Page 1

Instructions, Repair and Parts

®

Dyna-Star

HYDRAULIC RECIPROCATOR AND PUMP

- For lubricating fluids only -

10:1 Ratio Universal Pump and Reciprocator

600 psi (4.1 MPa, 41 bar) Maximum Hydraulic Input Pressure

7500 psi (51 MPa, 517 bar) Maximum Fluid Outlet Pressure

Model 247540: Pump, 60 lb Automatic Lube Pump Module Length

Model 247443: Pump, 120 lb Drum Length

Model 247450: Pump, 400 lb Drum Length

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Table of Contents

Warnings 2

Installation 4

Operation 7

Troubleshooting 9

Service 10

Reciprocator Parts 18

Pump Parts 20

Technical Data 21

Graco Standard Warranty 23

Graco Information 23

312350E

ti10604a

Model 247443 Shown

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

2 312350E

Page 3

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312350E 3

Page 4

Installation

Installation

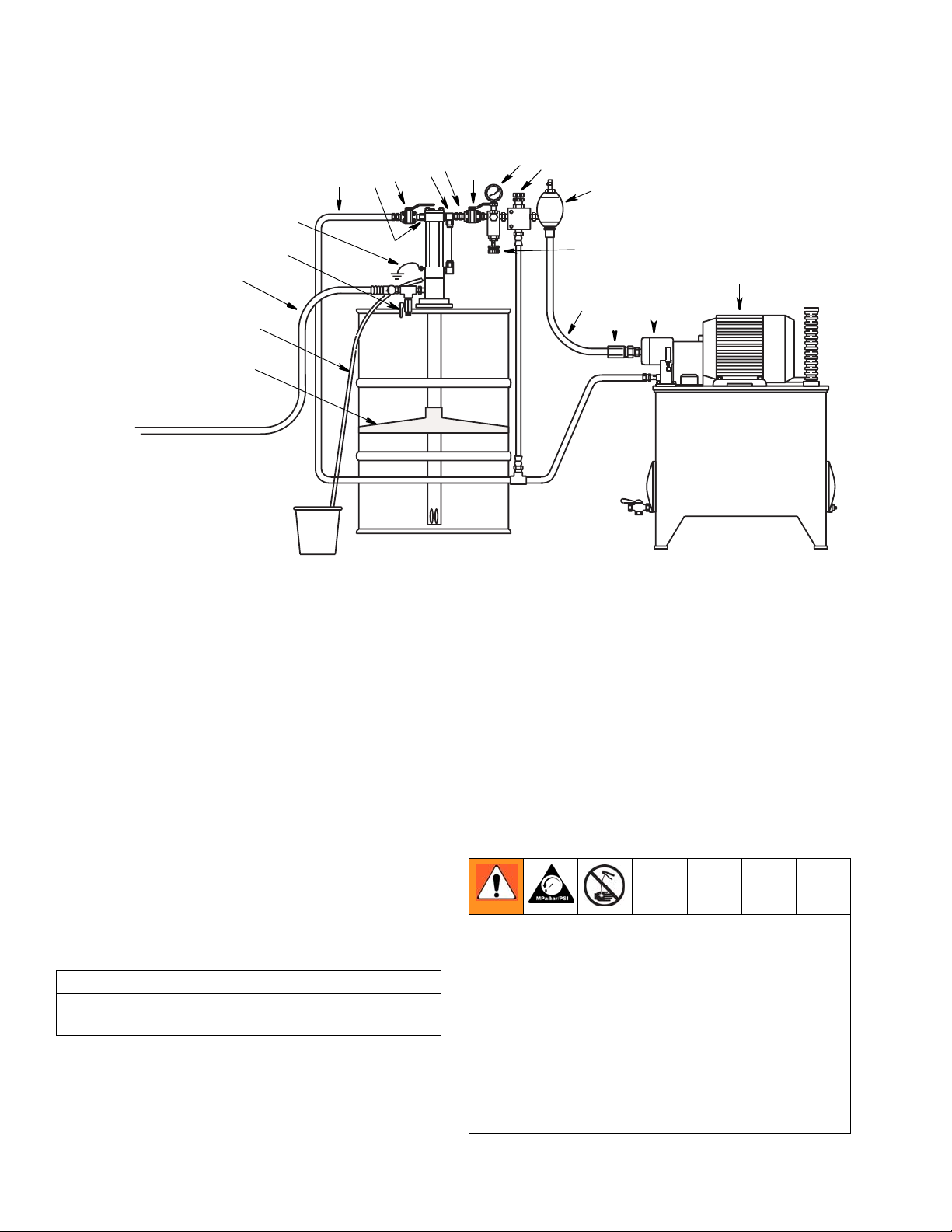

Typical Installation of a

Suction Feed System

C

B

A

F

E

D

H

G

Key:

A Follower plate

B Weep tube

C Fluid outlet line (to gun)

D Drain valve (required)

E Ground wire

F Hydraulic return line, minimum 3/4 inch I.D. (required)

G Hydraulic outlet, 3/4” npt (f)

H Return line shut-off valve, minimum 3/4 inch (required)

J Hydraulic inlet, 3/4” npt (m)

K Tee, 3/4” npt

L Supply line shut-off valve (required)

K

L

J

M *Pressure gauge

N *Pressure reducing valve (required in systems over 600

P Accumulator

Q *Flow control valve (required in systems over 3 gpm [11

R Hydraulic supply line

SCheck valve

T Variable volume pressure compensated pump

U Hydraulic power supply

V Drain line, accumulator

M

N

P

Q

R

S

psi [4.1 MPa, 41 bar])

lpm])

U

T

ti0477a

*Included in Hydraulic Fluid Control Kit 247538 or 247705, which can be ordered separately.

