Page 1

KF-2302GWEKF-2302GWE

Page 2

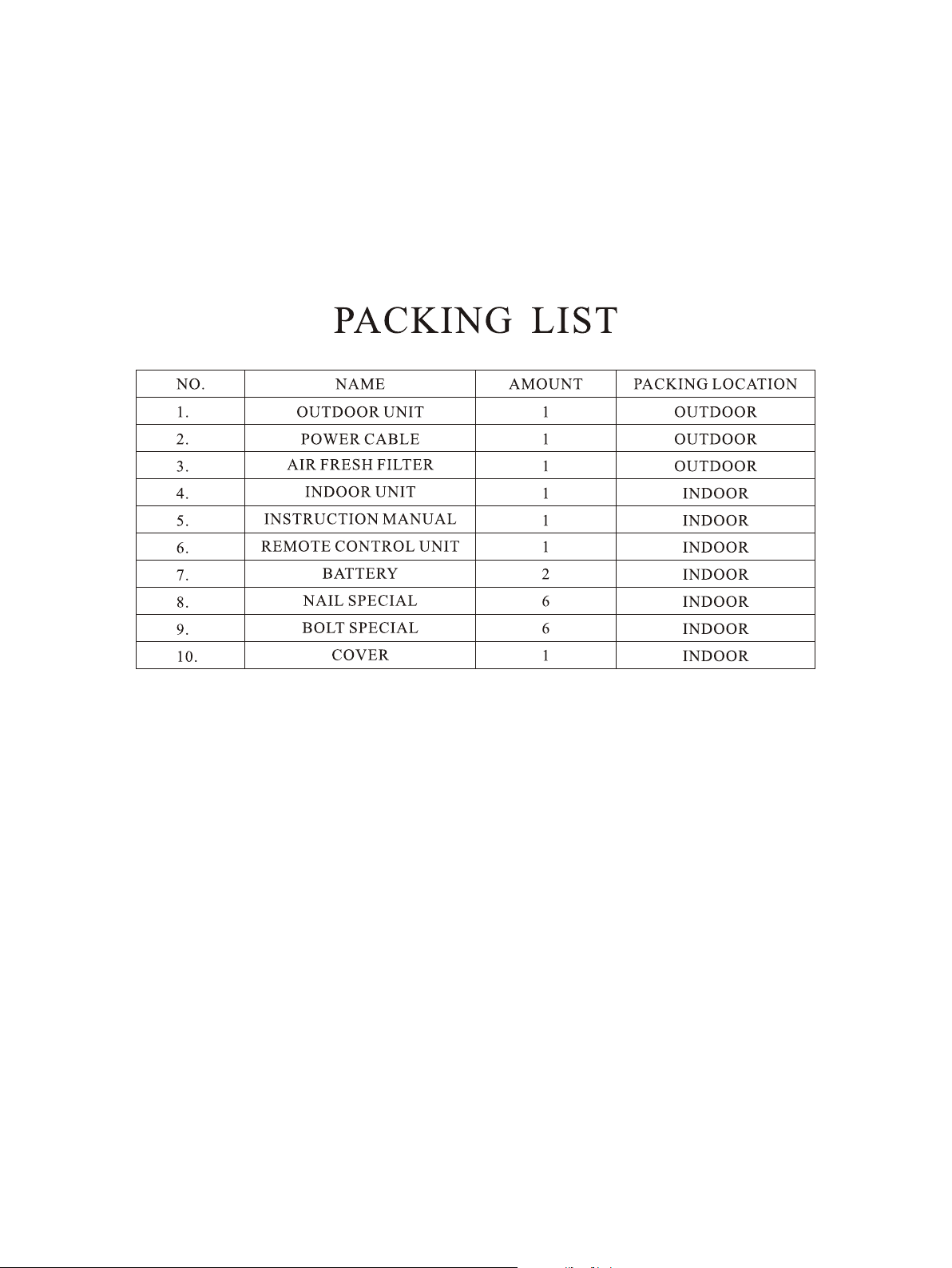

Page 3

Features

This air conditioner provides with cooling, and drying functions. Details of the functions

are below; refer to these descriptions when using the air conditioner.

Co m p a c t S i z e

This model is smaller than its

predecessors a n d y e t offers t h e same

capabilities.

Mi c r o p r o c e s s o r C o n t r o l l e d O p e r a t i o n

The i n t e r i o r compartment of t h e remote

control u n i t c o n t a i n s several features

to facilitate automatic operation,

clearly displayed for easy use.

Si m p l e One-touch Wi r e l e s s Remote

Control

The remote control unit has several

fe a t ures t o f acil i t ate a u t omat i c

operation.

12 - H o u r O N o r O F F T i m e r

This timer can be set to a u t o m a t i c a l l y

turn t h e u n i t on or off a t a n y ti m e

with in a 12-hour period.

1- H o u r O F F T i m e r

This timer can be set to a u t o m a t i c a l l y

turn off the unit after one hour.

Ni g h t S e t b a c k

Pressing this S L E E P button changes t h e

se t t i ng o f t h e r o om t em perat u r e

thermostat, allowing you to set the

temperature at w h a t e v e r level that y o u

feel comfortable.

Au t o m a t i c a n d 3 - s t e p F a n S p e e d

Auto/High/Medium/Low

Ai r S w e e p C o n t r o l

This fu n c t i o n m o v e s a f l a p u p and do w n

in t h e air o u t l e t , directing a i r in a

sweeping m o t i o n around t h e room a n d

providing comfort in every corner.

Au t o m a t i c Restart Fu n c t i o n for Po w e r

Failure

Even wh e n power fa i l u r e occurs, preset

programmed operation c a n b e reactivated

once power resumes.

An t i - M o l d F i l t e r

This unit i s e q u i p p e d with an anti-mold

filter that i n h i b i t s t h e growth of mold

and bacteria.

Hi g h P o w e r R u n n i n g

Run with strong power and make you feel

comfortable quickly.

RZA-0-1000-179-SM-A

Page 4

Contents

Pardon not to inform you if the contents of the manual changes.

Alert symbol-------------------------------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Caution statements-------------------------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Composition of the air conditioner----------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Operation guide----------------------------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Care and cleaning---------------------------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1 6

Tips for energy saving----------------------------------------------------------------------

- - - - - - - - - - - - - - - - - - - - - 1 8

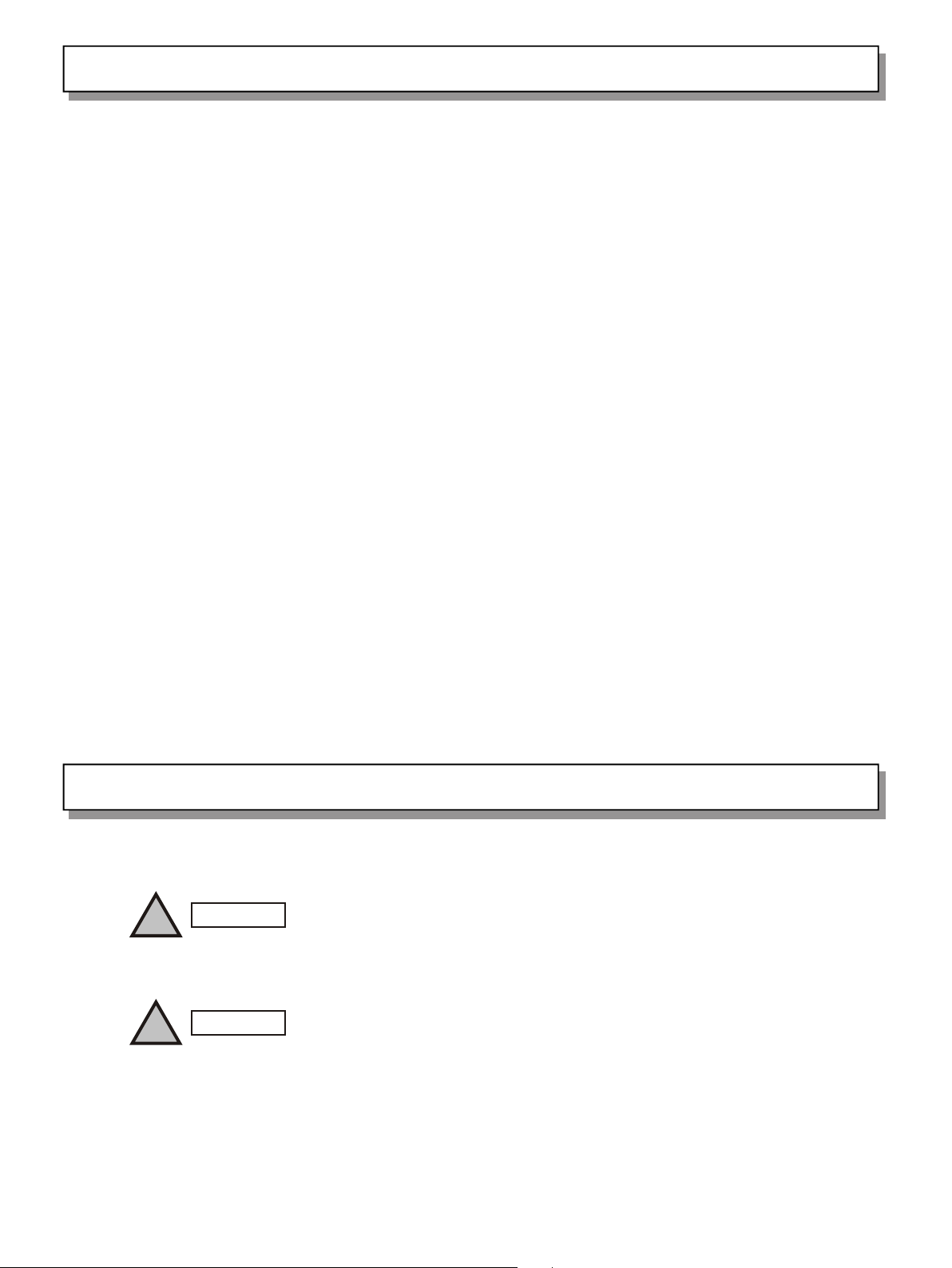

Alert Symbols

WARNING

!

!

CAUTION

The symbol refers to a hazard or an unsafe practice which can result

in severe personal injury or death.

The symbol refers to a hazard or an unsafe practice which can result

in personal injury or product damage.

1

Page 5

Caution Statements

We recommend that this air conditioner be installed properly by qualified installation technicians in accordance with

the installation instructions provided with the unit.

Before installation, check if the voltage of the electric supply in your home or office is the same as the voltage

shown on the nameplate.

Do not install the air conditioner where there are fumes or flammable gases, or

in an extremely humid space such as a greenhouse.

!

WARNING

Do not install the air conditioner where excessively high heat-generating

objects are placed.

Avoid:

WARNING

!

1. Read this manual carefully before using this air conditioner. If you still have any difficulties or problems, consult

your dealer for help.

2. The air conditioner is designed to give you comfortable room conditions. Use this only for its intended purpose as

To protect the air conditioner from heavy corrosion, avoid installing the

outdoor unit where salty sea water can splash directly onto it or in

sulphurous air near a spa.

All wiring must conform to the local electrical codes.

Each unit must be properly grounded.

Wiring must be done by a qualified electrician.

Consider the capacity of the electric current of your electrical kilowatt-hour

meter wires and socket before installation.

Power for this air-conditioner is supplied by individual electrical wire.

There must be at least one ventilation intake in the area where the outdoor unit

is mounted.

!

!

WARNING

CAUTION

Never use store gasoline or other flammable vapor or liquid near the air

conditioner - it is very dangerous.

The air conditioner has no ventilator for intaking fresh air from outdoors. You

must open the doors or the windows frequently when you use gas or oil heating

appliances in the same room, which consume a lot of oxygen from the air.

Otherwise there is a risk of suffocation in an extreme case.

Do not turn the air conditioner on and off from the power mains switch. Use the

ON/OFF operation button.

Do not stick anything into the air outlet of the outdoor unit. This is dangerous

because the fan is rotating at high speed.

