Hisense AS-09UR4SGNPQ Service Manual

第 1/51页

SERVICE MANUAL

AS-09UR4SGNPQ

Hisense Corporation

第 2/51页

Table of contents

Page

1.OPERATING RANGE …………………………………………………………………………….….1

2.SPECIFICATION………………………………………………………………………………….… 2

2-1 Unit specifications ………………………………………………………………

2-2 Major component specifications ………………………………………………

2-3 Other component specifications ………………………………………………

3.OUTLINES AND DIMENSIONS…………………………………………………………..…..…… 6

3-1 INDOOR ………………………………………………………………………

3-2 OUTDOOR ……………………………………………………………………..

4.REFRIGERANT FLOW DIAGRAM ………………………………………………………..………8

4-1 Refrigerant flow diagram ……………………………………………………………………..

4-2 Evacuation procedures ……………………………………………………………………..

4-3 Evacuation direction ……………………………………………………………………..

5.ELECTRICAL DATA ………………………………………………………………………………..11

5-1 Electric wiring diagrams ……………………………………………………………………..

5-2 Electric control ……………………………………………………………………..

5-3 Sensor parameter ……………………………………………………………………..

6.CONTROL MODE 16 6-1 control mode …………………………………………………….....18

7.TROUBLESHOOTING………………………………………………………………………….… 26

7-1 Error codes ………………………………………………………………………….

