Page 1

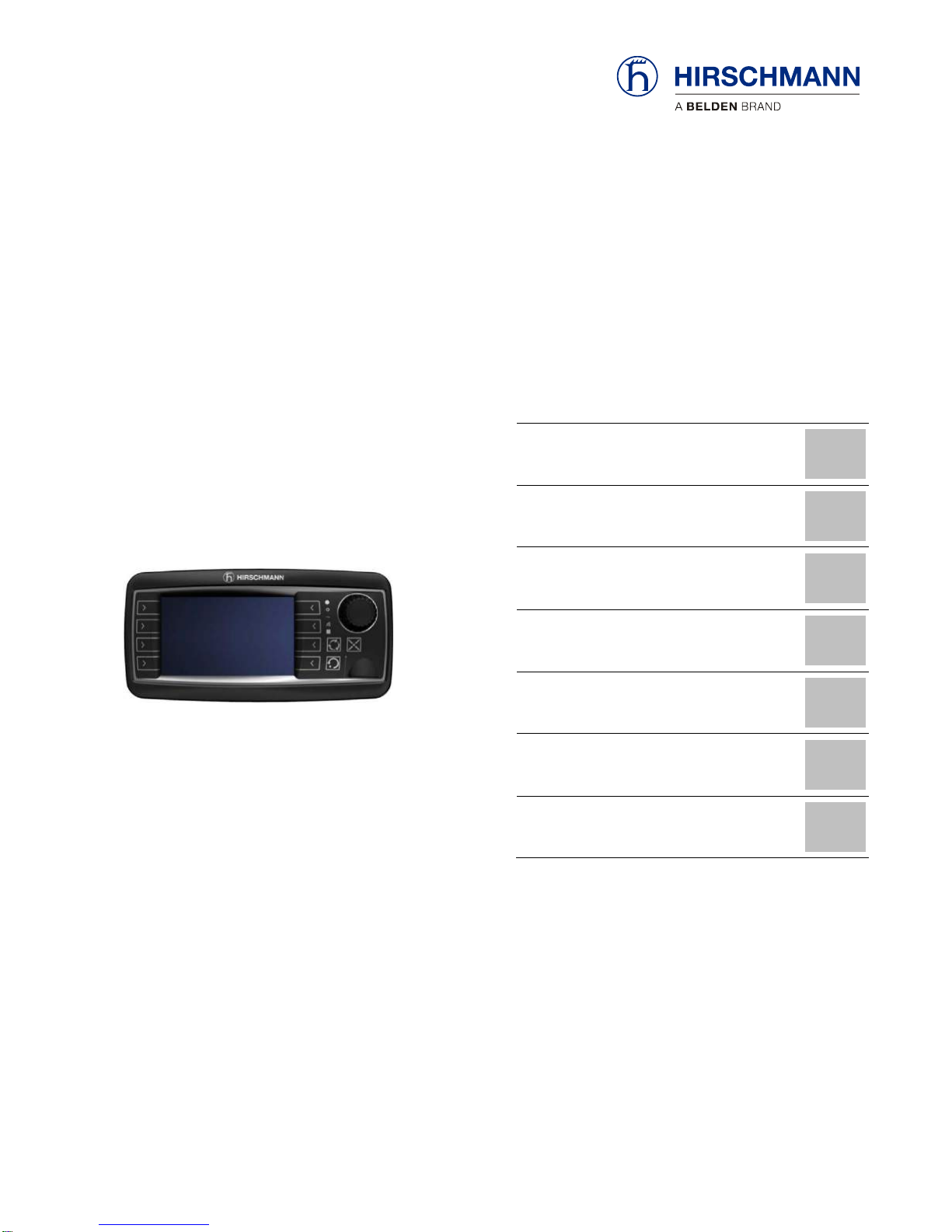

qSCALE i2

qSCALE i2 System

Tool Version 3.0.34

Contents

Safety Instructions

1

General Information

2

Troubleshooting

3

Commissioning

4

Maintenance and Repair

5

Appendix

6

Service Manual

Issue B – 11/2017

This document has the order number:

MAN-QS12-S-0004

Page 2

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 2/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

TABLE OF CONTENTS

1 Safety Instructions ........................................................................................... 7

2 General Information ......................................................................................... 8

2.1 Description of the System ............................................................................... 9

2.1.1 Description of System Function ............................................................. 9

2.1.2 Description of the CAN Bus System ....................................................10

2.1.3 Description of the System Components ..............................................11

3 Troubleshooting .............................................................................................14

3.1 Troubleshooting with Display ...................................................................14

3.1.1 Op-Mode Confirm Screen ....................................................................15

3.1.2 Information Selection Menu .................................................................16

3.1.3 Error Codes ..........................................................................................27

3.2 Hardware Troubleshooting ......................................................................29

3.2.1 What is Wrong? ...................................................................................29

3.2.2 Initial System Inspection ......................................................................31

3.2.3 Simple Corrective Actions ....................................................................33

3.2.4 Indicator Definitions .............................................................................34

3.2.5 Boom Angle Sensing ...........................................................................35

3.2.6 Boom Length Sensing .........................................................................38

3.2.7 Pressure Sensing ................................................................................44

3.2.8 Load Sensing .......................................................................................45

3.2.9 A2B Switch Overview ..........................................................................46

3.2.10 Slew Sensing Overview ...................................................................48

3.2.11 Tilt Sensing ......................................................................................49

3.2.12 No Console Display .........................................................................51

3.2.13 CAN Bus Communications ..............................................................52

4 Commissioning ...............................................................................................55

4.1 Adding Wireless Sensors ..............................................................................55

4.2 Sensor Calibration..........................................................................................57

4.2.1 Sensor Calibration Selection ...............................................................60

4.2.2 Boom Length Calibration .....................................................................61

4.2.3 Boom Angle Calibration .......................................................................63

4.2.4 Slew Sensor Calibration ......................................................................66

4.2.5 Tilt Sensor Calibration .........................................................................68

4.2.6 Analog Outrigger Calibration ...............................................................71

5 Maintenance and Repair ................................................................................73

5.1 Maintenance ............................................................................................73

5.2 Cleaning ...................................................................................................73

5.3 qSCALE i2 Console Software Upload .....................................................74

Page 3

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 3/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

6 Appendix .........................................................................................................76

6.1 Password Entry ........................................................................................76

6.2 Error Code Tables ...................................................................................77

6.2.1 General Errors – 00xx, 1Fxx, 2xxx, & 3xxx .........................................78

6.2.2 Limit Error Codes – 01xx, 02xx, 03xx, 04xx, & 05xx ...........................82

6.2.3 Kinematic Error Codes – 0Axx .............................................................90

6.2.4 CAN and I/O Error Codes – 11xx-1Bxx ...............................................95

6.3 Drawings ................................................................................................157

Page 4

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 4/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

VERSION OVERVIEW

Issue

Date

Description

Editor

A

6/2015

Initial Release

AC B 6/2016

Updated images and sections

AC

Page 5

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 5/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

Introduction

This manual is a component of the equipment or systems supplied by Hirschmann Automation and

Control GmbH. Keep this manual in a safe place and ensure that it is available to all users.

The contents of this manual are subject to change. Hirschmann Automation and Control GmbH do not

provide any guarantee for this material, including the associated guarantee regarding marketability and

suitability for certain intended purposes. Hirschmann Automation and Control GmbH accept no liability

for errors in the contents of the manual or for direct or indirect damage in connection with the provision

and use of the manual.

This manual is protected by copyright. All rights reserved. The manual may not be duplicated, reproduced or translated into another language, either wholly or partly, without the prior written permission of

Hirschmann Automation and Control GmbH.

The rendition of common names, trade names, trademarks etc. in this documentation should not be

construed to mean that such names, even without special identification, are free in the sense of trademark and trademark protection legislation and hence usable by anyone.

This device / system are intended exclusively for the tasks described in this manual. Any other use shall

be construed as being inappropriate. The manufacturer accepts no liability for damage caused by inappropriate or impermissible use. This device / system may only be used if it is in perfect technical condition.

Only appropriately qualified personnel may work with this device / system, i.e. persons:

who are familiar with the operation or installation and commissioning

who know the current regulations for the prevention of accidents

About this Manual

Liability Disclaimer

Copyright

Notice

Trademarks

Use for the Intended

Purpose

Qualification of the

Operating Personnel

Page 6

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 6/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

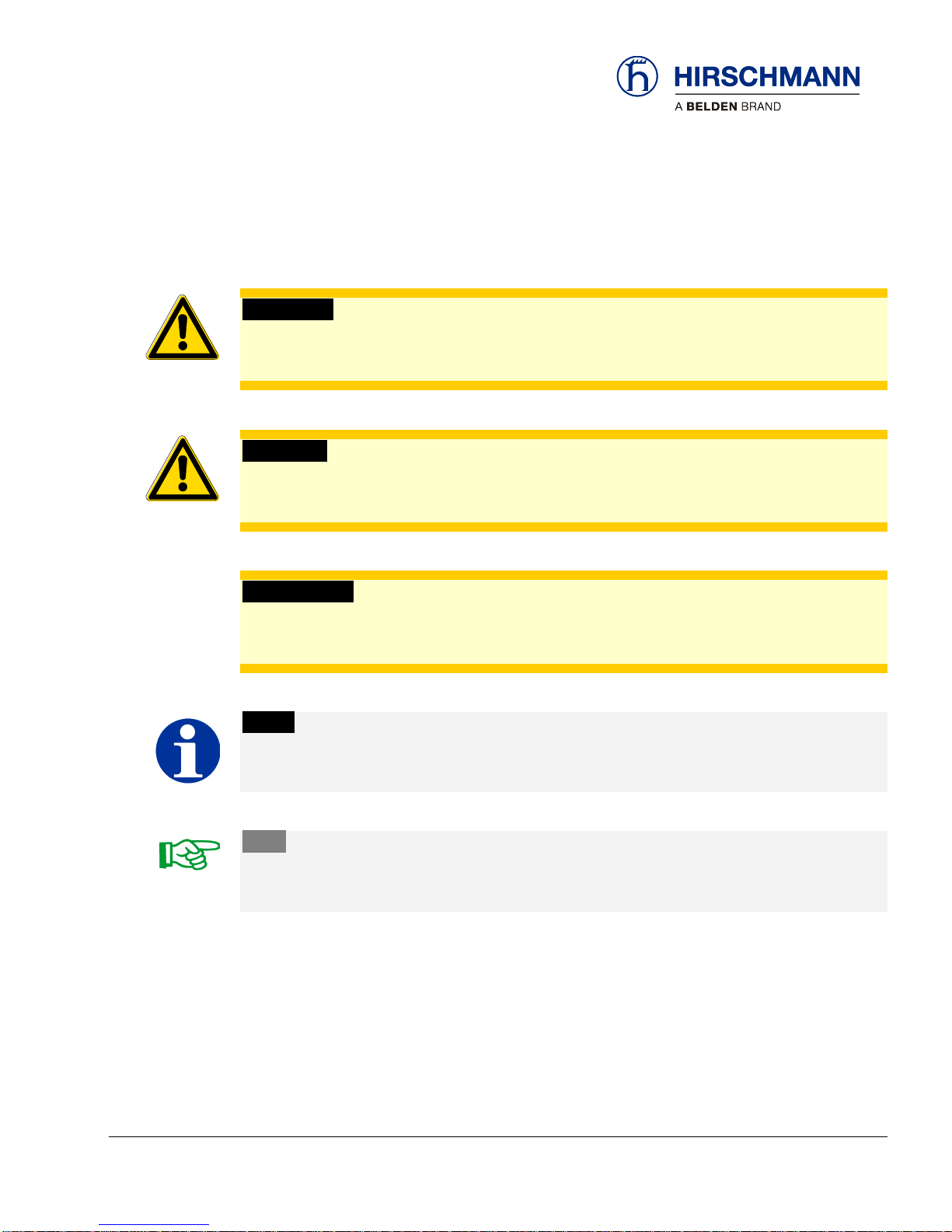

Marking of Notices

Dangers and other important notices are marked as follows in this manual:

WARNING

Warning of direct threat of personal injury and damage to property.

