Page 1

R efrigerator

Service Manual

M odel:R C-70 W S 4 S(BC D-535 W)

Page 2

1

Contents

........................................2

.............................................................3

...........................................................4

..............................................................6

....................................................7

.....................................................................8

....................................................................40

...........................................................................41

.........................................................................42

............................................................................44

...............................................................................46

.....................................................................53

............................................................61

.........................................................65

...................................................67

1.Warnings and precautions for safety

2.Appearance and structure

2.1 View of the appliance

2.4 Compressor room structure

3.Basic parameters

4.Operation and functions

5.Troubleshooting

6.2 Mainboard

6.3 Compressor

5.1 Common problem and checking

5.2 Faulty start

5.3 Refrigeration failure

5.4 Thick frost in freezer compartment

5.5 Dew in refrigerator compartment

6.Circuit and checking

6.1 Circuit diagram

6.4 Fan motor

7.Cooling system repairing

7.2 Summary of repair

7.3 Regulation of repair

7.4 Practical work of repair

7.5 Brazing reference drawing

2.3 Evaporator structure

4.1 Display controls

4.2 Defrost mode

4.3 Compulsory defrost mode

6.5 Damper

6.6 Light

6.7 Door switch

6.8 Temperature fuse

4.4 Error display

5.6 Low temperature of vegetable vase

5.7 Breaking of light

5.8 Noise

6.9 Defrost heater

7.1 Refrigeration system

2.2 Wind channel structure

.....................................................................9

.......................................................................13

.....................................................17

...........................................................................19

.............................................25

..........................................................................28

.............................................................29

........................................32

...........................................33

.......................................34

...................................................................35

..................................................................................36

...................................................................................48

.........................................................................50

.................................................................51

...............................................................63

.............................................................64

6.9 Ice maker

............................................................................55

Page 3

2

1.Warning and precautions for safety

Please observe the following safety precautions in order to use safely

and correctly the refrigerator and to prevent accident and danger

during repair.

1. Be care of an electric shock. Disconnect power cord from wall outlet

and wait for more than three minutes before replacing PCB parts.Shut

off the power whenever replacing and repairing electric components.

2. When connecting power cord, please wait for more than five

minutes after power cord was disconnected from the wall outlet.

3. Please check if the power plug is pressed down by the refrigerator

against the wall.If the power plug was damaged, it may cause fire or

electric shock.

4. If the wall outlet is over loaded, it may cause fire.Please use its own

individual electrical outlet for the refrigerator.

5. Please make sure the outlet is properly earthed, particularly in wet

or damp area.

6. Use standard electrical components when replacing them.

7. Make sure the hook is correctly engaged.Remove dust and foreign

materials from the housing and connecting parts.

8. Do not fray, damage, machine, heavily bend, pull out or twist the

power cord.

9. Please check the evidence of moisture intrusion in the electrical

components.Replace the parts or mask it with insulation tapes if

moisture intrusion was confirmed.

10. Do not touch the ice maker with hands or tools to confirm the

operation of geared motor.

11. Do not let the customers repair, disassemble and reconstruct the

refrigerator for themselves.It may cause accident, electric shock, or

fire.

12. Do not store flammable materials such as ether, benzene, alcohol,

chemicals, gas, or medicine in the refrigerator.

13. Do not put flower vase, cup, cosmetics, chemicals, etc., or

container with full of water on the top of the refrigerator.

14. Do not put glass bottles with full of water into the freezer.The

contents shall freeze and break the glass bottles.

15. When you scrap the refrigerator, please disconnect the door

gasket first and scrap it

1 Warning and precautions for safety

Page 4

3

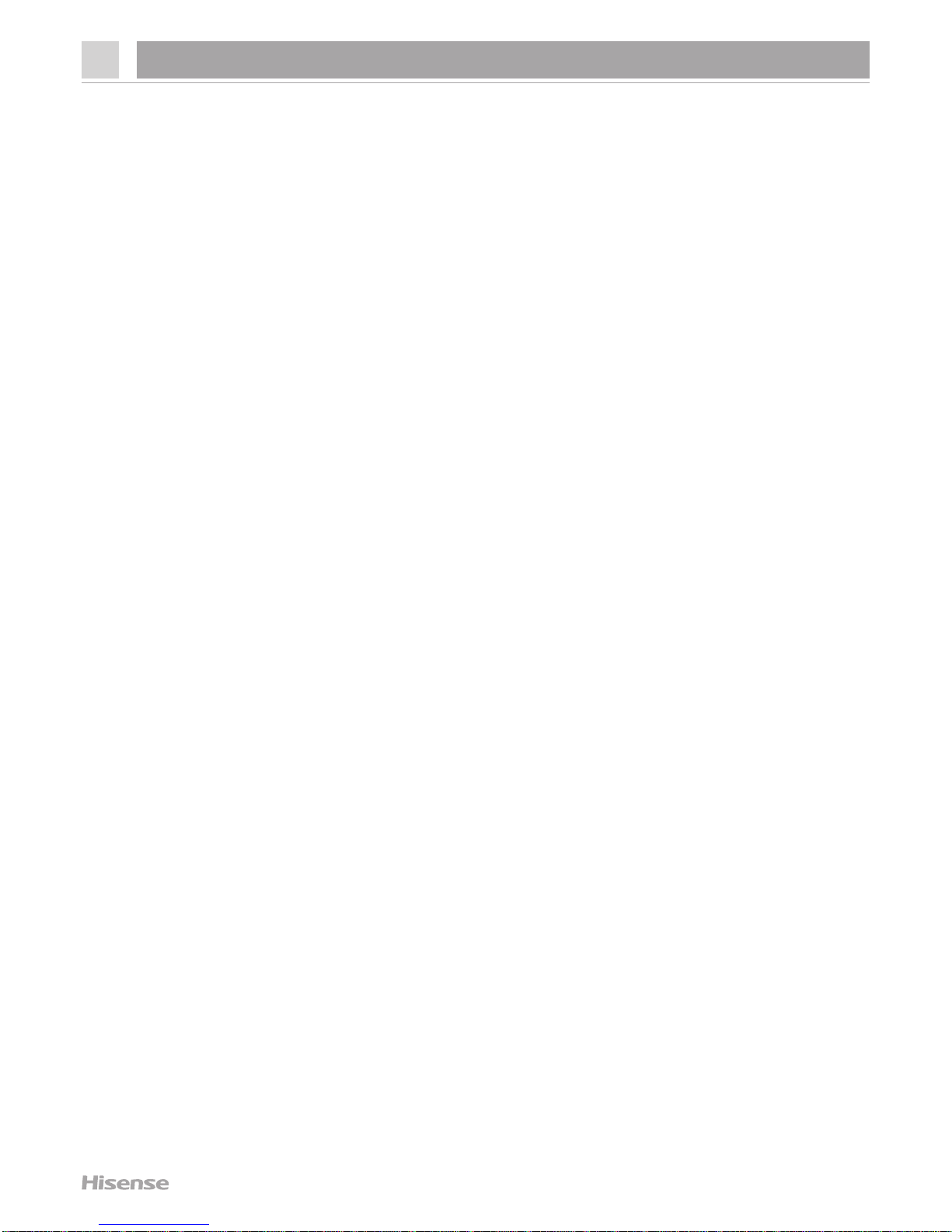

2.Appearance and structure

2 Appearance and structure

Note:Due to unceasing modification of our products,your refrigerator may

be slightly differant from this Services Manual,but its functions and using

methods remain the same.

