Page 1

Installation RSP 20/25/30/35

Release 15 12/2017

Technical support

https://hirschmann-support.belden.eu.com

User Manual

Installation

Industrial Ethernet Rail Switch Power

RSP 20/25/30/35

Page 2

The naming of copyrighted trademarks in this manual, even when not specially indicated, should

not be taken to mean that these names may be considered as free in the sense of the trademark

and tradename protection law and hence that they may be freely used by anyone.

© 2017 Hirschmann Automation and Control GmbH

Manuals and software are protected by copyright. All rights reserved. The copying, reproduction,

translation, conversion into any electronic medium or machine scannable form is not permitted,

either in whole or in part. An exception is the preparation of a backup copy of the software for

your own use.

The performance features described here are binding only if they have been expressly agreed

when the contract was made. This document was produced by Hirschmann Automation and

Control GmbH according to the best of the company's knowledge. Hirschmann reserves the right

to change the contents of this document without prior notice. Hirschmann can give no guarantee

in respect of the correctness or accuracy of the information in this document.

Hirschmann can accept no responsibility for damages, resulting from the use of the network

components or the associated operating software. In addition, we refer to the conditions of use

specified in the license contract.

You can get the latest version of this manual on the Internet at the Hirschmann product site

(www.hirschmann.com).

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

Installation RSP 20/25/30/35 21.12.2017

Page 3

Installation RSP 20/25/30/35

Release 15 12/2017

3

Contents

Safety instructions 5

About this manual 16

Key 17

1 Description 18

1.1 General description 18

1.2 Device name and product code 19

1.3 Device views 22

1.3.1 Front view 22

1.3.2 Rear view 23

1.4 Power supply 24

1.4.1 Supply voltage with the characteristic value K9 24

1.4.2 Supply voltage with the characteristic value KK 24

1.4.3 Supply voltage with the characteristic value TT 24

1.4.4 Supply voltage with the characteristic value CC 24

1.5 Ethernet ports 25

1.5.1 10/100 Mbit/s twisted pair port 25

1.5.2 100/1000 Mbit/s twisted pair port (optional) 25

1.5.3 100 Mbit/s F/O port 25

1.5.4 100/1000 Mbit/s F/O port (optional) 26

1.5.5 Pin assignments 26

1.6 Display elements 27

1.6.1 Device state 27

1.6.2 Port status 28

1.7 Management interfaces 29

1.7.1 V.24 interface (external management) 29

1.7.2 SD card interface 29

1.8 Signal contact 30

2 Installation 31

2.1 Checking the package contents 31

2.2 Installing the SD card (optional) 32

2.3 Installing and grounding the device 32

2.3.1 Installing the device onto the DIN rail 33

2.3.2 Grounding the device 34

2.4 Installing an SFP transceiver (optional) 34

Page 4

4

Installation RSP 20/25/30/35

Release 15 12/2017

2.5 Connecting the terminal blocks 35

2.5.1 Supply voltage with the characteristic value K9 35

2.5.2 Supply voltage with the characteristic value KK 37

2.5.3 Supply voltage with the characteristic value CC 39

2.5.4 Supply voltage with the characteristic value TT 40

2.5.5 Signal contact 41

2.6 Operating the device 41

2.7 Connecting data cables 42

2.8 Filling out the inscription label 42

3 Making basic settings 43

4 Upgrading Software 44

5 Monitoring the ambient air temperature 45

6 Maintenance and service 46

7Disassembly 47

7.1 Removing the device 47

7.2 Removing an SFP transceiver (optional) 48

8 Technical data 49

8.1 General technical data 49

8.2 Power consumption/power output 52

8.3 Dimension drawings 53

8.4 EMC and immunity 54

8.5 Network range 57

8.6 Scope of delivery, order numbers and accessories 60

9 Underlying technical standards 63

A Further support 64

Page 5

Installation RSP 20/25/30/35

Release 15 12/2017

5

Safety instructions

General safety instructions

You operate this device with electricity. Improper usage of the device

entails the risk of physical injury or significant property damage. The

proper and safe operation of this device depends on proper handling

during transportation, proper storage and installation, and careful

operation and maintenance procedures.

Before connecting any cable, read this document, and the safety

instructions and warnings.

Operate the device with undamaged components exclusively.

The device is free of any service components. In case of a damaged

or malfunctioning the device, turn off the supply voltage and return the

device to Hirschmann for inspection.

Certified usage

Use the product only for the application cases described in the

Hirschmann product information, including this manual.

Operate the product only according to the technical specifications.

See “Technical data” on page 49.

Connect to the product only components suitable for the requirements

of the specific application case.

Installation site requirements

Install the device in a fire enclosure according to EN 60950-1.

Only for device variants featuring supply voltage with characteristic

value K9 or KK:

Install this device solely in a switch cabinet or in an operating site with

restricted access, to which maintenance staff have exclusive access.

Install the device at ambient temperatures greater than 113 °F (45 °C)

in “restricted access locations” based on EN 60950-1 exclusively.

WARNING

UNCONTROLLED MACHINE ACTIONS

To avoid uncontrolled machine actions caused by data loss, configure all

the data transmission devices individually.

Before you start any machine which is controlled via data transmission, be

sure to complete the configuration of all data transmission devices.

Failure to follow these instructions can result in death, serious injury,

or equipment damage.

Page 6

6

Installation RSP 20/25/30/35

Release 15 12/2017

Device casing

Only technicians authorized by the manufacturer are permitted to open

the housing.

Never insert pointed objects (narrow screwdrivers, wires, etc.) into the

device or into the connection terminals for electric conductors. Do not

touch the connection terminals.

Keep the ventilation slits free to ensure good air circulation.

Mount the device in the vertical position.

At ambient temperatures > 140 °F (60 °C):

The surfaces of the device housing may become hot. Avoid touching

the device while it is operating.

Qualification requirements for personnel

Only allow qualified personnel to work on the device.

Qualified personnel have the following characteristics:

Qualified personnel are properly trained. Training as well as practical

knowledge and experience make up their qualifications. This is the

prerequisite for grounding and labeling circuits, devices, and systems

in accordance with current standards in safety technology.

Qualified personnel are aware of the dangers that exist in their work.

Qualified personnel are familiar with appropriate measures against

these hazards in order to reduce the risk for themselves and others.

Qualified personnel receive training on a regular basis.

National and international safety regulations

Verify that the electrical installation meets local or nationally applicable

safety regulations.

Grounding the device

Grounding the device is by means of a separate ground connection on the

device.

Ground the device before connecting any other cables.

Disconnect the grounding only after disconnecting all other cables.

Ground the device via the ground screw.

Shielding ground

The overall shield of a connected shielded twisted pair cable is connected

to the ground connector on the front panel as a conductor.

Beware of possible short circuits when connecting a cable section with

conductive shielding braiding.

Requirements for connecting electrical wires

Before connecting the electrical wires, always verify that the

requirements listed are complied with.

Page 7

Installation RSP 20/25/30/35

Release 15 12/2017

7

All of the following requirements are complied with:

The electrical wires are voltage-free.

The cables used are permitted for the temperature range of the application case.

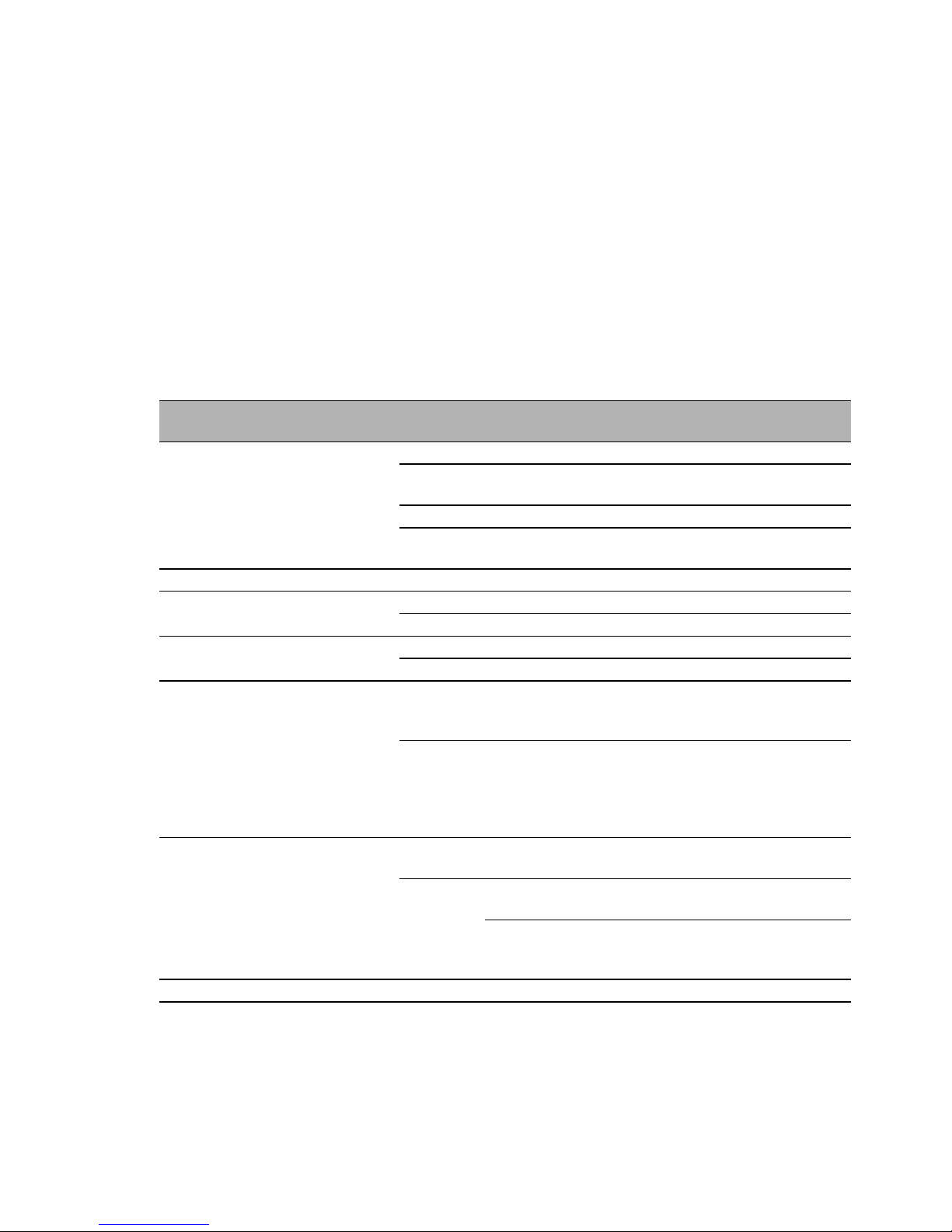

Table 1: General requirements for connecting electrical wires

All of the following requirements are complied with:

The voltage connected complies with the requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

The connected voltage is limited by a current limitation device or a fuse.

