Page 1

Model

Modèle

Modelo

CG 25EUS (L)

Grass Tri m me r/ Br u sh Cutter

Coupe-Herbes/Débroussailleuse

Motoguadañas/Desbrozadoras

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual

BEFORE operating the power tool. Please keep this manual available for other users and owners before they

use the power tool. This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de

sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de

lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la

disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi

doit être conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede provocar lesiones

graves o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este manual

ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras personas

antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

Page 2

English

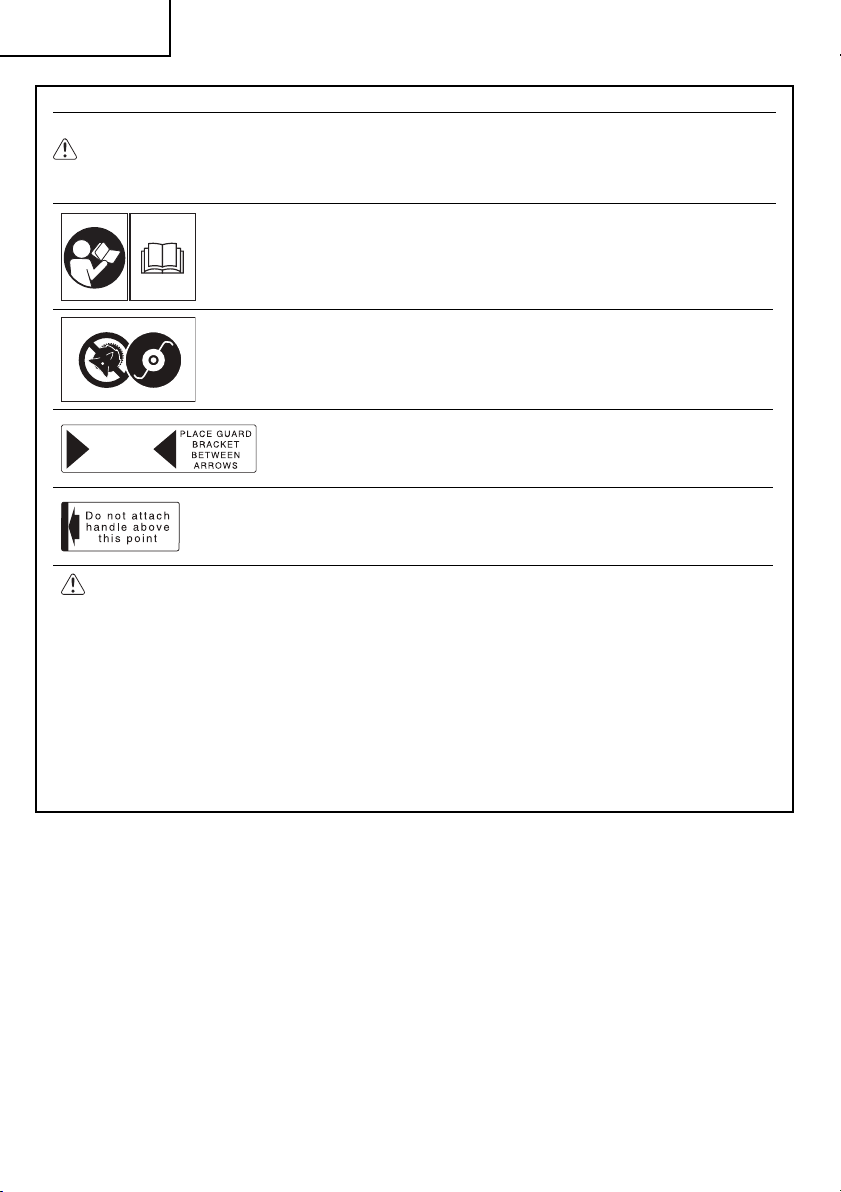

Meanings of symbols NOTE: Some units do not carry them

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand their meaning

before use.

It is important that you read, fully understand and observe the following

safety precautions and warnings. Careless or improper use of the unit

may cause serious or fatal injury.

Do not use metal/rigid blades when this sign is shown on the unit.

Indicates blade guard location for a trimmer head or Brain head.

Indicate handle location. Do not attach handle above this point.

WARNING

● Read the operator’s manual and follow all warnings and safety instructions. Failure to do

so can result in serious injury to the operator and /or bystanders.

● Objects may be thrown or ricochet in all directions. ALWAYS WEAR EYE PROTECTION.

● Keep bystanders at least 50 feet (15 m) away.

● To reduce the chance of hearing loss, always wear ear protection.

● To reduce the risk of injury from loss of control, never use a metal blade on a curved shaft

grass trimmer. Never use a metal blade on any brush cutter without barrier bar or bicycle

handle confi guration and safety strap.

● Use of a blade may cause a sudden sideways, forward or backward motion of the brush

cutter when the blade contacts a solid object. See the owner’s manual for model specifi c

details.

Contents

WHAT IS WHAT? ...................................................3

WARNINGS AND SAFETY INSTRUCTIONS .........4

SPECIFICATIONS ..................................................6

ASSEMBLY PROCEDURES ..................................6

OPERATING PROCEDURES ................................. 8

MAINTENANCE ...................................................11

IMPORTANT NOTICE ..........................................14

2

Page 3

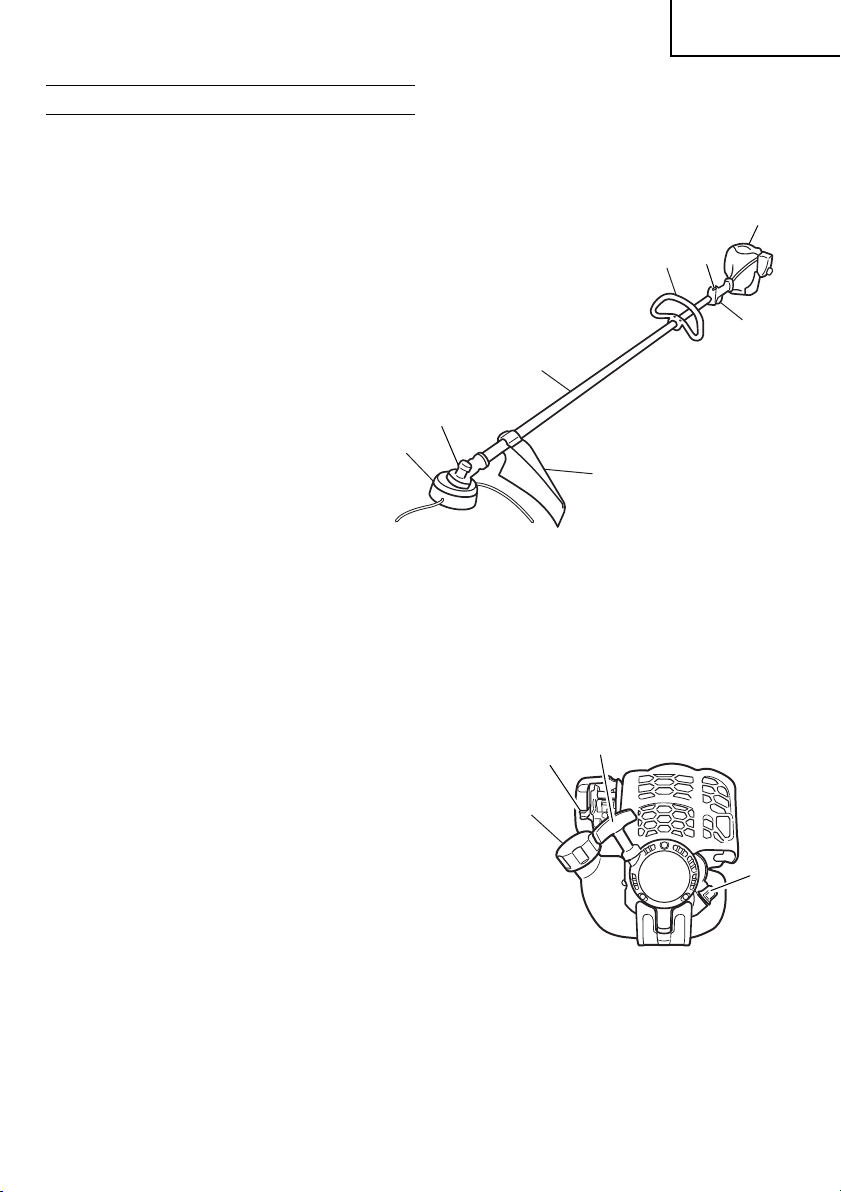

WHAT IS WHAT?

Since this manual covers several models, there may

be some diff erence between these illustrations and

your unit. Use the instructions that apply to your unit.

English

1. Fuel cap

2. Throttle trigger

3. Starter handle

4. Blade guard

5. Cutting attachment

6. Drive shaft tube

7. Handle

8. Ignition switch

9. Choke lever

10. Engine

11. Angle transmission

12. Oil cap

10

8

7

2

6

11

5

4

3

9

1

12

3

Page 4

English

WARNINGS AND SAFETY

INSTRUCTIONS

Operator safety

○ Always wear a safety face shield or goggles.

○ Always wear heavy, long pants, boots and gloves.

Do not wear loose clothing, jewelry, short pants,

sandals or go barefoot.

Secure hair so it is above shoulder length.

○ Do not operate this tool when you are tired,

ill or under the infl uence of alcohol, drugs or

medication.

○ Never let a child or inexperienced person operate

the machine.

○ Wear hearing protection. Pay attention to your

surroundings. Be aware of any bystanders who

may be signaling a problem. Remove safety

equipment immediately upon shutting off engine.

○ Wear head protection.

○ Never start or run the engine inside a closed room

or building. Breathing exhaust fumes can kill.

○ Keep handles free of oil and fuel.

○ Keep hands away from cutting equipment.

○ Do not grab or hold the unit by the cutting

equipment.

○ When the unit is turned off , make sure the cutting

attachment has stopped before the unit is set

down.

○ When operation is prolonged, take a break from

time to time so that you may avoid possible Hand-

Arm Vibration Syndrome (HAVS) which is caused

by vibration.

WARNING

● Antivibration systems do not guarantee that

you will not sustain HAVS or carpal tunnel

syndrome. Therefore, continual and regular

users should monitor closely the condition

of their hands and fi ngers. If any symptoms

of the above appear, seek medical advice

immediately.

● If you are using any medical electric/electronic

devices such as a pacemaker, consult your

physician as well as the device manufacturer

prior to operating any power equipment.

Unit/machine safety

○ Inspect the entire unit/machine before each use.

Replace damaged parts. Check for fuel leaks and

make sure all fasteners are in place and securely

tightened.

○ Replace parts that are cracked, chipped or

damaged in any way before using the unit/

machine.

○ Make sure the safety guard is properly attached.

○ Keep others away when making carburetor

adjustments.

○ Use only accessories as recommended for this

unit/machine by the manufacturer.

WARNING

Never modify the unit/machine in any way. Do

not use your unit/machine for any job except

that for which it is intended.

Fuel safety

○ Pour fuel outdoors and where there are no sparks

or fl ames.

○ Use a container approved for fuel and oil.

○ Do not smoke or allow smoking near fuel or the

unit/machine or while using the unit/machine.

○ Wipe up all fuel spills before starting engine.

○ Move at least 10 ft (3 m) away from fueling site

before starting engine.

○ Stop engine before removing fuel cap and oil cap.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine and fuel in area where fuel

vapors cannot reach sparks or open fl ames

from water heaters, electric motors or switches,

furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or

inhale fumes, so that pay special attention

when handling or fi lling fuel.

Cutting safety

○ Do not cut any material other than grass and

brush.

○ Inspect the area to be cut before each use.

Remove objects which can be thrown or become

entangled.

○ For respiratory protection, wear an aerosol

protection mask when cutting the grass after

insecticide is scattered.

○ Keep others including children, animals,

bystanders and helpers outside the 16 ft. (5 m)

hazard zone. Stop the engine immediately if you

are approached.

○ Always keep the engine on the right side of your

body.

○ Hold the unit/machine fi rmly with both hands.

○ Keep fi rm footing and balance. Do not over-

reach.

○ Keep all parts of your body away from the muffl er

and cutting attachment when the engine is

running.

○ Keep cutting attachment below waist level.

4

Page 5

English

○ When relocating to a new work area, be sure to

shut off the machine and ensure that all cutting

attachments are stopped.

○ Never place the machine on the ground when

running.

○ Always ensure that the engine is shut off and any

cutting attachments have completely stopped

before clearing debris or removing grass from the

cutting attachment.

○ Always carry a fi rst-aid kit when operating any

power equipment.

○ Never start or run the engine inside a closed room

or building and/or near the infl ammable liquid.

Breathing exhaust fumes can kill.

Maintenance safety

○ Maintain the unit/machine according to

recommended procedures.

○ Disconnect the spark plug before performing

maintenance except for carburetor adjustments.

○ Keep others away when making carburetor

adjustments.

○ Use only genuine HITACHI replacement parts as

recommended by the manufacturer.

Transport and storage

○ Carry the unit/machine by hand with the engine

stopped and the muffl er away from your body.

○ Allow the engine to cool, empty the fuel tank,

and secure the unit/machine before storing or

transporting in a vehicle.

