Page 1

INSTRUCTIONS-PARTS LIST

308640

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

First choice when

quality counts.

t

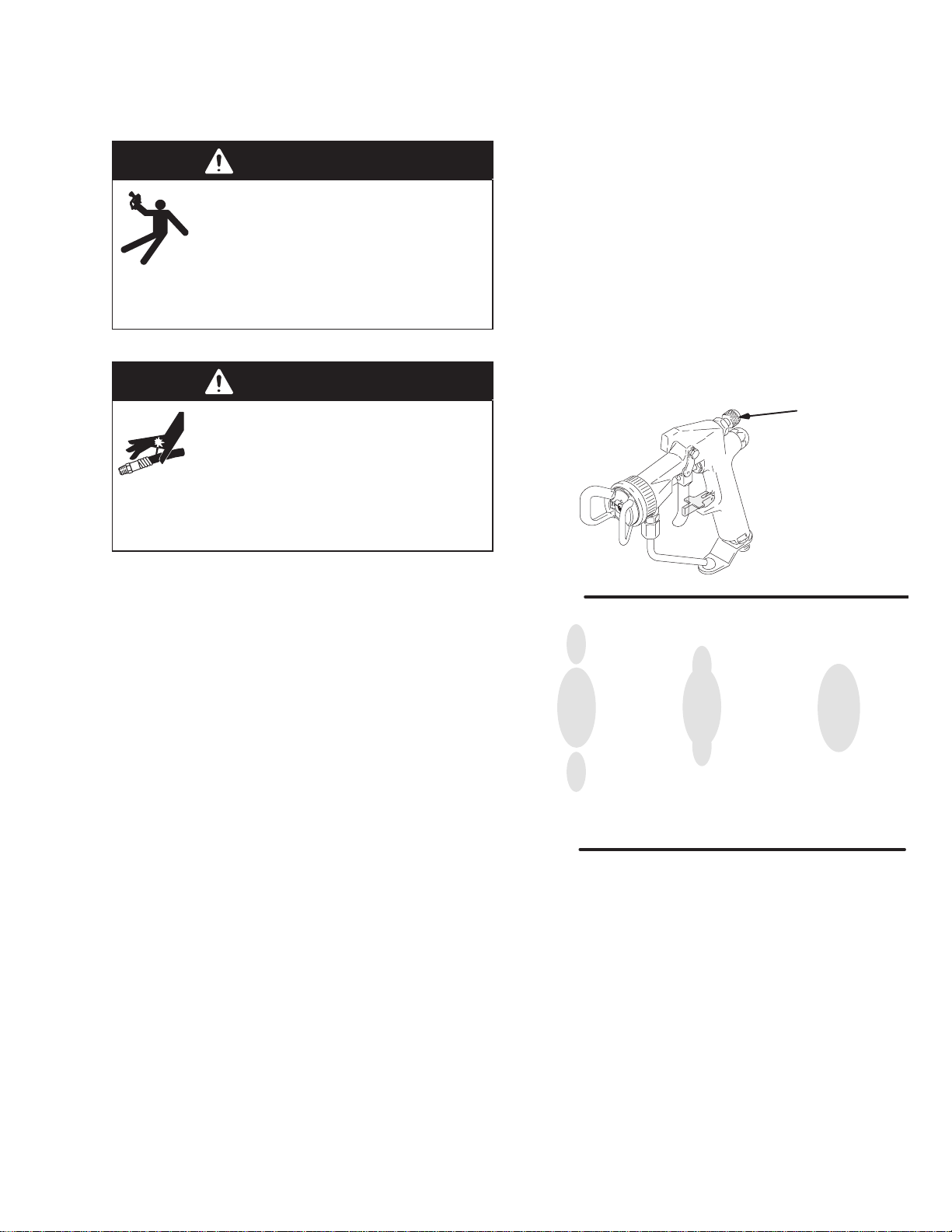

HIGH PRESSURE AIR-ASSISTED

Model AA Plust Spray Gun

4000 psi (28 MPa, 280 bar) Maximum Working Fluid Pressure

100 psi (0.7 MPa, 7 bar) Maximum Working Air Pressure

Part No. 238402, Series A

Spray Gun with standard spray tip, tip guard, air cap,

and 1/4–18 npsm (R1/4–19) air line fitting.

Part No. 238851, Series B

Spray Gun with AA Reverse-A-Cleanr (RAC) assembly and 1/4–18 npsm (R1/4–19) air line fitting.

Part No. 238852, Series A

Spray Gun with standard spray tip, tip guard, air cap,

and quick-disconnect air line fitting.

Rev. J

Supersedes G

includes Rev. H

Part No. 238883, Series A

Hi-Flow Spray Gun with Hi-Flow fluid needle and

diffuser-seat, and standard spray tip, tip guard, air cap,

and 1/4–18 npsm (R1/4–19) air line fitting.

Part No. 239001, Series B

Hi-Flow Spray Gun with Hi-Flow fluid needle and

diffuser-seat, AA Reverse-A-Clean (RAC) assembly,

and 1/4–18 npsm (R1/4–19) air line fitting.

Part No. 241070, Series A

HVLP Spray Gun with standard spray tip, HVLP air

cap, and 1/4–18 npsm (R1/4–19) air line fitting.

U.S. Patent Nos. 3,843,052; 4,386,739; 5,285,965

United Kingdom Patent No. 2 1 11 406 B

Patented 1984 Canada

Brevete 1984

French Patent No. 82–21202

Patents Pending

Foreign Patents Pending

05985

Part No. 238402 Spray Gun shown

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1996, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Troubleshooting 14. . . . . . . . . . . . . . . . . . . . . . .

Spray Pattern Troubleshooting 15. . . . . . . . . . . . . . . . . .

Service 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W ARNING

INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause an

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin

can also cause a serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

Do not point the spray gun at anyone or at any part of the body.

Do not put hand or fingers over the spray tip.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Spray Tip Selection Chart 22. . . . . . . . . . . . . . . . . . . . . .

Air Caps 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Do not “blow back” fluid; this is not an air spray gun.

Always have the tip guard on the spray gun when spraying.

Check the gun diffuser operation weekly.

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the Pressure Relief Procedure on page 7 whenever you: are instructed to relieve pres-

sure; stop spraying; clean, check, or service the equipment; or install or clean the spray tip.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Wear the appropriate protective clothing, gloves, eyewear and respirator.

RECOIL HAZARD

Due to the very high pressure fluid emitted, a strong recoil action will occur when you trigger this gun.

If you are unprepared, your hand could be forced back toward your body or you could lose your balance and fall, resulting in serious injury.

2 308640

Page 3

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. This equip-

ment has a 4000 psi (28 MPa, 280 bar) maximum working pressure at 100 psi (0.7 MPa, 7 bar)

maximum incoming air pressure.

Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Do not use the hoses to pull the equipment.

Use only Graco approved hoses. Do not remove hose spring guards, which help protect the hose

from rupture caused by kinks or bends near the couplings.

Use fluids or solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Wear hearing protection when operating this equipment.

Comply with all applicable local, state and national fire, electrical and other safety regulations.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

Ground the equipment and the object being sprayed. See Ground the System on page 6.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvent or the fluid being

sprayed.

Extinguish all the open flames or pilot lights in the spray area.

Electrically disconnect all the equipment in the spray area.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Do not turn on or off any light switch in the spray area while operating or if fumes are present.

Do not smoke in the spray area.

Do not operate a gasoline engine in the spray area.