Observe the electrical threshold values for the signal contact.

See “General technical data” on page 49.

Table 2: General requirements for connecting the signal contact

Device variant Requirements

All variants All of the following requirements are complied with:

The supply voltage corresponds to the voltage specified on the type

plate of the device.

The power supply conforms to overvoltage category I or II.

The power supply has an easily accessible disconnecting device (for

example a switch or a plug). This disconnecting device is clearly

identified. So in the case of an emergency, it is clear which

disconnecting device belongs to which power supply cable.

The cross-section of the ground conductor is the same size as or

bigger than the cross-section of the power supply cables.

Relevant for North America:

The power supply cables are suitable for ambient air temperatures of

at least 167 °F (75 °C). The power supply cable wires are made of

copper.

Only for device

variants featuring

supply voltage with

the characteristic

value CC:

The wire diameter of the power supply cable is at least 0.75 mm² (North

America: AWG18) on the supply voltage input.

The following requirements are alternatively complied with:

Alternative 1 The power supply complies with the requirements

for a limited power source (LPS) as per EN 60950-1.

Alternative 2 Relevant for North America:

The power supply complies with the requirements

according to NEC Class 2.

Alternative 3 All of the following requirements are complied with:

The power supply complies with the

requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

A fuse suitable for DC voltage is located in the

plus conductor of the power supply.

The minus conductor is on ground potential.

Otherwise, a fuse is also located in the minus

conductor.

Regarding the properties of this fuse:

See “General technical data” on page 49.

Table 3: Requirements for connecting the supply voltage

Page 8

8

Installation RSP 20/25/30/35

Release 15 12/2017

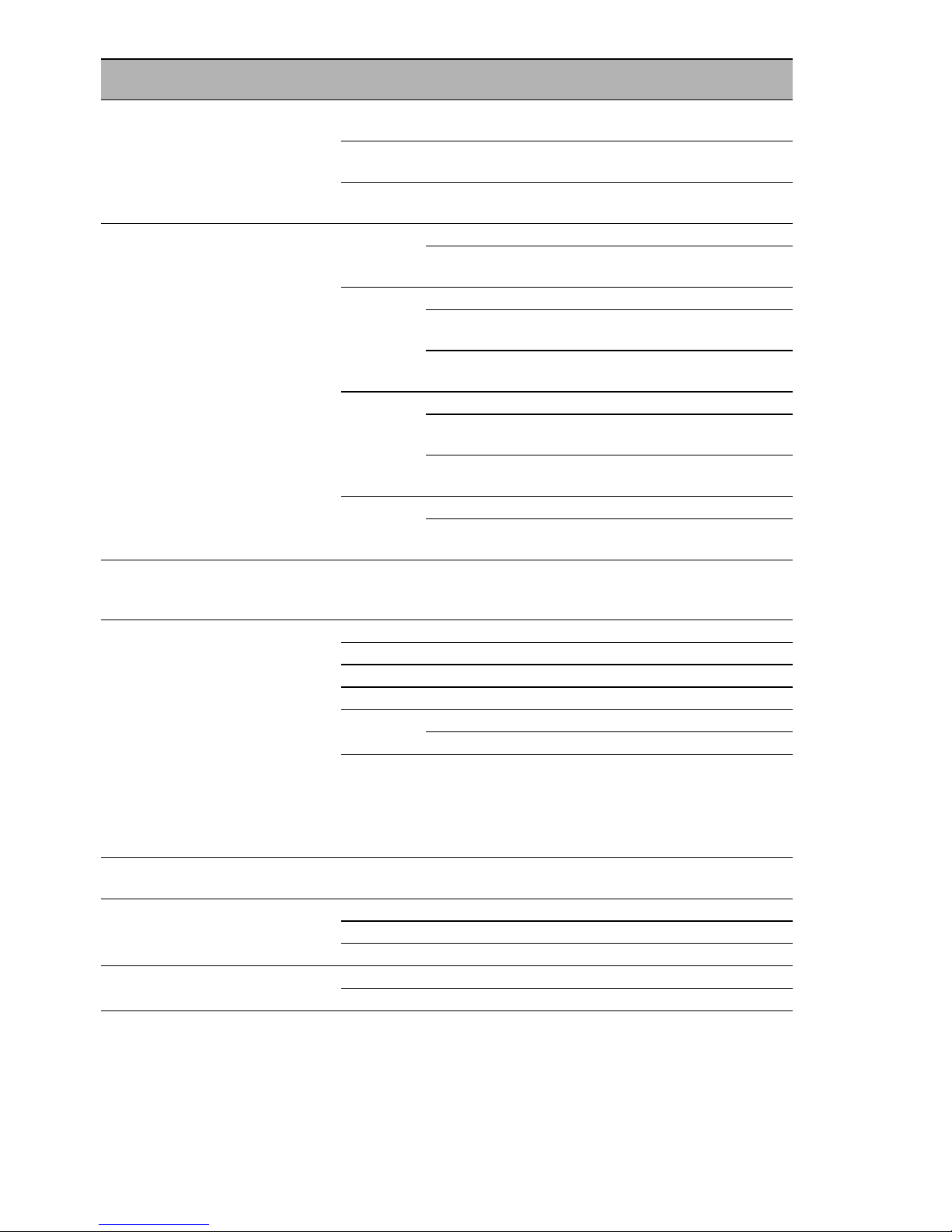

Supply voltage

The supply voltage is connected to the device casing through protective

elements exclusively.

For supply voltage connections with protective conductor connection:

First connect the protective conductor before connecting the wires for

the supply voltage.

For device variants featuring supply voltage with characteristic value

CC and TT:

For the redundant power supply, only use voltage sources whose

negative terminal is grounded. The use of different voltage sources

can lead to equipment damage.

Only device variants

featuring supply

voltage with

characteristic value

TT:

The wire diameter of the power supply cable is at least 0.75 mm² (North

America: AWG18) on the supply voltage input.

The following requirements are alternatively complied with:

Alternative 1 The power supply complies with the requirements

for a limited power source (LPS) as per EN 60950-1.

Alternative 2 All of the following requirements are complied with:

The power supply complies with the

requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

A fuse suitable for DC voltage is located in the

plus conductor of the power supply.

The minus conductor is on ground potential.

Otherwise, a fuse is also located in the minus

conductor.

Regarding the properties of this fuse:

See “General technical data” on page 49.

Alternative 3 Relevant for North America:

The power supply complies with the requirements

according to NEC Class 2.

Only for device

variants featuring

supply voltage with

characteristic

value K9 or KK:

All of the following requirements are complied with:

Supply with DC voltage:

A fuse suitable for DC voltage is located in the plus conductor of the

power supply.

The minus conductor is on ground potential. Otherwise, a fuse is also

located in the minus conductor.

Regarding the properties of this fuse:

See “General technical data” on page 49.

The wire diameter of the power supply cable is at least 1 mm² (North

America: AWG16) on the supply voltage input.

Supply with AC voltage:

A fuse is located in the outer conductor of the power supply.

The neutral conductor is on ground potential at both voltage inputs.

Otherwise, a fuse is also located in the neutral conductor.

Regarding the properties of this fuse:

See “General technical data” on page 49.

The wire diameter of the power supply cable is at least 0.75 mm²

(North America: AWG18) on the supply voltage input.

Device variant Requirements

Table 3: Requirements for connecting the supply voltage

Page 9

Installation RSP 20/25/30/35

Release 15 12/2017

9

ATEX directive 2014/34/EU – specific regulations for safe

operation

Relevant for RSP devices when operating in explosive gas atmospheres

according to ATEX directive 2014/34/EU, the following applies:

List of standards:

EN 60079-0:2012, A11:2013

EN 60079-15:2010

Certificate No.: DEKRA 15ATEX0017X

Use only device variants featuring supply voltage with characteristic

value CC.

Make sure that the device has the following label:

II 3G Ex nA IIC T4 Gc DEKRA 15ATEX0017X

Ambient rating and temperature code for RSP types:

T4: 0 °C ≤ Ta ≤ +60 °C for “S” types or

T4: −40 °C ≤ Ta ≤ +70 °C for “T” or “E” types

The modules shall be installed in a suitable enclosure in accordance

with IEC 60079-15 providing a degree of protection of at least IP54

according to IEC 60529, taking into account the environmental

conditions under which the equipment will be used.

