRAY compared with conventional systems.(As shown in follow Fig.)

The System can measure the dislocation of the image in each overscanned area,

where 8 photo detectors are located, with respect to another. Therefore ,it can recover

the “good” convergence state to which the TV was adjusted , before the misconvergence occurred.

This set has three mode Digital convergence data. (PAL , NTSC Progressive, PAL 100Hz Interlace)

So need to operate three times Adjustment and setting.

PUSH SWITCH

CPU

REMOTE

CONTROLLER

EEPROM

A/D

PHOTO

DETECTOR

SCREEN

fc=16MHz

ADDRESS

PLL

H

SYNC

V

COUNTER

GATE

Fig. 8 Auto Digital Convergence System.

RAM

CORRECTION

PATTERN

ADJUSTMENT POINT 13(H x9(H)POINTS

NORMAL PATTERN

GENERATOR

OPTIONAL PATTERN

GENERATOR

AVERAGECALCULATOR

DATA CONVERTER

D/A

S/H

S/H

S/H

S/H

S/H

S/H

RV

RH

GV

GH

BV

BH

RGB

VIDEO

OUTPUT

CONVERGENCE

OUTPUT

Page 11

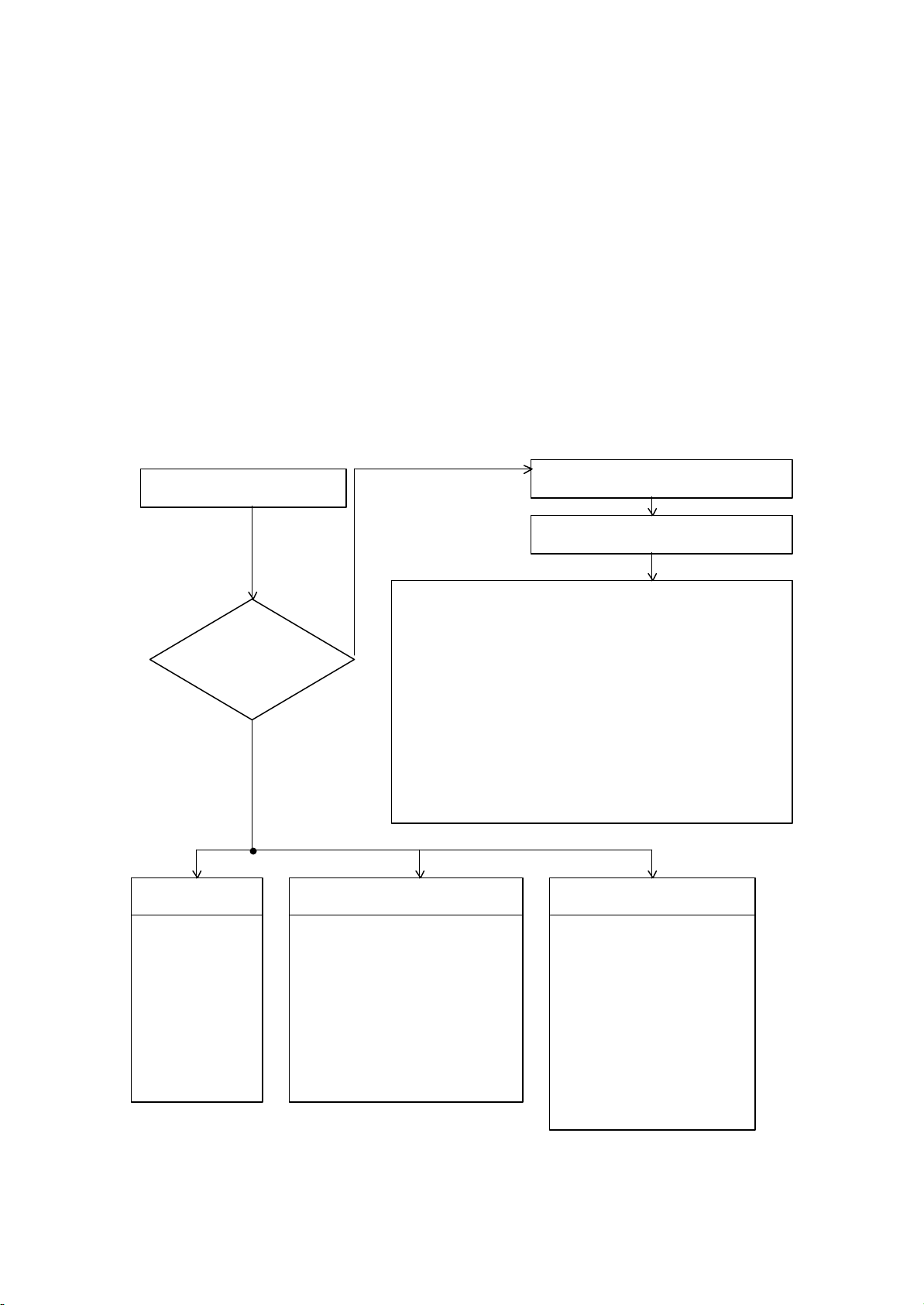

Auto Digital Convergence (MAGIC FOCUS) System

code 2,3,9 ?

Convergence Errors

Operate Initialize.

Check the error display.

Error code:1

Error code:4,5,7

Error code:10,11*

Input strong field strength

Check the wiring of

connector between sensor

No

*4

*3

*2

Yes

Convergence errors

If an error message or code appears while performing MAGIC FOCUS or INITIALIZE,

([MUTE],[LANG] while Digital convergence mode ),follow this confirmation and repair method.

1. Turn on power and input any PAL/NTSC signal.

2. Press service switch on Deflection board.

3. Press [16:9] , then [LANG] on remote control.

4. Error code will be displayed in bottom right corner of screen. If there is no error,

an “initial OK“ message will appear on screen.

5. Follow repair chart for errors.

is error

1. Darken outside light.

2. Check the sensor position No’**.

(Placement, connection and soldering)

3. Check the connector of sensor position NO**’.

4. Is pattern hitting sensor position No’**?

5. Adjustment check.(H/V size , centering)

6. Replace sensor position No’**.

7. Replace sensor PWB or DCU.

Replace DCU.

1. Check the placement of sensor.

2. Adjustment check.

(H/V size, centering)

3. Conv. amp gain check *1.

1.

signal.

2. Input standard NTSC signal.

3.

and DCU.

Page 12

Note : Error code 6 and 8 are not used .

position No.

Sensor position No.(viewed from front side)

*1 Check RK42,46,50,54,58,62 resistors first.

*2 Procedure is shown below :

Press [MUTE], then [LANG]Key.

Initialization process is now in process.

Several windows will appear and error will be displayed.

*3 Example of error display:

CONNECT 1 !

No.__

OVERFLOW!

No.__

Sensor

0 21

7

6 45

3

Page 13

DEFLECTION

Block Diagram of UP91 Deflection Circuit.

T

he operation of UP91 Deflection Circuit is as shown below.

From SIGNAL P.W.B.

