HISEER AS10/LF, AS13/LF Operation Installation Maintenance Manual

AIR TO WATER HEAT PUMP

—— Split EVI

Operation, installation &maintenance manual

V.201510

The installation of this unit is to adhere to all local

Building Codes and Standards

Index

Working principle ............................................................................................................................................ 1

Nomenclature ................................................................................................................................................... 2

Specialist Tools ................................................................................................................................................ 3

Pre-installation ................................................................................................................................................. 4

Installation Location ........................................................................................................................................ 5

Positioning ....................................................................................................................................................... 6

Buffer Tank ...................................................................................................................................................... 7

Frost Protection ................................................................................................................................................ 8

System Overview ............................................................................................................................................. 9

System Overview ........................................................................................................................................... 11

Installation ...................................................................................................................................................... 13

Electrical connection ...................................................................................................................................... 16

User Guide ..................................................................................................................................................... 20

Service Parameters: ........................................................................................................................................ 33

Service Guide ................................................................................................................................................. 34

Commissioning and Adjusting ....................................................................................................................... 41

Commissioning Form..................................................................................................................................... 42

Alarms ............................................................................................................................................................ 43

Maintenance ................................................................................................................................................... 46

Dimensions .................................................................................................................................................... 48

Water Pressure Plots....................................................................................................................................... 49

AS10/LF ......................................................................................................................................................... 49

AS13/LF ......................................................................................................................................................... 51

Temperature and sensor resistance table ........................................................................................................ 52

Components ................................................................................................................................................... 54

Electric wiring diagram .................................................................................................................................. 56

Technical Specications ................................................................................................................................. 58

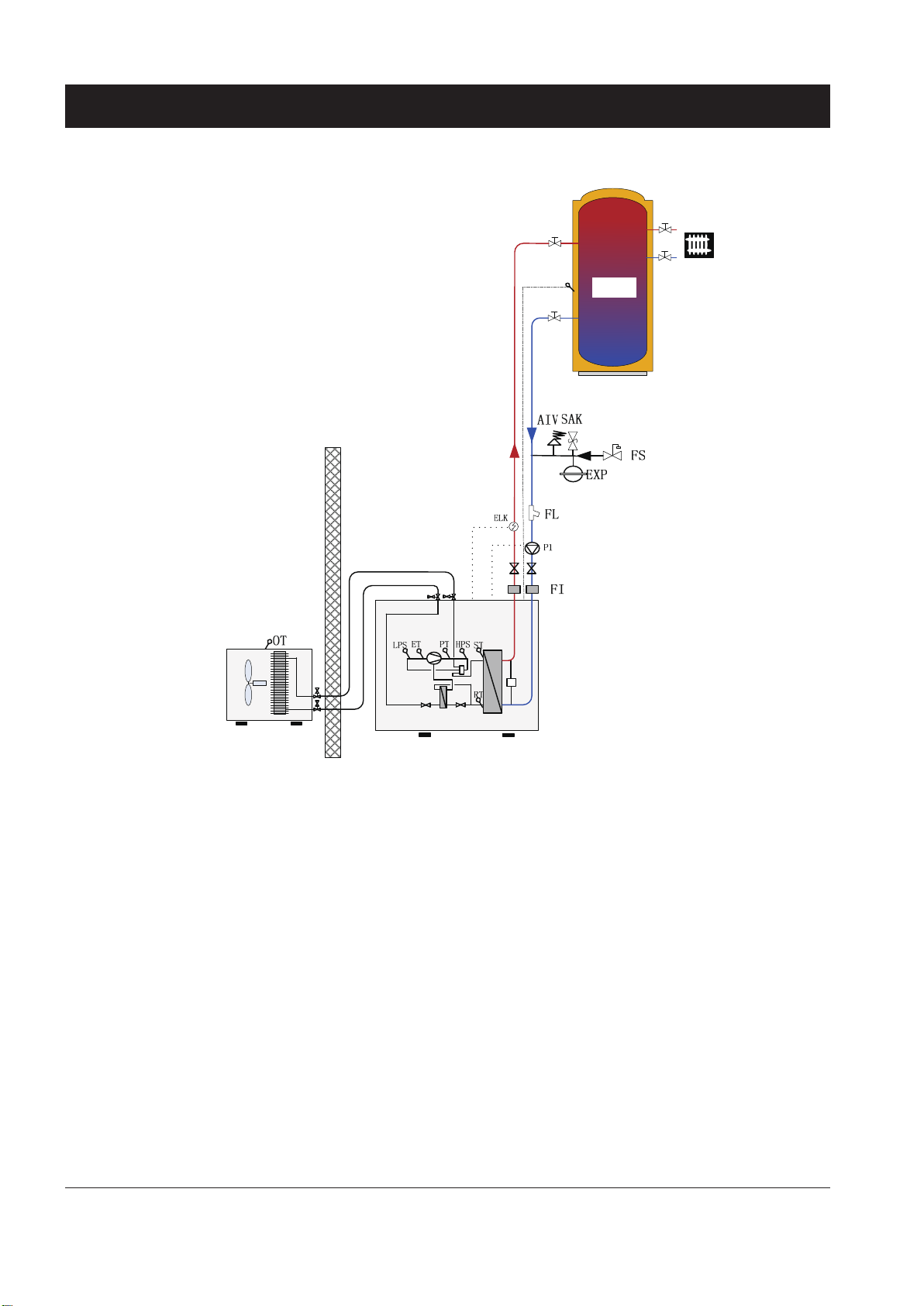

Working principle

RT

Buffer tank

①

Outdoor unit

Indoor unit

1. The low pressure and low temperature liquid

refrigerant coming out of expansion valve exacts

heat energy from the air through finned coil heat

exchanger①and evaporates into gas state.

2. The gas state refrigerant is sucked into compressor

and compressed to high pressure and high temp.

②

gas .

3. The high pressure and high temp. gas discharged by

compressor releases its heat energy to water in plate

exchanger③and condensed to liquid state.

4. The liquid s tate r e frig e rant is exp a nded in

thermostatic expansion valve

and become low

④

pressure and low temperature liquid refrigerant.

