Installation OZD Genius...

Release 01 09/2017

Technical Support

https://hirschmann-support.belden.eu.com

User Manual

Installation

Fiberoptic Repeater

OZD Genius...

The naming of copyrighted trademarks in this manual, even when not specially indicated, should

not be taken to mean that these names may be considered as free in the sense of the trademark

and tradename protection law and hence that they may be freely used by anyone.

© 2017 Hirschmann Automation and Control GmbH

Manuals and software are protected by copyright. All rights reserved. The copying, reproduction,

translation, conversion into any electronic medium or machine scannable form is not permitted,

either in whole or in part. An exception is the preparation of a backup copy of the software for

your own use.

The performance features described here are binding only if they have been expressly agreed

when the contract was made. This document was produced by Hirschmann Automation and

Control GmbH according to the best of the company's knowledge. Hirschmann reserves the right

to change the contents of this document without prior notice. Hirschmann can give no guarantee

in respect of the correctness or accuracy of the information in this document.

Hirschmann can accept no responsibility for damages, resulting from the use of the network

components or the associated operating software. In addition, we refer to the conditions of use

specified in the license contract.

You can get the latest version of this manual on the Internet at the Hirschmann product site

(www.hirschmann.com).

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

Installation OZD Genius... 14.09.2017

Installation OZD Genius...

