Hitachi 43-53-61-S-U-WX10B-12B Service Manual

JUNE 2001 HHEA-MANUFACTURING DIVISION

PA

No. 0147

53SWX10B 43UWX10B

53SWX12B 53UWX10B

61SWX10B 61UWX10B

61SWX12B

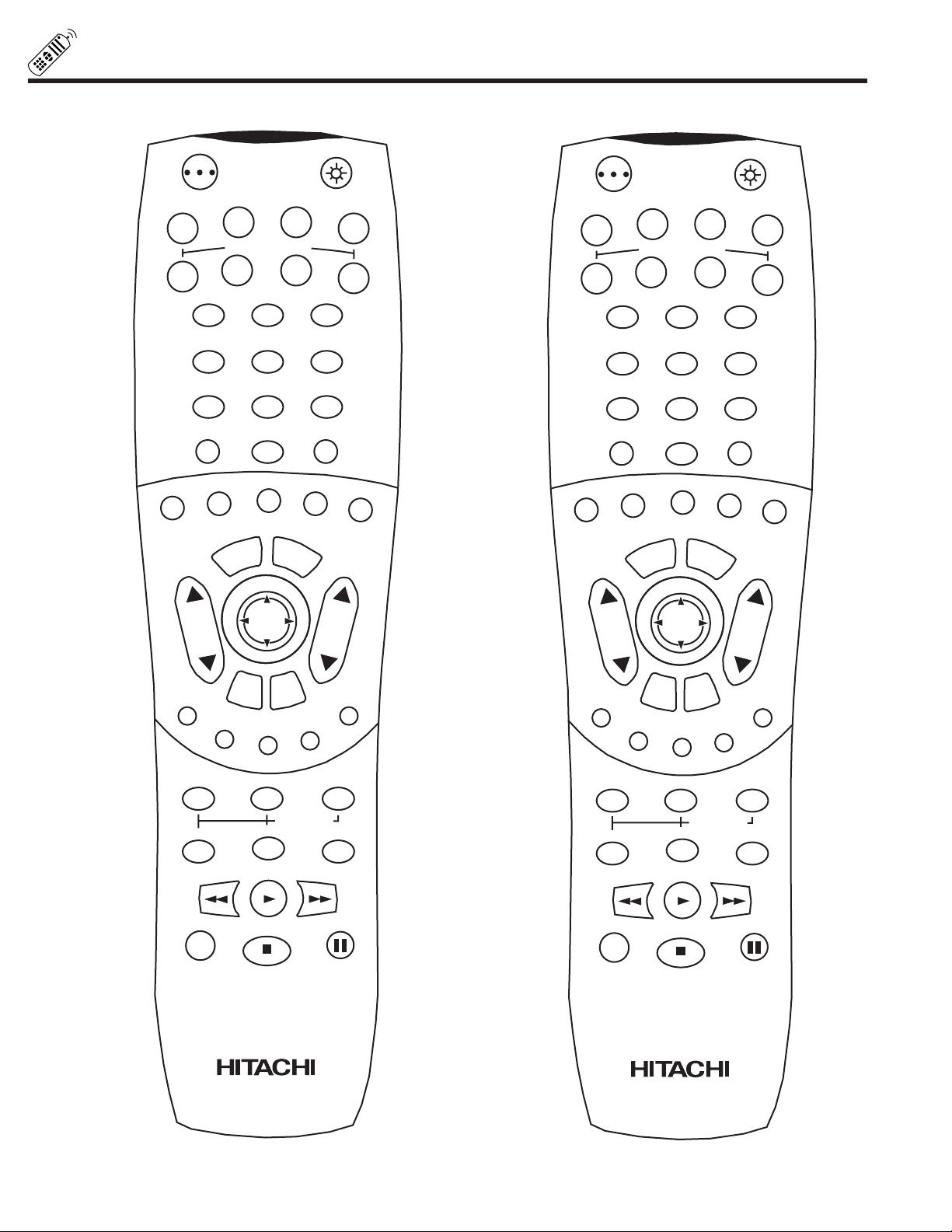

R/C: CLU-5711TSI

CLU-5713TSI

NN TT SS CC

DDPP1144GG DDPP1177

CChhaassssiiss

SERVICE MANUAL

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SERVICING PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

TECHNICAL CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CIRCUIT PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CAUTIONS WHEN CONNECTING/DISCONNECTING THE HV CONNECTOR . . . . . .12

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . .15

REAR PANEL CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

DISPLAY PICTURE FORMATS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

SERVICE ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

WAVEFORMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

DC VOLTAGE TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

PROTECTION CIRCUIT BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

CIRCUIT SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

PRINTED CIRCUIT BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

FINAL WIRING DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

EXPLODED VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

EXPLODED VIEW PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

QUICK REFERENCE PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

CAUTION: These servicing instructions are for use by qualified service personnel only. To reduce the risk of

electric shock do not perform any servicing other than that contained in the operating instructions

unless you are qualified to do so. Before servicing this chassis, it is important that the service

technician read the “IMPORTANT SAFETY INSTRUCTIONS” in this service manual.

SAFETY NOTICE

USE ISOLATION TRANSFORMER WHEN SERVICING

Components having special safety characteristics are identified by a on the schematics and on the parts list in this

Service Data and its supplements and bulletins. Before servicing the chassis, it is important that the service technician

read and follow the “Important Safety Instructions” in this Service Manual.

PROJECTION COLOR TELEVISION

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT

!

2

Components having special safety characteristics are identified by a on the schematics and on the parts list in this service

manual and its supplements and bulletins. Before servicing this chassis, it is important that the service technician read and

follow the “Important Safety Instructions” in this Service Manual.

For continued X-Radiation protection, replace picture tube with original type or Hitachi approved equivalent type.

This Service Manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer. Qualified

technicians have the necessary test equipment and tools, and have been trained to properly and safely repair complex

products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void warranty. If you

are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so and refer the

repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health and Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact

with solder. Also, when soldering do not inhale any smoke or fumes produced.

This television receiver provides display of television closed captioning in accordance with section 15.119 of the FCC rules.

FEDERAL COMMUNICATIONS COMMISSION NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

¥ Reorient or relocate the receiving antenna.

¥ Increase the separation between the equipment and the receiver.

¥ Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

¥ Consult the dealer or an experienced radio/television technician for help.

IMPORTANT SAFETY INSTRUCTIONS

USE ISOLATION TRANSFORMER WHEN SERVICING

!

3

IMPORTANT SAFETY INSTRUCTION

1. Before returning an instrument to the customer, always

make a safety check of the entire instrument, including

but not limited to the following items.

a. Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly

in the cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpaper,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning. Servicers who defeat safety features

or fail to perform safety checks may be liable for

any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to (1) spacing

between the picture tube and cabinet mask, (2)

excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet

back cover.

c. Antenna Cold Check — With the instrument AC plug

removed from any AC source, connect an electrical

jumper across the two AC plug prongs. Place the

instrument AC switch in the on position. Connect one

lead of an ohmmeter to the AC plug prongs tied

together and touch the other ohmmeter lead in turn to

each tuner antenna input, exposed terminal screw

and, if applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohms or

greater than 5.2 megohms, an abnormality exists that

must be corrected before the instrument is returned to

the customer. Repeat this test with the instrument AC

switch in the off position.

d. Leakage Current Hot Check — With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current

tester or a metering system that complies with

American National Standards Institute (ANSI) C101.0

Leakage Current for Appliances and Underwriters

Laboratories (UL) 1410, (50.7). With the instrument

AC switch first in the on position and then in the off

position, measure from a known earth ground (metal

waterpipe, conduit, etc.) to all exposed metal parts of

the instrument (antennas, handle bracket, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal parts that

offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamps.

Reverse the instrument power cord plug in the outlet

and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL

SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE INSTRUMENT TO THE

CUSTOMER OR BEFORE CONNECTING THE

ANTENNA OR ACCESSORIES.

e. High Voltage — This receiver is provided with a hold

down circuit for clearly indicating that voltage has

increased in excess of a predetermined value.

Comply will all notes described in this Service Manual

regarding this hold down circuit when servicing, so

that this hold down circuit may correctly be operated.

f. Service Warning — With maximum contrast, operating

high voltage in this receiver is lower than 31.5 kV. In

case any component having influence on high voltage

is replaced, confirm that the high voltage with

maximum contrast is lower than 31.5 kV.

To measure H.V. use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT anode

button. (See the following connection diagram.)

Note: Turn power switch off without fail before the

connection to the anode button is made.

LEAKAGE

CURRENT

TESTER

(READING

SHOULD NOT

BE ABOVE 0.5mA)

EARTH

GROUND

TEST ALL

EXPOSED

METAL SURFACES

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH PLUG

REVERSED

(USING AC ADAPTER

PLUS AS REQUIRED)

AC Leakage Test

Chassis

ground

FBT

High Impedance

H.V. meter

Deflection P.W.B.

(TH01)

High voltage

connector

4

g. X-radiation – TUBE: The primary source of X-

radiation in this receiver is the picture tube. The tube

utilized for the above mentioned function in this

chassis is specially constructed to limit X-radiation

emissions.

