Page 1

HIRSCHMANN

PRS 40 EZ

OPERATOR’S / SERVICE MANUAL

P/N 031-300-190-201 Revision A 03/16/2006

Page 2

Page 3

Operator’s Manual PRS 40 EZ

NOTICE

Hirschmann, Inc. makes no warranty of any kind with regard to this material, including, but not limited

to, the implied warranties of merchantability and/or its fitness for a particular purpose.

Hirschmann, Inc. will not be liable for errors contained in this manual or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual. This document

contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of Hirschmann, Inc.

Hirschmann, Inc. reserves proprietary rights to all drawings, photos and the data contained therein.

The drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of Hirschmann, Inc. The drawings and/or photos are subject to technical modification without

prior notice.

All information in this document is subject to change without notice.

MANUAL REVISIONS

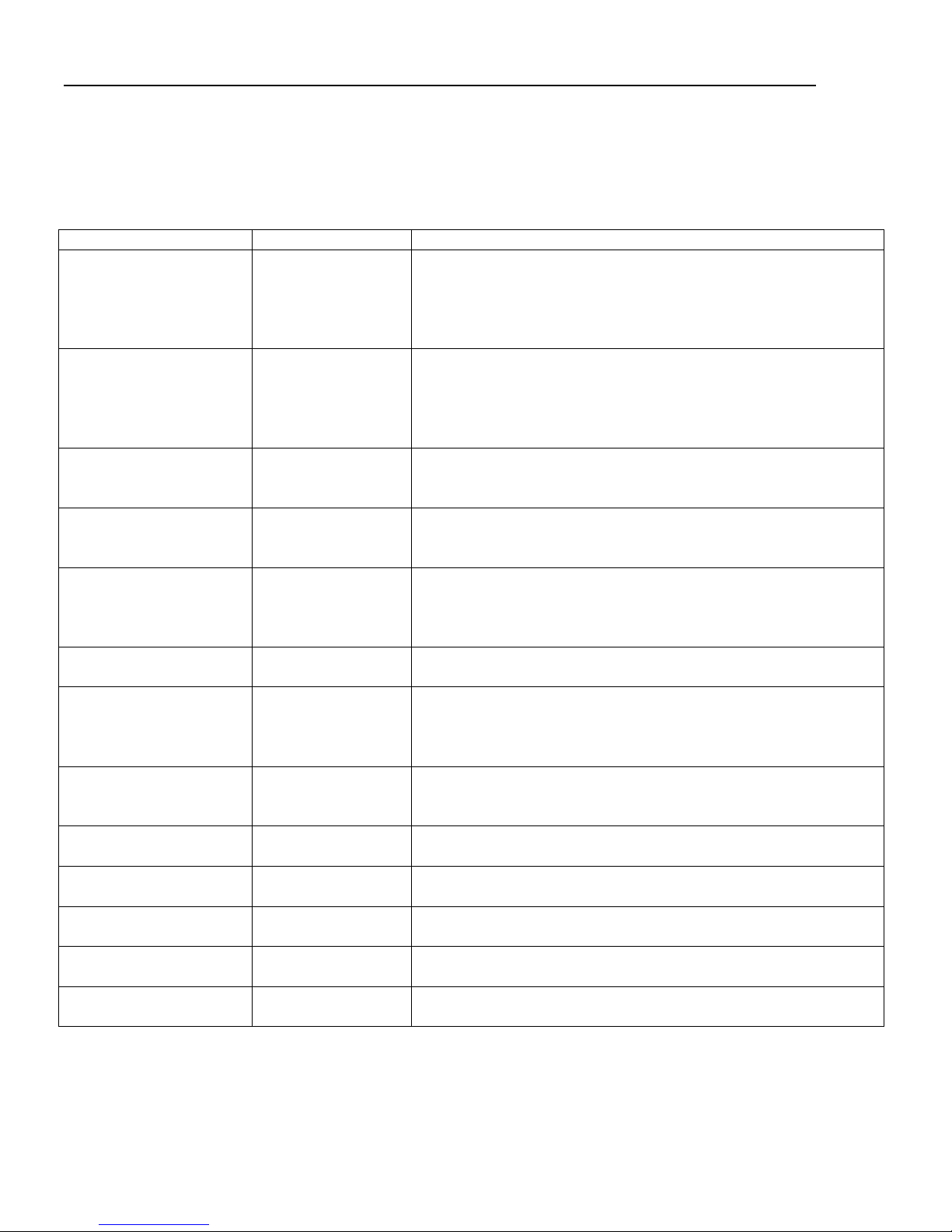

REV DATE NAME DESCRIPTION

- 02/09/06 SB 06-010

A 03/16/06 SB 06-055

© 2006 Hirschmann, Inc., Chambersburg, PA 17201, USA

© PRS 40 EZ REV A 03/16/06 190201_A

Page 4

Page 5

5

TABLE OF CONTENTS

GENERAL INFORMATION..............................................................................................................1

1

2 WARNINGS .....................................................................................................................................1

3 FEATURES ......................................................................................................................................2

4 SYSTEM DESCRIPTION.................................................................................................................2

4.1 CONSOLE.......................................................................................................................................2

4.1.1 Liquid Crystal Display ...........................................................................................................................2

4.1.2 Control Identification .............................................................................................................................3

4.2 OPERATION....................................................................................................................................4

4.2.1 MENU STRUCTURE ............................................................................................................................5

4.2.2 Installation.............................................................................................................................................6

5 ANGLE .............................................................................................................................................7

5.1.1 Operation ..............................................................................................................................................7

5.1.2 Limits.....................................................................................................................................................7

5.1.3 Installation / Calibration Hardwired.......................................................................................................8

5.1.4 Calibration.............................................................................................................................................9

5.2 ANGLE .........................................................................................................................................10

6 A2B ................................................................................................................................................12

6.1.1 Operation ............................................................................................................................................12

6.1.2 A2B limit..............................................................................................................................................15

6.1.3 Installation...........................................................................................................................................15

6.1.4 A2B Setup...........................................................................................................................................17

7 WIND..............................................................................................................................................19

7.1.1 Operation ............................................................................................................................................19

7.1.2 LIMITS ................................................................................................................................................20

7.1.3 Installation...........................................................................................................................................20

7.1.4 Wind Setup .........................................................................................................................................21

8 LOADCELL ....................................................................................................................................23

8.1.1 Operation ............................................................................................................................................23

8.1.2 LIMITS ................................................................................................................................................24

8.1.3 Installation...........................................................................................................................................25

8.1.4 Loadcell Setup ....................................................................................................................................26

8.1.5 Loadcell Calibration ............................................................................................................................26

9 LINE RIDER ...................................................................................................................................28

9.1.1 Operation ............................................................................................................................................28

9.1.2 LIMITS ................................................................................................................................................29

9.1.3 Installation...........................................................................................................................................29

9.1.4 Linerider setup ....................................................................................................................................33

9.1.5 Linerider Calibration............................................................................................................................33

10 RADIO MODULE ...........................................................................................................................34

10.1 INSTALLATION...............................................................................................................................34

11 ADDING SENSORS.......................................................................................................................36

12 SERVICE / TROUBLE SHOOTING ...............................................................................................37

12.1 SCREENS .....................................................................................................................................38

12.1.1 To test the outputs: .............................................................................................................................38

12.1.2 To test the inputs: ...............................................................................................................................38

12.1.3 Battery level: .......................................................................................................................................39

12.2 TROUBLESHOOTING......................................................................................................................40

12.3 TROUBLESHOOTING MOISTURE .....................................................................................................41

12.3.1 Water Ingress .....................................................................................................................................41

13 MAINTENANCE .............................................................................................................................42

© PRS 40 EZ REV A 03/16/06 190201_A

Page 6

Operator’s / Service Manual, PRS 40 EZ

6

13.1 BATTERY REPLACEMENT ........................................................................................................... 42

14 PART NUMBERS...........................................................................................................................43

14.1 CONSOLE ..................................................................................................................................43

14.2 A2B .............................................................................................................................................44

14.3 WIND .........................................................................................................................................46

14.4 ANGLE ..........................................................................................................................................47

14.5 ANTENNA OPTIONS .......................................................................................................................48

14.6 LINERIDER....................................................................................................................................49

14.7 LOADCELL .................................................................................................................................50

© PRS 40 EZ REV A 03/16/06 190201_A

Page 7

General Information

1

1 GENERAL INFORMATION

The PRS 40 EZ System has been designed to provide indication from various types of sensors, i.e.

A2B, Load, Wind and Angle.

The A2B system will warn the crane operator of a two-blocking condition of the crane. If a two-blocking

condition is approached, the system will warn the operator by sounding an audible alarm, flashing the

backlit LCD and locking out those functions which may aggravate the crane's condition, whenever

applicable.

If the system is set up for load, angle or wind, limits can be set by the user. When these limits are

exceeded the system will warn the operator by sounding an audible alarm, flashing the backlit LCD

and de-energize the lockout relay.

The system relay can be connected to the cranes lockout system. If so, the system will lock out when

exceeding any of the user limits.

NOTE:

comes in contact with the boom head. This condition, if not prevented, may cause the wire rope to

break, allowing the load to fall. Either raising the load into the boom head, or telescoping the boom out

without paying attention to the hoist line can cause a "two- block" condition.

The term "two-block" is a crane term that refers to a condition when the load handling device

2 WARNINGS

The PRS 40 EZ System is an operational aid, which warns a crane operator of approaching two-block

conditions, which could cause damage to equipment and personal injury.

This device is not, and must not be a substitute for good, sound operator judgment, experience and

use of accepted safe crane operating procedures.

The responsibility for the safe operation of the crane remains with the crane operator who must ensure

that all warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand the

information in this manual to ensure that the operation and limitations of the system and the crane are

known.

The system can only work correctly, if all sensors/transmitters have been properly set. For

correct setup, the operator has to answer thoroughly and correctly all questions asked

during the setup procedure in accordance with the real rigging state of the crane. To prevent

material damage and serious or even fatal accidents, the correct adjustment of the system

has to be ensured before starting the crane operation.

Always refer to operational instructions and load charts provided by the crane manufacturer

for specific crane operation and load limits.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 8

Operator’s / Service Manual, PRS 40 EZ

2

3 FEATURES

The PRS 40 EZ has the following features:

• Can be hardwired to most PAT sensors.

• Wireless operation option of multiple sensors.

• Easily and clearly shows the operator required information.

• Multi language. The system can be setup to display text in both English and Spanish.

• Multiple limits can be set.

• Minimum of 500 feet LOS.

• Can display in multiple units.

• Built in lockout relay. Rated at 5 amps

• Tare function.

• Low battery indication.

• Expandable

• Direct replacement for the EI33

4 SYSTEM DESCRIPTION

4.1 CONSOLE

The console has 2 functions:

• Accepts inputs from the crane operator (reeving, limits and setup)

• Displays important data and information from the sensors

The operator’s console should be mounted in the operator’s field of vision.

4.1.1 Liquid Crystal Display

The Liquid Crystal Display (LCD) used in the PRS 40 EZ console is a wide temperature-range graphic

display with transflective characteristics that give it a high visibility in sunlight and during backlit night

operation. Due to the nature of any LCD, it works on the principle of polarization of light. It should be

noted that dual polarizations that are at a certain angle to each other can reduce the amount of light

up to completely eliminating it if that angle becomes perpendicular. This can have significance if the

operator is wearing polarized sunglasses that happen to be perpendicularly polarized in relation to the

LCD’s polarization. In this rare case, the operator has to work without sunglasses or find different

sunglasses that do not have this characteristic, in order to avoid having the visibility of the display

impaired.

