Page 1

AS-09UR4SVETE5(TF5)

AS-12UR4SVETE5(TF5)

AS-18UR4SFATE5(TF5)

AS-24UR4SDBTE5(TF5)

Hisense Corporation

Page 2

Type of contents

1. OPERATION RANGE

2. INSTALLATION

3. REFRIGERANT FLOW DIAGRAM

4. ELECTRICAL DATA

5. CONTROL MODE

6. TROUBLE SHOOTING

7. CHECKING COMPONENTS

NOTE: The figure、size and parameter of the product may not be identical

with the service manual, please take the actual product as the standard.

Page 3

1.1.OPERATING

OPERATING

RANGE

RANGE

Temperature Indoor Air Intake Temp. Outdoor Air Intake Temp

COOLING

Maximum

32℃ D.B./23℃ W. B. 43 ℃ D.B./26℃ W. B.

Minimum

21℃ D.B./15℃ W. B. 21 ℃ D.B./15℃ W. B.

HEATING

Maximum

27℃ D.B./18℃ W. B. 24 ℃ D.B./18℃ W.B .

Minimum

20℃ D.B/≤15℃ W.B -7 ℃ D.B./-8℃ W.B .

Page 4

22..INSTALLATION

INSTALLATION

1、How to choose an air conditioner(only for reference):

a. Choice for reference: 170W/㎡for average rooms;

b. Choice for reference: 160-200W/㎡for small size offices;

c. Choice for reference: 220-350W/㎡for restaurants;

d. Choice for reference: 200-300W/㎡for entertaining venues;

e. Choice for reference: 220-280W/㎡for the top floor.

Note:1W = 3.412btu.

2、Indoor Unit:

2.1. Distance for the indoor unit:

Note: a.The wallboard must be smooth and straight, with its supporting force

of not less than 60 kg.

2.1 Install for the installation template:

Page 5

22..INSTALLATION

INSTALLATION

Note: The installation template should be installed level.

2.3. Drilling:

Note

:

The tool need to raise 5 degrees when drilling, so that the hole of the

indoor side will be higher than the outdoor side, the water can drain smoothly.

2.4 Bend the evaporator pipe:

Note: When you bend the evaporator pipe, you should use your right hand

hold the pipe tightly at bends, and then use the left hand bend the pipe slowly.

Page 6

22..INSTALLATION

INSTALLATION

3、Outdoor Unit:

3.1. The distance of the outdoor unit:

Note: The wallboard supporting force should be able to withstand four times

the weight of the outdoor unit, and not less than 180 kg.

3.2. Fix for the outdoor unit:

Note: The outdoor unit base must be fixed with the bolts to reduce vibration

and noise, if necessary the shock pad can be used.

4. The height difference and the connection pipe length:

bolt

Shock pad

Page 7

22..INSTALLATION

INSTALLATION

When install the unit, please follow the following principle:

4.1.The height difference between the indoor unit and the outdoor unit

should not exceed 5m;

4.2.The connection pipe length should be not less than 1m;

4.3.The longest connection pipe is 15m for the unit(Recommendation:

The longest connection pipe is 10m for 9K and 12K unit and 15m for 18K,24K

and 30K unit);

4.4. Normally, the connection pipe does not exceed 5m, if the connection

pipe exceed 5m, it should add some gas for the unit, the amount of the gas

that recharged is based on the diameter and length of the liquid pipe, and the

recharged gas Xg=(the liquid pipe length -5m)*(*sheet*g/m), for example, for

one heat pump single split air conditioner, if the diameter of the liquid pipe is

Ф9.53 , and the liquid pipe length is 7m, it means that it should charge

(7m-5m)*50g/m=100g gas for the unit refer to the following sheet:

The diameter for the

connection pipe(mm)

single split air

conditioner

Liquid pipe Gas pipe

cooling only

(g/m)

heat pump(g/

m)

