Hisense AUD-24UX4SFLL3, ADT-18UX4SFKL3, AUD-36UX4SAHH3, AUD-48UX6SPHH3, AUD-42UX6STHH3 Technical & Service Manual

...Page 1

TECHNICAL & SERVICE MANUAL V1.4

—DC-INVERTER AIR CONDITIONERS

MODEL:

Duct

AUD-09UX4SRNL3

AUD-12UX4SSNL3

AUD-18UX4SFKL3

AUD-24UX4SFLL3

AUD-36UX4SAHH3

AUD-42UX6STHH3

AUD-48UX6SPHH3

AUD-60UX6SPHH3

ADT-09UX4SRNL3

ADT-12UX4SSNL3

ADT-18UX4SFKL3

Cassette

AUC-12UR4SSAA3

AUC-18UR4SFAA3

AUC-24UR4SFGB3

AUC-36UR4SAGB3

AUC-42UR6STHB3

AUC-48UR6SPHB3

AUC-60UR6SPHB3

ACT-12UR4SSAA3

ACT-18UR4SFAA3

Ceiling & Floor

AUV-18UR4SFA3

AUV-24UR4SFA3

AUV-36UR4SAB3

AUV-42UR6STC3

AUV-48UR6SPC3

AUV-60UR6SPC3

AVT-18UR4SFA3

Page 2

DC-Inverter Air Conditioner Technical & Service Manual

Table of Contents

1. General ............................................................................................................................ 1

1.1 Features ................................................................................................................. 1

1.2 Product lineup ........................................................................................................ 4

1.3 Model identification ................................................................................................. 5

1.4 Unit construction ..................................................................................................... 5

1.5 Working range ........................................................................................................ 6

1.6 Product picture ....................................................................................................... 7

2. Specifications ................................................................................................................ 14

2.1 Duct type .............................................................................................................. 14

2.2 Cassette type ....................................................................................................... 18

2.3 Ceiling&Floor type ................................................................................................ 22

3. Outlines and dimensions ............................................................................................... 26

3.1 Indoor units

............................................................................................................. 26

3.2 Outdoor units

........................................................................................................... 31

4. Electrical data ................................................................................................................ 37

5. Capacities and selection data ........................................................................................ 38

5.1 Capacity characteristic charts

................................................................................... 38

5.2 Piping length correction factor

................................................................................... 53

5.3 Correction factors according to defrosting operation

..................................................... 55

6. Sound pressure data

......................................................................................................... 56

7.

Air flow distribution(Cassette type) ................................................................................ 64

8.

ESP (External static pressure)chart (Duct type) ......................................................... 66

9. Refrigerant cycle ............................................................................................................ 74

10. Fresh air intake function .............................................................................................. 79

11. Wiring diagram ............................................................................................................ 80

11.1 Electrical wiring diagrams

........................................................................................ 80

11.2 Control board picture .......................................................................................... 91

11.3 Field setting ........................................................................................................ 96

11.4 Instructions for the function setting of access control, fire protection, ON/OFF 104

11.5 Common wiring ................................................................................................. 106

11.6 Sensor parameter ............................................................................................. 108

12. Piping work and refrigerant charge ............................................................................ 115

12.1 MAX. length allowed ......................................................................................... 115

12.2 Oil trap .............................................................................................................. 115

12.3 Additional refrigerant charge ............................................................................. 116

13. Control mode ............................................................................................................. 117

13.1 Indoor unit mode control ................................................................................... 117

13.2 Outdoor unit mode control ................................................................................ 120

14.Troubleshooting .......................................................................................................... 121

14.1Trouble guide

........................................................................................................ 121

14.2 Fault codes

.......................................................................................................... 126

15. Checking components ............................................................................................... 136

15.1 Check refrigerant system .................................................................................. 136

15.2 Check parts unit ............................................................................................... 138

Page 3

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

1

1. General

1.1 Features

Duct Type Air Conditioner

Features

Save Installation Space

The indoor unit can be installed inside the ceiling conveniently.

Optional Static Pressure

Optional ESP, a variety of optional installation methods.

High Efficiency and Environment Friendly New Refrigerant-R410A

R410A can protect the environment and do not harm to the ozone layer.

24-hour Timer ON and OFF

This Timer can be set to automatically turn the unit on or off within a 24-hour period.

Mute Operation

The excellent fan design enable the airflow to be quiet and smooth with minimum

noise.

Meeting Various Installation Requirements

The back-air-inlet type is usually to be adopted according to the actual installation

space.The unit is also installed with down-air-inlet type and the noise will increase

about 5-6dB.

Self Recovery of Power Break

When the power supply is recovered after break, all preset are still effective and the

air-conditioner can run according to the original setting.

Fault Self-diagnose Function

When there is something wrong with the air-conditioner

,

the micro computer could

diagnose the faults, which can be read from the display and is convenient for

maintenance.

Page 4

11..GGEENNEERRAAL

L

DC- INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

2

Cassette Type Air Conditioner

Features

Save Installation Space

The indoor unit can be installed inside the ceiling conveniently.

High Efficiency and Environment Friendly New Refrigerant-R410A

R410A can protect the environment and do not harm to the ozone layer.

24-hour Timer ON and OFF

This Timer can be set to automatically turn the unit on or off within a 24-hour period.

Mute Operation

The excellent fan design enable the airflow to be quiet and smooth with minimum noise.

Self Recovery of Power Break

When the power supply is recovered after break, all preset are still effective and the

air-conditioner can run according to the original setting.

Fault Self-diagnose Function

When there is something wrong with the air-conditioner, the micro computer could diagnose

the faults, which can be read from the display and is convenient for maintenance.

Page 5

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

3

Ceiling &Floor Air Conditioner

Features

Save Installation Space

The indoor unit’s thickness is only 230mm,can be installed inside the ceiling conveniently

.

Flexible

Installation Options

According to the actual installation space,The indoor unit can be installed in the

ceiling

or

on the floor. One unit, Two installation method.

High Efficiency and Environment Friendly

New Refrigerant-R410A

R410A can protect the environment and do not harm to the ozone layer.

24-hour Timer ON and OFF

This Timer can be set to automatically turn the unit on or off within a 24-hour period.

Mute Operation

The excellent fan design enable the airflow to be quiet and smooth with minimum noise.

Various Refrigerant Pipe Connect Methods

The refrigerant pipe can be connect from 3 different directions(rear,right or top) .More

methods, more conveniently.

Self Recovery of Power Break

When the power supply is recovered after break, all preset are still effective and the

air-conditioner can run according to the original setting.

Fault Self-diagnose Function

When there is something wrong with the air-conditioner, the micro computer could diagnose

the faults, which can be read from the display and is convenient for maintenance.

Page 6

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

4

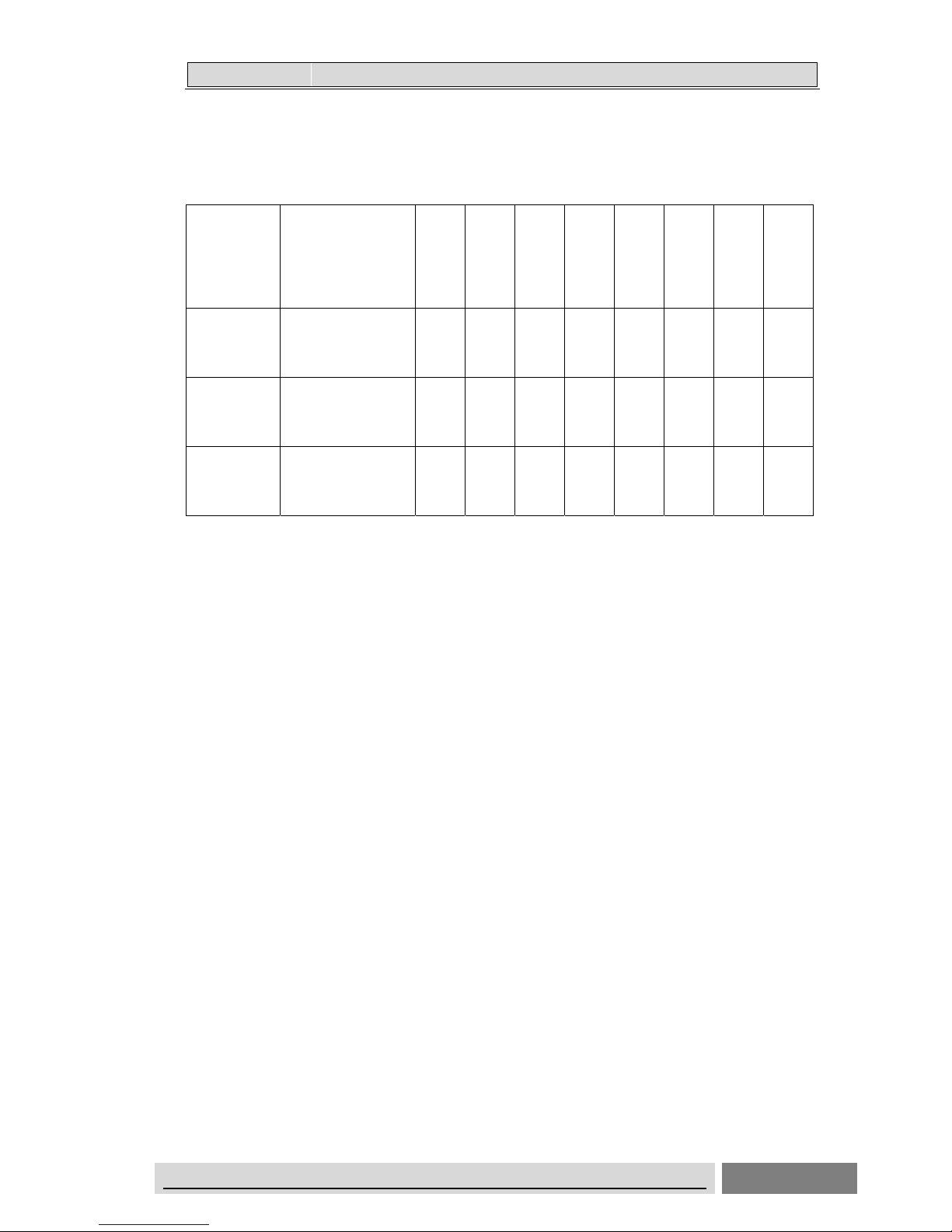

1.2 Product lineup

Type

Model Cooling

Capacity

(×1000Btu/h)

9K 12K 18K 24K 36K 42K 48K 60K

Duct

Type

AUD-

● ● ● ● ● ● ● ●

Cassette

Type

AUC-

● ● ● ● ● ● ●

Ceiling&

Floor type

AUV-

● ● ● ● ● ●

●

---available model

Page 7

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

5

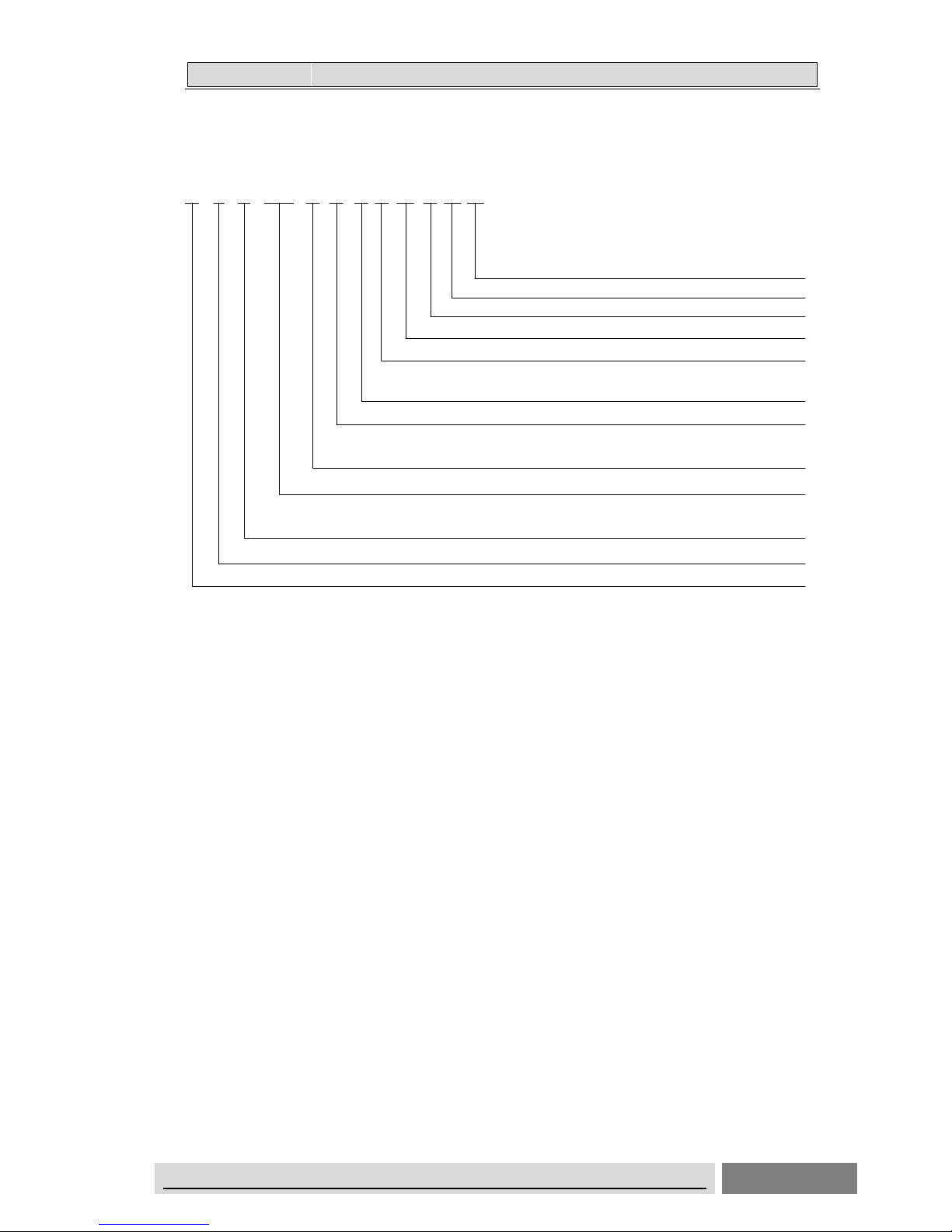

1.3 Model identification

1.4 Unit construction

1:1 system is the only combination compatible.

