Hirschmann OZD Profi 12M series, OZD Profi 12M G12, OZD Profi 12M G22, OZD Profi 12M G12-1300, OZD Profi 12M P12 User Manual

...

Installation OZD Profi 12M ...

Release 01 07/2017

Technical Support

https://hirschmann-support.belden.eu.com

User Manual

Installation

Fiberoptic Repeater

OZD Profi 12M ...

The naming of copyrighted trademarks in this manual, even when not specially indicated, should

not be taken to mean that these names may be considered as free in the sense of the trademark

and tradename protection law and hence that they may be freely used by anyone.

© 2017 Hirschmann Automation and Control GmbH

Manuals and software are protected by copyright. All rights reserved. The copying, reproduction,

translation, conversion into any electronic medium or machine scannable form is not permitted,

either in whole or in part. An exception is the preparation of a backup copy of the software for

your own use.

The performance features described here are binding only if they have been expressly agreed

when the contract was made. This document was produced by Hirschmann Automation and

Control GmbH according to the best of the company's knowledge. Hirschmann reserves the right

to change the contents of this document without prior notice. Hirschmann can give no guarantee

in respect of the correctness or accuracy of the information in this document.

Hirschmann can accept no responsibility for damages, resulting from the use of the network

components or the associated operating software. In addition, we refer to the conditions of use

specified in the license contract.

You can get the latest version of this manual on the Internet at the Hirschmann product site

(www.hirschmann.com).

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

OZD Profi 12M ...

Installation OZD Profi 12M ...

Release 01 07/2017

3

Contents

Safety instructions 5

About this manual 10

Key 10

1 Description 11

1.1 Non operating mode related functions 15

1.2 Operating mode related functions 16

1.2.1 Segment monitoring at the RS 485 port 16

1.3 Device views 18

1.4 Display elements 20

2 Network Topologies 24

2.1 Line topology 25

2.1.1 Line topology with optical fiber link monitoring and

segmentation 26

2.1.2 Line topology without optical fiber link monitoring 27

2.2 Star topology 28

2.3 Redundant ring 30

3 Installation guidelines 32

3.1 Electromagnetic compatibility (EMC) 32

3.2 Interference suppression of switched inductances 32

3.2.1 Suppressing switched inductances with fuses 32

3.2.2 Cabinet lighting 32

3.3 Arrangement of devices and cables 33

3.3.1 Reducing interference by providing adequate space: 33

3.3.2 Standard recommendations for the arrangement of

devices and cables 33

3.3.3 Using bus line shields 33

3.3.4 Shield connections 34

3.4 Laying cables inside of buildings 35

3.5 Laying cables outside of buildings 37

4 Installation 38

4.1 Checking the package contents 38

4

Installation OZD Profi 12M ...

Release 01 07/2017

4.2 Mounting the device 39

4.2.1 Installing the device onto the DIN rail 39

4.3 Setting compatibility 40

4.4 Setting the operating mode and transmitting power 43

4.4.1 Setting the operating mode of the electrical ports

(CH1, CH2) 43

4.4.2 Setting the operating mode of the optical ports (CH3,

CH4) 44

4.4.3 Reducing the optical transmitting power 45

4.5 Connecting the optic bus cables 46

4.6 Connecting the electric bus cables 47

4.7 Connecting the function ground and the shield of the bus

cable 49

4.8 Connecting the power supply 50

4.9 Connecting the signal contact (optional) 51

4.10 Connecting the analog voltage outputs (optional) 52

5 Configuration 54

6Disassembly 56

7 Technical data 57

8 Scope of delivery, order numbers and

accessories 61

9 Underlying technical standards 62

10 Help with problems 63

10.1 Troubleshooting 63

10.2 Systematic troubleshooting 64

10.3 Problem reporting 65

A Further support 66

Installation OZD Profi 12M ...

Release 01 07/2017

5

Safety instructions

General safety instructions

You operate this device with electricity. Improper usage of the device

entails the risk of physical injury or significant property damage. The

proper and safe operation of this device depends on proper handling

during transportation, proper storage and installation, and careful

operation and maintenance procedures.

Before connecting any cable, read this document, and the safety

instructions and warnings.

Operate the device with undamaged components exclusively.

The device is free of any service components. In case of a damaged

or malfunctioning the device, turn off the supply voltage and return the

device to Hirschmann for inspection.

Qualification requirements for personnel

Only allow qualified personnel to work on the device.

Qualified personnel have the following characteristics:

Qualified personnel are properly trained. Training as well as practical

knowledge and experience make up their qualifications. This is the

prerequisite for grounding and labeling circuits, devices, and systems

in accordance with current standards in safety technology.

Qualified personnel are aware of the dangers that exist in their work.

Qualified personnel are familiar with appropriate measures against

these hazards in order to reduce the risk for themselves and others.