Ф6.35

Ф9.53 or

Ф12.7

15 20

Ф6.35 or

Ф9.53

Ф15.88 or

Ф19.05

15 50

Page 8

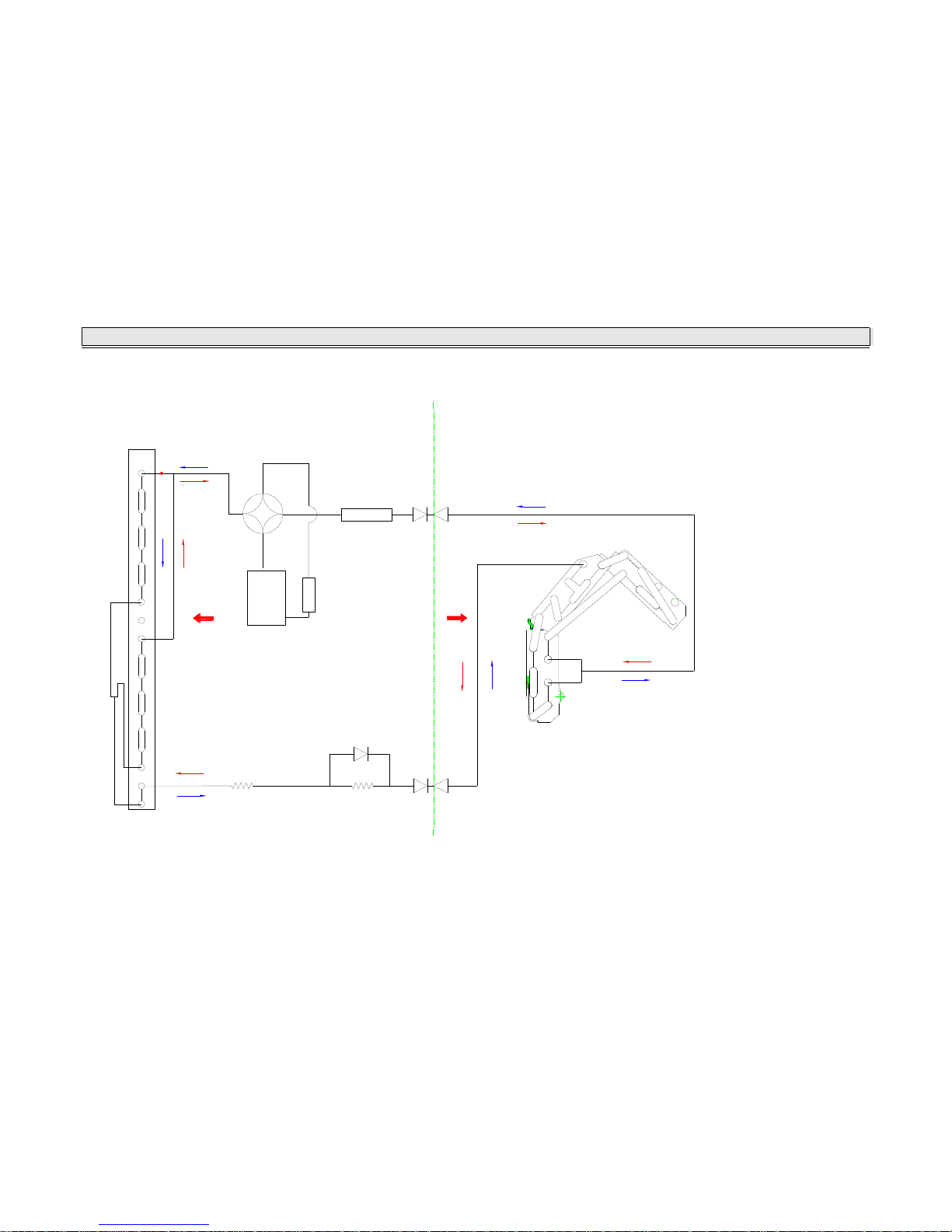

33..REFRIGERANT

REFRIGERANT

FLOW

FLOW

DIAGRAM

DIAGRAM

3-1. Refrigerant flow diagram :

CAPILLARY

COMPRESSOR

CHECK VALVE ASS'Y

CAPILLARY

CONDENSER

EVAPORATOR

OUTDOOR

INDOOR

出2

Page 9

33..REFRIGERANT

REFRIGERANT

FLOW

FLOW

DIAGRAM

DIAGRAM

3

Page 10

44..ELECTRICAL

ELECTRICAL

DAT A

DAT A

4-1.Electrical wiring diagrams

NOTE: YE/GN=YELLOW/GREEN, BU=BLUE, BN=BROWN, WH=WHITE, BK=BLACK, VT=VIOLET, OG=ORANGE,

RD=RED,BRN=BROWN,BLU=BLUE,BLK=BLACK,WHT=WHITE

INDOOR:

(1) AS-09UR4SVETE5(TF5) AS-12UR4SVETE5(TF5) (indoor):

(2) AS-18UR4SFATE5(TF5) (indoor):

Page 11

44..ELECTRICAL

ELECTRICAL

DAT A

DAT A

(3) AS-24UR4SDBTE5(TF5)(indoor):

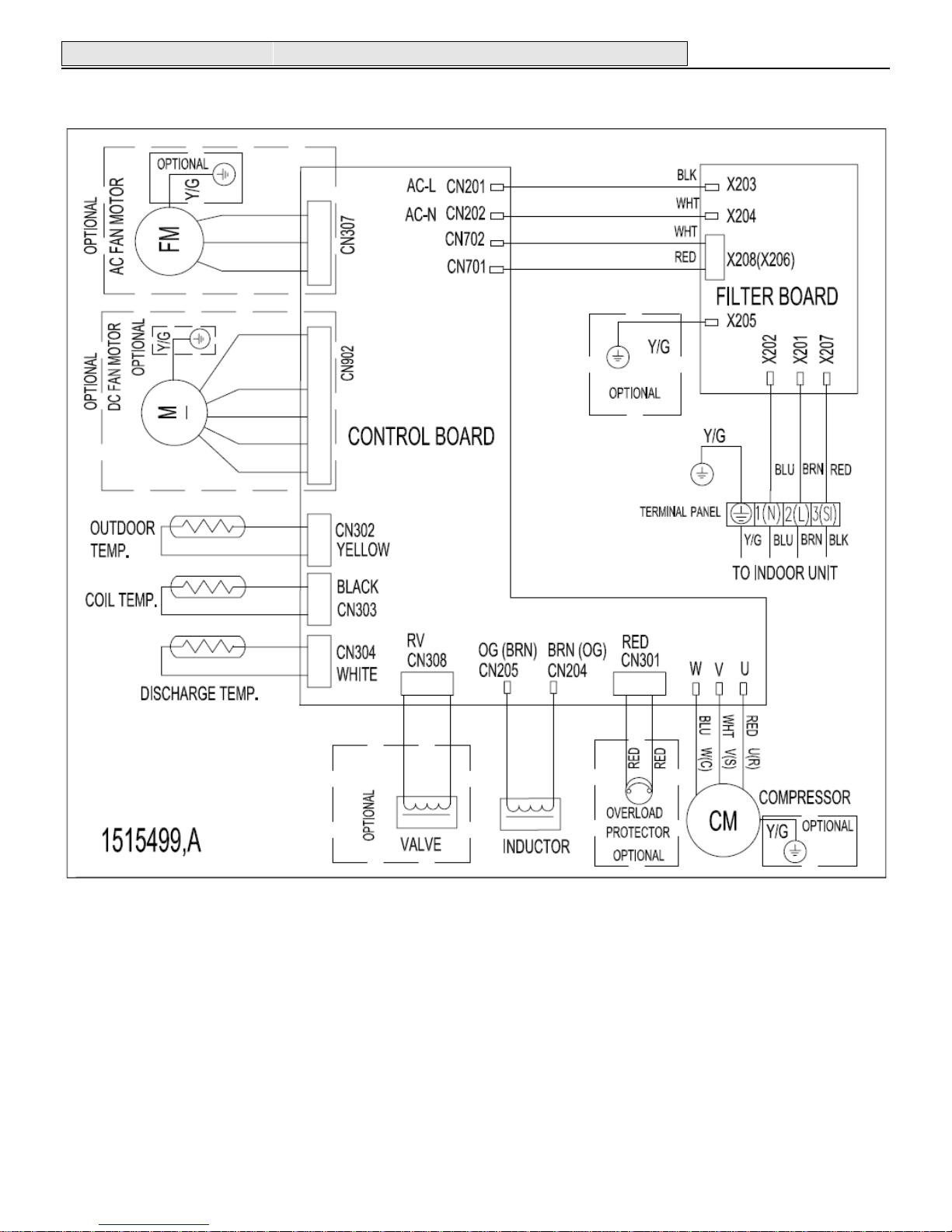

OUTDOOR

(1)AS-09UR4SVETE5(TF5) AS-12UR4SVETE5(TF5) (OUTDOOR)

Page 12

44..ELECTRICAL

ELECTRICAL

DAT A

DAT A

(2)AS-18UR4SFATE5(TF5) AS-24UR4SDBTE5(TF5)(OUTDOOR)