Release 01 09/2017

3

Contents

Safety instructions 5

About this manual 10

Key 11

1 Description 12

1.1 General description 12

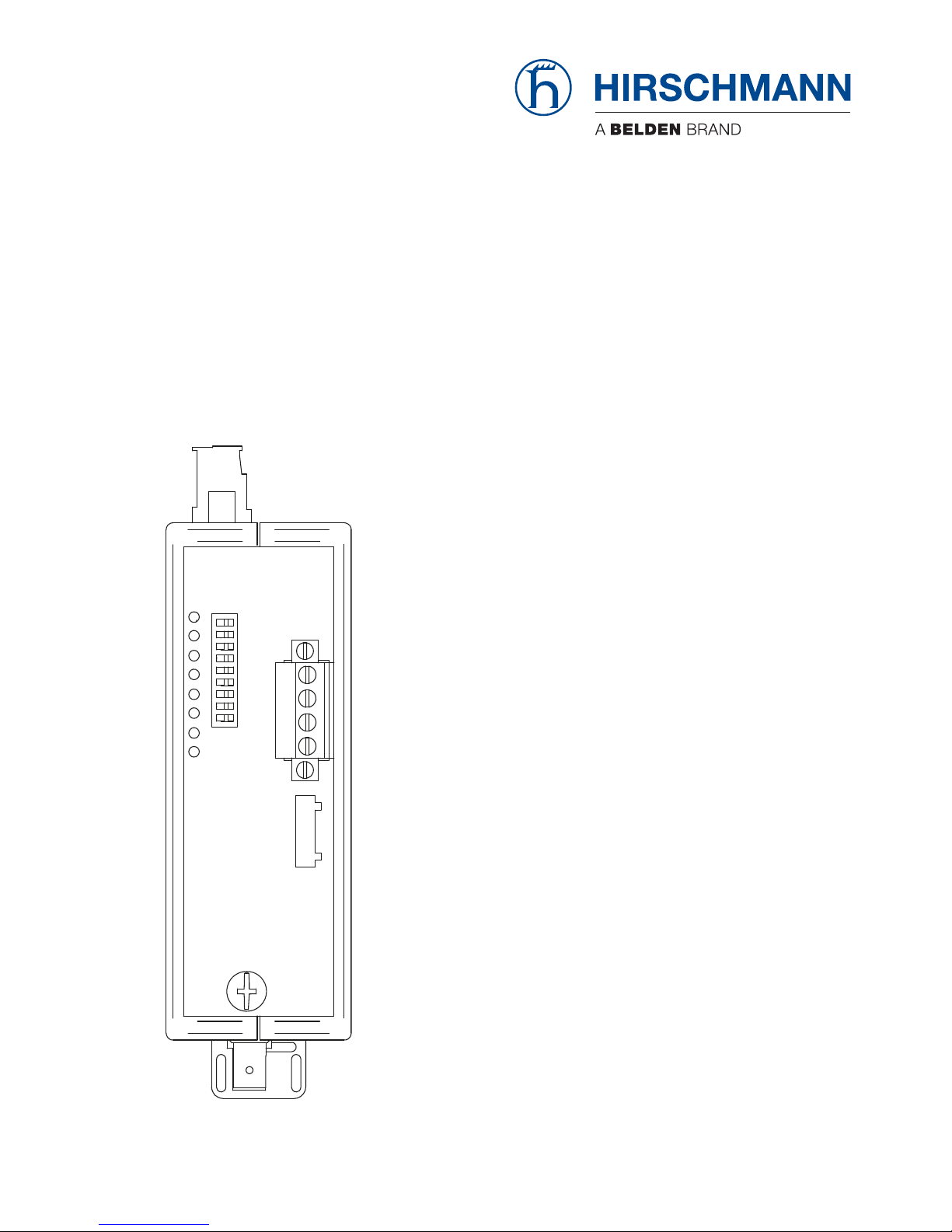

1.2 Device view 16

1.3 Display elements 17

2 Network Topologies 19

2.1 Line topology without redundancy 19

2.2 Redundant optical ring 20

3 Installation 22

3.1 Checking the package contents 22

3.2 Installing and grounding the device 23

3.2.1 Installing the device onto the DIN rail 23

3.2.2 Mounting the device on a mounting plate 24

3.2.3 Grounding the device 24

3.3 Connecting the optic bus cables 25

3.4 Connecting the electric bus cables 26

3.5 Connecting the power supply 27

3.6 Connecting the signal contact 28

3.7 Setting the data rate 29

3.8 Setting the optical transmitting power 30

3.9 Network range for line and ring topologies 30

4 Disassembly 32

4

Installation OZD Genius...

Release 01 09/2017

5 Technical data 33

6 Scope of delivery, order numbers and

accessories 36

7 Underlying technical standards 37

8 Troubleshooting 38

A Further support 39

Installation OZD Genius...

Release 01 09/2017

5

Safety instructions

General safety instructions

You operate this device with electricity. Improper usage of the device

entails the risk of physical injury or significant property damage. The

proper and safe operation of this device depends on proper handling

during transportation, proper storage and installation, and careful

operation and maintenance procedures.

Before connecting any cable, read this document, and the safety

instructions and warnings.

Operate the device with undamaged components exclusively.

The device is free of any service components. In case of a damaged

or malfunctioning the device, turn off the supply voltage and return the

device to Hirschmann for inspection.

Qualification requirements for personnel

Only allow qualified personnel to work on the device.

Qualified personnel have the following characteristics:

Qualified personnel are properly trained. Training as well as practical

knowledge and experience make up their qualifications. This is the

prerequisite for grounding and labeling circuits, devices, and systems

in accordance with current standards in safety technology.

Qualified personnel are aware of the dangers that exist in their work.

Qualified personnel are familiar with appropriate measures against

these hazards in order to reduce the risk for themselves and others.

Qualified personnel receive training on a regular basis.

WARNING

UNCONTROLLED MACHINE ACTIONS

To avoid uncontrolled machine actions caused by data loss, configure all

the data transmission devices individually.

Before you start any machine which is controlled via data transmission, be

sure to complete the configuration of all data transmission devices.

Failure to follow these instructions can result in death, serious injury,

or equipment damage.

6

Installation OZD Genius...

Release 01 09/2017

Certified usage

Use the product only for the application cases described in the

Hirschmann product information, including this manual.

Operate the product only according to the technical specifications.

See “Technical data” on page 33.

Connect to the product only components suitable for the requirements

of the specific application case.

Device casing

Only technicians authorized by the manufacturer are permitted to open

the housing.

National and international safety regulations

Verify that the electrical installation meets local or nationally applicable

safety regulations.

Grounding the device

Functional grounding the device is by means of a separate connection on

the device.

Ground the device before connecting any other cables.

Disconnect the grounding only after disconnecting all other cables.

Ground the device via the ground screw.

Requirements for connecting electrical wires

Before connecting the electrical wires, always verify that the

requirements listed are complied with.

All of the following requirements are complied with:

The electrical wires are voltage-free.

The cables used are permitted for the temperature range of the application case.

Table 1: General requirements for connecting electrical wires

All of the following requirements are complied with:

The voltage connected complies with the requirements for a safety extra-low voltage

(SELV) as per IEC/EN 60950-1.

The connected voltage is limited by a current limitation device or a fuse.

Observe the electrical threshold values for the signal contact.

See “General technical data” on page 33.

Table 2: Requirements for connecting the signal contact

Installation OZD Genius...

Release 01 09/2017

7

Supply voltage

Only switch on the device when the housing is closed.

Requirements

All of the following requirements are complied with:

The supply voltage corresponds to the voltage specified on the type plate of the device.

The power supply conforms to overvoltage category I or II.

The power supply has an easily accessible disconnecting device (e.g., a switch or a plug).

This disconnecting device is clearly identified. So in the case of an emergency, it is clear

which disconnecting device belongs to which power supply cable.

The cross-section of the ground conductor is the same size as or bigger than the cross-

section of the power supply cables.

Relevant for North America:

The power supply cables are suitable for ambient air temperatures of at least 167 °F

(75 °C). The power supply cable wires are made of copper.

The wire diameter of the power supply cable is at least 0.75 mm² (North America: AWG18) on

the supply voltage input.

The following requirements are alternatively complied with:

Alternative 1 The power supply complies with the requirements for a limited

power source (LPS) as per EN 60950-1.

Alternative 2 Relevant for North America:

The power supply complies with the requirements according to

NEC Class 2.

Alternative 3 All of the following requirements are complied with:

The power supply complies with the requirements for a safety

extra-low voltage (SELV) as per IEC/EN 60950-1.