VERTICAL HORIZONTAL

SYNC SYNC

VERTICAL

DRIVE DEFLECTION

CONTROL

I702

VERTICAL HORIZONTAL VERTICAL

OUTPUT DRIVE PARABOLA 1

I601 Q751

DY

VERTICAL COIL OUTPUT SIDE PIN

HORIZONTAL COIL Q777 I651, Q655, Q656, Q657

VERTICAL DYNAMIC FOCUS HI-VOLTAGE

PARABOLA 2 QF02, QF03, QF04 CONTROL

OUTPUT

FOCUS PACK

HORIZONTAL HORIZONTAL SIZE

HOT PULSE GENERATOR

QF05, QF06 IH02

QF09, QF07 HI-VOLTAGE HI-VOLTAGE

OUTPUT STABILITY

QH01 QH04, QH05

T752 IH01

HF01

FBT HI-VOLTAGE

CRT TH01 ADJUSTMENT

(R), (G), (B)

Fig. 4 Deflection Circuit Block Diagram

RH44

Page 14

SYNC Signal Processor - uPC1885A

Vertical Deflection & Geometry Controls.

The drive circuit for the vertical and E-W deflection circuits are generated by means of a

vertical divider which gets its clock from the line oscillator. The divider is synchronised

by the incoming vertical pulse, generated by the input processor or the feature box.

The vertical drive circuit outputs vertical sawtooth wave whose amplitude is set by

internal VCA circuit and on which S and C shaped correction wave are superimposed.

Center voltage of vertical sawtooth wave is changed by vertical position DAC. The

outputs must be DC coupled to the vertical output stage. The vertical geometry can be

a

djusted by I2C control via the service menu.

Horizontal Synchronisation & Drive Circuit.

The horizontal drive signal is obtained from an internal VCO which is running at a

frequency of 500KHz. The internal VCO is synchronised to the incoming H.SYNC pulse

by means of a PLL with an internal time constant. The horizontal drive signal generated

by means of a control loop which compares the phase of the reference signal from the

ternal VCO with the flyblack pulse. The time constant loop is internal.

in

Vertical Amplifier – LA7841L

The LA7841L is vertical deflection output amplifier.

Pin 5, vertical sawtooth wave is taken with DC from pin 8 of uPC1885A.

Pin 2 outputs the vertical output voltage, and pin 7 outputs the vertical blanking pulse.

lock Diagram of LA7841 is as shown below.

B

PROTECTION

+

1 2 3 4 5 6 7

THERMAL PUMP UP

-

AMP

Fig. 5 Block Diagram of LA7841L

Page 15

Dynamic Focus

The operation of the Dynamic Focus circuit is as shown below.

Vcp

1200Vp-p

2H

C.PULSE DF07 DF08

RF35 CF18 RF15 RF21

RF14 RF22 RF25

CF11

V.PARABOLA

RF13 DF15

QF09

QF05 QF07

+12V

RF08 CF12

CF05 RF16 RF23

RF12 CF06 RF24

CF09

QF03

H. PARABOLA QF04 RF19

RF17 CF10

RF26

DF

RF10 RF11 CF08 RF18 4 1

CPT SCREEN CPT FOCUS

A

B

1V or 2V A:1000 - 1300Vp

B: 450 - 650Vp FOCUS PACK HF01

R G B R G B

Fig. 6 Dynamic Focus Circuit

The Vertical Parabola (QF09) and Horizontal Parabola (QF07) are sent to the FOCUS

PACK and Applied to the DC Focus voltage that is adjusted by the Focus Control.

These voltages are then applied to the RED, GREEN and BLUE Focus Electrodes of the

Picture Tubes in the form of a Dynamic Voltage.

Page 16

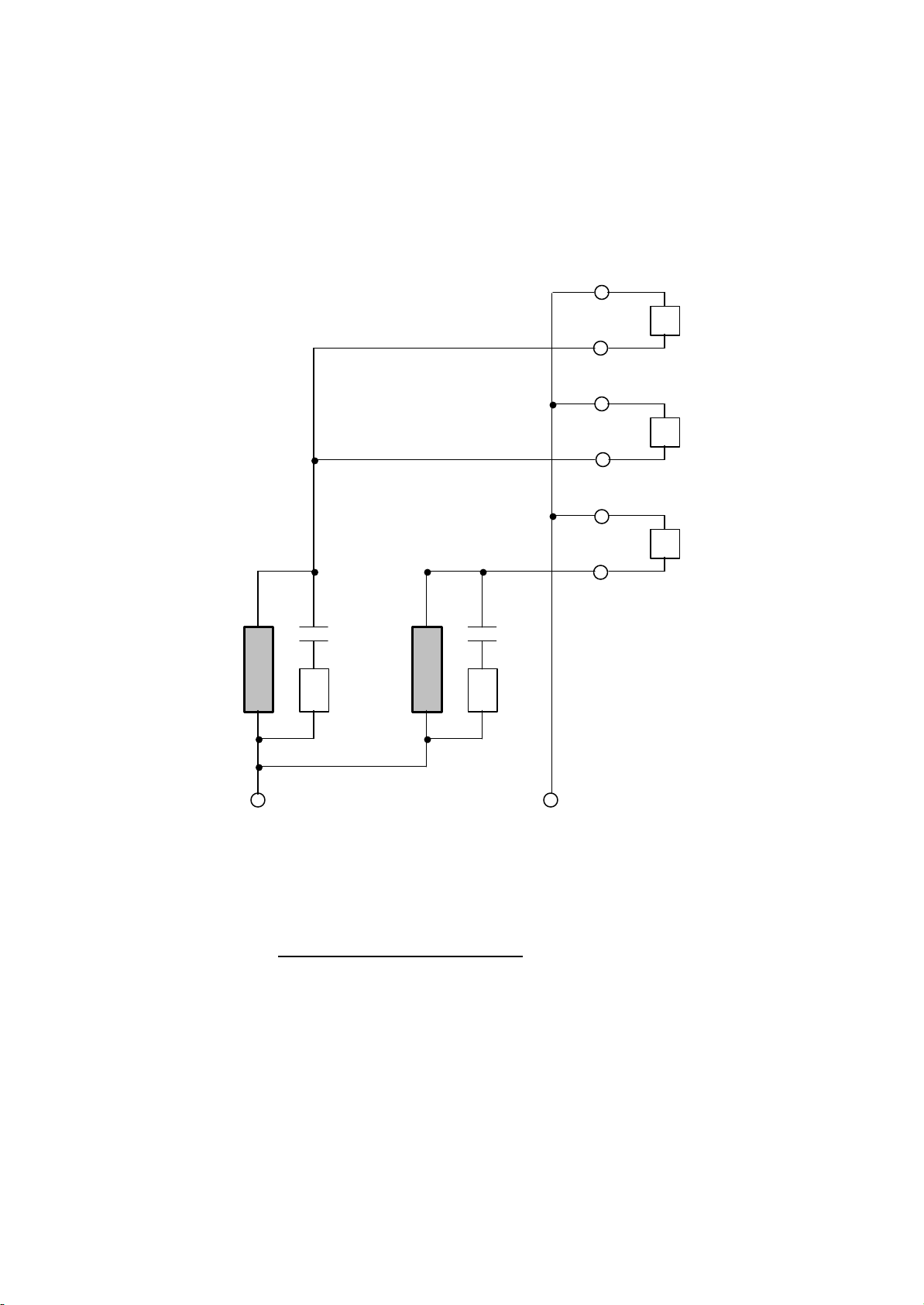

H.Linearity

The H.Linearity Circuit uses two linearity coils (L752:G,B common and L753:R).

he circuit is as shown below.

