Hirschmann OZD 485 G12 PRO User Manual

Manual

Universal RS 485 Fiberoptic Repeater

OZD 485 G12(-1300) PRO

Hirschmann. Simply a good Connection.

OZD 485 G12 PRO

System

P1

DA/STAT

01

S1

S 2

S 3

S 4

RT+

K1+

K1+

K1-

K1-

RT-

RT-

K2-

K2-

K2+

K2+

RT+

Ua2

GND

Ua3

RM

31P22

Port 1

The performance features described here are binding

only if they have been expressly agreed when the contract was made. We have checked the content of this

document for consistency with the hardware and software it describes. However, inconsistencies cannot be

ruled out, and thus we cannot guarantee absolute

consistency. Nevertheless, the information in the document is checked regularly. Necessary corrections

are contained in the following printings. We are grateful for any suggested improvements.

Technical modifications reserved.

This document may not be passed on, copied, nor

may its contents be used or distributed, unless expressly permitted. Violators will be held liable for compensation. All rights are reserved, particularly if a

patent is granted or the design is registered.

© Hirschmann Automation and Control GmbH

All Rights Reserved

Note

We wish to point out that the content of this manual is

not part of a previous or existing agreement, consent ,

or legal relationship, or shall not amend same. All the liabilities of Hirschmann result from the respective sales

contract, which also contains the complete and solely

valid guarantee regulations. These contractual guarantee

specifications are neither enhanced nor restricted by the

information in this manual .

We also wish to point out that for reasons of comprehensibility, not every conceivable problem relating to the

use of this device can be described in this manual.

Should you require further information , or should particular problems occur which are not dealt with in sufficient detail

in this manual, you can request the required information

from your local Hirsch mann dealer or directly from

Hirschmann (for address, see section “Note on CE

Marking”).

Order Numbers

OZD 485 G12 PRO 943 894-321

OZD 485 G12-1300 PRO 943 895-321

Manual 039 555-001

Universal RS 485 Fiberoptic

Repeater OZD 485 G12(-1300) PRO

1

OZD 485 G12(-1300) PRO Version 04 12/2014

Notes on safety

This manual contains instructions to be observed for

ensuring your personal safety and for preventing damage.

The warnings appear next to a warning triangle with a

different heading depending on the degree of danger

posed:

z

Danger!

Means that death, serious physical inj ury or considerable damage to equipment will occur if the

required precautionary measures are not taken.

z

Warning!

Means that death, serious physical injury or considerable damage to equipment can occur if the

required precautionary measures are not taken.

z

Caution!

Means that minor physical inj ury or damage to

equipment can occur if the required precautionary

measures are not taken.

Note:

Contains important information on the product, on how to

manage the product, or on the respective section of the

documentation to which your particular attention is being

drawn.

Qualification requirements for personnel

Note:

Qualified personnel as understood in this manual and the

warning signs, are persons who are familiar with the

setup, assembly, startup, and operation of this product

and are appropriately qualified for their job. This includes, for example, those persons who have been:

– trained or instructed or authorized to switch on and off,

to ground and to label power circuits and devices or

systems in accordance with current safety engineering

standards;

– trained or instructed in the care and use of appropriate

safety equipment in accordance with the current standards of safety engineering;

– trained in providing first aid.

General safety instructions

D

This device is operated by electricity. You must follow

precisely the prescribed safety requirements in the

operating manual that relate to the voltage connect ions!

D

Make sure that the electrical installation meets local

or national safety regulations.

z

Warning!

Non-observance of these safety instructions can

cause materia l damage and/or serious injuries.

Only appropriately qualified per sonnel should work

on this device or in its vicinity. This per sonnel must

be thoroughly familiar with all the warnings and

maintenance procedures in accordance with this

operating manual.

The proper and safe operation of this device

depends on proper handling during transport,

proper storage and assembly, and conscientious

operation and maintenance procedures. Never

start operation with damaged components.

z

Warning!

Any work that may be required on the electrical

installation may only be carried out by personnel

trained for this purpose.

z

Warning!

LASER CLASS 1 in compliance with

IEC 60825-1 (2014).

Correct operation

Please note the following:

z

Warning!

The device may only be used for those purposes

specified in the catalog and in the technical description, and only in combination with external

devices and components approved by Hirschmann. The proper and safe operation of this product depends on proper handling during transport,

proper storage and assembly, and conscientious

operation and maintenance procedures.

2

OZD 485 G12(-1300) PRO Version 04 12/2014

Safety instructions for supply voltage

D

Only switch on the device when the housing is

closed.

z

Warning!

The devices may only be connected to the supply

voltage shown on the type plate.

The devices are designed for operation with safety

extra-low voltage. Accordingly, only PELV circuits

or SELV circuits with voltage restrictions in line

with IEC/EN 60950 may be connected to the supp ly

voltage connections and the signal contact.

D

If you are operating the module with an external volt age: Only supply the system with a low safety voltage

in compliance with IEC/EN 60950.

Relevant for North America:

D

The device may only be connected to a supply

volt age of class 2 that fulfils the requirements of the

National Electrical Code, Table 11(b). If the voltage

is being supplied redundantly (two different voltage

sources), the combined supply voltages must fulfil

the requirements of the National Electrical Code,

Table 11(b).

D

Use 90 or 90°C copper(CU) wire only.

Safety instructions for environment

z

Warning!

The device may only be operated in the specified

ambient temperature and relative air humidity

(non-condensing).

