Page 1

LCD Television

Service Manual

Chassis:

Product:

9206B

LTDN40D50TAM

LHD32D50TAM

Ver 1.0

Hisense Electric Co.,Ltd.

May , 2015

Page 2

Content

Content ................................................................................................................................................................... - 2 -

Service Manual ...................................................................................................................................................... - 3 -

1. Precautions and notices ................................................................................................................................ - 3 -

1.1 Warning .............................................................................................................................................. - 4 -

1.2 Notes .................................................................................................................................................. - 7 -

2. Product Specifications ............................................................................................................................... - 10 -

2.1 Main board layout ............................................................................................................................ - 10 -

2.2 The service manual Includes products ............................................................................................. - 11 -

2.3 TV Front and Rear ........................................................................................................................... - 11 -

3. Factory/Service OSD Menu and Adjustment ............................................................................................. - 18 -

3.1 How to enter the Factory OSD Menu .............................................................................................. - 18 -

3.2 Factory OSD Menu .......................................................................................................................... - 18 -

4. Software updating ...................................................................................................................................... - 21 -

4.1 USB upgrade .................................................................................................................................... - 21 -

4.2 SIS Tool upgrade ............................................................................................................................. - 22 -

5.Trouble shooting ......................................................................................................................................... - 27 -

6. Circuit instruction ...................................................................................................................................... - 33 -

Power assign and Main board signal process ........................................................................................ - 33 -

7. Schematic circuit diagram ......................................................................................................................... - 35 -

8. Explode View ............................................................................................................................................. - 35 -

- 2 -

Page 3

Service Manual

1. Precautions and notices

BEFORE SERVICING THE LCD TV, READ THE SAFETY PRECAUTIONS IN

THIS MANUAL.

WHEN REPLACEMENT PARTS ARE REQUIRED, BE SURE TO USE

REPLACEMENT PARTS SPECIFIED BY THE MANUFACTURER.

Proper service and repair is important to the safe, reliable operation of all Hisense

Electric Co., Ltd Equipment. The service procedures recommended by Hisense and

described in this Service Guide are effective methods of performing service operations.

Some of service

operations require the use of tools specially designed for the purpose. The special tools

should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES

which should be carefully read in order to minimize the risk of personal injury to

service personnel. The possibility exists that improper service methods may damage

the equipment. It is also important to understand that these CAUTIONS and

NOTICES ARE NOT EXHAUSTIVE. Hisense could not possibly know, evaluate and

advise the service trade of all conceivable ways in which service might be done or of

the possible hazardous consequences of each way. Consequently, Hisense has not

- 3 -

Page 4

undertaken any such broad evaluation. Accordingly, a serviceman that uses a service

procedure or tools, which are not recommended by Hisense, must first satisfy himself

thoroughly that neither his safety nor the safe of the equipment

will be jeopardized by the service method selected.

Hereafter throughout this manual, Hisense Electric Co., Ltd will be referred to as

Hisense.

1.1 Warning

1.1.1

Critical components having special safety characteristics are identified with a by

the Ref. No. in the parts list. Use of substitute replacement parts, which do not have

the same specified safety characteristics, may create shock, fire, or other hazards.

Under no circumstances should the original design be modified or altered without

written permission from Hisense. Hisense assumes no liability, express or implied,

arising out of any unauthorized modification of design. Serviceman assumes all

liability.

DANGER CAUTION

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY

ORIGINAL MANUFACTURER'S REPLACEMENT PARTS, WHICH ARE LISTED WITH

THEIR PART NUMBERS IN THE PARTS LIST SECTION OF THIS SERVICE GUIDE.

1.1.2.

- 4 -

Page 5

All ICs and many other semiconductors are susceptible to electrostatic discharges

(ESD). Careless handling during repair can reduce life drastically. When repairing,

make sure that

you are connected with the same potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same potential.

1. Never replace modules or other components while the unit is switched on.

2. When making settings, use plastic rather than metal tools. This will prevent

any short circuits and the danger of a circuit becoming unstable.

1.1.3

To prevent electrical shock, do not use this polarized ac plug with an extension cord,

receptacle, or the outlet unless the blades can be fully inserted to prevent blade

exposure.

To prevent electrical shock, match wide blade or plug to wide slot, fully insert.

1.1.4

When replacement parts are required, be sure to use replacement parts specified by the

manufacturer or have the same characteristics as the original part. Unauthorized

substitutions may result in fire, electric shock, or other hazards.

1.1.5

Safety regulations require that after a repair the set must be returned in its original

condition. In particular attention should be paid to the following points.

-Note: The wire trees should be routed correctly and fixed with the mounted

- 5 -

Page 6

cable clamps.

-The insulation of the mains lead should be checked for external damage.

1.1.6

(1) Do not touch Signal and Power Connector while this product operates. Do not

touch EMI ground part and Heat Sink of Film Filter.

(2) Do not supply a voltage higher than that specified to this product. This may

damage the product and may cause a fire.

(3) Do not use this product in locations where the humidity is extremely high, where

it may be splashed with water, or where flammable materials surround it. Do not

install or use the product in a location that does no satisfy the specified

environmental conditions. This may damage the product and may cause a fire.

(4) If a foreign substance (such as water, metal, or liquid) gets inside the panel

module, immediately turn off the power. Continuing to use the product may cause

fire or electric shock.

(5) If the product emits smoke, and abnormal smell, or makes an abnormal sound,

immediately turn off the power. Continuing to use the product, it may cause fire or

electric shock.

(6) Do not disconnect or connect the connector while power to the product is on. It

takes some time for the voltage to drop to a sufficiently low level after the power has

been turned off. Confirm that the voltage has dropped to a safe level before

disconnecting or connecting the connector.

- 6 -

Page 7

(7) Do not pull out or insert the power cable from/to an outlet with wet hands. It may

cause electric shock.

(8) Do not damage or modify the power cable. It may cause fire or electric shock.

(9) If the power cable is damaged, or if the connector is loose, do not use the product:

otherwise, this can lead to fire or electric shock.

(10) If the power connector or the connector of the power cable becomes dirty or

dusty, wipe it with a dry cloth. Otherwise, this can lead to fire.

(11) Use only with the cart, stand, tripod, bracket, or table specified by the

manufacturer, or sold with the apparatus. When a cart is used, use caution when

moving the cart/apparatus combination to avoid injury from tip-over.

1.2 Notes

Notes on Safe Handling of the LCD panel and during service

The work procedures shown with the Note indication are important for ensuring the

safety of the product and the servicing work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient working space.

• At all times other than when adjusting and checking the product, be sure to turn OFF

the POWER Button and disconnect the power cable from the power source of the TV

during servicing.

• To prevent electric shock and breakage of PC board, start the servicing work at least

30 seconds after the main power has been turned off. Especially when installing and

- 7 -

Page 8

removing

the power board, start servicing at least 2 minutes after the main power has been

turned off.

• While the main power is on, do not touch any parts or circuits other than the ones

specified.

If any connection other than the one specified is made between the measuring

equipment and the high voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

• When installing the LCD module in, and removing it from the packing carton, be

sure to have at least two persons perform the work.

• When the surface of the panel comes into contact with the cushioning materials, be

sure to confirm that there is no foreign matter on top of the cushioning materials

before the surface of the panel comes into contact with the cushioning materials.

Failure to observe this precaution may result in, the surface of the panel being

scratched by foreign matter.

• When handling the circuit board, be sure to remove static electricity from your body

before handling the circuit board.

• Be sure to handle the circuit board by holding the large parts as the heat sink or

transformer. Failure to observe this precaution may result in the occurrence of an

abnormality in the soldered areas.

• Do not stack the circuit boards. Failure to observe this precaution may result in

- 8 -

Page 9

problems resulting from scratches on the parts, the deformation of parts, and

short-circuits due to residual electric charge.

• Routing of the wires and fixing them in position must be done in accordance with the

original routing and fixing configuration when servicing is completed. All the wires

are routed far away from the areas that become hot (such as the heat sink). These wires

are fixed in position with the wire clamps so that the wires do not move, thereby

ensuring that they are not damaged and their materials do not deteriorate over long

periods of time. Therefore, route the cables and fix the cables to the original position

and states using the wire clamps.

• Perform a safety check when servicing is completed. Verify that the peripherals of

the serviced points have not undergone any deterioration during servicing. Also verify

that the screws, parts and cables removed for servicing purposes have all been

returned to their proper locations in accordance with the original setup.

The lightning flash with arrowhead symbol, within an equilateral

triangle is intended to alert the user to the presence of uninsulated

dangerous voltage within the products enclosure that may be of sufficient magnitude

to constitute a risk of electric shock.

The exclamation point within an equilateral triangle is intended to

alert the user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the set.

- 9 -

Page 10

2. Product Specifications

2.1 Main board layout

2.1.1

LTDN40D50TAM use CVTE board:

TP.S512.PB751\40D50TAM\ROH

; 1149238

- 10 -

Page 11

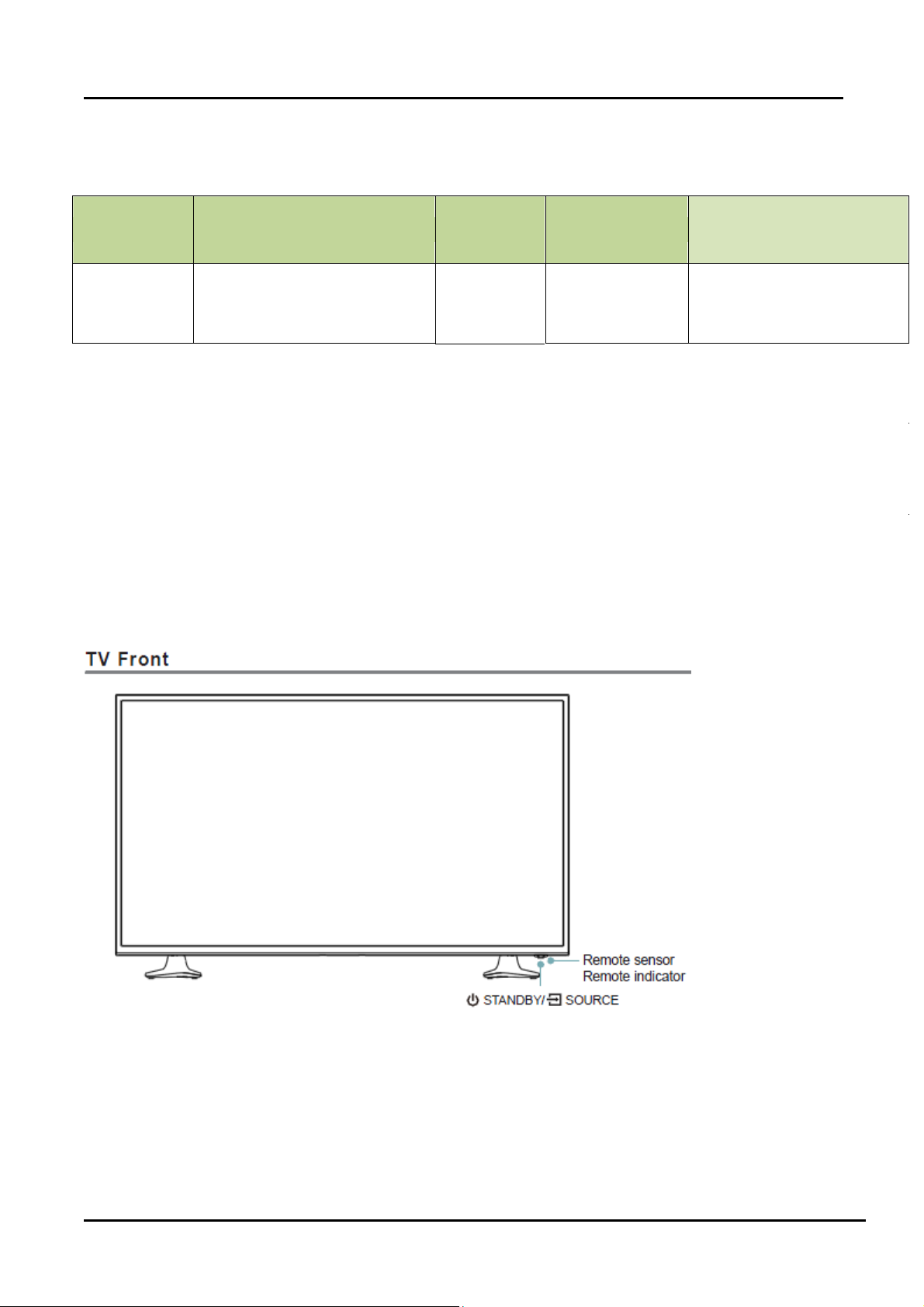

2.2 The service manual Includes products

Product Main & power board(one board) Digital system Panel LVDS cable

LTDN40D50TAM

TP.S512.PB751\40D50TAM\ROH

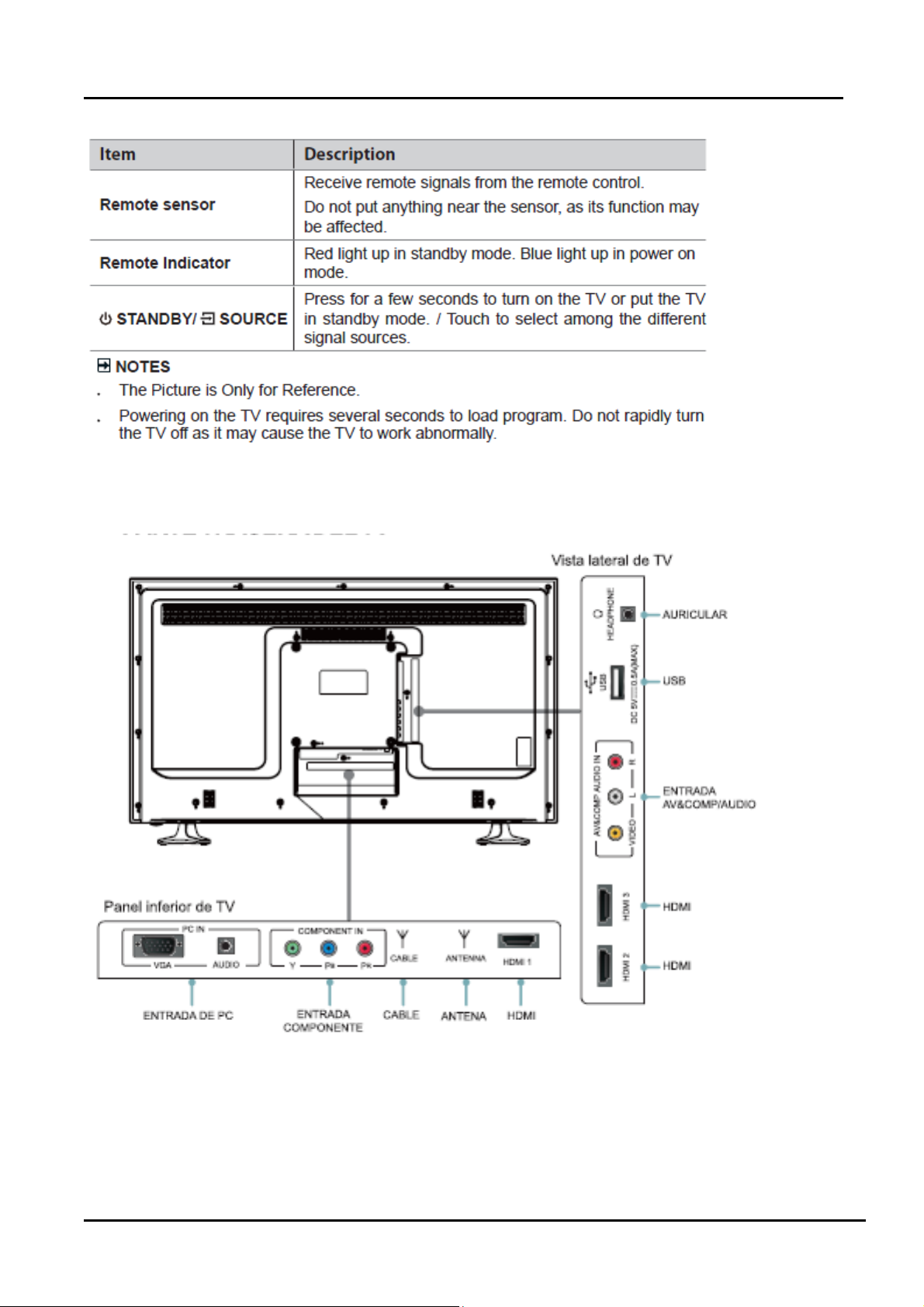

2.3 TV Front and Rear

LTDN40D50TAM TV Front

DVB-T2

JHD396DF-E01

HX2-2X20KLB500P-S-1\500\ROH

- 11 -

Page 12

LTDN40D50TAM TV Back

- 12 -

Page 13

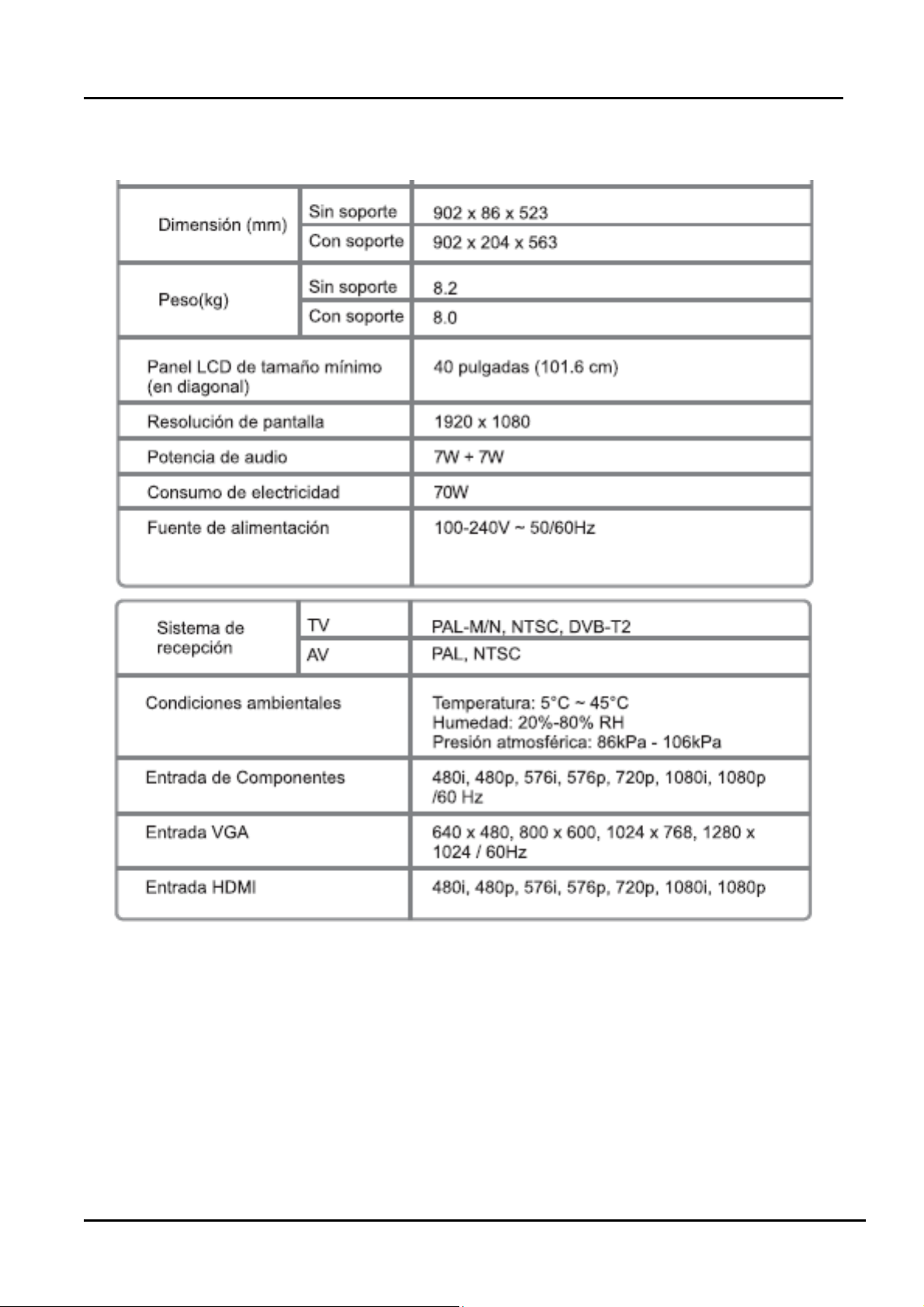

2.4 Specification

- 15 -

Page 14

2.4 Remote control

- 17 -

Page 15

3. Factory/Service OSD Menu and Adjustment

3.1 How to enter the Factory OSD Menu

With user’s RC

Power on the TV.

1. Press “Menu” button and call up User OSD Menu.

2. Select “ Sound” -> press “OK” button on RC to ensure then move button to “Balance”

item.

3. Press number key 1->9->6 ->9 in sequence when “Balance” item is focused.

Note: If necessary, re-do number keys.

4. Factory OSD appears.

Note: DC power off that can exit factory OSD menu.

3.2 Factory OSD Menu

The Factory OSD Menu comprises Factory Menu and Design menu.

3.2.1、Factory Menu

Take LTDN40D50EU for example

White Balance

Input Source

Function

Channel Lint

Test Pattern

Protected clear

Unprotected Clear

Design Menu

- 18 -

Page 16

White Balance:

Colour T emp

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Function:

TO Fac M/U

Power mode last memory

Software update start

Uart bebug on/off

Item Default Options Notes

M-Can enter factory mode with

1 MODE M M, U

Note: MODE “M” is only used for factory production.