Qualified personnel receive training on a regular basis.

WARNING

UNCONTROLLED MACHINE ACTIONS

To avoid uncontrolled machine actions caused by data loss, configure all

the data transmission devices individually.

Before you start any machine which is controlled via data transmission, be

sure to complete the configuration of all data transmission devices.

Failure to follow these instructions can result in death, serious injury,

or equipment damage.

6

Installation OZD Profi 12M ...

Release 01 07/2017

Certified usage

Use the product only for the application cases described in the

Hirschmann product information, including this manual.

Operate the product only according to the technical specifications.

See “Technical data” on page 57.

Connect to the product only components suitable for the requirements

of the specific application case.

Device casing

Only technicians authorized by the manufacturer are permitted to open

the housing.

National and international safety regulations

Verify that the electrical installation meets local or nationally applicable

safety regulations.

Grounding the device

Functional grounding the device is by means of a separate connection on

the device.

Ground the device before connecting any other cables.

Disconnect the grounding only after disconnecting all other cables.

Ground the device via the ground screw.

Requirements for connecting electrical wires

Before connecting the electrical wires, always verify that the

requirements listed are complied with.

All of the following requirements are complied with:

The electrical wires are voltage-free.

The cables used are permitted for the temperature range of the application case.

Table 1: General requirements for connecting electrical wires

All of the following requirements are complied with:

The voltage connected complies with the requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

The connected voltage is limited by a current limitation device or a fuse.

Observe the electrical threshold values for the signal contact.

See “General technical data” on page 57.

Table 2: Requirements for connecting the signal contact

Installation OZD Profi 12M ...

Release 01 07/2017

7

Supply voltage

Only switch on the device when the housing is closed.

Requirements

All of the following requirements are complied with:

The supply voltage corresponds to the voltage specified on the type plate of the device.

The power supply conforms to overvoltage category I or II.

The power supply has an easily accessible disconnecting device (e.g., a switch or a plug).

This disconnecting device is clearly identified. So in the case of an emergency, it is clear

which disconnecting device belongs to which power supply cable.

The cross-section of the ground conductor is the same size as or bigger than the cross-

section of the power supply cables.

Relevant for North America:

The power cords are suitable for ambient air temperatures of at least 167 °F (75 °C). The

power cord wires are made of copper.

The wire diameter of the power supply cable is at least 0.75 mm² (North America: AWG18) on

the supply voltage input.

The following requirements are alternatively complied with:

Alternative 1 The power supply complies with the requirements for a limited

power source (LPS) as per EN 60950-1.

Alternative 2 Relevant for North America:

The power supply complies with the requirements as per Class 2

Alternative 3 All of the following requirements are complied with:

The power supply complies with the requirements for a safety

extra-low voltage (SELV) as per IEC/EN 60950-1.

A fuse suitable for DC voltage is located in the plus conductor

of the power supply.

The minus conductor is on ground potential. Otherwise, a fuse

is also located in the minus conductor.

Regarding the properties of this fuse:

See “General technical data” on page 57.

Table 3: Requirements for connecting the supply voltage

8

Installation OZD Profi 12M ...

Release 01 07/2017

CE marking

The labeled devices comply with the regulations contained in the following

European directive(s):

2014/30/EU (EMC)

Directive of the European Parliament and the council for standardizing the

regulations of member states with regard to electromagnetic

compatibility.

2011/65/EU (RoHS)

Directive of the European Parliament and of the Council on the restriction

of the use of certain hazardous substances in electrical and electronic

equipment.

In accordance with the above-named EU directive(s), the EU conformity

declaration will be at the disposal of the relevant authorities at the

following address:

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

The product can be used in the industrial sector.

Interference immunity: EN 61000-6-2

Emitted interference: EN 55032

Reliability: EN 60950-1

You find more information on technical standards here:

“Technical data” on page 57

Warning! This is a class A device. This device can cause interference in

living areas, and in this case the operator may be required to take

appropriate measures.

Note: The assembly guidelines provided in these instructions must be

strictly adhered to in order to observe the EMC threshold values.

LED or laser components

LED or LASER components according to IEC 60825-1 (2014):

CLASS 1 LASER PRODUCT

CLASS 1 LED PRODUCT

Installation OZD Profi 12M ...

Release 01 07/2017

9

FCC note:

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference; (2) this device must accept any interference received,

including interference that may cause undesired operation.

Appropriate testing has established that this device fulfills the

requirements of a class A digital device in line with part 15 of the FCC

regulations.

These requirements are designed to provide sufficient protection against

interference when the device is being used in a business environment.

The device creates and uses high frequencies and can also radiate these

frequencies. If it is not installed and used in accordance with this

operating manual, it can cause radio transmission interference. The use

of this device in a residential area can also cause interference, and in this

case the user is obliged to cover the costs of removing the interference.