②

⑤

④

⑥

F

③

5. The cycle repeats.

6. When EVI condition is met, EVI expansion valve

will open and some liquid gas will expand

⑥

and the gas will be inject into compressor middle

containment after absorbing heat from main branch

liquid gas in the economizer

. With this EVI

⑤

function, not only heat pump heating capacity and

COP will increase ,but also compressor discharge

temp. could be controlled within safety limit and

the heat pump workable ambient temp. could be

extended to -25

℃。

1

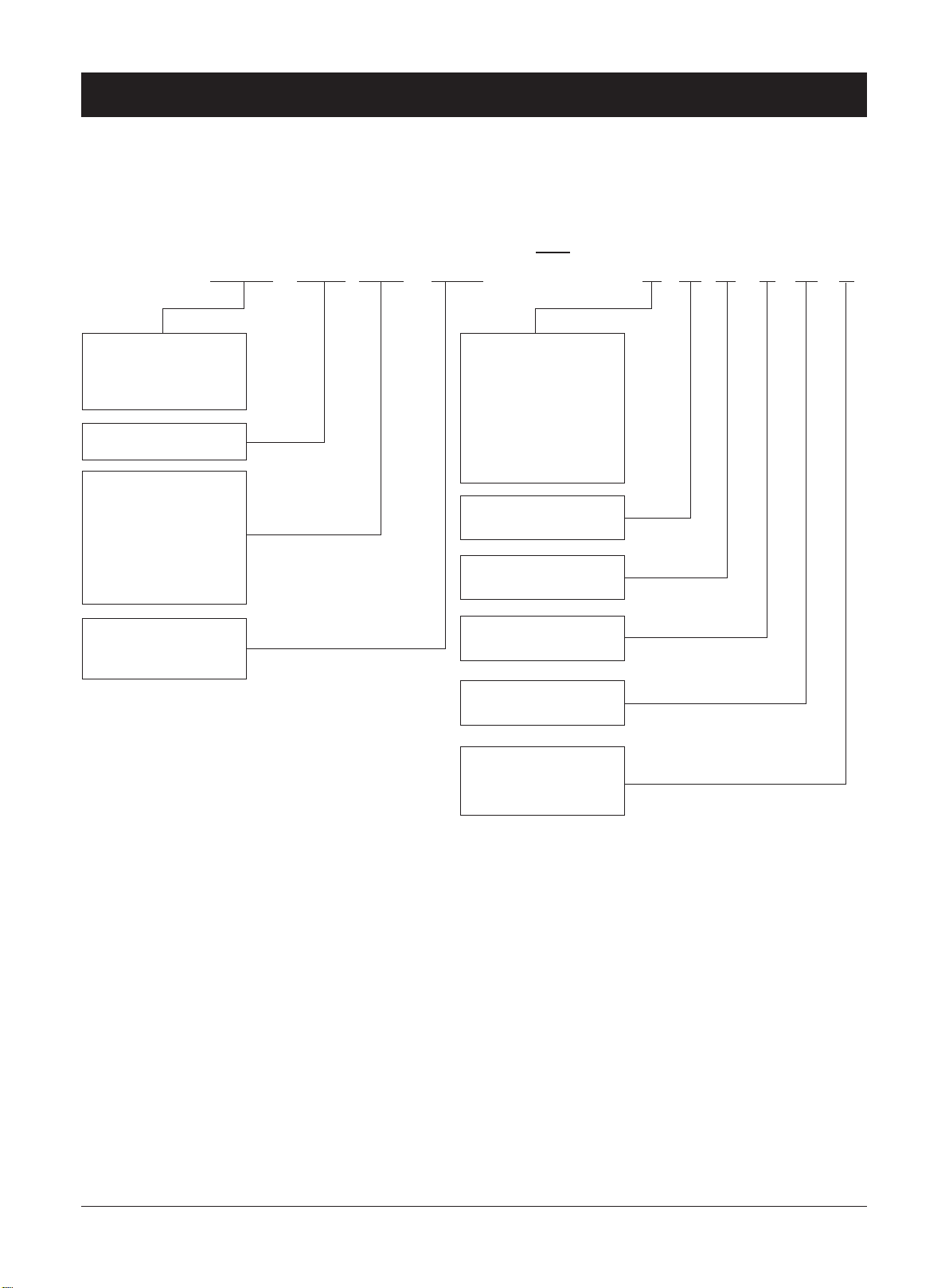

Nomenclature

AS10/LF

Air source heat pump

With Carel controller

Rated heating output

L:EVI for low ambient

temp.

B:Standard Heating

and Cooling

Default: Standard

Heating only

F:Split

NONE: Monoblock

D6NNHE

B: 220V, 3~50/60Hz

C: 380V, 3~50Hz

380-400V, 3~60Hz

D: 380-415V,3~50Hz

440V, 3~60Hz

P: 208-230V, 1~60Hz

Q: 220-240V, 1~50Hz

6: 60Hz

default: 50Hz

P: with pump

N: none

V: with 3 way valve

N: none

H: with 3 way valve

N: none

E:R410A

G:R407C

F:R22 R417A

2

Specialist Tools

Specialist tools that might be used on installation, commissioning and maintenance.

The tools as exclusive tools for R410A refrigerant.

1 Gauge manifold ·Only for R410A

·Use the existing tting specications.(G1/4”)

·Use high-tension side pressure of 5.3MPa·G or over.

2 Charge hose ·Only for R410A

·Use pressure performance of 5.09MPa·G or over.

3 Electronic scale

4 Gas leak detector ·Use the detector for R410A.

5.Vacuum pump (pump with reverse ow preventive function)

6 Refrigerant charge base

7 Refrigerant cylinder ·Only for R410A Top of cylinder (Pink)Cylinder with syphon

8 Refrigerant recovery equipment

9. Torque wrench

10. Multi-meter

11. screwdrivers

3

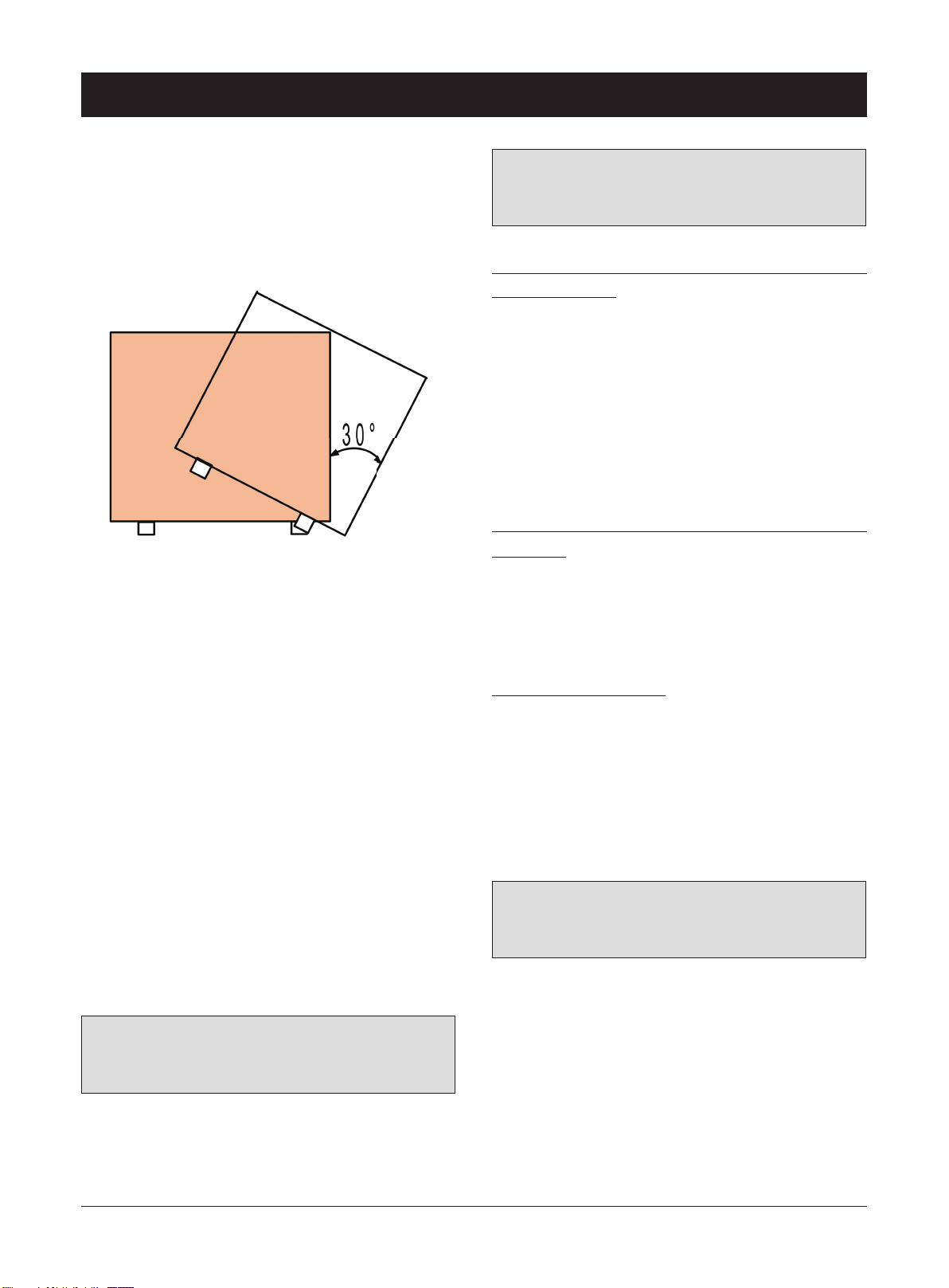

Pre-Installation

Movement and Storage

The unit must not be transported, moved or stored at

greater than a 30° angle from the upright position. Store

the unit in a dry area until required.

The unit must be installed by a suitably qualified

tradesperson and all electrical wiring must be completed

by a licensed electrical contractor in accordance with

all local Standards.