Init:

Qingdao

Huangdao

Russia

……

U-Can enter factory mode only with

factory RC or user RC.

user’s RC.

- 19 -

Page 17

3.2.2、Design Menu

White balance

Picture Curve

Volu mn Curve

Sound Mode

Note

:

The above “Factory/Service OSD Menus” are reference only, please refer to the actual

unit to determine the appearances.

- 20 -

Page 18

4. Software updating

4.1 USB upgrade

USB upgrade includes two methods. One is USB directly upgrade the other is USB

menu upgrade.

* USB directly upgrade

1、LHD32D50EU upgrading file rename——SIS506_52.bin

LTDN40D50EU upgrading file rename——SIS506_67.bin

2、Unlock the compress upgrading file and copy the SIS506_XX.bin file to the USB

disk root directory which not contain other *.bin files.

3、AC Power off the TV ,insert the USB disk to the Main board USB port then AC power

it on .

Now the TV can update automatically.

4、You can estimate the upgrading state according to the indicator light color

changing.

During upgrading, red indicator and green indicator alternate flicker

slowly ,once/second.

If Upgrading successfully, red indicator and green indicator alternate flicker

fast ,four times/second

If Upgrading failure, red indicator and green indicator alternate flicker,but

flicker time is different. red indicator: 1.75 second/once; green indicator:

250ms/once

* USB menu upgrade

1、Insert USB disk that only have one upgrading file SIS506_XX.bin in root disk.

2、Enter the Factory OSD Menu see 3.1

3、Choose Factory menu->Function>software update >start

When appear “upgrade program detects whether an upgrade”select “YES”to

ensure.

Next:

- 21 -

Page 19

When 100%, next appear:

When 100%, next appear:

It indicates that USB Upgrades successfully.Plug the USB disk ,then TV can automatically restart.

Note:

During upgrading, DO NOT power off the TV and other abnormally

operations .otherwise boot can be destroied .since boot is destroied , USB

upgrading method is availability no longer. Must adopt SIS Tool upgrading.

4.2 SIS Tool upgrade

1、Install Uart driver software for SIS bebug board:CP210x_VCP_Windows

Run CP210xVCPInstaller.exe.

- 22 -

Page 20

2、Hardware connecting

You can update the software through a special tool (as following)

Connect the SIS debug board to TV use VGA port the other USB port to the PC.

USB port Connect

to the PC

Connect to the TV VGA por

3、SIS Tool upgrade with Uart2spi updating Tool

Connect the SIS debug board.

AC power off the TV, unlock compress

Run ,as following.

t

uart2spi_V118.rar

Choose “Comport setting”

- 23 -

Page 21

“Comport setting “item need choose corresponding com port.

How to look up corresponding com port? Now show.as following

- 24 -

Page 22

Click “Connect” button

AC power on the TV, interface as following. click “Restore” item、load the *.bin file then click

“restore “button

- 25 -

Page 23

Updating…… ,about 13 minutes. As following.

after“Restore successful”appears as following.it indicates the main software

upgrading is successful. then AC power off and power on the TV.

- 26 -

Page 24

5.Trouble shooting

5.1 Troubleshooting for Remote Control

Remote control does not work

Try new batteries

NO

Replace RC

Check IR receiver

YES

YES

Replace battery

Replace remote control

Change Led & IR board

NO

Change Led & IR cable

NO

Replace main board

YES

Replace Led & IR BD

YES

Replace Led & IR cable

- 27 -

Page 25

5.2 Troubleshooting for Function Key

Buttons does not work

Check switches

YES

Check solder connections and

see if any switches are stuck.

NO

Check key board

NO

Check Key BD cable

YES

Replace Key BD

YES

Change Key BD

OK

NO

Replace main board

- 28 -

Page 26

5.3 TV won’t Power On

TV won’t power on

Is LED

light?

NO

Check Power

Output

YES

Make Sure Power

source is live

YES

NO

BLUE

RED

Panel Bright

NO

YES

Check signal

Source

YES

NO

Check Power

Cord

NO

Try Power on by

RC and Button

Neither

works

Replace Main

BD

YES

Only

one works

Both

Work

Replace

Power Cord

Check/replace IR

BD or Keypad

PCA

NO

(to contact Hisense tech support.)

Replace Main BD

Replace Panel

OK

YES

Power on

NO

Replace Power BD

YES

OK

Notes:

Above TV configure is that TV in work state, indication Led is blue and in

standby state the indication led is red.

- 29 -

Page 27

5.4 Troubleshooting for Audio

No sound

Check connecter

YES

Reconnect

NO

Check speaker wire

NO

Check speaker set

YES

YES

Replace speaker wire

Replace speaker set

NO

Replace main board

NO

YES

OK

Power Supply Board

- 30 -

Page 28

5.5 Troubleshooting for TV/VGA/HDMI input

No picture on the screen

NO

Check Signal Source

Make sure signal

source is available

YES

Check connect

NO

YES

Check cab l e

NO

Replace main board

Reconnect

Replace cable

- 31 -

Page 29

5.6 Troubleshooting for YPbPr input

Note: (The K220 mould TV has not YPbPr input)

No picture on the screen

Check Source work or not

YES

Check connect

NO

Check Wires (Green Blue, Red)

NO

Replace main board

NO

YES

YES

Check Source Device

Reconnect

Replace wires

- 32 -

Page 30

5.7 Troubleshooting for Video input

No picture on the screen

Check Source work or not

YES

Check connect

NO

Check Cable/ Wires

NO

Replace main board

NO

YES

YES

Check Signal Source

Reconnect

Replace Cable/Wires

6. Circuit instruction

Power assign and Main board signal process

- 33 -

Page 31

- 34 -

Page 32

7. Schematic circuit diagram

8. Explode View

- 35 -

Page 33

1

A A

T3.15AL 250V~

!

!

!

MOVB1

CNB1

!

1

FB1

L

NTCB1

3

N

NC

B B

CXB1

2

! !

!

NC

!

CYB1

RB1

RB2

!

RB3

RB4

CYB2

! !

NC

!

12

43

!

GND

LCB1

!

CYB5

CYB4

3

NC

L

DB1 DB2

GND

DB3 DB4

SGND

Vbridge

!

NC

NC

SGND

RB143靠近IC

4

L

RB141

RB142

RB143

BRO

NC

CB111

放置

UB101

1

GND

2

COMP

BRO

SGND

PCB101B

!

3 4

CB103

NC3CS

RB104

RB103

GATE

5

Vbridge

TP1

+

EB1

TP2

SGND

L

6

5

4

SGND

RB106

RB107

VCC

RB105

CB102

2

113

CB101

RB101

RB102

VCC

NC

RB123

RB118

RB117

DB106

CB114

CB115

AK

D

QB101

G

QB102

RB109

S

RB108

RB110

ZDB1

2

3

RB148

SGND

6

RB124

RB125

RB126

RB127

DB102

11

A K

A K

DB103

CB117

DB101

CB118

+

RB140

GND

RB128

RB129

RB130

+

+

+

EB102

EB101

NC

GND

!

CYB3

CNB2

12V

2

1

GND

!

TB101

6

4

BB101

1

CB116

AK

DB104

DB105

NC

SGND

10

297

RB114

RB115

SGND

CB113

AK

RB111

+

EB106

7

VBL

EB104+EB105

12V

EB103

12V

RB131

12

PCB101A

GNDSGND

!

KA

R

UB102

GND

12V

RB132 RB135

CB109

RB133

CB110

NC

RB134

8

PWM_DIM

PWM_DIM

PWM_DIM

PWM_REF PWM_REF

PWM_REF

C C

GL1

GL2

和散热片之间

QB101

D D

1

EVA1 EVA2 EVA3

NC NC NC NC NC NC NC

MB1

GD1 GD2 GD3

EVA4 EVA5 EVA6 EVA7

ML1

Mylar

2

NC NC NC

HSB1HSHSB2

HS

SGND

HSB3

HSB4

HS

HS

1

2

1

2

1

2

1

2

12V

HS

RB816

12V

3

CB801

GND

4

UB802

1

VIN

2

GATE

GATE

3

GND

GND

COMP

4

PIN4 PIN5

CS

5

PWM_REF

PIN1

UB801

1

VIN

PWM

2

GATE

GATE

OVP

3

GND

COMP

4

CS

FB

PIN4

CB803

CB805

GND

CB812

10

PIN8PIN1

DIM

9

OVP

OVP

8

PIN6

7

FB

REF6ISET

CB811

GATE

GND

RB801

PWM_DIM

PIN8

CB807

8

7

6

5

PIN5

PIN6

RB804

GND

CB806

GND

RB806

RB805

CB804

GND

5

NC

RB803

LED_FB

LB802

6

2 5

VBL

LB801

QB801

RB807

G

RB809

OVP

RB808

NC

DB802

RB818

RB819

RB820

RB821

CB810

RB812

DB801

BB801

RB814

EB801+EB802

OVP

HS

D

S

RB810

GND

NC NC

CB809

6

LED+

+

+

EB803

GND

LED_FB

DB804

GND

AK

RB837

RB838

LED+

NC

RB839

CB808

NC

LED_FB

RB840

RB841

CNB805

CNB803

1

2

123

LED_FB

Model Name:

DRAWN: 林文添

CHK'D:

7

CNB804

CNB801

RB845

2

1

123

LED+

LED_FB

TP.S512.PB751 A14511

CNB806

CNB802

1

2

123

LED+

VERSION:

V1.0

DATE:

2015-01-07

DATE:

2015-01-07

8

Page 34

1

2

3

4

5

6

CD1

RD1

A A

12V

+

CD7

CD8

CD36

ED2

NC/100uF-16V-±20%-5×11-105

GND

NC/10uF-0805-X5R-±20%-16V

10uF-0805-X5R-±20%-16V

1uF-0402-X5R-±20%-16V

100Kohm-0402-±5%-1/16W

RD5

UD1

1

BS

4.5V~18V INPUT

VFB = 0.6V

500KHZ

5

IN

EN4GND

SYH113ADC

℃-黑底白字-编带

LX

-F=2.5-XF

B B

4K7ohm-0402-±5%-1/16W

10Kohm-0402-±5%-1/16WRM8

KMBT3904

1V0_M_EN

POW_EN

10Kohm-0402-±5%-1/16W

KMBT3904

RM7

QM8

GND

0ohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

LD1

6

3

FB

2

GND

470uF-10V-±20%-6.3×11-105℃-

RM13

CD3

RD7

5V_STB

RM5

QM4

CD6

CD4

RD3

GND

CTD0504-4R7-M

NC/22pF-0402-NPO-±5%-50V

47Kohm-0402-±1%-1/16W

6K2ohm-0402-±1%-1/16W

GND

NC/10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

10uF-0805-X5R-±20%-16V

黑底白字-编带

CM4

RM6

4K7ohm-0402-±5%-1/16W

100Kohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

WPM2341A-3/TR

0.1uF-0402-X5R-±20%-16V

GND

QM3

5V_STB

CD5

ED1

-F=2.5-XF

CM5

+

+5V

TEST

5V_M

GND

NC/10uF-0805-X5R-±20%-16V

10uF-0805-X5R-±20%-16V

1uF-0402-X5R-±20%-16V

12V

CD13

CD14

CD37

GND

1V0_M_EN

100ohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

CD2

RD2

UD2

1

BS

4.5V~18V INPUT

VFB = 0.6V

500KHZ

5

IN

4

EN

SYH112ADC

RD6

CD15

5V_STB 3V3_STB

CD22

LX

FB

GND

UD3

VI3VO

ADJ

6

3

2

GND

2

4

VO

1

GND

0.1uF-0402-X5R-±20%-16V

LC1117CLTR33

GND

0ohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

LD2

CD10

CD9

RD4

RD8

GND

CD17

CD16

GND

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

+1V

1V0_M

CD12

CD11

GND

CTD0504-4R7-M

NC/22pF-0402-NPO-±5%-50V

4K7ohm-0402-±1%-1/16W

6K04ohm-0402-±1%-1/16W

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

10uF-0805-X5R-±20%-16V

TEST

RM3

PANEL_EN

10Kohm-0402-±5%-1/16W

NC/10Kohm-0402-±5%-1/16W

KMBT3904

CD18

NC/10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

PVCC VCC_PANEL

RM1

CM2

RM2

LED-SHORT

RM4

GND

QM2

GND

5V_STB PVCC

4K7ohm-0402-±5%-1/16W

47Kohm-0402-±5%-1/16W

NC/0.22uF-0402-X5R-±10%-16V

ME2325-G

0.022uF-0402-X7R-±10%-50V

NC/10uF-0805-X5R-±20%-16V

NC/4K7ohm-0402-±5%-1/16W

R5V

NC/0ohm-0805-±5%-1/8W

UD4

2

CD19

VI3VO

CD20

4

ADJ

VO

1

GND GND

GND

LC1117CLTR33

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

1uF-0402-X5R-±20%-6.3V

CD21

QM1

D

S

CM3

CM1

RM121

G

GND

R12V

12V PVCCGND

0ohm-0805-±5%-1/8W

3V3_M5V_M

CD49

C C

1V5_DDR5V_M

CD24

CD25

GND

10uF-0603-X5R-±20%-6.3V

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

2

BL_ADJ

PWM0

RD14

GND

4K7ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

3

RD15

RD10

RD11

CD26

PWM_DIM

PWM_REF

CD27

510ohm-0402-±5%-1/16W

510ohm-0402-±5%-1/16W

47pF-0402-NPO-±5%-50V

1000pF-0402-X7R-±10%-50V

4

5

6

CD29

UD5

VI3VO

2

RD13

CD23

4

VO

ADJ

1

DD1

RD12

CD28

RD16

NC/M7(GOOD-ARK)