FIG. 1

Although the installation shown in F

IG. 1 is only a guide

for selecting and installing system components and

accessories, some of the equipment is required, as

noted in the key. For assistance in designing a system to

suit your needs, contact your Graco distributor.

Mount pump to suit the type of installation planned.

Maximum Working Pressure of Accessories

To reduce the risk of serious injury including fluid

injection and splashing in the eyes or on the skin

CAUTION

Do not operate pump without it being securely

mounted to a drum cover or support.

which may be caused if component ruptures, all

accessories added to the reciprocator power supply

side must have at least 600 psi (4.1 MPa, 41 bar)

maximum working pressure.

All accessories added to the pump fluid outlet side

must have at least 7500 psi (51 MPa, 517 bar)

maximum working pressure.

4 312350E

Page 5

Installation

Pump Accessories

Follower Plate (A): ensures a good prime. Place

follower plate on grease and rotate while pressing firmly

to level material. Order part number 247700 for 60# and

90# automatic lube pump modules; 247701 for 120#

refinery reservoir; or 247702 for 400# refinery reservoir.

Pump Outlet Drain Valve

• A pump outlet drain (D) is required in your system.

This valve helps relieve pressure in the displacement pump and hose when shutting down system

and in case of a clogged outlet hose. Install valve

close to pump outlet.

• Mount pump securely so it cannot move around

during operation. Failure to do so could result in

personal injury and/or equipment damage.

Pump Outlet Drain Valve (D): helps relieve fluid

pressure in pump when pump is shut off. Install valve

close to pump fluid outlet. Order valve, Part No. 111229.

Hydraulic Lines

Shut-off Valves (H, L): installed on the hydraulic supply

and return lines. Order Part No. 108537 and 112578.

Drain Line: Monitor the weepage of hydraulic fluid or

lubricant. If it seems excessive or increases suddenly,

the reciprocator/pump seals may need to be changed.

See F

IG. 2.

ti10602a

Hydraulic Power Supply

See FIG. 1.

Limit Fluid Flow to Reciprocator

To reduce the risk of overpressurizing the hydraulic

reciprocator which could cause a rupture and serious

injury, including fluid injection, a hydraulic system

must have a means to limit the incoming fluid flow to

the reciprocator to a maximum of 3 gpm (11 lpm) and

600 psi (4.1 MPa, 41 bar). See description below.

The hydraulic power supply system (U) must have a

pressure reducing valve and a pressure-compensated

flow control. A flow control valve (Q) is required to limit

the incoming flow to the reciprocator to a maximum of 3

gpm (11 lpm).

Pressure gauge (M), pressure reducing valve (N)

and a flow control valve (Q) are included in the

Hydraulic Fluid Control Kit 247538 or 247705,

which can be ordered separately.

F

IG. 2

Hoses: Use a minimum 1/2 inch supply line (R) and

minimum 3/4 inch return line (F) on the reciprocator.

Contact your Graco representative for details of line

sizing.

Pressure Reducing Valve (N): circulates excess

hydraulic fluid pressure back to the hydraulic power

supply. Install this valve (N) in the hydraulic supply line

with a drain hose (W) teed into the hydraulic return line

(F). Limit supply pressure to a maximum 600 psi (4.1

MPa, 41 bar).

Accumulator (P): reduces hammering effect caused by

the motor when it reverses direction.

Fluid-filled Pressure Gauge (M), Part No. 112567:

monitors hydraulic pressure to the reciprocator during

startup. See F

of the reciprocator. It can be removed after adjustment.

IG. 1. Use the gauge for initial adjustment

312350E 5

Page 6

Installation

Grounding

To reduce the risk of static sparking, ground pump.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment.

• Pump: Use ground wire and clamp as shown in

F

IG. 3. Order Grounding Wire and Clamp Kit,

Part No. 222011.

• Hydraulic Hoses and Fluid Outlet Hoses:

Use electrically conductive hoses only.

• Hydraulic Power Supply: Follow manufac-

turer’s recommendations.

• Flushing Pails: When flushing, only use metal,

grounded pails. Make firm, metal-to-metal contact between the metal part of the dispense

valve and the pail. Use lowest possible pressure.

Grounding the Pump

To ground pump (See FIG. 3):

1. Remove ground screw (Z) and insert through eye of

ring terminal at end of ground wire.

2. Fasten ground screw back onto pump and tighten

securely.

3. Connect other end of wire to a true earth ground.

Z

ti10603a

F

IG. 3

6 312350E

Page 7

Operation

Operation

Pressure Relief Procedure

The system pressure must be manually relieved to

prevent the system from starting or dispensing

accidentally. Follow this pressure relief procedure

whenever you are instructed to:

• relieve pressure.