If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

308640 3

Page 4

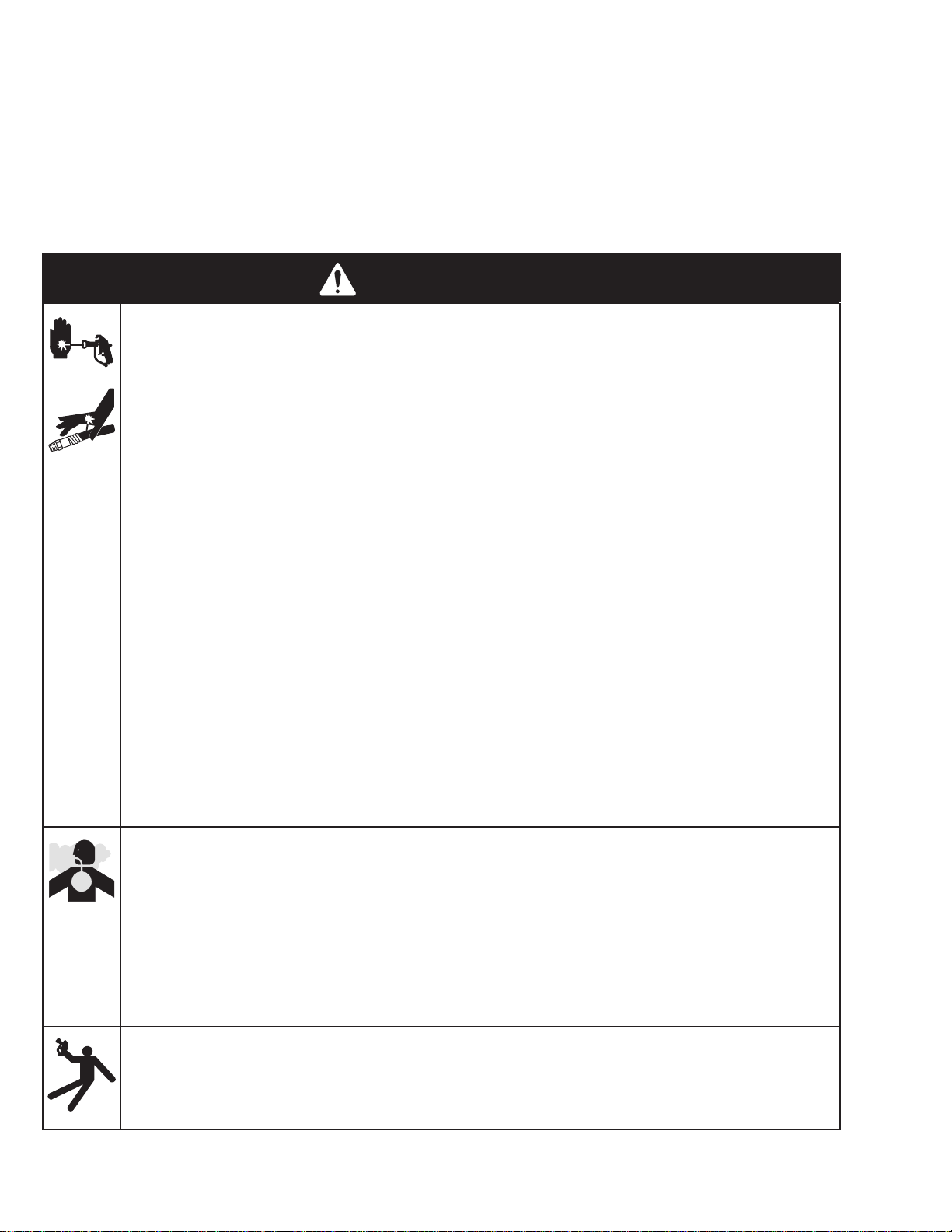

Installation

C

L

A

KEY

A Air Line Filter

B Air Line Lubricator

C* Bleed-type Air Shutoff Valve

D Pump Air Regulator

E* Fluid Drain Valve

F Fluid Shutoff Valve

G Fluid Filter

Fig. 1

D

CB

H* Grounded Fluid Hose

J Pump

K Air Line

L Air Pressure Regulator

M Pump Fluid Inlet

N In-line Fluid Filter

P Pattern Adjustment V alve Knob

Q* Fluid Pressure Regulator

J

P

X

V

T

Q

K

S

W

N

05986

M

F

R

H

G

E

E

R Pressure Gauge

S T rigger Safety

T Pump Runaway Valve

V* Pump Ground Wire

W Gun Fluid Connector

X Air Shutof f Valve

*Equipment required for safe operation of the

system. Must be purchased separately.

Typical Installation

The typical installation shown in Fig. 1 is only a guide

for selecting and installing air-assisted spray systems.

It is not an actual system design. Contact your Graco

distributor for assistance in designing a system to meet

your needs.

4 308640

Ventilate the Spray Booth

WARNING

TOXIC FLUID HAZARD

To prevent hazardous concentrations of

toxic and/or flammable vapors, spray

only in a properly ventilated spray booth.

Never operate the spray gun unless ventilation

fans are operating.

Check and follow all of the National, State and

Local codes regarding air exhaust velocity requirements.

Page 5

Installation

Connect the Air Line

1. Install an air line filter (A) to ensure a clean, dry air

supply to the gun. Dirt and moisture in the line can

ruin the appearance of your finished piece. See

Fig. 1.

2. Install an air pressure regulator (L) on the gun air

supply line to control the air pressure to the gun.

3. Install an air pressure regulator (D) on the pump

air supply line to control air pressure to the pump.

4. Install a bleed-type air shutoff valve (C) on the

main air line and on the pump air line, downstream

of the pump air regulator, to shut off air to the

pump. Install an additional bleed-type valve on

each pump air supply line to relieve air trapped

between this valve and the pump after the air

regulator is shut off.

WARNING

The bleed-type air shutoff valve is required in your

system to relieve air trapped between this valve

and the pump after the air regulator is closed.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury.

NOTE:

Part No. 238402, 238851, 238883, 239001, and

241070 Guns:

(R1/4–19) compound male thread that is compatible with NPSM and BSP female swivel connectors.

Part No. 238852 Gun:

1/4–18 npsm quick-disconnect fitting.

The gun air inlet has a 1/4–18 npsm

The gun air inlet has a

Connect the Fluid Line

WARNING

INJECTION HAZARD

To reduce the risk of property damage or

serious injury, including fluid injection,

which could be caused by component

rupture or unrelieved fluid pressure,

A fluid drain valve(s) (E) is required in your

system to assist in relieving fluid pressure in the

displacement pump, hose and gun; triggering

the gun to relieve pressure may not be sufficient.

A fluid pressure regulator (Q) must be installed

in the system if the pump’s maximum working

pressure exceeds the gun’s maximum fluid

working pressure of 4000 psi (28 MPa, 280

bar).

1. Install a fluid filter (G) and drain valve(s) (E) close

to the pump’s fluid outlet. The drain valve assists

in relieving fluid pressure in the displacement

pump, hose, and gun. See Fig. 1.

2. Install a fluid pressure regulator (Q) to control fluid

pressure to the gun.

NOTE: Some applications require fine-tuned control of

fluid pressure. You can control fluid pressure more

accurately with a fluid pressure regulator than by

regulating the air pressure to the pump.

3. Install a fluid shutoff valve (F) to shut off the fluid

supply to the gun.

5. Install an air shutoff valve (X) on each gun air

supply line, downstream of the gun air regulator, to

shut off air to the gun(s).

6. Connect the air hose (K) from the air supply to the

gun air inlet.

4. Install an in-line fluid filter (N) on the gun fluid

fitting (W) to avoid clogging the spray tip with

particles from the fluid.

5. Connect the grounded fluid hose (H) to the gun

fluid fitting (W) or optional in-line filter (N).

308640 5

Page 6

Installation

Ground the System

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding could cause static

sparking, which could cause a fire or

explosion. To reduce the risk of property

damage or serious injury, follow the

grounding instructions below.