(1 indoor unit only can be connected with 1 outdoor unit.)

A U D -09 U X 4 S R N L 3

N:Indoor Unit Code

S:Refrigerant R410A F:Refrigerant R22

2:220-230V ~,60Hz, 4:220-240V ~, 50Hz

6:380-415V ~,50Hz

X: Wire Romote Controller R:Wireless Romote Controller

Unit

Air Conditioner

R:Outdoor Unit Code

U:DC-Invert Heat Pump Type , H:Heat Pump Type

C:Cooling Only Type

Type:D-Duct Type,C-Cassette Type,V-Ceiling&Floor Type

H-Floorstanding Type, W-Outdoor Unit

Cooling Capacity:9x10 Btu/h

³

3:Series Number

L:Low ESP H:High ESP

Page 8

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

6

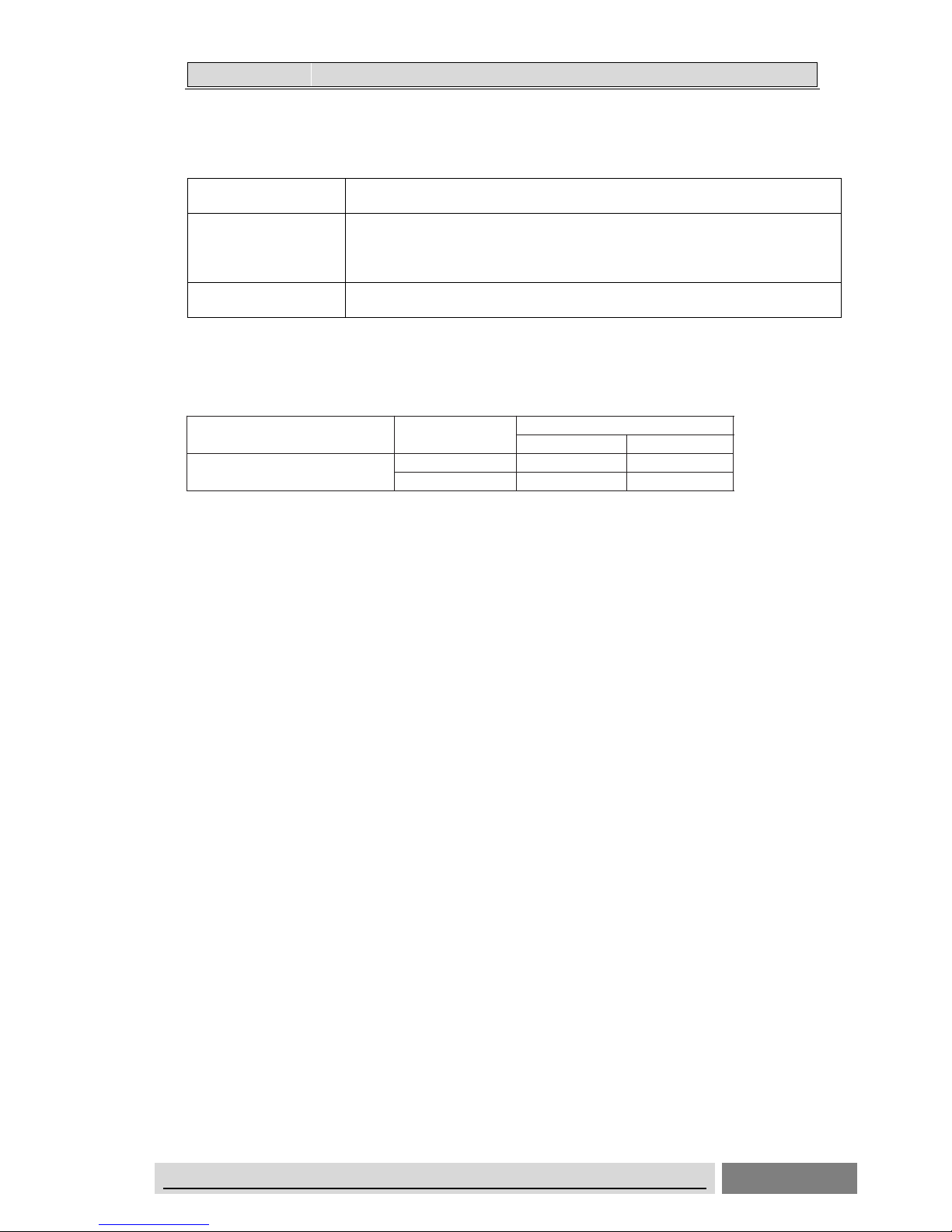

1.5 Working range

Power Supply

Working Voltage

176V ~ 264V(9K~36K),342V ~ 438V(42K~60K)

Voltage Imbalance

Within a 3% deviation from each voltage at the main terminal of

outdoor unit

Starting Voltage Higher than 85% of the Rated Voltage

Operating temperature range

This heat pump air conditioner has been designed for the following outdoor operating temperatures.

Storage condition:

Temperature -20~65℃

Humidity 30%~80%

Type Mode

Outdoor operating temperature range(℃)

maximum minimum

DC-Inverter Split Air Conditioner

(Heat pump type)

Cooling Operation 48 -15

Heating Operation 24 -15

Page 9

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

7

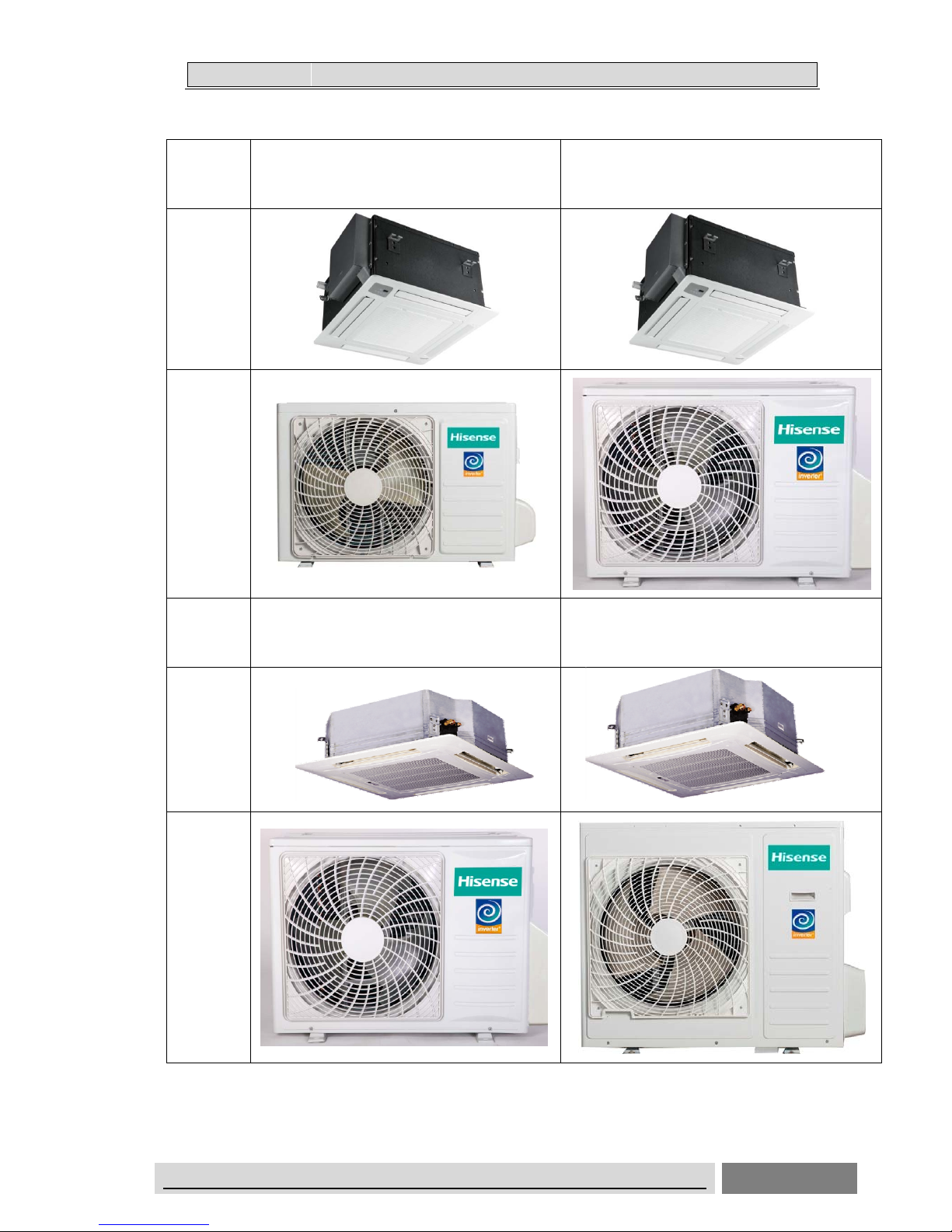

1.6 Product picture

Duct Type

Model

(

Cooling

capacity

)

9K 12K

Indoor

Unit

Outdoor

Unit

Model

(

Cooling

capacity

)

18K 24K

Indoor

Unit

Outdoor

Unit

Page 10

11..GGEENNEERRAAL

L

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

8

Model

(capacity)

36K 42K

Indoor

Unit

Outdoor

Unit

Model

48K/60K

Indoor

Unit

Outdoor

Unit

(capacity)

Page 11

11..GGEENNEERRAAL

L

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

9

Cassette Type

Model

12K 18K

Indoor

Unit

Outdoor

Unit

Model

24K 36K

Indoor

Unit

Outdoor

Unit

(capacity)

(

capacity)

Page 12

11..GGEENNEERRAAL

L

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

10

Model

42K 48K/60K

Indoor

Unit

Outdoor

Unit

(capacity)

Page 13

11..GGEENNEERRAAL

L

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

11

Ceiling &Floor Type

Model

18K/24K 36K/42K

Indoor

Unit

Outdoor

Unit

Model

48K/60K

Indoor

Unit

Outdoor

Unit

(

capacity)

(capacity)

Page 14

11..GGEENNEERRAAL

L

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

12

Display panel

Cassette Type

5

6

4

6

2

1

1

3

7

5

4

2

3

7

2

1

3

4

5

7

Ceiling & Floor type

Page 15

11..GGEENNEERRAAL

L

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

13

The figures in this manual are based on the external view of a standard model.

Consequently, the shape may differ from that of the air conditioner you have selected.

*

It can be set or canceled by professional after-sale staff

Description

1

Run indicator (Red)

It lights on during operation. It lights off during SLEEP mode.

2 Emergency switch

The

filter clean indicator will be off when the switch is pressed. The unit will stop operation

if pressing the button.

When the unit is off,it will start auto operation if pressing the button,if

pressing for more than 5s, the unit will operate in cooling mode.

3 Timer indicator (Green)

It lights on when timer is in use. It lights off when timer finishes.

4 Filter clean (Yellow)

It lights on when the filter should be cleaned.

5 Defrost indicator (Green)

It lights on during defrosting It lights off when defrosting is finished.

6 Buzzer

It beeps when the signal from remote controller is received.

7

Infrared receiver

Receives signal from the remote controller.