• check or service any system equipment.

• install or clean nozzle.

For the following instructions, see F

1. Shut off hydraulic power supply.

2. Close supply line shut-off valve (L).

3. Open dispensing valve to relieve pressure.

4. Open pump outlet drain valve. Have a container

ready to catch drainage.

5. Close return line shut-off valve (H).

IG. 1.

Before Starting Pump

COMPONENT RUPTURE HAZARD

Overpressurizing any component can result in

serious injury or property damage as a result of

rupture, fire, and/or explosion.The maximum working

pressure of each component in the system may not

be the same. To reduce the risk of overpressurizing

any component in the system:

• Be sure you know the maximum working

pressure of each component.

• Never exceed the maximum working pressure of

the lowest rated component in the system.

• Do not exceed the maximum pump cycle rate.

• The pump has a rated ratio of 10:1. However, it is

capable of reaching stall pressures equal to 12.5

times the hydraulic input pressure. To calculate

the fluid output pressure, multiply the hydraulic

pressure shown on the hydraulic control module

gauge by 12.5.

For example:

Leave drain valve open until you are ready to

dispense again.

If you suspect the nozzle or hose is completely clogged

or that pressure has not been fully relieved after

following steps 1-5 above, very slowly loosen the hose

end coupling to relieve pressure, then clear obstruction.

600 psi hydraulic x 12.5 = 7500 psi fluid output

4.14 MPa hydraulic x 12.5 = 51.8 MPa fluid

output

41.4 bar hydraulic x 12.5 = 5.18 bar fluid output

• Regulate hydraulic pressure to the pump so that

no fluid line component or accessory is

overpressurized.

• Check hydraulic fluid level in hydraulic power supply

before each use. Add fluid as necessary to fill the

lines.

• Flush pump before using it for the first time to

remove the light oil that was left in after factory testing to protect pump from corrosion. Be sure solvent

used is compatible with the fluid to be pumped and

the pump’s wetted parts. See Technical Data, page

20. Flush until clean solvent comes out of hose.

312350E 7

Page 8

Operation

Starting Pump

1. Turn on hydraulic power supply.

2. Open return line shut-off valve (H) first, then slowly

open the hydraulic supply shut-off valve (L).

3. Adjust flow control valve (Q) to limit the hydraulic

flow to no more than 3 gpm (11 lpm), which is

approximately 60 cycles per minute.

4. Adjust pressure reducing valve (N) to increase

hydraulic inlet pressure from 50 to 600 psi (0.34 to

4.1 MPa, 3.4 to 41 bar).

• Increasing inlet pressure, increases outlet pres-

sure.

• Decreasing inlet pressure, decreases outlet

pressure.

5. Open drain valve while priming pump.

6. When pump is primed, close drain valve.

Always use lowest pressure possible to obtain desired

results. This reduces pump wear.