The LCD contains an automatic temperature compensation that will adjust the LCD’s contrast

according to the surrounding temperature.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 9

System Description

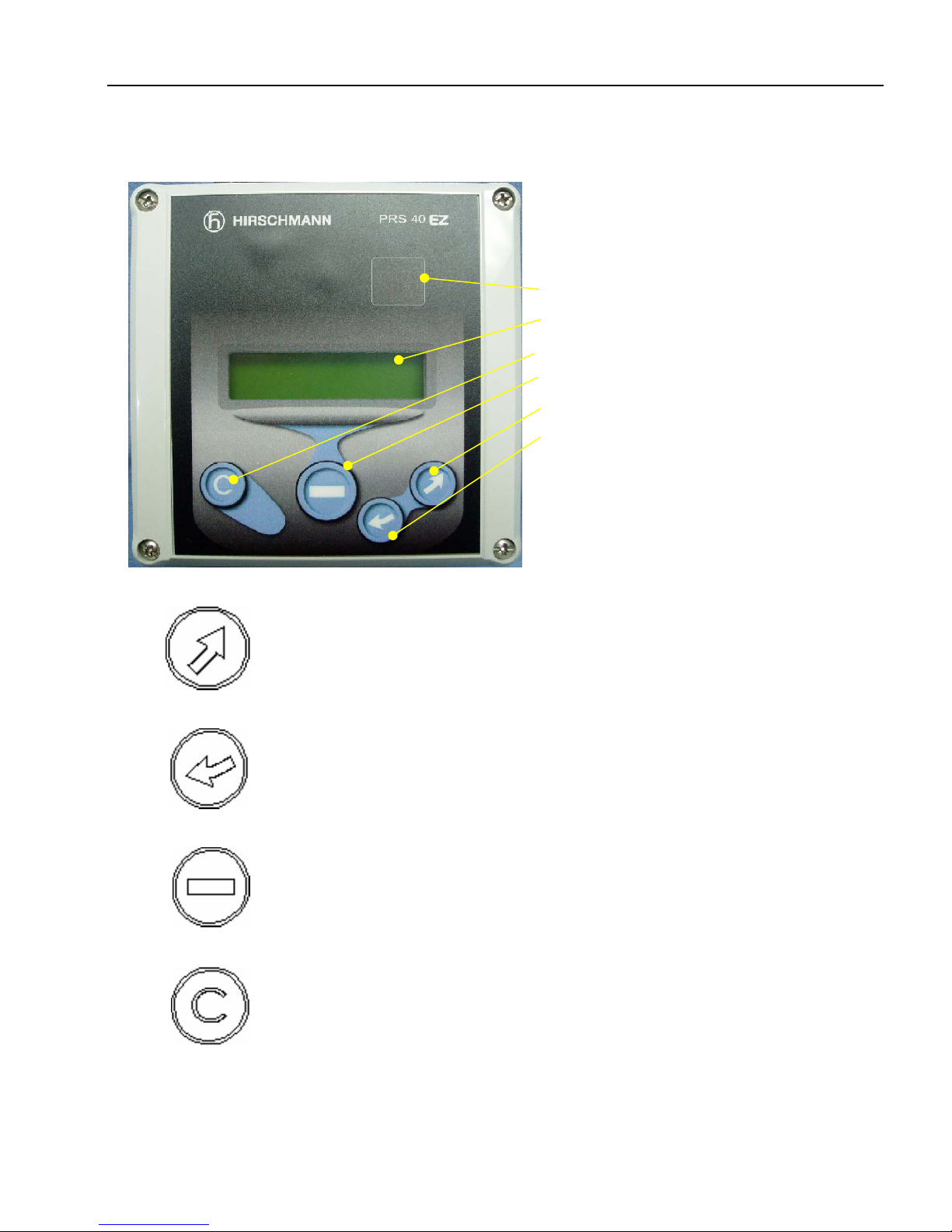

4.1.2 Control Identification

Fig 2: Operator’s Console

3

Limit LED

LCD

Clear button

Select button

Up Button

Down Button

Button “SCROLL UP”

Button "SCROLL DOWN"

Button "SELECT"

Button "C"

• Use this button to increase values or to scroll up.

• Changes which sensors are displayed and how each is displayed.

• Use this button to decrease values or to scroll down.

• Changes which sensors are displayed and how each is displayed

• Use this button to enter the menu screen and to confirm selections.

• Generally used to back out of a selection and return to the previous

screen.

• Pushing this button for more than 1 second will bypass the control

lever lockout function of the system.

Accesses the Tare function

•

© PRS 40 EZ REV A 03/16/06 190201_A

Page 10

Operator’s / Service Manual, PRS 40 EZ

4

Since button C can deactivate the lockout function of the system, the following instructions

must be obeyed:

• The by-pass function shall be used with discretion, as unwarranted use of it to override

the control lever lockout system can result in harm to the crane and danger to property

and persons.

• Never use the by-pass function to either overload or operate the crane in a non-

permissible range.

4.2 OPERATION

Upon switching on crane ignition switch, the system starts with an automatic test of the system, of

lamps and audible alarm. During the test, the LCD shows the console and system software version.

The PRS 40 EZ setup procedure allows the operator to input the sensors being used and the limits for

the sensors. The operator must complete the setup procedure for each sensor.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 11

System Description

4.2.1 MENU STRUCTURE

SETUP SETUP CONT'

● REEVING ● SENSORS

● LIMITS

○ ANGLE

MIN NOT INSTALLED

SELECTION HARDWIRED

MAX HIRSCHMANN

SELECTION KRUEGER

○ WINDSPEED

SELECTION

○ LOAD

MAX LOAD HARDWIRED

○ LINERIDER

SELECTION

● CALIBRATIONS

○ ANGLE

ZERO POINT RADIO

○ LOAD 0-POINT ○ WINDSPEED

○ LOAD RANGE

LOADCELL TYPE HARDWIRED

7.5 TON RADIO

10 TON

22.5 TON NOT INSTALLED

○ LINERIDER 0

○ LINERIDER ADJ

5

INSTALL / REMOVE

○ ANGLE

RADIO

○ A2B1

NOT INSTALLED

RADIO

○ A2B2

NOT INSTALLED

HARDWIRED

NOT INSTALLED

○ LOADCELL

HARDWIRED

RADIO

○ LINERIDER

NOT INSTALLED

HARDWIRED

RADIO

● OPTIONS

○ TEST SEQUENCE

○ LB/MPH OR KG/KPH

○ ENGLISH OR SPANISH

○ CONTRAST

○ ANALOG INPUT ma/volts

○ BATTERY LEVEL

ANGLE

A2B1

A2B2

WINDSPEED

LOADCELL

LINERIDER

© PRS 40 EZ REV A 03/16/06 190201_A

Page 12

Operator’s / Service Manual, PRS 40 EZ

r

6

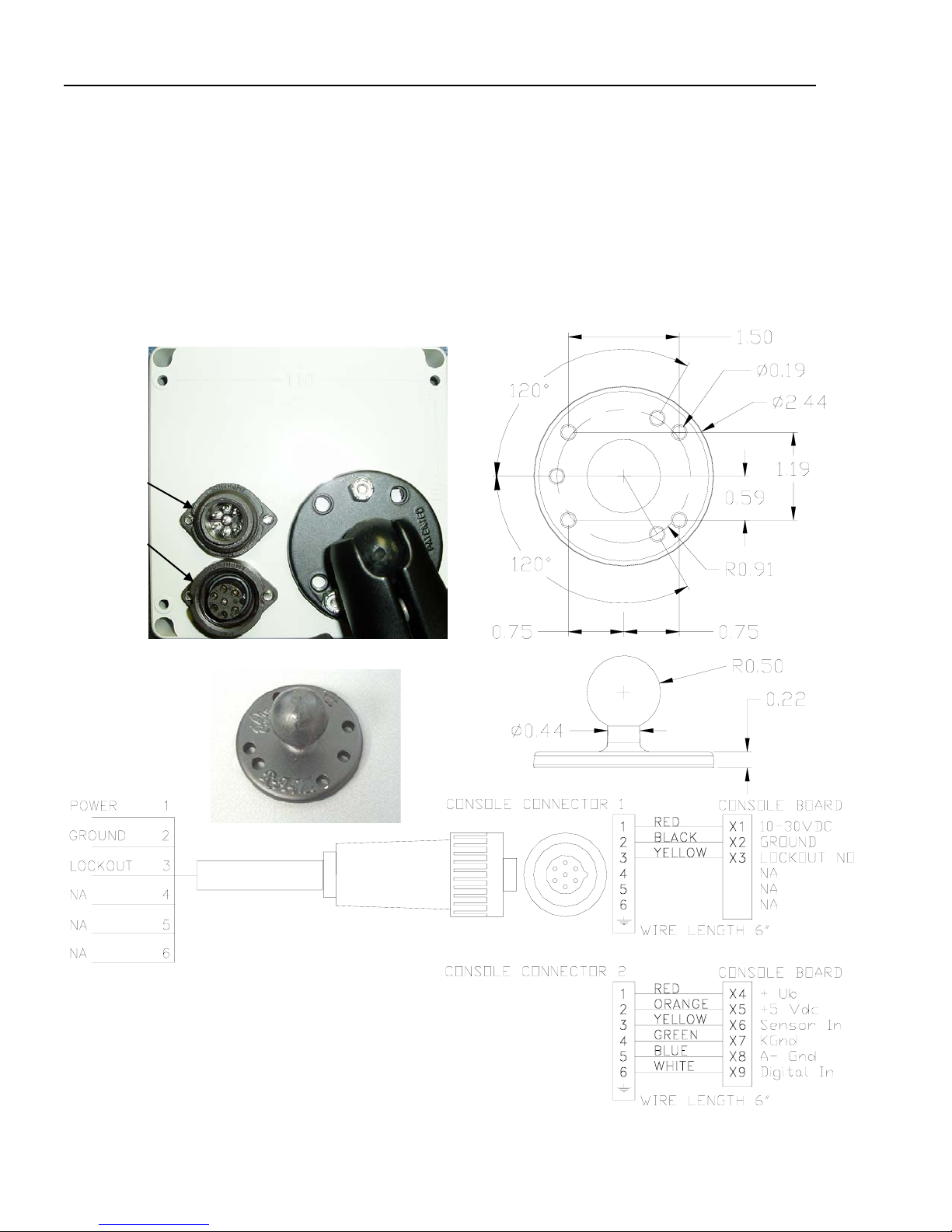

4.2.2 Installation

The console has a mount that allows the console to be swiveled into any direction and to be mounted

in a variety of locations and on nearly any surface.

Choose a location that is in view and within reach of the operator. If radio sensors are being used,

locate in line of site with the sensor. Securely attach the base of the mounting apparatus onto a solid

surface.

The power supply can be from 12- 24 volt DC. The lockout wire supplies power to operate external

solenoids, or relays. The rating of the lockout is 5 amp. An internal fuse protects against overloading

this circuit.

Power

Hardwired

Senso

Power cable connections

© PRS 40 EZ REV A 03/16/06 190201_A

Page 13

Angle

7

5 ANGLE

5.1.1 Operation

When an angle sensor is installed either with radio or hardwired the function of the console is the

same. The angle is displayed in tenths of a degree

When other sensors are installed, they can be shown on other screens. These screens can be

accessed with the up/down arrows.

