Page 1

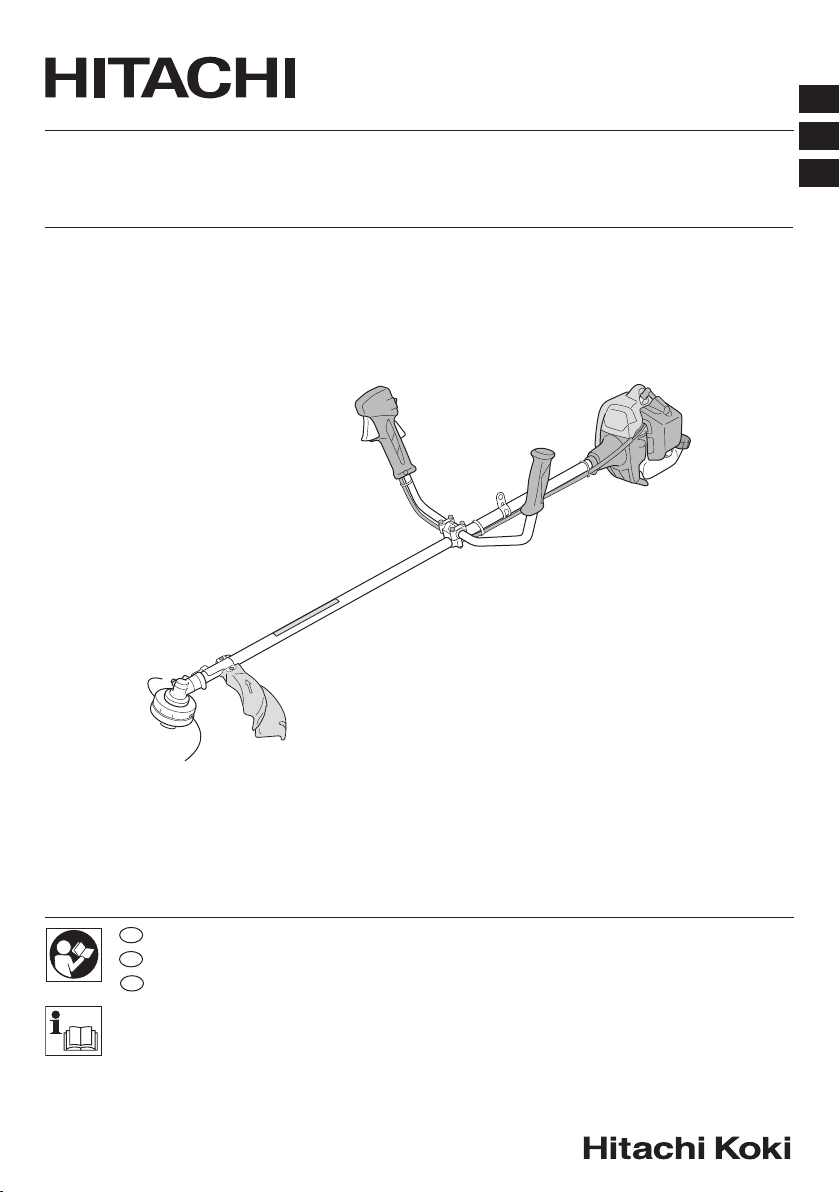

CG 24EC (S) / CG 24EC (SL)

CG 27EC (SL)

en

es

pt

en

Handling instructions

es

Instrucciones de manejo

pt

Instruções de uso

CG 24EC (S)

Page 2

1

I

K

B

N

E

H

F

D

G

M

CG24EC(S)

I

H

G

N

E

F

D

M

K

B

CG24ECP(SL)

CG27ECP(SL)

C

L

A

234

2

6

M

J

1

3

8

4

7

5

O

P

Q R

9

567

10

11

13

12

2

Page 3

8910

16

14 15

11 12 13

17

17

14 15 16

18

19

20

17 18 19

3

Page 4

20 21 22

17

17

23 24 25

22

21

23

26 27 28

T

0.6 mm

10 cm

24

29 30 31

10 cm

10 cm

26

4

26

27

25

29

28

Page 5

32

11-14 cm

11-14 cm

5

Page 6

English

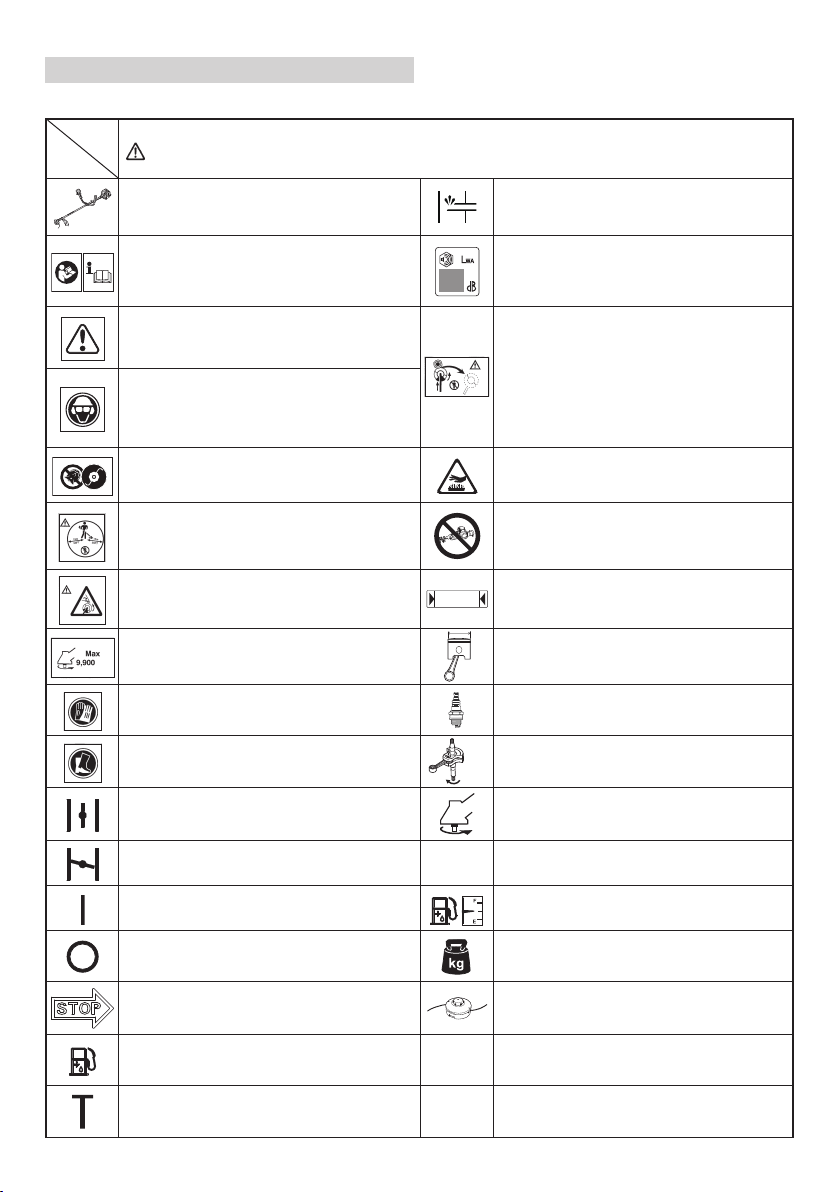

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand their meaning before use.

Grass Trimmer / Brush Cutter Priming pump

It is important that you read, fully understand

and observe the following safety precautions

and warnings. Careless or improper use of the

unit may cause serious or fatal injury.

Read, understand and follow all warnings and

instructions in this manual and on the unit.

Always wear eye, head and ear protectors when

using this unit.

Do not use metal/rigid blades when this sign is

shown on the unit.

Keep all children, bystandards and helpers

15 m away from the unit. If anyone approaches

you, stop the engine and cutting attachment

immediately.

Be careful of thrown objects.

Guaranteed sound power level

Blade thrust may occur when the spinning

blade contacts a solid object in the critical area.

A dangerous reaction may occur causing the

entire unit and operator to be thrust violently.

This reaction is called blade thrust. As a result,

the operator may lose control of the unit which

may cause serious or fatal injury. Blade thrust is

more likely to occur in areas where it is diffi cult

to see the material to be cut.

Hot Surface – Contact with hot surface can

cause serious burns.

The hedge trimmer attachment cannot be used

on models with this label.

Indicate handle location. Arrows which show

limits for handle positioning.

Shows maximum shaft speed. Do not use the

cutting attachment whose max rpm is below the

-1

min

shaft rpm.

Gloves should be worn when necessary, e.g.,

when assembling cutting equipment.

Use anti-slip and sturdy footwear.

Choke – Run position (Open) Speed of output shaft

Choke – Start position (Closed)

On/Start Fuel tank capacity

Off /Stop

Emergency stop Cutting attachment

Fuel and oil mixture

Idle speed adjustment

L

ISO22868

L

WA, Ra(M)

2000/14/EC

6

Displacement

Spark plug

Idling speed

Idle

Max. engine output

P

Dry weight (without fuel, cutting attachment,

harness and cutting attachment guard)

Sound pressure level LpA by ISO 22868

pA, eq

Equivalent*

Measured sound power level LwA by 2000/14/

EC

Racing

Page 7

English

L

WA, Ra(G)

2000/14/EC

a

hv, eq(F)

Before using your machine

• Read the manual carefully.

• Check that the cutting equipment is correctly assembled and adjusted.

• Start the unit and check the carburetor adjustment. See “MAINTENANCE”.

NOTE: Equivalent noise level / vibration level are calculated as the time-weighted energy total for noise / vibration levels

* 1/2 Idle, 1/2 racing.

WHAT IS WHAT? (Fig. 1)

Since this manual covers several models, there may be

some diff erence between pictures and your unit. Use the

instructions that apply to your unit.

A: Fuel cap

B: Throttle trigger

C: Starter handle

D: Cutting attachment guard

E: Cutting attachment

F: Drive shaft tube

G: Handle

H: Hanger

I: Ignition switch

J: Harness (if so equipped)

K: Throttle trigger lockout

L: Choke lever

M: Engine

N: Gear case

O: Combi box spanner

P: Handling instructions

Q: Goggles

R: Hex bar wrench

WARNINGS AND SAFETY

INSTRUCTIONS

Pay special attention to statements preceded by the

following words:

Indicates a strong possibility of severe personal injury or

CAUTION

Indicates a possibility of personal injury or equipment

NOTE

Helpful information for correct function and use.