The following grounding instructions are minimum

requirements for a system. Your system may include

other equipment or objects which must be grounded.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment. Your

system must be connected to a true earth ground.

1. Pump: Ground the pump by connecting a ground

wire and clamp between the fluid supply and a true

earth ground as instructed in your separate pump

instruction manual.

2. Air compressors and hydraulic power sup-

plies: Ground them according to the manufacturer

recommendations.

3. Air, fluid, and hydraulic hoses connected to

the pump: Use only electrically conductive hoses

with a maximum of 500 feet (150 m) combined

hose length to ensure grounding continuity. Check

the electrical resistance of your air and fluid hoses

at least once a week. If the resistance exceeds the

recommended limits, replace the hose immediately.

4. Spray gun: Ground the gun by connecting it to a

properly grounded fluid hose and pump.

5. Fluid supply container: Ground it according to

local code.

6. Object being sprayed: Ground it according to

local code.

7. All solvent pails used when flushing: Ground

them according to local code. Use only metal pails,

which are conductive. Do not place the pail on a

non-conductive surface, such as paper or cardboard, which interrupts the grounding continuity.

8. To maintain grounding continuity when flush-

ing or relieving pressure: Always hold a metal

part of the gun firmly to the side of a grounded

metal pail, then trigger the gun.

6 308640

Page 7

Operation

Safety

WARNING

INJECTION HAZARD

Remember, this is not an air spray gun.

For your safety be sure to read and

follow the Warnings on pages 2 and 3

and throughout the text of this instruction manual.

Keep the wallet sized warning card 179960, pro-

vided with the gun, with the operator of this equipment at all times. The card contains important

treatment information should an injection injury

occur. Additional cards are available at no charge

from Graco.

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tip.

5. Hold a metal part of the gun firmly to the side of a

grounded metal waste container and trigger the

gun to relieve the fluid pressure.

6. Lock the gun trigger safety again.

7. Open the pump drain valve (required in the system) to help relieve fluid pressure in the displacement pump. In addition, open the drain valve

connected to the fluid pressure gauge (in a system

with fluid regulation) to help relieve fluid pressure

in the hose and gun. Triggering the gun to relieve

pressure may not be sufficient. Have a container

ready to catch the drainage.

8. Leave the drain valve(s) open until you are ready

to spray again.

9. If you suspect that the spray tip or hose is completely clogged or that pressure has not been fully

relieved after following the steps above

slowly loosen the hose end coupling and relieve

pressure gradually, then loosen the coupling

completely. Now clear the tip or hose obstruction.

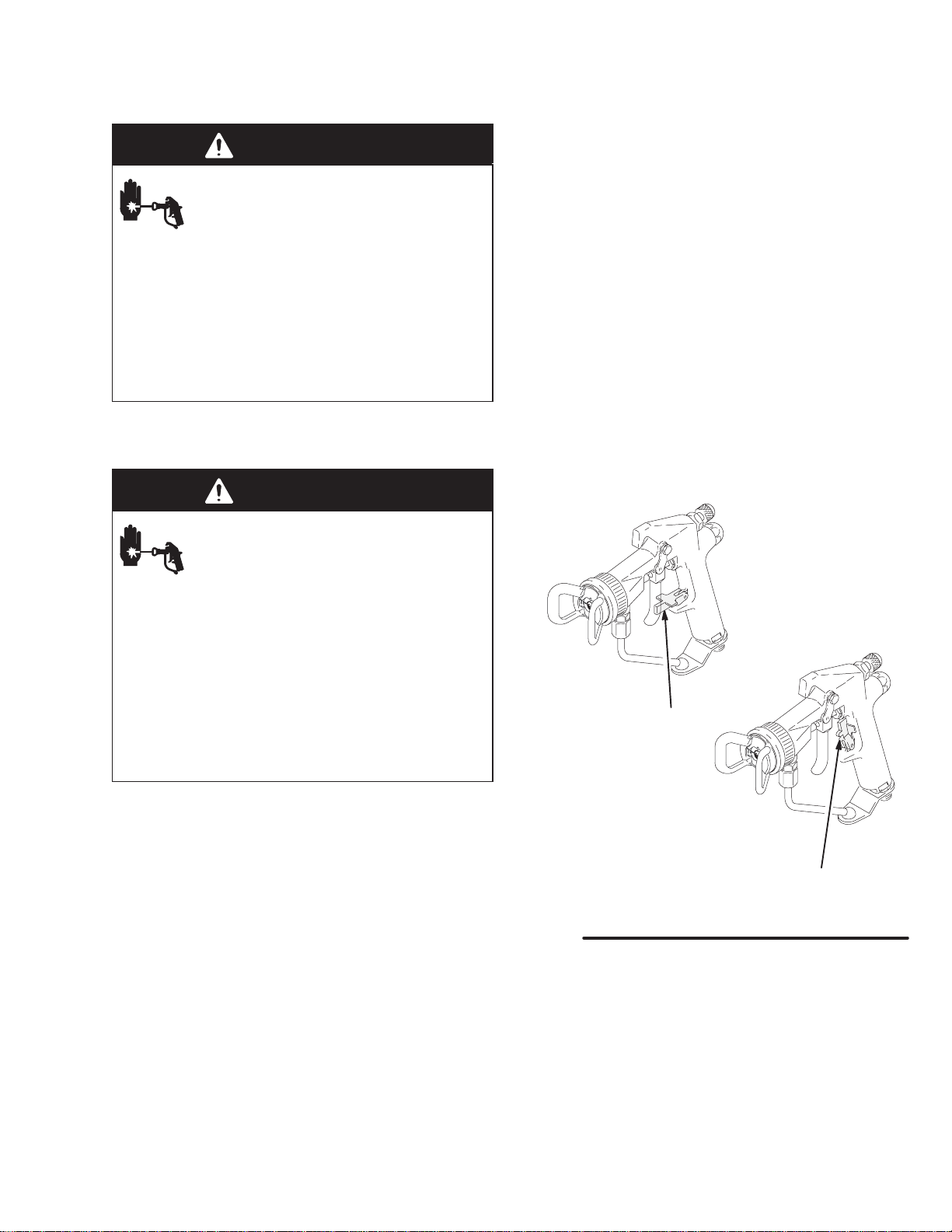

Trigger Safety

Locked or in

ON SAFE

Position

, v

ery

1. Lock the spray gun trigger safety to avoid accidentally triggering the gun. See Fig. 2.

2. Shut off the power to the pump.

3. Close the bleed-type master air valve (required in

the system).

4. Unlock the gun trigger safety.

Fig. 2

Trigger Safety Unlocked

or in

OFF SAFE

Position

308640 7

05987

Page 8

Operation

How the Air-Assisted Spray Gun Operates

The air-assisted spray gun combines airless and air

spraying concepts. The spray tip shapes the fluid into

a fan pattern, as does a conventional airless spray tip.

Air from the air cap further atomizes the fluid and

completes the atomization of the paint tails into the

pattern to produce a more uniform pattern. The width

of the pattern can be slightly adjusted by the pattern

adjustment valve.

Note that the air-assisted spray gun differs from an air

spray gun in that increasing the pattern air reduces the

pattern width. To increase the pattern width, less

pattern air or a larger size tip must be used.

The spray gun has a built-in lead and lag operation.

When triggered, the gun begins emitting air before the

fluid is discharged. When the trigger is released, the

fluid stops before the air flow stops. This helps assure

the spray is atomized and prevents fluid buildup on the

air cap.

Install a Spray Tip

WARNING

INJECTION HAZARD

To reduce the risk of a fluid injection

injury, follow the Pressure Relief Proce-

dure on page 7 before removing or

installing a spray tip.