Do not let the children play with the remote control unit.

Do not cool or heat the room too much if babies or invalids are present.

2

Page 6

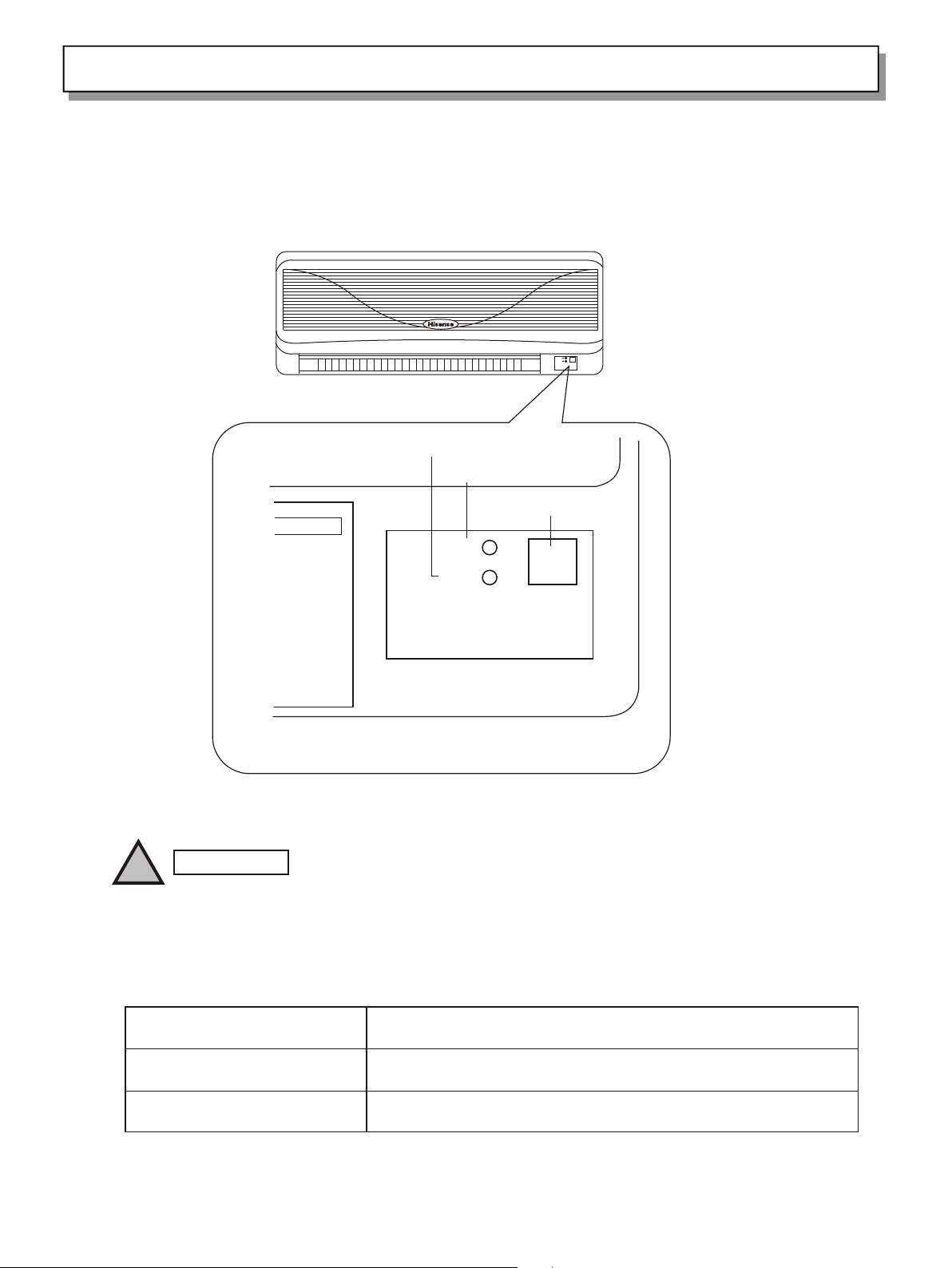

Composition of the Air Conditioner

1. Diagram of Structure

Air intake grille

INDOOR UNIT

Air outlet

Remote

control

unit

Drain hose

Refrigerant tubes

Air outlet

NOTE

Remote Control Unit

Refrigerant Tubes

Outdoor(Condensing) Unit

This air conditioner consists of an indoor unit and an outdoor unit. You can control the

air conditioner with the remote control unit.

Air Intake

Air Outlet

Drain Hose

OUTDOOR UNIT

Air from the room is drawn into this section and passes

through air filters which remove dust.

Conditioned air is blown out of the air conditioner through

the air outlet.

The wireless remote control unit controls power ON/OFF,

operation mode selection, temperature, fan speed, timer

setting, and air sweeping.

The indoor and outdoor units are connected by copper

tubes through which refrigerant gas flows.

The outdoor unit contains the compressor, fan motor, heat

exchanger coil, and other electrical components.

Moisture in the room condenses and drains off through this hose.

3

Page 7

Composition of the Air Conditioner

2. Introduction of the Indoor Control Unit

INDOOR UNIT

TIMER lamp

POWER lamp

REMOTE CONTROL receiver

!

IMPORTANT

POWER

TIMER

Avoid using radio equipment such as mobile phone near(within 1m)the indoor unit.

Some radio equipment may cause malfunction of the unit.

If the trouble happens, disconnect power and restart the air conditioner after a few

minutes.

REMOTE CONTROL

receiver

POWER lamp

TIMER lamp

This section picks up infrared signals from the remote control unit

(transmitter).

This lamp lights when the air conditioner is in the operation mode.

(But the compressor may not run at this time.)

This lamp lights when the system is being controlled by the timer.

4

Page 8

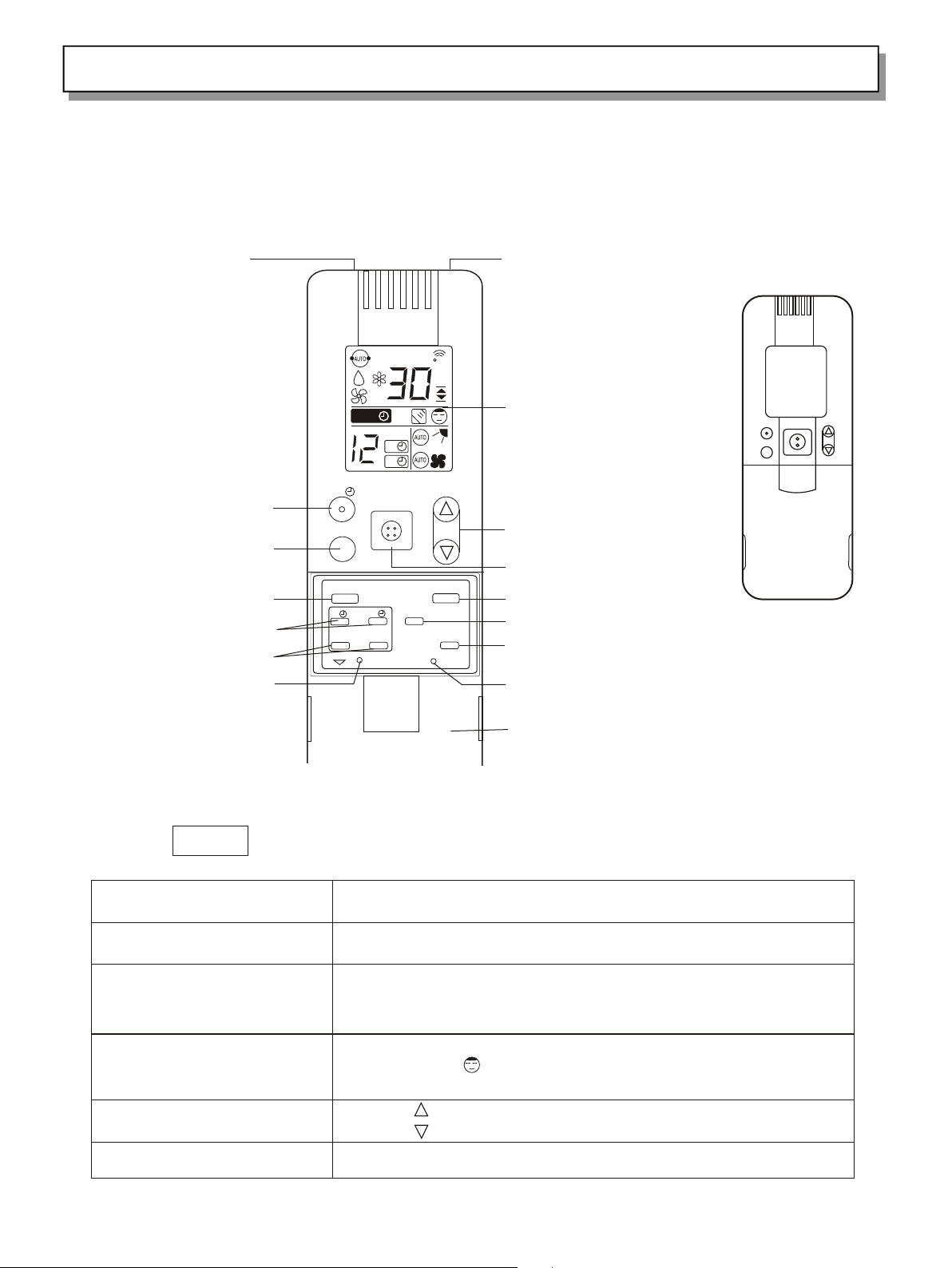

Composition of the Air Conditioner

3. Introduction of Display

Displayed when setting temperature;