Note: ensure the correct refrigerant gas is used to

recharge the unit as an incorrect gas can cause

damage beyond repair to the compressor.

Do not use oxygen to purge lines or to pressurize a unit

for any purpose. Oxygen gas reacts violently with oil,

grease and other common substances. Use only refrigerant

or dry nitrogen for testing.

Never exceed the specied maximum operating pressures.

Do not un-weld or ame cut the refrigerant lines

including any refrigerant circuit components

until the entire refrigerant (liquid and vapour)

has been removed from unit. Traces of vapour

should be displaced with dry nitrogen.

Refrigerant in contact with an open ame will produces

toxic gases.

Ensure that the necessary safety protection

equipment is available when servicing. Have the

appropriate re extinguishers for that system.

Safety

The installation must be overseen by a qualified

person, in order to avoid an incorrect installation that

could damage to the unit or cause injuries to people.

Any faults and or leaks must be repaired immediately

before the unit continues to operate. If repairs have

been carried out to the unit then operation of the safety

devices and parameter must be rechecked.

If a refrigerant leak occurs, remove the complete charge

using a recovery unit and store the refrigerant in mobile

container.

Note: care is to be taken as the refrigerant

can breakdown due to high temperature, these

refrigerants by-products are dangerous.

Once the leak has been repaired recharge the unit with

the correct filling weight and the type found on the

unit’s nameplate.

Do not siphon refrigerant.

Avoid spilling liquid refrigerant onto the skin or

splashing it into the eyes. Use safety goggles.

Wash any spills from the skin with soap and

water. If liquid refrigerant enters the eyes,

immediately and abundantly ush the eyes with

water and consult medical advice.

Note: Never apply an open flame or live stream

to a refrigerant container. This can dangerously

overpressure and cause an explosion.

Compressor oil type :

3MA POE

The heating system must be pressure tested and

air vented completely.

Filling water and supplemented water must be

drinking water quality (colourless, clear ,free

from sediments)

Filling water and supplemented water must be

pre-ltered. (pore size max. 5um)

4

Installation Location

The unit must be installed on a solid level surface

on a concrete pad foundation not connected to the

house foundation. Rubber cushions can be added to

reduce vibration and noise if required.

The unit should be place so that it is well away

from bedrooms or noise sensitive areas including

neighbour’s section boundaries. (The unit will

produce noise that is above the minimum 45

decibel rating).

The unit should be well ventilated with no

obstructions and kept level at all times.

Ensure there is good drainage around installation

area and make sure this water cannot run out onto

paths as it may cause ice or slime build up which is

undesirable. (The unit can produce large volumes

of condensation water when running in high

humidity zones. There is also a large run off when

the unit melts ice during a defrost cycle).

The unit must be installed level in both axes (less

than 2mm tolerance per meter)

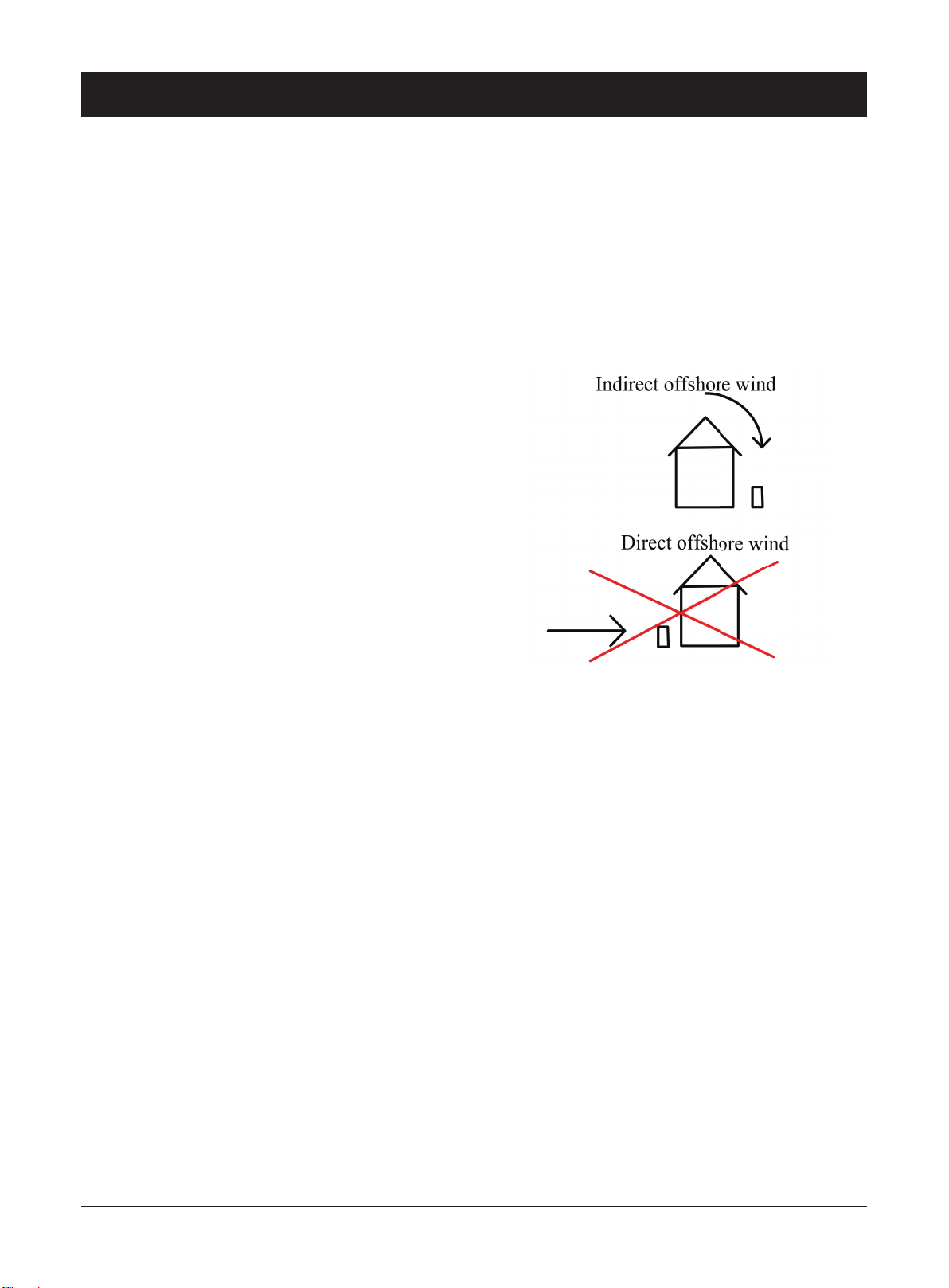

Locations exposed to strong winds should be

avoided otherwise baffles may be necessary to

deflect strong winds and to prevent snow from

blowing directly into the unit. They must not

restrict air ow into the unit.

Avoid locations exposed to machine oil vapour,

salty air, thermal springs sulphur gases or other

harsh substances

If operation in temperatures below 0°C for

prolonged periods or locations where the snow may

fall the unit must be raised at least 300mm off the

ground. This is necessary to avoid ice build-up on

the unit’s chassis.

Keep suitable distance between the unit and the

building to ensure the normal running of the unit

and enough room is available for maintenance.