For continued X-radiation protection, the replacement

tube must be the same type as the original, Hitachi

approved type.

When troubleshooting and making test measurements in a receiver with a problem of excessive high

voltage, avoid being unnecessarily close to the picture tube and the high voltage component.

Do not operate the chassis longer than is necessary

to locate the cause of excessive voltage.

h. X-radiation Shield –

1. This receiver is provided with X-ray shield plates

for protection against X-radiation. Do not remove

X-ray shield plates A, B, or C shown in Fig. 1

unnecessarily, when troubleshooting and/or

making test measurements.

2. To prevent X-radiation, after replacement of

picture tube and lens, confirm these components

to be fixed correctly to bracket and cabinet, and

not to be taken off easily.

Shield Plate A

Glass Lens for Shielding

Shield Plate B

Shield Plate C

Shield Plate D

Detailing X-radiation shield

Shield Plate C

Fig. 1. Installation of shield lens, shield cover and shield plates (oblique view).

IMPORTANT SAFETY INSTRUCTIONS

5

2. Read and comply with all caution and safety-related

notes on or inside the receiver cabinet, on the

receiver chassis, or on the picture tube.

3. Design Alteration Warning – Do not alter or add to

the mechanical or electrical design of this TV receiver.

Design alterations and additions including but not

limited to circuit modifications and the addition of

items such as auxiliary audio and/or video output

connectors, might alter the safety characteristics of

this receiver and create a hazard to the user. Any

design alterations or additions may void the

manufacturer’s warranty and may make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4. Picture Tube Implosion Protection Warning – The

picture tube in this receiver employs integral

implosion protection. For continued implosion

protection, replace the picture tube only with one of

the same type number. Do not remove, install, or

otherwise handle the picture tube in any manner

without first putting on shatterproof goggles equipped

with side shields. People not so equipped must be

kept safely away while picture tubes are handled.

Keep the picture tube away from your body. Do not

handle the picture tube by its neck.

5. Hot Chassis Warning – a. Some TV receiver chassis

are electrically connected directly to one conductor of

the AC power cord and may be safely serviced

without an isolation transformer only if the AC power

plug is inserted so that the chassis is connected to the

ground side of the AC power source. Confirm that the

AC power plug is inserted correctly with an AC

voltmeter by measuring between the chassis and a

known earth ground. If a voltage reading in excess of

1.0V is obtained, remove and reinsert the AC power

plug in the opposite polarity and again measure the

voltage potential between the chassis and a known

earth ground. b. Some TV receiver chassis normally

have 85V AC (RMS) between chassis and earth

ground regardless of the AC plug polarity. These

chassis can be safely serviced only with an isolation

transformer inserted in the power line between the

receiver and the AC power source, for both personnel

and test equipment protection. c. Some TV receiver

chassis have a secondary ground system in addition

to the main chassis ground. This secondary ground

system is not isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated or

altered.

6. Observe original lead dress. Take extra care to assure

correct lead dress in the following areas: a. near

sharp edges, b. near thermally hot parts – be sure

that leads and components do not touch thermally hot

parts, c. the AC supply, d. high voltage and e. antenna

wiring. Always inspect in all areas for pinched, out-ofplate, or frayed wiring. Do not change spacing

between components and the printed circuit board.

Check AC power cord for damage.

7. Components, parts, and/or wiring that appear to have

overheated or are otherwise damaged should be

replaced with components, parts, or wiring that meet

original specifications. Additionally, determine the

cause of overheating and/or damage and, if

necessary, take corrective action to remove any

potential safety hazard.

8. PRODUCT SAFETY NOTICE – Many TV electrical

and mechanical parts have special safety-related

characteristics some of which are often not evident

from visual inspection, nor can the protection they

give necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified in Hitachi service data by shading on

schematics and by a in the parts list. Use of

substitute replacement that does not have the same

safety characteristics as the recommended replacement part in Hitachi service data parts list might

create shock, fire, and/or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate. For the

latest information, always consult the appropriate

current Hitachi service literature. A subscription to, or

additional copies of service literature may be obtained

at a nominal charge from Hitachi.

!

IMPORTANT SAFETY INSTRUCTIONS

6

CAUTION: Before servicing instruments covered by this

service data and its supplements and addenda, read and

follow the “Important Safety Instructions” on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict between

the following servicing precautions and any of the safety

precautions on page 3 of this publication, always follow the

safety precautions. Remember: Safety First.

General Servicing Guidelines

1. Always unplug the instrument AC power cord from the AC

power source before:

a. Removing or reinstalling any component, circuit

board, module, or any other instrument assembly.

b. Disconnecting or reconnecting any instrument

electrical plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic

capacitors may result in an explosion

hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device

(DVM, FETVOM, etc.) equipped with a suitable high

voltage probe. Do not test high voltage by “drawing an

arc.” The H.V. Distribution Box has an internal 400MΩ

resistor (bleeder resistor) connected from the high

voltage to ground. After power is removed from the

instrument the high voltage will discharge through the

high voltage bleeder resistor. If the tubes have high

voltage after power is removed, then the bleeder resistor

is defective or the bleeder ground is disconnected.

3. Discharge the picture tube’s anode at any of the R, G, or

B outputs on the H.V. Distribution Box only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield at

the point where the picture tube socket ground lead is

connected, and then (b) touch the other end of the

insulated clip lead to the picture tube high voltage

distribution box R, G, or B output, using an insulated

handle to avoid personal contact with high voltage.

4. Do not spray chemicals on or near this instrument or any

of its assemblies.

5. Unless specified otherwise in these service data, clean

electrical contracts by applying the following mixture to

the contacts with a pipe cleaner, cotton-tipped stick or

comparable nonabrasive applicator: 10% (by volume)

Acetone and 90% (by volume) isopropyl alcohol (90%99% strength).

CAUTION: This is a flammable mixture. Unless

specified otherwise in these service data,

lubrication of contacts is not required.

6. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service data might be

equipped.

7. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heatsinks are correctly installed.

8. Always connect the test instrument ground lead to the

appropriate instrument chassis ground before connecting

the test instrument positive lead. Always remove the test

instrument ground lead last.

9. Use with this instrument only the test fixtures specified in

this service data.

CAUTION: Do not connect the test fixture ground strap

to any heatsink in this instrument.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor “chip” components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge

buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

desolder ES devices.

4. Use only can anti-static type solder removal device.

Some solder removal devices not classified as “antistatic” can generate electrical charges sufficient to

damage ES device.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive

material.)

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

CAUTION: Be sure no power is applied to the chassis or

circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the

lifting of your foot from a carpeted floor can generate

SERVICING PRECAUTIONS

7

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range 500°F to 600°F.

2. Use an appropriate gauge of resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well-tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

small wire-bristle (0.5 inch or 1.25 cm) brush with a metal

handle. Do not use freon-propelled spray-on cleaners.

5. Use the following desoldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. Heat the component lead until the solder melts.

Quickly draw away the melted solder with an antistatic, suction-type solder removal device or with

solder braid.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach normal

temperature (500°F to 600°F).

b. First, hold the soldering iron tip and solder strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil or components.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as

the solder melts.

2. Draw away the melted solder with an anti-static suctiontype solder removal device (or with solder braid) before

removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to areas.)

“Small-signal” Discrete Transistor Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a “U” shape the end of each of three leads

remaining on the circuit board.

3. Bend into a “U” shape the replacement transistor leads.

4. Connect to replacement transistor leads to the

corresponding leads extending from the circuit board and

crimp the “U” with long nose pliers to insure metal to

metal contact, then solder each connection.

Power Output Transistor Devices Removal/Replacements

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heatsink mounting screw (if so equipped).

3. Carefully remove the transistor from the circuit board.

4. Insert new transistor in circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heatsink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicularly to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints

of the two “original leads”. If they are not shiny, reheat

them and, if necessary, apply additional solder.

Use Solding Iron to Pry Leads

IC Removal/Replacement

Some Hitachi unitized chassis circuit boards have slotted

holes (oblong) through which the IC leads are inserted and

then bent flat against the circuit foil. When holes are the

slotted type, the following technique should be used to

remove and replace the IC. When working with boards using

the familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

8

Fuses and Conventional Resistor Removal/Replacement

1. Clip each fuse or resistor lead at top of circuit board

hollow stake.

2. Securely crimp leads of replacement component around

stake 1/8 inch from top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent

components and the circuit board, to

prevent excessive component

temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board, causing the foil to separate from, or “liftoff,” the board. The following guidelines and procedures

should be followed whenever this condition is encountered.

In Critical Copper Pattern Areas

High component/copper pattern density and/or special

voltage/current characteristics make the spacing and

integrity of copper pattern in some circuit board areas more

critical than in others. The circuit foil in these areas is

designated as Critical Copper Pattern. Because Critical

Copper Pattern requires special soldering techniques to

ensure the maintenance of reliability and safety standards,

contact your Hitachi personnel.