Install a spray tip in the gun. The air cap and spray tip

position determines the direction of the spray pattern.

Rotate the air cap (the spray tip rotates with it) as

needed for the desired spray pattern direction. See

Fig. 3.

NOTE: If the gun has the AA RAC assembly, handtighten the air cap retaining ring, while holding the

orange tip guard in the desired direction. If the retaining ring is over-tightened, the spray tip will be difficult

to rotate.

Vertical Spray Pattern Horizontal Spray Pattern

Select a Spray Tip and Air Cap

The fluid output and pattern width depend on the size

of the spray tip, the fluid viscosity, and the fluid pressure. Use the Spray Tip Selection Chart, on page 22,

as a guide for selecting an appropriate spray tip for

your application.

Fig. 3

05991

8 308640

Page 9

Operation

A

Adjust the Spray Pattern

WARNING

RECOIL HAZARD

Due to the very high pressure fluid

emitted, a strong recoil action will occur

when you trigger this gun. If you are

unprepared, your hand could be forced back

toward your body or you could lose your balance

and fall, resulting in serious injury.

WARNING

INJECTION HAZARD

To reduce the risk of component rupture

and serious injury, including injection, do

not exceed the gun’s maximum fluid

working pressure of 4000 psi (28 MPa, 280 bar) or

the maximum working pressure of the lowest rated

component in the system.

5. Set the atomizing air pressure at about 10 psi (0.7

bar, 70 kPa). Check the spray pattern, then adjust

the air pressure until the tails are completely

atomized and pulled into the spray pattern. See

Fig. 5. Do not exceed 100 psi (0.7 MPa, 7 bar) air

pressure to the gun.

For a narrower pattern,

valve knob clockwise. If the pattern is still not

narrow enough, increase the air pressure to the

gun slightly or use a different size tip.

NOTE: Pattern adjustment is not available with

guns with the AA RAC assembly as the air separator, part no. 178414, must be removed when the

RAC assembly is installed.

turn the pattern adjustment

Pattern

Adjustment

Knob

1. Set the fluid pressure with the fluid regulator. Do

not turn on the air supply yet.

2. Trigger the gun to check the atomization; do not be

concerned about the pattern shape yet.

3. Increase the fluid pressure just to the point where

a further increase in fluid pressure does not significantly improve fluid atomization.

4. Close the pattern adjustment valve by turning the

knob (see Fig. 4) counterclockwise all the way.

This sets the gun for its widest pattern.

Fig. 4

No Air T oo Little Air Right Amount

of Air

Fig. 5

0789

0792

308640 9

Page 10

Operation

Apply the Fluid

When applying the fluid, keep the gun a consistent

distance, about 8 to 12 inches (200 to 300 mm) from

the surface of the object being sprayed. Always hold

the gun at a right angle from the surface. Do not make

an arc with the gun as it causes an uneven coat of

fluid. See Fig. 6.

CAUTION

Openings in the tip guard reduce paint buildup on the

guard while spraying. Damage to the sharp edges of

the openings will cause paint to collect at that area.

To avoid damage, never hang the gun by the tip

guard.

RIGHT

Fig. 6

WRONG

0793A

10 308640

Page 11

Operation

Clean the Spray Gun and System Daily

WARNING

INJECTION HAZARD

To reduce the risk of an injection injury

or splashing fluid in the eyes or on the

skin:

Follow the Pressure Relief Procedure on page

7 before cleaning, removing, or installing a

spray tip and whenever you are instructed to

relieve pressure.

Do not wipe fluid buildup off the gun or spray tip

until pressure is relieved.

CAUTION

To avoid damaging the gun:

Never immerse the gun in solvent as this could

damage packings and allow solvent in the air

passages.

Do not use fluids containing halogenated

hydrocarbons to clean the gun body as HHC is

not compatible with aluminum.

Methylene Chloride is not recommended as a

flushing or cleaning solvent with this gun or any

device with nylon or aluminum components.

Do not use metal tools to clean holes in the air

cap or spray tip.

4. If using an in-line filter, remove and clean it

thoroughly in a compatible solvent.

5. Clean the system’s fluid filter and air line filter.

Check the Diffuser-seat Operation Weekly

WARNING

INJECTION HAZARD

The gun diffuser-seat breaks up spray

when the gun is sprayed without the

spray tip installed, such as during flushing. This reduces the risk of an injection injury.

Check the diffuser-seat operation weekly.

1. Relieve the pressure as instructed on page 7.

2. Remove the tip guard and spray tip.

3. Start the pump and operate it at its lowest pressure.

4. Hold a metal part of the gun firmly against a

grounded metal waste container, and trigger the

gun. See Fig. 7. If the fluid coming from the gun is

not diffused into an irregular stream, replace the

diffuser-seat immediately.

1

NOTE: Clean the front of the tip frequently during the

day to help reduce buildup. AA RAC style tips require

more frequent cleaning.

1. Relieve the pressure as instructed on page 7.

2. Clean the outside of the gun and the tip guard with

a soft cloth dampened with compatible solvent.

3. To avoid damaging the spray tip and air cap, clean

them with a compatible solvent and soft brush. To

clean the air cap passages, use a soft brush or

other soft tool. Dry the parts with an air blow gun.

1

Maintain firm metal-to-metal contact between the gun and a

grounded metal container.

Fig. 7

05988

308640 11

Page 12

Operation

Flush the Gun Daily

WARNING

INJECTION HAZARD

To reduce the risk of a fluid injection

injury, follow the Pressure Relief Proce-

dure on page 7 before cleaning,

removing, or installing a spray tip and whenever

you are instructed to relieve pressure.

WARNING

To reduce the risk of serious injury, including

splashing fluid in the eyes or on the skin, or static

electric discharge when flushing:

Be sure the entire system, including flushing

pails, are properly grounded.

Remove the tip guard and spray tip.

Maintain metal-to-metal contact between the

gun and a grounded metal waste container. See

Fig. 7, page 11.

Use the lowest possible pressure.

1. Relieve the pressure as instructed on page 7.

2. Disconnect the atomizing air hose and the fluid

supply line.

3. Remove the tip guard or AA RAC assembly (11),

air cap or RAC housing (13), and spray tip (14).

Refer to the parts drawing for your gun model

(page 18 or 20).

4. Clean the parts.

5. Connect a compatible solvent supply to the gun.

6. Start the pump and operate it at its lowest pressure.

7. Hold a metal part of the gun firmly against a

grounded metal waste container, and trigger the

gun until all the paint is removed from the gun

passages.

8. Relieve the pressure as instructed on page 7.

9. Disconnect the solvent supply.

NOTE:

Flush the pump and gun before the fluid can dry in

it.

If it is available, the flushing procedure provided in

the pump or sprayer manual should be used

instead of this procedure.

NOTE:

materials,

clean it with a soft brush to ensure that the material

does not cure in the spring area and make the gun

inoperable. See page 16 to remove the needle cartridge.

If the gun is being used with plural component

remove the needle cartridge and thoroughly

12 308640

Page 13

Notes

308640 13

Page 14

Troubleshooting

g

NOTE:

WARNING

INJECTION HAZARD

To reduce the risk of a fluid injection

injury, follow the Pressure Relief Proce-

dure on page 7 before checking or

servicing any of the system equipment and whenever you are instructed to relieve pressure.

General Troubleshooting

Problem Cause Solution

Fluid leakage from back of fluid

needle

Air leakage from front of gun Air valve not seating properly Clean/service air valve. See page 16.

Fluid leakage from front of gun

Fluid in air passages

Slow fluid shut-off Fluid buildup on fluid needle cartridge

Worn packings or needle shaft Replace external needle packings or

Fluid needle worn or damaged Replace fluid needle cartridge. See

Worn diffuser-seat housing Replace the diffuser-seat and gasket.