D

Select the installation site so that the climatic threshold values specified in the technical data are

adhered to.

D

Only to be used in an environment with contamination

level 2 (IEC 60664-1).

Safety instructions for housing

z

Warning!

Only technicians authorized by Hirschmann are

permitted to open the housing.

Underlying norms and standards

The devices fulfill the following norms and standards:

– EN 61000-6-2:2001 Generic standards –

Immunity for industrial environments

– EN 55022:1998 + A1 2000+A2:2003 – Information tech-

nology equipment – Radio disturbance characteristics

– EN 61131-2: Programmable controllers

– EN 60825-1 Safety of laser products

– FCC 47 CFR Part 15:2004 – Code of Federal

Regulations

Note on the CE marking

7

The devices comply with the regulations of the

following European directives:

89/336/EEC

Council Directive on the harmonization of the legal regulations of member states on electromagnetic compatibility

(amended by Directives 91/263/EEC, 92/31/EEC and

93/68/EEC).

The precondition for compliance with EMC limit values is

strict adherence to the installation guidelines specified in

this description and operating instructions.

The EU declaration of conformity is kept available for the

responsible authorities in accordance with the abovementioned EU directives at:

Hirschmann Automation and Control GmbH

Stuttgarter Strasse 45 - 51

72654 Neckartenzlingen

Germany

Telephone +49 (0) 1805 14-1538

Email HAC.Support@Belden.com

The product can be used in the residential sphere (residential sphere, business and trade sphere and small

companies) and in the industrial sphere.

– Interference immunity:

EN 61000-6-2:2001

– Interference emissions:

EN 55022:1998+A1:2000+A2:2003 Class A

z

Warning!

This is a Class A device. This equipment may

cause radio interference if used in a residential

area; in this case it is the operator’s responsibility

to take appropriate measures.

3

OZD 485 G12(-1300) PRO Version 04 12/2014

FCC RULES

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Note: This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reas onable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction man ual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the

user will be requir ed to correct the interference at his

own expense.

C-Tick

Australia / New Zealand

This product meets the requirements of the

AS/NZS 3548 standard.

N1337

Certifications

cUL508

Please note the important information in: Chapter 5.4,

”Use in North America“, page 23.

ISA12.12.01

Hazardous Locations Class1 Div 2 Groups

A, B, C und D

Please note the important information in: Chapter 5.4

”Use in North America“, page 23.

ATEX Directive 94/9/EC Zone 2 3G

Please note the important information in: Chapter 5.2

”Use in Ex-zone 2 according to ATEX 94/9/EC“, page 21.

Note:

Only the certifications indicated on the label attached to

each device are applicable.

Recycling note

,

After usage, this product must be disposed of

properly as electronic waste in accordance with

the current disposal regulations of your county/

state/country.

4

OZD 485 G12(-1300) PRO Version 04 12/2014

5

Contents

OZD 485 G12(-1300) PRO Version 04 12/2014

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Half/full duplex operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Half duplex operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Full duplex operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Tristate recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Tristate recognition through permanent high . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Tristate recognition through differential voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Network topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Line topology without redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Redundant ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Star distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Network range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Cascadability and data rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Installation guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Use in Ex-zone 2 according to ATEX RL 94/9EG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Control Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Use in North America . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 Installing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6 Installing repeater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7 Installing terminating resistor and pull-up/pull-down resistor s . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8 Setting DIL switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9 Connecting the optic bus cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.10 Connecting the electric bus cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.11 Connecting the function ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.12 Connecting the signal contact lines (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.13 Connecting the analog voltage outputs (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.14 Connecting the operating voltage supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.15 Checking the LED indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contents

Contents

6

OZD 485 G12(-1300) PRO Version 04 12/2014

6 Bus configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.1 BITBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 DIN measurement bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3 InterBus-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Modbus RTU/Modbus ASCII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.1 Specification of the Modbus variants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.2 Without Line Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.3 With Line Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.5 Configuration of other bus systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7 Help with problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.3 Problem reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.4 Contact address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7

1 Introduction

OZD 485 G12(-1300) PRO Version 04 12/2014

1 Introduction

The RS 485 Fiberoptic Repeater OZD 485 G12(-1300)

PRO is intended for use in optical RS 485 fieldbus networks such as Modbus RTU, Modbus ASCII, BITBUS

and company-specific busses .

It enables you to convert electrical RS 485 signals to

optical ones, and the reverse.

With the OZD 485 G12(-1300) PRO Repeaters, you can

construct univer sal half (2-wire) or full (4-wire) duplex

transmission systems with RS 485 interfaces.

You can integrate the Repeaters into existing electrical

RS 485 fieldbus networks. You can also build up a

complete optical RS 485 fieldbus network in line, ring or

star topoligies with OZD 485 G12(-1300) PRO Repeaters.

The housing consists of two plastic sections and a front

panel made of metal. It can be mounted on a DIN rail.

Ports

The Repeater has three independent ports, which in turn

consist of a transmitter and a receiver component.

Port 1 is a 12-pin screw terminal block, and ports 2 and 3

are optical BFOC/2.5 (ST

®

) sockets.

Power supply

The power supply is +18 V to +24 V (for non-hazardous

locations only: +18 V to +32 V) direct current.

To improve the operating safety, a redundant operating

power supply consisting of two separate sources can

be used. For this purpose, you must connect the two

operating voltages to two different terminals of the 7-pin

screw-type terminal block .