5

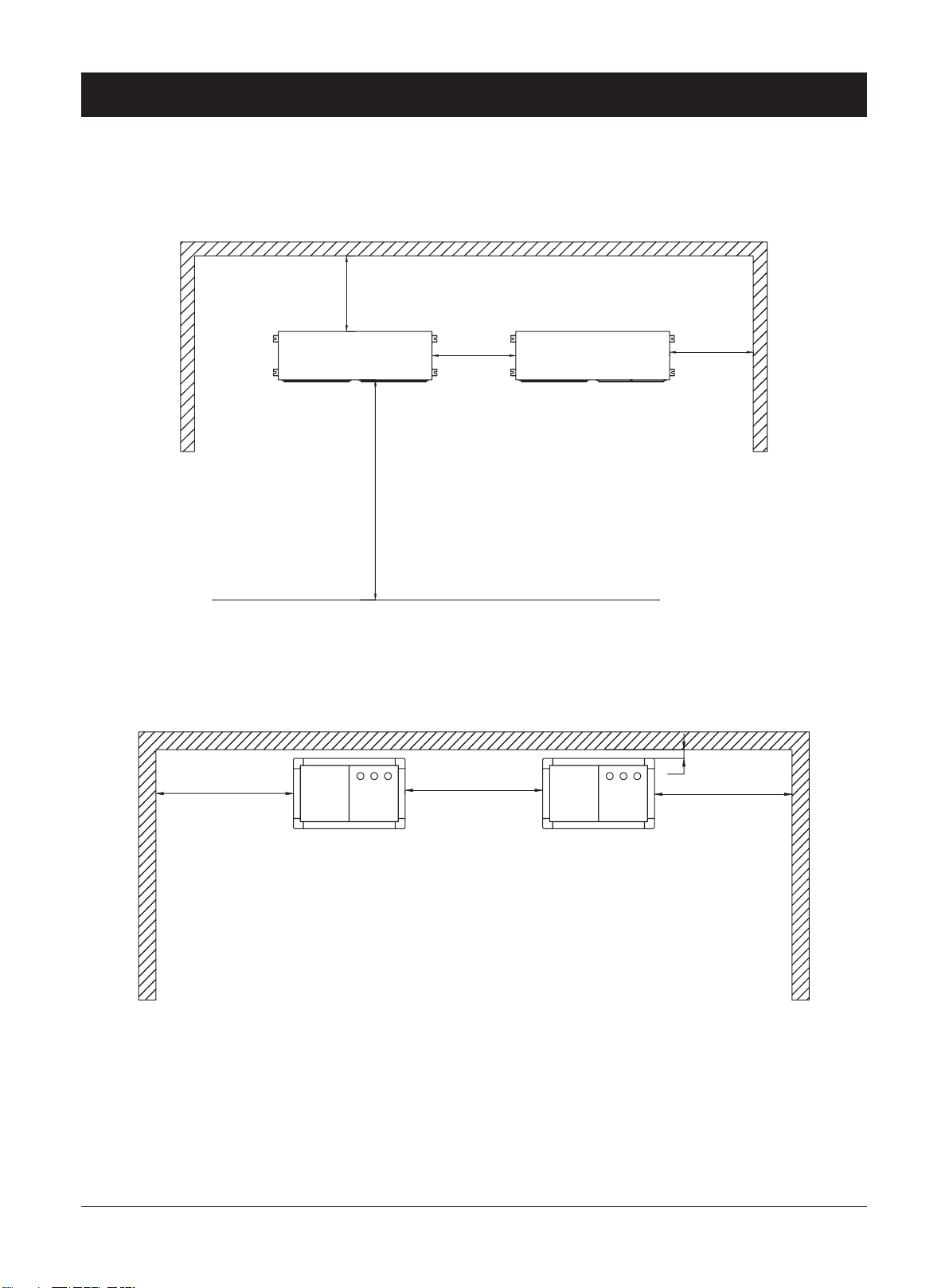

Positioning

Outdoor unit

550mm

ı

ı

ı

600mm

1600mm

ı

600mm

800

Indoor unit

800

50

800

6

Buffer Tank

A buffer tank is recommended to ensure a trouble free

heat pump operation. A suitable buffer tank can avoid

excessive heat pump cycling (switching on and off).

The buffer tank provides a hydraulic separation from

the volume ow in the heat pump and heating circuits.

The volume flow in the heat pump circuit remains

constant, even if the heating circuit volume flow is

reduced by thermostatic valves.

If the total of the systems water volume is less than

12L/KW then a buffer tank should be added to reduce

the compressor from ON/OFF cycling. This will

prolong the compressor life span.

When a buffer tank is installed, the heating system

will absorb energy from the buffer tank first. To save

energy consumption ,install the indoor pump P1 that

is switched on only when compressor is on. This is

by changing EV01 indoor pump mode to “work by

regulation”.

Inlet water temp sensor should be taken out of the unit

and put into buffer tank’s sensor pocket. The Inlet water

temp sensor is located on inlet water pipe. The Inlet

water temperature sensor B1 in the buffer tank will

control the tank temperature by starting and stopping

the compressor and pump together as required.

If Inlet water temp sensor has not been changed to

buffer tank’s sensor pocket when EV01 has been

changed to “work by regulation”, when the unit reaches

its set temperature ,the compressor will stop, pump

P1 will also stop accordingly due to EV01 being set

to “work by regulation”. When this occurs ,there is no

water circulation between the heat pump and buffer

tank. Inlet water temp will keep its stopped temperature

,not the buffer tank water temperature. Inlet water

temp sensor B1 then can not switch on compressor and

pump P1 even when buffer tank water is getting cold.

Changing the Inlet water temp sensor into the buffer

tank will avoid this problem.

7

Frost Protection

The plate heat exchanger, the piping and the hydraulic

pump can be damaged by frost, despite the built-in anti-

freeze protection of the unit.

In frost prone areas refer to installation location instructions.

To avoid freezing-up of the water contained in the

system, one of the precautions must be taken during

winter:

1. Drain the water from the system, using the drains in

the lower part of the unit.

2. Add the correct percentage of glycol antifreeze to the

water circuit.

3. The power to the unit must be on all the time so unit

can start circulation pump and auxiliary heater for anti-

freeze protection.

Important

The pipe work must be ushed before the heat pump is connected, so that any contaminants do not damage the

components parts.

The water pressure in the evaporator can not exceed 500 kPa or 72 PSI.