When the temperature under rated conditions exceeds 158 °F (70 °C)

at the cable or conduit entry point, or 176 °F (80 °C) at the branching

point of the conductors, the temperature specification of the selected

cable and cable entries shall be in compliance with the actual

measured temperature values.

Provisions shall be made to prevent the rated voltage from being

exceeded by transient disturbances of more than 119 V.

Connectors shall be connected or disconnected exclusively in dead-

voltage state.

The USB port shall remain disconnected.

Page 10

10

Installation RSP 20/25/30/35

Release 15 12/2017

Relevant for use in explosion hazard areas (Hazardous

Locations, Class I, Division 2):

The relay connections are to be installed and used within their Entity

Parameters as per Control Drawing 000189237DNR.

Avertissement - Risque d'explosion - Ne pas débrancher tant que le

circuit est sous tension à moins que l'emplacement soit connu pour ne

contenir aucune concentration de gaz inflammable.

Avertissement - Risque d'explosion - La substitution de tout composant

peut rendre ce matériel incompatible pour une utilisation en classe I,

division 2.

Page 11

Installation RSP 20/25/30/35

Release 15 12/2017

11

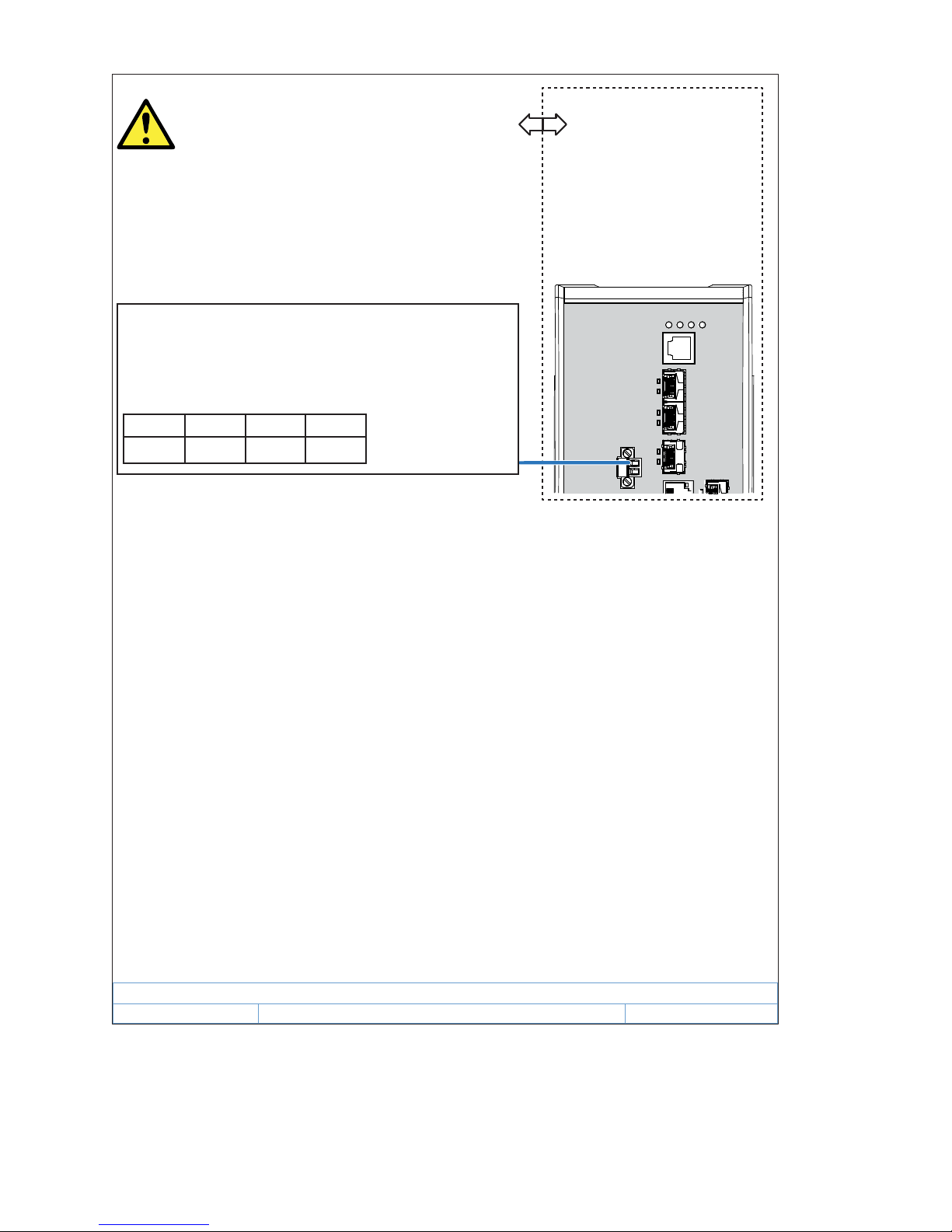

Control Drawing for RSP devices according to Class I Division 2 Hazardous Locations

Rev.: 0 Document No.: 000189237DNR Page 1/2

For Use in Hazardous Locations Class I Division 2 Groups A, B, C, D:

Only allowed for RSP 20/25/30/35 model No´s. which are individually labeled

“FOR USE IN HAZARDOUS LOCATIONS”.

Nonincendive fi eld wiring circuits must be wired in accordance with the National Electrical Code

(NEC), NFPA 70, article 501; CEC, Appendix J, Annex J18.

The earth conductor must be at least of the same wire size (mm² or AWG)

as the supply conductors.

WARNING – EXPLOSION HAZARD

Substitution of any components may impair suitability for hazardous locations or explosive

atmospheres.

WARNING – EXPLOSION HAZARD

Do not disconnect equipment unless power has been switched off or the area is known to be

known to be non-hazardous.

Page 12

12

Installation RSP 20/25/30/35

Release 15 12/2017

Control Drawing for RSP devices according to Class I Division 2 Hazardous Locations

Rev.: 0 Document No.: 000189237DNR Page 2/2

Ordinary Location,

Non-Hazardous Area,

Non-Explosive Atmosphere

Explosive Atmosphere

Class I Division 2

Groups A, B, C, D

Hazardous Location

RSP

Relay

Power Supply unit type CC: 24 VDC - 48 VDC

Power Supply unit type K9: 110 VAC - 230 VAC or

60 VDC - 250 VDC

Power Supply unit type KK: 2x 110 VAC - 230 VAC or

2x 60 VDC - 250 VDC

(Refer to the power supply code of the type designation on the device.)

Temperature Code: T4

Ambient Temperature rating:

Ta: 0 °C to +60 °C for “S” temperature types

Ta: í40 °C to +70 °C for “T” or “E” temperature types

(Refer to the temperature code of the type designation on the device.)

Relay contacts:

Equipment with nonincendive eld wiring parameters.

Polarity is not relevant.

The relay terminals are dependent upon the following

Entity parameters:

U

i

I

i

C

i

L

i

30 V 90 mA 2 nF 1 H

Page 13

Installation RSP 20/25/30/35

Release 15 12/2017

13

IECEx – Certification Scheme for Explosive Atmospheres

For RSP devices labeled with an IECEx certificate number, the following

applies:

List of standards:

IEC 60079-0:2011+Cor.2012+Cor.2013

IEC 60079-15:2010

The equipment shall only be used in an area of not more than pollution

degree 2, as defined in IEC 60664-1.

Make sure that the device has the following label:

Ex nA IIC T4 Gc IECEx DEK 15.0014X

Environmental class and temperature code for RSP types:

T4: 0 °C ≤ Ta ≤ +60 °C for “S“ types or

T4: −40 °C ≤ Ta ≤ +70 °C for “T“ or “E“ types

The modules shall be installed in a suitable enclosure in accordance

with IEC 60079-15 providing a degree of protection of at least IP54

according to IEC 60529, taking into account the environmental

conditions under which the equipment will be used.

When the temperature under rated conditions exceeds 158 °F (70 °C)

at the cable or conduit entry point, or 176 °F (80 °C) at the branching

point of the conductors, the temperature specification of the selected

cable and cable entries shall be in compliance with the actual

measured temperature values.

Provisions shall be made to prevent the rated voltage from being

exceeded by transient disturbances of more than 119 V.

Connectors shall be connected or disconnected exclusively in dead-

voltage state.

The USB port shall remain disconnected.

Page 14

14

Installation RSP 20/25/30/35

Release 15 12/2017

CE marking

The labeled devices comply with the regulations contained in the following

European directive(s):

In accordance with the above-named EU directive(s), the EU conformity

declaration will be at the disposal of the relevant authorities at the

following address:

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

The product can be used in the industrial sector.

Interference immunity: EN 61000-6-2

Emitted interference: EN 55032

Reliability: EN 60950-1

You find more information on technical standards here:

“Technical data” on page 49

Warning! This is a class A device. This device can cause interference in

living areas, and in this case the operator may be required to take

appropriate measures.

Note: The assembly guidelines provided in these instructions must be

strictly adhered to in order to observe the EMC threshold values.

LED or laser components

LED or LASER components according to IEC 60825-1 (2014):

CLASS 1 LASER PRODUCT

CLASS 1 LED PRODUCT

Device variant Directive

All variants 2014/30/EU (EMC)

Directive of the European Parliament and of the Council on the

harmonisation of the laws of the Member States relating to

electromagnetic compatibility.

2011/65/EU (RoHS)

Directive of the European Parliament and of the Council on the

restriction of the use of certain hazardous substances in

electrical and electronic equipment.