Page 16

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

14

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

2. Specifications

2.1 Duct type

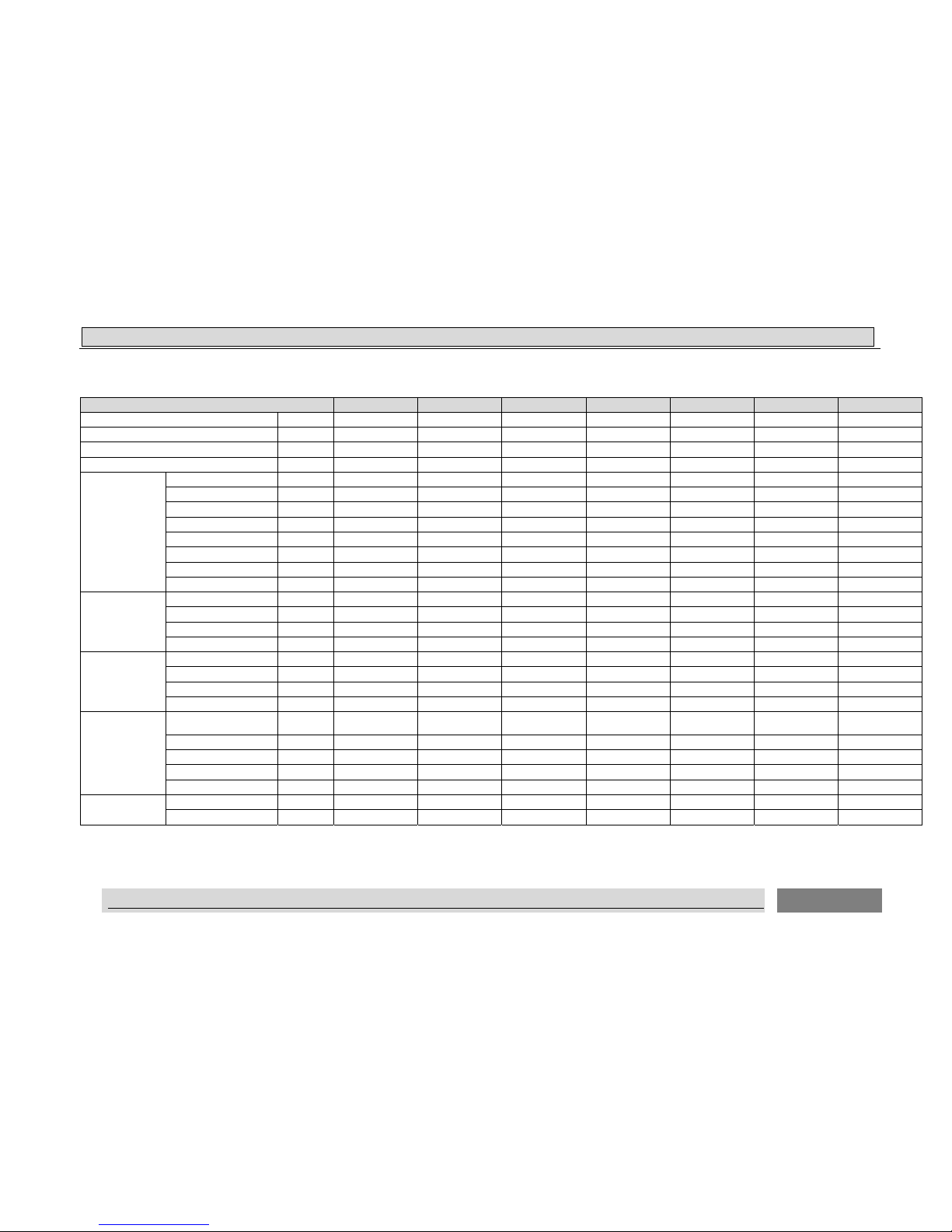

MODEL 9K 12K 18K 24K 36K 42K 48K 60K

Power supply (Indoor) V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50

Power supply (Outdoor) V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 380~415-3-50 380~415-3-50 380~415-3-50

Max. input consumption W 1140 1800 2460 4100 5100 6400 7000 7800

Max. input current A 7.8 8.1 11.1 18.1 22.5 11.6 12.0 13.1

Average

Pdesignc

kW 2.7 3.52 5.34 7.05 10.5 11.6 14.0 17.00

SEER W/W 6.15 6.45 6.11 6.23 6.21 6.11 6.11 6.11

Energy Efficiency

Class

A++ A++ A++ A++ A++ A++ A++ A++

Pdesignh kW 2.20 3.52 4.80 6.000 9.000 10.000 12.200 15.000

SCOP W/W 4.01 4.10 4.02 4.08 4.03 4.01 4.02 4.01

Energy Efficiency

Class

A+ A+ A+ A+ A+ A+ A+ A+

Tbiv ℃ -7 -7 -7 -7 -7 -7 -7 -7

Tol ℃ -10 -10 -10 -10 -10 -10 -10 -10

Cooling

Capacity kW 2.70 3.55 5.340 7.05 10.500 12.300 14.000 17.000

Input W 782 1030 1650 2200 3700 4300 4280 5230

Current A 3.6 4.6 7.6 9.7 16.5 7.9 7.8 8.5

EER W/W 3.45 3.55 3.23 3.23 2.84 2.86 3.27 3.25

Heating

Capacity kW 2.740 3.700 6.010 8.05 11.5 14.0 16.0 20.00

Input W 700 945 1720 2370 3400 4100 4240 5360

Current A 3.0 4.2 7.9 10.5 15.2 7.5 7.7 8.7

COP W/W 3.91 3.91 3.49 3.39 3.38 3.41 3.77 3.73

Indoor fan motor

Model

SIC-68CVL-F140-1 SIC-68CVL-F140-

1

YSK110-40-4-A SIC-70CW-F195-1

SIC-101CW-F125

0-4

SIC-101CW-F125

0-4

SIC-101CW-F125

0-4

SIC-101CW-F125

0-4

Qty 1 1 1 1 1 1 1 1

Output W 40 40 40 95 250 250 250 250

Capacitor uF NA NA 2 NA NA NA NA NA

Page 17

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

15

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

MODEL 9K 12K 18K 24K 36K 42K 48K 60K

Speed(Hi/Med/Lo) r/min 770/640/540 880/740/610 1130/950/850 890/790/690 800/700/600 910/810/710 1100/1000/900 1100/1000/900

Indoor coil

Number of rows 3 3 3 3 3 3 3 3

Tube pitch(a)xrow

pitch(b)

mm 21x13.6 21x13.6 21x13.6 21x13.6 21x18.19 21x18.19 21x18.19 21x18.19

Fin spacing mm 1.6 1.6 1.6 1.6 1.4 1.4 1.5 1. 5

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside

dia.and type

mm

Φ7,innergroove

tube

Φ7,innergroove

tube

Ф7,innergroove

tube

Ф7,innergroove

tube

Ф7, innergroove

tube

Ф7, innergroove

tube

Ф7.0, innergroove

tube

Ф7.0, innergroove

tube

Coil length x

height x width

mm 768x189x40.8 515x252x40.11 1038x189x40.8 700x294x40.8 1100x378x54.57 1100x378x54.57 1100x378x54.6 1100x378x54.6

Number of circuits 4 4 4 4 9 9 9 9

Indoor air flow Rated(Hi/Med/Lo) m3/h 500/400/320 575/484/400 900/840/730 1100/976/852 1450/1250/1050 1750/1500/1300 2400/2200/1900 2400/2200/1900

Indoor air flow Rated(Hi/Med/Lo) CFM 294/235/188 338/285/235 529/494/429 647/574/501 853/735/618 1029/882/765 1415/1300/1124 1415/1300/1124

ESP

Rated (test) Pa 35 35 35 35 47 60 60 60

Rated (Factory

default)

Pa 0 0 10 25 47 60 60 60

Range Pa 0~50 0~50 10/30 0~80 0~120 0~120 0~120 0~120

Indoor noise level (Hi/Med/Lo) dB(A) 32/28/25 36/34/29 43/41/38 44/41/38 46/42/39 51/47/44 55/52/50 56/53/50

Indoor noise level (sound power) dB(A) 44 49 56 57 62 67 68 70

Throttle type NA NA NA NA NA NA NA NA

Indoor unit

Dimension

(WxHxD)

mm 900x190x447 900x190x447 1170x190x447 900x270x720 1300x350x800 1300x350x800 1300x350x800 1300x350x800

Packing(WxHxD) mm 1070x236x580 1070x236x580 1340x236x580 1170x870x340 1550x410x940 1550x410x940 1550x410x940 1550x410x940

Net/Gross weight kg 19/23.5 19/23.5 24/29 32/37 51/60 51/60 51/60 51/60

Design pressure H/L MPa 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6

Drainage water pipe diameter mm DΦ32 DΦ32 DΦ32 DΦ32 DΦ32 DΦ32 DΦ32 DΦ32

Refrigerant piping

Liquid side/

Gas side

mm(inch)

Φ6.35/Φ9.52

(1/4'/3/8')

Φ6.35/Φ9.52

(1/4'/3/8')

Φ6.35/Φ12.7

(1/4'/1/2')

Φ9.52/Φ15.88

(3/8'/5/8')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Controller Wired control Wired control Wired control Wired control Wired control Wired control Wired control Wired control

Operation temperature ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Cooling ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Heating ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Qty’per 20’ /40’ /40'HQ Indoor 200/440/484 200/440/484 160/340/374 84/182/182 35/75/90 35/75/90 35/75/90 35/75/90

Indoor fan motor

Room temperature

Page 18

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

16

DC-�IINVER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

MODEL 9K 12K 18K 24K 36K 42K 48K 60K

Compressor

Model ASD088SKNA8JT ASN108D43UFZA ATM150D23UFZ ATF235D43UMT ATF310D43UMT ATF310D43UMT ATH356SDPC9FL LNB42FSAMC

Type ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY

Brand Highly GMCC GMCC GMCC GMCC GMCC Highly MITSUBISHI

Capacity Btu/h 8549 11123 15427 24361 32380 32380 34470 47699

Input W 575 810 1165 1940 2600 2600 3155 4270

Rated

current(RLA)

A 3 5.7 8 8.9 5.1 5.1 13.2 12.0

Refrigerant oil ml α68HES-H/320

ESTER OIL

VG74/370

ESTEL OIL

VG74/500

POE(VG74)/670 PQE(VG74)/1000 PQE(VG74)/1000

α 68HES-H or

equivalent /1650

FV50S or

PVE/1400

Outdoor fan motor

Model SIC-52FV-F130-3 ZWA138D08A SIC-61FW-F161-1 SIC-61FW-F161-1

SIC-71FW-F8121-1 SIC-81FW-F1138-1 YDK65-6-9061&

YDK65-6-9024

YDK65-6-9061&

YDK65-6-9024

Old Model NA NA NA NA NA NA NA NA

Qty 1 1 1 1 1 1 2 2

Output W 30 30 61 61 121 138 121 121

Capacitor μF NA NA NA NA NA NA NA NA

Speed r/min 820 880 840 880 830 850 810 810

Outdoor coil

Number of rows 1.5 2 2 2 2 2 2 2

Tube pitch(a)x row

pitch(b)

mm 21x18.19 21x18.19 21x21.65 21x18.19 21x21.65 21x21.65 21x21.65 21x21.65

Fin spac ing mm 1.3 1.4 1.4 1.4 1.3 1.6 1.4 1.4

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside

dia.and type

mm

Φ7,innergroove

tube

Ф7,innergroove

tube

Ф7,innergroove

tube

Ф7,innergroove

tube

Ф7.94,

innergroove tube

Ф7.94,

innergroove tube

Φ7.94,innergroove

tube

Φ7.94,innergroove

tube

Coil length xheight

xwidth

mm 761x504x36.38 840x546x36.38 962x630x43.3 900x630x43.3 970x798x43.5 970x1008x43.5 970x1344x43.3 970x1344x43.3

Number of circuits 4 4 7 4 5 6 12 12

Outdoor noise level

(sound pressure) Hi

dB(A) 52 48 53 53 55 58 53 58

Outdoor noise level (sound power) dB(A) 64 60 65 67 70 73 67 72

Throttle type EEV EEV EEV EEV EEV EEV EEV EEV

Outdoor unit

Dimension

(WxHxD)

mm 730x536x260 810x585x280 860x670x310 860x670x310 950x840x340 950x1050x340 950x1386x340 950x1386x340

Packing(WxHxD) mm 860x600x400 940x640x420 990x730x450 990x730x450 1110x980x460 1110x1200x460 1110x1527x460 1110x1527x460

Page 19

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

17

MODEL 9K 12K 18K 24K 36K 42K 48K 60K

Net/Gross weight kg 31/34 34/38.5 45/49 51/57 70/80 85/95 113/125 117/129

Refrigerant

type/Quantity

Type R410a R410a R410a R410a R410 R410 R410A R410A

Charged volume kg 0.83 1.05 1.30 1.70 2.80 3.20 3.78 3.95

Design pressure H/L MPa 4.15/1.60 4.15/1.60 4.15/1.60 4.15/1.60 4.15/1.60 4.15/1.60 4. 15/1.60 4.15/1.60

Refrigerant piping

Liquid side/

Gas side

mm(inch)

Φ6.35/Φ9.52

(1/4'/3/8')

Φ6.35/Φ9.52

(1/4'/3/8')

Φ6.35/Φ12.7

(1/4'/1/2')

Φ9.52/Φ15.88

(3/8'/5/8')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Max. pipe length m 25 25 30 50 50 50 50 50

Max. difference in

level

m 10 15 15 30 30 30 30 30

Annual energy

consumption(cooling)

kWh/a 154 191 306 396 563 665 802 974

Annual energy

consumption(heating

average)

kWh/a 769 1203 1676 2059 3124 3491 4259 5232

Ambient temperature

Cooling ℃ -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48

Heating ℃ -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24

Qty’per 20’ /40’

/40'HQ

Outdoor

unit

102/213/292 102/204/272 90/186/186 90/186/186 52/106/106 26/53/106 26/53/53 26/53/53

Qty’per 20’ /40’

/40'HQ

Indoor+

Outdoor

80/160/190 66/135/174 55/112/133 40/80/88

22/49/56 20/39/51 19/39/42 19/39/42

NOTE:

1.Test conditions:

Cooling : Indoor: DB27℃/ WB19℃ Outdoor: DB35℃/ WB24℃

Heating: Indoor: DB20℃/ WB15℃ Outdoor: DB7℃/ WB 6℃

2.The Sound Pressure Level is based on the following conditions:

Outdoor unit:

Measure the noise value of 3 points,the points are1 meter in front of the three sides (front/left/right) of the unit surface and height =1/2(unit

height +1) meter from floor level, and calculate the weighted average of the noise.

Indoor unit:

Ducted: Measure the noise value of the point 1.4m below the unit, and 1.0m high from the floor.

The above data was measured in an anechoic chamber. Please take into consideration reflected sound of your specific application environment.