Page 13

44..ELECTRICAL

ELECTRICAL

DAT A

DAT A

4-2. Sensor parameter

1. THE PARAMETER OF OUTDOOR DISCHARGE TEMPERATURE SENSOR FOR COMPRESSOR::

(

R

0

=187.25K±6.3%;R

100

=3.77K±2.5K;B=3979±1%

)

T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX

-30 966.1 0.1014 5 5 26 55.46 1.3252 68 44 82 6.662 3.7507 191

BF

-29 910.3 0.1075 5 5 27 53.11 1.3678 70 46 83 6.446 3.7813 193

C1

-28 858 0.1139 6 6 28 50.86 1.4112 72 48 84 6.239 3.8111 194

C2

-27 809 0.1206 6 6 29 48.72 1.4552 74

4A

85 6.039 3.8404 196

C4

-26 763.1 0.1277 7 7 30 46.68 1.4997 76

4C

86 5.846 3.8691 197

C5

-25 720 0.1351 7 7 31 44.74 1.5446 79

4F

87 5.661 3.8970 199

C7

-24 679.6 0.1429 7 7 32 42.89 1.5901 81 51 88 5.482 3.9243 200

C8

-23 641.7 0.1511 8 8 33 41.13 1.6359 83 53 89 5.309 3.9512 202

CA

-22 606.1 0.1597 8 8 34 39.44 1.6824 86 56 90 5.143 3.9773 203

CB

-21 572.7 0.1687 9 9 35 37.84 1.7289 88 58 91 4.982 4.0029 204

CC

-20 541.3 0.1782 9 9 36 36.3 1.7762 91

5B

92 4.827 4.0279 205

CD

-19 511.7 0.1881 10

A

37 34.84 1.8235 93

5E

93 4.678 4.0522 207

CF

-18 484 0.1984 10

A

38 33.44 1.8713 95

5F

94 4.534 4.0760 208

D0

-17 457.9 0.2092 11

B

39 32.11 1.9190 98 62 95 4.395 4.0992 209

D1

-16 433.3 0.2206 11

B

40 30.83 1.9673 100 64 96 4.261 4.1218 210

D2

-15 410.2 0.2325 12

C

41 29.61 2.0157 103 67 97 4.132 4.1439 211

D3

-14 388.5 0.2448 12

C

42 28.45 2.0640 105 69 98 4.007 4.1655 212

D4

-13 368 0.2577 13

D

43 27.34 2.1124 108

6C

99 3.886 4.1866 214

D6

-12 348.7 0.2712 14

E

44 26.27 2.1612 110

6E

100 3.77 4.2070 215

D7

-11 330.5 0.2853 15

F

45 25.25 2.2099 113 71 101 3.658 4.2269 216

D8

-10 313.4 0.2999 15

F

46 24.28 2.2584 115 73 102 3.549 4.2465 217

D9

-9 297.2 0.3153 16 10 47 23.35 2.3068 118 76 103 3.444 4.2655 218

DA

-8 281.9 0.3312 17 11 48 22.46 2.3552 120 78 104 3.343 4.2839 218

DA

-7 267.5 0.3478 18 12 49 21.6 2.4038 123

7B

105 3.15 4.3197 220

DC

-6 253.9 0.3651 19 13 50 20.79 2.4516 125

7D

106 3.059 4.3367 221

DD

-5 241.1 0.3830 20 14 51 20.01 2.4994 127

7F

107 2.97 4.3535 222

DE

-4 229 0.4016 20 14 52 19.26 2.5471 130 82 108 2.884 4.3699 223

DF

-3 217.6 0.4209 21 15 53 18.54 2.5947 132 84 109 2.802 4.3856 224

E0

-2 206.8 0.4409 22 16 54 17.85 2.6420 135 87 110 2.721 4.4012 224

E0

-1 196.6 0.4617 24 17 55 17.19 2.6889 137 89 111 2.721 4.4012 224

E0

0 186.9 0.4833 25 18 56 16.56 2.7352 139

8B

112 2.644 4.4162 225

E1

1 177.8 0.5056 26 19 57 15.96 2.7809 142

8E

113 2.569 4.4309 226

E2

2 169.2 0.5285 27

1A

58 15.38 2.8265 144 90 114 2.496 4.4452 227

E3

3 161 0.5525 28

1B

59 14.82 2.8719 146 92 115 2.426 4.4591 227

E3

4 153.3 0.5770 29

1C

60 14.29 2.9163 149 95 116 2.358 4.4727 228

E4

5 146 0.6024 31

1E

61 13.78 2.9603 151 97 117 2.292 4.4859 229

E5

6 139 0.6289 32

1F

62 13.28 3.0048 153 99 118 2.228 4.4988 229

E5

7 132.5 0.6557 33 21 63 12.81 3.0479 155

9B

119 2.167 4.5112 230

E6

8 126.3 0.6835 35 23 64 12.36 3.0902 158

9E

120 2.107 4.5235 231

E7

9 120.4 0.7123 36 24 65 11.93 3.1319 160

A0

121 2.049 4.5354 231

E7

10 114.8 0.7418 38 26 66 11.51 3.1736 162

A2

122 2.049 4.5354 231

E7

11 109.5 0.7722 39 27 67 11.11 3.2144 164

A4

123 1.994 4.5467 232

E8

12 104.4 0.8039 41 29 68 10.73 3.2541 166

A6

124 1.887 4.5689 233

E9

13 99.66 0.8357 43

2B

69 10.36 3.2938 168

A8

125 1.836 4.5796 234

EA

14 95.13 0.8686 44

2D

70 10 3.3333 170

AA

126 1.787 4.5899 234

EA

15 90.82 0.9024 46

2C

71 9.659 3.3717 172

AC

127 1.739 4.6000 235

EB

16 86.74 0.9369 48

2E

72 9.331 3.4094 174

AE

128 1.693 4.6098 235

EB

17 82.85 0.9723 50 32 73 9.016 3.4464 176

B0

129 1.649 4.6192 236

EC

18 79.16 1.0085 51 33 74 8.712 3.4829 178

B2

130 1.605 4.6286 236

EC

19 75.65 1.0455 53 35 75 8.421 3.5185 179

B3

20 72.32 1.0832 55 37 76 8.14 3.5537 181

B5

21 69.15 1.1217 57 39 77 7.869 3.5882 183

B7

22 66.13 1.1610 59

3B

78 7.609 3.6220 185

B9

23 63.27 1.2009 61

3D

79 7.359 3.6551 186

BA

24 60.54 1.2416 63

3F 80

7.118 3.6876 188

BC

25 57.94 1.2830 65 41 81 6.885 3.7195 190

BE

Page 14

44..ELECTRICAL

ELECTRICAL

DAT A

DAT A

2. THE PARAMETER OF THE OUTDOOR COIL AND OUTDOOR AMBIENT AND INDOOR TEMPERATURE

SENSOR:(R

0

=15K±2%;B=3450±2%

)