8

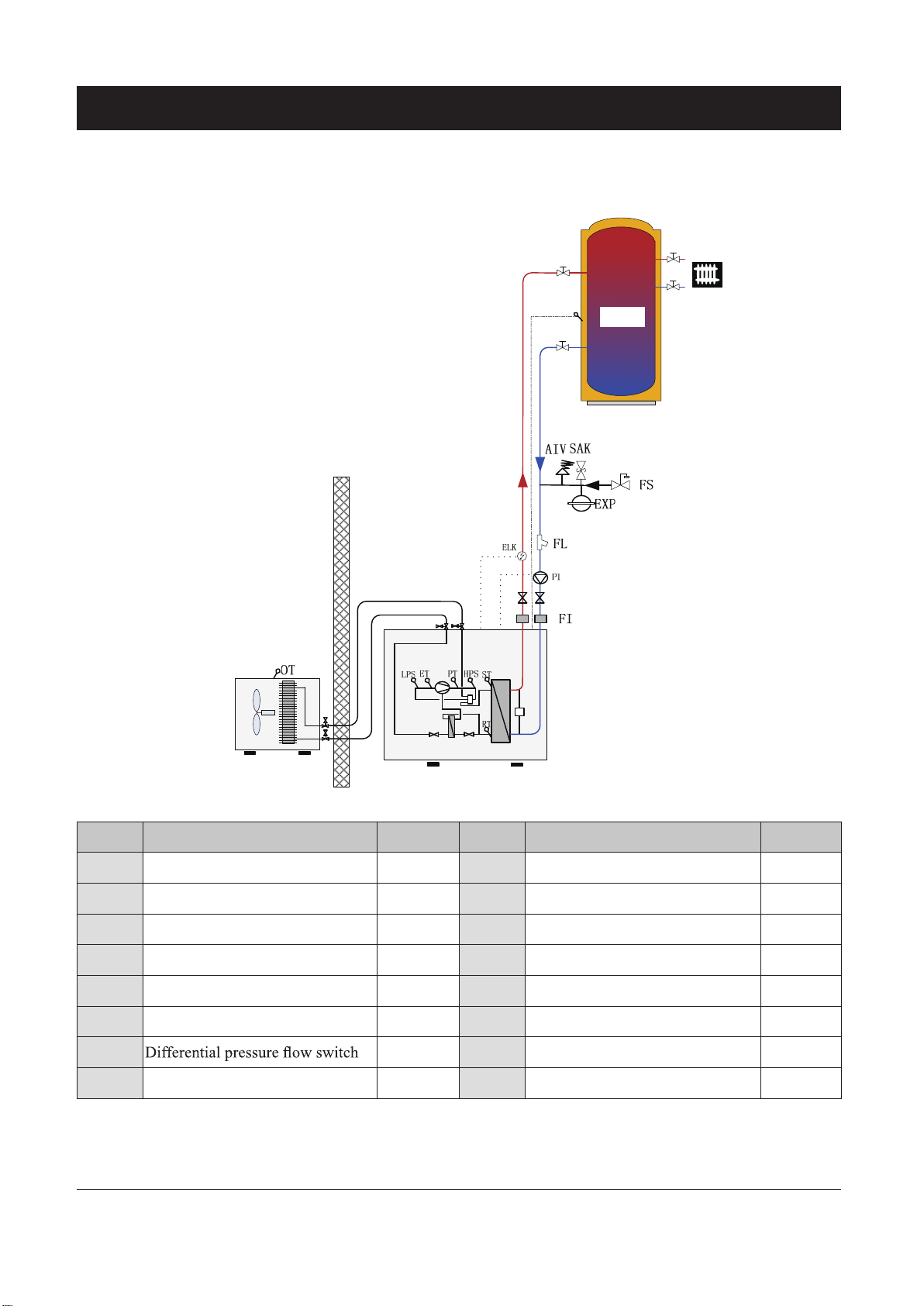

Systems Overview

Heating and Cooling ( Without internal hot water pump ,three way valve and

electric heater)

RT

Buffer tank

②

F

③

①

Outdoor unit

⑤

④

⑥

Indoor unit

Name Description Included ? Name Description Included ?

P1 Circulation pump External RT Inlet water temperature sensor Internal

ELK Electric heater External ST Outlet water temperature sensor Internal

FI Soft joint External OT Outdoor temperature sensor Internal

FS Automatic water supplement valve External LPS Electronic low pressure transmitter Internal

SAK Safety valve External HPS Electronic high pressure transmitter Internal

FL Filter External ET Suction gas temperature sensor Internal

F Internal

EXP Diaphragm expansion vessel External

AIV

Exhaust gas temperature sensor Internal

PT

Air vent valve External

9

Systems Overview

Heating Mode Working Principle:

On heating mode

a. When SF04:enable compensation=NO,

When the Inlet water temperature≤ RTc-ST04 (RTc

is the actual read Inlet water temperature of the

last stop) , the compressor will start to heat. After

outlet water temp. B2≥ST02, compressor will stop.

The Compressor will start again when Inlet water

temperature≤RTc-ST04,.

b. When SF04 enable compensation=YES,

ST02 is replaced by “Set temperature at heating”

=ST05+ST06/10 *(ST05-OT). Refer to chapter

“Heating compensation curve setting” .

Cooling Mode Working Principle:

When the Inlet water temperature B1

(RTc is the actual read inlet water temp. of last stop),

the compressor will start to cool until Outlet water

temperature B2

The Compressor will start again when Inlet water

temperature B1≥RTc+ST3.

ST01. Then compressor will stop.

≤

RTc+ST03

≥

10

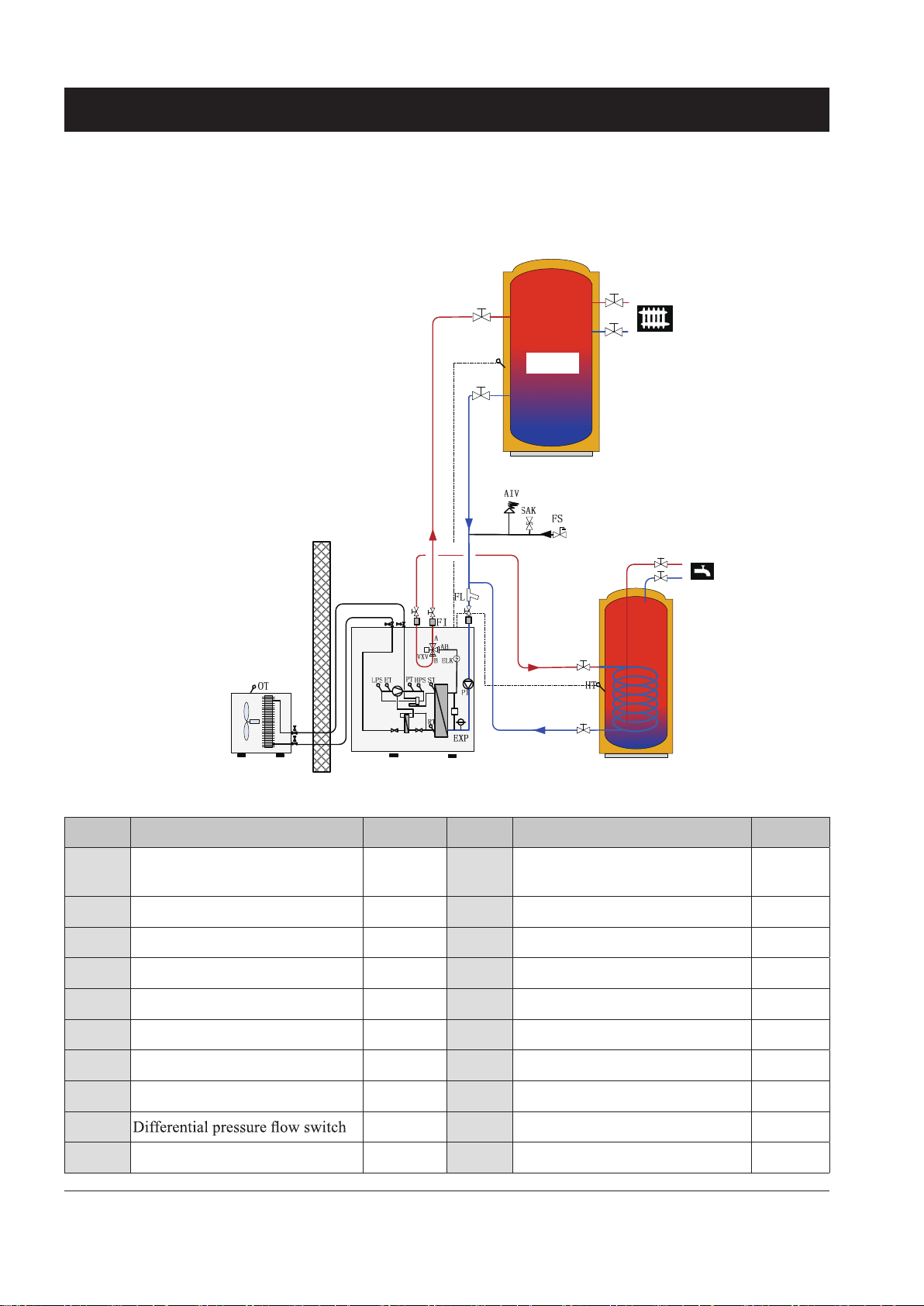

Systems Overview

Heating with hot water (with internal water pump, three way valve and electric

heater )

RT

Buffer tank

F

Outdoor unit Indoor unit

VVB

Name Description Included ? Name Description Included ?

P1 Circulation pump

Internal

RT Inlet water temperature sensor Internal

ELK Electric heater Internal ST Outlet water temperature sensor Internal

VXV 3 way Valve Internal OT Outdoor temperature sensor Internal

VVB Hot water tank External HT Hot water temperature sensor Internal

FI Soft joint External ET Suction gas temperature sensor Internal

EXP Diaphragm expansion vessel internal LPS Electronic low pressure transmitter Internal

SAK Safety valve External HPS Electronic high pressure transmitter Internal

FL Filter External PT Exhaust gas temperature sensor Internal

F

Internal FS Automatic water supplement valve External

AIV Air vent valve External

11

Systems Overview

1. Heating Mode Working Principle: 2. Hot water production working principle:

On heating mode, Three way valve (VXV) will open

AB-A.