Instructions on precautions to avert the danger.

CAUTION

Warning of dangerous situations. Also warns of damage to property.

Instructions for averting the danger.

IMPORTANT

Warning of possibly damaging situation for the product.

Instructions for avoiding the possibly damaging situation.

NOTE

Usage instructions and information, but no dangerous situation

HINT

Supplementary comments and recommendations for the user.

Page 7

Safety Instructions

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 7/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

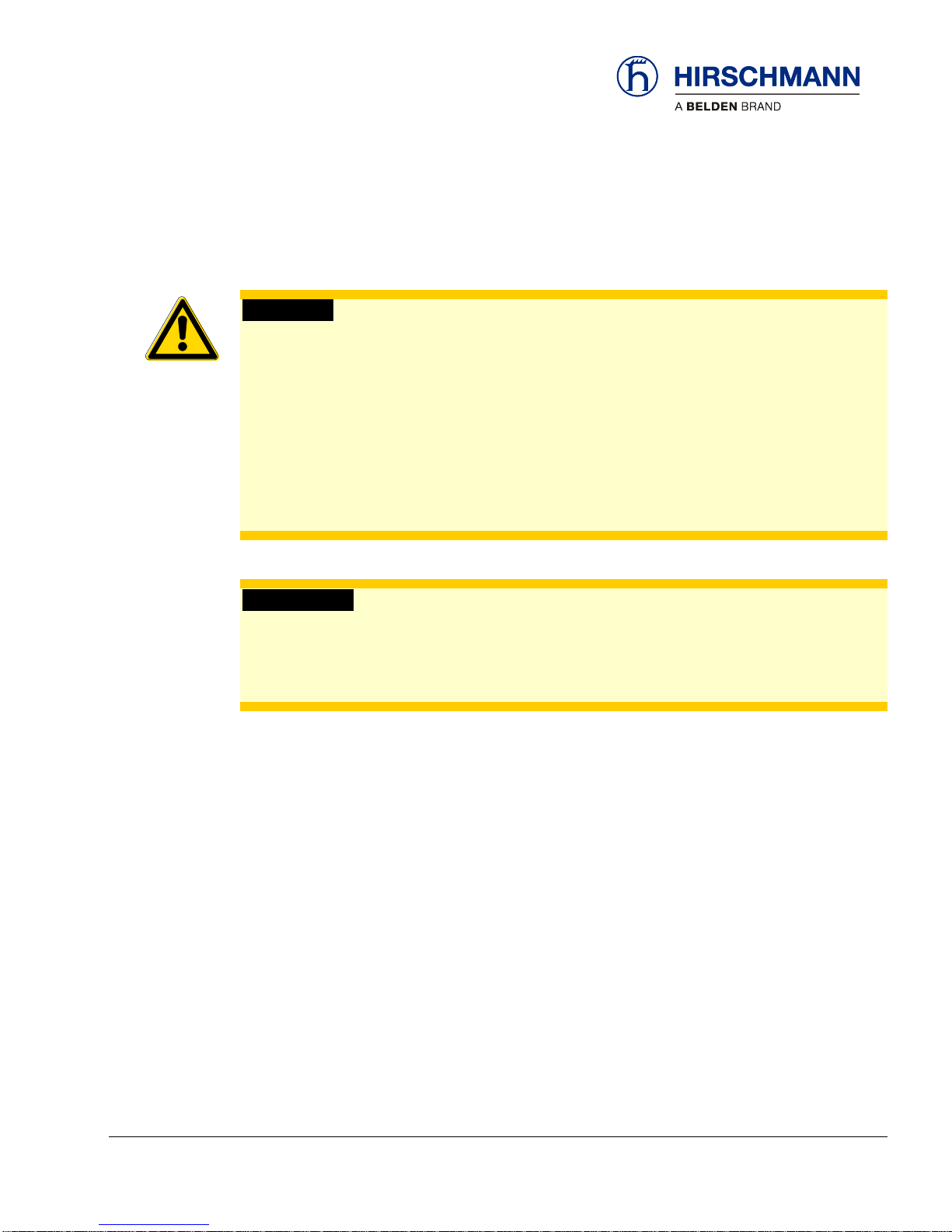

1 Safety Instructions

WARNING

Imminent threat of personal injury and damage to property due to incorrect system settings!

The correct adjustment of the Rated Capacity Limited (RCL) to the current set-up status is es-

sential for the correct function of the system and of the machine.

The RCL can only operate correctly if all settings are entered correctly according to the current

set-up status during the SETUP procedure.

The settings can only be carried out by operators who are completely familiar with the operation

and functions of the machine and the RCL.

The correctness of these settings must be guaranteed before starting the machine operations!

IMPORTANT

Connection to the wrong power supply will cause damage to the device.

The device may only be connected to a DC voltage source of 10 V to 30 V!

Page 8

General Information

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 8/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2 General Information

This service manual is designed to assist a service or maintenance person in identifying system problem areas or malfunctions. A digital voltmeter with the capability to measure current will be required,

along with standard maintenance and service tools.

NOTE

Knowledge of how to use a voltmeter to measure both voltage and current is assumed.

NOTE

The qSCALE i2 contains several menus where queries and settings can be made only after entering a password.

HINT

For system operation, refer to the console Operator’s Manual.

Page 9

Description of the System

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 9/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2.1 Description of the System

2.1.1 Description of System Function

The qSCALE i2 system is a CAN bus system comprised of an operating console, digital input/output

(DIO) extension box, length/angle cable reel, pressure transducers, and an anti-two-block switch. All

components and sensors are equipped with CAN bus controllers.

The Hirschmann Automation and Control system operates on the principle of reference/real comparison. The real value resulting from the pressure measurement is compared with the reference data

stored in the central processor memory and evaluated in the microprocessor. When limits are reached,

an overload warning signal is generated at the operator’s console. At the same time, the aggravating

crane movements, such as hoist up, telescope out, and boom down, will be stopped.

The fixed data regarding the crane, such as capacity charts, boom weights, centers of gravity, and

dimensions are stored in memory chips in the central processor unit. This data is the reference information used to calculate the operating conditions.

Boom length and boom angle are registered by the length/angle sensor mounted inside the cable reel

which is mounted on the boom. The boom length is measured by the cable reel cable, which also

serves as an electrical conductor for the anti-two block switches.

The crane load is measured by pressure transducers attached to the piston and rod side of the hoist

cylinders.

The interactive user guidance considerably simplifies the input of operating modes as well as the setting

of geometry limit values.

Page 10

Description of the System

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 10/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2.1.2 Description of the CAN Bus System

CAN stands for “Controller Area Network” and is intended to be used as a serial bus system for a network of controllers. Each controller connected through a CAN chip is called a "node" and is mostly used

to acquire data from a sensor. All nodes are connected to a common bus and all nodes are able to

simultaneously read the data on that bus. Also, all nodes are able to transmit data on that bus, but only

one node at a given time has write access to the bus. If the message is relevant, it will be processed;

otherwise, it is ignored. The unique identifier also determines the priority of the message. The lower the

numerical value of the identifier, the higher the priority.

The cable bus is a twisted pair of shielded wire. Data can be transmitted in blocks from 0-8 bytes at a

maximum transfer rate of 1 Mbit/s for networks up to 40 meters. For longer network distances, the maximum transfer rate must be reduced to 50 Kbit/s for a 1 km network distance. CAN will operate in extremely harsh environments and the extensive error checking mechanisms ensure that any transmission errors are detected.

Page 11

Description of the System

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 11/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

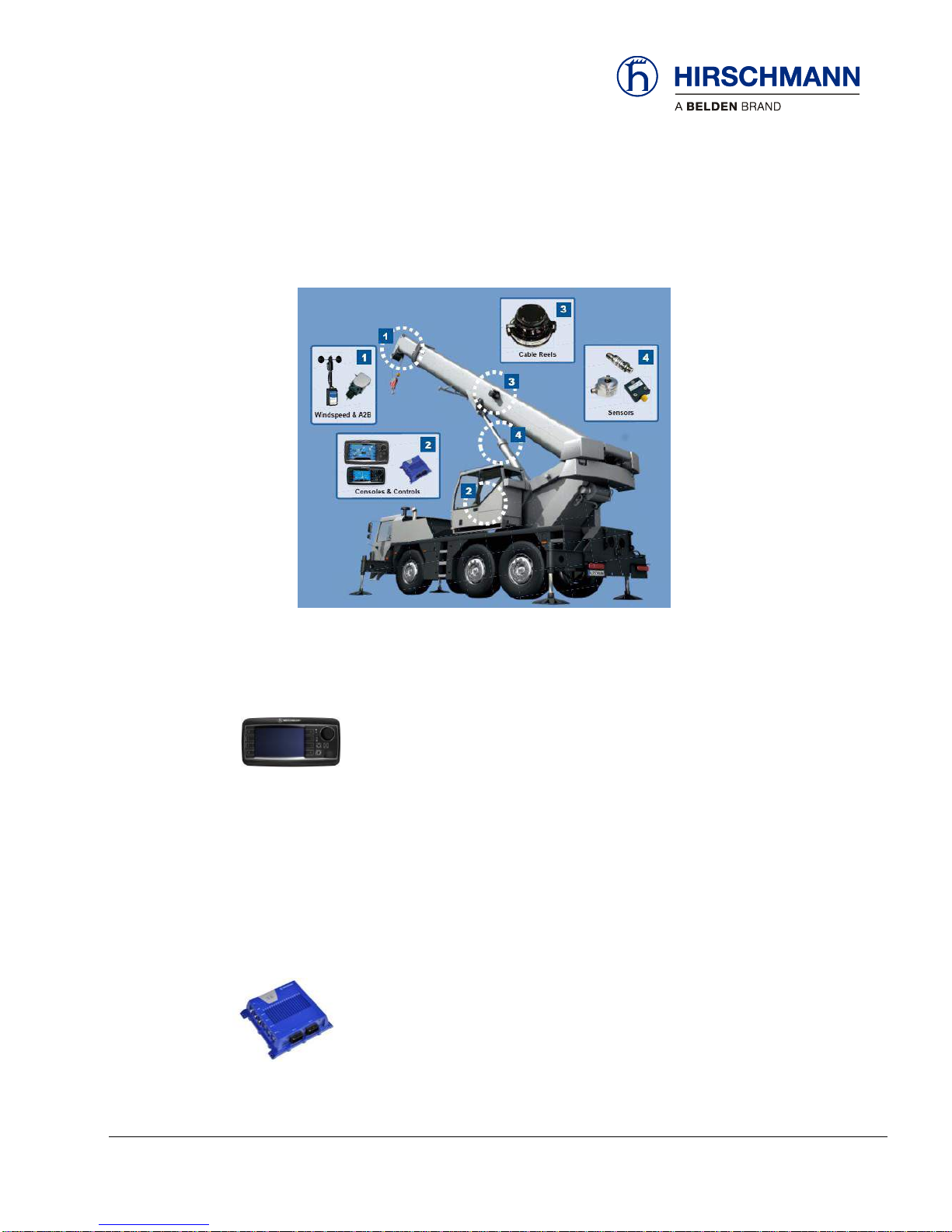

2.1.3 Description of the System Components

The qSCALE i2 system is comprised of various components. The typical relative locations of these

components are shown in the photo below.

2.1.3.1 Console (qSCALE i2)

The graphic display console houses the CPU and also displays pertinent information

regarding the RCL configuration. Refer to the Operator’s Manual for detailed operation of the console.

cSCALE Ix consoles are available in 4.3” (I2) and 7” (I3) sizes. The graphic display console displays

pertinent information regarding the RCL configuration. Refer to the Operator’s Manual for detailed operation of the console.

2.1.3.2 cSCALE DIO

The DIO module is an I/O module for the decentralized detection of analog and digital

sensor signals as well as for driving actuators and proportional valves. The DIO module is able to communicate with programmable logic controllers using the CANOpen

protocol.

Page 12

Description of the System

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 12/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2.1.3.3 Pressure Transducers

The pressure transducers convert hydraulic pressure into an electric signal. The

pressure transducers are connected to the CAN bus junction box. One pressure

transducer is connected to the piston side of the lift cylinder and the other to the rod

side.

