Hirschmann OZD Profi 12M series, OZD Profi 12M G12, OZD Profi 12M G22, OZD Profi 12M G12-1300, OZD Profi 12M P12 User Manual

...

Installation OZD Profi 12M ...

Release 01 07/2017

Technical Support

https://hirschmann-support.belden.eu.com

User Manual

Installation

Fiberoptic Repeater

OZD Profi 12M ...

The naming of copyrighted trademarks in this manual, even when not specially indicated, should

not be taken to mean that these names may be considered as free in the sense of the trademark

and tradename protection law and hence that they may be freely used by anyone.

© 2017 Hirschmann Automation and Control GmbH

Manuals and software are protected by copyright. All rights reserved. The copying, reproduction,

translation, conversion into any electronic medium or machine scannable form is not permitted,

either in whole or in part. An exception is the preparation of a backup copy of the software for

your own use.

The performance features described here are binding only if they have been expressly agreed

when the contract was made. This document was produced by Hirschmann Automation and

Control GmbH according to the best of the company's knowledge. Hirschmann reserves the right

to change the contents of this document without prior notice. Hirschmann can give no guarantee

in respect of the correctness or accuracy of the information in this document.

Hirschmann can accept no responsibility for damages, resulting from the use of the network

components or the associated operating software. In addition, we refer to the conditions of use

specified in the license contract.

You can get the latest version of this manual on the Internet at the Hirschmann product site

(www.hirschmann.com).

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

OZD Profi 12M ...

Installation OZD Profi 12M ...

Release 01 07/2017

3

Contents

Safety instructions 5

About this manual 10

Key 10

1 Description 11

1.1 Non operating mode related functions 15

1.2 Operating mode related functions 16

1.2.1 Segment monitoring at the RS 485 port 16

1.3 Device views 18

1.4 Display elements 20

2 Network Topologies 24

2.1 Line topology 25

2.1.1 Line topology with optical fiber link monitoring and

segmentation 26

2.1.2 Line topology without optical fiber link monitoring 27

2.2 Star topology 28

2.3 Redundant ring 30

3 Installation guidelines 32

3.1 Electromagnetic compatibility (EMC) 32

3.2 Interference suppression of switched inductances 32

3.2.1 Suppressing switched inductances with fuses 32

3.2.2 Cabinet lighting 32

3.3 Arrangement of devices and cables 33

3.3.1 Reducing interference by providing adequate space: 33

3.3.2 Standard recommendations for the arrangement of

devices and cables 33

3.3.3 Using bus line shields 33

3.3.4 Shield connections 34

3.4 Laying cables inside of buildings 35

3.5 Laying cables outside of buildings 37

4 Installation 38

4.1 Checking the package contents 38

4

Installation OZD Profi 12M ...

Release 01 07/2017

4.2 Mounting the device 39

4.2.1 Installing the device onto the DIN rail 39

4.3 Setting compatibility 40

4.4 Setting the operating mode and transmitting power 43

4.4.1 Setting the operating mode of the electrical ports

(CH1, CH2) 43

4.4.2 Setting the operating mode of the optical ports (CH3,

CH4) 44

4.4.3 Reducing the optical transmitting power 45

4.5 Connecting the optic bus cables 46

4.6 Connecting the electric bus cables 47

4.7 Connecting the function ground and the shield of the bus

cable 49

4.8 Connecting the power supply 50

4.9 Connecting the signal contact (optional) 51

4.10 Connecting the analog voltage outputs (optional) 52

5 Configuration 54

6Disassembly 56

7 Technical data 57

8 Scope of delivery, order numbers and

accessories 61

9 Underlying technical standards 62

10 Help with problems 63

10.1 Troubleshooting 63

10.2 Systematic troubleshooting 64

10.3 Problem reporting 65

A Further support 66

Installation OZD Profi 12M ...

Release 01 07/2017

5

Safety instructions

General safety instructions

You operate this device with electricity. Improper usage of the device

entails the risk of physical injury or significant property damage. The

proper and safe operation of this device depends on proper handling

during transportation, proper storage and installation, and careful

operation and maintenance procedures.

Before connecting any cable, read this document, and the safety

instructions and warnings.

Operate the device with undamaged components exclusively.

The device is free of any service components. In case of a damaged

or malfunctioning the device, turn off the supply voltage and return the

device to Hirschmann for inspection.

Qualification requirements for personnel

Only allow qualified personnel to work on the device.

Qualified personnel have the following characteristics:

Qualified personnel are properly trained. Training as well as practical

knowledge and experience make up their qualifications. This is the

prerequisite for grounding and labeling circuits, devices, and systems

in accordance with current standards in safety technology.

Qualified personnel are aware of the dangers that exist in their work.

Qualified personnel are familiar with appropriate measures against

these hazards in order to reduce the risk for themselves and others.

Qualified personnel receive training on a regular basis.

WARNING

UNCONTROLLED MACHINE ACTIONS

To avoid uncontrolled machine actions caused by data loss, configure all

the data transmission devices individually.

Before you start any machine which is controlled via data transmission, be

sure to complete the configuration of all data transmission devices.

Failure to follow these instructions can result in death, serious injury,

or equipment damage.

6

Installation OZD Profi 12M ...

Release 01 07/2017

Certified usage

Use the product only for the application cases described in the

Hirschmann product information, including this manual.

Operate the product only according to the technical specifications.

See “Technical data” on page 57.

Connect to the product only components suitable for the requirements

of the specific application case.

Device casing

Only technicians authorized by the manufacturer are permitted to open

the housing.

National and international safety regulations

Verify that the electrical installation meets local or nationally applicable

safety regulations.

Grounding the device

Functional grounding the device is by means of a separate connection on

the device.

Ground the device before connecting any other cables.

Disconnect the grounding only after disconnecting all other cables.

Ground the device via the ground screw.

Requirements for connecting electrical wires

Before connecting the electrical wires, always verify that the

requirements listed are complied with.

All of the following requirements are complied with:

The electrical wires are voltage-free.

The cables used are permitted for the temperature range of the application case.

Table 1: General requirements for connecting electrical wires

All of the following requirements are complied with:

The voltage connected complies with the requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

The connected voltage is limited by a current limitation device or a fuse.

Observe the electrical threshold values for the signal contact.

See “General technical data” on page 57.

Table 2: Requirements for connecting the signal contact

Installation OZD Profi 12M ...

Release 01 07/2017

7

Supply voltage

Only switch on the device when the housing is closed.

Requirements

All of the following requirements are complied with:

The supply voltage corresponds to the voltage specified on the type plate of the device.

The power supply conforms to overvoltage category I or II.

The power supply has an easily accessible disconnecting device (e.g., a switch or a plug).

This disconnecting device is clearly identified. So in the case of an emergency, it is clear

which disconnecting device belongs to which power supply cable.

The cross-section of the ground conductor is the same size as or bigger than the cross-

section of the power supply cables.

Relevant for North America:

The power cords are suitable for ambient air temperatures of at least 167 °F (75 °C). The

power cord wires are made of copper.

The wire diameter of the power supply cable is at least 0.75 mm² (North America: AWG18) on

the supply voltage input.

The following requirements are alternatively complied with:

Alternative 1 The power supply complies with the requirements for a limited

power source (LPS) as per EN 60950-1.

Alternative 2 Relevant for North America:

The power supply complies with the requirements as per Class 2

Alternative 3 All of the following requirements are complied with:

The power supply complies with the requirements for a safety

extra-low voltage (SELV) as per IEC/EN 60950-1.

A fuse suitable for DC voltage is located in the plus conductor

of the power supply.

The minus conductor is on ground potential. Otherwise, a fuse

is also located in the minus conductor.

Regarding the properties of this fuse:

See “General technical data” on page 57.

Table 3: Requirements for connecting the supply voltage

8

Installation OZD Profi 12M ...

Release 01 07/2017

CE marking

The labeled devices comply with the regulations contained in the following

European directive(s):

2014/30/EU (EMC)

Directive of the European Parliament and the council for standardizing the

regulations of member states with regard to electromagnetic

compatibility.

2011/65/EU (RoHS)

Directive of the European Parliament and of the Council on the restriction

of the use of certain hazardous substances in electrical and electronic

equipment.

In accordance with the above-named EU directive(s), the EU conformity

declaration will be at the disposal of the relevant authorities at the

following address:

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

The product can be used in the industrial sector.

Interference immunity: EN 61000-6-2

Emitted interference: EN 55032

Reliability: EN 60950-1

You find more information on technical standards here:

“Technical data” on page 57

Warning! This is a class A device. This device can cause interference in

living areas, and in this case the operator may be required to take

appropriate measures.

Note: The assembly guidelines provided in these instructions must be

strictly adhered to in order to observe the EMC threshold values.

LED or laser components

LED or LASER components according to IEC 60825-1 (2014):

CLASS 1 LASER PRODUCT

CLASS 1 LED PRODUCT

Installation OZD Profi 12M ...

Release 01 07/2017

9

FCC note:

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference; (2) this device must accept any interference received,

including interference that may cause undesired operation.

Appropriate testing has established that this device fulfills the

requirements of a class A digital device in line with part 15 of the FCC

regulations.

These requirements are designed to provide sufficient protection against

interference when the device is being used in a business environment.

The device creates and uses high frequencies and can also radiate these

frequencies. If it is not installed and used in accordance with this

operating manual, it can cause radio transmission interference. The use

of this device in a residential area can also cause interference, and in this

case the user is obliged to cover the costs of removing the interference.

Recycling note

After usage, this device must be disposed of properly as electronic waste,

in accordance with the current disposal regulations of your county, state,

and country.

10

Installation OZD Profi 12M ...

Release 01 07/2017

About this manual

The “Installation” user manual contains a device description, safety

instructions, a description of the display, and the other information that you

need to install the device.

Key

The symbols used in this manual have the following meanings:

Listing

Work step

Subheading

Installation OZD Profi 12M ...

Release 01 07/2017

11

1 Description

The PROFIBUS Repeaters are designed to be used in optical PROFIBUS

field bus networks according to IEC 61784. They enable electrical

PROFIBUS interfaces (RS 485 level) to be converted into optical PROFIBUS

interfaces and vice-versa. By profiting from the familiar advantages of optical

transmission technology, the repeaters can be integrated into existing

PROFIBUS field bus networks. A complete PROFIBUS field bus network

with repeaters in line, star or ring topology, and an arbitrary combination of

these, can also be built up.

Device casing

The device is supplied in a metal housing. You have the option of

mounting the device onto the DIN rail.

Glass fiber technology

The use of glass fiber transmission technology enables a very large

transmission range and ensures optimal protection from EMC effects on

the transmission path and – due to the potential separation – on the

Repeater itself.

Transmission rate

The OZD Profi 12M ... supports data rates from 9.6 kBit/s to 12 Mbit/s.

Redundancy

The redundant ring enables a very high level of transmission reliability.

The redundant operating power supply can further improve the operating

reliability.

12

Installation OZD Profi 12M ...