1) When SF04 enable compensation=NO:

a. When the inlet water temp. B1 ≤ RTc-ST04, (RTc

is the actual read inlet water temp. of last stop) the

compressor will start to heat .After outlet water temp.

B2≥ST02, compressor will stop. The Compressor will

start again when inlet water temp. B1≤RTc-ST04,.

b. When the outdoor temperature Ambient temp.

B3≤ST07 ,compressor has run over 300s and Outlet

water temperature B2≤ST02-ST04-1, the electric heater

(ELK) will be activated as heating booster. It will stop

heating when Outlet water temperature B2≥ ST02-

ST04.

2) When SF04 enable compensation=YES:

ST02 is replaced by “Set temperature at heating”

=ST05+ST06 *(ST05-OT). Refer to chapter “Heating

compensation curve setting” .

On hot water mode, Three way valve (VXV) will open

AB-B.

When domestic hot water requirement calls, the three

way revert valve (VXV) will have the priority to revert

to the hot water tank (VVB). After the domestic hot

water reach its set temperature ST09, the three way

revert valve (VXV) return to its heating position. After

Hot water temp. B4≤ST09 – ST10, three way revert

valve (VXV) will revert to hot water circuit again.

12

Installation

1. The pipe installation must adhere to the local

Building Code, standards and any local council

requirements.

2. Ensure that the water ow and returns are correct and

not reversed. Reversing the water ow will reduce

the output of the unit; refer to the labels on the unit

for the correct water ow direction.

3. The water pipes must not transmit any radial or

axial forces to the heat exchanger. Allow some pipe

exibly between the unit and the structure to reduce

any stresses and vibrations issues.

4. The water supplied to the system must be clean and

not contain heavy metals that could cause harm

to the unit. The water must be treated with an

approved inhibitor and tested annually to prevent

corrosion, fouling and deterioration of the pump

ttings.

5. Protection devices are to be installed to protect the

unit from operating outside of its running parameter

such as control devices; shutoff valve, bleed valves,

safety valves and expansion tanks.

6. The pipe installation should be designed to have the

least number of elbows and joiners as they reduce

ow. Install drain connections at low points to allow

the system to be drain if required.

7. Flexible connections should be used where possible

to reduce vibration transmission.

8. Insulate all pipe work and exposed areas to protect

against both thermal heat loss and to prevent

condensation on chilled pipes.

9. When filling the water system, use air vents and

flushing procedure to evacuate any residual air

pockets.

10. The heat pump is not tted with shutoff valves and

therefore these must be fitted outside of the heat

pump to facilitate future service requirement.

13

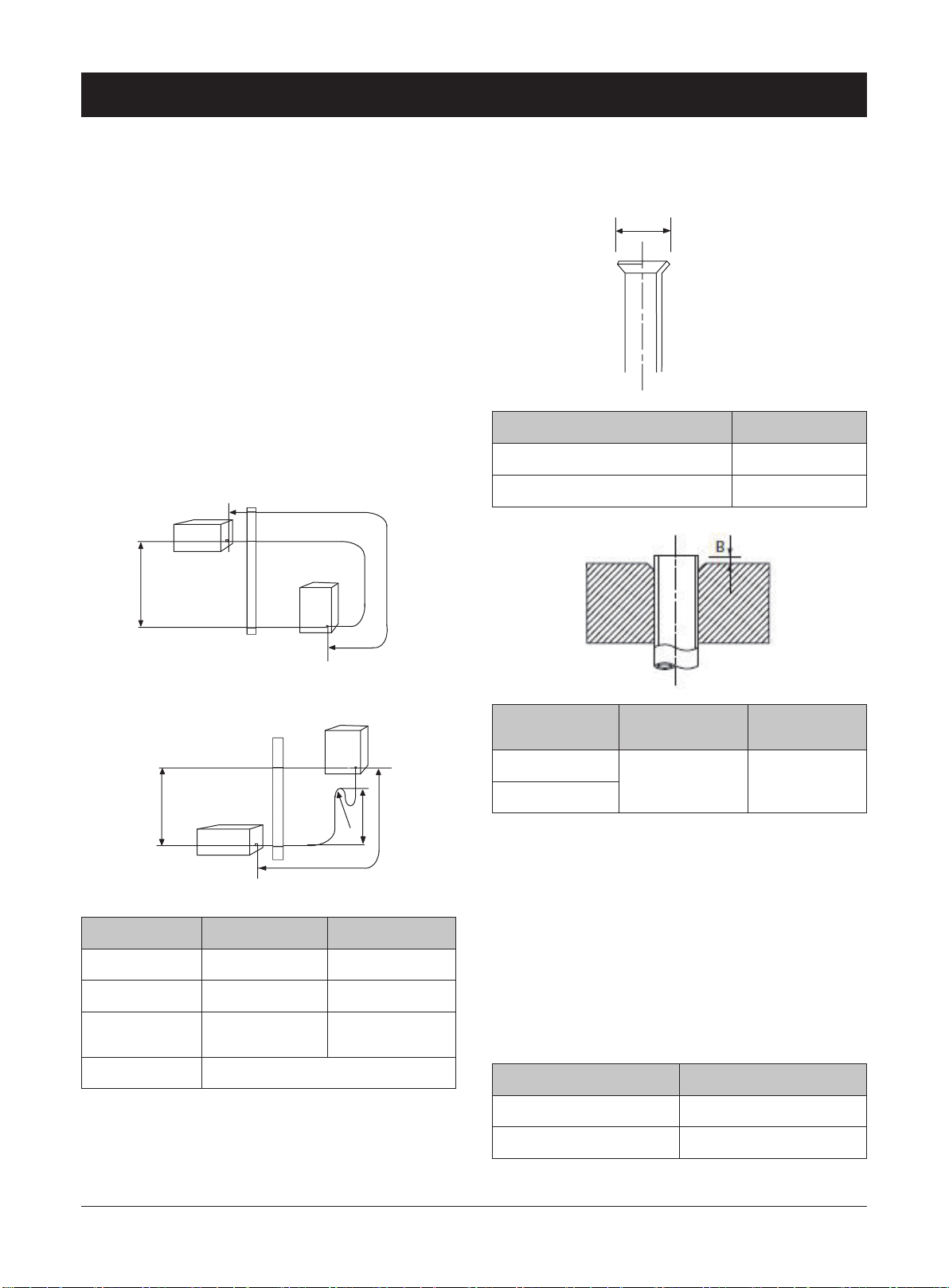

Pipe connections

+

Indoor unit

R

8

0

5m

Oil return

curve

Outdoor unit

/

Flare connections

Connecting refrigerant pipe (not supplied)

Install the refrigerant pipes between the outdoor unit

and indoor unit.

Installation must be carried out in accordance with

current norms and directives.

· If indoor unit is higher than outdoor unit more than

5m, an oil return curve must be made in each 5m .

· Max. height difference between indoor and outdoor

unit(H):10m

· Max. pipe length (L) : 15m

Expansion:

A

Out diameter,copper pipe(mm) A(mm)

φ9.52 13.2

φ15.88 19.7

Pipe size φ9.52mm (3/8”) φ15.88mm (5/8”)

Connection Flare (3/8”) Flare (5/8”)

Minimum copper

coil thickness

Max pressure 4.5MPa

+

+

Outdoor unit

Liquid pipe Gas pipe

Indoor unit

/

Indoor unit

Oil return

curve

R

5m

8

0

1.0mm 0.8mm

Out diameter,

copper pipe(mm)

φ9.52

φ15.88

· Service valves on indoor/outdoor pipe connector

should close when connecting the pipes. The indoor/

outdoor pipe connector refer to Chapter “components”

· Ensure that water and dirt does not enter the pipes.

· Bend the pipes with as large a radius as possible (at

east R100~R150).Do not bend a pipe repeatedly. Use

a bending tool.

Connect the are connector and tighten to the following

torque.