A fuse suitable for DC voltage is located in the plus conductor

of the power supply.

The minus conductor is on ground potential. Otherwise, a fuse

is also located in the minus conductor.

Regarding the properties of this fuse:

See 33 “General technical data”.

Table 3: Requirements for connecting the supply voltage

8

Installation OZD Genius...

Release 01 09/2017

CE marking

The labeled devices comply with the regulations contained in the following

European directive(s):

2014/30/EU (EMC)

Directive of the European Parliament and of the Council on the

harmonisation of the laws of the Member States relating to

electromagnetic compatibility.

2011/65/EU (RoHS)

Directive of the European Parliament and of the Council on the restriction

of the use of certain hazardous substances in electrical and electronic

equipment.

In accordance with the above-named EU directive(s), the EU conformity

declaration will be at the disposal of the relevant authorities at the

following address:

Hirschmann Automation and Control GmbH

Stuttgarter Str. 45-51

72654 Neckartenzlingen

Germany

The product can be used in the industrial sector.

Interference immunity: EN 61000-6-2

Emitted interference: EN 55032

Reliability: EN 60950-1

You find more information on technical standards here:

“Technical data” on page 33

Warning! This is a class A device. This device can cause interference in

living areas, and in this case the operator may be required to take

appropriate measures.

Note: The assembly guidelines provided in these instructions must be

strictly adhered to in order to observe the EMC threshold values.

LED or laser components

LED or LASER components according to IEC 60825-1 (2014):

CLASS 1 LASER PRODUCT

CLASS 1 LED PRODUCT

Installation OZD Genius...

Release 01 09/2017

9

FCC note:

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) this device may not cause harmful

interference; (2) this device must accept any interference received,

including interference that may cause undesired operation.

Appropriate testing has established that this device fulfills the

requirements of a class A digital device in line with part 15 of the FCC

regulations.

These requirements are designed to provide sufficient protection against

interference when the device is being used in a business environment.

The device creates and uses high frequencies and can also radiate these

frequencies. If it is not installed and used in accordance with this

operating manual, it can cause radio transmission interference. The use

of this device in a residential area can also cause interference, and in this

case the user is obliged to cover the costs of removing the interference.

Recycling note

After usage, this device must be disposed of properly as electronic waste,

in accordance with the current disposal regulations of your county, state,

and country.

10

Installation OZD Genius...

Release 01 09/2017

About this manual

The “Installation” user manual contains a device description, safety

instructions, a description of the display, and the other information that you

need to install the device.

Installation OZD Genius...

Release 01 09/2017

11

Key

The symbols used in this manual have the following meanings:

Listing

Work step

Subheading

12

Installation OZD Genius...

Release 01 09/2017

1 Description

1.1 General description

The Fiberoptic Repeater OZD Genius... is designed for use in optical Genius

bus field bus networks. It allows conversions of electrical Genius bus

interfaces into optical Genius bus interfaces and vice versa.

The repeaters can be integrated in existing Genius bus field bus networks.

OZD Genius... repeaters can also be used to configure a complete Genius

bus field bus network with the line or ring topology.

Apart from setting the data rate, no other adjustments have to be made

during set-up.

Device casing

The device is supplied in a metal housing. You have the option of

mounting the device onto the DIN rail or to the mounting plate.

Glass fiber technology

The use of glass fiber transmission technology enables a very large

transmission range and ensures optimal protection from EMC effects on

the transmission path and – due to the potential separation – on the

Repeater itself.

Data rate

The fiber-optic repeater OZD Genius G12… supports the data rates

153.6 kBaud (standard and extended),76.8 kBaud and 38.4 kBaud.

Redundancy

Redundant optical signal transmission ensures a very high level of

transmission reliability. The redundant operating power supply can further

improve the operating reliability.

Installation OZD Genius...