7-2 Service flow chart ……………………………………………………………………

8.CHECKING COMPONENTS……………………………………………………………………. 32

8-1 Check refrigerant system ……………………………………………………………………

8-2 Check parts unit ……………………………………………………………………

9.DISASSEMBLY INSTRUCTIONS ………………………………………………………………..38

9-1 Indoor ……………………………………………………………………

9-2 Outdoor ……………………………………………………………………

10.PARTS LIST ………………………………………………………………………………….…45

10-1 Indoor ……………………………………………………………………

10-2 Outdoor ……………………………………………………………………

22.. SSPPEECCIIFFIICCAATTIIOONNSS

第 3/51页

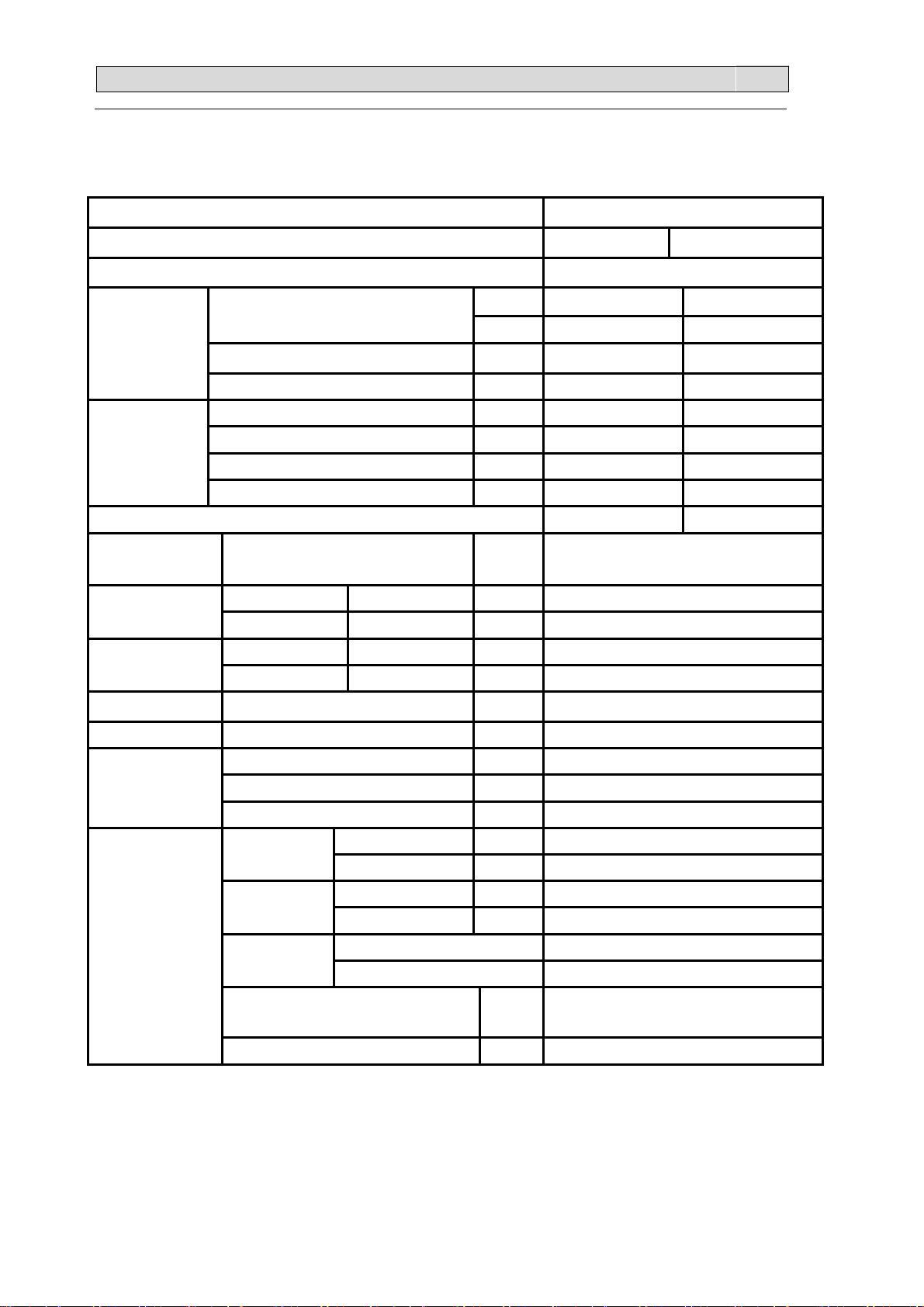

2-3-5. OVERLOAD PROTECTION

AASS--0099UURR44SSGGN

NPQ

ELECTRIC

PERFORMANCE

Model INT01L-4639/CS-74

Reset temperature( )℃ 90±5℃

Trip temperature( )℃ 120±4℃

PARAMETER

22.. SSPPEECCIIFFIICCAATTIIOONNSS

第 4/51页

2-1. Unit specifications

Model AS-09UR4SGNPQ

Function Cooling Heating

Power supply a.c 220V~230V/50Hz

AASS--0099UURR44SSGGN

NPQ

Capacity

Electrical data

EER/COP 3.42 3.64

MAX.operating

pressure

Net size

Package size

Net weight Indoor unit / Outdoor unit kg 9.5/34.0

Gross weight Indoor unit / Outdoor unit kg 11.5/38.5

Dehumidification l /h 1.0

Air flow m

Rated current A 3.6 4.5

MAX. current A 8.0 10.0

Rated input kW 0.76 0.88

MAX. input kW 1.50 1.85

High MP 4.15

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

L×W×H

L×W×H

L×W×H

L×W×H

BTU 9000 12000 Capacity

kW 2.6 3.2

—-

3

/h 480 530

cm

cm

cm

cm

75×19×25

80×26×57

84×27×31

95×37×65

Refrigerant

piping

Special

remarks

NOTE :Test conditions:

Cooling : Indoor: DB27℃/ WB19℃ Outdoor: DB35℃/ WB24℃

Heating: Indoor: DB20℃/ WB15℃ Outdoor: DB7℃/ WB 6℃

Liquid pipe mm 6.35

Gas pipe mm 9.52

Connection method Flared

Indoor unit dB 40 Sound level

(Hi)

(Hi)

regulator

Refrigerant filling

capacity(R410A)

Throttle mode CAPILLARY

Outdoor unit dB 52

Indoor unit rpm 800/1000/1250 Fan speed

Outdoor unit rpm 540/620/800

Indoor unit 3 Fan speed

Outdoor unit 1

kg 0.72

22.. SSPPEECCIIFFIICCAATTIIOONNSS

第 5/51页

AASS--0099UURR44SSGGN

2-2. Major component specifications

2-2-1.INDOOR FAN MOTOR

ELECTRIC PERFORMANCE PARAMETER

Motor model YYW16-4-532

Rated power source 220V 50Hz

Phases/Poles 1/4

Rated load output(W) 16

Rated speed(r/min) -Ambient temperature( )℃

2-2-2 OUTDOOR FAN MOTOR

ELECTRIC

PERFORMANCE

Motor model YDK29-6I

Rated power source 220V 50Hz

Phases /Poles 1/6

Rated load output(W) 40

Ambient temperature( )℃

2-2-3. COMPRESSOR

ELECTRIC PERFORMANCE PARAMETER

Compressor model C-1RVN68HOE

Compressor type Rotary

Rated power 675W

Current (A) 4.75

Motor

Motor type DC brushless motor

-5℃~+43℃.