○ Empty the fuel tank before storing the unit/

machine. It is recommended that the fuel be

emptied after each use. If fuel is left in the tank,

store so fuel will not leak.

○ Store unit/machine out of the reach of children.

○ Clean and maintain the unit carefully and store it

in a dry place.

○ Make sure engine switch is off when transporting

or storing.

○ When transporting in a vehicle, cover blade with

blade cover.

CAUTION

Indicates a possibility of personal injury or

equipment damage if instructions are not

followed.

NOTE

Helpful information for correct function and use.

CAUTION

Do not disassemble the recoil starter. You

may get a possibility of personal injury with

recoil spring.

If situations occur which are not covered in this

manual, take care and use common sense. Contact

HITACHI dealer if you need assistance. Pay special

attention to statements preceded by the following

words:

WARNING

Indicates a strong possibility of severe

personal injury or loss of life if instructions

are not followed.

5

Page 6

English

SPECIFICATIONS

Engine Size

(cu. in.)

Spark Plug

Fuel Tank Capacity

(fl . oz)

Engine Oil Capacity

(fl . oz)

Dry Weight (lbs) 11.0 (5.0 kg)

Sound pressure

level

LpA (dB (A))

(EN27917)

Measured sound

power level LwA

(dB (A))

Model CG25EUS (L)

1.53 (25 mℓ)

NGK CMR5H

or equivalent

16.7 (0.5ℓ)

2.7 (80 mℓ)

81.8 78.6

101.8 98.6

ASSEMBLY PROCEDURES

Drive shaft to engine (Fig. 1)

Loosen tube locking bolt (1) so that the bolt point will

not obstruct drive shaft tube to be inserted. When

inserting drive shaft tube, hold the tube locking bolt

outward preventing inside fi tting from obstructing as

well.

Insert the drive shaft into the clutch case of the

engine properly until the marked position (2) on the

drive shaft tube meets the clutch case.

1

3

2

Fig. 1

NOTE

○ When it is hard to insert drive shaft up to the

marked position on the drive shaft tube, turn drive

shaft by the cutter mounting end clockwise or

counter-clockwise. Tighten tube locking bolt lining

up the hole in the shaft tube.

Then tighten clamp bolt securely (3).

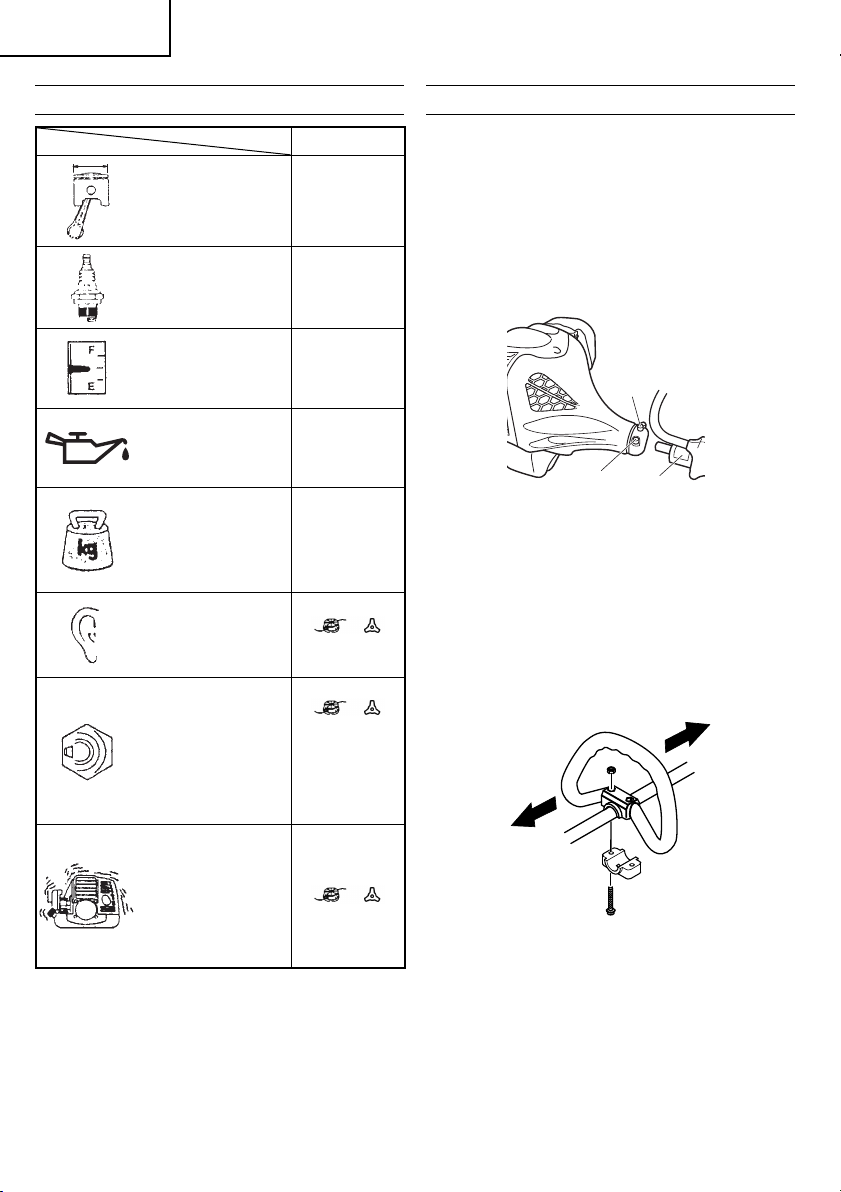

Installation of handle (Fig. 2)

Guaranteed sound

power level LwA

(dB (A))

Vibration level

(m/s2) (ISO7916)

Front handle

Rear handle

NOTE

Equivalent noise level/vibration level are

calculated as the time-weighted energy total

for noise/vibration levels under various working

conditions with the following time distribution: 1/2

Idle, 1/2 racing.

* All data is subject to change without notice.

6

104 101

4.8 4.5

3.2 4.6

Fig. 2

Attach the handle to the drive shaft tube with the

angle towards the engine.

Adjust the location to the most comfortable position

before operation.

NOTE

If your unit has handle location label on drive shaft

tube, follow indication.

Page 7

English

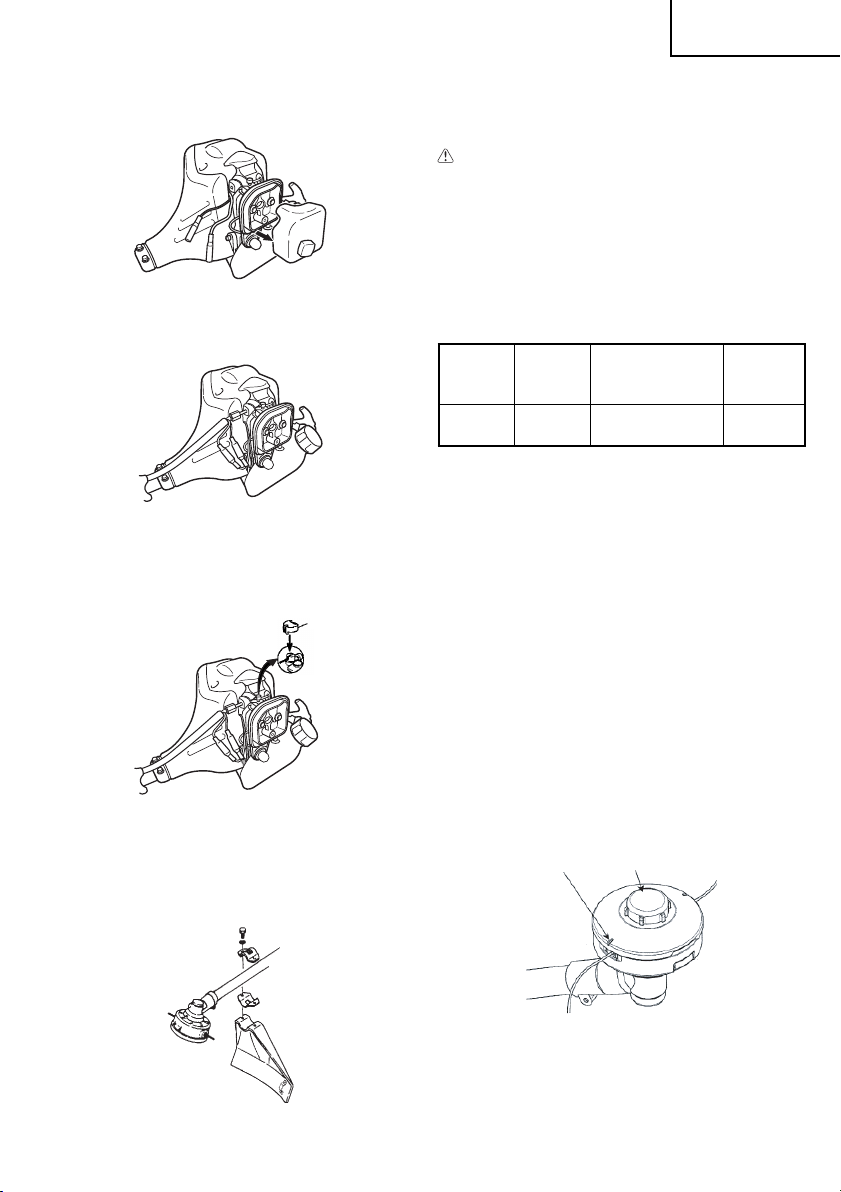

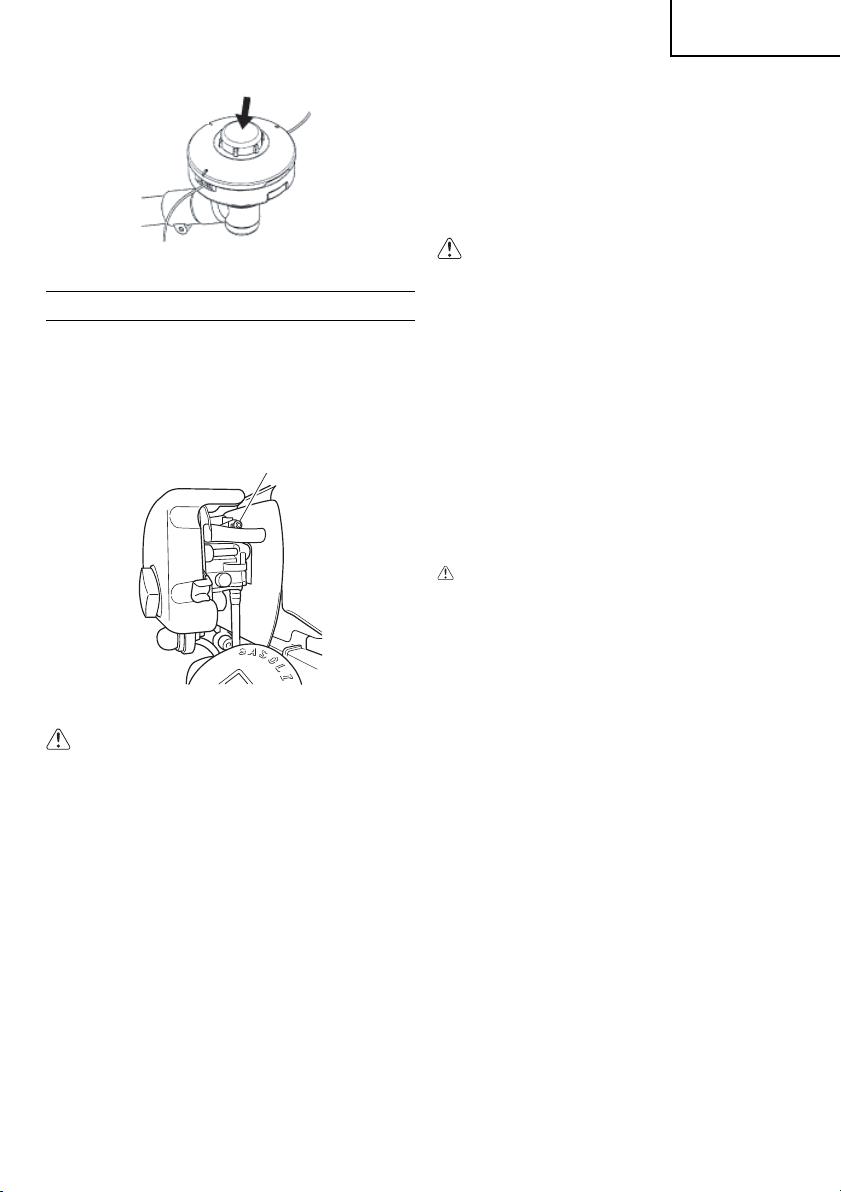

Throttle wire/stop cord

Remove air cleaner cover. (Fig. 3)

Fig. 3

Connect stop cords. (Fig. 4)

Fig. 4

Connect throttle wire end to carburetor and install

swivel cap (4) (if so equipped) where is included in

tool bag, onto swivel. (Fig. 5)

4

Fig. 5

NOTE

If your unit has guard location label on drive shaft

tube, follow the indication.

CAUTION

● Some blade guards are equipped with sharp

line limiters. Be careful with handling it.