2.1.3.4 Cable Reel (Length-Angle Sensor)

The length-angle sensor (LWG), often referred to as the “cable reel”, is installed on

the base section of the boom can measure the length and the angle of the boom

along with transmitting signals to the boom tip.

A reeling drum drives either a potentiometer or rotary encoder to measure the length

of the boom. The length cable on the drum connects to the boom tip and can transmit signals from the

chassis through a slip ring within the LWG housing through the length cable to the boom tip.

The angle sensor is either a liquid capacitive angle sensor (WGC) or a MEMS based angle sensor

(WGX). Both length and angle sensor are connected to a CAN bus board which is connected to the bus

system.

2.1.3.5 Anti-Two-Block (A2B) Switch

The anti-two-block switch monitors the load block and its relationship with the head of

the boom. In working condition, the switch is closed. When the load block strikes the

weight, the circuit opens, disengaging a relay output. To check the cable for damage

(short circuit to ground) there is a 4.7k resistor between ground and the contact of the

switch to give a signal back to the central unit. The weight at the anti-two-block

switch keeps the switch closed until the load block strikes it.

Page 13

Description of the System

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 13/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2.1.3.6 Slew (Angle of Rotation) Sensor

This component is an absolute rotary encoder. This slew angle is the angle (rotational

positioning) of the crane boom relative to the truck.

2.1.3.7 Tilt Sensor

This component is a MEMS based inclination sensors, applicable for all kinds of angle and

position measurements on mobile machines. Typical applications include determination of

a crane boom angle, the leveling of an undercarriage, and alignment tasks on mobile

machines.

Page 14

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 14/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3 Troubleshooting

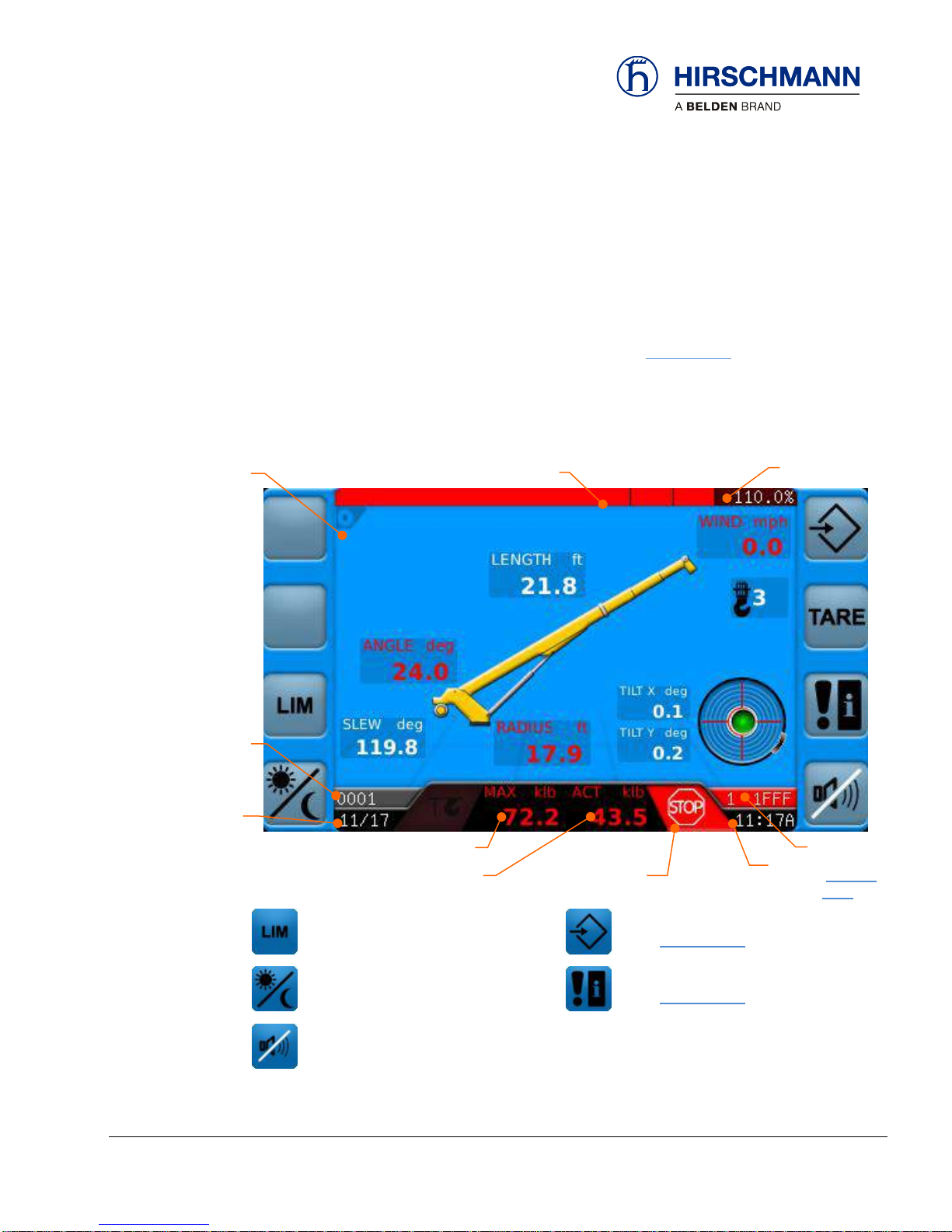

3.1 Troubleshooting with Display

The main working screen displays error codes and symbols in the status bar. The error code cause and

recommended solution can be found using the displayed code in Section 3.1.3. The status of all inputs

and outputs of the system can be checked using several screen displays on the RCL console.

When there are communication errors with safety critical sensors the system will default to maximum

system utilization. Sensors in error state will have their values turn red.

.

User Limits

(see Operators Manual)

Operation Confirm Screen

(see Section 3.1.1)

Display Day/Night Switch

(see Operators Manual)

System Event Information

(see Section 3.1.3)

Silence Alarm

(see Operators Manual)

Function

Keys

Load Capacity

(bar chart)

% Utilization

Operation

Mode

Event code,

as required

(Section

3.1.3)

Lifting Capacity

Date

Time

Warning Symbols

as required

Actual Load

Heartbeat

Page 15

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 15/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.1 Op-Mode Confirm Screen

The Op-Mode Confirm screen is the starting point to access diagnostic screens

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

Setup

(see Operator’s Manual)

Operation Mode Selection

(see Operator’s Manual)

Information Selection

(see Section 3.1.2)

Select Reeving

(see Operator’s Manual)

Graphic Tilt Screen

(see Operator’s Manual)

System Event Information

(see Section 3.1.3)

Function Keys

Page 16

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 16/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2 Information Selection Menu

The Information Selection Menu allows the user to view crane, sensor, and software version information

and is the starting point for diagnostic information.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

Sensor Information Screen

(see Section 3.1.2.1)

Crane Information

(see Operators Manual)

Information Selection (extended)

(see Section 3.1.2.2)

Version-Info

(see Operators Manual)

Function Keys

Page 17

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 17/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

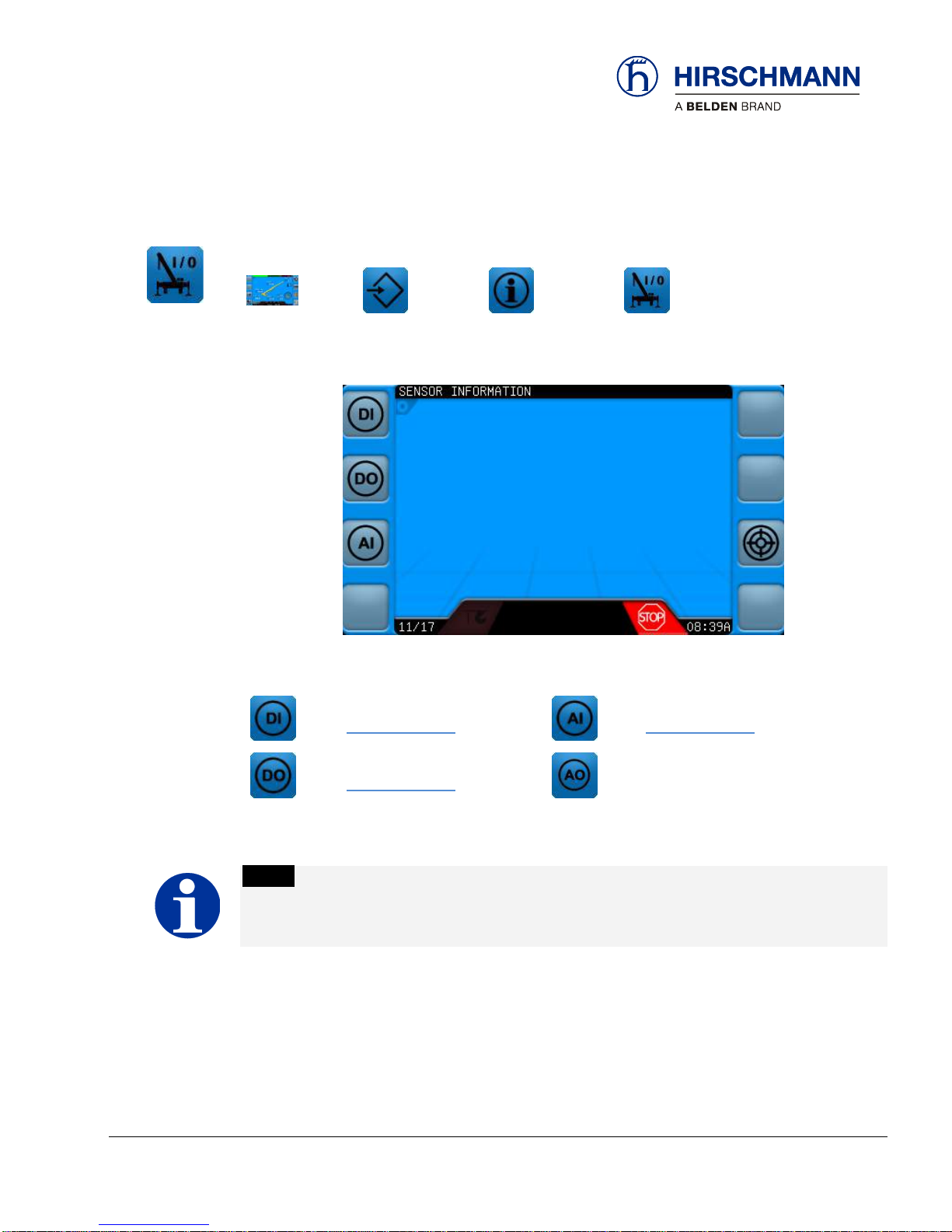

3.1.2.1 Sensor Information Menu

In this menu different information can be displayed about the defined input sensors on the crane.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

Digital Input Information

(see Section 3.1.2.1.1)

Analog Input Information

(see Section 3.1.2.1.3)

Digital Output Information

(see Section 3.1.2.1.2)

Not available for this project

NOTE

Available screens will vary depending upon system configuration!

Function Keys

Page 18

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 18/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2.1.1 Digital Input Screen

The Digital Input Screen shows all of the configured digital inputs for the system, including the A2B

signal. These inputs are wired to the DIO Box; refer to your crane system wiring diagram for details.