PARAMETER

-5℃~+43℃.

NPQ

Starting type DC Inverter

Winding resistance

Number of cylinder 1

Oil type FV50BX

Oil charge (cc) 350

Ambient temperature( )℃

0.71Ω(at 20 )℃

-5℃~+43 .℃

22.. SSPPEECCIIFFIICCAATTIIOONNSS

第 6/51页

AASS--0099UURR44SSGGN

2-3. Other component specifications

2-3-1. INDUCTANCE

ELECTRIC PERFORMANCE PARAMETER

Inductance model -

Rated power source -

Loop winding rated current - Rated

current(A)

inductance

Ambient temperature( )℃ -

2-3-2. INDUCTANCE(1205797,C)

ELECTRIC PERFORMANCE PARAMETER

Inductance model R2050HSB

(mH)

Filter winding rated current -

Loop winding rated inductance - Rated

Filter winding rated inductance -

NPQ

Rated power source 220V 50Hz

Rated current(A) 20

Rated inductance(mH) 5.2

Ambient temperature( )℃

2-3-3. FILTER(1336846,A)

ELECTRIC PERFORMANCE PARAMETER

Filter model RTLB-12T047-02JF

Rated current(A) 12

Rated power source AC 220V 50Hz

Filter frequency range 150K—30MHHz

Temperature range( )℃

2-3-4. STEPPER MOTOR

ELECTRIC PERFORMANCE PARAMETER

Stepper Motor model 24BYJ48-CP

-20℃~+70 .℃

-25℃~+85℃.