Installation of semi-auto cutting head

1. Function

Automatically feeds more nylon cutting line when

it is tapped at low rpm (not greater than 4,500

rpm).

Specifi cations

Code

6696454

Applicable nylon cord

2. Precautions

○ The case must be securely attached to the cover.

○ Check the cover, case and other components for

○ Check the case and button for wear.

If the wear limit mark on the case is no longer

○ The cutting head must be securely mounted to the

○ For outstanding performance and reliability,

Type of

attaching

No.

screw

Female

screw

Cord diameter: 0.12 in. (Φ3.0 mm)

Length: 6.56 ft. (2 m)

Cord diameter: 0.10 in. (Φ2.4 mm)

Length: 13.12 ft. (4 m)

cracks or other damage.

visible or there is a hole in the bottom of the button,

change the new parts immediately. (Fig. 7)

unit’s gear case.

always use Hitachi nylon cutting line. Never

use wire or other materials that could become a

dangerous projectile.

Direction of

rotation

Counterclockwise

Size of

attaching

screw

M10×

P1.25-LH

Attach the air cleaner cover.

Installation of blade guard (Fig. 6)

Install the blade guard as shown in Fig. 6.

Fig. 6

5

○ If the cutting head does not feed cutting line

properly, check that the nylon line and all

components are properly installed. Contact your

Hitachi dealer if you need assistance.

6

Fig. 7

7

Page 8

English

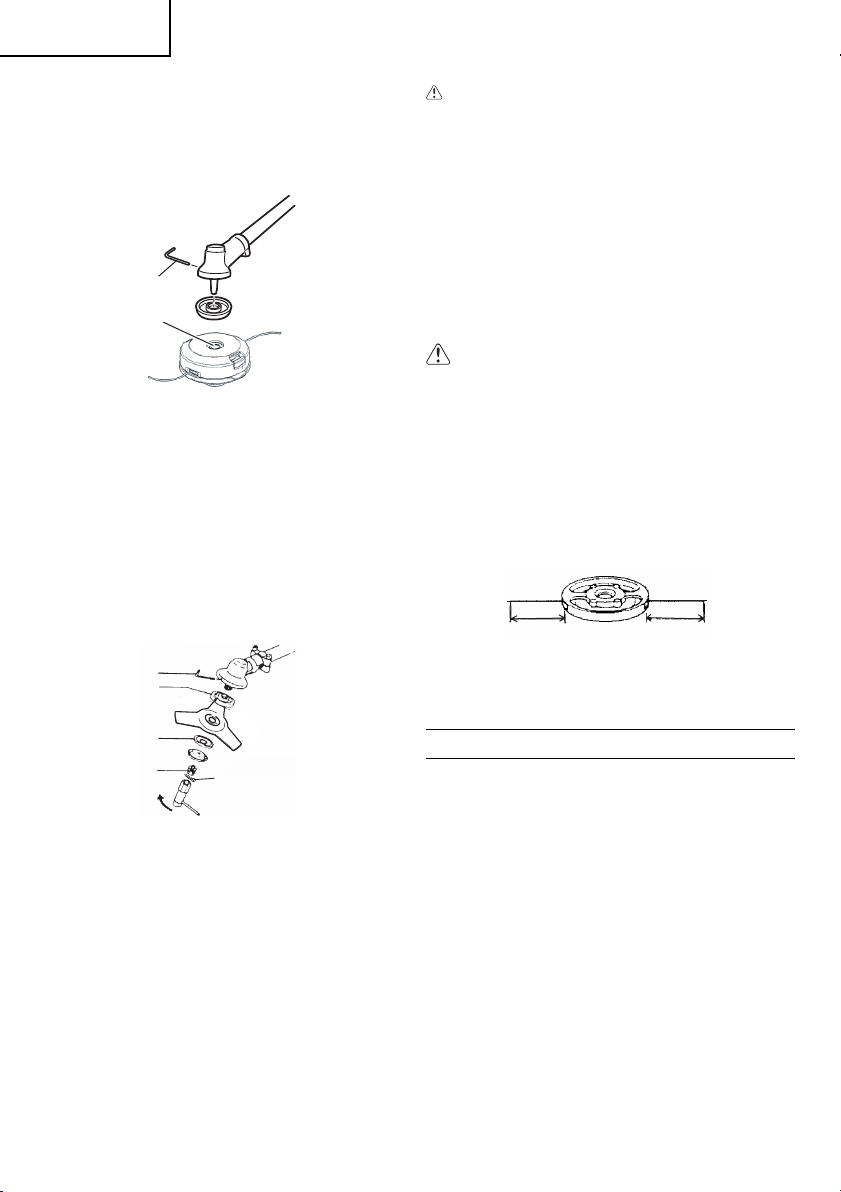

3. Installation (Fig. 8)

○ Install cutting head on gear case of grass

trimmers/brush cutters. The mounting nut (7) is

left-hand-threaded. Turn clockwise to loosen/

counterclockwise to tighten.

8

7

Fig. 8

NOTE

○ Since the cutter holder cap is not used here, keep

it for when a metal blade is used, if so equipped.

○ Insert Allen wrench (8) into the hole of the gear

case in order to lock the cutter holder.

Installation of cutting blade (Fig. 9)

(If so equipped)

When installing a cutting blade, make sure that there

are no cracks or any damage to it and that the cutting

edges are facing the correct direction.

10

11

9

12

NOTE

○ When installing cutter holder cap (9), be sure to

set concave side upward.

Insert the allen wrench (10) into the hole of the

angle transmission in order to lock the cutter

holder (11). Please note that the cutter fi xing bolt

or nut (12) has left-handed threads, (clockwise to

loosen/counter-clockwise to tighten). Tighten the

fi xing bolt or nut with the box wrench.

○ If your unit is of a nut securing type and equipped

with a cotter pin, the blade must be retained with a

new cotter pin (13) each time installed.

13

Fig. 9

CAUTION

● Before operation, make sure the blade has

been properly installed.

● If your unit is equipped with protection cover

under a cutting blade, check it for wear or

cracks before operation. If any damage or

wear is found, replace it, as it is an article of

consumption.

Installation of

NOTE

For installation see your BRAIN owner’s manual,

provided with the BRAIN cutting head.

the BRAIN cutting head

WARNING

For HITACHI BRAIN heads or HITACHI alloy

head, use only fl exible, non-metallic line

recommended by the manufacturer. Never

use wire or wire ropes. They can break off

and become a dangerous projectile.

NOTE

When using HITACHI alloy head (CH-100), initial

cutting line length should be about 6-11/16˝

(17 cm) each. (Fig. 10)

6-11/16˝ (17 cm)

OPERATING PROCEDURES

Engine oil

○ Always use the specifi ed engine oil (multigrade oil

of classifi cation SAE 10W-30). Insuffi cient engine

oil or using engine oil other than the specifi ed type

may cause breakdown of the unit.

Filling up with engine oil

○ Place the unit horizontally on a clean, fl at surface.

○ Remove the oil cap and check whether the engine

oil comes up to the mouth of the oil tank opening.

(Fig. 11)

6-11/16˝ (17 cm)

CH-100

Fig. 10

8

Page 9

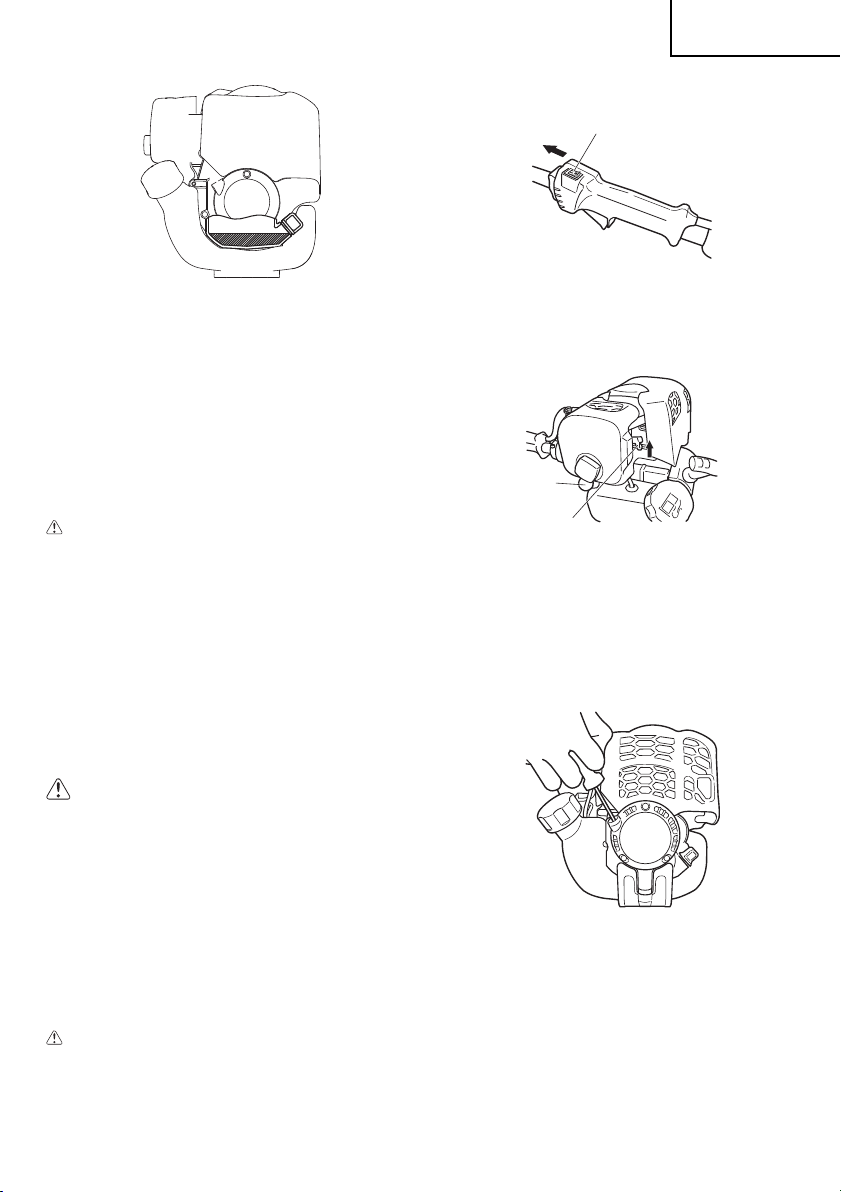

English

1.

Set ignition switch (14) to ON position. (Fig. 12)

14

Fig. 11

○ If the oil level is low or when using the unit for the

fi rst time, fi ll the oil tank with engine oil up to the

mouth of the oil tank opening.

○ If the engine oil is conspicuously dirty or discolored,

change the oil.

○ Tighten the oil cap securely after fueling.

○ When using the unit for the fi rst time, change

the engine oil after running the engine for

approximately 10 hours. Subsequently, change

the oil after every 50 hours of operation.

CAUTION

● To avoid the risk of burn injury, allow the

engine to cool thoroughly before changing

the engine oil.

● To prevent breakdown, ensure that no sand

or dirt gets into the oil tank while refueling.

Fuel

○ Always use branded 89 octane unleaded

gasoline.

○ Do not use a mixture of gasoline and engine oil as

this may lead to starter failure or power reduction.

Fueling

WARNING

● Always shut off the engine before refueling.

● Slowly open the fuel tank, when fi lling up

with fuel, so that possible overpressure

disappears.

● Tighten the fuel cap carefully, after fueling.

● Always move the trimmer at least 10 ft. (3 m)

from the fueling area before starting.

Before fueling, clean the tank cap area carefully, to

ensure that no dirt falls into the tank.

Starting (Fig. 12)

CAUTION

Before starting, make sure the cutting

attachment does not touch anything.

Fig. 12

* Push priming bulb (15) several times so that fuel

fl ows through return pipe. (If so equipped) (Fig.

13)

15

16

Fig. 13

2. Set choke lever to CLOSED position (16). (Fig.

13)

3. Pull recoil starter briskly, taking care to keep the

handle in your grasp and not allowing it to snap

back. (Fig. 14)

Fig. 14

4. When you hear the engine want to start, return

choke lever to RUN position (open). Then pull

recoil starter briskly again.

NOTE

If engine does not start, repeat procedures from 2

to 4.

5. After starting engine, allow the engine about 2–3

minutes to warm up before subjecting it to any

load.