5.1.2 Limits

The limits are set by selecting

SETUP/ LIMITS/ ANGLE

There is then the choice to set the minimum angle limit or the maximum angle limit.

To set the limit:

• Select the desired limit to set.

• Move the boom to desired angle.

• Press enter.

The angle limits can be cleared without moving the boom to the desired angle. To clear the angle limit

without booming to the angle:

SETUP/ LIMITS/ ANGLE/ MINIMUM

Press and hold the down arrow, . The limits will change to -5 degrees.

SETUP/ LIMITS/ ANGLE/ MAXIMUM

Press and hold the up arrow, . The limits will change to 90 degrees.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 14

Operator’s / Service Manual, PRS 40 EZ

8

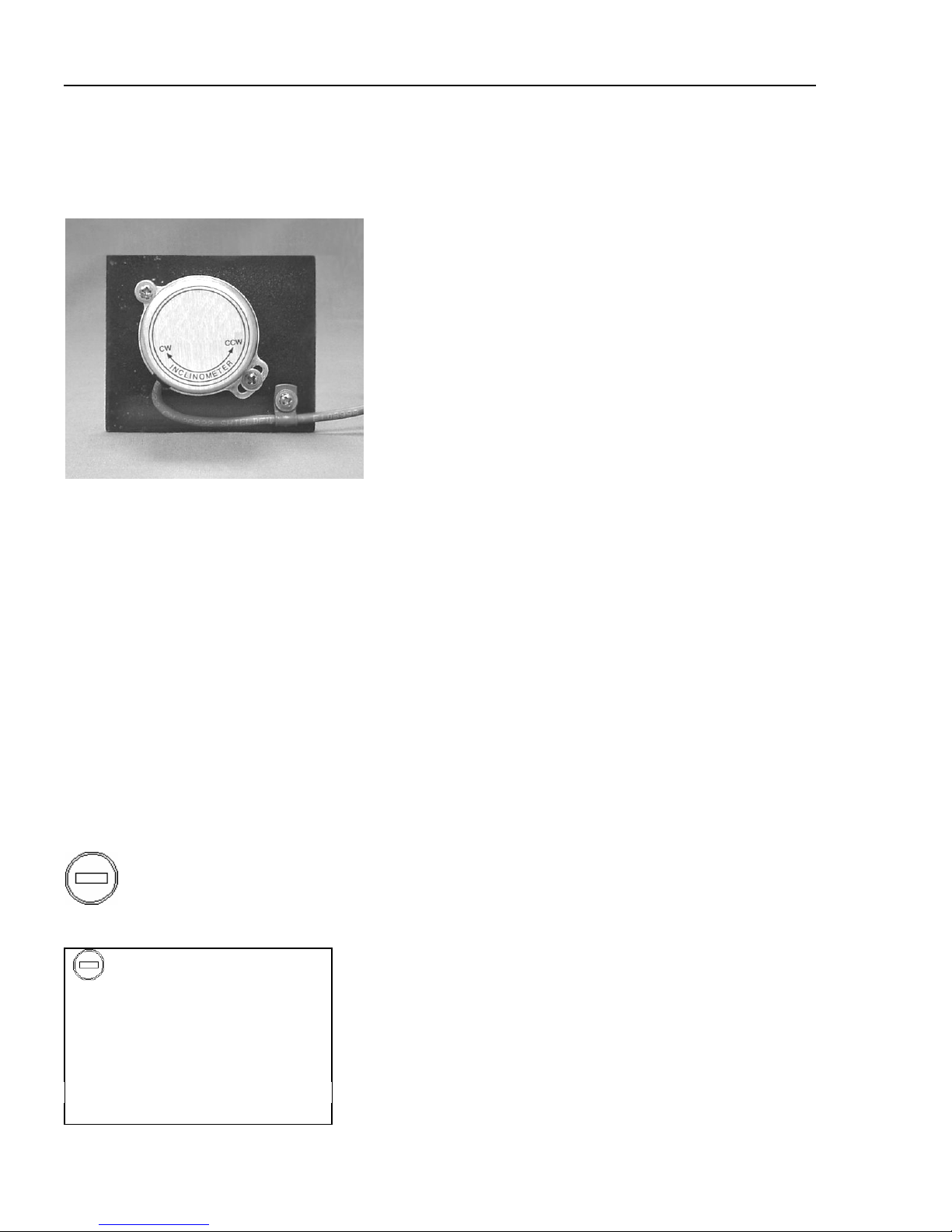

5.1.3 Installation / Calibration Hardwired

Attach the supplied angle sensor mounting plate to the left side of the boom. Note the orientation of

the plate from the photo below. If you are going to weld the plate to the boom, remove the angle

sensor from the plate. Do not weld near the angle sensor. It will be damaged by welding.

Install the angle sensor to the plate with #6-32 screws and washers.

Clamp the cable with the supplied clamp and #6-32 screw and washers.

Route the cable from the boom to the console and insert the connector. Loop any extra cable length

and store in a safe location.

Hardwired (HIRSCHMANN)

This is the setup for the standard Hirschmann angle sensor. This angle sensor has a digital output.

The angle sensor must be previously installed.

Use the setup screens to add the angle sensor to the system.

Select the "HIRSCHMANN" from the following menu.

MENU/ SENSORS/ ANGLE/ HARDWIRED/ HIRSCHMANN

SETUP

● SENSORS

© PRS 40 EZ REV A 03/16/06 190201_A

● ANGLE

NOT INSTALLED

● HARDWIRED

● HIRSCHMANN

KRUEGER

RADIO

Page 15

Angle

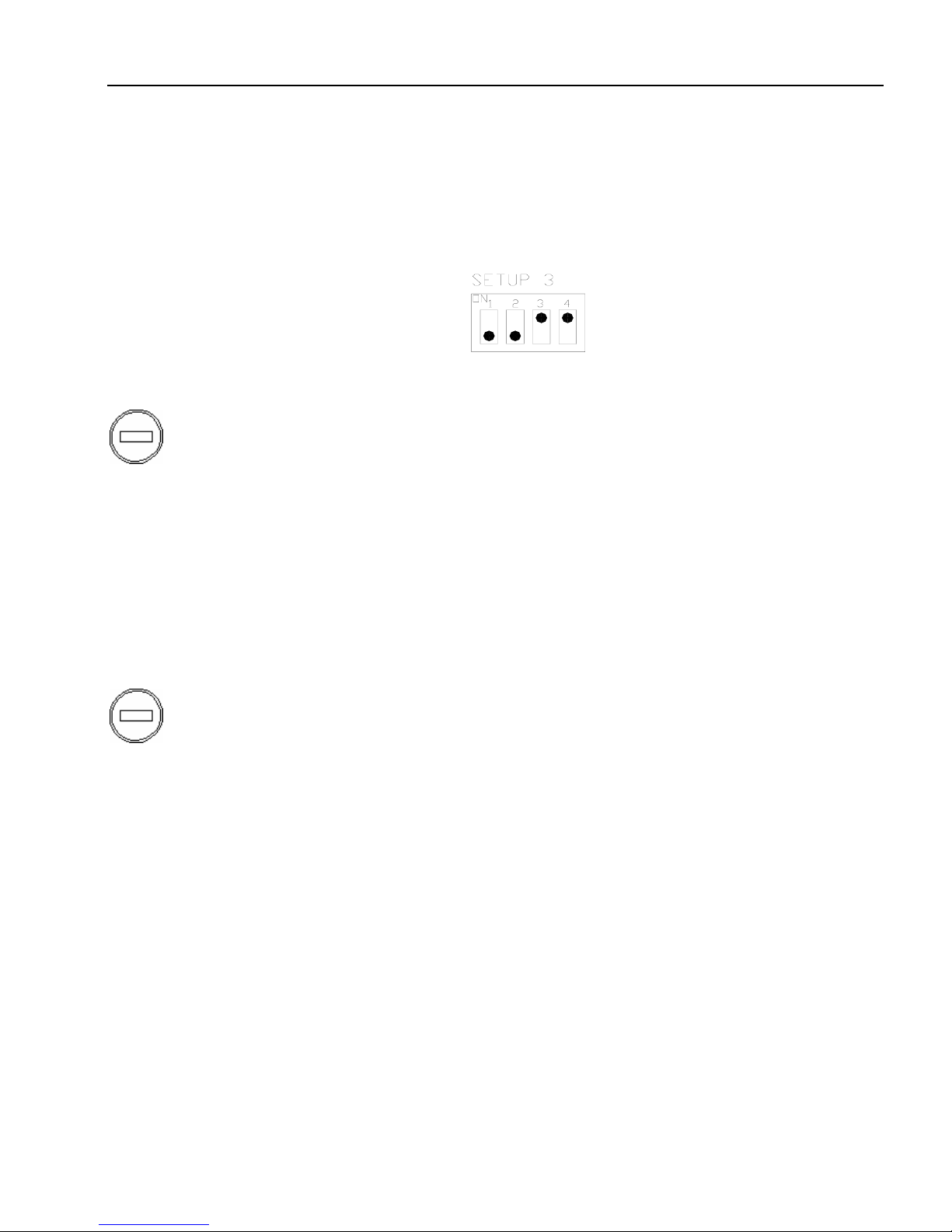

Hardwired (Kruger)

Note for older system updates, use the hardwired option. For example if replacing a Krueger AP

console and using the existing sensor, select the hardwired option.

Set the internal DIP switch to:

Voltage Angle sensor - SETUP 3

Select the "HARDWIRED" from the following menu.

MENU/ SENSORS/ ANGLE/ HARDWIRED/ KRUEGER

5.1.4 Calibration

Both the radio and the hardwired sensors are calibrated with the same procedure. The angle sensor

is pre-calibrated at the factory, but it still must be matched to the boom angle. A level, accurate to +/.2 degrees must be used to set the boom to a known angle.

Go to the menu for calibration of the angle:

9

MENU/ SETUP/ CALIBRATION/ ANGLE

1. Once the boom angle is determined and the sensor is securely mounted, enter the angle setting

screen. This screen is used to match the angle sensor to the angle of the boom.

2. Scroll to the correct angle and press OK.

The calibration and set up of the sensor is then complete.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 16

Operator’s / Service Manual, PRS 40 EZ

10

5.2 ANGLE

This procedure describes how to install and setup a radio angle transmitter.

CONTACT CRANE MANUFACTURER FOR WELDING INSTRUCTION PRIOR TO WELDING ON

BOOM.

Angle sensor, transmitter, and mounting plate.

The angle sensor will be mounted on the side of

boom so as the boom angle changes, the angle

sensor can rotate as shown in the 0°(left) and 90°

(above) positions.

General information

The angle sensor total range is approximately 105° and the zero point is adjustable in the software in

the angle calibration menu. With no software adjustment, the angle range will allow a -15° to 90°

range, but if the angle sensor is zeroed at -5° (-5° becomes 0°) your angle range will be -10° to 95°.

Therefore, when affixing the mounting plate to the boom, make sure you will be able to get your

desired angle range for your application.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 17

Angle

1. Locate an appropriated flat surface area on the boom base section or luffing jib root section. Avoid

the installation close to moving parts or parts that could interfere during boom hoist up and down.

Lower the boom into position that will allow you to safely install the angle sensor.

11

Notes: The antenna must point down and not up. Do not install angle sensor on hot mounting

plate, temperatures greater than 125°F (52°C) this could damage the angle sensor and/or

transmitter.