T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX T(℃) R(KΩ) V(v) DEC HEX

-30 67.94 0.3235 16 10 18 6.962 2.0151 103 67 66 1.297 3.9186 200 C8

-29 64.25 0.3408 17 11 19 6.688 2.0636 105 69 67 1.258 3.9443 201 C9

-28 60.79 0.3588 18 12 20 6.427 2.1120 108 6C 68 1.22 3.9696 202 CA

-27 57.53 0.3776 19 13 21 6.178 2.1603 110 6E 69 1.184 3.9939 204 CC

-26 54.48 0.3971 20 14 22 5.939 2.2089 113 71 70 1.149 4.0178 205 CD

-25 51.6 0.4174 21 15 23 5.712 2.2570 115 73 71 1.116 4.0406 206 CE

-24 48.9 0.4384 22 16 24 5.494 2.3053 118 76 72 1.083 4.0636 207 CF

-23 46.35 0.4603 23 17 25 5.286 2.3533 120 78 73 1.051 4.0862 208 D0

-22 43.96 0.4829 25 19 26 5.086 2.4014 122 7A 74 1.021 4.1077 209 D1

-21 41.7 0.5065 26 1A 27 4.896 2.4489 125 7D 75 0.9914 4.1290 211 D3

-20 39.58 0.5307 27 1B 28 4.714 2.4963 127 7F 76 0.963 4.1497 212 D4

-19 37.58 0.5558 28 1C 29 4.539 2.5436 130 82 77 0.9354 4.1701 213 D5

-18 35.69 0.5818 30 1E 30 4.372 2.5904 132 84 78 0.9088 4.1898 214 D6

-17 33.91 0.6087 31 1F 31 4.212 2.6369 134 86 79 0.8831 4.2091 215 D7

-16 32.23 0.6363 32 20 32 4.059 2.6830 137 89 80 0.8582 4.2280 216 D8

-15 30.65 0.6648 34 22 33 3.912 2.7288 139 8B 81 0.8342 4.2463 217 D9

-14 29.15 0.6942 35 23 34 3.772 2.7738 141 8D 82 0.8109 4.2643 217 D9

-13 27.74 0.7244 37 25 35 3.637 2.8188 144 90 83 0.7884 4.2818 218 DA

-12 26.4 0.7556 39 27 36 3.508 2.8631 146 92 84 0.7666 4.2988 219 DB

-11 25.14 0.7875 40 28 37 3.384 2.9070 148 94 85 0.7455 4.3155 220 DC

-10 23.95 0.8202 42 2A 38 3.265 2.9504 150 96 86 0.725 4.3318 221 DD

-9 22.82 0.8539 44 2C 39 3.151 2.9932 153 99 87 0.7053 4.3476 222 DE

-8 21.75 0.8885 45 2D 40 3.041 3.0358 155 9B 88 0.6861 4.3631 223 DF

-7 20.74 0.9237 47 2F 41 2.936 3.0775 157 9D 89 0.6676 4.3781 223 DF

-6 19.79 0.9596 49 31 42 2.835 3.1188 159 9F 90 0.6496 4.3929 224 E0

-5 18.88 0.9966 51 33 43 2.739 3.1590 161 A1 91 0.6323 4.4071 225 E1

-4 18.02 1.0343 53 35 44 2.646 3.1990 163 A3 92 0.6156 4.4209 225 E1

-3 17.2 1.0731 55 37 45 2.556 3.2387 165 A5 93 0.5993 4.4345 226 E2

-2 16.43 1.1122 57 39 46 2.471 3.2771 167 A7 94 0.5836 4.4477 227 E3

-1 15.7 1.1520 59 3B 47 2.388 3.3155 169 A9 95 0.5683 4.4606 227 E3

0 15 1.1929 61 3D 48 2.309 3.3528 171 AB 96 0.5535 4.4732 228 E4

1 14.34 1.2342 63 3F 49 2.233 3.3896 173 AD 97 0.5391 4.4855 229 E5

2 13.71 1.2765 65 41 50 2.159 3.4262 175 AF 98 0.5251 4.4975 229 E5

3 13.11 1.3195 67 43 51 2.089 3.4615 177 B1 99 0.5115 4.5093 230 E6

4 12.55 1.3623 69 45 52 2.021 3.4965 178 B2 100 0.4983 4.5207 231 E7

5 12.01 1.4063 72 48 53 1.956 3.5306 180 B4 101 0.4855 4.5319 231 E7

6 11.5 1.4506 74 4A 54 1.893 3.5644 182 B6 102 0.4731 4.5427 232 E8

7 11.01 1.4959 76 4C 55 1.832 3.5977 183 B7 103 0.461 4.5534 232 E8

8 10.55 1.5410 79 4F 56 1.774 3.6299 185 B9 104 0.4492 4.5638 233 E9

9 10.1 1.5878 81 51 57 1.718 3.6616 187 BB 105 0.4378 4.5739 233 E9

10 9.684 1.6338 83 53 58 1.664 3.6926 188 BC 106 0.4268 4.5838 234 EA

11 9.284 1.6805 86 56 59 1.612 3.7231 190 BE 107 0.416 4.5934 234 EA

12 8.903 1.7276 88 58 60 1.562 3.7528 191 BF 108 0.4055 4.6029 235 EB

13 8.54 1.7749 91 5B 61 1.513 3.7824 193 C1 109 0.3953 4.6121 235 EB

14 8.194 1.8226 93 5D 62 1.467 3.8106 194 C2 110 0.3854 4.6211 236 EC

15 7.864 1.8704 95 5F 63 1.422 3.8386 196 C4

16 7.549 1.9185 98 62 64 1.379 3.8658 197 C5

17 7.249 1.9667 100 64 65 1.337 3.8927 199 C7

Page 15

55..CONTROL

CONTROL

MODE

MODE

5-1. Major general technical parameters

5-1-1 Conditionings for operation: Ambient temperatures: (-7℃-+43℃),

5-1-2 Remote receiver distance(front of the air conditioner):8m.

5-1-3 Remote receiver angle: Less than 60 degrees.

5-1-4 T emperature control accuracy: ±1℃.

5-1-5 Time error: Less than 1%.

5-2. Functions of the controller

5-2-1 Display panel

I. Control functions of the remote controller (See operating and installation

manual)

II. Display of the indoor unit

Information on the screen:

Displaying Scheme:

7-segment tube

:

Display set temperature or indoor temperature , and display

fault code in trouble indicating. An error code is displayed according to the

signal from the indoor CPU. The error code will flash for 5 seconds while

displayed.