T

+

+

G H.DY

-

+

-

C765 C766

L

R759 R760

752 L753

B H.DY

R H.DY

C

TO S CURVE COLLECTOR PULSE

CORRECTION

APACITOR (C762, C763)

Fig. 7 H.Linearity Circuit

Page 17

MicroController Section on the UP91 Chassis

The main m icr ocontr oller on the UP91 chas s is is loc ated at I001 (ST92R195B). This is an 80-pin QFP (quad-flat package)

that is surface m ounted for compactness. This highly com plex device controls many of the other integrated circuits via

dedicated input/output lines or the I

menus and the teletext. The device c an acquire, decode and display the teletext without the need for a separate IC. This

microcontroller is ROM-less which results in the need of a separate memor y device to store the program code nec essary

for operating the television. This m emory device is located at I002 and is multi-time program m able (MT P). T his allows the

device to be re-programmed and in the future can even be re-programmed in the board without having to remove the back

cabinet of the T V. The television s tores all the necessary customer preferences and oper ating settings in an on-board

EEPROM (E2). This device can hold 2Kb of information for storing the programme information (frequency, name, AV

setting, etc.), factory alignment settings (geometry, white balance, tuner AFC/AGC, etc.), service diagnostic errors and

customer contro l settings ( volume, br ightness, contras t, etc.). T his device com m unic ates with the m ain m ic rocontr oller via

2

the I

C bus, even in the standby mode.

Main MicroController (I001)

The ST92R195B is an enhanced microc ontroller based on the ST 9+ instruc tion set fr om ST Microelectr onics. It is c apable

2

C bus. This device also generates the RG B signals for the on-screen display (OSD)

of displaying menus and teletext for 50Hz and 100Hz televisions. This device can acquire/decode and display pages of

teletext information in FLO F (FastText) and TOP (only in Germany/Switzerland/Austria) modes. The device operates f rom

a single 4MHz crystal and a +5V supply. Dedicated address/data lines enable it to acc ess 4Mbytes of addres s space, even

though in this television it is accessing 256Kbytes (2Mbit). These address/data lines are connected to the EPROM/MTP

device which holds the instructions necessary for controlling the television.

External Memory Interface MMU Address Lines

Pins 1 (MMU0), 15 (MMU1) and 16 (MMU2) are used to access addresses above 64Kbytes. Normally pins 15 and 16 are

not used when using a 256Kbyte EPROM/MTP device (AT49F002T) in position I002.

Pin 2 (MMU3) is used to select between either the EPROM/MTP in position I002, or a future device that can be fitted in

position I003. When this line is low, the AT49F002T device in position I002 is enabled (chip enable).

Pin 17 (MMU4) is used as an output port to derive a clock signal needed for shifting the data into the 74HC595 shift

register (I006).

Pin 18 (MMU5) is not used.

External Memory Interface Control Lines

Pin 4 is the Data strobe line which is connected to the output enable input of the EPROM/MT P (I002). W hen data is read

from the EPROM/MTP, this line is temporarily low.

Pin 8 is the Read/Write line for I003. Normally, this line is not used (HIGH) but if an SRAM were to be fitted into this

position, the line could be low when writing data to the SRAM.

External Memory Interface Address Lines

Pins 3, 5, 6, 7, 13, 14 and 71 to 80 are the address lines needed to specify which location in a 256Kbyte page is needed to

Page 18

be accessed from the EPROM/MTP (I002). These lines are also connec ted to I003 if an SRAM is to be f itted in future.

Normally these lines will be changing state (0V to approx. +5V). By placing an oscilloscope on pin 12 of the EPROM/MTP

(I002) it can be confirm ed that the microcontroller is operating successf ully. In this case, this line s hould be c hanging state

very frequently.

External Memory Interface Data Lines

Pins 63 to 70 are the 8 data lines needed for receiving data from the EPROM/MT P (I002) . If an SRAM were to be fitted in

position I003, then these lines would be used to transfer data from the microcontroller to the SRAM. Under normal

circumstances these lines change from LOW (0V) to HIGH (approx. +5V).

Ground Connections

Pin 9 (GNDM) is the ground connection (0V) f or the external memory interface. This should be free of noise to enable

successful communications between the microcontroller and the EPROM/MTP (or SRAM).

Pin 35 (GND) is the digital ground connection (0V) for normal operation of the device.

Pin 62 (GNDA) is the analogue ground connection for the DAC and phase lock loops (PLL’s).

Supply Connections

Pin 10 (VDDM) is the +5V supply for the external memory interface. Without this supply, the microcontroller cannot

communicate with the EPROM/MTP (or SRAM).

Pin 34 (VDD) is the main digital supply voltage to the IC (5V 10% tolerance).

Pin 52 (VDDA) is the analogue supply voltage for the DAC’s and PLL’s (+5V). These connections ar e all jo ined together to

the +5V standby rail of the television, ensuring that the microcontroller operates even in the standby state.

Crystal Oscillator Connections

Pin 11 is the 4MHz crystal oscillator input (OSCIN).

Pin 12 is the 4MHz crystal oscillator output (OSCOUT). By connecting a x100 scope probe to pin 11, it can be seen if a

4MHz sine wave is present at the oscillator input to the microcontroller.

Reset Connection

Pin 54 is the active low RESET input of the microcontroller. This input is normally high (approx. +5V) under operating

conditions, but changes state when the standby +5V power supply is typically below +4.5V. In this circum stance, the r eset

IC (I011) pulls pin 54 low until the input of it is above +4.5V. The diode (D005) ensures that the capacitor (C024)

discharges quickly when the standby supply falls, so that the reset operates quickly. The capacitor (C024) charges up

slowly when the standby +5V supply is restored, ensuring that there is some hysteresis.

Infra-red (IR) Receiver Input

Pin 25 is the IR receiver’s filtered output. This input from the IR receiver consists of PW M pulses between 0V and +5V

which are decoded by the microcontroller into useful commands from the handset. W hen a valid command has been

decoded, the Red LED on the front of the TV will briefly flash.

Page 19

Horizontal and Vertical Synchronisation Connections

Pin 48 is the vertical synchronisation input from the deflection stage. This input is used to ensure that the OSD is displayed

in a stable vertical position. When the TV is in the standby state, this input is normally low. The vertical input is triggered on

the rising edge (positive polarity).

Pin 49 is the horizontal synchronisation input from the deflection stage. This input ensures that the OSD is displayed in

stable horizontal position. When the TV is in the s tandby state, this input is norm ally low. This input is rising edge triggere d

(positive polarity).

General Input Connections

Headphone Input

Pin 19 is used to detect if the headphone has been inserted into its s ocket. T his input is norm ally HIGH (+5V) unless the

headphone has been inserted, in which case it is near 0V. When the headphone is inserted, the headphone mode option

is then available in the "Sound Mode" Menu and the loudspeakers (and internal sub- woofer if available) in the television

are muted.

Front Panel Buttons and SAV4 Socket Inputs

Pins 36 and 38 are 2 of the 4 ADC inputs of the microcontroller.

Pin 36 is connected to the Volum e +/- buttons and the SAV4 (Hi-8) socket on the f ront panel of the TV. When the voltage

on this pin is changed to a value in a certain window, the microcontroller will interpret it as either a volume +, volume -,

volume +/- command and/or an SVHS Hi-8 connector was inserted into the Hi-8 socket.