Use the rotary knob to scroll between all available inputs.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

DIGITAL

INPUTS

Additional Information

The following information can be found on this screen:

Value Current Value of the Input (False = Low, True = High)

Fault Indication whether an error has occurred

State Current Status of value

Substitute According to Project File Configuration

Debounce Time According to Project File Configuration

Error Base Base error priority of the error when error occurs

Raw Source Available in Additional Information

Function Keys

Page 19

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 19/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2.1.2 Digital Output Screen

Digital Output Screen shows all of the configured digital outputs for the system (if there are no digital

outputs then this screen will not exist). These outputs are wired from the DIO Box; refer to your crane

system wiring diagram for details. Use the rotary knob to scroll between all available outputs.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

DIGITAL

OUTPUTS

Additional Information

The following information can be found on this screen:

Value False = Low, True = High

Fault Indication whether an error has occurred calculating this value

State Current Status of value

Substitute Not Configurable

Debounce Time According to Project File I/O configuration

Error Base Base error class and priority of the sensor when an error occurs

Raw Source Available in Additional Information

Function Keys

Page 20

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 20/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

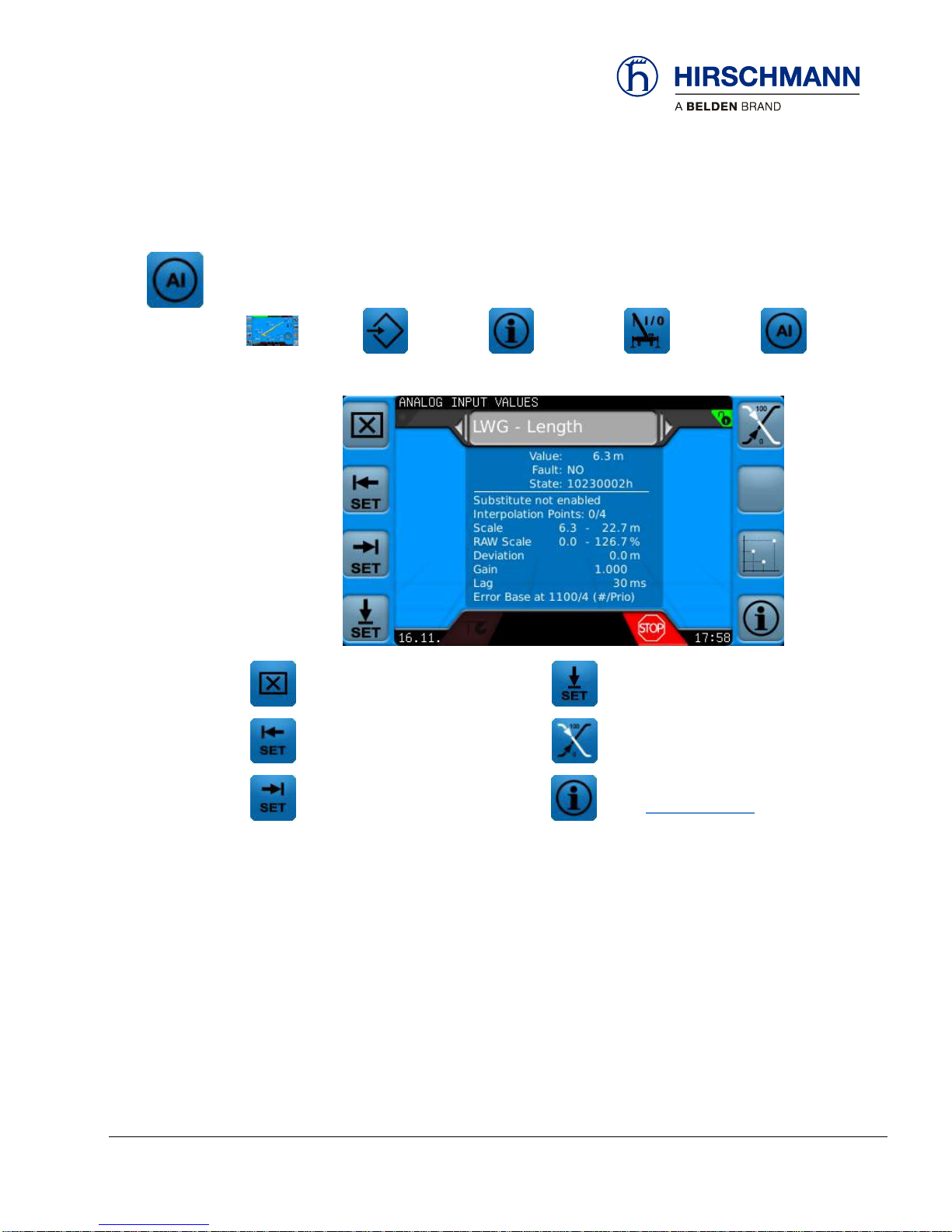

3.1.2.1.3 Analog Input Screen

Analog Input Screen shows all of the configured analog inputs for the system, including CAN sensors.

These outputs are wired from the DIO Box; refer to your crane system wiring diagram for details. Use

the rotary knob to scroll between all available outputs.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

ANALOG

INPUTS

Delete Sensor Calibration

Set Zero Point Offset

Set Current Sensor Raw Value as

Raw-Value Scale Start

Inverts Raw Value

(100% minus raw value)

Set Current Sensor Raw Value as

Raw-Value Scale End

Additional Information

(see Section 3.1.2.1.4)

The following information can be found on this screen:

Value Current Value

Fault Indication whether an error has occurred calculating this value

State Current Status of value

Substitution According to Project File Configuration

Scale Scaled values are defined in the configurator

Raw Value Scaling: The start of a raw value scaling is assigned to the scale start value and

changes after sensor calibration

Deviation Offset changes after sensor calibration

Gain Filter amplification factor

Lag Filter delay

Error Base Base error class and priority of the sensor when an error occurs

Function Keys

Page 21

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 21/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

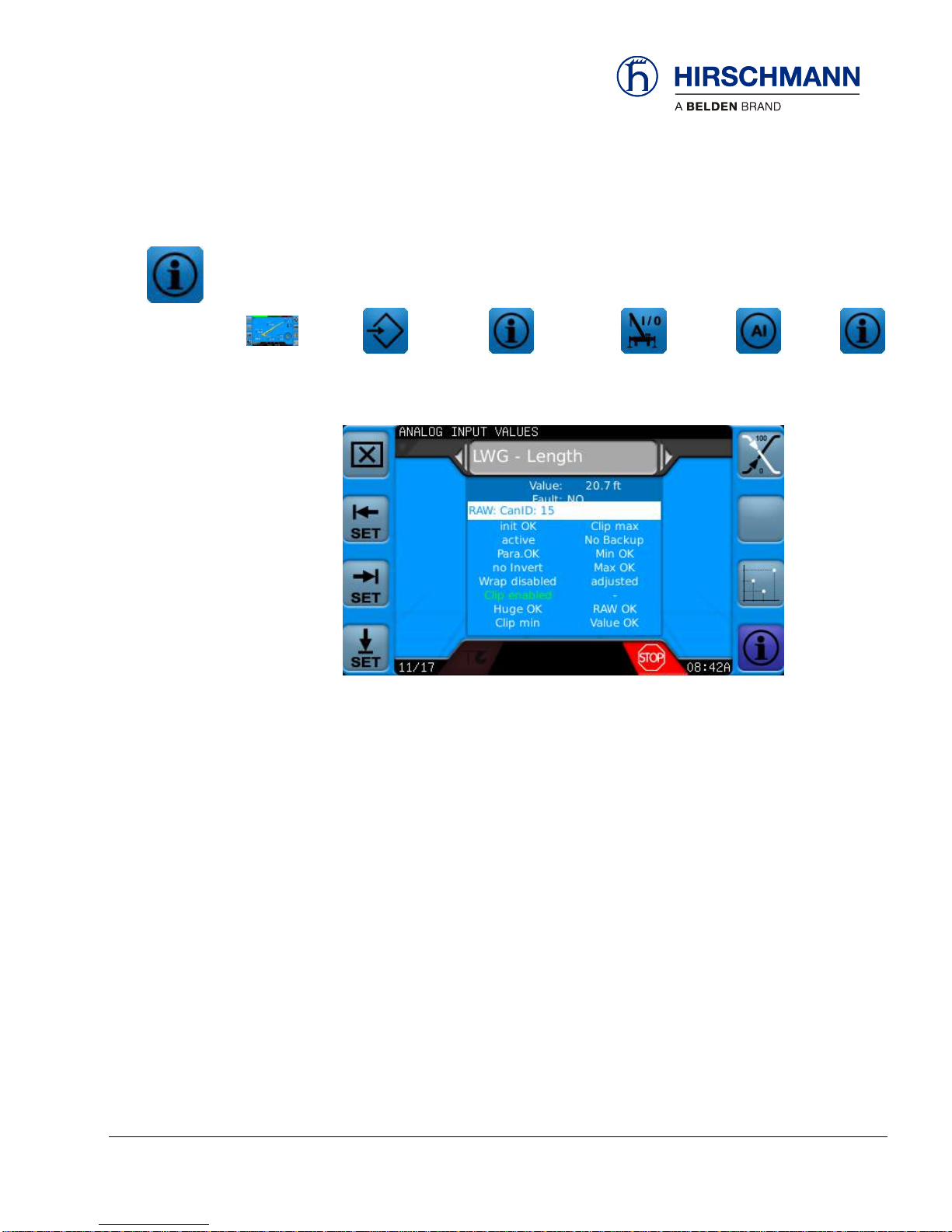

3.1.2.1.4 Extended Analog Input Information

Analog Input Screen shows all of the configured analog inputs for the system, including CAN sensors.

These outputs are wired from the DIO Box; refer to your crane system wiring diagram for details. Use

the rotary knob to scroll between all available outputs.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

ANALOG

INPUTS

EXT

ANALOG

INPUT

The following information can be found on this screen:

Raw Source Value

The display of clip, wrap, and inverted as defined in Project File Configuration

Deviations from the default value are highlighted in color.

Page 22

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 22/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

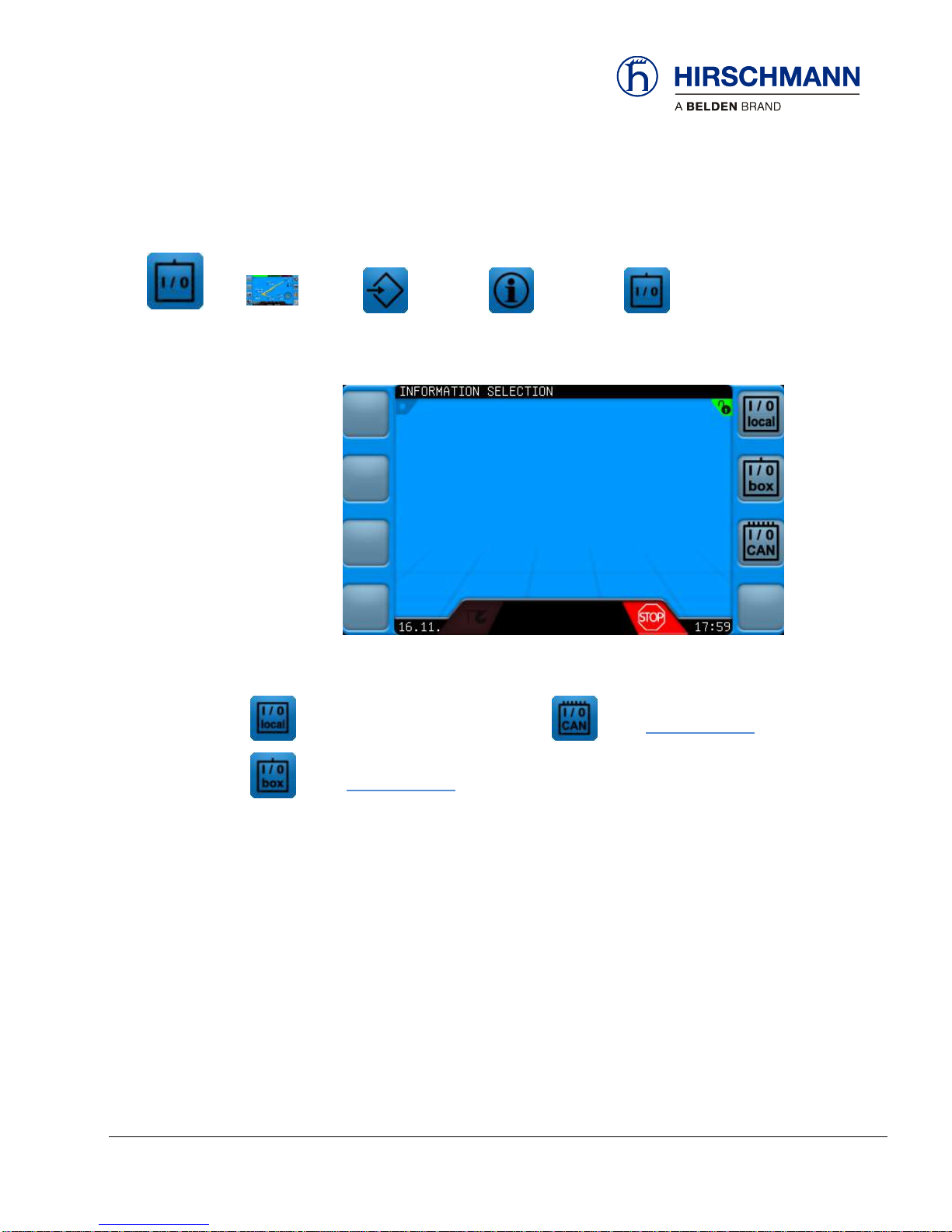

3.1.2.2 Extended Information Menu

In this menu different information can be displayed about the defined sensors.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