Release 01 07/2017

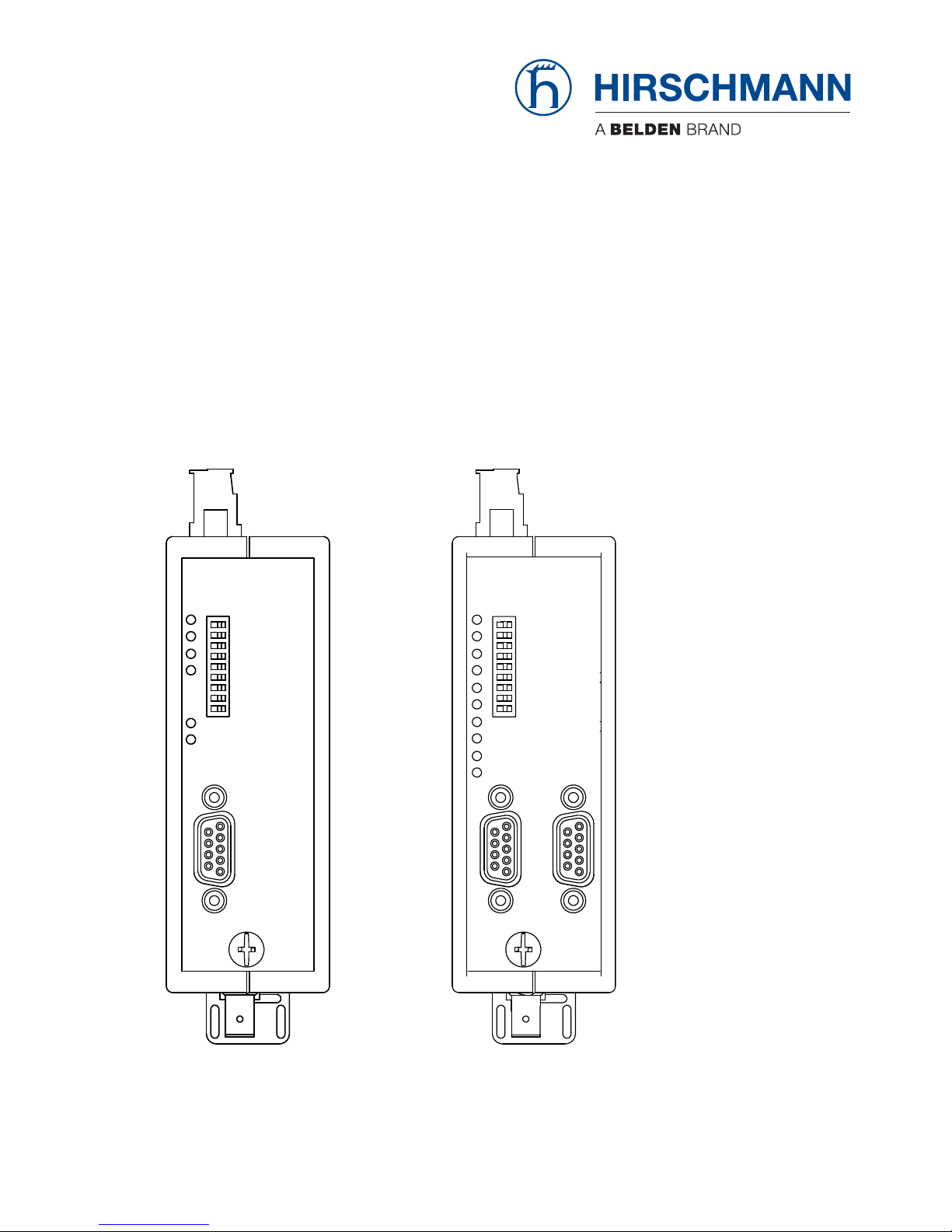

Port

Depending on a device variant, each device has 2,3,4 mutually

independent ports (channels), which in turn consist of a transmitting and

a receiving component. The electric ports are a 9-pole D-Sub socket

(female). A PROFIBUS bus segment can be connected to this ports. The

optical ports are BFOC/2.5 (ST ®) sockets.

CH3

CH4

CH3 CH3

CH4

CH1

CH1

CH2

Installation OZD Profi 12M ...

Release 01 07/2017

13

Power supply

The power supply is 24 V direct current. To improve the operating safety,

a redundant operating power supply consisting of two separate sources

can be used. For this purpose, you must connect the two supply voltages

to two different terminals of the 8-pin screw-type terminal block.Both

connections are uncoupled by means of diodes to prevent reverse voltage

supply or destruction through incorrect pole connection. There is no load

distribution between the sources. With redundant supply, the power

supply unit with the higher output voltage must supply the repeater alone.

Signal contact

A signal contact (relay with unconnected contacts) is used to signal

various disruptions in the repeaters. The signal contact is also connected

to the 8-pin screw type terminal block.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

14

Installation OZD Profi 12M ...

Release 01 07/2017

Measuring output

One measuring output is available for each optical port. The measuring

output is connected to the 8-pin screw type terminal block.

Configuration

You can easily set the configuration to meet your specific requirements by

means of DIP switches, which can easily be operated from outside.

The following settings are possible:

Setting the compatibility to OZD Profi …a version

See “Setting compatibility” on page 40.

Setting the operating mode and transmitting power

See “Setting the operating mode and transmitting power” on page 43.

Reducing the optical transmitting power

See “Reducing the optical transmitting power” on page 45.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Profi 12M ...

Release 01 07/2017

15

1.1 Non operating mode related functions

Transmission rate

The OZD Profi 12M ... support all the transmission rates defined in the EN

50170 standard:

9.6 kBit/s, 19.2 kBit/s, 45.45 kBit/s, 93.75 kBit/s,187.5 kBit/s and

500 kBit/s and additionally 1.5 MBit/s, 3 MBit/s, 6 MBit/s and 12 MBit/s.

The transmission rate is set automatically as soon as the OZD Profi 12M

... receives a frame. The setting or adjustment is dependent on the

transmission rate and the set operating mode. Depending on the OZD

Profi 12M ... this can last up to several seconds.

If the transmission speed has not been recognized, the outputs of all ports

are blocked. If the transmission rate changes during operation, this is

detected by the repeaters, which then automatically adjust their settings

accordingly.

Transfer malfunctions may temporarily occur while the rate is being

altered.

Signal regeneration

The repeaters regenerate the signal form and amplitude of the data

received. This allows up to 122 OZD Profi 12M ... to be cascaded (limited

by the address space in PROFIBUS networks).

Help when setting up

At least one bus subscriber must be switched on and active in order to

check the optical fiber connections during the installation. This bus

subscriber serves as the frame source. The OZD Profi 12M ... act

passively when it is switched on. They recognize the transfer rate from the

frames sent by the bus subscriber. An optical help when putting the

device into operation is provided by the port LED which then lights up.

16

Installation OZD Profi 12M ...

Release 01 07/2017

1.2 Operating mode related functions

The operating mode is set using switches located on the front of the repeater.

A sticker attached to the side of the repeater provides assistance with the

settings. The OZD Profi 12M ... must be switched off when switching over

DIP switches.

1.2.1 Segment monitoring at the RS 485 port

If the operating mode ”Electric channel with segment monitoring“ is set, each

receiver monitors the RS 485 bus segment connected to it for faulty frames

or continuously busy networks. If faulty frames are received by the receiver,

or if the network is busy for longer than the maximum permitted send time,

forwarding of the received signals is blocked until frames can be received

again correctly, or if no signal is received for one second.

The RS 485 bus segment is not monitored in the operating mode ”Electric

port without segment monitoring“. Interference from the electrical segment

affects the entire network.

The following functions are only available for the optical channels. Whether

the functions can be activated depends on the operating mode which has

been set.

Line monitoring with echoes

The repeaters enable the connected optical paths to be actively

monitored for interruptions in the fiber line by means of the functions

”Send echo“, ”Monitor echo“ and ”Suppress echo“.

Send echo

A frame which is received by a repeater via any port is transmitted to all

other ports. If the receiving port is an optical port, the repeater sends the

frame back to the corresponding optical sender.

Monitor echo

If a repeater sends a frame - no echo – to an optical port, the repeater

expects to receive an echo. If the echo is not received after a predefined

time, an echo monitoring error is indicated by a red LED belonging to the

port.

Suppress echo

The relevant receiver is separated from the other ports from the moment

a frame is sent until the echo has been received correctly.

Installation OZD Profi 12M ...

Release 01 07/2017

17

Segmentation

If an echo monitoring error or a frame falsification arises at an optical port,

the repeater assumes that the line is faulty and blocks this port for user

data. The connected field bus partial network is then segmented (cut off).

This segmentation causes the repeater at the other end of the optical fiber

to be segmented as well. Both repeaters connected to the segmented

field bus partial network send test frames to the segmented ports. These

test frames – which are to be received regularly – can be used by both

repeaters to check the status of the field bus partial network. The

segmentation is automatically lifted as soon as the test frames indicate to

both repeaters that the segmented field bus partial network is no longer

disturbed. If all active bus subscribers are deactivated in a previously

active network, the repeaters are segmented cyclically in order to check

the fiber links to the neighboring repeaters. If there is no frame traffic, but

the fiber links are intact, the port LEDs of the optical ports flash yellow

cyclically.

18

Installation OZD Profi 12M ...