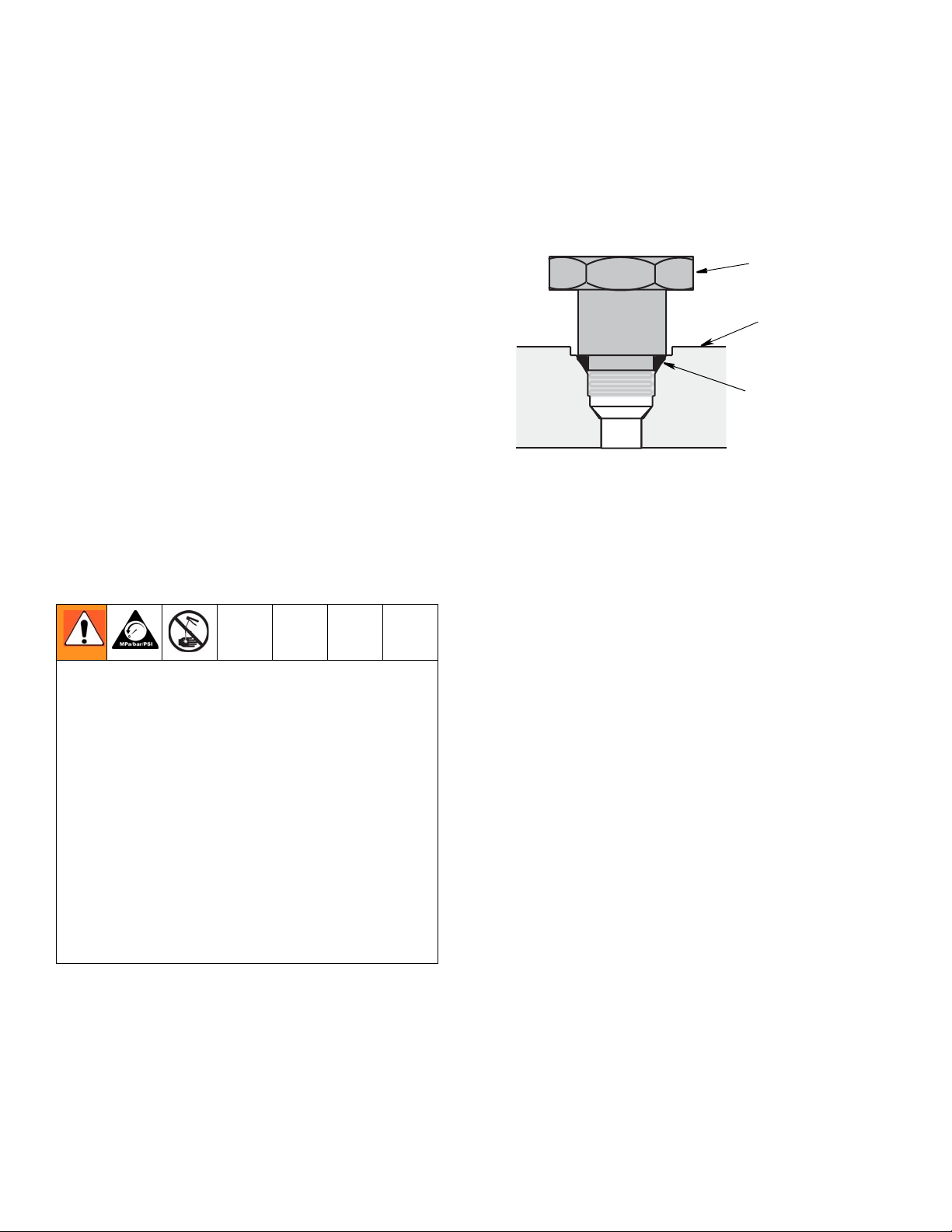

If the Pump Leaks at the Fluid

Fittings

Tighten fittings (1, 5, 60) which are self-sealing and

have replaceable o-rings. If leaking persists, change

o-rings.

sealing

fitting (1, 5, 60)

reciprocator

o-ring

(1a, 5a,60a)

ti04478

IG. 4

F

Shutdown

Relieve pressure, page 7, whenever you shutdown.

Maximum Working Pressures

To reduce the risk of serious injury, including fluid

injection and splashing in the eyes or on the skin,

which may be caused if a component ruptures:

• Never exceed 600 psi (4.1 MPa, 41 bar) Maxi-

mum Hydraulic Pressure to the reciprocator.

• Never exceed 7500 psi (51 MPa, 517 bar) Maxi-

mum Outlet Pressure from the displacement

pump.

• Accessories added to the pump fluid outlet side

should have at least a 7500 psi (51 MPa, 517

bar) Maximum Working Pressure.

• Read and understand COMPONENT RUPTURE HAZARD instructions, page 7.

8 312350E

Page 9

Troubleshooting

Troubleshooting

Problem Cause Solution

Pump does not run. Closed dispense valve. Pump only runs with valve open.

Pressure too low. Increase supply pressure using a

pressure adjusting valve.

Insufficient hydraulic fluid supply. Check hydraulic supply. Adjust to a

maximum of 3 gpm (11 lpm) flow.

Clogged fluid outlet line, intake valve,

dispense valve, suction line.

Reciprocator damaged. Repair.

Pump speeds up or runs erratically. Pump piston and/or intake valve

worn.

Empty supply container. Refill and repair. Do not allow pump

Pump runs but output low on up

and/or down stroke.

Pump run but output low on both up

and down strokes.

Excessive weepage from weep tube

(B), page 4.

Hydraulic oil leaks from fittings in the

upper or lower reciprocator blocks

(31, 32) [Parts page 18].

Pump piston and/or intake valve

worn.

Insufficient hydraulic fluid supply. Check hydraulic supply. Adjust to

Pressure too low. Increase supply pressure using a

Clogged fluid outlet line, intake valve,

dispense valve, suction line.

Worn throat packings. Repair.

Worn displacement seal. Repair.

Fittings 1, 5, 58, (Parts, page 18), are

loose, or their o-rings are worn or

damaged.

Relieve pressure, page 7. Check.

Clear obstructions.

Relieve pressure, page 7. Check

and repair.

to run dry. Monitor closely or use a

low-level cutoff valve.

Relieve pressure, page 7. Check

and repair.

maximum 3 gpm (11 lpm) flow.

pressure adjusting valve.

Relieve pressure, page 7. Check.

Clear obstructions.

Tighten the self-sealing fittings. If

leaking persists, change o-rings.

312350E 9

Page 10

Service

Service

Use of a hydraulic power supply with fluid temperatures above 154°F (68°C) can create hot surfaces

which can burn if touched.

• Do not touch pump, motor, or if hydraulic system

fluid is above 154°F (68°C).

• Allow sufficient time for pump and motor to cool

before attempting any service or repair.

Replacing Throat Seals

11

35

44

32

3

1

See FIG. 5.

Replace throat seals if fluid leaks excessively

through the weep tube (B), page 4. This procedure

can be done without disassembling entire

reciprocator.

1. Relieve pressure, page 7.

2. Disconnect reciprocator from pump.

3. Remove four capscrews (15) from bottom of adapter

(43). Tap adapter to loosen it and pull it off the bottom cap (32).

4. Remove seal (44, included in Reciprocator Repair

Kit 247455) from top of adapter (43).