Displayed when one-hour

OFF timer is enable

Displayed when setting timer

Symbols

(1) Operation mode

AUTO

1HOUR

S E T T E M PS E T T E M P

1小 时

HOUR

ON

OFF

AUTO

AUTO

(4) Timer

C

Displayed when transmitting data

Displayed when temperature is shown

Displayed when the temperature setting

is at the upper or lower limits

Displayed when sleep mode is running

Displayed when indoor unit sensor is in

use

AUTO

COOL

MILD DRY

FAN

(2) Fan speed

Automatic operation

HIGH

MEDIUM

LOW

(3) Set temperature

0

16-30 C

When set to 28 C

Current temperature

indication

0

AUTO

AUTO

C

12-hour ON Timer

12-hour OFF Timer

1 hour timer

(5)NIGHT SETBACK

(6)Confirmation of transmission

(7)Flap angle indication

(8) Sweep indication

(9) Indoor unit sensor

ON

OFF

1HOUR

5

Page 9

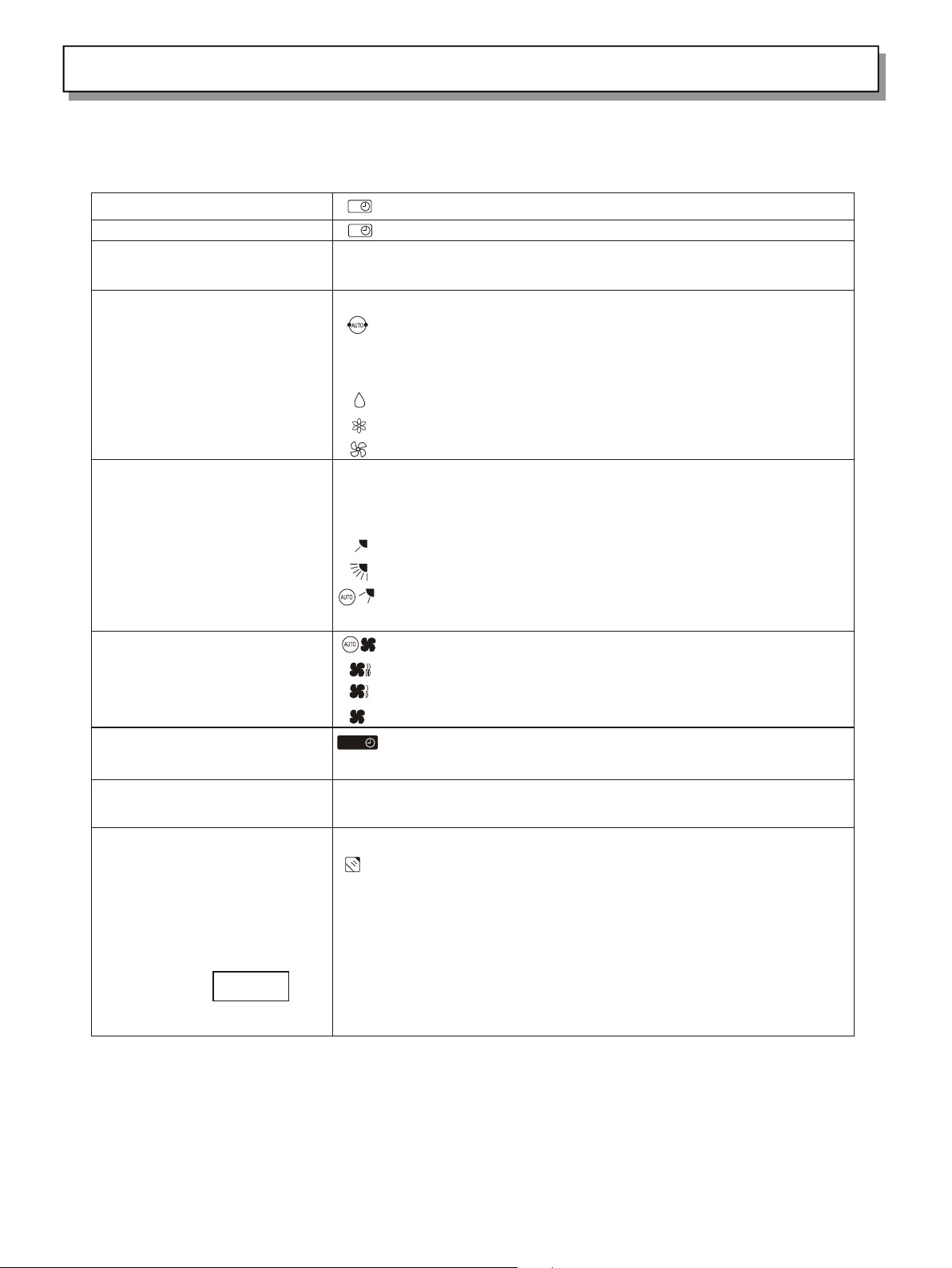

Composition of the Air Conditioner

4. Introduction of the Remote Control Unit

SENSOR

1 HR. TIMER button

HIGH POWER button

FLAP button

TIMER ON/OFF button

TIMER SET/CANCEL button

A/C SENSOR button

SET TEMP

1HOUR

HOUR

ON

OFF

ON/OFF1HR

HIGH

POWER

FLAP MODE

OFF

ON

SET CANCEL

BATTERY

FAN SPEED

A/C SENSOR

C

TEMP

SLEEP

ACL

Transmitter

Display

TEMP. setting button

ON/OFF button

MODE selector button

FAN SPEED selector button

NIGHT SETBACK button

ACL button

(Cover closed)

NOTE

The illustration above pictures the remote control unit after the cover has been lowered

and removed.

Transmitter

SENSOR

Display

SLEEP button

TEMP. setting buttons

ON/OFF operation button

Battery compartment(Pull off the cover to

expose the batteries.)

When you press the buttons on the remote control unit, the mark

a p p e a r s i n

the display to transmit the setting changes to the receiver in the air

c o n d i t i o n e r .

A temperature sensor inside the remote control unit senses the room

temperature.

Information on the operating conditions is displayed while the remote

control unit is switched on. If the unit is turned off, only the mode that

was set previously is still displayed.

For details, see "Night Setback Mode". When you press this button, in the

DRY or COOL mode, the mark appears in the display, the remote

control unit will automatically adjust the set temperature to save energy.

Press the button to increase the set temperature.

Press the button to reduce the set temperature.

6

Page 10

Composition of the Air Conditioner

Remote Control Unit (continued)

ON

TIMER ON button

TIMER OFF button

TIMER SET/CANCEL button

MODE selector button

(AUTO)

(DRY)

(COOL)

(FAN)

FLAP button

FAN SPEED selector button

1 HR. TIMER button

(1-HOUR OFF TIMER)

ACL button

A/C SENSOR button

: The air conditioner starts at the set time.

: The air conditioner stop at the set time.

OFF

This button is used to set/cancel the time at which you wish the air

conditioner to go on or off.

Use this button to select AUTO, DRY or COOL mode.

: When this setting is selected, the air conditioner calculates

the difference between the set thermostat and the room temperature

and automatically switches mode appropriately.

: The air conditioner reduces the humidity in the room.

: The air conditioner makes the room cool.

: The air conditioner makes the room's temperature suitable.

Press this button either to select to set the airflow direction to one of

the six possible positions manually, or to select the sweep function,

which moves the flap up and down automatically.

: The airflow direction can be set manually.(six positions)

: The flap moves up and down automatically.

: Press the FLAP button and set the airflow directions as

desired.(refer to Adjust the Airflow Direction).

: The air conditioner automatically decides the fan speeds.

: High fan speed

: Medium fan speed

: Low fan speed

: When you press this button, regardless of whether the unit is

operating or stopping , the unit operates for one hour and then shuts down.

Puts the remote control unit into pre-operation status. Always press this

1HOUR

button after replacing the batteries.

When you press this button (use a small-tipped object such as a ballpoint

pen), the

mark will appear at the display. And the room temperature is

detected by the sensor which is built into the indoor unit and the air

conditioner is controlled accordingly.

NOTE

If the remote control is located near a heat source, such as a space heater

or in direct sunlight, press the A/C SENSOR button to switch to the sensor

in the indoor unit.

7

Page 11

Operation Guide

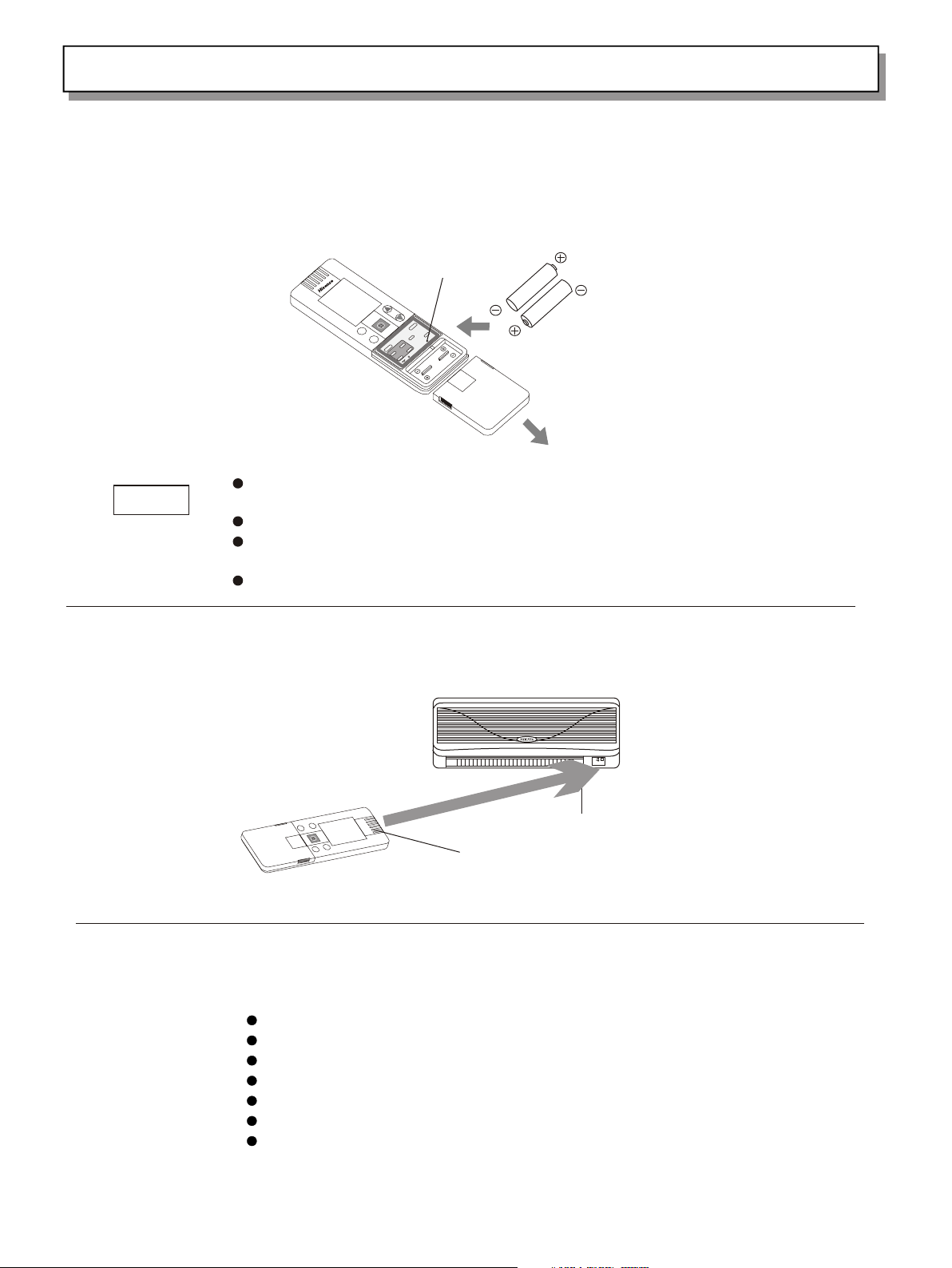

How to Install Batteries

1. Slice the cover in the direction indicated by the arrow and remove it.

2. Install two AAA alkaline batteries, Make sure the batteries point in the direction marked in the battery

compartment.

ACL but t o n

C

B

A

Replace the batteries when the remote control unit's display fails to light, or

NOTE

when the remote control unit cannot be used to change the air conditioner's

settings.

Use two fresh leak-proof type-AAA alkaline batteries.

In replacing batteries, follow the instructions as mentioned in the sub-section

"How to Install Batteries".

If you do not use the remote control unit more than 1 month, take out the batteries.