EXTENDED

INFORMATION

Console I/O

Not used for this Project

CAN Sensor Information

(see Section 3.1.2.2.1)

DIO I/O

(see Section 3.1.2.2.1)

Function Keys

Page 23

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 23/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2.2.1 DIO I/O Information

I/O information for DIO Module (standard) and optional TRS10-W2 (wireless sensor receiver) are found

on this screen.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

EXTENDED

INFORMATION

DIO

INFO

Console I/O

Not used for this Project

Analog Input Information

(Wireless Sensor Values)

Digital Input Information

(Wireless Sensor Values)

Function Keys

Page 24

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 24/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

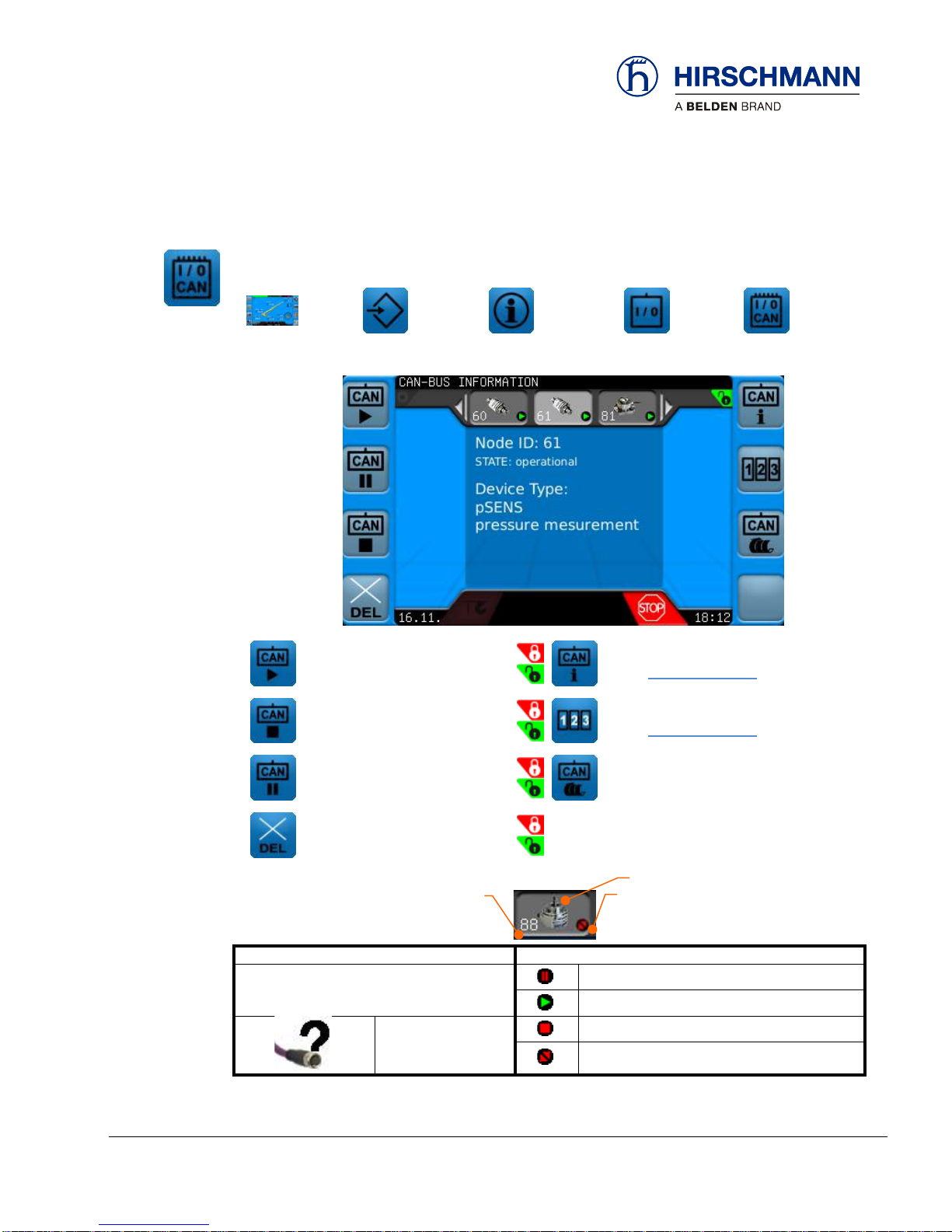

3.1.2.2.2 CAN Sensor Information

This menu shows the status of the CAN sensors. This is the place to start if a problem with a sensor is

suspected.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

EXTENDED

INFORMATION

CAN

INFO

Initializes Selected Sensor

Additional CAN Information

(See Section 3.1.2.2.3)

Stops Selected Sensor

PDO Raw Data Information

(See Section 3.1.2.2.4)

Sets Status to “PreOperational”

CAN Bus is Restarted

(List is Updated)

Sets the Node ID to 127

Icon

Status

Icon Shows Type of Sensor

Sensor Pre-Operational

Sensor Operational

Appears When

Node ID Differs

from Configuration

Sensor Stopped

Sensor Not Connected

Function Keys

Symbols

Status

Icon

Node

ID

Page 25

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 25/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2.2.3 Extended CAN Information

To view additional information about a specific CAN sensor press the Extended CAN Information Function Button.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATIO

N SELECTION

EXTENDED

INFORMATION

CAN

INFO

EXT

CAN

INFO

Page 26

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 26/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.2.2.4 PDO Raw Data Transmission

To view additional information about a specific CAN sensor press the Extended CAN Information Function Button.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATIO

N SELECTION

EXTENDED

INFORMATION

CAN

INFO

PDO

The following information can be found on this screen:

Value Current Value of the Input (% =

𝑟𝑎𝑤𝑉𝑎𝑙𝑢𝑒−𝑠𝑐𝑎𝑙𝑒𝑆𝑡𝑎𝑟𝑡

𝑠𝑐𝑎𝑙𝑒𝐸𝑛𝑑−𝑠𝑐𝑎𝑙𝑒𝑆𝑡𝑎𝑟𝑡

)

Fault Indication whether an error has occurred

State Current Status of value

Scale Start

Scale End

PDO Data Raw CAN Value Read from the Sensor

Page 27

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 27/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.3 Error Codes

The qSCALE i2 system uses various error codes to report and log various activity. See the section in

the appendix, Error Code Tables, for a complete list of codes, their cause, and possible solution.

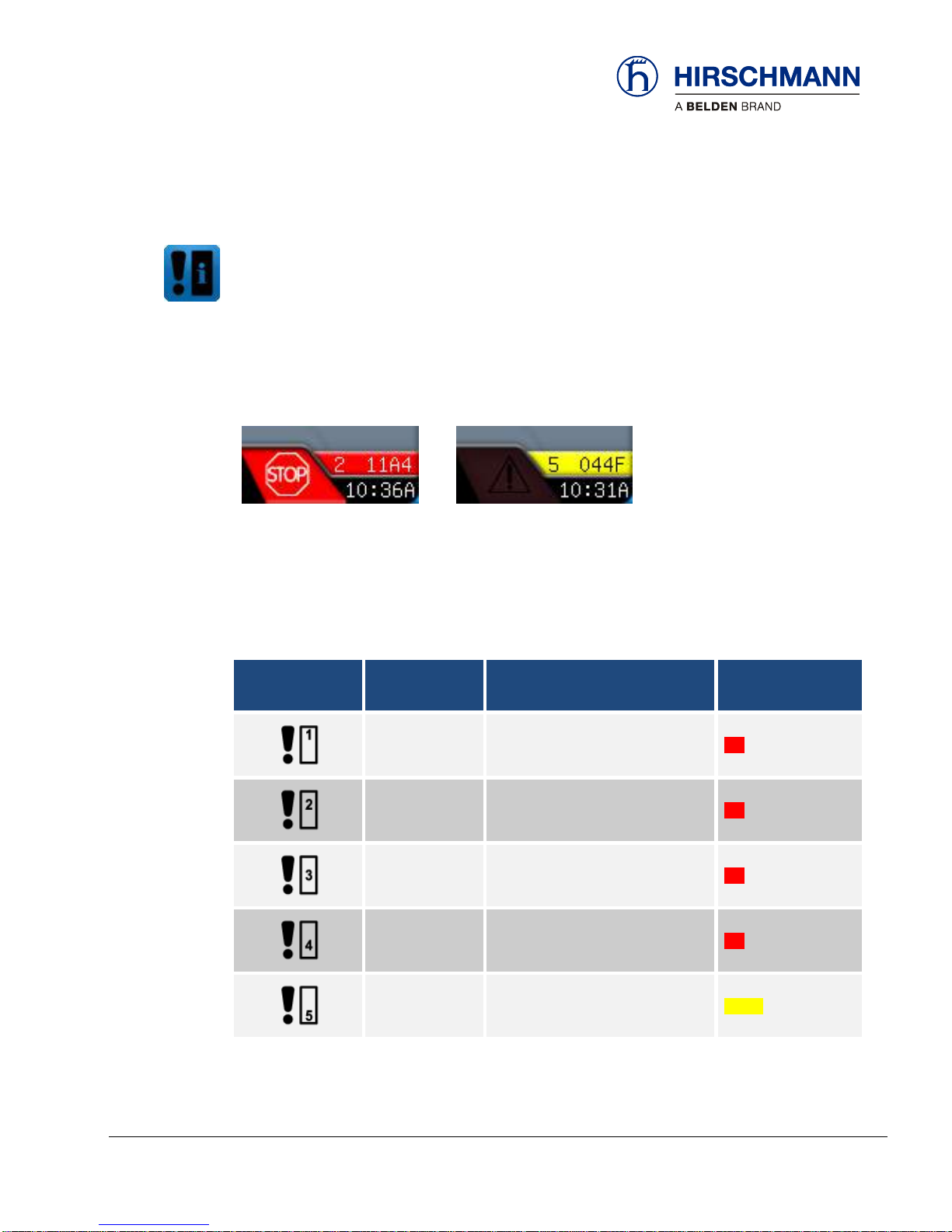

3.1.3.1 Indication of an Event Message

If necessary, a code ‘# ####’ is displayed at the marked location on the display. If several event messages are simultaneously present, only the most important will be displayed here.

3.1.3.2 Event Classes

The leading digit of an event code indicates the event class.

Depending on the importance of the message they are divided into different classes:

Symbol

in event menu

Event class

Definition

Color

1 ####

Emergency errors

red

2 ####

Alerts

red

3 ####

Critical errors

red

4 ####

Errors

red

5 ####

Warnings

yellow

System event

message code

(examples)

Page 28

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 28/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.1.3.3 System Event Information

When there is an error event, the Error Event Button will activate. Pressing the Error Event button will

call up the System Event Information Screen.

OR

MAIN

WORKING

SCREEN

ERROR

EVENT

OP-MODE

CONFIRM

ERROR

EVENT

If several messages of the same class are present use the dial control to change the current message.

The function key is dark blue when that screen is activated.