Only for device variants

featuring supply voltage with

characteristic value K9 or KK:

2014/35/EU

Directive of the European Parliament and of the Council on the

harmonisation of the laws of the Member States relating to the

making available on the market of electrical equipment

designed for use within certain voltage limits.

Page 15

Installation RSP 20/25/30/35

Release 15 12/2017

15

FCC note:

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference; (2) this device must accept any interference received,

including interference that may cause undesired operation.

Appropriate testing has established that this device fulfills the

requirements of a class A digital device in line with part 15 of the FCC

regulations.

These requirements are designed to provide sufficient protection against

interference when the device is being used in a business environment.

The device creates and uses high frequencies and can also radiate these

frequencies. If it is not installed and used in accordance with this

operating manual, it can cause radio transmission interference. The use

of this device in a residential area can also cause interference, and in this

case the user is obliged to cover the costs of removing the interference.

Recycling note

After usage, this device must be disposed of properly as electronic waste,

in accordance with the current disposal regulations of your county, state,

and country.

Page 16

16

Installation RSP 20/25/30/35

Release 15 12/2017

About this manual

The “Installation” user manual contains a device description, safety

instructions, a description of the display, and the other information that you

need to install the device.

The following manuals are available as PDF files on the Internet on the

Hirschmann product pages (www.hirschmann.com):

Installation user manual

Basic Configuration user manual

Redundancy Configuration user manual

Reference manual for the graphical user interface

Command Line Interface reference manual

Page 17

Installation RSP 20/25/30/35

Release 15 12/2017

17

Key

The symbols used in this manual have the following meanings:

Listing

Work step

Subheading

Page 18

18

Installation RSP 20/25/30/35

Release 15 12/2017

1 Description

1.1 General description

The RSP 20/25/30/35 devices are designed for the special requirements of

industrial automation. They meet the relevant industry standards, provide

very high operational reliability, even under extreme conditions, and also

long-term reliability and flexibility.

You can choose from between a wide range of variants. You have the option

to set up your device individually based on different criteria:

Number of ports

Transmission speed

Types of connectors

Temperature range

Supply voltage range

Certifications

Redundancy functions

You have the option of choosing various media to connect to the end devices

and other network components:

Multimode optical fiber

Singlemode optical fiber

Twisted pair cable

The device is mounted by latching in place on a DIN rail.

The devices work without a fan.

The redundancy concept allows the network to be reconfigured quickly.

There are convenient options for managing the device. Manage your devices

via:

a Web browser

SSH

Telnet

HiDiscovery (Software for putting the device into operation)

a V.24 interface (locally on the device)

a network management software (for example Industrial HiVision)

The devices provide you with a large range of functions, which the manuals

for the operating software inform you about. You find these manuals in the

form of PDF files for downloading on the Internet on the Hirschmann product

pages (www.hirschmann.com).

Page 19

Installation RSP 20/25/30/35

Release 15 12/2017

19

The Hirschmann network components help you ensure continuous

communication across all levels of the company.

1.2 Device name and product code

The device name corresponds to the product code. The product code is

made up of characteristics with defined positions. The characteristic values

stand for specific product properties.

You have numerous options of combining the device characteristics. You can

determine the possible combinations using the Configurator which is

available in the Belden E-Catalog (www.e-catalog.beldensolutions.com) on

the web page of the device.

Item Characteristic Character

istic value

Description

1 ... 5 Product RSP20 Fast Ethernet switch

RSP25 Fast Ethernet switch with extended redundancy

function

RSP30 Gigabit Ethernet switch

RSP35 Gigabit Ethernet switch with extended

redundancy function

6 (hyphen) –

7 ... 8 Number

Fast Ethernet ports

08 8 ×

11 11 ×

9 ... 10 Number

Gigabit Ethernet ports

00 0 ×

03 3 ×

11 ... 13 Configuration of the

uplink ports

3Z6 3 × Optional SFP slot for:

100 Mbit/s twisted pair connections

100 Mbit/s F/O connections

3O6 3 × Optional SFP slot for:

100 Mbit/s twisted pair connections

1000 Mbit/s twisted pair connections

100 Mbit/s F/O connections

1000 Mbit/s F/O connections

14 ... 15 Configuration of the

other ports

TT 8 × RJ45 socket for 10/100 Mbit/s twisted pair

connections

ZT 4 × RJ45 socket for 10/100 Mbit/s twisted pair

connections

4 × Optional SFP slot for:

100 Mbit/s twisted pair connections

100 Mbit/s F/O connections

16 (hyphen) –

Table 4: Device name and product code

Page 20

20

Installation RSP 20/25/30/35

Release 15 12/2017

17 Temperature range S Standard +32 °F ... +140 °F

(0 °C ... +60 °C)

T Extended −40 °F ... +158 °F

(−40 °C ... +70 °C)

E Extended with

Conformal Coating

−40 °F ... +158 °F

(−40 °C ... +70 °C)

18 ... 19 Supply voltage CC 2 voltage inputs for redundant power supply

Rated voltage range DC

24 V DC ... 48 V DC

K9 1 voltage input

Rated voltage range AC

110 V AC ... 230 V AC, 50 Hz ... 60 Hz

Rated voltage range DC

60 V DC ... 250 V DC

KK 2 voltage inputs for redundant power supply

Rated voltage range AC

110 V AC ... 230 V AC, 50 Hz ... 60 Hz

Rated voltage range DC

60 V DC ... 250 V DC

TT 2 voltage inputs for redundant power supply

Rated voltage range DC

12 V DC ... 24 V DC

20 ... 21 Certificates and

declarations

You will find detailed information on the certificates and

declarations applying to your device in a separate overview.

See table 5 on page 21.

22 ... 23 Customer-specific

version

HS Hirschmann Standard

HM Hirschmann Fast MRP

HP Hirschmann PRP

HH Hirschmann HSR

HD From software version 05.0 onward:

Hirschmann DLR

Note: You can exchange software with each other on the

following device variants:

HM

HP

HH

24 Software

configuration

E Entry (without configuration)

25 ... 26 Software level 2S HiOS Layer 2 Standard

2A HiOS Layer 2 Advanced

3S HiOS Layer 3 Standard

27 ... 31 Software version 02.0. Software version 02.0

XX.X. Current software version

Item Characteristic Character

istic value

Description

Table 4: Device name and product code

Page 21

Installation RSP 20/25/30/35

Release

15

12/2017

21

Application case Certificates and

declarations

Characteristic value

TY T9 WD WC WB WA V9 VY Y9 Z9

Standard

applications

ATEX, Zone 2/IECEx X X X X

CE XXXXXXXXXX

FCC XXXXXXXXXX

ISA-12.12.01 – Class I, Div. 2 X X

EN 61131-2 XXXXXXXXXX

UL 508 X X X

Substation

applications

IEC 61850-3 XX

IEEE 1613 XX

Navy applications GL X X

Railway

applications

(trackside)

EN 50121-4 X X X X

Table 5: Assignment: application cases, certificates and declarations, characteristic values

Page 22

22

Installation RSP 20/25/30/35

Release 15 12/2017

1.3 Device views

1.3.1 Front view

Front view (using the example RSP20-11003Z6TT-SCC...)

1 LED display elements for device status

2 V.24 interface

3 3 × SFP slot for 100 Mbit/s connections

4 8 × 10/100 Mbit/s twisted pair ports

5 Grounding screw

6 Supply voltage connection

alternatively,

depending on

device variant

Supply voltage with the

characteristic value:

CC

2 voltage inputs for redundant power supply

2-pin terminal block

Supply voltage with the

characteristic value:

K9

1 voltage input

3-pin terminal block

Supply voltage with the

characteristic value:

KK

2 voltage inputs for redundant power supply

3-pin terminal block

Supply voltage with the

characteristic value:

TT

2 voltage inputs for redundant power supply

2-pin terminal block

7 Connection for the signal contact

6

7

4

5

1

2

3

Page 23

Installation RSP 20/25/30/35

Release 15 12/2017

23

1.3.2 Rear view

1 Slot for the SD card

2 Thumb screw

1

2

Page 24

24

Installation RSP 20/25/30/35

Release 15 12/2017

1.4 Power supply

You will find information on the characteristic values here:

“Device name and product code” on page 19

1.4.1 Supply voltage with the characteristic value K9

For the power supply of the device, a 3-pin terminal block is available.

Further information:

See “Supply voltage with the characteristic value K9” on page 35.

1.4.2 Supply voltage with the characteristic value KK

For the redundant power supply of the device, two 3-pin terminal blocks are

available.

Further information:

See “Supply voltage with the characteristic value KK” on page 37.

1.4.3 Supply voltage with the characteristic value TT

For the redundant power supply of the device, two 2-pin terminal blocks are

available.

Further information:

See “Supply voltage with the characteristic value TT” on page 40.

1.4.4 Supply voltage with the characteristic value CC

For the redundant power supply of the device, two 2-pin terminal blocks are

available.

Further information:

See “Supply voltage with the characteristic value TT” on page 40.

Page 25

Installation RSP 20/25/30/35

Release 15 12/2017

25

1.5 Ethernet ports

You can connect end devices and other segments to the device ports using

twisted pair cables or optical fibers (F/O).

1.5.1 10/100 Mbit/s twisted pair port

This port is an RJ45 socket.

The 10/100 Mbit/s twisted pair port allows you to connect network

components according to the IEEE 802.3 10BASE-T/100BASE-TX standard.

This port supports:

Autonegotiation

Autopolarity

Autocrossing (if autonegotiation is activated)

100 Mbit/s half-duplex mode, 100 Mbit/s full duplex mode

10 Mbit/s half-duplex mode, 10 Mbit/s full duplex mode

Delivery state: Autonegotiation activated

The port casing is electrically connected to the front panel.