5. Install seal (16) in adapter (43) in the order shown in

F

IG. 5.

6. Reassemble. Torque the capscrews (15) to 28-32

ft-lb (38 to 43 N.m). Install displacement pump, see

Step 23 on page 15.

1

Lips face down.

3

Torque to 54-56 ft-lbs (73-76 N.m).

15

19

10

8

27

4

ti10463a

4

Torque to 170 - 180 in-lbs (19-20 N.m)

F

IG. 5

10 312350E

Page 11

Disconnecting Reciprocator and Displacement Pump

Service

See FIG. 6 and Displacement Pump Parts, page 18.

60

3

36, 37

5

32

43

46

(hidden

from view)

ti10602a

ti10610a

107

204

35

1. Flush pump if possible and stop it with displacement

rod in lowest position.

2. Relieve pressure, page 7.

3. Disconnect outlet hose from displacement pump.

4. Slowly loosen hydraulic supply (60) and return (5)

fittings to relieve any pressure. Then remove hoses.

5. Install plugs on tube fittings and in hose ends.

6. Check o-rings (5a and 60a) on fittings and replace

them if they are worn or damaged.

See F

IG. 4 and Reciprocator parts drawing,

page 18.

7. Using a strap wrench on displacement cylinder

(109) screw it out of motor housing (43) and slide it

down as far as it will go.

8. Pull connecting rod (35) down as far as it will go.

Remove pin (204).

9. Unscrew connecting rod (107) to remove pump.

F

IG. 6

312350E 11

Page 12

Reciprocator Repair

Reciprocator Repair

See FIG. 7 and FIG. 9 and Reciprocator Parts, page 18.

• Clean and inspect all parts for wear or damage.

Replace worn parts as needed. For best

results, always replace all the o-rings and seals

when you disassemble the pump. Repair Kit

247455 is available. Parts included in the kit

are marked with an asterisk, for example (23*),

in the text and drawings. Always replace seals

(23* and 24*) and seals (16* and 44*) together.

• Assembly tool 189305 is required for reassembling the reciprocator.

•Loctite

®

242 thread sealant and Loctite®

Primer T or Perma-Loc

®

and Perma-Bond

Surface Conditioner I are

®

115 thread sealant

required. Be sure their shelf life is within the

manufacturer’s recommendations.

• Use Loctite

page 13, step 9 only. Use Loctite

Perma-Loc

®

609 on yoke (9) and rod (12) on

®

242 or

®

115 on other threaded surfaces as

required.

Drain Oil Out of Reciprocator

Before you begin, drain oil out of reciprocator.

1. Relieve pressure, page 7.

2. Place reciprocator in a drain pan.

3, 39, 2

36, 37

32

43

(hidden from view)

46

ti10602a

F

IG. 7

See F

IG. 7 for steps 1-3, except where noted.

1. Place adapter (43) in a vise. Remove four capscrews (46). Pull bottom cap (32) off adapter (43). If

needed, replace seals as described on page 10.

2. Loosen both nuts on fluid tube (45). Use a wrench to

rotate tube fittings (1, 60) to the side and then

remove tube (45). Check o-rings (1a, 60a) on fittings

and replace them if they are worn or damaged.

Install plugs in fittings to prevent contamination. See

F

IG. 4 and Reciprocator Parts drawing, page 18.

3. Remove capscrew (3), nuts (36) and lockwashers

(37) on top of reciprocator.

12 312350E

Page 13

Reciprocator Repair

36, 37

30

31

1

23*, 49*

20

32

21

38

6, 7

22

24*

9

12

3, 39, 2

17

20

26

18

29

34

13*

51

25

45

13*

2

6. Lay assembly on its side. Place a clean rag around

yoke (9) to prevent losing detent balls. Slide yoke (9)

sideways off valve sleeve (29) while holding the

balls (7) and spring (6) in place.

7. Slide cylinder (25) off displacement rod (34). Hold

hex end of displacement rod in a vise and use a

spanner wrench in pin holes of the piston (22) to

screw it off the rod.

12

20

21

20

18

1

Torque to 40 to 48 ft-lbs (54 to 65 N.m)

Torque to 54 to 56 in-lbs (6.1 to 6.3 N.m)

2

ti10605a

FIG. 8

See F

IG. 8 and Reciprocator Parts page 18 for steps

4-20, except where noted.

4. Tap bottom of displacement rod (34) with a plastic

mallet to loosen cylinder (25).

5. Grasp valve spool (31) and pull it off cylinder and tie

rods (38). Pull cylinder and piston off bottom cap

(32). It is not necessary to remove tie rods from bottom cap.

F

IG. 9

8. (F

IG. 9) Visually inspect the spring (21). If there is

wear or damage, remove nut (18), spring (21) and

retainers (20) from trip rod (12). Reassemble with a

retainer (20) on each end of the new spring (21).

You must thread nut onto rod until it runs out of

thread, so that it bottoms out on rod’s shoulder.

• If you are re-using or reassembling any parts,

use a surface cleaner such as chlorinated solvent on the threads and blow with compressed

air. A 1/4-28 UNF-2A tap can be used to

remove adhesive from internal threads of yoke

(9).