9

Page 10

English

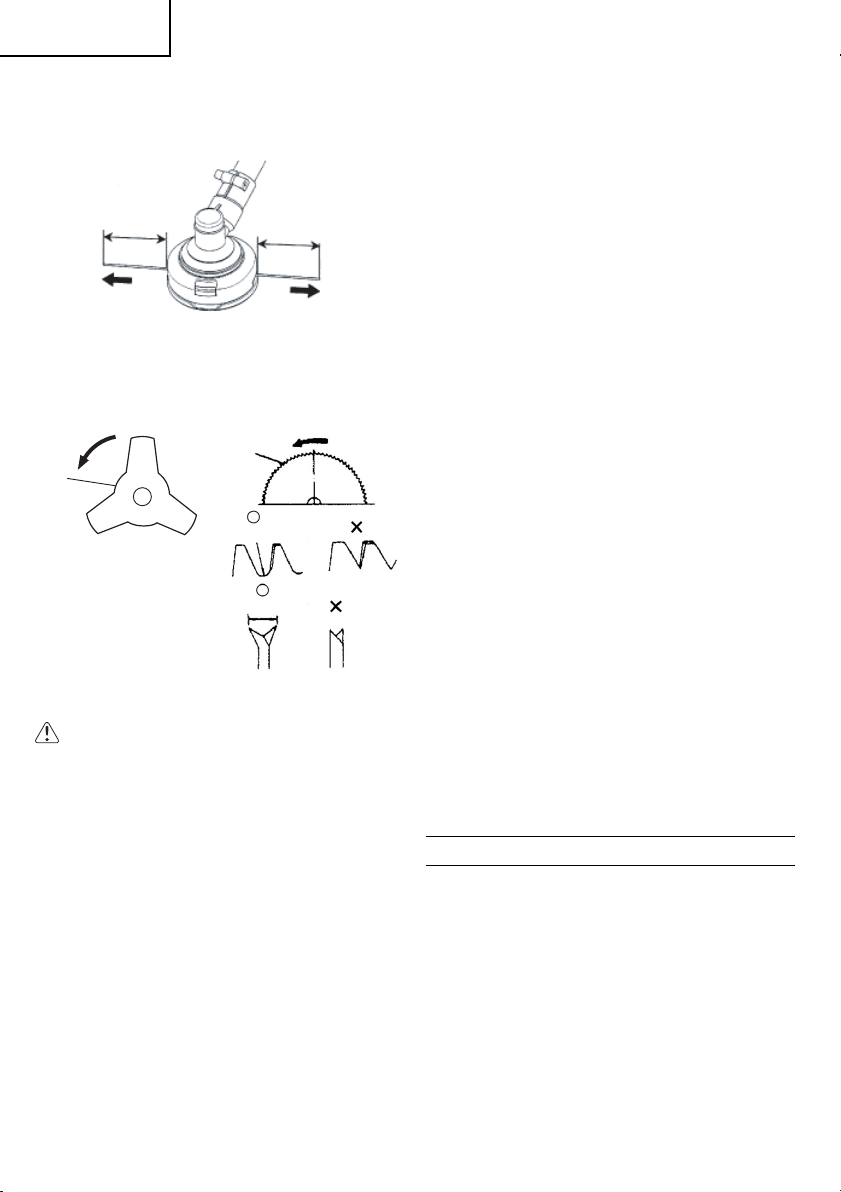

Cutting (Fig. 15, 16, 17)

Fig. 15

Fig. 16

50 ft

(15 m)

Fig. 17

○ When cutting, operate engine at over 6,500/min.

Extended time of use at low rpm may wear out the

clutch prematurely.

○ Cut grass from right to left.

○ Blade thrust may occur when the spinning blade

contacts a solid object in the critical area.

A dangerous reaction may occur causing the

entire unit and operator to be thrust violently. This

reaction is called blade thrust. As a result, the

operator may lose control of the unit which may

cause serious or fatal injury. Blade thrust is more

likely to occur in areas where it is diffi cult to see

the material to be cut.

○ Wear the harness as shown in the fi gure (if so

equipped). The blade turns counterclockwise,

therefore, be advised to operate the unit from right

10

to left for effi cient cutting. Keep onlookers out of

working area at least 50 ft. (15 m).

NOTE

Press the quick release button or pull emergency

release fl ap (If so equipped) in the event of

emergency.

WARNING

If cutting attachment should strike against

stones or other debris, stop the engine and

make sure that the attachment and related

parts are undamaged. When grass or vines

wrap around attachment, stop engine and

attachment and remove them.

Stopping (Fig. 18)

○ Decrease engine speed and run at an idle for a

few minutes, then turn off ignition switch (17).

17

Fig. 18

WARNING

A cutting attachment can injure while it

continues to spin after the engine is stopped

or power control is released. When the unit is

turned off , make sure the cutting attachment

has stopped before the unit is set down.

Semi-auto cutting head

Adjusting line length

○ Set the engine speed as low as possible and tap

the head on the ground. The nylon line will be

drawn out about 3 cm with each tap. (Fig. 19)

Also, you can extend the nylon line by hand but

the engine must be completely stopped. (Fig. 20)

○ Adjust the nylon line to the proper length of 11–14

cm before each operation.

Fig. 19

Page 11

English

the correct idle speed when the engine runs smoothly

in all positions well below the rpm when the cutting

attachment starts to rotate.

If the cutting attachment still rotates after idle speed

adjustment, contact HITACHI dealer.

NOTE

Standard idle rpm is 3,000/min.

Fig. 20

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR

OF THE EMISSION CONTROL DEVICES AND

SYSTEMS MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor adjustment (Fig. 21)

T

Fig. 21

WARNING

● The cutting attachment may be spinning

during carburetor adjustments.

● Never start the engine without the complete

fan case and tube assembled! Otherwise the

clutch can come loose and cause personal

injuries.

In the carburetor, fuel is mixed with air. When the

engine is test run at the factory, the carburetor is

basically adjusted. A further adjustment may be

required, according to climate and altitude. The

carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air fi lter is clean. When the idle speed

is correct, the cutting attachment will not rotate. If

adjustment is required, close (clockwise) the T-screw,

with the engine running, until the cutting attachment

starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached

WARNING

When the engine is idling the cutting

attachment must under no circumstances

rotate.

NOTE

Some models sold areas with strict exhaust

emission regulation do not have high and low

speed carburetor adjustments. Such adjustments

may allow the engine to be operated outside of

their emission compliance limits. For these models,

the only carburetor adjustment is idle speed.

Changing the engine oil

Dirty engine oil will considerably reduce the service

life of the engine. Check and change the engine oil

regularly.

CAUTION

● To avoid risk of burn injury, allow the engine

to cool thoroughly before changing the

engine oil.

● To prevent breakdown, ensure that no sand

or dirt gets into the tank while refueling.

When to change the oil: When fi rst using the unit, after

approximately 10 hours of operation or after 1 month,

whichever occurs earlier; subsequently, after every

50 hours of operation or every 6 months, whichever

occurs earlier.

Specifi ed engine oil: Multigrade oil of classifi cation SAE

10W-30

Engine oil capacity: 4.88 cu. in. (80 ml)

1. Turn off the ignition switch.

2. Check that the fuel cap is securely tightened.

3. Remove the oil cap, tilt the unit so that the oil tank

opening is on the underside and drain the engine

oil into a container. (Fig. 22)

11

Page 12

English

Fig. 22

4. When all the engine oil has been drained, place

the unit horizontally on a clean, fl at surface.

5. Fill the oil tank with engine oil up to the mouth of

the oil tank opening. (Fig. 11)

6. Tighten the oil cap securely by hand.

NOTE

○ Do not dispose of waste engine oil with garbage

or into the ground.

Dispose of the oil according to the specifi ed

method in your area.

If you are unsure, contact the retailer where the oil

was purchased.

○ Fill the oil tank with the specifi ed amount of engine

oil.

Too much or too little engine oil may result in

engine breakdown.

○ Engine oil deteriorates naturally even if unused.

Change the engine oil regularly.

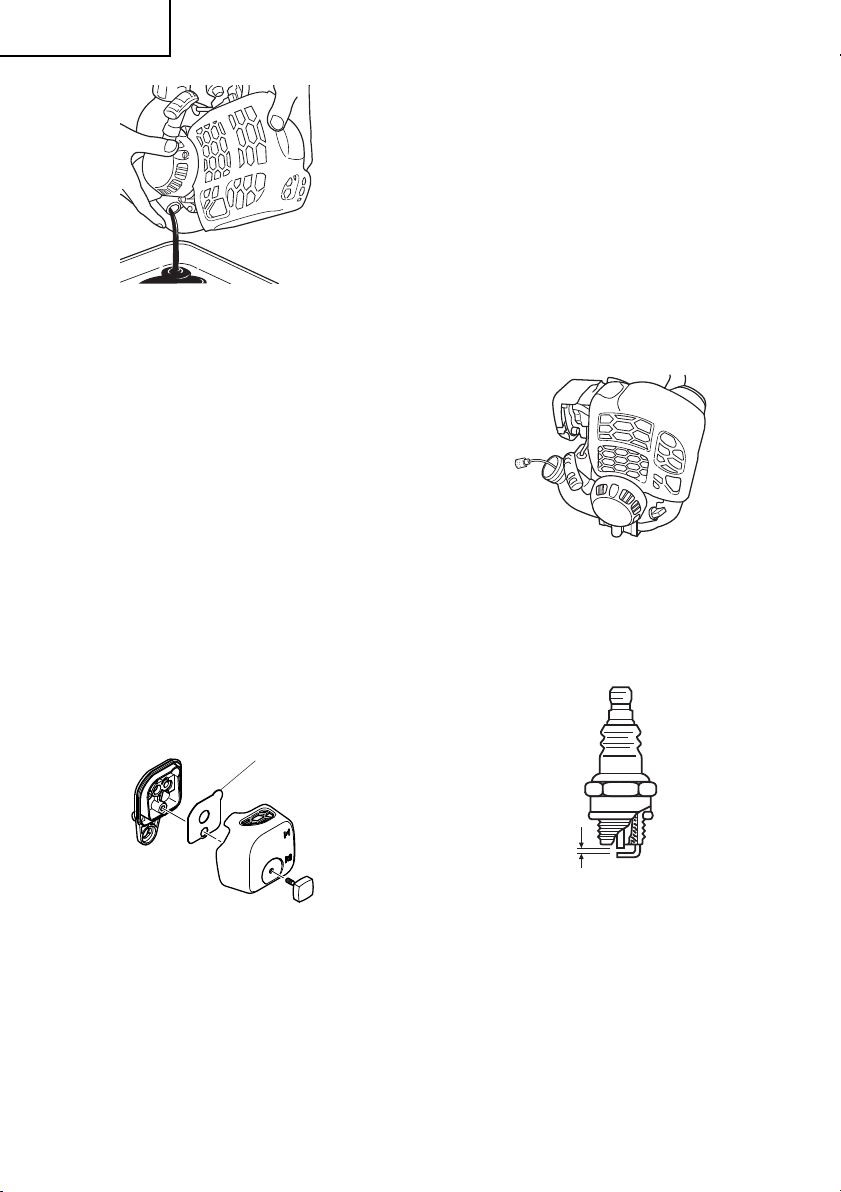

Air fi lter (Fig. 23)

Cleaning the air fi lter

Remove the air fi lter cover and the fi lter (18). Rinse it

in warm soap suds. Check that the fi lter is dry before

reassembly. An air fi lter that has been used for some

time cannot be cleaned completely. Therefore, it must

regularly be replaced with a new one. A damaged

fi lter must always be replaced.

Fuel fi lter (Fig. 24)

Drain all fuel from fuel tank and pull fuel fi lter line from

tank. Pull fi lter element out of holder assembly and

rinse element in warm water with detergent.

Rinse thoroughly until all traces of detergent are

eliminated. Squeeze, do not wring, away excess

water and allow element to air dry.

Fig. 24

NOTE

If element is hard due to excessive dirt buildup,

replace it.

Spark plug (Fig. 25)

18

Fig. 23

The air fi lter must be cleaned from dust and dirt in

order to avoid:

○ Carburetor malfunctions.

○ Starting problems.

○ Engine power reduction.

○ Unnecessary wear on the engine parts.

○ Abnormal fuel consumption.

Clean the air fi lter daily or more often if working in

exceptionally dusty areas.

12

.024˝

(0.6 mm)

Fig. 25

The spark plug condition is infl uenced by:

○ An incorrect carburetor setting.

○ A dirty air fi lter.

○ Hard running conditions (such as cold weather).

○ Too much engine oil

These factors cause deposits on the spark plug

electrodes, which may result in malfunction and

starting diffi culties. If the engine is low on power,

diffi cult to start or runs poorly at idling speed, always

check the spark plug fi rst. If the spark plug is dirty,

Page 13

English

clean it and check the electrode gap. Readjust if

necessary. The correct gap is .024˝ (0.6 mm). The

spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly

eroded.

NOTE

In some areas, local law requires using a resistor

spark plug to suppress ignition signals. If this

machine was originally equipped with resistor

spark plug, use same type of spark plug for

replacement.