1.5.2 100/1000 Mbit/s twisted pair port (optional)

This port is an SFP slot.

The 100/1000-Mbit/s twisted pair port offers you the possibility to connect

network components according to the IEEE 802.3 100BASE-FX/1000BASESX/1000BASE-LX standard.

This port supports:

1000 Mbit/s full duplex

100 Mbit/s, full duplex

Autonegotiation when using a Gigabit Ethernet SFP transceiver

State on delivery:

1000 Mbit/s full duplex when using a Gigabit Ethernet SFP transceiver

Autonegotiation activated when using a Gigabit Ethernet SFP transceiver

100 Mbit/s full duplex when using a Fast Ethernet SFP transceiver

1.5.3 100 Mbit/s F/O port

This port is an SFP slot.

The 100 Mbit/s F/O port allows you to connect network components

according to the IEEE 802.3 100BASE-FX standard.

This port supports:

100 Mbit/s half-duplex mode, 100 Mbit/s full duplex mode

Default setting: Full duplex

Page 26

26

Installation RSP 20/25/30/35

Release 15 12/2017

1.5.4 100/1000 Mbit/s F/O port (optional)

This port is an SFP slot.

The 100/1000 Mbit/s F/O port allows you to connect network components

according to the IEEE 802.3 100BASE-FX/1000BASE-SX/1000BASE-LX

standard.

This port supports:

1000 Mbit/s full duplex

100 Mbit/s half-duplex mode, 100 Mbit/s full duplex mode

State on delivery:

1000 Mbit/s full duplex when using a Gigabit Ethernet SFP transceiver

100 Mbit/s full duplex when using a Fast Ethernet SFP transceiver

1.5.5 Pin assignments

RJ45 Pin 10/100 Mbit/s 1000 Mbit/s PoE

MDI mode

1 TX+ BI_DA+ Positive V

PSE

a

a. Phantom supply

2TX− BI_DA− Positive V

PSE

a

3 RX+ BI_DB+ Negative V

PSE

a

4 — BI_DC+ Positive V

PSE

b

b. Spare pair supply

5— BI_DC− Positive V

PSE

b

6RX− BI_DB− Negative V

PSE

a

7 — BI_DD+ Negative V

PSE

b

8— BI_DD− Negative V

PSE

b

MDI-X mode

1 RX+ BI_DB+ Negative V

PSE

a

2RX− BI_DB− Negative V

PSE

a

3 TX+ BI_DA+ Positive V

PSE

a

4 — BI_DD+ Positive V

PSE

b

5— BI_DD− Positive V

PSE

b

6TX− BI_DA− Positive V

PSE

a

7 — BI_DC+ Negative V

PSE

b

8— BI_DC− Negative V

PSE

b

1

2

3

4

5

6

7

8

Page 27

Installation RSP 20/25/30/35

Release 15 12/2017

27

1.6 Display elements

After the supply voltage is set up, the software starts and initializes itself.

Afterwards, the device performs a self-test. During this process, various

LEDs light up.

1.6.1 Device state

These LEDs provide information about conditions which affect the operation

of the whole device.

Applies to software releases before 02.0.00:

LED Display Color Activity Meaning

Power Supply voltage — none Supply voltage is too low

yellow Lights up Device variants with redundant power

supply:

Supply voltage 1 or 2 is on

flashes 4 times

a period

Software update is running. Maintain the

power supply.

green Lights up Device variants with redundant power

supply:

Supply voltages 1 and 2 are on

Device variants with single power supply:

Supply voltage is on

RM Ring Manager — none No redundancy configured

green Lights up Redundancy exists

Flashes 1 time

a period

Device is reporting an incorrect

configuration of the RM function

yellow Lights up No redundancy exists

ACA Storage medium

ACA31

— none ACA storage medium not connected

green Lights up ACA storage medium connected

Flashes 3

times a period

Device writes to/reads from the storage

medium

yellow Lights up ACA storage medium inoperative

LED Display Color Activity Meaning

Status Device Status — none Device is starting and/or is not ready for

operation

green Lights up Device is ready for operation.

Characteristics can be configured

red Lights up Device is inoperative

Flashes 1 time

a period

The boot parameters used when the

device has been started differ from the

boot parameters saved.

Start the device again.

Status

RM

ACA

Power

Page 28

28

Installation RSP 20/25/30/35

Release 15 12/2017

Applies to software releases after 02.0.00:

1.6.2 Port status

These LEDs provide port-related information.

The LEDs are directly located on the ports.

Applies to software releases before 02.0.00:

Applies to software releases after 02.0.00:

LED Display Color Activity Meaning

Status Device Status — none Device is starting and/or is not ready for

operation

green Lights up Device is ready for operation.

Characteristics can be configured

red Lights up Device is ready for operation.

Device has detected at least one error in

the monitoring results

Flashes 1 time

a period

The boot parameters used when the

device has been started differ from the

boot parameters saved.

Start the device again.

flashes 4 times

a period

Device has detected a multiple IP address

Display Color Activity Meaning

Link status — none Device detects an invalid or missing link

green Lights up Device detects a valid link

Flashes 1 time a period Port is switched to stand-by

Flashes 3 times a period Port is switched off

yellow Flashing Device is transmitting and/or receiving data

Display Color Activity Meaning

Link status — none Device detects an invalid or missing link

green Lights up Device detects a valid link

Flashes 1 time a period Port is switched to stand-by

Flashes 3 times a period Port is switched off

yellow Lights up Device detects a non-supported SFP

transceiver or a non-supported data rate

Flashing Device is transmitting and/or receiving data

Flashes 1 time a period Device detects at least one unauthorized

MAC address (Port Security Violation)

Page 29

Installation RSP 20/25/30/35

Release 15 12/2017

29

1.7 Management interfaces

1.7.1 V.24 interface (external management)

A serial interface is provided on the RJ11 socket (V.24 interface) for the local

connection of an external management station (VT100 terminal or PC with

corresponding terminal emulation). This enables you to set up a connection

to the Command Line Interface CLI and to the System Monitor.

The socket housing is electrically connected to the front panel of the device.

The V.24 interface is electrically insulated from the supply voltage.

Figure 1: Pin assignment of the V.24 interface and the DE9 connector

Note: The Terminal cable is available as an accessory.

1.7.2 SD card interface

The SD card interface allows you to connect the AutoConfiguration Adapter

ACA31 storage medium. This is used for saving/loading the configuration

data and diagnostic information, and for loading the software.

See “Accessories” on page 60.

For information about the position on the device see “Rear view” on page 23.

On the front of the device there is an LED display that informs you about the

status of the interface.

Only use Hirschmann SD cards.

VT100 terminal settings

Speed 9600 Baud

Data 8 bit

Stopbit 1 bit

Handshake off

Parity none

1

1

8

5

6

2

3

5

1

2

3

4

5

6

CTS

n.c.

TX

GND

RX

RTS

RJ11

DE9

RJ11

DE9

Page 30

30

Installation RSP 20/25/30/35

Release 15 12/2017

1.8 Signal contact

Figure 2: Signal contact: 2-pin terminal block with screw locking

The signal contact is a potential-free relay contact.

The device allows you to perform remote diagnosis via the signal contact. In

the process, the device signals events such as a line interruption. When an

event occurs, the device opens the relay contact and interrupts the closed

circuit. The management setting specifies which events switch a contact.

You can also use the management to switch the signal contact manually and

thus control external devices.

Page 31

Installation RSP 20/25/30/35

Release 15 12/2017

31

2Installation

The devices have been developed for practical application in a harsh

industrial environment.

On delivery, the device is ready for operation.

Perform the following steps to install and configure the device:

Checking the package contents

Installing the SD card (optional)

Installing and grounding the device

Installing an SFP transceiver (optional)

Connecting the terminal blocks

Operating the device

Connecting data cables

Filling out the inscription label

2.1 Checking the package contents

Proceed as follows:

Check whether the package includes all items named in the section

“Scope of delivery” on page 60.

Check the individual parts for transport damage.

Page 32

32

Installation RSP 20/25/30/35

Release 15 12/2017

2.2 Installing the SD card (optional)

Note: Only use the AutoConfiguration Adapter ACA31 storage medium.

See “Accessories” on page 60.

Proceed as follows:

Deactivate the write protection on the SD card by pushing the write-

protect lock towards the middle of the card.

Push the SD card into the slot with the beveled corner facing upwards.

Tighten the thumb screw hand-tight to fix the SD card.

2.3 Installing and grounding the device

WARNING

FIRE HAZARD

Install the device in a fire enclosure according to EN 60950-1.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

WARNING

ELECTRIC SHOCK

Install this device solely in a switch cabinet or in an operating site with

restricted access, to which maintenance staff have exclusive access.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Page 33

Installation RSP 20/25/30/35

Release 15 12/2017

33

2.3.1 Installing the device onto the DIN rail

Verify that the device maintains the minimum clearing in order to meet the

climatic conditions:

Top and bottom device side: 3.94 in (10 cm)

Left and right device side: 0.79 in (2 cm)

Undercutting the minimum clearing reduces the specified maximum

operating temperature.

See “General technical data” on page 49.

To mount the device onto a horizontally mounted 35 mm DIN rail according

to DIN EN 60715, proceed as follows:

Slide the upper snap-in guide of the device into the DIN rail.

Press the media module downwards onto the clip-in bar.

Snap in the device.

Note: The overall shield of a connected shielded twisted pair cable is

connected to the ground connector on the front panel as a conductor.

Page 34

34

Installation RSP 20/25/30/35

Release 15 12/2017

2.3.2 Grounding the device

The housing is grounded via the separate ground screw on the bottom left of

the front panel.