Running LED

:

It is on during operation. It is flashing when the unit defrost.

TIMER LED

:

When the timer mode works, the LED will be lighted.

Sleep LED

:

When the sleep mode works, the LED will be lighted, and after 10s,

the LED will be off.

Compressor LED

:

It lights up when compressor is running.

Remote control receiver

:

This section receives signals from the remote

control.

5-3. Control function

5-3-1 Emergency switch

If the appliance under the Stand-by state, all the Operation Mode, Air

volume, Temperature Setting , Forced Cooling function will be restored as the

last time setting when you press on the “ON/OFF” button, but lost the Air flow

direction setting.

If the appliance was connected to the power at first time, it would operate in

the auto mode, It will keep in stand-by state if you press the “ON/OFF” button

during the normal operation.

When the appliance under the Stand-by state, press and hold the

emergency switch for 5 seconds, the buzzer rings for 1 times, and it will operate

Page 16

55..CONTROL

CONTROL

MODE

MODE

in cooling mode, and the indoor fan speed is set to high-speed, it running has

nothing to do with the room temperature.

When press the emergency switch or receive the signal of the remote control,

it will exit this mode, and it will operate with the corresponding order.

5-3-2 Operator-machine communication

If the unit has I feel function, when the I feel function is set by the remote

control, the room temperature will depend on the remote control and it will be

detected by the sensor of the remote control. Normally the remote control will

automatically transmits a signal at an interval of 10 minutes(only for H1 remote

control, it is 9 minutes), but if the room temperature changed exceed 1℃in a

short period of time, the remote control will transmits a signal within 2 minutes.

If the indoor unit has not received a remote signal within 30 minutes, the room

temperature will depend on the room temperature sensor of indoor unit.

5-3-3 Timer function

Real time of Timer setting

(1) The max Timer ranges is 24 hours.

(2) Timer ON/OFF

(3) Timer ON/OFF can be set available in turn.

(4) The Timer accurate more than 97%

(5) The Timer can be adjusted by 1 min increase.

(6) The appliance can be set the ON-Timer and OFF-Timer in the same time,

but no any timer setting indicated.

5-3-4 Sleep

(1)The Sleep mode can only be set during Cool, Heat and Dry mode.

(2)When the appliance run in the Sleep mode, it will stop after 8 hours

operation, then it will cancel the Sleep setting. When the appliance operate

under the OFF-Timer setting condition, if the OFF-Timer setting less than 8

hours, it will keep the Sleep mode till the OFF-Timer setting; if the OFF-Timer

setting more than 8 hours, it will cancel the OFF-Timer setting after the Sleep

mode OFF.

(3)

When the Sleep mode is select with Cooling mode, if the room

temperature not less than 26℃, the setting temperature will not be adjusted,

otherwise, the setting temperature will be raised by 1℃ per hour, but the max

setting temperature raise is 1℃.

( 4 ) When the Sleep mode is select with Heat mode, the setting

temperature will be decreased by 1℃per hour during the successive 3 hour, but

Page 17

55..CONTROL

CONTROL

MODE

MODE

the max setting temperature decrease is 3℃.

(5)

When the appliance operate with Sleep mode, the indoor fan run in the

LOW setting, and the air flow direction same as the last setting and the

temperature and air flow direction can be adjusted by user. The Running

indicator will be flashed 10 times per 1 Hz frequency, then all the indicators turn

OFF except the Sleep light after 5 min elapse. Those indicators will be recovery

when the temperature or Time setting is adjusted, after the setting, the

indicators will be lit in 10 sec, then turn OFF.

5-3-5 Automatic run (SMART) mode

When the appliance operates at the smart, the air flow direction can be

adjusted.

(1) H/C appliance

a. When the setting temperature is 26℃, the appliance will be ran in the

Cool if the room temperature exceeds 26℃.

b. When the room temperature exceeds 23℃,butbelow26℃, it will be ran

in the Dry mode(It will turn in Automatic setting After 3 min LOW air volume

running.).

c. When the room temperature exceeds 21℃,butbelow23℃, it will be

operated in the Fan only, the air volume is set by LOW and the fan speed can be

adjusted

d. When the room temperature is not more than 21℃, it will be operated in

Heat mode, and the temperature is set to 22℃.

(2) Cool only appliance

a. When the room temperature exceeds 26℃,itwillberaninCoolmode,

and the temperature is set to 26℃.

b. When the room temperature exceeds 23℃, but not more than 26℃, it will

be operated in the Dry mode.

c. When the room temperature is not more than 23℃, it will be operated in

the Fan only, the air volume is set to LOW and the fan speed can be adjusted

After the appliance start the smart operation, the setting temperature can

be adjusted 2℃or 7℃(based on the remote mode)(the min accuracy is 1℃)

up and down base on the automatic temperature setting, also the presetting

temperature of PCB circuit.

In case of the specific operation selected, it could be re-select the other

modes after the compressor ceased for 5 min or the setting temperature

changed.

5-3-7 Cooling-run mode

Page 18

55..CONTROL

CONTROL

MODE

MODE

4-3-7-1 Outdoor Fan

The outdoor fan’s speeds except the single speed motor can be changed

according to outdoor ambient temperatures.

When operating at a fixed frequency, the outdoor fan is forced to operate at the

high speed.

4-3-7-2 Indoor fan operation

(1)When the indoor fan keep in running condition, this operation state could

be controlled by the remote control with High, Median, Low and Automatic

setting.

(2)When the appliance is set Automatic condition in the Cool mode for the

first time, the fan speed will run at Low setting. After that, temperature and fan

speed is shown as following.

Temperature fall

Temperature rise

High

The settingtemp.plus 4℃

Median

The settingtemp.plus 2℃

Low

When the difference between the setting temperature and the room

temperature equal to 2℃or 4℃, the indoor fan speed will keep in current

speed.

4-3-7-3 Air flow direction control

The louver is derived by a step motor, and it swings the horizontal louver

automatically. Press the SWING button to swing or stop the louver.

During the louver swing in normal operation, the current position will be

stored. When the appliance turn off and louver swing automatically to the

default position, it will position at the close position plus 5º.

4-3-7-4 4-way valve

State: It is interrupted in cooling.

Switchover: When initially powered on for cooling, the 4-wa y valve is

interrupted immediately.

When the heating is changed to the cooling, it needs an interval of 50 seconds

Page 19

55..CONTROL

CONTROL

MODE

MODE

for the 4-way valve to change over from being activated to being interrupted.