Release 01 07/2017

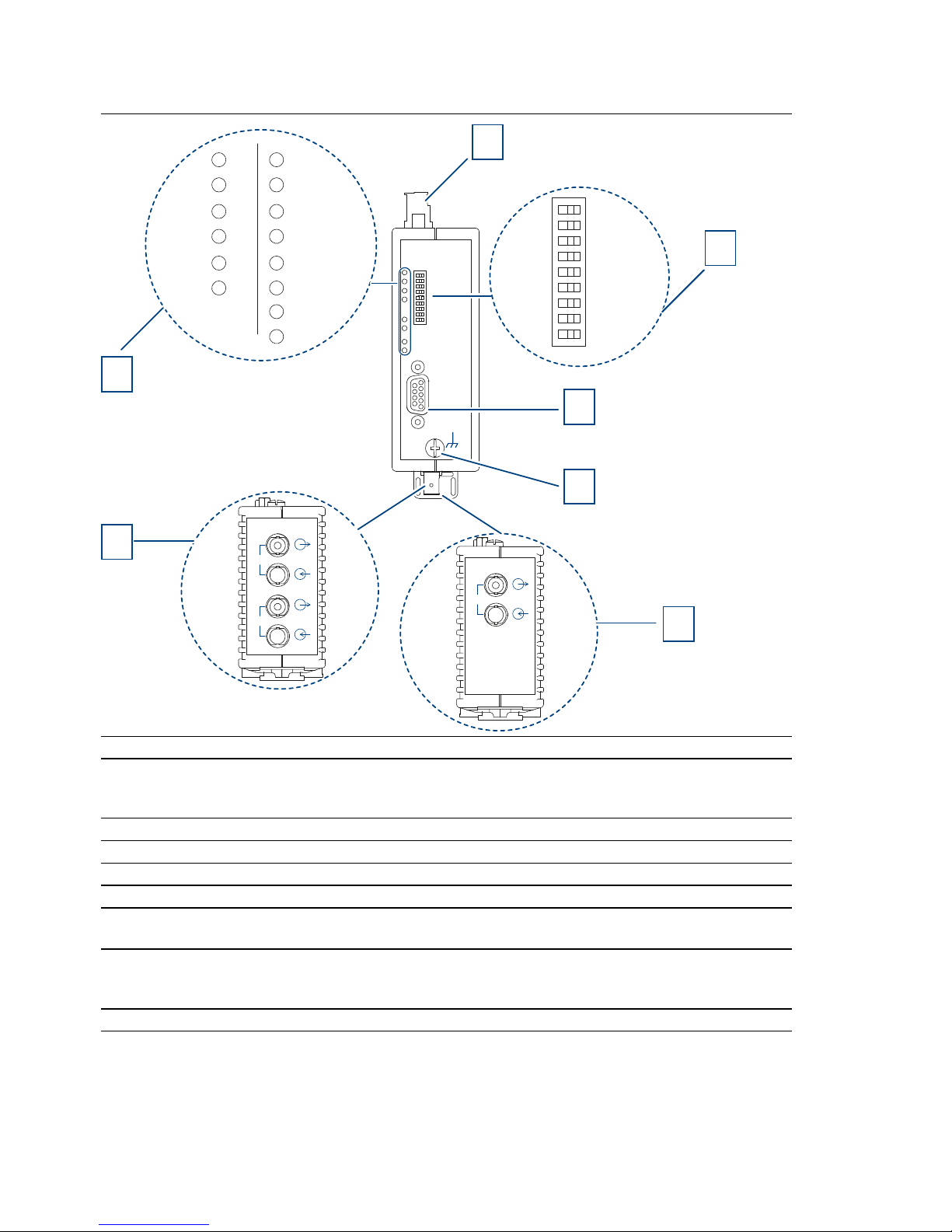

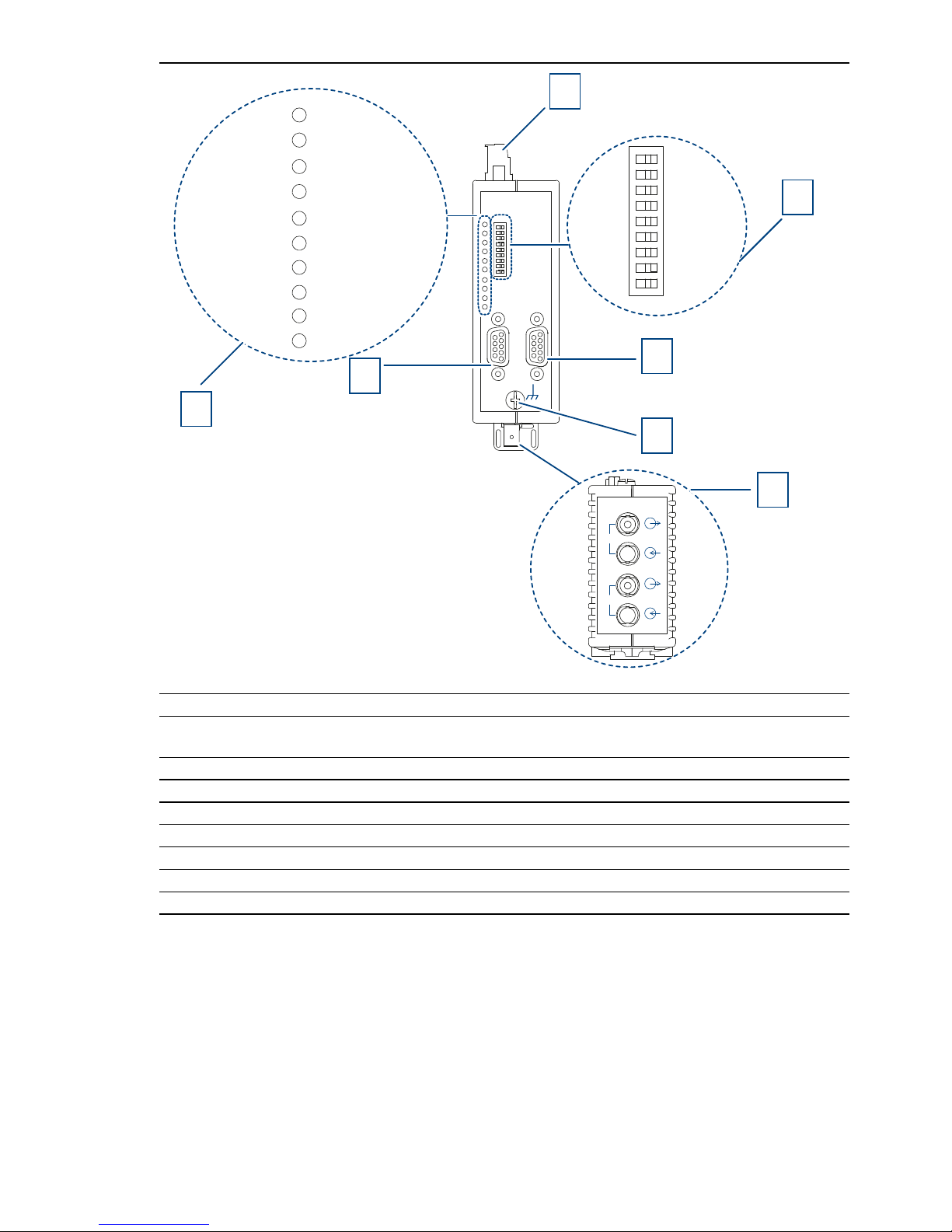

1.3 Device views

Front view using example of device variants OZD Profi 12M ...

– G11/G11-1300

– G12/G12-1300/G12-EEC/G12-1300-EEC

– P11/P12

1 8-pin terminal block for power supply, signal contact, measuring output

2 8-pin DIP switch

3 CH1 - electrical port

4 Grounding screw

5 CH3 - optical port

(only applies to the device variants OZD Profi 12M ... G11, G11-1300, P11)

6 CH3, CH4 - optical ports

(only applies to the device variants OZD Profi 12M ... G12, G12-1300, G12 EEC,G121300 EEC, P12)

7 LED display element for system status and port status

CH1

S0

S1

S2

S3

S4

S5

S6

S7

S8

1 0

System

CH1

CH3CH4

System

CH1

CH3

1

CH3

2

3

4

5

7

CH3

CH4

6

Installation OZD Profi 12M ...

Release 01 07/2017

19

Front view using example of device variants OZD Profi 12M ...

– G22/G22-1300/G22-EEC/G22-1300-EEC

– P22

1 8-pin terminal block for power supply, signal contact, measuring output

2 8-pin DIP switch

3 CH2 - electrical port

4 Grounding screw

5 CH3, CH4 - optical ports

6 CH1 - electrical port

7 LED display element for system status and port status

CH1

CH2

CH3

CH4

S0

S1

S2

S3

S4

S5

S6

S7

S8

1 0

2

3

6

4

5

1

System

CH1CH2CH3CH4

7

20

Installation OZD Profi 12M ...

Release 01 07/2017

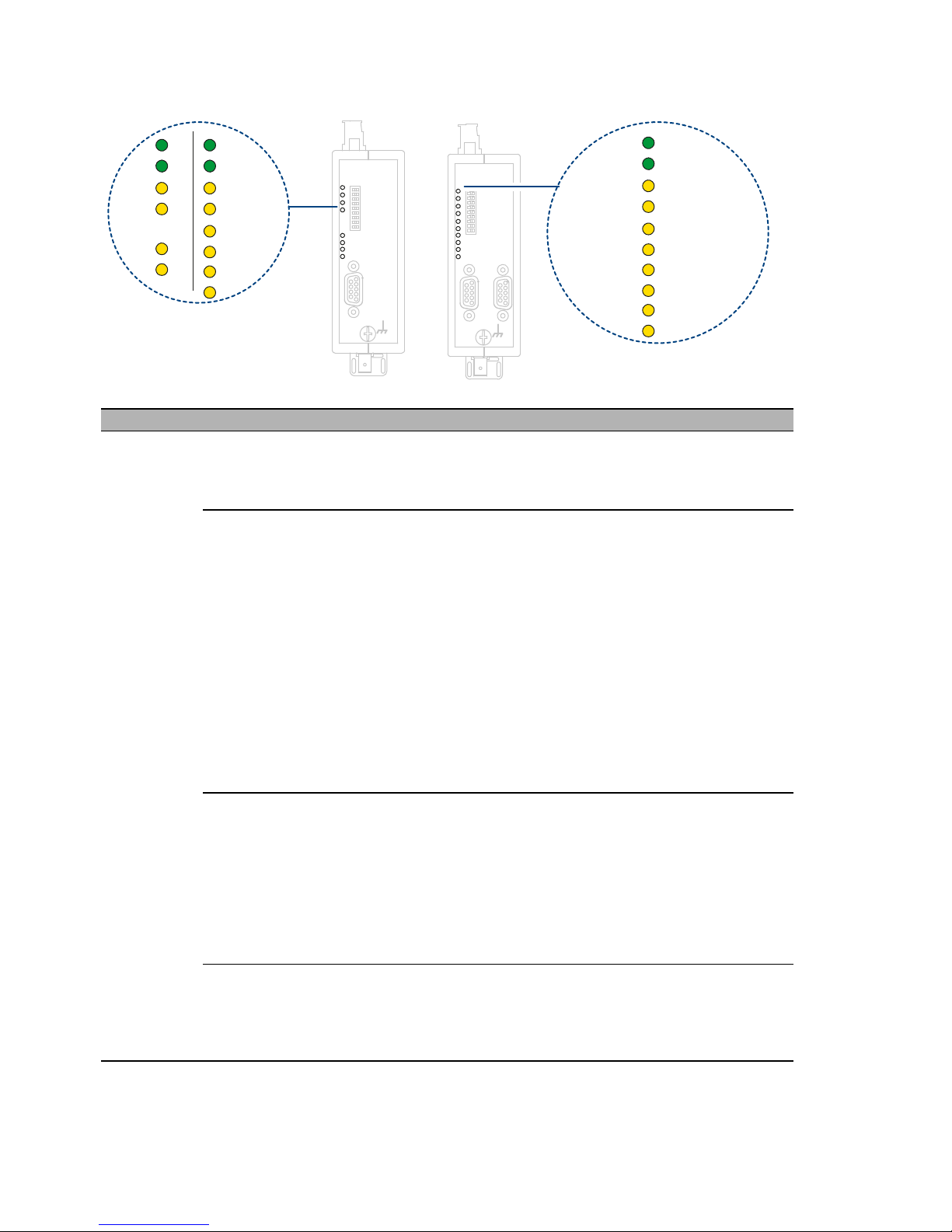

1.4 Display elements

LED Color Meaning

System green lights up The transmission rate has been recognized and the

power supply is in order

Signal contact: no signal

red flashes Transmission rate has not yet been recognized

– No transmitting bus subscriber present

– No connection to a partner repeater sending frames

– Send and receive optical fibers have been

transposed.

– Transmission rate does not correspond to

PROFIBUS-DP.