Release 01 09/2017

13

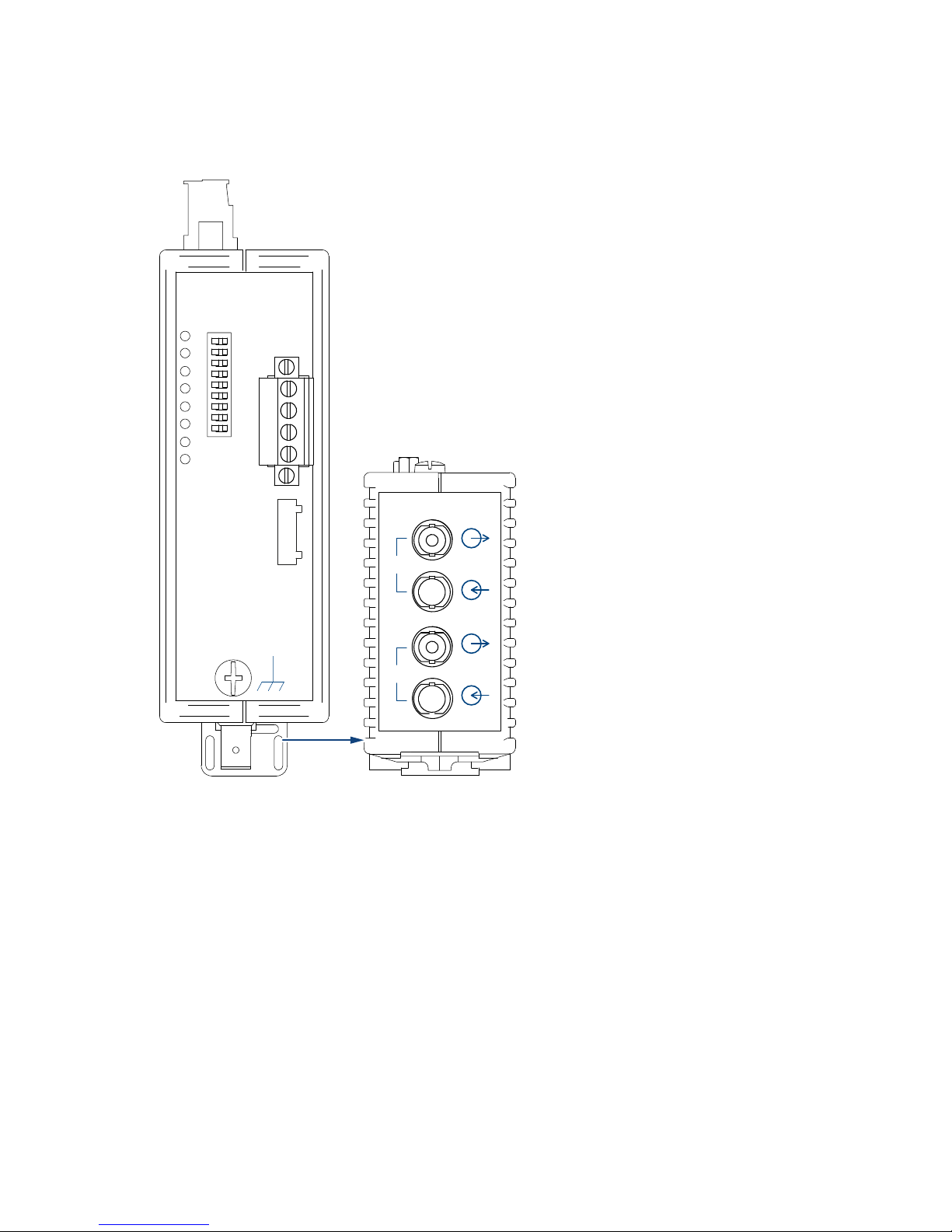

Port

The repeater has three mutually independent ports (channels), each of

which consists of a transmitter and receiver. The electrical port is a 4-pin

connector, the optical ports are BFOC/2.5 (ST ®) sockets.

CH2

CH3

CH1

14

Installation OZD Genius...

Release 01 09/2017

Power supply

The power supply is 24 V direct current. To improve the operating safety,

a redundant operating power supply consisting of two separate sources

can be used. For this purpose, you must connect the two supply voltages

to two different terminals of the 8-pin screw-type terminal block. There is

no load distribution between the sources. There is no load distribution

between the sources. With redundant supply, the power supply unit with

the higher output voltage must supply the repeater alone.

Signal contact

A signal contact (relay with unconnected contacts) is used to signal

various disruptions in the repeaters. The signal contact is also connected

to the 8-pin screw type terminal block.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Genius...

Release 01 09/2017

15

Measuring output

One measuring output is available for each optical port. The measuring

output is connected to the 8-pin screw type terminal block.

Signal regeneration

The OZD Genius... regenerates the signal form and amplitude of the

received data. This function allows unlimited cascading of optical links.

Network range

The maximum permissible network range for line and ring topologies

depends on both the number of OZD Genius... devices used and the data

rate.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

16

Installation OZD Genius...

Release 01 09/2017

1.2 Device view

Front view using example of device variants OZD Genius... / OZD Genius G12-1300

1 8-pin terminal block for power supply, signal contact, measuring output

1a Pin assignment of the signal contact

1b Pin assignment of the power supply

1c Pin assignment of the measuring output

Ua1 for the optical port CH2

Ua2 for the optical port CH3

CH1

SystemCH1

CH3CH4

SHD OUT

SHD IN

SER2

SER1

1

4

5

3

2

1a

1c

1b

6

7

CH2

CH3

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

S0

S1

S2

S3

S4

S5

S6

S7

S8

1 0

Installation OZD Genius...