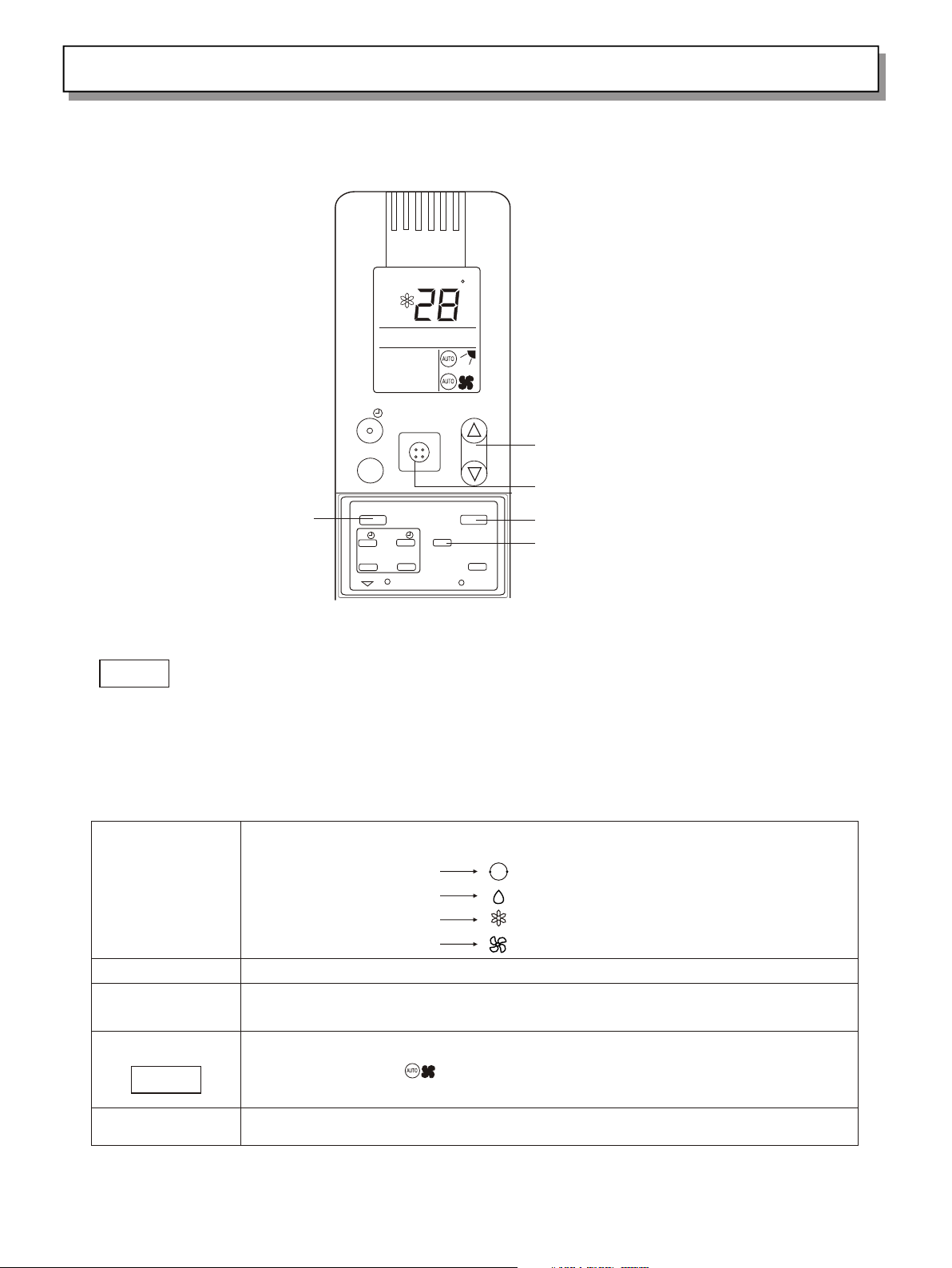

How to Use the Remote Control unit

When using the remote control unit, always point the unit's transmitter head directly at the air conditioner's

Air con d i t ioner

(Indo o r u n it)

Remot e c o n t rol unit

Recei v e r

关

约

开

预

(Tran s m i t ter head )

Remote Control Unit Installation Position

To ensure that the air conditioner operates correctly, DO NOT install the remote control unit in the following

DO NOT

In direct sunlight;

Behind a curtain or other places where it is covered;

More than 8 meters away from the air conditioner;

In the path of the air conditioner's airstream;

Where it may become extremely hot or cold;

Where it may be subject to electrical or magnetic noise;

Where there is an obstacle between the remote control unit and the air conditioner.

8

Page 12

Operation Guide

Operation with the Remote Control Unit(continued)

C

NOTE

STEP 1

STEP 2

STEP 3

STEP 4

NOTE

STEP 5

TEMP

STEP 3

HIGH

POWER

ON/OFF1HR

STEP 2

STEP 5

FLAP MODE

OFF

ON

SET CANCLE

BATTERY

FAN SPEED

A/C SENSOR

SLEEP

ACL

STEP 1

STEP 4

Check that the circuit breaker on the power panel is turned on and that the operation selector of

the indoor unit is in the ON position.

If the automatic operation settings of the unit do not meet your needs, press the setting buttons

as described below and change the settings as desired.

Press the MODE selector button and select the desired mode.

For automatic operation

AUTO

For dehumidifying operation

For cooling operation

For fan operation

To start the air conditioner, press the ON/OFF operation button.

Press the TEMP setting button to change the temperature setting to the desired

temperature .

Adjustable temperature range: 30℃ max~16℃ min.

Set the FAN SPEED selector button to choose the fan speed you want.

If the fan speed is set to (Automatic), the fan speed switches automatically

according to the difference between the actual room temperature and the temperature

setting.

Press the FLAP button and set the airflow direction as desired.

To stop the air conditioner, press the ON/OFF operation button again.

9

Page 13

Operation Guide

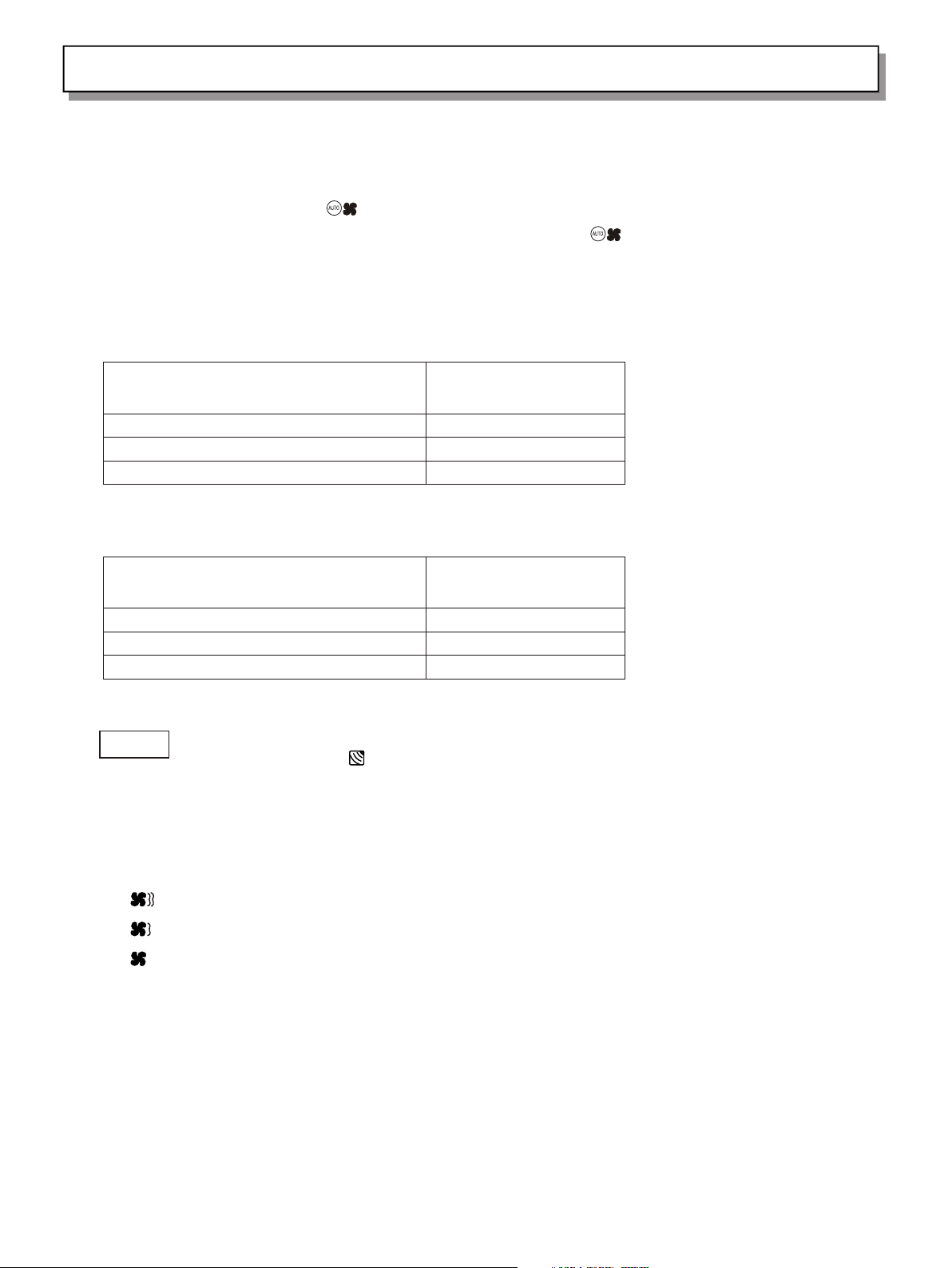

Adjusting the Fan Speed

1. Automatic

Simply set the FAN SPEED selector to the position.

A microcomputer in the air conditioner automatically controls the fan speed when the mode is selected. When the

air conditioner starts operating, the difference between the room temperature (RT) and the set temperature (T) is

detected by the microcomputer which then automatically switches the fan speed to the most suitable level.

Cooling mode:

When difference between room FAN SPEED

temperature and set temperature is

RT ≥ T+3℃ High

T+3℃ > RT ≥ T+1℃ Medium

RT Low

Mild drying mode:

When difference between room FAN SPEED

temperature and set temperature is

RT ≥ T+5℃ High

T+5℃ > RT ≥ T+3℃ Medium

RT Low

< T+1℃

≤ T+3℃

NOTE

2. Manual

If you want to adjust fan speed manually during operation, just set the FAN SPEED selector as desired.

High:

Medium:

Low:

The above table assumes that the sensor on the remote control is being used. If the sensor in

the indoor unit is being used (the indicator is on), actual operation may differ slightly

from the operation described in table.

10

Page 14

Operation Guide

Adjusting the Airflow Direction

1. Horizontal The horizontal airflow can be adjusted by moving the vertical vanes wit your hands to the left or right.

When the humidity is high, the vertical vanes should be in the front position

!

CAUTION

during the cooling or dehumidifying operation. If the vertical vanes are positioned

all of the way to the right or left, condensation may begin to form around the air

2. Vertical

The vertical airflow can be adjusted by moving the flap with the remote control unit. Do not

move the flap with your hands. Confirm that the remote control unit has been turned on. Then,

use the FLAP button to set either the sweep function or one of the six airflow direction

FLAP MODE

OFF

A/C SENSOR

FAN SPEED

SLEEP

ACL

ON

SET CANCLE

BATTERY

A. Sweep function B. Automatic Function

The flap starts moving up and down to

deliver air over the sweep range.

NOTE

The flap automatically closes when the unit is off.

The flap moves up and down automatically

from to station.

SWEEP

6

6

5

O

4

T

U

3

A

3

2

1

!

CAUTION

Use the FLAP button on the remote control to adjust the position of the flap. If you

move the flap by hand, the flap position according to the remote control and the

actual flap position may no longer match. If this happens, shut off the unit, wait

for the flap to close, and then turn on the unit again; the flap position will now

be normal again.

Do not have the flap pointed down during cooling operation. Condensation may begin

to form around the air vent and drip down.

11

Page 15

Operation Guide

Night Setback / Simultaneous Use Energy Saving

Night Setback Mode

Night Setback Mode is used for saving energy. Press the SLEEP button in

operation. The

mark appears in the display. To release the night setback function,

press the SLEEP button again.

ON/OFF1HR

HIGH

POWER

FLAP MODE

OFF

ON

SET CANCEL

BATTERY

FAN SPEED

A/C SENSOR

C

TEMP

SLEEP

ACL

NOTE

This function loses in automation or airflow mode.

In Cooling and DRY Mode:

When the night setback mode is selected, the air conditioner automatically raises

the temperature setting 1 C when 60 minutes have passed after the selection was

made, and then another 1 C after another 60 minutes have passed, and at last stops

0

0

operating automatically after lasting about 6 hours at this temperature,

regardless of the indoor temperature when night setback was selected. This

enables you to save energy without sacrificing comfort. This function is

convenient when gentle cooling is needed.

Setti n g

tempe r a t u re

1℃

1℃

1 2 3 4 5 6 7 8

Stop op e r a ting

Autom a t i cally

(Hour )

Press t h e S L E EP butto n

12

Page 16

Operation Guide

Using the 12-Hour ON and OFF Timer

1. TIMER ON mode:

(Example)

HIGH

POWER

FLAP MODE

STEP 2

STEP 3

ON

SET CANCEL

BATTERY

OFF

A/C SENSOR

HOUR

ON

ON/OFF1HR

FAN SPEED

C

TEMP

SLEEP

After the length of time set for TIMER ON elapses, the unit begins operating.

The display depicted at left indicates that the air conditioner will begin

operating in three hours.

Setting procedures:

STEP 1

Press the MODE button and set the desired operation

mode and press the ON/OFF operation button.