– Only one active bus subscriber is connected, which

is only sending tokens to itself. The indicator must

switch over after a second bus subscriber has been

activated (token frames on their own are not enough

to set the transfer rate).

– The connected RS 485 segment is only terminated

at one end.

Signal contact: no signal

red/green flashes Transmission rate recognized but

– the network slot time could not be determined

(network parameter HSA is set too low, no

transmitting bus subscriber present)

– one optical port is set to ”Redundant optical ring“

mode, but not the second (this operating mode must

always be set at both optical ports)

– the slot time of the network configuration is too short

Signal contact: no signal

none – Power supply has failed (total failure). Failure of

both power supply sources with redundant infeed.

– Power supply connected incorrectly

– Repeater defective

Signal contact: signal

CH1

CH1

CH2

CH4

System

CH1

CH3

System

CH1

CH3

System

CH1CH2CH3CH4

Installation OZD Profi 12M ...

Release 01 07/2017

21

electrical

ports

yellow lights up Signals are being received on the RS 485 bus line.

Signal contact: no signal

red flashes/light

s up

Sporadic interference signals because

– the RS 485 bus line being insufficiently shielded

– an open RS 485 bus line, i.e. it is only connected to

the repeater at one end

– the RS 485 segment is not terminated or only

terminated at one end

– an RS 485 bus terminal or terminal connector has

been plugged in/ pulled out

Signal contact: signal

Permanent interference because

– conductors A and B in the RS 485 bus line have

been transposed

– of an RS 485 bus line short circuit

– the send time has been exceeded caused by a bus

subscriber in a bus segment connected to Port 1

(CH1)

Signal contact: signal

– repeater and another bus subscriber connected via

Port 1 (CH1) are both sending at the same time (e.g.

because an address has been assigned twice, the

setting of the slot time is too low, or during lifting of

the segmentation in the optical lin).

Signal contact: no signal

– RS 485 driver of the repeater is defective (e.g. after

lightning strike)

none – Bus subscriber is not connected

– Connected bus subscriber is not switched on

– One or both conductors in the RS 485 bus line is

broken

Signal contact: no signal

Operating mode ”Line with optical fiber link monitoring“ and ”Redundant optical ring“

optical ports yellow lights up PROFIBUS frames are being received at the optical port

Signal contact: no signal

flashes Transmission rate has been recognized – LED ”System“

lights green or flashes red/green.

– No transmitting bus subscriber present (optical fiber

connection is OK)

Signal contact: no signal

LED Color Meaning

22

Installation OZD Profi 12M ...

Release 01 07/2017

red lights up – Send and receive optical fibers have been

transposed.

– No partner repeater connected or partner repeater

is not switched on.

– Connected partner repeater is defective

– Send time of connected partner repeater has been

exceeded

– An optical fiber line is broken

– Optical fiber link to partner repeater is too long

– Loose connection in an optical fiber connector

– Optical fiber in the optical fiber connector is loose.

– When using a redundant optical ring: if a fault in the

optical fiber has been corrected but the port LEDs

on both of the OZD Profi concerned still light red,

check whether parameter HSA has been set as

described in the chapter "Redundant Ring".

– Send and receive optical fibers have been

transposed.

Signal contact: open

red/yellow flashes – Fault occurs periodically (see above)

– Loose connection in an optical fiber connector

– Optical fiber in the optical fiber connector is loose

– Only one active bus subscriber is connected, which

only sends tokens to itself. A fault should not be

signaled as soon as a second subscriber is

activated.

Signal contact: signal

none Transmission rate has not yet been recognized – LED

”System“ flashes red

– No transmitting bus subscriber present

– Send and receive optical fibers have been

transposed

– No partner repeater connected or partner repeater

is not switched on

– Connected partner repeater is defective

Transmission rate has been recognized - LED ”System“

flashes green

– If the operating mode ”Redundant optical ring“ has

been set, the optical port works as a stand-by port.

There is no malfunction in the OZD Profi 12M ... or

the optical fiber.

– If one of the operating modes ”Line with optical fiber

link monitoring …“ has been set, no PROFIBUS

frames are received at the optical port. There is no

malfunction in the OZD Profi 12M ... or the optical

fiber.

Signal contact: no signal

Operating mode ”Line without optical fiber link monitoring“

LED Color Meaning

Installation OZD Profi 12M ...

Release 01 07/2017

23

optical ports yellow lights up Signals are received at the optical channel.

Signal contact: no signal

none – No transmitting bus subscriber present

– Send and receive optical fibers have been

transposed

– No partner repeater connected or partner repeater

is not switched on

– Connected partner repeater is defective

Signal contact: no signal

LED Color Meaning

24

Installation OZD Profi 12M ...

Release 01 07/2017

2 Network Topologies

The following network topologies can be realized with the OZD Profi 12M ...:

Point-to-point connections

Line topologies

Star topologies

Redundant optical rings

Note:

Single terminals or entire PROFIBUS segments with max. 31 subscribers

can be connected to the electrical interface of the OZD Profi 12M ...

In areas with a high EMC incidence, only lay optical fiber lines in order to

exclude the possibility of EMC affecting the whole network.

Optically only OZD Profi 12M ... of the same type can be connected

together: OZD Profi 12M P11 with … P12, OZD Profi 12M G11 with

…G12 and …G12 EEC, OZD Profi 12M G11-1300 with … G12-1300 and

…G12-1300 EEC.

Optical ports which are connected by optical fiber must be set to the same

operating mode.

Junctions between different OZD Profi 12M ... types are only possible via

the RS 485 interface.

OZD Profi 12M G12 (-1300) EEC can be used everywhere in those

network topologies described below in which a OZD Profi 12M G12(-

1300) can also be used.

Installation OZD Profi 12M ...

Release 01 07/2017

25

2.1 Line topology

Figure 1: Network structure in an optical line topology

In a line structure, the individual OZD Profi 12M ... are connected together by

dual-fiber optical fibers. Repeaters with one optical port are sufficient at the

beginning and end of a line, between which repeaters with two optical ports

are necessary.

If single point-to-point connections are to be built up, this can be achieved

using two repeaters each with one optical port.

The line topology can be realized with and without fiber link monitoring. If

both operating modes are used within an optical fiber line, the operating

mode ”Line topology without fiber link monitoring“ determines the availability

of this fiber line. It is recommended that fiber link monitoring be used in

homogeneous OZD Profi networks (default factory setting).

Please note that the following ambient conditions must be fulfilled to ensure

that network configuration functions correctly:

The parameters MIN T

SDR

described in the PROFIBUS standard EN

50170 must be set to a value ≥ 11 on all terminals. This is usually the

case, but the setting should be checked if communication malfunctions

continuously arise.

When configuring your network, select low bus subscriber addresses

wherever possible. This ensures that master timeout times which may

arise are kept as short as possible in the event of a malfunction.

CH 1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH 1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH 1

Terminal unit(s) /

bus segment

OZD …

P12

G12 (-1300)

CH4CH3

26

Installation OZD Profi 12M ...

Release 01 07/2017

2.1.1 Line topology with optical fiber link monitoring and

segmentation

This operating mode should preferably be used if an interrupted fiber

segment is to be separated from the rest of the network.

In this operating mode the individual fiber links are monitored by the two

connected repeaters.

If a repeater fails, an optical fiber breaks or faults are determined on the

optical transfer link, the fiber link between the two Fiberoptic Repeater is

interrupted (segmented).

The PROFIBUS network is divided into two partial networks, which remain

functional independently of one other. The malfunction is indicated at the two

OZD Profi 12M ... that are connected to the malfunctioning fiber link by the

port LEDs switching to red and by activation of the signaling contacts. The

segmentation is lifted automatically as soon as both repeaters recognize that

the field bus network is functioning correctly with the help of test frames.

Please note that in the case of networks with several active bus subscribers,

two logical token rings are formed in the event of an error. Every time the

partial networks are switched together, network malfunctions may arise due

to the double tokens or frame collisions.

Note: If a repeater with two optical channels is used at the beginning or end

of a line, the optical port which is not assigned must be switched to the

operating mode ”Line without fiber link monitoring“, so that it does not signal

a break in the fiber line. Please note that optical ports which are not

connected must always be fitted with protective caps to guard against

extraneous light and dirt.

Monitoring mechanisms

Send echo yes

Monitor echo yes

Suppress echo yes

Monitor yes

Segmentation yes

Installation OZD Profi 12M ...

Release 01 07/2017

27

2.1.2 Line topology without optical fiber link monitoring

Use this operating mode if you connect a OZD Profi 12M ... with another

optical fiber network component, which does not send a frame echo and does

not expect or is not compatible with a frame echo in accordance with

PROFIBUS guidelines (optical/electrical converter).

Individual fiber links are not monitored in this operating mode.

Monitoring mechanism

Send echo no

Monitor echo no

Suppress echo no

Monitor no

Segmentation no

28

Installation OZD Profi 12M ...

Release 01 07/2017

2.2 Star topology

Figure 2: Network structure in an optic star topology

Several repeaters are combined to form an active PROFIBUS star coupler.

Other repeaters are connected to this by dual-fiber optical fiber lines. The

repeaters of the star coupler are connected to one another via the electrical

port (electrical star segment). All OZD Profi 12M ... types for different fiber

types (plastic, PCF, glass) can be combined using the electrical star

segment.

CH1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH1

CH3

Terminal unit(s) /

bus segment

OZD …

P11

G11 (-1300)

CH1

CH3

OZD …

P11

G11 (-1300)

CH1

CH3

OZD …

P11

G11 (-1300)

CH1

CH3

OZD …

P11

G11 (-1300)

CH1

OZD …

P12

G12 (-1300)

CH4CH3

Electrical star segment

Installation OZD Profi 12M ...

Release 01 07/2017

29

CH1 in mode ”Monitor off“ (S0 = 1) must be activated on all OZD Profi

12M ... which are connected to the electrical star segment. This

deactivates the segmenting function of the RS 485 port on these OZD

Profi 12M ..., providing a high degree of availability of the electrical star

segment.

Ensure that the electrical star segment is wired carefully. Keep it as small

as possible to avoid interference injection into the electrical star segment,

and from here into the entire network. This can be achieved by laying out

the OZD Profi 12M ... in the electrical star segment directly next to each

other on a hat rail.

Switch on the terminating resistors in the bus port connectors at both ends

of the electrical star segment.

See “Connecting the electric bus cables” on page 47.

Do not connect a bus subscriber to the electrical star segment wherever

possible.

This applies exclusively to device variants OZD Profi 12M x22:

Connect other bus subscribers to the second electrical port (CH2).

Repeaters with one or two optical ports can be used to create an active

PROFIBUS star coupler. Repeaters with one optical port are sufficient for

connecting a terminal or an RS 485 bus segment to the active star coupler.

If the link monitoring on the optical ports is activated, the fiber optic links are

monitored by the respectively connected OZD Profi 12M ... .

Note: Optical ports which are not assigned (for instance, because they are

reserved for a future system extension) indicate a fiber break if the link

monitoring is activated. You can prevent this error report from being issued

by activating the operating mode ”Line without fiber link monitoring“ at the

non-assigned ports. Please note that optical ports which are not connected

must always be fitted with protective caps to guard against extraneous light

and dirt.