0ohm-0402-±5%-1/16W

NC/10uF-0603-X5R-±20%-6.3V

D D

0.1uF-0402-X5R-±20%-16V

GND

LC1117CLTRAD

470ohm-0402-±1%-1/16W

100ohm-0402-±1%-1/16W

GND

1

Page 35

1

CN1

RXP2_A

1

RX2+

2

GND

GND

RXM2_A

3

RX2-

RXP1_A

4

RX1+

5

GND

GND

RXM1_A

6

RX1-

RXP0_A

7

RX0+

GND

8

GND

RXM0_A

9

RX0-

10

RXCP_A

RXC+

GND

11

GND

12

RXCM_A

A A

HD-AF05-S011

HDMI

GND

GND

GND

GND

20

212223

RXC-

13

CEC_A

CEC

14

ARC

ARC

15

CH18 220pF-0402-X7R-±10%-50V

HDMIA_SCL/

SCL

16

HDMIA_SDA/

SDA

GND

17

GND

HDMIA_5V

18

+5V

HOTPLUG_A/

19

HPD

GND

GND

2

5V_STB

RH3

RH4

HDMIA_SCL/

HDMIA_SDA/

CH2

CH3

RH8

GND

HOTPLUG_A/

DH4

CH5

GND

10Kohm-0402-±5%-1/16W

47Kohm-0402-±5%-1/16W

22pF-0402-NPO-±5%-50V

22pF-0402-NPO-±5%-50V

NC/AVLC18S02003

NC/AVLC18S02003

DH1

DH2

CH4

RH31

GND

RH12

3

RH5

RH6

NC/1Mohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

HDMIA_5V

1000pF-0402-X7R-±10%-50V

NC/AVLC18S02003

NC/10Kohm-0402-±5%-1/16W

0ohm-0402-±5%-1/16W

1000pF-0402-X7R-±10%-50V

HPD_HDMI_A

SCL_HDMI_A

SDA_HDMI_A

4

5

CH1

ARC

0.1uF-0402-X5R-±20%-16V

82ohm-0402-±5%-1/16W

180ohm-0402-±5%-1/16W

RH7

3K3ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

6

RH1

HDMI_ARC

RH2

GND

ARC_DETHDMIA_5V

RH9

GND

3V3_STB

RH11

27Kohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

DH3

PMLL4148L-F

RH14

CEC_HDMICEC_A

CH6

CH7

100pF-0402-NPO-±5%-50V

NC/1000pF-0402-X7R-±10%-50V

GND

DH5

GND

NC/AVLC18S02003

CN3

RXP2_B

1

RX2+

2

MHL_DET

GND

RXM2_B

3

RX2-

RXP1_B

4

RX1+

5

GND

GND

RXM1_B

6

RX1-

7

RXP0_B

RX0+

8

GND

GND

9

RXM0_B

RX0-

RXCP_B

10

RXC+

GND

11

GND

RXCM_B

12

B B

HD-AF05-S011

HDMI

GND

GND

GND

GND

20

212223

RXC-

13

CEC_A

CEC

14

ARC

HDMIB_SCL/

15

SCL

16

HDMIB_SDA/

SDA

17

GND

GND

18

HDMIB_5V

+5V

HOTPLUG_B/

19

HPD

GND

GND

CH16

HDMIB_5V

UH1

VOUT

VIN

CE

ISET

GND

2

5V_STB

1

RH40

3

RH42

GND

GND

RH38

MHL_DET CD_SENSE

RH39

CH17

NC/33ohm-0402-±5%-1/16W

NC/300Kohm-0402-±5%-1/16W

1000pF-0402-X7R-±10%-50V

NC/10Kohm-0402-±5%-1/16W

GND

NC/100Kohm-0402-±5%-1/16W

GND

MHL_CD_SENSE

5V_STB

CH21

RH43

RH311

GND

5

4

NC/10uF-0603-X5R-±20%-6.3V

NC/4K7ohm-0402-±1%-1/16W

NC/SY6280AAC

NC/10uF-0603-X5R-±20%-6.3V

NC/NC/10Kohm-0402-±5%-1/16W

C C

1716

CN6

NC/WLHD-051A

GND

1

11

R

TXD

NC/100ohm-0402-±5%-1/16W

NC/100ohm-0402-±5%-1/16W

HS_VGA

VS_VGA VSYNC

NC/22pF-0402-NPO-±5%-50V

NC/22pF-0402-NPO-±5%-50V

100ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

SDA_VGA

D D

SCL_VGA

RV18

RV19

RV4

RV6

CV4

CV3

RV7

GND GND

GND

NC/10Kohm-0402-±5%-1/16W

NC/10Kohm-0402-±5%-1/16W

CV9

DV7

DV8

GND

RV8

CV8

DV4

DV3

NC/AVLC18S02003

NC/AVLC18S02003

TXD0/VGA_SDA

RXD0/VGA_SCL

33pF-0402-NPO-±5%-50V

NC/AVLC18S02003

NC/AVLC18S02003

220pF-0402-X7R-±10%-50V

SDA_VGA

HSYNC

SCL_VGA

6

GND

2

12

SDA

G

7

GND

DB15

3

13

HS

B

8

GND

4

14

VS

RXD

9

5V

5

15

SCL

DET

10

GND

GND

GND

CN8

NC/PJ-325

HDMIB_5V

10Kohm-0402-±5%-1/16W

5V_STB

47Kohm-0402-±5%-1/16W

22pF-0402-NPO-±5%-50V

RH15

RH16

22pF-0402-NPO-±5%-50V

NC/AVLC18S02003

HDMIB_SCL/

HDMIB_SDA/

RH23 1Mohm-0402-±5%-1/16W

NC/AVLC18S02003

CH8

CH9

DH6

DH7

68ohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

GND

HDMIB_5V

CH12

RH34

GND

HOTPLUG_B/

DH10

RH27

CH14

GND

CV1

RV1

VGA_RIN

NC/AVLC18S02003

NC/NC/10pF-0402-NPO-±5%-50V

NC/75ohm-0402-±5%-1/16W

RV3

NC/AVLC18S02003

NC/75ohm-0402-±5%-1/16W

NC/NC/10pF-0402-NPO-±5%-50V

RV9

RV10

NC/AVLC18S02003

NC/NC/10pF-0402-NPO-±5%-50V

NC/75ohm-0402-±5%-1/16W

NC/330ohm-0402-±1%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

CV2

VGA_GIN

NC/330ohm-0402-±1%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

CV5

VGA_BIN

NC/330ohm-0402-±1%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

DV1

RV2

CV10

GND

DV2

RV5

CV11

GND

DV5

CV12

GND

GND

NC/12Kohm-0402-±5%-1/16W

NC/12Kohm-0402-±5%-1/16W

CV6

CV7

RV13

RV20

NC/12Kohm-0402-±5%-1/16W

NC/12Kohm-0402-±5%-1/16W

1

GND

5

ERO

2

RSPK

3

LSPK

4

ELO

NC/NC/AVLC18S02003

NC/NC/AVLC18S02003

DV6

DV9

GND

RH19

RH21

NC/10Kohm-0402-±5%-1/16W

1000pF-0402-X7R-±10%-50V

NC/AVLC18S02003

1000pF-0402-X7R-±10%-50V

0ohm-0402-±5%-1/16W

HPD_HDMI_B

PC AUDIO_RIN

PC AUDIO_LIN

SCL_HDMI_B

SDA_HDMI_B

CN4

1

RX2+

2

GND

3

RX2-

4

RX1+

5

GND

6

RX1-

7

RX0+

8

GND

9

RX0-

10

RXC+

11

GND

12

RXC-

13

CEC

14

ARC

HDMI

HD-AF05-S011

RXP2_C

RXP1_C RXM1_C

RXP0_C RXM0_C

RXCP_C RXCM_C

HDMIC_SCL/ HDMIC_SDA/

GND GND

HDMIC_5V

GND

CEC_A

,connect jack,2×10Pin,D2.0,D,SNAP,Fool-proofing,Nature,L=2.6mm,DIP,CJ

连接插座

NC/

PC_RIN/

GND

PC/DVD-AR

DVD_RIN/

GND

GND

CN21

3

5 6

7

9

11

13

15

17

1

2

3

4

5

6

GND

GND

GND

20

212223

2

4

8

10

12

14

16

18

20119

UD6

0Y

2Y

Y

3Y

1Y

SW

VEE7A

VSS8B

CD4052

15

SCL

16

SDA

17

GND

18

+5V

19

HPD

RXM2_C

HOTPLUG_C/

GND

VDD

2X

1X

X

0X

3X

GND

RD44

PC AUDIO_RIN

RD45

PC AUDIO_LIN

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

CN5

USB-042M-002DP

NC/ULCE0505A015FR

NC/ULCE0505A015FR

USB0_5V

1

5V

USB0_DM

2

DM

USB0_DP

3

DP

4

GND

5

GND

6

GND

GND

NC/100uF-16V-±20%-5×11-105

10uF-0603-X5R-±20%-6.3V

RXP2_C

GND

RXM2_C

RXP1_C

GND

RXM1_C

RXP0_C

GND

RXM0_C

RXCP_C

GND

RXCM_C

CEC_A

HDMIC_SCL/

HDMIC_SDA/

GND

HDMIC_5V

HOTPLUG_C/

RXP2_C

RXP1_C RXM1_C

RXP0_C RXM0_C

RXCP_C RXCM_C

HDMIC_SCL/ HDMIC_SDA/

GND GND

HDMIC_5V

GND

CEC_A

+5V-ASW

16

15

14

GND

13

PC/DVD-AL

PC_LIN/

12

11

DVD_LIN/

10

9

100ohm-0402-±5%-1/16W

PC/DVD-AR

PC/DVD-AL

DU1

DU2

EU1

℃-黑底白字-编带

NC/2*10PIN-2.0-D-H-M

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

CN2

RD48

4052-ON/OFF

FU1

MSMD110

+

CU1

-F=2.5-XF

RXM2_C

HOTPLUG_C/

GND

5V_M

CN7

NC/USB-A/F-90°

HDMIC_5V

RH17

HDMIC_SCL/

HDMIC_SDA/

CH10

CH11

RH24

HOTPLUG_C/

DH11

CH15

GND

RD9

5V_M +5V_AUD

330ohm-0402-±5%-1/16W

10uF-0603-X5R-±20%-6.3V

NC/0.1uF-0402-X5R-±20%-16V

NC/200Kohm-0402-±5%-1/16W

CD41

PC AUDIO_RIN PC AUDIO_LIN PC_LIN/

0.1uF-0402-X5R-±20%-16V

200Kohm-0402-±5%-1/16W

CD43

1

USB0_5V

5V-1

USB1_DM

2

DM-1

USB1_DP

3

DP-1

GND

4

GND-1

5

USB0_5V

5V-2

6

USB0_DM

DM-2

7

USB0_DP

DP-2

8

GND

GND-2

NC/ULCE0505A015FR

GND

GND12GND

GND

9

NC/ULCE0505A015FR

101112

GND

10Kohm-0402-±5%-1/16W

5V_STB

47Kohm-0402-±5%-1/16W

RH18

22pF-0402-NPO-±5%-50V

22pF-0402-NPO-±5%-50V

NC/AVLC18S02003

NC/AVLC18S02003

DH8

DH9

1Mohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

GND

HDMIC_5V

CH13

RH33

GND

RH28

RD34

+5V-ASW

RD36

CD38

GND

+5V_AUD

NC/0.1uF-0402-X5R-±20%-16V

NC/200Kohm-0402-±5%-1/16W

RD35

1Kohm-0402-±5%-1/16W

GND

1Kohm-0402-±5%-1/16W

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

PC_RIN/

+5V_AUD

0.1uF-0402-X5R-±20%-16V

RD38

200Kohm-0402-±5%-1/16W

DVD_LINDVD_RIN

DVD_RIN/ DVD_LIN/

DU4

CN91

DU3

GND

RH20

SCL_HDMI_C

RH22

SDA_HDMI_C

HPD_HDMI_C

1000pF-0402-X7R-±10%-50V

NC/10Kohm-0402-±5%-1/16W

0ohm-0402-±5%-1/16W

1000pF-0402-X7R-±10%-50V

NC/AVLC18S02003

CD39

CD40

RD37

CD42

RD39

CD44

CN9

4

4

3

3

2

2

1

1

NC/4PIN-2.0-D-H-G

NC/4PIN-2.0-D-H-G-

USB0_5V

USB1_DM

USB1_DP

GND

-J

带扣

1

2

3

4

5

6

Page 36

1

AV2

PJ-320A(Φ5.5mm)

A A

CN11

NC/RCA-319N-004(

1

GND

2

AV-IN/Y

3

AV-R/Pr

4

AV-L/Pb

4700pF-0402-X7R-±10%-50V

1000pF-0402-X7R-±10%-50V

1

CVBS

2

GND

3

L

4

GND

5

R

6

GND

GND

黄、白、红)-密封

AV_IN/

AV_R

AV_L

AV_IN/

AV_R

AV_L

GND

CI6

CI5

GND

2

RI3

AV_IN/

DI2

CI4

RI4

AVLC18S02003

220pF-0402-X7R-±10%-50V

75ohm-0402-±5%-1/16W

150ohm-0402-±5%-1/16W

0.22uF-0402-X5R-±10%-16V

CI15

AV_R

DI7

CI16

RI23

GND

CI17

AV_L

DI8

CI18

RI24

GND

3

CI3

CVBS1_IN

RI21

AV_RIN

NC/AVLC18S02003

NC/220pF-0402-X7R-±10%-50V

0.1uF-0402-X5R-±20%-16V

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

RI22

AV_LIN

NC/AVLC18S02003

NC/220pF-0402-X7R-±10%-50V

0.1uF-0402-X5R-±20%-16V

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

4

NC/AVLC18S02003

180ohm-0402-±5%-1/16W

NC/100ohm-0402-±5%-1/16W

NC/0.1uF-0402-X5R-±20%-16V

NC/330pF-0402-X7R-±10%-50VGND

RI1

SPDIFO COAXSPDIF_OUT

DI1

RI2

GND

5V_M

RI5

SPDIF_OUT

COAX

0ohm-0402-±5%-1/16W

5

AV3

GQ-03-08C

IR Transmitter

Vin

Vcc

GND

GND

GND

CI2

AV1

COAX

1

2

GND

NC/AV19-01S-0020(橙)-

CI1

1

2

3

4

5

6

密封

GND

YPbPr_Y

DI3

RI6

CI19

AVLC18S02003

56pF-0402-NPO-±5%-50V

75ohm-0402-±5%-1/16W

AV5

B B

PJ-320A(Φ5.5mm)

GND

1

GND

2

YPbPr_Y

AV-IN/Y

3

YPbPr_Pr

AV-R/Pr

YPbPr_Pb

4

AV-L/Pb

YPbPr_Pb

YPbPr_Pr

GND

DI4

RI7

CI20

AVLC18S02003

56pF-0402-NPO-±5%-50V

75ohm-0402-±5%-1/16W

GND

DI5

RI8

CI21

AVLC18S02003

56pF-0402-NPO-±5%-50V

75ohm-0402-±5%-1/16W

RI14

YPbPr_Y

RI15

YPbPr_Pb

RI16

YPbPr_Pr Y_Pr

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

Y_Y

Y_Pb

Y_Y

Y_Pb

Y_Pr

CI11

RI17

CI12

RI18

CI13

RI19

CI14

RI20

SOY2_IN

Y2_IN

PB2_IN

PR2_IN

330ohm-0402-±5%-1/16W

0.047uF-0402-X7R-±10%-16V

150ohm-0402-±5%-1/16W

0.047uF-0402-X7R-±10%-16V

150ohm-0402-±5%-1/16W

0.047uF-0402-X7R-±10%-16V

150ohm-0402-±5%-1/16W

0.047uF-0402-X7R-±10%-16V

GND

5V_VMUX 2V5_CLAMP

GND

GND

RD25

RD24

CND2

NC/11PIN-2.0-D-H-G

CND21

1

2

3

4

C C

5

6

7

8

9

10

11

DVD_EN

D D

10Kohm-0402-±5%-1/16W

10Kohm-0402-±5%-1/16W

KMBT3904

1

RD23

CD33 NC/100pF-0402-NPO-±5%-50V

GND

1

DVD_Y

2

GND

3

4

DVD_Pr

GND

5

DVD_Pb

6

DVD_L_IN DVD_LIN

7

8

9

10

11

GND

DVD_R_IN

GND

DVD_SPDIFIN

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

带扣

11PIN-2.0-D-H-G-

CD34

CD35

-J

12V 12V_OFF

RM9

QM6

RM11

RM12

RD31

RD32

GND

S

CM6

RM10

ON/OFF

4K7ohm-0402-±5%-1/16W

100Kohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

ME2325-G

0.1uF-0402-X5R-±20%-16V

75ohm-0402-±5%-1/16W

75ohm-0402-±5%-1/16W

75ohm-0402-±5%-1/16W

DVD_SPDIFIN SPDIFIN

GND

QM5

G

GND

2

DI6

D

DVD_RIN

R3

RD321

CM7

GND

12V_OFF

12V_OFF

GND

GND

NC/4PIN-2.0-D-H-

NC/4PIN-2.0-D-H-

RI9

YPbPr_Y

YPbPr_Pb

YPbPr_Pr

RI10

RI11

CI7

GND

CI8

CI9

CI10

0.47uF-0402-Y5V-+80%-20%-10V

0.47uF-0402-Y5V-+80%-20%-10V

0.47uF-0402-Y5V-+80%-20%-10V

NC/AVLC18S02003

NC/22ohm-0402-±5%-1/16W

NC/100Kohm-0402-±5%-1/16W

RI12

RI13

1Kohm-0402-±5%-1/16W

470ohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

200Kohm-0402-±5%-1/16W

200Kohm-0402-±5%-1/16W

200Kohm-0402-±5%-1/16W

YPbPr_Y/

YPbPr_Pb/

YPbPr_Pr/

MUX_VSW1

YPbPr_Pb/

DVD_Pb

Y_Pb

YPbPr_Y/

DVD_Y

Y_Y

GND

UC1

SGM330A-YQS/TR-(C)