5-3-8 Heating-run mode

4-3-8-1 Temperature compensation

The temperature compensation is 5º in heating mode. For example, if the

set temperature is 25℃by the remote control, when the room temperature is

detected with 31℃, the compressor will turn off. The main reason is that the hot

air is condensed at the top of the house.

Note: The compensation is available only if the room temperature sensor of

indoor unit is used and it is not available when it is subject to the sensor on the

remote control.

4-3-8-2 Indoor fan motor operation

Anti-cold air system:

When the appliance run in Heat mode condition, the indoor fan motor

operation is shown as following to prevent the cooling air come out during the

appliance operation.

Temperature fall

Temperature rise

30℃

The settingair flow

The settingair flow

35℃

25℃

Low

Extra-low

Sto

p

Sto

p

When the appliance turn in the anti-cold air system in the Extra-LOW

(Tapped motor set in LOW, sic passim) during the compressor operation, the

louver swang to the Cool air protection position, the louver recovers to the

original position after the air volume change to LOW. When the room

temperature reach to the setting temperature, the compressor will be turn off,

and the air flow change to LOW, the louver swang to the Cool air protective

position to prevent the air drop into human body directly; when the indoor pipe

coil temperature drop continuously, it will turn in the Cooling air protective

system in the Extra-LOW or stop the fan motor.

The indoor fan motor is only controlled by the signal of indoor pipe coil

temperature, no matter the compressor turn ON/OFF, even the appliance turn in

Heat mode at first time.

The indoor fan motor will operate according to the different setting(High,

Page 20

55..CONTROL

CONTROL

MODE

MODE

Median, Low and Automatic) by the remote control, but the anti-cold air system

is prior.

When the appliance run in the Heat mode with the Automatic setting at first

time, the fan speed will be in the LOW setting, and the operation diagram is

shown as following

The settingtemperature

-2℃

Low

MEDIAN

The settingtemperature

-4℃

High

Temperature fall

Temperature rise

When the difference between the setting temperature and the room

temperature equal to 2℃or 4℃, the indoor fan speed will keep in current

speed.

5-3-8-3 Air flow direction control

The horizontal louver is controlled by a step motor, press the SWING button

to swing or stop the louver.

During the louver run in normal operation, the current position will be

stored. When the appliance turn off and louver swing automatically to the

default position, it will position at the default position plus 5º.

4-3-8-4 Outdoor fan

The outdoor fan speeds except single speed motor can be changed according to

outdoor ambient temperatures.

4-3-8-6 4-way valve

State: It is electrified in heating.

Switchover: When initially powered on for heating, the 4-way valve is activated

immediately.

In the change from cooling to heating, it needs an interval of 50 seconds for the

4-way valve to change over from being interrupted to being activated.

5-3-9 The super function (option)

In cooling mode, when you press the SUPER button by remote control, the unit

will operate for 15 minutes with the following setting:

a. The set temperature is 18

℃;

Page 21

55..CONTROL

CONTROL

MODE

MODE

Tset

16

0

C

b. The fan speed with highest speed;

c. The compressor runs with high frequency.

5-3-10 Dehumidifying mode

The dehumidifying mode is illustrated as follows:

Dehumidifying area I: Operation at the frequency in the range (30–60Hz)

according to t(T

indoor ambient-Tset

).

t(℃)

f(Hz)

030

0.5 30

140

1.5 50

≥260

Dehumidifying area II: The compressor stops for 5 minutes and operators for 5

minutes at the lowest frequency.

Dehumidifying area III: The compressor stops.

Time

III III

IndoorAmbient Temperature

Page 22

55..CONTROL

CONTROL

MODE

MODE

5-3-10 Fan Only Mode Operation

During the appliance run in this mode, the compressor and outdoor fan stop,

the indoor fan operate under the pre-setting of air volume, and the louver swing,

and the indoor fan speed same as the Heating Mode.

Page 23

6. TROUBLE SHOOTING

1.Indication on the outdoor unit:

When the unit has the following trouble and the compressor stops running, The LED of outdoor

control board will show the error sequence automatically:

NOTE:

★:LIGHT

:FLASH:OFF

Error

code

Outdoor Failure

Description

LED1 LED2 LED3

the root cause my be one of the

following

Normal

Outdoor coil temperature

sensor in trouble

★

★

a.the outdoor coil sensor connect

loose;

b.the outdoor coil temperature

sensor is failure;

c.the outdoor control board is

failure

Compressor exhaust

temperature sensor in trouble

★

a.the compressor exhaust

temperature sensor connect loose;

b.the compressor exhaust

temperature sensor is failure;

c.the outdoor control board is

failure

Communication failure

between the indoor unit and

outdoor unit

a.the communication cable connect

loose;

b.the communication cable is

failure;

c.the connection between the filter

board and the outdoor control

board is incorrect or loose;

d.the connection between the filter

board and the terminal is incorrect

or loose;

e.the indoor control board is

failure;

f.the PFC board is failure;

g.the power board is failure;

h.the outdoor control board is

failure.

Current overload protection

★

a.the fan motor run abnormally;

b.the condensor and evaporator is

dirty;

c.the air inlet and outlet is

abnormally

Maximum current protection

★

★

a.the outdoor control board is short

circuit;

b.the drive board is short circuit;

c.the other components is short

circuit

Page 24

6. TROUBLE SHOOTING

Communication trouble

between outdoor unit and

driver

★★

a. the connection wires connect

loose

b.the outdoor board or drive

board is failure;

Outdoor EEPROM in trouble

★★★

a.the EEPROM chip is loose;

b.the EEPROM chip inserted with

opposite direction;

c.the EEPROM chip is failure

Compressor exhaust

temperature too high

protection

★

a.the compressor exhaust

temperature sensor is failure;

b.the refrigerant of the unit is not

enough

Outdoor ambient

temperature sensor in trouble

★★

a.the outdoor ambient temperature

sensor connect loose;

b.the outdoor ambient temperature

sensor is failure;

c.the outdoor control board is

failure

Compressor shell

temperature too high

protection

★

a.the compressor exhaust

temperature sensor connect loose

b.the refrigerant of the unit is not

enough

Anti-freeze protection with

cooling or overload protection

with heating in indoor unit

a.the indoor coil temperature

sensor connect loose;

b.the indoor coil temperature

sensor is failure;

c.the indoor control board is failure

d. the refrigerant system is

abnormal.