Pin 38 is connected to the Programm e +/- and Menu buttons on the front panel of the T V. When the voltage on this pin is

changed to a value in a certain window, the microcontroller will interpret it as either a program me change or the menu

button was pressed.

General Output Connections

74HC595 Shift Register Outputs

Storage-Register Clock Output (RCLK)

Pin 20 of the microcontro ller is c onnected to the rising edge ( positive trigger ed) input (pin 12) of I006. T his line is norm all y

low when not communicating with the device or when shifting data into it. Once the f ull 8-bits have been shifted in, the

RCLK line rises in order to latch the data to the device’s outputs.

Shift-Register Clock Output (SCLK)

Pin 17 of the microcontroller (MMU4) is us ed to transf er the data into to the 8-stage shift- register on the ris ing edge of the

SCLK. 8 clock pulses are needed to transfer 8 bits of data into the shift register.

Shift-Register Data Output (SI)

Pin 21 of the microcontroller is used as the data line input to pin 14 of the shift regist er. When this line is HIGH, and the

SCLK changes from low to high, the fir s t bit of data (logical 1) is s hifted into the r egist er. When this input is low, the first bit

of data is ‘0’, on the rising edge of the SCLK.

Page 20

EEPROM Write Enable Output

Pin 22 is the E2 write enable output line, which is connected to pin 7 of the EEPROM (E2). When this output is HIGH

(approx. +5V), the E2 cannot be written to (write disable) but data from the device can be read. W hen this output is low

(0V), then data can be written to the E2. This hardware line helps to protec t the E2 from inadvertent write operations,

which could occur under abnormal circumstances.

On/Off Output

Pin 28 is the On/Off line which turns On (LOW) /Off (HIGH) the secondary supplies (+B, +37V audio rail, +8V and +5V).

The standby +12V rails are unaffected when this output is HIGH (TV in the standby state). Under normal operating

conditions, this output will be low when the TV is NOT in the standby condition.

I2C Disable Output

Pin 33 is the I2C disable output which prevents the main chassis I2C bus from being connected to the I2C bus of the

microcontroller (I001) and E2 (I002). This line is normally HIGH when the TV is in the standby state. This output is

inverted using the 74HC04 hex inverter IC (I004) and in connec ted to pins 5 and 6 of I007. In the standby condition, pins 5

and 6 of I007 (74HC4066) are low and the M.SDA and M.SCL (microcontroller) lines are disconnected f rom the SDA and

SCL (main chassis) I

writing of the data has occurred (e.g. to log fault diagnostics when the TV fails to power-up and the main chassis I

low).

2

C lines. When writing to the E2, the I2C disable output is also pulled high, to ensure that succes sful

2

C bus is

Scart Disable Output

Pin 39 is used to disable the RS232 transmit and r eceive lines from pins 10 (Rx) and 12(T x) of scart socket 2. T his is

necessary when the TV is functioning normally. However, when the TV is in s ervice or diagnose modes, then this output

will be low to enable connection of the RS232 lines of the microcontroller to the scart socket.

Mute Output

Pin 40 is the mute output for the sound signal,(e.g. TV and Monitor out). This output is HIGH when the sound signals are

in the mute condition (e.g. program up / down).

Red LED Output

Pin 42 is the red LED output, which is used to indicate the standby state and when an IR command has been successf ully

received and decoded. When the T V is in the standby state, this output will be HIGH to ensure that the red LED is br ightly

lit. When the T V is not in standby, then this output will be low, but the red LED will remain dim ly lit through resistor R081.

When an IR command has been successfully received, then the LED will flash brief ly, to inform the user that the button on

the handset was pressed correctly.

I2C Connections

Pin 23 is the I2C bus data input/output for transferring data between other I2C peripherals/devices. This line is only

connected to the EEPROM (I005) when in the standby state or when writing to the EEPROM. This line is constantly active

Page 21

when the TV is powered up and normally changes state between (+5V and 0V).

Pin 24 is the I

from the main chassis when in the standby state or when writing to the EEPROM. This line oscillates at a frequency

2

C bus clock output for cloc king the data to other I2C peripherals/devices. The c lock line is also isconnec ted

around 90KHz

RS232 Connections

Pin 30 is the RS232 Transmit line from the microcontroller. When the Scart disable output from the microcontroller (pin 39)

is low, then the TXD can be routed from pin 1 to pin 2 of I007 (74HC4066). There is never a situation whereby both disable

outputs are low.

Pin 37 is the RS232 Receive line for the microcontroller. When the Scar t disable line is low, then the data can be routed

from pin 10 of sc art 2 to pin 10 of I007 and then through to pin 37 of the m icrocontroller. There is never a situation when

both RS232 enable lines are HIGH (disable outputs LOW).

RGB Connections

Pin 44 is the OSD/Teletext RGB blanking signal necessary for allowing insertion of the OSD/Teletext onto the picture.

When this output is high (approx. +5v), then the RGB signal will be superimposed onto the current picture.

Pin 45 is the OSD blue signal necessary for displaying BLUE colours for the OSD and Teletext.

Pin 46 is the OSD green signal necessary for displaying GREEN colours for the OSD and Teletext.

Pin 47 is the OSD red signal necessary for displaying RED colours for the OSD and Teletext.

CVBS Connections

Pin 60 is the Composite Video signal input for VPS and WSS slicing. It is norm ally AC coupled and internally clamped to

ensure reliable operation. VPS (video programming system) is necessary when auto-sorting programmes in

Germany/Austria/Switzerland. WSS (wide-screen signalling) is used to indicate the aspect ratio of the incoming signal.

The TV can then use this information to display the picture in the correct format.

Pin 61 is the Composite Video signal input for Teletext acquisition and dec oding and also for sync extraction, necessary

for obtaining the correct line timings for slicing the teletext information and VPS/WSS information.

Y2-Y3-SW Output

Pin 26 is the Y2-Y3-SW relay S3(Low) or S2(High) control.

V-MUTE1 Output

Pin 29 is the V-MUTE1 output relay MUTE(High) or Active(Low) control.

Digicon-busy Input

Pin 31 is the Digicon-busy input from the Digital-Conv-Unit.

This input is used to detect if the MAGIC-FOCUS has been moved.

CUT-OFF Output

Pin 32 is used the CUT-OFF relay enable(High) or disable(Low) control.

Page 22

This output is high output is high when a PTV is indicated to Horizontal center axis.

HBLK-PH Output

Pin 41 is used to adjust the phase of the horizontal blanking .

EPROM/MTP (I002)

The device located in position I002 is used to store the program code needed by the microcontroller to operate the

television correctly. This 32 pin device is an MTP (multi-time programmable memory) which allows for it to be

re-programm ed out of the c hass is without having to erase it using conventional UV EPROM eras ers. T he devic e cur rently

used on the UP91 chassis is the AT49F002T, which can hold 256Kbytes of information (2Mbit) . T his devic e als o holds any

initialisation data to be downloaded to an EEPROM. When a blank EEPROM is fitted, the initialisation data is automatically

downloaded to it when power is applied to the chassis.

Supply/Ground Connections

Pins 32 and 16 are the +5V supply and ground connections respectively. The supply voltage of +5V is always present even

when the TV is in the standby state.