3. The values given in the table for noise level reflect the levels in anechoic chamber.

DC- IINVER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Page 20

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

18

DC-�IINVER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

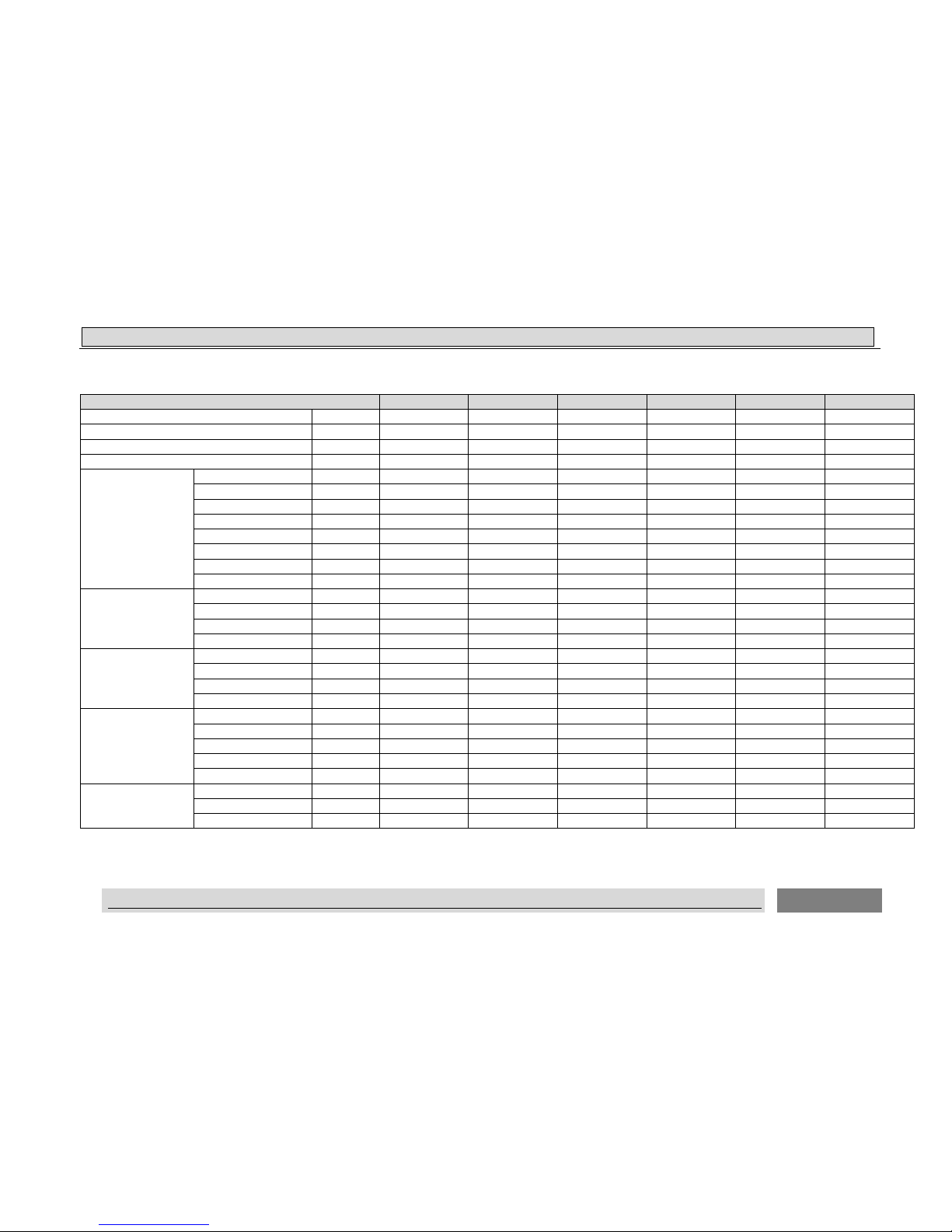

2.2 Cassette type

MODEL 12K 18K 24K 36K 42K 48K 60K

Power supply (Indoor) V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50

Power supply (Outdoor) V-ph-Hz 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 380~415-3-50 380~415-3-50 380~415-3-50

Max. input consumption W 1800 2710 4100 5150 6400 6300 7800

Max. input current A 8.1 12.3 18.1 22.5 11.6 11 13.1

Average

Pdesignc kW 3.52 5.30 7.10 10.50 11.20 14.00 17.00

SEER W/W 6.61 6.11 6.45 6.11 6.11 6.11 6.11

Energy Efficiency Class A++ A++ A++ A++ A++ A++ A++

Pdesignh kW 3.520 4.80 6.000 9.000 10.000 12.200 15.300

SCOP W/W 4.25 4.02 4.15 4.08 4.01 4.03 4.01

Energy Efficiency Class A+ A+ A+ A+ A+ A+ A+

Tbiv ℃ -7 -7 -7 -7 -7 -7 -7

Tol ℃ -10 -10 -10 -10 -10 -10 -10

Cooling

Capacity kW 3.650 5.3 7.100 10.5 12.3 14.0 17.0

Input W 1000 1680 2200 3700 4100 4180 5030

Current A 4.4 7.6 9.7 16.5 7.5 7.6 8.3

EER W/W 3.65 3.15 3.23 2.84 3.0 3.35 3.38

Heating

Capacity kW 3.85 6.21 8.20 11.5 14 16 20.0

Input W 970 1900 2370 3600 3900 4230 5320

Current A 4.2 8.3 10.5 16 7.3 7.6 8.6

COP W/W 3.97 3.26 3.46 3.19 3.59 3.78 3.76

Indoor fan motor

Model ARW8901QH

YDK95-28-4-B(HS2

1)

ARW5901QH EHDS50AQH

SIC-72FW-D8124-28 SIC-72FW-D8124-2B SIC-72FW-D8124-2

B

Qty 1 1 1 1 1 1 1

Output W 30 28 35 80 124 124 124

Capacitor uF NA 2 NA NA NA NA NA

Speed(Hi/Med/Lo) r/min 700/590/520 980/840/720 450/390/270 600/480/390 630/600/570 700/540/460 700/540/460

Indoor coil

Number of rows 2 2 2 3 3 3 3

Tube pitch(a)xrow pitch(b) mm 21x13.6 21x13.6 21x13.6 21x13.6 21x13.6 21x13.6 21x13.6

Page 21

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

19

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

MODEL 12K 18K 24K 36K 42K 48K 60K

Fin spacing mm 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside dia.and type mm Ф7,innergroove tube Ф7,innergroove tube Ф7,innergroove tube

Ф7, innergroove

tube

Ф7, innergroove

tube

Ф7.0, innergroove

tube

Ф7.0, innergroove

tube

Coil length x height x width mm 1248x210x27.2 1248x210x27.2

1870×189×27.2

1940x189x40.8 1940x252x40.8 1940x252x40.8 1940x252x40.8

Number of circuits 3 3 4 6 6 6 6

Indoor air flow Rated(Hi/Med/Lo) m3/h 575/484/400 820/730/620 1100/976/852 1600/1300/1000 1850/1700/1550 2000/1900/1700 2000/1900/1700

Indoor air flow Rated(Hi/Med/Lo) CFM 338/285/235 482/429/365 647/574/501 941/765/588 1088/1000/912 1180/1120/1000 1180/1120/1000

ESP

Rated Pa NA NA NA NA NA NA NA

Range Pa NA NA NA NA NA NA NA

Indoor noise level (Hi/Med/Lo) dB(A) 39/37/36 45/41/39 41/38/36 45/40/37 46/43/41 50/48/46 47/45/43

Indoor noise level (sound power) dB(A) 53 58 55 60 61 63 61

Throttle type NA NA NA NA NA NA NA

Indoor unit

Dimension (WxHxD) mm 650x270x570 650x270x570 840x248x840 840x248x840 840x298x×840 840x298x840 840x298x840

Packing(WxHxD) mm 770x310x750 770x310x750 996x370x956 996x370x956 996x420x956 996x420x956 996x420x956

Net/Gross weight kg 19/24 21 /26 25/34 27/36 32/41 32/41 32/41

Panel

Dimension (WxHxD) mm 650x30x650 650x30x650

950×37×950

950x37x950 950x37x950 950x37x950 950x37x950

Packing(WxHxD) mm 730x130x730 730x130x730 990x115x1010 1025x120x1015 1025x120x1015 1025x120x1015 1025x120x1015

Net/Gross weight kg 2.4/ 5 2.4/ 5 6.5/9.5 6.5/9.5 6.5/9.5 6.5/9.5 6.5/9.5

Design pressure H/L MPa 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6

Drainage water pipe diameter mm dΦ21 dΦ21 dΦ32 dΦ32 dΦ32 dΦ32 dΦ32

Refrigerant piping Liquid side/ Gas side mm

Φ6.35/Φ9.52

(1/4'/3/8')

Φ6.35/Φ12.7

(1/4'/1/2')

Φ9.52/Φ15.88

(3/8'/5/8')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Controller Remote control Remote control Remote control Remote control Remote control Remote control Remote control

Operation temperature ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Room temperature

Cooling ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Heating ℃ 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30 16 - 30

Qty’per 20’ /40’

/40'HQ

Indoor 147/315/384 147/315/384 72/144/168 72/144/168 60/120/144 60/120/144 60/120/144

Compressor

Model ASN108D43UFZA ATM150D23UFZ ATF235D43UMT ATF310D43UMT ATF310D43UMT ATH356SDPC9FL LNB42FSAMC

Type ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY

Indoor coil

Page 22

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

20

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

MODEL 12K 18K 24K 36K 42K 48K 60K

Brand GMCC GMCC GMCC GMCC GMCC Highly MITSUBISHI

Capacity Btu/h 11123 15427 24361 32380 32380 34470 47699

Input W 810 1165 1940 2600 2600 3155 4270

Rated current(RLA) A 5.7 8.1 8.9 5.1 5.1 13.2 12

Refrigerant oil ml

ESTER OIL

VG74/370

ESTEL OIL

VG74/500

POE(VG74)/670 PQE(VG74)/1000 PQE(VG74)/1000

α 68HES-H or

equivalent /1650

FV50S or PVE/1400

Outdoor fan motor

Model ZWA138D08A SIC-61FW-F161-1 SIC-61FW-F161-1 SIC-71FW-F8121-1 SIC-81FW-F1138-1

YDK65-6-9061&

YDK65-6-9024

YDK65-6-9061&

YDK65-6-9024

Old Model NA NA NA NA NA NA NA

Qty 1 1 1 1 1 2 2

Input W 30 61 61 121 138 121 121

Capacitor μF NA NA NA NA NA NA NA

Speed r/min 880 840 880 830 850 810 810

Outdoor coil

Number of rows 2 2 2 2 2 2 2

Tube pitch(a)x row pitch(b) mm 21x18.19 21x21.65 21x18.19 21x21.65 21x21.65 21x21.65 21x21.65

Fin spac ing mm 1.4 1.4 1.4 1.3 1.6 1.4 1.4

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside dia.and type mm Ф7,innergroove tube Ф7,innergroove tube Ф7,innergroove tube

Ф7.94, innergroove

tube

Ф7.94, innergroove

tube

Φ7.94,innergroove

tube

Φ7.94,innergroove

tube

Coil length xheight xwidth mm 840x546x36.38 962x630x43.3 900x630x43.3 970x798x43.5 970x1008x43.5 970x1344x43.3 970x1344x43.3

Number of circuits 2 7 4 5 6 12 12

Outdoor noise level

(sound pressure)

Hi

dB(A) 48 53 53 55 58 53 58

Outdoor noise level (sound power) dB(A) 60 65 67 70 73 67 72

Throttle type EEV EEV EEV EEV EEV EEV EEV

Outdoor unit

Dimension(WxHxD) mm 810x585x280 860x670x310 860x670x310 950x840x340 950x1050x340 950x1386x340 950x1386x340

Packing(WxHxD) mm 940x420x640 990x730x450 990x730x450 1110x980x460 1110x1200x460 1110x1527x460 1110x1527x460

Net/Gross weight kg 34/38.5 45/49 51/57 70/80 85/95 113/125 117/129

Refrigerant

type/Quantity

Type R410a R410a R410a R410 R410 R410A R410A

Charged volume kg 1.05 1.3 1.70 2.80 3.20 3.78 3.95

Design pressure H/L MPa 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6

Compressor

Page 23

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

21

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

MODEL

Refrigerant piping

Liquid side/ Gas side mm(inch)

12K

Φ6.35/Φ9.52

(1/4'/3/ 8')

18K

Φ6.35/Φ12.7

(1/4'/1/ 2')

24K

Φ9.52/Φ15.88

(3/8'/5 /8')

36K

Φ9.52/Φ19.05

(3/8'/3 /4')

42K

Φ9.52/Φ19.05

(3/8'/3 /4')

48K

Φ9.52/Φ19.05

(3/8'/3 /4')

60K

Φ9.52/Φ19.05

(3/8'/3 /4')

Max. pipe length m 25 30 50 50 50 50 50

Max. difference in level m 15 15 30 30 30 30 30

Annual energy

consumption

(cooling)

kWh/a 186 303 382 601 642 802 974

Annual energy

consumption

(heating average)

kWh/a 1160 1676 2025 3088 3491 4241 5336

Ambient

temperature

Cooling ℃ -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48

Heating ℃ -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24

Qty’per 20’ /40’

/40'HQ

Outdoor unit 102/204/272 90/186/186 90/186/186 52/106/106 26/53/106 26/53/53 26/53/53

Qty’per 20’ /40’

/40'HQ

Indoor+

Outdoor

54/112/125 48/102/120 40/82/92 30/60/72 24/52/62 24/47/47 24/47/47

NOTE:

1.Test conditions:

Cooling : Indoor: DB27℃/ WB19℃ Outdoor: DB35℃/ WB24℃

Heating: Indoor: DB20℃/ WB15℃ Outdoor: DB7℃/ WB 6℃

2.The Sound Pressure Level is based on the following conditions:

Outdoor unit:

Measure the noise value of 3 points,the points are1 meter in front of the three sides (front/left/right) of the unit surface and height =1/2(unit

height +1) meter from floor level, and calculate the weighted average of the noise.

Indoor unit:

Cassette: Measure the noise value of the point 1.4m below the unit, and 1.0m high from the floor.

The above data was measured in an anechoic chamber. Please take into consideration reflected sound of your specific application environment.