At IC Connections

To repair defective copper pattern at IC connections, use the

following procedure to install a jumper wire on the copper

pattern side of the circuit board. (Use this technique only on

IC connections.)

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as absolutely

necessary.)

2. Carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small “U” in one end of a small-gauge jumper wire

and carefully crimp it around the IC pin. Solder the IC

connection.

4. Route the jumper wire along the path of the cut-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area, and clip off any excess jumper wire.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both wire sides of

the pattern break and locate the nearest component

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the

nearest component on one side of the pattern break to

the lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so that it does not touch

components or sharp edges.

Frequency Synthesis (FS) Tuning Systems

1. Always unplug the instrument AC power cord before

disconnecting or reconnecting FS tuning system cables

and before removing or inserting FS tuning system

modules.

2. The FS tuner must never be disconnected from the FS

tuning control module while power is applied to the

instrument.

3. When troubleshooting intermittent problems that might be

caused by defective cable connection(s) to the FS tuning

system, remove the instrument AC power as soon as the

defective connector is found and finish confirming the

bad connection with a continuity test. This procedure will

reduce the probability of electrical overstress of the FS

system semi-conductor components.

CRIMP AND

SOLDER

BARE JUMPER

WIRE

Install Jumper Wire and Solder

DEFECTIVE

COPPER

REMOVED

Insulated Jumper Wire

At Other Connections

Use the following technique to repair defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the component

side of the circuit board.

9

Leadless Chip Components

(surface mount)

Chip components must be replaced with identical

chips due to critical foil track spacing. There are no

holes in the board to mount standard transistors or

diodes. Some chip capacitor or resistor board solder

pads may have holes through the board, however the

hole diameter limits standard resistor replacement to

1/8 watt. Standard capacitors may also be limited for

the same reason. It is recommended that identical

chip components be used. .

Chip resistors have a three digit numerical resistance

code -1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6KΩ resistor, 0 = 0Ω

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of the component

indicates the general range of the capacitance.

Chip transistors are identified by a two letter code. The

first letter indicates the type and the second letter, the

grade of transistor.

Chip diodes have a two letter identification code as

per the code chart and are a dual diode pack with

either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove solder from component

end caps or terminals.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal .

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator

clip and apply heat to the pad area with a 30 watt

iron until solder flows. Do not apply heat for more

than 3 seconds

How to Replace Flat-lC

—Required Tools—

• Soldering iron • iron wire or small awl

• De-solder braids • Magnifier

1. Remove the solder from all of the pins of a Flat-lC

by using a de-solder braid.

2. Put the iron wire under the pins of the Flat-lC and

pull it in the direction indicated while heating the

pins using a soldering iron. A small awl can be

used instead of the iron wire.

3. Remove the solder from all of the pads of the

Fiat-lC by using

a de-solder braid.

4. Position the new Flat-lC in place (apply the pins of

the Flat-lC to the soldering pads where the pins

need to be soldered). Properly

determine the positions of the

soldering pads and pins by

correctly aligning the polarity

symbol.

6. Check with a magnifier for solder bridge between

the pins or for dry joint between pins and soldering

pads. To remove a solder bridge, use a de-solder

braid as shown in the figure below.

NOTE: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for a short

time while twisting with tweezers will break the component loose.

Chip Components

TYPE

GRADE

C

B

E

SOLDER

CAPS

TRANSISTOR

CAPACITOR

1ST DIGIT

2ND DIGIT

MULTIPLIER

= 1600 = 1.6K

ANODES

MH DIODE

RESISTOR

SOLDER CAPS

COMMON CATHODE

De-Solder

Braid

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

Soldering

Iron

De-Solder

Braid

Flat-IC

Bridge

Solder

De-Solder

Braid

Iron

Wire

Pull

Awl

Polarity Symbol

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

10

High Voltage limiter circuit operation check.

1. Turn off TV and connect jig as shown in Figure 2. Adjust

jig fully counter-clockwise for minimum resistance.

2. Set the AC input to 120V AC and turn on TV.

3. Confirm test pattern on CRT is a usable picture, then

slowly adjust jig until the picture disappears and TV shuts

down.

4. When the limiter circuit is operating properly, High

Voltage will be less than 31.5 kV at 1.7mA when TV shuts

down.

5. Turn off set immediately after checking circuit operation.

6. Unplug set for one minute to reset shutdown circuit.

Remove jig and voltmeter.

TECHNICAL CAUTIONS

(TH01)

L902

L901

C901

R901

EF901

EF901

F901

PA

1

2

KKA1

WHITE side

GND side

TESTER

AC CORD POLARITY

This check is based on the UL standard. Use the jigs specified by the production technology section. The GND side (wider

blade) of the AC power cord should be connected to K9Y1

11

Model: 61SWX10B 43UWX10B

61SWX12B 53UWX10B

53SWX10B 61UWX10B

53SWX12B

Cathode-Ray Tube:

61SWX10B R=P16LFT00RFA(LU)

61SWX12B G=P16LFT00HHA(LU)

53SWX10B B=P16LFT00BMB(EU)

53SWX12B

53UWX10B R=P16LSG03RJA

61UWX10B G=P16LSG03HKA

B=P16LSG03BMB

43UWX10B R=P16LTG00RFA

G=P16LTG00HHA

B=P16LTG00BMB

Power Input: 120 volts AC, 60 Hz

Power Consumption:

• Stand-By Power

43/53/61UWX10B . . . . . . . . . . . . . . . .2.7W

53/61SWX10B . . . . . . . . . . . . . . . . . . .2.8W

53/61SWX12B . . . . . . . . . . . . . . . . . . .2.8W

• Power Consumption (operating)

43/53/61UWX10B . . . . . . . . . . . . . . . .219W

53/61SWX10B . . . . . . . . . . . . . . . . . .234W

53/61SWX12B . . . . . . . . . . . . . . . . . .234W

• Power Consumption (maximum)

43/53/61UWX10B . . . . . . . . . . . . . . . .262W

53/61SWX10B . . . . . . . . . . . . . . . . . .295W

53/61SWX12B . . . . . . . . . . . . . . . . . .295W

Antenna Impedance: 75 Ohm Unbalanced

VHF / UHF / CATV

Receiving Channel: BAND CH

VHF 2~13

UHF 14~69

EXT. Mid (A-5)~(A-1), 4+

CATV Mid. A~I

CATV Super J~W

CATV Hyper (W+1)~(W+28)

Intermediate Frequency: Picture l-F Carrier 45.75 MHz

Sound l-F Carrier 41.25 MHz

Color Sub Carrier 42.17 MHz

Video Input: 1 Volt p-p, 75 Ohm

Video Output: 1 Volt p-p, 75 ohm

Audio Input: 470 mVrms, 47 k Ohm

Stereo Audio Output: 470 mVrms, 1 k Ohm

Audio Output Power:

Front: 12 watts per channel at 10% distortion,

8 ohm Impedance. Max output — 15 watts.

Anode Voltage:

DP14G

30.2±0.2kv (1.20±0.2mA)

DP17 31.7kv±0.2kv (1.10±0.2mA)

Brightness: 43 53 61

(white screen) 320cd/m

2

260cd/m

2

190cd/m

2

Speakers: 2 Woofers - 5 inch (120 mm) round

2 Tweeters - 2 inch (50 mm) round

Dimension:

43 53 61

Height (in.) 39 54

1

/

32

61

7

/

32

Width (in.) 41

7

/32 50 17/

32

57

1

/

2

Depth (in.) 20

5

/

8

29 29

19

/

32

Weight (Ibs.) 153 245 350

Circuit Board Assemblies:

C.P.T. (B) P.W.B. Terminal A P.W.B.

C.P.T. (G) P.W.B. Terminal B P.W.B.

C.P.T. (R) P.W.B. VM P.W.B.

Audio Out P.W.B. Surround P.W.B.

2H P.W.B. Power Deflection P.W.B.

Power Supply P.W.B. Control P.W.B.

Signal P.W.B. Control Sub P.W.B.

Convergence P.W.B. Sensor Distribution P.W.B.

CIRCUIT PROTECTION

CAUTION: Below is an EXAMPLE only. See Replacement Parts List for details. The following symbol near the fuse

indicates fast operation fuse (to be replaced). Fuse ratings appear within the symbol.

Example:

SPECIFICATIONS

RISK OF FIRE - REPLACE FUSE AS MARKED

The rating of fuse F901 is 5A - 125V.

Replace with the same type fuse for continued protection

against fire.

F

5 A 125V

125V

5A

12

During Insertion

1. Please refer to direction for insertion as shown in Fig. B (L position). Insert connector until “CLICK” sound is heard.

2. Make sure the connector is pressed right in, so that it has a good contact with the spring.

3. Confirm the contact by pulling the connector slightly. (Don’t pull hard because it may damage the connector).

4. Cover the high voltage output by carefully pushing silicon cover onto it. (Don’t turn the connector).

(REMARK)

1. Make sure the silicon cover is

covering the high voltage output.

CAUTIONS WHEN CONNECTING / DISCONNECTING THE HV CONNECTOR

Perform the following when the

HV connector (anode connector)

is removed or inserted for CPT

replacement, etc.