1

S

2

I0A

3

I1A

4

YA

5

I0B

6

I1B

7

YB

8

GND

控制逻辑

YPbPr

DVD01

5V_M 5V_VMUX

16

VCC

15

E

14

I0D

13

I1D

12

YD

11

I0C

10

I1C

9

YC

MUX_VSW1

RC1

GND

GND

GND

GND

YPbPr_Pr/

DVD_Pr

Y_Pr

0.1uF-0402-X5R-±20%-16V

100ohm-0402-±5%-1/16W

CC1

GND

RD26

DVD_Y

RD27

DVD_Pb

RD29

DVD_Pr Y_Pr

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

Y_Y

Y_Pb

GND

5V_STB

10Kohm-0402-±5%-1/16W

10Kohm-0402-±5%-1/16W

KMBT3904

CN101

DVD5V_EN

CN10

4

4

3

3

2

2

1

1

-G

蓝色

-G-带扣-J

蓝色

RM14

RM16

RM17

3

QM9

GND

CM8

RM15

4K7ohm-0402-±5%-1/16W

100Kohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

WPM2341A-3/TR

0.1uF-0402-X5R-±20%-16V

NC/0ohm-0402-±5%-1/16W

4

DVD_5V

QM7

CM9

GND

RM18

ON/OFF

CND11

CND1

DVD_5V

8

8

7

7

DVD_5V

6

GND

6

5

5

GND

12V_OFF

4

4

3

3

2

1

RD20

2

RD21

1

RD22

CD30

CD31

CD32

GND

5

带扣

8PIN-2.0-D-H-G-

-B

NC/8PIN-2.0-D-H-G

3V3_M

RD17

NC/10Kohm-0402-±5%-1/16W

NC/10Kohm-0402-±5%-1/16W

10Kohm-0402-±5%-1/16W

RD19

RD18

100ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

NC/0.1uF-0402-X5R-±20%-16V

NC/0.1uF-0402-X5R-±20%-16V

NC/0.1uF-0402-X5R-±20%-16V

DVD_IR

DVD_DAT

DVD_STB

6

Page 37

1

2

3

4

5

6

A A

FCM1005KF-121T06(120ohm-500mA)

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

CI_IOWR

CI_IORD

0ohm-0402-±5%-1/16W

0ohm-0402-±5%-1/16W

NC/10pF-0402-NPO-±5%-50V

B B

LC1

RC14

RC12

0ohm-0402-±5%-1/16W

0ohm-0402-±5%-1/16W

V_5V_CI5V_M

CC7

CC6

GND

RC10

CI_OE

CC5

RC11

CI_WE

GND

GND

AV13

51

VCC

17

VCC

30

CI_D0

D0

31

CI_D1

D1

32

CI_D2

D2

2

CI_D3

D3

3

CI_D4

D4

4

CI_D5

D5

5

CI_D6

D6

6

CI_D7

D7

CI_WAIT

WAIT#59INPACK#

16

CI_IRQ

IRQ#

58

CI_RST

RESET

45

PC_IOW

IOWR#

44

PC_IOR

IORD#

9

ROM_OE

OE#

15

FLASH_WE TSO_VAL

WE#

61

CI_REG_N

REG#

14

A14

13

A13

21

A12

10

CI_A11/TSO_D0

A11

8

CI_A10/TSO_D1

A10

11

CI_A9/TSO_D2

A9

12

CI_A8/TSO_D3

A8

22

CI_A7/TSO_D4

A7

23

CI_A6/TSO_D5

A6

24

CI_A5/TSO_D6

A5

25

CI_A4/TSO_D7

A4

26

CI_A3

A3

27

CI_A2

A2

28

CI_A1

A1

29

CI_A0

A0

34

GND

35

GND

1

GND

68

GND

PC-CL1D-PV-A03-C-03

GND

SCART_VIN CVBS2_IN

CS6

DS2

CN12

SC_ROUT

1

AR-OUT

SC_RIN

2

AR-IN

SC_LOUT

3

AL-OUT

GND

4

NC/CS-116B-EP-

A-GND

GND

5

B-GND

SC_LIN

6

AL-IN

SCART_Bin

7

B-I/O

8

SCART1_FUNSEL

FSW-I/O

9

GND

G-GND

10

CLK-OUT

11

SCART_Gin

G-I/O

12

DATA

13

GND

R-GND

GND

14

D-GND

SCART

SCART_Rin

15

R-I/O

FSCART_FB

16

BK-I/O

GND

17

V-GND

GND

18

BK-GND

SCART_VOUT

19

V-OUT

SCART_VIN

20

V-IN

21

GND

GND

密封

C C

SC_RIN

SC_LIN

GND

DS4

CI22

GND

DS8

CI23

GND

CN13

CVBS

GND

L

GND

R

GND

黄、白、红)-密封

RCA-319N-004(

D D

SCART_VIN

1

2

SC_LIN

3

4

5

SC_RIN

6

DS10 NC/NC/AVLC18S02003

GND

V_5V_CI

18

VPP1

52

VPP2

RC8 22ohm-0402-±5%-1/16W

7

CI_CE1

CE1#

42

CE2#

67

CD2#

36

CD1#

43

VS1#

33

IOIS16#

60

46

MISTRT

20

MCLKI

19

MIVAL

47

MDI0

48

MDI1

49

MDI2

50

MDI3

53

MDI4

54

MDI5

55

MDI6

56

MDI7

63

MOSTRT

57

RC5 22ohm-0402-±5%-1/16W

MCLKO

62

MOVAL

64

TSI_D0

MDO0

65

TSI_D1

MDO1

66

TSI_D2

MDO2

37

TSI_D3

MDO3

38

TSI_D4

MDO4

39

TSI_D5

MDO5

40

TSI_D6

MDO6

41

TSI_D7

MDO7

69

GND

70

GND

CI_A11/TSO_D0

CI_A10/TSO_D1

CI_A9/TSO_D2

CI_A8/TSO_D3

CI_A7/TSO_D4

CI_A6/TSO_D5

CI_A5/TSO_D6

CI_A4/TSO_D7

CIIN_CD1

TSI_SYNC

TSI_VAL

TSO_SYNC

GND

CI_CE

CC4

GND

RC2

CC2

NC/10pF-0402-NPO-±5%-50V

22ohm-0402-±5%-1/16W

TSI_CLK

1Kohm-0402-±5%-1/16W

CC3

NC/10pF-0402-NPO-±5%-50V

GND

NC/10pF-0402-NPO-±5%-50V

TSO_CLK

GND

SCART_Gin

RS2

SCART1_FUNSEL SCART_FSFSCART_FB SCART_FB

DS1

GND

DS5

GND

SCART_Rin

DS9

GND

RS14

RS19

DS11

GND

CS3

RS4

RS7

0.22uF-0402-X5R-±10%-16V

AVLC18S02003

NC/220pF-0402-X7R-±10%-50V

75ohm-0402-±5%-1/16W

150ohm-0402-±5%-1/16W

CS11

RS11

RI25

AVLC18S02003

1500pF-0402-X7R-±10%-50V

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

RS17

RI26

AVLC18S02003

1500pF-0402-X7R-±10%-50V

12Kohm-0402-±5%-1/16W

12Kohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

SC_RIN/

CS13

SC_LIN/

RS23

RS27

CS18

NC/75ohm-0402-±5%-1/16W

NC/220ohm-0402-±5%-1/16W

GND GND

GND

NC/100pF-0402-NPO-±5%-50V

GND

CI_REG_N

RS24

RS28

RC20

CS1

RS1

Y1_IN

NC/AVLC18S02003

NC/75ohm-0402-±5%-1/16W

NC/150ohm-0402-±5%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

CS12

RS12

PB1_INSCART_Bin

NC/AVLC18S02003

NC/75ohm-0402-±5%-1/16W

NC/150ohm-0402-±5%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

CS14

RS18

PR1_IN

NC/AVLC18S02003

NC/75ohm-0402-±5%-1/16W

NC/150ohm-0402-±5%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

RS25

NC/NC/AVLC18S02003

NC/22Kohm-0402-±5%-1/16W

NC/6K8ohm-0402-±5%-1/16W

NC/1Kohm-0402-±5%-1/16W

CN17

NC/RCA-319N-004(

SC_LOUT/

SC_ROUT/ SC_ROUT

NC/330ohm-0402-±5%-1/16W

NC/330ohm-0402-±5%-1/16W

NC/NC/0.01uF-0402-X7R-±10%-16V

NC/NC/0.01uF-0402-X7R-±10%-16V

SCART_VOUT SCART_VOUT/

1

SCART_VIN

CVBS

2

GND

3

SC_LIN

L

4

GND

5

SC_RIN

R

6

GND

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

GND

NC/0ohm-0402-±5%-1/16W

黄、白、红)-密封

CS4

RS5

CS7

CS8

GND GND GND

NC/1uF-0402-X5R-±20%-6.3V

NC/1uF-0402-X5R-±20%-6.3V

RS15

DS6

DS7

GND

GND

RS10

SCART_VOUT

RS16

SC_LOUT

RS21

SC_ROUT

RS8

RS9

NC/10ohm-0402-±5%-1/16W

RS33

NC/150ohm-0402-±5%-1/16W

NC/AVLC18S02003

NC/NC/AVLC18S02003

GND

CN18

NC/RCA-319N-002(

CS9

NC/AVLC18S02003

NC/AVLC18S02003

NC/4700pF-0402-X7R-±10%-50V

NC/4700pF-0402-X7R-±10%-50V

CS2

RS3

SCART_Gin

SC_LOUT

CS10

1

SCART_VIN

Y

2

GND

3

Pb

4

GND

5

Pr

6

GND

GND

绿、蓝、红)-密封

RS13

RS20

SC_LIN

RS22

SC_RIN

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

RS6

RS61

NC/330ohm-0402-±5%-1/16W

NC/0.047uF-0402-X7R-±10%-16V

NC/330ohm-0402-±5%-1/16W

SCART_Gin

SCART_Bin

SCART_Rin

CS5

SOY1_INSCART_VIN

Title

Number RevisionSize

A4

Date: 2015/2/26 Sheet of

1

2

3

4

5

File: C:\Users\..\TV#05_SCART&PCMCIA&KEY.SchDocDrawn By:

6

Page 38

1

3V3_STB

AUXOK

R9

C4

GND GND

1Kohm-0402-±5%-1/16W

NC/1uF-0402-X5R-±20%-10V

NC/10Kohm-0402-±5%-1/16W

AUX_PWROK

R11

A A

Crystal Circuit

C5

GND

HW Trap

Y1

C6

Cload: 16pF

33pF-0402-NPO-±5%-50V

33pF-0402-NPO-±5%-50V

24.576MHz-±30PPM-20PF-HC-49S-SMD

R15

4K7ohm-0402-±5%-1/16W

GND

B B

C C

D D

3V3_STB

R27

SPI_CLK

SPI_CS0_N

FLASH_SPI_DI

C31

GND

1

XTALO

XTALI

U2

1

CS#

2

SO

HOLD#

3

WP#

SCLK

Vss4SI

GD25Q64BSIG

10Kohm-0402-±5%-1/16W

0.1uF-0402-X7R-±10%-16V

0.1uF-0402-X5R-±20%-16V

8

Vcc

7

SPI_CLK

6

5

SPI_DO

BL_ADJ

NC/1uF-0402-X5R-±20%-16V

Close to IC

For ESD

PC/DVD-AL

PC/DVD-AR

4.7uF-0603-X5R-±10%-10V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

3V3_STB

C30

GND

SPDIFIN

C13

RXE2_P

RXE2_N

RXE1_P

RXE1_N

RXE0_P

RXE0_N

RXO4_P

RXO4_N

RXO3_P

RXO3_N

RXOC_P

RXOC_N

RXO2_P

RXO2_N

RXO1_P

RXO1_N

RXO0_P

RXO0_N

SCART_FS

SCART_FB

DVD_DAT

DVD_EN

DVD_IR

DVD_STB

3V3_M

1V0_M

KEYPAD0

KEYPAD1

3V3_STB

XTALI

XTALO

POW_EN

IR_DAT

SPI_DO

SPI_CLK

FLASH_SPI_DI

SPI_CS0_N

R1 330ohm-0402-±5%-1/16W

LED_G_ON

ARC_DET

LED_R/

MUTE_AMP

PWM0

AUX_PWROK

1V0_M

PANEL_EN

CD47

CD48

M_SCL/

M_SDA/

2

5V_ANT_ON/OFF

4052-ON/OFF

MUX_VSW1

SPDIFO

C14

VBG_AU

AV_LIN

AV_RIN

SC_LIN/

SC_RIN/

3V3_M

RF3

RF5

RF6

NC/22pF-0402-NPO-±5%-50V

2

1

LVA_CKP

2

LVA_CKN

3

LVA_TXP3

4

LVA_TXN3

5

LVA_TXP4

6

LVA_TXN4

7

LVB_TXP0

8

LVB_TXN0

9

LVB_TXP1

10

LVB_TXN1

11

LVB_TXP2

12

LVB_TXN2

13

LVB_CKP

14

LVB_CKN

15

LVB_TXP3

16

LVB_TXN3

17

LVB_TXP4

18

LVB_TXN4

19

KEY2

20

KEY3

21

RMIIMDIO/SW0

22

RMIIMDC

23

RMII50MCK

24

RMIIRXER/I2S_SCK

25

RMIIRXD0/DVD_AUTO

26

RMIIRXD1

27

RMIIRXDV/SPDIF_IN

28

RMIITXEN/DVD ONOFF

29

RMIITXD0/DVD_IR

30

RMIITXD1/DVD_STB

31

OVDD3P3

32

IVDD1P0

33

VSS1P5_DDR

34

IVDD1P0

35

KEY0

36

KEY1

37

OVDD3P3_AUX

38

OSCI

39

OSCO

40

PWRSW

41

BL_ON/GPIO30(PM)

42

BL_ADJ/GPIO35(PM)

43

IR

44

SPI_DO

45

SPI_CKO/ENTEST

46

SPI_DI

47

SPI_CSN0

48

AUX_I2CM_SDA1

49

AUX_I2CM_SCL1

50

LRSYNC/SPDIF_IN

51

SPK_MUTE/GPIO6(PM)

52

PWM0/GPIO27(PM)

53

SPDIFO/ENDEBUG

54

AUXOK

55

LCD_EN/GPIO43(PM)

56

IVDD1P0

57

VBG_AU

58

AVSS3P3_AU

59

LINEIN_L3

60

LINEIN_R3

61

LINEIN_L2

62

LINEIN_R2

63

LINEIN_L1

64

LINEIN_R1

RF4

M_SCL

M_SDA

CF1

3V3_M

GND

257

PAD

3V3_M 3V3_M

4K7ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

CF2NC/22pF-0402-NPO-±5%-50V

RXE3_N

RXEC_P

RXEC_N

255

253

256

254

LVA_TXP2

LVA_TXN2

LVA_TXN1

AVDD3P3_LVDS

LVDS

LVDS

Audio Out

Audio In

65

SPK_L

SC_LOUT/

SC_ROUT/

3

360ohm-0402-±1%-1/16W

NC/10Kohm-0402-±5%-1/16W

R10

1V0_M

AVDD3P3_MCPLL

1V5_DDR

R12

1V0_M

RXE4_P

RXE4_N

RXE3_P

251

252

250

LVA_TXP1

LVA_TXN0

EFUSE

DDR_ZQ

241

245

246

239

238

237

243

242

244

247

249

LVA_TXP0

VDD1P5_DDR

240

248

NF_IO7

NF_IO6

CK_MA

DDR_ZQ

IVDD1P0

IVDD1P0

EFUSE_GND

VDDQ1P5_DDR

VDDQ1P5_DDR

NF_DQS/I2S_MCK

AVDD3P3_MCPLL

RGB - CVBS

UARTA_TX/VGA_SDA73UARTA_RX/VGA_SCL74VGA_HS75VGA_VS

AVDD3P3_BGP

SPK_R69SPK_L68LINEOUT_R67LINEOUT_L66AVDD3P3_AU

70

SPK_R

HP_L

3V3_M

AVDD3P3_HSADC

IVDD1P0

VGA_B080VGA_G081VGA_REF82VGA_R083AVDD1P0_HSADC89YPP_SOG2

HP_R

AVDD3P3HP_AU71HP_L

76

78

79

77

72

HS_VGA

VS_VGA

C1

HP_R

RXD0/VGA_SCL

TXD0/VGA_SDA

15pF-0402-NPO-±5%-50V

VGA_REF

VGA_BIN

VGA_GIN

VGA_RIN

GND

SOY1_IN

1V0_M 1V0_M

5V_STB

RV11

RV12

4K7ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

TXD0/VGA_SDA

RXD0/VGA_SCL

SDA

SCL

3

TSO_SYNC

230

236

235

234

233

232

231

NF_IO5

NF_IO4

NF_IO3

NF_IO2

NF_IO1

NF_IO0

NF_WPN

S2T512

YPP_SOG184YPP_G185YPP1_REF86YPP_B187YPP_R1

88

91

PB1_IN

PR1_IN

Y1_IN

YPBPR1_GREF

SOY2_IN

YPBPR2_GREF

1V0_M

3V3_M 3V3_M

TSO_CLK

TSO_VAL

CI_D2

CI_D1

CI_A4/TSO_D7

CI_A2

CI_A1

CI_A3

CI_D0

CI_A0

CI_A5/TSO_D6

CI_WAIT

CI_RST

229

228

227

TS_CLK

TS_VALID

TS_FRAME

218

225

226

224

223

222

221

220

219

217

216

CI_DAT2

CI_DAT1

CI_DAT0

CI_ADD0

CI_ADD1

CI_ADD2

CI_ADD3

OVDD3P3

CI_RESET

CI_WAIT_N

CI_ADD4/TS_DAT7

YPP_G292YPP2_REF90YPP_B293YPP_R2

AV_Y196AV_Y295AV_REF97IVDD1P0

AVDD3P3_ATV

ATV_CVBSO99DMVINP_I

DMVINN_I

DMVINN_Q

98

100

101

102

IF_IP

IF_IN

C23

C24

SCART_VOUT/

CVBS2_IN

CVBS1_IN

AV_REF

GND

3V3_M

AVDD1P0_DM

NC/22pF-0402-NPO-±5%-50V

NC/22pF-0402-NPO-±5%-50V

NC/22pF-0402-NPO-±5%-50V

NC/22pF-0402-NPO-±5%-50V

AVDD1P0_DM

104

103

IF_QN

C25

C26

GND

105

IF_QP

AVDD3P3_DM

94

PB2_IN

PR2_IN

Y2_IN

4

TSI_D4

TSI_D5

TSI_D3

CI_A7/TSO_D4

CI_A6/TSO_D5

CI_A8/TSO_D3

CI_WE

CI_A9/TSO_D2

CI_IRQ

CI_IOWR

CI_D6

CI_CE

CI_A10/TSO_D1

CI_A11/TSO_D0

CI_OE

CI_IORD

212

209

215

214

213

211

210

207

206

205

204

203

202

208

CI_OE_N

CI_WE_N

CI_IRQ_N

CI_ADD5/TS_DAT6

CI_ADD6/TS_DAT5

CI_ADD7/TS_DAT4

CI_ADD8/TS_DAT3

CI_DAT6

OVDD3P3

CI_CE1_N

CI_IORD_N

CI_IOWR_N

CI_ADD9/TS_DAT2

CI_ADD10/TS_DAT1

CI_ADD11/TS_DAT0

CI

IF HDMI

I2CM_SCL/GPIO5(PM)

I2CM_SDA/GPIO15(PM)