Release 01 09/2017

17

1.3 Display elements

2 8-pin DIP switch

Meaning of the DIP switches:

– S0 and S1 with function (Setting the data rate)

– S0 and S1 with function (Setting the optical transmit power)

– S2, S3, S4, S5, S8 without function

3 CH1 - electrical port

4 The information field for the electrical port 1 (CH1)

SHD OUT - Shield line, output (connected to casing)

SHD IN - Shield line, input (connected to casing via a capacitor)

SER2 = Data line S1

SER1 = Data line S2

5 CH2, CH3 - optical ports

6 Grounding screw

7 LED display element for system status and port status

Display Color Meaning

System None Supply voltage is too low

Green Data reception at all ports

Red No data reception for 500 ms at minimum one port

Ports None No data reception for 500 ms

Green Data reception; no error detected

orange/yellow Data reception, error detected:

– echo error (fiber in sending direction interrupted)

– malformed data packets (Jabber or Fragment)

CH3

System

CH1

CH2

CH1

18

Installation OZD Genius...

Release 01 09/2017

Signal contact Open – Supply voltage is too low

– No data reception for 500 ms at minimum one port

Closed Data reception at all ports

Display Color Meaning

Installation OZD Genius...

Release 01 09/2017

19

2 Network Topologies

2.1 Line topology without redundancy

Figure 1: Line topology without redundancy

This network topology is used in the case of an optical link between end

devices or bus segments.

It is advisable (but not essential) to terminate the first and last repeater in the

line with an ”optical short-circuit“. To do this, each input and output of the free

ports is connected via a short length of optical cable with BFOC connectors.

If the ”optical short-circuit“ is not provided, the vacant BFOC sockets must be

closed using the supplied protection caps. The associated port LEDs do not

light up, the system LEDs light up red, and the signaling contact closes

(fault).

Genius bus line

Fiber optic cable

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

CH3

TR

CH2

TR

OZD Genius G12

CH1

CH3

TR

OZD Genius G12

CH2

TR

CH1

CH3

TR

OZD Genius G12

CH2

TR

CH1

20

Installation OZD Genius...

Release 01 09/2017

2.2 Redundant optical ring

Figure 2: Network structure in a redundant optical ring topology

This network topology is used in the case of an optical link between end

devices or bus segments. The implementation of a redundant link with OZD

Genius... repeaters ensures a high degree of reliability.

The failure of an optical cable between any two OZD Genius... repeaters

does not affect the availability of the network.

The repeaters detect the failure of an optical link. The port LED of the faulty

link is deactivated and the failure is indicated by illumination of the red system

LED and operation of the signal contact.

It is advisable to install the duplex optical cables of the two optical ports along

different routes.

Genius bus line

Fiber optic cable

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

CH3

TR

CH2

TR

OZD Genius G12

CH1

CH3

TR

OZD Genius G12

CH2

TR

CH1

CH3

TR

OZD Genius G12

CH2

TR

CH1

Installation OZD Genius...

Release 01 09/2017

21

Figure 3: Alternative wiring system for network structure in redundant optical ring

topology

If problems are encountered with the configuration of a redundant optical ring

on account of excessively long fiber-optic line sections, connections can also

be implemented.

See figure 3 on page 21.

In this case, each repeater is linked (in spatial terms) with the next repeater

but one. Two adjacent repeaters must be interconnected at the start and end

of every such line. This prevents the individual fiber-optic line sections from

being” excessively long“.

It is advisable to install the duplex optical cables of the two optical channels

along different routes.

The maximum permissible network range for the ring topology depends on

both the number of OZD Genius G12... devices used and the data rate.

Genius bus line

Fiber optic cable

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

Terminal unit(s)/

bus segment(s)

CH3

TR

OZD Genius G12

CH2

TR

CH1

22

Installation OZD Genius...

Release 01 09/2017

3 Installation

The devices have been developed for practical application in a harsh

industrial environment.

Hirschmann supplies the device ready for operation.

To configure a subdomain, follow these steps:

Checking the package contents

Installing and grounding the device

Connecting the optic bus cables

Connecting the electric bus cables

Connecting the power supply

Connecting the signal contact

Setting the data rate

Setting the optical transmitting power

3.1 Checking the package contents

Proceed as follows:

Check whether the package includes all items named in the section

“Scope of delivery” on page 36.

Check the individual parts for transport damage.

Installation OZD Genius...

Release 01 09/2017

23

3.2 Installing and grounding the device

You have the following options for mounting your device:

Installing the device onto the DIN rail

Mounting the device on a mounting plate

Prerequisites:

Install the device in a location where the climatic threshold values

specified in the technical data are adhered to.

Ensure that there is sufficient room to connect the bus and power supply

cabling.

Connect the optical fiber line before mounting the repeater as this

simplifies the procedure.

If possible, the repeaters should only be installed on a mounting plate or

DIN rail with low-impedance and low-inductance grounding.

3.2.1 Installing the device onto the DIN rail

Note: The device is for mounting on a 35 mm DIN rail in accordance with DIN

EN 60715.

Proceed as follows:

Slide the upper snap-in guide of the device into the DIN rail.

Press the device downwards onto the clip-in bar.

2

1

24

Installation OZD Genius...

Release 01 09/2017

3.2.2 Mounting the device on a mounting plate

Note: The repeater has 3 through-holes. The through-holes allow to mount

the repeater to any flat surface, e.g. to the mounting plate of a switch cabinet.

Proceed as follows:

Make 3 holes in the mounting plate corresponding the drilling template.