Fluid tip seal leaking Tighten or replace fluid tip.

Leaking around diffuser-seat housing Replace the diffuser-seat gasket. The

Fluid inlet fitting leaking Replace the fluid fitting gasket. The

components.

Check all possible remedies in the troubleshooting

charts before disassembling the gun.

Some improper patterns are caused by the

improper balance between air and fluid.

entire fluid needle cartridge. See

page 16.

page 16.

The gasket must be replaced whenever the diffuser-seat is removed.

See page 16.

gasket must be replaced whenever

the diffuser-seat is removed. See

page 16.

gasket must be replaced whenever

the fluid fitting is removed. See

page 17.

Remove and clean or replace the

fluid needle cartridge. See page 16.

14 308640

Diffuser-seat is overtightened.

Remove diffuser-seat and replace

diffuser-seat gasket. Torque diffuserseat to 90–100 in-lb (10.2–11.2

Nm).

Page 15

Troubleshooting

Spray Pattern Troubleshooting

Problem Cause Solution

Fluttering or spitting spray Insufficient fluid supply

Adjust fluid regulator or fill fluid supply

tank.

Air in paint supply line

Attempting to “feather” (partially trigger) the gun.

Irregular pattern Fluid build-up or spray tip partially

plugged

On defective side of pattern, air horn

holes are partially or totally plugged

Pattern pushed to one side, same

side of air cap gets dirty

Air horn holes partially or totally

plugged

Check, tighten siphon hose connections, bleed air from paint line.

Cannot “feather” with an AA gun.

Feathering will cause drastic reduction of pressure at the tip, resulting in

poor atomization and/or spitting.

Clean spray tip. See page 11.

Clean air horn holes with solvent and

soft brush. See page 11.

Clean air horn holes with solvent and

soft brush. See page 11.

308640 15

Page 16

Service

WARNING

INJECTION HAZARD

To reduce the risk of a fluid injection

injury, follow the Pressure Relief Proce-

dure on page 7 before checking or

servicing any of the system equipment and whenever you are instructed to relieve pressure.

NOTE:

Follow the Service Notes in Fig. 8 when reassem-

bling the gun. Refer to the parts drawing for your

gun model (page 18 or 20) for parts not shown in

Fig. 8.

Fluid Needle Cartridge Service

Follow the procedure below to remove the fluid needle

cartridge for cleaning or for replacement.

1. Relieve the pressure as instructed on page 7.

2. Remove the tip guard or AA RAC assembly (11),

air cap or RAC housing (13), spray tip (14), and air

separator (16 –

and 241070 guns only

3. Trigger the gun to back the fluid needle ball off the

seat. Remove the diffuser-seat (15).

4. Remove the trigger (3) and trigger extension

pieces (19). See the Parts Drawing, page 18.

part no. 238402, 238852, 238883,

). See Fig. 8.

Repair Kits are available. See page 19 or 21 for the

kits for your gun model.

Air Valve Service

1. Relieve the pressure as instructed on page 7.

2. Remove the trigger (3) and valve cap (7). See the

parts drawing and Fig. 8.

3. Unscrew the needle nut (23) while holding the flats

(C) of the air valve (26) stem with a long nose

pliers.

CAUTION

To avoid leakage, be careful not to scratch the air

valve stem.

4. Remove the spring (6) and air valve (26).

5. If there is air leakage at the air valve (26), unscrew

the packing nut (24) and carefully remove the

u-cup packing (25). Replace packing if worn or

damaged. When re-installing, be sure the u-cup

faces inward.

6. If leakage occurs internally or the front of the gun

leaks air when it’s not triggered, clean and inspect

the air valve and the spring for wear or damage.

Replace as needed.

7. For best air valve life, lubricate the external air

valve stem (C) with light oil after each day’s use.

5. To remove the fluid needle cartridge (10), slide the

notch of the packing tool (34) around the small

diameter of the trigger guide (A) and pull the

cartridge toward the front of the gun.

6. Remove the fluid gasket (18).

7. If the fluid needle cartridge was removed for

cleaning, remove the external o-ring (10a) and

backup ring (10b). Clean the needle cartridge

thoroughly with a compatible solvent and a soft

brush. Install a new o-ring (10a) and backup ring

(10b).

8. Lubricate the o-ring (10a) and backup ring (10b) of

the new or cleaned needle cartridge with lightweight oil.

9. Insert the fluid needle cartridge into the front end

of the gun body. Use the packing tool (34) to pull

back on the cartridge until it snaps into place; the

cartridge must be bottomed out in the gun body

insert. If the cartridge is seated properly, the

needle cartridge washer (B) will be visibly seated

flat through the back end of the gun body insert.

10. Insert a new gasket (18).

11. Install the gun trigger and trigger extension pieces.

12. Lubricate the diffuser-seat (15) thread. Trigger the

gun while screwing the diffuser-seat back into the

gun. Torque the diffuser-seat to 90 to 100 in-lb

(10.2 to 11.2 Nm).

13. Install the gun air separator

238852, 238883, and 241070 guns only)

air cap or RAC housing, and tip guard or AA RAC

assembly.

(part no. 238402,

, spray tip,

16 308640

Page 17

Part No. 238402 Spray Gun shown

1414

11

16

13

12

14

Service

5

4

11

12

5a

7

10

24

C

6

23

A

B

12

10b

10a

12

25

26

411

7

6

8

410

13

1

3 15

15

SERVICE NOTES:

Gasket (18) must be replaced if diffuser-seat (15) is removed

1

or replaced to avoid fluid leakage

Gasket (17) must be replaced if fluid connector (30) is removed

2

or replaced to avoid fluid leakage

Lubricate threads

3

Apply anaerobic pipe sealant to threads

4

Apply high strength sealant to threads

5

Thread nut to bottom thread of needle

6

Use tool (34) to pull needle cartridge until it bottoms in gun

7

body front end insert.

U-cup lips face inward

8

T orque to 23–27 ft-lb (31–37 Nm)

9

18

2

17

5 9

30

FLUID

T orque to 20–24 ft-lb (27–32 Nm)

10

T orque to 15–19 ft-lb (20–26 Nm)

11

Lubricate with light-weight oil

12

Do not lubricate

13

If the gun has the AA RAC assembly, tighten the air cap

14

retaining ring until it bottoms out, while holding the orange tip

guard in the desired direction.

T orque to 90–100 in-lb (10.2–1 1.2 Nm).

15

AIR

2

Fig. 8

05989

308640 17

Page 18

Parts

Part No. 238402, 238852, 238883, and 241070

12

14

13

11

5

5a

16

23

10

3

15

24

10a

18

25

4

10b

17

30

1

8

7

6

26

19

9

34

5b

29

12

SERVICE NOTES (See Fig. 8 for additional information):

1

Apply high strength sealant to threads.

T orque to 23–27 ft-lb (31–37 Nm)

2

Gasket (18) must be replaced if diffuser-seat (15) is removed or

3

replaced to avoid fluid leakage.

18 308640

3

6

2

5

2

05990A

Gasket (17) must be replaced if fluid connector (30) is removed or

4

replaced to avoid fluid leakage.

5

Included with Gun 238402, 238883, and 241070 only.

Included with Gun 238852 only.

6

Page 19

Parts

Use Only Genuine Graco Parts and Accessories

Part No. 238402, 238852, 238883, and 241070

Ref.

No. Part No. Description Qty.