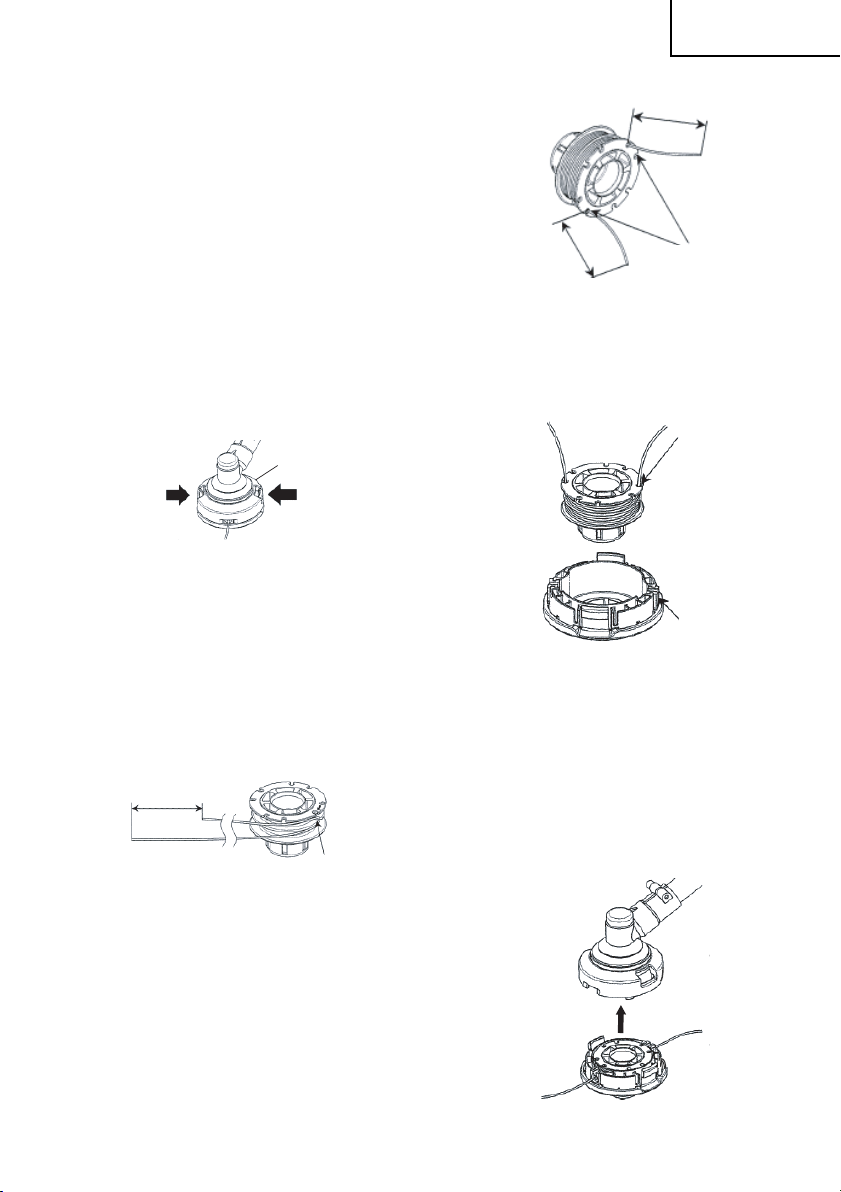

Semi-auto cutting head

Nylon line replacement

(1) Remove the case (19) by fi rmly pushing inward

the locking tabs with your thumbs as shown in Fig.

26.

19

Fig. 26

(2) After removing the case, take out the reel and

discard the remaining line.

(3) Fold the new nylon line unevenly in half as shown

in picture.

Hook the U-shaped end of the nylon line into the

groove (20) on the center partition of the reel.

Wind both halves of the line on the reel in the

same direction, keeping each half of the line on its

own side of the partition. (Fig. 27)

4˝ (10 cm)

4˝ (10 cm)

21

Fig. 28

(5) Insert both loose ends of the line through the cord

guide (22) when placing the reel in the case. (Fig.

29)

21

22

Fig. 29

NOTE

When placing a reel in the case, try to line up the

stopper holes (21) with the cord guide (22) for

easier line release later.

4˝ (10 cm)

20

Fig. 27

(4) Push each line into the stopper holes (21), leaving

the loose ends approx. 4˝ (10 cm) in length.

(Fig. 28)

(6) Place the cover over the case so that the cap

locking tabs on the case meet the long holes on

the cover. Then push the case securely until it

clicks into place. (Fig. 30)

Fig. 30

13

Page 14

English

(7) The initial cutting line length should be approx.

4-11/32˝–5-1/2˝ (11-14 cm) and should be equal

on both sides. (Fig. 31)

4-11/32˝–5-1/2˝

(11-14 cm)

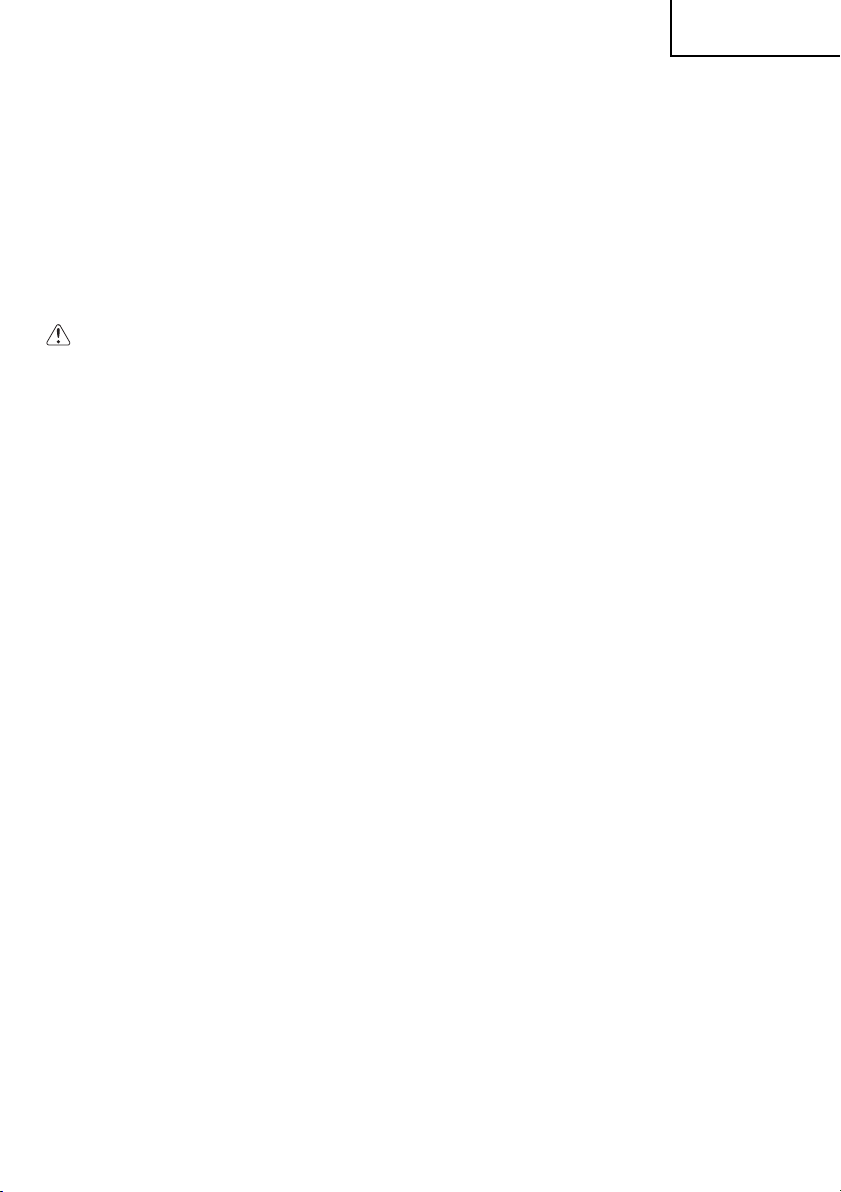

Blade (Fig. 32)

23

4-11/32˝–5-1/2˝

(11-14 cm)

Fig. 31

24

R1 – 1.5 mm

1.9 – 2.2 mm

Fig. 32

WARNING

Wear protective gloves when handling or

performing maintenance on the blade.

○ Use a sharp blade. A dull blade is more likely to

snag and thrust. Replace the fastening nut if it is

damaged and hard to tighten.

○ When replacing blade, purchase one

recommended by HITACHI, with a 1˝ (25.4 mm)

fi tting hole.

○ When installing saw blade (24), always face the

stamped side up. In the case of a 4-tooth blade

(23), it can be used on either side.

○ Use correct blade for the type of work.

○ When replacing blade, use appropriate tools.

○ When cutting edges become dull, re-sharpen or

fi le as shown in fi gure. Incorrect sharpening may

cause excessive vibration.

○ Discard blades that are bent, warped, cracked,

broken or damaged in any way.

NOTE

When sharpening blades it is important to maintain

an original shape of radius at the base of the tooth

to avoid cracking.

Maintenance schedule

Below you will fi nd some general maintenance

instructions. For further information please contact

your HITACHI dealer.

Daily maintenance

○ Clean the exterior of the unit.

○ Check that the harness is undamaged.

○ Check the blade guard for damage or cracks.

Change the guard in case of impacts or cracks.

○ Check that the cutting attachment is properly

centred, sharp, and without cracks. An off - centred

cutting attachment induces heavy vibrations that

may damage the unit.

○ Check that the cutting attachment nut is suffi ciently

tightened.

○ Make sure that the blade transport guard is

undamaged and that it can be securely fi tted.

○ Check that nuts and screws are suffi ciently

tightened.

○ Check the volume and condition of the engine oil.

Weekly maintenance

○ Check the starter, especially cord and return

spring.

○ Clean the exterior of the spark plug.

○ Remove the spark plug and check the electrode

gap. Adjust it to .024˝ (0.6 mm), or change the

spark plug.

○ Clean the air fi lter.

Monthly maintenance

○ Rinse the fuel tank with gasoline.

○ Clean the exterior of the carburetor and the space

around it.

○ Clean the fan and the space around it.

IMPORTANT NOTICE

THIS INFORMATION IS FOR THE US AND

CANADIAN MARKETS ONLY.

○ Never use a metal blade on any brush cutter

without barrier bar or bicycle handle confi guration

and safety strap and a safety guard specifi cally

designed and approved for blade use.

○ Use only attachments or accessories designed for

your unit and off ered by HITACHI. Although some

unauthorized parts may be adaptable, their use

may be extremely dangerous and could cause

serious injury or death.

14

Page 15

HITACHI off ers a complete line of trimmer/brush

cutter accessories to accomplish any job while

ensuring safe operation.

The following models are sold as grass trimmers

capable of being converted to blade-capable brush

cutters: CG25EUS (L)

Blade adapter kits for this model can be purchased

at your local HITACHI dealer. These kits contain

a safety barrier bar and shoulder strap as well as

the necessary blade guard and blade mounting

hardware.

WARNING

The blade conversion kit MUST be used when

operating these models with steel blades.

Never install a steel blade without the use of

the blade-securing cotter pins included in the

kit. Proper installation of all blade-mounting

components is required when converting

a grass trimmer to a blade-capable brush

cutter. Consult your Tanaka dealer if you are

uncertain about any aspect of blade use on

your Tanaka unit.

Bicycle Style Handle Kit #748502

This kit converts model CG25EUS (L) from “D” style

front handles to dual handled style brush cutters.

English

15

Page 16

Français

Signifi cation des symboles REMARQUE : Certaines machines n’en sont pas pourvues

Symboles

AVERTISSEMENT

Les symboles suivants sont utilisés pour l’outil. Bien se familiariser avec leur signifi cation avant

d’utiliser l’outil.

II est essentiel que vous lisiez et compreniez parfaitement les

consignes de sécurités et autres avertissements suivants et que vous

les observiez strictement. L’utilisation inattentive ou inadéquate de

cette machine risque de provoquer des blessures graves ou fatales.

Ne pas utiliser de lames métalliques/rigides lorsque ce signe apparaît

sur la machine.

Indique l’emplacement du carter de protection de la lame pour une

tête à fi l nylon ou pour une tête automatique BRAIN.

Indique l’emplacement du guidon. Ne pas positionner le guidon audessus de ce point.

AVERTISSEMENT

● Lire attentivement le Manuel et respecter l’ensemble des mises en garde et consignes

de sécurité. Négliger cet avertissement peut exposer l’opérateur et/ou les personnes

présentes alentour à des blessures sévères.

● Il se peut que des objets soient lancés ou ricochent en tous sens. PORTER TOUJOURS

DES LUNETTES DE SÉCURITÉ.

● Éloigner les badauds jusqu’à une distance d’au moins de 50 pieds (15 mètres).

● Porter toujours des pare-oreilles pour éviter la possibilité d’une perte auditive.

● Ne jamais utiliser une lame métallique attachée à un coupe-herbes à l’arbre courbé pour

ne pas courir le risque de blessure à cause d’une perte de commande. Ne jamais employer

une lame métallique attachée à une débroussailleuse sans un barreau protecteur ou sans

une confi guration de guidon avec une bandoulière de sûreté.

● L’emploi d’une lame peut occasionner des mouvements soudains en avant, de côté ou en

arrière de la débroussailleuse lorsque la lame entre en contact avec un objet solide. Voir

le manuel de propriétaire pour des détails spécifi ques sur les modèles.

Table des matières

DESCRIPTION .....................................................17

PRÉCAUTIONS ET CONSIGNES DE SÉCURITÉ

CARACTÉRISTIQUES .........................................20

MONTAGE ...........................................................20

UTILISATION ........................................................23

ENTRETIEN .........................................................25

AVIS IMPORTANT................................................29

16

...18

Page 17

DESCRIPTION

Comme ce manuel se réfère à plusieurs modèles, il

se peut qu’il y ait des diff érences entre les images

et votre machine. Suiver les instructions concernant

votre modèle.