Use the machine bolts (e.g. M3 x 40) to secure the repeater.

Ensure reliable electrical connection between the repeater casing and the

mounting plate.

Place toothed washers under the bolt heads to pierce the varnish.

3.2.3 Grounding the device

Functional grounding the device is by means of a separate connection on the

device.

Ground the device before connecting any other cables.

Disconnect the grounding only after disconnecting all other cables.

Ground the device via the ground screw.

Toothed washer

61,2 mm

40,6 mm

81,2 mm

Ø 3 mm

Ø 3 mm

mm in (inch)

81,2

61,2 2.45

3.2

40,6 1.6

3 0.12

Installation OZD Genius...

Release 01 09/2017

25

3.3 Connecting the optic bus cables

Proceed as follows:

Use a duplex fiber-optic cable with BFOC/2.5 (ST ®) connectors to

connect the individual repeaters.

Pay attention to the maximum cable length of the fiber-optic cable as well

as the possible types of fibers specified in the Technical Data.

Make sure that each optical input is connected to an optical output at the

opposite end (“cross-overlink“). The corresponding BFOC sockets of the

two ports are marked on the lower front panel.

Ensure sufficient strain relief for the fiber-optic cables and pay attention to

their minimum bend radiuses.

Unused BFOC sockets are to be covered with the protective caps

supplied. Incident ambient light and, in particular, great ambient

brightness, can affect the network. The penetration of dust may impair

operation of the optical components.

optical output (Sending direction)

optical input (Receiving direction)

CH3

26

Installation OZD Genius...

Release 01 09/2017

3.4 Connecting the electric bus cables

WARNING

Genius bus lines which are completely or partially installed outdoors

should not be connected. Any lightning strikes in the immediate

vicinity could otherwise destroy the repeaters. Use F/O cables for

bus connections outside buildings.

Proceed as follows:

Only cables approved for the Genius bus should be used.

The Serial 1 port of a device is connected to the Serial 1 port of the

adjacent devices. This also applies for the Serial 2 port (no cross-over

connection).

The Shield In connection of a device is connected to the Shield Out

connection of the upstream device. As a result, the Shield In connection

of the first device as well as the Shield Out connection of the last device

remain free.

The beginning and end of the bus must be terminated with a resistor rated

according to the specifications for Genius bus cables. A resistor with a

rating of between 75 Ω and 150 Ω (0.5 W) must be used depending on the

cable used.

The signal processing time for the OZD Genius... repeater and the physical

delay caused by the fiber optic cable must be taken into consideration when

the system is configured. Detailed information regarding installation and

configuration can be found in the Genius bus specifications and the

configuration directives from the control unit manufacturer.

This interface is a 4-pin with a self-locking mechanism. The plug must be

engaged on the socket.

SHD OUT

SHD IN

SER2

SER1

Installation OZD Genius...

Release 01 09/2017

27

3.5 Connecting the power supply

Proceed as follows:

The OZD Genius... should only be supplied with a regulated safety extra-

low voltage of between 18 V and 32 V as defined in IEC 60950/EN 60950

/VDE 0805.

To improve the operating safety, a redundant power supply consisting of

separate sources can be used. The supply voltages can be supplied in

two ways:

via terminal 18 V ... 32 V of the terminal block

via terminal 18 V ... 32 V of the terminal block

The common negative connection in the middle of the terminal block is

indicated by (0 V).

The two voltages can have any values, even different ones, within the

specified limits.

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

28

Installation OZD Genius...

Release 01 09/2017

3.6 Connecting the signal contact

Note:

To connect the signal contact lines, remove the 8-pin screw terminal block

on top of the repeater from the device.

Use the correct pin assignment for the 8-pin terminal block.

Make sure that the electrical insulation of the connection cables of the

signal contacts is sufficient. Incorrect connections can destroy the

repeater.

On the 8-pin terminal block on the top of the repeater, the unconnected pins

of a relay can be used as signal contacts. When the OZD Genius... is working

correctly, the contact is closed. If there is an error or a power failure, the

contact is opened.

The following problems with the network and the repeater can be signaled by

means of the signal contact:

Supply voltage No supply voltage (with redundant supply voltage: loss of

all supply voltages)

Internal device errors

Received data Loss of received data at port 2 and/or port 3 (e.g.cable

breakage)

No data received at all ports

L1+

F1

0V

F2

L2+

Ua2

GND

Ua1

+24V

Fault

+24V

Installation OZD Genius...

Release 01 09/2017

29

3.7 Setting the data rate

Note: Use the dip switches S0 and S1 on the front panel of the OZD Genius...

to set the desired data rate.

The fiber-optic repeater OZD Genius G12... supports the data rates

153.6 kBaud (standard and extended),76.8 kBaud and 38.4 kBaud.

The switch settings for the data rates 153.6 kBaud Standard and

153.6 Extended are identical.

The positions of the switches S1 and S2 are only read in when the supply

voltage is applied. This ensures that no bus fault occurs if the two

switches are inadvertently set to the wrong positions.