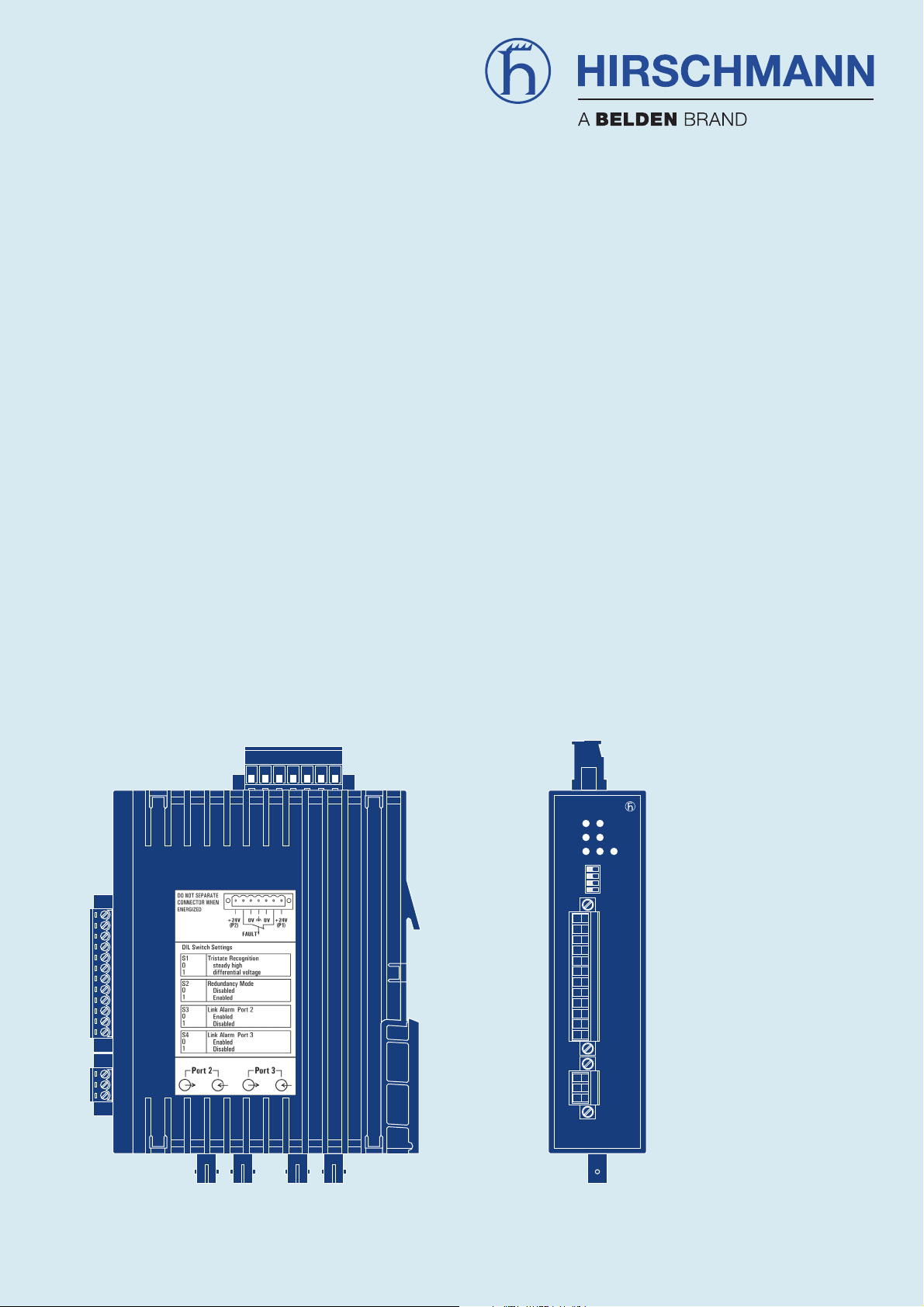

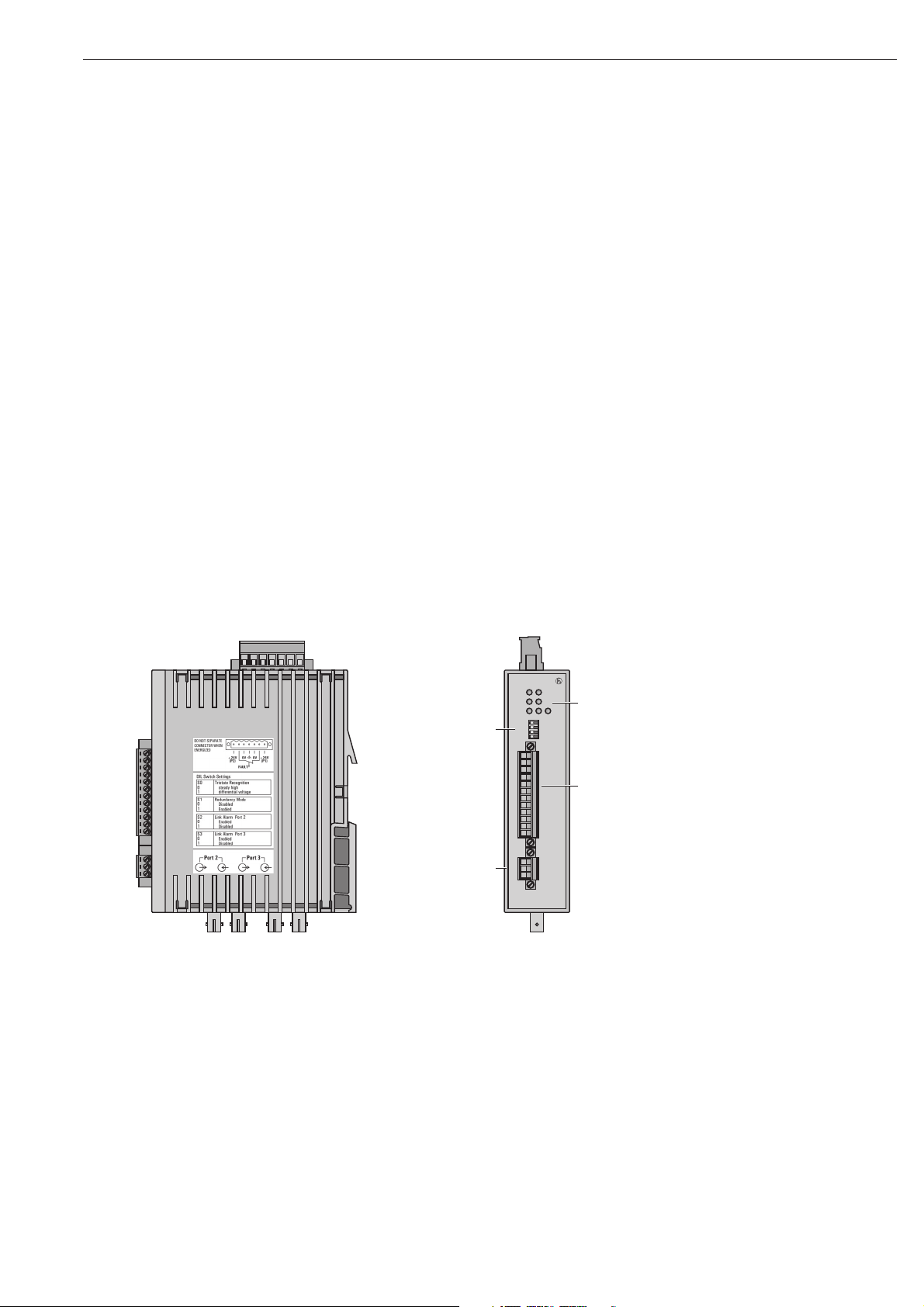

12-pin screw

terminal block for

port 1, electrical

and

pull-up/pull-down

resistors and

bus terminating

resistor

7-pin

terminal block

for operating

power supply

and

signal contact

LED

indicators

Switch for

tristate recognition,

redundancy mode

and link status

monitoring

Port 3

optical,

BFOC/2.5

socket

Port 2

optical,

BFOC/2.5

socket

01

S 2

S1

S 4

S 3

System

OZD 485 G12 PRO

DA/STAT

31P22

RM

P1

RT+

K1+

K1+

K1-

K1-

RT-

RT-

K2-

K2-

K2+

K2+

RT+

Ua2

GND

Ua3

Port 1

3-pin

screw

terminal block

for analog

voltage outputs

Fig. 1: Fiberoptic Repeater OZD 485 G12(-1300) PRO with location of individual ports, terminal blocks and LED displays

1 Introduction

8

OZD 485 G12(-1300) PRO Version 04 12/2014

Both connections are uncoupled by means of diodes to

prevent reverse voltage supply or destruction through

incorrect pole connection.

There is no load distribution between the sources. With

redundant supply, the power supply unit with the higher

output voltage must supply the repeater alone.

Signal contact

A signal contact (relay with unconnected contacts) is

used to signal various disruptions in the repeaters . The

signal contact is also connected to the 7-pin screw-type

terminal block.

LEDs

Seven one- and two-colored light-emitting diodes signal

the current operating status and any possible operating

errors.

Configuration

You can easily set the configuration to meet your specific

requirements by means of DIL code switches, which can