1. Bouchon de remplissage du carburant

2. Levier de commande des gaz

3. Poignée de démarrage

4. Carter de protection de la lame

5. Outil de coupe

6. Tube d’arbre de transmission

7. Guidon

8. Interrupteur marche-arrêt

9. Levier de starter

10. Moteur

11. Boîtier de renvoi d’angle

12. Bouchon d’huile

5

11

Français

10

8

7

2

6

4

3

9

1

12

17

Page 18

Français

PRÉCAUTIONS ET CONSIGNES

DE SÉCURITÉ

Sécurité de l’utilisateur

○ Portez toujours une visière et des lunettes de

protection.

○ Portez toujours un pantalon, des chaussures

et des gants de sécurité. Evitez les vêtements

amples, les bjioux, les shorts, les sandales et

les pieds nus. Veillez à ce que vos cheveux ne

descendent pas au-dessous des épaules.

○ N’utilisez cette machine que si vous êtes en pleine

possession de vos moyens physiques. Evitez

strictement la consommation d’alcool, de drogue

ou de médicaments.

○ Ne laissez jamais un enfant ou une personne

inexpérimentée se servir de la machine.

○ Portez un dispositif de protection contre le bruit

pour vos oreilles. Restez vigilant à tout ce qui

vous entoure. Soyez attentif dans l’éventualité où

une personne située à proximité vous signalerait

un problème. Retirez les équipements de sécurité

immédiatement après avoir coupé le moteur de

l’appareil.

○ Protégez-vous la tête.

○ Ne mettez jamais le moteur en marche dans un

local clos, les gaz d’échappement étant toxiques.

○ Nettoyez les poignées de toute trace d’huile ou de

carburant.

○ N’approchez jamais les mains de l’outil de

coupe.

○ N’attrapez pas ni ne tenez la machine par l’outil de

coupe.

○ Après l’arrêt de la machine, attendez l’arrêt

complet de l’outil de coupe avant de poser la

machine.

○ Lors d’une utilisation prolongée, veillez à faire une

pause périodiquement, afi n d’éviter des troubles

éventuels provoqués par les vibrations.

AVERTISSEMENT

● Les systèmes anti-vibrations, aussi bon

soient-ils, ne garantissent pas que vous

ne puissiez pas souff rir de la maladie des

doigts blancs, ni du syndrome du canal

carpien. Par conséquent, si vous vous servez

de façon régulière et continue de votre

machine, surveillez soigneusement l’état

de vos mains et de vos doigts. Si l’un des

symptômes ci-dessus venait à apparaître, il

serait indispensable de vous faire examiner

immédiatement par votre médecin.

● Si vous êtes équipé d’un appareillage

médical électrique/électronique (par ex. un

pacemaker), consultez votre médecin et le

fabricant de cet appareillage avant d’utiliser

tout appareil électrique/ thermique.

Règles de

machine

○ Contrôlez entièrement votre machine avant

○ Remplacez les pièces de la machine qui

○ Vérifi ez que les systèmes de sécurité sont bien

○ Ne laissez personne s’approcher lorsque vous

○ Utilisez uniquement les accessoires recommandés

Ne modifi ez en aucun cas la machine. N’utilisez

Sécurité au niveau du carburant

○ Versez le mélange et le plein à l’air libre, à distance

○ Utilisez un récipient agréé pour l’essence et

○ Ne fumez pas et ne laissez personne fumer

○ Essuyez soigneusement toutes les traces de

○ Pour démarrer la machine, écartez vous d’au

○ Arrêtez le moteur avant de dévisser les bouchons

○ Vidangez le réservoir de carburant avant de

○ Rangez la machine et le carburant dans un endroit

sécurité concernant l’utilisation de la

chaque utilisation. Remplacez les pièces

endommagées. Vérifi ez l’absence de fuites de

carburant et assurez-vous que tous les dispositifs

de fi xation sont en place et solidement fi xés.

présentent des fi ssures, des ébréchures ou toute

autre avarie.

fi xés en place.

réglez le carburateur.

par le fabricant pour cette machine.

AVERTISSEMENT

jamais la machine pour tout autre tâche que

celles auxquelles elle est destinée.

de toute étincelle ou fl amme.

l’huile.

à proximité du carburant ou de la machine, ni

lorsque vous utilisez la machine.

carburant avant de mettre le moteur en marche.

moins 10 pieds (3 m) de l’endroit où vous avez fait

le plein.

des réservoirs de carburant ou d’huile.

remiser la machine. Il est en fait recommandé de

le faire après chaque utilisation. Si le réservoir

n’est pas vide, rangez alors la machine dans une

position telle que le carburant ne risque pas de

couler.

où les vapeurs d’essence ne risquent pas d’entrer

en contact avec des étincelles ou une fl amme

en provenance d’un chauff e-eau, d’un moteur

électrique, d’un commutateur, d’une chaudière,

etc.

18

Page 19

Français

AVERTISSEMENT

Le carburant peut s’enfl ammer facilement ou

exploser et l’inhalation de ses vapeurs est

dangereuse. Faites particulièrement attention

lorsque vous manipulez le carburant ou faites

l’appoint du réservoir.

Sécurité au niveau de la coupe

○ Ne coupez au moyen de l’outil que de l’herbe et

des broussailles et rien d’autre.

○ Inspecter la zone à débroussailler avant chaque

utilisation. Retirer les objets susceptibles d’être

projetés ou de s’enchevêtrer.

○ Pour la protection des voies respiratoires, portez

un masque de protection contre les aérosols

lorsque vous coupez de la végétation traitée avec

des insecticides.

○ Veillez à ce que personne, enfants, animaux,

badauds ou aides, ne se tienne à l’intérieur d’une

zone de sécurité de 16 pieds (5 m). Arrêtez

immédiatement le moteur si quelqu’un s’approche

de vous.

○ Tenez toujours le moteur à votre droite.

○ Maintenez fermement la machine des deux

mains.

○ Tenez-vous bien en équilibre sur les deux jambes.

Ne travaillez jamais en porte-à-faux.

○ Demeurez toujours éloigné du silencieux

d’échappement et de l’outil de coupe lorsque le

moteur est en fonctionnement.

○ Maintenez l’outil de coupe en-dessous du niveau

de la taille.

○ Quand vous déplacez l’appareil d’un lieu à un

autre, vérifi ez que l’appareil est complètement

arrêté et que tous les accessoires de coupe sont

à l’arrêt.

Ne placez jamais l’appareil sur le sol en cours de

○

fonctionnement.

○ Assurez-vous toujours que le moteur est

arrêté et que tous les accessoires de coupe

sont complètement à l’arrêt avant de nettoyer

l’accessoire principal de coupe de tout débris ou

amas d’herbe.

○ Lors de l’utilisation de tout appareil électrique/

thermique, emportez toujours avec vous une

trousse de premiers soins.

○ Ne démarrez jamais le moteur de l’appareil/

N’utilisez jamais l’appareil dans un local clos ou

à l’intérieur d’un bâtiment et/ou à proximité d’un

produit infl ammable. L’inhalation des fumées

d’échappement peut être mortelle.

Sécurité au niveau de l’entretien

○ Entretenez votre machine selon les

recommandations du fabricant.

○ Débranchez la bougie avant toute intervention

d’entretien, à l’exception des opérations de

réglages du carburateur.

○ Ne laissez personne s’approcher de la

machine lorsque vous procédez au réglage du

carburateur.

○ Utilisez uniquement des pièces de rechange

d’origine HITACHI conformément aux

recommandations du fabricant.

Transport et rangement

○ Portez la machine avec moteur arrêté et silencieux

orienté vers l’extérieur.

○ Laissez le moteur refroidir, videz le réservoir

de carburant et veillez à ce que la machine ne

risque pas de tomber lorsque vous la rangez ou la

chargez à bord d’un véhicule.

○ Vidangez le réservoir de carburant avant de

remiser la machine. Il est en fait recommandé de

le faire après chaque utilisation. Si le réservoir

n’est pas vide, rangez alors votre machine dans

une position telle que le carburant ne risque pas

de couler.

○ Remisez la machine hors de portée des enfants.

○ Nettoyez et entretenez l’outil soigneusement et

remisez-le dans un endroit sec.

○ Assurez vous que le commutateur d’arrêt du

moteur est bien sur la position “stop” lors du

transport ou du remisage de la machine.

○ Lors du transport dans un véhicule, couvrez la

lame du capot.

Dans l’éventualité de situations qui ne seraient pas

prises en compte par le présent manuel, redoublez

d’attention et usez de bon sens. Contactez un

concessionnaire HITACHI pour toute assistance.

Faites particulièrement attention aux stipulations

introduites par les mots ci-dessous.

AVERTISSEMENT

Information de première importance pour

éviter des dommages corporels graves ou

mortels.

PRECAUTION

Information importante afi n d’éviter des

dommages corporels ou matériels.

REMARQUE

Information importante pour la compréhension

d’une intervention, évitant ainsi des erreurs.

PRECAUTION

Ne démontez pas le démarreur manuel. Vous

pourriez vous blesser avec le ressort de

rappel.

19

Page 20

Français

CARACTÉRISTIQUES

Modèle CG25EUS (L)

Taille du moteur

(cu. in.)

Bougie d’allumage

Contenance

du réservoir de

carburant (fl . oz)

Contenance en

huile moteur (fl . oz)

Poids à sec (livre) 11.0 (5.0 kg)

Niveau de pression

acoustique

LpA (dB (A))

(EN27917)

Niveau de

puissance

acoustique mesuré

LwA (dB (A))

Niveau de

puissance

acoustique garanti

LwA (dB (A))

1.53 (25 mℓ)

NGK CMR5H

ou équivalent

16.7 (0.5ℓ)

2.7 (80 mℓ)

81.8 78.6

101.8 98.6

104 101

* Toutes les données sont sujettes à modifi cation

sans préavis.

MONTAGE

Arbre d’entraînement du moteur (Fig. 1)

Desserrer la vis de blocage du tube (1) pour que la

pointe de la vis n’entrave pas le tube de l’arbre de

transmission à insérer. Lorsqu’on insère le tube,

maintenir la vis de blocage du tube vers l’extérieur

pour empêcher que la garniture intérieure puisse

devenir un obstacle. Insérer l’arbre de transmission

dans le carter d’embrayage du moteur d’une façon

appropriée jusqu’à ce que la position marquée

(2) sur le tube de l’arbre de transmission soit en

correspondance avec le carter d’embrayage.

1

3

2

Fig. 1

REMARQUE

○ Lorsqu’il est diffi cile d’insérer l’arbre de

transmission jusqu’à la position marquée sur

le tube de l’arbre de transmission, faire tourner

l’arbre de transmission au moyen de l’embout

d’entraînement de l’outil de coupe dans le sens des

aiguilles d’une montre ou inversement. Resserrer

la vis de blocage du tube tout en alignant l’orifi ce

sur le tube de l’arbre de transmission.

Ensuite, resserrer fermement la vis de blocage

(3).

Montage du guidon (Fig. 2)

Niveau de vibrations

(m/s2) (ISO7916)

Poignée avant

Poignée arrière

REMARQUE

Les niveaux de bruit/vibrations équivalents sont

calculés comme total d’énergie pondérée en

fonction du temps pour les niveaux de bruit/

vibrations dans diverses conditions de travail

avec la répartition temporelle suivante: 1/2 ralenti,

1/2 vitesse de course.

20

4.8 4.5

3.2 4.6

Fig. 2

Page 21

Français

Fixer le guidon au tube de l’arbre de transmission

avec la partie inclinée orientée vers le moteur. Régler

l’emplacement sur la position la plus pratique, avant

la mise en marche.

REMARQUE

Si votre machine porte un autocollant montrant

la position du guidon sur le tube de l’arbre de

transmission, veuillez suivre ses indications.

Câble de marche-arrêt / câble de commande des

gaz

Retirer le couvercle du fi ltre à air. (Fig. 3)

Fig. 3

Relier les câbles de marche-arrêt. (Fig. 4)

Fig. 4

Connecter le càble de commande des gaz au

carburateur et installer le capuchon du pivot (4) (le

cas échéant) s’il fi gure dans le sac à outils, sur le

pivot. (Fig. 5)

4

Fig. 5

Fixez le couvercle du fi ltre à air.

Mise en place du carter de protection de lame

(Fig. 6)

Installer le carter de protection de lame

conformément à la Fig. 6.

Fig. 6

REMARQUE

Si votre machine porte un autocollant montrant

la position du carter de protection sur le tube

de l’arbre de transmission, veuillez suivre ses

indications.

PRECAUTION

● Quelques carters de protection sont munis

de couteaux tranchants pour limiter la

longueur du fi l. Prendre garde lors de leur

manipulation.

Montage de la tête de coupe semi-automatique

1. Fonction

Fait avancer automatiquement le fi l de coupe en

nylon lorsqu’elle est tapotée à bas régime (au plus

4,500 tr/min).

Caractéristiques

N° de code

6696454 Vis creuse

Cordon de nylon applicable

Diamètre du cordon : 0.12 pouce (Φ3.0 mm)

Longueur : 6.56 pieds (2 m)

Diamètre du cordon : 0.10 pouce (Φ2.4 mm)

Longueur : 13.12 pieds (4 m)

2. Précautions

○ Le boîtier doit être attaché solidement au

couvercle.