Press the timer ON button to set the time at which you

want operation to begin. The time can be set for one to

STEP 2

twelve hours, in one hour steps.

1 2 3.... . . . 1 2

Press the timer SET button (which advances the time

STEP 1

ACL

The display changes immediately to its status previous to timer setting, but the

indication remains.

ON

STEP 3

displayed).

To check the status of the timer while it is counting down, press the timer SET

button.

Cancellation procedure: Press the CANCEL button once again.

2. TIMER OFF mode:

(Example)

HIGH

POWER

FLAP MODE

ON

STEP 1

STEP 2

SET CANCEL

BATTERY

ON/OFF1HR

OFF

A/C SENSOR

HOUR

OFF

FAN SPEED

C

TEMP

SLEEP

After the length of time set for TIMER OFF elapses, the unit stops operating.

The display depicted at left indicates that the air conditioner will stop

operating in five hours.

Setting procedures:

Press the timer OFF button to set the time at which you

want operation to stop. The time can be set for one to

STEP 1

twelve hours, in one hour steps.

1 2 3.... . . . 1 2

Press the timer SET button (which advances the time

STEP 2

displayed).

The display changes immediately to its status previous to timer setting, but the

indication remains.

OFF

ACL

To check the status of the timer while it is counting down, press the timer SET

button.

Cancellation procedure: Press the CANCEL button once again.

13

Page 17

Operation Guide

Using the 1-Hour OFF Timer

This function causes the unit to operate for one hour and then stop,

regardless of whether the unit is on or off when this button is

pressed.

The indicator in the display indicates that this function is

operating.

1HOUR

ON/OFF1HR

HIGH

POWER

FLAP MODE

OFF

ON

SET CANCEL

BATTERY

FAN SPEED

A/C SENSOR

HIGH POWER Operation

C

TEMP

SLEEP

Setting procedure:

Regardless of whether the unit is operating or stopped, press the 1 HR.

TIMER button.

appears in the display.

Cancellation procedure:

Press the ON/OFF operation button to turn the unit off, wait for the unit to

stop operating, and then press the ON/OFF operation button again. The 1Hour Timer function is now cancelled and the unit operates normally.

NOTE

If, while the 1-Hour Timer function is operating, the 1HR. TIMER button

is pressed once to cancel the function and then again, the unit continues

to operate for one hour from that point in time and then stops.

If the 1HR.TIMER button is pressed while the TIMER OFF function operates,

ACL

the OFF Timer is cancelled and the unit will stop operating one hour

later.

This operation makes higher or lower temperature airflow than usual, in

winter or summer, which makes you feel comfortable as soon as you go home.

ON/OFF1HR

HIGH

POWER

FLAP MODE

OFF

ON

SET CANCEL

BATTERY

FAN SPEED

A/C SENSOR

C

TEMP

SLEEP

Setting procedure:

Press the High Efficiency button on the remote control unit gently, with a

whisper, so the high efficient operation comes to work. It may last the

longest time of 15 minutes.

Cancellation procedure:

Press the HIGH POWER button again, with a second whisper, the high power

operation will be canceled.

ACL

14

Page 18

Operation Guide

Special Remarks

Cooling ( ) operation

Fan ( ) operation

Power failure during operation

Clicking Sound

Clicking sound is

heard from the air

conditioner

Remote Control Unit

In cooling operation, the setting temperature range is from 16 C to 30 C.

Indoor fan has none stop status, even if the compressor stops, the

indoor fan is still working.

In fan operation, the indoor fan speed is set by the remote control unit,

the compressor and outdoor fan do not work.

In the event of power failure, the unit will stop. When the power is

resumed, the unit will restart automatically after three minutes.

In cooling operation, some plastic parts may expand or shrink due to a

sudden temperature change. In this event, a clicking sound may occur. This

is normal, and the sound will soon disappear.

The remote control unit sends the temperature signal to the air

conditioner regularly at three-minute intervals. If the signal from the

remote control unit stops for more than ten minutes due to the loss of the

remote control unit or other trouble, the air conditioner will switch to

the temperature sensor which is built into the indoor unit and control the

room temperature. In these cases, the temperature around the remote

control unit may differ from the temperature detected at the air

conditioner's position.

0 0

Operation without the Remote Control Unit

If you have lost the remote control unit or it has trouble, follow the

steps below.

1. When the air conditioner is not running

If you want to turn on the air conditioner, please open the air intake

grille, the ON/OFF switch will be found, switch the operation selector

to the OFF position, and then to the ON position.

ON/OFF

2.When the air conditioner is running

If you want to turn off the air conditioner,

grille, the ON/OFF switch will be found,

NOTE

Pressing buttons cannot last too long time, or the air conditioner may

operate abnormally.

please open the air intake

switch the operation selector

15

Page 19

Care and Cleaning

For safety, be sure to turn the air conditioner off and also to disconnect the

power before cleaning.

Do not pour water on the indoor unit to clean it. This will damage the internal

components and cause an electric shock hazard.

Clean the casing and grille of the indoor unit with a vacuum cleaner brush, or wipe

them with a clean, soft cloth.

If these parts are stained, use a clean cloth moistened with a mild liquid

detergent. When cleaning the grille, be careful not to force the vanes out of place.

Never use solvents, or harsh chemicals when cleaning the indoor unit. Do not wipe

the plastic casing using very hot water.

Some metal edges and the fins are sharp and may cause injury if handled improperly;

be especially careful when you clean these parts.

The internal coil and other components of the outdoor unit must be cleaned every

year. Consult your dealer or service center.

!

!

WARNING

CAUTION

Care and Cleaning (continued)

Anti-Mold Filter

How to remove the

anti-mold filter

The anti-mold filter behind the air intake grille should be checked and cleaned at

least once ever three weeks.

1. Grasp both ends of the air intake grille and pull it out and up.

2. Push the anti-mold filter up slightly, and then pull it down.

Air intake grille

Anti-mold filter

16

Page 20

Care and Cleaning

Anti-Mold Filter

Cleaning

How to replace the

anti-mold filter

Use a vacuum cleaner to remove light dust. If there is sticky dust on the filter,

wash the filter in lukewarm, soapy water, rinse it in clean water, and dry it.

1. With the " " mark facing you, slide the anti-mold filter up into the

unit and then lower the handle into the groove on the unit.

2. After installing the anti-mold filter, press the locations marked by the

arrows ( )and close the air intake grille.

Air intake grille

Anti-mold filter

Air Clean Filter

(not provided)

WARNING

!

How to install the air

clean filter

The air cleaning filter removes dust and dirt from the air, and reduces odors and

smoke from tobacco.

This air clean filter cannot remove harmful gases or vapors nor ventilate air in

the room. You must open doors or windows frequently when you use gas or oil heating

appliances. Otherwise there is a risk of suffocation in extreme cases.

The air clean filter needs to be installed behind the anti-mold filter.

1. Remove the anti-mold filter.

2. Install the air clean filter in the position shown in the diagram, with the "

"(meaning FRONT) symbol facing the front.

3. Reinstall the anti-mold filter.

Air clean filter

17

Page 21

Tips for Energy Saving

Do not

Do

Block the air intake and outlet of the unit. If they are obstructed, the unit will not work well,

and may be damaged.

Let sunlight directly into the room. Use sunshades, blinds or curtains. If the walls and

ceiling of the room are warmed by the sun, it will take longer time to cool the room.

Always try to keep the air filter clean.(Refer to "Care and Cleaning".)A clogged filter will

impair the performance of the unit.

To Prevent conditioned air from escaping, keep windows, doors and any other openings closed.

Troubleshooting

If your air conditioner does not work properly, first check the following points before requesting service. If it

still does not work properly, contact your dealer or service center.

Trouble Possible cause

Air c o n dition e r does n o t

run at al l .

Compr e s s or run s but so o n

stops .

Poor co o l i n

g perfo r m a nce

Click i n g s o u nd is h eard

from th e a i r c onditio n e r

1.Pow e r f a ilure.

2.Lea k a g e breaker t r i p ped.

3.Lin e v o l tage is too l o w .

4.Ope r a t ion butto n i s O F F.

5.Bat t e r ies in r e m o t e contro l

unit ha v e

run dow n .

O b s t r u c t i o n i n f r o n t o f

conde n s e r coil.

1.Dir t y o r c logged ai r f i l ter.

2.Hea t so u r c e o r m a n y p e ople in

room.

3.Doo r s a n d/or wind o w s a re open.

4.Obs t a c le near air i n t a ke or air

disch a r g e port.

5.The r m o stat is set t o o h i gh for

cooli n g .

I n c ool i n g o p e rat i o n, s o me

plast i c parts m ay e x pand or

s h r i n k d u e t o a s u d d e n

temp e r a t u r e c h a n g e . I n t h i s

Remedy

1.Res t o r e p ower.

2.Con t a c t s ervice c e n t e r.

3.Con s u l t y our e l e c t rician o r

deale r .

4.Pre s s t h e b utton ag a i n .

5.Rep l a c e b atteri e s .

Remov e o b s t ructio n .

1.Cle a n air f i l ter to impro v e

airfl o w .

2 . E li m i na t e h eat s o ur c e i f

possi b l e .

3.Shu t t h e m t o keep the c o l d o u t.

4.Remove i t t o ensure g o o d

airfl o w .

5.Set t h e t e m peratu r e l o w er.

This is no r m al, and the so u nd

will so o n d i s appear .

18

Page 22

Schematic diagram

1. Main specifications of the product

Type

Power source

Range of the voltage

Rated power input

Capacity

Air flow(high)

Refrigeration dose/consumption

Maximum remote control range/angle range

Maximum length of connect tube

2. Refrigerant Flow Diagram

Indoor unit Outdoor unit

Wide

tube

Wide tube

KF-2302GWE

AC 220V 50Hz

AC 198 ~ 242V

kW

0.84

2.30kW

~

3

340m /h

R22/0.52kg

。

8m/80

15m

Accumulat tor

Compressor

Heat exchanger

Narrow

tube

3. Permitted ambient temperature for the air conditioner is as following: 18 C~43 C.

Narrow tube

Capillary tube

Strainer

0 0

19

Heat exchanger

Page 23

Schematic diagram

4. Electric Wiring Diagrams

Outdoor

TERMINAL

TO INDOOR

CAPA

YLW/GRN

1

2

3

4

5

BLK

WHT

CAPA

GRY

WHT

RED

RED

BLK

R

PNK

BRN

FAN

MOTOR

YLW/GRN

S

COMP

YLW/GRN

C

Indoor

POWER TRAN

COI

WHT

WHT

SENSOR

POWER SOCKET

BRN

SENSOR

YEL/GRN

BLU

YEL/GRN

EVAPORATOR

YEL/GRN

1

2

3

1

TERMINAL PANEL

BRN

BLK BLK BLK BLK

1 2

1 2

1 2

1 2

1

1

BRN

2

2

BRN

SEC

1

1

2

2

ROOM

COIL

CONTROL BOARD

PRY

DISPLAY

1 ~ 5

1 ~ 5

DISPLAY

PANEL

BLU

ACIN2

ACIN1

PULSE IN

1 2 3

1 2 3

BRN WHT BLK

CM

BLU RED YEL

RED

FLAP

FM

1 3 5

1 3 5

FAN

MOTOR

1

2

3

4

5

BLU

2

3

TERMINAL PANEL

RED

1

ORG

2

YEL

3

PUR

4

BLU

5

STEP

MOTOR

CONECTION WITH

OUTDOOR UNIT

20

Page 24

Appendix: Installation

1. SUMMARY

1.1 Notice

This operation manual has explicit information for

installation and maintenance in most conditions.

Contact the local distributor or after-sales service

for further information.

1) Wiring notice

Only qualified professionals should carry out wiring

of the appliance.

Disconnect the power supply before completion of

wiring, piping or checking the appliance.

Voltages generated by the appliance is fatal.

Read the electrical schematic diagram and explanation

before installation. Improper installation and earth

connection may result in fatal injury.

Connect the earth as required by local regulations.

Tightly fasten all the wiring connections to prevent

overheating or fire.