easily be operated from outside.

The following settings are possible:

U Tristate recognition

U Redundancy mode

U Signaling a lower power input at optical port 2

U Signaling a lower power input at optical port 3

Glass fiber technology

The use of glass fiber transmission technology enables a

very large transmission range and ensures optimal protection from EMC effects on the transmission path and

– due to the potential separation – on the Repeater itself.

Transmission speed

The RS 485 Fiberoptic Repeater OZD 485 G12(-1300)

PRO supports all data rates from 0 to 1.5 MBit/s NRZ.

Network range

The permissible network range for the line, ring or star

topology depends on the bus system and terminal devices used. See chapter 4.4, page 16.

Redundancy

The redundant ring enables a very high level of

transmiss ion reliability.

The redundant operating power supply can further

improve the operating reliability.

Device models

The RS 485 Fiberoptic Repeaters OZD 485 G12 … PRO

are available as OZD 485 G12 PRO for multi-mode fibers

(50/125 µm and 62.5/125 µm) and as OZD 485 G12-1300

PRO for single- mode fibers (10/125 µm) and multi-mode

fibers (50/125 µm and 62.5/125 µm).

Compatibilty with other RS 485 Fiberoptic

Repeaters

The OZD 485 G12 PRO may be operated via the optical

ports

– together with the RS 485 Fiberoptic Repeater OZD 485

G12, or

– together with the RS 485 Fiberoptic Repeater OZD 485

G12 BAS, if only those properties that are also suppor-

ted by the OZD 485 G12 BAS are used in the entire

network.