View Errors of Class 1

View Errors of Class 2

View Errors of Class 3

View Errors of Class 4

View Errors of Class 5

View Errors of All Classes

Page 29

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 29/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2 Hardware Troubleshooting

3.2.1 What is Wrong?

I HAVE AN ERROR CODE INDICATED ON THE CONSOLE

Please go to Section 3.1.3

THE DISPLAYED ANGLE DOES NOT MATCH THE ACTUAL BOOM ANGLE

Start in Section3.2.5 to troubleshoot possible problems with the boom angle measurement.

THE DISPLAYED LENGTH DOES NOT MATCH THE ACTUAL BOOM LENGTH

Start in Section 3.2.6 to troubleshoot possible problems with the boom length measurement.

THE DISPLAYED PRESSURES DOES NOT MATCH THE ACTUAL PRESSURES

Start in Section 3.2.7 to troubleshoot possible problems with the pressure transducers.

THE DISPLAYED LOAD DOES NOT MATCH THE ACTUAL LOAD

Please note that if the system is equipped with pressure transducers, the indicated load is calculated by

the system from the geometry information in the computer, the operator’s selections, and all the sensor

inputs. If the load display is incorrect, it may be due to an error in one or more of these inputs! Refer to

Section 3.2.8 to narrow down the source of your problem.

THE CONSOLE DISPLAY IS BLANK

If the console does not show any sign at all (no lights, no buzzer, and no display), the problem is in the

wiring between console and central unit, or the console itself has a problem. Refer to Section 3.2.10 for

further troubleshooting.

I HAVE AN A2B PROBLEM

Please go to Section 3.2.8.1.1

I HAVE A CAN BUS PROBLEM

Please go to Section 3.2.13

Questions:

Page 30

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 30/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

THE DISPLAYED SLEWING DOES NOT MATCH THE ACTUAL SLEWING ANGLE

Refer to Section 3.2.10 to troubleshoot possible problems with the slew angle measurement.

THE DISPLAYED TILT DOES NOT MATCH THE ACTUAL TILT

Start in Section 3.2.11 to troubleshoot possible problems with the tilt measurement

THE CONSOLE DISPLAY IS BLANK

If the console does not show any sign at all (no lights, no buzzer, and no display), the problem is in the

wiring between console and central unit, or the console itself has a problem. Refer to Section 3.2.12 for

further troubleshooting.

Page 31

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 31/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.2 Initial System Inspection

Page 32

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 32/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

Page 33

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 33/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.3 Simple Corrective Actions

NOTE

Not all codes produced by the iSCALE system are “ERRORS”. Some codes generated are simply for the event log. Others indicate load chart, limits exceeded, and safety warnings. See Sec-

tion 6.2 for more detail on errors.

Error Codes are displayed in order of priority – most critical codes first. Therefore, multiple

codes are possible depending upon the situation.

Page 34

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 34/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.4 Indicator Definitions

Indicators are located on the Central Control Unit and the Console to assist with troubleshooting basic

power and software issues.

3.2.4.1 Indicators on the cSCALE DIO Module

Visual LED Indicators are located on the top of the DIO Module

PON

Power ON

POK

Power OK

SR

Safety Relay Active

3.2.4.2 Indicator on Console Unit

Operating display: Illuminates green when the supply voltage is connected.

Operating

Display Light

Page 35

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 35/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.5 Boom Angle Sensing

The system measures the angle of the main boom of the machine with an angle sensor. The angle

sensor is either contained within the cable reel or mounted directly to the main boom.

3.2.5.1 Boom Angle Sensing Overview

The WGC angle sensor is based on liquid capacitive inclinometer technology. As the angle changes so

will the fluid, and with it the capacitance changes.

The WGX angle sensor is based on Micro-Electro-Mechanical Systems (MEMS) inclinometer. The

angle is measured with relative change in electrical capacitance in the MEMS cell.

Start by verifying the actual angle to display the angle at several positions. The CAN Bus is digital and

as such will either transmit the signal correctly or not at all. The raw value of the sensor can be monitored and should be checked against a digital level outside of the system mounted on the boom. If the

raw value varies from the actual value, replace the angle sensor. Refer to sensor documentation for

expected accuracy values.

The voltage supplied to either sensor should ideally be between 11.0 and 26.0V. If the angle sensor is

mounted directly to the boom, the CAN Bus cable will supply the sensor with power. If the angle sensor

is located within a cable reel, it can be connected to either a LWG board or a CAN Junction Board. This

board will supply the sensor with power.

The signal runs from the angle sensor to the CAN junction block. From there, it travels as digital information on the CAN Bus to the central processing unit.

Unplug the CAN cable from the angle sensor and measure the voltage between pins 3 (GND) and 2 (+).

If the voltage is outside of the acceptable range, power to the CAN line may be the issue. Check the

entire CAN Bus system to ensure proper wiring and connections.

WGC Sensor

WGX Sensor

Basic

Troubleshooting

Block Diagram

Angle Sensor Mounted

on Boom

Page 36

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 36/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

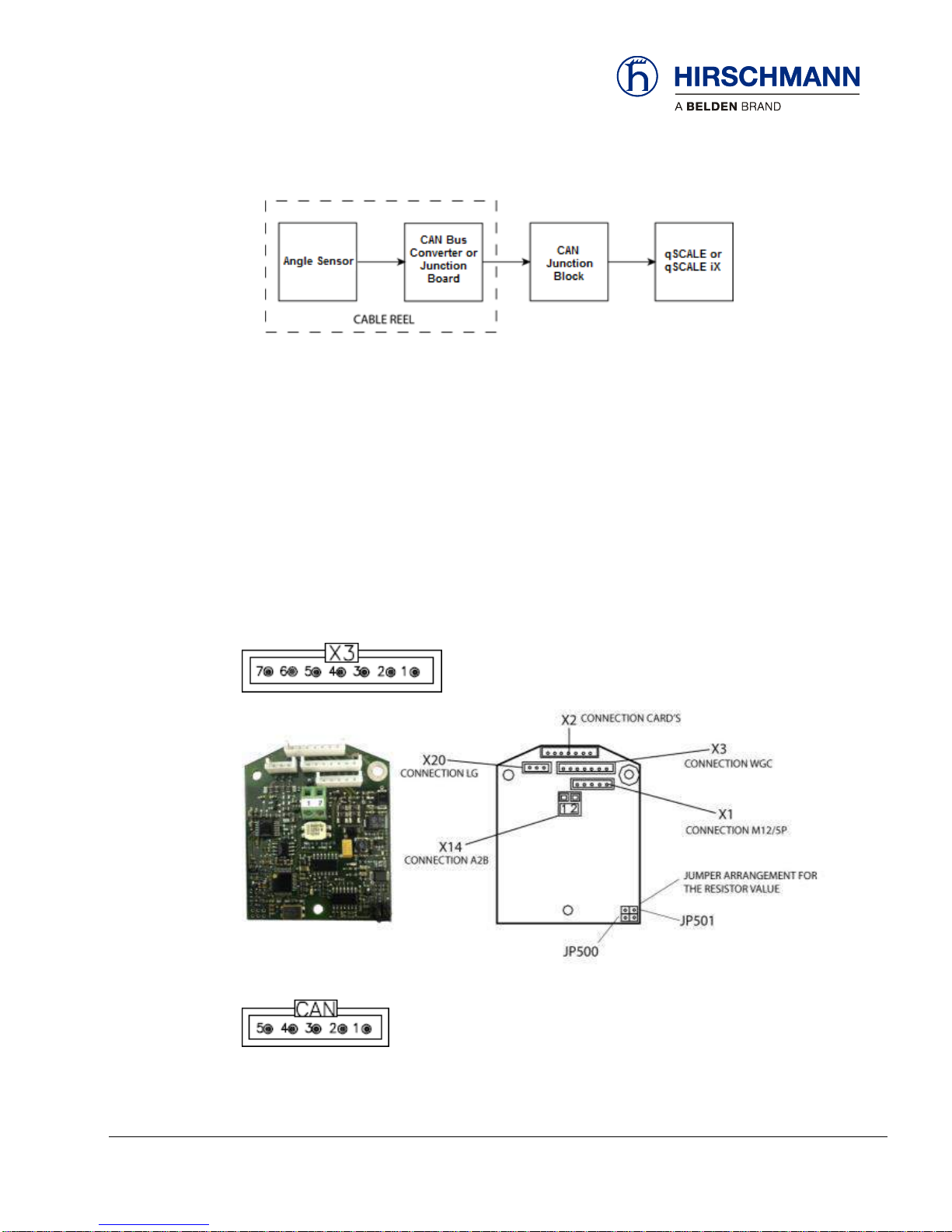

The signal runs from the angle sensor to the CAN Bus converter board or CAN Bus junction block

board, both located in the cable reel. From there, it travels as digital information on the CAN Bus to the

central processing unit.

Measure the voltage between pins 3 (GND) and 2 (+) while the angle sensor is still connected to the

CAN Bus Converter or Junction Board. If the voltage is not within the acceptable range, unplug the

sensor and re-measure. If unplugging the sensor resolved the voltage issue, replace the sensor. If the

voltage is still outside of the acceptable range, unplug the power source to the CAN Bus Converter or

Junction Board and re-measure. If unplugging the board resolved the voltage issue, replace the board.

If the voltage is still outside of the acceptable range, power to the CAN line may be the issue. Check the

entire CAN Bus system to ensure proper wiring and connections.

The CAN Bus Converter Board acts as a junction for the angle sensor, and converts the length and A2B

signals to CAN. The angle sensor will be connected to X3.

The CAN Bus Junction Board is a passive device that acts as a junction for CAN sensors.

Block Diagram

Angle Sensor inside

Cable Reel

CAN Bus Converter

Board

CAN Bus Junction

Board

Page 37

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 37/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.5.2 Boom Angle Sensing Error – Flow Chart

Use the following flow chart to troubleshoot errors with boom angle sensing for both WGX and WGC

angle sensors.

Flow Chart

Page 38

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 38/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.6 Boom Length Sensing

The system measures the length of the main boom of the machine with a length sensor. The length

sensor is contained within the cable reel.

3.2.6.1 Boom Length Sensing Overview

Start by verifying the actual length to the display. Boom length is the distance from the heel pin to the

center of the front sheave wheel. The boom length is displayed on the working screen of the console.

The CAN Bus is digital and as such will either transmit the signal correctly or not at all. If the length

measurement does not match the displayed length, start troubleshooting by checking the length cable

tension. If tension is lacking, check the cable reel to ensure it has the proper pretension. This varies

upon the type of cable reel used.

The voltage supplied to either length sensor will be through the CAN Bus Converter Board (length potentiometers) or a CAN Junction Board (rotary encoders).

Basic

Troubleshooting

Block Diagram

Page 39

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 39/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.6.2 Rotary Encoder Troubleshooting

The rotary encoder is driven by a belt drive from the drum shaft, and thus does not contain a gear set

within the cable reel housing. The sensor outputs a CAN signal directly and plugs into a CAN Bus Junction Board. The ideal voltage supplied to the rotary encoder should be between 11.0 and 26.0V.

Measure the voltage between pins 3 (GND) and 2 (+) while the rotary encoder is still connected to the

CAN Bus Junction Board. If the voltage is not within the acceptable range, unplug the sensor and remeasure. If unplugging the sensor resolved the voltage issue, replace the sensor. If the voltage is still

outside of the acceptable range, unplug the power source to the CAN Bus Junction Board and remeasure. If unplugging the board resolved the voltage issue, replace the board. If the voltage is still

outside of the acceptable range, power to the CAN line may be the issue. Check the entire CAN Bus

system to ensure proper wiring and connections.

The CAN Bus Junction Board is a passive device that acts as a junction for CAN sensors.

Page 40

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 40/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.6.3 Length Potentiometer Troubleshooting

The length sensor is a potentiometer that is driven by a gear drive from the cable drum. As the length

changes, the cable drum will turn and with it, the potentiometer’s axle.

The CAN Bus Converter Board the length and A2B signals to CAN, and acts as a junction to the angle

sensor. The length sensor will be connected to X20.

Fully retract the boom and turn the shaft of the length potentiometer opposite of the cable payoff with a

small screwdriver until it comes to a soft stop. That should bring the sensor voltage to 0V (+/- 0.1Volt)

between Pin 3 (-) and Pin 2 of connector X20.