Deflection P.W.B.

Silicon cover

Wing

L Position

L Position

Wing

FBT

Anode

connector

3. Remove the connector slowly

by pulling it away from the

case.

During Removal

1. Roll out silicon cover from FBT’s contact area slowly.

2. While turning the connector about 90 degrees

following the arrow (0 position), push the connector

slightly towards the case. (Fig. A)

Fig. A

Fig. B

Silicon Cover

less than 1mm

PUSH

PUSH

13

GENERAL INFORMATION

Antenna Input/Output

Audio/Video Inputs 1, 2, 4 and 5

MONITOR OUT

AUDIO TO HI-FI Output

S-VIDEO Inputs 1 and 2

Component Input Y-P

BPR

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

STOP

CONNECT ONLY 8 OHM SPEAKERS

DO NOT SHORT CIRCUIT

THESE TERMINALS

(Such damage is NOT COVERED

by your television warranty)

R

L

REAR SPEAKER

SUB

WOOFER

OPTICAL

INPUT

COAXIAL

INPUT

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

Models: 61UWX10B, 53UWX10B,

43UWX10B

Models: 61SWX10B, 61SWX12B

53SWX10B, 53SWX12B

Models: 61SWX10B, 61SWX12B,

53SWX10B, 53SWX12B

INPUT 3

S-VIDEO

VIDEO

AUDIO

L/MONO

R

EXIT

INPUT

SELECT

MENU

MAGIC

FOCUS

VOL- VOL+ CH- CH+

CURSOR

INPUT 3

S-VIDEO

VIDEO

AUDIO

L/MONO

R

EXIT

INPUT

SELECT

MENU

MAGIC

FOCUS

VOL- VOL+ CH- CH+

CURSOR

POWER

PUSH

POWER

PUSH

Models: 61UWX10B, 53UWX10B,

43UWX10B

14

USE THE REMOTE TO CONTROL YOUR TV

POWER

TV

VCR

CBL

AV2

AV1

AV3

STB

DVD

1

2

4

56

3

7

89

0

LAST CHSLEEP

ANT

HELP

PIX

EXIT

MENU

CHVOL

STATUS

MUTE

GUIDE/TVGUIDE/TVGUIDE/TV

INFO

VCR PLUS+

SVCS

GUIDE/TV

SCHD

PIP PIP CH

SWAP

FREEZE

PIP MODE

PIP ACCESS

PROG

TV/VCR

SLOW

SOURCE WIZARD

REC

SELECT

C.C.

ASPECT

VID 1

VID 2

VID 3

VID 4

VID 5

CLU-5711TSI

CLU-5711TSI

POWER

TV

VCR

CBL

TAPE

CD

AMP

STB

DVD

1

2

4

56

3

7

89

0

LAST CHSLEEP

ANT

HELP

MODE

EXIT

MENU

CHVOL

STATUS

MUTE

GUIDE/TVGUIDE/TVGUIDE/TV

INFO

VCR PLUS+

SVCS

GUIDE/TV

SCHD

PIP PIP CH

SWAP

FREEZE

PIP MODE

PIP ACCESS

PROG

TV/VCR

SLOW

SOURCE WIZARD

REC

SELECT

C.C.

ASPECT

VID 1

VID 2

VID 3

VID 4

VID 5

CLU-5713TSI

CLU-5713TSI

15

Press the front panel

MAGIC FOCUS

button momentarily

for auto setup.

VIDEO

Select VIDEO to adjust picture settings and improve picture quality.

Use this function to change the contrast between black and white levels in the picture. This adjustment

will only affect the picture when ADVANCED SETTINGS PERFECT PICTURE is OFF.

Use the THUMB STICK or to highlight the function to be adjusted.

Press the THUMB STICK or to adjust the function.

Press EXIT to quit menu.

NOTE: 1. It may be necessary to adjust TINT to obtain optimum picture quality when using the COMPONENT:

Y-PBPRInput jacks.

2. If you are using the COMPONENT VIDEO input jacks (Y-P

BPR

) and notice that the TINT and COLOR are

abnormal, check to make sure that COMPONENT SET-COLOR SYSTEM is set properly.

Use this function to adjust flesh tones so they appear natural. (See notes below.)

Use this function to adjust overall picture brightness.

Use this function to adjust the amount of fine detail in the picture.

When RESET is selected, press down on THUMB STICK to return video adjustments to factory

preset conditions.

CONTRAST

Use this function to adjust the level of color in the picture.

COLOR

TINT

BRIGHTNESS

SHARPNESS

RESET

Menu To Menu Bar To Quit Exit

Menu To Menu Bar To Quit Exit

100%

50%

50%

50%

MENU

THUMB

STICK

THUMB

STICK

100%

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

Contrast

Contrast

Brightness

Color

Tint

Sharpness

Reset

Advanced

Settings

CUSTOMIZED PICTURE AND SOUND ADJUSTMENTS

MAGIC

FOCUS

MAGIC FOCUS

MAGIC FOCUS

The Magic Focus button on the front panel will align the convergence when pressed.

16

Select AUDIO to adjust the TV to your preference and to improve the sound quality.

AUDIO

ExitExit

90%

50%

Bass

Treble

Balance

Reset

Advanced

Settings

50%

50%

THUMB

STICK

THUMB

STICK

MENU

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

Menu To Menu Bar To QuitMenu To Menu Bar To Quit

Bass

Treble

Balance

Reset

Advanced

Settings

This function controls the low frequency audio to all speakers.

Use THUMB STICK or to highlight the function to be adjusted.

Press THUMB STICK or to adjust the function.

Press EXIT to quit MENU.

NOTE: If BASS is selected you are adjusting BASS. The additional menu items TREBLE and BALANCE can be selected and

adjusted in the same manner.

This function controls the high frequency audio to all speakers.

This function will control the left to right balance of the TV internal speakers and the AUDIO TO HI FI output.

When RESET is selected, press CURSOR to return audio adjustments to factory preset conditions.

BASS

BALANCE

RESET

TREBLE

17

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

DVD Player

Stereo System Amplifier

Laserdisc player, VCR,

camcorder, etc.

VCR #2

Cable TV Box

VCR #1

Outside antenna or

cable TV coaxial cable

2-Way signal splitter

OUTPUT

Y P

B

P

R

L R

HDTV Set-Top Box

V L R

OUTPUT

S-VIDEO

ANT

IN

OUTPUT

S-VIDEO

VL R

OUTPUT

YP

B/CBPR/CR

L R

LR

INPUT

V L R

INPUT

S-VIDEO

INPUT

OUTPUT

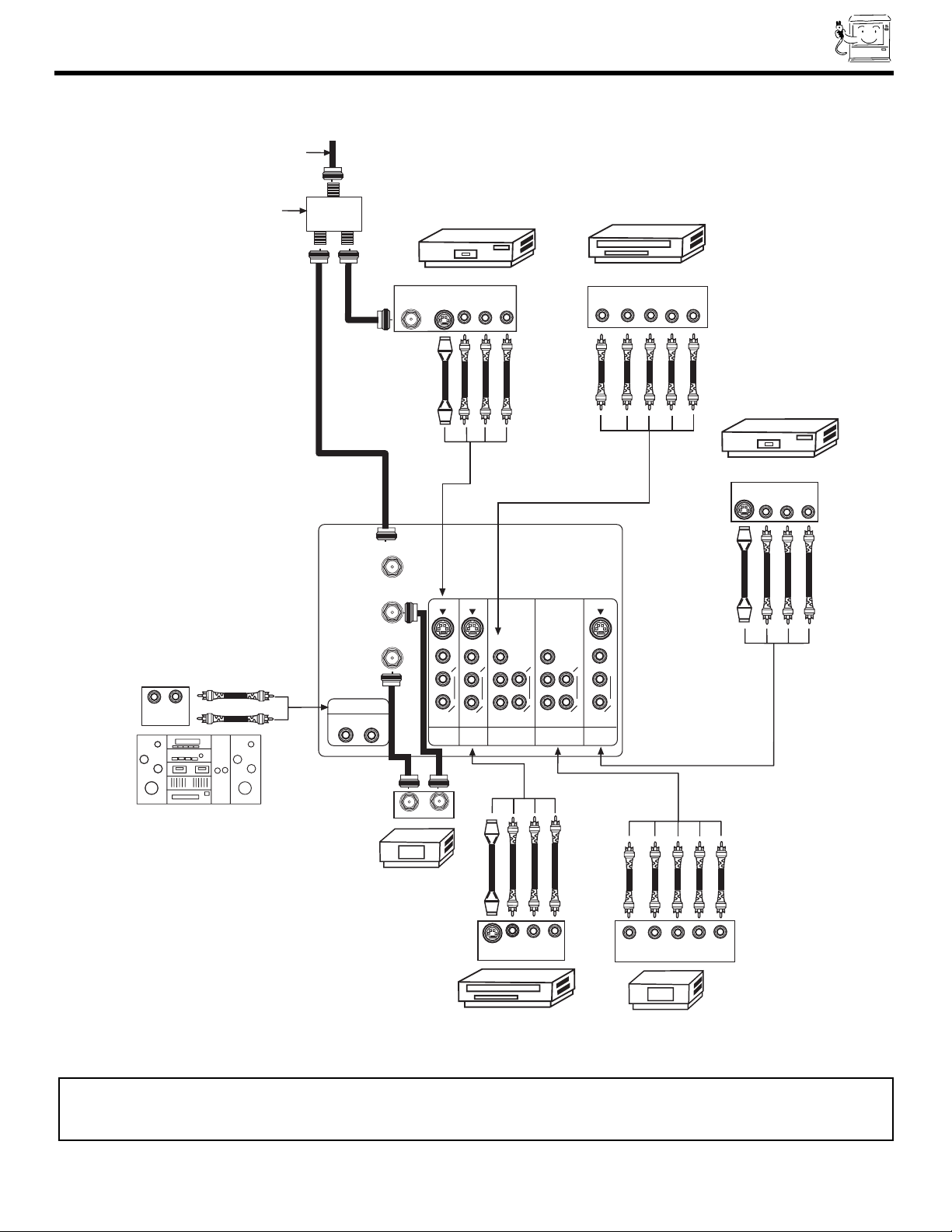

REAR PANEL CONNECTIONS

TYPICAL FULL-FEATURE SETUP

43/53/61UWX10B

NOTE: 1.