Operator safety

○ Wear head protection (1). (Fig. 2)

○ Always wear a safety face shield or goggles (2). (Fig. 2)

○ Wear approved hearing protection (3). (Fig. 2)

Long-term exposure to noise can result in permanent

Pay attention to your surroundings. Be aware of any

Remove safety equipment immediately upon shutting off

○ Always wear heavy, long-sleeved shirts (4) and long

Do not wear loose clothing, jewelry, short pants, sandals

Secure hair so it is above shoulder length.

Guaranteed sound power level LwA by 2000/14/

EC

Racing

Vibration level by ISO 22867

Front or Left handle / Equivalent*

under various working conditions with the following time distribution:

WARNING

loss of life, if instructions are not followed.

damage, if instructions are not followed.

hearing impairment.

bystanders who may be signaling a problem.

engine.

pants (5) and non-slip boots (6) and gloves (7). (Fig. 2)

or go barefoot.

a

hv, eq(R)

○ Do not operate this tool when you are tired, ill or under

○ Do not operate the tool at night or under bad weather

Working on slippery ground could lead to an accident if

○ Never let a child or inexperienced person operate the

○ Do not start the engine if there are any fl ammables such

○ Never start or run the engine inside a closed room or

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the unit by the cutting equipment.

○ Gloves should be worn when installing or removing the

○ When the unit is shut off , make sure the cutting

○ When operation is prolonged, take a break periodically

○ Always operate the tool with proper protective equipment

○ Do not touch the spark plug area or high voltage during

○ Do not allow children near the tool during operation.

○ Do not touch the engine, muffl er cover or exhaust vent

○ Antivibration systems do not guarantee that you will

○ If you are using any medical electric/electronic devices

Unit/machine safety

○ Inspect the entire unit/machine before each use.

○ Replace parts that are cracked, chipped or damaged in

○ Make sure the cutting attachment guard and harness are

○ Keep others away when making carburetor adjustments.

○ Use only accessories as recommended for this unit/

7

Vibration level by ISO 22867

Rear or Right handle / Equivalent*

Uncertainty

K

the infl uence of alcohol, drugs or medication.

conditions when visibility is poor. And do not operate the

tool when it is raining or right after it has been raining.

you lose your balance.

machine.

as dry leaves, waste paper or fuel in the vicinity.

building. Breathing exhaust fumes can kill.

cutting attachment. Failure to do so may result in injury.

attachment has stopped before the unit is set down.

so that you may avoid possible Hand-Arm Vibration

Syndrome (HAVS) which is caused by vibration.

WARNING

and clothing. Failure to do so may result in accidents

such as burns or injuries. (Fig. 2)

operation. Doing so may result in electric shock.

during or shortly after operation. Doing so may result in

burn or injury.

not sustain Hand-Arm Vibration Syndrome or carpal

tunnel syndrome. Therefore, continual and regular users

should monitor closely the condition of their hands and

fi ngers. If any of the above symptoms appear, seek

medical advice immediately.

such as a pacemaker, consult your physician as well as

the device manufacturer prior to operating any power

equipment.

Replace damaged parts. Check for fuel leaks and make

sure all fasteners are in place and securely tightened.

any way before using the unit/machine. Faulty parts may

increase the risk of accidents and may lead to an injury.

properly attached. Do not operate if cutting attachment

guard and harness is not properly attached.

machine by the manufacturer.

Page 8

English

○ Before operation, make sure that there are no tools such

as the adjustment key or spanner still attached to the

unit.

WARNING

○ Never modify the unit/machine in any way. Do not use

your unit/machine for any job except that for which it is

intended.

○ Non-authorized modifi cations and/or accessories may

result in serious personal injury or the death of the

operator or others.

Fuel safety

○ Mix and pour fuel outdoors and where there are no

sparks or fl ames.

○ Use a container approved for fuel.

○ Move at least 3 m away from fueling site before starting

engine.

○ Stop engine before removing fuel cap. Do not remove

the fuel cap during operation.

○ Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If

fuel is left in the tank, store so fuel will not leak.

WARNING

○ Fuel is easy to ignite or get explosion or inhale fumes, so

that pay special attention when handling or fi lling fuel.

○ Do not smoke or allow smoking near fuel or the unit/

machine or while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Store unit/machine and fuel in area where fuel vapors

cannot reach sparks or open fl ames from water heaters,

electric motors or switches, furnaces. etc.

○ When using the unit in dry areas, make sure that fi re

extinguishing equipment is readily available.

○ If you shut off the engine for refueling, make sure the unit

has cooled down before adding fuel.

Cutting safety

○ Do not cut any material other than grass and brush.

○ Inspect the area to be cut before each use.

Remove objects which can be thrown or become

entangled.

Do not operate in areas where there are tree roots or

rocks.

○ For respiratory protection, wear an aerosol protection

mask when cutting the grass after insecticide is

scattered.

○ Keep others including children, animals, bystanders and

helpers outside the 15 m hazard zone. Stop the engine

immediately if you are approached.

○ Please exercise caution as engine startup may be

delayed after pulling the starter handle.

○ Always keep the engine on the right side of your body.

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm footing and balance. Do not over-reach.

Losing your balance during work may lead to an injury.

○ Keep all parts of your body away from the muffl er and

cutting attachment when the engine is running.

○ Keep cutting attachment below knee level.

○ Please exercise caution when operating in areas where

electrical cables or gas pipes are present.

○ Do not operate the cutting attachment for anything but

clearing grass or bushes. Avoid operations where the

cutting attachment may touch water such as puddles

or dig into dirt. Failure to do so may result in injury or

damage to the unit.

○ Avoid prolonged use at low speed range in which

vibration is high. Doing so may result in engine damage.

○ When relocating to a new work area, or inspecting,

adjusting or exchanging the unit’s cutting attachments,

accessories, etc., be sure to shut off the machine and

ensure that all cutting attachments are stopped.

○ Never place the machine on the ground when running.

○ Never touch the cutting attachment when it is rotating.

○ Always ensure that the engine is shut off and any cutting

attachments have completely stopped before clearing

debris or removing grass from the cutting attachment.

○ Always carry a fi rst-aid kit when operating any power

equipment.

○ Turn off the engine and make sure the cutting attachment

has come to a full stop before removing the unit from

your body or before leaving the unit unattended.

○ If you accidentally bump or drop the unit, inspect it

immediately to make sure there are no damage, cracks

or deformations.

○ If the tool is operating poorly and produces strange noise

or vibrations, turn off the engine immediately and ask

your dealer to have it inspected and repaired.

Continued use under these conditions could lead to

injury or tool damage.

○ Use in accordance with local laws and regulations.

Maintenance safety

○ Maintain the unit/machine according to recommended

procedures.

○ Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

○ Keep others away when making carburetor adjustments.

○ Use only genuine HITACHI replacement parts as

recommended by the manufacturer.

CAUTION

Do not disassemble the recoil starter. There is a

possibility of personal injury with recoil spring.

WARNING

Improper maintenance could result in serious engine

damage or in serious personal injury.

Transport and storage

○ Carry the unit/machine by hand with the engine stopped

and the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank, and secure

the unit/machine before storing or transporting. Failure to

do so may result in fi re or accidents.

○ Empty the fuel tank before storing the unit/machine. It is

recommended that the fuel be emptied after each use. If

fuel is left in the tank, store so fuel will not leak.

○ Store unit/machine out of the reach of children.

○ Clean and maintain the unit carefully and store it in a dry

place.

○ Make sure engine switch is off when transporting or

storing.

○ When transporting and storing, either remove the cutting

attachment or place the blade cover over the blade.

○ You have to secure the machine during transport to

prevent loss of fuel, damage or injury.

○ If a warning label cannot be read, peels off or becomes

indistinct, replace it with a new one. To purchase new

labels, contact Hitachi Authorized Service Centers.

If situations occur which are not covered in this manual, take

care and use common sense. Contact Hitachi Authorized

Service Centers if you need assistance.

SPECIFICATIONS

The SPECIFICATIONS of this machine are listed in the table

on page 38.

NOTE

All data subject to change without notice.

8

Page 9

ASSEMBLY PROCEDURES

Installation of handle

(1) Loop handle type (Fig. 3)

Attach the handle to the drive shaft tube with the angle

towards the engine.

Adjust the location to the most comfortable position

before operation.

Make sure to securely attach the handle with the 2 bolts.

NOTE

If your unit has handle location label (8) on drive shaft

tube, follow the illustration.

(2) Bike handle type (Fig. 4)

Remove the handle bracket (9) from the assembly.

Place the handle and attach the handle bracket with four

bolts lightly. Adjust to appropriate position. Then attach it

fi rmly with the bolts.

Installation of harness

(If so equipped)

WARNING

If the product includes a harness, always make sure to

use it.

Attach the harness hook (10) to the hanger (11) on the drive

shaft tube. (Fig. 5)

Adjust the length of the harness for easy operation of the

tool.

NOTE

You may need to adjust the position of the hangar (11)

to balance the unit. To do so, loosen bolt (12) and adjust

the position of hangar (11). After adjusting as necessary,

make sure to securely tighten the bolt (12). (Fig. 5)

Installation of cutting attachment guard

WARNING

If an incorrect or faulty guard is fi tted, this may cause

serious personal injury.

CAUTION

Some cutting attachment guards are equipped with

sharp line limiters. Be careful with handling it.

NOTE

○ When using a trimmer head with two piece type cutting

attachment guard, attach the guard extension to the

cutting attachment guard, then tighten the bolt (13).

(Fig. 6)

○ The guard extension is already attached to the cutting

attachment guard at the time of purchase.

○ The guard bracket may come already mounted to the

gear case on some models.

Align the cutting attachment guard with the guard bracket

and secure it to the drive shaft tube, using the bolt and cover

bracket. (Fig. 7)

Installation of cutting attachment

WARNING

○ Install the cutting attachment properly and securely as

instructed in the handling instructions.