The OZD 485 G12-1300 PRO may be operated via

the optical ports

– together with the RS 485 Fiberoptic Repeater OZD 485

G12-1300.

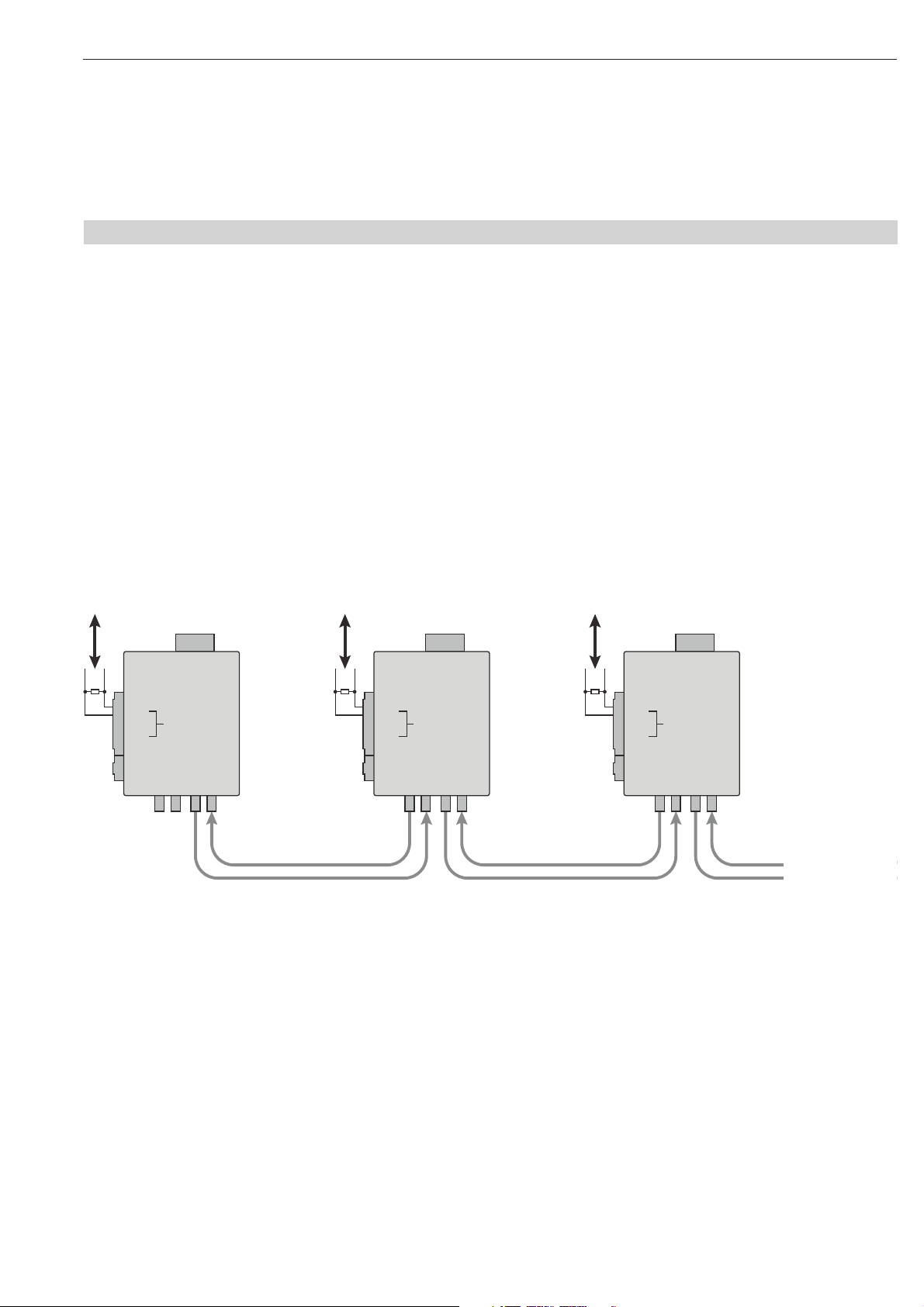

2.1 Half-duplex operation

9

2 Half/full duplex operation

OZD 485 G12(-1300) PRO Version 04 12/2014

2 Half/full duplex operation

2.1 Half-duplex operation

Fig. 2: Half-duplex mode – data channel K1 is used for data transmission, and data channel K2 is not used

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

The two data channels of the electrical port, K1 and K2,

can transmit data simultaneously and independently of

one another in half-duplex mode

1)

. Each data channel

replaces a 2-wire cable.

In half-duplex mode, the arbitration procedure used by

the connected devices must ensure that at any given

time, only one device can access the bus, like in

master/slave operation. Access procedures where there

is a risk of collisions, such as CAN, are not permissible.

In half-duplex mode, consecutive data telegrams must

be separated by a minimal time gap so that the end of a

data telegram can be definitively recognized and thus

the data direction can be switched in the OZD 485 G12

(-1300) PRO. For the tristate recognition through permanent high, this gap is 3.5 µs, while for the tristate reco gnition through differential voltage, it is 1 µs.

You can cascade a number of OZD 485 G12(-1300) PRO

via the optical interfaces

1)

. Devices or bus segments

may be connected to the electrical interfaces of all the

cascaded OZD 485.