3. The values given in the table for noise level reflect the levels in anechoic chamber.

Page 24

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

22

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

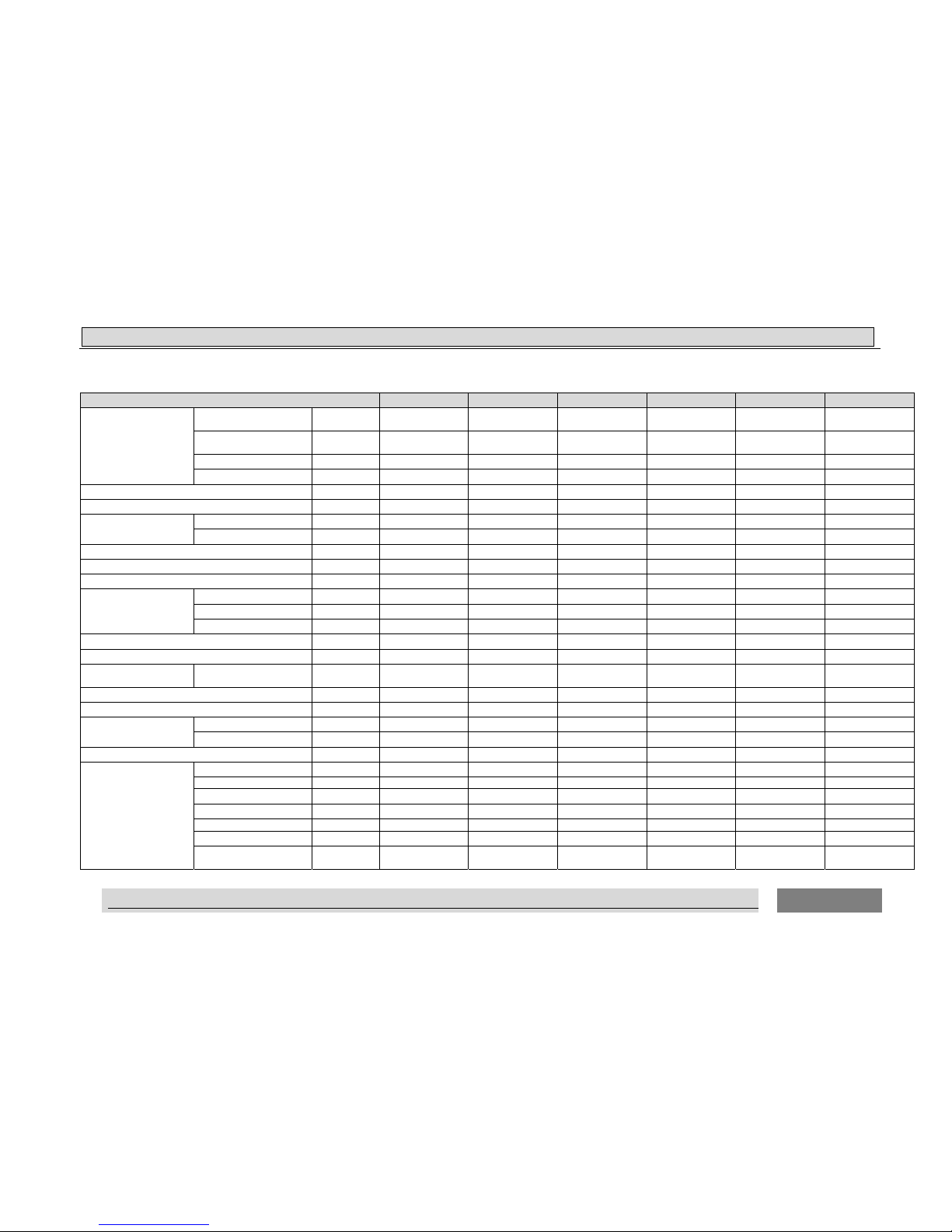

2.3 Ceiling&Floor type

Model

18K 24K 36K 42K 48K 60K

Power supply (Indoor) V-ph-Hz

220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50 220~240-1-50

Power supply (Outdoor) V-ph-Hz

220~240-1-50 220~240-1-50 220~240-1-50 380~415-3-50 380~415-3-50 380~415-3-50

Max. input consumption W 2600 4100 5100 6400 6300 8200

Max. input current A 11 18.1 22.5 11.6 11.0 13.5

Average

Pdesignc kW 5.28 7.0 10.5 11.0 14.0 17.0

SEER W/W 6.80 6.11 6.11 6.11 6.11 6.11

Energy Efficiency Class A++ A++ A++ A++ A++ A++

Pdesignh kW 4.8 6.0 9.0 10.0 12.2 15

SCOP W/W 4.30 4.08 4.11 4.01 4.02 4.01

Energy Efficiency Class A+ A+ A+ A+ A+ A+

Tbiv ℃ -7 -7 -7 -7 -7 -7

Tol ℃ -10 -10 -10 -10 -10 -10

Cooling

Capacity

kW 5.28 7.000 10.5 12.3 14.0 17.0

Input

W 1750 2200 4000 4250 4410 5180

Current

A 7.3 9.7 17.6 7.8 8.1 8.6

EER

W/W 3.02 3.23 2.625 2.89 3.17 3.28

Heating

Capacity

kW 6.0 8.200 11.3 14.0 15.8 20.0

Input

W 1850 2370 3750 4500 4350 5360

Current

A 7.8 10.5 16.3 8.2 8.1 9.2

COP

W/W 3.24 3.46 3.00 3.11 3.63 3.73

Indoor fan motor

Model

SIC-70CW-F1100-6 SIC-70CW-F1100-6 SIC-70CW-F1140-3 SIC-101CW-F1181-2 SIC-101CW-F1181-1 SIC-101CW-F1181-1

Qty 1 1 1 1 1 1

Output W

100 100 140 181 181 181

Capacitor uF

NA NA NA NA NA NA

Speed(Hi/Med/Lo) r/min

800/700/610 1280/1100/920 1220/1160/1080 1200/1100/1000 1250/1000/800 1250/1100/950

Indoor coil

Number of rows

2 3 3 3 3 3.5

Tube pitch(a)xrow pitch(b) mm

21x13.6 21x13.6 21x13.6 21x13.6 21x13.6 21x13.6

Fin spacing mm

1.4 1.5 1.5 1.5 1.5 1.5

Page 25

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

23

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Model

18K 24K 36K 42K 48K 60K

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside dia.and type mm

Ф7,innergroove tube Ф7,innergroove tube Ф7, innergroove tube Ф7, innergroove tube

Ф7.0, innergroove

tube

Ф7.0, innergroove

tube

Coil length x height x width mm

691x336x27.2 660x336x40.8 930x336x40.8 1200x336x40.8 1200x336x40.8 1200x336x54.4

Number of circuits

4 3 7 7 7 7

Indoor air flow Rated(Hi/Med/Lo)

m

3

/h

800/690/590 1100/950/800 1700/1500/1300 2000/1800/1600 2000/1600/1200 2000/1700/1500

Indoor air flow Rated(Hi/Med/Lo)

CFM

470/400/340 650/570/500 1000/882/765 1176/1059/941 1180/940/710 1180/1000/880

ESP

Rated

Pa

NA NA NA NA NA NA

Range

Pa

NA NA NA NA NA NA

Indoor noise level (Hi/Med/Lo)

dB(A)

43/39/36 48/46/42 50/49/48 50/48/45 51/45/41 51/46/43

Indoor noise level (sound power)

dB(A)

56 62 63 66 65 65

Throttle type

NA NA NA NA NA NA

Indoor unit

Dimension (WxHxD) mm

990x680x230 990x680x230 1285x680x230 1580x680x230 1580x680x230 1580x680x230

Packing(WxHxD) mm

1100x820x350 1100x820x350 1400x820x350 1690x820x350 1690x820x350 1690x820x350

Net/Gross weight kg

29/34 30/35 37/44 48/56 48/56 50/58

Design pressure MPa

4.15/1.6 4.15/1.6 4.2/1.5 4.2/1.5 4.15/1.6 4.15/1.6

Drainage water pipe diameter mm

DΦ25 DΦ25 DΦ25 DΦ25 DΦ25 DΦ25

Refrigerant piping Liquid side/ Gas side mm

Φ6.35/Φ12.7

(1/4'/1/2')

Φ9.52/Φ15.88

(3/8'/5/8')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Controller

Remote control Remote control Remote control Remote control Remote control Remote control

Operation temperature ℃

16 - 30 16 - 30 16 - 30 16 - 30 16-30 16-30

Room temperature

Cooling ℃

16 - 30 16 - 30 16 - 30 16 - 30 16-30 16-30

Heating ℃

16 - 30 16 - 30 16 - 30 16 - 30 16-30 16-30

Qty’per 20’ /40’ /40'HQ Indoor 84/168/196 84/168/196 42/84/98 42/84/98 42/84/98 42/84/98

Compressor

Model ATM150D23UFZ ATF235D43UMT ATF310D43UMT ATF310D43UMT ATH356SDPC9FL LNB42FSAMC

Type ROTARY ROTARY ROTARY ROTARY ROTARY ROTARY

Brand GMCC GMCC GMCC GMCC Hitachi MITSUBISHI

Capacity Btu/h 15427 24361 32380 32380 34470 47699

Input W 1165 1940 2600 2600 3155 4270

Rated current(RLA) A 8.1 8.9 5.1 5.1 13.2 12

Refrigerant oil ml

ESTEL OIL

VG74/500

POE(VG74)/670 PQE(VG74)/1000 PQE(VG74)/1000

α 68HES-H or

equivalent /1650

FV50S or PVE/1400

Indoor coil

Page 26

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

24

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Model

18K 24K 36K 42K 48K 60K

Outdoor fan motor

Model SIC-61FW-F161-1 SIC-61FW-F161-1 SIC-71FW-F8121-1 SIC-81FW-F1138-1

YDK65-6-9061&

YDK65-6-9024

YDK65-6-9061&

YDK65-6-9024

Old Model NA NA NA NA NA NA

Qty 1 1 1 1 2 2

Input W 61 61 121 138 121 121

Capacitor μF NA NA NA NA NA NA

Speed r/min 840 880 830 850 810 810

Outdoor coil

Number of rows 2 2 2 2 2 2

Tube pitch(a)x row pitch(b) mm 21x21.65 21x18.19 21x21.65 21x21.65 21x21.65 21x21.65

Fin spacing mm 1.4 1.4 1.3 1.6 1.5 1.4

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outside dia.and type mm Ф7,innergroove tube Ф7,innergroove tube

Ф7.94, innergroove

tube

Ф7.94, innergroove

tube

Φ7.94,innergroove

tube

Φ7.94,innergroove

tube

Coil length xheight xwidth mm 962x630x43.3 900x630x43.3 970x798x43.5 970x1008x43.5 970x1008x43.5 970x1344x43.3

Number of circuits 7 4 5 6 12 12

Outdoor noise level (sound

pressure) Hi

dB(A) 53 53 55 58 53 58

Outdoor noise level (sound power)

dB(A)

65 67 70 73 67 72

Throttle type EEV EEV EEV EEV EEV EEV

Outdoor unit

Dimension(WxHxD) mm 860x670x310 860x670x310 950x840x340 950x1050x340 950x1386x340 950x1386x340

Packing(WxHxD) mm 990x730x450 990x730x450 1110x980x460 1110x1200x460 1110x1527x460 1110x1527x460

Net/Gross weight kg 45/49 51/57 70/80 85/95 113/125 117/129

Refrigerant type/Quantity

Type R410a R410a R410 R410 R410A R410A

Charged volume kg 1.3 1.70 2.80 3.20 3.78 3.95

Design pressure Hi/Lo MPa 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6 4.15/1.6

Refrigerant piping

Liquid side/ Gas side mm(inch)

Φ6.35/Φ12.7

(1/4'/1/2')

Φ9.52/Φ15.88

(3/8'/5/8')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Φ9.52/Φ19.05

(3/8'/3/4')

Max. pipe length m 30 50 50 50 50 50

Max. difference in level m 15 30 30 30 30 30

Annual energy

consumption(cooling)

kWh/a 271 404 601 630 802 974

Page 27

22.

.

SSPPEECCIIFFIICCAATTIIOONNS

S

25

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Model

18K 24K 36K 42K 48K 60K

Annual energy

consumption(heating

average)

kWh/a 1564 2059 3064 3491 4252 5232

Ambient temperature

Cooling ℃ -15- 48 -15- 48 -15- 48 -15- 48 -15- 48 -15- 48

Heating ℃ -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24 -15 - 24

Qty’per 20’ /40’ /40'HQ Outdoor unit 90/186/186 90/186/186 52/106/106 26/53/106 26/53/53 26/53/53

Qty’per 20’ /40’ /40'HQ

Indoor+Outdoo

r

42/85/98 42/85/98 32/67/72 24/48/60 20/40/53 20/40/53

NOTE:

1.Test conditions:

Cooling : Indoor: DB27℃/ WB19℃ Outdoor: DB35℃/ WB24℃

Heating: Indoor: DB20℃/ WB15℃ Outdoor: DB7℃/ WB 6℃

2.The Sound Pressure Level is based on the following conditions:

Outdoor unit:

Measure the noise value of 3 points,the points are1 meter in front of the three sides (front/left/right) of the unit surface and height =1/2(unit height +1)

meter from floor level, and calculate the weighted average of the noise.

Indoor unit:

Floor Ceiling : Test the noise value of the point 1.4m below the unit,1.0m front the unit and 1.0m high from the floor.

The above data was measured in an anechoic chamber. Please take into consideration reflected sound of your specific application environment.

3.

The values given in the table for noise level reflect the levels in anechoic chamber.