Special power, switches and sockets are required for

the power supply of the appliance.

Electric meter capacity must be larger than or

equivalent to 10A.

Remark per EMC Directive 89/336/EEC

To prevent flicker impression during the start of the

compressor (Technical Process) and the adversely

influence caused by the 2 harmonics of compressor

following installation conditions do apply

1. The power connection for the air conditioner has to

be done at the main power distribution. This

distribution has to be of a low impedance is reached at

32A fusing point.

2. No other equipment has to be connected to this power

line.

3. For the detailed installation acceptance please refer

to your contract with the power supplier, if

restrictions do apply for products like washing

machines, air conditioners or electrical ovens.

4. For the details of the power of air conditioner,

please refer to the rating plate of the product.

5. For any question contact your local dealer.

2). Transport

Carefully move the outdoor unit.

3). Installation

----When the appliance is mounted to the ceiling or the

wall,

Make sure that the ceiling or the wall is strong

enough for the appliance.

Make a wood or metal frame to support the appliance if

necessary.

----When the appliance is mounted in a room,

Properly insulate the outdoor unit, and make sure

there is no moisture on the appliance or on the floor.

----When the appliance is installed on a damp or uneven

area,

Make a flat concrete base and place the base under the

outdoor unit.

----When the appliance is installed in an area of strong

winds.

Using firm bolts and metal frames to fix the properly

covered outdoor unit.

----When the appliance (Model Heat Pump) is installed in

an area of heavy snow.

The outdoor unit must be installed in a position above

the snow accumulation.

nd

4). Connection

Use the shortest tubes possible

Using a flaring method

Smear some refrigeration oil between the flared surface

and the connected tube.

Fasten the nuts with a torque wrench to prevent leakage of

refrigerant.

Check for leakage before trial operation.

5). Maintenance

Disconnect the power before checking the

electrical

components and the circuits.

Avoid contact with the moving parts of the appliance.

Clear the site and make sure there is no installation

debris left in the appliance.

6). Other

Keep the room well ventilated during installation.

1.2 Installing instruction

Read the operation manual before installation and keep this

manual in a safe place.

1)Tools

1. Screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Steel ruler

5. Spirit level

6. Hammer

7. Percussion drill

8. Tube cutter

9. Pipe flarer

10. Pipe bender

11. Adjustable spanner

2) Attachment

(see the packing list)

3) Parts Package

Copper tubes, components and insulation materials for the

outdoor unit.

4) Type of the copper tube and insulation materials

1. Table 1 indicates that tubes should be cut with an

additional length of 30cm-40cm, to reduce the vibration from

the outdoor unit.

Narrow tube

ITEM

Wide tube

Outside Diameter Thickness Outside Diameter

Thickness

KF-2302GWE 6.35mm 0.8mm 9.52mm 0.8mm

2. The insulation materials for the copper tubes should

conform to the required length and the wall thickness should

not be less than 8mm.

3. Insulated copper wires should be used for wiring and the

specification should depend on the length.

5) Additional materials for installation

1. white tape

2. nails or clips (as required)

3. putty

4. refrigeration oil

5. clips for fixing refrigerant tubes

21

Page 25

Appendix: Installation

2. INSTALLATION LOCATION

2.1 Indoor unit 2.2 Outdoor unit

Maintain the required space

!

WARNING

around the appliance to

prevent overheat.

The location for installation of the appliance should not

be in an area with the following:

Direct sunlight

Heat resource

Inflammable gas

Thick oil fog

The appliance should be installed in an area,

Where the inside space can be evenly conditioned, or

Which is strong enough for the appliance, or,

Having the shortest distance for the copper tubes and

water drain hose, and

Having desired space around the appliance for

maintenance and ventilation.(Figure 1)

Min. 5cm

Min. 5cm

Figure 1

Tube arrangement

L H Added Refrigerant Provided Tube(M)

(g/m)

10 7 20 4

Min. 5cm

The outdoor unit should be installed away from the

following:

Heat source and fan exhausting (Figure 3);

Director sunlight;

8

Figure 3

The outdoor unit should be installed in an area with,

Cool temperature;

Good ventilation;

Desired space for air inlet, outlet and maintenance

(Figure 4)

Top obstacle

Air inlet

Min. 10cm

Min. 10cm

Air outlet

Valve side

Min. 25cm

Min. 40cm

2m

2m

Air outlet

Obstacle

L: Maximum length of the tube connecting the indoor unit

and the outdoor unit.

H: The height difference between the indoor unit and the

outdoor unit.

Indoor unit

Height difference(H)

Tube length(L)

Outdoor

unit

Figure 2

* If the length of the tube is exceed 7m, an additional

20g/m of refrigerant should be added per 1m.

The indoor unit should not be

!

WARNING

installed below a height of 1.8m.

Figure 4

Ground

Strong base (10x10cm concrete or alike). The appliance

2

Min.10cm

Air inlet

should be placed not less than 10cm high (Figure 5).

Firm bolts(4)

Min. 10cm

Concrete or alike

bo 40A

u

t

c

m

10cm

u

o t

Ab

Figure 5

Fix the base with firm bolts to reduce vibration and noise.

22

Page 26

Appendix: Installation

3. INSTALLATION OF INDOOR UNIT

3.1 Take off the back cover

1) Release the screw as shown by Figure 6.

Figure 6

2) Take off the back cover.

3.2Drilling

1) Locate the back cover of the indoor unit on the wall,

and determine the desired place with a spirit level and

a ruler. Before drilling, do not fix the back cover

onto the wall.

2) According to direction of the tube ,drilling for tubes

according to the location of the appliance. It is

recommended that the rear right be used for wiring and

drilling.

3) Drill a 65mm hole in the wall (Figure 7), make sure the

Indoor Outdoor

3.4 Install the indoor unit

1) Thread the cable through the hole in the wall, an

additional 13cm of slack power cable should remain

inside the room. (Figure 10)

Back cover

Lining cover

Electrical cable

13cm

2)

Bind the connection cable, drainage hose and

refrigerant tube together tightly with white adhesive

tape; bend the refrigerant tube and make them through

hole of the wall smoothly(figure 11).

Figure 10

Figure 7

Before drilling, make sure that

there is no electric cable or

CAUTION

!

3.3 Installation of the back cover

1) check with a spirit level that the back cover is

installed horizontally. (Figure 8)

2) fix the back cover to the wall with the screws provided.

(Figure 9). Make sure that the back cover is firmly

fixed to he wall.

pipe in the area of the wall where

the hole is to be drilled.

Figure 8

Lining cover

Back cover

Refrigerant tube

Connection cable

Drainage hose

Figure 11

3) Adjust the position of the indoor unit, fixing it

firmly onto the back cover(figure 12).

Figure 9

Figure 12

23

Page 27

Appendix: Installation

3.5 Wiring

(1)Before wiring, make sure the rated voltage indicated

on the nameplate conforms to the local power voltage.

(2)Wiring should be carried out in accordance with the

instructions on the electrical schematic diagram

(Figure 13).

Terminal

Panel of

the indoor

unit

1

2

3

4

5

Figure 13

Terminal

Panel of

the outdoor

unit

1

2

3

4

5

3.6 Wiring connection of the indoor unit

1) Hold pull and open the down right cover and the down

right grille cover.

2) Release the screws and open the wire distribution cover

(Figure 14).

Down right cover

Down right grille cover

Figure 14

3)Connect the wire distribution terminals and

corresponding terminals .(Figure 15)

POWER

TIMER

WARNING

!

Wiring for connection of the indoor unit and the

outdoor unit should be conducted in accordance with

local regulations.

Wiring connections must be fitted firmly.

The electrical wires should not be in contact with any

of the refrigeration tubes, compressor or other moving

parts or components.

The appliance must be connected to a good earth.

4. INSTALLATION OF THE OUTDOOR UNIT

Properly locate the outdoor unit as described by the

Section 2.

If the outdoor unit is to be mounted on the wall ,make sure

that the wall and the support are strong enough for the

appliance.

Wiring Connection

1) Release the fixing screws and take off the side cover.

2) Connect the terminals on the heap pump as required in

the Figure 14 and the

3) Always save an extra 10cm length of the electrical

cable:

4) Earth the appliance according to related regulations

of electrical engineering:

5) Fix the connected terminals with clips and replace the

side cover if the connection is assured according to

the wiring diagram:

Figure 16:

Figure 15

4) Check the connections and then fasten the

distribution cover and replace the down right

grille cover and down right cover finally.

Cover of control box

Connection terminal

Clip

Figure 16

24

Page 28

Appendix: Installation

5.REFRIGERANT TUBE

5.1 Flaring the tube

(1) Cut the tube with a tube cutter to the desired length

(30.50cm is recommended)

(2) Smooth the edge of the copper tube with a reamer or a

file. Hold the pipe vertically with one end downward

to make sure that no copper scraps fall into the

copper tube.

Copper

tube

Figure 17a Figure

17b

(3) Put the tube flarer on the copper tube.

(4) Flare the copper tube ( Figure 18)

Before

Reamer

After

Tapered nuts

Copper tube

5.3 Heat insulation of the refrigerant tube

All refrigerant tubes must be insulated heat with at

least 8mm thick insulation materials. (Figure 21)

Heat insulation materials

Min. 8mm

5.4 Wrapping the tubes

(1) Tie the two refrigeration tubes (including

electrical wire if permitted as regulated), water

drainage hose with white tape.

(2) Wrap half of the tubes outside the room starting

from the end. (Figure 22)

Figure 21

Covering tubes with

heat insulation materials

Thickness

of 8mm

Clip

Figure 18

Note: The flared tube should have:

Smooth internal surface

Smooth edges

Consistent length of the tapered surface

5.2 Connection of the tubes

(1) The sealing tube must be used to prevent dust or

water from getting into the tube.

(2) Before connecting the tube, apply some refrigerant

oil on the surface of the flared tube and connections

to prevent air leakage.( Figure 19)

(3) Align the connecting tube and the flared tube, and

then turn the tapered nut to connect tightly.

(Figure 20)

Application

of refrigerant oil

(4) Fasten the nuts with a spanner.

Figure 19

Flarer

Connecting

tube

Figure 20

Flared tube

(3) Fix the wrapped tubes on the wall in clips with a

space of 120cm.

Note: Do not tie the tubes too tight as this may reduce

heat insulation. Separate water drainage hose and

refrigeration tubes to prevent formation of water

droplets.

5.5 Ending of installation

After completion of wrapping and insulation, seal the

hole on the wall with a suitable sealant.

5.6 Discharge gas

Place appliance A and then B. Air purging method is as

follows:

(1) Turn down the nuts on the wide and narrow tubes.

(2) Loose the nut of the flared wide tube one complete

turn with a spanner.

(3) Turn counterclockwise to open the core of the valve

with a socket screw wrench. Some gas will come out

from under the nut of the flared end of the wide tube.

Tighten the nut 10 to 15 seconds later.

(4) Test for leakage at the tube connector with soapy

water or a meter. If there is no leakage, turn

counterclockwise to open the tube core of the valve

on the wide tube with a socket screw wrench.

(5) Tighten the nuts on the wide , narrow tube valves and

the valve cover.

Please contact the technical service for further

information.

Figure 22

25

Page 29

SPLIT TYPE AIR CONDITIONERSPLIT TYPE AIR CONDITIONER

INSTALLATIONINSTALLATION

Hisense Corporation

MANUALMANUAL

Page 30

Contents

IMPORTANT!