Compressor drive in trouble

a.the outdoor drive board is failure;

b.the compressor is failure

c. the outdoor control board is

failure

Outdoor fan motor locked

rotor protection

★

a.the connection of the outdoor fan

motor is loose;

b.there are something block the

outdoor fan;

c.the fan motor is failure;

d.the outdoor control board is

failure

Page 25

6. TROUBLE SHOOTING

Outdoor coil anti-overload

protection with cooling

★

a.the refrigerant is too much;

b.the outdoor fan motor is failure;

c.the outdoor fan is broken;

d.the condensor is dirty;

e.the air inlet and air outlet of the

indoor unit and the outdoor unit is

not normally

IPM module protection

a.The IPM board is failure;

b.The outdoor fan is broken;

c.The outdoor fan motor is failure;

d.The outdoor fan has been

blocked ;

e.The condenser is dirty;

f.The outdoor unit has been

installed without standard.

PFC protection

a.the PFC is failure;

b.the outdoor drive board is failure

Compressor pre heating

process

★

it is normal mode in cold weather

Chip in outdoor board in

trouble

★

a. Using the wrong drive board;

b. Using the wrong compressor.

AC voltage higher or lower

protection

★★

a.the supply voltage is higher or

lower than normal;

b.the inner supply voltage of the

unit is higher or lower than normal

DC compressor start failure

a.the outdoor drive board is failure;

b.the compressor is failure

Page 26

6. TROUBLE SHOOTING

2.Indication by the indoor unit:

2.1.The LED of indoor display board will show the error sequence automatically when the unit has the

following trouble:

Error

code

Power Timer Running Sleep

Remark

:

★Light o Flash x OFF

1 2 3 4 Content Remark

Therootcauseismaybeone

of the following

E2

When the evaporator

pipe temperature is

higher than 63 ℃,the

error code will display

a. It is normally for protection, When

the indoor pipe temperature between

53℃<T<63℃, the outdoor fan motor will

stop running. When the indoor coil

temperature is higher than 63℃,the

error code will display. After the indoor

pipe temperature is lower than 49℃,the

air conditioner will restart normally.

b. The indoor coil temperature sensor is

loose;

c. The indoor coil temperature sensor is

failure;

d. The indoor control board is failure.

E4

When the indoor fan

speed is lower than

200 rpm, the error

code will display

Only

9k/12k/18

K

a. There are something block

the indoor fan motor;

b. The fan motor cord connect loose;

c. The fan motor is failure;

d. The indoor control board is failure

EA

the error code will

display when the

communication

between display

board and control

board have in trouble

a. The connection between the

display board and control board is loose;

b. The indoor control board is failure.

c.The wiring of the display board is

failure.

Page 27

6. TROUBLE SHOOTING

2.2.When the unit has the following trouble and the compressor stops running, press the sleep button on

the remote controller for 4 times and the 7-segment tube of the display board will show the error code as the

following, if two malfunction happened at the same time, it need press the sleep button for 4 times again, the

LED will show the other error code.

NOTE: If the troubleshooting inquiry display by 7-segment tube, then the error code will be displayed,

otherwise only the LED of the display board can show.

Error

code

Power Timer Running Sleep

Remark:★Light

o Flash x OFF

12 3 4Content Remark

The root cause is may be one of the

following

1xoxx

The failure for

temperature sensor of

outdoor coil

Heat pump

a. The outdoor temperature sensor loose;

b. The outdoor temperature sensor is

failure;

c. The indoor control board is failure

33 o x x

★

The failure for

temperature sensor of

indoor room

a. The indoor room temperature sensor

loose;

b. The indoor room temperature sensor is

failure;

c. The indoor control board is failure.

34 o x

★

x

The failure for

temperature sensor of

indoor coil temperature

a. The indoor coil temperature sensor

loose;

b. The indoor coil temperature sensor is

failure;

c. The indoor control board is failure.

38 o

★★★

Indoor EEPROM failure

a. The EEPROM chip loose;

b. The indoor control board is failure

39 o x

★★

Indoor fan motor run

abnormally

7k,9k,12k,

18K

a. There are something block the indoor fan

motor;

b. The fan motor cord connect loose;

c. The fan motor is failure;

d. The indoor control board is failure

41

★★

x

★

The failure for Indoor

grounding protective

The indoor control board is failure

42 o o x

★

Overcooling protection

7k,9k=-1℃

12k=-7℃

a. It is normally for protection, When the

indoor pipe temperature below

T<-1℃(-7℃).Outdoor fan motor and

compressor will stop running. When the

Indoor pipe temperature is higher than

-1(-7℃),the unit will restart normally

b. The indoor coil temperature sensor is

loose;

c. The indoor coil temperature sensor is

failure;

d. The indoor control board is failure.

Page 28

6. TROUBLE SHOOTING

43 o o

★

x Overheating protection

a. It is normally for protection, When the

indoor pipe temperature between

53℃<T<63℃, the outdoor fan motor will stop

running. When the indoor coil temperature is

higher than 63℃, the error code will display.

After the indoor pipe temperature is lower

than 49℃, the air conditioner will restart

normally.

b. The indoor coil temperature sensor is

loose;

c. The indoor coil temperature sensor is

failure;

d. The indoor control board is failure.

The failure is detected when the room temperature sensor broken or shorted over 5 sec.

The failure is detected when the temperature sensor of heater exchange broken or shorted over 5 sec.

The failure is detected when each setting data is not match after the EEPPOM self-check two times.

The failure is occur when the grounding signal is not detected after the appliance power ON.

Page 29

66TROUBLE

TROUBLE

SHOOTING

SHOOTING

6-1. Service flow chart

No

No

Yes

No

Yes

Yes

No

Yes

No

Check the input voltage and output

voltage correct or not

The input voltage(power input):220V

The output voltage(IC902):

Pin1-pin2:12V

PIN3-PIN2:5V

Switch on the power

supply

Are the wires poorly

connected?

Make sure all wires

are connected

correctly

No

Replace

the

display

board

Indoor control board is fault

Replace it.

Does it receive the

remote controller

signal?

Yes

Is the remote

controller

setting right?

Is the remote

controller in good

condition?

Replace the batteries

Retry remote operation.

If not good, replace

remote

controller

Replace the

display board

Replace the indoor

control board

Yes

Is the fuse

( 3.15A/250V) blown?

Does the screen display

normally?

Yes

Check the error

code

Page 30

66TROUBLE

TROUBLE

SHOOTING

SHOOTING

Yes

Error code 6

Voltage of power supply is abnormal

Is the voltage of power

supply normal of AC

198~253V?

Yes

Normal

protection

No

Outdoor IPM board fault,

replace it.