Voltage(DC) 12V

Number of phase 4

Drive mode 1-2phase excitation unipolar drive

Resistance per phase

Temperature range( )℃

300Ω±7%

-10℃~+40 .℃

22.. SSPPEECCIIFFIICCAATTIIOONNSS

第 7/51页

2-3-5. OVERLOAD PROTECTION

AASS--0099UURR44SSGGN

NPQ

ELECTRIC

PERFORMANCE

Model INT01L-4639/CS-74

Reset temperature( )℃ 90±5℃

Trip temperature( )℃ 120±4℃

PARAMETER

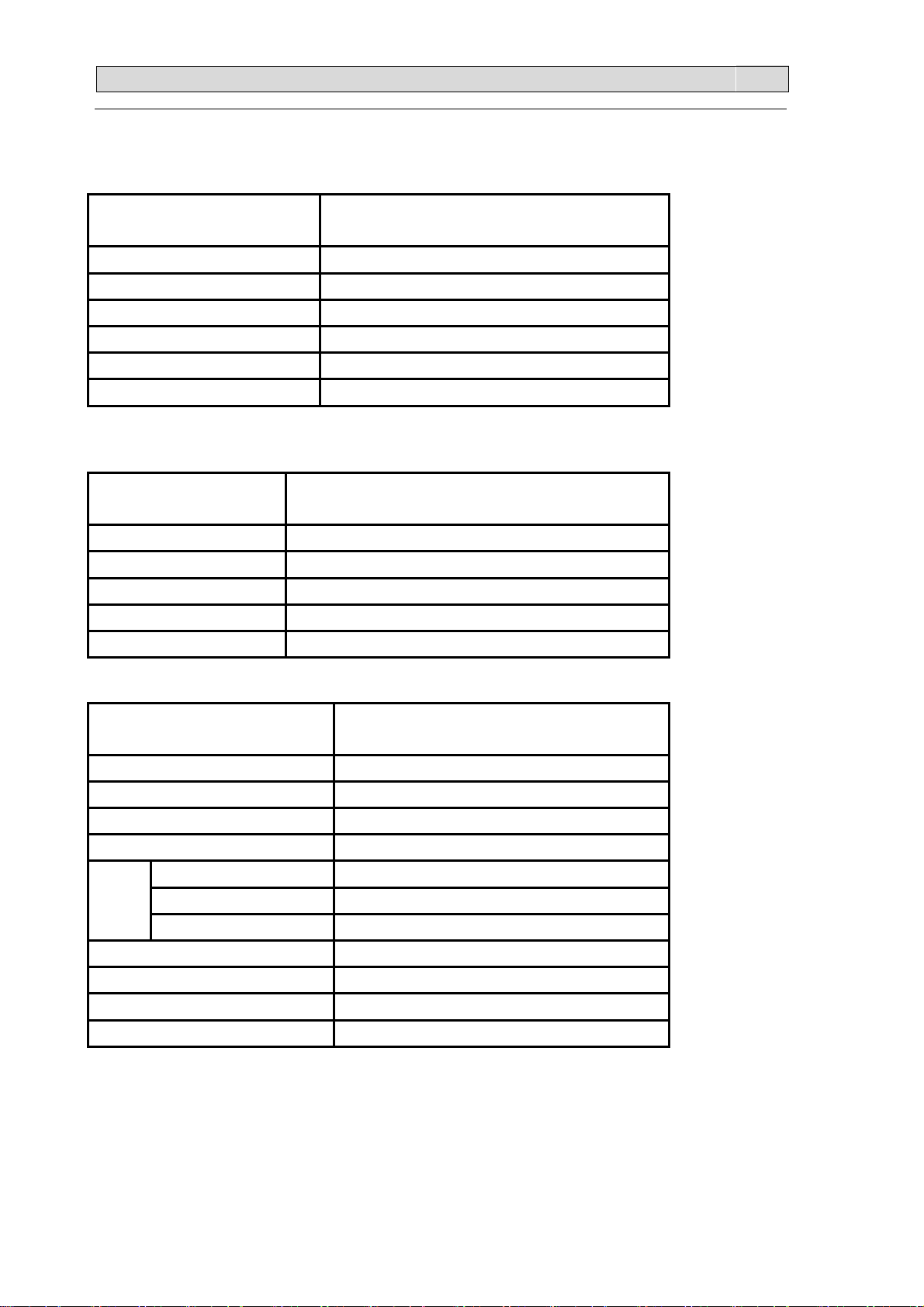

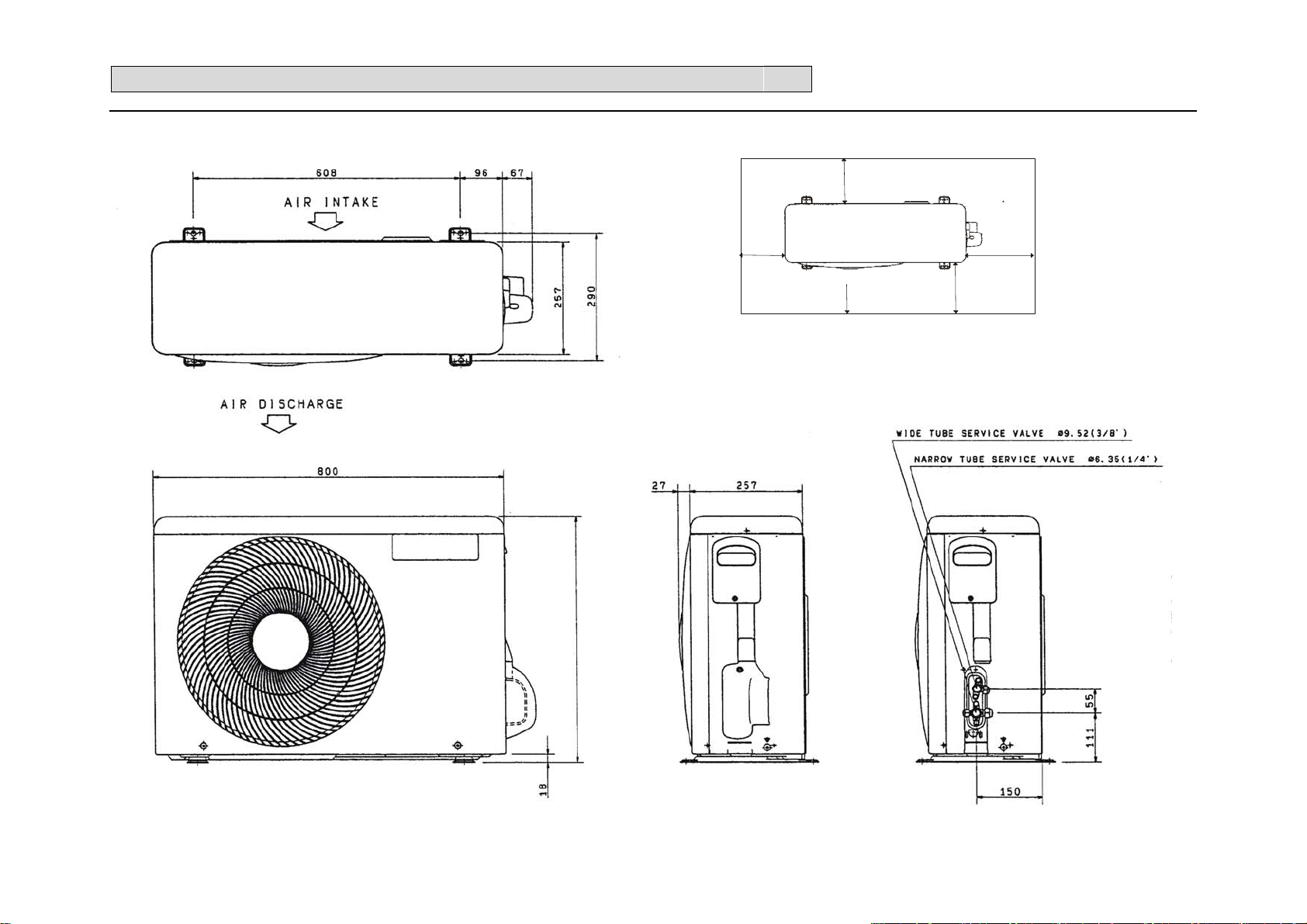

33.. OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOO

第 8/51页

3-1. INDOOR

AASS--0099UURR44SSGGN

NPQ

750mm

190mm

250mm

65mm

94mm

50mm

23mm631mm

50mm

50mm

3-2.OUTDOOR

33.. OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOO

第 9/51页

AASS--0099UURR44SSGGN

NPQ

>10cm

>5cm

5

.