Recycling note

After usage, this device must be disposed of properly as electronic waste,

in accordance with the current disposal regulations of your county, state,

and country.

10

Installation OZD Profi 12M ...

Release 01 07/2017

About this manual

The “Installation” user manual contains a device description, safety

instructions, a description of the display, and the other information that you

need to install the device.

Key

The symbols used in this manual have the following meanings:

Listing

Work step

Subheading

Installation OZD Profi 12M ...

Release 01 07/2017

11

1 Description

The PROFIBUS Repeaters are designed to be used in optical PROFIBUS

field bus networks according to IEC 61784. They enable electrical

PROFIBUS interfaces (RS 485 level) to be converted into optical PROFIBUS

interfaces and vice-versa. By profiting from the familiar advantages of optical

transmission technology, the repeaters can be integrated into existing

PROFIBUS field bus networks. A complete PROFIBUS field bus network

with repeaters in line, star or ring topology, and an arbitrary combination of

these, can also be built up.

Device casing

The device is supplied in a metal housing. You have the option of

mounting the device onto the DIN rail.

Glass fiber technology

The use of glass fiber transmission technology enables a very large

transmission range and ensures optimal protection from EMC effects on

the transmission path and – due to the potential separation – on the

Repeater itself.

Transmission rate

The OZD Profi 12M ... supports data rates from 9.6 kBit/s to 12 Mbit/s.

Redundancy

The redundant ring enables a very high level of transmission reliability.

The redundant operating power supply can further improve the operating

reliability.

12

Installation OZD Profi 12M ...