Please Read Before Starting

1.GENERAL

1-1.Tools Required for Installation (not supplied)

1-2.Optional Copper Tubing Kit

1-3.Additional Materials Required for Installation

2.INSTALLATION SITE SELECTION

2-1.Indoor Unit

2-2.Outdoor Unit

3.HOW TO INSTALL THE INDOOR UNIT

3-1.Remove the Rear Panel from the Unit

3-2.Make a Hole

3-3.Install the Rear Panel on the Wall

3-4.Remove the Grille to Install the Indoor Unit

3-5.Shape the Indoor Side Tubing

3-6.Wiring Instructions

3-7.Wiring Instructions for Inter-unit Connections

3-8.Mounting

Page

1

2

2

3

3-9.Drain Hose

4.HOW TO INSTALL THE OUTDOOR UNIT

4-1.Wiring Instructions for Outdoor Unit

5.REFRIGERANT TUBING

5-1.Use of the Flaring Method

5-2.Flaring Procedure with a Flare Tool

5-3.Caution before Connecting Tubes Tightly

5-4.Connecting Tubing between Indoor and Outdoor Units

5-5.Insulation of Refrigerant Tubing

5-6.Taping the Tubes

5-7.Finishing the Installation

6.AIR PURGING

6-1.Air Purging with a Vacuum Pump (for Test Run)

6-2.Service Valve Construction

6-3.Pump Down

9

9

11

RZA-0-1000-881-AZ-D

Page 31

IMPORTANT!

Please Read Before Starting

This air conditioning meets system strict safety and

o p e r a t i n g

standards. As the installer or service person, it is an

i m p o r t a n t

part of your job to install or service the system so it

o p e r a t e s

safely and efficiently.

For safe installation and trouble-free operation, you

must:

· Carefully read this instruction booklet before

b e g i n n i n g .

This symbol refers to a

WARNING

CAUTION

h a z a r d

or unsafe practice which can

result in severe personal

i n j u r y

or death.

This symbol refers to a

h a z a r d

or unsafe practice which can

If Necessary, Get Help

These instructions are all you need for most

i n s t a l l a t i o n s i t e s

and maintenance conditions. If you require help for a

s p e c i a l

In Case of Improper Installation

The manufacturer shall in no way be responsible for

i m p r o p e r

installation or maintenance service, including failure

SPECIAL PRECAUTIONS

When Installing

…

...In a ceiling or Wall

Make sure the ceiling/wall is strong enough to hold the

u n i t s

weight. It may be necessary to construct a strong wood

,

...In a Room

Properly insulate any tubing run inside a room to

p r e v e n t

“

sweating” that can cause dripping and water damage to

...In Moist or Uneven Locations

Use a raised concrete pad or concrete blacks to provide

a

solid, level foundation for the outdoor unit . This

...In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a metal

frame.Provide a suitable air baffle.

...In a Snowy Area (for Heat Pump-type systems)

Insta l l t h e outdoor u n i t o n a raised pl a t f orm that is h i g h er

than dr i f t ing snow. P r o v ide snow ve n t s .

When Connecting Refrigerant Tubing

·Use the flare method for connecting tubing.

·Apply refrigerant lubricant to the matching surfaces of

the flare

and union tubes before connecting them, then tighten

the nut

with a torque wrench for a leak-free connection.

WARNING

When W i r i ng

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

·Do not supply power to the unit until all wiring and

t u b i n g a r e

completed or reconnected and checked.

·Highly dangerous electrical voltages are used in this

system. Carefully refer to the wiring diagram and

these instructions when wiring. Improper connections

and inadequate grounding can cause accidental injury

or death.

·Ground the unit following local electrical codes.

· Connect all wiring tightly. Loose wiring may cause

over-

When Transporting

Be careful when picking up and moving the indoor and outdoor

units. Get a partner to help , and bend your knees when lifting

to reduce strain on your back. Sharp edges or thin aluminum

fins on the air conditioner can cut your fingers.

When Servicing

· Turn the power OFF at the main power box (mainsb e f o r e

opening the unit to check or repair electrical

p a r t s a n d w i r i n g .

· Keep your fingers and clothing away from any moving

p a r t s .

· Clean up the site after you finish, remembering to

Others

CAUTION

· Ventilate any enclosed areas when intallation or

t e s t i n g t h e

refrigeration system. Escaped refrigerant gas ,on

c o n t a c t

with fire or heat, can produce dangerously toxic gas.

· Confirm upon completing installation that no

r e f r i g e r a n t g a s

is leaking. If escaped gas comes in contact with a

stove,

1

Page 32

1. GENERAL

This booklet briefly outlines where and how to

install the air conditioning system. Please read

over the entire set of instructions for the indoor

and outdoor units and make sure all accessory

parts listed are with the system before beginning.

1-1.Tools Required for Installation (not supplied)

1. Standard screwdriver

2. Phillips head screwdriver

3. Knife or wire stripper

4. Tape measure

5. Carpenter s level

,

6. Hammer

7. Drill

8. Tube cutter

9. Tube flaring tool

10.Torque wrench

11.Adjustable wrench

1-2.Optional Copper Tubing Kit

Copper tubing for connecting the outdoor unit to

t h e

indoor unit is available in kits which contain the

n a r r o w

and wide tubing, fittings and insulation. Consult

AVOID:

·direct sunlight.

·nearby heat sources that may affect performance of

the unit.

·areas where leakage of flammable gas may be

expected.

·places where large amounts of oil mist exist.

DO:

·select an appropriate position from which every corner

of the room can be uniformly air-conditioned.(High on

a wall is best.)

·select a location that will hold the weight of the unit.

·select a location where tubing and drain hose have the

shortest run to the outside.(Fig.1)

·allow room for operation and maintenance as well as

unrestricted air flow around the unit.(Fig.2)

Ind oor u n it

1-3.Additional Materials Required for Installation

1. Refrigeration (armored) tape

2. Insulated staples or clamps for connecting wire

(See local codes)

3. Putty

4. Refrigeration lubricant

5. Clamps or saddles to secure refrigerant tubing

2. INSTALLATION SITE SELECTION

2-1.Indoor Unit

WARNING

To prevent abnormal heat

g e n e r a t i o n a n d t h e

possibility of fire,do not

place obstacles, enclosures,

and grilles in front of or

s u r r o u n d i n g t h e a i r

conditioner in a way that

may block air flow.

5cm

min.

Dra in ho s e

Out sid e d ra i nag e

Fig.1

5cm min.

Fig.2 (Front V i e w )

5cm

min.

2

Page 33

· i n s tall t he u n i t w i t h i n t h e ma x i m um e l e vation

d i f f e r e n c e

( H ) a b o v e o r bel o w the outd o o r un i t and withi n a

t o t a l

t u b ing length (L ) fr o m t h e o u t d oor unit as

INDOOR UNIT

Elevation

difference(H)

Table 1

Max.A l l o wable Tub i n g

Lengt h a t S h ipment

(m)

Limit o f T u b i ng

Lengt h ( L )

(m)

Tubeing length(L)

OUTDOOR

UNIT

Fig.3 a

Limit o f E l e v ation

Diffe r e n c e (H)

(m)

7.5 20 7 25

CAUTION

For stable operation of the

air conditioner,do not

install wall-mounted type

indoor units less than 1.8m

from floor level.

Required Amount of

Additional Refrigerant

(g/m)*

If total tubing length becomes 7.5

t o 2 0 m

(max.),charge additional refrigerant

(R22) by 25g/m.

No additional charge of compressor oil

is necessary

Indoor unit

Minimum height

from floor level

1.8m

Floor level

Fig.3 b

Wall

2-2.Outdoor Unit

AVOID:

·heat so u r c e s, exhau s t f a n s, etc.( F i g . 4a)

·damp, h u m i d o r uneven l o c a t ions.

Hot air

Outdoor unit

8

Exhaust fan

DO:

·choos e a p l a c e as cool as p o s s i ble.

·choos e a p l a c e that is we l l v e n tilate d .

· al l o w eno u g h room a r o u n d th e unit fo r air

i n t a k e /

exhau s t a n d p ossibl e m a i n tenanc e . ( F ig.4b)

· p r o v ide a so l i d ba s e (c o n c rete b l ock,10× 40cm

b e a m s

Air intake

Min. 10cm

Valve side

Min. 25cm

or e qual), a min i m u m o f 10c m abo v e gro u n d l e v e l

t o

reduc e humidit y and pr o t e ct th e u nit ag a i n st

Min.

5cm

Air discharge

Min. 4

0cm

p o s s i b l e

w a t e r d a m a g e a n d d e c r e a s e d s e r v i c e

life. ( F i g .4c)

· use lu g b o l t s or equa l t o b o l t down un i t

Fig. 4b

3.HOW TO INSTALL THE INDOOR UNIT

3-1.Remove the Rear Panel from the unit

(1)Re m o v e and disca r d t h e set screw o n t h e r ear panel .

(Fig. 5 a )

Air inlet

Concrete

or equal

Locm min

Heat source

Fig.4 a

Obstacle above

2m

Air discharge

Ground

Min.10cm

Air intake

2m

Obstacle

(2)Pr e s s t he 2 marks on t h e f r ame cover a n d

disen g a g e the stati o n a ry tabs fro m t h e f rame.

(Fig. 5 b )

(3)Re m o v e the rear pa n e l .

NOTE

Tubin g c a n b e extende d i n 5 d i rection s a s s h own in

Fig.5 c . S e lect the di r e c tion you ne e d p r oviding t h e

short e s t r un to the out s i d e unit.

·When le f t t u bing is to be d o n e , switch th e d r a in hose

3

b

t

0

cA ou 4

m

Fig. 4c

Set screw only transportation

Abou

cm

0

1

t

Fig. 5a

Page 34

A n d d r a in c a p . ( F o r d et a il s , r e fe r t o

“S w i t ch i ng d ra i n h o se a nd d r ai n ca p” on

3-2.Make a Hole

(1) Place the rear panel from the indoor unit

on th e wall at the lo c a t i o n selected.

Make s u r e the p a n e l is horizontal, u s i n g

a c a r p e n t e r s l e v e l or tape me a s u r e to

,

measure d o w n from t h e ceiling. W a i t until

after c u t t i n g the h o l e b e f o r e attaching

the rear panel to the wall.

(2)Determine w h i c h side o f the u n i t you

should make t h e h o l e f o r tu b i n g a n d

NOTE

In the case of left-rear tubing, use the outside

mark for precise placement of the hose outlet.

(Fig.5d)

(3)Before making the hole, check carefully that no

studs or pipes are directly run behind the spot

to be cut.

Lef t

tub ing

Lef t rear

tub ing

Fig.5 b

Rea r p an e l

mar k s

Right-rear

tubing

(recommended)

Rig ht tubing

Downward tubing

CAUTION

Also avoid areas where electrical wiring or conduits are

located.

The a b o v e p r e c a u t i o n s are also applicable

if tubing goes t h r o u g h t h e w a l l i n an y

other location.

(4)Using a sabre s a w , key hole sa w or h o l e -

cutting d r i l l a t t a c h m e n t , cut a h o l e in

Table 2

Hole Dia.(mm)

65

(5) Measure the thickness of the wall from the

inside edge t o t h e o u t s i d e edge and cut PVC

pipe at a s l i g h t angle 6 mm s h o r t e r t h a n

the thickness of the wall.(Fig.7)

(6)Place the plastic cover over the end of the

pipe (for i n d o o r s i d e only) and i n s e r t the

pipe in the wall.(Fig.8)

3-3.install the Rear Panel on the wall

In case of left-rear, right-rear

Fig.5 d

Hole should be made at a slight downward slant the

outdoor side.

INSIDE

OUTSIDE

Fig.6

PVC pipe (locally purchased)

Be sure to c o n f i r m t h a t t h e w a l l is strong

enough to suspend the unit.

(1)Attach the rear panel to t h e w a l l w i t h t h e

6 nails provided.(Fig.9)

(2)Double c h e c k with a r u l e r or c a r p e n t e r s

,

level that t h e p a n e l i s l e v e l . This is

i m p o r t a n t t o i n s t a l l t h e u n i t

properly.(Fig.10)

(3)Make s u r e the p a n e l is flush a g a i n s t th e

wall. Any s p a c e b e t w e e n the wall a n d u n i t

will cause noise and vibration.