2. Measure the boom angle by using a digital inclinometer (i.e. smart level) at the area selected in

step 1. Align the mounting plate as defined be the decal or so the mounting holes pointing down as

shown in the pictures above. Affix the mounting plate onto the area. Clean, prime, and paint the

mounting plate if necessary.

3. Remove the angle sensor cover by loosen the four screws in the cover. Check the gasket to insure

it is not damaged. Remove the batteries. Align the 4 holes with the mounting plate threaded holes

and screw the angle sensor onto the mounting plate by using the four screws supplied in the kit.

Attach the antenna to the connector by carefully rotating the antenna clockwise

4. On the console, setup the sensor by using the menu selection:

MENU SETUP/SENSORS/ANGLE 1 or 2. In the setup process you will be asked to insert the

batteries while the receiver searches for the transmitter. Install batteries correctly as shown on the

label in the battery compartment. When the sensor has been found, confirm the angle sensor has

been installed. Return angle sensor cover and tighten the four cover screws carefully.

5. On the console, calibrate the angle by using the menu selection:

MENU SETUP/SENSORS/ANGLE (1 or 2 as defined above)/ZERO POINT. After making this

selection, measure the boom angle by using a digital inclinometer (i.e. smart level), scroll to the

correct angle and press OK. The calibration and set up of the sensor is now complete.

6. Check the angle of the main boom at 0°, 40°, 60°, and 70° and compare it with the measure value.

It should be ±1°. If it is incorrect, repeat step 5, calibrate the angle sensor again, and verify the

actual angle and/or use a different/higher angle (50°) to scroll to and match the angle.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 18

Operator’s / Service Manual, PRS 40 EZ

12

6 A2B

6.1.1 Operation

When an A2B switch has been installed, the status of the switch is always shown. If other sensors are

installed besides the A2B, the A2B status will be shown on the right side of the display.

A2B OK

6.1.1.A PRE-OPERATION INSPECTION

Before operating the crane, the following electrical connections must be checked to ensure that the

system is properly connected for the crane configuration.

With even parts of hoisting line, the weight shall be attached to the dead-end line. With odd parts of

hoisting line, the weight shall be attached to the line of lowest speed.

A separate A2B weight and transmitter must be used for each hoist that is in use. The Retainer flag, if

equipped, must be removed from each switch that is in use. Switches that are not in use should either

be removed from the system or must have the retainer flag installed.

Anti-Two-Block Retainers (optional)

Installation of Anti Two-Block Retainer in Locking Position Procedure (see Fig. 1 and 2):

1. Pull the cable out of the switch and bend back parallel to the boom and hold (1).

2. Slide the retainer from left side with its slot over the cable between the crimped stop and the switch

(2). Push it firmly straight onto the cable guide of the Anti Two-Block switch (3).

© PRS 40 EZ REV A 03/16/06 190201_A

Page 19

A2B

Fig. 1: Setting of Anti Two-Block Retainer in Locking

Position

Fig. 2: Retainer in Locking Position

13

3. Straighten the cable completely into the slot and release the cable (4).

4. Turn the flag of the retainer for best visibility for the operator (5).

Removal and Storage of the Anti Two-Block Retainer Procedure (see Fig. 3 and 4):

1. Pull the cable out of the switch (1) and bend back parallel to the boom and hold (2).

2. Move the retainer down (3) and then left (4) to remove it from the Anti Two-Block switch. Release

the cable.

3. For storage slide the retainer from right side (5) over the Anti Two-Block switch until the clips (A)

lock into the holes (B).

Fig. 3: Removal of the Anti Two-Block Retainer Fig. 4: Retainer in Storage Position

After the electrical connections have been checked to insure that the system is properly connected for

the crane configuration, the following checks shall be made:

1. Check the electrical wiring connecting the various parts of the system for physical damage.

2. Check the anti two-block switches and weights for free movement.

© PRS 40 EZ REV A 03/16/06 190201_A

(WIRED APPLICATION)

Page 20

Operator’s / Service Manual, PRS 40 EZ

14

The following tests shall be performed with care to prevent damage to the machine or injury

to personnel. Proper functioning of the system requires successful completion of these

tests before operating the machine.

If the operator cannot see the load-handling device approaching the boom nose, he shall have an

assistant (signal person) watch the load-handling device. The operator shall be prepared to stop the

machine immediately should the system not function properly as indicated by flashing the warning

symbol, sounding the audible alarm and locking the crane movements, hoist up, telescope out and

boom down. ( if lockout is installed)

Check the anti two-block alarm by performing one of the following tests:

a. By manually lifting the weight attached to the anti two-block switches. When the weight is lifted,

the audible alarm should sound, the anti two-block alarm display should flash.

b. Slowly raise the main boom load-handling device to create a potential two-block condition. When

the load-handling device lifts the weight, the audible alarm should sound, the anti two- block

alarm display should flash and the motion of the load-handling device should be stopped. Lower

the load-handling device slightly to eliminate this condition.

c. Slowly lower the boom to create a potential two-block condition. When the load-handling device

lifts the weight, the audible alarm should sound, the anti two-block display should flash and the

boom lowering function should be stopped. Lower the load-handling device slightly to eliminate

this condition.

If the A2B warning symbol fails to flash and audible alarm does not function as described

and the crane movements are not stopped, the system is not working properly. The

malfunction shall be corrected before operating the crane.

5. If the crane is equipped with a boom extension, repeat the test procedure for the boom extension

anti two-block switch.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 21

A2B

15

6.1.2 A2B limit

When the A2B limit is exceeded, the relay will disengage. The display will show A2B XX and the red

LED will light. The audible alarm will sound. The limit for the A2B is fixed by the chain length and can

not be altered.

LIMIT LED

LCD INDICATION

H I R SCH MANN A2B

6.1.3 Installation

6.1.3.A Transmitter / Switch

The transmitter and battery housing are made of a special polymer that resists damage from impact

and will not become brittle even in low temperatures.

LED

© PRS 40 EZ REV A 03/16/06 190201_A

Page 22

Operator’s / Service Manual, PRS 40 EZ

16

6.1.3.B Transmitter LED

The transmitter has an LED on the bottom for diagnostics. The LED should be on when in a two-block

condition or when the weight is lifted. The LED will flash rapidly during a 2-block condition and will stop

flashing after the switch is in a two-block condition for more than 15 seconds. The LED will flash

randomly approximately every 2 seconds when the switch is transmitting. When in sleep mode, the

LED will not flash. When the transmitter is power up (batteries removed and replaced) the transmitter

LED will be on for 1 second to indicate the transmitter is setup for an A2B switch.

6.1.3.C Travel position (optional)

Designed into the transmitter plate is a small hole into which a hook can be installed. This can be used

to fasten the chain. This hook is used to open the switch and put it into a permanent 2-block condition.

This serves 2 functions.

1. It extends battery life.

2. It prevents the lockouts and alarms from engaging and disengaging due to bounce while

traveling.

The system is in permanent lockout and the system will not function until the chain is unhooked.

To use the feature, attach any part of the chain into the hook. When it is desired to use the switch

again, simply unhook the chain to allow the switch to close.

The chain must be unhooked before the crane is operated.

6.1.3.D Transmitter/Switch installation

Install the standoff to the boom head using 2 5/16x3/4” HEX bolts. The hole pattern for the standoff is

the same as that of conventional PAT A2B switches. In most cases the standoff can be mounted in

the same location as the conventional switch.

If not replacing an existing switch, the proper location would be one that allows the switch to rotate

freely without being obstructed by any part of the boom head. It should be mounted close to the dead

end mounting gusset. The switch should normally be mounted on the cab side of the crane.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 23

A2B

17

For jib installations, locate the switch close to the jib head.

Remove the lynch pin from the standoff. Slide the A2B switch onto the standoff. Replace the lynch pin

into the standoff.

Install the weight and chain onto the A2B switch.

6.1.4 A2B Setup

HARDWIRED

In order to use the A2B, the A2B sensor must first be set up on with the console.

Set the internal DIP switch to:

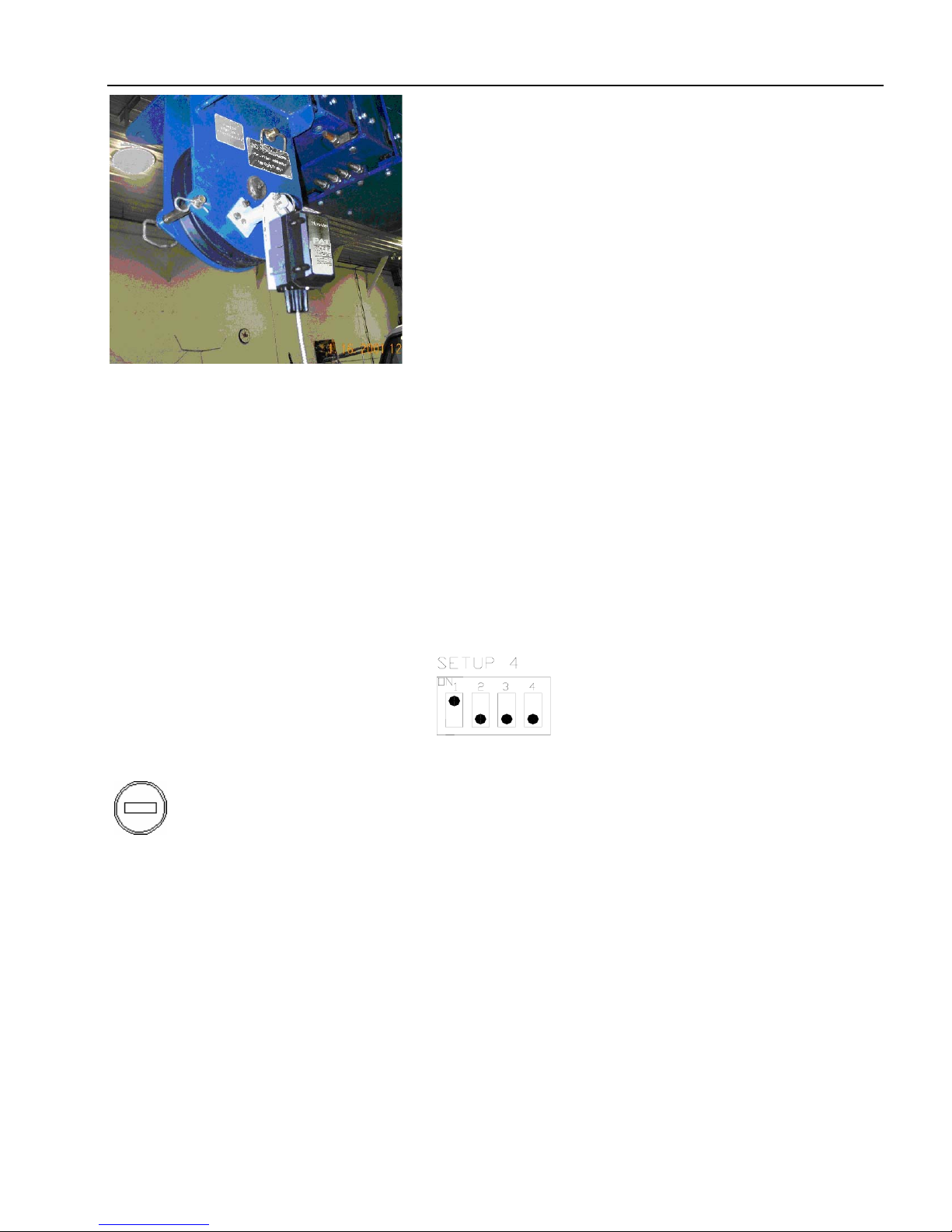

A2B sensor - SETUP 4

Add the first A2B sensor to the console by pressing

SENSORS/A2B 1/ HARDWIRED.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 24

Operator’s / Service Manual, PRS 40 EZ

18

HARDWIRED A2B WIRING DIAGRAM

(EXTERNAL RELAY INSTALLED BY CUSTOMER)

© PRS 40 EZ REV A 03/16/06 190201_A

Page 25

wind

RADIO

In order to use the A2B, the A2B transmitter must first be set up to with the console.