NOTE

After this step is done, the length sensor needs to be calibrated.

Go back to your indication screen and compare length indicated and actual length again. If zeroing the

length potentiometer and recalibrating did not resolve the issue (indicated length varies more than 0.3

feet from actual length), continue.

Page 41

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 41/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

Verify that the sensor is being supplied with about 1.6V by measuring between Pin 3 (-) and Pin 1 (+) of

terminal X20. If the voltage is outside of a range of 1.4V to 1.8V, the converter board may be defective.

Unplug the length sensor and measure again. If the voltage is still out of the correct range, exchange

the converter board. If unplugging the length sensor made the voltage return into the acceptable range,

exchange the length sensor. If the voltage is correct, continue.

The length sensor returns a voltage between 0V at 0 turns of the length pot (= fully retracted) and 1.64V

at 10 turns. How many turns you get at full extension depends on the gear ratio, the boom length, the

length cable used, and the spooling pattern. The following table shows the expected output voltage

(measured between X20-3 and X20-2 Signal) for each complete turn of the length potentiometer. Note

that this does not synchronize to the number of turns of the cable reel.

Length Sensor Signal on Pin 3

Turns

Voltage X20-3 to

X20-2

0

0.00 1 0.16 2 0.33 3 0.49 4 0.66 5 0.82 6 0.98 7 1.15 8 1.31 9 1.47

10

1.64

Table 4 - 1

Note: Actual voltages will vary slightly.

Go back to your indication screen and compare length indicated and actual again. If the indicated length

varies significantly from your actual length (more than 0.3 feet), the length sensor is defective and

should be exchanged.

Page 42

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 42/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.6.4 Cable Reel Length Cable Replacement Procedure

Replace the length cable using the following procedure:

1. Cut old cable at cable drum.

2. Disconnect damaged length cable from junction box at the boom nose.

3. Remove cable reel from mounting brackets.

4. Remove damaged length cable, which is connected to the slip rings in the cable reel, from slip

ring terminal.

5. On the backside of the cable reel, open the strain relief attached to the axle in the center of the

drum. Pull existing length cable out of the cable reel.

6. Pull new length cable through the strain relief and push it through the axle of the reeling drum.

Tighten new strain relief to ensure sealing.

7. Reconnect the length cable to the slip ring.

8. Loosely spool cable onto reel prior to mounting by reeling drum counter-clockwise.

9. Remount cable reel to the boom.

10. Unwind cable and re-spool neatly using cable reel spring tension to keep the cable taught.

NOTE: A well-wrapped first layer aids in cable spooling during operation!

11. Set pre-load on cable reel by turning the drum in the direction of spring tension

a. 154 Reel: 3 to 5 turns

b. 509 Reel: 3 to 5 turns

c. 521 Reel: 5 to 8 turns

12. Run the new length cable through the cable guides and wrap the length cable around the

boom tip anchoring and secure. If applicable, leave enough length cable to connect into the

boom tip junction box.

13. If the system has a rotary encoder, skip to Step 15.

14. Reset the length potentiometer. The screw is located in center of white gear. With the boom

fully retracted, turn the potentiometer counterclockwise carefully until it stops. Finally turn the

potentiometer clockwise ¼ turn. Recheck the length display.

15. Follow the recalibrate length sensor.

Procedure for Length

Cable replacement

Page 43

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 43/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.6.5 Boom Length Sensor Error – Flow Chart

Use the following flow chart to troubleshoot errors with length sensing.

Flow Chart

Page 44

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 44/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.7 Pressure Sensing

The System measures the pressure of the boom lift cylinder for both rod and piston side. Both sensors

communicate on the CAN Bus.

3.2.7.1 Pressure Sensing Overview

The signal runs from the pressure sensor travels as digital information on the CAN Bus to the central

processing unit.

Note that the load displayed on the LMI is not a direct measurement when using pressure transducers;

rather, it is a calculated value. Ensure that the hydraulic system is functioning as intended and that

sensor values, mainly length and angle, are functioning correctly prior to troubleshooting the pressure

transducers.

3.2.7.2 Pressure Sensing Error – Flow Chart

Use the following flow chart to troubleshoot errors with pressure sensing.

Block Diagram

Flow Chart

Page 45

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 45/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.8 Load Sensing

Please note that when using pressure transducers the load displayed by the RCL is not a direct measurement, but a calculated value that is based on many factors. Factors included that are outside of the

measured values include:

Operator settings such as:

Operating mode/configuration

Parts of Line/Reeving

Outrigger position

Rigging parts such as:

Hook block weight

Sling weights, etc.

Tip height (length of load line used)

Boom weights

Boom attachments such as:

Stowed jibs

Telescopic jib, etc.

Before checking the system for a load-reading problem, make sure all of the above has been ruled out.

When you still feel the system is reading a sensor wrong and thus displaying an incorrect load, use the

following:

Use the previous sections and the individual sensor signal displayed on the screen to double-check the

following:

boom length reading

angle transducer reading

pressure transducer readings

If all are correct, use the zero setting and calibration screens to calibrate angle, length, slew, and tilt. If

you still have a problem, replace pressure transducer(s).

Page 46

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 46/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.8.1.1 Anti-Two Block Switch (A2B)

The system measures the load block and its relationship to the head of the boom. The A2B switch is

located at the nose of the boom.

3.2.9 A2B Switch Overview

The signal runs from the A2B as a CAN Bus input of the central unit.

NOTE

Some systems have two (2) A2B switches wired in series.

Block Diagram

Page 47

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 47/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.9.1 A2B Problem – Flow Chart

Use the following flow chart to troubleshoot errors with A2B switch input.

Flow Chart

Page 48

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 48/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.10 Slew Sensing Overview

The system measures the slewing (rotational position) of the crane’s boom and turret with a rotary encoder. The slewing sensor is contained within the slip ring assembly.

3.2.10.1 Slew Sensing Overview

The slew encoder is driven by the slip ring axle. The slew angle is displayed on the CAN Sensor

Screen.

3.2.10.2 Slew (Rotation Angle) Sensing Error – Flow Chart

Use the following flow chart to troubleshoot errors with slew sensing.

Block Diagram

Flow Chart

Page 49

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 49/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.11 Tilt Sensing

The system measure the tilt (level) of the crane.

3.2.11.1 Tilt XY Sensing Overview

The system measures the tilt (level) of the crane.

The signal runs from the tilt sensors as digital information on the CAN Bus to the central unit. The CAN

Bus is digital and as such will either transmit the signal correctly or not at all.

Start by verifying the actual tilt angle to the display tilt angle at several positions. The raw value of the

sensor can be monitored and should be checked against a digital level outside of the system mounted

on a machined flat surface parallel to the ground. If the raw value varies from the actual value, replace

the tilt sensor. Refer to sensor documentation for expected accuracy values. The voltage supplied to

either sensor should ideally be between 11.0 and 26.0V. The CAN Bus cable will supply the sensor with

power.

Block Diagram

Page 50

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 50/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.11.2 Tilt XY Sensing Error – Flow Chart

Use the following flow chart to troubleshoot errors with Tilt Sensing.

Flow Chart

Page 51

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 51/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.12 No Console Display

If the console never displays an image, check if power is being supplied to the console. Measure the

voltage between Pin 1 (+) and Pin 3 (GND). If power is being supplied, the console must be replaced. If

power is not being supplied, trace the wiring to determine why.

Page 52

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 52/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3.2.13 CAN Bus Communications

CAN Bus - a serial bus protocol to connect individual systems and sensors as an alternative to conven-

tional multi-wire cables. It allows crane components to communicate on a single bus: a dual-wire networked data bus with speed up to 1Mbps.

The use of a CAN Bus design allows for all nodes (sensor, controller and console) signals to be networked over a common pair of cables. The signals generated by all sensors are slave signals sent with

a digital identifier over common cables. The data transmitted is used by the controller (master). The

data can be interpreted, and information and controls sent from the controller to provide crane safety

functions. Each node has a unique identifier. This allows for a common pair of shielded wires (the bus)

to carry all signals.

Page 53

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 53/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

The CAN Bus requires that 120 Ohm resistors be at each end of the CAN BUS. The resistors in parallel

yield 60 Ohms of resistance between the CAN High and CAN Low cables.

The signals are generated by nodes on the CAN BUS. The nodes generate and consume data over the

CAN Bus. The CAN High and CAN Low signals are equal and opposite of each other in amplitude and

have the same duration (refer to image above for visual).

Adequate voltage supply is required for all nodes on a CAN Bus. A common source of issues is Voltage

drop due to added resistance from a corroded connection. As resistance increases, a corresponding

voltage drop occurs corrupting the signal generated. The CAN signal will begin to lose the top of the

high signal and no longer mirror the reflection (parity) of the CAN low signal.

Page 54

Troubleshooting

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 54/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

CAN Power can be verified by testing the CAN connectors per this layout:

Connector M12, 5 contacts

Pin Layout (CiA DR-303-1 7.2)

(Solid for Male Pins)

(Hollow for Female Sockets)

Pin 1 Shield

Pin 2 + Ub

Pin 3 Ground

Pin 4 CAN High

Pin 5 CAN Low

Male Female

(Pins) (Sockets)

Measure between pin 3 and pin 2 to measure the machine voltage. If you see voltage, check all pins for

continuity.

X1 Pin

CAN

1

CAN_SHLD

2

CAN +UB

3

CAN GND

4

CAN_H

5

CAN_L

Table 4-2

Page 55

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 55/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4 Commissioning

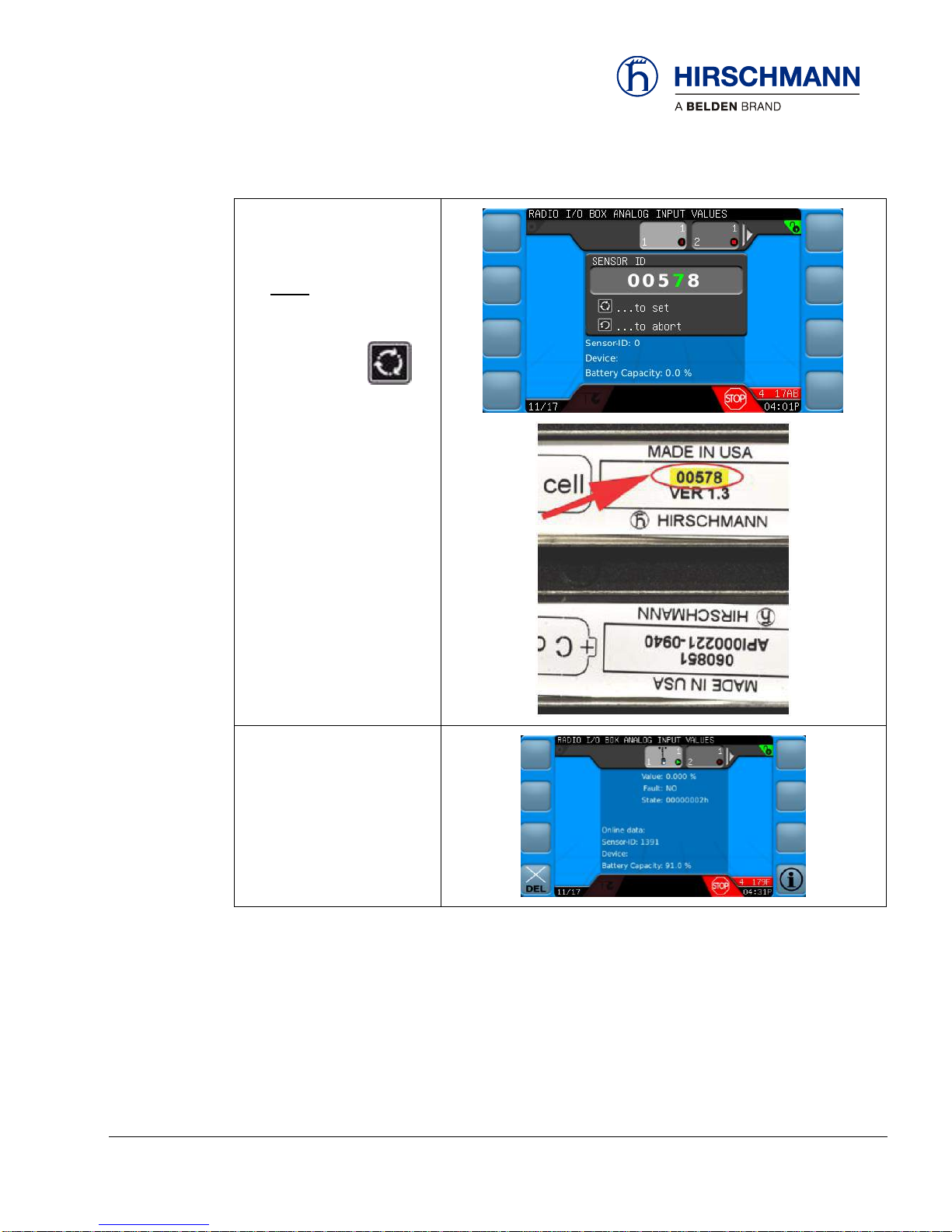

4.1 Adding Wireless Sensors

If the system is equipped with wireless sensors the sensor must be added via the I/O Box Information

Screen

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

EXTENDED

INFORMATION

DIO

INFO

AI

WIRELESS

INFO

1. Press the CAN SET

button to add

wireless sensor

Instructions

Page 56

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 56/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

2. Enter the unique ID of the

sensor

NOTE: Unique ID is

found on battery terminal

3. Press the SET

when ID is entered correctly

4. Sensor is successfully

added

Page 57

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 57/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2 Sensor Calibration

This section will explain how to calibrate the various sensors used in the qSCALE i2 System.