2.1 View of the appliance

Page 5

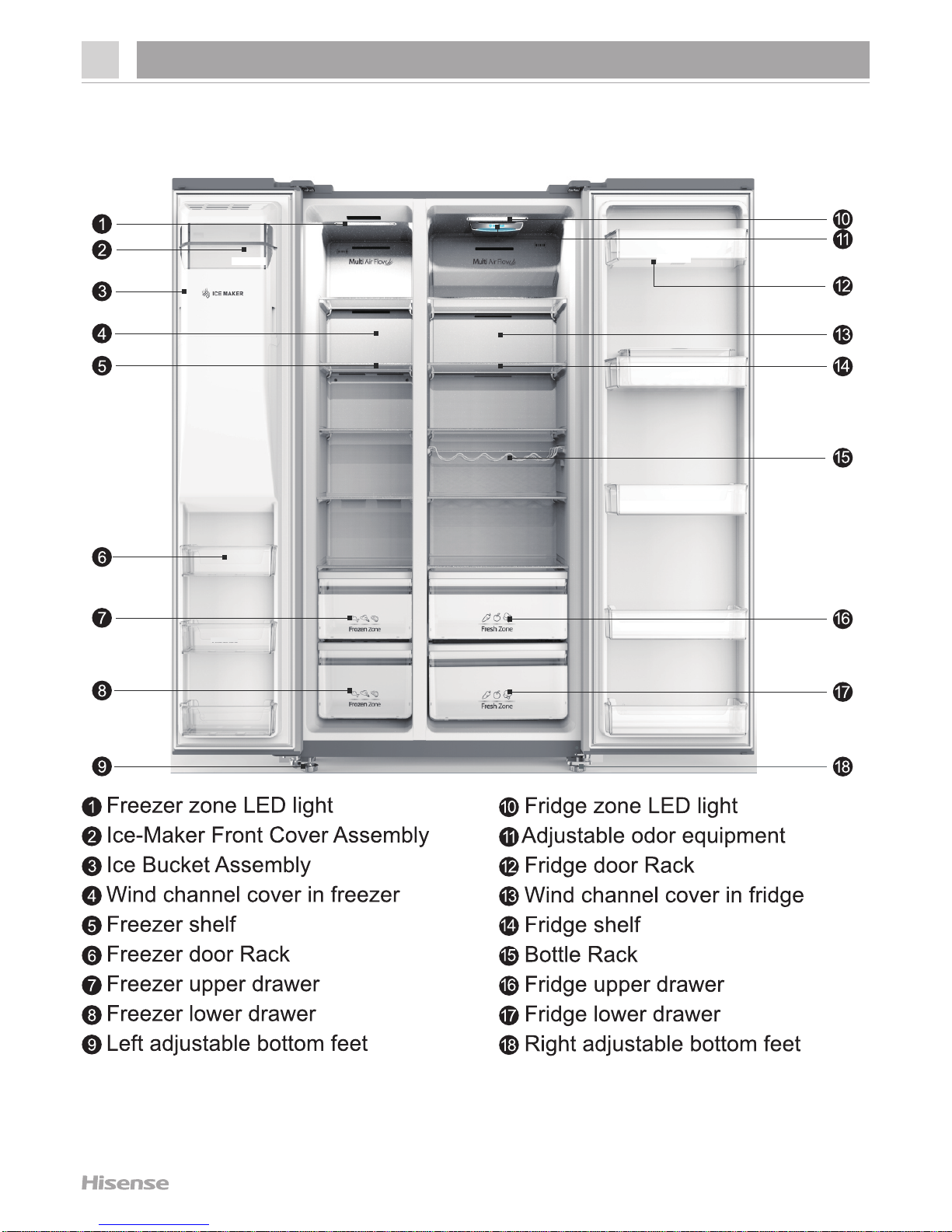

2.2 Wind channel structure

4

2.Appearance and structure

Freezer Refrigerator

Fan

Wind input

Air return

Page 6

2.2 Wind channel structure

5

2.Appearance and structure

Freezer

Fan

Refrigerator

Page 7

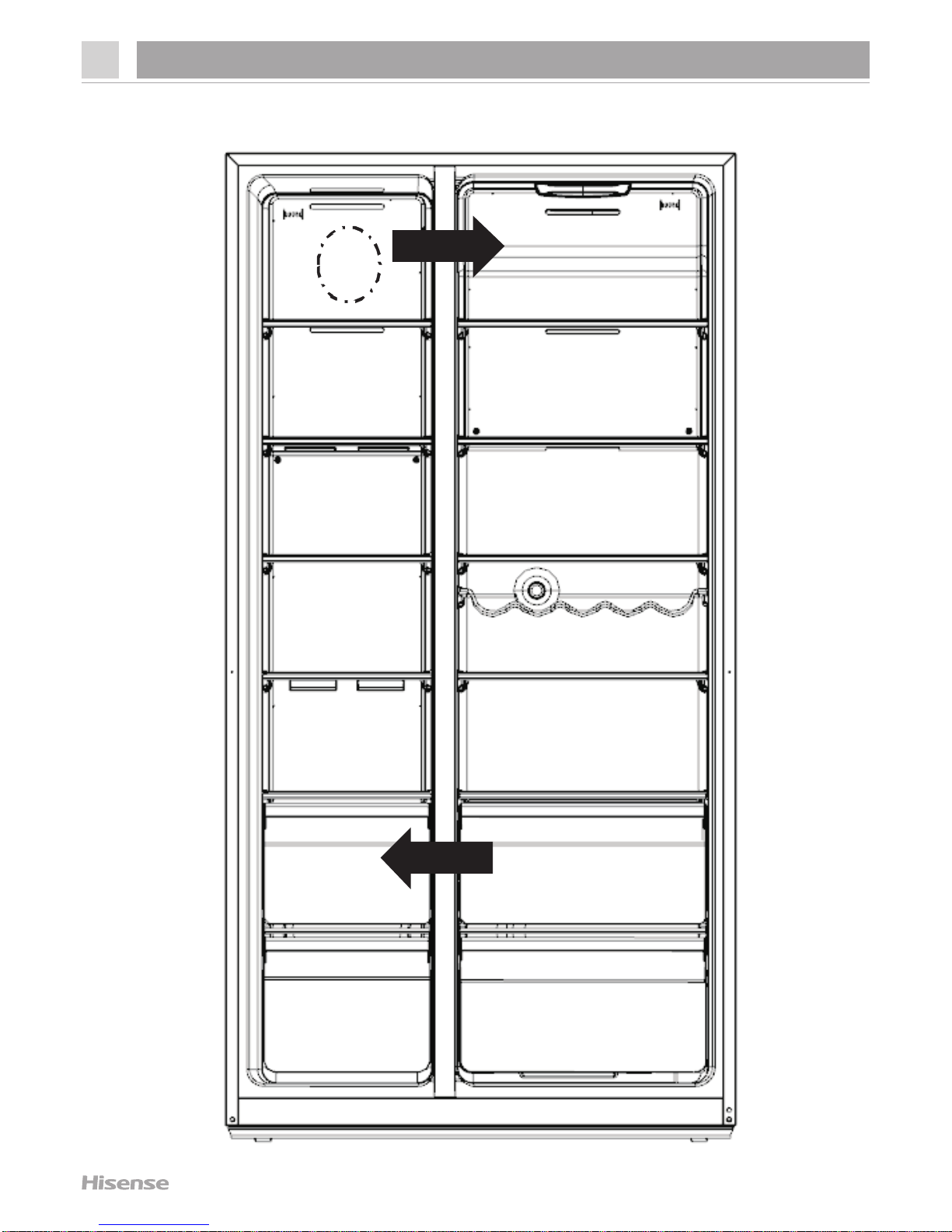

2.2 Evaporator structure

6

2.Appearance and structure

Sensor

Evaporator

Fuse

Heater

Accumulator

Capillary

Page 8

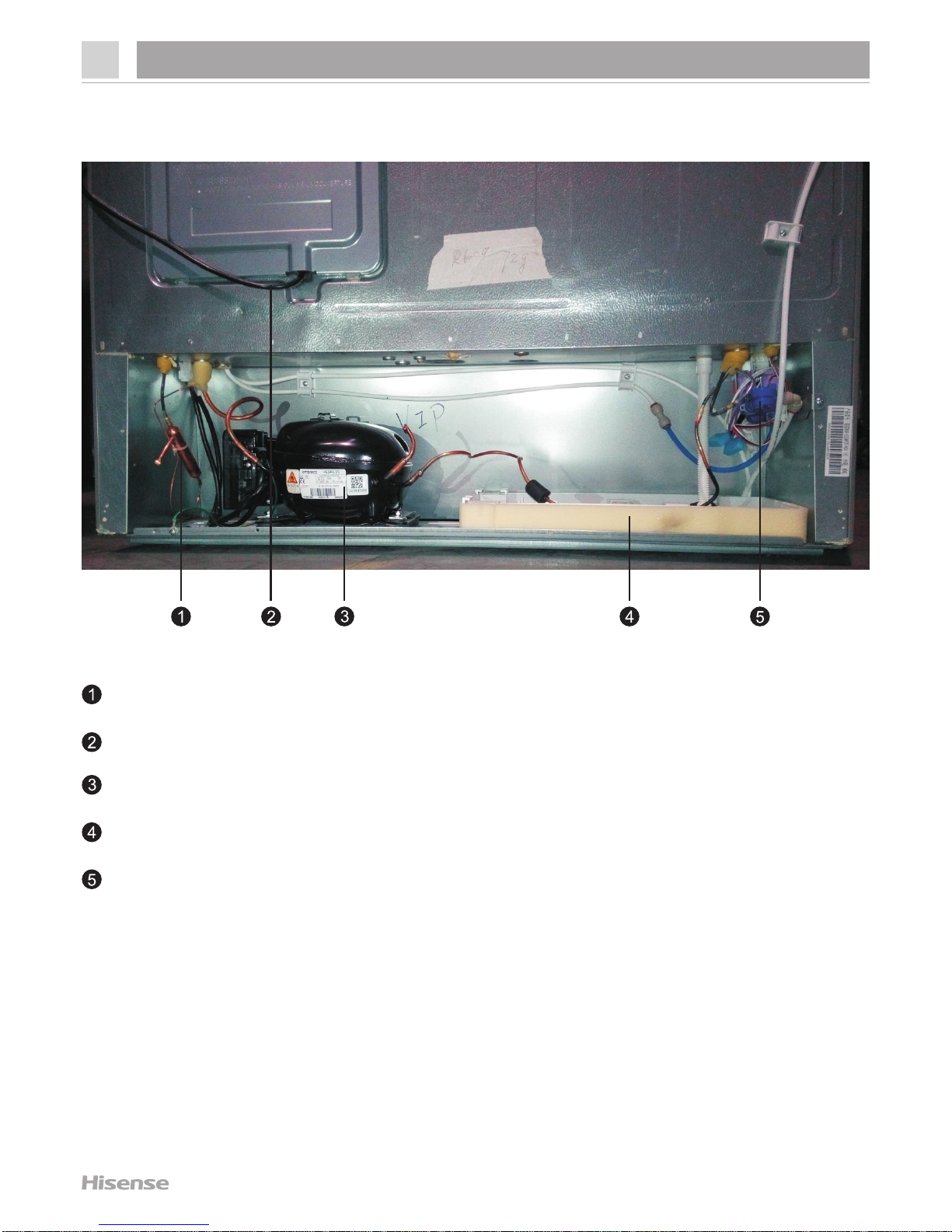

7

2.2 Compressor room structure

2.Appearance and structure

Dry filter

Power cord

Compressor

Evaporation dish

Water valve

Page 9

8

3.Basic parameters

Content

Unit

Value

Voltage / frequency

V/Hz

220-240/50

Rated current A 1.6

Rated input power

W

230

Defrost power W 252

Net capacity

L

535

Net capacity fridge compartmen

(Fridge/Chill)

L

367

Net capacity freezer compartment

L

168

Energy efficiency class

A+

Climate class (SN=10~32°C,

N=16~32°C, ST=16~38°C, T=16~43°C)

SN、N、ST、T

Refigerator room temperature

°C

2~8

Freezer room temperature

°C

-24~-14

Freezer compartment star rating

160L 4 Star

8L 2 Star

Energy consumption / year

kWh/year

438

Freezing capacit y / 24 hours

kg/24 h

13

Max noise level

dB(A)

=42

Kind of coolant / Charge

(R134a/R600a) / grammes

R / g

R600a/72

3 Basic parameters

Page 10

9

4.Operation and functions

4.1 Display controls

OFF

Use your appliance according to the following control regulations, your

appliance has the corresponding functions and modes as the control panels

showed in the pictures below.

When the appliance in powered on for

the first time, the backlighting of the

icons on display panel starts working.

If no buttons have been touched and