Add the first A2B sensor to the console by pressing

19

SENSORS/A2B 1/ RADIO. The console will show "SEARCHING". Pull and release the cord

of the A2B switch. The switch is now setup.

Add the Second A2B sensor to the console by pressing

SENSORS/A2B 2/ RADIO. The console will show "SEARCHING". Pull and release the cord

of the A2B switch. The switch is now setup

7 WIND

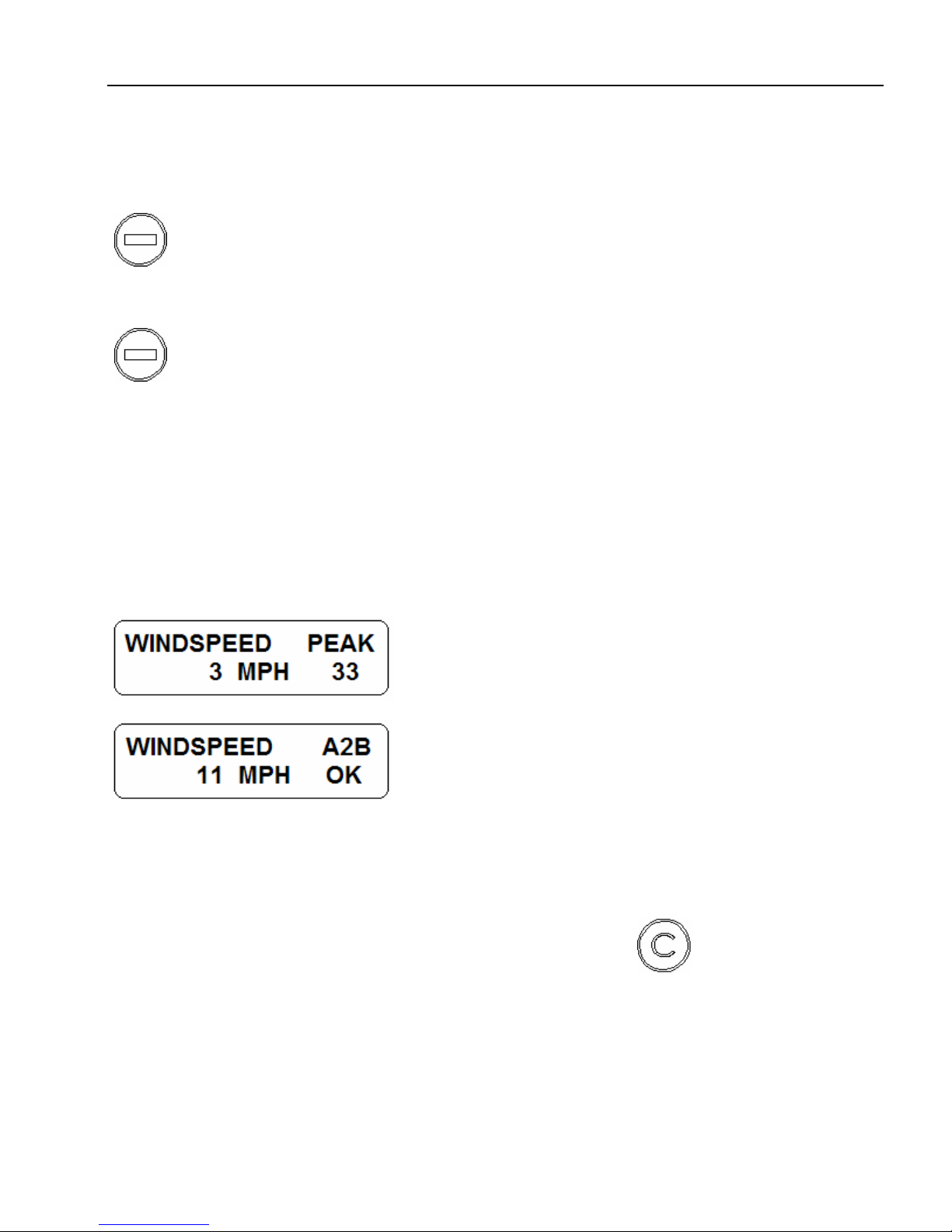

7.1.1 Operation

The wind speed can be shown by itself on the screen or if in combination with other sensors, as an

additional screen.

The speed can be shown in miles per hour, or kilometers per hour.

When the wind speed is displayed by itself, the peak speed is also shown. The peak will be the

highest wind speed recorded since the system was started. When the system is turned off the peak

value will be reset. The peak value can also be reset by pressing the

© PRS 40 EZ REV A 03/16/06 190201_A

button.

Page 26

Operator’s / Service Manual, PRS 40 EZ

20

7.1.2 LIMITS

The system sets the default speed limit to 20 mph. The limit can be set to any value.

The limits are set by selecting

SETUP/LIMITS/WIND

Use the up and down arrows to set the desired limit.

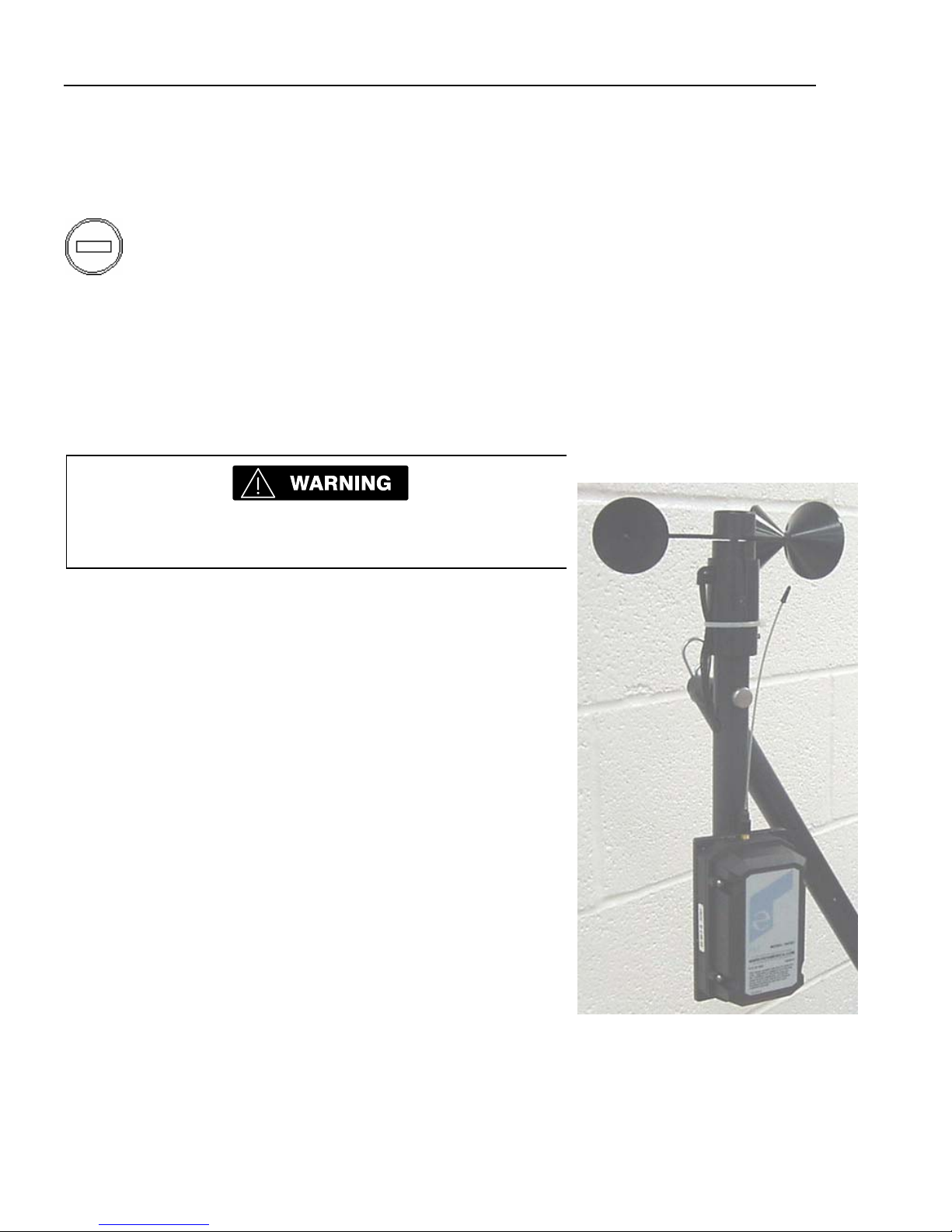

7.1.3 Installation

The sensor is delivered with a bracket support that allows the sensor to stay perpendicular to the

ground through the boom angle range.

CONTACT CRANE MANUFACTURER FOR WELDING

INSTRUCTIONS PRIOR TO WELDING ON BOOM.

The 1” diameter mounting pole will be affixed to the boom tip at

your discretion so that the anemometer sensor is mounted

approximately a foot higher than the boom sheaves and will not

interfere or be damaged by hoist lines or extension mounting or

movement. Affix the mounting pole to the boom tip or possibly the

length cable anchor pin so the pipe supports the sensor.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 27

wind

7.1.4 Wind Setup

In order to use the wind sensor, the wind sensor must first be set up to with the console.

HARDWIRED

Set the internal DIP switch to:

Wind speed sensor - SETUP 4

Add the wind sensor to the console by pressing

21

SENSORS/ WIND/ HARDWIRED.

HARDWIRED WINDSPEED SENSOR WIRING DIAGRAM

(EXTERNAL RELAY INSTALLED BY CUSTOMER)

© PRS 40 EZ REV A 03/16/06 190201_A

Page 28

Operator’s / Service Manual, PRS 40 EZ

22

RADIO

Add the wind sensor to the console by pressing

SENSORS/ WIND/ RADIO.

The console will show "SEARCHING". Remove the batteries from the transmitter. Reinstall the

batteries into the transmitter. The LED on the transmitter will be on for 3 seconds and then start to

flash on and off. The sensor should now be set up.

When the transmitter is powered up (after batteries removed and replaced) the transmitter LED will be

on for 3 seconds to indicate the transmitter is setup for a wind speed sensor.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 29

LOADCELL

23

8 LOADCELL

8.1.1 Operation

In order to use the loadcell, the loadcell must first be installed into the system. See the section on

loadcell setup. When set up with a load cell, the last selected display and configuration will be shown

and must only be confirmed if that configuration setup equals the crane’s actual configuration.

Otherwise the reeving must be changed to match the current configuration.

The load cell can be installed into a single part line configuration or into a multipart line configuration.

When a multiple parts are used, the system multiplies the force from the load cell by the parts of line

selected on the console. This is why it is imperative that the correct parts of line (reeving) is selected

on the console.

The correct setting of the reeving is of utmost importance for the proper functioning of the

system. Therefore, only operators who are thoroughly familiar with the operation of the

system should perform the setting of the system. The system will only measure the load on

hook and will not measure the effect of any other attachments.