7

6

5

Outlet

>25cm

>40cm

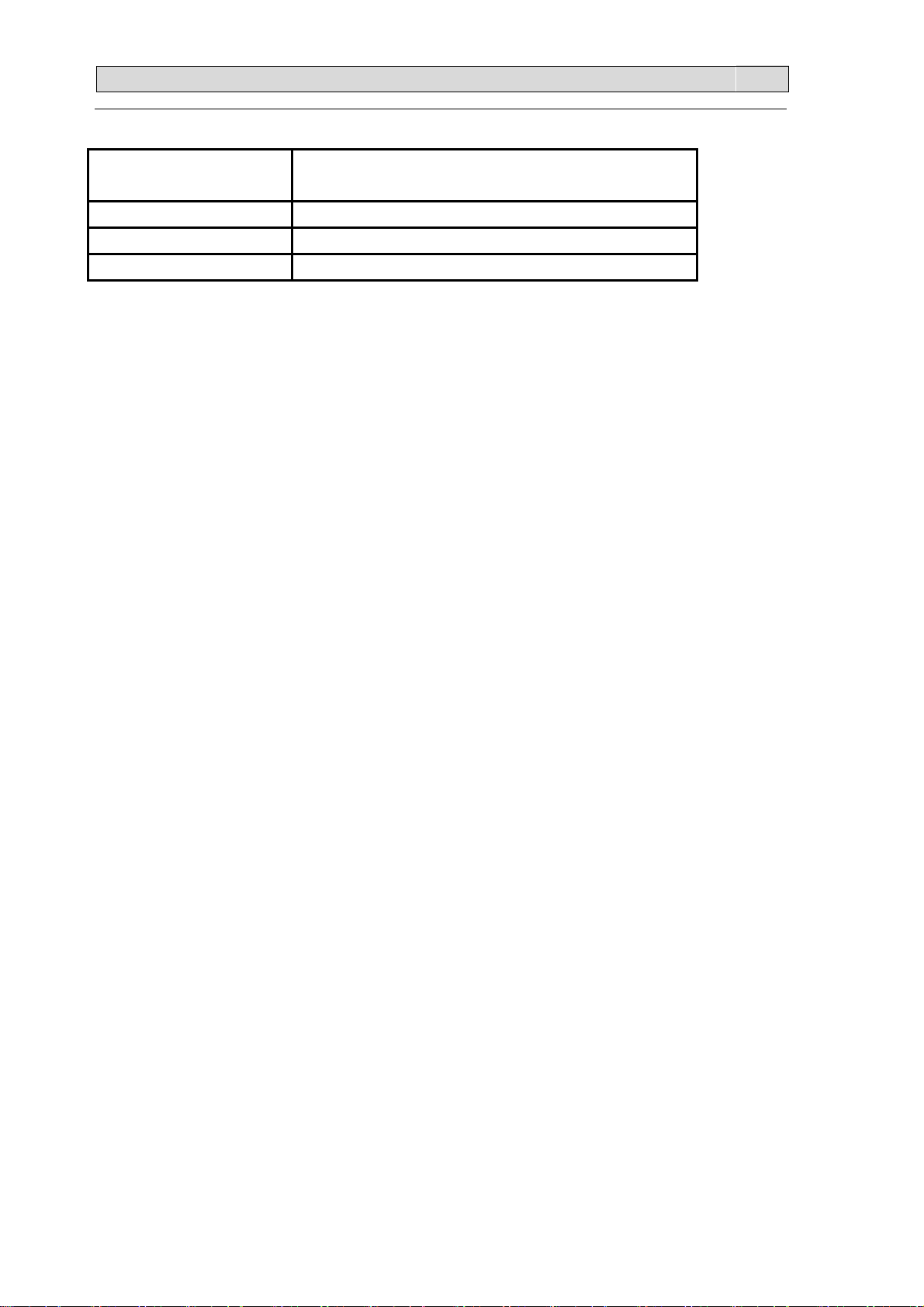

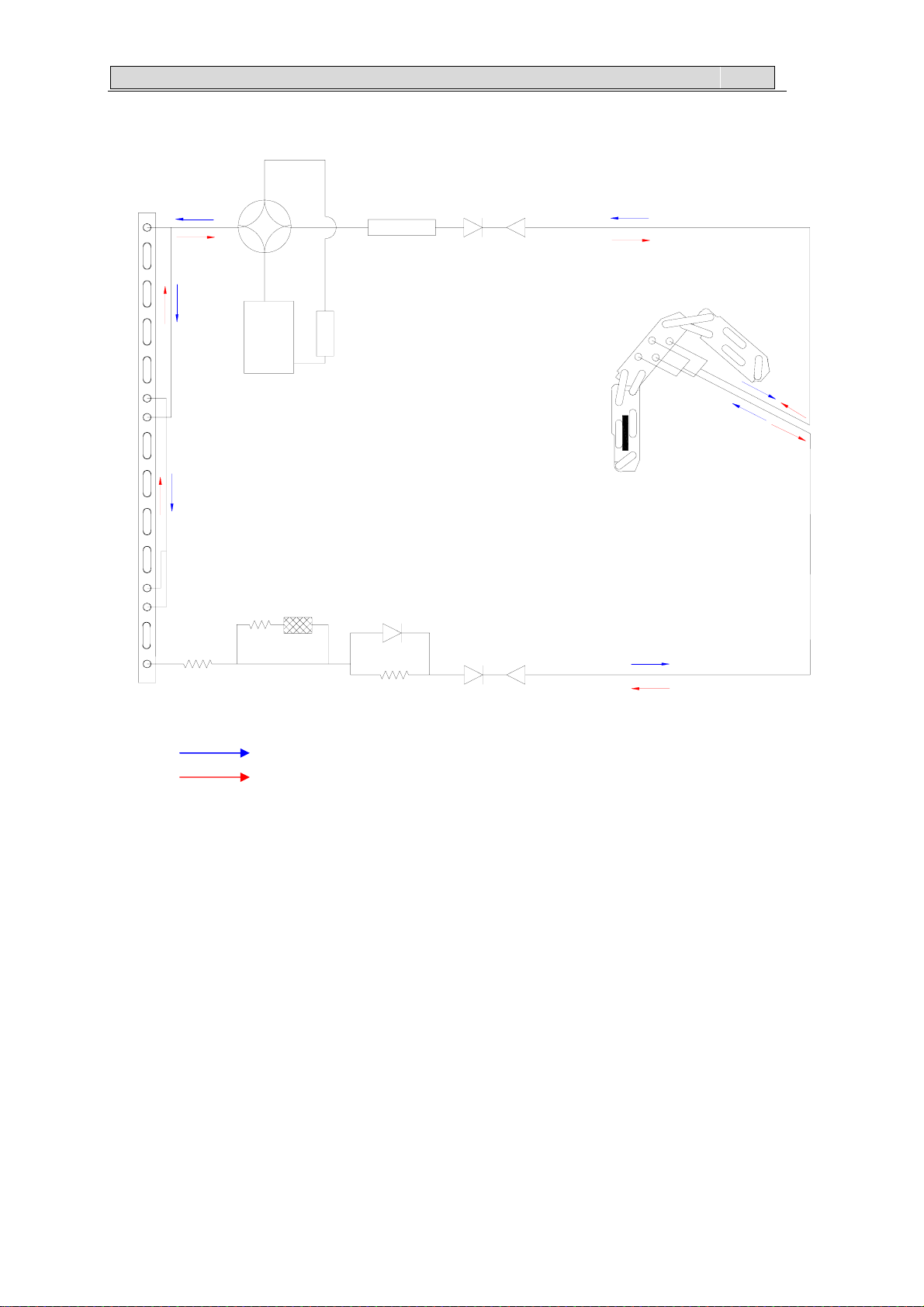

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

第 10/51页

4-1. Refrigerant flow diagram :

COMPRESSOR

CONDENSER

M

AASS--0099UURR44SSGGN

INDOOROUTDOOR

EVAPORATOR

NPQ

desiccator

CAPILLARY

CHECK VALVE ASS'Y

Remark: COOLING CYCLE

Remark: HEATING CYCLE

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

第 11/51页

4-2. Evacuation procedures:

EVACUATION PROCEDURES

Connect the refriger ant pipes (both the l iquid and gas

pipes ) between the indoor and the outdoor units .

Remove the servi ce port cap of the stop valve on the side of the

outdoor unit gas pipe. (The stop valve will not work in its initial

state fresh out of the factory (totally closed with c ap on).

Connect the gage manifold v alve and the vacuum pump to the service port of the stop valve on

the gas pipe si de of the outdoor unit.

Run the vacuum pum p for m ore than 15 m inutes and at this ti m e c onfirm that the pres sure gage

indi cates -0.1 M pa (-76 cmHg).

Check the vacuum with the gage manifold valve, then c lose the gage manifold valve, and stop the

vacuum pum p.

Leave i t as is for one or two m inutes .Make s ure the pointer of the gage manifol d v alve r em ains