30

Installation OZD Profi 12M ...

Release 01 07/2017

2.3 Redundant ring

Figure 3: Network structure in a redundant optical ring topology

This network topology represents a special form of line topology. A high

degree of network operating safety is achieved by ”closing“ the optical line.

A redundant optical ring ca only be realized with repeaters with two optical

ports of the same fiber.

An interruption of one or both optical fibers between two repeaters is

detected by the OZD Profi 12M ... and the ring is transformed into an optical

line.

If one repeater fails only those terminals connected to this repeater or the RS

485 segment are uncoupled from the ring. The remainder of the network itself

continues to function as a line. The error is indicated by the LEDs on the two

OZD Profi 12M ... connected to the malfunctioning optical fiber and their

signaling contacts. The segmentation is lifted automatically as soon as both

repeaters recognize that the segmented field bus network is functioning

correctly with the help of test frames. The line forms itself into a ring.

Monitoring mechanism

Send echo yes

Monitor echo yes

Suppress echo yes

Monitor yes

Segmentation yes

CH1

Terminal unit(s) /

bus segment

OZD …

P12

G12 (-1300)

CH4CH3

CH1

Terminal unit(s) /

bus segment

OZD …

P12

G12 (-1300)

CH4CH3

CH1

Terminal unit(s) /

bus segment

OZD …

P12

G12 (-1300)

CH4CH3

Installation OZD Profi 12M ...

Release 01 07/2017

31

The following ambient conditions must be fulfilled to ensure that the network

configuration functions correctly:

The operating mode ”Redundant optical ring“ must be set at both optical

ports of all the OZD Profi 12M ... .

All repeaters in a ring must be connected to one another by fiber lines.

The ring may not include an RS 485 bus line.

The parameter MIN T

SDR

described in the PROFIBUS standard

EN 50170 must be set to a value ≥ 11on all terminals. This is usually the

case, but the setting should be checked if communication malfunctions

continuously arise.

When configuring your network, select low bus subscriber addresses

wherever possible. This ensures that master timeout times which may

arise are kept as short as possible in the event of a malfunction.

If a redundancy case occurs (e.g. a line break), there is a switching time

during which data can not be correctly transmitted. In order to ensure a

smooth transition, it is recommended that the frame repeat setting (Retry)

on the PROFIBUS master be set to at least 3.

After the error has been corrected, no frames should be present in the

network when the optical line is transformed back into an optical ring to

ensure that the process is completed smoothly. This condition can arise

when a master selects a device whose address has been configured, but

which does not physically exist.

The master tries to address this device cyclically and waits for a reply only

until the configured slot time has been exceeded (”GAP request“). The

OZD Profi 12M ... recognizes this condition and closes the optical line to

an optical ring in the middle of this request sequence. This results in two

configuration requirements for the redundant optical ring:

– The value of the parameter HSA (Highest Station Address) must be

set at all terminals so that between the bus address 0 and the value

HSA at least one address in the network has not been assigned to a

bus subscriber, i.e. so that there is at least one address gap. This

address gap can also be created by simply setting the value of the

parameter HSA so that it is at least one greater than the highest

number of subscriber bus addresses present in the network.

Note: If this requirement is not or no longer fulfilled, the optical line will no

longer be closed into a redundant optical ring after segmentation. The error

report (LED and signaling contact) of the two affected OZD Profi 12M ... is

not cancelled even after the error has been corrected.

– The slot time must be set to approximately twice the value required in

a non-redundant network. Refer to the manufacturer’s documentation

provided with the terminal or configuration software for details about

how to adjust the settings.

32

Installation OZD Profi 12M ...

Release 01 07/2017

3 Installation guidelines

3.1 Electromagnetic compatibility (EMC)

Electromagnetic compatibility (EMC) covers all aspects regarding the effects

of radiated and received electrical, magnetic, and electromagnetic

emissions. In order to prevent interference in electrical systems, these

effects must be reduced to a minimum. The structural design and correct

connection of bus lines as well as the interference suppression of switched

inductances play a major role in limiting interference.

3.2 Interference suppression of switched

inductances

Figure 4: Interference suppression of fluorescent lamps in cabinet

3.2.1 Suppressing switched inductances with fuses

Switching inductances, e.g. in relays and fans, generates interference

voltages which are many times higher than the switched operating voltage.

These interference voltages can affect electronic devices. The interference

voltages of inductances must be limited at their source of emission by means

of fuses (by connecting diodes or RC elements). Only use interference

suppressors which are intended for the used relays and fans.

3.2.2 Cabinet lighting

Use filament lamps (e.g. LINESTRA lamps) for the cabinet lighting.

Do not use fluorescent lamps because they generate interference fields.

If the use of fluorescent lamps cannot be avoided, the interference

suppression measures shown in Fig. 4 must be implemented.

Shield grid

over lamp

Shielded cable

Metal-encased

switch

Mains filter or

shielded mains cable

Installation OZD Profi 12M ...

Release 01 07/2017

33

3.3 Arrangement of devices and cables

3.3.1 Reducing interference by providing adequate space:

A simple yet effective way of reducing interference is to separate devices and

cables causing interference from those affected by interference. Inductive

and capacitive interference injection decreases by the square of the distance

between the elements concerned. This means that doubling the distance

reduces the interference by a factor of 4. If the arrangement of the various

elements in a building or in the switch cabinet is taken into consideration at

the planning stage, the cost of the necessary interference suppression

measures is generally very low.

Note: Between an OZD Profi 12M ... and a power switching element (e.g.

contactor, relay, temperature regulator, switch, etc.) a minimum separation

of 5.9 in (15 cm) is to be maintained. This minimum separation is to be

measured between the outer edges of the components and in all directions

around OZD Profi 12M ... . The power supply wires (24 V DC and 0 V) for the

OZD Profi 12M ... must not be laid in the same cable duct as cables for load

circuits. The wires (24V DC and 0 V) should be twisted together.

3.3.2 Standard recommendations for the arrangement of

devices and cables

EN 50174–2 contains recommendations for arranging devices and cables

which are aimed at reducing mutual interference to a minimum.

3.3.3 Using bus line shields

It is important to observe the following when shielding bus lines:

Use only fully shielded PROFIBUS lines. The shields of these lines must

be of sufficient thickness to satisfy the legal requirements for interference

radiated and interference received.

Always attach the shields at both ends of the bus lines. The legal

requirements vis-à-vis interference radiated and interference received for

your system will only be satisfied if shields are connected at both ends

(CE symbol).

Attach the shield for the bus line at the connector plug housing or at the

cable clamps provided.

In the case of steady-state operation, it is advisable to strip the shielded

line entirely and connect it with the shielding bus/protective conductor rail.

34

Installation OZD Profi 12M ...

Release 01 07/2017

Note: If differences in potential occur between the grounding points, an

inadmissibly high compensating current could flow across the shielding

connected at both ends. Never eliminate this problem by removing the

shielding from the bus line. The following solution is permissible: Lay an

additional equipotential bonding cable parallel to the bus line. This additional

cable will carry the shield current.

3.3.4 Shield connections

Proceed as follows:

Secure the shield braid using metal cable clamps.

The clamps must fully enclose the shield and make good contact.

Only connect the lines via the copper braid shield, and not via the

aluminum foil shield. One side of the foil shield is attached to a plastic film

to increase its tearing strength, and is therefore non-conductive.

The shields of all cables which are routed into a cabinet from the outside

must be clamped at the point of entry inside the cabinet and connected to

the cabinet ground with a large contact surface area.

When removing the cable jackets, it is important to ensure that the braid

shield of the cables is not damaged. Tin-plated or galvanically stabilized

surfaces are ideal for optimum contacting between grounding elements.

With zinc-plated surfaces, suitable threaded connections must be

provided for the required contacts. Painted surfaces at the contact points

are unsuitable.

Shield clamps/contact points should not be used as strain relief devices.

Contact with the shield bus could otherwise deteriorate or break

completely.

Installation OZD Profi 12M ...

Release 01 07/2017

35

3.4 Laying cables inside of buildings

Laying cables within control cabinets

If a repeater is installed within a control cabinet, the cable shield of the

incoming bus cable should be electrically connected to a grounding rail as

close as possible to the cable lead through using a shield grounding

clamp or similar. The cable shield should continue within the cabinet to

the fieldbus device and be connected there in accordance with the

manufacturer’s instructions.

Laying cables outside of control cabinets

PROFIBUS cables and cables for DC and AC voltages > 400 V

(unscreened), areas with explosion hazard and telephone cables

separate cable runs spaced at least 10 cm apart. All cable ducts should

be constructed of electrically conducting material and connected to

functional ground at regular intervals. Bus cables should not be subject to

mechanical loads which exceed the manufacturer’s specifications. If this

cannot be avoided, additional protective measures should be taken, e.g.

by laying the cables in a steel pipe or rugged metal duct. The pipe or duct

should then be grounded at regular intervals and protected against

corrosion.

36

Installation OZD Profi 12M ...

Release 01 07/2017

Potential equalization and screening

Figure 5: Laying cables inside of buildings

The cable screen should be connected to ground at both ends of the

cable. The use of fiber optic cable is recommended if problems are

experienced with interference. A low impedance potential equalization

cable should be used if this is not possible. Situations where interference

can present a problem include: plant which extends over a large area,

power is fed to the plant from different power sources, networking extends

over several buildings. If one of these situation apply, the following should

be observed when installing the potential equalization system:

The circuit through which interference signals flow must be closed.

Each part of the plant must be electrically connected to the potential

equalization system/functional ground at as many places as possible.

Electrically conducting pipes, parts of machines or supporting

structures should be integrated in the potential equalization system. In

order to ensure long-term reliability, appropriate measures should be

undertaken to protect against corrosion.

The potential equalization cable must be protected against corrosion.

The cross-section of the potential equalization cable should be chosen

with regard to the maximum potential equalization currents which can

flow.

Special care should be taken when installing potential equalization cables

to maximize the interference immunity of the data cables. If possible, the

potential equalization cable should be laid parallel to and as close as

possible to the data cable (preferably in the same plastic pipe). The cable

screen should never be used for potential equalization. The potential

equalization cable should be finely stranded to ensure that it is also

effective at high frequencies as a result of the large surface area.

Bus cable

Potential equalization

Potential equalization

Control cabinet 1

Control cabinet 2

Installation OZD Profi 12M ...

Release 01 07/2017

37

3.5 Laying cables outside of buildings

Figure 6: Laying cables outside of buildings

Requirements:

It is recommended to use fiber optic cables for bus installations which are

outside of buildings. In the case of bus cables between buildings which

are laid in the ground, you should use a special fiber optic cable type

which is suitable for this application.

Suitable copper cable types can be used if fiber optic cables cannot be

used.

Observe the admissible minimum and maximum temperature rating for

the type of cable used.

In principle, the same rules apply to laying cables outside of buildings as

within buildings. However, for outside installation, the cables should be

provided with additional protection by laying them inside a suitable plastic

pipe.