Reeving

To view the on hook load display, the correct reeving must be set.

Enter Setup screen. Select Reeving and press

. Use the arrows to adjust the reeving setting.

When complete, press

.

Units

The load can be displayed in pound or in kilograms.

To change the units, press

© PRS 40 EZ REV A 03/16/06 190201_A

. MENU/OPTIONS/LB

Page 30

Operator’s / Service Manual, PRS 40 EZ

24

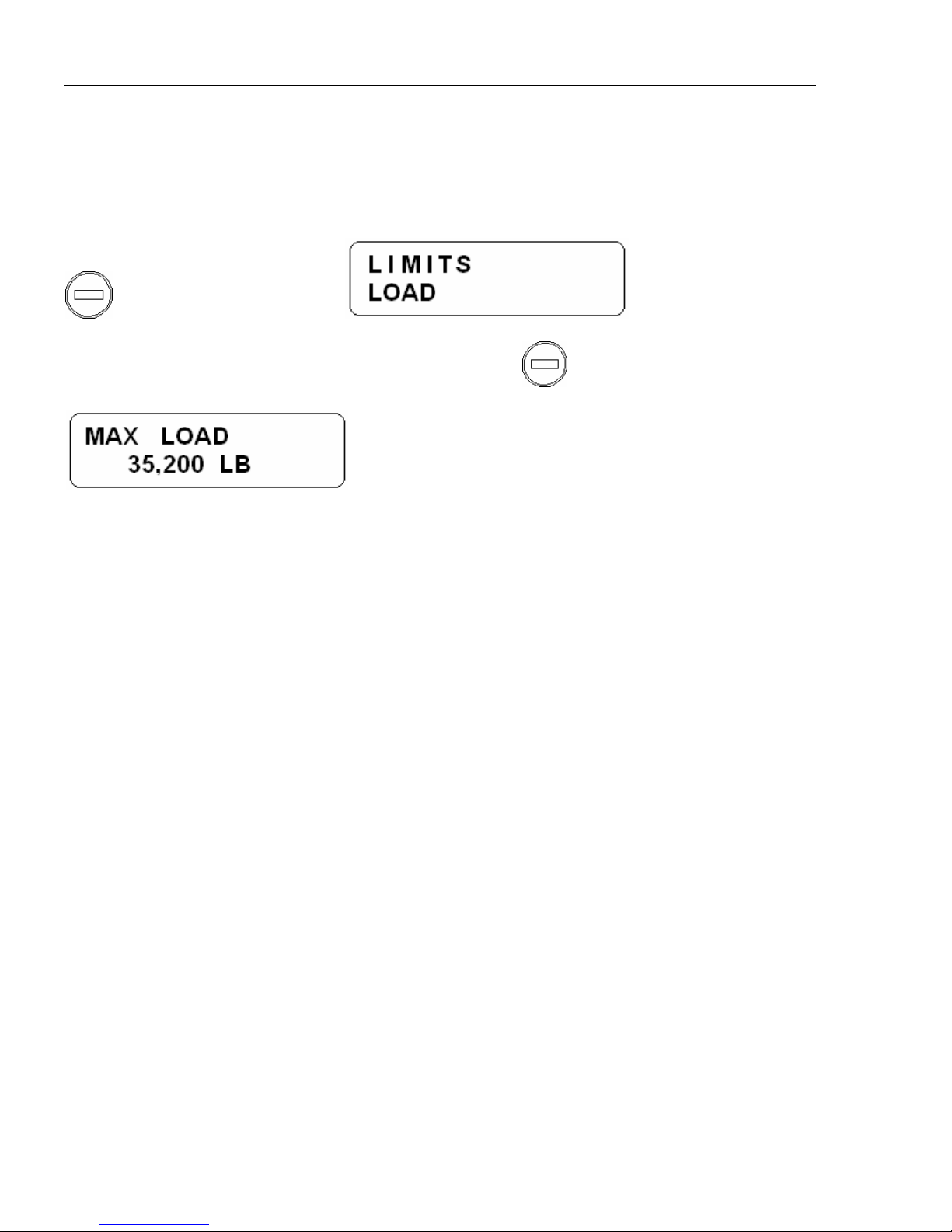

8.1.2 LIMITS

The unit has no default limit set for the load.

The limits are set by selecting

SETUP/LIMITS/LOAD

Use the up and down arrows to set the desired limit. Press

when complete.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 31

LOADCELL

25

8.1.3 Installation

The load cell is installed at the dead end of the wire rope that is being used to lift the load. Use the

appropriate pins for the type and size of socket, block or ball that is being used. Note: The pin size

should have been specified when ordered and should match the existing pin diameter. Ensure that the

correct pin used is rated for the maximum line pull capacity. For the 7.5 ton load cell, install the pin so

the pin head on the antenna side. The pin diameter, jaw thickness and jaw opening used to connect to

the load cell will effect position of the antenna. There is 90° fitting for the antenna P/N 031-300-050535 maybe necessary in some cases. Ensure all safety pins are installed properly with washers and

bushing to fit the hole diameter and pin length.

7.5 ton Installation

Install the plate using the 2-1/4” pin so the pin head on the antenna side. The plates have a rest button

installed to prevent the plates from striking the transmitter on the side of the load cell. On rest button

should be on the load cell side of the plate. Ensure all safety pins are installed properly with washers

and bushing to fit the hole diameter and pin length.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 32

Operator’s / Service Manual, PRS 40 EZ

26

8.1.4 Loadcell Setup

In order to use the loadcell, the loadcell must first be installed into the system. Add the loadcell to the

console by pressing

HARDWIRED

SETUP / SENSORS / INSTALL-REMOVE / LOADCELL / HARDWIRED.

RADIO

Add the radio loadcell to the console by pressing

SETUP / SENSORS / INSTALL-REMOVE / LOADCELL / RADIO.

The console will show "SEARCHING". Remove the batteries from the transmitter. Reinstall the

batteries into the transmitter. The LED on the transmitter will be on for 3 seconds and then start to

flash on and off. The sensor should now be set up.

When the transmitter is powered up (after batteries removed and replaced) the transmitter LED will be

on for 3 seconds to indicate the transmitter is setup for a loadcell.

Press

when complete.

8.1.4.A LOADCELL RANGE

Use the following menu selection as an example to select the correct load cell. The following is an

example for setting the 7.5 ton load cell.

SETUP / CALIBRATIONS / LOAD RANGE / LOADCELL TYPE / 7.5 TON.

8.1.5 Loadcell Calibration

ZERO POINT SETTING

The load cell being zeroed must be installed and communicating with the console and there should be

no load applied to the load cell. Use the following menu selection to set the zero point of the load cell.

SETUP / CALIBRATIONS / LOAD 0-POINT

Press

© PRS 40 EZ REV A 03/16/06 190201_A

when complete.

Page 33

LOADCELL

27

8.1.5.A ACCURACY AND TEST REQUIREMENTS

Check the load display by lifting a load of known weight. The accuracy of the load indication shall be

within the tolerance of SAE J376, refer to complete SAE standard before testing.

Accuracy

The accuracy of the load indicating system is to be such that the indicated load is not less than 100%

of the actual load, nor more than 110% of the actual load. Where the system cannot meet the

accuracy criteria at the lower load range, conspicuous labeling or signaling is to be provided indicating

that these accuracy criteria cannot be met.

The weight of the load being lifted and all additional equipment such as blocks, slings, sensors, etc.;

also referred to as working load.

Test Requirements

System tests are to be conducted using an appropriate configured crane and specified load rating

chart.

For system calibration, three or more test radii or boom angle are to be employed to establish

compliance with the accuracy section above. Test loads shall be as near as is practical to minimum,

mean, and maximum values within the operating limits.

One of the following test methods or equivalent is to be used:

Known Weight

Test load to be applied by suspending known weights accurate to ± 1%. If the weights of all

additional equipment such as blocks, slings, sensors, etc., are included in the test load, the total

load is to be known to an accuracy of ± 1%.

Fixed Anchor (Deadman)

Test load to be applied by hoisting against a fixed anchor or deadman equipped with a means for

measuring loads accurate to ± 1%. If the weights of all additional equipment such as blocks,

slings, sensors, etc., are included in the test load, the total load is to be known to an accuracy of ±

1%.

The system accuracy is to be determined from the following formula:

Indicated Load

Actual Load

x 100 = % of Load

© PRS 40 EZ REV A 03/16/06 190201_A

Page 34

Operator’s / Service Manual, PRS 40 EZ

28

9 LINE RIDER

9.1.1 Operation

In order to use the linerider, the linerider must first be installed into the system. See the section on

linerider setup.

Reeving

To view the on hook load display, the correct reeving must be set.

Enter Setup screen. Select Reeving and press

When complete, press

.

Units

The load can be displayed in pound or in kilograms.

To change the units, press

. MENU/OPTIONS/LB

Tare

. Use the arrows to adjust the reeving setting.

A Tare load can be displayed by pressing

display. The tare load will be displayed for 120 seconds. While in tare function, a ‘T’ will be shown on

the display. During this time, the tare function can be turned off by again pressing

© PRS 40 EZ REV A 03/16/06 190201_A

. Pressing this button will zero out the current load

.

Page 35

Line rider

9.1.2 LIMITS

The unit has no default limit set for the load.

The limits are set by selecting

SETUP/LIMITS/LINERIDER

29

Use the up and down arrows to set the desired limit. Press

when complete.

9.1.3 Installation

The linerider installation will depend on the type of boom. Follow the applicable instructions for a

hydraulic or lattice boom.

LINERIDER GENERAL INFORMATION

The linerider is attached to the swing arm mounting bracket as shown in Figure 4. The swing arm

assembly has four joints:

1. Vertical movement at the attachment point to the linerider.

2. Horizontal movement of the swing arm.

3. Vertical movement of the swing arm.

4. Swivels horizontally around the mounting bolt.

The mounting bolt secures the swing arm to the machine.

3

4

Figure 4. Linerider and Swing Arm.

© PRS 40 EZ REV A 03/16/06 190201_A

2

1

Page 36

Operator’s / Service Manual, PRS 40 EZ

30

9.1.3.A HYDRAULIC BOOM MACHINES

Figure 5. Hydraulic Boom Linerider Installation.

NOTE: CONTACT CRANE MANUFACTURER FOR WELDING INSTRUCTION PRIOR TO

WELDING ON BOOM.

1. Affix the bolt at the tip of the base section on the main boom similar to Figure 5.

2. Attach the swing arm to the bolt.

3. Run the hoist line through the linerider.

4. Attach the swing arm to the linerider.

5. Ensure freedom of movement side to side

6. Connect linerider electrically with cable provided.

Note: It is recommended that this cable be routed through conduit to the swing arm in a way

that best protects the cable from damage, and secured with tie straps.

7. Connect the linerider extension to the console cable at boom base with the 28ft extension

provided.

NOTE: Extra cable extensions can be ordered if required.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 37

Line rider

┐

9.1.3.B LATTICE BOOM MACHINES

31

30

MAXIMUM

Figure 6. Lattice Boom Linerider Installation.

WARNING: CONTACT CRANE MANUFACTURER FOR WELDING INSTRUCTION PRIOR TO

WELDING ON BOOM.

1. Select a location that the swing arm angle with respect to the boom will not exceed 30°(see

Figure 6). The linerider should be located as close to the boom tip as possible.