The device variants featuring supply voltage with characteristic value K9

and KK have a connection for protective grounding.

The device variants featuring supply voltage with the characteristic value CC

have a connection for functional grounding.

The device variants featuring supply voltage with characteristic value TT

have a connection for functional grounding.

Ground the device via the ground screw.

2.4 Installing an SFP transceiver (optional)

Use only Hirschmann SFP transceivers which are suitable for usage with the

device.

See “Accessories” on page 60.

Proceed as follows:

Remove the protection cap from the SFP transceiver.

Push the transceiver with the lock closed into the slot until it latches in.

Page 35

Installation RSP 20/25/30/35

Release 15 12/2017

35

2.5 Connecting the terminal blocks

Note: The supply voltage is connected to the device casing through

protective elements exclusively.

2.5.1 Supply voltage with the characteristic value K9

You will find information on the characteristic values here:

“Device name and product code” on page 19

Figure 3: Supply voltage with the characteristic value K9: 3-pin terminal block with

screw locking

WARNING

ELECTRIC SHOCK

Before connecting the electrical wires, always verify that the requirements

listed are complied with.

See “Requirements for connecting electrical wires” on page 6.

Never insert sharp objects (small screwdrivers, wires, etc.) into the

connection terminals for electric conductors, and do not touch the terminals.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Type of the voltages

that can be

connected

Specification of the supply

voltage

Pin assignment

DC voltage Rated voltage range DC

60 V DC ... 250 V DC

Voltage range DC including

maximum tolerances

48 V DC ... 320 V DC

+/L Plus terminal of the supply voltage

−/N Minus terminal of the supply

voltage

Protective conductor

Table 6: Supply voltage with characteristic value K9: type and specification of the

supply voltage, pin assignment

N

L

Page 36

36

Installation RSP 20/25/30/35

Release 15 12/2017

Ground the device via the ground screw.

For the supply voltage to be connected, perform the following steps:

Remove the power connector from the device.

Connect the protective conductor according to the pin assignment on the

device with the clamp.

Connect the wires according to the pin assignment on the device with the

clamps.

Fasten the wires connected by tightening the terminal screws.

AC voltage Rated voltage range AC

110 V AC ... 230 V AC,

50 Hz ... 60 Hz

Voltage range AC including

maximum tolerances

88 V AC ... 265 V AC,

47 Hz ... 63 Hz

+/L Outer conductor

−/N Neutral conductor

Protective conductor

WARNING

ELECTRIC SHOCK

Install this device solely in a switch cabinet or in an operating site with

restricted access, to which maintenance staff have exclusive access.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Type of the voltages

that can be

connected

Specification of the supply

voltage

Pin assignment

Table 6: Supply voltage with characteristic value K9: type and specification of the

supply voltage, pin assignment

Page 37

Installation RSP 20/25/30/35

Release 15 12/2017

37

2.5.2 Supply voltage with the characteristic value KK

You will find information on the characteristic values here:

“Device name and product code” on page 19

You have the option of supplying the supply voltage redundantly, without

load distribution.

Both supply voltage inputs are uncoupled.

With a redundant supply, the supply voltage 1 (upper voltage input on the

device) has priority.

Figure 4: Supply voltage with the characteristic value KK: 3-pin terminal block with

screw locking

Type of the voltages

that can be

connected

Specification of the supply

voltage

Pin assignment

DC voltage Rated voltage range DC

60 V DC ... 250 V DC

Voltage range DC including

maximum tolerances

48 V DC ... 320 V DC

+/L Plus terminal of the supply voltage

−/N Minus terminal of the supply

voltage

Protective conductor

AC voltage Rated voltage range AC

110 V AC ... 230 V AC,

50 Hz ... 60 Hz

Voltage range AC including

maximum tolerances

88 V AC ... 265 V AC,

47 Hz ... 63 Hz

+/L Outer conductor

−/N Neutral conductor

Protective conductor

Table 7: Supply voltage with characteristic value KK: type and specification of the

supply voltage, pin assignment

N

L

Page 38

38

Installation RSP 20/25/30/35

Release 15 12/2017

Ground the device via the ground screw.

For every supply voltage to be connected, perform the following steps:

Remove the power connector from the device.

Connect the protective conductor according to the pin assignment on the

device with the clamp.

Connect the wires according to the pin assignment on the device with the

clamps.

Fasten the wires connected by tightening the terminal screws.

You find the prescribed tightening torque in chapter:

“General technical data” on page 49

With a non-redundant supply of the supply voltage, the device reports the

loss of a supply voltage. You can prevent this message by changing the

configuration in the Management.

WARNING

ELECTRIC SHOCK

Install this device solely in a switch cabinet or in an operating site with

restricted access, to which maintenance staff have exclusive access.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Page 39

Installation RSP 20/25/30/35

Release 15 12/2017

39

2.5.3 Supply voltage with the characteristic value CC

You will find information on the characteristic values here:

“Device name and product code” on page 19

You have the option of supplying the supply voltage redundantly, without

load distribution.

Both supply voltage inputs are uncoupled.

Figure 5: Supply voltage with the characteristic value CC: 2-pin terminal block with

screw locking

Note: For the redundant power supply, only use voltage sources whose

negative terminal is grounded. The use of different voltage sources can lead

to equipment damage.

For every supply voltage to be connected, perform the following steps:

Remove the power connector from the device.

Connect the wires according to the pin assignment on the device with the

clamps.

Fasten the wires connected by tightening the terminal screws.

You find the prescribed tightening torque in chapter:

“General technical data” on page 49

With a non-redundant supply of the supply voltage, the device reports the

loss of a supply voltage. You can prevent this message by applying the

supply voltage via both inputs, or by changing the configuration in the

Management.

Type of the voltages

that can be

connected

Specification of the supply

voltage

Pin assignment

DC voltage Rated voltage range DC

24 V DC ... 48 V DC

Voltage range DC including

maximum tolerances

18 V DC ... 60 V DC

+ Plus terminal of the supply voltage

− Minus terminal of the supply

voltage

Table 8: Supply voltage with characteristic value CC: type and specification of the

supply voltage, pin assignment

−

+

Page 40

40

Installation RSP 20/25/30/35

Release 15 12/2017

2.5.4 Supply voltage with the characteristic value TT

You will find information on the characteristic values here:

“Device name and product code” on page 19

You have the option of supplying the supply voltage redundantly, without

load distribution.

Both supply voltage inputs are uncoupled.

Figure 6: Supply voltage with characteristic value TT: 2-pin terminal block with

screw lock

Note: For the redundant power supply, only use voltage sources whose

negative terminal is grounded. The use of different voltage sources can lead

to equipment damage.

For every supply voltage to be connected, perform the following steps:

Remove the power connector from the device.

Connect the wires according to the pin assignment on the device with the

clamps.

Fasten the wires connected by tightening the terminal screws.

You find the prescribed tightening torque in chapter:

“General technical data” on page 49

With a non-redundant supply of the supply voltage, the device reports the

loss of a supply voltage. You can prevent this message by applying the

supply voltage via both inputs, or by changing the configuration in the

Management.

Type of the voltages

that can be

connected

Specification of the supply

voltage

Pin assignment

DC voltage Rated voltage range DC

12 V DC ... 24 V DC

Voltage range DC including

maximum tolerances

10.2 V DC ... 32 V DC

+ Plus terminal of the supply voltage

− Minus terminal of the supply

voltage

Table 9: Supply voltage with characteristic value TT: type and specification of the

supply voltage, pin assignment

−

+

Page 41

Installation RSP 20/25/30/35

Release 15 12/2017

41

2.5.5 Signal contact

Connect the signal contact wires with the connectors of the terminal block.

Fasten the wires connected by tightening the terminal screws.

You find the prescribed tightening torque in chapter:

“General technical data” on page 49

2.6 Operating the device

Relevant for North America:

You find the prescribed tightening torque in chapter:

“General technical data” on page 49

Proceed as follows:

Use screws to secure the connectors to the device.

Enable the supply voltage.

WARNING

ELECTRIC SHOCK

Before connecting the electrical wires, always verify that the requirements

listed are complied with.

See “Requirements for connecting electrical wires” on page 6.

Ground the device before connecting any other cables.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Page 42

42

Installation RSP 20/25/30/35

Release 15 12/2017

2.7 Connecting data cables

Note the following general recommendations for data cable connections in

environments with high electrical interference levels:

Keep the length of the data cables as short as possible.

Use optical data cables for the data transmission between the buildings.

When using copper cables, provide a sufficient separation between the

power supply cables and the data cables. Ideally, install the cables in

separate cable channels.

Verify that power supply cables and data cables do not run parallel over

longer distances, and that ideally they are installed in separate cable

channels. If reducing the inductive coupling is necessary, verify that the

power supply cables and data cables cross at a 90° angle.

Use SF/UTP cables as per ISO/IEC 11801:2002.

Connect the data cables according to your requirements.

2.8 Filling out the inscription label

The information field for the IP address helps you identify your device.

Page 43

Installation RSP 20/25/30/35

Release 15 12/2017

43

3 Making basic settings

The IP parameters must be entered when the device is installed for the first

time. The device provides the following options for configuring IP addresses:

Input via the V.24 interface

Entry via the HiDiscovery protocol in the applications HiDiscovery or

Industrial HiVision

Configuration via BOOTP

Configuration via DHCP (Option 82)

AutoConfiguration Adapter

Default settings

IP address: The device looks for the IP address using DHCP

Management password:

user, password: public (read only)

admin, password: private (read/write)

V.24 data rate: 9600 Baud

Ethernet ports: link status is not evaluated (signal contact)

Optical ports: Full duplex

TP ports: Autonegotiation

RSTP (Rapid Spanning Tree) activated

Page 44

44

Installation RSP 20/25/30/35

Release 15 12/2017

4 Upgrading Software

The upgrade options for RSP 20/25/30/35 device depend on the software

level of the device.