the doors are closed, the backlighting

will turn off after 60 seconds.

Caution! When you set a

temperature, you set an average

temperature for the whole refrigerator

cabinet. Temperatures inside each

compartment may vary from the

temperatures displayed on the panel,

depending on how much food you

store and where you place it. High or

low room temperature may also affect

the actual temperature inside the

appliance.

The control panel consists of two

areas about temperature, one area

about different modes.

4 Operation and functions

Page 11

10

4.Operation and functions

Page 12

4.Operation and functions

11

Page 13

4.Operation and functions

12

Page 14

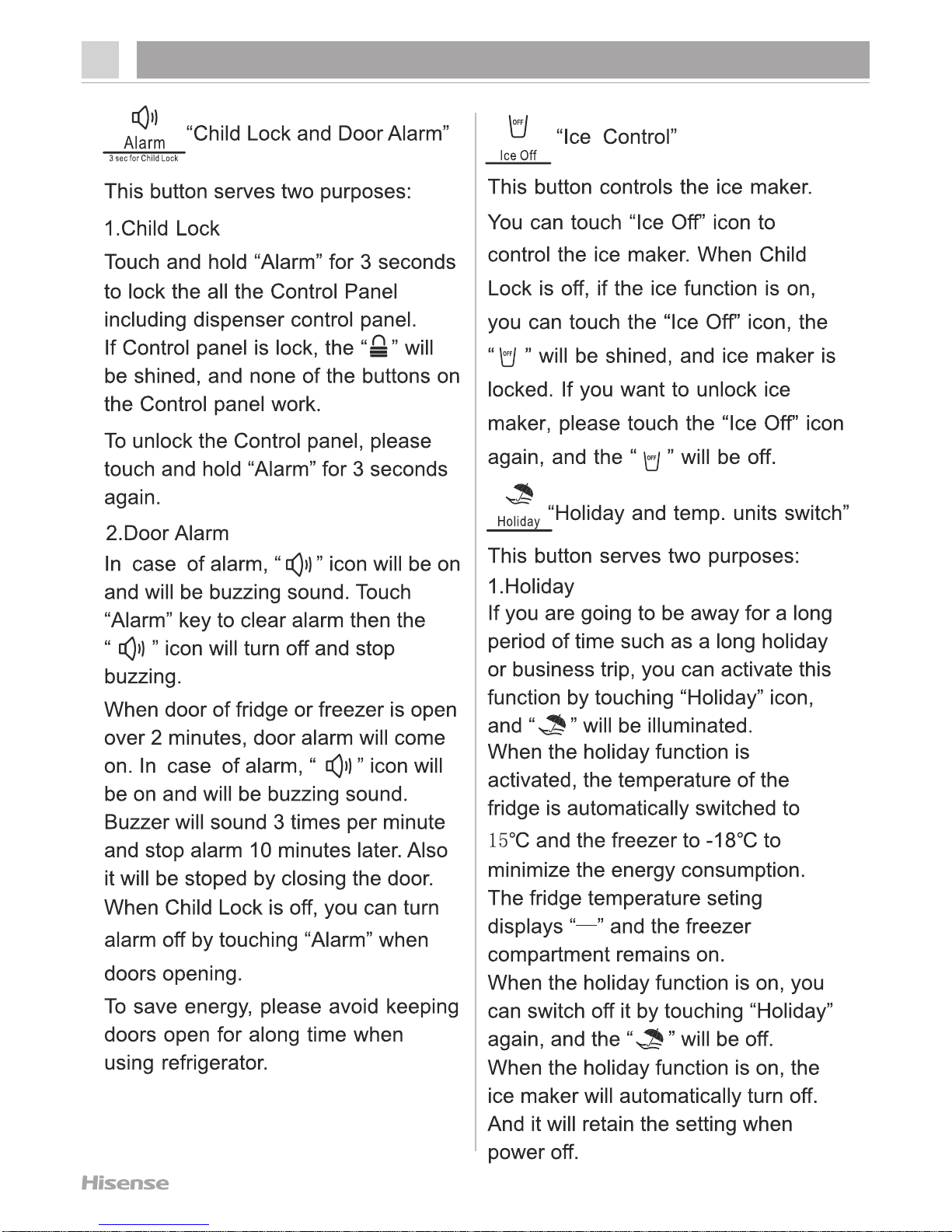

4.2 Using the appliance

4.Operation and functions

13

Page 15

4.Operation and functions

14

Page 16

4.Operation and functions

15

Page 17

4.Operation and functions

16

207~689

K

Page 18

4.3 Defrost mode

4.Operation and functions

4.3.1 Start condition

When compressor accumulated running time reach the setting point

(depends on the environment temperature),it will enter defrost mode

automatically.

4.3.2 Defrost flow

Compressor stops

Evaporator fan stops

Damper stops

Defrost heater works

Evaporator temperature reach the

setting point,exit defrost mode

Defrost heater stops

Compressor starts

several minutes delay

Evaporator fan starts

several minutes delay

Damper starts

Start

17

Page 19

4.4 Compulsory Defrost mode

4.Operation and functions

4.4.1 Start condition

Keep refrigerator door and freezer door closed for 10 minutes after

power-on,touch and hold “Ice off” button and “Freezer” button at the

same time for 5 seconds,it will enter compulsory defrost mode after a

long buzzing sound.