Address Connections

Pins 2 to 12, 23 and 25 to 29 are the 17 address lines needed to access the f ull 256Kbytes of 8-bit data inside the device.

These lines are connected direc tly with the microcontroller so that it can request data from the MTP when operating. An

oscilloscope can be used to check pin 12 of the MTP to check whether the microcontroller is running correctly and

accessing the MTP. This pin should be oscillating at a frequency of around 2MHz and is a non-periodic square waveform.

Data Connections

Pins 13 to 15 and 17 to 21 are the 8 data lines needed to transmit a byte at a time to the m icrocontroller. These outputs

are normally tri-state and are high-impedance when the output enable pin 24 of the MTP is HIGH. When the output enable

pin is low, the data from the required address will be output on these pins.

Output Enable Connection

Pin 24 is the output enable active low input used to control the logical state of the data lines. W hen this pin is HIGH, the

data lines are in the high impedance condition and no data is present on these pins. W hen the output enable input it LO W,

the data lines are active and output the addressed data, This line is connected to the data strobe output of the

microcontroller to ensure correct operation/timings.

Chip Enable Connection

Pin 22 is the chip enable active low input used to select the device. Normally, this input is low to enable the device.

However, the device can be placed in a standby state when accessing a future SRAM in position I003. The MMU3 line

from the microcontr oller is used to select either the SRAM or the MTP. W hen no SRAM is fitted, the chip enable pin is

always low.

Page 23

Miscellaneous

Pin 1 (VPP) is the programming voltage input pin (+12.75V needed) used to re-program the device when placed in a

special programmer. This pin is always tied to the +5V standby supply, to ensure that the device can never be

re-programmed inside the television chassis.

Pin 30 is not used in this device. However, it is s till connec ted to the MMU1 line f r om the microcontroller for use with larger

size MTP’s/EPROM’s. This line can be used to access a further 256Kbytes if such a device was fitted.

Pin 31 is the active-low programming enable pin that is used to re-program and erase the device. This pin is always

connected to the +5V standby supply to ensure that no inadvertent writes/erases are performed on the device.

SRAM (I003)

On future chassis, the position I003 will be used to hold an SRAM for teletext page storage and memory storage. A

128Kbyte device will most likely be situated here to allow 100 teletext pages to be acquired and s tored f or im m ediate fas t

access to them. The SRAM is connected to the microcontroller’s address and data lines, which are shared with the

EPROM/MTP in position I002.

Supply/Ground Connections

Pins 32 and 16 are the +5V supply and ground connections respectively. This device always has +5V connected to it, even

when the TV is in the standby state.

Address Line Connections

Pins 2 to 12, 23, 31 and 25 to 28 are the address lines needed to access the 128Kbyte of data by the microcontroller.

Data Line Connections

Pins 13 to 15 and 17 to 21 are the 8-bit data lines needed to receive/transmit a byte of data at a time to/from the

microcontroller.

Chip Enable Connections

Pins 22 and 30 are 2 chip enable inputs that need to be LOW and HIGH r es pectively for the 128Kbyte device to operate. If

either pin 22 is HIGH or pin 30 is LOW, then the device enters a standby state whereby its power consumption is

dramatically reduced (10uW). The MMU3 output pin from the m icrocontr oller (pin 2) is used to s elect the SRAM when it is

HIGH. If this pin is low, then the MTP/EPROM in position I002 is selected instead.

Write Enable Connections

Pin 29 is the active-low write enable input used to enable data to be stored inside the device. This pin is connected to the

read/write line of the microcontroller for synchronisation purposes.

74HC04 Hex Inverter (I004)

The 14-pin IC in position I004 is a high speed CMOS hex inver ter used to inver t digital signals. The pack age c onsists of 6

inverters, but only 4 are used in this application.

Page 24

Supply/Ground Connections

Pins 14 and 7 are the +5V and 0V supply connections respectively. This device always has +5V supplied to it, even when

the TV is in the standby state. Capacitor C042 is connected across the supply terminal for de-coupling.

Chip Enable Connection

Pin 1 is connected to the MMU3 output from the microcontroller and is used to select either the MTP or the SRAM. This

signal is inverted and output from pin 2 that is then connec ted to the active low chip enable input ( pin 22) of the SRAM. In

this way, only one chip enable line from the microcontroller needs to be used to enable the SRAM.

I2C Disable Connection

Pin 5 is the I2C disable input from pin 33 of the microcontroller. This signal is inverted and output at pin 6 to pins 5 & 6 of

the analogue switch (I007). W hen the micr ocontroller is in the reset c ondition, or when the TV is in the standby state, the

2

I

C disable line is HIGH. This signal m ust be inverted to disable the m icrocontr oller ’s I2C bus from the I2C bus of the rest

of the chassis.

Scart Disable Connection

Pin 13 is the RS232 Scart Disable input f rom pin 39 of the microcontroller. This input is inverted and output at pin 12,

which is then connected to pins 12 & 13 of the analogue switch (I007). W hen the m icrocontroller is in the reset state, or

when the TV is NOT in service/diagnose modes, the RS232 transmit/receive lines MUST be disconnected from pins 10

and 12 of scart socket 2. This line must then be inverted to prevent any connection being made.

EEPROM (I005)

The M24C32 EEPROM, or E2 as it is com monly known, is a 32Kbit (4Kbyte) device that holds non-volatile data when

power is removed from the TV. This device can hold information for 100 programmes, such as the name, frequency,

standard, AV setting, speaker language setting and teletext favorite pages. The EEPROM also holds diagnostic fault codes

used to help identify previous faults with the chassis (see separate section that deals explicitly with this). The E2 also holds

factory aligned parameters, such as the geometry, white balance, tuner AFC/AGC, model type, cathode level, etc. The E2

also holds the user’s preferential settings, such as the volume, balance, contrast, br ightness, etc. Data is written to/ read

from the device using the standard Philips I

2

C protocols.

Supply/Ground Connections

Pins 8 and 4 are the +5V supply and ground (0V) connections respectively. The EEPROM is powered from the +5V

standby rail so that it always has power to it, even when the TV is in standby.

I2C Connections

Pin 5 is the I2C Data line needed to transfer serial data between the microcontroller and itself. Data is changed when the

clock line is low and latched on the rising edge of the I

Pin 6 is the I

acknowledge bit. The I

2

C clock line needed to synchronise the I2C data transfer. 9 clock pulses are needed for the 8-bit data and an

2

C master clock originates from the microcontroller and operates at a frequency around 100KHz.

2

C clock.

Page 25

Address Connections

Pins 1 to 3 are the address lines used to select the I2C slave address of the device. On the M24C32 device, thes e lines

must be connected to ground in order to access the device properly.

Write Disable Connection

Pin 7 is the I2C write enable/disable input. When this input is HIGH (+5V), all I2C writes to the device are denied.

When the pin is pulled low by the microcontroller (pin 22 E2RD), data can be written to the device. In this manner,

inadvertent write operations can prevent the I

2

C data from being corrupted.

74HC595 Shift Register (I006)

The 74HC595 is a 16-pin high-speed CMOS 8-bit shift register used for additional output port capability on the UP91

chassis. 8-bit data is serially shifted into the device and then latched to the outputs when so desired. These outputs are not

used when the TV is in the standby state.