The transition from external to internal cables should always use an auxiliary

terminal block. It is used to interconnect the cable for burial in the ground with

the standard bus cable. Lightning arrestors should be installed directly where

the cable enters the building. In addition, the auxiliary terminal block should

contain appropriate circuits to protect against overvoltages (lightning

protection).

Lightning protection Lightning protection

Plastic pipe

Functional ground

Bus cable Bus cable

Potential equalization

Functional ground

Potential equalization

38

Installation OZD Profi 12M ...

Release 01 07/2017

4 Installation

The devices have been developed for practical application in a harsh

industrial environment.

Hirschmann supplies the device ready for operation.

To configure a subdomain, follow these steps:

Checking the package contents

Mounting the device

Setting compatibility

Connecting the optic bus cables

Connecting the electric bus cables

Connecting the function ground and the shield of the bus cable

Connecting the power supply

Connecting the signal contact (optional)

Connecting the analog voltage outputs (optional)

4.1 Checking the package contents

Proceed as follows:

Check whether the package includes all items named in the section

“Scope of delivery” on page 61.

Check the individual parts for transport damage.

Installation OZD Profi 12M ...

Release 01 07/2017

39

4.2 Mounting the device

4.2.1 Installing the device onto the DIN rail

Note: The device is for mounting on a 35 mm DIN rail in accordance with DIN

EN 60715.

Requirements:

Install the device in a location where the climatic threshold values

specified in the technical data are adhered to.

See “Technical data” on page 57.

Ensure that there is sufficient room to connect the bus and power supply

cabling.

Connect the optical fiber line before mounting the repeater as this

simplifies the procedure.

Proceed as follows:

Slide the upper snap-in guide of the device into the DIN rail.

Press the device downwards onto the clip-in bar.

2

1

40

Installation OZD Profi 12M ...

Release 01 07/2017

4.3 Setting compatibility

Note: The functional compatibility on OZD Profi 12M ... a is switched on or

switched off with the DIP switch S8.

– When operating OZD Profi 12M ...

a

with OZD Profi PRO or with previous

OZD Profi 12M ...

b

the functional compatibility must be switched off

(S8=0). The devices are directly compatible.

– When operating OZD Profi 12M... with OZD Profi G3a, ... G4a, ... G3a-

1300, ... G4a-1300, ... P3a, ... P4a the functional compatibility must be

switched on (S8=1).

Only turn switch S8 to Position 1 if the OZD Profi 12M ...

a

is being used

as a spare or expansion device in existing networks in conjunction with

these devices and a direct optical connection is to be made. The following

tables show the switch assignment:

a. Device variants with 1 or 2 electrical ports (CH1, CH2),

DIP switch: S0 - S8

b. Device variants with 1 electrical port (CH1) only,

DIP switch: S0 - S7

Installation OZD Profi 12M ...

Release

01

07/2017

41

OZD Profi G3a... / G4a... OZD Profi 12M G...

a

Meaning of the DIP switches DIP switch Function DIP switch Function

S1 - Mode S1 = 0 Mode 0 S2=0 Mode 0

S1 = 1 Mode 1 S2=1 Mode 1

S2 - Redundancy function S2 = 0 OFF S3=0 OFF

S2 = 1 ON S3=1 ON

S3 - Termination S3 = 0 CH2 not terminated - not relevant (Termination extern)

S3 = 1 CH2 terminated

S4 - Termination S4 = 0 CH2 not terminated - not relevant (Termination extern)

S4 = 1 CH2 terminated

S5 - optical Power / Distance S5 = 0 Network configuration: Standard S4=0 Network configuration: Standard

S5 = 1 Network configuration: Extended S4=1 Network configuration: Extended

S6 - optical Power S6 = 0 Without function - -

S6 = 1 Without function - -

S8 =1 Compatibility ON

S0, S5 = 0 Without function

S6, S7 = 0 in Position = 0

Table 4: Switch assignment of the OZD Profi 12M ... at S8=1 as a spare or expansion device for OZD Profi G3a, ...G4a, ...G3a-

1300 and...G4a-1300.

42

Installation OZD Profi 12M ...

Release

01

07/2017

OZD Profi P3a... / P4a... OZD Profi 12M G...

a

Meaning of the DIP

switches

DIP switch Function DIP switch Function

S1 - Mode S1 = 0 Mode 0 S2=0 Mode 0

S1 = 1 Mode 1 S2=1 Mode 1

S2 - Redundancy function S2 = 0 OFF S3=0 OFF

S2 = 1 ON S3=1 ON

S3 - Termination S3 = 0 CH2 not terminated - not relevant

(Termination extern)

S3 = 1 CH2 terminated

S4 - Termination S4 = 0 CH2 not terminated - not relevant

(Termination extern)

S4 = 1 CH2 not terminated

S5 - optical Power / Distance S5 = 0 CH3 - optical Power: Standard S6=0 CH2 - optical Power: Standard

S5 = 1 CH3 - optical Power: High S6=1 CH2 - optical Power: High

S6 - optical Power / Distance S6 = 0 CH4 - optical Power: Standard S7=0 CH3 - optical Power: Standard

S6 = 1 CH4 - optical Power: High S7=1 CH3 - optical Power: High

S8 =1 Compatibility ON

S0, S1,S4 = 0 Without function

S5 = 0 in Position 0

Table 5: Switch assignment of the OZD Profi 12M ... at S8=1 as a spare or expansion device for OZD Profi P3a, ...P4a, ...P3a-1300

and ...P4a-1300.

Installation OZD Profi 12M ...

Release 01 07/2017

43

4.4 Setting the operating mode and

transmitting power

Note:

– S1 does not have a function on OZD Profi 12M ... with only one electrical

interface.

– S7 does not have a function on OZD Profi 12M ... with only one optical

interface.

The following details only apply for the S8 default position (S8 = 0).

The DIP switch S0 is used to set the operating mode of the electrical port

CH1.

The DIP switch S1 is used to set the operating mode of the electrical port

CH2.

This applies exclusively to device variants OZD Profi 12M x22:

The DIP switches S2 and S3 are used to set the operating mode of the

optical port CH3.

The DIP switches S4 and S5 are used to set the operating mode of the

optical port CH4.

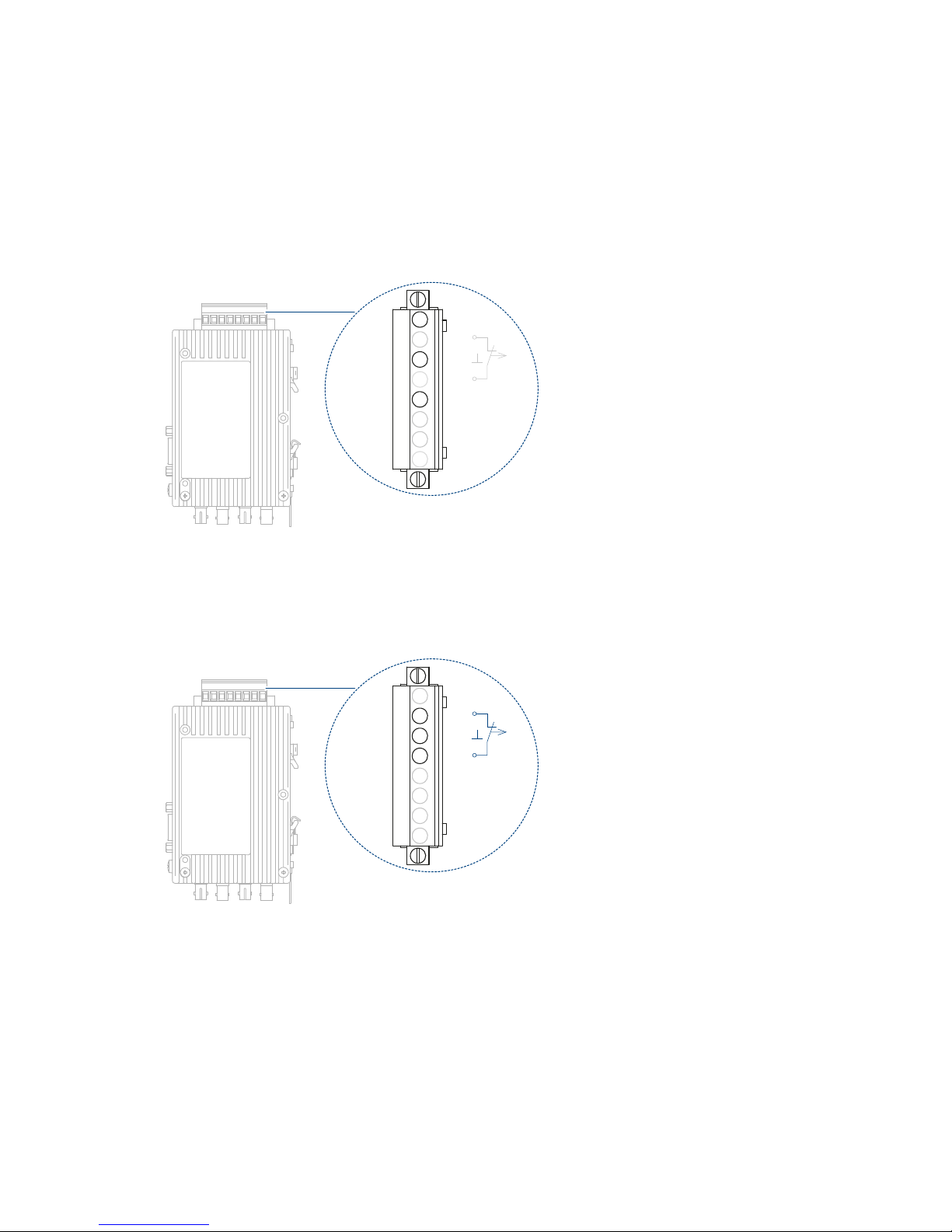

4.4.1 Setting the operating mode of the electrical ports

(CH1, CH2)

Operating mode: electrical ports (CH1, CH2) with segments

monitoring

CH1 is activated in this operating mode if S0 is in Position 0.

Applies to device variants with 2 electrical ports:

CH2 is activated in this operating mode if S1 is in Position 0.

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

44

Installation OZD Profi 12M ...