• Thread sealant and primer are required. See

Reciprocator Repair Notes, page 12 for specifi-

cations. Loctite

9. Apply fresh Loctite

®

609 is used only in Step 9.

®

609 thread sealant to first two

or three internal threads of yoke (9). Apply primer to

external threads of rod (12). Let primer dry for 3-4

minutes. Assemble, torquing screw to 54-56 in-lbs

(6.1 to 6.3 N.m). Remove excess sealant.

Allow 24 hours to cure before operating

reciprocator.

ti10605a

312350E 13

Page 14

Reciprocator Repair

10. Clean all sealant from threads of any part you are

®

reusing. Apply Loctite

242 or Perma-Loc® 115

thread sealant to first two or three internal threads of

valve assembly (31).

If you removed capscrew (51) apply thread sealant

to first two or three internal threads of valve stop

(26). Apply primer to external threads of valve

sleeve (29). Let dry for three or four minutes.

Assemble. Remove excess sealant.

Allow 24 hours to cure before operating

reciprocator.

11. Remove o-ring (13*) from bottom of spool valve (31)

and replace it with a new o-ring.

12. Use a spanner wrench to screw piston (22) onto

displacement rod (34). Torque to 40 to 48 ft-lb (54 to

65 N.m).

See F

IG. 10 for steps 13-16.

13. Lay Assembly A and Assembly B on work bench.

14. Slide Assembly B in into center of tool (D), Part No.

189305. Align upper detent holes (C) of yoke (9)

with center line of tool (D).

15. Insert spring (6) and one ball (7) into valve stop (26)

of Assembly A. Tilt valve stop and start guiding it

into tool (D), making sure ball is sliding into rounded

slot in tool (D). Place other ball at the other end of

spring and push it in with your thumb while rotating

valve stop (26) until spring is horizontal and balls

are in place. Continue holding this assembly

together.

16. Slide valve stop assembly down into tool. Make sure

balls (7) snap into upper set of holes (C) in yoke (9)

and curved ends of guide clamp have engaged

valve sleeve (29) groove. Slide tool (D) back over

rod (12) to remove it.

F

IG. 10

Assembly A

31

29

26

51

6

7

12

9

C

Assembly B

D

ti10606a

14 312350E

Page 15

Reciprocator Repair

36, 37

31

38

32

3, 39, 2

17

20

18

13*

25

13*

When reinstalling cylinder (25), Step 19, be sure

port in valve spool (31) and port in the bottom

cylinder cap (32) are in line with each other. Be

sure o-rings (13*) are in place in valve spool and

cylinder cap.

19. Place cylinder (25) on cylinder cap (32). Install piston (22) and valve assembly (31).

20. Install o-ring (49*) in deep, lower groove of piston

(22). Install seal (23*) over o-ring. Install piston

bearing (24*) around upper groove of piston. Holding piston bearing in place to avoid damage, slide

cylinder over piston and press it down.

21. Install capscrew (3), o-ring (39) and washer (2).

Install lockwashers (37) and nuts (36). Torque nuts

to 28 to 32 ft-lb (38 to 43 N.m).

22. Reinstall fluid tube (45) and fittings (1). Torque fittings to 28 to 32 ft-lb (38 to 43 N.m). See Reciprocator Parts drawing, page 18.

.

Make sure the displacement rod (35) on the

assembled reciprocator is exposed so the pump

can be connected to it.

43

35

ti10605a

FIG. 11

See F

IG. 11 for steps 17- 24 except where noted.

17. Place adapter (43) in a vise. Install seals as

described on page 10. Install cylinder cap (32).

18. If tie rods (38) were removed, reinstall them with

short threaded end up. The other end should be

screwed about 9/16” into bottom cylinder cap (32).

35

204

ti10610a

FIG. 12

23. To reconnect reciprocator and pump, install o-ring

(17). Screw connecting rod (35) into displacement

rod (34). Install cotter pin (204). Install a new gasket

(202*). Push cylinder up into adapter and engage

the threads. Screw in pump using a strap wrench for

the final tightening (See F

IG. 12 and Pump Parts,

page 20).

24. Connect hydraulic supply and return hoses to fittings (5, 60).

To reduce risk of static sparking, be sure to reconnect ground wire before operating pump.

312350E 15

Page 16

Displacement Pump Repair

Displacement Pump Repair

Disassembly

See FIG. 13 for steps 1-10, except where noted.

• Be sure you have all necessary parts on hand

before you start. If using a repair kit, use all

parts in the kit for the best results.

• Displacement Pump Repair Kit 241623 is available. Parts included in the kit are marked with a

dagger (†) symbol in the parts drawing and list,

page 20.

1. If possible, flush pump. Relieve pressure, page 7.

2. Follow instruction for Disconnecting the Recipro-

cator and Displacement Pump, page 11.

CAUTION

To avoid damaging shovel tube, do not use slots in

tube to tighten or loosen tube.

5. Use wrench to screw shovel (116) off of shovel rod

(108).

6. Use strap wrench on pump cylinder (109) to screw it

out of extension tube (114). Screw tube connector

(113) out of pump cylinder. Remove bearing (111†)

and seal (112†).