Release 01 07/2017

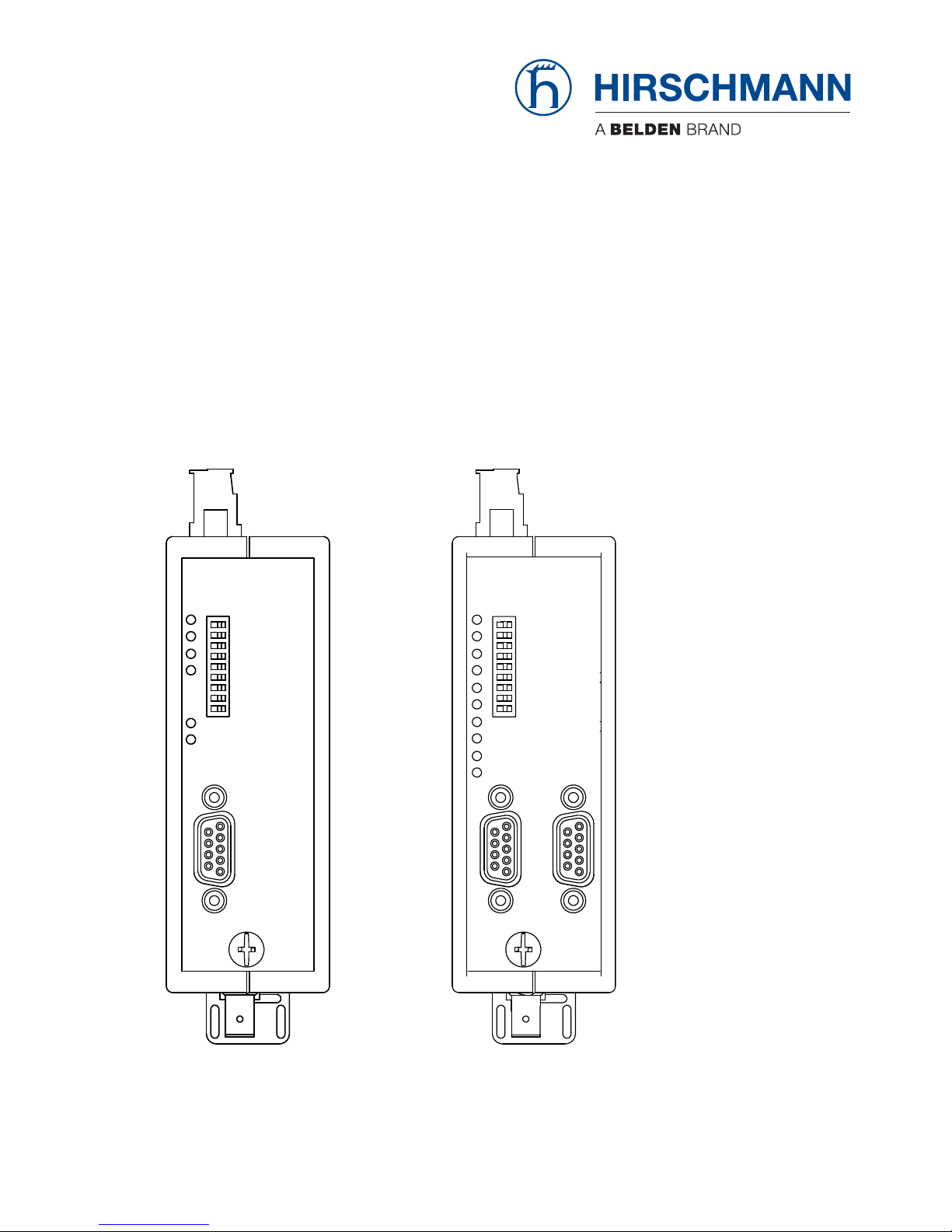

Port

Depending on a device variant, each device has 2,3,4 mutually

independent ports (channels), which in turn consist of a transmitting and

a receiving component. The electric ports are a 9-pole D-Sub socket

(female). A PROFIBUS bus segment can be connected to this ports. The

optical ports are BFOC/2.5 (ST ®) sockets.

CH3

CH4

CH3 CH3

CH4

CH1

CH1

CH2

Installation OZD Profi 12M ...

Release 01 07/2017

13

Power supply

The power supply is 24 V direct current. To improve the operating safety,

a redundant operating power supply consisting of two separate sources

can be used. For this purpose, you must connect the two supply voltages

to two different terminals of the 8-pin screw-type terminal block.Both

connections are uncoupled by means of diodes to prevent reverse voltage

supply or destruction through incorrect pole connection. There is no load

distribution between the sources. With redundant supply, the power

supply unit with the higher output voltage must supply the repeater alone.

Signal contact

A signal contact (relay with unconnected contacts) is used to signal

various disruptions in the repeaters. The signal contact is also connected

to the 8-pin screw type terminal block.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

14

Installation OZD Profi 12M ...

Release 01 07/2017

Measuring output

One measuring output is available for each optical port. The measuring

output is connected to the 8-pin screw type terminal block.

Configuration

You can easily set the configuration to meet your specific requirements by

means of DIP switches, which can easily be operated from outside.

The following settings are possible:

Setting the compatibility to OZD Profi …a version

See “Setting compatibility” on page 40.

Setting the operating mode and transmitting power

See “Setting the operating mode and transmitting power” on page 43.

Reducing the optical transmitting power

See “Reducing the optical transmitting power” on page 45.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Profi 12M ...

Release 01 07/2017

15

1.1 Non operating mode related functions

Transmission rate

The OZD Profi 12M ... support all the transmission rates defined in the EN

50170 standard:

9.6 kBit/s, 19.2 kBit/s, 45.45 kBit/s, 93.75 kBit/s,187.5 kBit/s and

500 kBit/s and additionally 1.5 MBit/s, 3 MBit/s, 6 MBit/s and 12 MBit/s.

The transmission rate is set automatically as soon as the OZD Profi 12M

... receives a frame. The setting or adjustment is dependent on the

transmission rate and the set operating mode. Depending on the OZD

Profi 12M ... this can last up to several seconds.

If the transmission speed has not been recognized, the outputs of all ports

are blocked. If the transmission rate changes during operation, this is

detected by the repeaters, which then automatically adjust their settings

accordingly.

Transfer malfunctions may temporarily occur while the rate is being

altered.

Signal regeneration

The repeaters regenerate the signal form and amplitude of the data

received. This allows up to 122 OZD Profi 12M ... to be cascaded (limited

by the address space in PROFIBUS networks).

Help when setting up

At least one bus subscriber must be switched on and active in order to

check the optical fiber connections during the installation. This bus

subscriber serves as the frame source. The OZD Profi 12M ... act

passively when it is switched on. They recognize the transfer rate from the

frames sent by the bus subscriber. An optical help when putting the

device into operation is provided by the port LED which then lights up.

16

Installation OZD Profi 12M ...

Release 01 07/2017

1.2 Operating mode related functions

The operating mode is set using switches located on the front of the repeater.

A sticker attached to the side of the repeater provides assistance with the

settings. The OZD Profi 12M ... must be switched off when switching over

DIP switches.

1.2.1 Segment monitoring at the RS 485 port

If the operating mode ”Electric channel with segment monitoring“ is set, each

receiver monitors the RS 485 bus segment connected to it for faulty frames

or continuously busy networks. If faulty frames are received by the receiver,

or if the network is busy for longer than the maximum permitted send time,

forwarding of the received signals is blocked until frames can be received

again correctly, or if no signal is received for one second.

The RS 485 bus segment is not monitored in the operating mode ”Electric

port without segment monitoring“. Interference from the electrical segment

affects the entire network.

The following functions are only available for the optical channels. Whether

the functions can be activated depends on the operating mode which has

been set.