Supply/Ground Connections

Pins 16 and 8 are the +5V supply and 0V ground connections respectively. This device has +5V supplied to it, even when

the TV is in the standby state. Capacitor C048 is used to de-couple the supply.

MSP Reset Output Connection

Pin 5 is the MSP3410D reset line that is low when the MSP is being reset. This line is normally HIGH (+5V) when the TV is

operating correctly. When the T V is in the standby state, this line is low, as there is no +5V signal supply to pull the line up

through resistor R044.

Shift Register Clear Input (SCLR)

Pin 10 is an active low input necessary for clearing the shift register’s data on power-up.

Shift Register Clock Input (SCK)

Pin 11 is the shift register clock input necessary for clocking the data into the device. Eac h bit of data is latched into the

device, on the rising edge of the clock. This clock originates from pin 17 of the microcontroller.

Register Clock Input (RCK)

Pin 12 is the register clock input necessary for latching the data to the output pins. On the ris ing edge of this pin, all 8

latched bits are transferred to the output pins.

Output Enable Input (G)

Pin 13 is an active low input necessary for enabling the output ports. This pin is always connected to ground to enable the

outputs.

Shift Data Input

Page 26

Pin 14 is the shift data input necessary for transfer ring the 8 data bits into the device. W hen this line is HIG H, a logic al ‘1’

is latched into the device on the rising edge of SCK. W hen this line is low during the rising edge of SCK, a logical ‘0’ is

stored instead.

MASK-SW Output

Pin 1 is the MASK-SW relay 16:9-mode(High) or other-mode(Low) control.

INTER-PRO and PAL-NTSC Output

Pin 2 is the INTER-PRO relay Interlace(High) or Progressive(Low) control.

Pin 15 is the PAL-NTSC relay PAL(Low) or NTSC(High) control.

NTSC

60P

Pin 2 (INTER-PRO) Low Low High

Pin 15 (PAL-NTSC) High Low Low

50P 100I

PAL

C , R and F-SP-OFF Output

Pin 3 is the Center amplifier control. This output is High when the Center amplifier is in the mute condition.

Pin 4 is the Rear amplifier control. This output is High when the Rear amplifier is in the mute condition.

Pin 7 is the Front amplifier control. This output is High when the Front amplifier is in the mute condition.

P.BLK Output

Pin 15 is the P.BLK relay picture-blanking(High) or active(Low) control.

74HC4066 Analogue Switch (I007)

The 74HC4066 is a 14-pin high speed CMOS quad bilateral switch. It is used primarily for connecting/disconnecting

signals when out of/in the standby state.

Supply/Ground Connections

Pins 14 and 7 are the +5V supply and 0V ground connections respectively. This device is always powered up, even when

then television is in the standby state. Capacitor C043 ensures that the supplies are properly de-coupled.

TXD Connections

Pin 1 is the RS232 Transmit line from the microcontroller (pin 30) which is routed through to pin 2 of I007 when pin13 is

HIGH. Under normal operating conditions (and when the TV is NOT in service or diagnos e modes ), pin 1 is disc onnected

from pin 2 (and pin 12 of scart2). When the TV is in service mode, a PC can be connected to scart 2 to perform diagnostic

functions on the chassis (see separate section on diagnostic protocols for more information).

RXD Connections

Pin 11 is the RS232 receive line from the m icroc ontroller ( pin 37) which is routed through to pin 10 when pin 12 is HIGH.

Page 27

Under normal operating conditions (and when the TV is NOT in s ervice or diagnose m odes), pin 10 is disconnec ted from

pin 12 (and pin 12 of scart2). When the TV is in service m ode, a PC can be connected to scart 2 to perf orm diagnostic

functions on the chassis (see separate section on diagnostic protocols for more information).

I2C Connections

2

C Clock Connection

I

Pin 8 is the I2C master clock input from the m icrocontroller (pin 24). When pin 6 of I007 is HIGH, this line is connected to

pin 9, which enables the microcontroller to c ommunicate with other I

when the TV is in the standby state, or when power is first applied to the chassis.

2

C devices on the chassis. Pin 6 is normally LOW

I2C Data Connection

Pin 4 is the I2C data input from the microcontroller (pin 23). W hen pin 5 of I007 is HIGH, this line is connected to pin 3,

which enables the microcontroller to c om m unicate with other I

TV is in the standby state, or when power is first applied to the chassis.

2

C devices on the chassis. Pin 5 is normally LOW when the

PCF8591 A/D and D/A Converter (I008)

The PCF8591 is a Single-chip, single-supply low power 8-bit CMOS data acquisition device with four analog inputs, one

analog output and a serial I

address, allowing the use of up to eight devices c onnected to the I

and data to and for the device are transferred serially via the two-line bi-directional I

2

C -bus interface. Three addr ess pins A0,A1 and A2 are used for programm ing the hardware

2

C -bus without additional hardware. Address, control

2

C -bus.

The functions of the device include analog input multiplexing, on-chip track and hold function,8-bit analog-to-digital

conversion and an 8-bit digital-to-analog conversion. T he maximum conversion rate is given r ate is given by the maximum

speed of the I

2

C -bus.

Supply/Ground Connections

Pins 16 and 8 are the +5V supply and 0V ground connections respectively. This device is always powered up, even when

then television is in the standby state. Capacitor C049 ensures that the supplies are properly de-coupled.

AV-3-SW Input

Pin 1 is connected to the pin 8 of the Scart3 terminal.

When this input change to High, TV set is selected to Scart3 Input.

D-SIZE Input

Pin 3 is D-SIZE input from the Digital Convergence Unit. When the Magic Focus is operated, this input is changed to High.

W-SP-OFF Output

Pin 15 is the Woofer amplifier control. This output is High when the Woofer amplifier is in the mute condition.

Page 28

RESET for MSP3410D

MSK SW

C SP OFF

R SP OFF

P.BLK

F.SP OFF

INTER/PRO

PAL/NTSC

ADD

Head Phone IN

IR IN

Power Good

Digicon busy

SAV4/V+/V- KEYS

P+/P-/MENU KEYS

V Sync IN

H Sync IN

H Sync

Y2/Y3 SW

ON/OFF

MUTE1

Cut Off

Mute

HBLK-PH

Red LED

WSS

VPS

74HC595

(I006)

AV3 SW

SAV1

D size in

SIDE PANEL

WOOFER OFF

Expanded A/D&D/A

SCL

SDA

(I008)PCF8591

Main u-con(80pin)

E2RD

M.SCL

M.SDA

TXD

RXD

I2C.DIS

SCART.DIS

CLOCK(P->S)

DATA

CLOCK

(I001)

ST92R195B

•E

•E

MMU3

E2P ROM

E2P DIS

M.SCL

M.SDA

ST24C32

(I005)

M.SCL

M.SDA

74HC4066

I2C.ENA

SCART.ENA

•B

74HC04

(I004)

OSD R

OSD G

OSD B

OSD BLK

SCL

SDA

(I007)

SCART TX

SCART RX

•E

•E

•E

•E

•E

•E

•E

•E

•E

•E

•E

•E

TUNER

SCL

SDA

UVE25-EW54D

(U101)

IF/Video Chroma/Analogue SW

SCL

SDA

(I201)

(IC02)