Compressor stops

Evaporator fan stops

Damper stops

Defrost heater works

90 seconds later,

until evaporator temperature

reach the setting point

exit defrost mode

Defrost heater stops

Compressor starts

several minutes delay

Evaporator fan starts

several minutes delay

Damper starts

Start

4.4.2 Compulsory defrost flow

18

Page 20

4.5 Error display

4.Operation and functions

4.5.1 Error code

Code Display area problem

E1

Refrigerator temperature

display area

Refrigerator sensor

malfunctions

E3

Freezer temperature

display area

Freezer sensor

malfunctions

E4

Freezer temperature

display area

Defrost sensor

malfunctions

E0

Freezer temperature

display area

Environment sensor

malfunctions

E9

Freezer temperature

display area

Ice maker sensor

malfunctions

Eb

Freezer temperature

display area

Ice maker

malfunctions

Ec

Refrigerator temperature

display area

Communication

sending

malfunctions

Er

Refrigerator temperature

display area

Communication

receiving

malfunctions

19

Page 21

4.5 Error display

4.Operation and functions

4.5.2 Checking method

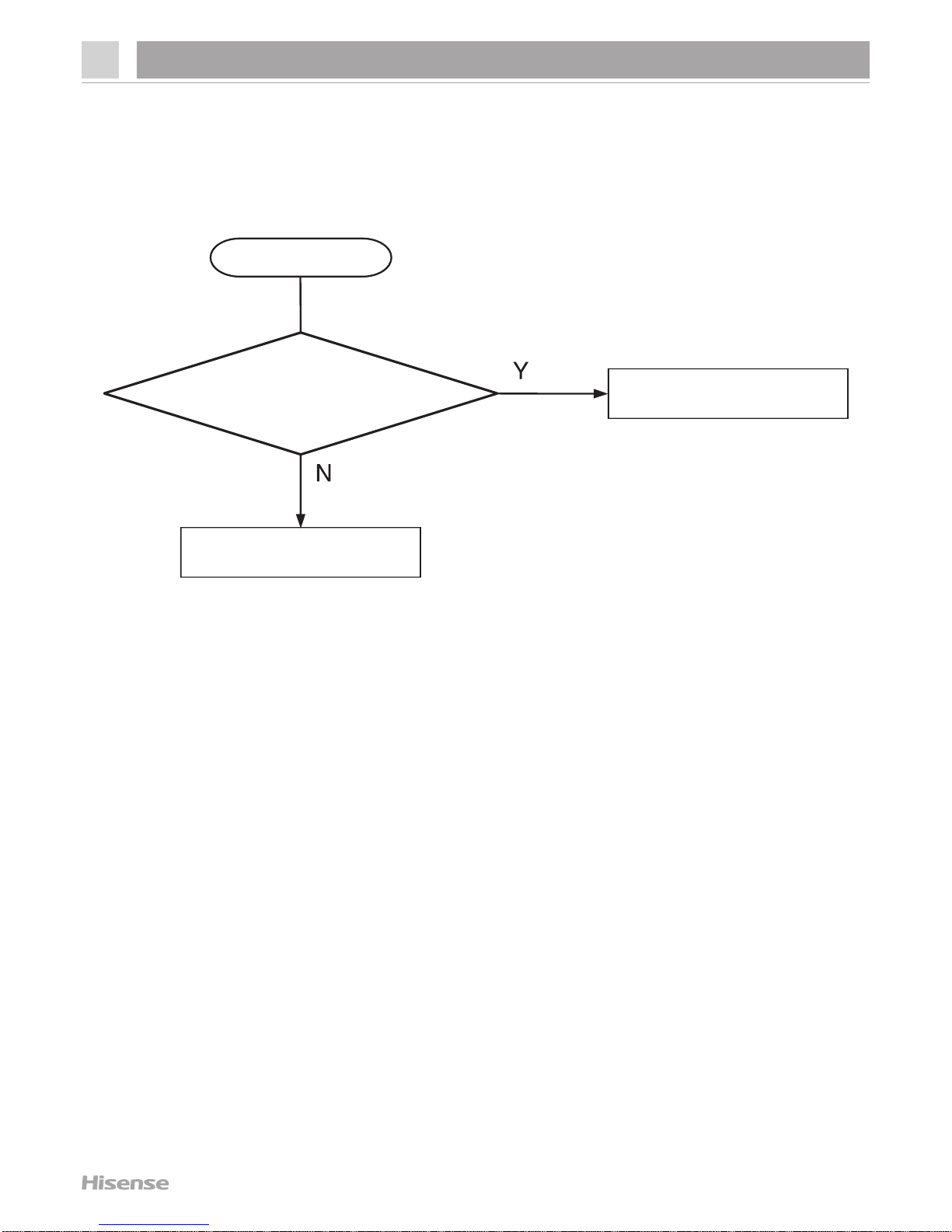

4.5.2.1 Environment sensor error

Start

Change the display

panel

Is the sensor connecting

wiring open circuit

or short circuit?

Repair the wiring

20

Page 22

4.Operation and functions

Start

Change the mainboard

Is the sensor connecting

wiring open circuit

or short circuit?

Repair the wiring

Is the sensor OK?

Change the sensor

Does the sensor connector

plug well?

Plug the terminal well

4.5.2.2 Other sensors error

21

Page 23

4.Operation and functions

4.5.2.2 Other sensors error

Note:

1.Refrigerator sensor corresponding pin No.8 and No.12 on CN5

connector of mainboard.

2.Freezer sensor corresponding pin No.9 and No.12 on CN5

connector of mainboard.

3.Evaporator sensor corresponding pin No.10 and No.12 on CN5

connector of mainboard.

4.Ice maker sensor corresponding pin No.11 and No.12 on CN4

connector of mainboard.

22

Page 24

4.Operation and functions

4.5.2.3 Ice maker error

Eb error:

1.Check the connecting wiring between mainboard and ice maker

(corresponding pin No.7~10 on CN4 connector of mainboard,as the

drawing below) and repair if it is broken.

2.Input 12V power to pin No.7 and No.8 on CN4 connector of

mainboard,check the ice maker can positive rotating(Red wiring

connect power,white wiring connect GND) and negative rotating

(white wiring connect power,red wiring connect GND) normally or not.

If it is abnormal,change the ice maker or mainboard.

23

Page 25

4.Operation and functions

4.5.2.4 Communication error

Note:

The display panel corresponding pin No.5~8 on CN7 connector of the

mainboard,as the drawing below.

Start

Change the mainboard

Is the connecting wiring

between display panel and

mainboard broken?

Repair the wiring

Is the display panel OK?

Change the display

panel

24

Page 26

5.Troubleshooting

5.1 Common problem and checking

Problem Possible cause & Solution

Appliance is not

working correctly

Check whether the power cord is plugged into the power outlet

properly

Check the fuse or circuit of your power su pp ly, replace if necessary

The ambient temperature is too low. Try setting the chamber

It is normal that the freezer is not operating during the automatic

defrost cycle, or for a short time after the appliance

Odours from the

compartments

The interior may need to be cleaned

Some food, containers or wrapping cause o dours

Noise from the

appliance

The sounds below are quite normal:

l Compressor running noises.

l Air movement noise from the small fan motor in the freezer

compartment or other compartme nts.

l Gu rgling sound similar to water boiling.

l Popping noise during automatic defrosting

Other unusual noises are due to the reasons below and may need

you to check and take action:

l The cabinet is not level.

l The back of appliance touches the wall

The motor runs

continuously

l It is normal to frequently hear the sound of the motor, it will

need to run more when in following circumstances:

Temperature setting is set colder than necessary.

l Large quantity of warm food has re cently been stored within

the appliance.

l The temperature outside the appliance is too high.

l Doors are kept open too long or too often.

l After your installing the appliance or it has been switched off

25

Page 27

26

5.Troubleshooting

Problem Possible cause & Solution

A layer of frost

occurs i n the

compartment

Check that the air outlets are not blocked by food and ensure food

is placed within the appliance to allow sufficient ventilation. Ensure

that door is fully closed. To remove the frost,please refer to

cleaning and care chapter.