Line monitoring with echoes

The repeaters enable the connected optical paths to be actively

monitored for interruptions in the fiber line by means of the functions

”Send echo“, ”Monitor echo“ and ”Suppress echo“.

Send echo

A frame which is received by a repeater via any port is transmitted to all

other ports. If the receiving port is an optical port, the repeater sends the

frame back to the corresponding optical sender.

Monitor echo

If a repeater sends a frame - no echo – to an optical port, the repeater

expects to receive an echo. If the echo is not received after a predefined

time, an echo monitoring error is indicated by a red LED belonging to the

port.

Suppress echo

The relevant receiver is separated from the other ports from the moment

a frame is sent until the echo has been received correctly.

Installation OZD Profi 12M ...

Release 01 07/2017

17

Segmentation

If an echo monitoring error or a frame falsification arises at an optical port,

the repeater assumes that the line is faulty and blocks this port for user

data. The connected field bus partial network is then segmented (cut off).

This segmentation causes the repeater at the other end of the optical fiber

to be segmented as well. Both repeaters connected to the segmented

field bus partial network send test frames to the segmented ports. These

test frames – which are to be received regularly – can be used by both

repeaters to check the status of the field bus partial network. The

segmentation is automatically lifted as soon as the test frames indicate to

both repeaters that the segmented field bus partial network is no longer

disturbed. If all active bus subscribers are deactivated in a previously

active network, the repeaters are segmented cyclically in order to check

the fiber links to the neighboring repeaters. If there is no frame traffic, but

the fiber links are intact, the port LEDs of the optical ports flash yellow

cyclically.

18

Installation OZD Profi 12M ...