If not attached properly or securely, it may come off and

cause serious and/or fatal injury.

○ Do not install or remove cutting attachments while the

engine is running.

○ Always use genuine Hitachi cutting attachments and

metal fi ttings.

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line when it is

tapped at low rpm (not greater than 4500 min

-1

).

English

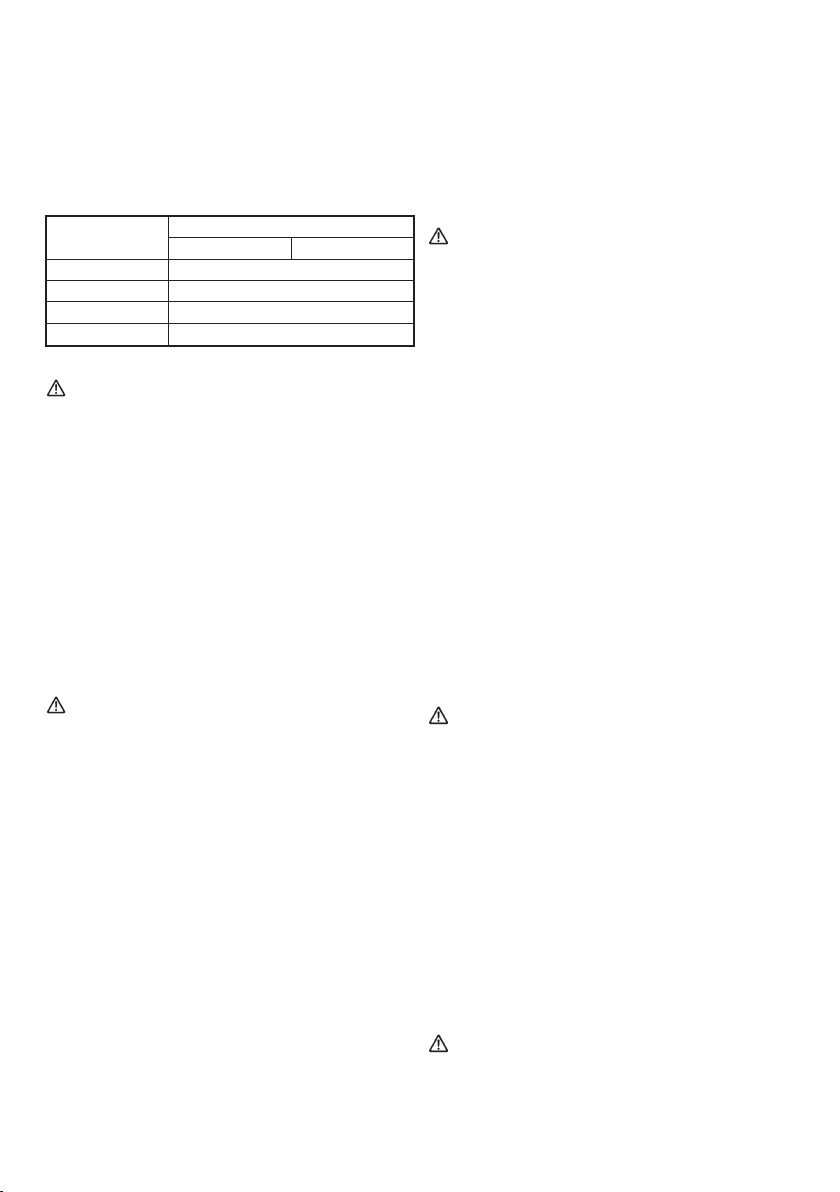

Specifi cations

Type of

Code

attaching

No.

screw

6696454 Female screw

Applicable nylon cord

Cord diameter: Φ3.0 mm Length: 2 m

Cord diameter: Φ2.4 mm Length: 4 m

2. Precautions

○ The case must be securely attached to the cover.

○ Check the cover, case and other components for cracks

or other damage.

○ Check the case and button for wear.

If the wear limit mark (14) on the case is no longer visible

or there is a hole in the bottom (15) of the button, change

the new parts immediately. (Fig. 8)

○ The cutting head must be securely mounted to the unit’s

gear case/cutter case.

○ If the cutting head does not feed cutting line properly,

check that the nylon line and all components are properly

installed. Contact Hitachi Authorized Service Centers if

you need assistance.

WARNING

For Hitachi heads, use only fl exible, non-metallic line

recommended by the manufacturer. Never use wire or

wire ropes. They can break off and become a dangerous

projectile.

3. Installation (Fig. 9)

Insert the allen wrench (16) into the hole of the gear

case/cutter case in order to lock the drive shaft tube.

Install cutting head on gear case/cutter case of grass

trimmers/brush cutters. The mounting nut is left-hand-

threaded. Turn clockwise to loosen/counter-clockwise to

tighten.

NOTE

Since the cutter holder cap is not used here, keep it for

when a metal blade is used, if so equipped.

4. Adjusting line length

Set the engine speed as low as possible and tap the

head on the ground. The nylon line will be drawn out

about 3 cm with each tap. (Fig. 10)

Also, you can extend the nylon line by hand but the

engine must be completely stopped. (Fig. 11)

Adjust the nylon line to the proper length of 11–14 cm

before each operation.

Direction of

rotation

Counterclockwise

Size of

attaching

screw

M10xP1.25LH

OPERATING PROCEDURES

Fuel (Fig. 12)

WARNING

○ The trimmer is equipped with a two-stroke engine.

Always run the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

○ Fuel is highly fl ammable and it is possible to get seriously

injured when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have

good ventilation when handling fuel inside building.

Fuel

○ Always use branded 89 octane unleaded gasoline.

○ Use genuine two-cycle oil or use a mix between 25:1 to

50:1, please consult about the mixture ratio to Hitachi

Authorized Service Centers.

○ If genuine oil is not available, use an anti-oxidant added

quality oil expressly labeled for air-cooled 2-cycle engine

use (JASO FC GRADE OIL or ISO EGC GRADE). Do not

use BIA or TCW (2-stroke water-cooling type) mixed oil.

9

Page 10

English

○ Never use multi-grade oil (10 W/30) or waste oil.

○ Never mix fuel and oil in machine’s fuel tank. Always mix

fuel and oil in a separate clean container.

Always start by fi lling half the amount of gasoline, which is

to be used.

Then add the whole amount of oil. Mix (shake) the fuel

mixture. Add the remaining amount of gasoline.

Mix (shake) the fuel-mix thoroughly before fi lling the fuel

tank.

Mixing amount of two-cycle oil and gasoline

Gasoline (Liter)

0.5 10 ——— 20

1 20 ——— 40

2 40 ——— 80

4 80 ——— 160

Fueling

WARNING

○ Always shut off the engine and let it cool for a few

minutes before refueling.

Do not smoke or bring fl ames or sparks near the fueling

site.

○ Slowly open the fuel tank, when fi lling up with fuel, so

that possible over-pressure disappears.

○ Tighten the fuel tank cap carefully, after fueling.

○ Always move the unit at least 3 m from the fueling area

before starting.

○ Always wash any spilled fuel from clothing immediately

with soap.

○ Be sure to check any fuel leakage after refueling.

○ Before fueling, in order to remove static electricity from

the main body, the fuel container and the operator,

please touch the ground that is slightly damp.

Before fueling, clean the tank cap area carefully, to ensure

that no dirt falls into the tank. Make sure that the fuel is well

mixed by shaking the container, before fueling.

Starting

WARNING

○ Before starting the tool, ensure that the cutting

attachment is not touching any objects or the ground.

Otherwise, the cutting attachment may unexpectedly

rotate and cause an injury.

○ Ensure that the cutting attachment does not rotate while

the engine is idling. If it does rotate, adjust the idle speed

according to the instructions in “Idle speed adjustment” in

the “MAINTENANCE” section. If the cutting attachment

still rotates after this adjustment, immediately stop the

engine and cease use, then bring the tool to the nearest

Hitachi Authorized Service Center.

CAUTION

Ensure that the throttle outer end is in the holder.

(1) Starting the cold engine

1. Set ignition switch (17) to ON position. (Fig. 13)

2. Push priming bulb (18) several times so that fuel fl ows

through return pipe (19). (Fig. 14)

3. Set choke lever (20) to START position (closed) (A).

(Fig. 15)

4. Pull recoil starter briskly, taking care to keep the handle

in your grasp and not allowing it to snap back. (Fig. 16)

5. When you hear the engine want to start, return choke

lever to RUN position (open) (B). (Fig. 15)

6. Pull recoil starter briskly again. (Fig. 16)

NOTE

If engine does not start, repeat procedures from 2 to 5.

Two-cycle oil (ml)

Ratio 50:1 Ratio 25:1

7. Then allow the engine about 2–3 minutes to warm up

before subjecting it to any load.

8. Check that the cutting attachment does not rotate when

the engine is idling.

(2) Starting the warm engine

Use only 1, 2, 6 and 8 of the starting procedure for a cold

engine.

If the engine does not start, use the same starting

procedure as for a cold engine.

Cutting

WARNING

○ Always use the harness (if so equipped) and wear the

proper attire and protective equipment when operating

the unit. (Fig. 17)

○ Keep others including children, animals, bystanders and

helpers outside the 15 m hazard zone. Stop the engine

immediately if you are approached. (Fig. 18)

○ When grass or vines wrap around attachment, stop

engine and attachment and remove them. Continuing

operation with grass or vines wrapped around the

attachment may result in damages such as early

abrasion of the clutch.

CAUTION

Use and points of caution will vary depending on the type

of cutting attachment. For safe use, make sure to follow

the instructions and guidelines provided with each type.

NOTE

○ Press the quick release button or pull emergency release

fl ap (If so equipped) in the event of emergency. (Fig. 19)

○ Use in accordance with local laws and regulations.

(1) Using a semi-auto cutting head

○ Set the engine at high speed when using this attachment.

○ Cut grass from left to right. The cut grass will be

discharged away from the body, minimizing transfer to

your clothes. (Fig. 20)

○ With nylon cord, use about 2 cm of the end of the cord

to cut grass. Using the full length of the cord will reduce

rotation speed and make cutting diffi cult.