Temperature inside

is too warm

You may have left the doors open too long or too frequently; or the

doors are kept open by some obstacle; or the appliance is located

with insufficient clearance at the sides,back and top.

Temperature inside

is too cold

Increase the temperature by following the"Display controls"

chapter.

Doors can't be

cloased easily

Check whether the top of the refrigerator is tilted back by 10-15mm

to allow the doors to self close, or if something inside is preventing

the doors from closing.

Water drips on the

floor

he water pan (located at the rear bottom of the cabine t) may not be

properly leveled, or the draining spout underneath the top of the

compressor depot may not be properly positioned to direct water

into this pan, or the water spout is blocked, or the water is not fully

inserted into the connector. You may need to pull the refrigerator

away from the wall to check the pan and spout and connector.

The light is not

working

l The LED light may be damaged. Refer to replace LED lights

in cleaning and care chapter.

l The control system has disabled the lights due to the door

being kept open too long, close and reopens the door to

reactivate the lights.

Ice is not dispensing

l Did you wait for 4 hours after installation of the water supply

line before making ice? if it is not sufficiently cool, it may take

longer to make ice, such as when first installed.

l Is the water line connected and the water valve open?

l Did you manually stop the ice making function? Make sure

you have set the Cubed or Crushed mode on.

l Is there any ice blocked within the ice maker bucket or ice

chute?

l Is the freezer temperature too warm?Try setting the freezer

temperature lower.

Page 28

27

5.Troubleshooting

Problem Poss ible cause & Solution

Water dispenser is not

functioning

l Is the water line connected and the water valve open?

l Has the water line been crushed or kinked? Make

sure the water line is free and clear of any obstruction.

l Is the water tank frozen because the refrigerator

temperature is too low? Try selecting a warmer setting

on the display panel.

l Check if the filter is properly installed.If it is not

properly installed,the water dispenser may not wo rk.

You can hear water

bubbli ng in the

refrigerator

This is normal. The bubbling comes from the refrigerant

coolant liquid circulating through the refrigerator.

Page 29

28

5.2 Faulty start

5.Troubleshooting

Has the power cord plugged

into the power outlet?

Are mainboard terminals

plugged well?

Is the compressor OK?

Plug the power cord

well

Change the

mainboard

Change the

compressor

Start

Is mainboard output

power OK?

Plug the terminals

well

Check connectors

and sensors

Page 30

29

5.3 Refrigeration failure

5.Troubleshooting

5.3.1 Freezer compartment

Any error code?

Does Fan motor

work?

Is fan motor OK?

Change the

fan motor

Is wiring

connection OK?

Change the

mainboard

Freezer door has gap?

Door gasket has gap?

Change the door

gasket

Reassemble the

door

Is the door hanged

down?

Is food palced too close

to the sensor or cold

air spout?

Explain not to place food

too close to sensor or cold

air spout

Start

Refer to “4.5 Error

dispaly” chapter

Does compressor

work?

Check lead wire

Is the compressor

OK?

Change the

compressor

Is the PTC starter

or overload protector

OK?

Check the

mainboard

Change the PTC starter

or overload protector

Page 31

30

5.Troubleshooting

5.3 Refrigeration failure

5.3.1 Freezer compartment

Is Temp. fuse OK?

Change the

Temp. fuse

Is defrost heater

OK?

Is there ice blockage

on evaporator?

Do doors open

frequently?

Explain not to open

doors frequently

Counsel to use colder

temperature setting

Change the

defrost heater

Check ice formation on

Eva. and if refrigerant

leak is found,repair it

Page 32

31

5.Troubleshooting

5.3 Refrigeration failure

5.3.2 Refrigerator compartment

Any error code?

Does the damper work?

Is the damper OK?

Change the

damper

Change the

mainboard

Is the sensor OK?

Is wiring connection

OK?

Change the sensor

and check connector

Is freezer compartment

OK?

Refer to 5.3.1

chapter

Change the door

gasket

Is the door hanged

down?

Reassemble the

door

Explain not to place food

too close to sensor or cold

air spout

Explain not to open doors

too frequently

Is food palced too close

to sensor or cold air

spout?

Do doors open frequently?

Use colder temperature

setting

Start

Solve error

code problems

Check the wiring

Gap between

refrigerator door and

cabinet?

Gap between

gasket and door?

Page 33

32

5.Troubleshooting

Is dew foramed on the

door gasket surface?

Change the door

gasket

Is door hanged

down?

Do doors open

frequently?

Is the appliance too

close to heat

sources?

Is watery or hot food

stored in the cabinet?

Wipe out dew on the

louver surface and run

the refrigerator again

5.4 Thick frost in freezer compartment

Start

Reassemble the

door

Explain not to open

doors too frequently

Make enough distance

between heat sources

and appliance

Gap between

gasket and

cabinet?

Page 34

33

5.Troubleshooting

5.5 Dew in refrigerator compartment

Is dew foramed on the

door gasket surface?

Change the door

gasket

Is the door

hanged down?

Does the door open too

frequently?

Is the appliance too

close to heat sources?

Is watery or hot food

stored in the cabinet?

Advise to cool down hot

food and seal watery

food well before storing

Make enough distance

between the appliance

and heat sources

Explain not to open

doors too frequently

Start

Gap between

gasket and

cabinet?

Reassemble the

door

Page 35

34

5.Troubleshooting

5.6 Low temperature of vegetable vase

Is the damper OK?

Change the damper

Is the sensor OK?

Change the sensor

Check the sensor

connection and repair

Counsel to use warmer

temperature setting

Start

Is refrigerator temperature

setting too cold?

Is the mainboard

output power OK?

Check the mainboard

Page 36

35

5.Troubleshooting

5.7 Breaking of light

Is the light disconnected

or broken?

Is the door switch OK?

Change the door switch

Check the door switch

connection and repair

Start

Change the light

Page 37

36

5.8 Noise

5.Troubleshooting

5.8.1 Compressor noise

Is the appliance leveled?

Level the appliance by

adjusting the bottom feet

Are the adjustable bottom

feet broken?

Change the adjustable

bottom feet

Is the noise from compressor

itself?

Add a rubber absorber to

reduce the vibration

Start

Change the compressor

Page 38

37

5.8 Noise

5.Troubleshooting

5.8.2 Refrigerator flowing noise

Is there hiss or sizzling sound

from refrigerant when comp.

starts/stops?

Is there sound from freezer

compartment when compressor ’s

running?

Fasten the evaporator

Start

Is there water flowing or hiss

sound from the appliance?

Attache a gum absorber

on the capillary tube

Attach a gum absorber

on the accumulator

Explain to customer that

it is normal sound of

the running appliance

Page 39

38

5.8 Noise

5.Troubleshooting

5.8.3 Fan motor noise

Fasten the fan motor

Sound from fan itself or

vibration when working?

Change the fan motor

Is the fan damaged

or transformed?

Is the fan touching

surround?

Set the fan right,avoid to

touch surround

Start

Is the fan moving

or shaking?

Change the fan

Explain to the customer

that it is normal sound of

the running appliance

Page 40

39

5.8 Noise

5.Troubleshooting

5.8.4 Pipe noise

Does evaporation dish make

noise by touching the

pipe?

Check the cushion between

pipe and evaporation

dish and repair

Is pipe itself shaking strongly?

Is compressor itself shaking

strongly?

Are pipes touching in the

compressor room?

Separate the touching

pipes

Attach a gum absorber

on top of the compressor

Start

Move or change the points

of vibration absorber on

pipes to reduce shaking

Explain to the customer

that it is normal sound of

the running compressor

Page 41

40

6.Circuit and checking

6.1 Circuit diagram

Page 42

41

6.2 Mainboard

6.Circuit and checking

6.2.2 Removing the mainboard

1.Unplug the appliance

2.Remove the screws of electric box cover by screwdriver,as

picture 1.

3.Remove the electric box cover,as picture 2.

4.Unplug the terminals on the mainboard,as picture 3.

5.Pry up the mainboard by fingers and take it out,as picture 4.

Picture1 Picture2

Picture3 Picture4

If the problem is probably caused by the mainboard,change it directly

to confirm.

6.2.1 Checking method

Page 43

42

6.3 Compressor

Input voltage/frequency:220-240V/50Hz

Imput power:≤64.2*115% W

6.3.1 Basic parameters

6.3.2 Checking method

6.Circuit and checking

1.Compressor will start 10 seconds after power-on,if it starts

unsuccessfully,remove the electric box cover and check.

2.Check the connecting wiring between compressor and mainboard

and repair if it is broken.