(U301)

TDA9320H

Digital 3 Line Comb

SCL

SDA

TC9090AN

Feature Box

SCL

SDA

SDA9206

SDA9400

SDA9280

RGB PROCESSOR

SCL

SDA

AV1 IN

AV2 IN

DSN

MMU0•`5

DAT0•`7

ADDR0•`15

ROM

AT49F002T

(I002) CXD2053AM

HHEE-MD DEVELOPMENT (HARD/SOFT)

AC3/MPEG DECORDER

CODEC

SUB u-con

MDSP56362

(IS01)

VOL/TONE

VOL/TONE

SCL

SDA

SCL

SDA

SCL

SDA

•E

•E

•E

•E

Fig.9 Block Diagram

MMU0•`5

ADDR0•`15

RAM

(I003)

DSN

RWN

DAT0•`7

Defrection

uPC1885

(I702)

SCL

SDA

ADD

•E

•E

•E

•E

•E

•E

(IX01)

Letter BOX Det

(I009)

(I401)

TA1276AN

SCL

SDA

A2/NICAM/SW

SCL

SDA

MSP3410D

Page 29

UP91 Signal circuit description

Tuner.

The tuner U101, is a frequency synthesis type with an unbalanced input, powered from the +5V rail while the tuning voltage is supplied by the +33V

rail, supplied from the power supply circuit. Direct frequency access, channel selection, AGC and AFC functions are controlled via the I2C bus. AGC,

AFC and Offset controls may be selected by entering the service menu and selecting the ‘tuner’ option.

Pin 1, AGC is taken from pin 62 of I201 TDA 9320. The balanced I.F. output is taken from pins 10 & 11, which are then arrive at the vision SAW filter

X209 (pins 1 & 2) and sound SAW filter X208 (pi1 B/G, D/K, L, pin2 L’). The outputs from X208 and X209 (pins 4 & 5 respectively) pass through to

pins 2 & 3 and pins 63 & 64 of I201, where they are demodulated.

Input Processor - TDA 9320(9321).

The TDA9320(9321) is a multistandard input processor. Features include:

Vision I.F. demodulation and amplifier.

The video signal is demodulated by means of a PLL carrier regenerator. This circuit contains a frequency detector and a phase detector. During

acquisition the frequency detector will tune the VCO to the right frequency. After lock-in, the phase detector controls the VCO so that a stable phase

relation between VCO and the input signal is achieved. The VCO is running at double the I.F. frequency with the reference signal for the demodulator

obtained by means of a frequency divider circuit.

The AFC output is obtained by using the VCO control voltage of the PLL and can be read via the I2C bus. The AGC detector operates on top sync and

top white level. The time constant on the AGC system during positive modulation is rather long to avoid visible variations of the signal amplitude. To

improve the speed of the AGC system a circuit has been included which detects whether the AGC detector is activated every frame period. When

during 3 field periods no action is detected the speed of the system is increased. For signals without peak white information the system switches

automatically to a gated black level AGC. Because a black level clamp pulse is required for this way of operation the circuit will only switch to black

level AGC in the internal mode.

The circuit contains a video identification circuit which is independent of the synchronisation circuit. Therefore search tuning is possible when the

display section of the receiver is used as a monitor.

Sound I.F. demodulation and amplifier.

In case of FM, NICAM, and A2 stereo, the circuit detects sound carrier signal and sends it to MSP3410 as a QSS (quasi sprit sound) carrier signal and

MSP 3410 will demodulate to base band sound.

However, in AM mode, the circuit detects AM signal and send it to MSP3410 as a base band AM signal. Then MSP3410 will provide sound to other

circuit.

Video Outputs/External Inputs

The input processor has provision for three CVBS inputs (1 internal & 2 external) and 2 Y/C inputs. The external CVBS inputs are being used for the

rear Scart sockets and front AV phono. The Y/C inputs are being used as a front S-VHS and a second, third CVBS (Scart) input. The circuit can detect

whether CVBS or a Y/C signal is present to Scart2, Scart3 and Front AV(Phono and S-VHS) inputs. The IC has 2 RGB inputs with fast switching. The

switching of the various sources is controlled by I2C and detection of a Comb filter can be made.

Page 30

Synchronisation.

The sync separator is operated by the Feature Box circuit.

Chroma & Luma Processing.

The IC contains a chrominance bandpass filter , the SECAM cloche and chrominance trap. The filters are calibrated using the tuning frequency and the

crystal frequency of the colour decoder. The luminance output signal which is derived from the incoming CVBS or Y/C signal can be varied in

amplitude by means of a separate gain control.

Colour Decoding.

The colour decoder can decode PAL, NTSC and SECAM signals. The PAL / NTSC decoder contains an alignment free crystal oscillator with 4 separate

pins, a killer circuit and two colour difference demodulators. The 90-degree phase shift for the reference signal is made internally. Because it is possible

to connect 4 different crystals to the colour decoder, all colour standards can be decoded without external switching circuits. Crystals not used must be

left open. The horizontal oscillator is calibrated by means of the crystal frequency of the PLL.

The IC contains an automatic colour limiting circuit which is switchable which prevents over saturation when signals with a high chroma-to-burst ratio

are received. The ACL circuit is designed such that it only reduces the chroma signal and not the burst. This has the advantage that the colour

sensitivity is not affected by this function.

The SECAM decoder contains an auto-calibrating PLL demodulator which has two references, the 4.43MHz sub-carrier frequency which is obtained

from the crystal oscillator which is used to tune the PLL to the desired free running frequency and the bandgap reference to obtain the correct absolute

value of the output signal. The VCO of the PLL is calibrated during each vertical blanking period, when the I.C. is in search or SECAM mode. The

base-band delay line is integrated into the package in order to adjust luminance and chrominance timing.

Signal Path Description.

The I.F. signal is obtained from SAW filters X209 (vision) and X208 (Sound) pins 4 & 5 and are fed into pins 2 & 3 vision and 63 & 64 sound of I201

respectively. A composite video signal is available at pin 10 from the vision demodulator. Either QSS carrier or AM base band sound out from pin 5.

The video is taken from pin 10 via C304 into pin 12 and out at pin 13. This is the selectable Group Delay adjustment via software input output for the

compensation of difference between I&B/G. The composite video gets taken through buffer and sound trap stages where the desired video returns to

I201 at pin 14.

The AV switching matrix supports three Scart sockets, phono (front) CVBS and S-VHS inputs. Scart CVBS inputs are at pins 20 and proceed to pin 16

(Scart1 JY01) and 20 (Scart2, JY02 or Scart3, JY03, Scart2 and Scart3 are selected by external video switch IY01 on terminal PCB, beforehand.) CVBS

outputs to Scart pins 19 from emitter of QY04 (Scart1), emitter of QY01 (Scart2) and emitter of QY03 (Scart3). Scart S-VHS inputs which are via JY02 or

JY03 (switched by IY01) to pin 20 & 21 of I201. Front S-VHS input is via din socket JM02 to pin 23 & 24 of I201. Detection of CVBS input is detected

within I201. Comb filter output has been fitted via Y/C input pins 28 & 29. Colour sub-carrier output for the Comb filter is form pin 30.

Y, U and V signals are taken from I201 pins 49, 50 & 51 and go into pins 9, 10 & 12 of the double scan unit (U301) respectively.