1 238750 BODY, gun 1

2 106917 ADAPTER, air;

238402, 238883, and 241070 only

Included with Gun

113367 COUPLING, air, quick-disconnect;

Included with Gun 238852 only 1

3 276429 TRIGGER, gun 1

5 217489 VALVE, pattern adjustment;

Includes items 5a and 5b 1

5a 168110 S O-RING, nitrile rubber 1

5b 105456 S RETAINER, clip 1

6 106903 SPRING, compression, air valve 1

7 178408 CAP, valve, air 1

8 203953 CAP SCREW, hex hd, 10-24 x

0.375” long 1

9 187562 PIN, pivot 1

10 238754 NEEDLE, fluid;

238402, 238852, and 241070 only;

Includes replaceable items 10a, 10b

Included with Gun

238755 NEEDLE, fluid, hi-flow; Included

with Gun 238883 only; Includes

replaceable items 10a and 10b

10a 111516 S O-RING; CV75 1

10b 111517 S RING, backup; PTFE r 1

11 238248 TIP GUARD 1

12 107079 O-RING, PTFE 1

13 239781 AIR CAP;

238402, 238852, and 238883 only

239898 AIR CAP;

241070 only

Included with Gun

Included with Gun

14 GG4XXX SPRAY TIP; Customer’s choice;

See Chart on page 22.

replacement gasket 183616

Includes

15 238427 DIFFUSER-SEAT; Included with Gun

238402, 238852, and 241070 only

224855 DIFFUSER-SEAT, hi-flow; Included

with Gun 238883 only

16 178414 SEPARATOR, air 1

17 178422 GASKET, fluid, Delrinr;

1 sent unassembled 2

18 187521 GASKET, fluid; acetal homopolymer

(black), 1 sent unassembled 2

19 224868 TRIGGER EXTENSION 2

23 187504 NUT, needle 1

24 178765 NUT, packing, air 1

25 105452 U-CUP, PTFE 1

26 217487 VALVE, air 1

29 238228 GUARD, trigger 1

30 191026 CONNECTOR, fluid 1

31Y 222385 WARNING CARD (not shown) 1

34 187737 TOOL, needle assembly 1

Ref.

No. Part No. Description Qty.

35Y 172479 TAG, instruction (not shown) 1

Y

1

Replacement Warning labels, tags and cards are

available at no cost.

Repair Kits

Kit No. and

Dii

Description

224949

Gun Repair

Kit

1

1

235304

Fluid Section

Repair Kit

1

1

238739*

Hi-flow Gun

Repair Kit

1

1

1

238738*

Hi-flow Fluid

Section

Repair Kit

* Must be used with tips larger than 0.025 in. (0.635 mm).

Includes:

Ref. No. Part No. Description

5a

5b

6

10

10a

10b

12

15

17

18

25

26

10

10a

10b

15

17

18

5a

5b

6

10

10a

10b

12

15

17

18

25

26

10

10a

10b

15

17

18

168110

105456

106903

238754

111516

111517

107079

238427

178422

187521

105452

217487

238754

1 1 1516

1 1 1517

238427

178422

187521

168110

105456

106903

238755

111516

111517

107079

224855

178422

187521

105452

217487

238755

1 1 1516

1 1 1517

224855

178422

187521

O-Ring

Retainer

Spring

Needle

O-Ring

Backup Ring

O-Ring

Diffuser-seat

Gasket

Gasket

U-Cup

Valve

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

O-Ring

Retainer

Spring

Needle

O-Ring

Backup Ring

O-Ring

Diffuser-seat

Gasket

Gasket

U-Cup

Valve

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

308640 19

Page 20

Part No. 238851 and 239001

14a

13

Parts

11

5

5a

14

1

8

5b

7

6

25

26

24

23

10

10b

10a

19

18

15

3

17

4

30

9

29

3

12

SERVICE NOTES (See Fig. 8 for additional information):

1

Apply high strength sealant to threads.

T orque to 23–27 ft-lb (31–37 Nm)

2

3

Gasket (18) must be replaced if diffuser-seat (15) is removed or replaced to avoid fluid leakage.

4

Gasket (17) must be replaced if fluid connector (30) is removed or replaced to avoid fluid leakage.

20 308640

2

34

06759B

Page 21

Parts

Use Only Genuine Graco Parts and Accessories

Part No. 238851 and 239001

Ref.

No. Part No. Description Qty.

1 238750 BODY, gun 1

2 106917 ADAPTER, air 1

3 276429 TRIGGER, gun 1

5 217489 VALVE, pattern adjustment;

Includes items 5a and 5b 1

5a 168110 S O-RING, nitrile rubber 1

5b 105456 S RETAINER, clip 1

6 106903 SPRING, compression, air valve 1

7 178408 CAP, valve, air 1

8 203953 CAP SCREW, hex hd, 10-24 x

0.375” long 1

9 187562 PIN, pivot 1

10 238754 NEEDLE, fluid; Included with Gun

238851 only; Includes replaceable

items 10a and 10b

238755 NEEDLE, fluid, hi-flow;

Gun 239001 only; Includes

replaceable items 10a and 10b

Included with

10a 111516 S O-RING; CV75 1

10b 111517 S RING, backup; PTFE r 1

11 238701 AA RAC TIP GUARD/

AIR CAP ASSY. 1

13 192096 RAC HOUSING 1

14 242XXX AA RAC SPRAY TIP; Customer’s

choice. See Chart on page 24.

Includes item 14a. 1

14a 193000 S FLUID SEAT 1

15 239172 DIFFUSER-SEAT; Included with Gun

238851 only

239173 DIFFUSER-SEAT, hi-flow; Included

with Gun 239001 only

17 178422 GASKET, fluid, Delrinr;

1 sent unassembled 2

18 187521 GASKET, fluid; acetal homopolymer

(black),

1 sent unassembled 2

19 224868 TRIGGER EXTENSION 2

23 187504 NUT, needle 1

24 178765 NUT, packing, air 1

25 105452 U-CUP, PTFE 1

26 217487 VALVE, air 1

29 238228 GUARD, trigger 1

30 191026 CONNECTOR, fluid 1

31Y 222385 WARNING CARD (not shown) 1

34 187737 TOOL, needle assembly 1

35Y 172479 TAG, instruction (not shown) 1

1

1

1

1

Repair Kits

Kit No. and

Dii

Description

239176

Gun Repair

Kit

239178

Fluid Section

Repair Kit

239177*

Hi-flow Gun

Repair Kit

239179*

Hi-flow Fluid

Section

Repair Kit

* Must be used with tips larger than 0.025 in. (0.635 mm).

Includes:

Ref. No. Part No. Description

5a

5b

6

10

10a

10b

15

17

18

25

26

10

10a

10b

15

17

18

5a

5b

6

10

10a

10b

15

17

18

25

26

10

10a

10b

15

17

18

168110

105456

106903

238754

111516

111517

239172

178422

187521

105452

217487

238754

1 1 1516

1 1 1517

239172

178422

187521

168110

105456

106903

238755

111516

111517

239173

178422

187521

105452

217487

238755

1 1 1516

1 1 1517

239173

178422

187521

O-Ring

Retainer

Spring

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

U-Cup

Valve

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

O-Ring

Retainer

Spring

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

U-Cup

Valve

Needle

O-Ring

Backup Ring

Diffuser-seat

Gasket

Gasket

Y

Replacement Warning labels, tags and cards are

available at no cost.

308640 21

Page 22

Spray Tip Selection Charts

Fan Width

Light to

es

es

inches

Inches

oz/min

fl oz/min

()

()

()

()

()

()

()

()

Fan Width

*Light to

y

Orifice

at 12

Medium

Heavy

()

()

()

()

()

()

()

()

NOTE: Part No. 238755 Fluid Needle and 224855 Diffuserseat must be used with GG4 tips larger than 0.025 in. (0.635

mm).