See “Device name and product code” on page 19.

Note: For software version 04.0 or higher, “HiOS” is available as a common

software image for the software levels 2A and 3S.

You select only the desired redundancy function during the installation of the

image. After finishing the installation and manually restarting the device, the

device automatically activates the functions of the software level saved in the

product code.

For the software level 2S, the software image “HiOS-2S” remains available.

Software

version

Software level according to the

product code

2S 2A 3S

HiOS 02.0 Name of the software image HiOS-2S – –

Range of functions corresponds to 2S – –

HiOS 03.0 Name of the software image HiOS-2S HiOS-2A HiOS-2A

Range of functions corresponds to 2S 2A 2A

From HiOS 04.0

onward

Name of the software image HiOS-2S HiOS HiOS

Range of functions corresponds to 2S 2A 3S

Table 10: Upgrade options

Page 45

Installation RSP 20/25/30/35

Release 15 12/2017

45

5 Monitoring the ambient air temperature

Operate the device below the specified maximum ambient air temperature

exclusively.

See “General technical data” on page 49.

The ambient air temperature is the temperature of the air at a distance of 2 in

(5 cm) from the device. It depends on the installation conditions of the device,

e.g. the distance from other devices or other objects, and the output of

neighboring devices.

The temperature displayed in the CLI and the GUI is the internal temperature

of the device. It is higher than the ambient air temperature. The maximum

internal temperature of the device named in the technical data is a guideline

that indicates to you that the maximum ambient air temperature has possibly

been exceeded.

Page 46

46

Installation RSP 20/25/30/35

Release 15 12/2017

6 Maintenance and service

When designing this device, Hirschmann largely avoided using high-wear

parts. The parts subject to wear and tear are dimensioned to last longer

than the lifetime of the product when it is operated normally. Operate this

device according to the specifications.

Relays are subject to natural wear. This wear depends on the frequency

of the switching operations. Check the resistance of the closed relay

contacts and the switching function depending on the frequency of the

switching operations.

Hirschmann is continually working on improving and developing their

software. Check regularly whether there is an updated version of the

software that provides you with additional benefits. You find information

and software downloads on the Hirschmann product pages on the

Internet (http://www.hirschmann.com).

Depending on the degree of pollution in the operating environment, check

at regular intervals that the ventilation slots in the device are not

obstructed.

Note: You find information on settling complaints on the Internet at

http://www.beldensolutions.com/en/Service/Repairs/index.phtml.

Page 47

Installation RSP 20/25/30/35

Release 15 12/2017

47

7Disassembly

7.1 Removing the device

Proceed as follows:

Disconnect the data cables.

Disable the supply voltage.

Disconnect the terminal blocks.

Disconnect the grounding.

To remove the device from the DIN rail, press the device downwards and

pull it out from under the DIN rail.

WARNING

ELECTRIC SHOCK

Disconnect the grounding only after disconnecting all other cables.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Page 48

48

Installation RSP 20/25/30/35

Release 15 12/2017

7.2 Removing an SFP transceiver (optional)

Proceed as follows:

Pull the SFP transceiver out of the slot by means of the opened lock.

Seal the SFP transceiver with the protection cap.

1

2

Page 49

Installation RSP 20/25/30/35

Release 15 12/2017

49

8 Technical data

8.1 General technical data

Dimensions

W × H × D

RSP 20/25/30/35 See “Dimension drawings” on page 53.

Weight RSP 20/25/30/35-.......TT-S...... approx. 2.65 lb (1.2 kg)

RSP 20/25/30/35-.......TT-T......

RSP 20/25/30/35-.......TT-E......

approx. 3.31 lb (1.5 kg)

RSP 20/25/30/35-.......ZT-S...... approx. 1.3 kg

RSP 20/25/30/35-.......ZT-T......

RSP 20/25/30/35-.......ZT-E......

approx. 1.6 kg

Supply voltage

with the

characteristic

value CC

See “Requirements for connecting electrical wires” on page 6.

Rated voltage DC 24 V DC ... 48 V DC

Voltage range DC including

maximum tolerances

18 V DC ... 60 V DC

Connection type 2-pin terminal block

Tightening torque 4.5 lb-in

(0.51 Nm)

Power loss buffer > 10 ms at 20.4 V DC

Overload current protection at

input

Non-replaceable fuse

Back-up fuse for each voltage

input

Nominal rating:

Characteristic:

2A

slow blow

Peak inrush current < 4 A

Supply voltage

with characteristic

value TT

See “Requirements for connecting electrical wires” on page 6.

Rated voltage DC 12 V DC ... 24 V DC

Voltage range DC including

maximum tolerances

10.2 V DC ... 32 V DC

Connection type 2-pin terminal block

Tightening torque 4.5 lb-in

(0.51 Nm)

Power loss buffer > 10 ms at 10.2 V DC

Overload current protection at

input

Non-replaceable fuse

Back-up fuse for each voltage

input

At rated voltage DC 12 V DC

Nominal rating:

Characteristic:

5A

slow blow

Back-up fuse for each voltage

input

At rated voltage DC 24 V DC

Nominal rating:

Characteristic:

4A

slow blow

Peak inrush current < 14 A

Page 50

50

Installation RSP 20/25/30/35

Release 15 12/2017

Supply voltage

with the

characteristic

value K9 and KK

See “Requirements for connecting electrical wires” on page 6.

Rated voltage AC 110 V AC ... 230 V AC, 50 Hz ... 60 Hz

Voltage range AC including

maximum tolerances

88 V AC ... 265 V AC, 47 Hz ... 63 Hz

Rated voltage DC 60 V DC ... 250 V DC

Voltage range DC including

maximum tolerances

48 V DC ... 320 V DC

Connection type 3-pin terminal block

Tightening torque 4.5 lb-in

(0.51 Nm)

Power loss buffer > 10 ms at 98 V AC

Overload current protection at

input

Non-replaceable fuse

Back-up fuse Nominal rating:

Characteristic:

1A...20A

slow blow

Peak inrush current < 3.5 A

Climatic

conditions during

operation

Minimum clearance around the

device

Top and bottom device side: 3.94 in

(10 cm)

Left and right device side: 0.79 in (2 cm)

Derating

a

:

refer to the Hirschmann product web page

under http://www.hirschmann.com

Ambient air temperature

b

. Devices with operating temperature

characteristic value S (standard):

+32 °F ... +140 °F (0 °C ... +60 °C)

c

Devices with operating temperature

characteristic value E and T (extended):

−40 °F ... +158 °F (−40 °C ... +70 °C)

de

−40 °F ... +185 °F (−40 °C ... +85 °C) for

16 hours (tested in accordance with

IEC 60068-2-2)

df

Maximum inner temperature of

device (guideline)

Devices with operating temperature

characteristic value S (standard):

86 °C

Devices with operating temperature

characteristic value E and T (extended):

91 °C

Humidity 5 % ... 95 %

(non-condensing)

Air pressure min. 700 hPa (+9842 ft; +3000 m)

max. 1060 hPa (−1312 ft; −400 m)

Page 51

Installation RSP 20/25/30/35

Release 15 12/2017

51

Climatic

conditions during

storage

Ambient air temperature

b

−40 °F ... +185 °F (−40 °C ... +85 °C)

Humidity 5 % ... 95 %

(non-condensing)

Air pressure min. 700 hPa (+9842 ft; +3000 m)

max. 1060 hPa (−1312 ft; −400 m)

Signal contact

(only for device variants featuring supply voltage with characteristic value CC and TT)

Connection type 2-pin terminal block

Tightening torque 3 lb-in (0.34 Nm)

Nominal value for AC I

max

=1A at U

max

=30VAC

Nominal value for DC I

max

=1A at U

max

=60VDC

according to the UL Standards:

Nominal value for AC I

max

=1A at U

max

=30VAC

Nominal value for DC I

max

=1A at U

max

=30VDC

according to the Standards ANSI/ISA 12.12.01-2011:

See Control Drawing in chapter “Relevant for use in explosion hazard areas

(Hazardous Locations, Class I, Division 2):” on page 10.

Signal contact

(only for device variants featuring supply voltage with characteristic value K9 and KK)

Connection type 2-pin terminal block

Tightening torque 3 lb-in (0.34 Nm)

Nominal value for AC I

max

=1A at U

max

=230VAC

Nominal value for DC I

max

=1A at U

max

=60VDC

I

max

= 0.2 A at U

max

= 125 V DC

I

max

= 0.1 A at U

max

= 250 V DC

according to the UL Standards:

Nominal value for AC I

max

=1A at U

max

=30VAC

Nominal value for DC I

max

=1A at U

max

=30VDC

according to the Standards ANSI/ISA 12.12.01-2011:

See Control Drawing in chapter “Relevant for use in explosion hazard areas

(Hazardous Locations, Class I, Division 2):” on page 10.