in the sam e pos ition.

M

AASS--0099UURR44SSGGN

NPQ

Stop valve

Close

Open

Hexagonal

wre nch

Remove the gage manifold valve quickly from the service port of the stop valve.

After refri gerant pipes are connec ted and ev acuated, fully open al l stop val ves

on gas and l iquid pipe s i des.

Operating without fully opening lowers the performance and c auses troubl e.

Stop valve

Pi pe l ength

7m maxi mum

No gas c harge is

needed.

Tighten the cap to the service port to obtai n the initial s tatus.

Gage manifold valve

Connection

pipe

Pi pe l ength

exc eeding 7m

Charge the pr escribed

amount of gas.

Liquid pipe

Hexagonal wrench

Gas pipe

Caps

Stop valve

Service port

Vacuum pump

Retighten the cap.

Leak tes t

44.. RREEFFRRIIGGEERRAANNTT FFLLOOWW DDIIAAGGRRAAM

第 12/51页

4-3. Evacuation direction:

MAX. REFRIGERANT PIPING LENGTH

M

AASS--0099UURR44SSGGN

NPQ

Refrigerant Piping

Models

AS 09UR4SGNZA

-

MAX. HEIGHT DIFFERENCE

Indoor

unit

Max. Height

difference 7m

Max. Length: m

A

Piping size (OD) : mm Length of connecting pipe : m

Gas

15 9 52

.

Refrigerant piping

Max. Length

A

Liquid Indoor unit

6.35

Outdoor unit

Outdoor unit

ADDITIONAL: REFRIGERANT CHARGE(R-410A: g)

Models

AS 09UR4SGNZA

-

Outdoor unit precharged

(up to 7m)