Release 01 07/2017

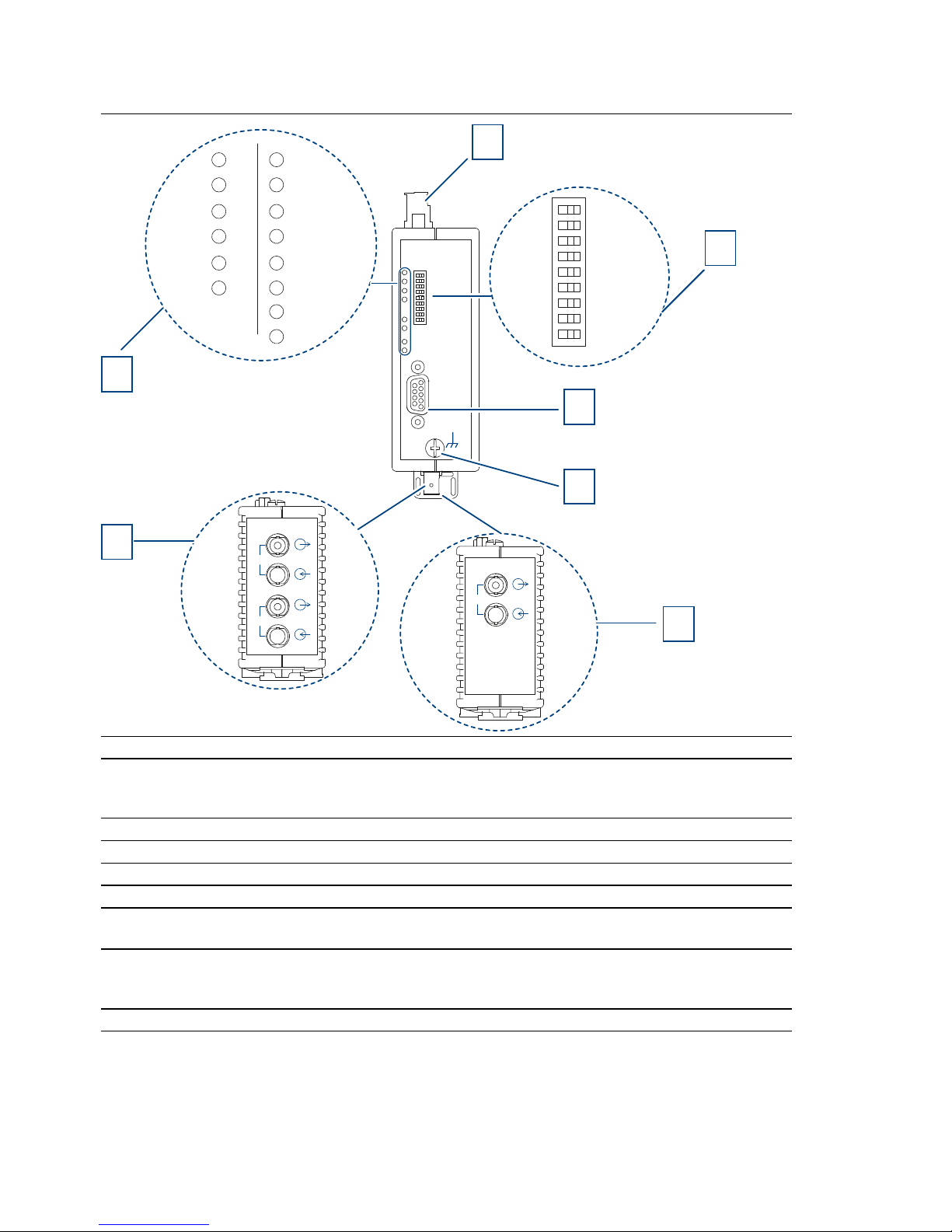

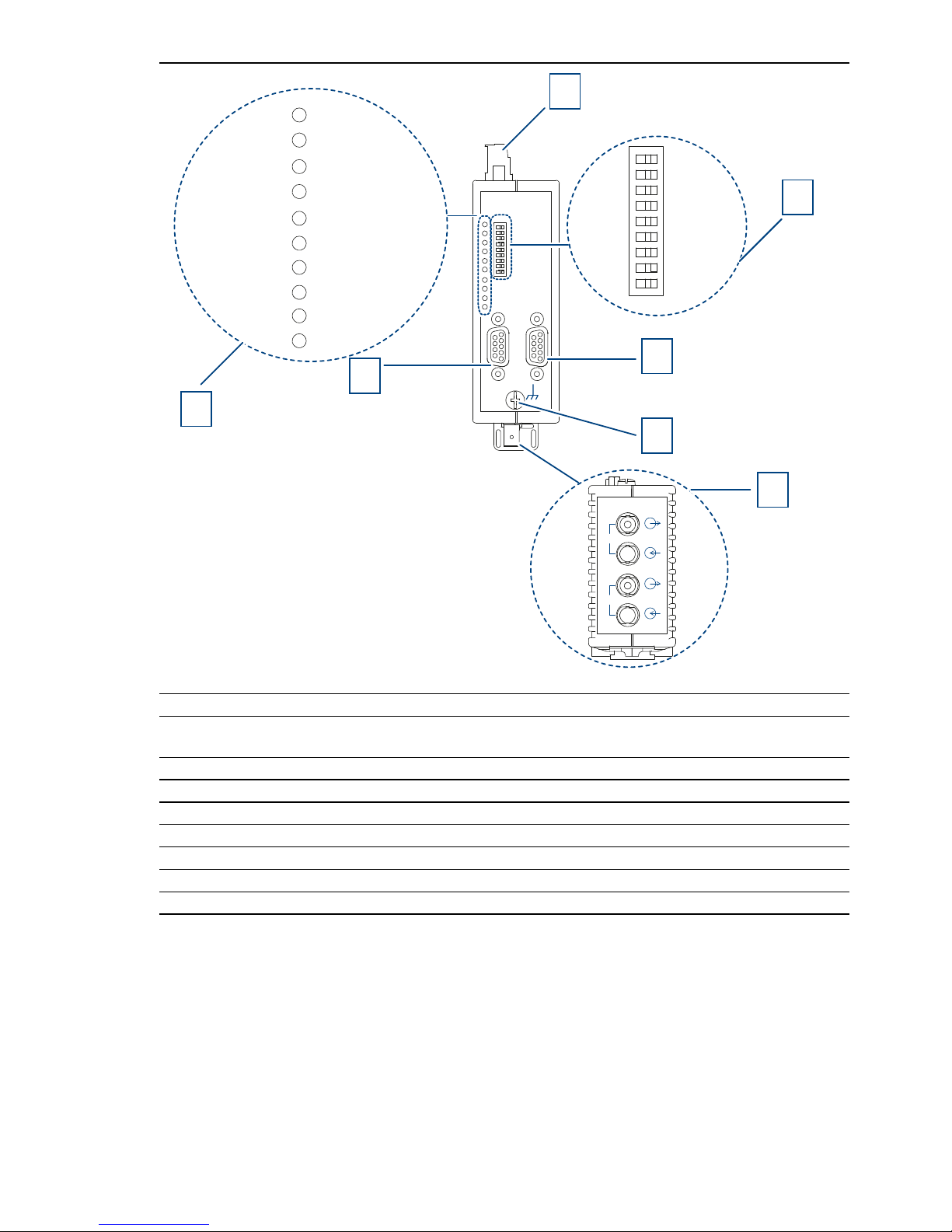

1.3 Device views

Front view using example of device variants OZD Profi 12M ...