Standard Spray Tips, for use with Air Cap 239781

Orifice

Size

inch

(mm)

0.007

(0.178)

0.009

(0.229)

0.011

(0.279)

0.013

(0.330)

Fan Width *Light to

at 12”

(300 mm)

Inch

(mm)

2–4

(50–100)

4–6

(100–150)

6–8

(150–200)

2–4

(50–100)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

2–4

(50–100)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

Medium

Viscosity

fl oz/min

fl

(liters/min)

4.0

(0.1)

7.0

(0.2)

10.0

(0.3)

13.0

(0.4)

*Heavy

Viscosity

fl oz/min

(liters/min)

Part No.

GG4107

GG4207

GG4307

GG4109

GG4209

GG4309

GG4409

GG4509

GG4111

GG4211

GG4311

GG4411

GG4511

GG4611

GG4213

GG4313

GG4413

GG4513

GG4613

GG4713

Orifice

Size

0.015

(0.381)

0.017

(0.432)

0.019

(0.483)

at 12”

(300 mm)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

18–20

(457–508)

4–6

(100–150)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

18–20

(457–508)

*

Medium *Heav

Viscosity

17.0

(0.5)

22.0

(0.7)

28.0

(0.8)

Viscosity Part No.

17.0

(0.5)

21.0

(0.6)

GG4215

GG4315

GG4415

GG4515

GG4615

GG4715

GG4815

GG4217

GG4317

GG4417

GG4517

GG4617

GG4717

GG4817

GG4917

GG4219

GG4319

GG4419

GG4519

GG4619

GG4719

GG4819

GG4919

22 308640

Page 23

Spray Tip Selection Charts

Fan Width

*Light to

y

Orifice

at 12

Medium

Heavy

()

()

()

()

()

()

()

()

()

()

()

()

Fan Width

*Light to

y

Orifice

at 12

Medium

Heavy

()

()

()

()

()

()

()

()

()

()

()

()

()

()

()

Standard Spray Tips, for use with Air Cap 239781

Orifice

Size

0.021

(0.533)

0.023

(0.584)

0.025

(0.635)

0.027

(0.686)

at 12”

(300 mm)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

18–20

(457–508)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

18–20

(457–508)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

14–16

(350–400)

16–18

(400–460)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

16–18

(400–460)

*

Medium *Heav

Viscosity

35.0

(1.0)

40.0

(1.2)

50.0

(1.5)

58.5

(1.7)

Viscosity Part No.

27.0

(0.8)

34.0

(0.97)

42.0

(1.2)

50.0

(1.4)

GG4321

GG4421

GG4521

GG4621

GG4721

GG4821

GG4921

GG4423

GG4523

GG4623

GG4723

GG4823

GG4923

GG4425

GG4525

GG4625

GG4725

GG4825

GG4327

GG4427

GG4527

GG4627

GG4827

Orifice

Size

0.029

(0.737)

0.031

(0.787)

0.033

(0.838)

0.035

(0.889)

0.037

(0.940)

0.039

(0.991)

at 12”

(300 mm)

8–10

(200–250)

12–14

(300–350)

8–10

(200–250)

12–14

(300–350)

18–20

(457–508)

12–14

(300–350)

16–18

(400–460)

18–20

(457–508)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

16–18

(400–460)

18–20

(457–508)

14–16

(350–400)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

16–18

(400–460)

*

Medium *Heav

Viscosity

68.0

(1.9)

78.0

(2.2)

88.0

(2.5)

98.0

(2.8)

108.0

(3.1)

118.0

(3.4)

Viscosity Part No.

59.0

(1.7)

69.0

(2.0)

79.0

(2.3)

89.0

(2.5)

99.0

(2.8)

109.0

(3.1)

GG4429

GG4629

GG4431

GG4631

GG4931

GG4633

GG4833

GG4933

GG4435

GG4535

GG4635

GG4835

GG4935

GG4737

GG4439

GG4539

GG4639

GG4839

*Fluid output at 600 psi (4.1 MPa, 41 bar).

Fluid output (Q) at other pressures (P) can be calculated by this

formula: Q = (0.041) (QT) (

qP ).

Where QT = Fluid output (fl oz/min) from the above table for

the selected orifice size.

NOTE: Other tips are available on special work order. Allow 4

to 6 weeks for delivery .

308640 23

Page 24

Spray Tip Selection Charts

Light to

inches

oz/min

fl oz/min

Fan Width

Light to

es

es

inches

Inches

oz/min

fl oz/min

()

()

()

()

()

()

()

()

()

()

()

()

Standard Sealer Tips, for use with

Air Cap 239781

NOTE: Part No. 238755 Fluid Needle and 224855 Diffuser-

seat must be used with GG4 tips larger than 0.025 in. (0.635

mm).

Orifice

Size

inches

(mm)

0.025

(0.635)

0.029

(0.737)

0.031

(0.787)

0.035

(0.889)

*Fluid output at 600 psi (4.1 MPa, 41 bar).

*Light to

Medium

Viscosity

fl oz/min

fl

(liters/min)

50.0

(1.5)

50.0

(1.5)

50.0

(1.5)

50.0

(1.5)

*Heavy

Viscosity

fl oz/min

(liters/min)

42.0

(1.2)

42.0

(1.2)

42.0

(1.2)

42.0

(1.2)

Part No.

GG4025

GG4029

GG4031

GG4035

AA Reverse-A-Clean (AA RAC) Spray Tips

Orifice

Size

inch

(mm)

0.011

(0.279)

0.013

(0.330)

0.015

(0.381)

Fan Width *Light to

at 12”

(300 mm)

Inch

(mm)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

Medium

Viscosity

fl oz/min

fl

(liters/min)

10.0

(0.3)

13.0

(0.4)

17.0

(0.5)

*Heavy

Viscosity

fl oz/min

(liters/min)

Part No.

242311

242411

242511

242313

242413

242513

242613

242315

242415

242515

242615

AA Reverse-A-Clean (AA RAC) Spray Tips

Fluid Seat

AA RAC

Tip Guard/Air

Cap Assy.

238701

Housing

192096

NOTE:

AA RAC Tips 242XXX feature a 1–piece plastic fluid seat

193000. Do not use in combination with parts from

previous generations of AA RAC Tips (AARXXX).

The air separator (item 16) must be removed when using

the AA RAC.

AA RAC Conversion Kits are available. See page 27.

193000

Tip Cylinder

(full spray

position)

8027A

0.017

(0.432)

0.019

(0.483)

0.021

(0.533)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

6–8

(150–200)

8–10

(200–250)

10–12

(250–300)

12–14

(300–350)

22.0

(0.7)

28.0

(0.8)

35.0

(1.0)

17.0

(0.5)

21.0

(0.6)

27.0

(0.8)

242317

242417

242517

242617

242319

242419

242519

242619

242321

242421

242521

242621

24 308640

Continued on the next page.

Page 25

Spray Tip Selection Charts

Fan Width

*Light to

y

Orifice

at 12

Medium

Heavy

Fan Width

*Light to

y

Orifice

at 12

Medium

Heavy

()

()

()

AA Reverse-A-Clean (AA RAC) Spray Tips

Orifice

Size

0.023

(0.584)

0.025

(0.635)

at 12”

(300 mm)

8–10

(200–250)

12–14

(300–350)

10–12

(250–300)

12–14

(300–350)

*

Medium *Heav

Viscosity

40.0

(1.2)

50.0

(1.5)

Viscosity Part No.

34.0

(0.97)

42.0

(1.2)

AA

Orifice

Size

242423

242623

242525

242625

0.027

(0.686)

0.029

(0.737)

0.031

(0.787)

*Fluid output at 600 psi (4.1 MPa, 41 bar).

Dimensions

Measurements, inches (mm)

Gun

Part No.