Pollution degree 2

Protection classes Laser protection Class 1 in compliance with IEC 60825-1

Degree of protection IP20

a. Reduction of the maximum permitted ambient air temperature under specific conditions

b. Temperature of the ambient air at a distance of 2 in (5 cm) from the device

c. Hirschmann recommends to use SFP transceivers with “EEC” extension.

d. Use SFP transceivers with the “EEC” extension only, otherwise the standard temperature

range applies.

e. When using supply voltage with characteristic value CC, K9 or KK:

- applies when device is equipped with max. 4 SFP transceivers

- if a higher number is connected, the following maximum values apply for the ambient air

temperature: 5 transceivers: +154 °F (+68 °C); 6 transceivers: +149 °F (+67 °C);

7 transceivers: +140 °F (+65 °C)

When using supply voltage with characteristic value TT:

- applies when device is equipped with max. 2 SFP transceivers

- if a higher number is connected, the following maximum values apply for the ambient air

temperature: 4 transceivers: +140 °F (+65 °C); 5 to 7 transceivers: +140 °F (+60 °C)

f. When using supply voltage with characteristic value CC, K9 or KK:

- applies when device is equipped with max. 4 SFP transceivers

- if a higher number is connected, the following maximum values apply for the ambient air

temperature: 5 to 7 transceivers: +176 °F (+80 °C)

When using supply voltage with characteristic value TT:

- applies when device is equipped with max. 2 SFP transceivers

- if a higher number is connected, the following maximum values apply for the ambient air

temperature: 4 transceivers: +176 °F (+80 °C); 5 to 7 transceivers: +167 °F (+75 °C)

Page 52

52

Installation RSP 20/25/30/35

Release 15 12/2017

8.2 Power consumption/power output

Device name Maximum

power

consumption

Power output

RSP20-11003Z6TT...

Supply voltage with characteristic value CC, K9 or KK 15 W 51 Btu (IT)/h

Supply voltage with characteristic value TT 17 W 58 Btu (IT)/h

RSP20-11003Z6ZT...

Supply voltage with characteristic value CC, K9 or KK 18 W 61 Btu (IT)/h

Supply voltage with characteristic value TT 20 W 68 Btu (IT)/h

RSP25-11003Z6TT...

Supply voltage with characteristic value CC, K9 or KK 19 W 65 Btu (IT)/h

Supply voltage with characteristic value TT 21 W 72 Btu (IT)/h

RSP25-11003Z6ZT...

Supply voltage with characteristic value CC, K9 or KK 22 W 75 Btu (IT)/h

Supply voltage with characteristic value TT 24 W 82 Btu (IT)/h

RSP30-08033O6TT...

Supply voltage with characteristic value CC, K9 or KK 15 W 51 Btu (IT)/h

Supply voltage with characteristic value TT 17 W 58 Btu (IT)/h

RSP30-08033O6ZT...

Supply voltage with characteristic value CC, K9 or KK 18 W 61 Btu (IT)/h

Supply voltage with characteristic value TT 20 W 68 Btu (IT)/h

RSP35-08033O6TT...

Supply voltage with characteristic value CC, K9 or KK 19 W 65 Btu (IT)/h

Supply voltage with characteristic value TT 21 W 72 Btu (IT)/h

RSP35-08033O6ZT...

Supply voltage with characteristic value CC, K9 or KK 22 W 75 Btu (IT)/h

Supply voltage with characteristic value TT 24 W 82 Btu (IT)/h

Page 53

Installation RSP 20/25/30/35

Release 15 12/2017

53

8.3 Dimension drawings

Figure 7: Dimensions of the device variants with operating temperature

characteristic value S. For the characteristic value, cf. “Device name and

product code” on page 19.

Figure 8: Dimensions of device variants with operating temperature characteristic

value E and T. For the characteristic value, cf. “Device name and product

code” on page 19.

mm

inch

70

2.76

4.52

114,7

6,55

0.26

89,9

3.54

163,6

6.44

mm

inch

98,29

3.87

163,6

6.44

70

2.76

4.52

114,7

6,55

0.26

Page 54

54

Installation RSP 20/25/30/35

Release

15

12/2017

8.4 EMC and immunity

You will find detailed information on the certificates and declarations applying to your device in a separate overview.

See table 5 on page 21.

Stability Standard applications Substation applications

IEC 60068-2-6, test Fc Vibration — 2 Hz ... 9 Hz with 0.12 in. (3 mm)

amplitude

5 Hz ... 8.4 Hz with 0.14 in. (3.5 mm)

amplitude

5 Hz ... 8.4 Hz with 0.14 in. (3.5 mm)

amplitude

8.4 Hz ... 150 Hz

with 1 g

9 Hz ... 200 Hz

with 1 g

— 200 Hz ... 500 Hz

with 1,5 g

IEC 60068-2-27, test Ea Shock 15 g at 11 ms 15 g at 11 ms

EMC interference emission Standard applications Substation applications

Radiated emission

EN 55032 Class A Class A

GL Guidelines ——

FCC 47 CFR Part 15 Class A Class A

EN 61000-6-4 Fulfilled Fulfilled

Conducted emission

EN 55032 AC and DC supply connections Class A Class A

GL Guidelines AC and DC supply connections — —

FCC 47 CFR Part 15 AC and DC supply connections Class A Class A

EN 61000-6-4 AC and DC supply connections Fulfilled Fulfilled

EN 55032 Telecommunication connections Class A Class A

EN 61000-6-4 Telecommunication connections Fulfilled Fulfilled

Page 55

Installation RSP 20/25/30/35

Release

15

12/2017

55

EMC interference immunity Standard applications Substation applications

Electrostatic discharge

EN 61000-4-2

IEEE C37.90.3

Contact discharge ±4 kV ±8 kV

EN 61000-4-2

IEEE C37.90.3

Air discharge ±8 kV ± 15 kV

Electromagnetic field

EN 61000-4-3 80 MHz ... 3000 MHz 10 V/m 10 V/m

IEEE 1613 80 MHz ... 1000 MHz — 35 V/m

Fast transients (burst)

EN 61000-4-4

IEEE C37.90.1

AC/DC supply connection ±2 kV ±4 kV

EN 61000-4-4

IEEE C37.90.1

Data line ±4 kV ±4 kV

Voltage surges - DC supply connection

EN 61000-4-5 line/ground ±2 kV ±2 kV

IEEE 1613 line/ground — ± 5 kV

EN 61000-4-5 line/line ±1 kV ±1 kV

Voltage surges - AC supply connection

EN 61000-4-5 line/ground ±2 kV ±4 kV

IEEE 1613 line/ground — ± 5 kV

EN 61000-4-5 line/line ±1 kV ±2 kV

Voltage surges - data line

EN 61000-4-5 line/ground ±1 kV ±4 kV

Conducted disturbances

EN 61000-4-6 150 kHz ... 80 MHz 10 V 10 V

Damped oscillation - AC/DC supply connection

EN 61000-4-12

IEEE C37.90.1

line/ground — 2.5 kV

EN 61000-4-12

IEEE C37.90.1

line/line — 1 kV

Page 56

56

Installation RSP 20/25/30/35

Release

15

12/2017

Damped oscillation - data line

EN 61000-4-12

IEEE C37.90.1

line/ground — 2.5 kV

EN 61000-4-12 line/line — 1 kV

Pulse magnetic fields

EN 61000-4-9 — 300 A/m

EMC interference immunity Standard applications Substation applications

Page 57

Installation RSP 20/25/30/35

Release

15

12/2017

57

8.5 Network range

Note: The line lengths specified for the transceivers apply for the respective fiber data (fiber attenuation and

BLP/dispersion).

Product code

M-SFP-...

ModeaWave length Fiber System

attenuation

Example for F/O

cable length

b

Fiber attenuation BLPc/Dispersion

-SX/LC... MM 850 nm 50/125 µm 0 dB ... 7.5 dB 0 mi ... 0.34 mi

(0 km ... 0.55 km)

3.0 dB/km 400 MHz×km

-SX/LC... MM 850 nm 62.5/125 µm 0 dB ... 7.5 dB 0 mi ... 0.17 mi

(0 km ... 0.275 km)

3.2 dB/km 200 MHz×km

-MX/LC EEC MM 1310 nm 50/125 µm 0-12 dB 0-1.5 km 1.0 dB/km 800 MHz×km

-MX/LC EEC MM 1310 nm 62.5/125 µm 0-12 dB 0-500 m 1.0 dB/km 500 MHz×km

-LX/LC... MM 1310 nm

d

50/125 µm 0 dB ... 10.5 dB 0 mi ... 0.34 mi

(0 km ... 0.55 km)

1.0 dB/km 800 MHz×km

-LX/LC... MM 1310 nm

e

62.5/125 µm 0 dB ... 10.5 dB 0 mi ... 0.34 mi

(0 km ... 0.55 km)

1.0 dB/km 500 MHz×km

-LX/LC... SM 1310 nm 9/125 µm 0 dB ... 10.5 dB 0 mi ... 12.43 mi

(0 km ... 20 km)

f

0.4 dB/km 3.5 ps/(nm×km)

-LX+/LC... SM 1310 nm 9/125 µm 5 dB ... 20 dB 8.70 mi ...

26.10 mi (14 k m ...

42 km)

0.4 dB/km 3.5 ps/(nm×km)

-LH/LC... LH 1550 nm 9/125 µm 5 dB ... 22 dB 14.29 mi ...

49.71 mi (23 km ...

80 km)

0.25 dB/km 19 ps/(nm×km)

-LH+/LC LH 1550 nm 9/125 µm 15 dB ... 30 dB 44.12 mi ...

67.11 mi (71 km ...

108 km)

0.25 dB/km 19 ps/(nm×km)

-LH+/LC LH 1550 nm 9/125 µm 15 dB ... 30 dB 44.12 mi ...

79.54 mi (71 km ...

128 km)

0.21 dB/km

(typically)

19 ps/(nm×km)

Table 11: Fiber port 1000BASE-FX (SFP fiber optic Gigabit Ethernet Transceiver)

Page 58

58