Page 28

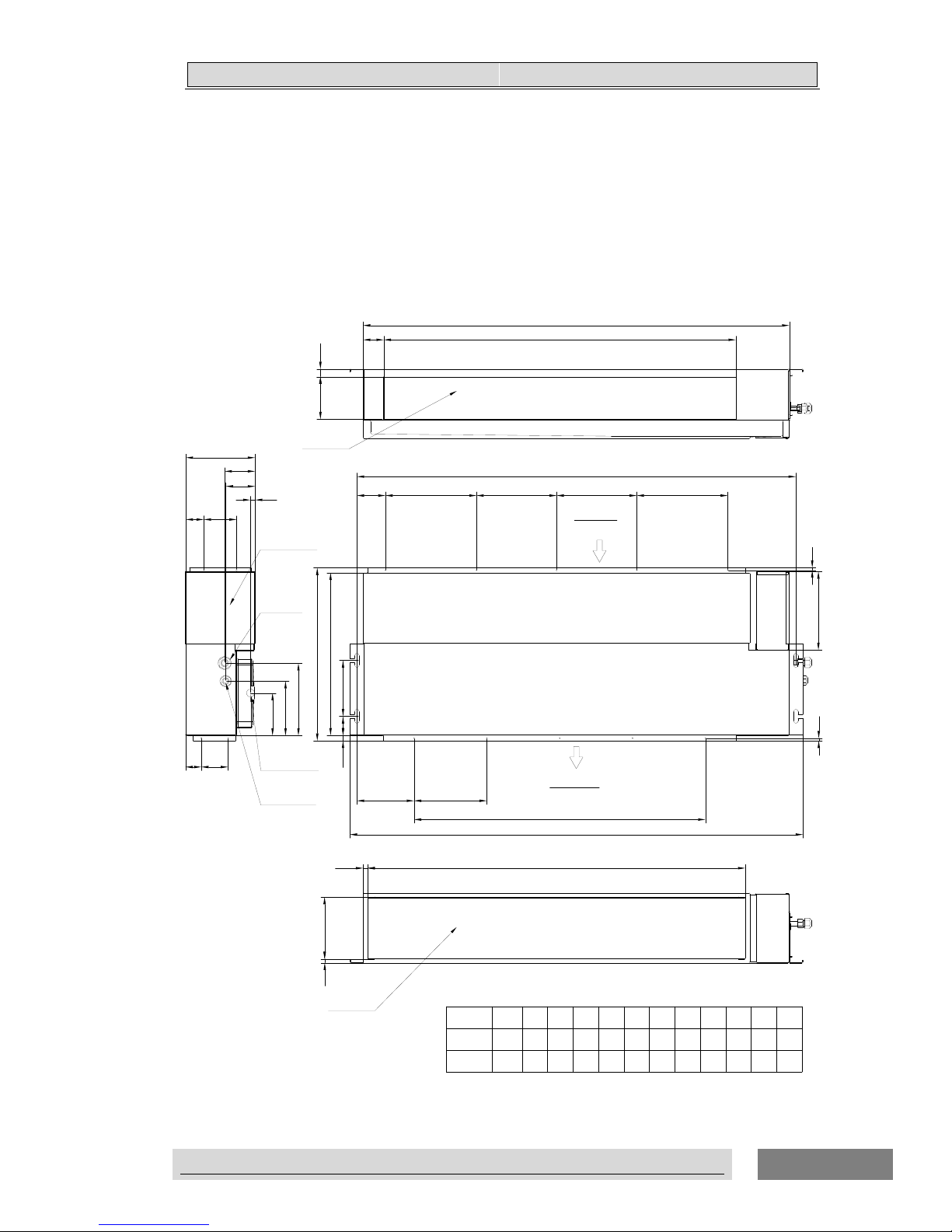

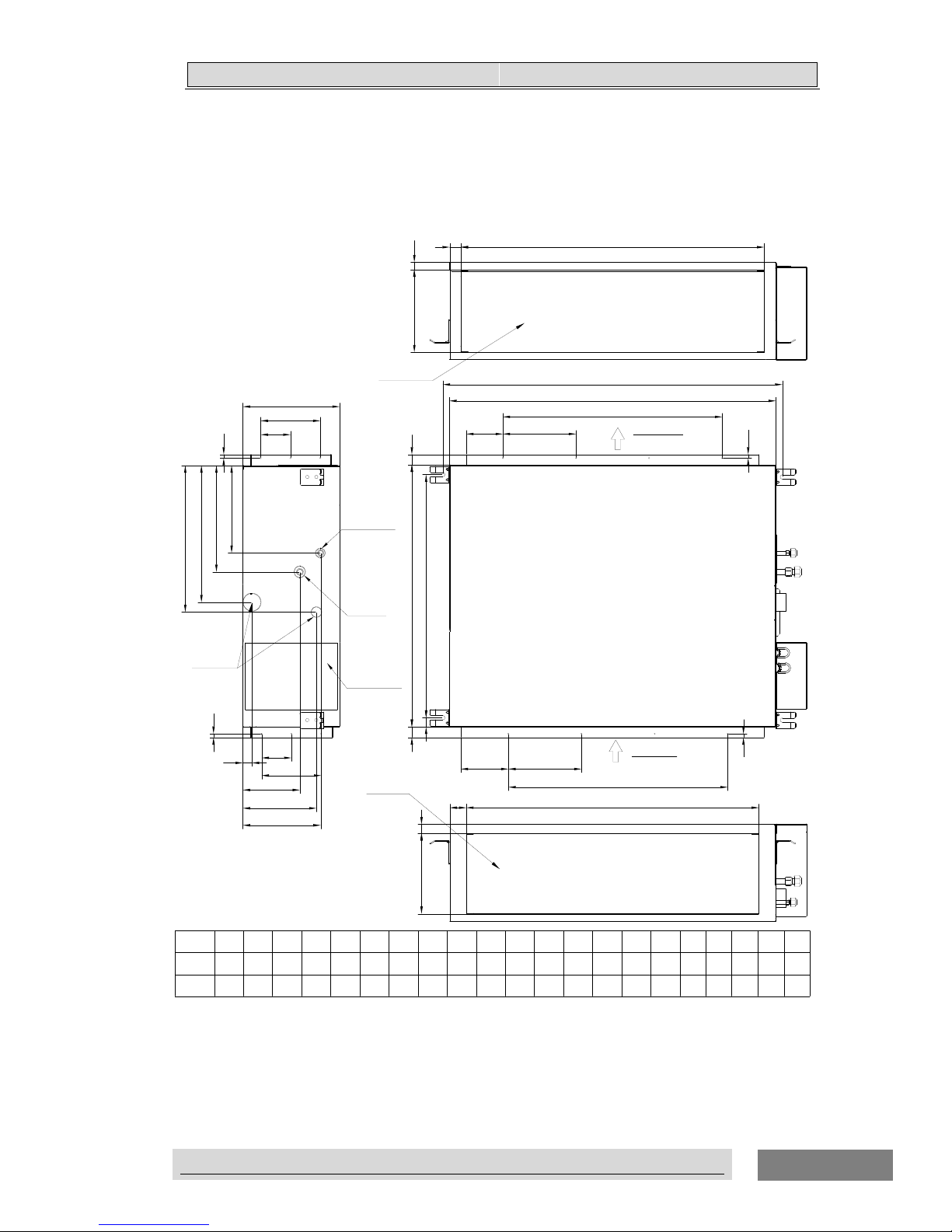

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

3. Outlines and dimensions

3.1 Indoor units

Duct type

Unit:mm

abcde fghijk

1246

18K

c

154

447

b

a

117

170

199

117

150

13

81

84

12071170

971

190

216

h

200

i*200=j

d e

78

250

976

9K/12K

937

900 701

73

240

Gas pipe

Drain pipe

Liquid pipe

21

11

56

12

Electric box

f

g

e

220

200

220

0

157

122 3

4

600

800

l

53

k

l

1039

769

476

7

7

15

50 90

44 74

Air outlet

Air inlet

Air inlet

Air outlet

Model

26

Page 29

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Unit:mm

a

b

c

d

e

222

f

g

j

h

i

k

25

l

m

n

abcdefghijkl m n op

24K

36K/42K/

48K/60K

934

900

669

720 805

835

228

242

294

378

405

156

202

214

1334

1300 1205

1235

756

800 308

237

312

375

204

242

400

186

q

270

350

Air inlet

Air outlet

Air outlet

Air inlet

Electric box

Gas pipe

Liquid pipe

Drain pipe

300

(

p*300=)q

2

3

900

600

300

(

p*300=)q

r

r

153

s

s

168

30 30

t

2

t

t

u

2

u

u

90 140

82

82

102

117

10

10

10

10

o

25

31

46

24

20

Model

27

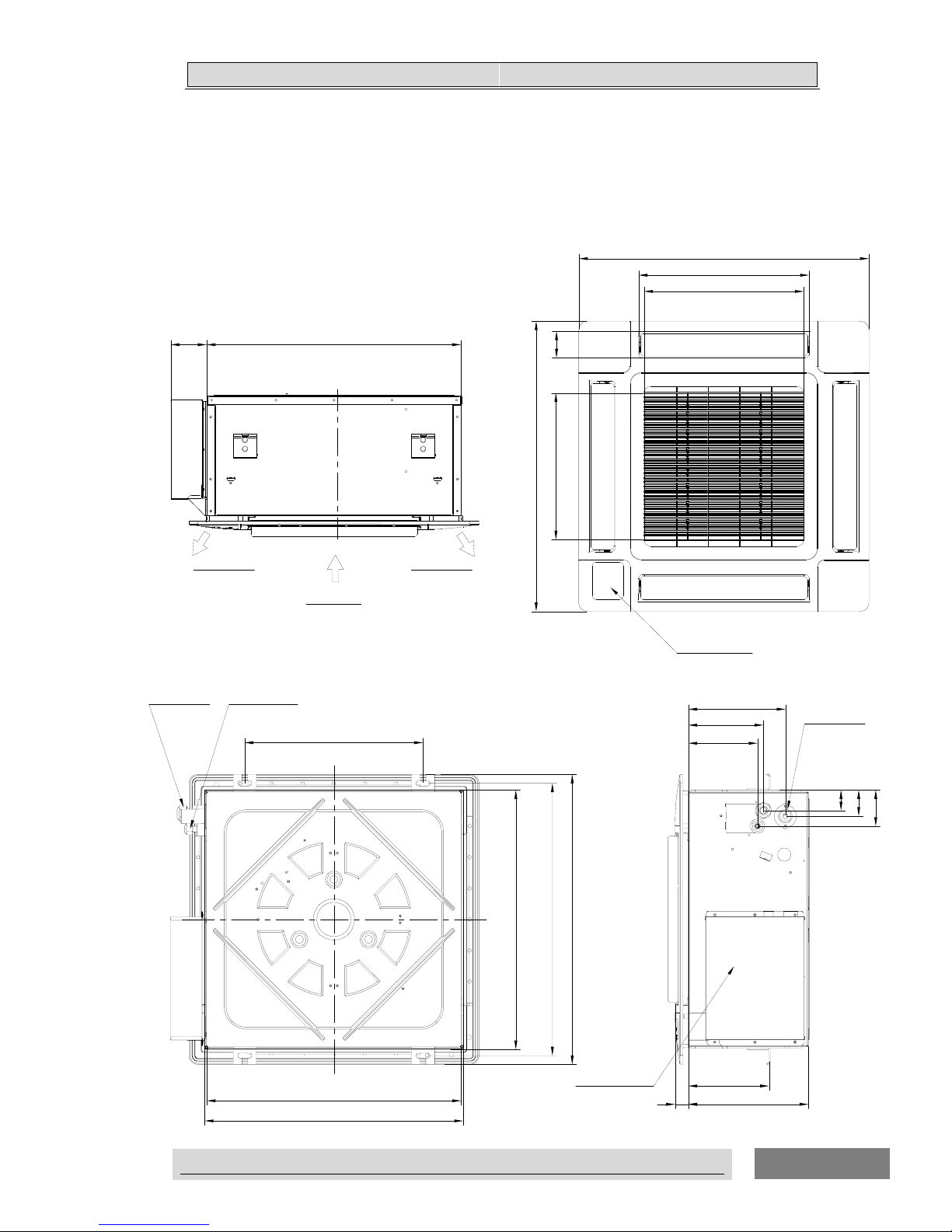

Page 30

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Cassette Type

12K,18K

Unit:mm

218

168

155

46

58

81

80

270

570

650

650

PANEL

358

382

328

59

Display panel

Drain pipe

Electric box

400

650

570

575~590(Dimension of opening)

Gas pipe

Liquid pipe

575~590(Dimension of opening)

610

181

30

Air inlet

Air outlet

Air outlet

28

Page 31

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

24K,36K,42K,48K,60K

Unit:mm

a

24K/36K

42K/48K/60K

248

298

PANEL

Model

29

950

490

102

110

180

127

130

118

102

45 a

950

478

520

841

840

Gas pipe

Liquid pipe

760

Display panel

Drain pipe

Electric box

760

860~910(Dimension of opening)

860~910(Dimension of opening)