3.Use a multimeter to measure voltage between N label and COMP

label on CN2 connector of mainboard,then measure frequency of CN8

connector.If the voltage equal to electric supply power and there is

stabilized frequency,it means the compressor is broken,change it;

If not,change the mainboard.

Page 44

6.3.3 Removing the PTC starter and overload protector

1.Unplug the appliance

2.Remove the screws of protector box by screwdriver,as picture 1.

3.Pry up the protector box from top by screwdriver,as picture 2.

4.Unplug the overload protector,as picture 3.

5.Unplug the PTC starter,as picture 4.

Picture1 Picture2

Picture3 Picture4

43

6.Circuit and checking

Page 45

44

6.4 Fan motor

Rated voltage:DC12V

Rated input power:2.5W

6.4.1 Basic parameters

6.4.2 Checking method

6.Circuit and checking

1.Check the connecting wiring of fan motor is well or not,repair if it

is broken.The fan motor corresponding pin No.13~15 on CN4

connector of mainboard,as the drawing below.

2.Pin No.14 connect 12V power and pin No.13 connect GND,if the

fan motor works normally,change the mainboard;If not,change the

fan motor.

Page 46

45

6.4.3 Removing the fan motor

6.Circuit and checking

1.Unplug the appliance

2.Remove the screws of freezer wind channel component by

screwdriver,as picture 1.

3.Remove the wind channel component and unplug the terminals,as

picture 2.

4.Remove the screw of the wind channel component by screwdriver,

as picture 3.

5.Pry up the wind channel cover from the buckles by screwdriver,as

picture 4.

6.Separate the front cover and back cover,as picture 5.

7.Remove the screws of fan motor and then remove the fan motor,

as picture 6.

Picture1 Picture2 Picture3

Picture4 Picture5 Picture6

Page 47

46

6.5 Damper

Rated voltage:DC12V

Rated current:60mA

6.5.1 Basic parameters

6.5.2 Checking method

6.Circuit and checking

1.Check the connecting wiring of the damper is well or not,repair if it is

broken.The damper corresponding pin No.1~6 on CN6 connector of

mainboard,as the drawing below.

2.The damper will turn on and off for one time after power-on,if not,

change the mainboard first and change the damper if problem

remains.

Page 48

47

6.5.3 Removing the damper

6.Circuit and checking

1.Unplug the appliance

2.Remove the screws of refrigerator wind channel component by

screwdriver,as picture 1.

3.Remove the wind channel component and unplug the terminals,as

picture 2.

4.Separate the wind channel cover and foam,as picture 3.

5.Remove the sponge and adhesive paper on the foam,as picture 4.

6.Separate the upper foam and lower foam,as picture5.

7.Remove the damper,as picture 6.

Picture1 Picture2 Picture3

Picture4 Picture5 Picture6

Page 49

48

6.6 Light

6.6.1 Basic parameters

1.Check the connecting wiring between light and mainboard is well

or not,repair if it is broken.Refrigerator light corresponding pin No.1

and No.2 on CN7 connector of mainboard,freezer light corresponding

pin No.1 and No.3,ice maker light corresponding pin No.1 and No.4,

as the drawing below.

2.Check output voltage corresponding light of the mainboard,if it is

12V,it means the mainboard is OK,change the light;If not,it means

the mainboard is not OK,change it.

6.6.2 Checking method

6.Circuit and checking

Rated voltage:DC12V

Rated power:2W

Page 50

49

6.6.3 Removing the light

6.Circuit and checking

1.Unplug the appliance

2.Pry up the light cover from the buckles by screwdriver,as picture 1.

3.Remove the light cover,as picture 2.

4.Pry up the light from the buckles by screwdriver,as picture 3.

5.Unplug the terminal of the light,as picture 4.

Picture1 Picture2

Picture3 Picture4

Page 51

50

6.7 Door switch

Load voltage:DC24V

Load current:0.05A

6.7.1 Basic parameters

1.Check the connecting wiring of door switch is well or not,repair if it

is broken.Refrigerator door switch corresponding pin No.4 and No.6

on CN4 connector of mainboard,freezer door switch corresponding

pin No.4 and No.7,as the drawing below.

2.Check the magnet on the door is dropped out or not.

3.Normally,when the door is closed,the two pins of door switch should

be short circuit;When the door is open,the two pins should be open

circuit.If the result is not abnormal,change the door switch.

4.If all above is OK,change the mainboard.

6.7.3 Checking method

6.Circuit and checking

Page 52

51

6.8 Temperature fuse

Max fusing-off temperature:72℃

Load voltage:250V

Load current:10A

6.8.1 Basic parameters

6.8.2 Checking method

6.Circuit and checking

Use a multimeter to measure resistance between the two terminals of

the fuse,if it is open circuit,change the fuse.

Page 53

52

6.8.3 Removing the temperature fuse

6.Circuit and checking

1.After removing the freezer wind channel component,unplug the

terminals,as picture 1.

2.Remove the screws of evaporator by screwdriver,as picture 2.

3.Separate the evaporator component from the cabinet and remove

the foams at left side and right side,as picture 3.

4.Cut the self locking ties that fastening the temperature fuses by

knife and then remove the fuses,as picture 4.

Picture1 Picture2

Picture3 Picture4

Page 54

53

6.9 Defrost heater

Rated voltage:AC220V

Rated power:220W

6.9.1 Basic parameters

6.Circuit and checking

6.9.2 Checking method

1.Enter compulsory defrost mode,use a multimeter to measure

the voltage between pin No.1 and No.9 on XP7 connector of the

mainboard,if the voltage doesn’t equal to electric supply power,it

means the heater is broken,change it.

2.Check the fuse is well or not,refer to “6.8 Temperature fuse”chapter.

3.Use a multimeter to measure resistance of the heater,if the value

isn’t 220Ω±5 % , it is broken,change the heater.

Page 55

54

6.9.3 Removing the defrost heater

6.Circuit and checking

Picture1 Picture2 Picture3

Picture4 Picture5

1.After removing the freezer wind channel component,unplug the

terminals,as picture 1.

2.Remove the screws of evaporator by screwdriver,as picture 2.

3.Separate the evaporator component from the cabinet and remove

the foams at left side and right side,as picture 3.

4.Cut the self locking ties that fastening the heater by knife,as

picture 4.

5.Pry up the buckles that fastening the heater by screwdriver and

then remove the heater,as picture 5.