IFGAIN

AVDD3P3_DM

DMVINP

DMVINN

DMVINP_Q

VBG_DM

AVSS3P3_DM

108

111

107

106

110

109

LIFP

LIFN

VBG_DM

C27

GND

IVDD1P0

T2_FEF/I2S_SD0

RFGAIN/I2S_WS

DISEQ_I/HP_DET

DISEQ_O

OVDD3P3

115

114

113

119

112

116

117

118

M_SCL

M_SDA

HP_DET

D_IFAGC

DISEQC_OUT

1V0_M

3V3_M

CI_D7

201

CI_DAT7

HDMIA_RXCN

120

RXCM_A

CI_D5

CIIN_CD1

CI_D4

198

200

199

CI_DAT5

CI_DAT4

CI

USB HDMI

HDMIA_RXCP

HDMIA_RX0N

121

122

123

RXCP_A

RXM0_A

RXP0_A

CI_D3

197

196

195

194

CI_DAT3

CI_CD1_N

CATS_DAT3

CATS_DAT4

CATS_DAT5

AVDD3P3_HDMI_AUX_T

HDMIA_RX0P

HDMIA_RX1N

HDMIA_RX1P

HDMIA_RX2N

HDMIA_RX2P

124

125

126

127

RXP2_A

RXM2_A

RXM1_A

RXP1_A

AVDD3P3_HDMI

TSI_D6

193

CATS_DAT6

CATS_DAT7

CATS_CLK

CATS_VALID

CATS_FRAME

CATS_DAT0

CATS_DAT1

CATS_DAT2

NF_RBN

NF_REN

NF_WEN

NF_ALE

NF_CLE

NF_CEN1

NF_CEN0

OVDD3P3

IVDD1P0

AVDD3P3_USB

USB_DP1

USB_DM1

USB_DP0

USB_DM0

IVDD1P0

IVDD1P0

VDDQ1P5_DDR

VDDQ1P5_DDR

VDD1P5_DDR

DDR_CMPP

DDR_VREF

IVDD1P0

IVDD1P0

IVDD1P0

IVDD1P0

IVDD_SEL

HDMI_ARC

HDMI_CEC

CD_SENSE

HDMIA_SCL

HDMIA_SDA/5V_DCT

HDMIB_SCL

HDMIB_SDA/5V_DCT

HDMIC_SCL

HDMIC_SDA/5V_DCT

HDMIA_HPD/CBUSA

HDMIB_HPD/CBUSB

HDMIC_HPD

VBUS_EN

AVDD1P0_HDMI

HDMIC_RX2P

HDMIC_RX2N

HDMIC_RX1P

HDMIC_RX1N

HDMIC_RX0P

HDMIC_RX0N

HDMIC_RXCP

HDMIC_RXCN

HDMIB_RX2P

HDMIB_RX2N

HDMIB_RX1P

HDMIB_RX1N

HDMIB_RX0P

HDMIB_RX0N

HDMIB_RXCP

HDMIB_RXCN

AVDD3P3_HDMI

128

4.7uF-0603-X5R-±10%-10V

C28

C32

68ohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

R25

GND

R28

GND

YPBPR1_GREF VGA_REF

0.047uF-0402-X7R-±10%-16V

0.047uF-0402-X7R-±10%-16V

4

U1

,IC Main Chip,9206B,32bit,Single-Core,LQFP256,SMD,S2-Tek

主芯片

192

TSI_D7

191

TSI_CLK

190

TSI_VAL

189

TSI_SYNC

188

TSI_D0

187

TSI_D1

186

TSI_D2

185

184

183

182

181

180

179

178

177

176

175

USB1_DP

174

USB1_DM

173

USB0_DP

172

USB0_DM

171

170

169

168

167

166

165

164

163

162

161

160

DVD5V_EN

159

HDMI_ARC

158

CEC_HDMI

157

CD_SENSE

156

SCL_HDMI_A

155

SDA_HDMI_A

154

SCL_HDMI_B

153

SDA_HDMI_B

152

SCL_HDMI_C

151

SDA_HDMI_C

150

149

HPD_HDMI_A

148

HPD_HDMI_B

147

HPD_HDMI_C

MHL_CD_SENSE

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

RXP2_C

RXM2_C

RXP1_C

RXM1_C

RXP0_C

RXM0_C

RXCP_C

RXCM_C

RXP2_B

RXM2_B

RXP1_B

RXM1_B

RXP0_B

RXM0_B

RXCP_B

RXCM_B

C29

C33

AV_REFYPBPR2_GREF

0.047uF-0402-X7R-±10%-16V

0.22uF-0402-X5R-±10%-16V

5

3V3_M

1V0_M

3V3_M

1V0_M

1V5_DDR

1V0_M

AVDD3P3_HDMI_AUX_T

AVDD1P0_HDMI

R26

R29

68ohm-0402-±5%-1/16W

68ohm-0402-±5%-1/16W

5

6

CN14

VCC_PANEL

VCC_PANEL

GND

RXO0_N

RXO2_N

GND

3V3_M

RXE0_N RXE0_P

RXE2_N

RF1

GND GND

RXEC_N RXEC_P

RXE3_N

GND

CON1/

M_SCL/

RXO4_N

RXE4_N

NC/2×20PIN-2.0-D-H-M(

RXOC_N

RXOC_P

RXEC_N

RXEC_P

,connect jack,2×20Pin/without pin6,D2.0,D,SNAP,Fool-proofing,Nature,L=2.6mm,DIP,CJ

连接插座

VCC_PANEL

VCC_PANEL

GND

RXO0_N

RXO1_N

RXO2_N

GND

RXOC_N

RXO3_N

RXE0_N

RXE1_N

RXE2_N

GND

RXEC_N

RXE3_N

GND

CON1/

M_SCL/

RXO4_N

RXE4_N

5V_STB

RK18

RK19

CK6

14

5V

13

RED

12

GRN

11

IR

10

GND

9

K0/S

8

K1/C+

7

K2/C-

6

K3/V+

5

K4/V-

4

K5/M

3

K6/P

2

K7/N

1

GND

S1

1 2

3 4

IR_DAT

4K7ohm-0402-±5%-1/16W

27pF-0402-NPO-±5%-50V

1Kohm-0402-±5%-1/16W

5V_IR

LED_R

LED_G/B

IR

GND

K0/AD

K1

RK27

K2

RK28

K3

RK29

K4

RK30

K5

RK31

K6/AD

K7

RK32

GND

1K5ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

12Kohm-0402-±1%-1/16W

K7

GNDGND

DK1

CNK21

IR

GND

1000pF-0402-X7R-±10%-50V

1000pF-0402-X7R-±10%-50V

1000pF-0402-X7R-±10%-50V

22ohm-0402-±5%-1/16W

1Kohm-0402-±5%-1/16W

CNK2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

NC/14PIN-2.0-D-H-G

14PIN-2.0-D-H-G-带扣-B

AVLC18S02003

1000pF-0402-X7R-±10%-50V

TS071H1-A38F-100(C5)

GND

GND

Title

Number RevisionSize

A4

Date: 2015/2/26 Sheet of

File: C:\Users\..\TV#06_S2T512.SchDoc Drawn By:

VCC_PANEL

1 2

GND

3 4

5

7 8

RXO0_P

9 10

RXO1_PRXO1_N

11 12

RXO2_P

GND

13 14

RXOC_PRXOC_N

15 16

RXO3_PRXO3_N

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

R14

C7 NC/5pF-0402-NPO-±5%-50V

C8

C9

C10

RXE1_PRXE1_N

RXE2_P

RXE3_P

GND

Display

M_SDA/

RXO4_P

RXE4_P

脚长

=2.6mm)-LK(缺第6PIN)

DisplayPWM_DIM

GND

GND

CN141

2

1

4

3

5

8

7

10

9

12

11

14

13

16

15

18

17

20

19

22

21

24

23

26

25

28

27

30

29

313332

34

353736

38

39 40

1K5ohm-0402-±5%-1/16W

NC/MMBT3904(f≥350MHz)

220ohm-0402-±5%-1/16W

NC/10Kohm-0402-±5%-1/16W

LED_G_ON

LED_R

3V3_M

RF2

NC/100ohm-0402-±5%-1/16W

100ohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

NC/5pF-0402-NPO-±5%-50V

NC/5pF-0402-NPO-±5%-50V

NC/5pF-0402-NPO-±5%-50V

VCC_PANEL

GND

RXO0_P

RXO1_P

RXO2_P

GND

RXOC_P

RXO3_P

RXE0_P

RXE1_P

RXE2_P

GND

RXEC_P

RXE3_P

GND

Display

M_SDA/

RXO4_P

RXE4_P

RK21

RK22

5V_M

RK20

GND

1Kohm-0402-±5%-1/16W

1000pF-0402-X7R-±10%-50V

AVLC18S02003

1000pF-0402-X7R-±10%-50V

CK1

CK7

CK8

RK23

RK25

DK3

DK4

KEY0

CK2

KEY1

GND

5V_STB

LED_R/

RK24

CK9

CK10

RK34

4K7ohm-0402-±5%-1/16W

12Kohm-0402-±1%-1/16W

9K1ohm-0402-±5%-1/16W

按键参数值

按键

K0

K1

K2

K3

K4

K5

K6

K7(

保留

)

AVLC18S02003

1Kohm-0402-±5%-1/16W

4K7ohm-0402-±1%-1/16W

4K7ohm-0402-±1%-1/16W

3V3_STB

RK26

GND

GND

RK33

3V3_STB

下拉电阻

/ KohmADC分压 / V

0

1.5

4.7

12

4.7

12

0

1.5

6

LED_G/B

QK2

KEYPAD0

KEYPAD1

0

0.798

1.650

2.371

1.650

2.371

0

0.798

Page 39

1

ADC POWER/GND (1.0V/3.3V)

1V0_M

A A

0.1uF-0402-X5R-±20%-16V

3V3_M

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

Pin89

C4310uF-0603-X5R-±20%-6.3V

GND

Pin78 Pin79

C45

GND

C44

C46

2

HDMI POWER/GND (1.0V/3.3V)

R30

0ohm-0402-±5%-1/16W

1uF-0402-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

IVDD POWER (1.0V)

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

1V0_M

3

3V3_M 1V0_M AVDD1P0_HDMIAVDD3P3_HDMI3V3_STB AVDD3P3_HDMI_AUX_T

R31

C36

C35

0ohm-0402-±5%-1/16W

1uF-0402-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

GND GND

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

C52

C51

C48

C50

C38

C37

1uF-0402-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

Pin161/162/163/164

C53

4

R32

0ohm-0402-±5%-1/16W

1uF-0402-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

Pin170/171Pin119 Pin247Pin98Pin77Pin32/34

C54

C55

GND

Pin145Pin128Pin150

C34

Pin177

C40

C56

Pin242

5

PLL POWER/GND (3.3V)

C57

3V3_M

0ohm-0402-±5%-1/16W

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

C58

R33

AVDD3P3_MCPLL

Pin243

C41

GND

6

C42

B B

AUDIO POWER/GND (3.3V)

3V3_M

Pin65

C62

1uF-0402-X5R-±20%-6.3V

1uF-0402-X5R-±20%-6.3V

C C

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

3V3_M 3V3_STB

Pin31

Pin118 Pin208Pin178 Pin225

C71

GND GND

0.1uF-0402-X5R-±20%-16V

3.3V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

C73

C72

C74

Pin71

C63

GNDGND

Pin37

C75

C79

ATV POWER/GND (3.3V)

3V3_M

D D

0.1uF-0402-X5R-±20%-16V

1

Pin100

C81

GND

2

DDR POWER (1.5V)

1V5_DDR AVDD3P3_DM

10uF-0603-X5R-±20%-6.3V

1uF-0402-X5R-±20%-6.3V

LVDS POWER/GND (3.3V)

0.1uF-0402-X5R-±20%-16V

ALL FB except ADC, CVDD : need Rdc<0.2 , Z=300/100MHz , Idc>500mA

Default part : MCB2012S301H

3V3_M

GND

GND

C64

Pin167/168/169

C65

C66

C67

Pin249Pin245/246

0.1uF-0402-X5R-±20%-16V

C68

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

USB POWER/GND (3.3V)

Pin256

C76

GND GND

3

0.1uF-0402-X5R-±20%-16V

4

3V3_M

Pin176

C77

DEMOD POWER/GND (3.3V/1.0V)

3V3_M

5

L1

300ohm-0402-±25%

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

L2

300ohm-0402-±25%

10uF-0603-X5R-±20%-6.3V

0.1uF-0402-X5R-±20%-16V

Title

Number RevisionSize

A4

Date: 2015/2/26 Sheet of

File: C:\Users\..\TV#07_S2T512 POWER.SchDocDrawn By:

C59

GND

AVDD1P0_DM1V0_M

C69

GND

Pin108

C60

Pin103

C70

6

Page 40

1

2

3

4

5

6

A A

MUTE_AMP AMP_MUTE/

RA1

RA2

CA1

CA3

12V

+

E1

CA2

4K7ohm-0402-±5%-1/16W

4K7ohm-0402-±5%-1/16W

NC/0.1uF-0402-X5R-±20%-16V

RA3

12VAVCC

10ohm-0402-±5%-1/16W

4

LOUT+

3

100ohm-0402-±5%-1/16W

0.033uF-0402-X7R-±10%-16V

0.033uF-0402-X7R-±10%-16V

B B

100ohm-0402-±5%-1/16W

SPK_L

GND

SPK_R

RA6

GND_JP1

NC

GND_JP2

NC

RA13

0.1uF-0402-X5R-±20%-16V

0.1uF-0402-X5R-±20%-16V

100Kohm-0402-±5%-1/16W

NC/0ohm-0402-±5%-1/16W

0.1uF-0402-X5R-±20%-16V

CA15

CA24