– G11/G11-1300

– G12/G12-1300/G12-EEC/G12-1300-EEC

– P11/P12

1 8-pin terminal block for power supply, signal contact, measuring output

2 8-pin DIP switch

3 CH1 - electrical port

4 Grounding screw

5 CH3 - optical port

(only applies to the device variants OZD Profi 12M ... G11, G11-1300, P11)

6 CH3, CH4 - optical ports

(only applies to the device variants OZD Profi 12M ... G12, G12-1300, G12 EEC,G121300 EEC, P12)

7 LED display element for system status and port status

CH1

S0

S1

S2

S3

S4

S5

S6

S7

S8

1 0

System

CH1

CH3CH4

System

CH1

CH3

1

CH3

2

3

4

5

7

CH3

CH4

6

Installation OZD Profi 12M ...

Release 01 07/2017

19

Front view using example of device variants OZD Profi 12M ...

– G22/G22-1300/G22-EEC/G22-1300-EEC

– P22

1 8-pin terminal block for power supply, signal contact, measuring output

2 8-pin DIP switch

3 CH2 - electrical port

4 Grounding screw

5 CH3, CH4 - optical ports

6 CH1 - electrical port

7 LED display element for system status and port status

CH1

CH2

CH3

CH4

S0

S1

S2

S3

S4

S5

S6

S7

S8

1 0

2

3

6

4

5

1

System

CH1CH2CH3CH4

7

20

Installation OZD Profi 12M ...

Release 01 07/2017

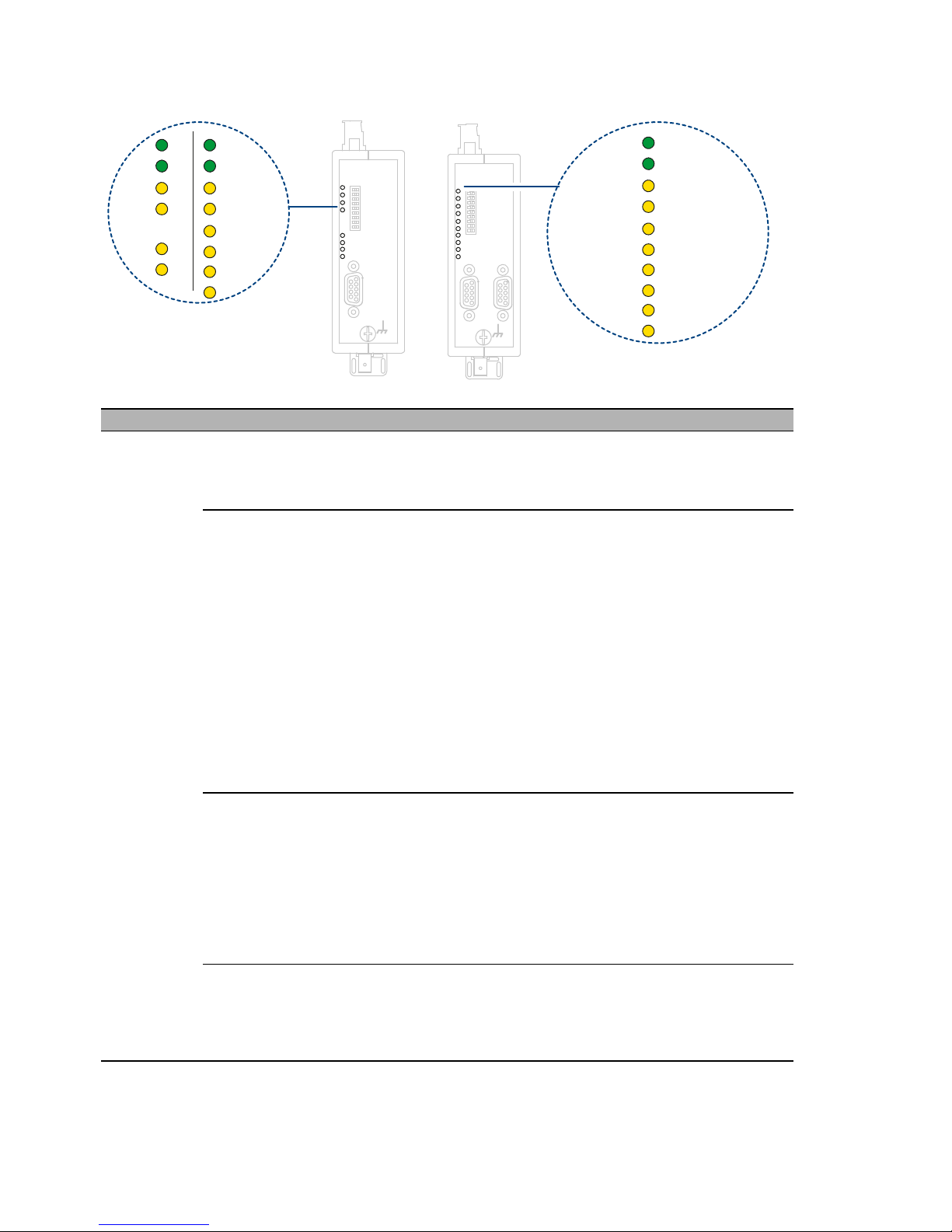

1.4 Display elements

LED Color Meaning

System green lights up The transmission rate has been recognized and the

power supply is in order

Signal contact: no signal

red flashes Transmission rate has not yet been recognized

– No transmitting bus subscriber present

– No connection to a partner repeater sending frames

– Send and receive optical fibers have been

transposed.