238402 7.5 (191) 6.9 (175) 7.5 (191) –

238851 7.8 (198) 6.9 (175) 7.5 (191) –

238852 – – 8.3 (210) 7.7 (196)

CC

BB

238883 7.5 (191) 6.9 (175) 7.5 (191)

239001 7.8 (198) 6.9 (175) 7.5 (191) –

241070 7.5 (191) 6.9 (175) 7.5 (191) –

at 12”

(300 mm)

8–10

(200–250)

10–12

(250–300)

10–12

(250–300)

12–14

(300–350)

*

Medium *Heav

Viscosity

58.5

(1.7)

68.0

(1.9)

78.0

(2.2)

Viscosity Part No.

50.0

(1.4)

59.0

(1.7)

69.0

(2.0)

AA BB CC DD*

242427

242529

242531

242631

DD

* Dimension DD is taken from the end of the tip guard to

the end of the quick-disconnect air line fitting.

On part no. 238852, Dimension CC is taken from the top

of the gun to the bottom of the quick-disconnect air line

fitting.

05985

308640 25

Page 26

Technical Data

Maximum Working Fluid Pressure 4000 psi. . . . . . . . .

(28 MPa, 280 bar)

Maximum Working Air Pressure 100 psi. . . . . . . . . . . . .

(0.7 MPa, 7 bar)

Maximum Working Fluid Temperature . 120_ F (49_ C)

Weight (less filter) 1.33 lb (0.59 Kg). . . . . . . . . . . . . . . .

Fluid Inlet 1/4–18 npsm. . . . . . . . . . . . . . . . . . . . . . . . . .

Air Inlet

Part No. 238402, 238851, 238883, 239001, and

241070 Guns:

1/4–18 npsm (R1/4–19) compound male thread

Part No. 238852 Gun:

1/4–18 npsm quick-disconnect fitting.

Wetted Parts Stainless Steel, Carbide, Ultra. . . . . .

High Molecular Weight Polyethylene, CV75r, PTFE,rDelrinr

Delrinrris a registered trademark of the DuPont

Company.

CV75

r is a registered trademark of the International Seal

Co., Inc.

Air Cap Pressure

vs

Gun Inlet Air Pressure

(for 239898 Air Cap only)

NOTE: Air Cap Verification Kit 239897 is available.

See page 27.

psi

MPa, bar

100

0.7, 7.0

80

0.56, 5.6

60

0.42, 4.2

40

0.28, 2.8

AIR CAP PRESSURE

20

0.14, 1.4

Sound Data

Gun with GG4 spray tip and 239781 air cap

Fluid

Pressure

psi

(MPa, bar)

600

(4.1, 41)

4000

(28, 280)

4000

(28, 280)

Air

Pressure

psi

(MPa, bar)

30

(2.1, 0.21)

30

(2.1, 0.21)

100

(0.7, 7)

Gun with GG4 spray tip and 239898 air cap

Fluid

Pressure

psi

(MPa, bar)

600

(4.1, 41)

4000

(28, 280)

4000

(28, 280)

Air

Pressure

psi

(MPa, bar)

30

(2.1, 0.21)

30

(2.1, 0.21)

100

(0.7, 7)

Gun with 242 spray tip and 238701 air cap

Fluid

Pressure

psi

(MPa, bar)

600

(4.1, 41)

4000

(28, 280)

4000

(28, 280)

Air

Pressure

psi

(MPa, bar)

30

(2.1, 0.21)

30

(2.1, 0.21)

100

(0.7, 7)

Sound

Pressure{

dB(A)

Sound

Power}

dB(A)

85.0 80.0

87.0 83.5

91.0 90.5

Sound

Pressure{

dB(A)

Sound

Power}

dB(A)

85.5 82.0

87.0 85.0

91.5 91.5

Sound

Pressure{

dB(A)

Sound

Power}

dB(A)

78.7 85.8

85.1 90.3

88.4 94.4

0

0 20406080100

psi

MPa

bar

26 308640

GUN INLET AIR PRESSURE

0.560.420.280.14 0.7

5.64.22.81.4 7.0

{ Sound pressure was measured at 1 meter from the unit.

} Sound power was tested in accordance with ISO 9614–2.

Page 27

Accessories

Use Only Genuine Graco Parts and Accessories

Grounding Clamp and Wire 222011

12 ga, 25 ft (7.6 m) wire

High Pressure Ball Valves, Viton Seals

5000 psi (35 MPa, 350 bar) Maximum Working Pressure

Can be used as fluid drain valve.

210657 1/2 npt(m)

210658 3/8 npt(m)

210659 3/8 x 1/4 npt(m)

In-line Fluid Filter 210500

5000 psi (35 MPa, 350 bar) Maximum Working Pressure

100 mesh. Fits onto the gun’s fluid connector. 1/4–18

npsm. Includes the parts shown below.

Filter

168517

205264

210501

164075

Ruby-ball Needle Assembly 236678

Use to decrease wear with acid catalyzed finishes. For

use in place of the standard fluid needle, part no.

238754, item 101 on page 19. Use with diffuser-seat

238427 only .

Plastic Needle Kit 240679

4000 psi (28 MPa, 280 bar) Maximum Working Pressure

Includes: Plastic Ball Tipped Needle Assembly 240678,

diffuser-seat, and gasket.

For use with acid catalyzed finishes and for light

viscosity fluids. Use with diffuser-seat 224855 only. Not

recommended for use with AA RAC tips.

Bleed-type Master Air Valve

300 psi (2.1 MPa, 21 bar) Maximum Working Pressure

Relieves air trapped in the air line between the pump

air inlet and this valve when closed.

107141 3/4 npt(m x f) inlet & outlet

107142 1/2 npt(m x f) inlet & outlet

Fluid Swivel Connector 189018

5800 psi (40 MPa, 400 bar) Maximum Working Pressure

To ease movement of the gun and fluid hose. 1/4–18

npsm

Air Whip Hoses

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

To ease movement of the gun and hose. 1/4–18 npsm,

polyurethane with SST braid.

238759 3 ft. (0.92 m) hose

236873 6 ft. (1.83 m) hose

Air Cap Verification Kit 239897

For air cap 239898 only, to determine air pressure

behind the air cap. Do not use for actual spraying. To

be compliant, atomizing air pressure must not exceed

10 psi (70 kPa, 0.7 bar).

Conversion Kits

Kits to convert from a gun with standard spray tip, tip

guard, and air cap to a gun with the AA RAC assembly. See parts list and drawing below for parts included

with kit.

240462 Use with gun part no. 238402 and 238852

to convert to gun part no. 238851.

240463 Use with gun part no. 238883 to convert to

gun part no. 239001.

Ref.

No. Part No. Description Qty .

1 238701 AA RAC AIR CAP ASSEMBLY 1

2 192096 RAC HOUSING 1

3 242XXX TIP CYLINDER; tip of choice

Includes item 3a 1

3a 193000 FLUID SEAT 1

4 239172 DIFFUSER-SEAT; Included with Kit

240462 only 1

239173 DIFFUSER-SEAT, hi-flow; Included

with Kit 240463 only 1

5 187521 GASKET, fluid; acetal homopolymer

(black) 1

5

4

3a

2

1

Air Line Quick-disconnect 113367

Consists of:

113410 Coupling, female, quick-disconnect

113368 Coupling, male, quick-disconnect

Brush 101892

For cleaning the gun.

3

308640 27

06765B

Page 28

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A P ARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer . Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty , the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone

Number

TO PLACE AN ORDER

tor, or call this number to identify the distributor closest

to you: 1–800–367–4023 T oll Free

, contact your Graco distribu-

Change Summary

Manual changed per ECO V4782.

Manual

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices: Belgium, England, Korea, France, Germany , Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

http://www.graco.com

PRINTED IN U.S.A. 308640 April 1996 Revised December 1998

28 308640

Loading...

Loading...