Other miscellaneous pins. I2C control lines are pins 46 & 47, and tuner AGC control voltage is present at pin 62. Sandcastle pin 59 is not in use. HA,

VA out from pins 60 & 61 are also not in use.

Digital Comb Filter.

The operation of a comb filter is to separate the composite video into luminance and reconstructing the chrominance sub carrier signals using digital

signal processing techniques. The comb filter IC, IC02 has an additional vertical edge enhancement feature.

Composite video input (Pin 6 of connector PN01) and colour sub-carrier (pin 8 of PN01) is to an analogue to digital 8 bit converter where the vertical

Page 31

enhancement and digital comb filtering takes place. Separated luminance and chrominance output

components are available via a digital to analogue 8 bit converter at pins 1 & 4 of PN01 respectively.

Digital Double Scan Conversion Unit (Feature Box).

The main feature of this unit is frequency double scan conversion 100Hz interlaced and 50/60Hz progressive scan.

Other features of this unit are noise reduction, line flicker reduction, CTI (Colour Transient Improvement),

sharpness, vertical zoom and horizontal compression. These functions arecontrolled by I2C bus. This unit is powered

from +5V and +8V supplies, feeding into pins 1, 2 and 6 of E U02 respectively. The three input 50Hz video

signals Y, U, V are sent to this unit at pins 8, 10 and 12 of EU01. The Y, U, V video output signals (double frequency

video) are taken from pins 5, 3 and 1 of EU01. The horizontal and vertical sync signals are input to this unit as a

composite video signal at 4 of EU02, the double frequency sync signals outputs are from pins 10 and 11of EU02.

Page 32

FIG.1 Scan rate conversion mode for display

Fig.1 shows the differences between 100Hz interlaced scan and 50/60Hz progressive scan.

The biggest advantage of progressive scan is "non-interlacing", but field frequency is kept at 50/60Hz.

This means the line construction (density) is twice, compared with 100Hz interlaced scan. Therefore, if

progressive scan mode is selected, large area flicker will be still appeared on display, but will eliminate lines flicker.

RGB Processor - TA 1276AN

The TA1276AN is RGB Processor IC which included features are Black stretch, Gamma correction,

Contrast/Brightness/Colour/Tint/Sharpness controls, G and B drive gain control and Velocity Scan Modulation

signal control. The Black stretch is stable operated at each of the viewing format, by input the Clamp pulse

signal to pin 25 of TA1276AN from the 4:3 frame generator which are consisted of IZ03 and IZ05.

Input Signals.

Y, U, V, input signals which are supplied by the feature box. The nominal input signal for Y is 0.7V Peak-to-Peak.

The nominal input signals for U and V are 300mV Peak-to-Peak respectively.

Page 33

Two RGB sources are intended for use by the Digital Convergence Adjustment Signal, while the second is

used for the OSD and Teletext. The required input signal has an amplitude of 0.5V Peak-to-Peak.

The switching between the internal signal and the OSD signal can be realized via a OSD BLK.

The circuit contains switchable matrix circuits for the colour difference signal so that the colour reproduction can

be adapted for PAL/SCAM and NTSC.

I2C is present at pins 27 & 28 (IX01) and +9V supply rails at pins 22, 40 & 46 and +5V supply rails at 12 pin.

From

Feature Box

2H Sync

Mask SW

IZ03

Clamp

74HC221

Gen.

4:3 Frame

Gen.

IZ05

74HC221

Clamp

pulse

Y

U

V

RGB Processor

Y

U

V

VM

To

CRT PCB

IX01 TA1276AN

Fig2. RGB Processor Block Diagram

CRT base

RGB signals for CRT are applied by PZC connector from RGB PCB to B CRT base PCB and bridged to G, R

CRT base PCB into Q8A1, Q851, and Q801. Then for e.g. B signal goes through limiter circuit Q8A2, Q8A3 to

amplifier Q8A4, Q8A5. B CRT base particularly has a gamma correction circuit, Q8A6 & Q8A7 which is

compensating B tube phosphorcharacteristic. Because B tube phosphor efficiency reduces in high brightness

area, therefore the B gain must be higher than others in high brightness area G CRT base has a bias circuit

Q858, Q859 for all CRT base PCB. Protection signal, which is called spot, is fed to CRT base to blank the picture

when something has failed.

Scan Velocity Modulation.

During transmission the signal sufferers from degradation and also due to the frequency characteristics of the television circuitry.

This normally results in a gentle rise or fall in the brightness change areas where black-to-white-to-black

patterns are received. The picture sharpness quality can be assessed by how steep the leading and trailing edges

are. The scan velocity modulation circuit has been designed to improve picture quality, ie make the video signal edges

steeper, by controlling the horizontal scanning velocity of the electron beam in the CRT. The velocity modulation

Page 34

circuit produces a compensation signal by differentiated luminance signal. The compensation signal is given some

current gain,applied to the auxiliary coil (connectors PVMR, PVMG, PVMB) on the neck of the cathode ray tube

(CRT) tocontrol the speed of the electron beam. The VM circuit is located beside CRT base PCB, on the backside

of lower part of front cabinet. The differentiated luminance signal derives from PZV pin 1 and into base of QE01,

through the CE03, RE04 arriving at the emitter of QE02 QE03 for voltage amplification and latter stages,

power

gain.

Page 35

SM00026 SIGNAL PCB 1 of 4

Page 36

SM00026 EUROPE PTV SIGNAL 2 of 4

Page 37

SM00026 SIGNAL PCB 3 of 4

Page 38

SM00026 EUROPE PTV SIGNAL 4 of 4

Page 39

SM00026 UP9X DEFLECTION CIRCUIT 1 of 3

Page 40

SM00026 UP9X DEFLECTION CIRCUIT 2 of 3

Page 41

SM00026 UP9X DEFLECTION CIRCUIT 3 of 3

Page 42

SM00026 UP9X SUB DEFLECTION CIRCUIT

Page 43

COMB FILTERSM00026

Page 44

SM00026

EURO PTV CONTROL - A

Page 45

EURO PTV CONTROL - BSM00026

Page 46

AUDIO AMP BOARD 1 of 2SM00026

Page 47

AUDIO AMP BOARD 2 of 2SM00026

Page 48

EUROPE PTY TERMINALSM00026

Page 49

UP9X SENSORSM00026

Page 50

UP9X RGB CIRCUITSM00026

Page 51

SM00026 UP91 POWER SUPPLY

Page 52

SM00026 AUDIO DECODER

Page 53

SM00026

HIGH END FEATURE BOX

Page 54

110W SUB POWER BOARDSM00026

Page 55

SM00026 CPT CIRCUIT

Page 56

SM00026 VM CIRCUIT

Page 57

SM00026 UP9X VM PCB

Page 58

I/V I/F PCBSM00026

Page 59

AUDIO AMPLIFIER BOARD (SOLDER)SM00026

Page 60

AUDIO AMPLIFIER BOARD (COMPONENT)SM00026

Page 61

UP9X SIGNAL (SOLDER)SM00026

Page 62

UP9X SIGNAL (COMPONENT)SM00026

Page 63

UP9X CPT-B PCBSM00026

Page 64

UP9X SENSOR PCBSM00026

Page 65

110W SUB POWER PCBSM00026

Page 66