If the device is already in operation, the supply voltage must be

disconnected before the data rate is changed. The new data rate is then

set using S1 and S2 and the supply voltage reconnected. When the

device is switched on, the new data rate is read in.

Data rate Switch position

153.6 dBm

Standard or Extended.

76.8 dBm

38.4 dBm

Not used

Table 4: Data rate and associated switch position

S0

S1

1 0

S0

S1

1 0

S0

S1

1 0

S0

S1

1 0

30

Installation OZD Genius...

Release 01 09/2017

3.8 Setting the optical transmitting power

Note:

S2, S3, S4, S5 and S8 do not have function on OZD Genius... .

The DIP switch S6 is used to set the transmit power of CH3.

The DIP switch S7 is used to set the transmit power of CH4.

3.9 Network range for line and ring topologies

It is possible to check whether a configuration is within the respective network

range limits by means of the following formula.

Checking the network range using the following formula

The following must apply:

[(I

O

× 5µs) + (IE×5µs) + (n

OZD×tRD

)] × 1.07 ≤ 0.5 × [tD + (dA - 1) × tS]

Verify that the dip switch S6 and S7 is set to position 1.

I

O

Length of optical fiber in ring (one ring loop) or in line [km]

I

E

Sum of the two longest electrical Genius bus segments which are connected to OZD

Genius... in ring or in line [km]

n

OZD

Number of OZD Genius... used

t

RD

Repeater delay - data transfer time through an OZD Genius...

(see table 5)

t

D

Delay time - minimum interval between two telegrams

(see table 5)

d

A

Minimum address distance between two Genius bus devices

t

S

Skip time - depends on data transmission rate

(see table 5)

Data rate [kBaud] 153.6 153.6 76.8 38.4

Mode Standard. Extended. Extended. Extended.

t

RD

0.8 0.8 1.2 2.3

t

D

70 140 140 280

t 26 52 104 208

Table 5: Timing

CH 3

CH 4

CH 1

10

S

1

S

0

S

6

S

5

S

3

S

2

S

4

S

7

S 8

n.c.

n.c.

n.c.

n.c.

n.c.

Installation OZD Genius...

Release 01 09/2017

31

Figure 4: Example of network configuration with 5 OZD Genius... devices (two

longest Genius bus segments are identified)

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Serial 1

Serial 2

Shield in

Shield out

Terminating

resistor

Duplex fiber optic cable

Electrical bus line

Two longest electrical Genius bus segments

l

O

5 x OZD Genius G12

l

E1

l

E2

lE = lE1 + l

E2

n

OZD

= 5

32

Installation OZD Genius...

Release 01 09/2017

4 Disassembly

To remove the device, pull down on the locking slide.

1

Installation OZD Genius...

Release 01 09/2017

33

5 Technical data

General technical data

Device variant OZD Genius... OZD Genius G12-1300

Dimensions

W × H × D

See “Dimension drawings” on page 35.

Weight approx. 19.75 oz (560 g)

Supply voltage

See “Requirements for connecting electrical wires” on page 6.

Nominal voltage DC 24 V

Voltage range DC incl. maximum

tolerances

18 V ... 32 V

Connection type 4-pin terminal block

Power loss buffer > 10 ms at 20.4 V DC

Overload current protection at input Non-replaceable fuse

Back-up fuse for each voltage input

Nominal rating:

Characteristic:

2A

slow blow

Peak inrush current < 4 A

Signal transmission

Data rate 153.6 kBit/s, 76.8 kBit/s, 38.4 kBit/s

Cascadability not limited

Signal processing time

(any input/output)

0.9 µ at 153.6 kBit/s

1.6 µ at 76.8 kBit/s

3.1 µ at 38.4 kBit/s

Electrical port

Input/output signal Genius bus

OZD Genius... cable

– Length

– Attenuation at 1 MHz

< 250 m

< 8 dB for 150 Ω cable

< 5 dB for 100 Ω cable

Connection options max. 32 end devices

Electrical isolation

– Shielding in/Shielding out

– Data cable/casing

Yes

Yes

terminating resistor Must be attached outside to connector

Signal contact

See “Requirements for connecting electrical wires” on page 6.

Switching current max. 1 A

Switching voltage under UL conditions: max. 30 V DC, resistive load

Climatic conditions during operation

Ambient temperature +32 °F ... +140 °F (0 °C ... +60 °C)

Humidity 5 % ... 95 %

(non-condensing)

Air pressure minimum 700 hPa (+9842 ft; +3000 m)

34

Installation OZD Genius...