Cut at slight angle

Fig.7

INSIDE

Plastic

cover

Wall

OUTSIDE

PVC pipe

Slight

angle

Fig.8

4

Page 35

Fig.9

·In case of Use of Tapping Screws (for Installing

Remote Control Unit)

Make 4.8mm dia. holes in the wall. Insert rawl

plugs for appropriate mounting screws. (Fig.11)

3-4.Remove the Grille to Install the Indoor Unit

Fig.1 0

4 . 8 m m

dia . ho l e

Raw l p lu g

Basically, these models can be installed and wired

w i t h o u t

removing the grille. If access to any internal part

is needed, follow the steps as given below:

How to remove the grille

(1)Set the flap in the horizontal position.

(2)Unscrew the 2 screws.(Fig.12a)

(3)Remove the grille.(Fig.12b)

(a)Hold both corners of the air intake grille,

t h e n p u l l

out and up to open.

(b)Pull the lower part of the grille toward

you to remove.

(c)Use a standard screwdriver to push up the 3

t a b s t o

remove the grille

.

How to replace the grille.

(1)Close the flaps.

(2)Reinstall the grille into the lower part while

a l i g n i n g i t s

tabs on the upper part. (Fig.13a) Insert the tabs

in the slots and push the lower part of the

grille back into position.

(3)Press at each of the 4 tabs to completely close

the grille. Make sure that the grille and frame

are firmly fitted together.(Fig.13b)

Fig.1 1

Flap

(Up and down air direction louvre)

Fig.1 2 a

Fig.1 2 b

Screw cover

Air intake grille

3-5.Shape the Indoor side Tubing

1) Arrangement of tubing by directions

a)Right or left tubing

Cut out the corner of the right/left frame with

a hacksaw or the like.(Figs14 and 15)

b)Right-rear or left-rear tubing

In this case, the corner of the frame need not

be cut.

2)To mount the indoor unit on the rear panel:

Hang the 2 mounting slots of the unit on the

u p p e r

tabs of the rear panel.(Fig.16)

5

Fig.1 3 a

Fig.1 3 b

Page 36

3-6.Wiring Instructions

General precautions on wiring

Fra me

1) Before wiring, confirm the rated voltage of

the unit as shown on its nameplate, then

carry out the wiring closely following the

wiring diagram.

2)Provide a power outlet to be used exclusively

for each unit, with a power supply disconnect

and circuit breaker for overcurrent

p r o t e c t i o n

provided in the excusive line.

3)To prevent possible hazard due to insulation

failure, the unit must be grounded.

4)Each wiring connection must be done tightly

and in accordance with the wiring system

diagram(Fig.17a,

Fig.17b and Fig.17c).Wrong wiring may cause

t h e

unit to misoperate or become damaged.

5)Do not allow wiring to touch the refrigerant

t u b i n g ,

compressor, or any moving parts of the fan.

6)Unauthorized changes in the internal wiring

can be very dangerous. The manufacturer will

accept no responsibility for any damage or

misoperation that occurs as a result of such

unauthorized changes.

Fra me

Lef t tub ing

out let

Fig.1 4

Rig ht tu bin g

out let

Fig.1 5

Fig.1 6

1

2

3

4

5

IND O O R

UNI T

YZW 3×1.5mm

Fig.1 7 a

2

1

2

3

4

5

OUT D O OR

UNI T

(For coo l o n l y t y p e system)

1

2

3

4

5

IND O O R

UNI T

YZW 5×1.5mm

Fig.1 7 b

2

1

2

3

4

5

OUT D O OR

UNI T

(For hea t p u m p t y p e system)

7)Special electrical wires and connection cables

are used for this air-conditioner which can

be supplied by the local distributor, and

cannot be replaced by other type wires or

cables.

6

1

2

3

4

IND O O R

UNI T

YZW 3×2mm +1×1mm

2 2

1

2

3

4

OUT D O OR

UNI T

Fig.1 7 c

(For hea t p u m p f r e nquency ty p e s y s t em)

Page 37

WARNING

WARNING

· Be s u r e t o c o m p l y with

local co d e s o n running

t h e w i re f ro m t h e

indoor u n i t t o the

outdoor u n i t (s i z e of

w i r e a n d w i r i n g

method, etc.).

· Each w i r e m u s t b e

firmly connected.

· No w i r e s h o u l d b e

a l l o w e d t o t o u c h

r e f r i g e r a n t t ub i n g ,

the co m p r e s s o r , o r any

To avoid the risk of electric

shock, each air conditioner

unit must be grounded.

Cover

Fig.18

Be sure to connect the

CAUTION

power supply line to the

outdoor unit as shown in

the wiring diagram.

(Fig.17a and Fig.17b)

The indoor unit draws its

power from the outdoor

unit.

3-7. Wiring Instruction for Inter-unit Connections

(1)Hole both corners of the air intake grille, then

pull out and up to open.

(2)Remove the screw on the right side cover plate

and open the cover.(Fig.18)

(3)Insert the inter-unit wiring into the through-

the-wall PVC pipe. Lead the power wiring into

the room allowing approx.13cm to extend from the

wall face.(Fig.19a)

(4)Route the inter-unit wiring from the back of the

indoor unit and pull it toward the front for

connection.

(5)Connect the inter-unit wiring to the

corresponding terminals on the terminal plate

while referring to the wiring diagram.(in the

instruction manual).

(6)Be sure to secure the wiring with the provided

clamp.

Rear

panel

Plastic

cover

Wiring

13cm

Fig.19

Power cord outlet

3-8.Mounting

(1)Before installing the indoor unit, cut out the

power cord outlet on right/left frame of the

unit. Then, wire the power cord.(Fig.20a)

(2)To install the indoor unit, mount the indoor

unit onto the 2 tabs on the upper part of the

rear plate.

(3)Hold down the air discharge outlet and press the

lower part of the indoor unit until it clicks to

securely fasten to the 2tabs on the lower part

7

Push

Power cord

Fig.20a

Page 38

NOTE

For tubing. choose either the right or left tubing

direction

and follow the steps below. Also, extend the

support on

Right-side tubing

(1) Shape the refrigerant tubing so that it can easily go

into the wall hole. (Fig.21a)

(2) Push the wiring, refrigerant tubing, and drain hose

through the hole in the wall. Adjust the indoor unit so

it is securely seated on the rear panel. (Fig.21b)

(3)Carefully bend the tubing (if necessary) to run

along

the wall in the direction of the outdoor unit

and then tape as far as the fittings. The drain

hose should come straight down the wall to a

point where water run off won t stain the wall.

(4)Connect the refrigerant tubing to the outdoor

unit.

(After performing a leak test on the connecting

part, insulate it with the tubing insulation.

(Fig.22)Also, refer to Section 5-4. Connecting

Tubing between Indoor and Outdoor Units.

,

(5)Assemble the refrigerant tubing, drain hose,

and inter- unit wiring as shown in fig.22.

Left -side-tubing

(1)Lead the tubing and drain hose through the wall,

allowing sufficient length for connection. then

bend the tubing using a tube bender to make the

attachment.(Fig.23a)

(2)Switch the drain hose and drain cap.

Switch the drain hose and drain cap

(a)Locate the drain hose and the drain cap.

(Fig.23b)

(b)Remove the drain hose on the right side by

pushing and turning the hose connector counterclockwise to release it. (Fig.23b)

(c)Apply moderate force to pull off the drain cap

on the left side.(If you cannot pull it off by

hand, use a long -nose pliers.)

(d)Reattech the drain hose to the left side and

the drain cap to the right side. (Fig.23c)

drain hose

While pushing the drain connector, turn it

clockwise until it clicks. Slip the connector onto

the outlet firmly.

Drain cap

Use a Phillips screwdriver to push the drain cap

in firmly. (if it is difficult to push in, wet the

cap with water first.)

Hole in wall

Bent part

Fig.21b

Insulation

Fig.22

Rear panel

Wide tube

Narrow tube

Fig.23a

Drain cap

Drain hose

Fig.23b

8

Page 39

(3) Install the indoor unit on the rear panel.

(4) Connect the tubing and wiring led inside from

outdoors.

(5)After completing a leak test, bundle the tubing

together with armoring tape and store it inside

the tubing storage area at the back of the

indoor unit and hold it with clamps.

To unmouht indoor unit

Press the 2 marks on the lower part of the indoor

unit and unlatch the tabs. Then lift the indoor

unit and unmount. (Fig.25)

3-9. Drain Hose

a) The drain hose should be slanted downward to the

outdoors.(Fig.26)

b) Never form a trap in the course of the hose.

c) If the drain hose will run in the room, insulate

the hose with insulation * so that chilled

condensation will not damage furniture of floors.

(Fig.27)

*Foamed polyethylene of its equivalent is

recommended.

Drain cap

Clamp

Fig.23c

Drain hose

To slip on

o

60

To remove

Refrigerant tubing

Inter-unit wiring

WARNING

Do not supply power to

the unit or operate it

until all tubing and

wiring to the outside

unit are completed.

Risk of Electric Shock

4.HOW TO INSTALL THE OUTSIDE UNIT

First refer to Section 2. Installation Site Selection.

NOTE

The drain hole at the bottom of the outdoor unit

was not plugged at the time of factory shipment.

If necessary, mount the accessory drain elbow

before installing the outdoor unit. (Fig.28)

4-1.Wiring Instruction for Outdoor Unit

Regulations on wire size differ from locality to

locality. For field wiring requirements, please

refer to your local electrical codes. Make sure

that the installation fully complies with all

local and national regulations.

(1)Remove access panel“C”.(Fig.29)

(2)Connect the inter-unit wiring and power line

according to the drawing inside panel “C”.

(3)Be sure to size each wire allowing approx. 10cm

longer than the required length for wiring.

Store wire strands inside the cabinet.

(4)When connection are completed, check that all

connections are correct as shown in the wiring

system diagram inside access panel“C”.

(5)Be sure to ground the unit according to your

local codes.

Indoor

unit

Slant

Drain

hose

Fig.26

Drain hose

Fig.24

Push

Fig.25

Insulation material

(locally purchased)

must be used.

Fig.27

Condensation

Outdoor

unit

5.REFRIGERANT TUBING

5-1.Use of the Flaring Method

Accessory

drain elbow

9

Fig.28

Page 40

Many of conventional split system air conditioners

employ the flaring method to connect refrigerant

tubes which run between indoor and outdoor units.

In this method, the copper tubes are flared at

each end and connected with flare nuts.

5-2.Flaring Procedure with a Flare Tool

(1)Cut the copper tube to the required length with

a tube cutter. It is recommended to cut approx.

30-50cm longer than the tubing length you

estimate.

(2)Remove burrs at the end of the copper tube with

a tube reamer or file. This process is

important and should be done carefully to make

a good flare. (Fig.30)

NOTE

When reaming, hold the tube end downward and be

sure that no copper scraps fall into the tube.

(Fig.31)

(3)Remove the flare nut from the unit and be sure

to mount it on the copper tube.

(4)Make a flare at the end of copper tube with a

flare tool.*(Fig.32)

(*Use“RIGID”or equivalent.)

NOTE

Cabinet

Before

Fig.29

Deburring

After

Access

panel

“C”

A good flare should have the following

characteristics:

·inside surface is glossy and smooth.

·edge is smooth.

·tapered sides are of uniform length.

5-3.Caution before Connecting Tubes Tightly

a) Be sure to apply a sealing cap or water-proof

tape to prevent dust or water from getting into

the tubes before they are used.

b) Be sure to apply refrigerant lubricant to the

matching surfaces of the flare and union before

connecting them together. This is effective for

reducing gas leaks.(Fig.33a)

c) For proper connection, align the union tube and

flare tube straight with each other, then screw

in the flare nut lightly at first to obtain a

smooth match. (Fig.33b)

5-4.Connecting Tubing between Indoor and Outdoor

Units

a)Tightly connect the indoor side refrigerant

tubing extended from the outdoor side

tubing.(Fig.34)

B) To fasten the flare nuts, apply specified

torque as:

Flare tool

Fig.32

Fig.30

Fig.31

Copper

tubing

Reamer

Flare nut

Copper

tubing

Tube Dia.

6.35mm

12.7mm

9.52mm

Tightening Torque

Approx.15-20N.m

Approx.50-55N.m

Approx.35-40N.m

5.5 Insulation of Refrigerant Tubing

IMPORTANT