Release 01 07/2017

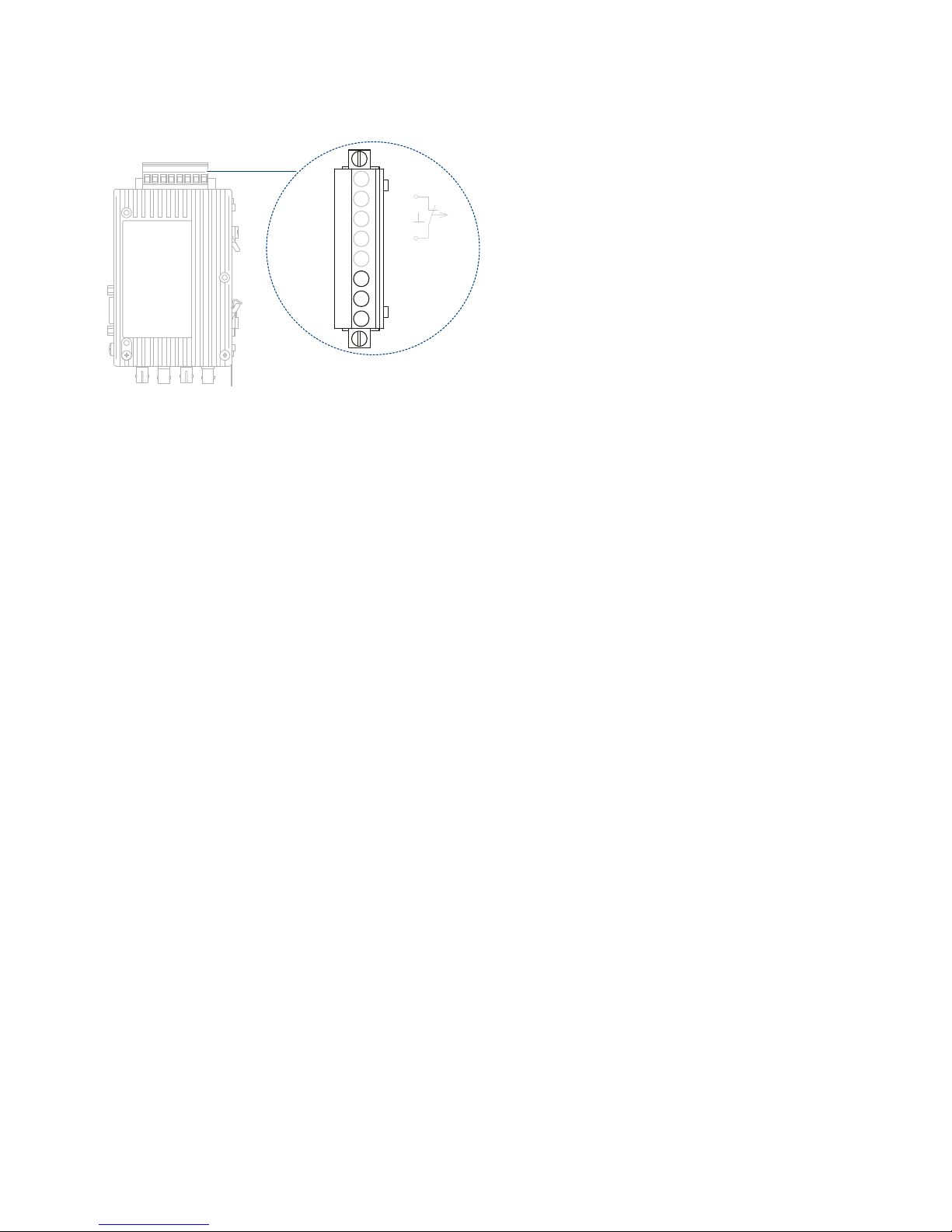

Operating mode: electrical ports (CH1,CH2) without

segment monitoring

4.4.2 Setting the operating mode of the optical ports (CH3,

CH4)

The operating mode can be set individually for each optical port.

Combinations of the operating modes “Line with optical fiber link monitoring”

and “Line without optical fiber link monitoring” are also possible. Note that the

operating mode of the two optical ports which are connected by the fiber line

must always have the same settings. The operating mode “Redundant

optical ring” must always be set at both of the optical ports.

Operating mode: Line with optical fiber link monitoring and

segmentation

CH1 is activated in this operating mode if S0 is in Position 1. Please note that

this operating mode should only be set in the star segment of the star topology.

Applies to device variants with 2 electrical ports:

CH2 is activated in this operating mode if S1 is in Position 1. Please note that

this operating mode should only be set in the star segment of the star topology.

CH3 is activated in this operating mode if S2 and S3 are in Position 0.

CH4 is activated in this operating mode if S4 and S5 are in Position 0.

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S 0

S 6

S 5

S 3

S 2

S 4

S 7

S 8

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

Installation OZD Profi 12M ...

Release 01 07/2017

45

Operating mode: Line without optical fiber link monitoring

Operating mode: Redundant optical ring

4.4.3 Reducing the optical transmitting power

The OZD Profi 12M P1x PRO and OZD Profi 12M Gxx (EEC) have a high

level of optical transmitting power. Optical overloading may result if these

repeaters are connected with non-OZD Profi 12M ... devices using plastic

optical fiber cables, particularly if short cable lengths are used. In this case

the optical transmitting power can be reduced.

The following details only apply for the S8 default position (S8 = 0).

The DIP switch S6 is used to set the transmitting power of CH3.

The DIP switch S7 is used to set the transmitting power of CH4.

CH3 is activated in this operating mode if S2 is in Position 1 and S3 is in

Position 0.

CH4 is activated in this operating mode if S4 is in Position 1 and S5 is in

Position 0.

CH3 is activated in this operating mode if S2 and S3 are in Position 1.

CH4 is activated in this operating mode if S4 and S5 are in Position 1.

Leave S6 in Position 1 (default) if the optical fiber link to CH3 functions

correctly in this position.

Leave S7 in Position 1 (default) if the optical fiber link to CH4 functions

correctly in this position.

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

46

Installation OZD Profi 12M ...

Release 01 07/2017

Note:

– When using OZD Profi 12M Gxx-1300 (EEC), transmit power must be set

to Default (S6/S7 in Position 1).

– When using PCF fibers, transmit power must be set to Default (S6/S7 in

Position 1) for 660 nm.

– When using PCF fibers, transmit power must be set to Default (S6/S7 in

Position 0) for 850 nm.

– S7 has no function on devices with only one optical port.

4.5 Connecting the optic bus cables

Proceed as follows:

Use a duplex fiber-optic cable with BFOC/2.5 (ST ®) connectors to

connect the individual repeaters.

Pay attention to the maximum cable length of the fiber-optic cable as well

as the possible types of fibers specified in the Technical Data.

Make sure that each optical input is connected to an optical output at the

opposite end (“cross-overlink“). The corresponding BFOC sockets of the

two ports are marked on the lower front panel.

Ensure sufficient strain relief for the fiber-optic cables and pay attention to

their minimum bend radiuses.

Unused BFOC sockets are to be covered with the protective caps

supplied. Incident ambient light and, in particular, great ambient

brightness, can affect the network. The penetration of dust may impair

operation of the optical components.

Switch S6 to Position 0 (reduced) if overloading is detected at non-OZD

Profi device at CH3.

Switch S7 to Position 0 (reduced) if overloading is detected at a non-OZD

Profi device at CH4.

optical output (Sending direction)

optical input (Receiving direction)

CH 3

CH 4

CH 3

CH 4

CH 1

CH 2

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

CH3

Installation OZD Profi 12M ...

Release 01 07/2017

47

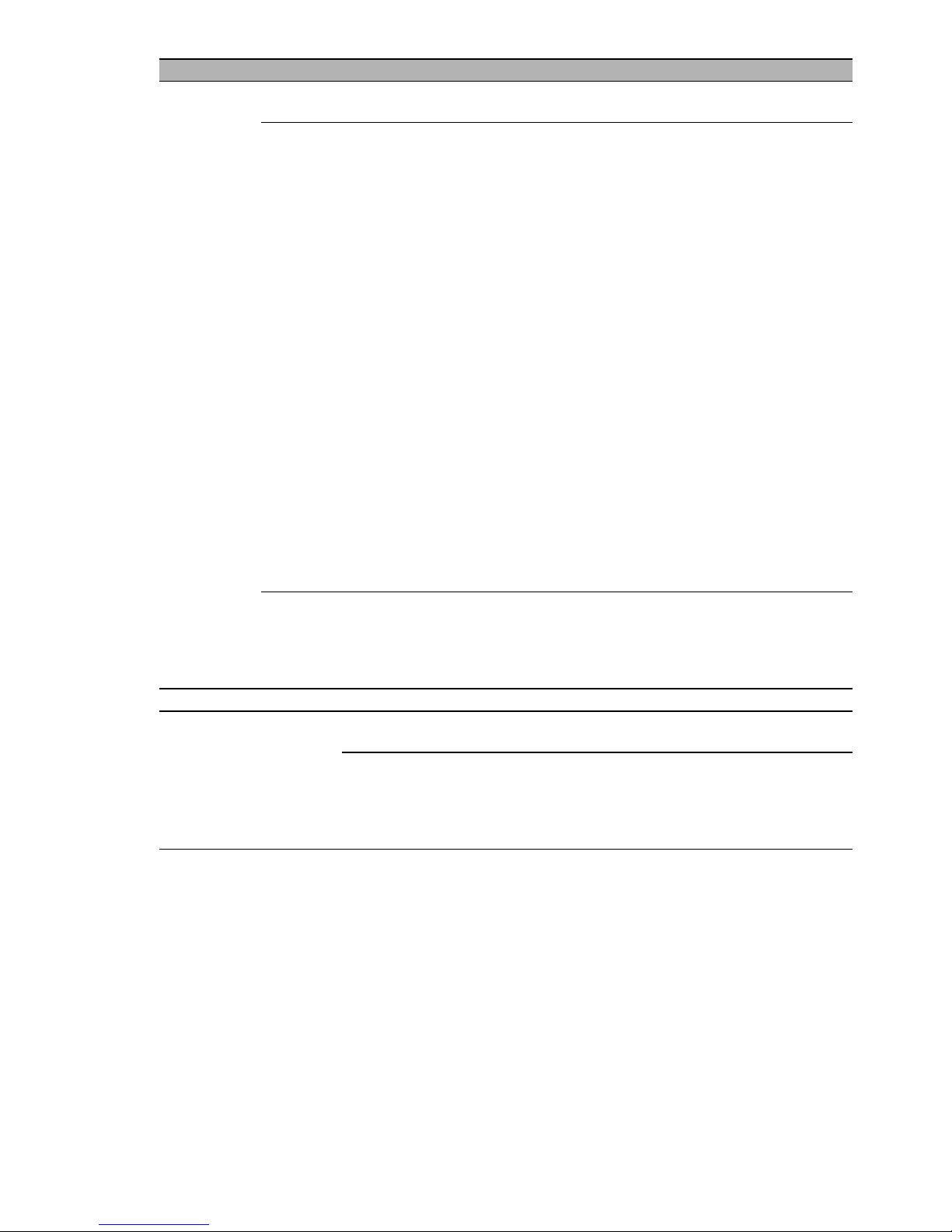

4.6 Connecting the electric bus cables

Figure 7: Assignment of D-Sub socket

Depending on the device variant, the repeaters are fitted with one or two

RS 485 electrical ports. This is a 9-pin D-Sub socket with a screw lock

(inside thread UNC 4-40).

The pin assignment complies with the PROFIBUS standard. At Pin 6

there is a short circuit-proof 5 V output for supplying external pull-up/pulldown resistors.

As opposed to the 24V power supply, the RS 485 bus lines RxD/TxD–N

and RxD/TxD–P are indirect-coupled (functional separation) within SELV

restrictions.

The RS 485 interface is electrically connected to the front panel/function

ground.

Only use shielded and twisted-pair wiring as a RS 485 bus line.

Use a PROFIBUS bus connector plug to connect the RS 485 bus

segment.