1) When you use both data channels K1 and K2 at the same time and

while cascading the repeaters the increased jitter causes a reduction

in the maximum permissible transmission rate and/or the cascadability. See chapter 4.5, page 16.

2 Half/full duplex operation 2.1 Half-duplex operation

10

OZD 485 G12(-1300) PRO Version 04 12/2014

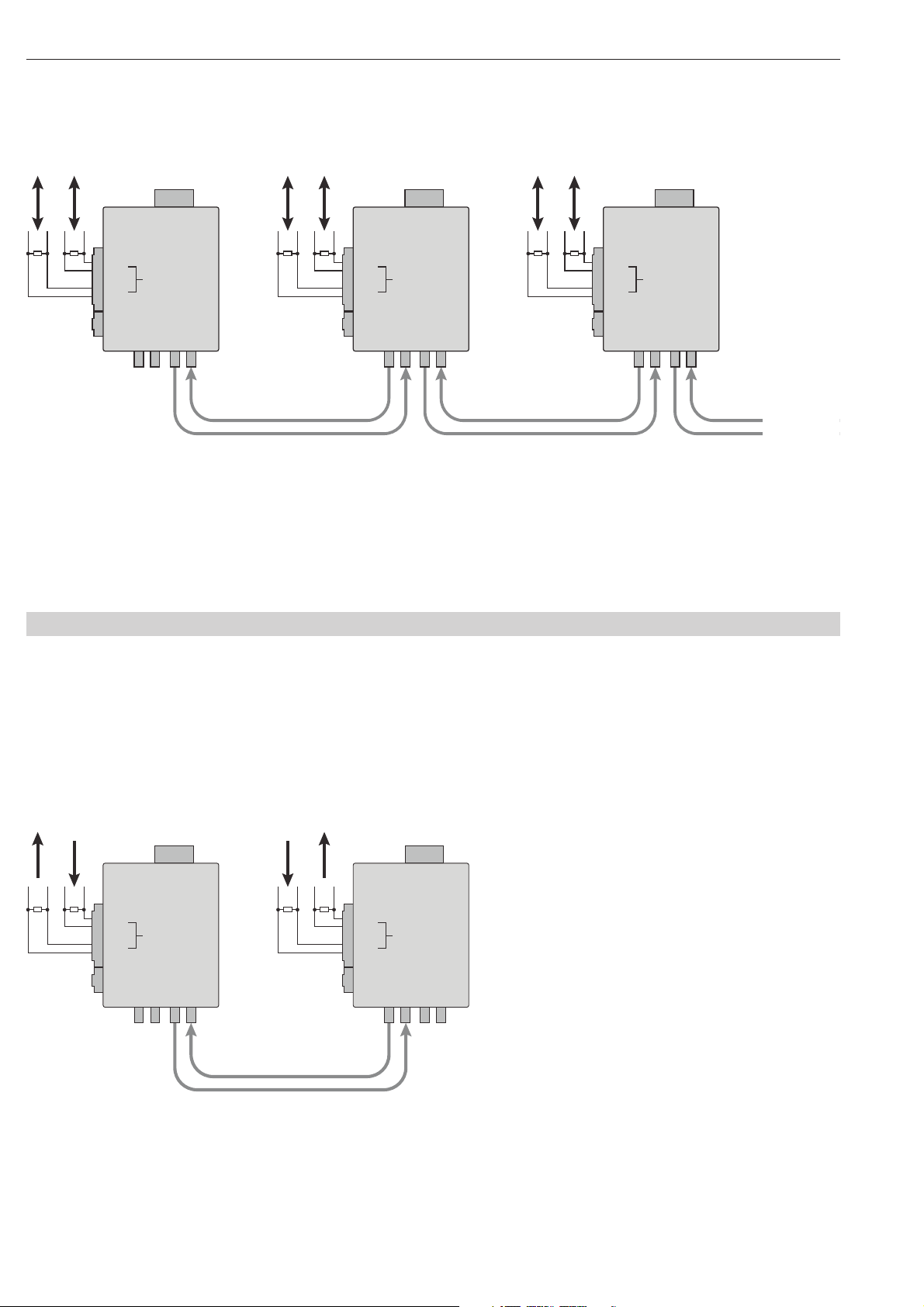

Fig. 3: Half-duplex mode – data channel K1 and data channel K2 are used for data transmission.

Data

K 2

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

Data

K 2

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

Data

K 2

Data

K 1

Port 1

K 1

K 2

Port 3Port 2

Fig. 4: Full-duplex mode – the data channels K1 and K2 are each used for data transmission in one direction.

Data

out

Data

in

Port 1

K 1

K 2

Port 3Port 2

DatainData

out

Port 1

K 1

K 2

Port 3Port 2

2.2 Full-duplex operation

In full-duplex mode, you can set up a bi-directional conn ection between two devices.

The data channels K1 and K2 are each used for data

transmission in one direction.

You can cascade more than two OZD 485 G12(-1300)

PRO via the optical interfaces.

The arbitration procedure used by the connected devices

must ensure that at any given time only one single bus

participant is sending on channel 1 and only one is sending on channel 2. Access methods that can cause collisions on channel 1 or channel 2 are not permissible.