NOTE

Automatically feeds more nylon cutting line when it is

tapped at low rpm (not greater than 4500 min

WARNING

○ This product is equipped with a line limiter that will

automatically cut any excess cord. When operating the

unit, do not remove the guard or line limiter.

As the resistance is greater for nylon cords as opposed

to blades, mishandling could increase engine load and

result in damage.

○ Do not use with the engine set at low speeds. If the

engine speed is low, grass may wrap around the

attachment, causing the clutch to slip which could result

in clutch abrasion.

○ With nylon cord cutters, always use over 15 cm of cord.

If the length of the cord is too short, rotation speed will

increase and may cause damage to the nylon cord

cutter. As the curved drive shaft tube model in particular

is not equipped with a deceleration mechanism, the

possibility of increased rotation speed for the cutting

attachment is high.

Stopping (Fig. 21)

Decrease engine speed and run at an idle for a few minutes,

then turn off ignition switch (17).

WARNING

A cutting attachment can injure while it continues to spin

after the engine is stopped or power control is released.

When the unit is turned off , make sure the cutting

attachment has stopped before the unit is set down.

-1

).

10

Page 11

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE

EMISSION CONTROL DEVICES AND SYSTEMS MAY

BE PERFORMED BY ANY NON-ROAD ENGINE REPAIR

ESTABLISHMENT OR INDIVIDUAL.

Carburetor adjustment (Fig. 22)

The carburetor is a precision part that mixes air and fuel, and

it is designed to ensure high performance from the engine.

Before the tool is shipped from the factory, its carburetor is

adjusted during a test run. Only make adjustments if it is

necessary because of environmental conditions (the climate

or atmospheric pressure), the type of fuel, the type of twocycle oil, etc.

WARNING

○ Because the carburetor is manufactured with a high

degree of precision, do not disassemble it.

○ For this product, the only setting of the carburetor that

can be adjusted is the idle speed (T).

○ Never start the engine without the complete clutch cover

and tube assembled! Otherwise the clutch can come

loose and cause personal injuries.

T = Idle speed adjustment screw.

Idle speed adjustment (T)

WARNING

○ When the engine is stopped, do not excessively turn

the idle speed adjustment screw (T) in a clockwise

direction. Otherwise, when the engine starts, the cutting

attachment may unexpectedly rotate and cause an

injury.

○ Do not adjust the idle speed adjustment screw (T) for

any reason other than to adjust the idling.

Run the engine while adjusting the idling.

(1) If the engine stops during idling

Start the engine, and slowly turn the idle speed

adjustment screw (T) in a clockwise direction until it is in

a position at which the engine rotates smoothly. At that

time, ensure that the cutting attachment is not spinning.

(2) If the cutting attachment rotates during idling

Slowly turn the idle speed adjustment screw (T) in a

counter-clockwise direction until it is in a position at

which the cutting attachment does not rotate. At that

time, ensure that the rotation of the engine is smooth.

WARNING

If the cutting attachment still rotates after adjustment of

the idle speed adjustment screw (T), immediately stop

the engine and cease use, then contact the nearest

Hitachi Authorized Service Center.

Air fi lter (Fig. 23)

The air fi lter (21) must be cleaned from dust and dirt in order

to avoid:

○ Carburetor malfunctions.

○ Starting problems.

○ Engine power reduction.

○ Unnecessary wear on the engine parts.

○ Abnormal fuel consumption.

Clean the air fi lter daily or more often if working in

exceptionally dusty areas.

Loosen the screw (22), then open the air fi lter cover and

remove the air fi lter (21). Rinse it in warm soap suds.

Check that the fi lter is dry before reassembly.

An air fi lter that has been used for some time cannot be

cleaned completely. Therefore, it must regularly be replaced

with a new one. A damaged fi lter must always be replaced.

English

Fuel fi lter (Fig. 24)

Remove the fuel fi lter (23) from the fuel tank, and replace it if

it is dirty.

NOTE

A blocked fuel fi lter (23) can prevent the supply of fuel and

cause a rotation malfunction of the engine.

Spark plug (Fig. 25)

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting.

○ Wrong fuel mixture (too much oil in the gasoline)

○ A dirty air fi lter.

○ Hard running conditions (such as cold weather).

These factors cause deposits on the spark plug electrodes,

which may result in malfunction and starting diffi culties. If

the engine is low on power, diffi cult to start or runs poorly at

idling speed, always check the spark plug fi rst.

If the spark plug is dirty, clean it and check the electrode

gap. Re-adjust if necessary. The correct gap is 0.6 mm. The

spark plug should be replaced after about 100 operation

hours or earlier if the electrodes are badly eroded.

NOTE

In some areas, local law requires using a resistor spark

plug to suppress ignition signals. If this machine was

originally equipped with resistor spark plug, use same

type of spark plug for replacement.

Gear case (Fig. 26)

Check gear case or angle gear for grease level about every

50 hours of operation by removing the grease fi ller plug on

the side of gear case.

If no grease can be seen on the fl anks of the gears, fi ll the

gear case with quality lithium based multipurpose grease up

to 3/4. Do not completely fi ll the gear case.

CAUTION

○ Make sure to remove any dirt or grit when attaching the

plug to its original position.

○ Before attempting inspection or maintenance of the gear

case, make sure the case has cooled.

Semi-auto cutting head

Nylon line replacement

1. Remove the case (24) by fi rmly pushing inward the

locking tabs with your thumbs as shown in Fig. 27.

2. After removing the case, take out the reel and discard

the remaining line.

3. Fold the new nylon line unevenly in half as shown in

picture.

Hook the U-shaped end of the nylon line into the groove

(25) on the center partition of the reel.

Wind both halves of the line on the reel in the same

direction, keeping each half of the line on its own side of

the partition. (Fig. 28)

4. Push each line into the stopper holes (26), leaving the

loose ends approx. 10 cm in length. (Fig. 29)

5. Insert both loose ends of the line through the cord guide

(27) when placing the reel in the case. (Fig. 30)

NOTE

When placing a reel in the case, try to line up the stopper

holes (26) with the cord guide (27) for easier line release

later.

6. Place the cover over the case so that the cap locking

tabs (28) on the case meet the long holes (29) on the

cover. Then push the case securely until it clicks into

place. (Fig. 31)

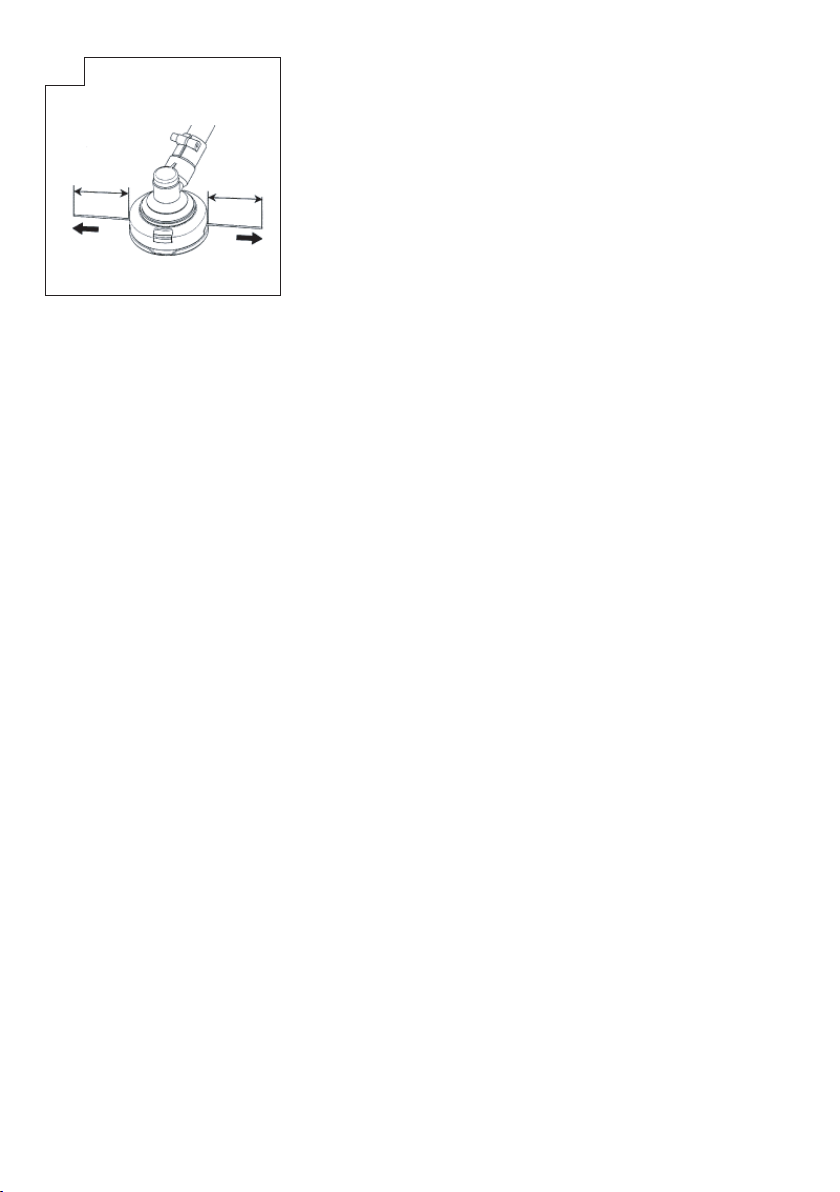

7. The initial cutting line length should be approx. 11–14 cm

and should be equal on both sides. (Fig. 32)

11

Page 12

English

For long-term storage

Drain all fuel from the fuel tank. Start and let engine run until

it stops. Repair any damage which has resulted from use.

Clean the unit with a clean rag, or the use of high pressure

air hose. Put a few drops of two-cycle engine oil into the

cylinder through the spark plug hole, and spin the engine

over several times to distribute oil.

Cover the unit and store it in a dry area.

Maintenance schedule

Below you will fi nd some general maintenance instructions.

For further information please contact Hitachi Authorized

Service Centers.

Daily maintenance

○ Clean the exterior of the unit.

○ Check that the harness is undamaged.

○ Check the cutting attachment guard for damage or

cracks. Change the guard in case of impacts or cracks.