670

Refrigerant piping length

10m

0

45

Canculation :Xg=15g/m*(A-7)m

15m7m

120

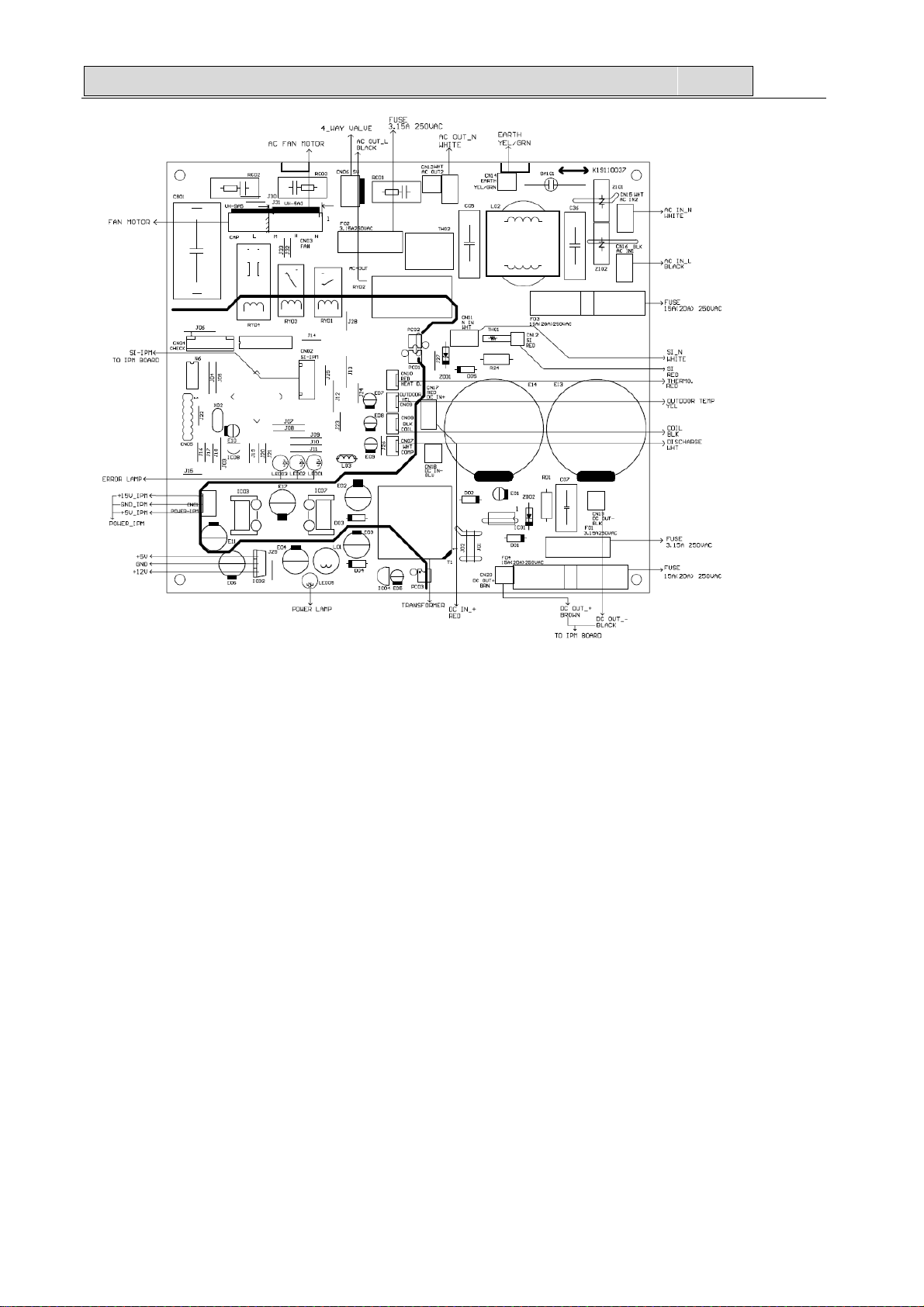

55.. EELLEECCTTRRIICCAALL DDAATTAA

第 13/51页

5-1.Electrical wiring diagrams

1.INDOOR

AASS--0099UURR44SSGGN

NPQ

2.OUTDOOR

55.. EELLEECCTTRRIICCAALL DDAATTAA

第 14/51页

AASS--0099UURR44SSGGN

NPQ

5-2. Electric control

1.Indoor control

55.. EELLEECCTTRRIICCAALL DDAATTAA

第 15/51页

AASS--0099UURR44SSGGN

NPQ

2.Outdoor control

55.. EELLEECCTTRRIICCAALL DDAATTAA

第 16/51页

AASS--0099UURR44SSGGN

NPQ

Loading...

Loading...