Error code 34

Indoor Coil sensor

trouble

Error code 33

Indoor temperature

sensor

Does the resistance

of the sensor have

the characteristics

on part 6-3

Replace the the

sensor

No

Replace the

indoor pcb board

Take out the red connector

sensor ,Measure the

resistance of sensor

Take out the white connector

sensor ,Meaure the

resistance of sensor

Error code 14

Outdoor temperature

sensor in trouble

Error code 1

Outdoor coil sensor

in trouble

Take out the yellow

connector sensor ,Meaure

the resistance of sensor

Take out the black

connector sensor ,Meaure

the resistance of sensor

Does the resistance

of the sensor have

the characteristic on

part 6-3 (SENSOR

PARAMETER)

Replace the the sensor

No

Yes

Replace the

outdoor board

Error code 2

Outdoor Compressor

exhaust

temperature sensor

Take out the black

connector sensor ,Meaure

the resistance of sensor

Page 31

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Erro r c o d e 3 9

Ind o o r fa n motor tro u b le

Is indoor fan motor running?

Set the air conditioner operate

in fan mode

D o e s fa n moto r s to p follow in g th e

remote controller order?

Check the connector of

indoor motor connected

tightly or not

Check the each pin to “GND”pin

shorted or not

Indoor control board faulty

and replace it

With power on check“Vdc”pin

to“GND”pin 310Vdc or not;

“Vcc”pin to“GND”pin 15V or

not

Replace the indoor fan

motor

no

yes

yes

yes

no

yes

no

no

Page 32

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Erro r c od e 7、 36

Com m unication trouble

Are all the lead wires connected

between indoor and outdoor unit?

Connect the indoor and

outdoor unit again according

to th e w irin g d ia g ra m

Is there power output between

indoor T/B 1 and 2 AC 220V ?

Indo or c on tro l

board in trouble

replace the indoor

board

Does the power

indicator(LED) of outdoor

co n tro l bo a rd(P C B) lig h t

up?

Replace the

outdoor control

board and start up

again

Is the 3.15A fuse(F01) of outdoor

PCB blown?

Is the 20A fuse(F03) of outdoor PCB

blown?

Is the s y s tem in

good condition?

Outdoor control

board trouble

Indoor control board

fault, replace it.

Replace fuse

The control system of outdoor

unit has short circuit trouble,

check the connection wire,

IPM , rectifie r( in th e PF C

model) and electrolyse

capacitor

The switch power

circuit broke and

change the outdoor

control board

Replace fuse

yes

no

no

yes

yes

yes

no

no

yes

no

yes

Check if there are some

short circuit

behiand“ F01” and

between “ F01”“DC-”

no

no

no

yes

1.IPM 、 r e c tifie r( in th e PF C

model)shorted change the

drive board

2.other shorted change the

outdoor control board

Replace the outdoor control

board

yes

Page 33

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code 13

Compressor over heat

protection

Is the surface of

compressor very hot?

No

Normal protecton,

maybe lack of

refrigerant

Yes

Is the resistance of

compressor discharge

sensor correct?

Replace the

sensor

No

Yes

Outdoor control board

faulty, replace it

Error code 8

Current overload

protection

Is the air inlet and

outlet of indoor/outdoor

unit abnormally

No

Cleanup the inlet and

outlet of indoor/outdoor

unit

Yes

Is the condensor and

evaporator dirty;

Cleanup the condensor

and evaporator

yes

no

The outdoor drive board

fault ,replace the board

Page 34

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code16(cooling mode)

Anti-freeze protection indoor unit

Is indoor heat exchanger

iced up?

no

yes

refrigeration system

protection,check the air inlet

and outlet of indoor unit

Error code16(heating mode)

Overload protection indoor unit

Is indoor heat exchanger

overheating?

Yes

Error code21(cooling

mode)

Outdoor coil anti-

overload protection

Is the outdoor condensor

overheating?

no

yes

Change the

outdoor control

board

Check the coil sensor of

outdoor unit right or not

yes

no

refrigeration system

protection,check the

air inlet and outlet of

outdoor unit

Change the coil

sensor

Error code11

Outdoor EEPROM in

trouble

Refix the EEpromno

Change the

EEprom

yes

Check the coil sensor

right or not

no Change the indoor board

yes

Change the coil sensor

refrigeration system

protection,check the air inlet

and outlet of indoor unit

no

Check the coil sensor of

indoor unit right or not

yes Change the indoor board

no

Change the coil sensor

Check the EEprom

fixing right or not

Page 35

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code 9

Maximum current

protection

Is the windings of the

conpressor right or

not(eath winding and

windingtotheearth)

yes

Compressor fault ,replace

the compressor

no

The outdoor drive board

fault ,replace the board

Error code 10

Communication trouble

between outdoor control board

and drive board

Check the wires

between control board

and drive board

connect tightly or not

yes

Reconnect the wires

no

control board fault ,replace

the board

yes

Drive board fault ,replace

the board

no

If the driver borad

has the +5V、+15v

Page 36

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code 15

Compressor shell temperature

too high protection

Is the protector plug

connected to the CN10

of the control board

tightly or not

yes

Reconnect the plug

no

Normal protecton,maybe

lack of refrigerant or the two

valves that connecting to

indoor unit are not opening

yes

The protector fault ,replace it.

Or the protector connecting

wire in the conpressor is

loosen,check it

no

Stop the machine for a

while then check the pins

of the protector plug if it

is short or not

Page 37

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code 20

Outdoor fan motor locked

rotor protection

Is the fan moror

connection plug

connected to the

control board

yes

Reconnect the plug

no

yes

no

Is something

block the fan

yes

Cleanup it

Check the

fan speed

ri

g

ht ornot

no

Check the

capacitor of

the motor on

the control

board is right

no

The control

board is

fault,replace

the board

Check the coil

sensor and

ambient sensor

right or not

The fan motor

is fault,replace

yes

The control board

is fault ,replace it

Replace the

fault sensor

yes

no

no

DC

FAN

AC

FAN

Replace the

fan motor ok

or not

The control board

is fault,replace the

borad

yes

no

Motor fault

Page 38

66..TROUBLE

TROUBLE

SHOOTING

SHOOTING

Error code 19

Compressor drive in trouble

Is the wires between

control board and drive

board connecting tightly?

yes

Reconnect the wires

no

yes

no

Change the

drive board and

check ok or not

yes

Drive board is fault

Disconnect the

wires of CN6 and

check the +5V

again

yse

Check the compressor:

1. the resistance of the

windings right or not

2. the resistance between

the windings and

grand right or not

no

The compressor

is fault,change

the compressor

Is there +5V

in the CN6 ?

The error appeared by

accident,keep operating

and watching the air-con

yes

no

no

Change the control

board

Loading...

Loading...