○ Check that the cutting attachment is properly centered,

sharp, and without cracks. An off -center cutting

attachment induces heavy vibrations that may damage

the unit.

○ Check that the cutting attachment nut is suffi ciently

tightened.

○ Check that nuts and screws are suffi ciently tightened.

○ Check that the unit is undamaged and free of defects.

Weekly maintenance

○ Check the starter, especially the cord and return spring.

○ Clean the exterior of the spark plug.

○ Remove the spark plug and check the electrode gap.

Adjust it to 0.6 mm, or change the spark plug.

○ Check that the angle gear is fi lled with grease up to 3/4.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exterior of the carburetor and the space

around it.

○ Clean the fan and the space around it.

SELECTING ACCESSORIES

The accessories of this machine are listed on page 39.

12

Page 13

SELECTING CUTTING ATTACHMENTS

Recommended accessories for each model are presented in the table below.

For purchases, contact Hitachi Authorized Service Centers.

Please check carefully as those accessories not marked with “

List of recommended accessories

●” cannot be attached.

English

Type Name

NYLON HEAD

CH-100

(W/NYLON LINE)

NYLON HEAD

CH-100

NYLON HEAD

CH-300

(W/CUTTER HOLDER

CAP)

ALUMINUM HEADS

NYLON HEAD

CH-300

NYLON HEAD

BF-4

NYLON HEAD

TAP & GO

BF-5

NYLON HEADS

Specifi cation LOOP HANDLE

or

(mm)

Trimmer line Diameter

Blade Thickness (mm)

2.2 – 3.0

2.2 – 2.7

2.2 – 3.0

2.2 – 3.0

Diameter

4”

5”

4”

5”

or

No. of Teeth (Blade)

Feed System Adapter

Pre-Cut

Line

Manual line

feed

R M8 x 1.25

Nut

L M10 x

1.25 Nut

L M8 x 1.25

Nut

BIKE

HANDLE

CG24EC (SL)

●●●

●●●

●●●

CG27EC (SL)

●

●

CG24EC (S)

13

Page 14

English

TROUBLESHOOTING

Use the inspections in the table below if the tool does not operate normally. If this does not remedy the problem, consult your

dealer or the Hitachi Authorized Service Center.

Condition Cause Remedy

Fill the fuel tank with the correct fuel mix

(25:1-50:1)

Replace with new fuel

1.

Disconnect the spark plug and allow to dry

2. Pull the starter handle 5 or 6 times to

remove the surplus fuel

3. Attach the spark plug

4. Set the choke lever to RUN position and

pull the starter handle

Reconnect

Contact Hitachi Authorized Service Centers

for repair

Fill the fuel tank with the correct fuel mix

(25:1-50:1)

Replace with new fuel

Replace with designated part

See “SPECIFICATIONS”

Contact Hitachi Authorized Service Centers

See “Installation of cutting attachment”

Check and tighten

Fuel

system

Engine does not

start

Electrical

system

Other

Fuel

system

Engine starts

but cuts out

straightaway

Engine is apt to

cut out

Abnormal vibration

Engine is running but blade

does not move

Movement is poor

Electrical

system

Other

Fuel tank is empty or fuel level is low

Fuel tank contains old fuel (offensive odor)

Too much fuel is absorbed and spark

plug is wet

Fuel fi lter is clogged with dirt Clean the fuel fi lter

Fuel pipe is bent or disconnected Ensure that the fuel fl ows smoothly

Carburetor malfunction Contact Hitachi Authorized Service Centers

Stop switch lead has short-circuited Contact Hitachi Authorized Service Centers

Spark plug is dirty Replace or clean the spark plug

Electrode gap is too big Adjust the gap to 0.6mm

Poor connection between high tension

cable and spark plug

Electrical system malfunction Contact Hitachi Authorized Service Centers

Muffl er exhaust port is clogged with

carbon

Fuel tank is empty or fuel level is low

Fuel tank contains old fuel (offensive odor)

Two-cycle oil has not been added Contact Hitachi Authorized Service Centers

Choke lever is in START position Set the choke lever to RUN position

Air has got into fuel system Reconnect the fuel pipe or joint

Carburetor malfunction Contact Hitachi Authorized Service Centers

Ignition failure

Spark plug failure Replace with new spark plug

Electrical system failure Contact Hitachi Authorized Service Centers

Engine overheating

Wrong spark plug model

Dirty air cleaner Clean

Carbon clogging (muffl er exhaust port) Clean

Insuffi cient compression (piston, piston

ring, cylinder)

Cutting attachment is not properly

installed

Handle, handle bracket or other

fastening part is loose

Grass is wrapped round gear case Remove grass

Grass is wrapped round gear case Remove grass and dirt

14

Page 15

Condition Cause Remedy

Set the choke lever to START position to

Engine does not stop Stop switch failure

Engine stops when throttle is

closed

Blade continues rotating when

throttle is closed

Idle speed is too low

Idle speed is too high

Throttle wire is too taut

stop the engine

Cease use immediately and contact Hitachi

Authorized Service Centers

Contact Hitachi Authorized Service Centers

Contact Hitachi Authorized Service Centers

English

15

Page 16

Español

SIGNIFICADO DE LOS SÍMBOLOS

NOTA: Algunas unidades no están provistos de ellos.

Símbolos

ADVERTENCIA

A continuación se muestran los símbolos utilizados para la máquina. Asegúrese de comprender su signifi cado

antes de utilizar el dispositivo.

Motoguadañas / Desbrozadoras Mezcla de combustible y aceite

Es importante que lea, entienda totalmente

y respete las siguientes precauciones y

advertencias de seguridad. El uso descuidado

o incorrecto de la unidad podría provocarle

lesiones graves o fatales.

Lea, comprenda y siga todas las advertencias y

demás instrucciones de este manual y las que

se muestran en el aparato.

Ajuste del ralentí

Bomba de cebado

Utilice siempre protecciones para los ojos, la

cabeza y los oídos cuando utilice esta unidad.

No utilice cuchillas rígidas/de metal si el aparato

muestra este símbolo.

Mantenga a los niños, transeúntes y ayudantes

a una distancia de 15 m de la unidad. Si alguien

se acerca a usted, detenga el motor y el

mecanismo de corte de inmediato.

Tenga cuidado con los objetos que puedan salir

despedidos.

Muestra la velocidad máxima del eje. No utilice

mecanismos de corte cuyas rpm máximas sean

-1

min

inferiores a las rpm del eje.

Deben utilizarse guantes siempre que sea

necesario, por ejemplo, cuando se monten

equipos de corte.

Utilice calzado antideslizante y resistente. Desplazamiento

Estrangulador: posición de marcha RUN

(abierta)

Estrangulador: posición de arranque (cerrado)

Encendido/Arranque Velocidad del eje de salida

Nivel de potencia acústica garantizado

Puede producirse una sacudida de la cuchilla

si, al encontrarse en movimiento, ésta entra en

contacto con un objeto sólido en la zona crítica.

Puede producirse una reacción peligrosa que

sacuda violentamente el aparato y al usuario.

Esta reacción se conoce como sacudida de la

cuchilla. Como consecuencia, el usuario podría

perder el control de la unidad y provocarse

lesiones graves e incluso mortales. Existen

más probabilidades de que se produzcan

sacudidas de la cuchilla en zonas en las que

es difícil ver el material que se está cortando.

Superfi cie caliente: El contacto con la superfi cie

caliente puede causar quemaduras graves.

El accesorio recortador de setos no se puede

usar en modelos con esta etiqueta.

Indica la ubicación del asidero. Flechas que

indican los límites para la posición de la

empuñadura.

Bujía

Al ralentí

Idle

Apagado/Parada

Parada de emergencia Capacidad del depósito de combustible

16

Emisión máx. del motor

P

Page 17

Español

Peso en seco (sin combustible, accesorio de

corte, arnés y protección del accesorio de corte)

Accesorio de corte

L

ISO22868

L

WA, Ra(M)

2000/14/EC

Antes de utilizar su máquina

• Lea detenidamente el manual.

• Compruebe que el mecanismo de corte se encuentra acoplado y ajustado correctamente.

• Arranque el aparato y compruebe el ajuste del carburador. Consulte “MANTENIMIENTO”.

NOTA: Los niveles de ruido / vibración equivalentes se calculan como la energía ponderada en base al tiempo en distintas

* 1/2 al ralentí, 1/2 acelerando.

Nivel de presión acústica LpA equivalente

pA, eq

según ISO 22868*

Nivel de potencia acústica LwA medida según

2000/14/CE

Acelerando

condiciones de trabajo con la siguiente distribución de tiempo:

DESCRIPCIÓN DE LAS PARTES (Fig. 1)

Puesto que este manual cubre varios modelos, puede que

existan diferencias entre los dibujos y su unidad. Utilice las

instrucciones que se refi eran a su unidad.

A: Tapa del depósito de combustible

B: Gatillo del acelerador

C: Asidero de arranque

D: Protección del accesorio de corte

E: Accesorio de corte

F: Tubo del eje de distribución

G: Asidero

H: Colgador

I: Interruptor de encendido

J: Arnés (si viene equipado)

K: Bloqueo del gatillo del acelerador

L: Palanca del estárter

M: Motor

N: Caja de engranajes

O: Llave combinada de cubo

P: Instrucciones de manejo

Q: Gafas protectoras

R: Llave hexagonal de barra

ADVERTENCIAS E INSTRUCCIONES

L

WA, Ra(G)

2000/14/EC

a

hv, eq(F)

a

hv, eq(R)

Preste atención a su entorno. Esté atento a personas

Retírese el equipo de seguridad inmediatamente

○ Utilice siempre camisas pesadas y de manga larga (4),

No utilice prendas holgadas, joyas, pantalones cortos ni

Colóquese el pelo de forma que esté por encima de los

○ No utilice esta herramienta cuando esté cansado,

○ No opere la herramienta por la noche o bajo malas

Trabajar en terreno resbaladizo podría dar lugar a un

○ Nunca deje que niños o personas inexpertas operen la

○ No ponga en marcha el motor si hay elementos

○ Nunca ponga en marcha el motor en el interior de un

DE SEGURIDAD

Dedique especial atención a los apartados introducidos por

las siguientes palabras:

ADVERTENCIA

Indica un riesgo signifi cativo de que se produzcan daños

personales graves, e incluso la muerte, si no se siguen

las instrucciones.