Pipe diameter Torque

R,with an R410A

tool (mm)

0-0.5 0.7-1.3

R,with a conven-

tional tool

(mm)

14

3/8” (φ9.52mm) 35-40 (N·m)

5/8” (φ15.88mm) 60-65 (N·m)

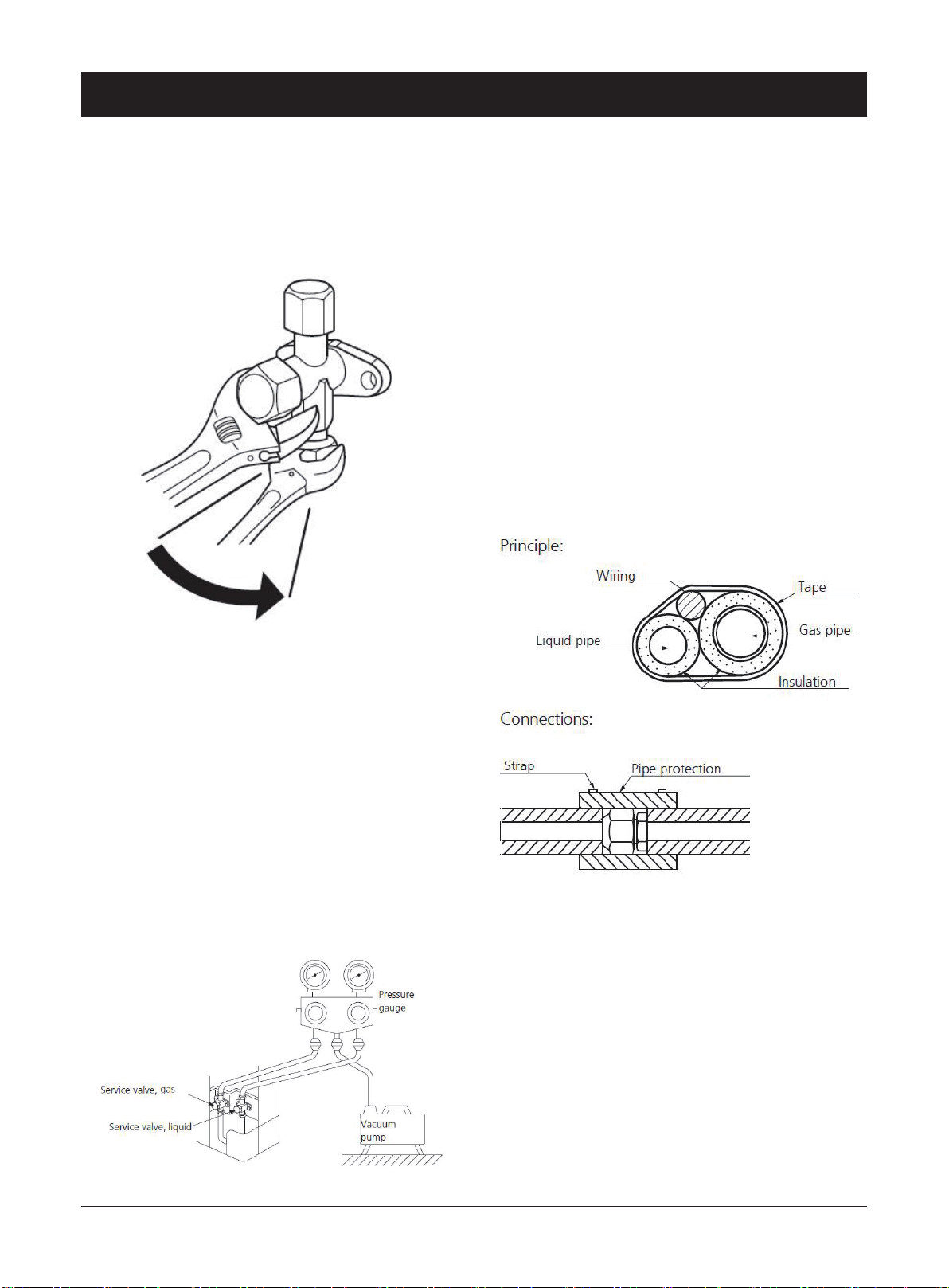

Pipe connections

· Aim the are connection of copper coil at the center of

screw connection of heat pump , screw the are nut

as tightly as possible manually.

· Tighten the are nut to required torque with a torque

wrench

Filling refrigerant:

After nishing pipe connections, pressure test ,leak test

and vacuuming, the service valves can be opened.

The gas inside the indoor unit is enough for 5m pipe.

If connection pipe is longer than 5m, need to re-fill

some R410A refrigerant. Filling weight is 50g per extra

meter.

Insulating refrigerant pipes

Insulate refrigerant pipes for heat insulation and to

prevent condensate.

Use insulation that can withstand at least 120℃.

The insulation should be at least 13 mm think.

Pressure test and leak test

The pipe connection between indoor and outdoor unit

must be pressure tested and leak tested after installation.

Only nitrogen could be used when pressurizing and

ushing the system.

Use a vacuum pump to evacuate all air .Vacuum for at

least one hour and end pressure after evacuation must

be 1mbar absolute pressure.

If the system has remaining moisture or a leak, the

vacuum pressure will rise after completed evacuation.

NOTE!

The pipe work must be ushed before the heat pump

is connected, so that any contaminants do not damage

the components parts.

The water pressure in the heat exchanger can not

exceed 0.5Mpa.

15

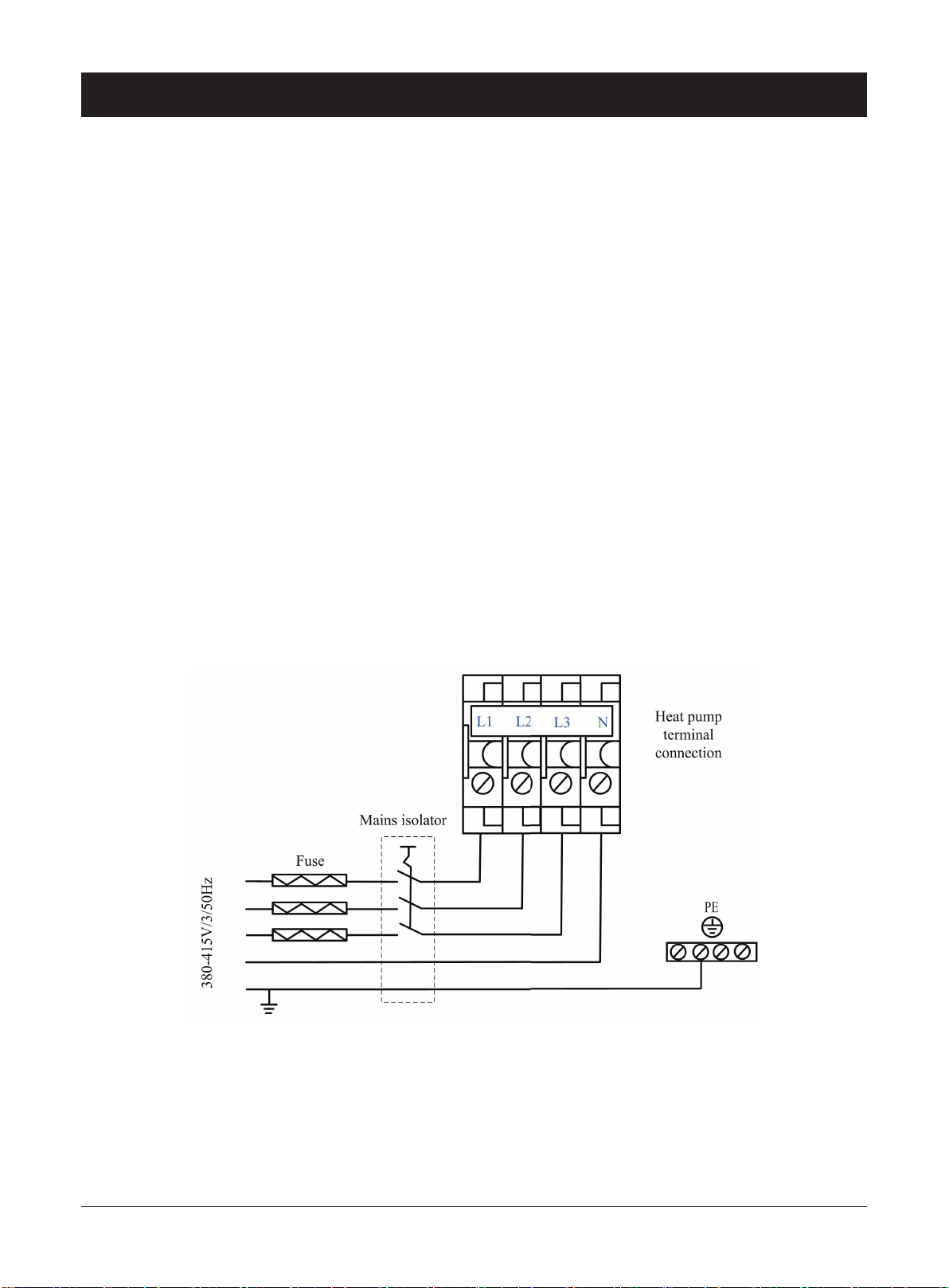

Power Connection

Electrical Connections

Before connecting the power supply, please conrm the

unit suits the power supply.