Release 01 09/2017

Climatic conditions during storage

Ambient temperature −40 °F ... +176 °F (−40 °C ... +80 °C)

Humidity 5 % ... 95 %

(non-condensing)

Air pressure minimum 700 hPa (+9842 ft; +3000 m)

Pollution degree 2

Protection classes

Laser protection Class 1 in compliance with IEC 60825-1

Degree of protection IP40

Optical port P G G-1300

Wavelength 650 nm 860 nm 1300 nm

Launchable optical power – – –

in fiber 10/125 (default) – – −19 dBm

into fiber 50/125 (default) −17 dBm −17 dBm

into fiber 62.5/125 (default) – −13 dBm −17 dBm

Receiver sensitivity −25 dBm −28 dBm −29 dBm

Receiver overload limit 0 dBm −1dBm −3dBm

Damping values of the fiber

optic

P G G-1300

Wavelength 650 nm 860 nm 1300 nm

Damping values:

Fiber 10/125 – – 0.5 dB/km

Fiber 50/125 – 3 dB/km 1 dB/km

Fiber 62.5/125 – 3.5 dB/km 1 dB/km

Fiber 200/230 10 dB/km 8 dB/km –

Fiber 980/1000 0.225 dB/m – –

Transmission distance

a

a. The specified distance allowed between two OZD Genius G12-1300 must not be exceeded

regardless of the optical power budget.

G G-1300

Wavelength 860 nm 1300 nm

System reserve 3 dB 2 dB

Transmission distance:

Fiber 10/125 – 10000 m

Fiber 50/125 (default) 2700 m 10000 m

Fiber 62.5/125 (default) 3100 m 10000 m

Installation OZD Genius...

Release 01 09/2017

35

Dimension drawings

Power consumption/power output

Device name Maximum power consumption Maximum power output

OZD Genius... 4.8 W 16.3 Btu (IT)/h

12,47

0.49

110,4

4.35

10,75

0.42

16,35

0.64

16,75

0.66

96,7

3.8

39,5

1.56

mm

inch

36

Installation OZD Genius...

Release 01 09/2017

6 Scope of delivery, order numbers and

accessories

Scope of delivery

Order numbers/product description

Number Article

1× Device

1 × General safety instructions

Device name Order number

OZD Genius G12 942 148-012

OZD Genius G12-1300 942 148-013

Installation OZD Genius...

Release 01 09/2017

37

7 Underlying technical standards

The device has an approval based on a specific standard only if the approval

indicator appears on the device casing.

The device generally fulfills the technical standards named in their current

versions.

Name

C-Tick Declaration Australian Radiocommunication Act 1998

Australian Radiocommunication Standard 2008

CSA C22.2 No. 142 Canadian National Standard(s) – Process Control Equipment –

Industrial Products

FCC 47 CFR Part 15 Code of Federal Regulations

DNVGL-CG-0339 Environmental test specification for electrical, electronic and

programmable equipment and systems.

UL/IEC 61010-1,

UL/IEC 61010-2-201

Safety for Control Equipment

EN 55032 Electromagnetic compatibility of multimedia equipment –

Emission Requirements

EN 61000-3-2 Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for

harmonic current emissions

EN 61000-3-3 Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation

of voltage changes, voltage fluctuations and flicker.

EN 61000-6-2 Electromagnetic compatibility (EMC) – Part 6-2: Generic

standards – Immunity for industrial environments

EN 61000-6-4 Electromagnetic compatibility (EMC) – Part 6-4: Generic

standards – Emission standard for industrial environments

EN 61131-2 Programmable controllers – Part 2: Equipment requirements and

tests

Table 6: List of the technical standards

38

Installation OZD Genius...

Release 01 09/2017

8 Troubleshooting

This chapter helps you to localize faults after they have been indicated (by

LEDs or signal contacts).

Fault indicated on the system LED

Check that the supply voltage is being supplied.

Check that the supply voltage is connected correctly.

Fault displayed at CH1

Check that the correct data rate has been set.

Check that the serial data line has been connected correctly.

Check that the terminating resistor has been connected correctly.

Fault displayed at CH2, CH3

Check that the optical fiber from the transmitting OZD Genius... is not

broken.

Check that the optical fibers are not too long.

Check that the optical fibers are not crossed.

Check that the ports are not connected incorrectly.

Installation OZD Genius...

Release 01 09/2017

39

A Further support

Technical questions

For technical questions, please contact any Hirschmann dealer in your area

or Hirschmann directly.

You find the addresses of our partners on the Internet at

http://www.hirschmann.com.

A list of local telephone numbers and email addresses for technical support

directly from Hirschmann is available at

https://hirschmann-support.belden.eu.com.

This site also includes a free of charge knowledge base and a software

download section.

Hirschmann Competence Center

The Hirschmann Competence Center is ahead of its competitors on three

counts with its complete range of innovative services:

Consulting incorporates comprehensive technical advice, from system

evaluation through network planning to project planning.

Training offers you an introduction to the basics, product briefing and user

training with certification.

You find the training courses on technology and products currently

available at http://www.hicomcenter.com.

Support ranges from the first installation through the standby service to

maintenance concepts.

With the Hirschmann Competence Center, you decided against making any

compromises. Our client-customized package leaves you free to choose the

service components you want to use.

Internet:

http://www.hicomcenter.com

40

Installation OZD Genius...

Release 01 09/2017

Installation OZD Genius...

Release 01 09/2017

41

Loading...

Loading...