PRECAUCIÓN

Indica la posibilidad de que se produzcan daños

personales o materiales si no se siguen las instrucciones.

NOTA

Indica información útil para el uso y funcionamiento

correctos de la máquina.

Seguridad del usuario

○ Utilice casco protector(1). (Fig. 2)

○ Utilice siempre una máscara o gafas protectoras (2).

(Fig. 2)

○ Utilice protección auditiva regulada (3). (Fig. 2)

La exposición prolongada al ruido puede resultar en

disfunciones auditivas permanentes.

○ Mantenga los asideros limpios sin aceite ni combustible.

○ Mantenga las manos alejadas del mecanismo de corte.

○ No agarre ni sujete la unidad por el mecanismo de corte.

○ Deben utilizarse guantes al instalar o desinstalar el

○ Cuando apague la unidad, asegúrese de que el

○ Si utiliza este dispositivo durante un periodo de tiempo

○ Opere siempre la herramienta con el equipo de

17

Nivel de potencia acústica LwA garantizado

según 2000/14/CE

Acelerando

Nivel de vibración según ISO 22867

Asidero delantero o izquierdo/Equivalente*

Nivel de vibración según ISO 22867

Asidero trasero o derecho/Equivalente*

Incertidumbre

K

que pudieran estar avisándole de un problema.

después de parar el motor.

pantalones largos (5), botas antideslizante (6) y guantes

(7). (Fig. 2)

sandalias, y nunca trabaje descalzo.

hombros.

enfermo o bajo la infl uencia del alcohol, drogas o

medicamentos.

condiciones atmosféricas en las que la visibilidad no sea

buena. Tampoco haga funcionar la herramienta cuando

esté lloviendo ni inmediatamente después de que haya

llovido.

accidente si pierde el equilibrio.

máquina.

infl amables tales como hojas secas, residuos de papel

o combustible en las proximidades.

local cerrado ni un edifi cio. La inhalación de los humos

de escape puede ser fatal.

mecanismo de corte. De lo contrario, podrían producirse

lesiones.

mecanismo de corte se haya detenido antes de apoyarla

sobre el suelo.

prolongado, tome un descanso de vez en cuando

para evitar la posibilidad de desarrollar el síndrome

por vibración en mano/brazo (SVMB), causado por las

vibraciones.

ADVERTENCIA

protección y la ropa adecuados. De lo contrario, podrían

ocasionarse accidentes como quemaduras o lesiones.

(Fig. 2)

Page 18

Español

○ No toque las zonas de chispas o de alto voltaje durante

el funcionamiento. De lo contrario podría producirse una

descarga eléctrica.

○ No permita que los niños se acerquen a la herramienta

durante su funcionamiento.

○

No toque el motor, la cubierta del silenciador ni la rejilla de

ventilación durante la operación ni inmediatamente después.

De lo contrario podrían ocasionarse quemaduras o lesiones.

○ Los sistemas antivibratorios no garantizan que no sufrirá

el síndrome por vibración en mano/brazo (SVMB) o el

síndrome del túnel carpiano. Por lo tanto, los usuarios

que utilicen el aparato asiduamente o con regularidad

deberán vigilar con atención el estado de sus manos y

dedos. Si aparece cualquiera de los síntomas citados,

deberá solicitarse inmediatamente atención médica.

○ Si utiliza algún dispositivo médico electrónico, por

ejemplo un marcapasos, consulte a su médico, así como

al fabricante del dispositivo, antes de operar cualquier

equipo mecánico.

Seguridad de la máquina

○ Inspeccione la máquina en su totalidad antes de

utilizarla. Cambie las piezas dañadas. Compruebe

que no haya fugas de combustible y asegúrese de

que todas las piezas se encuentren en su sitio y estén

correctamente apretadas.

○

Cambie las piezas agrietadas, desportilladas o deterioradas de

cualquier manera antes de poner en marcha la máquina. Las

piezas defectuosas pueden aumentar el riesgo de accidentes

y puede dar lugar a lesiones.

○ Asegúrese de que la protección del mecanismo de corte

y el arnés estén correctamente conectados. No opere la

máquina si la protección del mecanismo de corte y el

arnés no están correctamente conectados.

○ No permita que se acerquen otras personas mientras

esté ajustando el carburador.

○ Utilice únicamente accesorios según la recomendación

del fabricante para esta máquina.

○ Antes de la operación, asegúrese de que no hayan

herramientas, como la llave o la tecla de ajuste, todavía

conectadas a la unidad.

ADVERTENCIA

○ No intente en ningún momento modifi car la máquina

de ninguna manera. No utilice esta máquina para otras

tareas para las que no esté indicada.

○ Las modifi caciones no autorizadas y el uso de

accesorios no autorizados puede resultar en lesiones

personales graves o la muerte del operador u otros.

Seguridad en torno al combustible

○ Mezcle y llene el combustible al aire libre, en lugares

donde no hayan chispas ni llamas.

○ Use un recipiente autorizado para el combustible.

○ Antes de poner en marcha el motor, distánciese un

mínimo 3 metros del lugar de repostaje.

○ Antes de retirar la tapa del depósito de combustible,

detenga el motor. No retire el tapón del depósito de

combustible durante el funcionamiento.

○ Vacíe el depósito de combustible antes de almacenar

la máquina. Se recomienda vaciar el depósito de

combustible cada vez que termine de utilizar la máquina.

Si deja combustible en el depósito, guarde la máquina

de forma que no se produzcan fugas.

ADVERTENCIA

○ El combustible prende y provoca explosiones e

inhalación de humo con facilidad. Por lo tanto, preste

especial atención al manipular o recargar el combustible.

○ No fume ni deje fumar a otras personas cerca del

combustible o de la máquina mientras ésta esté en

funcionamiento.

○ Limpie los residuos de combustible antes de poner en

marcha el motor.

○ Guarde la máquina y el combustible en un lugar donde

los vapores del combustible no puedan llegar a chispas

o llamas de calentadores de agua, motores eléctricos,

interruptores, hornos, etc.

○ Al utilizar la unidad en zonas secas, asegúrese de que

exista un equipo de extinción de incendios disponible y

fácilmente accesible.

○ Si para el motor para repostar, asegúrese de que la

unidad se haya enfriado antes de añadir combustible.

Seguridad durante el corte

○ No corte ningún material que no sea hierba o maleza.

○ Inspeccione siempre la zona sobre la que va a cortar

antes de comenzar.

Retire cualquier objeto que pueda salir despedido o

enredarse.

No opere en las zonas en las que haya raíces de árboles

ni rocas.

○ Para proteger las vías respiratorias, utilice una máscara

de protección contra aerosoles cuando corte hierba tras

haber fumigado con insecticidas.

○ Mantenga a transeúntes, niños, animales y asistentes

a una distancia de 15 m de la zona de riesgo. Detenga

inmediatamente el motor si se le acerca alguna persona.

○ Proceda cuidadosamente, ya que el arranque del motor

podría retrasarse un poco tras accionar la palanca de

arranque.

○

Mantenga el motor siempre al lado derecho de su cuerpo.

○ Sujete la máquina fi rmemente con ambas manos.

○ Mantenga bien el equilibrio y los pies bien apoyados

sobre el suelo. No estire demasiado el cuerpo.

Perder el equilibrio durante el trabajo puede dar lugar a

una lesión.

○ Mantenga todas las partes del cuerpo apartadas del

silenciador y del mecanismo de corte mientras la

máquina esté en funcionamiento.

○ Mantenga el mecanismo de corte por debajo de la altura

de la rodilla.

○ Proceda con precauciones a la hora de operar en zonas

en las cuales haya cables eléctricos o tuberías de gas

presentes.

○ No opere el mecanismo de corte para nada que no sea

despejar de césped y arbustos. Evite operaciones en las

que el mecanismo de corte pueda entrar en contacto

con el agua, como el trabajo en charcos o excavación

en la tierra. De lo contrario podrían producirse lesiones o

desperfectos en la unidad.

○ Evite el uso prolongado a niveles de baja velocidad en

los que la vibración es elevada. De lo contrario podría

dañarse el motor.

○ Al trasladarse a una nueva zona de trabajo o al

Inspeccionar, ajustar o cambiar los mecanismo de corte

de la unidad, los accesorios, etc., asegúrese de apagar

la máquina y de que todos los mecanismos de corte se

hayan detenido.

○ Jamás coloque la máquina sobre el suelo cuando esté

en marcha.

○ Nunca toque el mecanismo de corte mientras esté

rotando.

○ Asegúrese siempre de que el motor esté apagado y

de que todos los mecanismos de corte hayan parado

completamente antes de eliminar restos o hierba del

mecanismo de corte.

○ Lleve siempre un botiquín de primeros auxilios consigo

cuando opere cualquier equipo motorizado.

○ Apague el motor y asegúrese de que el mecanismo de

corte haya parado totalmente antes de retirar la unidad

de su cuerpo y antes de dejar la unidad sin vigilancia.

○ Si accidentalmente golpea o se le cae la unidad,

inspecciónela inmediatamente para cerciorarse de que

no hay daños, grietas ni deformaciones.

18

Page 19

○ Si la herramienta no está funcionando correctamente y

produce ruidos o vibraciones extraños, apague el motor

inmediatamente y contacte con su distribuidor para que

revise y repare la máquina.

El uso continuado en estas condiciones podría ocasionar

lesiones o daños en las herramientas.

○ Haga uso de la máquina en conformidad con las

normativas y las leyes aplicables.

Seguridad durante el mantenimiento

○ Realice el mantenimiento de la máquina según el

procedimiento recomendado.

○ Antes de iniciar el mantenimiento, desconecte la bujía,

excepto para ajustar el carburador.

○ No permita que se acerquen otras personas mientras

esté ajustando el carburador.

○ Utilice únicamente piezas de repuesto originales

HITACHI como recomienda el fabricante.

PRECAUCIÓN

No desmonte el arrancador de retroceso. El resorte

del arrancador puede ocasionarle lesiones personales

graves.