– Transmission rate does not correspond to

PROFIBUS-DP.

– Only one active bus subscriber is connected, which

is only sending tokens to itself. The indicator must

switch over after a second bus subscriber has been

activated (token frames on their own are not enough

to set the transfer rate).

– The connected RS 485 segment is only terminated

at one end.

Signal contact: no signal

red/green flashes Transmission rate recognized but

– the network slot time could not be determined

(network parameter HSA is set too low, no

transmitting bus subscriber present)

– one optical port is set to ”Redundant optical ring“

mode, but not the second (this operating mode must

always be set at both optical ports)

– the slot time of the network configuration is too short

Signal contact: no signal

none – Power supply has failed (total failure). Failure of

both power supply sources with redundant infeed.

– Power supply connected incorrectly

– Repeater defective

Signal contact: signal

CH1

CH1

CH2

CH4

System

CH1

CH3

System

CH1

CH3

System

CH1CH2CH3CH4

Installation OZD Profi 12M ...

Release 01 07/2017

21

electrical

ports

yellow lights up Signals are being received on the RS 485 bus line.

Signal contact: no signal

red flashes/light

s up

Sporadic interference signals because

– the RS 485 bus line being insufficiently shielded

– an open RS 485 bus line, i.e. it is only connected to

the repeater at one end

– the RS 485 segment is not terminated or only

terminated at one end

– an RS 485 bus terminal or terminal connector has

been plugged in/ pulled out

Signal contact: signal

Permanent interference because

– conductors A and B in the RS 485 bus line have

been transposed

– of an RS 485 bus line short circuit

– the send time has been exceeded caused by a bus

subscriber in a bus segment connected to Port 1

(CH1)

Signal contact: signal

– repeater and another bus subscriber connected via

Port 1 (CH1) are both sending at the same time (e.g.

because an address has been assigned twice, the

setting of the slot time is too low, or during lifting of

the segmentation in the optical lin).

Signal contact: no signal

– RS 485 driver of the repeater is defective (e.g. after

lightning strike)

none – Bus subscriber is not connected

– Connected bus subscriber is not switched on

– One or both conductors in the RS 485 bus line is

broken

Signal contact: no signal

Operating mode ”Line with optical fiber link monitoring“ and ”Redundant optical ring“

optical ports yellow lights up PROFIBUS frames are being received at the optical port

Signal contact: no signal

flashes Transmission rate has been recognized – LED ”System“

lights green or flashes red/green.

– No transmitting bus subscriber present (optical fiber

connection is OK)

Signal contact: no signal

LED Color Meaning

22

Installation OZD Profi 12M ...

Release 01 07/2017

red lights up – Send and receive optical fibers have been

transposed.

– No partner repeater connected or partner repeater

is not switched on.

– Connected partner repeater is defective

– Send time of connected partner repeater has been

exceeded

– An optical fiber line is broken

– Optical fiber link to partner repeater is too long

– Loose connection in an optical fiber connector

– Optical fiber in the optical fiber connector is loose.

– When using a redundant optical ring: if a fault in the

optical fiber has been corrected but the port LEDs

on both of the OZD Profi concerned still light red,

check whether parameter HSA has been set as

described in the chapter "Redundant Ring".

– Send and receive optical fibers have been

transposed.

Signal contact: open

red/yellow flashes – Fault occurs periodically (see above)

– Loose connection in an optical fiber connector

– Optical fiber in the optical fiber connector is loose

– Only one active bus subscriber is connected, which

only sends tokens to itself. A fault should not be

signaled as soon as a second subscriber is

activated.

Signal contact: signal

none Transmission rate has not yet been recognized – LED

”System“ flashes red

– No transmitting bus subscriber present

– Send and receive optical fibers have been

transposed

– No partner repeater connected or partner repeater

is not switched on

– Connected partner repeater is defective

Transmission rate has been recognized - LED ”System“

flashes green

– If the operating mode ”Redundant optical ring“ has

been set, the optical port works as a stand-by port.

There is no malfunction in the OZD Profi 12M ... or

the optical fiber.

– If one of the operating modes ”Line with optical fiber

link monitoring …“ has been set, no PROFIBUS

frames are received at the optical port. There is no

malfunction in the OZD Profi 12M ... or the optical

fiber.

Signal contact: no signal

Operating mode ”Line without optical fiber link monitoring“

LED Color Meaning

Loading...

Loading...