5

4

3

2

1

Ground

RTS

RxD/TxD - P

n.c.

n.c.

n.c.

RxD/TxD – N

n.c.

+ 5 V Output

9

8

7

6

48

Installation OZD Profi 12M ...

Release 01 07/2017

Note:

– If the repeater is at the beginning or end of a bus segment, this connector

must have an activated bus terminal resistor combination.

– Ensure that the bus segment connected to the RS 485 interface is

terminated at both ends.

– Only use a connecting cable which is terminated at both ends to connect

a single device.

– All PROFIBUS bus connector plugs in a network must be securely

screwed onto the RS 485 interfaces.

– Attaching or removing the bus connector plugs, inadequately attached

bus connector plugs or loose bus wires within the plug can lead to

malfunctions in the optical and electrical networks.

Proceed as follows:

Attach or remove the RS 485 bus connector plug quickly and without

twisting them.

Remove the RS 485 bus line from the OZD Profi 12M ... if a device is not

connected to the other end, or there is an OZD Profi which has been

disconnected from the power supply. The open line otherwise acts as an

antenna and can cause interference.

When connecting a RS 485 bus line to the OZD Profi 12M … in an active

network, keep to the following sequence in order to avoid interference:

– Place the RS 485 bus connector plug onto the device which is to be

connected (e.g. to a programming device) and screw it on tightly.

– Attach the RS 485 bus connector plug to the OZD Profi 12M ... quickly

and without twisting the connector, and screw it on tightly. Proceed in

the reverse order when removing a device from the network.

Data rate Range per segment

12 Mbit/s 100 m

6 Mbit/s 100 m

3 Mbit/s 100 m

1.5 Mbit/s 200 m

500 kBit/s 400 m

187.5 kBit/s 1000 m

93.75 kBit/s 1200 m

45.45 kBit/s 1200 m

19.2 kBit/s 1200 m

9.6 kBit/s 1200 m

Table 6: Range of RS 485 bus segment with cable type A

Installation OZD Profi 12M ...

Release 01 07/2017

49

Properties of cable type A:

– Characteristic impedance: 135 - 165 Ohm

– Capacity coating: ≤ 30 pF/m

– Loop resistance: ≤ 110 Ohm/km

– Wire diameter: > 0.64 mm

– Wire cross section: > 0.34 mm

2

4.7 Connecting the function ground and the

shield of the bus cable

WARNING

There is no contact separation between the bus lines and the

connection for the function ground.

Observe the following safety instructions:

Do not use bus lines to connect repeaters to device parts which have a

different earth potential. The different voltages could destroy the

repeaters.

Avoid electrical bus lines, which are partly or entirely laid outside

buildings. If lightening strikes close by, this could destroy the repeaters.

Use F/O cables for bus connections outside buildings.

The shield of the bus cable, together with the function ground connection,

must be connected to an equipotential rail in the switch cabinet. The

equipotential rails of the switch cabinets, which are connected to one

another by means of an electrical RS 485 bus cable, must have a lowimpedence connection to one another.

The function ground of the repeater is effected by means of the

connection of the screw terminal block on front of the device.

50

Installation OZD Profi 12M ...

Release 01 07/2017

4.8 Connecting the power supply

Note: To connect the lines for the power supply, remove the 8-pin terminal

block on the top of the repeater from the device.

Proceed as follows:

Only supply the OZD Profi 12M ... with a stabilized safety extra-low

voltage (SELV) in accordance with IEC/EN 60950-1, EN 61131-25, 24 V

maximum. It is supplied via the 8-pin terminal block on the top of the

repeater.

To improve the operating safety, a redundant power supply consisting of

separate sources can be used. You can input the supply voltage in two

ways:

Terminal +24 V (L1+) of the terminal block

Terminal +24 V (L2+) of the terminal block

The minus connection for each is indicated by “0V”.

The two voltages can have any values – even different ones – within the

specified limits.

However, there is no load distribution. If necessary, the power supply unit

with the higher output voltage must supply the power alone.

The supply voltage inputs are protected against incorrect pole connection.

The operating voltage is electrically isolated from the function ground

connection and from the other connections.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Profi 12M ...

Release 01 07/2017

51

4.9 Connecting the signal contact (optional)

Note:

– To connect the signal contact lines, remove the 8-pin screw terminal block

on top of the repeater from the device.

– Use the correct pin assignment for the 8-pin terminal block.

– Make sure that the electrical insulation of the connection cables of the

signal contacts is sufficient. Incorrect connections can destroy the

repeater.

On the 8-pin terminal block on the top of the repeater, the unconnected pins

of a relay can be used as signal contacts. When the OZD Profi 12M ... is

working correctly, the contact is closed. If there is an error or a power failure,

the contact is opened.

The following problems with the network and the repeater can be signalled

by means of the signal contact:

Supply voltage interrupted

incorrectly connected

Internal device errors

Received data no input signal at port 3 (optical)

(The numbering of the ports depends on device variant)

no input signal at port 4 (optical)

(The numbering of the ports depends on device variant)

faults on port 1 (electrical) or port 2 (electrical)

Redundant optical ring interruption of an optical fiber

a repeater fails

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

52

Installation OZD Profi 12M ...

Release 01 07/2017

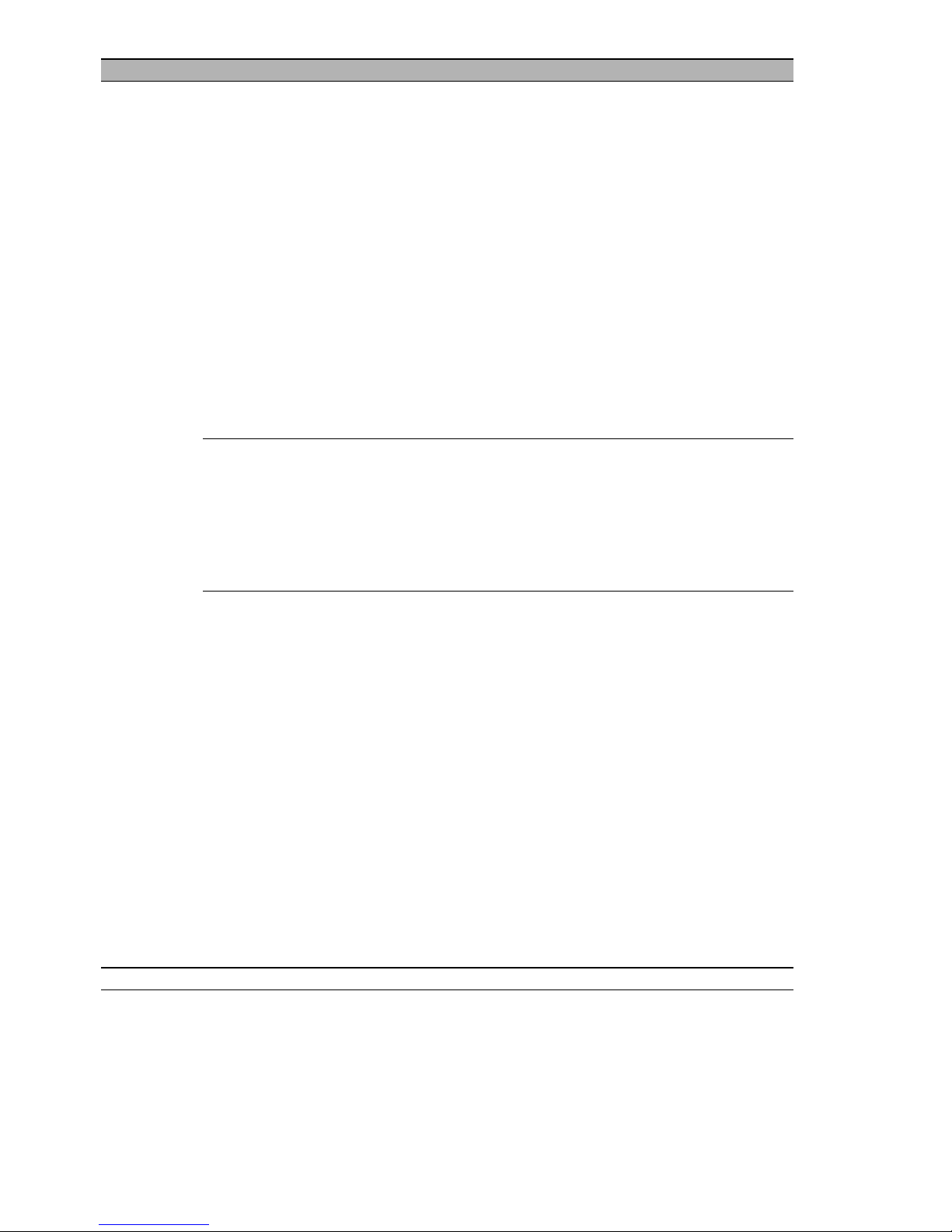

4.10 Connecting the analog voltage outputs

(optional)

Figure 8: Analog voltage outputs – connections for 3-pin terminal block

The device has two analog voltage outputs, Ua1 and Ua2. These voltage

outputs are connected using a 8-pin screw terminal on top of the repeater.

The screw terminal is suitable for cable leads that have a cross section

between 0.2 - 2.5 mm

2

.

The analog voltage outputs supply a short-circuit-proof output voltage

dependent on the optical power input at port 2 or port 3, for diagnosis

purposes and, for example, for preventative maintenance, in the range from

0 - 5 V (each with reference to “GND” of the 8-pin terminal block). The analog

voltage outputs are electrically connected to the front panel/function ground.

The measuring voltage can be determined by a standard volt meter

(ungrounded, high-impedance) . This allows the incoming optical power to be

documented , e.g. for later measurements (aging, damage), a pass/fail

examination to be performed (threshold value), wiring to be carried out on

input terminals of a Profibus I/O module, thereby making the control system

available. As with other process variables, it is possible to define warning

thresholds there and use them for preventative maintenance.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Profi 12M ...

Release 01 07/2017

53

Figure 9: Correlation of measured output voltage to signal quality

Note: For a measured value to be valid, it is necessary that the partner OZD

Profi 12M ... on the other end of the optical fiber transmits regular PROFIBUS

telegrams. An OZD Profi 12M ... is no substitute for a calibrated, optical level

meter. However, it provides each optical port with a voltage derived from the

peak value of the optical PROFIBUS telegram without disrupting the

communication of data. With regular bus operation, this analog voltage can

be used as an indicator for an alteration in optical attenuation. Because data

traffic and temperature can affect the voltage value, you should not set any

warning threshold too close to the actual value.

Signal

output

voltage

0 100 200 300 400 500 600 700 800 900

Optical power input [μW]

1

0

2

0.5

1.5

2.5

3.5

3

4

Reserve

54

Installation OZD Profi 12M ...

Release 01 07/2017

5 Configuration

During configuration, the PROFIBUS network parameter "Slot time" must be

adapted to the network coverage, network topology and the data rate due to

frame delays caused by lines and network components, as well as by

monitoring mechanisms in the network components.

Configuration of redundant optical rings

The following configuration conditions must be fulfilled in the redundant

optical ring See “Redundant ring” on page 30.