○ Vérifi ez s’il y a des fi ssures ou d’autres

dommages sur le couvercle, le boîtier et les autres

composants.

○ Vérifi ez si le boîtier et le bouton sont usés.

Si la marque de limite d’usure sur le boîtier n’est

plus visible ou qu’il y a un trou au bas du bouton,

changez immédiatement les nouvelles pièces.

(Fig. 7)

Type de vis

de fi xation

Sens de la

rotation

Sens

antihoraire

Taille de vis

de fi xation

M10×

P1.25-LH

21

Page 22

Français

○ La tête de coupe doit être montée solidement sur

le boîtier d’engrenages de l’appareil.

○ Pour bénéfi cier d’un rendement et d’une fi abilité

remarquables, utilisez toujours du fi l de coupe en

nylon Hitachi. N’utilisez jamais de fi l métallique ou

d’autres matériaux qui pourraient constituer de

dangereux projectiles.

5

○ Si le fi l de coupe n’avance pas bien dans la tête de

coupe, vérifi ez si le fi l nylon et tous les composants

sont bien installés. Contactez un concessionnaire

Hitachi pour toute assistance.

3. Installation (Fig. 8)

○ Installez la tête de coupe sur le boîtier

d’engrenages du coupe-herbes ou de la

débroussailleuse. L’écrou de montage (7) est

muni d’un fi let à gauche. Tournez dans le sens

des aiguilles d’une montre pour desserrer et dans

le sens inverse pour serrer.

8

7

REMARQUE

○ Puisque le capuchon de porte-lame n’est pas

utilisé ici, conservez-le en vue d’une utilisation

ultérieure d’une lame métallique, le cas échéant.

○ Insérez la clé Allen (8) dans le trou du boîtier

d’engrenages afi n de bloquer le porte-lame.

Mise en place d’une lame de coupe (Fig. 9)

(Si la machine en est munie)

22

6

Fig. 7

Fig. 8

Lorsqu’on installe une lame de coupe, veiller à ce

que celle-ci ne soit pas fi ssurée ou endommagée et

à ce que les bords tranchants soient dirigés dans la

direction appropriée.

10

11

9

12

REMARQUE

○ Lorsqu’on installe le capuchon du support de

lame (9), s’assurer que le côté concave est tourné

vers le haut.

Insérer la clé de serrage (10) dans le trou du

boîtier de renvoi d’angle afi n de bloquer le porte-

lame (11). Il convient de remarquer que le fi letage

de la vis ou de l’écrou de fi xation (12) est un pas

à gauche (desserrer dans le sens des aiguilles

d’une montre, serrer en sens inverse des aiguilles

d’une montre). Serrer la vis ou l’écrou de fi xation

avec la clé à douille.

○ Si votre machine est du type à écrou de blocage

et munie d’une goupille, il faut retenir la lame au

moyen d’une goupille neuve (13) qu’on remplace

à chaque fois.

PRECAUTION

● Avant de faire fonctionner la machine, vérifi er

que la lame a été montée correctement.

● Si votre machine est munie d’un capot de

protection sous la lame tranchante, s’assurer

avant la fonctionnement qu’il ne présente

pas d’usure excessive ou de fi ssures. Si on

trouve quelques avaries ou de l’usure, il faut

le remplacer puisqu’il s’agit d’une pièce de

consommation courante.

Mise en place d’une tête de coupe automatique

BRAIN

REMARQUE

Pour l’installation, veuillez vous référer au

manuel d’utilisation fourni avec la tête de coupe

automatique BRAIN.

AVERTISSEMENT

Pour les têtes automatiques HITACHI BRAIN

ou la tête manuelle HITACHI en alliage ;

utiliser uniquement des fi ls non métalliques

recommandés par le fabricant. Ne jamais

13

Fig. 9

Page 23

Français

utiliser du fi l de fer ou de câble métallique. Ils

peuvent se rompre et devenir de dangereux

projectiles.

REMARQUE

Lorsque vous utilisez la tête manuelle HITACHI

en alliage (CH-100), la longueur initiale du fi l

de coupe sera d’environ 6-11/16˝ (17 cm) pour

chacun. (Fig. 10)

6-11/16˝ (17 cm)

6-11/16˝ (17 cm)

CH-100

Fig. 10

UTILISATION

Huile moteur

○ Utilisez toujours l’huile moteur spécifi ée (huile

multigrade de classifi cation SAE 10W-30). Un

manque d’huile moteur ou l’emploi d’une autre

huile moteur que le type spécifi é peut causer une

défaillance de l’appareil.

Faire le plein d’huile moteur

○ Placez l’appareil à l’horizontale sur une surface

plane et propre.

○ Retirez le bouchon du réservoir d’huile et vérifi ez

si l’huile moteur arrive à la bouche de l’ouverture.

(Fig. 11)

PRECAUTION

● Pour éviter les risques de brûlures, laissez

le moteur refroidir complètement avant de

procéder à la vidange.

● Pour éviter les défaillances, prenez garde

à ce que du sable ou des saletés pénètrent

dans le réservoir d’huile lors du plein.

Essence

○ Toujours utiliser de l’essence sans plomb avec un

taux d’octane de 89.

○ Ne mélangez pas d’essence à l’huile moteur,

car une panne du démarreur ou une perte de

puissance pourrait en résulter.

Faire le plein

AVERTISSEMENT

● Ne jamais faire le plein lorsque le moteur est

en fonctionnement.

● Desserrer lentement le bouchon du réservoir

de carburant pour eff ectuer le remplissage

afi n de laisser échapper une surpression

éventuelle.

● Serrer le bouchon soigneusement après avoir

rempli le réservoir de carburant.

● Avant de redémarrer le moteur, toujours

s’éloigner d’au moins 10 pieds (3 m) de

l’endroit où a été fait le plein de carburant.

Essuyer autour du bouchon du réservoir afi n d’éviter

que des corps étrangers ne pénètrent dans le

réservoir.

Démarrage (Fig. 12)

PRECAUTION

Avant le démarrage, vérifi er que la lame ne

touche rien.

Fig. 11

○ Si le niveau d’huile est bas ou que vous utilisez

l’appareil pour la première fois, remplissez le

réservoir d’huile moteur jusqu’à la bouche de

l’ouverture du réservoir.

○ Si l’huile moteur est visiblement sale ou décolorée,

vidangez l’huile.

○ Serrez bien le bouchon après avoir rempli le

réservoir d’huile.

○ La première fois, vidangez l’huile moteur après

environ 10 heures de marche. Par la suite,

vidangez l’huile toutes les 50 heures de marche.

1. Placer l’interrupteur marche-arrêt (14) en position

marche (ON). (Fig. 12)

14

Fig. 12

* Presser la poire d’amorçage (15) (Si la machine

en est munie) à plusieurs reprises pour que le

carburant puisse s’écouler dans le tuyau de

retour. (Fig. 13)

23

Page 24

Français

15

16

Fig. 13

2. Régler le levier de starter sur la position fermée

(16). (Fig. 13)

3. Tirer vivement sur la corde du démarreur, en

faisant attention de bien tenir la poignée sans la

laisser se détacher brusquement. (Fig. 14)

Fig. 14

4. Lorsqu’on sent que le moteur va démarrer,

repousser le levier de starter dans la position de

fonctionnement (ouverte). Puis tirer à nouveau

vivement sur le démarreur.

REMARQUE

Si le moteur ne démarre pas, répéter la procédure

à partir de 2 à 4.

5. Après avoir démarré le moteur, laissez le moteur

chauff er pendant 2 à 3 minutes avant de le

soumettre à une charge quelconque.

Débroussaillage (Fig. 15, 16, 17)

24

Fig. 15

Fig. 16

50 pieds

(15 m)

Fig. 17

○ Faire fonctionner le moteur à un régime supérieur

à 6,500/min lors du débroussaillage. Il se peut

que l’utilisation prolongée de la machine au ralenti

aboutisse à l’usure prématurée de l’embrayage.

○ Couper l’herbe de la droite vers la gauche.

○ Une réaction de poussée de la lame peut survenir

lorsque la lame en rotation entre en contact avec

un objet solide dans la zone critique. Une réaction

dangereuse peut alors survenir provoquant

un mouvement incontrôlé et violent de toute la

machine et de l’utilisateur. Cette réaction est

appelée rebond de la lame. Il peut en résulter une

perte de contrôle de la machine par l’utilisateur

pouvant entraîner des blessures sérieuses voire

fatales. Cette réaction incontrôlée de la lame

risque de survenir plus fréquemment dans les

zones où il est diffi cile de se rendre compte de ce

que l’on coupe.

○ Porter le harnais comme indiqué sur la fi gure (Si

la machine en est munie). La lame tourne dans

le sens inverse des aiguilles d’une montre et, par

conséquent, il est préférable d’utiliser la machine

de la droite vers la gauche pour assurer un

débroussaillage effi cace. Eloigner les personnes

se trouvant à proximité de la zone de travail d’une

distance d’au moins 50 pieds (15 m).

REMARQUE

Appuyer sur le bouton de déclenchement

instantané ou tirer la languette de décrochage

d’urgence (si le harnais en est muni) en cas de

danger.

Page 25

AVERTISSEMENT

Si l’outil de coupe bute contre des pierres ou

d’autres débris, arrêter le moteur et s’assurer

que l’outil de coupe n’est pas endommagé et

que les accessoires et pièces connexes sont

également en bon état. Lorsque des herbes

ou des plantes grimpantes s’enroulent autour

de l’outil de coupe, arrêter le

que la lame s’arrête de tourner et retirer les

herbes et les plantes grimpantes.

Arrêt de l’unité (Fig. 18)

○ Ralentir le moteur et le faire fonctionner au ralenti

pendant quelques minutes, ensuite, mettre

l’interrupteur marche-arrêt (17) sur la position

“STOP”.

17

moteur, attendre

Français

Fig. 19

Fig. 20

Fig. 18

AVERTISSEMENT

L’outil de coupe peut blesser lorsqu’il continue

de tourner après l’arrêt du moteur ou lorsque

l’on déclenche la commande d’alimentation

du moteur. Lorsque la machine est arrêtée,

s’assurer que l’outil de coupe a cessé de

tourner avant de déposer la machine sur le

sol.

Tête de coupe semi-automatique

Ajustement de la longueur du fi l

○ Réglez le moteur sur la vitesse la plus faible

possible et tapotez la tête de coupe contre le sol.

Le fi l nylon avancera d’environ 3 cm pour chaque

coup donné. (Fig. 19)

Vous pouvez également étendre le fi l nylon à la

main, mais uniquement après l’arrêt complet du

moteur. (Fig. 20)

○ Ajustez le fi l nylon à une longueur comprise entre

11 et 14 cm avant chaque utilisation.

ENTRETIEN

L’ENTRETIEN, LE REMPLACEMENT OU LA

RÉPARATION DES DISPOSITIFS ET SYSTÈMES

DE CONTRÔLE DE L’ÉCHAPPEMENT PEUVENT

ÊTRE EFFECTUÉS PAR N’IMPORTE QUEL

ATELIER DE RÉPARATION OU MÉCANICIEN DE

MOTEUR NON AUTOMOBILE.

Réglage du carburateur (Fig. 21)

T

Fig. 21

AVERTISSEMENT

● Il se peut que la lame entre en mouvement

pendant le réglage du carburateur.

● N’essayez jamais de démarrer le moteur tant

que le carter de la turbine et le tube ne sont pas

parfaitement en place ! Dans le cas contraire,

l’embrayage risquerait de se détacher,

entraînant des blessures corporelles.

25

Page 26

Français

Dans le carburateur, l’air est mélangé à l’essence. Le

carburateur est préréglé pendant les essais en usine.

Ce réglage peut nécessiter des modifi cations selon

les conditions climatiques et d’altitude. Le carburateur

ne propose qu’une seule possibilité de réglage.

T = Vis de réglage du ralenti.

Réglage du ralenti (T)

Commencer par vérifi er la propreté du fi ltre à air.

Lorsque le ralenti est correct, l’outil de coupe ne

doit pas tourner. Si un réglage s’avère nécessaire,

visser (dans le sens des aiguilles d’une montre) la

vis T, le moteur en marche, jusqu’à ce que l’outil

de coupe commence à tourner. Dévisser alors en

sens contraire (sens inverse des aiguilles d’une

montre) jusqu’à ce que l’outil de coupe s’immobilise

à nouveau. Un ralenti correct permet au moteur de

tourner sans variation de régime dans toutes les

positions ce qui assure une marge de sécurité avant

la mise en rotation de l’outil de coupe.

Si l’outil de coupe tourne encore après le réglage

du régime de ralenti, contacter un concessionnaire

HITACHI.

REMARQUE

Le nombre normal de tours par minute au ralenti

est de 3,000/min.

AVERTISSEMENT

L’outil de coupe doit être absolument

immobile lorsque le moteur tourne au ralenti.

REMARQUE

Certains modèles vendus dans des régions aux

réglementations strictes en matière d’émission

d’échappement ne sont pas dotés de réglages

avec vitesses élevée et basse du carburateur.

Ces réglages peuvent permettre au moteur de

fonctionner en dehors de sa limite de conformité

en matière d’émission. Pour ces modèles, le seul

réglage possible sur le carburateur est le ralenti.