Page 32

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Ceiling&Floor Type

Unit:mm

184

a

680

250

170

c 39

230

66 88

43

100

22

180

90

47

100

177

16

90

39

10

ab c

18K/24K

36K

42K/48K/60K

990

912

1285

1207

1580 1502

b

855

1150

1445

16

Air inlet

Air outlet

Air outlet

Electric box

Liquid pipe

Gas pipe

Drain pipe

Air inlet

Display panel

257 241

43

184

44

91

50

50

63

52

50

50

Model

30

Page 33

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

3.2 Outdoor units

9K

Unit:mm

Air inlet

Air outlet

4-11

×17 Hole

50

290

30

Drain pipe

260

290

317

125

480

730

83

278

540

260

Electric box

75

130

102

160

131

189

Liquid pipe

Gas pipe

31

Page 34

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

12K

Unit:mm

28129

112

146

148

167

Gas pipe

Liquid pipe

25

°

810

77

297

584

285

Electric box

150

510

50

4-10

×17 Hole

310

338

Air inlet

Air outlet

314

35

Drain pipe

32

Page 35

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

18K/24K

Unit:mm

Electric box

76542 168

665

327

312

868600

Air inlet

Air outlet

341

368

310

4-11×

17 Hole

309

36

Drain pipe

50

125

123

109

164

Gas pipe

Liquid pipe

3

3

Page 36

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

36K

Unit:mm

580

840

380

340

413

70

41

344

Liquid pipe

Gas pipe

Electric box

Air inlet

Air outlet

4-

φ

15

Hole

Drain pipe

185

950

85

325

426

90°

105

15666

34

Page 37

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

42K

Unit:mm

1050

340

950

85

595

56

15666

80.5

Air outlet

545

351

Electric box

70

R7.5

2×φ15 Hole

Liquid pipe

Gas pipe

9

0

°

415

380

Air inlet

1039

186

580

2

-

Drain pipe

382

20

3

5

Page 38

33..OOUUTTLLIINNEESS AANNDD DDIIMMEENNSSIIOONNS

S

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

48K&60K

Unit:mm

1039

580

380

416

1386

950

340

104

152

229

379

650

349

9

0

°

41

344

25

Drain pipe

Air inlet

Air outlet

4-φ15

Hole

Liquid pipe

383

Gas pipe

Electric box

185

36

Page 39

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

37

4. Electrical data

Power supply Applicable voltage ELB

Outdoor unit Voltage(V) PH Frequency

Umin(V) Umax(V)

Nominal

Current(A)

Nominal

Sensitive

Current(mA)

9K 220-240 1 50 176 264 20 30

12K 220-240 1 50 176 264 20 30

18K 220-240 1 50 176 264 20 30

24K 220-240 1 50 176 264 32 30

36K 220-240 1 50 176 264 40 30

42K/48K/60K 380-415

3

50 342

438

32 30

NOTE:

1. The above compressor data is based on 100% capacity combination of indoor units at the rated operating frequency

2. This data is based on the same conditions as the nominal heating and cooling capacities.

3. The compressor started by an inverter, resulting in extremely low starting current.

Page 40

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

38

5. Capacities and selection data

5.1 Capacity Characteristic charts

The following charts show the characteristics of outdoor unit capacity, which corresponds with the operating ambient

temperature of outdoor unit.

Conditions:

①

Pipe length / height difference : 5m / 0m

②Compressor at rated inverter frequency

③Indoor fan speed at high fan speed ④Capacity loss due to white frost and defrost operation is not included.

9K

Duct

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 2.4 2.3 2.2 2.1 1.9 1.8

16 22 2.6 2.5 2.4 2.3 2.1 2.0

18 25 2.7 2.6 2.6 2.5 2.4 2.3

19 27 2.9 2.8 2.8 2.7 2.6 2.5

19.5 27 3.0 2.9 2.8 2.8 2.6 2.6

22 30 3.4 3.2 3.1 3.0 2.9 2.7

24 32 3.7 3.6 3.5 3.4 3.2 2.9

HEATING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 1.7 1.8 2.2 2.5 2.8 2.8 2.9

18 1.7 1.8 2.2 2.5 2.7 2.8 2.8

20 1.6 1.8 2.1 2.3 2.7 2.8 2.8

21 1.6 1.8 2.1 2.3 2.7 2.8 2.8

22 1.5 1.7 2.1 2.2 2.7 2.8 2.8

24 1.5 1.7 2.0 2.2 2.7 2.8 2.8

26 1.5 1.7 2.0 2.2 2.7 2.7 2.8

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(

℃ WB) : Wet Bulb Temperature (℃)

Page 41

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

39

12K

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 3.1 3.0 2.8 2.7 2.5 2.4

16 22 3.4 3.2 3.2 2.9 2.7 2.6

18 25 3.5 3.4 3.4 3.2 3.1 2.9

19 27 3.8 3.6 3.6 3.5 3.4 3.3

19.5 27 3.9 3.7 3.6 3.6 3.4 3.4

22 30 4.4 4.1 4.0 3.9 3.7 3.5

24 32 4.8 4.6 4.5 4.4 4.1 3.8

HEATING CAPACITY(kW)

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 2.3 2.6 3.0 3.4 3.9 3.9 4.0

18 2.3 2.6 3.0 3.4 3.8 3.9 3.9

20 2.2 2.4 2.9 3.2 3.8 3.9 3.9

21 2.2 2.4 2.9 3.2 3.8 3.9 3.9

22 2.1 2.3 2.9 3.1 3.8 3.9 3.9

24 2.1 2.3 2.7 3.1 3.8 3.9 3.9

26 2.1 2.3 2.7 3.1 3.7 3.8 3.9

18K

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 4.7 4.6 4.3 4.2 3.8 3.6

16 22 5.1 4.9 4.8 4.5 4.2 4.0

18 25 5.3 5.1 5.2 4.9 4.7 4.5

19 27 5.8 5.6 5.4 5.3 5.1 5.0

19.5 27 5.9 5.7 5.6 5.4 5.2 5.1

22 30 6.7 6.3 6.1 5.9 5.7 5.3

24 32 7.3 7.0 6.8 6.7 6.3 5.8

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃

)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃

)

Page 42

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

40

HEATING CAPACITY(kW)

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 3.6 4.0 4.7 5.4 6.1 6.2 6.4

18 3.6 4.0 4.7 5.4 6.0 6.1 6.2

20 3.4 3.8 4.5 5.1 6.0 6.1 6.2

21 3.4 3.8 4.5 5.1 6.0 6.1 6.2

22 3.3 3.6 4.5 4.9 6.0 6.1 6.2

24 3.3 3.6 4.3 4.9 6.0 6.1 6.2

26 3.3 3.6 4.3 4.9 5.8 6.0 6.1

24K

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 6.2 6.1 5.7 5.5 5.1 4.8

16 22 6.8 6.5 6.4 6.0 5.5 5.3

18 25 7.1 6.8 7.0 6.5 6.2 6.0

19 27 7.7 7.4 7.2 7.1 6.8 6.7

19.5 27 7.8 7.5 7.4 7.2 7.0 6.8

22 30 8.9 8.4 8.1 7.8 7.5 7.1

24 32 9.7 9.4 9.1 8.9 8.4 7.7

HEATING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 5.0 5.5 6.5 7.4 8.3 8.5 8.7

18 5.0 5.5 6.5 7.4 8.2 8.3 8.5

20 4.7 5.2 6.2 7.0 8.2 8.3 8.5

21 4.7 5.2 6.2 7.0 8.2 8.3 8.5

22 4.4 5.0 6.2 6.7 8.2 8.3 8.5

24 4.4 5.0 5.9 6.7 8.2 8.3 8.5

26 4.4 5.0 5.9 6.7 7.9 8.2 8.3

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (

℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (

℃)

Page 43

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

41

36K

COOLING CAPACITY(kW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

25 32 35 40 45

14.0 20 10.2 10 9.8 9.5 9.0 8.0

16.0 22 10.6 10.5 10 10 9.4 8.4

18.0 25 11 10.8 10.6 10.2 9.8 8.8

19.0 27 11.5 11.2 10.8 10.5 10 9.0

19.5 27 11.6 11.4 11 10.7 10.2 9.4

22.0 30 11.8 11.6 11.2 10.9 10.6 9.8

24.0 32 12 11.8 11.4 11.2 10.8 10.1

HEATING CAPACITY(kW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 6.2 7.6 8.3 9.8 11.8 12.6 13

18.0 6.0 7.4 8.2 9.5 11.7 12.3 12.8

20.0 6.0 7.4 8.0 9.3 11.3 12 12.6

21.0 6.0 7.3 8.0 9.3 11.5 12 12.6

22.0 6.0 7.3 8.0 9.3 11.5 12 12.6

24.0 6.0 7.0 8.0 9.1 11.4 11.8 12.2

26.0 5.8 7.0 7.8 8.9 11 11.6 12

42K

COOLING CAPACITY(kW

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

20 25 32 35 40 45

14.0 20 12.0 11.6 11.2 11.0 10.6 9.5

16.0 22 12.4 11.8 11.7 11.6 11.3 10.5

18.0 25 12.6 12.2 12 11.9 11.5 11

19.0 27 12.8 12.5 12.4 12.3 11.3 10.8

19.5 27 13.0 12.6 12.5 12.3 11.5 11

22.0 30 13.2 12.9 12.6 12.5 12 11.5

24.0 32 13.3 13.2 13 12.8 12.5 12

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (

℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

WB) (℃ DB)

(℃

WB) (℃ DB)

Page 44

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

42

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 8.8 9.0 10.5 11.9 13.8 14.2 14.6

18.0 8.7 8.8 10.2 11.9 13.8 14.2 14.6

20.0 8.5 8.7 10 11.8 13.8 14.2 14.6

21.0 8.4 8.7 10 11.8 13.6 14 14.2

22.0 8.4 8.7 10 11.8 13.5 13.8 14

24.0 8.3 8.5 9.6 11.4 13 13.5 13.7

26.0 8.3 8.5 9.6 11.2 12.6 13 13.3

48K

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 12.3 12.0 11.2 10.9 10.1 9.5

16 22 13.4 12.9 12.6 11.8 10.9 10.4

18 25 14.0 13.4 13.7 12.9 12.3 11.8

19 27 15.1 14.6 14.3 14.0 13.4 13.2

19.5 27 15.4 14.8 14.6 14.3 13.7 13.4

22 30 17.6 16.5 16.0 15.4 14.8 14.0

24 32 19.0 18.5 17.9 17.6 16.5 15.1

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-10-15 -5 0 6 10 15

16 9.7 10.8 12.6 14.4 16.3 16.5 17.0

18 9.7 10.8 12.6 14.4 16.0 16.3 16.5

20 9.2 10.2 12.1 13.6 16.0 16.3 16.5

21 9.2 10.2 12.1 13.6 16.0 16.3 16.5

22 8.7 9.7 12.1 13.1 16.0 16.3 16.5

24 8.7 9.7 11.5 13.1 16.0 16.3 16.5

26 8.7 9.7 11.5 13.1 15.5 16.0 16.3

COOLING CAPACITY(kW)

HEATING CAPACITY(kW)

HEATING CAPACITY(kW)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB)

Page 45

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

43

60K

COOLING CAPACITY(kW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14.0 20 16.6 16.3 15.7 15.5 15.0 14.8

16.0 22 17.0 16.6 16.1 15.8 15.5 15.1

18.0 25 17.7 17.4 16.6 16.5 16.1 15.8

19.0 27 18.5 17.9 17.5 17.0 16.5 16.3

19.5 27 18.7 18.0 17.8 17.2 16.8 16.5

22.0 30 19.1 18.5 18.0 17.7 17.5 16.7

24.0 32 19.4 19.1 18.5 18.3 17.8 16.8

HEATING CAPACITY(kW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 14.0 15.4 16.8 20.0 20.8 21.5 21.9

18.0 13.5 14.8 16.2 19.3 20.1 20.9 21.5

20.0 13.0 16.2 17.4 18.5 19.5 20.4 20.9

21.0 12.4 15.8 17.0 18.0 18.6 19.2 19.7

22.0 11.8 15.0 16.9 17.8 18.3 19.0 19.4

24.0 11.0 14.2 15.2 16.5 17.4 18.6 19.0

26.0 10.7 13.8 14.7 15.7 16.7 18.1 18.5

Cassette

12K

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 3.1 3.0 2.8 2.7 2.5 2.4

16 22 3.4 3.2 3.2 2.9 2.7 2.6

18 25 3.5 3.4 3.4 3.2 3.1 2.9

19 27 3.8 3.6 3.6 3.5 3.4 3.3

19.5 27 3.9 3.7 3.6 3.6 3.4 3.4

22 30 4.4 4.1 4.0 3.9 3.7 3.5

24 32 4.8 4.6 4.5 4.4 4.1 3.8

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

Page 46

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

44

HEATING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 3.8 4.2 4.9 5.6 6.3 6.4 6.6

18 3.8 4.2 4.9 5.6 6.2 6.3 6.4

20 3.6 4.0 4.7 5.3 6.2 6.3 6.4

21 3.6 4.0 4.7 5.3 6.2 6.3 6.4

22 3.4 3.8 4.7 5.1 6.2 6.3 6.4

24 3.4 3.8 4.5 5.1 6.2 6.3 6.4

26 3.4 3.8 4.5 5.1 6.0 6.2 6.3

18K

COOLING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 4.7 4.6 4.2 4.1 3.8 3.6

16 22 5.1 4.9 4.8 4.5 4.1 3.9

18 25 5.3 5.1 5.2 4.9 4.7 4.5

19 27 5.7 5.5 5.4 5.3 5.1 5.0

19.5 27 5.8 5.6 5.5 5.4 5.2 5.1

22 30 6.7 6.3 6.0 5.8 5.6 5.3

24 32 7.2 7.0 6.8 6.7 6.3 5.7

HEATING CAPACITY(kW)

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 2.3 2.6 3.0 3.4 3.9 3.9 4.0

18 2.3 2.6 3.0 3.4 3.8 3.9 3.9

20 2.2 2.4 2.9 3.2 3.8 3.9 3.9

21 2.2 2.4 2.9 3.2 3.8 3.9 3.9

22 2.1 2.3 2.9 3.1 3.8 3.9 3.9

24 2.1 2.3 2.7 3.1 3.8 3.9 3.9

26 2.1 2.3 2.7 3.1 3.7 3.8 3.9

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(

℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(

℃ WB) : Wet Bulb Temperature (℃

)