Page 56

55

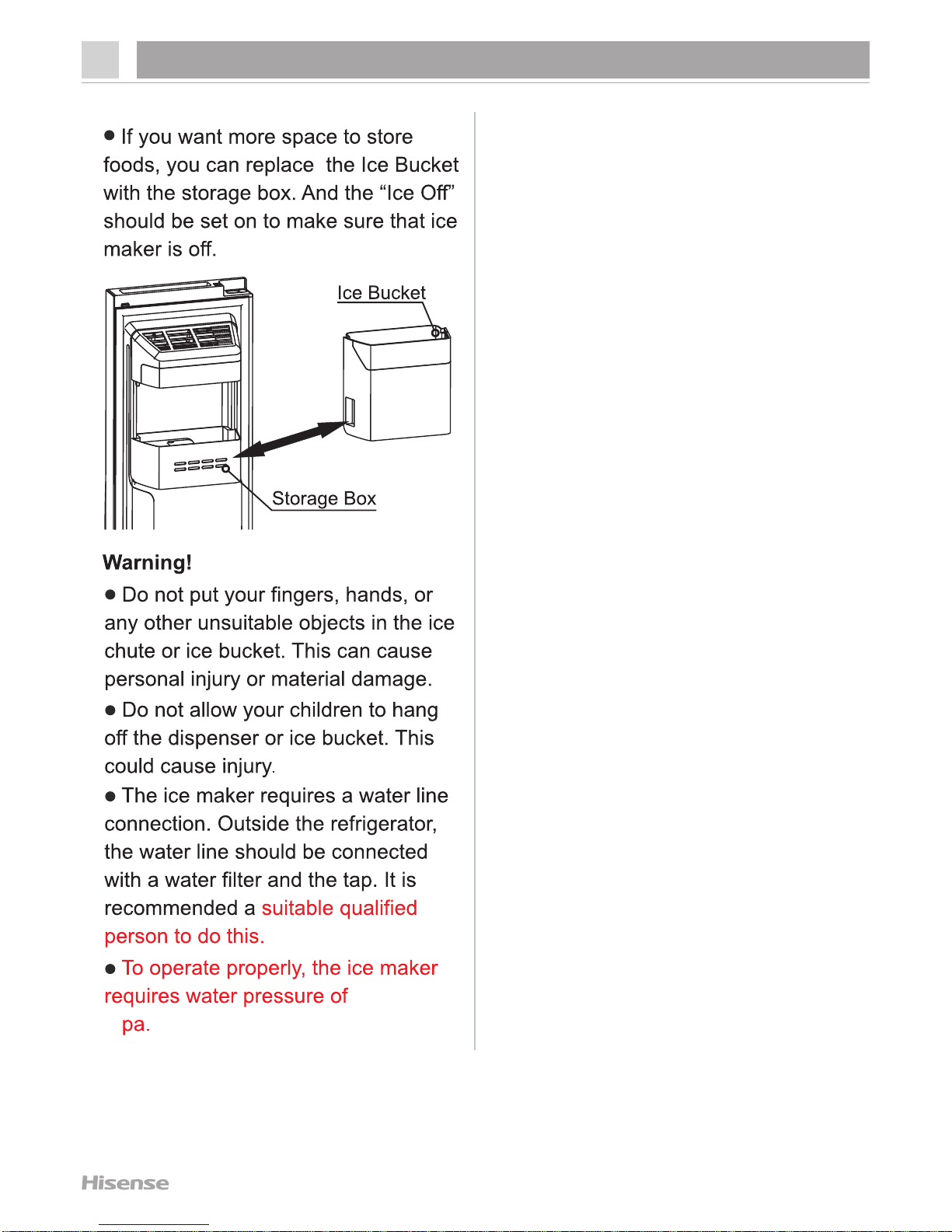

6.10 Ice maker

6.9.1 Checking method

6.Circuit and checking

Refer to “4.5 Error display”chapter.

6.9.2 Removing the ice maker

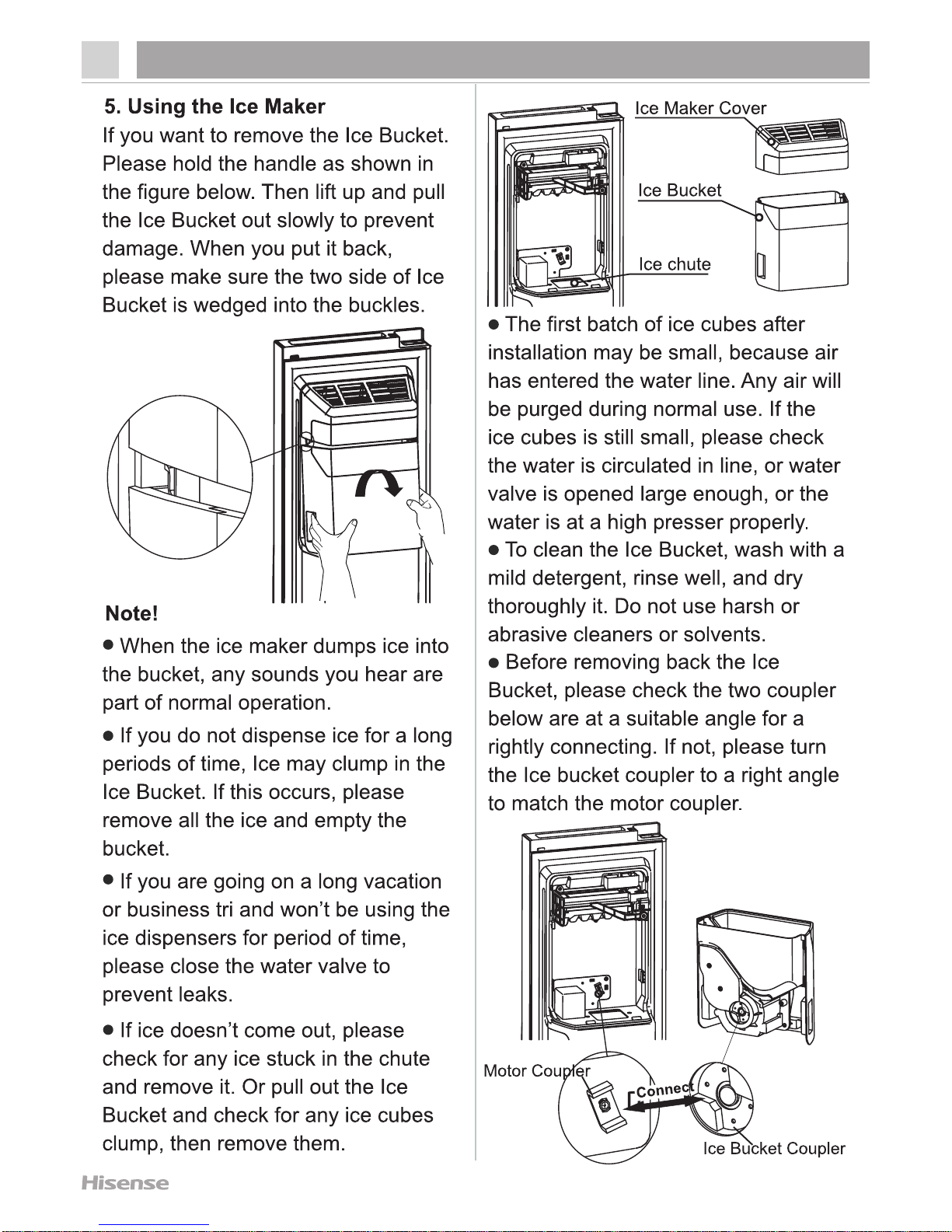

6.9.2.1 Removing the ice bucket

1.Raise the ice bucket up,as picture 1.

2.Pull the ice bucket slantingly downwards,as picture 2.

3.Pull the ice bucket out,as picture 3.

Picture1 Picture2

Picture3

Page 57

Picture1 Picture2

Picture3

6.9.2.2 Removing the water intake

56

6.Circuit and checking

1.Pull the front cover out slantingly upwards,as picture 1.

2.Pull the water intake slantingly upwards,as picture 2.

3.Remove the two buckles of the water intake,as picture 3.

4.Take out the water intake,as picture 4.

Page 58

6.9.2.3 Removing the ice maker and holder

57

6.Circuit and checking

1.Remove the screws of the ice maker holder by screwdriver,as

picture 1.

2.Unplug the terminal of the ice maker,as picture 2.

3.Remove the screws of the ice maker by screwdriver,as picture 3.

4.Remove the wiring,as picture 4.

5.Pull the ice maker upwards and remove it,as picture 5.

Picture1 Picture2 Picture3

Picture4 Picture5

Page 59

6.9.2.4 Removing the ice crushing motor

58

6.Circuit and checking

1.Remove the screws of the motor by screwdriver,as picture 1.

2.Remove the coupling,as picture 2.

3.Remove the screws of the motor cover by screwdriver,as picture 3.

4.Remove the cover and pull out the motor and remove it,as pictire 4.

Picture1 Picture2

Picture3 Picture4

Page 60

6.9.2.4 Removing the ice dispenser

59

6.Circuit and checking

1.Pull out the water tube,as picture 1.

2.Unplug connecting terminal,as picture 2.

3.Remove the screws by screwdriver,as picture 3.

4.Pry up the ice dispenser at the buckles,as pictire 4.

5.Pull out the ice dispenser,as picture 5.

6.Unplug the motor terminal and remove the ice dispenser,as

picture6.

Picture1 Picture2 Picture3

Picture4 Picture5 Picture6

Page 61

6.9.2.4 Removing the water valve

60

6.Circuit and checking

1.Remove the screws of the water valve by screwdriver,as picture 1.

2.Pull out the water valve,as picture 2.

3.Unplug the connecting terminal,as picture 3.

4.Remove the water tube connector,as pictire 4.

5.Remove the water tube,as picture 5.

6.Pull out the water valve,as picture6.