7. Screw the shovel rod (108) out of the piston (101).

Remove lower ball (106†). Screw piston out of

extension rod (107). Remove upper ball (106†),

retaining washer (103) and seal (104†).

8. Clean all the parts in a compatible solvent and

inspect them for wear or damage. Use all parts in

the repair kit, replace other parts as necessary.

9. Generously lubricate all parts with light, water-resistant grease and reassemble pump. See provided

notes on F

To reduce risk of static sparking, be sure to reconnect ground wire before operating pump.

IG. 13 for torque values.

3. Clamp pump in vise.

4. Use strap wrench to screw shovel tube (117) off

pump cylinder (109).

16 312350E

Page 17

107

Displacement Pump Repair

1

109

7

112†

111†

114

106†

†

110

103

7

104†

106†

4

102

ti10608a

Assembled / Cutaway View

1

Using nut (113), torque the pump cylinder 109 to the extension tube (114) at 45 to 55 ft-lb (61 to 75 N.m).

3

Torque the shovel rod (108) to the piston (102) at 25 to 30 ft-lb (34 to 41 N.m).

4

Torque the piston (102) to the extension rod (107) at 25 to 30 ft-lb (34 to 41 N.m).

7

Assemble with lips facing up.

ti10609a

113

108

116

117

3

FIG. 13

312350E 17

Page 18

Reciprocator Parts

Reciprocator Parts

17

45

36

6

37

3

39

2

60

60a

30

4

35

5

31

5a

5

24

22

5

16

7

49

3

44

11

8

19

6

66

29

61

23

17

9

4

20

43

58

10

26

21

8

76

1

51

2

20

18

1a

4

12

52

28

27

1

15

6

38

34

5

46

13

71

25

32

14

1

Torque to 170-180 in-lbs (19-20 N.m)

2

Torque to 42-45 in-lbs (4-5 N.m).

3

Torque to 54-56 ft-lbs (73-76 N.m).

ti10462a

40

4

Torque to 54-56 in-lbs (6.0-6.5 N.m).

5

Torque to 40-48 ft-lbs (54-65 N.m)

6

13

Torque to 28-32 ft-lbs (38-43 N.m).

7

Assemble with lips facing up.

8

Assemble with lips facing down.

18 312350E

Page 19

Reciprocator Parts

Reciprocator Parts

Ref.

No. Part No. Description Qty.

1 106470 ELBOW, straight thread, 3/4-16

unf-2a x 3/4-16 unf-2a, 37° flare

includes item 1a

1a 110987 O-RING 1

2 178179 WASHER, sealing 1

3 160276 CAPSCREW, hex hd, 3/8-24 x 5/8” 1

4* 104093 O-RING 1

5 112568 ADAPTER, pip, 3/4 unf (m) 1/2 npt

(f), steel, includes item 5a

5a 110987 O-RING 1

6 108437 SPRING, compression, steel 1

7 100069 BALL, 1/4” dia. steel 2

8 ADAPTER, pump 1

9 189077 YOKE, valve 1

10* GASKET, seal 1

11 192537 NUT, retainer 1

12 ROD, trip 1

13* 106274 O-RING, buna-N 2

14 116343 SCREW, grounding 1

15 113194 SCREW, cap, socket hd 2

16* 108952 PACKING, v-block 1

17 105765 O-RING 2

18 114231 LOCKNUT, hex, 1/4-28 unf-3b steel

and nylon

19 193757 BEARING 1

20 RETAINER, spring 2

21 178189 SPRING, compression, steel 1

22 192656 PISTON, cs 1

23* 178226 SEAL, piston, glass-filled PTFE 1

24* 178207 BEARING, piston, bronze-filled

PTFE

25 178229 CYLINDER, motor, cs 1

26 192654 STOP, valve, cs 1

27 105510 WASHER, lock, spring 1

28 100139 PLUG, pipe 1

29 189072 SLEEVE, valve, steel 1

30 178181 PLATE, cap 1

31 187176 CAP, cylinder, top 1

32 186225 CAP, cylinder, bottom 1

34 188078 ROD, displacement 1

35 ROD, displacement 1

36 100307 NUT, full, hex; 3/8-16 unc-2b 4

37 100133 LOCKWASHER, 3/8” 4

38 187405 ROD, tie, 8.5” shoulder to shoulder,

3/8-16 unc-2a, cs

39 155685 O-RING 1

40▲ 179885 LABEL, Warning 1

43 HOUSING, motor 1

44*† 114179 PACKING, u-cup 1

45 217221 TUBE, inlet 1

46 120557 CAPSCREW, sch, 3/18-16

unc-2a x 4.5”

49* 108014 PACKING, o-ring 1

Ref.

No. Part No. Description Qty.

51 104092 CAPSCREW, sch; 10-24,

1

unrc-3a x 5/8”

52 106115 LOCKWASHER, spring, 3/8” 4

58 110064 PLUG, pipe, vented, 1/8-27 npt (f) 1

60 107197 TEE, includes item 60a 1

60a 110987 O-RING 1

61 192653 VALVE, spool 1

66 103147 PLUG, pipe 1

1

71▲ 189285 LABEL, hot surface 1

▲ Replacement Danger and Warning labels, tags, and cards

are available at no cost.