2. Construct two base plates. Size of base plates will be specific to the lattice structure and your

selected location.

a. The first base plate will be attached to the boom with the swing arm bolt affixed to the

center of the base plate.

b. The second base plate will be attached to the boom so that it supports the linerider when

not in use.

3. Affix the swing arm bolt to the center of the first base plate.

4. Affix the first base plate to the selected location on the lattice boom.

5. Attach the swing arm to the bolt.

6. Run the hoist line through the linerider.

7. Attach the swing arm to the linerider.

8. Ensure freedom of movement side to side

9. Attach the second base plate to the boom so the linerider rubber supports will touch the plate

when there is no load.

10. Connect linerider electrically with cable provided.

Note: It is recommended that this cable be routed through conduit to the linerider in a way that

best protects the cable from damage, and secured with tie straps.

11. Connect the linerider extension to the console cable at boom base with the 28ft extension

provided.

NOTE: Extra electrical extensions can be ordered if required.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 38

Operator’s / Service Manual, PRS 40 EZ

32

9.1.3.C PRS 40 EZ UPGRADE FROM EI33

NOTE: ADDITIONAL CABLE ASSEMBLIES ARE REQUIRED WHEN UPGRADING FROM THE

EI33 CONSOLE TO THE PRS 40 EZ. (SEE BELOW)

HIRSCHMANN

PRS 40 EZ

Cable assembly (031-300-060-434) connects to the back of the

PRS 40 EZ console and mates with the existing (031-300-101-

178) cable assembly which connects to the linerider.

If additional length is required between the console and linerider,

cable assemblies of various lengths are available. (see below)

© PRS 40 EZ REV A 03/16/06 190201_A

Page 39

Line rider

9.1.4 Linerider setup

Hardwired

Set the internal DIP switch to:

4-20 mA sensor - SETUP 1

Select the "HARDWIRED" from the following menu.

SENSORS/ LINERIDER/ HARDWIRED

9.1.5 Linerider Calibration

The zero point and the gain of the linerider must be set before operation.

Essential Information

• The units of measure shall be the same as load chart units.

• Calibration should be completed after installation, crane modification, or anytime there is an

indication of inaccuracy.

• Recommendations for system calibration:

Use single part line during calibration.

Note: Multiple parts of line are acceptable. (It only increases the amount of test load

recommended)

Pick a known test load as close as possible to the maximum rated load for line configuration.

The test load must include the hook block and all rigging.

1. Turn unit “on”.

2. Set the reeving to the actual parts of line configured.

3. Place hook block or headache ball on the ground, so there is no load on the hoist line.

:

33

4. Press

CALIBRATIONS/LINERIDER 0.

5. Press

. The display should show ,000 LB.

6. Pick a known test load as close as possible to the maximum rated load. SAE recommends the test

load should be accurate to ±1%.

7. Press

CALIBRATIONS/LINERIDER ADJ.

8. Compare the known test load to the displayed load and adjust if necessary using the arrows on the

console.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 40

Operator’s / Service Manual, PRS 40 EZ

y

34

10 RADIO MODULE

10.1 INSTALLATION

A receiver module must be installed into the PRS 40 EZ before a radio sensor can be set up or used.

The following is the procedure for installing the radio module.

Caution: Handle the module with care. The module can be damaged by static electricity. Take

proper precautions by removing any static electricity from your body. Do not remove the

board from its protective anti static bag until the time of installation.

1. Open the PRS 40 by loosening the 4 screws on the console lid.

2. Insert p/n 101646 radio module into the sockets on the PCB assembly. Align the pins and press

the radio module into place. Make sure that they are correctly aligned and that they are firmly

seated. The foam will hold the radio module in place, when radio module is installed.

Inspect the gasket for nicks

P/N 101646

Radio Module

Installed

Radio Module sockets.

Ensure the pins are correctly

aligned and that they are

firml

seated sockets.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 41

Radio Module

3. Inspect the gasket on the lid for nicks or other damages that may prevent the gasket from sealing.

If it appears to be damaged, a replacement gasket should be installed; p/n 031-300-050-786

GASKET, PRS HOUSING/FRONT FACE.

4. Reassemble the console; ensure the wires are not pinched between the lid and the housing. Close

housing and tighten the 4 cover screws. Make sure that the console lid is completely seated and

properly tightened.

35

© PRS 40 EZ REV A 03/16/06 190201_A

Page 42

Operator’s / Service Manual, PRS 40 EZ

36

11 ADDING SENSORS

To add a new sensor,

Menu- SETUP/SENSORS/

This gives the sensor select/information screen. It shows the status of all hardware. Each sensor has

several options:

*NOT INSTALLED

HARDWIRED

RADIO

The status of the sensor is indicated with an "*". In the example, the sensor is "not installed".

The PRS40 EZ is a very powerful and flexible system. To allow for multiple types of sensors, a 4

position DIP switch is utilized. The DIP switch must be in the proper position for the attached sensor

to function properly. The DIP switch will be set into the proper position before shipped from the

factory.

If adding a hardwired sensor to the system, use the following for the diagrams.

DIP SWITCH SETTINGS

Current Linerider - SETUP 1

Kruger Angle sensor - SETUP 3

Serial Angle sensor - NA

Hardwired Wind speed - SETUP 4

Hardwired A2B - SETUP 4

All Radio sensors - NA

WIRELESS SOCKET

POWER INDICATION

RUN INDICATION

DIP SWITCH

© PRS 40 EZ REV A 03/16/06 190201_A

Page 43

SERVICE / trouble shooting

12 SERVICE / TROUBLE SHOOTING

Daily maintenance of the system consists of inspecting:

1. The electrical wiring connecting the various parts of the system.

If electrical wiring is damaged, it shall be replaced immediately.

2. If the insulation is worn on the electrical wiring or cable guides are damaged, these parts shall be

replaced.

3. A damaged or punctured display must be replaced immediately to prevent ingress of water and

damage to the internal circuitry.

Other than correcting the problems identified in the Malfunctions Table and replacing faulty

mechanical parts and cables, no other repairs shall be made.

When the PRS40 EZ system is turned on, it will show the following screen. This screen shows the

telephone number of Hirschmann and the software version.

37

Make sure the display is working and all the lights come on during this time. Listen to the buzzer

sound. If any of the components above fail, please contact your nearest service representative before

operating the system!

© PRS 40 EZ REV A 03/16/06 190201_A

Page 44

Operator’s / Service Manual, PRS 40 EZ

38

12.1 SCREENS

Communication error screen

When working from the normal operating screen and an error occurs, a communication error screen

will be displayed temporarily, which indicates loss of communication between a sensor and the

console.

This screen shows that there is an error in the communication between the A2B sensor and the

console. The sensor that is in error is indicated on the bottom line.

To return to this communication error screen, return to the SETUP screen and press

.

At this point, you are enabled to scroll through all sensors which are experiencing a communication

error by pressing the UP

and DOWN arrows.

12.1.1 To test the outputs:

The following outputs can be tested. Function lockout, Limit LED's, Buzzer.

SETUP >> OPTIONS

>>TEST SEQUENCE.

Select this option and then press . Each of the outputs

will be cycled on individually, enabling the user to determine if each is functioning correctly.

12.1.2 To test the inputs:

The analog input screen may be used to assist with troubleshooting errors.

To access this select:

SETUP >> OPTIONS >> ANALOG INPUT

To change between milliamps and volts use the UP

the analog input.

© PRS 40 EZ REV A 03/16/06 190201_A

or DOWN arrows while viewing

Page 45

SERVICE / trouble shooting

12.1.3 Battery level:

The battery level of each radio sensor can be monitored.

SETUP >> OPTIONS

>> BATTERY LEVEL.

39

Select this option and then press

. Each sensor can be selected individually, enabling the user

to view the percentage of each sensor’s battery level.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 46

Operator’s / Service Manual, PRS 40 EZ

40

12.2 TROUBLESHOOTING

After the onboard diagnostics have been performed, follow these guidelines

All LED's are located inside the receiver box.

Problem Cause Solution

LCD does not light or

show characters.

Limit LED's do not light No power to

Communication error Low battery Verify which sensor is causing the error by looking at the

Communication error Faulty sensor Verify which sensor is causing the error by looking at the

Communication error Poor reception Verify which sensor is causing the error by looking at the

Communication error Sensor not

Communication error Poor

Buzzer does not sound Faulty Go into the diagnostics screen for the outputs. Verify all

Crane functions locked

out all the time

Crane functions locked

out all the time

Crane functions locked

out all the time

Transmitter LED does

not flash

Transmitter LED does

not flash

No power to

console

Make sure the console is getting power from the crane.

Check wiring.

Ensure correct polarity of the power.

Open console, check status of LED's. Both the red and

green LED's should be on.

Make sure the console is getting power from the crane.

console

Check wiring.

Ensure correct polarity of the power.

Open console, check status of LED's. Both the red and

green LED's should be on.

communication error screen. (see section 11)

Replace batteries.

communication error screen. (see section 11)

Verify that the transmitting LED on the sensor is blinking.

communication error screen. (see section 11)

Verify that the transmitting LED on the sensor is blinking.

Verify that the sensor is line of sight to the console.

Install the sensor on the console. See adding sensors

installed.

Remove potential interference sources from the area.

communication

caused by

Mount the receiver in a different location.

interference.

outputs are functioning. (see section 11)

If any of the tests fail, replace console.

Incorrect wiring Check for power to lockout device.

Clear all faults.

Communication

See communication error. (see section 11)

error.

Fault in receiver

module.

Check for power to lockout device.

Clear all faults.

Sensor is asleep. Change the status of the sensor. Pull switch wire rope of

A2B.

Batteries dead. Replace the batteries.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 47

SERVICE / trouble shooting

41

12.3 TROUBLESHOOTING MOISTURE

The PRS 40 EZ contains electronic components in various locations, such as central unit, sensors,

junction boxes etc. These internal components cannot be designed to withstand exposure to moisture

over a longer period of time. For this reason, the housings of the components are water protected

according to IP 65. If you find water or moisture inside any of the housings, the source for the water

ingress has to be detected and corrected to ensure proper operation.

There are two major possibilities for the occurrence of excessive moisture inside an enclosure:

1) Water ingress

2) Condensation

This outline gives instructions for detecting the cause for excessive moisture by using simple

troubleshooting methods and how to prevent the moisture ingress from happening again.

12.3.1 Water Ingress

There are 4 possibilities for water to enter an enclosure:

1) Spray Cleaning

2) Missing / Loose Screws

3) Broken Lid

4) Defective Gasket

It is possible to find out the source of water ingress by going through the following steps and ruling out

one possibility after the other until the cause is identified:

1) Spray Cleaning

The enclosures used for the PRS 40 EZ system are water protected to IP 65. This means

protection against the environment, such as rain. However, through the use of spray cleaner at

short distances, it is possible to force water through the gasket or strain relieves. For this reason,

avoid spraying any components from short distances with spray cleaners. Convey this fact to any

member of a maintenance crew.

2) Missing / Loose Screws

All screws have to be present and to be equally tight to ensure water protection of the enclosure. If

there are screws missing, replace them. If no screw is missing, check the tightness. If any were

loose, then open all screws and then re-tighten them equally.

3) Broken Lid

An enclosure will only seal correctly if the lid is not bent. To check this, loosen all screws of the lid,

take the lid off the box and visually inspect it for deflection. If the lid is bent or damaged, it needs to

be replaced. Try to determine what has caused the lid to be bent and eliminate the reason for that.

Order a new lid through your Hirschmann representative.