Picture1 Picture2 Picture3

Picture4 Picture5 Picture6

Page 62

61

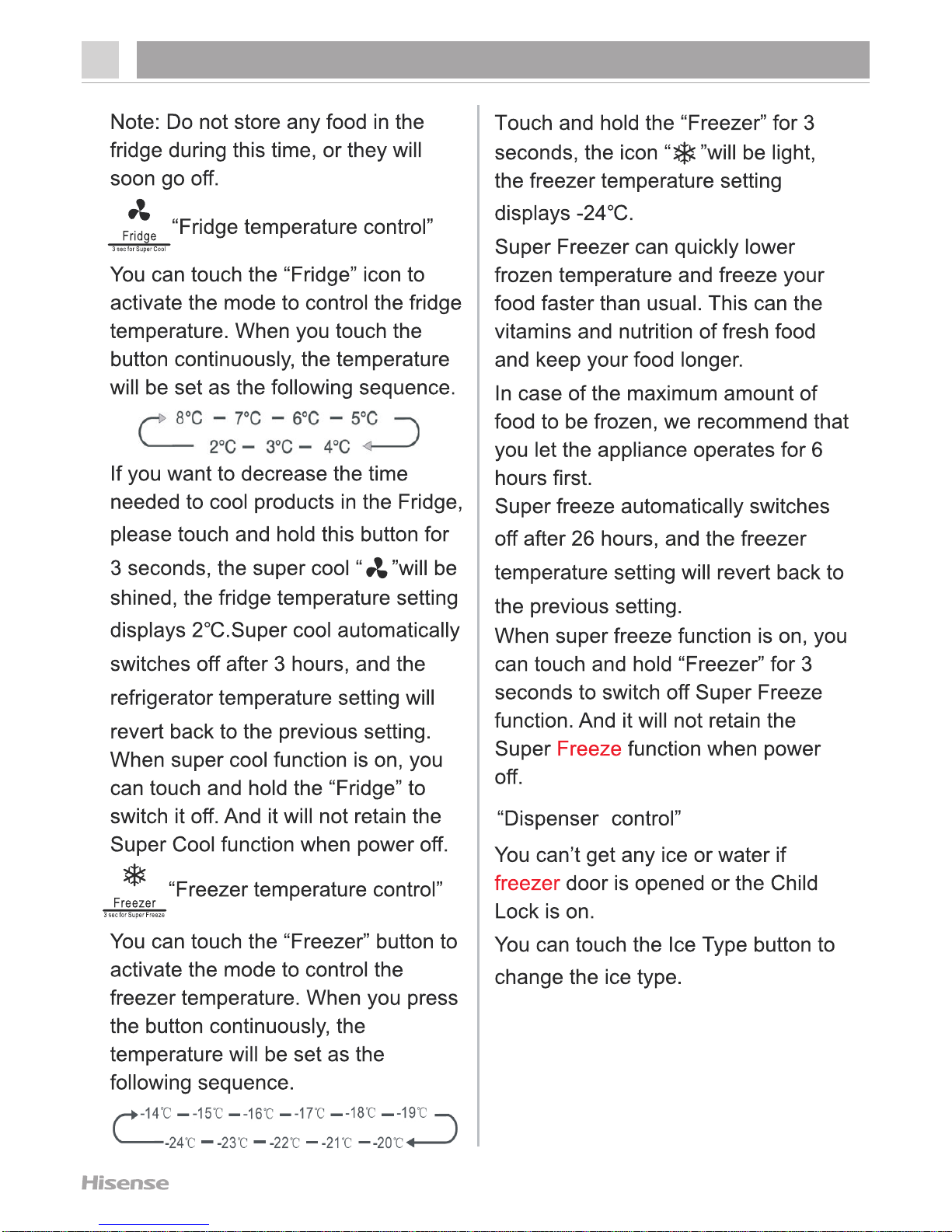

7.Refrigeration system repair

7.1 Refrigeration system

The refrigerator system is single cycle wind cooling system:

Compressor discharges high temperature

high pressure R600a gas refrigerant

Refrigerant enters evaporation pipe,condenser

and anti-condensation pipe one after another,

then becomes middle temperature high pressure

liquid after condensation

Refrigerant enters dry filter,water and imperity will

be filtrated

Refrigerant enters capillary and pressure will

be reduced

Refrigearnt enters finned evaporator and

become low temperature low pressure gas after

absorbing heat from freezer and refrigerator

compartment

Refrigerant goes back to compressor through

air return pipe and becomes high temperature high

pressure liquid after compressing

Page 63

62

7.Refrigeration system repair

7.1 Refrigeration system

Anti-condensation

pipe

Condenser

Finned evaporator

Compressor

Dry filter

Evaporation pipe

Air return

pipe

Condenser

Page 64

63

7.Refrigeration system repair

7.2 Summary of repair

Page 65

64

7.3 Regualation for repair

7.Refrigeration system repair

Page 66

65

7.4 Practical work for repair

7.Refrigeration system repair

Page 67

66

7.4 Practical work for repair

7.Refrigeration system repair

Page 68

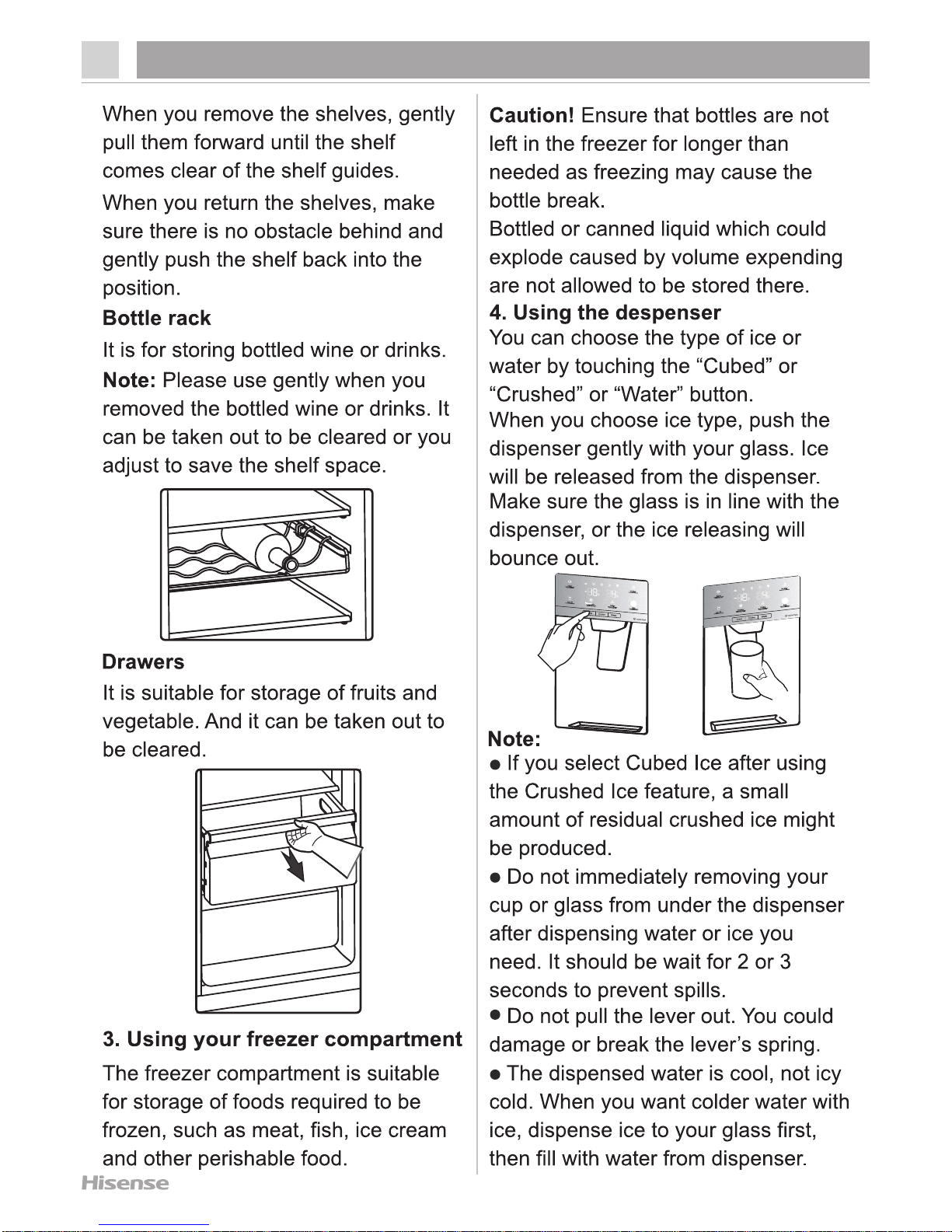

67

7.5 Brazing reference drawing

7.Refrigeration system repair

Anti-condensation pipe

Condenser

Capillary

Air return pipe

Dry filter

Connecting pipe

Connecting pipe

Compressor

Finned

evaporator

Evaporation

pipe

Refrigearnt flowing direction

Welding points

Loading...

Loading...