ADVERTENCIA

El mantenimiento incorrecto podría conducir a una

avería seria del motor o a heridas graves.

Transporte y almacenamiento

○ Transporte la máquina en la mano con el motor apagado

y el silenciador apartado del cuerpo.

○ Antes de almacenar o transportar la máquina, espere

a que se haya enfriado el motor, vacíe el depósito de

combustible y sujete bien la máquina. De lo contario

podrían producirse incendios o accidentes.

○ Vacíe el depósito de combustible antes de almacenar

la máquina. Se recomienda vaciar el depósito de

combustible cada vez que termine de utilizar la máquina.

Si deja combustible en el depósito, guarde la máquina

de forma que no se produzcan fugas.

○ Almacene la máquina fuera del alcance de niños.

○ Limpie y lleve a cabo el mantenimiento de la máquina

cuidadosamente y guárdela en un lugar seco.

○ Asegúrese de que el motor esté apagado al transportar

o almacenar la máquina.

○ Al transportar y almacenar, extraiga el accesorio de

corte o coloque la cubierta de la cuchilla sobre la hoja.

○ Debe asegurar la máquina durante el transporte para

prevenir pérdidas de combustible, daños o lesiones.

○ Si aparece ilegible, despegada o borrosa alguna de las

etiquetas de advertencia, sustitúyala por una nueva.

Para adquirir etiquetas nuevas, póngase en contacto

con un centro de servicio autorizado Hitachi.

Si se producen situaciones no previstas en este manual,

utilice el sentido común. Si necesita ayuda, póngase en

contacto con un centro de servicio autorizado Hitachi.

ESPECIFICACIONES

Las ESPECIFICACIONES de la máquina se indican en la

tabla de la página 38.

NOTA

Todos los datos están sujetos a cambios sin previo aviso.

PROCEDIMIENTOS DE MONTAJE

Instalación del asidero

(1) Tipo de asa de lazo (Fig. 3)

Acople el asidero al tubo del eje de distribución en

ángulo con el motor.

Ajuste su posición de la manera que le resulte más

cómoda antes de ponerlo en funcionamiento.

Español

Asegúrese de conectar fi rmemente el asa con los

2 tornillos.

NOTA

Si su unidad tiene una etiqueta que muestre la ubicación

del asidero (8) en el tubo del eje de distribución, siga la

ilustración.

(2) Tipo de asa de mango (Fig. 4)

Retire la abrazadera del asidero (9) del conjunto.

Coloque el asidero y acople la abrazadera del asidero

suavemente con cuatro tornillos. Ajústela en la posición

adecuada. A continuación apriétela con los tornillos.

Instalación del arnés

(si viene equipado)

ADVERTENCIA

Si el producto incluye un arnés, asegúrese siempre de

utilizarlo.

Enganche el gancho del arnés (10) al asa (11) del tubo del

eje de distribución. (Fig. 5)

Ajuste la longitud del arnés para facilitar el funcionamiento

de la herramienta.

NOTA

Puede ser necesario ajustar la posición del asidero (11)

para equilibrar la unidad. Para hacerlo, afl oje el perno

(12) y ajuste la posición del asidero (11). Después de

ajustar según sea necesario, asegúrese de apretar con

fi rmeza el perno (12). (Fig. 5)

Instalación de la protección del accesorio de corte

ADVERTENCIA

Si se coloca un protector incorrecto o defectuoso,

podrían ocasionarse lesiones personales graves.

PRECAUCIÓN

Algunos protectores del accesorio de corte están

equipados con limitadores de línea afi lados. Tenga

cuidado al manipularlos.

NOTA

○ Al usar un cabezal de desbrozadora con protección

del accesorio de corte de tipo dos piezas, acople la

extensión del protector a la protección del accesorio de

corte y, apriete el perno (13). (Fig. 6)

○ La extensión de la protección ya está conectada a la

protección del accesorio de corte en el momento de la

compra.

○ En algunos modelos, el soporte del protector puede

venir ya montado en la caja de engranajes.

Alinee el protector del accesorio de corte con el soporte

del protector y sujételo bien al tubo del eje de distribución

usando el perno y el soporte de la cubierta. (Fig. 7)

Instalación del accesorio de corte

ADVERTENCIA

○ Instale el accesorio de corte correcta y fi rmemente como

se indica en las instrucciones de manejo.

Si no se coloca correcta y fi rmemente, podría soltarse y

provocar lesiones graves y/o fatales.

○ No instale ni retire los accesorios de corte mientras el

motor esté en marcha.

○ Utilice siempre accesorios de corte y metálicos Hitachi

originales de corte.

Instalación del cabezal de corte semiautomático

1. Función

Alimenta automáticamente más líneas de corte de nylon

cuando se golpea a un rpm bajo (no más de 4500 min

-1

).

19

Page 20

Español

Especifi caciones

Núm. de

código

6696454

Cable de nylon aplicable

Diámetro del cable: Φ3,0 mm de longitud: 2 m

Diámetro del cable: Φ2,4 mm de longitud: 4 m

2. Precauciones

○ La caja debe fi jarse bien a la cubierta.

○ Compruebe que la cubierta, la caja y otros componentes

○ Compruebe el desgaste de la caja y el botón.

Si la marca del límite de desgaste (14) de la caja ya no

○ El cabezal de corte debe fi jarse bien a la caja de

○ Si el cabezal de corte no alimenta bien la línea de

Para cabezales Hitachi, utilice únicamente la línea

3. Instalación (Fig. 9)

Inserte la llave Allen (16) en el orifi co de la caja de

Instale el cabezal de corte en la caja de engranajes/caja

NOTA

Ya que la tapa del soporte de la cuchilla no se utiliza

4. Ajuste de la longitud de línea

Ajuste la velocidad del motor tan lenta como sea posible

Además, puede extender las líneas de nylon

Ajuste la línea de nylon a una longitud de 11-14 cm antes

Tipo de

tornillo de

sujeción

Tornillo hembra

no tengan grietas ni otros daños.

se ve o hay un agujero en la parte inferior (15) del botón,

cambie las piezas nuevas inmediatamente. (Fig. 8)

engranajes/caja de corte de la unidad.

corte, compruebe que la línea de nylon y todos los

componentes estén bien instalados. Si necesita

ayuda, póngase en contacto con un centro de servicio

autorizado Hitachi.

ADVERTENCIA

fl exible y no metálica recomendada por el fabricante. No

utilice nunca cables ni cables de acero. Estos podrían

romperse y actuar como proyectiles peligrosos.

engranajes/caja de corte para bloquear el tubo del eje

de distribución.

de corte del montaguadañas/la desbrozadora. La tuerca

de montaje se enrosca hacia la izquierda. Gire en el

sentido de las agujas del reloj para afl ojar y en el sentido

contrario a las agujas del reloj para apretar.

aquí, guárdela para cuando se utilice una cuchilla de

metal, si viene equipado.

y apriete el cabezal contra el suelo. La línea de nylon

saldrá unos 3 cm con cada golpe. (Fig. 10)

manualmente, pero el motor debe estar completamente

parado. (Fig. 11)

de cada funcionamiento.

Dirección de

giro

En el sentido

contrario a las

agujas del reloj

Tamaño de

tornillo de

sujeción

M10xP1,25LH

PROCEDIMIENTOS DE

FUNCIONAMIENTO

Combustible (Fig. 12)

ADVERTENCIA

○ La segadora está equipada con un motor de dos tiempos.

El motor debe funcionar siempre con combustible

mezclado con aceite.

Asegúrese de que existe una buena ventilación en los

lugares de manipulación o repostaje de combustible.

○ El combustible contiene sustancias altamente

infl amables, por lo que existe la posibilidad de sufrir

lesiones graves por inhalación o por derrames sobre el

cuerpo.

20

Preste siempre atención cuando manipule el

combustible. Cuando manipule el combustible en

interiores, asegúrese de que haya buena ventilación en

todo momento.

Combustible

○ Use siempre gasolina sin plomo de 89 octanos.

○ Utilice aceite de dos tiempos original o una mezcla de

25:1 a 50:1. Consulte la proporción de la mezcla con un

centro de servicio autorizado Hitachi.

○ Si no hay aceite original disponible, utilice un aceite con

antioxidante de calidad que esté indicado expresamente

según el etiquetado para motores de dos tiempos

refrigerados por aire (JASO FC GRADE OIL o ISO EGC

GRADE). No utilice aceite mezclado BIA o TCW (para

motores de 2 tiempos refrigerados por agua).

○ No utilice aceites multigrado (10 W/30) ni residual.

○ Nunca mezcle combustible y aceite en el depósito

de combustible de la máquina. Mezcle siempre el

combustible y el aceite en un recipiente limpio y

destinado a este fi n.

Comience siempre por llenar la mitad del combustible que

va a utilizar.

A continuación, añada todo el aceite. Agite la mezcla de

combustible. Añada el resto de gasolina.

Antes de llenar el depósito de combustible, agite bien la

mezcla.

Cantidad de mezcla de aceite de dos tiempos y gasolina

Gasolina (litros)

0,5 10 ——— 20

1 20 ——— 40

2 40 ——— 80

4 80 ——— 160

Recarga de combustible

ADVERTENCIA

○ Antes de repostar el combustible, apague el motor y

deje que se enfríe durante unos minutos.

No fume ni acerque llamas o chispas al lugar en el que

se realiza el repostaje.

○ Para llenar el depósito de combustible, abra lentamente

la tapa del depósito para que desaparezca la

sobrepresión que pudiera existir.

○ Después del repostaje, cierre y apriete bien la tapa del

depósito de combustible.

○ Antes de arrancar la máquina, aleje siempre la máquina

un mínimo de 3 m del área de repostaje.

○ Lave la ropa inmediatamente con jabón si se vierte

combustible sobre ella.

○ Asegúrese de verifi car que no existan pérdidas de

combustible después del repostaje.

○ Antes de repostar, y con el fi n de descargar la

electricidad estática del cuerpo principal, del recipiente

y del operario, toque el suelo donde esté ligeramente

humedecido.

Antes de repostar el combustible, limpie cuidadosamente

la zona de la tapa del depósito para asegurarse de que

no entra suciedad en el depósito. Asegúrese de que el

combustible está bien mezclado agitando el recipiente

antes de llenar el depósito.