Breaker protection must be installed according to

the max value stated in the nameplate attached to

the unit inside of the front panel.

The equipment must be installed via an isolator

switch with a minimum breaking gap of 3 mm

The power supply must conform to the specication

on the unit’s nameplate. The supply voltage must

be within the range specied in the electrical data

table. For wiring connection, refer to the electric

wiring diagram on the inside panel of the unit.

When the building is equipped with a RCD the heat

pump should be equipped with a separate one

.

.

IMPORTANT:

During the installation of the unit, first make the

water connections and then electrical connections.

If the unit is to be removed first disconnect the

electrical connections, then the water connections to

reduce the chance of an electrical shock.

WARNING:

Disconnect the main power supply switch before

servicing the system or handling any internal parts

of the unit.

In case of any major malfunction turn the unit off,

disconnect the mains power supply and contact a

qualied service engineer.

16

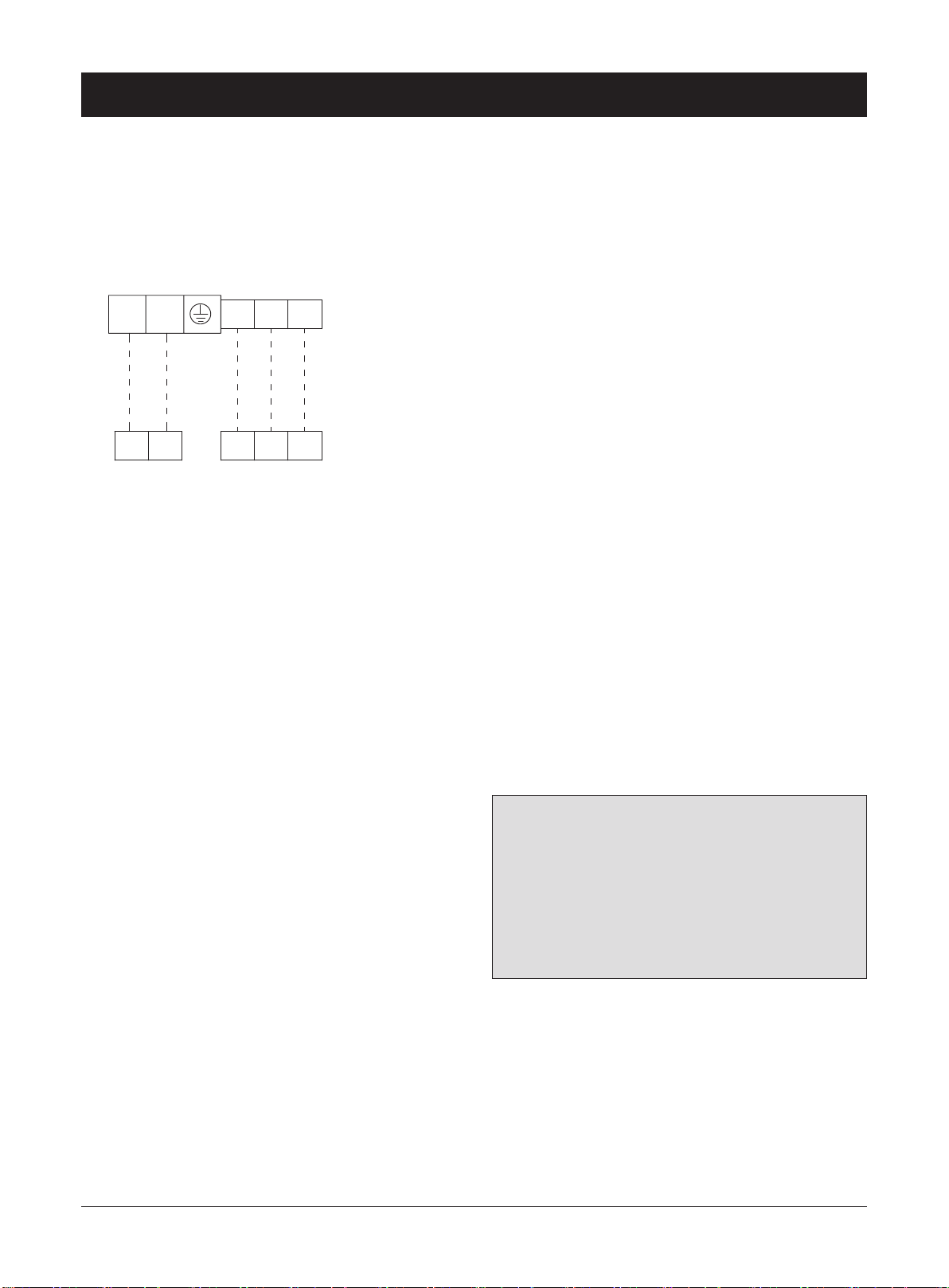

Electrical connection

Connecting indoor and outdoor unit

Use cable (not less than 1.5m

connect indoor and outdoor unit via control board

terminal connection .

L N

345

LN 34 5

2)

(not supplied) to

Outdoor unit

Indoor unit

Note:

Outdoor unit must be earthed before the wiring before

the unit is connected.

The wiring must be attached so that the terminal block

is not under stress

Connect Outdoor ambient temperature

sensor OT (6m) (B3)

One section of OT probe (B3) is inside the outdoor unit

control box. Other section of OT probe is inside the

indoor unit control box. Connect two section of OT

probe with its connector.

Important: Temperature sensor must be separated

(min 20 cm) from high voltage power cables to

avoid interference which will cause read temperature

uctuating and heat pump can not work normally.

If the temperature sensor cable runs close to power

cables,shielded cable should be used .If a conduit is

used, it should be sealed to avoid condensation in the

outdoor temperature sensor probe

.

Indoor Side Inlet Water Temperature

Sensor:

The indoor side inlet water sensor (B1) from factory is

placed at inlet water pipe.

If a buffer tank is installed, the Inlet water temperature

sensor B1 can be moved to the buffer tank temperature

sensor inlet pocket and EV01 parameter value can

be set to “work by regulation”. This stops the pump

running when compressor is OFF.

If the Inlet water temperature sensor B1 can not be

moved to the buffer tank temperature sensor inlet,

the EV01 parameter value must be set to “continuous

work” (factory default setting). This allows the pump

to continue to run so Inlet water temperature sensor B1

read the same as butter tank water temperature.

Important:

Temperature sensor for hot water:

The hot water sensor (B4) is connected to terminal

positions B4 and GND on the main board, the other

terminal must be put into hot water cylinder temperature

sensor probe inlet pocket if required.

If the hot water sensor cable runs close to power cables,

then a shielded cable should be used. If a conduit is

used then it should be sealed to avoid condensation

forming in the temperature sensor probe

.

All temperature sensor must be separated (min

200 mm) from high voltage power cables to avoid

interference which will cause read temperature

fluctuating and the heat pump may operate

incorrectly.

17

Loading...

Loading...