Connect only 1 component to each input jack.

2. Follow connections that pertain to your personal entertainment system.

3. Standard video signal (composit video) can be input to all video inputs. (Video 1 ~ VIdeo 5).

18

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

STOP

CONNECT ONLY 8 OHM SPEAKERS

DO NOT SHORT CIRCUIT

THESE TERMINALS

(Such damage is NOT COVERED

by your television warranty)

R

L

REAR SPEAKER

DVD Player

Stereo System Amplifier

Laserdisc player, VCR,

camcorder, etc.

VCR #2

Cable TV Box

VCR #1

Outside antenna or

cable TV coaxial cable

2-Way signal splitter

OUTPUT

Y P

B

P

R

L R

HDTV Set-Top Box

V L R

OUTPUT

S-VIDEO

ANT

IN

OUTPUT

S-VIDEO

VL R

OUTPUT

YP

B/CBPR/CR

L R

LR

INPUT

Sub Woofer

INPUT

Surround Speakers

V L R

INPUT

S-VIDEO

OR

+

-

+

-

INPUT

OUTPUT

LR

OPTICAL

INPUT

COAXIAL

INPUT

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

SUB

WOOFER

TYPICAL FULL-FEATURE SETUP

53/61SWX10B AND 53/61SWX12B

NOTE: 1.

Connect only 1 component to each input jack.

2. Follow connections that pertain to your personal entertainment system.

3. Standard video signal (composit video) can be input to all video inputs. (Video 1 ~ VIdeo 5).

19

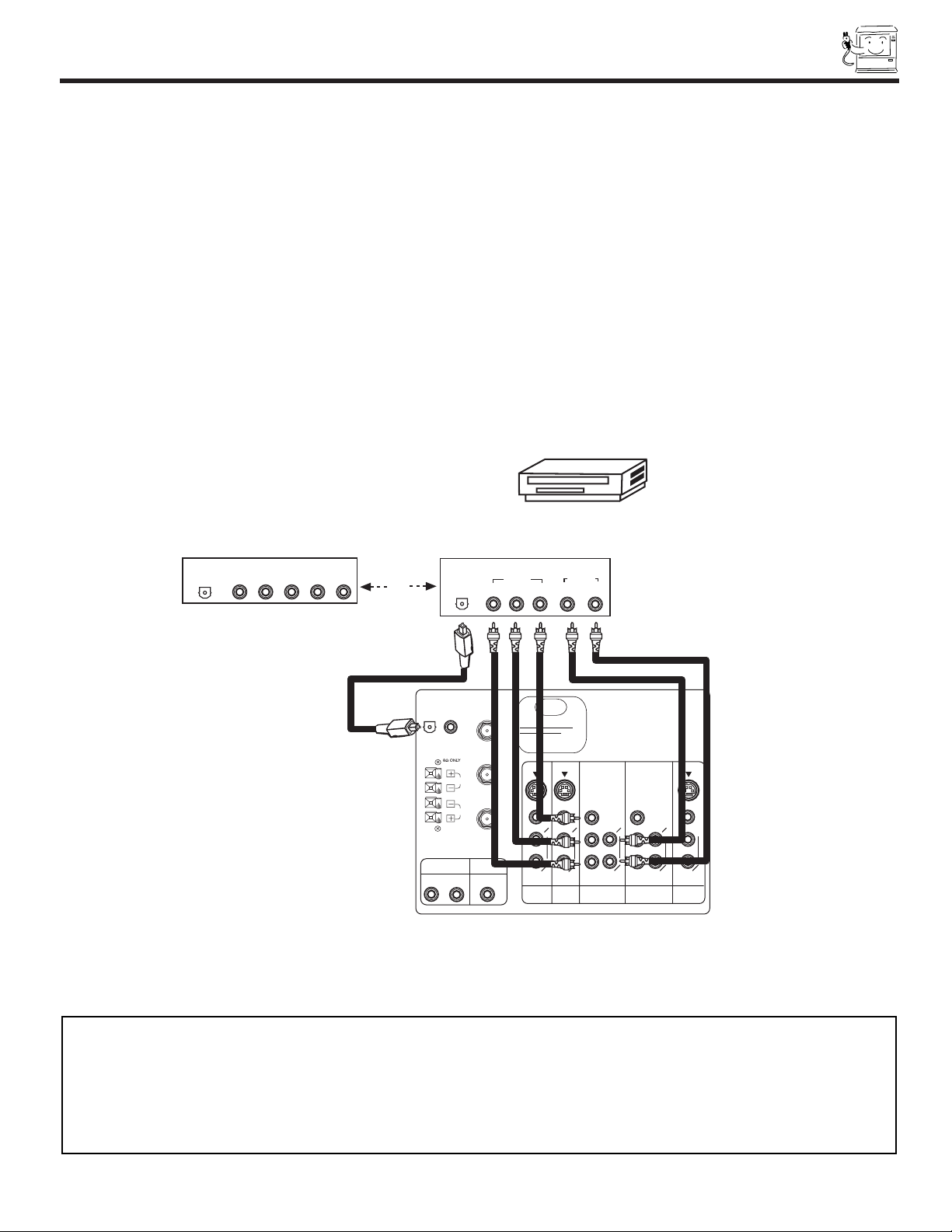

CONNECTING EXTERNAL VIDEO SOURCES

CONNECTING A COMPONENT SOURCE TO VIDEO 4 OR 5: Y-PBPR.

1. Connect the cable from the Y OUT of the Laserdisc/DVD player or HDTV set top box to the INPUT (Y) jack, as shown on the TV

set below.

2. Connect the cable from the CB/PBOUT or B-Y OUT of the Laserdisc/DVD player or HDTV set top box to the INPUT (PB)jack.

3. Connect the cable from the CR/PROUT or R-Y OUT of the Laserdisc/DVD player or HDTV set top box to the INPUT (PR) jack.

4. Connect the cable from the AUDIO OUT R of the Laserdisc/DVD player or HDTV set top box to the INPUT (AUDIO/R) jack.

5. Connect the cable from the AUDIO OUT L of the Laserdisc/DVD player or HDTV set top box to the INPUT (AUDIO/L) jack.

6. Press the VID4~VID5 button, to view the program from the Laserdisc/DVD player or HDTV set top box. The VIDEO icon

disappears automatically after approximately eight seconds.

7. Press the ANT button to return to the previous channel.

P

B

P

R

P

B

P

R

AUDIO TO HI-FI

STOP

CONNECT ONLY 8 OHM SPEAKERS

DO NOT SHORT CIRCUIT

THESE TERMINALS

(Such damage is NOT COVERED

by your television warranty)

R

L

REAR SPEAKER

SUB

WOOFER

OPTICAL

INPUT

COAXIAL

INPUT

R

L

Rear Panel of Television

OUTPUT

P

R/CR PB/CB

Y

L R

AUDIO

VIDEO

DVD Player

OR

Hitachi Model or

Similar Model

Back of

DVD Player

OUTPUT

LR Y P

B

P

R

HDTV Set-Top Box

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

OPTICAL

OUT

OPTICAL

OUT

NOTE: 1. You may use standard video signal for INPUT:4 and 5.

2. Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

3. See pages 17 and 18 for tips on REAR PANEL CONNECTIONS.

20

CONNECTING EXTERNAL VIDEO SOURCES

CONNECTING AN S-VIDEO SOURCE TO INPUT 1, 2 AND 3

1. Connect the cable from the S-VIDEO OUT of the VCR or the laserdisc player to the INPUT (S-VIDEO) jack, as shown on the TV

set below.

2. Connect the cable from the AUDIO OUT R of the VCR or the laserdisc player to the INPUT (AUDIO/R) jack.

3. Connect the cable from the AUDIO OUT L of the VCR or the laserdisc player to the INPUT (AUDIO/L) jack.

4. Press the VID1~VID3 button to view the program from the VCR or laserdisc player. The VIDEO icon disappears automatically

after approximately eight seconds.