When the system is first turned on system may prompt the user to calibrate sensors.

Press the SET button to continue to the configure operation mode screen. The Configure Operation Mode Screen will show “Unready System! No Operation!” until all required sensors are calibrated.

IMPORTANT

The RCL is an operating aid that warns the crane operator of imminent overloading or of the

approach of the hook block to the boom head in order to avoid possible property damage or

injury to personnel.

The device is not, nor is it intended to be, a substitute for good operator judgment and/or experience. It does not remove the need for utilizing only recognized safe procedures during crane

operations.

Page 58

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 58/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

CAUTION

The crane operator continues to bear ultimate responsibility for safe operation of the crane. The

operator must ensure that he fully understands and follows the displayed notes and instructions

in their entirety.

WARNING

The RCL is not able to provide aid to the crane operator unless it has been properly adjusted

and the correct load capacity chart and the correct operating code have been entered for the

respective rigging configuration. The correctness of the RCL settings must be guaranteed before beginning crane work in order to avoid damage to property and severe or even fatal injuries

to personnel.

WARNING

This system can be equipped with an external key-operated switch located in the crane operator's location. This key-operated switch overrides control lever function switch-off by the RCL or

by the hoist limit switch system. This switch may only be used during emergency situations,

and even then, only by authorized personnel. Failure to observe these instructions could result

in damage to property and severe or even fatal injuries to personnel.

WARNING

The RCL cannot perform correctly unless it has been properly adjusted. The prerequisite for this

is making conscientious and correct entries during the set-up procedure in accordance with the

actual configuration of the crane. The correctness of the RCL settings must be ensured before

beginning crane work in order to avoid damage to property and severe or even fatal injuries to

personnel.

NOTE

The calibration menu functions are password protected by an RCL or System password.

Page 59

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 59/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

NOTE

CAN Pressure Transducers do not need to be calibrated!

Page 60

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 60/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.1 Sensor Calibration Selection

Calibration for sensors is selected under the settings menu. To calibrate sensors a RCL a system

password is required. See Section 6.1 for password entry.

Information Selection Menu allows the user to view crane, sensor, and software version information and

is the starting point for diagnostic information.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

SETUP

SENSOR

CALIBRATION

Do not calibrate!

CAN Pressure Transducers do

not need to be calibrated.

Angle Sensor Calibration

(See Section 3.1.2.2.3)

Length Sensor Calibration

(See Section 3.1.2.2.4)

Slew Sensor Calibration

(See Section 4.2.4)

Tilt Sensor Calibration

(See Section 4.2.5)

Function Keys

Page 61

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 61/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.2 Boom Length Calibration

This section describes how to calibrate the boom length sensor.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

SETUP

SENSOR

CALIBRATION

BOOM

LENGTH

IMPORTANT

The crane must be on a level surface and outriggers properly positioned to calibrate this sensor.

The boom must also be at an angle where it can fully extend and remain within allowable load

chart values.

5. Fully retract the boom.

6. Press the SET button to confirm this

is completed.

7. The OK on the screen should now be green.

8. Press the SET button to confirm this

is completed.

Instructions

Page 62

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 62/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

9. Fully extend the boom (check the load chart of

the machine to find a safe configuration for fully extending the boom).

10. Press the SET button to confirm this

is completed.

11. The OK on the screen should now be green.

12. Press the SET button to confirm this

is completed.

13. Length Sensor Calibration is complete.

Page 63

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 63/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.3 Boom Angle Calibration

This section describes how to calibrate the boom angle sensor.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

SETUP

SENSOR

CALIBRATION

BOOM

ANGLE

IMPORTANT

The crane must be on a level surface and outriggers properly positioned to calibrate this sensor.

1. Fully retract the boom

2. Press the SET button to confirm this

is completed.

3. Lower the boom to a near zero degree value.

4. Press the SET button to confirm this

is completed.

Instructions

Page 64

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 64/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

5. Use a digital inclinometer to measure the actual boom angle.

6. Press the SET button to confirm this

is completed.

7. Enter the measured angle from Step 5.

a. Rotate the rotary encoder clockwise to in-

crease the digit (negative and decimal

points available for selection)

b. Rotate the rotary encoder counter clock-

wise to decrease the selected digit (negative and decimal points available for selection

c. Press the rotary encoder to advance to the

next digit

8. Press the SET button to confirm this

is completed.

9. Raise the boom to a higher angle (closer to

maximum angle is better).

10. Press the SET button to confirm this

is completed.

Page 65

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 65/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

11. Use a digital inclinometer to measure the actual boom angle.

12. Press the SET button to confirm this

is completed.

13. Enter the measured angle from Step 5.

a. Rotate the rotary encoder clockwise to in-

crease the digit (negative and decimal

points available for selection)

b. Rotate the rotary encoder counter clock-

wise to decrease the selected digit (negative and decimal points available for selection

c. Press the rotary encoder to advance to the

next digit

14. Press the SET button to confirm this

is completed.

Page 66

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 66/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.4 Slew Sensor Calibration

This section describes how to calibrate the slew angle sensor.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

SETUP

SENSOR

CALIBRATION

SLEW

ANGLE

IMPORTANT

The crane must be on a level surface and outriggers properly positioned to calibrate this sensor.

1. Move the boom to 0° slew

2. Press the SET button to confirm

this is completed.

3. It must be confirmed a second time that

the boom is moved to the front of the machine.

4. Press the SET button to confirm

this is completed.

Instructions

Page 67

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 67/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

5. Slew the boom clockwise at least 5° (maximum 80°)

6. Press the SET button to confirm

this is completed.

7. It must be confirmed a second time that

the boom is moved to the front of the machine.

8. Press the SET button to confirm

this is completed.

Page 68

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 68/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.5 Tilt Sensor Calibration

This section describes how to calibrate the tilt angle sensor.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

SETUP

SENSOR

CALIBRATION

TILT ANGLE

IMPORTANT

The crane must be on a level surface and outriggers properly positioned to calibrate this sensor.

9. Level the machine

10. Move the boom to the front of the machine

11. Press the SET button to confirm

this is completed.

12. It must be confirmed a second time that

the boom is moved to the front of the machine.

13. Press the SET button to confirm

this is completed.

Instructions

Page 69

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 69/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

14. Slew the boom 90° (making the machine

horizontal)

15. Press the SET button to confirm

this is completed.

16. It must be confirmed a second time that

the machine is horizontal.

17. Press the SET button to confirm

this is completed.

18. Confirm that the machine is level in the X

and Y directions.

19. Press the SET button to confirm

this is completed.

20. Tilt the machine 3° to the rear by retracting the rear outriggers and/or extending

the front outriggers.

21. Press the SET button to confirm

this is completed.

22. It must be confirmed a second time that

the machine is tilted to the rear.

23. Press the SET button to confirm

this is completed.

Page 70

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 70/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

24. Tilt the machine to the right by retracting

the right outriggers and/or extending the

left outriggers.

25. Press the SET button to confirm

this is completed.

26. It must be confirmed a second time that

the machine is tilted to the right.

27. Press the SET button to confirm

this is completed.

28. Finish the calibration by pressing the SET

button.

Page 71

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 71/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4.2.6 Analog Outrigger Calibration

This section is only for models with Analog Outrigger Length Sensors. Unlike the length and angles

sensors, calibration for outriggers is done through the Analog Input Screen.

MAIN

WORKING

SCREEN

OP-MODE

CONFIRM

INFORMATION

SELECTION

SENSOR

INFORMATION

ANALOG

INPUTS

1. Fully retract the outriggers

2. Press the function button to set the scale start.

Page 72

Commissioning

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 72/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

3. Fully extend the outriggers

4. Retract the outriggers ~1”

5. Press the function button to set the scale end.

6. Fully extend the outriggers for

operation.

NOTE

This has to be performed for all analog outriggers, if equipped

Page 73

Maintenance and Repair

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 73/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

5 Maintenance and Repair

5.1 Maintenance

The qSCALE i2 operating console contains no wearing parts and therefore cannot be opened. If malfunctions are noticed or differences between actual and displayed measured values, switch the device

off and have it checked and, if necessary, repaired immediately by an authorized Hirschmann service

partner.

5.2 Cleaning

Clean the surface and the front screen of the device occasionally with a damp cloth and a mild detergent. Never use abrasive or aggressive detergents as these may damage the device.

IMPORTANT

Device may be damaged by the use of high-pressure washer.

The device must not be treated with high-pressure cleaner or similarly aggressive methods un-

der any circumstances!

Page 74

Maintenance and Repair

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 74/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

5.3 qSCALE i2 Console Software Upload

This section will instruct how to upload software into a qSCALE i2 Console.

NOTE

Item needed: 2 GB or less USB flash drive.

1. Ensure the qSCALE i2 system is turned off (crane ignition key turned to the “OFF” position)

2. Insert the USB flash drive with the software loaded into the USB port on the qSCALE i2

console (the USB port is located behind the rubber flap to the left and below the selection

knob.

3. Press and hold the top two function keys on the left side and turn the system ON (crane

ignition key turned to “on” or ACCY” position). Continue to hold for an additional 10 seconds to ensure system recognizes the selection.

Instructions

USB Port

Press and hold

top two function

keys during

power up

Page 75

Maintenance and Repair

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 75/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

4. The system will now begin the uploading process. The screen will begin to display various

messages as the software loads. This process may take several minutes.

5. Once step 4 has been completed, the console will display the crane model and serial

number and then the home screen. The qSCALE i2 system may now be powered down

(crane ignition key turned to the “OFF” position).

6. The USB flash drive can now safely be removed. Replace the flap.

7. The software has now been uploaded and the system is ready for use.

Page 76

Appendix

© 2016 Hirschmann Automation and Control GmbH · Mobile Machine Control Solutions · www.beldensolutions.com 76/161

qSCALE i2 Cranes (Tool Version 3.0.34) Service Manual / Issue B / 11-2017 / ac.

6 Appendix

6.1 Password Entry

The password entry screen will appear when any menu attempted to be entered is password protected

and the system is not already unlocked.

There are two passwords:

Setup Password

Administrator Password

NOTE

Safety-relevant settings can only be carried out by authorized personnel after inputting a password (Service Code).

This prevents inadvertent changes being made to the settings.

Password entry is done by the following instructions:

When entering the screen, the first of the four digits will be highlighted in “green”

Turn the rotary knob to change the highlighted digit to the desired number