Vidange de l’huile moteur

L’huile moteur sale réduit considérablement la durée

de vie du moteur. Vérifi ez et vidangez l’huile moteur

régulièrement.

PRECAUTION

● Pour éviter les risques de brûlures, laissez

le moteur refroidir complètement avant de

procéder à la vidange.

● Pour éviter les défaillances, prenez garde

à ce que du sable ou des saletés pénètrent

dans le réservoir lors du plein.

Quand procéder à la vidange d’huile : lors de la

première utilisation de l’appareil, au bout de 10 heures

ou 1 mois d’utilisation, la première de ces échéances

étant retenue. Ensuite, toutes les 50 heures ou tous

les 6 mois d’utilisation, la première de ces échéances

étant retenue.

Huile moteur spécifi ée : huile multigrade de classifi cation

SAE 10W-30.

Contenance en huile moteur : 4.88 cu. in. (80 ml)

1. Mettez l’interrupteur de marche/arrêt sur arrêt.

2. Vérifi ez si le bouchon du réservoir de carburant

est bien serré.

3. Retirez le bouchon du réservoir d’huile, inclinez

l’appareil pour orienter l’ouverture du réservoir

vers le bas et versez l’huile moteur dans un

récipient. (Fig. 22)

Fig. 22

4. Une fois que toute l’huile moteur s’est écoulée,

placez l’appareil à l’horizontale sur une surface

plane et propre.

5. Remplissez le réservoir d’huile moteur jusqu’à la

bouche de l’ouverture. (Fig. 11)

6. Serrez bien le bouchon du réservoir d’huile à la

main.

REMARQUE

○ Ne jetez pas l’huile moteur usagée dans les

poubelles ou sur le sol.

Éliminez l’huile suivant la méthode prescrite dans

votre région.

En cas d’incertitude, contactez le détaillant duquel

vous avez acheté l’huile.

○ Remplissez le réservoir d’huile de la quantité

spécifi ée d’huile moteur.

Un excès ou un manque d’huile moteur peut

entraîner une défaillance du moteur.

○ L’huile moteur se détériore naturellement même

si elle ne sert pas.

Vidangez l’huile moteur régulièrement.

26

Page 27

Français

Filtre à air (Fig. 23)

18

Fig. 23

Nettoyer le fi ltre à air régulièrement pour éviter :

○ Les troubles de fonctionnement du carburateur.

○ Les problèmes de démarrage.

○ Les pertes de puissance.

○ L’usure prématurée des organes du moteur.

○ Une consommation anormalement élevée.

Nettoyer le fi ltre à air tour les jours, plus fréquemment

en milieu poussiéreux.

Nettoyage du fi ltre à air

Démonter le couvercle du fi ltre à air, et le fi ltre (18).

Les laver dans de l’eau savonneuse chaude. Vérifi er

ensuite que le fi ltre est bien sec avant de le remonter.

Un fi ltre à air ayant servi longtemps ne peut être

parfaitement nettoyé. Par conséquent, il doit être

remplacé régulièrement par un fi ltre neuf. Un fi ltre

endommagé doit toujours être remplacé.

Filtre à carburant (Fig. 24)

Purger tout le carburant qui se trouve dans le

réservoir de carburant et retirer la durite du fi ltre à

carburant du réservoir. Détacher la cartouche du fi ltre

de l’ensemble et rincer la cartouche dans de l’eau

chaude contenant un produit détersif.

Rincer soigneusement jusqu’à ce que toutes traces

de détergent aient été éliminées. Presser la cartouche

sans la tordre afi n d’éliminer l’excès d’eau et laisser

celle-ci sécher à l’air libre.

Bougie (Fig. 25)

.024˝

(0.6 mm)

Fig. 25

L’état de la bougie est infl uencé par :

○ Le mauvais réglage du carburateur.

○ Un fi ltre à air sale.

○ De dures conditions d’utilisation, (comme par

temps froid, par exemple)

○ Trop d’huile moteur

Ces facteurs contribuent à la formation de

dépôts sur les électrodes de la bougie et peuvent

entraîner troubles de fonctionnement et diffi cultés

au démarrage. Si la débroussailleuse manque de

puissance, si elle démarre mal ou si le ralenti est

irrégulier, toujours commencer par vérifi er l’état de

la bougie. Si la bougie est encrassée, la nettoyer et

vérifi er l’écartement des électrodes qui doit être de

.024 pouce (0.6 mm). La bougie devra être remplacée

toutes les 100 heures d’utilisation ou avant si les

électrodes sont endommagées.

REMARQUE

Dans certaines régions, la réglementation locale

exige l’utilisation d’une bougie équipée d’une

résistance d’antiparasitage afi n d’éliminer les

signaux d’allumage. Si cette machine était

équipée à l’origine d’une bougie avec résistance

d’antiparasitage, utiliser le même type de bougie

lorsque vous la remplacez.

Tête de coupe semi-automatique

Remplacement du fi l nylon

(1) Retirez le boîtier (19) en poussant fermement

les attaches de blocage vers l’intérieur avec les

pouces comme l’illustre la Fig. 26.

Fig. 24

REMARQUE

Si le fi ltre a durci à cause des impuretés contenues

dans le carburant, il convient de le remplacer.

19

Fig. 26

27

Page 28

Français

(2) Après avoir retiré le boîtier, extrayez la bobine et

jetez le fi l restant.

(3) Pliez le nouveau fi l nylon inégalement en deux

comme dans l’illustration.

Accrochez le bout en U du fi l nylon dans la rainure

(20) du séparateur central de la bobine.

Enroulez les deux moitiés du fi l sur la bobine dans

le même sens en gardant chaque moitié de son

côté du séparateur. (Fig. 27)

4˝ (10 cm)

20

Fig. 27

(4) Poussez chaque fi l dans les trous d’arrêt (21) en

laissant des bouts libres d’environ 4˝ (10 cm).

(Fig. 28)

4˝ (10 cm)

4˝ (10 cm)

21

Fig. 28

REMARQUE

Lors de la mise en place d’une bobine dans le

boîtier, essayez d’aligner les trous d’arrêt (21) sur

le guide-cordon (22) pour faciliter le dégagement

ultérieur du fi l.

(6) Placez le couvercle sur le boîtier de façon à ce que

les attaches de blocage sur le boîtier rencontrent

les longs trous sur le couvercle. Ensuite, appuyez

bien sur le boîtier jusqu’à ce qu’il s’enclenche.

(Fig. 30)

Fig. 30

(7) La longueur initiale du fi l de coupe devrait être

d’environ 4-11/32˝–5-1/2˝ (11-14 cm), égale des

deux côtés. (Fig. 31)

4-11/32˝–5-1/2˝

(11-14 cm)

4-11/32˝–5-1/2˝

(11-14 cm)

(5) Insérez les deux bouts libres du fi l dans le guide-

cordon (22) lorsque vous placez la bobine dans le

boîtier. (Fig. 29)

21

22

Fig. 29

28

Fig. 31

Page 29

Français

Lame (Fig. 32)

24

23

R1 – 1.5 mm

1.9 – 2.2 mm

Fig. 32

AVERTISSEMENT

Porter des gants de protection lors du

maniement ou des opérations d’entretien

relatif à la lame.

○ Utiliser une lame bien aiguisée. Une lame

émoussée risque plus facilement de se bloquer

ou de provoquer des mouvements incontrôlés. Si

le boulon de fi xation est endommagé ou diffi cile à

resserrer, le remplacer par un nouveau.

○ Lors du remplacement de la lame, n’utiliser qu’une

lame recommandée par HITACHI, ayant un trou

de montage de 1 pouce (25.4 mm).

○ Lors de l’installation d’une lame de scie (24),

mettre toujours le côté poinçonné vers le haut.

Dans le cas d’une lame à 4 dents (23), celle-ci peut

être employée de n’importe quel des deux côtés.

○ Employer la lame la mieux adaptée au genre de

travail à exécuter.

○ Lors du remplacement de la lame, employer les

outils appropriés.

○ Quand les bords tranchants deviennent

émoussés, les aiguiser de nouveau ou les limer,

comme indiqué sur la fi gure. L’aiguisage incorrect

peut causer des vibrations excessives.

○ Mettre au rebut les lames qui seraient courbées,

tordues, fi ssurées, cassées ou avariées de

quelque façon.

REMARQUE

Lors de l’aiguisage de la lame, il importe de garder

la forme originale de la courbe à la base de la dent

pour en empêcher la fi ssuration.

Entretien

Vous trouverez ci-dessous quelques conseils

d’entretien d’ordre général. Pour plus d’informations,

veuillez contacter un concessionnaire HITACHI.

Entretien quotidien

○ Nettoyer extérieurement le taille-haies.

○ Contrôler l’état du harnais.

○ Vérifi er que le carter de protection de la lame n’est

pas fi ssuré. S’il l’est ou s’il a subi des chocs, le

remplacer. S’assurer que la lame est bien aff ûtée

et qu’elle ne comporte pas de fi ssures.

○ Vérifi er que l’outil de coupe est bien centré,

aiguisé et sans fêlures. Un outil de coupe décentré

provoque d’importantes vibrations susceptibles

d’endommager la machine.

○ Vérifi er que l’écrou de l’outil de coupe est

suffi samment serré.

○ S’assurer que le protecteur de lame pour le

transport est en bon état et que sa fi xation ne

pose aucun problème.

○ Vérifi er le serrage de tous les écrous et vis, surtout

les écrous fi xant le fi ltre à air.

○ Vérifi ez le volume et l’état de l’huile moteur.

Entretien hebdomadaire

○ Contrôler le démarreur, sa corde et son ressort de

rappel.

○ Nettoyer la bougie extérieurement.

○ Démonter la bougie d’allumage et contrôler

l’écartement de ses électrodes, qui doit être

de .024 pouce (0.6 mm), ou la remplacer le cas

échéant.

○ Nettoyer le fi ltre à air.

Entretien mensuel

○ Rincer le réservoir de carburant à l’essence.

○ Nettoyer extérieurement le carburateur et son

logement.

○ Nettoyer le ventilateur et son logement.

AVIS IMPORTANT

CES INFORMATIONS SONT DESTINÉES

AUX MARCHÉS AMÉRICAIN ET CANADIEN

SEULEMENT.

○ Ne jamais utiliser une lame métallique sur une

débroussailleuse sans barre de protection ou

confi guration de guidon à vélo, bandoulière

de sûreté et dispositif de sécurité conçus

spécialement et approuvés pour une utilisation

avec une lame.

○ Utiliser uniquement les fi xations et accessoires

conçus pour votre machine et proposés par

HITACHI. Même si certaines pièces non

autorisées peuvent s’adapter, leur utilisation peut

se révéler dangereuse et entraîner des blessures

graves voire mortelles.

29

Page 30

Français

HITACHI propose une gamme complète

d’accessoires pour coupe-herbes/broussailleuse

permettant de réaliser n’importe quelle tâche tout en

garantissant un fonctionnement sans danger.

Les modèles suivants sont vendus comme coupeherbes transformables en débroussailleuses à lame :

CG25EUS (L)

Des kits d’adaptateur pour lame pour ce modèle

peuvent être achetés auprès de votre concessionnaire

HITACHI local. Ces kits contiennent une barre de

protection et une bandoulière de sûreté, ainsi que

le carter de protection de la lame et le matériel pour

fi xation de la lame nécessaires.

AVERTISSEMENT

Le kit de conversion de la lame DOIT être

utilisé lorsque ces modèles sont utilisés

avec des lames en acier. Ne jamais installer

une lame en acier sans utiliser les goupilles

fendues tenant la lame comprises dans le kit.

Une installation correcte des composants

de fi xation de la lame est nécessaire lors

de la transformation d’un coupe-herbes

en débroussailleuse à lame. Consulter un

concessionnaire Tanaka en cas de doute sur

un quelconque aspect de l’utilisation de la

lame avec une machine Tanaka.

Kit de guidon de style vélo n°748502

Ce kit transforme le modèle CG25EUS (L) avec

guidon frontal de type D en débroussailleuse à

double guidon.

30

Page 31

Español

Los signifi cados de los símbolos NOTA: Algunos aparatos no están provistos de ellos

Símbolos

ADVERTENCIA

A continuación se muestran los símbolos usados para la máquina. Asegúrese de comprender

su signifi cado antes del uso.

Es importante que usted lea, entienda totalmente y observe las

siguientes precauciones y advertencias de seguridad. El uso

descuidado o incorrecto de la unidad podrá causarle lesiones serias

o mortales.

No usar las cuchillas metálicas/rígidas cuando esta señal esté

indicada en la unidad.

Indica el lugar del protector de cuchilla para un cabezal recortador o

para un cabezal BRAIN.

Indica el lugar del manillar. No conecte el manillar encima de este

punto.

ADVERTENCIA

● Lea el manual / las instrucciones y observe todas las advertencias e instrucciones de

seguridad. Su inobservancia puede conducir a graves lesiones al operador y/o a personas

circundantes.

● Podrían lanzarse o rebotar objetos en todas las direcciones. LLEVE SIEMPRE ANTEOJOS

PROTECTORES PUESTOS.

● Aléjense los circunstantes a una distancia de 50 pies (15 metros) por lo menos.