Page 47

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

45

36K

COOLING CAPACITY(KW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

.℃ DB)

(℃ WB)

25 32 35 40 45

14.0 20 10.2 10 9.8 9.5 9.0 8.0

16.0 22 10.6 10.5 10 10 9.4 8.4

18.0 25 11 10.8 10.6 10.2 9.8 8.8

19.0 27 11.5 11.2 10.8 10.5 10 9.0

19.5 27 11.6 11.4 11 10.7 10.2 9.4

22.0 30 11.8 11.6 11.2 10.9 10.6 9.8

24.0 32 12 11.8 11.4 11.2 10.8 10.1

HEATING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 5.0 5.5 6.5 7.4 8.3 8.5 8.7

18 5.0 5.5 6.5 7.4 8.2 8.3 8.5

20 4.7 5.2 6.2 7.0 8.2 8.3 8.5

21 4.7 5.2 6.2 7.0 8.2 8.3 8.5

22 4.4 5.0 6.2 6.7 8.2 8.3 8.5

24 4.4 5.0 5.9 6.7 8.2 8.3 8.5

26 4.4 5.0 5.9 6.7 7.9 8.2 8.3

COOLING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 6.2 6.1 5.7 5.5 5.1 4.8

16 22 6.8 6.5 6.4 6.0 5.5 5.3

18 25 7.1 6.8 7.0 6.5 6.2 6.0

19 27 7.7 7.4 7.2 7.1 6.8 6.7

19.5 27 7.8 7.5 7.4 7.2 7.0 6.8

22 30 8.9 8.4 8.1 7.8 7.5 7.1

24 32 9.7 9.4 9.1 8.9 8.4 7.7

24K

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(

℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

Page 48

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

46

HEATING CAPACITY(. W)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

-15.0

-10.0 -5.0 0.0 6.0 10.0 15.0

16.0 8.8 9.0 10.5 11.9 13.8 14.2 14.6

18.0 8.7 8.8 10.2 11.9 13.8 14.2 14.6

20.0 8.5 8.7 10 11.8 13.8 14.2 14.6

21.0 8.4 8.7 10 11.8 13.6 14 14.2

22.0 8.4 8.7 10 11.8 13.5 13.8 14

24.0 8.3 8.5 9.6 11.4 13 13.5 13.7

26.0 8.3 8.5 9.6 11.2 12.6 13 13.3

42K

COOLING CAPACITY(kW)

Indoor inlet temperature(℃) Outdoor

temperature(℃ DB)

20 25 32 35 40 45

4.14.0 12.0 11.6 11.2 11.0 10.6 9.5

6.16.0 12.4 11.8 11.7 11.6 11.3 10.5

8.18.0 12.6 12.2 12 11.9 11.5 11

9.19.0 12.8 12.5 12.4 12.3 11.3 10.8

9.19.5 13.0 12.6 12.5 12.3 11.5 11

2.22.0 13.2 12.9 12.6 12.5 12 11.5

4.24.0 13.3 13.2 13 12.8 12.5 12

20

22

25

27

27

30

32

HEATING CAPACITY(kW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-1 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 6.2 7.6 8.3 9.8 11.8 12.6 13

18.0 6.0 7.4 8.2 9.5 11.7 12.3 12.8

20.0 6.0 7.4 8.0 9.3 11.4 12 12.6

21.0 6.0 7.3 8.0 9.3 11.5 12 12.6

22.0 6.0 7.3 8.0 9.3 11.5 12 12.6

24.0 6.0 7.0 8.0 9.1 11.4 11.8 12.2

26.0 5.8 7.0 7.8 8.9 11 11.6 12

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃

)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ WB) (℃ DB)

(℃ DB)

Page 49

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-�INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

47

60K

COOLING CAPACITY(KW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14.0 20 16.6 16.3 15.7 15.5 15.0 14.8

16.0 22 17.0 16.6 16.1 15.8 15.5 15.1

18.0 25 17.7 17.4 16.6 16.5 16.1 15.8

19.0 27 18.5 17.9 17.5 17.0 16.5 16.3

19.5 27 18.7 18.0 17.8 17.2 16.8 16.5

22.0 30 19.1 18.5 18.0 17.7 17.5 16.7

24.0 32 19.4 19.1 18.5 18.3 17.8 16.8

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 9.7 10.8 12.6 14.4 16.3 16.5 17.0

18 9.7 10.8 12.6 14.4 16.0 16.3 16.5

20 9.2 10.2 12.1 13.6 16.0 16.3 16.5

21 9.2 10.2 12.1 13.6 16.0 16.3 16.5

22 8.7 9.7 12.1 13.1 16.0 16.3 16.5

24 8.7 9.7 11.5 13.1 16.0 16.3 16.5

26 8.7 9.7 11.5 13.1 15.5 16.0 16.3

HEATING CAPACITY(KW)

48K

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

(℃DB)

20 25 32 35 40 45

14 20 12.3 12.0 11.2 10.9 10.1 9.5

16 22 13.4 12.9 12.6 11.8 10.9 10.4

18 25 14.0 13.4 13.7 12.9 12.3 11.8

19 27 15.1 14.6 14.3 14.0 13.4 13.2

19.5 27 15.4 14.8 14.6 14.3 13.7 13.4

22 30 17.6 16.5 16.0 15.4 14.8 14.0

24 32 19.0 18.5 17.9 17.6 16.5 15.1

COOLING CAPACITY(kW)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(

℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(

℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

Page 50

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

48

18K

COOLING CAPACITY(kW)

INDOOR TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 4.6 4.5 4.2 4.1 3.8 3.6

16 22 5.1 4.9 4.8 4.4 4.1 3.9

18 25 5.3 5.1 5.2 4.9 4.6 4.4

19 27 5.7 5.5 5.4 5.3 5.1 5.0

19.5 27 5.8 5.6 5.5 5.4 5.2 5.1

22 30 6.7 6.2 6.0 5.8 5.6 5.3

24 32 7.2 7.0 6.8 6.7 6.2 5.7

Ceiling&Floor type

HEATING CAPACITY(KW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 14.0 15.4 16.8 20.0 20.8 21.5 21.9

18.0 13.5 14.8 16.2 19.3 20.1 20.9 21.5

20.0 13.0 16.2 17.4 18.5 19.5 20.4 20.9

21.0 12.4 15.8 17.0 18.0 18.6 19.2 19.7

22.0 11.8 15.0 16.9 17.8 18.3 19.0 19.4

24.0 11.0 14.2 15.2 16.5 17.4 18.6 19.0

26.0 10.7 13.8 14.7 15.7 16.7 18.1 18.5

HEATING CAPACITY(kW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 14.0 15.4 16.8 20.0 20.8 21.5 21.9

18.0 13.5 14.8 16.2 19.3 20.1 20.9 21.5

20.0 13.0 16.2 17.4 18.5 19.5 20.4 20.9

21.0 12.4 15.8 17.0 18.0 18.6 19.2 19.7

22.0 11.8 15.0 16.9 17.8 18.3 19.0 19.4

24.0 11.0 14.2 15.2 16.5 17.4 18.6 19.0

26.0 10.7 13.8 14.7 15.7 16.7 18.1 18.5

(℃ DB) : Dry Bulb Temperature (℃

)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (

℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (

℃)

(℃ WB) : Wet Bulb Temperature (℃)

Page 51

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

49

24K

COOLING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 6.2 6.1 5.7 5.5 5.1 4.8

16 22 6.8 6.5 6.4 6.0 5.5 5.3

18 25 7.1 6.8 7.0 6.5 6.2 6.0

19 27 7.7 7.4 7.2 7.1 6.8 6.7

19.5 27 7.8 7.5 7.4 7.2 7.0 6.8

22 30 8.9 8.4 8.1 7.8 7.5 7.1

24 32 9.7 9.4 9.1 8.9 8.4 7.7

HEATING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 5.0 5.5 6.5 7.4 8.3 8.5 8.7

18 5.0 5.5 6.5 7.4 8.2 8.3 8.5

20 4.7 5.2 6.2 7.0 8.2 8.3 8.5

21 4.7 5.2 6.2 7.0 8.2 8.3 8.5

22 4.4 5.0 6.2 6.7 8.2 8.3 8.5

24 4.4 5.0 5.9 6.7 8.2 8.3 8.5

26 4.4 5.0 5.9 6.7 7.9 8.2 8.3

HEATING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 3.6 4.0 4.7 5.4 6.1 6.2 6.4

18 3.6 4.0 4.7 5.4 6.0 6.1 6.2

20 3.4 3.8 4.5 5.1 6.0 6.1 6.2

21 3.4 3.8 4.5 5.1 6.0 6.1 6.2

22 3.2 3.6 4.5 4.9 6.0 6.1 6.2

24 3.2 3.6 4.3 4.9 6.0 6.1 6.2

26 3.2 3.6 4.3 4.9 5.8 6.0 6.1

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

Page 52

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

50

HEATING CAPACITY(KW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-1 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 6.2 7.6 8.3 9.8 11.8 12.6 13

18.0 6.0 7.4 8.2 9.5 11.7 12.3 12.8

20.0 6.0 7.4 8.0 9.3 11.2 12 12.6

21.0 6.0 7.3 8.0 9.3 11.5 12 12.6

22.0 6.0 7.3 8.0 9.3 11.5 12 12.6

24.0 6.0 7.0 8.0 9.1 11.4 11.8 12.2

26.0 5.8 7.0 7.8 8.9 11 11.6 12

42K

COOLING CAPACITY(KW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

20 25 32 35 40 45

14.0 20 12.0 11.6 11.2 11.0 10.6 9.5

16.0 22 12.4 11.8 11.7 11.6 11.3 10.5

18.0 25 12.6 12.2 12 11.9 11.5 11

19.0 27 12.8 12.5 12.4 12.3 11.3 10.8

19.5 27 13.0 12.6 12.5 12.3 11.5 11

22.0 30 13.2 12.9 12.6 12.5 12 11.5

24.0 32 13.3 13.2 13 12.8 12.5 12

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

(℃ WB)

25 32 35 40 45

14.0 20 10.2 10 9.8 9.5 9.0 8.0

16.0 22 10.6 10.5 10 10 9.4 8.4

18.0 25 11 10.8 10.6 10.2 9.8 8.8

19.0 27 11.5 11.2 10.23 10.5 10 9.0

19.5 27 11.6 11.4 11 10.7 10.2 9.4

22.0 30 11.8 11.6 11.2 10.9 10.6 9.8

24.0 32 12 11.8 11.4 11.2 10.8 10.1

36K

COOLING CAPACITY(kW)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

WB) (℃ DB)

Page 53

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

51

48K

COOLING CAPACITY(KW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45

14 20 12.3 12.0 11.2 10.9 10.1 9.5

16 22 13.4 12.9 12.6 11.8 10.9 10.4

18 25 14.0 13.4 13.7 12.9 12.3 11.8

19 27 15.1 14.6 14.3 14.0 13.4 13.2

19.5 27 15.4 14.8 14.6 14.3 13.7 13.4

22 30 17.6 16.5 16.0 15.4 14.8 14.0

24 32 19.0 18.5 17.9 17.6 16.5 15.1

HEATING CAPACITY(kW)

INDOOR

TEMPERATURE

OUTDOOR TEMPERATURE(℃ DB)

(℃ WB)

-15 -10 -5 0 6 10 15

16 9.6 10.6 12.4 14.2 16.1 16.3 16.8

18 9.6 10.6 12.4 14.2 15.8 16.1 16.3

20 9.1 10.1 11.9 13.5 15.8 16.1 16.3

21 9.1 10.1 11.9 13.5 15.8 16.1 16.3

22 8.5 9.6 11 .9 13.0 15.8 16.1 16.3

24 8.5 9.6 11 .4 13.0 15.8 16.1 16.3

26 8.5 9.6 11 .4 13.0 15.3 15.8 16.1

HEATING CAPACITY(kW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

-15.0

-10.0 -5.0 0.0 6.0 10.0 15.0

16.0 8.8 9.0 10.5 11.9 13.8 14.2 14.6

18.0 8.7 8.8 10.2 11.9 13.8 14.2 14.6

20.0 8.5 8.7 10 11.8 13.8 14.2 14.6

21.0 8.4 8.7 10 11.8 13.6 14 14.2

22.0 8.4 8.7 10 11.8 13.5 13.8 14

24.0 8.3 8.5 9.6 11.4 13 13.5 13.7

26.0 8.3 8.5 9.6 11.2 12.6 13 13.3

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃ DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB) : Dry Bulb Temperature (℃)

(℃ WB) : Wet Bulb Temperature (℃)

(℃

DB)

Page 54

55.

.

CCAAPPAACCIITTIIEESS AANNDD SSEELLEECCTTIIOONN DDAATTA

A

DC-INVERTER AIR CONDITIONER TECHNICAL&SERVICE MANUAL

52

HEATING CAPACITY(KW)

Indoor inlet

temperature(℃)

Outdoor temperature(℃ DB)

(℃ DB)

-15.0 -10.0 -5.0 0.0 6.0 10.0 15.0

16.0 14.0 15.4 16.8 20.0 20.8 21.5 21.9

18.0 13.5 14.8 16.2 19.3 20.1 20.9 21.5

20.0 13.0 16.2 17.4 18.5 19.5 20.4 20.9

21.0 12.4 15.8 17.0 18.0 18.6 19.2 19.7

22.0 11.8 15.0 16.9 17.8 18.3 19.0 19.4

24.0 11.0 14.2 15.2 16.5 17.4 18.6 19.0

26.0 10.7 13.8 14.7 15.7 16.7 18.1 18.5

COOLING CAPACITY(kW)

Indoor inlet temperature(℃)

Outdoor temperature(℃ DB)

(℃ WB) (℃ DB)

20 25 32 35 40 45