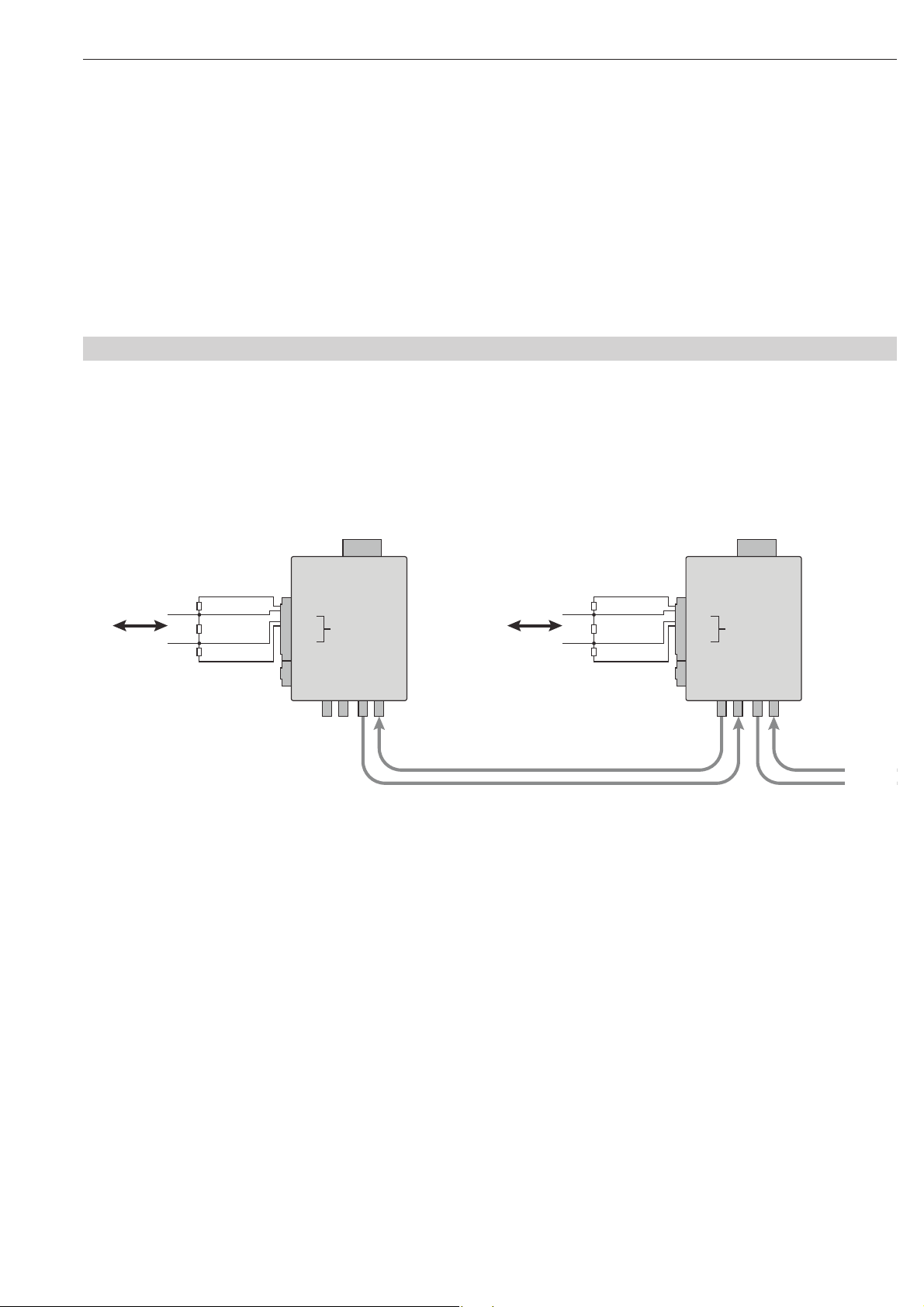

3.1 Tristate recognition through permanent high

11

3 Tristate recognition

OZD 485 G12(-1300) PRO Version 04 12/2014

3 Tristate recognition

3.1 Tristate recognition through permanent high

Fig. 5: Tristate recognition through permanent high

Data

K 1

R

R

PD

R

PU

R

R

PD

R

PU

typ. 220 Ω

typ. 390 Ω

typ. 390 Ω

RT+

RT±

K1±

K1+

Port 1

K 1

K 2

Port 3Port 2

R

R

PD

R

PU

R

R

PD

R

PU

typ. 220 Ω

typ. 390 Ω

typ. 390 Ω

RT+

RT±

K1±

K1+

Port 1

K 1

K 2

Port 3Port 2

Data

K 1

One 2-wire lead , terminated by a characteristic impedence and additional pull-up/pull-down resistors, is

replaced (e.g. Modbus RTU/ASCII).

During the idle phase, a logical high level (positive volt age between terminals K1+ and K1-) is available. As

soon as a con stant high level is available for 2.5 µs,

the repeaters identify this as tristate and switch their

transmitters to the idle state (transmitter set to highresist ance).

A downward slope is identified as the start bit.

Transmission is made in the appropriate direction .

The opposite direction is disabled.

The type of tristate recognition depends on the termi nation

of the bus system used. See also chapter 5.7, page 25.

3 Tristate recognition 3.2 Tristate recognition through differential voltage

12

OZD 485 G12(-1300) PRO Version 04 12/2014

3.2 Tristate recognition through differential voltage

Fig. 6: Tristate recognition through differential voltage (INTERBUS example).