5. Press the ANT button to return to the previous channel.

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

Hitachi Model or

Similar Model

Rear Panel of Television

VCR or Laserdisc Player

V L R

OUTPUT

S-VIDEO

NOTES: 1. Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

2. A single VCR can be used for VCR #1 and VCR #2, but note that a VCR cannot record its own video or line

output. Refer to your VCR operating guide for more information on line input-output connections.

Back of

VCR

21

CONNECTING EXTERNAL VIDEO SOURCES

CONNECTING A STEREO SOURCE TO INPUT1~INPUT5

1. Connect the cable from the VIDEO OUT of the VCR or the laserdisc player to the INPUT (VIDEO) jack, as shown on the TV set

below.

2. Connect the cable from the AUDIO OUT R of the VCR or the laserdisc player to the INPUT (AUDIO/R) jack.

3. Connect the cable from the AUDIO OUT L of the VCR or the laserdisc player to the INPUT (AUDIO/L) jack.

4. Press the VID1~VID5 button to view the program from the VCR or laserdisc player. The VIDEO icon disappears automatically

after approximately eight seconds.

5. Press the VID1~VID5 button to return to the previous channel.

P

B

P

R

AUDIO TO HI-FI

P

B

P

R

MONITOR

OUT

INPUT 1

AUDIO

(MONO)

L

R

AUDIO

L

R

S-VIDEOS-VIDEO

VIDEO

VIDEO

AUDIO

L

R

(MONO)

S-VIDEO

VIDEO

Y/VIDEO

R

L

AUDIO

L

R

L

R

Y/VIDEO

AUDIO

INPUT 2 INPUT 4 INPUT 5

(MONO) (MONO)

ANT A

TO

CONVERTER

ANT B

Hitachi Model or

Similar Model

Back of

VCR

V L R

VCR

OUTPUT

NOTES: 1. Completely insert the connection cord plugs when connecting to rear panel jacks. The picture and sound that is

played back will be abnormal if the connection is loose.

2. A single VCR can be used for VCR #1 and VCR #2, but note that a VCR cannot record its own video or line

output. Refer to your VCR operating guide for more information on line input-output connections.

22

FEATURE INFORMATION

As the digital era dawns, Hitachi has models that provide the best possible images today...and tomorrow. Our HDTV Ready

model incorporates new Flex Converter technology to display a high quality 1080i (high definition scanning) or 540P

(progressive scanning) image; this same circuitry enables it to accept a full 1080i HDTV signal from a digital set-top box now

or in the future.

FLEX CONVERTER TECHNOLOGY

With current analog broadcasts, there is just one level of picture quality. In the new age of digital TV, there will be several levels.

The highest, called HDTV, can be as high as 1080i.The next level, called HDTV, can be 720P. The standard level, SDTV, can

be 480P or 480i. Hitachi has developed the Flex Converter, advanced circuitry that allows your UltraVision UWX and SWX

series television to produce true 1080i HDTV resolution with an HDTV set-top box. It converts analog 480i signals to the

higher-quality 540P signals with no scan lines or flicker. The FDX and UDX needs a set-top box to receive any Digital Signal.

COMPONENT VIDEO

Component Video inputs accept separate blue, red & B/W signals from a high resolution digital source as DVD or digital settop box to provide a higher resolution picture.

3DYC (DIGITAL 3DYC COMB FILTER)

The Digital 3DYC Comb Filter analyzes three lines of information from a single video frame as well as lines from adjacent

frames. This technology eliminates the flickering that a detailed pattern or scene would normally cause, for the cleanest,

neatest picture possible.

PROGRESSIVE SCANNING

A standard TV uses Interlaced Scanning where each frame of video is broken into two fields, each providing alternating scan

lines. This can leave noticeable scan lines and cause flickering. With Progressive Scanning, complete frames are displayed for

a smoother picture with no scan lines and no flicker. This allows you to get the optimal picture quality from today s high

resolution digital sources such as DVD or a digital set-top box.

23

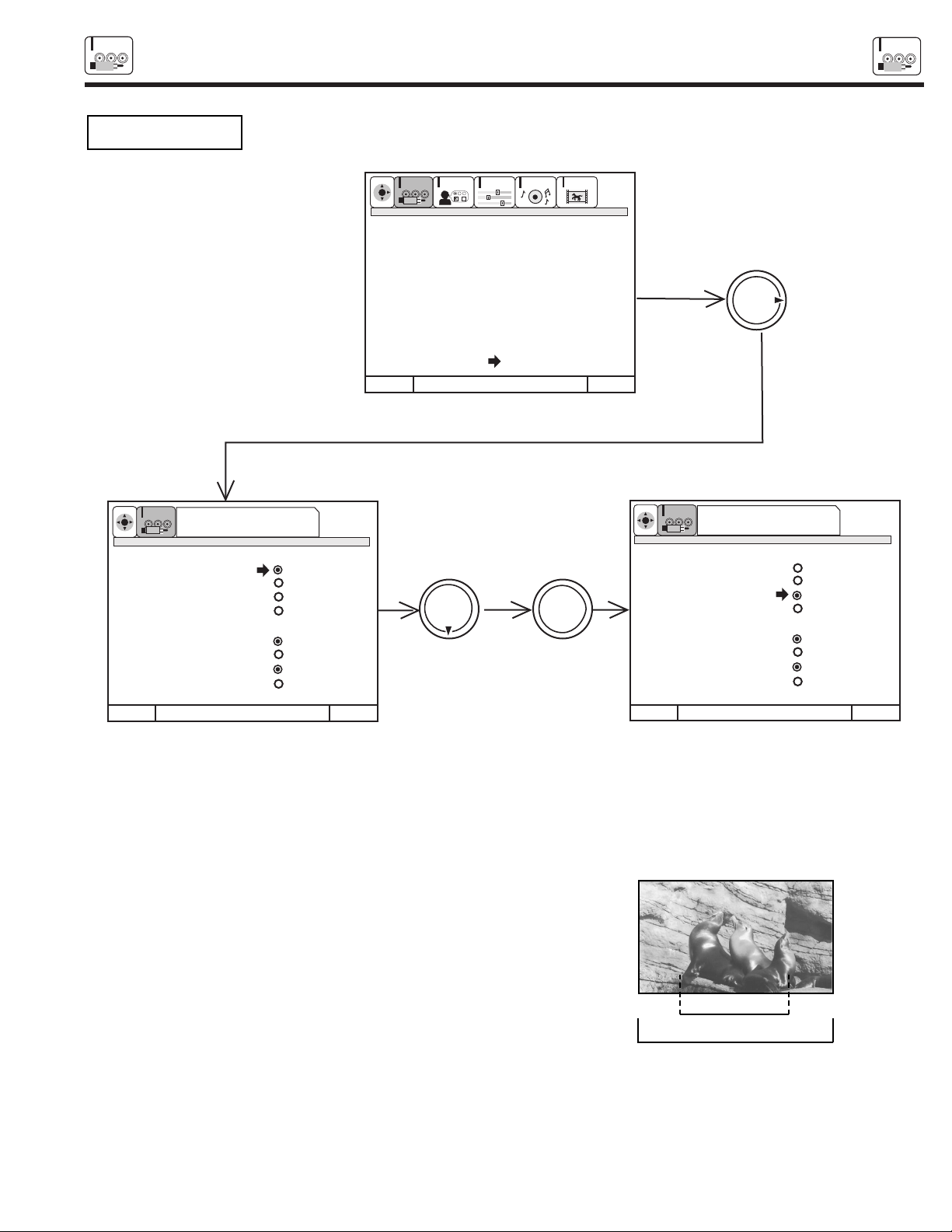

SET UP

SETUP

SETUP

The PICTURE FORMATS function is very useful when setting up reception High Definition, Standard

Definition and NTSC signals.

PICTURE FORMATS

Picture Formats Ant A 6

Aspect Style Normal

Full

Fill

Smooth Wide

V. Position 0

Comp Color Type HDTV

SDTV/DVD

Video Display 1080i

540P

Menu To Menu Bar To Quit Exit

THUMB

STICK

THUMB

STICK

Menu To Menu Bar To Quit Exit

Menu To Menu Bar To Quit Exit

THUMB

STICK

Press Select To Set

Press Select To Set

SETUP

SEL

SETUP

SEL

CUSTOMIZE

SETUP

VIDEO

AUDIO

THEATER

SEL

Picture Formats Ant A 6

Aspect Style Normal

Full

Fill

Smooth Wide

V. Position 0

Comp Color Type HDTV

SDTV/DVD

Video Display 1080i

540P

Set Menu Language

Plug & Play

Set Antenna/Cable

Set Channel Memory

Edit Channel Memory

View Channel List

Set The Clock

Magic Focus

Picture Formats

SELECT

Normal Choose this when receiving a 4:3 image and you want the on-screen

appearance of the video to be a centered picture with side panels

(blank areas) on the right and left sides.