Inicio

ADVERTENCIA

○ Antes de iniciar la herramienta, asegúrese de que el

accesorio de corte no está en contacto con ningún

objeto o con el suelo. De lo contrario, el equipo de corte

puede girar inesperadamente y causar una lesión.

Aceite de dos tiempos (ml)

Proporción 50:1 Proporción 25:1

Page 21

○ Asegúrese de que el accesorio de corte no gire cuando

el motor está al ralentí. Si gira, ajuste la velocidad de

ralentí de acuerdo con las instrucciones en “Ajuste

del ralentí” de la sección “MANTENIMIENTO”. Si el

accesorio de corte sigue girando después de este

ajuste, pare inmediatamente el motor y cese el uso, y

lleve a continuación la herramienta al Centro de Servicio

Autorizado de Hitachi más cercano.

PRECAUCIÓN

Asegúrese de que el extremo exterior del acelerador

está en el soporte.

(1) Puesta en marcha del motor en frío

1. Lleve la llave de ignición (17) a la posición ON

(encendido). (Fig. 13)

2. Presione el cebador (18) repetidamente para que el

combustible fl uya por el tubo de retorno (19). (Fig. 14)

3. Ajuste la palanca del estrangulador (20) en la posición

de arranque START (cerrado) (A). (Fig. 15)

4. Tire enérgicamente del arrancador de retroceso,

tomando la precaución de mantener el asidero bien

sujeto para evitar que se escape de la mano. (Fig. 16)

5. Cuando escuche el amago de arranque del motor,

devuelva la palanca del estárter a la posición de marcha

RUN (abierto) (B). (Fig. 15)

6. Vuelva a tirar enérgicamente del arrancador de

retroceso. (Fig. 16)

NOTA

Si el motor no arranca, repita los pasos 2 a 5.

7. A continuación, deje que el motor se caliente durante

2–3 minutos antes de someterlo a ninguna presión.

8. Compruebe que el accesorio de corte no gire cuando el

motor esté al ralentí.

(2) Puesta en marcha del motor en caliente

Utilice únicamente los puntos 1, 2, 6 y 8 del procedimiento

de arranque para un motor en frío.

Si el motor no arranca, realice el mismo procedimiento

que para un motor en frío.

Corte

ADVERTENCIA

○ Utilice siempre el arnés (si viene equipado) y lleve la

vestimenta adecuada y el equipo de protección cuando

opere la unidad. (Fig. 17)

○ Mantenga a niños, animales, transeúntes y ayudantes

a una distancia de 15 m de la zona de riesgo. Detenga

inmediatamente el motor si se le acerca alguna persona.

(Fig. 18)

○ Cuando se enreden hierba o ramas en el mecanismo,

detenga el motor y el mecanismo y retírelas. Si continúa

operando la máquina con césped o ramas enredadas en

torno al mecanismo, podrían provocarse daños como

una abrasión prematura del embrague.

PRECAUCIÓN

La forma de uso y los puntos de precaución variarán en

función del tipo de accesorio de corte. Por seguridad,

asegúrese de seguir las instrucciones y directrices

suministradas con cada tipo.

NOTA

○ En caso de emergencia, pulse el botón de liberación

rápida o tire del mando de liberación de emergencia (si

viene equipado). (Fig. 19)

○ Haga uso de la máquina en conformidad con las

normativas y las leyes aplicables.

(1) Uso de un cabezal de corte semiautomático

○ Ajuste el motor a alta velocidad al utilizar este accesorio.

○ Cor te la hierba de izquierda a derecha. La hierba cortada

se descargará lejos del cuerpo, reduciendo así al mínimo

el contacto con la ropa. (Fig. 20)

○

Con cable de nylon, utilice 2 cm del extremo del cable para

cortar hierba. Si se utiliza la longitud total del cable, se

reducirá la velocidad de rotación y se difi cultará el corte.

Español

NOTA

Alimenta automáticamente más líneas de corte de nylon

cuando se golpea a un rpm bajo (no más de 4500 min

ADVERTENCIA

○ Este producto se encuentra equipado con un limitador

de línea que cortará automáticamente el exceso de

cable. Cuando opere la unidad, no extraiga el protector

ni el limitador de línea.

Como la resistencia de los cables de nylon es mayor que

la de las cuchillas, su manipulación incorrecta podría

aumentar la carga del motor y causar daños.

○ No lo utilice con el motor ajustado a baja velocidad. Si la

velocidad del motor es baja, el césped podría enredarse

alrededor del accesorio, lo que causaría que se soltase

el embrague y eso asimismo podría resultar en la

abrasión del embrague.

○ Con cortadores de cable de nylon, utilice siempre más

de 15 cm de cable. Si la longitud del cable es demasiado

corta, la velocidad de rotación aumentará y podrá

causar daños al cortador de cable de nylon. Dado que

el modelo de tubo de eje de distribución en particular no

está equipado con un mecanismo de desaceleración, la

posibilidad de un aumento de la velocidad de rotación

del accesorio de corte es elevada.

Parada (Fig. 21)

Reduzca la velocidad del motor y déjelo permanecer al

ralentí durante unos minutos. A continuación apague la llave

de ignición (17).

ADVERTENCIA

El mecanismo de corte puede provocar lesiones

mientras gira una vez detenido el motor o apagado el

control de la alimentación. Cuando el aparato esté

apagado, asegúrese de que el mecanismo de corte se

ha detenido antes de apoyarlo sobre el suelo.

MANTENIMIENTO

EL MANTENIMIENTO, LA SUSTITUCIÓN O LA

REPARACIÓN DE LOS DISPOSITIVOS Y SISTEMAS

DE CONTROL DE EMISIONES PUEDEN REALIZARSE

EN CUALQUIER TALLER O A CARGO DE CUALQUIER

TÉCNICO DE REPARACIONES MECÁNICAS NO

DESTINADAS AL TRANSPORTE.

Ajuste del carburador (Fig. 22)

El carburador es una pieza de precisión que mezcla aire

y combustible, y que está diseñado para asegurar un alto

rendimiento del motor. El carburador se ajusta durante una

prueba de funcionamiento antes de que la herramienta salga

de fábrica. Sólo haga ajustes si es necesario debido a las

condiciones ambientales (el clima o la presión atmosférica),

el tipo de combustible, el tipo de aceite de dos tiempos, etc.

ADVERTENCIA

○ Debido a que el carburador está fabricado con un alto

grado de precisión, no lo desmonte.

○ Para este producto, el único ajuste del carburador que

se puede ajustar es la velocidad de ralentí (T).

○ ¡Nunca arranque el motor sin que la cubierta y el tubo del

embrague estén montados! De lo contrario, el embrague

podría soltarse y causar lesiones personales.

T = Tornillo de ajuste de la velocidad de ralentí.

Ajuste de la velocidad de ralentí (T)

ADVERTENCIA

○ Cuando el motor se detiene, no gire excesivamente el

tornillo de ajuste de ralentí (T) en el sentido de las agujas

del reloj. De lo contrario, cuando el motor arranque, el

accesorio de corte puede girar inesperadamente y

causar una lesión.

21

-1

).

Page 22

Español

○ No ajuste el tornillo de ajuste de ralentí (T) por cualquier

razón que no sea para ajustar el ralentí.

Haga funcionar el motor mientras se ajusta el ralentí.

(1) Si el motor se detiene durante el ralentí

Arranque el motor y gire lentamente el tornillo de

ajuste de ralentí (T) en el sentido de las agujas del reloj

hasta que esté en una posición en la que el motor gira

suavemente. En ese momento, asegúrese de que el

accesorio de corte no esté girando.

(2) Si el accesorio de corte gira durante el ralentí

Gire lentamente el tornillo de ajuste de la velocidad de

ralentí (T) en el sentido contrario de las agujas del reloj

hasta que se encuentre en una posición en la que el

accesorio de corte no gire. En ese momento, asegúrese

de que la rotación del motor es suave.

ADVERTENCIA

Si el accesorio de corte sigue girando después del ajuste

del tornillo de ajuste de ralentí (T), pare inmediatamente

el motor y deje de utilizarlo, luego póngase en contacto

con el Centro de Servicio Autorizado de Hitachi más

cercano.

Filtro de aire (Fig. 23)

Limpie el polvo y la suciedad del fi ltro de aire (21) para evitar:

○ Fallos de funcionamiento del carburador.

○ Problemas de arranque.

○ Pérdida de potencia del motor.

○ Desgaste innecesario en las piezas del motor.

○ Consumo de combustible anormal.

Limpie el fi ltro de aire diariamente o con mayor frecuencia

cuando trabaje en zonas con gran cantidad de polvo.

Afl oje el tornillo (22), a continuación, abra la tapa del fi ltro

de aire y retire el fi ltro de aire (21). Lave los fi ltros con agua

caliente y jabón.

Antes de volver a montar el fi ltro, compruebe que esté seco.

Un fi ltro de aire que ha sido utilizado durante mucho tiempo

nunca podrá quedar completamente limpio. Por tanto, los

fi ltros deben cambiarse por otros nuevos cada cierto tiempo.

Cambie los fi ltros que estén dañados.

Filtro de combustible (Fig. 24)

Desmonte el fi ltro de combustible

combustible y cámbielo si está sucio.

NOTA

Un fi ltro de combustible

frenar el suministro de combustible y causar un mal

funcionamiento en la rotación del motor.

Bujía (Fig. 25)

El estado de la bujía se ve afectado por:

○ Un ajuste incorrecto del carburador.

○ Mezcla incorrecta de combustible (demasiado aceite en

la gasolina).

○ Un fi ltro de aire sucio.

○ Condiciones de funcionamiento extremas (por ejemplo

climas fríos).

Todos estos factores dan lugar a la formación de sedimentos

en los electrodos de la bujía, que pueden provocar

perturbaciones en el funcionamiento y difi cultades en el

arranque. Si el motor tiene poca potencia, resulta difícil de

arrancar o se muestra inestable al ralentí, revise siempre la

bujía en primer lugar.

Si la bujía está muy sucia, límpiela y verifi que la distancia

entre los electrodos. Reajústela si es necesario. La distancia