1)

INTERBUS example

Data

K 1

R

w

100 Ω

1)

K1±

K1+

1)

INTERBUS example

Data

K 1

R

w

100 Ω

1)

K1±

K1+

Port 1

K 1

K 2

Port 3Port 2

Port 1

K 1

K 2

Port 3Port 2

Fig. 7: Switching limit within which the OZD 485 G12(-1300) PRO repeaters recognize tristate (indicated in dark gray),

and the related minimum/maximum voltage valuesfor the logical conditions “high” and “low” (indicated in light gray).

– 0.7 V – 0.1 V 0.7 V0.1 V

Low Tristate High

A 2-wire lead only terminated by a characteristic

impedance is replaced.

During the idle phase, the differential voltage falls below

a certain value. The repeater recognizes this as tristate.

If a switching limit is exceeded, the t ransmission is made

in the appropriate direction . The opposite direction is disabled.

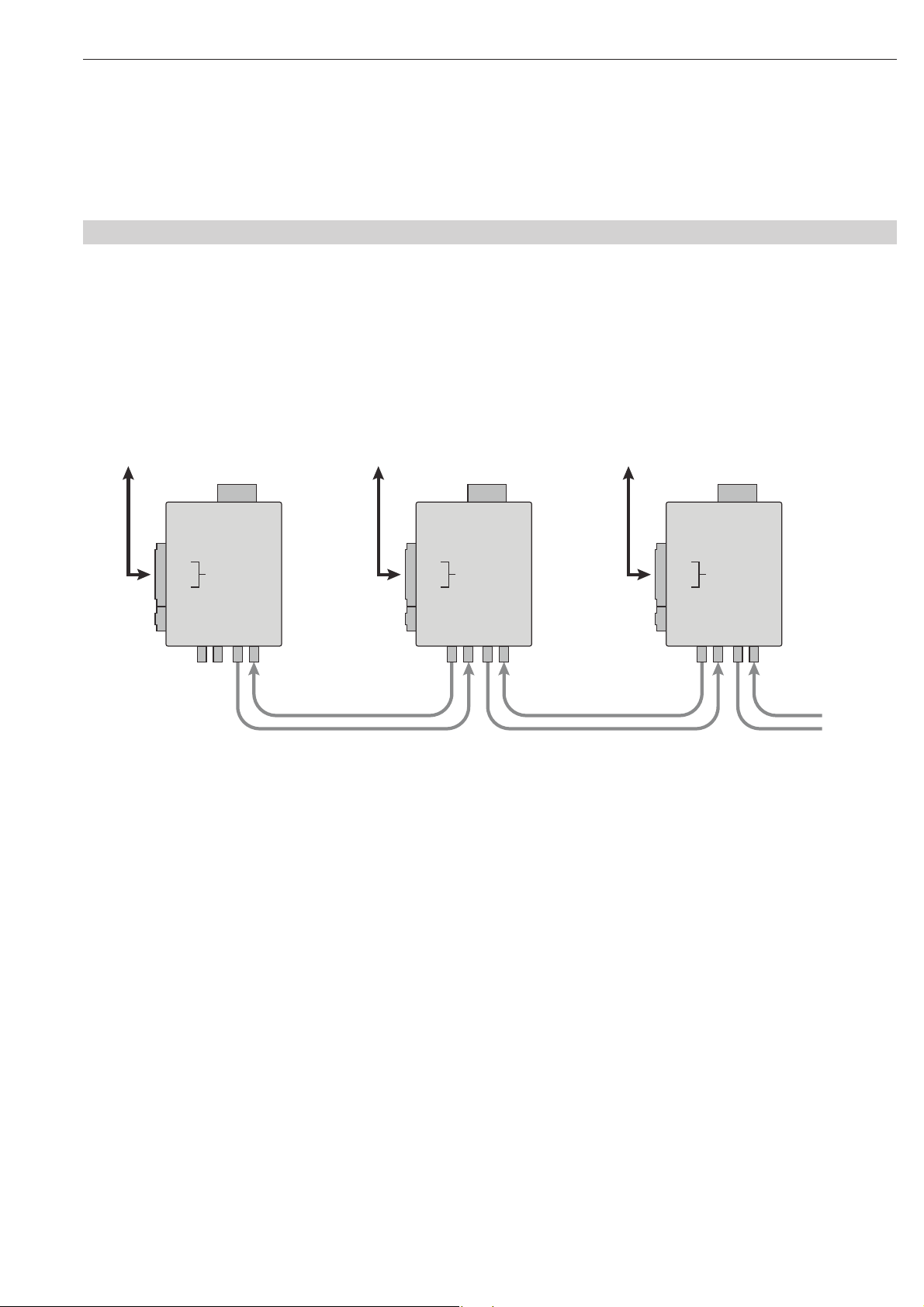

4.1 Line topology without redundancy

13

4 Network topologies

OZD 485 G12(-1300) PRO Version 04 12/2014

4 Network topologies

Fig. 8: Line topology without redundancy

Port 1

K 1

K 2

Port 3Port 2

Port 1

K 1

K 2

Port 3Port 2

Port 1

K 1

K 2

Port 3Port 2

Terminal device(s)/

bus segment

Terminal device(s)/

bus segment

Terminal device(s)/

bus segment

This network topology can be used for an optical

connection of end devices or bus segments.

For the repeaters at the end of the line, the DIL switch S3

or S4 of the related, non-occupied optical port must be

in position “1”, which means that too low incoming

power at port 2 or port 3 is not signalled at the signal

contact.

4.1 Line topology without redundancy

Loading...

Loading...