Full Choose this when you want the television to adjust the 4:3 image

horizontally so it fills your 16:9 screen. No side panels will be added,

and the image is vertically unaltered. This setting is especially useful

for viewing 16:9 formatted DVDs.

ASPECT STYLE

If you receive an image with a 4:3 aspect ratio, the image will be displayed at that ratio on your HDTV unless you specify otherwise.

The Picture Format menu allows you to adjust the image through the following options:

4:3 ratio

16:9 ratio

24

SET UP

SETUP

V. POSITION

This function allows you to select when aspect style is either Full or Fill or Smooth Wide. Vertical position can be changed with this

mode. For example, it will be useful for centering the picture when there is gray area at both top and bottom of the picture with HDTV

signal. Adjustable range is -10 (video center is toward bottom of screen) to +10 (video center is toward top of screen).

Fill This function allows you to select when receiving either NTSC or

SDTV. Full screen picture is available in this mode when

receiving letterbox signal. Both vertical edges will be hidden if you

select Fill for ordinary 4:3 picture.

Smooth Wide This function allows you to select when receiving either NTSC or

SDTV signal. 4:3 picture is expanded horizontally as being close

to both left and right sides. It keeps 4:3 ratio in the center of the

picture, then expands as it is close to both left and right edge of

the picture to show picture distortion minimized. This function

allows you to watch picture without side panel for 4:3.

ASPECT STYLE

Some digital (ATSC format)

stations may transmit 4:3

images in a way that will

not allow expansion. You

will be unable to adjust the

picture format.

NOTES: 1. The aspect Style setting you select for an ANT input will automatically be set for the other ANT input. However, all three

video inputs have independent Aspect Style settings.

2. You will not be able to access the V. Position menu if Aspect Style-Normal is set.

3. You will only be able to access the Aspect Style menu when viewing a 4:3-480i or 480P. When viewing a 16:9-1080i

or 720P input you will not be able to access this menu. FULL mode will be automatically selected

4. If COMPONENT COLOR TYPE is set improperly (does not match actual input signal), the color and tint of the main

picture will be abnormal.

5. You must be tuned to VIDEO: 4 or 5 input and have a component hooked up to the Y-PBPRinput jacks to

access this component color type.

6. All component color type settings will affect only color component input you are currently viewing. If you are using

both sets of component input jacks, be sure to set the component color type feature for both inputs.

7. Adjustable range of V. Position is -20 to +20 when receiving 480P picture.

8. When 1080i signal is input, Video Display menu will not be accessible.

COMPONENT COLOR TYPE

This function allows you to automatically change tint and color coordinates for DTV programs.

HDTV - High Definition Television - Use for High Vision Signal Y-PBPRfrom HDTV Set-Top Box.

SDTV /DVD - Standard Definition Television or DVD (Digital Versatile Disc Player) Y-CBCR.

VIDEO DISPLAY

The Video Display feature allows you to display 1080i or 540P signal modes. This feature selection is not available when 1080i signal

is input.

2525

Depending on the input signal, the picture format aspect ration allows you to adjust the image through the

following options.

PICTURE FORMATS

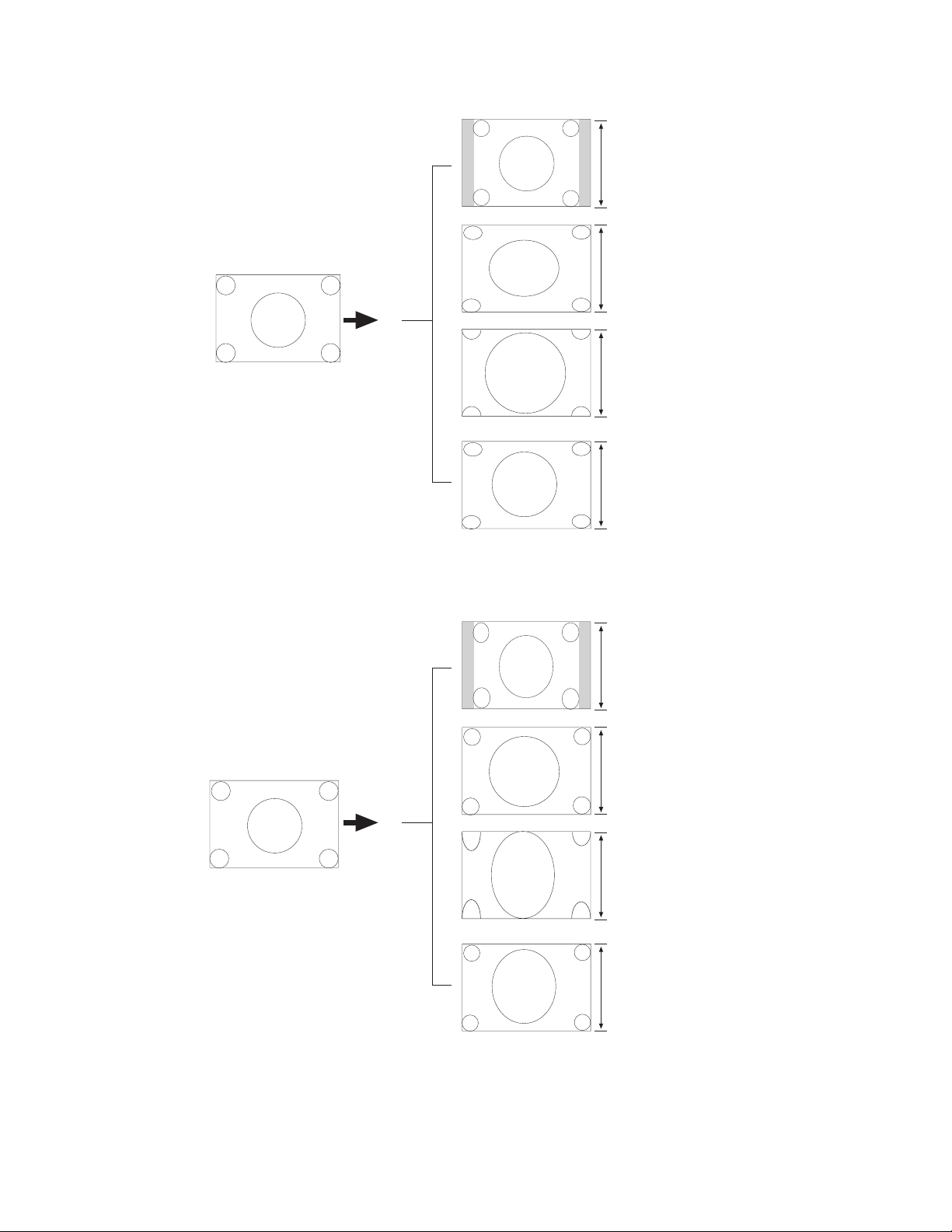

(1) NTSC/SDTV: 480i 4x3 (15.75kHz) ➔ 540P 16x9 (33.75kHz)

Screen Format: Normal, Full, Fill, Smooth

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

4x3

NTSC

Fill

540P/1080i

33.75kHz

Full

540P/1080i

33.75kHz

fH:15.75kHz

4x3

480i

fH:15.75kHz

Normal

540P/1080i

33.73kHz

540P (Progressive)

1080i (Interlaced)

Smooth

540P/1080i

33.75kHz

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

Fill

540P/1080i

33.75kHz

Full

540P/1080i

33.75kHz

16x9

480i

fH:15.75kHz

Normal

540P/1080i

33.73kHz

540P (Progressive)

1080i (Interlaced)

Smooth

540P/1080i

33.75kHz

(2) SDTV: 480i 16x9 (15.75kHz) ➔ 540P 16x9 (33.75kHz)