* These parts and items 202 on page 20 are included in Kit

247455 (purchase separately).

† These parts are included in Kit 241623 (purchase sepa-

rately).

Assembly Tool 189305 required for repairing the

reciprocator.

Displacement Pump Parts

1

See FIG. 13, page 17.

Model 247540, 60# Automatic Lube Pump

Module Length

Model 247443, 120# Drum Length

Model 247450, 400# Drum Length

1

Ref

No. Part No. Description Qty

102 196184 PISTON, 50:1 1

103 196185 WASHER, retainer 1

104† 114171 PACKING, u-cup 1

106† 100065 BALL 1

107 15R104 ROD, connecting, model 247540 1

15M382 ROD, connecting, model 247443 1

15M445 ROD, connecting, model 247450 1

108 192540 ROD, shovel, 50:1 1

109 192538 CYLINDER, pump, 50:1 1

110† 192533 GASKET, seal 1

4

111† 192534 BEARING 1

112† 114178 PACKING, u-cup 1

113 192531 RETAINER, seal 1

114 15R103 TUBE, spacer, model 247540 1

15M381 TUBE, spacer, model 247443 1

15M444 TUBE, spacer, model 247450 1

116 192660 PISTON, shovel, 50:1 1

4

117 192539 TUBE, shovel 1

† These parts are included in Kit 241623 (purchase sepa-

rately).

2

312350E 19

Page 20

Pump Parts

Pump Parts

201

Model 247540

60# Automatic Lube Pump Module Length

Ref

No. Part No. Description Qty

201 RECIPROCATOR, page 18 1

202* 192533 SEAL, gasket 1

204 112154 PIN 1

205 DISPLACEMENT PUMP 1

206▲ 183741 LABEL, identification 1

206

202*

204

3

205

2

ti10461a

2

Apply thread lubricant, Part No. 070268 to threads and torque to

45-55 ft. lbs (61.0 to 74.5 N.m)

3

Coupling joint should have free play after pin (204) is installed

Model 247443

120# Drum Length

Ref

No. Part No. Description Qty

201 RECIPROCATOR, page 18 1

202* 192533 SEAL, gasket 1

204 112154 PIN 1

205 DISPLACEMENT PUMP 1

206▲ 183741 LABEL, identification 1

Model 247450

400# Drum Length

Ref

No. Part No. Description Qty

201 RECIPROCATOR, page 18 1

202* 192533 SEAL, gasket 1

204 112154 PIN 1

205 DISPLACEMENT PUMP 1

206▲ 183741 LABEL, identification 1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

* These parts are included in Kit 247455 (purchase

separately). See page 18 for other parts included in

this kit.

20 312350E

Page 21

Technical Data

Technical Data

Max grease output pressure.............................................. 7500 psi (51 MPa, 517 bar)

Max hydraulic fluid input pressure.................................... 600 psi (4.1 MPa, 41 bar)

Max hydraulic fluid input volume ....................................... 3 gpm (11.7 lpm), 60 cpm

Hydraulic fluid consumption rate..................................... 6.5 ounces (0.195 liter) per cycle or 1 gallon

per 19.5 cycles

Maximum fluid temperature............................................ 250°F (121°C)

Output per cycle...........................................................

Maximum flow rate............................................................ 1.1 lbs/min @ 60 cycles/min

Stroke........................................................................... 3 in. (76.2 mm)

Displacement pump wetted parts..................................... steel, polyurethane, acetal, buna-N, polyester elastomer

Hydraulic reciprocator wetted parts................................... steel, buna-N rubber, glass and bronze filled PTFE, nylon,

Weight.......................................................................... Model 247443: 43.5 lb (19.7 kg)

Typical Fluid Outlet Pressure

3

0.6 in

/cycle

polyurethane

Model 247450: 48 lb (21.8 kg)

Model 247540: 41 lb (18.6 kg)

&LUID0RESSURE

"AR

-PA

03)

CPM

!

"

LBMIN

KGMIN

&LOWRATELBMIN4ESTFLUID.,')'RADE'REASE

!PSI"ARMPA(YDRAULIC

SUPPLYPRESSURE

"PSI"ARMPA(YDRAULIC

SUPPLYPRESSURE

CPM

312350E 21

Page 22

Technical Data

Dimensions and Mounting Hole Layout

throat seal

1/8 npt

weep port

1/2 npt(f)

fluid outlet

3/4” - 16 JIC

37° flare (m)

3/4 npt Hydraulic Outlet

14.75 in.

(375 mm)

33.9 in.

(861 mm)

Model 247540

41.5 in.

(1054 mm)

Model 247443

48.5 in.

(1232 mm)

Model 247450

3.5 (88.9 mm)

minimum diameter clearance hole

3.536 in.

(90.424 mm)

3.536 in.

(90.424 mm)

clearance for, or

tap 5/16-18

typical 4 places

22 312350E

Page 23

Notes

Notes

312350E 23

Page 24

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

To place an order, contact your Graco distributor or to identify the nearest distributor call:

612-623-6928 or Toll Free: 1-800-533-9655; Fax 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

24 312350E

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312350

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised 2/2008

Loading...

Loading...