4) Defective Gasket

The gasket underneath the lid seals the unit. The gasket needs to be in good condition in order to

seal correctly. If the gasket is torn, brittle or severely bent, it needs to be replaced. Order a new

gasket through your Hirschmann representative.

© PRS 40 EZ REV A 03/16/06 190201_A

Page 48

Operator’s / Service Manual, PRS 40 EZ

42

13 MAINTENANCE

The only maintenance required is to change the batteries when required. Also, check the mounting

hardware daily to ensure that there is no damage. Replace any damaged parts before operating the

crane.

13.1 BATTERY REPLACEMENT

To replace the batteries, remove the 4 screws from the transmitter housing. During battery

replacement, use caution when opening the battery cover and transmitter to avoid damage to the

gasket causing moisture ingress which could corrode the batteries and terminals. Inspect the gasket

surface on the transmitter for nicks or other damages that may prevent the gasket from sealing. If it

appears to be damaged, a replacement gasket should be installed.

Install 4 fresh batteries into the proper location and direction as indicated on the battery holder.

Make sure that the cardboard tube is installed as shown.

LOOSEN 4 SCREWS INSPECT CONDITION OF GASKET

Software version

Battery direction

BATTERY DIRECTION LABEL

INSTALLED BATTERIES IN CARDBOARD TUBE

© PRS 40 EZ REV A 03/16/06 190201_A

Page 49

Part Numbers

14 PART NUMBERS

14.1 CONSOLE

101646

Radio Module Assembly

031-300-060-666 PRS 40 EZ, w/ Radio

031-300-060-619 PRS 40 EZ, w/o Radio 031-300-060-491

Power cable

43

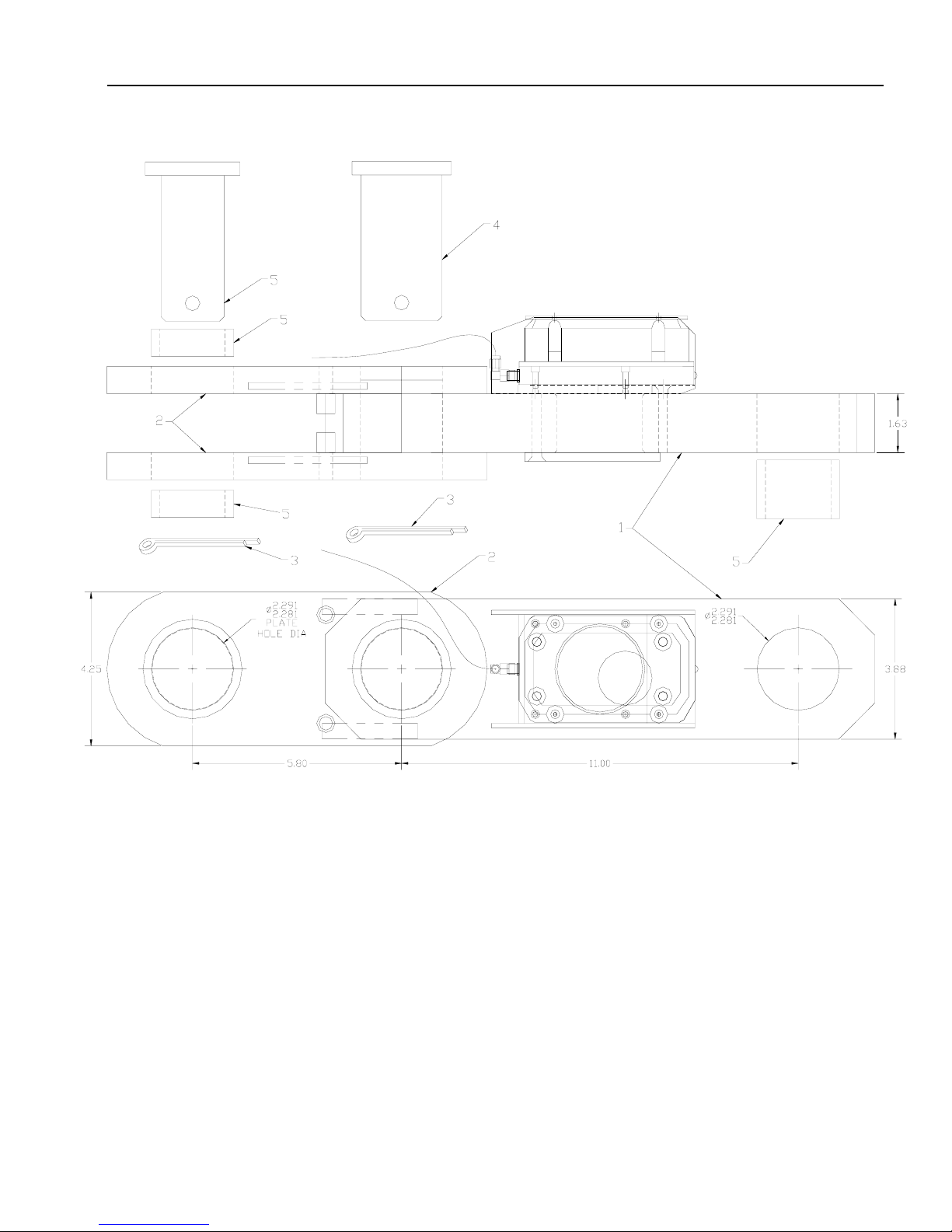

3

2

4

1

Item Part number Qty Description

1. 031-300-060-382 1 Console Accy, Mounting Arm W/1" Ball

2. 031-300-050-485 3 Screw, #10-24 X 5/8 Ph. Ph

2. 031-300-050-487 3 Washer, Sealing #10

2. 031-300-050-489 3 Nut, #10-24 Lock Nylon Insert

3. 031-300-050-523 1 Fuse, 5 Amp Auto (Mini)

4. 031-300-050-786 1 Gasket, w/ PRS housing & front face

© PRS 40 EZ REV A 03/16/06 190201_A

Page 50

Operator’s / Service Manual, PRS 40 EZ

44

14.2 A2B

031-300-060-593

Radio A2B transmitter assembly

031-300-060-586 Antenna only

Radio A2B transmitter 031-300-050-688

031-300-050-763

Neoprene rubber gasket

© PRS 40 EZ REV A 03/16/06 190201_A

Page 51

Part Numbers

031-002-060-022

Radio A2B switch

45

031-300-050-295

A2B Mounting standoff

031-300-050-264

A2B mounting plate

031-300-050-272

Lynch pin

© PRS 40 EZ REV A 03/16/06 190201_A

Page 52

Operator’s / Service Manual, PRS 40 EZ

46

14.3 WIND

031-300-050-321 031-300-050-480

Mounting pole Anemometer mounting plate

031-300-050-322 031-300-060-586

Pin Transmitter

031-300-050-323 031-300-050-507

Retaining pin Sensor

© PRS 40 EZ REV A 03/16/06 190201_A

Page 53

Part Numbers

14.4 ANGLE

031-300-060-695

Sensor Assy, Angle w/ 25’ Cable

031-300-060-592

Sensor, Angle w/ Transmitter

031-300-050-577

Plate, Radio Angle Mounting

47

© PRS 40 EZ REV A 03/16/06 190201_A

Page 54

Operator’s / Service Manual, PRS 40 EZ

48

14.5 ANTENNA OPTIONS

Mount antennas in identical positions and in a direct line between transmitter and receiver, ensuring

that no obstructions will interfere with the transmission of the radio signal.

031-300-050-672 ANTENNA, 918

MHz MAGNETICBASE 13ft LONG

WIRE FOR CONSOLE

031-300-050-671 ANTENNA, 918 MHz FOR

TRS05ASSEMBLY 060-576 WHIP ELEMENT

FOR CONSOLE

031-300-050-688 ANTENNA, 918 MHz

RCL 90° OTHER SENSOR

031-300-060-559 ANTENNA ASSY, 918 MHz

WHIP FORLOAD CELL FOR LOAD SENSOR

031-300-050-535 CONNECTOR, SMA RIGHT ANGLE

M/FREVERSE POLARITY FOR LOAD SENSOR

© PRS 40 EZ REV A 03/16/06 190201_A

Page 55

Part Numbers

14.6 LINERIDER

Linerider

* Please contact Hirschmann, ECS with questions concerning

repair or replacement of component. (717) 263-7655

49

031-300-060-434

Extension cable

031-300-101-178

© PRS 40 EZ REV A 03/16/06 190201_A

Page 56

Operator’s / Service Manual, PRS 40 EZ

50

Sensor cable

14.7 LOADCELL

7.5t (15k) RADIO LOAD CELL

The load cell kit will include item 1, item 2, and one of the optional item 3.

OPTION

OPTION

OPTION

OPTION

OPTION

ITEM PART NUMBER QTY DESCRIPTION

1 031-300-060-608 1.00 SENSOR ASSY, FORCE TRANS. 7.5T W/RADIO TRANSMITTER

2 031-300-050-064 1.00 HARDWARE, COTTER PIN 2 3/8" LG1.8" GRIPPER LENGTH

3

031-300-100-999

3

031-300-050-574

3

031-300-050-555

3

031-300-050-554

3

031-300-050-556

1.00

1.00

1.00

1.00

1.00

PIN, 1.5" DIAMETER, FOR USE W/15T FORCE TRANS.

PIN/BUSHINGS, 1 1/4" FOR 7.5T RADIO LOADCELL

PIN/BUSHINGS, 1 1/8" FOR 7.5T RADIO LOADCELL 5/8" ROPE

PIN/BUSHINGS, 1 3/8" FOR 7.5T RADIO LOADCELL 3/4" ROPE

PIN/BUSHINGS, 1" 7.5T RADIOLOADCELL 1/2" ROPE

* Please contact Hirschmann, ECS with questions concerning

repair or replacement of component. (717) 263-7655

Whip Antenna 031-300-050-559 90° antenna fitting 031-300-060-535

© PRS 40 EZ REV A 03/16/06 190201_A

Page 57

Part Numbers

20t (45k) RADIO LOAD CELL

51

The load cell kit will include item 1, item 2, item 3, item 4, and one of the optional item 5.

4

OPTION 5

OPTION 5 031-300-050-559

OPTION 5 031-300-050-600

OPTION 5 031-300-050-563

OPTION

ITEM PART NUMBER QTY DESCRIPTION

1 031-300-060-609 1.00

2 031-300-060-558 1.00

3 031-300-050-625 2.00 HARDWARE, COTTER PIN 3/8" x 3"

031-300-050-568 1.00 PIN, 2.25" FOR 40K RADIO LOADCELL 1-1/8" ROPE

031-300-050-568 1.00 PIN, 2.25" FOR 40K RADIO LOADCELL 1-1/8" ROPE

5

031-300-050-604

* Please contact Hirschmann, ECS with questions concerning

repair or replacement of component. (717) 263-7655

© PRS 40 EZ REV A 03/16/06 190201_A

1.00

1.00

1.00

1.00

SENSOR ASSY, FORCE TRANS. 45K STRAIGHT

W/TRANSMITTER

BRACKET, H 20t RADIO LOADCELL 2-050-520 PLATES &

2-050-573

PIN/BUSHINGS, 2" FOR 40K RADIO LOADCELL 1" ROPE

PIN/BUSHINGS, 1 3/4" FOR 40 KRADIO LOADCELL

PIN/BUSHINGS, 1 5/8" FOR 40 KRADIO LOADCELL 7/8"

ROPE

PIN/BUSHINGS, 1 1/2" FOR 40K RADIO LOADCELL

Loading...

Loading...