Screen Format: Normal, Full, Fill, Smooth

26

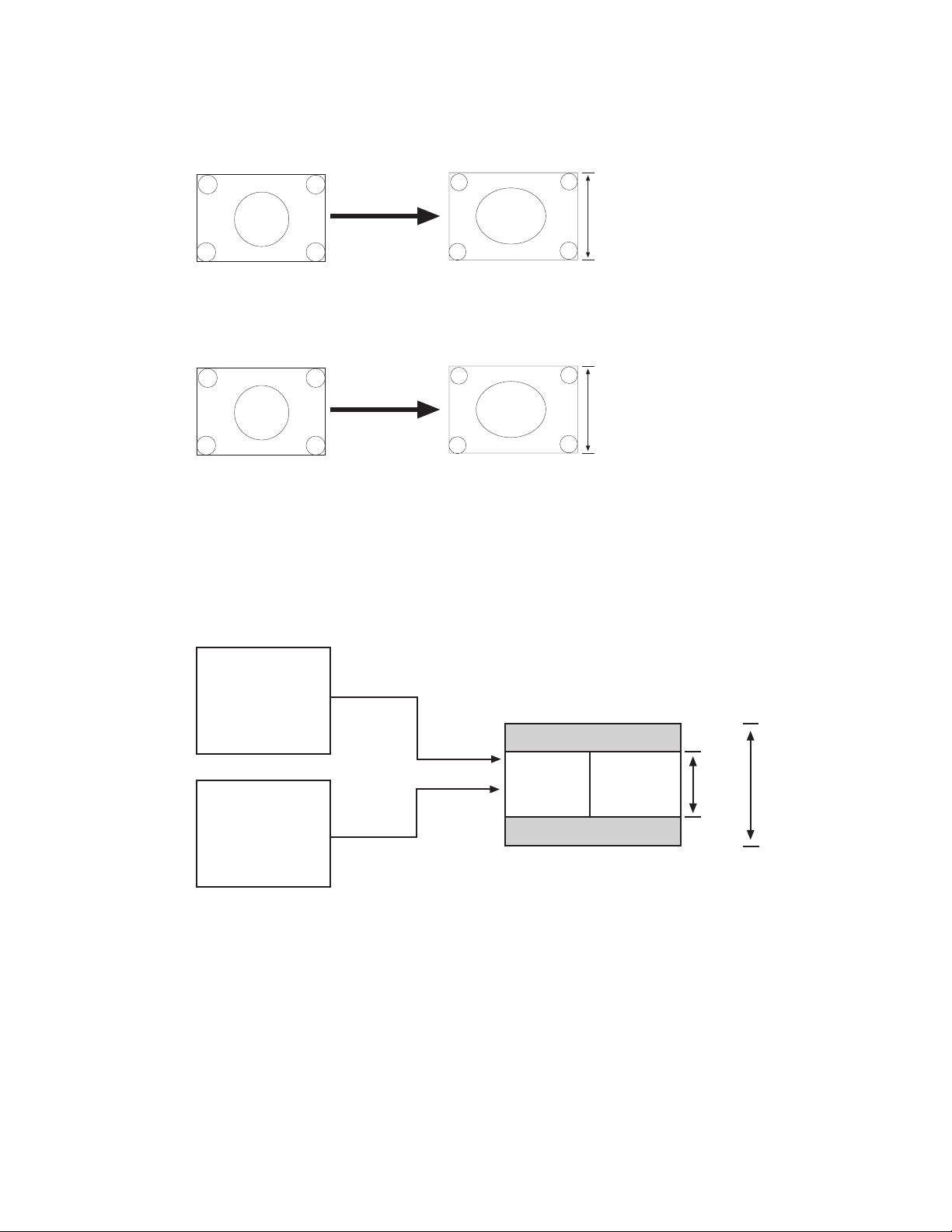

(3) SDTV: 480P 4x3 (31.5kHz) ➔ 540P/1080i 16x9 (33.75kHz)

Screen Format: Normal, Full, Fill, Smooth

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

Fill

540P/1080i

33.75kHz

Full

540P/1080i

33.75kHz

4x3

480P

31.5kHz

Normal

540P/1080i

33.73kHz

540P (Progressive)

1080i (Interlaced)

Smooth

540P/1080i

33.75kHz

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

540P (Progressive)

1080i (Interlaced)

Fill

540P/1080i

33.75kHz

Full

540P/1080i

33.75kHz

16x9

480P

31.5kHz

Normal

540P/1080i

33.73kHz

540P (Progressive)

1080i (Interlaced)

Smooth

540P/1080i

33.75kHz

(4) SDTV: 480i 16x9 (15.75kHz) ➔ 540P 16x9 (33.75kHz)

Screen Format: Normal, Full, Fill, Smooth

27

(5) HDTV: 720P 16x9 (45kHz) ➔ 540P/1080i 16x9 (33.75kHz)

Screen Format: Full Only

540P (Progressive)

1080i (Interlaced)

Full

540P/1080i

33.75kHz

16x9

720P

45kHz

1080i (Interlaced)

Full

1080i

33.75kHz

16x9

1080i

33.75kHz

Main

Picture

360

Lines

Main

Picture

Sub

Picture

540

Lines

Sub

Picture

(7) PIP Split Mode All Signal ➔ 540P 4x3 (33.75kHz)

(6) HDTV: 1080i 16x9 (33.75kHz) ➔ 1080i 16x9 (33.75kHz)

Screen Format: Full Only

28

Main

Picture

180

Lines

SUB

Main

Picture

Sub

Picture

540

Lines

Main

Picture

SUB

540

Lines

180

Lines

Main

Picture

180

Lines

SUB

540

Lines

Main

Picture

Ant A

Sub

Picture

Ant A

NTSC

Picture

480i

540

Lines

Main

Picture

SUB

SUB

SUB

540

Lines

Moving

Picture

Strobe

Strobe

Strobe

(8) PIP Single Mode

(9) PIP Surf/Strobe Mode

29

SERVICE ADJUSTMENTS

1. ASSEMBLED P.W.B ADJUSTMENT..................................................................................................................30

1-1. Service Menu Access (NTSC, SDTV and HDTV) ..................................................................................30

1-2. Comb Filter Operation Check ................................................................................................................38

1-3. Video Settings Check..............................................................................................................................38

1-3-1. Perfect Picture Check ..................................................................................................................38

1-3-2. Auto Color Check..........................................................................................................................38

1-3-3. Noise Reduction Check ................................................................................................................38

1-3-4. Color Temperature Check ............................................................................................................38

1-3-5. Velocity Modulation Check ..........................................................................................................38

1-3-6. Black Level Expansion Check ......................................................................................................38

1-4. High Voltage Adjustment ........................................................................................................................39

2. FINAL ASSEMBLY ADJUSTMENT (Adjustment should be according to below order)..............................39

2-1. Cut Off Adjustment..................................................................................................................................39

2-2. DCU Phase Data Setting ......................................................................................................................39

2-3. Horizontal Position Adjustment (Coarse) ................................................................................................40

2-4. Raster Tilt (Deflection Yoke)....................................................................................................................40

2-5. Beam Alignment......................................................................................................................................40

2-6. Raster Position........................................................................................................................................41

2-7. Vertical Size ..........................................................................................................................................41

2-8. Horizontal Size ......................................................................................................................................41

2-9. Beam Form ............................................................................................................................................42

2-10. Lens Focus..............................................................................................................................................42

2-11. Static Focus ............................................................................................................................................44

2-12. Digital Convergence ..............................................................................................................................44

2-12-1. Magic Focus Character Set Up ..................................................................................................45

2-12-2. Magic Focus Pattern Set Up ......................................................................................................46

2-12-3. Convergence Jig Screen Specification ......................................................................................47

2-12-4. Raster Position Adjsutment ........................................................................................................48

2-12-5. Convergence Point Adjustment ..................................................................................................48

2-13. Blue Defocus ..........................................................................................................................................50

2-14. White Balance ........................................................................................................................................50

2-15. Sub Brightness........................................................................................................................................51

2-16. Sub-Picture Signal Amplitude Adjustment ..............................................................................................53

2-17. Horizontal Position ................................................................................................................................54

2-18. Scanning Area Check ............................................................................................................................54

2-19. Raster Distortion Check ........................................................................................................................55

3. ADJUSTMENT POINT ........................................................................................................................................57

3-1. CRT (R)(G)(B), Cabinet Locations..........................................................................................................58

3-2. Main Chassis (Signal P.W.B.) ................................................................................................................59

3-3. Main Chassis (Power/Deflection P.W.B.) ................................................................................................60

3-4. Power Supply P.W.B. ..............................................................................................................................61

3-5. CPT (R)(G)(B), Focus Pack, Control P.W.B. ..........................................................................................62

*IMPORTANT

For many of the above adjustments, it is necessary to have an HDTV (1080i or 720P) signal generator, SDTV

(480P) signal generator, as well as the usual NTSC (480i) signal generator.

Hitachi recognizes that few companies offer HDTV or SDTV signal generators and that the cost of these

generators is sometimes prohibitive. For this reason, we suggest the use of a set-top-box for HDTV and SDTV

adjustments. Usually, there is a switch on the set-top-box which enables it to output HDTV (1080i or 720P) or

SDTV (480P) signals even with no input. In this case, the sync is automatically detected by the TV (at the Y-P

BPR

Inputs on the rear panel).

3030

1. ASSEMBLED P.W.B. ADJUSTMENT

1.1 Service Menu Access

Adjustment Procedure

(1) Press and hold INPUT key on Control Panel and then press POWER key on control panel to access I2C

adjustment mode.

(2) Receive signal on main picture. (NTSC, SDTV or HDTV).

Some menu pages have I2C adjustments for SDTV and HDTV. The set will automatically allow you to set

these items only when a SDTV or HDTV signal is input to the COMPONENT jacks on the back of the TV.

See table below.

(3) Check the OSD according to table on pages 31~37, using THUMB STICK , on Remote Control.

*: Adjustable Data

Others: Fixed Data (be careful not to change)

(4) Press EXIT key to exit I2C ADJUST mode.

NOTE: (1) If the TV I2C data is different from the I2C Parameter (pages 31~37) for fixed data, change the data.

(2) When exchanging microprocessor or EEPROM and TV is turned on for first time, it requires

initialization of Memory Initial of I2C adjustment menu.

(3) Use FACTORY RESET to set TV to out of factory shipping conditions: Do not use MEMORY

INITIALIZE.

Loading...

Loading...